Haier AU282XHBAA Schematic

SERVICE MANUAL

Commercial Air Conditioning

3HP fixed frequency free multi

AU282XHBAA

AF072XCBAA AS072XCBAA AE072XCBAA AB072XCBAA

AF092XCBAA AS092XCBAA AE092XCBAA AB092XCBAA

AF122XCBAA AS122XCBAA AE122XCBAA AB122XCBAA

AF142XCBAA AS142XCBAA AE142XCBAA AB142XCBAA

●

Features

●Auto-check function

●Auto –restart function (optional )

●Group control function

●Room card function for ceiling concealed type

●Weekly timer (optional)

●Variable Control modes

●The total capacity of indoor unit can be more than that of outdoor unit.

●With new environment friendly refrigerant R407C

HAIER GROUP

MANUAL CODE: SYJS-023-03 REV: 2 EDITION: 2005.03

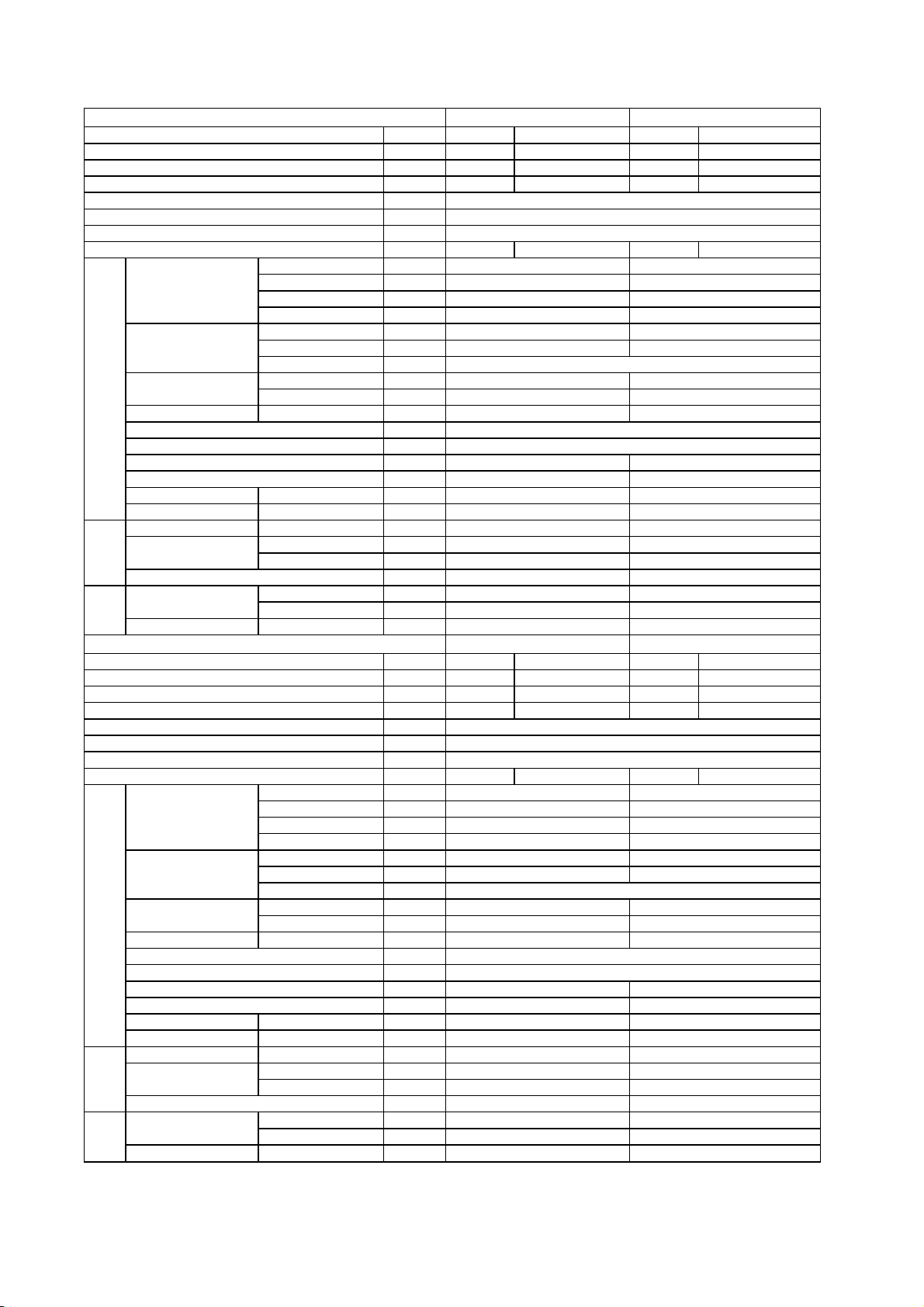

CONTENTS

CONTENTS

Contents

1. Description of products & features

2. Specification

3. Safety precaution

4. Net dimension of indoor and outdoor

5. Installation instructions

6. Parts and functions

7. Remote controller functions

8. Refrigerant diagram

9. Electrical control functions

10. Diagnostic information (trouble shooting)

11. Electrical data

12. Exploded view and parts lists

13. Performance curves

14. Noise level charts

15. Air velocity distribution

1.DESCRIPTION OF PRODUCTS & FEATURES

1.1. Products code explanation

A U 28 2 X H B A A

Climate type: T1 (see table 1)

Design number (A stands for design sequence,fixed frequency type)

Product type: A stands for heat pump type, refrigerant is R22

B stands for heat pump type, refrigerant is R407C

M stands for cool only type, refrigerant is R22

N stands for cool only type, refrigerant is R407C

Appearance character

Product series: X stands for 1 to 2, 1 to 3, 1 to 4

Applicable voltage: 2 stands for 220-240V/50Hz,

4 stands for 220V/60Hz,N stand for 380V/50Hz

Cooling / Heating capacity,28=28000BTU/h

Product type : “B” stands for cassette type, “C” stands for convertible

type, ”D” stands for duct, “S” stands for split type, ”Q” stands for chiller

system, "E" stands for ceiling concealed type, “U” stands for outdoor

unit

Air Conditioner

1.2 Brief Introduction for T1、T2、T3 working condition

Climate type

Type of Air

Conditioner

Cooling Only

Heat pump

Electricity Heating

T1 T2 T3

18 ℃~43℃ 10℃~35℃ 21℃~52℃

-7℃~43℃ -7℃~35℃ -7℃~52℃

~43℃ ~35℃ ~52℃

1.3 Operating Range of Air Conditioners

Temp. Mode Rated Maximum Minimum

Cooling

Heating

Indoor

Outdoor

Indoor

Outdoor

DB ℃

WB ℃

DB ℃

WB ℃

DB ℃

WB ℃

DB ℃

WB ℃

27 32 18

19 23 14

35 43 10

24 26 6

20 27 15

14.5 --- --

7 24 -7

6 18 ---

1.4 Product character

1.4.1 Operating individually and operating simultaneously

The unit can realize individual operation which can control one unit running, stop, and adjusting running

mode. Also the unit can operate simultaneously which control multi indoor units at the same time.

1.4.2 Variable quantity of indoor unitIf you want to add or reduce the quantity of indoor units (of course

the match must correspond with the design), it can meet your need at any time. More convenient, more

random.

1.4.3 Universal outdoor unit, multiform indoor unit

We realize universal outdoor unit, and 6 kinds of indoor unit, choose freely according to customer’s favor

and indoor decoration, more stylish and more beautiful

1.4.4 The total capacity of indoor unit can be more than that of outdoor unit.

When all the indoor units are running at the same time, the actual capacity of every indoor unit is

proportional according to outdoor capacity.

1.4.5 Long distribution pipe and high drop

The unit can realize long distribution pipe and high drop, the detailed information please refer to the

specification, consequently, the installation can be more free, and can meet various need of the

customer.

1.4.6 Ceiling concealed type unit be equipped with high efficiency filter, and its high static pressure

can be up to 30Pa, running more silent, making room air more comfortable and more clean.

1.4.7 The ceiling concealed type can realize the “Room Card” function, and take it convenient for

hotel management.

1.4.8 Auto-check function

The unit can display the malfunction codes on the control board by using advanced auto-check

technology ,convenient for user find and dwell with the abnormal running.

