Page 1

Instruction Manual

BL1.5 • BL3 • BL5

BL7 • BL10

BL15 • BL20

Dosing Pumps

www.hannainst.com

Page 2

Dear Customer,

Thank you for choosing a Hanna product.

Please read this instruction manual carefully

before using the pump.

If you need additional technical information,

do not hesitate to e-mail us at

tech@hannainst.com.

These instruments are in compliance with the

directives.

WARRANTY

All Hanna Instruments pumps are warranted for

one year against defects in workmanship and materi-

als when used for their intended purpose and maintained according to instructions.

This warranty is limited to repair or replacement free

of charge. Damages due to accident, misuse, tampering or lack of prescribed maintenance are not covered. If service is required, contact the dealer from

whom you purchased the instrument. If under warranty, report the model number, date of purchase,

serial number and the nature of the failure. If the

repair is not covered by the warranty, you will be

notified of the charges incurred. If the instrument is to

be returned to Hanna Instruments, first obtain a Returned Goods Authorization Number from the Customer Service department and then send it with shipment costs prepaid. When shipping any instrument,

make sure it is properly packaged for complete pro-

tection.

TABLE OF CONTENTS

Preliminary Examination ............................. 3

General Description..................................... 5

Flow Rate Chart .......................................... 7

Functional Description................................. 9

Specifications............................................ 10

V alve / Hose Assembly Diagram.................11

Installation................................................. 12

Operational Guide ..................................... 21

Troubleshooting Guide............................... 23

Maintenance ............................................. 25

Chemical Compatibility Guide ................... 27

Accessories.............................................. 29

CE Declaration of Conformity .................... 31

PRELIMINARY EXAMINATION

Remove the pump from the packing material and examine it carefully to make sure

that no damage has occurred during shipping. If there is any noticeable damage,

notify your Dealer.

Each pump is supplied complete with:

• 7 m (23') LDPE suction and discharge

tubing

• Instruction manual

Note: Save all packing material until you

are sure that the pump functions correctly. Any defective item must be

returned in the original packaging together with the supplied accessories.

READ ATTENTIVELY THE INSTRUCTIONS

BEFORE INSTALLING OR

OPERATING YOUR PUMP

The BL electronic dosing pumps are easy to

use. We recommend, however, that you read

the entire manual before using the pump.

Familiarity with the features and controls of

the unit will give you a better idea of the

dosing potential and help reduce operator

errors. Please operate the pump only as

directed in the instruction manual. Follow all

general safety guidelines during operation.

Remember: electrical devices are potentially

hazardous. Check that the voltage of the

installation matches the voltage indicated

on the specification label on the back of the

pump. Always be sure the pump is grounded.

Note: It is the responsibility of the user to

install and ground the pump properly; it is highly recommended to install an external switch.

32

Page 3

Always store chemicals in safe, out of reach

places. Follow the directions for use with

each chemical. Do not assume chemicals

are the same because they look alike. Hanna

Instruments cannot be held responsible for

the misuse of chemicals or the pump.

Always wear protective clothing (gloves and

safety glasses) when working near chemical

dosing pumps. When pumping chemicals,

make sure all tubes are securely attached to

the fittings. It is recommended that tubing is

shielded to prevent possible injury in case

of rupture or accidental damage.

Avoid using a pipe wrench or pliers on plastic parts and connectors. These are best

tightened with an open end or crescent

wrench. Avoid overtightening these parts

as this could cause damage to the seats

and threads.

If a hose is used, it should be securely

fastened to columns, walls, braces, etc. This

will ensure that the hose connection will remain tight and leak free. Shield the hose

from direct sunlight. Sunlight can cause an

autocatalytic reaction with some chemicals

and weaken the hose walls.

The arrow on the pump head indicates the

direction of chemical flow and should always point upwards (vertically). Never position the pump horizontally with suction and

discharge valves horizontal. Locate the pump

in an area out of the reach of children and

pets.

All pumps undergo stringent tests to ensure

that they comply with their stated specifications and are calibrated at the maximum

rated pressure.

GENERAL DESCRIPTION

BlackStone pumps are equipped with a single

control for pump output.

Flow range is continuously adjustable from 0

to 100% of the maximum capacity through a

graded dial on the front of the pumps.

Seven models are available, each with a different dosing capacity:

BL 20 18.3 lph (4.8 gph) @ 0.5 bar (7.4 psi)

BL 15 15.2 lph (4.0 gph) @ 1 bar (14.5 psi)

BL 10 10.8 lph (2.9 gph) @ 3 bar (43.5 psi)

BL 7 7.6 lph (2.0 gph) @ 3 bar (43.5 psi)

BL 5 5.0 lph (1.3 gph) @ 7 bar (101.5 psi)

BL 3 2.9 lph (0.8 gph) @ 8 bar (116 psi)

BL 1.5 1.5 lph (0.4 gph) @ 13 bar (188.5 psi)

High quality materials

To provide the maximum protection for parts

that are in contact with aggressive chemicals, diaphragms, hose connectors and pump

heads are produced using materials as PVDF

and PTFE.

54

Page 4

The ball valves are constructed in glass. The

body is made of fiber-reinforced polypropylene for strength and durability.

Reliability through simplicity

All BlackStone pumps use the positive displacement solenoid method of pumping. This

method has fewer moving parts than a standard motor-driven pump, and does not have

the mechanical failures associated with conventional pumps.

BlackStone's Positive Displacement design

has several distinct advantages over other

types of mechanical designs:

• It is more accurate. Each stroke of the

piston is precisely the same as the stroke

before it ... and the stroke after it.

• Positive displacement allows for easier selfpriming.

• Pumping pressure is as high as 12 bar

(176 psi). This allows you to install your

pump in the widest variety of tank-to-tank

and tank-to-in-line applications.

• High accuracy and repeatability. A wirewound potentiometer and solid state electronics are combined to achieve greater

precision and control.

