Page 1

Installation Manual of Room Air Conditioner

Read this manual before installation

Explain sufficiently the operating means to the user

according to this manual.

Necessary Tools for Installation

1.Driver

2.Hacksaw

3.Hole core drill

4.Spanner(17,19 and 26mm)

Accessory parts

No. Accessory parts

Remote controller

1

2

3

4

5

6

7

8

9

R-03 dry battery

Mounting plate

Drain hose

Steel nail, cement

4X25

Screw

Plastic cap

Cover

Cushion

Pipe supporting plate

4X50

Number

of

articles

1

2

1

1

6

4

1

4

1

5.Torque wrench(17mm,22mm,26mm)

6.Pipe cutter

7.Flaring tool

8.Knife

9.Nipper 12.Reamer

10.Gas leakage detector or

soap-and-

water solution

11.Measuring tape

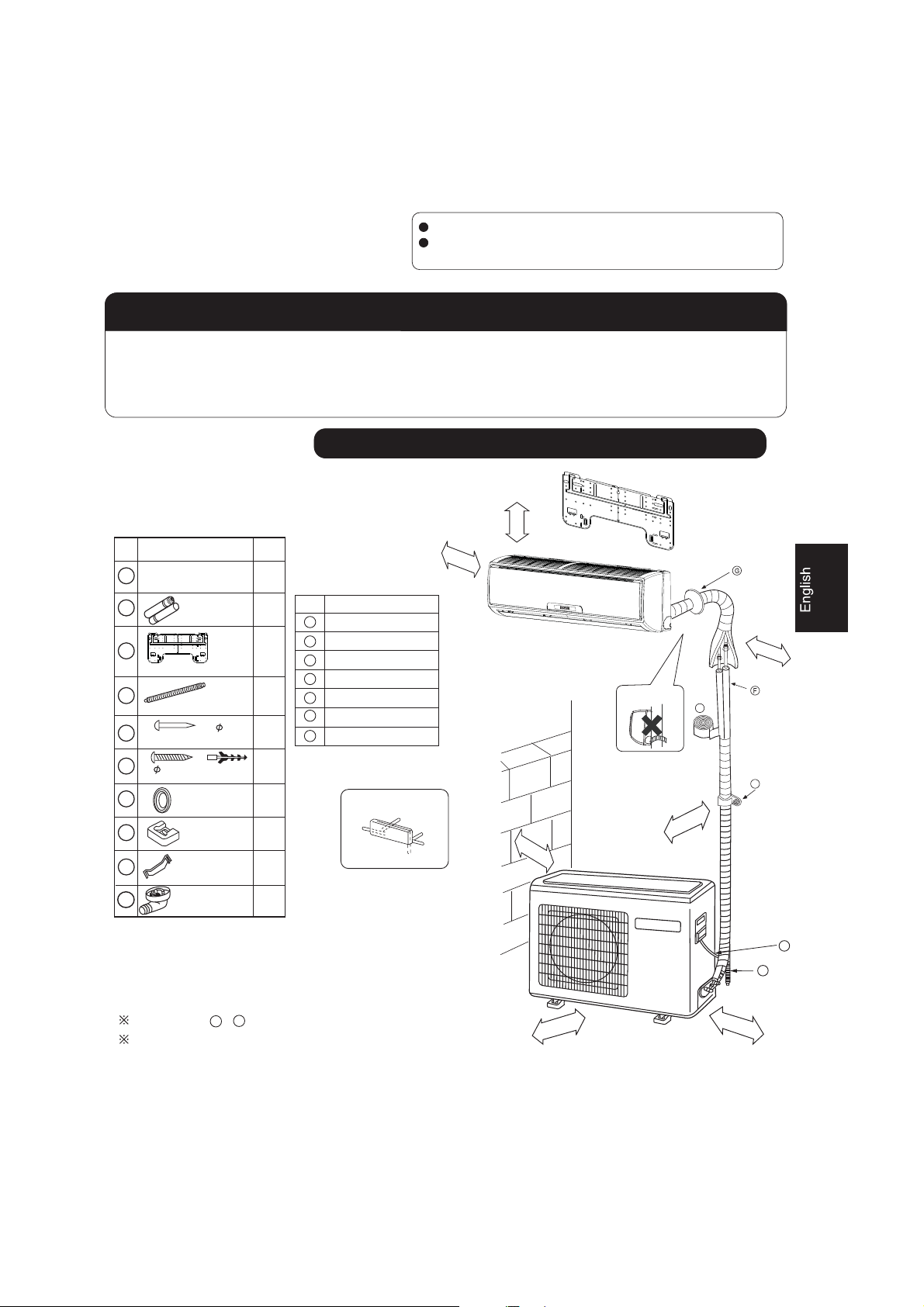

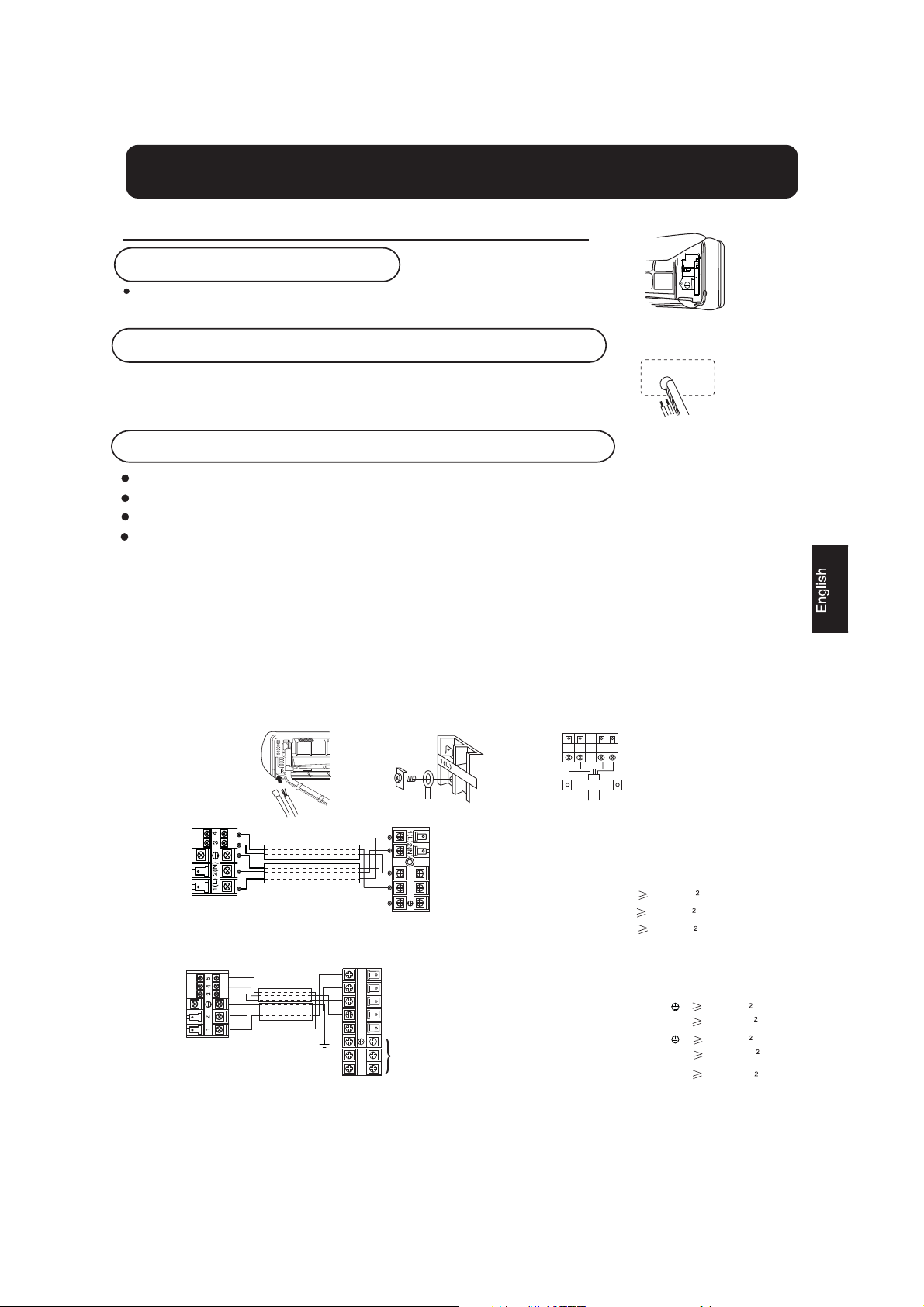

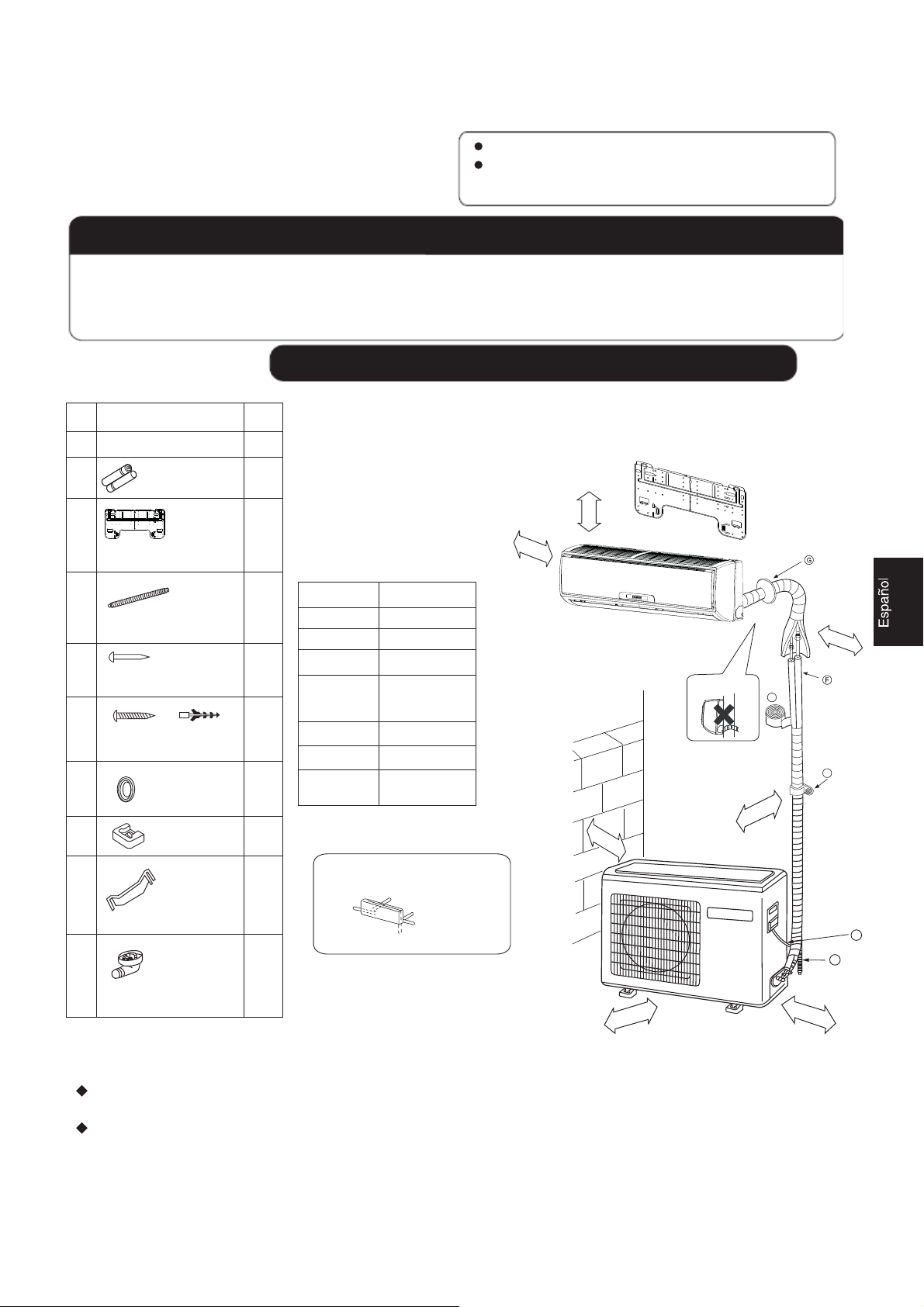

Drawing for the installation of indoor and outdoor units

mc5nahterom

mc01nahterom

Optional parts for piping

Mark

Parts name

A

Non-adhesive tape

Adhesive tape

B

Saddle(L.S) with screws

C

Connecting electric cable

D

for indoor and outdoor

Drain hose

E

F

Heating insulating material

Piping hole cover

G

Arrangement of piping directions

Left

Rear left

Bel

ow

Rear

right

Right

Attention must be paid to

the rising up of drain hose

mc01nahterom

mc01nahterom

A

C

mc0

1

nahterom

10

Drain-elbow

The marks from to in the figure are the parts numbers.

A

1

G

The distance between the indoor unit and the floor should be

more than 2m.

