Haier 3U55S2SR2FA, AB35S2SC1FA, AB25S2SC1FA, 5U105S2SS2FA, AB50S2SC1FA Service Manual

...

SYJS-07-2018 REV.A Edition: 2018-07

R32 Super Match

II

Multi Split

CONTENTS

Part 1 General Information .......................................................................................................................................1

1. Lineup ......................................................................................................................................................................1

2. Feature ....................................................................................................................................................................3

Part 2 Indoor Units-4-Way Cassette Type................................................................................................................5

1. Feature ....................................................................................................................................................................6

2. Specication ............................................................................................................................................................8

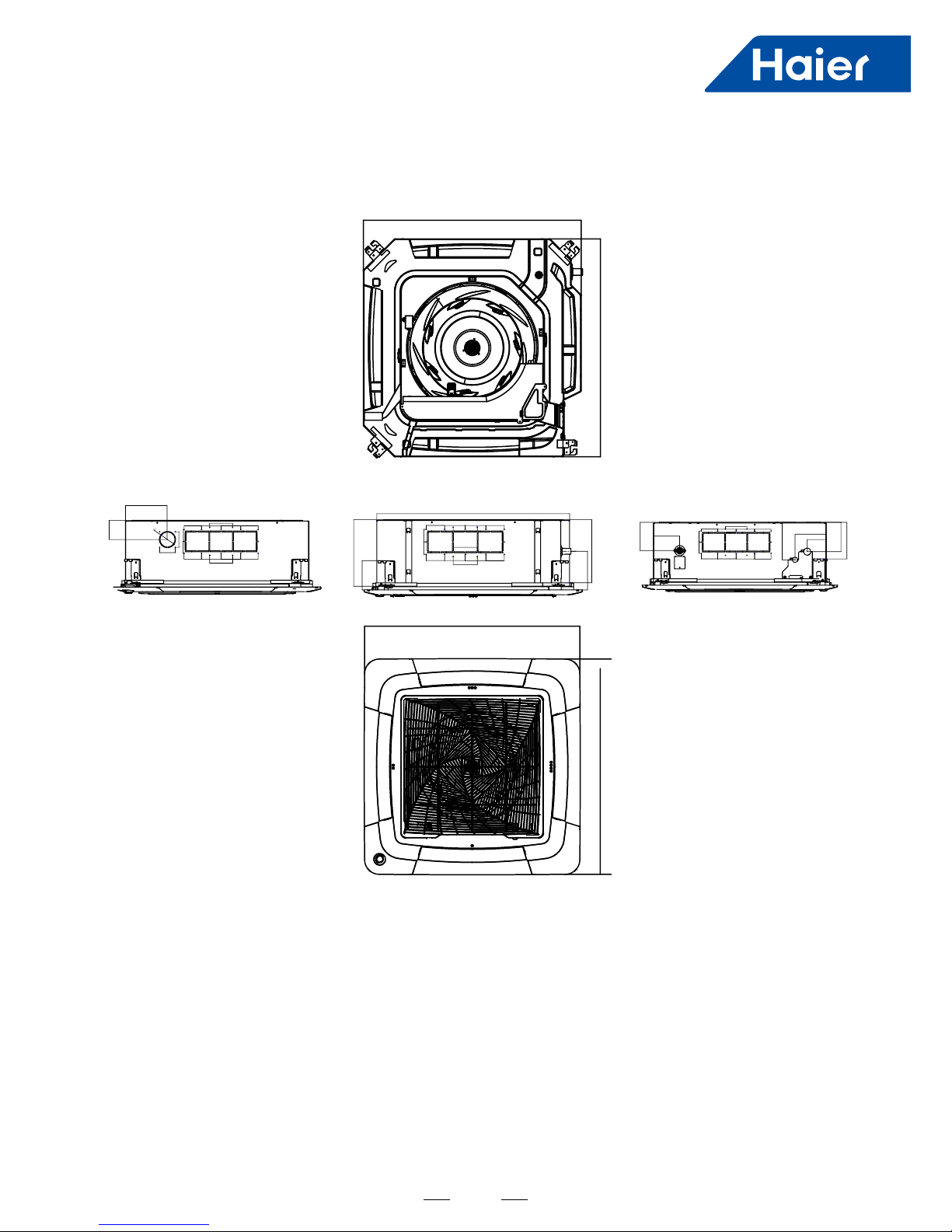

3. Dimension..............................................................................................................................................................12

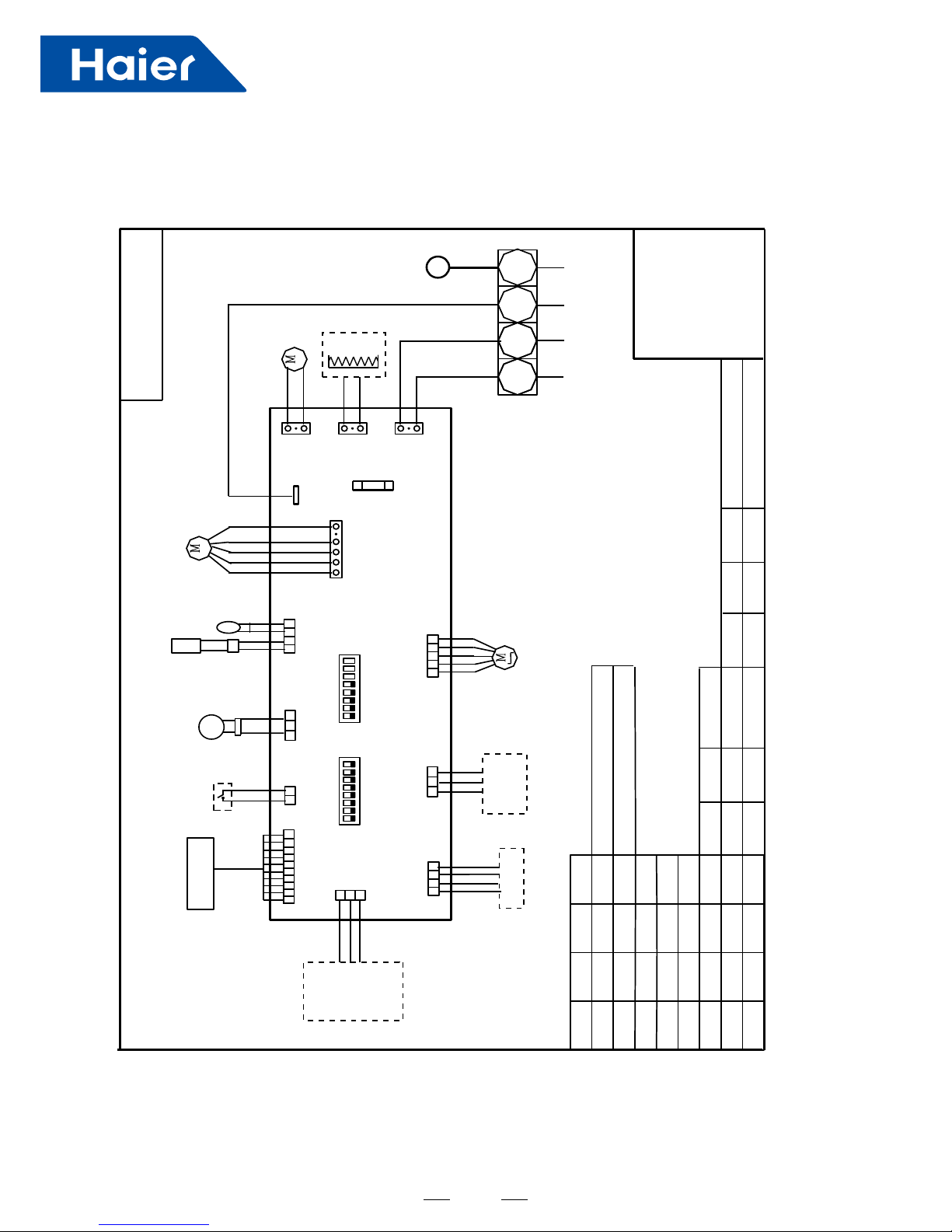

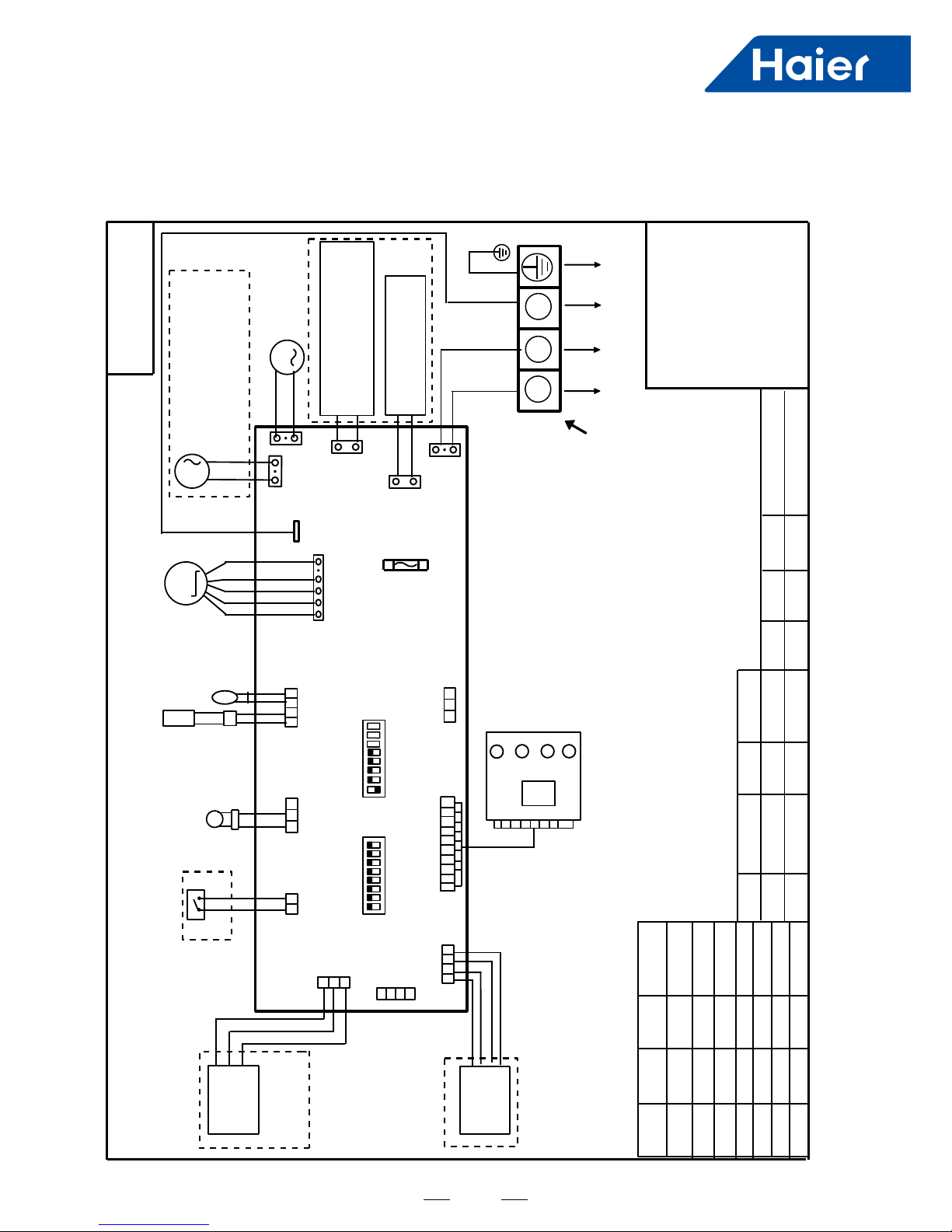

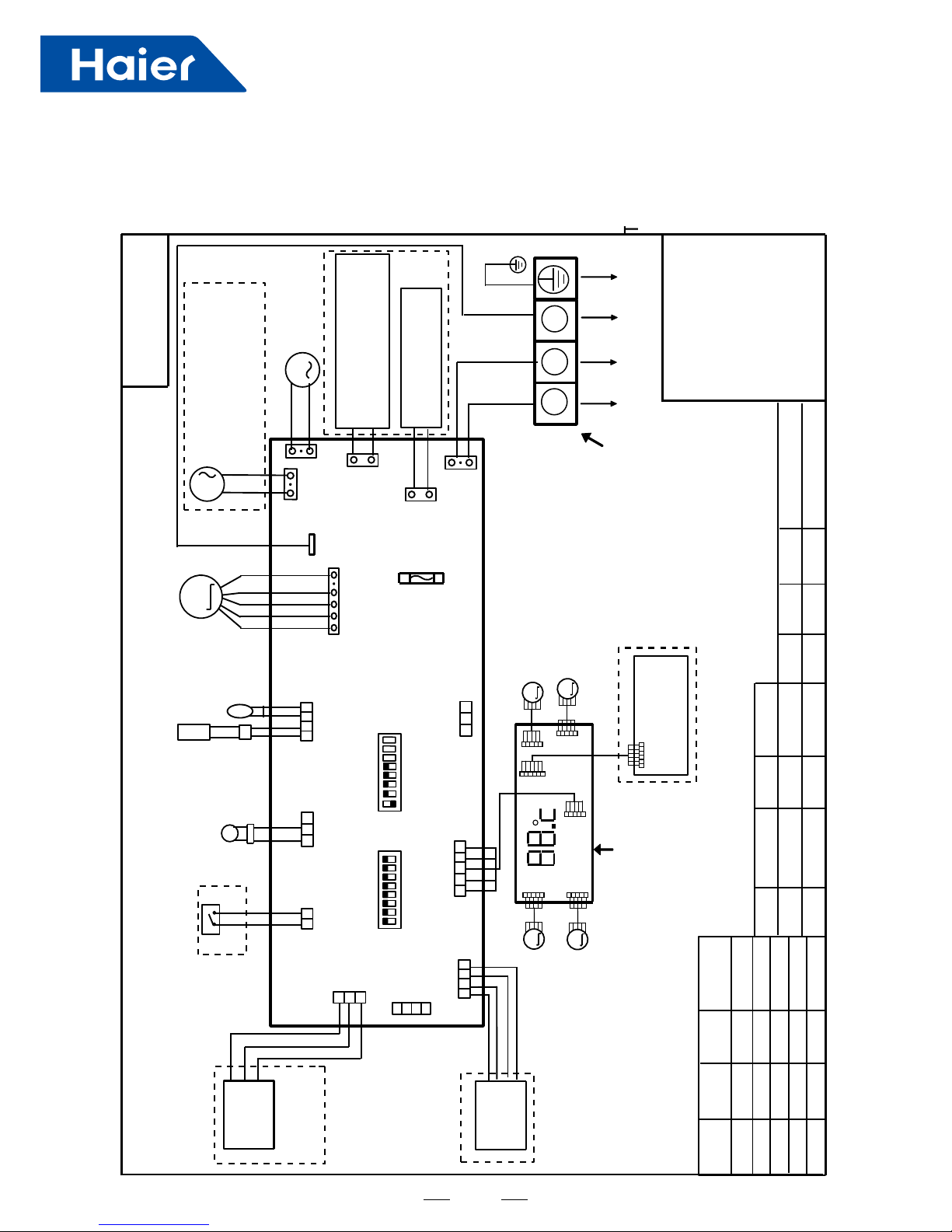

4. Wiring Diagram ......................................................................................................................................................14

5. Air Velocity and Temperature Distribution ..............................................................................................................17

6. Sound Pressure level ............................................................................................................................................19

7. Installation .............................................................................................................................................................21

Part 3 Indoor Units -Low Pressure Slim Duct Type ..............................................................................................33

1. Feature ..................................................................................................................................................................34

2. Specication ..........................................................................................................................................................36

3. Dimension..............................................................................................................................................................44

4. Wiring Diagram ......................................................................................................................................................45

5. Airow and Static Pressure Chart ..........................................................................................................................46

6. Installation .............................................................................................................................................................48

Part 4 Indoor Units -Medium Pressure Slim Duct Type .......................................................................................59

1. Specication ..........................................................................................................................................................60

