Page 1

Hafler

INSTALLATION

fbd

OPERATION

Please refer to this serial

number in all communications

regarding this equipment.

Page 2

SPECIFICATIONS INTRODUCTION

8

OHM POWER RATING: 325 watts continuous aver-

age power per channel at less than

.025%

total harmonic

distortion from

2OHz

to 20kHz with both channels driven.

4 OHM POWER RATING: 450 watts continuous average power per channel at less than

.035%

total harmonic

distortion from

2OHz

to 20kHz with both channels driven.

8

OHM BRIDGED POWER RATING:

900 watts continuous average power at less than 0.035%

total harmonic distortion from

2OHz

to

2OkHz.

IM DISTORTION (IHF):

Less than .O 1% from 1 watt to 325 watts, both channels

into

8

ohms.

FREQUENCY RESPONSE INTO

8

OHMS:

-3dB, 4Hz

and

1OOkHz

at 1 watt

-.5dB, 1OHz

and 40kHz at 1 watt

SIGNAL TO NOISE RATIO, UNWEIGHTED:

Exceeds 95dB referred to 325 watts into 8 ohms,

100 dB (A-weighted)

TYPICAL CHANNEL SEPARATION:

2OHz: >

80dB

1kHz: >

75dB

20kHz:

> 6OdB

DAMPING FACTOR: 300 up to

1kHz

into 8 ohms.,

200upto

1OkHz

into8ohms.

SLEW RATE: 1

kHz, 12OV

p-p square wave: 40 volts

per microsecond.

VOLTAGE GAIN: 29dB

INPUT IMPEDANCE: 47,000 ohms, balanced

INPUT SENSITIVITY: 1.95 volts rms per phase for

325 watts into

8

ohms.

POWER CONSUMPTION:

12OV 6OHz

Line:

325 watts into 8 ohms both channels:

132OVA

450 watts into 4 ohms both channels:

18OOVA

SIZE: 3-

1/2”

high,

19”

wide,

14”

deep behind faceplate,

l-1/2” in front of faceplate including handles

NET WEIGHT: 40 lbs.

SHIPPING WEIGHT: 42

lbs.

ALL SPECIFICATIONS SUBJECT TO CHANGE

WITHOUT NOTICE.

The Hafler PRO5000 is a high power, low profile, two

channel power amplifier intended for professional sound

installations. It is the result of modern packaging combined

with the performance and reliability characteristics found

in previous Hafler designs. The PRO5000 has an optimized

combination of features needed for a professional power

amplifier: high power, small package size, rugged case

construction, balanced inputs, full bridgeability for mono

applications, continuously variable DC fan for quiet operation, and a variety of simple, yet effective protection

systems. Above all, however, the PRO5000 maintains the

well known

Hafler

tradition of superior sounding power

amplifiers.

OVERVIEW OF AMPLIFIER

The PRO5000 is a standard two-rack height fan cooled

design utilizing fully complimentary drive circuits and

lateral type MOSFET output transistors. The amplifier has

full subtractor balanced input circuits for good noise rejection. The drive circuitry is a high performance arrangement

with a double differential JFET input stage. Film capacitors

are used throughout the circuitry to ensure minimum degradation of the audio signal.

The 19” extruded aluminum front panel includes handles

for ease of installation, separate gain controls for each

channel, signal present and clipping indicators for both

channels, and the power switch which has a pilot lamp. The

rear panel has both

1/4”

phone and XLR connectors for the

inputs,

5-way

binding posts for the outputs, a switch to

bridge the amp for mono mode. and a switch to connect or

disconnect the audio ground from the chassis ground.

The protection systems include separate power supply

fuses on DCV+ and

DCV-

for each channel, thermal

sensing circuits that monitor output device temperature and

correspondingly control the DC fan, a relay to disengage

the load if excessive DC offset is detected or if the output

device temperature becomes too high, a delay to avoid

dangerous turn-on/off transients, and an AC line fuse if all

else fails. This amplifier does not have, and by virtue of

design, does not need the current limiting circuits which are

required to protect conventional bipolar or vertical MOSFET

output devices. The less common lateral

MOSFETs

used in

Hafler

amplifiers inherently limit the current ONLY under

abnormal conditions, thus avoiding ‘thermal runaway’ and

subsequent device destruction. This gives the dual advantage of greater reliability from simpler circuitry, and the

elimination of one of the chief causes of distorted signals

the harsh sounds of the actuation of complex protective

circuits.

-l-

Page 3

1.

Read Instructions

AII

the safety and operating instructions of your

Hafler

equipment should be read before power is applied to

the equipment.

2.

Retain Instructions

These safety and operating instructions should be held

for future reference.

3.

Heed Warnings

All warnings on the equipment and in the operating

instructions are important and should be followed.

4.

Follow instructions

All operating and use instructions are important and

should be followed.

5.

Heat

The equipment should be kept away from areas of high

temperature, such as heater vents, radiators, stoves/

ovens, fireplaces, etc.

6.

