Page 1

DUCT TYPE AIR CONDITIONER

OPERATION MANUAL AND INSTALLATION MANUAL

Please read this manual carefully before installation.

Keep this operation manual for future reference.

No.0150509256 C

Page 2

Page 3

DUCT TYPE AIR CONDITIONER

OPERATION MANUAL AND INSTALLATION MANUAL

Contents

AD48HS1ERA

AD60HSIERA

Cautions

Safety Precautions

Parts and Functions

Operation

Installation Manual For Wire Controller

Heating Mode

Care and Maintenance

Troubleshooting

Precaution for Installation

Is The Unit Installed Correctly

Installation Procedure

13

14

15

16

19

20

21

3

4

6

9

English

Please read this manual carefully before installation.

Keep this operation manual for future reference.

Page 4

Page 5

Cautions

Disposal of the old air conditioner

Before disposing an old air conditioner that goes out of use, please make sure it's inoperative and safe. Unplug the air conditioner

in order to avoid the risk of child entrapment.

It must be noticed that air conditioner system contains refrigerants, which require specialized waste disposal. The valuable

materials contained in a air conditioner can be recycled. Contact your local waste disposal center for proper disposal of an old

air conditioner and contact your local authority or your dealer if you have any question. Please ensure that the pipework of your

air conditioner does not get damaged prior to being picked up by the relevant waste disposal center, and contribute to environmental

awareness by insisting on an appropriate, anti-pollution method of disposal.

Disposal of the packaging of your new air conditioner

All the packaging materials employed in the package of your new air conditioner may be disposed without any danger to the

environment.

The cardboard box may be broken or cut into smaller pieces and given to a waste paper disposal service. The wrapping bag

made of polyethylene and the polyethylene foam pads contain no fluorochloric hydrocarbon.

All these valuable materials may be taken to a waste collecting center and used again after adequate recycling.

Consult your local authorities for the name and address of the waste materials collecting centers and waste paper disposal

services nearest to your house.

Safety Instructions and Warnings

Before starting the air conditioner, read the information given in the User's Guide carefully. The User's Guide contains very

important observations relating to the assembly, operation and maintenance of the air conditioner.

The manufacturer does not accept responsibility for any damages that may arise due to non-observation of the following

instruction.

Damaged air conditioners are not to be put into operation. In case of doubt, consult your supplier.

Use of the air conditioner is to be carried out in strict compliance with the relative instructions set forth in the User's Guide.

Installation shall be done by professional people, don't install unit by yourself.

For the purpose of safety, the air conditioner must be properly grounded in accordance with specifications.

Always remember to unplug the air conditioner before opening inlet grill. Never unplug your air conditioner by pulling on

the power cord. Always grip plug firmly and pull straight out from the outlet.

All electrical repairs must be carried out by qualified electricians. Inadequate repairs may result in a major source of

danger for the user of the air conditoiner.

Do not damage any parts of the air conditioner that carry refrigerant by piercing or perforating the air conditioner's tubes

with sharp or pointed items, crushing or twisting any tubes, or scraping the coatings off the surfaces. If the refrigerant

spurts out and gets into eyes, it may result in serious eye injuries.

Do not obstruct or cover the ventilation grille of the air conditioner. Do not put fingers or any other things into the inlet/outlet

and swing louver.

Do not allow children to play with the air conditioner. In no case should children be allowed to sit on the outdoor unit.

This appliance is not intended for use by persons (including children) with reducedphysical, sensory or mental capabilities, or

lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by

a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

3

Page 6

Safety Precautions

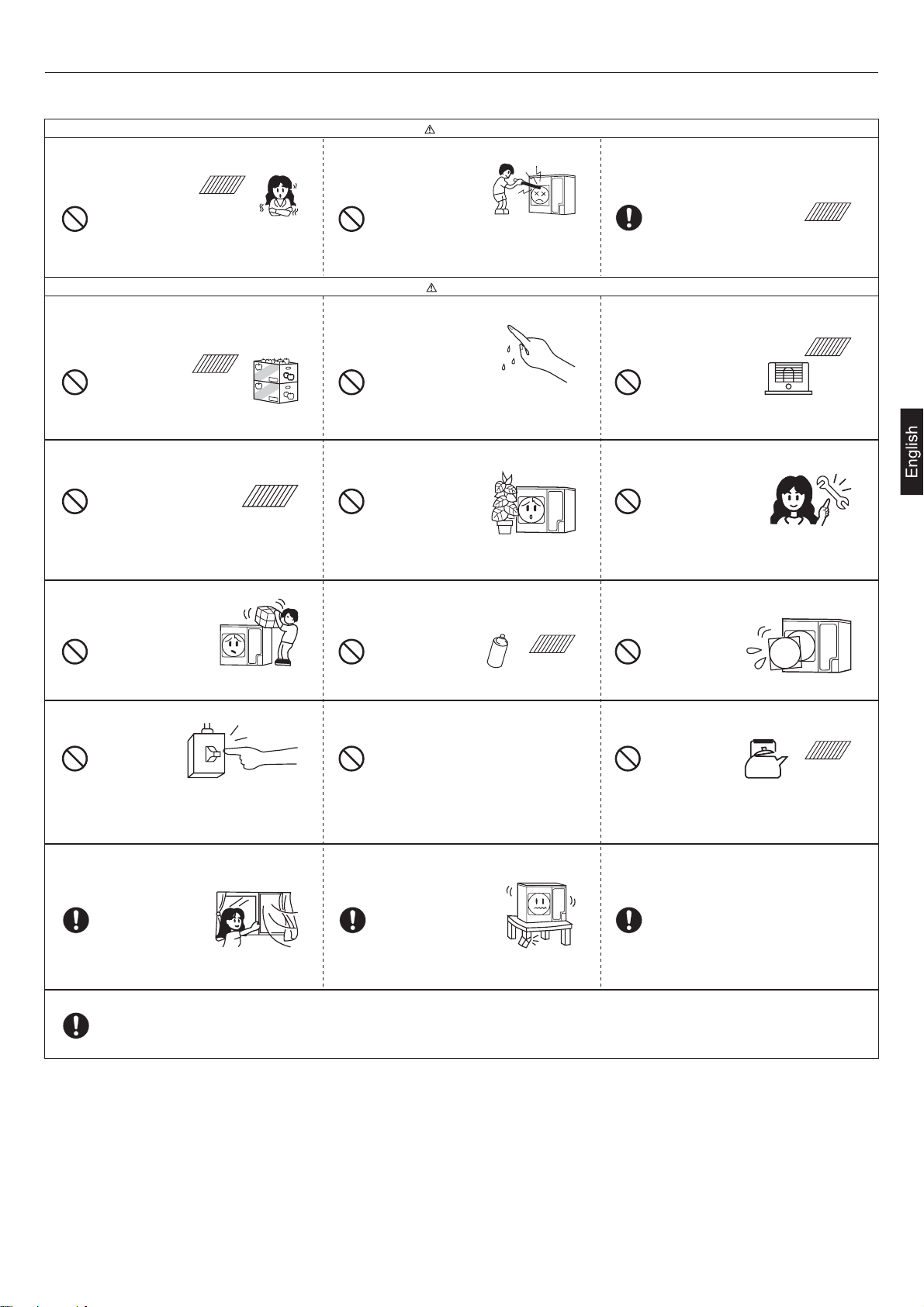

Before starting to use the system, read carefully this "SAFETY PRECAUTIONS" to ensure a proper operation of the system.

Safety precautions described here are classified to " WARNING" and " CAUTION". Precautions which are shown

in the column of " WANING" means that an improper handing could lead to a grave result like a death, serious injury,

etc. However, even if precautions are shown in the column of " CAUTION", a very serious problem could occur depending

on situation. Make sure to observe these safety precautions faithfully because they are very important information to ensure

the safety.

Symbols which appear frequently in the text have following meanings.

Strictly prohibited.

Observe instructions faithfully.

Provide a positive grounding.

When you have read through the manual, keep it always at hand for read consultation. If the operator is replaced, make

sure to hand over this manual to the new operator.

CAUTIONS FOR INSTALLATION

WARNING

The system should be applied to places as office,

restaurant, residence and the like.

Application to inferior environment such as an

engineering shop, could cause equipment

malfunction and serious injury or death.

Do not install nearby the place where may have

leakage of flammable gas.

If the gas leakes and gathers around, it may cause

the fire.

Where strong winds may prevail, the system

should be fixed securely to prevent a collapse.

The system should be installed by your dealer or

a professional installer.

Installation by yourself is not encouraged because

it could cause such problems as water leakage,

electrical shock or fire accident by some improper

handing.

CAUTION

Depending on the place of installation, a circuit

breaker may be necessary.

ON

OFF

Unless the circuit breaker is installed, it could cause

elecrical shocks.

Install on the place where can endure the weight

of air conditioner.

When you need some optional devices such as a

humidifier, electric heater, etc., be sure to use the products

which are recommended by us. These devices should

be attached by a professional installer.

Installation by yourself is not encouraged because it could

cause such problems as water leakage, electrical shock

or fire accident by some improper handing.

Drain pipe should be arranged to provide a positive

draining.

If the pipe is arranged improperly, furniture or the

likes may be damaged by leaked water.

Make sure the system is grounded.

Bodily injury could result by a collapse. Bodily injury could result by a careless installation. Grounding cable should never be connected to

a gas pipe, city water pipe, lightning conductor

rod or grounding cable of telephone. If the

grounding cable is not set properly, it could cause

electric shocks.

CAUTIONS FOR TRANSFER OR REPAIR

WARNING

Modification of the system is strictly prohibited. When the system needs a

repair, consult your dealer.

Improper practice of repair could cause water leakage, electric shock or

fire.

When the air conditioner is relocated, contact your dealer or a professional

installer.

Improper practice of installation could cause water leakage, electric shock

or fire.

4

Page 7

Safety Precautions

CAUTIONS FOR OPERATION

You should refrain from exposing your body directly

to cool wind for a long time.

It could affect your physical condition or cause

some health problems.

The system should never be used for any other

purposes than intended such as for preservation

of food, flora and fauna, precision devices or work

of art.

WARNING

Do not poke the air inlet or outlet with a bar, etc. When any abnormal condition (scorching smell or

Since the internal fan is operating with a high

speed, it could cause an injury.

CAUTION

Do not handle switches with a wet hand. Combustion apparatus should not be placed

others) is found, stop the operation immediately

and turn off the power switch. Then consult your

dealer.

If you continue the operation without removing the

cause, it could result in a trouble, electric shock

or fire.

allowing a direct exposure to wind of air conditioner.

problems.

Do not wash the air conditioner with water.

It could cause electric shocks. It will not be good for their health. Use of steel or copper wire in place of a fuse is

Neither stand on the air conditioner nor

place something on it.

object.

Do not use the power switch to turn on or off the

system.

It could cause a fire or water leakage. There is a risk of injury. If the system is operated at the vicinity of such

When operating the system simultaneously with

a combustion apparatus, indoor air must be

ventilated frequently.

ON

OFF

It could cause electric shocks.It could cause deterioration of food or other

Do not install the system where the air outlet

reaches directly the flora and fauna.

It is strictly prohibited to place a container of

combustible gas or liquid near the air conditioner

or to spray it directly with the gas or liquid.

Do not touch the air outlet section while the swing

louver is operating.

Check occasionally the support structure of the

unit for any damage after a use of long period of

time.

Incomplete combustion could occur on the

apparatus.

Make sure to use a fuse of proper electric rating.

strictly prohibited because it could result in a trouble

or fire accident.

Do not operate the system while the air outlet grill

is removed.

There is a risk of injury.It could cause a fire accident.There are risks of falling or injury by collapsed

Do not use such equipment as a water heater, etc.

around the indoor unit or the wire controller.

equipment which generates steam, condensed

water may drip during cooling operation or it could

cause a fault current or short-circuit.

When cleaning the system, stop the operation and

turn off the power switch.

Insufficient ventilation could cause an oxygen

deficiency accident.

Do not put water containers on the unit such as a flower vase, etc.

If the water enters into the unit and damages the electric insulation material, it may cause electric shock.

If the structure is not repaired immediately, the

unit could topple down to cause a personal injury.

Cleaning should never be done while the internal

fans are running with high speed.

5

Page 8

Safety Precautions

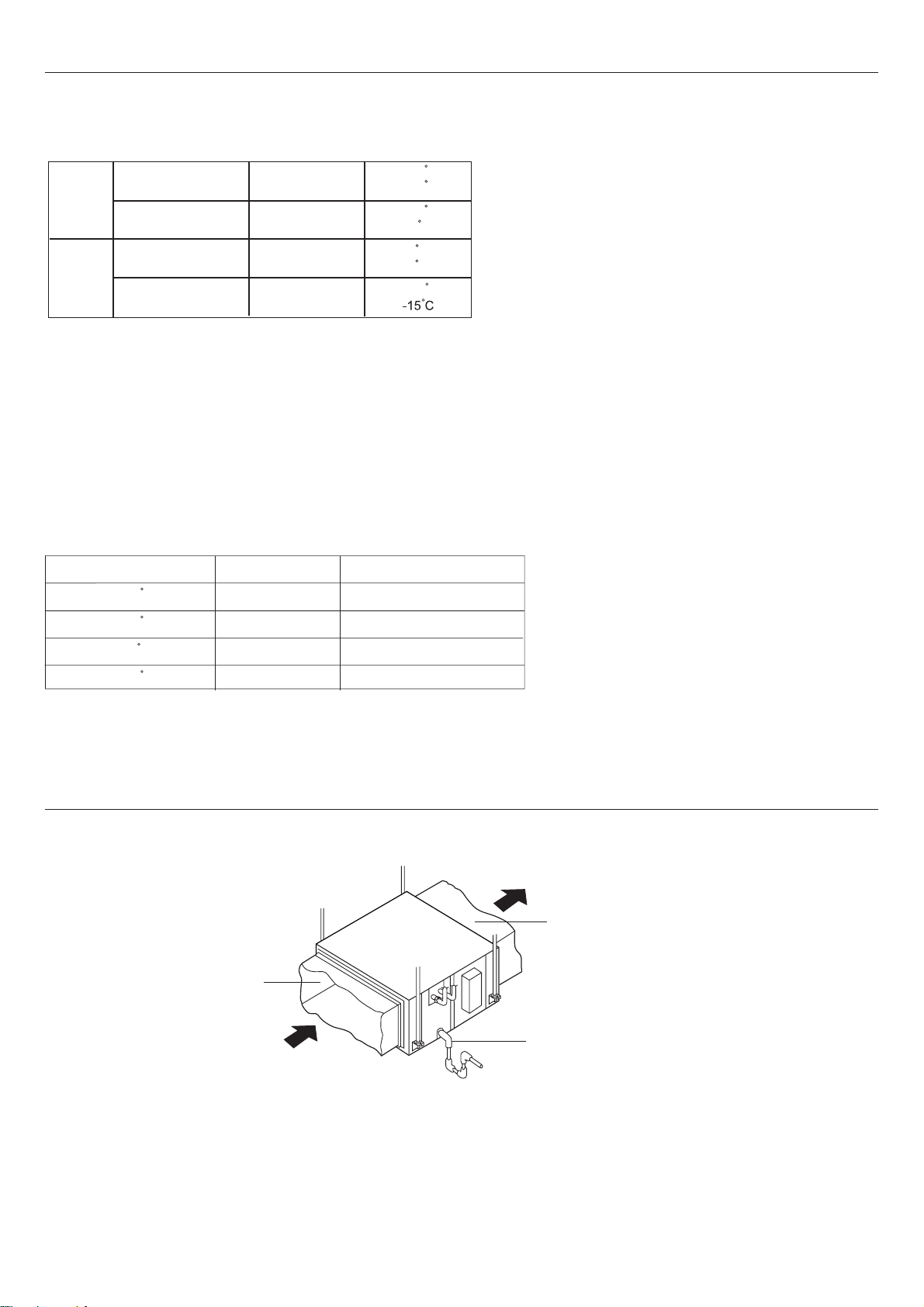

The machine is adaptive in following situation

1. Applicable ambient temperature range:

Cooling

Heating

Indoor temperature

Outdoor temperature

Indoor temperature

Outdoor temperature

max. DB/WB

min. DB/WB

max. DB/WB

min. DB/WB

max. DB/WB

min. DB/WB

max. DB/WB

min. DB/WB

32/23 C

18/14 C

46/26 C

10/6 C

27 C

15 C

24/18 C

2. If the supply cord is damaged, it must be replaced by the manufacturer or its service agent or a similar qualified person.

3. If the fuse on PC board is broken, please change it with the type of T 3.15A /250VAC.

4. The wiring method should be in line with the local wiring standard.

5. The power cable and connecting cable are self-provided.

The connecting cable should be H05RN-F 4G 0.75mm

2

.

All the cables shall have got the European authentication certificate. During installation, when the connecting cables

break off, it must be assured that the grouding wire is the last one to be broken off.

6. The breaker of the air conditioner should be all-pole switch, and the distance between its two contacts should be no

less than 3mm.

7. The indoor unit installation height is at least 2.5m.

8. In order to obtain the Unit's best performances, the fan speed is recommended according to the following conditions.

outdoor ambient temp.

