Page 1

®

High-output, temperature controlled

soldering station

Instruction Manual

●

Thank you for purchasing the FM-202 soldering station. This

high-output, temperature controlled soldering station uses a

composite tip, incorporating heater and sensor functions into

one element. Several process control features, unique to the

FM-202, make it applicable to a broad range of soldering

applications.

Please read this manual before operating the FM-202. Keep

this manual readily accessible for reference.

●

TABLE OF CONTENTS

1. PACKING LIST ................................................................ 1

2. SPECIFICATIONS ........................................................... 1

3. WARNINGS, CAUTIONS, NOTES AND EXAMPLES ..... 2

4. PART NAMES..................................................................3

5. INITIAL SETUP ...............................................................3

6. OPERATION ....................................................................5

7. TIP IDENTIFICATION NUMBER ..................................... 9

8. PARAMETER SETTINGS ............................................. 10

9. MAINTENANCE ............................................................ 12

10. ERROR MESSAGES .................................................... 14

11. TROUBLE SHOOTING GUIDE ..................................... 15

12. PARTS LIST .................................................................. 17

13. TIP STYLES .................................................................. 20

14. APPENDIX A .................................................................22

15. WIRING DIAGRAM ....................................................... 23

Page 2

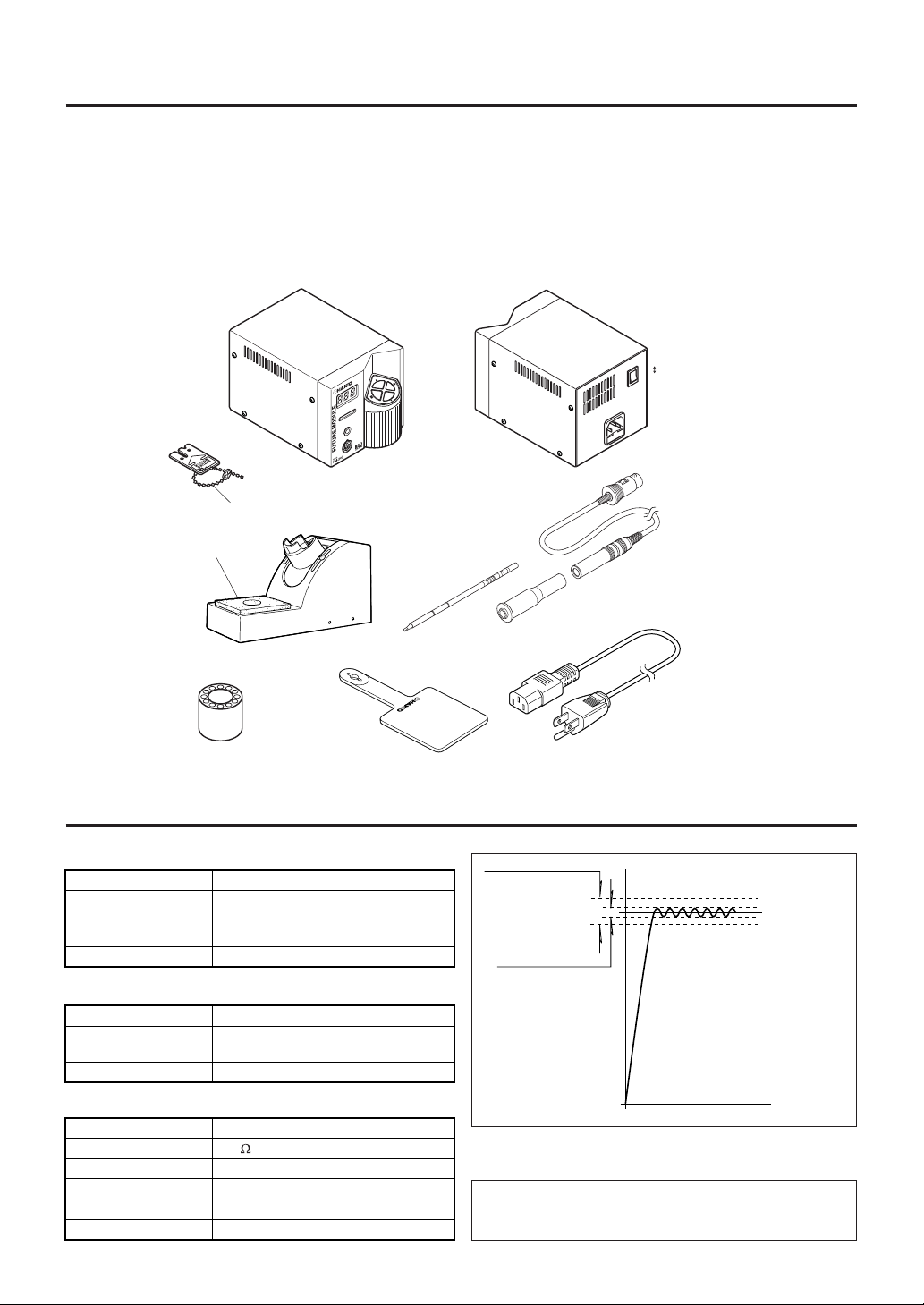

1. PACKING LIST

FM-202 soldering station ................................1

FM-2021 connector assembly ........................ 1

Sleeve .............................................................1

Sleeve stopper ................................................1

Power cord ...................................................... 1

Control card, with chain ..................................1

Control card

Cleaning

sponge

Card chain

Iron holder

FM-202

Soldering station

Tip (not included)

Heat resistant pad ........................................... 1

Tip tray ............................................................1

Iron holder ....................................................... 1

Cleaning sponge ............................................. 1

Instruction manual .......................................... 1

Tips (not included)

ON

OFF

FM-2021 connector assembly

Sleeve

Sleeve stopper

Tip tray

Heat resistant pad

2. SPECIFICATIONS

● FM-202 soldering station

Power consumption

Temperature range

Temperature accuracy

Temperature stability

● Station

Output

Dimensions

(l x w x h)

Weight

● Soldering iron

Power consumption

Tip to ground resistance

Tip to ground potential

Length, less cord

Weight, less cord

Length of cord

1

75 W (Max. 130 W)

200 – 450

±10

See Figure 1.

±5

24 V

178 x 119 x 117 mm

(7.0 x 4.7 x 4.2 in)

2,700 g (5.9 lb.)

70 W (24 V)

< 2

< 2 mV

188 mm (7.4 in.) with 2.4D tip

30 g (0.067 lb./1.07 oz.)with 2.4D tip

1.2 m (4 ft)

C (400 – 840°F)

°

C (±18°F) of set temperature.

°

C (±9°F) at idle temperature

°

Power cord

Accuracy: ±10°C (±18°F)

Set temperature

Stability: ±5°C (±9°F)

Temperature

Time

Figure 1. Temperature accuracy and stability.

NOTE:

This product is protected against electrostatic discharge.

Specifications and design are subject to change without notice.

Page 3

3.

WARNINGS, CAUTIONS, NOTES AND EXAMPLES

Warnings, cautions and notes are placed at critical points in this manual to direct the

operator’s attention to significant items. They are defined as follows:

WARNING: Failure to comply with a WARNING may result in serious injury or

death.

CAUTION: Failure to comply with a CAUTION may result in injury to the

operator, or damage to the items involved. (Two examples are

given below.)

