Page 1

Medical Device Manufacturing Enterprise License No.:

No. 20050143 license granted by Shandong Food and Drug Administration for

manufacturing medical devices

Registration No.:

No. 2580116 in 2008 approved by Shandong Food and Drug Administration for

manufacturing medical devices (updated)

This series of freezers is in conformity with the registration standard YZB/Lu

0174-2009.

Haier

Group

Haier

Group

Haier

Haier Group

Group

[Company name]:

[Registered address]:

[Manufacturing address]:

[Tel.]:

[Fax]:

[Postal code]:

Sincere

Sincere

Sincere

Sincere Forever

Forever

Forever

Forever

Certificate of Quality

Inspector:

Qingdao Haier Medical and Laboratory Products Co., Ltd.

Haier Industrial Park, Qianwangang Road, Economic and Technological

Development Zone, Qingdao

Haier Industrial Park, Qianwangang Road, Economic and Technological

Development Zone, Qingdao

0532-88936043

0532-88936010

266555

Special No.:0270500015

Version:1stversion in 2009

V98497

Medical

Medical

Medical

Medical Low-Temperature

Low-Temperature

Low-Temperature

Low-Temperature Freezer

Freezer

Freezer

Freezer Operating

Operating

Operating

Operating Instructions

DW-40L508

It applies to the storage of various articles at low temperature by the clinical,

medical, scientific research and inspection departments, etc.

Please read this manual carefully before use.

Please keep this manual for future reference.

It is only suitable for sale and use in Chinese Mainland.

Instructions

Instructions

Instructions

Page 2

Contents

Contents

Contents

Contents

Before use

Product

features ……………………………………… ... ..........................................

Components ……………………………………………………………… . 2

Safety

precautions …………………………… ... ………………………… ... ........

Precautions for handling …………………………………………… .. … ... 6

Precautions for use ……………………………………………………… .. 7

Start to use

Installation ……………………………………………………………… ... . 8

Use ………………………………………………………………… ... ......... 9

Temperature adjustment and setting ……………………………………… . 11

Display and alarm ……………………………………………… ... .............. 12

Remote alarm terminals.. ………………………………………………… .. 13

Maintenance and repair

Routine maintenance …………………………………………… ... .............. 14

Fault clearance.. ……………………………………………………… .. … . 15

Equipment scrapping …………………………………………………… .. 15

Rechargeable battery recycling …………………………………… ... ......... 16

Technical data

Specifications …………………………………………………………… .. 17

Refrigeration principle and circuit diagram ……………………………… . 17

Options …………………………………………………………………… . 18

After-sales service ………………………………………………………… 21

1

Product

Product

Product

Product features

features

features

features

3

It adopts computer control and digit al temperature display. The temperature of

computer display panel is adjustable within the range of +20 ℃ ~-45 ℃ and the

temperature for normal use should be within the range of -20

~-40

℃

.

℃

It has the function of power-on time delay protection.

It is equipped with an internationally famous compressor imported from another

country, achieving higher refrigerating capacity.

It is mainly used for the cryopreservation of blood, biomaterials, vaccines and

electronic components as well as the low temperature test of special materials,

etc.

It is suitable for the laboratories of blood banks, hospitals, quarantine stations,

colleges/universities, scientific research institutes and electronic & chemical

enterprises, etc.

The double-door structure allows for easier access.

Due to continuous product improvement, your Haier low-temperature freezer may

be slightly different from that shown in this manual, and we hereby apologize for

this.

The contents of this manual are subject to change without notice.

We

hereby promise to provide a complete set of “ 1+5 ” value-added services for you when

you require installation or maintenance service for any Haier product.

“ 1 ” : it means installation service will be done well only once.

“ 5 ” : it means 5 combined services:

a. Safety test service: we will perform safety test in electricity and make a thorough

explanation.

b. Explanation and instruction in use: we will explain and instruct you how to use and

maintain the products properly for a longer product life and energy saving.

c. Product maintenance: after installation or repair, we will help you perform maintenance

on the products to prolong their life, save energy and use them in a good manner.

d. One-stop service marketing: if you want to purchase other products, we will provide you

with one-stop service including on-site design, delivery, installation, maintenance and

repair.

e. Site cleaning service: we will clean the site after completing service.

We

appreciate your supervision on our service. If we do not fully keep our promise, please

make a complaint by calling 4006 999999. Once it is proved to be true, we will pay you

RMB100 as a bonus for doing so.

Haier

is

Haier

Haier

Haier is

looking

is

looking

is looking

looking forward

forward

forward

forward to

to

your

to

to your

participation!

your

participation!

your participation!

participation!

Please see the real product for its appearance, color or pattern.

It is prohibited to store those articles with strict temperature requirements such

as living creatures and flowers, etc.

