Haier AU282FHERA, AU482FIERA, AU48NFIERA, AU60NFIERA Installation Manual

No. 0150506826

Please read this manual carefully before using this air conditioner

Please keep this manual safely for future use

OUTDOOR UNIT

INSTALLATION MANUAL

EN

MANUALE DI INSTALLAZIONE

IT

MANUEL D’INSTALLATION

FR

INSTALLATIONSANLEITUNG

DE

MANUAL DE INSTALACIÓN

ES

R410A MRVII-S

AU282FHERA

AU482FIERA

AU48NFIERA

AU60NFIERA

AU282FHERA AU482FIERA AU48NFIERA AU60NFIERA

CE

Tutti i prodotti sono conformi alle seguenti normative europee:

- Direttiva 73/23/EEC Basso Voltaggio

- Direttiva 2006/95/EC Basso Voltaggio

- Direttiva 89/336/EEC Compatibilità elettromagnetica

ROHS

Il prodotto è conforme alla normativa 2002/95/EEC sulla restrizione d’uso di

sostanze inquinanti negli apparecchi elettrici ed elettronici.

WEEE

Informativa al consumatore come previsto dalla normativa europea

2002/96/CE riguardante i rifiuti di apparecchiature elettriche ed elettroniche.

SPECIFICHE DI SMALTIMENTO:

Il climatizzatore è contrassegnato con questo simbolo,

ciò significa che i prodotti elettrici ed elettronici non

possono essere smaltiti insieme ai rifiuti domestici non

differenziati. Non cercare di demolire il sistema da soli:

la demolizioni dei sistemi di condizionamento, nonché il

recupero del refrigerante, dell’olio e di qualsiasi altra

parte devono essere eseguiti da un installatore qualifi-

cato in conformità alla legislazione locale e nazionale

vigente in materia.I climatizzatori devo essere trattati presso una struttura specializzata nel riutilizzo, riciclaggio e recupero dei materiali. Il corretto smaltimento del prodotto eviterà le possibili conseguenze negative all’ambiente e alla

salute dell’uomo. Per maggiori informazioni contattare l’installatore o le autorità locali. Le batterie devono essere tolte dal telecomando e smaltite separatamente conformemente alla legislazione locale e nazionale vigente in materia.

CONFORMITÀ ALLE DIRETTIVE EUROPEE PER I MODELLI:

Haier Industrial Park, No.1 Haier Road, Qingdao, P.R.China

IT

AU282FHERA AU482FIERA AU48NFIERA AU60NFIERA

CE

All the products are in conformity with the following European provision:

- Low Voltage Directive 73/23/EEC

- Low Voltage Directive 2006/95/EC

- Electromagnetic CompatibilitY 89/336/EEC

ROHS

The products are fulfilled with the requirements in the directive 2002/95/EEC of the

European parliament and of the council on the Restriction of the use of Certain Hazardous Substances in Electrical and Electronic Equipment (EU RoHS Directive)

.

WEEE

In accordance with the directive 2002/96/CE of the European parliament,

herewith we inform the consumer about the disposal requirements of the

electrical and electronic products.

DISPOSAL REQUIREMENTS:

Your air conditioning product is marked with this sym-

bol. This means that electrical and electronic products

shall not be mixed with unsorted household waste.

Do not try to dismantle the system yourself: the dis-

mantling of the air conditioning system, treatment of

the refrigerant, of oil and of other part must be done

by a qualified installer in accordance with relevant

local and national legislation.

Air conditioners must be treated at a specialized treatment facility for re-use,

recycling and recovery. By ensuring this product is disposed of correctly, you

will help to prevent potential negative consequences for the environment and

human health. Please contact the installer or local authority for more information. Battery must be removed from the remote controller and disposed of

separately in accordance with relevant local and national legislation.

EUROPEAN REGULATIONS CONFORMITY FOR THE MODELS:

EN

AU282FHERA AU482FIERA AU48NFIERA AU60NFIERA

CE

Tous les produits sont conformes aux directives européennes suivantes:

- Directive 73/23/CEE Basse tension

- Directive 2006/95/CE Basse tension

- Directive 89/336/CEE Compatibilité électromagnétique

ROHS

L'appareil est conforme à la directive 2002/95/CEE relative à la limitation de

l'utilisation de certains substances dangereuses dans les équipements électriques et électroniques.

DEEE (WEEE)

Information au consommateur comme le prévoit la directive européenne

2002/96/CE relative aux déchets d'équipements électriques et électroniques.

SPECIFICATIONS POUR L'ELIMINATION:

Ce pictogramme, apposé sur le climatiseur, signifie

que les équipements électriques et électroniques ne

peuvent pas être éliminés avec les déchets ménagers

non triés. Ne pas essayer de démanteler l'équipement

soi-même: le démantèlement des systèmes de clima-

tisation, ainsi que la récupération du frigorigène, de

l'huile et de toute autre partie doivent être effectués

par un installateur qualifié conformément à la législation locale et nationale en vigueur en la matière. Les climatiseurs doivent être

traités dans un centre spécialisé dans la réutilisation, le recyclage et la valorisation des matériaux. L'élimination correcte de ces appareils permet d'éviter les effets nocifs sur l'environnement et la santé humaine. Pour plus de

renseignements contacter l'installateur ou les autorités locales. Les piles doivent être retirées de la télécommande et éliminées séparément, conformément à la législation locale et nationale en vigueur en la matière.

CONFORMITÉ AUX DIRECTIVES EUROPÉENNES POUR LES MODÈLES:

FR

Haier Industrial Park, No.1 Haier Road, Qingdao, P.R.China

AU282FHERA AU482FIERA AU48NFIERA AU60NFIERA

CE

Alle Produkte erfüllen die folgenden europäischen Richtlinien:

- Niederspannungsrichtlinie 73/23/EWG

- Niederspannungsrichtlinie 2006/95/EG

- EMV-Richtlinie 89/336/EWG

ROHS

Das Produkt erfüllt die Richtlinie 2002/95/EWG zur Beschränkung der Verwendung bestimmter gefährlicher Stoffe in Elektro- und Elektronikgeräten.

WEEE

Verbraucherinformation laut europäischer Richtlinie 2002/96/EG zu Elektround Elektronik-Altgeräten.

HINWEISE ZUR ENTSORGUNG:

Das Klimagerät ist mit diesem Symbol gekennzeich-

net, das darauf hinweist, dass Elektro- und Elektronik-

geräte getrennt vom Hausmüll entsorgt werden müs-

sen. Verschrotten Sie die Anlage nicht selbst: die Ver-

schrottung von Klimaanlagen, sowie die Rückgewin-

nung des Kältemittels, des Öls und aller sonstigen Tei-

le müssen durch einen qualifizierten Installateur in

Übereinstimmung mit den einschlägigen geltenden

örtlichen und nationalen Vorschriften erfolgen. Die Klimageräte müssen bei

einem Unternehmen entsorgt werden, das auf die Verwertung, das Recycling

und die Rückgewinnung der Materialien spezialisiert ist. Die richtige Entsorgung des Produkts hilft negative Auswirkungen auf Umwelt und Gesundheit

zu vermeiden. Für weitere Informationen wenden Sie sich bitte an den Installateur oder die örtlichen Behörden. Die Batterien müssen aus der Fernbedienung entfernt und in Übereinstimmung mit den einschlägigen geltenden örtlichen und nationalen Vorschriften getrennt entsorgt werden.

ÜBEREINSTIMMUNG MIT DEN EUROPÄISCHEN RICHTLINIEN FÜR DIE MODELLE:

DE

AU282FHERA AU482FIERA AU48NFIERA AU60NFIERA

CE

Todos los productos están en conformidad con las siguientes Normativas

Europeas:

- Bajo Voltaje directiva 73/23/EEC

- Bajo Voltaje directiva 2006/95/EC

- Compatibilidad electromagnética 89/336/EEC

ROHS

Los productos cumplen los requisitos de la directiva 2002/95/EEC del parlamento Europeo y el consejo regulador Del uso de materiales peligrosos en

equipamientos eléctricos Y electrónicos. (EU RoHS Directiva).

WEEE

De acuerdo con la directiva 2002/96/CE del parlamento Europeo, Informamos al consumidor acerca del reciclage de los productos Electrónicos y

eléctricos.

REQUISITOS PARA LA ELIMINACIÓN:

Su acondicionador de aire está marcado con este

símbolo. Esto significa que los productos eléctricos y

electrónicos no deben mezclarse con el resto de resi-

duos domésticos no clasificados.

No intente desmontar el sistema usted mismo: El des-

mantelamiento del acondicionador de aire, así como

el tratamiento del refrigerante, aceite y otros compo-

nentes, debe ser efectuado por un instalador competente de acuerdo con las normas locales y nacionales aplicables. Los acondicionadores de aire deben ser tratados en instalaciones especializadas para

su reutilización, reciclaje y recuperación. Al asegurarse de desechar este producto de la forma correcta, està contribuyendo a evitar posibles consecuencias negativas para el entorno y para la salud de las personas. Contacte, por

favor, con el instalador o con las autoridades locales para obtener más información. Las pilas del control remoto deben extraerse y eliminarse por separado y de acuerdo con la normativa local y nacional aplicable.

CONFORMIDAD EUROPEA DE LAS REGULACIONES PARA LOS MODELOS:

ES

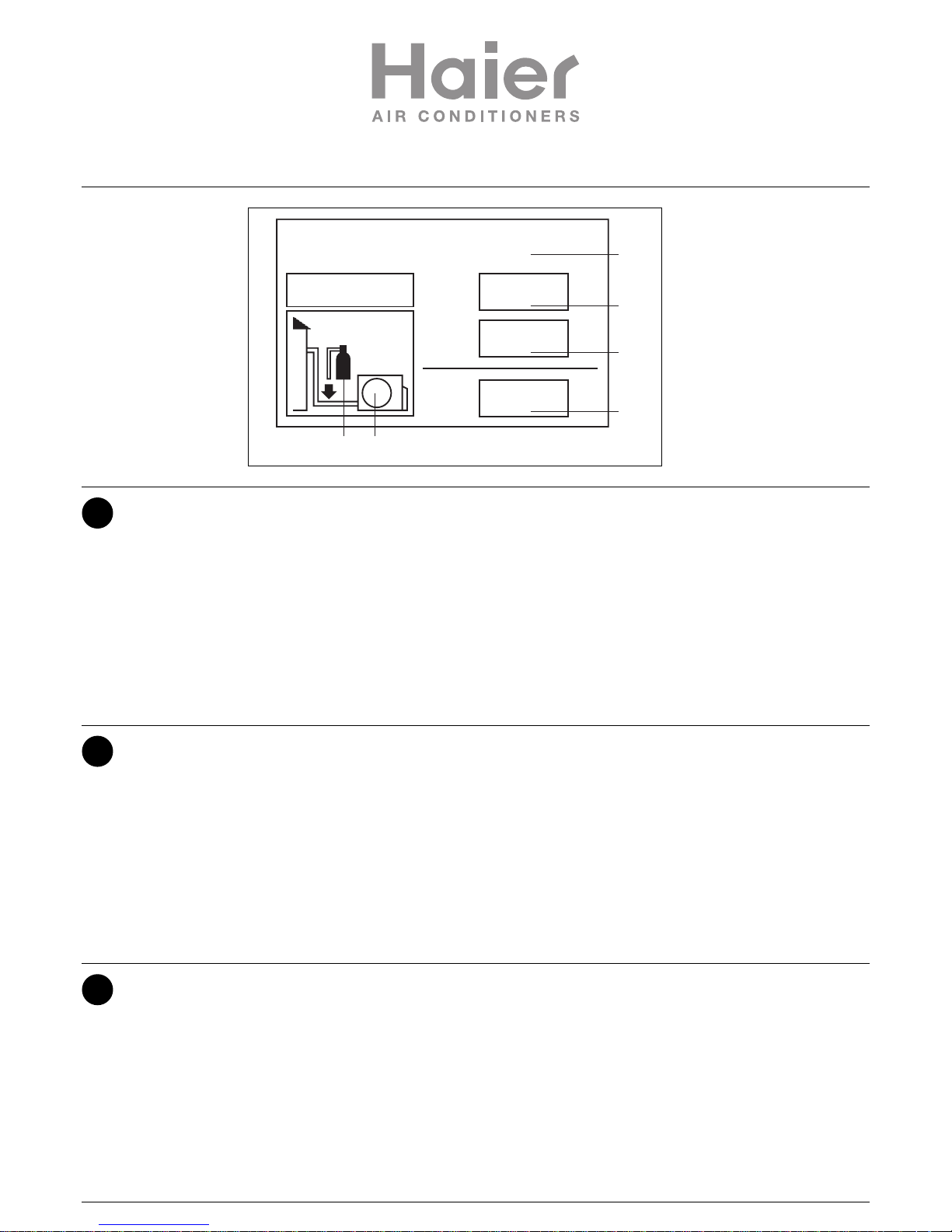

Questo prodotto contiene gas fluorurati ad effetto serra inclusi nel Protocollo

di Kyoto. Non liberare tali gas nell’atmosfera.

Tipo di refrigerante: R410A

Valore GWP*: 1975

*

GWP = potenziale di riscaldamento globale

Compilare con inchiostro indelebile,

• 1 la carica di refrigerante di fabbrica del prodotto

• 2 la quantità di refrigerante aggiuntiva nel campo e

• 1+2 la carica di refrigerante totale

sull’etichetta di carica del refrigerante fornita con il prodotto

L’etichetta compilata deve essere collocata in prossimità della portata di carica del prodotto (ad esempio, nell’interno del coperchio della valvola d’intercettazione).

