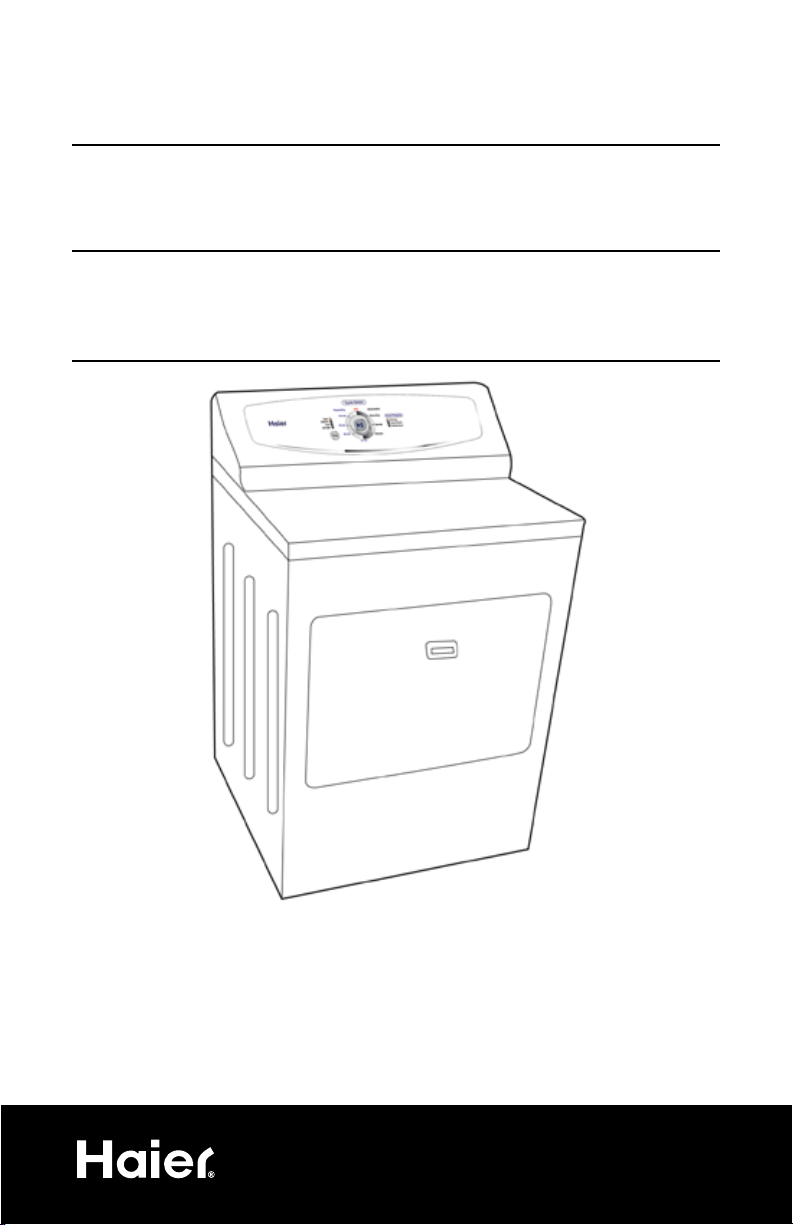

Page 1

User Manual and Installation Instructions

Gas & Electric Dryer

User Manual and Installation Instructions

Sèche-linge Genesis

Manual para el usuario e instrucciones

de instalación. Secadora a gas y eléctrica

(Picture for illustration purposes only. Actual model may vary per model purchased.)

Model #/ Modéle #/ Para Modelo de #

RDE/RDG 350AW

Quality n Innovation n Style

Page 2

English

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS .......................................2-4

INSTALLATION INSTRUCTIONS ..............................................5-17

Tools and Materials Required ............................................................ 5

Electrical Requirements ..................................................................... 5

Unpacking Your Dryer ..................................................................... 6

Exhaust System Requirements ........................................................... 7

Gas Supply Requirements ................................................................ 9

Location of Your Dryer ................................................................... 10

Manufactured (Mobile) Home Instruction .........................................11

Electrical Installation ...................................................................... 12

3-Wire Cord Connections .............................................................. 13

4-Wire Cord Connections .............................................................. 14

Gas Connections ..........................................................................15

Replacement Parts .........................................................................17

PAGE

OPERATING INSTRUCTIONS ............................................... 18-24

Understanding the Control Panel ......................................................18

Preparations before Drying .............................................................19

Load clothes into Dryer ................................................................... 20

Auto Dry Cycle ..............................................................................21

Timed Dry Cycle ............................................................................22

Other Features .............................................................................. 23

Normal Operating Sounds ..............................................................24

Tips .............................................................................................. 24

CARE AND CLEANING GUIDE

TROUBLESHOOTING .................................................................. 25

LIMITED WARRANTY .................................................................26

.......................................................24

Page 3

English

WARNING

IMPORTANT SAFETY INSTRUCTIONS

Before beginning installation, carefully read these instructions. This will simplify

the installation and ensure the dryer is installed correctly and safely.

NOTE: The electrical service to the dryer must conform with local codes and

ordinances and the latest edition of the National Electrical Code, ANSI/

NFPA 70 or in Canada, CSA C22.1 Canadian Electrical Code Part 1.

NOTE: The gas service to the dryer must conform with local codes and

ordinances and the latest edition of the National Fuel Gas Code, ANSI

Z223.1 or in Canada, CAN/CGA B149.1.

NOTE: The dryer is designed under ANSI Z21.5.1 or ANSI/UL 2158 - CAN/

CSA C22.2 No. 112-97 (latest editions) for HOME USE ONLY. This

dryer is not recommended for commercial application such as restaurants,

beauty salons, etc.

For your safety the information in this manual must be

Combustible materials, gasoline, and other flammable vapors and

liquids must not be stored near the dryer.

WHAT TO DO IF YOU SMELL GAS

1. Do not try to light any appliance

2. Do not touch any electrical switch. Do not use any phone in

your building.

3. Clear the room, building, or area of all occupants.

4. Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

5. If you cannot reach your gas supplier, call the Fire Department.

Installations must be performed by a qualified or licensed

contractor, plumber, or gasfitter qualified or licensed by the state,

province, or region where this appliance is being installed.

followed to minimize the risk of fire or explosion or to

prevent property damage, personal injury or loss

of life.

21

Page 4

English

IMPORTANT SAFETY

INSTRUCTIONS

WARNING - To reduce the risk of fire, electric shock, or

injury to persons when using your appliance, follow the

basic precautions, including the following:

1. Read all of the instructions before using this appliance.

2. Don’t dry articles that have been previously cleaned in, washed in,

soaked in, or spotted with gasoline, dry clean solvents or other

flammable explosive sub stains as they give off vapors which could

ignite or explode.

3. Do not allow children to play on or in the appliance. Close

supervision of children is necessary when the appliance is used near

children.

4. Before the appliance is removed from service or discarded, remove

the door to the drying compartment.

5. Do not reach into the appliance if the drum is moving.

6. Do not install or store this appliance where it will be exposed to

water and/or to the weather.

7. Do not tamper with controls.

8. Do not repair or replace any part of the appliance or attempt any

servicing unless specifically recommended in the user-repair

instructions that you understand and have skills to carry out.

9. Do not use fabric softeners or products to eliminate static unless

recommended by the manufacturers of the fabric softener or

product.

10. Do not use heat to dry articles or products to eliminate static unless

recommended by the manufacturers of the fabric softener or

product.

11. Clean lint screen before or after each load.

12. Keep area around the exhaust opening and adjacent surrounding

areas free from the accumulation of lint, dust and dirt.

13. Keep the dryer area clear and free from items that would obstruct

the flow of combustion and ventilation air through the louvered panel

located on the rear of the dryer.

14. The interior of the appliance and the exhaust duct should be cleaned

periodically by qualified service personnel.

3

Page 5

English

15. Do not place items exposed to cooking oils in your dryer. Items

contaminated with cooking oil may contribute to a chemical reaction

than could cause a load to catch fire.

16. If material has been used with any flammable liquids or solids, it

should not used in the dryer until all terraces of flammable liquids

and its fumes have been removed.

17. This dryer must be properly installed in accordance with the

installation instructions before it is used. See grounding instructions in

the installations sections.

18. Proper grounding must be ensured to reduce the risk of electric shock

and fire. Check with a qualified electrician or service personnel if you

are in doubt as to whether the dryer is properly grounded.

19. Use the dryer only for its intended purpose: drying clothes.

20. Always disconnect dryer from electrical supply before attempting any

service. Disconnect power cord by grasping the plug, not the cord.

21. Replace worn power cord and/or loose plugs.

22. To reduce the risk of electric shock or fire, do not use extension cords

or adapters to connect dryer electrical power source.

SAVE THESE

INSTRUCTIONS

DANGER

Risk of child entrapment. Before you throw away your old dryer,

take off the door so that children may not get trapped inside.

Thank you for using our Haier

product. This easy-to-use manual

will guide you in getting the best

use of your dryer.

Remember to record the model and

serial number. They are on a label

in back of the dryer.

Staple your receipt to your manual.

You will need it to obtain warranty service.

Model number

Serial number

Date of purchase

4

Page 6

WARNING

English

INSTALLATION INSTRUCTIONS

1. Clothes dryer installation must be performed by a

2. Install the clothes dryer according to the manufacturer’s

3. To reduce the risk of severe injury or death, follow all

Risk of Fire:

qualified installer.

instructions and local codes.

installation instructions.

SAVE THESE INSTRUCTIONS

Tools and materials required

• Phillips-Head and flathead screwdrivers

• Channel-lock adjustable pilers

• 1/2-inch open-end wrench

• Carpenter’s level

• Measuring tape (12ft. min.)

• Duct tape

• Pipe thread sealer (Gas)

• Rigid or flexible metal 4 inch (102cm) duct

• Vent hood

Safety Warning:

1. Before starting installation, make sure that the gas shut off valve is in the

2. All old gas connectors and gas piping should be discarded.

off position.

ELECTRICAL REQUIREMENTS

Electric Dryer:

C ircuit

Individual 30 Amp branch circuit fused with 30 Amp time-delay fuses or circuit

breakers. Use seperately fused circuits for washers and dryers, and DO NOT

operate a washer and dryer on the same circuit.

P ower Supply

3 or 4 wire, 240 Volt, 1 Phase, 60Hz, AC

(Canada - 240 Volt, 1 Phase, 60 Hz, AC)

P ower Supply Cord Kit

(Not supplied when sold in US. Must be purchased to meet local electrical

codes.) The dryer MUST employ a 3-conductor power supply cord NEMA

10-30 Type SRDT rated at 240 Volt AC minimum, 30 Amp, with 3 open end

5

(RDE350AW)

Page 7

spade lug connectors with upturned ends or closed loop connectors and marked

for use with clothes dryers.

(When sold in Canada - 4-wire power supply cord provided and

attached on dryer)

Dryers being installed in a manufactured (mobile) home MUST employ a

4-wire power supply cord NEMA 14-30 type SRDT or ST (as required) rated

to 240 Volt AC minimum, 30 Amp, with 4 open-end spade lug connectors

with upturned ends or closed loop connectors and marked for use with clothes

dryers. See Electrical Connections for more information on a 4-wire system.

O utlet Receptacle

NEMA 10-30R receptacle should be located so the power supply cord is

accessible when the dryer is in the installed position. (Canada - NEMA 14-30R

receptacle)

ELECTRICAL REQUIREMENTS

Gas Dryer: (RDG350AW)

C ircuit

Individual 15 Amp branch circuit fused with 15-Amp maximum time delay fuse

or circuit breakers.

P ower Supply

3 wire, 120 Volt, 1 Phase, 60Hz, AC

P ower Supply Cord

The dryer is equipped with a 120 Volt 3-wire power supply cord.