2. Dimension..............................................................................................................................................................71

3. Wiring Diagram ......................................................................................................................................................76

4. Airow and Static Pressure Chart ..........................................................................................................................80

5. Instalaltion .............................................................................................................................................................85

Part 5 Outdoor Units .............................................................................................................................................105

1. Feature ................................................................................................................................................................106

2. Dimension............................................................................................................................................................117

3. Wiring Diagram ....................................................................................................................................................121

4. Wiring Connection ...............................................................................................................................................124

5. Piping Diagram ....................................................................................................................................................127

6. Limitation Values on Pipe lnstallation ..................................................................................................................131

7. Combination and the Data ...................................................................................................................................134

8. Performance Curve .............................................................................................................................................160

9. Sound Pressure level ..........................................................................................................................................163

10. Installation Instructions ......................................................................................................................................167

Part 6 Electric Control and Troubleshooting ......................................................................................................195

1. Indoor PCB Photo................................................................................................................................................196

2. Outdoor unit PCB Photo, Dip Switch Setting and Function .................................................................................206

3. Diagnostic Code ..................................................................................................................................................223

4. Trouble Shooting .................................................................................................................................................233

1

Part 1 General Information

1. Lineup ......................................................................................................................................................................1

2. Feature ....................................................................................................................................................................2

