Page 1

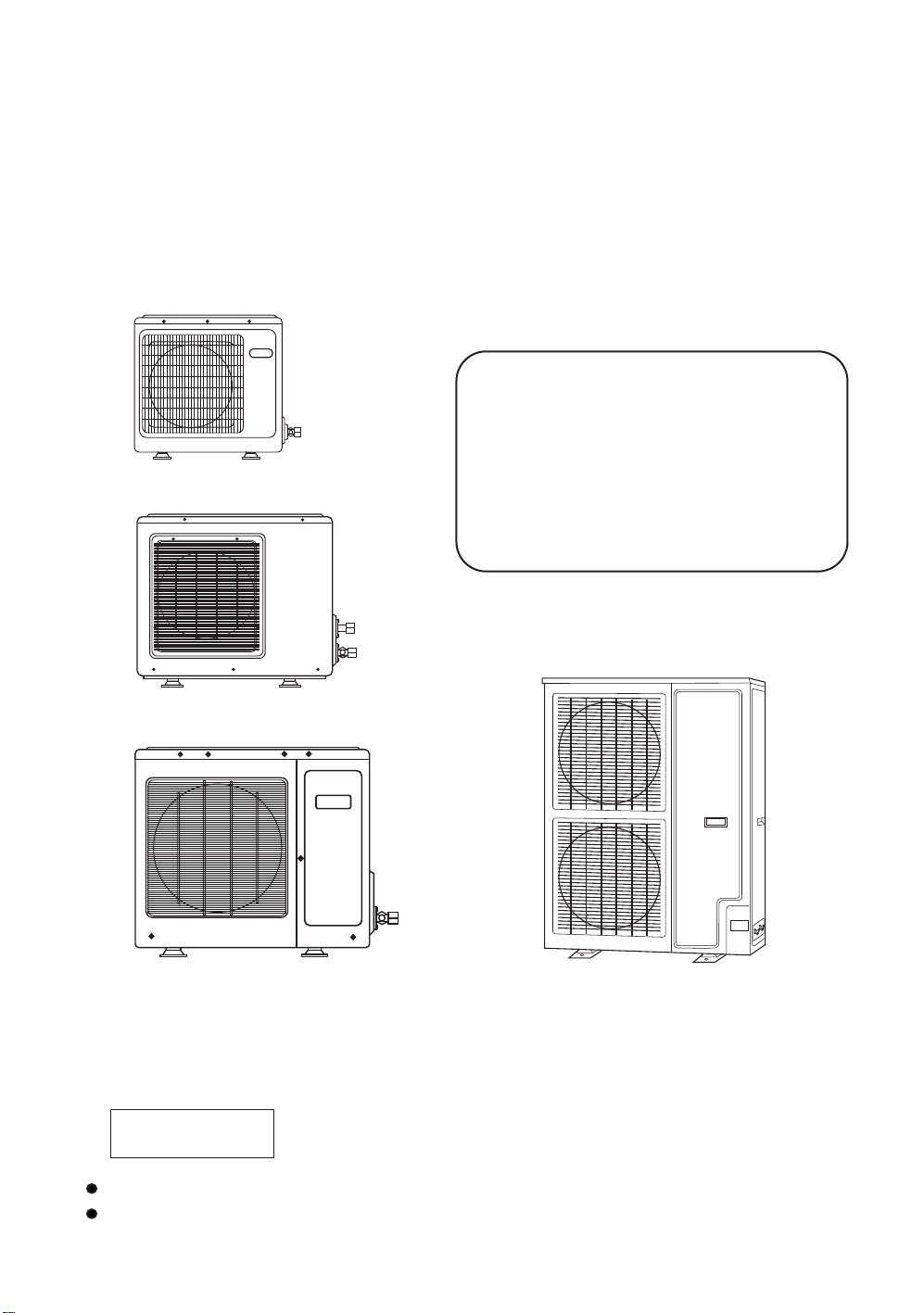

ROOM AIR CONDITIONER

OUTDOOR UNIT

INSTALLATION INSTRUCTIONS

CONTENTS

Name of Parts----------------------1

AU182AEEAA

Safety Cautions------------------2-3

Installation Procedure---------4-13

AU242AGEAA

AU282AHEAA

AU28NAHEAA

No.0010577959

D

Before using the air conditioner,please read this manual carefully.

Please keep this manual properly for future use.

