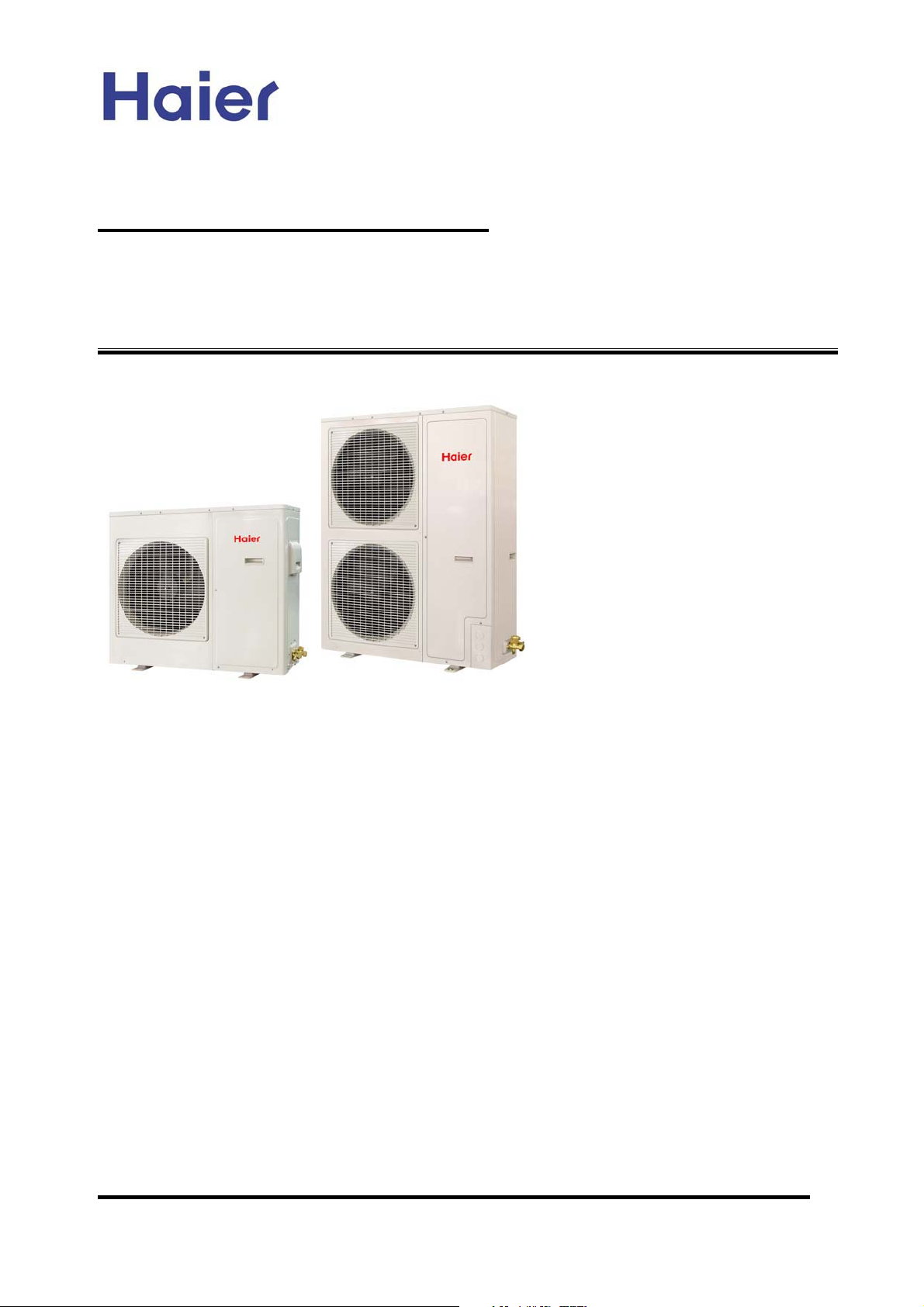

Haier AU242FHBIA, AU482FIBIA, AU48NFIBJA AC Schematic

Commercial Air Conditioning

SERVICE MANUAL

Models

AU242FHBIA

AU482FIBIA

AU48NFIBJA

And its indoor units

zFeatures

zNew cassette unit, with 700*700 panel and new unit body

zNew PCB for cassette indoor unit and outdoor unit, much stabler

zMutiple indoor unit types: cassette type, ceiling concealed type, and wall

mounted type

zFree combination, total indoor capacity can be 50%~130% of outdoor capacity

zMultiple control types, infrared control+wired control

zIndividual operation for every indoor uint, energy saving

zNew refrigerant control device: MP2A, MP3A

zAuto restart function

zLong piping and high drop between indoor and outdoor

zRefrigerant: R407C

Manual code: SYJS-017-05REV.0 Edition: 2005-11-22

Commercial Air Conditioner Model: AU242FHBIA,

AU482FIBIA, AU48NFIBJA

CONTENTS

Contents………………………………………………………...2

1. Description of products & features………………………..3

2. Specification…………………………………………………6

3. Safety precaution…………………………………………...14

4. Net dimension……………………………………………….16

5. Installation instructions………..……………………………21

6. Parts and functions………………………………………….53

7. Controller functions.............………………………………..21

8. Electrical control functions…………………………………71

9. Wiring diagrams…………………………………………….95

10. Failure code and troubleshooting………………………..99

11. Noise level……………………………………...................121

12. Performance curves......................................................124

-2-

Commercial Air Conditioner Model: AU242FHBIA,

AU482FIBIA, AU48NFIBJA

1.DESCRIPTION OF PRODUCTS & FEATURES

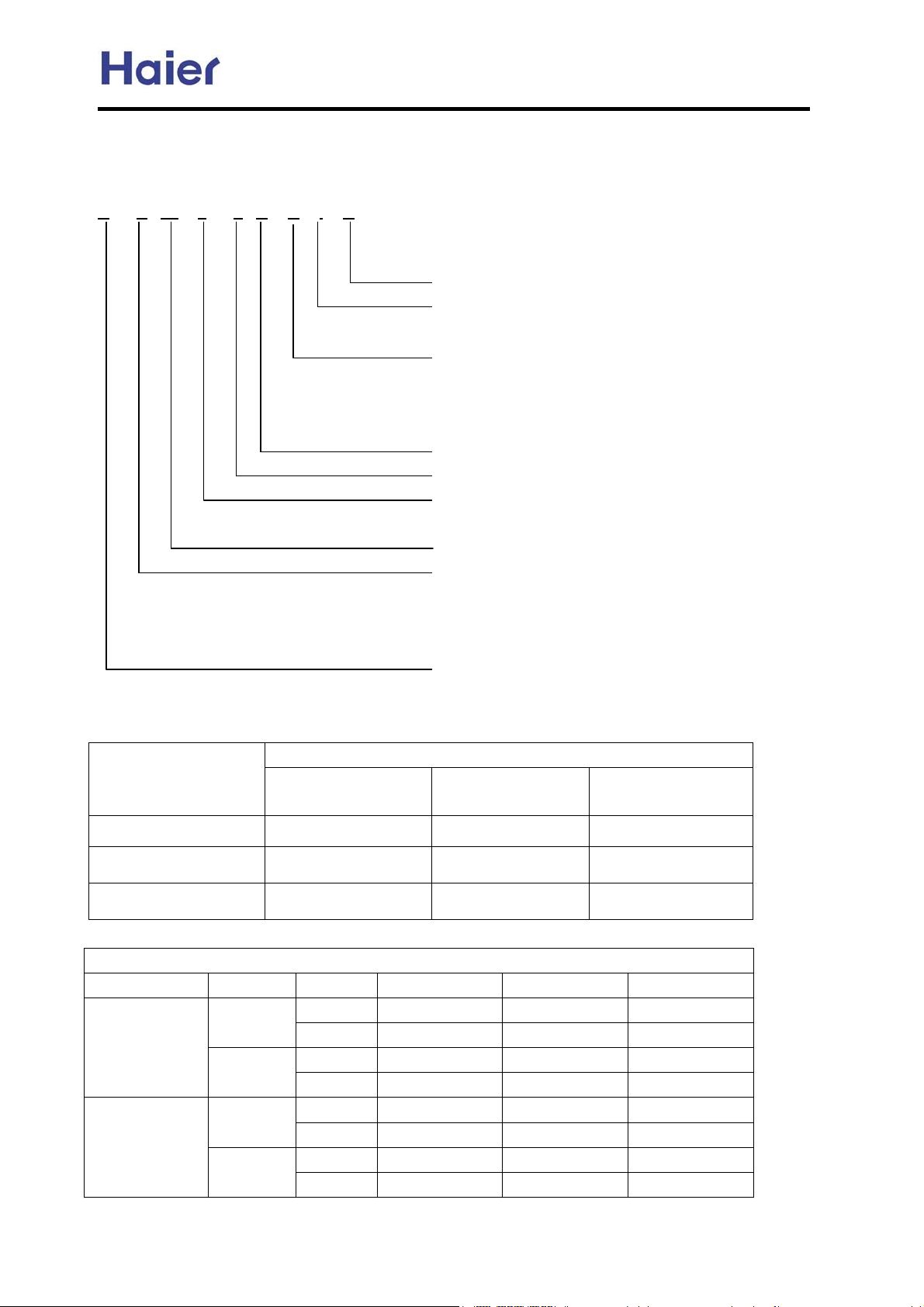

1.1. Products code explanation

A B 14 2 F C B I A

Climate type: T1 (see table 1)

Design number (I stands for design sequence, inverter

frequency type)

Product type: A stands for heat pump type, refrigerant is R22

B stands for heat pump type, refrigerant is R407C

M stands for cool only type, refrigerant is R22

N stands for cool only type, refrigerant is R407C

Appearance code

Product series: F stands for MRV

Applicable voltage: 2 stands for 220-230V/50Hz,

4 stands for 220V/60HzˈN stand for 380-400V/50Hz

Cooling / Heating capacity,14=14000BTU/h

Product type : “B” stands for cassette type, “C” stands for

convertible type, ”D” stands for duct, “S” stands for split

type, ”Q” stands for chiller system, "E" stands for ceiling

concealed type, “U” stands for outdoor unit

Air Conditioner

1.2 Brief Introduction for T1ǃT2ǃT3 working condition

Climate type

Type of Air

Conditioner

Cooling Only

Heat pump

Electricity Heating

T1 T2 T3

18 ć~43ć 10ć~35ć 21ć~52ć

-7ć~43ć -7ć~35ć -7ć~52ć

~43ć ~35ć ~52ć

1.3 Operating Range of Air Conditioners

Working temperature range

Rated Maximum Minimum

Cooling

Heating

Indoor

outdoor

Indoor

outdoor

DBć

WBć

DBć

WBć

DBć

WBć

DBć

WBć

27 32 18

19 23 14

35 43 -5

24 26 --

20 27 15

14.5 -- --

7 24 -15

6 18 --

-3-

Commercial Air Conditioner Model: AU242FHBIA,

AU482FIBIA, AU48NFIBJA

1.4 Product features

New designed panel 700*700 with the 600*600 cassette unit

New designed swing louver with the non smooth surface, which can hold back the condensant water.

New designed filter lock, which will fix the filter more firmly than before.

Adopts the stepping motor, give the louver a larger swing angel.

New fan with bigger diameter fan blade, sending out larger air flow.

The cassette indoor unit adopts the panel whose dimension is identical to that of ceiling, after installation,

the unit will be accordant with the decoration decor.

Free combination, total indoor capacity can be 50%~130% of that of outdoor capacity

The outdoor unit can match with all types of indoor unit with the allowable capacity, such as the cassette

type, the ceiling concealed type, the wall mounted type, etc.

Optional control types: infrared remote controller and wired controller

The unit can be controlled by the smart infrared remote controller YR-H71, which can realize many

functions such as heating, cooling, fan, swing, fresh, health, filter up/down, electric heating, etc.

Furthermore, the remote controller can be compatible with many old controllers, more convenient for

utilizing.

If the unit is with wired controller YR-E06, which can realize remote control type by adding an infrared

controller YR-H71.

Auto-check function

The unit can display the malfunction codes on the control board by using advanced auto-check

technology, convenient for user find and dwell with the abnormal running.

Auto–restart function (optional)

All indoor units have auto-restart function. When the power supply cut off suddenly, the unit will

automatically recover the previous running mode once the power supply is on.

New refrigerant control device: MP2A, MP3A

The new refrigerant control device MP2A and MP3A replace the previous device MP2 and MP3. The new

device includes gas pipe and liquid pipe, more convenient for installation than before.

-4-

Commercial Air Conditioner Model: AU242FHBIA,

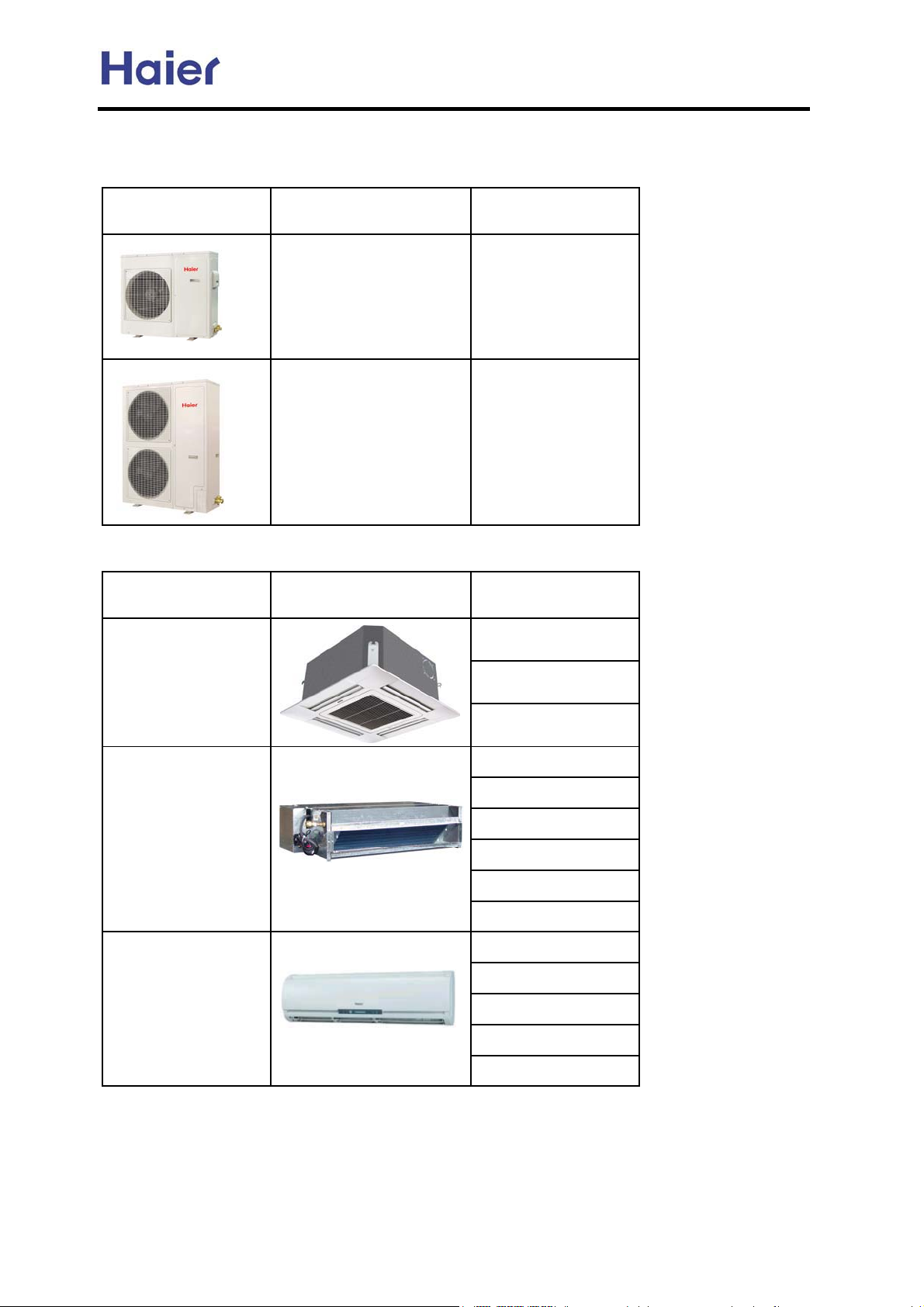

Total unit:

outdoor units

appearance model refrigerant

AU482FIBIA, AU48NFIBJA

indoor units

type appearance model

Four way cassette

AU242FHBIA

AU482FIBIA

AU48NFIBJA

R407C

R407C

AB092FCBIA

AB142FCBIA

AB182FCBIA

Ceiling concealed

Wall-mounted

(colorful screen)