1

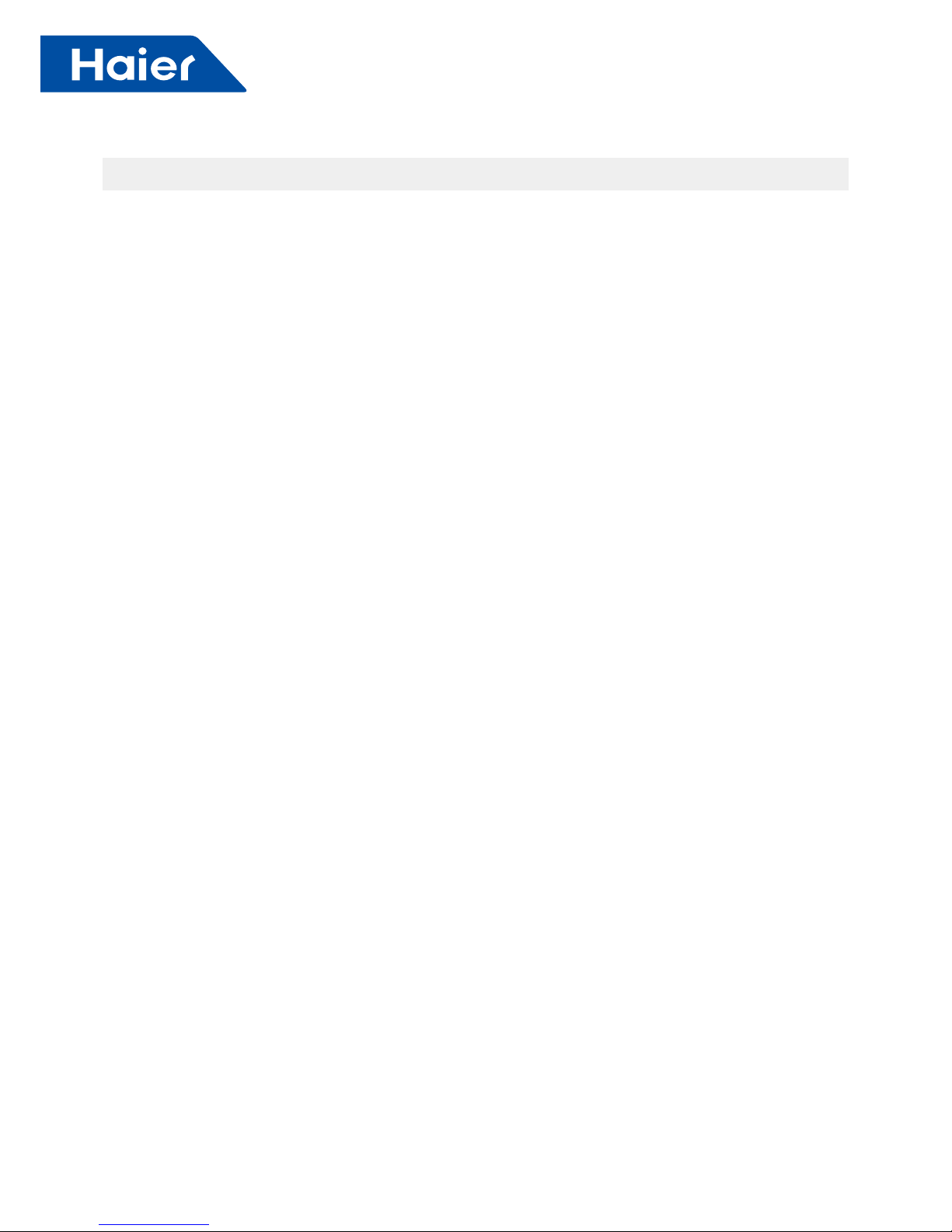

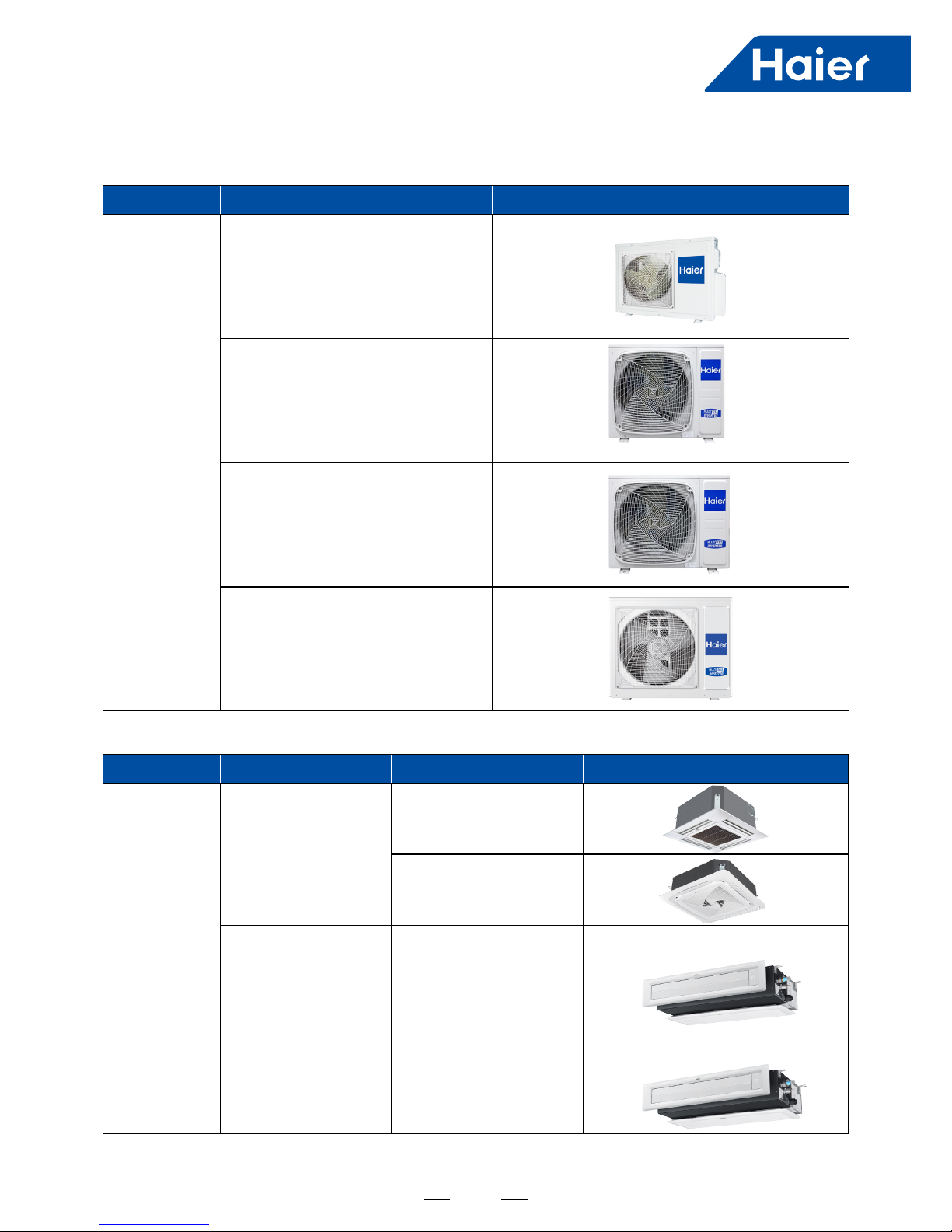

Model Apperance

Indoor Unit

4-Way Cassette

AB25S2SC1FA

AB35S2SC1FA

AB50S2SC1FA

AB71S2SG1FA

Low ESP Duct

AD25S2SS1FA

AD35S2SS1FA

AD25S2SS2FA

AD35S2SS2FA

AD50S1SS2FA

AD50S2SS2FA

AD71S2SS1FA

AD71S2SS2FA

Model Apperance

Outdoor Unit

1U71S2SG1FA

3U55S2SR2FA

3U70S2SR2FA

4U75S2SR2FA

4U85S2SR2FA

5U105S2SS2FA

1. Lineup

2

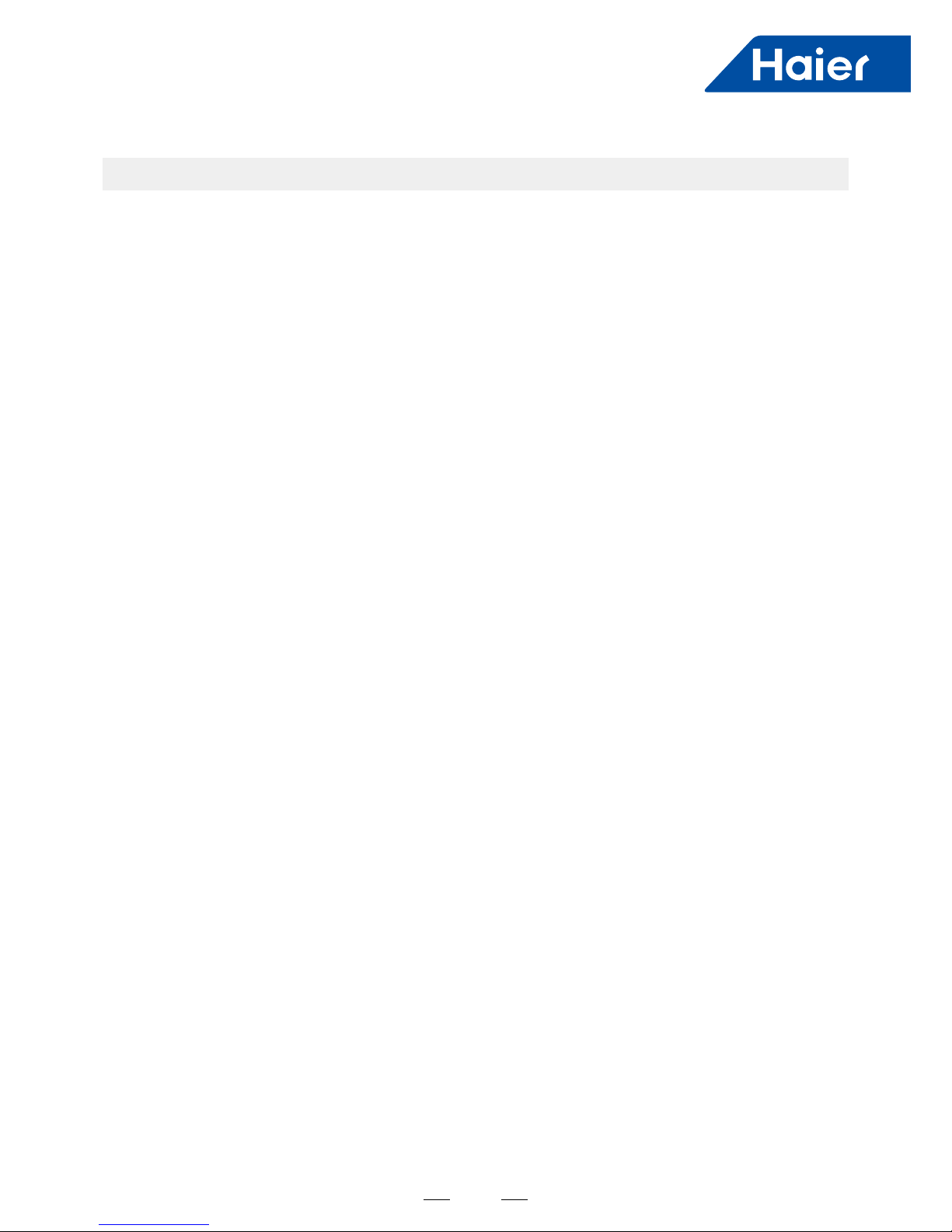

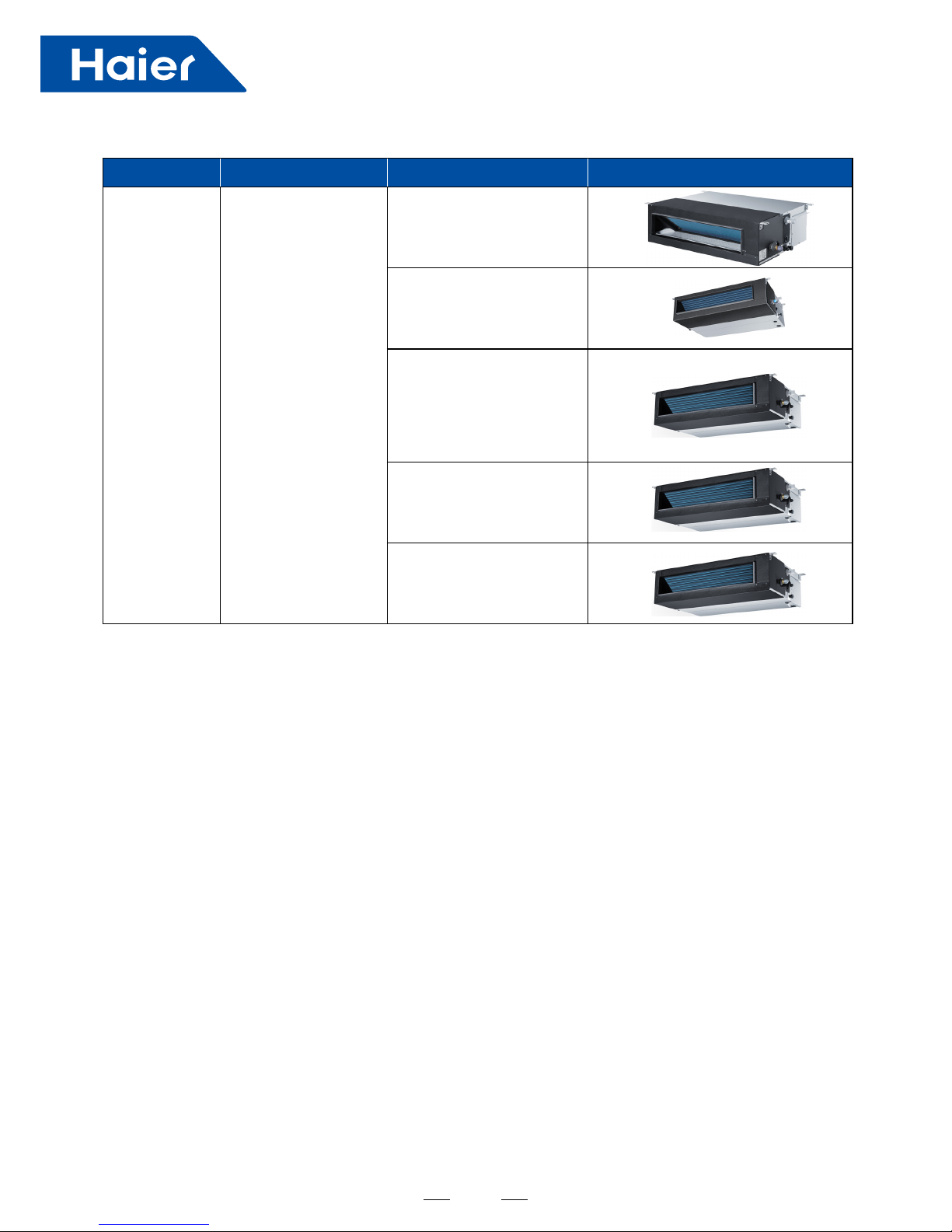

Model Apperance

Indoor Unit Medium Pressure Duct

AD35S2SM3FA

AD50S2SM1FA

AD71S2SM1FA

AD71S2SM3FA

AD90S2SM3FA

AD105S2SM3FA

AD125S2SM3FA

AD140S2SM3FA

3

2. Feature

Clean Design

High Comfort

High Efciency

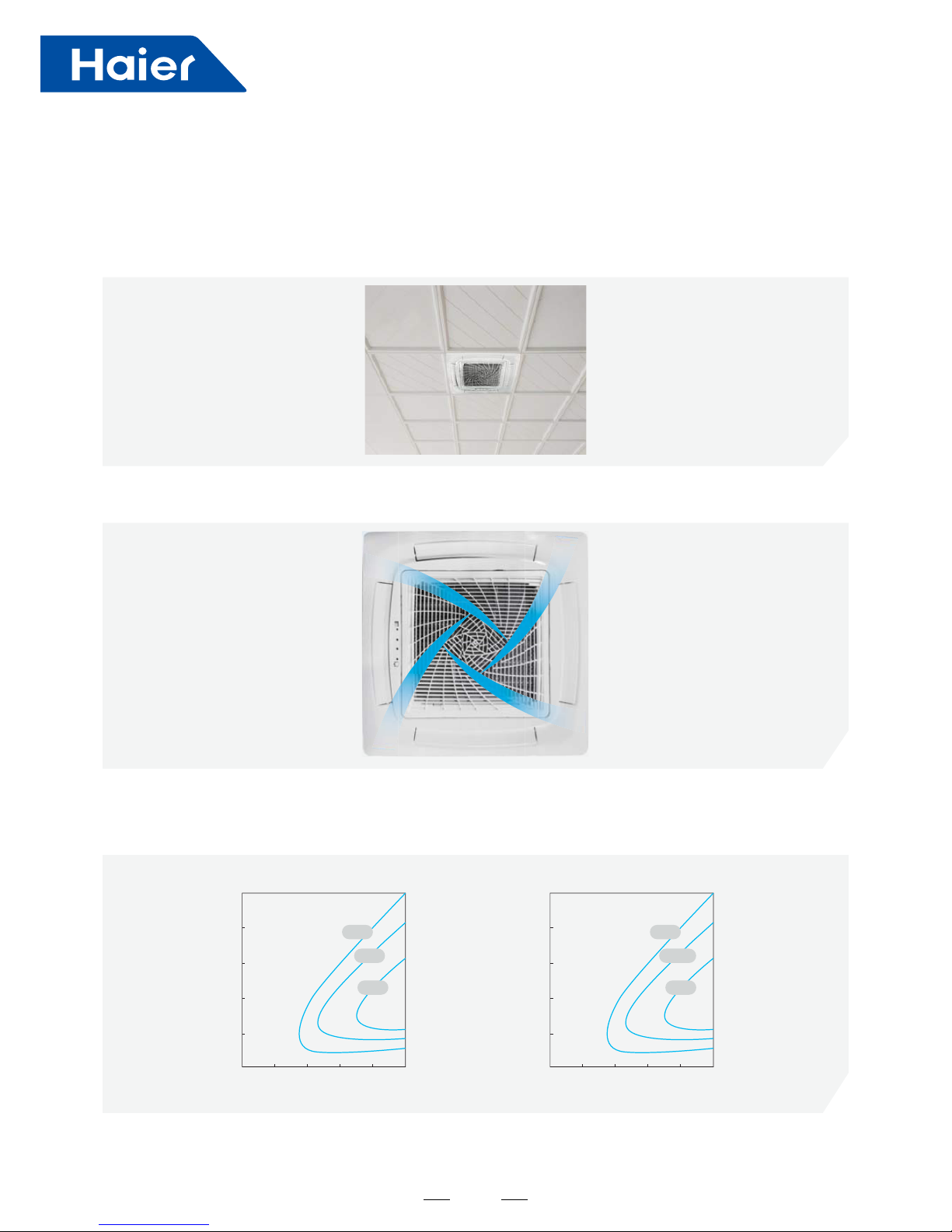

The outdoor unit takes no screw clean design in the top cover, this design makes people comfort when they are

watching the outdoor unit;

New outdoor unit and indoor unit design to get a ultra high SEER/SCOP A+++/A++ which is reaching the world

class energy efciency (3U55)

The new outdoor unit takes 550mm diameter large fan design, multi split II outdoor unit can provide same air ow

but with lower fan rotation speed, then the sound level reduce 3-4 dB(A) comapred with rst generation multi split

outdoor unit;

550mm

4

Installation Friendly

External General Stop Valve

Easy Start Up & Maintenance

The outdoor unit takes external general stop valve in all outdoor unit design, installer can vaccum/charge just one

time with no extra dismantlement, save lots of time;

In start up & maintenance, PC monitor can connect with outdoor unit by TD-02, read all indoor unit & outdoor

unit running parameter, also with the function to show parameter & curve.

When malfunction happens, show failure code.

General

stop valve

5

Part 2 Indoor Units-4-Way Cassette Type

1. Feature ....................................................................................................................................................................6

2. Specication ............................................................................................................................................................8

3. Dimension..............................................................................................................................................................12

4. Wiring Diagram ......................................................................................................................................................14

5. Air Velocity and Temperature Distribution ..............................................................................................................17

6. Sound Pressure level ............................................................................................................................................19

7. Installation .............................................................................................................................................................21

6

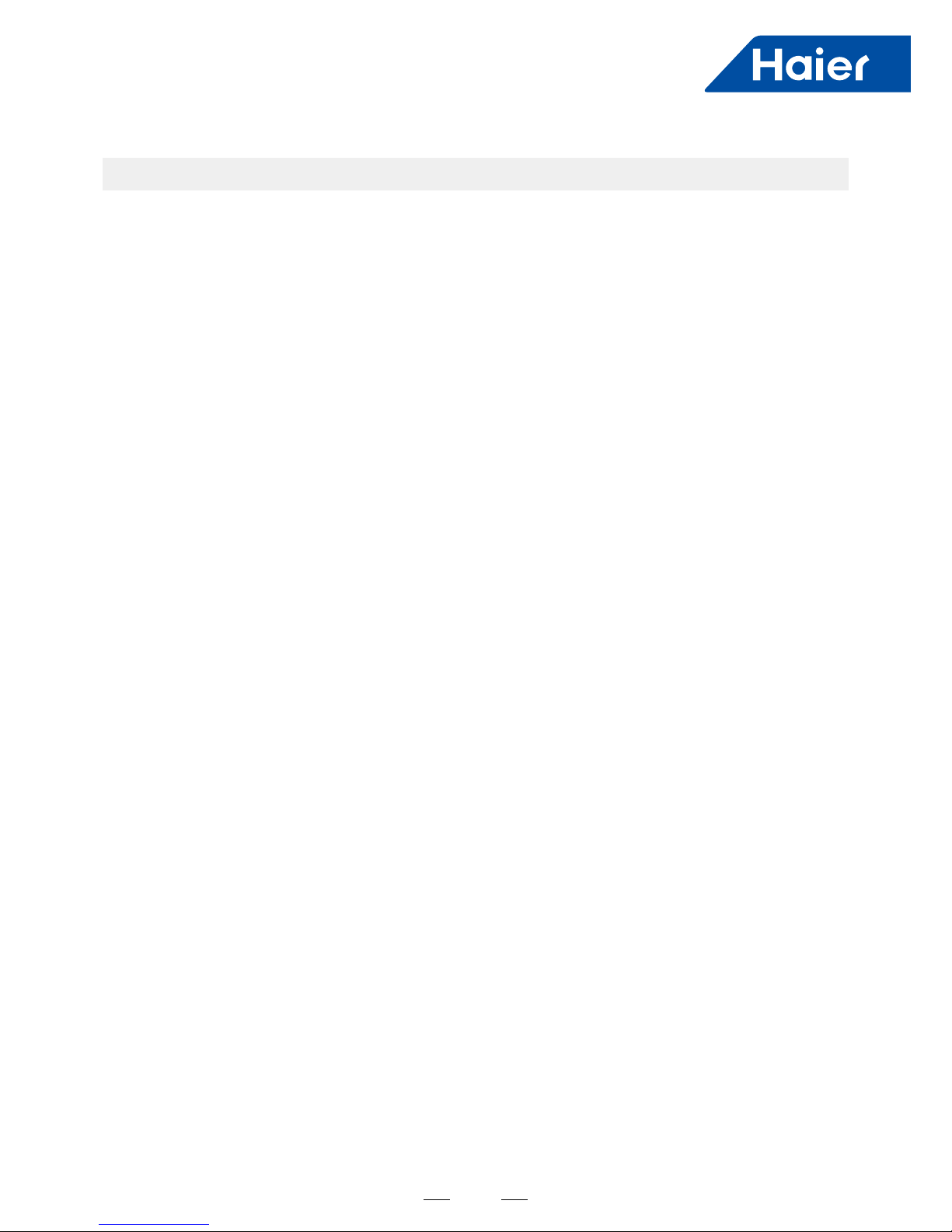

1. Feature

Appearance

Energy Efciency

DC Fan Motor

"Spiral" panel

The new 620mm*620mm panel is very t for thestandard decoration panel, won't cover otherthings like light, looks

more beautiful;

Compared to conventional AC fan motor, DC fan motor is more efciency.

AC Motor Effciency DC Motor Effciency

“Spiral” concept, “Haier” image;

The new 620mm*620mm panel

20

0

2004 00 6008 00 1000

40

60

80

100

45%

35%

25%

20

0

2004 00 6008 00 1000

40

60

80

100

90%

87.5%

85%

Torque(kgfcm)

Rev(r/min) Rev(r/min)

Torque(kgfcm)

7

Four aps can be controlled individually, airow can be controlled according to end user needs. Increase comfort;

Individual Flap Control

Comfort

Installation Friendly

Easy Access Electrical Box Design

The electrical box is located in the unit, you can just make maintenance by openning the panel .

Horizontal

Adjustable

Downward

corner installation solution

Fixed

8

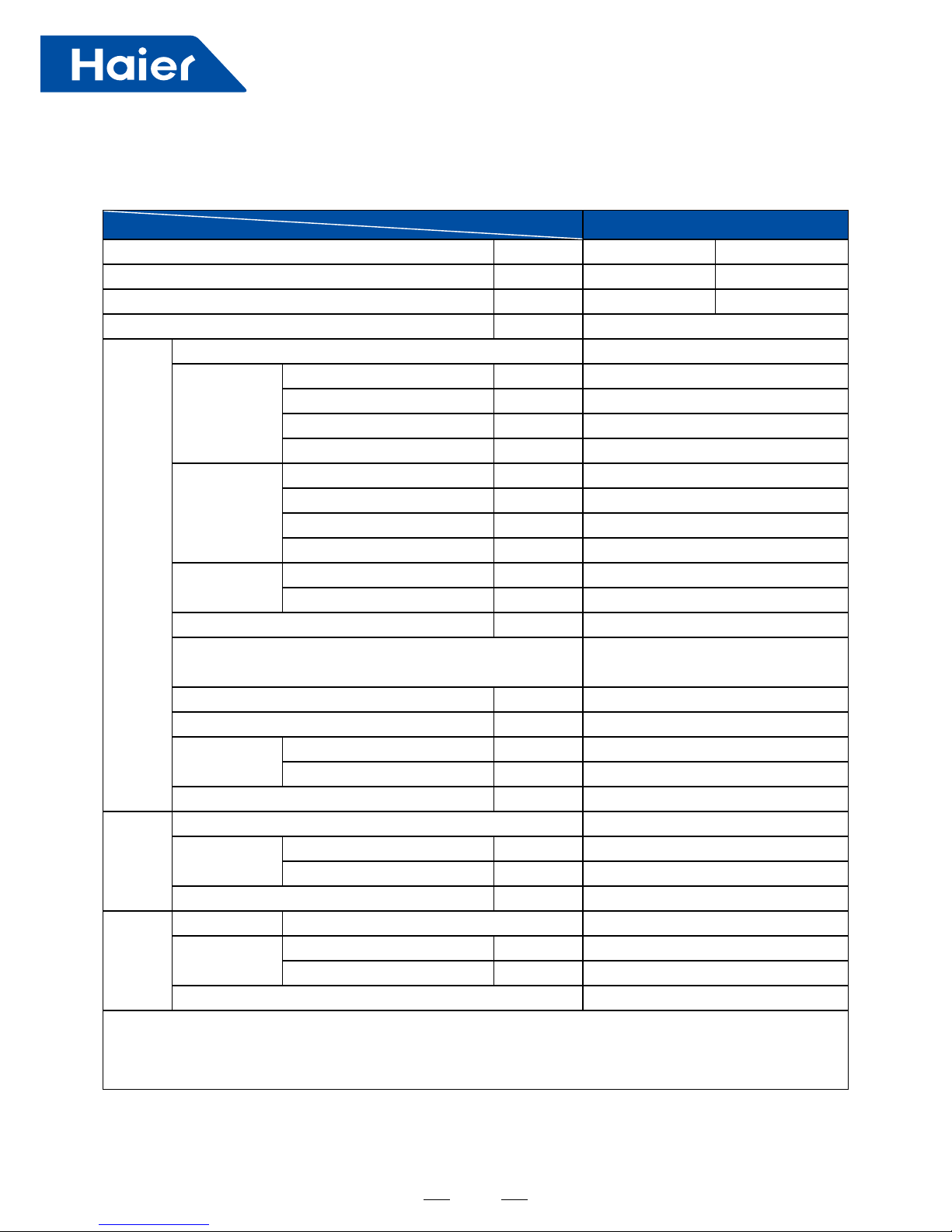

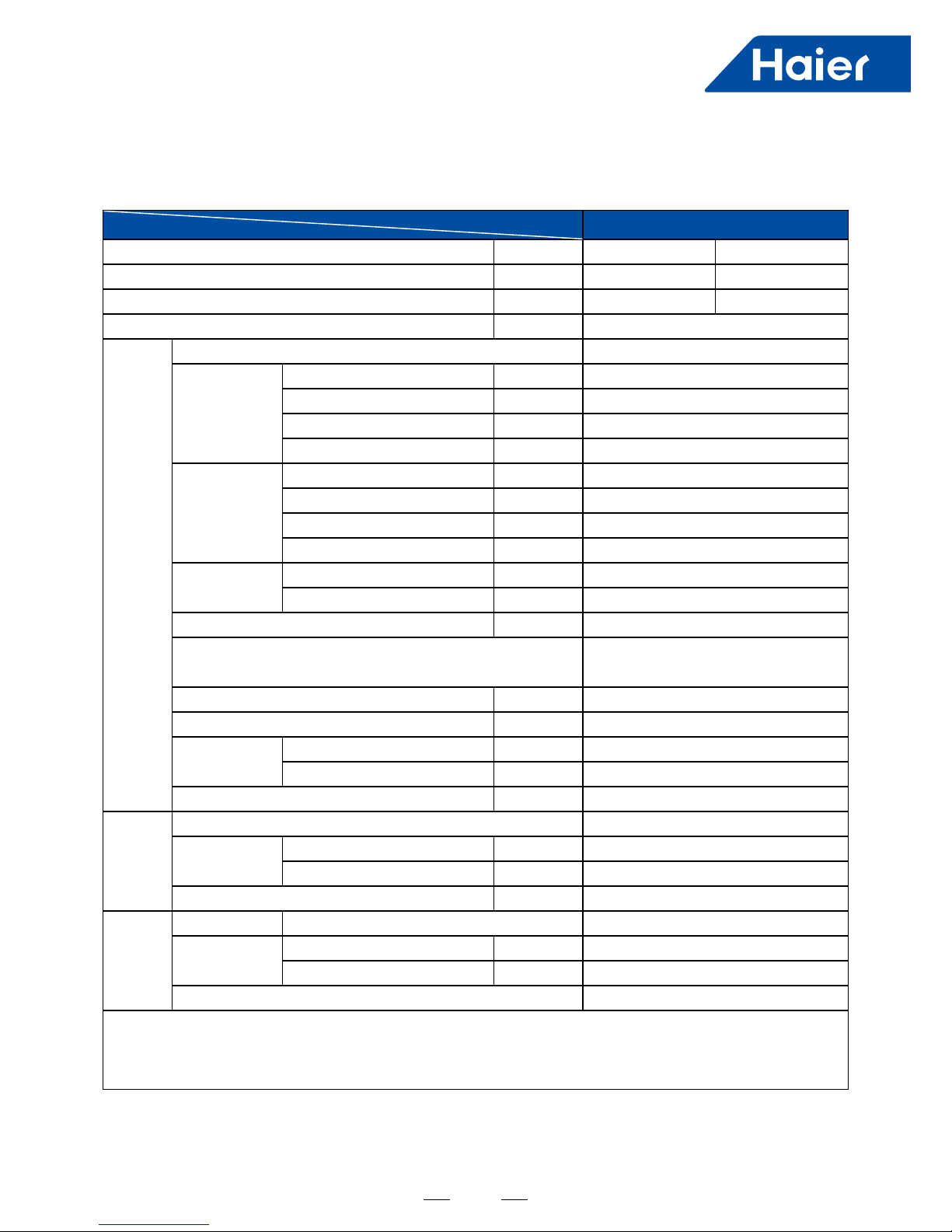

2. Specication

Item Model AB25S2SC1FA

Function —— Cooling Heating

Capacity W 2600 3200

Sensible heat ratio W 0.71 /

Dehumidifying capacity 10-³xm³/h 1.0

Indoor unit

Power supply 1PH, 220-240V~, 50/60Hz

Fan

Type × Number —— Centrifugal*1

Speed(H-M-L) r/min 690/620/560/500

Fan motor output/input power W 10/15

Air-ows (H-M-L) m³/h 620/520/450/350

Heat exchanger

Type / Diameter mm Inner grooved pipe/φ7.0

Row —— 1

Total area m² 0.272

Temp.scope °C 2.0-7.0

Dimension

(LxWxH)

