Page 1

DOC023.52.90161

FP 360 sc

User Manual

01/2010, Edition 1B

© HACH-LANGE GmbH, 2010. All rights reserved. Printed in Germany

Page 2

Page 3

Table of Contents

Section 1 Specifications ........................................................................................................................ 5

1.1 Dimensions ........................................................................................................................................ 6

Section 2 General information............................................................................................................... 7

2.1 Safety information............................................................................................................................... 7

2.1.1 Use of hazard information.......................................................................................................... 7

2.1.2 Precautionary labels .................................................................................................................. 7

2.2 Product overview ................................................................................................................................ 8

2.3 Measuring principle............................................................................................................................. 8

2.4 Product components........................................................................................................................... 8

2.4.1 FP 360 sc sensor ...................................................................................................................... 9

2.5 Function test ....................................................................................................................................... 9

Section 3 Installation............................................................................................................................ 11

3.1 Connect sensor cable....................................................................................................................... 11

3.2 Installation options............................................................................................................................ 13

3.2.1 Installation with the chain mount kit ......................................................................................... 13

3.2.2 Installation of chain mount kit for sensors with cleaning unit ................................................... 13

3.2.2.1 Install the cleaning unit hose........................................................................................... 13

3.2.3 Installation with flow cell........................................................................................................... 15

Section 4 Operation.............................................................................................................................. 17

4.1 User interface and navigation ........................................................................................................... 17

4.2 Sensor setup..................................................................................................................................... 17

4.3 Sensor data logger ........................................................................................................................... 17

4.4 Menu structure.................................................................................................................................. 18

4.4.1 SENSOR STATUS................................................................................................................... 18

4.4.2 SENSOR SETUP..................................................................................................................... 18

4.5 Calibration......................................................................................................................................... 20

4.5.1 Factory calibration.................................................................................................................... 20

4.5.2 Process calibration/adjustment................................................................................................ 20

4.5.2.1 Determination of factors and adjustment of slope........................................................... 20

4.5.2.2 Multi-point calibration ...................................................................................................... 21

4.5.3 Check the zero point................................................................................................................ 21

4.5.4 Adjustment of slope and zero point; multi-point calibration......................................................21

4.5.4.1 Adjust the slope (FACTOR) ............................................................................................ 21

4.5.4.2 Adjust the zero point (OFFSET)...................................................................................... 22

4.5.4.3 Multi-point calibration (2 to 5-point calibration) ............................................................... 22

Section 5 Maintenance ......................................................................................................................... 23

5.1 Maintenance schedule...................................................................................................................... 23

5.2 Maintenance for the connectors on the sensor................................................................................. 23

5.3 Cleaning the measurement windows................................................................................................ 24

3

Page 4

Table of Contents

Section 6 Troubleshooting ...................................................................................................................25

6.1 Error messages.................................................................................................................................25

6.2 Warnings ...........................................................................................................................................25

6.3 Replacement parts ............................................................................................................................25

Section 7 Replacement parts and accessories ..............................................................................27

7.1 Sensor options ..................................................................................................................................27

7.2 Replacement parts ............................................................................................................................27

7.3 Accessories.......................................................................................................................................27

Section 8 Contact information ............................................................................................................29

Section 9 Warranty and Liability..........................................................................................................31

Appendix A Modbus register ..............................................................................................................33

Index.......................................................................................................................................................35

4

Page 5

Section 1 Specifications

Specifications are subject to change without notice.

Measurement

UV fluorescent measurement process for polycyclic aromatic

Measurement method

Low measurement range

Measuring range

High measurement range

Display units ppb, ppm, μg/L, mg/L

Reproducibility 2.5% of measurement value at a constant temperature

Measurement accuracy

Limit of detection 1.2 ppb (PAH)

Hydrocarbons (PAH)

Excitation wavelength: 254 nm

Emission (measurement) wavelength: 360 nm

0 to 50 ppb and 0 to 500 ppb in relation to PAH calibration standard,

corresponding to 0.1 to 1.5 ppm and 0.1 to 15 ppm of oil calibration

standard

0 to 500 ppb and 0 to 5000 ppb in relation to PAH calibration standard,

corresponding to 0.1 to 15 ppm and 0.1 to 150 ppm of oil calibration

standard

5% of measurement value ±2% from measurement range limit

at a constant temperature

Response time 10 s (T90)

Calibration

Sensor software

Software version From 1.14

Equipment properties

Measurement sensor Stainless steel version 2.8 kg, titanium version 1.8 kg

Weight

Flow cell Approximately 0.6 kg, including installation board approximately 2.0 kg

Sensor Max. 30 bar

Pressure range

Flow cell Max. 1 bar

Measurement sensor

(Ø × length)

Dimensions

Flow cell (L × W × D)