AE072FCBKA

AE092FCBKA

AE122FCBKA

AE142FCBKA

AE182FCBKA

AE242FCBKA

AS072FCBHA

AS092FCBHA

AS122FCBHA

AS142FCBHA

AS182FCBHA

-5-

Commercial Air Conditioner Model: AU242FHBIA,

AU482FIBIA, AU48NFIBJA

2. SPECIFICATION

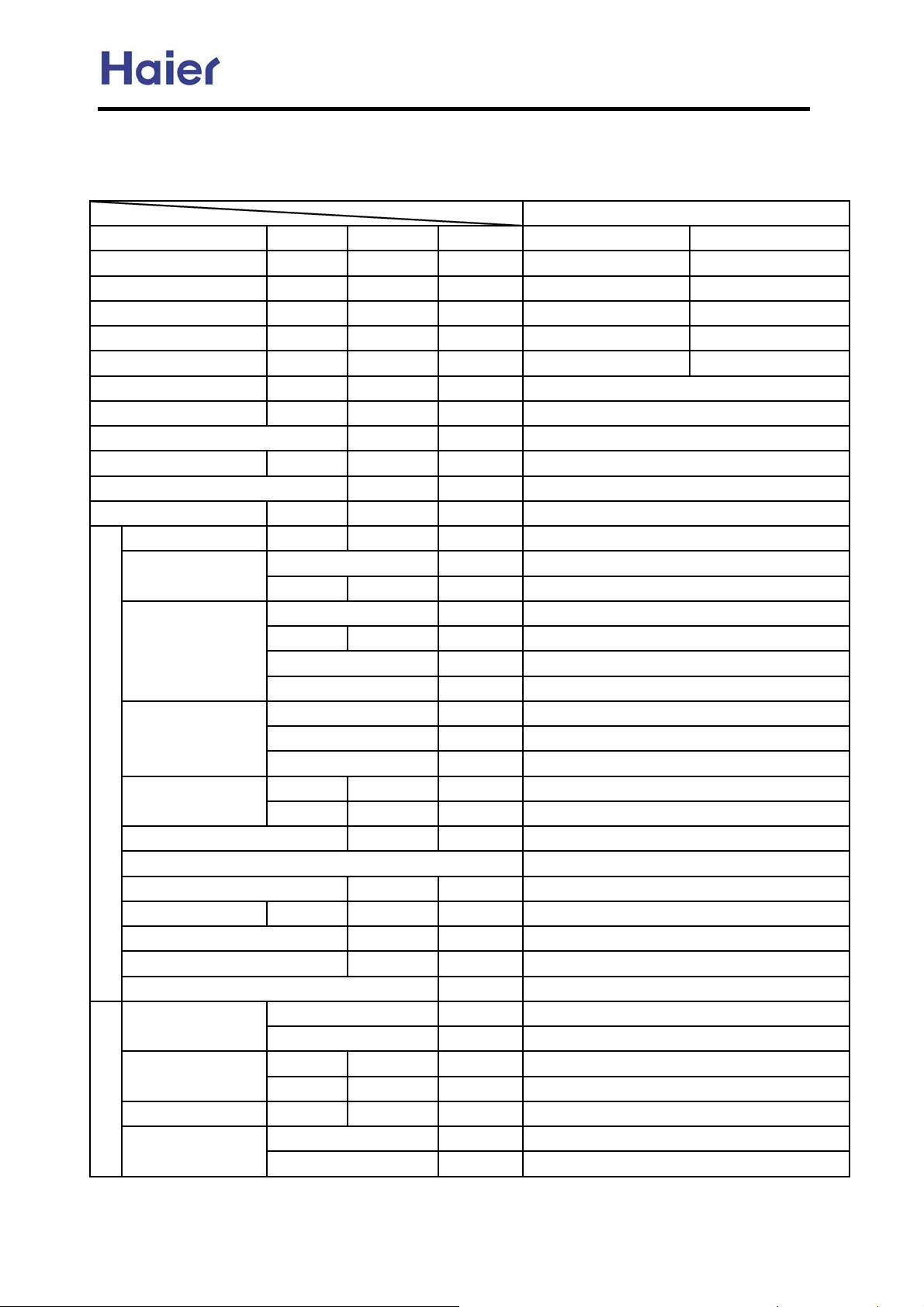

AU242FHBIA

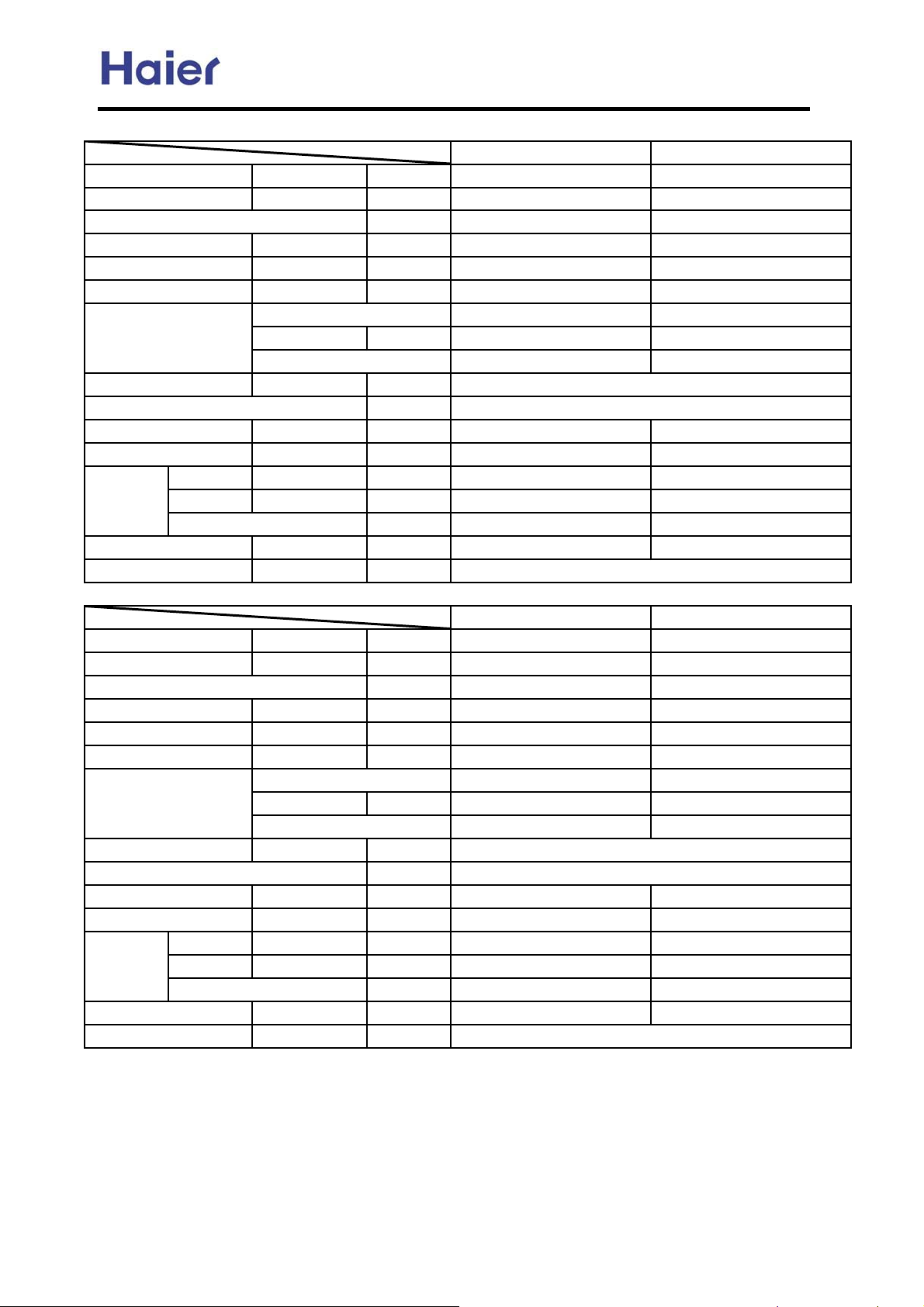

Item Model AU242FHBIA

Function cooling heating

Capacity BTU/h

Capacity W

Total power input

Max. power input

EER or COP

W

W

W/W 2.2 2.55

Power cable

Power source

Running /Max.Running current

NˈVˈHz

A / A

Start Current A

Working frequency range Hz

Fuse A

Unit model (color)

Compressor

Model / Manufacture

Type

Type × Number

Fan

Speed r/min

Fan motor output power kW

Air-flow(H-M-L) m³/h

Type / Diameter mm

Heat exchanger

Dimension

Outdoor unit

Row*fin pintch

Temp. scope

External

Package

˄L×W×H˅

˄L×W×H˅

ć

mm×mm×mm

mm×mm×mm

Refrigerant control method mm/mm

Defrosting

Volume of Accumulator L

Noise level dB(A)

material of reduce noise

crankcase heater power W

Weight (Net / Shipping)

Refrigerant

Type / Charge g

kg / kg

Recharge quantity g/m

Pipe

Liquid mm

Gas mm

PIPING

Connecting Method

Between I.D &O.D

MAX.Drop

MAX.Piping length

m

m

24000 27000

7030 7910

3200 3100

3800 3800

2

6mm

1PH,220-230V~,50Hz

cooling: 18A/21A heating: 17/21A

--

30-105

3.15A 250V AC

AU242FHBIA (white)

C-7RB267H03AA/ SANYO SHENYANG

ROTARY

AXIAL*1

840±30/780±30/550±50

60*1

3240

inner grooved copper pipe ¶9.52

2*1.5mm

--

948X830X340

1050X979X440

EEV

AUTO

--

58

--

30

74/89

R407C/3200

ij9.52 liquid pipe: 65g/mhactual length

¶9.52

¶15.88

flared

outdoor upper: 30, outdoor lower: 20

50

-6-

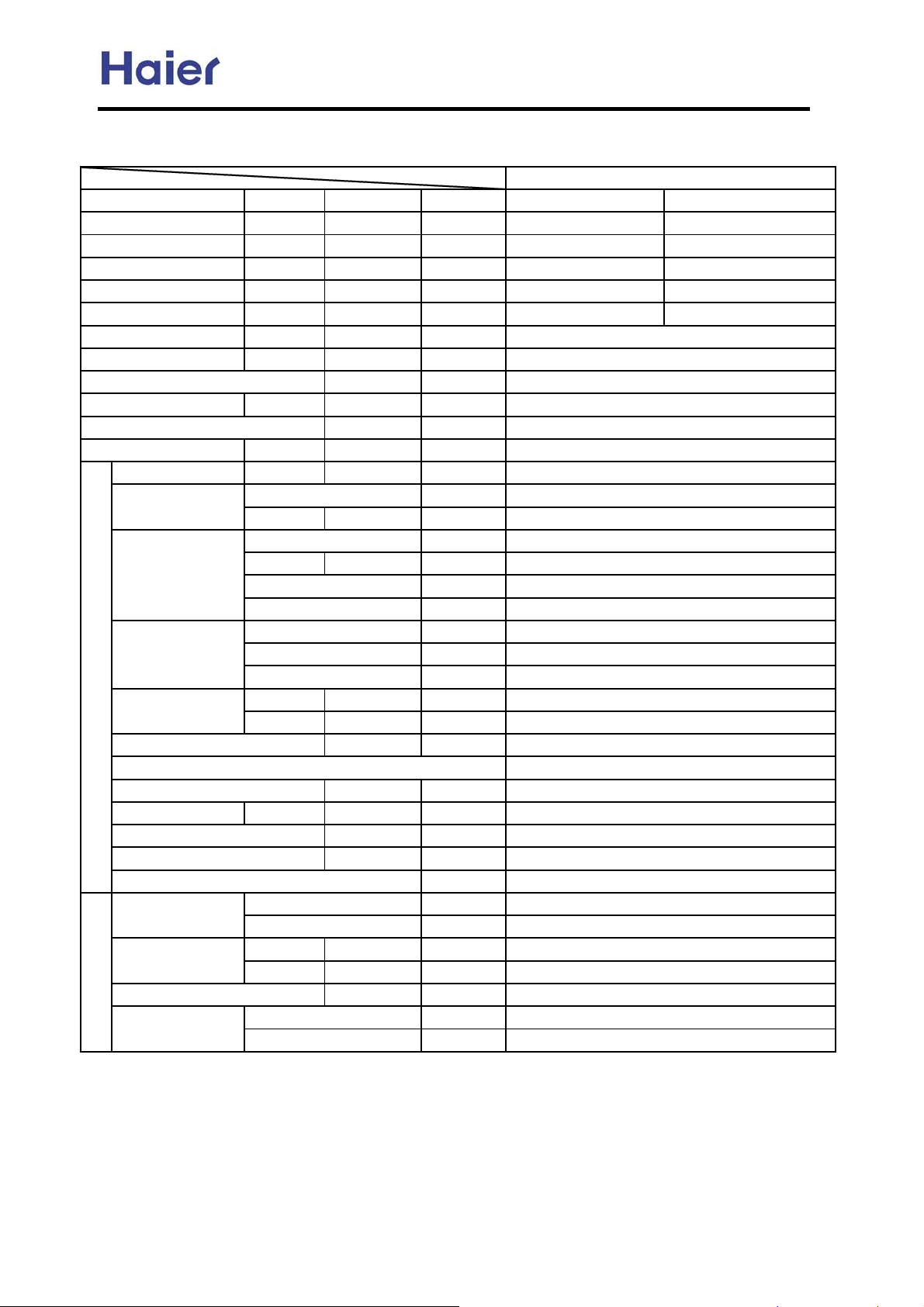

AU482FIBIA

Commercial Air Conditioner Model: AU242FHBIA,

AU482FIBIA, AU48NFIBJA

Item Model

AU482FIBIA

Function cooling heating

Capacity BTU/h

Capacity W

Total power input

Max. power input

EER or COP

W

W

W/W

Power cable

Power source

Running /Max.Running current

NˈVˈHz

A / A

Start Current A

Working frequency range Hz

Fuse A

Unit model (color)

Compressor

Model / Manufacture

Type

Type × Number

Fan

Speed r/min

Fan motor output power kW

Air-flow(H-M-L) m³/h

Type / Diameter mm

Heat exchanger

Dimension

Outdoor unit

Row*fin pintch

Temp. scope

External

Package

˄L×W×H˅

˄L×W×H˅

ć

mm×mm×mm

mm×mm×mm

Refrigerant control method mm/mm

Defrosting

Volume of Accumulator L

Noise level dB(A)

material of reduce noise

crankcase heater power W

Weight (Net / Shipping)

Refrigerant

Pipe

PIPING

Connecting Method

Between I.D &O.D

Type / Charge g

Recharge quantity g/m

Liquid mm

Gas mm

MAX.Drop

MAX.Piping length

kg / kg

m

m

48000 61000

14000 18000

6500 6000

7500 7500

2.15 3.00

2

16mm

1PH,220-230V~,50Hz

cooling: 34A/42A heating: 30/40A

--

30-105

3.15A 250V AC

AU482FIBIA (white)

EEV48FAL1/MITSUBISHI ELECTRIC

SCROLL

AXIAL*2

920±30r/min/840±40r/min/560±50r/min

65*2

7480

inner grooved copper pipe ¶9.52

2*1.5mm

43-60

1250X948X340

1375X1050X440

EEV

AUTO

--

58

--

40

120/135

R407C/4200

ij9.52 liquid pipe: 65g/mhactual length

¶9.52

¶19.05

flared

outdoor upper: 30, outdoor lower: 20

100

-7-

AU48NFIBJA

Commercial Air Conditioner Model: AU242FHBIA,

AU482FIBIA, AU48NFIBJA

Item Model

Function

Capacity BTU/h

Capacity W

Total power input

Max. power input

EER or COP

W

W

W/W

Power cable

Power source

Running /Max.Running current

NˈVˈHz

A / A

Start Current A

Working frequency range Hz

Fuse A

Unit model (color)

Compressor

Model / Manufacture

Type

Type × Number

Fan

Speed r/min

Fan motor output power kW

Air-flow(H-M-L) m³/h

Type / Diameter mm

Heat exchanger

Dimension

Outdoor unit

Row*fin pintch

Temp. scope

External

Package

˄L×W×H˅

˄L×W×H˅

ć

mm×mm×mm

mm×mm×mm

Refrigerant control method mm/mm

Defrosting

Volume of Accumulator L

Noise level dB(A)

material of reduce noise

crankcase heater power W

Weight (Net / Shipping)

