Page 1

USER MANUAL

Automatic Drum

Washing Machine

HWD-D1200TXVE

HWD-D1200TXVEME

HWD-D1000TXVE

HWD-D1000TXVEME

Page 2

Table of contents

page no.

Before use

Parts .......................................................................................................... 1

Safety instructions ................................................................................. 2 - 4

Installation ............................................................................................ 5 - 6

Functions .............................................................................................. 7 - 8

Using the appliance

Programme selection ................................................................................. 9

Preparation .............................................................................................. 10

Using your appliance ........................................................................ 11 - 12

Other functions ....................................................................................... 13

Maintenance

Maintenance .................................................................................... 14 - 15

Trouble shooting ..................................................................................... 16

Technical specifications ............................................................................ 17

Page 3

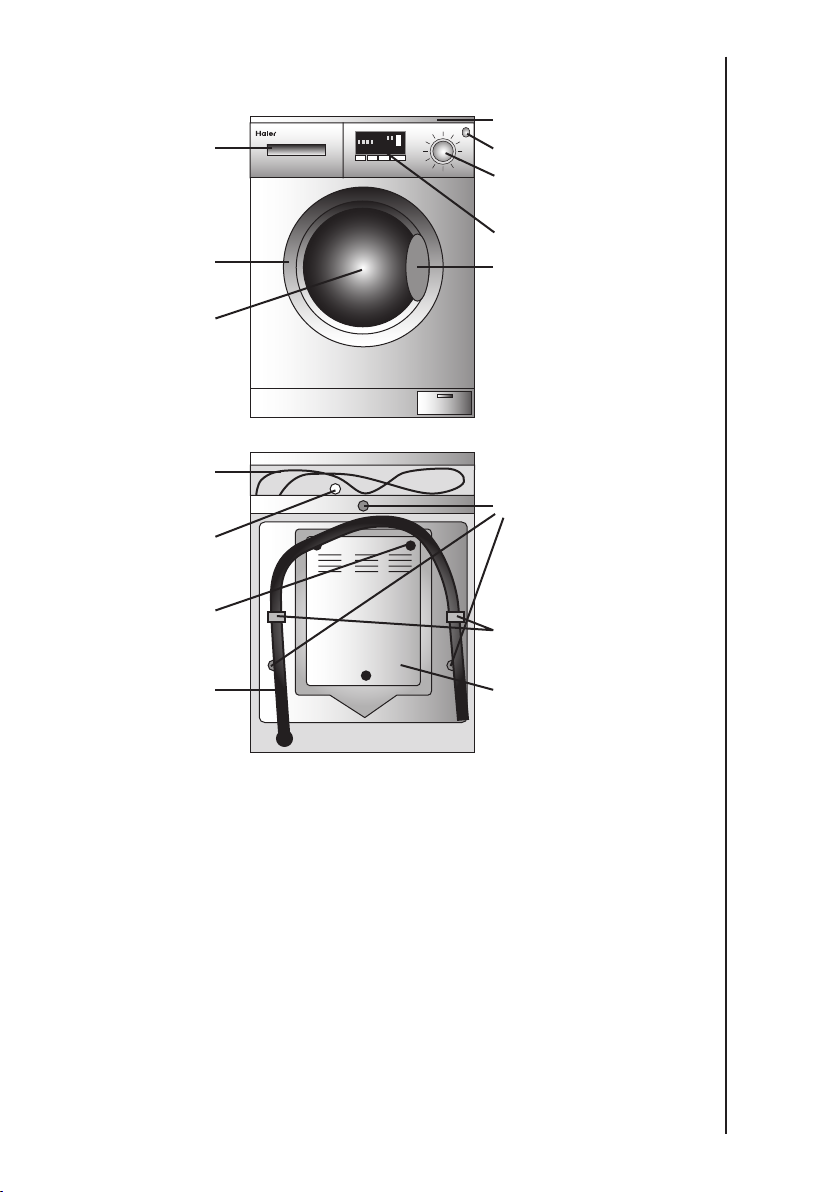

Parts

Detergent

dispenser

Door

Porthole

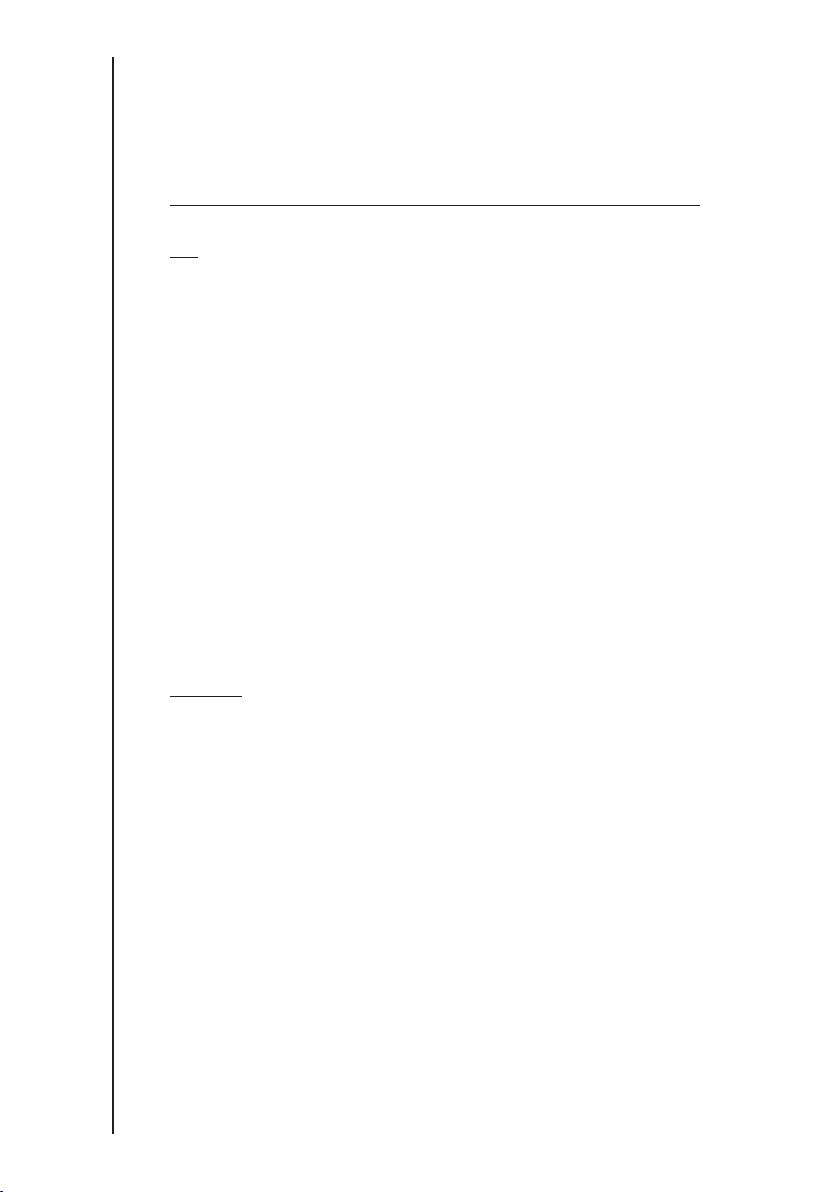

Power cable

Earthing terminal

Back plate

screws (3)

Drain hose

Top panel

Power button

Selection dial

Display

Door handle

Packing bolts (3)

Hose clip

Back plate

This diagram may vary slightly with the layout of the washing machine you

have just purchased due to technical improvements.

NOTICE

Please read these instructions carefully before using this appliance. The

instructions contain important information which will help you get the

best out of the appliance and ensure safe and proper installation, use and

maintenance.

