Haier AU222XFERA Schematic

Commercial Air Conditioning

SERVICE MANUAL

Models

AS072XVERA

AS092XVERA

AS122XVERA

AU182XFERA

AU222XFERA

Features

High energy efficiency

Newly designed V-appearance for wall mounted unit, step or stepless air flow

control

New outdoor unit with valve cover plate, also the grille is changed from metal

one to plastic one

Adjustable heating temperature compenstation

Free combination, multiple connection types with different types of indoor

unit, total indoor load can be up to 135% than the standard match

Infrared control type

Central control and full automation, if connected with a central controller

New friendly refrigerant R410a, zero ODP, environment protection

Advanced technology, DC inverter control function

Health airflow and sterilize function for wall mounted unit, more healthy

Weekly timer (standard)

Group control function

Auto restart function

Low ambient temperature heating (-15 degree) function

Room card function

Manual code: SYJS-013-05REV.3

Edition: 2007-04-14

Commercial Air Conditioner Model: AU18/222XFERA

AS072/092/122XVERA

CONTENTS

Contents………………………………………………………....2

1. Description of products & features………………………...3

2. Specification………………………………………………….6

3. Safety precaution……………………………………………

10

4. Net dimension of indoor and outdoor……………………..12

5. Installation instructions………..……………………………1

6. Parts and functions………………………….………………3

7. Remote controller YR-H65...……………………………….3

3

6

7

8. Refrigerant diagram…………………………………………45

9. Electrical control functions………………………………….4

10. Diagnostic information and trouble shooting...………….5

11. Electrical data………………………………………………6

12. Performance curves.......................................................7

13. Noise level.....................................................................7

14. Air velocity distribution...................................................7

7

9

5

1

5

8

-2-

Commercial Air Conditioner Model: AU18/222XFERA

AS072/092/122XVERA

1.Description of products & features

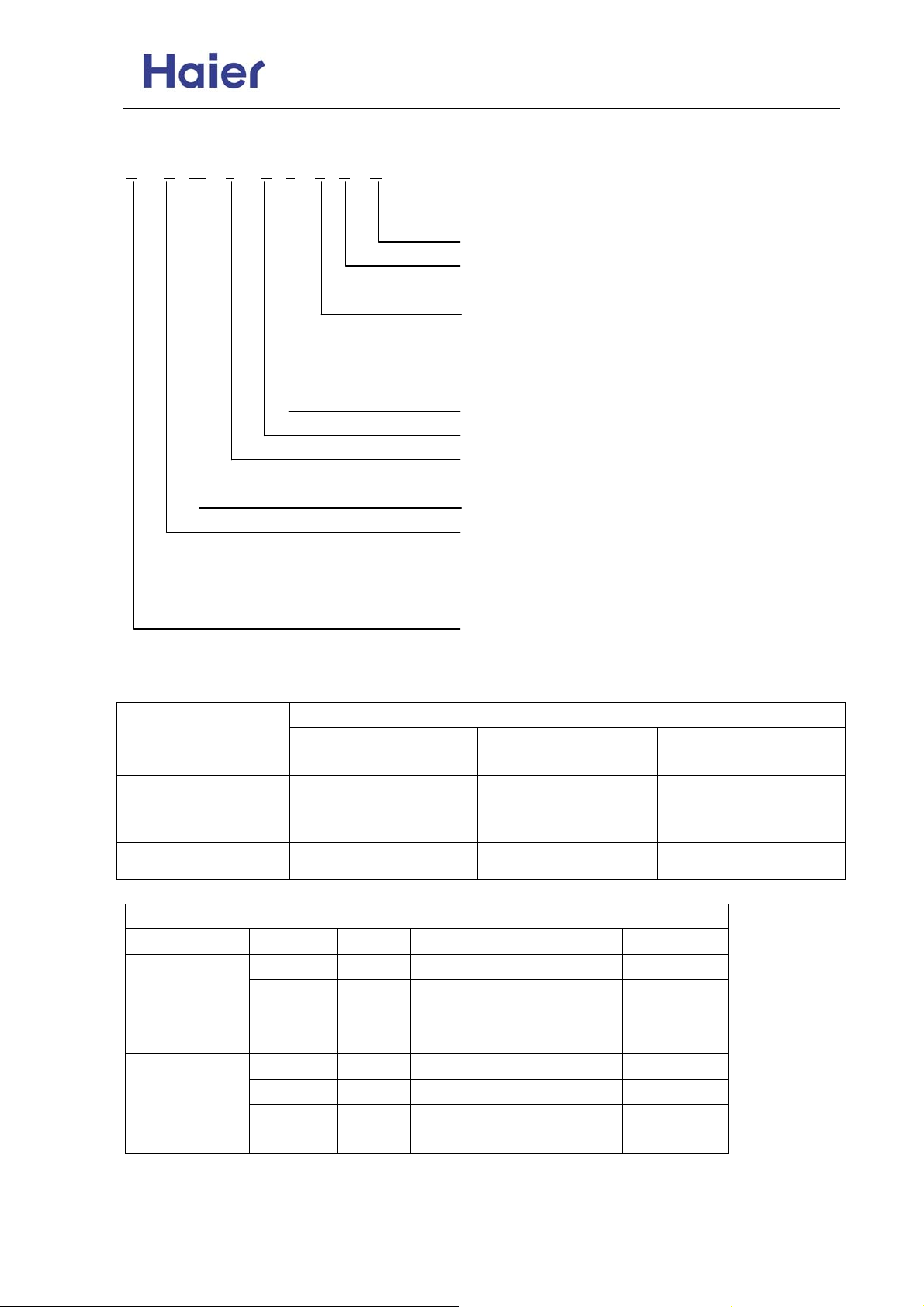

1.1. Products code explanation

U 18 2 X F E R A

A

Climate type: T1 (see table 1)

Design number (R stands for design sequence, DC inverter

type)

Product type: A stands for heat pump type, refrigerant is R22

B stands for heat pump type, refrigerant is R407C

E stands for heat pump type, refrigerant is R410A

N stands for cool only type, refrigerant is R407C

Appearance character

Product series: X stands for multi-split series

Applicable voltage: 2 stands for 220-230V/50Hz,

4 stands for 220V/60Hz,N stand for 380-400V/50Hz

Cooling / Heating capacity,18=18000BTU/h

Product type : “B” stands for cassette type, “C” stands for

convertible type, ”D” stands for duct, “S” stands for wall

mounted type, "E" stands for ceiling concealed type, “U”

stands for outdoor unit

Air Conditioner

1.2 Brief Introduction for T1、T2、T3 working condition

Climate type

Type of Air

Conditioner

Cooling Only

Heat pump

Electricity Heating

T1 T2 T3

18 ℃~43℃ 10℃~35℃ 21℃~52℃

-7℃~43℃ -7℃~35℃ -7℃~52℃

~43℃ ~35℃ ~52℃

1.3 Operating Range of Air Conditioners

Working temperature range

Rated Maximum Minimum

Cooling

Heating

Indoor

outdoor

Indoor

outdoor

DB℃

WB℃

DB℃

WB℃

DB℃

WB℃

DB℃

WB℃

27 32 18

19 23 14

35 43 10

24 26 6

20 27 15

14.5 -- --

7 24 -15

6 18 --

-3-

Commercial Air Conditioner Model: AU18/222XFERA

AS072/092/122XVERA

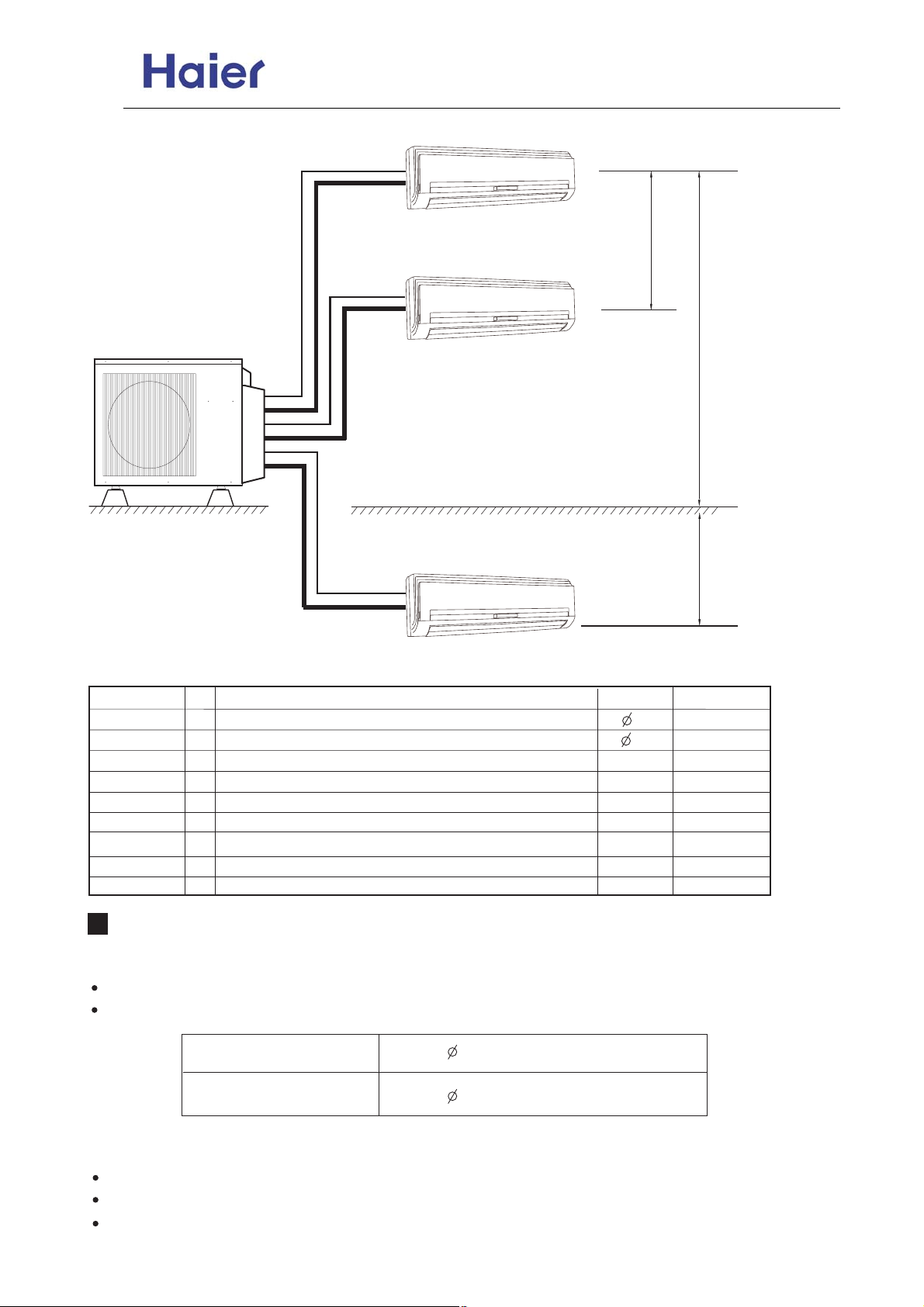

1.4 Product features

High efficienct, universal outdoor unit

The outdoor unit can match with wall mounted type, duct and cassette type indoor unit. One set

outdoor can match with multiple indoor units, up to 3 sets. Even when you have already installed

the air conditioner, if you want to add or reduce one unit, go ahead freely as long as your operation

complies with our design. Greatly convenient for designer and installer.

Total indoor load can be up to 135% than the standard match

The total capacity of all indoor units can be 135% more than the mominal cooling capacity, but the

total indoor cooling capacity will not be increased.

Newly designed V- appearance indoor unit

The wall mounted type indoor unit adopts the newly designed V appearance, more fashion, more

beautiful. The unit is designed with the health airflow and sterilize function, which will make the air

more healthy. Also the air blow direction can be set as step or stepless control, much convenient to

control.