> 40 C

operation mode

cooling

recommended fan speed

low

< 20 C

< -5 C

> 18 C

cooling

heating

heating

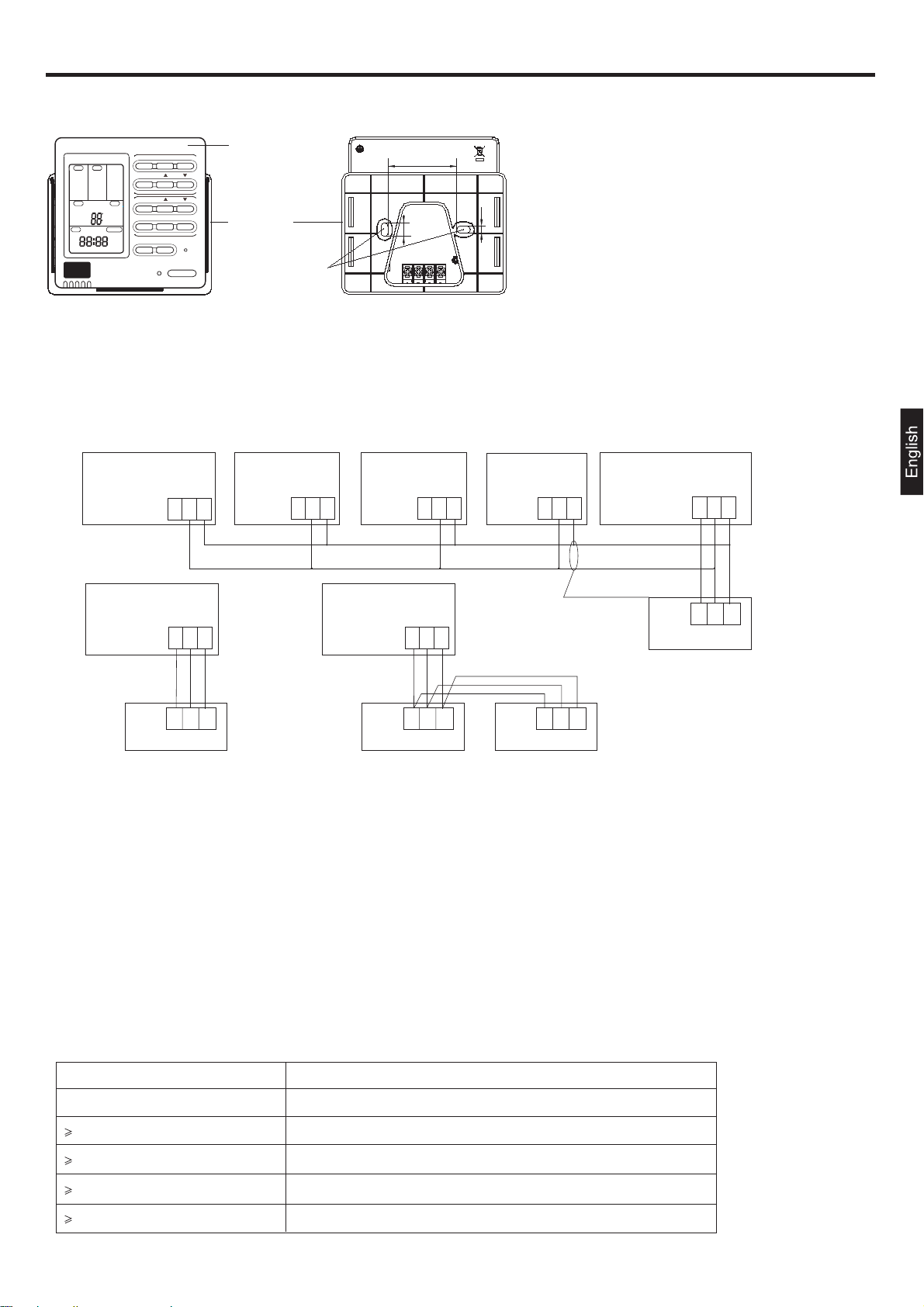

Parts and Functions

Indoor Unit

Duct

Air inlet

high

low

high

Air outlet

Duct

Drain pipe

6

Page 9

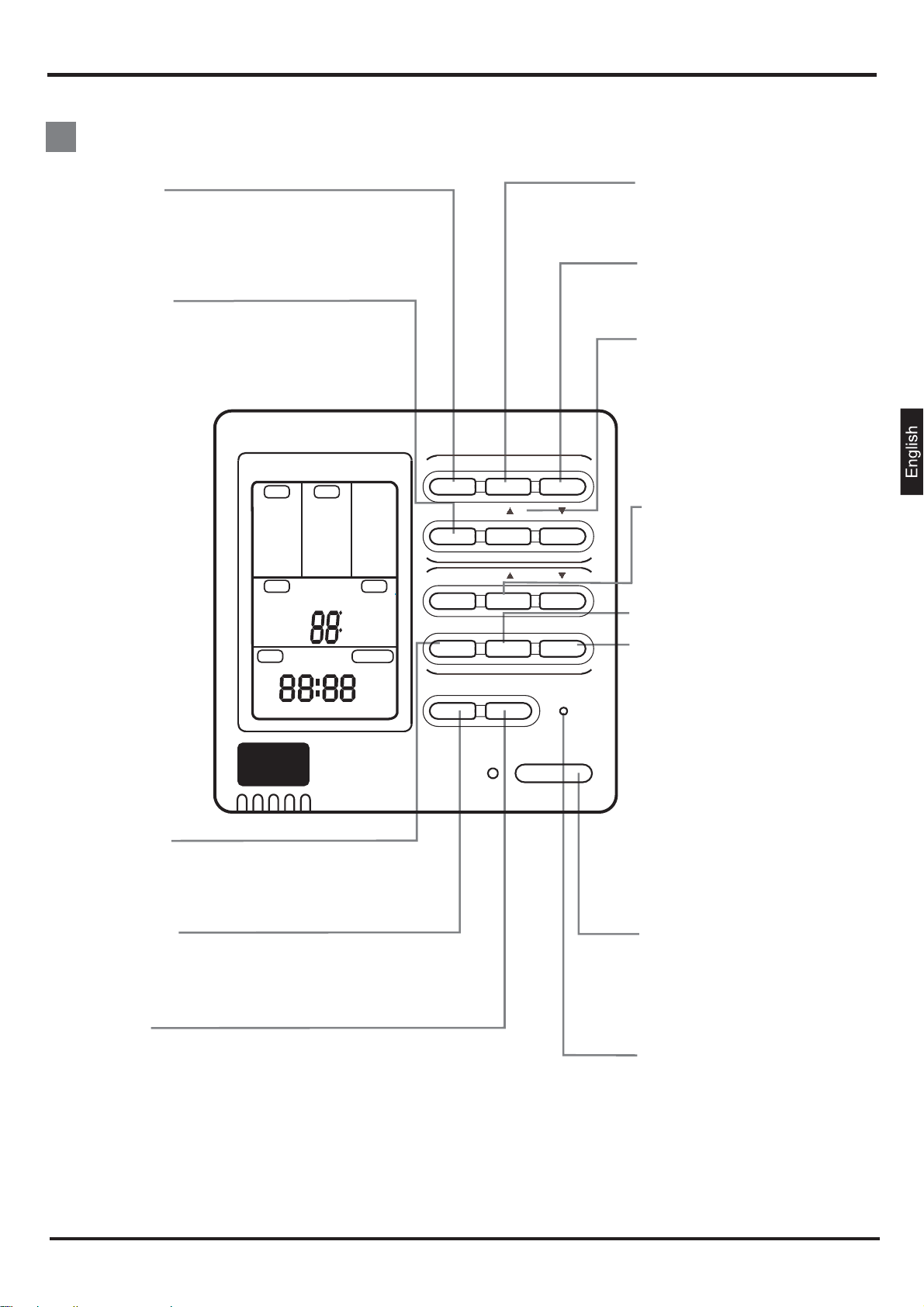

Parts and Functions

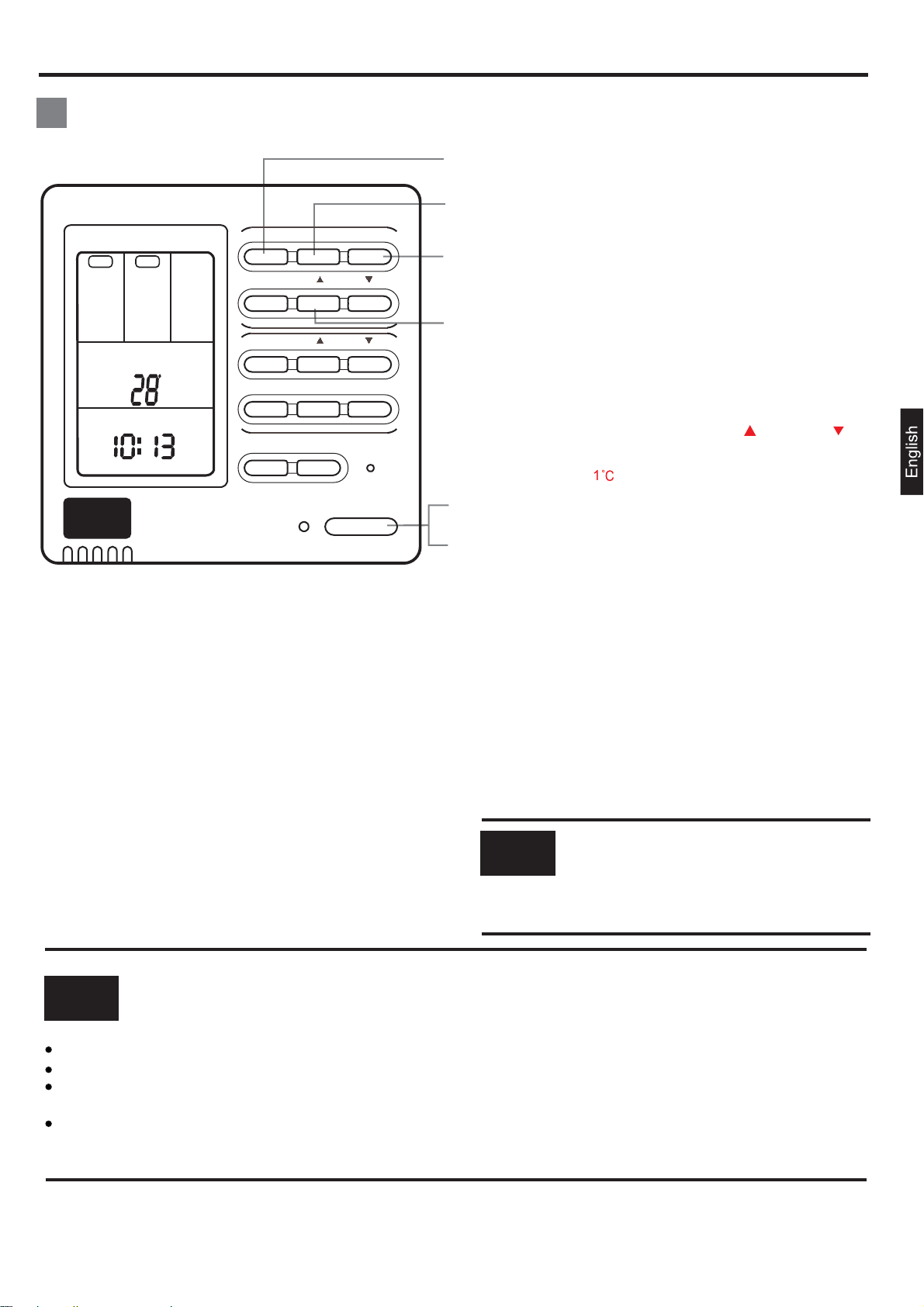

Buttons of the wire controller

Mode switch

Choose running mode

Health switch

Used to control oxygen

function and negative ion

MODE

AUTO

FAN ONLY

COOL

DRY

HEAT

TES

HEALTH

UNIT NO.

CEN. ADD.

SYS. ADD.

CLOCK UP DOWN

TIMER

ON

OFF

DAILY

FAN

AUTO

HIGH

MED

LOW

FIX

CHECK

DEMAND

OPERATION

ROOM TEMP.

C

SET TEMP.

F

VENTILATION

RECOVERY

CENTRAL

STANDBY

PRE-HEAT

DEFROST

FILTER

SWING

MANUAL

AUTO

NORMAL

MODE FAN SWING

HEALTH

CLOCK

TIMER

CHECK FILTER

ON/OFF

TEMP

TIME

SET RECOVERY

RESET

Fan speed switch

Change wind speed

Swing switch

Open and close air flap

TEMP switch

Used for changing set

temperature

Time switch

It is used to regulate setting time.

Clock, timing and address setting

Air change switch

It is used to open and close air

change function. The mode is as

follows:

No display-air change (automatic)air change (RECOVERY)-air

change (NORMAL)

Timing switch

It is used for choosing

timing running

Self-inspection

switch

It is used for inspection

service

Filter reset

After cleaning air inlet

and filter, press

this switch. The unit

begins to run

ON/OFF switch

Do on and off function. The unit is

on when pressing it; and is off

when pressing it again (needn't to

open front cover)