Ventilation

The equipment should be used in an area suitable for

proper ventilation. Care should be taken to not impede

airflow in and around the cabinet. Do not mount on a

carpeted shelf or in an enclosure consisting of more than

five sides. Allow for proper clearance above the equipment.

7.

Water and Moisture

8.

The equipment should not be used in or around water

such as a bathtub, sink, or swimming area. Also, the

equipment should not be used in areas prone to flooding

-

such as a basement.

Power Sources

The equipment should be connected only to a power

source of the same voltage and frequency as that listed

on the rear panel near the power cord entry point.

9.

Power Cord Protection

NOTICE - IMPORTANT SAFETY INFORMATION

DO NOT DISPOSE OF - KEEP FOR FUTURE REFERENCE

Safety Instructions

Power cords should be run so that they do not interfere

with the movement of

objects

in the room - people, fan

blades, utility carts, etc. Also, care should be taken that

the cord is not pinched or cut, and placed so that it is not

in danger of being pinched or cut, as in under a rug,

around a tight corner, etc.

10.

11.

12.

13.

14.

15.

Grounding and Polarization

The power supply cord is of a polarized type designed

to reduce the risk of electric shock sustained from a live

cabinet. It is assumed to be of a suitable length for most

uses of the equipment. The use of extension cords and

power strips is discouraged unless they are of suitable

rating to deliver the required current for safe equipment

operation and can be used so that the polarization of

the plug is not defeated. If an extension cord is required,

it is important that the blades of the plug be able to insert

fully into the receptacle. Professional amplifiers with a

S-conductor line cord must never have the ground pin

of the plug defeated.

Non-Use Periods

During extended periods of non-use the power supply

cord should be kept unplugged from the power source.

Cleaning

The equipment should be cleaned only as detailed by

the owners manual.

Object

and Liquid Entry

Care should be taken so that

objects

and/or liquids,

such as cleaning fluids, are not spilled into the enclosure

of the equipment.

Damage Requiring Service

HafIer

equipment should be serviced by qualified ser-

vice personnel when:

A.

B.

C.

D.

E.

The power supply cord or plug has been

damaged; or

Objects

have fallen, or liquid has been spilled

into the equipment; or

The equipment has been exposed to rain; or

The equipment does not appear to operate

normally or exhibits a marked change in performance; or

The equipment has been dropped, or the enclosure damaged.

Servicing

The user should not attempt to service the equipment

beyond that which is described in the manual. All other

service

should be referred to qualified service person-

nel.

-2-

Page 4

16. Carts and Stands

The equipment should be used only with a cart or stand

of sufficient strength and stability for the use intended.

16A.

An equipment and cart combination should be moved

with care. Quick stops, excessive force, and uneven

surfaces may cause the equipment and cart combination

to topple.

