Page 1

DOC022.52.90472

GANIMEDE P and GANIMEDE N laboratory machine

User manual

06/2013, Edition 1A

© HACH-LANGE GmbH. , 2013. All rights reserved. Printed in Germany

Page 2

Page 3

Table of contents

Section 1 Technical data ........................................................................................................................5

Section 2 General information...............................................................................................................7

2.1 Safety information............................................................................................................................... 7

2.1.1 Hazard notes in this manual ...................................................................................................... 7

2.1.2 Warning labels ........................................................................................................................... 7

2.1.3 Chemical and biological safety ..................................................................................................8

2.1.4 Safety around source lamps ......................................................................................................8

2.2 Product overview ................................................................................................................................ 9

2.2.1 Product overview of the Ganimede P ........................................................................................ 9

2.2.2 Product overview of the Ganimede N ........................................................................................ 9

2.3 Scope of delivery .............................................................................................................................. 10

2.4 Front and rear view........................................................................................................................... 10

2.4.1 Sample changer....................................................................................................................... 10

2.4.2 Open-loop control unit.............................................................................................................. 11

2.4.3 Analysis unit............................................................................................................................. 12

Section 3 Installation............................................................................................................................ 17

3.1 Installation of the components..........................................................................................................17

3.1.1 Operating environment ............................................................................................................ 17

3.1.2 Installation of the devices......................................................................................................... 17

3.1.3 Installation of the cables .......................................................................................................... 19

3.1.4 Installation of the tubes............................................................................................................ 20

3.1.4.1 Installation of the tubes for the Ganimede P................................................................... 20

3.1.4.2 Installation of the tubes for the Ganimede N................................................................... 23

3.1.5 Installation of the sample tray .................................................................................................. 26

3.2 Open-loop control unit ...................................................................................................................... 27

3.2.1 Overview of the display and keys of the open-loop control unit............................................... 27

3.2.2 Switch-on of the open-loop control unit.................................................................................... 28

3.3 Reagents .......................................................................................................................................... 28

3.3.1 Reagents for Ganimede P ....................................................................................................... 28

3.3.2 Reagents for Ganimede N ....................................................................................................... 29

3.3.3 Storage .................................................................................................................................... 29

3.3.4 Reagents reserve..................................................................................................................... 29

3.4 Ganimede P sample preparation...................................................................................................... 29

3.4.1 Load the sample tray ............................................................................................................... 29

3.5 Ganimede N sample preparation...................................................................................................... 31

3.5.1 Load the sample tray ............................................................................................................... 31

Section 4 Operation.............................................................................................................................. 35

4.1 Operation of the open-loop control unit ............................................................................................ 35

3

Page 4

Table of contents

4.2 Menu structure of the open-loop control unit.....................................................................................36

4.2.1 Menu structure .........................................................................................................................36

4.2.2 Start of a measurement series .................................................................................................40

4.2.3 Calibration (recording of multi-point calibrations).....................................................................41

4.2.3.1 Ganimede P.....................................................................................................................41

4.2.3.2 Ganimede N ....................................................................................................................42

4.2.4 Rinse ........................................................................................................................................42

4.2.5 Stop..........................................................................................................................................43

4.2.6 Data/current..............................................................................................................................43

Section 5 Maintenance..........................................................................................................................45

5.1 Sample changer ................................................................................................................................45

5.2 Open-loop control unit.......................................................................................................................45

5.3 Analysis unit ......................................................................................................................................45

5.3.1 Mount the cover........................................................................................................................45

5.3.2 Downtime .................................................................................................................................46

5.3.3 Tube change ............................................................................................................................46

5.3.3.1 Insertion of the tube in a pump........................................................................................46

5.3.4 Clean the analysis cuvette .......................................................................................................47

5.3.5 Cleaning of the analysis unit ....................................................................................................49

Section 6 Troubleshooting ...................................................................................................................51

6.1 Error messages on the open-loop control unit ..................................................................................51

6.2 Error messages on the analysis unit .................................................................................................51

Section 7 Replacement parts and accessories ................................................................................53

7.1 Replacement parts ............................................................................................................................53

7.2 Accessories.......................................................................................................................................53

Section 8 Contact information ............................................................................................................55

Section 9 Warranty and liability ...........................................................................................................57

Appendix A Interface protocol.............................................................................................................59

4

Page 5

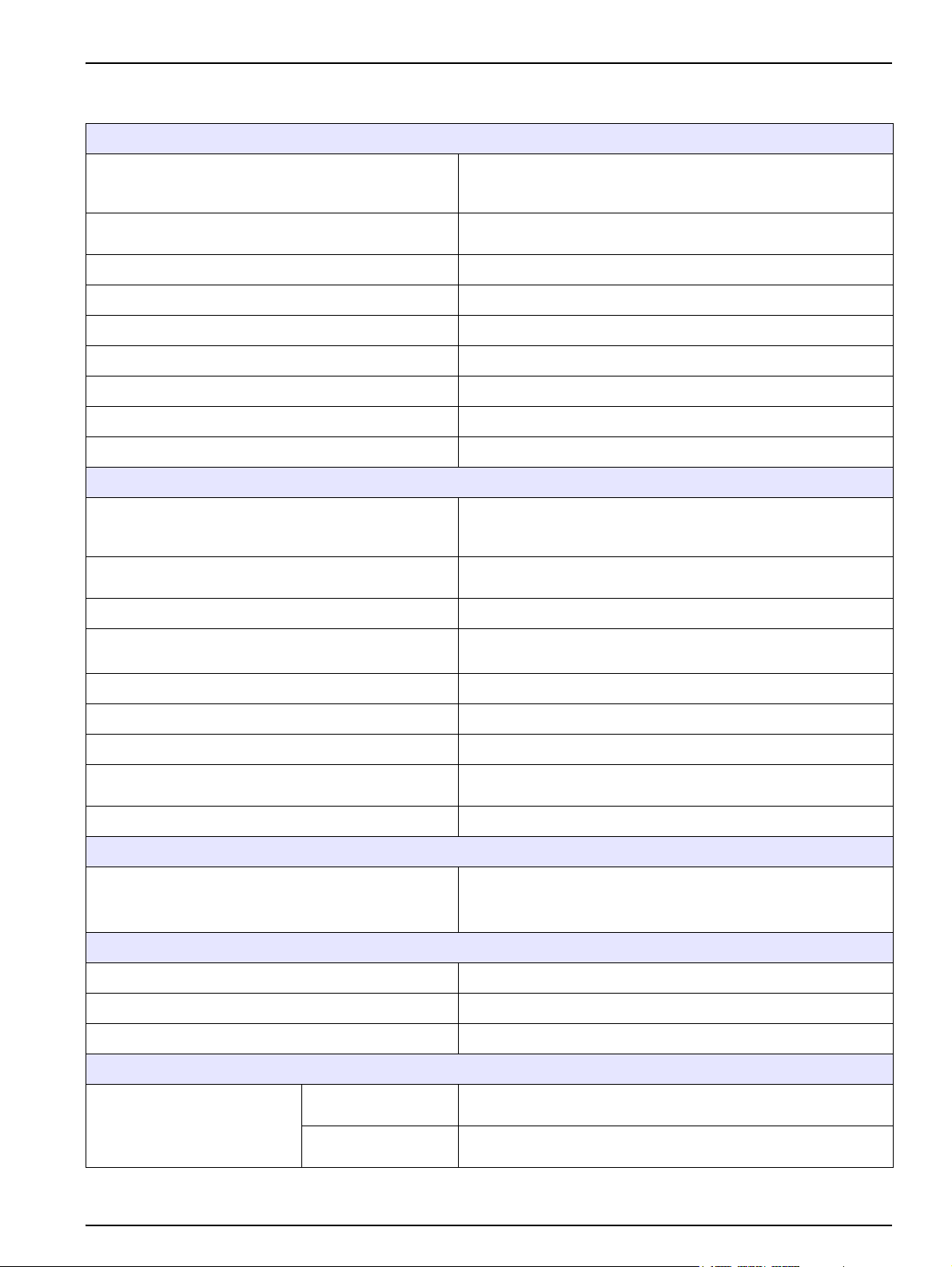

Section 1 Technical data

Subject to change.

Ganimede P analysis unit

Ganimede P for the automatic serial analysis of orthophosphate

Typ e

Photometric method

Total P digestion Rapid digestion at 150 °C and 6 bar

Sample pH pH 2 – 11

and total phosphate in the analytical laboratory, consisting of

analysis unit, sample changer and control unit

By means of ammonium molybdate in accordance with DIN EN

1189 of December 1996

Measurement range 0.01 – 3.8 mg/L PO

Measurement accuracy ±0.03 mg/L at 1 mg/L

Measurement wavelength 880 nm

Calibration 2-point calibration and 10-point calibration

Processing time per sample 4 minutes for single determination

Ganimede N analysis unit

Ganimede N for the automatic serial analysis of inorganically and

Typ e

Photometric method

Digestion Alkaline digestion at 150 °C and 8 bar

Measurement range

Reproducibility of the measurement results < 2 % at 15 mg/L

Carryover < 1 % within a measurement range

Measurement wavelengths 210 nm and 228 nm

Calibration

organically bound nitrogen in the analytical laboratory, consisting

of analysis unit, sample changer and open-loop control unit

By means of UV self-absorption at 210 nm and 228 nm in

accordance with DIN EN ISO 11 905-1

Low measurement range 0.5 – 30 mg/L TN

High measurement range 30 – 150 mg/L TN

2-point calibration and multiple-point calibration

(2–11 measurement points)

-P

4

B

B

Processing time per sample 7 minutes for single determination

Sample changer

Sample tray for 36 × 25 mL or

Sample tray

Environmental conditions

Temperature range 15 – 35 °C

Relative humidity < 75 %, non-condensing

Air pressure 75 – 106 kPa

Equipment properties

Analysis unit

Particle mobility

Sample changer

Sample tray for 53 × 15 mL

Tray diameter 240 mm

According to DIN 38402; the prerequisites of EN 1484 TOC of

> 100 µm are significantly exceeded

According to DIN 38402; the prerequisites of EN 1484 TOC of

> 100 µm are significantly exceeded with 1 mm (sample needle)