Refrigerant

Type / Charge g

kg / kg

Recharge quantity g/m

Pipe

Liquid mm

Gas mm

PIPING

Connecting Method

Between I.D &O.D

MAX.Drop

MAX.Piping length

m

m

AU48NFIBJA

cooling heating

48000 61000

14000 18000

6000 6000

7000 7000

2.33 3.00

2

4mm

3N~,380-400V,50Hz

cooling: 10.5A/13A heating: 10.5/13A

--

25-95

3.15A 250V AC

AU48NFIBJA (white)

AEV60FCHMT/MITSUBISHI ELECTRIC

SCROLL

AXIAL*2

920±30 r/min/840±40r/min/560±50r/min

65*2

7480

inner grooved copper pipe ¶9.52

2*1.5mm

43-60

1250X948X340

1375X1050X440

EEV

AUTO

--

58

--

40

120/135

R407C/4400

ij9.52 liquid pipe: 65g/mhactual length

¶9.52

¶19.05

flared

outdoor upper: 30, outdoor lower: 20

100

-8-

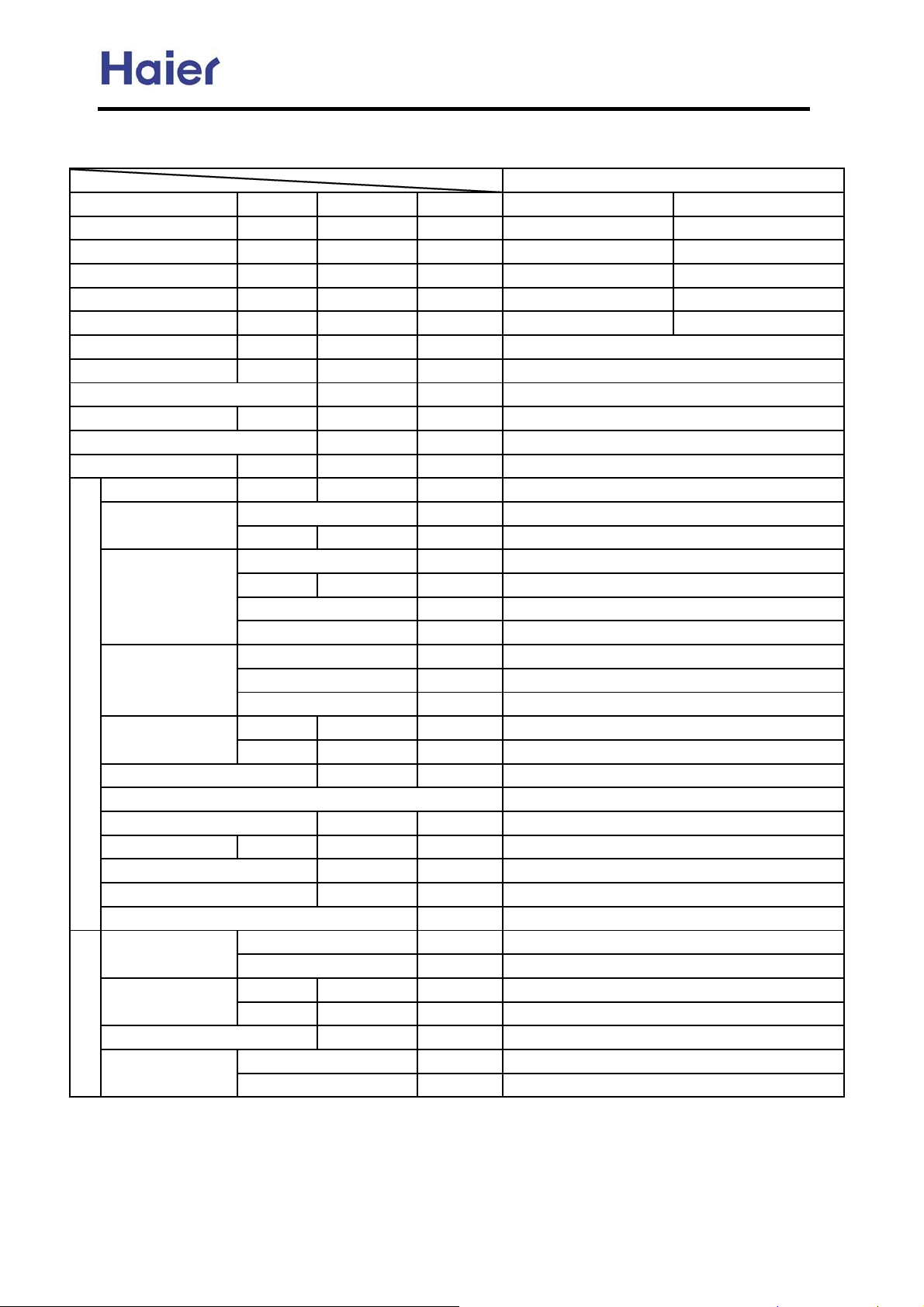

Commercial Air Conditioner Model: AU242FHBIA,

Indoor:

Item model

Cooling capacity Btu/h

Heating capacity Btu/h

Cooling capacity W

Heating capacity W

Dehumidifying capacity

Power source

Running current A

Starting current A

Refrigerant

Noise level(H/M/L) dB(A)

Type × Number

Fan

Heat exchanger

Refrigerant control method

Dimension(L×W×H)

Panel dimension (L×W×

H)

Weight(unit/panel)

Liquid mm (inch)

Piping

Suited area m2

Controller type

Gas mm (inch)

Connection method

Air-flow(H-M-L) m³/h

Fan motor output W

starting mothod

External

Shipping

External

Shipping

Net kg / kg

Shipping kg / kg

10ϋ³×m³/h

NˈVˈHz

mm×mm×mm

mm×mm×mm

mm×mm×mm

mm×mm×mm

AU482FIBIA, AU48NFIBJA

AB092FCBIA AB142FCBIA

9000 12000

11000 14000

2800 3600

3200 4000

1.6 2.1

1PH 220V-230V~ 50HZ 1PH 220V-230V~ 50HZ

-- --

11

R407C R407C

42/--/-- 42/--/--

centrifugal fan×1 centrifugal fan×1

700/--/-- 700/--/--

55 55

PG PG

Combination of wave cranny radiation fin and copper

Capillary + EEV

660×570×260 660×570×260

710×675×360 710×675×360

700×700×60 700×700×60

740×735×105 740×735×105

19.0/2.8 19.0/2.8

23.5/4.8 23.5/4.8

6.35 (1/4") 6.35 (1/4")

12.7 (1/2") 12.7 (1/2")

flared flared

12~23 17~27

remote controller

Item model

Cooling capacity Btu/h

Heating capacity Btu/h

Cooling capacity W

Heating capacity W

Dehumidifying capacity

Power source

Running current A

Starting current A

Refrigerant

Noise level(H/M/L) dB(A)

Type × Number

Fan

Heat exchanger

Refrigerant control method

Dimension(L×W×H)

Panel dimension (L×W×

H)

Weight(unit/panel)

Liquid mm (inch)

Piping

Suited area m2

Controller type

Gas mm (inch)

Connection method

Air-flow(H-M-L) m³/h

Fan motor output W

starting mothod

External

Shipping

External

Shipping

Net kg / kg

Shipping kg / kg

10ϋ³×m³/h

NˈVˈHz

mm×mm×mm

mm×mm×mm

mm×mm×mm

mm×mm×mm

AB182FCBIA

17000

19000

5000

5500

2.1

1PH 220V-230V~ 50HZ

--

1

R407C

42/--/--

centrifugal fan×1

700/--/--

55

PG

Combination of wave

cranny radiation fin and

copper pipe

Capillary + EEV

660×570×260

710×675×360

700×700×60

740×735×105

19.0/2.8

23.5/4.8

6.35 (1/4")

12.7 (1/2")

flared

22~33

remote controller

-9-

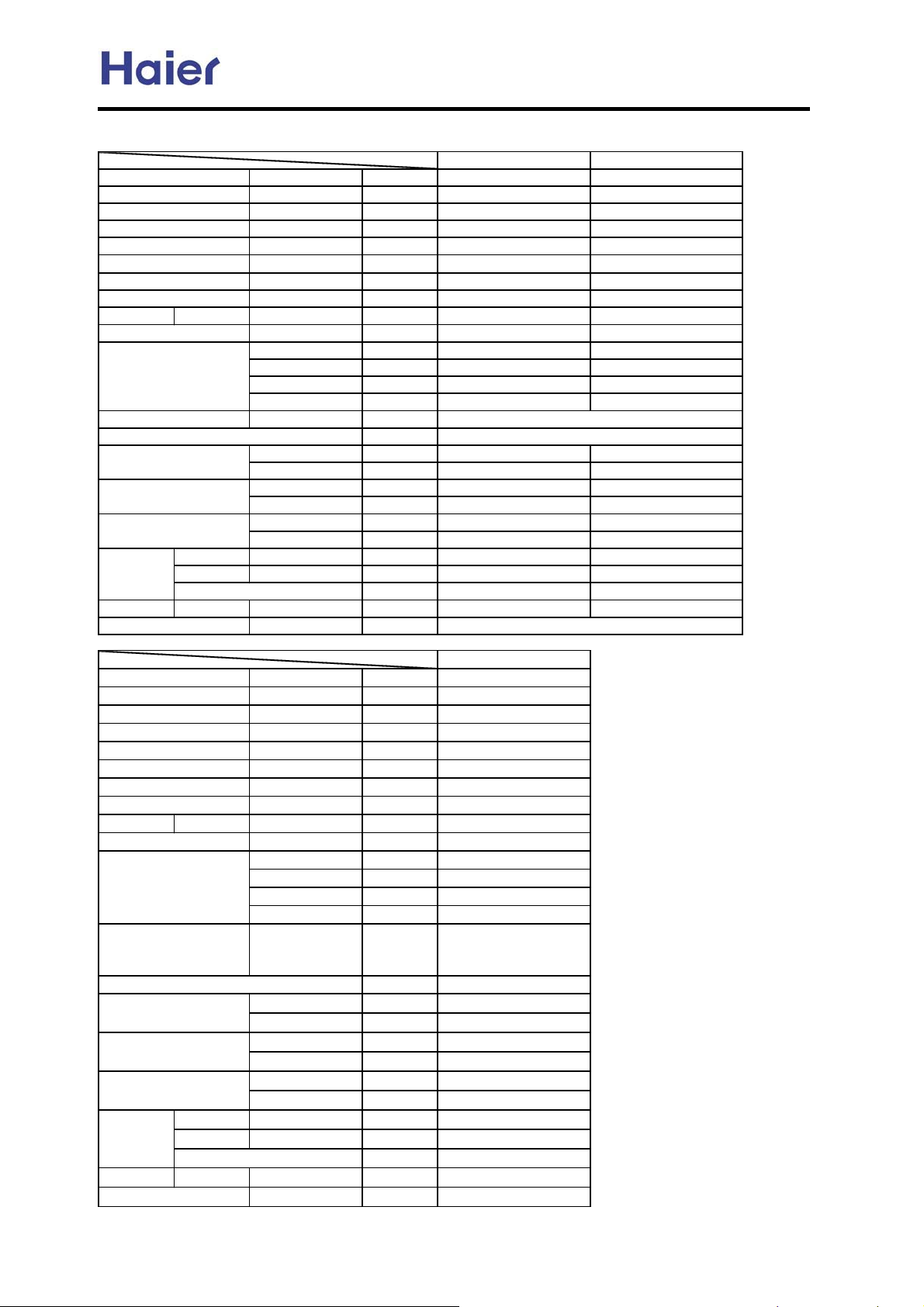

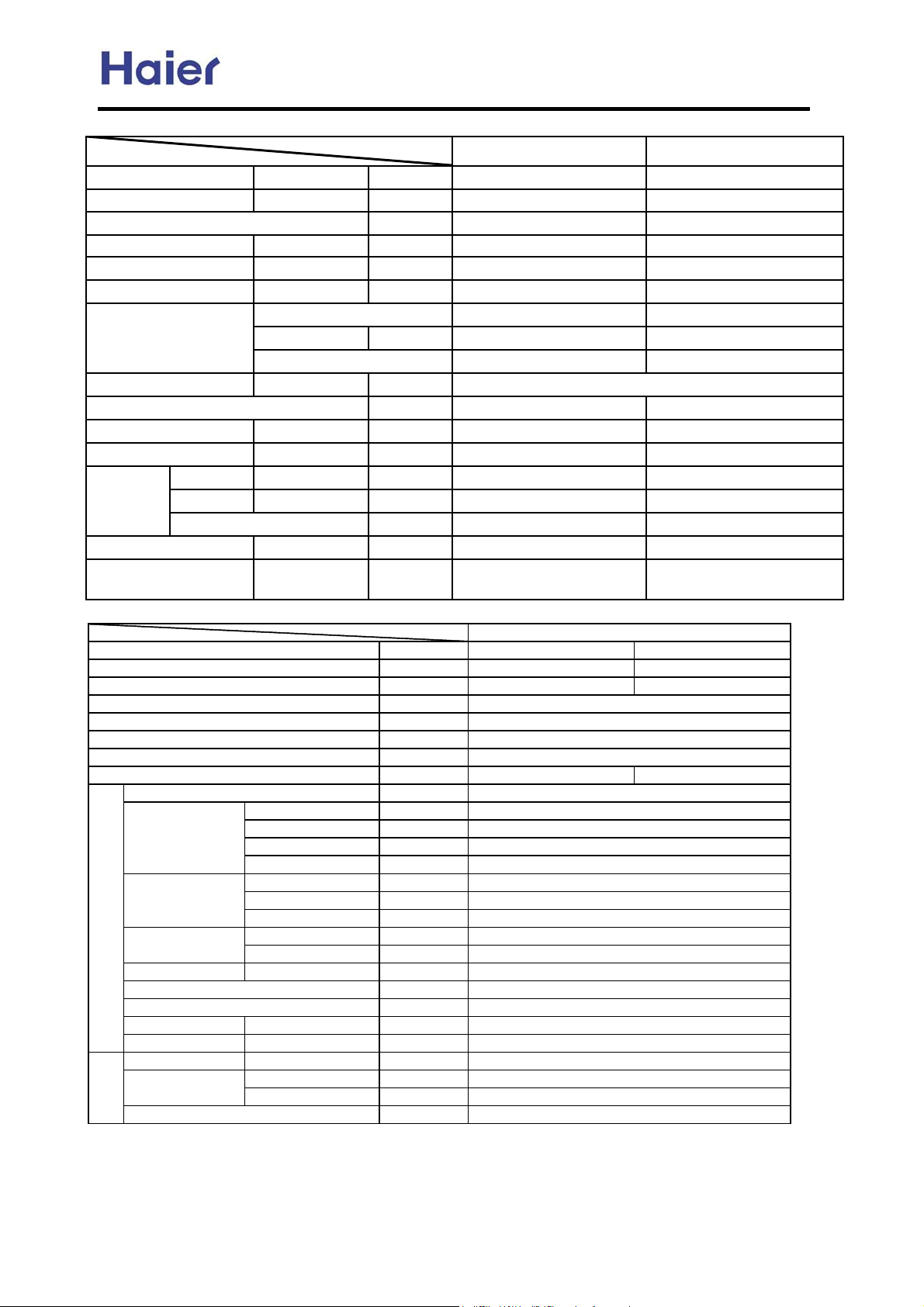

Commercial Air Conditioner Model: AU242FHBIA,

AU482FIBIA, AU48NFIBJA

Item model

AE072FCBKA AE092FCBKA

Cooling capacity Btu/h 7000 9000

Heating capacity Btu/h 9000 11000

Dehumidifying capacity

Power source

10ϋ³×m³/h

NˈVˈHz

1.2 1.6

1PH 220V-230V 50HZ 1PH 220V-230V 50HZ

Refrigerant R407C R407C

Noise level(H/M/L) dB(A) 36/32/29 36/32/29

Type × Number centrifugal fan×2 centrifugal fan×2

Fan

Air-flow(H-M-L) m³/h 520 / 420 / 300 520 / 420 / 300

starting mothod Relay control Relay control

Heat exchanger

Refrigerant control method

Dimension ˄L×W×H˅

Weight

External

Net kg 18 18

mm×mm×mm

Combination of wave cranny radiation fin and copper

Capillary + EEV

674×225×450 674×225×450

Liquid mm 6.35 6.35

Piping

Gas mm 9.52 9.52

Connection method flared flared

Suited area m2 8~16 11~21

Controller type

wired controller or remote controller

Item model

AE122FCBKA AE142FCBKA

Cooling capacity Btu/h 12000 14000

Heating capacity Btu/h 14000 16000

Dehumidifying capacity

Power source

10ϋ³×m³/h

NˈVˈHz

1.8 2

1PH 220V-230V 50HZ 1PH 220V-230V 50HZ

Refrigerant R407C R407C

Noise level(H/M/L) dB(A) 42/38/32 42/38/32

Type × Number centrifugal fan×2 centrifugal fan×2

Fan

Air-flow(H-M-L) m³/h 650 / 550 / 400 700/ 550 / 400

starting mothod Relay control Relay control

Heat exchanger

Refrigerant control method

Dimension ˄L×W×H˅

Weight

External

Net kg 20 20

mm×mm×mm

Combination of wave cranny radiation fin and copper

Capillary + EEV

828×225×450 828×225×450

Liquid mm 6.35 6.35

Piping

Gas mm 12.7 12.7

Connection method flared flared

Suited area m2 12~23 17~27

Controller type

wired controller or remote controller

-10-

Commercial Air Conditioner Model: AU242FHBIA,

z

Z

Z

AU482FIBIA, AU48NFIBJA

Item model

AE182FCBKA AE242FCBKA

Cooling capacity Btu/h 18000 24000

Heating capacity Btu/h 20000 28000

Dehumidifying capacity

Power source

10ϋ³×m³/h

NˈVˈH

Refrigerant

Noise level(H/M/L) dB(A)