Newly designed guarding plate of valve

In order to protect the valve against the dust, the rain or the snow, etc. we add a

guarding plate to the valve.

Adopt the much friendlier refrigerant R410a

The air conditioner system adopts the greatly friendly refrigerant R410a, which is protective for the

ozone layer and is good to avoid the earth getting warmer. Benefit for the environment.

Adopt the advanced DC inverter technology

The system adopts the advanced DC inverter technology, which can consume less power energy to

realize the equal efficiency, saving money for you.

With air inlet filter, enhance the air quality

The high efficiency filter can collect the dirt and remove the bacterium, which can be installed on the

easy-to-unload place, convenient to be cleaned.

Convenient infrared remote controller

This remote controller YR-H65 can realize the healthy air flow and sterilize function, it is mobile type

appearance, so smart and compact.

And the infrared controller can be equipped with the controller holder, convenient to fix

the remote controller.

-4-

Commercial Air Conditioner Model: AU18/222XFERA

AS072/092/122XVERA

Auto–restart function (optional)

All indoor units have auto-restart function. When the power supply cut off suddenly, the unit will

automatically recover the previous running mode once the power supply is on.

Self-diagnostic function

In the course of operation, if the failure occurs, the failure code will display on the wired controller or

on the operation panel. Then according to the failure code chart, you can eliminate the failure soon.

Central control function, if connected with a detector and a central controller

That is convenient for building management.

Weekly timing function, if connected with a detector and a weekly timer

Adjustable heating temperature compensation

In heating mode, the temperature compensation can be adjusted by the remote controller. If you do

not want the compensation, you can set the compensation as 0 degree.

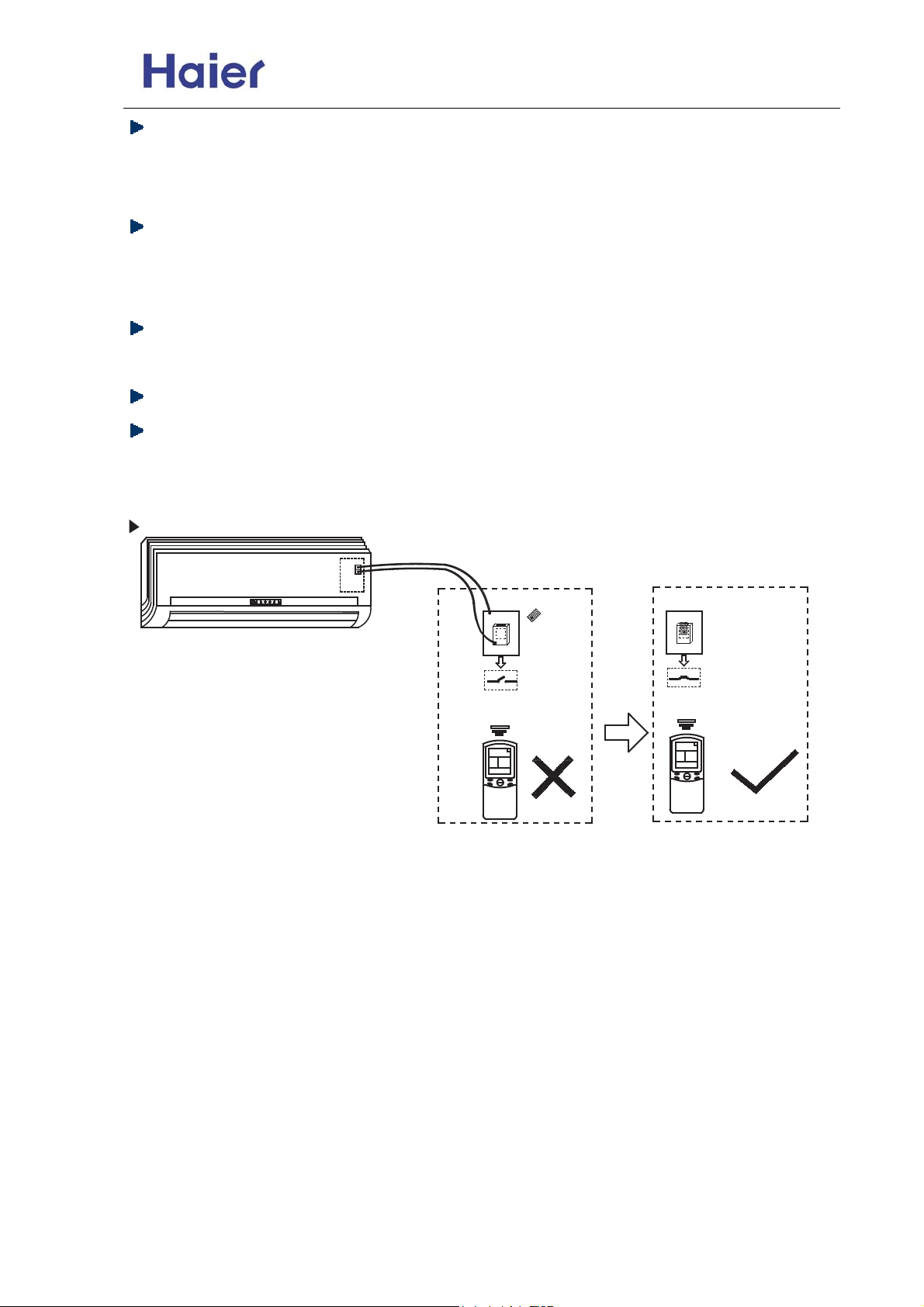

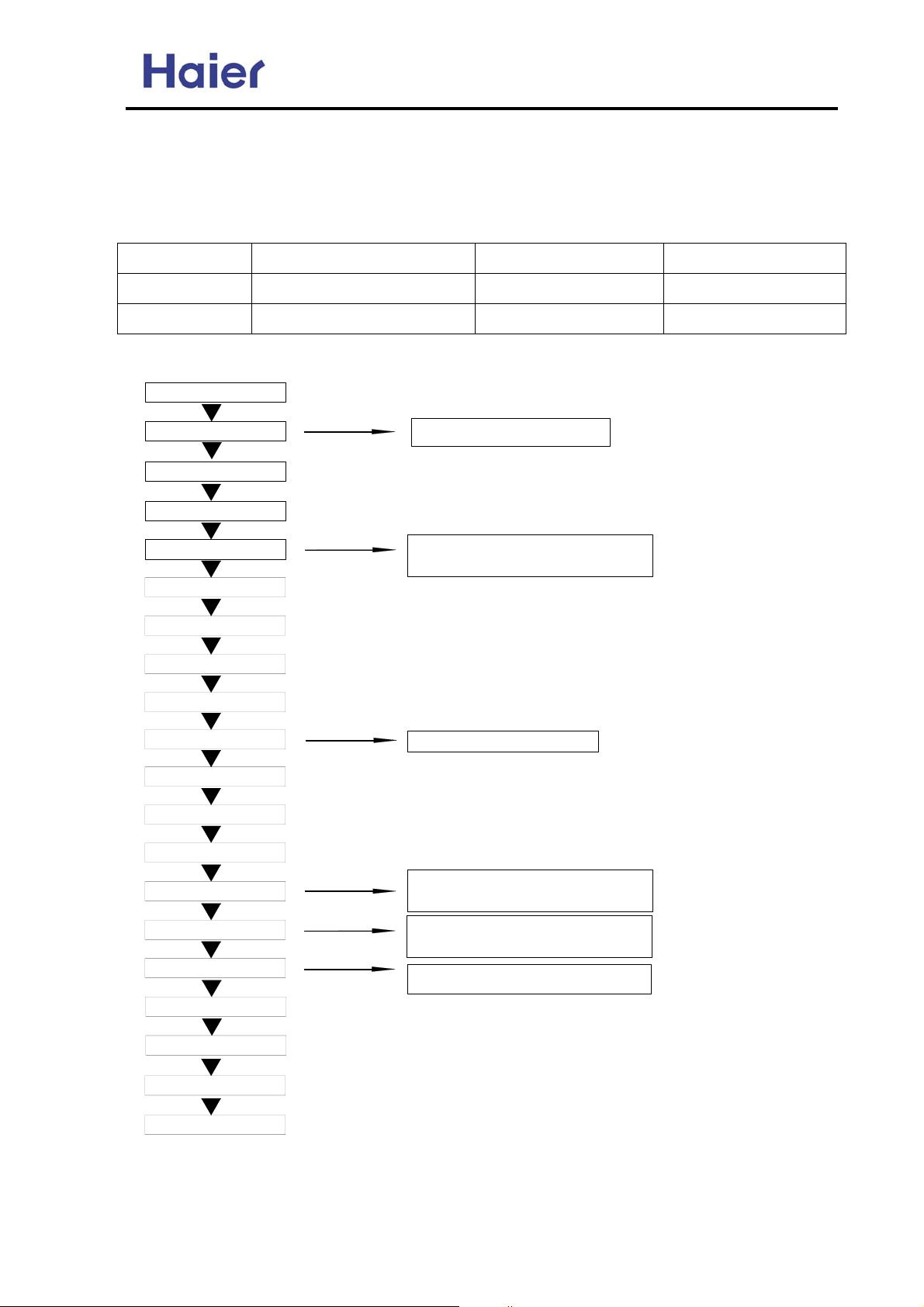

When room card function is available,indoor will be controlled as below figure:

ON

ON

OFF

OFF

When room card is disconnected

When room card is connected

-5-

Commercial Air Conditioner Model: AU18/222XFERA

AS072/092/122XVERA

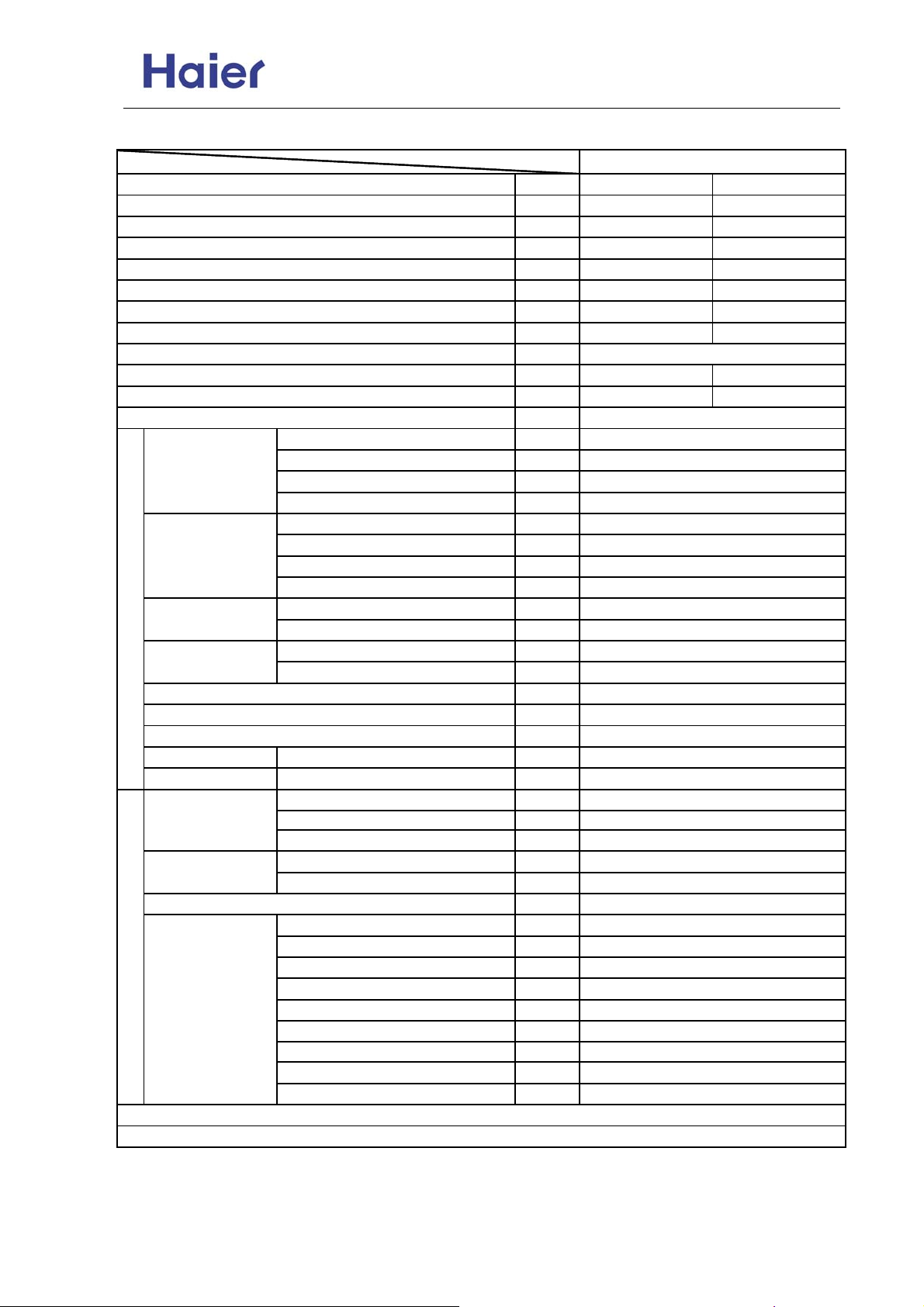

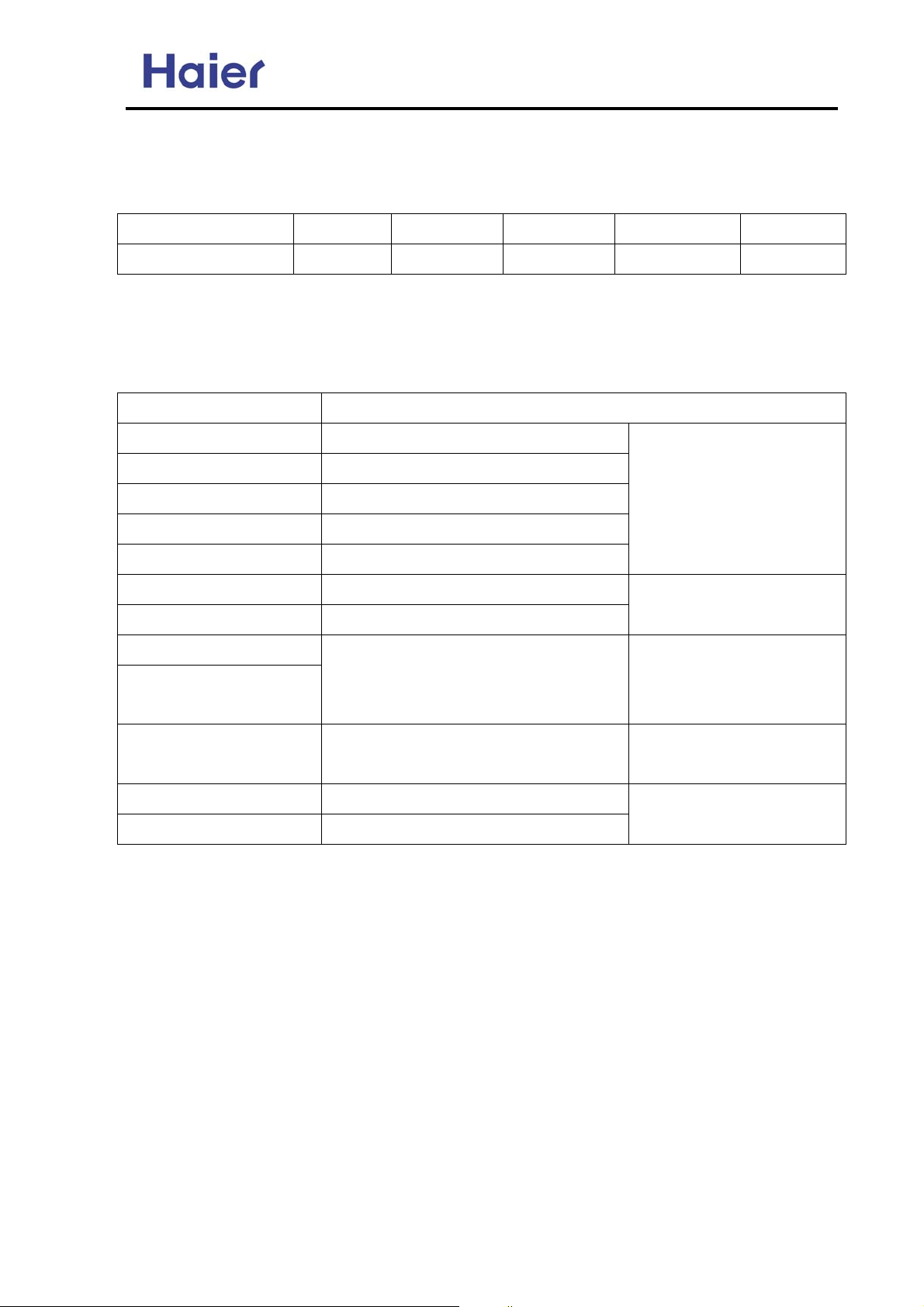

2. Specification

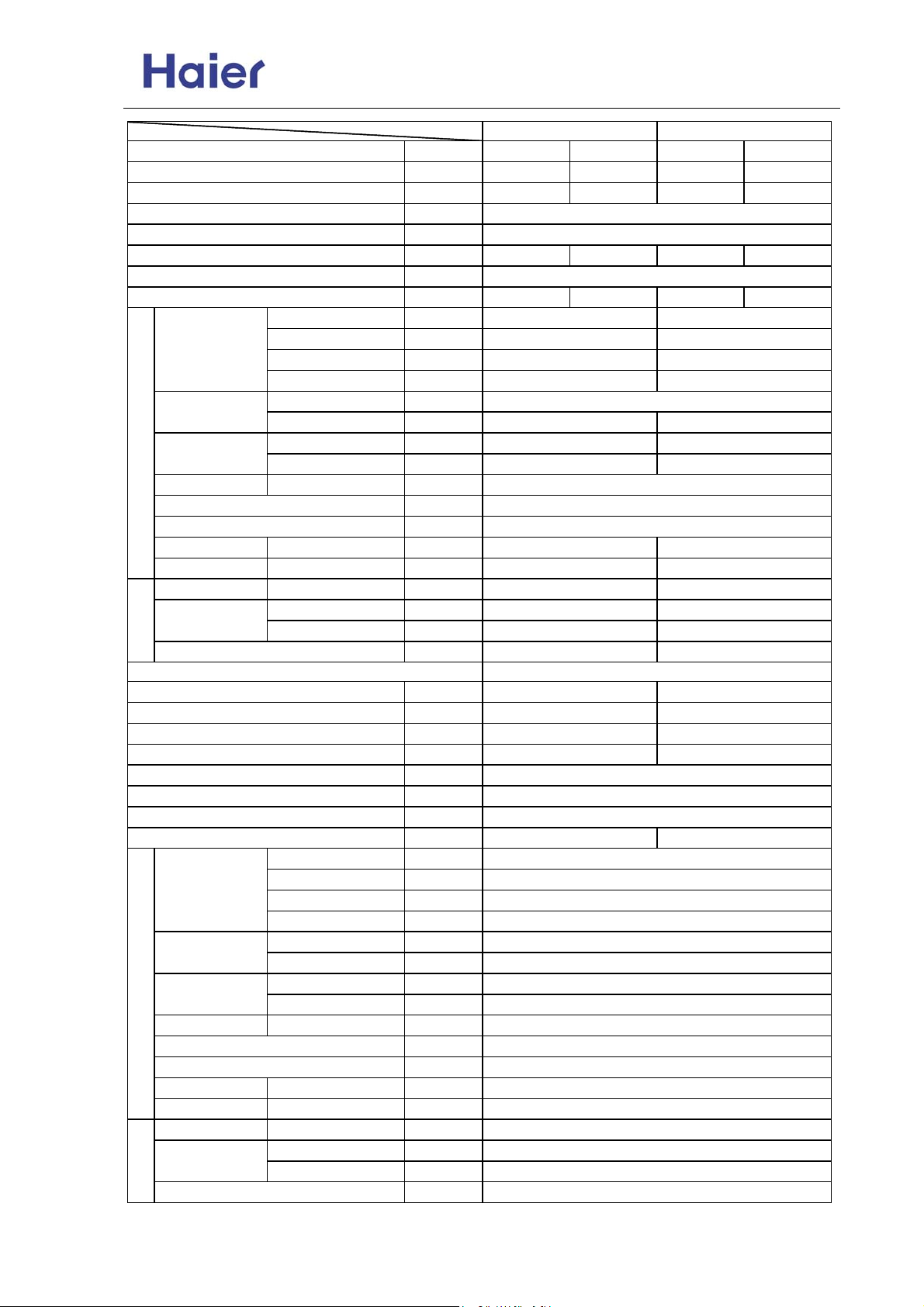

Item Model AU182XFERA

Function

Rating capacity

Power input

EER / COP

Minimum capacity

Power input

Maximum capacity

Power input

Power source

Max.Running current

Power facor(under rating power input)

Fuse size (recommended size)

Compressor

Fan

Heat exchanger

Outdoor unit

Dimension

(L×W×H)

Refrigerant control method

Defrosting method

Crankcase heater power

Noise level H/M/L dB(A)

Weight Net / Shipping kg / kg

Refrigerant R410A / 2.0

Pipe 3* Φ6.35

Connecting method

Between I.D &O.D

Piping

1. The above performance data are from the combination of AU182XFERA+2*AS092XVERA+AS122XVERA.

2. Large drop and long piping installation will obviously reduce the totao capacity.

Model / Manufacture ——

Oil charge and type ——

Type ——

Number ——

Type × Number ——

Speed r/min

Motor output power W

Air-flows (H/M/L) m³/h

Type / Diameter mm

Face area m²

External mm

Package mm

Type / Charge kg

No need to recharge m

Recharge g/m

Liquid mm

Gas mm

Drop between IU & OU

Piping length between IU & OU

Total liquid piping length

Drop between indoor units m

Max.Drop between IU & OU m

Max.Drop between IU & OU m

Max.Drop between indoor units m

Max.Piping length between IU & m

Max.Total liquid piping length

——

W 5300 7000

W 1650 1800

W/W

W 1500 1800

W 500 500

W

W

——

A / A 10.2 10.2

—— 99% 99%

A

——

——

W

——

m

m

m

m

Cooling Heating

3.21 3.88

5800 7400

2300 2300

1PH, 220-230V~, 50Hz

25

TNB175FLBM1 / MISTUBISHI ELEC.