5

Page 6

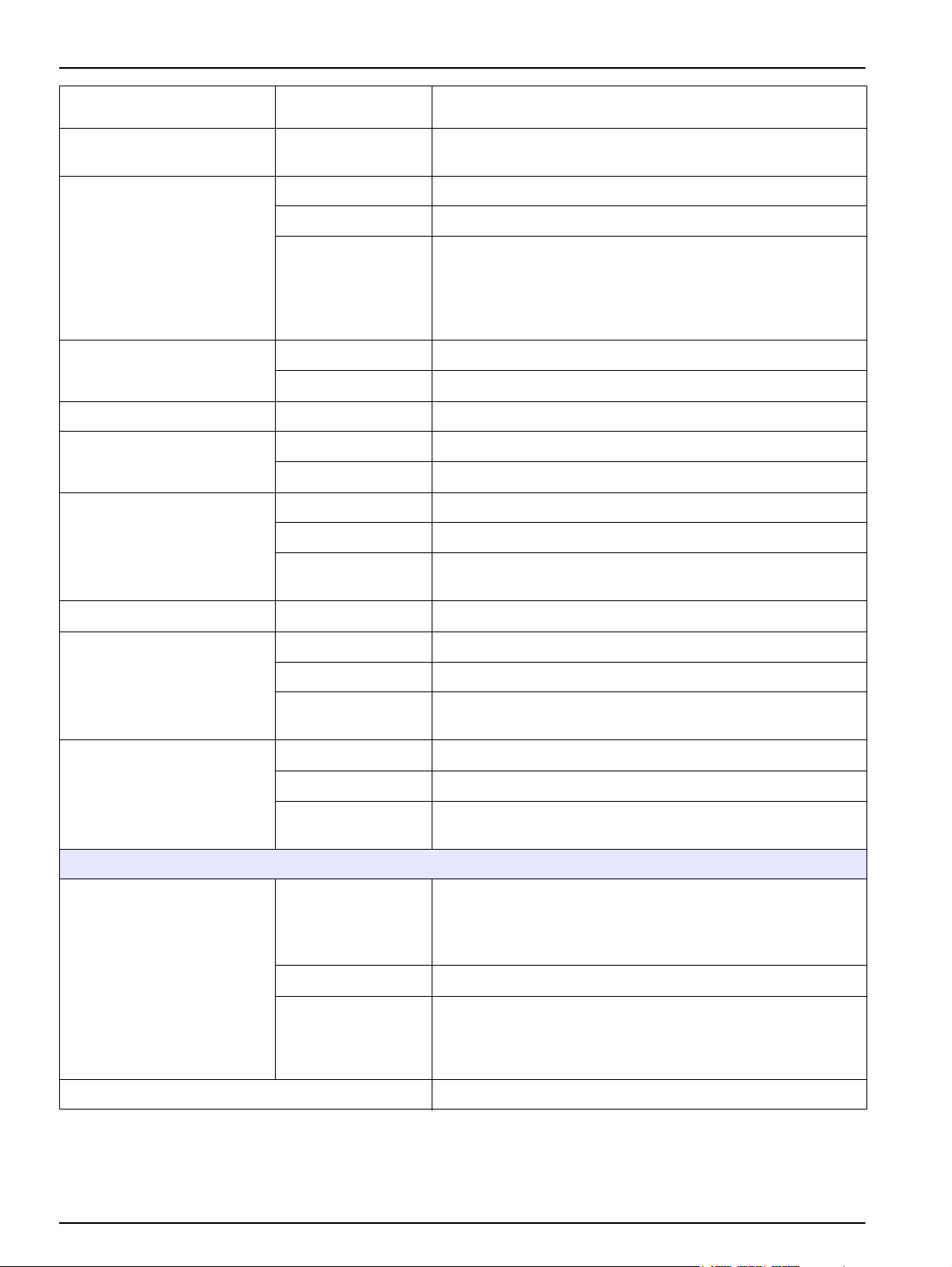

Technical data

Tube material Analysis unit

Display

Power connector

Protection class

Housing protection rating Sample changer IP 20

Overvoltage category

Power consumption

Open-loop control

unit

Analysis unit 230 V +5%/-15%, 50 Hz

Sample changer 100–240 V, +5%/-15%, 50/60 Hz

Open-loop control

unit

Analysis unit Class I

Sample changer Class I

Analysis unit II

Sample changer II

Analysis unit 150 VA

Sample changer 48 VA

Open-loop control

unit

Ismaprene, thermoplastic elastomer on polypropylene basis,

almost opaque beige, suitable for the food and medical sectors.

5.7-inch color display

External power supply:

Input: 100–240 V, 50/60 Hz

Output: 15 VDC, 2 A

Or rechargeable battery operation: Rechargeable battery pack:

15 V, 6 rechargeable batteries, type HHR-200A

20 VA

Solution class Sample changer 1

Analysis unit 370 × 710 × 360 mm (14.57 × 27.95 × 14.17 inches)

Dimensions (W×H×D)

Weight

Other

Interface

Sample changer 280 × 210 × 390 mm (11.02 × 8.27 × 15.35 inches)

Open-loop control

unit

Analysis unit 40 kg

Sample changer 5 kg (packed)

Open-loop control

unit

Analysis unit

Sample changer RS 232 (9-pole Sub-D connector) for analysis unit

Open-loop control

unit

65 × 245 × 190 mm (2.56 × 9.65 × 7.48 in.)

2.7 kg (packed)

2 x IR interfaces to the open-loop control unit on the front side

1 x RS 232 (9-pole Sub-D socket) for sample changer

2 x RS 232 C for PC/LIMS

1 x Centronics for printer

Wireless connection to LIMS or printer for the transfer of the

results with IR interfaces

Serial RS 232 interface for PC or CCD scanner

8-pole round socket for PS/2 compact keyboard

Certification CE compliant

6

Page 7

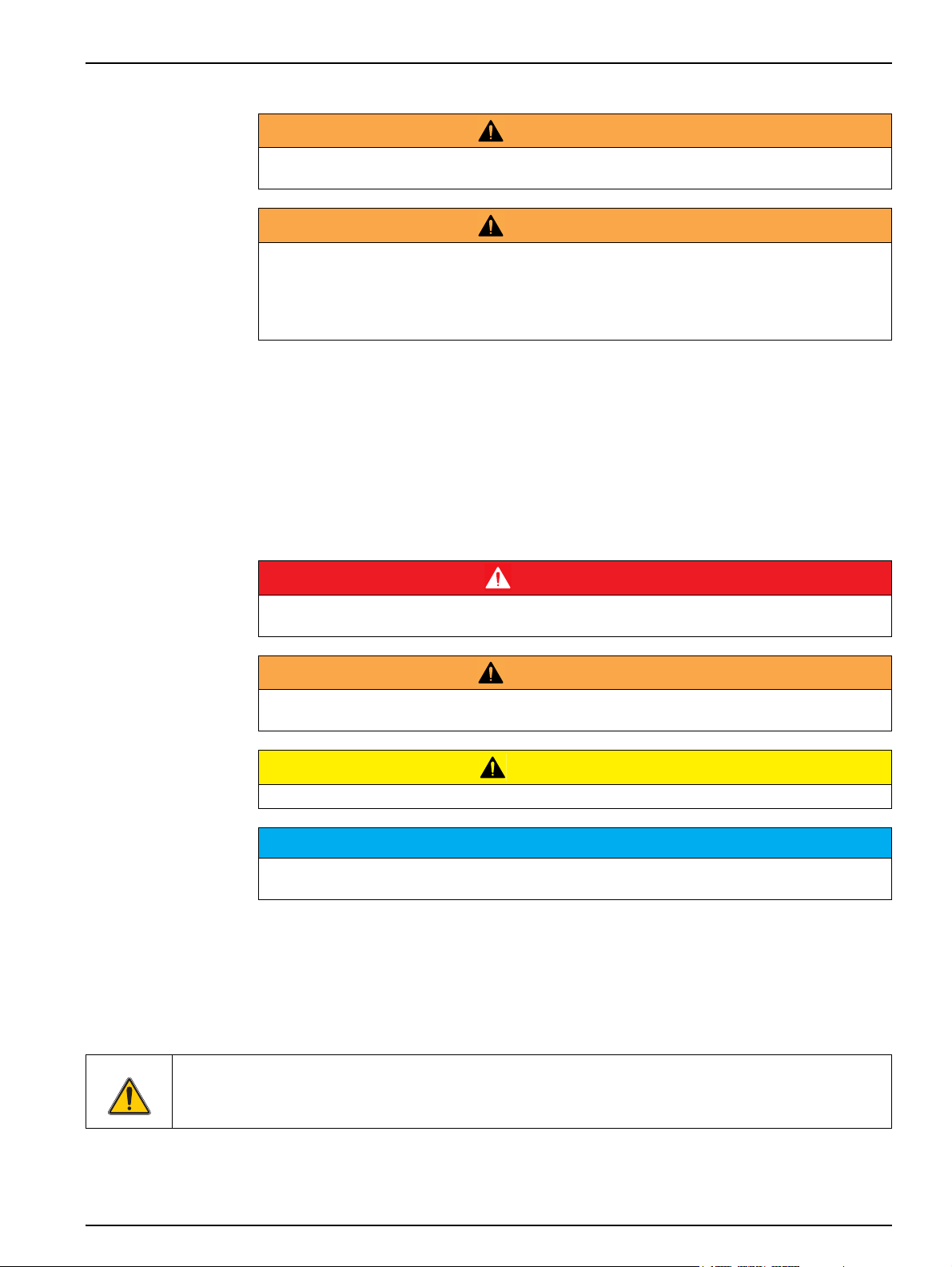

Section 2 General information

WARNING

It is forbidden to remove, bypass or override safety devices, safety functions and monitoring

devices.

WARNING

The manufacturer is not responsible for any damages due to misapplication or misuse of this

product including, without limitation, direct, incidental and consequential damages, and totally

excludes such damages as permitted under applicable laws.

The user is solely responsible to identify critical application risks and install appropriate

mechanisms to protect processes during a possible equipment malfunction.

2.1 Safety information

Read this entire manual carefully before unpacking, setting up or operating the device.

Pay attention to all hazard and warning notes. Failure to do so could result in serious

injury to the operator or damage to the device.

To prevent damage to or impairment of the device's protection equipment, the device may

only be used or installed as described in this manual.

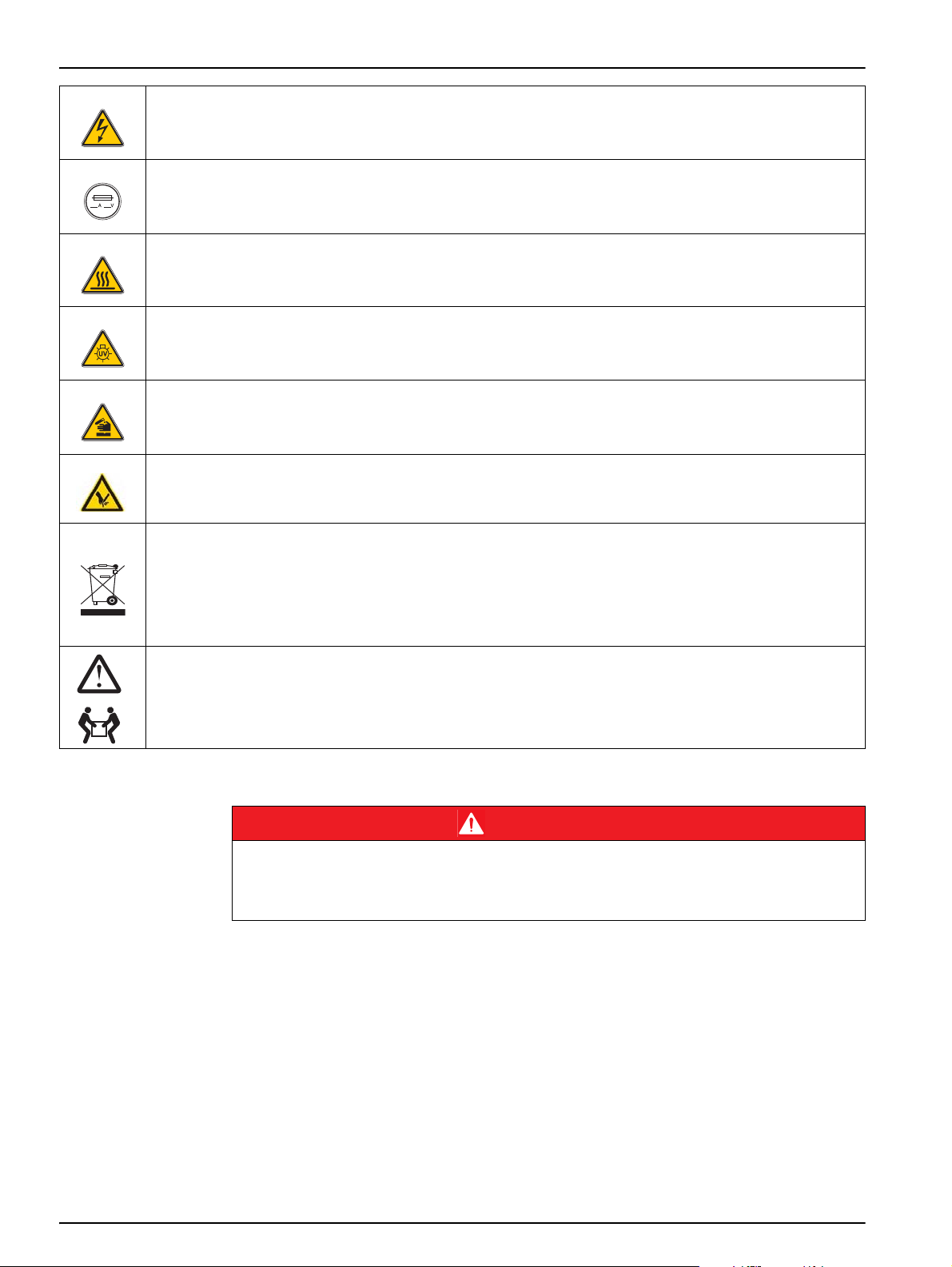

2.1.1 Hazard notes in this manual

Indicates a potentially or imminently hazardous situation that, if not avoided, can result in death or

serious injury.

Indicates a potentially or imminently dangerous situation that, if it is not avoided, can lead to

death or to serious injuries.

Indicates a possible dangerous situation that can have minor or moderate injuries as the result.

