Commercial Air Conditioning

SERVICE MANUAL

Model

HPU-42CV03

HPU-42HV03

Features

Long distribution pipe and high drop

The outdoor can match with multiple types indoor unit of the same capacity

The indoor unit is identical for heat pump and cooling only unit

Infra red remote controller

Central control and full automation, if connected with a central controller

Optional safety devices and much more precision control device

Auto-restart function

Manual code: SYJS-016-06REV.0

Edition: 2006-06-12

Commercial Air Conditioner Model: HPU-42CV03

HPU-42HV03

CONTENTS

Contents………………………………………………………...1

1. Description of products & features………………………..2

2. Specification…………………………………………………4

3. Safety precaution……………………………………………7

4. Net dimension of indoor and outdoor……………………..9

5. Installation instructions………..……………………………10

6. Parts and functions…………………………………………21

7. Infrared controller functions………………………………..22

8. Refrigerant diagram....………………………………………39

9. Electrical control functions…………………………………41

Diagnostic information (trouble shooting)..……………..47

10.

11. Electrical data....................……………………………….53

1

Commercial Air Conditioner Model: HPU-42CV03

HPU-42HV03

1.DESCRIPTION OF PRODUCTS & FEATURES

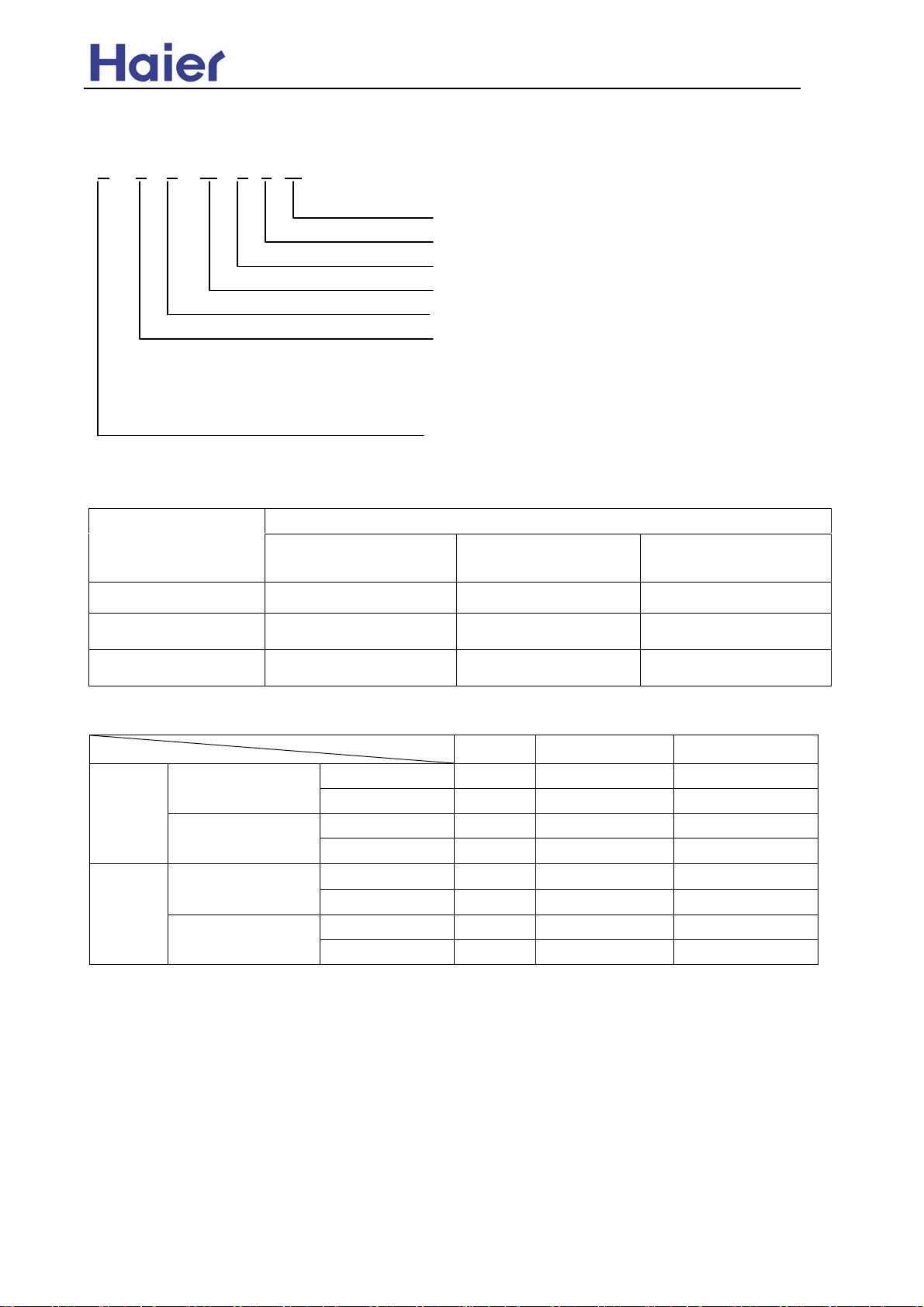

1.1. Products code explanation

H P U - 42 C V 03

1.2 Brief Introduction for T1、T2、T3 working condition

Power supply type: 03 stands for 200-220V, 50Hz

Design sequence

C: cooling; H: heating

Cooling capacity: 42=42000BTU/h

U: single split unit

Product type : “B” stands for cassette type, “C” stands for

convertible type, ”D” stands for duct, “S” stands for split

type, ”P” stands for cabinet system, "E" stands for ceiling

concealed type.

Haier Brand Air Conditioner

Climate type

Type of Air

Conditioner

Cooling Only

T1 T2 T3

18 ℃~43℃ 10℃~35℃ 21℃~52℃

Heat pump

-7℃~43℃ -7℃~35℃ -7℃~52℃

Electricity Heating

~43℃ ~35℃ ~52℃

1.3 Operating Range of Air Conditioners

Temp. Mode Rated Maximum Minimum

Cooling

Heating

Indoor

Outdoor

Indoor

Outdoor

DB ℃

WB ℃

DB ℃

WB ℃

DB ℃

WB ℃

DB ℃

WB ℃

27 32 15

19 23 14

35 43 -5

24 26 6

20 27 10

14.5 --- --

7 23 -10

6 18 ---

2

Commercial Air Conditioner Model: HPU-42CV03

1.5 Product features

1.5.1 Outdoor unit

Flexible and easy installation

The outdoor can meet the higher request of installation. From the specifications, you will find for

each unit, how long and how high the piping will be, which will be convenient for design and installation.

Optional safety devices and much more precision control device

a. Ambient temperature sensor, coil temperature sensor and compressor temperature sensor

make the temperature control and defrosting control more precise.

b. High/low pressure switch can feel the discharging pipe pressure and suction pipe pressure on

time and precisely. If the pressure is too low or too high, it will stop the compressor to prevent it

being damaged for the sake of pressure.

c. 3 minutes delay protection for the compressor, the device can protect the compressor from

some damages and make the compressor have a long life.

Silent operation

.