No.0010516146

D

E

mc06

na

hterom

1nahterom

mc5

Page 2

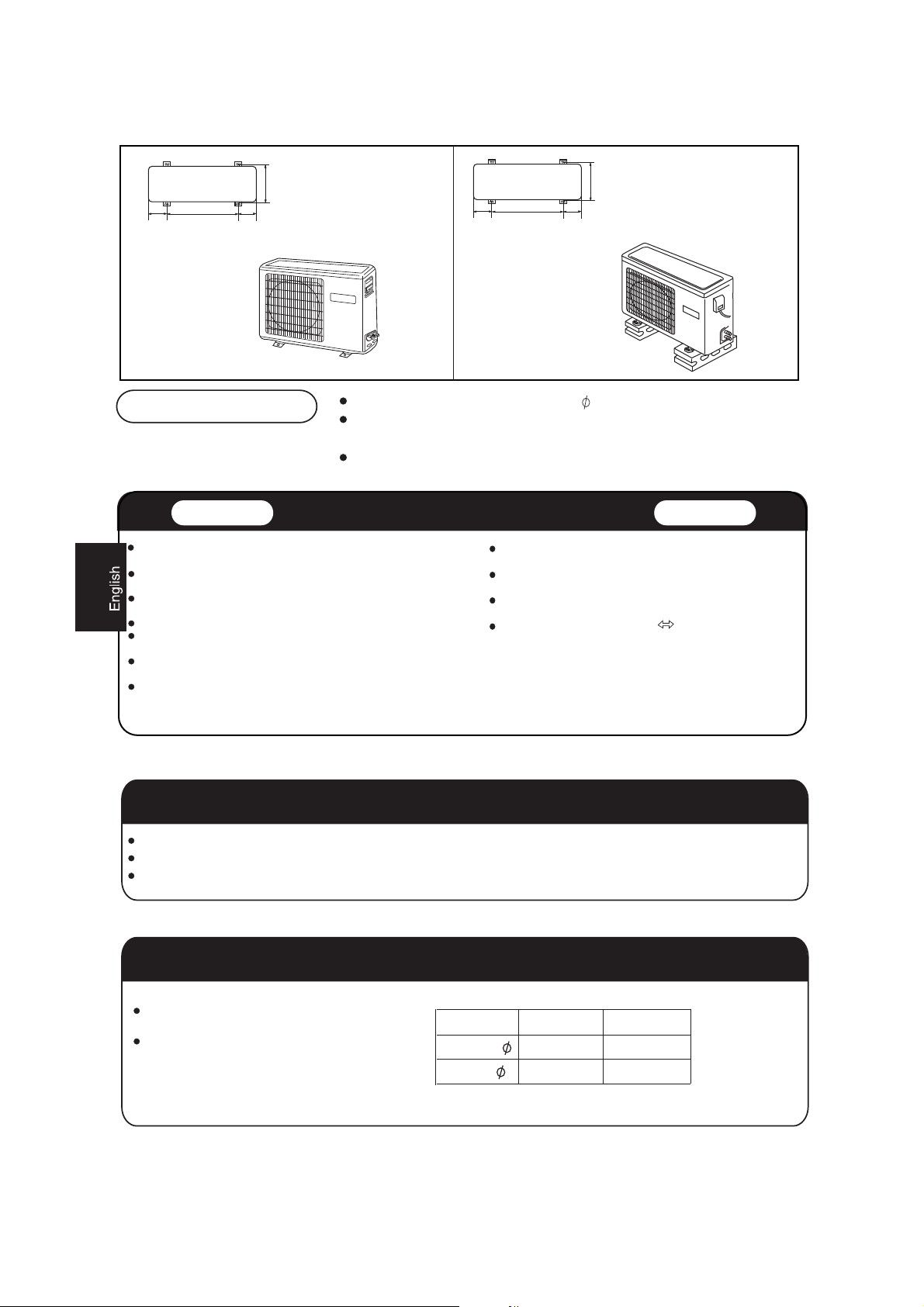

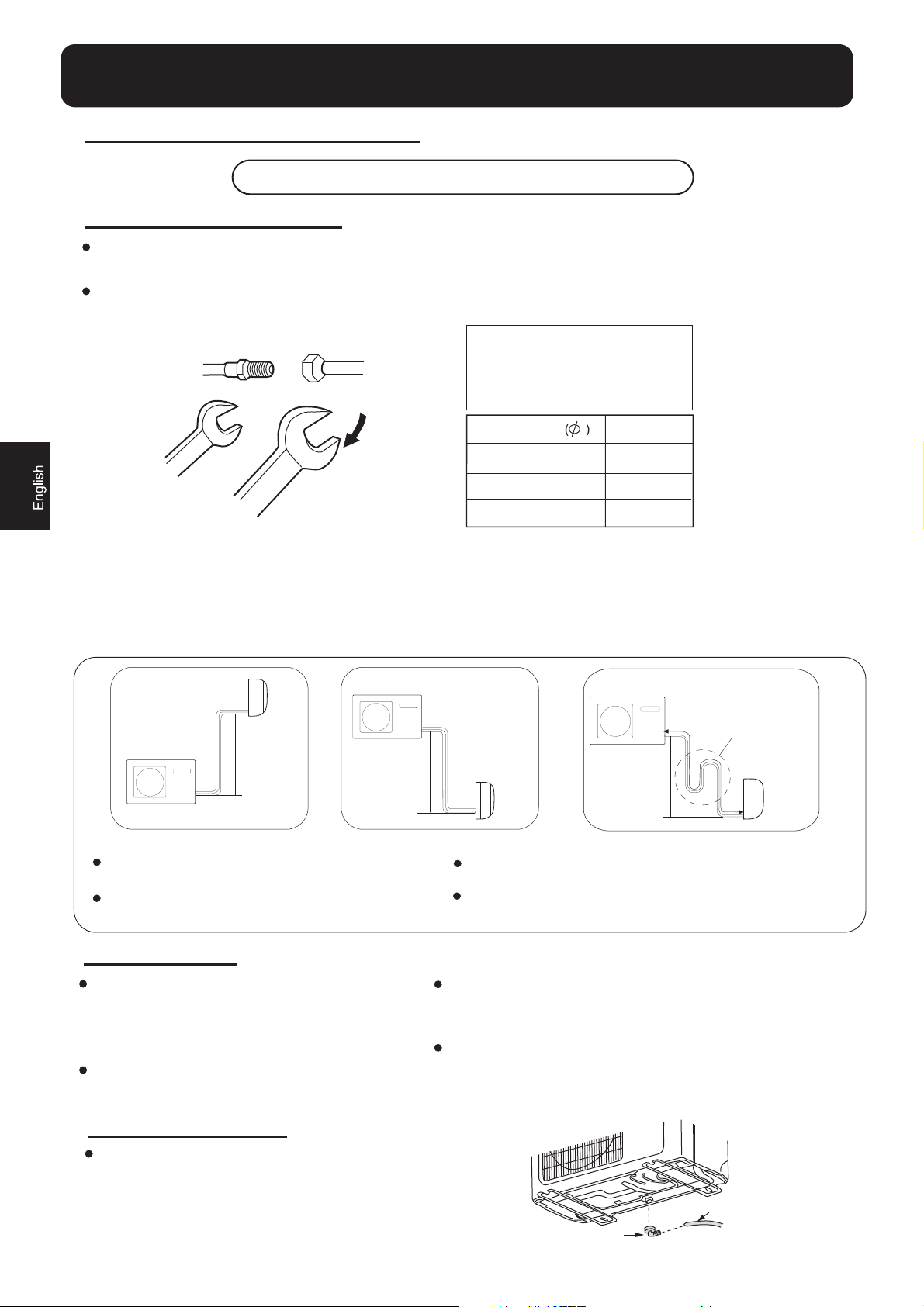

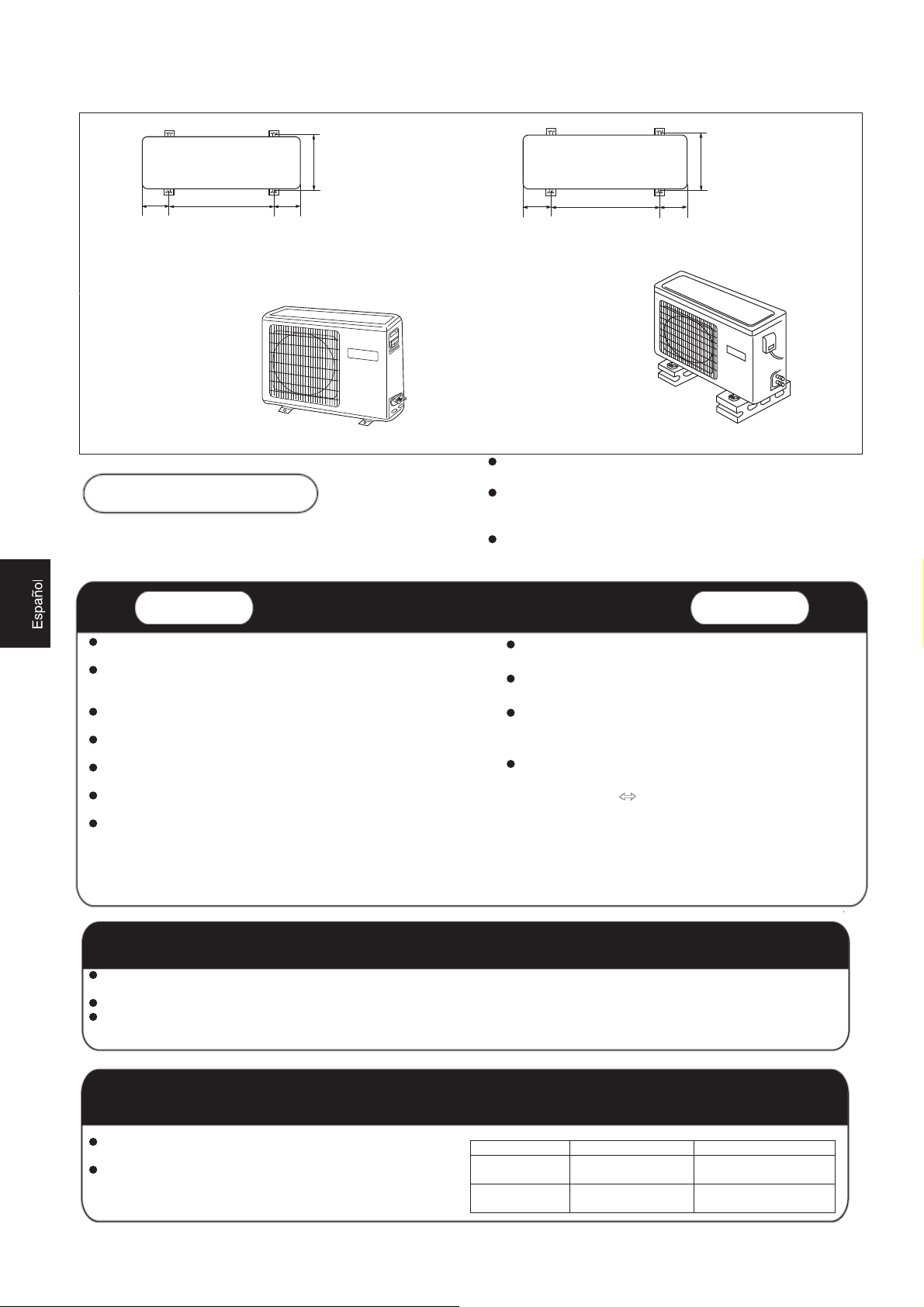

140

500 140

Floor fixing dimensions

of the outdoor unit

(Unit:mm)

256

115

580

Floor fixing dimensions

of the outdoor unit

(Unit:mm)

115

5.913

HSU-07HEA03/R2

HSU-09HEA03/R2

HSU-09HEA103

HSU-12HEA03/R2

HSU-18HEA03/R2

Fixing of outdoor unit

/R2

Fix the unit to concrete or block with bolts( 10mm) and nuts firmly and horizontally.

When fitting the unit to wall surface, roof or rooftop, fix a supporter surely with nails

or wires in consideration of earthquake and strong wind.

If vibration may affect the house, fix the unit by attaching a vibration-proof mat.

Indoor Unit

Place, robust not causing vibration, where the body can be supported

sufficiently.

Place, not affected by heat or steam generated in the vicinity, where

inlet and outlet of the unit are not disturbed.

Place, possible to drain easily, where piping can be connected with the

outdoor unit.

Place, where cold air can be spread in a room entirely.

Place, nearby a power receptacle, with enough space around. (Refer

to drawings).

Place where the distance of more than lm from televisions, radios,

wireless apparatuses and fluorescent lamps can be left.

In the case of fixing the remote controller on a wall, place where the

indoor unit can receive signals when the fluorescent lamps in the room

are lightened.

Selection of Installation Place

HSU-22HEA03/R2

Outdoor Unit

Place, which is less affected by rain or direct sunlight and is

sufficiently ventilated.

Place, possible to bear the unit, where vibration and noise are

not increased.

Place, where discharged wind and noise do not cause a

nuisance to the neighbors.

Place, where a distance marked is available as illustrated

in the above figure.

Power Source

Before inserting power plug into receptacle, check the voltage without fail. The power source is the same as the corresponding name plate.

Install an exclusive branch circuit of the power.

A receptacle shall be set up in a distance where the power cable can be reached. Do not extend the cable by cutting it.

Selection of pipe

To this unit, both liquid and gas pipes shall be insulated

as they become Iow temperature in operation.

Use optional parts for piping set or pipes covered with

equivalent insulation material.

Liquid pipe ( )

Gas pipe ( ) 9.52mm(3/8")

1

For 07 09 12

6.35mm(1/4")

For 18 22

6.35mm(1/4")

12.7mm(1/2")

Page 3

Indoor unit

Indoor unit

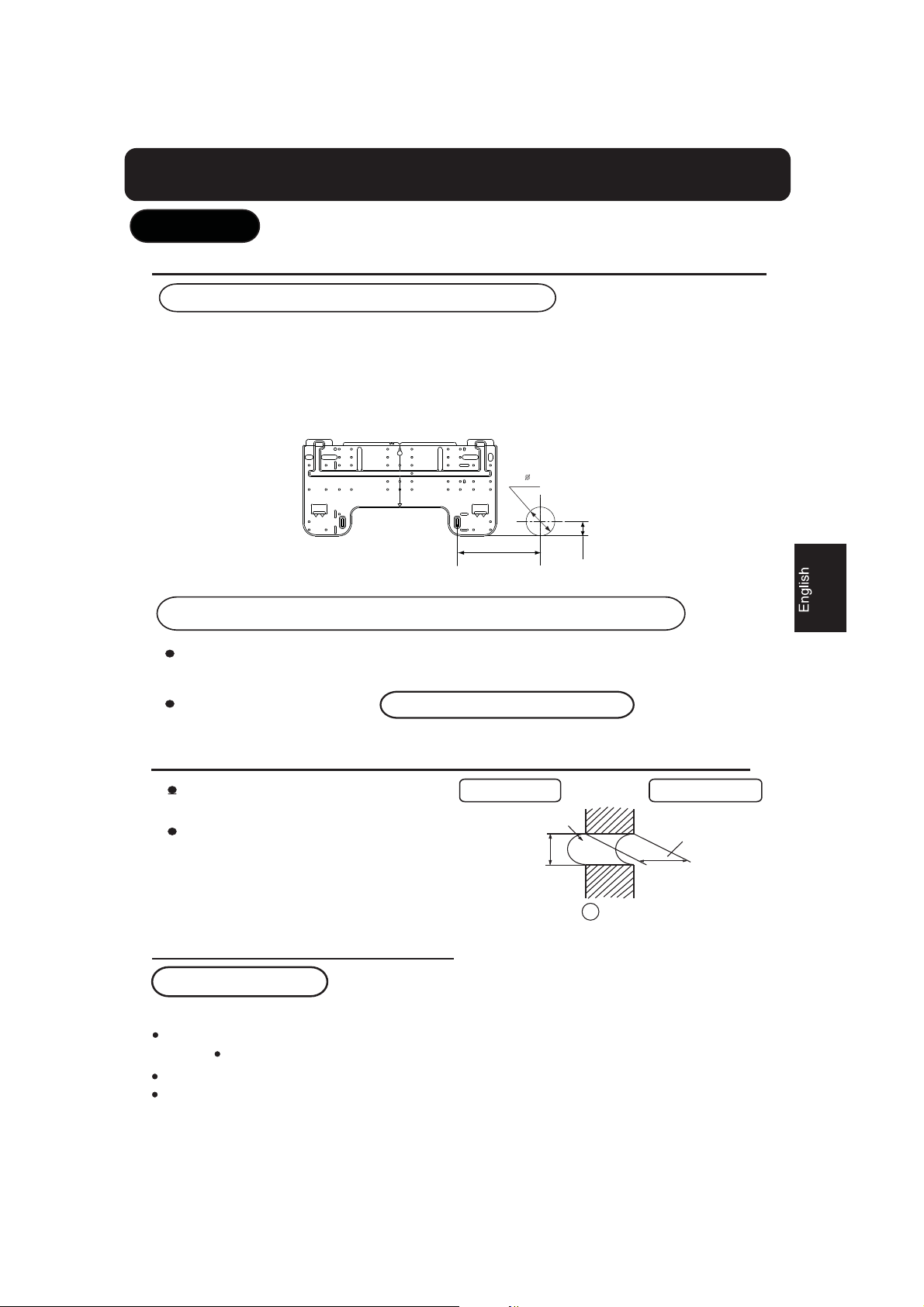

1.Fitting of the Mounting Plate and Positioning of the wall Hole

When the mounting plate is first fixed

1.Carry out, based on the neighboring pillars or lintels, a proper leveling for the plate to be

fixed against the wall, then temporarily fasten the plate with one steel nail.