2.4 3

1PH 220V-230V 50H

1PH 220V-230V 50H

R407C R407C

48 / 43 / 36 48 / 43 / 36

Type × Number centrifugal fan×2 centrifugal fan×2

Fan

Air-flow(H-M-L) m³/h 1000 /900/700 1000 /900/700

starting mothod Relay control Relay control

Heat exchanger

Combination of wave cranny radiation fin and

Refrigerant control method Capillary + EEV Capillary + EEV

Dimension ˄L×W×H˅

Weight

External mm×mm×mm

Net kg 25 25

Liquid mm 9.52 9.52

Piping

Gas mm 15.88 15.88

Connection method flared flared

Suited area

Controller type

m

2

23~36 32~49

wired controller or remote

controller

wired controller or remote

controller

Item Model

Function

Capacity

Capacity

Dehumidifying capacity

Power cable

Communication cable

Power source

Running current

Unit model (color)

Fan CROSS×1

Heat exchanger

Dimension

Indoor unit

(L×W×H)

Drainage pipe material, diameter mm

Controller type

Refrigerant control

Noise level H/M/L dB(A)

Weight Net / Shipping kg / kg

Refrigerant Type ——

Pipe 6.35

Piping

Connecting method

Type × Number ——

Speed r/min

Motor output power W

Air-flows (H/M/L) m³/h

Type / Diameter mm

Total area m²

Temp. scope

External mm

Package mm

Liquid mm

Gas mm

—— Cooling Heating

BTU/h 18000 20000

W 5200 5800

10ϋ³×m³/h

——

——

N, V, Hz

A / A 0.10 0.10

——

ć

——

——

——

3 × (1.0~1.5mm2 )

2x(0.75~1.25mm2 )

AS182FCBHA (white)

TP2M / 6.35×0.7

cooling: 6~7 / heating: 43~60

Phone type infrared

AS182FCBHA

2.0

1, 220~230, 50

1350/1150/900

25

760/630/560

about 0.15

928×197×265

1025×309×330

PVC, 11.4/16.4

EEV

44/41/38

11/14

R407C

12.7

Flared

-11-

Commercial Air Conditioner Model: AU242FHBIA,

(

)

(

)

(

)

AU482FIBIA, AU48NFIBJA

Item Model

Function

Capacity

Capacity

Dehumidifying capacity

10ϋ³×m³/h

Power cable

Communication cable

Power source

N, V, Hz

Running current

Unit model (color)

Fan

Type × Number ——

Speed r/min

Motor output power W

Air-flows (H/M/L) m³/h

Heat exchanger

Type / Diameter mm

Total area m²

Temp. scope

Dimension

Indoor unit

(L×W×H)

External mm

Package mm

Drainage pipe material, diameter mm

Controller type

Refrigerant control

Noise level H/M/L dB(A)

Weight Net / Shipping kg / kg

Refrigerant Type ——

Pipe

Piping

Connecting method

Liquid mm

Gas mm

Item Model

Function

Capacity

Capacity

Dehumidifying capacity

10ϋ³×m³/h

Power cable

Communication cable

Power source

N, V, Hz

Running current

Unit model (color)

Fan

Type × Number ——

Speed r/min

Motor output power W

Air-flows (H-M-L) m³/h

Heat exchanger

Type / Diameter mm

Total area m²

Temp. scope

Dimension

Indoor unit

(L×W×H)

External mm

Package mm

Drainage pipe material, diameter mm

Controller type

Refrigerant control

Noise level H/M/L dB(A)

Weight Net / Shipping kg / kg

Refrigerant Type ——

Pipe

Piping

Connecting method

Liquid mm

Gas mm

AS072FCBHA AS092FCBHA

—— Cooling Heating Cooling Heating

BTU/h 7000 9500 9000 10000

W 2000 2800 2600 3200

1.0 / 1.0 /

——

——

1.0~1.5mm

3 ×

0.75~1.25mm

2x

2

2

1, 220~230, 50

A / A 0.10 0.10 0.10 0.10

——

AS072FCBHA (white) AS092FCBHA (white)

CROSS×1 CROSS×1

1050/900/800 1250/1050/900

25 25

520/410/300 600/500/410

TP2M / 6.35×0.7

about 0.15 about 0.15

ć

cooling: 6~7 / heating: 43~60

795×197×265 795×197×265

880×315×330 880×315×330

PVC, 11.4/16.4

——

——

Phone type infrared

EEV

36/33/29 37/35/30

7.6/10.6 7.6/10.6

R407C

6.35

12.7

——

Flared

AS122FCBHA AS142FCBHA

—— Cooling Heating Cooling Heating

BTU/h 12000 15000 14000 17000

W 3500 4500 4000 5000

1.6 / 2.0 /

——

——

3 × 0.75mm

2x

0.75~1.25mm

2

2

1, 220~230, 50

A / A 0.15 0.15 0.15 0.15

——

AS122FCBHA (white) AS142FCBHA (white)

CROSS×1 CROSS×1

1250/1050/900 1250/1050/900

25 25

630/520/410 640/570/450

TP2M / 6.35×0.7

about 0.20 about 0.20

ć

cooling: 6~7 / heating: 43~60

795×197×265 928×197×265

880×315×330 1025×309×330

PVC, 11.4/16.4

——

——

Phone type infrared

EEV

39/37/30 44/41/38

7.6/10.6 11/14

R407C

6.35

12.7

——

Flared

-12-

Commercial Air Conditioner Model: AU242FHBIA,

AU482FIBIA, AU48NFIBJA

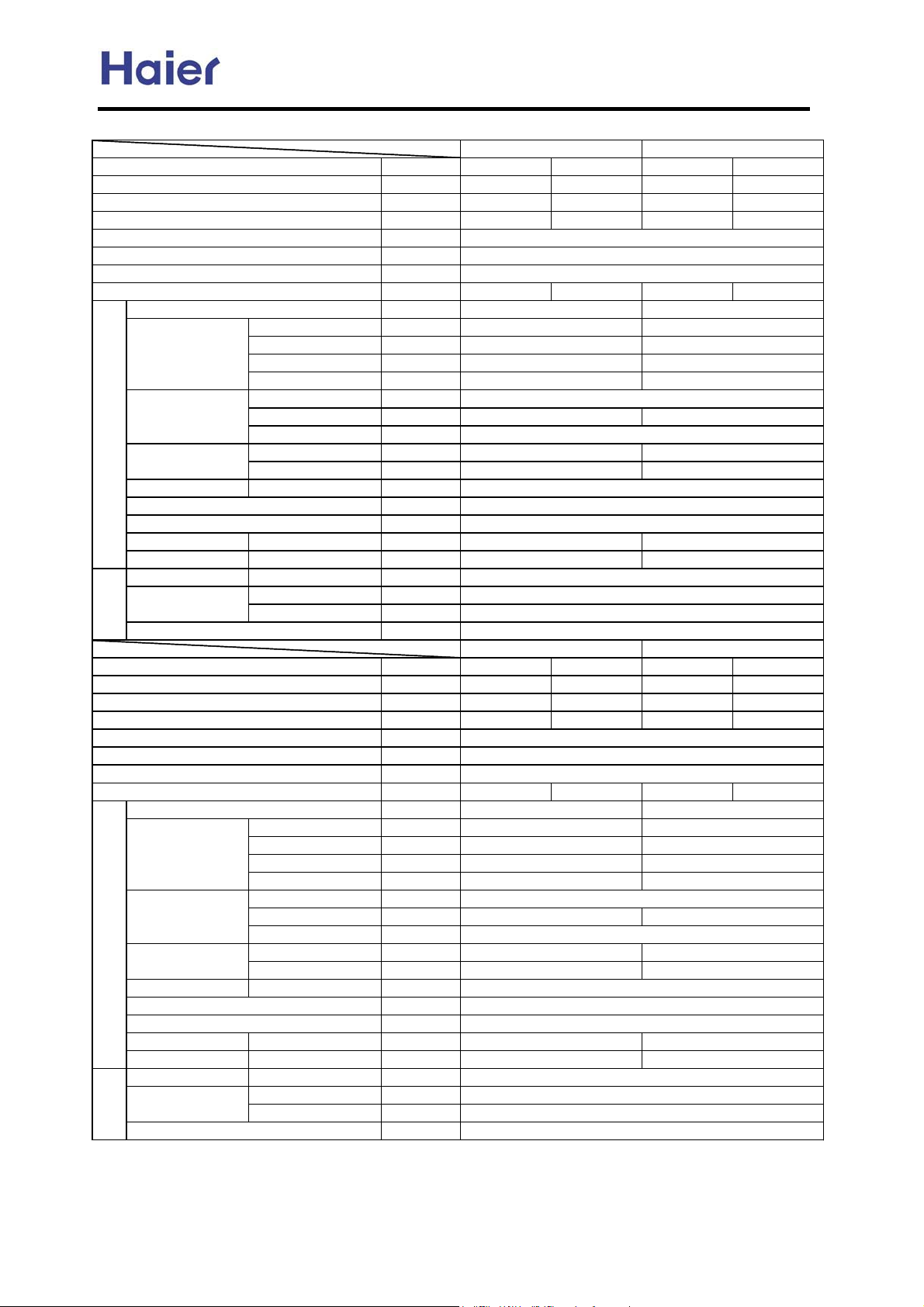

Norminal condition: indoor temperature (cooling): 27 ćDB/19ćWB, indoor temperature (heating): 20 ćDB

Outdoor temperature(cooling): 35ćDB/24ćWB, outdoor temperature(heating): 7 ćDB/6ćWB

The noise level will be measured in the third octave band limited values, using a Real Time Analyser calibrated sound

intensity meter. It is a sound pressure noise level. The detailed method please refer to the following information:

Installation state: the unit should be placed on the flat floor or be mounted in horizontal direction.

Testing method:

mounting-on-wall unit: built-in-ceiling unit: duct unit without auxiliary duct:

2m

duct

0.8m

1.4m

1.4m

1m

outdoor unit:

1.air outlet from side: the noise level is the average sound pressure level measured from front, left, right

directions.

2.air outlet from top: the noise level is the average sound pressure level measured from front, back, left,

right directions.

measured point:

H ( height to the ground) = (h (unit height) + 1m) /2

and, it is 1m to each side.

1m

1m

1m

h

Note: Ĵ is the real

time analyser position

1m

-13-

Commercial Air Conditioner Model: AU242FHBIA,

AU482FIBIA, AU48NFIBJA

3. Safety precaution

Carefully read the following information in order to operate the airconditioner correctly.

Below are listed three kinds of Safety Cautions and Suggestions.

WARNING!

CAUTION!

INSTRUCTIONS: These information can ensure the correct operation of the machine.

Be sure to conform with the following important Safety Cautions.

The Safety Cautions should be at hand so that they can be checked at any time when needed.

If the conditioner is transferred to the new user, this manual should be as well transferred to the new user.

Incorrect operations may result in severe consequences of death or serious injuries.

Incorrect operations may result in injuries or machine damages; in some cases may

cause serious consequences.

WARNING!

If any abnormal phenomena is found

(e. g.smell of firing), please cut off the

power supply immediately, and contact

the dealer to find out the handling

method.

In such case, to continue using the

conditioner will damage the conditioner,

and may cause electrical shock or fire

hazard.

Don't dismantle the outlet of the

outdoor unit.

The exposed fan is very dangerous

which may harm human beings.

switch

off

After the unit being used for a long time,

the base should be checked for any

damages.

If the damaged base is not repaired, the

unit may fall down and cause accidents.

When the unit needs maintenance and

repairment, please call dealer to handle it.

Incorrect maintenance and repairment

may cause water leak, electrical shock

and fire hazard.

-14-

Commercial Air Conditioner Model: AU242FHBIA,

AU482FIBIA, AU48NFIBJA

WARNING!

Installed electrical-leaking circuit

breaker.

It easily cause electrical shock without

circuit breaker.

Air-conditioner can't be installed in

the environment with inflammable

gases because the inflammable gases

near to air-conditioner may cause fire

hazard.

Please let the dealer be responsible for

installing the conditioner.

Incorrect installation may cause water

leak, electrical shock and fire hazard.

Call the dealer to take measures to

prevent the refrigerant from leaking.

Nothing or nobody is permitted to

placed on or stand on outdoor unit.

The falling of goods and people may

cause accidents.

Don't operate the air-conditioner with

damp hands.

Otherwise will be shocked.

If conditioner is installed in a small

room be sure to take every measure in

order to prevent suffocation accident

even in case of refrigerant leakage.

When conditioner is removed or

reinstalled, dealer should be responsible

for them.

Incorrect installation may cause water

leaking, electrical shock and fire hazard.

Connect earthing wire.

Earthing wire should not be connected to the gas pipe, water pipe,

lightning rod or phone line, in-correct

earthing may cause shock.

Only use correctly-typed fuse.

May not use wire or any other materials

replacing fuse, other-wise may cause

faults or fire accidents.

Use discharge pipe correctly to ensure

efficient discharge.

Incorrect pipe use may cause water

leaking.