External mmxmmxmm 570*570*260

Package mmxmmxmm 718*680*380

Drainage pipe (Material,I.D/O.D) mm PVC 26/32

Control type(Remote/Wired) Remote YR-HBS01(O) or Wired YR-E17(O)

Fresh air hole dimension mm 95

Electricity Heater kW None

Noise level

(H-M-L)

Sound power level dB(A) 52

Sound pressure level dB(A) 36/33/30/27

Weight(Net/Shipping) kg/kg 17/20

Panel

Panel model(Color) PB-700IB(White)

Dimension

External(L*W*H) mmxmmxmm 700*700*60

Package(L*W*H) mmxmmxmm 740*750*115

Weight(Net/Shipping) kg/kg 2.8/4.8

Piping

Refrigerant Type R32

Pipe

Liquid mm Φ6.35(1/4)

Gas mm Φ9.52(3/8)

Connecting method Flared

Norminal condition: indoor temperature (cooling): 27°CDB/19°CWB, indoor temperature (heating): 20°CDB

Outdoor temperature(cooling): 35°CDB/24°CWB, outdoor temperature(heating): 7°CDB/6°CWB

The noise level will be measured in the third octave band limited values, using a Real Time Analyser calibrated sound

intensity meter.

9

Item Model AB35S2SC1FA

Function —— Cooling Heating

Capacity W 3500 4000

Sensible heat ratio W 0.71 /

Dehumidifying capacity 10-³xm³/h 1.5

Indoor unit

Power supply 1PH, 220-240V~, 50/60Hz

Fan

Type × Number —— Centrifugal*1

Speed(H-M-L) r/min 690/620/560/500

Fan motor output/input power W 10/15

Air-ows (H-M-L) m³/h 620/520/450/350

Heat exchanger

Type / Diameter mm Inner grooved pipe/φ7.0

Row —— 2

Total area m² 0.544

Temp.scope °C 2.0-7.0

Dimension

(LxWxH)

External mmxmmxmm 570*570*260

Package mmxmmxmm 718*680*380

Drainage pipe (Material,I.D/O.D) mm PVC 26/32

Control type(Remote/Wired) Remote YR-HBS01(O) or Wired YR-E17(O)

Fresh air hole dimension mm 95

Electricity Heater kW None

Noise level

(H-M-L)

Sound power level dB(A) 52

Sound pressure level dB(A) 36/33/30/27

Weight(Net/Shipping) kg/kg 18.5/22

Panel

Panel model(Color) PB-700IB(White)

Dimension

External(L*W*H) mmxmmxmm 700*700*60

Package(L*W*H) mmxmmxmm 740*750*115

Weight(Net/Shipping) kg/kg 2.8/4.8

Piping

Refrigerant Type R32

Pipe

Liquid mm Φ6.35(1/4)

Gas mm Φ9.52(3/8)

Connecting method Flared

Norminal condition: indoor temperature (cooling): 27°CDB/19°CWB, indoor temperature (heating): 20°CDB

Outdoor temperature(cooling): 35°CDB/24°CWB, outdoor temperature(heating): 7°CDB/6°CWB

The noise level will be measured in the third octave band limited values, using a Real Time Analyser calibrated sound

intensity meter.

10

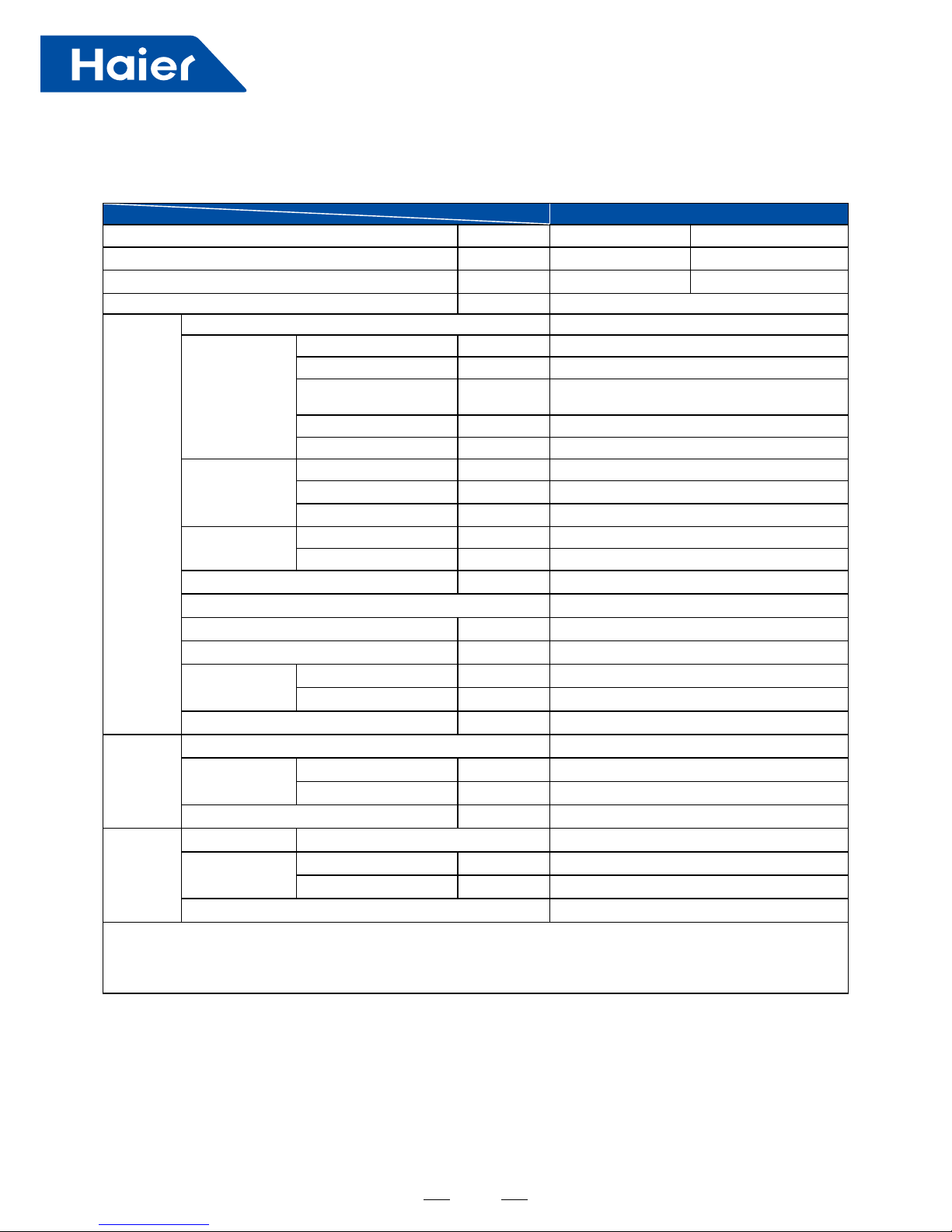

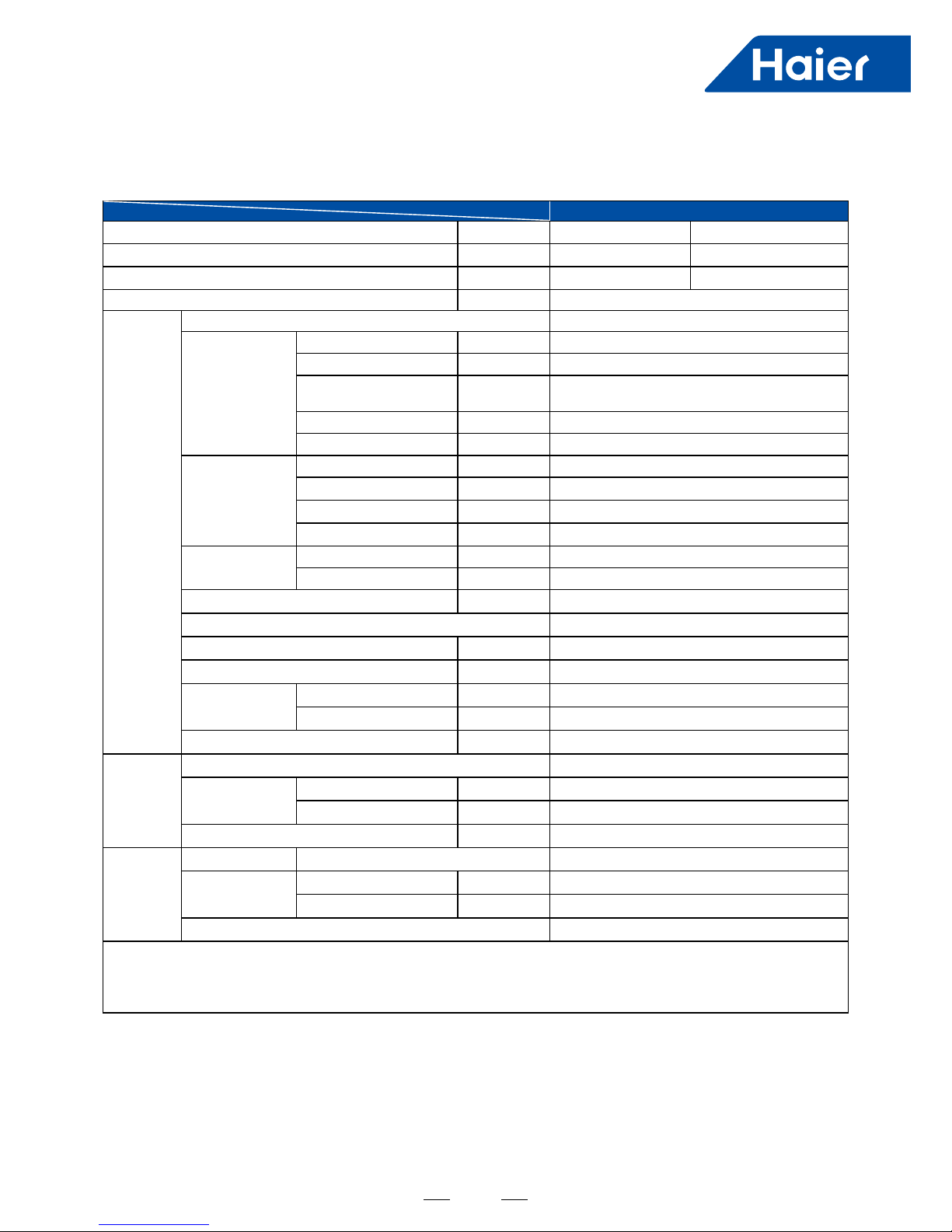

Item Model AB50S2SC1FA

Function —— Cooling Heating

Capacity W 5000 5500

Sensible Heat Ratio W 0.71 /

Dehumidifying Capacity 10-³xm³/h 2.2

Indoor Unit

Power Supply 1PH, 220-240V~, 50/60Hz

Fan

Type × Number —— Axial Fiow*1

Speed (H-M-L) r/min 800/700/600

Fan Motor Output/Input

Power

W 33/50

Air-Flows (H-M-L) m³/h 700/620/500

External Static Pressure pa 0

Heat Exchanger

Type / Diameter mm Inner Grooved Pipe/¢7.0

Row —— 2

Total Area m² 1.25

Dimension

(LxWxH)

External mmxmmxmm 570x570x260

Package mmxmmxmm 718x680x380

Drainage Pipe (Material, I.D/O.D) mm PVC 27/31

Control Type (Remote/Wired) Remote YR-HBS01

Fresh Air Hole Dimension mm None

Electricity Heater kW None

Noise Level

(H-M-L)

Sound Power Level dB (A) 55

Sound Pressure Level dB (A) 42/37/35

Weight (Net/Shipping) kg/kg 18.5/22

Panel

(Optional)

Panel Model (Color) PB-700KB

Dimension

External (L*W*H) mmxmmxmm 700/700/60

Package (L*W*H) mmxmmxmm 740/750/115

Weight (Net/Shipping) kg/kg 2.8/4.8

Piping

Refrigerant Type R32

Pipe

Liquid mm Φ6.35 (1/4)

Gas mm Φ12.7 (1/2)

Connecting Method Flared

Norminal condition: indoor temperature (Cooling): 27℃DB/19℃WB, indoor temperature (Heating): 20℃DB

Outdoor temperature (Cooling): 35℃DB/24℃WB, outdoor temperature (Heating): 7℃DB/6℃WB

The noise level will be measured in the third octave band limited values, using a Real Time Analyser calibrated

sound intensity meter.

11

Item Model AB71S2SG1FA

Function —— Cooling Heating

Capacity W 7100 8000

Sensible Heat Ratio W 0.71 /

Dehumidifying Capacity 10-³xm³/h 1.0

Indoor Unit

Power Supply 1PH, 220-240V~, 50/60Hz

Fan

Type × Number —— Centrifugal*2

Speed (H-M-L) r/min 650/600/550/500

Fan Motor Output/Input

Power

W 45/50

Air-Flows (H-M-L) m³/h 1260/1070/820/680

External Static Pressure pa 0

Heat Exchanger

Type / Diameter mm Inner Grooved Pipe/¢7.0

Row —— 2

Total Area m² /

Temp.Scope °C 2.0-7.0

Dimension

(LxWxH)

External mmxmmxmm 840*840*204

Package mmxmmxmm 990*990*310

Drainage Pipe (Material, I.D/O.D) mm PVC 26/32

Control Type (Remote/Wired) Remote YR-HBS01(O)

Fresh Air Hole Dimension mm None

Electricity Heater kW None

Noise Level

(H-M-L)

Sound Power Level dB (A) 55

Sound Pressure Level dB (A) 36/33/29/26

Weight (Net/Shipping) kg/kg 27/32

Panel

(Optional)

Panel Model (Color) PB-950KB

Dimension

External (L*W*H) mmxmmxmm 950/950/50

Package (L*W*H) mmxmmxmm 1000/1000/110

Weight (Net/Shipping) kg/kg 6.5/9

Piping

Refrigerant Type R32

Pipe

Liquid mm Φ9.52 (3/8)

Gas mm Φ15.88 (5/8)

Connecting Method Flared

Norminal condition: indoor temperature (Cooling): 27℃DB/19℃WB, indoor temperature (Heating): 20℃DB

Outdoor temperature (Cooling): 35℃DB/24℃WB, outdoor temperature (Heating): 7℃DB/6℃WB

The noise level will be measured in the third octave band limited values, using a Real Time Analyser calibrated

sound intensity meter.