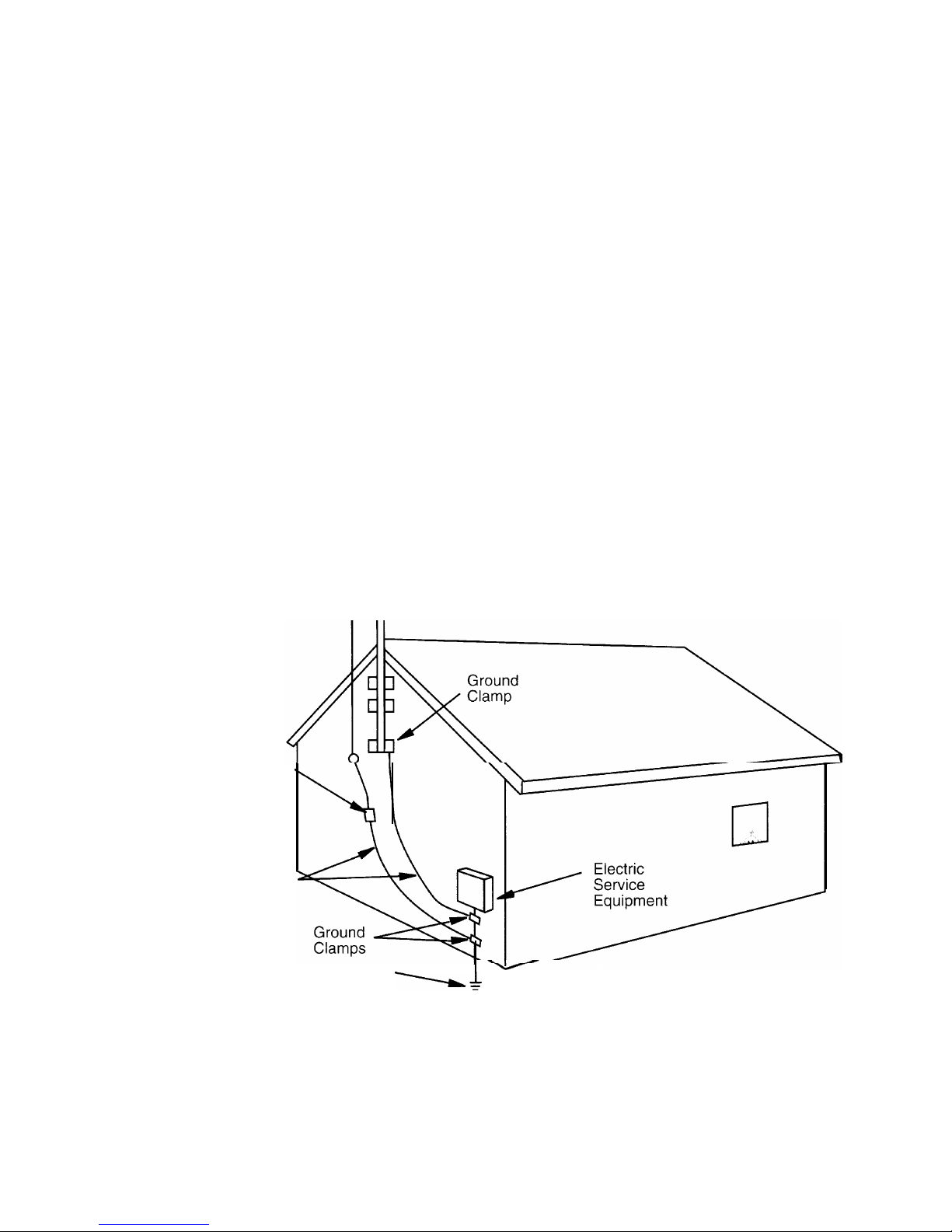

17. Power Lines

An outdoor antenna should be located away from power

lines.

18.

Outdoor Antenna Grounding

If an outside antenna is to be used with the

HafIer

Tuner,

be sure that the antenna system is grounded so as to

provide some protection against voltage surges and built

up static charges. Section 8 10 of the National

Electrical

Code,

ANSl/NFPA

No.

70-

1984,

provides information

with respect to the proper grounding of the mast and

supporting structure, grounding of the lead-in wire to an

antenna discharge unit, size of grounding conductors,

location of antenna discharge unit, connections to

grounding electrodes, and requirements for the grounding electrode. See Figure

1.

EXAMPLE OF ANTENNA GROUNDING AS

PER NATIONAL ELECTRICAL CODE

Antenna

Lead In

Wire

7

Antenna

Discharge Unit

.

(NEC Section 810-20)

Grounding Conductors

(NEC Section 810-21)

Power Service

Grounding

\+

Electrode System

(NEC Art 250, Part H)

FIGURE 1

-3-

Page 5

INSTALLATION

MOUNTING

The front panel is designed to fit a standard

19”

rack at 3-

l/

2” intervals or alternatively the unit may be stacked. NOTE:

When rack mounting the

PRO5000,

the rear of the amplifier

must be fastened to the rack via the rear mounting holes to

eliminate large torque forces on the faceplate. The feet may

be removed if desired when rack mounting.

VENTILATION

Do not block the air flow into or out of the amplifier. Air is

drawn in through the vents in the front panel, and is

exhausted out the side vents. Therefore, when rack mounting

in a cabinet, allow sufficient space between the inside walls

of the rack and the amplifier chassis, (at least 2 inches). If

the cabinet has a front door, the door must have large enough

vents to allow enough volume air flow for each amplifier in

the rack, (80 CFM per PRO5000 should be adequate). A

good alternative is to augment the air flow with a rack

mounted fan that pressurizes the space in front of the

amplifiers and/or evacuates the air space in the rear of the

cabinet.

The PRO5000 includes a removable dust filter assembly

attached to the outside of the front intake vents. This filter

should be removed occasionally and cleaned. To remove,

gently squeeze the ends inward and pull the filter frame

straight out from the front panel. The foam filter element

may then be removed from the frame and shaken or blown

out with compressed air. If the foam is particularly dirty, it

may be washed with mild soap and warm water. Replacement foam elements are available from the factory, part

number HWH-392.

CONNECTIONS

AC LINE CORD:

High power output puts heavy demands on the AC supply

to the amplifier. A single PRO5000 delivering 4 ohm rated

power will heavily load a typical 15 amp circuit. Multiple

amplifiers will need to be connected to a circuit capable of

delivering the required current (see specifications), in order

for the amplifiers to produce the expected audio power.

The PRO5000 is normally wired for

12OV 6OHz

operation,

as in the USA. The transformer can be rewired to accommodate other line voltages upon request. Note that the value

of the internal AC line fuse (near the power switch), should

be changed when converting from lower line voltages

(

12OV

or less use a 15 amp Slo-Blo), to higher line voltages

(200V and up use a

7-1/2

amp Slo-Blo). Never wire the

amplifier for a lower line voltage than what is supplied in an

attempt to obtain greater output power. Such an attempt will

very likely damage parts in the amplifier not rated for the

higher voltages that will result, and the warranty will be

voided.

A

3-wire

grounded power cord is supplied. It must be

connected to a properly grounded (earthed) AC receptacle

for safety. Do not break off the ground pin on the plug to

avoid using the proper adapter for

2-wire

receptacles.