A contiene gas fluorurati ad effetto serra inclusi nel protocollo di Kyoto

B carica di refrigerante di fabbrica del prodotto: vedi targhetta con il nome

dell’unità

C quantità di refrigerante aggiuntiva nel campo

D carica di refrigerante totale

E unità esterna

F cilindro del refrigerante e collettore di carica

INFORMAZIONI IMPORTANTI SUL REFRIGERANTE UTILIZZATO

Haier Industrial Park, No.1 Haier Road, Qingdao, P.R.China

1

1+2=

kg

R410A

2

kg

2=

1=

B

C

D

FE

kg

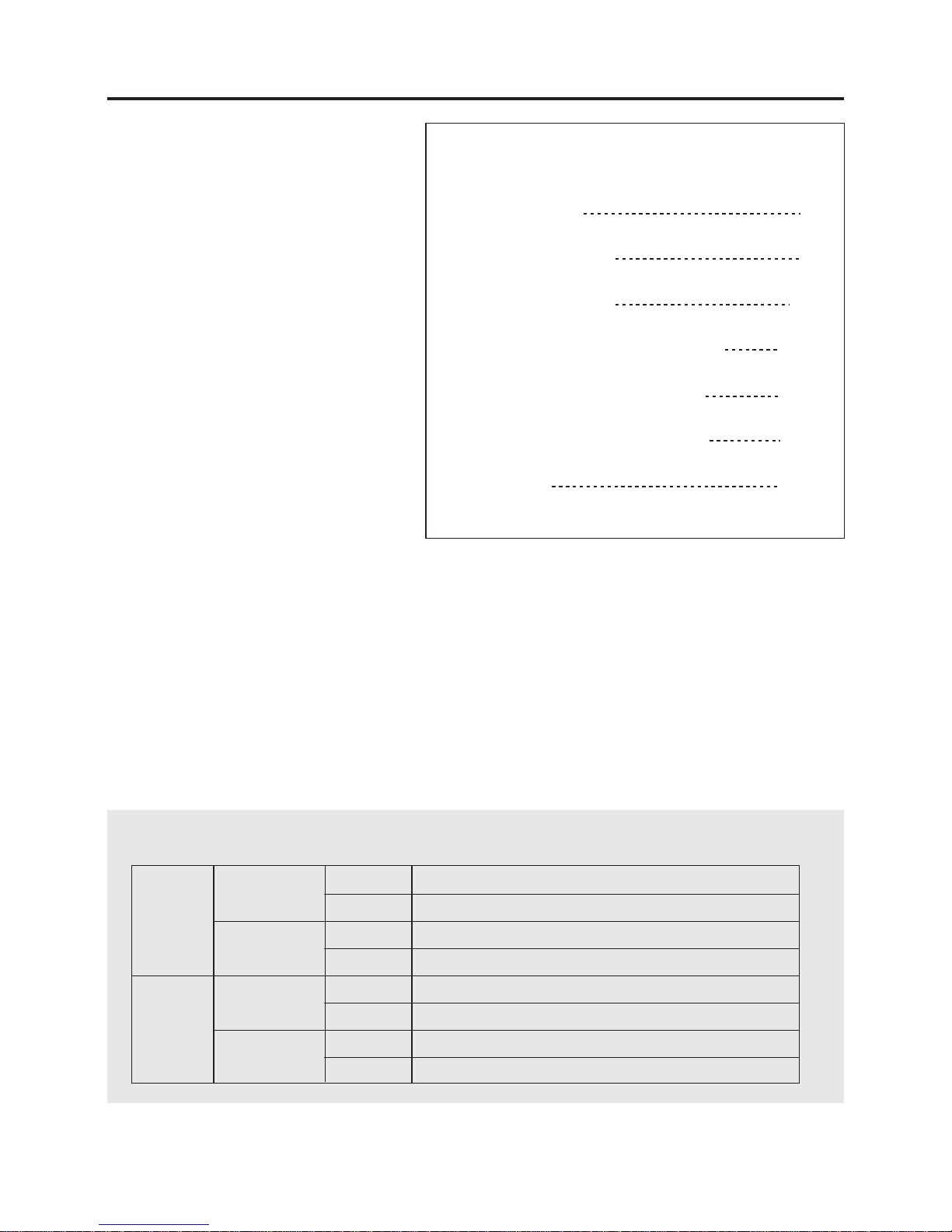

Contains fluorinated greenhouse gases

covered by the Kyoto Protocol

A

This product contains fluorinated greenhouse gases covered by the Kyoto

Protocol. Do not vent into the atmosphere.

Refrigerant type: R410A

GWP* value: 1975

*

GWP = global warming potential

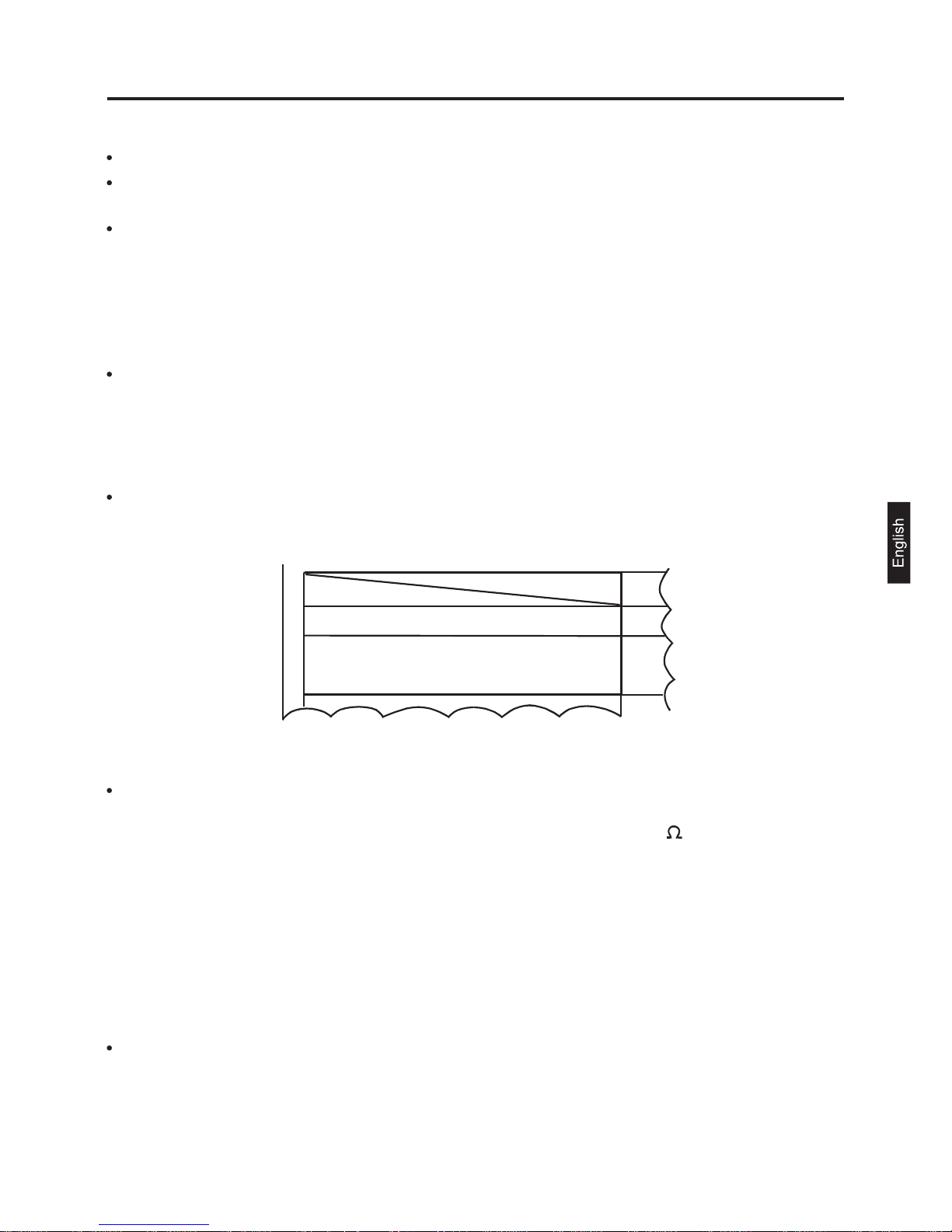

Please fill in with indelible ink,

• 1 the factory refrigerant charge of the product

• 2 the additional refrigerant amount charged in the field and

• 1+2 the total refrigerant charge

on the refrigerant charge label supplied with the product.

The filled out label must be adhered in the proximity of the product charging

port (e.g. onto the inside of the stop valve cover).

A contains fluorinated greenhouse gases covered by the Kyoto Protocol

B factory refrigerant charge of the product: see unit name plate

C additional refrigerant amount charged in the field

D total refrigerant charge

E outdoor unit

F refrigerant cylinder and manifold for charging

IT

IMPORTANT INFORMATION REGARDING THE REFRIGERANT USED

EN

Ce produit contient des gaz à effet de serre fluorés encadrés par le protocole de Kyoto. Ne pas laisser les gaz s’échapper dans l’atmosphère.

Type de réfrigérant: R410A

Valeur GWP*: 1975

*

GWP = potentiel de réchauffement global

Prière de compléter à l’encre indélébile,

• 1 la charge de réfrigérant d’usine du produit

• 2 la quantité de réfrigérant supplémentaire chargée sur place et

• 1+2 la charge de réfrigérant totale

sur l’étiquette de charge de réfrigérant fournie avec le produit.

L’étiquette complétée doit être apposée à proximité de l’orifice de recharge

du produit (par ex. à l’intérieur du couvercle de la vanne d’arrêt).

A contient des gaz à effet de serre fluorés encadrés par le protocole de

Kyoto

B charge de réfrigérant d’usine du produit: voir plaquette signalétique de

l’unité

C quantité de réfrigérant supplémentaire chargée sur place

D charge de réfrigérant totale

E unité extérieure

F cylindre de réfrigérant et collecteur de recharge

INFORMATION IMPORTANTE RELATIVE AU RÉFRIGÉRANT UTILISÉ

FR

Haier Industrial Park, No.1 Haier Road, Qingdao, P.R.China

1

1+2=

kg

R410A

2

kg

2=

1=

B

C

D

FE

kg

Contains fluorinated greenhouse gases

covered by the Kyoto Protocol

A

Dieses Produkt enthält fluorierte Treibhausgase, die durch das Kyoto-Protokoll abgedeckt werden. Lassen Sie Gase nicht in die Atmosphäre ab.

Kältemitteltyp: R410A

GWP* Wert: 1975

*

GWP = Treibhauspotential

Bitte füllen Sie am Kältemittelbefülletikett, das im Lieferumfang des Gerätes

enthalten ist, mit abriebfester Tinte wie folgt aus:

• 1 die werkseitige Kältemittelbefüllung des Produktes

• 2 die am Montageort befüllte zusätzliche Kältemittelmenge und

• 1+2 die gesamte Kältemittelbefüllung

Das ausgefüllte Etikett muss in der Nähe der Kältemittel-Einfüllöffnung angehängt werden (z. B. auf der Innenseite der Absperrventilabdeckung).

A Enthält fluorierte Treibhausgase, die durch das Kyoto-ProtoKoll abge-

deckt werden

B werkseitige Kältemittelbefüllung des Produktes: siehe Typenschild der

Einheit

C zusätzliche am Montageort befüllen Kältemittelmenge

D gesamte Kältemittelbefüllung

E Außeneinheit

F Kältemittelzylinder und Sammelleitung für die Befüllung

WICHTIGE INFORMATIONEN HINSICHTLICH DES VERWENDETEN KÄLTEMITTELS

DE

Este producto contiene los gases fluorados de efecto invernadora regulados

por el Protocolo de Kioto. No vierta gases a la atmósfera.

Tipo de refrigerante: R410A

Valor GWP*: 1975

*

GWP = Potencial de calentamiento global

Rellene con tinta indeleble,

• 1 la carga de refrigerante de fábrica del producto

• 2 la cantidad adicional de refrigerante cargado en campo y

• 1+2 la carga total de refrigerante

En la etiqueta de carga de refrigerante suministrada con el producto.

La etiqueta rellenada debe pegarse cerca de la conexión de carga del producto (p.ej. en el interior de la cubierta de la válvula de tope).

