Air Cooled Module Water Chiller

Installation, operation and technical manual

Heat pump / Cooling only

R22 refrigerant

100KW

Haier Commercial Air Conditioning

3PH, 380V, 50Hz

MANUAL CODE: SYJS-035-06REV.2 2008-04-30

HAIER CHILLER

2

TABLE OF CONTENTS

1. Nomenclature……………………………………………………………………………………………………..3

2. Product character…………………………………………………………………………………………………3

3. Specifications……………………………………………………………………………………………………..5

4. Dimension data…………………………………………………………………………………………………...7

5. Installation and debugging………………………………………………………………………………………8

Water system installation diagram…………………………………………………………………………….11

9.

6. Refrigerant circuit……………………………………………………………………………………………….10

7.

Auxiliary electric heating function control. ……………………………………………………………………14

10. Water pump operation control(valid when water pump and the unit controlled simultaneously)……….14

11. The terminal simultaneous control…………………………………………………………………………….15

12. Wired controller functions………………………………………………………………………………………16

14. Maintenance………………………………………………………………………………………….........…....34

8. Wiring diagrams………………………………………………………………………………………………....13

14. Control functions………………………………………………………………………………….........…........28

HAIER CHILLER

3

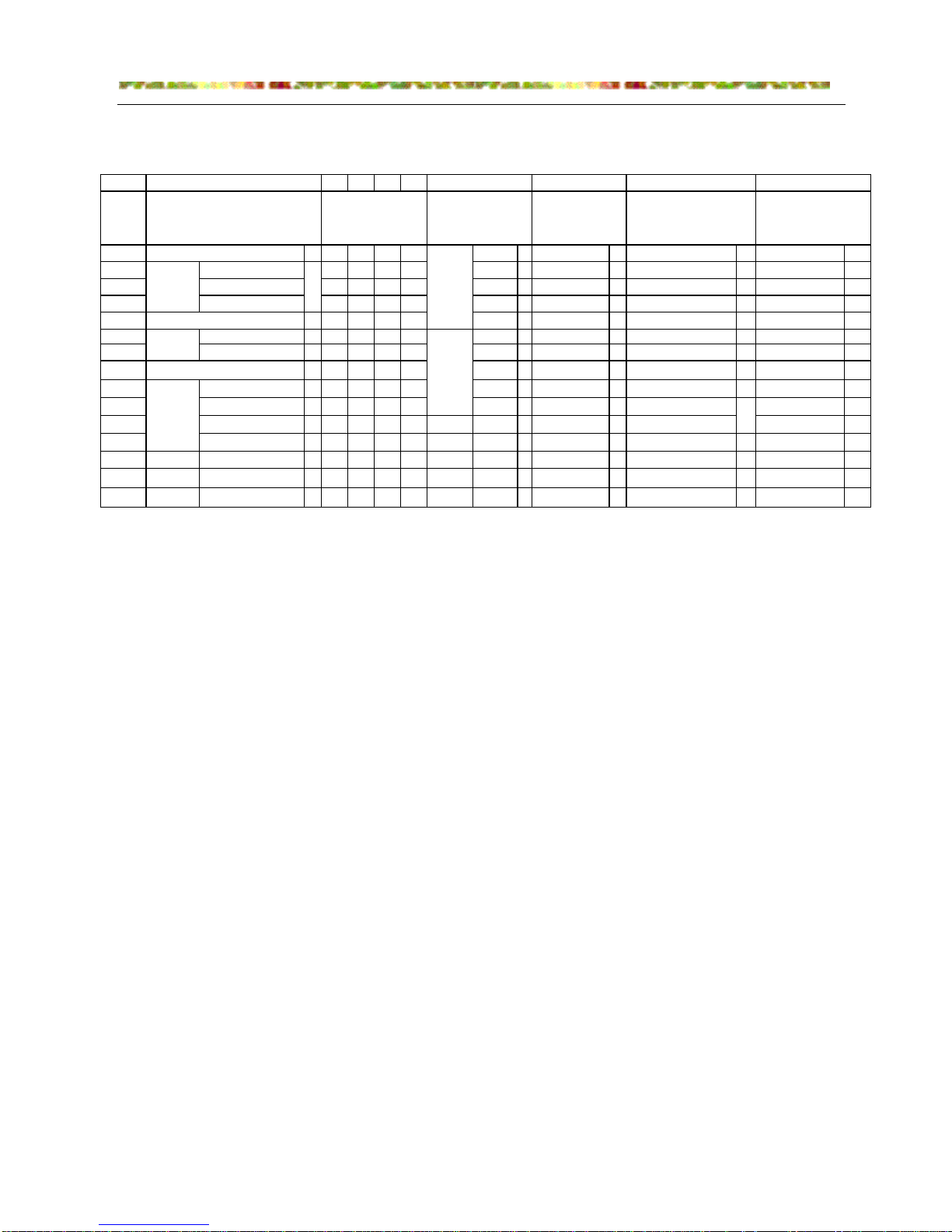

1. Nomenclature

2. Product character

a. Installation conveniently, no need the special machine room and water tower; can be installed on the

roof or out of the room. Widely application for cinema, hospital, hotel, school, commercial building, etc.

b. Utilize flexible scroll compressor. And adopts three compressors in parallel technology. The master unit

will control all compressors run or stop due to the water outlet temp. Optimum refrigerant distribution

technique and minimum-deformation design. Adoption of rolling bearing and non-lubricated bearing.

Excellent heating effect at low temperature. Broad range of working temperature and suitability for high

condensation temperature.

c. Shell & Tube and U type inner grooved finned coil heat exchanger.

High efficient water side heat exchanger: in cooling, the water side heat exchanger is as evaporator; in

heating, it is as condenser. The freezed water flows outside of the pipe, and the refrigerant flows in the

pipe. Optimum design, reliable operation, reasonable structure, perfect performance.

d. Central control technology, indoor unit be connected with controller by dual core non-polar wire. The

indoor units can be controlled individually or simultaneously, more convenient, more energy saving.

One central air conditioning system can include max. 16 sets of module unit. Through the dip switch on

PCB you can set unit No. of every module unit, and every unit is connected by RS485 port. Compact

1 3456

chiller

system

C

C

1069 R22 Aair cooled A

100-115V, 60Hz 1

fixed frequency A-G

air cooled 0237 R407C B water cooled W

220-240V, 50Hz 2

inverter H-Q

water cooled 0 0 1 2 R132 C earth source E

115-220V, 50/60Hz 3

DC inverter R-Z

earth source R134a D

220-220V, 60Hz 4

A

R410a E

110V, 50-60Hz 5

H

R22 M

220V, 50-60H

z

6

R

R407C N

127V, 60Hz 7

W

R123 O

240V, 50Hz 8

Cassatte

B

R134a P

110-220V, 50/60Hz 9

Duct

D

R410a Q 330V, 50Hz A

Cabinet

P

400V, 50Hz B

Wall mounted

S

3300V, 50Hz

C

6600V, 50Hz D

380-400V, 50Hz N

415V, 50Hz M

Code Explanation for chiller

compressor type

capacity (for

Centrifugal chiller:

Rt; other: KW)

product type unit character

2

7

89

heat

pump

cooling

only

10

Air-cooled module chiller

suitable voltage design number

Light

chiller

Water-cooled cabinet chiller

Hydronic

system

Centrifugal chiller

Screw

chiller

single-packaged

I

split-packaged

structure, convenient for electric installation.

e. Fan coil simultaneous control technology: indoor fan coil can be controlled individually or centrally.

Every indoor unit is connected to the individual controller or central controller through dual-core

non-polar wire to realize the cental control. When one indoor starts up, the central air conditioning

HAIER CHILLER

4

system will start up automatically. When all indoors arrive the set temperature, the master unit will stop.

Energy saving.

f. Auto check technology: The system can check the operation status automatically; all kinds of sensors

will transmit the operation parameters to the chip. By pressing the buttons, all the parameters can

display on the liquid crystal screen. When the unit occurs failure in operation, the failure will display on

the LED so that the malfunction can be solved soon.

g. Password control function: According to the user setting, the password control function can be used.

Therefore the control to the unit will be more reliable and more flexible.

h. Equipped with RS-485 physical connector, perfect network communication ability.

i. Module structure design, the system can be produced or transported as module unit. Every system is

independent, and they are spare part for each other, however which cooling circuit is abnormal, the

other systems do not be affected by the abnormal system, and furthermore they will run in shape.

Module structure can reduce the cost of transport and installation greatly, more convenient.

j. Heat exchanger of air side is designed much larger, enlarge heat transmission area, lower the

temperature drop of transmission. Consequently, the chiller can run in cool mode even at high

temperature of 45celsius degree in summer, and also can run in heat mode at low ambient temperature

of –15celcius degree in winter with good performance.

k.

Safety and protection devices: phase reverse protection device, high and low pressure switch, freeze

protection device, overheat protection device, overload protection device, etc. Also, with Timer ON/OFF,

AUTO operation, defrosting, etc. functions.