Easy installation

Designed with mounting holes in the base as

well as rear panel, BlackStone pumps can be

installed on a wall as well as directly on top

of tanks and drums.

There is no need for additional hardware.

All the controls and pump assemblies are

conveniently located on the front of the unit.

If the operator must access the pump head

or control panel for any reason, there is no

need to dismount the unit.

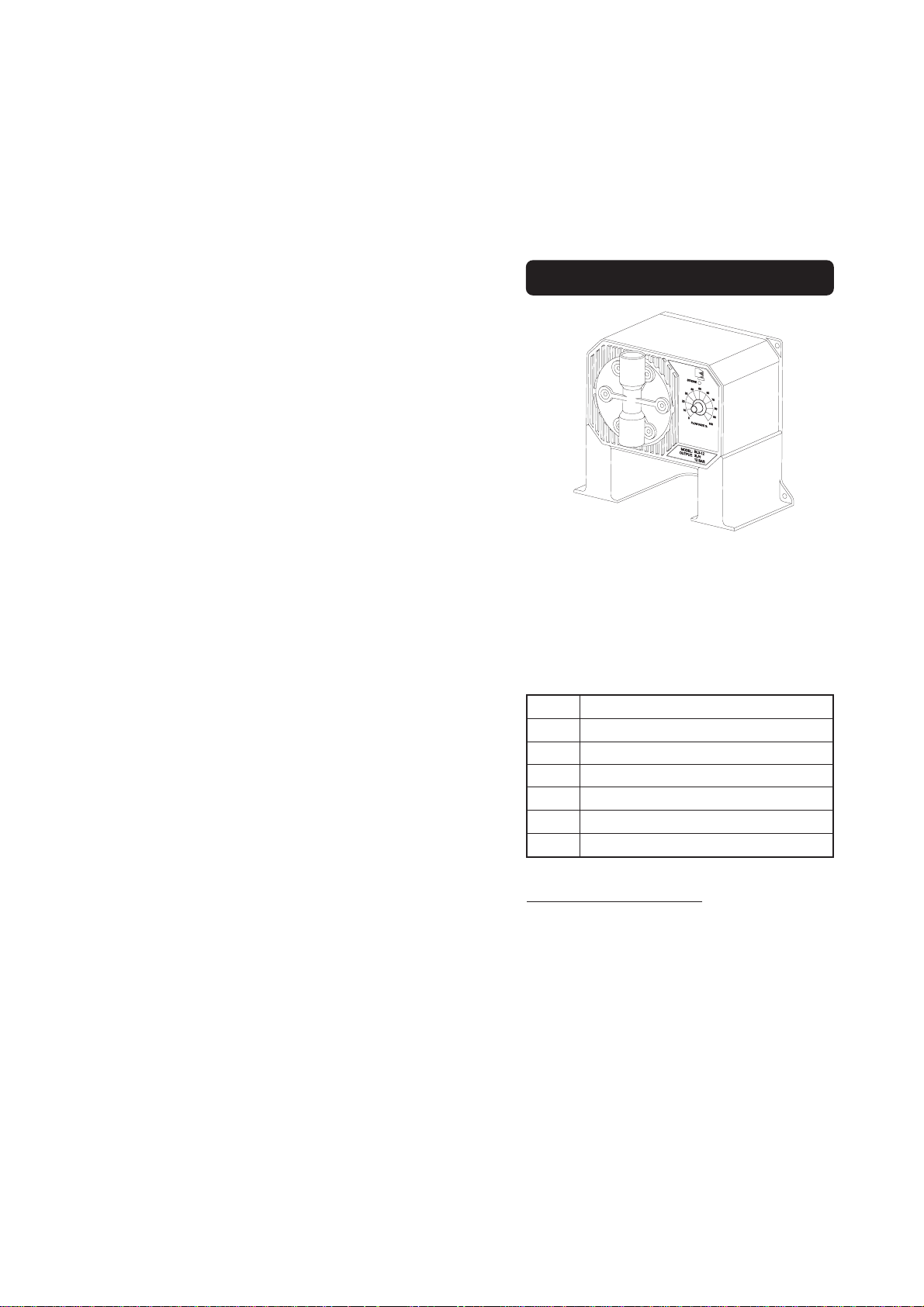

FLOW RATE CHART

The following charts show the relationship

between their flow rate and pressure.

An increase of pressure in the system decreases the flow rate.

BL1.5

bar (psi) lph (gph)

0.5 (7.4) 8.3 (2.20)

1 (14.7) 6.8 (1.80)

2 (29.4) 5.4 (1.43)

3 (44.1) 5.2 (1.38)

4 (58.8) 4.8 (1.27)

5 (73.5) 4.5 (1.19)

6 (88.2) 4.1 (1.08)

7 (102.9) 3.2 (0.85)

8 (117.6) 2.9 (0.77)

9 (132.3) 2.1 (0.56)

10 (147) 1.8 (0.48)

11 (161.7) 1.7 (0.45)

12 (176.4) 1.6 (0.42)

BL3

Pump outpu t with 120 strokes/minu t e

18,0

16,0

14,0

12,0

L

P

10,0

H

8,0

6,0

4,0

2,0

0,0

0,5123456789101112

BAR

9,0

8,0

7,0

6,0

L

P

5,0

H

4,0

3,0

2,0

1,0

0,0

0,5123456789101112

BL1.5

Pump outpu t with 12 0 stro kes /minut e

BAR

BL3

bar (psi) lph (gph)

0.5 (7.4) 15.8 (4.18)

1 (14.7) 12.2 (3.23)

2 (29.4) 9.3 (2.46)

3 (44.1) 7.9 (2.09)

4 (58.8) 6.5 (1.71)

5 (73.5) 5.0 (1.32)

6 (88.2) 4.0 (1.06)

7 (102.9) 3.3 (0.87)

8 (117.6) 2.9 (0.77)

