Page 1

SYJS-04-2017 REV.A Edition: 2017-04

service manual

R32

Page 2

CONTENTS

Part 1 General Information .......................................................................................................................................1

1. Indoor/outdoor unit models................................................................................................................................2

2. Feature .................................................................................................................................................................3

Part 2 Indoor Units ....................................................................................................................................................5

1. Specification ........................................................................................................................................................6

2. Dimension ..........................................................................................................................................................12

3. Wiring diagram ..................................................................................................................................................14

4. Air velocity and temperature distribution .......................................................................................................17

5. Installation .........................................................................................................................................................21

Part 3 Outdoor Units ...............................................................................................................................................42

1. Specification ......................................................................................................................................................43

2. Dimension ..........................................................................................................................................................52

3. Wiring diagram ..................................................................................................................................................55

4. Wiring connection .............................................................................................................................................58

5. Refrigerant diagram ..........................................................................................................................................60

6. Limitation values on pipe installation .............................................................................................................63

7. Combination and the data ................................................................................................................................65

8. Sound pressure level ........................................................................................................................................79

9. Outdoor performance curves ...........................................................................................................................83

10. Installation........................................................................................................................................................88

Part 4 Electric Control and Debugging ................................................................................................................112

1. Indoor unit PCB photo, dip switch setting and function .............................................................................113

2. Outdoor unit PCB photo, dip switch setting and function ..........................................................................120

3. Diagnostic code ...............................................................................................................................................137

4. Trouble shooting .............................................................................................................................................141

5. Controller function ..........................................................................................................................................159

Appendix Sensor characteristic ........................................................................................................................175

Page 3

1

Part 1 General Information

1. Indoor/outdoor unit models................................................................................................................................2

2. Feature .................................................................................................................................................................3

Page 4

2

1.

Indoor/outdoor unit models

Compact cassette

AB25S2SC1FA

AB35S2SC1FA

Low ESP duct

AD25S2SS1FA

AD35S2SS1FA

Medium ESP duct

AD50S2SM1FA

AD71S2SM1FA

Indoor unit models

1U71S2SG1FA

3U52S2SG1FA

3U68S2SG1FA

4U70S2SH1FA

4U85S2SH1FA

Outdoor unit models

Page 5

3

2. Feature

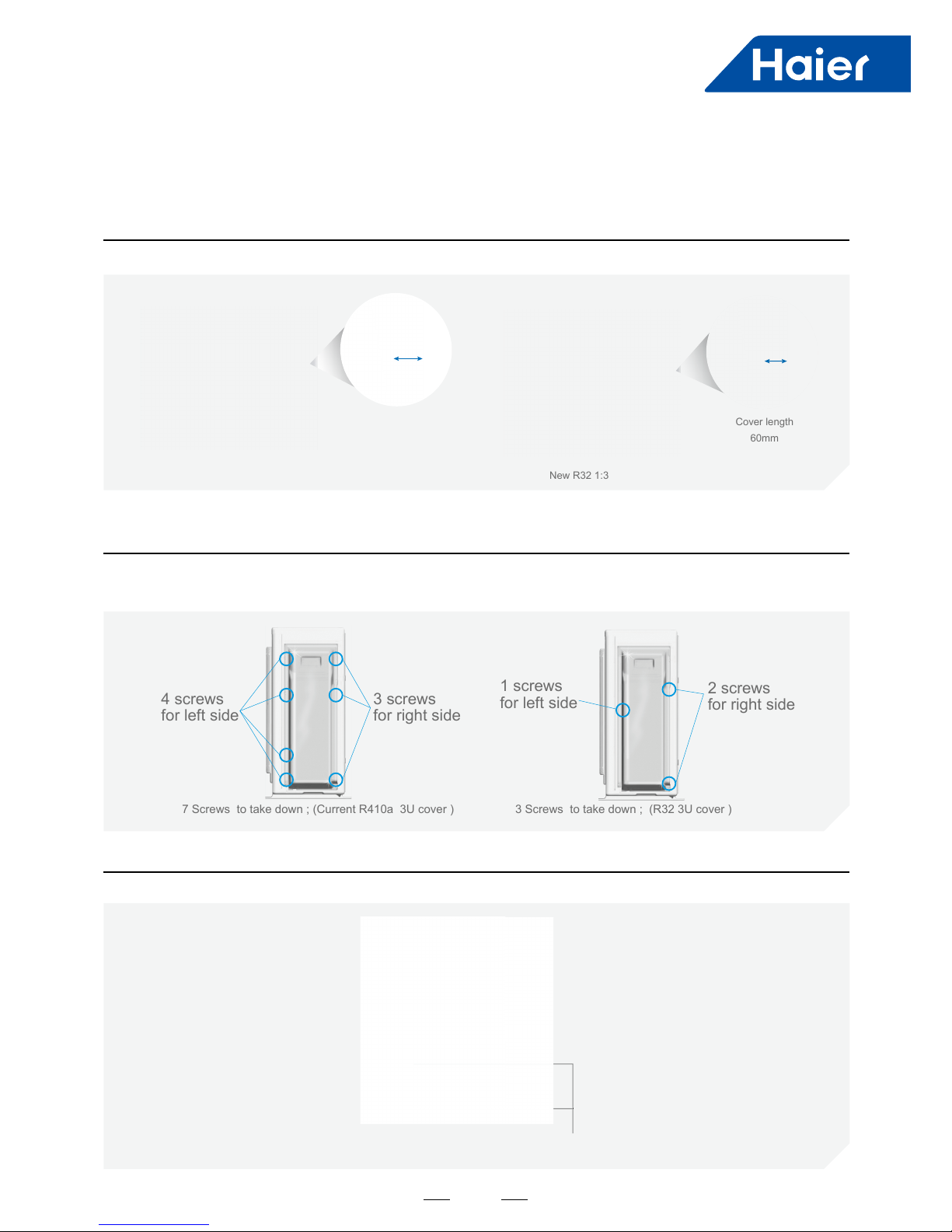

New valve cover design

Less screws to open valve cover

Easy to vacuum

Appearance

Installation

Compared with the current 1:3 valve cover , we design the new valve cover , which is more slim in the appearance;

In the installation course , installer need to take down the valve cover , then to do wiring and piping , next is the

comparison in taking down the valve cover;

General stop valve vacuum every indoor unit from one valve only , save time. ( for 1:4 outdoor unit)

Current R410a 1:3

Cover length

72.5mm

New R32 1:3

Cover length

60mm

3 screws

for right side

7 Screws to take down ; (Current R410a 3U cover )

4 screws

for left side

3 Screws to take down ; (R32 3U cover )

2 screws

for right side

1 screws

for left side

General stop valve

Page 6

4

Easy to carry

Easy start up & maintenance

Left & right two handles are easy for two people carry the units;

* “88” screen show compressor frequency or failure code,

* On site testing software check all running data ;

This two tools make easy start up & maintenance ;

handle

handle

handle

handle

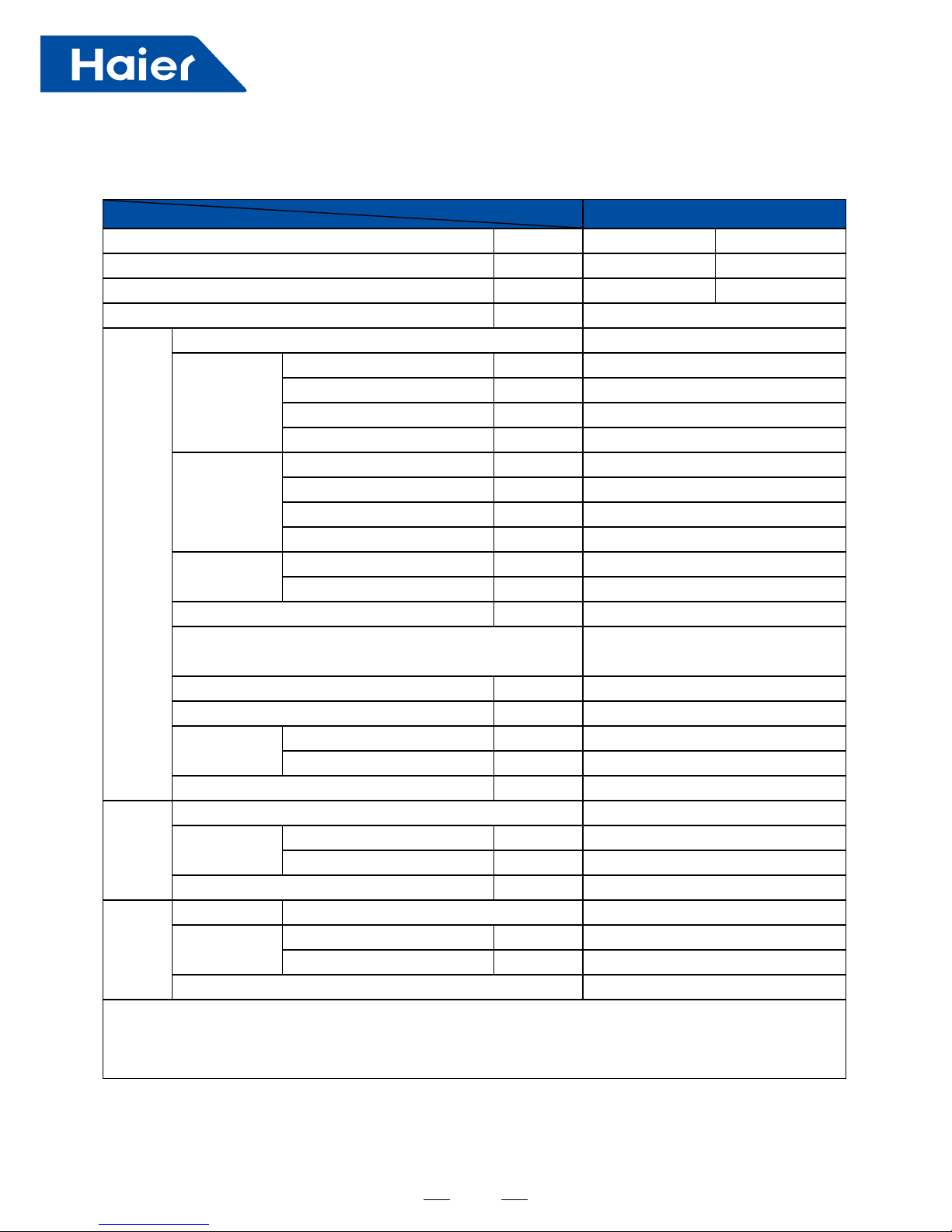

Cooling only /heating only

Central control/BMS control

Solution Supplier

Cooling only /heating only function for special requirement;

Central control / BMS control function meet the various needs for designer;

Note: BMS control is the function in the future

Central control

BMS control

12345678 12345678

ON

ON

SW5

SW5-1 ON cooling only

SW5-2 ON heating only

SW5

Page 7

5

Part 2 Indoor Units

1. Specification ..........................................................................................................................................................6

2. Dimension ...........................................................................................................................................................12

3. Wiring diagram ....................................................................................................................................................14

4. Air velocity and temperature distribution .............................................................................................................17

5. Installation ...........................................................................................................................................................21

Page 8

6

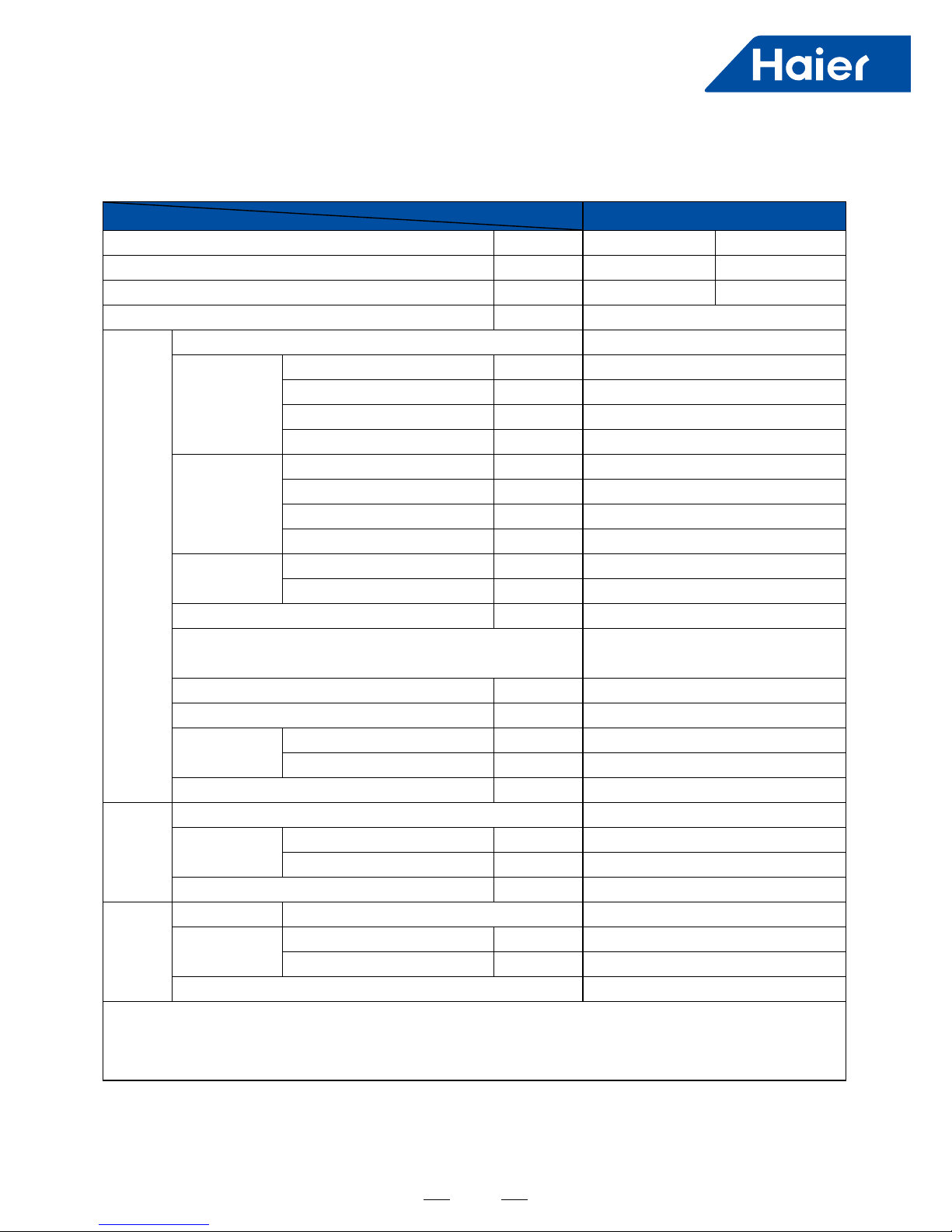

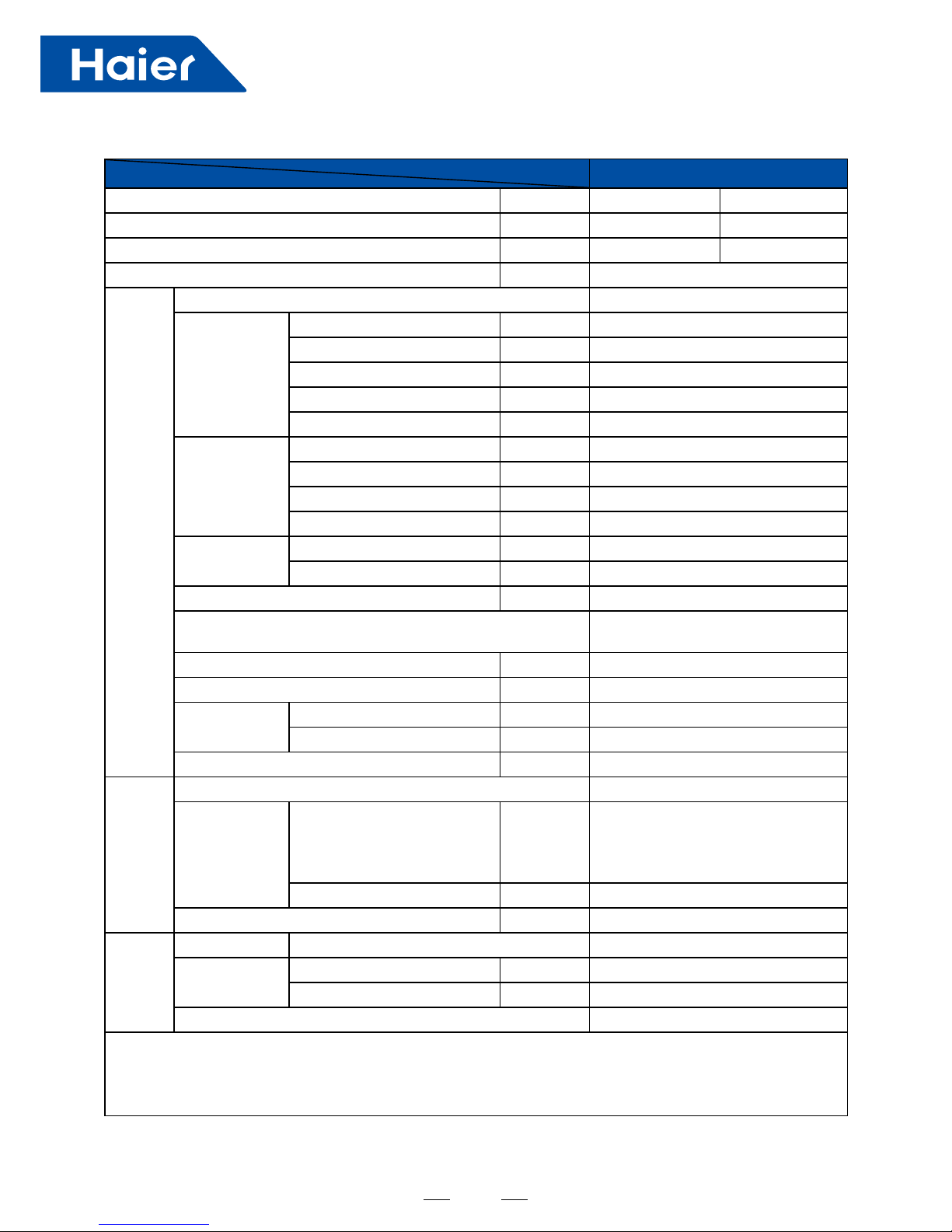

Item Model AB25S2SC1FA

Function —— Cooling Heating

capacity W 2600 3200

sensible heat ratio W 0.71 /

Dehumidifying capacity 10-³xm³/h 1.0

indoor unit

power supply 1PH, 220-240V~, 50/60Hz

Fan

Type × Number —— centrifugal*1

Speed(H-M-L) r/min 690/620/560/500

Fan motor output/input power W 10/15

Air-ows (H/M/L) m³/h 620/520/450/350

Heat exchanger

Type / Diameter mm inner grooved pipe/¢7.0

Row —— 1

Total area m² 0.272

Temp.scope

℃

2.0-7.0

Dimension

(LxWxH)

External mmxmmxmm 570*570*260

Package mmxmmxmm 718*680*380

Drainage pipe (material,I.D/O.D) mm PVC 26/32

control type(Remote/Wired) Remote YR-HBS01(O) or Wired YR-E17(O)

Fresh air hole dimension mm 95

Electricity Heater kW none

Noise level(H-

M-L)

Sound power level dB(A) 52

Sound pressure level dB(A) 36/33/30/27

weight(Net/Shipping) kg/kg 17/20

panel

panel model(color) PB-700IB(White)

Dimension

External(L*W*H) mmxmmxmm 700*700*60

Package(L*W*H) mmxmmxmm 740*750*115

Weight(Net/Shipping) kg/kg 2.8/4.8

Piping

Refrigerant Type R32

Pipe

Liquid mm Φ6.35(1/4)

Gas mm Φ9.52(3/8)

Connecting method Flared

Norminal condition: indoor temperature (cooling): 27℃DB/19℃WB, indoor temperature (heating): 20℃DB

Outdoor temperature(cooling): 35℃DB/24℃WB, outdoor temperature(heating): 7℃DB/6℃WB

The noise level will be measured in the third octave band limited values, using a Real Time Analyser calibrated sound

intensity meter.