HAIER CHILLER

5

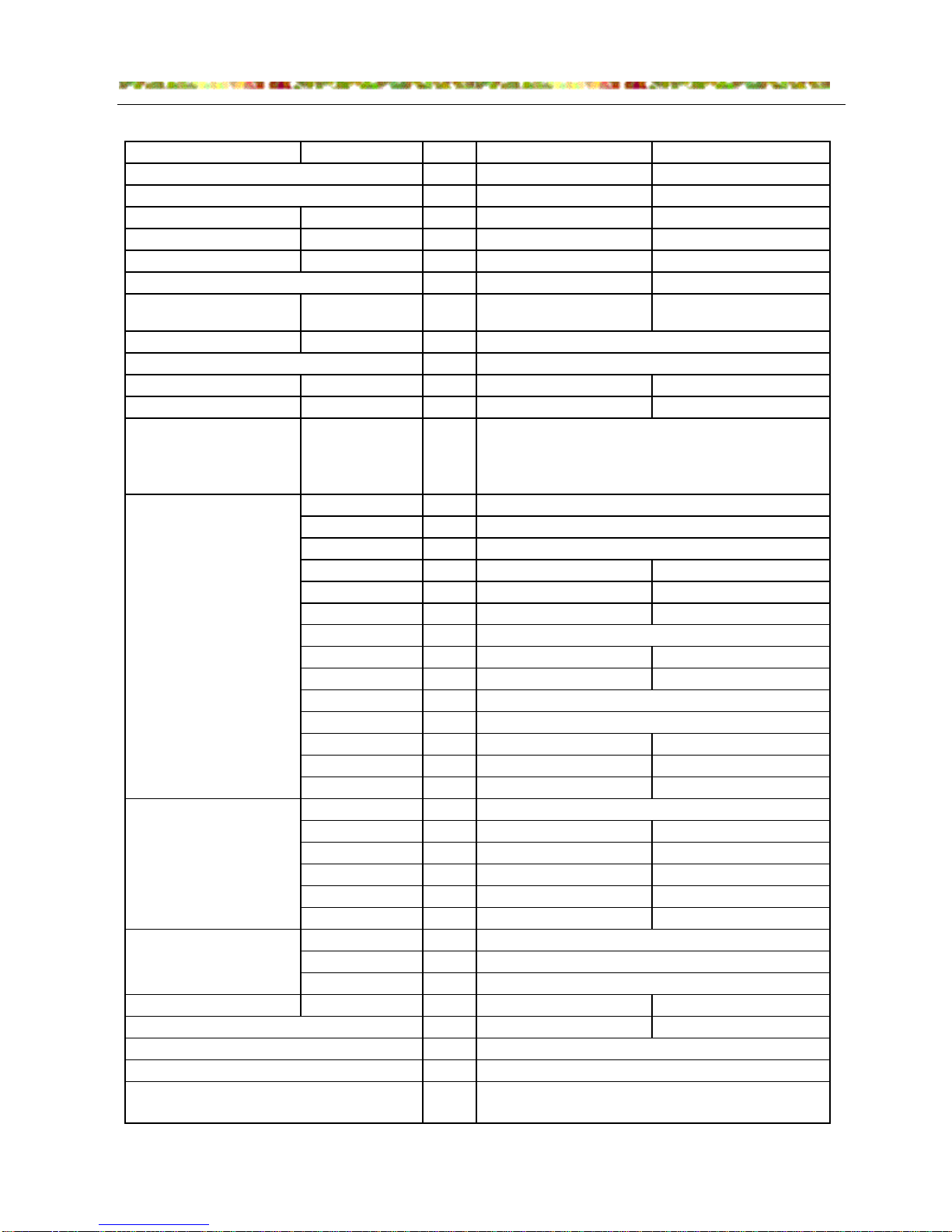

3. Specifications

Model CA0100MANB CA0100AANB

KW 98 98

KW / 105

Total power input KW

Start current A 164 164

Running current A 21 21

A 67.5 67.5

Recommended circuit

breaker

A

GV2-M22C(23A)/GV2-

M16C(10)

GV2-M22C(23A)/GV2-

M16C(10)

Power supply

Appearance colour Haier gray Haier gray

Capacity control step 3 3

Safety&functional

protection

model

type/manufacture

COP

quantity set 3 3

power input KW 9.98Kw 9.98Kw

rated power KW 10.1*3 10.1*3

power supply

running current A 17 17

starting current A

159A(380V,50Hz) 159A(380V,50Hz)

oil type

oil charge ml

crankcase heater W 72 72

weight kg 71 71

rated speed rpm 2900 2900

type

quantity set 3 3

rated power KW 0.75*3 0.75*3

running current A 2.5 2.5

Air flow m3/h

Fan speed rpm

length mm

width mm

height mm

Refrigerant charge(R22) kg 30 30

Refrigeration system (circuit quantity) 3 3

Refrigeration control method

Nominal cooling capacity

Nominal heating capacity

Max. running current (in the electric control box)

Running control method

3PH, 380V, 50Hz

fully automation

axial flow

Air side heat exchanger

Fan

External dimension

Water side heat exchager

water-lackage delay protection,high and low pressure

switch, freeze protection device, overheat protection

device, overload protection device, phase loss &

sequence protection

JT335D-Y1L

shell & tube heat exchanger, working pressure 1.0MPa

Compressor

2635

1350

2136

SUNISO4GSDID-K

3000

cross finned coil, inner grooved copper pipe&dydrophilic

aluminum finned coil

hermetic scroll / DAIKIN

3.41

3PH, 50Hz

thermostatic expansion valve

32.25 32.25

9000*3 9000*3

960 960

HAIER CHILLER

6

Water flow m3/h 18 18

Water resistance kPa 50 50

mm 65 65

Noise level DB/(A) 66 66

Net weight kg 1100 1100

Running weight kg 1150 1150

Casing

The noise level will be measured in the third octave band limited values, using a Real Time Analyser calibrated

sound intensity meter. The noise level is measured at 2meter in front of the unit, 1.5 meter high to the ground.

When starting up the complete unit, the compressor will start up one by one and will not start up together.

The permitted range of voltage is 380±10%

Nominal working condition (cooling ):water inlet temp. 1

2

℃, water outlet temp. 7℃, ambient temp. 35℃。

Nominal working condition (heating ):water inlet temp. 40℃, water outlet temp. 45 ℃, ambient temp. (DB)7℃,

(WB)

6℃

Water pipe diameter

polyester painted galvanized steel plate, Haier gray

HKZSKLUO MXWNS\SXW MXXUSWQ MKYKMS\a + SWY]\ YX_OZ MXZZOM\ M]Z^O

@WY]\ YX_OZ ,A_-

<VLSOW\ \OVY0 ,l-

>XXUSWQ MKYKMS\a ,AI-

IK\OZ X]\UO\ \OVY0 ,l-

241

231

216

:1

86

5204

4904

4603

4302

3:02

<VLSOW\ \OVY0

<VLSOW\ \OVY0

dfc

dec

dch

kc

jh

ic

fibj

ffbj

fcbi

ejbh

egbh

HKZSKLUO MXWNS\SXW ROK\SWQ MKYKMS\a + SWY]\ YX_OZ MXZZOM\ M]Z^O

<VLSOW\ \OVY0 ,l-

?OK\

SWQ MKYKMS\a ,AI-

@WY]\ YX_OZ ,A_-

IK\OZ X]\UO\ \OVY0 ,l-

<VLSOW\ \OVY0

<VLSOW\ \OVY0

HAIER CHILLER

7

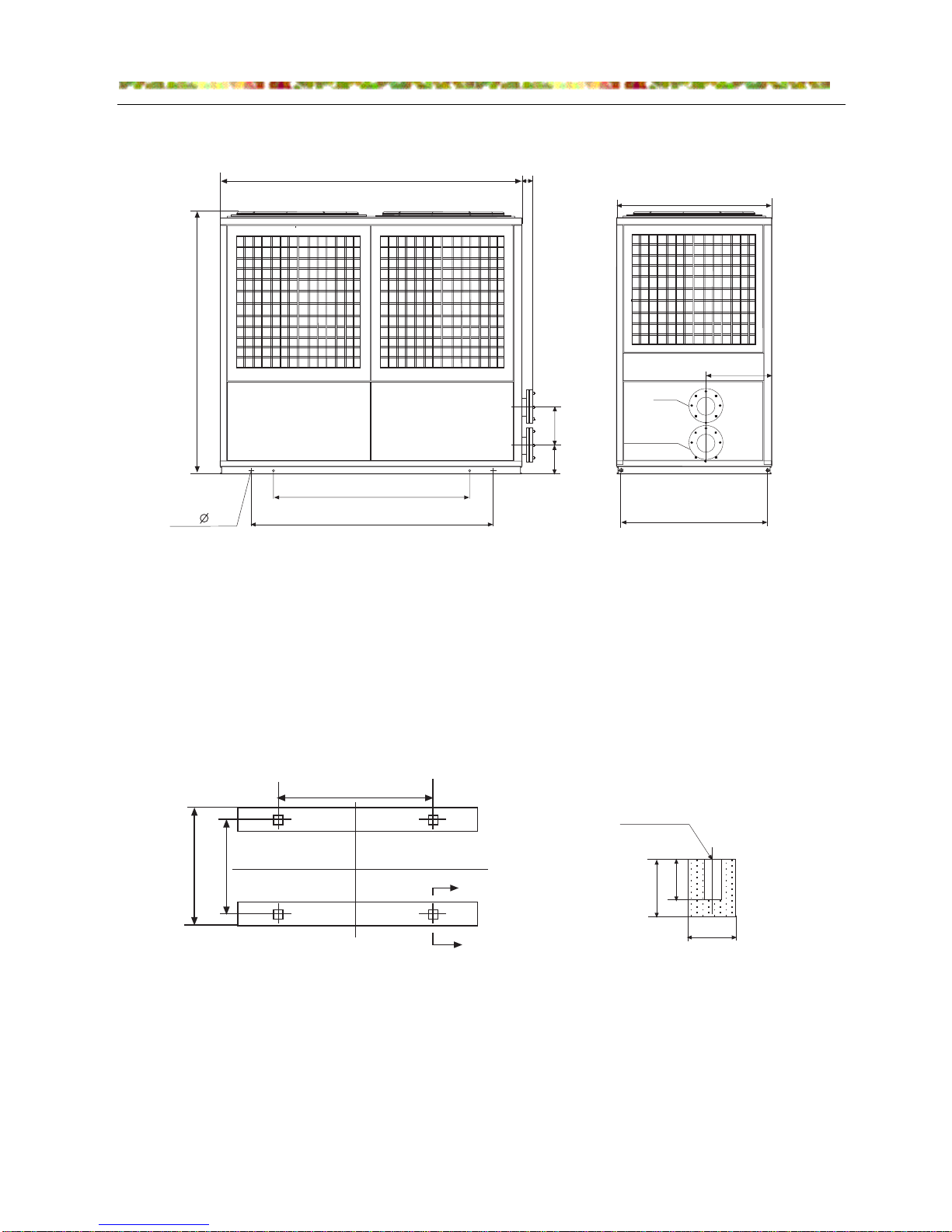

4. Dimension data

4.1 Installation dimension

4.2 Foundation dimension

4.2.1 The bearing capacity of the foundation shall be designed according to the unit's operation weight.

4.2.2 The foundation can be beam channel (designed by the installer according to the unit outline

dimension) or concrete structure, and the surface of the foundation shall be flat.