A Contiene los gases fluorados de efecto invernadora regulados por el

Protocolo de Kioto

B Carga de refrigerante de fábrica del producto: véase placa de especifi-

caciones técnicas de la unidad

C Cantidad adicional de refrigerante cargado en campo

D Carga total de refrigerante

E Unidad exterior

F Cilindro del refrigerante y dosificador de carga

INFORMACIÓN IMPORTANTE EN RELACIÓN AL REFRIGERANTE UTILIZADO

ES

FZ8>8KMJWF

FZ:>8KNJWF

FZ:>SKNJWF

FZ<6SKNJWF

Ulease read this manual carefully before using

Peep this operation manual for future reference

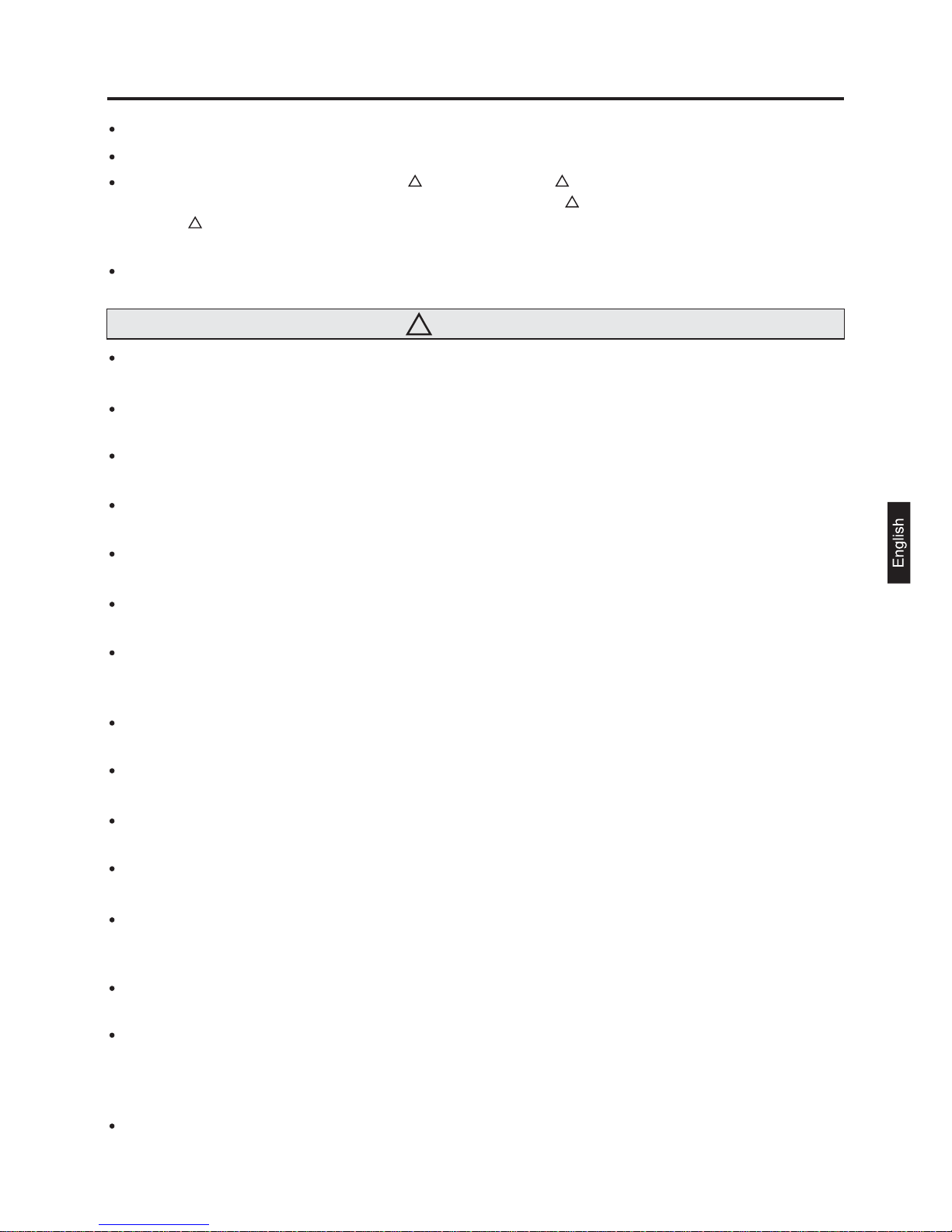

RW[NN3X adopts +simultaneous control+

type2 all indoors should be heating or

cooling simultaneously4

Yo use the air conditioner normally2 please perform as to the below conditions4

Yo protect compressor2 before startup2

the unit should be electrified for over 78

hours4 Nf the unit is not used for a long

time2 please cut off the power to save

energy2 or the unit will consume the

power4

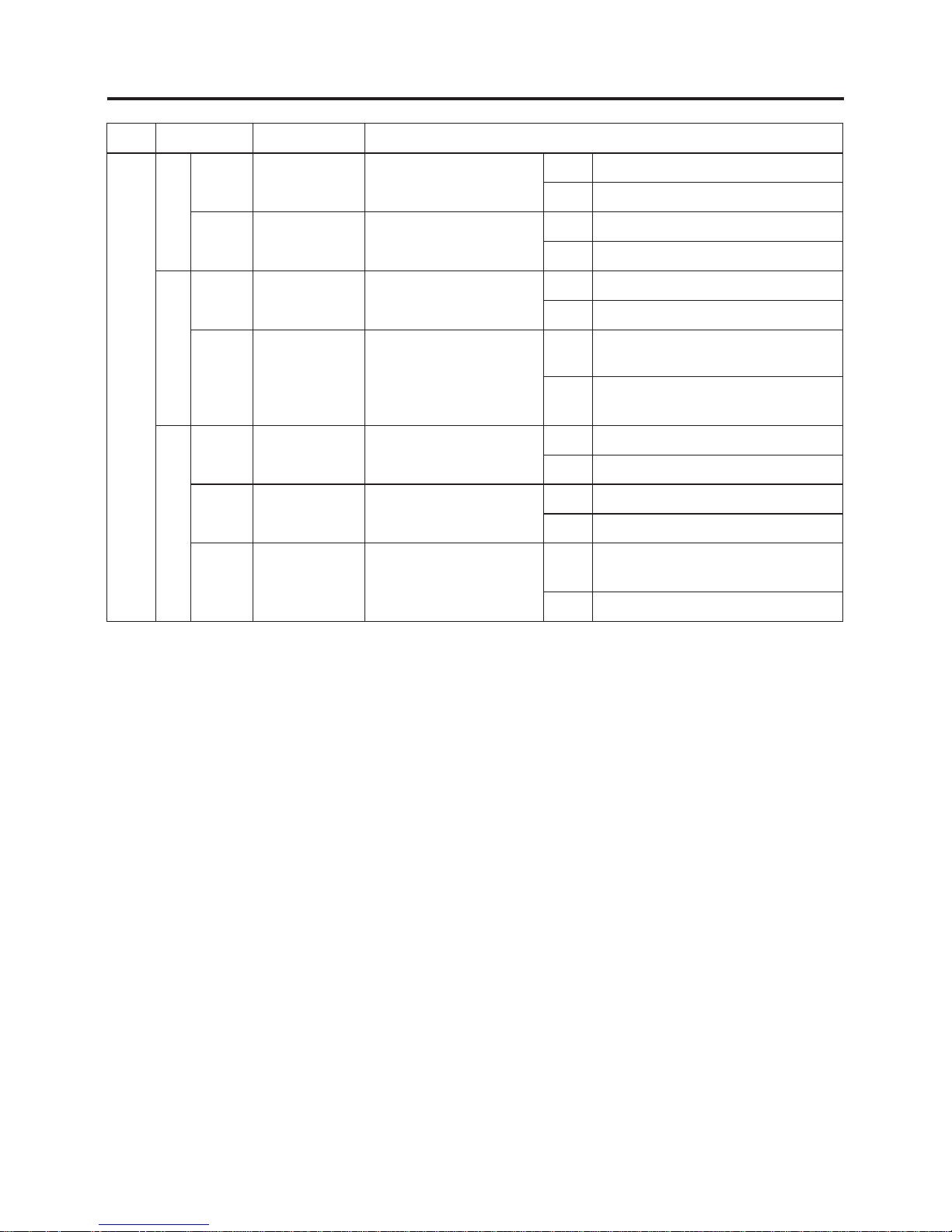

cooling

dry

heating

indoor

outdoor

indoor

outdoor

max4

min4

max4

min4

max4

min4

max4

min4

IG@ 98

\G@ 7;

IG@ 7>

IG@ :9

IG@ 3;

IG@ 8=

IG@ 7;

IG@ 87

IG@ 37;

\G@ 89

\G@ 7:

\G@ 8<

O

O

O

O

O

O

O

O

O

O

O

O

.C9D5F=A; 05A;9 B: z=D |BA8=F=BA9D

738

93:

;379

7:37;

7<388

8938:

8;38<

Zser Ranual

WZY[XY[

Xafety precaution

Nnstallation instruction

Nnstallation procedure

Yrial operation and the performance

Jlectric wiring and the application

Rethod of installation and trial run

Kailure code

Tperation condition@

Nf the air conditioner is transferred to the others2 this manual should be tranferred together4

Yhe installation or the maintenance should be performed by the authorized agency4 Tr the

non3specialized operation will cause water leakage2 electric shock or fire etc accidents4

Yhe installation should be executed as per the manual2 or the faulty installation will cause

water leakage2 electric shock or fire etc accidents4

Ulease install the unit at the space which can bear the weight4 Tr the unit will drop down to

cause the human injury4

Yhe installation should defend against the typhoon2 and the earthquake etc4 Fbnormal

installation will cause the unit fall down4

Zse the correct cable and make reliable earthing4 Kix the terminal firmly and the loose

connection will cause heating or fire etc accident4

Yhe wiring should be in shape and can not be raised4 Ge earthed firmly and can not be clipped

by the electric box cover or the other plate4 Yhe incorrect installation will cause heating or fire4

\hen setting or transferring the unit2 there should not be other air into the refrigerant system

except for W:76F4 Yhe gas mixture will cause the abnormal high pressure which will cause

break or human injury etc accidents4

\hen installation2 please use the accessories with the unit or the special parts2 or it will cause

water leakage2 electric shock2 fire2 refrigerant leakage etc accidents4

Ion-t lead the water drainage pipe into the drainage groove with the poisonous gas2 such as

sulphur4 Tr the poisonous gas will enter indoor4

Nn installation or after installation2 please confirm if there is refriegerant leakage2 please take

measures for ventilation4 Yhe refrigerant will cause poisonous gas as meeting fire4

Ion-t install the unit at the place where there may be flammable gas leakage4 Nn case the gas

leaks and gather around the unit2 it will cause fire4

Yhe drainage pipe should be installed as per the manual to confirm the fluent drainage4 Flso

take measures for heat insulation against dew drop4 Nncorrect water pipe installation will cause

water leakage even and make the things wet4

Kor the liquid pipe and the gas pipe2 take measures for heat insulation too4 Nf there is no heat

insulation2 the dew drop will wet the things4

Gefore installation2 please read +Xafety precaution+ carefully to confirm the correct installation4

Yhe mentioned precaustion includes +L\FWSNSL+ and +LHFZYNTS+4 Yhe precausion caused

death or heavy injury for faulty installation will be listed in +

L

\FWSNSL+4 Jven the cautions

listed in +

L

HFZYNTS+ also may cause serious accident4 Xo both of them are related to the

safety2 and should be executed severely4

Ffter installation2 perform a trial and confirm everything normal2 then introduce the operation

manual to the user4 Gesides2 put the manual to the user and ask them to preserve it carefully4

7

Yhis appliance is not intended for use by persons .including children/ with reducedphysical2

sensory or mental capabilities2 or lack of experience and knowledge2 unless they have been

given supervision or instruction concerning use of the appliance by a person responsible for

their safety4

Hhildren should be supervised to ensure that they do not play with the appliance4

L

\FWSNSL

Xafety precaution

L

8

HFZYNTS

Jxecute earthing for the unit4 Gut the earthing wire can not be connected to the gas pipe2 water

pipe2 lightening rod or the telephone earthing wire4 Nmproper earthing will cause electric shock4

Ion-t install the unit at the place where leaks the flammable gas4 Tr it will cause fire4

Jxecute the water drainage pipe according to the manual2 improper installation will cause water

leakage to wet the family things4

Yhe outdoor fan can not face to the flower or the other vegetable2 or the blowing gas will make

the flower dried up4

Ulease ensure the maintenance room2 if not2 it will cause the maintenance person damaged4

\hen installing the unit on the roof or the other high place2 to prevent the person falling down2

please set the fixed ladder and the railing at the passage4

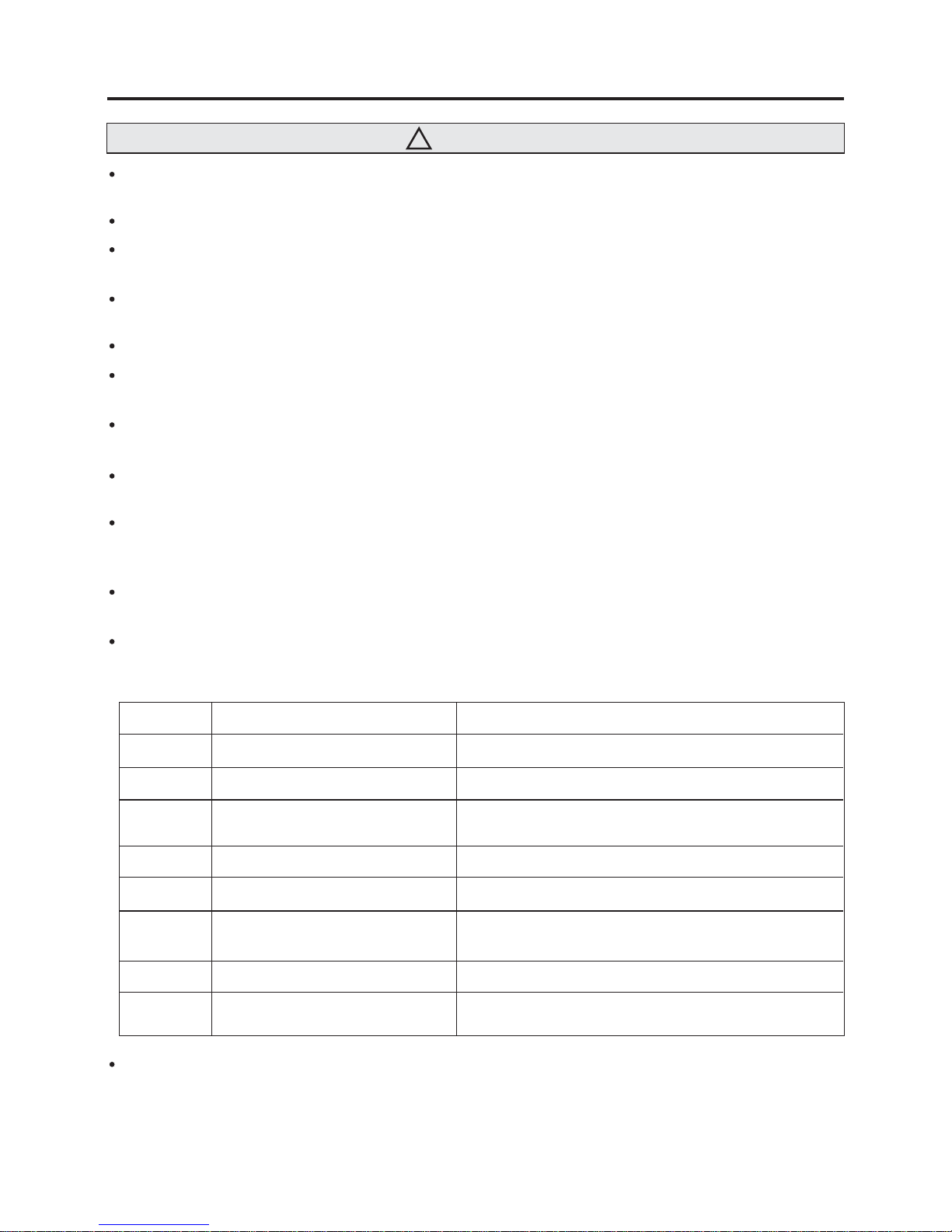

Zse the two3end spanner2 and fasten the nut at proper torque4 Ion-t fasten the nut excessively

against the flared setion broken4 Tr it will cause refrigerant leakage and lack of oxygen4

Yake measures for heat insulation to the refrigerant pipe2 or there will be water leakage or dew

drop to wet the family things4

Ffter finishing the refrigerant pipe2 make leakage test by charging the nitrogen4 Nn case the

refrigerant leaks in a small room and exceeds the limited concentration2 it will cause lack of

oxygen4

Ion-t use the other refrigerant except for W:76F4 Yhe W:76F pressure is 74< times higher than

W88 pressure4 Yhe refrigerant W:76F tank is marked with pink sign4

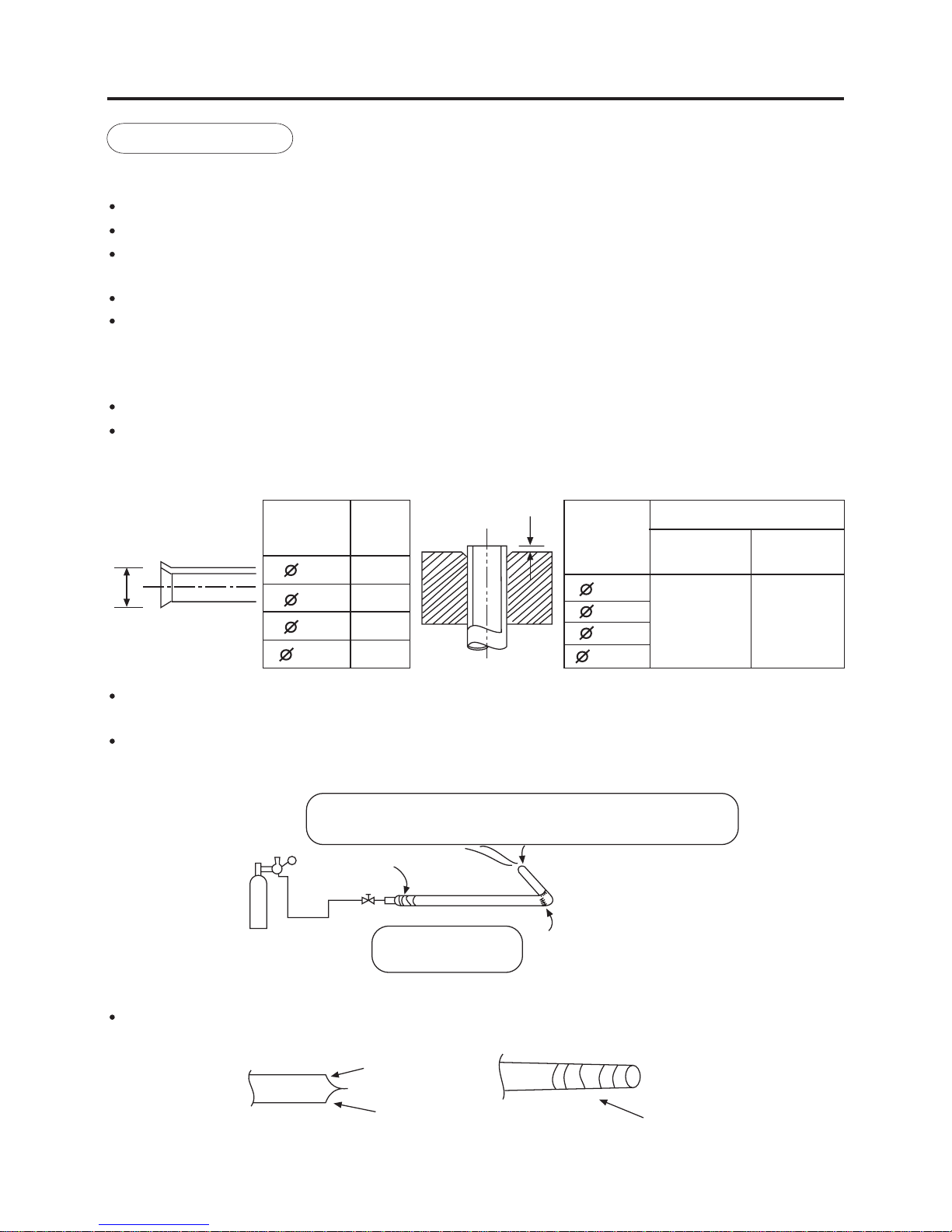

Fgainst charging different refrigerant2 we changed the stop valve diameter of the W:76F unit4

