Page 1

User Manual

Washing Machine

10kg

DIRECT MOTION

Temp

Spin

Delay Start/Pause

Speed Up

Speed

HWF10DW1

Page 2

2

3

Index

Thank you for purchasing a Haier product

Please read these instructions carefully before using this appliance. It contains

important information which will help you get the best out of your appliance and

ensure safe and proper installation, use, care and cleaning. Keep this manual in a

convenient place so you can always refer to it for safe and proper use.

If you sell the applican ce, give it away, or leave it behind when you move, make

sure you alse pass on this manual so that the new owner can become familiar with

all features and safety warnings.

Legend

Yes

No

General information and tips

Warning! Important safety information!

Environmental information

Safety............................................................................................................ 4-5

Installation.................................................................................................. 6-7

Product description.....................................................................................

Control panel............................................................................................ 9 -11

Programmes.................................................................................................

Consumption................................................................................................

12

13

Daily use.................................................................................................. 14 -17

Care and cleaning................................................................................ 18-20

Troubleshooting..................................................................................... 21-23

Technical data.............................................................................................. 24

8

Disposal

The presence of this symbol on the product,

accessories or materials that goes with this

information indicates that at the end of its useful

life the product or its electronic accessories (e.g.

cable, Aqua Stop hose) should not be disposed

with other household waste. To prevent possible

damage to the environment or human health from

uncontrolled waste disposal, please sepa rate these

items from other types of waste and recycle them.

This will promote the sustainable reuse of material

resources. Household users should contact either

the retailer where they purchased the product or

relevant local authorities to find out how they can

take this item for environmentally safe recycling

and safety. Business users should contact their

supplier and check the conditions of the purchase.

product and its electronic accessories should

This

not be mixed with other commercial waste.

Page 3

Safety

4 5

Safety

This appliance is intended to be used in household and similar applications such

as:

... staff ki tchen areas in shops, offices and other working environments;

... farm houses;

... by clients in ho tels, motels and other residential type e nvironments;

... bed and breakfast type e nvironments;

... a reas for communal use in blocks of flats or in launde rettes;

... max. capacity 10 kg,water pressure 0.03-1MPa.

Before switching on the appliance for the

first time...

...make sure all transport bolts are removed.

...make sure the power cord is not caught under or in

the appliance and there is no damage or risk for

damaging.

...make sure the power circuit fuse is rated for 10A.

...use a sepa rate earthed socket for the power supply.

...make sure the plug is always accessible.

...hold the plug and not the electric cable when

unplugging the power supply.

...check that hose joints and connections are firm and

by opening tap check for any water leaks.

...do not switch on the appliance until everything is

properly installed!

Do not …

...all ow children or infirm persons to play with the

appliance or packing materials.

...install the applian ce outdoors in a damp pla ce, or in

an area which may be prone to water leaks such as

under or near a sink unit. In the event of a water leak

cut power supply and allow the machine to dry

naturally.

...expose machine to any frost, heat or di rect sunlight.

...touch or use the appliance when barefoot or with

wet or damp hands or feet.

...use flammable de tergent or dry cleaning agent.

...use any flammable sprays in close vicinity to the

appliance.

...remove or insert the plug in p resence of flammable

gas.

...place the appliance directly on a carpet, or close to

a wall or furniture.

During daily use of the appliance...

The appliance is not to be used by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge,

unless they have been given supervision or in struction concerning use of the

appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the

appliance.

...supervise children.

Ensure that they don’t play with the applicance and

its packaging.

...ensure that appliance is not used by people with

reduced physical, sensory or mental capabilities, or lack

of experience and knowledge.

...pull up zips, fix loose th reads and take care for small

items to prevent laundry from being entangled. If

necessary, use an appropriate bag or net.

...switch off at the wall socket after each wash

programme to save electricity and for safety.

...keep the l ower part of the porthole clean and open

door and detergent dr

to prevent odours.

...a damaged power cord is only to be replaced by the

manufacturer, service agent or other specifically

qualified peopl e.

