Haier HR-135A Parts Manual

HR-135A

REFRIGERATOR

Service Manual

CONTENT

1. 1.SPECIFICATION LIST…………….…….2

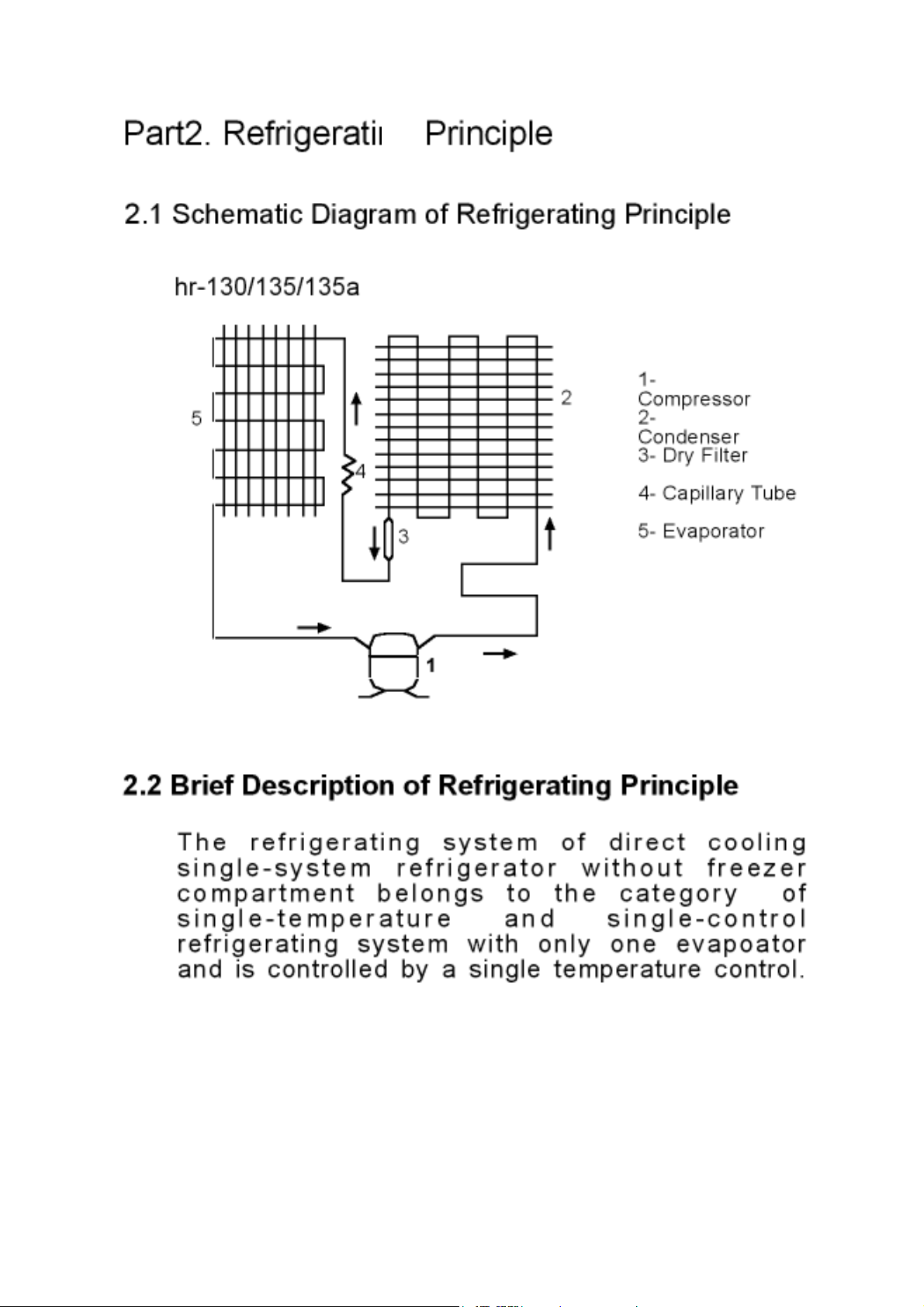

2.REFRIGERATING PRINCIPLE...…...….3

