Page 1

instruction manual

X

X

X

E

E

T

T

T

H

H

H

I

I

I

T

T

T

R

AA

C

R

A

R

C

C

O

O

O

A

A

A

N

N

N

K

K

K

K

K

K

O

O

O

H

H

H

REVISION D - MAY 2000

J

J

J

3

3

3

1

1

1

0

0

0

0

0

0

Page 2

- CONTENTS -

PAGE.

INTRODUCTION. 3.

CHARACTERISTICS AND SPECIFICATIONS. 4.

SAFETY. 5.

THEORY OF OPERATION. 7.

APPLICATIONS. 8.

INSTALLATION. 9.

SETTING UP THE HJ3100. 9.

OPTIONS. 10.

OPERATION. 16.

MAINTENANCE. 17.

TROUBLESHOOTING. 18.

WHERE TO GO FOR SERVICE. 19.

APPENDIX A. PARTS AND ACCESSORIES. 20.

APPENDIX B. TECHNICAL INFORMATION. 22.

OUTLINE DRAWINGS. 22.

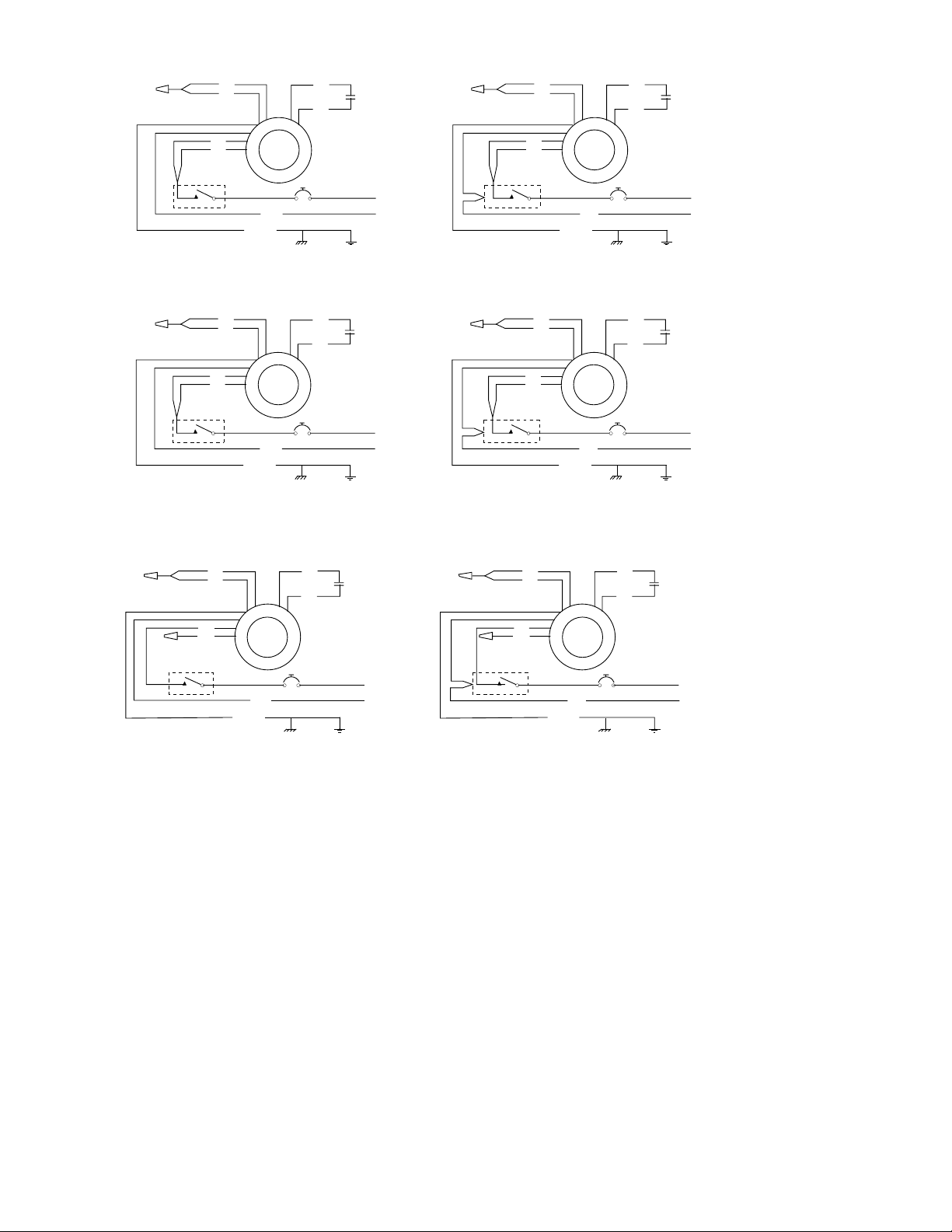

WIRING DIAGRAMS. 23.

APPENDIX C. WARRANTY INFORMATION. 25.

ILLUSTRATIONS AND DIAGRAMS.