...Use the hose-set supplied with the appliance. Old

hose-sets should not be reused.

awer if applian

ce is not in use

Do not ...

...connect water inlet valve to the hot water supply.

... touch the door during the washing process, as it may

get hot.

...place heavy objects or sources of heat or damp on top

of the appliance.

...hot wash from rubber or sponge-like materials.

...open detergent drawer during any wash cycle.

...force the door to open, it is fitted with a self-lock

device and will open shortly after wash cycle end.

...open the door if the water level is visible over the

porthole.

...cover or encase the applian ceduring operation or after

wards as it will restrict any moisture or dampness to

evaporate .

Page 4

Installation

76

Installation

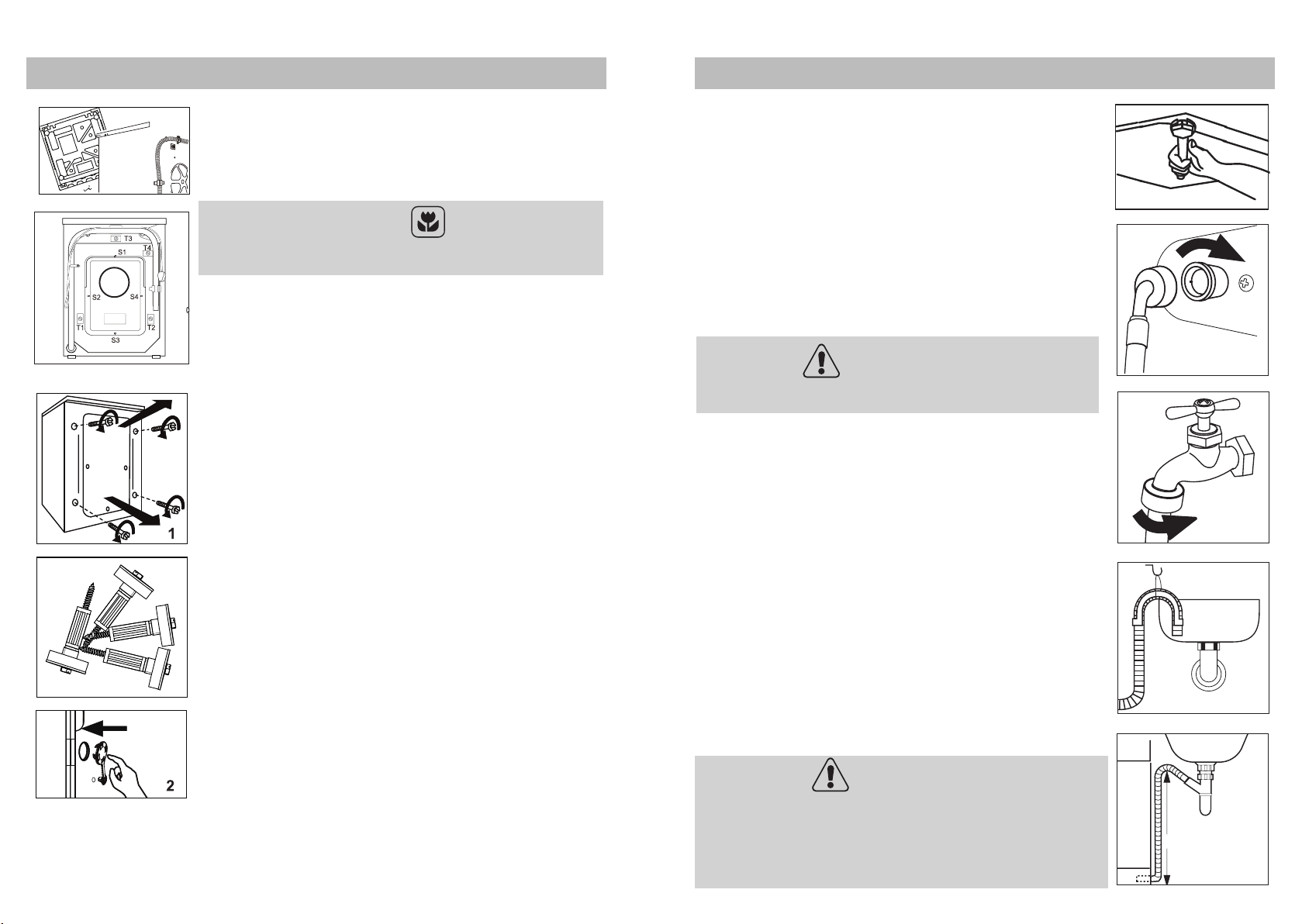

Preparation

Remove all packaging material including polystyrene

base. While opening the package, water drops may be

seen on plastic bag and porthole. This is normal as a

result from water tests and quality control in the factory.

Note: Packaging disposal:

Keep all packaging material out of children’s reach and

dispose them in an environmentally friendly manner.

Installing bottom plate

1. Lay the washing machine down to its sid e, window

upwards, bottom side towards operator. Insert the

bottom plate into the cabinet, then fixed with 2 screws

to the cabinet on the window side.

Removing the transportation bolts

The transportation bolts a re designed for clamping

antivibration components inside the appliance during

transportation.

2. Remove all 4 bolts.

4. Adjust all feets to achieve a complete level

position.This will minimize vibrations and noise

during use. It will also reduce wear and tear. We

recommend to use a spirit level for adjustment. Floor

should be as stable and flat as possible.

Inlet hose

1. Connect inlet hose to the machines water inlet valve .

2. Connect inlet hose to a water tap.

3. Tighten inlet hose connections and turn on water

supply. Check for any water leaks. Stop all water

leaks before continuing with installation.

Warning!

Appliance is only qualified for cold water supply!

Drain hose

Drainage could be installed in dif ferent ways.

Nevertheless, level of drain hose has to reach between

80-100 cm.

If possible al ways keep drain hose fixed to the clip at