NOTE: A NOTE indicates a procedure or point that is important to the process being

described.

EXAMPLE: An EXAMPLE is given to demonstrate a particular procedure, point or

process.

CAUTION

When power is ON, tip temperatures will be between 200 and 450°C (400 to 840°F).

To avoid injury or damage to personnel and items in the work area, observe the

following:

● Do not insert any foreign substance or incompatible tip into the process gate.

● Do not insert the tip end of the cartridge into the process gate.

● Do not touch the tip or the metal parts near the tip.

● Do not allow the tip to come close to, or touch, flammable materials.

● Inform others in the area that the unit is hot and should not be touched.

● Turn the power off when not in use, or left unattended.

● Turn the power off when connecting the FM-2021 or storing the FM-202.

● Do not remove or damage the bar code sticker.

CAUTION

To prevent accidents or damage to the FM-202, be sure to observe the following:

● Do not use the FM-202 for applications other than soldering.

● Do not allow the FM-202 to become wet, or use it with wet hands.

● Do not modify the FM-202.

● Use only genuine Hakko replacement parts.

● Do not bend or damage the control card. If the card does become damaged, do not force the

card into the station slot.

● Do not strike the iron against hard objects to remove excess solder. This will damage the

iron.

● Remove power and iron cords by holding the plug – not the wires.

● Be sure the work area is well ventilated. Soldering produces smoke.

2

Page 4

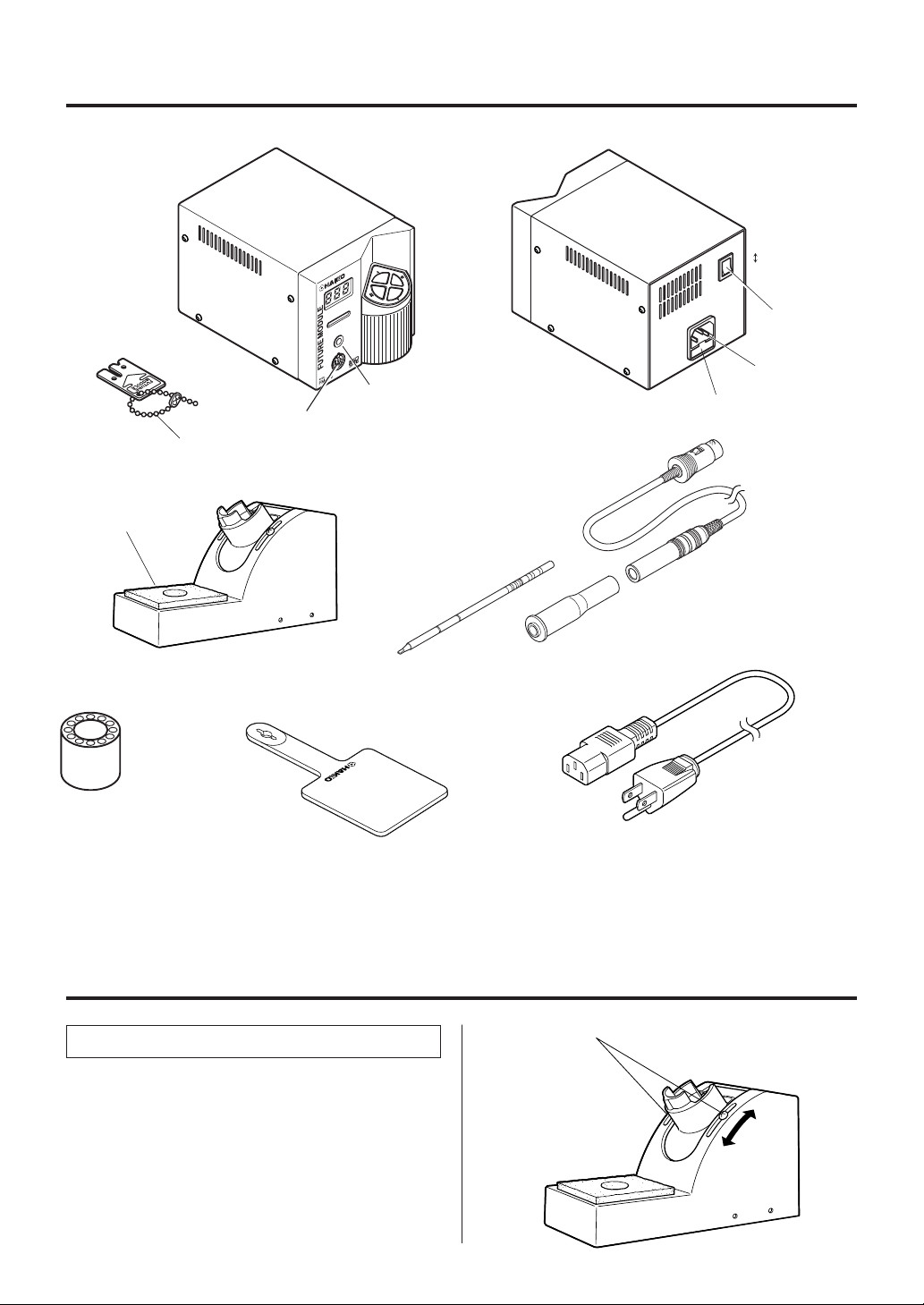

4. PART NAMES

ON

OFF

Power switch

Control card

Cleaning

sponge

Iron holder

Tip tray

Card chain

Receptacle

Heat resistant pad

FM-202

Soldering station

Process gate

Tip (not included)