Reset key

When in abnormal state, push the

reset key with a spike, which may

return the unit to normal

7

Page 10

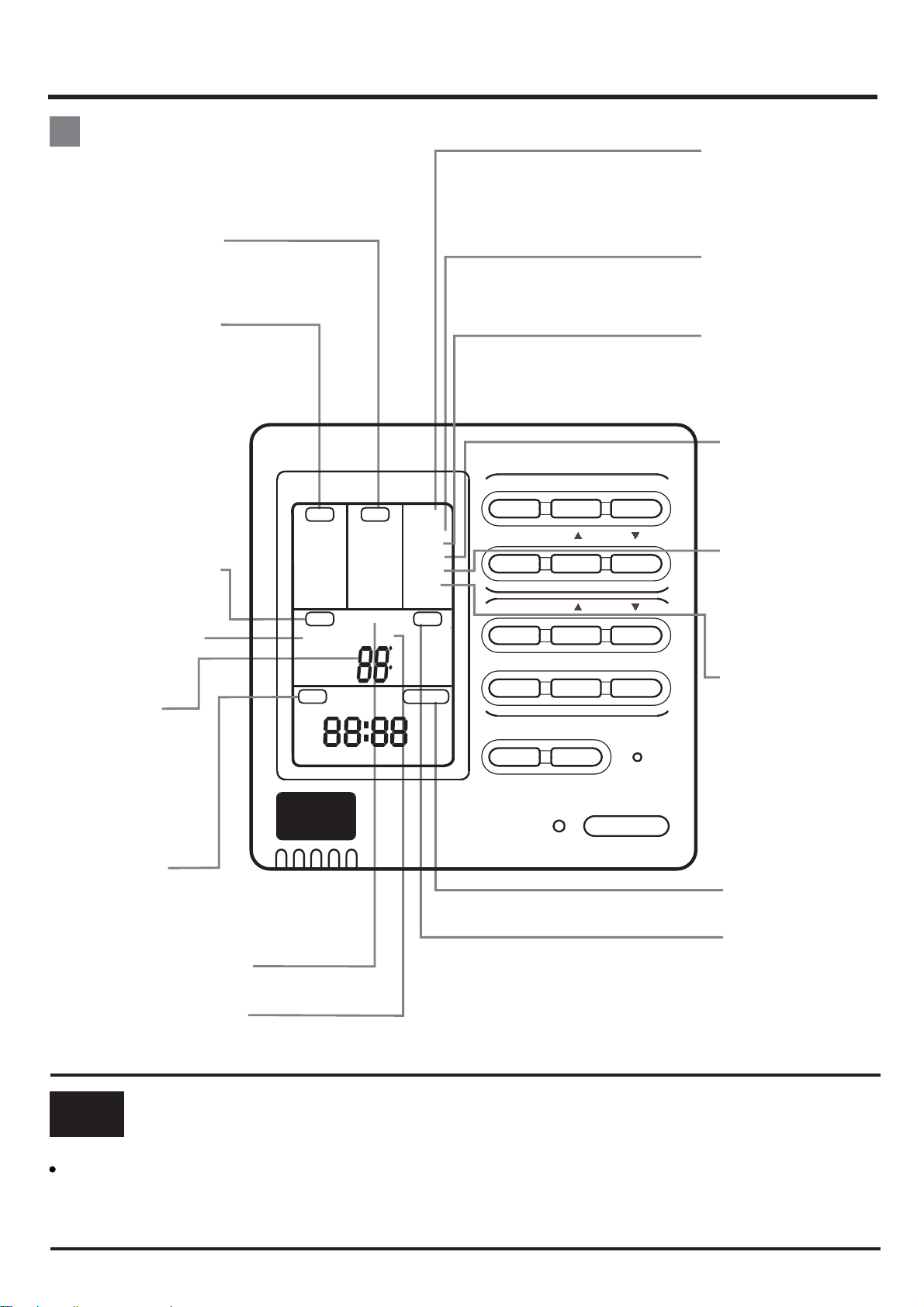

Parts and Functions

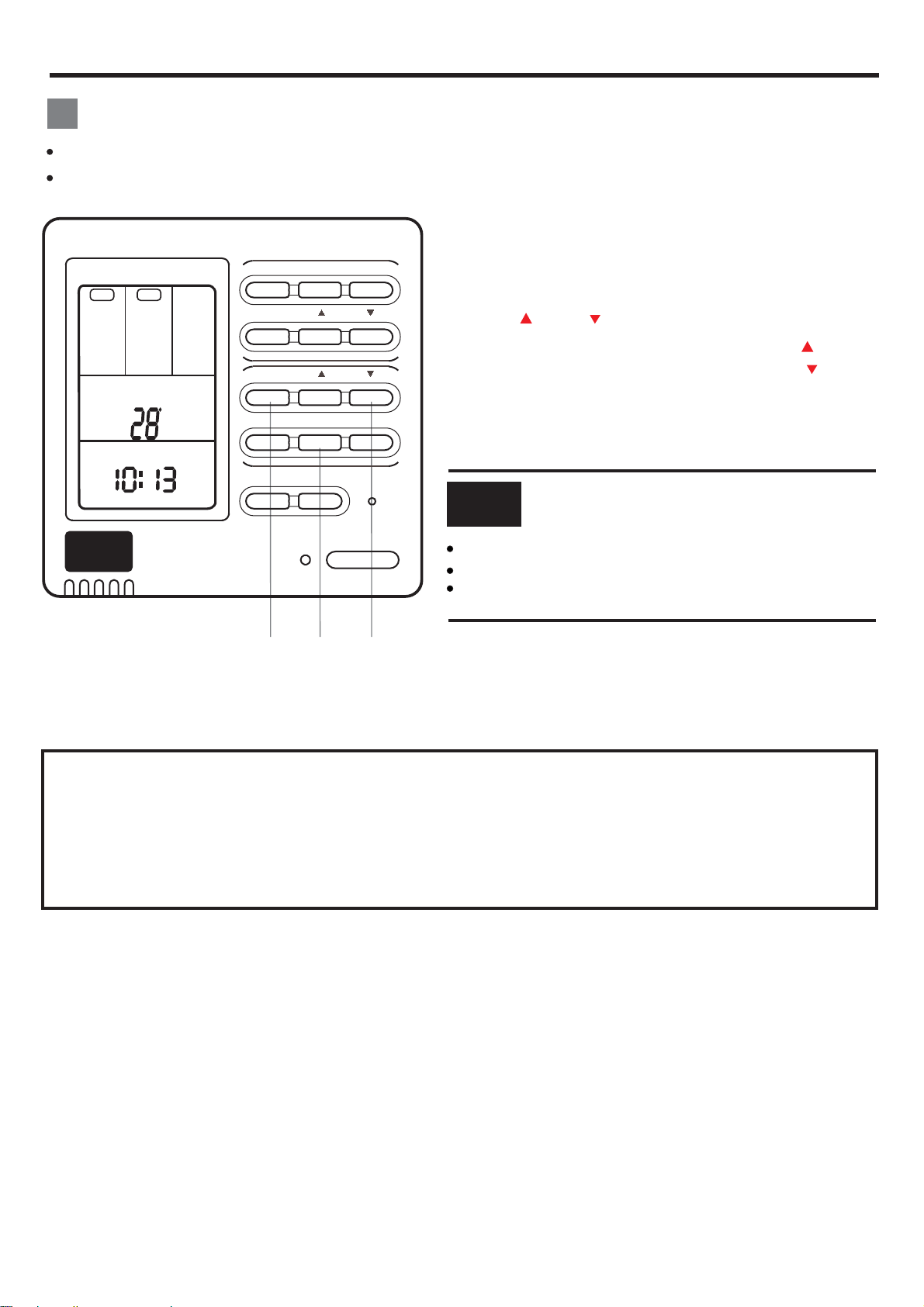

Display of the wire controller

Air volume display

Display the setting speed

Running mode display

Show the selected mode

FAN ONLY

Health function display

Unit number display

Temperature

display

Display the room

temperature, setting

temperature, and

unit number

Timing operation

display

Show timing operation

content

UNIT NO.

CEN. ADD.

SYS. ADD.

TIMER

OFF

DAILY

MODE

AUTO

COOL

DRY

HEAT

TES

HEALTH

CLOCK UP DOWN

ON

FAN

AUTO

HIGH

MED

LOW

FIX

CHECK

DEMAND

C

F

CENTRAL

OPERATION

STANDBY

PRE-HEAT

DEFROST

FILTER

SWING

MANUAL

ROOM TEMP.

SET TEMP.

VENTILATION

AUTO

RECOVERY

NORMAL

MODE FAN SWING

HEALTH

CLOCK

TIMER

CHECK FILTER

ON/OFF

TEMP

TIME

SET RECOVERY

RESET

Centralized display

When controlled by

centralized controller, this

information is shown.

Running display

When the compressor

runs, it displays.

Standby display

When the unit is on

power and in

standby mode,"standby"

is shown.

When in preheating

status, "preheating" is

shown.

After heating, "defrost"

is shown when

defrosting.

Filter screen warning

sign

When the sign is

shown, please clean

the filter screen

Air change display

Inspection status display

Demand display

When forced to run,"DEMAND"

will be displayed.

Remarks

The models in the manual don't have health, filter reset and Air change function.

8

Wind swing display

Page 11

Operation

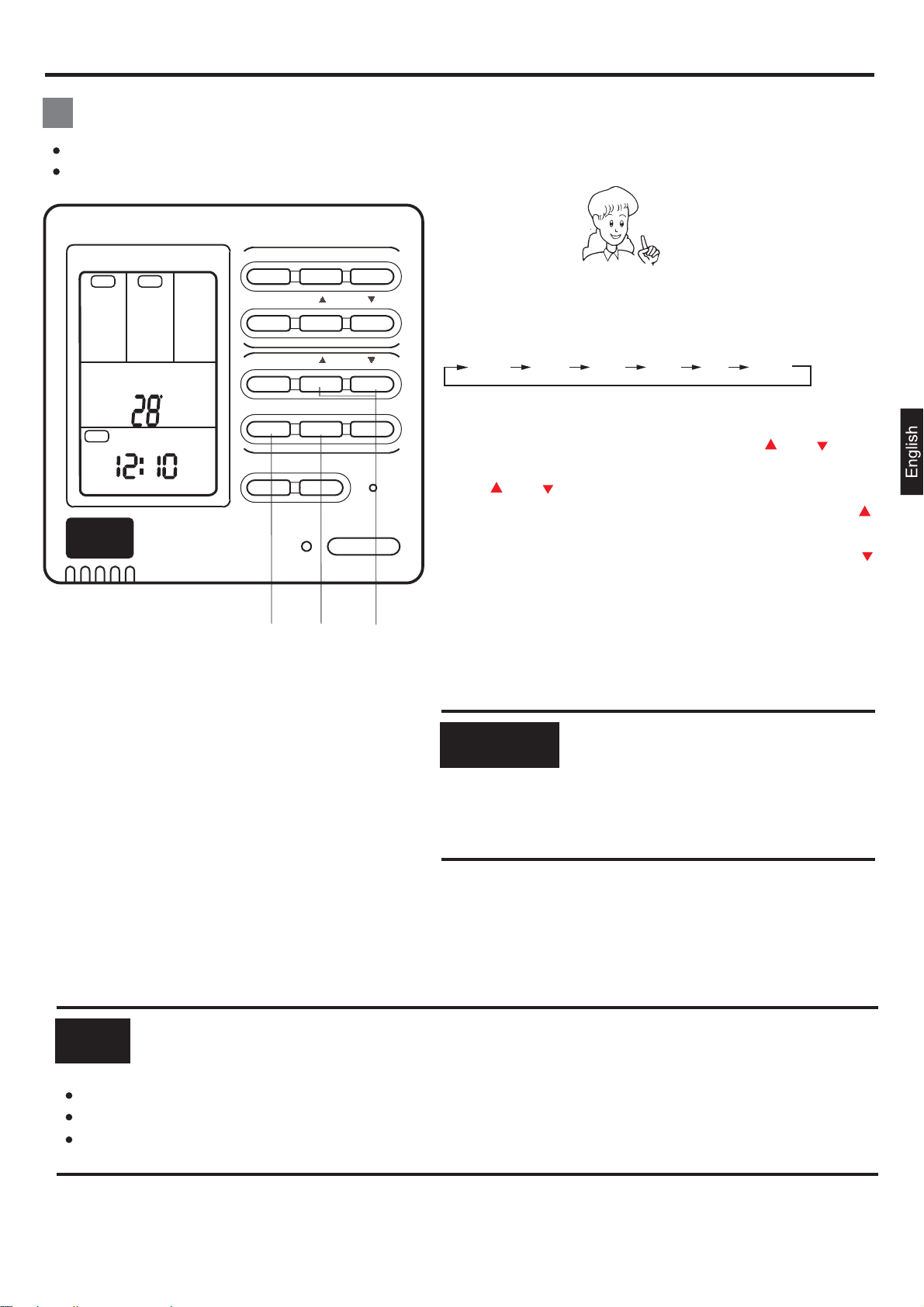

ON/OFF operation

CLOCK

FAN

HIGH

OPERATION

ROOM TEMP.

C

MODE

COOL

MODE FAN SWING

HEALTH

CLOCK

TIMER

CHECK FILTER

ON/OFF

TEMP

TIME

SET RECOVERY

RESET

Press ON/OFF switch on line controller directly

2

The line controller displays the running state in the latest

4

time (timing and swing state may not be displayed).

1. Press "ON/OFF" switch.

5

The air conditioner starts operating, and the light on the

wired controller is on.

3

2.Choose operation mode.

Press "mode"switch to change to

"AUTO"---"FAN ONLY"---"COOL"---"DRY"---"HEAT".

3.Press "TEMP" switch

Change set temperature:press" TEMP " or "TEMP "

every time, [SET] will display,and set temperature will

increase/reduce

1

4.Press "FAN SPEED" switch

FAN ONLY Operation:

6

Press "FAN SPEED" switch to change to

"HIGH"--"MED"--"LOW"--"HIGH"

In AUTO,COOL,DRY,HEAT Operation:

Press "FAN SPEED" switch to change to

"AUTO"--"HIGH"--"MED"--"LOW"--"AUTO"

5.Press "swing" switch on the line controller to

swing the wind screen.

6.Press "ON/OFF"switch, off.

The light on the line controller is off.

Note

Several seconds after the operation of the line controller,

the setting of the unit will change.

Remarks

Avoid pressing "ON/OFF" switch frequently.

Do not press line controller or switches by sharp objects.

The temperature is on the basis of the setting value. The wind temperature may not reach the setting value because of

the outer air conditioner and system protection.

When the wired controller is power on, the screen fully displays it for two seconds. and clock zone "8888"-"888"-"88""8" flicker for 30 seconds. All the switches are invalid at the time.

9

Page 12

Operation

Present time setting

The timing is based on the real time. Thus, the real time should be regulated in advance.

The clock regulation steps are as follows:

1.Press "CLOCK" switch

"CLOCK" flickers, and the time displayed is the real time.

2.Press " " and " " to regulate the time.

MODE

FAN

HIGH

OPERATION

MODE FAN SWING

HEALTH

TEMP

HEAT

TIME

SET RECOVERY

RESET

CLOCK UP

ROOM TEMP.

C

CLOCK

TIMER

CHECK FILTER

ON/OFF

123

Setting of power failure compensation function

The time increases a minute each time you press " " switch.

The time decreases a minute each time you press " " switch.

3.Press "setting" switch. The setting is achieved.

Notes

If not in timing, the screen displays the real time.

If in timing, the screen displays the timing time.

If you want to know the real time, go to the first step.

When SW1-6 on PCB of wire controller is OFF, it will be in power failure compensation. If the SW1-6 is ON, it has no

compensation function.

When the power is on after blackout, the unit will return to the former state if compensation function is set. Otherwise, it

will stop. When restarting the unit, press "ON/OFF" switch on wired controller.

10

Page 13

Operation

Timing setting

OFF timing: when a set time has elapsed, the unit stops running.

ON timing: when a set time has elapsed, the unit starts.

MODE FAN SWING

MODE

COOL

TIMER

ON

FAN

HIGH

ROOM TEMP.

C

OPERATION

HEALTH

CLOCK

TIMER

CHECK FILTER

ON/OFF

SET RECOVERY

123

TEMP

TIME

RESET

1.Press "TIME" switch.

The display changes with the following sequence:

2.Set up "TIMER"

When timing ON or timing OFF flickers, press " " or " " to

regulate the time

Press" "or " "set up ON/OFF time.

The setting time increases ten minutes each time you press " "

switch.

The setting time decreases ten minutes each time you press " "

switch.

When setting timing ON and timing OFF at the same time,

press "timing" switch to change the setting item.

3.Time setting is achieved. Press"setting"switch.

ON

OFF

on

OFF

Press "ON/OFF" switch firstly,

and set up operation mode.

Please regulate the clock in

advance before using the

timing function.

on

OFF

CYCLE

no display

Cancel timing

If you want to change the timing mode to normal operation,

press "timing" until there is no timing display. When the

timing is invalid, the mode is in normal operation.

parts of wired controller explanation :

1.The unit starts or stops at the setting time. Meanwhile, it displays the timing time.

2."ON Timing, OFF timing and circulation"means that the unit is on and off at the setting time everyday.

Notes

The shorter setting time will be carried out firstly.

If the ON timing and OFF timing are the same, the setting is invalid.

Even in timing condition, you may start or close the unit through pressing "ON/OFF" switch.

11

Page 14

Operation

Query indoor malfunction history:

In the state of power on or power off, press [CHECK] button, enter the malfunction-querying mode of all indoor units in

the group. Then [CHECK] and [UNIT NO.] will display, and the actual indoor numbers will be displayed in some sequence

(unit number is in decimals). At the same time, in the time region, there will be the current malfunction and the latest time

malfunction, the displaying format is [XX:YY], in which XX stands for the current malfunction, if normal, it will display "--";

YY stands for the latest time malfunction. The failure code of every unit will display for 3 seconds. After the failure codes

of all indoor units in the whole group are displayed, the mode will quit automatically.