Measurement sensor

Materials

Flow cell

Shackle Stainless steel 1.4301

Factory calibration with UV fluorescence calibration standard, custom

adaptation possible

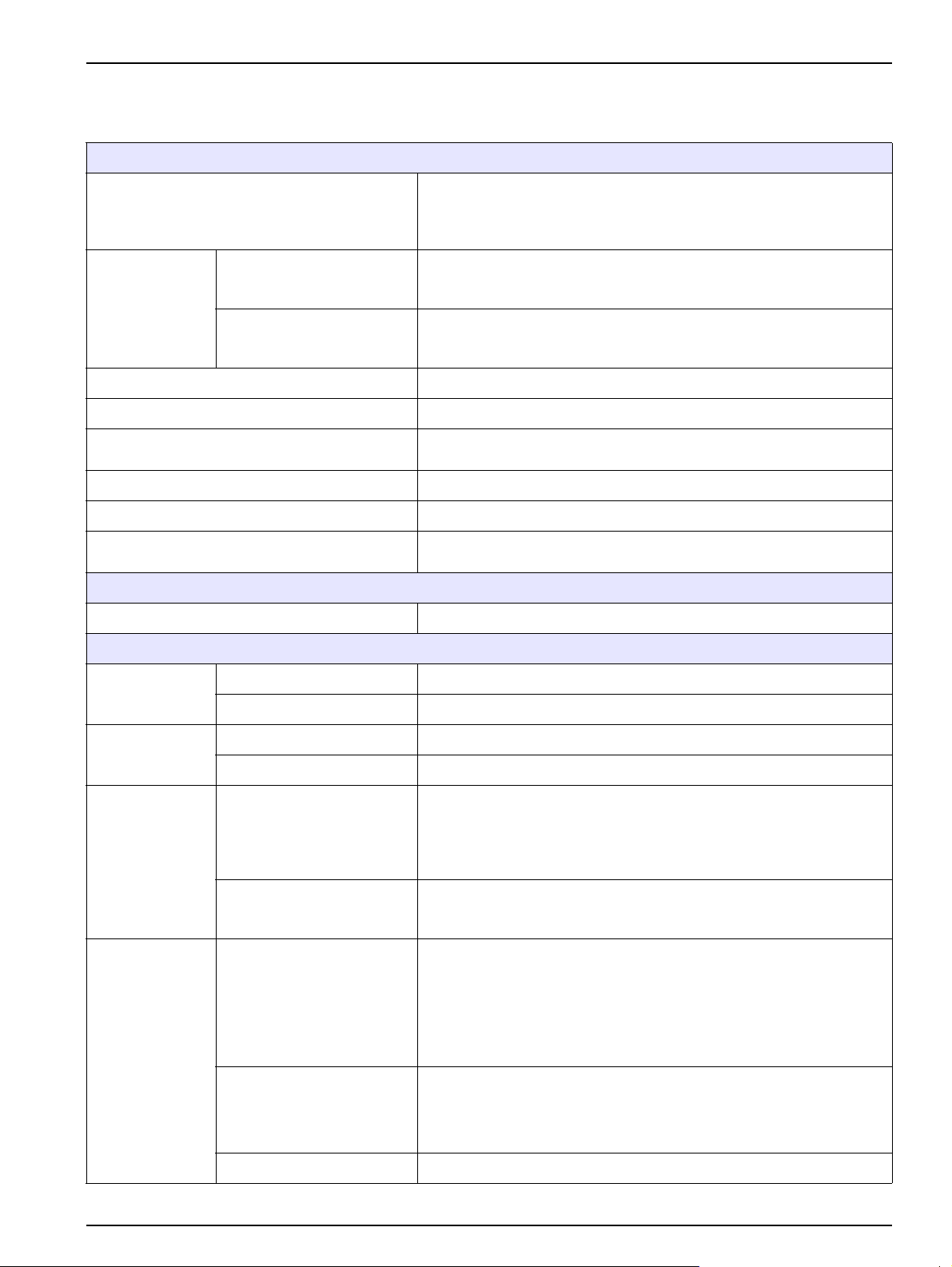

68 mm x 306 mm (2.68 in. x 12.05 in.)

(without plugs or suspension pin)

68 mm x 399 mm (2.68 in. x 15.71 in.) (including suspension pin)

68 mm x 413 mm (2.68 in. x 16.26 in.)

(with additional cleaning option)

98 mm x 98 mm x 150 mm (3.86 in. x 3.86 in. x 5.91 in.) (without

fittings),

installation board: 600 x 300 x 10 mm (23.62 in. x 11.81 in. x 0.39 in.)

Housing: stainless steel 1.4571 or titanium

Optic bracket: POM

Housing bolts: stainless steel 1.4571

Measurement window: synthetic quartz glass (Suprasil)

Gaskets (housing): Viton

Gaskets (measurement window): NBR (Nitrile Butadiene Rubber)

Housing: POM

Installation board: PVC

Gaskets: NBR (Nitrile Butadiene Rubber)

Fittings: nickel-plated brass

5

Page 6

Specifications

Environment considerations

Sample temperature 1 to 40 °C (34 to 104 °F)

–5 to +45 °C (23 to 113 °F)

Ambient temperature

Sensor distance - wall/ground min. 100 mm (3.94 in.) (recommended)

Miscellaneous

Cable length 1.5 or 10 m, extension cable up to total maximum length of 40 m

Measurement sensor wetted by at least half from the measuring

medium:

–25 to +55 °C (-13 to 131 °F)

Connection

information

Inspection interval

Maintenance requirements

Compliance CE

Warranty 2 years

Sensor side 8-pin, type of protection IP68, PUR

Controller side M12, type of protection IP67

Every 2 years; 1/year service agreement by request, with warranty

extension up to 5 years

Clean the measurement window, if necessary. Intervals are dependent

on the measuring medium.

1.1 Dimensions

Figure 1 Sensor without and with cleaning unit

1 Sensor without cleaning unit 2 Sensor with cleaning unit

6

Page 7

Section 2 General information

2.1 Safety information

Please read this entire manual before unpacking, setting up or operating this equipment.

Pay attention to all danger and caution statements. Failure to do so could result in serious

injury to the operator or damage to the equipment.

Make sure that the protection provided by this equipment is not impaired, do not use or

install this equipment in any manner other than that specified in this manual.

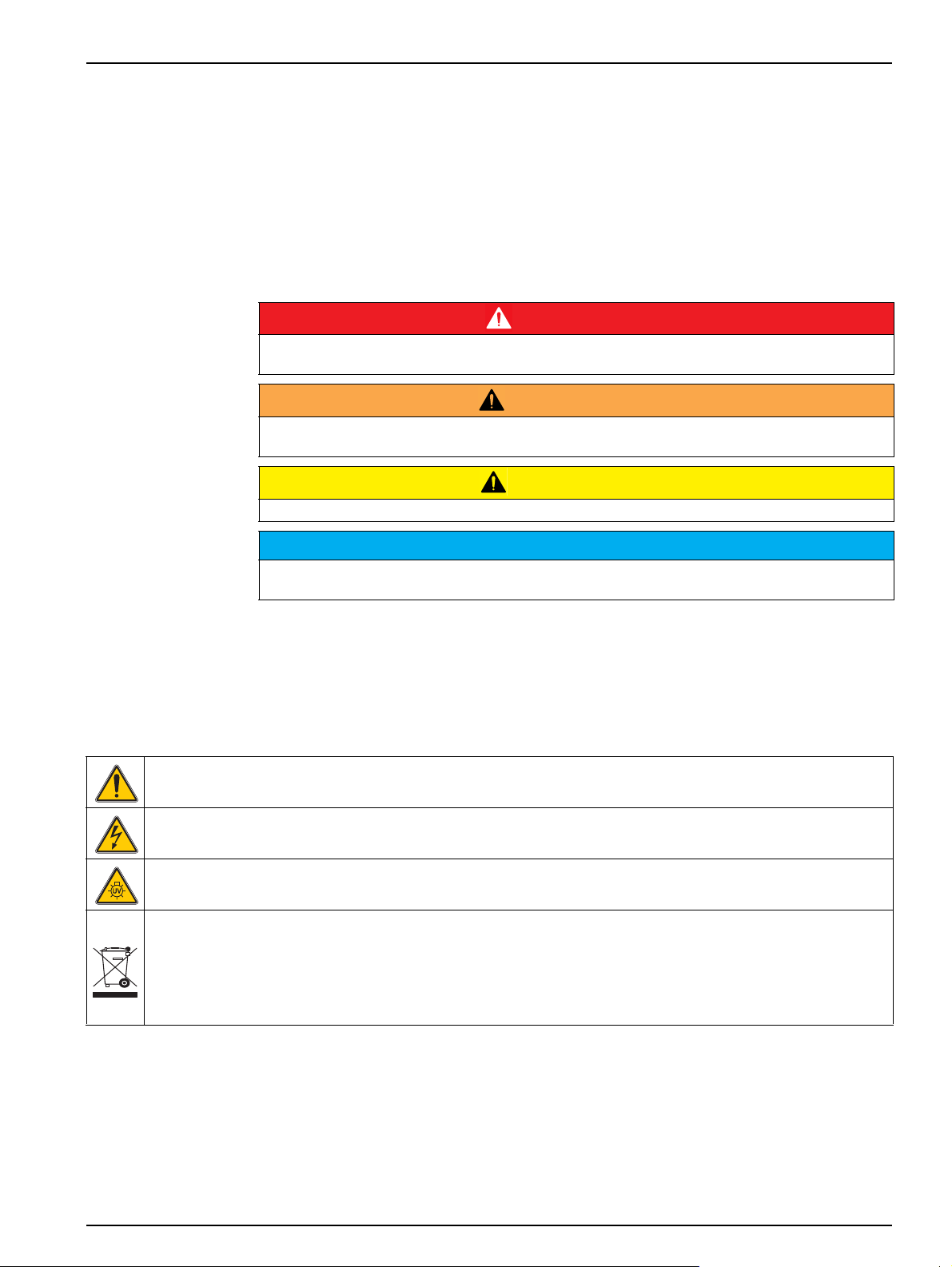

2.1.1 Use of hazard information

DANGER

Indicates a potentially or imminently hazardous situation which, if not avoided, will result in death

or serious injury.