2. Make sure once more the proper level of the plate, by hanging a thread with a weight from

the central top of the plate, then fasten securely the plate with the attachment steel nail.

3. Find the wall hole location A using a measuring tape

B= 60mm

A=145mm

30mm

When the mounting plate is fixed side bar and lintel

Fix to side bar and lintel a mounting bar, Which is separately sold, and then fasten

the plate to the fixed mounting bar.

Refer to the previous article, " When the mounting plate is first fixed ", for the

position of wall hole.

2.Making a Hole on the Wall and Fitting the Piping Hole Cover

Make a hole of 60 mm in diameter,

slightly descending to outside the wall.

Install piping hole cover and seal it

off with putty after installation

Indoor side

Wall hole

60mm

(Section of wall hole)

G

Piping hole pipe

Outdoor side

Thickness

of wall

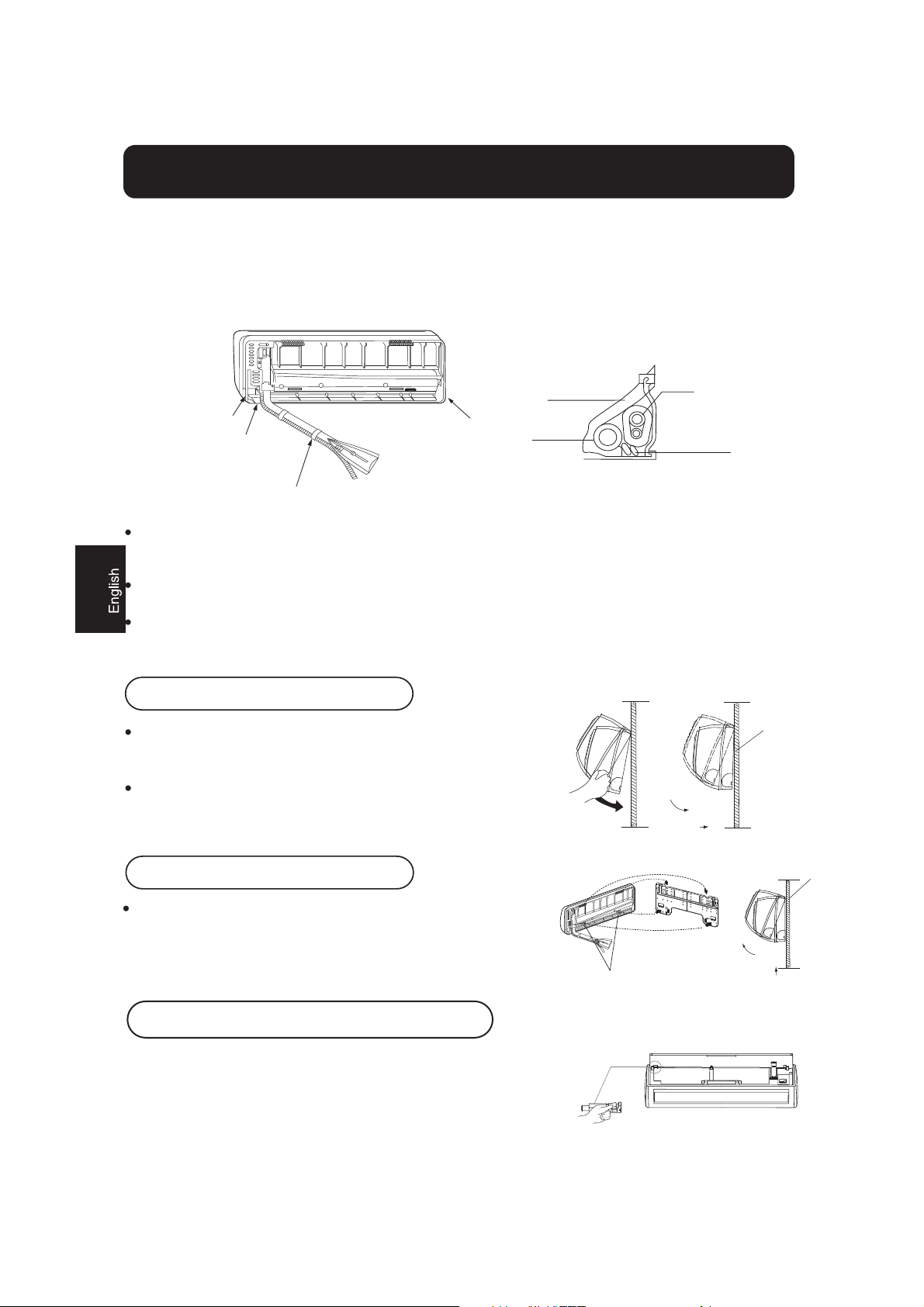

3.Installation of the Indoor Unit

Drawing of pipe

[ Rear piping ]

Draw pipes and the drain hose, then fasten them with the adhesive tape

[ Left Left-rear piping ]

In case of left side piping, cut away, with a nipper, the lid for left piping.

In case of left-rear piping, bend the pipes according to the piping direction to the mark of hole for left-rear

piping which is marked on heat insulation materials.

2

Page 4

Indoor unit

1. Insert the drain hose into the dent of heat insulation materials of indoor unit.

2. Insert the indoor/outdoor electric cable from backside of indoor unit, and pull it out on the front side, then

connect them.

3. Coat the flaring seal face with refrigerant oil and connect pipes.

Cover the connection part with heat insulation materials closely, and make sure fixing with adhesive tape

Heat insulation

material

Lid for right piping

Lid for under piping

Fix with adhesive tape

Indoor/outdoor electric cable and drain hose must be bound with refrigerant piping by protecting tape.

Lid for left piping

Drain hose

Piping

Indoor/outdoor

electric cable

[Other direction piping]

Cut away, with a nipper, the lid for piping according to the piping direction and then bend the pipe according

to the position of wall hole. When bending, be careful not to crash pipes.

Connect beforehand the indoor/outdoor electric cable, and then pull out the connected to the heat insulation

of connecting part specially.

Fixing the indoor unit body

Hang surely the unit body onto the upper notches of the

mounting plate. Move the body from side to side to verify

its secure fixing.

In order to fix the body onto the mounting plate,hold up

the body aslant from the underside and then put it down

perpendicularly.

mounting plate

Unloading of indoor unit body

When you unload the indoor unit,please use your hand to arise

the body to leave agraffe,then lift the bottom of the body outward

slightly and lift the unit aslant until it leaves the mounting plate.

Easily-demount cleaning of indoor unit

Inlet grille can be taken down

Open the inlet grille,press the button of unlock in the left,then push

it out of the socket and take out the inlet grille.

3

mounting plate

agraffe

Page 5

Indoor unit

Connecting the indoor/outdoor Electric Cable

Removing the wiring cover

Remove terminal cover at right bottom corner of indoor unit, then

take off wiring cover by removing its screws.

When connecting the cable after installing the indoor unit

1. Insert from outside the room cable into left side of the wall hole, in which

the pipe has already existed.

2. Pull out the cable on the front side, and connect the cable making a loop.

When connecting the cable before installing the indoor unit

Insert the cable from the back side of the unit, then pull it out on the front side.

Loosen the screws and insert the cable ends fully into terminal block, then tighten the screws.

Pull the cable slightly to make sure the cables have been properly inserted and tightened.

After the cable connection, never fail to fasten the connected cable with the wiring cover.

Note: When connecting the cable, confirm the terminal number of indoor and outdoor units carefully. If wiring

is not correct, proper operation can not be carried out and will cause defect.

1. If the supply cord is damaged, it must be replaced by the manufacturer or its service agent or a similar

qualified person. The type of connecting wire is H05/07RN-F or 245IEC57(YZW).

2. If the fuse on PC board is broken please change it with the type of T. 3.15A/250V.

3. The wiring method should be in line with the local wiring standard.

4. After installation, the power plug should be easily reached.

5. A breaker should be incorporated into fixed wiring. The breaker should be all-pole switch and the

distance between its two contacts should be not less than 3mm.

Indoor unit

Indoor unit

HSU-07HEA03/R2

HSU-09HEA03/R2

HSU-09HEA103/R2

HSU-12HEA03/R2

HSU-18HEA03/R2

HSU-22HEA03/R2

Outdoor unit

21

3

4

5

L

N

Outdoor unit

3

4

POWER

Power cable:

-mod 07-09-12:

- mod 18:

-mod 22:

connecting wiring:

-mod 07-09-12:

-mod 18:

3G1.0mm

3G2.5mm

3G2.5mm

LǃNǃ :

3ǃ4:

LǃNǃ

3ǃ4:

-mod 22:

:

3G1.0mm

2X0.75mm

3G2.5mm

2X0.75mm

6G0.75mm

4

Page 6

Outdoor unit

1.Installation of Outdoor Unit

Install according to

Drawing for the installation of indoor and outdoor units

2.Connection of pipes

To bend a pipe, give the roundness as large as possible not to crush the pipe ,and the bending radius

should be 30 to 40 mm or longer.

Connecting the pipe of gas side first makes working easier.

The connection pipe is specialized for R410A.

Half union

Flare nut

Spanner

Torque wrench

Be careful that matters, such as wastes of sands, etc. shall not enter the pipe.

The standard pipe length is 5m. If it is over 7m, the function of the unit will be affected. If the pipe has

to be lengthened, the refrigerant should be charged, according to 20 g/m. But the charge of refrigerant

must be conducted by professional air conditioner engineer. Before adding additional refrigerant,

perform air purging from the refrigerant pipes and indoor unit using a vacuum pump,then charge

additional refrigerant.

Forced fastening without careful

centering may damage the

threads and cause a leakage of

gas.

Pipe Diameter

Liquid side 6.35mm(1/4")

Gas side 9.52mm(3/8")

Gas side 12.7mm(1/2")

Fastening torque

18N.m

42N.m

55N.m

Outdoor unit

Indoor unit

B

A

Outdoor unit

CAUTION

Max.Elevation:

A

A

max

max

1=10m

2=15m

(07k 09k 12k)

(18k 22k)

In case the elevation A is more than 5m,

oil trap shoud be installed every 5~7m

3.Connection

Use the same method on indoor unit. Loosen

the screws on terminal block and insert the

plugs fully into terminal block, then tighten the

screws.

Insert the cable according to terminal number

in the same manner as the indoor unit.

4.Attaching Drain-Elbow

Outdoor unit

B

A

Indoor unit

A

In case A is more than 5m

Max. Length:

In case the

max

B

1=15m

max

2=25m

B

pipe length B is more than 7m,

(07k 09k 12k)

(18k 22k)

the refrigerant should be charged, according to 20 g/m.

If wiring is not correct, proper operation can

not be carried out and controller may be

damaged.

Fix the cable with a clamp.

Oil trap

B

Indoor unit

If the drain-elbow is used, please attach it as

figure.

Note: Only for heat pump unit.

Drain hose

Drain elbow

5

Page 7

Outdoor unit

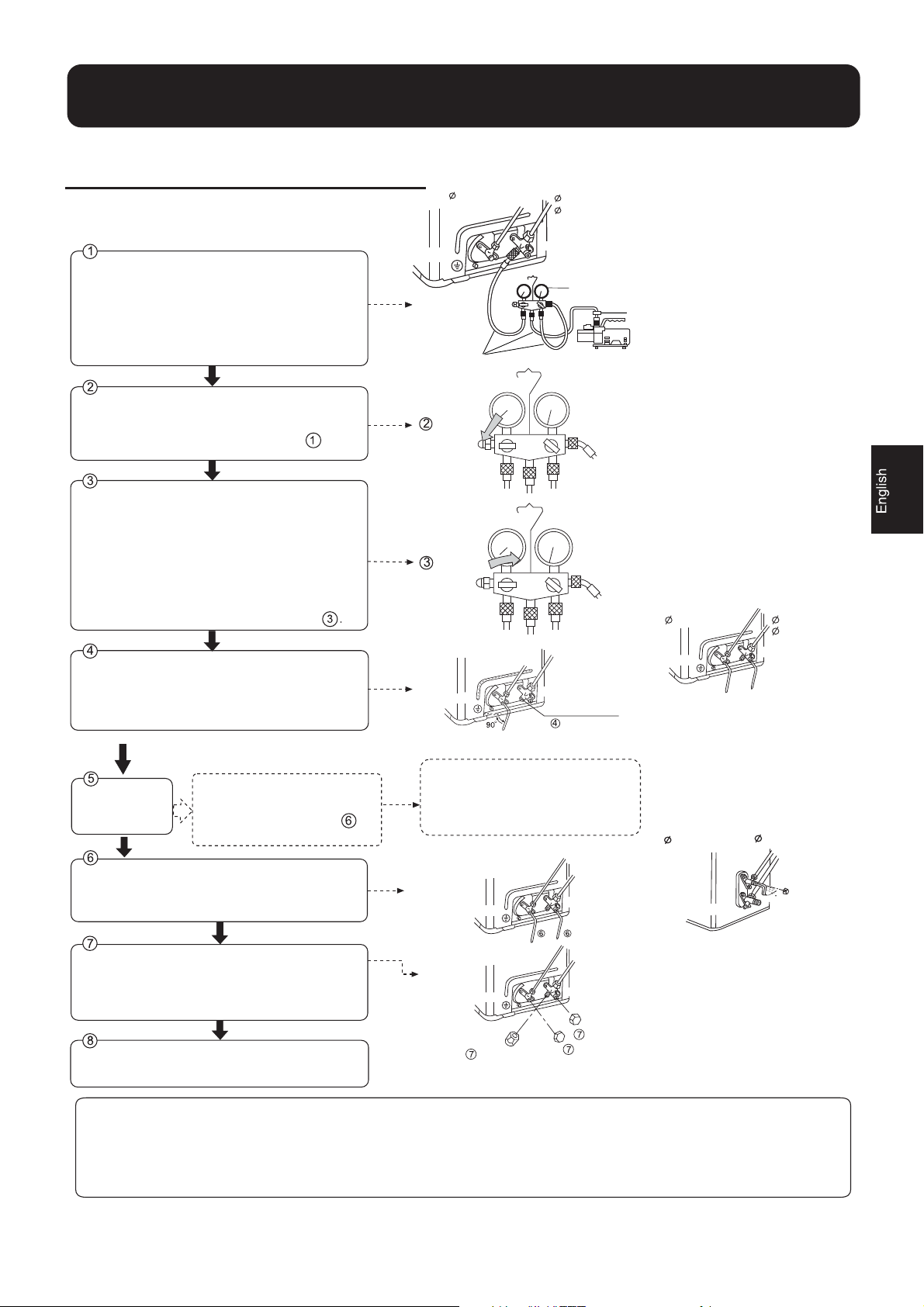

5.Purging Method:To use vacuum pump

Detach the service port's cap of 3-way valve, the

valve rod's cap for 2-way valve and 3-way's, connect

the service port into the projection of charge hose

(low) for gaugemanifold.Then connect the projection

of charge hose (center) for gaugemanifold into

vacuum pump.