HPU-42HV03

1.5.2 Steady cabinet indoor unit

Powerfull running & long distance air sending

The unit can run powerfully and supply large volume of cooled air to the room. Long distance and

large angle air sending ensures average temperature distribution, bring you much more comfortable

indoor environment in the shortest time.

Newly designed display panel, more simple

On the display panel there are power, operation, timer, and electric heating indicator, from which

you can find the operation state directly, and the indicator flash times can show the failure.

Malfunction Auto-checking

Failure codes displayed by LED or controllers are so detailed for us to find the fail place more

quickly, and can judge the failure content easily.

Powerfull/Soft function

Special button on remoto controller is used to set powerful working or soft working.

Single fan outdoor, more compact

Central control function, if connected with a detector and a central

controller

3

g

g

Commercial Air Conditioner Model: HPU-42CV03

HPU-42HV03

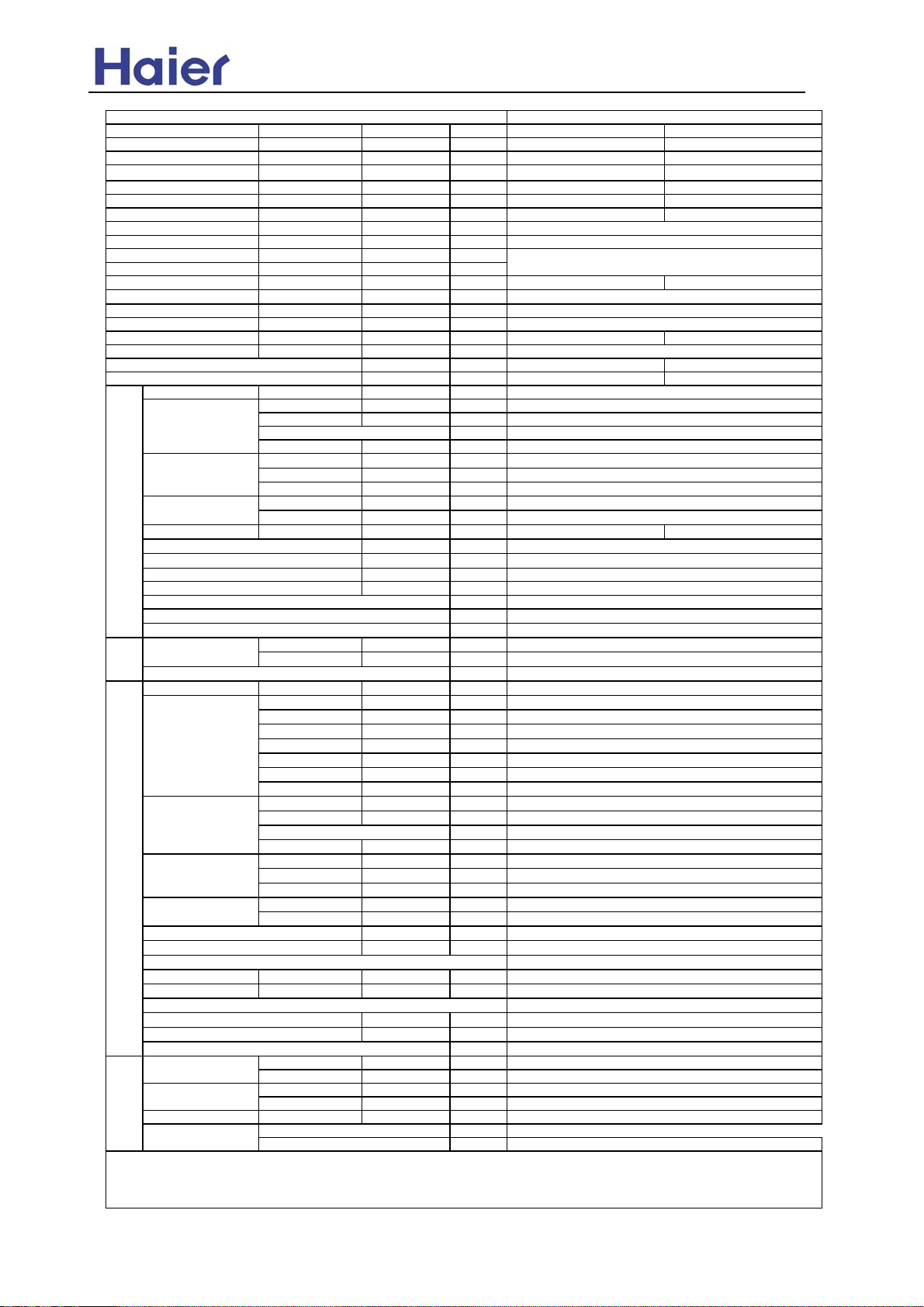

2. SPECIFICATION

item Model

Function

Capacity BTU/h

Capacity kW

Sensible heat ratio

Total power input

Max. power input

EER or COP

Dehumidifying capacity

Power cable section

Signal cable section

Connecting cable section

Wired control cable for wired control unit section

Power source N, V, Hz

Running /Max.Running current

Start Current A

Class of anti electric shock

Circuit breaker A

Max. operating pressure of heat side Mpa

Max. operating pressure of cold side Mpa

Unit model (color)

Fan

Heat exchanger

Dimension

Air sending angle

Indoor unit

Drainage pipe (material , I.D./O.D.) mm

Control type (Remote /wired /model)

Fresh air hole dimension mm

Outlet distribution hole dimension mm

Electricity Heater

Noise level (H-M-L)

Weight (Net / Shipping)

Dimension

Panel

Weight (Net / Shipping)

Unit model (color)

Compressor

Fan

Heat exchanger

Outdoor unit

Dimension

Drainage pipe (material , I.D./O.D.) mm

Refrigerant control method mm/mm

Defrosting

Volume of Accumulator L

Noise level dB(A)

Type of Four way valve

material of reduce noise

crankcase heater power W

Weight (Net / Shipping)

Refrigerant

Pipe

PIPING

Connecting Method

Between I.D &O.D

Norminal condition: indoor temperature (cooling): 27℃DB/19℃WB, indoor temperature (heating): 20℃DB

Outdoor temperature(cooling): 35℃DB/24℃WB, outdoor temperature(heating): 7℃DB/6℃WB

The noise level will be measured in the third octave band limited values, using a Real Time Analyser calibrated sound intensity meter. It is a sound pressure noise level.