Indicates a situation that, if it is not avoided, can lead to damage to the device. Information that

requires special emphasis.

Note: Information that supplements points in the main text.

2.1.2 Warning labels

DANGER

WARNING

CAUTION

NOTICE

Read all labels and tags attached to the device. Failure to do so could result in personal

injury or damage to the device.

This symbol, if noted on the instrument, references the instruction manual for operation and/or safety

information.

7

Page 8

General information

18-32 kg (39.7-70.5 lbs

This symbol may be found on an enclosure or barrier within the product and indicates a risk of electric shock

and/or death by electrocution.

If shown on the device, this symbol indicates the location of a fuse or current limiter.

If shown on the device, this symbol indicates a component that can be hot and must not be touched without

precautionary measures.

This symbol indicates that a UV lamp is used in the device.

If shown on the device, this symbol indicates dangerous chemical substances. The handling of chemicals and

the execution of maintenance on chemical feed equipment of the device may only be carried out by qualified

personnel who are trained to work with chemicals.

If shown on the device, this symbol indicates dangerous places on the device that can result in crushing or

surface damage. Only operate the device with closed safety covers.

Electrical equipment marked with this symbol may no longer be disposed of in unsorted European domestic or

public disposal systems after 12 August 2005. In conformity with the applicable provisions, consumers in the

EU must return old electrical equipment to the manufacturer for disposal from this date. This is at no charge to

the user.

Note: Contact the manufacturer or supplier for instructions on how to return end-of-life devices,

manufacturer-supplied electrical accessories and all auxiliary items for pro per disposal.

When carrying or transporting the instrument components or instrument and if the total weight is more than

18 kg, make sure that suitable lifting equipment is used and/or that the instrument components or instrument

are/is carried by two people.

2.1.3 Chemical and biological safety

Potential danger with contact with chemical/biological substances.

Working with chemical samples, standards and reagents can be dangerous. Make yourself

familiar with the necessary safety procedures and the correct handling of the chemicals before

the work and read and follow all relevant safety data sheets.

Normal operation of this instrument may involve the use of hazardous chemicals or

biologically harmful samples.

• Before handling these substances observe all danger notes and safety information

printed on the containers of the original solutions and in the safety data sheet.

DANGER

• Dispose of all consumed solutions in accordance with the national regulations and

laws.

• Select the type of protective equipment accordingly

2.1.4 Safety around source lamps

The source lamps are operated at high temperatures.

8

Page 9

To avoid the risk of electrocution, make sure the instrument is disconnected from the

power source before changing the lamps.

Health hazard caused by ozone.

Hazardous levels of ozone can be generated when the UV lamp is not cooled.

Health risk due to UV light.

UV light can cause irritation to the eyes and skin. Protect eyes and skin from direct exposure to

UV light.

Do not look directly at an energized lamp without UV safety glasses.

Burn hazard. Allow the lamp(s) to cool for at least 30 minutes before maintaining/replacing them.

2.2 Product overview

General information

CAUTION

WARNING

CAUTION

The instrument may not be used in dangerous environments.

The manufacturer and its suppliers reject any express or indirect guarantee for use with high-risk

activities.

Any use other than use in accordance with requirements defined in the user manual leads to the

loss of the warranty claims and can lead to personal injury and property damage, for which the

manufacturer assumes no liability.

2.2.1 Product overview of the Ganimede P

In combination with the ready-to-use GaniChem P GCA 100 reagent kit, the Ganimede P

enables a rapid and automated serial analysis of PO

orthophosphate in accordance with DIN EN 1189 of December 1996.

The digestion of the total phosphate takes place as high-temperature digestion.

The phosphate content is determined as phosphorus molybdenum blue at 880 nm.

2.2.2 Product overview of the Ganimede N

In combination with the ready-to-use GaniChem N GCA 200 reagent kit, the Ganimede N

enables a quick and automated serial analysis of inorganically and organically bound

nitrogen in aqueous samples in accordance with DIN EN ISO 11 905-1.

WARNING

NOTICE

and PO4-P as total phosphate or

4

Inorganically and organically bound nitrogen is oxidized to nitrate with peroxodisulfate by

means of alkaline digestion at 150

The nitrate content is photometrically measured by means of UV self-absorption in a

differential measurement at 210

°C and 8 bar.

nm and 228 nm.

9

Page 10

General information

2.3 Scope of delivery

Please check that the order is complete. If anything is missing or damaged, please contact

the manufacturer or retailer.

• Sample changer

• Open-loop control unit

• Analysis unit P or analysis unit N

2.4 Front and rear view

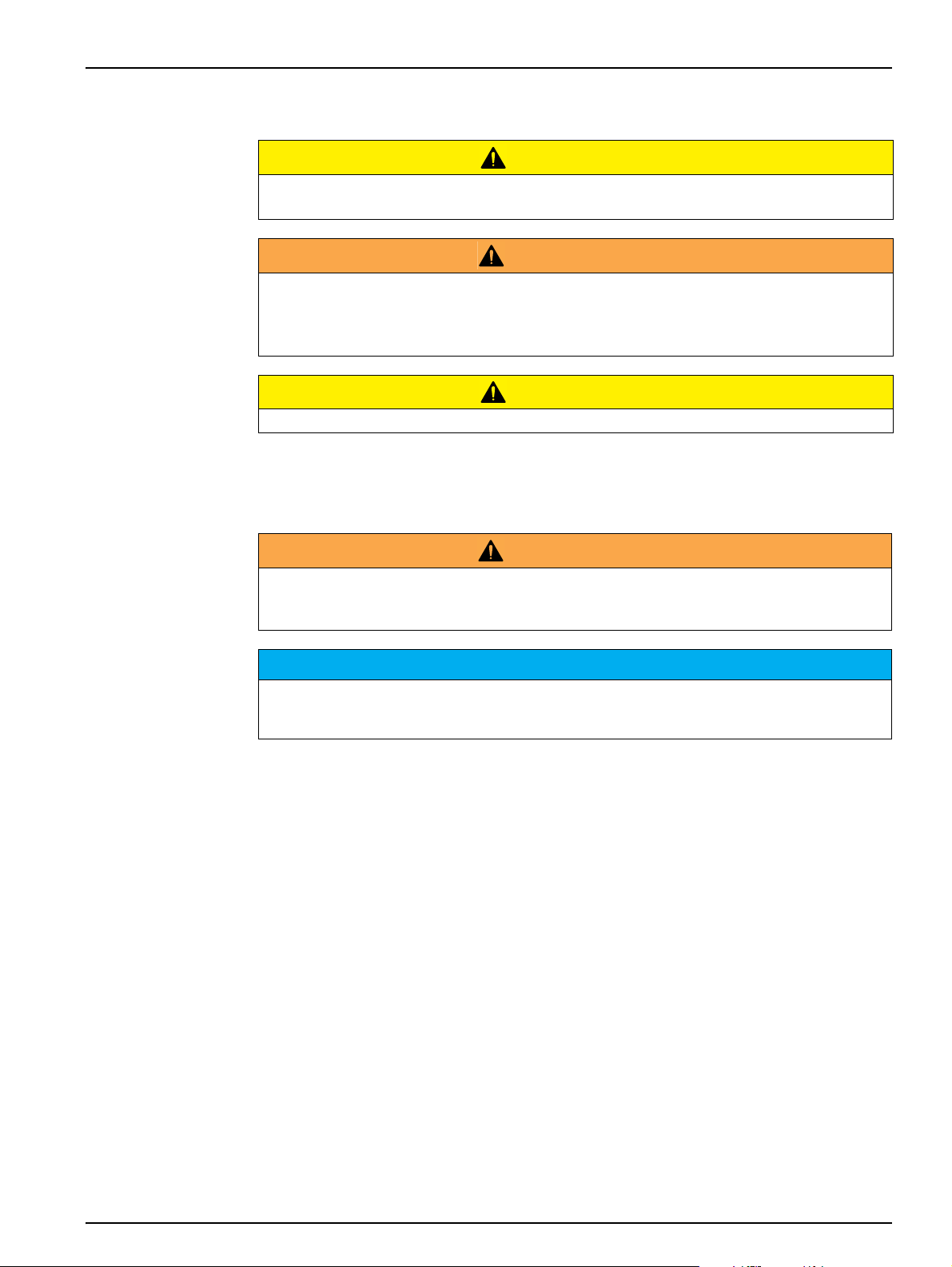

2.4.1 Sample changer

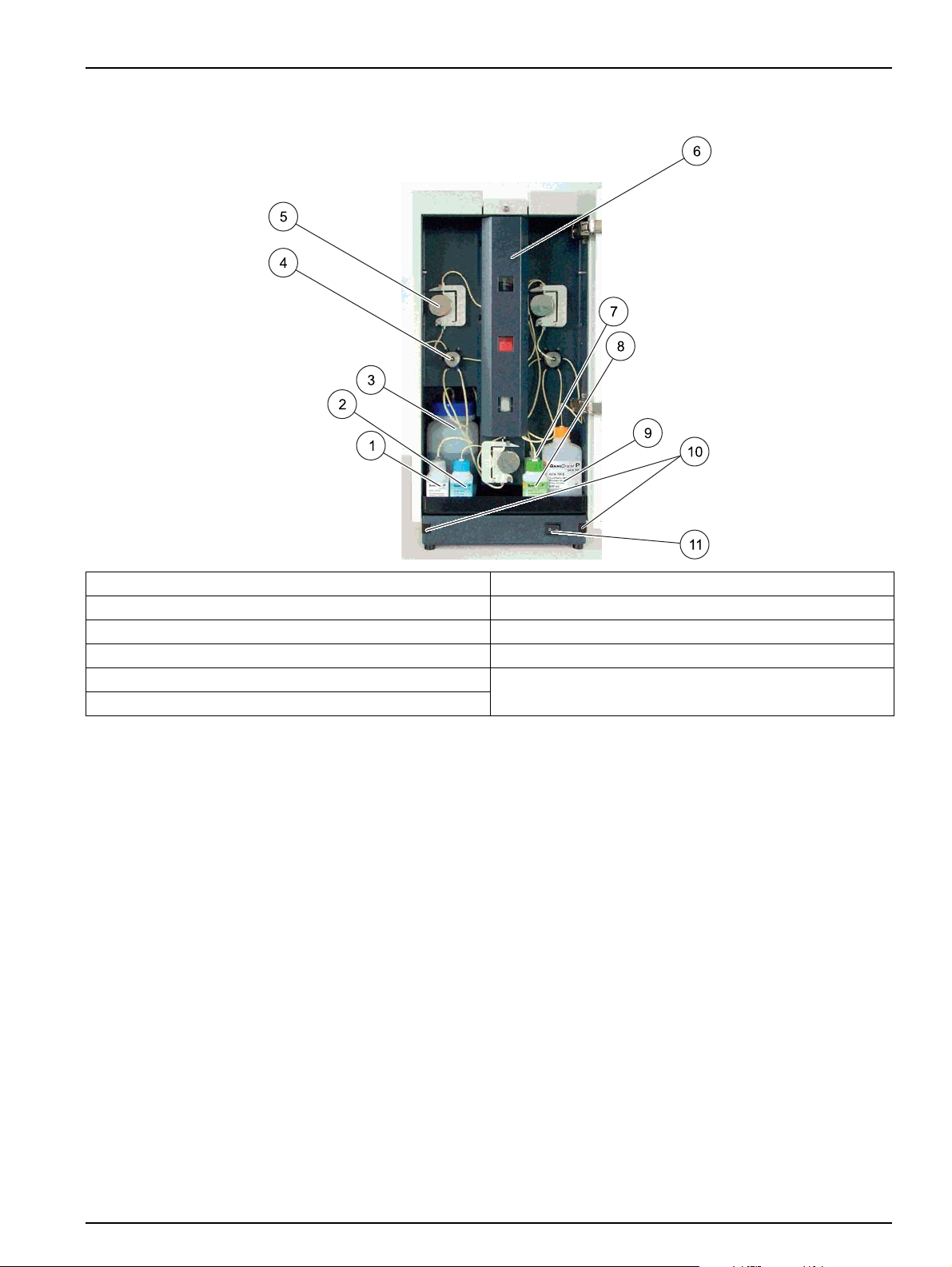

Figure 1 Front view of sample changer

1 Sample changer arm 5 Reset button

2 Sample needle 6 Sample tray (here, 36 positions for 30-mL sample

3 Rinsing vessel for sample needle

4 Sample containers 7 Light-emitting diode

10

containers; a sample tray with 53 positions for 18-mL

sample containers is optionally available)