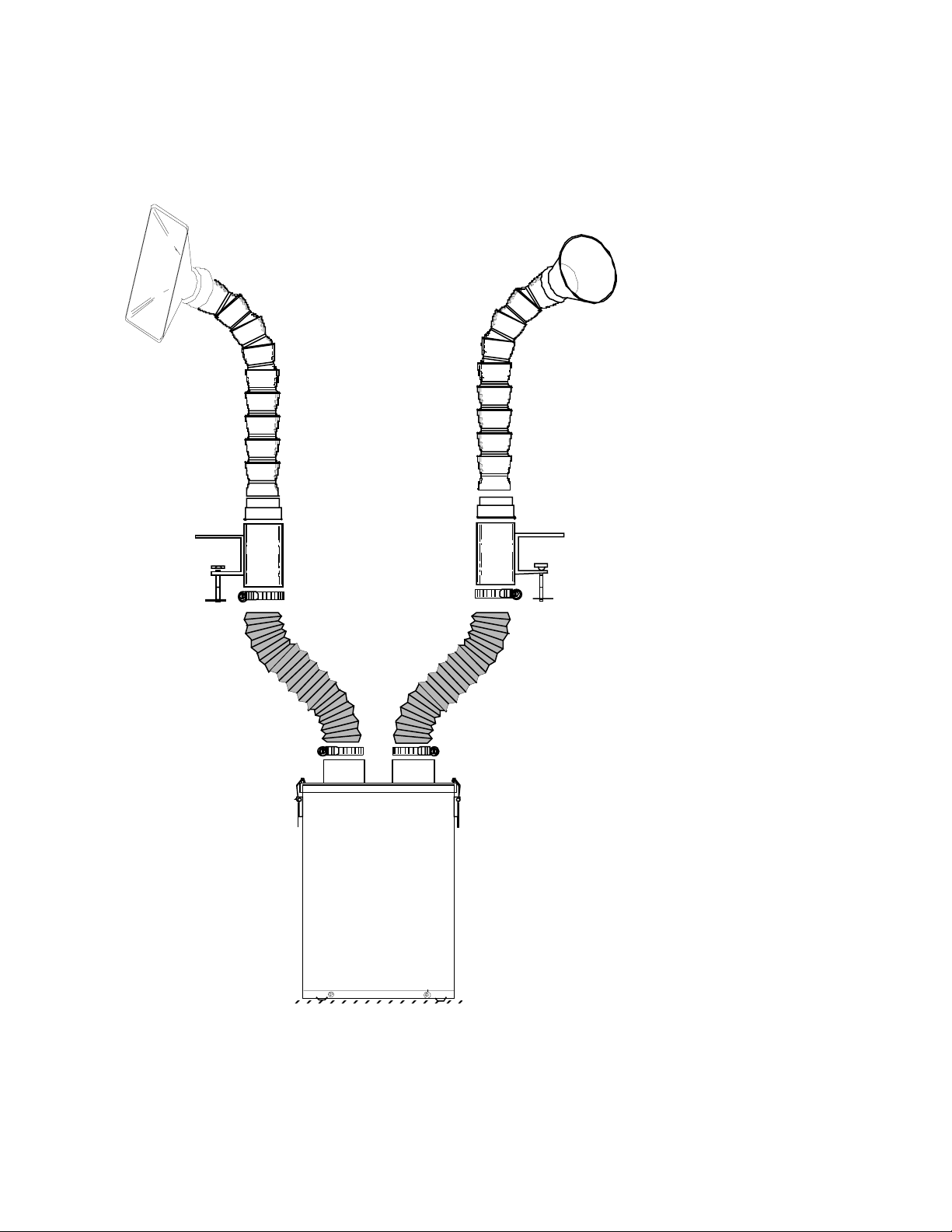

THE HAKKO HJ3100 FRONTISPIECE

FIGURE 1. THE HAKKO FILTER SYSTEM. 7.

FIGURE 2. REQUIRED CLEARANCES FOR INSTALLATION. 9.

FIGURE 3. BASIC HJ3100-02 INSTALLATION. 10.

FIGURE 4. ALTERNATE INSTALLATION - TWO PORT COVER. 11.

FIGURE 5. ALTERNATE INSTALLATION - ARTICULATED HOSES 12.

FIGURE 6. TYPICAL INSTALLATION - FOUR PORT COVER. 13.

FIGURE 7. TYPICAL INSTALLATIONS USING RIGID DUCTING. 14.

FIGURE 8. TYPICAL INSTALLATION - FOUR ARTICULATED ARMS. 15.

FIGURE 9. ILLUSTRATED PARTS BREAKDOWN, HJ3100. 21.

FIGURE B-1. OUTLINE DRAWINGS. 22.

FIGURE B-2. WIRING DIAGRAMS. 23-24.

TABLES.

TABLE I. SPECIFICATIONS, GENERAL. 4.

TABLE II. SPECIFICATIONS, ENVIRONMENTAL. 4.

TABLE A-I. ACCESSORIES. 20-21.

TABLE A-II. ALSIDENT SYSTEM

®1

ACCESSORIES. 21.

TABLE B-I. WIRING DIAGRAM GUIDE. 23.

1 A registered trademark of Alsident System AS, Hammel, Denmark. See figure 7 and table A-II.

©1997, AMERICAN HAKKO PRODUCTS, INC.

all rights reserved

2

Page 3

A

MERICAN HAKKO PRODUCTS, INC. RESERVE THE RIGHT TO CHANGE THE SPECIFICATIONS CONTAINED IN THIS MANUAL

AT THEIR DISCRETION AT ANY TIME

, WITHOUT NOTICE.

For the latest specifications pertaining to the Hakko HJ3100, or any Hakko product, contact your nearest authorized Hakko distributor,

your regional Hakko manager, or American Hakko Products’ Customer Service.

Additional copies of this manual or other Hakko literature may be obtained from:

American Hakko Products, Inc.

Customer Service

25072, Anza Drive

Santa Clarita, California 91355

USA

Telephone: (661) 294-0090 Toll free: (800) 884-2556 Facsimile: (661) 294-0096

E-mail:

Customer Service: support@hakkousa.com

Technical: engineering@hakkousa.com

Marketing: marketing@hakousa.com

3

©1997, AMERICAN HAKKO PRODUCTS, INC.

all rights reserved

Page 4

INTRODUCTION.

Congratulations! You have purchased the most adaptable and efficient small fume extraction system on the market - the Hakko

HJ3100. To get the most out of your system, please read this manual thoroughly before installing and operating the HJ3100.

NOTE.

American Hakko Products strongly recommends that especial attention be given the sections

on ‘Safety and Applications’ and ‘Operation’.

THE PURPOSE OF FUME EXTRACTION.

Soldering work involves both metallic and organic compounds. The solders themselves contain, besides tin and lead, various levels of

zinc, arsenic, cadmium, antimony and other metals. Fluxes necessary for soldering contain activators to enhance their cleaning

properties; these activators are typically organic acids. Such compounds, when heated, release byproducts of incomplete combustion,

which in turn can contain noxious fumes, particulate matter, aerosols, and gasses. Prolonged breathing of these contaminants can lead

to both short- and long-term operator irritations and illness.

THIS MANUAL.

This manual provides the user with the basic information required to properly use and maintain the Hakko HJ3100 fume extraction

system. Spare parts and accessories are described in the Appendix.

THE HAKKO HJ3100.

The Hakko HJ3100 fume extraction unit is designed expressly for use at soldering stations. It extracts the contaminated air directly at

the source. This contributes to a healthier and more productive work environment, and assists in achieving recommended health and

safety requirements for local exhaust ventilation and contaminant removal.

Salient features of the Hakko HJ3100 include:

A heavy-duty, maintenance-free brushless motor adaptable to either 100/125 or 220/230VAC, 50/60 Hz

A three-stage HEPA filtering process

One to four station fume extraction capability

A wide range of accessories (see Appendix A)

©1997, AMERICAN HAKKO PRODUCTS, INC.

all rights reserved

4

Page 5

CHARACTERISTICS AND SPECIFICATIONS.

CONTROLS.

The only control for the HJ3100 is a power switch. The motor is equipped with a thermal overload sensor, which will turn power off

should the motor temperature exceed 160 to 180

0

F. Units manufactured after August 15, 1997 (serial numbers HJ3100-7001 and up)

are fitted with circuit breakers as well.

TABLE I. TECHNICAL SUMMARY.