Open the handle at low in gaugemanifold, operate

vacuum pump. If the scale-moves of gause (low)

reach vacuum condition in a moment, check again.

Vacuumize for over 15min. And check the level gauge

which should read -0.1 MPa (-76 cm Hg) at low

pressure side. After the completion of vacuumizing,

close the handle 'Lo' in gaugemanifold and stop the

operation of the vacuum pump.

Check the condition of the scale and hold it for 1-2min.

If the scale-moves back in spite of tightening, make

flaring work again, the return to the beginning of .

Open the valve rod for the 2-way valve to an angle of

anticlockwise 90 degrees.

After 6 seconds, close the 2-way valve and make

the inspection of gas leakage.

In case of gas leakage, tighten

No gas leakage?

parts of pipe connection. If

leakage stops, then proceed

steps.

2-way valve

Open

Close

2-way valve

If it does not stop gas leakage, discharge

whole refrigerants from the service port.

After flaring work again and vacuumize,

fill up prescribed refrigerant from the gas

cylinder

Liquid Side

6.35mm(1/4")

Tube(for R410A)

Open

90

o

Gas Side

9.52mm(3/8")

12.7mm(1/2")

3-way valve

Gaugemanifold(for R410A)

Vacuum pump(for R410A)

3-way valve

Service port

90ofor 6 sec.

Anti countercurrent joint

Liquid Side

6.35mm(1/4")

2-way valve

HSU-07HEA03/R2

HSU-09HEA03/R2

HSU-09HEA103/R2

HSU-12HEA03/R2

HSU-18HEA03/R2

Liquid Side

6.35mm(1/4")

Gas Side

9.52mm(3/8")

12.7mm(1/2")

3-way valve

Gas Side

12.7mm(1/2")

Detach the charge hose from the service port, open

2-way valve and 3-way. Turn the valve rod anticlockwise

until hitting lightly.

To prevent the gas leakage, turn the service port's

cap, the valve rod's cap for 2-way valve and 3-way's

a little more than the point where the torque increases

suddenly.

After attaching the each caps, check the gas leakage

around the caps.

CAUTION:

1.If the refrigerant of the air conditioner leaks, it is necessary to

discharge all the refrigerant. Vacuumize first, then charge the liquid

refrigerant into air conditioner according to the amount marked on

the name plate.

2-way valve

3-way valve

2-way valve

90

3-way valve

HSU-22HEA03/R2

2-way valve

Service port cap

2.Please do not let other cooling medium, except specified one (R410A),

or air enter into the cooling circulation system. Otherwise, there will be

abnormal high pressure in the system to make it crack and lead to

personal injuries.

3-way valve

Valve rod cap

Valve rod cap

6

Page 8

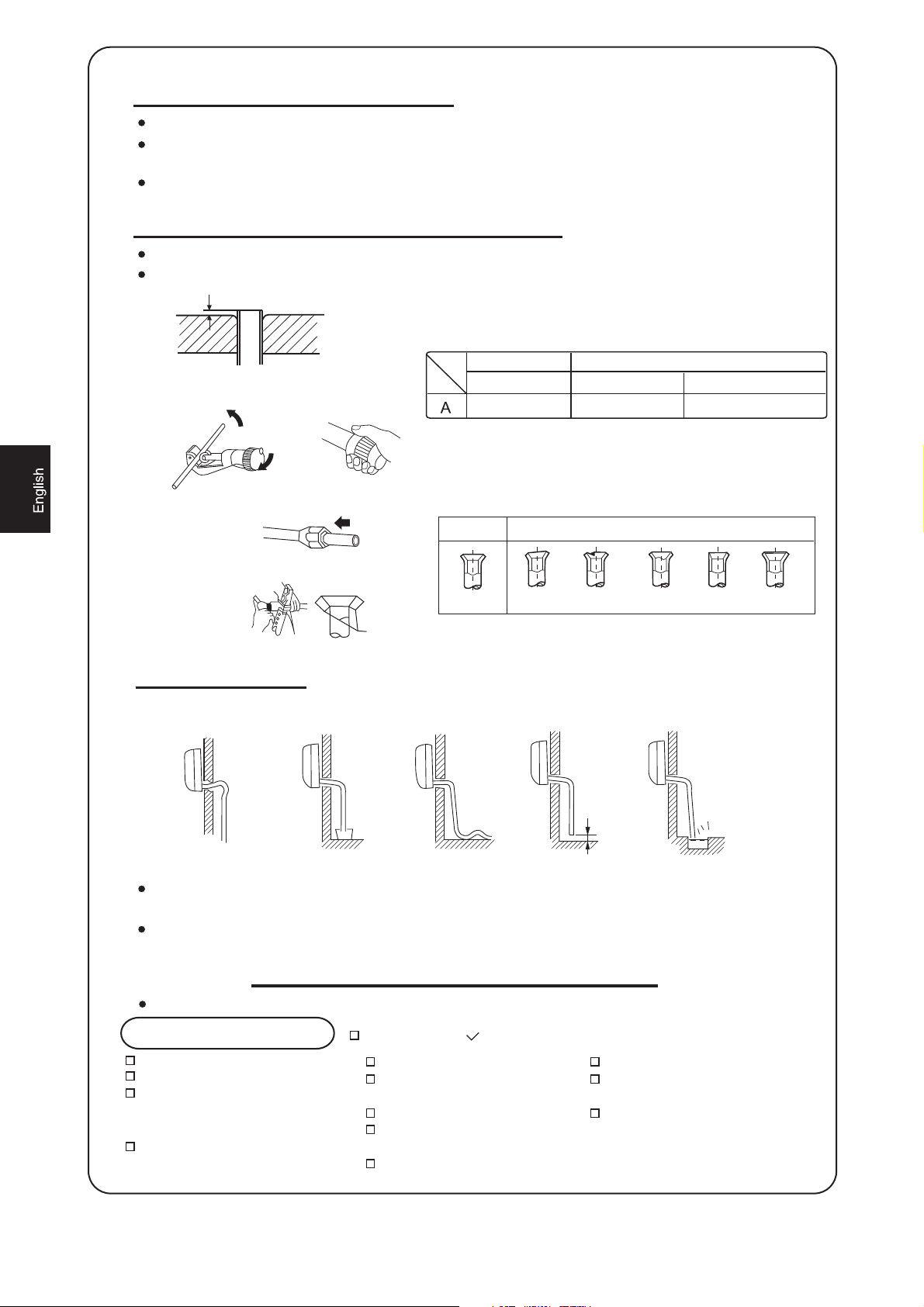

1.Power Source Installation

The power source must be exclusively used for air conditioner. (Over I0A)

In the case of installing an air conditioner in a moist place, please install an

earth leakage breaker.

For installation in other places, use a circuit breaker as far as possible.

2.Cutting and Flaring Work of Piping

Pipe cutting is carried out with a pipe cutter and burs must be removed.

After inserting the flare nut, flaring work is carried out.

A

1.Cut pipe

Flare tooling die

2.Remove burs

Flare tool for R410A

Clutch-type

0~0.5mm 1.0~1.5mm 1.5~2.0mm

clutch-type(Rigid-type)

Conventional flare tool

3.Insert the flare nut

Correct

Incorrect

4.Flare pipe

Lean Damage of flare Crack Partial Too outside

3.On Drainage

Please install the drain hose so as to be downward slope without fail.

Please don't do the drainage as shown below.

Wing-nut type (Imperial-type)

Less than 5cm

It becomes high midway.

The end is immersed

in water.

It waves. The gap with the ground

is too small

There is the bad smell

from a ditch

Please pour water in the drain pan of the indoor unit, and confirm that drainage is

carried out surely to outdoor.

In case that the attached drain hose is in a room, please apply heat insulation

to it without fail.

Check for Installation and Test Run

Please kindly explain to our customers how to operate through the instruction manual.

Check Items for Test Run

Gas leak from pipe connecting?

Heat insulation of pipe connecting?

Are the connecting wirings of

indoor and outdoor firmly inserted

to the terminal block?

Is the connecting wiring of indoor

and outdoor firmly fixed?

Put check mark in boxes

Is drainage securely carried out?

Is the earth line securely

connected?

Is the indoor unit securely fixed?

Is power source voltage abided

by the code?

Is there any noise?

7

Is the lamp normally lighting?

Are cooling and heating (when

in heat pump) performed normally?

Is the operation of room temperature

regulator normal?

Page 9

Manual de instalación de aparato de aire acondicionado

Lea este manual antes de la instalación

Explique el uso del aparato al usuario siguiendo

las instrucciones de este manual.

Herramientas necesarias para realizar la instalación

1. Destornillador 5. Llave dinamométrica (17 mm, 22 mm, 26 mm) 9. Alicate 12. Avellanador

2. Sierra para metales 6. Cortador de tubo

3. Taladro 7. Llave para tuercas cónicas

4. Llave (17, 19 y 26 mm) 8. Cuchilla 11. Metro

Diagrama para la instalación de aparatos interiores y exteriors

10. Detector de fugas de gas o

solución de agua jabonosa

Accesorios

Nº

ķ

ĸ

Ĺ

ĺ

Ļ

ø 4X50

Clavo de acero, cemento

ļ

Tapón de plástico

Ľ

ľ

Ŀ

Placa de soporte del tubo

ŀ

Accesorio

Control remoto

Batería seca R-03

Placa de montaje

Manguera de drenaje

Tornillo ø4X25

Cubierta

Acolchado

Número

de

artículos

1

2

1

1

6

4

1

4

1

1

Componentes opcionales para la

instalación de los tubos

Marca

࿆

࿇

࿈

࿉

࿊

࿋

࿌

Organización de la dirección de los tubos

Izquierda

Nombre del

componente

Cinta no adhesiva

Cinta adhesiva

Soporte (L.S) con

tornillos

Conexión de

cable eléctrico

para interior y

exterior

Manguera de

drenaje

Material aislante

de calor

Cubierta de

orificio de

entubación

Izquierda trasera

Izquierda derecha

Derecha

Inferior

más de 10 cm

más de 5 cm

más de 10 cm

Il faut faire attention à la

remontée du tuyau de drainage

más de 10 cm

más de 10 cm

A

C

D

E

Codo de drenaje

Las marcas de la a la que se muestran

࿆

࿌

en la figura representan los componentes.

La distancia entre la unidad interior y el suelo debe

ser superior a 2 m.

más de

60 cm

más de 15 cm

8

Page 10

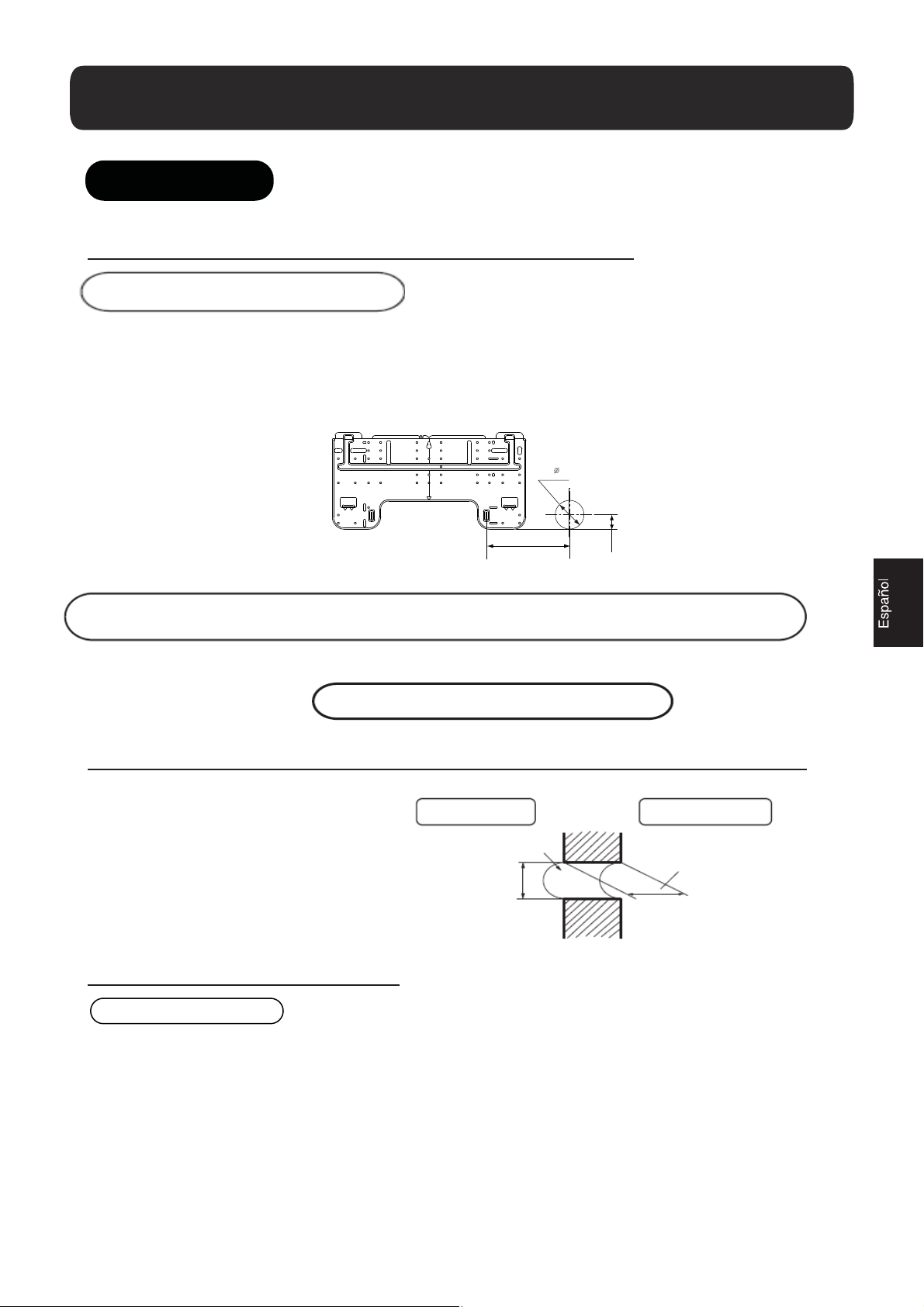

652

140

500 140

Dimensiones de fijación al suelo de la unidad

exterior

(Unidades: mm)

HSU-07HEA03/R2

HSU-09HEA03/R2

HSU-09HEA103/R2

HSU-12HEA03/R2

HSU-18HEA03/R2

Fijación de la unidad exterior

319.5

115

580

115

Dimensiones de fijación al suelo de la unidad

exterior

(Unidades: mm)

HSU-22HEA03/R2

Fije la unidad a un bloque de cemento con pernos (ø10 mm) y

tuercas firme y horizontalmente.