English

Note: This dryer is equipped with a three-prong grounding plug for your

protection against shock hazard and should be plugged into a properly

grounded three-prong receptacle. Do not under any circumstance cut or

remove grounding prong from plug.

Unpacking Your Dryer

1. Remove all packaging material. This includes the foam base and all adhesive

tape holding the dryer accessories inside and outside.

2. Inspect and remove any remains of packaging, tape or printed materials

before using the dryer.

6

Page 8

English English

EXHAUST SYSTEM REQUIREMENTS

WARNING

The following are specific requirements for

proper and safe operation of your dryer. Failure

to follow these instructions can create excessive

drying times and fire hazards.

1. Do not use plastic flexible duct to exhaust the dryer. Excessive lint can build up

inside exhaust system and create a fire hazard and restrict air flow. Restricted

air flow will increase drying time. If your present system is made up of plastic

duct or metal foil duct, replace it with a rigid or flexible metal duct. Ensure

present duct is free of any lint prior to installing dryer duct.

2. The dryer must not be exhausted into any gas vent, chimney, wall, ceiling or

any concealed space of a building. The dryer exhaust system MUST be

exhausted to the outdoors. If the dryer is not exhausted outdoors, some

fine lint will be expelled into the laundry area. An accumulation of lint in any

area of the home can create a health and fire hazard.

3. Exceeding the length of duct pipe or number of elbows allowed in the

“Maximum Length” chart can cause an accumulation of lint in the exhaust

system. Plugging the system could create a fire hazard, as well as increase

drying times.

4. Do not screen the exhaust ends of the vent system. Lint can become caught in

the screen, increasing drying time. Use an approved vent hood to terminate the

duct outdoors, and seal all joints with duct tape.

5. All male duct pipe fittings must be installed downstream with the flow of air.

6. Exhaust duct must not be connected or secured with screws or other fastening

devices which extend into the interior of the duct.

7. Do not allow combustible material (clothing, draperies/curtains, paper, etc.) to

come in contact with exhaust system.

Explosion hazard:

Do not install the dryer where gasoline or other flammables are kept or

stored. If the dryer is installed in a garage, it must be a minimum of 18

inches (45.7cm) above the floor. Failure to do so can result in death,

explosion, fire or burns.

Exhaust Requirements:

Use only 4 inch (10.2cm) diameter (minimum) rigid of flexible metal duct and

approved vent hood which has a swing-out damper hat open when the dryer is

in operation. When the dryer stops, the dampers automatically close to prevent

drafts and the entrance of insects and rodents. To avoid restricting the outlet,

7

Page 9

maintain a minimum of 12 inches (30.5cm) clearance between the vent hood

and the ground or any other obstruction. The vent flap should be able to move

freely, although vertical orientation of the exhaust system is acceptable. Certain

extenuating circumstances could affect the performance of the dryer:

1. Only rigid metal duct work should be used.

2. Venting vertically through a roof may expose the exhaust system to down

drafts causing an increase in vent restriction.

3. Running the exhaust system through an uninsulatedarea may cause

condensation and faster accumulation of lint.

4. Compression of crimping of the exhaust system will cause an increase in

vent restriction.

The exhaust system should be inspected and cleaned a minimum of every 12

months with normal usage. The more the dryer is used the more often you

should check the exhaust system and vent hood for proper operation.

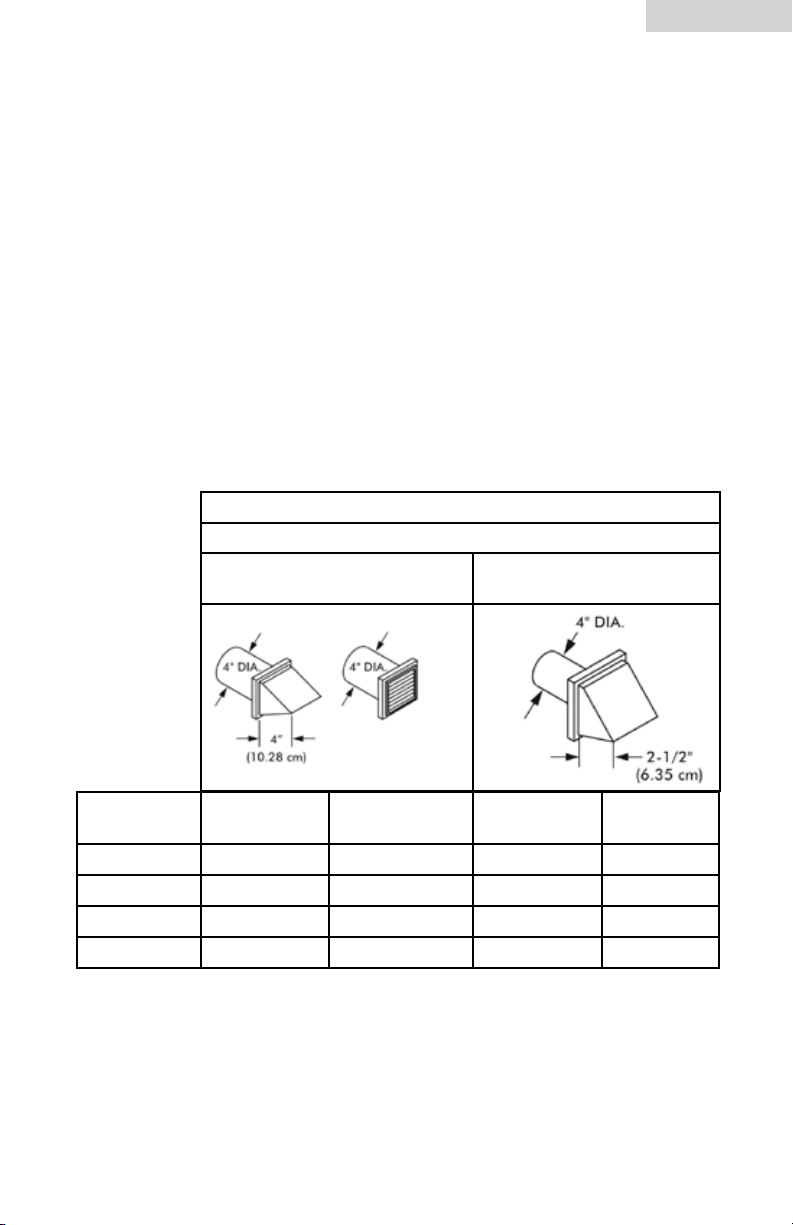

RECOMMENDED MAXIMUMM

Exhaust Hood Types

Recommended Use only for short

run installations

No. of 90º

elbows

0 90 ft. 55 ft. 60 ft. 45 ft.

1 60 ft. 40 ft. 45 ft. 30 ft.

2 45 ft. 30 ft. 35 ft. 20 ft.

3 35 ft. 20 ft. 25 ft. 15 ft.

Rigid Metal Flexible Metal Rigid Metal Flexible

Metal

8

Page 10

English English

WARNING

GAS SUPPLY REQUIREMENTS

Replace copper connecting pipe that is not plasticcoated. Stainless steel or plastic-coated brass MUST

be used.

1. Installation MUST conform with local codes. In the absence of local codes,

installation must conform with the National Fuel Gas Code, ANSI Z223.1 (latest

edition) or in Canada, the current CAN/CGA B149.1

2. The gas supply line should be 1/2 inch (1.27cm) pipe.

3. If codes allow, flexible metal tubing may be used to connect your dryer to the

gas supply line. The tubing MUST be constructed of stainless steel or plasticcoated brass.

4. The gas supply line MUST have an individual manual shutoff valve installed

within 6 feet (183cm) of the dryer in accordance with the National Fuel Gas

Code, ANSI Z223.1/NFPA 54.

In Canada, an individual manual shut-off valve MUST be installed in

accordance with the B149.1, Natural Gas and Propane Installation Code.

5. A 1/8 inch (0.32cm) N.P.T. plugged tapping, accessible for test gauge

connection, MUST be installed immediately upstream of the gas supply

connection to the dryer.

6. The dryer MUST be disconnected from the gas supply piping system during

any pressure testing of the gas supply piping system at test pressures in excess

of 1/2 psig (3.45kPa).

7. The dryer MUST be isolated from the gas supply piping system during any

pressure testing of the gas supply piping system at test pressures equal to or

less than 1/2 psig (3.45 kPa).

9

Page 11

LOCATION OF YOUR DRYER

Do Not Install Your Dryer:

1. In an area exposed to dripping water or outside weather conditions.

2. In an area where it will come in contact with curtains, thick carpet, or anything

that will obstruct the flow of combustion and ventilation air.

3. On carpet, floor must be solid with a maximum slope of 1inch (2.54 cm). Any

floor unevenness should be corrected with leveling legs located on the bottom

of the dryer.

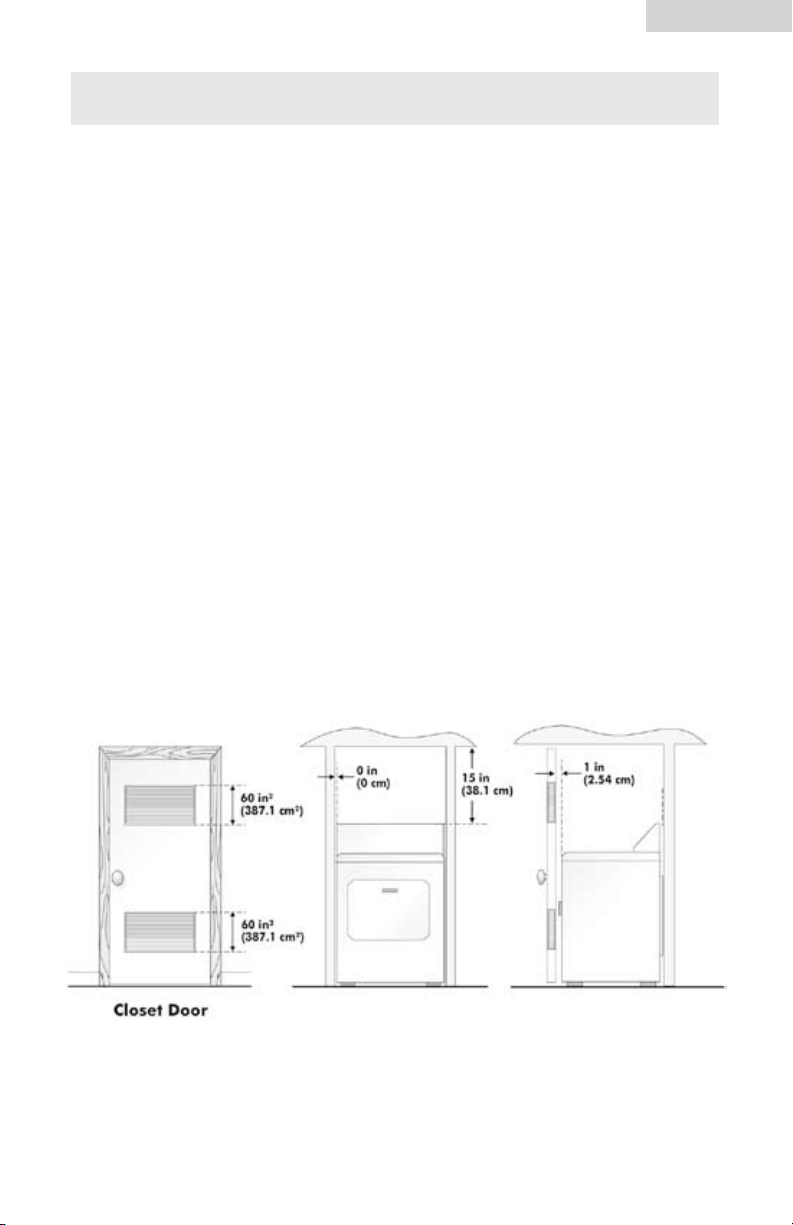

Installation in Alcove or Closet:

1. DO NOT install your dryer in a closet with a solid door.

2. A dryer installed in a bedroom, bathroom, alcove or closet MUST be

exhausted outdoors.