4.2.3 A 10~20mm rubber anti-vibration cushion shall be used between unit and foundation.

4.2.4 The unit can be fixed on the foundation by using anchor bolt with 16 or 18mm diameter.

2711 +?JNOCIIHJF >KIE,

2491+>KHNOHJF >KIE,

5- 29

ACOEM HJIEO

ACOEM @POIEO

=KPJDCOHKJ

?JNOCIIHJF >KIE

2520

115

2136

258

303

1290

475

1350

2711

?

?

?/? QHER;

LMENEO GKIE

211B211

461

311

361

1540

1290

HAIER CHILLER

8

5. Installation and debugging

5.1 Freight Check

All the units are tightly fastened on the wooden pallet by the bolts. Before leaving factory, the units

are all checked and pre-filled with refrigerant and refrigerant oil, both of which are the precise amount

the unit operation needs.

When user receives the product, he shall check it carefully to confirm if there is product damage in

transportation and to confirm all the pre-ordered parts are received. If there is any damage, he shall

immediately inform the transportation person and claim for compensation according to relevant clauses.

If there is problem except for surface damage, he shall immediately inform our company.

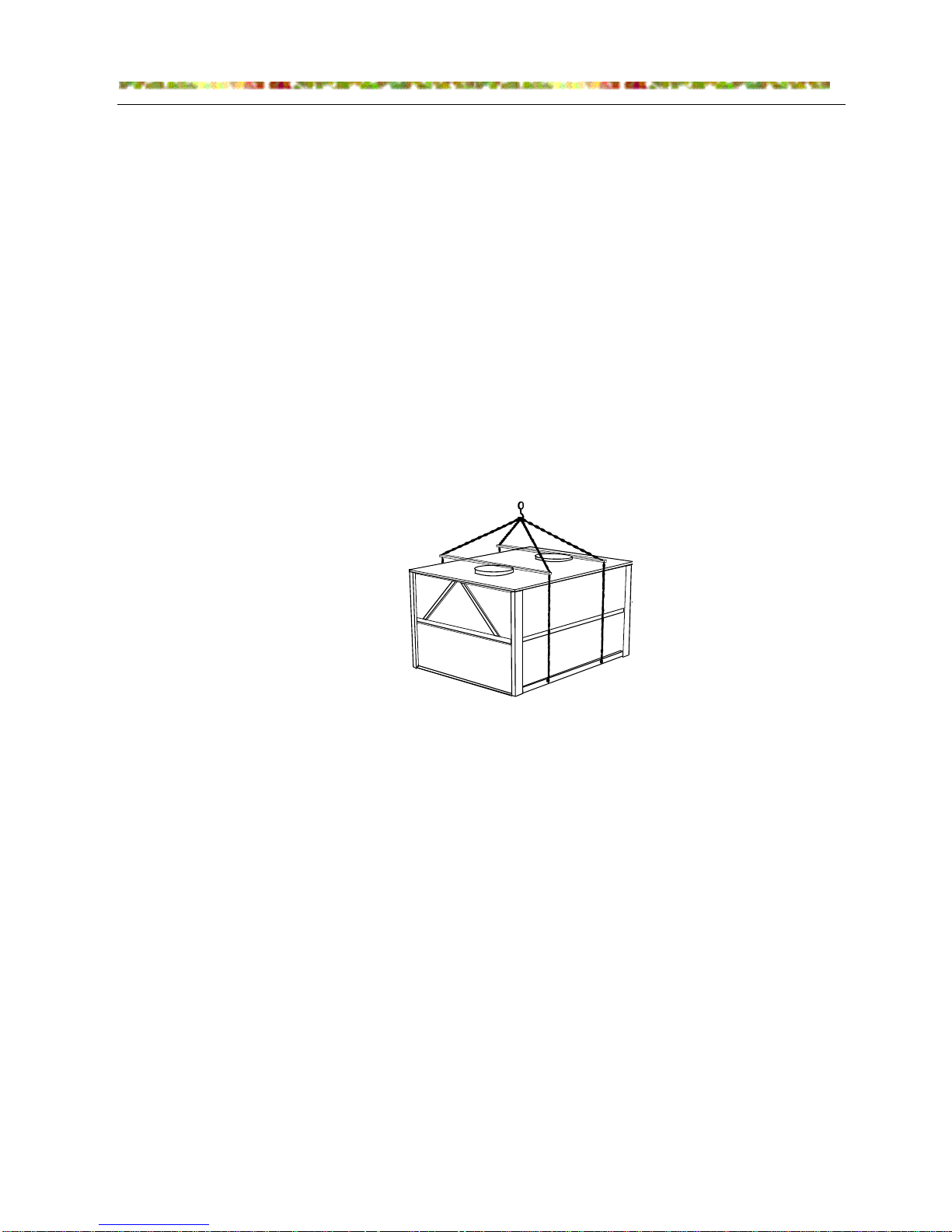

5.2 Transportation

In order to be convenient to carry the unit, the user shall use forklift or crane. When using crane,

there shall be proper partition to protect the top and side panel of the unit (as Figure shown). During

carrying, the unit shall be kept level, and the gradient shall not exceed 30°. Try to avoid units damage

due to improper operation.

5.3 Unwrap the packaging

After putting the unit on the site, cut the packing strap and remove the outer crate. Unscrew the

tightening bolt and remove the wood pallet from the bottom of the unit.

5.4 Selection of Installation Place

5.4.1 The installation place shall be plane, the foundation surface shall be flat, and the supporting surface

can bear the operating weight of the unit.

5.4.2 The unit shall not be installed in a place where there is too much dust, corrosive gas, high humidity or

insects gathers easily, fallen leaves and other contaminative matters.

5.4.3 Recommend that maintemance space among units should be over 400mm.

5.4.4 There shall be over 1.5m space around the unit to be convenient for ventilation and maintenance.

5.4.5 Try to keep the unit away from sunshine and rain, it is recommended to cover the unit with shed, but

be sure there is a space over 3m above the air outlet for releasing heat easily.

5.4.6 An anti-vibration cushion about 10-20mm shall be equipped between the unit and the foundation.

After adjusting level, fasten the anchor bolt.

5.4.7 For the heat pump unit, there shall be a drain for the condensate.

HAIER CHILLER

9

5.4.8 The installation and thermal insulation of the water pipes of the air conditioning system shall be

designed and instructed by the professionals and shall implement the relevant regulations of the Installation

Standard for HV & AC.

5.4.9 The external water pipe system must be equipped with anti-vibration hose, water filter, electronic

water cleaner, check valve, drain valve, discharging valve, stop valve and expansion tank, etc. The

expansion tank shall be installed 1-1.5m higher than the system top, and its capacity is about 1/10 of the

total water amount of the system. The air release valve shall be installed between the top of the system and

the expansion tank, and the water tank and the pipe shall be thermal insulated.

5.4.10 The water supply system must match the water pump with proper water flow and proper head to

ensure the supply for the unit normally.

5.4.11 The unit must be equipped with a water filter in front of the water inlet pipe and use the mesh with

16~40-mesh filter.

5.4.12 The anti-vibration hose must be used between water pump and unit, between water pump and water

pipe of system. At the same time, the pipes and the water pump shall have bracket to prevent the unit from

receiving force.

5.4.13 Wash and thermal insulation of system water pipes shall be done before connecting the pipe with the unit.

5.5 Safety Precautions

5.5.1The system pressure and electric parts will cause danger to the installation and maintenance of the air

conditioner, so only the authorized personnel with qualification can perform the installation, operation and

maintenance of the air conditioner.

5.5.2Please comply with the protection measures and safety warnings marked on the documents, labels

and nameplate on the unit.

5.5.3 Please comply with various safety regulations, wearing safety glasses and working gloves, and when

welding, wear the fireproof clothes.

Warning: Before maintaining the unit, cut off the main power supply of the unit,

otherwise electric shock will cause.

5.5.4 When maintaining, only the original parts shall be used and pay attention to correct installation, and

the parts must be installed in their original position.

5.5.5 During unit operation, the temperature of some parts of the refrigerant circuit may exceed 70℃, so

that the untrained personnel shall not make bold to remove the protection panel of the unit.

5.5.6 Unit shall not be installed in the air containing explosive gases.

5.5.7 If the heat pump type unit operates under the condition below 0℃, it must be installed in a place

300mm higher than the ground, which can not only prevent the bottom plate from freezing, but also prevent

the accumulated snow from reaching this height to influence the unit's normal operation. The unit shall be

installed on a flat surface (the max. deviation of the ground level shall not exceed 2mm/m.)