9 (132.3) 2.5 (0.66)

10 (147) 2.2 (0.58)

11 (161.7) 1.9 (0.50)

12 (176.4) 1.5 (0.40)

BL5

bar (psi) lph (gph)

0.5 (7.4) 15.8 (4.18)

1 (14.7) 12.2 (3.23)

2 (29.4) 10.8 (2.86)

3 (44.1) 9.3 (2.46)

4 (58.8) 7.9 (2.09)

5 (73.5) 6.5 (1.72)

6 (88.2) 5.8 (1.53)

7 (102.9) 5.0 (1.32)

8 (117.6) 4.3 (1.14)

9 (132.3) 4.0 (1.06)

10 (147) 3.6 (0.95)

18,0

16,0

14,0

12,0

L

P

10,0

H

8,0

6,0

4,0

2,0

0,0

0,512345678910

BL5

Pump output with 120 strokes/minute

BAR

76

Page 5

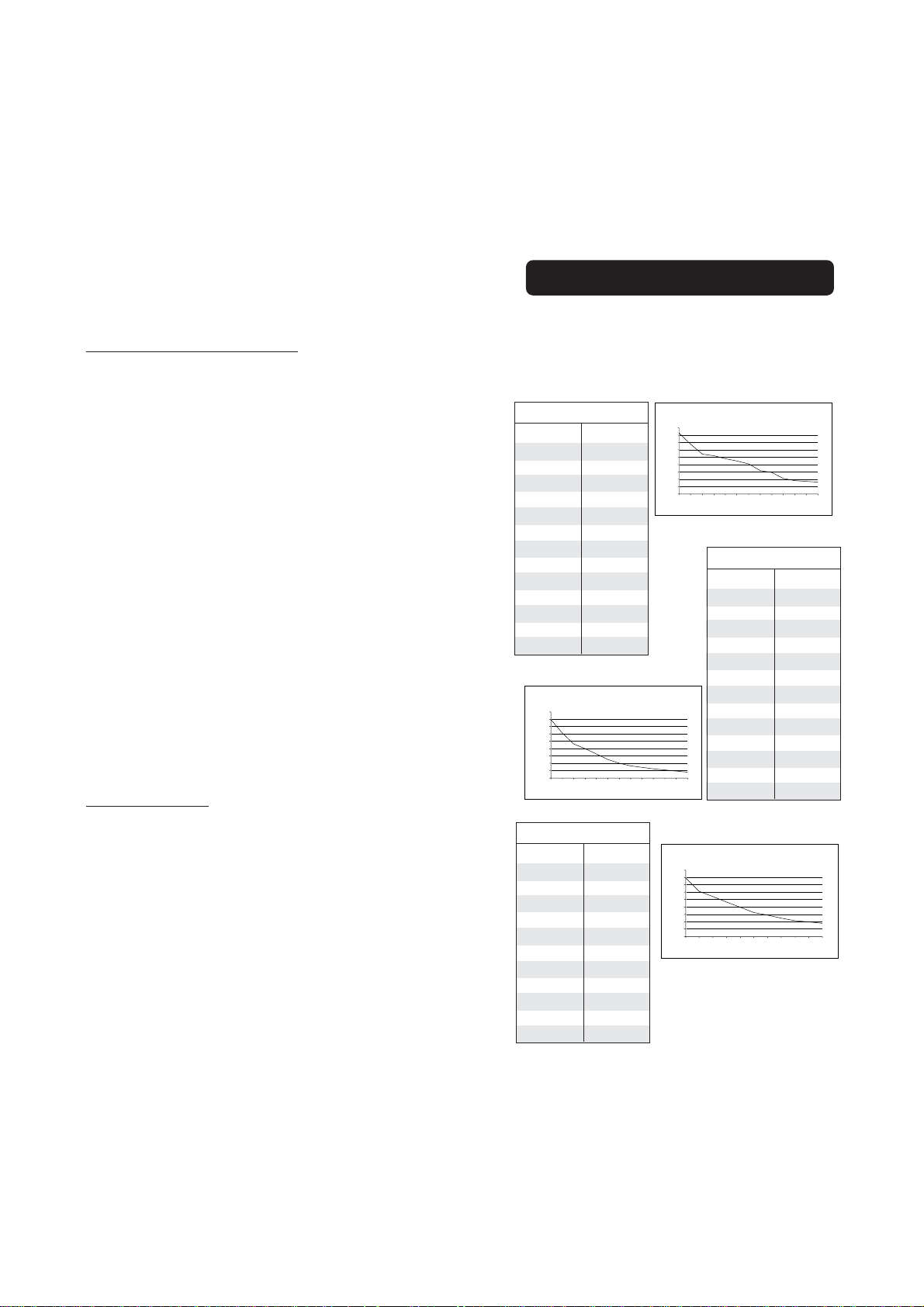

BL7

Pump outpu t with 120 strokes/minu t e

20,0

18,0

16,0

14,0

L

12,0

P

10,0

H

8,0

6,0

4,0

2,0

0,0

0,5123 45678

BAR

BL7

bar (psi) lph (gph)

0.5 (7.4) 17.2 (4.55)

1 (14.7) 13.6 (3.60)

2 (29.4) 10.8 (2.86)

3 (44.1) 7.6 (2.01)

4 (58.8) 6.0 (1.59)

5 (73.5) 5.7 (1.51)

6 (88.2) 5.4 (1.43)

7 (102.9) 4.4 (1.16)

8 (117.6) 3.6 (0.95)

FUNCTIONAL DESCRIPTION

BL10

bar (psi) lph (gph)

0.5 (7.4) 18.3 (4.84)

1 (14.7) 15.2 (4.02)

2 (29.4) 13.6 (3.60)

3 (44.1) 10.8 (2.86)

4 (58.8) 9.4 (2.49)

