Haier AU282FHAHA Service Manual

Commercial Air Conditioner

Service Manual

Model:

AU282FHAHA

Features:

●Single AC inverter compressor unit

●Central control by one central controller

●Auto-restart

●Max. 5 indoor units can be connected

●Refrigerant: R22

●Super long piping length and large drop

between indoor unit and outdoor unit

●Individual operation for every indoor uint, energy saving

● Negative ion generator(optional)

MANUAL CODE:SYJS-019-05 rev. 0 Edition:2005-01-25

Commercial Air Conditioner Model: A282FHAHA

CONTENTS

Contents……..............................................…...………...……........1

1. Description of Products & Features….......………………...…….2

2. Specifications…………………………. ………………..........……6

3. Safety precaution………………………….........…………………7

4. Net dimensions of outdoor unit…….......…………......................9

5. Installation instructions ………………….......…. ………………..10

6. Parts and functions …………………......………..…… ..………..27

7. Remote controller functions………………………….……….......28

8. Refrigerant diagram…………………………..……………...........29

9. Electrical control functions……………………………………......30

10. Diagnostic information(trouble shooting)…………….…….......42

11. Electrical data.........................................…………….…….......45

12. Exploded views and parts lists...............……………. …….......49

13. Perdormance curves……………............................... …….......53

14. Noise level charts.....……………............................... ……......54

- 1 -

Commercial Air Conditioner Model: A282FHAHA

1. Description of product & features

1.1 Nomenclature

A U 28 2 F H A H A

1 2 34 5 6 7 8 9 10

1:Product type symbol ( A stands for air conditioner)

2:Product model ( U stands for air conditioner outdoor unit)

34: Product specification ( 28 stands for nominal cooling capacity is 28000

BTU)

5:Applicable voltage ( 2 stands for 1PH/220 V/50 Hz)

6:Product series ( F stands for free combination)

7:Appearance character ( H stands for 3 HP outdoor unit)

8:Product type ( A stands for heat pump type, refrigerant is R22)

9:Design serial number

10:Climate type ( A stands for T1 climate)

- 2 -

Commercial Air Conditioner Model: A282FHAHA

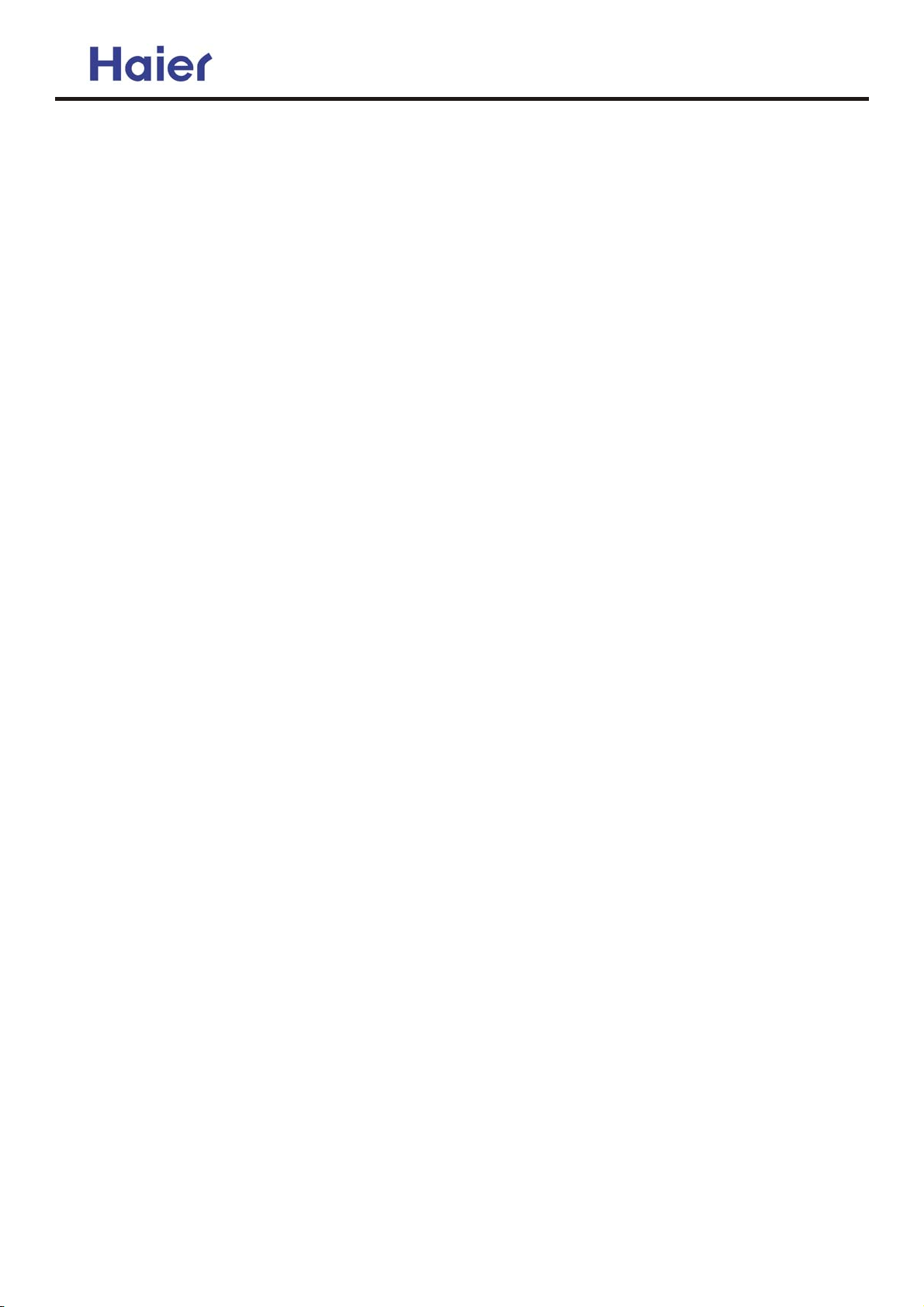

1.2 Outdoor unit parameters

Note:

AU282

FHAHA

Refrig

erant

R22 28000 32000 14000 36000 5

Nominal

capacity(BTU/h)

cooling heating Min. Max.

Indoor units capacity

connected(BTU/h) Appearance Model

Max.

indoor

units

1. The designed capacity when installing(total capacity of indoor units

connected to outdoor unit) < 130% of rated capacity of the outdoor unit.

2. Total working capacity of indoor units should be not over 100% of rated

capacity of the outdoor unit.

3. All the indoor units of the H-MRV series can be matched freely under

the 130% of the its cooling capacity(28000Btu/h), but when the matching

capacity of indoor units exceeds 100% of the outdoor unit, the efficiency

will reduce.