1. Specification

Page 9

7

Item Model AB35S2SC1FA

Function —— Cooling Heating

capacity W 3500 4000

sensible heat ratio W 0.71 /

Dehumidifying capacity 10-³xm³/h 1.5

indoor unit

power supply 1PH, 220-240V~, 50/60Hz

Fan

Type × Number —— centrifugal*1

Speed(H-M-L) r/min 690/620/560/500

Fan motor output/input power W 10/15

Air-ows (H/M/L) m³/h 620/520/450/350

Heat exchanger

Type / Diameter mm inner grooved pipe/¢7.0

Row —— 2

Total area m² 0.544

Temp.scope

℃

2.0-7.0

Dimension

(LxWxH)

External mmxmmxmm 570*570*260

Package mmxmmxmm 718*680*380

Drainage pipe (material,I.D/O.D) mm PVC 26/32

control type(Remote/Wired) Remote YR-HBS01(O) or Wired YR-E17(O)

Fresh air hole dimension mm 95

Electricity Heater kW none

Noise level(H-

M-L)

Sound power level dB(A) 52

Sound pressure level dB(A) 36/33/30/27

weight(Net/Shipping) kg/kg 18.5/22

panel

panel model(color) PB-700IB(White)

Dimension

External(L*W*H) mmxmmxmm 700*700*60

Package(L*W*H) mmxmmxmm 740*750*115

Weight(Net/Shipping) kg/kg 2.8/4.8

Piping

Refrigerant Type R32

Pipe

Liquid mm Φ6.35(1/4)

Gas mm Φ9.52(3/8)

Connecting method Flared

Norminal condition: indoor temperature (cooling): 27℃DB/19℃WB, indoor temperature (heating): 20℃DB

Outdoor temperature(cooling): 35℃DB/24℃WB, outdoor temperature(heating): 7℃DB/6℃WB

The noise level will be measured in the third octave band limited values, using a Real Time Analyser calibrated sound

intensity meter.

Page 10

8

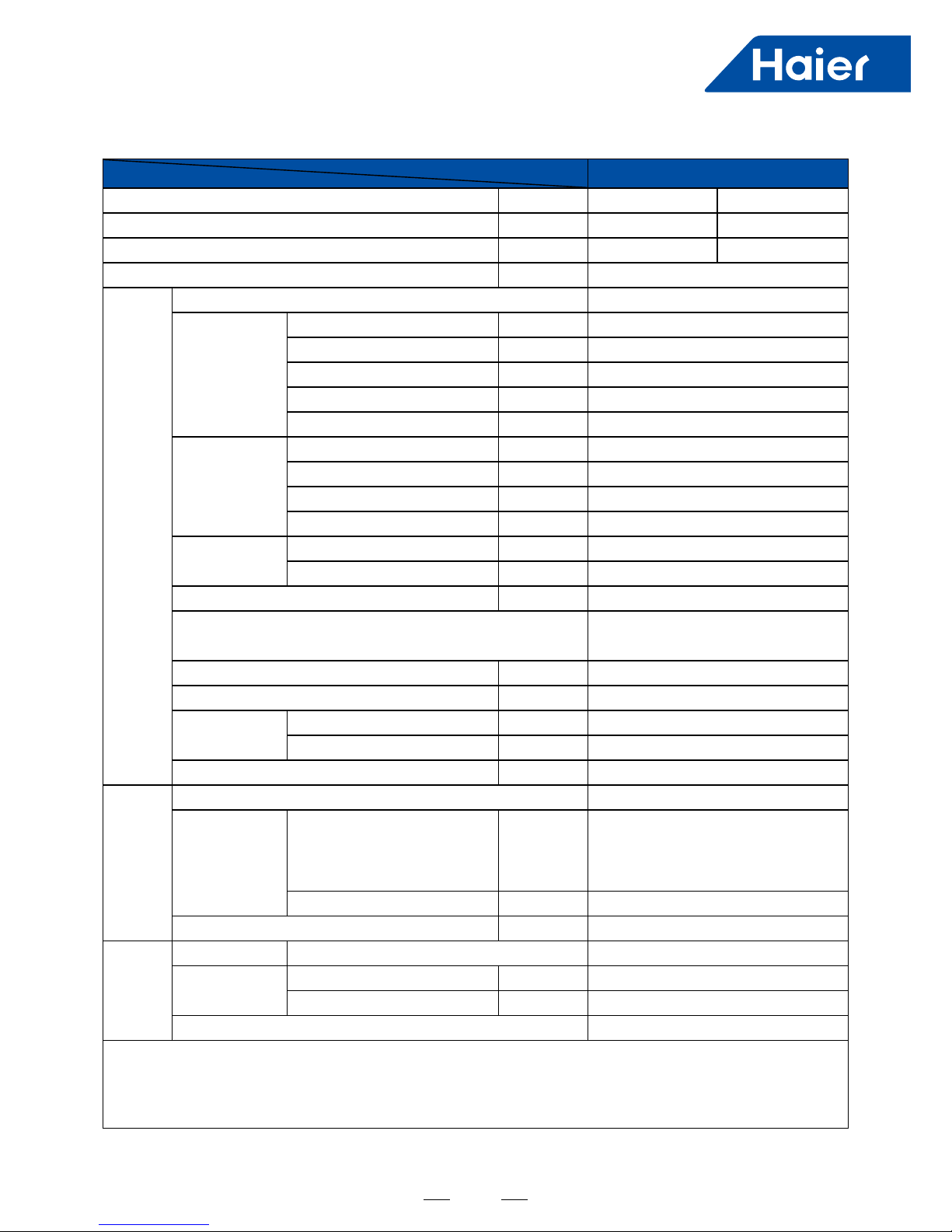

Item Model AD25S2SS1FA

Function —— Cooling Heating

capacity W 2500 3000

sensible heat ratio W 0.71 /

Dehumidifying capacity 10-³xm³/h 1.0

indoor unit

power supply 1PH, 220-240V~, 50/60Hz

Fan

Type × Number —— centrifugal*2

Speed(H-M-L) r/min 850/750/650/600

Fan motor output/input power W 11/15

Air-ows (H/M/L) m³/h 530/460/390/330

External static pressure pa 0/10/20/30

Heat exchanger

Type / Diameter mm inner grooved pipe/¢7.0

Row —— 2

Total area m² 0.11

Temp.scope

℃

2.0-7.0

Dimension

(LxWxH)

External mmxmmxmm 850x420x185

Package mmxmmxmm 1045x540x270

Drainage pipe (material,I.D/O.D) mm PVC 27/31

control type(Remote/Wired) Wired YR-E17(O) or Remote YR-HBS01(O)

Fresh air hole dimension mm none

Electricity Heater kW none

Noise level(H-

M-L)

Sound power level dB(A) 51

Sound pressure level dB(A) 33/30/26/23

weight(Net/Shipping) kg/kg 16/21

panel

(

optional

)

panel model(color) P1B-890IA/D

Dimension

External(L*W*H) mmxmmxmm

890/190/100

(outlet panel)/

890/290.5/32.4

(inlet panel)

Package(L*W*H) mmxmmxmm 938/335/220

Weight(Net/Shipping) kg/kg 4/5

Piping

Refrigerant Type R32

Pipe

Liquid mm Φ6.35(1/4)

Gas mm Φ9.52(3/8)

Connecting method Flared

Norminal condition: indoor temperature (cooling): 27℃DB/19℃WB, indoor temperature (heating): 20℃DB

Outdoor temperature(cooling): 35℃DB/24℃WB, outdoor temperature(heating): 7℃DB/6℃WB

The noise level will be measured in the third octave band limited values, using a Real Time Analyser calibrated sound

intensity meter.

Page 11

9

Item Model AD35S2SS1FA

Function —— Cooling Heating

capacity W 3500 4000

sensible heat ratio W 0.71 /

Dehumidifying capacity 10-³xm³/h 1.5

indoor unit

power supply 1PH, 220-240V~, 50/60Hz

Fan

Type × Number —— centrifugal*2

Speed(H-M-L) r/min 950/850/750/700

Fan motor output/input power W 16/21

Air-ows (H/M/L) m³/h 600/480/420/350

External static pressure pa 0/10/20/30

Heat exchanger

Type / Diameter mm inner grooved pipe/¢7.0

Row —— 2

Total area m² 0.11

Temp.scope

℃

2.0-7.0

Dimension

(LxWxH)

External mmxmmxmm 850x420x185

Package mmxmmxmm 1045x540x270

Drainage pipe (material,I.D/O.D) mm PVC 27/31

control type(Remote/Wired) Wired YR-E17(O) or Remote YR-HBS01(O)

Fresh air hole dimension mm none

Electricity Heater kW none

Noise level(H-

M-L)

Sound power level dB(A) 53

Sound pressure level dB(A) 35/32/29/26

weight(Net/Shipping) kg/kg 16/21

panel

(

optional

)

panel model(color) P1B-890IA/D

Dimension

External(L*W*H) mmxmmxmm

890/190/100

(outlet panel)/

890/290.5/32.4

(inlet panel)

Package(L*W*H) mmxmmxmm 938/335/220

Weight(Net/Shipping) kg/kg 4/5

Piping

Refrigerant Type R32

Pipe

Liquid mm Φ6.35(1/4)

Gas mm Φ9.52(3/8)

Connecting method Flared

Norminal condition: indoor temperature (cooling): 27℃DB/19℃WB, indoor temperature (heating): 20℃DB

Outdoor temperature(cooling): 35℃DB/24℃WB, outdoor temperature(heating): 7℃DB/6℃WB

The noise level will be measured in the third octave band limited values, using a Real Time Analyser calibrated sound

intensity meter.

Page 12

10

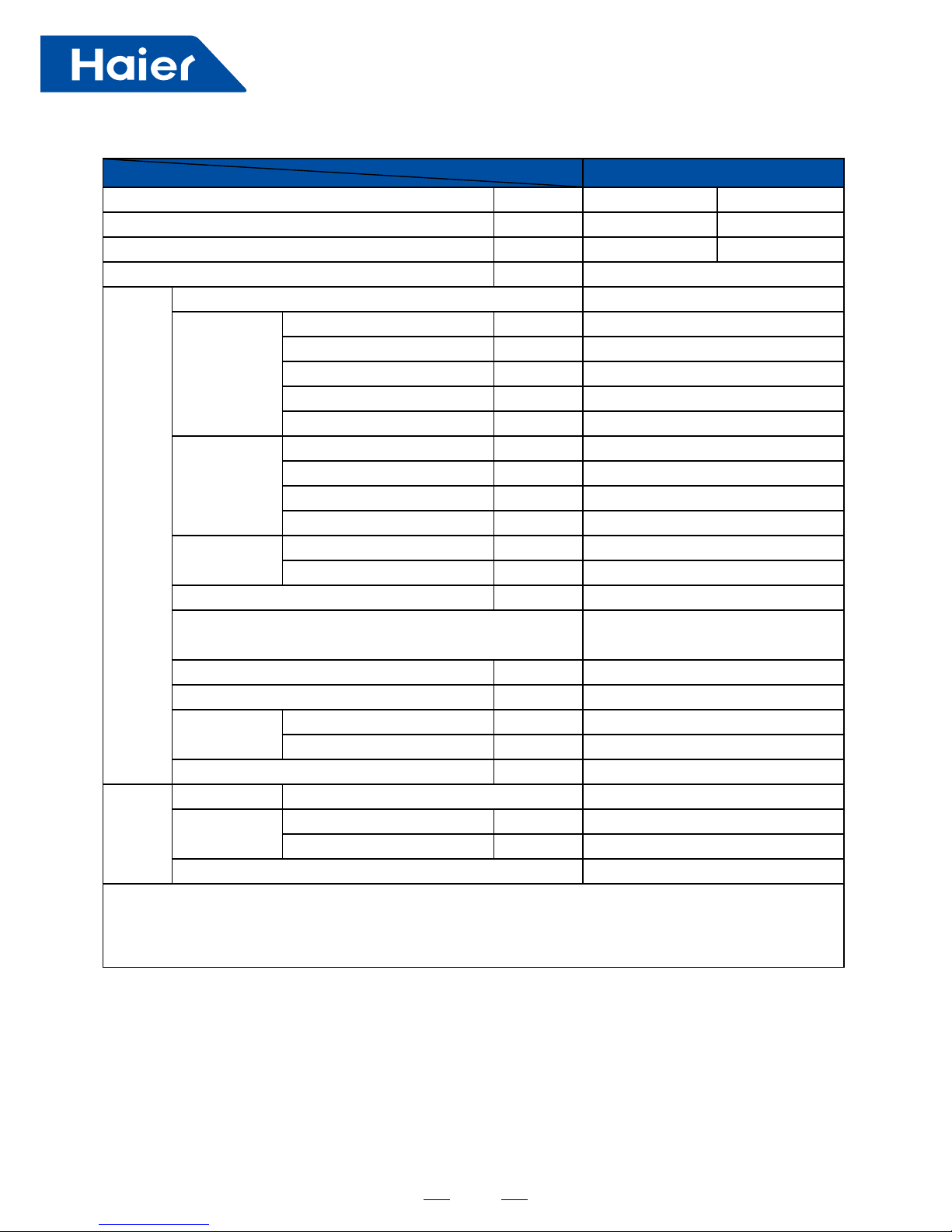

Item Model AD50S2SM1FA

Function —— Cooling Heating

capacity W 5000 6000

sensible heat ratio W 0.73 /

Dehumidifying capacity 10-³xm³/h 1.8

indoor unit

power supply 1PH, 220-240V~, 50/60Hz

Fan

Type × Number —— centrifugal*2

Speed(H-M-L) r/min 900/820/770/720

Fan motor output/input power W 45/70

Air-ows (H/M/L) m³/h 1080/900/780/660

External static pressure Pa 150/130/120/110/100/90/70/50/37/25

Heat exchanger

Type / Diameter mm inner grooved pipe/¢7.0

Row —— 2

Total area m² /

Temp.scope

℃

2.0-7.0

Dimension

(LxWxH)

External mmxmmxmm 957/655/250

Package mmxmmxmm 1170/860/340

Drainage pipe (material,I.D/O.D) mm PVC 25/29

control type(Remote/Wired) Wired YR-E17(O) or Remote YR-HBS01(O)

Fresh air hole dimension mm 145

Electricity Heater kW none

Noise level(H-

M-L)

Sound power level dB(A) 57

Sound pressure level dB(A) 37/34/32/29

weight(Net/Shipping) kg/kg 26/33

Piping

Refrigerant Type R32

Pipe

Liquid mm Φ6.35(1/4)

Gas mm Φ12.7(1/2)

Connecting method Flared

Norminal condition: indoor temperature (cooling): 27℃DB/19℃WB, indoor temperature (heating): 20℃DB

Outdoor temperature(cooling): 35℃DB/24℃WB, outdoor temperature(heating): 7℃DB/6℃WB

The noise level will be measured in the third octave band limited values, using a Real Time Analyser calibrated sound

intensity meter.

Page 13

11

Item Model AD71S2SM1FA

Function cooling heating

Capacity KW 7.1(2.0~8.2) 8.0(2.5~8.5)

Sensible heat ratio 0.74 /

Total power input KW 2.15(0.6~2.6) 2.16(0.6~2.6)

Max. power input W

3000 3000

EER or COP W/W 3.30 3.71

Dehumidifying capacity 10

-

³×m³/h 2.5

Power cable H05RN-F 4G 6.0mm2

Power source N, V, Hz

1PH, 220-240V~, 50/60Hz

Running /Max.Running current A / A 9.7(2.3-12)/16 9.8(2.3-12)/16

Start Current A 3

Indoor unit

Unit model (color) AD71S2SM1FA

Fan

Type × Number CENTRIFUGALX2

Speed(H-M-L) r/min 1130/950/820/780

Fan motor output/ input power W 85/111

Air-ow(H-M-L) m³/h 1440/1140/900/800

External static pressure Pa 25/37//50/70/90/100/110/120/130/150

Heat

exchanger

Type / Diameter mm inner grooved pipe/φ7.0

Row 3

Total Area m² 7.668

Dimension

External(L×W×H) mm×mm×mm 957/655/250

Package(L×W×H) mm×mm×mm 1170/860/340

Drainage pipe (material , I.D./O.D.) mm PVC 25/29

Controller

(O-Optional,S-Standard)

Wired YR-E16(O)/YR-E17(S)

Fresh air hole dimension mm NONE

Electricity Heater kW NONE

Sound power Noise level (H-M-L) dB(A) 58

Sound pressure Noise level (H-M-L) dB(A) 42/38/35

Pipe

Liquid Pipe(mm) 9.52

Gas Pipe(mm) 15.88

Connecting Method ared

Weight (Net / Shipping) kg / kg 31.2/36.8

Norminal condition: indoor temperature (cooling): 27℃DB/19℃WB, indoor temperature (heating): 20℃DB

Outdoor temperature(cooling): 35℃DB/24℃WB, outdoor temperature(heating): 7℃DB/6℃WB

The noise level will be measured in the third octave band limited values, using a Real Time Analyser calibrated sound intensity

meter. It is a sound pressure noise level.