Page 3

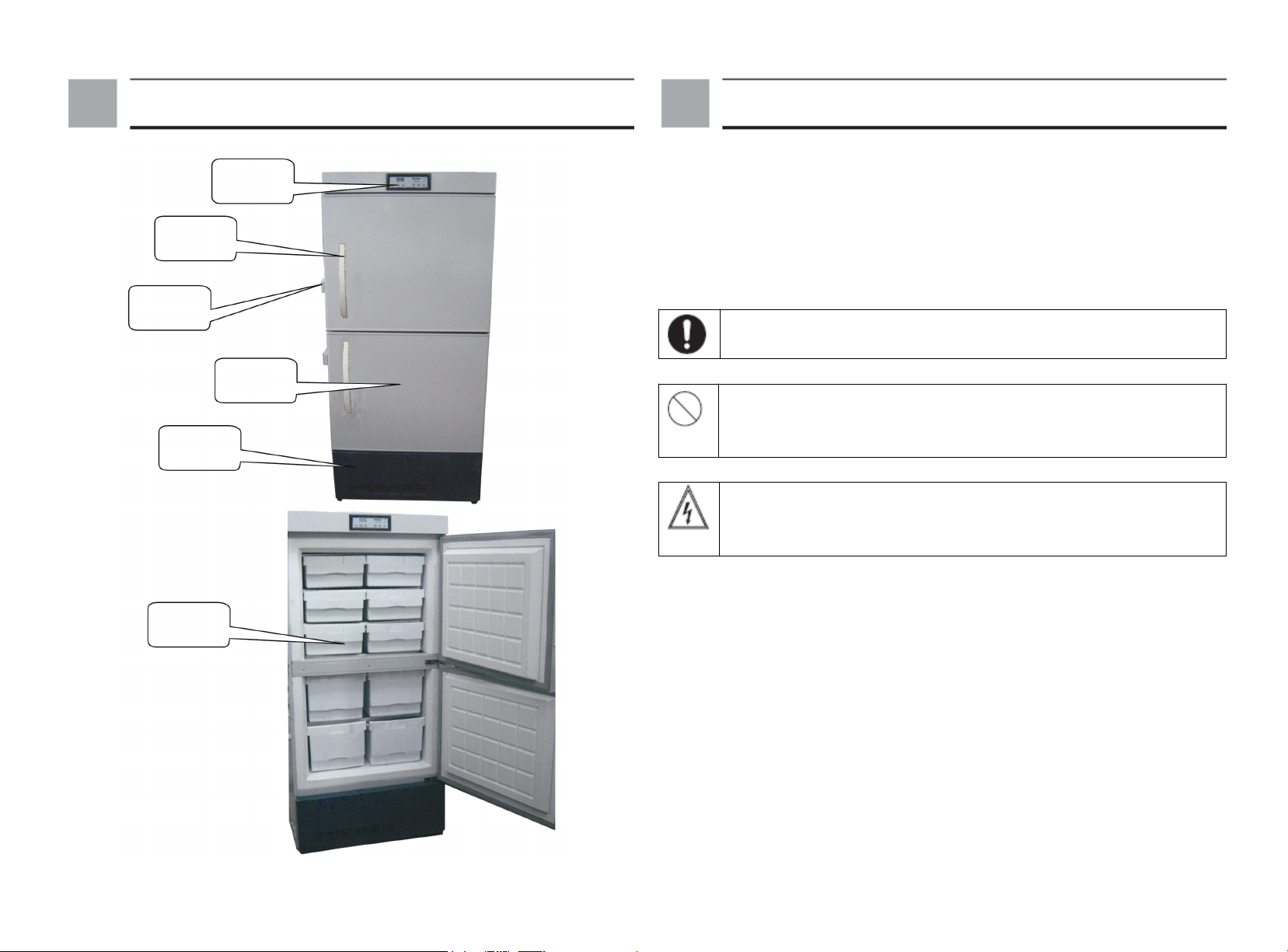

Components

Components

Components

Components Safety

Safety

Safety

Safety precautions

precautions

precautions

precautions

Handle

Door snap

close

Front cover of

compressor

compartment

Drawer

Control

panel

Outer door

Please always follow all important safety regulations in this manual; otherwise you

must take full responsibility for the consequences.

Please follow all precautions and regulations in this manual to avoid possible injury

of the user and any other person.

“ Caution ” , “ prohibition ” and “ warning ” signs are as follows:

The contents marked with this “ caution ” sign involve safety of both the

product and user and must be strictly followed.

The contents marked with this “ prohibition ” sign describe absolutely

prohibitory behaviors and must be strictly followed; otherwise the freezer

may be damaged or the user may be injured.

This sign is marked on the covers of high-voltage electric appliances to

avoid electric shock. These covers shall be removed by a qualified

engineer or maintainer.

Page 4

Safety

Safety

Safety

Safety precautions

precautions

precautions

precautions

Safety

Safety

Safety

Safety precautions

precautions

precautions

precautions

Please use special power supply (AC 220V~/50Hz) marked on the freezer’s

rating plate. If the voltage used is below 198V or above 242V , an automatic voltage

stabilizer of 4000W and above should be additionally installed. If power cord needs

to be extended, the extension cord must not be less than 2mm

2

in sectional area and

more than 3m in length. Using the power supply of any voltage or frequency other

than that marked on the rating plate may result in fire hazard or electric shock.

The freezer’s power cord is provided with a three-pin (grounded) plug which is

suitable for standard three-wire (grounded) socket. In any case, do not cut of remove

the grounding pin of power cord. Be sure to ensure firm connection and good contact

between the plug and socket; otherwise fire hazard may occur.

Please use a power socket with ground wire to avoid electric shock. If the power

socket is not grounded, be sure to ask a qualified technician to install grounding wire.

Never ground the freezer through gas pipe, water pipe, telephone line or lighting

arrester; otherwise it may result in electric shock or other dangers.

Never use the freezer in the open air. If it is exposed to rain, electric leakage or

electric shock may occur.

The freezer must be installed only by a qualified technician or maintainer;

otherwise electric shock or fire hazard may occur.

The freezer must be installed firmly on solid ground. In case of unfirm ground

or improper location, it may topple or cause personal injury.

Never install the freezer in a humid place or in a location exposed to

splash/spray water; otherwise electric leakage or electric shock may occur due to

lower insulation level.

Neither store inflammable, explosive or volatile substances in the freezer nor

use flammable spray near the freezer; otherwise explosion or fire hazard may occur.

Never store corrosive products such as acid and alkali in the freezer; otherwise

internal components or electric parts may be damaged.

Never insert any metal object such as iron nail or iron wire into any hole/gap or any

vent for internal air circulation; otherwise the contact between these objects and

moving parts may cause electric shock or personal injury.

If poisonous, harmful or radioactive substances are stored in it, please use the

freezer in a safe area. Improper use may be harmful to health or environment.