- 3 -

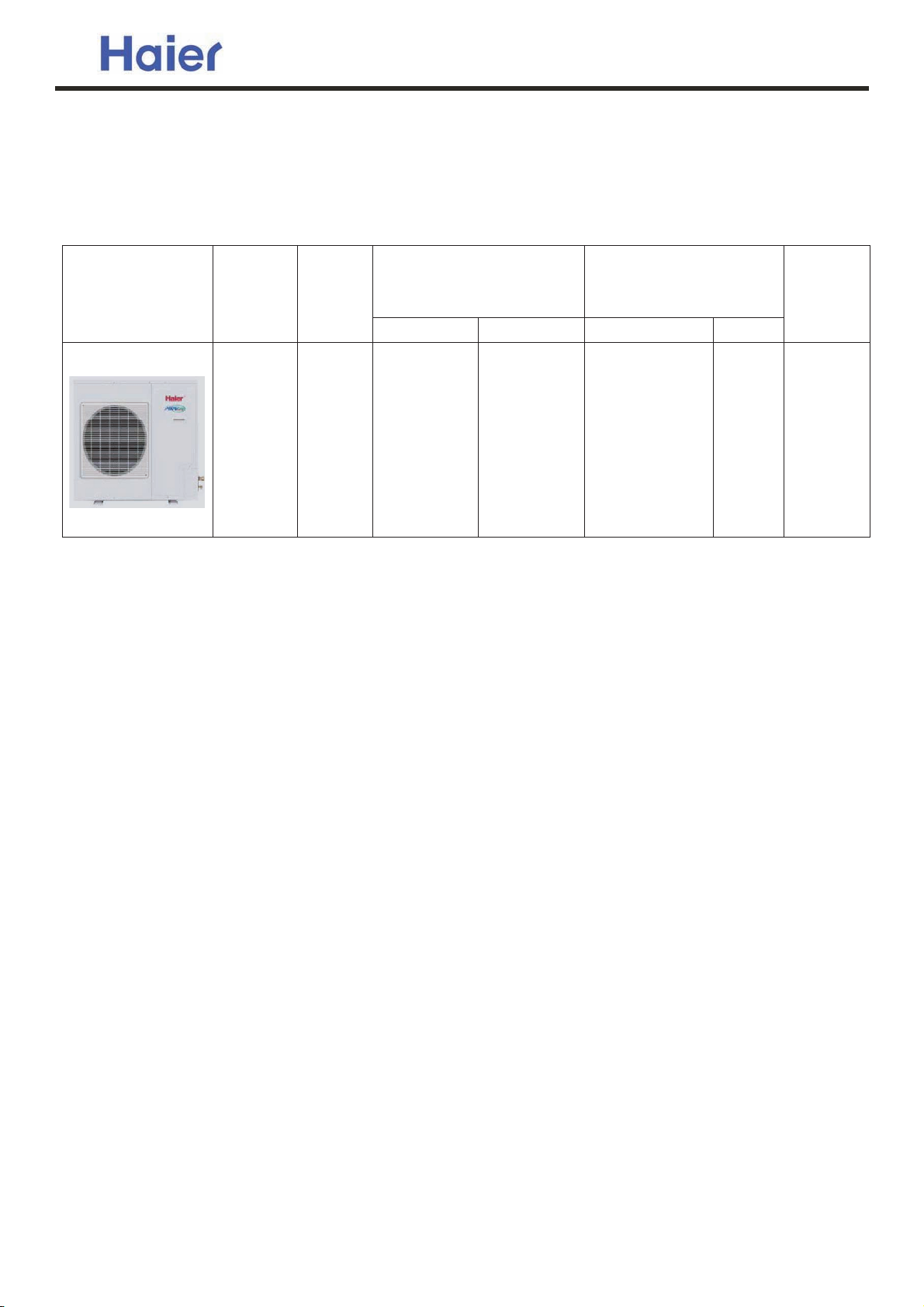

1.3 Types of indoor units

type appearance model refrigerant

Four way cassette

Commercial Air Conditioner Model: A282FHAHA

capacity(BTU/h)

cooling heating

AB092FCAHA R22 9000 12000

AB142FCAHA R22 14000 17000

AB182FCAHA R22 18000 21000

Convertible AC182FCAHA R22 18000 21000

AE072FCAKA R22 7000 9000

AE242FCAKA R22 24000 28000

AE092FCAKA R22 9000 11000

Ceiling concealed

Cabinet

AE122FCAKA R22 12000 14000

AE142FCAKA R22 14000 16000

AE182FCAKA R22 18000 21000

AE212FCAKA R22 21000 24000

AP182FAAHA R22 18000 21000

Wall-mounted

AS062FMAHA R22 6000 8000

AS072FMAHA R22 7000 9000

AS092FMAHA R22 9000 13000

AS122FMAHA R22 12000 14000

AS182FTAHA R22 18000 21000

- 4 -

Commercial Air Conditioner Model:

AU282FHAHA

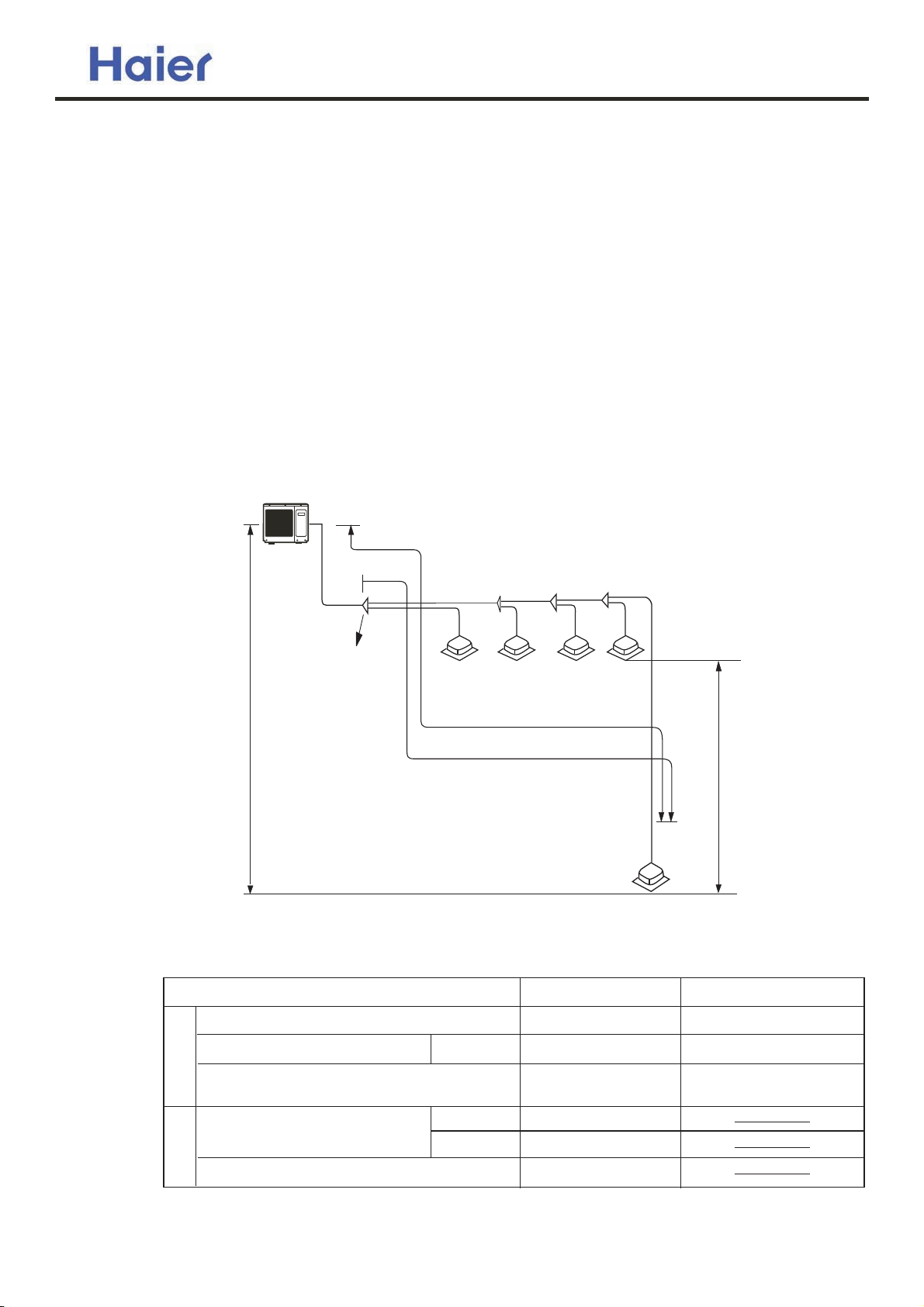

1.4. Character of Products

1) The length of horizontal refrigerant pipe can be 35m,the total pipe length can reach

50m, the height difference between indoor units and outdoor unit can reach 30m, the

height drop between indoor units can be up to 10m. Refer to the figure below.

2) 1000m super far distance communication between indoor and outdoor units, convenient

control and easy to enlarge the scale of units assembly.

3) Indoor units can be controlled separately.

4) Equipped with computer-checking interface, conveniently for service work.

5) Far distance flow of refrigerant, and distribute refrigerant intelligently and reasonably

according to the needs of each room, high efficient and energy saving.

6) Display trouble code automatically.

7) Healthy negative ion generation function can refresh the air and excite the oxygen,it is optional.