Page 14

12

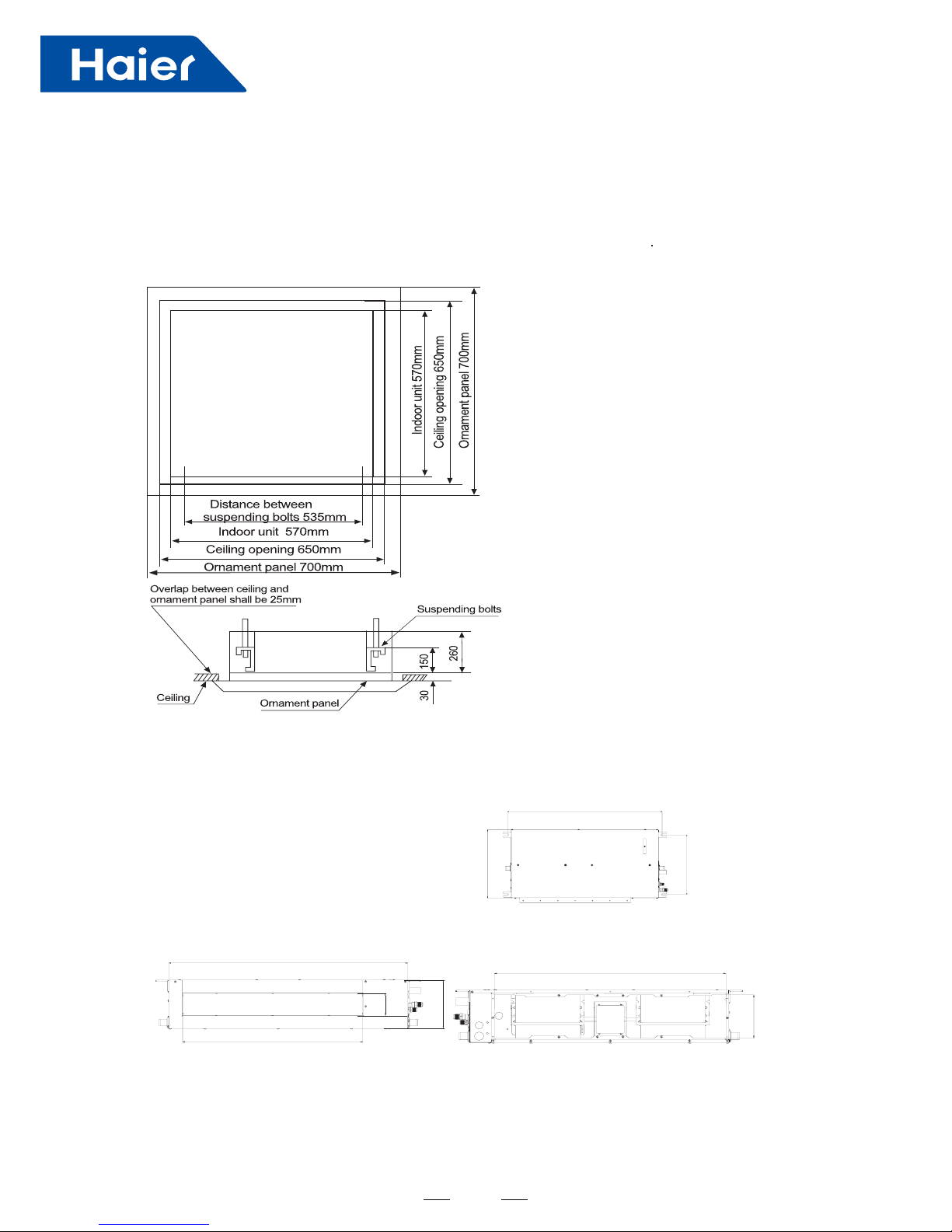

AB25S2SC1FA AB35S2SC1FA

AD25S2SC1FA AD35S2SC1FA

420

370

892

850

185

640

90

760

152

2. Dimension

957

990

1050

595.5

655

720

250

148

57

57

57

103

797

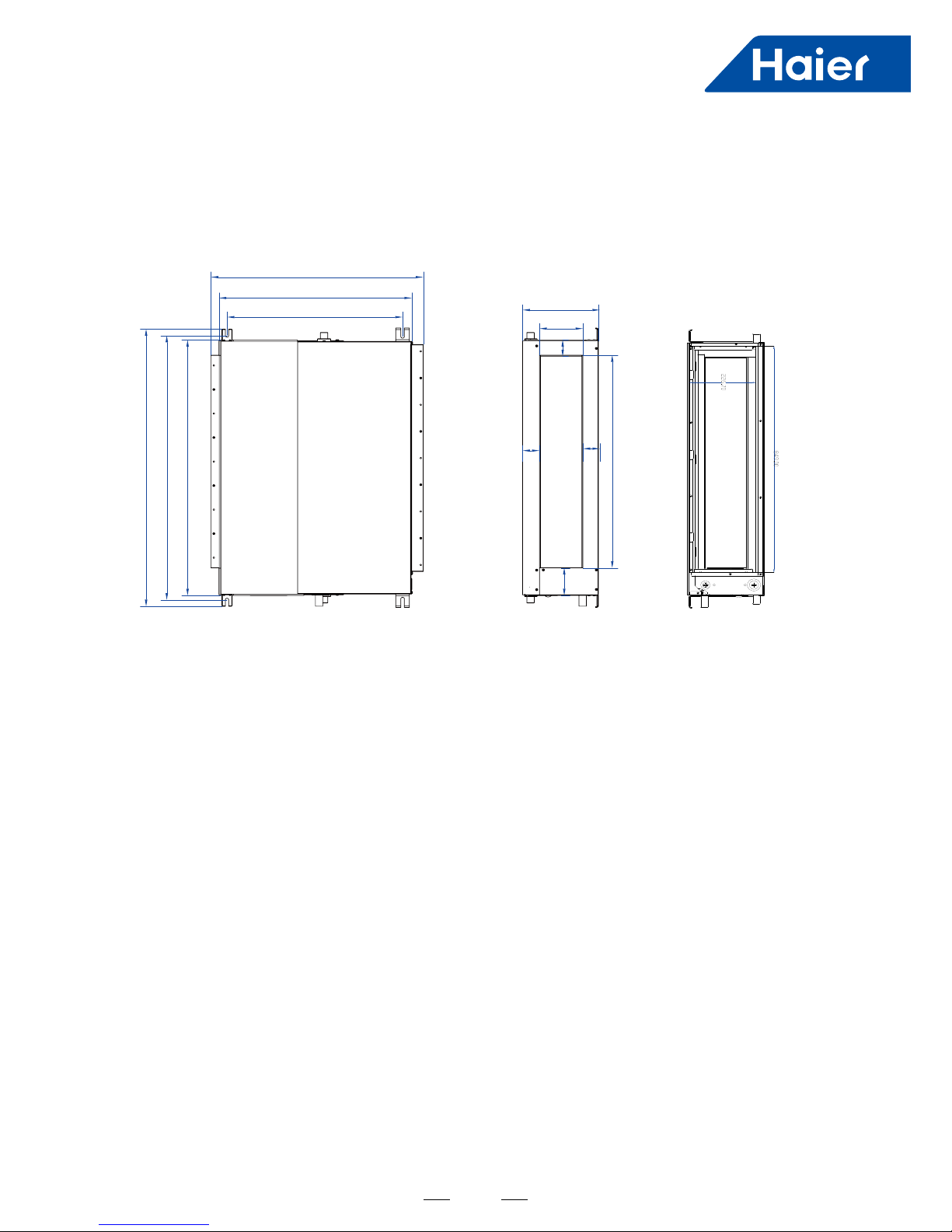

Note: The cushion pasted in the bottom plate isn't included in the thickness data.

unit : mm

Page 15

13

957

990

1050

595.5

655

720

250

148

57

57

57

103

797

Note: The cushion pasted in the bottom plate isn't included in the thickness data.

AD50S2SM1FA AD71S2SM1FA

Page 16

14

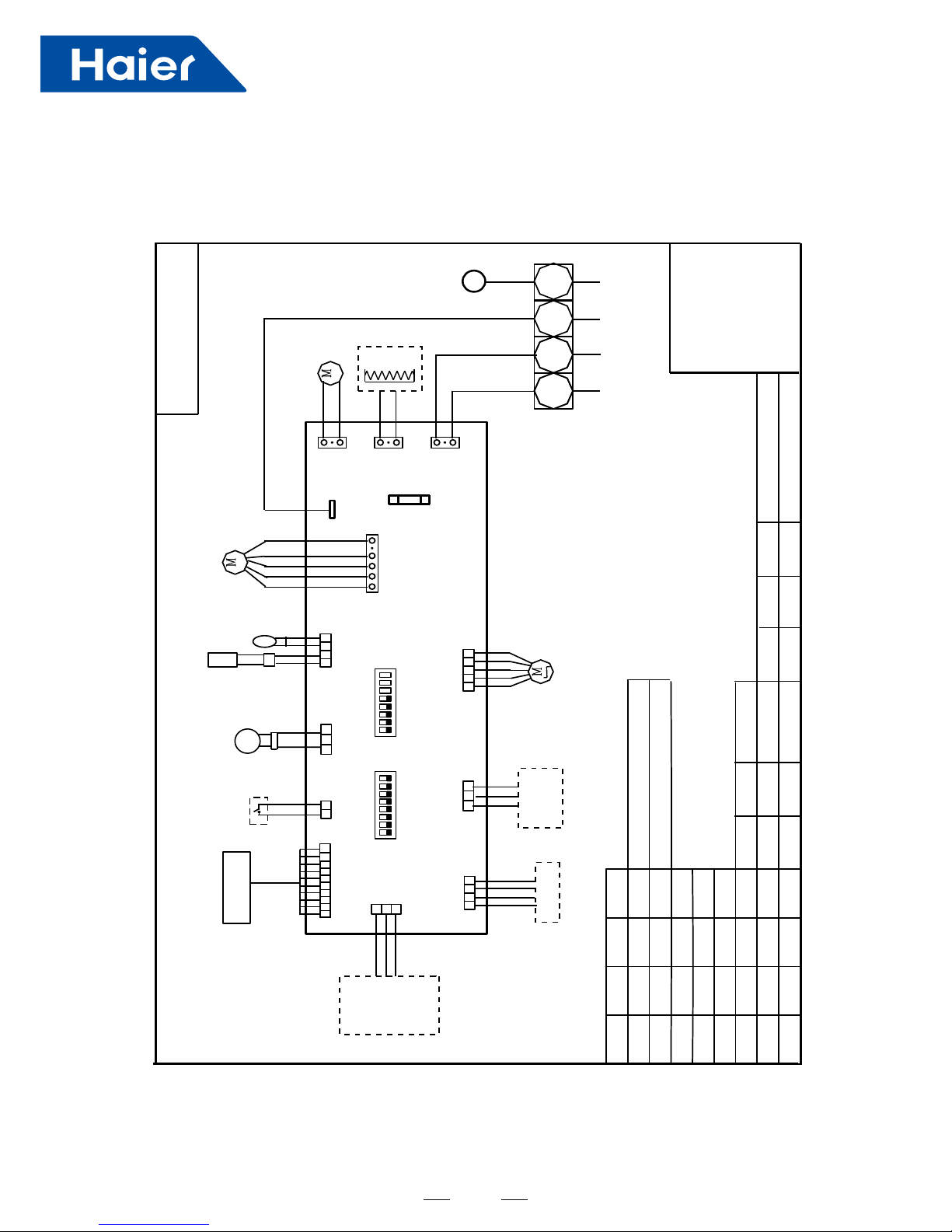

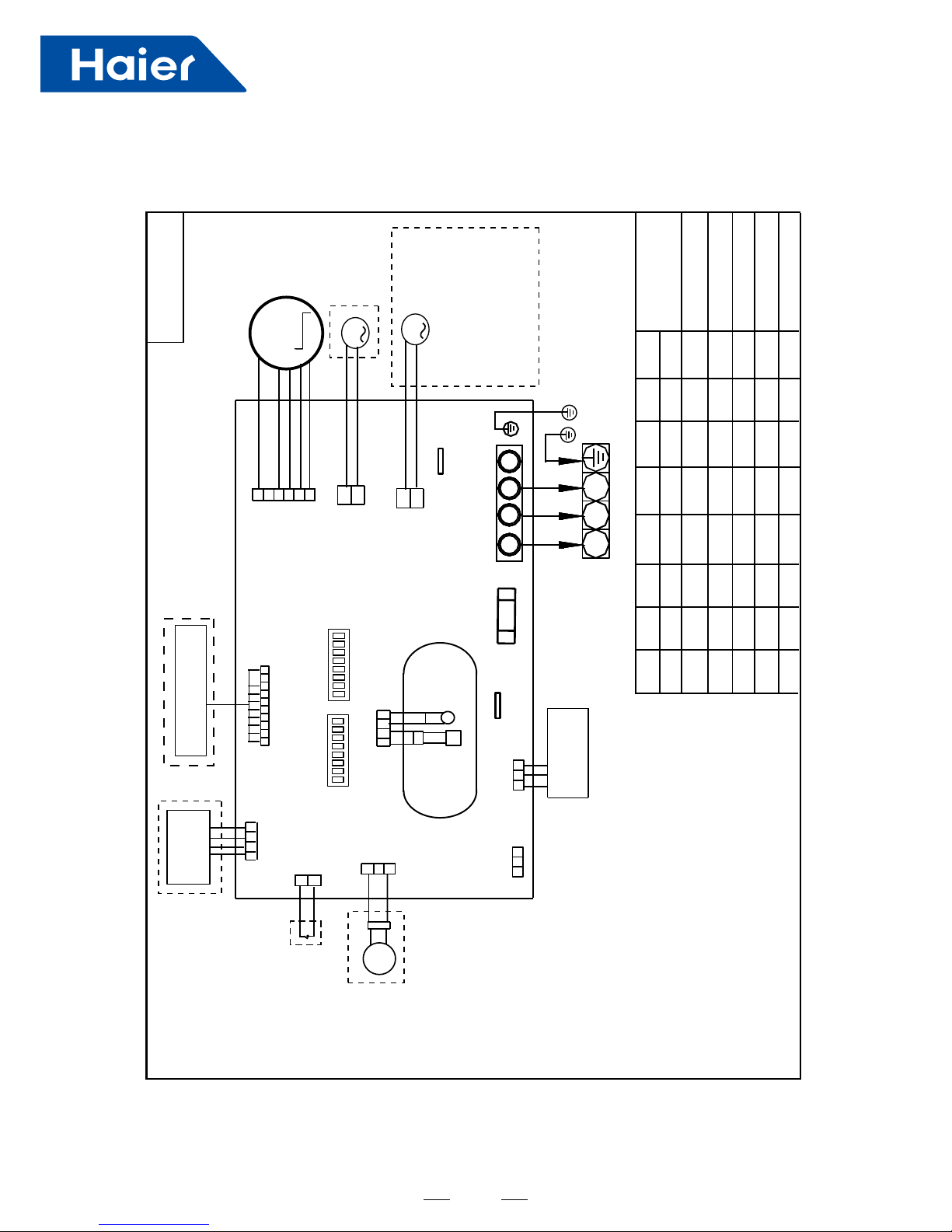

3. Wiring diagram

AB25S2SC1FA AB35S2SC1FA

TO OUT DOOR

0150523323

BM1-1

BM1-7

BM1-8

TYPE DEFINE

OFFOFF

BM1-2 BM1-3

BTU

B:BLACK

R:RED

W:WHITE

Y/G:YELLOW/GREEN

TEMP.

SENSOR

ROOM

SENSOR

FLOAT

SWITCH

HEATER

PUMP

UP/DOWN

CN9

CN1

CN6

PANNEL

CN4

CN11

CN19

CN13

CN3

ON

CN7

CN21

T5A/250VAC

FUSE

BM3

2

1

3

B

W

R

Y/G

OFF OFF OFF

ON OFF OFF

OFF ON OFF

ON ON OFF

OFF OFF ON

ON OFF ON

OFF ON ON

ON ON ON

9000

12000

18000

24000

28000

36000

48000

60000

NOTE1.DASHED PART ARE OPTIONAL.

2. USER SHOULD NOT TO SET BM1 AND BM3

CH1

OFF OFF

BM1-4

BM1-5

BM1-6

OFF

OFF

CN16

G

CN8

G

TEMP.

PIPING

DC FAN

ROOMCARD

U-HOME

WIRED

CONTROLLER

B

A

C

BA

C

REMOTE

CENTRAL

87654321

ON

BM1

OFF

87654321

N

OFF

Room card

available

unavailable

ON

AB25S2SC1FA

AB35S2SC1FA

Default

Page 17

15

AD25S2SC1FA AD35S2SC1FA

Y/G:YELLOW/GREEN

NOTE:

1.DASHED PARTS ARE OPTIONAL.

2.

USER SHOULD NOT SET SW01 AND

SW03 WITHOUT GUIDENCE.

3.WHEN ONE WIRED CONTROLLER CONTROL MULTIPLE INDOOR UNIT,

IT CAN CONNECT ANOTHER INDOOR UNIT BY CN22 OR CN22-1.

WHEN TWO WIRD CONTROLLERS CONTROL ONE INDOOR UNIT,

THE WIRED CONTROLLER NEED CONNECT WITH CN22 AND CN22-1.

TEMP.

SENSOR

ROOM

SENSOR

PIPING

TEMP.

ROOMCARD

R O T O M N A F C D

SW03

FUSE

WIRED

CONTROLLER

FLOAT

SWITCH

WIFI

MODULE

PUMP

TO OUT DOOR

2

1

3

Y/G

M

12345678

ON

INFRARED

REMOTE RECEIVER

M

B

A

C

B

A

C

OFF

0150523322

2

1

3

N L S

B A

C

SW01

12345678

ON

OFF

FRESH AIR MOTOR

(SW01-6 select OFF) /

EXTERNAL ALARM OUTPUT

(SW01-6 select ON)

( Contact rating_230VAC,3A)

M

CN21

Heater_L

CH4

Heater_N

CH2

CN5

CN4

CN34

CN16

CH1

SW01-1

SW01-2

SW01-3

OFF

SW01-4

SW01-5

SW01-6

SW01-7

SW01-8

MODEL

OFF

AD35S2SS1FA

OFF

OFF

OFF

ON

ON

OFF

CN13

CN6

CN41

CN22

CN22-1

4.SW03-5

->SW03-08 ARE USED FOR

ADDRESS SETTING ON THE

SITUATION OF ONE WIRED CONTROLLER CONTROL MORE THAN

ONE INDOOR UNIT.

5.REFER TO SERVICE MANUL TO GET MUCH MORE DETAILS

ABOUT THE STATIC PRESSURE LEVEL SELECTION.

CN1

AD25S2SS1FA

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

SW03-1 SW03-2 SW03-3 SW03-4 SW03-5 SW03-6 SW03-7 SW03-8

OFF OFF OFF OFF OFF OFF OFF OFF

FOR ALL

DUCT MODEL

Page 18

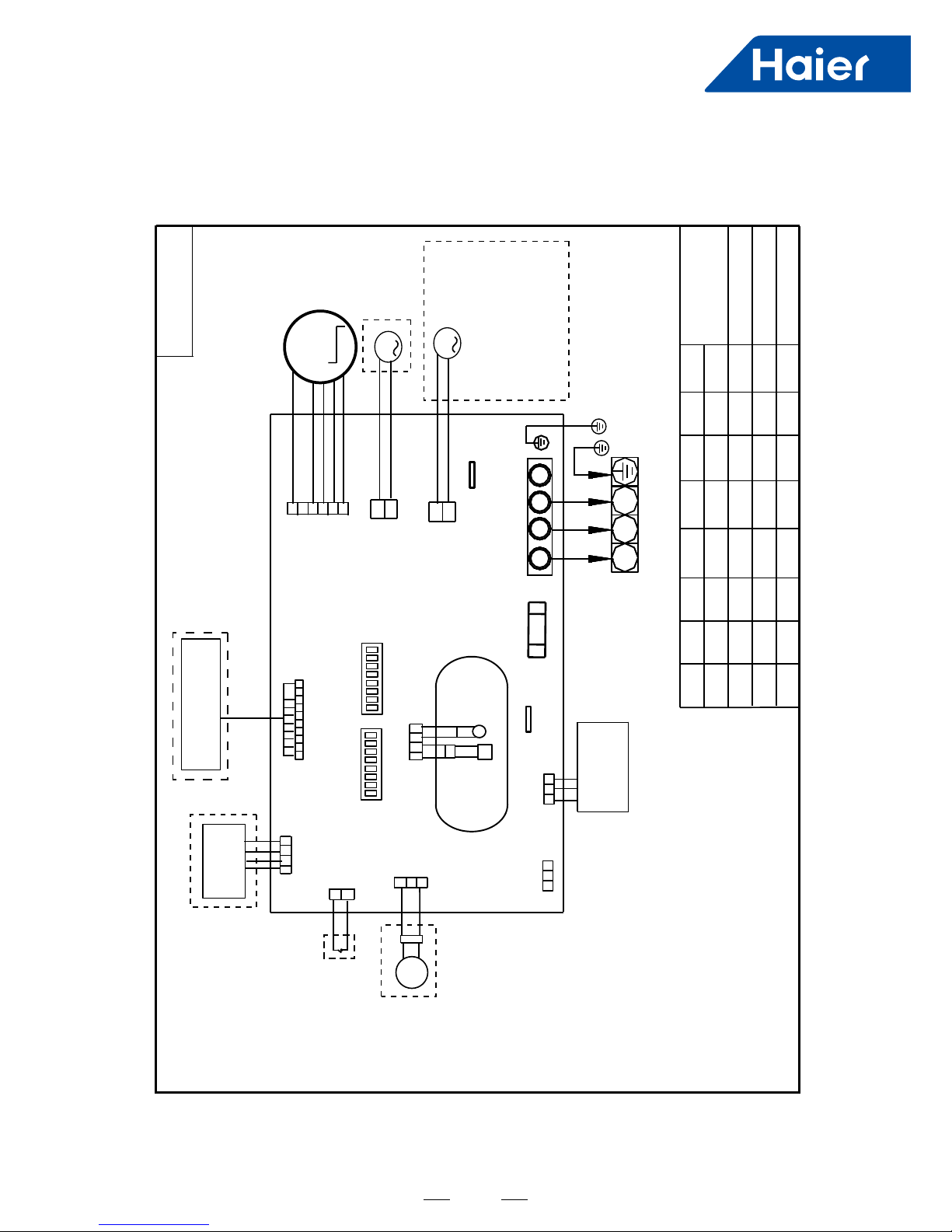

16

AD50S2SM1FA AD71S2SM1FA

Y/G:YELLOW/GREEN

NOTE:

1.DASHED PARTS ARE OPTIONAL.