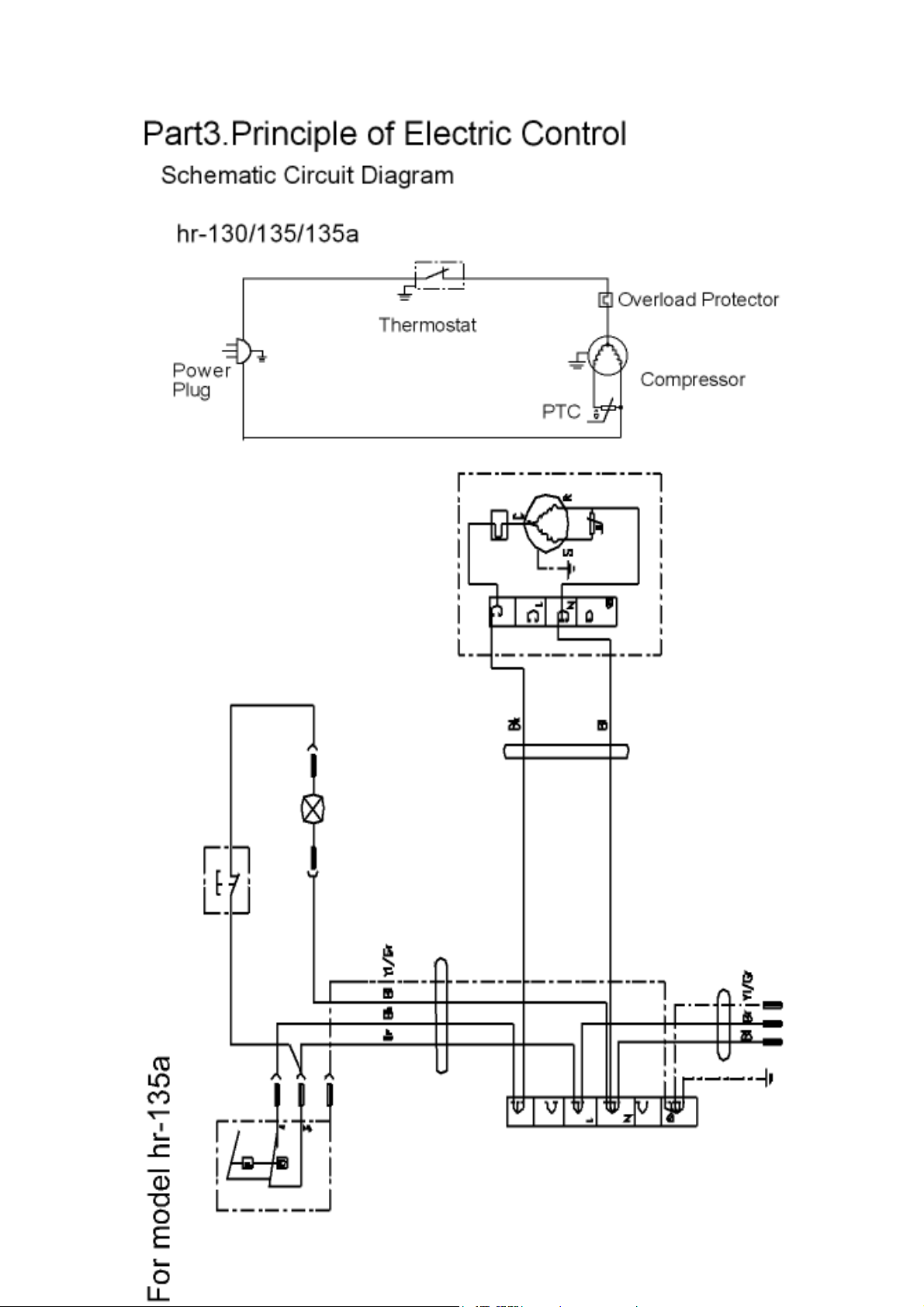

3.PRINCIPLE OF ELECTROIC CONTROL...4-5

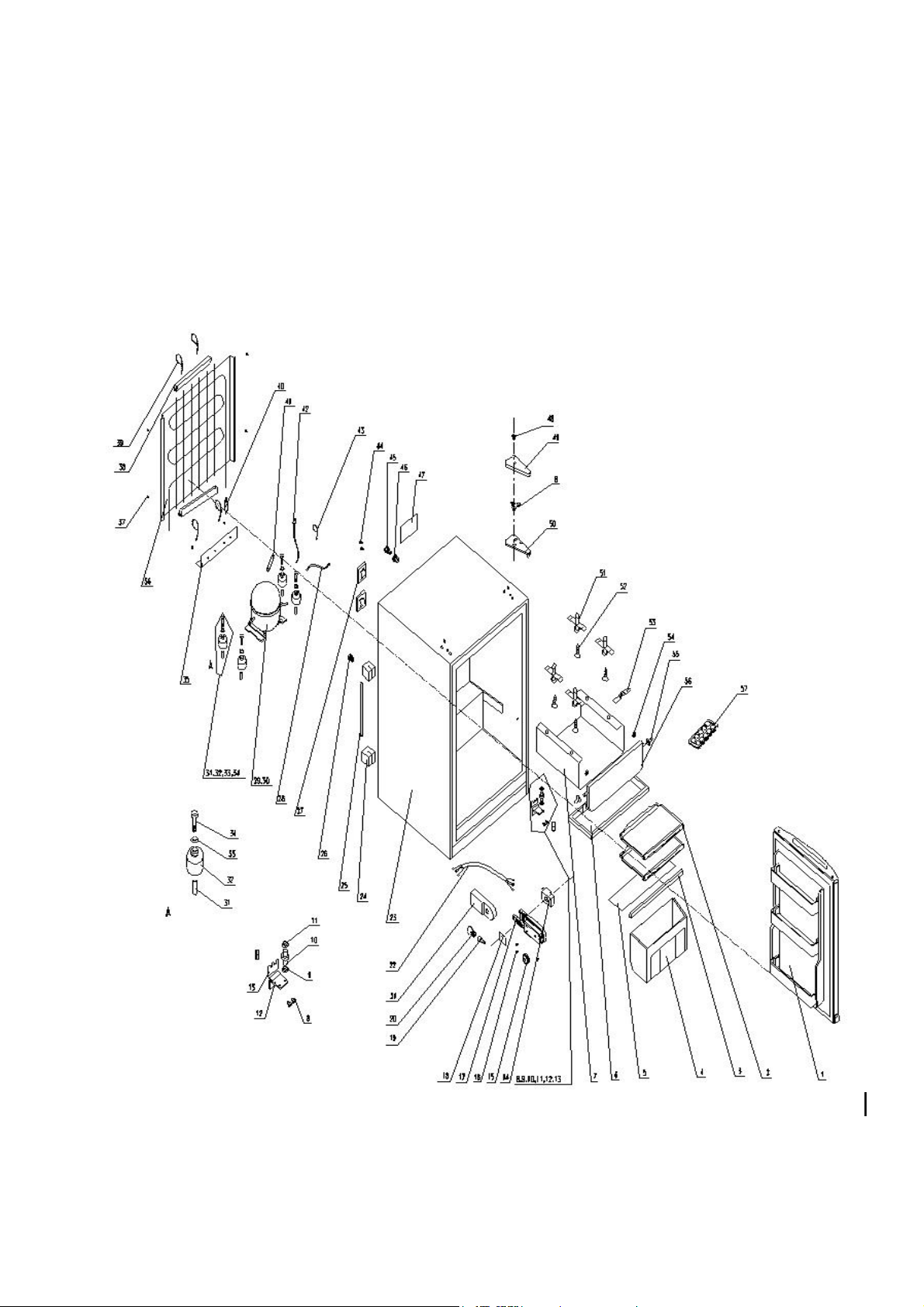

4.ASSEMBLY FIGURE……..………………6

5.PARTS LIST…..……………………….…7~8

6.TROUBLESHOOT TABLE….……..…9~46

7. REPLACEMENT PARTS LIST...46

Features

Small fridge, humidity and freshness retained

No freezer, super freeze

Curve appearance

Europe style

Haier Group

Part 4. Assembly figure:

Exploded View

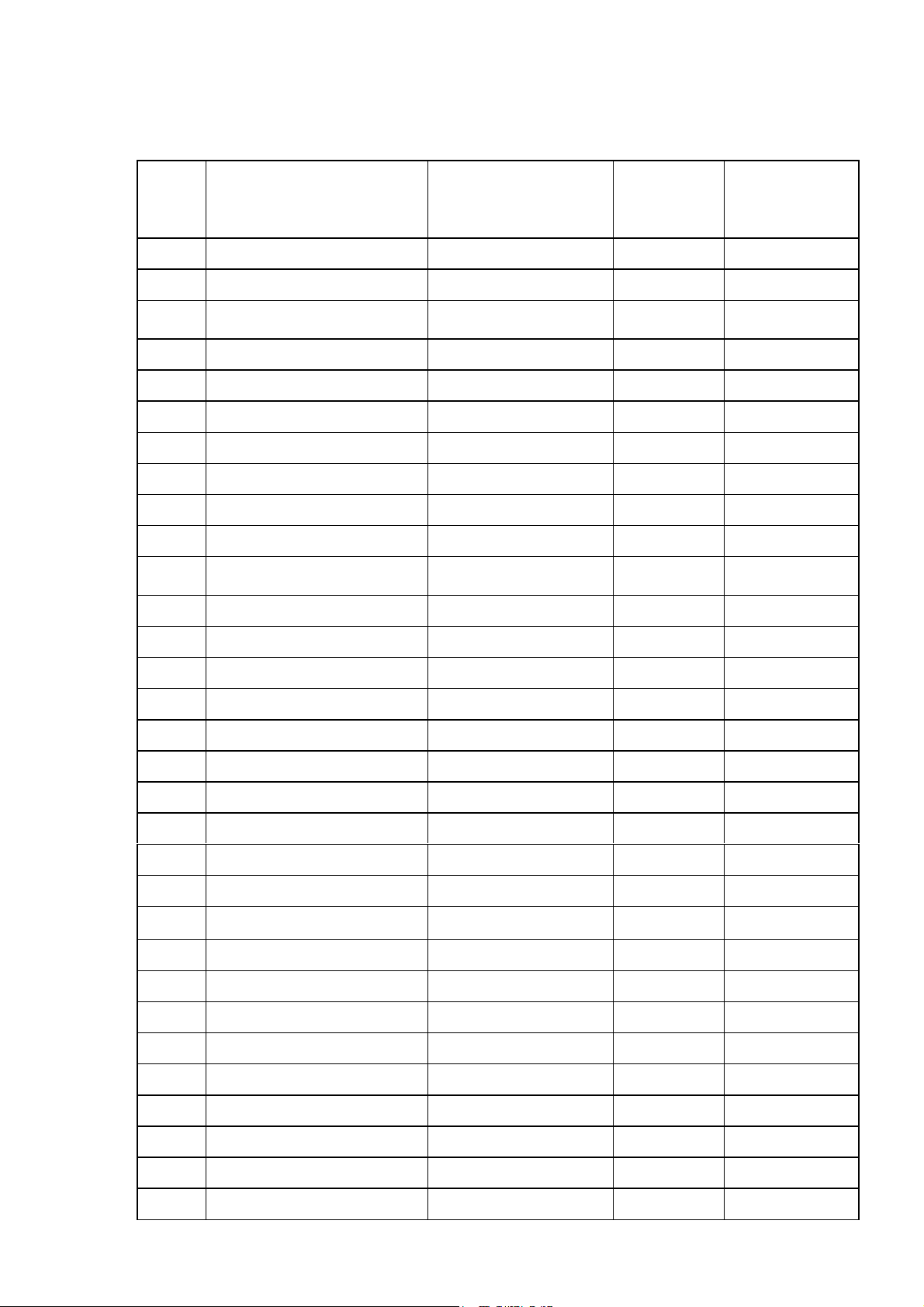

Part 5. Specification list:

NO. In

exploded

view

1

2

3

4

5

6

7

8

9

10

11

12

Name of part Part specialized code QTY. Unit price(USD)