In case of leakage of inflammable gas such as coal gas, please close the valve

involved in gas leakage, open windows for exhaust ventilation and do not plug in or

unplug the freezer.

Be sure to disconnect the freezer from its power supply before carrying out any

repair or maintenance on the freezer in order to avoid electric shock or personal

injury.

Make sure that no drug or suspended particles in and around the freezer will be

breathed in at the time of repair or maintenance; otherwise they may result in health

hazard.

Never pour water directly onto the freezer; otherwise electric shock or short

circuit may occur.

The freezer must not be disassembled, repaired or modified by the user himself.

If an unauthorized person does so, fire hazard or personal injury may occur due to

improper operation.

In case of abnormal operation, please unplug the freezer. If the freezer goes on

operating under abnormal state, electric shock or fire hazard may occur.

If the freezer is left unused for a long time in an unsupervised area, please keep

children away from it and make sure that its doors cannot be fully closed.

If the freezer is turned off, it should be turned on again after at least 5 minutes to

avoid damage to the compressor or system. Be sure to unplug the freezer before

carrying out any repair or maintenance. Never roll or damage the power cord.

Equipment scrapping should be done by qualified persons. The doors should be

removed to avoid accidents such as suffocation.

When disconnecting the freezer’s plug from the power socket, please grasp it and

do not pull the power cord; otherwise electric shock or fire hazard due to short circuit

may occur.

Never touch any electrical component such as power plug or any switch with a

wet hand; otherwise electric shock may occur.

When turning it on again after power failure or power-off, be sure to check the

freezer’s settings. The change of settings may deteriorate those articles stored in the

freezer.

Do not put any container filled with water or any heavy object on the freezer. If

the container or heavy object drops, personal injury may occur; in addition, the water

may reduce the insulation level, resulting in electric leakage or electric shock.

Do not climb the freezer or put any article on the freezer; otherwise it may topple,

resulting in personal injury or damage to the freezer.

Page 5

Safety

Safety

Safety

Safety precautions

precautions

precautions

precautions

Precautions

Precautions

Precautions

Precautions for

for

for

for use

use

use

use

When closing a door, please hold its handle to prevent your fingers from being

pinched.

Do not store glass bottles or canned products in the freezer because frost crack

may occur and result in personal injury.

Do not touch any item stored in the freezer with a bare hand. Touching a frozen

item or the freezer’s inner wall with a bare hand may cause frostbite.

At the time of repair, wear a pair of gloves to avoid injury by a sharp edge or

corner.

If the freezer is to be left unused for a long time, pull out its power plug to avoid

electric shock, electric leakage or fire hazard resulting from the aging of power cord.

Put plastic bags out of the children’s reach because they may cause suffocation.

Precautions

Precautions

Precautions

Precautions for

for

handling

for

handling

for handling

handling

1. Before unpacking, a fork lift or bale clamping device may be used to move the

freezer.

If a fork lift is used to move the freezer, insert its fork into the bottom of wood

bottom bracket from both sides of the freezer.

If a bale clamping device is used to move the freezer, clamp the freezer from the

bottom of wood bottom bracket and only clamp both sides of the freezer.

2. After unpacking, the freezer can be moved by its castors.

Note: Never tilt the freezer more than 45 ° when moving it.

If the freezer is turned on for the first time or has not been used for a long time, its

rechargeable battery may at low charge level because it has been fully discharged.

This is not a fault. In this case, make the freezer operate continuously for about 6

days to fully charge the battery.

When the freezer is operating, the surface around the doorframe of shell may get

hot. This is not a fault. The reason is that anti-condensation pipes are installed around

the opening to prevent condensate from forming around the cabinet shell.

Make sure that the freezer’s internal temperature has been low enough before

putting articles in the freezer and the articles are put in the freezer in batches to

prevent temperature rise.

The displayed temperature of low-temperature freezer means the temperature at

the temperature-sensing probe in the preservation compartment. Sometimes it is

different from actual temperature in the center of preservation compartment, but it

will be gradually close to the actual temperature.

There is a through-hole on the freezer’s rear panel for leading out the test wire

inside the freezer. After leading out the test wire, be sure to stuff the test hole with

heat-insulating material again; otherwise the temperature inside the preservation

compartment will not be low enough and condensate may form around the outside of

through-hole.

Clean the freezer with diluted neutral detergent (undiluted detergent will damage

the plastic composition. Please refer to the detergent instructions for the dilution

method). Do not use a brush, acid, gasoline, soap powder, polishing powder or hot

water to clean the freezer because they may damage the painted surface and

plastic/rubber parts. The point we must pay special attention to is that any volatile

solvent such as gasoline should not be used on plastic/rubber parts.

After the freezer operates for a period of time, there will be a layer of frost on its

inner wall. Thick layer of frost will affect the freezer’s refrigerating effect and increase

power consumption. Therefore defrosting should be done by the provided scraper or the

defrosting key on the control panel when the thickness of frost reaches about 5mm.

Before defrosting, please take out all articles stored in the freezer and put them in

another freezer for preservation to avoid the deterioration of articles due to

temperature rise.

There are many cooling coils on the shelves. Therefore do not remove the frost on

the shelves with any sharp tool such as knife, ice chisel or screwdriver, etc. Be

careful not to scratch the evaporating pipes in the process of defrosting; otherwise the

freezer will be unable to work normally.

If the freezer is to be left unused for a long time, please disconnect it from the

power supply and turn off the battery switch.

Page 6

Installation

Installation

Installation

Installation

Use

Use

Use

Use

Installation environment

1. Ambient temperature: 5 ℃ ~28 ℃ ; maximum temperature 32 ℃ ; ideal temperature

18 ℃ ~25 ℃ ; if necessary, please use the air conditioning system.