Page 11

General information

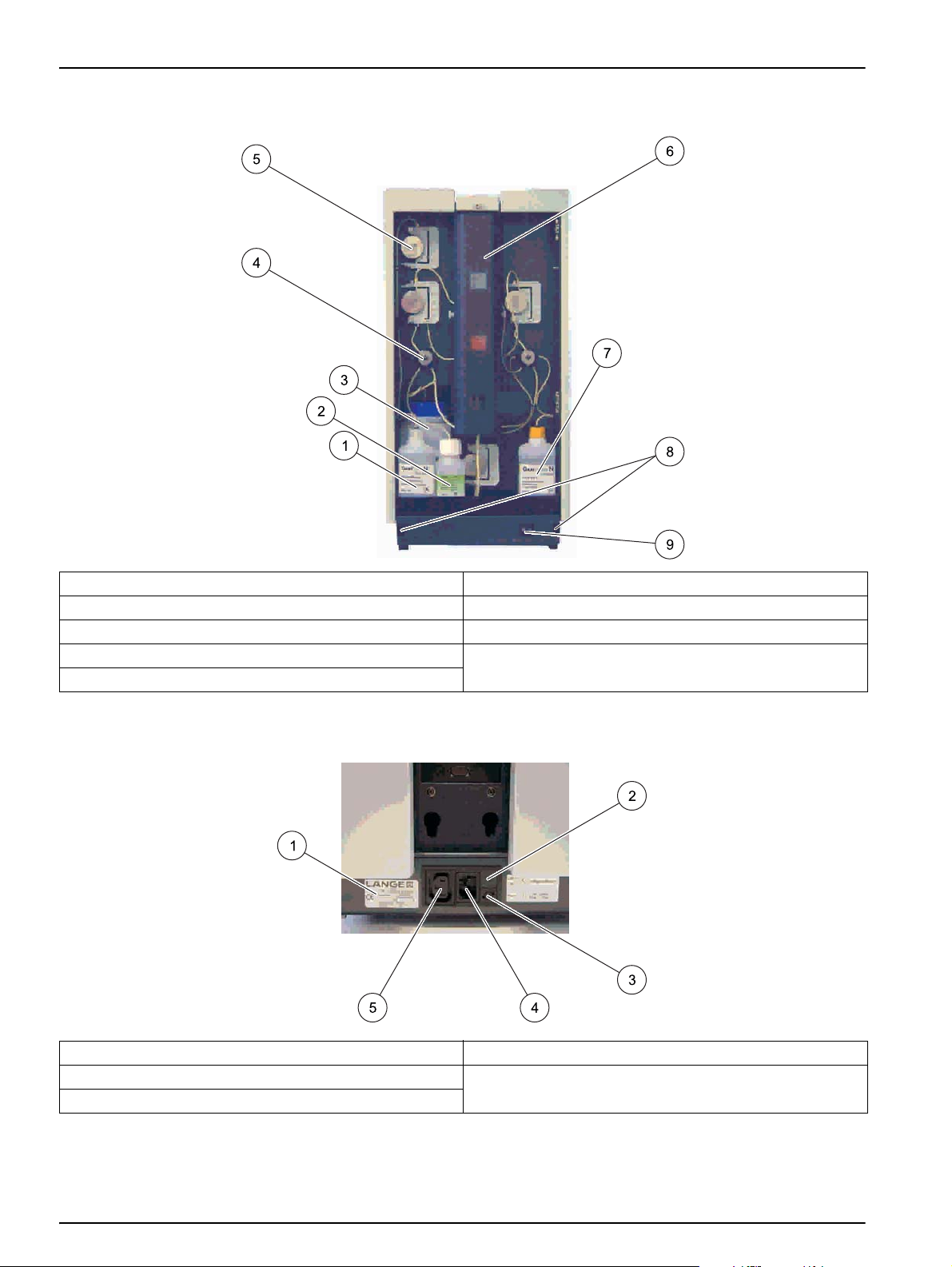

Figure 2 Rear view of sample changer

1 Sample needle 6 Suction tube for rinse water

2 Fuse (2× T 1.25 A L, 250 VAC) 7 Drain hose

3 Power switch 8 Type plate

4 Power connector 9 Rinsing vessel for sample needle

5 Interface for the analysis unit connection cable

2.4.2 Open-loop control unit

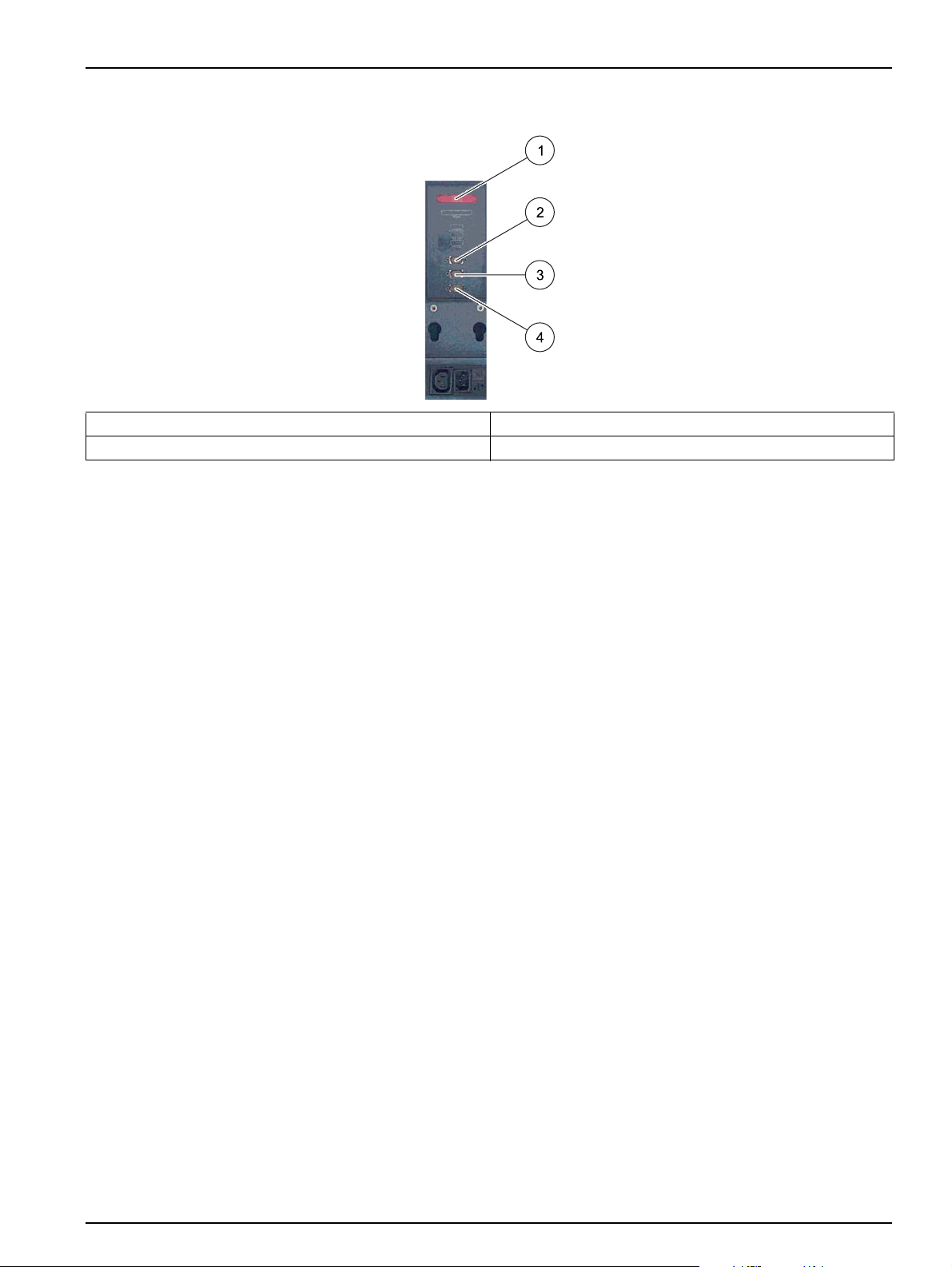

Figure 3 Front view of the open-loop control unit

1 Shortcut keys 4 Alphanumeric keys

2 Graphical display 5 Menu keys

3 Cursor keys

11

Page 12

General information

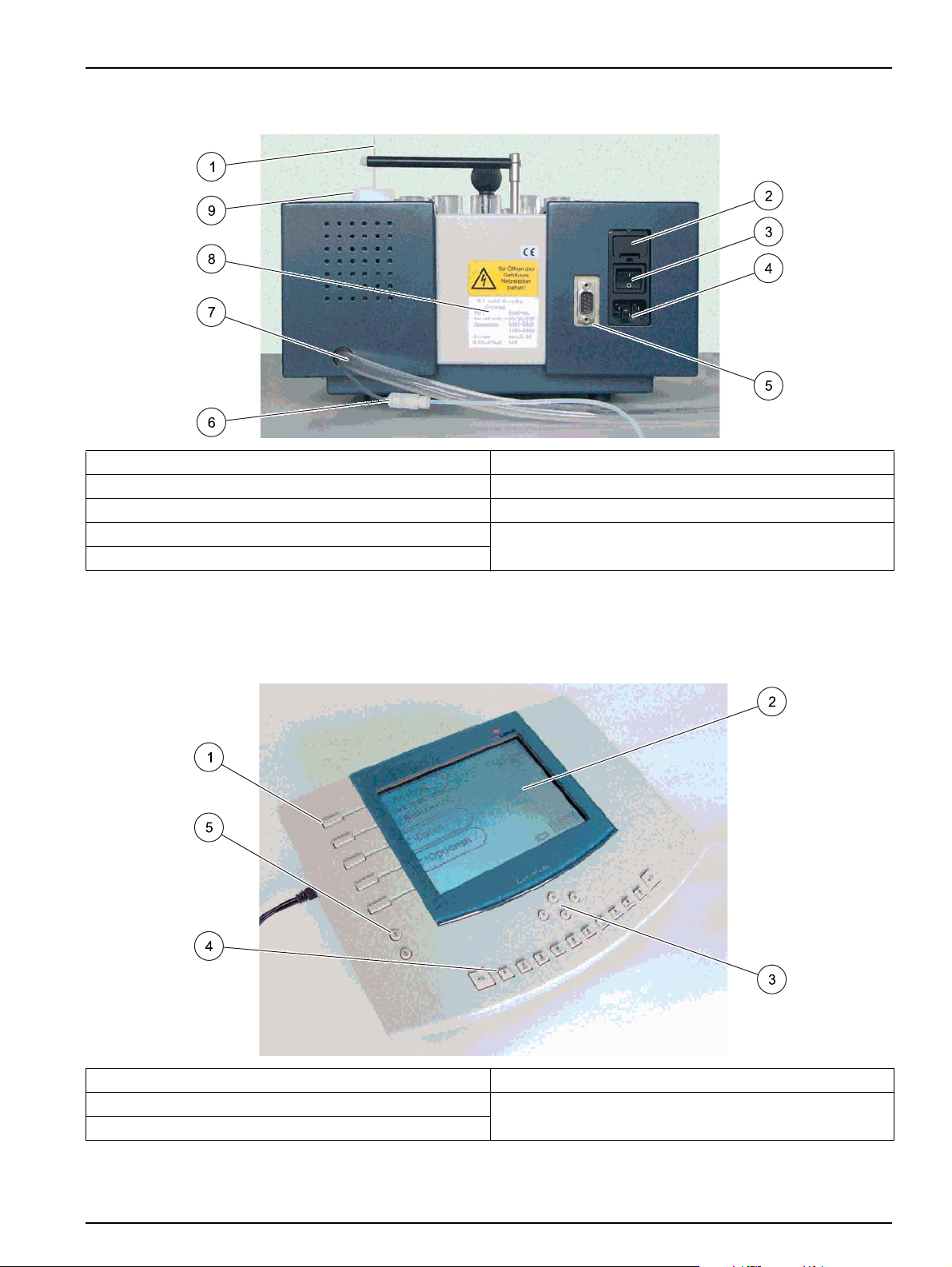

Figure 4 Detailed view of the open-loop control unit

1 IR interface 4 Power switch

2 RS 232 interface for PC and hand-held scanner 5 Power connector

3 Interface for compact keyboard

2.4.3 Analysis unit

Figure 5 Front view of analysis unit

1 Analysis cuvette monitoring window 4 IR interfaces

2 LCD display of the current sample 5 Power switch

3 Digestion cuvette monitoring window

12

Page 13

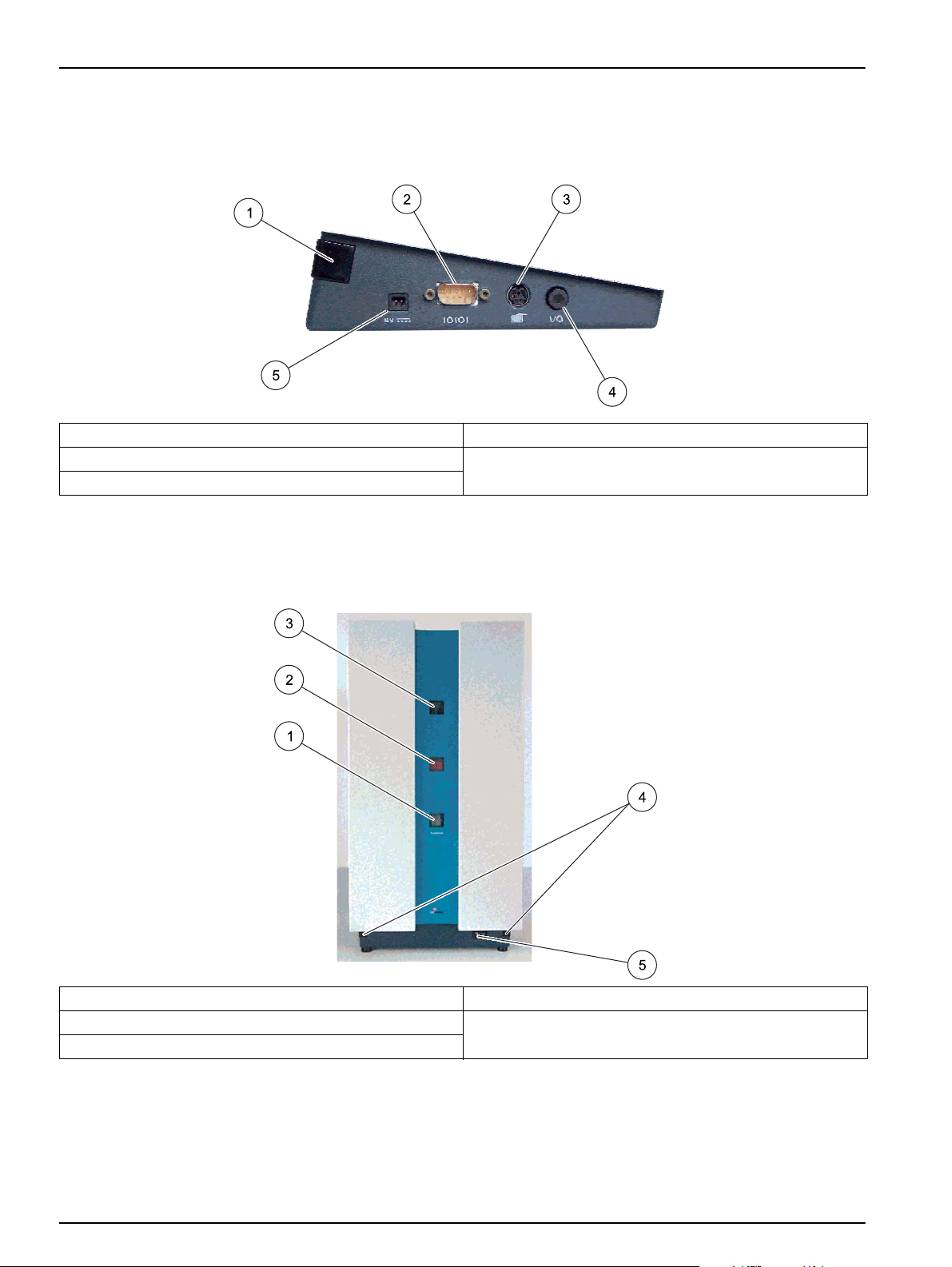

Figure 6 Interior view of analysis unit P

General information

1 Digestion solution A 7 Acid solution D

2 Color solution B 8 Reduction solution C

3 Waste bottle 9 Distilled water

4 Valve 10 IR interfaces

5 Pump 11 Power switch

6 Safety cover

13

Page 14

General information

Figure 7 Interior view of analysis unit N

1 Acid solution A 6 Safety cover

2 Digestion solution B 7 Distilled water

3 Waste bottle 8 IR interfaces

4 Val ve 9 Power switch

5 Pump

Figure 8 Analysis unit power connector

1 Type plate 4 Power connector

2 230 V/115 V voltage selector switch 5 Sample changer power connector

3 T3A L fuse, 250 V

14

Page 15

Figure 9 Analysis unit interfaces

1 Printer interface 3 RS 232 socket

2 Sample changer interface 4 RS 232 connector

General information

15

Page 16

General information

16

Page 17

Section 3 Installation

3.1 Installation of the components

The instrument may not be used in dangerous environments.

The manufacturer and its suppliers reject any express or indirect guarantee for use with high-risk

activities.

Any use other than use in accordance with requirements defined in the user manual leads to the

loss of the warranty claims and can lead to personal injury and property damage, for which the

manufacturer assumes no liability.

Unpack all supplied parts carefully, as they are highly sensitive in part to shock and

impact. Read the user manual prior to installation and proceed exactly as described.

3.1.1 Operating environment

Observe the following points to allow the instrument to function normally and give a long

operating life.

• Position the instrument securely on a flat surface taking care to remove any objects

from under the device.

WARNING

NOTICE

• The ambient temperature must be 15 °C to 35 °C (60 °F to 95 °F).

• The relative humidity must be lower than 75% (no condensate formation).

• A minimum clearance of 15 cm (5.9inches) must be ensured above and on all sides of

the device; this allows the air to circulate and prevents overheating of the electric

components. The dosage arm of the sample changer must be able to move freely.

• Do not operate or store the instrument in extremely dusty, humid or wet locations.

• Make sure that no liquids enter the instrument and immediately wipe away any liquids

that contact the instrument.

• Protect the instrument against vibrations, direct sunlight, corrosive gases as well as

strong magnetic and/or electric fields.

• Only use genuine replacement parts and accessories.

• The instrument must be serviced by the manufacturer's service department at the

prescribed intervals.

3.1.2 Installation of the devices

When carrying or transporting the instrument components or instrument and if the total weight is

more than 18 kg, make sure that suitable lifting equipment is used and/or that the instrument

components or instrument are/is carried by two people.

WARNING

The carrying strap provided must be used to be able to carry the analysis unit safely over

short distances.

17

Page 18

Installation

Figure 10 Use of the carrying strap

1 Slip the carrying strap over the analysis unit as shown in

the illustration.

2 Carefully tip the analysis unit to the side and guide the

outer parts of the carrying strap behind the feet of the

unit. Proceed in the same way on the opposite side.

1. Place the analysis unit on a stable and level tabletop. Level out any unevenness with

the rear adjustable feet.

2. Remove the transport locking screws on the bottom of the sample changer.

To do so, tip the sample changer to the side and remove the screws above the

corresponding sign.

3. Position the sample changer to the left of the analysis unit on a stable and level

tabletop.

4. Place the open-loop control unit near (approx. 0.5 m 1.64 ft) to the analysis unit.

Note: Communication between the analysis unit and the open-loop control unit takes place via

IR interfaces.

3 Tightly pull the carrying belt upwards at the front and

back sides.

4 The analysis unit must now be transported safely over a

short distance by two people.

18

Page 19

3.1.3 Installation of the cables

Danger of an electric shock.

Use only the supplied power cable.