WARNING

Indicates a potentially or imminently hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION

Indicates a potentially hazardous situation that may result in minor or moderate injury.

Indicates a situation which, if not avoided, may cause damage to the instrument. Information that

requires special emphasis.

Note: Information that supplements points in the main text.

2.1.2 Precautionary labels

Read all labels and tags attached to the instrument. Personal injury or damage to the

instrument could occur if not observed. A symbol on the instrument is referenced in the

manual with a precautionary statement.

This is the safety alert symbol. Obey all safety messages that follow this symbol to avoid potential injury. If on the

instrument, refer to the instruction manual for operation or safety information.

This symbol indicates that a risk of electrical shock and/or electrocution exists.

This symbol shows that a UV lamp is used in the equipment.

Electrical equipment marked with this symbol may not be disposed of in European domestic or public disposal

systems after 12 August 2005. In conformity with European local and national regulations (EU Directive

2002/96/EC), European electrical equipment users must now return old or end-of life equipment to the manufacturer

for disposal at no charge to the user.

Note: For return for recycling, please contact the equipment producer or supplier for instructions on how to return

end-oflife equipment, producer-supplied electrical accessories, and all auxiliary items for proper disposal.

NOTICE

7

Page 8

General information

2.2 Product overview

DANGER

This product is not suitable for use in potentially explosive atmospheres.

WARNING

The UV rays from the flash bulb are harmful to eyes and skin. Do not look directly through the

measurement window during operation under any circumstances. Remove the measurement

sensor from operation before carrying out any maintenance or installation work.

The FP 360 sc sensor is a UV fluorimeter used to continuously measure the concentration

of PAH (polycyclic aromatic hydrocarbons) in water. The measurement values can be

converted to reflect the total oil content for mineral oils using lab data.

The sensor may need to be installed with additional accessories depending on its area of

application.

Area of application Installation with Sensor variants

Open channels, shafts, tanks (solid

matter max. 200 mg/L)

Measurement media without solid

matter with continuous, low sample

throughput

Do not apply the sensor to any hard mechanical effects.

2.3 Measuring principle

The measuring principle is based on the fluorescent properties of PAHs. After excitation

caused by UV rays, PAHs emit light with longer wavelengths after a short time delay. The

intensity of this light is measured. This measuring principle is considerably more sensitive

than absorption and scattered light measurement. It is possible to detect even the slightest

trace of PAH contamination in water. PAHs are integral parts of most mineral oil products

and are a very specific indicator of oil contamination in water bodies and process water.

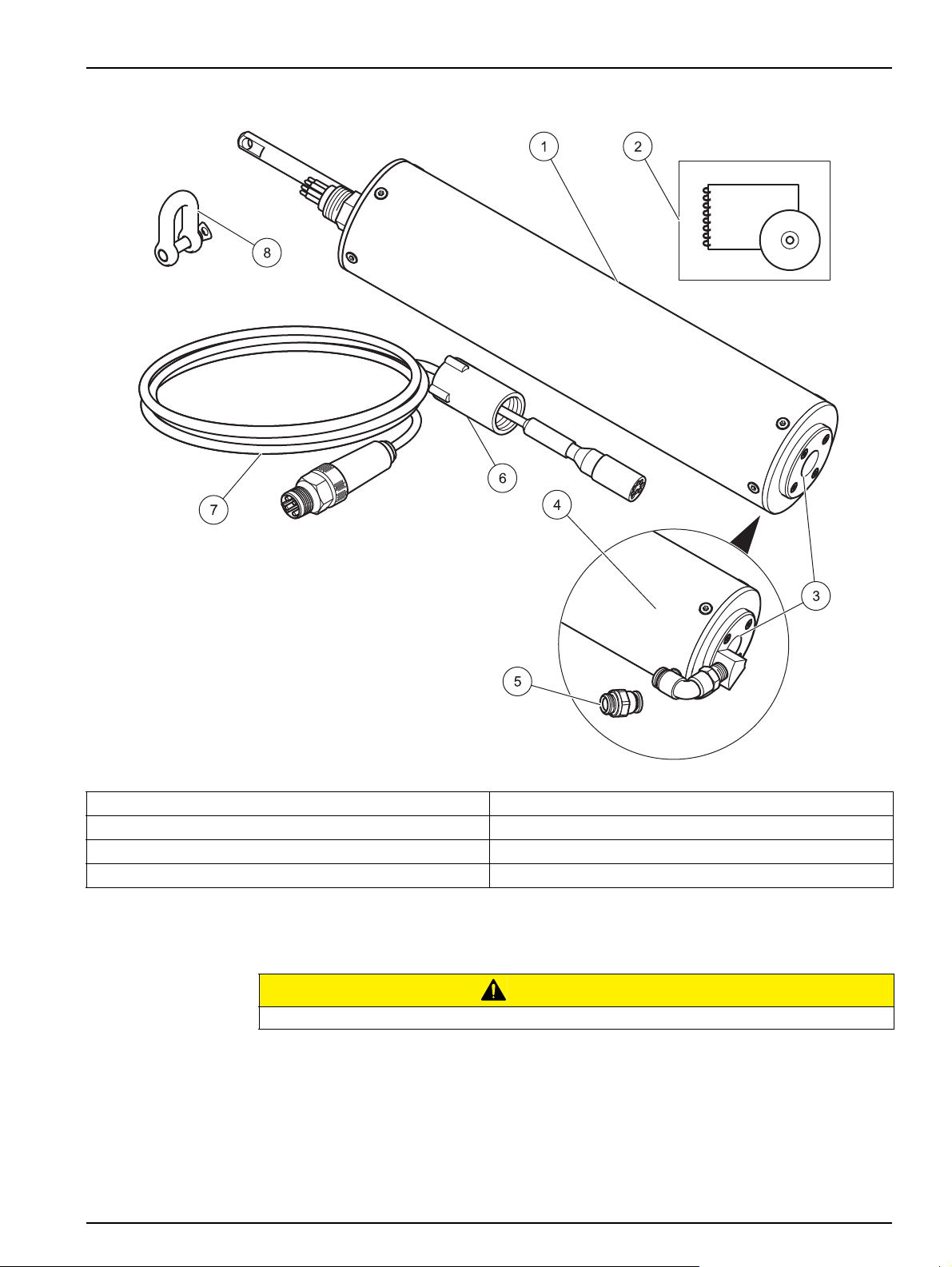

2.4 Product components

Each sensor is supplied with

• a connector cable with safety sleeve,

• a shackle,

• a basic user manual and

Chain mount kit Sensor with or without cleaning unit

Flow cell Sensor without cleaning unit

• a CD.

The sensor is available in a variety of types (refer to section 7.1 on page 27). Refer to

Figure 2 to make sure that all components have been received. If any of these items are

missing or damaged, contact the manufacturer or a sales representative immediately.

