Page 1

DOC023.52.03045

FILTRAX

User Manual

08/2012 Edition 3A

© HACH-LANGE GmbH, 2003, 2010, 2012. All rights reserved. Printed in Germany.

Page 2

Page 3

Contents

Section 1 Technical data............................................................................................................................................... 3

Section 2 General information ..................................................................................................................................... 5

2.1 Safety information...................................................................................................................................................... 5

2.1.1 Use of hazard information ................................................................................................................................ 5

2.1.2 Precautionary labels ........................................................................................................................................ 5

2.2 Applications ............................................................................................................................................................... 6

2.3 Functional description................................................................................................................................................ 6

2.4 Items supplied ........................................................................................................................................................... 7

2.5 Instrument layout ....................................................................................................................................................... 8

2.5.1 Control unit....................................................................................................................................................... 8

2.5.2 Module carrier .................................................................................................................................................. 8

2.5.3 Sample tubes ................................................................................................................................................... 9

2.5.4 Filter modules .................................................................................................................................................. 9

Section 3 Installation....................................................................................................................................................11

3.1 Mechanical installation ............................................................................................................................................ 13

3.1.1 Dimensions .................................................................................................................................................... 13

3.2 Installing control unit with control unit bracket LZX676 ........................................................................................... 16

3.3 Connecting tubes..................................................................................................................................................... 20

3.4 Electrical connections.............................................................................................................................................. 25

3.5 Connection to process instruments ......................................................................................................................... 27

Section 4 Commissioning........................................................................................................................................... 30

4.1 Placing instrument in operation ............................................................................................................................... 30

4.2 Taking instrument out of operation .......................................................................................................................... 32

4.2.1 Filter modules ................................................................................................................................................ 32

4.2.2 Control unit..................................................................................................................................................... 32

Section 5 Operation..................................................................................................................................................... 34

5.1 Using the keypad..................................................................................................................................................... 34

5.2 Menu overview ........................................................................................................................................................ 35

5.3 [+DEVICEDATA] menu .......................................................................................................................................... 36

5.4 [+SIGNALS] menu................................................................................................................................................... 37

5.5 [+OP.COUNTERS] menu ........................................................................................................................................ 38

5.6 [+SERVICE] menu................................................................................................................................................... 39

Section 6 Maintenance ................................................................................................................................................ 42

6.1 Maintenance work ................................................................................................................................................... 42

6.1.2 Every 3 months .............................................................................................................................................. 43

6.1.3 Every 12 or 24 months ................................................................................................................................... 44

6.1.4 Menu-based cleaning..................................................................................................................................... 45

6.1.5 Cleaning with cleaning container (option) ...................................................................................................... 46

Section 7 Faults, causes, rectification ...................................................................................................................... 49

7.1 Messages ................................................................................................................................................................ 49

7.2 Warnings ................................................................................................................................................................. 49

7.3 Faults....................................................................................................................................................................... 50

7.4 Voltage drop (power failure) .................................................................................................................................... 50

1

Page 4

Contents

Section 8 Spare parts................................................................................................................................................... 51

Section 9 Warranty and liability..................................................................................................................................53

Section 10 Contact ......................................................................................................................................................55

2

Page 5

Section 1 Technical data

Table 1-1 FILTRAX

Supply: 230 V (option 115 V) ±10% AC, 50-60 Hz

Device with system components: 1500 VA

Cable Heater off

Power consumption:

Sample volume: approx. 900 ml/h for up to 3 process photometers

Head: Module carrier – control unit: 3 m ; control unit – process instrument: 7 m

2 m

10 m

20 m

30 m

150 VA

150 VA

150 VA

150 VA

Max. (-20° C)

start-up

450 VA

950 VA

1500 VA

2100 VA

Cont. (-20° C)

< 200 VA

< 300 VA

< 400 VA

< 500 VA

Outputs:

(use screened cable!)

Cable length:

User maintenance: approx. 1h / month

Medium temperature: +5° C to +40° C

Ambient temperature -20° C to +40° C

Enclosure rating: IP 55

Fuses:

Mass:

Dimensions:

Certification:

Fault signalling contact: floating contact (230 V, max. 3 A)

Warning contact: floating contact (230 V, max. 3 A)

Service interface: RS 232

Suction tube: 5 m (heated)

Sample tube: 2 m (unheated)

Sample tube: 10 m (heated), 20 m (heated), 30 m (heated)

T 4A E; 250V (2 ×)

T 7A E; 250V (2 ×)