The detailed method please refer to the following information:

Type × Number

Speed(H-M-L) r/min

Fan motor output power kW

Air-flow(H-M-L) m³/h

Type / Diameter mm

Total Area m²

Temp. scope

External

Package

External

Package

Model / Manufacture

Oil model

Oil type

Oil charging

Type

Protection type

Starting method

Type × Number

Speed r/min

Fan motor output power kW

Air-flow(H-M-L) m³/h

Type / Diameter mm

Row / Fin pitch

Temp. scope

External

Package

Type / Charge g

Recharge quantity g/m

Liquid mm

Gas mm

MAX.Drop 30

MAX.Piping length 50

(L×W×H)

(L×W×H)

(L×W×H)

(L×W×H)

(L×W×H)

(L×W×H)

W

W 4400

W/W

10‐³×m³/h

A / A

℃

mm×mm×mm

mm×mm×mm

kW

dB(A)

kg / kg

mm×mm×mm

mm×mm×mm

kg / kg

℃

mm×mm×mm

mm×mm×mm

kg / kg

m

m

coolin

41000 ----

12.0

70% ----

3700 ----

3.24 ----

//

Cooling 6.9A/7.8A Heating 7.0/8.3

CLASS I ----

2.8 ----

2.8 ----

HPU-42CV03

5.0

5G×2.5mm

4G×0.75mm

3N,380-400V,50HZ

50

20

HPU-42CV03(WHITE)

centrifugal

430/405/370

0.09

1750

inner grooved/φ7

0.45

1850×600×350

1980×660×420

Remote

/

/

51

59/70

/

/

/

HPU-42CV03(WHITE)

VR54KS-TFP-542/COPELAND

3GS

1360

SCROLL

Inner thermal protection

hard startup

Axial*2

840

0.06

6000

inner grooved/φ9.52

2/1.6

948*340*1250

1090*410*1350

Capillary tube

Automatic

/

59

/

/

/

106/111

R22/3400

65

φ9.52

φ19.05

Flared

heatin

2

2

----

Commercial Air Conditioner Model: HPU-42CV03

HPU-42HV03

item Model

Function

Capacity BTU/h

Capacity kW

Sensible heat ratio

Total power input

Max. power input

EER or COP

Dehumidifying capacity

Power cable section

Signal cable section

Connecting cable section

Wired control cable for wired control unit section

Power source N, V, Hz

Running /Max.Running current

Start Current A

Class of anti electric shock

Circuit breaker A

Max. operating pressure of heat side Mpa

Max. operating pressure of cold side Mpa

Unit model (color)

Fan

Heat exchanger

Dimension

Air sending angle

Indoor unit

Drainage pipe (material , I.D./O.D.) mm

Control type (Remote /wired /model)

Fresh air hole dimension mm

Outlet distribution hole dimension mm

Electricity Heater /

Noise level (H-M-L)

Weight (Net / Shipping)

Dimension

Panel

Weight (Net / Shipping)

Unit model (color)

Compressor

Fan

Heat exchanger

Outdoor unit

Dimension

Drainage pipe (material , I.D./O.D.) mm

Refrigerant control method mm/mm

Defrosting

Volume of Accumulator L

Noise level dB(A)

Type of Four way valve

material of reduce noise

crankcase heater power W

Weight (Net / Shipping)

Refrigerant

Pipe

Connecting Method

PIPING

Between I.D &O.D

Norminal condition: indoor temperature (cooling): 27℃DB/19℃WB, indoor temperature (heating): 20℃DB

Outdoor temperature(cooling): 35℃DB/24℃WB, outdoor temperature(heating): 7℃DB/6℃WB

The noise level will be measured in the third octave band limited values, using a Real Time Analyser calibrated sound intensity meter. It is a sound pressure noise level.

The detailed method please refer to the following information:

Type × Number

Speed(H-M-L) r/min

Fan motor output power kW

Air-flow(H-M-L) m³/h

Type / Diameter mm

Total Area m²

Temp. scope

External

Package

External

Package

Model / Manufacture

Oil model

Oil type

Oil charging

Type

Protection type

Starting method

Type × Number

Speed r/min

Fan motor output power kW

Air-flow(H-M-L) m³/h

Type / Diameter mm

Row / Fin pitch

Temp. scope

External

Package

Type / Charge g

Recharge quantity g/m

Liquid mm

Gas mm

MAX.Drop

MAX.Piping length 50

(L×W×H)

(L×W×H)

(L×W×H)

(L×W×H)

(L×W×H)

(L×W×H)

W

W 4400

W/W

10‐³×m³/h

A / A

℃

mm×mm×mm

mm×mm×mm

kW

dB(A)

kg / kg

mm×mm×mm

mm×mm×mm

kg / kg

℃

mm×mm×mm

mm×mm×mm

kg / kg

m

m

cooling heating

41000 44000

12.0 13.0

70%

3700 4000

3.24 3.25

//

Cooling 6.9A/7.8A Heating 7.0/8.3

CLASS I CLASS I

2.8 2.8

2.8 2.8

HPU-42HV03

5.0

5G×2.5mm

4G×0.75mm

3N,380-400V,50HZ

HPU-42HV03(WHITE)

centrifugal

430/405/370

inner grooved/φ7

1850×600×350

1980×660×420

HPU-42HV03(WHITE)

VR54KS-TFP-542/COPELAND

Inner thermal protection

hard startup

inner grooved/φ9.52

948*340*1250

1090*410*1350

Capillary tube

Automatic

2

2

50

20

0.09

1750

0.45

Remote

/

51

59/70

/

/

/

3GS

1360

SCROLL

Axial*2

840

0.06

6000

2/1.6

/

59

/

/

40

106/111

R22/3400

65

φ9.52

φ19.05

Flared

30

4900

Commercial Air Conditioner Model: HPU-42CV03

HPU-42HV03

Installation state: the unit should be placed on the flat floor or be mounted in

horizontal direction.

Testing method:

standing-on-floor unit: If the unit cooling capacity is over 28000W, the noise level should be

measured at the front, left, right directions respectively.

1m

1m

outdoor unit:

1.air outlet from side: the noise level is the average sound pressure level measured from front, left,

right directions.

2.air outlet from top: the noise level is the average sound pressure level measured from front, back,

left, right directions.

measured point:

H ( height to the ground) = (h (unit height) + 1m) /2

and, it is 1m to each side.