door assembly

shelf

glass board decorative

strip

vegetable tray

glass board

water basin 00602111449 1

evaporator

oval head screw

spring washer

hinge axle 00601470309 1

lower hinge adjustment

plate

lower hinge base 0060800746 1

0060802286

0060211286

00602111181

0060211159

0060402034

00609310091

0064084005

0064240002

0067744127 1

1

2

1

1

1

1

2

1

door adjustment plate 0067744009 1

13

thermostat 0066151098 1

14

kbob

15

screw

16

thermostat cover

17

lamp

18

lamp holder

19

reflector plate

20

lamp cover

21

connection cable

22

foaming cabnit

23

damping pad

24

faom soft tube

25

cable seal sleeve

26

tempreture sensor fixture

27

0067402748

0064082915

0060211431

0060604048

0066072016

0069721001

0069000241

0060613192

0060802311

0067403142

0069540008

0060211012

0067412148

1

3

1

1

1

1

1

1

1

2

1

1

1

ground cable assembly

28

compressor

29

compressor accessory

30

fixing sleeve

31

0060612001

00605040112

00605050112

0060145577

1

1

1

4

rubber washer

32

0060405099

4

washer

33

hex bolt

34

water retaining 0060145153 1

35

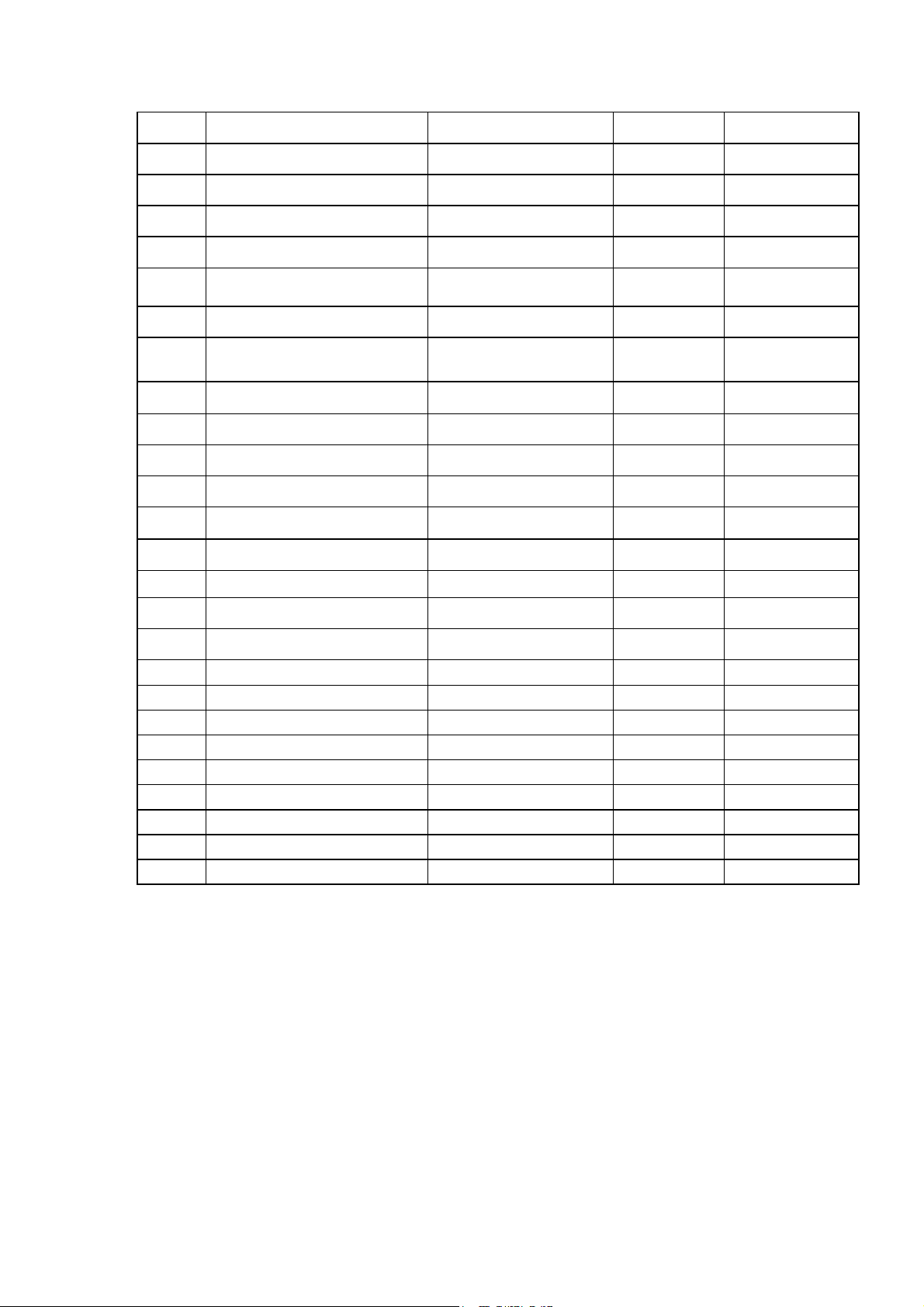

louver condensor

36

hexagon heag self taping

37

screw

38 CAPILLARY TUBE CLIP

39 CONDENSER PROTECTION COVER

drier filter

40

suction tube

41

power cable

42

cable fixing clip 0060215118 1

43

screw

44

45 Conductor duct

46 Cable seal sleeve

name plate

47

0060147208

0060804011

0060502046

0060801078

0067401764

0067402764

00605030028

0060143039

0060611074

0064098005

0060214001 1

0060211012

00607136401

4

4

1

4

4

2

1

1

1

2

1

1

48

49

50

51

52

53

54

55

56

57

phlips sunk screw

upper hinge box

upper hinge part

evaporator hanger

screw

tempreture sensor clip

door shock pad 0060212009 2

axle sleeve

evaporator door

ice tray

0064082808

0060213466

0060938396

0060215003

0064082803

00601470510

0060215013

00602111390

0060211445

1

1

1

4

4

2

2

1

1

Part 6. Troubleshooting and Repair

7.1 Normal Phenomena—Not Troubles for Refrigerators

In a domestic refrigerator, there is not only a complicated electric

control system, but also a refrigerating system that is difficult to

discern whether it is in a good working condition. Both the systems

are related and affect each other. If a certain part of a refrigerator

works abnormally .Its refrigerating efficiency will

decrease ,operation properties will become unstable ,or even it

cannot be used normally for those serious cases.

Refrigerators are generally of larger volume ,once troubles

appear ,to send them to a service department is really a tough

thing ,if such is the case ,the user will always be in

suspense ,sometimes ,normal phenomena will be erroneously

regarded as troubles .Therefore ,before we deal with the topics of

frequently occurring troubles of refrigerators and their

remedies ,we should firstly give a brief account of some normal

phenomena which are not troubles .In case any one of such

phenomena occurs ,there is no need to worry about it ,and the user

can use it at total ease .

1).When the compressor of a refrigerator has just stopped

running ,a rumbling sound can be heard from inside its