12

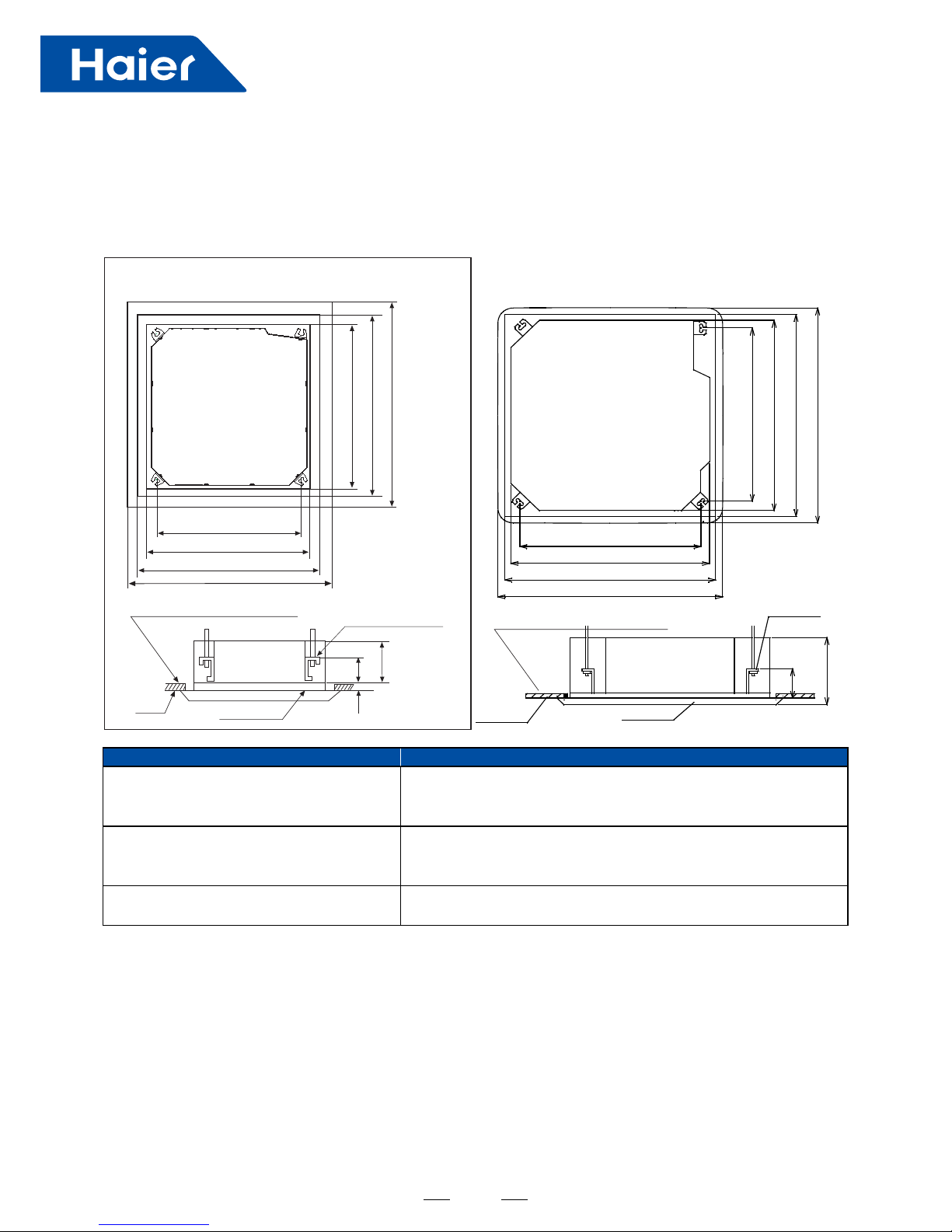

3. Dimension

AB25S2SC1FA AB35S2SC1FA AB50S2SC1FA

13

840

840

840

80

5454

80 90

950

950

90 80

168

275

105

288

80

90

90

105

80

80

90

90

80

90

54 54

71

71

191

191

75

128

90 90

105

105

80

128

80

80 80

54 54

90

90

90

105

90

80

183

143

178

152

93

138

AB71S2SG1FA

14

4. Wiring Diagram

AB25S2SC1FA AB35S2SC1FA

TO OUT DOOR

0150523323

BM1-1

BM1-7

BM1-8

TYPE DEFINE

OFFOFF

BM1-2 BM1-3

BTU

B:BLACK

R:RED

W:WHITE

Y/G:YELLOW/GREEN

TEMP.

SENSOR

ROOM

SENSOR

FLOAT

SWITCH

HEATER

PUMP

UP/DOWN

CN9

CN1

CN6

PANNEL

CN4

CN11

CN19

CN13

CN3

ON

CN7

CN21

T5A/250VAC

FUSE

BM3

2

1

3

B

W

R

Y/G

OFF OFF OFF

ON OFF OFF

OFF ON OFF

ON ON OFF

OFF OFF ON

ON OFF ON

OFF ON ON

ON ON ON

9000

12000

18000

24000

28000

36000

48000

60000

NOTE1.DASHED PART ARE OPTIONAL.

2. USER SHOULD NOT TO SET BM1 AND BM3

CH1

OFF OFF

BM1-4

BM1-5

BM1-6

OFF

OFF

CN16

G

CN8

G

TEMP.

PIPING

DC FAN

ROOMCARD

U-HOME

WIRED

CONTROLLER

B

A

C

BA

C

REMOTE

CENTRAL

87654321

ON

BM1

OFF

87654321

N

OFF

Room card

available

unavailable

ON

AB25S2SC1FA

AB35S2SC1FA

Default

15

TO OUT DOOR UNIT

SW1-1

TYPE DEFINE

Cassette

Y/G:YELLOW/GREEN

RD:RED WHT:WHITE

BLK:BLACK

******************

.

SENSOR

CN1

CN11

CN19

SW3(BM3)

2

1

3

BLK

WHT

RD

OFF OFF ON

9.0

10.5

NOTE:

1.DASHED PARTS ARE OPTIONAL.

2.USER SHOULD NOT CHANGE THE

DIP SWITCH SW1 SW3 WITHOUT GUIDENCE

3.SW3-5->SW3-8 ARE USED FOR WIRED CONTROLLER

ADRESS SELECT. SW3-1->SW3-4 ARE RESERVED.

CH1

OFF

OFF

TEMP

.

PIPING

DC FAN MOTOR

BA

C

87654321

SW1(BM1)

87654321

N

(SLIM)

Room card

available

ON

Y/G

0150527035

L

WiFi

MODULE

B

A

C

WIRED

CONTROLLER

M

SENSOR

TEMP.

ROOM

ROOM CARD

CN3

CN6

T5A 250VAC

CN16

DRAIN

PUMP

M

CN9

CN10

CN4

FUSE

FLOAT

SWITCH

CN13

INDOOR UNIT

MAIN CONTROL

BOARD

I.R .RECEIVER :

INFRARED REMOTE

RECEIVER .

TEMP.:TEMPERATURE

ON

OFF

ON

62NC

A

B

M

FRESH AIR MOTOR /

EXTERNAL ALARM OUTPUT

(FUNCTION IN FUTURE )

( Contact rating_230VAC,3A)

CAPACITY

(KW)

SW1-2

SW1-3

OFF ON

ON

OFF

ON

ON

12.5

ON

ON

ON

14.0

SW1-4

unavailable

OFF

ON

SW1-5

COOL HEAT

COOL ONLY

HEAT PUMP

SW1-6

SW1-7

SW1-8

OFF

OFF

ON

INDOOR UNIT

TERMINAL BLOCK

CN8

7.1

ON

ON

OFF

ELECTRIC HEATING TERMINAL

RATING_230VAC,3A

CONNECT TO THIRD PARTY RELAY

CN15

ELECTRIC HEATING

THERMOSTAT / FUSE

(INSIDE PANEL,

WITHOUT

DIGITAL

DISPALY)

INFRARED

REMOTE

RECEIVER

CN21

5.0

ON

OFF

OFF

ON

OFF

OFF

3.5

AB50S2SC1FA

16

TO OUT DOOR UNIT

SW1-1

TYPE DEFINE

Cassette

Y/G:YELLOW/GREEN

RD:RED WHT:WHITE

BLK:BLACK

******************

.

SENSOR

CN1

CN11

CN19

SW3(BM3)

2

1

3

BLK

WHT

RD

OFF OFF ON

9.0

10.5

NOTE:

1.DASHED PARTS ARE OPTIONAL.

2.USER SHOULD NOT CHANGE THE

DIP SWITCH SW1 SW3 WITHOUT GUIDENCE

3.SW3-5->SW3-8 ARE USED FOR WIRED CONTROLLER

ADRESS SELECT. SW3-1->SW3-4 ARE RESERVED.

CH1

OFF

OFF

TEMP

.

PIPING

DC FAN MOTOR

BA

C

87654321

SW1(BM1)

87654321

N

(SLIM)

Room card

available

ON

Y/G

0150527033

L

I.R .RECEIVER

(WITH DIGITAL

DISPLAY)

WiFi

MODULE

.

B

A

C

WIRED

CONTROLLER

M

SENSOR

TEMP

.

ROOM

ROOM CARD

CN3

CN6

T5A 250VAC

CN16

DRAIN

PUMP

M

CN9

CN10

CN4

CN14

FUSE

FLOAT

SWITCH

CN13

CN4

CN3

CN2

CN7

CN1

CN6

INTELLIGENT

MOVE EYE DEVICE

M

M

LOUVER

STEP MOTOR4

LOUVER

STEP MOTOR3

M

M

LOUVER STEP

MOTOR2

LOUVER STEP

MOTOR1

INDOOR UNIT

MAIN CONTROL

BOARD

I.R .RECEIVER :

INFRARED REMOTE

RECEIVER .

TEMP.: TEMPERATURE

ON

OFF

ON

62NC

A

B

M

FRESH AIR MOTOR /

EXTERNAL ALARM OUTPUT

(FUNCTION IN FUTURE )

( Contact rating_230VAC,3A)

CAPACITY

(KW)

