Page 1

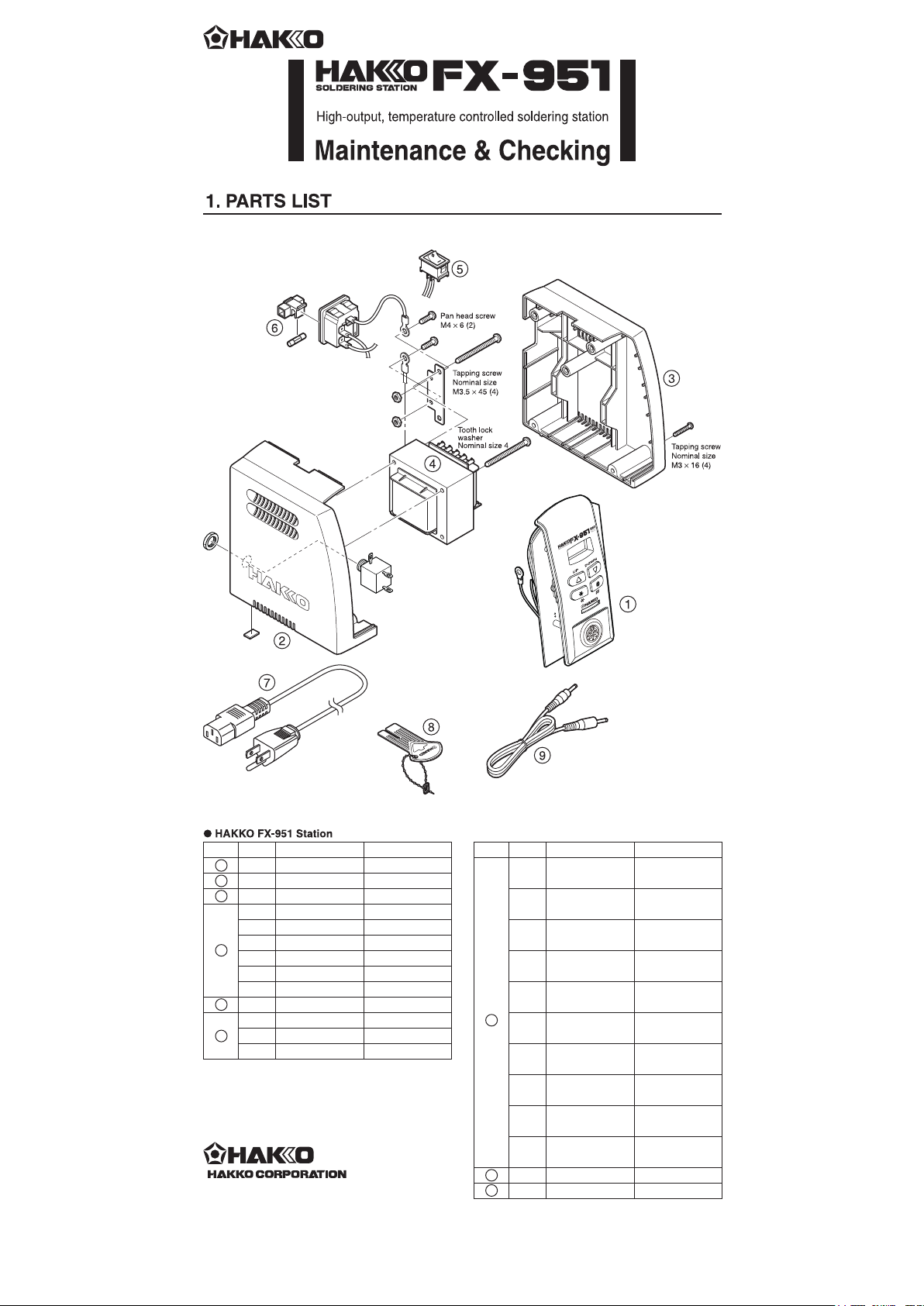

Item No.

Part No.

1

B3732

2

B3255

3

B2978

B2979

B2983

B2836

4

B2984

B2985

B3067

5

B2852

B2403

6

B3011

B2987

HEAD OFFICE

TEL:+81-6-6561-3225 FAX:+81-6-6561-8466

http://www.hakko.com E-mail:sales@hakko.com

Please access to the following address for the other Sales affiliates.