the back of the appliance.

General information and tips:

Keep the transportation bolts in a sa fe place for later

use. If the machine is to be moved to another location,

replace transportation bolts contrariwise to prevent

damage.

3. Fill the transportation bolt holes with blanking plugs.

1. Drain hose to sink

Use the drain hose bracket to keep drain hose end retained and out of any water level.

Fix the bracket securely to avoid dr

ational movements.

2. Drain hose to sink siphon

Connection has to be securely sealed and fixed to corresponding adapter above the siphoning part!

opping due to oper-

Warning!

The drain hose should not be submerged in water and

should be securely fixed and leak-free. If the drain hose

is placed on the ground or if the pipe is at a height of

less than 80 cm, the washing machine will continuously

drain while being filled (self-siphoning).

80 - 100 cm

Page 5

Production description

10kg

DIRECT MOTION

Delay Start/Pause

8 9

10kg

Temp

Spin

Speed Up

Speed

DIRECT MOTION

Temp

Speed Up

Spin

Speed

Delay Start/Pause

Control panel

(a-g)

S5 S6

This drawing may be slightly different from the layout of the washing machine you have

just purchased.

1. Door

2. Detergent/Softener drawer

3. Worktop

4. Control panel

5. Pump filter cover

6. Adjustable feet

1 Transportation bolts (T1-T4)

2 Back cover

3 Back cover screws(S1-S6)

4 Power cord

5 Water inlet valve

6 Drain hose

Accessories

Check the accessories and literature in accordance with this list.

Inlet hose

assembly

5 blanking plugs

Drain hose

bracket

1. Detergent/Softener drawer

2. Display

3. programme selector

4. “On/Off” button

5. Function buttons (a-g)

a. Delay

b. Speed up

c. Temperature

d. Spin Speed

e. Extra Rinse

f. Water Level

g. Start/Pause

Detergent drawer

Open the drawer and you will see two compartments

Compartment 1: De tergent or Washing powder

Compartment 2: Softener, Conditioning agent etc.

The recommendation on the type of detergents is

dependant on the various washing temperatures.

Please refer to the manual of detergent.

Display

If the appliance is on display will light up the actual status on six different sections (see

next pages). During operation display will be deactivated after a while (Energy saving

mode) until programme selector is turned at random.