1.4.9 Auto –restart function (optional );

All indoor units have auto-restart function. When the power supply cut off suddenly, the unit will

automatically recover the previous running mode once the power supply is on.

1.4.10 Group control function

1.4.11 Weekly timer (optional)

1.4.12 Variable Control modes

Wired remote control ;

Remote control;

*Group control: a. With remote monitor function; b. Auto changeover function

2. SPECIFICATIONS

Item Model AU282XHBAA

Function

Capacity

Capacity

Total power input

Max. power input

EER or COP

Dehumidifying capacity

Power cable

Communication cable

Power source

Running / Max.Running current

Start current (system A / system B)

Fuse size (recommended size)

Compressor

Fan

Heat exchanger

Dimension

(L×W×H)

Drainage pipe material, diameter mm

Refrigerant control method

Defrosting method

Type of 4-way valve

Material of reduce noise

Crankcase heater power

Noise level H/M/L dB(A)

Weight Net / Shipping kg / kg

Refrigerant

Pipe

Connecting method

Piping

Between I.D &O.D

Model / Manufacture ——

Oil charge and type ——

Type ——

Number ——

Type × Number ——

Speed r/min

Motor output power W

Air-flows (H/M/L) m³/h

Type / Diameter mm

Total area m²

Temp. scope

External mm

Package mm

Type / Charge g

No need to recharge m

Recharge g/m

Liquid mm

Gas mm

Drop between IU & OU

Drop between indoor units

Piping length

Total length

——

BTU/h

W

W

W

W/W

10‐³×m³/h

——

——

N, V, Hz

A / A 15.0/17.0 14.0/16.0

A

A

℃

——

——

——

——

W

——

m

m

m

m

Cooling Heating

28000 32000

8200 9300

3400 3400

3900 3900

2.40 2.80

//

3 × 3.0mm

2

8x(0.75~1.25mm

1, 220~230, 50

35.0 / 35.0

30

PG260X2CS-4KT1 / TOSHIBA

720 CC (RB68AF/T68/α68TF)

Rotary (Fix speed)

2

Axial × 1

50 / 840+50 / 590+50

1000+

60

4000/3000/2000

TP2M / 9.52x0.35

0.77

cooling: 43~60 / heating: 6~7

948x340x830

1050x440x979

/

Capillary tube

Automatic

DPF-6

XPE

/

58/-/-

74/89

R407C / 1900 × 2

Piping length less than 5 meters in one system

35

Φ6.35

Φ12.7

Flared

≤5 (per way)

≤5 (per way)

≤10 (per way)

≤20 (2 ways)

2

)

* Long piping length and large drop between the indoor and outdoor unit (which exceeds standard value) will obviously reduce the capacity.

Item Model AS072XCBAA AS092XCBAA

Function

Capacity

Capacity

Dehumidifying capacity

Power cable

Communication cable

Power source

Running current

Fan

Heat exchanger

Dimension

(L×W×H)

Drainage pipe material, diameter mm

Controller type

Refrigerant control Capillary tube

Fresh air hole dimension /

Electricity Heater

Noise level H/M/L dB(A)

Weight Net / Shipping kg / kg

Refrigerant

Pipe

Piping

Connecting method

Type × Number ——

Speed r/min

Motor output power W

Air-flows (H/M/L) m³/h

Type / Diameter mm

Total area m²

Temp. scope

External mm

Package mm

Type ——

Liquid mm

Gas mm

——

BTU/h

W

10‐³×m³/h

——

——

N, V, Hz

A / A 0.10 0.10 0.10 0.10

℃

——

——

mm

——

——

Cooling Heating Cooling Heating

7000 8000 9000 10000

2000 2300 2600 2900

1.0 / 1.0 /

3 × (1.0~1.5mm2 )

2x(0.75~1.25mm2 )

1, 220~230, 50

CROSS×1 CROSS×1

900/800/700 900/800/700

25 25

400/350/300

400/350/300

TP2M / 6.35×0.7

about 0.15 about 0.15

cooling: 6~7 / heating: 43~60

795×197×265 795×197×265

863×304×330 863×304×330

PVC, 11.4/16.4

Phone type infrared

/

37/35/30 37/35/30

7.6/10.6 7.6/10.6

R407C

6.35

12.7

Flared

Item Model AS122XCBAA AS142XCBAA

Function

Capacity

Capacity

Dehumidifying capacity

Power cable

Communication cable

Power source

Running current

Fan

Heat exchanger

Dimension

(L×W×H)

Drainage pipe material, diameter mm

Controller type

Refrigerant control Capillary tube

Fresh air hole dimension /

Electricity Heater /

Noise level H/M/L dB(A)

Weight Net / Shipping kg / kg

Refrigerant

Pipe

Piping

Connecting method

Type × Number ——

Speed r/min

Motor output power W

Air-flows (H-M-L) m³/h

Type / Diameter mm

Total area m²

Temp. scope

External mm

Package mm

Type ——

Liquid mm

Gas mm

——

BTU/h

W

10‐³×m³/h

——

——

N, V, Hz

A / A 0.15 0.15 0.15 0.15

℃

——

——

mm

——

——

Cooling Heating Cooling Heating

12000 13000 14000 16000

3500 3900 4100 4600

1.6 / 1.6 /

3 × 0.75mm

2

2x(0.75~1.25mm2 )

1, 220~230, 50

CROSS×1 CROSS×1

1100/1000/900 1100/1000/900

25 25

550/500/450 550/500/450

TP2M / 6.35×0.7

about 0.20 about 0.20

cooling: 6~7 / heating: 43~60

795×197×265 795×197×265

863×304×330 863×304×330

PVC, 11.4/16.4

Phone type infrared

39/37/30 39/37/30

7.6/10.6

7.6/10.6

R407C

6.35

12.7

Flared

Item Model AF072XCBAA AF092XCBAA

Function

Capacity

Capacity

Dehumidifying capacity

Power cable

Communication cable

Power source

Running current

Fan CROSS × 2 CROSS × 2

Heat exchanger

Dimension

(L×W×H)

Drainage pipe material, diameter mm

Controller type

Refrigerant control

Fresh air hole dimension

Electricity Heater

Noise level H/M/L dB(A)

Weight Net / Shipping kg / kg

Refrigerant

Pipe 6.35 6.35

Piping

Connecting method

Type × Number ——

Speed r/min

Motor output power W

Air-flows (H/M/L) m³/h

Type / Diameter mm

Total area m²

Temp. scope

External mm

Package mm

Type ——

Liquid mm

Gas mm

——

BTU/h

W

10‐³×m³/h

——

——

N, V, Hz

A 0.25 0.25 0.25 0.25

℃

——

——

mm

——

——

Cooling Heating Cooling Heating

7000 8000 9000 10000

2000 2300 2600 2900

1.0 / 1.0 /

3 × (1.0~1.5mm2 )

2x(0.75~1.25mm2 )

1, 220~230, 50

900/800/700 900/800/700

50

500/450/400 500/450/400

TP2M / 7.94×0.35 TP2M / 7.94×0.35

about 0.25 about 0.25

50

cooling: 6~7 / heating: 43~60

720×205×630 720×205×630

780×280×690 780×280×690

PVC, 11.4/16.4 PVC, 11.4/16.4

Phone type infrared controller

Capillary tube

//

//

38/36/34 38/36/34

17/20.7 17/20.7

R407C R407C

12.7 12.7

Flared

Flared

Item Model AF122XCBAA AF142XCBAA

Function

Capacity

Capacity

Dehumidifying capacity

Power cable

Communication cable

Power source

Running current

Fan CROSS × 2 CROSS × 2

Heat exchanger TP2M / 7.94×0.35 TP2M / 7.94×0.35

Dimension

(L×W×H)

Drainage pipe material, diameter mm

Controller type

Refrigerant control

Fresh air hole dimension

Electricity Heater

Noise level H/M/L dB(A)