BL15

Pump output with 120 strokes/minute

20,0

18,0

16,0

14,0

L

12,0

P

10,0

H

8,0

6,0

4,0

2,0

0,0

0,5 1 2 3

BAR

BL20

bar (psi) lph (gph)

0.5 (7.4) 18.3 (4.84)

1 (14.7) 15.2 (4.02)

2 (29.4) 13.6 (3.60)

BL10

Pump output with 120 strokes/minute

20,0

18,0

16,0

14,0

L

12,0

P

10,0

H

8,0

6,0

4,0

2,0

0,0

0,5 1 2 3 4

BAR

BL15

bar (psi) lph (gph)

0.5 (7.4) 18.3 (4.84)

1 (14.7) 15.2 (4.02)

2 (29.4) 13.6 (3.60)

3 (44.1) 10.8 (2.86)

BL20

Pump output with 120 strokes/minute

20,0

18,0

16,0

14,0

L

12,0

P

10,0

H

8,0

6,0

4,0

2,0

0,0

0,5 1 2

BAR

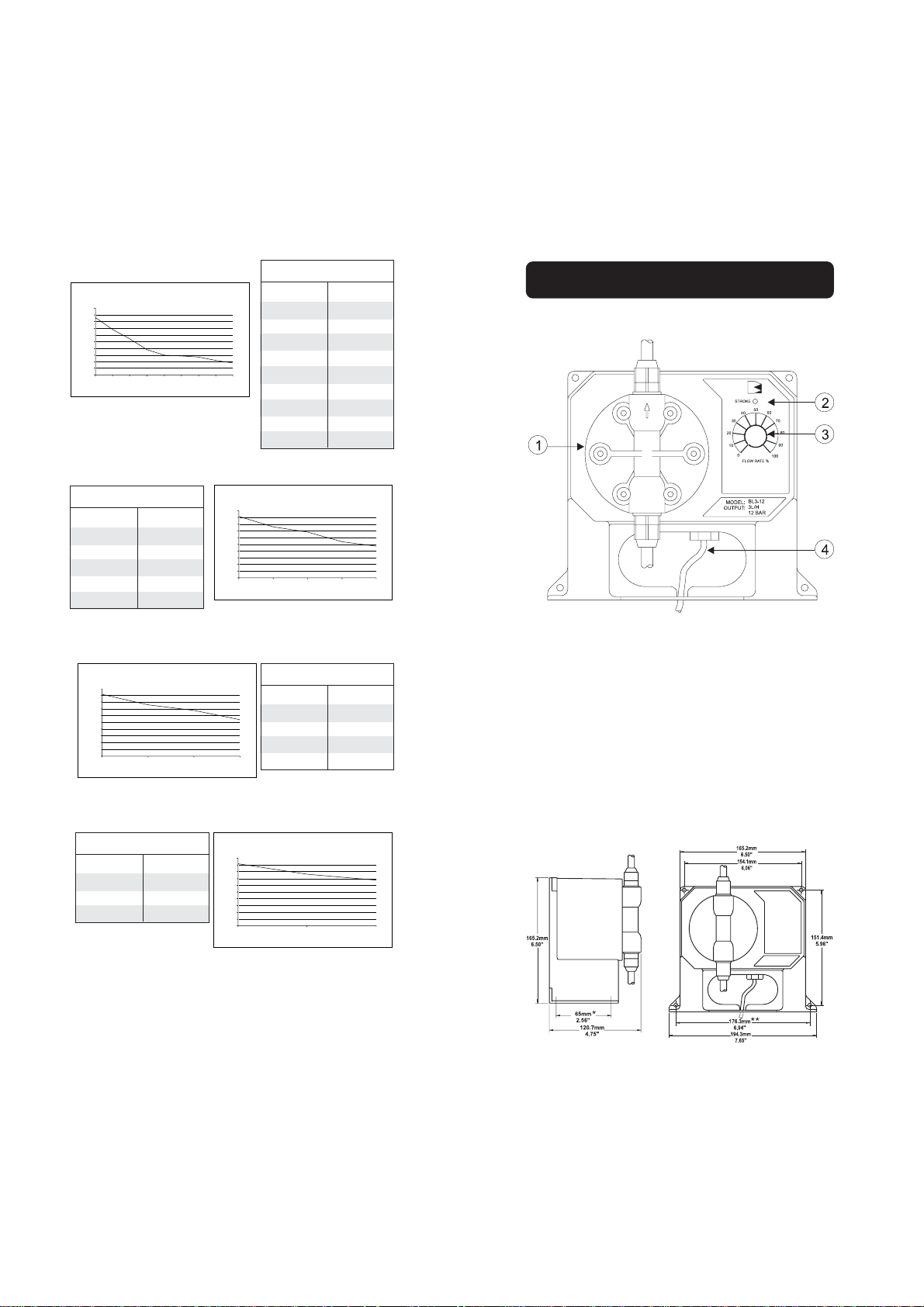

1. Pumphead

2. Stroke LED

3. Flow Rate % Knob

4. Power Cord

MECHANICAL DIMENSIONS

98

Page 6

SPECIFICATIONS

MAX FLOW RATE

BL1.5 1.5 lph (0.4 gph) @ 13 bar (188.5 psi)

BL3 2.9 lph (0.8 gph) @ 8 bar (116 psi)

BL 5 5.0 lph (1.3 gph) @ 7 bar (101.5 psi)

BL7 7.6 lph (2.0 gph) @ 3 bar (43.5 psi)

BL10 10.8 lph (2.9 gph) @ 3 bar (43.5 psi)

BL15 15.2 lph (4.0 gph) @ 1 bar (14.5 psi)

BL20 18.3 lph (4.8 gph) @ 0.5 bar (7.4 psi)

Adjustable from 0 to 100% of

maximum pump capacity

MATERIAL

PUMP CASING fiber-reinforced polypropylene

VALVES glass balls + O-rings in FPM/FKM

PUMPHEAD PVDF

DIAPHRAGM PTFE

TUBING polyethylene

SELF PRIMING Max. height: 1.5 m (5')

POWER SUPPLY

BL...-1 100/115 Vac; 50/60 Hz

BL...-2 220/240 Vac; 50/60 Hz

MAX POWER CONSUMPTION 200 W

PROTECTION IP65

ENVIRONMENT 0 to 50°C (32 to 122°F)

95% RH max

DIMENSIONS 194 x 165 x 121 mm (WxHxD)

(7.6 x 6.5 x 4.8")

WEIGHT 3 kg (6.6 lb.)