SIGNAL INPUT:

Both

1/4”

phone and XLR balanced connectors are provided on the back panel. These connectors are wired in

parallel for each channel, so that either may be used with no

further switching. The unused connector may be used to

“daisy chain” other amplifiers from the same source using

the appropriate cables.

To achieve maximum noise rejection, balanced lines should

be used for the inputs (two out-of-phase polarity signal

conductors plus a ground shield). The XLR connectors are

wired for the IEC international standard, which connects

the #1 pin to the ground shield; the

#2

pin as the

noninverting or ‘hot’ signal; and the #3 pin as the inverting or

‘return’ signal. The phone jacks are wired with the sleeve

as the ground shield; the tip as the non-inverting signal; and

the ring as the inverting signal. Note that in other equipment the two signal connectors are sometimes interchanged

from what is stated here-it is therefore wise to check for

consistency among the equipment being installed.

For an unbalanced input line (one signal conductor and a

ground shield), connect the signal conductor to the

noninverting input, and connect the ground shield to the input

ground AND the inverting input of the amplifier. Note that

with a two conductor

1/4”

phone jack, this connection is

automatically made, assuming that the sleeve (which is

longer than that of a three circuit phone jack and includes

the ring) is the ground shield and the tip is the signal. In this

case, simply insert the phone jack fully into the input of the

amplifier.

For bridged mono operation, only use the channel A input

and set the mono/stereo switch to mono. Make no connection to the channel B input jacks. In this mode the channel

A gain control determines the gain of the amplifier. See

below for a description of loudspeaker connection in this

mode.

To prevent noise or hum, it is essential that all input

connections are secure, and that the cables are not frayed or

loosely connected to the plug.

OUTPUT:

The red and black binding posts will accept a variety of

speaker lead terminations, the most convenient of which

-4-

Page 6

are the ‘banana’ plug connectors with

3/4”

spacing. Bare

wire can be inserted through the vertical holes in the shafts,

which are visible when the caps are unscrewed. To be

certain that no strands of wire are unsecured, it is best to tin

the wire end before insertion. Alternatively, a spade lug

soldered

to the wire end will make a good connection.

Make all connections between loudspeakers and the amplifier with the power shut off to avoid loudspeaker damage.

Select wire of sufficient size to preserve the high damping

factor of the

PRO5000.

The minimum recommended wire

size is #1

6

gauge when high power output is expected.

Larger wire sizes are necessary for long runs, or if the

speaker impedance is less than

8

ohm.

PHASING:

Consistent phase relationships are important when connecting speakers in order to enable full bass reproduction as

well as midrange and high frequency time alignment. To be

sure all speakers in a system are wired in phase to the

amplifier, each

ground or - speaker terminal should be

connected to its black ground terminal on the

PRO5000,

and the speakers + terminal to the corresponding red

terminal. Speaker connecting cable identifies one wire

from the other by color of the wire, or by marking or

coloring the insulation. NOTE: In the special case of

monophonic operation of the

PRO5000,

(described below)

different speaker connections are employed.

GROUNDING

The black output terminals of the PROS000 are connected

together internally and grounded to the chassis. This facilitates the use of external devices which use a common

ground connection, such as some headphone junction boxes.

You must be sure that the ground or shield connection from

such a device goes to a black terminal on the

PRO5000.

NOTE: No such connection may be made when the

PROS000 is connected for bridged mono operation.

The back panel of the PRO5000 also contains a chassis/

float groundswitch forground isolation. This switch should

be set for minimum system hum and/or noise.

BRIDGED MONO OPERATION:

To drive a single loudspeaker with increased power capability, the PRO5000 can be operated in the bridged mode

which drives both channels with the same signal and

combines their output to deliver more than 900 watts to an

8

ohm speaker. In this arrangement, the speaker is connected only to the two red output terminals. The channel A

terminal is the

"+",

and the channel B terminal is the

"-"

connection. No connections should be made to either black

output terminal in this configuration.

OPERATION

APPLYING POWER:

Standard practice is to turn power amplifiers on last and off

first in the chain of electronics. This minimizes the likelihood of damage to the load from turn-on and turn-off

transients generated by source equipment. The PROS000

provides built-in protection from such transients by incorporating a delay of approximately 3 seconds before the

relay connects the loudspeakers. If a longer delay is required, contact the

Hafler

Technical Service Department.

The pilot lamp in the power switch will glow whenever

power is applied to the

PRO5OOO.

If it does not light, check

for a blown internal AC line fuse. Otherwise, check the line

circuit breaker for a fault.

FRONT PANEL INDICATORS:

The presence of any signal above the noise

floor

will

activate the green ‘Signal’ lights for each channel. The red

‘Clip’ indicators are activated by a comparator circuit which

triggers when the output distortion level reaches approximately 3%. They indicate when the demands of the amplifier exceed its output capability. Because the dynamics of

good source material may include steep waveforms which

reach these limits for a small fraction of a second, normal

actuation would cause them to flicker so briefly that the eye

would miss it. In the interest of giving maximum information, a “hold” circuit is included which extends these brief

pulses to about

1/4

of a second, so they will be clearly

visible. However, these occasional flashes do not indicate

that the amplifier is being substantially overdriven. Thus,

these lamps may operate quite differently from similarly

marked indicators on other amplifiers.