Yo enhance the compression consistance2 we also changed the flared pipe dimension4 Urepare

the W:76F specially tools according to the below table4

\hen charging refrigerant2 the refrigerant must be taken out as liquid state from the tank4

W:76F specially tool

gauge manifold

torque spanner

a

b

c

d

e

f

g

h

range@MUz:4;RUa2QUz8RUa

pressure@MU@;49RUa2QU@94;RUa

can not use the measurable charging tank

must be with reverse stop valve

can not use freon leakage detector2but the

Me detector

Wemarks

charge hose

electronic balance for

charging W:76F

flare tool

copper pipe gauge for

adjusting projecting margin

vacuum pump adapter

leakage detector

Xafety precaution

9

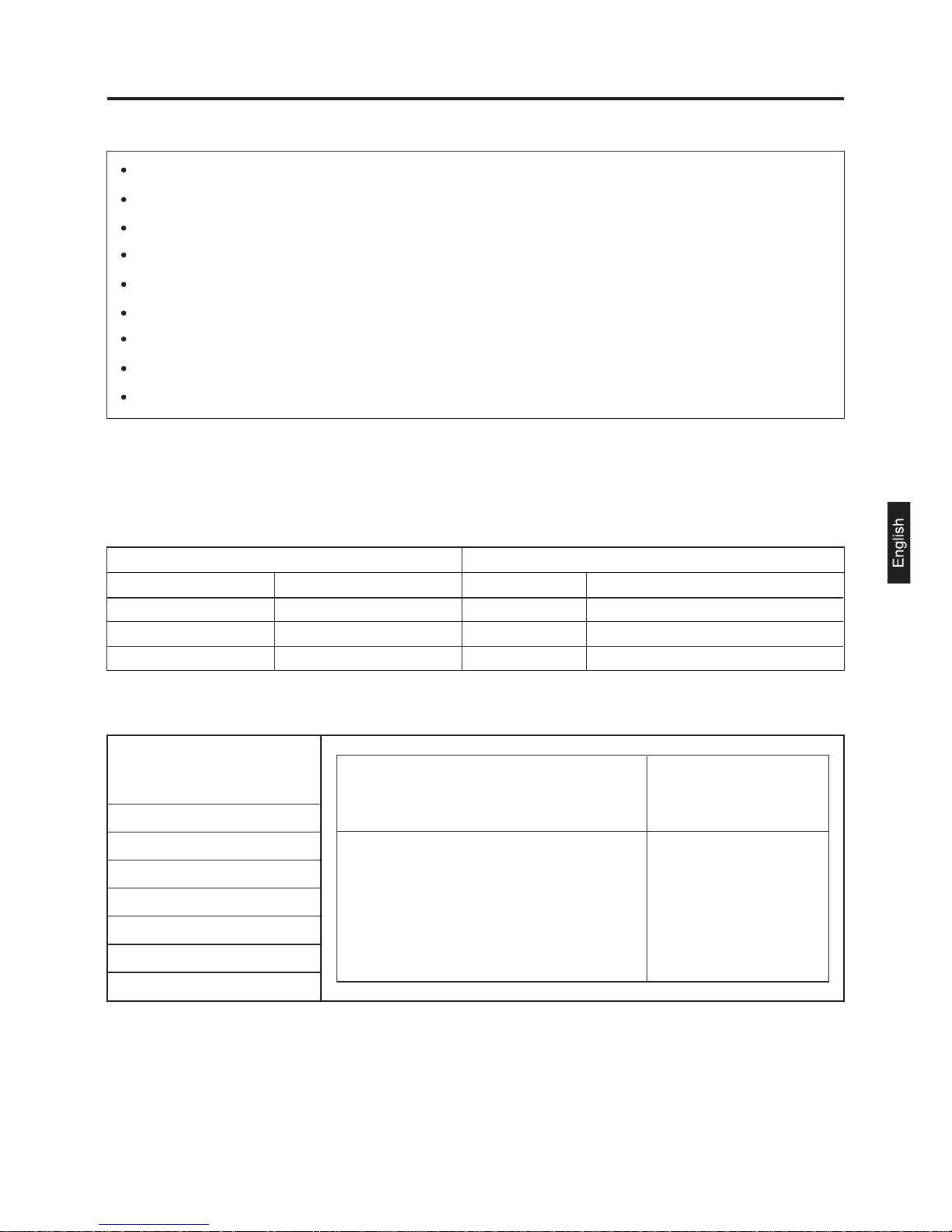

Nf the connected units quantity and the total capacity is in the allowable rangeE

Nf the refrigerant pipe length is in the limited rangeE

Nf the pipe size is properE Fnd if the pipe is installed horizontallyE

Nf the branch pipe is installed horinzontally or verticallyE

Nf the additional refrigerant is counted correctly and weighed by the standard balanceE

Nf there is refrigerant leakageE

Nf all the indoor power supplies can be on5off simultaneouslyE

Nf the power voltage is in compliance with the data marked on the rating labelE

Nf the address of indoors has been setE

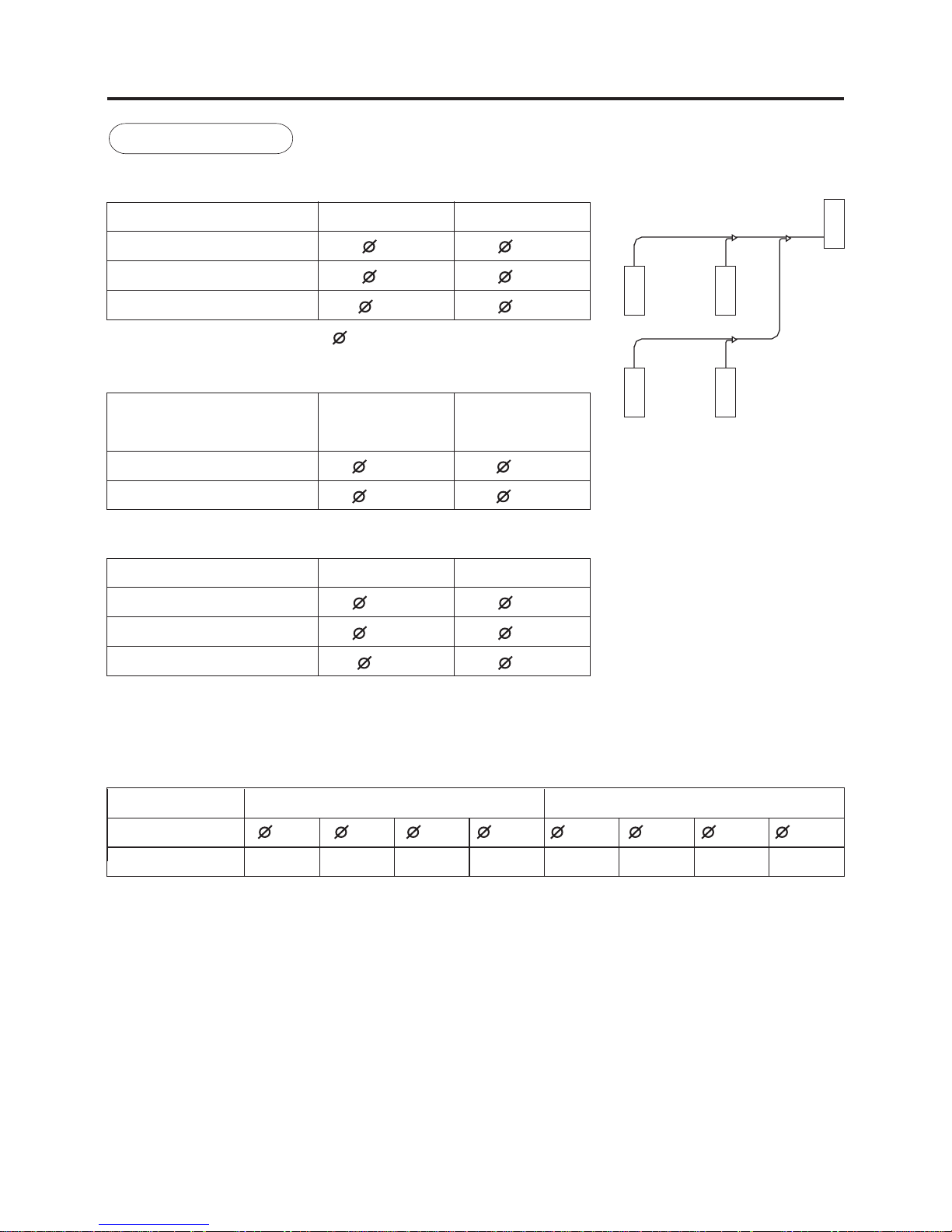

indoor

capacity .766\/

outdoor

combination type indoor Vty total indoor capacity .766\/

>6

7;6

7>6

single

single

single

;

>

?

:6376:

=;37?;

?6389:

indoor capacity .766\/

88

8>

9<

:6

:;

;<

=7

KVL3G99;F

total indoor capacity .766\/

less than 99;

branch pipe

.optional/

Sotice@

Yotal capacities of indoor units being used M 766, of rated capacities of outdoor unit

Nnstallation instruction

Nn installation2 please check specially the below items@

puq {9:BD9 =AEF5??5F=BA

7/ Gefore installation2 check if the model2 power supply2 pipe2 wires and parts purchased

respectively are correct4

8/ Hheck if the indoors and outdoors can be combined as the following4

:

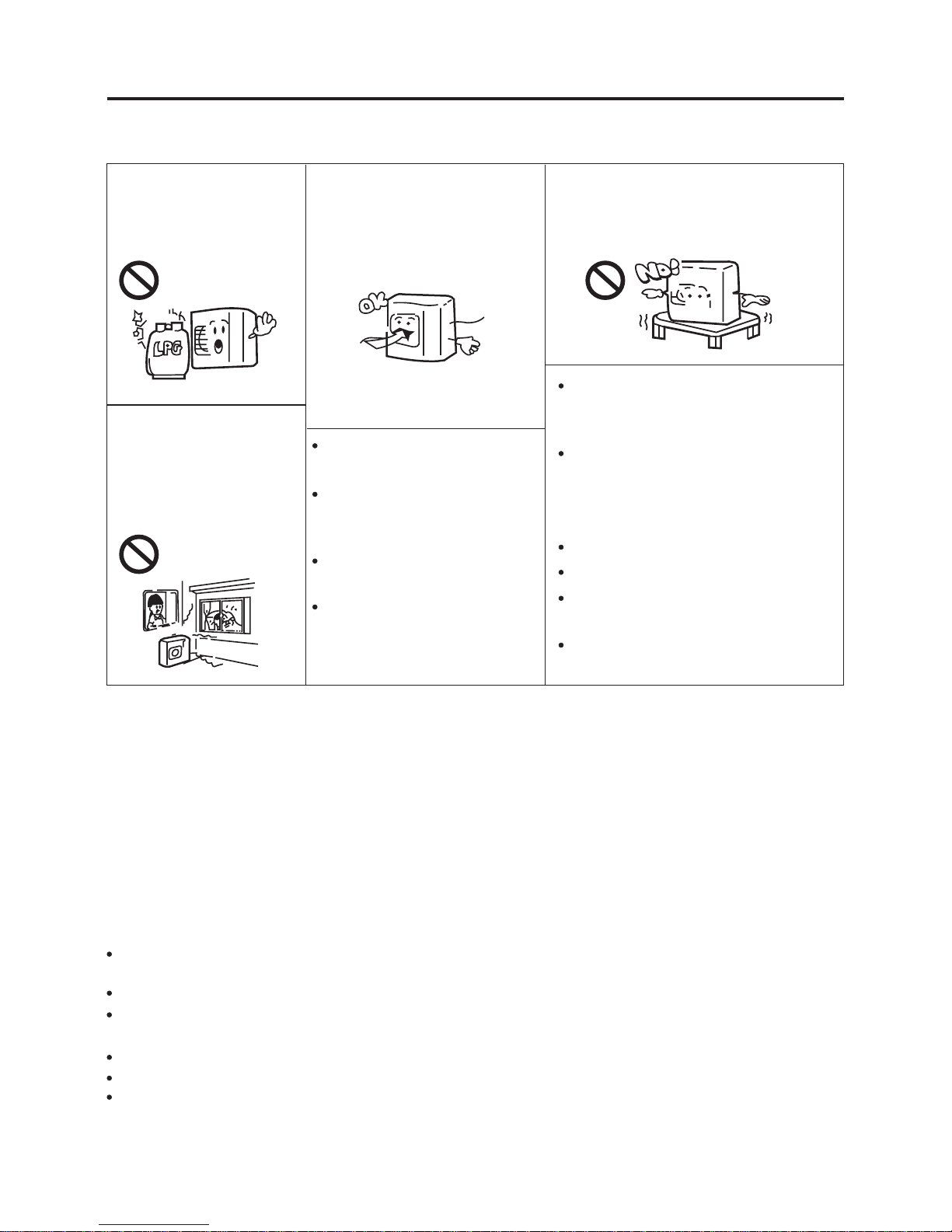

Fir3conditioner can-t be

installed in the place with

inflammable gas4 Tr it

will cause fire hazard4

Yhe unit should be installed at the

strong enough place4 Tr it will cause

vibration and noise4

Yhe unit should be

installed at the place

where the cold5hot air or

noise will not interfere

the neighbours4

Yhe unit is better not be installed

at the below places2 or it will

cause damage4

Yhe place where there is

corrosive gas .spa area etc/4

Yhe place blowing salty air

.seaside etc/4

Jxsits the strong coal smoke4

Yhe place with high humidity4

Yhe place where there is device

emitting Mertzian waves4

Yhe place where voltage changes

greatly4

Nn transportation2 please don-t dismantle the packaging2 and move the unit to the installation

location as closely as possible4

Nf the packaging must be dismantled2 hang up the unit with rope against damage4

Ion-t hang the unit only at two points4 \hen hanging the unit2 don-t sit on the unit4 Yhe unit

should be upright4

\hen removing the unit with the forklift2 put the fork into the special hole at bottom of the unit4