Programme selector

By turning the dial one of 16 programmes can be

will be displayed.

selec

ted,

its default settings

Warranty-card

User manual

“On/Off” button

Touch this button gently to switch on . The display will illuminate . Touch it

again for about 2 seconds to switch off. If no panel element or programme is

activated after a whil e, the machine will shut down automatically.

Page 6

10 11Control panel-function buttons

Display symbolsControl panel-

To get best results in each programme Haier has well defined specific default

settings. If there is no special requirement default settings are recommended.

According to these factory settings many programme parameters and

additional functions could be individually changed.

“Delay”-Start time delay (Button a)

Touch it to increase programme end time in increments

of 30 minutes at most 24hr. Press the Start/Pause

button once you are satisfied with the delayed end time.

You will note the countdown of the delay time commence and subsequently the remaining programme

cycle time will be displayed. The related symbol to the

operation will display.

a b

“Speed Up” (button b)

Touch it to reduce washing time.

General information and tips:

End time must always be longer than programme cycle time. Otherwise

operation will start immediately, and the end time chosen will be never reached.

f g

“Water Level” (button f)

Touch it to select a p roper level of water. When selecting from L1 to L3, the water level increase gradually.

“

Start/Pause

Touch it to start or interrupt the currently

displayed programme.

” (button g)

“Child Lock” (button a+b)

The “Child Lock” function stops any further changes

to the set program. To active, hold the “Delay” and

“Speed Up” buttons at the same time for 3 seconds.

Panel elements will be blocked after hearing an

indicating voice. To deactivate the “Child Lock” hold

the “Delay” and “Speed Up” buttons at the same time

for 3 seconds.

Display

The display shows following information:

1. Washing time

2. End time del ay

3. Error codes and servi ce information

c d

“Temp” (button c)

Touch it to change the washing temperature of the

programme. If there is no value the water is not he ated.

“Spin Speed” (button d)

Touch it to change or deselect the spin of the program-

e

me. If there is no value, the laundry will not spin.

Symbols of the display:

Remaining operation time

Remaining dealy

time

Time display

“ Extra Rinse” (but ton e)

Touch it to rinse the laundry more intense with fresh

water. This is recommended for people with sensitive

skin. Zreo to three additional rinse cycles are available.

Running weighing

cycle

Running Washing

cycle

Running Rinse

cycle

Running spin/

drainage cycle

Page 7

Programmes

12 13

Consumption

Programme table

1. Washing powder compartment

2. Detergent compartment

3. Softener compartment

Programme Temp. Preset 1 2 Fibre Type Preset

1. Cotton

2. Eco

3. Towels

4. Duvet

5. Allergy

6. Rinse

7. Spin

8. Drum Clean

9. Daily Wash

10. Mix

3

Cotton/Synth.

Cotton/Synth.

Towels

Duvet

Cotton/Synth.

Cotton farics

Cotton/Synth.

1000 rpm

1000 rpm

1000 rpm

800 rpm

1000 rpm

1000 rpm

1000 rpm

600 rpm

1000 rpm

1000 rpm

The indicated consumption values may differ in local conditions.

Washing

Programme Max load

kg

1. Cotton

2. Eco

3. Towels

4. Duvet

5. Allergy

6. Rinse

7. Spin

8. Drum Clean

9. Daily Wash

10. Mix

11. Express 15

12. Delicate

13. Bedding

14. Synthetic

15. Sport

16. Baby Care

10

10

5

3

5

5

10

0

3

10

3

3

7

5

3

5

Rinse

Times

2

2

2

2

3

2

0

1

2

2

1

2

3

2

1

3

WaterLTemp

L-1

L-1

L-1

L-1

L-1

L-1

L-1

L-1

L-1

L-1

L-1

L-1

L-1

L-1

L-1

30

30

60

40

60

90

30

30

30

30

30

40

time

h:min

Auto

Auto

1:36

1:07

1:51

0:26

0:07

1:00

0:56

Auto

0:15

0:56

1:42

Auto

1:01

1:35

Spin drying

performance

%

60

11. Express 15

12. Delicate

Bedding

13.