KEEP THIS MANUAL

Keep this manual in a convenient location so you can refer to it to check safe

and proper use of the appliance. If you sell or give the appliance to someone

else, or leave it behind when you move house, make sure you also pass on

this manual so that the new owner can become familiar with the appliance

and safety warnings.

1

Page 4

Safety instructions

Using your appliance will be simple, but please make sure read the following

to get the best out of it and to ensure your own safety.

BEFORE SWITCHING THE APPLIANCE ON FOR THE FIRST TIME:

DO

✓ Ensure you connect the appliance directly to a domestic mains water

supply.

✓ Ensure that the appliance is situated on a firm level base.

✓ Ensure that the electrical system meets the requirement laid out in the

installation section of this document.

✓ Use a separate earthed socket for the power supply.

✓ Make sure that the plug is accessible.

✓ Make sure that the power cable is not caught under or in the appliance

and avoid damage to the power cable.

✓ Check that hose joints and connections are firm and no water can leak.

If joints are loose or there is leakage, turn off the tap and repair. Do not

use the washing machine until the hoses are properly fixed.

DO NOT

✗ Connect the appliance to the power supply until installation is

complete.

✗ Install the appliance outdoors or in a damp place. In the event of a

water leak allow the machine to dry naturally.

✗ Expose the appliance to heat sources or direct sunlight to prevent

plastic and rubber components from aging.

✗ Use an appliance with missing parts.

2

Page 5

DURING DAILY USE OF THE APPLIANCE

DO

✓ Unplug the appliance before carrying out any maintenance or repair.

✓ Hold the plug and not the electric cable when unplugging the washing

machine.

✓ Keep the door slightly open when not in use to prevent formation of

odours.

✓ After each wash programme, turn off the machine and switch it off at

the mains to save electricity and for safety. Wipe clean the lower part of

the porthole.

✓ Pull up zips and fix loose threads to prevent the items from being

entangled. If necessary, put small items into a net bag or pillow.

DO NOT

✗ Touch or use the appliance when barefoot or with wet or damp hands

or feet.

✗ Use flammable detergent or dry cleaning agent.

✗ Open the detergent drawer during the wash cycle.

✗ Use any flammable sprays in close vicinity to the appliance

✗ Remove or insert the plug in the presence of flammable gas

✗ Place heavy objects or sources of heat or damp on the top of the

appliance.

✗ Obstruct the ventilation openings at the base of the appliance.

✗ Attempt to repair the appliance yourself. Contact the manufacturer or

their approved service agent.

✗ Allow children or the infirm to play with the appliance or packing

materials, without adult supervision.

✗ Touch the porthole during the washing process – it gets hot!

✗ Force the door open. The door is fitted with a self-lock device and will

not open until 2-3 minutes after the washing machine stops.

✗ Open the door if the water level is visibly over the porthole.

✗ Use the appliance if the power cable is damaged. It must be replaced

by the manufacturer, its approved service agent or similarly qualified

persons in order to avoid a hazard.

✗ Wash foam rubber or sponge-like materials on a hot wash.

✗ Cover the appliance.

3

Page 6

Safety instructions

Electrical connection (UK ONLY)

For your safety please read the following information

Warning: This appliance must be earthed.

The appliance must be connected to a 220 volt 240 cycle AC supply by

means of a three pin socket, suitably earthed and should be protected by a

13 amp fuse.

The appliance is supplied with a standard 3 pin mains plug fitted with a 13

amp fuse. Should the fuse require replacement, it must be replaced with a

13 amp fuse approved to BS1362.

The plug contains a removable fuse cover that must be refitted when the

fuse is replaced. In the event of the fuse cover being lost or damaged, the

plug must not be used until a replacement cover has been obtained.

When disposing of the appliance the plug should be cut off as close to

the plug body as possible and the fuse should be removed to prevent an

electrical hazard. Dispose of the plug safely.

The use of adapters, multiple connectors and/or extension cables is not

recommended.

How to wire a 13 amp plug.