Part Name

Front panel assy.

Case/Left

Case/Right

Transformer

Transformer

Transformer

Transformer

Transformer

Transformer

Power switch

Fuse/250V-2A

Fuse/250V-2A

Fuse/250V-1A

Specifications

With rubber feet

With rubber feet

100V

110V

120V

220V

230V

240V

100-110V

120V

220-240V

http://www.hakko.com

© 2005-2015 HAKKO Corporation. All Rights Reserved.

Item No.

7

8

9

Part No.

B2419

Power cord, 3-wire

cord & American plug

B2421

Power cord, 3-wire

cord but no plug

B2422

Power cord, 3-wire

cord & BS plug

B2424

Power cord, 3-wire

cord & European plug

B2425

Power cord, 3-wire

cord & BS plug

B2436

Power cord, 3-wire

cord & Chinese plug

B2426

Power cord, 3-wire

cord & Australian plug

B3508

Power cord, 3-wire

cord & American plug

B3550

Power cord, 3-wire

cord & SI plug

B3616

Power cord, 3-wire

cord & BR plug

B2972

Control card

B3253

Connecting cable

Part Name

Specifications

120V USA

India

220V KTL

230V CE

230V CE

China

MA01442XZ150501

2015.5

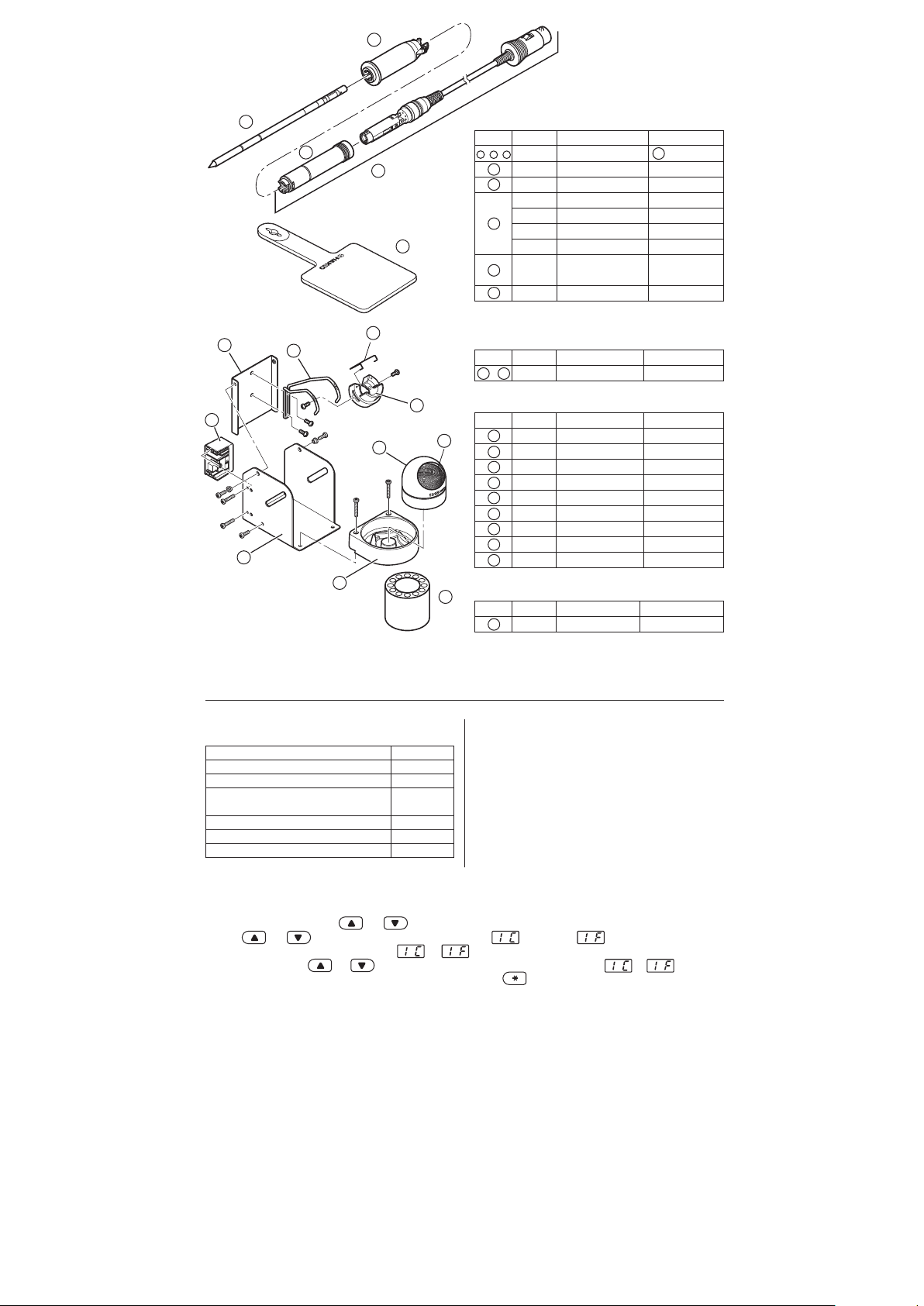

Page 2

3

4

2

1

5

6

7

4

3

2

1

8

5

●

Item No.

1 , 3 , 5

●

Item No.

●

Item No.

9

●

1

Item No.

HAKKO FM-2027

Part No.

FM2027-01

1

FM2027-02

2

B3215

B3216

B3217

3

B3218

B3219

4

5

B2300

Iron Holder

Part No.

-

1 9

FH200-01

Iron Holder Parts

Part No.

1

B3001

2

B2791

3

B3248

4

B3251

5

B3249

6

B3250

7

B3252

8

599B-02

599-029

9

Tip tray

Part No.

1

B2756

Part Name

Conversion kit

Connector assembly

Connector cover

Sleeve assembly

Sleeve assembly

Sleeve assembly

Sleeve assembly

Tip

Heat resistant pad

Part Name

Iron holder

Part Name

Iron receptacle

Tip fixing spring

Holder for iron receptacle

Iron holder base

Cleaner base

Stay

Switch case assembly

Tip cleaner

Cleaning wire

Part Name

Tip tray

Specifications

3

is yellow

Yellow

Orange

Blue

Green

See back page:

'TIP STYLES'

Specifications

With 599B

Specifications

With screws

With rubber feet

With rubber feet

Specifications