2.SW03-4 IS AT ON POSITION,DO NOT CHANGE

THE SETTINGS OF SWITCHS WITHOUT GUIDANCE.

3.WHEN ONE WIRED CONTROLLER CONTROL MULTIPLE INDOOR UNIT,

IT CAN CONNECT ANOTHER INDOOR UNIT BY CN22 OR CN22-1.

WHEN TWO WIRD CONTROLLERS CONTROL ONE INDOOR UNIT,

THE WIRED CONTROLLER NEED CONNECT WITH CN22 AND CN22-1.

TEMP.

SENSOR

ROOM

SENSOR

PIPING

TEMP.

ROOMCARD

R O T O M N A F C D

SW03

FUSE

WIRED

CONTROLLER

FLOAT

SWITCH

WIFI

MODULE

PUMP

TO OUT DOOR

2

1

3

Y/G

M

12345678

ON

REMOTE RECEIVER

M

B

A

C

B

A

C

OFF

0150523302

2

1

3

N L S

B A

C

SW01

12345678

ON

OFF

FRESH AIR MOTOR

(SW01-6 select OFF) /

EXTERNAL ALARM OUTPUT

(SW01-6 select ON)

( Contact rating_230VAC,3A)

M

CN21

Heater_L

CH4

Heater_N

CH2

CN5

CN4

CN34

CN16

CH1

SW01-1

SW01-2

SW01-3

ON

SW01-4

SW01-5

SW01-6

SW01-7

SW01-8

MODEL

OFF

AM24LP2VHA

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

OFF

ON

ON

ADH071M3ERG

OFF

OFF

ON

CN13

CN6

CN41

CN22

CN22-1

4.SW03-5

->SW03-08 IS USED FOR

ADDRESS SETTING ON THE

SITUATION OF ONE WIRED CONTROLLER CONTROL MORE THAN

ONE INDOOR UNIT.

5.REFER TO SERVICE MANUL TO GET MUCH MORE DETAILS

ABOUT THE STATIC PRESSURE LEVEL SELECTION.