Outdoor unit

Drop height between indoor and outdoor units

L

L

L

2

a b

f

H up to

30mm

L

1

First branch piping

Length of the longest piping L up to 50m

3

g

Indoor unit

4

e

c

h

d

i

Drop height between indoor units

Length of the longest piping after the first

branch piping L

Piping length

Total length of piping (actual length)

Longest piping L

Piping length of indoor unit which is furthest to the first

branch piping L

Drop height

Drop height between indoor and

outdoor unit H

Drop height between indoor units h

Actual length

Upper outdoor

Lower outdoor

up to 35m

Permissible value

50m

35m

15m

30m

20m

10m

h up to 10m

Piping part

L1+L2+L3+L4+a+b+c+d+e

L1+L2+L3+L4+e

L2+L3+L4+e

- 5 -

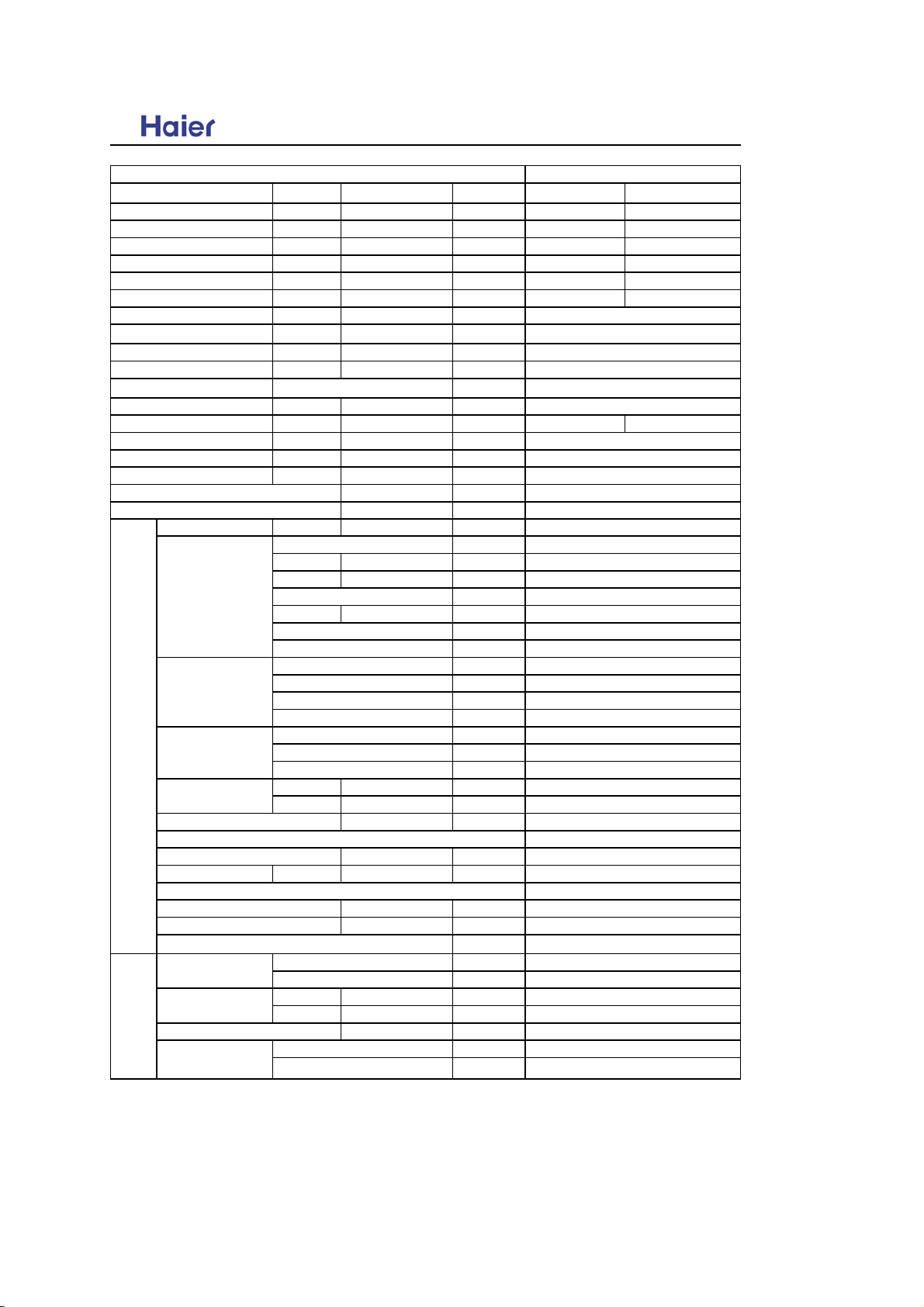

Commercial Air Conditioning

(

,

(

Model:AU282FHAHA

Specifications

Item Model

Function

Capacity BTU/h

Capacity W

Sensible heat ratio

Nominal power input

Max. power input

EER or COP

Dehumidifying capacity

W

W

W/W

10‐³×m³/h

Power cable section

Signal cable section

Connecting cable section

Wired control cable For wired control unit section

Power source Ph, V, Hz

Running /Max.Running

A / A

Start Current A

Class of anti electric shock

Circuit breaker A

Max. operating pressure of heat side Mpa

Max. operating pressure of cold side Mpa

Unit model (color)

Model / Manufacture

Oil model

Oil type

Compressor

Oil charging

Type

Protection type

Starting method

Type × Number

Fan

Speed(H-M-L) r/min

Fan motor output power kW

Air-flow(H-M-L) m³/h

Finned,Inner grooved copper/9.52

Heat exchanger

Outdoor unit

Dimension

Type / Diameter mm

Row / Fin pitch

Temp. scope

External

Package

(L×W×H)

(L×W×H)

℃

mm×mm×mm

mm×mm×mm

Refrigerant control method mm/mm

Defrosting

Volume of accumulator L

Noise level dB(A)

Type of Four way valve

material of reduce noise

crankcase heater power W

Weight (Net / Shipping)

Refrigerant

Pipe

Connecting Method

PIPING

Between I.D &O.D

Type / Charge g

Recharge quantity g/m

Liquid mm

Gas mm

MAX.Drop 30

MAX.Piping length 50

kg / kg

m

m

Norminal condition:

indoor temperature (cooling): 27℃DB/19℃WB, indoor temperature (heating): 20℃DB

Outdoor temperature(cooling): 35℃DB/24℃WB, outdoor temperature(heating): 7℃DB/6℃WB

AU282FHAHA

cooling heating

28000 32000

8000 9500

//

3500 3000

4400 3500

//

/

3 X 6 mm

1.0-1.5)mm

2 X

1-1.5)mm

3 X

3 X (0.5-0.75)mm2,shielded

1/220/50

18/22 16/18

/

Class 1

45

2.65

2.65

WHITE

THS20MC6-Y/HITACHI

SUNISO-4GSI

/

720+/- 20ml

scroll

by thermistors

Inverter,soft-start

Axial fan/1

840/780/550

65

3600

2/1.5mm

/

948X340X830

1090X410X970

EEV+capillary

automatic

/

57

electromagnetic

/

/

74/89

R22/2200

/

9.52

15.88

Flared

2

2

shielded

2

- 6 -

Commercial Air Conditioner Model: A282FHAHA

3 SAFETY PRECAUTIONS

Please read these "Safety Precautions" first then accurately execute the installation work.

Though the precautionary points indicated herein are divided under two headings, and

those points which are related to the strong possibility of an installation done in error

CAUTION

resulting in death or serious injury are listed in the section. However, there is also a

possibility of serious consequences in relationship to the points listed in the section as well.

In either case, important safety related information is indicated, so by all means, properly observe all that is mentioned.

After completing the installation, along with confirming that no abnormalities were seen from the operation tests, please

explain operating methods as well as maintenance methods to the user (customer) of this equipment, based on the owner's

manual.

Moreover, ask the customer to keep this sheet together with the owner's manual.

WARNING

WARNING

CAUTION

WARNING

This system should be applied to places of office, restaurant, residence and the like. Appliaction to inferior

environment such as engineering shop could cause equipment malfunction.

Please entrust installation to either the company which sold you the equipment or to a professional contractor.

Defects from improper installations can be the cause of water leakage, electric shocks and fires.

Execute the installation accurately, based on following the installation manual. Again, improper installations can

result in water leakage, electric shocks and fires.

When a large air-conditioning system is installed to a small room, it is necessary to have a prior planned

countermeasure for the rare case of a refrigerant leakage, to prevent the exceeding of threshold concentration.

In regards to preparing this countermeasure, consult with the company from which you purchased the equipment,

and make the installation accordingly. In the rare event that a refrigerant leakage and exceeding of threshold

concentration does occur,there is the danger of a resultant oxygen deficiency accident.

For installation, confirm that the installation site can sufficiently support heavy weight. When strength is insufficient,

injury can result from a falling of the unit.

Execute the prescribed installation construction to prepare for earthquakes and the strong winds of typhoons and

hurricanes, etc. Improper installations can result in accidents due to a violent falling over of the unit.

For electrical work, please see that a licensed electrician executes the work while following the safety standards

related to electrical equipment, and local regulations as well as the installation instructions, and that only exclusive

use circuits are used.

Insufficient power source circuit capacity and defective installment execution can be the cause of electric shocks and

fires.

Accurately connect wiring using the proper cable, and insure that the external force of the cable is not conducted to

the terminal connection part, through properly securing it. Improper connection or securing can result in heat

generation or fire.

Take care that wiring does not rise upward, and accurately install the lid/service panel. Its improper installation can

also result in heat generation or fire.