GAIN CONTROLS:

The gain controls for each channel are precision potenti-

ometers, designed for very low distortion. Unless there is a

specific purpose for an intermediate setting (such as level

matching), the gain controls are usually fully advanced

clockwise. This is the setting for which the amplifier’s

sensitivity and voltage gain are specified. Note that in the

bridged mono mode, the channel A control determines the

gain of the amplifier.

DC OFFSET:

If at any time the DC voltage rises to an unsafe level at the

outputs. the relay will disconnect the loudspeakers from the

amplifier. It should be noted that very high levels of low

frequency energy can sometimes imitate DC at the output,

and might activate the relay protection inappropriately. If

this becomes a problem, the level of DC protection provided

can be changed by consulting the

factory.

Page 7

PRO 5000 FUNCTIONAL BLOCK DIAGRAM

TEMPERATURE

SENSORS

-1

FAN

SPEED

CONTROL

RELAY/

RELAY

\

TIMER

KICKOUT

/’

OFFSET

’

DETECTOR

OUTPUT

SIGNAL

DETECTOR

c

’ --,

, ; LIGHT

lo’

s’G

DESIGNATOR PART DESCRIPTION

T201

Transformer

DB201

Diode Bridge

F201

10A Fuse

SW201 Power Switch

SW202 Grounding Switch

C201, C202

Capacitor 20,000

C203

Capacitor .01 (UL approved)

C204

Capacitor

.01

TS201

Inrush Limiter

J201 (J203)

Binding Post, Black

J202 (J204)

Binding Post, Red

CLIP

>

DETECTOR

<

CHASSIS PARTS LIST

PART

#

TT-PRO5000

SSH-609

FS-010

SWH-144

SWH-103

CER-209

CD-103A

CD-103/20

SSH-618

CCH-1

10B

CCH-1

1OR

-6-

Page 8

Page 9

Page 10

PRO 5000 PARTS LIST

DESIGNATOR

PART DESCRIPTION

DESIGNATOR:

“B”

Channel

(“A”

Channel)

PART

#

DESIGNATOR

PART DESCRIPTION PART

#

(Cl)

Cl9

(C2)

c20 (C3)

CZl (C4)

c22

(C5)

C23 (C6)

C24

(C7)

c25 (C8)

C26

(C9)

C27 (CID)

C28 (Cll)

c29

(Cl2)

c30 (Cl3)

c31 (Cl4)

C32

(Cl5)

c33

(Cl6)

c34

(Cl7)

c35 (Cl8)

C37

(C36)

C42

(C38)

c43

(C39)

c44

(C40)

c45

(C41)

c52 (C46)

c53 (C47)

c54

(C48)

c55

(C49)

C56

(C50)

c57

(C51)

C58

c59

C60

C61

C62

C63

C64

C65

C66

C67

C68

CR7

(CRl)

CR8

(CR2)

CR9

(CR3)

CR10

(CFi4)

CR31

(CR5)

CR12

(CR6)

CR13

CR14

CR19

(CRi5)

CR20

(CRl6)

CR21 (CRl7)

CR22 (CRl8)

CR23

CR24

CR25

CR26

CR27

CR28

Unused number

330

pfd,

Polypropylene

10 pfd

Dipped MIca

1 mfd, Polycarbonate

1000 mfd, Non-Polar

001 mfd, Polypropylene

001 mfd, Polypropylene

220

pfd,

Polypropylene

1

mfd,

Polycarbonate

1

mfd,

Polycarbonate

1

mfd, Polycarbonate

100 mfd,

Electrolytic

100 mfd,

Electrolytic

I mfd,

Polycarbonate

1 mfd. Polycarbonate

01

mfd Polycarbonate

I

mfd, Polycarbonate

Unused number

680

pfd, Dipped Mica

680 pfd, Dipped Mica

680

pfd, Dipped Mica

47 mfd, Polyester

47 mfd Polyester

4 7 rnfd

ElectrolytIc

33 mfd Polyester

4 7 mfd, Non-Polar

33 mfd Polyester

033 mfd, Polypropylene

1 mfd. Polyester

39

mfd,

Polyester

39 mfd, Polyester

39 mfd Polyester

1 mfd Non-Polar

1

mfd, Electrolytic

1

mfd,

V-Series

1

mfd,

V-Series

1000

mfd,

Electrolytic

1000 mfd,

ElectrolytIc

10 mfd,

ElectrolytIc

10

mfd,

ElectrolytIc

FDH400 Diode

FDH400

Diode

1

N4148 Diode

1 N5245B Zener

Diode, 15V

1

N5245B

Zener

Diode, 1%

1 N4 148

Diode

1 N4

148

Diode

1

N4148

Diode

MV5754S LED Green

1 N4 148

Diode

1 N4 148

Diode

MV64530

LED, Red

1N4148

Diode

1

N4148

Diode

I

N4003

Diode

1

N4003 Diode

1

N4003

Diode

1

N4003

Diode

F3

(Fl)