1m

1m

1m

h

1m

Note: ⊙ is the real time

6

Commercial Air Conditioner Model: HPU-42CV03

HPU-42HV03

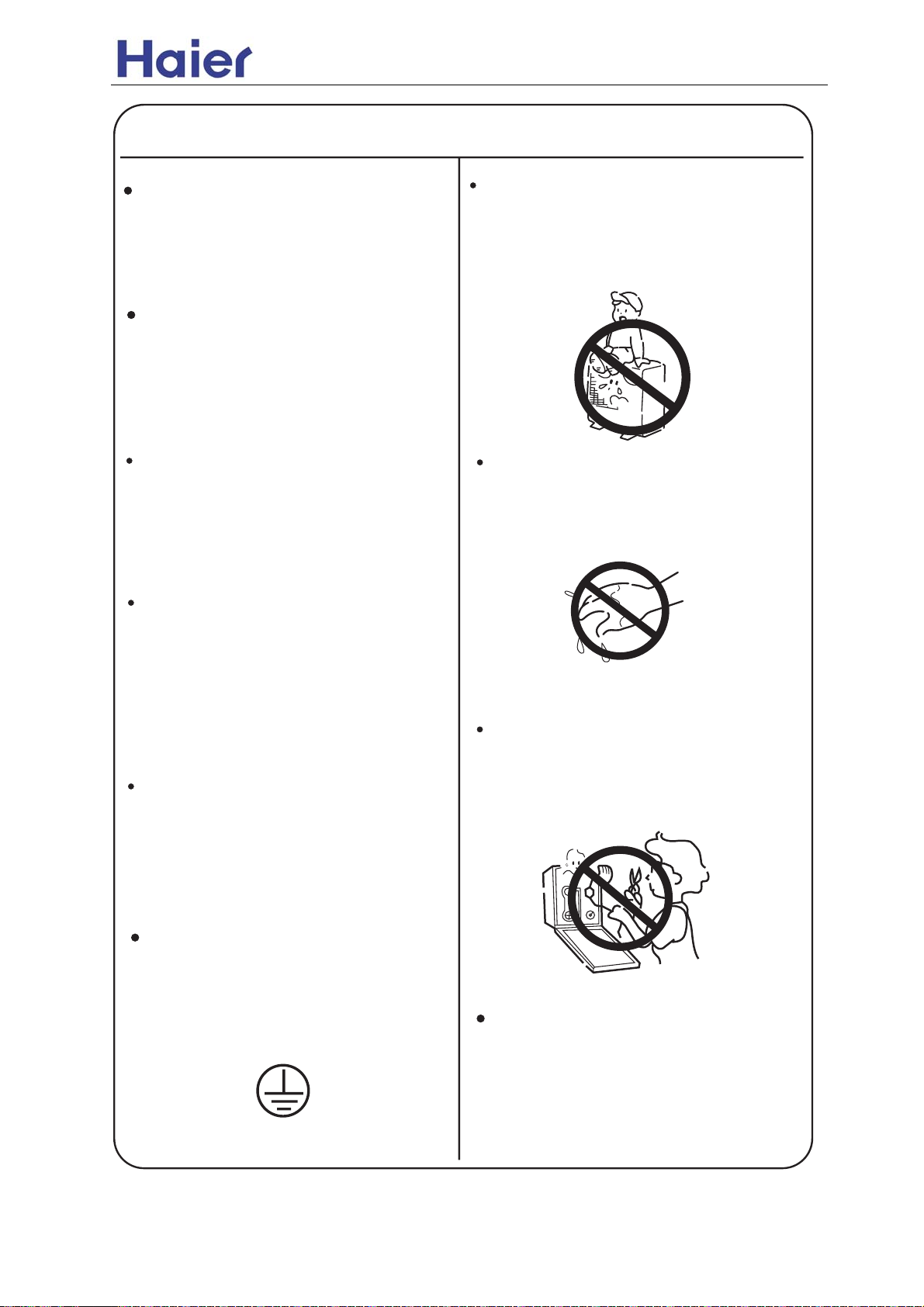

3. Safety precaution of indoor and outdoor

Carefully read the following information in order to operate the airconditioner correctly.

Below are listed three kinds of Safety Cautions and Suggestions.

WARNING!

CAUTION!

INSTRUCTIONS: These information can ensure the correct operation of the machine.

Be sure to conform with the following important Safety Cautions.

The Safety Cautions should be at hand so that they can be checked at any time when needed.

If the conditioner is transferred to the new user, this manual should be as well transferred to the new user.

Incorrect operations may result in severe consequences of death or serious injuries.

Incorrect operations may result in injuries or machine damages; in some cases may

cause serious consequences.

WARNING!

If any abnormal phenomena is found

(e. g.smell of firing), please cut off the

power supply immediately, and contact

the dealer to find out the handling

method.

In such case, to continue using the

conditioner will damage the conditioner,

and may cause electrical shock or fire

hazard.

switch

off

After a long time use of air-conditioner

the base should be checked for any

damages.

If the damaged base is not repaired, the

unit may fall down and cause accidents.

Don't dismantle the outlet of the

outdoor unit.

The exposure of fan is very dangerous

whichmay harm human beings.

When need maintenance and repairment,

call dealer to handle it.

Incorrect maintenance and repairment

may cause water leak, electrical shock

and fire hazard.

7

Commercial Air Conditioner Model: HPU-42CV03

HPU-42HV03

Installed electrical-leaking circuit

breaker.

It easily cause electrical shock without

circuit breaker.

Air-conditioner can't be installed in

the environment with inflammable

gases because the inflammable gases

near to air-conditioner may cause fire

hazard.

WARNING!

No goods or nobody is permitted to

placed on or stand on outdoor unit.

The falling of goods and people may

cause accidents.

Please let the dealer be responsible for

installing the conditioner.

Incorrect installation may cause water

leak, electrical shock and fire hazard.

Call the dealer to take measures to

prevent the refrigerant from leaking.

If conditioner is installed in a small

room be sure to take every measure in

order to prevent suffocation accident

even in case of refrigerant leakage.

When conditioner is deinstalled or

reinstalleddealer should be responsible

Incorrect installation may cause water

leaking, electrical shock and fire hazard.

for them.

Don't operate the air-conditioner with

damp hands.

Otherwise will be shocked.

Only use correctly-typed fuse.

May not use wire or any other materials

replacing fuse, other-wise may cause

faults or fire accidents.

Connect earthing wire.

Earthing wire should not be connected to the gas pipe, water pipe,

lightning rod or phone line, in-correct

earthing may cause shock.

Earthing

Use discharge pipe correctly to ensure

efficient discharge.

Incorrect pipe use may cause water

leaking.

8

Commercial Air Conditioner Model: HPU-42CV03

HPU-42HV03

4. Net dimension of indoor and outdoor

1818

38

185 185

70

580

30

52

380

1250

38

Screw Hole

(M10)

950

340

88

Power wiring Terminal

25

350

1851

16

600

350

336

500

Commercial Air Conditioner Model: HPU-42CV03

HPU-42HV03

5. Installation Instructions

5.1 Outdoor unit installation

Necessary Tools:

1.Screwdriver

2.Hacksaw

3.70mm diameter hole drill

4.Spanner(dia.17,27mm)

5.Spanner(dia.14,17,27mm)

6.Pipe cutter

7.Flaring tool

8.Knife

9.Nipper

10.Gas leakage detector

or soap water

11.Tape measure

12.Reamer

13.Refrigerant oil

Installation Position

●Place strong enough to support the unit weight, and will not cause vibration and noise.

●Place where discharged air and noise do not cause interference to the neighbors, and is sufficiently

ventilated.

●Place where is less affected by rain or direct sunlight and sea breeze.