CN1

AD71S2SM1FA

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

OFF

OFF

OFF

OFF

OFF OFF

ON

AD50S2SM1FA

SW03-1

SW03-2

SW03-3

FOR ALL DUCTED

MODEL

SW03-4 SW03-5 SW03-6

SW03-7

SW03-8

OFF OFF OFF OFF OFF OFF OFF ON

Page 19

17

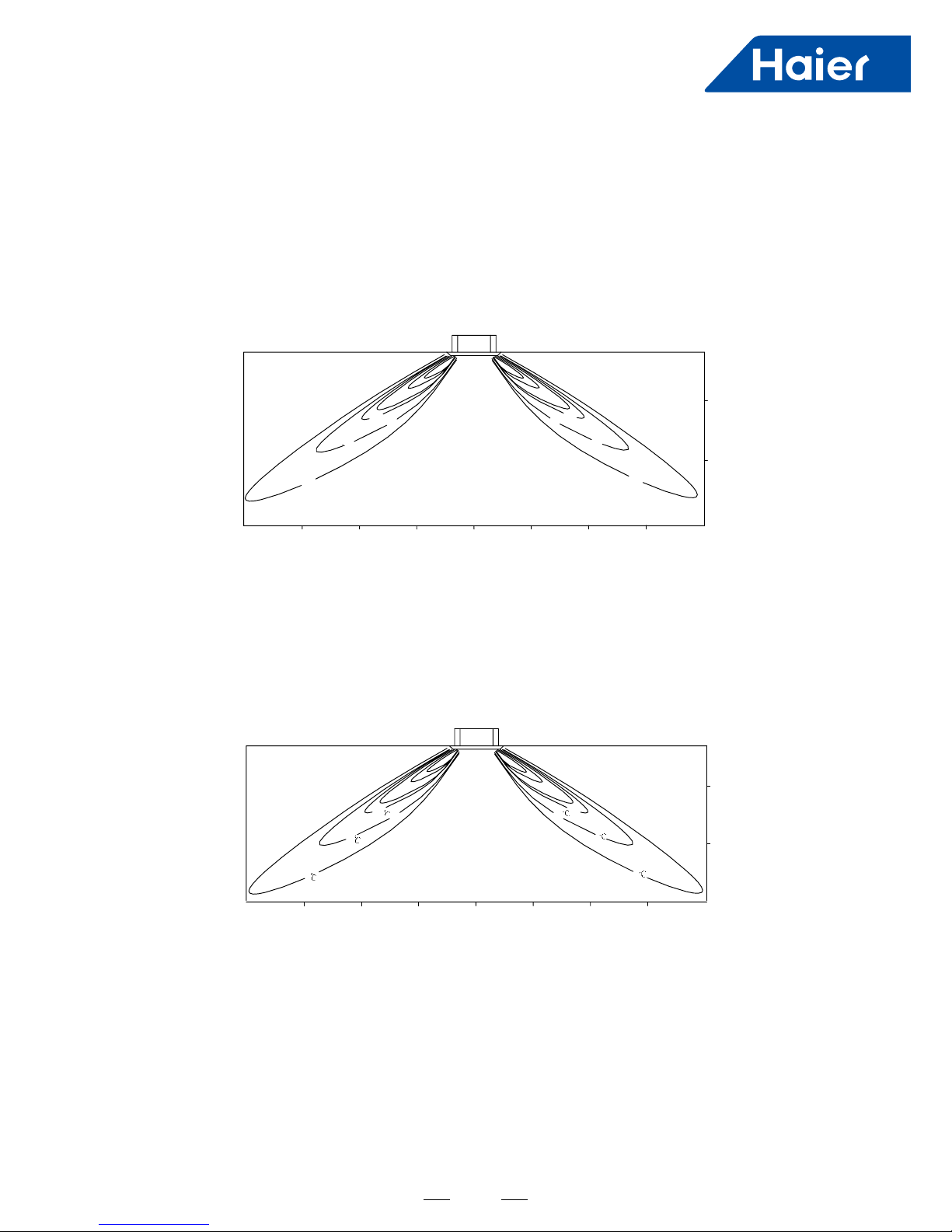

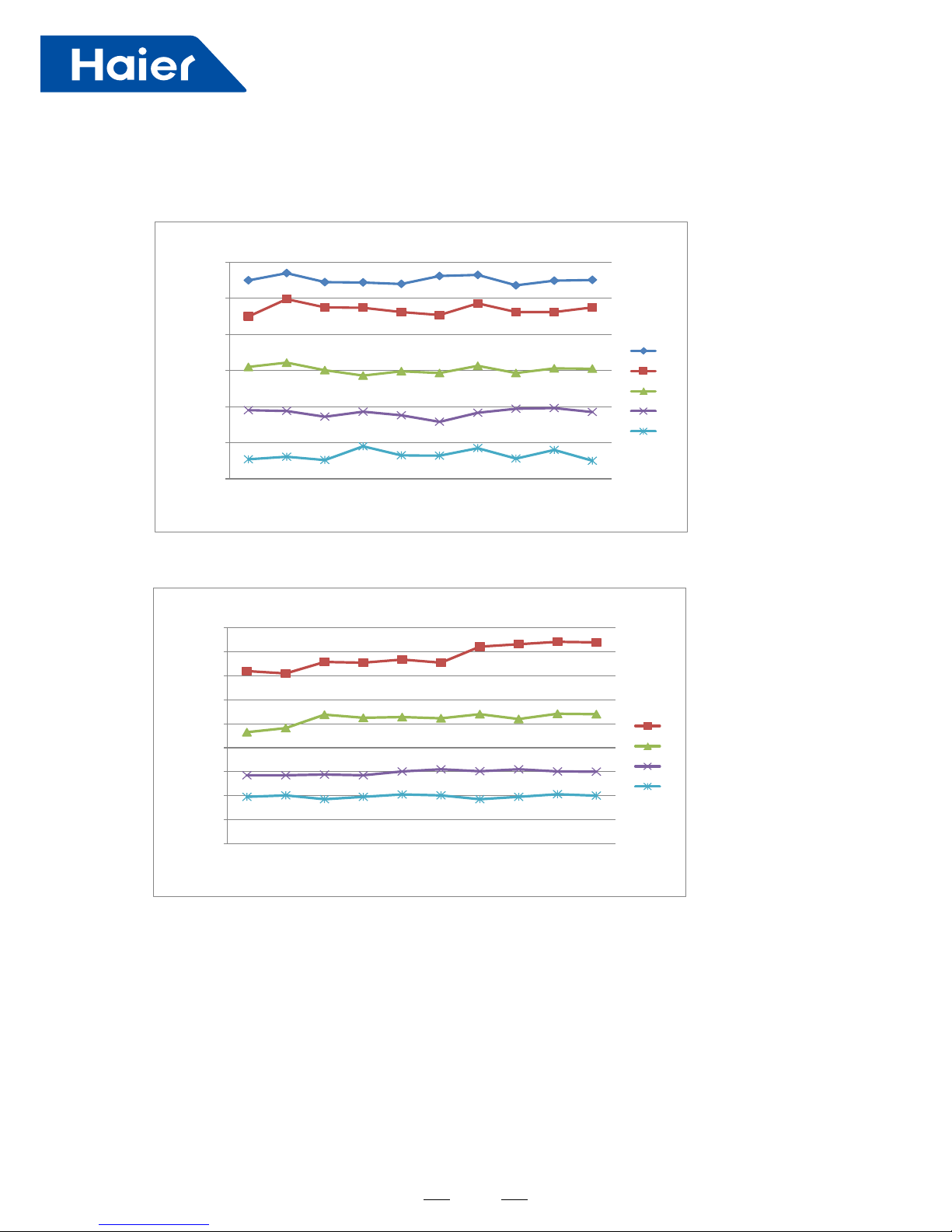

4. Air velocity and temperature distribution

a. Cooling / Air Velocity Distribution

Cooling

Blowy angle:40

Air Velocity Distribution

1.5m/s

1.5m/s

1.0m/s

1.0m/s

0.5m/s

2.7m

2m

2m2m

1m

1m

1m

4m

3m

3m

4m

0m

0m

0.5m/s

b. Cooling / Temperature Distribution

Cooling

Blowy angle:40

Temperature Distribution

27

52

22

22

27

25

2.7m

2m

1m

0m

4m

3m

2m

1m

0m

1m

2m 3m

4m

AB25S2SC1FA AB35S2SC1FA

Page 20

18

2.7m

2m

1m

0m

1.5m/s

1.5m/s

1.0m/s

1.0m/s

0.5m/s

2m2m

1m

1m

4m

3m

3m

4m

0m

0.5m/s

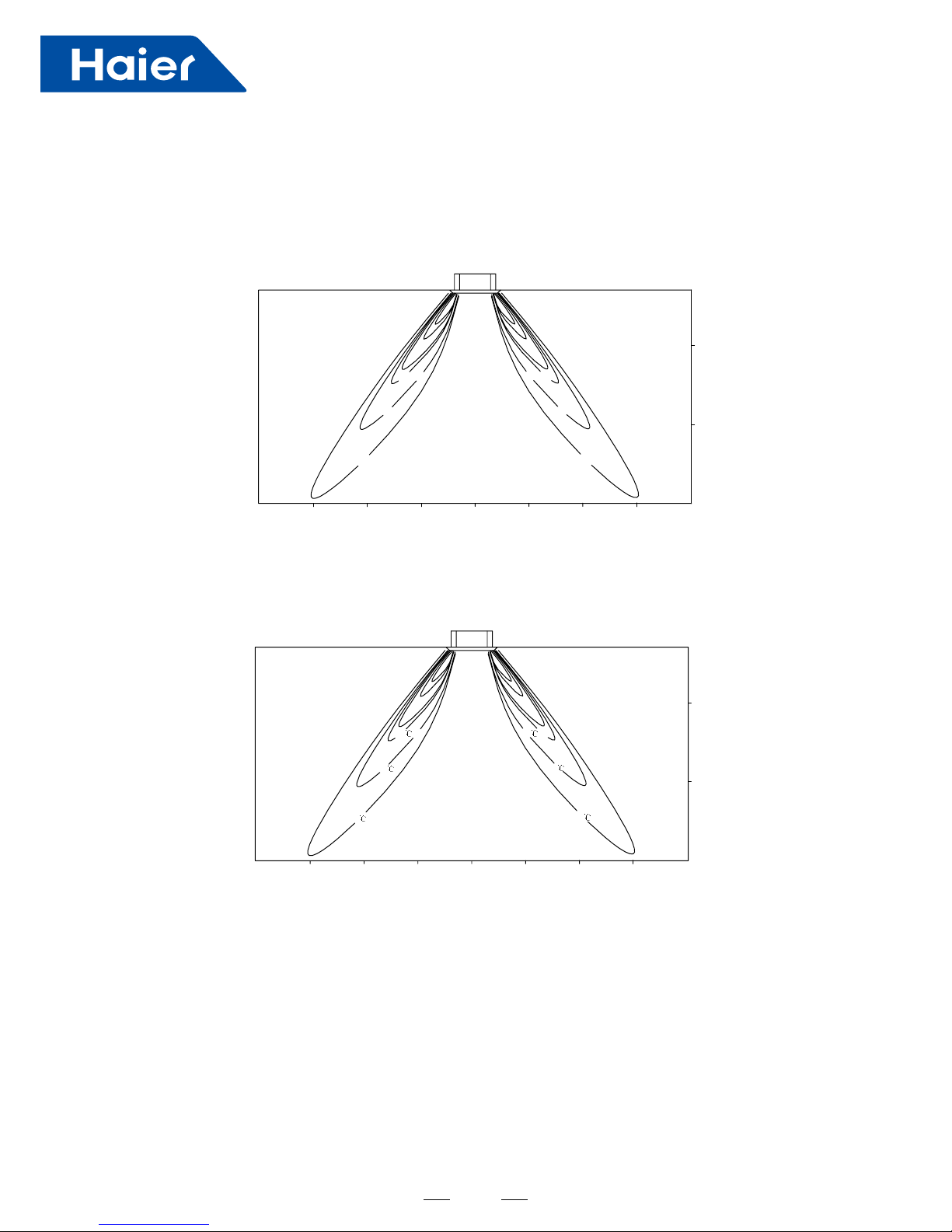

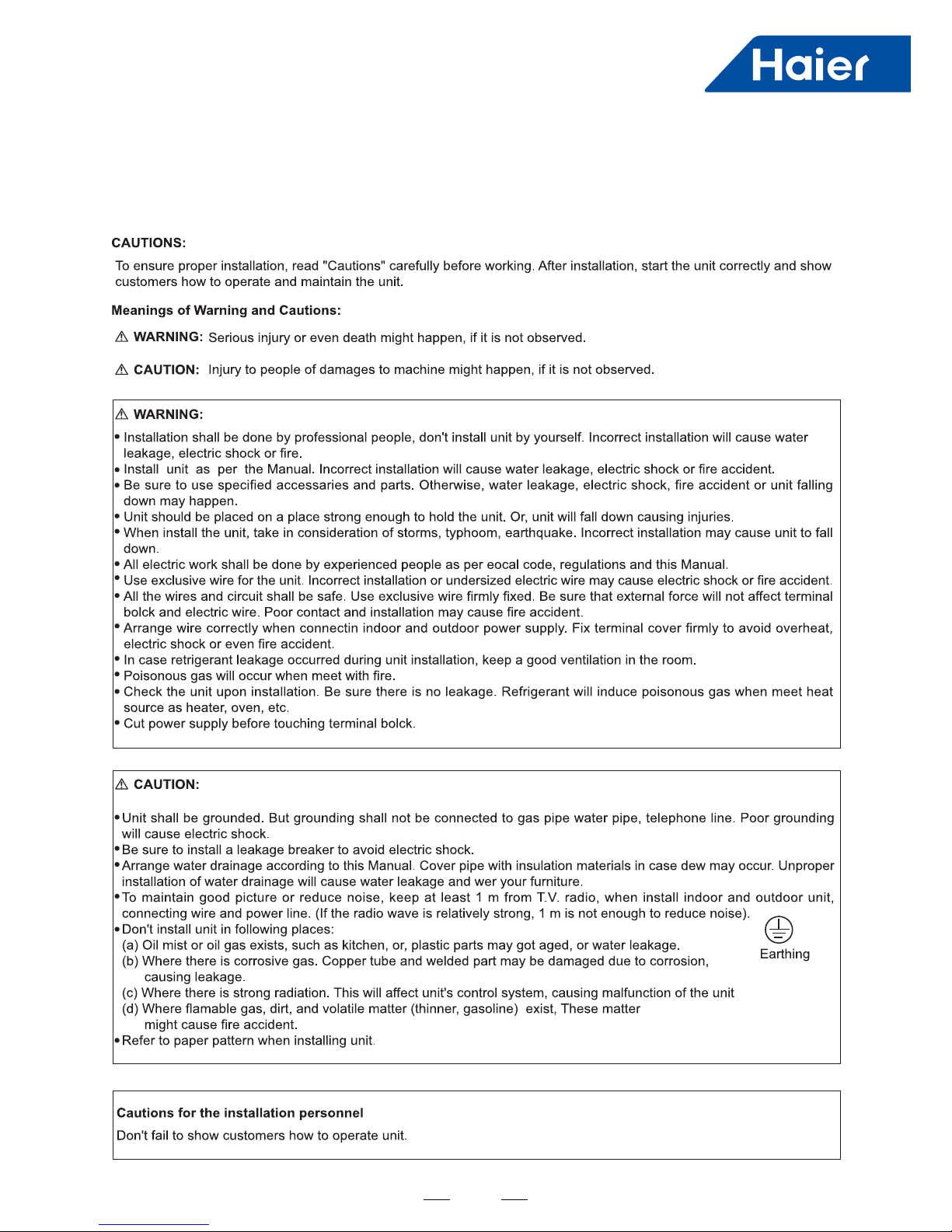

c. Heating / Air Velocity Distribution

Heating

Blowy angle:70

Air velocity Distribution

d. Heating / Temperature Distribution

Heating

Blowy angle:70

Temperature Distribution

22

27

25

22

25

27

4m

3m

2m2m

1m

1m

3m

4m

0m

2.7m

2m

1m

0m

Page 21

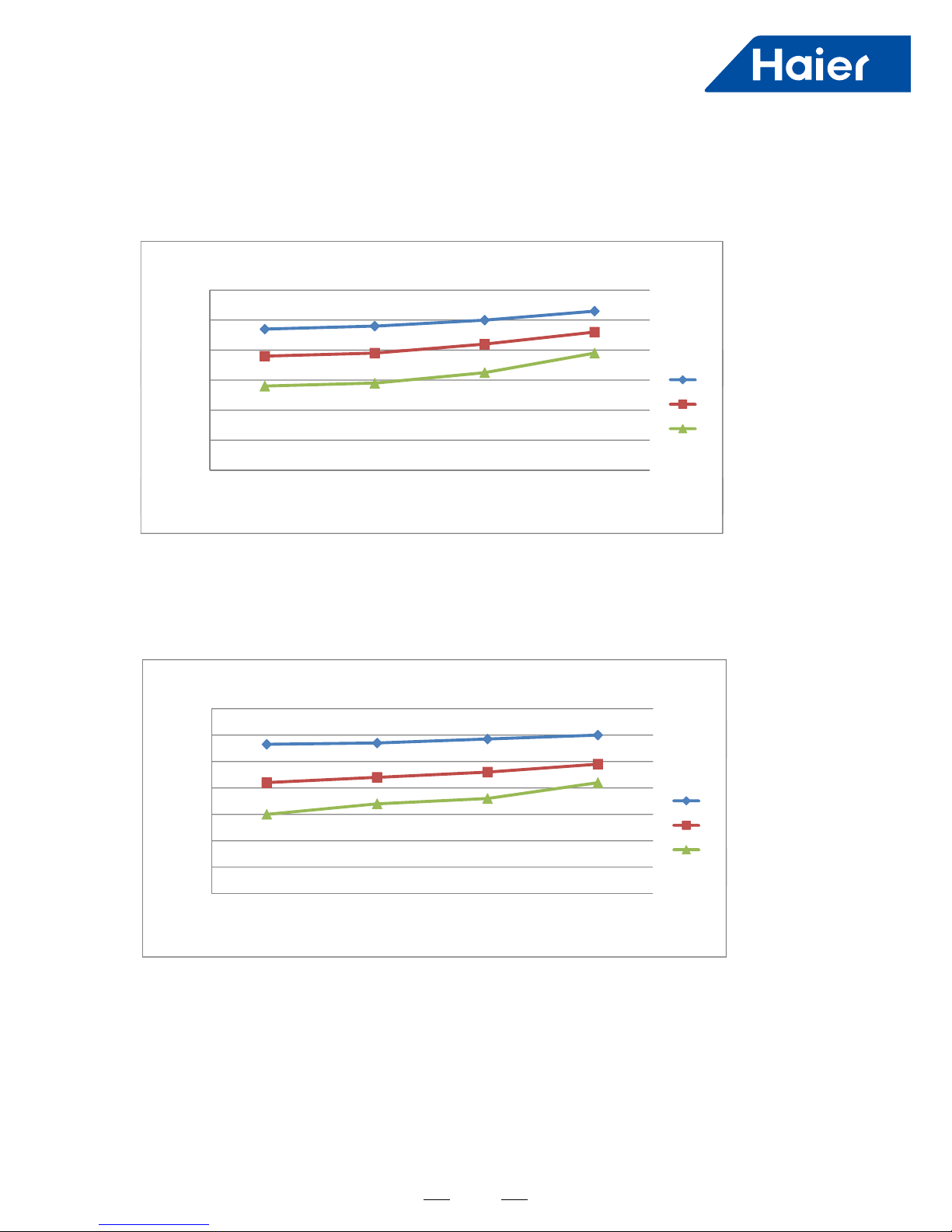

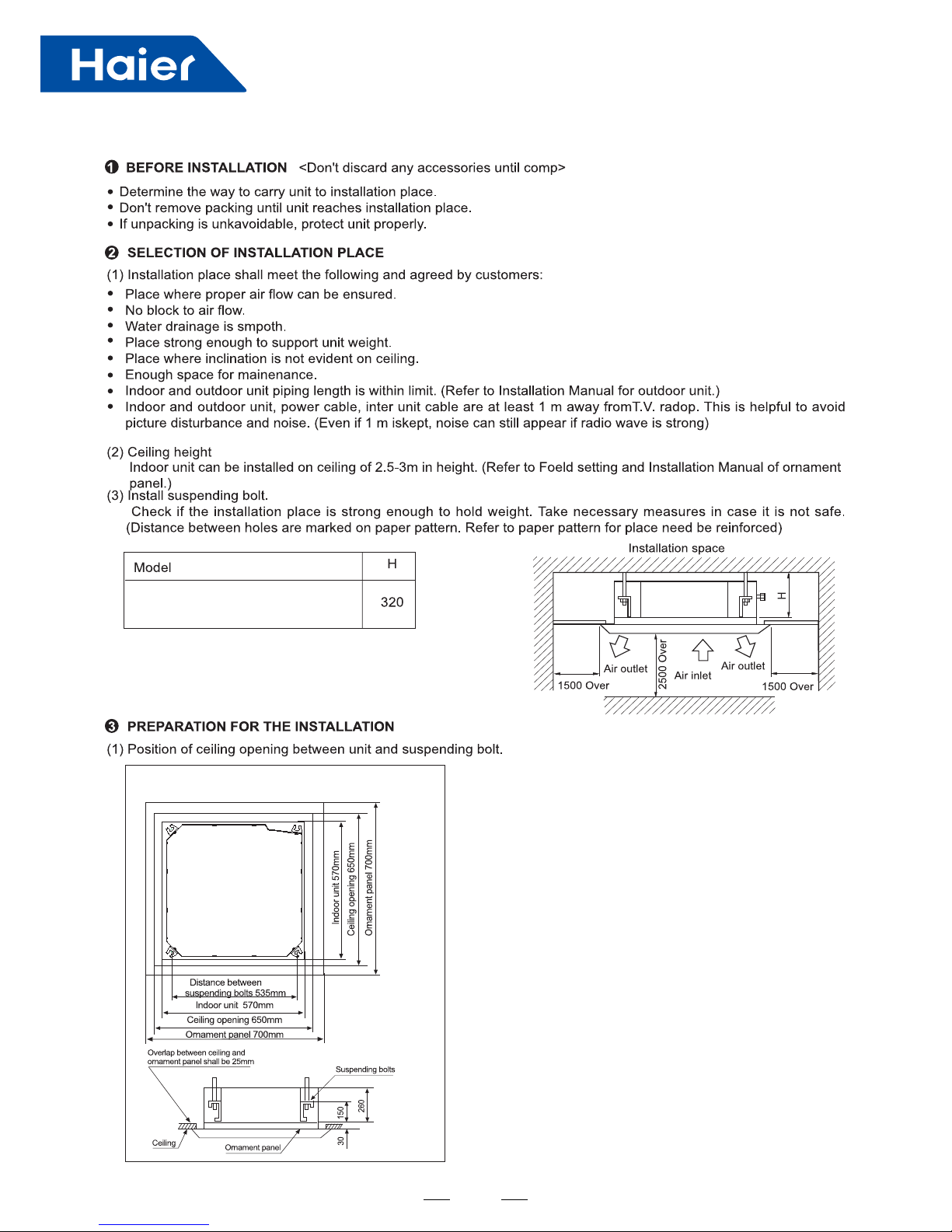

19

300

400

500

600

ow m3/h

AIR FLOW AND STATIC PRESSURE CHART

H

0

100

200

300

400

30 Pa 20 Pa 10 Pa 0 Pa

air flow m 3

static pressure (Pa)

H

M

L

500

600

700

h

AIR FLOW AND STATIC PRESSURE CHART

30 Pa 20 Pa 10 Pa 0 Pa

static pressure (Pa)

100

200

300

400

500

600

air flow m3/h

H

M

L

0

100

30 Pa 20 Pa 10 Pa 0 Pa

static pressure (Pa)

L

AD25S2SS1FA

AD35S2SS1FA

Temperature distribution

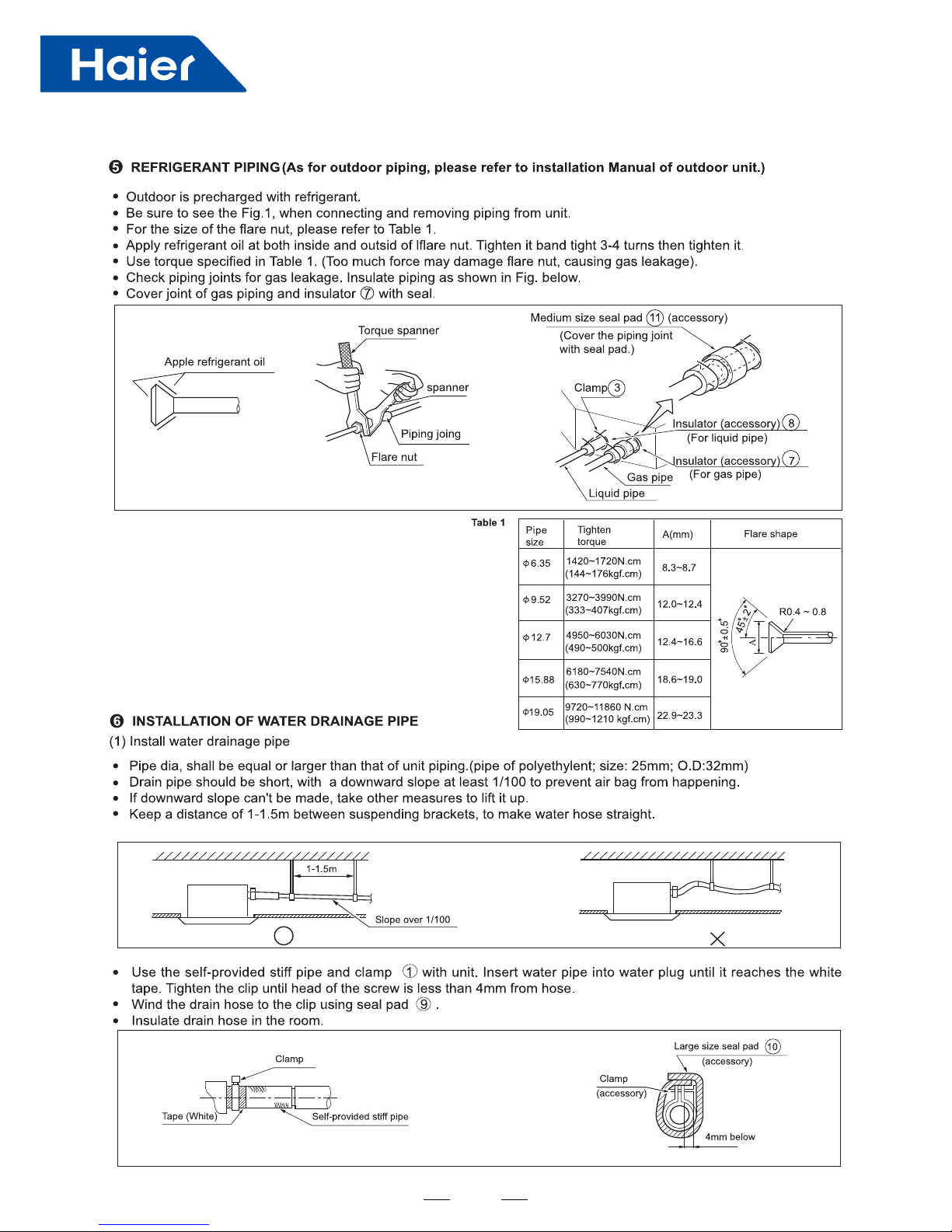

Page 22

20

600

700

800

900

1000

1100

1200

150Pa 130Pa 120Pa 110Pa 100Pa 90Pa 70Pa 50Pa 37Pa 25Pa

air flow m3/h

static pressure (Pa)

AIR FLOW AND STATIC PRESSURE CHART

S-H

H

M

L

S

AD50S2SM1FA

AD71S2SM1FA

600

700

800

900

1000

1100

1200

1300

1400

1500

150Pa 130Pa 120Pa 110Pa 100Pa 90Pa 70Pa 50Pa 37Pa 25Pa

air flow m3/h

static pressure (Pa)

AIRFLOW AND STATIC PRESSURE CHART

H

M

L

S

Page 23

21

5. Installation

For AB25S2SC1FA/AB35S2SC1FA

1. Installation procedure

Page 24

22

AB25S2SC1FA

AB35S2SC1FA

AB25S2SC1FA

AB35S2SC1FA

Page 25

23

Page 26

24

Page 27

25

AB25S2SC1FA

AB35S2SC1FA

Page 28

26

Page 29

27

For AD25S2SC1FA/AD35S2SC1FA

Installation procedure

AD25S2SS1FA

AD35S2SS1FA

Page 30

28

AD25S2SS1FA AD35S2SS1FA

AD25S2SS1FA AD35S2SS1FA

Page 31

29

Page 32

30

AD25S2SS1FA AD35S2SS1FA

Page 33

31

Page 34

32

The specification of power cable is HO5RN-F3G 4.0mm .

The specification of cable between indoor unit to outdoor unit is HO5RN-F4G 2.5mm

2

2

Page 35

33

For AD50S2SM1FA/AD71S2SM1FA

Installation procedure

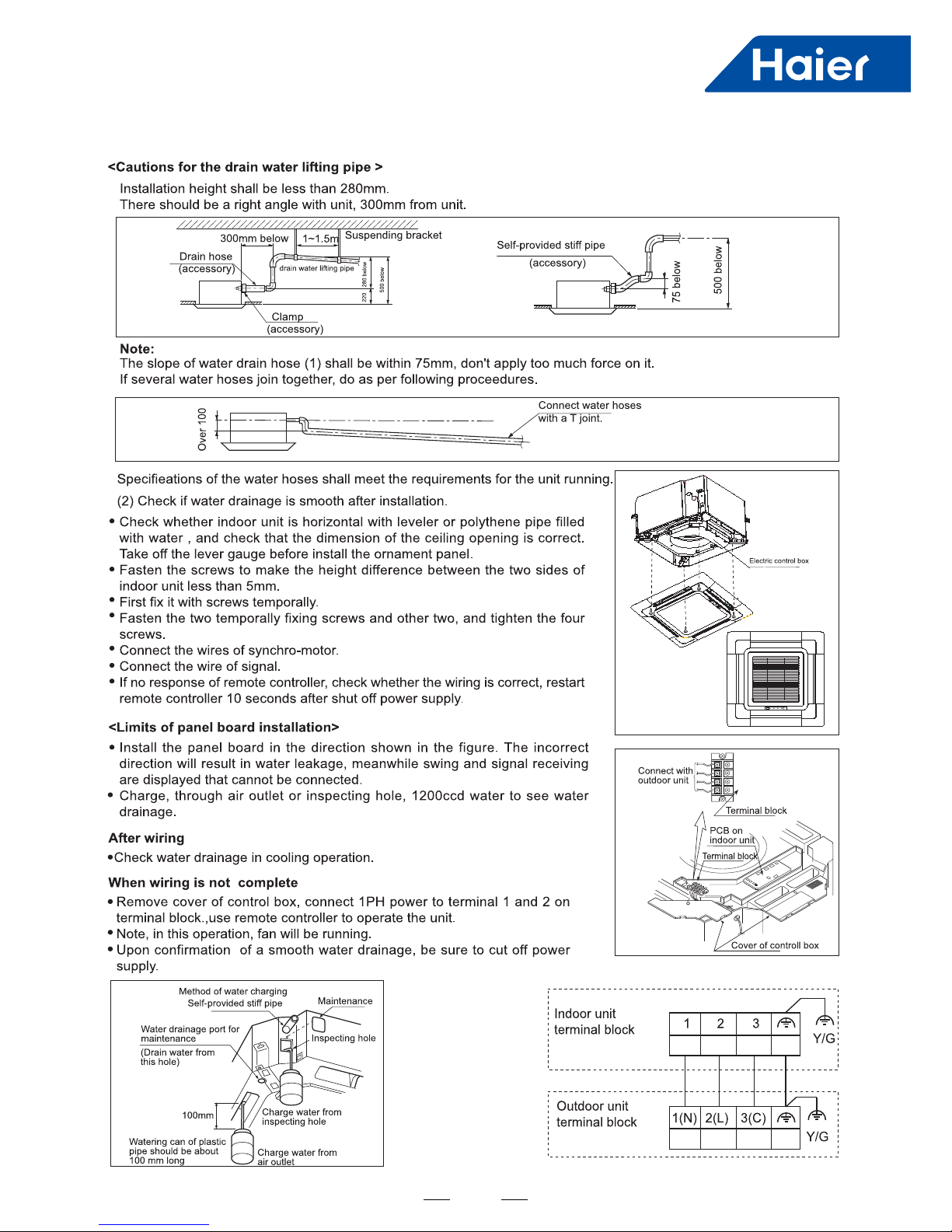

1. Applicable ambient temperature range:

The machine is adaptive in following situation

Cooling

Heating

Indoor temperature

Outdoor temperature

Indoor temperature

Outdoor temperature

max. DB/WB

min. DB/WB

max. DB/WB

min. DB/WB

max. DB/WB

min. DB/WB

max. DB/WB

min. DB/WB

32/23 C

18/14 C

46/26 C

10/6 C

27 C

15 C

24/18 C

-15 C

2. If the supply cord is damaged, it must be replaced by the manufacturer or its service agent or a similar qualified person.

3. If the fuse on the indoor PC board is broken please change it with the type of T 6.3A /250VAC(For series 24,28,36,48).

4. The wiring method should be in line with the local wiring standard.

5. The power cable should be:

H05RN-F 3G 4.0mm

2

;

The connecting cable should be:

H05RN-F 4G 2.0mm

2

All the cables shall have got the European authentication certificate. During installation, when the connecting cables

break off, it must be assured that the grouding wire is the last one to be broken off.

6. The power cable and conne

ct cable should be self-provided.

7. The breaker of the air conditioner should be all-pole switch, and the distance between its two contacts should be no

less than 3mm.

8. The indoor unit installation height is at least 2.5m.

9. A leakage breaker must be installed.

10.

For AD50S2SM1FA AD71S2SM1FA

,we can get the 10 different ESP through adjust wired controllerYR-E17,please refer

below:

AD50S2SM1FA AD71S2SM1FA

Stacc pressure

grade

1 2 3

5

4

7

6

8 9 10

Stacc pressure 25Pa 37Pa 50Pa 70Pa 90Pa 100Pa 110Pa 120Pa 130Pa 150Pa

Adjsutment metchod bywired controller YR-E17:In the state of ON and non screen saving state, press Fan+ Set keys for

5s to enter stac pressure grade adjustmentstate with stac pressure icon flashing and current stacpressure grade

stacally displaying. Press key↑↓ to changestac pressure grade, then press Set key to confirm.

Details please refer to wired controller operaon & installaon manual.