Fuse

1OA

F4

(F2)

Fuse

1OA

FM1

Fan

L2

(Ll)

P2

(Pl)

P4

(P3)

P6

(P5)

P8

(P7)

Q21 (Ql)

a22 (Q2)

U23 (Q3)

Q24 (Q4)

Q25

(Q5)

Q26 (Q6)

Q27 (Q7)

Q28

@3)

Q29 (Q9)

Q30

(QlO)

Q31 (Qll)

Q32

(Ql2)

Q33

(Ql3)

Q34

(Qi4)

Q35

(Qi5)

Q36

(Ql6)

Q37

(Ql7)

Q38

(Ql8)

Q39

(Ql9)

Q40 (Q20)

Q43 (Q41)

Q44 (Q42)

Q45

Q46

Q47

Inductor

I

4

mH

Pot 1000 Ohm

Trimmer

Pot 500 Ohm

Trimmer

Pot 5000 Ohm Volume

Pot 500 Ohm

Trimmer

2SKl63

N-Channel JFET

2SKl63

N-Channel JFET

2SJ74

P-Channel JFET

2SJ74

P-Channel JFET

2N5550 BI

Polar

2N5550

Bi-Polar

2N5401

Bi-Polar

2N5401

Bi-Polar

ZN5401

Bi-Polar

2N5550

Bl-Polar

2N5415

Bi-Polar

2N3440

Bi-Polar

2N2222 Bi-Polar

2N3440

Bi-Polar

2N5415 Bf-Polar

2SKl76

N-Channel MOSFET

2SKl76

N-Channel MOSFET

2SJ56

P-Channel MOSFET

2SJ.56 P-Channel MOSFET

Unused Number

2SKl76

N-Channel MOSFET

2SJ56

P-Channel MOSFET

MPSA06 Bl-Polar

MPSA06 Bl-Polar

2N6490

Bl-Polar

Fl36

(Rl)

R37

(R2)

R38 (R3)

R39

(R4)

R40

(R5)

R41

(R6)

I?42

(R7)

R43 (Ra)

R44

(R9)

R45

(RIO)

R46

(Rll)

R47

(Rl2)

R48 (Rl3)

2

43k

Ohm,

1/4w,

Ia0

47 5k Ohm,

1/4w.

1%

47 Ohm

lf4w. 500

47 Ohm

1/4w, 500

68 Ohm

1/4w, 500

47 Ohm

1/4w, 500

47 Ohm,

114~ 500

1000

Ohm,

1/4w, lo~0

1000 Ohm,

1/4w? 1%

6 8k Ohm,

1/4w, 500

47 5k Ohm

114~. 1%

2 43k Ohm,

1/4w,

lo0

270 Ohm,

1/4w 500

CPP-331

CM-100

CPC-104

CERNP-108

CPP-102

CPP-102

CPP-221

CPC-104

CPC-104

CPC-104

CER-107D

CER-1 07D

CPC-104

CPC-104

CPP-1 03A

CPC-1

04

CM-681

CM-681

CM-681

CP-474

CP-474

CER-475B

CP-334

CERNP-475A

CP-334

CPP-333

CP-104A

CP-394E

CP-394E

CP-394E

CERNP-105A

CER-105C

cv-104

cv-104

CER-108B

CER-108B

CER-106

CER-106

SS-163

SS-163

SS-162

ss-212

ss-212

SS-162

SS-162

SS-162

SSH-704

SS-162

SS-162

SSH-706

SS-162

SS-162

SS-161

SS-161

SS-161

SS-161

FS-010

FS-010

FAN-P5000

l-r-l 4

RV-1

02

RVH-501 A

RV-502D

RVH-501 A

SSH-614T

SSH-614T

SSH-617DT

SSH-617DT

SSH-613

SSH-613

SSH-708

SSH-708

SSH-708

SSH-613

SSH-616

SSH-612

SSH-611

SSH-612

SSH-616

SSH-607

SSH-607

SSH-608

SSH-608

SSH-607

SSH-608

SS-102A

SS-102A

ss-113

RMP/4-2431

RMP/4-4752

RC/4-470

RC/4-470

RC/4-680

RC/4-470

RC/4-470

RMP/4-1001

RMP/4-1001

RC/4-682

RMP/4-4752

RMP/4-2431

RC/4-271

R49

(Rl4)

R50 (Rl5)

R51 (Rl6)

R52

(Rl7)

R53 (Rl8)

R54 (Rl9)

R55 (RZO)

R56

(R21)

R57

(R22)

R58

(R23)

R59

(R24)

R60

(R25)

R61

(R26)

R62

(R27)

R63

(R28)

R64

(R29)

R65

(R30)

R66

(R31)

R67

(R32)

R68 (R33)

R69

(R34)

R70

(R35)

R71

R72

R73

R74

R75

R76

R77

R78

R79

R80

R81

R82

R85

(R83)

R86

(R84)

RlOO

(R87)