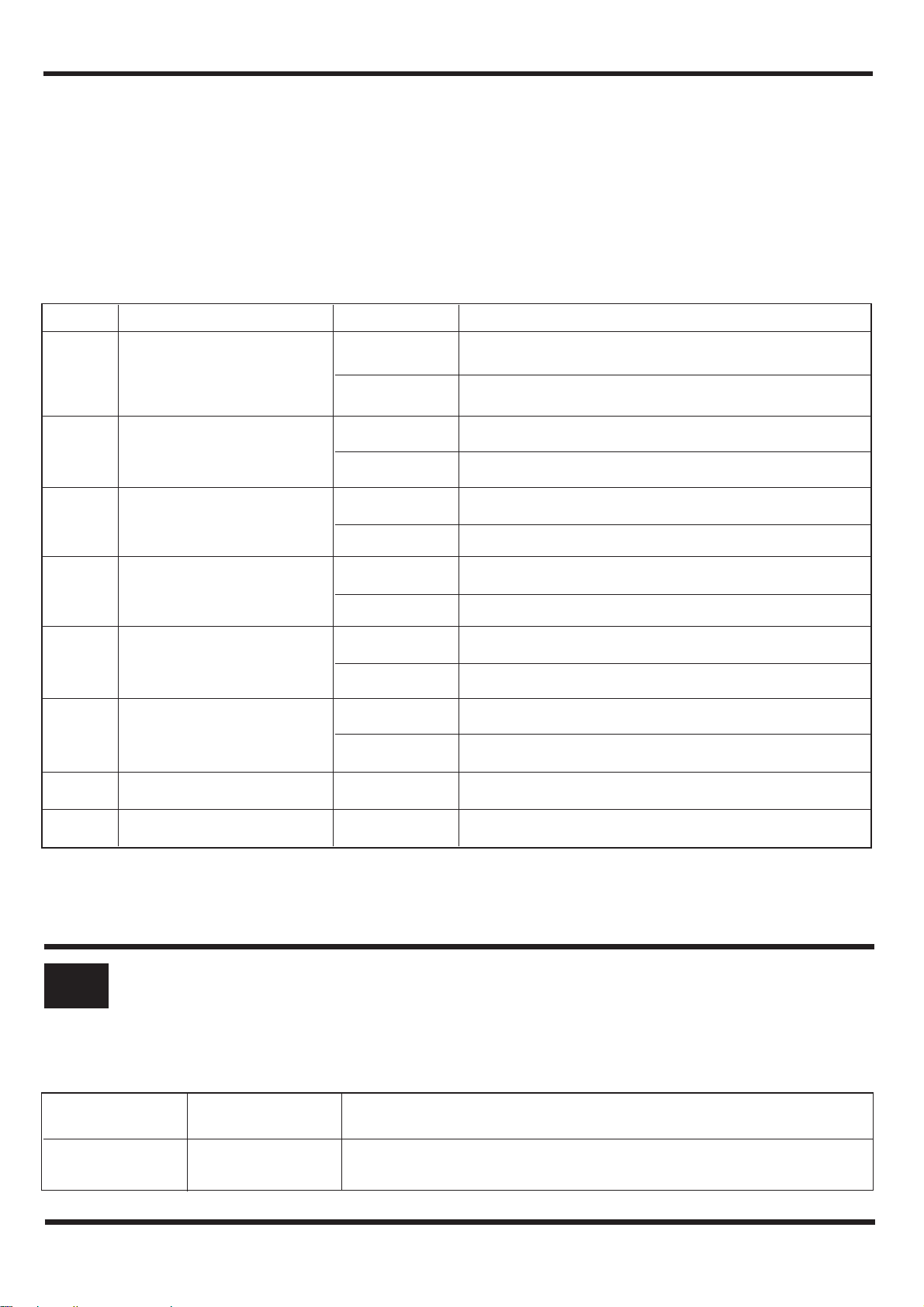

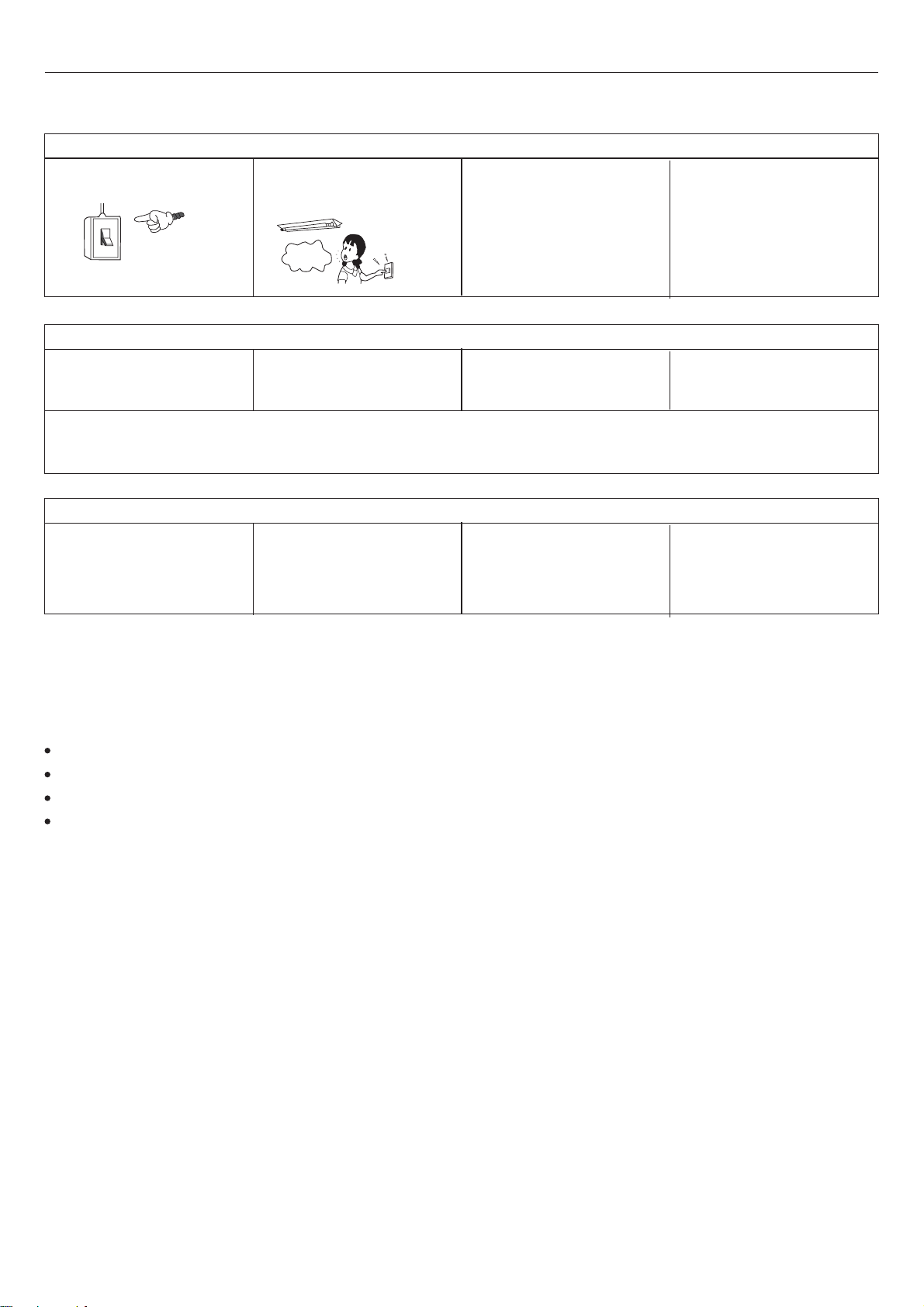

How to change the function switches?

No. Type State of switch Function description

SW1-1

SW1-2

SW1-3

SW1-4

SW1-5

SW1-6

Select the master or

the slave controller

Select the controller

mode

Room temperature

display option

o

26

lock

Temperature sensor

position option

Auto restart

Factory Seting ON default settingSW1-7

ON set as the slave controller

OFF set as the master controller

ON

OFF

ON

OFF

ON

OFF

ON

OFF

standard controller

air handler controller

visible room temperature

invisible room temperature

o

lock

o

lock

Unavailable 26

available 26

Sensor of the controller

Sensor in the unit

ON unavailable

OFF

available

Factory Setting OFF default settingSW1-8

Notes

1. Switches or jumper wire must be adjusted when the wire controller is powered off. If the wire controller is

powered on, the above operations will be invalid.

2. Function difference between master wire controller and slave one:

Contrastive

items

Master wire

controller

Function All of functions

Slave wire controller

Only with below functions: ON/OFF, MODE, FAN

SPEED, SET TEMP., SWING

12

Page 15

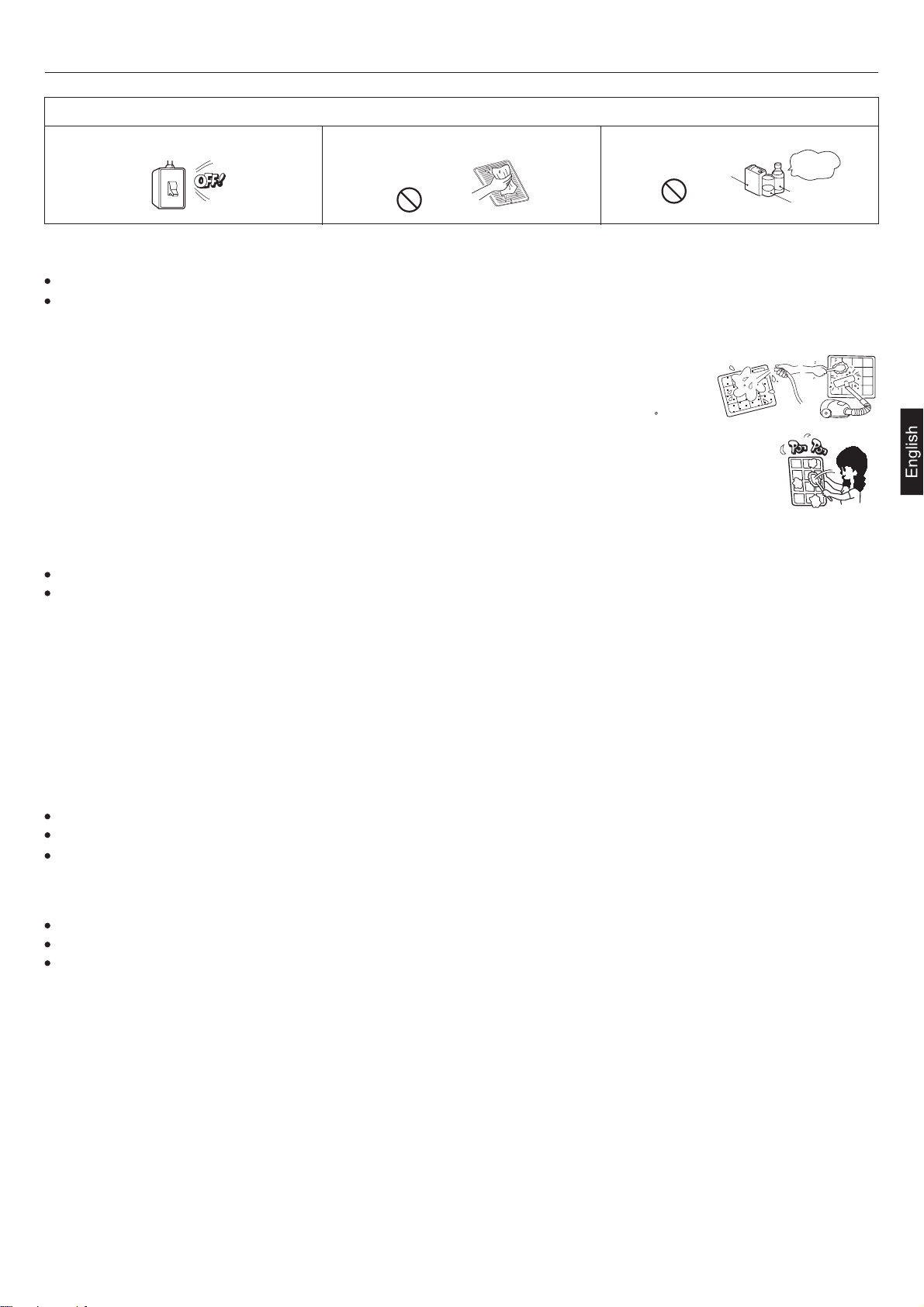

Installation Manual For Wire Controller

1. Take down wire controller from the holder

2. Install the controller holder

According to the position of 2 screw holes on the

FAN ONLY

CEN. ADD.

SYS. ADD.

TIMER

DAILY

HEALTH

UNIT NO.

ON

OFF

MODE

AUTO

COOL

DRY

HEAT

TES

FAN

AUTO

HIGH

MED

LOW

FIX

CHECK

DEMAND

CLOCKUP DOWN

C

F

CENTRAL

OPERATION

STANDBY

PRE-HEAT

DEFROST

SWING

MANUAL

ROOM TEMP.

SET TEMP.

VENTILATION

RECOVERY

NORMAL

FILTER

AUTO

MODE FAN SWING

TEMP

HEALTH

TIME

CLOCK

SET RECOVERY

TIMER

CHECK FILTER

RESET

Wire controller

52¡ 0.2

Bracket

10.45

holder, drill 2 holes on the wall, and strike the wood

stopper to the holes respectively.

Then align the 2 screw holes of wired controller

holder to the wood stopper, fix the holder on the wall

5.3

with wood screw.

Note:Try a wall as flat as possible for installation.

ON/OFF

Screw holes

Don't use excessive force to tighten screws,

otherwise, the holder will be damaged.

3.Wiring instruction

Use shielded wire between indoor and wire controller.And be earthed on one side, or the unit will not work normally

because of interference.

Note:Confirm the terminal connection firmly, and do not get in tough with shielded wire.

4.Place wire controller on the holder, and pay attention not to pressing any wires.

5. Wiring connections of wire controller:

A

Wire controller

A B C

Indoor 15Indoor NIndoor 2Indoor 1

Indoor 16

Wire controller Wire controller Wire controller Wire controller

A B C A B C A B C A B C

(master unit)

BC

Indoor 1

Wire controller

Polar wire

Wire controller

A B C A B C

A B C

Indoor 1

Wire controller

Polar wire

Wire controller

A B C

Control wiring

of wire

controller,

polar.

Polar wire

A B C

Wire controller

A B C

Wire controller

There are three methods to connection wire controller and the indoor units:

A.One wired controller can control max. up to 16 sets of indoor units, and 3 pieces of polar wire must connect the wire

controller and the master unit (the indoor unit connected with wire controller directly), the others connect with the master

unit through 2 pieces of polar wire.

B. One wire controller controls one indoor unit, and the indoor unit connects with the wire controller through 3 pieces of

polar wire.

C. Two wired controllers control one indoor unit. The wire controller connected with indoor unit is called master one, the

other is called slave one. Master wire controller and indoor unit; master and slave wire controllers are all connected

through 3 pieces of polar wire.

6. Communication wiring:

The wire controller is equipped with special communication wiring in the accessories. 3-core terminal (1-white 2-yellow

3-red) is connected with the terminal A, B, C of wire controller respectively.

The communication wiring is 5 meter long; if the actual length is more than it, please distribute wiring according to below

table:

Communication wiring length(m) Dimensions of wiring

< 100 0.3mm2x3-core shielded wire

100 and <200 0.5mm2x3-core shielded wire

200 and <300 0.75mm2x3-core shielded wire

2

300 and <400 1.25mm

400 and <600 2mm

x3-core shielded wire

2

x3-core shielded wire

*One side of the shielded sheet of communication wire must be earthed.

13

Page 16

Heating Mode

"HOT KEEP" function

"HOT KEEP"is operated in the following cases.

When heating is started:

In order to prevent blowing out of cool wind, the indoor unit fan stopped according to the room temperature which heating

operation is started. Wait for approx. 2 to 3 minute, and the operation will be automatically changed to the ordinary heating

mode.

Defrosting operation (in the heating mode):

When it is liable to frost, the heating operation is stopped automatically for 5 to 12 minutes once per approx. one hour,

and defrosting is operated. After defrosting is completed, operation mode is automatically changed to ordinary heating

operation.

When the room thermostat is actuated:

When room temperature increases and room temperature controller actuates, the fan speed is automatically changed to

stop under low temperature condition of indoor heat exchanger. When room temperature decreases, air conditioner

automatically changes over to ordinary heating operation.

Warming Operation

Heat pump type warming

With the heat pump type warming, the mechanism of heat pump that concentrate heat of outdoor air with the help of

refrigerant to warm the indoor space, is utilized.

Defrosting operation

When a room is warmed with a heat pump type air conditioner, frost accumulates on the heat exchanger of outdoor unit

along with the drop of indoor temperature. Since the accumulated frost reduces the effect of warming, it is necessery to

automatically switch the operation to the defrosting mode. During the defrosting operation, heating operation is interrupted.

Atmospheric temperature and warming capacity

Warming capacity of heat pump type air conditioner decreases along with the drop of outdoor temperature. When the

warming capacity is not sufficient, it is recommended to use another heating implement.

Period of warm-up

Since the heat pump type air conditioner employs a method to circulate warm winds to warm

the entire space of a room, it takes time before the room temperature rises.

It is recommendable to start the operation a little earlier in a very cold morning.

14

Page 17

Care and Maintenance

Points to observe

Turn off the power supply switch. Do not touch with wet hand. Do not use hot water or volatile liquid.

Do not

use!

Benzine

Tooth powder

ON

OFF

CAUTION

Do not open the inlet grill until fan stops completely.

Fan will continue rotating for a while by the law of inertia after operation is being stopped.

Cleaning the air filter

1.Clean the air filter by lightly tapping it or with the cleaner. It is more effective to clean

the air filter with water.

If the air filter is very dirty, dissolve neutral detergent in the lukewarm water (approx. 30 C),

rinse the air filter in the water, and thoroughly wash the air filter off the detergent

in the plain water.

2.After drying the air filter, set it up on the air conditioner.

Thinner

CAUTION

Do not dry the air filter with fire.

Do not run the air conditioner without the air filter.

Care and Cleaning of the unit

Clean with soft and dry cloth.

If it is very dirty, dissolve neutral detergent in the lukewarm water and make the cloth wet with the water. After wiping,

clean off the detergent using clean water.

Post-Season Care

Operate the unit with FAN mode on a fair day for about half a day to dry the inside of the unit well.

Stop operation and turn off the power supply switch. Electric power is consumed even the air conditioner is in stop.

Clean the air filter and set it in the place.

Pre-Season Care

See that there are no obstacles blocking the air inlet and air outlet of both indoor and outdoor units.

Make sure that the air filter is not dirty.

Cut in the power supply switch 12 hours before starting run.

15

Page 18

Troubleshooting

Please check the following things about your air conditioner before making a servie call.

Unit fails to start

Is the power source switch

adjust cut in?

ON

OFF

Power supply switch is not

ON.

Is city supply power in normal? Isn't the signal receiving

section exposed to the direct

sunlight or strong illumination?

Power

stoppage?

Cooling or heating is not sufficient

Isn't the earth leakage breaker

in action?

It is dangerous. Turn off the

power supply switch

immediately and contact the

sales dealer.

Is the thermostat adjust as

required?

Isn't the air filter dirty? Isn't any doors or windows

left open?

Doesn't any obstacle exist at

the air inlet or outlet?

Isn't the swing louver horizontal? (At HEATING mode)

If swing louver is horizontal, the blow wind does not reach floor.

Cooling is not sufficient

Isn't sun-shine invading direct? Isn't any unexpected heating

load generated?

Isn't the room much crowded?

The wind does not blow during

heating operation

Isn't it warming up?

When the air conditioner does not operate properly after you have checked the above mentioned items or when the following

phenomenon is observed, stop the operation of the air conditioner and contact your sales dealer.

The fuse or breaker often shuts down.

Water drops off during cooling operation.

There is a irregularity in operation or abnormal sound is audible.

When the CHECK LED1 (red) flickers, an irregularity has occurred in the air conditioner.

16

Page 19

Troubleshooting

The followings are not malfunction

Water flowing sound is heard.

Shuru

Shuru

When the air conditioner is started, when the compressor starts or stops during

operation or when the air conditioner is stopped, it sometimes sounds "shuru shuru"

or "gobo gobo". It is the flowing sound of the refrigerant, and it is not a trouble.

This is caused by heat expansion or contraction of plastics.Cracking sound is heard.

It smells. Air which blows out from the indoor unit sometimes smells. The smell results from

residents of tobacco smoke or cosmetics stuck inside of unit.

During operation, white fog comes

out of indoor unit.

When the air conditioner is used at restaurant etc. where dense edible oil fume is

always exists, white fog sometimes blows out of air outlet during operation. In this

case consult sales dealer for cleaning the heat exchanger.

It is switched into the FAN mode

during cooling.

To prevent frost from being accumulated on the indoor unit heat exchanger, it is

sometimes automatically switched to the FAN mode but it will soon return to the

cooling mode.

The air conditioner can not be

restarted soon

after it stops.

Unit does

not start

Air does not blow or the fan speed

can not be changed during

Even if the operation switch is turned on, cooling, dehumidifying or heating is not

operable for three minutes after the conditioner is stopped. Because the

protecting circuit is activated (During this time air conditioner operates

in fan mode).