Control unit: approx. 22 kg

Module carrier with 5 m suction tube: approx. 9 kg

Sample tube 10 m: approx. 5 kg

Sample tube 20 m: approx. 10 kg

Sample tube 30 m: approx. 15 kg

Mounting pipe 2 m: approx. 5 kg

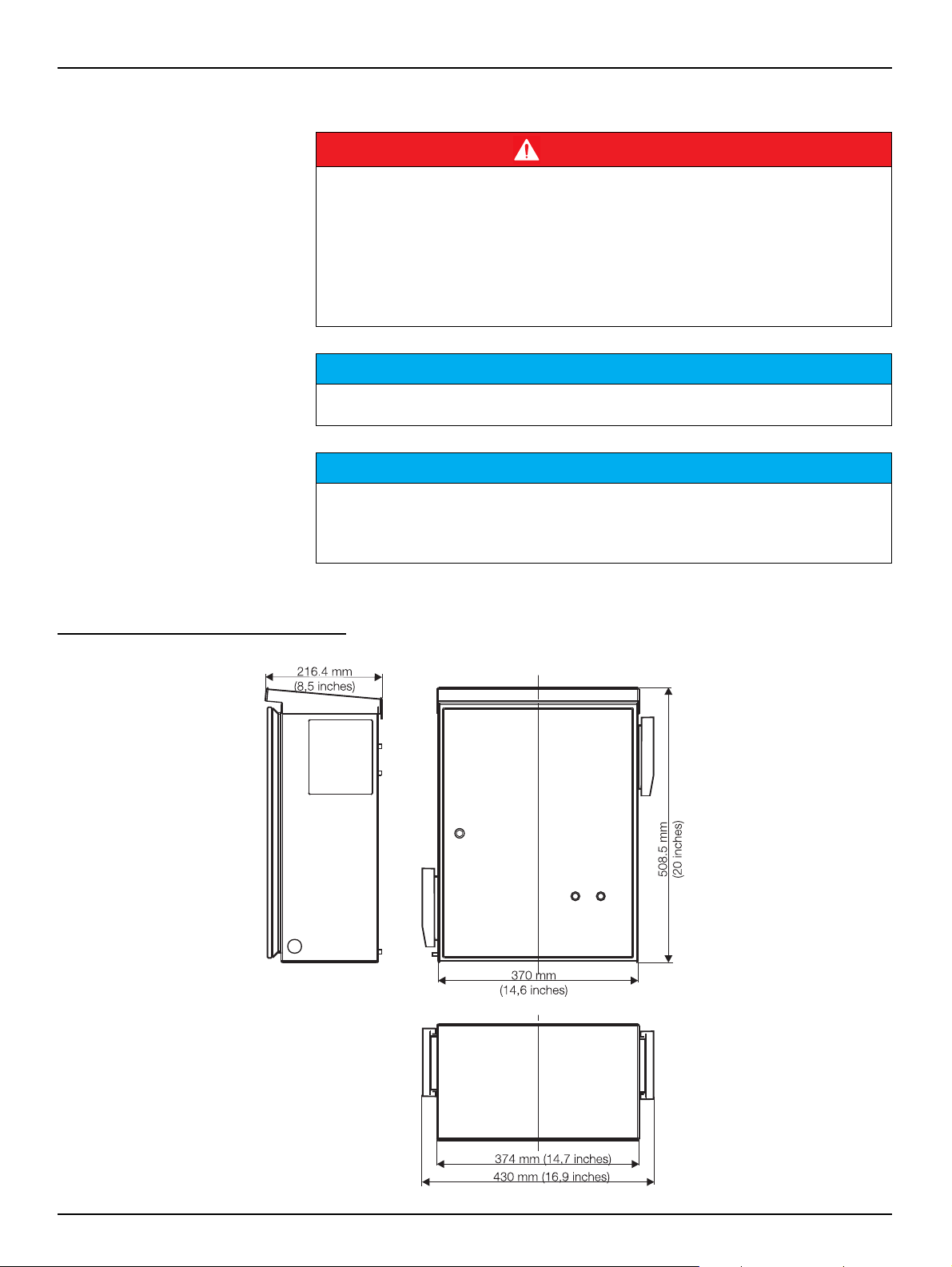

Control unit (W x H x D): 430 x 530 x 220 mm

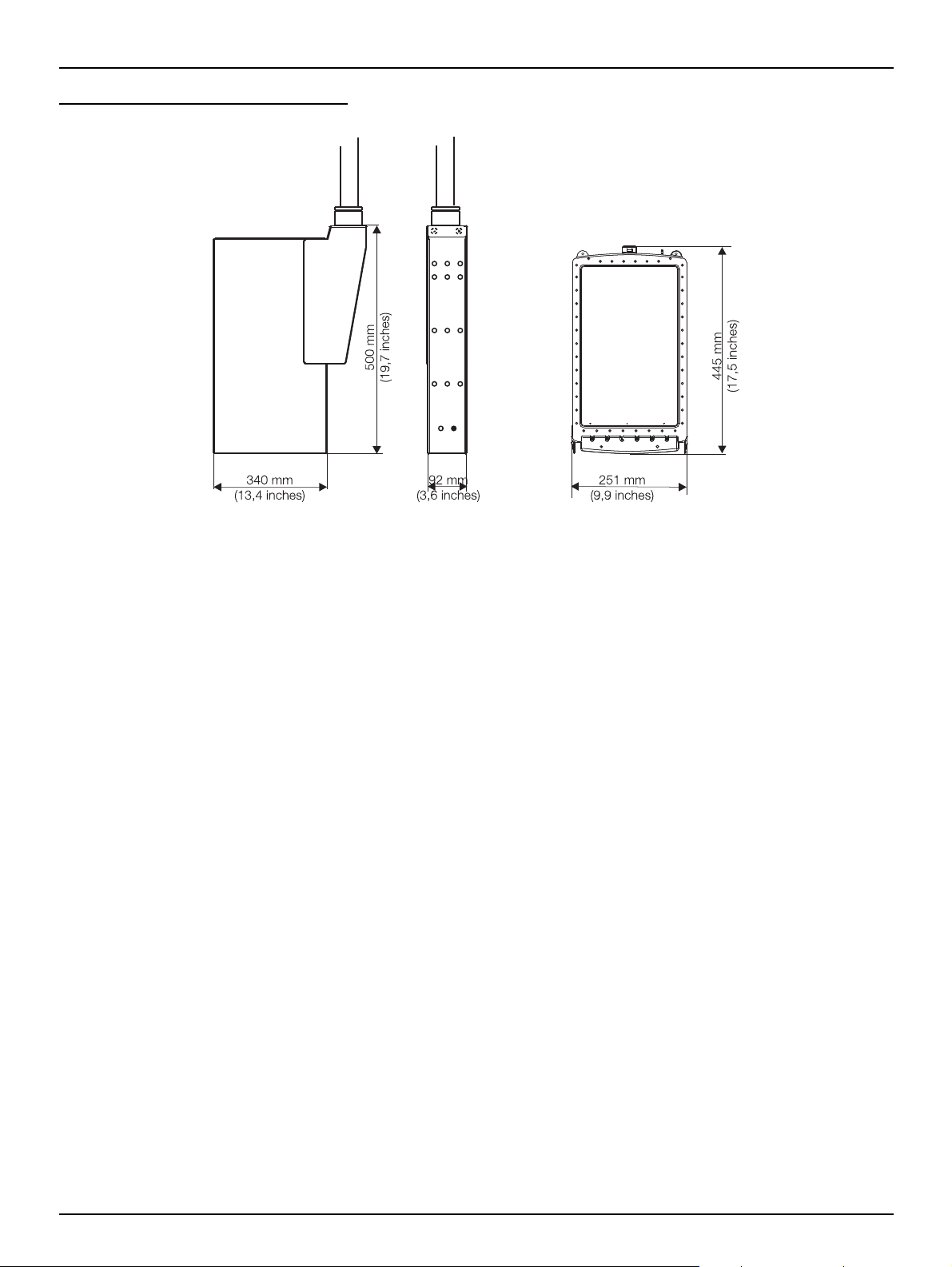

Module carrier (W x H x D): 92 x 500 x 340 mm

CE. The manufacturer clarifies conformity with the applicable EU safety guidelines

and EMC guidelines.

Subject to change without notice.

3

Page 6

Technical data

4

Page 7

Section 2 General information

2.1 Safety information

Please read this entire manual before unpacking, setting up or operating this

equipment. Pay attention to all danger, warning and caution statements. Failure to

do so could result in serious injury to the operator or damage to the equipment.

Make sure that the protection provided by this equipment is not impaired, do not

use or install this equipment in any manner other than that specified in this

manual.