2. PARAMETER SETTINGS

The HAKKO FX-951 comes from the factory with

the following values preset.

Temperature scale

Power save

Low temperature alarm setting

Resetting the supervisor or

operator control setting

Setting temperature

Buzzer setting (C-E sound, S-E sound)

Buzzer setting (Set temperature alert)

Fahrenheit

0 min.

300°F

4 0

750°F

ON

ON

● Entering the parameter

1 °C or °F temperature display

1. Turn power OFF.

2. Insert the control card into the card slot in the front of the unit.

3. Press and hold down the and buttons simultaneously, and then turn power ON.

4. Hold and buttons down until the display shows (Celsius) or (Fahrenheit).

When either the display shows either or , the station is in parameter input mode.

● Pressing either the and button will cause the display to alternate between or .

● When the desired scale is displayed, select by pressing the button. The system will automatically

sequence to power save mode.

The HAKKO FX-951 has the following six parameters:

1) °C or °F temperature display selection

2) Power save

3) Low temperature alarm setting

Resetting the supervisor/operator control setting

4)

5) Buzzer setting (C-E sound, S-E sound)

6) Buzzer setting (Set temperature alert)

Once the station enters parameter mode, set the parameters

in the order shown below. After all the parameters have been

set, normal operation will be resumed.

Page 3

2 Power save setting

Set the time from the placement of the soldering iron on

the iron holder to the activation of the sleep function.

NOTE:

When not using the power save function, do

not connect the iron holder and the soldering

station with the connecting cable.

Power save example:

2 0 Sleep (immediately after the soldering iron

is placed on the iron holder)

210 Sleep (10 minutes after the soldering iron is

placed on the iron holder)

230 Auto-power shutoff (30 minutes after the

soldering iron is placed on the iron holder)

NOTE:

The power save time can be set in steps of

one minute (30 minutes max.)