3. No other fuel burning appliance shall be installed in the same closet as the

gas dryer.

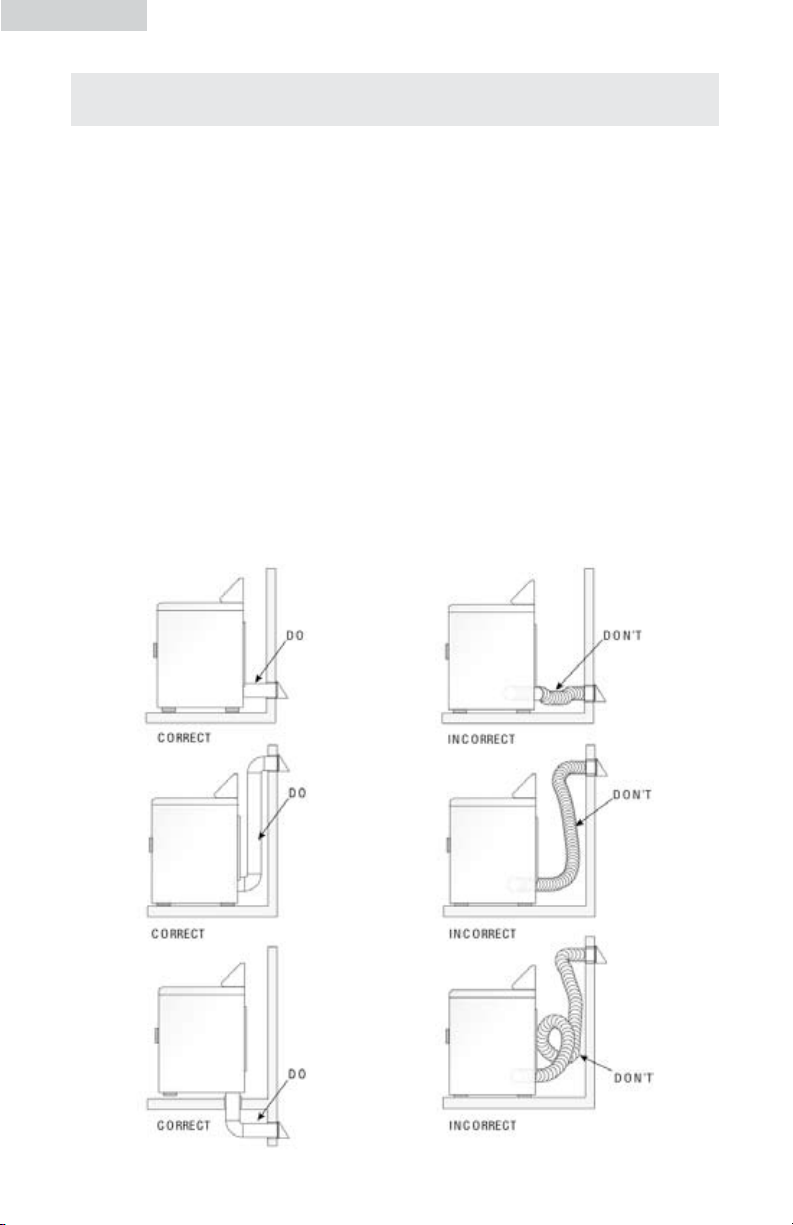

4. Refer to the images on this page to ensure the installation provides the

minimum amount of clearance required for ventilation.

5. When installing the dryer in a closet with a door, a minimum of 120 square

inches (774.2 square cm) of ventilation in the door is required. Openings must

be equally divided at the top and bottom of the door and airflow must be

unobstructed. A louvered door with equivalent air openings for the length of

the door is acceptable.

10

Page 12

English

MANUFACTURED (MOBILE) HOME INSTALLATION

1. Dryer MUST be exhausted outside (outdoors, not beneath the manufactured

home) using metal ducting that will not support combustion. Metal ducting must

be 4 inch (10.16 cm) in diameter with no obstructions. Rigid metal duct

is preferred.

2. If dryer is exhausted through the floor and area beneath the manufactured

home is enclosed, the exhaust system MUST terminate outside the enclosure

with the termination securely fastened to the mobile home structure.

3. When installing a gas dryer into a manufactured home, a provision must be

made for outside make up air. This provision is to be not less than twice the

area of the dryer exhaust outlet.

4. This dryer MUST be fastened to the floor using P/N 0030807899

Manufactured Home Installation Kit. Follow the instructions supplied with

the kit.

5. Refer to previous sections for other important venting requirements.

6. Installation must conform to current Manufactured Home Construction & Safety

Standard (which is a Federal Regulation Title 24 CFR-Part 32-80) or when

such standard is not applicable, with American National Standard for Mobile

Homes. In Canada, the CSA Z240 is applicable.

Page 13

English

WARNING

ELECTRICAL INSTALLATION

WARNING

The following are specific requirements for proper

and safe electrical installation of your dryer.

Failure to follow these instructions can create

electrical shock and/or fire hazard.

ELECTRIC Dryer (RDE350AW)

1. This appliance must be properly grounded. Electrical shock can result if the

dryer is not properly grounded. Follow the instructions in this manual for

proper grounding.

2.

Do not use an extension cord with this dryer. Some extension cords are not

designed to withstand the amounts of electrical current this dryer utilizes and

can melt, creating electric shock and/or fire hazard. Locate the dryer within

reach of the receptacle for the length power cord to be purchased, allowing

some slack in the cord. Refer to the electrical requirements in this manual for

the proper power cord to be purchased.

3. A UL approved strain relief must be installed onto power cord. If the strain

relief is not attached, the cord can be pulled out of the dryer and can be cut

by any movement of the cord, resulting in electrical shock.

4. Do not use an aluminum wire receptacle with copper-wired power cord and

plug (or vice versa ). A chemical reaction occurs between copper and

aluminum and can cause electrical shorts. The proper wiring and receptacle

is a copper-wired power cord with a copper-wired receptacle.

Note: Dryers operating on 208 Volt power supply sill have longer drying times

than operation on 240 Volt power supply.

Improper connection of the equipment grounding conductor can

result in a risk of electrical shock. Check with a licensed

electrician if you are in doubt as to whether the appliance is

properly grounded.

GAS Dryer (RDG350AW)

1. Gas dryers are equipped with a factory installed three-prong 15 Amps ~120

Volts (grounding) plug for your protection against shock hazard and should be

plugged directly into a properly grounded three-prong receptacle. Do not cut

or remove the grounding prong from this plug.

1211

Page 14

English

ELECTRICAL CONNECTIONS

ELECTRIC Dryer (RDE350AW)

3-Wire Cord Connection (US models only)

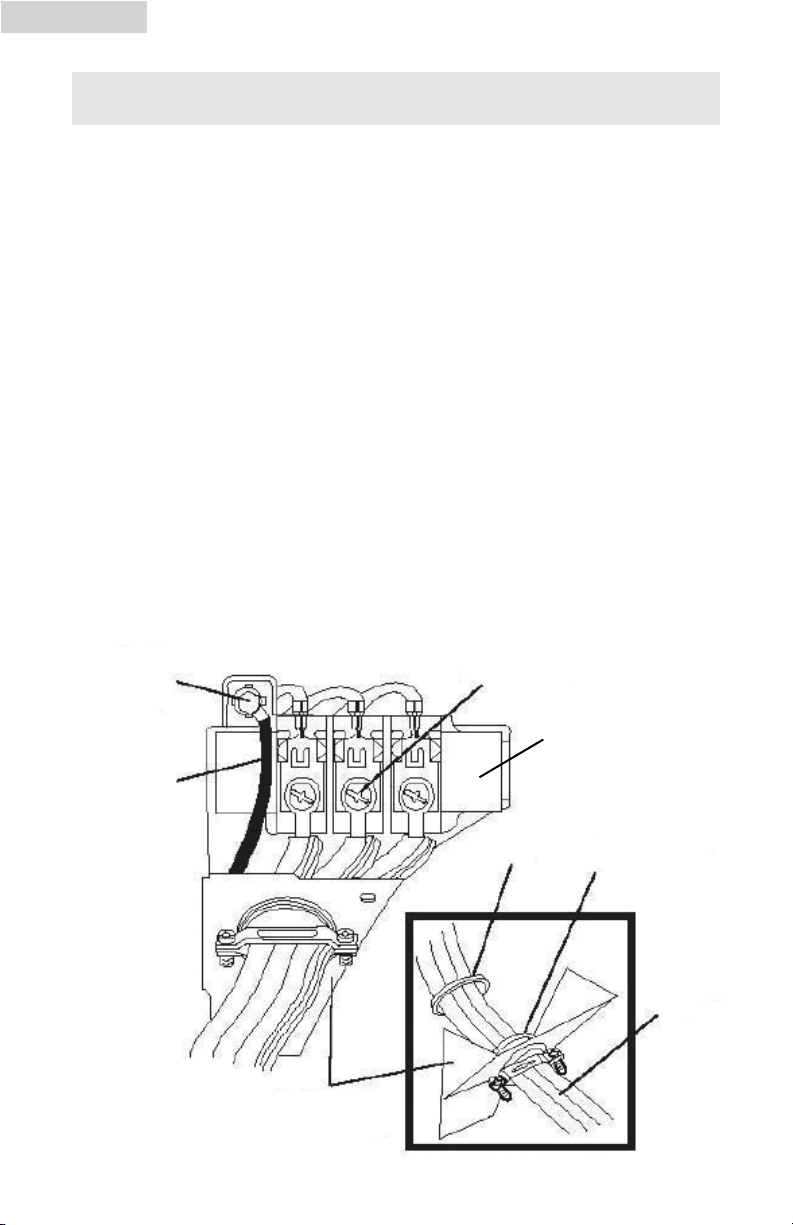

1. Remove the screws securing the terminal block access cover and the strain

relief mounting bracket located on the back of the dryer’s upper corner.

2.

Install a U.L. approved strain relief into the power cord entry hole of the

mounting bracket. Finger tighten the nut only at this time.

3. Thread a U.L. Approved 30 Amp. Power cord, NEMA 10-30 Type SRDT,

through the strain relief.

4. Attach the power cord neutral (center wire) conductor to the brass colored

center terminal on the terminal block. Tighten the screw securely.

5. Attach the remaining two power cord outer conductors to the outer brass

colored terminals on the terminal block. Tighten both screws securely.

Warning: Do not make a sharp bend or crimp wiring/conductor at

6. Reattach the strain relief mounting bracket to the back of the dryer with two

screws. Tighten screws securely.

7. Tighten the screws securing the cord restraint firmly against the power cord.

8. Tighten the strain relief nut securely so that the strain relief does not turn.

9. Reinstall the terminal block cover.

connections.