14. Synthetic

15. Sport

16. Baby Care

Cotton/Synth.

Cotton farics

Bedding

Chemical

fibre fabrics

Sports Wear

Cotton/Synth.

1000 rpm

600 rpm

1000 rpm

1000 rpm

1000 rpm

1000 rpm

General information and tips:

Standard programme for the Energy and Water Labelling according to

AS/NZS 2040.2

Eco, 40 ℃, 1400 rpm,

Eco, 40℃, 1400rpm is the program for a normally soiled cotton load.

others are default setting.

Page 8

1514

Daily useDaily use

This appliance is only for domestic use inside the house. If it is used for

commercial, industrial or not intended purposes any Haier guarantee will not

be valid anymore. Consider instructions on each garment label and wash only

machine-washable laundr y.

Power supply

Connect the washing machine to the power supply

(220V to 240V/50Hz).

Water connection

Turn on the tap. The water must be clean and clea r.

Warning!

Before use, check for leakage in the joints between the tap and the inlet hose

by turning on the tap.

Preparing laundry

Sort out clothes according to fabric (cotton, synthetics, wool or silk) and to how dirty they are. Pay

attention to the care labelling of washing labels.

Separate white clothes from coloured ones. Wash

coloured textiles first by hand to check if they fade

or run.

Empty pockets (keys, coins, etc.) and remove

harder decorative objects (e.g. brooches).

Loading the appliance

Open the door and put in the washing machine piece by piece. Close the door

carefully.

Don‘t overload. Check if you can put a hand upright on top of load.

General information and tips:

After installation or long down time , run programme “Drum Clean“ with no

load and add detergent in washing agent compartment to remove possibly

corruptive residues.

Selecting detergent

Washing efficiency and performance will vary depending on detergent quality. Use only machine wash

approved detergent and if needed specific detergents, e.g. for synthetic and woolen fabric. Be mindful

of always detergent manufacturer recommendations.

General information and tips:

Remove detergent residues before next wash cycle. Please follow given

detergent dosage recommendation.

Garments without hems, delic ates and finely woven

textile such as f ine curtains are to be put into a

wash bag (hand or dry cleaning would be better).

Close zippers and hooks, make sure the buttons are

sewn on tightly and place small items such as socks,

belts, bras, etc. in a wash bag.

Unfold large pie ces of fabric such as bed sheets,

bedspreads etc.

Turn jeans and printed, decorated or color-intensive

textiles inside out; If possible, wash them separately.

Warning!

Non-textile, as well as small, loose or sharp-edged items may cause malfunctions

and damage of clothes and appliance.

Adding detergent

Slide out the detergent drawer and put the required

chemicals into corresponding compartments. Push

back the drawer gently.

Select a programme

To get the best washing results, select the program

that is most suitable to the laundry type loaded.

Select program by turning the p rogram selector dial.

Page 9

Daily use Daily use

16 17

Add individual selections

Select required options and settings refer to “Control

panel”.

Temp

Speed Up

Spin

Speed

Start wash programme

Delay Start/Pause

Touch “Start/Pause” button to start. Appliance

operates according to selected settings. Changes are

only possible by cancelling wash programme.

Geeneral information and tips:

1. For safety reasons the door is locked partially during the washing cycle. It is

only possible to open the door at the end of the programme or after the

programme was cancelled correctly (see description ab ove).

2. In case of high water level, high water temperature and drum spinning it is

impossible to open the door, Lock- is displayed.

Interrupt- cancel wash programme

To interrupt a running programme press gently

“Start /Pause” button. Press it again to resume

operation.

To cancel a running programme and all its individual

settings activate “Start/Pause” and then hold

“On/Off” for about 3 seconds.

Care chart

Geeneral information and tips:

Choose programme settings carefully refering to icons on each laudry label

and “Care chart”. Removing laundry promptly at the end of cycle will minimise

weinkling.

After washing

Turn off the water supply and unplug the power cord.

Open the door to prevent formation of moisture and

odours. Leave it open while not used.