- 7 -

Commercial Air Conditioner Model: A282FHAHA

SAFETY PRECAUTIONS

WARNING

When setting up or moving the location of the air conditioner, do not mix air etc. or anything other than the designated

refrigerant (please see nameplate) within the refrigeration cycle.

Rupture and injury caused by abnormal high pressure can result from such mixing.

Always use accessory parts and authorized parts for installation construction. Using parts not authorized by this

company can result in water leakage, electric shock, fire and refigerant leakage.

The position of indoor unit must be above the floor 2.5m.

CAUTION

Execute proper grounding. Do not connect the ground wire to a gas pipe, water pipe, lightening rod or a telephone

ground wire.

Improper placement of ground wires can result in electric shock.

The installation of an earth leakage breaker is necessary depending on the established location of the unit. Not

installing an earth leakage breaker may result in electric shock.

Do not install the unit where there is a concern about leakage of combustible gas.

The rare event of leaked gas collecting around the unit could result in an outbreak of fire.

For the drain pipe, follow the installation manual to insure that it allows proper drainage and thermally insulate it to

prevent condensation. Inadequate plumbing can result in water leakage and water damage to interior items.

- 8 -

Commercial Air Conditioner Model:

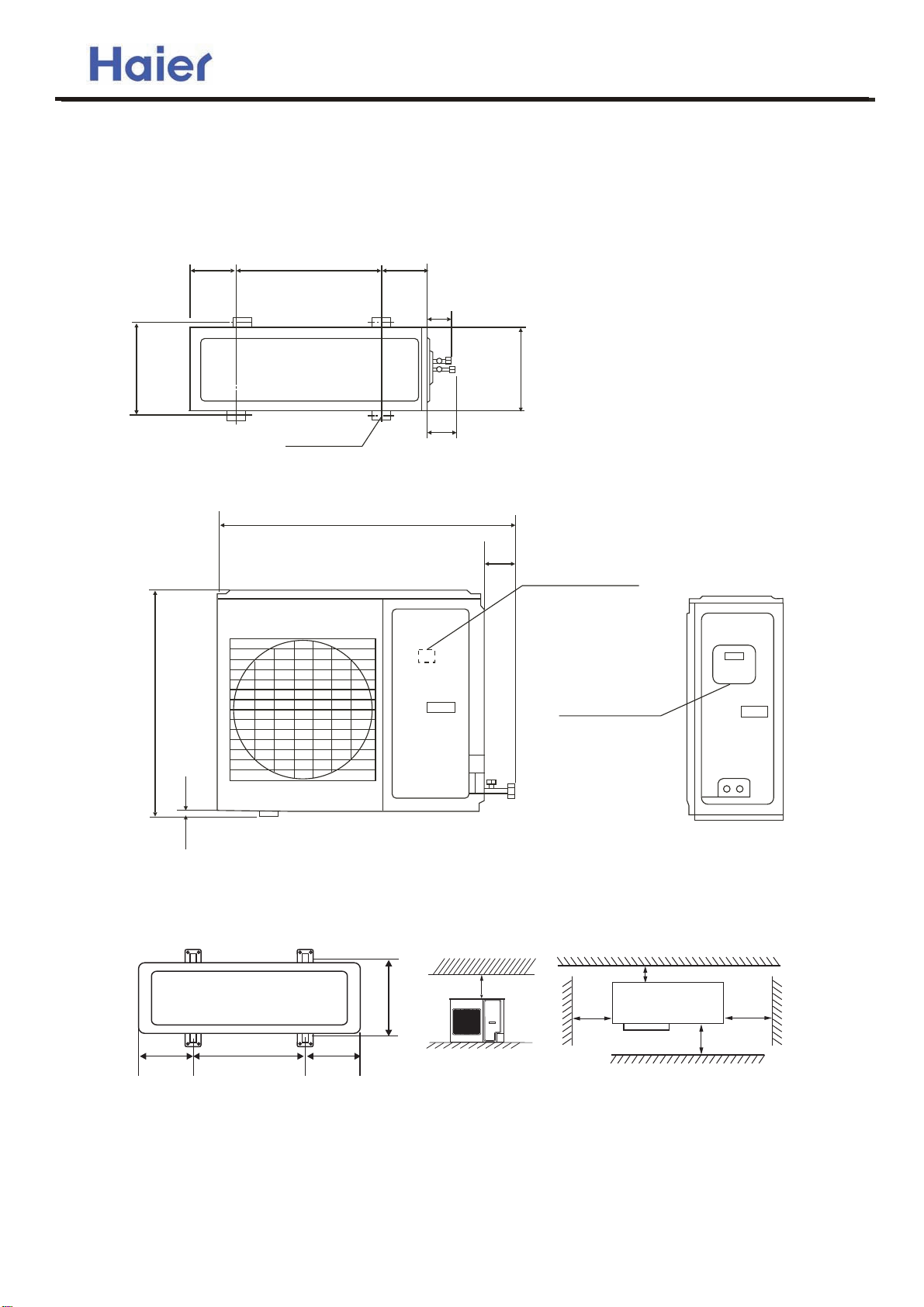

4. Dimensional drawing of outdoor unit

AU282FHAHA

380

840

190 190

580

Screw Hole

(M10)

1018

55

340

70

70

Power Wiring Terminal

Power Wiring

Distribution Hole

25

190 190

580

More than 60cm

380

Installation dimension

of outdoor unit (mm)

>10cm

>10cm

>15cm

>60cm

- 9 -

Commercial Air Conditioner Model:

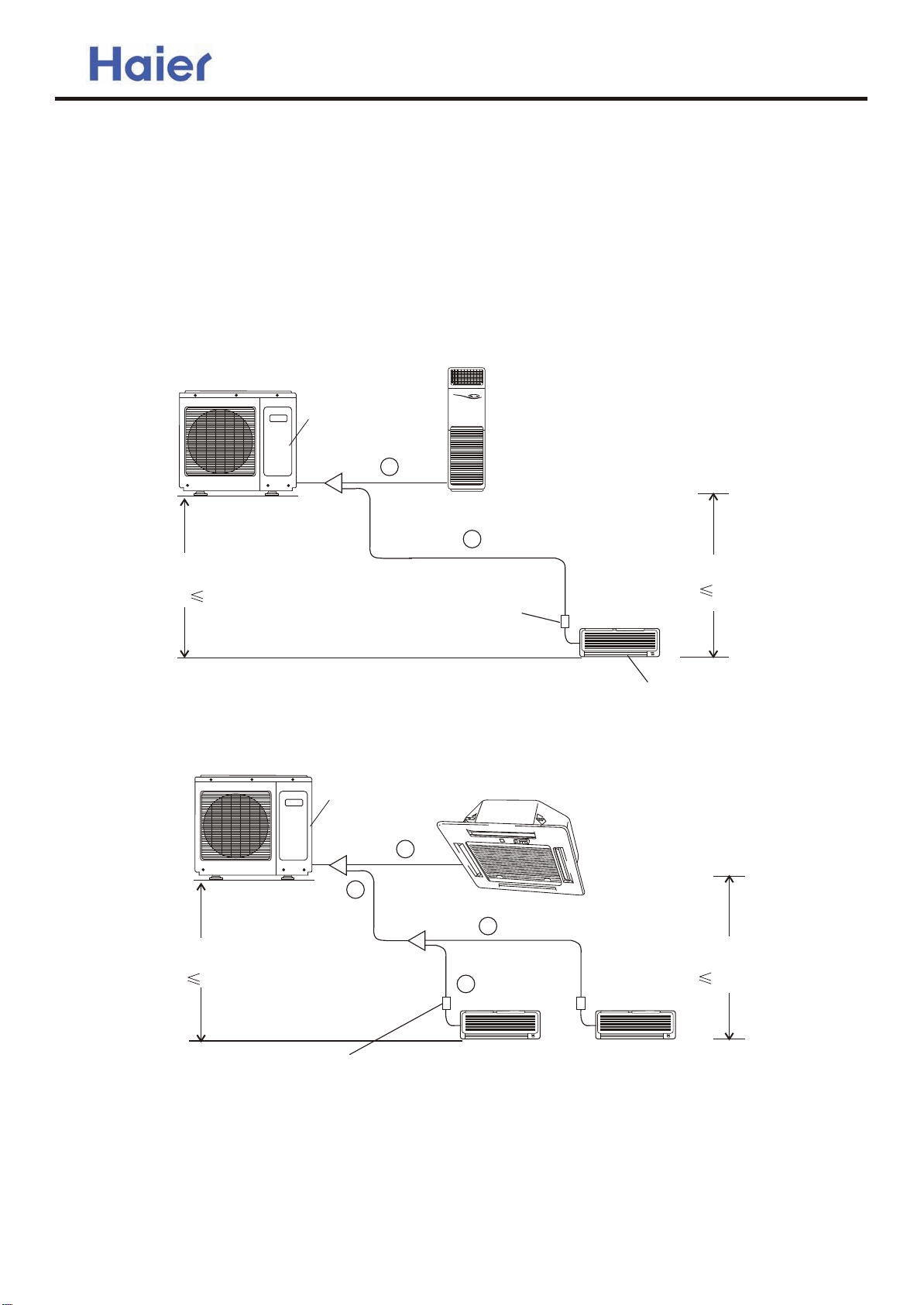

5. Installation instructions

5.1 Installation diagram of indoor & outdoor unit

Notice:

1. Designed capacity (total capacity of the whole connected indoor units) while installation

should be not over 130% of rated capacity of the outdoor unit .