●Place with enough space to ventilation

●The unit cannot be installed on an unspecified metal frame

●It shall not be less than 2.5m high from the ground to the unit if installed close to the street

●Easy for maintenance

Fixing of the unit

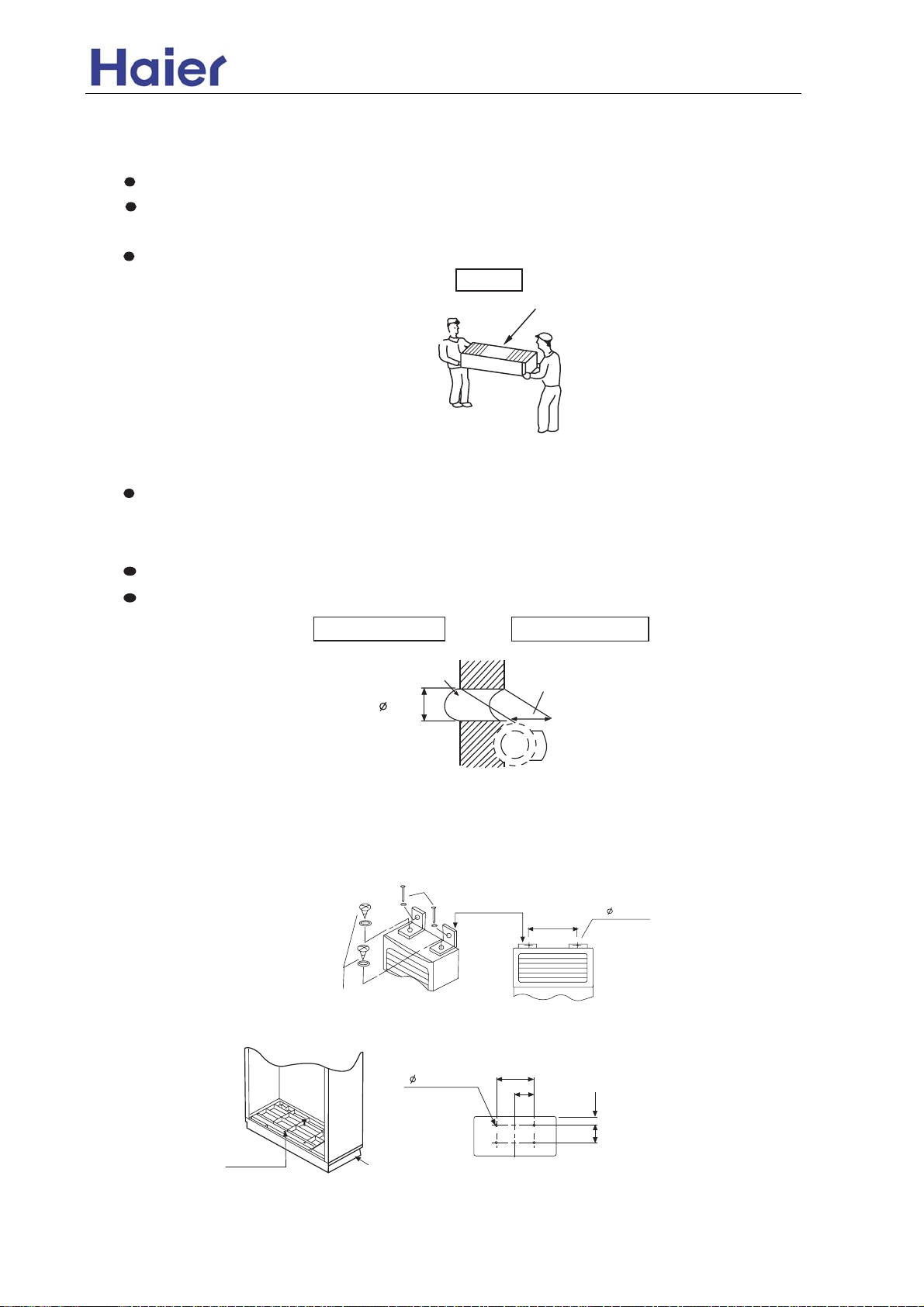

1.Position of the wall hole

The hole through the wall must be decided as per installation place and pipe direction. Please refer to the

installation drawings.

2. Making the wall hole

Drill a hole of 120*70mm with a little slope to the exterior through the wall as follows:

10

Commercial Air Conditioner Model: HPU-42CV03

HPU-42HV03

Installation Space

Installation where the area with strong winds.

Install the unit so that the air outlet section of the unit must NOT be faced

toward wind direction.

Fixing of the unit

Fix outdoor unit using M10 bolt to concrete floor horizontally.

If installed on the wall or on top of a roof, bracket should be fixed securely to

resist earthquake or storms.

Use rubber pad during installation against unit vibration.

over 30cm

580

380

over 10cm

over 10cm

over 15cm

over 60cm

Installation dimension of outdoor unit(mm)

190

190

Refrigerant piping

Outline piping

Flare connection

Piping size

Indoor

unit

Liquid pipe

Gas pipe

Connect the flare nuts to the pipes, and then flare the pipes.

9.52x0.8mm

15.88x1.0mm

3-way stop valve

Gas pipe

Outdoor

unit

Liquid

pipe

2-way stop valve

90+0.5

11

Commercial Air Conditioner Model: HPU-42CV03

HPU-42HV03

Precautions for refrigerant piping

Do not twist or crush piping.

Be sure that no dust is mixed in piping.

Bend piping with as wide angle as possible.

Keep insulating both gas and liquid piping.

Check flare-connected area for gas leakage.

Piping connection

Connecting method (indoor unit)

Apply refrigerant oil at half union as large and flare nut.

To bend a pipe, give the roundness as possible not to crush

the pipe.

When connecting pipe, hold the pipe centre to centre then

screw nut on by hand, refer to Fig.

Be careful not to let foreign matters, such as sands enter

the pipe.

Forced fastening without centering

may damage the threads and cause

a gas leakage.

Pipe diameter

Liquid pipe 6.35mm

Liquid pipe 9.52mm

Gas pipe 12.7mm

Gas pipe 15.88mm

Gas pipe 19.05mm

Fastening torque

14.2-17.2N.m

32.7-39.9N.m

49.5-60.3N.m

61.8-75.4N.m

97.2-118.6N.m

Air discharging method

After finishing connection of refrigerant pipe, it shall perform air tightness test.

The air tightness test adopts nitrogen tank to give pressure according to the pipe connection

mode as the following figure shown.

The gas and liquid valve are all in close state. In order to prevent the nitrogen entering the

circulation system of outdoor unit, tighten the valve rod before giving pressure (both gas

and liquid valve rods).

Low pressure gauge

Indoor

Outdoor

3-way valve totally closed

(Gas side)

High pressure gauge

VL

VH

Meter separator

Completely tightened

Flare part

Discharging valve

Completely tightened

Flare part

Mainhole

Dropping valve

Indoor units

2-way valve totally closed

(Liquid side)

Outdoor units

12

Nitrogen tank

Commercial Air Conditioner Model: HPU-42CV03

HPU-42HV03

Precautions for refrigerant piping

Do not twist or crush piping.

Be sure that no dust is mixed in piping.

Bend piping with as wide angle as possible.

Keep insulating both gas and liquid piping.

Check flare-connected area for gas leakage.

Piping connection

Connecting method (indoor unit)

Apply refrigerant oil at half union as large and flare nut.

To bend a pipe, give the roundness as possible not to crush

the pipe.

When connecting pipe, hold the pipe centre to centre then

screw nut on by hand, refer to Fig.

Be careful not to let foreign matters, such as sands enter

the pipe.

Forced fastening without centering

may damage the threads and cause

a gas leakage.

Pipe diameter

Liquid pipe 6.35mm

Liquid pipe 9.52mm

Gas pipe 12.7mm

Gas pipe 15.88mm

Gas pipe 19.05mm

Fastening torque

14.2-17.2N.m

32.7-39.9N.m

49.5-60.3N.m

61.8-75.4N.m

97.2-118.6N.m

Air discharging method

After finishing connection of refrigerant pipe, it shall perform air tightness test.