Green Ground

Screw

Neutral

Ground Wire

13

Strain Relief

Mounting Bracket

Brass Terminal

Terminal Block

Nut

Tighten Nut to

These Threads

Power Cord

Page 15

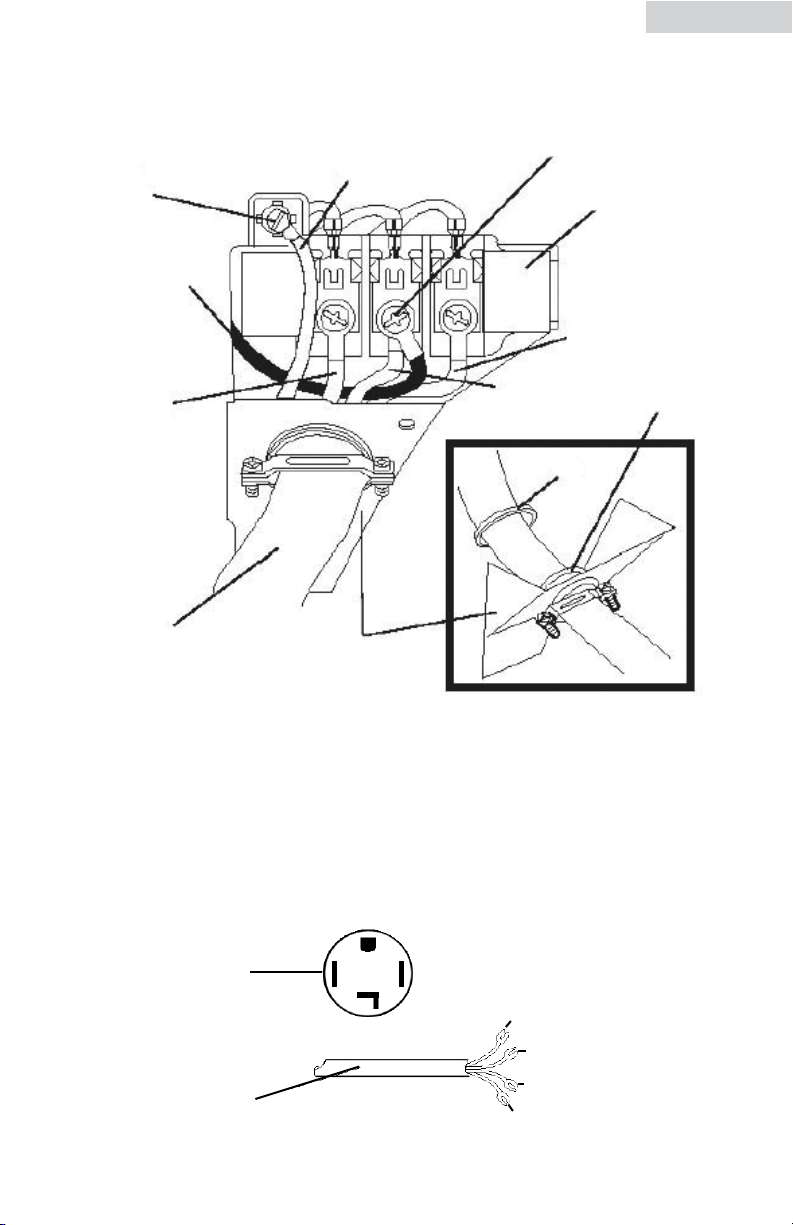

ELECTRIC Dryer (RDE350AW)

4-Wire Cord Connections (US Models Only)

Green Ground

Screw

Neutral

Ground Wire

Red

Green Power Cord

Ground Wire

Brass Terminal

White

Nut

English

Terminal Block

Black

Tighten Nut to

These Threads

Power Cord

Strain Relief

Mounting Bracket

1. Remove the screws securing the terminal block access cover and the strain

relief mounting bracket located on the back of the dryer upper corner.

2. Install a UL approved strain relief into the power cord entry hole of the

mounting bracket . Finger tighten the nut only at this time.

3. Remove the green neutral ground wire from the green ground screw located

above the terminal block.

Typical Conductor

Receptacle

Conductor Cord

Typical 4

Black 240V

White Neutral

Red 240V

Green Ground

14

Page 16

English

WARNING

4. Thread a U.L. approved 30 Amp power cord. NEMA 14-30 type ST or SRDT

through the strain relief.

5. Attach the green power cord ground wire to the cabinet with green ground

screw.

6. Attach the white (neutral) power cord conductors to the outer cord and the

green ground wire from the dryer harness to the brass-colored center

terminal on the terminal block. Tighten the screw securely.

7. Attach the red and black power cord conductors to the outer brass-colored

terminals on the terminal block.

Warning: Do not make a sharp bend or crimp the wiring /conductor at

connections.

8. Tighten the screws securing the cord restraint firmly against the power cord.

9. Tighten the strain relief nut securely so that the strain relief does not turn.

10. Reinstall the terminal block cover.

GAS CONNECTIONS

GAS Dryer (RDG350A)

NOTE: DO NOT connect the dryer to L.P. gas service without

1. Remove the shipping cap from gas pipe at the rear of the dryer.

2. Connect a 1/2 inch (1.27cm) I.D. semi-rigid or approved pipe from gas supply line to

3. Open the shutoff valve in the gas supply line.

4. Test all connections by brushing on a soapy water solution. NEVER TEST FOR GAS

5. Connect the exhaust duct to the outside exhaust system. Use duct tape to seal all joints.

6. With the dryer in its final position, adjust one or more of the legs until the dryer is resting

7. Plug the power cord into a grounded outlet. NOTE: check to ensure power is OFF at

8. Turn on the power at the circuit breaker/fuse box.

9. Run the dryer through a cycle check for proper operation.

NOTE: On gas dryers, before the burner will light, it is necessary for the gas line to

NOTE: Follow instructons supplied with kit.

15

converting the gas valve. An L.P. Conversion Kit must be

installed by a qualified gas technician.

the 3/8 inch (0.96cm) pipe located on the back of the dryer. Use a 1/2 inch to 3/8

inch (1.27cm to 0.96cm) reducer for a connection. Apply an approved thread sealer

that is resistant to the corrosive action of liquified gases on all pipe connections.

LEAKS WITH AN OPEN FLAME.

solid on all four legs. Place a level on top of the dryer. THE DRYER MUST BE LEVEL

AND RESTING SOLID ON ALL FOUR LEGS.

circuit breaker/fuse box before plugging the power cord into the outlet.

Before operating the dryer, make sure the dryer area is clean and free

from combustible materials, gasoline, and other flammable vapors. Also

see that nothing (such as boxes, clothing, etc.) obstructs the flow of

combustion and ventilation air through the louvered panel located on the

rear of the dryer.

be bled of air. If the burner does not light within 45 seconds the first time

the dryer is turned on, the safety switch will shut the burner off. If this

happens, turn the dryer to “OFF” and wait 5 minutes before making

another attempt to light.

Page 17

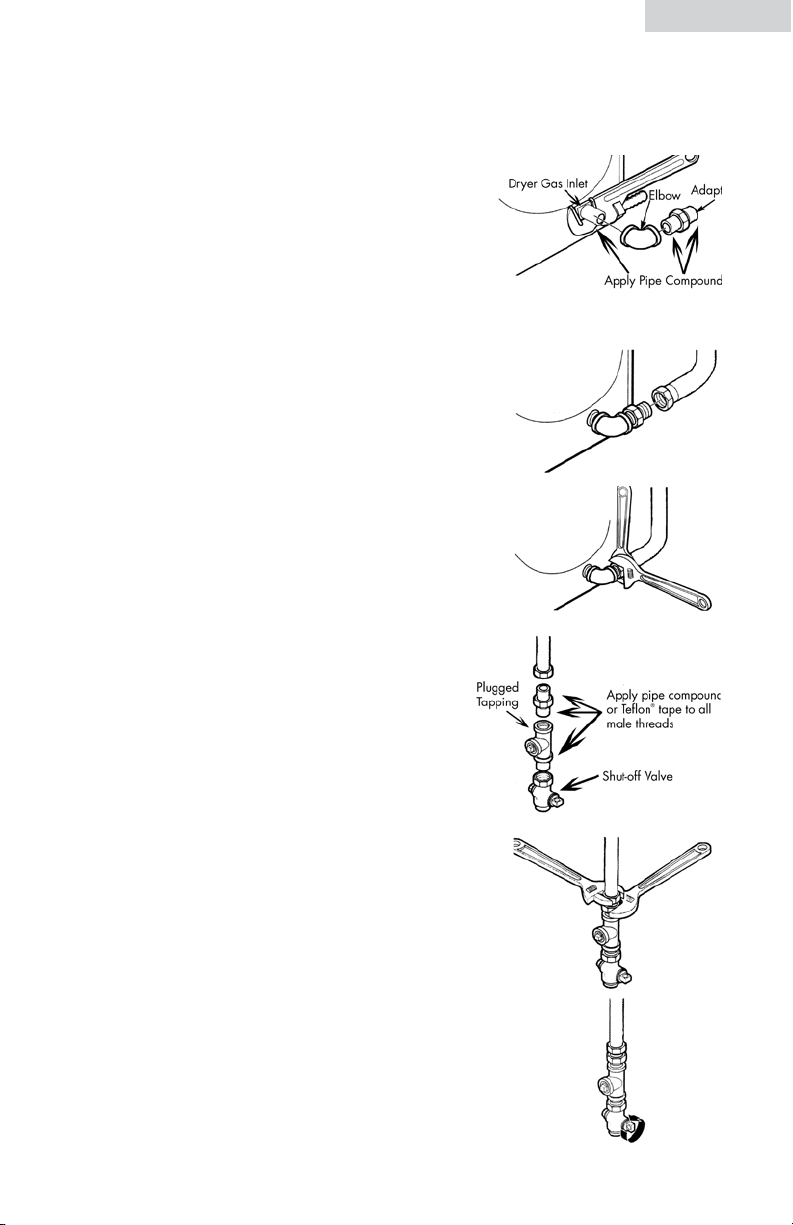

CONNECTING THE DRYER TO THE GAS SUPPLY

A) Connect female 3/8” NPT elbow to gas

inlet on dryer. Then connect 3/8” flare

union adapter to female elbow.

IMPORTANT: To prevent the inlet from

twisting, please use a pipe

wrench to secure the dryer

gas inlet. Affix Teflon®

tape or pipe compound to

adapter and gas inlet.

B) Attach the flexible metal gas line connector

to the adapter.

C) Make sure flexible gas line seal is secure.

Use two wrenches for the best possible

connection.

English

D) To check gas inlet pressure, attach 1/8”

NPT plugged tapping to dryer gas line shutoff valve. Then connect flare union adapter

to plugged tapping. Affix Teflon® tape

to the threads of the adapter and plugged

tapping to ensure seal.

E) Use two adjustable wrenches to tighten

every connection.

IMPORTANT: Do not overtighten!

F) Open gas shut-off valve.

16

Page 18

WARNING

WARNING

WARNING

English

English English

REPLACEMENT PARTS

Replacement parts and accessories for US and Canada can be purchased

through Haier America at 1-800-313-8495

Label all wires prior to disconnection when servicing controls.

Wiring errors can cause improper and dangerous operation. Check

unit for proper operation after servicing.

Discard or destroy the carton and plastic bags after the dryer is

unpacked. Children should not be allowed to use them to play with.

Cartons covered in rugs, bedspreads or plastic sheets can become

an airtight chamber and cause suffocation leading to death. Make

all packing materials inaccessible to children.

The instructions in this manual and all other literature included with

this dryer can not cover every possible condition and situation that

may occur. Good safe practice and caution must be applied when

installing, operating, and maintaining any appliance. If you are in

doubt after installing, call a certified electrician to install and wire

the dryer.