8

Page 9

General information

2.4.1 FP 360 sc sensor

Figure 2 FP 360 sc sensor

1 FP 360 sc measurement sensor 5 6 mm fitting for cleaning unit (depending on model)

sic user manual with CD 6 Safety sleeve

2 Ba

3 Me

4 Se

asurement window 7 Connector cable

nsor with cleaning unit (depending on model) 8 Shackle

2.5 Function test

CAUTION

Before power is applied, refer to the controller operation instructions.

After the components are removed from the package, do a function test.

1. Con

2. Ap

nect the connector cable to the sensor (8-pin polarized connector) and an

appropriate sc controller (5-pin polarized connector) (refer to section 3.1 on page 11).

ply power to the sc controller. The display is activated and the sensor goes to

measurement mode.

The sensor ticks quietly and regularly.

9

Page 10

General information

3. Cover the sensor measurement window with a sheet of white paper (do not use

recycled paper).

4. Vary the distance between the measurement window and the paper.

The measurement value on the display will change accordingly.

Note: In air, the measurement value displayed is not exactly zero due to reflections on the window

surface (refer to section 4.5.3 on page 21).

10

Page 11

Section 3Installation

Personal injury hazard. Only qualified personnel should conduct the tasks described in this section

of the manual.

If the sensor is not fully inserted, sun protection is recommended in high ambient temperatures

and intense solar radiation to protect against thermal and UV effects.

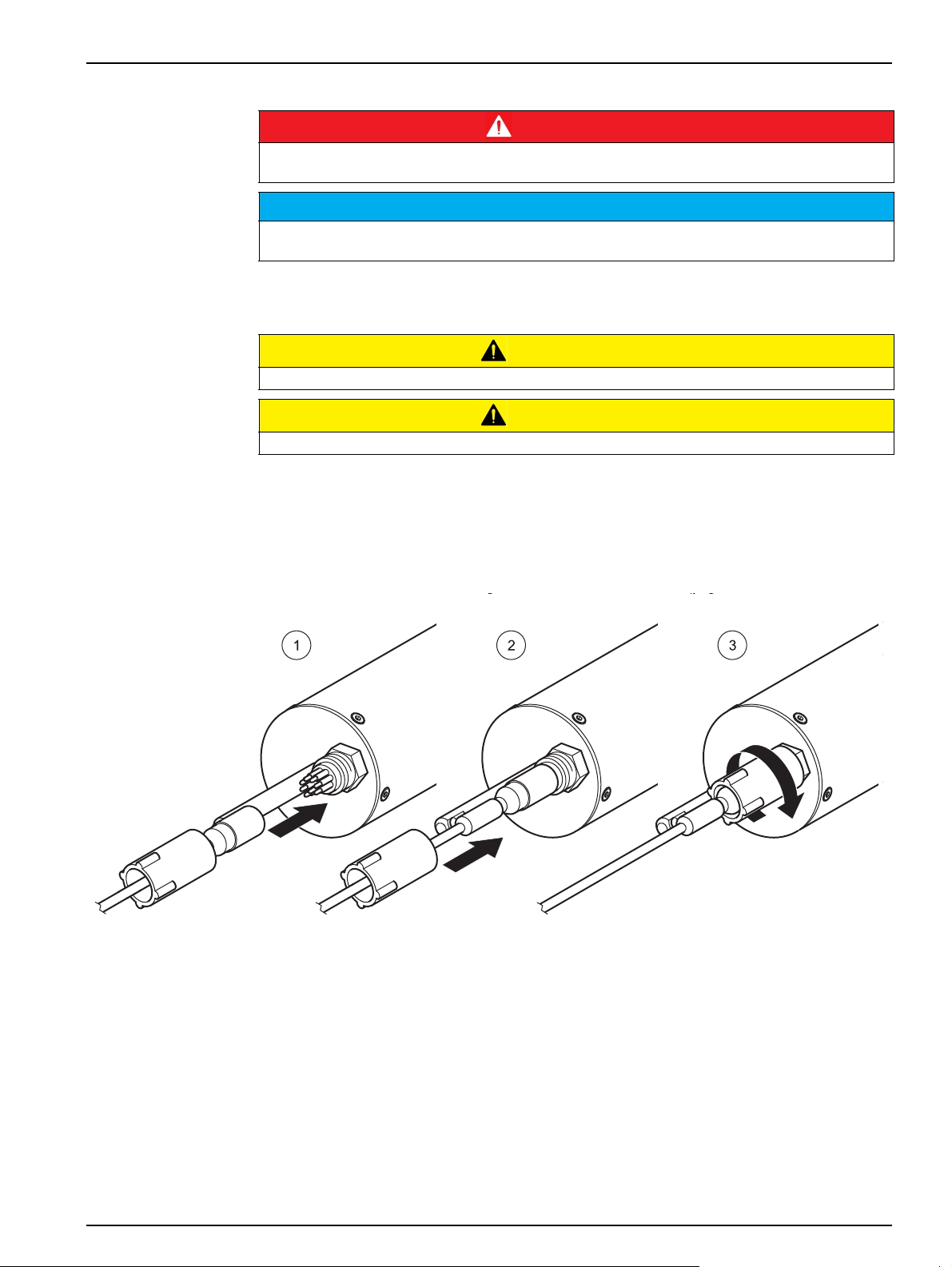

3.1 Connect sensor cable

Always put the cables and hoses in a position that does not bend or cause a trip hazard.

Before power is applied, refer to the controller operation instructions.

1. Connect the polarized socket on the connector cable to the sensor plug (8-pin plug)

(refer to Figure 3 step 1).

DANGER

NOTICE

CAUTION

CAUTION

2. Push the

3. Hand-t

ighten the safety sleeve in position (step 3).

Figure 3 Connect the sensor cable to the sensor

safety sleeve on the plug (step 2).

4. Remo

5. Con

Note: Connector cables are available in various lengths (refer to section 7.2 on page 27). Maximum

overall cable length is 40 m (131,23 ft).

ve the protective cap on the controller socket and keep it to seal the connector

opening in case the sensor must be removed.

nect the sensor to the controller using the keyed quick-connect fitting.

Hand-tighten (refer to Figure 4).

11

Page 12

Installation

6

1 2

5

3

4

Figure 4 Connect the sensor to the controller

Figure 5 Pin configuration

Number Description Standard cable, cable color

1 +12 VDC brown

2 Ground black

3 Data (+) blue

4 Data (–) white

5 Screen Screen (gray)

6 Guide

12

Page 13

3.2 Installation options

The sensor may need to be installed with additional optional accessories depending on

the area of application (refer to section 7.3 on page 27).

Note: Refer to the documentation supplied with the accessories for detailed installation instructions.

3.2.1 Installation with the chain mount kit

The FP 360 sc sensor is installed with the chain mount kit in open channels, shafts and

tanks.

Installation

Figure 6 FP 360 sc measurement sensor with chain mount kit

3.2.2 Installation of chain mount kit for sensors with cleaning unit

3.2.2.1 Install the cleaning unit hose

Note: An air hose is required, to operate the sensor with the optional cleaning unit. An oil-free

compressed air (6 bar) and a solenoid valve or the HOAB compressed air cleaning system is also

required (refer to section

With the HOAB compressed air cleaning system, replace the end of the hose connection

that is connected to the compressed air on the underside of the instrument with the

straight 6 mm fitting (refer to Figure 2 on page 9, item 5) supplied with the probe.