RIO1

(R88)

RIO2 (R89)

R103 (R90)

R104

(R91)

RlO5

(R92)

RIO6

(R93)

RIO7

(R94)

RIO8

(R95)

RlO9 (R96)

RI10

(R97)

RI11

(R98)

RI12

(R99)

RI29 (Rll3)

RI30 (Rll4)

RI31 (Rll5)

RI32 (Rll6)

R133

(Rll7)

Rl34 (Ril8)

Rl35 (Ril9)

Rl36 (Rl20)

Rl37 (Rl21)

Rl38

(Rl22)

Rl39 (Rl23)

Rl40

(Rl24)

Rl41 (Rl25)

Rl42

(Rl26)

Rl43

(Rl27)

Rl44 (Rl28)

Rl45

RI46

R147

Rl48

RI49

RI50

RI51

R152

R153

Rl54

Rl55

Rl56

Rl57

Rl5a

Rl59

Rl60

Rl61

R162

R163

Rl64

Rl65

SW1

SW2

TS2

(TSI)

Ul

u3

(U2)

u4

u7

vJ5)

U6

U8

u9

UlO

J4

CJ2)

J3

CJl)

J5

J6

J7

J8

J9

270 Ohm,

1/4w,

5%

1000 Ohm,

114~~

5%

1000 Ohm,

114~~

5%

100 Ohm,

1/4w, 500

100 Ohm,

1/4w, 500

47k Ohm, 1/4w.

5”&

560 Ohm,

l/4w,

5%

470 Ohm,

1/4w,

5%

10 Ohm,

1/4w,

5%

47 Ohm,

1/4w, 50f0,

Carbon

47

Ohms 1/4w,

5% Carbon

220 Ohm,

1/4w, 5%

470 Ohm,

1/2w, 5%

470 Ohm, 1/2w, 5%

220 Ohm,

1/2w, 5Ob

220 Ohm,

1/2w, 500

10 Ohm,

1/4w, 500

I

Ohm,

low,

5%

IO

Ohm. 5w

5’1~

47k Ohm, 1/4w,

5%

33k

Ohm? 1/4w, 5%

47k

Ohm? 1/4w, 500

47k

Ohm< 1/4w, 500

82k

Ohm,

1/4w, 5%

220k Ohm,

1/4w,

5%

15 8k

Ohm,

1/4w, lo0

82 5k Ohm, 1/4w, lo0

33k Ohm, 1/4w, 5%

2 2k Ohm, 1/4w,

50!,

1Ok

Ohm.

1/4w,

5%

1 k Ohm,

1/4w 500

51 1 k Ohm,

1/4w,

1%

681 k Ohm,

1/4w,

1%

681 k Ohm,

1/4w, lo0

470 Ohm 1/2w,

5%

220 Ohm 1/2w,

500

2 2k Ohm. 1/4w

5O&

2 2k Ohm,

1[4w, !?i”jO

47k Ohm,

114~. 500

47k Ohm,

1/4w 500

1OOk

Ohm,

114~.

5%

1OOk

Ohm,

114~.

5%

1 lk Ohm,

1/4w,

lo0

39k Ohm,

1/4w. 5%

11 k Ohm,

1/4w% lo0

11 k Ohm, l/4wq 1%

10.7k

Ohm,

1/4w,

lo0

11 k Ohm,

1/4w, lo&

llkOhm, 1/4w,

lo0

1

OOk

Ohm, 1/4w, 5%

47k Ohm, 1/4w,

5%

560 Ohm,

114~. 5O&

4.7 Ohm,

114~. 500

6 8k

Ohm,

1/4w, 5°,0

470k Ohm, 1/4w,

500

470k Ohm, 1/4w,

500

I

OOk

Ohm, 1/4w,

500

2 43k Ohm, 1/4w,

1%

1 8k Ohm.

114~. 500

68k Ohm, I /4w,

500

1Ok

Ohm

114~. 500

IOOk

Ohm. 1/4w, 5%

39k

Ohm.

1/4w, 500

I

meg Ohm,

1/4w~

5%

6 8k Ohm. 1/4w

50t0

12Ok

Ohm,

1/4w, 5%

12Ok

Ohm.

1/4w, 5%

182k

Ohm. 1/4w 5%

l82k

Ohm. 1/4w

500

22k Ohm,

1/4w. 50Q

1Ok

Ohm,

li4w. 500

1 Ok Ohm

114~. 5%

22k Ohm,

114~. 500

10 meg Ohm,

1/4w, 500

10 meg Ohm, 1/4w

500

I

meg Ohm,

1/4w 500

4 7k Ohm,

114~. 5O0

1Ok

Ohm

714~

5%

IOOk

Ohm, 1/4w

500

15Ok

Ohm,

1/4w, 500

IO meg Ohm,

1/4w, 500

4 7k Ohm

114~. 500

4 7k Ohm 1/4w, 5%

1 Ok Ohm.

1/4w, 500

IOk

Ohm.