HAIER CHILLER

10

water

side

heat

exchanger

thermostatic

expansion valve

liquid side

glass

filter drier

one way

valve

accumulator

water

inlet

hole

Cooling

Heating

Cooling

water

outlet

hole

air side heat

exchanger

compressor

gas-liquid

segregater

four-way

valve

water

outlet

hole

water

inlet

hole

water

side

heat

exchanger

air side heat

exchanger

gas-liquid

segregater

compressor

thermostatic

expansion valve

liquid side

glass

filter drier

accumulator

CA0100AANB

CA0100MANB

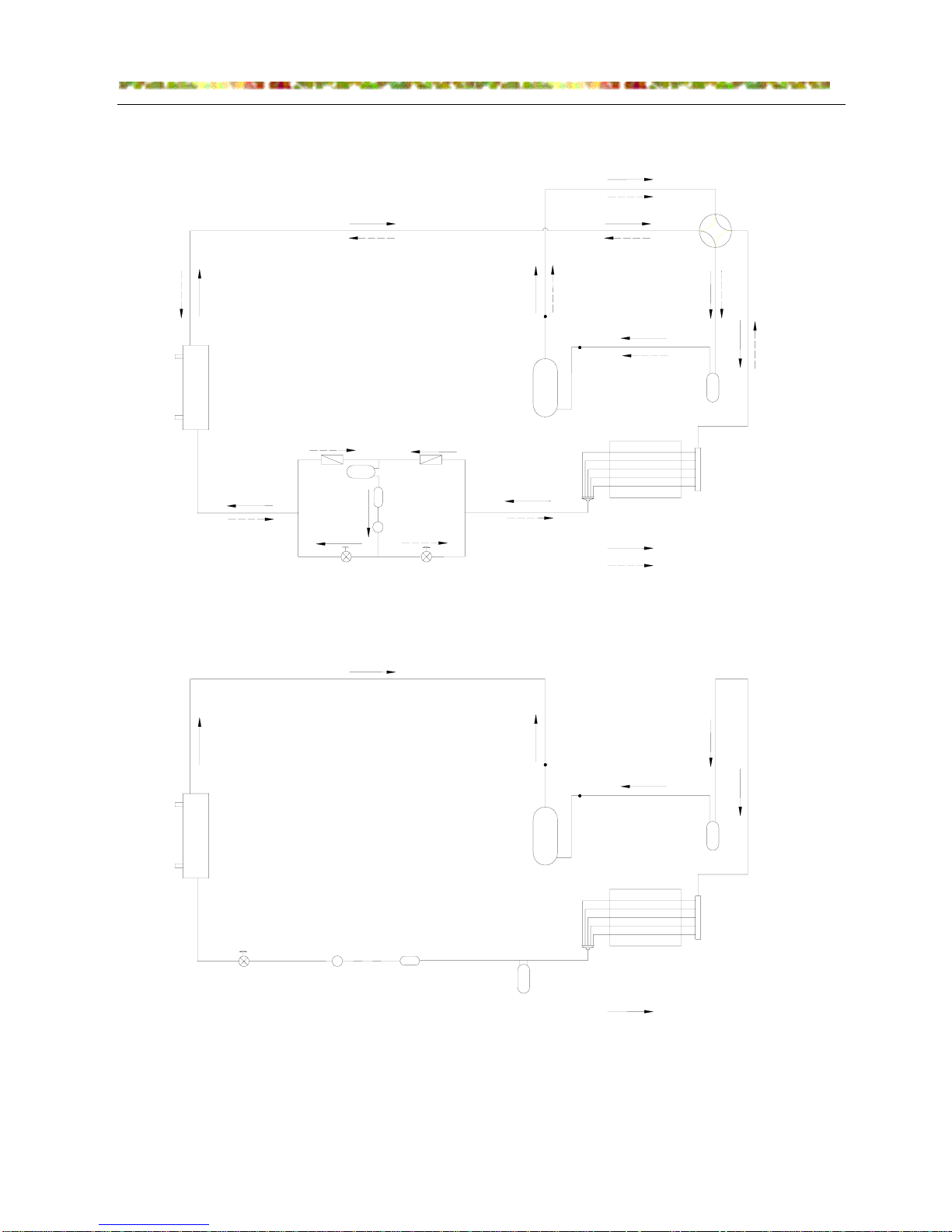

6. Refrigerant circuit

HAIER CHILLER

11

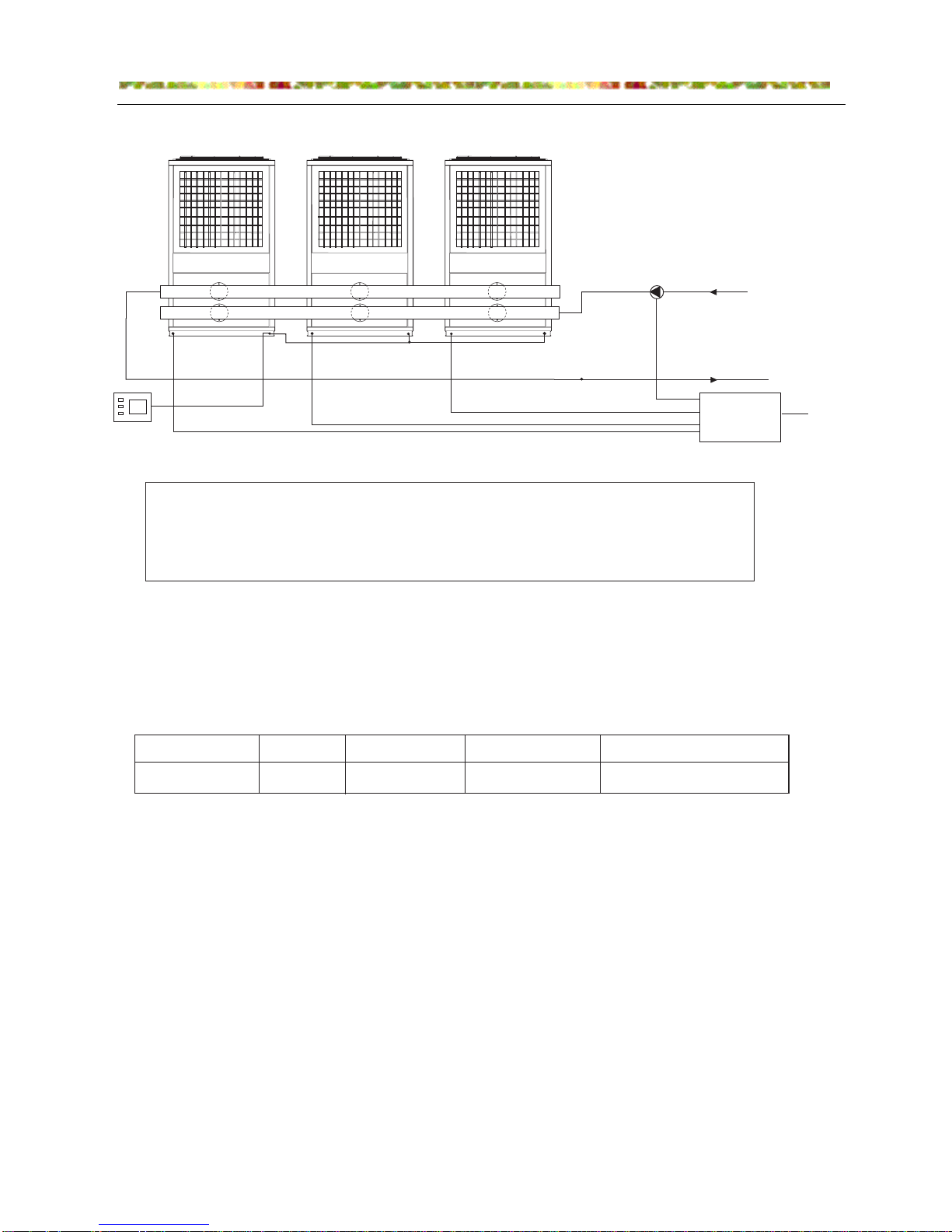

7. Water system installation diagram

6@=B8 D=D9

,CG9v

mj }@9K=6@9 <CF9 >C=BG nj .E9FFHE9 ;5H;9

oj 1CG5@ J5G9E E9GHEB F9BFCE =BFG5@@ D@579 pj 1<9EACA9G9E

qk mmk mqj 0GCD I5@I9 rj yLjD5FF I5@I9

sj -B9jJ5L I5@I9 tj }@9K=6@9 >C=BG

uj 35G9E .HAD mlj 35G9E FGE5=B9E

mnj 9@97GE=75@ J5G9E DEC79FFCE moj xHGC 8=F7<5E;=B; 5=E I5@I9 g<=;<9FG =B G<9 J5G9E FLFG9Ah

mpj |KD5BF=CB J5G9E G5B? mrj {E5=B I5@I9

J5G9E =B@9G

J5G9E

CHG@9G

8E5=B5;9

<C@9

CI9E:@CJ <C@9

mp

mo

mmmnmmmlmnu

msrq

pn

n

p

m

o

m

mr mq

19EA=B5@

rl

ml

69GJ99B pq jmoq

q

J5G9E FHDD@L

<C@9

3<9B 7=E7H@5G=CB J5G9E EHBF :CE G<9 :=EFG G=A9i 7@CF9 G<9 =B@9G 5B8 CHG@9G I5@I9 g,Ckqh5B8 CD9B G<9 6LjD5FF

I5@I9 g,Ckrhk 3<9B J5G9E DHAD JCE?F :CE 5 J<=@9i 7@95B G<9 J5G9E :=@G9E F7E99Bk 3<=@9 9BFHE=B; G<5G G<9E9 =F

BC =ADHE=GL =B G<9 9KG9EB5@ 7=E7H@5G=CB FLFG9Ai CD9B =B@9G 5B8 CHG@9G I5@I9 g,Ckqh5B8 7@CF9 G<9 6LjD5FF I5@I9

g,Ckrhk 1<9Bi G<9 HB=G =F =B BCEA5@ CD9E5G=CBk

,CG9v

J<9B G<9 =BFG5@@5G=CB =F CI9Ei G<9 GCG5@ J5G9E CHG@9G G9AD9E5GHE9 F9BFCE =B G<9 A5=B AC8H@9 AHFG 69 :=K98 CB

G<9 ;9B9E5@ J5G9E CHG@9G D=D9@=B9k .5L 5GG9BG=CB G<5G 5 F97G=CB C: 6@=B8 D=D9 gNti *wrlAAh 69 E9F9EI98 :CE

G<9 =BFG5@@5G=CB C: G9AD9E5GHE9 F9BFCE 8HE=B; F=G9 89F=;B 5B8 G<5G G<9 =BF9EG @9B;G< C: 6@=B8 D=D9 =F qlAAk

3<9B =BFG5@@=B; G<9 F9BFCEi D@579 G<9 F9BFCE 69B95G< G<9 6@=B8 D=D9 5B8 =B>97G FCA9 E9:E=;9EBGB C=@ =BGC G<9

6@=B8 D=D9k 1<9 @9I9@ C: G<9 E9:E=;9E5G=CB C=@ F<CH@8 69 5G @95FG mlAA CI9E G<9 F9BFCEk 1C A=B=A=M9 <95G GE5BF:9E

9EECEi =G =F B979FF5EL GC 58CDG G<9EA5@ =BFH@5G=CB A95FHE9Fk

35G9E 0LFG9A ~BFG5@@5G=CB {=5;E5A

{=5;E5A C: J5G9E D=D9 7CBB97G=CB 69GJ99B G<E99 HB=GF

HAIER CHILLER

12

CX\O;

1. The connecting wire of the unit only refer to the power wire for power supply and communication

control wire. The control wire in the electric box attached with the unit had been connected properly

before they left factroy, the user shall not change by themselves.

2. The working currents of the unit are shown in the following table, when wiring, it must to ensure the

unit can work normally.