Adjsutment metchod by Infrared remote controller+Infrared receiver RE-02:Step a:set the Infrared remote controller at

condion: FAN mode ,fan speed high Step b:then aim the remote contr

oller at the infrared remote receiver RE-02,

press HEALTH buon 4+N mes(1≤N≤10,integer)within 12 seconds ,then the receiver will beep N+1 mes ,the

stac pressure level N is been set successfully.

Note:For Infrared remote controller YR-HBS01, need press ON/OFF buon make the controller’s at OFF status first,then

open the buon cover press FRESH buon will enter FAN mode interface.

Page 36

34

Avoid installation and use at those places listed below.

Places exposed to oil splashes or steam (e.g. kitchens and machine plants).

Installation and use at such places incur deteriorations in the performance or corrosion with the heat exchanger or damage

in molded synthetic resin parts.

Places where corrosive gas (such as sulfurous acid gas) or inflammable gas (thinner, gasoline etc.) in generated or

remains. Installation and use at such places cause corrosion in the heat exchanger and damage in molded synthet

ic

resin parts.

Places adjacent to equipment generating electromagnetic waves or high-frequency waves such as in hospitals.

Generated noise may cause malfunctioning of the controller.

NOTE

All wiring of this installation must comply with NATIONAL, STATE AND LOCAL REGULATIONS. These instructions

do not cover all variations for every kind of installation circumstance. Should further information be desired or should particular

problems occur, the matter should be referred to your local distr

ibutor.

WARNING

BE SURE TO READ THESE INSTRUCTIONS CAREFULLY BEFORE BEGINNING INSTALLATION. FAILURE TO FOLLOW

THESE INSTRUCTIONS COULD CAUSE SERIOUS INJURY OR DEATH, EQUIPMENT MALFUNCTION AND/OR

PROPERTY DAMAGE.

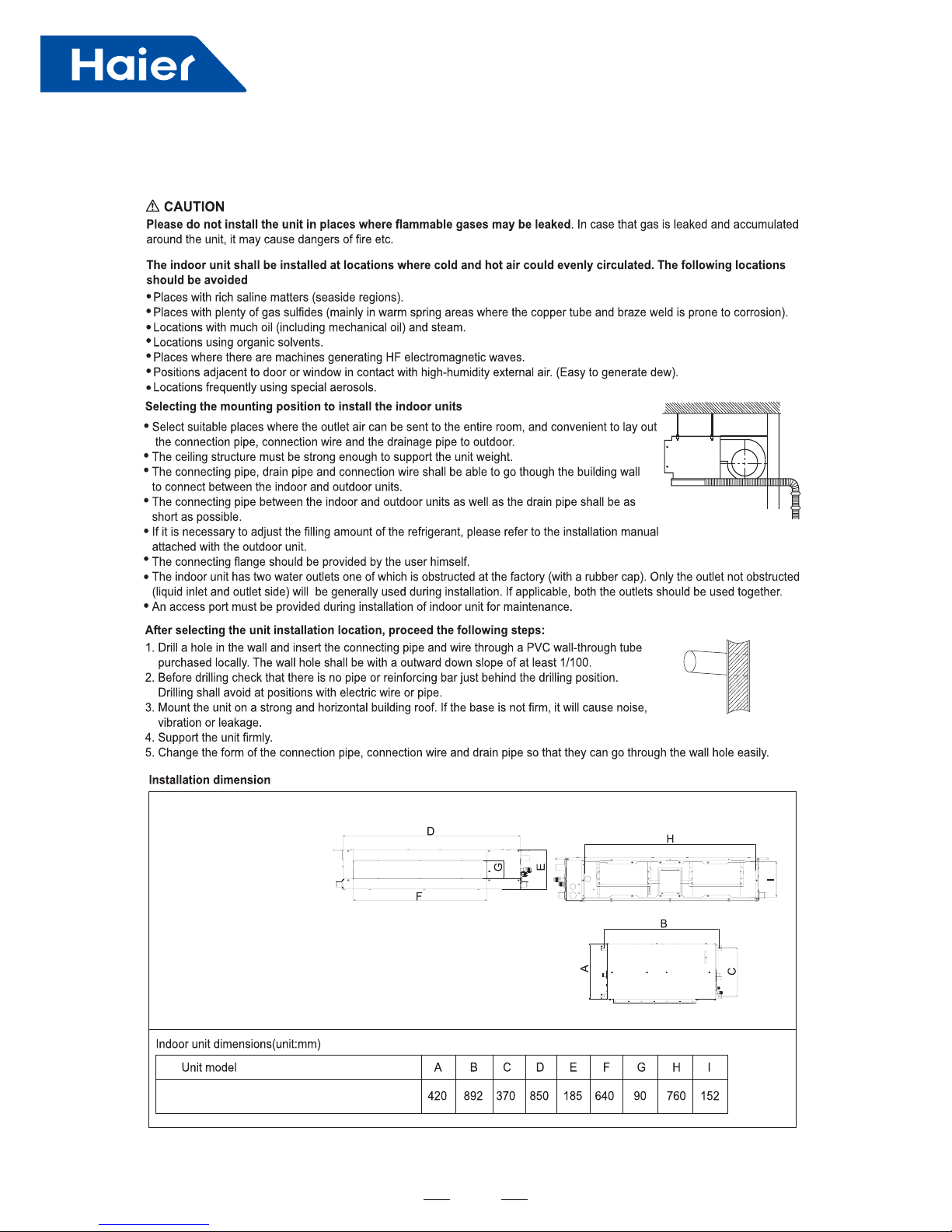

Preparation of indoor unit

Before or during the installation of the unit, assemble necessary optional panel etc. depending on the specific type.

Select places for installation satisfying following conditions and at the same time obtain the consent on the part

of your client user.

Places where chi

lled or heated air circulates freely. When the installation height exceeds 3m warmed air stays close to

the ceiling. In such cases, suggest your client users to install air circulators.

Places where perfect drainage can be prepared and sufficient drainage.

Places free from air disturbances to the suction port and blowout hole of the indoor unit, places where the fire alarm

may not malfunction or short-circuit.

Places with the environmental dew-point temperature is lower than 28 and the relative humidity is less than 80 %.

(When installin

g at a place under a high humidity environment, pay sufficient attention to the prevention of dewing such

as thermal insulation of the unit. )

Ceiling height shall have the following height.

50mm

Obstacle

Installation space

C

Combination

with silent

panel

366mm

a.

b.

c.

d.

e.

a.

b.

c.

100mm 100mm

Pipe size

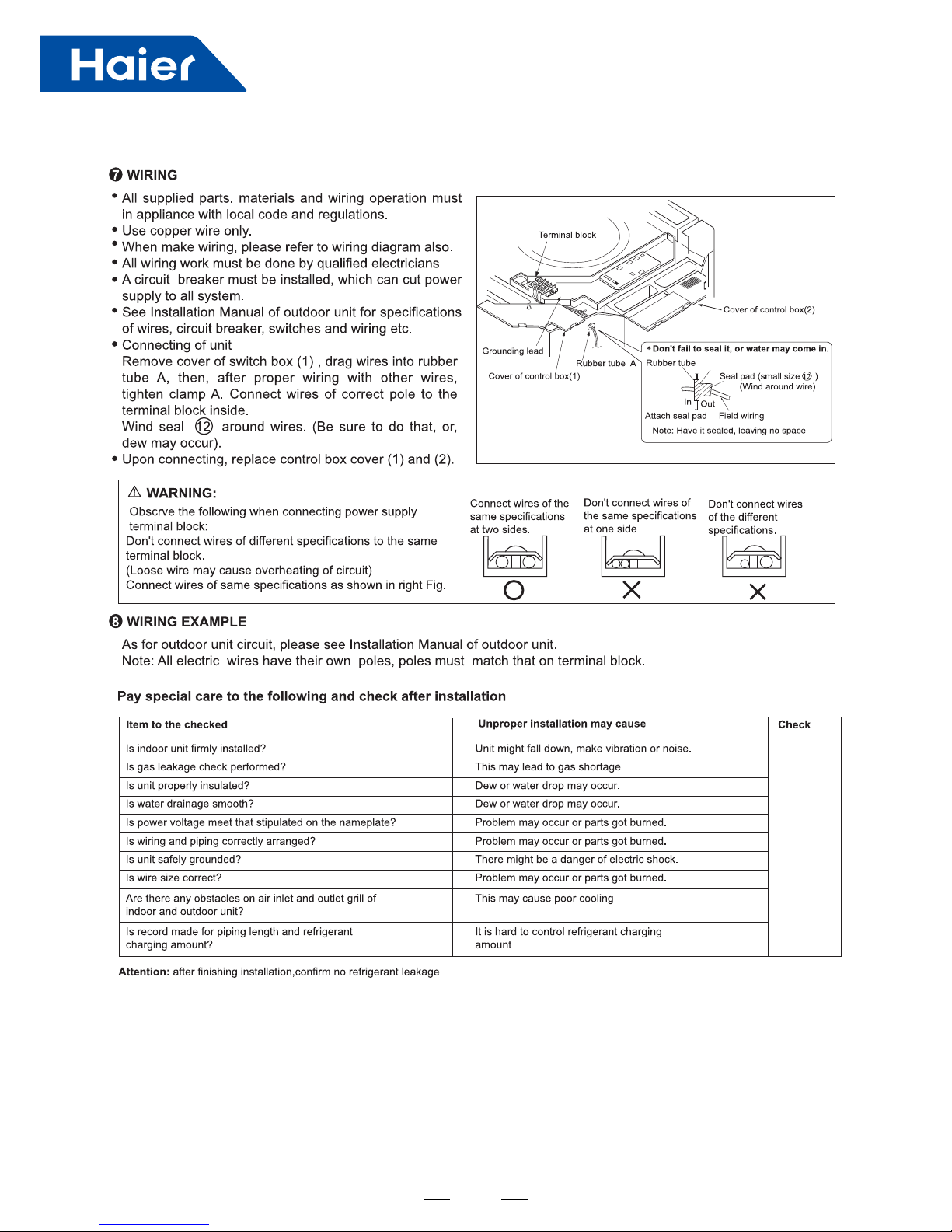

AD50S2SM1FA AD71S2SM1FA

AD50S2SM1FA

AD71S2SM1FA

Model Liquid side Gas side

9.52mm 15.88mm

6.35mm 12.7mm

Page 37

35

AD50S2SM1FA AD71S2SM1FA

Dimensions

A(mm)

B(mm) C(mm)

Model

D(mm) E(mm) F(mm)

983 1433 1493 595 740 800

AD50S2SM1FA AD71S2SM1FA

Page 38

36

21mmAD50S2SM1FA AD71S2SM1FA

Unit model The size of drain opening

Page 39

37

Page 40

38

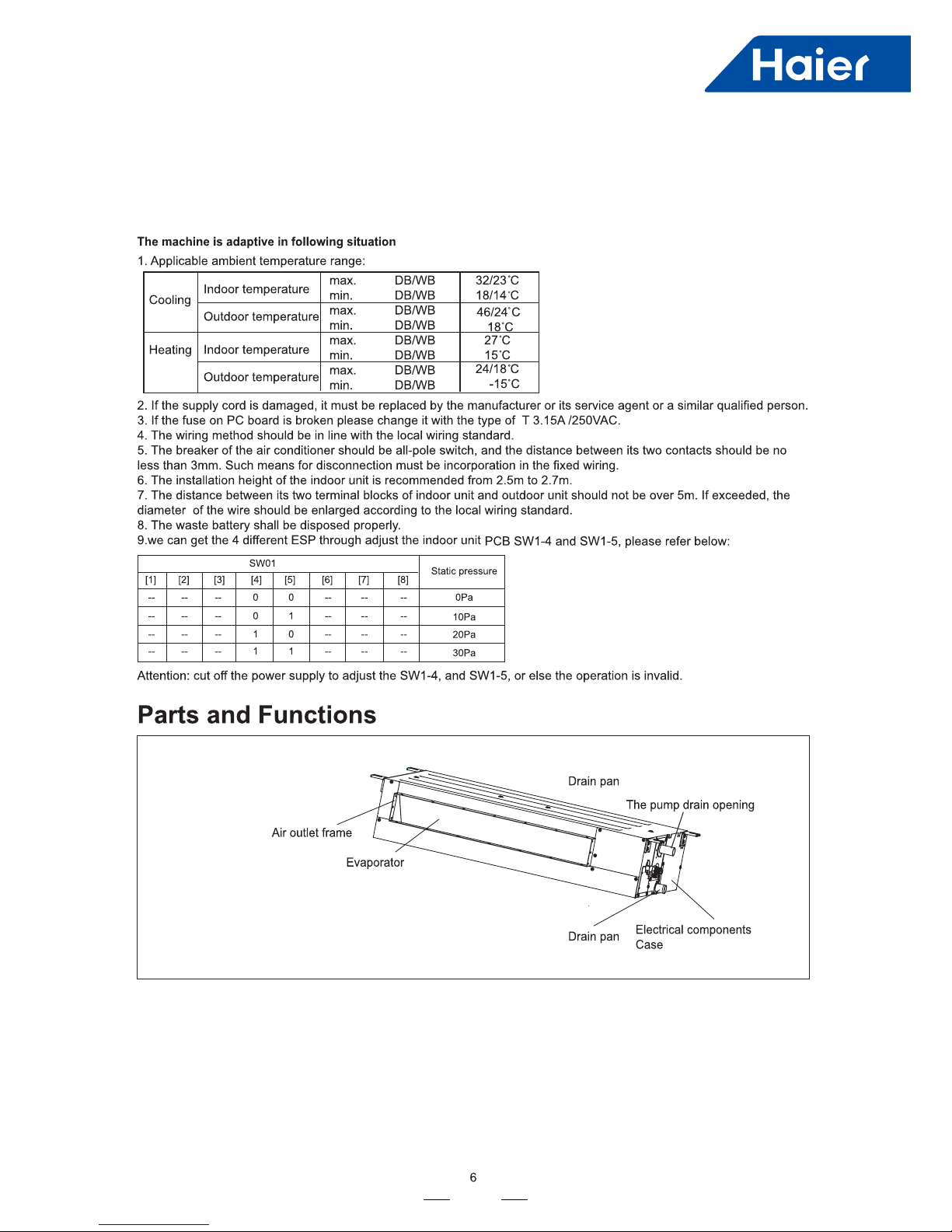

Selection of size of power supply and interconnecting wires

Select wire sizes and circuit protection from table below. (This table shows 20 m length wires with less than 2% voltage drop.)

Item

Model

Phase

Switch

breaker

(A)

Circuit breaker

Overcurrent

protector

rated capacity

(A)

Power source

wire size

(minimum)

(mm

2

)

Switch

breaker(A)

Earth leakage breaker

Leak

current(mA)

301 40 26 4.0 40AD50S2SM1FA AD71S2SM1FA

The specification of power cable is HO5RN-F3G 4.0mm .

The specification of cable between indoor unit to outdoor unit is HO5RN-F4G 2.5mm

2

2

POWER SUPPLY & INDOOR-OUTDOOR CONNECTION:

Make wiring to supply power to the outdoor unit, so that the power for the indoor unit is supplied by outdoor

unit terminal blocks.

WIRED CONTROLLER& INDOOR PCB CONNECTION(one for one wiring type):

.

Note:When do the wired controller & indoor PCB wiring work for model AD50/71S2SM1FA,do not connect

the shielded wired to the unit’s shell,do not parallel wiring with strong electric lines within 0.3 meters, please

keep strong lines and the signal lines separately.

INDOOR UNIT PCB

CN22

WIRED

CONTROLLER

CON1

A

B

C

A

B

C

Page 41

39

- The installation of pipe-work shall be kept to a minimum.

- Pipe-work shall be protected from physical damage and shall not be installed in an unventilated space, if that space is

smaller than Amin(2m2).

- Compliance with national gas regulations shall be observed.

- Mechanical connections shall be accessible for maintenance purposes.

- The minimum floor area of the room: 2 m2.

- The maximum refrigerant charge amount: 1.7 kg.

- Information for handling, installation, cleaning, servicing and disposal of refrigerant.

- Warning: Keep any required ventilation openings clear of obstruction.

- Notice: Servicing shall be performed only as recommended by the manufacturer.

Unventilated areas

- Warning: The appliance shall be stored in a well-ventilated area where the room size corresponds to the room area as

specified.

- Warning: The appliance shall be stored in a room without continuously operating open flames (e.g. an operating gas

appliance) and ignition sources (e.g. an operating electric heater).

Qualification of workers

- Specific information about the required qualification of the working personnel for maintenance, service and repair

operations.

- Warning: Every working procedure that affects safety means shall only be carried out by competent persons.

Examples for such working procedures are:

- breaking into the refrigerating circuit.

- opening of sealed components

- opening of ventilated enclosures.

Information on servicing

- Prior to beginning work on systems, safety checks are necessary to ensure that the risk of ignition is minimized.

- Work shall be undertaken under a controlled procedure so as to minimized the risk of flammable gas or vapor being

present while the work is being performed.

- Work in confined spaces shall be avoided. The area around the workspace shall be sectioned off. Ensure that the conditions

within the area have been made safe by control of flammable material.

Checking for presence of refrigerant

- The area shall be checked with an appropriate refrigerant detector prior to and during work. The leak detection equipment

should be suitable for use with all applicable refrigerants, i.e. non-sparking, adequately sealed or intrinsically safe.

Presence of fire extinguisher

- If any hot work is to be conducted, appropriate fire extinguishing equipment shall be available to hand. Have a dry powder

or CO2 fire extinguisher adjacent to the charging area.

No ignition sources

- All possible ignition sources, including cigarette smoking, should be kept sufficiently far away from the site of installation,

repairing, removing and disposal. Prior to work taking place, the area around the equipment is to be surveyed to make sure

that there are no flammable hazards or ignition risks. “No Smoking” signs shall be displayed.

Ventilated area

- Ensure that the area is in the open or that it is adequately ventilated before breaking into the system or conducting any hot

work. A degree of ventilation shall continue during the period that the work is carried out. The ventilation should safely disperse

any released refrigerant and preferably expel it externally into the atmosphere.

Checks to the refrigeration equipment

- Where electrical components are being changed, they shall be fit for the purpose and to the correct specification. At all

times the manufacturer’s maintenance and service guidelines shall be followed. If in doubt, consult the manufacturer’s

technical department for assistance.

The following checks shall be applied to installations

- The charge size is in accordance with the room size within which the refrigerant containing parts are installed;

- The ventilation machinery and outlets are operating adequately and are not obstructed;

- If an indirect refrigerating circuit is being used, the secondary circuit shall be checked for the presence of refrigerant;

- Marking to the equipment continues to be visible and legible. Markings and signs that are illegible shall be corrected;

- Refrigeration pipe or components are installed in a position where they are unlikely to be exposed to any substance which

may corrode refrigerant containing components, unless the components are constructed of materials which are inherently

resistant to being corroded or are suitably protected against being so corroded.

Cautions

Page 42

40

Checks to electrical devices

- Repair and maintenance to electrical components shall include initial safety checks and component inspection

procedures. If a fault exists that could compromise safety, then no electrical supply shall be connected to the circuit until it

is satisfactorily dealt with. If the fault cannot be corrected immediately but it is necessary to continue operation, an

adequate temporary solution shall be used. This shall be reported to the owner of the equipment so all parties are

advised.

- Initial safety checks shall include:

• that capacitors are discharged: this shall be done in a safe manner to avoid possibility of sparking;

• that no live electrical components and wiring are exposed while charging, recovering or purging the system;

• that there is continuity of earth bonding.