2. Ambient humidity: less than 80% RH. If maximum working temperature is 32 ℃ ,

the ambient humidity should be less than 57% RH.

3. Avoid a lot of dust.

4. Avoid mechanical swing or vibration.

5. Altitude of the working position: less than 2000m.

6. Input voltage: 220V~ ± 10%.

* Notes:

1. The low-temperature freezer is relatively sensitive to ambient temperature, and

therefore it cannot operate normally if it is installed in any environment other than the

above-mentioned. In this case, please change the environment and then use the freezer.

2. It is prohibited to install the freezer in the open air. If the freezer is exposed to rain,

electric leakage or electric shock may occur.

Installation location

For normal operation and optimum performance, the freezer’s installation location

should meet the following requirements:

1. The freezer must not be installed in a narrow and enclosed space. The door body

of the room where the freezer is installed must not be smaller and lower than the

freezer and must ensure normal pass-through of the freezer to avoid difficulty in

repair in case of any fault; otherwise the freezer cannot be restored in time,

resulting in deterioration of the articles stored in the freezer.

2.

At

least

30cm

should

be

reserved

around the

freezer for ventilation

and

heat

dispersion.

3. The freezer must be installed on flat floor.

4. The freezer must be installed in a well-ventilated place without direct sunlight.

5. The freezer should not share a socket with any other device. Ensure firm

connection between the plug and the socket.

6. Do not twist or press the power cord.

7. If

the

power cord

needs

to be

extended, the extension cord

must be

of

220V~

and 15A.

8. Please check the working voltage before use and consider using a voltage

stabilizer of 3kw and above in those areas with unstable voltage to ensure normal

input voltage within 220V~ ± 10%.

9. The freezer must be grounded reliably.

10. If the power socket is equipped with ground wire, please check it for reliable

grounding before use.

If the power socket is not equipped with ground wire, be sure to ask a qualified

technician to install proper ground wire.

Installation

1. Remove all packing materials and tapes

Remove all packing materials and tapes for transport.

2. Adjust the legs

Clockwise turn the adjustable legs to extend them out and rest on the floor. Make

sure that the freezer is not moved when it is in use.

3. Grounding

Warning

Warning

Warning

Warning

Please use a power socket with ground wire. If the power socket is not grounded,

be sure to ask a qualified technician to install proper ground wire.

Never ground the freezer through gas pipe, water pipe, telephone line or lighting

arrester, etc.; otherwise electric shock may occur.

The power socket must be accessible after installation in order to disconnect the

power cord from the power socket in an emergency.

The freezer’s air vent must not be covered by anything.

Commissioning

Commissioning

Commissioning

Commissioning

When use the freezer for the first time, please follow the steps:

1. After installation, be sure to leave the freezer still for at least 24 hours before

turning it on.

2. When the freezer is empty, connect the power cord to a special socket of proper

specifications.

3. Turn on the rechargeable battery switch (it can be seen from the freezer’s back)

on the electric cabinet of compressor compartment at the top of freezer’s back. If

the switch is not turned on, low battery charge alarm will be given at the time of

test.

4. When alarm sound is heard, please press the “ Cancel buzz ” key to stop buzz.

5. Set the desired temperature: turn on the freezer without putting anything in the

freezer and observe the freezer for normal start and stop at least 24 hours. If so,

it means that the freezer’s performance is normal.

6. After confirming normal performance, put articles to be stored in the freezer.

Page 7

Use

Use

Use

Use

Caution

The freezer should be in the charge of a specially assigned person. He/she checks

and records the freezer’s running condition (every 2-4 hours). And, in case of a fault

or power failure, the temperature inside the freezer will rise. If the fault cannot be

cleared in a short time, please take out all articles stored in the freezer and put them

in another freezer meeting their temperature requirement to avoid deterioration.

Before putting articles to be stored in the freezer, make sure that the freezer’s

temperature range meets the temperature requirement of these articles. Otherwise

they may deteriorate because the freezer cannot reach the required temperature,

resulting in loss.

Due to the inertia of refrigeration, there is a certain difference between actually

displayed temperature and set temperature (the lower set temperature, the less

temperature difference and vice versa). It is normal.

Prohibition

All low-temperature freezers are storage equipment. It is strictly prohibited to put

too many relatively hot items in the freezer at a time; otherwise the compressor will

keep working for a long time without stop and be damaged easily and the

temperature will not reduce. Be sure to put articles in batches and make the

temperature inside the freezer reduce in steps to the desired temperature.

Do not accelerate defrosting by using any tool or method not approved by the

freezer’s manufacturer.

Do not damage the refrigerating loop.

Dot use any appliance not approved by the freezer’s manufacturer in the freezer.

Operation after power failure

The freezer can memorize the settings. In case of power failure, the freezer will still

operate with the parameters set before power failure when power supply resumes.

Temperature

Temperature

Temperature

Temperature adjustment

adjustment

adjustment

adjustment and

and

setting

and

setting

and setting

setting

The freezer’s temperature is set and

adjusted as follows:

1. Unlocking

When the “ Lock ” indicator lights up, all keys except the “ ” key are locked.

Press and hold the “ ” key for 5s, the display area for internal temperature will

show F0 and “ 0 ” will flash; then press the “ ” key, the display area for internal

temperature will show F1; finally press the “ Set ” key, the keyboard will unlock

and the display panel will show internal temperature. If any key is pressed in 10s,

the keyboard will automatically be locked.