17

Page 19

English

OPERATING INSTRUCTIONS

RDE/RDG 350AW

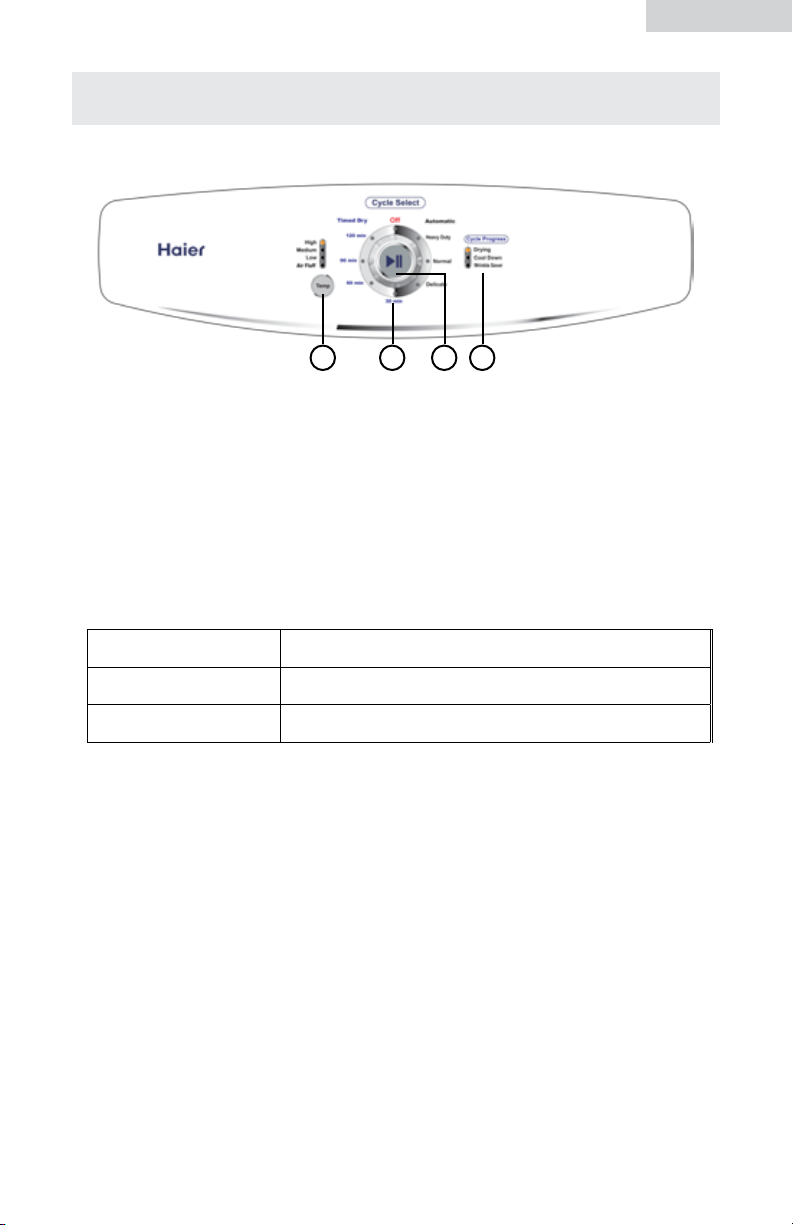

Understanding the Control Panel

1 2 3 4

Note: Features may vary per model.

Temp Button: (1)

• Used to set drying temperatures. There are four available drying temperatures to

choose from: High, Medium, Low, and Air Fluff.

Cycle Select Dial: (2)

• Select the from 3 Auto-Dry cycles (Heavy Duty, Normal, and Delicates), or

4 Time Dry Cycles (30,60,90 or 120 minutes)

Heavy Duty Heavyweight material such as jeans or bath towels.

Normal Normal drying

Delicate Drying small quantity clothes and delicate fabric.

Start/Pause Button (3)

• Push to start after selecting the dry cycle and setting the temperature. Push once

to pause. Push again to start after pushing.

Cycle Progress: (4)

• This indicates the process the cycle is currently in. At the end of the dry cycle

the dryer will automatically go in the wrinkle saves mode. Here the dryer tub

will tumble periodically for 1 hour after the dry cycle is completed. To stop

simply open the door and remove the clothes.

18

Page 20

English

PREPARATIONS BEFORE DRYING

• Sort clothes of the same kind (cotton, synthetics, woolen) to dry.

• Dark and light colored clothes should be separately dried. Fabrics prone to

losing lint and those prone to adhering lint shall be separately dried. Clothes

prone to falling lint should be turned inside out before putting into the dryer.

• Make sure buttons and ornaments on the clothes are high temperature

resistant and won’t damage drum surface. Before loading, the clothes should

have their zippers zipped up, buttons and hooks done up and belts tied so as to

avoid entanglement or other obstacles.

• If possible, turn out the clothes pockets for uniform drying.

• Check if clothes remain soiled. If so, wash them again, otherwise soils may be

permanently set.

• Small articles should be collected in a mesh bag before loading and drying, so

as to avoid entanglement and ensure easy removal.

• Make sure the power socket is reliably grounded. The grounding terminal should

not be connected to gas or tap water pipelines.

• Make sure exhaust duct has been properly connected.

• Make sure lint filter is clean and properly installed. If lint filter is not in place,

tumbling items could enter the exhaust system and cause damage to the dryer.

Note: Applies to Auto Dry cycle and Timed Dry cycle.

Page 21

LOAD CLOTHES INTO DRYER

• The appropriate load should be 1/3 ~ 1/2 of the drum volume. Avoid too

much load, as space is needed to allow clothes free rotation for uniform and

wrinkle-proof drying.

• When drying big articles, only 2-3 pieces should be loaded at a time and

supplemented with small and medium-sized articles.

• For delicate clothes or less load, two towels may be added to get better

drying and wrinkle-proof effects.

• Do not excessively dry clothes to avoid wrinkles, shrinkage, roughness,

electro-static charge accumulation, and/or more lint.

English

2019

Page 22

English English

AUTO DRY CYCLE

RDE/RDG 350AW

1. Turn the knob to any program except “OFF” to power on. The control panel

will beep once and the dryer will change from “OFF” to the operating status.

2. Set the cycle select dial to required auto dry cycle. The temperature level is

preprogrammed. To change this setting:

• Press the “Temp” button to set a suitable drying temperature.

• After powering on and selecting the cycle, the dryer selects the pre

programmed temperature. If a different drying temperature is required,

press the “Temp” button to select. There are four available drying

temperatures: High, medium, Low, and Air Fluff.

• Press Start/Pause button.

• When starting the machine, close the door first, then press this button.

• If a pause is needed during drying, press this button. Pressing again will

resume operation.

21

Page 23

TIMED DRY CYCLE

RDE/RDG 350AW

1. Turn the knob to any program except “OFF” to power on. The control panel

will beep once and the dryer will change from “OFF” to the operating status.

If Start/Pause button is not pressed five minutes after powering on, the dryer

will automatically return to OFF status.

2. Set the cycle select dial to Timed Dry Cycle.

3. There are 4 preprogrammed times to choose from 30,60,90 and 120

minutes.

4. When starting the machine close the door first, then press the start/pause

button. If a pause is needed during drying, press this button. Pressing again

will resume operation.

22

Page 24

English English

Other Features

Your dryer also has the following features for your convenience:

Lint Filter:

• All dryers come with a lint filter that needs to be cleaned before or after every

use (read “Care and Cleaning Guide” Section).

Leveling Legs:

• Your dryer has four leveling legs which are located in the front and rear corners

of your dryer. After installing your dryer in its final position, you can level your

dryer.

• Leveling legs can be adjusted by turning them clockwise to raise your dryer or

by turning them counterclockwise to lower your dryer.

End of Cycle Signal:

• At the end of the dry cycle an audible signal will beep to alert you that the

dryer has completed drying the load.

Wrinkle Saver:

• At the end of the dry cycle the dryer will automatically go into the wrinkle saver

mode. Here the dryer tub will tumble periodically for 1 hour after the dry cycle

is completed. To stop simply open the door and remove the clothes.

23

Page 25

NORMAL OPERATING SOUNDS

The following sounds are normal during the operation of the dryer.

• Tumbling sound: this is normal as the heavy wet clothes in the dryer are

continuously being tossed around.

• Air rushing noise: this happens as the dryer drum spins and the air is rushing

through the dryer drum.

Tips

• For best drying results, clean the lint filter before or after every use.

• Do not overload the dryer.

• Balance the dryer load evenly throughout the dryer for the best result.

•

Drying time depends on many variables: load size, type of fabric and

moisture in it, heat and moisture in the room, electric voltage, length of the

exhaust duct, etc.

• To eliminate guessing and to conserve energy,it is recommend for certain

clothes to dry on an auto-drying setting.

• Always follow the fabric care instructions supplied by the garment manufacturer.

CARE AND CLEANING GUIDE

• Lint filter needs to be cleaned before

or after each use for your unit to

operate at optimum efficiency. The

filter can be removed by pulling on

the tabs located on the inside of the

dryer door. The filter may be washed

or vacuumed. Remove the excess

water from the filter by gently shaking the filter. This will remove dust and

particles trapped in the filter. Lint built up in screen will restrict airflows, which

causes longer drying times. After cleaning, slide the filter back in place. Do not

use your dryer without the lint filter.

• Do not use any type of spray cleaner when cleaning the interior.

• Hazardous fumes or electric shock could occur. If dryer drum becomes stained,

clean the drum with damp cloth. Remove any residue before drying next load.

• Clean the cabinet with mild soap and water. Do not use harsh or abrasive

cleaners, as this could damage the dryer.

• Clean the duct and the vent on a regular basis to avoid clogging which could

affect the efficiency of the dryer.

Lint Filter

24

Page 26

English English

TROUBLESHOOTING

Dryer does not operate:

• Check if unit is plugged in. The plug may have come loose.

• Check if the electrical wall receptacle is of proper voltage.

• Check if the circuit breaker needs to be reset, or if the fuse needs to

be replaced.

• Check if the unit is in the “off” mode. Press start button again.

• Check if the door is open.

Dryer is working but not drying the clothes:

• Unit may be overloaded. The dryer drum should be at most half full.

• Check exhaust ducts and vents. Vents should be free of obstruction.

• Duct should be dust - and lint - free, and cleaned regularly.

• Dryer load need to be resorted. Heavy clothes may need to be separated

from regular clothes.

• Bulk clothes may require repositioning.

• If the clothes dries unevenly a higher dry setting may be required, or clothes

in the dryer need to be resorted.

Dryer makes noise when drying:

• Check for coins, loose change, buttons and other heavy objects that could be

causing the noise.

• Dryer may need to be leveled.

• Read operating guide for normal operating sounds.

Static:

• Caused by over drying. Adjust for shorter drying time.

• Mixed with synthetics fabric. Sort and separate different fabric.

• Use a fabric softener.

25 26

Page 27

LIMITED WARRANTY

Full ONE Year Warranty

For 12 months from the date of original retail

purchase, Haier will repair or replace any part

free of charge including labor that fails due to a

defect in materials or workmanship.

Limited Warranty

After only year from the original retail purchase

date Haier shall provide a part at no cost, as

indicated below, to replace said part as a result

or a defect in materials or workman ship, Haier

is solely responsible for the cost of the part.

All other costs such as the cost of the part. All

other costs such as labor trip charge, etc are the

responsibility of the owner.

Haier will provide All Parts.

Second through Fifth Year.

NOTE: This warranty commences on the date

the item was purchased and the original

purchase receipt must be presented to the

authorized service representative before

warranty repairs are rendered.

Exceptions: Commercial or Rental Use

warranty.

90 days labor from date of original purchase.

90 days parts from date of original purchase

NO OTHER WARRANTY APPLIES.

For Warranty Service

Contact your nearest authorized service center.

All service must be performed by a Haier

authorized service center. For the name and

telephone number of the nearest authorized

service center please call

1-877-337-3639.

Before calling please have available the

following information:

Model number and serial number of your

appliance( found on the rear of the unit on the

upper left hand side).

The name and address of the dealer you

purchased the unit from and the date of

purchase.

A clear description of the problem.

A proof of purchase (sales receipt).

This warranty covers appliances within the

continental united States. Puerto Rico and

Canada .

What is not covered by this warranty:

Replacement or repair of household fuses, circuit

breakers, wiring or plumbing.

A product whose original serial number has

been removed or altered.

Any service charges not specifically identified as

normal such as normal service area or hours.

Damage to clothing.

Damage incurred in shipping

Damage caused by improper installation

or maintenance.