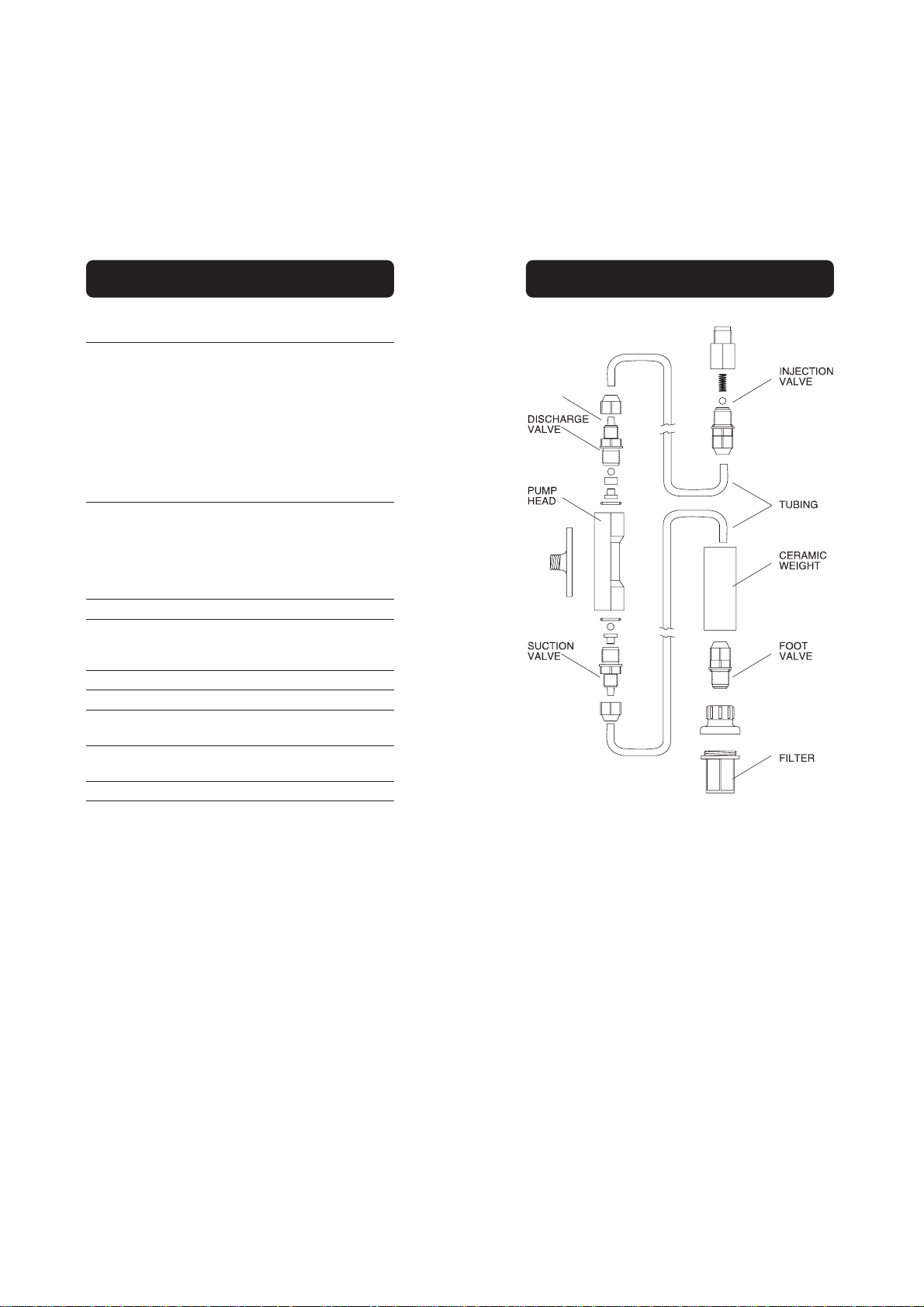

VALVE / HOSE ASSEMBLY DIAGRAM

NECK

1110

Page 7

INSTALLATION

Materials Needed

•LDPE hose (7 meter / 22 feet) (included)

or other type of tubing (PTFE, for example)

more suitable for a specific application (optional)

Optional Accessories

•4 each, ceramic weights ( HI 721008)

•1 each, foot valve assembly (HI 721005)

• 1 each, injection valve assembly (HI 721004)

Location

A suitable location should:

• be near to a power source

• be conveniently close to the injection point

• allow easy access to the flow rate control

and pipe or hose connections

• be no more than 1.5 meters (5 feet) above

the operating position of the suction valve

assembly.

Dimensions for Installation

BlackStone pumps are designed for permanent installation.

The pump can be mounted directly on a wall

or tank.

Power Requirements

BlackStone pumps are designed to operate

to specifications within the following voltage

ranges:

100 - 130 Volts for -1 models

200 - 240 Volts for -2 models

To ensure maximum performance, check the

voltage at the point of supply to verify that it

is sufficient. It is recommended that you install a 1 Amp circuit breaker between the

pump and the power supply. This will give

additional protection to the internal circuit

and provide a convenient way to disconnect

the power supply prior to servicing the pump,

if needed.

Injection Point

• Choose an injection point that allows you

to mount the injection valve assembly vertically.

• The spring in the injection valve assembly

(HI 721004) adds approximately 1.5 bar of

back pressure. If pumping into a high back

pressure, the spring should be removed.