●

When the sleep function is activated, the temperature

of the tip begins to drop.

●

When the display shows , pressing any button

When the station enters the parameter input mode,

the procedure is as follows.

Press the button once.

The power save function

Press the button

(10 times).

Press the button once.

Press the button

(20 times).

Press the button once.

works immediately after

the soldering iron is

placed on the iron holder.

When 10 minutes have elapsed since

the soldering iron was placed on the

iron holder, the temperature drops to

200°C/400°F automatically and the

station enters the power save mode.

When 30 minutes have elapsed since

the soldering iron was placed on the

iron holder, power to the heater will

be automatically shut off (auto power

shutoff).

the power will be turned on again.

NOTE:

The sleep function does not work in case the setting temperature is less than 300°C/570°F.

●

When the auto-power shutoff function is activated and power to the heater is shut off, the buzzer sounds three times.

●

When the display shows , and to begin soldering, cycle the power switch OFF, then ON.

3 Resetting the low temperature alarm tolerance setting

The unique function alerts the operator when the sensed temperature drops below

a set limit. Should this occur, an error message will be displayed, and the buzzer

will sound continuously. When the temperature returns within the allowable range,

the buzzer will stop.

1.

When the station enters low-temperature alarm tolerance setting mode, the hundreds digit begins flashing. Enter and store

the value in the same manner as described in “Changing the temperature setting.”

2.

If you enter a value exceeding the allowable range shown to the left, you will be brought back to entering a value in the

hundreds digit. If this occurs, reenter a correct value.

3.

Once the value is stored, the system will automatically sequence to resetting the supervisor/operator control setting mode.

Range of allowable low

temperature alarm tolerance

for ℃: 30 - 150℃

for ℉: 50 - 300℉

Example:

When the setting temperature is 350°C and the low temperature alarm tolerance is 100°C, buzzer will sound when the

tip temperature will drop over 250°C.

4. Resetting the supervisor/operator control setteing

To change the supervisor/operator control settings, the procedure is as follows.

● The display will show or when this mode is entered.

: No offset value can be entered without inserting the card.

: An offset value can be entered without inserting the card.

Pressing the or button will change and .

When the desired setting is displayed, select by pressing button.

5. Buzzer setting (C-E sound, S-E sound)

● In the buzzer sound setteing mode, which sets whether to sound the buzzer when a sensor error or

soldering iron error occurs, or is displayed.

: The buzzer does not sound.

: The buzzer sound

Select or and press the button.

6. Buzzer setting (Set temperature alert)

● In the buzzer sound setteing mode, which sets whether to sound the buzzer when a sensor error or

soldering iron error occurs, or is displayed.

: The buzzer does not sound.

: The buzzer sound

Select or and press the button.

The system will exit the parameter setting mode and begin heater control.

It is now ready for normal operation.

Page 4

3. CHECKING PROCEDURE

FM-2027

FM-2027

4. ERROR MESSAGES

● Sensor Error

●

Low-temperature alarm tolerance error

EXAMPLE:

350°C (400°C – 50°C)

Set temperature

Set temperature Low-temperature

●

Heater terminal short-circuit error

Low-temperature

alarm tolerance

OR

650°F (750°F – 100°F)

alarm tolerance

● Soldering iron error

When there is the possibility that a failure has occurred in the sensor or

heater (including the sensor circuit), is displayed and the power is

shut down.

The sensor error also occurs if the tip is not inserted properly.

If the sensor temperature falls below the difference between the current

temperature setting and the low-temperature alarm tolerance, is

displayed and the warning buzzer sounds. When the tip temperature

rises to a value within the set tolerance, the buzzer will stop sounding.

EXAMPLE:

Assume that the temperature setting is 400°C/750°F and the

tolerance 50°C/100°F. If the temperature continues to decrease and

finally falls below the value indicated below while the heating element

is on, the displayed value starts blinking to indicate that the tip

temperature has dropped.

will flash, and the buzzer will sound continuously, when the tip is

inserted wrong way round, an incompatible tip is inserted, or a foreign

object has found its way into the connector.

will be displayed if the connector cord is not attached to the

station OR the wrong soldering iron is connected.