670CC, MEL 56

Twin Rotary (DC inverter)

1

Axial × 1

850/ 700/ 500

35

about 3000

TP2M / 7.0

about 0.52

928/288/680

1015/405/760

PMV

Automatic by reversible cycle

35

51/-/-

54 / 60

30

20

3* Φ9.52

Flared

≤5

≤10

≤30

≤1

10(indoor unit lower than outdoor unit)

15 (indoor unit higher than outdoor unit)

5

25

45

-6-

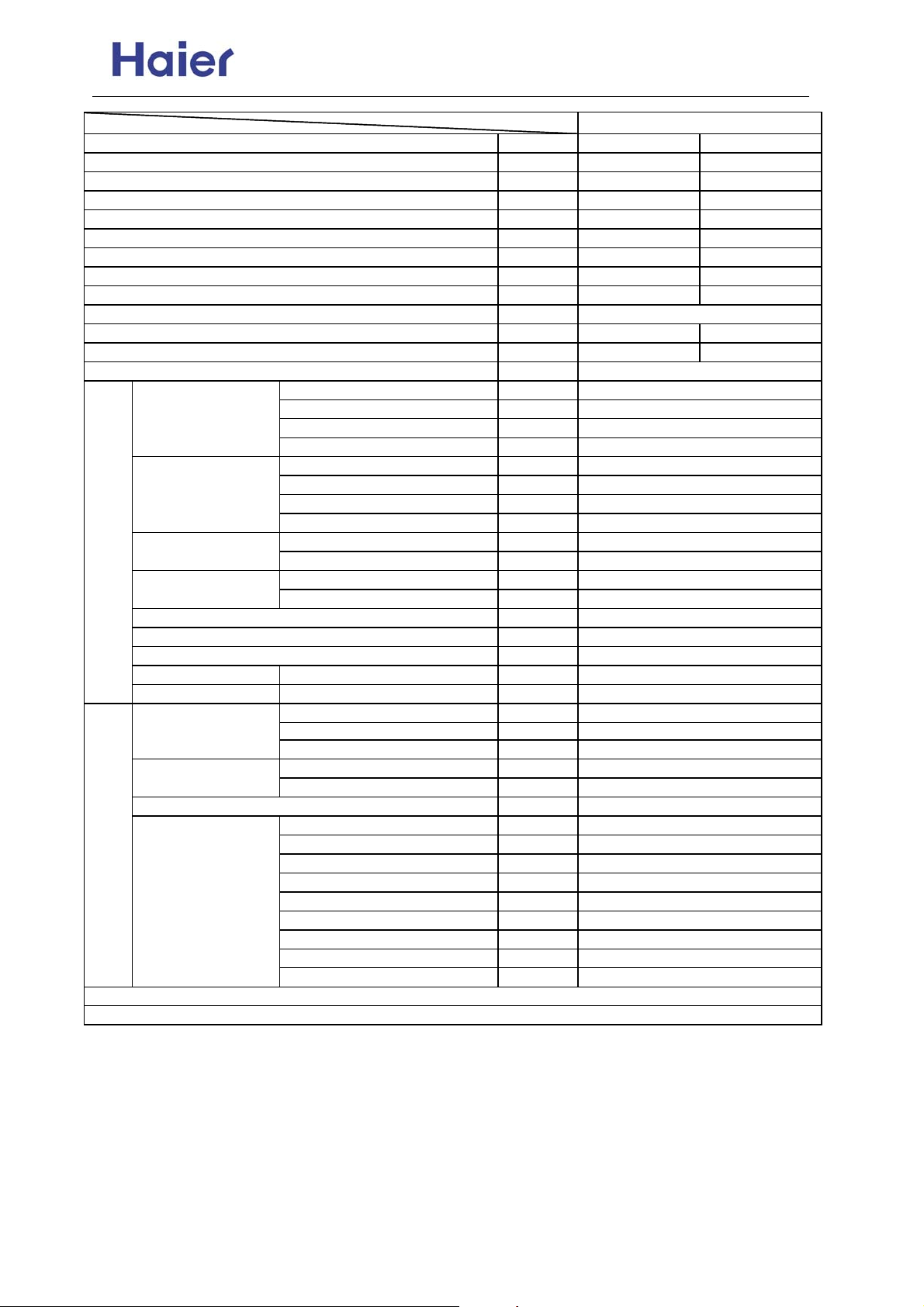

Commercial Air Conditioner Model: AU18/222XFERA

AS072/092/122XVERA

Item Model AU222XFERA

Function

Rating capacity

Power input

Current input

EER / COP

Minimum capacity

Power input

Maximum capacity

Power input

Power source

Max.Running current

Power facor(under rating power input)

Fuse size (recommended size)

Compressor

Fan

Heat exchanger TP2M / 7.0

Outdoor unit

Dimension

(L×W×H)

Refrigerant control method PMV

Defrosting method

Crankcase heater power 35

Noise level H/M/L dB(A)

Weight Net / Shipping kg / kg

Refrigerant R410A / 2.0

Pipe 3* Φ6.35

Connecting method

Between I.D &O.D

Piping

1. The above performance data are from the combination of AU222XFERA+AS092XVERA+2*AS122XVERA.

2. Large drop and long piping installation will obviously reduce the total capacity.

Model / Manufacture ——

Oil charge and type ——

Type ——

Number ——

Type × Number ——

Speed r/min

Motor output power W

Air-flows (H/M/L) m³/h

Type / Diameter mm

Face area m²

External mm

Package mm

Type / Charge kg

No need to recharge m

Recharge g/m

Liquid mm

Gas mm

Drop between IU & OU

Piping length between IU & OU

Total liquid piping length

Drop between indoor units m

Max.Drop between IU & OU m

Max.Drop between IU & OU m

Max.Drop between indoor units m

Max.Piping length between IU & m

Max.Total liquid piping length

——

W 6400 7300

W 2100 2000

A 9.3 8.9

W/W

W 1500 1800

W 500 500

W

W

——

A / A 12.9 12.9

—— 99% 99%

A

——

——

W

——

m

m

m

m

Cooling Heating

3.04 3.65

6800 7500

2900 2900

1PH, 220-230V~, 50Hz

25

TNB175FLBM1 / MISTUBISHI

670CC, MEL 56

Twin Rotary (DC inverter)

1

Axial × 1

960/ 700/ 500

35

about 3200

about 0.52

928/288/680

1015/405/760

Automatic by reversible cycle

55/-/-

54 / 60

30

20

3* Φ9.52

Flared

≤5

≤10

≤30

≤1

10(indoor unit lower than outdoor unit)

15 (indoor unit higher than outdoor

5

25

45

-7-

Commercial Air Conditioner Model: AU18/222XFERA

AS072/092/122XVERA

Item Model

Function

Capacity

Capacity

Power cable

Communication cable

Dehumidifying capacity

Power source

Running current

Fan CROSS×1

Heat exchanger TP2M / 7×0.35

Dimension

(L×W×H)

Drainage pipe material, diameter mm

Controller type

Refrigerant control

Noise level H/M/L dB(A)

Weight Net / Shipping kg / kg

Refrigerant

Pipe 6.35 6.35

Piping

Connecting method

Item

Function

Capacity

Capacity

Dehumidifying capacity

Power cable

Communication cable

Power source

Running current

Fan

Heat exchanger TP2M / 7×0.35

Dimension

(L×W×H)

Drainage pipe material, diameter mm

Controller type

Refrigerant control

Noise level H/M/L dB(A)

Weight Net / Shipping kg / kg

Refrigerant

Pipe

Piping

Connecting method

Type × Number ——

Speed r/min

Motor output power W

Air-flows (H/M/L) m³/h

Type / Diameter mm

Total area m²

External mm

Package mm

Type ——

Liquid mm

Gas mm

Type × Number ——

Speed r/min

Motor output power W

Air-flows (H-M-L) m³/h

Type / Diameter mm

Total area m²

External mm

Package mm

Type ——

Liquid mm

Gas mm

——

BTU/h

W

——

——

10‐³×m³/h

N, V, Hz

A / A 0.15 0.15 0.15 0.15

——

——

——

——

BTU/h

W

10‐³×m³/h

——

——

N, V, Hz

A / A

——

——

——

AS072XVERA AS092XVERA

Cooling Heating Cooling Heating

7000 8000 9000 10000

2000 2300 2500 2900

3 × (1.0~1.5mm2 )

2x(0.75~1.25mm2 ), must be shielded

1.0 / 1.0 /

1,220-230~, 50

1150/1050/950 1200/1100/1000

27 27

480/430/380

about 0.15 about 0.15

795*197*265

880×315×330 880×315×330

PVC, 11.4/16.4

Infrared (YR-H65)

PMV on outdoor unit

36/33/30 38/34/31

7.6/10.6 7.6/10.6

R410A R410A

9.52 9.52

Flared

AS122XVERA

Cooling

11000

3200

1.6

3 × (1.0~1.5mm2 )

2x(0.75~1.25mm2 ), must be shielded

1, 220~230, 50

0.15 0.15

CROSS×1

1250/1150/1050

27

550/480/430

about 0.20

795×197×265

880×315×330

PVC, 11.4/16.4

Infrared (YR-H65)

PMV on outdoor unit

39/36/33

7.6/10.6

R410A

6.35

9.52

Flared

CROSS×1

520/450/390

795×197×265

Flared

Heating

13000

3800

/

-8-

Commercial Air Conditioner Model: AU18/222XFERA

AS072/092/122XVERA

Norminal condition: indoor temperature (cooling): 27℃DB/19℃WB, indoor temperature (heating): 20℃

DB

Outdoor temperature(cooling): 35℃DB/24℃WB, outdoor temperature(heating): 7℃DB/6℃WB

The noise level will be measured in the third octave band limited values, using a Real Time Analyser

calibrated sound intensity meter. It is a sound pressure noise level. The detailed method please refer to

the following information:

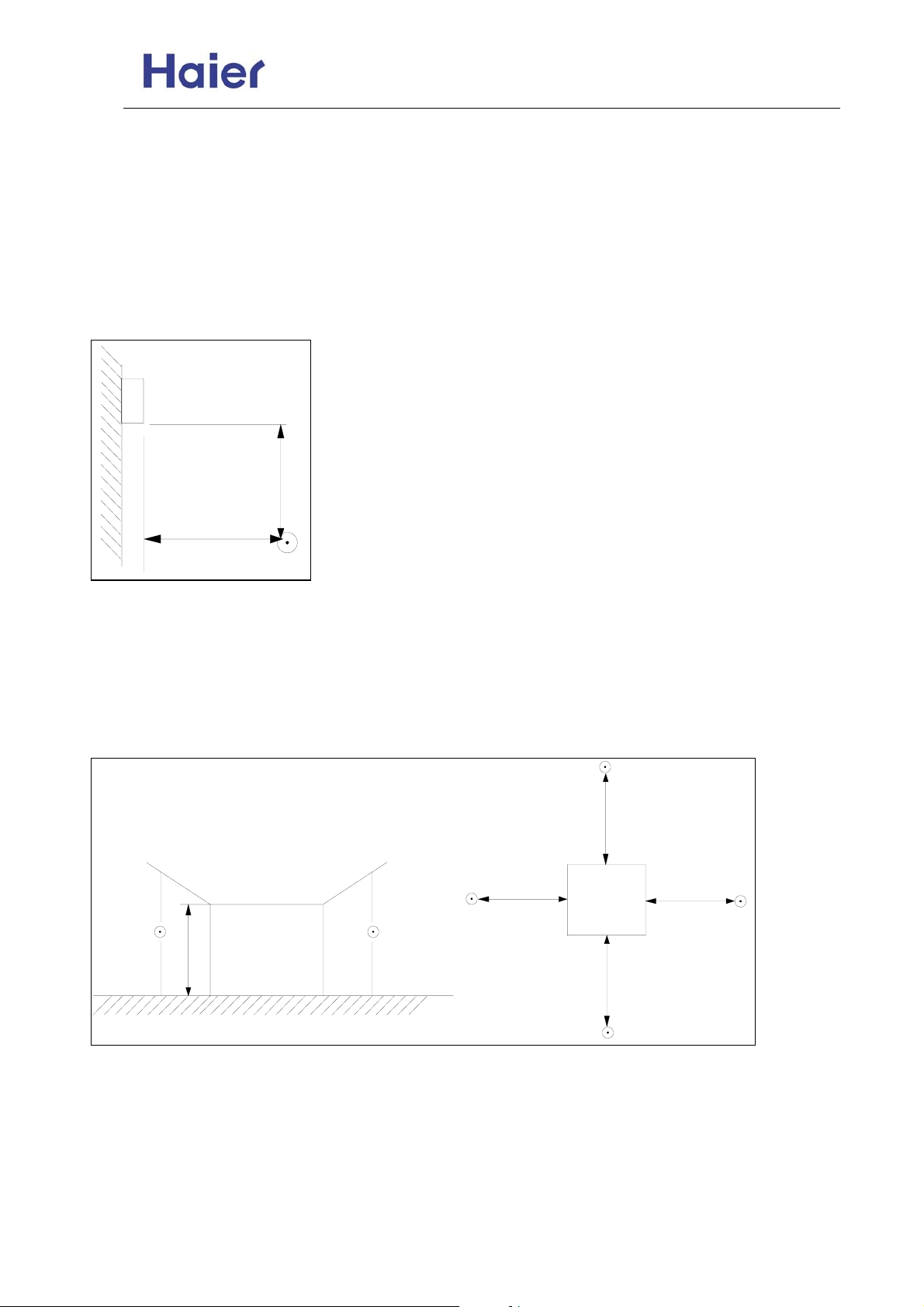

Installation state: the unit should be placed on the flat floor or be mounted in horizontal direction.