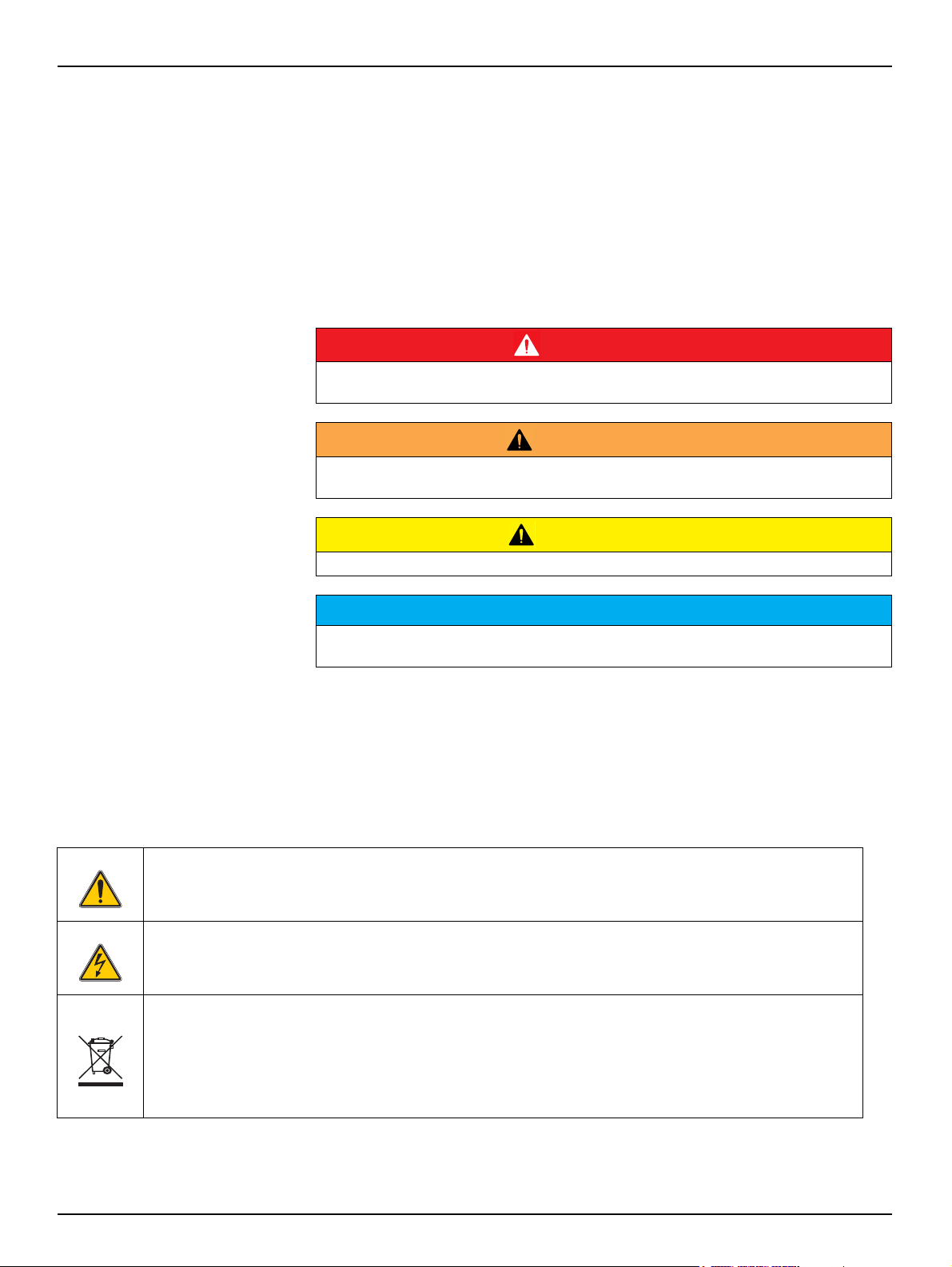

2.1.1 Use of hazard information

Indicates a potentially or imminently hazardous situation which, if not avoided, will result

in death or serious injury.

Indicates a potentially or imminently hazardous situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous situation that may result in minor or moderate injury.

Indicates a situation which, if not avoided, may cause damage to the instrument.

Information that requires special emphasis.

Note: Information that supplements points in the main text.

2.1.2 Precautionary labels

DANGER

WARNING

CAUTION

NOTICE

Read all labels and tags attached to the instrument. Personal injury or damage to

the instrument could occur if not observed. A symbol on the instrument is

referenced in the manual with a precautionary statement.

This is the safety alert symbol. Obey all safety messages that follow this symbol to avoid potential injury. If on

the instrument, refer to the instruction manual for operation or safety information.

This symbol indicates that a risk of electrical shock and/or electrocution exists.

Electrical equipment marked with this symbol may not be disposed of in European domestic or public disposal

systems after 12 August 2005. In conformity with European local and national regulations (EU Directive

2002/96/EC), European electrical equipment users must now return old or end-of life equipment to the

manufacturer for disposal at no charge to the user..