1LD=75@ 3=E=B; 5B8 .=D9 zCBB97G=CB

+5FG9E +C8H@9

0@5I9jAC8H@9

35G9E ~B@9G

35G9E -HG@9G

.CJ9E

{=FGE=6HG=CB

yCK

3=E98 zCBGEC@@9E

0@5I9jAC8H@9

o

m

n

p

q

m

m

n

,CG9v

mk 2B=G .CJ9E 0HDD@L zCE8 pk 35G9E .HAD .CJ9E zCE8

nk +C8H@9j65F98 2B=G zCAAHB=75G=CB 3=E9 qk z56@9 GC 2B=G .CJ9E {=FGE=6HG=CB yCK

ok 2B=G -D9E5G=CB zCBGEC@@9E 3=E=B;

q4nqAA

n

gmolKohxrskqxqnkqx

/5G9 zHEE9BG +5K=AHA zHEE9BG *C7?98jECGCE zHEE9BG

/9:9E9B79 z56@9 097G=CB5@ xE95

2B=G +C89@

zxlmllxx,y

zxlmll+x,y

HAIER CHILLER

13

8. Wiring diagrams

a. The unit wiring diagram

HAIER CHILLER

0010452203 for CA0100AANB

K1

K2

K3

K4

K5

K6

K7

K8

K9

U1

U13

U2

U3

U4

U5

U6

U7

U8

U9

U10

U11

U12

14

HAIER CHILLER

15

b. The driving wiring diagram

c. The communication wiring diagram

9. Auxiliary electric heating function control

The auxiliary electric heating function will be performed in low ambient temperature. Connect the water

inlet/outlet pipe with auxiliary electric heater to the total water inlet/outlet pipe, in the electric control box of

the master module, there is the control port of auxiliary electric heating (only with 220V output, not supply

the electric heating control part).

10. Water pump operation control (valid when water pump and the unit controlled

simultaneously)

In the electric control box, there is the freezed water pump simultaneous control port (only with 220V

output, not supply the water pump control part). When the unit is in standby state, water pump will not start

up; when the unit enters working state from standby state, start up water pump firstly; when the unit enters

standby state from working state or stop state, 30seconds later, water pump will stop automatically. In stop

state, when water outlet temp. is no more than 3 degree and more than 2 degree, the water pump will start

up; when water outlet temp. is no more than 2 degree, start up one module in heating and stop until water

temp. arrives 8 degree.

slave

unit 15

slave

unit 1

master

circuit

breaker

circuit

breaker

circuit

breaker

12V

GND

A

A

B

GND

CN102A COMM

No.n slave

unit PCB

B

A

B

…

12V

B

GND

GND

A

No.1 slave

unit PCB

CN102A C OMM

A

B

B

A

12V

GND

main unit PCB

CN102A COMM

GND

MCU

HAIER CHILLER

16

11. The terminal simultaneous control

Connect the passive port of the terminal controller to the simultaneous control port in the controller of

the master module unit. When the unit is running and the controller is in simultaneous control state, when

one of terminal unit starts up, the chiller system will start up automatically. When all the terminal units stop,

the chiller system will stop later.

When in electric wiring, please pay attention to the following:

a. The wires are the power supply cable and the communication wire. The wires with the unit have been

fixed properly, and should not be modified by the user. Use four-core shield wire when install the

communication wire and earth one end of the shield layer. Do not put the communication wire and

high voltage wire together, or the communication error will occur.

b. The unit running current is as below table:

model Rated current Max. current Rocked current

Cable section for

reference

CA0100* 52.5A 67.5A (130*3)A 5*24mm

2

HAIER CHILLER

17

12. Wired controller functions

?Yb_[Qg bSaUU];

JQ]U[ TYb_[Qg

G^TU TYb_[Qg

>[^SZ TYb_[Qg

X^da \Y]dcU

MY\Ua bUccY]W TYb_[Qg

OXU] cXU Q__[YQ]SU Yb Y] bUQaSX ^a bUccY]W \^TU

Q]T cY\U _QaQ\UcUa ^_UaQcY^]- cXYb h^]U TYb_[Qgb

\^TU Q]T cY\U _QaQ\UcUa/

C

LG

>^TU TYb_[Qg

JQaQ\UcUa.bUccY]W Y]TYSQcY^]

AQd[c S^TU Y]TYSQcY^]

JQaQ\UcUa 0 VQd[c S^TU

KUbc^aQR[U VQd[c S^TU Y]TYSQcY^]

LUaY^db VQd[c Y]TYSQcY^]

MU\_UaQcdaU TYb_[Qg

C

LG

MY\U.bUccY]W TYb_[Qg

N]Yc ]d\RUa TYb_[QgY]W h^]U

EUg_QT ^V fYaUT S^]ca^[[Ua

MDG@K

>F>IE

MDG@ M@GJ

C@<M@K

GI?@

K@L@M

Idc_dc U`dY_\U]c TYb_[Qg

IJMDIHL

fQcUa _d\_

[^SZ

XUQcUa

5.fQg

eQ[eU

TUVa^bc

S^\_aUbb^a

^dcUa

VQ]

2

3

4

S^^[Y]W

XUQcY]W

6

7

3

6

9

5

2

7

4

8

5

8

9

HAIER CHILLER

18

Controller system is constituted by 1 to 16 HAC-F3S-H PCB and one or many MCU. parallel connect

each MCU when use many MCU.

There should be at least one main module PCB in the system, the address of which is 0000 and the No.

is 1#. From the module PCB can connect max. 15 and address can be setted from 0001 to 1111, set No.

from 2# to 15#. Each PCB must be setted address differently in the system.

Setting method of module number

1. Press the DOWN, M and T button.

2. Input the password (0000) to come into the program.

3. Press S button after you input four zero.

4. The LED will display six code(A, B, C, D, E, F). They stand for six kind of data.

A --- unfreeze data

B --- work temp

C --- protect

D --- work data

E --- password setting

F --- number module setting

5. Press UP or DOWN to choose F and S to confirm it.

6. You will see an “A” symbol.

7. Press DOWN button, “B” will be added. And repeat press DOWN, “C” will be added. Repeat this

process till A B C D E F displayed.

8. Press M button twice to quit the program.

9. The LED will display “---” after you quit the program and last 26 seconds or so. The program is

resetting during this period.

10. Start the chiller according to normal process

12.1 Operation and guidance

There are 11 Touch buttons on the control panel for On/Off operation, mode selection, parameter query,

Module PCB

(1#)

Module PCB

r(2#)

Module PCB

r(3#)

MCU

RS485

Module PCB

(4#)

Module PCB

(16#)

HAIER CHILLER

19

temperature setting, clock setting, timer setting, reset/dark. General layout of all touch buttons is illustrated

in the above diagram. Press valid button once or receive signal by remote control, LCD will display the

corresponding mode, backlight lightens, the buzzer gives a beep, and backlight is off 10 seconds later

automatically.

12.2 Control functions

1. Working mode: cooling → heating

2. Working method: auto running operation

3. Monitor type: real time monitoring (resumable fault, serious fault protection): query display (real

time temperature detection)

4. Intelligent operation when a sensor fault occurs.

5. LCD backlight (yellow/green light, blue light, white light)

6. Fault alarm

7. Remote receiving function (informed before being ordered)

8. Resumable fault protection

9. Serious fault protection.

12.3 Buttons operation instructions

12.3.1 Clock adjustment

Press [CLOCK] into the clock adjustment. Firstly the minute indicator flashes, which shows that you

can adjust clock by pressing [▲] and [▼] keys. Press [▲] once, the number is increased by 1, press time

key [▼] once, the number is decreased by 1. If pressing time [▲] and [▼] keys for a long time, the number

will increase and decrease automatically.

Press [CLOCK] again in the minute setting mode to enter hour setting mode.

Time adjustment can be cycled by pressing [CLOCK] key. If the controller is not operated within a fixed

period of time, it will quit time adjustment automatically.

12.3.2 Timer setting

Press [TIMER] to enter timer setting. Timer setting sequence is as follows: minute setting of TIMER ON,

hour setting of TIMER ON, minute setting of TIMER OFF, hour setting of TIMER OFF,

repeating/combination timer setting, cancellation of timer setting.

In the timer setting mode, the adjustment of [▲] and [▼] keys is as the same as clock adjustment.

12.3.3 On/Off operation

When unit is off, red indicator of controller lightens. Start up the unit by pressing [On/Off].

When unit is on, green indicator of controller lightens. Stop the unit by pressing [On/Off].

Caution: if the controller is used to set the interlink function of the indoor fan coil and the controller

receives no interlink signal, green indicator of controller will lighten when the appliance is working. If serious

faults are present, red indicator of controller will lighten.

HAIER CHILLER

20

12.3.4 Mode setting.

Press [MODE] to enter the mode setting. Controller recognizes controller mode automatically. Mode

setting cycles between cooling and heating.

12.3.5 Temperature-setting

When the unit is on, you can adjust controller to set temperature. Press the [▲] and [▼] keys, the

temperature will increase and decrease accordingly. The max and min temperature values are determined

by controller.

12.3.6 Fault query

When a fault occurs, symbol of “unit” glistens and also fault code displays in the fault code displaying

zone. Corresponding unit number also glistens at the interval of 2 seconds, press [query] key will display

fault code in the fault code displaying zone.

If there are several faults, press [▲] and [▼] key, you can see fault codes in turns.

12.3.7 Temperature query

Press the [QUERY] key, you can check temperatures and unit state. On normal condition, unit number

represents the running unit. Press the [QUERY] key, you can chose unit number that is activated, and the

chosen unit number glistens quickly at the intervals of 0.5 second.

When the unit is in query mode, press time key [▲] and [▼], you can see fault code in turn. Press

temperature key [▲] and [▼], you can see the temperatures of all units.

When the unit temperature is in query mode, the code of sensor from P01 to P08 is shown on the code

displaying zone, temperature displaying zone presents the corresponding temperature. The sensor that is

not equipped to the controller will not be displayed.

12.3.8 Output equipments status query

When the unit is in query mode, equipment output status will be shown on the controller.

12.4 Functions descriptions

12.4.1 System structure

A. single unit system

B. Multi units system: integrating an outdoor unit and several indoor units into a centralized controlling

system by RS-485 bus. The multi system use one water system; the outdoor unit controls interlinked

operation of system pump and other indoor units use the same water system. The master unit

harmonizes the whole system, and the slave units are consistent with the master unit. When the

working mode of the master unit changes, all slave units change accordingly. When the master unit is

off, all slave units can’t be turned on.

12.4.2 Unit number setting

The system is a central air conditioner controlling system consisting of one wired controller and 16

modules numbered from 1 to 16. Every controller panel is assigned with a different address according to

HAIER CHILLER

21

the number of system modules used. There is a dip switch which includes 4-digit set on the controlling

panel, according to which we can set the module number of unit. After the communication between a

module and the wired controller is established, there is one lighting dot representing it on the wired

controller.