Other Considerations

• If you are mounting the system to a wall,

column, etc., be sure it is strong enough

to support the weight of the entire system.

• The ambient temperature of the pump,

when in operation, should be between 0

and 50°C (32 to 122°F) and should be

protected from direct exposure to outdoor

elements (direct sunlight, rain, extreme temperatures, high humidity, etc.).

• Generally speaking, the shorter the suction

distance, the more efficient the pump operates.

1312

Page 8

-

• The pump should be placed in a conventional location that will allow easy access

to the control and connections. It should be

placed so that regular visual inspections of

the connections and hoses are facilitated.

Vertical Surface Mounting

Once you have selected the best installation

site, simply screw or bolt the unit into a wall

or mounting panel above the chemical feed

tank.

The 4 mounting screw holes on the pump

will accommodate up to a 5 mm (3/16")

screw or bolt (remember to use heavy screws

or bolts to secure the system).

Be sure you do not over tighten and cause

excessive stress on the mounting holes.

Electrical Connections

Note: All cables must be according to local

electrical codes.

For safety of the users, the pump has to

be grounded.

The pump should be connected to a single

phase power source.

Color coding for wires:

Blue - Live

Brown - Neutral

Yellow/Green - Ground (earth)

It is recommended that the system be connected to a power line/leg equipped with a

circuit breaker of 1 Amp.

Permanent Connection using 3/8"PVC pipe

All piping for the

pump feed and discharge should be

plumbed to the location of the pump.

The threads on both

valve assemblies allow the use of standard 3/8" (European)

pipe fittings for per-

UNION CONNECTION

ADAPTER

DISCHARGE VALVE

PUMP

SUCTION VALVE

ADAPTER

FOOT VALVE

FILTER

Diagram for Rigid Pipe Hose

manent pipe connections.

The foot valve assembly (HI 721005)

should always hang

vertically and not lay

horizontal on the

bottom of the tank

or drum.

A vertical assembly

will ensure that the

valve is positioned

properly and prevent

loss of prime.

For the U.S. standard installations, use PVC

adapters to connect the suction and discharge valves to the PVC pipe.

Hose Connections

• Cut a long enough

section of the

hose to reach the

suction valve of the

pumphead from

1514

Page 9

the feed tank. Allow some slack in the

hose and be sure it is not kinked or twisted.

• Slip a hose connector

onto the hose over the

head valve and up to

the bottom of the

threads ensuring it is

fully seated.

•Slide the connector up

to the threads and

tighten to form a seal.

•Repeat the same installation procedure for

the hose connections on the discharge end

with the injection assembly (HI 721004).

•Slip the ceramic weight

(HI 721008) and a connector over the other end

of the hose.

• Attach the foot valve assembly (HI 721005) to

the hose and slide the

connector up to the

threads and tighten to

form a seal.

• Secure the hose so that its movement is

minimized when the pump is operating. Excessive hose movement could cause the

connectors to loosen and result in leakage.

1716

Page 10

LEGEND

HOSE PIPE

CONNECTION

RESEVOIR

MANUAL

SHUTOFF

VALVE

PUMP

FILTER /

FOOT VALVE

CHECK VALVE

Assembling the Hose to the Valve

The end of the valve is specially tapered to

form a leak free seal when the hose is properly installed.

Be sure to seat the hose completely so that

there is no gap. Push the hose until it covers

the end of the valve completely.

Suction and Discharge Valves

The suction and discharge valves located on

the pumphead should not be interchanged as

they are different internally. The discharge

valve is fitted with a valve guide and will not

function properly if used on the suction side.

EXAMPLE OF TYPICAL INSTALLATIONS

Flooded Suction Installation

Suggested Installation

for consistent output

when using a low

stroke rate. Also suggested for highly viscous chemicals.

A slight suction pressure avoids self-priming problems, especially with high viscosity liquids.

Suction Lift Installation

Suggested installation

for most in-line applications with nominal

output and pressures.

The maximum selfpriming height is 1.5

m (5 ft.). It is advisable

to install a level controller in order to stop

the pump when feed

tank liquid level is low.

1918

Page 11

Uphill Installation

Suggested installation

whenever the supply is

located higher than the

discharge point; typically a waste water application.

It is important to install the Injection valve

to prevent siphoning.

Downhill Installation

Suggested installation when pumping from

one container to another, each at different

levels and with only nominal pressure.

OPERATIONAL GUIDE

START-UP

At start-up, purge all chemical gases and air

from the suction tubing, valves and pump

head. Start the pump.

When all the air or gas is vented, the solution being metered will appear in the output

line.

Note: Only when operating under pressure,

the pump must be started unloaded.

An external Flow Rate

Control (potentiometer) on

the face of the pump allows to adjust the flow up

to 100% of the pump's

rated capacity.

A LED indicator will light up each time a

stroke begins.

2120

Page 12

Operating Pressure and Back Pressure

Operating pressure is a combination of back

pressure plus all of the other resistances to

flow present in your system.

BlackStone Pumps are designed to dose their

rated output at the operating (rated) pressure.

Therefore, rated pressure of the pump you

install should be close to operating pressure

present in the system.

Too little back pressure can cause the pump

to overdose.

To prevent this from happening on a low back

pressure installation, a spring has been added

to the discharge/anti-siphon valve assembly

(HI 721004).

When pumping into a high back pressure,

the spring should be removed.

Actual Flow Rate

The actual flow rate depends upon the operating pressure which includes resistance at

the injection fittings, hose and piping, the

chemical viscosity and suction lift. The Flow

Rate Control adjusts the flow up to 100% of

the rated output. Less back pressure will

increase the output, more will decrease it.

To determine the correct setting for your

application, use the following procedure.

1. Be sure that the pump is primed and that

the output connections are completed at

the injection point.

2. Place the foot valve assembly (HI 721005) in a graduated container with 500

mL of the solution to be

dosed.