SW1-2

SW1-3

OFF ON

ON

OFF

ON

ON

12.5

ON

ON

ON

14.0

SW1-4

unavailable

OFF

ON

SW1-5

COOL HEAT

COOL ONLY

HEAT PUMP

SW1-6

SW1-7

SW1-8

OFF

OFF

ON

INDOOR UNIT

TERMINAL BLOCK

CN8

7.1

ON

ON

OFF

ELECTRIC HEATING TERMINAL

RATING_230VAC,3A

CONNECT TO THIRD PARTY RELAY

CN15

ELECTRIC HEATING

THERMOSTAT / FUSE

AB71S2SG1FA

17

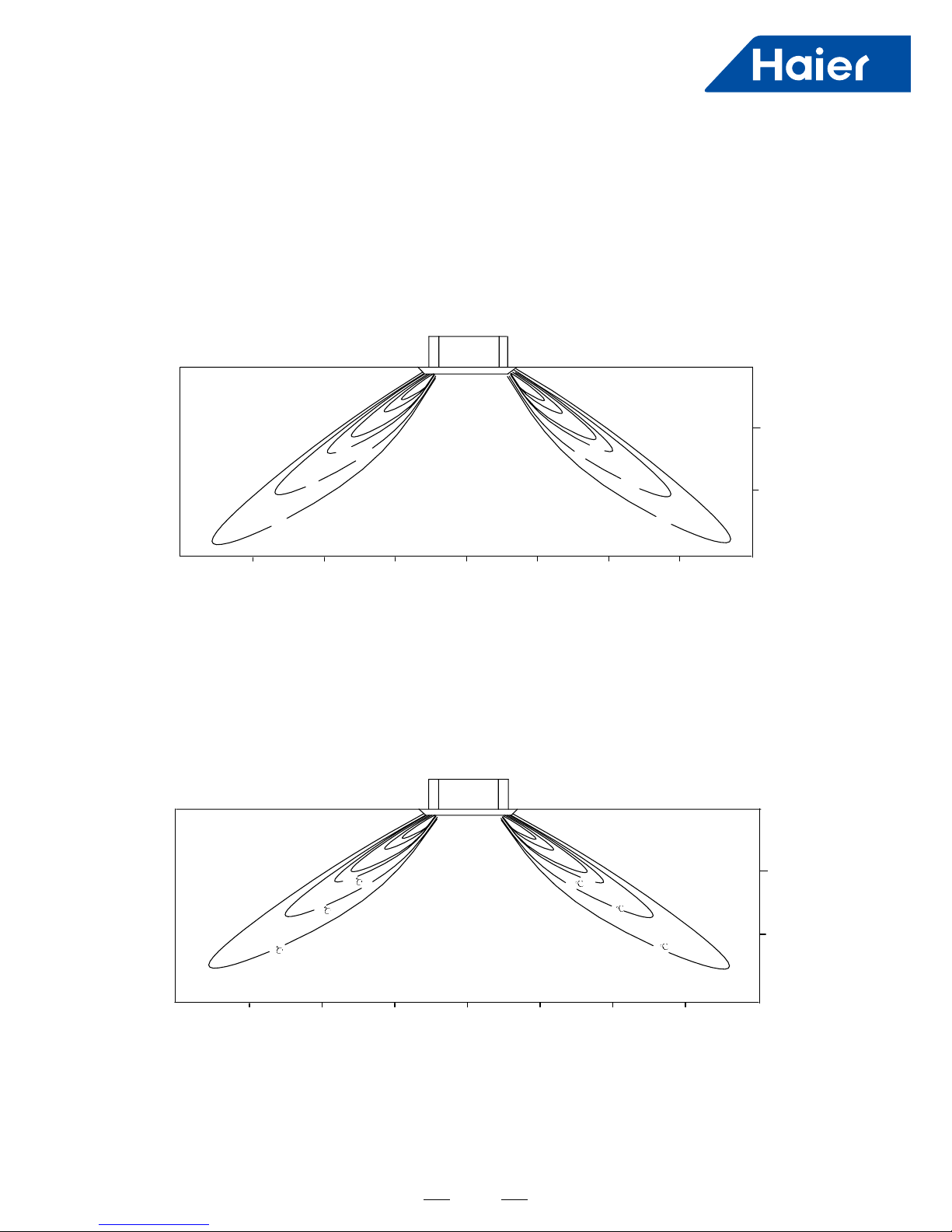

5. Air Velocity and Temperature Distribution

2m2m

1m

1m

4m

3m

3m

4m

0m

1.5m/s

1.5m/s

1.0m/s

1.0m/s

0.5m/s

2.7m

2m

1m

0m

0.5m/s

a. Cooling / air velocity distribution

Cooling

Blowy angle: 40

Air velocity distribution

b. Cooling / temperature distribution

Cooling

Blowy angle:4 0

Temperature distribution

2.7m

27

25

22

27

25

22

4m

3m

2m2m

1m

1m

3m

4m

0m

2m

1m

0m

AB25S2SC1FA AB35S2SC1FA AB50S2SC1FA AB71S2SG1FA

18

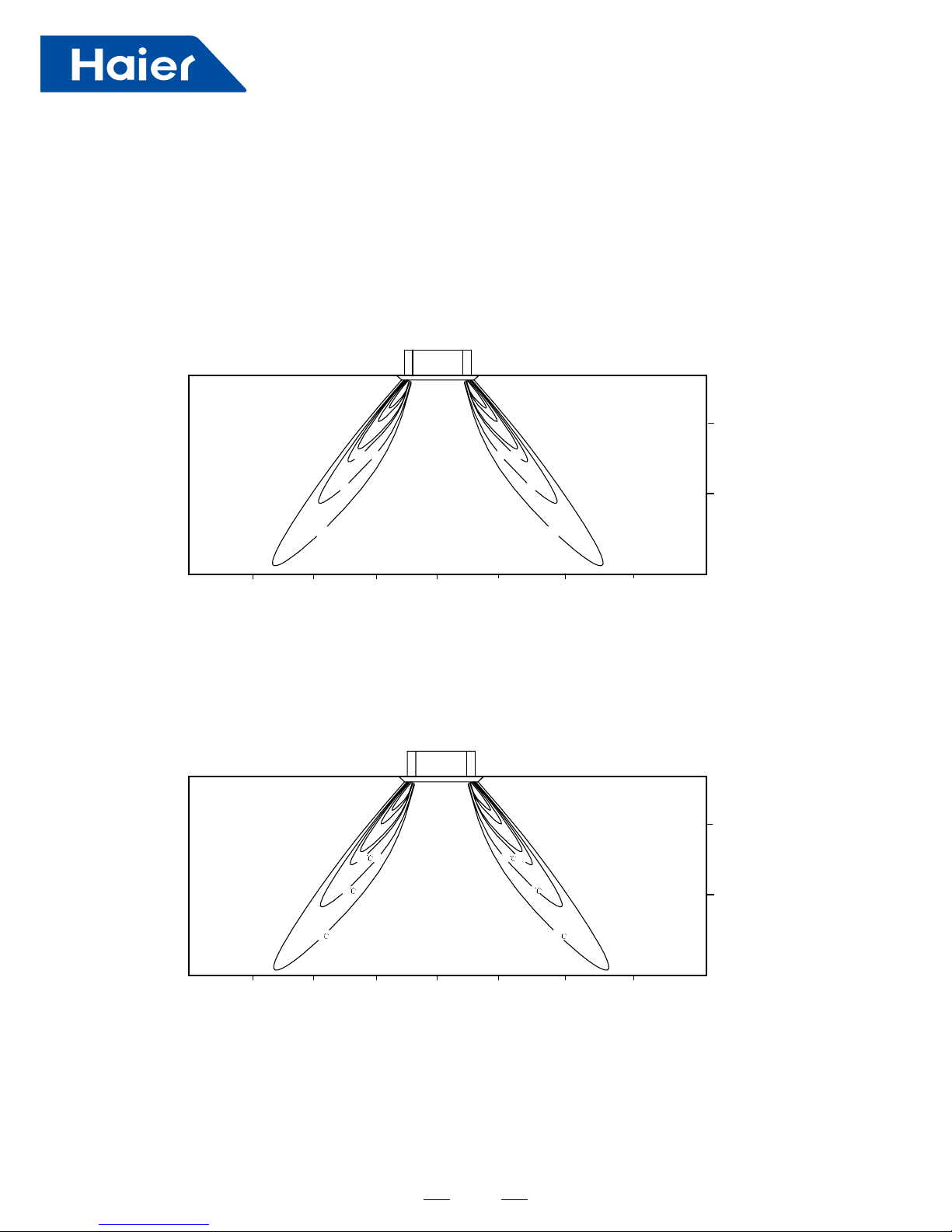

c. Heating / air velocity distribution

Heating

Blowy angle:70

Air velocity distribution

d.

Heating / temperature distribution

Heating

Blowy angle:70

Temper

Ature distribution

2.7m

2m

1m

0m

1.5m/s

1.5m/s

1.0m/s

1.0m/s

0.5m/s

2m2m

1m

1m 3m

3m

4m4m

0m

0.5m/s

22

27

25

22

25

27

2.7m

2m

1m

0m

2m2m

1m

1m 3m

3m

4m4m

0m

19

0.0

5.0

10.0

15.0

20.0

25.0

30.0

35.0

40.0

45.0

50.0

55.0

2

5.

0

3

1.

5

4

0.

0

5

0.

0

6

3.

0

8

0.

0

1

00

.0

1

25

.0

1

60

.0

2

00

.0

2

50

.0

3

15

.0

4

00

.0

5

00

.0

6

30

.0

8

00

1

.0

00

0

1

.

0

25

0

1

.

0

60

0

2

.

0

00

0

2

.

0

50

0

3

.

0

15

0

4

.

0

00

0

5

.

0

00

0

6

.

0

30

0

8

.

0

00

1

0

0

.

0

0

0

1

0

2

.0

5

00

1

6

.

0

0

0

2

0

0

.0

0

00

.0

Third octave band frequency Hz

Sound pressure level DB

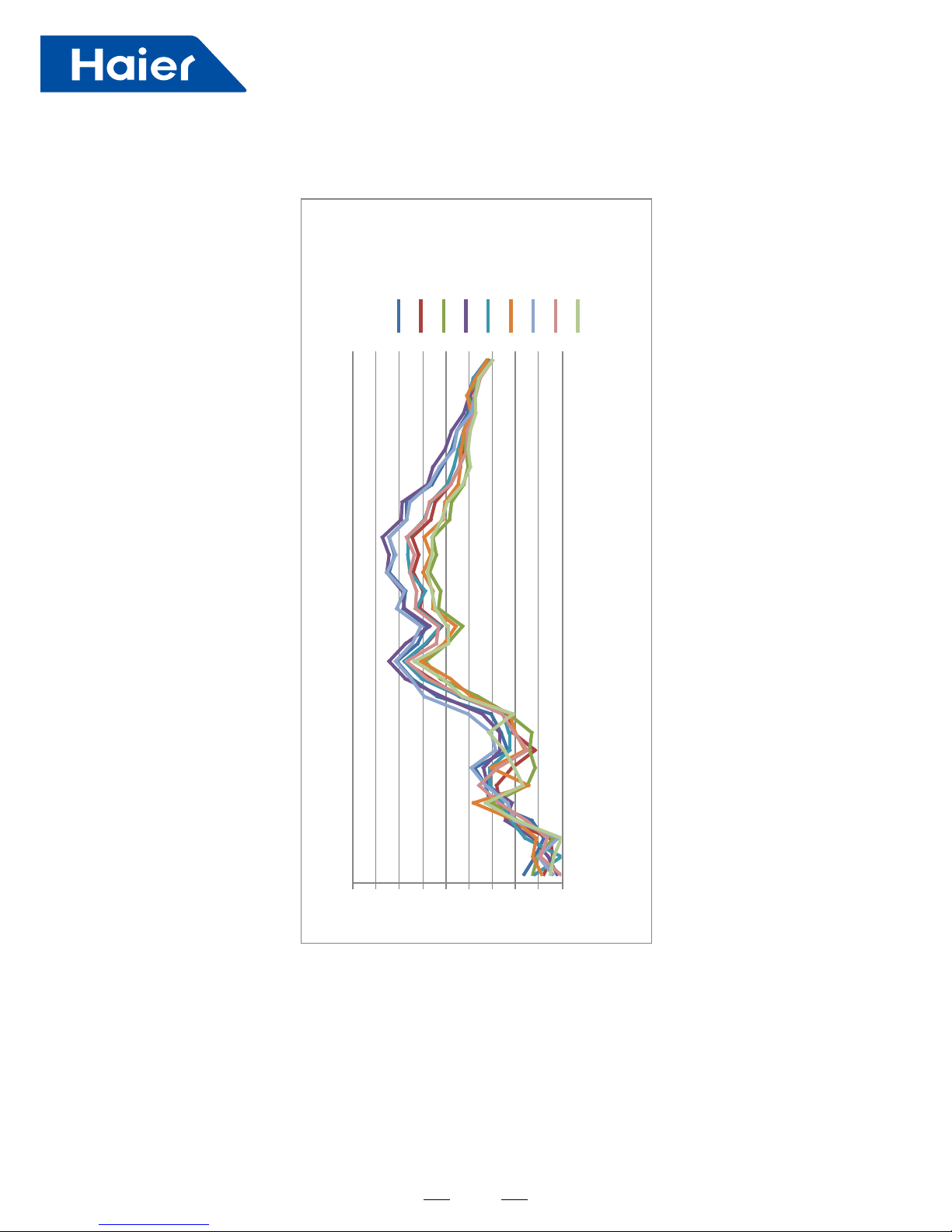

cooling high

cooling med

cooling low

fan high

fan med

fan low

heating high

heating med

heating low

1/3 octave band noise level-AB50S2SC1FA

Third octave band frequency Hz

Noise level-AB24ES1ERA (S)

8

11

41

71

02

32

62

92

23

53

83

14

44

74

05

35

2

5

3

1.

5

4

0

5

0

6

3

8

0

1

00

1

25

1

60

2

00

2

50

3

15

4

00

5

00

6

30

8

00

1

00

0

1

25

0

1

60

0

2

00

0

2

50

0

3

15

0

4

00

0

5

00

0

6

30

0

8

00

0

1

00

00

1

25

1

00

60

00

0

2

00

00

Sound pressure level DB

wol gnitaeh

elddim gnitaeh

hgih gnitaeh

wol gnilooc

elddim gnilooc

hgih gnilooc

wol naf

elddim naf

hgih naf

6. Sound Pressure level

20

0.00

5.00

10.00

15.00

20.00

25.00

30.00

35.00

40.00

45.00

2

5

4

0

6

3

1

0

0

1

6

0

2

5

0

4

0

0

6

3

0

1

0

0

0

1

6

0

0

2

5

0

0

4

0

0

0

6

3

0

0

1

0

0

0

0

1

6

0

0

0

Third octave band frequency Hz

1/3 octave band noise level-AB71S2SG1FA

Fan-high

Fan-med

Fan-low

Coo ling-high

Coo ling-med

Coo ling-low

Hea ting-high

Hea ting-med

Hea ting-low

Sound pressure level DB

21

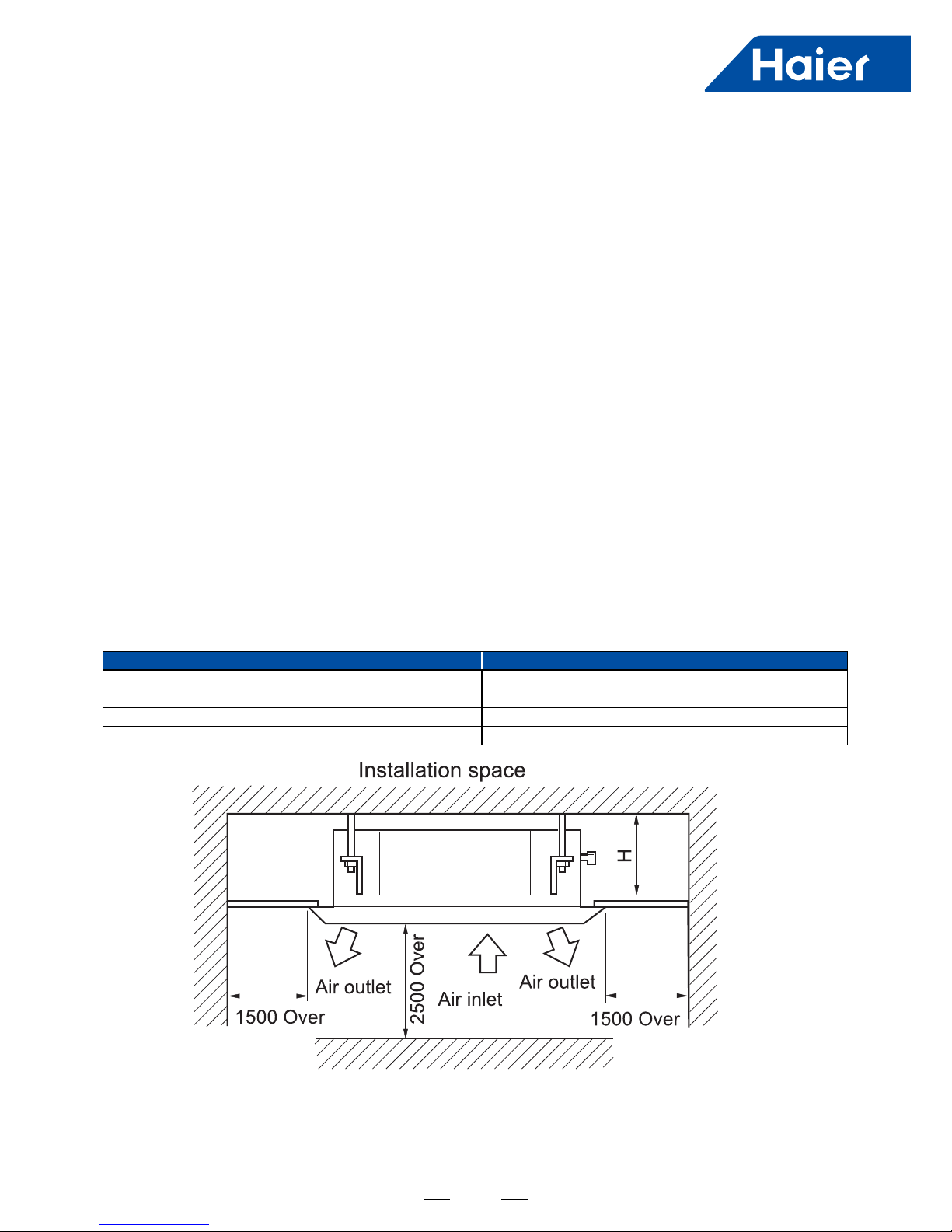

7. Installation

①

Before Installation

②

Selection Of Installation Place

<Don't discard any accessories until comp>

(1) Installation place shall meet the following and agreed by customers

(2) Ceiling height

Indoor unit can be installed on ceiling of 2.5-3m in height. (Refer to foeld setting and installation manual of

ornament panel.)

(3) Install suspending bolt.

Check if the installation place is strong enough to hold weight. Take necessary measures in case it is not safe.

(Distance between holes are marked on paper pattern. Refer to paper pattern for place need be reinforced)

• Determine the way tocarry unit toinstallation place.

• Don't remove packing until unit reaches installation place.

• If unpacking is unkavoidable, protect unit properly.

• Place where proper air ow can be ensured.

• Noblock toair ow.

• Water drainage is smpoth.

• Place strong enough to support unit weight.

• Place where inclination is not evident on ceiling.

• Enough space for mainenance.

• Indoor and outdoor unit piping length is within limit. (Refer to Installation Manual for outdoor unit.)