AU36NAIEAA

AU362AIEAA

AU48NAIEAA

AU60NAIEAA

Page 2

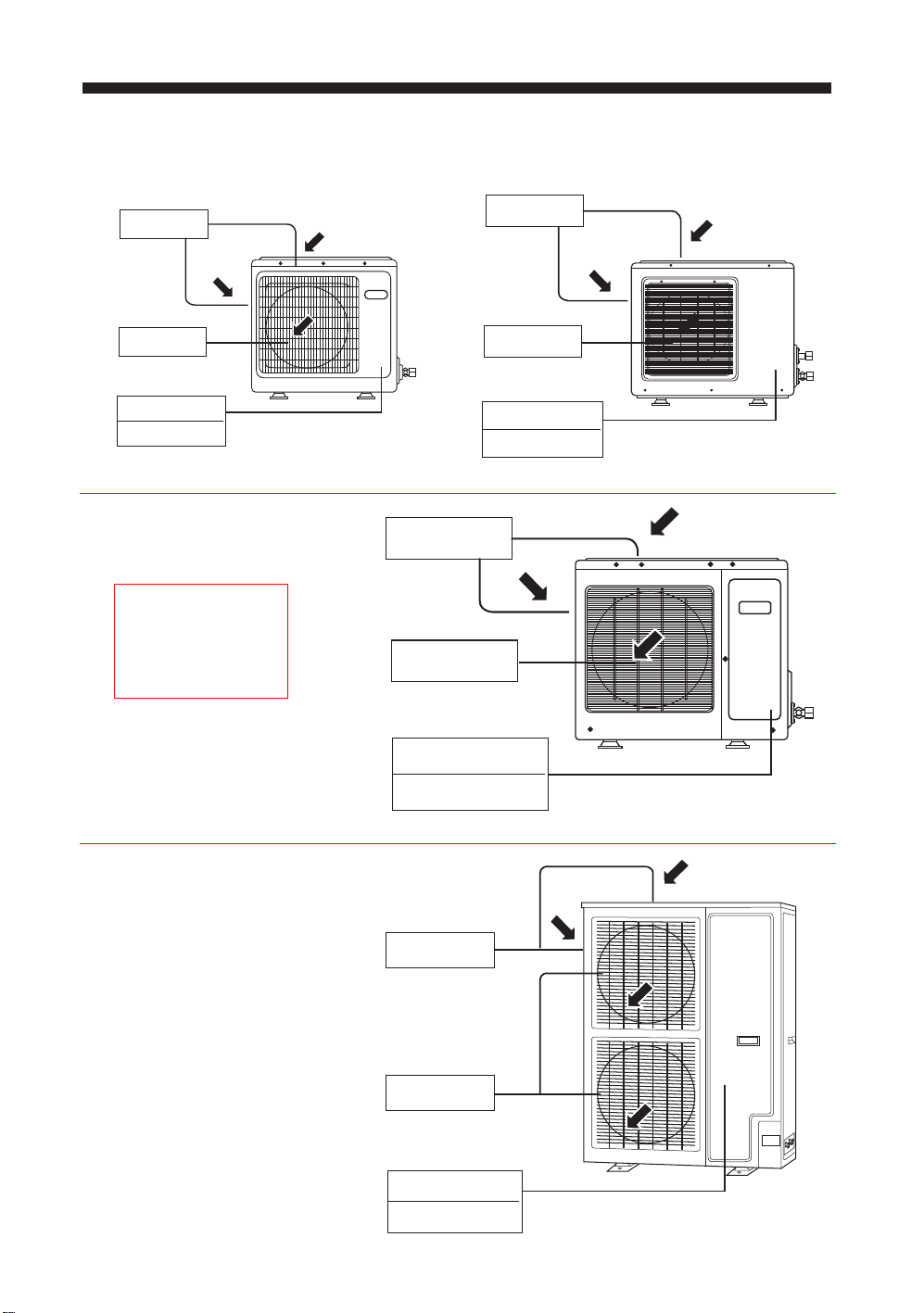

Name of Parts

AU242AGEAAAU182AEEAA

Air inlet

Air outlet

Compressor

(Inside of unit)

AU282AHEAA

AU28NAHEAA

Air inlet

Air outlet

Compressor

(Inside of unit)

Air inlet

Air outlet

AU36NAIEAA

AU362AIEAA

AU48NAIEAA

AU60NAIEAA

Compressor

(Inside of unit)

Air inlet

Air outlet

Compressor

(Inside of unit)

1

Page 3

Safety Cautions

Carefully read the following information in order to operate the airconditioner

correctly.

Below are listed three kinds of Safety Cautions and Suggestions.