2. Total capacity of all running indoor units during usage should be not over 100% of rated

capacity of the outdoor unit.

The following is examples:

1) Model: Indoor unit AS092FMAHA AP182FAAHA

Outdoor unit

1

AU282FHAHA

Drop height between

indoor and outdoor

units h 30m

2) Model: Indoor unit AS092FMAHA AB142FCAHA

Drop height between

indoor and outdoor

units h 30m

Electronic expansion valve

Outdoor unit

1

1

2

Drop height between

indoor h 10m

Indoor unit

2

Drop height between

2

indoor h 10m

Electronic expansion valve

- 10 -

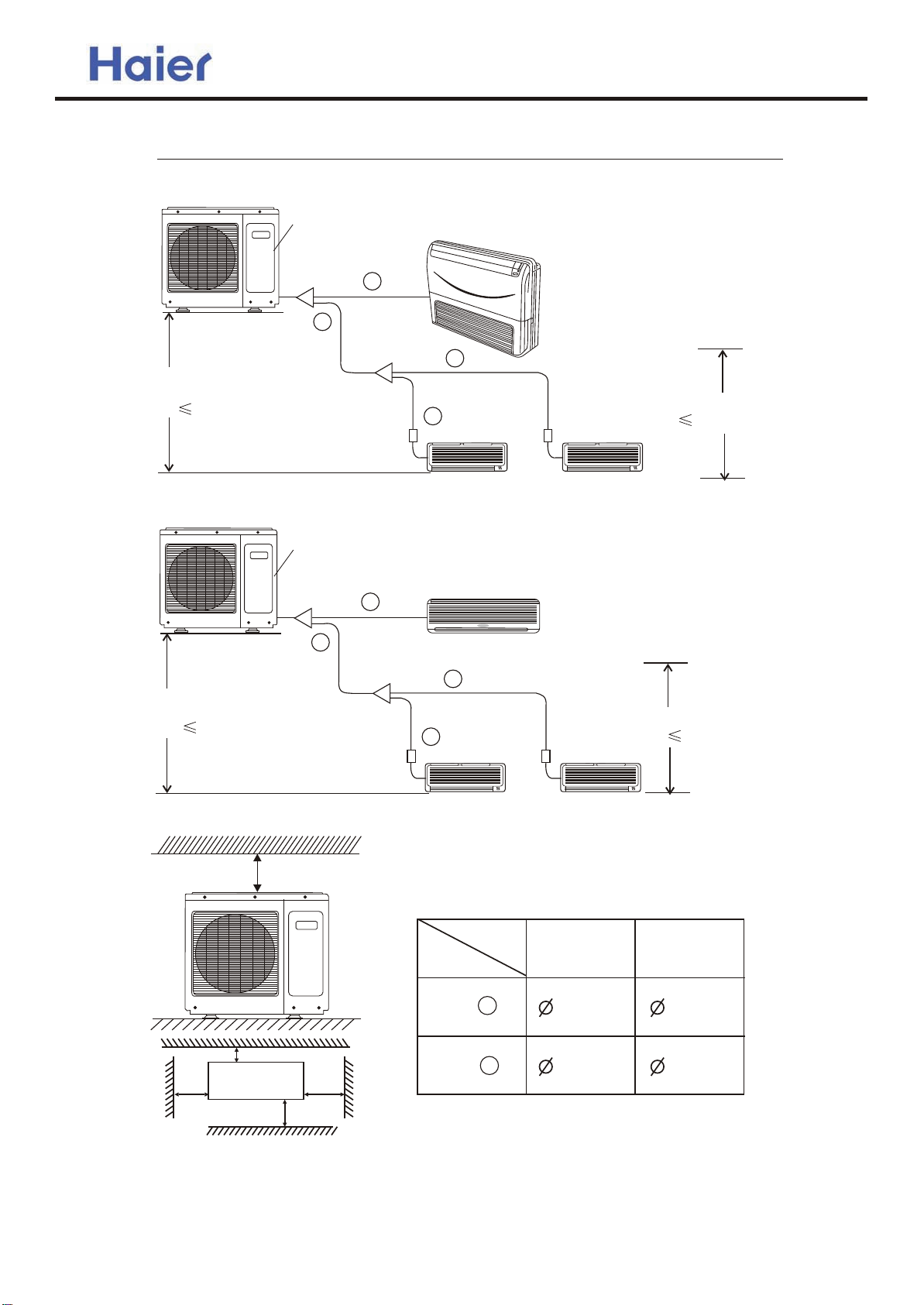

Commercial Air Conditioner Model:

3) Model: Indoor unit AS092FMAHA AC142FCAHA

Outdoor unit

1

1

Drop height between

indoor and outdoor

units h 30m

4) Model: Indoor unit AS092FMAHA AS142FTAHA

2

AU282FHAHA

2

Drop height between

indoor h 10m

Drop height between

indoor and outdoor

units h 30m

Over 60cm

Outdoor unit

1

1

2

Drop height between

2

indoor h 10m

Pipe

Position

Gas pipe Liquid pipe

>10cm

>10cm

>60cm

>15cm

Part

Part

- 11 -

1

2

15.88mm

9.52mm

12.7mm 6.35mm

Commercial Air Conditioner Model: A282FHAHA

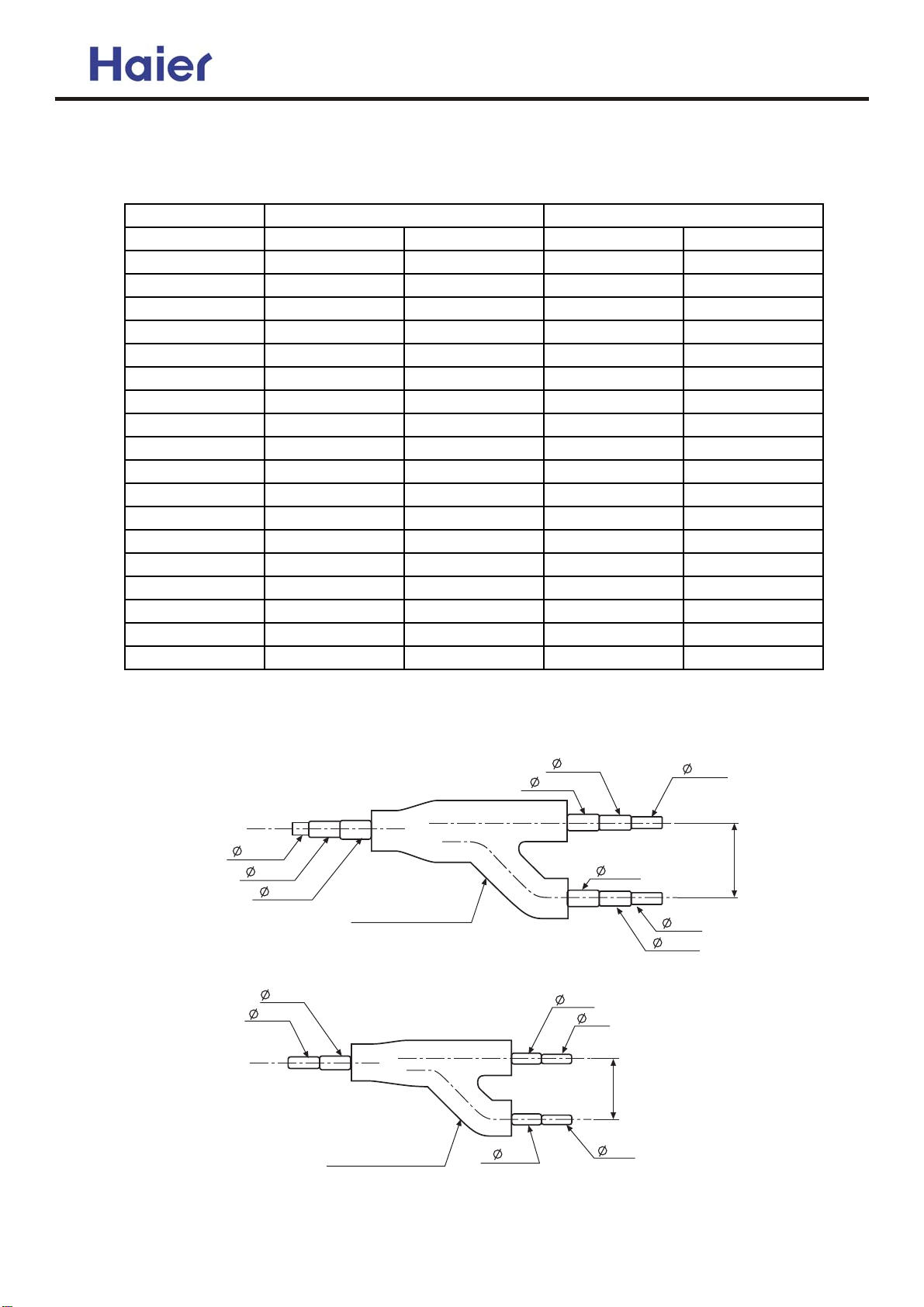

5.2 Piping dimensions charts

model

liquid pipe gas pipe

mm inch mm inch

AU55 9.52 3/8" 19.05 3/4"

AB09 6.35 1/4" 12.7 1/2"

AB14 6.35 1/4" 12.7 1/2"

AB18 9.52 3/8" 15.88 5/8"

AC18 9.52 3/8" 15.88 5/8"

AE07 6.35 1/4" 9.52 3/8"

AE09 6.35 1/4" 9.52 3/8"

AE12 6.35 1/4" 12.7 1/2"

AE14 6.35 1/4" 12.7 1/2"

AE18 9.52 3/8" 15.88 5/8"

AE21 9.52 3/8" 15.88 5/8"

AE24 9.52 3/8" 15.88 5/8"

AP18 9.52 3/8" 15.88 5/8"

AS06 6.35 1/4" 9.52 3/8"

AS07 6.35 1/4" 9.52 3/8"

AS09 6.35 1/4" 12.7 1/2"

AS12 6.35 1/4" 12.7 1/2"

AS18 9.52 3/8" 15.88 5/8"

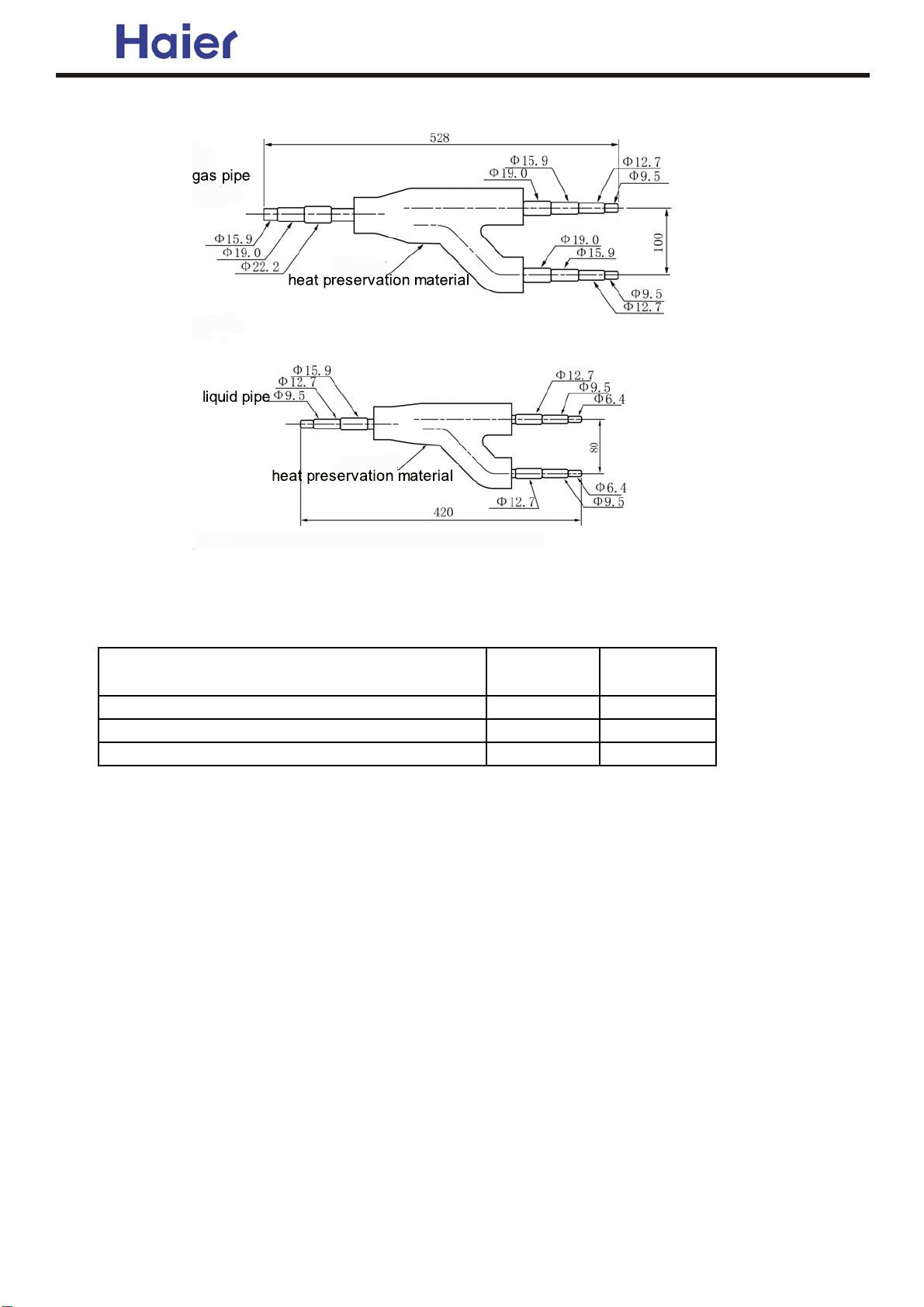

5.3 Y-shape manifold pipe

model: FQG-B120

<gas side>

9.52

12.7

15.88

<liquid side>

9.52

6.35

heat preservation

material

heat preservation

material

12.7

15.9

12.7

12.7

9.52

15.88

75

9.52

9.52

75

9.52

12.7

Dimension is the out diameter connecting to the tubing.

- 12 -

FQG-B180

g

Commercial Air Conditioner Model: AU282FHAHA

gas pipe

heat preservation material

liquid pipe

heat preservation material

Refrigerant pipes between manifold pipes

Total refrigerating amount of indoor unit

Gas side Liquid side

roup after the manifold pipe

Less than 38220Btu/h 15.9 9.52

38220~61157Btu/h 19.05 9.52

61157~126137Btu/h 25.4 12.7

Note: 1. Y-shape manifold pipe can be placed in horizontal or vertical

direction

2. The manifold pipes must be welded with hard-solder

3. Pay attention to cut off the unnecessary part from its middle

parts of each joint, and to remove burr.