Testing method:

mounting-on-wall unit:

0.8m

outdoor unit:

1.air outlet from side: the noise level is the average sound pressure level measured from front, left, right

directions.

2.air outlet from top: the noise level is the average sound pressure level measured from front, back, left, right

directions.

measured point:

H ( height to the ground) = (h (unit height) + 1m) /2

and, it is 1m to each side.

1m

1m

1m

1m

h

Note: ⊙ is the real time analyser position

1m

-9-

Commercial Air Conditioner Model: AU18/222XFERA

AS072/092/122XVERA

3. Safety precaution

Carefully read the following information in order to operate the airconditioner correctly .

Below are listed three kinds of Safety Cautions and Suggestions.

WARNING!

CAUTION!

INSTRUCTIONS: These information can ensure the correct operation of the machine.

Be sure to conform with the following important Safety Cautions.

The Safety Cautions should be at hand so that they can be checked at any time when needed.

If the conditioner is transferred to the new user, this manual should be as well transferred to the new user.

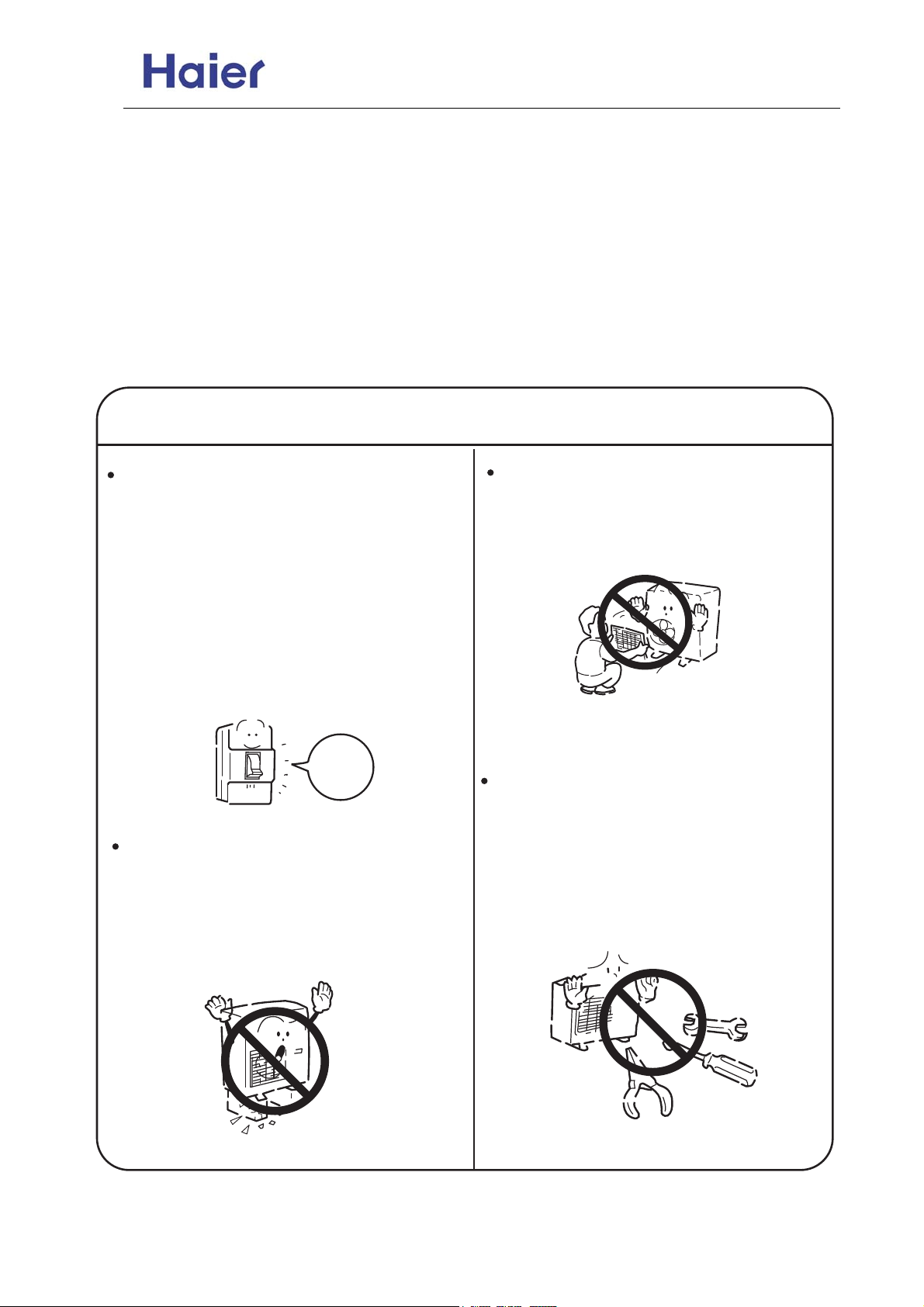

If any abnormal phenomena is found

(e. g.smell of firing), please cut off the

power supply immediately , and contact

the dealer to find out the handling

method.

In such case, to continue using the

conditioner will damage the conditioner,

and may cause electrical shock or fire

hazard.

Incorrect operations may result in severe consequences of death or serious injuries.

Incorrect operations may result in injuries or machine damages; in some cases may

cause serious consequences.

WARNING!

Don't dismantle the outlet of the

outdoor unit.

The exposed fan is very dangerous

which may harm human beings.

switch

After the unit being used for a long time,

the base should be checked for any

damages.

If the damaged base is not repaired, the

unit may fall down and cause accidents.

off

When the unit needs maintenance and

repairment, please call dealer to handle it.

Incorrect maintenance and repairment

may cause water leak, electrical shock

and fire hazard.

-10-

Commercial Air Conditioner Model: AU18/222XFERA

AS072/092/122XVERA

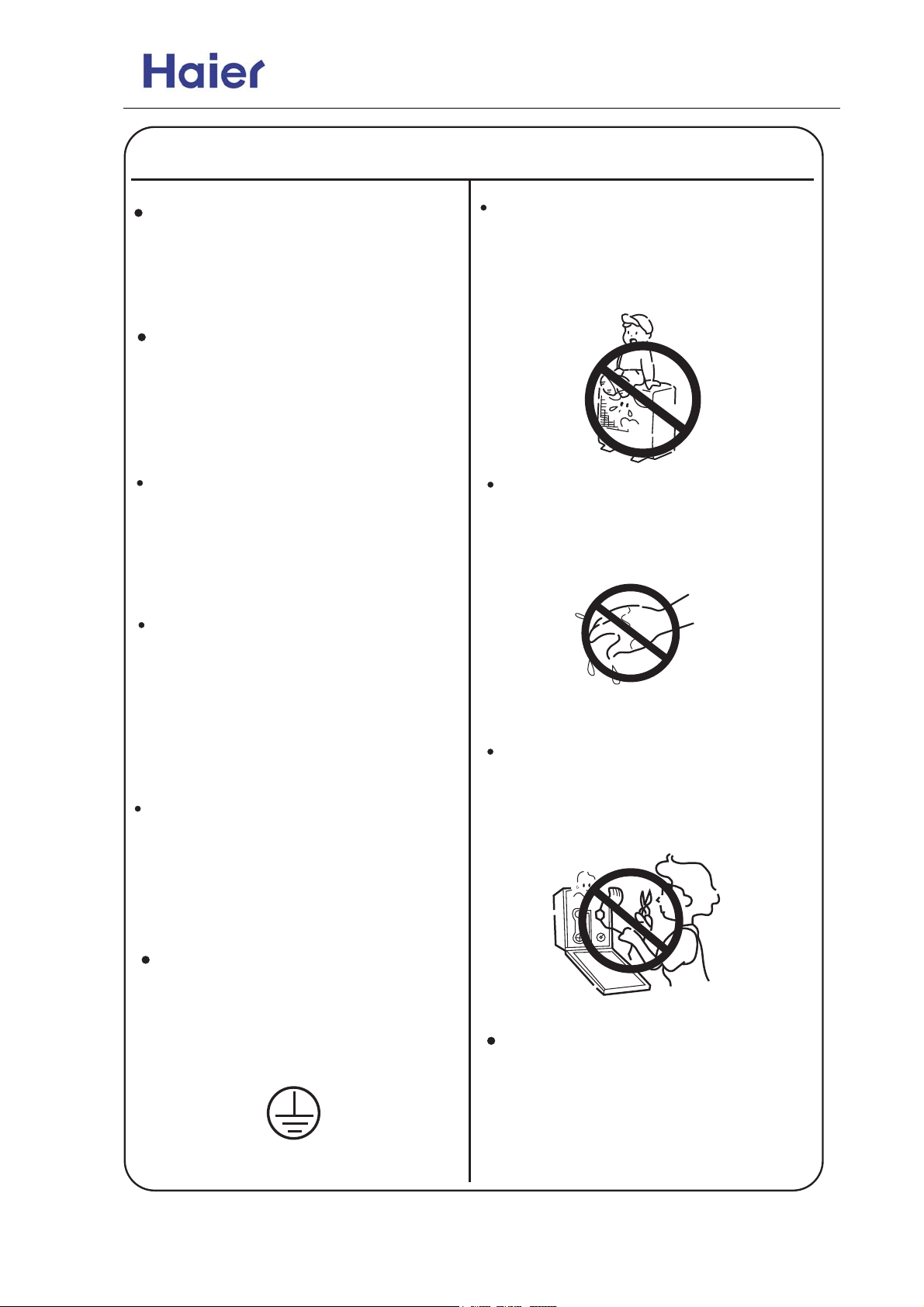

WARNING!

Installed electrical-leaking circuit

breaker .

Nothing or nobody is permitted to

placed on or stand on outdoor unit.

It easily cause electrical shock without

circuit breaker.

The falling of goods and people may

cause accidents.

Air-conditioner can't be installed in

the environment with inflammable

gases because the inflammable gases

near to air-conditioner may cause fire

hazard.

Please let the dealer be responsible for

installing the conditioner .

Don't operate the air-conditioner with

damp hands.

Incorrect installation may cause water

leak, electrical shock and fire hazard.

Otherwise will be shocked.

Call the dealer to take measures to

prevent the refrigerant from leaking.

If conditioner is installed in a small

room be sure to take every measure in

order to prevent suffocation accident

even in case of refrigerant leakage.

When conditioner is removed or

reinstalled, dealer should be responsible

for them.

Incorrect installation may cause water

leaking, electrical shock and fire hazard.

Only use correctly-typed fuse.

May not use wire or any other materials

replacing fuse, other-wise may cause

faults or fire accidents.

Connect earthing wire.

Earthing wire should not be connected to the gas pipe, water pipe,

lightning rod or phone line, in-correct

earthing may cause shock.

Earthing

Use discharge pipe correctly to ensure

efficient discharge.

Incorrect pipe use may cause water

leaking.