WARNING!

CAUTION!

INSTRUCTIONS: These information can ensure the correct operation of the machine.

Be sure to conform with the following important Safety Cautions.

The Safety Cautions should be at hand so that they can be checked at any time when needed.

If the conditioner is transferred to the new user, this manual should be as well transferred to the

new user.

Incorrect operations may result in severe consequences of death or serious injuries.

Incorrect operations may result in injuries or machine damages; in some cases may

cause serious consequences.

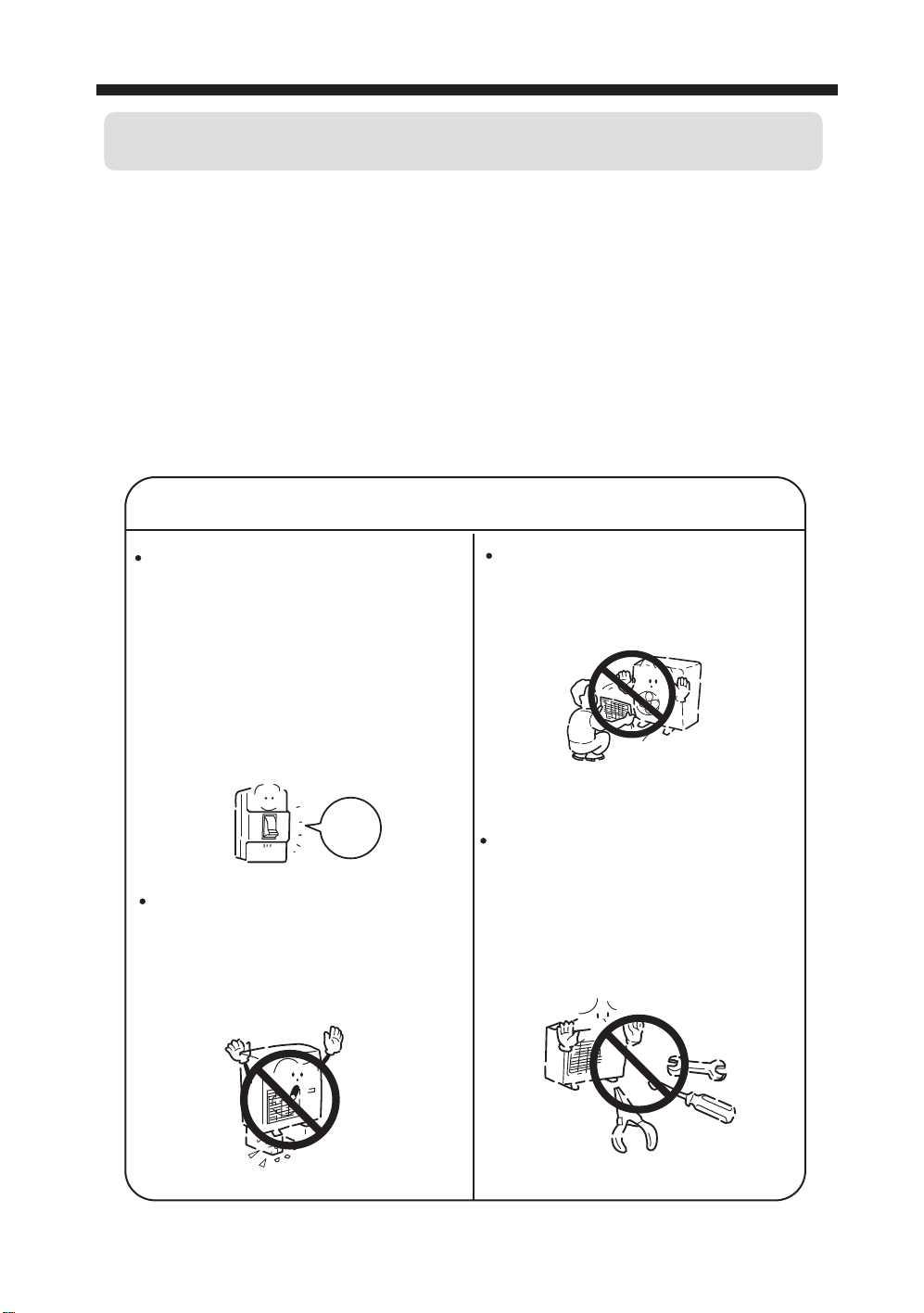

WARNING!

If any abnormal phenomena is found

(e. g.smell of firing), please cut off the

power supply immediately, and contact

the dealer to find out the handling

method.