Characteristic

Input voltage

Current, amperes

Power consumption, watts

Motor power rating, hp

Vacuum pump rating, one port, ft3/min

Motor and blower data.

100 v.

_

115 v._

100 v, 50/60 Hz 115 v, 50/60 Hz 230 v, 50/60 Hz

†

@

4.25

365

1/5

90

3.0

350

1/5

100

1.50

350

1/5

100

230 VX

60 Hz

†

X

With pre-filter and HEPA/carbon filter installed.

Vacuum pump rating, two ports, ft3/min

Vacuum pump rating, one port, ft3/min

Vacuum pump rating, two ports, ft3/min

Fasco 70624794, revn A

†

160

140

260

180

150

280

180

150

280

Noise level at 2 meters: 59 dBA without optional 999-171 muffler

54 dBA with optional 999-171 muffler

Filters:

Pre-filter Per Hakko specification 999-136

HEPA/carbon filter Per Hakko drawing 999-137

Dimensions (all dimensions in inches; see Figure B-1 for outline drawings):

Width 11.00

Depth 9.00

Height 18.00

Weight (approx.) including HEPA/carbon filter 18 lbs.

TABLE II. ENVIRONMENTAL SPECIFICATIONS.

Ambient operating temperature

Storage temperature

Ambient operating humidity

Storage humidity

o

0

to 50o C (32o to 122o F.)

o

-40

to 125o C (-40o to 257o F.)

90% relative humidity maximum (non-condensing)

90% relative humidity maximum (non-condensing)

5

©1997, AMERICAN HAKKO PRODUCTS, INC.

all rights reserved

Page 6

SAFETY.

For maximum operator and workplace safety, as well as optimum performance, be sure to follow all

safety, application and

maintenance instructions and guidelines in this manual. Where material safety data sheets or other relevant information is available

regarding the substances and equipment generating the fumes to be extracted, read them carefully and compare the data contained

therein with the warnings and limitations in this manual.

DISCLAIMER.

American Hakko Products hereby disclaims all responsibility for any personal injury, property

damage, fine, citation, or penalty imposed by any government or private entity resulting from any

use, misuse or misapplication of this product; for any failure of the user to regularly maintain the

product according to the instructions contained herein; or any failure of the user to adequately

monitor fume extraction exhaust air and the ambient workplace air for the presence of harmful

levels of gases, fumes and particulates.

COMPLIANCE WITH APPLICABLE ENVIRONMENTAL AND PERSONNEL SAFETY REGULATIONS IS

THE SOLE RESPONSIBILITY OF THE USER.

WARNING.

FAILURE TO COMPLY WITH THE APPLICATION AND MAINTENANCE INSTR UCTIONS, FILTER

REPLACEMENT SCHEDULES, MONITORING RECOMMENDATIONS AND SAFETY GUIDELINES GIVEN IN

THIS MANUAL, OR WITH OTHER RELEVANT PRODUCT SAFETY INFORMATION SUCH AS MATERIAL

SAFETY DATA SHEETS PROVIDED WITH THE SUBSTANCES AND EQUIPMENT GENERATING THE FUMES

TO BE EXTRACTED MAY RESULT IN RISK OF SERIOUS INJURY, FIRE OR EXPLOSION.

SAFETY GUIDELINES.

WARNING

Fume extraction systems are not to be used as substitutes for personal protective devices such as

respirators for removing substances such as carbon monoxide, methane, ethylene, acetylene and

other potentially hazardous or noxious gases. Failure to use such personal protective devices may

result in serious injury or death. If in doubt, consult your industrial hygienist or American Hakko

Products.

For safe and effective performance, American Hakko recommends these guidelines be followed:

1. HEPA filters - hazardous particulate matter

The filter used in the Hakko HJ3100 is certified to be a 'hospital grade' HEPA-type filter

2

. HEPA (High Efficiency Particulate Air)

filters will become loaded with particulates during normal operation. It must be replaced at regular intervals to ensure proper

operation. The level of use, and the amount and composition of the contaminates peculiar to a given application, will dictate the

frequency of replacement. As the filter becomes loaded, air-flow through the system will be reduced; this will eventually become

noticeable to operators at the several stations being serviced.

The exhaust air from the Hakko HJ3100 and the ambient air in the workplace should be monitored, using appropriate and adequate

measuring and detection devices, to guarantee compliance with applicable OSHA and NIOSH regulations.

2. Particle filters.

American Hakko offers a cellulose particle filter as an option for the HJ3100. This filter is intended for use in grinding and shaping

operations where dust and chips are produced. It is rated at 85% ASHRAE against particles of 1 micron and larger in size. The particle

filter can be cleaned and reused up to five times; the preferred method of cleaning is to vacuum out the detritus with an industrial

vacuum cleaner. It is possible to clean the filter with water or compressed air. If that is the method of choice, take extreme care lest the

debris find its way into the operator's eyes or the local aquifer.

2 Hospital grade filters have efficiencies greater than 95% per MIL-STD-282.

©1997, AMERICAN HAKKO PRODUCTS, INC.

all rights reserved

6

Page 7

3. Activated carbon filters.

The standard filter used in the Hakko HJ3100 contains an activated carbon element built into the filter. It, too, will become saturated

with adsorbed contaminants. The activated carbon portion of the main filter unit is designed to last the life of the main HEPA filter;

however, if the fumes being extracted are other than soldering flux fumes, measuring the exhaust air for the presence of such

contaminants will indicate when this portion of the filter is depleted.

Hakko also offers an activated carbon filter cartridge, part number 999-182, for applications where odor removal is the prime

consideration. This filter should be used with a pre-filter, to keep particles out of the main filter.

Both carbon filters have an adsorption rating of 80-85%.

4. Pre-filters.

The pre-filter is a treated fiberglass pad, rated at 86% arrestance. It removes coarse particles from the intake air. Because it traps these

particles before they can reach the main HEPA/carbon filter, it will become clogged far more rapidly. It will require more frequent

replacement than will the main filter; its useful life depends upon use and the nature of contaminants being removed.

5. Flammable vapors and gases.

If flammable vapors or gases (e. g. isopropyl alcohol used for cleaning) are present in the workplace air, even in small concentrations,

they will be adsorbed by the filters. The user has the responsibility of ensuring that such vapors or gases do not constitute a personnel

hazard.

-DANGER!-

NEVER USE THE HAKKO HJ3100 TO EXTRACT FUMES FROM HIGHLY FLAMMABLE LIQUIDS AND GASES!

THERE IS A SERIOUS RISK OF SEVERE INJURY OR DEATH DUE TO EXPLOSION OR FIRE.

Certain airborne contaminants, when in contact with activated carbon, can undergo chemical reactions resulting in heat. The Hakko

HJ3100 MUST NOT be used to extract fumes from these substances.