-11-

Commercial Air Conditioner Model: AU18/222XFERA

AS072/092/122XVERA

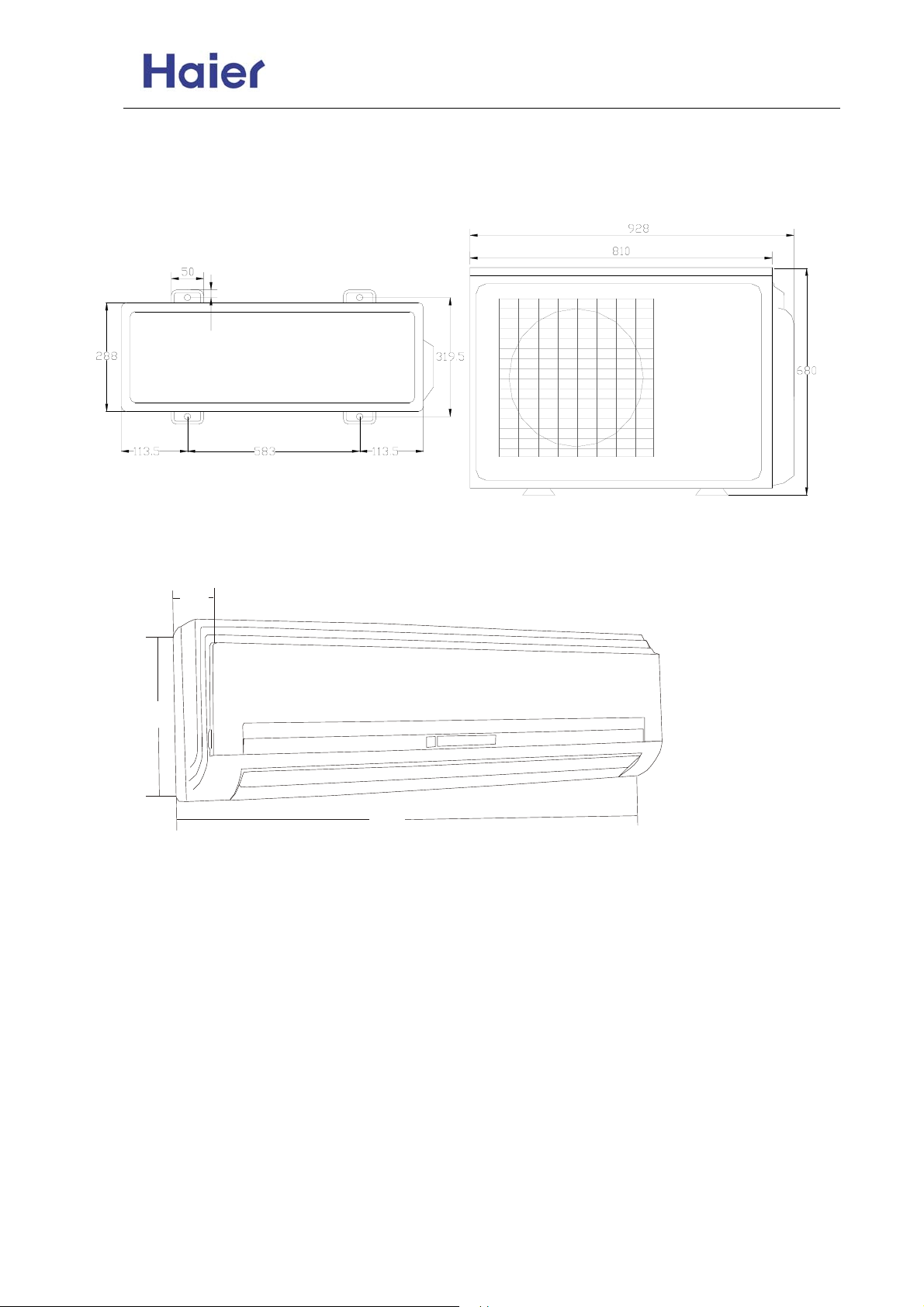

4. Net dimension of indoor and outdoor

AU18/222XFERA:

37,1-85463

18

Wall mounted unit:

305

225

870

-12-

Commercial Air Conditioner Model: AU18/222XFERA

AS072/092/122XVERA

5. Installation Instructions

■R410A

The working pressure of R410A is approximately 1.6 times higher than R22. Because the oil in the

refrigerant is different, please do not mix them.

Refrigerant R22 (single) R410A (mixed) R407C (mixed)

Oil Mineral oil (SONTEX 200LT) Synthetic oil (POE oil) Synthetic oil (POE oil)

Pressure ratio 1 Approx. 1.6 Approx. 1.1

■Operation flow

prepare work schedule

refrigerant inspection

operation chart preparation

indoor unit installation

refrigerant piping work

drain piping work

duct work

insulation work

remote controller installation

electric wiring work

outdoor unit foundation work

outdoor unit installation

refrigerant piping connection

leakage test

evacuation and drying

additional refrigerant charging

gas leakage check

maintenance panel installation

trial running and adjustment

hand over

1. Always inspect the used refrigerant

2. Always use the specified refrigerant

1. Use piping material of the specified thickness

2. Do not use dirty pipe

3. Always flow nitrogen during welding work

1. Do not connect the power supply

1. Charge the nitrogen to the set pressure

2. 24 hours later,check if the pressure in the pipe

has reduced

1. Air purging by refrigerant is prohibited seriously

2. Use a special vacuum pump with reverse check

mechanism

1. Calculate the refrigerant additional charging

amount, and charge a suitable amount.

-13-

Commercial Air Conditioner Model: AU18/222XFERA

AS072/092/122XVERA

■Piping material

1. Use the correct refrigerant piping and materials for R410A

2. For the pipe wall thickness, see the table below:

Pipe diameter Φ6.35 Φ9.52 Φ12.7 Φ15.88 Φ19.1

Pipe wall thickness 0.8 0.8 0.8 1.0 1.2

Note: Always observe and comply with the local regulations when installing the refrigerant piping.

■Tools

R410A work requires a number of special tools (* symbol). Since the tools used in R22 work

cannot be used for R410A, provide the tools separately.

Tool name Process and application

Pipe cutter Piping cutting

*Flaring tool Pipe flaring work

*Torque wrench Flare nut connection

Expander Expansion at pipe connection

Pipe bender Pipe bending work

Nitrogen gas Pipe oxidation prevention

Welder Pipe brazing

*Gauge manifold

*Charging hose

*Vacuum pump (with

adapter)

Electronic scale

Gas leakage detector Gas leakage test

Vacuum evacuation and refrigerant

charging operation check

Vacuum drying

■Work precautions

Refrigerant piping work

Air tightness test

Air tightness test

Refrigerant additional

charging

Refrigerant additional

charging

Refrigerant check: Before work, check the used refrigerant and prepare materials matched to the

refrigerant.

Refrigerant piping: Observe the basics of refrigerant piping to avoid the unnecessary problems. In

addition, when performing the welding work, seal in the nitrogen gas to the pipes, and prevent it

from the oxidation.

Leak pressure detection: Perform seal detection and make sure there is no refrigerant leakage.

Vacuum drying: If the vacuum pump has not the reverse flow check mechanism, use the pump

together with a reverse flow check adapter.

Additional refrigerant: Charge a suitable amount of refrigerant with a special R410A gauge

manifold and charging hose.

-14-

Commercial Air Conditioner Model: AU18/222XFERA

AS072/092/122XVERA

5.1 Outdoor Installation

Cautions

All electrical repairs must be carried out by qualified

electricians. Inadequate repairs may result in a major

source of danger for the user of the air conditoiner.

Do not damage any parts of the air conditioner that

carry refrigerant by piercing or perforating the air

conditioner's tubes with sharp or pointed items,

crushing or twisting any tubes, or scraping the

coatings off the surfaces. If the refrigerant spurts out

and gets into eyes, it may result in serious eye

injuries.

Do not obstruct or cover the ventilation grille of the

air conditioner. Do not put fingers or any other things

into the inlet/outlet and swing louver.

Do not allow children to play with the air conditioner.

In no case should children be allowed to sit on the

outdoor unit.

Specifications

2. If the supply cord is damaged, it must be replaced

by the manufacturer or its service agent or a similar

qualified person.

3. If the fuse on PC board is broken please change it

with the type of T 3.15A /250VAC or T 25A/250VAC.

Please check the circuit diagram about the fuse

replaced.

4. The wiring method should be in line with the local

wiring standard.

5. The power cable and connecting cable are self-

provided. The requirement of the power cable to the

outdoor unit: H05RN-F 3G 4.0mm

Model

AU182XFERA

AU222XFERA

Cable type

H05RN-F 3G 4.0mm

2

2

All the cables shall have got the Local authentication

certificate.

The refrigerating circuit is leak-proof.

6. The breaker of the air conditioner should be all-pole

The machine is adaptive in following

situation

1. Applicable ambient temperature range:

Maximum:D.B/W.B 32 C/23 C

Minimum:D.B/W.B 18 C/14 C

Maximum:D.B 43 C/26 C

Minimum:D.B

Maximum:D.B 27 C

Minimum:D.B 20 C

Maximum:D.B/W.B 24 C/18 C

Minimum:D.B/W.B -15 C

10 C/6 C

Cooling

Heating

Indoor

Outdoor

Indoor

Outdoor

switch; and the distance between its two contacts

should be no less 3mm. Such means for disconnection

must be incorporation in the fixed wiring.

7. The waste battery shall be disposed properly.

Safety precautions

To ensure proper installation, please read this safety precautions carefully before the installation. After

installation, start the unit correctly and ensure that you show the customer how to operate and maintain

the units.

WARNING!

CAUTION!

Incorrect operations may result in severe consequences of death or serious injuries.

Incorrect operations may result in injuries or machine damages; in some cases may

cause serious consequences.

-15-

Commercial Air Conditioner Model: AU18/222XFERA

AS072/092/122XVERA

WARNING

Installation work must be carried out by professional qualified people, do not install the unit by

yourself. Incorrect installation will cause water leakage, electric shock and potentially fire.

Install the unit as per the manual. Incorrect installation will cause water leakage, electric

shock or fire risk.

Be sure to use specified accessories and parts. Otherwise, water leakage, electric shock, fire risk

or unit falling down may occur .

Mounting position must be strong enough to hold the unit. Or, the unit will potentially fall down

causing injuries.

When installing the unit, take in consideration storms and high winds. Incorrect installation may

cause the unit to fall down.

All electric work should be carried out by experienced personnel as per current regulations and

this manual. Incorrect installation or undersized electric cable may cause electric shock or fire risk.

All circuits must be earthed. Ensure that no external forces will affect the terminal block and electric

cable. Poor wiring and installation may cause fire risk.

Arrange wire connection between connecting the indoor and outdoor power supply correctly. Fix

terminal cover firmly to avoid overheating, electric shock or even fire risk.

In the case of a refrigerant leakage during unit installation, keep the room well ventilated.

Check the unit upon installation. Be sure there is no leakage. Refrigerant will induce a poisonous

gas subject to heat.

Isolate power supply before touching terminal block.

WARNING

All units shall be earthed. The earth must not be connected to a gas pipe, water pipe, or telephone

line. Poor earthing could cause electric shock.

Be sure to install a circuit breaker to avoid electric shock.

Arrange water drainage according to this manual. Cover pipe with insulation materials to prevent

condensation occuring. Improper installation of water drainage will cause water leakage.

To maintain good picture or reduce noise, keep the unit at least 1m from T.V. or radio,

when installing the communication wire and power supply. (If the radio wave is relatively strong,

1m is not enough to reduce the interference).

Do not install the unit in following places:

(a) Oil mist or oil gas exists, such as kitchen, or, plastic parts may age, or water leakage.

(b) Where there is corrosive gas. Copper tube and welded part may be damaged due to corrosion

causing leakage.

(c) Where there is strong radiation. It will affect the unit's control system, causing malfunction of

the unit.

(d) Where there are flammable gas, dirt, and volatile matter (thinner, gasoline) exist, these items

will cause a fire risk.

-16-

Commercial Air Conditioner Model: AU18/222XFERA

AS072/092/122XVERA

Installation accessories

The following accessories are supplied together with the outdoor unit.