Diagram of module code number:

Switch 1 Switch 2 Switch 3 Switch 4 Controller No.

OFF OFF OFF OFF Outdoor unit

OFF OFF OFF ON Indoor unit 1

OFF OFF ON OFF Indoor unit 2

OFF OFF ON ON Indoor unit 3

OFF ON OFF OFF Indoor unit 4

OFF ON OFF ON Indoor unit 5

OFF ON ON OFF

Indoor unit 6

OFF ON ON ON Indoor unit 7

ON OFF OFF OFF Indoor unit 8

ON OFF OFF ON Indoor unit 9

ON OFF ON OFF Indoor unit 10

ON OFF ON ON Indoor unit 11

ON ON OFF OFF Indoor unit 12

ON ON OFF ON Indoor unit 13

ON ON ON OFF Indoor unit 14

ON ON ON ON Indoor unit 15

Dip switch (TYPE ADDRESS) used to set the unit type

12.4.3 Operation modes:

Cooling, heating

12.4.4 Control functions

a. Indoor fan coil interlink function

When setting the indoor fan interlink, control panel detects On/Off mode of the interlink switch at

anytime. When one or more indoor fan coils open, interlink switch closes, the system is operates. When all

the indoor fan coils close, interlink switch is disconnected for 30s, the system stop working now. When the

interlink switch of one indoor fan closes and the indoor fan has been off for at least 3 minutes, the system

will restart.

Switch 1 Switch 2 Function name Function specification

ON ON Cooling only Cooling Only mode

OFF OFF Heat pump +electric heat Cooling, heating, auxiliary electric

heating

Caution: Type must be set according to requirements.

HAIER CHILLER

22

b. Timer On/Off

Timer on, timer off, cycling timer setting and combination timer setting can be chosen through wired

controller. Each combination timer setting is valid for within 24 hours and cycling timer setting is valid all the

time. The combination timer setting can be selected only when the code [SA09] is set as Off, and the

cycling timer setting can be selected only when the code [SA09] is set On.

c. Temperature sensor compensation

In some special cases, if the sensor lead is too long or the installation of indoor fan is limited by

installing space, the measured temperature of sensor needs compensation and correction. This function

can be achieved by revising code [PC01] and [PC08]. If one code is set as cancelled “---”, it means the

respective temperature sensor is cancelled. Corresponding function and protection function will be

cancelled as well.

d. Unit power-off memory

e. Fault alarm and query

f. Return water temperature, environment temperature and coil pipe temperature display and query.

g. Unit operating code set and reset

h. System clock set and display

i. Compressor operating average energy consumption

The system records the operation time of every compressor separately, those with a shorter operation

time will start first when the system starts, and those with a longer time will close first when the system

closes.

j. Defrosting options

12.4.5 Protection and safety

a. Over-load protection for cooling operation

The outdoor coil temp. will rise if the cooling load too high, when the temperature is higher than [EP02],

over-load protection will be activated.

b. Over-temperature protection for heating operation

When the system is in the process of heating, in order to avoid fault of inner coil pipe due to

over-temperature, if the return water temperature is higher than [EP04], over-temperature protection will be

activated.

c. Frost-proof in winter

In order to avoid circulated water being frozen in the winter, controller will protect the system.according

to code [EP07]. Controller has 2-level frost-proof protection, the Level 1 protection starts the circulating

pump, auxiliary electric heating at a fixed intervals. The Level 2 protection starts the heating system of

compressor to heat the circulated water.

d. Flow protection switch

HAIER CHILLER

23

When the there is no or litter water flow in the pipe, the switch will cuts off control circuit to close the

unit, protect the unit and compressor.

e. Overload protection of compressor

There is a crankcase-heater and a thermal overload relay equipped on the compressor.

Crankcase-heater can preheat the lubrication oil to make sure that the compressor is adequately lubricated.

Thermal overload relay can prevent damage of compressor.

12.5 Parameter-setting display and parameter-setting

12.5.1 Parameter display

When the appliance is operating or in standby mode, press “query” key to check the system temp.:

No. Parameter code Code number

1 P01 general return water temperature of the system

2 P02 Liquid pipe of 1# system

3 P03 Liquid pipe of 2# system

4 P04 Liquid pipe of 3# system

5 P05 Outdoor temperature

6 P06 1# coil pipe temperature

7 P07 2# coil pipe temperature

8 P08 3# coil pipe temperature

12.5.2 Parameter-setting method

When the appliance is off, pressing [query] key for 5 seconds until the wired controller gives a beep

then let it go to enter code-setting operation.

12.5.3 System function parameter selection

Parameter name Unit

number

Original

setup

ON OFF

Defrost option SA04 OFF Defrosting during

compressor operation

Defrosting at intervals of

compressor operation

Mode option SA07 OFF Operating mode can be

changed when the

appliance is in stand-by

mode or in operating

mode

Operating mode can not

be changed when the

appliance is in operating

mode

Power-failure

compensation

SA08 OFF Controller remains the

original mode set after the

power supply is restored.

Controller remains off after

the power supply is

restored.

Combination and

cycling timer

setting option

SA09 ON Cycling timer setting

(cycling every 24 hours)

Combination timer setting

(timer-setting is valid for

24 hours)

Interlink function SA10 OFF Terminal interlink is

allowed

Terminal interlink is not

allowed

12.5.4 Temperature sensor compensation parameter

HAIER CHILLER

24

Parameter name Unit number Original setup min max cancellation

General return water temperature PC01

0 ℃ -9 ℃ 9 ℃

(1)

1# liquid pipe temperature PC02

0 ℃ --9 ℃ 9 ℃

_ _

2# liquid pipe temperature PC03

0 ℃ --9 ℃ 9 ℃

_ _

3# liquid pipe temperature PC04

0 ℃ --9 ℃ 9 ℃

_ _

Outside environment temperature PC05

0 ℃ --9 ℃ 9 ℃

_ _

1# external pipe temperature PC06

0 ℃

--9

℃

9 ℃

_ _

2# external pipe temperature PC07

0 ℃

--9

℃

9 ℃

_ _

3# external pipe temperature PC08

0 ℃ --9 ℃ 9 ℃

_ _

12.5.5 System operating temperature parameter

Parameter name Unit number Original setup Max Min cancellation

Loading water return difference

temperature

SP01

2℃ 5℃ 1℃

Unloading water return difference

temperature

SP02

2℃ 5℃ 1℃

Cooling external circuit temperature SP05

15℃ 50℃ 0℃

- -

Heating external circuit temperature SP06

25℃ 50℃ 0℃

- -

12.5.6 System operating temperature parameter

Parameter name Unit number Original setup Max Min cancellation

Loading water return difference

temperature

SP01

2℃ 10℃ 1℃

Unloading water return difference

temperature

SP02

2℃ 10℃ 1℃

Electric-heating initiating water

return temperature

SP03

50℃ 70℃ 20℃

Cooling external circuit temperature SP05

15℃ 50℃ 0℃

Heating external circuit temperature SP06

25℃ 50℃ 0℃

12.5.7 System operating time parameter

Parameter name Unit

number

Original

setup

Max Min Cancellation

Interval between temperature

detections

SC01 10sec 120sec 1sec

Interval between start-ups SC02 30 sec 120sec 5sec

Interval between stops SC03 30 sec 120sec 5sec

Pre-start time of outdoor fan SC04 10 sec 60sec 1sec

Delayed stop time of outdoor fan SC05 5 sec 60sec 1sec

Backlight illumination time SC06 10sec 60sec 3sec _ _

LCD illumination time during

parameter searching

SC07 10sec 30sec 3sec

HAIER CHILLER

25

12.5.8 Protection temperature parameter

Name Unit

number

Original

setup

Max Min Cancellation

Cooling and frost-proof protection EP01 4°C 10°C -5°C _ _

Heating and over-temperature

protection

EP04 60°C 80°C 55°C _ _

Winter frost-proof protection EP07 3°C 8°C -2°C

12.5.9 Protection time parameter

Name Unit

number

Original

setup

Max Min Cancellation

Time of compressor startup protection EC01 3min 10 min 1 min

Time of compressor operating EC02 3min 10 min 1 min

Time of shielded low-side pressure

inspection

EC05 30sec 120

sec

0 sec

Protection duration EC06 3sec 10 sec 1 sec

Time of flow switch inspection EC07 10sec 60 sec 1 sec

12.5.10 Defrost parameter

Name Unit number Original setup max min Cancellation

Defrosting activating external

circuit temperature

HF01 8°C 20°C 0°C

Defrosting activating external and

external pipe conditions

HF02 8°C 20°C 1°C

Defrosting activating external pipe

temperature

HF03 -8°C 0°C -19°C

Defrosting deactivating external

pipe temperature

HF04 10°C 20°C 0°C

Defrosting activating time condition

(cumulative)

HF05 4min 90min 30min

Defrosting deactivating time

condition

HF06 8min 15min 2min

Caution: The factory settings should not be changed without authorization. The manufacturer will not be

responsible for any damages caused thereof.