Power receptacle

Fuse

FM-2021 connector assembly

Sleeve

Sleeve stopper

Power cord

5. INITIAL SETUP

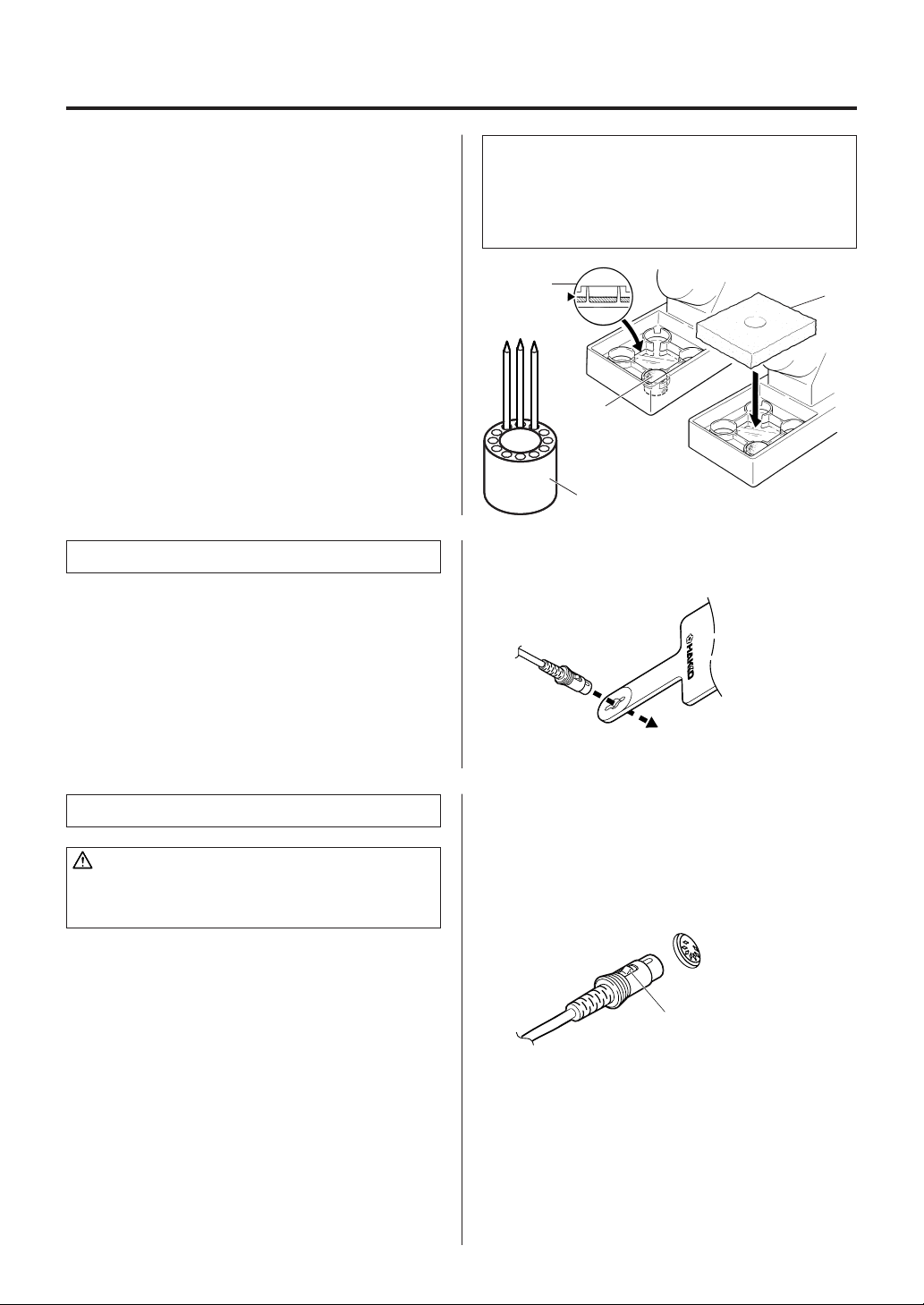

A. Iron holder

1. Adjust the height of the iron holder to suit, as

follows:

i. Loosen the adjusting screws.

ii. Set the iron holder to the desired height.

iii. Tighten the screws.

3

1

Page 5

2. Put the small cleaning sponge in one of the

5

four holes in the iron holder base.

3. Add water to the level shown in the accompanying illustration. The small sponge

will keep the large sponge moist through

capillary action.

4. Wet the large cleaning sponge, squeeze it

dry, and put it on the iron holder base.

Procedure 2-4 -ORWet the large cleaning sponge, squeeze it

dry, and put it on the iron holder base.

5. Place the spare tips in the tip tray.

B. Connector cord

Pass the connector cord through the hole in the

heat resistant pad.

NOTE:

Be sure the cleaning sponge is kept CLEAN and DAMP.

A dirty sponge will transfer contaminants to the soldering

tip, reducing thermal efficiency and possibly causing

defective solder joints. A dry sponge will abrade the

soldering tip, reducing its life.

3

2

4

C. Soldering station

CAUTION:

Be sure the power switch is OFF before connecting or

disconnecting the soldering iron cord. Failure to do so

may result in damage to the circuit board.

1. Insert the power cord into the receptacle at

the back of the station.

2. Insert the connector cord into the receptacle

at the front of the station.

3. Plug the power cord into a grounded wall

socket. The FM-202 is protected against

electrostatic discharge and must be

grounded for full efficiency.

When the plug clicks ,

it is fully inserted.

Push the plug in as far as

it will go, and try to remove it

without pressing the release pin.

If it stays in the receptacle

it is properly seated.

Receptacle

4

Page 6

6. OPERATION

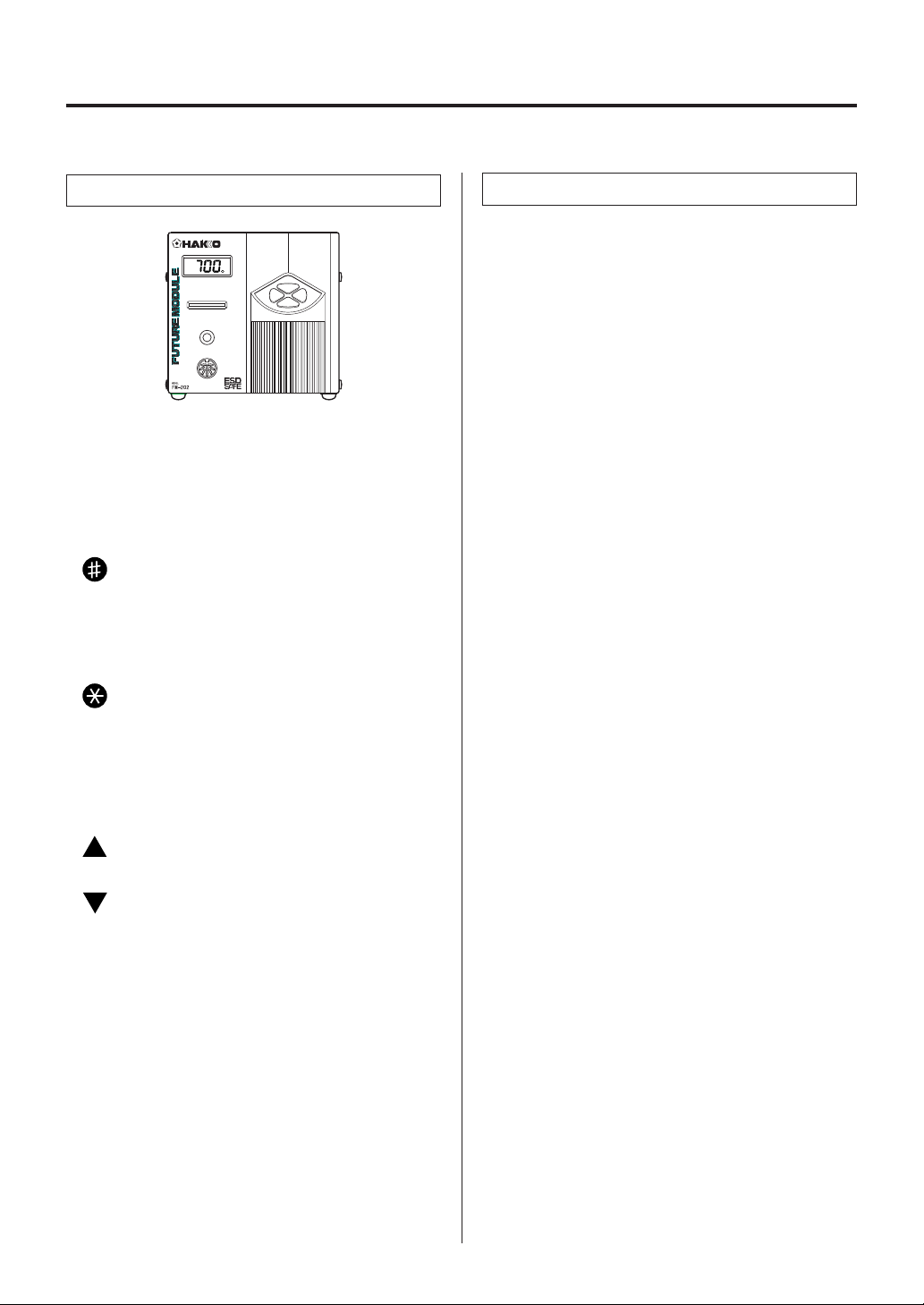

Controls and displays

Controls

The front panel of the FM-202 soldering station

has four control buttons, the process gate, the

receptacle, and the card slot. The power switch

is on the back panel.