evaporator .This is a sound caused by the flowing of refrigerant in

the evaporator tubing .Because the pressure difference is still

greater after the compressor has just stopped running ,the

refrigerant will flow for a certain time , therefore ,this sound is a

normal phenomenon.

2).A click sound can often be heard from the refrigerator .This is a

normal sound produced by the pull-in or release of the armature

of a current deadweight start relay when starting the

compressor .The compressor motor will produce a slight and

uniform sound while it is running .This sound is not easy to be

heard in the daytime ,but of course it can be heard distinctly at

night.

3).The compressor consists of an electric motor and a compressing

apparatus .During its normal operation ,the motor’s stator core and

windings will rise to a temperature in the range of 100

,and the temperature of the piston and cylinder of the

~110

compressing mechanism can also reach as above 100

heat produced when compressing refrigerant .Most of the heat

radiates to the air through the compressor casing ,therefore ,its

due to the

casing is generally at a temperature between 85 ~90 ,it is very

hot ,particularly in summer when the ambient temperature is

higher .All these are normal phenomena .

4).For the direct cooling refrigerator ,a kind of irregular crack

sound can be often heard when the compressor is running for a

certain period of time or has just stopped its running .This sound is

caused by the stress relief due to expansion and contraction when

temperature changes ,and will not affect the normal application of

refrigerator .

7.2 Common Troubles in Refrigerators and Their

Remedies

Causes for troubles occurring in refrigerators are closely related to

the quality of components and workmanship in assembling by

manufacturers as whether refrigerators are properly used and

maintained .The parameters generally used to express the working

conditions of a refrigerator include the temperature inside the

refrigerator ,operation rate ,electric power consumption ,noise

level ,and other functional indexes .If any one of these parameters

is beyond its permissible range ,this indicates that there is a fault or

trouble in the refrigerator .

During the whole service life of a refrigerator ,the probability of

troubles occurring within a union time is called its failure

rate .Making a comparison between the control circuit system of a

refrigerator and its refrigerating system ,we can find that the failure

rate of the former is higher ,and that of the thermostat is the

highest . In troubleshooting ,the first thing you must do is to

determine where the trouble comes from --- the control system or

the refrigerating system .There is general no trouble indicating

instrument mounted on the domestic refrigerator ,locations and

natures of troubles should be determined according to their

respective features ,therefore ,experience in servicing is very

important to troubleshooting .Service technicians with rich

experience can correctly locate them and take reasonable remedy

measures based on their comprehensive analysis of trouble

characteristics as well as operating conditions for various kinds of

refrigerators .