Si instala la unidad sobre una pared, techo o tejado, instale un

soporte con clavos o cables considerando la posibilidad de

terremotos o viento fuerte.

Si la vibración afectase a la casa, fije la unidad instalando una

alfombra de absorción de vibraciones.

Unidad interior

Coloque la unidad sobre una superficie que pueda soportarla

correctamente y no provoque vibraciones.

Asegúrese de que el lugar no se ve afectado por calor o vapor

o en las cercanías y donde la unidad pueda funcionar sin

generad

perturbaciones.

Asegúrese de que el lugar permita un drenaje sencillo y en el que

puedan conec

Asegúrese de que el aire frío pueda distribuirse uniformemente por la

.

sala

Coloque la unidad interior cerca de una toma de suministro eléctrico

con es

Coloque la unidad interior de modo se encuentre a más de 1 m de

te

levisiones, radios, a

En el caso de fijar el control remoto a una pared, colóquelo donde la

unidad

lám

paras fluorescentes de la sala.

tarse los tubos a la unidad exterior.

pacio suficiente alrededor. (Consulte los diagramas).

paratos inalámbricos y lámparas fluorescentes.

interior pueda recibir su señal mientras estén encendidas las

Selección del lugar de instalación

Seleccione el lugar menos afectado por la lluvia o la

luz solar directa y suficientemente ventilado.

Elija un lugar que permita soportar el peso de la

unidad y que no amplifique el ruido y las vibraciones.

Seleccione un lugar en el que los residuos y el viento

ge

nerado por la unidad no cause una molestia a los

vecinos.

Coloque la unidad en un lugar en el que pueda

dis

ponerse de la distancia de separación marcada

el símbolo

con

en la figura anterior.

Unidad exterior

Fuente de alimentación

Antes de insertar el enchufe de alimentación en la toma, compruebe que el voltaje no falla. La fuente de alimentación es la que figura

en la placa de datos nominales.

stale el aparato en un circuito dedicado de alimentación.In

Debe existir una toma al alcance del cable de alimentación. No prolongue el cable cortándolo.

Selección de tubo

En esta unidad los tubos de líquido y gas deben aislarse debido

a su baja temperatura de funcionamiento.

Utilice componentes opcionales para conjuntos de entubación o

tubos cubiertos con material de aislamiento equivalente.

Tubo de

líquido

Tubo de gas

(ø)

9

(ø)

Para 07 09 12 Para 18 22

mm (1/4")

mm (1/4")

6,35

mm (3/8") 12,7 mm (1/2")

9,52

6,35

Page 11

Unidad interior

Unidad interior

1. Instalar la placa de montaje y ubicar el orificio en la pared

Al fijar por primera vez la placa de montaje

1. Nivele correctamente la placa a fijar contra la pared basándose en pilares o dinteles cercanos y fije

temporalmente la placa con un clavo de acero.

2. Asegúrese de nuevo de que la placa se encuentre bien nivelada colgando una plomada desde el punto superior

central de la placa. Una vez comprobado, fije la placa con el clavo de acero de fijación.

3. Busque la ubicación del orificio de pared A utilizando un metro.

B= 60mm

A=145mm

30mm

Al montar la placa de montaje fijándola a una barra lateral y un dintel

y Fije una barra de montaje (se vende por separado) a la barra lateral y el dintel, y asegure la placa a la barra de

montaje fijada.

y Consulte la sección anterior " Al fijar por primera vez la placa de montaje " para más información

acerca del orificio de la pared.

2.Practicar un orificio en la pared e instalar la cubierta del orificio de entubación

pendiente ligeramente descendiente hacia el

exterior de la pared.

séllela con masilla después de la instalación.

3. Instalación de la unidad interior

Extracción de los tubos

z Practique un orificio de 60 mm de diámetro con

Cara interior Cara exterior

Orificio de pared de Grosor de la pared z Instale la cubierta del orificio de entubación y

60mm

(Sección del orificio de pared) ࿌ Orificio de entubación

[ Entubación trasera ]

z Extraiga los tubos y la manguera de drenaje y fíjelos con cinta adhesiva

[ Izquierda y Entubación trasera izquierda ]

z En caso de realizar la entubación por el lado izquierdo, corte con una cuchilla la cubierta de la entubación

izquierda.

z En caso de realizar la entubación a través de la parte trasera izquierda, doble los tubos de acuerdo con la

dirección de entubación que figura en la marca del orificio de entubación trasera izquierda, ubicada sobre

los materiales aislantes.

10

Page 12

Unidad interior

1 Pase la manguera aislante a través del hueco de los materiales de aislamiento de calor de la unidad interior.

2 Inserte los cables eléctricos de interior / exterior a través de la parte trasera de la unidad interior y tire de

ellos desde la parte delantera. Conéctelos entonces.

3 Cubra la cara de sellado con aceite refrigerante y conecte los tubos.

Cubra la conexión con material aislante de calor y asegúrese de fijarla con cinta adhesiva.

Cable eléctrico de interior/exterior

Cubierta de entubación derecha

Cubierta de entubación inferior

Fijación con cinta adhesiva

Material aislante de calor Entubación

Manguera de drenaje

Cubierta de entubación izquierda

Los cables eléctricos de interior/exterior deben conectarse a la entubación del refrigerante utilizando cinta protectora.

[Entubación en otra dirección]

Corte con una cuchilla la cubierta de entubación de acuerdo con la dirección de entubación y doble los tubos de

acuerdo con la posición del orificio en la pares. Tenga cuidado de no romper los tubos al doblarlos.

Conecte previamente el cable eléctrico de interior / exterior y tire de la conexión al aislante de calor del componente

de conexión.

Fijación de la unidad interior

Cuelgue con seguridad la unidad de las muescas

superiores de la placa de montaje. Mueva el bastidor

hacia los lados para verificar que la fijación se haya

realizado de la forma correcta.

Para fijar el bastidor a la placa de montaje, sostenga el

aislante del bastidor desde debajo y colóquelo en

posición perpendicular.

placa de montaje

Descarga de la unidad interior

Al descargar la unidad interior, utilice la mano para

levantar el bastidor y separarlo del gancho. Levante

entonces la parte inferior del bastidor llevándolo hacia

fuera ligeramente hasta que la unidad se separe de la

placa de montaje.

Desmontaje de la unidad interior para su limpieza

La rejilla de entrada se puede retirar

Abra

la rejilla de entrada, presione el botón de bloqueo

situado a la izquierda y presione a través de la ranura para

extraer la rejilla de entrada.

placa de montaje

gancho

11

Page 13

Unidad interior

Conexión de los cables eléctricos de interior/exterior

Extraer la cubierta del cableado

Extraiga la cubierta de los terminales situada en la esquina inferior derecha de la unidad

interior. Extraiga entonces la cubierta del cableado desenroscando los tornillos.

Al conectar el cable después de instalar la unidad de interior

1 Inserte desde fuera el cable en la sala a través del lado izquierdo del orificio de la pared en

el que ya se encuentra el tubo.

2 Tire del cable desde el lado delantero y conecte el cable creando un bucle.

Al conectar el cable antes de instalar la unidad de interior

Inserte el cable desde la parte trasera de la unidad y tire desde la parte delantera.

Afloje los tornillos e inserte los extremos del cable en el bloque de terminales. Apriete entonces los tornillos.

Tire ligeramente del cable para asegurarse de que los cables han quedado correctamente insertados y apretados.

Después de conectar el cable, no olvide fijar el cable conectado con la cubierta de cable.

Nota: Al conectar el cable, confirme el número de terminales de las unidades interior y exterior detenidamente. Si el

cableado no se ha realizado correctamente no se podrá utilizar el aparato correctamente, provocándose un defecto.

1 Si el cable de alimentación está dañado deberá ser reemplazado por el fabricante, agente de servicio o

profesional cualificado. El tipo de cable de conexión es H05/07RN-F o 245IEC57 (YZW).

2 Si el fusible de la placa PC está roto, cámbielo por otro de tipo T. 3,15ª / 250 V.

3 El método de cableado debe ajustarse a las normas de cableado locales.

4 Después de la instalación, la toma de alimentación debe ser accesible.

5 Debe instalarse un interruptor en el cableado fijo. La distancia entre los dos contactos del interruptor no debe

ser inferior a 3 mm.

Unidad

interior

Unidad

interior

HSU-22HEA03/R2

HSU-07HEA03/R2

HSU-09HEA

HSU-09HEA103/R2

HSU-12HEA03/R2

HSU-18HEA03/R2

03/R2

Unidad

exterior

21

3

4

5

L

N

3

4

Unidad

exterior

ALIMENTACIÓN

12

Cable de alimentación:

-mod 07-09-12:

-mod 18:

-mod 22:

cableado de conexión:

-mod 07-09-12:

-mod 18:

LǃNǃ :

3ǃ4:

LǃNǃ

3ǃ4:

-mod 22:

3G1.0mm

3G2.5mm

3G2.5mm

:

3G1.0mm

2X0.75mm

3G2.5mm

2X0.75mm

6G0.75mm

Page 14

Unidad exterior

1. Instalación de la unidad exterior

Instale la unidad exterior de acuerdo con el diagrama de instalación de unidades interiores y exteriores.

2. Conexión de los tubos

Para doblar un tubo, intente hacer la curva lo más suave posible para no aplastar el tubo. El radio de doblado debe ser

superior a 30 o 40 mm.

Será más sencillo conectar en primer lugar el tubo de gas.

El tubo de conexión es especial para el tipo R410A.

Media unión Tuerca cónica

Si se fuerza la fijación sin aplicar centrado podrían

dañarse los tubos y provocarse una fuga de gas.

Diámetro del tubo(ø) Par de apriete

Lado de líquido 6,35 mm

(1/4")

Lado de gas 9,52mm (3/8") 42N.m

Llave

Llave dinamométrica

Lado de gas 12,7mm (1/2") 55N.m

Procure que no penetren materiales, como residuos o arena, en el tubo.

La longitud estándar del tubo es de 5 m. Si el tubo tiene más de 7m, se verán afectadas las funciones de la unidad. Si es

necesario alargar el tubo, deberá cargarse refrigerante adicional a razón de 20 g / m. No obstante, la carga de

refrigerante deberá ser realizada por un ingeniero profesional en aire acondicionado. Antes de añadir refrigerante

adicional, realice una purga de aire desde los tubos refrigerantes y la unidad interior utilizando una bomba de vacío y

cargue después el refrigerante adicional.

18N.m

Unidad exterior

Unidad interior

B

A

B

Unidad interior

A

Unidad exterior

PRECAUCIÓN

Elevación máx.: A máx1 = 10 m Longitud máx.: B máx1 = 15 m

A máx2 = 15 m

En caso de que la elevación A sea superior a 5 m, el filtro de aceite

debe instalarse cada 5 ~ 7 m.

(07k 09k 12k)

(18k 22k)

En caso de que la longitud del tubo B sea

superior a 7 m, deberá cargarse el refrigerante

Unidad exterior

B

A

In case A is more than 5m

B máx

2 = 25 m

a razón de 20 g / m.

3. Conexión

Utilice el mismo método con la unidad interior.

Afloje los tornillos del bloque de terminales e

inserte los tapones completamente en los

mismos. Apriete entonces los tornillos.

Inserte el cable de acuerdo con el número del

terminal, de la misma forma que hizo con la

unidad interior.

Si el cableado no es correcto, no podrá

alcanzarse la orientación correcta y el controlador

podría resultar dañado.

Fije el cable con un alicate.

4. Instalación del codo de drenaje

Filtro de aceite

Unidad interior

(07k 09k 12k)

(18k 22k)

Si utiliza un codo de drenaje, instálelo como indica la figura.

Nota: sólo para la unidad de bomba de calor.

13

Manguera de

drenaje

Codo de drenaje

Page 15

Unidad exterior

5. Método de purga: para utilizar una

bomba de vacío

Válvula de 2 vías

Retire el tapón del puerto de mantenimiento de la

válvula de 3 vías (G), el tapón del vástago de la

válvula de 2 vías (L) y las 3 vías (G), y conecte el

puerto de mantenimiento a la manguera de

proyección de carga (inferior) del colector. Conecte

entonces la manguera de proyección de carga

(central) del colector a la bomba de vacío.

Abra la espita inferior del colector y accione la

bomba de vacío. Si el indicador de la escala

(inferior) alcanza la condición de vacío por un

momento, compruebe de nuevo el punto

Succione durante 15 minutos. Compruebe el

nivel medido, que deberá ser de -0,1 Mpa (-76

cm Hg) en el lado de baja presión. Tras finaliza

la succión, cierre la espita inferior del colector y

detenga la bomba de vacío.

Compruebe el funcionamiento de las escala y

manténgala durante 1-2 min. Si la escala

retrocede en lugar de aumentar, aplique de

nuevo el ensanche y vuelva al punto (3).

Abra el vástago de la válvula de 2 vías 90

grados hacia la izquierda.

Después de 6 segundos, cierre la válvula de 2

vías e inspeccione si existen fugas de gas.

¿No existen

fugas de gas?

En caso de que exista una fuga de

gas, apriete las conexiones de los

tubos. Si la fuga se detiene,

avance

6

1

r

Válvula de 2 vías

pasos.

Lado de líquido

6, 35 mm (1/4")

Tubo (para R410A)

Lado de gas

9,52mm (3/8")

12,7mm (1/2")

Válvula de 3 vías

Colector (para R410A)

Bomba de vacío(para R410A)

Abrir

Cerrar

Válvula de 3 vías

Puerto de mantenimiento

Abrir

o

90

Si la fuga de gas no se detiene,

descargue todo el refrigerante a través

del puerto de mantenimiento. Después

de realizar de nuevo la operación de

conicidad y succión, rellene con el

refrigerante especificado desde el

cilindro de gas.

o

90 durante 6 seg.