7.3 on page 27).

13

Page 14

Installation

Figure 7 Install the cleaning unit hose

14

Figure 8 FP 360 sc measurement sensor with cleaning unit and chain mount kit

Page 15

3.2.3 Installation with flow cell

The FP 360 sc sensor with flow cell is installed for samples free of solids and particulates

and limited sample flows.

Installation

Figure 9 Installation with flow cell

15

Page 16

Installation

16

Page 17

Section 4 Operation

4.1 User interface and navigation

The sensor can be used with sc controllers from sc100. Refer to the controller

documentation for keypad description and navigation information.

4.2 Sensor setup

When the sensor is connected for the first time, the sensor serial number is displayed as

the name of the sensor. To change the sensor name:

1. Open the MAIN MENU.

2. Select SENSOR SETUP and confirm.

3. Select the corresponding sensor and confirm.

4. Select CONFIGURE and confirm.

5. Select EDIT NAME and confirm.

6. Edit the name and confirm to return to the SENSOR SETUP menu.

Complete sensor configuration in the same manner, with the following menu options

selected:

• SET PARAMETER

• SELECT UNITS

• AVERAGE

• LOG SETUP

• GAIN VALUE

4.3 Sensor data logger

There is a data log and event log available for each sensor.

In the data log, the measurement data are stored at preset intervals; the event log stores

events such as configuration changes, alarm messages and warning messages. Both logs

can be exported to CSV format (refer to the controller manual).

17

Page 18

Operation

4.4 Menu structure

4.4.1 SENSOR STATUS

SELECT SENSOR (if there is more than one sensor)

ERROR LIST Possible error messages: SENSOR ERROR

WARNING LIST

4.4.2 SENSOR SETUP

SELECT SENSOR (if there is more than one sensor)

CALIBRATE

SET OUTMODE Behavior of the outputs during calibration and zero point adjustment

HOLD

ACTIVE

SET TRANSFER

SENSOR MEASURE Current, uncorrected measurement value

CONFIGURE

FACTOR

OFFSET

2 POINT

3 POINT

4 POINT

5 POINT

FACTOR

OFFSET

2 POINT

3 POINT

4 POINT

5 POINT

SET CAL DEFLT Security query, reset to (FACTOR=1, OFFSET=0)

Possible warning messages: TEST/MAINT, BULB CHANGE, LAST CONFIGUR, TARGET

VALUE

Note: Refer to Section 6 on page 25 for a list of all possible error and warning messages

together with a description of all necessary countermeasures to be taken.

FACTOR: 0.1 to 100

OFFSET: –1000 to +1000

Is shown when FACTOR has been selected under CONFIGURE.

Refer to section 4.5 on page 20 for detailed information.

Is shown when OFFSET has been selected under CONFIGURE.

Refer to section 4.5 on page 20 for detailed information.

Is shown when 2 POINT has been selected under CONFIGURE.

Refer to section 4.5 on page 20 for detailed information.

Is shown when 3 POINT has been selected under CONFIGURE.

Refer to section 4.5 on page 20 for detailed information.

Is shown when 4 POINT has been selected under CONFIGURE.

Refer to section 4.5 on page 20 for detailed information.

Is shown when 5 POINT has been selected under CONFIGURE.

Refer to section 4.5 on page 20 for detailed information.

18

Page 19

4.4.2 SENSOR SETUP (Continued)

SELECT SENSOR (if there is more than one sensor)

CONFIGURE

EDIT NAME

SET PARAMETER

SELECT UNITS

AVERAGE

LOG SETUP

GAIN VALUE

SET DEFAULTS

DIAG/TEST

PROBE INFO

SENSOR NAME Device name

EDIT NAME

SERIAL NUMBER Device serial number

RANGE 0 to 500 or 0 to 5000

MODEL NUMBER Item no. Sensor

CODE VERSION Sensor software

COUNTER

OPERATING HOURS Operating hours counter

MAINTENANCE Counter counting down days

BULB CHANGE Counter counting down days

TEST/MAINT

SET OUTMODE Equipment output behavior in the SERVICE menu

HOLD

ACTIVE

SET TRANSFER

SIGNALS

LAMP CURR Flash lamp intensity

DIAG/TEST Zero point and slope check with external standards

REDADING OFFSET

CUBE CAL

Name can include up to 16 characters,

DEFAULT CONFIG: sensor serial number

PAH: Measurement value related to PAH calibration standard

OIL: Measurement value related to oil calibration standard

DEFAULT CONFIG: PAH

ppb, ppm, μg/L, mg/L,

DEFAULT CONFIG: ppb

1 to 300 s,

DEFAULT CONFIG: 3 s

5 s, 30 s, 1 min, 2 min, 3 min, 4 min, 5 min, 6 min, 10 min, 15 min, 30 min,

DEFAULT CONFIG: 10 min

Range 0 to 500 ppb: AUTO, 0.01 to 50, 0.01 to 500,

Range 0 to 5000 ppb: AUTO, 0.01 to 500, 0.01 to 5000

DEFAULT CONFIG: AUTO

Security query,

reset to preset configuration for all menu options listed above.

Password-protected access for the service

Operation

19

Page 20

Operation

4.5 Calibration

4.5.1 Factory calibration

The calibration curve zero point and slope are preset. Retrospective calibration of these

basic settings is generally not required outside of the inspection intervals.

Do regular zero point checks to make sure that impurities or faults are being detected

(refer to section 4.5.3 on page 21).

If the zero signal increases due to the measuring medium components or the installation

conditions, you can compensate for this influence via an offset correction. Carry out a lab

analysis of the sample to do this. If there is no PAH/oil contamination in the measuring

medium, enter the measurement value shown by the device as the offset (refer to section

4.5.4.2 on page 22).

4.5.2 Process calibration/adjustment

The sensor is pre-calibrated with various concentrations of a special calibration standard

in ultra-pure water. These ideal measurement conditions rarely occur in reality. The

measurement values shown are qualitative trend indicators if no adjustment is made to the

on-site measurement conditions.

If you require quantitatively correct measurement values, either a slope adjustment or a

multi-point calibration needs to be carried out. Both of these operations must be carried

out on site using lab analysis data. Basic prerequisites for quantitative measurements are

precise knowledge about the oil type in occurrence and constant measurement conditions,

e.g. in cool water in a heat exchanger. If several oils are present in varying quantities, it is

generally not possible to carry out a quantitative measurement.

If the measurement conditions change, you must check the accuracy of the results again

through lab analyses and make any adjustments where necessary.

The measurement conditions can change in terms of

• Composition of PAH or oil impurities

• Distribution of impurities in water

• Tem p

• Measuring medium composition

• Measurement sensor and measurement window

4.5.2.1 Determination of factors and adjustment of slope

To adjust the slope:

1. At the sensor installation site, draw a lab sample of the measuring medium and

promptly analyze the sample for PAH and oil content.

2. Make a note of the measurement value shown on the controller at the time of the

sample being taken. Make sure the correct unit is shown for the measurement value,

e.g. as ppm oil.

3. Repeat steps 1 and 2 several times.

4. Use the sample value and the value shown on the controller at the time of sampling

to calculate a factor.