\hen being hanged2 the rope should be : pieces of steel cable with over <mm diameter4

Uut the cushion at the contact section between steel cable and the unit against the distortion

or damage4

pwq 2D5AECBDF5F=BA

Yhe place where the water

can flow fluently4

Yhe place where no other

heat source will affect the

unit4

Uay attention to the snow

against clogging the outdoor4

Nn installation2 install the anti3

vibration rubber between the

unit and the bracket4

Nnstallation instruction

Sote@

74 Nn snowy area2 install the unit under the bracket or the snow3proof cover against the

accumulative snow on the unit4

84 Io not install the unit at the place where the flammable gas will leak4

94 Nnstall the unit at the strong enough place4

:4 Nnstall the unit at the flat place4

;4 \hen being installed at the place with strong wind2 set the air outlet of the unit and the wind

direction vertical4 Flso fix the unit with the screw4

<4 \hen opening the electric box cover for maintenance2 please fix the cover with screw firmly4

pvq ,AEF5??5F=BA C?579 E9?97F=BA

Yhe unit should be installed

at the place with good

ventilation4 So obstacle at the

air inlet5outlet4 Fnd no strong

wind blows the unit4

Yhe installation space refers

to the latter info4

;

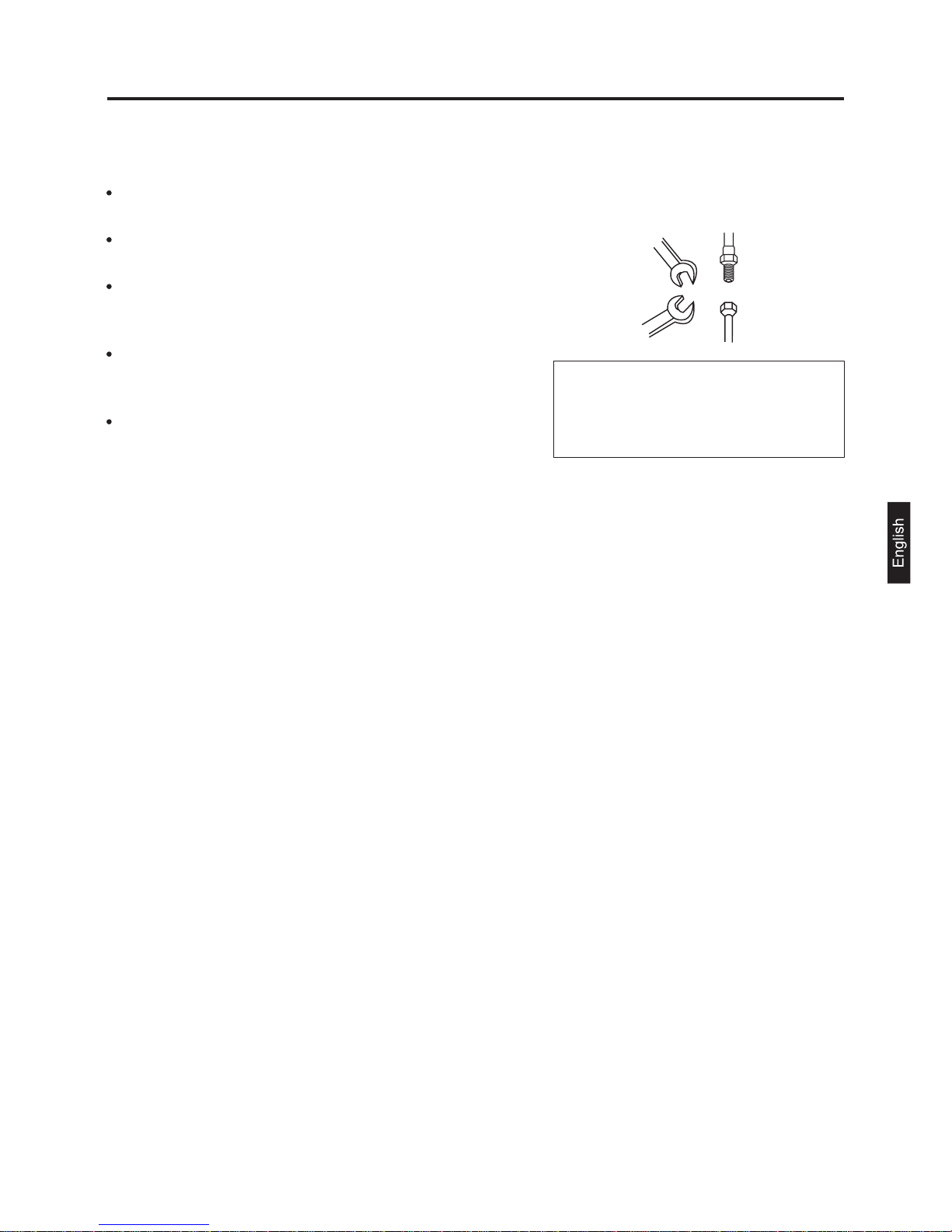

zs 09:D=;9D5AF C=C9 7BAA97F=BA

\hen fastening and loosing the nut2

operate with double spanners2

because only one spanner cannot

execute firmly4

Nf threading the nut as not aiming

at the center2 the screw thread will

be damaged2 further it will cause

leakage4

spanner

spanner

connector

nut

Yo ensure the efficiency2 the pipe should be

as short as possible4

Iaub the refrigerant oil on the connector and

the flare nut4

\hen bending the pipe2 the bending semi3

diameter should be as large as possible

against the pipe being broken or bent4

\hen connecting the pipe2 aim at the center

to thread the nut by hand and tighten it with

the double spanners4

Ion-t let the impurity such as sand2 water etc

into the pipe4

/=C9 7BAA97F=BA @9F<B8y

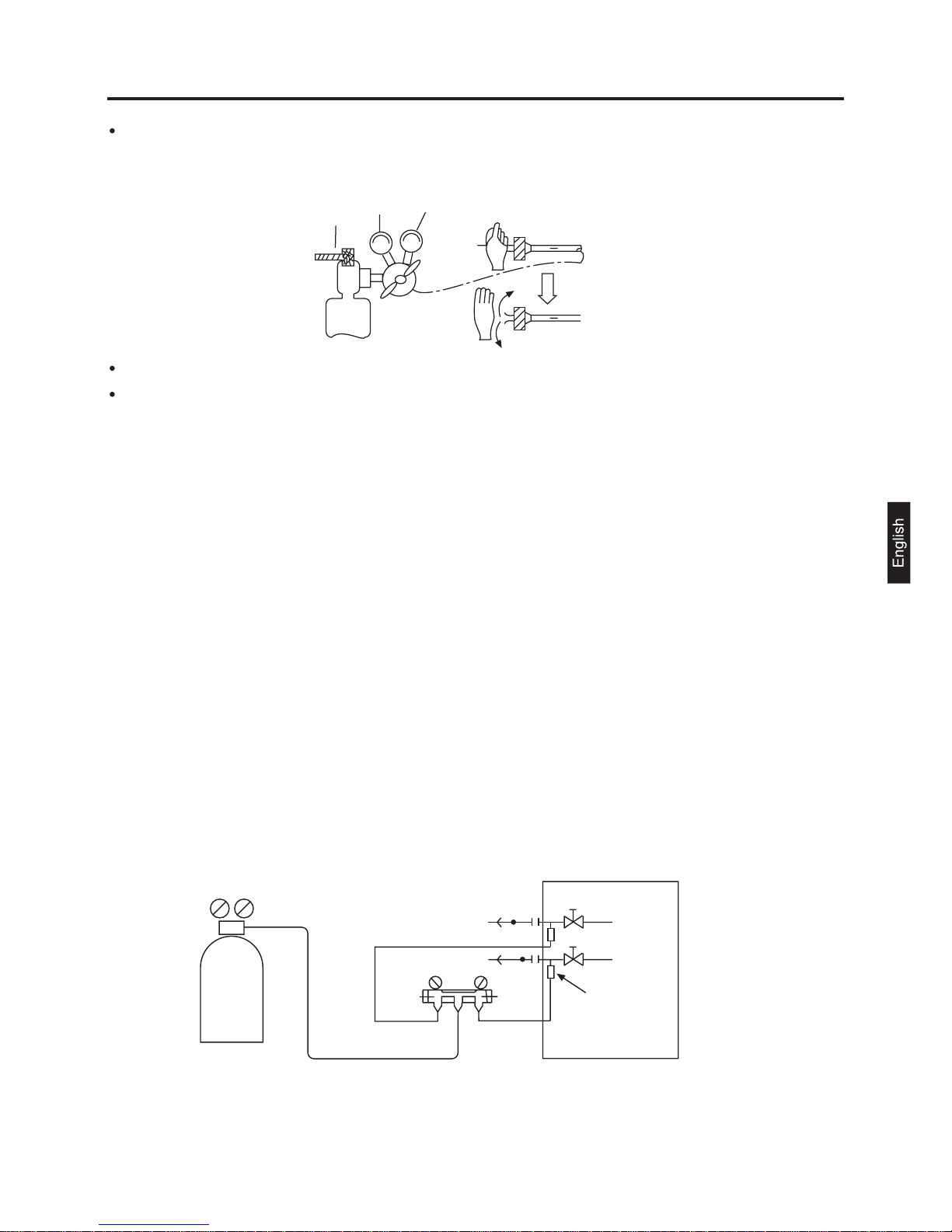

74 \hen welding the connector with hard solder2 charge nitrogen into the pipe against oxidation4

Tr the oxygen film in the pipe will clog the capillary and the expansion valve2 even caue the

deathy accident4

84 Yhe refrigerant pipe should be clean4 Nf the water and the other impurity enter the pipe2

charge the nitrogen to clean the pipe4 Yhe nitrogen should flow under the pressure of about

64;Rpa and when charging the nitrogen2 stop up the end of the pipe by hand to enhance the

pressure in the pipe2 then loose the hand .meanwhile stop up the other end/4

94 Yhe piping installation should be executed after the stop valves are closed4

:4 Gefore welding the valve and the pipes2 use the wet cloth to cool down the valve and the

pipes4

;4 \hen the connection pipe and the branch pipe need to be cut down2 please use the special

shears and cannot use the saw4

|5GF=BAE =A C=C=A; =AEF5??5F=BAy

/=C9 @5F9D=5? 5A8 EC97E E9?97F=BA

74 Ulease select the refrigerant pipe of the below material4

Raterial@ the phosphoric oxidize seamless copper pipe2 model@ H7886Y3758M .diameter is

over 7?46;/A H7886Y36.diameter is below 7;4>>/4

84 Yhickness and specs@

Honfirm the pipe thickness and specs according to the pipe selection method.the unit is with

W:76F2 if the pipe over 7?46; is 63type2 the pressure preservation will be bad2 thus it must be

758M type and over the min4 thickness4

94 Yhe branch pipe must be from Maier4

:4 \hen installing the stop valve2 refer to the relative operation instruction4

;4 Yhe pipe installation should be in the allowable range4

<4 Yhe installation of branch pipe and gather pipe should be performed according to the relative