Junta de retención de contracorriente

Lado de líquido

6,35mm (1/4")

Válvula de 2 vías

Válvula de 3 vías

HSU-07HEA03/R2

HSU-09HEA03/R2

HSU-09HEA103/R2

HSU-12HEA03/R2

HSU-18HEA03/R2

Lado de líquido

6,35mm (1/4")

Lado de gas

Lado de gas

9,52mm (3/8")

12,7mm (1/2")

12,7mm (1/2")

Desconecte la manguera de carga del puerto

de mantenimiento y abra las válvulas de 2 y 3

vías. Gire el vástago de la válvula hacia la

izquierda hasta que golpee ligeramente.

Para evitar fugas de gas, gire el tapón del

puerto de mantenimiento y el tapón del vástago

de las válvulas de 2 y 3 vías un poco por

encima del punto en el que la torsión aumenta

súbitamente.

Después de instalar los tapones, compruebe si

existen fugas de gas a su alrededor.

PRECAUCIÓN:

1. Si existen fugas de refrigerante en el aire acondicionado

será necesario descargar todo el refrigerante. Succione

primero, y cargue líquido refrigerante en el acondicionador de

aire de acuerdo con la cantidad marcada en la placa de valores

nominales.

Válvula de 2 vías

Válvula de 3 vías

Válvula de 2 vías

HSU-22HEA03/R2

Válvula de 2 vías

Tapa del puerto de

mantenimiento

2. Por favor, no permita que penetren otros medios de refrigeración

(excepto el especificado, R410A) o aire en el sistema de circulación del

refrigerante. Si ocurriese, se acumularía una presión anormalmente

alta en el sistema que podría provocar roturas y lesiones personales.

Válvula de 3 vías

Tapa del vástago de válvula

Tapa del vástago de válvula

14

90

Válvula de 3 vías

Page 16

1. Instalación de la fuente de alimentación

La fuente de alimentación debe utilizarse exclusivamente con el aparato de aire acondicionado. (Más de

10 A)

En caso de instalar el aire acondicionado en un lugar húmedo, instale un interruptor de fugas de masa.

Para realizar la instalación en otro lugar, utilice un interruptor de circuito situado lo más lejos posible.

2. Trabajos de corte y conicidad de los tubos

El corte del tubo se realiza con un cortador de tubos. Deberán eliminarse las rebabas.

Después de insertar la tuerca cónica deberá procederse a realizar los trabajos de conicidad.

A

Herramienta de

conicidad para

Cuchilla de conicidad

1. Cortar el tubo 2. Eliminar las

rebabas

R410A

De tipo

acoplamiento

A 0~0,5 mm 1,0~1,5 mm 1,5~2,0 mm

3. Insertar la tuerca cónica

4. Practicar la conicidad del tubo

Correcto Incorrecto

DelgadoDaño de conicidad Grieta Parcial Demasiado fuera

3. Durante el drenaje

Instale la manguera de drenaje formando una pendiente descendiente.

No realice el drenaje como se muestra a continuación.

Herramienta de conicidad

convencional

De tipo

acoplamiento

(tipo rígido)

De tipo palometa

(tipo imperial)

Menos de 5 cm

Se alza por la mitad.

El extremo está

sumergido en agua.

Está ondulado.

La separación con el suelo

es demasiado pequeña

Se aprecia mal olor de

una acequia

Deposite agua en la bandeja de drenaje de la unidad interior y confirme que el drenaje se realiza

correctamente hacia fuera.

En caso de que la manguera de drenaje se encuentre en una sala, asegúrese de aplicar aislante de calor.

Prueba de instalación y ejecución de la prueba

Explique al cliente cómo utilizar el aparato utilizando el manual de instrucciones.

Puntos de prueba

¿Existe una fuga de gas en la

conexión del tubo?

¿Aislamiento de calor de la

conexión del tubo?

¿Están los cables de conexión

interiores y exteriores firmemente

insertados en el bloque de

terminales?

¿Están los cables de conexión

interior y exterior fijados

firmemente?

Escriba una marca √ en los cuadros

¿Se ha realizado el drenaje

correctamente?

¿Está la línea de tierra conectada

con seguridad?

¿Está la unidad interior fijada con

seguridad?

¿Cumple la normativa la fuente de

voltaje?

¿Se aprecian ruidos?

¿Está la lámpara iluminada

normalmente?

¿Se realizan normalmente las

operaciones de calentamiento (con

la bomba de calor) y refrigeración?

¿Funciona correctamente el

regulador de temperatura de la

sala?

15

Page 17

Manuale di installazione per condizionatore ad aria per ambienti

Prima dell'installazione leggere questo manuale

Spiegare in modo sufficiente il funzionamento

dell'apparecchio all'utente in base a quanto indicato

in questo manuale.

Attrezzi necessari per l'installazione

1.Cacciavite 5.Chiave dinamometrica (17mm, 22mm, 26mm) 9.Pinza 12.Alesatore

2.Seghetto a mano 6.Taglia tubi

3.Trapano alesatore 7.Flangiatubi

4.Chiave fissa (17,19 e 26mm) 8.Coltello 11.Nastro di misurazione

Disegno per l'installazione dell'elemento interno e di quello esterno

Accessori

N.

ķ

Accessori

Telecomando

Numero

di articoli

1

10.Rilevatore di perdite di gas o

soluzione di acqua saponata

ĸ

Batteria secca R-03

Ĺ

Piastra di montaggio

ĺ

Tubo di scarico

Ļ

Chiodo in acciaio ø 4X50,

cemento

ļ

Vite ø4X25, Calotta in

plastica

Ľ

Copertura

ľ

Cuscinetto

Ŀ

Piastra di sostegno tubo

ŀ

2

Componenti opzionali per le tubature

1

1

6

4

1

4

1

1

Contrassegno

࿆

࿇

࿈

࿉

࿊

࿋

࿌

Disposizione del tracciato dei tubi

Sinistra posteriore

Sinistra

Nome

componente

Nastro non

adesivo

Nastro adesivo

Carrello (L.S) con

viti

Cavo elettrico di

connessione per

elemento interno

ed esterno

Tubo di scarico

Materiale isolante

per riscaldamento

Tappo per foro

per tubi

Sinistra destra

Destra

Sotto

più di 10 cm

più di 5 cm

più di

1

0 cm

Bisogna prestare attenzione

più di

all’ innalzamento del

tubo di scarico

1

0 cm

A

C

più di 10 cm

D

E

Raccordo di scarico

I contrassegni da a nella figura indicano i

࿆

࿌

numeri dei componenti

La distanza tra l'elemento interno e il pavimento

dovrebbe essere superiore a 2 m.

16

più di 60

cm

più di 15 cm

Page 18

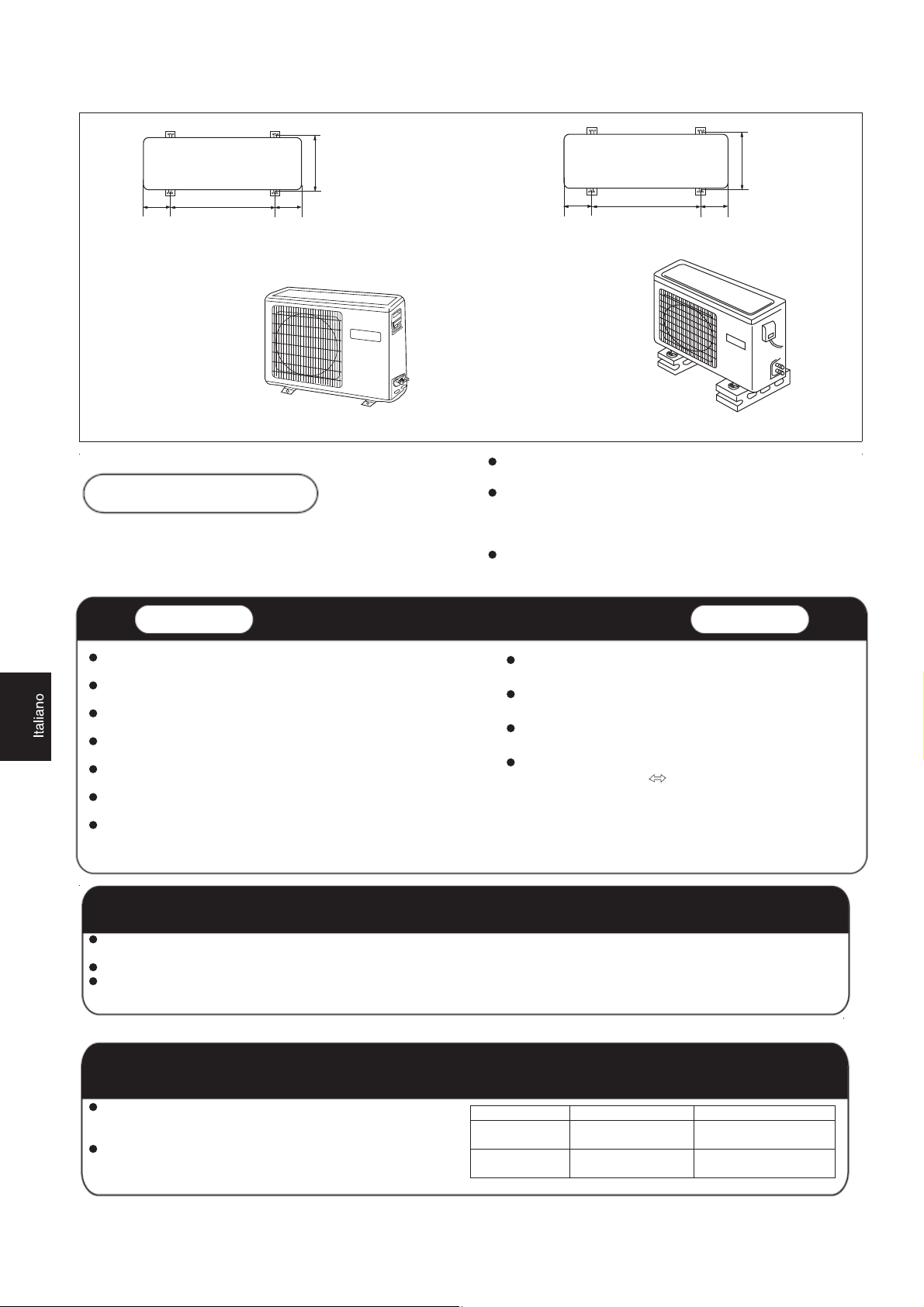

140

50

0 140

652

319.5

115

580

115

Dimensioni per il fissaggio al suolo

dell'elemento esterno

(Unità:mm)

HSU-07HEA03/R2

HSU-09HEA03/R2

HSU-09HEA103/R2

HSU-12HEA03/R2

HSU-18HEA03/R2

Fissaggio dell'elemento esterno

Componente interno

Luogo resistente, che non sia fonte di vibrazioni, dove il corpo

dell'ap

parecchio possa essere sostenuto a sufficienza.

Luogo non interessato dal calore o dal vapore generato nelle

vicinanze, in

Luogo in cui sia semplice effettuare lo scarico, dove i tubi possano

essere collegati

Luogo in cui l'aria fredda possa diffondersi completamente nella

stanza.

Luogo accanto a una presa di corrente, contornato da spazio

sufficiente. (Fare riferimento ai disegni).

Luogo in cui si possa lasciare una distanza superiore a 1 m da

te

levisori, radio, apparecchi senza fili e lampade al neon.

Nel caso di sospensione del telecomando a parete, metterlo dove

l'elemento interno può ricevere segnali quando nella stanza sono

accese delle la

cui l'ingresso e l'uscita dell'unità non siano disturbati.

con l'elemento esterno.

mpade al neon.

Scelta del luogo di installazione

Dimensioni per il fissaggio al suolo

dell'elemento esterno

(Unità:mm)

HSU-22HEA03/R2

Fissare l'unità al calcestruzzo o al blocco mediante bulloni

(ø10 mm) e dadi, in modo saldo e in senso orizzontale.

Collegando l'unità alla superficie di una parete, al tetto o sulla

sommità di un tetto, fissare in modo sicuro un sostegno

mediante chiodi o cavi, tenendo in considerazione possibili

scosse sismiche o venti forti.

Se l’edificio può essere interessato da vibrazioni, fissare

l'elemento collegando una platea di fondazione anti-vibrazioni.

Componente esterno

Il luogo meno interessato dalla pioggia o dalla luce

retta del sole e che sia sufficientemente ventilato.

di

Luogo in grado di sostenere l'elemento, senza

aumento di vibrazioni e rumorosità.

Luogo in cui il flusso d'aria rilasciato e il rumore

prodotto non causino disturbo ai vicini.

Luogo in cui sia disponibile una distanza

contrass

egnata da

, come illustrato nella figura

sopra riportata.

Alimentazione

Prima di inserire la spina nella presa, controllare con precisione la tensione consentita. La sorgente di alimentazione è quella riportata

sulla piastra con il nome corrispondente.

stallare un circuito di derivazione esclusivo per l'alimentazione. In

Bisogna inserire una presa a una distanza tale per cui possa essere raggiunta con il cavo di alimentazione. Non prolungare il cavo

tagliandolo.

Scelta del tuboe

Con questa unità, tanto i tubi per i liquidi quanto quelli per i gas

devono essere isolati in quando scendono a basse temperature

durante il funzionamento.

Usare elementi opzionali per serie di tubi o tubi coperti con

materiale isolante equivalente.

Tubo per

liquidi (ø)

Tubo per gas

(ø)

17

07 09 12 Per 18 22

Per

6,35

mm (1/4") 6,35 mm (1/4")

9,52

mm (3/8") 12,7 mm (1/2")

Page 19

Componente interno

Componente interno

1.Inserimento della piastra di montaggio e posizionamento del foro sulla parete

Quando si fissa prima la piastra di montaggio

1. Basandosi sui pilastri o sulle architravi vicini, effettuare un livellamento corretto, in modo che la piastra possa

essere fissata al muro, poi fissare in modo provvisorio la piastra con un chiodo in acciaio.

2. Accertarsi nuovamente che il livello a cui è fissata la piastra sia corretto, sospendendo un filo a piombo dal centro

della sommità della piastra, poi fissare saldamente la piastra con il chiodo in acciaio destinato ad attaccarla.

3. Individuare il punto di posizionamento del foro A sulla parete utilizzando un nastro di misurazione

B= 60mm

A=145mm

30mm

Quando la piastra di montaggio è fissata su una trave laterale o su un'architrave

y Fissare una barra di sostegno, venduta separatamente, alla trave laterale e all'architrave e poi fissare la piastra alla

barra di sostegno precedentemente fissata.

y Per il posizionamento del foro sulla parete, fare riferimento al punto precedente, " Quando si fissa prima la

piastra di montaggio

" .