12.6 Fault alarm and query

12.6.1 Fault parameter display and query

No. Description Fault

code

Solution Remarks

1 Transmission error Eo : 00 Unit stops Serious fault

2 Open/short circuit of general return water Eo : 01 Unit stops Serious fault

3 Main module phase sequence protection Eo : 03 Unit stops Serious fault

4 Main module flow protection Eo : 04 Unit stops Serious fault

5 1#compressor overload protection Er: 01 1#compressor stops Serious fault

6 2#compressor overload protection Er: 02 2#compressor stops Serious fault

HAIER CHILLER

26

7 3#compressor overload protection Er: 03 3#compressor stops Serious fault

8 1#system high pressure protection Er: 04 System 1 stops Serious fault

9 2#system high pressure protection Er: 05 System 2 stops Serious fault

10 3#system high pressure protection Er: 06 System 3 stops Serious fault

11 Secondary module flow protection Er: 07 Secondary module stops Serious fault

12 1#system low pressure protection Er: 11 System 1 stops Serious fault

13 2#system low pressure protection Er: 12 System 2 stops Serious fault

14 3#system low pressure protection Er: 13 System 3 stops Serious fault

15 Open/short circuit of temperature–sensing

circuit of liquid pipe 1

Er: 14 System 1 stops Serious fault

16 Open/short circuit of temperature–sensing

circuit of liquid pipe 2

Er: 15 System 2 stops Serious fault

17 Open/short circuit of temperature–sensing

circuit of liquid pipe 3

Er: 16 System 3 stops Serious fault

18 Outdoor fan overload protection Er: 17 Unit stops Serious fault

19 Secondary module phase sequence protection Er: 18 Secondary module stops Serious fault

20 Open/short circuit of temperature–sensing

circuit of coil pipe 1

Pr: 01 Defrosting without

inspection

Restorable

21 Open/short circuit of temperature–sensing

circuit of coil pipe 2

Pr: 02 Defrosting without

inspection

Restorable

22 Open/short circuit of temperature–sensing

circuit of coil pipe 3

Pr: 03 Defrosting without

inspection

Restorable

23 Cooling and frost-proof protection of 1 # system Pr: 04 Protective operating (no

maintenance needed)

Restorable

24 Cooling and frost-proof protection of 2 # system Pr: 05 Protective operating (no

maintenance needed)

Restorable

25 Cooling and frost-proof protection of 3 # system Pr: 06 Protective operating (no

maintenance needed)

Restorable

26 Open/short circuit of external circuit

temperature-sensing circuit

Po; 01 Defrosting without

inspection

Restorable

27 Frost-proof protection in winter Po; 06 Protective operating (no

maintenance needed)

Restorable

12.6.2 When a fault is present, controller gives an alarm and fault module number glistens. Pressing the

query key now can show the fault code and the fault can be resolved automatically.

12.6.3 After the fault is resolved, the indication of a serious fault will still display, only after pressing the

“reset/dark” key will the system return to operating condition before the fault occurred. As for restorable

faults, such as temperature sensor fault, when the fault is resolved, the unit restores automatically.

12.7 Main technical parameter

12.7.1 Running voltage

Transformer of controller: primary side 220V/AC second side ① 16V/AC

Frequency 50HZ second side ② 11.5V/AC

HAIER CHILLER

27

12.7.2 Operation condition

Operation ambient temp.: -10℃—+60℃

Preserved ambient temp.: -20℃—+70℃

Relative humidity: 40%—98%

12.7.3 Temp. sensor

System total return water temp. sensor: 3470-502±1%

System total outlet water temp. sensor: 3470-502±1%

Module outlet water temp. sensor: 3470-502±1%

Outdoor ambient temp. sensor: 3470-502±1%

1# outdoor coil temp. sensor: 3470-502±1%

2# outdoor coil temp. sensor: 3470-502±1%

3# outdoor coil temp. sensor: 3470-502±1%

12.7.4 Precise

Sample temp. precise of each sensor: ±1℃

Precise of temp. control: ±1℃

Timer error in 24 hours is less than 20 senconds

12.7.5 Communication distance

Max. communication distance between controllers: 1.2km

Max. distance when MCU use the power from PCB: 100m

Max. distance when MCU use the power from local: 1.2km

12.7.6 Power output

Compressor: 5A*3 (AC contactor is connected outside)

Outdoor fan motor: 5A (AC contactor is connected outside)

Four-way valve: 5A*3

Cooling(heating) water pump: 5A (AC contactor is connected outside)

Electric heater: 5A (AC contactor is connected outside)

12.8 Inspection before operation

1. Voltage is consistent with requirement; phase voltage and phase current are balaced.

2. Inspecting the power source connection, especially section of the power cord, earthing and

connecting terminal.

3. Water pipe must keep clean without impurities. At last, flush the pipe 2 or 3 times (bypassing the

system), make sure that all the impurities and oxides have been washed out.

4. make sure that water source has been connected properly, if the water pump is not subject to

interlock control, start water pump before starting the unit.

5. Check if the water circulating system works well, water system has enough water, and make sure

HAIER CHILLER

28

that there is no leakage and air bubbles.

12.9 Inspection of operation status

Please inspect the items as follows:

1. Temperature of water entering into the heat exchanger

2. Temperature of water returning from the heat exchanger

3. Flow rate at the exit of the heat exchanger

4. Operating current of compressor upon start-up or during stable operation

5. Operating current of fan upon start-up or during stable operation

When the appliance is in cooling process, please use a built-in spindle valve to inspect the saturated

temperature (related to pressure) in the working mode

Referring to the requirements as follows:

1. High pressure side: saturated temperature is about 15-18°C higher than the temperature at the inlet

of condenser.

2. Low pressure side: saturated temperature is about 5-7°C lower than temperature at the outlet of

condenser.

3. When the appliance is the heating process, the water temperature should not be high than 50°C.

12.10 Operating range:

Cooling Min Max

Outdoor temperature + 25°C. +50°C.

Return water temperature +7°C. +15°C.

Heating Min Max

Outdoor temperature -10°C. +25°C.

Water temperature at outlet +25°C. +55°C.

HAIER CHILLER

29

13. Control functions

13.1 Cooling mode

13.1.1 Enter cooling mode

Control the system total return water temp.: the setted temp. of cooling mode is 12℃;

Control the system total outlet water temp.: the setted temp. of cooling mode is 12℃;

13.1.2 Startup procedure in cooling condition

PCB will startup the unit as following procedure when PCB performs the start order from MCU, or more

than one terminal work in simultaneous control, or time of Timer ON reached.

a. Running lamp on the MCU changes from red to green;

b. Main control cooling(heating) water pump start, detect the water flow switch continually;

c. Module PCB upload or download by the determination of return water temp. or outlet water temp. after

the water flow switch working normally.

13.1.3 Stop procedure in cooling condition

PCB will stop the unit as following procedure when PCB performs the stop order from MCU, or all

terminals stop, or time of Timer OFF reached, or stops becuause of error.

a. Running lamp on the MCU changes from green to red;

b. Compressors ordinal stop, the interval time is 5 senconds;

c. Outdoor fan motor time-delay [SC05] close when all the compressors in module have closed;

d. Cooling(heating) water pump close 1 minute later.

13.1.4 Cooling temp. control procedure

MCU control the start/stop of compressor by comparing the total return or outlet water temp. T

tr/o of the

master module with the setting temp. T

s during cooling.

Control the system total return water temp.: the setted temp. of MCU is 10℃--25℃;

Control the system total outlet water temp.: the setted temp. of MCU is 5℃--25℃;

When T

tr/o≥Ts + [SP01], MCU enter upload area, compressor will begain cooling if it can meet the startup

protect time≥[EC01]; When T

tr/o<Ts, MCU enter download area, compressor will standby if it can meet the

startup protect time ≥ [EC02]; When T

s≥Ttr/o>Ts+[SP01], the compressor will keep its original state, there is

a setted difference temp. [SP01] to prevent compressor from conversing ON/OFF frequently; When

T

tr/o<Ts-[SP01], PCB entering Emergency stop area and all stop at the 5 senconds interval.

HAIER CHILLER

30

Fig. 14-1 Compreesor running diagram in cooling mode

13.1.5 Cooling (heating) water pump running regulation

Cooling (heating) water pump will startup when PCB working or protection in winter, the working of pump

is concerned with the state of water flow switch.

a. The water pump PCB detect water flow switch continually after the pump working for 10 seconds. If

water flow switch OFF, enter normal running state.

b. When pump has started for 10 seconds or during working, if the water flow switch of master module

keep opening for [EC07], all equipments of systerm will stop, [UNIT] will flash and display failure code

[Eo:04]. if the water flow switch of slave module keep opening for [EC07], all equipments of this module will

stop, the corresponding module No. will flash and display failure code [Eo:07].

13.1.6 Protection during cooling state

PCB will dectect the possible failure when working and manage accordingly under cooling mode.

a. Anti-freeze protection (failure code [Pr:07])

Start conditions for anti-freeze protection:

① Compressor works;

② Water outlet temp. T

ou<[EP01] and keeps for 1 minute.

When enter anti-freeze protection, the corresponding module No. will flash and display failure code

[Pr:07] on MCU, all compressors in the corresponding module will stop for protection.

Quit conditions for anti-freeze protection:

① Water outlet temp. T

ou≥[EP01]+3℃, failure disappear;

② Resume cooling after compressor meet the stop time of protection.

b. Temp. sensor failure protection

① When the system total return temp. sensor damage, the system [UNIT] will flash and display [Eo:01]

code, system will stop for protection;

② When the system total outlet temp. sensor damage, the system [UNIT] will flash and display [Eo:02]

code, module will stop for protection;

③ When the module total outlet temp. sensor damage, the corresponding module No. will flash and

OFF

ON

Compressor

state

Ts-[SP01] T

s

Ts+[SP01]

T

tr/o

Upload

area

Standby

area

Download

area

Emergency

stop area

HAIER CHILLER

31

display [Er:08] code, the corresponding module will stop for protection;

④ When the outdoor ambient temp. sensor damage, the system [UNIT] will flash and display [Po:01]

code;

⑤ When the condenser coil temp. sensor of No.1 module damage, the corresponding module No. will

flash and display [Pr:01] code;

⑥ When the condenser coil temp. sensor of No.2 module damage, the corresponding module No. will

flash and display [Pr:02] code;

⑦ When the condenser coil temp. sensor of No.3 module damage, the corresponding module No. will

flash and display [Pr:03] code;

13.2 Heating mode

13.2.1 Enter heating mode

Control the system total return water temp.: the setted temp. of heating mode is 40℃;

Control the system total outlet water temp.: the setted temp. of heating mode is 40℃;

13.2.2 Startup procedure in heating condition

PCB will startup the unit as following procedure when PCB performs the start order from MCU, or more

than one terminal work in simultaneous control, or time of Timer ON reached.

a. Running lamp on the MCU changes from red to green;

b. Main control cooling(heating) water pump start, detect the water flow switch continually;

c. The 4-way vlave will open and enter standby state after the water flow switch working normally.

d. Module PCB upload or download by the determination of return water temp. or outlet water temp. after

the water flow switch working normally.

13.2.3 Stop procedure in heating condition

PCB will stop the unit as following procedure when PCB performs the stop order from MCU, or all

terminals stop, or time of Timer OFF reached, or stops becuause of error.

a. Running lamp on the MCU changes from green to red;

b. Compressors ordinal stop, the interval time is 5 senconds;

c. Outdoor fan motor time-delay [SC05] close when all the compressors in module have closed;

d. Cooling(heating) water pump and 4-way valve close 1 minute later.