CAUTION

Page 5

5. TIP STYLES

T15-B SHAPE-B

T15-B2 SHAPE-0.5B

115

(4.53)

139

(5.46)

T15-B3 SHAPE-0.7B

ø5.5

(ø0.22)

T15-B4 SHAPE-0.4B

Unit: mm (in.)

T15-BL SHAPE-BL

SHAPE B

SHAPE BC

SHAPE C

SHAPE D

R0.2

7.5

(R0.008)

(0.30)

T15-BLL SHAPE-BL LONG

R0.2

15

(R0.008)

(0.59)

T15-BC1 SHAPE-1BC

T15-BCF1*

1

ø

(ø0.04)

1.1

45°

(0.04)

11.5

(0.45)

T15-BC28 SHAPE-2.8BC

2.8

ø

(ø0.11)

60°

17.6

3.2

(0.13)

T15-D08 SHAPE-0.8D

(0.02)

T15-D32 SHAPE-3.2D

0.5

(0.02)

T15-DL52 SHAPE-5.2D LONG

(0.69)

ø0.8

(ø0.03)

1.6

(0.06)

(0.37)

ø3.2

3.2

(0.13)

9.5

(ø0.13)

5

(0.20)

0.5

R0.5

10

(R0.02)

(0.39)

T15-BC2 SHAPE-2BC

T15-BCF2*

2

ø

(ø0.08)

2.1

45°

(0.08)

T15-C1 SHAPE-1C

T15-D12 SHAPE-1.2D

T15-D4 SHAPE-4D

T15-XD15 SHAPE-1.5XD

1

(0.04)

0.5

(0.02)

0.5

(0.02)

1

ø

ø1.2

ø4

11.5

(0.45)

(ø0.04)

60°

(0.47)

(ø0.05)

(0.39)

(ø0.16)

4

(0.16)

12

3

(0.12)

10

8.5

(0.33)

R0.7

(R0.03)

(0.20)

T15-BC3 SHAPE-3BC

T15-BCF3*

3

ø

(ø0.12)

45°

3.3

(0.13)

T15-CF2* SHAPE-2C

2

(0.08)

T15-D16 SHAPE-1.6D

(0.02)

T15-D52 SHAPE-5.2D

ø2

0.5

1.2

(0.05)

(ø0.08)

ø1.6

ø5.2

(ø0.20)

10

(0.39)

60°

(0.71)

(ø0.06)

(0.14)

10

(0.39)

(0.28)

(0.31)

18

3.5

7

5

8

R0.4

5

(R0.02)

(0.20)

T15-BC12 SHAPE-1.2BC

1.2

ø

(ø0.05)

60°

3

ø

3

(0.12)

0.4

(0.02)

0.5

(0.02)

(ø0.12)

60°

1.1

(0.04)

ø3.2

15

(0.59)

19.5

(0.77)

ø2

(ø0.08)

(0.20)

(ø0.13)

(0.28)

(0.39)

5

7

10

1.5

(0.06)

T15-CF3* SHAPE-3C

T15-D2 SHAPE-2D

T15-DL32 SHAPE-3.2D LONG

R0.2

12

(R0.008)

(0.47)

T15-BC15 SHAPE-1.5BC

1.5

ø

(ø0.06)

1.7

60°

0.5

(0.02)

ø4

4

ø

(ø0.16)

ø2.4

(ø0.16)

45°

(ø0.09)

11.5

(0.45)

17

(0.67)

11.5

(0.45)

10

(0.39)

(0.87)

4

(0.16)

22

(0.07)

T15-C4 SHAPE-4C

T15-CF4*

T15-D24 SHAPE-2.4D

T15-DL4 SHAPE-4D LONG

1

(0.04)

SHAPE I

SHAPE J

ø5.2

(ø0.20)

1.2

(0.05)

T15-I SHAPE-I

R0.2

(R0.008)

3.5

(0.14)

30°

R0.2

(R0.008)

9

(0.35)

(0.51)

9.5

(0.37)

12

(0.47)

ø1.5

(ø0.06)

9.5

0.7

(0.37)

13

(0.03)

R0.2

(R0.008)