Important

The wires in the mains lead on this

appliance are coloured in accordance with

the following code:

Green and Yellow – Earth

Blue - Neutral

Brown - Live

As this may not correspond with your installation, proceed as follows:

The green and yellow wire must be connected to the terminal in the plug

which is marked with the letter E or with the earth symbol ~ or coloured

green and yellow,

The blue wire must be connected to the terminal marked N.

The brown wire must be connected to the terminal marked L.

4

Page 7

Installation

Caution: protective gloves should be warn

• Remove all the packing materials

(including the foam base) to prevent

vibration during use, as show in Fig. 1.

On opening, water drops may be visible

on the appliance. This is a normal

phenomenon.

• Check that the appliance is also supplied with the following:

User

manual

Quantity 1 1 1 1 3

• Remove the packing bolts as shown in

Fig. 2.

The packing bolts are designed for

support of internal components during

transit.

Before use:

1. Remove the back plate.

2. Remove the three packing bolts on

the back plate and take out the hose.

3. Replace the back plate.

4. Fill the holes left by the packing bolts

with the plastic plugs provided.

Attention: The packing bolts and hose

should be kept in a safe place for later

use.

Quality

certificate

1

Water

hose

2

Hose clip

Plastic

plugs

• Levelling the appliance

There are adjustable feet under the

bottom of the appliance. Before use,

the appliance should be adjusted, as

show in Fig. 3, so that it is level. This

will minimise vibrations and thus noise

during use. It will also reduce wear and

tear. We recommend using a spirit level

to level the appliance.

3

5

Page 8

Installation

Connecting the hose to the cold

water supply

1. Connect the nut on the water

inlet hose to the connector on

the water valve. Ensure all seals

are in place.

2. Tighten the nut to secure the

hose.

Drain hose

• The height of the drainage outlet must

be between 80-100cm. To prevent the

drain hose from dropping, attach it

using the drain hose clip at the back of

the washing machine.

• Use the hose clip to secure the end

of the drain hose and to prevent the

outflow of water. It is recommended

that the length of the drain hose is not extended by way of a hose extension.

In case of absolute need, we recommend that the extension has the same

diameter as the existing hose and does not exceed 250cm in length.

Water inlet hose nut

Water inlet valve connector

Note: The drain hose should not be underwater and should be securely fixed

and leak-free. When the drain hose is placed on the ground or the height

of the pipe is less than 80cm, the washing machine will continuously drain

while being filled (self-syphoning).

Connection to the power supply

Before connecting to the power supply, make sure that:

• The socket is suitable or the maximum power of the washing machine (for

safety, fuses in the power circuit should be rated for no less than 13A).

• The supply voltage should be within the values indicated on the

specifications page.

• The power supply socket and the plug of the washing machine should

be compatible. If they are not compatible, refer to a washing machine

technician or Haier designated service engineer for power cable replacement.

• The washing machine should be earthed and in compliance with applicable

law.

• Additional earthing cables should not be necessary if the socket and plug are

earthed.

• If required, an additional earthing cable should be installed on the upper

6

back of the washing machine and earthed.

Page 9

7

Cont r ol p a nel

A. Power button G. Start/Pause button

B. Programme selection dial H. button

C. D etergent distribution drawer I. Dry button

D. Spin speed setting button J. Extra rinse button

E. D isplay K. Delay button

F. Wash status indicator L. Wash temperature button

Fu n ct io n s

A. P ower button

Press this button to switch on the washing machine. Press it again to switch

it off.

B. Pro g r amme selection dial

Turn the dial clockwise or anti-clockwise to select the required programm e.

(Refer to Program me selection guide).

C. Detergen t distr ibut ion drawer

Programme descriptions are printed on the front of

the detergent distributor, there are three detergent

compartments numbered 1, 2, 3.

Box 1: Standard washing - extra-fast washing

Box 2: Softener

Box 3: Pre-washing detergent

D. Spin speed setting butto n

Touch this button to select the desired speed. Refer to page 10 for guidance

on spin speeds.