2.Ricavare un foro sulla parete e inserire il tappo per i fori delle tubature

z Ricavare un foro del diametro di 60 mm,

scendendo leggermente fuori dalla parete.

z Inserire il coperchio per i fori dei tubi e stuccarlo

dopo l'installazione

Lato interno Lato esterno

60mm

(Sezione del foro a parete) ࿌ G Tubo per foro per tubature

Foro a parete Spessore del muro

3.Installazione dell'elemento interno

Disegno del tubo

[ Vista posteriore del tubo ]

z Tracciare i tubi e il tubo di scarico, poi fissarli con il nastro adesivo

Sinistro y vista posteriore della tubatura posta sulla sinistra ]

[

z In caso di tubazioni inserite sul lato sinistro, asportare con l'ausilio di una pinza, il coperchio per le tubazioni

del lato sinistro.

z In caso si abbiano tubi posti sul lato posteriore sinistro, piegare i tubi secondo la direzione delle condutture

indicata dal contrassegno sul foro per tubi posti sul lato posteriore sinistro che è marcato sui materiali

termoisolanti.

18

Page 20

Componente interno

1 Inserire il tubo di scarico nella tacca presente sui materiali termoisolanti dell'elemento interno.

2 Inserire i cavi elettrici per interni/esterni dal retro dell'elemento interno e tirarli fuori dal lato frontale, poi

effettuare il loro collegamento.

3 Ricoprire con uno strato di

Copri

re bene l'elemento di connessione con materiali termoisolanti e fissarli saldamente con nastro adesivo

olio refrigerante la facciata con il dispositivo di tenuta svasato e collegare i tubi.

Tubature

Cavi elettrici interni/esterni

Coperchio per le tubature

poste sulla destra

Coperchio per le tubature

poste sul lato inferiore

Fissaggi con nastro adesivo

Cope

rchio per le tubature poste sulla sinistra

Materiale termoisolante

Tubo di scarico

I cavi elettrici interni/esterni e il tubo di scarico devono essere legati ai tubi contenenti il liquido refrigerante con nastro

di protezione.

[Tubature con altre direzioni]

Asportare, con una pinza, il coperchio per le tubature secondo la direzione delle tubature e poi piegare i tubi secondo

la posizione del foro sul muro. Effettuando la piegatura fare attenzione a non danneggiare i tubi.

Collegare in primo luogo i cavi elettrici interni/esterni e poi estrarre quello connesso specificatamente al

termoisolamento dell'elemento di connessione.

Fissaggio del corpo dell'elemento interno

Sospendere in modo sicuro il corpo dell'elemento

fissandolo alle tacche superiori presenti sulla piastra di

montaggio. Spostare il corpo dell'elemento da lato a lato

per verificare che sia fissato in modo sicuro.

Per fissare il corpo sulla piastra di montaggio, sostenere

il

corpo obliquamente dal basso e poi posarlo

perpendicolarmente.

piastra di montaggio

Asportare e abbassare il corpo dell'elemento esterno

Nell'asportare e abbassare il corpo dell'elemento

esterno, usare le mani per sollevare il corpo in modo

che si svincoli dal gancio che lo trattiene, sollevare poi il

fondo

del corpo spingendolo leggermente verso

l'esterno e poi sollevare trasversalmente l'elemento fino

a che non esce dalla piastra di montaggio.

Smontare facilmente l'elemento interno per poterne effettuare la pulizia

La griglia di immissione può essere rimossa

Aprire

la griglia di immissione, premere il pulsante di

sblocco sulla sinistra, poi spingere la griglia di immissione

fuori dalla sua sede e rimuoverla.

19

gan

piastra di montaggio

cio

Page 21

Componente interno

Collegamento del cavo elettrico per interni/esterni

Asportazione della copertura dei fili elettrici

Togliere la copertura dei morsetti posta sull'angolo inferiore destro dell'elemento interno, poi

asportare la copertura dei fili elettrici togliendone le viti.

Quando si collega il cavo dopo aver inserito l'elemento interno

1 Inserire dall'esterno il cavo destinato alla stanza nel lato sinistro del foro sulla parete, in cui il

tubo esisteva già.

2 Estrarre il cavo sul lato anteriore e collegarlo creando un circuito.

Quando si collega il cavo prima di aver installato l'elemento interno

Inserire il cavo dal retro dell'unità, poi estrarlo sul lato anteriore.

Allentare le viti e inserire completamente le estremità del cavo nella morsettiera, poi serrare le viti.

Tirare leggermente il cavo per accertarsi che sia stato inserito e serrato correttamente.

Dopo aver effettuato la connessione dei cavi, non trascurare mai di coprire il cavo collegato con la copertura di

protezione dei fili elettrici.

Nota: Quando si connette il cavo, verificare con attenzione il numero dei morsetti collegati all'elemento interno e a

quello esterno. Se il cablaggio non è corretto non si potrà avere un funzionamento corretto e ciò provocherà dei guasti.

1 Se il cavo di alimentazione è danneggiato, deve essere sostituito dalla casa produttrice o dal suo agente

responsabile per l'assistenza o da altro soggetto con qualifica analoga. Il tipo di cavo di connessione da

utilizzare è: H05/07RN-F o 245IEC57(YZW).

2 Se il fusibile sul circuito PC è rotto, sostituirlo con il tipo T. 3,15A/ 250V.

3 Il metodo di cablaggio utilizzato dovrebbe essere conforme con gli standard di cablaggio adottati a livello

locale.

4 Dopo l'installazione deve essere facile raggiungere la spina della corrente.

5 Nel cablaggio fisso dovrebbe essere inserito un interruttore di circuito. L'interruttore dovrebbe essere

omnipolare e la distanza tra i suoi due contatti dovrebbe essere non inferiore a 3mm.

Componente

rno

inte

Componente

interno

HSU-07HEA03/R2

HSU-09HEA

HSU-09HEA10

HSU-12HEA03/R2

HSU-18HEA03/R2

HSU-22HEA03/R2

03/R2

3/R2

21

3

4

5

L

N

Componente

esterno

3

4

Componente

esterno

ALIMENTAZIONE

20

Câble d'alimentation :

-mod 07-09-12:

-mod 18:

-mod 22:

branchement du câblage:

-mod 07-09-12:

-mod 18:

3G1.0mm

3G2.5mm

3G2.5mm

LǃNǃ :

3ǃ4:

LǃNǃ

3ǃ4:

-mod 22:

:

3G1.0mm

2X0.75mm

3G2.5mm

2X0.75mm

6G0.75mm

Page 22

Componente esterno

1.Installazione del componente esterno

Procedere all'installazione secondo il Disegno per l'installazione dell'elemento interno e di quello esterno

2.Collegamento dei tubi

Per piegare un tubo, conferire la massima rotondità possibile in modo da non danneggiare il tubo, il raggio di curvatura

dovrebbe essere di 30-40 mm o maggiore.

Collegare prima il tubo del lato del gas rende il lavoro più semplice.

Il tubo di connessione è particolarmente adatto per il refrigerante R410A.

unione parziale

dado svasato

Un fissaggio forzato, privo di attenta centratura può

provocare danni ai fili e causare una perdita di gas.

diametro del tubo(ø) coppia di serraggio

Lato del liquido 6,35 mm

18N.m

(1/4")

Lato del gas 9,52mm (3/8") 42N.m

Chiave fissa

Chiave dinamometrica

Lato del gas 12,7mm (1/2") 55N.m

Fare attenzione che materiali, come detriti di sabbia ecc., non penetrino nel tubo.

La lunghezza standard del tubo è di 5 m. Se esso supera i 7 m di lunghezza, il funzionamento dell'apparecchio potrebbe

risentirne. Se è necessario allungare il tubo, bisognerebbe aggiungere refrigerante secondo un rapporto di 20 g/m.

L'aggiunta di liquido refrigerante, tuttavia, deve essere effettuata da un tecnico esperto specializzato in condizionatori.

Prima di aggiungere ulteriore liquido refrigerante, effettuare uno spurgo dell'aria dai tubi del refrigerante e dall'elemento

interno con l'ausilio di una pompa per vuoto, poi aggiungere refrigerante aggiuntivo.

Componente esterno

Componente interno

B

A

Componente esterno

A

B

Componente interno

Componente esterno

A

B

Sifone per l'olio

Componente interno

ATTENZIONE

Elevazione massima: Amax1=10m

Amax

2=15m

(07k 09k 12k)

(18k 22k)

Nel caso in cui l'elevazione di A superii5m,ogni 5~7m dovrebbe

essere installato un sifone per l'olio

3.Connessione

Usare lo stesso metodo per l'elemento interno.

Allentare le viti sulla morsettiera e inserire

completamente le spine nella morsettiera, poi

un funzionamento corretto e ciò provocherà dei

guasti al circuito di controllo.

serrare le viti.

Inserire il cavo in base al numero di morsetto,

nello stesso modo adottato per l'elemento interno.

4. Collegamento del raccordo di scarico

Se si utilizza un raccordo di scarico, si prega di collegarlo

come nella figura.

Nota: Solo per la pompa termica.

In case A is more than 5m

Lunghezza massima: Bmax1=15m

Bmax

Nel caso in cui la lunghezza del tubo B sia

superiore a 7 m, dovrebbe essere addizionato

refrigerante, secondo un rapporto di 20 g/m.

Se il cablaggio non è corretto non si potrà avere

Fissare il cavo con un gancio.

Raccordo di scarico

(07k 09k 12k)

2=25m

(18k 22k)

Tubo di scarico

21

Page 23

Componente esterno

5.Metodo per eseguire lo spurgo: utilizzare

una pompa per il vuoto

Staccare il tappo della valvola a 3 uscite (G) della porta di

servizio, la calotta di protezione dell'asta delle valvole a 2

uscite (L) e (G), collegare la porta di servizio al

prolungamento del tubo di scarico (basso) per il manometro.

Collegare poi il prolungamento del tubo di scarico (centro) per

il manometro alla pompa per il vuoto.

Aprire

la manopola posizionata in basso sul manometro, far

funzionare la pompa per il vuoto. Se l'indicatore del

manometro (basso) raggiunge la condizione di vuoto in un

istante, controllare nuovamente quanto esposto al punto ķ

A spirare sottovuoto per più di 15min. Verificare il

lilvello del manomentro, la lettura deve essere di

-0.1 MPa (-76 cm Hg) sul lato a bassa

pressione. Dopo aver completato l'operazione,

chiudere la manopola "Lo" (Bassa) del raccordo

del manometro e fermare la pompa del vuoto.

Controlla le condizioni della scala graduata e

tenerla per 1-2min. Se la scala torna indietro

ripetere l'operazione di svasatura e tornare

all'inizio di (3).

A prire il rubinetto della vavola a 2 vie per 90°

gradi in senso antiorario.

Dopo 6 secondi, chiudere la valvola a 2 vie e

ripetere l'ispezione per verificare la presenza di

perdite di gas.

In

Non

ci sono

fuoriuscite di

gas?

Staccare il tubo della ricarica dall'apertura di servizio,

aprire la valvola a 2 vie e e quella a vie. Ruotare il

rubinetto della valvola in senso antiorario fino a serrarlo

leggermente.

caso si riscontrino fuoriuscite di gas,

stringere i raccordi del tubo. Se la

fuoriuscita cessa, procedere con le

operazioni descritte al punto

.

Valvola a 2 vie

Valvola a 2 vie

Se ciò non arresta la fuoriuscita di gas, far uscire

tutto il refrigerante dalla porta di servizio. Dopo aver

effettuato nuovamente lo spurgo e creato

nuo

refrigerante prescritta traendola dal cilindro del gas

Valvola a 2 vie

Lato liquido

6,35mm(1/4")

Tubo (per R410A)

lato gas

9,52mm(3/8")

12,7mm(1/2")

Valvola a 3 vie

Pompa del vuoto (per R410A)

Apre

Chiude

Valvola a 3 vie

Porta di servizio

Apre

o

90

vamente il vuoto, inserire la quantità di

o

per 6 sec.

90

Valvola a 3 vie

Collettore manometro (per R410A)

Giunzione per evitare il ritorno

Lato liquido Lato gas

6,35mm(1/4")

Valvola a 2 vie

HSU-07HEA03/R2

HSU-09HEA03/R2

HSU-09HEA103/R2

HSU-12HEA03/R2

HSU-18HEA03/R2

Lato liquido

6,35mm(1/4")

Valvola a 2 vie

9,52mm(3/8")

12,7mm(1/2")

Valvola a 3 vie

Lato gas

12,7mm(1/2")

90

Valvola a 3 vie

Per evitare le perdite di gas, ruotare il tappo del

rubinetto della valvola a 2 vie e di quello della valvola a

3 vie un po' oltre il punto di serraggio, in cui la

resistenza aumenta immediatamente.

aver collegato ciascuna calotta, controllare se vi siano

Dopo

fuoriuscite di gas attorno ad esse.

ATTENZIONE:

1.Se ci sono perdite di liquido refrigerante del condizionatore, è necessario

far uscire tutto il liquido refrigerante. Creare prima il vuoto, successivamente

caricare il liquido refrigerante nel condizionatore nella quantità

contrassegnata sulla targa riportante il nome.

HSU-22HEA03/R2

Valvola a 2 vie

Tappo porta di

servizio

Non introdurre altro tipo di refrigerante, diverso da quello specificato (R410A), e non

2.

lasciar penetrare aria nell'impianto di circolazione del refrigerante. Altrimenti, nel sistema

si produrrà un'alta pressione anomala, che ne provocherà la rottura e causerà lesioni alla

persona.

Valvola a 3 vie

Tappo rubinetto valvola

Tappo rubinetto valvola

22

Page 24

1.Installazione della sorgente di alimentazione

La sorgente di alimentazione deve essere utilizzata esclusivamente per il condizionatore. (Più di 10A)

Se si installa un condizionatore in un luogo umido, installare un interruttore di perdita della terra.

Per installazioni in altre sedi, usare il più possibile un interruttore di circuito.

2. Taglio e svasatura dei tubi

Il taglio dei tubi viene eseguito con un taglia tubi e le sbavature devono essere eliminate.

Dopo aver inserito un dado svasato si effettua la svasatura.

A

Stampo per la svasatura

1.Tagliare il tubo 2. Eliminare le

sbavature

3. Inserire il dado svasato

4. Effettuare la svasatura del tubo

3.Informazioni relativamente allo scarico

Installare il tubo di scarico in modo che abbia l'inclinazione verso il basso, senza commettere errori.

Non effettuare il drenaggio come sotto indicato.