Damage from misuse, abuse accident, fire,

flood, or acts of nature.

Damage from service other than on authorized

Haier dealer or service center.

Damage from incorrect electrical current,

voltage or supply.

Damage resulting from any product

modification, alteration or adjustment not

authorized by Haier.

Adjustment of consumer operated controls as

identified in the owners manual.

Hoses, knobs, lint trays and all attachments,

accessories and disposable parts.

Labor, service transportation, and shipping

charges for the removal and replacement of

detective parts beyond the initial

12-month period.

Damage from other than normal household use.

Any transportation and shipping charges.

THIS LIMITED WARRANTY IS GIVEN IN LIEU

OF ALL OTHER WARRANTIES EXPRESSED

OR INCLUDING THE WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE

The remedy provided in this warranty is

exclusive and is granted in lieu of all

other remedies.

This warranty does not cover incidental or

consequential damages so the above limitations

may not apply to you .Some states do not allow

limitations on how long on implied warranty

lasts, so the above limitations may not

apply to you.

This warranty gives you specific legal rights,

and you may have other rights, which vary,

from state to state.

Haier America

New York, NY 10018

Page 28

Francais

TABLE DES MATIèRES

PAGE

INSTRUCTIONS IMPORTANTES DE SÉCURITÉ ..................... 28-30

INSTRUCTIONS D’INSTALLATION ....................................... 31-43

Outils et matériaux requis ...............................................................31

Installations électriques prérequises ..................................................31

Déballage de votre sécheuse .......................................................... 32

Exigences du système d’échappement ..............................................33

Exigences de l’approvisionnement en gaz ......................................35

L’emplacement de votre sécheuse ...................................................36

Instructions pour maison préfabriquée (mobile) .................................. 37

Installation électrique ..................................................................... 38

Branchement d’un câble à 3 fils .....................................................39

Branchement d’un câble à 4 fils .....................................................40

Branchement du gaz .....................................................................41

Pièces de remplacement ................................................................43

INSTRUCTIONS D’UTILISATION ........................................... 44-50

Comprendre le panneau de contrôle ................................................ 44

Préparations avant le séchage .........................................................45

Remplissage de la sécheuse ............................................................ 46

Cycle de séchage automatique ........................................................ 47

Cycle de séchage avec minuterie ..................................................... 48

Autres caractéristiques ................................................................... 49

Sons de fonctionnement normaux .....................................................50

Conseils ........................................................................................50

GUIDE D’ENTRETIEN ..................................................................50

DÉPANNAGE .............................................................................. 51

GARANTIE LIMITÉE .....................................................................52

27 28

Page 29

Francais

INTRUCTIONS IMPORTANTE DE SÉCURITÉ

Avant de commencer l’installation de votre sécheuse, lisez attentivement ces

instructions, pour en faciliter l’installation et assurer que la sécheuse est installée

correctement et en toute sécurité.

NOTE: Le branchement électrique de la sécheuse doit être conforme aux

ordonnances et aux codes locaux et à l’édition la plus récente du

National Electrical Code, ANSI / NFPA 70 ou, au Canada, CSA C22.1

du Code canadien de l’électricité Partie 1.

NOTE: Le branchement au gaz de la sécheuse doit être conforme aux

ordonnances et aux codes locaux et à l’édition la plus récente du

National Fuel Gas Code ANSI Z223.1 ou, au Canada, CAN/CGA

B149.1.

NOTE: La sécheuse est conçu sous ANSI Z21.5.1 ou ANSI / UL 2158 - CAN

CSA C22.2 n ° 112-97 (éditions les plus récentes) pour utilisation

domestique SEULEMENT. Cette sécheuse n’est pas recommandée pour

l’usage commercial, tel que les restaurants ou les salons de beauté.

AVERTISSEMENT! Pour votre sécurité, les informations contenues

dans ce manuel doivent être suivies pour réduire les risques

d’incendie ou d’explosion, et pour prévenir les dommages matériels,

les blessures ou même la mort.

Les matériaux combustibles, l’essence et autres liquides et vapeurs

inflammables ne doivent être rangés près de la sécheuse.

QUE FAIRE SI VOUS DÉTECTEZ UNE ODEUR DE GAZ

1. N’allumez aucun électroménager

2. Ne touchez pas aux interrupteurs électriques; n’utilisez pas de

téléphone dans votre immeuble.

3. Évacuez la pièce, l’immeuble et les environs de tous les occupants

4. Appelez immédiatement votre fournisseur de gaz d’un téléphone

voisin. Suivez les directives du fournisseur de gaz.

5. Si vous ne pouvez rejoindre votre fournisseur de gaz, appeler les

pompiers

Les installations doivent être effectuées par une personne

(contractant, plombier, ou installateur de gaz) qualifiée ou agrée

par l’état, la province ou la région où l’appareil est installé.

Page 30

Francais

INSTRUCTIONS IMPORTANTES DE SÉCURITÉ

AVERTISSEMENT – le risque d’incendie, de choc électrique, ou

de blessure lors de l’utilisation de votre appareil, suivez les

précautions de base, notamment les suivantes :

1. Lire toutes les instructions avant l’utilisation de la sécheuse

2. Ne séchez pas les articles qui ont précédemment trempé, été nettoyés,

lavés, ou aspergés d’essence ou d’autres solvants inflammables ou

explosifs qui pourraient s’enflammer ou exploser.

3. Ne laissez pas les enfants jouer sur ou dans la sécheuse. Une

surveillance adéquate et nécessaire lorsque l’appareil est utilisé près

des enfants.

4. Avant de se débarrasser de la sécheuse, enlevez la porte du

compartiment de séchage.

5. Ne mettez pas la main dans la sécheuse si le tambour est en

mouvement

6. Ne pas installer ou entreposer l’appareil où il serait exposé à l’eau ou

aux intempéries.

7. Ne pas modifier les commandes

8. Ne pas réparer ou remplacer une partie de l’appareil à moins d’être

recommandé dans les instructions d’entretien que vous aurez comprises

et êtes en mesure d’effectuer.

9. Ne pas utiliser d’assouplissants ou de produits anti-statiques à moins

d’être recommandé par le fabricant d’assouplissant ou de produit anti

statique.

10. Ne pas sécher à haute température les articles ou produits anti

statiques à moins d’être recommandé par le fabricant d’assouplissant

ou de produit anti-statique

11. Nettoyez le filtre à charpie avant ou après chaque brassée

12. Gardez la région environnante du système d’échappement propre et

évitez l’accumulation de charpie, de poussière ou de saleté

13. Gardez la région environnante de la sécheuse propre et exempte de

choses qui pourrait entraver le flux de combustion et d’air au travers

le panneau à abat-son situé à l’arrière de la sécheuse.

14. L’intérieur de l’appareil et le tuyau d’échappement devraient être

nettoyés périodiquement par du personnel qualifié

29 30

Page 31

Francais

15. Ne pas mettre d’articles exposés à des huiles de cuisson dans votr

sécheuse. Les articles contaminés par l’huile de cuisson peuvent

contribuer à une réaction chimique qui pourrait amener votre brassée

à s’enflammer.

16. Si le matériel a été utilisé avec des liquides ou des solides

inflammable, il ne devrait pas être utilisé dans la sécheuse avant que

toutes traces du liquide et ses émanations aient été enlevées.

17. Cette sécheuse doit être installée correctement et conformément aux

instructions d’installation avant de l’utiliser. Voir les instructions de

mise à la terre dans la section d’instructions d’installation.

18. La mise à la terre doit être assurée afin de réduire le risque de choc

électrique et d’incendie. Consulter un électricien ou personnel qualifié

e si vous avez des doutes quant à savoir si la sécheuse est

correctement mise à la terre.

19. Utiliser la sécheuse seulement pour le séchage des vêtements.

20. Toujours débrancher la sécheuse avant de tenter sa réparation

Débranchez en tirant sur la fiche et non sur le câble d’alimentation.

21. Remplacez un câble d’alimentation usé et/ou une fiche ébranlée

22. Pour réduire les risques de feu ou de choc électrique, n’utiliser pas de

rallonge ou d’adaptateur de fiche pour brancher la sécheuse

CONSERVEZ CES INSTRUCTIONS

DANGER

Risque d’enfermer un enfant. Avant de vous débarrasser de votre

vieille sécheuse, enlevez la porte de sorte que les enfants de pour-

ront pas y rester coincés.

Merci d’utiliser notre produit Haier.

Ce guide d’utilisation simple vous

guidera pour faire le meilleur usage

de votre sécheuse.

Souvenez-vous d’inscrire le numéro

de série et le numéro de modèle

de la sécheuse qui se trouvent à

l’arrière de celle-ci.

Brochez votre reçu à votre guide d’utilisation.

Vous en aurez besoin pour avoir accès au service de garantie.

Numéro de modèle

Numéro de série

Date d’achat

Page 32

Francais

INSTRUCTIONS D’INSTALLATION

PRUDENCE, Risque de feu:

1. L’installation de la sécheuse doit être faite par un installateur qualifié

2. Installez la sécheuse selon les instructions du fabricant et les codes locaux

3. Pour réduire le risque de blessures graves ou de mort, suivre toutes les

Outils et matériaux requis

• Tournevis plat et étoile

• Pinces à verrouillage réglable

• Clé ½ pouce

• Un niveau

• Gallon à mesurer (au moins 12 pi.)

• Ruban adhésif à conduits (duct tape)

• Scellant à filet

• Tuyau en métal souple ou rigide de 4 pouce (10.2cm)

• Hotte

AVERTISSEMENT DE SÉCURITÉ:

1. Avant de commencer l’installation, s’assurer que l’interrupteur pour le

gaz est bien en position éteinte

2. Tous les anciens conduits et connecteurs de gaz doivent être jetés

CONSERVER CES INSTRUCTIONS

INSTALLATIONS ÉLECTRIQUE PRÉREQUISES

Sécheuse électrique: (RDE350AW)

Circuit électrique

Circuit individuel de dérivation 30 Amp avec des fusibles à délai ou disjoncteurs

30 Amp. Utilisez des circuits séparés pour la laveuse et la sécheuse, et NE PAS

les utiliser sur le même circuit électrique.

Alimentation électrique

Câble à 3 ou 4 fil, 240 Volt, 1 Phase, 60Hz, AC

(Canada - 240 Volt, 1 Phase, 60 Hz, AC)

Filage électrique

(Non fournis lorsque vendu au États-unis. Doit être acheté pour répondre aux

codes électriques locaux.) La sécheuse DOIT être munie d’un câble d’alimentation

à 3 fils conducteurs NEMA 10-30 de type SRDT, évalué à 240 Volt AC

minimum, 30 Amp, avec 3 connecteurs, marqué pour l’utilisation avec une

sécheuse.

(Lorsque vendue au Canada, le câble d’alimentation à 4 fils et fourni et fixé à la

sécheuse.)

Les sécheuses qui sont installées dans une maison préfabriquée (ou mobile)

DOIVENT être munies d’un câble d’alimentation à 4 fils conducteurs NEMA

14-30 type SRDT ou ST (dépendamment des exigences) évalué à 240 Volt

31 32

Page 33

Francais

AC minimum, 30 Amp, avec 3 connecteurs, marqué pour l’utilisation avec une

sécheuse. Voir la rubrique de connexions électriques pour plus d’informations sur

les systèmes à 4 fils.

Prise de courant

Une prise NEMA 10-30R devrait être localisée de sorte que le fil électrique soit

accessible quand la sécheuse est en potion installée. (Canada : prise NEMA

12-40R)

INSTALLATIONS ÉLECTRIQUES PRÉREQUISES

Sécheuse au gaz : (RDG350AW)

Circuit électrique

Circuit individuel de dérivation 30 Amp avec des fusibles à délai ou disjoncteurs

30 Amp.

Alimentation électrique

3 fils, 120 volts, 1 phase, 60Hz, AC

Filage électrique

La sécheuse est munie d’un câble 120 volts avec 3 fils.