In such case, to continue using the

conditioner will damage the conditioner,

and may cause electrical shock or fire

hazard.

Don't dismantle the outlet of the

outdoor unit.

The exposure of fan is very dangerous

whichmay harm human beings.

switch

off

After a long time use of air-conditioner

the base should be checked for any

damages.

If the damaged base is not repaired, the

unit may fall down and cause accidents.

When need maintenance and repairment,

call dealer to handle it.

Incorrect maintenance and repairment

may cause water leak, electrical shock

and fire hazard.

2

Page 4

Safety Cautions

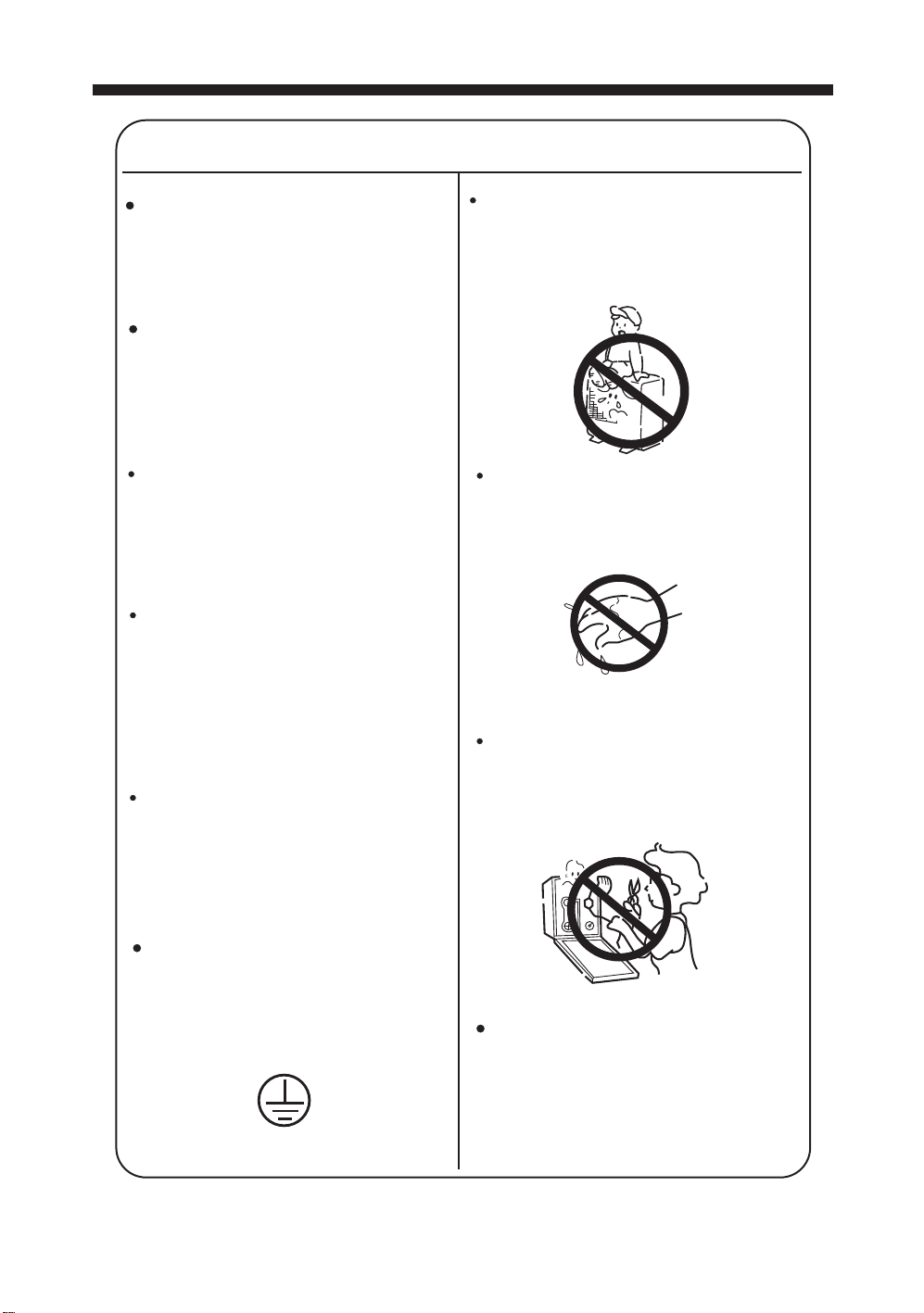

WARNING!