20

5. Find an average value from the factors.

Page 21

6. Enter the factor as the slope (refer to section 4.5.4.1 on page 21).

Example for engine oil Example for naphthalene

Lab value: 4.0 ppm oil

Measurement value shown

Calculated factor: 1.67

1

At the time of sampling

1

: 2.4 ppm oil

Lab value: 420 ppb PAH

Measurement value shown1: 120 ppb PAH

Calculated factor: 3.5

It is advisable to adjust the slope if the following conditions apply:

Operation

• If th

• Th

e measuring sample is PAH-/oil free, the measurement value must almost be zero.

e factors calculated from the lab values must enable a sensible average value to be

derived.

If these conditions do not apply, do a multi-point calibration.

Note: If both the zero point and the slope must be changed, use a 2-point calibration (refer to

section 4.5.4.3 on page 22).

4.5.2.2 Multi-point calibration

In the event of a multi-point calibration, enter the lab value as the target value and the

value shown as the actual value. Make sure that all values are entered in the same unit,

e.g. oil in ppm. (refer to section 4.5.4.3 on page 22).

4.5.3 Check the zero point

• Medium: ultra-pure water

• T

arget value: < 1 ppb. Clean the window in the event of deviations.

Use a glass container (not plastic) large enough to enable the measurement to be taken

with an 8 to 10

1000 mL glass beaker). Place a black, non-reflective underlay under the container and

switch off artificial lights during the measurement process.

Note: In air, the measurement value displayed is not exactly zero due to reflections on the window

surface. This is standard sensor behavior and not an indicator of malfunction.

cm distance between the measurement window and the base (e.g. a

Note: Always use

can contain organic compounds.

ultra-pure water. Distilled water and demineralized water are not suitable as these

4.5.4 Adjustment of slope and zero point; multi-point calibration

4.5.4.1 Adjust the slope (FACTOR)

1. Open the MAIN MENU.

2. Select SENSOR SETUP an

3. Sele

4. Select CALIB

5. Select CONFIGURE

6. Sele

7. Enter

8. Go

ct the corresponding sensor and confirm.

RATE and confirm.

and confirm.

ct FACTOR and confirm.

the calculated factor and confirm.

back to the MAIN MENU or the Measurement mode display.

d confirm.

21

Page 22

Operation

4.5.4.2 Adjust the zero point (OFFSET)

1. Open the MAIN MENU.

2. Select SENSOR SETUP and confirm.

3. Select the corresponding sensor and confirm.

4. Select CALIBRATE and confirm.

5. Select CONFIGURE and confirm.

6. Press OFFSET and confirm.

7. Enter the required offset and confirm.

8. Go back to the MAIN MENU or the Measurement mode display.

4.5.4.3 Multi-point calibration (2 to 5-point calibration)

Note: Multi-point calibration means that the pairs must be input in ascending order.

1. Open the MAIN MENU.

2. Select SENSOR SETUP and confirm.

3. Select the corresponding sensor and confirm.

4. Select CALIBRATE and confirm.

5. Select CONFIGURE and confirm.

6. Select the type of calibration, e.g. 2 POINT and confirm.

7. Select 1PAIR and confirm.

8. Edit the TARGET VALUE and confirm.

9. Edit the ACTUAL VALUE and confirm.

10. Repeat the process for 2PAIR and confirm.

11. Go back to the MAIN MENU or the Measurement mode display.

22

Page 23

Section 5 Maintenance

The inside of the sensor is maintenance-free.

The cleanliness of the measurement window in the sensor head has an impact on the

accuracy of measurements. Check the measurement window at regular intervals to make

sure it is clean. The required frequency of these checks is dependent on the measuring

medium. Also do a check in the event of unusually high measurement values and clean

the measurement window if necessary (refer to section 5.3 on page 24).

For sensors with a cleaning unit, adjust the frequency of cleaning to the measurement

conditions. The inspection interval must be shortened to reflect any increase in solid

matter.

Individual components of the suspension device (shackle and chain of the chain mount kit) are

made of stainless steel and may corrode.

5.1 Maintenance schedule

NOTICE

Interval Maintenance task

Visual inspection

System inspection Every 2 years Check plugs and flash bulb.

Calibration check Every 2 years Check calibration

1

When operated according to factory settings and appropriate use

Contact the manufacturer's service department every 2 years to arrange sensor

inspection, testing, calibration and seal replacement. The flash bulb is also replaced every

4 years.

Application-dependent Check for contamination and corrosion.

5.2 Maintenance for the connectors on the sensor

The 8-pin connector on the sensor is designed for constant usage under water. The

connector is lubricated with high-performance grease at the factory and does not require

any additional maintenance from the recommended sensor inspection cycles.

To maintain the performance of the connectors:

• Protect the neoprene components of the connector against high temperatures and

intense solar radiation. If this cannot be avoided, moisten the dried out neoprene

components with clean, clear water. Subsequently, loosen the connector.

• The pins must always be lightly lubricated. Only apply a very thin film of lubricant.

Recommended lubricants are Loctite

The lubricant must not come into contact with the measurement window.

8021 as a spray or Molykote 44 Medium.

1

• Rinse out grains of sand and solid matter from the cable socket.

• To loosen the connector, unscrew the safety sleeve and pull out the plug longitudinally.

• Avoid flexing the plug and pulling on the cable.

• Do not loosen the connector at ambient temperatures below 0 °C. Heat the neoprene

components carefully to temperatures above 0 °C and then loosen the connector.

• Avoid kinks or tight bend in the cables.

23

Page 24

Maintenance

5.3 Cleaning the measurement windows

Cleaning agents can be hazardous to health.

Wear protective equipment and avoid direct contact with cleaning fluids.

Other cleaning agents can damage the material. Damage caused by cleaning carried out

incorrectly is not covered by the warranty.

1. Rinse the sensor with fresh water until all attached solid matter has been removed.

2. Use pure acetone and a soft, clean cloth (e.g. camera lens cleaning paper) to

carefully remove the deposits on the measurement window. Avoid sharp objects on

the measurement window surface.

3. Rinse the residue from the cleaning agent with fresh water.

CAUTION

NOTICE

24

Page 25

Section 6 Troubleshooting

6.1 Error messages

Possible sensor errors displayed by the sc controller.

Displayed errors Definition Resolution

SENSOR ERROR Electronic defect Call manufacturer customer service

6.2 Warnings

Possible sensor warning messages displayed by the sc controller.

Displayed warnings Definition Resolution

DIAG/TEST Counter expired Call manufacturer customer service

BULB CHANGE Counter expired Call manufacturer customer service

LAST CONFIGUR

TAR GET VAL UE

Changed configuration was

not accepted

With multi-point calibration,

values not entered in

ascending order

Send configuration again

Enter calibration values in ascending order

6.3 Replacement parts

Designation Quantity Service life

Flash bulb 1 4 years

O-Rings 4 2 years

25

Page 26

Troubleshooting

26

Page 27

Section 7 Replacement parts and accessories

7.1 Sensor options

Description Cat. no.