E. D isplay

Information such as rem aining wash time, tem perature and speed setting

and error messages are shown here.

F. W ash sta tus in dicato r

This light shows the stage of the cycle of the selected programm e.

C

KIJ H G

F E L A

B

1 2 3

D

WashRinse Spin Dry

Delay Extrarinse Dry Start/Pause

Time

Quickwash

Wool

Synthetics

Cotton&Linen

Prewash

Wash

Rinse

Spin

Dry

Iron

Air wash

Page 10

Functions

G. Start/Pause button

When the washing machine is connected to the power socket and a

programme is selected, touch this button to start operation. Touch this

button again during operation to pause the programme. The display screen

will flash and the machine will be paused. Press the button again and the

programme will continue.

H. button

Economy wash. This function automatically adjusts water consumption,

wash time and heating time.

The wash load range is:

Prewash: 1kg~6kg;

Cotton: 1kg~6kg;

Synthetic: 1kg~3kg;

Quick wash: 1kg~3kg;

Wash: 1kg~6kg;

Rinse: 1kg~6kg;

Spin: 1kg~6kg

I. Dry button

Touch this button, the corresponding light will come on and the appliance

will dry the laundry after the last spin cycle.

J. Rinse hold button

Rinse hold helps reduce the creasing and odours that occur when you leave

damp laundry in the appliance after the cycle has finished. The laundry

stays in the water from the last rinse until you deselect the rinse hold button

which will then start the spin programme to finish off the cycle.

K. Delay button

Touch this button and the washing machine will start operation after the

selected delay period. The corresponding indicator will go on. The delay

range is 0.5-24 hours. Each touch of this button increases the delay by half

an hour. After the delay is selected, press the Start/ Pause button to start

countdown (the time is displayed on the screen until the programme ends).

Note: The delay time must be longer than the programme time, otherwise

the washing machine will start the wash programme immediately.

L. Wash temperature button

Touch this button and the wash temperature will be displayed on the

screen. Select a suitable temperature according to the type of laundry. The

corresponding light will come on.

8

Page 11

Programme selection guide

1

Cotton & Linen

2

3

Synthetic fabrics

4

5

cotton, linen and

synthetic fabrics

6

Cotton, linen and

synthetic fabrics

7

Cotton, linen and

synthetic fabrics

8

Cotton, linen and

synthetic fabrics

9

Cotton, linen and

synthetic fabrics

10

Cotton, linen and

synthetic fabrics

11

Cotton, linen and

synthetic fabrics

Setting

Laundry

Prewash

Heavy-soiling

Cotton fabric

Synthetics

Wool

Wool fabrics

Quick Wash

Lightly-soiled

Wash

Rinse

Spin

Dry

Iron

Air wash

Default Setting

* 30°C 40°C

50°C 60°C 90°C

* 30°C 40°C

50°C 60°C 90°C

* 30°C 40°C

50°C 60°C

* 30°C 40°C *

* 30°C 40°C

* 30°C 40°C

50°C 60°C

*

*

The laundry is completely dry when the cycle is complete.

The laundry is completely dry when the cycle is complete.

Air refresh wash for small items that need a quick refresh

Default

Setting

1200rpm

40°C

1200rpm

40°C

1200rpm

40°C

1200rpm

40°C

40°C

1200rpm

40°C

1200rpm

Comp 1 Comp 2 Comp 3

*

(e.g. school uniforms)

Detergent

★

★

★

★

★

★

X O X

X X X

O

O X

O X

O X

O X

O X

★

NOTE: “O” indicates that softener can be added if need;

“★” indicates that detergent must be added;

“X” indicates that detergent must not added;

“*” indicates cold water.

1) The wash temperature indicates the maximum temperature.

2) The wash temperature refers to the maximum temperature.

The wash cycle times are intended as a guide only. The actually used time may

vary due to different water pressure, initial water temperature etc.