• Four control buttons:

– Initiates the Tip ID entry mode. When

pressed for less than one second, the

stored Tip ID is displayed. When pressed

for more than one second, the Tip ID

entry mode is activated.

– Initiates the temperature setting mode.

When pressed for less than one second,

the stored temperature is displayed.

When pressed for more than one

second, the temperature entry mode is

activated.

– Increases the value in the appropriate

display window.

– Decreases the value in the appropriate

display window.

Displays

The FM-202 has a three-digit display element.

Depending upon the selected mode, it will

display:

• Normal mode:

Sensor temperature (tip temperature)

• Data entry:

Selected quantity (see ‘data entry procedures’

for exact characteristics)

• Temperature scale:

°C or °F, depending upon selection

• Error detection:

Refer to ‘ERROR MESSAGES’ section

In addition, a single heater lamp will flash when

the station has reached the desired temperature,

indicating that it is ready for use.

An audible buzzer is provided to alert the

operator:

• When the station has reached the set temperature. The buzzer will sound once.

• When the tip is inserted into the process gate,

the buzzer will sound once when the Tip ID

bar code has been read.

• When the low temperature threshold has

been crossed, the buzzer will sound

continuously. The buzzer will shut off once the

sensed temperature returns to the acceptable

range.

• When a foreign substance, an incompatible

tip, or the soldering end of the tip is inserted

into the FM-2021, the display will flash and

the buzzer will sound continuously.

• When the auto power shutoff is activated and

power to the heating element is turned off, the

buzzer will sound three times.

• When the process gate cannot read the Tip ID

bar code, the buzzer will sound three times.

• When a tip insert into the process gate while

the tip is already in the FM-2021, buzzer will

sound irregularity.

• When the tip is properly inserted into the

connector, the buzzer will sound once.

5

Page 7

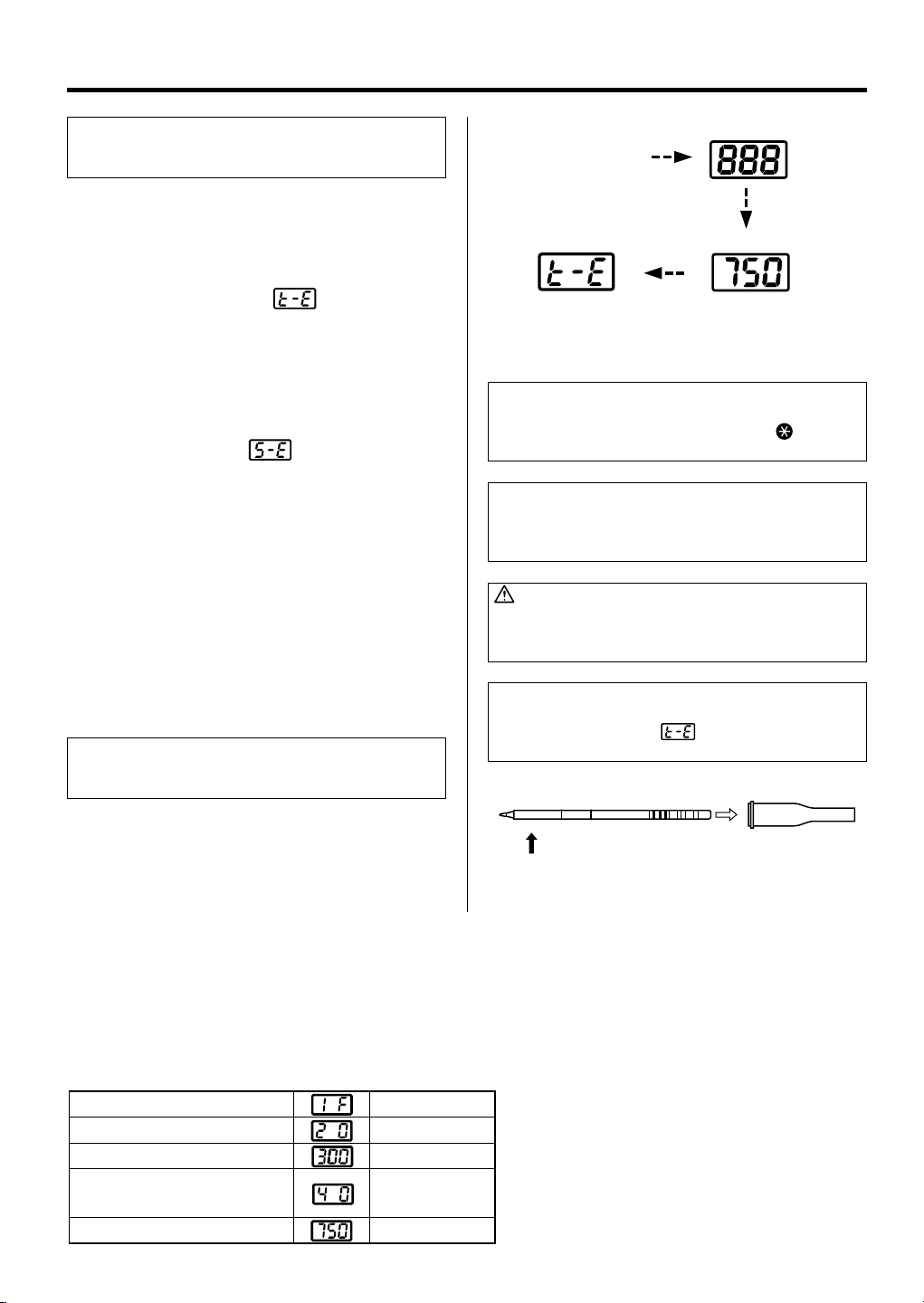

NOTE:

This procedure must be followed EVERY TIME THE

STATION IS TURNED ON.

1. If a tip is in the connector, remove it; remove

the tip from the sleeve assembly as well.

2. Turn the power switch ON.

Turn the switch ON.

TIN error

Display

Setting temperature

3. The display will show

and the LED on

the connector will flash.

4. Enter Tip ID as follows:

Insert the Tip ID end of the tip into the

process gate until the buzzer sounds once.

Tip ID data are displayed for one second.

The display shows

. The LED indicator

will stop flashing. Indicating that they are

now stored.

(Refer to Appendix A for manual entry.)

5. Inserting the tip:

Hold the head part of the tip and insert the tip

into the sleeve assembly. Push until the

sleeve assembly touches the ring round the

tip; at this point the tip should not be forced

further into the sleeve assembly .

There are no orientation requirements.

NOTE:

Once the tip is inserted into the connector, heat control

begins.

and

LED lamp at the connector begins to flash.

NOTE:

The FM-202 is preset at 750 F . at the factory .

Check the temperature setting by pressing the

The set temperature will be displayed for two seconds.