Range 0 to 50/500 ppb, stainless steel housing, cable length 10 m without cleaning unit LXV441.99.11101

Range 0 to 50/500 ppb, stainless steel housing, cable length 10 m with cleaning unit and fittings

ot in connection with flow cell)

(n

Range 0 to 50/500 ppb, stainless steel housing, cable length 1.5 m without cleaning unit LXV441.99.11301

Range 0 to 50/500 ppb, titanium housing, cable length 10

Range 0 to 50/500 ppb, titanium housing, cable length 10 m with cleaning unit and fittings (not

in connection with flow cell)

Range 0 to 50/500 ppb, titanium housing, cable length 1.5 m without cleaning unit LXV441.99.12301

Range 0 to 500/5000 ppb, stainless steel housing, cable length 10 m without cleaning unit LXV441.99.21101

Range 0 to 500/5000 ppb, stainless steel housing, cable length 10 m with cleaning unit and

fittings (not in conn

Range 0 to 500/5000 ppb, stainless steel housing, cable length 1.5 m without cleaning unit LXV441.99.21301

Range 0 to 500/5000 ppb, titanium housing, cable length 10 m without cleaning unit

Range 0 to 500/5000 ppb, titanium housing, cable length 10 m with cleaning unit and fittings

(not in connection with flow cell)

Range 0 to 500/5000 ppb, titanium housing, cable length 1.5 m without cleaning unit LXV441.99.22301

ection with flow cell)

m without cleaning unit LXV441.99.12101

LXV441.99.11201

LXV441.99.12201

LXV441.99.21201

LXV441.99.22101

LXV441.99.22201

7.2 Replacement parts

Description Cat. no.

Connector cable 1.5 m LZY623

Connector cable 10 m

Shackle, stainless steel 1.4301 LZY668

Gasket and screw set for flow cell

Fitting set for flow cell LZY626

Pressure ring and angle bracket for flow cell

Chain mount kit instructions DOC273.99.90164

Flow cell instructions DOC273.99.90165

LZY624

LZY625

LZY674

7.3 Accessories

Description Cat. no.

Extension cable (5 m/16.40 ft) LZX848

Extension cable (10 m/32.81 ft)

Extension cable (15 m/49.21 ft) LZX850

Extension cable (20 m/65.62 ft)

Extension cable (30 m/98.43 ft) LZX852

Flow cell on prefabricated wall including gasket set

V4A chain mount kit LZX914.99.11110

HOAB compressed air cleaning system, 230 V

HOAB compressed air cleaning system, 115 V, HACH Lange version 6860003.99.0001

Hose for air and measuring medium 5 m, 6/4 mm external/internal diameter

Hose for air and measuring medium 10 m, 6/4 mm external/internal diameter LZY620

Hose for air and measuring medium 25 m, 6/4 mm external/internal diameter LZY621

LZX849

LZX851

LZY669

6860103.99.0001

LZY619

27

Page 28

Replacement parts and accessories

7.3 Accessories (table continued)

Description Cat. no.

Hose for measuring medium 5 m, 8/6 mm external/internal diameter LZY672

Hose for measuring medium 10 m, 8/6 mm external/internal diameter LZY673

28

Page 29

Section 8 Contact information

HACH Company

World Headquarters

P.O. Box 389

Loveland, Colorado

80539-0389 U.S.A.

Tel (800) 227-HACH

(800) -227-4224

(U.S.A. only)

Fax (970) 669-2932

orders@hach.com

www.hach.com

HACH LANGE GMBH

Willstätterstraße 11

D-40549 Düsseldorf

Tel. +49 (0)2 11 52 88-320

Fax +49 (0)2 11 52 88-210

info@hach-lange.de

www.hach-lange.de

HACH LANGE

Rorschacherstrasse 30 a

CH-9424 Rheineck

Tel. +41 (0)71 886 91 11

Fax +41 (0)71 886 91 66

info@hach-lange.ch

www.hach-lange.ch

Repair Service in the

United States:

HACH Company

Ames Service

100 Dayton Avenue

Ames, Iowa 50010

Tel (800) 227-4224

(U.S.A. only)

Fax (515) 232-3835

HACH LANGE LTD

Pacific Way

Salford

GB-Manchester, M50 1DL

Tel. +44 (0)161 872 14 87

Fax +44 (0)161 848 73 24

info@hach-lange.co.uk

www.hach-lange.co.uk

HACH LANGE FRANCE

S.A.S.

8, mail Barthélémy Thimonnier

Lognes

F-77437 Marne-La-Vallée

cedex 2

Tél. +33 (0)8 20 20 14 14

Fax +33 (0)1 69 67 34 99

info@hach-lange.fr

www.hach-lange.fr

Repair Service in Canada:

Hach Sales & Service

Canada Ltd.

1313 Border Street, Unit 34

Winnipeg, Manitoba

R3H 0X4

Tel (800) 665-7635

(Canada only)

Tel (204) 632-5598

Fax (204) 694-5134

canada@hach.com

HACH LANGE LTD

Unit 1, Chestnut Road

Western Industrial Estate

IRL-Dublin 12

Tel. +353(0)1 46 02 5 22

Fax +353(0)1 4 50 93 37

info@hach-lange.ie

www.hach-lange.ie

HACH LANGE SA

Motstraat 54

B-2800 Mechelen

Tél. +32 (0)15 42 35 00

Fax +32 (0)15 41 61 20

info@hach-lange.be

www.hach-lange.be

Repair Service in

Latin America, the

Caribbean, the Far East,

Indian Subcontinent, Africa,

Europe, or the Middle East:

Hach Company World

Headquarters,

P.O. Box 389

Loveland, Colorado,

80539-0389 U.S.A.

Tel +001 (970) 669-3050

Fax +001 (970) 669-2932

intl@hach.com

HACH LANGE GMBH

Hütteldorferstr. 299/Top 6

A-1140 Wien

Tel. +43 (0)1 9 12 16 92

Fax +43 (0)1 9 12 16 92-99

info@hach-lange.at

www.hach-lange.at

DR. LANGE NEDERLAND

B.V.

Laan van Westroijen 2a

NL-4003 AZ Tiel

Tel. +31(0)344 63 11 30

Fax +31(0)344 63 11 50

info@hach-lange.nl

www.hach-lange.nl

HACH LANGE APS

Åkandevej 21

DK-2700 Brønshøj

Tel. +45 36 77 29 11

Fax +45 36 77 49 11

info@hach-lange.dk

www.hach-lange.dk

HACH LANGE LDA

Av. do Forte nº8

Fracção M

P-2790-072 Carnaxide

Tel. +351 214 253 420

Fax +351 214 253 429

info@hach-lange.pt

www.hach-lange.pt

HACH LANGE KFT.

Vöröskereszt utca. 8-10.

H-1222 Budapest XXII. ker.

Tel. +36 (06)1 225 7783

Fax +36 (06)1 225 7784

info@hach-lange.hu

www.hach-lange.hu

HACH LANGE AB

Vinthundsvägen 159A

SE-128 62 Sköndal

Tel. +46 (0)8 7 98 05 00

Fax +46 (0)8 7 98 05 30

info@hach-lange.se

www.hach-lange.se

HACH LANGE SP.ZO.O.

ul. Opolska 143 a

PL-52-013 Wrocław

Tel. +48 (0)71 342 10-83

Fax +48 (0)71 342 10-79

info@hach-lange.pl

www.hach-lange.pl

HACH LANGE S.R.L.

Str. Căminului nr. 3

Sector 2

RO-021741 Bucureşti

Tel. +40 (0) 21 205 30 03

Fax +40 (0) 21 205 30 17

info@hach-lange.ro

www.hach-lange.ro

HACH LANGE S.R.L.