9

Page 12

Preparing for a cycle

Detergent selection

Only special low foam detergent should be used in automatic drum washing

machines. For blended or wool fabrics, special detergent should be used.

Dry cleaning solvent should not be used.

Caution: do not use too much detergent.

Laundry treatment

• Sort out clothes according to type and extent of dirt. There are three

types of clothes; cotton, synthetic and woollen (silk) fabrics.

• Separate white clothes from coloured clothes. If whites and coloureds are

combined for one load, make sure the coloureds are colourfast.

- Remove all objects from pockets that may cause damage to the

machine, such as keys and coins.

- Clothing with frayed edges or yarns should be put in a wash bag or

equivalent before washing.

- Repair damaged clothing, loose buttons or damaged zips and hooks

before washing.

- Bed sheets and tableware should be loosely loaded and not folded.

• This washing machine is for household use and designed for

mechanically washable clothes. When washing, separate clothes

according to their labels.

Wash load

10

Type Cotton Synthetic Delicate Quick

Max load 6 kg 3 kg 2 kg 3 kg

Spin speeds

Program

prewash 1000rpm 40°C 1200rpm 40°C

Cotton 1000rpm 40°C 1200rpm 40°C

Synthetic 800rpm 40°C 800rpm 40°C

Wool 800rpm 40°C 800rpm 40°C

Cashmere 400rpm 40°C 400rpm 40°C

Silk 400rpm 40°C 400rpm 40°C

Quick 1000rpm 40°C 1200rpm 40°C

Single Wash / / / /

Single Rinse 1000rpm 40°C 1200rpm 40°C

Single Spin / / / /

Single Drain / / / /

Default setting Default setting

speed Temperature speed Temperature

Page 13

Programme times

NO. Program Default time (minute)

1 Prewash 133

2 Cotton & Linen 116

3 Synthetic 72

4 Wool 60

5 QuickWash 12

6 Wash 61

7 Rinse 24

8 Spin 11

9 Dry 150

10 Iron 60

11 Air wash 30

Using your appliance

1. Loading

Open the door, put in the laundry piece by piece and then tightly close

the door.

Notes:

1)

Before the first run of the appliance it is advisable to run the machine

empty on a quick wash with no detergent to clean through the system.

2) Do not overload the washing machine.

• Overalls

• Blended fabric clothes (approx. 800g) • Underwear (approx. 70g)

• Woollen blankets (approx. 3000g) • Jeans (approx. 800g)

• Socks (blended fabrics approx. 50g) • Shirts (approx. 300g)

• Jackets (cotton approx. 800g) • Pyjamas (approx. 200g)

• Single bed sheets (cotton approx. 800g)

(cotton approx. 950g) • T-shirt (approx. 300g)

2. Adding detergent

Slide out the detergent drawer and add the required detergent and

softening agent into the correct places. Push back the drawer.

Caution:

1) Do not add liquid detergent to compartment 1 or 3.

2) On a prewash programme, detergent should be added to both

compartments 1 and 3. For other programmes, do not add detergent

to compartment 3.

3) Always refer to the clothing manufacturer’s guidelines prior to

washing.

11

Page 14

Using your appliance

3. Selecting washing programme

To get the best wash, an appropriate washing programme should be

selected according to the type of laundry.

4. Washing temperature settings

Set the washing temperature as required, otherwise set at position *

when a cold wash is acceptable.

5. Function selection buttons

Select functions as required (refer to the “Functions” section). Otherwise

keep all the buttons deselected.

6. Washing

Press the Start/Pause button and the washing machine will automatically

commence the selected wash cycle.

7. Finish

The washing machine will stop operation automatically when a wash

cycle ends and the “End” symbol will be displayed. Open the door and

take out the laundry. Then switch the machine off at the mains to save

electricity and for safety.

Hints for saving energy

12

During operation

1. Use a full wash load.

2. Do not overload the washing machine.

3. Prewash or soak heavily soiled clothes. Use a stain remover to remove the

worst stains. These actions reduce the need to wash garments at a high

temperature.