Page 10

Care and cleaning Care and cleaning

18 19

Cleaning the detergent drawer

Clean the drawer from detergent residues regularly.

Pull out the drawer until it stops (1) and press the

release button (2) to remove the drawer. Then flush the

drawer with water until it is clean and insert the

drawer back in the appliance.

Cleaning the machine

Unplug the machine during cleaning and maintenance. Use a soft cloth with

soap liquid to clean the machine case and rubber components. Do not use

organic chemicals or corrosive solvents.

Cleaning the drum

Remove accidentally washed metal parts, such as pins, coins, etc. from the

drum because they cause rust stains and damage. Use a non-chloride cleaner

for removing rust stains. Observe the warning hints of the cleaning agent

manufacturer. Do not use any hard objects or steel wool for cleaning.

Cleaning the machine

If the appliance is left idle for a long period:

Pump filter

Clean the fil ter once a month and check the pump filter

immediately if the appliance:

doesn´t drain the water.

Warning!

Scalding Risk! Water in the pump filter can be very

hot!Before and action please ensure water has cooled down.

1. Turn off and unplug the machine.

2. Open service flap at the right corner of appliance front.

3. Provide a flat container to catch leach water. There could

be bigg amounts!

4. Pull the drain hose out and hold its end above the

container .

5. Take the sealing plug out of the drain hose.

6. After complete drainage close drainhose and push it

back into the machine.

1. Pull out the power plug.

2. Turn off water supply.

3. Open the door to prevent formation of moisture and

odours. Let door open while not used.

4. To prevent drying out, do not le ave the dispenser

lids open for a long period of time.

5. Empty, clean and dry the detergent drawer.

Before next usage check carefully power cord, water

inlet and drain hose. Make sure everything is properly

installed and no leakage..

7. Unscrew and remove counter clockwise the pump.

8. Remove contaminants and dirt.

9. Clean pump fil ter carefully.

10. Refix it thoroughly.

11. Close service flap.

General information and tips:

Pump filter sealing has to be clean and unhurt. If the lid is

not full tightened, water will escape . The filter must be in

place, or it may lead to leakage.

Page 11

Care and cleaning Troubleshooting

20

21

Display code

Water inlet valve and inlet valve filter

To prevent blockage of water supply by solid substance

like lime clean regularly the inlet valve filter.

Unplug the power cord and turn off the water

supply.

Unscrew the water inlet hose at the back of the

appliance as well as on the tap.

Remove the filters and flush them with water and a

brush.

Insert the filter and install the inlet hose.

Choose the best Detergent

Universal

ECO

Synthetic

Cotton

Express 15

Delicate

L

P

o Optional

L/P

L/P

L/P

L

-

Detergent

iL

diuq

Powder

No-

Colour

L/P

L/P

L/P

L

-

Delicate

-

L

-

L

Temperature range in °C

Special

dloc

06

40 - 90

---

---

-

-

-

-

-

-

If using liquid detergent, it is not recommended to activate the delayed

start. Refer to the detergent manufacturers packaging for recommended

dosage!

info: Modern washing detergents at low temperatures.

Softener

O

O

O

O

O

Code Cause

Auto

1:25

Automatic load detection

Remaining wash cycle time.

19:30 Remaining delay end time Likely showing the delay end operation.

Lock

Door cannot be opened due

to water level or hot water

in the drum,or if the drum is

End

still moving,wait for it to stop

before attempting to open

the door.

End of cycle.

Drainage error, water not

emptied

E2 Lock – error with door

E4

Water level not reached after

8 minutes.

E8

Water protective level-error.

F3

F4

Temperature sensor-error.

Heating error (Appears at the

end of a cycle)

F7 Motor - error.

FA

FCX

(X=1,2,)

Unb

Water level sensor error.

Electronic control - error.

Unbalanced load and not able

to spin.

Solution

Laundry weight detection in process.

please wait until p rogram cycle time is

displayed.

Wait for the program to end or cancel

the program and select the Spin

ramme,

the drum, to avoid scalding , select the

Rinse programme and leave it to wash

for several minutes then select the

Spin program.