If another power cable without a protective earth contact is used or if the sample changer is

connected to a mains connection without a ground connection, there is the danger of an electric

shock for the operator and of the destruction of the device.

Electrical and fire hazards.

Use only the supplied power cable.

Only qualified experts may perform the tasks described in this section of the manual, while

adhering to all locally valid safety regulations.

Removable power cables must not be replaced with inadequately dimensioned power cables.

Installation

DANGER

WARNING

WARNING

NOTICE

Use only an earthed socket for the connection of this device to the power supply.

If you are not sure if the socket is earthed, have this checked by a qualified electrician.

The power plug serves in addition to the power supply to isolate the device quickly from the

mains where necessary.

This is recommended when the instrument is not used for a long time, and can prevent potential

dangers in the event of a fault.

Therefore, make sure that socket to which the device is connected is easy to reach by each user

at all times.

1. Select the appropriate mains voltage (230 V or 115 V) for the region with the voltage

selector switch on the rear side of the analysis unit.

2. Connect the analysis unit to an earthed mains socket with the power cable (230 volts

+5 %/-15 %/50 Hz).

3. Optionally, connect a printer or PC to the corresponding interface of the analysis unit

4. Connect the SAMPLER interface of the analysis unit to the sample changer interface

with the connection cable (XLH917).

5. Connect the sample changer to the "sample changer power connector" on the

analysis unit with the power cable.

Note: Use only the supplied power cable.

6. Connect the external power supply unit of the open-loop control unit to an earthed

mains socket (230 volt +5 %/-15 %/50 Hz).

Note: Use only the external LZV563 power supply unit.

Note: The open-loop control unit is equipped for rechargeable battery operati on. The char ge

status is indicated permanently on the display. A red battery symbol indicates a weak

rechargeable battery. The battery symbol is shown in black when the rechargeable battery is

being charged. The fully charged rechargeable battery enables an operating time of

approximately 2.5 hours.

19

Page 20

Installation

7. Optionally, connect a hand-held scanner or a keyboard to the corresponding interface

of the open-loop control unit.

3.1.4 Installation of the tubes

Potential danger with contact with chemical/biological substances.

Working with chemical samples, standards and reagents can be dangerous. Make yourself

familiar with the necessary safety procedures and the correct handling of the chemicals before

the work and read and follow all relevant safety data sheets.

Risk of injury to the eyes, skin and respiratory tract

During work with chemicals and/or solvents, it is absolutely necessary to pay attention to the

relevant accident prevention regulations and to wear suitable personal protective equipment for

the eyes, face, hands and body, and/or respiratory protection.

Make sure that the system is only unpacked, assembled, connected and operated by qualified

and trained personnel.

Make sure that the waste container and the drain hose are always positioned lower than the

sample changer. The rinsing fluid must be able to flow unimpeded.

Make sure that the tubes are not kinked or jammed.

Check the capacity of the waste bottles constantly.

DANGER

WARNING

3.1.4.1 Installation of the tubes for the Ganimede P

1. Install all tubes of the analysis unit in accordance with Figure 11 Tube plan for

analysis unit P, page 22.

2. Screw the large blue lid onto the empty waste bottle (1500 mL).

Note: The waste bottle can take the reagent and sample waste from 100 individual

determinations.

3. Connect reagents GCA 100 with the corresponding lids of the same color.

4. Install sample tube A.

To do so, lead the free end of sample tube A out through the left-hand side of the

analysis unit housing.

Connect the upper end of the sample needle with sample tube A.

5. Insert the sample needle into the guide of the sample changer arm.

Note: The sample needle must not reach the bottom of the sample container when magnetic

rods are used.

6. Install the suction tube for the rinse water of the sample needle.

To do so, connect the end with a screw thread to the permanently mounted tube on

the rear side of the sample changer.

Insert the free end of the suction tube into a bottle of distilled water.

Note: It is essential that the needle rinser is connected in order to make sure that a sample

batch drains faultlessly. Sufficient rinse water (distilled water) must be available at all times.

20

Page 21

Installation

7. Install the drain hose.

Attach one end of the suction tube to the white tube connection on the rear side of

the sample changer.

Insert the free end of the drain hose into a suitable waste container.

Note: The waste container and the drain hose must always be positioned lower than the sample

changer. The rinsing fluid must be able to drain unimpeded; the drain hose must not be kinked!

Check the capacity of the waste bottle.