4. Reduce the amount of detergent or choose standard or delicate wash

programmes for lightly soiled clothes.

5. Choose the correct washing temperature. Choose the lowest

temperature setting appropriate for the load.

6. Do not use more detergent than required.

Page 15

Other functions

1. Control panel lock function:

To prevent children from accidentally changing the settings, the control panel can be

locked by pressing the “Temperature” and “Delay” buttons at the same time. After the

panel is locked, the sign “LOCK” and the remaining wash time will be displayed on the

LED alternately. Now all the function keys except the power switch are locked. Press the

key combination again to cancel this function.

2. Power-off memory function:

This machine has a power-off memory function. In the event of unintentional power

failure or if the power has to be cut during a programme cycle, the present cycle will be

saved and operation will resume when the power is switched on again.

3. Error display messages:

1:16 Remaining time 1 hour and 16 minutes.

0:01 Remaining time 1 minute.

60°C Wash temperature is 60°C.

--°C No heat (cold wash).

0 No Spin.

800 Spin speed 800r/min.

L--1 Manually selected code when laundry weight is less than 1kg.

L--A Manually selected code when drum is nearly full.

End Programme is finished.

Err1: Cause: Door is not shut properly.

Solution: Shut the door properly.

Err2: Cause: Drainage error, water not emptied within 4 minutes.

Solution: Clean the filter and check the drain hose for blockage. Take care on

Err3: Cause: Temperature sensor error.

Solution: Contact an approved service engineer.

Err4: Cause: Heating element error or laundry overload that leads to a failure to

Solution: Reduce load and then start washing again or contact an approved

Err5: Cause: Water level not met in 8 minutes.

Solution: Make sure that tap is turned on and water pressure is normal. If

Err6: Cause: dehumidification/ heating error.

Solution: Please contact an approved service engineer.

Err7: Cause: Motor overheat error.

Solution: Please contact an approved service engineer.

Err8: Cause: Water overflow

Solution: Please contact an approved service engineer.

Err9: Cause: Dryer temperature sensor error.

Solution: Please contact an approved service engineer.

Er10: Cause: Water level sensor error.

Solution: Please contact an approved service engineer.

Er12: Cause: Dryer water level sensor error.

Er13: Cause: Dryer heater error.

Solution: Please contact an approved service engineer.

Un6: Cause: Laundry is unevenly distributed.

Solution: Redistribute laundry to balance the drum. If the problem persists,

EUAr: Cause: Communication error.

Solution: Please contact an approved service engineer.

removing filter in case any water remains in the unit. If the error persists, please

contact an approved service engineer.

reach the set temperature within the specified time (This message is displayed

at the end of a programme).

service engineer.

problem still persists, please contact an approved service engineer.

Solution: Check whether clothes are dry or not and whether there is water still in

the drum. If so allow excess humidity to escape from the appliance and try the

drying cycle again. If the error persists please contact an approved service engineer.

please contact an approved service engineer.

13

Page 16

Maintenance

1. Turn off the water tap and pull out electricity plug after each wash. Open

the porthole to prevent formation of moisture and odours. If the washing

machine is left idle for a long period, drain the water in the machine and

replace the drain hose.

2. Unplug the machine during cleaning and maintenance. Use a soft

cloth dampened with soap liquid to clean the machine case and rubber

components. Do not use organic chemicals or corrosive solvents.

3. Clean the detergent distribution drawer

regularly. Swing out the drawer, flush it

clean with water and then replace it.

4. Clean the filter Cleaning methods (once a month)

14

1 2

1) Push out the outer cover (Fig. 1);

2) Screw out filter by turning counter clockwise (Fig. 2);

3) Flush clean with running water;

4) Replace the filter by turning clockwise and remount the cover (Fig. 3);

Caution: The filter must be in place, or it may lead to leakage.