Installed electrical-leaking circuit

breaker.

It easily cause electrical shock without

circuit breaker.

Air-conditioner can't be installed in

the environment with inflammable

gases because the inflammable gases

near to air-conditioner may cause fire

hazard.

Please let the dealer be responsible for

installing the conditioner.

Incorrect installation may cause water

leak, electrical shock and fire hazard.

Call the dealer to take measures to

prevent the refrigerant from leaking.

If conditioner is installed in a small

room be sure to take every measure in

order to prevent suffocation accident

even in case of refrigerant leakage.

When conditioner is deinstalled or

reinstalleddealer should be respon-

sible for them.

Incorrect installation may cause water

leaking, electrical shock and fire hazard.

No goods or nobody is permitted to

placed on or stand on outdoor unit.

The falling of goods and people may

cause accidents.

Don't operate the air-conditioner with

damp hands.

Otherwise will be shocked.

Only use correctly-typed fuse.

May not use wire or any other materials

replacing fuse, other-wise may cause

faults or fire accidents.

Connect earthing wire.

Earthing wire should not be connected to the gas pipe, water pipe,

lightning rod or phone line, incorrect earthing may cause shock.

Earthing

Use discharge pipe correctly to ensure

efficient discharge.

Incorrect pipe use may cause water

leaking.

3

Page 5

Installation Procedure

Installation of outdoor unit

1. Accessories

Edging

"Edging" for protection of electric wires from an

opening edge.

2. Selection of the place of installation

Select the place of installation satisfying the following conditions and, at the

same time, obtain a consent from the client or user.

Place where air circulates.

Place free from heat radiation from other heat sources.

Place where drain water may be discharged.

Place where noise and hot air may not disturb the neighborhood.

Place where there is not heavy snowfall in the winter time.

Place where obstacles do not exist near the air inlet and air outlet .

Place where the air outlet may not be exposed to a strong wind.

Place surrounded at four sides are not suitable for installation. A 1m or more

of overhead space is needed for the unit.

Mount guide-louvers to place where short-circuit is a possibility.

When installing several units, secure sufficient suction space to avoid short

circuiting.

(1) Open space requirement around the unit

Note :

(1). Fix the parts with screws

(2).Don't intake the strong wind directly to the

outlet air-flow hole.

(3).A one meter distance should be kept from the

unit top

(4).Don't block the surroundings of the unit with

sundries

Unit: mm

III

500

open

150

Wind direction

L2

Air

inlet

Distance

L1

L2

L3

Case

Air inlet

Air outlet

I

open

300

150

L3

500

(Servicing

space)

L1

II

open

300

300

(2) Installation where the area with strong winds.

Install the unit so that the air outlet section of the unit must NOT be faced

toward wind direction.

NO

4

Page 6

Installation Procedure

Installation of outdoor unit

3. Installation of outdoor unit

(1) Installation

Fix the unit in a proper way according to the condition of a place where it is

installed by referring to the following .

AU182AEEAA

(a) Concrete foundation (b) Foundation anchor

Unit

Anchor bolt

Unit

Concrete foundation

To fix by bolts

AU242AGEAA

Concrete foundation

Anchor bolt

(a) Concrete foundation (b) Foundation anchor

Unit

Anchor bolt

AU282AHEAA AU28NAHEAA

Unit

Concrete foundation

To fix by bolts

Concrete foundation

Anchor bolt

(a) Concrete foundation (b) Foundation anchor

Unit

Anchor bolt

AU362AIEAA AU36NAIEAA AU48NAIEAA AU60NAIEAA

(a) Concrete foundation

Unit

Concrete foundation

To fix by bolts

Concrete foundation

Anchor bolt

(b) Foundation anchor

Unit

Anchor bolt

Note: (1) Give enough room for the concrete foundation to fix by anchor bolts.

(2) Place the concrete foundation deep enough.

Concrete foundation

To fix by bolts

Concrete foundation

Anchor bolt

Install the unit so that the angle of inclination must be less than 3 degrees.