Wait for

three

minutes

When it is excessively cooled during dehumidifying, the blower automatically repeats

reducing and lowering the fan speed.

dehumidifyin.

During operation, operation mode

has changed over automatically.

Water or steam generates from

the outdoor unit during heating.

Isn't the AUTO mode selected?

In the case of AUTO mode, operation mode is changed automatically from cooling

to heating or vise-versa according to the room temperature.

This results when frost accumulated on the outdoor unit is removed (during defrosting

operation).

17

Page 20

Troubleshooting

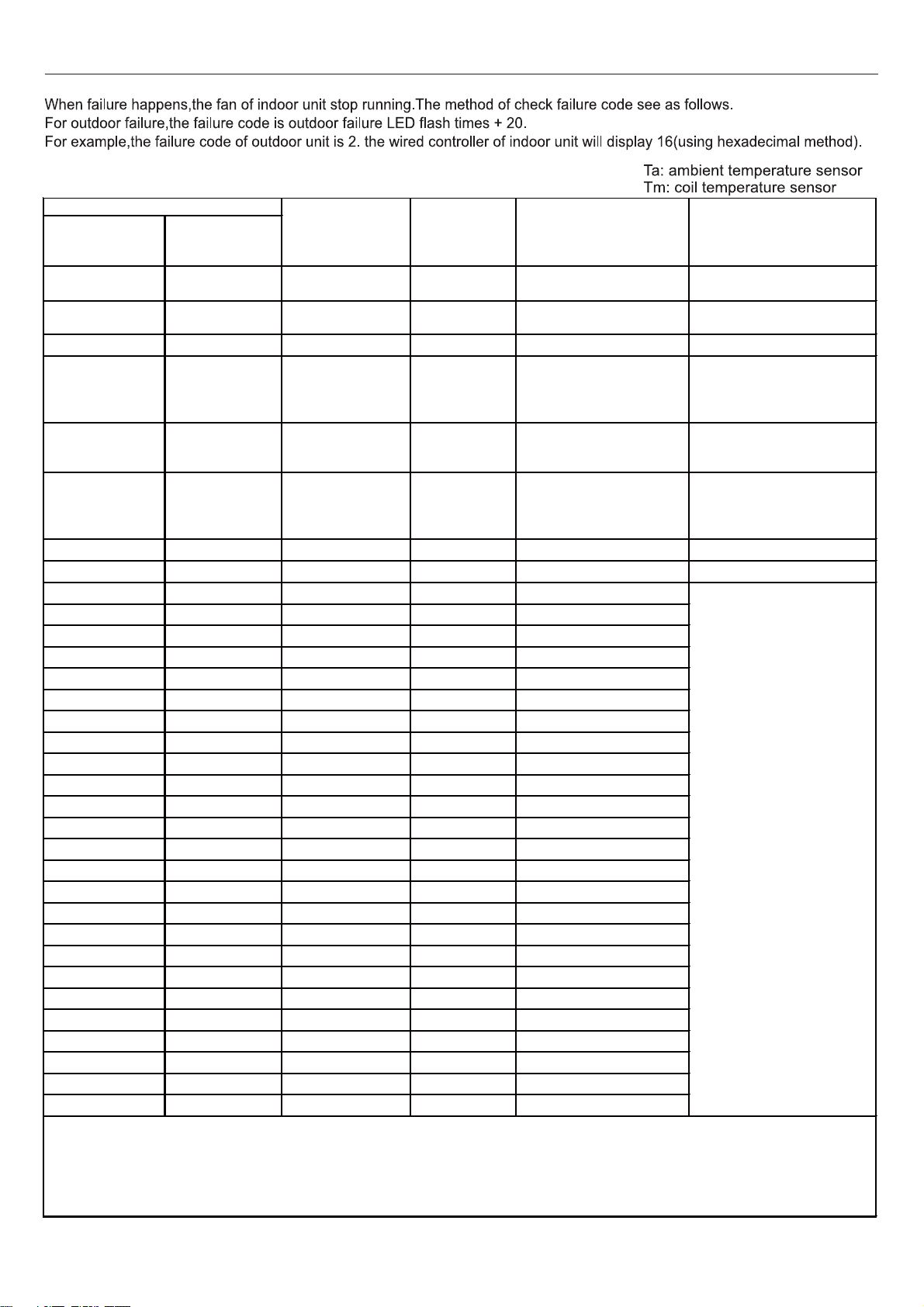

Failure code(from receive board) Failure code(from wired

Flash times of

Timing LED(or

indoor PCB LED4)

0 1 01 E1 Temperature sensor Ta faulty Sensor disconected,or broken,or

0 2 02 E2 Temperature sensor Te faulty Sensor disconected,or broken,or

0 4 04 F8 EEPROM WRONG Faulty indoor unit PCB

0707E9Abnormal communication

08NO EEROR

0 12 0C E0 Drainage system abnormal Pump motor disconnected,or at

0 13 OD EF Zero cross sigal wrong Zero cross sigal detected wrong

0 16 10 F3 Indoor mode abnormal Different from outdoor unit mode

2 1 15 / Outdoor unit abnormal

2 2 16 / Outdoor unit abnormal

2 4 18 / Outdoor unit abnormal

2 5 19 / Outdoor unit abnormal

2 7 1B / Outdoor unit abnormal

2 8 1C / Outdoor unit abnormal

2 9 1D / Outdoor unit abnormal

3 0 1E / Outdoor unit abnormal

3 1 1F / Outdoor unit abnormal

3 2 20 / Outdoor unit abnormal

3 3 21 / Outdoor unit abnormal

3 5 23 / Outdoor unit abnormal

3 6 24 / Outdoor unit abnormal

3 7 25 / Outdoor unit abnormal

3 8 26 / Outdoor unit abnormal

3 9 27 / Outdoor unit abnormal

4 3 2B / Outdoor unit abnormal

4 4 2C / Outdoor unit abnormal

4 7 2F / Outdoor unit abnormal

4 8 30 / Outdoor unit abnormal

4 9 31 / Outdoor unit abnormal

5 8 3A / Outdoor unit abnormal

5 9 3B / Outdoor unit abnormal

6 3 3F / Outdoor unit abnormal

6 4 40 / Outdoor unit abnormal

1. For the indoor failure,only running LED ON remote receiver will indicate.

2. For the outdoor failure,timer LED and running LED will indicate.timer LED of remote receiver stands for ten's place,and running LED stands for one's

place.timer LED will flash firstly,2 seconds later,running LED will flash too. Afer that,4 seconds later,they will flash in turns again.Flash times equals to the

failure code of outdoor plus.

20.For example,failure code of outdoor is 2,the indoor unit should display 22.As a result,timer LED flashes twice firstly,then running LED flashes twice.

3.To get much more details of outdoor unit failure,Please refer to the the outdoor unit trouble shooting list.

Flash times of

Running LED(or

indoor PCB LED3)

controller)

CODE DISPLAY

Failure code(from

panel controller)

E8 Abnormal communication

Trouble shooting

between indoor and outdoor

units

between indoor wired controller

and indoor unit PCB

Possible reasons

at wrong position,or short circuit

at wrong position,or short circuit

Wrong connection,or the wires be

disconected,or wrong address

setting of indoor unit,or faulty

power supply or faulty PCB

Abnormal communication between

indoor wired controller and indoor

unit PCB

wrong position,or the float switch

broken down,or the float switch

disconected,or at wrong position.

Refer to the outdoor unit trouble

shooting

list

18

Page 21

Precaution For Installation

Please read these "Safety Precautions" first then accurately execute the installation work.

Though the precautionary points indicated herein are divided under two headings, and , those

points which are related to the strong possibility of an installation done in error resulting in death or serious injury are

listed in the section. However, there is also a possibility of serious consequences in relationship to the

points listed in the section as well. In either case, important safety related information is indicated, so by all

means, properly observe all that is mentioned.

After completing the installation, along with confirming that no abnormalities were seen from the operation tests, please

explain operating methods as well as maintenance methods to the user (customer) of this equipment, based on the owner's

manual. Moreover, ask the customer to keep this sheet together with the owner's manual.

This system should be applied to places as office, restaurant, residence and the like. Application to inferior environment

such as engineering shop could cause equipment malfunction.

Please entrust installation to either the company which sold you the equipment or to a professional contractor. Defects

from improper installations can be the cause of water leakage, electric shocks and fires.

Execute the installation accurately, based on following the installation manual. Again, improper installations can result

in water leakage, electric shocks and fires.

When a large air-conditioning system is installed to a small room, it is necessary to have a prior planned countermeasure

for the rare case of a refrigerant leakage, to prevent the exceeding of threshold concentration. In regards to preparing

this countermeasure, consult with the company from which you perchased the equipment, and make the installation

accordingly. In the rare event that a refrigerant leakage and exceeding of threshold concentration does occur, there is

the danger of a resultant oxygen deficiency accident.

For installation, confirm that the installation site can sufficiently support heavy weight. When strength is insufficient,

injury can result from a falling of the unit.

Execute the prescribed installation construction to prepare for earthquakes and the strong winds of typhoons and

hurricanes, etc. Improper installations can result in accidents due to a violent falling over of the unit.

For electrical work, please see that a licensed electrician executes the work while following the safety standards related

to electrical equipment, and local regulations as well as the installation instructions, and that only exclusive use circuits

are used. Insufficient power source circuit capacity and defective installation execution can be the cause of electric

shocks and fires.

Accurately connect wiring using the proper cable, and insure that the external force of the cable is not conducted to

the terminal connection part, through properly securing it. Improper connection or securing can result in heat generation

or fire.

Take care that wiring does not rise upward, and accurately install the lid/service panel. Its improper installation can

also result in heat generation or fire.

When setting up or moving the location of the air conditioner, do not mix air etc. or anything other than the designated

refrigerant (R410A) within the refrigeration cycle. Rupture and injury caused by abnormal high pressure can result from

such mixing.

Always use accessory parts and authorized parts for installation construction. Using parts not authorized by this company

can result in water leakage, electric shock, fire and refrigerant leakage.

WARNING

CAUTION

WARNING

WARNING

CAUTION

CAUTION

Execute proper grounding. Do not connect the ground wire to a gas pipe, water pipe, lightning rod or a telephone ground

wire. Improper placement of ground wires can result in electric shock.

The installation of an earth leakage breaker is necessary depending on the established location of the unit. Not installing

an earth leakage breaker may result in electric shock.

Do not install the unit where there is a concern about leakage of combustible gas. The rare event of leaked gas collecting

around the unit could result in an outbreak of fire.

For the drain pipe, follow the installation manual to insure that it allows proper drainage and thermally insulate it to

prevent condensation. Inadequate plumbing can result in water leakage and water damage to interior items.

19

Page 22

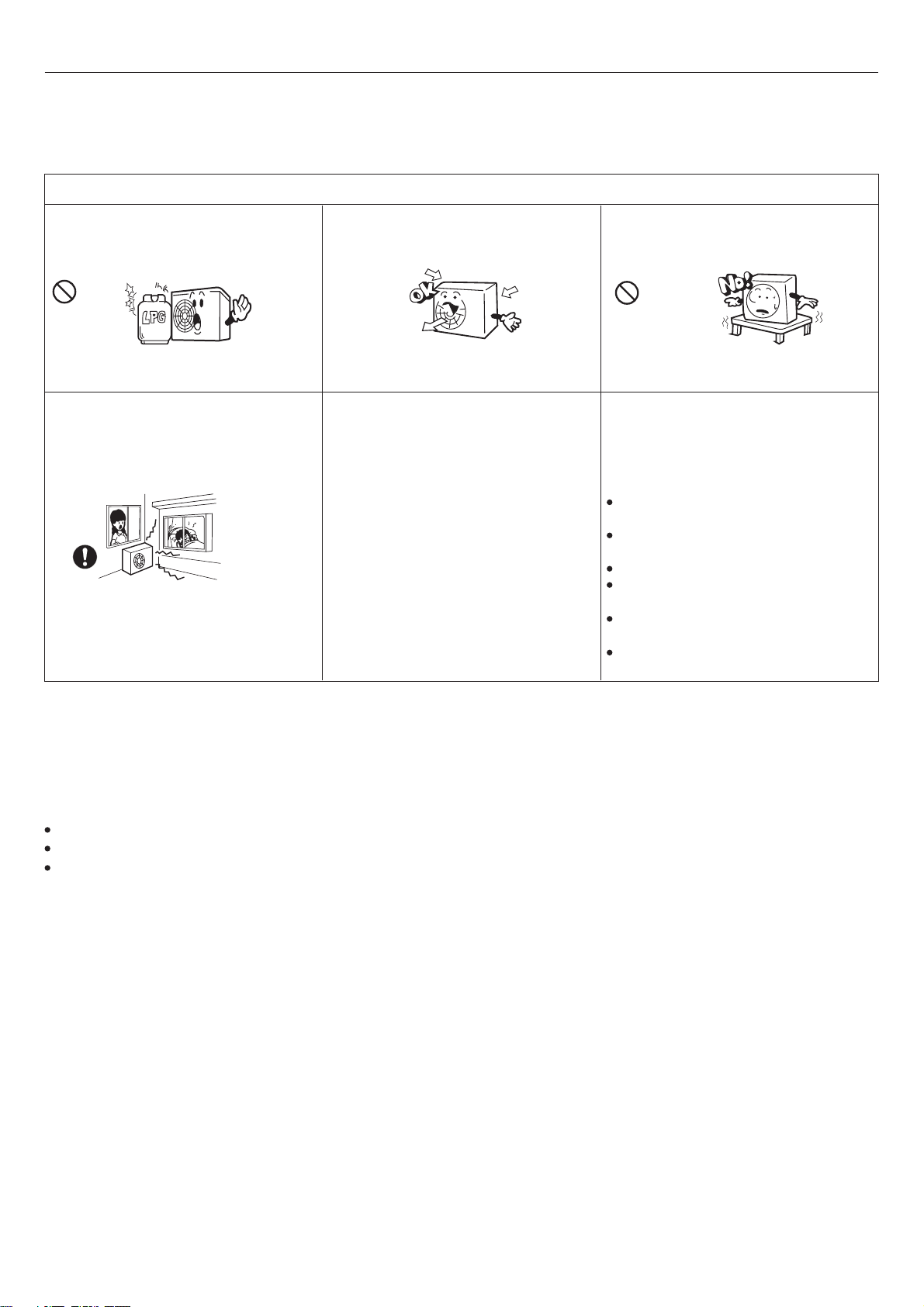

Is The Unit Installed Correctly

Confirm the following items for safe and comfortable use of air conditioner.

The installation work is to be burden on the sales dealer, and do not conduct it by yourself.

Installation place

Avoid installing the air conditioner near

the place where possibility of inflammable

gas leakage exists.

Explosion (Ignition) may occur.

Select the place so as not to annoy

neighbor with the hot air or noise.

Install the unit at well ventilated place. Install the air conditioner firmly on the

foundation that can fully support the

weight of the unit.

If not, it may cause vibration or noise.If some obstacle exist, it may cause

capacity reduction or noise increase.

Snow protection work is necessary

where outdoor unit is blocked up by snow.

It is advisable not to install the air conditioner at the following special place.

It may cause malfunction, consult the

sales dealer when you have to install

the unit on such a place.

For details consult your sales dealer.

The place where corrosive gas generates

(Hot spring area etc.)

The place where salt breeze blows

(Seaside etc.)

The place where dense soot smoke exists

The place where humidity is extraordinarily high

The place where near the machine which

radiates the electromagnetic wave

The place where voltage variation is considerably large

Electric work

The electric work must be burden on the authorized engineer with qualification for electric work and grounding work, and

the work must be conducted in accordance with electric equipment technical standard.

The power source for the unit is to be of exclusive use.

An earth leakage breaker should be installed.(This is necessary to prevent electric shock.)

The unit must be grounded.

When you change your address or the installation place

Special technology is required for removal or reinstallation of air conditioner, consult the sales dealer. Besides, construction

expense is charged for removal or reinstallation.

For inspection and maintenance

The capacity of air conditioner will decrease by contamination of inside of unit when it is used for about three years although

depending upon the circumstances under which it is used, and so in addition to the usual maintenance service, special

inspection/maintenance service is necessary. It is recommended to make a maintenance contract (charged) by consulting

your sales dealer.

20

Page 23

Installation Procedure

Indoor Unit

NOTE

All wiring of this installation must comply with NATIONAL, STATE AND LOCAL REGULATIONS. These instructions

do not cover all variations for every kind of installation circumstance. Should further information be desired or should particular

problems occur, the matter should be referred to your local distributor.

WARNING

BE SURE TO READ THESE INSTRUCTIONS CAREFULLY BEFORE BEGINNING INSTALLATION. FAILURE TO FOLLOW

THESE INSTRUCTIONS COULD CAUSE SERIOUS INJURY OR DEATH, EQUIPMENT MALFUNCTION AND/OR

PROPERTY DAMAGE.

Before installation (Before finishing installation, do not throw the attached parts installation needs)

Confirm the way to move the unit to the installation place.

Before moving the unit to the installation place, do not remove their packages. When having to remove the package, use

a soft material or protection board with rope to lift the unit assembly to avoid unit damage or bumping a scrape.

Choose installation place

The chosen installation place should meet the following requirements and get the user's consent.

Place ensures ideal airflow distribution.

The passage of airflow has no obstacles.