No.

1

2

3

Drawing

Name of parts

Drainage elbow

Rubber cushion

ClampClap

Quantity

1

4

1

Choose the installation place

Place, robust not causing vibration, where the body can be supported sufficiently.

Place, not affected by heat or steam generated in the vicinity, where inlet and outlet of the unit are not

disturbed.

Place, possible to drain easily, where piping can be connected with the outdoor.

Place,where cold air can be spread in a room entirely.

Place, nearby a power receptacle, with enough space around.(Refer to drawings).

Place, where the distance of more than 1m from televisions, radios, wireless apparatuses and fluorescent

lamps can be left.

In the case of fixing the remote controller on a wall, place where the indoor unit can receive signals when

the fluorescent lamps in the room are lightened.

-17-

Commercial Air Conditioner Model: AU18/222XFERA

AS072/092/122XVERA

Installation drawings of indoor and outdoor units

1. Do not connect the embedded branch piping and the outdoor unit when only carrying out piping work

without connecting the indoor unit in ordor to add another indoor unit later. Make sure that no dirt or

mositure gets into eigher side of the embedded branch piping.

2.It is impossible to connect the indoor unit for one room only. Be sure to connect at least 2 rooms.

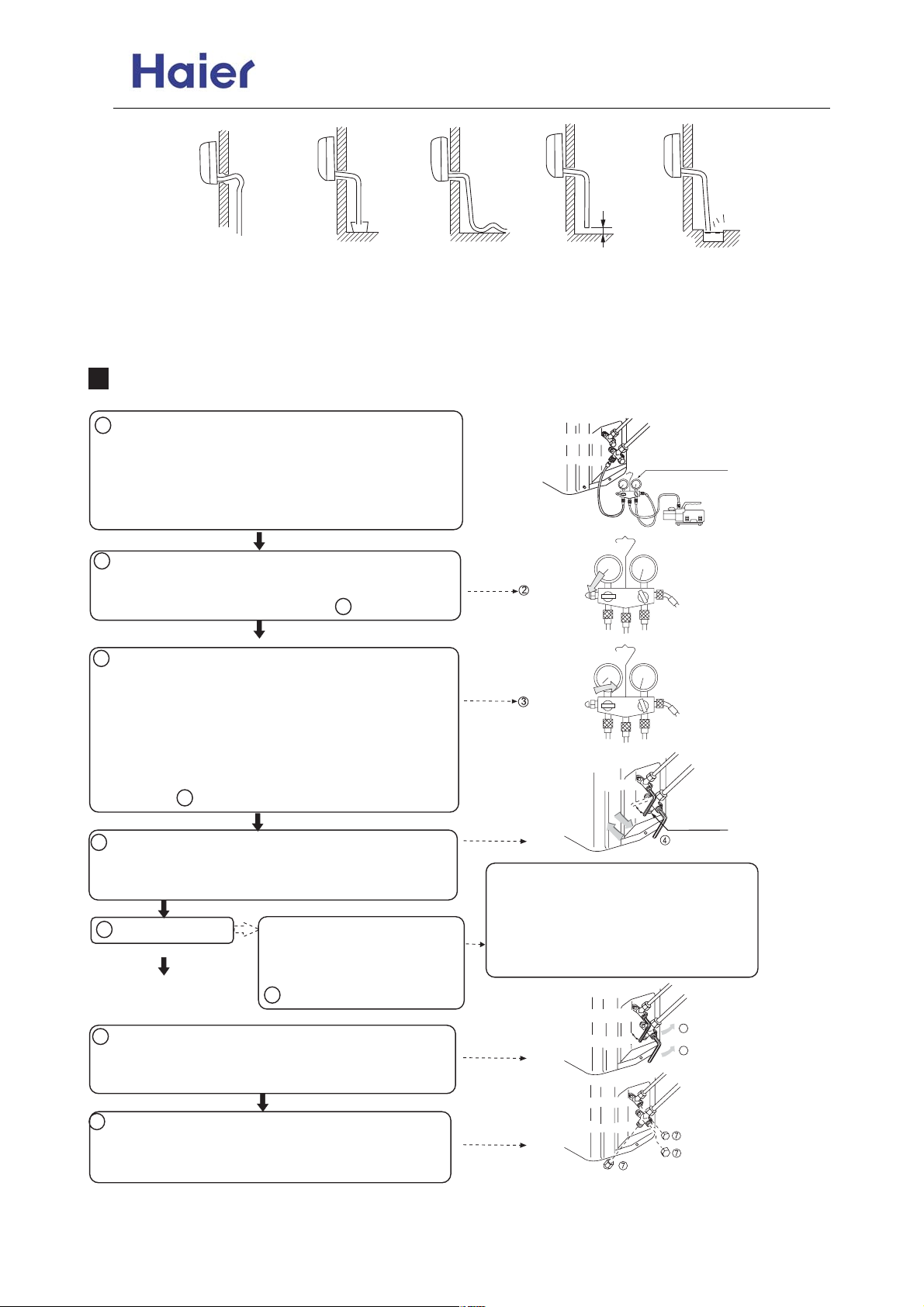

Arrangement of piping directions

Rear left

Rear right

Below

Attention must be

paid to the rising up

of drain hose

Right

More than 10cm

Wrap the insulation pipe with the

finishing tape from bottom to top.

More than 5cm

Left

Cut thermal insulation pipe to an

appropriate length and wrap it with

tape, making sure that no gap is left in

the insulation pipe's cut line.

more than 10cm

more than 10cm

more than 25cm

more than 60cm

If there is the danger of the unit failing or overturning, fix the unit with foundation bolts, or with wire or other

means.

If the location does not have good drainage, place the unit on a level mounting base(or a plastic pedestal).

Install the outdoor unit in a level position. Failure to do so may result in water leakage or accumulation.

-18-

Commercial Air Conditioner Model: AU18/222XFERA

AS072/092/122XVERA

Power source

Before inserting power plug into receptacle, check the voltage without fail. The power source is the

same as the corresponded nameplate.

Install an exclusive branch circuit of the power.

A receptacle shall be set up in a distance where the power cable can be reached. Do not extend the

cable by cutting it.

Matching of the indoor and outdoor units

AU182XFERA

Combination

1:2

1:3

A

BC

07 12

09 09

09 12

12 12

07 07 07

07 07 09

07 07 12

07 09 09

07 09 12

09 09 09

09 09 12

Remark

*

*

*

AU222XFERA

Combination

1:2

1:3

A

07 1

09

09 1

1

07 07 09

07 07 12

07 09 09

07 09 12

09 09 09

09 09 12

09 12 12

BC

4

12

4

12

Remark

*

*

*

*

WARNING!

Combinations those marked * can not be applied where the temperature in winter is too low and in

summer is too higher to avoid bad heating or cooling effect.

Limitations on the installation

1.Precautions on installation

Check the strength and level of the installation ground so that unit will not cause any operating vibration

or noise after installation.

In accordance with the foundation drawing in fix the unit securely by means of the foundation bolts.

It is best to screw in the foundation bolts unit their length are 20 mm from the foundation surface.

2.Selecting a location for installation of the indoor units

The maxinum allowable length of refrigerant piping, and the maxmum allowable height

difference between the outdoor and indoor units, are listed below.

(The shorter the refrigerant piping, the better the performance. Connect so that the

piping is as short as possible. Shortest allowable length per room is 3m)

-19-

Commercial Air Conditioner Model: AU18/222XFERA

AS072/092/122XVERA

3. Limitations data on the piping work .

L1

A

h

L2

B

H +

L3

H -

C

The piping length information, please refer the following table.

Item

A, B, C liquid pipe

A, B, C Gas pipe

L1 (one way)

L2 (one way)

L3 (one way)

L1+L2+L3 m Total liquid piping length

h

H +

H -

Unit

Size of the liquid side connection pipe

mm

mm

Size of the gas side connection pipe

Pipe length when the compressor connects with two indoor units

m

m

Pipe length when the compressor connects with two indoor units

m

Pipe length when the compressor connects only one indoor unit

m

Drop between every two indoor units

m

Drop between the outdoor unit and the indoor unit

m

Drop between the outdoor unit and the indoor unit

Descriptions

Standard

6.35

9.52

*10

*10

*10

*30 *45

*1

*5

*5

Maximum

/

/

*30

*30

*30

*5

*15

*10

Refrigerant piping work

1. Selection of pipe

To this unit, both liquid and gas pipes shall be insulated as they become low temperature in operation.

Use optional parts for piping set or pipes covered with equivalent insulation material.

Liquid pipe

Gas pipe

6.35mm ( 1/4'' ) x 0.8mm

9.52mm ( 3/8'' ) x 0.8mm

2. Connection of pipe

Apply refrigerant oil on half union and flare nut.

To bend a pipe, give the roundness as large as possible not to crush the pipe.

Connecting the pipe of gas side firstly makes working easier.

-20-

Commercial Air Conditioner Model: AU18/222XFERA

AS072/092/122XVERA

Flare nutHalf union

Torque wrenchSpanner

Forced fastening without careful centering may damage the threads

and cause a leakage of gas.

Pipe Diameter ( )

Liquid Side 6.35mm (1/4'')

Fastening Torque

18N.m

Gas Side 9.52mm (3/8'') 50N.m

3. Attaching Drain-Elbow

If the drain-elbow is used, please attach it as figure.

Hose

Drain elbow

4.Cutting and Flaring work of piping

Pipe cutting is carried out with a pipe cutter and burs must be removed.

After inserting the flare nut, flaring work is carried out.

A

Liquid side

Pipe diameter* Size A (mm)

6.35mm(1/4")

0.8~1.5

Gas side

9.52mm(3/8")

Flare tooling dia.

Correct

Lean

Damage of flare

Incorrect

Crack Partial

5.On drainage

Please install the drain hose so as to be downward slope without failure.

Please don't do the drainage as shown below.

-21-

1.0~1.5

Too outside

Commercial Air Conditioner Model: AU18/222XFERA

AS072/092/122XVERA

Less than 5cm

It becomes high midway.

The end is immersed

in water

It waves. It gap with the

ground ts too small.

There is the bad

smell from a ditch.

Please pour water in the drain pan of the indoor unit, and confirm that drainage is carried out serely

to outdoor.

In case that the attached drain hose is in a room, please apply heat insulation to it without fail.

Purging method: to use vacuum pump

Liquid stop valve

1 .Detach the service port's cap of 3-way valve, the valve

rod's cap for 2-way valve and 3-way valves, connect the

service port into the projection of charge hose (low) for

gaugemanifold. Then connect the projection of charge

hose (center) for gaugemanifold into vacuum pump.

2 .Open the handle at low in gaugemanifold, operate

vacuum pump. If the scale-moves of gause (low) reach

vacuum condition in a moment, check 1 again.

3 .Vacuumize for over 15min. And check the level gauge

which should read -0.1MPa (-76 cm Hg) at low pressure

side. After the completion of vacuumizing, close the handle

'Lo' in the vacuum pump. Check the condition of the scale

and hold it for 1-2min. If the scale-moves back in spite of

tightening, make flaring work again, then return to the

beginning of 3 .

4 .Open the valve rod for the 2-way valve to and an angle

of anticlockwise 90 degree. After 6 seconds, close the 2-

way valve and make the inspection of gas leakge.

5 .No gas leakage?

In case of gas leakage, tighten

parts of pipe connection. If

leakage stops, then proceed

6 steps.

6 .Detach the charge hose from the service port, open

2-way valve and 3-way. Turn the valve rod anticlockwise

until hitting lightly.

7 .To prevent the gas leakage, turn the service ports cap,

the valve rodis cap for 2-way valve and 3-way's a little

more than the point where the torque increases suddenly.

2 way valve

3 way valve

Open

Close

2 way valve

If it does not stop gas leakage, discharge

whole refrigerants from the service port.

After flaring work again and vacuumize, fill

up prescribed refrigerant from the gas

cylinder.