30°

0.8

(0.24)

(0.03)

ø1.4

12.7

(0.50)

6

(0.28)

(ø0.06)

R0.3

15

(0.59)

7

2

(0.08)

(R0.012)

T15-ILS SHAPE-ILST15-IL SHAPE-IL

R0.15

13.5

(R0.006)

(0.53)

T15-JD16 SHAPE-1.6JD

6

(0.24)

30°

ø1.6

4.5

(0.18)

(ø0.06)

0.6

(0.02)

4.5

(0.18)

T15-JL02 SHAPE-0.2JLT15-J02 SHAPE-0.2J T15-JD14 SHAPE-1.4JD

7.5

(0.30)

30°

R0.2

(R0.008)

9.3

(0.37)

T15-JS02 SHAPE-0.2JS

1.6

(0.06)

30°

7.9

(0.31)

R0.2

(R0.008)

Page 6

5. TIP STYLES

SHAPE K

SHAPE R

SHAPE SB

TUNNEL

T15-K SHAPE-K

ø4.7

(ø0.19)

45°

2

(0.08)

T15-R20 SHAPE-2.0R

1.3

(0.05)

T15-SB02 SHAPE-0.2SB

R0.2

(R0.008)

T15-SBS04 SHAPE-0.4SBS

R0.4

(R0.016)

T15-1001** TUNNEL 5.1 x 4.6

4.6

(0.18)

T15-1006** TUNNEL 6.9 x 11.4

11.4

(0.45)

T15-1201** QUAD 13.6 x 8.5

6.7

ø4.5

(ø0.18)

1.6

(0.06)

5.1

(0.26)

2.3

(0.09)

2.0

4.5

(0.18)

14

(0.55)

4.5

(0.18)

14

(0.55)

(0.20)

4.5

(0.18)

8.7

(0.34)

(0.09)

(0.59)

(0.08)

6.9

2.3

15

(0.27)

(0.18)

5.2

(0.20)

4.5

T15-KF SHAPE-KF

ø4.7

(ø0.19)

45°

17

(0.67)

T15-R23 SHAPE-2.3R

2.3

ø4.6

(0.09)

(ø0.18)

1.8

1.5

(0.06)

(0.07)

T15-SB03 SHAPE-0.3SB

R0.3

(R0.01)

T15-SBS07 SHAPE-0.7SBS

R0.7

(R0.03)

T15-1002** TUNNEL 5.1 x 10.4

10.4

(0.41)

T15-1007** TUNNEL 7.9 x 18.8

18.8

(0.74)

T15-1202** QUAD 10.3 x 10.3

6.7

(0.18)

(0.65)

(0.12)

13

(0.51)

(0.26)

2.3

(0.09)

4.5

16.5

3

5.1

(0.20)

(0.18)

9.3

(0.13)

(0.22)

4.5

7.9

(0.37)

3.2

5.7

(0.31)

(0.22)

5.5

T15-KL SHAPE-KL

(ø0.19)

ø4.7

45°

1.5

(0.06)

11

(0.43)

T15-R27 SHAPE-2.7R

5.2

2.7

(0.21)

(0.11)

2

(0.08)

T15-SB05 SHAPE-0.5SB

R0.5

(R0.02)

T15-1003** TUNNEL 9.5 x 18.3

18.3

(0.72)

T15-1008** TUNNEL 19.5 x 10.2

10.2

(0.40)

T15-1203** QUAD 12.8 x 12.8

(0.41)

20.9

(0.12)

2.5

(0.10)

10.5

11.1

(0.82)

(0.44)

(0.13)

19.5

(0.77)

3

(0.20)

9.5

3.2

(0.24)

T15-KU SHAPE-KU

(0.05)

T15-R34 SHAPE-3.4R

5

(0.37)

(0.22)

6

5.5

(0.07)

T15-SB08 SHAPE-0.8SB

T15-1004** TUNNEL 9.5 x 15.8

15.8

(0.62)

T15-1009** TUNNEL 13.4 x 20.5

(0.81)

T15-1204** QUAD 17.9 x 17.9

1.2

1.8

20.5

ø3

(ø0.12)

ø5.8

(0.07)

R0.8

(R0.03)