When importing outside air, it should be imported directly from outdoors. (If the pipe can not be extended, it also can not

be imported from top)

Place ensures enough space for maintenance.

The pipe length between indoor and outdoor unit is in the permitted limit (referring to outdoor unit installation part).

The indoor unit, outdoor unit, electric wire and connection wire is at least 1m away from television and radio. This is to

avoid the image disturbance and noise caused by the above mentioned home appliance. (Even if 1m away, if the

electromagnetic wave is too strong, it can also cause noise.)

The indoor unit can install on the ceiling, which height is no more than 3m.

Install and use the hoisting screw. Check if the installation place can bear the weight of unit assembly. If not certain,

strengthen it before install the unit.

Over 100 Over 900

Air out

Air in

Checking meatus

(600x600)

Over 300

Over 200

Ceiling

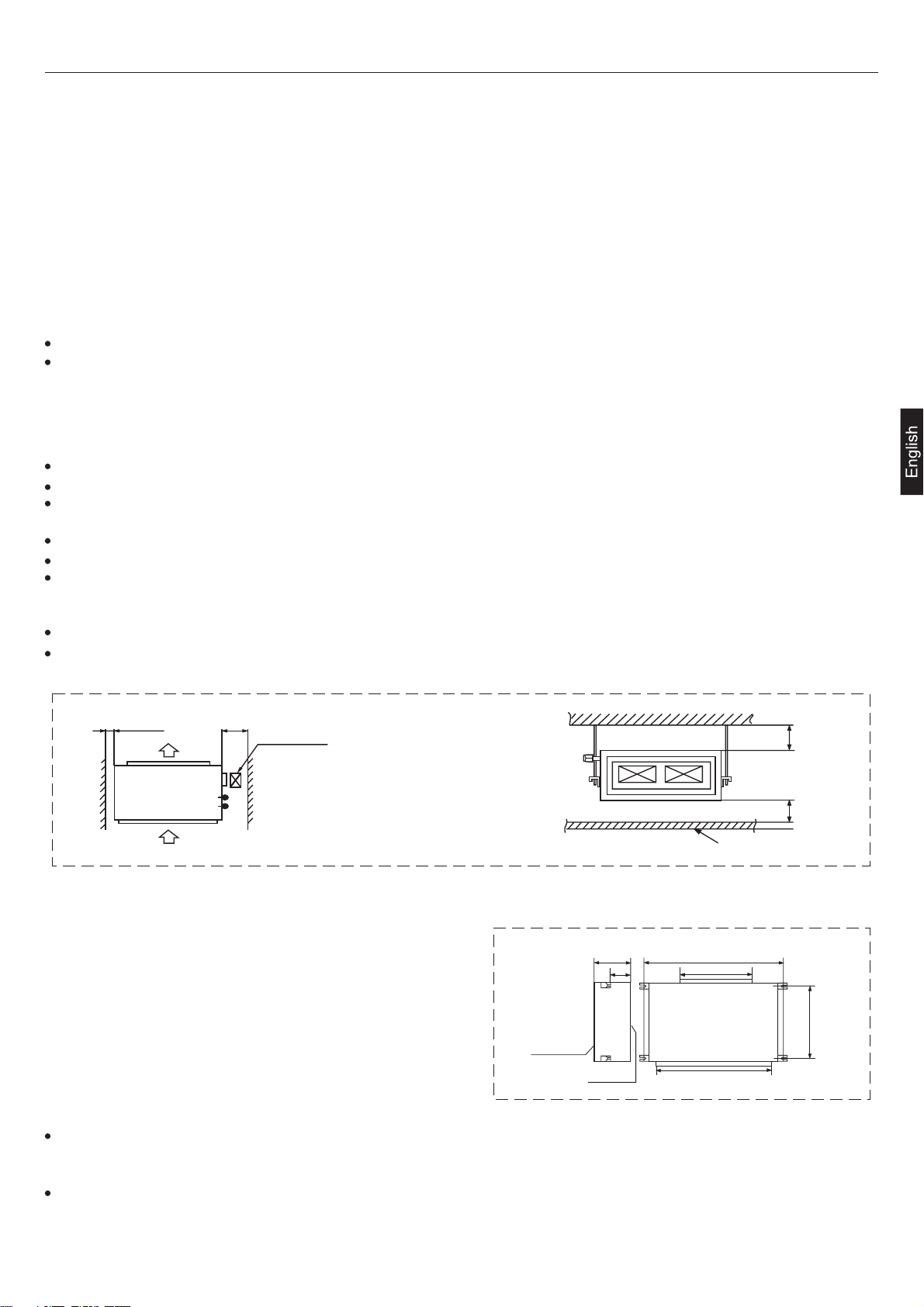

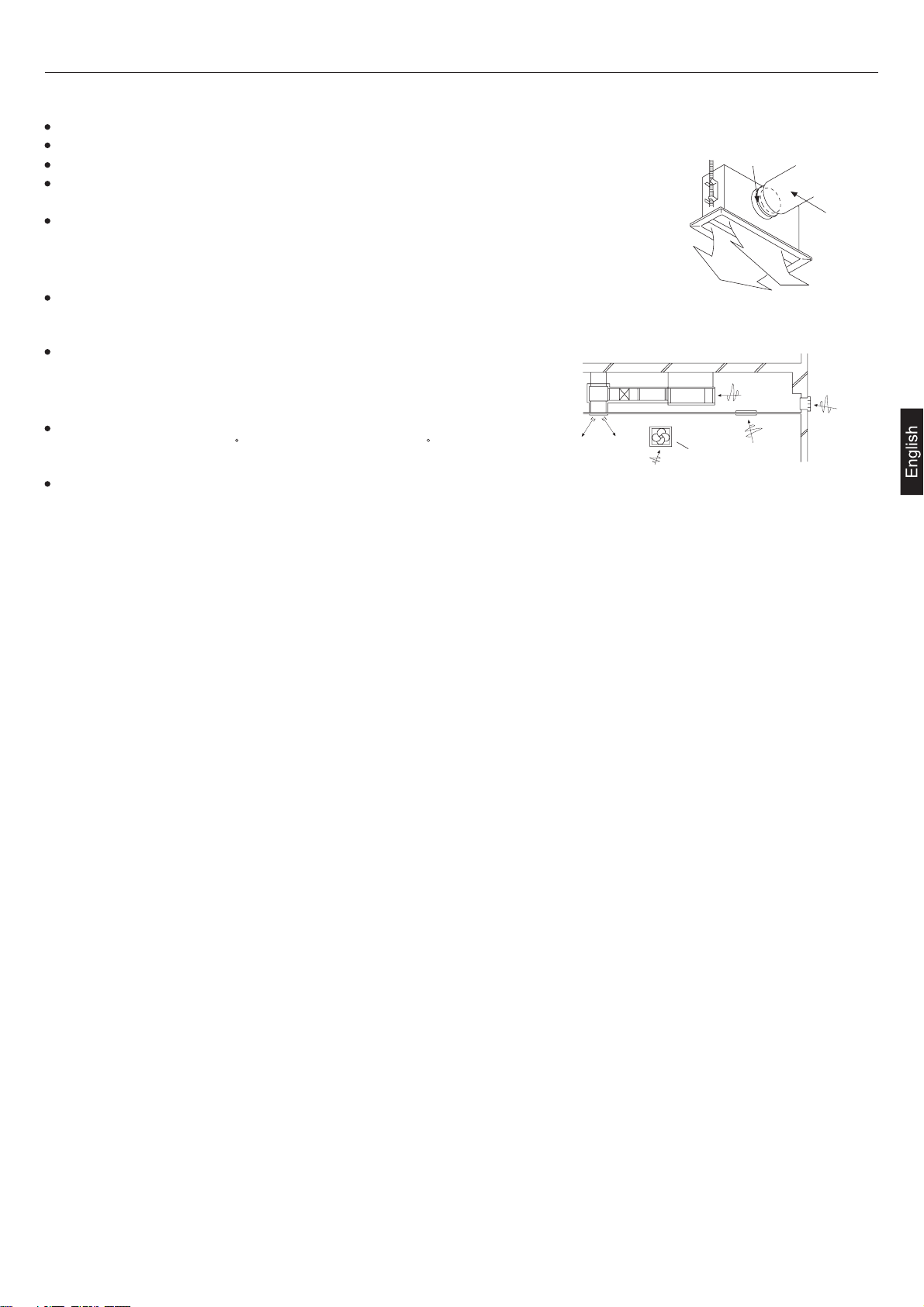

Installation for indoor unit

1.The position relation among hoisting screw (unit: mm)

1270

853

794

1103

Down side

360

250

Up side

2.If necessary, cut the opening installation and checking needed on the ceiling. (If having ceiling)

Before installation, finish the preparation work of all the pipes (refrigerant, drainage) and wire (wire controller connection

wire, indoor and outdoor unit connection wire) of indoor unit, so that after installation, they can be immediately connected

with outdoor unit.

Cut the opening on the ceiling. Maybe it needs to strengthen the ceiling to keep the ceiling even and flat and prevent the

ceiling from vibration. For details, please consult to the builder.

21

Page 24

Installation Procedure

Indoor Unit

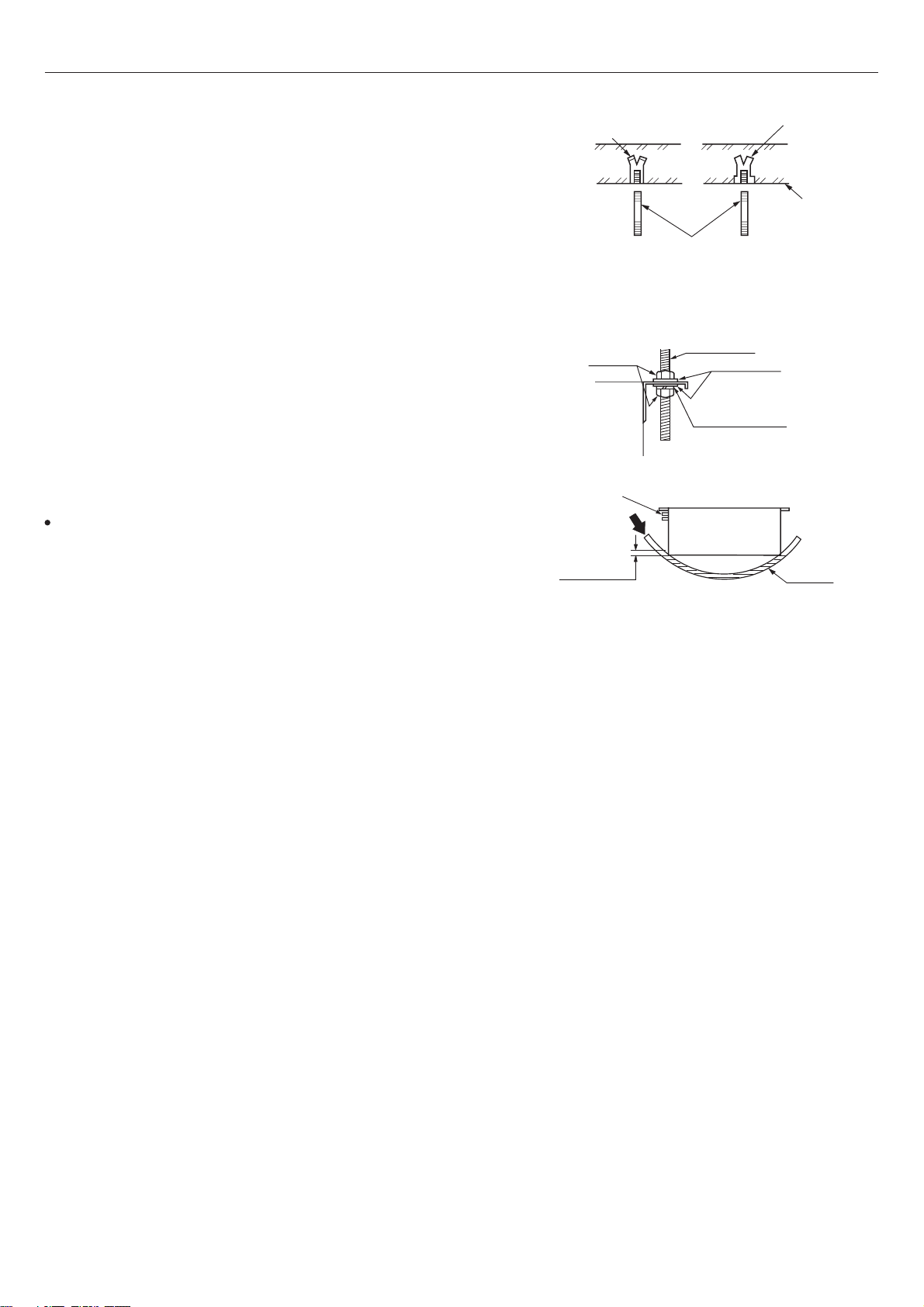

3. Hanger bolts installation

Use care of the piping direction when the unit is installed.(Use

M10 screw bolt)

In order to bear the weight of the unit, for existed ceiling, using

foundation screw bolt, and for new ceiling, using burying embedded

screw bolt, burying screw bolt or spot supplied other parts.

Before going on installation, adjust the gaps with ceiling.

4. Installation of indoor unit

Fix the indoor unit to the hanger bolts.

If required, it is possible to suspend the unit to the beam, etc.

Directly by use of the bolts without using the hanger bolts.

Note

When the dimensions of main unit and ceiling holes does not

match, it can be adjusted with the slot holes of hanging bracket.

5. Adjusting to the levelness

(a) Adjust the out-of levelness using a level or by the following

method.

Make adjustment so that the relation between the lower surface

of the unit proper and water level in the hose becomes as given

below.

(b)Unless the adjustment to the levelness is made properly,

malfunctioning or failure of the float switch may occur.

Hole-in anchor

Hole-in plug

M10 nut

Main unit

Piping side

Supply water

Water level

0~5 mm

(0~0.2")

Bring the piping side slightly lower.

Insert

Concrete

Hanging bolt M10

Hanging bolt

M10 washer

M10 spring washer

PVC hose

22

Page 25

Installation Procedure

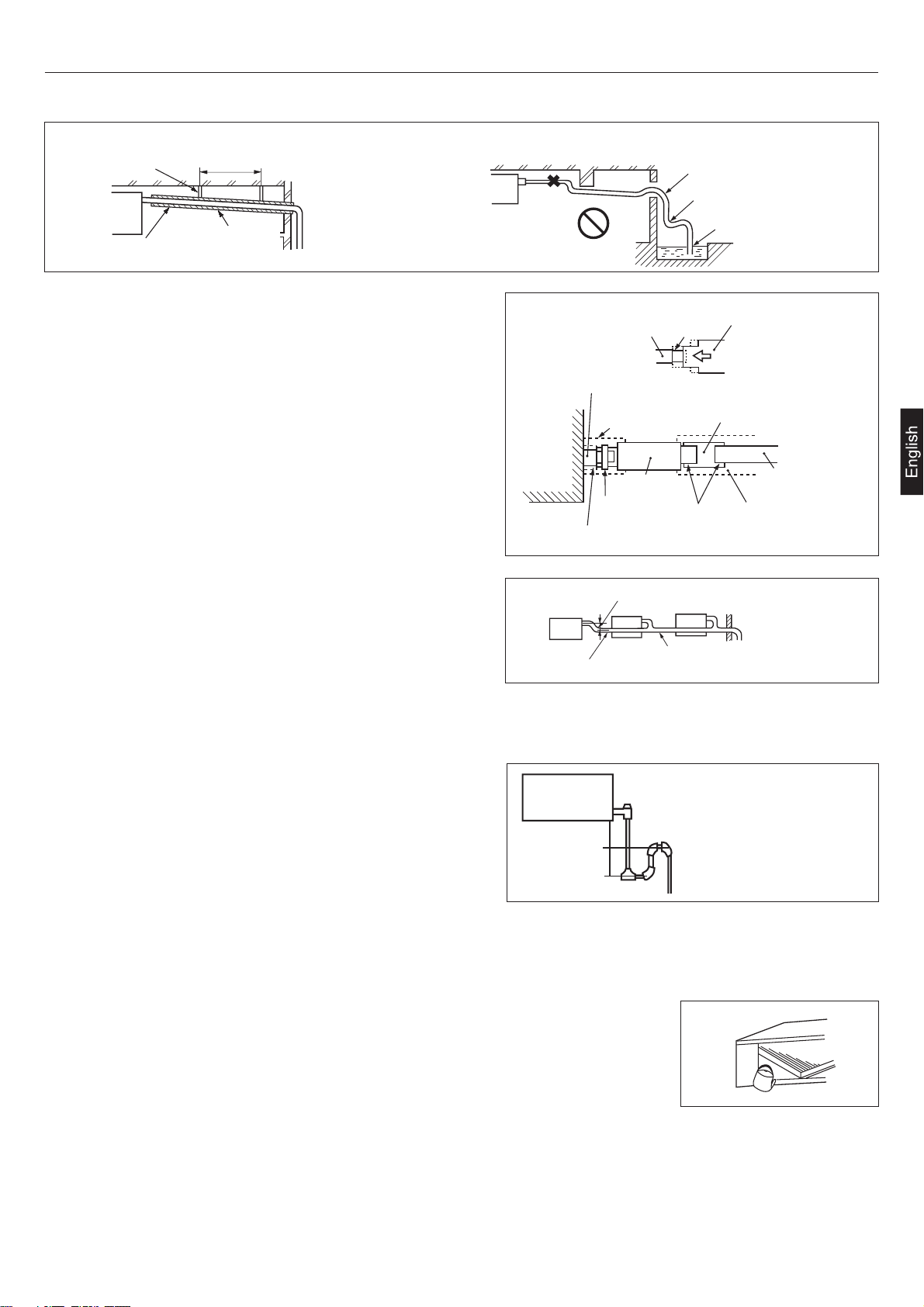

(a)

Drain piping should always be in a downhill grade (1/50~1/100) and avoid riding across an elevation or making traps.