13.2.4 Heating temp. control procedure

MCU control the start/stop of compressor by comparing the total return or outlet water temp. T

tr/o of the

master module with the setting temp. T

s during heating.

Control the system total return water temp.: the setted temp. of MCU is 25℃--45℃;

Control the system total outlet water temp.: the setted temp. of MCU is 25℃--50℃;

When T

tr/o≤Ts - [SP01], MCU enter upload area, compressor will begain heating if it can meet the startup

protect time ≥ [EC01]; When T

tr/o>Ts, MCU enter download area, compressor will standby if it can meet the

HAIER CHILLER

32

startup protect time ≥ [EC02]; When Ts - [SP01] <Ttr/o≤Ts, the compressor will keep its original state, there is

a setted difference temp. [SP01] to prevent compressor from conversing ON/OFF frequently; When

T

tr/o>Ts+[SP02], PCB entering Emergency stop area.

Fig. 14-2 Compreesor running diagram in heating mode

13.2.5 Protection during heating state

PCB will dectect the possible failure when working and manage accordingly under heating mode.

a. Overheating protection (failure code [Pr:08])

Start conditions for overheating protection:

① If water outlet temp. of module T

ou rise, when Tou≥ [EP04], enter overheating protection;

② When enter overheating protection, the corresponding module No. will flash and display failure code

[Pr:08] on MCU, compressor and outdoor fan motor will stop, cooling (heating) water pump will keep

running and will stop when T

ou< [EP04]-4℃, compressor will begin heating according to the flow when the

start conditions of compressor are meeted.

b. Auxiliary electric heating procedure

Auxiliary electric heating will work when all the following conditions are meeted:

① Auxiliary electric heating has been allowed by MCU (electric heating is defaulted as working when unit

start);

② When select heat pump+ electric heating mode, outdoor ambient temp. T

oa<[EP06];

③ When select heat pump+ electric heating mode, T

s-Ttr/o>2℃.

Electric heating will stop if any condition as the following is meeted:

① Water outlet temp. sensor damage;

② The temp. of stop condition is meeted;

③ Overheating protection.

c. Temp. sensor failure protection

① When the system total return temp. sensor damage, the system [UNIT] will flash and display [Eo:01]

OFF

ON

Compressor

state

Upload

area

Standby

area

Download

area

Emergency

stop area

Ts-[SP01]

T

s

Ts+[SP02]

T

tr/o

HAIER CHILLER

33

code, system will stop for protection;

② When the system total outlet temp. sensor damage, the system [UNIT] will flash and display [Eo:02]

code, module will stop for protection;

③ When the module total outlet temp. sensor damage, the corresponding module No. will flash and

display [Er:08] code, the corresponding module will stop for protection;

④ When the outdoor ambient temp. sensor damage, the system [UNIT] will flash and display [Po:01]

code, cancel the enter condition of system defrost by outdoor ambient temp. sensor, system will enter

defrost by judging the coil temp. senor of condenser;

⑤ When condenser the coil temp. sensor of No.1 module damage, the corresponding module No. will

flash and display [Pr:01] code, cancel the enter condition of corresponding module defrost by outdoor

ambient temp. sensor, enter defrost as other modules;

⑥When the condenser coil temp. sensor of No.2 module damage, the corresponding module No. will

flash and display [Pr:02] code, cancel the enter condition of corresponding module defrost by outdoor

ambient temp. sensor, enter defrost as other modules;

⑦When the condenser coil temp. sensor of No.3 module damage, the corresponding module No. will

flash and display [Pr:03] code, cancel the enter condition of corresponding module defrost by outdoor

ambient temp. sensor, enter defrost as other modules.

Note: If all the condenser coil temp. sensors damage, defrost in timer defrost mode.

d. Anti-freeze protection in winter (failure code [Pr:06])

It is needed to use anti-freeze protection in winter to prevent heating or cooling water from freezing when

unit stops during winter, Start conditions for anti-freeze protection:

① The unit stops;

② When the system water total return temp. T

tr or system water total outlet temp. Ttou≤[EP07] +3℃,

enter anti-freeze protection, cooling (heating) water pump start, run for 5 minutes and then stop for 30

minutes. When T

tou≤[EP07], compressor enter heating mode, auxiliary electric heating will working.

When enter anti-freeze protection, system [UNIT] will flash and display failure code [Po:06] on MCU, quit

the protection when the following conditions are meeted:

① Air conditioner startup;

② When the system water total return temp. T

tr and system water total outlet temp. Ttou≥[EP07] +6℃,

quit anti-freeze protection;

③ water flow abnormal.

13.3 Defrost opertion

13.3.1 Start conditions for defrost

a. Compressor accumulative running time

The influence of outdoor ambient temp. can be selected to be considered or not when accumulate the

running time according to [PC04] and [HF01] parameters.

HAIER CHILLER

34

If the compressor accumulative running time over the setted value [HF05], one of the enter conditions is

meeted.

b. Temp. difference condition between outdoor coil and outdoor ambient temp.

Outdoor coil temp. T

oc will be lower than outdoor ambient temp. Toa for the heating operation of

compressor, if set [HF02] parameter, defrost can be started when Toa–Toc≥[HF02]. If [HF02] is setted

cancel, Outdoor coil temp. sensor and outdoor ambient temp. sensor are damage, this condition is

cancelled.

c. Outdoor coil temp. condition

Outdoor coil temp. condition is determined by [HF03] parameter. Deforst will not startup untill T

oc≤[HF03]

is meeted. If [HF02] and [HF03] are valid synchronously, enter defrost when both are meeted. If neither

[HF02] or [HF03] is cancelled or outdoor coil temp. sensor damage, enter defrost when time condition is

meeted.

13.3.2 Multi units defrost simultaneously

If one unit of the modules meet the above single unit deforst enter conditions, other units will enter defrost

together and ignore the coil temp. condition.

13.3.3 Quit conditions for defrost

After entering defrost, running at least 3 minutes, then judge if deforst can be quited according to the

transformation of compressor pressure, coil temp. and deforst time, deforst can be quited if any one of the

conditions is meeted.

a. Quit deforst when compressor in high pressure

When compressor defrost and cause pressure rise, after high pressure switch open, the unit will quit

defrost.

b. Outdoor coil temp.

When compressor defrost and cause outdoor coil temp. rise, when T

oc≥[HF04], the unit will quit defrost.

c. Time condition for quit deforst

[HF06] has been setted the longest time for deforsting, when deforst exceed the setted time [HF06],

deforst will quited no matter the outdoor coil has meeted the setted value [HF04] or not.

13.3.4 Quit condition for multi units defrost simultaneously

if there are other units defrost when one unit meet the quit conditions, the unit will stop and standby untill

all the units are quit seforst and then heating again.

13.3.5 Deforst procedure

[SA04] has setted two deforst procedure: when set [SA04] ON, compressor will change to defrost directly

without stop; when set [SA04] OFF, compressor will stop firstly and begain deforsting after 4-way valve has

conversed.

HAIER CHILLER

35

14 Maintenance

Note: Before performing any maintenance and repair to the unit, please cut off power

supply. Electricity leakage will cause body injury.

In order to exert the unit's performance fully, must pay attention to the following items:

a. Electric connection: The cables for communication must be shielded and protected by

means of single-end earthing. Wiring of communication cables together with power cables is

prohibited. the power supply provided should be within the compressor permitted range. Confirm

there is no wrong connection in terminals and the main panel of AC contact, etc. Confirm all the

electric connections are not loose; all the electric components (AC contactor and relay, etc.) are

connected firmly and safely. Especially pay attention to the condition of the connecting wire between

control components and electric control box and power cord. The power wire shall not be warped,

and the insulation cover shall not have cracks and cut. Check the energy consumption in starting and

operating the unit is in the permitted range.

b. Water system connection: confirm the water system does not leak water. If the unit has not been

used for a long period, it is necessary to open the drain valve of the water pump to empty the water pump,

tube pipe or shell pipe type heat exchanger and all the water in the pipes. If the ambient temperature

may drop below 0℃, it is more necessary to be done. If the water in the unit is not emptied, the main

switch of the power supply must keep close, and the unit is set in heating mode, thus it can prevent from

freezing by the heating temperature sensor. Do be careful when cleaning the filter

c. Cleaning of tube in tube (shell&tube) heat exchanger: when using the unit, for example,

when using hard water, sometimes it will produce dirty. In this condition, it is recommended to

install the filter to remove dirty. The heat exchanger shall use cleaning solution to be washed; the

solution can be weak acid solution, use pump to drive the cleaning solution in the heat exchanger.

In order to fulfill a better cleaning effect, the circulation flow speed of the acid solution shall be

1.5 times of normal water flow, if can use acid solution to wash the pipe in an opposite direction

again, the effect will be better. Finally, use a large amount of water to repeatedly wash the acid

solution clean. The unit shall be cleaned periodically, not until the unit is blocked. The cleaning

frequency is determined by the water quality being used, but generally, once a year is rather

reasonable.

d. Refrigerant circuit: Confirm the refrigerant and refrigerant oil does not leak from the

compressor. Check if the pressure in the high/low pressure side is normal. Check the inside cleanness

of the plate type heat exchanger by pressure drop.

e. Control: Check and the location of the total return water temperature sensor and the temperature

difference, and then make adjustments accordingly. Check the operation of all relays, high/low pressure

protection device and controls.

HAIER CHILLER

36

MAINTENANCE

a. Before replacing any component of the refrigeration circulation, make sure the refrigerant has been

evacuated from both the high side and the low side of the unit. The control elements of refrigeration system

are highly sensitive and they must be handled very carefully if a replacement is required. Make sure they

are not overheated during the welding process by protecting them with wet cloth. The parts should not be

exposed to the oxyacetylene flame directly.

b. If needing to replace the refrigerant of the unit, its quantity shall be in accordance with the data

on the nameplate. Before replacing, the previous gas must be released as empty as possible.

c. During operation, all the panels must be installed properly, including the panel on the control

box.

d. If it must cut the pipes of the refrigerant circuit, the pipe cuter must be used, do not use the

tools that will produce copper scraps. All the pipes of the refrigerant circuit are copper pipes special for

cooling.

HAIER CHILLER

Sincere Forever

Haier Group

Haier Industrial Park, No.1, Haier Road

266101, Qingdao, China

http://www.haier.com

Loading...

Loading...