Repairs to sealed components

- During repairs to sealed components, all electrical supplies shall be disconnected prior to any removal of sealed

covers, etc. If it is absolutely necessary to have an electrical supply to equipment during servicing, then a permanently

operating form of leak detection shall be located at the most critical point to warn of a potentially hazardous situation.

- Ensure that by working on electrical components, the casing is not altered in such a way that the level of protection is

affected, including damage to cables, excessive number of connections, terminals not made to original specification,

damage to seals, incorrect fitting of glands, etc.

- Ensure that the apparatus is mounted securely.

- Ensure that seals or sealing materials have not degraded to the point that they no longer serve the purpose of

preventing the ingress of flammable atmospheres. Replacement parts shall be in accordance with the manufacturer’s

specifications.

Repair to intrinsically safe components

- Do not apply any permanent inductive or capacitance loads to the circuit without ensuring that this will not exceed the

permissible voltage and current permitted for the equipment in use.

- Intrinsically safe components are the only types that can be worked on while live in the presence of a flammable

atmosphere.

- Replace components only with parts specified by the manufacturer. Other parts may result in the ignition of refrigerant

in the atmosphere from a leak.

Cabling

- Check that cabling will not be subject to wear, corrosion, excessive pressure, vibration, sharp edges or any other

adverse environmental effects. The check shall also take into account the effects of aging or continual vibration from

sources such as compressors or fans.

Detection of flammable refrigerants

Removal and evacuation

- The refrigerant charge shall be recovered into the correct recovery cylinders and the system shall be “flushed” with

OFN to render the unit safe. This process may need to be repeated several times.

- Compressed air or oxygen shall not be used for purging refrigerant systems.

- Flushing shall be achieved by breaking the vacuum in the system with OFN and continuing to fill until the working

pressure is achieved, then venting to atmosphere, and finally pulling down to a vacuum. This process shall be repeated

until no refrigerant is within the system. When the final OFN charge is used, the system shall be vented down to

atmospheric pressure to enable work to take place.

- The vacuum pump is not close to any ignition sources and that ventilation is available.

Charging procedures

- Ensure that contamination of different refrigerants does not occur when using charging equipment. Hoses or lines

shall be as short as possible to minimise the amount of refrigerant contained in them.

- Cylinders shall be kept upright.

- Ensure that the refrigeration system is earthed prior to charging the system with refrigerant.

- Label the system when charging is complete (if not already).

- Extreme care shall be taken not to overfill the refrigeration system.

- Prior to recharging the system, it shall be pressure-tested with the appropriate purging gas. The system shall be leaktested on completion of charging but prior to commissioning. A follow up leak test shall be carried out prior to leaving the

site.

Decommissioning

- Before carrying out this procedure, it is essential that the technician is completely familiar with the equipment and all

its detail.

- Prior to the task being carried out, an oil and refrigerant sample shall be taken in case analysis is required prior to reuse of reclaimed refrigerant.

- Electrical power must be available before the task is commenced.

Page 43

41

- Become familiar with the equipment and its operation.

- Isolate system electrically.

- Before attempting the procedure, ensure that:

• mechanical handling equipment is available, if required, for handling refrigerant cylinders;

• all personal protective equipment is available and being used correctly;

• the recovery process is supervised at all times by a competent person;

• recovery equipment and cylinders conform to the appropriate standards.

- Pump down refrigerant system, if possible.

- If a vacuum is not possible, make a manifold so that refrigerant can be removed from various parts of the system.

- Make sure that cylinder is situated on the scales before recovery takes place.

- Start the recovery machine and operate in accordance with manufacturer's instructions.

- Do not overfill cylinders. (No more than 80 % volume liquid charge).

- Do not exceed the maximum working pressure of the cylinder, even temporarily.

- When the cylinders have been filled correctly and the process completed, make sure that the cylinders and the

equipment are removed from site promptly and all isolation valves on the equipment are closed off.

- Recovered refrigerant shall not be charged into another refrigeration system unless it has been cleaned and checked.

Labelling

- Equipment shall be labelled stating that it has been de-commissioned and emptied of refrigerant. The label shall be

dated and signed.

- Ensure that there are labels on the equipment stating the equipment contains flammable refrigerant.

Recovery

- When transferring refrigerant into cylinders, ensure that only appropriate refrigerant recovery cylinders are employed.

- Ensure that the correct number of cylinders for holding the total system charge are available. All cylinders to be used

are designated for the recovered refrigerant and labelled for that refrigerant (i.e. special cylinders for the recovery of

refrigerant).

- Cylinders shall be complete with pressure-relief valve and associated shut-off valves in good working order. Empty

recovery cylinders are evacuated and, if possible, cooled before recovery occurs.

- The recovery equipment shall be in good working order with a set of instructions concerning the equipment that is at

hand and shall be suitable for the recovery of all appropriate refrigerants.

- A set of calibrated weighing scales shall be available and in good working order. Hoses shall be complete with leakfree disconnect couplings and in good condition. Before using the recovery machine, check that it is in satisfactory

working order, has been properly maintained and that any associated electrical components are sealed to prevent ignition

in the event of a refrigerant release.

- The recovered refrigerant shall be returned to the refrigerant supplier in the correct recovery cylinder, and the relevant

waste transfer note arranged.

- Do not mix refrigerants in recovery units and especially not in cylinders.

- If compressors or compressor oils are to be removed, ensure that they have been evacuated to an acceptable level to

make certain that flammable refrigerant does not remain within the lubricant.

- The evacuation process shall be carried out prior to returning the compressor to the suppliers.

- Only electric heating to the compressor body shall be employed to accelerate this process.

Page 44

42

1. Specification ......................................................................................................................................................43

2. Dimension ..........................................................................................................................................................52

3. Wiring diagram ..................................................................................................................................................55

4. Wiring connection .............................................................................................................................................58

5. Refrigerant diagram ..........................................................................................................................................60

6. Limitation values on pipe installation .............................................................................................................63

7. Combination and the data ................................................................................................................................65

8. Sound pressure level ........................................................................................................................................79

9. Outdoor performance curves ...........................................................................................................................83

10. Installation .......................................................................................................................................................88

Part 3 Outdoor Units

Page 45

43

1. Specification

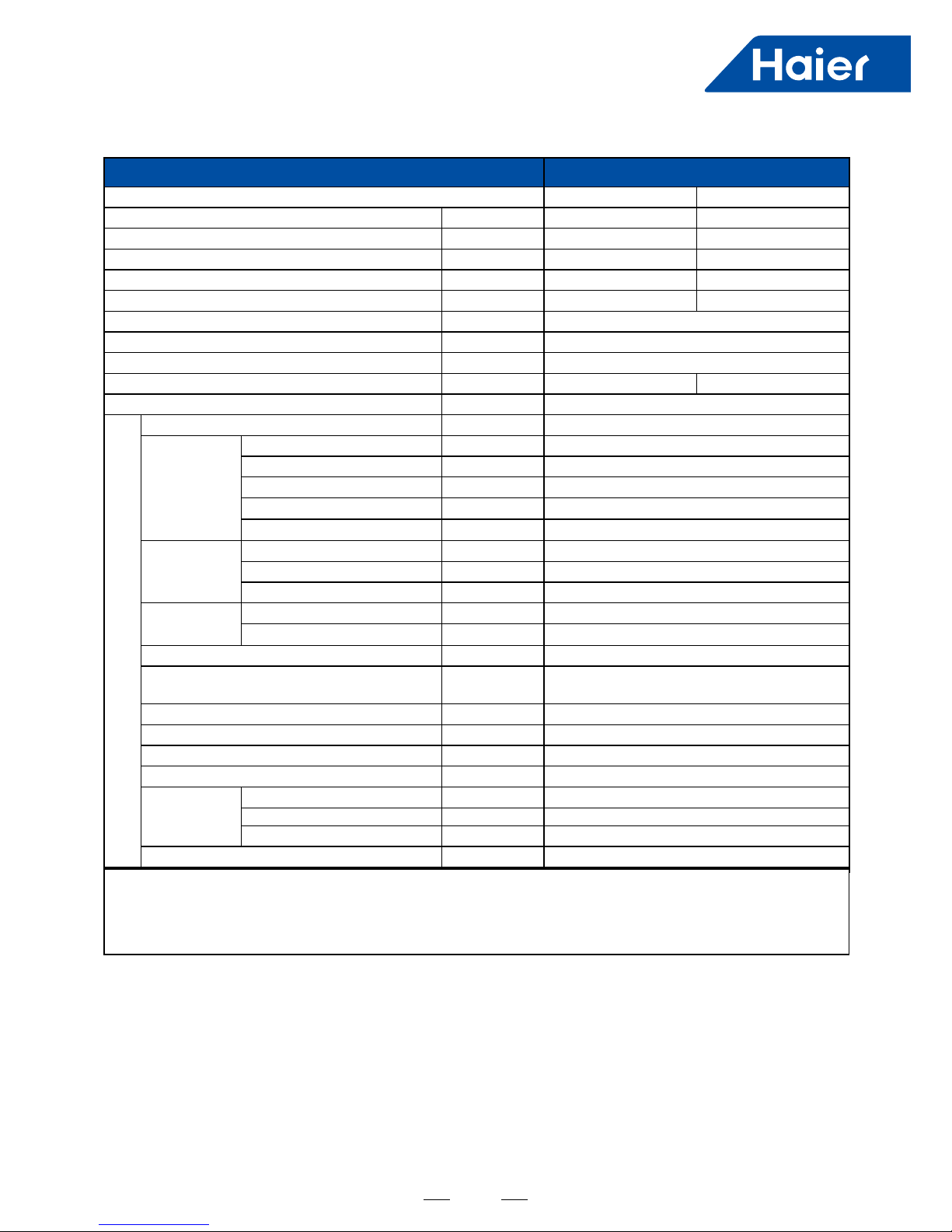

Item Model 1U71S2SG1FA

Power cable H05RN-F 4G 6.0mm2

Communication cable/Connecting cable H05RN-F 4G 2.5mm2

Power source N, V, Hz 1PH,220-230VAC,50/60HZ

Start Current A 3 3

Outdoor

unit

Unit model (color) 1U71S2SG1FA(WHITE)

Compressor

Model / Manufacture SNB130FGYM2/SNB130FGYMC-L1(MGC

)

Oil model FV50S

Oil type PVE

Oil charging 500CC

Type Rotary

Fan

Type × Number axial×1

Speed r/min 950/830/750/700/500/420/300

Fan motor output/input

power pow

W 97/70

Air-ow(H-M-L) m³/h 3000

Heat

exchanger

Type / Diameter mm TP2M/Φ7.9

Row / Fin pitch 2/1.65

Dimension

External(L×W×H

)

mm×mm×mm 860/308/730

Package(L×W×H

)

mm×mm×mm 995x420x815

Drainage pipe (material , I.D./O.D.) mm /

Refrigerant control method mm/mm 1.8mmEEV+Φ3.0*Φ1.8*200mmCapillary

Defrosting AUTO

Volume of Accumulator L NONE

Sound power Noise level (H-M-L) dB(A) 70

Sound pressure Noise level (H-M-L) dB(A) 57

Type of Four way valve SHF-4-10A

material of reduce noise felt

crankcase heater power W /

Weight (Net / Shipping) kg / kg 49/52

PIPING

Refrigerant

Type / Charge g R32/1600

Maximum pipe length without

recharge refrigerant

m 5

GWP 2088

Recharge quantity g/m 45

Pipe

Liquid mm 9.52

Gas mm 15.88

Connecting Method Flared

Between I.D

&O.D

MAX.Drop m 15

MAX.Piping length m 25

Working

temp.

Cooling(Min-Max) °C -10~46

Heating(Min-Max) °C -15~24

Norminal condition: indoor temperature (cooling): 27°C DB/19°C WB, indoor temperature (heating): 20°C DB

Outdoor temperature(cooling): 35°C DB/24°C WB, outdoor temperature(heating): 7°C DB/6°C WB

The noise level will be measured in the third octave band limited values, using a Real Time Analyser calibrated sound

intensity meter. It is a sound pressure noise level.

Page 46

44

Item Model 3U52S2SG1FA

Function - Cooling Heating

Rating capacity W 5200 6500

Cooling Pdesign W 5200

Heating Pdesign(-10℃) W 4600

Rated power input (indoor + outdoor) W 1150 1340

Rated current input (indoor + outdoor) A 5.50 6.30

EER / COP W/W 4.5 4.8

SEER / SCOP W/W 8.5 4.2

Minimum capacity W 1500 1800

Minimum power input W 550 550

Maximum capacity W 7000 8100

Maximum power input (indoor + outdoor) W 3400 3400

Power source - 1PH, 220-240V~, 50/60Hz

Max.Running current (indoor + outdoor) A / A 14.2 14.2

Power facor(under rating power input) - 99% 99%

Starting current A 4

Fuse size (recommended size) A 25

Outdoor unit

Compressor

Model / Manufacture - SVB172FNPMC/ MELCOM

Oil charge and type - 600CC/FW68S

Type - Twin Rotary (DC inverter)

Number - 1

Fan

Type × Number - Axial × 1

Speed r/min High 820

Motor output/input power W 80/100

Air-ows (H/M/L) m³/h about 2000

Heat exchanger

Type / Diameter mm TP2M / 7.0

row - 2

Face area m² about 0.52

Dimension

(WxDxH)

External mm 860/308/730

Package mm 1005/423/815

Refrigerant control method - PMVs

Defrosting method - Automatic by reversible cycle

Crankcase heater power W NONE

Noise level

Sound power level dB(A) 65

Sound pressure level dB(A) 52

Weight Net / Shipping kg / kg 53/56

Page 47

45

Item Model 3U52S2SG1FA

Piping

Refrigerant

Type / Charge kg R32 / 1.6

GWP 675

No need to recharge m 30

Recharge g/m 20

Pipe

Liquid mm 3* Φ6.35

Gas mm 3* Φ9.52

Connecting method - Flared

Between

I.D &O.D

Drop between IU & OU m ≤7.5

Piping length between IU & OU m ≤10

Total liquid piping length m ≤30

Drop between indoor units m ≤1

Max.Drop between IU &OU m 15

Max.Drop between indoor units m 7.5

Max.Piping length between IU & OU m 25

Max Cable length between IU & OU m 30

Max.Total length m 60

Working temperature

Cooling °C -10~46

Heating °C -15~24

Tdisignh: -10°C Tbivalent: -7°C TOL: -15°C

Pto: 30W Psb: 10W Pck: 0W Poff: 0W

Cooling

A (Cap/EER) 5199W/4.17

Heating

A (Cap/COP) 4796W/2.77 Tol (Cap/COP) 4900W/2.75

B (Cap/EER) 4246W/6.42 B (Cap/COP) 3359W/3.91 Tb (Cap/COP) 4796W/2.77

C (Cap/EER) 3080W/8.64 C (Cap/COP) 2252W/4.91 Cd (cooling) 0.25

D (Cap/EER) 3196W/11.64 D (Cap/COP) 2036W/5.91 Cd (heating) 0.25

Max. cooling condition

Indoor

temperature:

32°C/23°C

Max. heating condition

Indoor temperature: 27°C/-°C

Outdoor

temperature:

46°C/-°C

Outdoor temperature: 24°C/18°C

kWh/annum 210 kWh/annum-average 1522 kWh/annum-warm 1309

1. The above performance data are from the combination of 3U68S2SG1FA+3*AS25S2SN1FA.

2. Large drop and long piping installation will obviously reduce the total capacity.

Page 48

46

Item Model 3U68S2SG1FA

Function - Cooling Heating

Rating capacity W 6900 7700

Cooling Pdesign W 6900

Heating Pdesign(-10℃) W 5300

Rated power input (indoor + outdoor) W 1720 2200

Rated current input (indoor + outdoor) A 7.55 9.60

EER / COP W/W 3.7 4.2

SEER / SCOP W/W 7.5 4.1

Minimum capacity W 1500 1800

Minimum power input W 550 550

Maximum capacity W 8200 9000

Maximum power input (indoor + outdoor) W 3400 3400

Power source - 1PH, 220-240V~, 50/60Hz

Max.Running current (indoor + outdoor) A / A 14.2 14.2

Power facor(under rating power input) - 99% 99%

Starting current A 4

Fuse size (recommended size) A 25

Outdoor unit

Compressor

Model / Manufacture - SVB172FNPMC/ MELCOM

Oil charge and type - 600CC/FW68S

Type - Twin Rotary (DC inverter)

Number - 1

Fan

Type × Number - Axial × 1

Speed r/min High 820

Motor output/input power W 80/100

Air-ows (H/M/L) m³/h about 2500

Heat exchanger

Type / Diameter mm TP2M / 7.0

row - 2

Face area m² about 0.52

Dimension

(WxDxH)

External mm 860/308/730

Package mm 1005/423/815

Refrigerant control method - PMVs

Defrosting method - Automatic by reversible cycle

Crankcase heater power W NONE

Noise level

Sound power level dB(A) 67

Sound pressure level dB(A) 54

Weight Net / Shipping kg / kg 53/56

Page 49

47

Item Model 3U68S2SG1FA

Piping

Refrigerant

Type / Charge kg R32 / 1.6

GWP 675

No need to recharge m 30

Recharge g/m 20

Pipe

Liquid mm 3* Φ6.35

Gas mm 3* Φ9.52

Connecting method - Flared

Between

I.D &O.D

Drop between IU & OU m ≤7.5

Piping length between IU & OU m ≤10

Total liquid piping length m ≤30

Drop between indoor units m ≤1

Max.Drop between IU &OU m 15

Max.Drop between indoor units m 7.5

Max.Piping length between IU & OU m 25

Max Cable length between IU & OU m 30

Max.Total length m 60

Working temperature

Cooling °C -10~46

Heating °C -15~24

Tdisignh: -10°C Tbivalent: -7°C TOL: -15°C

Pto: 30W Psb: 10W Pck: 0W Poff: 0W

Cooling

A (Cap/EER) 6963W/3.22

Heating

A (Cap/COP) 5087W/2.78 Tol (Cap/COP) 5106W/2.75

B (Cap/EER) 4923W/5.98 B (Cap/COP) 3370W/3.84 Tb (Cap/COP) 5087W/2.61

C (Cap/EER) 3109W/9.12 C (Cap/COP) 2150W/4.87 Cd (cooling) 0.25

D (Cap/EER) 3321W/12.17 D (Cap/COP) 2110W/6.07 Cd (heating) 0.25

Max. cooling condition

Indoor

temperature:

32°C/23°C

Max. heating condition

Indoor temperature: 27°C/-°C

Outdoor

temperature:

46°C/-°C

Outdoor temperature: 24°C/18°C

kWh/annum 322 kWh/annum-average 1843

kWh/annum-

warm

1709

1. The above performance data are from the combination of 3U68S2SG1FA+3*AS25S2SN1FA.

2. Large drop and long piping installation will obviously reduce the total capacity.

Page 50

48

Item Model 4U70S2SH1FA

Function - Cooling Heating

Rating capacity W 7100 8400

Cooling Pdesign W 7100

Heating Pdesign(-10℃) W 6000

Rated power input (indoor + outdoor) W 1700 2000

Rated current input (indoor + outdoor) A 7.50 8.70

EER / COP W/W 4.4 4.5

SEER / SCOP W/W 7.2 4.2

Minimum capacity W 1500 1800

Minimum power input W 550 550

Maximum capacity W 9000 9500

Maximum power input (indoor + outdoor) W 4300 3500

Power source - 1PH, 220-240V~, 50/60Hz

Max.Running current (indoor + outdoor) A / A 18.8 15.2

Power facor(under rating power input) - 99% 99%

Starting current A 5

Fuse size (recommended size) A 25

Outdoor unit

Compressor

Model / Manufacture - TVB220FAEMC-L/ MELCOM

Oil charge and type - 870CC/ FW68S

Type - Twin Rotary (DC inverter)