Weight Net / Shipping kg / kg

Refrigerant

Pipe 6.35 6.35

Piping

Connecting method

Type × Number ——

Speed r/min

Motor output power W

Air-flows (H/M/L) m³/h

Type / Diameter mm

Total area m²

Temp. scope

External mm

Package mm

Type ——

Liquid mm

Gas mm

——

BTU/h

W

10‐³×m³/h

——

——

N, V, Hz

A 0.25 0.25 0.25 0.25

℃

——

——

mm

——

——

Cooling Heating Cooling Heating

12000 13000 14000 16000

3500 3900 4100 4600

1.6 / 1.6 /

3 × 0.75mm

2

2x(0.75~1.25mm2 )

1, 220~230, 50

1100/1000/900 1100/1000/900

50 50

700/650/600 700/650/600

about 0.25 about 0.25

cooling: 6~7 / heating: 43~60

720×205×630 720×205×630

780×280×690 780×280×690

PVC, 11.4/16.4 PVC, 11.4/16.4

Phone type infrared controller

Capillary tube

//

//

38/36/34 38/36/34

17/20.7 17/20.7

R407C R407C

12.7 12.7

Flared Flared

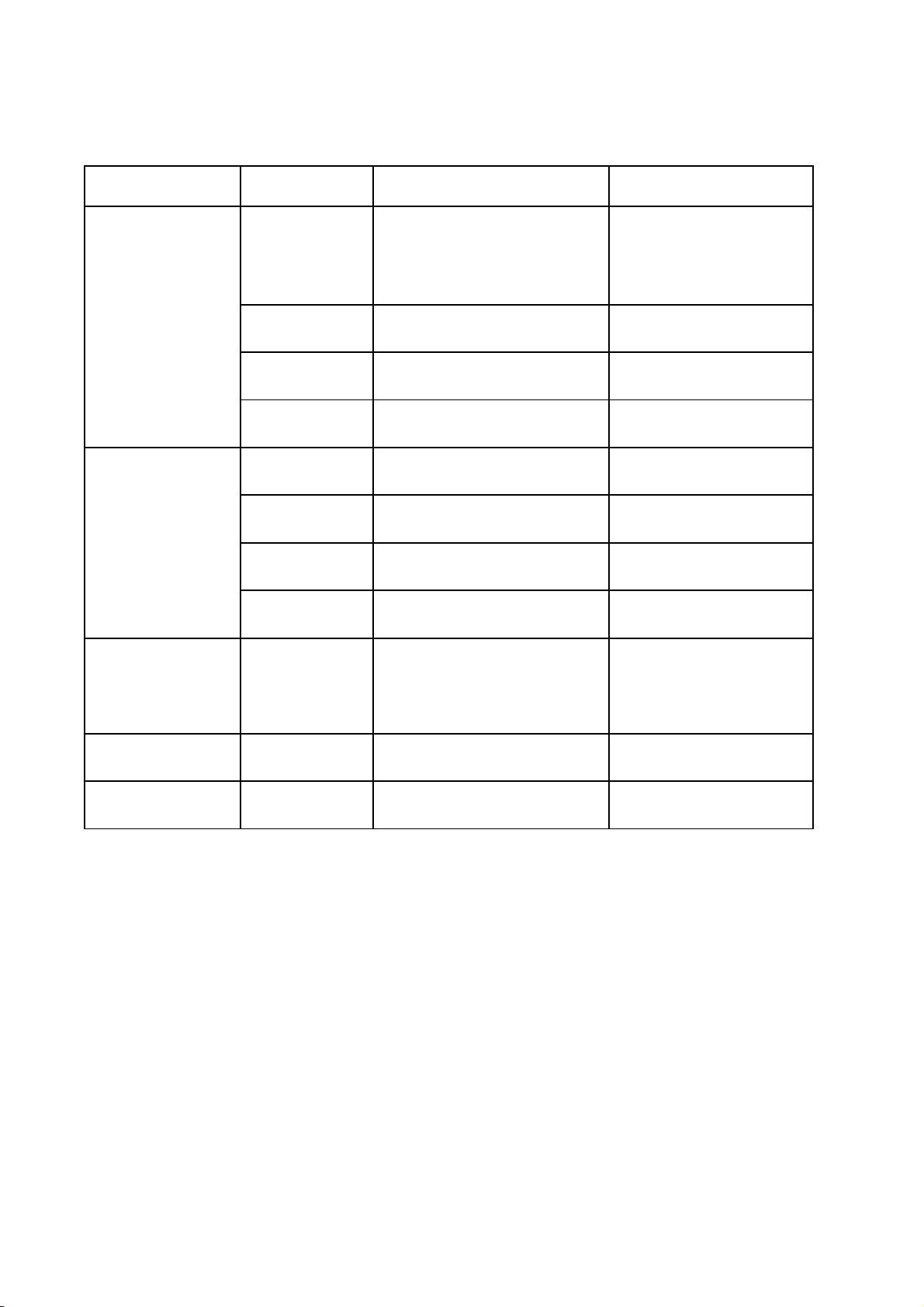

Item Model

Function

Capacity

Capacity

Dehumidifying capacity

Power cable

Communication cable

Power source

Running current

Fan CENTRIFUGAL × 1 CENTRIFUGAL × 1

Heat exchanger TP2M / 9.52×0.8

Dimension

(L×W×H)

Drainage pipe material, diameter mm

Controller type

Refrigerant control

Fresh air hole dimension

Electricity Heater

Noise level H/M/L dB(A)

Weight Net / Shipping kg / kg

Refrigerant

Pipe 6.35 6.35

Piping

Connecting method

Dimension

(L×W×H)

Panel

Weight Net / Shipping

Type × Number ——

Speed r/min

Motor output power W

Air-flows (H/M/L) m³/h

Type / Diameter mm

Total area m²

Temp. scope

External mm

Package mm

Type ——

Liquid mm

Gas mm

External mm

Package mm

——

BTU/h

W

10‐³×m³/h

——

——

N, V, Hz

A 0.20 0.20 0.20 0.20

℃

——

——

mm

——

——

kg / kg

Item Model

Function

Capacity

Capacity

Dehumidifying capacity

Power cable

Communication cable

Power source

Running current

Fan CENTRIFUGAL × 1

Heat exchanger TP2M / 9.52×0.8 TP2M / 9.52×0.8

Dimension

(L×W×H)

Drainage pipe material, diameter mm

Controller type

Refrigerant control

Fresh air hole dimension

Electricity Heater

Noise level H/M/L dB(A)

Weight Net / Shipping kg / kg

Refrigerant

Pipe 6.35 6.35

Piping

Connecting method

Dimension 630×630×80 630×630×80

Panel

Weight Net / Shipping

* o.d.=outer diameter; i.d.=inner diameter

Type × Number ——

Speed r/min

Motor output power W

Air-flows (H/M/L) m³/h

Type / Diameter mm

Total area m²

Temp. scope

External mm

Package mm

Type ——

Liquid mm

Gas mm

External mm

Package mm

——

BTU/h

W

10‐³×m³/h

——

——

N, V, Hz

A 0.20 0.20 0.20 0.20

℃

——

——

mm

——

——

kg / kg

AB072XCBAA AB092XCBAA

Cooling Heating Cooling Heating

7000 8000 9000 10000

2000 2300 2600 2900

1.0 / 1.0 /

3 × (1.0~1.5mm2 )

2x(0.75~1.25mm2 )

1, 220~230, 50

750/610/540 750/610/540

40 40

650/580/550 650/580/550

about 0.25 about 0.25

cooling: 6~7 / heating: 43~60

700×570×276

775×715×361 775×715×361

PVC, 32/26(o.d./I.d.*) PVC, 32/26(o.d./I.d.*)

Phone type infrared controller

Capillary tube

100 100

//

43/40/37 43/40/37

24/26 24/26

R407C R407C

12.7 12.7

Flared

630×630×80 630×630×80

680×680×155 680×680×155

4.2/6.3 4.2/6.3

AB122XCBAA AB142XCBAA

Cooling Heating Cooling Heating

12000 13000 14000 16000

3500 3900 4100 4600

1.6 / 1.6 /

3 × 0.75mm

2x(0.75~1.25mm2 )

1, 220~230, 50

750/610/540 750/610/540

40 40

650/580/550

about 0.25 about 0.25

cooling: 6~7 / heating: 43~60

700×570×276

775×715×361 775×715×361

PVC, 32/26(o.d./I.d.*) PVC, 32/26(o.d./I.d.*)