21

Page 22

Installation

Figure 11 Tube plan for analysis unit P

1 Pump 1 10 Reaction solution C

2 Digestion cuvette 11 Pump 4

3 Overpressure discharge 12 Analysis cuvette

4 Pump 3 13 Waste bottle

5 Pump 3 14 Color solution B

6 Air intake 15 Digestion solution A

7 Val ve 2 16 Valve 1

8 Distilled water 17 Sample tube 1 sample feed coming from the sample

9 Acid solution D

changer

22

Page 23

Identification

Color in tube

plan

Table 1 Tube overview for analysis unit P

Length

Dia-

meter

Colored

adapter

Installation

Connected:

A: (included in

the scope of

delivery of the

sample

changer)

B Red 140 mm 2.67 mm -

C Pink 380 mm 3.04 mm Yellow/blue

D Gray 300 mm 3.04 mm -

E Green 530 mm 3.2 mm Yellow/blue

F Blue 450 mm 3.2 mm -

G Green 300 mm 3.04 mm -

H Orange 180 mm 3.04 mm -

J Black 550 mm 3.53 mm

K Purple 500 mm 4.17 mm

L Black 300 mm 3.04 mm -

Black 400 mm 2.67 mm -

Gray/green/g

reen

Gray/black/p

urple

Sample changer sample needle

-> Left-hand side of the analysis unit housing

-> Valve 1 connection f

Valve 1 connection b

-> Left-hand analysis cuvette

Valve 1 connection g

-> Pump 1

-> Digestion cuvette

Digestion solution A

-> Valve 1 connection d

Right-hand analysis cuvette

-> Pump 2

-> Valve 2 connection g

Color solution B

-> Valve 2 connection e

Reduction solution C

-> Valve 2 connection c

Distilled water

-> Valve 2 connection b

Analysis cuvette

-> Pump 3

Lower analysis cuvette

-> Pump 4

-> T-piece -\> Valve 1 connection c

and -\> Waste bottle

Acid solution D

-> Valve 2 connection d

3.1.4.2 Installation of the tubes for the Ganimede N

1. Install all tubes of the analysis unit in accordance with Figure 12 Tube plan for

analysis unit N, page 25.

2. Screw the large blue lid onto the empty waste bottle (1500 mL).

Note: The waste bottle can take the reagent and sample waste from 100 individual

determinations.

3. Connect the GCA 200 reagents with the corresponding lids of the same color.

4. Install sample tube A.

To do so, lead the free end of sample tube A out through the left-hand side of the

analysis unit housing.

Connect the upper end of the sample needle with sample tube A.

5. Insert the sample needle into the guide of the sample changer arm.

Note: The sample needle must not reach the bottom of the sample container when magnetic

rods are used.

23

Page 24

Installation

6. Install the suction tube for the rinse water of the sample needle.

To do so, connect the end with a screw thread to the permanently mounted tube on

the rear side of the sample changer.

Insert the free end of the suction tube into a bottle of distilled water.

Note: It is essential that the needle rinser is connected in order to make sure that a sample

batch drains faultlessly. Sufficient rinse water (distilled water) must be available at all times.

7. Install the drain hose.

Attach one end of the suction tube to the white tube connection on the rear side of

the sample changer.

Place the free end of the drain hose in a suitable waste container.

Note: The waste container and the drain hose must always be positioned lower than the sample

changer. The rinsing fluid must be able to drain unimpeded; the drain hose must not be kinked!

Check the capacity of the waste bottle.

24

Page 25

Figure 12 Tube plan for analysis unit N

Installation

1 Tube routing 9 Distilled water

2 Pump 1 10 Pump 4

3 Pump 3 11 Analysis cuvette

4 Digestion cuvette 12 Waste bottle

5 Overpressure discharge 13 Digestion solution B

6 Pump 3 14 Acid solution A

7 Valve 2 15 Valve 1

8 O-ring for tube routing 16 Sample tube 1 sample feed coming from the sample

changer

25

Page 26

Installation

Identification

Color in tube

plan

Table 2 Tube overview for analysis unit N

Length

Dia-

meter

Colored

adapter

Connected:

A: (included in

the scope of

delivery of the

sample

changer)

B Black 950 mm 3.2 mm Yellow/blue

C Purple 380 mm 3.2 mm Blue/yellow

D Red 215 mm 2.7 mm Blue/yellow

E Green 550 mm 3.2 mm Gray

F Purple 230 mm 3.5 mm -

G Red 220 mm 3.0 mm -

H Orange 220 mm 3.0 mm -

J Blue 250 mm 3.0 mm

Gray 400 mm 2.67 mm -

Black/purple/

gray

Sample changer sample needle

-> Left-hand side of the analysis unit housing

-> Valve 1 connection f

Acid solution A

-> Pump 3

-> Left-hand analysis cuvette

Valve 1 connection g

-> Pump 1

-> Digestion cuvette

Digestion cuvette

-\> Valve 2 connection d

Valve 2 connection g

-> Pump 2

-> Right-hand analysis cuvette

Valve 2 connection e

-> Lower right-hand analysis cuvette (air)

Digestion solution B

-> Valve 1 connection d

Distilled water

-> Valve 2 connection b

Valve 2 connection c

-> T-piece -\> Pump 4 -\> Lower analysis

cuvette

-> T-piece -\> Waste bottle

-> Valve 1 connection c

3.1.5 Installation of the sample tray

Possible risk of injury due to the sample needle.

Make sure that the system is only installed by qualified and trained personnel.

The position designations for the sample containers are printed next to the sampling

openings.

1. Make sure that the sample changer is switched off.

2. Load the sample containers with at least 15 mL of homogenized samples and zero or

standard solution. Add magnetic rods if necessary.

3. Place the filled sample containers on the sample tray without interruption, starting

with position 1.

4. Place the sample tray on the spindle of the sample changer from above.

5. Turn the sample tray until it locks.

6. Switch on the sample changer.

WARNING

26

Page 27

7. The sample tray is subsequently turned automatically to the correct position and the

sample needle dips into the rinsing solution.

Note: A sample stray for 53 samples of 15 mL each is available for special applications.

The reset button on the front left-hand side of the housing is used for initialization of the

sample changer. The reset button must not be actuated during a sample series.

The green light-emitting diode on the front left-hand side of the housing indicates that the

sample changer is in operation.

3.2 Open-loop control unit

3.2.1 Overview of the display and keys of the open-loop control unit

Figure 13 Overview of the display and keys

Installation

1 Menu keys 4 Display and input area

2 Shortcut keys 5 Cursor keys

3 Menu selection 6 Alphanumeric keys

Error messages

Error messages are shown in red on the display. Press the top menu key in order to be

able to continue to work.

Exit the menu

Press the top menu key.

Edit selection lists

Selection with the cursor keys. Press the enter key to confirm the selection.

Alphanumeric keys

Numbers, letters and special characters can be entered with the alphanumeric keys.

27

Page 28

Installation

Table 3 Assignment of the alphanumeric keys

Key abc ABC

1 _ 1 . : , ( ) % 1 ? _ 1 . : , ( ) % 1 ?

2 ABC a b c 2 ä à á â ã å æ ç A B C 2 Ä À Á Ã Å Æ Ç

3 DEF d e f 3 è é ê D E F È É

4 GHI g h i 4 G H I 4

5 JKL j k l 5 J K L 5

6 MNO m n o 6 ö ò ó ô õ Ø œ ñ m n o 6 ö ò ó õ Ø ñ

7 PQRS p q r s 7 ß P Q R S 7

8 TUV t u v 8 ü ù ú û t u v 8 ü ù ú û

9 WXYZ w x y z 9 W X Y Z 9

0 + + - 0 / \* + - 0 / \ *

3.2.2 Switch-on of the open-loop control unit

The open-loop control unit is switched on with the power switch on the left-hand side of the

housing.

The open-loop control unit is ready for operation after the manufacture's logo is shown.

The charge status of the battery, as well as the date and time, are shown on the display

next to the main menu.

Upon delivery, the open-loop control unit is set to the correct national language, date and

time. If these values are not entirely correct, they can be changed in the menu option

OPTIONS, DATE/TIME and OPTIONS, LANGUAGE.

The main menu options are accessed with the adjacent shortcut keys.

3.3 Reagents

3.3.1 Reagents for Ganimede P

The GCA 100 reagents for the automated orthophosphate and total phosphate

determination are designed for 100 determinations. The principle of the reaction complies

with DIN EN 1189 of December 1996.

Phosphate ions react in acid solution with molybdate and antimony ions to form an

antimony–phosphomolybdate complex that is reduced to phosphorus molybdenum blue

by means of ascorbic acid.

The opened solutions can be kept for seven days at room temperature.

Prepare the reagents according to the work instructions enclosed in the reagent

packaging.

28

NOTICE

The Ganimede P and the ready-to-use GaniChem-P GCA 100 reagent kit are optimally adapted

for each another. The use of third-party chemicals can result in the impairment of the results and

the whole system.

The guarantee claim only remains valid with the use of GaniChem-P GCA 100.

Page 29

3.3.2 Reagents for Ganimede N

The GCA 200 reagents for the automated sum determination of inorganically and

organically bound nitrogen are each designed for 100 determinations.

Inorganically and organically bound nitrogen is oxidized to nitrate with peroxodisulfate by

means of an alkaline digestion. The nitrate content is photometrically measured by means

of UV self-absorption in a differential measurement at 210

The opened solutions can be kept for seven days at room temperature.

Prepare the reagents according to the work instructions enclosed in the reagent

packaging.

The analysis unit N and the ready-to-use GaniChem-N GCA 200 reagent kit are adapted

optimally for each another. The use of third-party chemicals can result in the impairment of the

results and the whole system.

The guarantee claim only remains valid with the use of GaniChem-N GCA 200.

3.3.3 Storage

The original substances are stored at room temperature. The fully prepared solutions are

stored in the refrigerator for brief storage (e.g. over a weekend).

Installation

nm and 228 nm.

NOTICE

The reagents remain in the analysis unit when the Ganimede is used daily.

3.3.4 Reagents reserve

A package of GCA 100 for Ganimede P or GCA 200 for Ganimede N is designed for

100

single analyses, and appropriate pre-rinsing amounts for 4–5 analysis series are

included per package. The maximum number of determinations can be reduced from 100

in the event of a higher number of analysis series per package.

A waste bottle can hold the reagent waste and sample waste of one package (i.e. 100

single determinations).

The exact reagent reserves of the chemicals can be shown by means of the menu items

OPTIONS, REAGENT STATUS.

3.4 Ganimede P sample preparation

• Samples must lie within the pH range 2–10.

• Samples that contain substances that react aggressively with Viton, e.g. solvents,

must be diluted.

• Samples containing particulates must be homogenized with a disintegrator for 30

seconds.

• Homogenized samples in positions 1 to 27 can be stirred with magnetic rods with the

sample tray for 36 sample containers.

• The sample containers are suitable for one-time use only. Residues of cleaning

agents can lead to increased phosphate findings.

3.4.1 Load the sample tray

Each sample tray is a sample batch.

If multi-point calibration is to be used, a standard curve with 2–11 measurement points

must be recorded before the measurement series. The device refers to this recorded

curve during measurement operation.

29

Page 30

Installation

Alternatively, it is possible to work with a two-point calibration. In addition, a zero standard

solution, or alternatively two standard solutions, is/are positioned in positions 35 and 36.

To do so, load the sample tray as follows:

• According to the sample batch, the sample tray is loaded with the samples from

position 1.

• For a two-point calibration, the standards are positioned with the measurement series

on a sample tray for 36 sample containers as follows:

Position 35: GCZ 100 zero solution

Position 36: standard, e.g. 0.2 mg/L PO

-P GCS 050

4

Alternatively:

Position 35: 1st standard, e.g. 0.2 mg/L PO

Position 36: 2nd standard, e.g. 2 mg/L PO

-P GCS 050

4

-P GCS 100

4

Single and double determinations can be carried out. For double determinations, the

sample is drawn from a container twice. The settings refer to the whole sample tray.

Two sample containers must be filled with the sample if the orthophosphate and total

phosphate content is to be determined from a sample. The allocation of the determination

method (orthophosphate or total P) to the position numbers of the sample containers is

performed during definition of the sample batch with the open-loop control unit. If

necessary, the use of the sample tray for 53 sample containers is recommended.