6. Disposing of used filters.

All used filters must be handled with care. They may contain hazardous substances such as lead, flux residue, asbestos, organic

compounds, or airborne pollutants extracted from the ambient air. Always use appropriate personal protection equipment (protective

gloves, respirators, and the like) when handling used filters, and dispose of them in plastic containment bags. Local regulations will

dictate the means of disposal.

Filters containing potentially hazardous substances must be handled with extreme caution. Use the material safety data sheet(s)

pertinent to the substance(s) and dispose of such filters per instructions from your local environmental authority.

©1997, AMERICAN HAKKO PRODUCTS, INC.

all rights reserved

7

Page 8

THEORY OF OPERATION.

The HJ3100 is a high-mass flow, low-vacuum system, which means that it depends upon air flow across the work area for effective

fume extraction. Contaminated air is captured from the workplace surrounding the soldering station by the hood or hoods, and

transferred to the HJ3100 by flexible or rigid ducts. Within the HJ3100, two filters, comprising three stages of filtering, remove the

contaminants from the air. The purified air is then returned to the area where the HJ3100 is located.

Because the HJ3100 depends upon mass flow for its operation, free flow of air must be guaranteed between the station where fumes

are to be extracted and the main filter unit. The maximum length of flexible duct recommended for greatest efficiency is 25 feet of

unimpeded 3" duct. The maximum length of rigid duct is not significant, as this duct does not materially restrict air flow.

F

ILTERING.

There are three stages of filtering (Figure 1, below, illustrates the Hakko filtering process):

The pre-filter is made of a treated polyester material. It removes coarse particles, such as dust, that may be suspended in the air,

and thus extends the service life of the HEPA filter. Particles as small as 30 microns diameter are trapped by the pre-filter. It

should be checked at least once a week, and replaced when clogged. Under normal conditions

3

this will be every two to three

weeks.

The main HEPA/carbon filter purifies the air in two ways:

•= The HEPA filter consists of a pleated fiberglass paper medium, thus providing the greatest amount of surface area within the

volume of the filter case. It is rated as a 'hospital grade HEPA filter' - greater than 98% efficiency per the DOP test - and

removes particles as small as 0.3 micron.

•= The activated carbon filter adsorbs gases and odors from the filtered air. Adsorption efficiency is 80%.

•= This filter should be changed every four months or 640 hours of use, whichever comes first.

The carbon filter adsorbs gases and odors from the filtered air at an adsorption efficiency of 84%. It has a much larger

surface area than the carbon portion of the standard HEPA/carbon filter, hence a longer life. It should always be used with a prefilter to preclude being clogged by particulate matter.

incoming

air

incoming

air

incoming

air

pre-filter

pre-filter

exhaust

air

HEPA/carbon

filter

activated

carbon

exhaust

air

activated

carbon

filter

exhaust

air

pre-filter

(optional)

cellulose

filter

Figure 1a

The standard Hakko filter.

The Hakko activated carbon filter

Figure 1b

Figure 1c

The Hakko particulate filter.

3 Normal conditions’ - Defined as single-shift operation, eight hours per day, five days per week.

©1997, AMERICAN HAKKO PRODUCTS, INC.

all rights reserved

8

Page 9

APPLICATIONS.

SOLDERING STATION FUME EXTRACTION.

The Hakko HJ3100 is specially engineered to remove particulate and gaseous contaminants from soldering work stations. As many as

four stations may be serviced by one HJ3100, depending upon the accessories selected. The HJ3100 is a high-mass flow, low-vacuum

system, which means that it uses air flow across the work area for effective fume extraction. The user may choose from the following

options, or mix them at need:

Bench hoods (‘plenums’) for work on printed circuit boards. Both large and small hoods are available.

Supported or free-standing hoods and nozzles for solder pots or small flow systems. These devices may be mounted on either stiff or

flexible ducting. Several types of support hardware and ducting are offered.

Articulated arms for work where flexibility is desired.

Refer to the section on ‘Setup’ for some typical layouts. Appendix A contains descriptions of the accessories available for different

applications.

PARTICULATE EXTRACTION FROM MACHINING OPERATIONS.

The Hakko HJ3100 can be used to remove fine particles and dust from machining and grinding operations, provided that these

particles and dust do not contain, or are not coated by, flammable or corrosive materials. The pre-filter must be checked more

frequently when the HJ3100 is so used.

©1997, AMERICAN HAKKO PRODUCTS, INC.

all rights reserved

9

Page 10

INSTALLATION.

SETTING UP THE HJ3100.

These installation instructions and descriptions are perforce general, because no two installations are the same. The sample

descriptions and diagrams that follow are intended to give the user an indication of the several ways in which the Hakko HJ3100 may

be used. American Hakko Products will be pleased to help you arrive at the appropriate layout and choice of accessories to fit your

requirements.