NOTE: Cette sécheuse est munie avec une fiche à trois broches pour la mise à

la terre, pour éviter les chocs électriques et devrait être branché à une

prise électrique mise à la terre (à trois trous). La broche de mise à la terre

devrait être arrachée ou coupée de la fiche sous aucun prétexte.

Déballage de votre sécheuse

1. Retirez tous les matériaux d’emballage. Cela inclut la base de mousse et tout

le ruban adhésif qui fixe les accessoires à l’intérieur comme à l’extérieur de la

sécheuse.

2. Inspectez et enlevez tout reste d’emballage, de ruban adhésif ou de documents

imprimés avant d’utiliser la sécheuse.

Page 34

Francais

EXIGENCES DU SYSTèME D’ÉCHAPPEMENT

AVERTISSEMENT

Les exigences suivantes doivent être respectées pour

le fonctionnement de votre sécheuse, en toute sécurité.

Un non-respect de ces instructions peut engendrer un

temps de séchage plus longs et des risques d’incendie.

1. Ne pas utiliser un conduit d’échappement en plastique souple. Un excès de

charpie peut s’accumuler à l’intérieur du système d’échappement, créer

un risque d’incendie et restreindre la circulation de l’air. Une circulation

d’air inadéquate augmente le temps de séchage. Si votre ancien système

d’échappement est fait de plastique, remplacez-le avec un conduit en métal

souple ou rigide, et s’assurer que le conduit n’a pas d’accumulation de

charpie.

2. Le système d’échappement de la sécheuse ne doit pas être évacué dans un

conduit de gaz, une cheminée, un mur, un plafond ou autre endroit fermé. Le

système d’échappement de la sécheuse doit aller directement à l’extérieur

Sinon, des charpies pourront s’accumuler dans la buanderie. Une accumulation

de charpie dans n’importe quel endroit de la maison peut être néfaste sur la

santé et peut causer des risques d’incendie.

3. Dépasser les limites de longueur de conduit ou le nombre suggéré de coudes

(voir tableau de longueurs maximums) peut causer une accumulation de charpie

dans le système d’échappement. Le branchement du système pourrait donc

créer des risques d’incendie ou augmenter le temps de séchage.

4. Ne pas mettre de filtre au bout du conduit d’échappement. Les charpies

pourraient bloquer le filtre et augmenter le temps de séchage. Utilisez plutôt

une hotte approuvée pour envoyer le conduit d’échappement dehors, et bien

sceller les joints avec du ruban adhésif (duct tape)

5. Tous les raccords mâles du conduit doivent être installés en aval du courant

d’air.

6. Le conduit d’échappement ne doit pas être fixé avec des vis ou tout autre

dispositif de fixations qui dépasse à l’intérieur du conduit.

7. Ne laissez pas de matériaux combustibles (vêtements, draperies, papier, etc

entrer en contact avec le système d’échappement

Risque d’explosion

N’installez pas la sécheuse où l’essence ou d’autres substances

inflammables sont entreposées. Si la sécheuse est installée dans un garage,

il faut la surélever d’au moins 18 pouces (45.7cm) du plancher. Omettre

de faire cela pourrait entraîner la mort, une explosion, un incendie ou des

brûlures.

33 34

Page 35

Francais

Exigences du conduit d’échappement

Utilisez un conduit d’échappement en métal rigide ou solide avec un diamètre

d’au moins 4pouce (10.2cm) et une hotte munie d’un clapet de ventilation

qui s’ouvre lorsque la sécheuse fonctionne. Lorsque la sécheuse s’arrête, le

clapet se ferme automatiquement pour prévenir les courants d’air et l’entrée

des insectes et des rongeurs. Pour éviter de bloquer de la sortie, maintenez un

minimum de 12 pouces (30.5cm) entre la hotte et le sol ou tout autre obstacle.

Le clapet doit pouvoir ouvrir et fermer librement, bien que l’orientation verticale

du système d’échappement soit acceptable. Certaines circonstances pourraient

avoir une influence sur la performance de la sécheuse :

1. Seul les conduits en métal rigide devraient être utilisés.

2. Faire passer le tuyau d’échappement verticalement par le toit peut

engendrer des courant d’air descendants qui peuvent bloquer l’air du système

d’échappement.

3. Faire passer le tuyau d’échappement par un endroit non isolé peut créer de la

condensation et une accumulation de charpie plus rapide.

4. Toute compression du système d’échappement cause une restriction d’air

Le système d’échappement devrait être vérifié et nettoyé au minimum à tous

les 12 mois, avec usage régulier. Plus la sécheuse est utilisée souvent, plus

il faudra vérifier le système d’échappement et la hotte pour s’assurer d’un

fonctionnement normal.

Longueur maximum recommandée

RECOMMENDED MAXIMUMM

Type de hotte

Exhaust Hood Types

Recommandé

Recommended Use only for short

Quantité de

No. of 90º

coudes 90°

elbows

0 90 ft. 55 ft. 60 ft. 45 ft.

1 60 ft. 40 ft. 45 ft. 30 ft.

2 45 ft. 30 ft. 35 ft. 20 ft.

3 35 ft. 20 ft. 25 ft. 15 ft.

Métal rigide

Rigid Metal Flexible Metal Rigid Metal Flexible

Métal Flexible

Usage à court terme

seulement

run installations

Métal rigide

Métal Flexible

Metal

34

Page 36

Francais

EXIGENCES DE L’APPROVISIONNEMENT EN GAZ

AVERTISSEMENT

Remplacez les tuyaux de cuivre qui ne sont pas recouvert de plastique. Les tuyaux

utilisés DOIVENT être fait de cuivre plastifié ou d’acier inoxydable.

1. L’installation DOIT être conforme aux codes locaux. S’il n’y a pas de codes

locaux, l’installation doit être conforme au National Fuel Gas Code ANSI

Z223.1 (dernière édition) ou au Canada, CAN/CGA B149.1 (dernière

édition)

2. Le tuyau d’approvisionnement en gaz devrait avoir un diamètre de ½ pouce

(1.27cm).

3. Si les codes le permettent, un tuyau de métal flexible peut être utilisé pour

brancher la sécheuse à l’approvisionnement en gaz. Le tuyau DOIT être fait de

cuivre plastifié ou d’acier inoxydable.

4. L’approvisionnement en gaz doit être muni d’une valve d’arrêt manuel installée

à un maximum de 6 pieds (183cm) de la sécheuse, conforme au National Fuel

Gas Code, ANSI Z223.1/NFPA 54.

Au Canada, une valve d’arrêt manuel doit être installé conformément au code

B149.1 du Code d’installation de gaz naturel et propane

5. Un N.P.T de 1/8 de pouce (0.32cm) doit être installé directement en amont de

la connexion de l’approvisionnement en gaz de la sécheuse, et accessible

pour la vérification.

6. La sécheuse DOIT être débranchée de l’approvisionnement en gaz durant

les vérifications de pression dans les lignes de gaz lorsque les tests sont d’une

pression égale ou inférieure à ½ psig (3.45 kPa).

7. La sécheuse DOIT être isolée du système d’approvisionnement en gaz durant

les vérification de pression dans les lignes de gaz lorsque les tests sont d’une

pression égale ou inférieur à ½ psig (3.45kPa).

35 36

Page 37

Francais

L’EMPLACEMENT DE VOTRE SÉCHEUSE

N’installez pas votre sécheuse :

1. à un endroit exposé à un écoulement d’eau ou aux intempéries.

2. à un endroit où elle pourrait entrer en contact avec des rideaux, des tapis

épais ou quoique ce soit qui pourrait obstruer les système de ventilation de la

sécheuse

3. Sur le tapis, le plancher doit être solide et ne devrait pas avoir une pente de

plus que 1 pouce (2.54cm). Toute inégalité du plancher devrait être corrigée

à l’aide des dispositifs de mise à niveau situés sous la sécheuse.

Installation dans une alcôve ou un placard

1. N’INSTALLEZ PAS votre sécheuse dans un placard avec une porte solide

2. Une sécheuse installée dans une chambre à coucher, une salle de bain, une

alcôve ou un placard DOIT avoir un système d’échappement qui sort

directement dehors.

3. Aucun autre appareil qui effectue une combustion ne doit être installé dans le

même placard qu’une sécheuse au gaz

4. Référez-vous au dessins sur cette page pour vous assurez que l’installation ait

l’espace pour le dégagement requis au tour de la sécheuse pour la ventilation

5. Lorsque vous installez une sécheuse dans un placard avec une porte, un

minimum de 120 pouces carrés (774.2 cm carrés) de ventilation est

nécessaire. Les ouvertures doivent être égales au haut et au bas de la porte

et ne doivent pas être obstruées. Une porte à abat-son avec une ouverture

équivalente pour la longueur de la porte est acceptable.

Porte du placard

36

Page 38

Francais

INSTALLATION DANS UNE MAISON PRÉFABRIQUÉE (MOBILE)

1. La sécheuse doit avoir un système d’échappement qui sort directement dehors

(et non pas sous la maison) avec un tuyau de métal qui supportera pas la

combustion. Le tuyau de métal doit avoir un diamètre de 4 pouces (10.16cm

et ne doit pas être obstrué. De préférence, le tuyau serait de métal rigide

2. Si le système d’échappement passe par le plancher et le vide sanitaire et que

celui-ci n’est pas aéré, les system s’échappement DOIT aboutir dehors avec la

fin fixée solidement à la structure de la maison

3. Lorsque vous installez une sécheuse au gaz dans une maison mobile, une

provision d’air doit être faite, et ne devrait pas être plus petite que 2 fois la

région de la sortie de la sécheuse

4. Cette sécheuse DOIT être fixée au sol, utilisant la trousse d’installation P/N

0030807899 pour maison mobile. Suivez les instructions fournies avec la

trousse.

5. Référez-vous aux sections précédentes pour d’autres informations importantes

sur la ventilation.

6. L’installation doit être conforme à la plus récente version du Manufactured

Home Construction & Safety Standard (qui constitue un règlement fédéral, titre

24 CFR-Part 32-80) ou lorsque non disponible, au American National

Standard for Mobile Homes. Au Canada, le CSA Z240 est applicable.

Installation correcte

Installation correcte

Installation correcte

À faire

À faire

À faire

Installation incorrecte

Installation correcte

Installation incorrecte

Installation incorrecte

À ne pas

faire

À ne pas

faire

À ne pas

faire

37 38

Page 39

Francais

INSTALLATION ÉLECTRIQUE

AVERTISSEMENT

Les exigences suivantes doivent être respectées pour une

installation électrique sécuritaire et correcte. Le non-respect

de ces instructions peut provoquer des chocs électriques et /

ou risques d’incendie.

SÉCHEUSE ÉLECTRIQUE (RDE350AW)

1. Cet appareil doit être mis à la terre correctement. Les chocs électriques

peuvent subvenir si la sécheuse n’est pas mise à la terre correctement. Suivez

les instructions dans ce manuel pour faire une mise à la terre correcte.

2. N’utilisez pas de rallonge avec cette sécheuse. Certaines rallonges ne sont

pas conçues pour résister à la quantité de courant utilisé par une sécheuse

et peuvent fondre, créant ainsi des risques de chocs électriques ou d’incendie.

Installez la sécheuse à portée d’une prise de courant. Référez-vous au

prérequis électriques de ce manuel pour acheter le bon fil électrique.

3. Un passe-fils approuvé par UL doit être installé sur le fil électrique. S’il n’est

pas installé, le fil peut être sortie de la sécheuse et résulter en choc électrique.

4. N’utilisez pas une prise de courant d’aluminium avec une fiche et un fil

électrique de cuivre (ou vice versa). Une réaction chimique entre l’aluminium

et le cuivre peut causer des courts-circuits. Le branchement correct est un filage

et d’une fiche de cuivre dans une prise de cuivre.