2. Temperature setting

In initial power-on state, press the “ Set ” key, the display screen will show L0 and

“ 0 ” will flash; press this key again, the display screen will show the default

temperature setting (i.e. -30 ℃ ) and the second digit will flash. (If the freezer is

not used for the first time, the display screen will show the temperature set last

time) Adjust the freezer to the desired temperature by pressing the “ ” key to

switch the flashing digit and pressing the “ ” key to change the value of current

flashing digit, and then press the “ Set ” key to confirm and memorize the

temperature setting. Temperature setting range: (-20 ℃ ~-45 ℃ )

3. High temperature alarm setting

After unlocking, press the “ Set ” key, the display screen will show L0 and “ 0 ”

will flash; press the “ ” key, the display screen will show L1; press the “ Set ” key

again, the display screen will show the default temperature setting for high

temperature alarm with the second digit flashing (the default temperature setting

for high temperature alarm is internal temperature setting +10. Note: When

showing the temperature, the “ ” sign followed by digits means the “ + ” sign)

and then adjust the temperature setting by pressing the “ ” key to switch the

flashing digit and pressing the “ ” key to change the value and sign of current

flashing digit; after finishing setting, press the “ Set ” key to memorize the setting.

Temperature setting range for high temperature alarm: maximum displayed

temperature ≥ set temperature for high temperature alarm - set temperature ≥ 5 ℃ ;

otherwise use the default setting.

4. Low temperature alarm setting

After unlocking, the display screen will show L0 and “ 0 ” will flash. Press the

“ ” key twice, the display screen will show flashing L2; press the “ Set ” key, the

display screen will show the default temperature setting for low temperature

alarm with the second digit flashing (the default temperature setting for low

temperature alarm is internal temperature setting -10), and then adjust the

temperature setting by pressing the “ ” key to switch the flashing digit and

pressing the “ ” key to change the value of current flashing digit; after finishing

setting, press the “ Set ” key to memorize the setting. Temperature setting range

for low temperature alarm: minimum displayed temperature ≤ set temperature for

low temperature alarm - set temperature ≤ -5 ℃ ; otherwise use the default setting.

Page 8

Display

Display

Display

Display and

and

alarm

and

alarm

and alarm

alarm

Display

Display

Display

Display and

and

alarm

and

alarm

and alarm

alarm

Upon connecting to the power supply, the freezer will be on and the display screen

will show the freezer’s internal temperature.

Prompts for the working state of display panel:

“ Lock ” indicator: if the indicator lights up, it means that all keys are locked to

avoid misoperation.

“ Alarm ” indicator: if the indicator lights up or flashes, it means that a fault occurs.

Functions of keys:

Cancel buzz: in the locked or unlocked state, press the “ Cancel buzz ” key at the

time of alarm, the alarm sound will be cancelled and the visual alarm will not be

cancelled.

Alarm test: it is used to test normal working state of the alarm system and low

battery charge level. In the unlocked state, press this key, all the indicators will light

up, the buzzer will give an alarm and all digital tubes display “ 8 ” . In the locked state,

press this key at the time of alarm, corresponding fault alarm code will display.

Please identify the fault causes according to the table below.

Alarm State Fault

High

temperature

alarm

Low

temperature

alarm

Power-dow

n alarm

Over-high

ambient

temperature

Abnormal

sensor

Low

battery

charge

level

When the internal

temperature is higher

than the set temperature

for high temperature

alarm

When the internal

temperature is lower

than the set temperature

for low temperature

alarm

Power-down of the

freezer

Ambient temperature

above 38 ℃

Internal main sensor at

fault

Ambient temperature

sensor at fault

Insufficient battery

charge or the battery

switch is not on

code

E9 The indicator

E10 The indicator

/ The alarm

E14 The indicator

E6 The indicator

E0 The indicator

E5 The indicator

Indication Buzzer

flashes

flashes

indicator

flashes; black

screen and

actual internal

temperature

show alternately

flashes

flashes

flashes

flashes 3 times

When the freezer is

turned on for the first

time, the buzzer alarm

function is activated

after 5 hours according

to the default settings; in

normal operation, the

buzz alarm is given after

15min

the buzz alarm is given

after 30s

Buzz alarm

Note: If several alarms sound simultaneously, each fault code displays 3s.

Note:

Always turn on the battery switch before starting the freezer. The freezer will enter

normal working state and charge the battery upon connecting to an AC power supply

meeting its requirements. In case of AC power failure, the battery will energize the

display screen for normal display. When the voltage of battery reduces to less than a

specified value due to discharge, it will stop energizing the display screen and thus

the display screen will not display any longer. When the battery is able to supply

electricity normally, to completely cut off the freezer’s power supply, just pull out its

AC power cord and turn off its battery switch. Then the display screen will not

display any longer.

Time

setting

Time

setting

Time

Time setting

setting for

for

automatic

for

automatic

for automatic

automatic alarm

alarm

recovery

alarm

recovery

alarm recovery

recovery

At the time of alarm, press the “ Cancel buzz ” key on the display panel, buzz alarm

will be cancelled (remote alarm will not be cancelled).

If alarm conditions remain, the buzz alarm will automatically recover after a pause of

30min.

Remote

Remote

Remote

Remote alarm

alarm

terminals

alarm

terminals

alarm terminals

terminals

The remote alarm terminals are located in the compressor compartment at the back of

freezer . Alarm signals are sent by these terminals with carrying capacity of DC

30V,

2A.

Contact output:

In normal conditions, both ends of connecting wire of remote alarm terminals are

open circuit. In alarm conditions, both ends of connecting wire of remote alarm

terminals are closed circuit.

To use the remote alarm function, connect the circuit as shown in the figure below.

Note: The remote alarm function is limited to three alarm modes - high temperature

alarm, low temperature alarm and power-down alarm.

Page 9

Routine

Routine

Routine

Routine maintenance

maintenance

maintenance

maintenance

Fault

clearance

Fault

clearance

Fault

Fault clearance

clearance

Warning

To

avoid electric shock or personal injury, be sure to disconnect the freezer from power supply

before carrying out any repair or maintenance.

Make sure that no drug or suspended particles around the freezer will be breathed in at the

time of maintenance; otherwise they may result in health hazard.