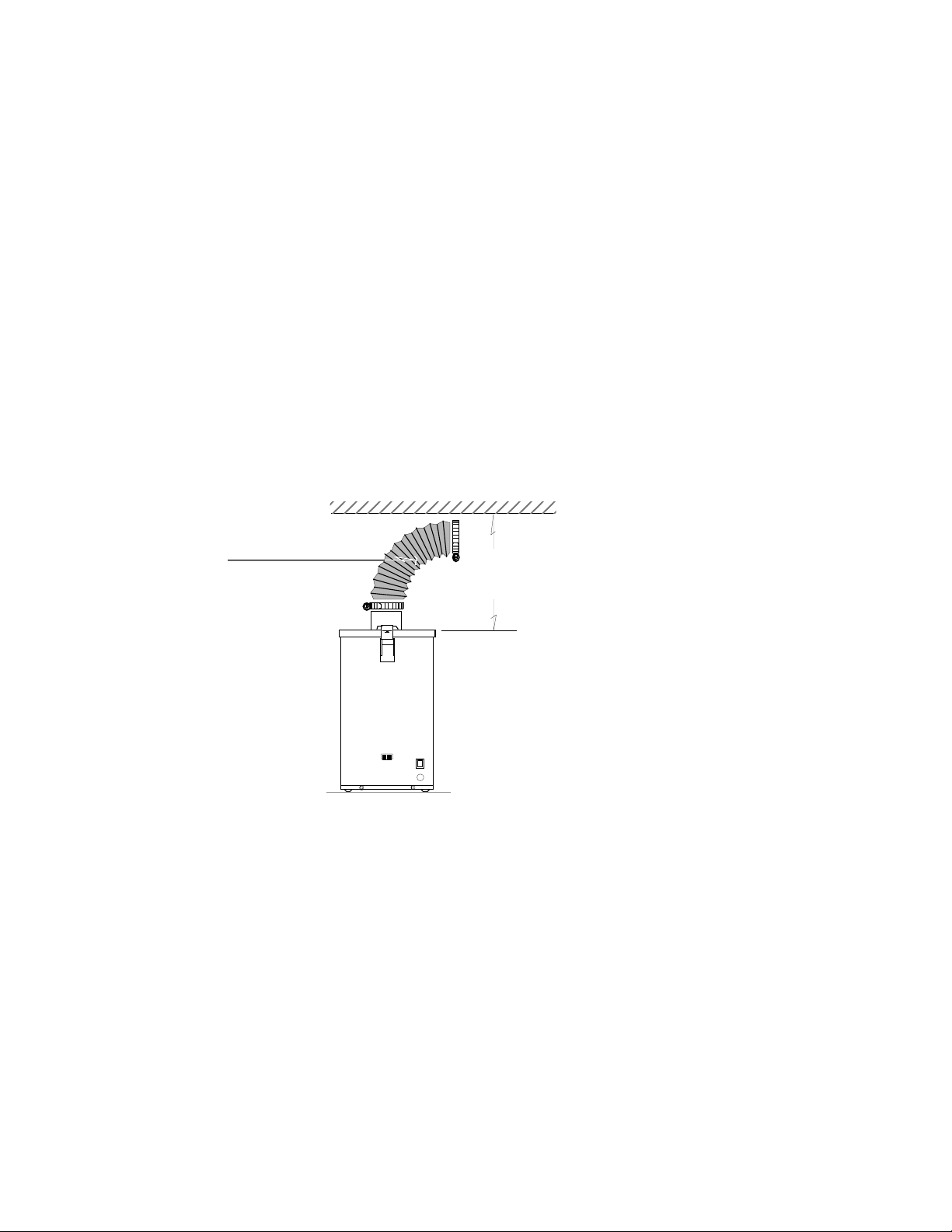

Basic installation.

The Hakko HJ3100 may be installed in any location, and at any orientation, that allows access to the power switch, and to the filters

when servicing is required. Figure 4, below, gives the minimum clearances required for installation. Following is a basic check list.

Before operating the Hakko HJ3100, take note of these simple instructions:

1. Place the Hakko HJ3100 in a convenient location near an appropriate electrical outlet.

2. Ensure that exhaust air from the HJ3100 will not stir up unwanted dust, or adversely affect nearby operations.

3. Allow sufficient clearance to remove the top cover for access to the filters. See figure A-1 for an outline drawing of the unit.

4. Before attaching accessories to, or starting, the HJ3100, remove the top cover and verify that all filters are properly positioned.

5. If noise in the work area is a concern, attach a 999-171 muffler to the exhaust grille of the HJ3100. This will reduce the output noise

by 5 dBA.

Bottom of bench

999-189 3" Neoprene duct

minimum bend radius = 3"

11.5" (two ports)

16" (four ports)

Figure 2.

Required clearances for installation.

10

©1997, AMERICAN HAKKO PRODUCTS, INC.

all rights reserved

Page 11

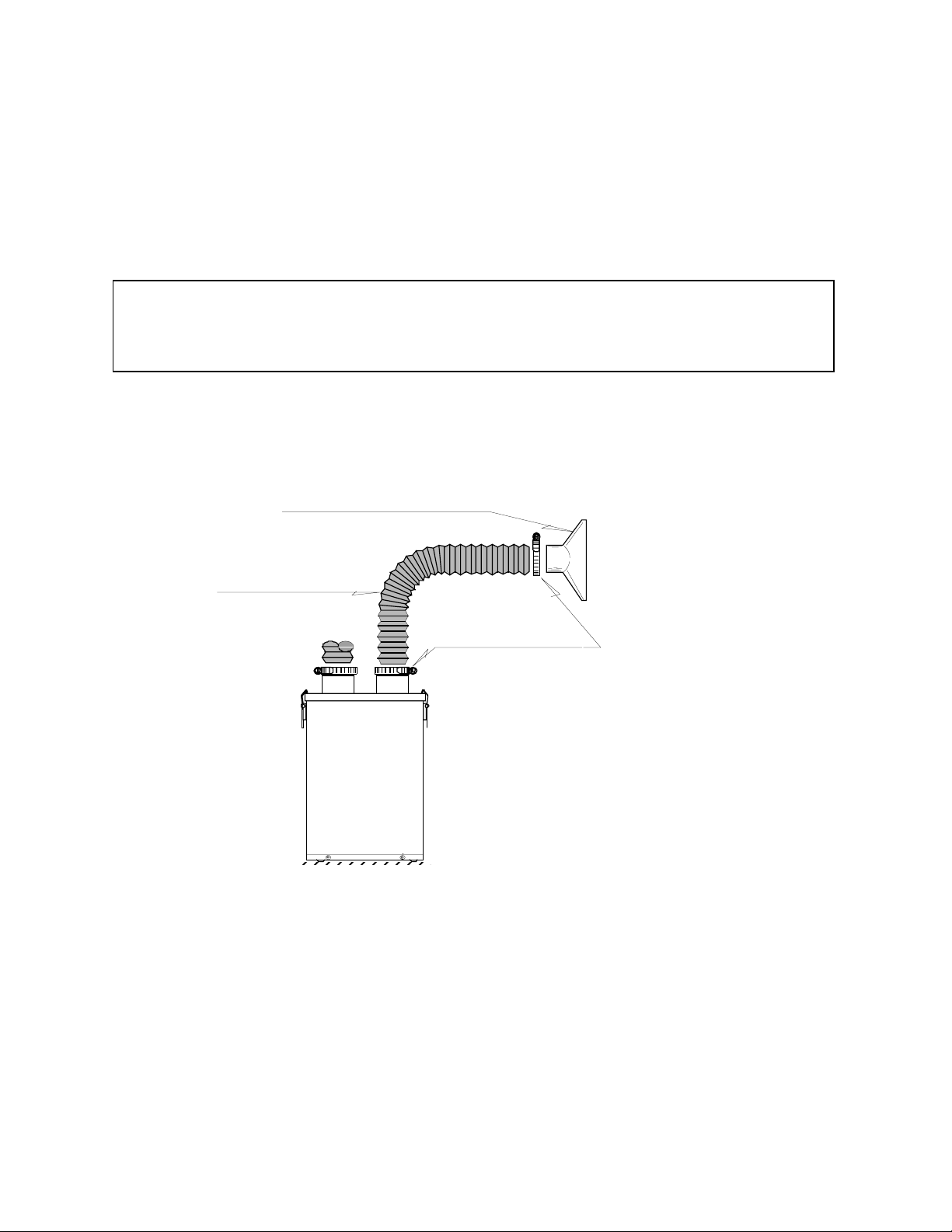

OPTIONS.