Via Riccione, 14

I-20156 Milano

Tel. +39 02 39 23 14-1

Fax +39 02 39 23 14-39

info@hach-lange.it

www.hach-lange.it

HACH LANGE S.R.O.

Lešanská 2a/1176

CZ-141 00 Praha 4

Tel. +420 272 12 45 45

Fax +420 272 12 45 46

info@hach-lange.cz

www.hach-lange.cz

HACH LANGE

8, Kr. Sarafov str.

BG-1164 Sofia

Tel. +359 (0)2 963 44 54

Fax +359 (0)2 866 15 26

info@hach-lange.bg

www.hach-lange.bg

HACH LANGE S.L.U.

Edif. Arteaga Centrum

C/Larrauri, 1C- 2ª Pl.

E-48160 Derio/Vizcaya

Tel. +34 94 657 33 88

Fax +34 94 657 33 97

info@hach-lange.es

www.hach-lange.es

HACH LANGE S.R.O.

Roľnícka 21

SK-831 07 Bratislava –

Vaj nory

Tel. +421 (0)2 4820 9091

Fax +421 (0)2 4820 9093

info@hach-lange.sk

www.hach-lange.sk

HACH LANGE SU

ANALİZ SİSTEMLERİ

LTD. ŞTİ.

Hilal Mah. 75. Sokak

Arman Plaza No: 9/A

TR-06550 Çankaya/ANKARA

Tel. +90 (0)312 440 98 98

Fax +90 (0)312 442 11 01

bilgi@hach-lange.com.tr

www.hach-lange.com.tr

29

Page 30

Contact information

HACH LANGE D.O.O.

Fajfarjeva 15

SI-1230 Domžale

Tel. +386 (0)59 051 000

Fax +386 (0)59 051 010

info@hach-lange.si

www.hach-lange.si

HACH LANGE MAROC

SARLAU

Villa 14 – Rue 2 Casa

Plaisance

Quartier Racine Extension

MA-Casablanca 20000

Tél. +212 (0)522 97 95 75

Fax +212 (0)522 36 89 34

info-maroc@hach-lange.com

www.hach-lange.ma

ΗΑCH LANGE E.Π.Ε.

Αυλίδος 27

GR-115 27 Αθήνα

Τηλ . +30 210 7777038

Fax +30 210 7777976

info@hach-lange.gr

www.hach-lange.gr

HACH LANGE E.P.E.

27, Avlidos str

GR-115 27 Athens

Tel. +30 210 7777038

Fax +30 210 7777976

info@hach-lange.gr

www.hach-lange.gr

HACH LANGE D.O.O.

Ivana Severa bb

42 000 Varaždin

Tel. +385 (0) 42 305 086

Fax +385 (0) 42 305 087

info@hach-lange.hr

www.hach-lange.hr

30

Page 31

Section 9 Warranty and Liability

The manufacturer warrants that the product supplied is free of material and manufacturing

defects and undertakes the obligation to repair or replace any defective parts at zero cost.

The warranty runs for 24 months. If a maintenance contract is taken out within 6 months of

purchase, the warranty period is extended to 60 months.

With the exclusion of the further claims, the supplier is liable for defects including the lack

of assured properties as follows: all those parts that, within the warranty period calculated

from the day of the transfer of risk, can be demonstrated to have become unusable or that

can only be used with significant limitations due to a situation present prior to the transfer

of risk, in particular due to incorrect design, poor materials or inadequate finish will be

improved or replaced, at the supplier's discretion. The identification of such defects must

be reported to the supplier in writing without delay, but no later than 7 days after the

identification of the fault. If the customer fails to notify the supplier, the product is

considered approved despite the defect. Further liability for any direct or indirect damages

is not accepted.

If instrument-specific maintenance and servicing work defined by the supplier is to be

performed within the warranty period by the customer (maintenance) or by the supplier

(servicing) and these requirements are not met, claims for damages due to the failure to

comply with the requirements are rendered void.

Any further claims, in particular claims for consequential damages cannot be made.

Consumables and damage caused by improper handling, poor installation or incorrect use

are excluded from this clause.

The process instruments of the manufacturer are of proven reliability in many applications

and are therefore often used in automatic control loops to provide the most economical

possible operation of the related process.

To avoid or limit consequential damage, it is therefore recommended to design the control

loop such that a malfunction in an instrument results in an automatic change over to the

backup control system. This establishes the most secure operating condition for the

environment and for the process.

31

Page 32

Warranty and Liability

32

Page 33

Appendix A Modbus register

Table 1 Sensor Modbus registers

Register# Data type Length R/W Description

40001 Unsigned integer 1 R Reserved

40002 Float 2 R Measurement value as PAH, unit PPB

40004 Float 2 R Measurement value as PAH, unit PPM

40006 Float 2 R Measurement value as OIL, unit PPB

40008 Float 2 R Measurement value as OIL, unit PPM

40016 String 6 R Serial number

40022 String 8 R/W Name of location

40030 Unsigned integer 1 R/W Choose the parameter, 47=PAH, 48=OIL

40031 Unsigned integer 1 R/W

40040 Float 2 R/W Offset for calibration

40042 Float 2 R/W Factor for calibration

40050 Unsigned integer 1 R/W Logging interval from 5 sec to 1800 sec

40051 Unsigned integer 1 R/W Measuring interval from 1 sec to 300 sec

40052 Unsigned integer 1 R/W

40055 Unsigned integer 1 R/W Set output mode for calibration

40056 Unsigned integer 1 R/W Set output mode for service

40057 Float 2 R Version of application file

40059 Float 2 R The entry is for the application file

40061 Float 2 R Version of the probe

40063 Unsigned integer 1 R The entry is for the device driver file

40064 Unsigned integer 1 R The entry is for the device driver file

40065 Unsigned integer 1 R The entry is for the device driver file

40066 Integer 1

40067 Integer 1 R

40068 Unsigned integer 2 R Operating hours of analyzer

R

Measurement units

38=ppb, 39= g/L, 2=ppm, 0=mg/L

Amplification for the low/high range probe,

AUTO,

0=

1= 0.01 to 50/500 PPB,

2= 0.01 to 500/5000 PPB

Days left until exchanging lamp,

negative values show that exchange is overdue

Days left until maintenance,

negative values show that service is overdue

33

Page 34

Modbus register

34

Page 35

Index

A

Areas of application ................................................... 8

C

Calibration .................................................................. 5

Chain mount kit ........................................................ 13

D

Data logger .............................................................. 17

Dimensions ................................................................ 6

E

Error messages ........................................................ 25

F

Flow cell ................................................................... 15

Function test .............................................................. 9

I

Inspection interval ...................................................... 6

Measurement accuracy .............................................. 5

Measuring method ..................................................... 5

Measuring principle .................................................... 8

Measuring range ........................................................ 5

Modbus register ....................................................... 33

P

Precautionary labels ................................................... 7

Pressure range ........................................................... 5

Product contents ........................................................ 8

R

Reproducibility ............................................................ 5

Response time ........................................................... 5

S

Safety information ...................................................... 7

Safety sleeve ............................................................ 11

Specifications ............................................................. 5

System configuration ................................................ 17

M

Maintenance schedule ............................................. 23

W

Warnings .................................................................. 25

Wearing parts ........................................................... 25

35

Page 36

Index

36

Loading...

Loading...