Earthing

-15-

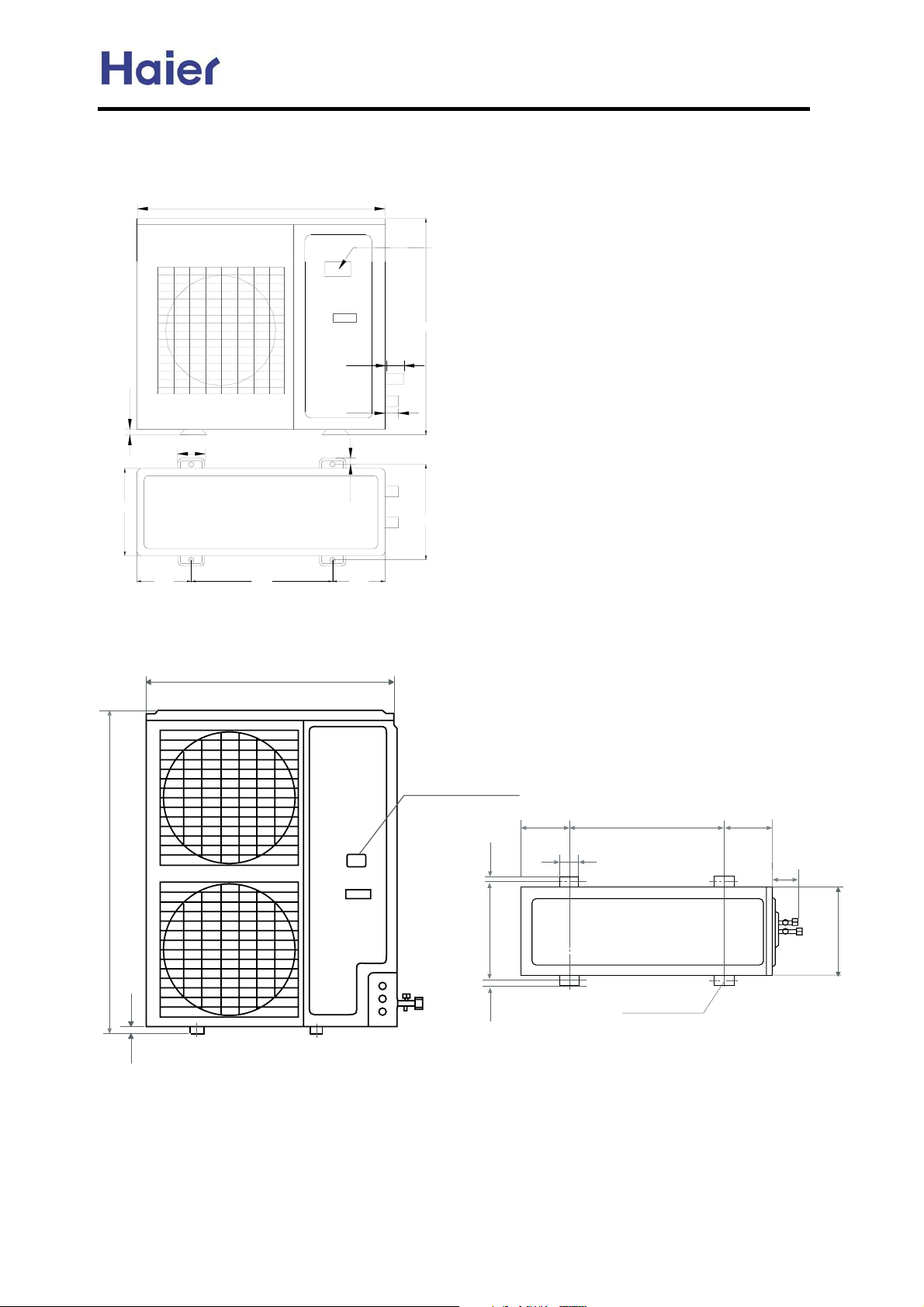

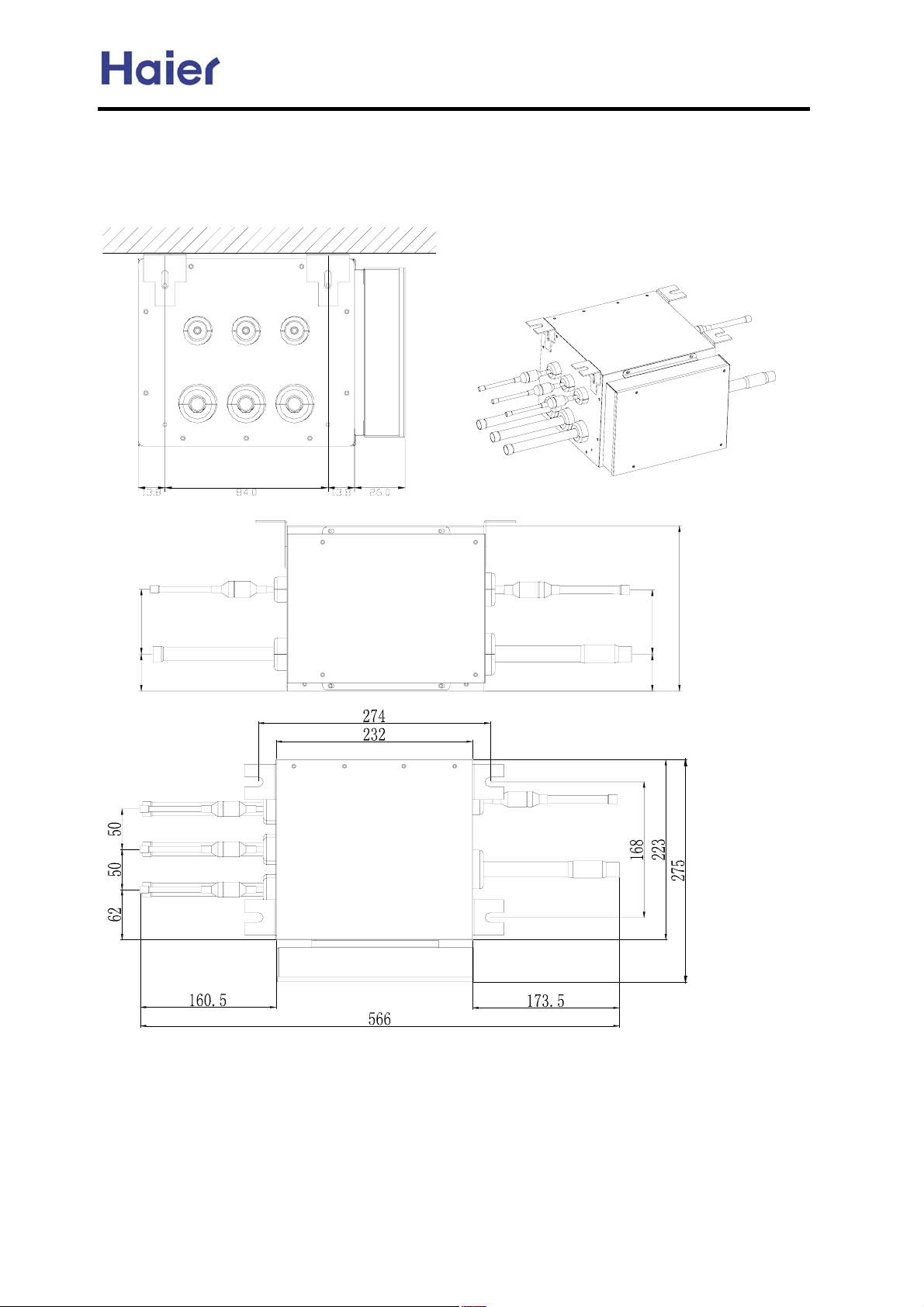

4. Net dimension

AU242FHBHA

948

Commercial Air Conditioner Model: AU242FHBIA,

AU482FIBIA, AU48NFIBJA

Power wiring terminal

840

70

25

340

AU48*

184

70

580

948

55

18

184

380

Power wiring Terminal

184 184

580

1250

25

18

380

18

-16-

70

55

340

Screw Hole

(4xM10)

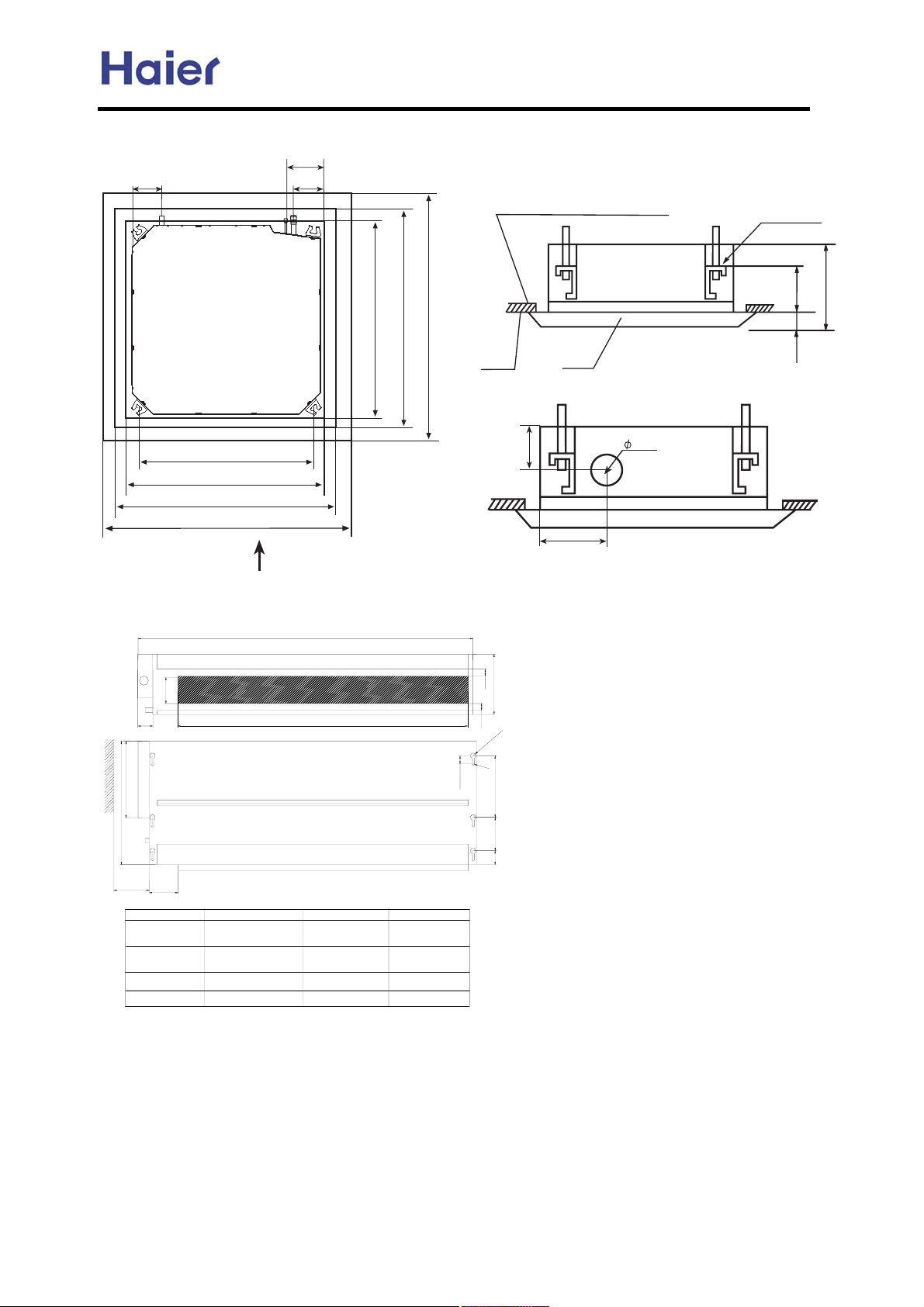

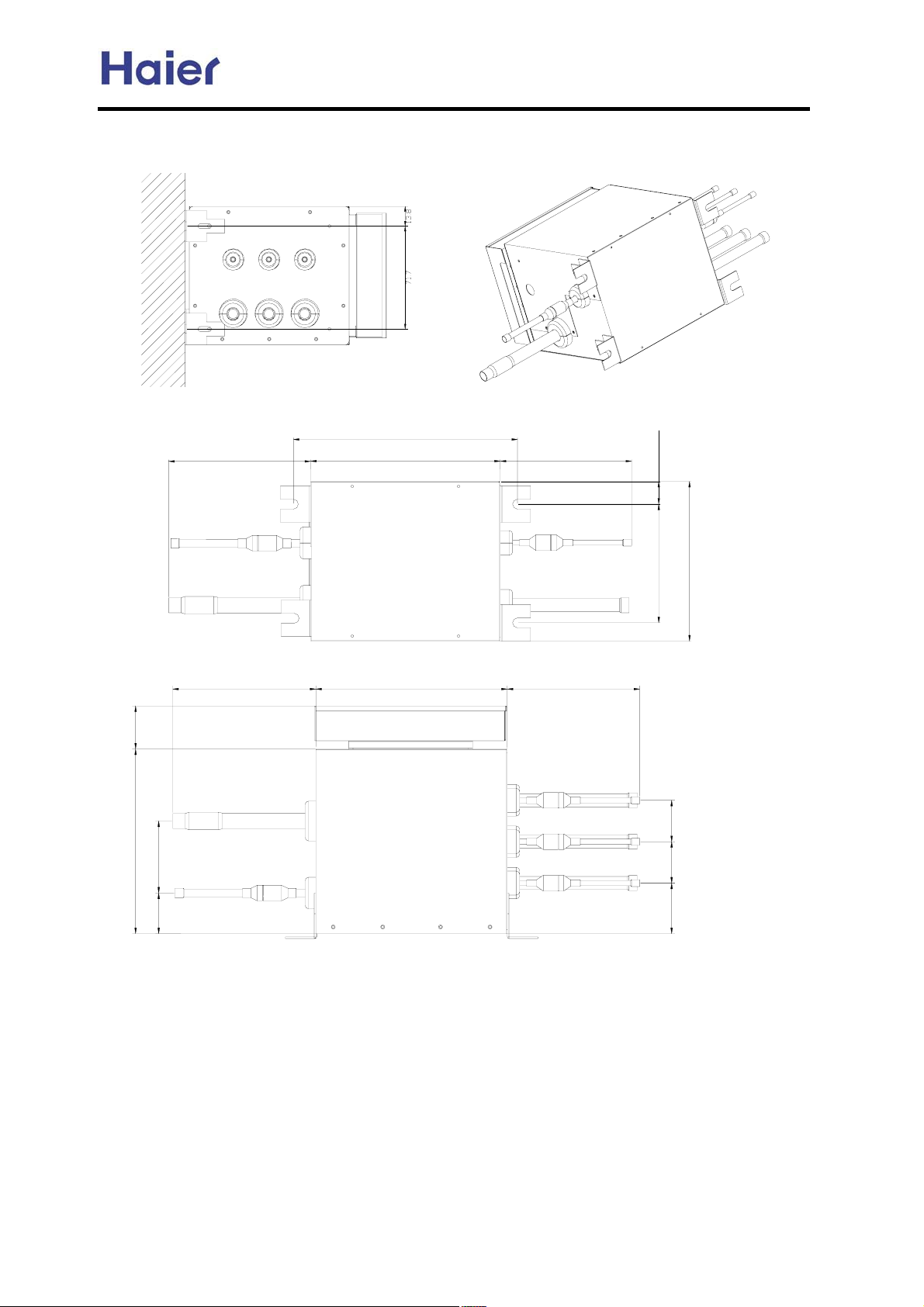

AB** Cassette unit:

B9

LXIQTIOM VQVM

:;9

A9

OIY VQVMRQW[QL VQVM

Commercial Air Conditioner Model: AU242FHBIA,

AU482FIBIA, AU48NFIBJA

U\MXRIVML LQYZITKM JMZ]MMT ZPM KMQRQTO

ITL ZPM VITMRC ;>SS

Y[YVMTYQUT PURLMX

:>9SS

<;9SS

><>SS 7JMZ]MMT Y[YVMTYQUT VURMY8

>@9SS 7QTLUUX [TQZ LQSMTYQUT8

?>9SS 7KMQRQTO UVMTQTO LQSMTYQUT8

@99SS 7VITMR LQSMTYQUT8

GFEH D

AE** Ceiling concealed unit

100

54

240

C

>@9SS 7QTLUUX [TQZ LQSMTYQUT8

?>9SS 7KMQRQTO UVMTQTO LQSMTYQUT8

@99SS 7VITMR LQSMTYQUT8

KMQRQTO

:A9

VITMR

B>

?9SS

NXMYP IQX PURM

:=9

GFEH D

b

25

225

a

25

10

R

R

5

30

29(5

unit model

AE072FCBKA

AE092FCBKA

AE122FCBKA

AE142FCBKA

AE182FCBKA

AE242FCBKA

55

93

615

704

858

990

a

b

650

800

1020

1350

c

452

452

452

452

-17-

AS** series

Commercial Air Conditioner Model: AU242FHBIA,

AU482FIBIA, AU48NFIBJA

O

:=DAI

P

Q

FH@AE

AS072FCBHA AS092FCBHA

AS122FCBHA

AS142FCBHA AS182FCBHA

=

462

6/5

>

/32

?