Three Essentials for Checkup

1) Look

a) Check the tubing of refrigerating system for cracks and

various welding points for leaks ;if leakage occurs ,an oil stain

can be seen definitely .

b) Check the suction and exhaust pressure values (high pressure

and low pressure) of compressor to see whether they are normal .

c) Pay attention to the speed of temperature drop inside both the

refrigerator compartment and freezer compartment .It is

abnormal if the speed of temperature drop is obviously slower

than the corresponding normal speed .

d) Check the environment to see whether it is suitable for placing

a refrigerator .

e) Check refrigerator door seal ,case ,table surface and heat

insulation layer .

2) Listen

a) Listen to the noises produced when the compressor is running

Hums from a fully enclosed aggregate unit is the sound caused by

overload indicating that the motor cannot be started

normally ,meanwhile ,a clattering sound can be heard from inside

the start relay ,which is produced because the start contacts cannot

be released normally .A whistling sound is caused by the high

pressure gas flowing out of the crack of the pressure tube inside the

compressor ,and clucks are the sound of striking after the

suspended spring inside the compressor has broken .

During the normal operation of compressor ,a slight and uniform

hum sound due to undulation of electric current can be heard

generally ,this is a normal phenomenon .However ,if it sounds like

“tong ,tong …”,i.e.,an impact sound inside the compressor ,this

means that a large quantity of wet vapour of refrigerant or

refrigerating oil has come into the compressor cylinder ;if it sounds

like “dang ,dang…”, a striking sound of metal parts inside the

compressor ,this means that some moving parts have loosened

(note to differentiate this sound from those formed during starting

or stopping the compressor).

b) Listen to the sound caused by the flowing of gas in

the evaporator

Open the refrigerator door while the compressor is in

operation ,incline your ear and listen attentively the gas flow sound

inside the evaporator .If it sounds like gentle whistling

accompanied by a sound similar to water flowing ,this is the sound

produced by the normal circulation of refrigerant within the

evaporator .In case only the gas flowing sound can be heard and

there is no water flowing sound ,this indicates that the refrigerant

has already percolated .If neither the flowing sound nor the gas

sounds from the evaporator can be heard ,this means that the filter

or capillary has been clogged .

3)Touch and Feel

a) Feel the compressor when running ,its temperature should be

generally less than 90

in case of running for a longer period of time ).

b) After the compressor has operated normally for 5~10

minutes ,ouch and feel the condenser ,the temperature of its upper

part should be higher than that of its lower part (or its right part is

hotter than its left part ,depending on the type of condenser

coil ),this indicates that the refrigerant is circulating . If the

condenser is not hot ,this means the leakage of refrigerant .In

case the condenser radiates heat for only several minutes and then

cools down ,this means that the filter and capillary have been

in the normal state (it may exceed 90

clogged .As for the forced air cooling condenser ,hot air will be

blown out of it ;this means that the system is out of order .

c) Feel the filter’s temperature .During the normal operation of

refrigerating system ,the temperature on the filter’s surface

should be a little higher than the ambient temperature ;if you

touch it with your hand ,you will have a sense of slight heat .In

case dew condensation appears due to the fact that its temperature

is obviously lower than the ambient temperature ,this means that

most meshes of its screen has been clogged ,resulting in an

obstructed flowing of refrigerant ,thus causing a drop in

temperature due to throttling .

d) Feel the temperature of exhaust gas from the refrigerating

system .the exhaust gas should be very hot and this is the normal

working state .For those refrigerator with enclosed type of

compressor refrigerating system ,no frost or dew drop will from

on the gas suction tube ,otherwise ,there is something wrong in

the system (Frosting and dew condensation may appear for a very

short time period when just starting the machine ,this is a normal

phenomenon ).

Because a refrigerator is a combination of several

components ,they are related and have influence on each other .In

case an abnormal phenomenon has been found through the above-

mentioned checkups ,you need not to make a hasty conclusion

based on only one abnormal phenomenon .It is advisable to find

out two or more abnormal phenomenon ,or conduct

troubleshooting comprehensively with the aid of instruments or

other ways ,because several kinds of troubles may share a common

abnormal phenomenon ,and two or more abnormal phenomena

may occur simultaneously due to a certain trouble .With this

Loading...

Loading...