5

Unit

Page 7

Installation Procedure

(2) Installation sketch of outdoor unit

AU182AEEAA

Installation of outdoor unit

640

25

AU242AGEAA

860

780

Power Wiring Terminal

Power Wiring

Distribution Hole

Power Wiring Terminal

Power Wiring

Distribution Hole

730

500

630

308

270

335

AU282AHEAA AU28NAHEAA

948

840

25

Power Wiring Terminal

Power Wiring

Distribution Hole

6

580

380

340

Page 8

Installation Procedure

AU362AIEAA AU36NAIEAA AU48NAIEAA AU60NAIEAA

948

Power

wiring

Terminal

Installation of outdoor unit

580

1250

25

4. Refrigerant piping

(1) Outline piping

AU182AEEAA

Flare connection

Gas pipe

Indoor

unit

Liquid

pipe

Flare connection

380

3-way stop valve

Outdoor

unit

2-way stop valve

340

AU242AGEAA AU282AHEAA AU28NAHEAA AU362AIEAA AU36NAIEAA

AU48NAIEAA AU60NAIEAA

Flare connection

Indoor

unit

Gas pipe

Liquid

pipe

Flare connection

3-way stop valve

Outdoor

unit

3-way stop valve

7

Page 9

Installation Procedure

(2) Piping size

Refrigerant piping

AU182AEEAA

AU242AGEAA

AU282AHEAA

AU28NAHEAA

AU36NAIEAA

AU362AIEAA

AU48NAIEAA

AU60NAIEAA

Liquid pipe

Gas pipe

Liquid pipe

Gas pipe

Liquid pipe

Gas pipe

6.35x0.8mm

12.7x1.0mm

9.52x0.8mm

15.88x1.0mm

9.52x0.8mm

19.05x1.0mm

90+0.5

Install the removed flare nuts to

the pipes to be connected, then

flare the pipes.

(3) Limitations for one way piping length and vertical height difference.

Model

AU182AEEAA

AU242AGEAA AU282AHEAA

AU28NAHEAA

AU362AIEAA AU36NAIEAA

AU48NAIEAA AU60NAIEAA

Precautions for refrigerant piping

One way piping length

less than 20 m less than 10 m

less than 30 m

less than 50 m

Vertical height difference

(between indoor and outdoor)

less than 15 m

less than 30 m

Do not twist or crush piping.

Be sure that no dust is mixed in piping.

Bend piping with as wide angle as possible.

Keep insulating both gas and liquid piping.

Check flare-connected area for gas leakage.

(4) Piping connection

Connecting method (indoor unit)

Apply refrigerant oil at half union as large and flare nut.

To bend a pipe, give the roundness as possible not to crush

the pipe.

When connecting pipe, hold the pipe centre to centre then

screw nut on by hand, refer to Fig.

Be careful not to let foreign matters, such as sands enter

the pipe.

Pipe dia Fastening torque

Liquid pipe 6.35mm

Liquid pipe 9.52mm

Forced fastening without centering

may damage the threads and cause a

gas leakage.

Gas pipe 12.7mm

Gas pipe 15.88mm

Gas pipe 19.05mm

14.2-17.2N.m

32.7-39.9N.m

49.5-60.3N.m

61.8-75.4N.m

97.2-118.6N.m

8

Page 10

Installation Procedure

Refrigerant piping

5. Air discharging method

After finishing connection of refrigerant pipe, it shall perform air tightness test.

The air tightness test adopts nitrogen tank to give pressure according to the pipe connection

mode as the following figure shown.

The gas and liquid valve are all in close state. In order to prevent the nitrogen entering the

circulation system of outdoor unit, tighten the valve rod before giving pressure (both gas

and liquid valve rods).

Indoor

Outdoor

Low pressure peizometer

3-way valve totally closed

(Gas side)

High pressure peizometer

VL VH

Meter separator

Completely tightened

Completely tightened

Indoor units

First step: 0.3MPa (3.

0kg/cm2g) pressurize

over 3 minutes.

Second step: 1.5Mpa

(15kg/cm2g) pressurize

over 3 minutes. Large

leakage will be found.

Third step: 3.0 MPa

(30kg/cm2g) pressurize

about 24 hours. Little

leakage will be found.

Flare part

Flare part

SWEAT

JOINT

Discharging valve

3-way valve totally closed

(Liquid side)

LINE

PRESSURE

SERVICE

HOUSE

GAUGE

TUBING

BRING

BRAZED

LARGE

SLIP-ON

CONNECTOR

Manhole

Outdoor units

Dropping valve

CYLINDER

PRESSURE

GAUGE

Nitrogen tank

CYLINDER

OF

NITROGEN

Check if the pressure drops

The pressure does not drop-passed

The pressure drops-check the leaking point.

From pressurizing to 24 hours later, each 1* difference of ambient temperature

will make 0.01MPa(0.1kg/cm2g) pressure change. It shall be corrected during test.

Checking the leaking point

In the first to third test steps, if the pressure drops, check the leakage in each joint

use sense of hearing, feeling and soap water, etc. methods to find the leaking point.