The standard HJ3100 comes without any accessories, so the user can select those most suitable to the installation. For most

applications, each port of the HJ3100 can be hooked up as shown in Figure 3, below; this is offered as HJ3100-02. This is a simple

and direct installation providing a good degree of flexibility. American Hakko recommends a maximum of six feet of hose per side for

maximum efficiency, although longer runs may be used effectively.

Figures 4 through 7 show representative applications of several HJ3100 accessories. These illustrations are not meant to be

comprehensive, as Hakko accessories may be combined in many more configurations depending upon the application to hand. Many

other variations are possible; ask your Hakko representative or American Hakko Products for information.

HELPFUL HINTS FOR ALL INSTALLATIONS.

1. Be sure that all hose clamps (e. g. 999-169) are firmly tightened.

2. Be sure that all bench clamps (e. g. 999-188) are firmly tightened.

3. Be sure that all hoods are securely attached to their respective ducts.

4. If reducers are used (e.g. Fig. 7), put them as close as possible to the air intake (hood or other attachment).

Electrostatic discharge protection.

Although the probability of electrostatic discharge from the Hakko HJ3100 fume extraction system is small, many ESD-safe

accessories are provided for use where such protection is a concern. They are noted in Tables A-I and A-II, Appendix A, AS ‘ESD’.

As these accessories are conductive, setting up requires that there be no break in the circuit from the collecting device to the main

body.

999-138 rectangular hood (standard)

3" I. D. duct

999-147 light flex

HJ3100

999-169 hose clamp

2 places per side as shown

Figure 3.

Basic HJ3100-02 installation.

One side shown.

11

©1997, AMERICAN HAKKO PRODUCTS, INC.

all rights reserved

Page 12

Figure 4.

Alternate installation - two port cover with bench clamps.

Figure 4.

An alternate installation -

two port cover using optional bench clamps.

999-151 benchtop hood

999-169 hose clamps

999-189 3" neoprene duct

three feet per side nominal

999-169 hose clamps

999-188 bench clamp

with coupler

999-169 hose clamps

999-189 3" neoprene duct

three feet per side nominal

999-169 hose clamps

HJ3100

©1997, AMERICAN HAKKO PRODUCTS, INC.

all rights reserved

12

Page 13

999-196 rectangular hood (L)

999-195 round hood (R)

999-194 2.5" articulated hose

three feet per side nominal

999-197 adapters

999-188 bench clamp

with coupler

999-169 hose clamps

999-189 3" neoprene duct

three feet per side nominal

999-169 hose clamps

HJ3100

Figure 5.

Using articulated ESD-safe hose and hoods.

©1997, AMERICAN HAKKO PRODUCTS, INC.

all rights reserved

13

Page 14

NOTE:

999-152 3" ESD duct may be substituted.

1

Figure 6.

Typical installation - four port cover.

The most popular application of the four-port cover uses the small bench-top hoods, as shown here. Any other 3" accessories may be

used, save the large bench-top hoods, as the air flow with four such hoods will be marginal.

999-168 benchtop hood

('mini-plenum')

999-169 hose clamps

999-189 3' neoprene duct

Maximum length, each: three feet

999-169 hose clamps

999-188 bench clamp

with coupler

999-169 hose clamps

999-152 3" ESD flex duct

Maximum length, each: three feet

999-169 hose clamps

999-173 four 3" port cover

HJ3100

1

©1997, AMERICAN HAKKO PRODUCTS, INC.

all rights reserved

14

Page 15

Figure 7.

Typical installation(s) using rigid ducting.

Rigid ducting is used when a nominally free-standing fume hood is desired. The duct/hood combination will remain in place without

the need for holding brackets. American Hakko offers two types of rigid ducting, as shown above.

999-167 2" suction tube (L)

999-153 round hood (R)

999-636 hose clamps (L)

999-169 hose clamps (R)

999-186 2" stainless steel duct (L)

999-144 stiff flex duct (R)

999-177 bench clamp

with reducer (L)

999-188 bench clamp

with coupler (R)

999-169 hose clamps

999-152 3" ESD flex duct

Maximum length, each: three feet

999-169 hose clamps

999-173 four 3" port cover

HJ3100

©1997, AMERICAN HAKKO PRODUCTS, INC.

all rights reserved

15

Page 16

999-164 articulated arms

(nozzles not shown - see table A-II)

999-165 bench mount brackets

999-636 hose clamps

999-150 2" ESD flex duct

one foot

999-636 hose clamps

999-163 3" to 2" reducer

999-169 hose clamps

999-189 3" neoprene duct

(two feet max.)

999-169 hose clamps

999-173 four 3" port cover

HJ3100

This illustrates the Alsident System

Figure 8.

®

articulated arms (see footnote on page 1). Nozzles are not shown; refer to Table A-II for options.

Typical installation - four articulated arms.

©1997, AMERICAN HAKKO PRODUCTS, INC.

all rights reserved

16

Page 17

OPERATION.

Operating the HJ3100 is simplicity itself. Merely plug it in, turn it on, and place the ducts and hoods as required for the work station.

No adjustment is necessary. The extractors, hoods and ducts are designed to efficiently remove soldering fumes, dust, particles and

odors.

Although the Hakko HJ3100 is one of the safest pieces of equipment available, we should like to apprise you of the following:

These basic safety measures must be observed to prevent shock, injury or fire when

using electrical devices:

Read these instructions thoroughly before operating the Hakko HJ3100.

Do not use this unit to extract flammable or explosive gases.

Do not use this unit to extract corrosive materials other than those found in solders and

fluxes.

Do not expose the power cord to heat, oil or sharp edges.

Make sure the main unit is stable and secure.

Always switch the Hakko HJ3100 OFF before opening the lid.

Use only HAKKO replacement filters.

Protect the main unit from moisture.

Do not use the HJ3100 to extract water, water vapor or steam.

CAUTION.

©1997, AMERICAN HAKKO PRODUCTS, INC.

all rights reserved

17

Page 18

MAINTENANCE.

The filters are the only parts of the HJ3100 that need maintenance. Figure 9, below, shows the major parts of the HJ3100.

Top cover

Case

Pre-filter

Main filter

Bottom cover, with feet

Blower

Motor

Power switch

Circuit breaker

Motor support

Power cord hole

Figure 9.

Illustrated parts breakdown, Hakko HJ3100.

FILTERS.

The pre-filter should be checked every day under normal operating conditions, and replaced when dirty.

The HEPA/carbon filter, or activated carbon filter, should be replaced every four months, or 640 hours, in normal use. ‘Normal

use’ is defined as single shift 40-hour week operation.

CAUTION

THESE FILTERS CANNOT BE CLEANED.