The air tightness test adopts nitrogen tank to give pressure according to the pipe connection

mode as the following figure shown.

The gas and liquid valve are all in close state. In order to prevent the nitrogen entering the

circulation system of outdoor unit, tighten the valve rod before giving pressure (both gas

and liquid valve rods).

Indoor units

Indoor

Completely tightened

Completely tightened

Outdoor

Flare part

Flare part

3-way valve totally closed

(Gas side)

2-way valve totally closed

(Liquid side)

13

Low pressure gauge

High pressure gauge

VL

Discharging valve

Mainhole

Outdoor units

Dropping valve

VH

Meter separator

Nitrogen tank

Commercial Air Conditioner Model: HPU-42CV03

HPU-42HV03

First step: 0.3MPa (3.0kg/cm2g) pressurize over 3 minutes.

Second step: 1.5Mpa (15kg/cm2g) pressurize over 3 minutes. Large leakage will

be found.

Third step: 3.0 MPa (30kg/cm2g) pressurize about 24 hours. Little leakage will be

found.

Check if the pressure drops

If the pressure does not drop, the unit is passed

If the pressure drops, please check the leaking point.

After pressurizing for 24 hours, each 1 C difference of ambient temperature

will result in 0.01MPa(0.1kg/cm2g) pressure change. It shall be corrected during test.

Checking the leaking point

From the first to third steps, if the pressure drops, check the leakage in each joint

by the sense of hearing, feeling or soap water, etc. to find the leaking point.

After confirming the leaking point, welding it again or tighten the nut tightly again.

Piping and indoor unit vacuumizing

Use vacuum pump to perform vacuumizing. It is strictly forbidden to use the

refrigerant to remove the air inside the system.

After air tightness test and discharging all the nitrogen, connect the vacuum pump

as the following figure shown.

Indoor units

It shall use the vacuum pump of (lower than -755mmHg)high vacuum degree and large air

discharging (over 40l/min).

The vacuumizing time depends on the length of the connecting pipe, generally is 1~2 hours.

When vacuumizing, it shall be confirmed both gas and liquid side valves are closed.

If after 2 hours vacuumizing, it cannot reach the vacuum degree below -755mmHg, it can be

vacuumized for other 1 hour.

If after 3 hours vacuumizing, it still cannot reach the vacuum degree below -755mmHg, check

if there is any leaking point and repair the them.

Indoor

Completely tightened

Completely tightened

Outdoor

Flare part

Flare part

3-way valve totally closed

(Gas side)

2-way valve totally closed

(Liquid side)

14

Low pressure gauge

V L

Discharging valve

Vacuum pump

Outdoor units

High pressure gauge

VH

Meter separator

P

Commercial Air Conditioner Model: HPU-42CV03

HPU-42HV03

If after over 2 hours vacuumizing, the vacuum degree is below -755mmHg, close the V

meter separator and stop vacuumizing. 1 hour later to confirm if the vacuum degree changes. If changes,

it indicates there is leaking point in the system. Check the leaking point and

repair.

After finishing the above vacuumizing, change the vacuum pump into refrigerant pump to charge the

refrigerant.

Charging amount of refrigerant

When the total length (L) of the two indoor units' connecting pipe is less than 5m, it is unnecessary to

charge additional refrigerant.

If the connecting pipe (L) exceeds 5m, it shall charge Mg additional refrigerant per meter.

That is: Refrigerant charging amount = (L-5) x M (g)

For the unit with liquid pipe 6.35mm, M=30

For the unit with liquid pipe 9.52mm, M=65

Only in COOLING operation can charge the additional refrigerant.

When charging, the refrigerant shall be charged from the charging nozzle of low pressure vavle.

Be carefull when charging refrigerant, do not let the air mix into the system,and must charge the additional

refrigerant in liquid condition.

L and VH on the

Piping connection of outdoor unit.

Connect the connecting pipe and inlet and outlet liquid pipe according to the piping

method.

Purging method

Discharge the air out of the indoor unit and the refrigerant pipe by vacuumizing

(1) Fasten all the nuts of the indoor and outdoor pipes to make these parts out of leakage.

(2) Under the condition of the complete close of the indoor and outdoor valve center (both

liquid and gas side),dismount the repair valve cap.Vacuumizing through the charge

mouth of the repair valve.

(3) After vacuumizing fasten the repair valve,and dismount the cap of the big and small

stop valve,then loosen the stop valve center completely and fasten the big and small

stop valve.

Extra charging amount of the refrigerant

When piping is longer than 5 m, charge additional refrigerant specified in this list.

Pipe length

Refrigerant charge (g)

5m 10m 15m 20m

750 1125375

25m

1500

30m

1875

15

Commercial Air Conditioner Model: HPU-42CV03

HPU-42HV03

5.2 Indoor unit installation

B]gd`Um cZ k\c`Y ib]h

Pfm hc Vf]b[ h\Y dUW_YX ib]h hc h\Y ]bghU``Uh]cb d`UWY1

S\Yb ]h ]g bYWYggUfm hc ibdUW_ h\Y ib]h/ VY WUfYZi` bch hc XUaU[Y h\Y ib]h1 SfUd ]h k]h\

bm`cb YhW1

?ZhYf ibdUW_]b[/ VY gifY hc d`UWY h\Y ib]h k]h\ h\Y Zfcbh g]XY hc VY id1

KchY= S\Yb XY`]jYf]b[/ Xcb,h \c`X d`Ugh]W

dUfhg giW\ Ug ]b`Yh cf cih`Yh [f]`` YhW1

D]l]b[ cZ h\Y ib]h

Mcg]h]cb cZ h\Y kU`` \c`Y

SU`` \c`Y g\ci`X VY XYW]XYX UWWcfX]b[ hc ]bghU``h]cb d`UWY UbX d]d]b[ X]fYWh]cb1 -fYZYf

hc ]bghU``Uh]cb XfUk]b[g.

JU_]b[ U \c`Y

BY`]jYfm

DUW]b[ id

Bf]`` U \c`Y cZ :3aa X]U1 k]h\ U `]hh`Y g`cdY hckUfXg cihg]XY1

GbghU`` d]d]b[ \c`Y WcjYf UbX gYU` ]h k]h\ dihhm UZhYf ]bghU``Uh]cb1

GKBLLN OGBC

kU`` \c`Y

:3aa

- Afcgg gYWh]cb cZ kU`` \c`Y .