manual4

Nnstallation procedure

<

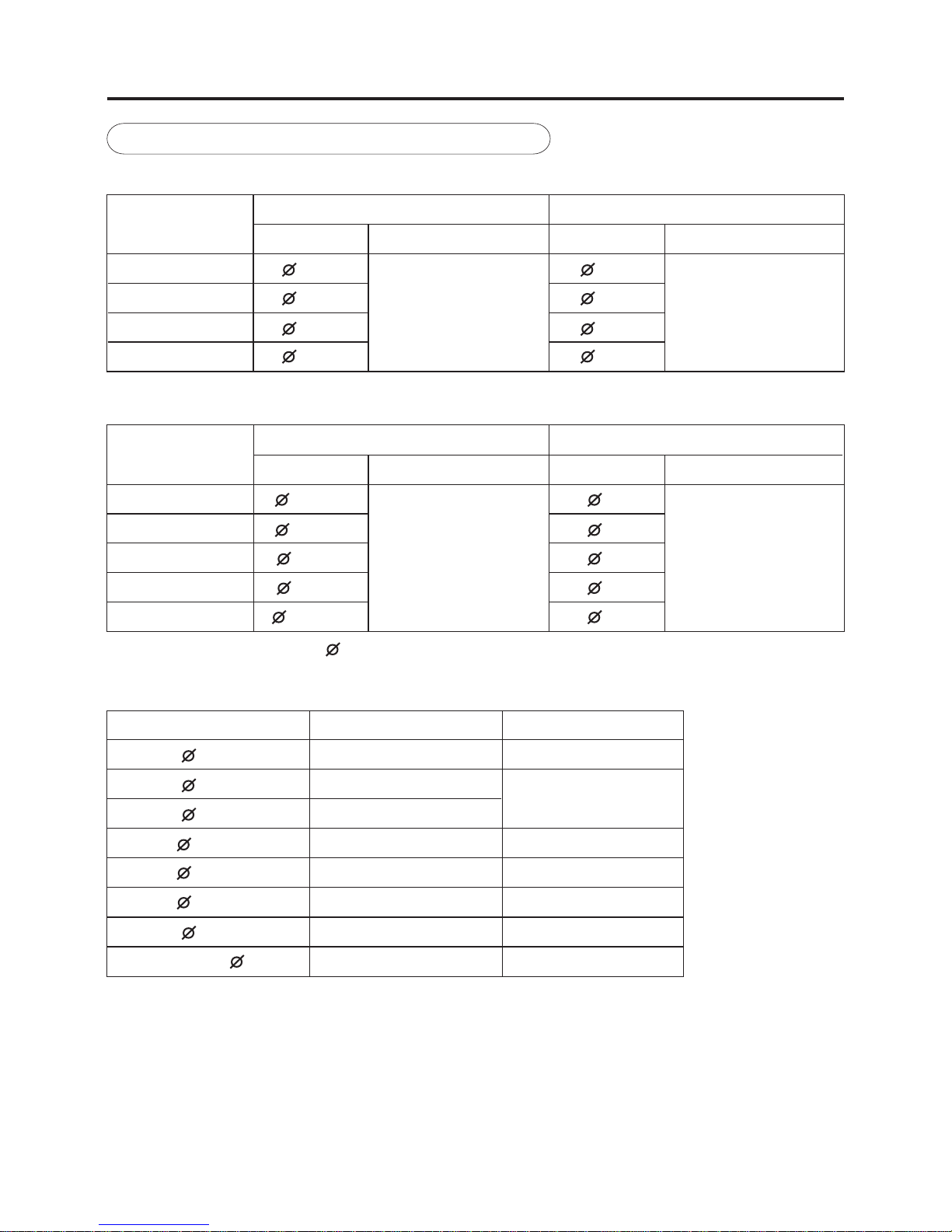

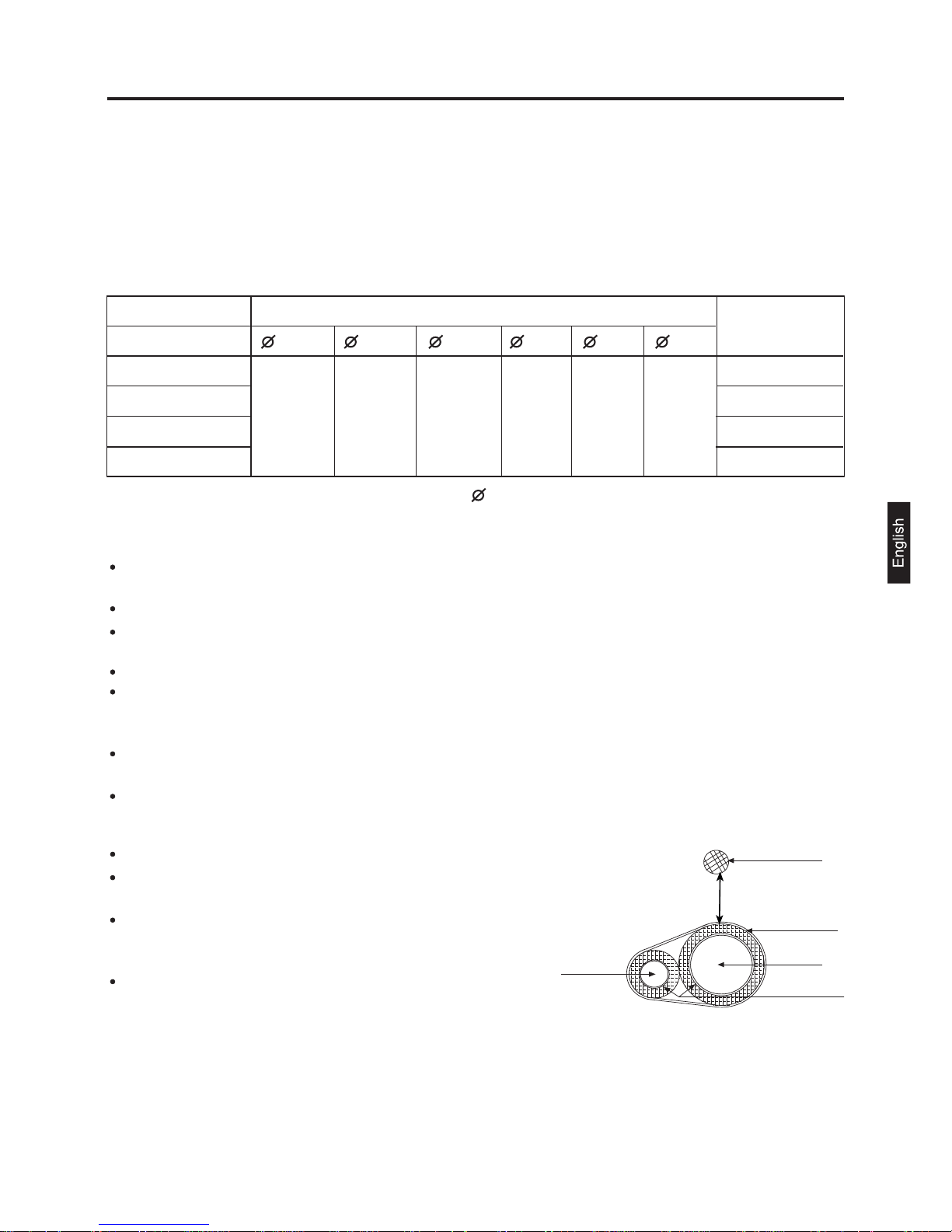

/=C9 EC97=:=75F=BAy

c

aa

b

b

aa

74 Uipe |a} diameter .between indoor and branch pipe/ .depends on indoor pipe/

88{8>

9<{;<

=7

?4;80 <49;

784= <49;

7;4>> ?4;8

Nndoor .x

766\/

Las pipe Qiquid pipe

84 Uipe |b} diameter .between branch pipes/

B778 7;4>>

7?46;778M]B89:

?4;8

Yotal indoor capacity after

the branch pipe .x766\/

?4;8

Las pipe Qiquid pipe

Sote@

\hen the distance from outdoor to the longest indoor is over 96m2 the main pipe should be the

enlarged diameter4

94 Uipe |c} diameter . outdoor pipe diameter/

Tutdoor capacity.766\/

>6

7;6

7>6

7;4>>

7?46;

7?46; ?4;8

Las pipe Qiquid pipe

?4;8

?4;8

Hopper pipe selection@

Sote@ Nf the copper pipe with outer diameter 7?46; is coil pipe2 the thickness should be over 7474

<49; ?4;8 784= 7;4>>

64> 64> 746 746

7?46; 88488 8;48: 8>4;>

746 747 748 74:

softness Malf3hardnesshardness

Tuter diameter

Rin4 thickness

0FX6?8RHJWF-s gas pipe is

784=

Nnstallation procedure

=

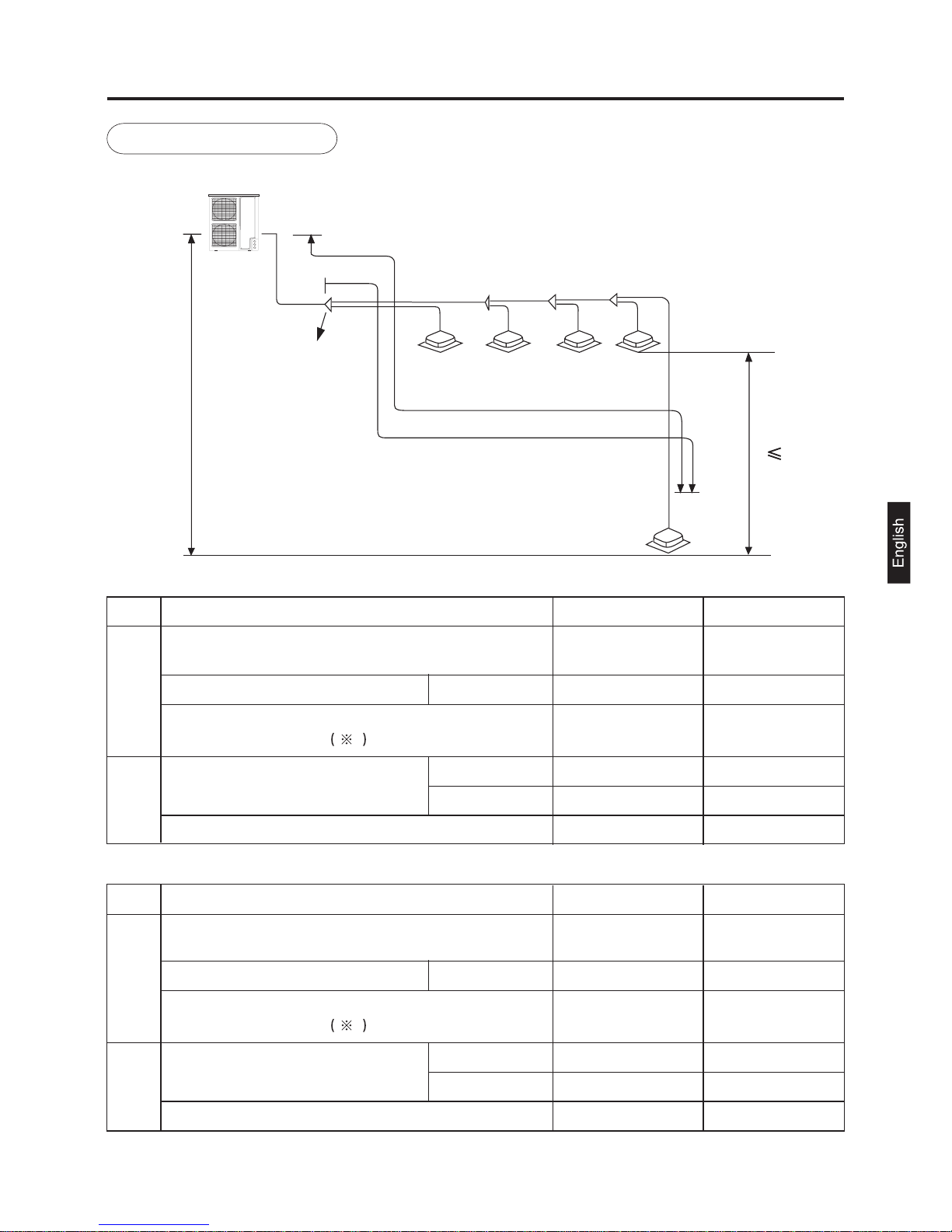

-BA; C=C9 5A8 <=;< 8DBC

74 Fllowable pipe length and height difference

Qength of the longest piping after the

first branch piping Q

g

Q

:

hi

Qength of the longest piping Q

Q

8

Q

7

h 76m

f

Q

9

ab

c

d

e

Tutdoor unit

Kirst branch piping

Nndoor unit

Irop height between indoor and outdoor units

Irop height between

indoor units

Uiping length

Irop

height

\\

\\

\\

Uiping part

766m

=6m

96m

96m

86m

76m

Uermissible value

Qongest piping Q

Uiping length of indoor unit which is furthest to the

first branch piping Q

Irop height between indoor and

outdoor unit M

Irop height between indoor units h

Yotal length of piping .actual length/

Fctual length

Zp outdoor

Znder outdoor

FZ:>{<6 type@ Raximal length and drop height permissible of refrigerant piping

Q81Q91Q:1e

Q71Q81Q91Q:1a

1b1c1d1e

Q71Q81Q91Q:1e

Uiping length

Irop

height

\\

\\

\\

Uiping part

;6m

9;m

7;m

96m

86m

76m

Uermissible value

Qongest piping Q

Uiping length of indoor unit which is furthest to the

first branch piping Q

Irop height between indoor and

outdoor unit M

Irop height between indoor units h

Yotal length of piping .actual length/

Fctual length

Zp outdoor

Znder outdoor

FZ8>8 type@ Raximal length and drop height permissible of refrigerant piping

Q81Q91Q:1e

Q71Q81Q91Q:1a

1b1c1d1e

Q71Q81Q91Q:1e

Nnstallation procedure

>

3A=F C=C9 EC97 5A8 7BAA97F=BA @9F<B8 pGA=Fy @@q

F4 Tutdoor unit

Rodel

7;4>>

7?46;

7?46;

Klared joint

?4;8

?4;8

?4;8

Klared joint

Las pipe side Qiquid pipe side

Iiameter Honnecting method Iiameter Honnecting method

FZ8>8KMJWF

FZ:>SKNJWF

FZ<6SKNJWF

G4 Nndoor unit

Las pipe side

Rodel

Hapacity

784=

7;4>>

Klared joint

Qiquid pipe side

Iiameter

Honnecting method

Iiameter

Honnecting method

8:

7>

7<

78

6?

Klared joint

?4;8

784=

784=

<49;

?4;8

<49;

<49;

<49;

H4 Uipe spec and the torque

Sot less than

8>4;>

diameter Yhickness.mm/

64>

64>

746

746

746

748

Yorque.S4m/

7<{86

:6{;6

?6{786

766{7:6

\\

<49;

?4;8

784=

7;4>>

7?46;

8;4:

Rore than 74:

747

88488

Sote@ Nf the copper pipe with outer diameter 7?46; is coil pipe2 the thickness should be over 7474

\\

\\

7?46; ?4;8

FZ:>8KNJWF

FX6?8RHJWF-s gas pipe is

784=

Nnstallation procedure

?

Tutdoor unit type

{D5A7< C=C9

total indoor capacity.766\/ model.optional/

less than 99; KVL3G99;F

Granch pipe selection@

Sote@

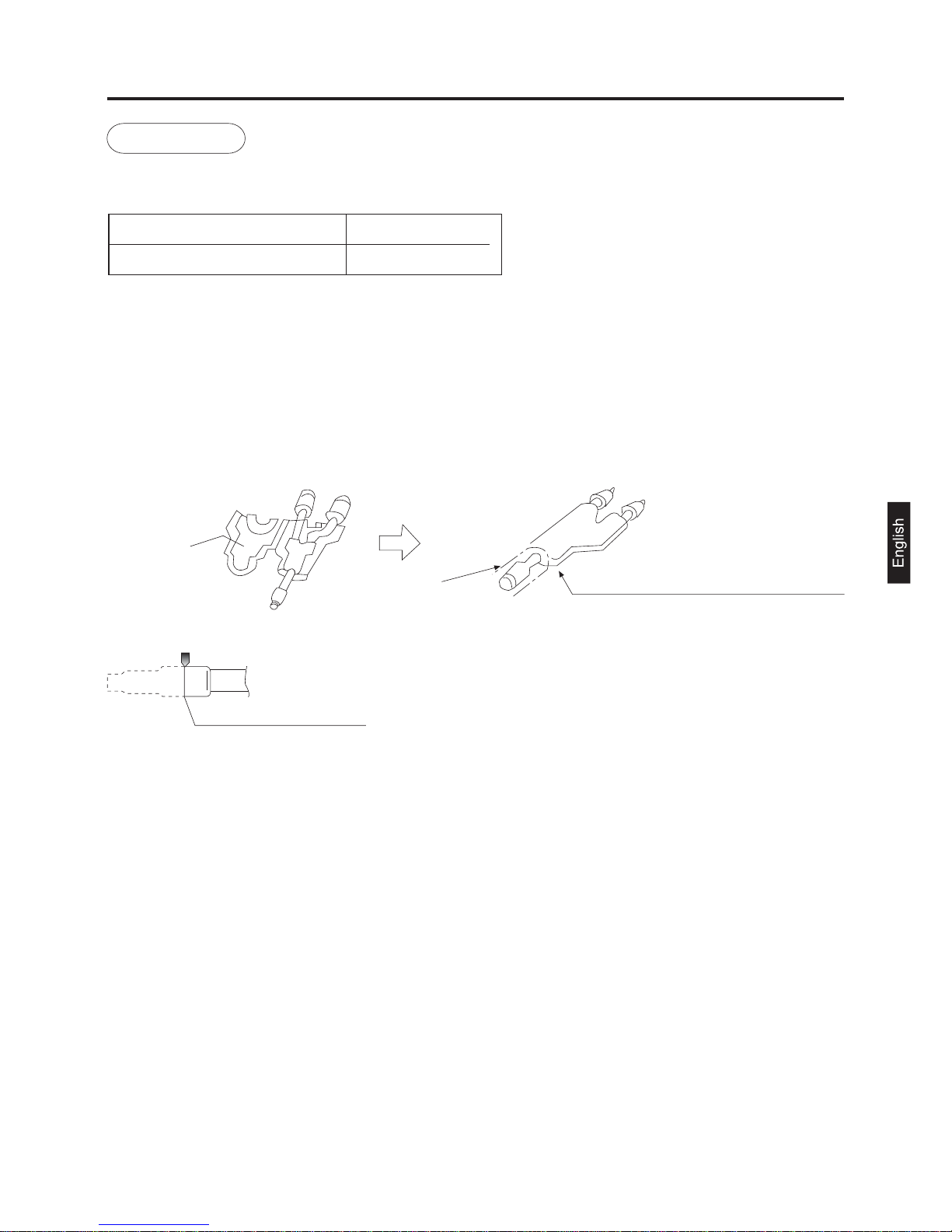

74 \hen connecting the pipe and the

outdoor2 please pay attention to the outdoor

pipe dimension4

84 \hen adjusting the diameter among

pipes and among the units2 please must execute at the branch pipe side4

94 \hen welding with hard solder2 please must blow nitrogen4 Nf not2 a number of oxide will be

produced and cause heavy damage4Gesides2to prevent water and dust into the pipe2 please

make the brim as outer roll4

Hut off pipe with the cutter

Hut off at the middle

Fdhesive side

Urepare on field

Xeal the connection and wrap the

heat insulator with adhesive tape

Nnstallation procedure

76

/=C=A; =AEF5??5F=BA

Ulease don-t let the pipe and the parts in the unit collide each other4

Yhe connection between outdoor liquid pipe and the distributing pipe is flared type4 Ulease

expand the pipe with the special tool for W:76F after installing the expanding nut4 Gut if the

projecting pipe length has been adjusted with the copper pipe gauge2 you can use the original

tool to expand the pipe4

Xince the unit is with W:76F2 the expanding oil is ester oil2 not the mineral oil4