Note: Les sécheuse sur un branchement de 208 volts on un encore un temps de

séchage plus élevés que celles sur un branchement de 240 volts.

AVERTISSEMENT: Un branchement mis à la terre incorrect peut résulter en

chocs électriques. Demandez à un électricien si vous êtes en doute.

SÉCHEUSE AU GAZ (RDG350AW)

1. Les sécheuses au gaz sont munies d’une fiche à trois broches 15 Amp ~

120 volts installée en usine (pour mise à la terre) pour votre protection contre

les chocs électrique. La fiche devrait être branchée directement dans une

prise de courant adéquate Ne jamais couper ou ôter la broche de mise à la

terre.

Page 40

Francais

BRANCHEMENT ÉLECTRIQUE

Sécheuse électrique

Branchement avec câble à 3-fils (modèles américains seulement)

1. Enlevez les vis fixant la couverture d’accès du bloc terminal et le support de

passe-fils situés sur le dos du coin supérieur de la sécheuse.

2. Installez un passe-fils approuvé par UL sur le trou duquel sort le câble. Ne

resserrez l’écrou qu’à la main pour le moment.

3. Filetez un câble de 30 Amp approuvé par UL, NEMA 10-30 de type SRDT,

par le passe-fils.

4. Attachez le fil neutre du câble (fil central) au terminal cuivré du bloc terminal

Bien visser les vis.

5. Attachez les deux fils conducteurs restants deux terminaux cuivrés aux

extrémités du bloc terminal. Bien visser les deux vis.

AVERTISSEMENT: Ne pas plier les fils; plutôt les enrouler autour de la vis.

6. Rattachez le support du passe-fils à l’arrière de la sécheuse avec deux vis.

Bien visser.

7. Vissez les vis qui retiennent le câble.

8. Vissez le passe-fils de sorte qu’il ne bouge pas.

9. Réinstallez la couverture d’accès du bloc terminal

Green Ground

Vis verte de mise

Screw

à la terre

Terminal cuivré

Brass Terminal

Bloc terminal

Fil neutre de

mise à la terre

Écrou

Support du passe-fils

Serrez l’écrou

Câble

39 40

Page 41

Sécheuse Électrique (RDE350AW)

Branchement à câble à 4 fils (modèles américains seulement)

Vis de mise à

la terre verte

Fil de mise à la

terre neutre

Rouge

Fil de mise à la terre

vert

Terminal de cuivre

Noir

Blanc

Écrou

Bloc terminal

Resserrez

l’écrou ici

Francais

Câble

électrique

Support du passe-fils

1. Enlevez les vis fixant la couverture d’accès du bloc terminal et le support de

passe-fils situés sur le dos du coin supérieur de la sécheuse.

2. Installez un passe-fils approuvé par UL sur le trou duquel sort le câble. Ne

resserrez l’écrou qu’à la main pour le moment.

3. Retirez le fil de mise à la terre vert de la vis de mise à la terre situé au haut du

bloc terminal

Prise de courant

typique

Câble à 4 fils

typique

Noir 240V

Blanc neutre

Rouge 240V

Vert mise à la terre

Page 42

Francais

4. Filetez un câble de 30 Amp approuvé par UL, NEMA 10-30 de type SRDT,

par le passe-fils.

5. Attachez le fil vert de mise à la terre au cabinet de la vis verte de mise à la

terre

6. Attachez le fil blanc (neutre) au fil externe et le fil de mise à la terre neutre au

terminal cuivré du centre sur le bloc terminal. Bien visser.

7. Attachez le fil noir et le fils rouge aux terminaux cuivrés de part et d’autre du

fil blanc sur le bloc terminal.

AVERTISSEMENT: Ne pas plier les fils; plutôt les enrouler autour de la vis

8. Vissez les vis qui retiennent le câble.

9. Vissez le passe-fils de sorte qu’il ne bouge pas.

10. Réinstallez la couverture d’accès du bloc terminal

BRANCHEMENT AU GAZ

Sécheuse au gaz (RDG350AW)

NOTE: NE PAS brancher la sécheuse à un service

1. Retirez le bouchon d’expédition à l’arrière de la sécheuse

2. Branchez un tuyau semi-rigide ou approuvé de ½ pouce (1.27cm) de la ligne

de gaz au tuyau de 3/8 de pouce (0.96cm) à l’arrière de la sécheuse.

Utilisez un réducteur 1/ 2 à 3/8 de pouce (1.27cm à 0.96cm) pour le

raccordement. Utilisez du scellant à filet approuvé qui résiste à la corrosion

causée par les gazes liquéfiés à tous les raccordements.

3. Ouvrez la valve d’arrêt manuel de la ligne de gaz

4. Testez tous les raccordements avec une solution d’eau savonneuse pour

s’assurer de leur étanchéité. NE JAMAIS CHERCHER LES FUITES DE GAZ À

L’AIDE D’UNE FLAME.

5. Connectez le tuyau d’échappement au système d’échappement et utilisez du

ruban adhésif (duct tape) pour sceller tous les joints.

6. Mettez la sécheuse à l’endroit désirer et ajustez pour que les 4 pattes touchent

par terre. Mettre au niveau. LA SÉCHEUSE DOIT ÊTRE AU NIVEAU ET BIEN

SUR SES 4 PATTES.

7. Branchez la fiche électrique dans la prise mise à la terre. N.B. : S’assurer que

le disjoncteur est éteint avant d’effectuer le branchement.

8. Allumez le disjoncteur.

ATTENTION: Avant de mettre la sécheuse en marche, assurez-vous que

l’environnement immédiat de la sécheuse est exempt de tout matériau

combustible, gaz, ou autres vapeurs inflammables. Assurez-vous aussi que rien

ne bouche le trou de ventilation à l’arrière de la sécheuse.

9. Mettre la sécheuse en marche pour s’assurer de son bon fonctionnement.

NOTE: Pour les sécheuses au gaz, il est nécessaire de le tuyau se vide de

son air avant de pouvoir s’allumer. Si le brûleur ne s’allume pas dans les 45

secondes suivant la première mise en marche de l’appareil, l’interrupteur de

sûreté l’éteindra. Si cela se produit, arrêtez la sécheuse et attendez 5 minutes

avant d’essayer de nouveau.

NOTE: Suivez les instructions fournies avec la trousse.

41 42

d’approvisionnement en gaz LP sans convertir la valve. Une

trousse de conversion LP doit être installé par un technicien

qualifié.

Page 43

Francais

BRANCHEMENT DE LA SÉCHEUSE À L’APPROVISIONNEMENT EN GAZ

A) Connectez le coude 3/8” NPT femelle à

l’entrée de gaz de la sécheuse. Connectez

ensuite l’adaptateur arrondi au coude

femelle.

IMPORTANT: Pour empêcher l’entrée de gaz

de se tordre, utilise une clé à tuyau pour bien

fixer l’entrée de gaz de la sécheuse. Utiliser du

ruban Teflon® ou appliquez du scellant à tuyau

à l’adaptateur à a l’entrée de gaz.

B) Fixez le connecteur de la ligne de gaz en

métal flexible à l’adaptateur.

C) Assurez-vous de l’étanchéité du raccord de

la ligne de gaz flexible. Utilisez deux clés

pour bien visser.

D) Pour vérifier la pression à l’entrée de gaz,

fixez un robinet branché de 1/8”

NPT à la valve d’arrêt manuel de la

ligne d’approvisionnement en gaz. Fixez un

adaptateur arrondi au robinet. Utiliser du

ruban Téflon® sur le raccord de

l’adaptateur et du robinet pour assurer

l’étanchéité.

Robinet

branché

Utiliser du ruban Téflon® sur

tous les filets mâles

E) Utilisez 2 clés ajustables pour bien visser

tout les raccords, en prenant soin de ne pas

TROP visser.

F) Ouvrir la valve d’arrête de la ligne de gaz.

Valve d’arrêt

Page 44

Francais

PIèCES DE REMPLACEMENT

Les pièces de remplacement et les accessoires pour les États-unis et le Canada

peuvent être commandés en appelant Haier America au 1-800-313-8495

ATTENTION: Étiquetez tous les fils avant de débrancher pour l’entretien. Des

erreurs de filage peuvent engendrer un fonctionnement incorrect ou dangereux.

Bien vérifier les branchements après l’entretien de l’appareil

AVERTISSEMENT: Jetez les cartons et les sacs de plastique après avoir déballé

la sécheuse. Les enfants ne devraient pas jouer avec. Les cartons recouverts de

tapis, couvertures ou de feuilles de plastique peuvent causer la suffocation et

entraîner la mort. Assurez-vous que tous les déchets d’emballage sont hors de la

portée des enfants.

AVERTISSEMENT: Les instructions dans se guide et les autres documents fournis

avec la sécheuse ne peuvent prévoir toutes les situations possibles. Un usage de

bon sens est nécessaire durant l’installation, opération et l’entretien de l’appareil.

Dans le doute, consultez un électricien qualifié pour installer le filage de la

sécheuse.

43 44

Page 45

Francais

INSTRUCTIONS D’UTILISATION

RDE/RDG 350AW

Comprendre le panneau de contrôle

1 2 3 4

NOTE:: Les caractéristiques peuvent varier selon le modèle

Bouton Temp (1)

• Choisir la température. Choix de 4 températures pour le séchage, soit élevée,

moyenne, basse et duvet d’air (High, Medium, Low et Air Fluff, respectivement)

Cadran Cycle Select (2)

• Choisir parmi 3 cycles de séchage automatique (Auto-Dry), robuste, normal et

délicat (Heavy Duty, Normal et Delicates, respectivement), ou 4 cycles avec

minuterie (Time Dry) de 30, 60, 90 ou 120 minutes.

Heavy Duty

Normal

Delicate

Pour les tissus tels que le denim (jeans) et les serviettes de bain.

Séchage normal

Pour sécher les petites quantités de vêtements et les tissus délicats.

Bouton Start/Pause (3)

• Appuyez sur le bouton de mise en marche (Start) après avoir choisi la

température et le cycle de séchage. Pour temporairement arrêter le cycle,

appuyer de nouveau, et encore pour remettre en marche.

Cycle Progress (4)

• Ceci indique la progression du cycle. À la fin du cycle de séchage, la sécheuse

tombe en mode anti-froissement automatiquement. Pendant ce mode, la

sécheuse culbute périodiquement pendant 1 heure après la fin du cycle

de séchage. Pour arrêter la sécheuse, simplement ouvrir la porte et retirer les

vêtements.

Page 46

Francais

PRÉPARATIONS AVANT LE SÉCHAGE

• Triez les vêtements par matériel (cotons, synthétiques, tricots)

• Les couleurs foncées et les couleurs pâles devraient être séchées séparément.

Les tissus qui perdent de la charpie et ceux qui les attirent devraient être séchés

séparément. Les vêtements qui ont tendance à perdre de la charpie devraient

être séchés à l’envers.

• Assurez-vous que les boutons et garnitures résistent à la chaleur et n’abîmeront

pas l’intérieur du tambour. Avant de les mettre à la sécheuse, toutes les

fermetures éclairs montées, et les boutons, crochets out ceintures attachés pour

éviter que les vêtements deviennent trop mêlés.

• Si possible, sortez les poches de vêtements pour un séchage uniforme.

• Vérifiez que les vêtements ne sont pas tachés. Si c’est le cas, relavez-les, sinon

les taches pourraient être permanentes.

• Les petits articles devraient être placée dans un sac en filet pour éviter de se

mêler et pour en simplifier la manutention

• Assurez-vous du bon branchement de mise à la terre. Le terminal de mise à la

terre ne devrait pas être branché à l’entrée de gaz ou d’eau.