The following table and illustration show an example of a sample tray load for a two-point

calibration:

Table 4 Sample tray load for 36 sample containers, Ganimede P

Position Load

35 GCZ 100 zero solution

36 GCS 050 standard solution

1 Sample 1 orthophosphate

2 Sample 1 total phosphate

3 Sample 2 orthophosphate

4 Sample 2 total phosphate

5 Sample 3 orthophosphate

6 Sample 3 total phosphate

7 Sample 4 orthophosphate

8 etc. Sample 4 total phosphate, etc.

30

Page 31

Figure 14 Example of a sample tray load, Ganimede P

Installation

1 Zero solution 3 Samples

2 Standard solution 4 Empty positions

3.5 Ganimede N sample preparation

• Samples that contain substances that react aggressively with Viton, e.g. solvents,

must be diluted.

• Samples containing particulates must be homogenized with a disintegrator for 30

seconds.

• Homogenized samples in positions 1 to 27 can be stirred with magnetic rods with the

sample tray for 36 sample containers.

• The sample containers are suitable for one-time use only.

3.5.1 Load the sample tray

Each sample tray is a sample batch.

If multi-point calibration is to be used, a standard curve with 2–11 measurement points

must be recorded before the measurement series. The device refers to this recorded

curve during measurement operation.

Alternatively, it is possible to work with a two-point calibration. To do so, two standard

solutions are each positioned in positions 33 and 36 for the low and high measurement

range.

For this, load the sample tray as follows:

• According to the sample batch, the sample tray is loaded with the samples from

position 1.

31

Page 32

Installation

• For a two-point calibration, the standards are positioned with the measurement series

on a sample tray for 36 sample containers as follows:

Position 33: 1st low standard, e.g. 0.5 mg/L TN

Position 34: 2nd low standard, e.g. 30 mg/L TN

Position 35: 1st high standard, e.g. 30 mg/L TN

Position 36: 2nd high standard, e.g. 100 mg/L TN

The low standards can be selected freely in the range 0.5–30 mg/L TN

standards can be selected freely in the range 30–150 mg/L TN

GCZ 100

B

GCS 050

B

GCS 050

B

GCS 100

B

; the high

B

.

B

Single and double determinations can be carried out. For double determinations, the

sample is drawn from a container twice. The settings refer to the whole sample tray.

The following table and illustration show an example of a sample tray load for a two-point

calibration:

Table 5 Sample tray load for 36 sample containers, Ganimede N

Position Load

33 1st low standard, e.g. 0.5 mg/L TN

34 2nd low standard, e.g. 30 mg/L TN

35 1st high standard, e.g. 30 mg/L TN

36 2nd high standard, e.g. 100 mg/L TN

1 Sample 1

2 Sample 2

3 Sample 3

4 Sample 4

5 Sample 5

6 etc. Sample 6 etc.

GCZ 100

B

GCS 050

B

GCS 050

B

GCS 100

B

32

Page 33

Figure 15 Example of a sample tray load, Ganimede P

Installation

1 Low-range standard solution 3 Samples

2 High-range standard solution 4 Empty positions

33

Page 34

Installation

34

Page 35

Section 4 Operation

4.1 Operation of the open-loop control unit

The sample batch is defined with the open-loop control unit according to:

• Parameter (phosphate with Ganimede P or nitrogen with Ganimede N)

• Number of samples

• Single or double determination

• Orthophosphate or total phosphate determination with Ganimede P

or low or high measurement range with Ganimede N

• Analysis as PO

• Dilution factor

• User etc.

Defined sample batches can be saved and retrieved again, modified or copied at any time.

Thus, a new definition of repeated sample batches is omitted.

A two-point calibration, or alternatively a multi-point calibration, can be used in

measurement operation.

For a multi-point calibration, a standard curve must be recorded before the measurement

series. At least five standards are prescribed according to DIN. Optionally, an individual

standard curve is also possible with 2–11 measurement points. The device refers to this

recorded curve during measurement operation if desired.

Alternatively, a two-point calibration can be used during a measurement series with

Ganimede P. To do so, a zero solution (GCZ 100) and a standard are positioned in

positions 35 and 36, or alternatively two different standard solutions.

With Ganimede N, a two-point calibration is used by positioning two standard solutions for

the low and high measurement ranges in each position from 33 to 36.

The operation of the open-loop control unit is carried out via an external keypad or via the

alphanumeric keys of the open-loop control unit. The color graphical display shows the

operation of the different menu levels. Error messages, erroneous entries and abnormal

measurements are presented in color.

, PO4-P or P2O5 with Ganimede P

4

The communication of the open-loop control unit and the analysis unit takes place via the

IR interface. In order to enable a connection, the open-loop control unit must be brought

near (approximately 0.5

data that defines the sample batch is sent. The measurement procedure is started

automatically and the connection is disconnected.

The analysis unit saves all raw data during the measurement. This data can be retrieved

by the open-loop control unit at any time during or after the measurement. For this, the

connection via the IR interface is established again, the measurement results are

transmitted and displayed as a table in the open-loop control unit.

If the sample batch is processed completely and all data is sent, the connection is

disconnected automatically. The measurement results can be displayed, edited and sent

to the PC, printer and LIMS by means of the open-loop control unit.

meters) to the analysis unit. A connection is established, then the

35

Page 36

Operation

4.2 Menu structure of the open-loop control unit

4.2.1 Menu structure

Analysis

Samples

Display of a list of all saved sample batches (maximum 30) for the various

Analysis X batch Y

Calibrate Save measured standard curves

Phosphorus Phosphate parameters for Ganimede P

Standard curve 1 Storage location for standard curve 1 with 2 to 11 measurement points

Add Add standard

Remove Remove standard

Graph Show standard series as a graph

Measure Measure standard absorbance

User Input of the username

Standard curve 2

Standard curve 3

Nitrogen Nitrogen parameters for Ganimede N

Standard curve 1 Storage location for standard curve 1 with 2 to 11 measurement points

low

Add Add standard

Remove Remove standard

Graph Show standard series as a graph

Measure Measure standard absorbance

Users Input of the username

high

Add Add standard

Remove Remove standard

Graph Show standard series as a graph

Measure Measure standard absorbance

Users Input of the username

Standard curve 2

Standard curve 3

Rinse A rinse of the system must be run for longer downtime and after every workday.

Stop

parameters (phosphate or nitrogen).

Selection of the desired batch starts the measuring procedure

Storage location for standard curve 2 with 2 to 11 measurement points, all submenus

the same as standard curve 1

Storage location for standard curve 3 with 2 to 11 measurement points, all submenus

the same as standard curve 1

Storage location for standard curve 1 in the low measurement range with 2 to 11

measurement points

Storage location for standard curve 1 in the high measurement range with 2 to 11

measurement points

Storage location for standard curve 2 with 2 to 11 measurement points, all submenus

the same as standard curve 1

Storage location for standard curve 3 with 2 to 11 measurement points, all submenus

the same as standard curve 1

Interrupts the analysis series, e.g. in the event of damage, errors occurring or

incorrect load

36

Page 37

4.2.1 Menu structure

Edit

Program Create and save a new sample batch

Phosphorus Definition of a sample batch for phosphorus

Name Name, maximum 20 characters long, for the sample batch e.g. Well 1-10

Users

Measurements Single or double determination

Calibration

Sample data Opens an input window for the description of individual samples.

Position Automatic numbering (1–36)

Sample Sample name, maximum 13 characters long

Method Total phosphate or orthophosphate

Express as PO

Unit Selection of the unit mg/L, g/L, µg/L, mmol/L, mg/100 g or Ext.

Control standard

Dilution The selection of a dilution factor against which the result is to be offset

Factor Freely definable specific sample factor (0.001 – 9999)

Sampling Date and time of sampling

Note Note regarding the sample, maximum 30 characters long

Nitrogen Definition of a sample batch for nitrogen

Name Name, maximum 20 characters long, for the sample batch e.g. Well 1-10

User

Measurements Single or double determination

Calibration

Sample data Opens an input window for the description of individual samples.

Position Automatic numbering (1–36)

Sample Sample name, maximum 13 characters long

Method Low measurement range (0.5–30 mg/L TN

Express as TN

Unit Selection of the unit mg/L, g/L, µg/L, mmol/L, mg/100 g or Ext.

Control standard

Dilution The selection of a dilution factor against which the result is to be offset

Factor Freely definable specific sample factor (0.001 – 9999)

Sampling Date and time of sampling

Note Note regarding the sample, maximum 30 characters long

Name of the user. The usernames must be defined beforehand under the menu

option EDIT, USER.

Two-point calibration with two selectable standard concentrations or

Multi-point calibration with access to standard curve 1, 2 or 3 (the standard curve

must first be recorded under the menu option ANALYSIS, CALIBRATION)

, PO4-P or P2O

4

A control standard with freely selectable concentration and permissible deviation can

also be measured on the sample tray.

Control standard selection YES or NO.

Name of the user. The usernames must be defined beforehand under the menu

option EDIT, USER.

Two-point calibration with two selectable standard concentrations in the low and high

measurement range respectively or

Multi-point calibration with access to standard curve 1, 2 or 3 (the standard curve

must first be recorded under the menu item ANALYSIS, CALIBRATION)

A control standard with freely selectable concentration and permissible deviation can

also be measured on the sample tray.

Control standard selection YES or NO.

5

) or high (30–150 mg/L TNB)

B

Operation

37

Page 38

Operation

4.2.1 Menu structure

Modify Saved sample batches can be modified.

Modify Selection list of all saved sample batches. Select the desired sample batch.

Name Name, maximum 20 characters long, for the sample batch e.g. Well 1-10

User

Measurements Single or double determination

Calibration

Sample data Opens an input window for the description of individual samples.

Position Automatic numbering (1–36)

Sample Sample name, maximum 13 characters long

Method

Express as

Unit Unit selection mg/L, g/L, µg/L, mmol/L, mg/100 g or Ext.

Control standard

Dilution The selection of a dilution factor against which the result is to be offset

Factor Freely definable specific sample factor (0.001 – 9999)

Sampling Date and time of sampling

Note Note regarding the sample, maximum 30 characters long

Erase The saved sample batch can be erased

Erase Selection list of all saved sample batches. Select the desired sample batch.

Copy The saved sample batch can be saved under a new name.

Copy Selection list of all saved sample batches. Select the desired sample batch.

Users Up to 19 usernames with maximum 10 characters.

New Definition of a new username

Erase Deletion of a username

Dilution

New Definition of a new dilution stage

Erase Deletion of a dilution stage

Name of the user. The usernames must be defined beforehand under the menu

option EDIT, USER.

Two-point calibration with two selectable standard concentrations or

Multi-point calibration with access to standard curve 1, 2 or 3 (the standard curve

must be recorded under the menu option ANALYSIS, CALIBRATION)

Total phosphate or orthophosphate and/or

low measurement range (0.5–30 mg/L TN

, PO4-P or P2O5 or

PO

4

TN

A control standard with freely selectable concentration and permissible deviation can

also be measured on the sample tray.

Control standard selection YES or NO.

Display of nine predefined dilution stages that can be changed individually. A further

11 dilution stages can be saved.

) or high (30–150 mg/L TNB)

B

38

Page 39

4.2.1 Menu structure

Data

After a connection to the analysis unit has been established, a list of current

measurement results is shown.

In addition to the mean value, both single results and single absorbances are

Current

Express as The sample name can be changed.

Unit The unit mg/L, g/L, µg/L, mmol/L, mg/100 g or Ext. can be changed.

Dilution If the dilution factor is changed, the result is calculated again automatically.

Factor If the sample-specific factor is changed, the result is calculated again automatically.

Sampling The date and time of the sampling can be changed

Note The comment on the sample, a maximum of 30 characters long, can be changed

Display Display of all saved measurement results for the individual sample batches.

Data/display Selection list of all saved sample batches. Select the desired sample batch.

Output

PC

Printers

LIMS

displayed for a double determination. Measurement results that are beyond the

selected measurement range are shown in red.

Note: A new measurement can be started only if the results of the previous

measurement are transferred completely to the open-loop control unit and the

indicator display of the analysis unit is no longer flashing.

Output of the saved measurement results of the different sample batches to the PC,

printer or a LIMS system.

Transfer of the measurement results to the PC via the RS 232 interface of the

open-loop control unit.

Transfer of the measurement results to the analysis unit by means of the IR interface

and then on to the printer via the RS 232 interface of the analysis unit.

Transfer of the measurement results to the analysis unit by means of the IR interface

and then on to the LIMS system via the RS 232 interface of the analysis unit.