With the unit set up vertically,fix the fitting metal to the unit with screws, then fix the

fitting metal to the wall with cement nail and washer, as shown below:

Cement nail

Fitting metal

Screw

Moreover, if want to fix the unit more firmly, you should fix the bottom panel to the

ground with concrete bolts,as shown below:

LQPBLLN OGBC

kU`` h\]W_bYgg

330

2- 10 hole

Fitting hole

4- 14 hole 30 depth

Bottom Panel

16

260

130

79

202

(79)

(202)

Commercial Air Conditioner Model: HPU-42CV03

HPU-42HV03

x045{..{5-10 1* {05-q*{.. 2.{5~v

D]l h\Y Ubh]0ZU`` d`UhY hc h\Y kU`` k]h\ gWfYkg gc h\Uh h\YfY ]g bc W`YUfUbWY VYhkYYb h\Ya1

S]h\ h\Y ib]h gYh id jYfh]WU``m/ Z]l h\Y Ubh]0ZU`` d`UhY hc h\Y ib]h k]h\ gWfYkg k\]`Y aU_]b[ Ub

UX^ighaYbh Uh h\Y `cb[ dcfh]cb cZ h\Y \c`Y gc h\Uh h\YfY ]g bc W`YUfUbWY VYhkYYb h\Y iddYf

gifZUWY UbX h\Y Ubh]0ZU`` d`UhY1

x045{..{5-10 1* yq4,{2~} /~5{.

D]l hc h\Y ib]h k]h\ gWfYkg gc h\Uh h\YfY ]g bc W`YUfUbWY VYhkYYb h\Y Ubh]0ZU`` d`UhY UbX h\Y ib]h1

?ZhYf WcbZ]fa]b[ h\Uh h\Y ib]h \Ug VYYb gYh id jYfh]WU``m hc h\Y Z`ccf/ Z]l ]h hc h\Y Z`ccf k]h\ Vc`h1

z-2-0+ |100~|5-10

AcbbYWh]b[ aYh\cX

41

?dd`m fYZf][YfUbh c]` Uh \U`Z ib]cb UbX Z`UfY bih1

Pc VYbX U d]dY/ []jY h\Y fcibXbYgg Ug `Uf[Y Ug dcgg]V`Y bch hc WfUg\ h\Y d]dY1

S\Yb WcbbYWh]b[ d]dY/ \c`X h\Y d]dY WYbhfY hc WYbhfY h\Yb gWfYk bih cb Vm \UbX/fYZYf

hc D][1

@Y WUfYZi` bch hc `Yh gibXf]Yg/ giW\ Ug gUbXg YbhYf h\Y d]dY1

DcfWYX ZUghYb]b[ k]h\cih WYbhYf]b[ aUm

XUaU[Y h\Y h\fYUXg UbX WUigY U [Ug `YU_U[Y1

I]ei]X d]dY <185aa-62;+.

EUg d]dY 4<138aa-627+.

M]dY X]U DUghYb]b[ hcfeiY

5<17K1a

44:1:K1a

51 M]d]b[ WcbbYWh]cb cZ ]bXccf ib]h

?ffUb[YaYbh cZ d]d]b[ UbX XfU]bU[Y d]dY

˛´¶¨+

˛´¶¨-

¿“/„

˜£˚‰•¸

‰¡¿

?ZhYf cdYb]b[ ]b`Yh [f]``/ mci k]`` gYY U Wcbhfc`

Vcl Ug g\ckb ]b h\Y D][1

NYacjY h\Y WcjYf VYZcfY k]f]b[ kcf_1

17

Commercial Air Conditioner Model: HPU-42CV03

HPU-42HV03

Cut away, with a hammer or a saw, the lid for piping according to piping direction.

Insulation material

Copper tube

Drain hose

Connecting electric cable

for indoor and outdoor unit

According to the piping method, connect the piping on indoor unit with union of connecting

pipe.

Arrange the piping as per the wall hole and bind drain hose connecting electric cable and

piping together with polyethylene tape.

Insert the bound piping connecting electric cable and drain hose through wall hole to connect

with outdoor unit.

Arrangement of drain hose

Drain hose shall be placed in under place.

There should be a slope when arrange drain hose. Avoid up and down waves in drain hose.

Indoor unit

Up

If humidity is high, drain pipe( especially in room and indoor unit ) must be covered

with insulation material.