Number - 1

Fan

Type × Number - Axial × 1

Speed r/min High 860

Motor output/input power W 100/125

Air-ows (H/M/L) m³/h about 3500

Heat exchanger

Type / Diameter mm TP2M / 7.0

Row - 2

Face area m² about 0.75

Dimension

(WxDxH)

External mm 948/340/840

Package mm 1040/430/1000

Refrigerant control method - PMVs

Defrosting method - Automatic by reversible cycle

Crankcase heater power W NONE

Noise level

Sound power level dB(A) 70

Sound pressure level dB(A) 56

Weight Net / Shipping kg / kg 76/87

Page 51

49

Item Model 4U70S2SH1FA

Piping

Refrigerant

Type / Charge kg R32 / 2.5

GWP 675

No need to recharge m 40

Recharge g/m 20

Pipe

Liquid mm 4* Φ6.35

Gas mm 3* Φ9.52+1*Φ12.7

Connecting method - Flared

Between

I.D &O.D

Drop between IU & OU m ≤7.5

Piping length between IU & OU m ≤10

Total liquid piping length m ≤40

Drop between indoor units m ≤1

Max.Drop between IU &OU m 15

Max.Drop between indoor units m 7.5

Max.Piping length between IU & OU m 25

Max Cable length between IU & OU m 30

Max.Total length m 70

Working temperature

Cooling °C -10~46

Heating °C -15~24

Tdisignh: -10°C Tbivalent: -7°C TOL: -15°C

Pto: 60W Psb: 12W Pck: 0W Poff: 0W

Cooling

A (Cap/EER) 7071W/4.11

Heating

A (Cap/COP) 4963W/2.75 Tol (Cap/COP) 5260W/2.39

B (Cap/EER) 5663W/6.23 B (Cap/COP) 3545W/4.02 Tb (Cap/COP) 4963W/2.75

C (Cap/EER) 3791W/8.44 C (Cap/COP) 2353W/4.77 Cd (cooling) 0.25

D (Cap/EER) 3651W/11.63 D (Cap/COP) 3033W/6.65 Cd (heating) 0.25

Max. cooling condition

Indoor

temperature:

32°C/23°C

Max. heating condition

Indoor temperature: 27°C/-°C

Outdoor

temperature:

46°C/-°C

Outdoor temperature: 24°C/18°C

kWh/annum 372 kWh/annum-average 2126 kWh/annum-warm 1023

1. The above performance data are from the combination of 4U70S2SH1FA+3*AS25S2SN1FA+1*AS35S2SN1FA.

2. Large drop and long piping installation will obviously reduce the total capacity.

Page 52

50

Item Model 4U85S2SH1FA

Function - Cooling Heating

Rating capacity W 8400 9500

Cooling Pdesign W 8400

Heating Pdesign(-10℃) W 7000

Rated power input (indoor + outdoor) W 2400 2350

Rated current input (indoor + outdoor) A 10.50 10.40

EER / COP W/W 3.8 4.3

SEER / SCOP W/W 7.0 4.3

Minimum capacity W 1500 1800

Minimum power input W 550 550

Maximum capacity W 9800 10500

Maximum power input (indoor + outdoor) W 4300 3500

Power source - 1PH, 220-240V~, 50/60Hz

Max.Running current (indoor + outdoor) A / A 18.8 15.2

Power facor(under rating power input) - 99% 99%

Starting current A 5

Fuse size (recommended size) A 25

Outdoor unit

Compressor

Model / Manufacture - TVB220FAEMC-L/ MELCOM

Oil charge and type - 870CC/ FW68S

Type - Twin Rotary (DC inverter)

Number - 1

Fan

Type × Number - Axial × 1

Speed r/min High 860

Motor output/input power W 100/125

Air-ows (H/M/L) m³/h about 3500

Heat exchanger

Type / Diameter mm TP2M / 7.0

row - 2

Face area m² about 0.75

Dimension

(WxDxH)

External mm 948/340/840

Package mm 1040/430/1000

Refrigerant control method - PMVs

Defrosting method - Automatic by reversible cycle

Crankcase heater power W NONE

Noise level

Sound power level dB(A) 70

Sound pressure level dB(A) 56

Weight Net / Shipping kg / kg 76/87

Page 53

51

Item Model 4U85S2SH1FA

Piping

Refrigerant

Type / Charge kg R32 / 2.5

GWP 675

No need to recharge m 40

Recharge g/m 20

Pipe

Liquid mm 4* Φ6.35

Gas mm 3* Φ9.52+1*Φ12.7

Connecting method - Flared

Between

I.D &O.D

Drop between IU & OU m ≤7.5

Piping length between IU & OU m ≤10

Total liquid piping length m ≤40

Drop between indoor units m ≤1

Max.Drop between IU &OU m 15

Max.Drop between indoor units m 7.5

Max.Piping length between IU & OU m 25

Max Cable length between IU & OU m 30

Max.Total length m 70

Working temperature

Cooling °C -10~46

Heating °C -15~24

Tdisignh: -10°C Tbivalent: -7°C TOL: -15°C

Pto: 60W Psb: 12W Pck: 0W Poff: 0W

Cooling

A (Cap/EER) 8360W/3.54

Heating

A (Cap/COP) 6535W/2.81 Tol (Cap/COP) 5973W/2.32

B (Cap/EER) 5806W/5.98 B (Cap/COP) 4030W/4.10 Tb (Cap/COP) 6535W/2.81

C (Cap/EER) 3767W/8.47 C (Cap/COP) 2462W/4.98 Cd (cooling) 0.25

D (Cap/EER) 3786W/10.73 D (Cap/COP) 2840W/6.24 Cd (heating) 0.25

Max. cooling condition

Indoor

temperature:

32°C/23°C

Max. heating condition

Indoor temperature: 27°C/-°C

Outdoor

temperature:

46°C/-°C

Outdoor temperature: 24°C/18°C

kWh/annum 454 kWh/annum-average 2442

kWh/annum-

warm

1192

1. The above performance data are from the combination of 4U85S2SH1FA+3*AS25S2SN1FA+1*AS35S2SN1FA.

2. Large drop and long piping installation will obviously reduce the total capacity.

Page 54

52

2. Dimension

1U71S2SM1FA

860

633

unit : mm

Page 55

53

A valve

Liquid pipe 2 way valve : 6.35mm

Gas pipe 3 way valve : 9.52mm

B valve

Liquid pipe 2 way valve : 6.35mm

Gas pipe 3 way valve : 9.52mm

C valve

Liquid pipe 2 way valve : 6.35mm

Gas pipe 3 way valve : 9.52mm

3U52S2SG1FA 3U68S2SG1FA

Page 56

54

3406

21

50

Liquid pipe

Φ

6.35(flared) 1/4

Gas pipe

Φ

9.52(flared) 3/8(A,B,C unit)

Φ

12.7(flared) 1/2(D unit)

D unit connection

C unit connection

B unit connection

A unit connection

Handle

311

408

28

163

45

315

840

948

Indoor and outdoor

connect wiring hole

537

(30*48)

Handle

Handle

Air outlet

Air inlet

Air inlet

184 580 184

70

380

413

35

35

340

4U70S2SH1FA 4U85S2SH1FA

Page 57

55

3. Wiring diagram

1U71S2SM1FA

B:BLACK

Y/G:YELLOW/GREEN

W:WHITE

OR:ORANGE

BL:BLUE

R:RED

AC-N OUT

CN9

CN10

AC-L OUT

M

CN22

CN3

PE

POWER SUPPLY

W

Y/G

CN36

COMB

COMA

N

R

CN1

CN2

AC-N

AC-L

FUSE1

T25A 250VAC

CN24

CN23

MODULE COM

MODULE POWER

TO

INDOOR UNIT

CN3

CN10

B

BL

BL

OR

CN5

CN1

CN4

CN8

CN9

CN2

CN11

CN6

CN7

REACTOR

B

R(U)

S(V)

C(W)

B

W

R

DC FAN

MAIN CONTROL PCB

DRIVE MOUDLE

E

E

Y/G

W

B

Y/G

1(N)

2(L)

3(C)

W

BL

U

V

W

P N

AC-L

LI

AC-N L0

CN25

N

P

CN28

N

L

CN11

4-WAY

VALVE

G

G

B

CAP

CN15

VALVE A

LECTRIC

XPANSION

M

VALVE

MOTOR

NOTES:

THE DOTTED PARTS

ARE OPTIONAL

CAP

CAP

COMPRESSOR

DON'T TOUCH CAPACITOR, EVEN AF TER PLUG-OFF ( DANGER OF ELECTRI C SHOCK)

The capacitor retains high vol

tage even after the plug-off.

For your safety, be sure to wait at least 5 minutes. after

plug off and use a tester to confirm the voltage between

connector P and N is less than DC 10V before start servicing.

CN7

CN6

AC-N OUT

AC-L

OUT

W

B

CAUTION

WARNING

FUSE2

T1

A

250VAC

QX

CN47

SUCTION

TEMPERATURE

SENSOR

DEFROST

TEMPERATURE

SENSOR

COMPRESSOR

TEMPERATURE

SENSOR

AMBIENT

TEMPERATURE

SENSOR

TC

CS HW

CN17

G:GREY

Page 58

56

3U52S2SG1FA 3U68S2SG1FA

PMV_A

PMV_B

PMV_C

PMV_RE

1 23 4 56 78

FILTER

SW3 SW4

SW2SW1

CN12 CN13

CN9

GND

CN11

CN8

DISP

TO Module

ELECTRONIC

CONTROL UNIT

P2(N)

POWER

CIRCUIT

BOARD

Y/G

M

CN16

Td

Te

Ts

Ta

Tc

CN17

CN18

LED_G

LED_R

CN34

DC FAN

MOTOR

250VAC

FUSE

M

To Indoor

Units C

CN14

LP

250VAC T3.15A

FUSE

CN5

4-WAY VALVE

Toci

M

M

FG

Vsp

Vcc

CN7

CN15

HP

ACN

ACL

W

U

COMPRESSOR

V

+

-

BR

BL

REACTOR

U

V

W

N(-)

P(+)

MODULE

ON

4321

ON

M

DISP

COMM

2

1

3

Y/G

To Indoor

Units B

2

1

3

Y/G

To Indoor

Units A

2

1

3

CON8

CON9

Vdc

L N

4

3

Power

CN2

CN23

CN21

SW6 SW5

Tm

CN12

P1(L)

CN1

RL1

Y/G

ON

4321

CN2 CN3

CN1

CN4

SW1

OR: Orange B: Black BL: Blue R: Red

Y/G: Yellow/Green W: White BR:Brown

Toci: Outdoor Condensing inlet Temp. sensor

Tc: Condensing Temp. Sensor

Ts: Compressor Suction Temp. Sensor

Ta: Ambient Temp. Sensor

Td: Compressor Discharge Temp. Sensor

Te: Defrosting Temp. Sensor

Tm: Module Temp. Sensor

Tc1(a/b/c):Condensing Temp. Sensor for

Indoor Units a/b/c (Gas Pipe)

Tc2(a/b/c):Condensing Temp. Sensor for

Indoor Units a/b/c (Liquid Pipe)

*

The dashed part is optional.

B

W

W

W

B

B

R

Definition of SW5

1

2

3

4

5

6

7

8

Restrict of Max Current: ON→Less than 15A; OFF→Adjust by machine types

3U52S2SG1FA

Temperature Correction: ON→Available; OFF→Unavailable (Default)

Definition of SW1

1

2

3

4

Normal Operating(Default)

OFF

OFF

OFF

OFF

ON

OFF OFF

OFF

OFF

ON OFF

OFF

OFF

OFF

ON

OFF

Compulsive Heating

Compulsive Cooling

Rated Operating

Definition of SW6

1

2

3

4

OFF

OFF

OFF

OFF

OFF

OFF OFF

ON

ON

ON

ON ON

Centralized Control

Address=1

Address=2

Address=16

---------------

---- ---- ---- ----

CRANKCASE

HEATER

R

R

R

Y/G

W

B

OFF

OFF

ON

P7

P6

P5

P4

P3

W

B

1 23 4 56 78

ON

SW7

4321

5

W

B

OFF

0150520843

CN24 A-TC1

CN25 B-TC1

CN26 C-TC1

CN29 A-TC2

CN30 B-TC2

CN31 C-TC2

3

4

A

B

Center Controller

3U68S2SG1FA

OFF

OFF

ON

R

BR

CN10

ACL ACN

RI

RO

Time Defrost Valid

OFF

OFF OFF ON

CN2

PTC

CN6

Defrosting Parameter: ON→6° ; OFF→8°(Default)

OFF OFF

ON ON

ON

Cooling & Heating

(Default)

Cooling Only

Available

Heating Only

Available

REACTOR

CAPACITOR

BOARD

ON ON ON ON

Detection for Wrong Wiring

Page 59

57

4U70S2SH1FA 4U85S2SH1FA

PMV_A

1 23 4 56 78

PTC

SW3 SW4

SW2SW1

CN12

LP

HP

CN13

CN9

GND

CN11

CON8

CN8

CN5

DISPLAY

TO Module

ELECTRONIC

CONTROL UNIT

M

Td

Te

Ts

Ta

Tc

LED_G

LED_R

CN6

4-WAY VALVE

DC FAN

MOTOR

M

CN14

250VAC T3.15A

FUSE

Toci

CON9

FG

Vsp

Vcc

CN7

CN16

ACN

ACL

ON

4321

ON

DISPLAY

COMM

Vdc

L N

Power

CN2

CN23

CN21

SW6 SW5

W

W

B

B

R

W

U

COMPRESSOR

R

V

B

W

PMV_B

M

CN17

PMV_C

M

CN18

PMV_D

M

CN19

PMV_RE

M

CN15

CRANKCASE

HEATER

Definition of SW6

1

2

3

4

OFF

OFF

OFF

OFF

OFF

OFF OFF ON

ON

ON

ON ON

Centralized Control

Address=1

Address=2

Address=16

---------------

---- ---- ---- ----

Definition of SW5

SW5-1

SW5-2

SW5-3

SW5-4

SW5-5

SW5-6

SW5-7

SW5-8

OFF

Defrosting Parameter: ON→6° ; OFF→8°(Default)

Restrict of Max Current:

ON→Less than 15A; OFF→Adjust by machine types

4U70S2SH1FA

Temperature Correction:

ON→Available; OFF→Unavailable (Default)

Definition of SW1

SW1-1

SW1-2

SW1-3

SW1-4

Normal Operating(Default)

OFF

OFF

OFF

OFF

ON

OFF

OFF

OFF

OFF

ON

OFF

OFF

OFF

OFF

ON OFF

Compulsive Heating

Compulsive Cooling

Rated Operating

Y/G

To Indoor

Units D

2

1

3

Y/G

To Indoor

Units C

2

1

3

Y/G

To Indoor

Units B

2

1

3

Y/G

OR: Orange B: Black BL: Blue BR:Brown

Y/G: Yellow/Green R: Red W: White

Toci: Outdoor Condensing inlet Temp. sensor

Tc: Condensing Temp. Sensor

Ts: Compressor Suction Temp. Sensor

Ta: Ambient Temp. Sensor

Td: Compressor Discharge Temp. Sensor

Te: Defrosting Temp. Sensor

Tm: Module Temp. Sensor

Tc1(a/b/c/d/e):Condensing Temp. Sensor

for Indoor Units a/b/c/d/e (Gas Pipe)

Tc2(a/b/c/d/e):Condensing Temp. Sensor

for Indoor Units a/b/c/d/e (Liquid Pipe)

*

The dashed part is optional.

R

R

R

ON

OFF

P2(N)

POWER

CIRCUIT

BOARD

T25A 250VAC

FUSE

P1(L)

RL1

P7

P6

P5

P4

P3

W

B

Y/G

ON

4321

CN2

CN3

CN1

CN4

SW1

4321

5

1 23 4 56 78

ON

SW7

W

W

B

B

0150520846

CN24 A-TC1

CN25 B-TC1

CN26 C-TC1

CN29 A-TC2

CN30 B-TC2

CN31 C-TC2

CN27 D-TC1 CN32 D-TC2

OFF

ON

ON ON

4U85S2SH1FA

Y/G

To Indoor

Units A

2

1

3

R

C2

C1

A

B

To Center

Controller

OFF

OFF

ON

OFF

Time Defrost Valid

R1

MODULE

R0

Reactor

ACL

ACN

U

W

V

CN10

Tm

CN12

B

W

3

4

CN2

+

-

BR

BL

CAPACITOR

BOARD

N(-)

P(+)

CN34

FILTER

CN1

OFF OFF

ON

ON

ON

Cooling &

Heating

(Default)

Cooling Only

Available

Heating Only

Available

REACTOR

ON ON ON ON

Detection for Wrong Wiring

Page 60

58

1PH, 220-240V, 50/60Hz

Indoor Unit A Indoor Unit B Indoor Unit C

Indoor

Outdoor

A B

C

Power Supply Cable:

H05RN-F3G 4.0mm²

Connecting Cable:

H05RN-F4G 2.5mm²

Connecting Cable:

H05RN-F2G 2.5mm²

3U52S2SG1FA 3U68S2SG1FA

Connect the connecting wires between indoor and outdoor units and ensure the sequence numbers on terminals

match with each other.

4. Wiring connection

Page 61

59

1PH, 220-240V, 50/60Hz

Power Supply Cable:

H05RN-F3G 4.0mm²

Connecting Cable:

H05RN-F4G 2.5mm²

Connecting Cable:

H05RN-F2G 2.5mm²

4U70S2SH1FA 4U85S2SH1FA

Connect the connecting wires between indoor and outdoor units and ensure the sequence numbers on terminals

match with each other.

Page 62

60

5. Piping diagram

reniarts

rosserpmoc

pots yaw-4

evlav

evlav pots yaw-2

)edis diuqil(

pots yaw-3

evlav

)edis sag(

resnednoc

rotaropave

lioc epip

rosnes.pmet

gnitaeh

gnilooc

egrahcsid

rosnes.pmet

reniarts

tneibma

rosnes.pmet

reniarts

cinortcele

evlav noisnapxe

1U71S2SM1FA

Page 63

61

-pmoC

rosser

.pmet egrahcsiD

rosnes

liO

rotarapes

ebut yrallipaC

0041*0.1Ø*7.2Ø

erusserp hgiH

hctiws

evlav yaw-4

rosnes epiP

icoT

.pmet noitcuS

rosnes

erusserp woL

hctiws

rotalumuccA

roodtuO

taeh

regnahcxe

.pmet

rosnes

rotubirtsiD

reniartS

O VEE

evlav kcehC

EEV A

reniartS

rosnes .pmet epip diuqil A tinU

A tinu roodnI

EEV B

reniartS

rosnes .pmet epip diuqil B tinU

B tinu roodnI

EEV C

reniartS

rosnes .pmet epip diuqil C tinU

C tinu roodnI

epip sag A tinU

rosnes .pmet

epip sag B tinU

rosnes .pmet

sag C tinU

epip

rosnes .pmet

A tinu roodnI

B tinu roodnI

C tinu roodnI

:lioc evlav yaw-4

FFO

ON