3. Switch the pump from OFF

to the 100% setting and

run until the system has

been fully reprimed. Switch

OFF and refill the container

to the 500 mL level.

4. Switch the pump ON to

the estimated setting and

run for a specific amount

of time (e.g. 1 minute).

Count the number of

strokes, length of time,

and volume pumped.

Note: It is suggested that you run the test for

as long as possible to maximize the

accuracy.

For example, if at the maximum setting of

100% you find you pumped 200 mL in one

minute, your hourly output would be 12 liters/hour (200 mL x 60 min. = 12000 mL/hr).

If your application called for 9 liters/hour,

turn the Flow Rate Control to 7 (9/12). Run

the test again to verify the results.

TROUBLESHOOTING GUIDE

Electrical

The pump does not operate when turned ON:

• Check the power supply and connections.

Voltage should be between 100 - 130 Vac

for -1 models and between 200 - 240 Vac

for -2 models.

• Check wiring color scheme. See Installation section or call for technical assistance.

Liquid

The pump operates but does not prime:

• Check for a clogged or loose filter on the

suction valve assembly. Retighten if

necessary.

• Check to see if the pump is too high above

the foot valve assembly (HI 721005) in the

feed tank. This vertical distance should not

2322

Page 13

exceed 1.5 meters (5 feet). Either lower the

pump or raise the feed tank.

• Check the pumphead, suction and

discharge valves for blockage.

Pump flow rate is reduced:

• Check the pumphead, discharge and injection valve assembly for any clogging. Clean

and reassemble.

• Check for any additional back pressure created since the last flow rate was conducted.

• Check for any changes in the viscosity of

the chemicals being used. Increase the %

flow by adjusting the Flow Rate control to a

higher setting and run a Flow Rate test.

• Be sure that valves have been properly installed in the pumphead.

Leakage at the connections:

• Be sure that the hose is fully seated and

hose connectors are tight.

• Be sure that valves are tight and O-rings

are in place.

Leakage around the pumphead:

• Be sure that the valves are tight and Orings are in place and the head screws

(hex bolts) are tight.

MAINTENANCE

Your BlackStone Pump is designed to give

you years of trouble-free service. Maintenance should be the preventative type, that

is, periodic cleaning and inspecting for any

damage or leakage.

Cleaning the Suction, Discharge and Injection Valves

Remove the valves from the pumphead,

the injection fitting and the feed.

Keep the suction and discharge valves separated as they are not interchangeable.

Disassemble each valve and clean it with a

neutral liquid. Inspect the PVDF springs.

After cleaning the glass balls, inspect them

for any excessive wear due to abrasion from

the chemical. Replace if necessary with parts

from HI 721102, HI 721103, HI 721104 and

HI 721105.

When reinstalling the valves into the

pumphead, tighten by hand first and then

with a wrench ¼ to ½ turn.

Inspecting the hose (if used as supplied

with the pump)

Inspect to see if the hose has worn out or

weakened due to the chemicals. Pay particular attention for any signs of abrasion or

discoloration. Also check the connectors to

ensure they are tight.

Replace if necessary with parts from HI

720032.

2524

Page 14

Cleaning the Pumphead

The pumphead should be cleaned at regular

intervals and at least once a year. Remove

the deposits that form in the cavities with a

solution that is neutral to the chemical the

pump has been dosing. Inspect the head

for any cracks or worn areas.

Replace if necessary with parts from the

pumphead spare part HI 721106 (for BL7,

BL10, BL15 and BL20) or HI 721107 (for

BL1.5, BL3 and BL5).

SCHEDULED MAINTENANCE

After 50 hours

Tight the pumphead screws with a torque

force of 2.5 Nm (22" lbf).

After 12 months

It is recommended to replace HI 721102, HI

721103 (suction and discharge valves assemblies) as well as the O-rings. The LDPE

hose can also deteriorate over time and, for

safety reasons, should also be changed

with HI 720032.

After 24 months

It is recommended to replace HI 721102, HI

721103, HI 720032 and HI 721106 (for BL7,

BL10, BL15 and BL20) or HI 721107 (for

BL1.5, BL3 and BL5).

CHEMICAL COMPATIBILITY GUIDE

Partial Listing of Chemicals that can be

used with BlackStone Pumps

(Rated for 45°C. For higher temperatures

consult your dealer or nearest Hanna Service Center)

Adipic Acid

Alcohol Amyl

Alcohol, Diacetone

Alcohol, Isopropyl

Alcohol, Methyl

Aluminium, Ammonium Sul-

fate

Aluminium Chloride

Aluminium Sulfate

Alums

Ammonium Carbonate

Ammonium Chloride

Ammonium Fluoride

Ammonium Hydroxide

Ammonium Nitrate

Ammonium Phosphate

Ammonium Sulfate

Aqua Ammonia

Arsenic Acid

Barium Carbonate

Barium Chloride

Barium Hydroxide

Barium Sulfate

Beer

Beet Sugar Liquors

Bismuth Carbonate

Back Liquor

Bleach

Borax

Boric Acid

Bromic Acid

Butyric Acid

Calcium Bisulfite

Calcium Carbonate

Calcium Chlorate

Calcium Chloride

Calcium Hydroxide

Calcium

Hypochlorite

Calcium Nitrate

Calcium Sulfate

Carbonic Acid

Castor Oil

Caustic Soda

Chloral Hydrate

Chromic Acid 50%

Citric Acid

Copper Chloride

Copper Cyanide

Copper Nitrate

Copper Sulfate

Corn Oil

Cottonseed Oil

Cresylic Acid

Crude Oil

Dextrose

Detergents (general)

Diesel Fuel

Dictyl Phthalate

Disodium Phosphate

Ethanol (1-95%)