Operation

39

Page 40

Operation

4.2.1 Menu structure

Options

About Display of the program version, control files and operating hours

Reagent status Display of the reagent quantity and the range

Reagent status

Reagent status 100

Date/time Input of date and time for the open-loop control unit.

Display contrast Set the display contrast.

Lighter

Darker

Interfaces Configuration of the interfaces for PC/scanner and LIMS system

PC/scanner

Scanner

XON / XOFF

9600 Baud rate

None Parity

LIMS

9600 Baud rate

None Parity

Printers Display of the connected printers on the open-loop control unit and analysis unit

Language Selection list of available languages

Display of the number of samples that can be analyzed with the remaining reagent

quantity.

Reset of the sample counter after the analysis unit has been loaded with a new

reagent kit.

4.2.2 Start of a measurement series

1. Load the sample tray according to the sample batch with the samples starting from

position 1.

Note: The data is overwritten if a sample batch is already stored. A copy must be created

beforehand if the data is to be retained.

2. If a multi-point calibration is selected for the calibration of the measurement series,

the device refers to one of the three saved calibration curves.

For Ganimede P, the following applies:

The standards are placed on the sample tray with the measurement series as follows

for a two-point calibration:

• Position 35: zero solution, GCZ 100

• Position 36: standard, e.g. 0.2 mg/L PO

Alternatively:

• Position 35: 1st standard, e.g. 0.2 mg/L PO

• Position 36: 2nd standard, e.g. 2 mg/L PO

For Ganimede N, the following applies:

The standards are placed on the sample tray with the measurement series as follows

for a two-point calibration:

• Position 33: 1st low standard, e.g. 0.5 mg/L TN

• Position 34: 2nd low standard, e.g. 30 mg/L TN

• Position 35: 1st high standard, e.g. 30 mg/L TN

-P GCS 050

4

-P GCS 050

4

-P GCS 100

4

GCZ 100

B

GCS 050

B

GCS 050

B

40

Page 41

• Position 36: 2nd high standard, e.g. 100 mg/L TNB GCS 100

Operation

The low standards can be selected freely in the range 0.5–30 mg/L TN

standards can be selected freely in the range 30–150 mg/L TN

3. Place the sample tray on the sample changer.

4. Switch on the analysis unit and the sample changer.

5. Select the desired sample batch with the cursor keys and the enter key.

A connection to the analysis unit is established automatically via the IR interface

(maximum distance 0.5 meters).

6. Select the desired parameter (phosphorus or nitrogen).

The measuring procedure is started.

Note: The open-loop control unit must not be moved or removed during the transmission

procedure. The whole data transfer is shown on the display.

The open-loop control unit/analysis unit connection is disconnected automatically.

7. Close the window with the upper menu key.

4.2.3 Calibration (recording of multi-point calibrations)

4.2.3.1 Ganimede P

In the storage locations for STD. CURVE 1, 2 and 3, standard curves with 2 to 11

measurement points are measured and stored. The device refers to these stored curves if

the sample batch is to be processed after the multi-point calibration.

; the high

B

.

B

1. Select standard curves 1, 2 or 3.

The selected standard curve is opened; standard curves that have already been

stored can be modified individually.

2. Select the standard concentration to be changed and confirm the input.

3. Enter the standard concentration with the alphanumeric keys or the connected

keypad and confirm the input.

4. Add further standard measurement points or remove points with the shortcut keys.

5. Open the standard series graphically with the GRAPH shortcut key.

The standard curve can be printed out with Enter.

6. Measure the standard absorbances with the MEASURE shortcut key.

7. Load the sample changer with the desired standard solutions in ascending order from

position 1.

The standard solutions GCS 050 and GCS 100 with 0.2 mg/L and 2 mg/L PO

-P and

4

their dilutions are recommended.

8. Make the analysis unit ready for operation.

9. Switch on the analysis unit and the sample changer.

10. Start the measurements of the standard solutions with the MEASURE shortcut key.

A connection to the analysis unit is established automatically via the IR interface.

11. Select the phosphorus parameter.

The measuring process is started.

Note: The open-loop control unit must not be moved or removed during the transmission

procedure. The whole data transfer is shown on the display.

41

Page 42

Operation

4.2.3.2 Ganimede N

12. Confirm the input with the top menu key and close the window.

In the storage locations for STD. CURVE 1, 2 and 3, standard curves, with 2 to 11

measurement points each in the low and high measurement range, are measured and

stored. The device refers to these stored curves if the sample batch is to be processed

after the multi-point calibration.

1. Select standard curves 1, 2 or 3 and the low or high measurement range.

The selected standard curve is opened; standard curves that are already stored can

be modified individually.

2. Select the standard concentration to be changed and confirm the input.

3. Enter the standard concentration with the alphanumeric keys or the connected

keypad and confirm the input.

4. Add further standard measurement points or remove points with the shortcut keys.

5. Open the standard series graphically with the GRAPH shortcut key.

The standard curve can be printed out with Enter.

6. Measure the standard absorbances with the MEASURE shortcut key.

4.2.4 Rinse

7. Load the sample changer with the desired standard solutions in ascending order from

position 1.

The standard solutions GCZ 100, GCS 050 and GCS 100 with 0.5 mg/L, 30 mg/L and

100 mg/L TN

and their dilutions are recommended.

B

8. Make the analysis unit ready for operation.

9. Switch on the analysis unit and the sample changer.

10. Start the measurements of the standard solutions with the MEASURE shortcut key.

A connection to the analysis unit is established automatically via the IR interface.

11. Select the nitrogen parameter.

The measuring process is started.

Note: The open-loop control unit must not be moved or removed during the transmission

procedure. The whole data transfer is shown on the display.

12. Confirm the input with the top menu key and close the window.

Note: If only one measurement range (high or low) is stored under the standard curve 1, 2 or 3, only

samples of the corresponding measurement range can be measured with this standard curve.

Combinations of different standard curves (e.g. standard curve 1 low and st andard curve 2 high) are

not possible.

42

A rinse of the system with cleaning solution (GCR 100 for Ganimede P and GCR 200 for

Ganimede N) is necessary every working day.

1. Remove the reagent bottles and close the bottles tightly with the corresponding

color-marked lids.

2. Store reagents in the refrigerator.

Note: The reagents can be kept for a maximum of seven days after opening.

3. Connect the bottles with cleaning solutions to the corresponding lid under

consideration of the color markings.

Page 43

4.2.5 Stop

Operation

4. Check the capacity of the waste bottle.

5. Start the rinse procedure with the RINSE shortcut key.

6. Switch on the prepared analysis unit.

7. Confirm the safety prompt.

A connection to the analysis unit is established automatically via the IR interface.

8. Select the desired parameter.

The rinse process is started. The rinsing of the analysis unit is finished after two

minutes and the system can be switched off.

In the event of damage, an error or an incorrect load, the analysis series can be

interrupted immediately with the STOP shortcut key. A connection to the analysis unit is

established automatically via the IR interface.

1. Select and confirm the desired parameter.

The measurement series is interrupted.

2. Close the window with the upper menu key.

If the error or damage cannot be fixed without switching off the analysis unit, proceed as

follows:

4.2.6 Data/current

3. Replace the reagent bottles with the cleaning solutions and activate RINSE.

4. Connect the reagent bottles with the analysis unit again for further analyses.

5. Load the sample tray.

6. Define the sample batch.

7. Start with ANALYZE.

After the connection has been established, a list of the latest current measurement results

is shown with the Data/CURRENT menu option. In addition to the mean value, both single

results and single absorbances are displayed for a double determination. Measurement

results that are beyond the selected measurement range are shown in red.

1. Select DATA and CURRENT.

A connection to the analysis unit is established.

2. Select the desired parameter.

The list of current results opens.

3. Select the result to be edited with the cursor keys and confirm with the enter key.

The measurement results can now be edited.

The sample name, the unit, the indication of the result, e.g. as PO

the sample collection time and the note can be changed.

If the dilution factor or the sample-specific factor is changed, the result is calculated

again automatically.

The position, result, method and measurement time components cannot be changed

afterwards.

, PO4-P or P2O5,

4

4. Select CALIBRATION DATA in order to display the calibration that was carried out.

43

Page 44

Operation

The input is carried out via the alphanumeric keys of the open-loop control unit or via a

connected compact keyboard.

Note: A new measurement can be started only if the results of the previous measurement are

transferred completely to the open-loop control unit and the indicator display of the analysis unit is

no longer flashing.

44

Page 45

Section 5 Maintenance

5.1 Sample changer

The sample changer must be disconnected from the mains during cleaning. The PTFE sealing

rings in the housing on the sample arm, on the rinsing vessel and the sealing ring on the tray

holder must not be removed!

Further repairs can only be carried out by the manufacturer's service departments.

The sample changer is a maintenance-free device. For safe and accurate operation, it is

necessary to keep the device clean. A soft cloth that is moistened with water should be

used for (external) cleaning. It must be made sure that no fluid penetrates the device

during cleaning!

In the event of an overflow of the rinsing vessel or spillage of small amounts of liquid over

the sample changer, the sample changer must be switched off (the power plug must then

be disconnected!) and cleaned (in order to dry it). If larger quantities of liquid enter into the

device, it must be made sure that the device is dried completely before switching it back

on.

5.2 Open-loop control unit

DANGER

The open-loop control unit is cleaned with a soft cloth that is moistened with water.

Further repairs can only be carried out by the manufacturer's service departments.

5.3 Analysis unit

Under no circumstances may the digestion cuvette and its supply and drainage lines be opened

or manipulated.

If an over-pressure is intercepted by the dual protection system, the analysis unit must be

switched off and the service department must be informed in order to avert damage to the device.

Burn hazard

Only remove the cover with the power plug pulled out and with a cooling time of a few minutes.

All defects that cannot be repaired by means of a tube change or by means of cleaning the

analysis cuvette, may only be repaired by the service personnel authorized by the

manufacturer.

For the cleaning of the cuvette and for the tube change, it is necessary to remove the

cover in the middle of the device with the lateral knurled screws.

DANGER

DANGER

5.3.1 Mount the cover

1. Hook the cover onto the upper housing edge.

2. Guide the tubes into the recesses on the right and left.

3. Press on the cover.

4. Make sure that no tube is jammed.

5. Fasten the cover with the knurled screws.

45

Page 46

Maintenance

5.3.2 Downtime

In the event of downtime, e.g. overnight or over weekends, a rinse of the system with

cleaning solution (GCR 100) must be carried out.

1. In each case, remove a reagent bottle and seal it with the original lid of the same

color.

The opened reagents are stored in the refrigerator.

Note: The opened reagents can be kept for a maximum of seven days at room temperature.

2. Connect the bottles with cleaning solutions to the corresponding lids.

3. Check the capacity of the waste bottle.

4. Start the rinse process with the open-loop control unit.

The process is finished after four minutes and the system can be switched off.

In the switched-off state, all tubes should be disconnected from the pump-tube clamps to

slacken them, in order to guarantee the intended service life.

1. Press the nose of the clamp downward (1) and to the right (2).

The clamp swivels downward (3) and is held in the holder (4).

The tube is now slackened.

For start-up, the tubes must be tensioned in the tube clamps again.

2. Swivel the clamp upward.

3. Press the nose downward and the clamp to the left.

Figure 16 Slacken a tube in a pump

1 Press the nose downward. 3 Swivel the clamp downward.

2 Press the clamp to the right. 4 The clamp is held in the metal holder.

5.3.3 Tube change

A change of the whole tube set is necessary every three months. The tubes become

porous due to the thermal and mechanical load.

5.3.3.1 Insertion of the tube in a pump

1. Place the tube with the colored tabs in the groove above and below the clamp (1).

46

Page 47

2. Mount the clamp in the metal holder (2) from below. In so doing, tilt the clamp forward

slightly.

3. Swivel the clamp upward (3).

4. Press the nose downward (4) and the clamp to the left (5).

Note: It is recommended to change one tube at a time in order to prevent mix-ups, i.e. each

removed tube is immediately replaced with the corresponding new tube.

Figure 17 Insertion of the tube in a pump

Maintenance

1 Place the tube with the colored tabs in the groove above

and below the clamp.

2 Mount the clamp in the metal holder from below. 5 Press the clamp to the left.

3 Swivel the clamp upward.

4 Press the nose downward.

5.3.4 Clean the analysis cuvette

DANGER