.64

-18-

Commercial Air Conditioner Model: AU242FHBIA,

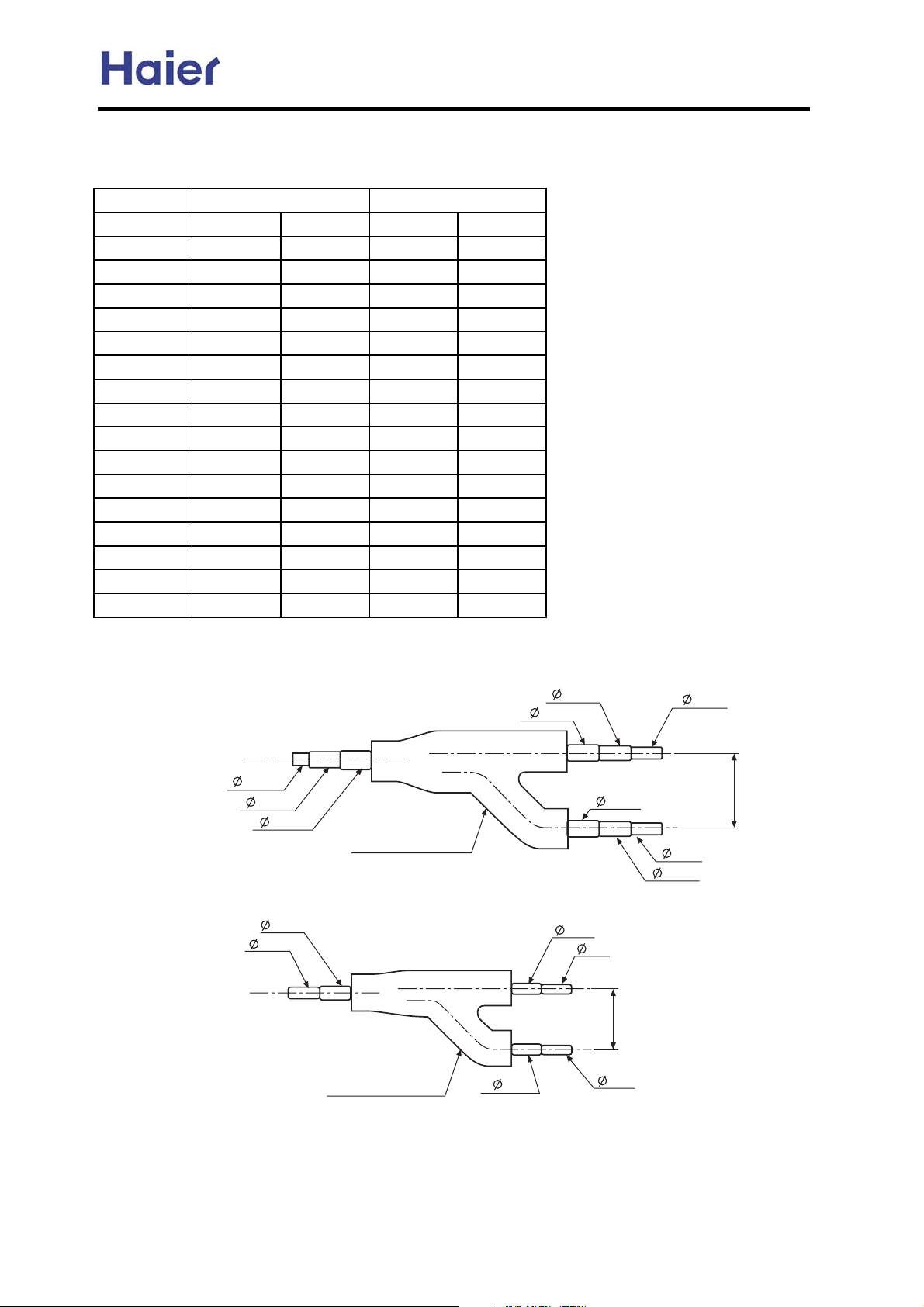

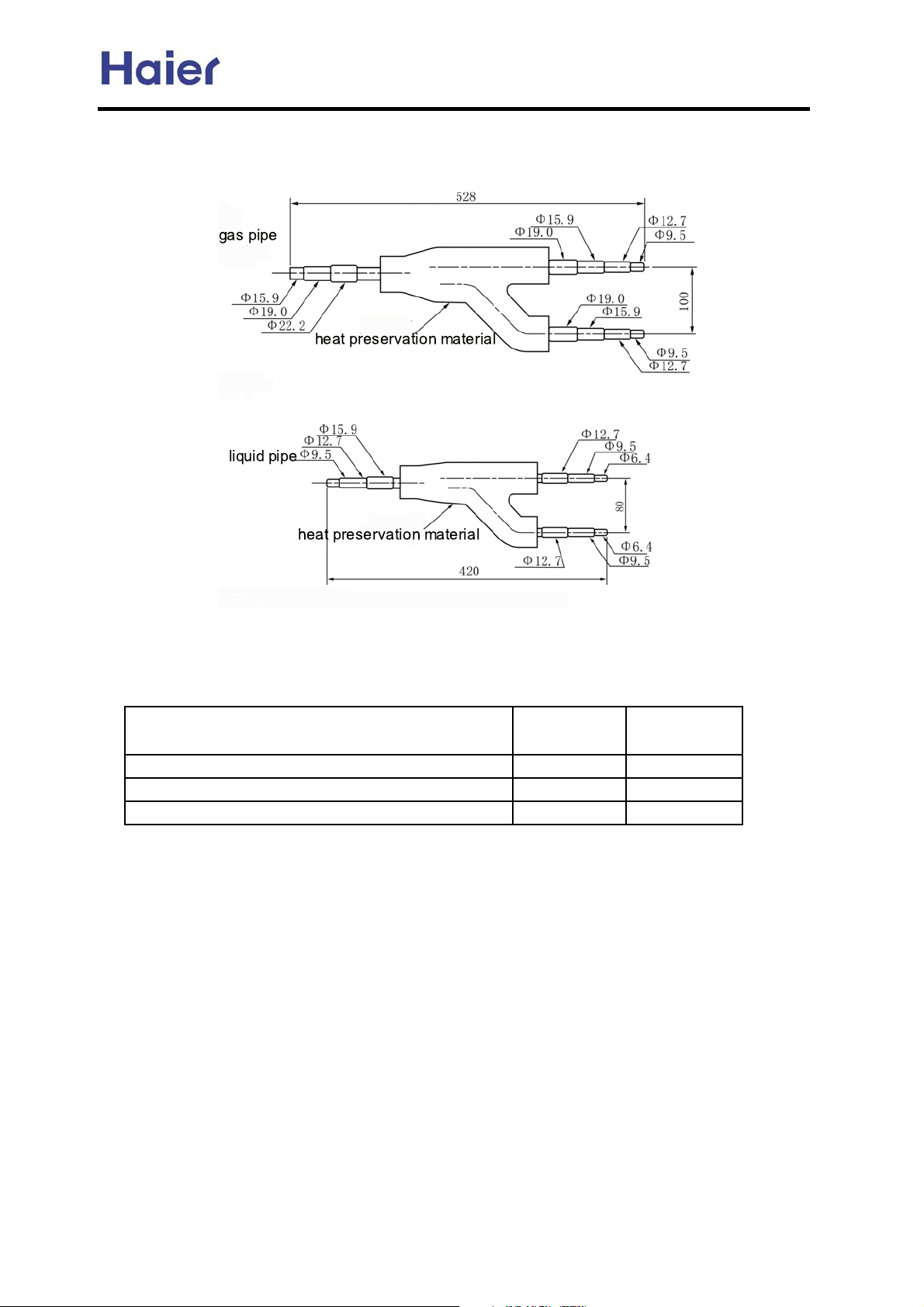

Dimensions for MP2A, MP3A:

Installation on the horizontal ceiling:

horizontal ceiling

AU482FIBIA, AU48NFIBJA

-19-

Installation on the vertical wall (adjust the installation position by fixing holder):

vertical wall

Commercial Air Conditioner Model: AU242FHBIA,

AU482FIBIA, AU48NFIBJA

-20-

Commercial Air Conditioner Model: AU242FHBIA,

5. Installation Instructions

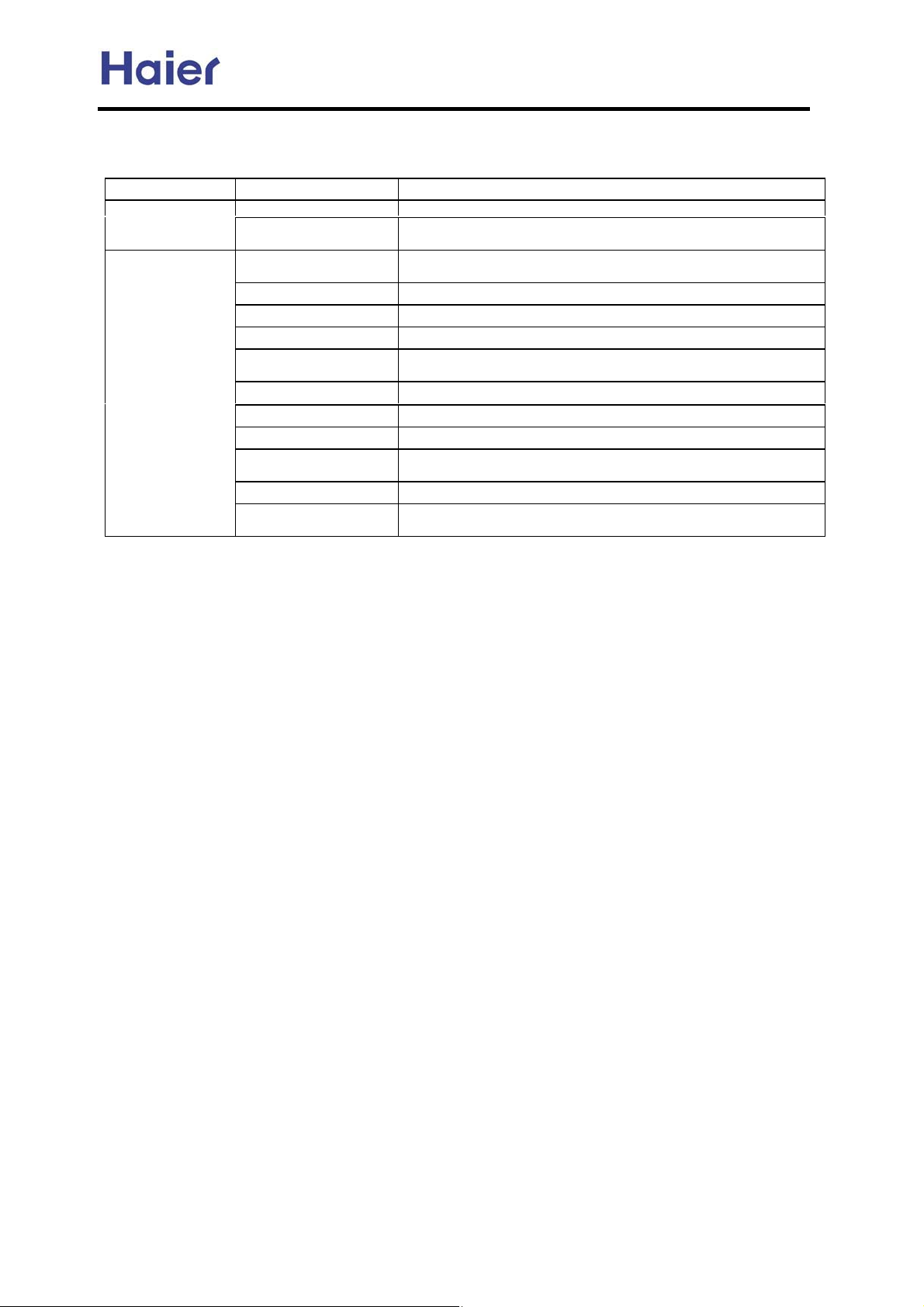

5.1 Piping dimension chart

AU482FIBIA, AU48NFIBJA

model

liquid pipe gas pipe

mm inch mm inch

AU24 9.52 3/8" 15.88 5/8"

AU48 9.52 3/8" 19.05 3/4"

AB09 6.35 1/4" 12.7 1/2"

AB14 6.35 1/4" 12.7 1/2"

AB18 6.35 1/4" 12.7 1/2"

AE07 6.35 1/4" 9.52 3/8"

AE09 6.35 1/4" 9.52 3/8"

AE12 6.35 1/4" 12.7 1/2"

AE14 6.35 1/4" 12.7 1/2"

AE18 9.52 3/8" 15.88 5/8"

AE24 9.52 3/8" 15.88 5/8"

AS07 6.35 1/4" 12.7 1/2"

AS09 6.35 1/4" 12.7 1/2"

AS12 6.35 1/4" 12.7 1/2"

AS14 6.35 1/4" 12.7 1/2"

AS18 6.35 1/4" 12.7 1/2"

5.2 Y-shape manifold pipe

model: FQG-B120

<gas side>

9.52

12.7

15.88

<liquid side>

9.52

6.35

heat preservation

material

heat preservation

material

12.7

15.9

12.7

12.7

9.52

15.88

75

9.52

9.52

75

9.52

12.7

Dimension is the out diameter connecting to the tubing.

-21-

FQG-B180

g

Commercial Air Conditioner Model: AU242FHBIA,

AU482FIBIA, AU48NFIBJA

Refrigerant pipes between manifold pipes

Total refrigerating amount of indoor unit

Gas side Liquid side

roup after the manifold pipe

Less than 38220Btu/h 15.9 9.52

38220~61157Btu/h 19.05 9.52

61157~126137Btu/h 25.4 12.7

Note: 1. Y-shape manifold pipe can be placed in horizontal or vertical

direction

2. The manifold pipes must be welded with hard-solder

3. Pay attention to cut off the unnecessary part from its middle

parts of each joint, and to remove burr.

-22-

Commercial Air Conditioner Model: AU242FHBIA,

AU482FIBIA, AU48NFIBJA

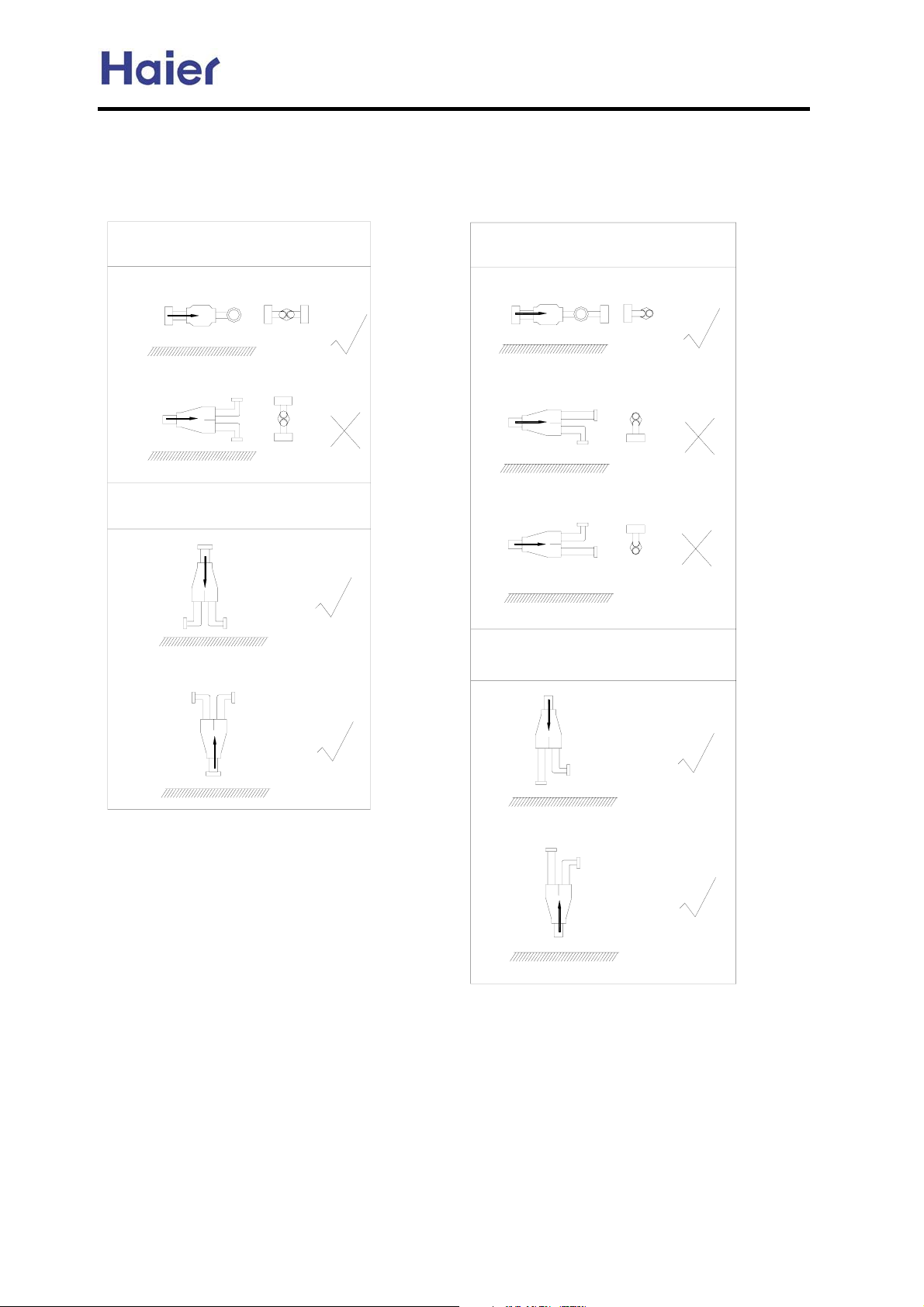

In the file, the figure marked with "Ĝ" is permitted, and the figure marked with "h" is prohibited.

You can confirm the position according to the actual condition.