Slope

Good

Down

Bad

18

Commercial Air Conditioner Model: HPU-42CV03

w.~|53-| 7-3-0+

KchY=

C`YWhf]W k]f]b[ aigh VY XcbY Vm eiU`]Z]YX dYfgcb1

QgY WcddYf k]fY cb`m/ h\Y dUfUaYhYf cZ WcbbYWh]b[ WUV`Y ]g F3:NK0D 7E 31:8aa

P\Y dckYf WUV`Y g\ci`X VY cjYf 8E518aa5/ h\Y dckYf WUV`Y ]g gY`Z0dfcj]XYX1

P\Y dckYf gidd`m WcbbYWhg Zfca h\Y cihXccf ib]h1

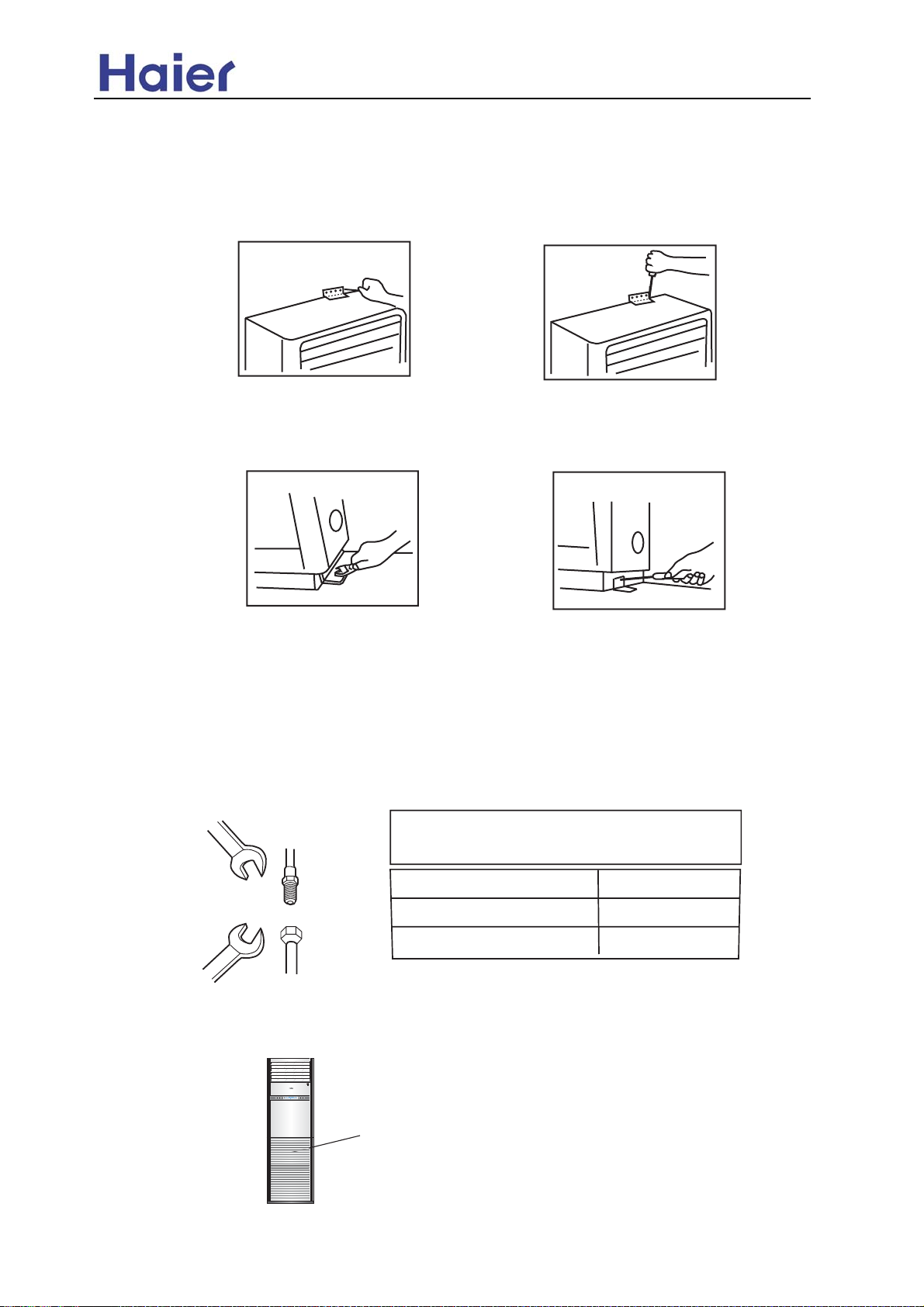

S]f]b[ cZ ]bXccf ib]h

GbgYfh h\Y WUV`Y Zfca cihg]XY h\Y kU`` \c`Y k\YfY d]d]b[ U`fYUXm Yl]gh1

Mi`` ]h cih Zfca Zfcbh1

IccgYb hYfa]bU` gWfYkg UbX ]bgYfh WUV`Y YbX Zi``m ]bhc hYfa]bU` V`cW_/ h\Yb h][\hYb ]h1

Mi`` h\Y WUV`Y [Ybh`m hc aU_Y gifY ]h ]g h][\h1

NYd`UWY WcjYf UZhYf k]f]b[1

S]f]b[ cZ cihXccf ib]h

GbgYfh h\Y WUV`Y Zfca ]bg]XY h\Y kU`` \c`Y

k\YfY d]d]b[ U`fYUXm Yl]ghg1

Mi`` ]h cih Zfca Zfcbh1

IccgY hYfa]bU` gWfYk UbX ]bgYfh WUV`Y YbX Zi``m

]bhc hYfa]bU` V`cW_/ h\Yb h][\hYb ]h1

Mi`` h\Y WUV`Y [Ybh`m hc aU_Y gifY ]h ]g h][\h1

NYd`UWY WcjYf UZhYf k]f]b[1

KchY=

S\Yb WcbbYWh]b[ ]bXccf UbX cihXccf k]fY/ W\YW_ h\Y biaVYf cb ]bXccf UbX cihXccf

hYfa]bU` V`cW_g1 PYfa]bU`g cZ gUaY biaVYf UbX gUaY Wc`cf g\U`` VY WcbbYWhYX Vm

h\Y gUaY k]fY1

GbWcffYWh k]f]b[ aUm XUaU[Y U]f WcbX]h]cbYf,g Wcbhfc``Yf cf WUigY cdYfUh]cb ZU]`ifY1

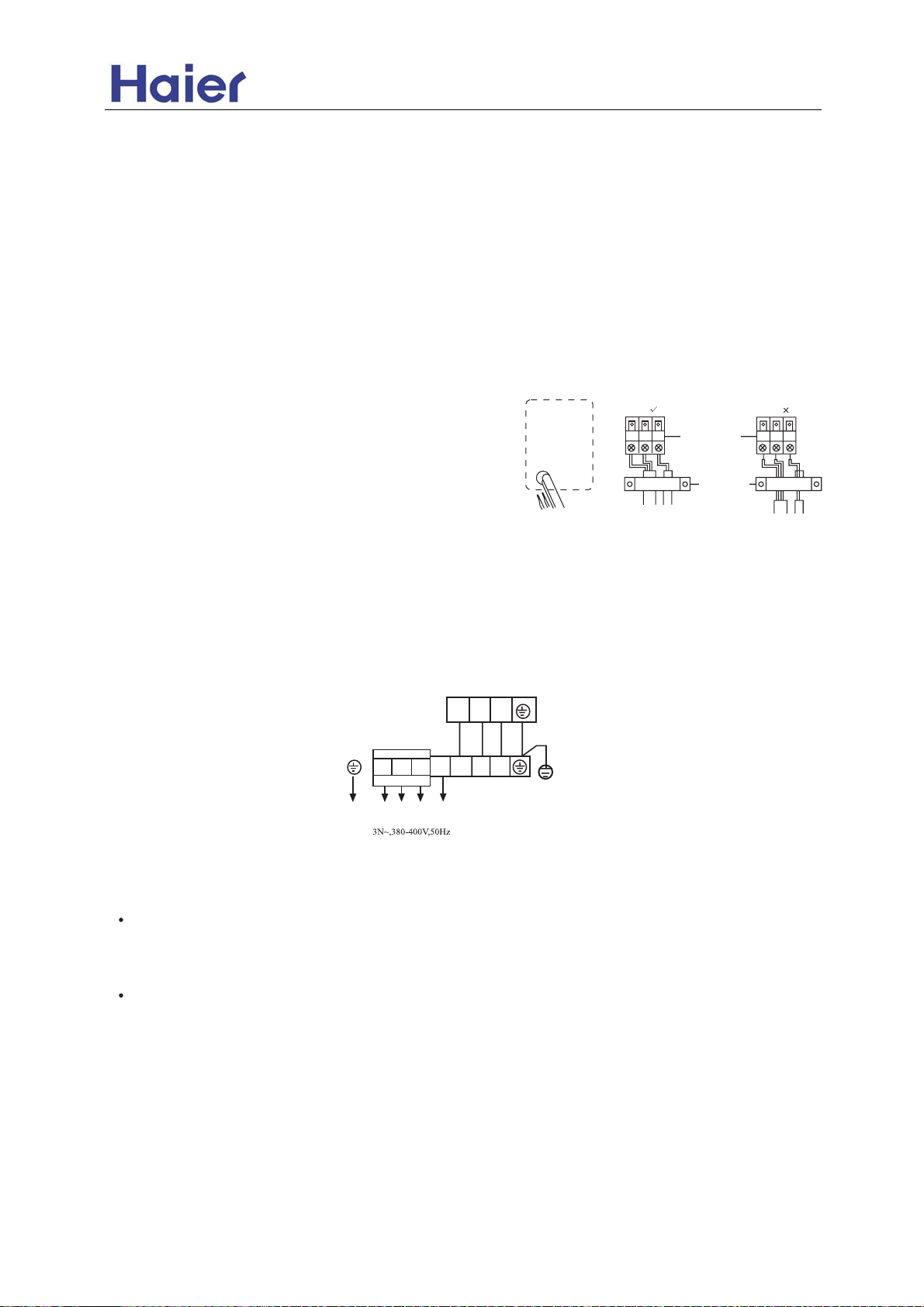

HPU-42CV03 HPU-42HV03

123

Y/G

POWER SUPPLY

N 1 2 3R S T

Y/G

LH KL

HPU-42HV03

hYfa]bU` V`cW_

hUV`Y W`Uad

5

1

19

Loading...

Loading...