Phone type infrared controller

Capillary tube

100 100

//

43/40/37 43/40/37

26/28 26/28

R407C R407C

12.7

Flared Flared

680×680×155 680×680×155

4.2/6.3

2

CENTRIFUGAL × 1

TP2M / 9.52×0.8

700×570×276

Flared

650/580/550

700×570×276

12.7

4.2/6.3

Item Model AE072XCBAA AE092XCBAA

Function

Capacity

Capacity

Dehumidifying capacity

Power cable

Communication cable

Power source

Running current

Fan AXIAL× 1

Heat exchanger TP2M / 9.52×0.8 TP2M / 9.52×0.8

Dimension

(L×H×D)

Drainage hole Diameter mm

Controller type

Refrigerant control

Fresh air hole dimension

Electricity Heater

Noise level SH/H/M/L* dB(A)

Weight Net / Shipping kg / kg

Refrigerant

Pipe

Piping

Connecting method

Type × Number ——

Speed (SH/H/M/L*) r/min

Motor output power W

Air-flows (SH/H/M/L*) m³/h

Type / Diameter mm

Total area m²

Temp. scope

External mm

Package mm

Type ——

Liquid mm

Gas mm

——

BTU/h

W

10‐³×m³/h

——

——

N, V, Hz

A 0.68 0.68 0.68 0.68

℃

——

——

mm

——

——

Cooling Heating Cooling Heating

7000 8000 9000 10000

2000 2300 2600 2900

1.0 / 1.0 /

3 × (1.0~1.5mm2 )

2x(0.75~1.25mm2 )

1, 220~230, 50

AXIAL × 1

1310/1235/1120/885 1310/1235/1120/885

40 40

808/754/687/543

about 0.1 about 0.1

808/754/687/543

cooling: 6~7 / heating: 43~60

674*225*450

816*288*526 816*288*526

O.D.=20, I.D.=18

Wired controller

Capillary tube

100 100

//

43/38/35/32 43/38/35/32

18/20 18/20

R407C R407C

6.35 6.35

12.7 12.7

Flared Flared

674*225*450

Item Model AE122XCBAA AE142XCBAA

Function

Capacity

Capacity

Dehumidifying capacity

Power cable

Communication cable

Power source

Running current

Fan AXIAL× 1 AXIAL × 1

Heat exchanger TP2M / 9.52×0.8 TP2M / 9.52×0.8

Dimension

(L×H×D)

Drainage pipe material, diameter mm

Controller type

Refrigerant control

Fresh air hole dimension

Electricity Heater

Noise level SH/H/M/L* dB(A)

Weight Net / Shipping kg / kg

Refrigerant

Pipe 6.35 6.35

Piping

Connecting method

* SH/H/M/L: Super high/High/Medium/Low, the values are measured in the condition: external static pressure is 0Pa.

Type × Number ——

Speed (SH/H/M/L*) r/min

Motor output power W

Air-flows (SH/H/M/L*) m³/h

Type / Diameter mm

Total area m²

Temp. scope

External mm

Package mm

Type ——

Liquid mm

Gas mm

——

BTU/h

W

10‐³×m³/h

——

——

N, V, Hz

A 1.35 1.35 1.35 1.35

℃

——

——

mm

——

——

Cooling Heating Cooling Heating

12000 13000 14000 16000

3500 3900 4100 4600

1.6 / 1.6 /

3 × 0.75mm

2

2x(0.75~1.25mm2 )

1, 220~230, 50

1384/1350/1300/1230 1384/1350/1300/1230

50

1051/1007/985/930 1051/1007/985/930

about 0.12 about 0.13

50

cooling: 6~7 / heating: 43~60

828*225*450 828*225*450

976*288*526 976*288*526

O.D.=20, I.D.=18

Wired controller

Capillary tube

100 100

//

45/42/40/38 45/42/40/38

20/22 20/22

R407C R407C

12.7 12.7

Flared Flared

characteristic for sensors

model part number part name characteristic

1.R25=5KΩ±1%,

001A3900153 ambient temp sensor

AU282XHBAA

AU422XIBAA

AF- 001A3900059 coil temp sensor

AE- 001A3900006 gas pipe temp sensor

AB- 001A3900006 gas pipe temp sensor

0010450243 A system coil temp sensor

0010450398

0010451344

0010451343

0010450243 A system coil temp sensor

0010450398

0010451344

A system discharging temp

sensor

B system discharging temp

sensor

ambient temp sensor, B

system coil temp sensor

A system discharging temp

sensor

B system discharging temp

sensor

B25/50=3450K±1%

2.R25=5KΩ±1%,

B25/50=3450K±1%

R25=5KΩ±1%,

B25/50=3450K±1%

R80=50KΩ±3%,

B25/80=4450K±3%

R80=50KΩ±3%,

B25/80=4450K±3%

R25=5KΩ±1%,

B25/50=3450K±1%

R25=5KΩ±1%,

B25/50=3450K±1%

R80=50KΩ±3%,

B25/80=4450K±3%

R80=50KΩ±3%,

B25/80=4450K±3%

1.R25=10KΩ±3%,

B25/50=3700K±3%

2.R25=23KΩ±2.5%,

B25/50=4200K±3%

R25=10KΩ±3%,

B25/50=3700K±3%

R25=10KΩ±3%,

B25/50=3700K±3%

SAFETY PRECAUTIONS

3 SAFETY PRECAUTIONS

Please read these "Safety Precautions" first then accurately execute the installation work.

Though the precautionary points indicated herein are divided under two headings, and

those points which are related to the strong possibility of an installation done in error

CAUTION

resulting in death or serious injury are listed in the section. However, there is also a

possibility of serious consequences in relationship to the points listed in the section as well.

In either case, important safety related information is indicated, so by all means, properly observe all that is mentioned.

After completing the installation, along with confirming that no abnormalities were seen from the operation tests, please

explain operating methods as well as maintenance methods to the user (customer) of this equipment, based on the owner's

manual.

Moreover, ask the customer to keep this sheet together with the owner's manual.

WARNING

WARNING

CAUTION

WARNING

This system should be applied to places of office, restaurant, residence and the like. Appliaction to inferior

environment such as engineering shop could cause equipment malfunction.

Please entrust installation to either the company which sold you the equipment or to a professional contractor.

Defects from improper installations can be the cause of water leakage, electric shocks and fires.

Execute the installation accurately, based on following the installation manual. Again, improper installations can

result in water leakage, electric shocks and fires.

When a large air-conditioning system is installed to a small room, it is necessary to have a prior planned

countermeasure for the rare case of a refrigerant leakage, to prevent the exceeding of threshold concentration.

In regards to preparing this countermeasure, consult with the company from which you purchased the equipment,

and make the installation accordingly. In the rare event that a refrigerant leakage and exceeding of threshold

concentration does occur,there is the danger of a resultant oxygen deficiency accident.

For installation, confirm that the installation site can sufficiently support heavy weight. When strength is insufficient,

injury can result from a falling of the unit.

Execute the prescribed installation construction to prepare for earthquakes and the strong winds of typhoons and

hurricanes, etc. Improper installations can result in accidents due to a violent falling over of the unit.

For electrical work, please see that a licensed electrician executes the work while following the safety standards

related to electrical equipment, and local regulations as well as the installation instructions, and that only exclusive

use circuits are used.

Insufficient power source circuit capacity and defective installment execution can be the cause of electric shocks and

fires.

Accurately connect wiring using the proper cable, and insure that the external force of the cable is not conducted to

the terminal connection part, through properly securing it. Improper connection or securing can result in heat

generation or fire.

Take care that wiring does not rise upward, and accurately install the lid/service panel. Its improper installation can

also result in heat generation or fire.

- 10 -

SAFETY PRECAUTIONS

WARNING

When setting up or moving the location of the air conditioner, do not mix air etc. or anything other than the designated

refrigerant (please see nameplate) within the refrigeration cycle.

Rupture and injury caused by abnormal high pressure can result from such mixing.

Always use accessory parts and authorized parts for installation construction. Using parts not authorized by this

company can result in water leakage, electric shock, fire and refigerant leakage.

The position of indoor unit must be above the floor 2.5m.