NOTE:

If the buzzer sounds three times when the tip is inserted

into the process gate, there has been a reading error.

Reinsert the tip.

CAUTION:

Refrain from inserting foreign objects, the wrong end of

the tip, or incompatible tips into the process gate.

Damage may result.

NOTE:

When the power has been cycled, Tip ID is no longer

stored in the station and

as shown at right or in Appendix A.

will flash. Reenter Tip ID

button.

6. When the set temperature is reached, the

buzzer sounds and the heater lamp at the

lower right of the temperature display starts

blinking.

Factory settings

The FM-202 comes from the factory with the

following values preset:

Temperature scale

Auto power shutoff

Low temperature alarm setting

Resetting the supervisor or

operator control setting

Set temperature

Fahrenheit

disabled

300 F

Tip ID controlled

with inserting the

card.

750 F

Hold this part to insert tip into sleeve assembly

and put into the connector.

6

Page 8

● Control card

● Changing the temperature setting

Each FM-202 comes with a small card, which

inserts into the Card slot on the front of the unit.

This card is used when entering data for the

process control function (a temperature value is

to be changed, or data are to be entered). Any

FM-202 card can be used with any FM-202

soldering station.

Example: 700 to 840°F

1. Insert the control card into the slot in the

front of the unit.

• The hundreds digit will begin to flash,

indicating that the unit is in the TEMPERATURE SET mode and data may be

entered.

2. Entering the hundreds digit

• Press the or button to set the

desired value. Only 4, 5, 6, 7, or 8 can be

selected. (In °C mode, 2, 3, or 4 can be

selected.)

When the desired value is displayed,

press the button to enter. The tens digit

will begin to flash.

3. Entering the tens digit

• Press the or button to set the

desired value. Any value from 0 to 9 can

be selected. When the desired value is

displayed, press the button to enter.

The units digit will begin to flash.

CAUTION:

The control card must be inserted into the card slot in the

correct direction for data to be entered.

Insert the card.

Press the or button.

Press the button once.

Press the or button.

Press the button once.

4. Entering the units digit

• Press the or button to set the

desired value. When the desired value is

displayed, press the button to enter.

The desired temperature is now entered

into the system memory and heater

control will begin.

NOTE:

If power is switched off or lost during the execution of this

procedure, no data will be entered. The entire procedure

must be repeated from step 1.

7

Press the button once.

Page 9

When the station is ON and the

control card is in the station, the

data entry procedure is:

● Replacing the tip

Removing and inserting the tip:

Removing the tip: Hold the connector and

pull the tip and sleeve assembly out of the

connector. (If the tip is hot, hold it with the

heat-resistant pad.)

Remove the tip from the sleeve assembly.

Inserting the tip: Hold head part and insert

the tip into the sleeve assembly. Push until

the sleeve assembly touches the ring round

the tip; at this point the tip should not be

forced further into the sleeve assembly.

Put the tip into the connector.

Enter Tip ID for new tip (see page 9).

Insert the new tip firmly into the connector.

(If the tip is not properly inserted, will

be displayed.)

a. Hold the button down for at least one

second.

b. The current temperature setting will be

displayed, then the hundreds digit will begin

to flash. This indicates that the station has

entered the temperature setting mode.

c. Follow steps 1-4 on the preceeding page.

NOTE:

When the button is pressed for less than one second,

the current temperature setting is displayed.

Remove tip from sleeve assembly

Hold this part to insert tip into sleeve assembly

and put into the connector.

CAUTION:

The tip can be very HOT. Use the heat-resistant pad for

handling hot tips, but do not hold the hot portion of the tip,

even with the pad, for a long time.

There are no orientation requirements.

8

Page 10

7. TIP IDENTIFICATION NUMBER

● Entering the Tip ID

Bar codeTip ID

1Y100CB3 01

T7-D24

Part number Serial number

CAUTION:

Do not damage or remove the Tip ID bar code sticker.

Method 1 –

How to read out the bar code of

the tip into the FM-202:

Soldering tips have different thermal characteristics, depending upon their mass, shape, and

surface area. It should be obvious that the tip

temperature at idle will not be the same for a fine

tip as it will be for a heavy chisel tip, although the

set temperature may be the same for each tip. The

FM-202 processor incorporates the ability to

electronically compensate for tip geometry

variations using Tip IDs. Each FM-202 tip style has

a specific Tip ID; whenever a tip is changed, the

Tip ID should be entered into the FM-202 for most

effective process control.

There are two ways to enter Tip ID data into the

FM-202:

See below or page 6 of this manual. This procedure

is the simplest and most common.

See Appendix A of this manual, when the Tip ID is

not readable for some reason.

1. Insert the tip (connector side) into the

process gate in the front of the station.

2. Insert the tip until the buzzer sound once.

The display shows . The LED

indicator will stop flashing. Now the tip

identification number has been stored.

9

NOTE:

When the buzzer sounds three times is reading error, insert

the tip again.

CAUTION:

Do not insert the tip opposite side or other incompatible tip.

CAUTION:

When tip is inserting the FM-2021, the process gate cannot

read the bar code. If a tip insert into the process gate while

the tip is already in the FM-2021, buzzer will sound

irregularity. Remove the tip from the FM-2021 for reading the

Tip ID.

Page 11

8. PARAMETER SETTINGS

● Entering the parameters

(1) °C or °F temperature display

The FM-202 has the following four parameters:

1) °C or °F temperature display selection

2) Auto power shutoff

3) Low-temperature alarm tolerance setting

4)

Supervisor or operator control setting

Once the station enters parameter mode, set the

parameters in the order shown below. Once all the

parameters have been set, normal operation will

be resumed.

1. Turn power OFF.

2. Insert the control card into the card slot in the

front of the unit.

3. Press and hold down the button , and then

turn power ON.

4. The display will show the Tip ID for one second.

Hold the or button down until the display

shows (Celsius) or (Fahrenheit).

When either of these are displayed, the station

is in parameter input mode.

• Pressing either the or button will cause

the display to alternate between or

.

• When the desired scale is displayed, select

by pressing the button. The system will

automatically sequence to auto power shutoff

mode.

(2) Auto power shutoff

This is an optional setting. When it is

activated and the soldering iron is not used

for 30 minutes, the power to the heating

element is shutoff automatically and the

buzzer will sound three times. When the

temperature decreases to 100°C/200°F the

display will show . To resume soldering,

cycle the power switch OFF, then ON. The

power will be turned on automatically if you

hit any button before the temperature

decreases to 100°C/200°F.

To bypass this procedure and continue to

resetting the low temperature alarm

tolerance setting press the button once.

To change the auto power shutoff setting, the

procedure is as follows.

• The display will show or when this

mode is entered.

• Using or button will change and

.

The autopower shutoff is operational only when

is selected.

• Press the button to enter the parameter. This

will store the setting in system memory and the

system will automatically sequence to the low

temperature alarm tolerance setting mode.

NOTE:

Every time the power turn OFF, the Tip ID is not stored to the

station. is flashing. read out bar code or entering the

Tip ID again.

10

Page 12

(3) Resetting the low temperature

alarm tolerance setting

This unique function alerts the operator when

the sensed temperature drops below a set limit.

Should this occur, an error message

will

be displayed, and the buzzer will sound

continuously. When the temperature returns

within the allowable range, the buzzer will stop.