2 way valve

3 way valve

2 way valve

3 way valve

Gas stop valve

Gauge maifold(R410A)

Vacuum pump(R410A)

3 way valve

0

90

90

Service port cap

Service port

0

for 6 sec.

6

6

Valve rod cap

Valve rod cap

-22-

Commercial Air Conditioner Model: AU18/222XFERA

AS072/092/122XVERA

CAUTION:

If the refrigerant of the air conditioner leaks, it is necessary

to make all the refrigerant out. Vacuumize first, then charge

the liquid refrigerant into air conditioner according to the

amount marked on the nameplate.

2 way valve

3 way valve

2 way valve

3 way valve

2 way valve

o

90

10s

3 way valve

6.35mm

(1/4")

9.52mm

(3/8")

6.35mm

(1/4")

9.52mm

(3/8")

6.35mm

(1/4")

9.52mm

(3/8")

To indoor unit A

To indoor unit B

To indoor unit C

Wiring work

1. Electric wiring

Note:

The air conditioner must use special circuit , and wiring by the qualified electrician according to the

wiring rules specified in national standard.

The grounding wire and the neutral wire shall be strictly separated. Connect the neutral wire with

grounding wire is incorrect.

The electric leakage breaker must be installed.

All the electric wire must be copper wire.When wiring,there shall keep a proper distance between the

power line and communication wire to avoid twist together. Otherwise,signal disturbance will occur,and

the air conditioner can not operate normally. Power supply: 1PH, 220-230V~, 50Hz.

The wiring method of power line is Y connection. If the power line is damaged, in order to avoid

risk of electric shock, it must be replaced by the manufacturer or its repair center or other similar

qualified person.The connecting cable must be shielded.

Fuse: T3.15A 250VAC T25A 250VAC (Please check with the outdoor unit wiring diagram.)

Please check the circuit diagram about the fuse replaced.

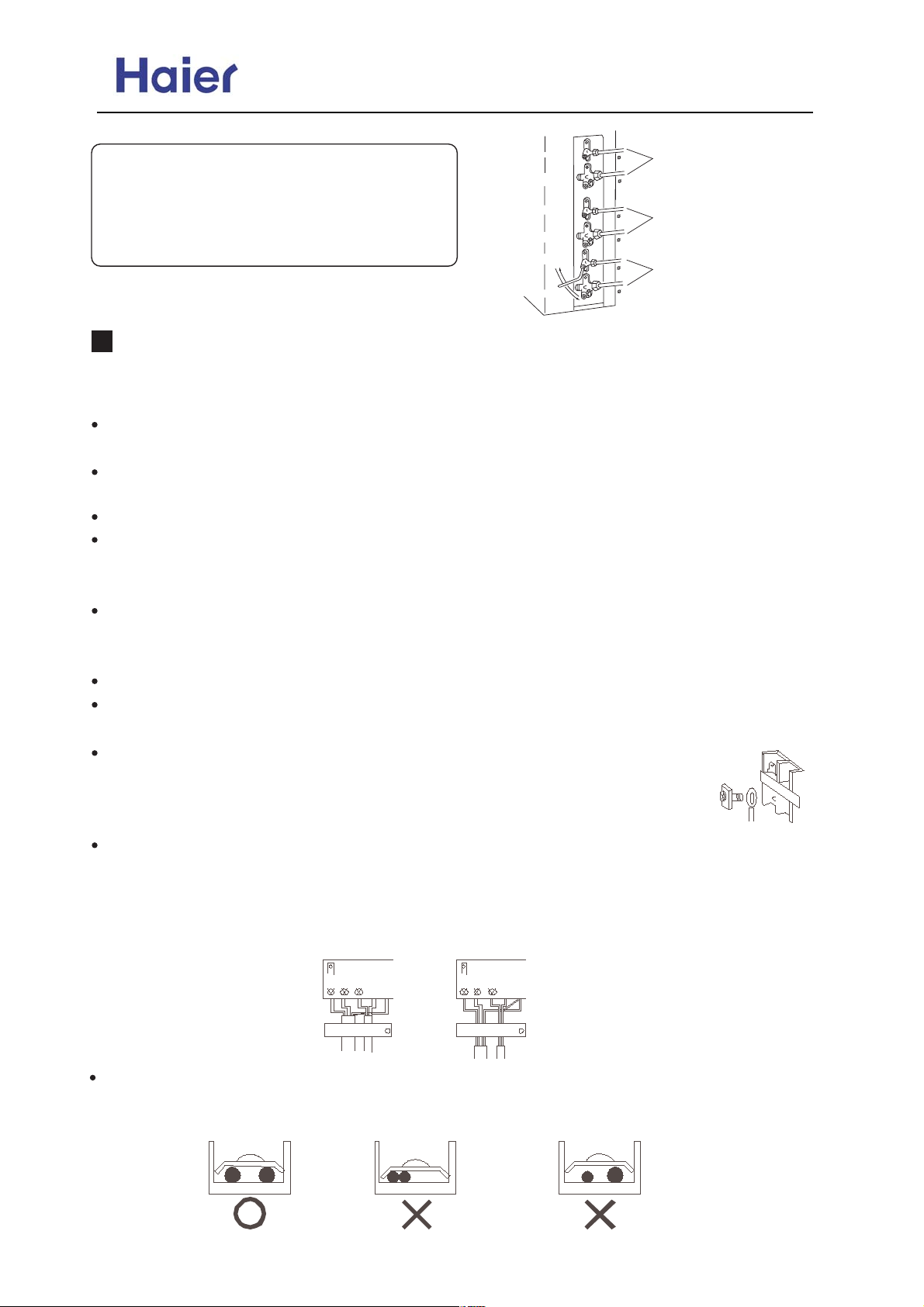

2. Wiring method

Wiring method of ring terminals

For the connection wire with ring terminals, its wiring method is as shown in

the right figure: remove the connecting screw, put the screw through the ring on the

end of the wire, then connect to the terminal block and fasten screw.

Wiring method of straight terminals

For the connection wire without orbicular terminals, its wiring method is: loosen

the connection screw, and insert the end of the connection wire completely into the Terminal block,

then fasten the screw. Slightly pull the wire outwards to confirm it is firmly held.

Wiring Method for

Ring Terminal Block

Correct Pressing

Wrong Pressing

Terminal

block

Pressing

Clamps

Crimp connection method for wires without terminals

Connect the wire with

same diameter to the

two sides of the terminal

Do not connect the

wire with same diameter

to the same side

-23-

Do not connect the

wire with different

diameters

Commercial Air Conditioner Model: AU18/222XFERA

AS072/092/122XVERA

Crimp connection method for connection wire

After connection,the wire must be fastened by wire cover. The wire cover shall press on the protection

coat of the connection wire,as shown in right top figure.

Note:When connecting the wiring,confirm the terminal number of indoor and outdoor units carefully.

Incorrect wiring will damage the controller of air conditioner or the unit can not operate.

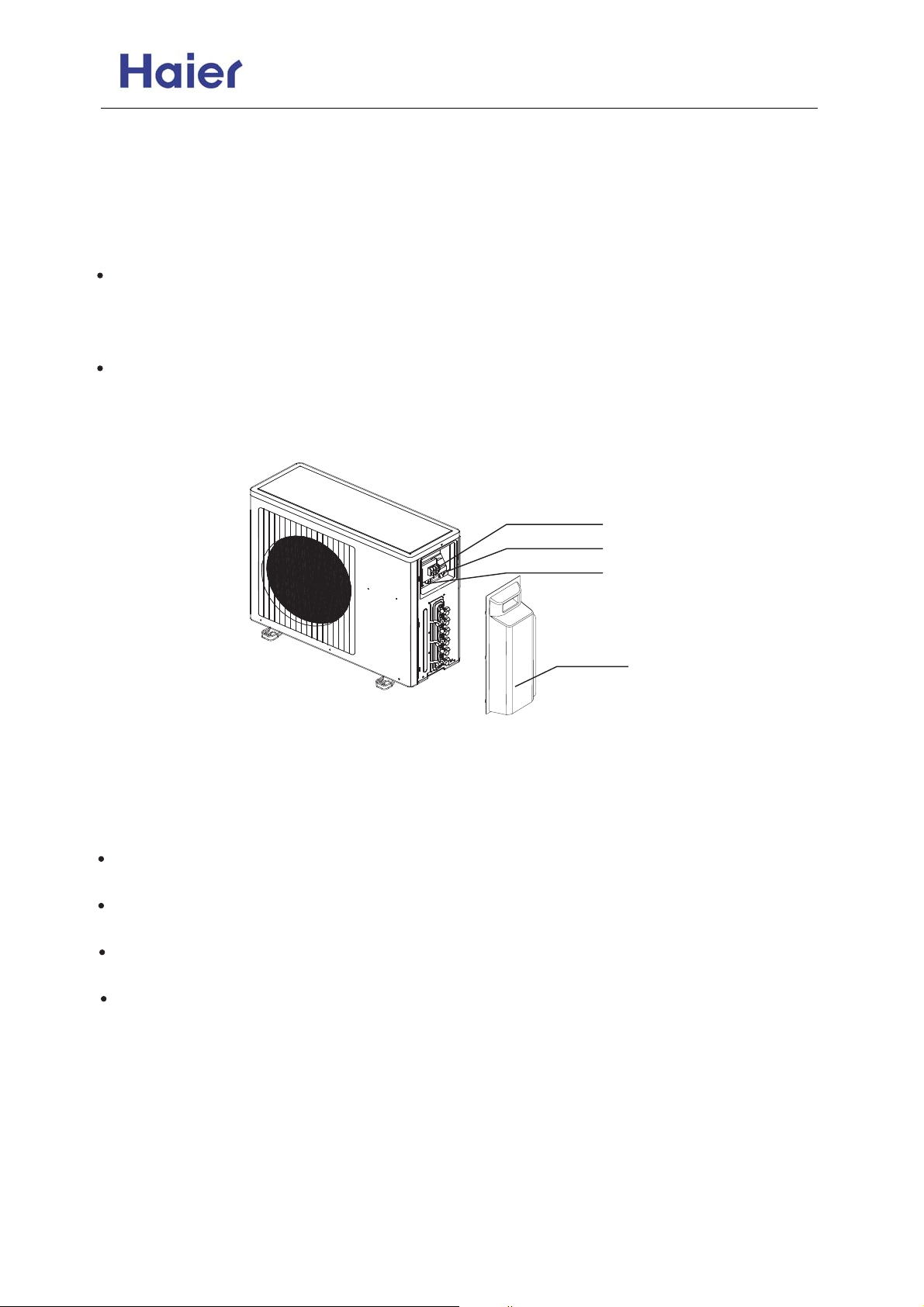

3. Wiring method of outdoor unit:

Power line

Remove the repair board of the outdoor unit and loosen the wire cover A,then put the live wire, neutral

wire and grounding wire through the wire cover ,and connect them to terminal block correspondingly. After connection, fasten wire cover to its previous state.

Communication wire of indoor unit.

Loosen wire cover , put the communication wire through the wire cover B, and connect them to

terminal block correspondingly. After connection, fasten wire cover B to its previous state.

Note: Power line and communication wire are provided by consumers themselves.

Terminal block

Wire cover A

Wire cover B

Valve cover

4. Wiring method of indoor unit

Loosen wire cover and connect the power line and communication wire of indoor unit to the

terminal correspondingly.

Note:

When connecting power line to power supply terminal, please pay attention to the following items:

Do not connect the power line with different dimensions to the same connection wire end.

Improper contact will cause heat generation.

Do not connect the power line with different dimensions to the same grounding wire end.

Improper contact will affect protection.

Keep a proper distance between the communication wire and the power line. Otherwise, abnormal

communication will occur because of disturbance.

Do not connect the power line to the connecting end of communication wire.

Incorrect connection will cause damage to the connected unit.

-24-

Loading...

Loading...