The refrigerant flow direction is always from the collective side to the divided side.

horizontal

vertical

floor surface

floor surface

floor surface

horizontal

floor surface

floor surface

floor surface

vertical

floor surface

floor surface

floor surface

-23-

Commercial Air Conditioner Model: AU242FHBIA,

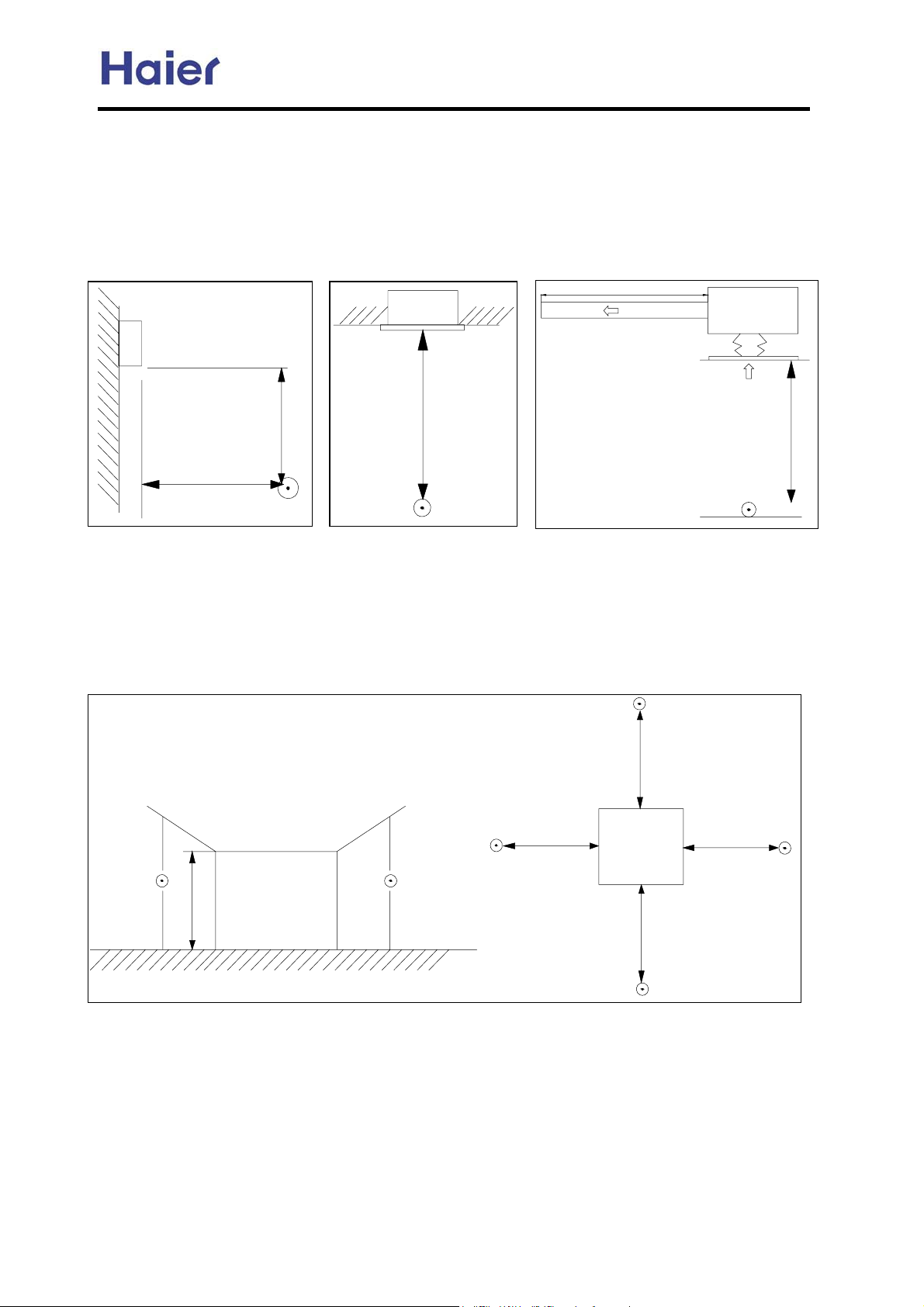

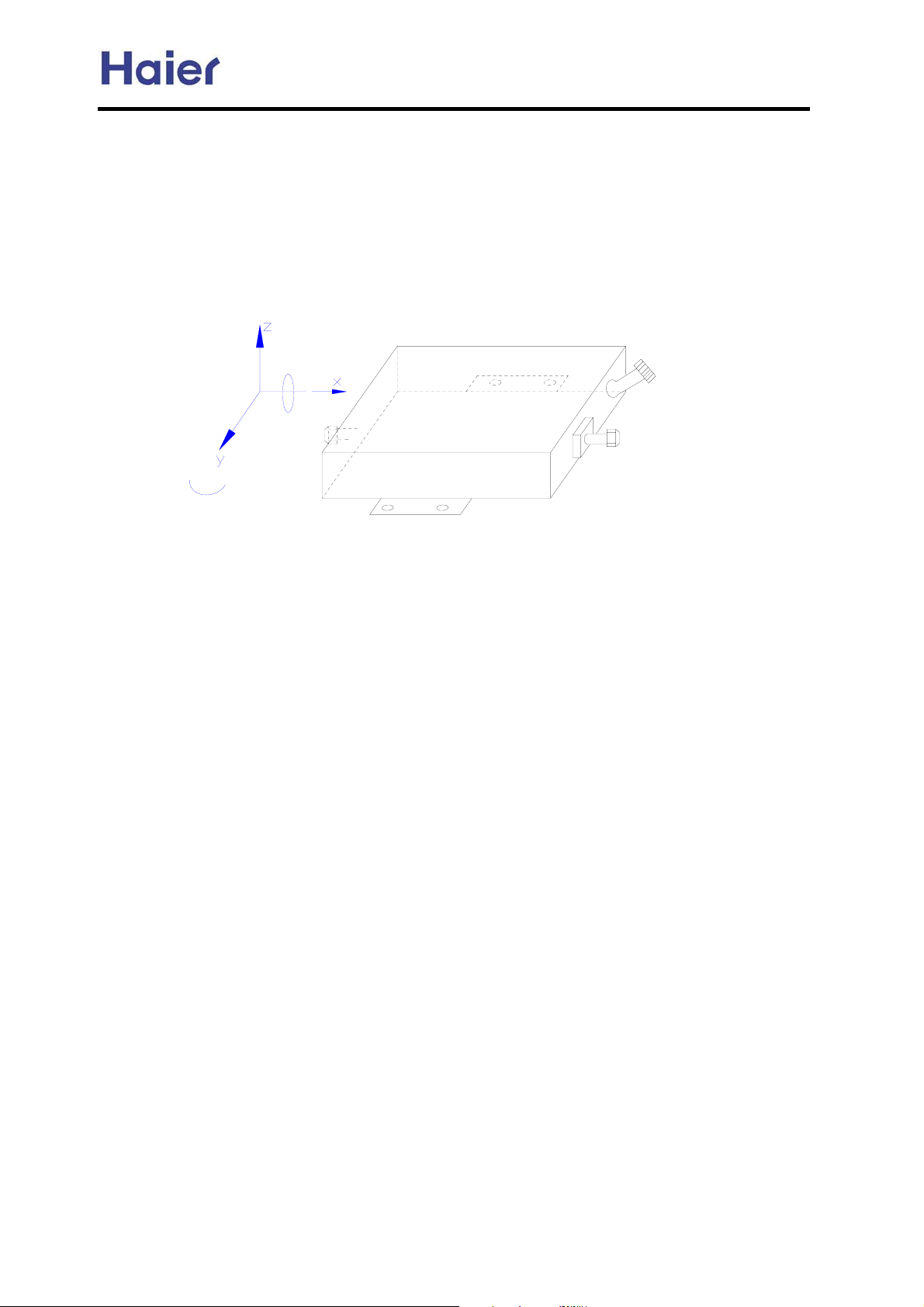

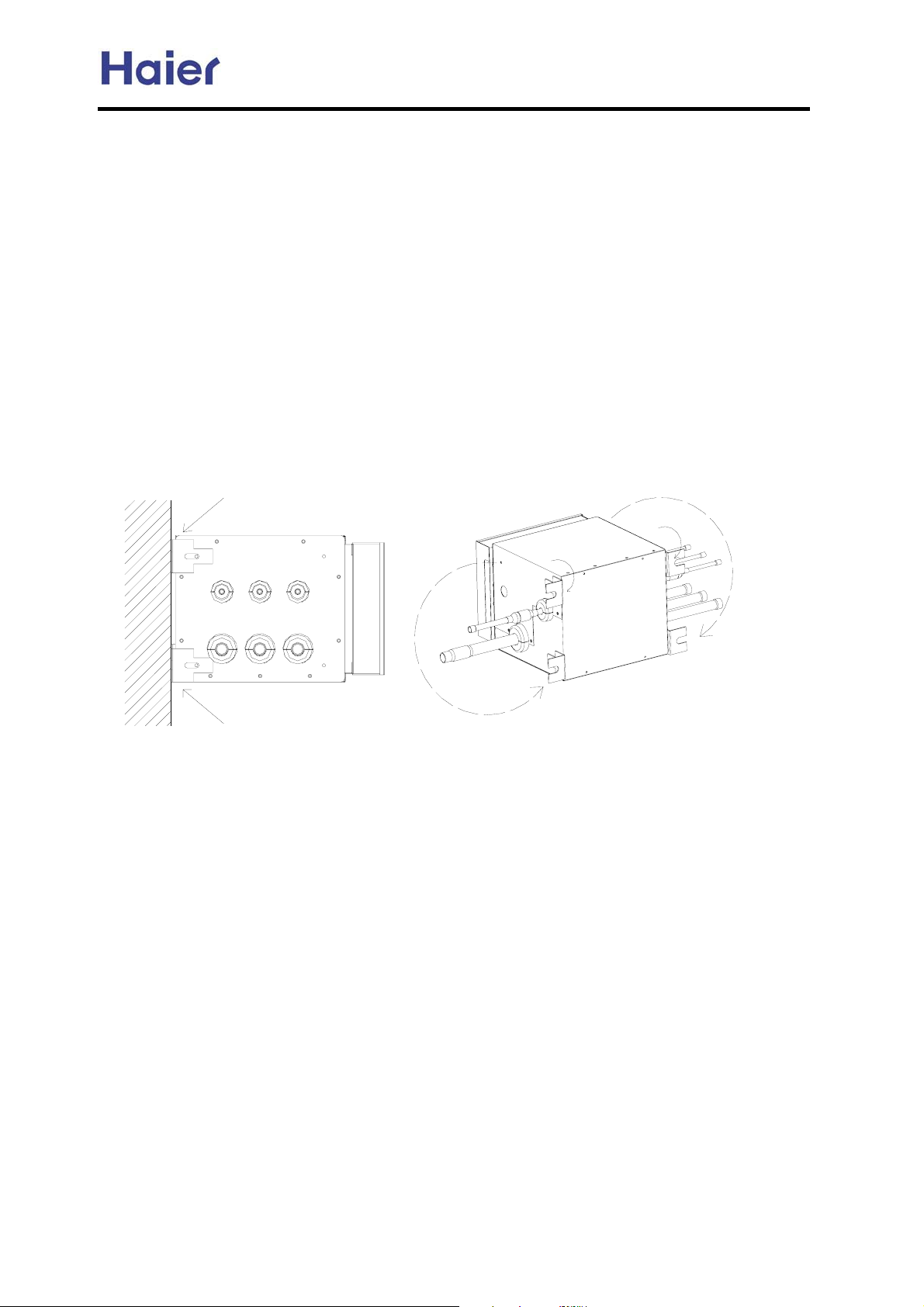

5.3 Instructions for the Electrical Expansion Valve Boxes

The E.E.V.B. general information for the C-MRV and H-MRV indoor units.

1. Installation position

AU482FIBIA, AU48NFIBJA

0°

360°

180°

Z: vertical direction

X, Y: horizontal direction

2. Installation place

The box should be installed where the place:

a. do not have vibrations;

b. easy to piping with the indoor and the outdoor unit, and the distance from the box to the indoor unit

should not exceed a certain value;

c. do not have a heat or steam source nearby;

d. should be sunless and be dry;

e. should be well ventilated and rainproof;

0°

wiring connector

liquid pipe in/out

f. do not have a strict noise restriction, because when working the box may make some noise;

-24-

Commercial Air Conditioner Model: AU242FHBIA,

AU482FIBIA, AU48NFIBJA

5.4 MP2A, MP3A Installation Requirement

1. Cautions

1.1 The place should be strong enough to support this equipment, no vibrantion;

1.2 The place where is convenient to install the indoor unit, outdoor unit and the refrigerant pipe, and

the length of the pipe is in the permitted range;

1.3 No heat source and gas source nearby;

1.4 The place has enough space for installation and maintenance;

1.5 Donpt installation in the place in the state of high temperature and high humidity for a long time;

1.6 The place with good ventilation, no direct sunshine and rain;

1.7 Donpt install the unit near the bedroom because of the refrigerant flow noise;

Please refer to the cautions and warnings in the operation manual about the other safety cautions.

2. Installation Method

2.1 MP2A, MP3A can be installed on the horizontal ceiling or the vertical wall by adjusting the fixing

holder. The maintenance plate should be installed on the place easy to maintain and near the place,

there should be checking hole with 600mm*600mm (adjust the fixing holder as below figure).

vertical wall

2.2 The equipment has been dealt with the EPS heat insulation material, so the drainage pipe needs

not any other treatments.

2.3 The pipe connected to indoor is led from the branch pipe of the equipment. The gas pipe

diameter can realize to match with different diameters by the changing pipe according to the

indoor pipe diameter request.

2.4 In installation, the equipment gradient should be in the range of 5¤, or it may cause electronic

expansion valve body in the equipment leakage or the other bad control failure.

2.5 Bolt, screw cap and gasket to fix the equipment will not be supplied by factory.

3. Wiring Connection

3.1 The wire and refrigerant pipe must be connected to the corresponding place (refer to marks on

the equipment and the terminal block as 1,2,3).

3.2 Wiring diagram is sticked on the back of cover plate, and the wiring must be performed

according to the wiring diagram, or the control will be bad or indoor and the equipment will be

damaged.

3.3 After wiring, the wires must be fixed with the wire clip firmly, in case that the electric control parts

are damaged or occurs person injury.