CAUTION

Execute proper grounding. Do not connect the ground wire to a gas pipe, water pipe, lightening rod or a telephone

ground wire.

Improper placement of ground wires can result in electric shock.

The installation of an earth leakage breaker is necessary depending on the established location of the unit. Not

installing an earth leakage breaker may result in electric shock.

Do not install the unit where there is a concern about leakage of combustible gas.

The rare event of leaked gas collecting around the unit could result in an outbreak of fire.

For the drain pipe, follow the installation manual to insure that it allows proper drainage and thermally insulate it to

prevent condensation. Inadequate plumbing can result in water leakage and water damage to interior items.

- 11 -

4. Net dimension of indoor and outdoor

4.1 Outdoor unit: AU282XHBAA

340

830

380

416

>600

185

580

950

1024

>100

>100

>150

>600

4.2 Indoor units

Model: CONSOLE TYPE

Model: WALL MOUNTED TYPE

440

783

225

model

Haier

a

b

c

a

b

c

AS072XCBAA AS092XCBAA

AS122XCBAA AS142XCBAA

795

265

182

Model: CASSETTE TYPE

Model: CEILING CONCEALED TYPE

UPDATED

e

d

f

g

Installation dimension: (Unit: mm)

TYPE

AE072XCBAA,

AE122XCBAA,

AE212XCBAA

AE092XCBAA

AE142XCBAA

c

b

a

a b c d e f g i

615

770

1064

648

804 225

1099

452

452

452

225

225

55

55

55

125

225

125

225

225 100

125

i

100

100

The unit capacity and performance mode:

(A stands for A system, B stands for B system. For testing result, we will not recommend 12000BTU/h unit to you)

AU282XHBAA+072XCBAA*4 as followings:

A:

AF072*1

cooling

heating

Performance mode

Nominal capacity(BTU/h) 12000 12000 14000 14000 28000

Rated power input(W): 1550 1550 1550 1550 3100

Rated current(A) 7.5 7.5 7.5 7.5 15.0

Nominal capacity(BTU/H) 9000 9000 16000 16000 32000

Rated power input(W): 1800 1800 1500 1500 3000

Rated current(A) 9.0 9.0 7.0 7.0 14.0

AS072*1

AB072*1

AE072*1

AU282XHBAA+092XCBAA*4 as followings:

A:

AF092*1

cooling

heating

Performance mode

Nominal capacity(BTU/h) 12000 12000 14000 14000 28000

Rated power input(W): 1550 1550 1550 1550 3100

Rated current(A) 7.5 7.5 7.5 7.5 15.0

Nominal capacity(BTU/H) 9000 9000 16000 16000 32000

Rated power input(W): 1800 1800 1500 1500 3000

Rated current(A) 9.0 9.0 7.0 7.0 14.0

AS092*1

AB092*1

AE092*1

AU282XHBAA+07XCBAA*2+14XCBAA*1

B:

AF072*1

AS072*1

AB072*1

AE072*1

B:

AF092*1

AS092*1

AB092*1

AE092*1

A:

AF072*2

AS072*2

AB072*2

AE072*2

A:

AF092*2

AS092*2

AB092*2

AE092*2

B:

AF072*2

AS072*2

AB072*2

AE072*2

B:

AF092*2

AS092*2

AB092*2

AE092*2

A:

AF072*2

AS072*2

AB072*2

AE072*2

A:

AF092*2

AS092*2

AB092*2

AE092*2

B:

AF072*2

AS072*2

AB072*2

AE072*2

B:

AF092*2

AS092*2

AB092*2

AE092*2

cooling

heating

A:

AF072*1

Performance mode

Nominal capacity(BTU/h) 12000 14000 14000 28000

Rated power input(W): 1550 1550 1550 3100

Rated current(A) 7.5 7.5 7.5 15.0

Nominal capacity(BTU/H) 9000 16000 16000 32000

Rated power input(W): 1800 1500 1500 3000

Rated current(A) 9.0 7.0 7.0 14.0

AS072*1

AB072*1

AE072*1

B:

AF142*1

AS142*1

AB142*1

AE142*1

A:

AF072*2

AS072*2

AB072*2

AE072*2

A:

AF072*2

AS072*2

AB072*2

AE072*2

B:

AF142*1

AS142*1

AB142*1

AE142*1

AU282XHBAA+09XCBAA*2+14XCBAA*1

cooling

heating

A:

AF092*1

Performance mode

Nominal capacity(BTU/h) 12000 14000 14000 28000

Rated power input(W): 1550 1550 1550 3100

Rated current(A) 7.5 7.5 7.5 15.0

Nominal capacity(BTU/H) 9000 16000 16000 32000

Rated power input(W): 1800 1500 1500 3000

Rated current(A) 9.0 7.0 7.0 14.0

AS092*1

AB092*1

AE092*1

B:

AF142*1

AS142*1

AB142*1

AE142*1

A:

AF092*2

AS092*2

AB092*2

AE092*2

AU282XHBAA+142XCBAA*2 as followings:

A:

cooling

heating

AF142*1

Performance mode

Nominal capacity(BTU/h) 14000 14000

Rated power input(W): 1550 1550

Rated current(A) 7.5 7.5

Nominal capacity(BTU/H) 16000 16000

Rated power input(W): 1500 1500

Rated current(A) 7.0 7.0

AS142*1

AB142*1

AE142*1

AF142*1

AS142*1

AB142*1

AE142*1

Must pay special attention to the match style, to see the following table:

A to 2 B to 2 A to 1 B to 1

072XCBAA*2 072XCBAA *2

142XCBAA *1 142XCBAA *1

092XCBAA*2 092XCBAA*2

Pipe connections:

AF092*2

AS092*2

AB092*2

AE092*2

B:

A:

B:

AF142*1

AS142*1

AB142*1

AE142*1

1 TO 4

Outdoor unit

A1

A2

B1

B2

A1

A2

Indoor units

B1

B2

1 TO 3

Outdoor unit

A1

A2

B1

B2

1 TO 2

Outdoor unit

Indoor units

A1

A2

Indoor units

B1

A1 B1

A1

A2

B1

B2

Admissible pipe length and drop between the units:

a. Max. single distance piping length of unit A 1、unit A2 、unit AB1、unit B2: 25m;

b. Max. drop between A1 unit and A2 unit、B1unit and B2 unit:5m;

Refrigerant recharge:

Distribute pipes for unit A1、unit A2、unit B1、 unit B2 are supplied 5m as standard, if it is longer than 5m,

recharge refrigerant as 35g/m.

Communication Wire connection:

1. The indoor unit whose liquid pipe is connected to A1 in A system is called unit A1, its communication wire

of A1(3)、 A1(4) should be connected to A1(P)、A1(Q) respectively.

2. The indoor unit whose liquid pipe is connected to A2 in A system is called unit A2, its communication wire

of A2(3) 、A2(4) should be connected to A2(P)、A2(Q) respectively.

3. The indoor unit whose liquid pipe is connected to B1 in B system is called unit B1, its communication wire

of B1(3) 、B1(4) should be connected to B1(P)、B1(Q) respectively.

4. The indoor unit whose liquid pipe is connected to B2 in B system is called unit B2, its communication wire

of B2(3) 、B2(4) should be connected to B2(P)、B2(Q) respectively.