The value is stored in the FM-202 as described

below:

EXAMPLE:

If the set temperature is 650°F and the low temperature

alarm is 100°F, the alarm will trip when the sensed

temperature goes below 550°F.

NOTE:

The threshold limits are: 30 – 150°C; 60 – 300°F.

If a value outside these limits should be entered, the

system will revert to the beginning of the mode, the

hundreds digit will flash, and the procedure must be

restarted.

To bypass this procedure, press the button

three times.

Range of allowable low-temperature alarm

tolerance

For °C: 30 – 150°C

For °F: 60 – 300°F

1. When the station enters low-temperature

alarm tolerance setting mode, the hundreds

digit begun flashing. Enter and store the

value in the same manner as described on

page 7 “Changing the temperature setting.”

2. If you enter a value exceeding the allowable

range shown to the left, you will be brought

back to entering a value in the hundreds

digit. If this occurs, reenter a correct value.

3. Once the value is stored, the system will

automatically sequence to the resetting the

supervisor or operator control setting.

(4) Supervisor or operator control

setting

This mode allows control over the Tip ID data

entry to be assigned to a card-holder.

NOTE:

Whether the card is inserted or not, process gate works.

11

To change the control selection, proceed as

follows:

1. When the mode is entered, the display will

show or

: Tip ID cannot be entered without

inserting the control card.

: Tip ID can be entered without

inserting the control card.

2. Pressing either the or button will

cause the display to alternate between

and .

3. When the desired setting is displayed, select

by pressing button.

The system will exit the parameter setting

mode and begin heater control.

It is now ready for normal operation.

Page 13

9. MAINTENANCE

● Tip maintenance

1. Tip temperature

2. Cleaning

3. After use

4. When the unit is not being used

and the auto power shutoff is not

active.

High temperatures shorten tip life and may

cause thermal shock to components. Always

use the lowest possible temperature when

soldering. The excellent thermal recovery

characteristics of the FM-202 ensure effective

soldering at low temperatures.

Always clean the soldering tip before use, to

remove any residual solder or flux adhering to it.

Use a clean and moist cleaning sponge (provided

with the FM-202) or the Hakko 599 tip cleaner.

Contaminants on the tip have many deleterious

effects, including reduced heat conductivity,

which contribute to poor soldering performance.

Always clean the tip and coat it with fresh solder

after use. This guards against oxidation.

Never allow the unit to idle at a high temperature

for extended periods. This will allow the tip to

become oxidized. Turn the power switch OFF. If

it is to be out of service for several hours, it is

advisable to pull the power plug as well.

5. Inspecting and cleaning the tip

This procedure, if followed daily, will materially

add to tip life.

a. Set the temperature to 250°C (482°F).

b. When the temperature stabilizes, clean the

tip (see 2, above) and check the condition of

the tip. If the tip is badly worn or deformed,

replace it.

c. If the solder plated part of the tip is covered

with black oxide, apply fresh solder, containing flux, and clean the tip again. Repeat

until all the oxide is removed, then coat the

tip with fresh solder.

CAUTION:

NEVER file the tip to remove oxides!

d. Turn the power OFF and remove the tip,

using the heat resistant pad. Set the tip

aside to cool.

e. Remaining oxides, such as the yellow dis-

coloration on the tip shaft, can be removed

with isopropyl alcohol.

12

Page 14

● Checking Procedure

WARNING:

Unless otherwise directed, carry out these procedures with the power switch OFF and the power UNPLUGGED.

■ Check for a broken heater or

sensor

■ Check the grounding line

2

5

3

7

4

1

8

6

■ Checking the connection cord

for breakage

Black

Green

Red

White

Blue

1. Check for a broken heater or sensor

Measure the resistance

across this position.

1Y100CB3

T7-D24

Verify the electrical integrity of the heater and

sensor.

Measure the resistance of the heater and

sensor while at room temperature (15 to 25°C;

59 to 77°F). It should be 8Ω±10%. If the

resistance exceeds these limits, replace the tip.

1. Unplug the connection cord from the station.

2. Measure the resistance value between Pin 2

and the tip.

3. If the value exceeds 2Ω (at room temperature),

perform the tip maintenance described on p.12.

If the value still does not decrease, check the

connection cord for breakage.

1. Remove the soldering tip and the sleeve

assembly.

2. Turn the front piece of the FM-2021 clockwise

and remove the cover.

3. Measure the resistance values between the

connector and the lead wires at the socket as

follows:

Pin 1 – Red Pin 2 – Green

Pin 3 – Black Pin 5 – White

If any value exceeds 0Ω or is , replace the

FM-2021.

■ Replacing the fuse

13

1. Unplug the power cord from the power receptacle.

2. Remove the fuse holder.

3. Replace the fuse.

4. Put the fuse holder back in place.

Page 15

10. ERROR MESSAGES

● Sensor Error

● Low-temperature alarm

tolerance error

EXAMPLE:

350°C (400°C – 50°C)

Set temperature

650°F (750°F – 100°F)

Set temperature

Low-temperature alarm tolerance

OR

Low-temperature alarm tolerance

When there is the possibility that a failure has

occurred in the sensor or heater (including the

sensor circuit), is displayed and the power

is shut down.

NOTE:

The sensor error also occurs if the tip is not inserted

properly.

If the sensor temperature falls below the difference between the current temperature

setting and the low-temperature alarm

tolerance, is displayed and the warning

buzzer sounds. When the tip temperature rises

to a value within the set tolerance, the buzzer

will stop sounding.

EXAMPLE:

Assume that the temperature setting is 400°C/750°F and

the tolerance 50°C/100°F. If the temperature continues to

decrease and finally falls below the value indicated below

while the heating element is on, the displayed value

starts blinking to indicate that the tip temperature has

dropped.

● Heater terminal short circuit

error

● Tip ID error

● Soldering iron error

will flash, and the buzzer will sound

continuously, when the tip is inserted wrong

way round, an incompatible tip is inserted, or a

foreign object has found its way into the

connector.

will flash, and the buzzer will sound three

times, if the process gate cannot read the Tip

ID.

will be displayed if Tip ID has not been

entered.

will be displayed, and the buzzer will

sound continuously, if the connector cord is not

attached to the station OR the wrong soldering

iron is connected.

14

Page 16

11. TROUBLE SHOOTING GUIDE

WARNING:

• Before checking the inside of the FM-202 or replacing parts, be sure to disconnect the power

plug. Failure to do so may result in electric shock.

● The unit does not

operate when the power

switch is turned on.

● The tip does not heat up.

• The sensor error is

displayed.

● Solder does not wet the

tip.

● The tip temperature is

too high.

CHECK : Is the power cord and/or the connection plug dis-

connected?

ACTION

CHECK : Is the fuse blown?

ACTION

CHECK : Is the power cord disconnected?

ACTION

CHECK : Is the tip inserted properly?

ACTION

CHECK : Is the connection cord and/or the heater/sensor broken?

ACTION

CHECK : Is the tip temperature too high?

ACTION

CHECK : Is the tip contaminated with oxide?

ACTION

CHECK : Is the connection cord broken?

ACTION

CHECK : Is the entered tip identification number correct?

ACTION

: Connect it.