3

Page 17

Maintenance

5. To prevent blockage to the water supply

by ingress of foreign substances, clean the

water inlet and inlet filter regularly.

6. If the machine is to be moved to a distant place, replace the vibration

absorbing locks (packing screws, rubber gaskets) removed before

installation to prevent damage as shown below.

Remove the lock cover

and take out the three

rubber plugs.

Insert the transit bolts. Insert the rubber gaskets.

Tighten with a spanner. Replace the back cover.

7. If the washing machine is left idle for a long period, pull out the electrical

plug and turn off the water tap. Open the door to prevent formation of

moisture and odours. Let the door open while not used.

15

Page 18

Trouble shooting

In the unlikely event of difficulties with your appliance please follow the trouble

shooting guide below. If the problem persists, contact an approved service

engineer. If an error code is displayed, please refer to the error code guide below.

Problem Possible cause How to correct the problem

The washing machine

fails to operate

Washing machine does

not fill with water

• Incorrect connection to

power supply

• Power failure

• Door is not properly closed

• Machine has not been

switched on

• Water tap is not turned on

• Water pressure is too low

• The inlet hose is kinked

• Water supply failure

• The programme selection

dial is not properly set

• The door is not properly

closed

• Check power supply.

• Check that door is properly

closed.

• Check that machine is on.

• Check water supply is to a

domestic mains supply and that

tap is fully open.

• Check that hoses are not bent

or crushed.

• Turn dial to correct position.

• Check that door is properly

closed.

The machine is

continuously filling and

draining

Drainage failure

Strong vibration during

spin cycle

Operation stops before

completion of the wash

cycle

Excessive foam in the

drum

Operation stops for a

period of time

• Drain hose is too low

• Drain hose is blocked

• End of drain hose is over

100cm above the floor

level

• Some packing fixing bolts

not removed

• Washing machine on an

uneven surface

• Machine is overloaded

• Water or electricity failure

• Washing machine is in

soaking cycle

• The detergent is not a low

foam type

• Excessive detergent has

been used

• Washing machine is in

anti-crease soaking cycle

• Washing machine gives an

error message

• Check that the height of the

drain hose is above 80cm

• Check drain hose

• Check packing bolts

• Use a spirit level to ensure the

appliance is level

• Reduce amount of laundry in

the appliance below the max

level

• Check power and water supply

• Check detergent type.

• Use less detergent

• Wait until cycle is complete.

• See error messages on previous

pages.

16

Page 19

17

M odel / Item HWD-D 1000T X VE/M E HWD-D1200 TXVE/M E

Power Source 22 0-2 40 V/ 50H z 220-240 V/ 50 Hz

Working C urrent

(M ax) (A)

10 10

Tap Water Pressure

(M Pa)

0. 03 P 1 0. 03 P 1

Washing Power (W) 20 0 20 0

Spinning Power ( W ) 350 450

M ax Load ( kg) 6 6

Spinning Speed ( M ax)

(r/m in)

10 00 12 00

Washing Procedure 11 11

Water Heating Power

(W )

10 00 10 00

Heating Power (W) 100 0 100 0

External Dimension

(H xDxW ) mm

85 0 x 590 x 595 850 x 5 90 x 595

Weight ( kg) 82 82

Washing N oise 54 . 3 54. 3

Spinning N oise 71. 8 71 . 8

Tech n i ca l sp eci-ca t io n

≤ ≤

≤ ≤

Page 20

We apologise for any inconvenience caused by minor inconsistencies in

these instructions, which may occur as a result of product improvement and

development.

The symbol on the product or on its packaging indicates that

this product may not be treated as household waste. Instead it should be

handed over to the applicable collection point for the recycling of electrical

and electronic equipment. By ensuring this product is disposed of correctly,

you will help prevent potential negative consequences for the environment

and human health, which could otherwise be caused by inappropriate waste

handling of this product. For more detailed information about recycling

this product, please contact your local council office, your household waste

disposal service or the shop where you purchased the product.

Loading...

Loading...