Cleaning of the freezer

Clean the freezer once a month. Regular cleaning makes the freezer always brand-new.

Wipe off a little dust on the shell, inner compartments and all accessories of the freezer

with a dry cloth. If the freezer is very dirty, remove the dirt with a clean cloth and neutral

detergent, then wipe off the residual detergent with a wet cloth, and finally wipe the freezer

with a dry cloth. (Undiluted detergent may damage plastic parts. Please refer to the detergent

instructions for the dilution method.)

Never pour water onto the shell or into the preservation compartment of freezer; otherwise

the insulation layer may be damaged, resulting in faults.

The compressor and other mechanical parts are fully enclosed and require no lubrication.

Remove the frost or ice on the inner wall once a month.

Removal of frost on the inner wall

Frost usually forms on internal shelve, which may cause clearance between the cabinet body

and door seal and thus result in poor refrigerating effect.

along with the freezer for defrosting. The following procedure is the method of defrosting

through emptying the freezer.

Note: Do not use any tool with sharp edges or corners such as knife or screwdriver for

defrosting.

1. Take out all articles stored in the freezer and put them in another freezer or in a container

with freezing liquid carbon dioxide.

2. Turn off the power switch.

3. Open outer doors and leave them open for a period of time for defrosting.

4. Wipe off water at the bottom of cabinet body with a dry cloth.

5. After cleaning the cabinet body, turn on the freezer again.

6. Put back the articles in the sufficiently cooled freezer.

Or you may use the “ Defrost ” key to defrost: after unlocking the keyboard, press and hold the

“ Defrost ” key for 5s, the compressor will stop running. This key doesn ’ t have automatic return

function. Therefore it is necessary to press and hold it for 5s again after defrosting ends, and

the compressor will resume normal running.

Battery maintenance

When the low-temperature freezer keeps working continuously, please test the battery

charge level every 15 days (please refer to the section of alarm test function on Page 12 for the

test method). In case of low battery charge level, make sure that the battery switch is on and

the battery is charged. When the battery has been charged for consecutive 7 days, please retest

the battery charge level. In normal conditions, the battery charge should be full. If low battery

charge level remains, it is recommended to replace the rechargeable battery.

The battery with power-down alarm function is a consumable item with 3-year service life.

If the battery has been used for more than 3 years, it may not act at the time of alarm. It is

recommended to replace the battery earlier. Please contact a Haier after-sales service

technician for the battery replacement.

You

may use the ice scraper provided

If the freezer goes wrong, please check the following possible fault points before

asking for repair:

Failure to start

Is the connection of power supply normal? Is the main power switch on?

Is supply voltage too low?

Were many articles put in the freezer at a time?

Poor cooling

Is ambient temperature too high?

Are the doors closed tightly? (The frost between the cabinet body and the door

seal may reduce the sealing performance of doors)

Is the temperature setting correct?

Is the freezer away from direct sunlight?

Is the freezer close to a heat source?

Are the rubber hole cover and heat-insulating materials of test through-hole placed

correctly?

Were many uncooled items put in the freezer in past several hours? (In this case,

the problem is temporary.

You

may raise the set temperature and then gradually

reduce it after the freezer starts and stops normally in a short time.)

Noise

Is the freezer installed on solid ground?

Is the freezer’s shell contact with any object?

Has the freezer been leveled by adjusting its legs?

Is the freezer in low-temperature running state?

If the freezer ’ s internal temperature is relatively high due to many items in it,

sometime it make noises. The noise will lower with the reduction of temperature in

the preservation compartment.

Please check whether the noise is from the compressor (the compressor noise of

low-temperature equipment is louder than that of household appliances)

Knocking sound. It may be caused by rapid cooling and contraction of internal

components. In this case, please make the freezer’s temperature reduce gradually

without abrupt temperature reduction in a short time.

Equipment

Equipment

Equipment

Equipment scrapping

scrapping

scrapping

scrapping

Warning

If the freezer is left unused for a long time in an unsupervised area, please keep

children away from it and make sure that its doors cannot be fully closed. Equipment

scrapping should be done by qualified persons. Be sure to remove the doors to avoid

accidents such as suffocation.

Page 10

Rechargeable

Rechargeable

Rechargeable

Rechargeable battery

A

rechargeable battery is built in the freezer and is recyclable. When the battery’s

battery

battery

battery recycling

recycling

recycling

recycling

service life expires, please contact local battery recycling organizations for check or

proper disposal of the battery.

1. Position of the battery

The battery built-in the freezer is used for power-down alarm and located in the

electric cabinet.

Caution

There are high-voltage electrical components in the electric cabinet.

To

avoid electric shock, the cover of electric cabinet must be opened only by a

qualified engineer or maintainer.

2. Removal of the battery

1) Turn off the power switch and pull out the plug from the power socket.

2) Screw off the screws on the cover of electric cabinet with a screwdriver.

3) Pull out the battery’s connecting plug.

4) Remove the battery’s fixing clip and then take out the battery.

5) Recycle or properly dispose the battery as required.

Prohibition

When replacing the battery, make sure that the brown wire is connected to the

battery’s positive pole and the blue wire to the battery’s negative pole. Do not

misconnect; otherwise the charging circuit of computer board would be burned out

easily and the battery cannot be charged.

Specifications

Specifications

Specifications

Specifications

Technical data

Model Ambi

DW-4

0L508

ent

tempe

rature

( ℃ )

10~32

Classif

ication

of

electric

shockproof

protect

ion

I

Tempe

rature

range

( ℃ )

-20~-40490 220V~/5

Effe

ctive

volu

me

(L)

Rated

voltage/fr

equency

0Hz

Rat

ed

cur

rent

(A)

4.2 63

Inp

Wei

ut

ght

po

(Kg

we

)

r

(W

)

170 280 840 × 89

0

Mixe

d

refrig

erant

(g)

Overall

dimensi

ons

(D × W ×

H)(mm)

5 × 1860

Conn

ection

type

Y

Note: With ambient temperature at 25 ℃ , minimum temperature inside the freezer can

reach -40 ℃ .