- 13 -

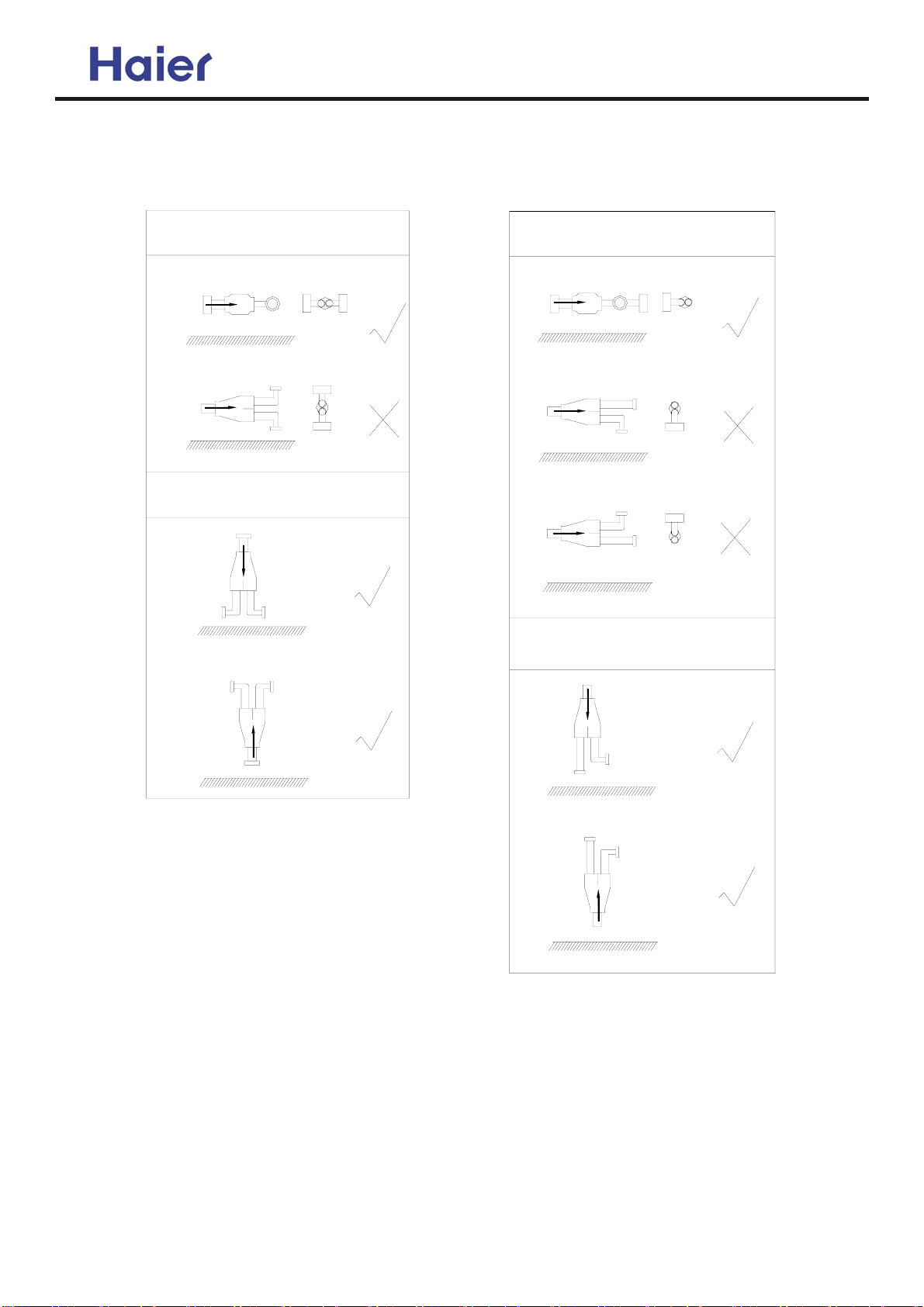

Commercial Air Conditioner Model: AU282FHAHA

In the file, the figure marked with "√" is permitted, and the figure marked with "×" is prohibited.

You can confirm the position according to the actual condition.

The refrigerant flow direction is always from the collective side to the divided side.

horizontal

vertical

floor surface

floor surface

floor surface

horizontal

floor surface

floor surface

floor surface

vertical

floor surface

floor surface

floor surface

- 14 -

Commercial Air Conditioner Model: AU282FHAHA

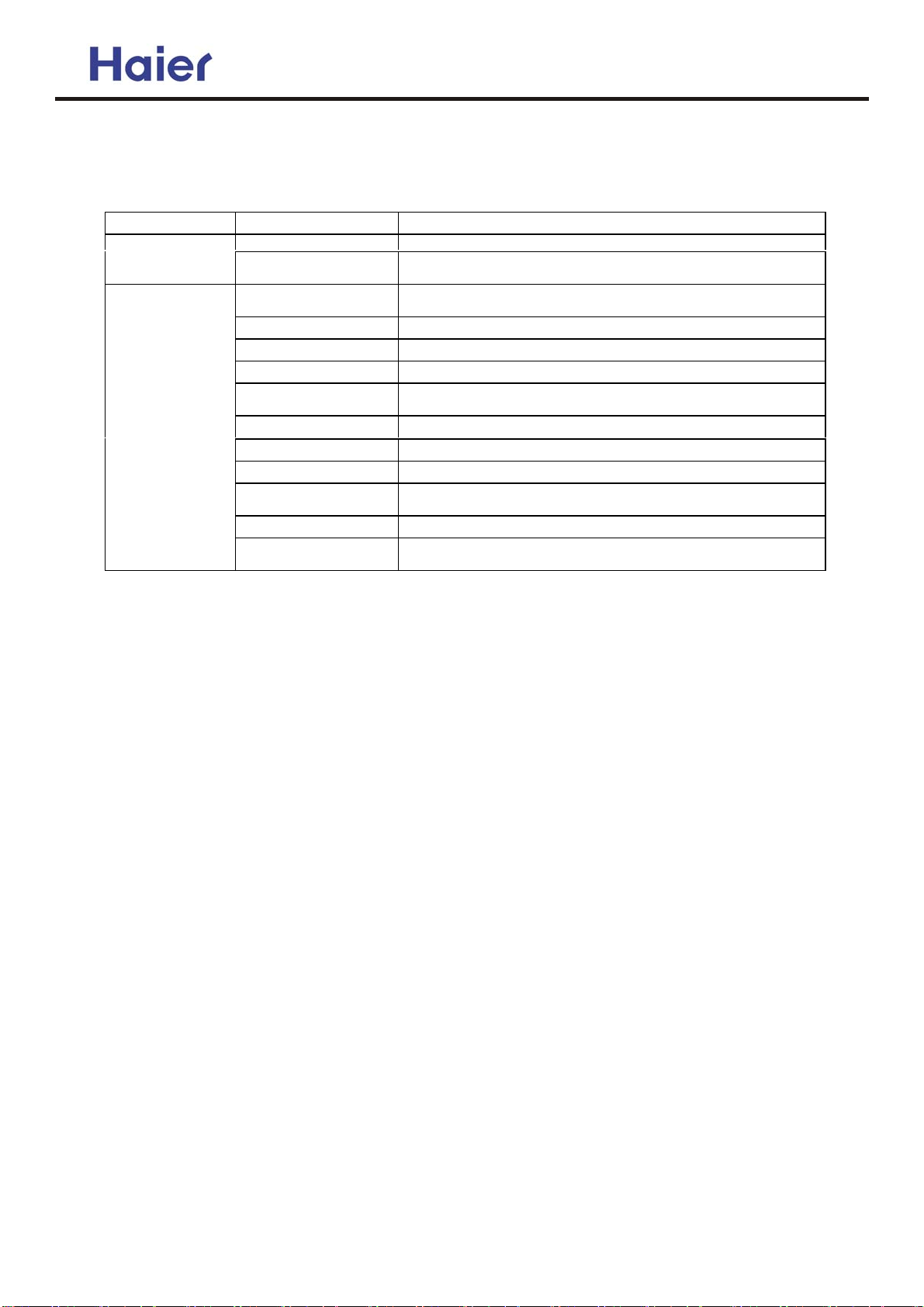

5.4 The Order of Installation Work

Item

Before installation Work division -to ascertain the person responsible for installation of pipes and wiring

Installation of indoor and

Work

Work Main points

Make installation

diagram

outdoor unit

Refrigerant pipe work -Pay attention to dry, clean and seal

Drain pipe work -Slant downward

Heat insulation work -No gaps in the joint of heat insulation material

Wiring work (control

wire, power cord)

Set every set switch -Should be complied with control wiring system diagram

Airtight test -Close all the gas, liquid valves

Vacuum drying -Should the vacuum pump that can reach 200Pa vacuity

Additional refrigerant -Write down the additional refrigerant amount on the outdoor unit body

Test run adjustment -Do test run to indoor unit one by one to verify if there is wrong pipes

Training of use and

maintenance

-to ascertain the pipe installation dimension and position of electronic

expansion valve, to make control wiring system diagram

-to prevent the ventilation from short circuit and guarantee repair space

-Choose the proper wire and cord

and record table

-Explain to user, simultaneously provide all the documents

The above work order is general knowledge, they may be changed to be complied with the

specific work site.

5.5 Attentive matters of safety

l Before installing, do read this [Attentive matters of safety] carefully to guarantee the

proper installation.

l The below attentive matters are divided into [warning] and [note] two parts. When the

wrong installation occur, it is very possible death and severe injury and other serious

accidents will happen. For those items are listed in [warning] part. But even the items

listed in [note] part can also cause serious accidents. Above all, both the two parts are

very important contents related to safety, so they must be obeyed.

l After installation, do test run to verify everything is normal, after that please explains the

use method and maintenance method to the user according to the operation manual.

Additionally, give the installation manual together with operation manual to the user and

ask them to keep them properly.