After confirming the leaking point, welding it again or tighten the nut tightly again.

9

Page 11

Installation Procedure

Refrigerant piping

6. Piping and indoor unit vacuumizing

Use vacuum pump to perform vacuumizing. It is strictly forbidden to use the

refrigerant to remove the air inside the system.

After air tightness test and discharging all the nitrogen, connect the vacuum pump

as the following figure shown.

Indoor

Outdoor

Low pressure peizometer

3-way valve totally closed

(Gas side)

High pressure peizometer

V L VH

Meter separator

Completely tightened

Completely tightened

Indoor units

Flare part

Flare part

Discharging valve

P

Vacuum pump

Outdoor units

3-way valve totally closed

(Liquid side)

It shall use the vacuum pump of (lower than -755mmHg)high vacuum degree and large air

discharging (over 40l/min).

The vacuumizing time depends on the length of the connecting pipe, generally is 1~2 hours.

When vacuumizing, it shall be confirmed both gas and liquid side valves are closed.

If after 2 hours vacuumizing, it cannot reach the vacuum degree below -755mmHg, it can be

vacuumized for other 1 hour.

If after 3 hours vacuumizing, it still cannot reach the vacuum degree below -755mmHg, check

if there is any leaking point and repair the them.

If after over 2 hours vacuumizing, the vacuum degree is below -755mmHg, close the V

and VH on the meter separator and stop vacuumizing. 1 hour later to confirm if the vacuum

degree changes. If changes, it indicates there is leaking point in the system. Check the leaking

point and repair.

After finishing the above vacuumizing, change the vacuum pump into refrigerant pump to

charge the refrigerant.

7. Charging amount of refrigerant

When the total length (L) of the two indoor units' connecting pipe is less than 5m, it is

unnecessary to charge additional refrigerant.

If the connecting pipe (L) exceeds 5m, it shall charge Mg additional refrigerant per meter.

That is: Refrigerant charging amount = (L-5) x M (g)

For AU182AEEAA, M=30

For AU242AGEAA, AU282AHEAA, AU28NAHEAA, AU362AIEAA,

AU36NAIEAA , AU48NAIEAA, AU60NAIEAA, M=65

Only in COOLING operation can charge the additional refrigerant.

When charging, the refrigerant shall be charged from the charging nozzle of low pressure vavle.

Be carefull when charging refrigerant, do not let the air mix into the system,and must charge the

additional refrigerant in liquid condition.

L

10

Page 12

Installation Procedure

Electric wiring

5. Electric wiring

WARNING

DANGER OF BODILY INJURY OR DEATH

TURN OFF ELECTRIC POWER AT CIRCUIT BREAKER OR POWER

SOURCE BEFORE MAKING ANY ELECTRIC CONNECTIONS.

GROUND CONNECTIONS MUST BE COMPLETED BEFORE MAKING

LINE VOLTAGE CONNECTIONS.

(1) Selection of size of power supply and interconnecting wires.

Precautions for Electric wiring

Electric wiring work should be conducted only by authorized personnel.

Do not connect more than three wires to the terminal block. Always use round

type crimped terminal lugs with insulated grip on the ends of the wires.

Use copper conductor only,the parameter of connecting cable is H05RN-F 4G

0.75mm2,but for AU182AEEAA,the parameter of connecting cable should be

H05RN-F 3G 2.0mm2+H05RN-F 1x0.75mm

The wiring method should be in line with the local wiring standard.

The breaker of the air conditioner should be all-pole switch; and the distance

between its two contacts should be no less 3 mm.

If the supply cord is damaged, it must be replaced by the manufacturer or its

service agent or a similar qualified person.

If the fuse on PC board is broken please change it with the type of T3.15A/250VAC.

Note: the power cable and connecting cable are self-provided.

Select wire sizes and circuit protection from table below. (This table shows 20 m

length wires with less than 2% voltage drop.)

Circuit breaker

(A)

Overcurrent protector

rated capacity (A)

Model

Item

Phase

Switch breaker

2

Power source

wire size

(minimum)

(mm2)

Earth leakage breaker

Switch

breaker(A)

Leak

current(mA)

AU182AEEAA

AU242AGEAA

AU282AHEAA

AU362AIEAA

AU28NAHEAA

AU36NAIEAA

AU48NAIEAA

AU60NAIEAA

1 40 26 2.5

1 40 26 4.0 40 30

1 40 26 6.0 40 30

3 30 2.5 3020

3

30 20 4.0

40

30

(2) Wiring connection

Make wiring to supply power to the outdoor unit, so that the power for the indoor

unit is supplied by terminals.