Name

Qty.

Model

DW-40L508 1 1 1 1 2 2

Warranty

Card

Operating

Instructions

Plastic bag Ice scraper Thrust shelf Door handle

subassembly

Note: Thrust shelves are installed at the back of freezer to ensure a certain distance

between the freezer and wall.

Refrigeration

Refrigeration

Refrigeration

Refrigeration principle

Schematic

Schematic

Schematic

Schematic refrigeration

refrigeration

refrigeration

refrigeration diagram

principle

principle

principle and

diagram

diagram

diagram

and

circuit

and

circuit

and circuit

circuit diagram

diagram

diagram

diagram

Page 11

Refrigeration

Refrigeration

Refrigeration

Refrigeration principle

principle

principle

principle and

and

circuit

and

circuit

and circuit

circuit diagram

diagram

diagram

diagram

Options

Options

Options

Options

Options

Options

Options

Options

1. Temperature recorder

Ask a qualified technician or an after-sales maintainer to install the temperature recorder as follows:

1) Remove the cover plate of temperature recorder.

2) Install the temperature recorder in place and then fix it to the front panel with screws.

3) Remove the screws of electric cabinet in the compressor compartment and then connect the

connecting wires of temperature recorder respectively to the freezer’s live wire and neutral

wire.

4) Lead the sensor of temperature recorder in the freezer through internal sensor duct at the back

of compressor compartment. The sensor duct is from the sensor through-hole at the back of

freezer to the compressor compartment.

5) Disassemble the holder of internal temperature sensor in the cabinet, fix the recorder’s sensor

and internal temperature sensor together, seal the sensor hole on the cabinet body and install

the cover in place.

6) Bundle the connecting wires of recorder in the compressor compartment with cable clips.

7) Fix and restore the cover of electric cabinet and the left panel of compressor compartment

respectively with screws.

Warning

Before installing the temperature recorder, be sure to switch off the power supply; otherwise

electric shock or fire hazard may occur.

Installation

Installation

Installation

Installation and

In order to operate and use the recorder correctly, please operate as follows:

1)

You

2) Switch on the backup power supply, i.e. 9V DC battery in the upper left corner of recorder.

3) Change a piece of new recording paper (see the figure below).

4) Remove the plastic cap from the recording pen and close the recorder’s door.

Note: The recorder will not work until internal temperature reaches the recorder’s recording range.

Power

Power

Power

Power supply

When the freezer works, the recorder uses AC power supply in normal conditions. If AC power

supply goes wrong, the recorder’s LED indicator will flash to indicate abnormal power supply. And,

the recorder will go on recording internal temperature by using backup battery. Each backup battery

can support the recorder for about 30h (Note: In case of low battery charge level, replace the battery

in time to avoid corrosion of battery switch due to overdue replacement.

please turn off the battery switch when the freezer is not in use. Please install a backup battery in

place to ensure normal recording in case of power failure during normal use). The recorder’s LED

indicator will continuously flash until main power supply (AC power supply) is switched on and the

backup battery is replaced. In case of low backup battery charge level, the recorder’s LED indicator

will flash to indicate the need of battery replacement.

Repair

and

Repair

and

Repair

Repair and

and replacement

If the recorder’s green LED flashes, there are two checking methods:

and

running

and

running

and running

running

will see the recorder upon opening its door.

supply

supply

supply

replacement

replacement

replacement of

of

the

of

the

of the

the recorder

recorder

recorder

recorder ’

’

s

backup

’

s

backup

’ s

s backup

backup battery

battery

battery

battery

To

save battery charge,

Page 12

Options

Options

Options

Options

After-sales

After-sales

After-sales

After-sales service

service

service

service

1. Remove the backup battery (9V DC), if the LED goes out and the recorder stops working, it

means that the recorder’s main power supply goes wrong. In this case, please check for power

failure, short circuit and loose connecting wire, etc. If the main power supply is in good

condition after repair, the recorder will work normally. Then install the backup battery in place,

if the LED stops flashing, it means that the backup battery is normal; if the LED goes on

flashing, it means that the backup battery is at low charge level and needs replacement until

the green LED lights up and does not flash.

2. Remove the backup battery, if the LED goes on flashing and the recorder works normally, it

means that the main power supply is normal and the backup battery is at low charge level and

needs replacement until the green LED lights up and does not flash.

Change

Change

Change

Change of

of

recording

of

recording

of recording

recording paper

paper

paper

paper

Change the recording paper as follows:

1. Find out the “ Press ” button (3#) in the upper left corner on the recorder’s front panel.

2. Press and hold this button (3#) for about 1s until the recording pen starts moving towards the

left of recording paper.

3. When the recording pen entirely moves out of the recording paper, loosen the center bolt and

change the used recording paper with a piece of new recording paper by carefully aligning the

time line on the paper with the time slot on the panel (there is a small slot on the left of panel.

Please see the attached figure).

4. Retighten the center bolt, then press and hold the button (3#) to make the recording pen reset

and start recording temperature.

5. Check whether the recording pen writes well on the paper or not. If not, you may adjust its

beam to make the penpoint contact with the recording paper.

(Note: Do not damage the

penpoint and beam. If it is difficult to adjust, you may remove the beam with a screwdriver,

bend it with a little force and reinstall it in place by repeating the above operations).

6.