• Indoor and outdoor unit, power cable, inter unit cable are at least 1m away fromT.V. radop. This is helpful to avoid

picture disturbance and noise. (Even if 1m iskept, noise can still appear if radio wave is strong)

Model H

AB25S2SC1FA AB35S2SC1FA AB50S2SC1FA 320

AB25S2SC2FA AB35S2SC2FA AB50S2SC2FA 320

AB50S2SF1FA 236

AB71S2SG1FA 257

22

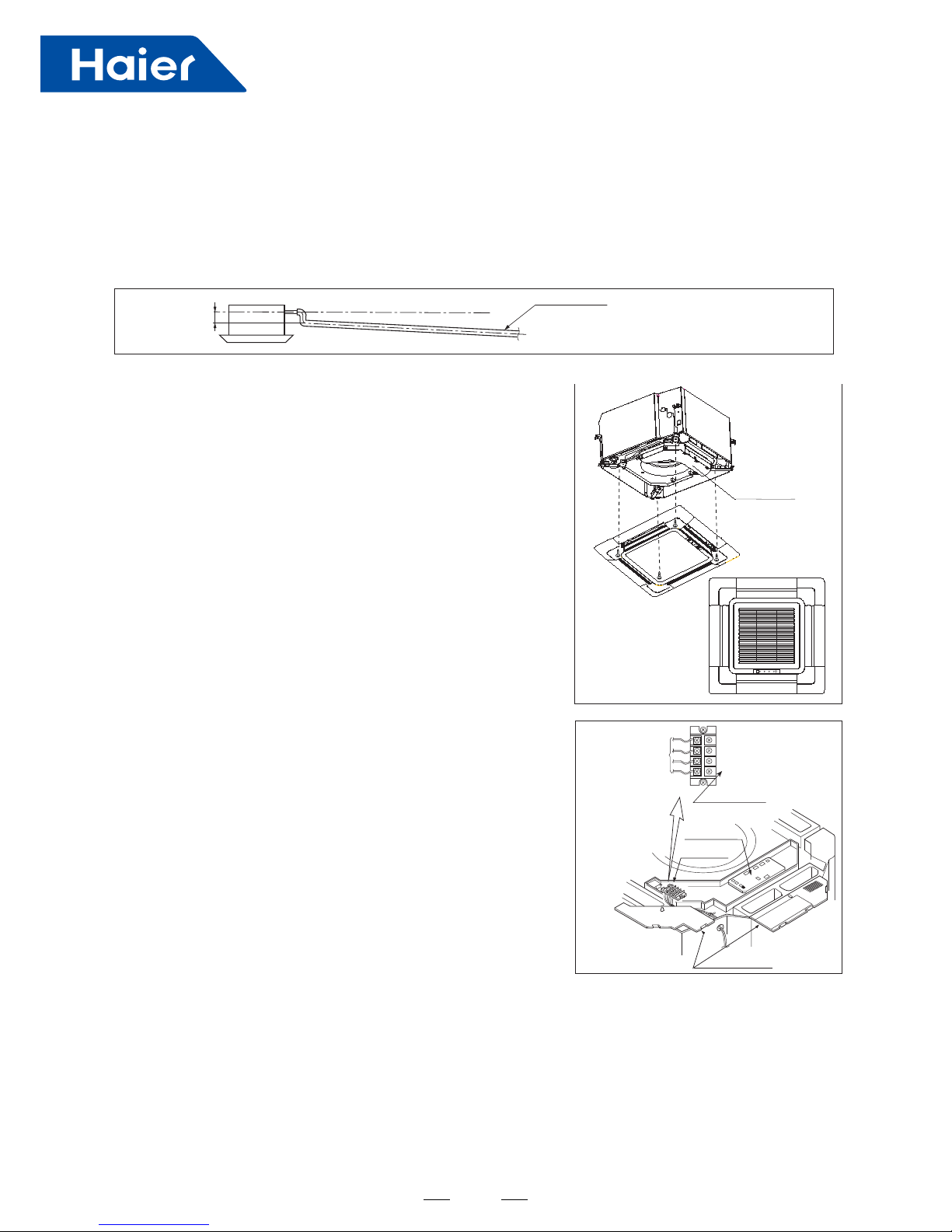

Indoor Unit Panel

AB25S2SC1FA

AB35S2SC1FA

AB50S2SC1FA

PB-700IB

AB25S2SC2FA

AB35S2SC2FA

AB50S2SC2FA

PB-620KB

AB50S2SF1FA

AB71S2SG1FA

PB-950KB

(2) Cut an opening in ceiling for installation if necessary. (When ceiling already exists.)

(3) Install a suspending bolt. (Use a M10 bolt)

• Refer to paper pattern for dimension of ceiling hole.

• Connect all pipings (Refrigerant, water drainage), wirings (Inter unit cable) to indoor unit, before installation.

• Cut a hole in ceiling, may be a frame should be used to ensure a smooth surface and to prevent vibration.

• Contact your real estate dealer

• To support the unit weight, anchor bolt shall be used in the case of already exists ceiling. For new ceiling, use

builtin type bolt or parts prepared in the eld.

• Before going on installing adjust space between ceiling.

Note: All the above mentioned parts shall be prepared in eld.

③

Preparation for the Installation

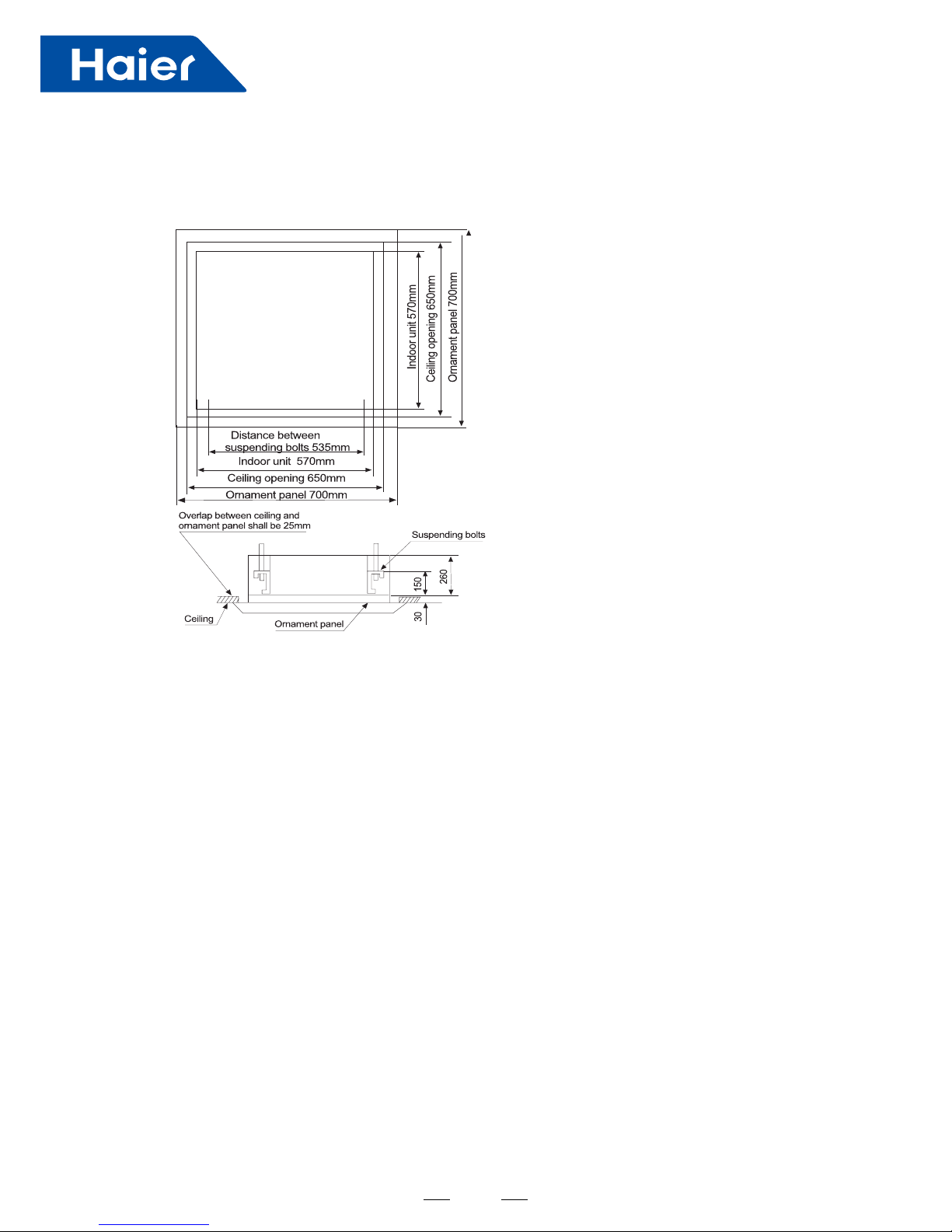

(1) Position of ceiling opening between unit and suspending bolt.

236

AB25S2SC1FA AB35S2SC1FA AB50S2SC1FA

AB50S2SF1FA AB71S2SG1FA

AB25S2SC2FA AB35S2SC2FA AB50S2SC2FA

Distance between

Distance between

Indoor unit 570mm

Ceiling opening 650mm

Ornament panel 700mm

Indoor unit 840mm

Ceiling opening 890mm

Ornament panel 950mm

suspending bolts 535mm

suspending bolts 765mm

Indoor unit 570mm

Indoor unit 840mm

Ceiling opening 650mm

Ceiling opening 890mm

Ornament panel 700mm

Ornament panel 950mm

Overlap between ceiling and

ornament panel shall be 25mm

Overlap between ceiling and

ornament panel shall be 25mm

Suspending bolts

Suspending bolts

Ceiling

Ceiling

Ornament panel

Ornament panel

150

130

260

30

Distance between sus

pending bolts 765mm

236

AB50S2SF1FA AB71S2SG1FA

Distance between

Indoor unit 840mm

Ceiling opening 890mm

Ornament panel 950mm

suspending bolts 765mm

Indoor unit 840mm

Ceiling opening 890mm

Ornament panel 950mm

Overlap between ceiling and

ornament panel shall be 25mm

Suspending bolts

Ceiling

Ornament panel

130

Distance between sus

pending bolts 765mm

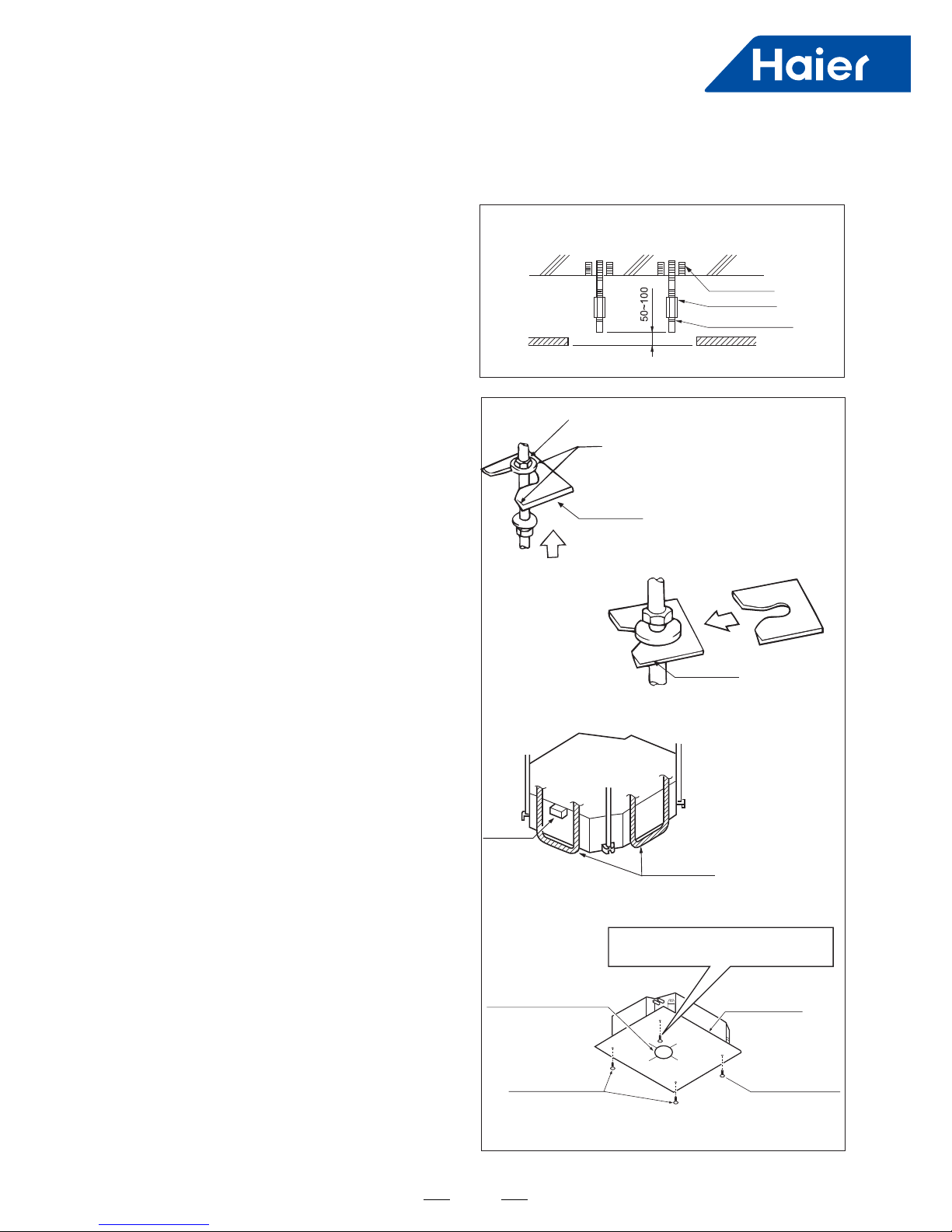

23

(5) Remove the washer mounlting ② and tighten the

nut above.

(6) Remove the paper pattern.

④

Installation of Indoorunit

(1) Install unit temporally

Put suspending bracket on the suspending bolt.

Be sure to use nut and washer at both ends of the

bracket.

(2) As for the dimensions of ceiling hole, see paper

pattern. Ask your real estate dealer for details.

Center of the hole is marked on the paper pattern.

Center of the unit is marked on the card in the unit

and on the paper pattern.

Mount paper pattern ⑤ onto unit using 3 screws

⑥

Fix the corner of the drain pan at piping outlet.

In The Case of New Ceiling

<Aer Inslallalion on the Ceiling>

(3) Adjust unit to its right position.

(Refer to preparation for the installation-(1))

(4) Check units horizontal level.

Watert pump and ating switch is installed inside

indoor unit, check four corners of the unit for its level

using horizontal compartor or PVC tube with water. (If

unit is tilting against the direction of water drainage,

problem may occur on oating switch, causing water

leakage.)

Installation example

Roof

Anchor bolt

Long nut

Suspending bolt

Ceiling

Nut (Prepare in feild)

Washer (Prepared in feild)

Suspending bolts

Fasten (Double nuts)

Insert

Washer fixing pad

(Prepared in feild)

[Secure the washer firmly]

Polythene pipe

Screws at the piping outlet is

fixed at the cornerof drain pan.

Center of ceiling hole

Paper pattern

Screw (Accessory)

Paper pattern⑤

Screw (Accessory)

[Fix the paper pattern]

Level

24

In the Case of Ceiling Already Exisls

(1) Install unit temporally

Put suspending bracket on the suspending bolt.

Be sure touse nut and washer at both ends of the bracket. Fix the bracket rmly.

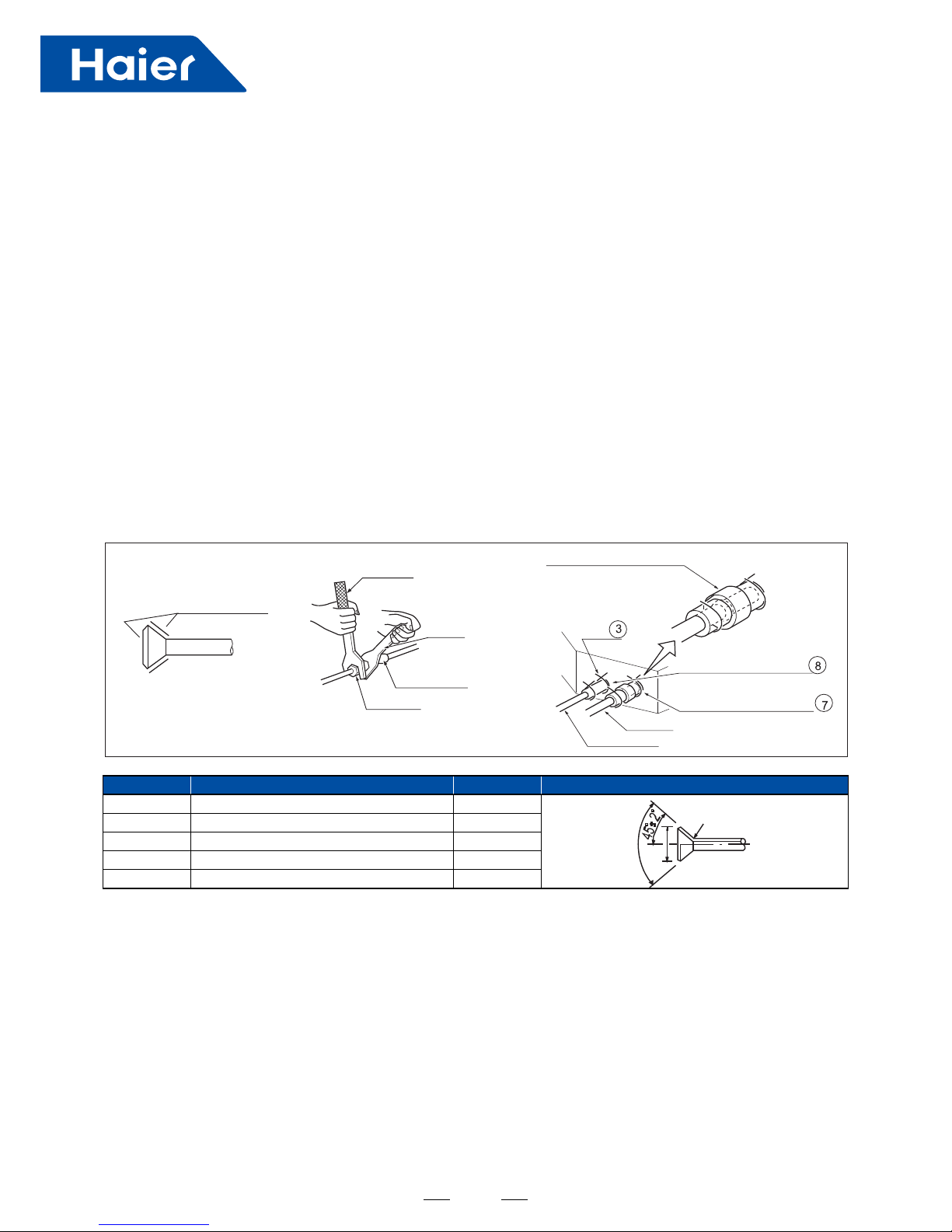

• Outdoor is precharged with refrigerant.