Note: Because the customers themselves match the communication wire, and the P and Q are

nonpolar, the customers must use shielded communication wires.

ky*r{ pnovr nxq pyxxrp}uxs pnovrg

jy{ fbbbhlmat ,cehlmat ~xu}|g

XW[QY PNOTQ

>/5GC,<62= 0-4UU

jy{ wy{r }tnx dcbbbhlmat ~xu}|g

XW[QY PNOTQ

>/5GC,<62= 1-/UU

iyxxrp}uxs *u{uxs quns{nwg

jy{ pn||r}}r nxq q~p}` pyx|yvr }+zr ~xu}|g

DJI:DDG JC?I

I;GB?C?7A 8AD9@

?C:DDG JC?I

I;GB?C?7A 8AD9@

PWVVQPZSVR PNOTQ

1

>/3GC,< 6/-54UU1\1

PWVVQPZSVR PNOTQ

1

>/3GC,< 6/-54UU1\1

AC

L8

M.=

EDL;G HJEEAM6

0E>+11/,12/K^+4/>]

0123

M.=

70 71 80 81

EFEFEFEF

M.=

0123

M.=

0123

EDL;G HJEEAM6

0E>+11/,12/K^+4/>]

0123

M.=

M.=

jy{ *nvv }+zr ~xu}|g

DJI:DDG JC?I

I;GB?C?7A 8AD9@

?C:DDG JC?I

I;GB?C?7A 8AD9@

AC

L8

M.=

EDL;G HJEEAM6

0E>+11/,12/K^+4/>]

32 10

EDL;G HJEEAM6

0E>+11/,12/K^+4/>]

M.=

EDL;G HJEEAM6

0E>+11/,12/K^+4/>]

EDL;G HJEEAM6

0E>+11/,12/K^+4/>]

70 71 80 81

EFEFEFEF

32 10

M.=

EDL;G HJEEAM6

0E>+11/,12/K^+4/>]

M.=

EDL;G HJEEAM6

0E>+11/,12/K^+4/>]

32 10

EDL;G HJEEAM6

0E>+11/,12/K^+4/>]

32 10

EDL;G HJEEAM6

0E>+11/,12/K^+4/>]

M.=

M.=

5. Installation

Installation diagram of indoor & outdoor unit

Outdoor unit

Piping data.

Gas pipe mm 12.7

L1 m Suggest 10m Max. :30m

Pipe length of one way L2 m Suggest 10m Max. :25m

L3 m Suggest 10m Max. :25m

Drop between indoor Indoor unit up m Suggest 5m Max. :15m

and outdoor unit Indoor unit down m Suggest 5m Max. :10m

No need to recharge: when piping length of one way is less than 5 meters.

1

L1 means the piping length when the system only connects with one indoor unit.

2

L2, L3 means the piping length when the system connects with 2 indoor units.

3

Long piping length and large drop between indoor unit and outdoor unit will reduce the

performance capacity obviously.

A 2

L1

AS142

L2

B 1

B 2

AS072

AS092

3

3

3

3

3

L3

1

2

2

Installation tools

1. Screw

2. Steel saw

3. Drill (70mm dia.)

4. Spanner [17, 27mm dia.]

5. Spanner [14, 17, 19, 27mm]

6. Pipe cutter

7. Flarer

8. Knife

9. Pliers

10. Leakage detector or soap water

11. Tape measure

12. Scraping knife

13. Refrigerant oil

14. Vacuum pump

15. Nitrogen tank

Standard accessories

The following parts mentioned

in this instruction is optional.

The following are accessories attached with the unit,

they can be used with the need of installation

Shape, name

Rubber cushion

Quantity Remarks

4

1

1

Mark

,

Parts name

A B C D E F

Adhesive

tape

Pipe supporting

plate

Connection pipe

Drain hose

Insulation material

Powder

5. Installation

Installation instruction

Before installing, do read this Safety precautions carefully to guarantee the proper installation.

The below attentive matters are divided into Warning and Note two parts. When the

wrong installation occur, it is very possible death and severe injury and other serious accidents will

happen. For those items are listed in Warning part. But even the items listed in Note

part can also cause serious accidents. Above all, both the two parts are very important contents

related to safety, so they must be obeyed.

After finishing the installation work, do test run to verify everything is normal. After that please

explain the using and maintenance methods to the user. Additionally, give this installation manual

and operation manual to the user and ask them to keep it properly.

!

The distributing shop, where you bought the air conditioner, or the specified shops shall do the

installation work. If you do the installation work by yourself, the improper installation will cause

water leakage, electric shock fire and other accidents.

The installation work shall be in line with what the installation manual specified. If installation

is not proper, water leakage, electric shock, fire and other accidents will occur.

Install the air conditioner to a place where can definitely stand its weight. Places not firm enough

will cause drop down of unit resulting in body hurt.

The installation work shall be preventive to typhoon and earthquake. If the installation work is

not met with the requirements, overturn of the unit will occur resulting in accidents.

The wiring work shall be done by a qualified person and referred to the technical standard of

electric equipment , indoor wiring regulation and what the manual specified. Do use

special circuit. If the capacity of the circuit is not enough or bad work, electric shock, fire and other

accidents will happen.

Using the specified cable to do wiring work and connecting firmly and properly. Fix the connecting

part of the terminals to prevent it from the external force.Improper connection and fixing will cause

heating and fire etc. accidents.

Wiring shall be kept in correct shape avoiding extrusion. After installation, the electric box cover

and the external panel shall not nip the wire. Improper installation will cause heating and fire etc.

accidents.

When setting or moving the air conditioner do not let the air and things alike get into the

refrigeration system except the specified refrigerant (R407C). If air and other things enter

abnormal high pressure will occur, which easily cause break and body injuries etc. accidents.

When installing, do use the accessories or specified parts. If not using the parts specified by our

company, water leakage, electric shock, fire and refrigerant leakage will occur.

Do not lead the drainpipe to drain where the sulfur gas may be involved. Otherwise, the poisonous

gas will enter into the indoor.

During installation, if refrigerant leakage occurs, do the ventilation work immediately. As soon as

the refrigerant gas meets fire, poisonous gas will be produce. If the refrigerant gas enters into room

and meet the air blowing heater, heater or stove etc. fire source, the poisonous gas may be produced.

After installation, confirm there is no leakage of refrigerant.

Do not install the unit in a place where the combustible gas may be leaked. In any case the

combustible gas leaks and accumulated around the unit, fire accident will occur.

Do heat insulation work to the refrigerant gas pipes and liquid pipes to reach the purpose of heat

preservation. If the heat insulation measure is not sufficient, water generated by condensing dew

will drip leading to wet the floor and indoor articles.

!

!

Warning

!

!

!

Note

Do grounding work.Do not connect the grounding wire to gas pipe,tap,lighting rod or telephone

line.Improper grounding will cause electric shock.

After electric installation,power on them to do electric leakage test.

In some places the creepage breaker shall be installed.If do not install the breaker, electric shock

may occur.

Installation of outdoor unit

Choosing of installation position

Installation position

Do not install the air

conditioner near to a

place where flammable

gas may leak.

Explosion may be caused

(fire)

Choose a place where the

cold/heat air or noise may

not disturb the neighbors.

Install the air conditioner in a

place where good ventilation

can be guaranteed.

If there are some obstacles,

it may lower the working

power of the unit or

increase noise.

It is deadly necessary to

prevent from accumulation

of snow near the outdoor

unit to keep it away from

being blocked by

accumulated snow.

Install the air conditioner on base

that can definitely support the weight

of the unit.

Otherwise, vibration or noise may

be caused.

The following special places are not

suitable to install air conditioner,

otherwise, trouble may be caused.

When you install the air conditioner

in these places, please consult with

the distributor.

Places generate corrosive gas

(hotspring area, etc.)

Places blow salt air (seaside, etc.)

Places have heavy soot.

Places have very high humidity.

Places near an electromagnetic

wave generator.

Places with large voltage fluctuation.

Installation fixation

1. According to dimonsion shown in the following figure,

fix the installation bracket tightly in the chosen

installation area.

2. Then use screws to fix the outdoor unit on the

installation bracket.

380

190 190

Installation dimension of outdoor unit (mm)

580

Over 60cm

>10cm

>10cm

Outdoor unit

>15cm

>60cm

Installation procedure Connection of pipes

Warning

!

During installation, if refrigerant leakage

occurs, take ventilation measurement

immediately.

As soon as the leaked refrigerant gas

meets f re, poisonous gas will generate.i

After finishing installation, confirm the

refrigerant gas does not leak.

If the refrigerant gas leaks in the room,

once it meets heater, burner and gas

stove or other. fire source, the poisonous

gas will generate.

I. Connection of pipes

1 Method of pipe connection

The pipe shall be as short as possible to guarantee efficiency.

Daub the refrigerant oil on the connection and flare nut.

When bending the pipes, give the roundness as large as possible, to avoid crashing the

pipes.

To connect the pipe, fit the center and screw the nut with hand, then use spanner or

torque wrench to tighten it. The fastening torque as shown in below table. As shown in

figure.