: Investigate why the fuse blew and then replace the fuse. If

the cause can not be determined, replace the fuse. If the

fuse blows again, send the unit in for repair.

: Connect it.

: Insert the tip completely.

: See the appropriate section of this manual regarding how

to check the connection cord and/or the heater/sensor for

breakage.

: Set the appropriate temperature.

: Remove the oxide (see “Tip maintenance” on P. 12).

: See “Checking the connection cord for breakage” on

P. 13.

: Enter the correct value.

● The tip temperature is

too low.

● The soldering iron error

is displayed.

15

CHECK : Is the tip contaminated with oxide?

ACTION

CHECK : Is the entered tip identification number correct?

ACTION

CHECK : Is the other soldering iron connected? Or the FM-2021

ACTION

: Remove the oxide (see “Tip maintenance” on P. 12).

: Enter the correct value.

plug disconnected?

: Turn the power switch OFF and connect the FM-2021 or

Hakk 912 soldering iron. Turn the power switch ON.

Page 17

● The low-temperature

alarm tolerance error

occurs frequently.

CHECK : Is the tip too small for the items to be soldered?

ACTION

CHECK : Is the setting value for the low-temperature alarm

ACTION

: Use a tip with a larger thermal capacity.

tolerance too low?

: Increase the setting value.

● Tip ID error is

displayed

● Heater terminal short

circuit error

is

displayed

CHECK : Is the procedure of the entering tip identification number

correct?

ACTION

NOTE:

If reinsert the tip into the process gate and buzzer sounding three times. Try

to insert again or entering the Tip ID by hand operation.

CHECK : Is the tip for FM-2021?

ACTION

NOTE:

This error does not display when not entering the Tip ID.

: Entering correctly.

: Turn the power switch OFF and insert the genuine FM-2021

tip. Turn the power switch ON.

16

Page 18

12. PARTS LIST

NOTE:

Spare or repair parts do not include

mounting screws, if they are not

listed on the description. Screws

must be ordered separately.

● FM-202 Station

Item

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Part No.

Control card

B2749

Front panel

B2741

Button set for control panel

B2742

P.W.B. (temperature setting,

B2745

display and process gate)

Process gate switch

B2747

Process gate support

B2746

P.W.B. (temperature control

B2744

and connector)

Rubber foot

B2748

Chassis

B2740

Locking spacer

B2757

Transformer

B2743

Power receptacle

B2384

Fuse, 250V-3A

B2761

Power switch

B1084

Cover

B2739

Power cord,

B2419

3 core & American plug

Part Name

16

15

Description

with control panel,

display window and slit

4 each

Set of 4

Set of 2

4 each

with rubber foot

5 each

120V

External tooth

lock washer

Nominal size 4 (2)

13

Pan head screw

M4 x 55 (2)

14

12

Pan head screw with

spring washer M4 x 6 (2)

Binding head screw

M3 x 6 (8)

Spring washer

Nominal size 4 (2)

External

tooth

lock washer

Nominal

size 4

Pan head screw

w/spring washer,

plain washer

M4 x 8 (4)

11

Pan head screw with

spring washer M4 x 6

Tapping screw

Nominal size

3 x 10 (3)

Pan head screw

with spring washer

M3 x 6 (2)

External tooth

lock washer

Nominal size 4

9

Pan head screw

w/spring washer,

plain washer

M3 x 10 (2)

Tapping screw

Nominal size 2.6 x 8 (3)

Tapping screw

Nominal size

3 x 8 (2)

10

5

7

Pan head screw

M1.6 x 8 (2)

Nut

M1.6 (2)

7

Nut M3 (2)

Tapping screw

Nominal size

2.6 x 10 (4)

4

4

Plain washer

Nominal size 3 (2)

4

Nut M2 (2)

Spring washer

Nominal size 2 (2)

6

3

4

2

1

8

Pan head screw

M2 x 25 (2)

1817

Page 19

2

3

2

4

Pan head screw

(M3 x 5) (2)

1

Item No.

1

2

3

4

5

Part No.

FM2021-01

B2750

B2751

B2300

Part Name

Connector assembly

Sleeve

Sleeve stopper

Tip

Heat resistant pad

Description

With O-rings

5

5

Iron Holder

1

3

•

Item No.

Iron Holder Parts

•

Item No.

1~5

1

2

3

4

5

6

Par t No.

C1459

Par t No.

B2753

B2754

A1490

B2405

B2755

B2756

Part Name

Iron holder

Part Name

Iron receptacle

Iron holder base

Cleaning sponge

Rubber foot

Retaining clip

Tip tray

Description

Description

With two screws

(With bottom plate,

rubber foot)

4 ea.

4

19

6

Page 20

13. TIP STYLES

21

115

139

ø5.5

T7-D08 SHAPE-0.8D Chisel T7-D12 SHAPE-1.2D Chisel T7-D16 SHAPE-1.6D Chisel T7-D24 SHAPE-2.4D Chisel

0.5

(0.02)

(0.12)

ø0.8

(0.03)

3

9.5

(0.37)

0.5

(0.02)

4.3

(0.17)

ø1.2

(0.05)

0.5

10

(0.39)

(0.02)

T7-D32 SHAPE-3.2D Chisel T7-D4 SHAPE-4D Chisel T7-D52 SHAPE-5.2D Chisel

(0.008)

30°

R

(0.0

(0.16)

R0.2

(0

0.2

08)

ø4

(0.16)

4

7.5

(0.3)

1.2

(0.05)

T7-LI SHAPE-LI Long Sharp Conical

9.5

(0.37)

T7-C1 SHAPE-1C Bevel

1

.6

.0

6

)

7.9

(0.31)

ø3.2

(0.13)

0.5

(0.02)

1.6

(0.06)

T7-B2 SHAPE-2B Conical

R0.5

(0.02)

10

(0.39)

(0.2)

5

0.5

(0.02)

T7-I SHAPE-I Sharp Conical

T7-JL02 SHAPE-0.2RLB Bent T7-JS02 SHAPE-0.2RSSB Bent

7

.5

(0

.3

)

30°

R0.2

(0.008)

9.3

(0.37)

ø1.6

3.5

(0.14)

(0.31)

R0.2

(0.008)

ø1

ø5.2

8

(0.04)

(0.06)

60

(0.47)

(0.2)

°

10

(0.39)

(0.28)

12.7

(0.5)

12

ø2.4

(0.09)

0.5

(0.02)

4.1

(0.16)

10

(0.39)

T7-B SHAPE-B Conical

R

0

(0.008)

.2

7

(0.3)

7.5

T7-J02 SHAPE-0.2RSB Bent

3

.5

(0

.14

)

30°

R0.2

)

8

0

.0

(0

12

(0.47)

T7-BC1 SHAPE-1BC Bevel

ø1

(0.04)

°

5

4

11.5

(0.45)

Unit: mm (in.)