This should allow the drum to cool down.

Clean pump filter.

Check drain hose for block

ensure it is installed properly.

Check if water supply and water pressure

is normal.

Drain hose is self-syphoning.

Auto release. Otherwise contact the

af ter sales servi ce.

Contact the after sales servi ce.

Contact the after sales servi ce.

Contact the after sales servi ce.

Contact the a fter sales service.

Check and balance the laundry load in

the drum. Also reduce the load if too

heavy. Restart with a spin program.

In case there is still hot water in

Shut the door properly

Contact the after sales servi ce.

prog-

age, and

Page 12

Troubleshooting Troubleshooting

2322

In case of power failure

The current programme and its setting

When power supply is restored, operation will be

resumed.

If a power failure cuts an operating wash programme

door opening is mechanically blocked. To get out any

laundry water level should not be seen in the glassy

porthole of the door. - Danger of burns! Water level has

to be lowered as described in “Pump filter”. Not till then

pull level(A) beneath service flap until door as unlocked

by a gentle click. Afterwards refix all parts.

Troubleshooting without displ ay code

Problem Cause Solution

Washing machine

fails to operate

Washing machine

will not fill with

wate.

Machine is

draining while

being filled.

Drainage failure.

1. Power failure

2. Machine hasn’t been switched

on.

3. Door is not properly closed.

4. Programme is not yet started

1. No water

2. Inlet hose is kin ked.

3. Inlet hose filter is blocked.

4. Water pressure is less than

0.03Mpa.

5. Door is not properly closed.

6. Water supply failure.

1. Height of d rain hose is bel ow

80cm.

2. Drain hose end could reach

into water.

1. Drain hose is bloc ked.

2. Pump filter is blocked.

3. Drain hose end is higher than

100cm above floor l evel.

1. Check power supply.

2. Switch the machine on.

3. Close the door p roperly.

4. Press “START/PAUSE”

button.

1. Check water tap.

2. Check inlet hose.

3. Unblock inlet hose filter.

4. Check water pressure.

5. Close the door properly.

6. Ensure the water supply.

1. Make sure that drain hose is

properly installed.

2. Make sure the drain hose is

not in water.

1. Unblock drain hose.

2. Clean pump filter.

3. Make sure that drain hose is

properly installed.

will be saved.

Problem Cause Solution

Strong vibration

while spinning.

Operation stops

for a period of

time.

Operation stops

before completing wash cycle.

1. Not all transportation bolts

have been removed.

2. Appliance has no solid

position.

3. Machine load is not correct.

1. Applian ce displays error code.

2. Problem due to load pattern.

3. Programme performs soaking

cycle.

Water or electric failure.

1. Remove all transportation

bolts.

2. Ensure solid g round and

a levelled position.

3. Check load weight and

balance.

1. Consider displ ay codes.

2. Reduce or adjust load.

3. Cancel programme and

restart.

Check power and water

supply.

Excessive foam

floats drum and/or

detergent drawer.

Automatic adjust-

of washing duration will be adjusted. affect functionality.

ment

time

Spinning fails Unbalance of laundry. Check machine load.Run the

1. Detergent is not a appropriate.

2. Excessive use of detergent in

manually dosage.

Washing programme

1. Check detergent recom mendations.

2. Reduce amount of dete rgent.

This is normal and doesn‘t

Spin programme again.

General information and tips:

If too much foam is visible during spin cycle, the motor will stop and drain

pump will activate for 90 seconds. If that elimination of foam fails up to 3

times, programme ends without spinning.

Page 13

Technical data

Basic technical information regarding the appliance

24

Power source

Max. working current (A)

Water pressure (MPa)

Nominal load ( kg)

Max spinning speed (rpm)

Washing programmes

Max. power (W)

Dimensions (HxDxW mm)

Net. weight (kg)

Power consumption of the off-mode (W)

220-240V/50Hz

10

0.03 P 1

10

1400

16

2000

850x600x595

74

0.2

Power consumption of the left-on mode (W)

0.2

Loading...

Loading...