Flangiatubi per

R410A

Tipo frizione Tipo frizione

A 0~0,5mm 1,0~1,5mm 1,5~2,0mm

Corretto Non corretto

Inclinato Svasatura danneggiata Parziale Troppo in fuori

Flangiatubi tradizionale

(tipo rigido)

Rottura

Tipo a galletto

(sistema imperiale)

Meno di 5 cm

Si solleva a metà percorso. L'estremità rimane

immersa nell'acqua.

La distanza dal suolo è

Ondeggia.

troppo ridotta

Il canale di scolo emette

un cattivo odore

Versare acqua nella vaschetta di raccolta condensa dell'elemento interno e accertarsi che il drenaggio

all'esterno abbia effettivamente avuto luogo.

Nel caso in cui il tubo di scarico si trovi in una stanza, applicare senza indugio ad esso l'isolamento termico.

Controllo dell'installazione e test di funzionamento

Spiegare ai clienti come far funzionare l'apparecchio, facendo riferimento al manuale di istruzioni.

Elementi da controllare effettuando

una prova di funzionamento

Perdita di gas dai collegamenti dei

tubi?

I collegamenti dei tubi sono dotati di

isolamento termico?

I cavi di connessione dell'elemento

interno e di quello esterno sono

saldamente inseriti nella

morsettiera?

Il cablaggio di connessione interno

ed esterno è fissato saldamente?

Inserire il segno di spunta √ nelle

caselle

Il drenaggio è stato eseguito in

modo sicuro?

La linea della terra è stata collegata

senza alcun dubbio?

L'elemento interno è fissato in modo

sicuro?

La tensione della sorgente di

alimentazione è conforme al

codice?

Si avvertono rumori?

La lampada si accende in modo

normale?

La refrigerazione e il riscaldamento

(quando è in funzione una pompa

termica) vengono svolti in modo

normale?

Il funzionamento del dispositivo di

regolazione della temperatura nella

stanza è normale?

23

Page 25

Manuel d'installation du climatiseur de pièce

Lisez ce manuel avant installation

Expliquez suffisamment le mode d'emploi à

l'utilisateur, dans le respect du présent manuel.

Outils nécessaires à l'installation

1.Tournevis 5.Clé dynamométrique (17mm, 22mm, 26mm) 9.Pince 12.Alésoir

2.Scie à métaux 6. Coupe-tuyau

3. Perceuse à prélever des

carottes

7. Outil à évaser

4. Clé (17, 19 et 26mm) 8.Couteau

10. Détecteur de fuite de gaz ou

solution d'eau savonneuse

11. Mètre ruban

Pièces accessoires

No.

ķ

ĸ

Pièces accessoires

Télécommande

Batterie sèche R-03

Ĺ

Plaque de fixation

ĺ

Tuyau de vidange

Ļ

ø 4X50

Clou en acier, pour béton

ļ

Vis ø4X25 Bouchon en

plastique

Ľ

ľ

Couvercle

Coussin

Nombre

d'articles

1

2

1

1

6

4

1

4

Dessins d'installation des unités intérieure et extérieure

plus de

Pièces optionnelles pour la tuyauterie

Repère Nom des pièces

࿆

࿇

࿈

࿉

࿊

࿋

࿌

Ruban non

adhésif

Ruban adhésif

Semelle (L.S)

avec vis

Câble de

branchement

électrique pour

l'intérieur et

l'extérieur

Tuyau de vidange

Matériau

d'isolation

calorifique

Capot de trou de

tuyau

10cm

plus de 5cm

plus de

10cm

Il faut

faire attention

remontée du tuyau de drainage

à la

plus de 10cm

plus de 10cm

A

C

Ŀ

Plaque de fixation du tuyau

ŀ

Coude de drainage

1

1

Disposition des sens de tuyaux

Arrière gauche

Gauche Gauche

Dessous

Les repères de ࿆ à࿌ sur la figure sont des références de

pièces.

La distance entre l'unité intérieure et le sol doit être supérieure à

2m.

Droite

24

D

E

plus de 15cm

plus de 60cm

Page 26

140

50

0 140

65

2

115

580

319.5

115

Dimensions de fixation au sol de l'unité

extérieure (Unité: mm)

HSU-07HEA03/R2

HSU-09HEA03/R2

HSU-09HEA103/R2

HSU-12HEA03/R2

HSU-18HEA03/R2

Fixation de l'unité extérieure

Unité intérieure

Endroit robuste n'entraînant pas de vibration, où le corps peut être

soutenu efficacement.

Endroit non soumis à de la chaleur ni à de la vapeur produite

alentours,

pertur

Endroit où une vidange rapide est possible, où la tuyauterie peut être

raccordée

Endroit où l'air frais peut être répandu intégralement dans la pièce.

Endroit proche d'une prise secteur, avec assez d'espace autour.

(Référez-vous aux dessins).

Endroit situé à une distance de plus de lm de toute télévision, radio ;

le

En cas de fixation de la télécommande sur un mur, placez là à un

endroi

éclairages fluorescen

et où l'entrée et la sortie de l'appareil ne sont pas

bées.

à l'unité extérieure.

pareils sans fil et les lampes fluorescentes peuvent rester.

s ap

t où l'unité intérieure peut recevoir les signaux lorsque les

ts de la pièce sont allumés.

Choix du lieu d'installation

Dimensions de fixation au sol de l'unité

extérieure (Unité: mm)

HSU-22HEA03/R2

Fixez l'unité sur du ciment ou des dalles à l'aide de boulons

(10mm) et d'écrous, fermement et horizontalement.

Lorsque vous montez l'unité sur une surface murale, un toit ou

un dessus de toit, fixez un support de façon sûre à l'aide de

clous ou de fils, pour prendre en considération un tremblement

de terre et un vent violent.

Si la maison est soumise à des vibrations, fixez l'unité en

attachant un mât à l'épreuve des vibrations.

Unité extérieure

Endroit peu affecté par la pluie ou la lumière directe du

soleil, et suffisamment ventilé.

Endroit pouvant supporter l'unité, et qui ne risque pas

d'accroitre les vibrations ou le bruit.

Endroit où l'évacuation d'air et le bruit ne représentent

pas une nuisance pour le voisinage.

Endroit où une distance marquée

comme

illustré sur la figure ci-dessus.

est disponible

Source d'alimentation

Avant d'insérer la fiche d'alimentation dans la prise, ne manquez pas de vérifier la tension. La source d'alimentation doit correspondre

à la valeur nominale sur la plaque.

stallez sur une dérivation spécifique du circuit d'alimentation. In

Une prise doit être installée à une distance permettant d'être atteinte par le cordon d'alimentation. Ne coupez pas le câble pour le

prolonger.

Choix du tuyau

Pour cette unité, les tuyaux à liquide comme à gaz doivent être

isolés car ils descendent en température en fonctionnement.

Utilisez des pièces optionnelles pour la tuyauterie ou les tuyaux

couverts de matériau isolant équivalent.

Tubo per

liquidi (ø)

Tubo per gas

(ø)

25

Pour

07 09 12 Pour 18 22

mm (1/4")

6,35

9,52 mm (3/8")

6,35 mm (1/4")

12,7

mm (1/2")

Page 27

Unité intérieure

Unité intérieure

1. Monter la plaque de fixation et positionner le trou sur le mur

Lors de la première installation de la plaque de fixation

1. Effectuez, en vous basant sur des piliers ou des linteaux voisins, une mise à niveau appropriée pour que la plaque

soit fixée contre le mur, puis fixez temporairement la plaque avec un clou en acier.

2. Assurez-vous une fois de plus que la plaque est de niveau, en suspendant un fil lesté d'un poids en partie centrale,

sur le haut de la plaque, puis fixez fermement la plaque avec les clous de fixation en acier.

3. Repérez l'emplacement du trou sur le mur A à l'aide du mètre ruban

B= 60mm

A=145mm

30mm

Lorsque la plaque de fixation est attachée à une barre latérale et à un linteau

y Fixez sur la barre latérale et sur le linteau une barre de montage, vendue séparément, puis attachez la plaque à la

barre de montage ainsi fixée.

y Référez-vous au paragraphe précédent, " Lors de la première installation de la plaque de fixation ",

pour la position du trou mural.

2. Percer un trou sur le mure et monter le capot de trou de tuyau

z Faites un trou de 60 mm de diamètre,

descendant légèrement vers l'extérieur du mur.

z Installez le capot du trou de tuyau et

étanchéifiez le avec du mastic après installation

3. Installation de l'unité intérieure

Dessin du tuyau

Côté intérieur

Trou du mur

60mm

(Section of du trou du mur) ࿌ Tube de trou de tuyauterie

Côté extérieur

Épaisseur du mur

[Tuyauterie arrière ]

z Tirez les tubes et le tuyau de drainage, puis fixez les avec du ruban adhésif

Tuyauterie gauche y arrière-gauche ]

[

z En cas de tuyauterie arrière gauche, coupez avec une pince le cache pour la tuyauterie à gauche.

z En cas de tuyauterie arrière-gauche, pliez les tubes selon le sens des tubes indiqué sur le trou pour

tuyauterie arrière-gauche, qui est marqué sur les matériaux d'isolation calorifique.

26

Page 28

Unité intérieure

1 Insérez le tuyau de drainage dans le creux du matériau d'isolation de l'unité intérieure.

2 Insérez le câble électrique intérieur/extérieur depuis l'arrière de l'unité intérieure, et tirez le en face avant, puis

connectez-le.

3 Recouvrez la face du joint évasé d'huile de réfrigération et reliez les tubes.

Couv

rez la pièce de raccord avec du matériau isolant calorifique de façon serrée, et assurez-vous de le fixer avec du

rub

an adhésif

Matériau d'isolation calorifique Tuyauterie

Cache pour tuyauterie

à droite

Cache pour tuyauterie

essous

en-d

Fixez avec du ruban adhésif

Le câble électrique intérieur/extérieur et le tuyau de drainage doivent être liés au tuyau de réfrigérant par du ruban de

protection.

[Autre sens de tuyauterie]

che pour tuyauterie à gauche

Ca

Tuyau de vidange

Câble é

intérieur/extérieur

lectrique

Coupez, avec une pince, le cache de tuyauterie selon le sens de la tuyauterie, puis pliez les tubes selon la position du

trou dans le mur. Lors du pliage, faites attention à ne pas écraser les tubes.

Branchez à l'avance le câble électrique intérieur/extérieure, puis sortez la connexion de l'isolant calorifique,

spécifiquement au niveau des pièces de connexion.

Fixer le corps de l'unité intérieure

Suspendez de façon sure le corps de l'unité sur les encoches

supérieures de la plaque de fixation. Déplacez le corps d'un

côté à l'autre

Afin d'attacher le corps sur la plaque de fixation, maintenez le

corps de travers par le dessous et baissez-le ensuite

pe

rpendiculairement.

pour vérifier qu'il est correctement fixé.

Décharger le corps de l'unité intérieure

Lorsque vous démontez l'unité intérieure, veuillez utiliser votre

main pour soulever le corps et enlever l'attache, puis soulever

le dessous du corps légèrement vers l'extérieur, puis soulevez

l'unité de travers jusqu'à ce qu'elle quitte la plaque de fixation.

at

tache

Plaque de fixation

Plaque de fixation

Démontage facile pour nettoyage de l'unité intérieure

La grille d'entrée peut être enlevée

Ouvrez la grille d'entrée, appuyez sur le bouton de déverrouillage

sur

la gauche, puis poussez pour le sortir de la douille et sortez la

grille d'entrée.

27

Page 29

Unité intérieure

Connecter le câble électrique intérieur/extérieur

Enlever le cache du câblage

Enlevez le cache des bornes dans le coin inférieur droit de l'unité intérieure, puis enlevez le

cache du câblage en ôtant ses vis.

Lors du branchement du câble après installation de l'unité intérieure

1 Insérez depuis l'extérieur de la pièce vers le côté gauche du trou mural, dans lequel le tuyau

existe déjà.

2 Sortez le câble par la face avant et branchez le en faisant une boucle.

Lors du branchement du câble avant installation de l'unité intérieure

Insérez le câble depuis la face arrière de l'unité, puis tirez-le depuis la face avant.

Desserrez les vis et insérez entièrement les extrémités du câble dans le bornier, puis serrez les vis.

Tirez légèrement sur le câble pour vous assurer que les câbles ont été correctement insérés et serrés.

Après le branchement du câble, n'oubliez jamais d'attacher le câble connecté avec le cache du câblage. Remarque :

Lorsque vous branchez le câble, confirmez avec précaution les numéros des bornes des unités intérieure et extérieure.

Si le câblage n'est pas correct, le bon fonctionnement ne peut pas être assuré et un défaut en résulte.

1 Si le cordon d'alimentation est endommagé, il doit être remplacé par le fabricant ou un de ses agents de

maintenance, ou une personne qualifiée similairement. Le type de fil de connexion est H05/07RN-F ou

245IEC57(YZW).

2 Si le fusible du circuit imprimé est cassé, veuillez le remplacer par le type T. 3.15A/250V.

3 La méthode de câblage doit être en accord avec les normes locales de câblage.

4 Après installation, la prise électrique doit rester facilement accessible.

5 Le câblage fixe doit incorporer un coupe-circuit. Le coupe-circuit doit commuter chaque phase et la distance

entre les deux contacts ne doit pas être inférieure à 3mm.

Unité

intérieure

Unité

intérieure

HSU-07HEA03/R2

HSU-09HEA

HSU-09HEA10

HSU-12HEA03/R2

HSU-18HEA03/R2

HSU-22HEA03/R2

03/R2

3/R2

Unité

extérieure

21

3

4

5

L

N

3

4

Unité

extérieure

PUISSANCE

28

Câble d'alimentation :

-mod 07-09-12:

-mod 18:

-mod 22:

branchement du câblage:

-mod 07-09-12:

-mod 18:

3G1.0mm

3G2.5mm

3G2.5mm

LǃNǃ :

3ǃ4:

LǃNǃ

3ǃ4:

-mod 22:

:

3G1.0mm

2X0.75mm

3G2.5mm

2X0.75mm

6G0.75mm

Page 30

Unité extérieure

1. Installation de l'unité extérieure

Installez selon les dessins d'installation pour les unités intérieure et extérieure

2. Branchement des tubes

Pour plier un tube, donnez un rayon le plus grand possible de façon à ne pas écraser le tube, le rayon de courbure doit

être entre 30 et 40, ou plus.

Le fait de brancher le tube du côté gaz en premier facilite le travail.

Le tube de connexion est spécial pour le R410A.

Demi-raccord

Écrou évasé

Un montage en forcer sans précaution de centrage peut

endommager les filetages et provoquer une fuite de gaz.

Diamètre du tube (ø) Couple de serrage

Côté liquide 6.35mm(1/4") 18N.m

Côté gaz 9.52mm(3/8") 42N.m

Côté gaz 12.7mm(1/2") 55N.m

élC

élC