Do not attempt to clean the pre-filters, HEPA/carbon filters, or activated carbon filters for reuse.

Cleaning the filters will only damage them severely and render them useless. This, in turn, will

result in unfiltered air being returned to the environment. Unfiltered air can also damage the

motor.

The particulate filter can be cleaned and reused. It is not necessary to use a pre-filter with the particulate filter. Intervals

between cleanings may vary with the application; a good sign that the filter wants cleaning is a loss of air-flow through the

pickup accessory. Recommended methods of cleaning are, in order: 1) Vacuum out the débris with a shop vacuum; 2) Blow the

accumulated material out with clean dry air; 3) Wash the filter in clean water. If either 2) or 3) is chosen, eye protection is

suggested, and the waste must be disposed of according to local regulations.

Hoods and ducts.

Hoods and ducts should be cleaned periodically to remove accumulated residue. Isopropyl alcohol is recommended for this.

The ducts usually require cleaning every four months due to build-up of flux and solder residue inside them. This will become

evident to the eye. Inspect flexible ducts for cracks and change them when necessary.

The plastic ‘stiff flex’ duct, 999-144, may loosen over time and fail to maintain its position. This condition usually obtains after

the duct has been adjusted many times. Should this happen, compress and tighten the duct as follows:

Compress the duct by pressing down from the top (where the hood is) toward the bottom.

Tighten the duct by twisting the base counterclockwise.

Set to the desired position.

18

©1997, AMERICAN HAKKO PRODUCTS, INC.

all rights reserved

Page 19

TROUBLE-SHOOTING.

Those occasions when trouble-shooting might be required are rare. However, if certain conditions occur, you may refer to this section.

The conditions requiring your attention are:

1. The unit quits running. The power switch is on but nothing happens.

a. The motor has overheated. The overtemperature switch will keep it from operating until it has cooled down. This is usually

30 minutes. Meanwhile, you can:

i. Check each station. Make sure that the pickup ducts are not blocked.

ii. Check the air outlets at the bottom and side of the HJ3100 unit. Make sure they are not blocked.

b. There is an electrical problem that has caused a fuse to blow. There is a fuse in the motor/blower unit; later models also have

a circuit breaker on the case.

i. If the circuit breaker has blown (the reset button is exposed), DO NOT reset until you have checked the wiring for shorts

or other defects, including the inadvertent intrusion of foreign objects.

ii. Turn the HJ3100 OFF and remove the power plug from the receptacle. See the wiring diagrams in Appendix B to verify

integrity of the wiring (that loose wires, disconnected wires, broken wires &c do not exist).

2. The unit runs but does not have any air flow.

a. A station (or stations) is (are) blocked.

i. See 1 i, ii above.

ii. Inspect all flexible ducts. Make sure they are not kinked, blocked, or pinched. If they are, correct the situation or replace

the ducts.

iii. Inspect the hoods. Make sure they are not blocked or plugged.

b. There is an opening in the setup, allowing air to enter the unit.

i. Inspect all connections. Tighten or reset where necessary.

c. The blower wheel has come adrift from the motor shaft. This has been simulated during test and is exemplified by a marked

change in the sound coming from the HJ3100. Instead of the steady whirr of a properly operating unit, it will be a high-pitched whirr

accompanied by clanking noises. Should this be suspected:

i. Turn the HJ3100 OFF and remove the power plug from the receptacle.

.

ii. Set the main body on a bench and remove the screws holding the bottom cover.

iii. Remove the bottom cover.

iv. Inspect the assembly for structural integrity.

If the blower is loose, close the unit and return it to your Hakko distributor for repair.

d. The motor/blower does not turn. This becomes evident when there is no air flow and the sound made by the HJ3100 is a

hum. If this is suspected, return the HJ3100 to your Hakko distributor for repair.

3. If you encounter a problem that defies solution by these means, call your Hakko representative.

DO NOT ATTEMPT TO OPEN THE HJ3100 WITH POWER APPLIED.

YOU ARE EXPOSING YOURSELF TO SERIOUS INJURY OR DEATH.

WARNING!!

©1997, AMERICAN HAKKO PRODUCTS, INC.

all rights reserved

19

Page 20

WHERE TO GO FOR SERVICE.

American Hakko Products offers design and installation assistance for HJ3100 customers. Our staff is available to aid you in all

aspects of fume extraction.

Should your Hakko HJ3100 ever need service, your local Hakko Representative should be able to meet all your needs. For direct

assistance, call Customer Service at American Hakko Products:

Telephone: (661) 294-0090

Toll free: (800) 88-HAKKO (884-2556)

Facsimile: (661) 294-0096

E-mail:

Customer Service: support@hakkousa.com

Technical: engineering@hakousa.com

Marketing: marketing@hakkousa.com

©1997, AMERICAN HAKKO PRODUCTS, INC.

all rights reserved

20

Page 21

APPENDIX A: PARTS AND ACCESSORIES.

TABLE A-I. - ACCESSORIES FOR THE HJ3100.

In keeping with American Hakko Products’ continuing dedication to product excellence, these accessories may be changed in form,

fit, or function at any time. The following accessories are offered for use with the Hakko HJ3100:

D

ESCRIPTION

PRE-FILTER

Pack of five

PART NO.

999-136

DESCRIPTION

HOOD, bench top,

large (‘plenum’)

Clear

PART NO.

999-146

999-151

ESD

18.5" x 6.5" x 7.5"

FILTER

HEPA/carbon

Particle

Activated carbon

COVER,

3" x 2 port

3" x 4 port

ESD

999-137

999-178

999-182

999-172

999-173

HOOD, bench top,

small (‘miniplenum’)

ESD only

9.0" x 4.5" x 5.5"

DUCTING4

2" esd

3" light flex

3" medium flex

3" stiff flex

3" esd

3" neoprene (esd)

2" stainless

999-168

999-150

999-147

999-145

999-144

999-152

999-189

999-186

steel(esd)

HOOD,

rectangular,

999-138

MUFFLER

999-171

3" x 8"

ESD

HOOD, round

6" diameter

ESD

999-153

BENCH CLAMP

with 3" to 2"

reducer

999-177

ESD

CLAMP, hose

2.5"

3.5"

ESD

999-636

999-169

BENCH CLAMP

with 3" coupler

999-188

ESD

BRACKET,

hood

free-standing

999-159

Reducer, round

3" to 2" plastic

3.5"

ESD

4 999-189 ducting is sold in 6’ lengths only. All other ducting is sold by the foot.

©1997, AMERICAN HAKKO PRODUCTS, INC.

all rights reserved

999-163

21

Page 22

APPENDIX A: PARTS AND ACCESSORIES.