-25-

Commercial Air Conditioner Model: AU242FHBIA,

AU482FIBIA, AU48NFIBJA

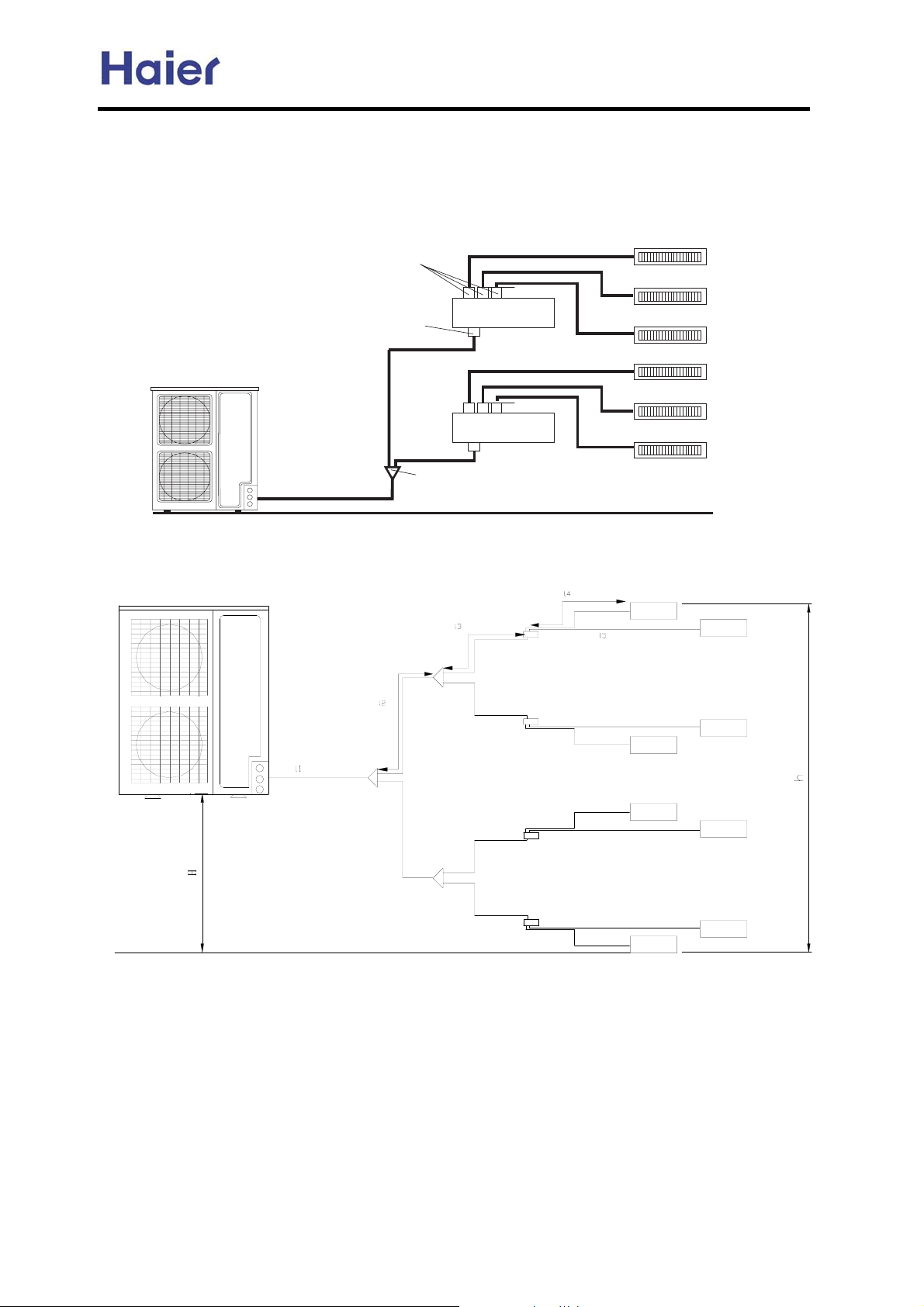

5.5 Connecting figure:

670 ;9E := LJ=< >FI KMF AE<FFI LEAKJ- GC=9J= ;FE>AID K@= 670 HL9EKAKO 9;;FI<AE? KF K@= 9;KL9C AE<FFI LEAKJ/

671 ;9E := LJ=< >FI K@I== AE<FFI LEAKJ- GC=9J= ;FE>AID K@= 671 HL9EKAKO 9;;FI<AE? KF K@= 9;KL9C AE<FFI LEAKJ/

5EJK9CC9KAFE D=K@F< AJ :=CFM- M@A;@ FECO K9B=J 671 9J 9E =N9DGC=/ 7C=9J= G9O 9KK=EKAFE K@9K K@= ?9J GAG=J

AEJK9CC9KAFE AJ 9J K@= J9D= 9J K@= ;FE<AKAFE MAK@FLK 670+671,/

AE<FFI CAHLA< GAG=

FLK<FFI CAHLA< GAG=

8.J@9G= D9EA>FC< GAG=

Piping length and drop between units

Haier

QRP

QRP

AE<FFI 2

AE<FFI 3

AE<FFI 4

AE<FFI 20

AE<FFI 30

AE<FFI 40

+

-26-

Commercial Air Conditioner Model: AU242FHBIA,

AU482FIBIA, AU48NFIBJA

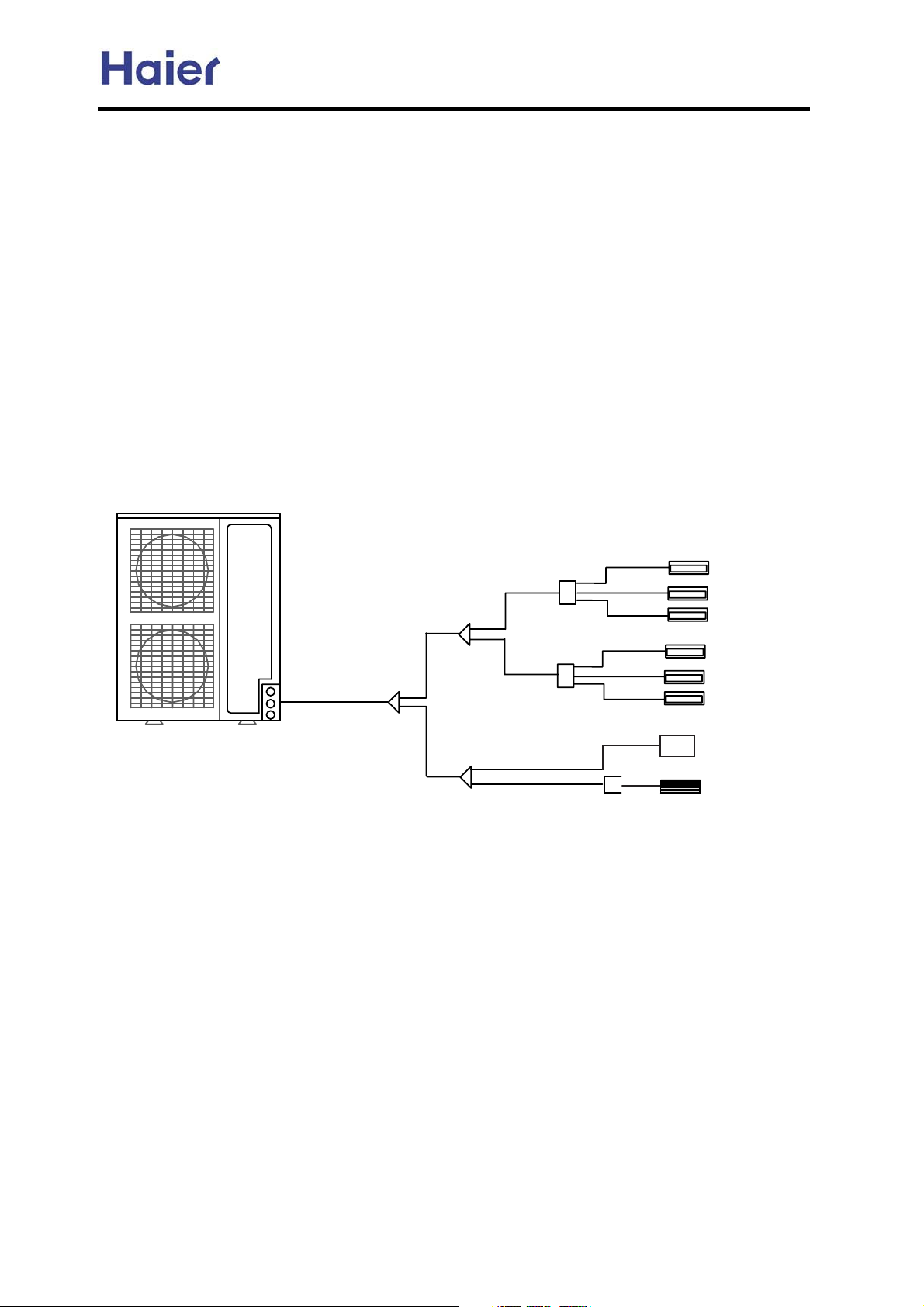

1) When connected with 8 units,indoor units refer to <admissible combination examples>

2) Total length=l1+l2*2+l3*4+l4*4+l5*4<=100m

3) Max. piping length =(l1+l2+l3+l5)<=70m

4) Max. piping length between the indoor unit and the first branch pipe<=30m

5) Max. drop between outdoor unit and indoor unit: H<=30m(indoor above

outdoor);H<=20m(indoor below outdoor)

6) Max. drop between the two indoor units : h<=10m

7) Expansion valve is less than 15m to its corresponding indoor unit

8) Only wall mounted types are connected with expansion valves.

9) The expansion valves of different indoor models are different.

10)The first branch pipe must use FQG-180,the others use less than it.

Combination example:

8 by 1:

Haier

AE07

AE07

MP3A

MP3A

EEV

AE07

AE07

AE07

AE07

AB09

AS07

Note:

1.AU24 can connect with max. 5 indoor units, and AU48 can connect with max. 8 indoor units, but pay

attention that the total indoor capacity can not exceed 130% of outdoor cooling capacity.

2.

The ceiling concealed unit must connect with the outdoor unit through the MP2A or MP3A; the wall mounted

unit must connect with the outdoor unit through the exterior EEV box; while for the cassette unit, because it has

the built-in EEV, so it need not anything and it can connect to outdoor directly.

-27-

Commercial Air Conditioner Model: AU242FHBIA,

AU482FIBIA, AU48NFIBJA

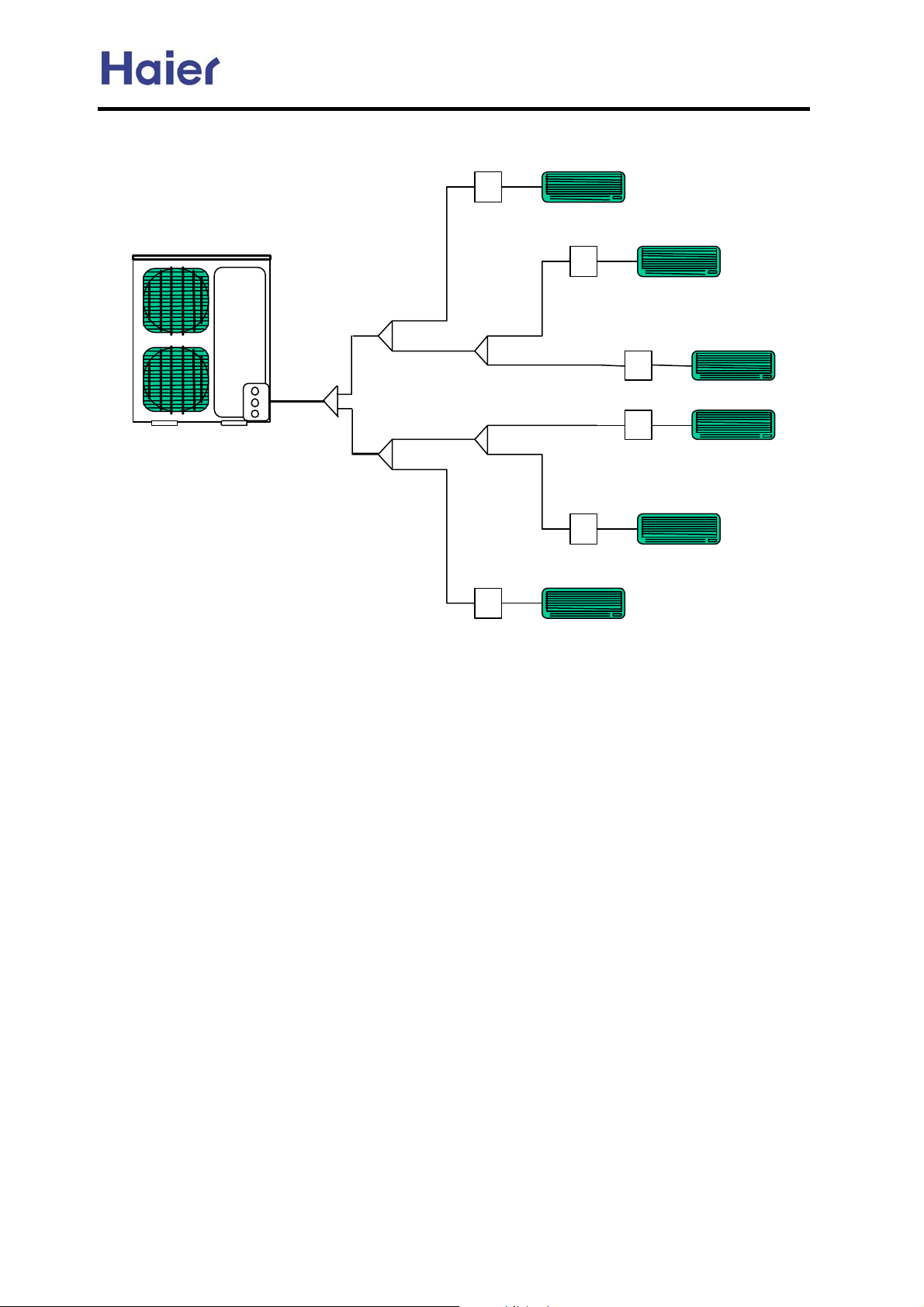

6 by one

AU48-

AS09 (or other 9000BTU units)

AS09 (or other 9000BTU units)

Haier

AS09 (or other 9000BTU units)

AS09 (or other 9000BTU units)

AS09 (or other 9000BTU units)

EEV

AS09 (or other 9000BTU units)

-28-

Commercial Air Conditioner Model: AU242FHBIA,

5.6 The Order of Installation Work

AU482FIBIA, AU48NFIBJA

Item

Before installation Work division -to ascertain the person responsible for installation of pipes and wiring

Work

Installation of indoor and

Work Main points

Make installation

diagram

outdoor unit

Refrigerant pipe work -Pay attention to dry, clean and seal

Drain pipe work -Slant downward

Heat insulation work -No gaps in the joint of heat insulation material

Wiring work (control

wire, power cord)

Set every set switch -Should be complied with control wiring system diagram

Airtight test -Close all the gas, liquid valves

Vacuum drying -Should the vacuum pump that can reach 200Pa vacuity

Additional refrigerant -Write down the additional refrigerant amount on the outdoor unit body

Test run adjustment -Do test run to indoor unit one by one to verify if there is wrong pipes

Training of use and

maintenance

-to ascertain the pipe installation dimension and position of electronic

expansion valve, to make control wiring system diagram

-to prevent the ventilation from short circuit and guarantee repair space

-Choose the proper wire and cord

and record table

-Explain to user, simultaneously provide all the documents

The above work order is general knowledge, they may be changed to be complied with the

specific work site.

5.7 Attentive matters of safety

Before installing, do read this [Attentive matters of safety] carefully to guarantee the

proper installation.

The below attentive matters are divided into [warning] and [note] two parts. When the

wrong installation occur, it is very possible death and severe injury and other serious

accidents will happen. For those items are listed in [warning] part. But even the items

listed in [note] part can also cause serious accidents. Above all, both the two parts are

very important contents related to safety, so they must be obeyed.

After installation, do test run to verify everything is normal, after that please explains the

use method and maintenance method to the user according to the operation manual.

Additionally, give the installation manual together with operation manual to the user and

ask them to keep them properly.

Warning

The distributing shop, where you bought the air conditioner, or the specified shops shall

do the installation work. If you do the installation work by yourself, the improper

installation will cause water leakage, electric shock fire and other accidents.

The installation work shall be in line with what the installation manual specified. If

installation is not proper, water leakage, electric shock, fire and other accidents will

occur.

Install the air conditioner to a place where can definitely stand its weight. Places not firm

enough will cause drop down of unit resulting in body hurt.

The installation work shall be preventive to typhoon and earthquake. If the installation

-29-

Commercial Air Conditioner Model: AU242FHBIA,

AU482FIBIA, AU48NFIBJA

work is not met with the requirements, overturn of the unit will occur resulting in

accidents.

The wiring work shall be done by a qualified person and referred to the “technical

standard of electric equipment”, “indoor wiring regulation” and what the manual

specified. Do use special circuit. If the capacity of the circuit is not enough or bad work,

electric shock, fire and other accidents will happen.

Using the specified cable to do wiring work and connecting firmly and properly. Fix the

connecting part of the terminals to prevent it from the external force. Improper

connection and fixing will cause heating and fire etc. accidents.

Wiring shall be kept in correct shape avoiding extrusion. After installation, the electric

box cover and the external panel shall not nip the wire. Improper installation will cause

heating and fire etc. accidents.

When setting or moving the air conditioner do not let the air and things alike get into the

refrigeration system except the specified refrigerant. If air and other things enter,abnormal

high pressure will occur, which easily cause break and body injuries etc.

When installing, do use the accessories or specified parts. If not using the parts specified

by our company, water leakage, electric shock, fire and refrigerant leakage will occur.

Do not lead the drainpipe to drain where the sulfur gas may be involved. Otherwise, the

poisonous gas will enter into the indoor.

During installation, if refrigerant leakage occurs, do the ventilation work immediately. As

soon as the refrigerant gas meets fire, poisonous gas will be produce. If the refrigerant gas

enters into room and meet the air blowing heater, heater or stove etc. fire source, the

poisonous gas may be produced. After installation, confirm there is no leakage of

refrigerant.

Do not install the unit in a place where the combustible gas may be leaked. In any case

the combustible gas leaks and accumulated around the unit, fire accident will occur.

Do heat insulation work to the refrigerant gas pipes and liquid pipes to reach the purpose

of heat preservation. If the heat insulation measure is not sufficient, water generated by

condensing dew will drip leading to wet the floor and indoor articles.

Do not damage the power line or change it arbitrarily to avoid occurrence of fire or

electric shock.

Do not extend the power line or using other electric appliance in the same power

receptacle to avoid fire or electric shock.

Note

Do grounding work. Do not connect the grounding wire to gas pipe, tap, lighting rod or

telephone line. Improper grounding will cause electric shock.

In some places the electric leakage breaker shall be installed. If do not install the breaker,

electric shock may occur.

After installation, power on to do electric leakage detecting test.

-30-

Loading...

Loading...