• Be sure tosee the Fig.1, when connecting and removing piping from unit.

• For the size of the are nut, please refer to Table 1.

• Apply refrigerant oil at both inside and outsid of lare nut. Tighten it band tight 3-4 turns then tighten it.

• Use torque specied in Table 1. (Too much force may damage are nut, causing gas leakage).

• Check piping joints for gas leakage. Insulate piping as shown in Fig. below.

• Cover joint of gas piping and insulator 7 with seal.

(2) Adjust the height and position of the unit. (Refer to preparation for the installation (1) ).

(3) Proceed with ③ and ④ of "In the case of new ceiling".

⑤

Refrigerant Piping (As for outdoor piping, please refer to installalion manual of outdoor unit.)

Apple refrigerant oil

Torque spanner

Medium size seal pad ⑪ (accessory)

Cover the piping joint

with seal pad)

Clamp

Liquid pipe

Gas pipe

Insulator (accessory)

(For liquid pipe)

Insulator (accessory)

For gas pipe

Spanner

Piping joing

Flare nut

Table 1

Pipe Size Tighten Torque A (mm) Flare Shape

φ6.35 1420-1720N.cm (144-176 kgf.cm) 8.3-8.7

9.52 3270-3990N.cm (333-407 kgf.cm) 12.0-12.4

12.7 4950-6030N.cm (490-500 kgf.cm) 12.4-16.6

15.88 6180-7540N.cm (630-770 kgf.cm) 18.6-19.0

19.05 9720-11860N.cm (990-1210 kgf.cm) 22.9-23.3

A

R0.4 - 0.8

90°±0.5°

25

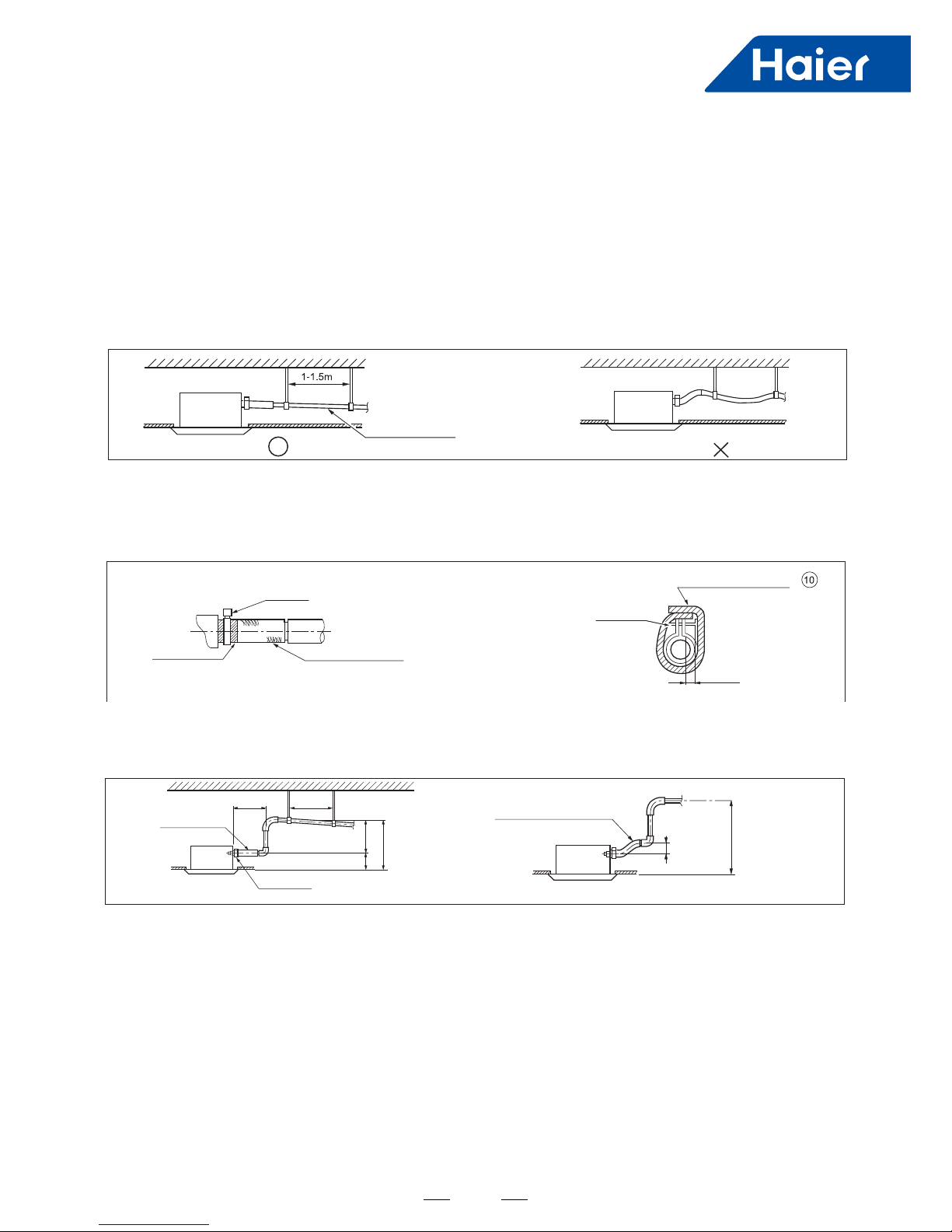

<Caulions for the Drain Waler Lifting Pipe >

Installation height shall be less than 280mm.

There should be a right angle with unit, 300mm from unit.

300mm below

1~1.5m

Clamp

(accessorry)

Drain hose

(accessory)

drain water lifting pipe

Suspending bracket

self-provided stiff pipe

75 below

500 below

(accessory)

220 280 below

500 below

⑥

Installation of Waterdrainage Pipe

(1) Install water drainage pipe

• Pipe dia, shall be equal or larger than that of unit piping. (Pipe of polyethylent; size 25mm; O.D 32mm)

• Drain pipe should be short, with a downward slope at least 1/100 toprevent air bag from happening.

• If downward slope can t be made, take other measures to lift it up.

• Keep a distance of 1-1.5m between suspending brackets, tomake water hose straight.

• Use the self-provided stiff pipe and clamp ① with unit. Insert water pipe into water plug until it reaches the white

tape. Tighten the clip until head of the screw is less than 4mm from hose.

• Wind the drain hose to the clip using seal pad ⑨ .

• Insulate drain hose in the room.

Apple refrigerant oil

Torque spanner

Medium size seal pad ⑪ (accessory)

Cover the piping joint

with seal pad)

Clamp

Liquid pipe

Gas pipe

Insulator (accessory)

(For liquid pipe)

Insulator (accessory)

For gas pipe

Spanner

Piping joing

Flare nut

Table 1

Apple refrigerant oil

Torque spanner

Medium size seal pad ⑪ (accessory)

Cover the piping joint

with seal pad)

Clamp

Liquid pipe

Gas pipe

Insulator (accessory)

(For liquid pipe)

Insulator (accessory)

For gas pipe

Tape (White)

Clamp

Self-provided stiff pipe

Clamp

Large size seal pad

(accessory)

4mm below

(accessory)

Spanner

Piping joing

Flare nut

Table 1

26

The slope of water drain hose (1) shall be within 75mm, don't apply too much force on it.

If several water hoses join together, do as per following proceedures.

Specieations of the water hoses shall meet the requirements for the unit running.

Note:

(2) Check if water drainage is smooth after installation.

• Check whether indoor unit is horizontal with leveler or polythene pipe

lled with water, and check that the dimension of the ceiling opening is

correct. Take off the lever gauge before install the ornament panel.

• Fasten the screws to make the height difference between the two

sides of indoor unit less than 5mm.

• First x it with screws temporally.

• Fasten the two temporally xing screws and other two, and tighten the

four screws.

• Connect the wires of synchro-motor.

• Connect the wire of signal.

• If no response of remote controller, check whether the wiring is

correct, restart remote controller 10 seconds after shut off power supply.

• Install the panel board in the direction shown in the gure. The

incorrect direction will result in water leakage, meanwhile swing and

signal receiving are displayed that cannot be connected.

• Charge, through air outlet or inspecting hole, 1200ccd water to see

water drainage.

• Check water drainage in cooling operation.

<Limits of Panel Board Installalion>

After Wiring

300mm below

1~1.5m

Clamp

(accessorry)

Over 100

Drain hose

(accessory)

drain water lifting pipe

Suspending bracket

self-provided stiff pipe

75 below

500 below

(accessory)

Connect water hoses

with at joint.

220 280 below

500 below

75 below

500 below

Electric control box

Connect with

outdoor unit

Terminal block

PCB on

indoor unit

Terminal block

Cover of controll box

27

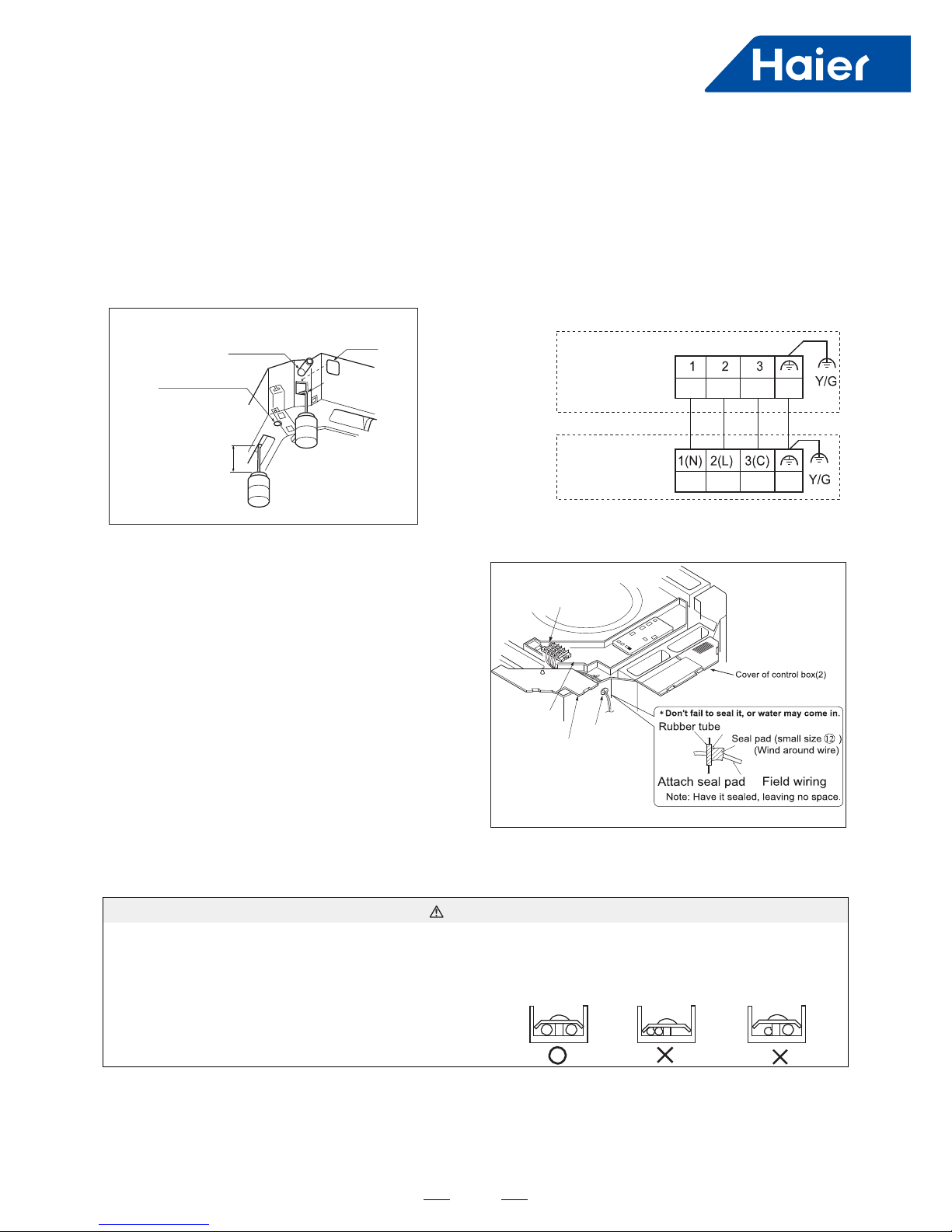

⑦

WIRING

• All supplied parts. materials and wiring operation must in

appliance with local code and regulations.

• Use copper wire only.

• When make wiring, please refer towiring diagram also.

• All wiring work must be done by qualied electricians.

• A circuit breaker must be installed, which can cut power

• supply toall system.

• See Installation Manual of outdoor unit for specications

of wires, circuit breaker, switches and wiring etc.

• Connecting of unit

Remove cover of switch box (1), drag wires into rubber tube

A, then, after proper wiring with other wires, tighten clamp A.

Connect wires of correct pole to the terminal block inside.

Wind sea 12 around wires. (Be sure to do that, or, dew may

occur).

• Upon connecting, replace control box cover (1) and (2).

Obscrve the following when connecting power supply

terminal block.

Don't connect wires of different specications to the same

terminal block.

(Loose wire may cause overheating of circuit)

Connect wires of same specications as shown in right Fig.

Connect wires

of the same

specications

at twosides.

Don't connect

wires of the same

specications

at one side.

Don't connect

wires of the same

specications

at one side.

WARNING:

Terminal block

Grounding lead

Cover of control box(1)

In

Out

Rubber tube A

AB25S2SC1FA

Method of water charging

Self-provided stiff pipe

Water drainage port for

maintenance

(Drain water from

this hole)

100mm

Watering can of plastic

pipe should be about

100 mm long

Charge water from

inspecting hole

Charge water from

air outlet

Indoor unit

terminal block

Outdoor unit

terminal block

Maintenance

Inspecting hole

AB35S2SC1FA

AB50S2SC1FA

AB25S2SC2FA

AB35S2SC2FA

AB50S2SC2FA

AB50S2SF1FA

AB71S2SG1FA

300mm below

1~1.5m

Clamp

(accessorry)

Over 100

Drain hose

(accessory)

drain water lifting pipe

Suspending bracket

self-provided stiff pipe

75 below

500 below

(accessory)

Connect water hoses

with at joint.

Electric control box

Connect with

outdoor unit

Terminal block

PCB on

indoor unit

Terminal block

Cover of controll box

220 280 below

500 below

• Remove cover of control box, connect 1PH power to terminal 1 and 2 on terminal block. Use remote controller to

operate the unit.

• Note, in this operation, fan will be running.

• Upon conrmation of a smooth water drainage, be sure to cut off power supply.

When Wiring is not Complele

Loading...

Loading...