1/4w,

1%

IOk

Ohm. 1/4w

lo0

Stereo-Mono

Switch

Relay

Thermistor

LM393 Comparator

NE5532 Op-Amp

NE5532 Op-Amp

LM393 Comparator

TL072 Op-Amp

LM339-Comparator

7815 Regulator

7915 Regulator

114

inch stereo jack

XLR

jack

9 pin molex header

8

pin molex header

8 pin molex header

2 pin molex header

Harness, not pictured

Comp

Comp

RCt4-271

RCl4-102

RCl4-102

RCl4-101

RC/4-101

RCl4-473

RC/4-561

RCl4-470

RCl4-100

RC/4-470C

RCl4-470C

RCl4-221

RC/2-471

RC/2-471

RC/2-221

RC/2-221

RC/4-

100

RWlO-010

uw5-010

FiCl4-473

RCl4-333

RCi4-473

RCl4-473

RCl4-823

RCl4-224

RMP/4-I

582

RMPl4-8252

RCl4-333

RCl4-222

RC/4-

103

RC/4-I

02

RMP/4-5112

RMP/4-6813

RMPf4-6813

RCi2-471

RC/2-221

RCl4-222

RCl4-222

RC/4-473

RCl4-473

RC/4-104

RC/4-104

RMP/4-1102

RCi4-393

RMP/4-1102

RMPi4-1102

RMPf4-1072

RMP/4-1102

RMPl4-I

102

RC/4-I

04

RCl4-473

RC/4-561

RCf4-047

RCl4-682

RCl4-474

RCl4-474

RC/4-104

RMP/4-2431

RCf4-182

RC/4-683

RC/4-103

RC/4-

104

RCf4-393

RC/.&

105

RCf4-682

RC/4-

124

RC/4-

124

RMPl4-1823

RMPl4-1823

RCf4-223

RC/4-103

RC/4-103

RC/4-223

RC/4-106

RC/4-106

RCl4-105

RCl4-472

RCf4-103

RCl4-

103

RCl4-

154

RC/4-

106

RCl4-472

RCl4-472

RC/4-103

RMPf4-1002

RMPl4-1002

SWH-130

SWH-148

SSH-730

SS-207

SSH-667

SSH-667

SS-207

ss-143

ss-140

SSH-625

SSH-626

CC-581

CCH-209

CCH-212

CCH-176

CCH-I

76

CCH-213

FAH-107

Parts values and types subject to change without prior notice.

9-

Page 11

THERMAL PROTECTION:

The PRO5000 is equipped with a unique protection system

that continually monitors the temperature of the output

devices and takes corrective action to prevent damage to

the amplifier as a result of overheating. Under most conditions, the

PRO5OOO’s

cooling system can dissipate the

heat required to maintain safe operating temperatures, and

the unit will play continuously. If the amplifier is driven at

high volumes into speakers with an impedance of less than

4 ohms, and/or there is inadequate ventilation, the

heatsink

could heat to a level that would cause the protection

circuitry to shut the unit off for a short time (normally less

than 1 minute), to prevent damage. The PRO5000 will

return to normal operation, and if the overheating condition

is still present the cycle will repeat. In this case, check the

surroundings of the amplifier to ensure sufficient air flow

into and out of the vents. Otherwise, check the load impedance connected to the outputs to see if it is far below 4

ohms.

FUSES:

The PRO5000 is supplied with an internal 15 ampere

Slo-

Blo

AC line fuse. For continued protection, replace this

fuse only with the same type and rating. The fuse is located

on the inside wall near the power switch.

The four power supply fuses on the printed circuit board are

there to protect the output devices if excessive current is

drawn (e.g. a short circuit across the output terminals).

Replace only with 10 ampere 3AG type fuses.

FACTORY SERVICE AND LIMITED

WARRANTY

If you encounter any difficulty or have any questions

concerning your PRO5000 Amplifier, please call our

Customer service Department weekdays, 8 a.m. to

3:30

p.m., Mountain Standard Time, at 602-967-3565.

Should you have any doubts as to whether the amplifier is

malfunctioning and requires service, please call us before

sending in for repair. All units being returned (regardless of

warranty status) must receive a Return Authorization (RA)

number. In addition, we can offer troubleshooting assistance

that may simplify or even eliminate the need for factory

service.

The Hafler PRO5000 Amplifier is warranted to the original

owner

(non-transferrable)

for three years form the date of

purchase, including parts, labor, and return shipping costs

within the continental United States, Alaska, and Hawaii.

This warranty applies only to products

sold in the United

States of America.

For warranties outside the U.S.A., please

contact

your local

agent.

It is the owner’s responsibility to pay shipping (preferably

United Parcel Service, UPS) to the factory: collect shipments will not be accepted. Units under warranty should be

accompanied by a copy of the dated Bill of Sale. Use the

original carton and all packing material, with the RA

number clearly marked on the outside of the package. Be

sure to include a return address, the RA number, a daytime

telephone number, and a brief description of the difficulty,

including whether it occurs continuously or intermittently.

This warranty gives you

specific legal rights. You

may also

have

other rights which vary from state to state.

-10-

Loading...

Loading...