TABLE A-I. - ACCESSORIES FOR THE HJ3100 (CONTINUED)

In keeping with American Hakko Products’ continuing dedication to product excellence, these accessories may be changed in form,

fit, or function at any time. The following accessories are offered for use with the Hakko HJ3100:

D

ESCRIPTION

HOSE,

articulated

2.5" I. D.

ESD

NOZZLE,

rectangular

6" x 3.5"

ESD

PART NO.

999-194

999-196

DESCRIPTION

NOZZLE, round,

4.5"

ESD

ADAPTER, duct

Sheet metal

ESD

PART NO.

999-195

999-197

22

©1997, AMERICAN HAKKO PRODUCTS, INC.

all rights reserved

Page 23

TABLE A-II.

®

ACCESSORIES.

The following Alsident System 50

ALSIDENT SYSTEM

®

ESD-safe accessories are available for use with the Hakko HJ3100. Alsident extractor hoods are

designed on the Coanda principle of laminar flow, which makes them highly efficient. Alsident extractor arms may be set and locked

in place. These accessories are available in 2" diameter only.

D

ESCRIPTION

HAKKO

PART NO

ESCRIPTION

D

.

HAKKO

PART NO

.

ARM,

articulated

NOZZLE,

suction,

8"

HOOD, clear,

polycarbonate,

11" x 12"

999-164

999-166

999-170

BRACKET, bench

999-165

TUBE, suction, 8.25"

999-167

23

©1997, AMERICAN HAKKO PRODUCTS, INC.

all rights reserved

Page 24

APPENDIX B.

TECHNICAL INFORMATION.

Outline drawings.

Figure B-1 is a dimensioned outline drawing of the Hakko HJ3100.

9.00

11.00

1.75

15.50

0.25

Figure B-1.

Outline drawings, HJ3100.

Shown with standard cover, 999-172

©1997, AMERICAN HAKKO PRODUCTS, INC.

all rights reserved

24

Page 25

WIRING DIAGRAMS.

Several motors have been used in the Hakko HJ3100. Table B-I correlates the motor types and unit serial numbers with the wiring

diagrams which follow, and indicate which diagrams refer to the versions with illuminated switches.

Motor types used are:

Fasco 70624xxx: 115 volt, 50/60 Hz only. Motor A. Prototype and pre-production only.

Fasco 70624356: 100 volt or 115 volt, 50/60 Hz, depending upon wiring. Motor B.

Fasco 70624794 rev. A: 100/115 volt or 230 volt, 50/60 Hz, depending upon wiring. Motor C.

The list of characteristics and specifications pertaining to each version may be found on page 5.

TABLE B-I.

WIRING DIAGRAM RESOLUTION.

PLAIN SWITCH B-2a

ILLUMINATED

MOTOR A

n/a

MOTOR B 100 V

B-2c

B-2d

MOTOR B 115 V

B-2e

B-2b, B-2f

MOTOR C 100/115 V

B-2g

B-2h

MOTOR C 230 V

B-2j

B-2k

SWITCH

SWITCH.

SWITCH.

21

BLK

3

M

BLK

GRN

WHT

LINE.

BLK

WHT

21

BLK

M

GRN

WHT

LINE.

Figure B-2a. Figure B-2b.

SWITCH.

12

BLK

RED

5 a. (some units)

M

BLK

GRN

WHT

LINE.

SWITCH.

3

12

BLK

RED

WHT

5 a. (some units)

M

BLK

GRN

WHT

LINE.

Figure B-2c. Figure B-2d.

25

©1997, AMERICAN HAKKO PRODUCTS, INC.

all rights reserved

Page 26

a

a

a

wht

power

switch

123

blk

blu

orn

red

red

wht

grn/yel

M

5

brn

3 mfd. 370 Vac c

brn

circuit breaker

blk

LINE

orn

red

blk

blu

power

switch

12

red

grn/yel

M

wht

brn

brn

circuit breaker

blk

5

3 mfd. 370 Vac cap

LINE

Figure B-2e. Figure B-2f.

wht

power

switch

123

blk

blu

orn

red

red

wht

grn/yel

M

5

brn

3 mfd. 370 Vac c

brn

circuit breaker

blk

LINE

orn

red

blk

blu

power

switch

12

red

grn/yel

M

wht

brn

brn

circuit breaker

blk

5

3 mfd. 370 Vac cap

LINE

Figure B-2g. Figure B-2h.

wht

blu

red

blk

orn

power

switch

1

2

red

wht

grn/yel

M

5

brn

3 mfd. 370 Vac cap

brn

circuit breaker

blk

LINE

power

switch

123

blu

red

blk

orn

M

red blk

wht

grn/yel

brn

brn

circuit breaker

5

3 mfd. 370 Vac c

LINE

Figure B-2j. Figure B-2k.

26

©1997, AMERICAN HAKKO PRODUCTS, INC.

all rights reserved

Page 27

APPENDIX C.

WARRANTY.

American Hakko Products, Inc. warrants that all products sold to a buyer will be of new materials and free from defects in material or

workmanship for a period of ninety (90) days.

The validity of requests for warranty repairs or exchanges will be determined by American Hakko Products only.

P

OWER SUPPLY ELECTRONICS

Not applicable to the HJ3100.

H

EATING ELEMENTS

Not applicable to the HJ3100.

A

LL OTHER ITEMS

All other items, excluding fuses and circuit breakers, are subject to a ninety (90) day warranty covering materials and workmanship.

P

ROCEDURES FOR WARRANTY HANDLING

Repairs will be conducted at and by:

American Hakko Products, Inc.

25072, Anza Dr.

Santa Clarita, California 91355

Telephone: (661) 294-0090

Facsimile: (661) 294-0096

All users of this equipment or parts thereof under the terms of this warranty must obtain a Return Authorization number (RA) from

American Hakko Products before the equipment is returned. American Hakko will not accept shipments for repair or warranty service

without this number. The sender is responsible for all shipping charges. The buyer of the equipment is solely responsible for providing

complete and correct information on the equipment being returned.

27

©1997, AMERICAN HAKKO PRODUCTS, INC.

all rights reserved

Page 28

AMERICAN HAKKO PRODUCTS MEET OR EXCEED ALL APPLICABLE

MILITARY AND CIVILIAN SPECIFICATIONS, INCLUDING

MIL-STD-2000B. J-STD-001B,

AND IPC-A-610.

©2000, AMERICAN HAKKO PRODUCTS, INC.,

A

LL RIGHTS RESERVED.

®

AMERICAN HAKKO PRODUCTS, INC.

25072 Anza Dr., Santa Clarita, Calif. 91355, USA

Voice: 661-294-0090 Facsimile: 661-294-0096

Toll free: 1-800-88-HAKKO (884-2556)

www.hakkousa.com

M-1004

Loading...

Loading...