\hen connecting the pipes2 close the valves fully4

Urotect the pipe end against the water2 impurity into the pipes .welding after being flat2

or being sealed with adhesive tape/4

Gend the pipe as large semi3diameter as possible.over : times of the pipe diameter/4

\hen connecting the expanding pipe2 fasten the pipes with double3spanner4 Yhe torque refers

to the former info4

Nmportant

F

F

6

364:

<49;

?4;8

784=

7;4>>

?47

7948

7<4<

7?4=

Jxpanding pipe@F.mm/

G

pipe outer

diameter

Urojecting length of pipe to be expanded@G.mm/

<49;

?4;8

784=

7;4>>

when it is hard pipe

6364; 746374;

pipe outer

diameter

special tool

for W:76F

the former

tool

welding

adhesive tape

flat

Urotect the pipe end against the water2 impurity into the pipes .welding after being flat2 or being

sealed with adhesive tape/4

Xeal the pipe end with adhesive tape or the stopper

to increase the resistance2 fill up the pipe with nitrogen4

BS8D

taping

Tnly nitrogen

gas can be used

brazing

Yhe outdoor gas pipe and the refrigerant distributing pipe2 as well the refrigerant distributing

pipe and the branch pipe should be welded with hard solder4

\eld the pipe at the same time charge the nitrogen4 Tr it will cause a number of impurity .a

film of oxidation/ to clog the capillary and the expansion valve2 further cause the deadly failure4

Nnstallation procedure

77

source valve

7st side

8nd side

hand

648RUa

Yhe refrigerant pipe should be clean4 Yhe nitrogen should flow under the pressure of about

648Rpa and when charging the nitrogen2 stop up the end of the pipe by hand to enhance the

pressure in the pipe2 then loose the hand .meanwhile stop up the other end/4

\hen welding the valve and the pipes2 use the wet cloth to cool down the valve and the

pipes4

\hen connecting the pipes2 close the valves fully4

{s -95>5;9 F9EF

74 Yhe outdoor unit has been executed the leakage test in the factory4 Ffter connecting the

distributing pipe2 execute the leakage test from the outdoor check valve and the indoor4

Gesides2 while testing2 the valves should be close4

84 Wefer to the below figure to charge the nitrogen into the unit to take a test4 Sever use the

chlorin2 oxygen2 flammable gas in the leakage test4 Fpply pressure both on the gas pipe and the

liquid pipe4

94 Fpply the pressure step by step to the target pressure4

a4 Fpply the pressure to 64;RUa for more than ; minutes2 confirm if pressure goes down4

b4 Fpply the pressure to 74;RUa for more than ; minutes2 confirm if pressure goes down4

c4 Fpply the pressure to the target pressure .:46RUa/2 record the temp4 and the pressure4

d4 Qeave it at :46RUa for over 7 day2 if pressure does not go down2 the test is passed4

Reanwhile2 when the temp4 changes for 7degree2 pressure will change 6467RUa as well4

Horrect the pressure4

e4 Ffter confirmation of a{d2 if pressure goes down2 there is leakage4 Hheck the brazing

position2 flared position by laying on the soap4 modify the leakage point and take another

leakage test4

:4 Ffter leakage test2 must execute the evacuation4

gauge manifold

Qo

Mi

Qo handle

Mi handle

nitrogen

to indoor

outdoor

gas pipe

check valve

gas pipe

check hole

Nnstallation procedure

78

|s ~H57G5F=BA

Jvacute at the check valve of liquid stop valve and both sides of the gas stop valve4

Yo prevent the different oil into the pipe2 please use the special tool for W:76F2 especially for

gauge manifold and charging hose4

Yo prevent the compressor oil into the refrigerant cycle2 please use the anti3counter3flow

adapter4

Gecause the unit is with refrigerant W:76F2 the below issues should be paid attention@

Yighten torque as the table below@

less than =

=4>;

.RF]7;4=/

less than 96

8?4:

.RF]9?48/

79

>4>

.RF]7:4=/

shaft

.valve body/

cap

.cover/

Y3shape nut

.check joint/

Yighten torque S4m

for gas pipe

for liquid

pipe

}s |<97> H5?H9 BC9D5F=BA

Tpen5close method@

Yake down the valve cap4

Yurn the liquid stop valve and the gas stop valve with hexangular spanner until it stops4 Nf

opening the valve strongly2 the valve will be damaged4

Yighten the valve cap4

Tperation procedure@

leakage test passed

evacuation begins

evacuation ends

check vacuum

charge refrigerant

after reaching 3767PUa or less

.below 3=;;mmMg/2 let the

vacuum pump running

continuously for over 7hour4

leave it for over 7

hour2 vacuum

pointer does not

arise4

if vacuum pointer arises2 it shows there is water or leakage in the

system2 please check and modify it2 and then evacuate again4

~s z88=F=BA5? D9:D=;9D5AF 7<5D;=A;

Hharge the additional refrigerant as liquid state with the gauge4

Nf the additional refrigerant can not be charged totally when the outdoor stops2 charge it at the

trial mode4

Nf the unit runs for a long period in the state of lack of refrigerant2 compressor will occur failure4

. the charging must be finished within 96 minutes especially when the unit is running2 menawhile

charging the refrigerant/4

Nnstallation procedure

79

Sote@

Yo prevent the different oil into the pipe2 please use the special tool for W:76F2 especially for

gauge manifold and charging hose4

Rark the refrigerant type in different colour on the tank4 W:76F is pink4

Rust not use the charging cylinder2 because the W:76F will change when transferring to the

cylinder4

\hen charging refrigerant2 the refrigerant should be taken out from the tank as liquid state4

Rark the counted refrigerant volume due to the distributing pipe length on the label4

*=J F<9 D9:D=;9D5AF C=C9

Nn operation2 the pipe will vibrate and expand or shrink4 Nf not being fixed2 the refrigerant will

focus on one part to cause the broken pipe4

Yo prevent the central stress2 fix the pipe for every 839m4

Sote@ Kor

FZ8>8KMJWF

2 when pipe diameter is <49;2 if the pipe length is within 7;m2 additional

refrigerant is unnecessary4

Rodel 88488 7?46; 7;4>> 784= ?4;8 <49;

649; 648; 647= 6477 646;: 64688

additonal refrigerant charging per meter.kg5m/

charge when

out of factory

84<kg

:4>kg

;46kg

FZ8>8KMJWF

FZ<6SKNJWF

FZ:>SKNJWF

H4 Wefrigerant charging and additional charging

F4 Hharging amount when out of factory excludes the refrigerant in the pipe4

G4 Yhe unit only is charged the standard volume of refrigerant .distributing pipe length is 6m/4

Fdditional charging amountCactual length of liquid pipe x additional amount per meter liquid pipe

Fdditional charging amountCQ7L649;1Q8L648;1Q9L647=1Q:L64771Q;L646;:1Q<L64688

Q7@ total length of 88488 liquid pipe Q8@ total length of 7?46; liquid pipe

Q9@ total length of 7;4>> liquid pipe Q:@ total length of 784= liquid pipe

Q;@ total length of ?4;8 liquid pipe Q<@total length of <49; liquid pipe

:4>kgFZ:>8KNJWF

Honnectionwire

Qiquid pipe

Meat insulator

Las pipe

Fdhesive tape

over 86cm

+95F =AEG?5F=BA

Las pipe and liquid pipe should be heat insulated separately4

Yhe material for gas pipe should endure the high temperature over

786O4Yhat for liquid pipe should be over =6O`

Yhe material thickness should be over 76mm2 when ambient temp4

is 96O2 and the relative humidity is over >6,2 the material thickness

should be over 7;mm4

he material should cling the pipe closely without gap2

then be wrapped with adhesive tape4 Yhe connection

wire can not be put together with the heat insulation material and

should be far at least 86cm4

Nnstallation procedure

7:

xr@=AGF9 89?5K :GA7F=BA

Nf starting up the unit after being powered off2 the compressor will run about ; minutes later

against being damaged4

|BB?=A;t<95F=A; BC9D5F=BA

Nndoor units can be controlled individually2 but cannot run in cool and heat mode at the same

time4 Nf the cool mode and the heat mode are existing simultaneously2 the unit set latter will be

standby2 and the unit set earlier will run normally4 Nf the F5H manager sets the unit at cooling or

heating mode fixedly2 the unit can not run at the other modes4

Nn operation if outdoor temp4 arises2 indoor fan motor will turn to low speed or stop4

+95F=A; @B89 7<5D57F9D=EF=7

}9:DBEF=A; =A <95F=A; @B89

Nn heating mode2 outdoor defrosting will affect the heating efficiency4 Yhe unit will defrost for

about 8{76 minutes automatically2 at this time2 the condensate will flow from outdoor2 also in

defrosting2 the vapour will appear at outdoor2 which is normal4 Nndoor motor will run at low speed

or stop2 and outdoor motor will stop4

2<9 GA=F BC9D5F=BA 7BA8=F=BA

Yo use the unit properly2 please operate the unit under the allowed condition range4

Nf operating beyond the range2 the protection device will act4

Yhe relative humidity should be lower than >6,4 Nf the unit runs at the humidity over >6, for a

long period2 the dew on the unit will drop down and the vapour will be blowed from air outlet4

Migh pressure switch is the device which can stop the unit automatically when the unit runs

abnormally4

\hen the high pressure switch acts2 the cooling5heating mode will stop but the running QJI on

wired controller will be light still4 Yhe wired controller will display failure code4

\hen the following cases occur2 the protection device will act@

Nn cooling mode2 air outlet and air inlet of outdoor are clogged4

Nn heating mode2 indoor filter is sticked with ductA indoor air outlet is clogged4

\hen protection device acts2 please cut off the power source and re3start up after eliminating

the trouble4

/DBF97F=BA 89H=79 pEG7< 5E <=;< CD9EEGD9 EI=F7<q

Yrial operation and the performance

7;

4<9A CBI9D =E :5=?GD9

\hen power is failure in running2 all the operations will stop4

Ffter being electrified again2 if with re3satrt up function2 the unit can resume to the state before

power off automaticallyA if without re3satrt up function2 the unit needs to be switched on again4

\hen abnormal occurs in running because of the thunder2 the lightning2 the interference of car

or radio2 etc2 please cut off the power source2 after eliminating the failure2 press +TS5TKK+ button

to start up the unit4

+95F=A; 75C57=FK

Yhe heating mode adopts the heat pump type that absorbs outdoor heat energy and releases

into indoor4 Xo if outdoor temperature goes down2 the heating capacity will decrease4

indoor model@

Woom So4

e4g4 Nndoor F2 system 72 Kloor 8 8K37F

1KEF9@ @5D>E

Tn the condition that multi RW[NN3X systems are installed2 in order to confirm the relationship

between outdoor and indoor2 please make marks on outdoor electric control box cover to indicate

the connected indoor unit4 Fs the below figure@

2D=5? BC9D5F=BA

Yrial operation

Nn trial operation2 refer to the information of performance section4 \hen the unit can not start

up at the room temperature2 make trial operation for outdoor4

Honfirm the compressor bottom getting hot4

Jxcept for the condition that there is only one master unit connected .no slave unit/2 under the

other conditions2 open fully the outdoor operating valves .gas side2 liquid side/4 Nf operating the

unit without opening the valves2 compressor failure will occur4

Honfirm all indoor units being electrified4 Nf not2 water leakage will occur4

Reasure the system pressure with pressure gauge2 at the same time2 operate the unit4

Gefore trial operation@

Gefore being electrified2 measure the resistor between power terminal block .live wire and neutral

wire/ and the earthed point with a multimeter2 and check if it is over 7R

4 Nf not2 the unit can

not operate4

Yo protect compressor2 electrify the outdoor unit for at least 78 hours before the unit runs4Nf the

crankcase heater is not electrified for < hours2 the compressor will not work4

Yrial operation and the performance

7<

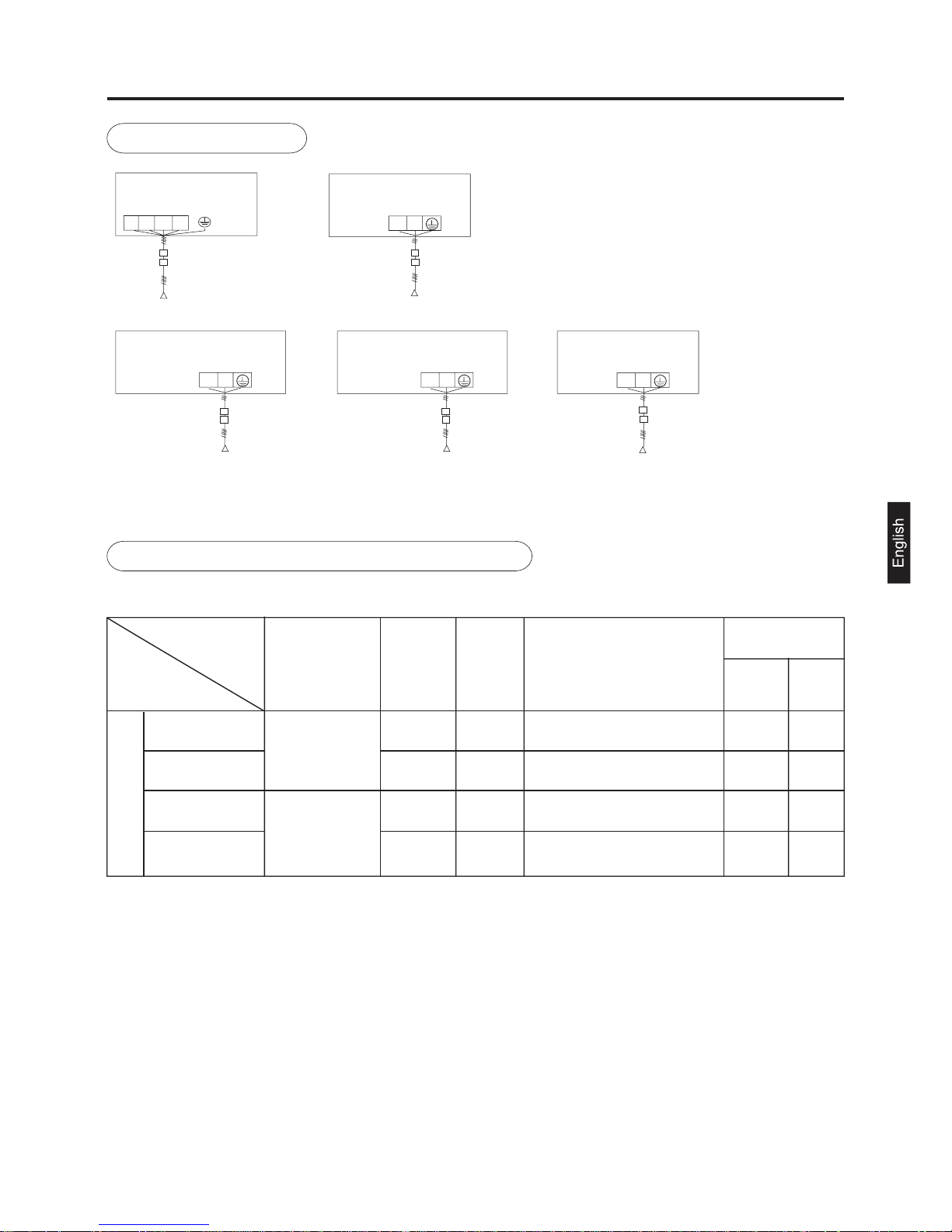

|B@@GA=75F=BA I=D=A; :=;GD9

< =89:

89: 89:

indoor 9

< =89:

indoor :

< =8 9 :

indoor ;

< =89 :

indoor <

< =89:

89: 89: 89:

outdoor

< =

indoor 7

< =89 :

indoor 8

89

:

communication wire with polarity

wired

controller

wired

controller

wired

controller

wired

controller

wired

controller

wired

controller

Yhe outdoor and all indoor units are in parallel through 8 non3polar wires4

Yhree wiring methods between wired controller and indoor unit@

F4 7 to multi .group control/@ one wired controller controls 8{7< indoors2 as shown in above figure2

indoor 7{indoor 8@ indoor 8 is wired control master unit2 the others are wired control slave units4

\ired controller and the master indoor .directly connected to wired controller/ is connected by 9

polar wiresA the other indoors and the master indoors are connected by 8 polar wires4

G4 7 to 7 .one wired controller controls one indoor/@ as shown in above figure2 indoor 9{ indoor

:2 indoor and wired controller are connected by 9 polar wires4

H4 8 to 7 .two wired controller controls one indoor/@ as shown in above figure2 indoor <4 Jither of

wired controllers can be set as master wired controller2 and the other is slave wired controller4

Raster5slave wired controller2 and master5indoor are connected by 9 polar wires4

\hen indoor is controlled by remote controller2 refer to the +wired control master unit5wired control

slave unit5remote control unit table+4F2 G2 H on signal terminal block need not wires and not connect

the wired controller4

Jlectric wiring and the application

7=

/BI9D I=D=A; :=;GD9

Nndoor and outdoor use their individual power source4 Fll indoors use one power source4 Rust

install the leakage breaker and the over current breaker2 or electric shock will occur4

a4 Uower cable must be fixed firmly4

b4 Jach outdoor must be earthed well4

c4 \hen power cable exceeds the range2 thichen it appropriately4

leakage breaker

Q7

Q8

Q9

S

outdoor

power source@ 9S{2 9>63:66[2 ;6Mz

Q

S

indoor 9

.non wall mounted unit/

power source@ 7UM2 8863896[{2 ;6Mz

Q

S

indoor 7

.wall mounted unit/

power source@ 7UM2 8863896[{2 ;6Mz

over current breaker

leakage breaker

over current breaker

Q

S

indoor 8

.wall mounted unit/

power source@ 7UM2 8863896[{2 ;6Mz

leakage breaker

over current breaker

over current breaker

leakage breaker

FZ:>{<6SKNJWF

Q

S

outdoor

power source@ 7UM2 8863896[{2 ;6Mz

over current breaker

leakage breaker

FZ8>8KMJWF

FZ:>8KNJWF

1C97E :BD CBI9D 756?9 5A8 7B@@GA=75F=BA I=D9

7UM2

8863896[{2

;6Mz

74 Tutdoor power source and power cable

FZ8>8KMJWF

model

circuit

breaker

.F/

power

cable

section

.mm

8

/

earthing wire

section

.mm

8

/

screw

item

<R;

power

source

individual power

9S{2

9>63:66[2

;6Mz

rated current of residual

current circuit breaker.F/

leakage current .mF/

response time.s/

96F 96mF below 647X

FZ:>SKNJWF

FZ<6SKNJWF

<

:

:

96

86

86

86F 96mF below 647X

86F 96mF below 647X

:R;

:R;

FZ:>8KNJWF 76 ;6 ;6F 96mF below 647X 76 R;

Jlectric wiring and the application

7>

84 Nndoor power source2 communication wire between indoor and outdoor2 among indoors

a4 Uower cable and communication wire must be fixed firmly4

b4 Jach indoor must be earthed well4

c4 \hen power cable exceeds the range2 thichen it appropriately4

d4 Xhielded layer of communication wires must be connected together and be earthed at single

point4

e4 Hommunication wire total length cannot exceed 7666m4

item

power

cable

section

.mm8/

wire

length

.m/

j

76

x76 and j7;

x7; and j88

x88 and j8=

8

94;

;4;

76

89

8:

8=

:8

86

96

:6

;6

86F2 96mF2 below 647s

96F2 96mF2 below 647s

:6F2 96mF2 below 647s

;6F2 96mF2 below 647s

83core L .64=;3846mm

8

/

shielded wire

indoor total

current .F/

rated current

of overcurrent

breaker.F/

communication wire section

outdoor5indoor

.mm

8

/

indoor5indoor

.mm

8/

rated current of residual

current circuit breaker.F/

leakage current .mF/

response time.s/

94 Hommunication wire for wired controller

a4 Xhielded layer of communication wire must be earthed at one end4

b4 Yhe total length cannot exceed <66m4

v766

x766 and j866

x866 and j966

wire length.m/ wire spec

649mm8w.93core/ shielded wire

wire length.m/ wire spec

64;mm8w .93core/ shielded wire

64=;mm

8

w .93core/ shielded wire

Nd66 and 7e66

Ne66 and 7g66

748;mm8w.93core/ shielded wire

8mm

8

w .93core/ shielded wire

HS89

HS87

F2G2H to wired

controller

signal terminal

block

TKK

TS

HS96

X\6>3_<`

TS

control type

socket

5dip switch

wired control

master unit

wired control

slave unit

remote control

short connected

short connected short connected

disconnected disconnected

disconnected

blank blank to remote receiver

G2H to wired

controller

F2G2H not to wired

controller

Sote@

74 Nn the above figure2 the state in the frame is set when out of factory4

84 Yhe indoor controlled by master5slave wired controller and the indoor controlled by

individual wired controller are all wired controlled master indoor4

94 Yhe remote receiver is equipped with a wire which can be inserted in HS874

:4 Hontrol type and the switchover

a/ Nndoor unit can be controlled by wired controller or remote controller4

b/ \hen installation2 the installer must set the unit due to the control type and wiring type4

Xwitchover between wired control master5slave unit 5remote control unit2 set when installation@

Jlectric wiring and the application

7?

So4 setting type setting method remarks

Xet by hand

Xet by

wired

controller

set on field

74X\68 on indoor UHG is TS .upper/A

84 Yhe detailed position refers to the below table4

set on field

74 X\68 on indoor UHG is TKK.down/2 set when out of

factory4

84 Uress +KNQYJW+ on wired controller continuously for 76

seconds into central control setting mode2 and select the

indoor central control address by +YJRU153+4

94 Yemp4 area indicates@ system address1]]2 press +YJRU153

+2 the unit number will change +66{9K+ .66 is So472 9K

is So4<:/2 and the initialization is 664

:4 Ffter selecting the number2 press +XJY+ to save itA if

pressing other buttons or no pressing within 7; seconds2

it will quit automatically and keep the former setting4

7

8

central

control

address

central

control

address

X\68

789:;<=>

6666666

6666667

6666676

6666677

6666766

6666767

6666776

6666777

6667666

6667667

6667676

6667677

6667766

6667767

6667776

6667777

6676666

6676667

6676676

6676677

6676766

X\68

789:;<=>

central

control

address

N

O

P

Q

R

S

T

U

V

NM

NN

NO

NP

NQ

NR

NS

NT

NU

NV

OM

ON

789:;<=>

6767776

6767777

6776666

6776667

6776676

6776677

6776766

6776767

6776776

6776777

6777666

6777667

6777676

6777677

6777766

6777767

6777776

6777777

QT

QU

QV

RM

RN

RO

RP

RQ

RR

RS

RT

RU

RV

SM

SN

SO

SP

SQ

X\68

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

7

6676776 OP7

6676767 OO

7

6767767 QS

7

6767766 QR

7

6767677 QQ

7

6676777 OQ7

6677666 OR7

6677667 OS7

6677676 OT7

6677677 OU

7

6677766 OV7

6677767 PM7

6677776 PN7

6677777 PO7

6766666 PP7

6766667 PQ7

6766676 PR7

6766677 PS7

6766766 PT7

6766767 PU7

6766776 PV7

6766777 QM7

6767666 QN7

6767667 QO7

6767676 QP7

Nndoor central control address table .set by hand/

Hommunication address between indoor and outdoor setting by hand@

7st2 8nd bit of X\69 are TS2 the latter six bits can confirm the communication address2 the address

setting refers to the +central control address setting table+4 Kor example2 the communication

address is >2 the dip switch of X\69 is 776667774

us ,A8BBD 79AFD5? 7BAFDB? 588D9EE E9FF=A; @9F<B8

Jlectric wiring and the application

86

74Yhe communication

address between

master5slave wired

controller and the outdoor

is different4

84 Nf central control is

necessary2 all indoor

central control addresses

in one group are identical2

while the indoor address

in different groups is

different too4

HS89

HS87

F2G2H to wired

controller

signal

terminal

block

TKK

TS

HS96

X\6>3_<`

TS

indoor UHG

wired control

master unit

wired control

slave unit

remote control

short connected

short connected short connected

disconnected disconnected

disconnected

blank blank to remote receiver

G2H to wired

controller

F2G2H not to wired

controller

+6+

X\67

_7`3_:`

7{7; .different

dialing setting

on X\67 for

the slave units

in one group

+6+

remarks

Sote@ Nn the above figure2 the state in the frame is set when out of factory4

vs ,A8BBD 7BAFDB? FKC9 E9?97F=BA

X\67

_7`3_:`

74 \hen one wired controller controls one indoor2 multiple

wired controllers control one indoor2 or indoor is controlled

by remote controller2 the switch needs not be changed4

84 \hen one wired controller controls multiple indoors2 the

switch of master unit is 62 while the slave units are at the

position from 7 to 7;4

at +6+

X\68

all at

+TKK+

X\69

74 \hen setting central controlled address by wired controller2

it need not change4

84 \hen setting central controlled address by hand2 refers

to the setting table74

HS8<

HS8;

output in series2 connected to testing device4

HS8=

HS8>

HS89

\hen being controlled by wired controller2 it is connectedA

when being controlled by remote controller2 it is disconnected4

indoor UHG

item

parts state function

dip switch

all at

+TKK+

connected

disconnected

disconnected

disconnected

disconnected

\hen setting communication address between indoor and

outdoor automatically2 it needs not change4 \hen setting by

hand or by wired controller2 refers to the setting table84

connected after being powered on2 indoor JJ[ opens 8

minutes fully4

connected after being powered on2 indoor in time shorting

function

jumper

ws19FF=A; EF5F9 5A8 F<9 :GA7F=BA 89:=A5F=BA B: /|{ 5A8 I=D98 7BAFDB??9D I<9A BGF B: :57FBDK

Jlectric wiring and the application

87

red

green

red

green

yellow

failure

indicator of communication with wired controller4 Xhows indoor

sending signal to wired controller

indicator of communication with wired controller4 Xhows indoor

receiving signal from wired controller

QJI72 QJI8 used in combination4 Nf communication between

wired controller and indoor is normal2 QJI72 QJI8 will flash

regularly4Nf there is slave wired controller2 KV^ of QJI7 of

slave controller will be low4

indicator of communication with outdoor4 Xhows indoor sending

signal to outdoor

indicator of communication with outdoor4 Xhows indoor receiving

signal to outdoor

QJI92 QJI: used in combination4 Nf communication between

indoor and outdoor is normal2 QJI72 QJI8 will flash regularly4

KV^ of red QJI is lower than that of green QJI4

in normal state2 it is TKK4 Honfirm the failure due to the indicator

flashes times

in normal state2 it is TKK4 Nndicate when JJ[ is open5close

fully4

HS96

TS@ change high5mid5low fan speedA TKK@ the fixed fan

speed.for duct type/4

HS8?

HS97 indoor trial operation

TS

dip switch

disconnected

connected

disconnected

TS

TS

TS

connected after being powered on2 indoor JJ[ closes 8

minutes fully4

\hen being controlled by wired controller2 it is connectedA

when being controlled by remote controller2 it is disconnected4

TS@ be controlled by wired controllerA TKK@ be controlled by

remote controller

indoor UHG

item

parts

state

function

jumper

01O

Fir inlet temp4 YF compensation value

X\6=3_;`

TS

TS

TKK

TKK TKK

TS

TKK

TS

YF correction valueX\6=3_:`

/O+EIH EB B>?HEFK,

3O

5O

indicator

X\6>

3_<`

X\6>

3_7`

X\6=

3_;`

X\6=

3_:`

QJI7

QJI8

QJI9

QJI:

QJI;

QJI<

Jlectric wiring and the application

88

item

parts state function

7

changeover between

celsius and fahrenheit

TKK

TS

TKK

O69

O6< 7

6O6=

dip switchresistor

wired controller

diode

TKK

changeover between

master and slave

wired controller

set as slave wired controller

set as master wired controller

set as Kahrenheit

set as celsius

selection of room

temp4 display

no room temp4 display

room temp4 display

position selection of

room temp4sensor

adopt the room temp4sensor in

indoor

adopt the room temp4sensor in

wired controller

auto restart selection

with auto restart function

without auto restart function

time3shorting function

indoor time shorting

without time shorting

compulsory defrost

send compulsory defrost signal

to indoor

normal state

Tnly when two wired controllers control one indoor2 one of the wired controllers can be set as

slave wired controller4

TS

Jlectric wiring and the application

X\67

37

TS

TKK

X\67

38

TS

TKK

I8

I7 TKK

6

7

6

7

6

7

TKK

TKK

Loading...

Loading...