For the detailed wiring connection with the indoor units, see the corresponding indoor

operation and instruction manual.

11

30

30

30

Page 13

Installation Procedure

For: AU182AEEAA

Electric wiring

To Indoor Unit

OUTDOOR UNIT

TERMINAL BLOCK

1 2 3

FIG.1

For :, AU242AGEAA, AU282AHEAA, AU362AIEAA

To Indoor Unit

Y/G

POWER SUPPLY:

L N

1PH, 220-230V~, 50Hz

1 2 3

OUTDOOR UNIT

TERMINAL BLOCK

FIG.2

For: AU28NAHEAA, AU36NAIEAA, AU48NAIEAA, AU60NAIEAA

To Indoor Unit

R S T

N 1 2 3

Y/G

Y/G

OUTDOOR UNIT

TERMINAL BLOCK

POWER SUPPLY:

380-400V, 3N~, 50Hz

FIG.3

WARNING

DO NOT CONNECT THE NEUTRAL WIRE TO , OR PHASE.

N R S

INTERCONNECTING WIRES MUST BE WIRED ACCORDING TO FIG.1

FIG.2 FIG.3.INCORRECT WIRING CAUSE EQUIPMENT DAMAGE.

(3) Wiring procedure

1) Remove set screws on the side before taking off the front panel toward

the direction shown in figure.

2) Connect wires to the terminal block correctly and fix the wires with a

wire clamp equipped nearby the terminal block.

3) Route the wires in a proper way and penetrate the wires through the

opening for electric wiring on the side panel.

T

12

Page 14

Installation Procedure

Electric wiring

6. Test run

CAUTION

THIS UNIT WILL BE STARTED INSTANTLY WITHOUT "ON" OPERATION

WHEN ELECTRIC POWER IS SUPPLIED.BE SURE TO EXECUTE "OFF"

OPERATION BEFORE ELECTRIC POWER IS DISCONNECTED FOR

SER VICING.

This unit has a function of automatic restart system after recovering power stoppage.

(1) Before starting test run (for all Heat pump models)

Confirm whether the power source breaker (main switch) of the unit has been

turned on for over 12 hrs to energize the crankcase heater in advance of operation.

(2) Test run

Run the unit continuously for about 30 minutes, and check the following.

Suction pressure at check joint of service valve for gas pipe.

Discharge pressure at check joint on the compressor discharge pipe.

Temperature difference between return air and supply air for indoor unit.

The following consults are according to the EMC testing.

Through poor conditions of the electrical MAINS, shortly voltage drops can

appear when starting the EQUIPMENT. This can influence other equipment

(eg. Blinking of a lamp ). But if the Mains-Impedance Zmax value can meet

the below chart, such disturbances are not expected. (In case of need, you may

contact your local supply authority for further information ).

Model Zmax value

AU60NAIEAA <0.2708OHM

AU48NAIEAA

AU36NAIEAA

AU282AHEAA AU362AIEAA

AU242AGEAA

<0.2984OHM

<0.2830OHM

<0.0741OHM

<0.2721OHM

7. Trouble display

Failure description

Room temp. sensor abnormal

Indoor coil temp. sensor abnormal

Outdoor temp. sensor abnormal

Outdoor coil temp. sensor abnormal/

(compressor discharge temp. sensor)

Over-current malfunction/ power supply abnormal

High / Low pressure abnormal

Communication malfunction between indoor and wired controller

Communication malfunction between indoor and outdoor abnormal

Drainage system malfunction

Alarm of exterior annunciator

Coil gas pipe temp. Sensor abnormal

Temperature protection malfunction

13

Code on wired Flash times of indoor

controller receiver board

01 Power LED flashes 1 time

02 Power LED flashes 2 times

4A Power LED flashes 3 times

49 Power LED flashes 4 times

48 Power LED flashes 5 times

53 Power LED flashes 6 times

07 Power LED flashes 8 times

06 Power LED flashes 9 times

08 Power LED flashes 10 times

0B Power LED flashes 11 times

03 Power LED flashes 12 times

0D Power LED flashes 13 times

Page 15

HAIER GROUP

Qingdao Haier Air Conditioner Electric Co., Ltd.

Address: Haier Garden, Qianwangang Road, Economic Development Zone,

Qingdao, Shandong 266500, P.R.China

Web Site: http://www.haier.com

Loading...

Loading...