Be careful alien matters, such as sands, water etc.shall not enter the pipes.

Forced fastening without careful

centring may damage the threads

and cause gas leakage.

Using the specified fastening torque to fasten nuts.

Pipe diameter(mm)

6.35

12.7

Installation torque(N.m)

11.8(1.2kgf.m)

49.0(5.0kgf.m)

Spanner

Spanner

Joint

Nut

Fastening torque(N.m)

13.7(1.4kgf.m)

53.9(5.5kgf.m)

Installation procedure Connection of pipe

2.Method of cutting and flaring pipe

Cut and flare pipe

Use pipe cutter to cut the pipe, the burrs must be removed.

After inserting the flarer, perform flared nut.

Flaring pipes.

A

Flarer

Correct

Slant

When joint connecting, no gap shall

be left in the joint, the insulating

material shall be overlapped.

Break Crack

150

Diameter of pipe

6.35mm(1/4")

12.70mm(1/2")

Uncorrect

Branch pipe

Insulating material

Partial

Dimension

(mm)

A

0.8~1.5

1.0~2.0

Too outside

Connecting pipe in site

Insulating material

Insulating material (arranged in site)

Thickness: Over 10mm

Installation procedure Connection of pipes

4.Pipe connection of the outdoor unit.

Referring to the installation diagram in page 4, connect the indoor unit with outdoor unit, by

using the pipe connection method.

II Test of airtight quality

After connection of the refrigerant pipes, carry out airtight quality test. In this test, pressurize to the

pipes as shown in the below figure by using nitrogen tank.

Close the valves of the gas side and liquid side totally.

The nitrogen may enter the cycle system of the outdoor unit, so that, before pressurizing, the valve rods

must be fastened.(Both the gas side and liquid side)

For each of the refrigerant system, pressurize from the discharge valve of gas side in procedure.

When doing airtight quality test, it is absolutely forbidden to use oxygen, flammable gas and poisonous

gas.

If the hi-pressure valve of the outdoor unit is 3-way valve.

Stop valve close

Indoor side

Joint

Joint

Outdoor side

Welding part

Welding part

Fasten

Fasten

(Gas side)

Gas discharging

valve

Indoor unit

Stop valve close

(Liquid side)

When the hi-pressure valve of the outdoor unit is 2-way valve.

3-way valve close

Indoor side Outdoor side

Welding part

Joint

(Gas side)

Fasten

Low pressure

meter

Gas discharging valve

Outdoor unit

Low pressure

meter

Gas discharging valve

High pressure

meter

VL VH

Instrument

distributor

Pressure

reducing

valve

High pressure

meter

VL VH

Instrument

distributor

Nitrogen

Indoor unit

Joint

Welding part

Fasten

Outdoor unit

2-way valve

(Liquid side)

Pressure

reducing

valve

Nitrogen

Installation procedure Connection of pipes

III Vacuumizing of the pipes and indoor unit (using vacuum pump to vacuumize, it is strictly

forbidden to use refrigerant purging)

Choose of vacuum pump: it shall choose those that can reach a good vacuity ( Lower 200Pa ) and

have a large air discharge amount (over 40L/min).

After finishing the airtight quality test and discharging the nitrogen, connect the instrumental

diverter to the 3-way discharge valve, then connect the vacuum pump according to the below figure.

If the hi-pressure valve of the outdoor unit is 3-way valve.

Indoor side

Outdoor side

Low pressure

meter

Stop valve close

(Gas side)

VL VH

High pressure

meter

Instrument

distributor

Fasten

Fasten

Fasten

Fasten

Indoor unit

Stop valve close

(Liquid side)

When the hi-pressure valve of the outdoor unit is 2-way valve .

Indoor side

Outdoor side

Joint

Fasten

Joint

Fasten

Gas discharging valve

Gas discharging

valve

Outdoor unit

Low pressure

3-way valve close

meter

(Gas side)

Gas discharging valve

P

Vacuum pump

High pressure

meter

VL VH

Instrument

distributor

P

Indoor unit

Outdoor unit

2-way valve

(Liquid side)

When the hi-pressure valve of the outdoor unit is 2-way valve:

(1) Firstly connect indoor, outdoor power supplies, and communication lines, then set addresses

of indoor units and check their correctness.

(2) Determine running mode according to indoor temperature: Set to cooling mode when indoor

temperature Ta 23 set to heating mode when Ta<23 .

(3) Keep stop valve of outdoor unit close , and start the indoor unit according to running mode

determined by indoor temperature.

Vacuum pump

Installation procedure Connection of pipes

(4) Watch the status of outdoor unit compressor, disconnect the general power supply for the air

conditioner assembly after the compressor unit starts.

If the hi-pressure valve of the outdoor unit is 3-way valve:

Without starting the machine, simply exhaust to vacuum (vacuum degree<200Pa) directly from

hi-presser and low-pressure valves(strictly in compliance with operation steps defined in instruction

manual for outdoor unit) after machine connecting pipe is well done.

Vacuumize 2~3 hours according to the length of the pipe. When vacuumizing, confirm the gas side

and liquid side of the 2-way valve and 3-way valve shall be in full close state.

When it is not lower than 200Pa after 2 hours or more vacuumizing, vacuumize for another

1 hour. If after more than 3 hours vacuumizing it is still not lower than 200Pa, the leak part shall be

found.

When it is lower than 200Pa after more than 2 hours vacuumizing, close both the valve VL and

VH of the diverter, then close the vacuum pump. Place it there to observe if the vacuity changes.

If it changes, it indicates leakage exists, so the leak part shall be found.

After finishing the above vacuumizing work, replace the vacuum pump with refrigerant tank and

turn to the refrigerant charging procedure.

V Charging of refrigerant

1.Calculation of additional charging amount of refrigerant

After finishing vacuumizing work, replace the vacuum pump with refrigerant tank and turn to the

refrigerant additional charging procedure.

Calculation of additional charging amount of refrigerant

Quantity of filled refrigerant before the machine leaving factory does not consider supplement

for extension tubes while spot installation. After practical installation is finished, it is necessary to fill

supplement refrigerant into extension tubes provided that the length of spot liquid tube>0m.

Filling method is as the following.

Calculation method:

Quantity of supplement refrigerant is determined by specification and actual length of the spot

liquid tube.

Calculation formula:

Quantity of spot supplement refrigerant = actual length necessary supplement refrigerant

quantity per meter of the tube.

E.g.: Uuantity of spot supplement refrigerant(R407C)=(L1-5) 0.035kg/m)

L1: Actual total length of 6.35 liquid tube in one system

Uuantity of spot supplement refrigerant(R407C)=[(L2-5)+(L3-5)] 0.035kg/m)

L2, L3: Actual length of 6.35 liquid tube in the B1, B2 way.

2.Charging of refrigerant

Close all valves of outdoor unit, and charge refrigerant from air discharge valve of gas side.

When can not charge the specified amount, firstly, open all the valves, both liquid side and gas side,

of outdoor unit,then switch the valve of gas side to close state a little.Under this condition, do cooling

operation and charge refrigerant from the discharge valve of gas side. At this time, adjust the valve

of the refrigerant tank to make the refrigerant in Gas State when it is absorbed by system.

When refrigerant leakage making refrigerant lack in system occurs, all of the system shall be

recovered and recharge it according to specified amount.

3.Opening of the refrigerant pipe

Open all the valves of outdoor unit

Installation procedure Refrigerant

The systems use regrigerangt R407C. This refrigerant itselt is innocuous, noncombustible safety

refrigerant. But then, when arranging the air conditioner equipment, it is necessary to take some

steps to take precautions against in case of the indoors refrigerant leakage. Such as, the room

size shall be taken into account to avoid making the concentration of the refrigerant not exceed the

concentration limit and other relevant steps. The concentration limit is the concentration that is not

harmful to human body and can take emergency steps to treat the concentration of Freon.

Concentration limit of R407C:0.3kg/m

3

Indoor unit

Indoor unit

If the indoor unit leaks, all the refrigerant in

the syetem will leak out

1.Sequence of refrigerant concentration affirmance

Calculate the refrigerant concentration according to the following sequence.

(1) Calculate the total refrigerant-charging amount of each of the refrigerating system(kg).