Drain Piping

Good piping

Suspension

bolts

Heat

insulation

(b)

When connecting the drain pipe to unit, pay suffcient attention

1.5m ~ 2m

A downhill grade

of 1/100 or more

not to apply excess force to the piping on the unit side. Also,

fix the piping at a point as close as possible to the unit.

(c)

For drain pipe, use hard PVC general purpose pipe VP-25(I.D.1")

which can be purchased locally. When connecting, insert a

PVC pipe end securely into the drain socket before tightening

securely using the attached drain hose and clamp. Adhesive

must not be used connection of the drain socket and drain

hose (accessory).

(d)

When constructing drain piping for several units, position the

common pipe about 100 mm below the drain outlet of each

unit as shown in the sketch. Use VP-30(11/4") or thicker pipe

for this purpose.

Improper piping

Avoid riding across an elevation

Air vent

Drain socket

Drain socket

Pipe cover(large)

[for insulation]

Main unit

Pipe cover(small) [for insulation]

(accessory)

Secure the elevation as high as possible (approx. 100 mm)

(accessory)

Drain hose

(accessory)

Clamp

(accessory)

Keep free from traps

Do not pipe under water

Stage

difference

part

Adhesion

Drain hose

VP-25 joint

(field purchased)

Pipe cover [for insulation]

(field purchased)

VP-25

(field purchased)

The stiff PVC pipe put indoor side should be heat insulated.

(e)

(f)

Avoid putting the outlet of drain hose in the places with irritant gas generated. Do not insert the drain hose directly into

A downhill grade of 1/100 or more

VP-30

drainage, where the gas with sulfur may be generated.

(g)

Because the drain spout is at the position, which negative

pressure may occur. So with the rise of water level in the drain

pan, water leakage may occur. In order to prevent water leakage,

we designed a backwater bend. The structure of backwater

bend should be able to be cleaned. As the right figure shown,

use T type joint. The backwater bend is set near the air

conditioner.

H1H2

H1=100mm or the static pressure of

air sending motor

H2=1/2H1 (or between 50~100mm)

As figure shown, set a backwater bend in the middle of drain

hose.

Drainage Test

(1)

Conduct a drainage test after completion of the electrical work.

(2)

During the trial, make sure that drain flows properly through the piping and that no

water leaks from connections.

(3)

In case of a new building, conduct the test before it is furnished with the ceiling.

(4)

Be sure to conduct this test even when the unit is installed in the heating season.

Procedures

(a)

Supply about 1000 cc of water to the unit through the air outlet using a feed water pump.

(b)

Check the drain while cooling operation.

23

Page 26

Installation Procedure

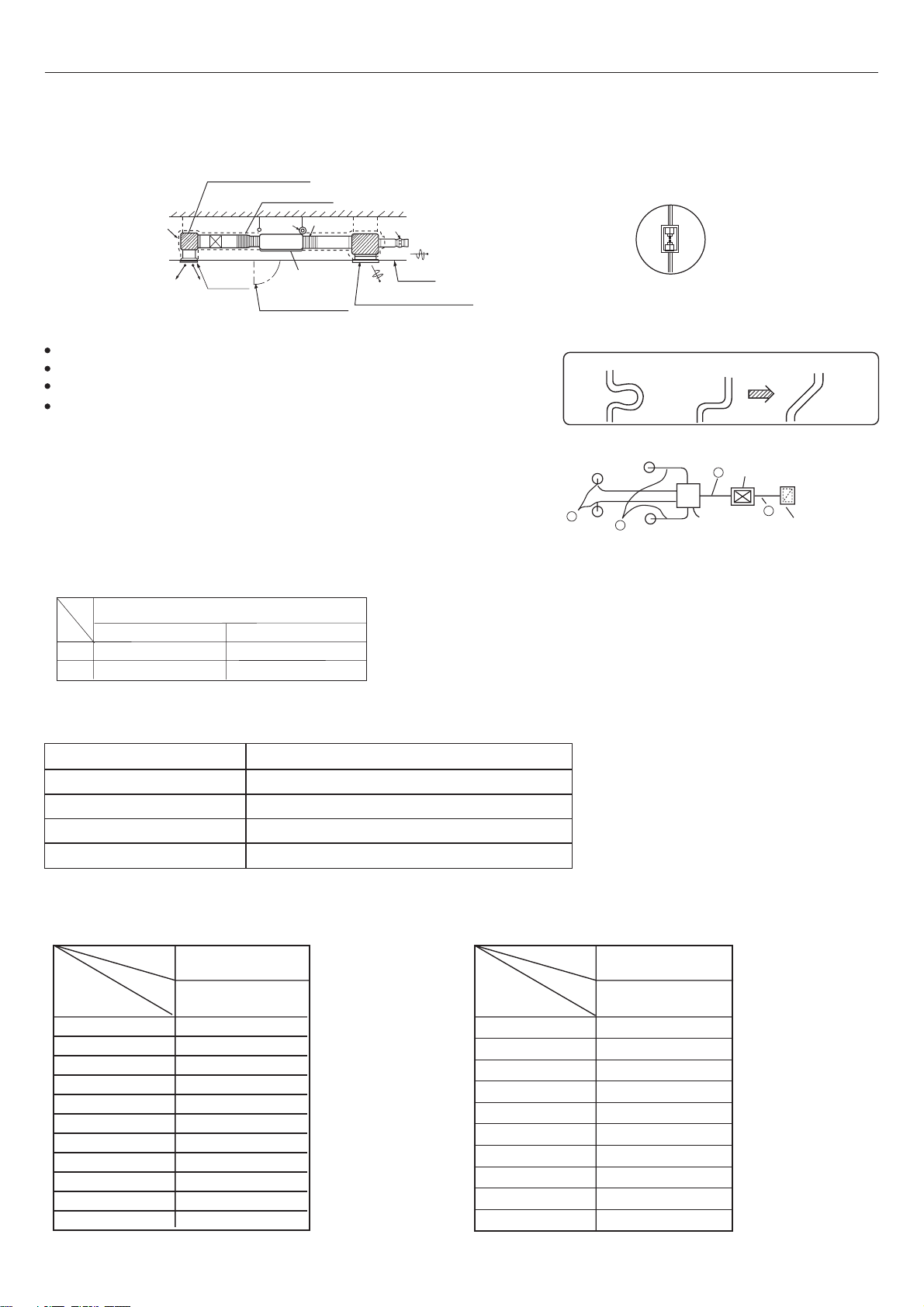

Air Duct

Please consult the after-sales service personnel for the choosing and installation of suction inlet, suction duct, discharging

outlet and discharging duct. Calculating the design drawing and outer static pressure, and choose the discharging duct

with proper length and shape.

muffler cavity (air sending)

Sacking joint

Insulation

Air outlet

A

Air conditioner

main unit

Checking meatus

Air volume adjuster

Ceiling

Air suction grille with air filter

The length difference among every duct is limited below 2:1.

Reduce the length of duct as possible as can.

Reduce the amount of bend as possible as can.

Use heat insulation material to bind and seal the part connecting main

unit and the flare part of air discharging duct. Perform duct installation

work, before the fitment of ceiling.

Calculation method of the dimension of the simple quadrate air duct

Presuming the unit length friction impedance of the duct is

1Pa/m, when the dimension of one side of the air duct is

fixed as 250mm, as shown below:

AD48HS1ERA AD60HS1ERA

Air volume

2400m3/h(40m3/min) 250x560(mmxmm)

A

600m3/h(10m3/min)

B

Duct

250x190(mmxmm)

Enlarging chart of profile chart A

Vibration resistance hook

B

A

Static pressure

box

A

Air conditioner

Good exampleBad exampleBad example

A

Equipped with

air filter (bought)

The calculation of duct resistance (the simple calculation is as follow table)

Straight part

Bend part

Air out part

Static pressure box

Air inlet grille (with air filter)

Calculate as per 1m length 1Pa, 1Pa/m

Each bend takes as a 3~4m long straight duct

Calculate as 25Pa

Calculate as 50Pa/each

Calculate as 40Pa/each

The chosen chart of simple duct

Note:1Pa/m=0.1mmAg/m

Shape

Item

Air volume

3

/h(m3/n)

m

100

200

300

400

500

600(10)

800

1,000

1,200(20)

1,400

1,600

Shape

Item

Square duct

Dimension

(mmxmm)

250 x 60

250 x 90

250 x 120

250 x 140

250 x 170

250 x 190

250 x 230

250 x 270

250 x 310

250 x 350

250 x 390

Air volume

3

/h(m3/n)

m

1,800(30)

2000

2400

3,000(50)

3,500

4,000

4,500

5,000

5,500

6,000(100)

Square duct

Dimension

(mmxmm)

250 x 430

250 x 470

250 x 560

250 x 650

250 x 740

250 x 830

250 x 920

250 x 1000

250 x 1090

250 x 1180

24

Page 27

Installation Procedure

The attentive matters in installation of air suction and discharging duct

Recommend to use anti-frost and sound-absorbing duct. (locally bought)

The duct installation work should be finished before the fitment of ceiling.

The duct must be heat insulated.

The specific air-discharging outlet should be installed at the place where the

airflow can be reasonably distributed.

The surface should leave a checking meatus for checking and maintenance.

The examples of improper installation

Do not use air inlet duct and take the ceiling inner side as duct instead.

The result is because of the irregular outer air mass, strong wind and

sunshine, the humidity is increased.

There may be water drop on the outside of duct. For cement and other

new constructions, even if not taking ceiling inner side as duct, the

humidity will also be so high. At this time, use glass fiber to perform

heat preservation to the whole. (use iron net to bind the glass fiber)

Maybe exceeding the unit operation limit (for example: when indoor

dry bulb temperature is 35 C, wet bulb temperature 24 C), it may lead

to overload of compressor.

Affected by the capacity of air discharging fan, the strong wind in the

outer duct and wind direction, when unit air sending volume exceeds

the limit, the discharged water of heat exchanger will overflow, leading

to water leakage.

Special air discharging outlet

Use screw bolt to fix

Air

Air

Improper example

Air discharging fan

Air Duct

Duct

25

Page 28

Installation Procedure

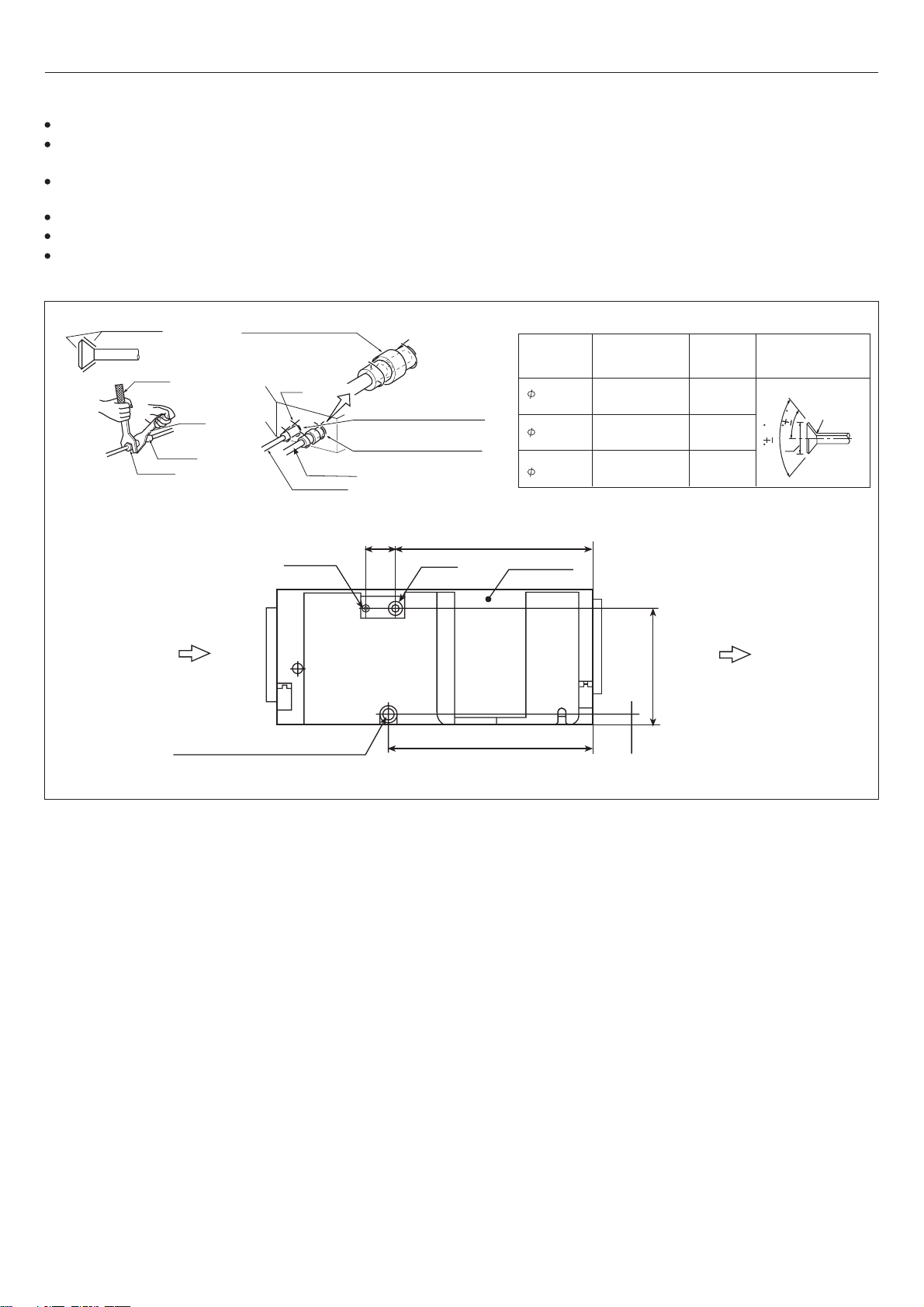

Refrigerant Pipe

The gas side pipe, liquid side pipe must be faithfully heat insulated, if no heat insulation, it may cause water leakage.

The outdoor unit has been charged with refrigerant.

When connect the pipe to the unit or dismantling the pipe from the unit, please follow the figure shown, use spanner and

torque spanner together.

When connect cone nut, the inner side and outside of cone nut should paste with refrigerant oil. Use hand to twist 3-4

rings, then fasten with spanner.

Referring to Table I to confirm the fasten torque. Too tight may damage nut leading to leakage.

Check if the connection pipe leaks, then do heat insulation treatment, as below figure shown.

Only use seal cushion to bind the joint part of air pipe and heat insulation parts.

Paste the refrigerant oil here

Torque spanner

Spanner

Pipe joint

Cone nut

Drain hose connection mouth

VP25 PVC pipe

Middle size seal cushion (accessory)

(Use seal cushion to

bind the pipe joint)

Clamp

Heat insulation (accessory)

(for liquid pipe)

Heat insulation (accessory)

(for gas pipe)

Gas pipe

Liquid pipe

80 510

Liquid pipe

Air inlet Air outlet

Gas pipe

530

Table I

Specification

of pipe

9.52mm

15.88mm

19.05mm

Electric box

Upper

Down side

Tighten torque

3270~3990 N.cm

(333~407 kgf.cm)

6180~7540 N.cm

(630~770 kgf.cm)

9720~11860 N.cm

(990~1210 kgf.cm)

310

30

Cone

dimension

A (mm)

12.0~12.4

18.6~19.0

22.9~23.3

Cone

45 2

A

90 0.5

R0.4~0.8

26

Page 29

Installation Procedure

WARNING

DANGER OF BODILY INJURY OR DEATH

TURN OFF ELECTRIC POWER AT CIRCUIT BREAKER OR POWER SOURCE BEFORE MAKING ANY ELECTRIC

CONNECTIONS.

GROUND CONNECTIONS MUST BE COMPLETED BEFORE MAKING LINE VOLTAGE CONNECTIONS.