Ethylene Dichloride

Ethylene Glycol

Fatty Acids

Ferric Chloride

Ferric Nitrate

Ferric Sulfate

Ferrous Chloride

Ferrous Sulfate

Fluoboric Acid

Fluosilicic Acid

Formaldehyde

Fruit Juice Pulp

Fuel Oil

Gallic Acid

Gasoline, Refined

Glucose

Glycerine or Glycerol

Glycolic Acid 30%

Hexane

Hydrazine

Hydrobromic Acid 20%

Hydrochloric Acid (Con-

centrated)

2726

Page 15

Hydrochloric Acid (Diluted)

Hydrofluoric Acid 60%

Hydrogen Sulfide

Aqueous Solution

Hypochlorous Acid

Kerosene

Lactic Acid

Lard Oil

Lauric Acid

Lead Acetate

Linoleic Acid

Linseed Oil

Lithium Salts

Magnesium Carbonate

Magnesium Chloride

Magnesium Hydroxide

Magnesium Nitrate

Magnesium Oxide

Magnesium Sulfate

Maleic Acid

Malic Acid

Mercuric Chloride

Methanol

Methyl Sulfate

Milk

Mineral Oils

Naptha Petroleum

Nickel Chloride

Nickel Sulfate

Nitric Acid 50%

Oils and Fats

Oleic Acid

Olive Oil

Oxalic Acid

Palmitric Acid

Perchloric Acid 70%

Perchloroethylene

Petroleum Oils (sour)

Phenol

Phosphoric Acid

Photographic Solutions

Plating Solutions

Potassium Carbonate

Potassium Bromide

Potassium Chlorate

Potassium Chloride

Potassium Cyanide

Potassium Ferrocyanide

Potassium Hydroxide

Potassium Nitrate

Potassium Permanganate

10%

Potassium Phosphate

Potassium Sulfate

Propyl Alcohol

Propylene Dichloride

Sea Water

Silver Nitrate

Silver Plating Solutions

Soaps

Sodium Acetate

Sodium Bicarbonate

Sodium Bisulfate

Sodium Bisulfite

Sodium Borate

Sodium Chlorate

Sodium Chloride

Sodium Cyanide

Sodium Fluoride

Sodium

Hexametaphosphate

Sodium Hydroxide 50%

Sodium Hypochlorite 18%

Sodium Metaphosphate

Sodium Nitrate

Sodium Peroxide

Sodium Phosphate

Sodium Silicate

Sodium Sulfate

Sodium Sulfide

Sodium Sulfite

Sodium Thiosulfate

Sour Crude Oil

Stannic Chloride

Stannous Chloride

Stearic Acid

Sulfur

Sulfuric Acid Concentration

Sulfurous Acid

Tannic Acid

Tanning Liquors

Tartaric Acid

Tetrachlorethane

Tetraethyl Lead

Tetralin

Tin Salts

Vegetable Oils

Vinegar

Water Acid, Mine

Water, Fresh

Water, Distilled

Water, Salt

Whiskey

Wines

Zinc Chloride

Zinc Sulfate

ACCESSORIES

SPARE PARTS

HI 721102 Discharge Valve

(Glass Ball, Valve O-Ring, Hose

Connector)

HI 721103 Suction Valve (Glass Ball, Valve

O-Ring, Hose Connector)

HI 721003 10 x Glass Balls

10 x Valve O-Rings

HI 721004 Injection Valve Assembly

CHECK

PVDF

SPRING

BALL

VALVE ASSEMBLYINJECTION NIPPLE KYNAR®

HI 721005 Foot Valve Assembly

HI 721006 PVDF Springs, 4 pcs

HI 720032 LDPE Hose - 100 m (330')

Page 16

HI 721008 Ceramic Weights, 4 pcs

HI 721101 Pumphead, O-Ring, 6 screws and

washers

HI 721106 (for BL7, BL10, BL15 and BL20)

Pumphead

Large PTFE Diaphragm

Aluminum Piston

Aluminum Disk

CE DECLARATION OF CONFORMITY

HI 721107 (for BL1.5, BL3 and BL5)

Pump-head

Small PTFE Diaphragm

Aluminum Piston

OTHER ACCESSORIES

HI 731326 Calibration screwdriver (20 pcs)

Recommendations for Users

Before using these products, make sure that they are entirely suitable for the

environment in which they are used.

Operation of these instruments in residential area could cause unacceptable

interferences to radio and TV equipments, requiring the operator to take all necessary

steps to correct interferences.

Any variation introduced by the user to the supplied equipment may degrade the

instruments' EMC performance.

Hanna Instruments reserves the right to

modify the design, construction and appearance of its products without advance notice.

Page 17

SALES AND TECHNICAL SERVICE CONTACTS

Australia:

Tel. (03) 9769.0666 • Fax (03) 9769.0699

China:

Tel. (10) 88570068 • Fax (10) 88570060

Egypt:

Tel. & Fax (02) 2758.683

Germany:

Tel. (07851) 9129-0 • Fax (07851) 9129-99

Greece:

Tel. (210) 823.5192 • Fax (210) 884.0210

Indonesia:

Tel. (21) 4584.2941 • Fax (21) 4584.2942

Japan:

Tel. (03) 3258.9565 • Fax (03) 3258.9567

Korea:

Tel. (02) 2278.5147 • Fax (02) 2264.1729

Malaysia:

Tel. (603) 5638.9940 • Fax (603) 5638.9829

Singapore:

Tel. 6296.7118 • Fax 6291.6906

South Africa:

Tel. (011) 615.6076 • Fax (011) 615.8582

Taiwan:

Tel. 886.2.2739.3014 • Fax 886.2.2739.2983

Thailand:

Tel. 66.2619.0708 • Fax 66.2619.0061

United Kingdom:

Tel. (01525) 850.855 • Fax (01525) 853.668

USA:

Tel. (401) 765.7500 • Fax (401) 765.7575

For e-mail contacts and complete list of Sales and

Technical offices, please see www.hannainst.com

MANBLR2

11/05

Loading...

Loading...