45°

(0.43)

(ø0.23)

1.8

11

3.4

(0.13)

(0.08)

10.5

(0.41)

11.1

(0.44)

(0.13)

2

3.2

14.8

5.7

(0.22)

9.5

(0.37)

5.5

(0.22)

13.4

(0.58)

(0.53)

4.3

(0.17)

6

(0.24)

T15-1205** QUAD 23.4 x 17.3

T15-R48 SHAPE-4.8R

4.8

ø7.2

(0.19)

(ø0.28)

1.8

2.3

(0.09)

(0.07)

T15-SBC04 SHAPE-0.4SBC

(ø0.02)

ø0.45

60°

0.6

(0.55)

(0.02)

T15-1005** TUNNEL 9.5 x 13.2

13.2

(0.52)

T15-1010** TUNNEL 19.5 x 12

12

(0.47)

14

11.1

20.9

(0.82)

(0.12)

9.5

(0.44)

3.2

(0.13)

19.5

3

(0.37)

5.5

(0.22)

(0.77)

6

(0.24)

5.2

(0.21)

QUAD

SPATULA

SPECIAL

APPLICATIONS

TYPE

8.5

9.7

(0.33)

ø1.5

2

(ø0.06)

(0.08)

(0.28)

4

(0.16)

(0.67)

(0.38)

(0.22)

16.5

7.2

9.5

(0.37)

17

5.5

17.7

(0.65)

(0.70)

7.3

(0.29)

13.6

(0.54)

14.8

(0.58)

T15-1206** QUAD 22.5 x 16.5

22.5

(0.89)

23.7

(0.93)

T15-1401** SPATULA 10.4

10.4

(0.41)

T15-1603** SHAPE-1.8MM LONG REACH CHISEL

1.2

(0.05)

10.3

10.3

(0.41)

11.5

(0.45)

T15-1207** QUAD 15.5 x 15.5

15.5

(0.61)

16.7

(0.66)

T15-1402** SPATULA 15.7

15.7

(0.62)

11.5

(0.41)

(0.45)

5.5

(0.22)

15.5

16.7

(0.61)

(0.66)

6.5

(0.26)

2

(0.08)

7.2

(0.28)

9.5

(0.37)

T15-1605** SHAPE-LONG REACH BENT CHISEL

3

1

(0.14)

(0.04)

30°

5

(0.2)

R0.75

(R0.03)

12.8

(0.50)14(0.55)

12.8

(0.50)

14

(0.55)

T15-1208** QUAD 15.8 x 15.8

15.8

(0.62)

17

(0.67)

T15-1403** SPATULA 21.2

21.2

(0.83)

19

(0.75)

6.7

(0.26)

15.8

(0.62)17(0.67)

17.9

(0.70)

19

(0.75)

7

(0.28)

2

(0.08)

7.2

(0.28)

9.5

(0.37)

T15-BCM2 SHAPE-2BC

Bevel with indent**

2.1

(0.08)

17.9

(0.70)19(0.75)

7

(0.27)

T15-1209** QUAD 8.4 x 8.4

8.4

9.6

(0.33)

8.4

(0.33)

9.6

(0.38)

0.9

(0.04)

(0.07)

1.8

(0.38)

5.5

(0.22)

T15-1406** SPATULA 40

(1.57)

ø2

(ø0.08)

45°

11.5

(0.45)

23.4

(0.92)

24.6

(0.97)

T15-1210** QUAD 15.4 x 12.8

15.4

(0.61)

16.6

(0.65)

2

40

T15-BCM3 SHAPE-3BC

Bevel with indent**

3.3

(0.13)

2.1

(0.08)

3.5

(0.14)

17.3

12.8

(0.50)14(0.55)

(0.08)

(0.28)

ø3

(ø0.12)

18.5

(0.68)

7.2

10.5

(0.41)

45°

(0.39)

10

(0.73)

7.3

(0.29)

7

(0.28)

* Tinned on the soldering surface only.

** The iron tips marked with double asterisks (**) have a temperature accuracy of ±25°C (±45°F), when used with the default offset.

Others have a temperature accuracy of ±15°C (±27°F), when used with the default offset.

Loading...

Loading...