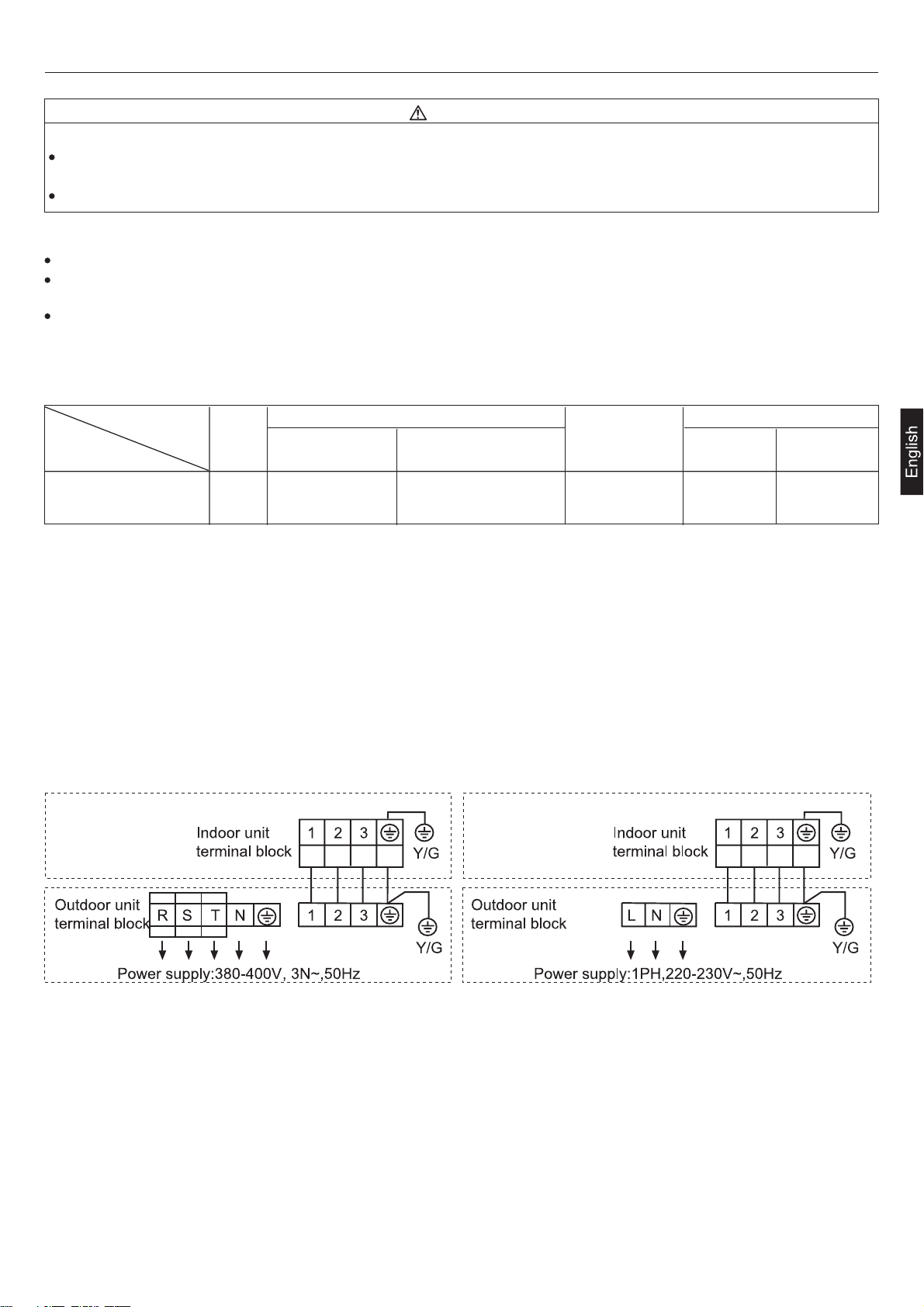

Precautions for Electrical wiring

Electrical wiring work should be conducted only by authorized personnel.

Do not connect more than three wires to the terminal block. Always use round type crimped terminal lugs with insulated

grip on the ends of the wires.

Use copper conductor only.

Selection of size of power supply and interconnecting wires

Select wire sizes and circuit protection from table below. (This table shows 20 m length wires with less than 2% voltage drop.)

Electrical Wiring

Item

Phase

Model

AD48HS1ERA

AD60HS1ERA

Wiring connection

Make wiring to supply power to the outdoor unit, so that the power for the indoor unit is supplied by terminals.

Switch breaker

330 4.0 3020 30

Circuit breaker

(A)

Overcurrent protector

rated capacity (A)

Power source

wire size

(minimum)

2

(mm

)

Earth leakage breaker

Switch

breaker(A)

Leak

current(mA)

27

Page 30

Page 31

APARATO DE AIRE ACONDICIONADO DE TIPO

CONDUCTOS

MANUALES DE USO E INSTALACIÓN

AD48HS1ERA

AD60HSIERA

Contenido

Precauciones para el uso

Límites de funcionamiento

Denominación de los componentes

Componentes y funciones

Funcionamiento

Manual de instalación del controlador

de cableado

Modo Calefacción

Mantenimiento

Guía para la búsqueda de las averías

Diagnóstico mod. Inverter

Precauciones para la instalación

Para una instalación correcta

Instalación de la unidad interior

Tubos de desagüe del agua de

condensación

Instalación de los conductos de

salida del aire

Tuberías refrigerante

Conexiones eléctricas

3

4

4

5

7

11

12

13

14

15

16

17

18

21

22

23

24

Español

Lea detenidamente este manual antes de instalar el aparato.

Guarde este manual de uso para futuras consultas.

Page 32

Haier Industrial Park, No.1 Haier Road, Qingdao, República Popular China

CONFORMIDAD DE LOS MODELOS

SEGÚN LAS NORMATIVAS EUROPEAS

CE

Todos los productos cumplen los requisitos de las siguientes

normas europeas:

- Directiva de baja tensión 73/23/CEE

- Directiva de baja tensión 2006/95/CE

- Compatibilidad electromagnética 89/336/CEE

- Compatibilidad electromagnética 2004/108/CE

ROHS

Los productos cumplen los requisitos de la directiva 2002/95/

CEE establecida por el Parlamento Europeo y el Consejo sobre

la Restricción del uso de determinadas sustancias peligrosas en

aparatos eléctricos y electrónicos (Directiva RoHS de la Unión

Europea).

WEEE

De acuerdo con la directiva 2002/96/CE del Parlamento Europeo,

se informa al consumidor acerca de los requisitos que han de

cumplirse para deshacerse de productos eléctricos y electrónicos.

REQUISITOS DE DESECHO:

por sí mismo: tanto el desmontaje del sistema de aire

acondicionado como la manipulación del refrigerante, el

aceite y cualquier otro componente deben ser llevados

a cabo por un instalador cualificado, de acuerdo con la

legislación local y nacional aplicable. Los aparatos de aire

acondicionado deben ser tratados en instalaciones de

manipulación especializadas para su reutilización, reciclado

y recuperación. Al garantizar la correcta eliminación de

este producto, estará contribuyendo a evitar las posibles

consecuencias negativas que podría provocar sobre el

medioambiente y la salud humana. Póngase en contacto

con el instalador o la autoridad local pertinente si desea

obtener más información. Las pilas deben ser extraídas del

mando a distancia y eliminadas de forma independiente, de

acuerdo con la legislación local y nacional aplicable.

Su aparato de aire acondicionado ha sido

marcado con este símbolo que significa que

los productos de tipo eléctrico y electrónico

no deben mezclarse con la basura doméstica

sin clasificar. No intente desmontar el sistema

INFORMACIÓN IMPORTANTE ACERCA DEL REFRIGERANTE UTILIZADO

Contiene gases uorados de efecto invernadero

regulados por el Protocolo de Kioto.

Kg

Kg

Kg

Este producto contiene gases fluorados de efecto invernadero

regulados por el Protocolo de Kioto. No los libere a la atmósfera.

Tipo de refrigerante: R410A

Valor GWP*: 1975 1975

GWP = Potencial de contribución al calentamiento global

Escriba con tinta indeleble:

• 1 La carga de refrigerante que contiene el producto de fábrica

• 2 La cantidad de refrigerante adicional cargada in situ y

• 1+2 La carga total de refrigerante en la etiqueta de refrigerante

suministrada con el producto. Una vez escritos los datos

correspondientes, la etiqueta deberá adherirse cerca de la

conexión de carga del producto (por ejemplo, sobre la parte interna

de la cubierta de la válvula de retención).

A Contiene gases fluorados de efecto invernadero regulados por

el Protocolo de Kioto.

B Carga de refrigerante que contiene el producto de fábrica:

consulte la placa de características de la unidad.

C Cantidad de refrigerante adicional cargada durante la

instalación.

D Carga total de refrigerante.

E Unidad exterior

F Botella de refrigerante y analizador de carga.

Page 33

• Antes de usar el climatizador leal presente manual de

instrucciones

• Las precauciones de seguridad que figuran a continuación

se subdividen en PELIGRO y ATENCIÓN. La palabra

PELIGRO corresponde a precauciones que, en caso de no

observarse, pueden comportar serias consecuencias como

muerte, lesiones graves, etc. No obstante, la palabra

ATENCIÓN también corresponde a precauciones que, en

caso de no observarse, pueden causar serios problemas,

según la situación.

• Conserve las Precauciones de seguridad siempre a mano,

para que pueda consultarlas siempre que sea necesario.

PELIGRO

No dirija el flujo de aire frío directamente

sobre las personas y no deje disminuir

demasiado la temperatura ambiente, ya

que podría ocasionar problemas de

salud.

No introduzca objetos en la rejilla de

aspiración o en la boca de salida de la

unidad exterior mientras el climatizador

esté en funcionamiento. El ventilador que

gira a alta velocidad puede ocasionar heridas graves.

En caso de mal funcionamiento como olor de quemado, pare

inmediatamente el aparato y desenchúfelo de la toma de

corriente. Póngase en contacto con el servicio de asistencia.

En estos casos, si el climatizador siguiera funcionando podría

sufrir graves daños, o podría producirse un incendio.

ATENCIÓN

No use el aparato para conservar

comida, obras de arte, aparatos de

precisión, para la cría de animales o el

cultivo de plantas.

No toque el interruptor con las manos

mojadas.

No instale el aparato cerca de una

chimenea u otro aparato para la

calefacción.

No vierta agua sobre el climatizador para limpiarlo

No ponga plantas o animales

directamente expuestos al flujo del aire.

Use un fusible con las especificaciones

eléctricas adecuadas.

No use en modo alguno cable de cobre

o de acero en lugar del fusible.

No apoye ningún objeto sobre el aparato

ni se suba encima del mismo.

No coloque bombonas de gas inflamable

y no utilice líquidos en spray cerca del

aparato.

No ponga el climatizador en marcha si se

ha retirado la rejilla de salida de la unidad

exterior.

No pare o ponga en marcha el aparato

mediante el interruptor de alimentación.

No toque la zona de salida del flujo de

aire mientras el deflector esté en movimiento.

No coloque hervidores ni similares cerca

de la unidad interior y del mando a

distancia: el agua de condensación que

puede acumularse debido al vapor

generado puede provocar un cortocircuito

Ventile la estancia de vez en cuando si al

mismo tiempo está funcionando un

electrodoméstico a gas.

Una ventilación insuficiente puede

ocasionar asfixia.

Verifique periódicamente que el soporte

de la unidad exterior esté en perfectas

condiciones.

Antes de limpiar el aparato, apague el climatizador y

desconecte la alimentación.

No apoye jarrones con flores o recipientes con agua sobre

el aparato.

Póngase en contacto con el servicio de asistencia para

eventuales reparaciones.

Operaciones no adecuadas podrían ocasionar

electrocuciones, incendios y pérdidas de agua.

Póngase en contacto con el servicio de asistencia en caso de

mudanza. Operaciones no adecuadas podrían ocasionar

electrocuciones, incendios y pérdidas de agua.

Precauciones para el uso

3

Page 34

Límites de funcionamiento

Gama útil de las temperaturas ambiente:

BS: Temperatura con

Bulbo Seco

BH: Temperatura con

Bulbo Húmedo

• Si el cable de alimentación está dañado, deberá ser sustituido por personal del servicio de asistencia o en cualquier caso por personal cualificado.

• Si el fusible de la tarjeta electrónica salta, sustituirlo por uno del tipo T.3.15A/250VAC.

• El método de cableado debe estar en línea con el estándar local..

• Se entrega sin los cables de alimentación y de conexión.

• Instale un disyuntor; la distancia entre los dos contactos debe ser de cómo mínimo 3 mm.

• La altura mínima de instalación de la unidad interior es de 2,5 metros.

• Todos los cables deben tener el certificado de autenticidad Europea.

• Se entrega sin los cables de alimentación y de conexión.

• Si durante la instalación se rompe un cable, asegúrese de que el cable de toma de tierra no sea interrumpido.

Temperatura interna

Temperatura externa

Temperatura interna

Temperatura externa

Refrigeración

Calefacción

máx. BS/BH

mín. BS/BH

máx. BS/BH

mín. BS/BH

máx. BS

mín. BS

máx. BS/BH

mín. BS

32/23°C

18/14°C

46/26°C

10/6°C

27°C

15°C

24/18°C

-15°C

• Para obtener las mejores prestaciones se aconseja programar la velocidad del ventilador en función de los valores que figuran en la tabla:

Especificaciones del cable de conexión:

H05RN-F 4G 0.75mm

2

Temperatura ambiente Modo operativo

Velocidad del ventilador

aconsejada

> 40°C Refrigeración baja

< 20°C Refrigeración alta

< -5°C Calefacción baja

> 18°C Calefacción alta

Denominación de los componentes

4

Unidad interior

Conducto

Entrada aire

Tubo de desagüe

del agua de condensación

Salida aire

Conducto

Page 35

5

Componentes y funciones

Botones del controlador de cableado

Interruptor de modo

Elija el modo de

funcionamiento.

Interruptor de modo

saludable

Se utiliza para controlar

la función de oxígeno y

los iones negativos.

Interruptor de velocidad del

ventilador

Permite cambiar la velocidad del

aire.

Interruptor de oscilación

Permite abrir y cerrar el deector de

aire.

Interruptor

TEMPERATURA

Se utiliza para cambiar la

temperatura establecida.

Interruptor de temporización

Se utiliza para regular el

tiempo establecido.

Interruptor de

temporización

Se utiliza para elegir el

funcionamiento en modo

de temporización.

Interruptor de

autoinspección

Se utiliza para el

servicio de inspección.

Restablecimiento del

ltro

Después de limpiar la

entrada y el ltro de aire,

pulse este interruptor.

La unidad comenzará a

funcionar.

Conguración del reloj, de la

temporización y de la dirección

Interruptor de cambio de aire

Se utiliza para abrir y cerrar la

función de cambio de aire. El modo

es el siguiente:

No hay indicación-Cambio de

aire (automático)-Cambio de aire

(RECUPERACIÓN)-Cambio de aire

(NORMAL)

Interruptor de ENCENDIDO y

APAGADO

Función de encendido y apagado.

La unidad se enciende al pulsar

este interruptor y se apaga cuando

se vuelve a pulsar (no es necesario

abrir la tapa frontal).

Botón de restablecimiento

Si se produce un estado anómalo,

pulse el botón del establecimiento

con un objeto alado. Esta

operación puede devolver el estado

de funcionamiento normal a la

unidad.

Page 36

6

Componentes y funciones

Pantalla del controlador de cableado

Indicación centralizada

Cuando se gobierna mediante

el controlador centralizado, se

muestra esta información.

Indicación del volumen

de aire

Mostrar la velocidad

establecida

Indicación del modo de

funcionamiento

Mostrar el modo

seleccionado

Indicación de la función

del modo saludable

Indicación del número

de la unidad

Indicación de la

temperatura

Mostrar la

temperatura de

la habitación,

la temperatura

establecida y el

número de unidad

Indicación del modo de

funcionamiento

Cuando el compresor está en

funcionamiento, se muestra esta

información.

Indicación del modo de espera

Cuando la unidad recibe

alimentación y se encuentra el

modo de espera, se muestra el

mensaje "Standby" (Espera).

En el estado de

precalentamiento,

se muestra mensaje

"Preheating"

(Precalentamiento).

Después del

calentamiento, se

muestra el mensaje

“Defrost” (Desescarcha)

cuando se realiza el

desescarche.

Indicación de

advertencia de la

pantalla del ltro

Cuando se muestre

la indicación, limpie la

pantalla del ltro.

Indicación del

funcionamiento en

modo de temporizador

Mostrar el contenido de

funcionamiento en modo

de temporizador

Indicación del estado de

inspección

Indicación de demanda

Si se fuerza su funcionamiento, se

mostrará “DEMAND” (DEMANDA).

Comentarios

•--Los modelos del manual no tienen las funciones Saludable, Restablecimiento del ltro y Cambio de aire.

Indicación del

cambio de aire

Indicación de la

oscilación del aire

Page 37

7

Funcionamiento

ENCENDIDO y APAGADO

Pulse el interruptor ON/OFF (ENCENDIDO/APAGADO) de

la línea directamente.

El controlador de línea muestra el estado de funcionamiento

de la última vez (el tiempo y el estado oscilación no se

pueden mostrar).

1. Pulse el interruptor "ON/OFF" (ENCENDIDO/

APAGADO).

El aparato de aire acondicionado comenzará a funcionar y

la luz del controlador de cableado se iluminará.

2. Elija el modo de funcionamiento.

Pulse el interruptor "Mode" (Modo) para cambiar entre

"AUTOMÁTICO"—"SOLO VENTILADOR"—

"REFRIGERACIÓN"—"SECO"—"CALEFACCIÓN".

3. Pulse el interruptor "TEMP".

Cambie la temperatura establecida: Pulse TEMP

TEMP cada vez. [SET] se mostrará en la pantalla y la

temperatura establecida aumentará o reducirá 1°C

o

Comentarios

4. Pulse el interruptor "FAN SPEED" (VELOCIDAD DEL

VENTILADOR).

Funcionamiento en modo SOLO VENTILADOR:

Pulse el interruptor "FAN SPEED" (VELOCIDAD DEL

VENTILADOR) para cambiar entre

"ALTA"-"MEDIA"-"BAJA"-"ALTA".

5. Pulse el interruptor "Swing" (Oscilación) del

controlador de línea para hacer oscilar el aire.

6. Pulse el interruptor "ON/OFF" (ENCENDIDO/