Refrigerant charging amount of outdoor system + Additional refrigerant charging amount

=Total refrigerant charging amount of the refrigerating equipment(kg).

Refrigerant charging amount of outdoor system: Refrigerant charging amount when air

conditioner leaves factory.

Additional refrigerant charging amount: Additional refrigerant charging amount according

to the site pipe length and pipe diameter.

(2) Calculate the minimum size of the room suitable for the indoor unit assembly(m ).

3

(3) Calculate the concentration of refrigerant:

Total refrigerant charging amount of refrigerating equipment/the minimum room size suitable

for indoor unit assembly(m ) Refrigerant concentration limit:0.3kg/m

3

3

2.Countermeasure when exceeding the concentration limit

(1) Set an effective opening for ventilation and fresh air.

Cut an intake respectively on the upper and lower part of the door which areas are equivalent

to 0.15% grounding area, or cut an intake in other part of the room.

(2) Reduce the total refrigerant charging amount of the refrigerating equipment

Shorten the refrigerant pipe length. Reduce the installation place distance between the

outdoor unit and the indoor unit to shorten the refrigerant pipe length, so that reduce the

total refrigerant charging amount of the refrigerating equipment.

(3) Establish ventilation and fresh air system

Establish a mechanical equipment for fresh air to keep the refrigerant concentration below

the concentration limit (normal ventilation).

When can not ventilate the normally, please set an alarm apparatus linked with the

mechanical ventilation equipment.

Installation procedure Electric wiring

Electric wiring

Note:

The air conditioner must use special circuit (over 30A), and wiring by the qualified

electrician according to the wiring rules specified in national standard.

The grounding wire and the neutral wire shall be strictly separated. Connect the neutral

wire with grounding wire is incorrect.

The electric leakage breaker must be installed.

All the electric wire must be copper wire.When wiring,there shall keep a proper distance

between the power line and communication wire to avoid twist together.Otherwise,signal

disturbance will occur,and the air conditioner can not operate normally.

Power supply:1PH,220-230V~,50Hz.

The wiring method of power line is Y connection. If the power line is damaged,in order

to avoid risk of electric shock, it must be replaced by the manufacturer or its repair center

or other similar qualified person.

Specification of wire and short circuit protector in site wiring:

Fuse: 30A 250VAC

Type

Contents

Specificat on

i

Parameter

Power line

YZW

3x3.0mm

Short circuit

protector

2

30A

Connection signal wire

2x(0.75~1.25mm )

Note:The signal wire must be shielded .

Wiring method

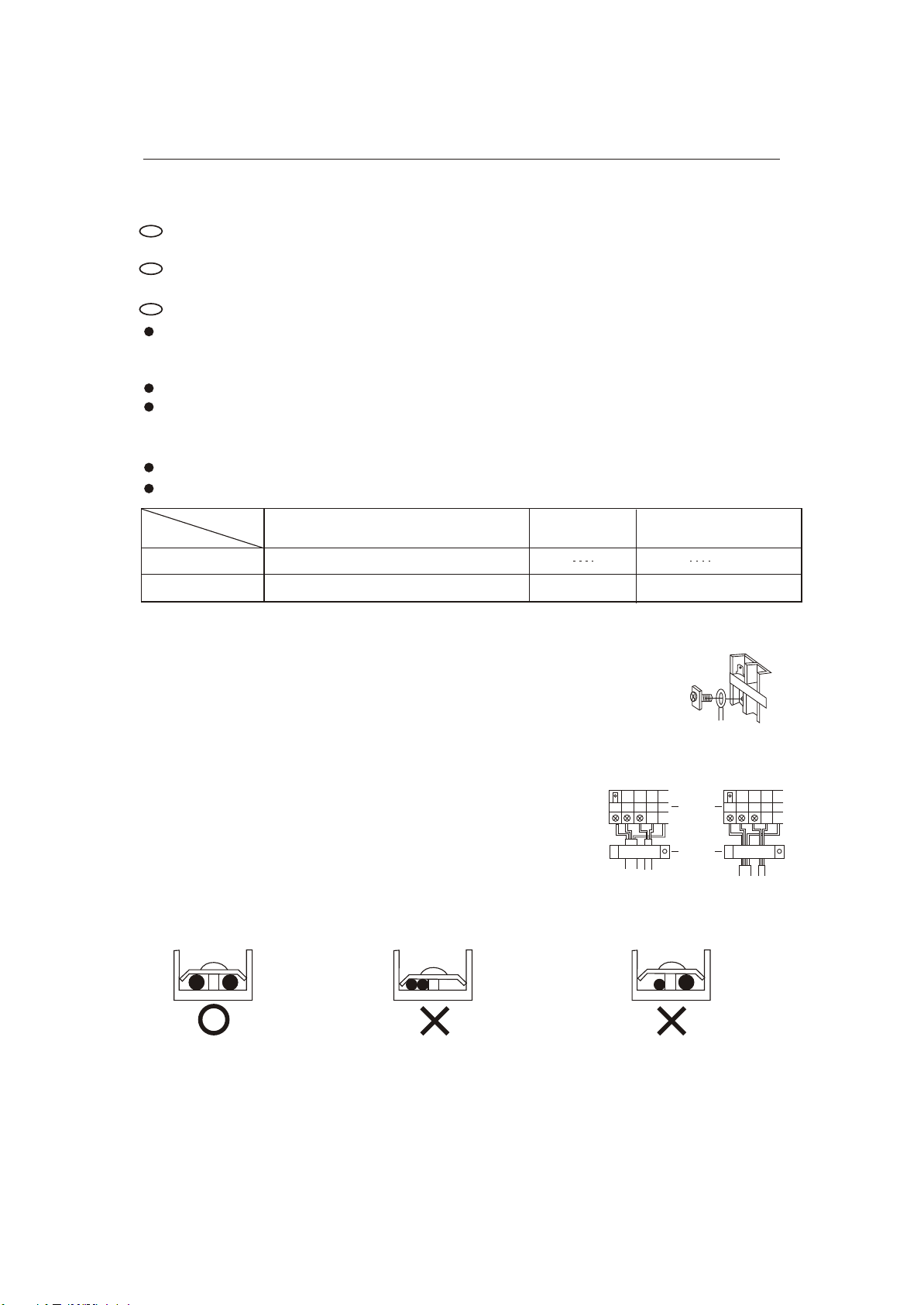

1. Wiring method of orbicular terminals

For the connection wire with orbicular terminals, its wiring method

is as shown in the right figure: remove the connecting screw, put the

screw through the ring on the end of the wire, then connect to the

terminal block and fasten screw.

2. Wiring method of straight terminals

For the connection wire without orbicular terminals, its wiring

method is: loosen the connection screw, and insert the end of

the connection wire completely into the Termina l block, then

fasten the screw. Slightly pull the wire outwards to confirm it is

firmly held

3. Crimp connection method for wires without terminals

Connect the wire with

same diameter to the

two sides of the terminal

Do not connect the

wire with same diameter

to the same side

Correct Pressing

Do not connect the

wire with different

diameters

Wiring Method for

Ring Terminal Block

Wrong Pressing

Terminal

block

Pressing

Clamps

2

Crimp connection method for connection wire

After connection,the wire must be fastened by wire cover. The wire cover shall press on the

protection coat of the connection wire,as shown in right top figure.

Note:When connecting the wiring,confirm the terminal number of indoor and outdoor units

carefully. Incorrect wiring will damage the controller of air conditioner or the unit can not

operate.

Installation procedure Electric wiring

Wiring method of outdoor unit:

Power line

Remove the repair board of the outdoor unit and loosen the wire cover A,then put the live

wire, neutral wire and grounding wire through the wire cover A,and connect them to

terminal block correspondingly. After connection, fasten wire cover A to its previous

state.

Communication wire of indoor unit

Loosen wire cover B ,put the communication wire through the wire cover B, and connect

them to terminal block correspondingly. After connection, fasten wire

cover B to its previous state.

Note: Power line and communication wire are provided by consumers themselves.

Termial

Wring clamp

B

A

Wiring method of indoor unit

Power line and communication wire of indoor unit

Loosen wire cover and connect the power line and communication wire of indoor unit to

the terminal correspondingly.

Loading...

Loading...