To

ensure the recorder’s accurate recording, please calibrate the recording pen after each paper

change as follows: press and hold the button (3#) until the recording pen moves out of the

recording paper, then press and hold the button (3#) again until the recording pen return to the

recording paper, at which time the pen will pause at the outmost temperature graduation mark

on the recording paper (this graduation mark is not necessarily with temperature value, but it

must be the outmost graduation mark). If the pen does not pause in this position, you may

adjust its position by using 1# or 2# arrow within 5s to make the penpoint align with the

outmost graduation mark. If you don ’ t finishing the adjustment of pen within 5s, please repeat

step 6.

Calibration

Calibration

Calibration

Calibration and

and

adjustment

and

adjustment

and adjustment

adjustment of

of

the

of

the

of the

the recorder

recorder

recorder

recorder

The recorder has been accurately adjusted before leaving the factory and will not be affected even if

power interruption. If it indeed needs adjustment, please do as follows:

1. Keep the freezer operating continuously and then make it record the temperature curve for at least

2h after it enters stable state (the fluctuation of displayed temperature is relatively regular).

2. Put a standard thermocouple in a bottle with about 100ml of 10% glycerite, and then put the

bottle and the recorder’s sensor together in the freezer (the recorder’s sensor must not be

contact with any solution).

3. The glycerite bottle with thermocouple is stored in the freezer for about 4h. When the

temperature of glycerite in the bottle is identical with the freezer’s internal temperature,

compare temperature values of the standard thermocouple and recorder, if they are not the

same, you may adjust the recorder’s recorded value by using the adjusting buttons on the left

(1#) or right (2#) of panel to make it in conformity with the thermocouple’s indicated value.

Note: The recording pen starts moving 5s after the button is released.

Note:

The

Note:

The

Note:

Note: The

The recorder

for

special

for

special

for

for special

special cases.

recorder

recorder

recorder has

cases.

cases.

cases.

has

already

has

already

has already

already been

been

calibrated

been

calibrated

been calibrated

calibrated before

before

leaving

before

leaving

before leaving

leaving the

the

factory;

the

factory;

the factory;

factory; do

do

do

do not

not

adjust

not

adjust

not adjust

adjust it

it

except

it

except

it except

except

The freezer is guaranteed for free by our company for one (1) year calculated from the date of

purchase (the invoice shall prevail). Main components (including compressor, condenser, evaporator,

main control panel and display panel) are guaranteed for free by our company for three (3) years.

Warranty card: when you need common consultation or repair, please contact our local

after-sales service center with both warranty card and purchase invoice on hand and keep the

warranty card properly.

Beware of

electric

shock!

There are

such

components

as control

board and

contactor,

etc. in the

electric

cabinet.

Label for protection against electric shock:

Warn the user not to open the electric

cabinet at random.

Before power-on, please turn on the

battery switch on the electric cabinet at

the back of freezer. If the freezer is to

be left unused for a long time, please

power off first, and then turn off the

battery switch.

Label for the use of rechargeable battery:

Describe the precautions for the use of

rechargeable battery

Rechargeable battery switch

Label for the rechargeable battery switch:

Show the position of rechargeable battery

switch

Grounding sign

Label for operation instructions and

precautions:

Instruct the user in operation and relevant

precautions

Operation Steps and Precautions for the Low-temperature Freezer

Unlocking

When the “ Lock ” indicator lights up, all keys except the “ ” key are

locked. Press and hold the “ ” key for 5s, the display area for internal

temperature will show F0 and “ 0 ” will flash; then press the “ ” key, the

display area for internal temperature will show F1; finally press the “ Set ”

key, the keyboard will unlock.

Temperature setting

In the unlocked state, press the “ Set ” key , the display screen will show L0

and “ 0 ” will flash; press this key again, the display screen will show the

former temperature setting with the second digit flashing. Adjust the

freezer to the desired temperature by pressing the “ ” key to switch

the flashing digit and pressing the “ ” key to change the value of current

flashing dig it, and then press the “ Set ” key to confirm and memorize the

temperature setting. Temperature setting range: (-20 ℃ ~-40 ℃ )

Precautions

1. After initial installation or movement, please adjust the legs and

make them rest on the floor to make sure that the freezer will not move

during use, then leave the freezer still for at least 24h before turning it on.

2. When using the freezer, maximumly control the room

temperature below 28 ℃ (If ambient temperature is above 32 ℃ , the

cooling efficiency will reduce rapidly. Also, if ambient temperature is

above 32 ℃ for a long time, the compressor will be damaged or its

service life will reduce. In this case, it is recommended to install an air

conditioner).

3. The freezer should use an independent power socket of the

carrying current above 16A and reliable grounding.

4. Before power-on, please turn on the battery switch on the electric

cabinet at the back of freezer. If the freezer is to be left unused for a long

time, please power off first, and then turn off the battery switch.

5. Maximumly control the time of each opening within 1min, and

wipe off all ice and water on the door seal before closing the freezer’s

doors to ensure high sealing performance.

6. To extend the freezer’s service life and reduce energy

consumption, it is recommended to set the temperature in the range of -20

℃ ~-40 ℃ on the premise that the safety of items in the freezer is

guaranteed.

7. The freezer is used for the storage of items at low temperature

and not used for quick freezing. It must not be forced to quickly freeze a

large quantity of hot products or large-volume liquid products.

8. If the freezer does not refrigerate in 2-3 hours after power on,

please unplug it and contact our after-sales service enter as soon as

possible.

9. In case of alarm or any other fault, please clear the fault

according to the prompts on the display panel. If there is no prompt or

you cannot clear the fault, please do not disassemble the freezer by

yourself but immediately contact our after-sales service center to ask a

qualified maintainer for fault clearance.

Fault codes are as follows:

High temperature

alarm

Low temperature

alarm

Over-high ambient

temperature alarm

______Haier Group customer service hotline (for the whole

country): 4006-999999

E9 Main sensor fault

alarm

E10 Ambient temperature

sensor fault alarm

E14 Low battery charge

level or battery

switch off

E6

E0

E5

Loading...

Loading...