Warning

l The distributing shop, where you bought the air conditioner, or the specified shops shall

do the installation work. If you do the installation work by yourself, the improper

installation will cause water leakage, electric shock fire and other accidents.

l The installation work shall be in line with what the installation manual specified. If

installation is not proper, water leakage, electric shock, fire and other accidents will

occur.

l Install the air conditioner to a place where can definitely stand its weight. Places not firm

enough will cause drop down of unit resulting in body hurt.

l The installation work shall be preventive to typhoon and earthquake. If the installation

- 15 -

Commercial Air Conditioner Model: AU282FHAHA

work is not met with the requirements, overturn of the unit will occur resulting in

accidents.

l The wiring work shall be done by a qualified person and referred to the “technical

standard of electric equipment”, “indoor wiring regulation” and what the manual

specified. Do use special circuit. If the capacity of the circuit is not enough or bad work,

electric shock, fire and other accidents will happen.

l Using the specified cable to do wiring work and connecting firmly and properly. Fix the

connecting part of the terminals to prevent it from the external force. Improper

connection and fixing will cause heating and fire etc. accidents.

l Wiring shall be kept in correct shape avoiding extrusion. After installation, the electric

box cover and the external panel shall not nip the wire. Improper installation will cause

heating and fire etc. accidents.

l When setting or moving the air conditioner do not let the air and things alike get into the

refrigeration system except the specified refrigerant (R22). If air and other things enter,

abnormal high pressure will occur, which easily cause break and body injuries etc.

accidents.

l When installing, do use the accessories or specified parts. If not using the parts specified

by our company, water leakage, electric shock, fire and refrigerant leakage will occur.

l Do not lead the drainpipe to drain where the sulfur gas may be involved. Otherwise, the

poisonous gas will enter into the indoor.

l During installation, if refrigerant leakage occurs, do the ventilation work immediately. As

soon as the refrigerant gas meets fire, poisonous gas will be produce. If the refrigerant gas

enters into room and meet the air blowing heater, heater or stove etc. fire source, the

poisonous gas may be produced. After installation, confirm there is no leakage of

refrigerant.

l Do not install the unit in a place where the combustible gas may be leaked. In any case

the combustible gas leaks and accumulated around the unit, fire accident will occur.

l Do heat insulation work to the refrigerant gas pipes and liquid pipes to reach the purpose

of heat preservation. If the heat insulation measure is not sufficient, water generated by

condensing dew will drip leading to wet the floor and indoor articles.

l Do not damage the power line or change it arbitrarily to avoid occurrence of fire or

electric shock.

l Do not extend the power line or using other electric appliance in the same power

receptacle to avoid fire or electric shock.

Note

l Do grounding work. Do not connect the grounding wire to gas pipe, tap, lighting rod or

telephone line. Improper grounding will cause electric shock.

l In some places the electric leakage breaker shall be installed. If do not install the breaker,

electric shock may occur.

l After installation, power on to do electric leakage detecting test.

- 16 -

Commercial Air Conditioner Model:

AU282FHAHA

5.6 Installation procedure Connection of pipes

Warning

!

During installation, if refrigerant leakage

occurs, take ventilation measurement

immediately.

As soon as the leaked refrigerant gas

meets f re, poisonous gas will generate.i

After finishing installation, confirm the

refrigerant gas does not leak.

If the refrigerant gas leaks in the room,

once it meets heater, burner and gas

stove etc. fire source, the poisonous gas

will generate.

I. Choosing of pipes

The choosing of pipe material, dimension and branch pipe shall be complied with the

installation figure in page 4~5.

II. Connection of pipes

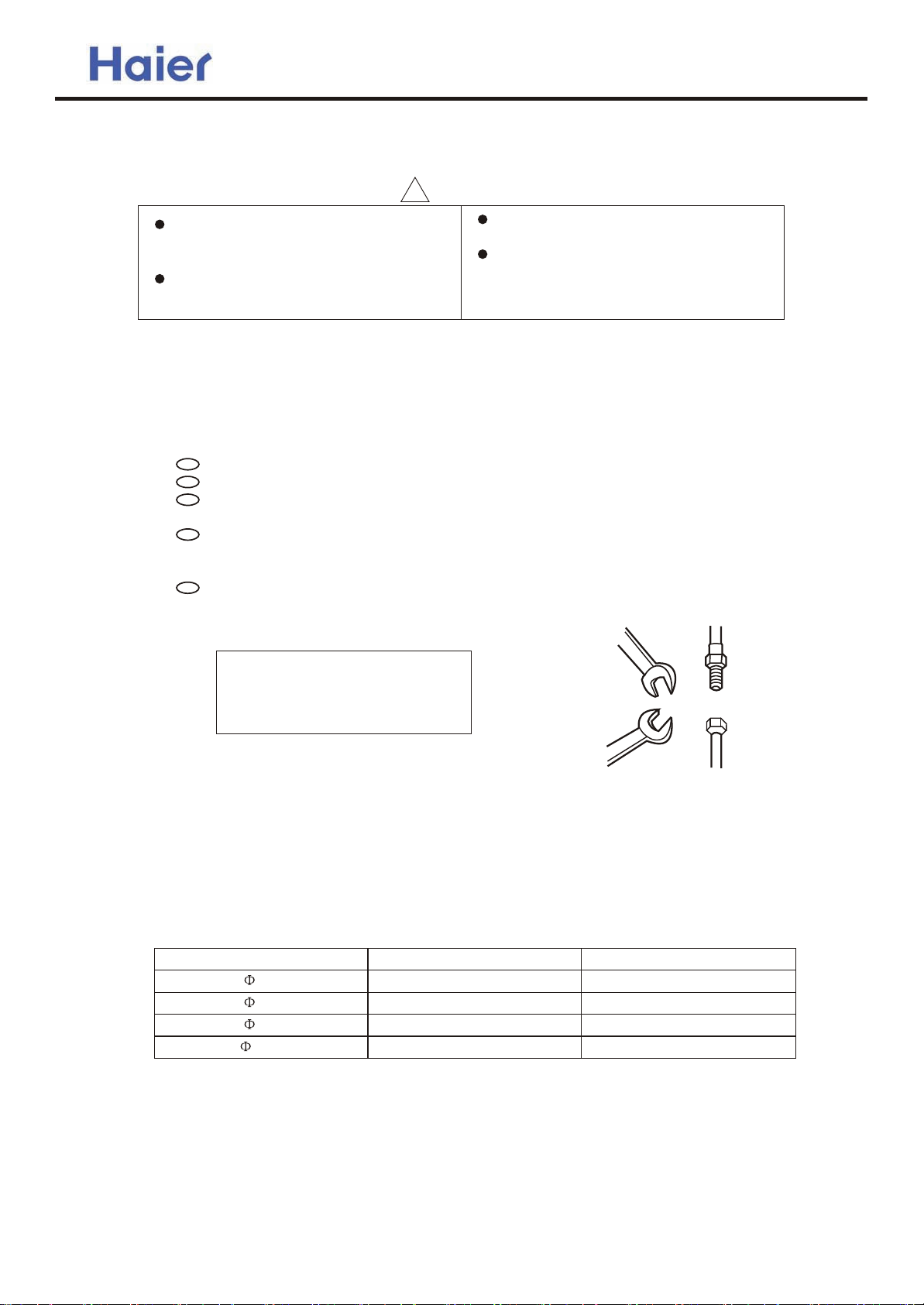

1 Method of pipe connection

The pipe shall be as short as possible to guarantee efficiency.

Daub the refrigerant oil on the connection and flare nut.

When bending the pipes, give the roundness as large as possible, to avoid crashing the

pipes.

To connect the pipe, fit the center and screw the nut with hand, then use spanner or

torque wrench to tighten it. The fastening torque as shown in below table. As shown in

figure.

Be careful alien matters, such as sands, water etc.shall not enter the pipes.

Spanner

Forced fastening without careful

centring may damage the threads

and cause gas leakage.

Spanners

2.Welding of pipes

(1) In welding, the nitrogen shall be used to avo d oxidation of the pipe inner part.

(2) The refrigerating pipe shall use clean new pipes. When working, it shall take steps to

prevent water and dust from entering.

(3) When loosening and tightening the nuts, two spanners shall be used. If using one

spanner, it can not reach the desired degree of tightness.

Using the specified fastening torque to fasten nuts.

Pipe diameter(mm)

6.35

9.52

12.7

15.88

Installation torque(N.m)

11.8(1.2kgf.m)

24.5(2.5kgf.m)

49.0(5.0kgf.m)

78.4(8.0kgf.m)

i

Fastening torque(N.m)

13.7(1.4kgf.m)

29.4(3.0kgf.m)

53.9(5.5kgf.m)

98.0(10.0kgf.m)

Joint

Nut

- 17 -

Loading...

Loading...