T7-BCF1 SHAPE-1BC Bevel

(Tinned on the soldering surface only)

ø1

(0.04)

45°

11.5

(0.45)

T7-BCF2 SHAPE-2BC Bevel

(Tinned on the soldering surface only)

ø2

(0.08)

45°

11.5

(0.45)

T7-C4 SHAPE-4C Bevel T7-CF4 SHAPE-4C Bevel

ø4

(0.16)

°

45

11.5

(0.45)

T7-BC12 SHAPE-1.2BC Bevel

(Tinned on the soldering surface only) (Tinned on the soldering surface only)

(0.05)

ø1.2

1.5

60°

(0.06)

15

(0.59)

T7-BC28 SHAPE-2.8BC Bevel

(Tinned on the soldering surface only)

ø2.8(0.11)

60°

3.2(0.13)

17.6

(0.69)

(Tinned on the soldering surface only)

ø4

(0.16)

°

45

11.5

(0.45)

T7-BC15 SHAPE-1.5BC Bevel

ø1.5

(0.06)

60°

1.7

(0.07)

17

(0.67)

T7-BC3 SHAPE-3BC Bevel

ø3

(0.12)

45°

10

(0.39)

T7-KF SHAPE-KF Knife

ø4.6(0.18)

2.4

(0.09)

5°

4

17

(0.67)

T7-BC2 SHAPE-2BC Bevel

ø2

(0.08)

°

45

11.5

(0.45)

T7-BCF3 SHAPE-3BC Bevel

(Tinned on the soldering surface only)

ø3

(0.12)

°

45

10

(0.39)

T7-KL SHAPE-KL Knife

ø4.7

(0.19)

°

1.5

(0.06)

45

11

(0.43)

20

Page 21

T7-KU SHAPE-KU Knife

Unit: mm (in.)

T7-R20 SHAPE-2.0R Slot T7-R23 SHAPE-2.3R Slot T7-R27 SHAPE-2.7R Slot

1.2

(0.05)

ø3

(0.12)

45°

11

(0.43)

1.3

(0.05)

2.0

ø4.5(0.18)

1.6

(0.06)

(0.08)

(0.2)

2.3

(0.09)

ø4.6(0.18)

1.5

5.2

(0.06)

1.8

(0.07)

(0.2)

5.2

5.8

(0.23)

T7-R34 SHAPE-3.4R Slot T7-R48 SHAPE-4.8R Slot T7-1001 SOP5.1 x 4.6 T7-1002 SOP5.1 x 10.4

18.3

(0.72)

1.8

(0.07)

3.4

ø5.8(0.23)

1.8

(0.07)

9.5

11.1(0.44)

3.2

(0.13)

(0.13)

(0.37)

(0.22)

(0.2)

2.3

5.2

(0.09)

T7-1004 SOP9.5 x 15.8T7-1003 SOP9.5 x 18.3 T7-1006 SOP6.9 x 11.4

5.5

15.8

(0.62)

(0.19)

4.8

ø7.2(0.28)

1.8

(0.07)

9.5

11.1(0.44)

3.2

(0.13)

(0.2)

(0.37)

(0.22)

5.1

(0.2)

6.7(0.26)

5.2

4.6

(0.18)

(0.09)

2.3

4.5

(0.18)

10.4

(0.41)

6.7(0.26)

T7-1005 SOP9.5 x 13.2

9.5

(0.37)

11.1(0.44)

13.2

5.5

(0.52)

(0.13)

3.2

5.5

(0.22)

11.4

(0.45)

8.7(0.34)

T7-1009 SOP13.4 x 20.5T7-1008 SOP19.5 x 10.2T7-1007 SOP7.9 x 18.8 T7-1201 PLCC13.6 x 8.5

8.5

(0.33)

9.7

(0.38)

18.8

(0.74)

7.9

9.3(0.37)

3.2

(0.13)

(0.31)

(0.22)

13.4

19.5(0.77)

20.9(0.82)

5.5

10.2

(0.4)

(0.12)

3

6

(0.24)

20.5

(0.81)

(0.53)

14.8(0.58)

4.3

(0.17)

(0.24)

13.6(0.54)

6

14.8

(0.58)

T7-1204 PLCC17.9 x 17.9T7-1203 PLCC12.8 x 12.8T7-1202 PLCC10.3 x 10.3 T7-1205 PLCC23.4 x 17.3

(0.11)

2.7

5.2(0.2)

(0.08)

5.1

(0.2)

2.3

(0.09)

6.9

(0.27)

2.3

(0.09)

2

(0.2)

4.5

(0.18)

4.5

(0.18)

5.5

(0.22)

5

14

12.8(0.5)

(0.55)

5.5

(0.22)

17.9(0.7)

19(0.75)

19(0.75)

17.9(0.7)

5.5

(0.22)

23.4(0.92)

24.6(0.97)

10.3(0.41)

11.5

(0.45)

11.5

(0.45)

10.3(0.41)

5.5

(0.22)

12.8(0.5)

14(0.55)

T7-1206 PLCC22.5 x 16.5 T7-1207 PLCC15.5 x 15.5 T7-1208 PLCC15.8 x 15.8 T7-1209 PLCC8.4 x 8.4

17(0.67)

15.8(0.62)

5.5

(0.22)

22.5(0.89)

23.7(0.93)

17.7(0.7)

16.5(0.65)

5.8

(0.23)

15.5(0.61)

16.7(0.66)

15.5(0.61)

16.7(0.66)

(0.2)

5

15.8(0.62)

17(0.67)

T7-1401 Spatula 15.7

2

(0.08)

15.7

(0.62)

7.2

(0.28)

21

8.4

(0.33)

9.6

(0.38)

8.4

(0.33)

17.3(0.68)

9.6

(0.38)

18.5(0.73)

(0.23)

(0.22)

5.8

5.5

Page 22

14. APPENDIX A

How to enter the tip identification number into the FM-202:

1. Insert the card to unlock the system.

2. Press the button and hold for more

than one second.

• The station will go into Tip ID input mode.

The tens place digit begins to flash. Refer to

the tip identification number marked on the

bar code sticker.

NOTE:

When the button is pressed for less than one second,

the stored Tip ID settings are displayed.

3. Entering a value in the tens place digit

• Using the or button, enter a value in

the tens place digit. When the entered

value is displayed, press the button.

The units digit begins to flash.

4. Entering a number in the units digit

• Perform the same steps used to enter the

value in the tens place digit. After entering

a number in the units digit, press the

button. The display shows will be

flashing. Now the tip identification number

has been stored. The temperature will be

controlled using this tip identification

number.

Example:

When the tip identification number is 07.

Press the button

for at least one second.

Press the button once.

Press the or button.

Press the button once.

NOTE:

When tip is inserting the FM-2021 and changing the Tip

ID, no display but display the setting temperature.

22

Page 23

15. WIRING DIAGRAM

P.W.B/Temperature setting

P.W.B./ Display

P.W.B./

process

gate B

P.W.B./

process

gate A

5

CN5

1

15

CN4

1

CN6

1

Process gate

switch

P.W.B./

Temperature control

11

CN3

6

1

CN1

1

CN9

Connector board

Power switch

Power receptacle

White

Black

1

2

Ground

6

HEAD OFFICE

4-5, SHIOKUSA 2-CHOME, NANIWA-KU, OSAKA, 556-0024 JAPAN

TEL:+81-6-6561-3225 FAX:+81-6-6561-8466

http://www.hakko.com

AMERICAN HAKKO PRODUCTS, INC.

28920 N. AVENUE WILLIAMS VALENCIA CA 91355, U.S.A.

TEL: (661) 294-0090 FAX: (661) 294-0096

Toll Free (800)88-HAKKO www.hakkousa.com

4 2 5 5 6

23

Jan. 2002

MA01085JU020108

Loading...

Loading...