Note: For return for recycling, please contact the equipment producer or supplier for instructions on how to

returnend-oflife equipment, producer-supplied electrical accessories, and all auxiliary items for proper disposal.

5

Page 8

General information

2.2 Applications

The FILTRAX sampling system is a device for the filtration and pumping of waste

water samples from the activated sludge tank or final clarification tank for

supplying process instruments with samples free of solids.

Any use other than use in accordance with requirements defined in the user manual

leads to the loss of the warranty claims and can lead to personal injury and property

damage, for which the manufacturer assumes no liability.

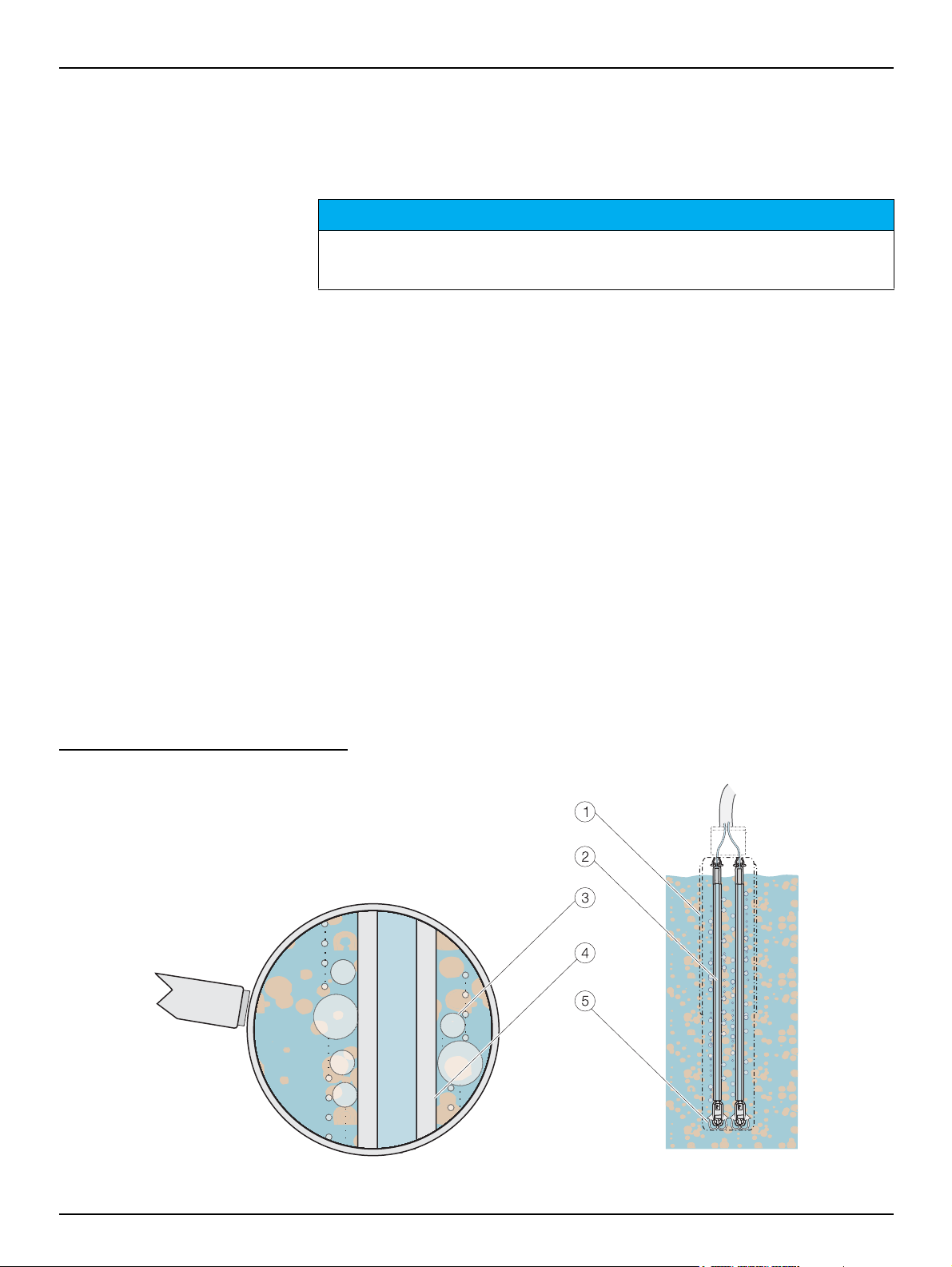

2.3 Functional description

The FILTRAX sampling and sample conditioning system comprises two

components: a control unit and module carrier.

The module carrier (1) is immersed at the place the samples are to be taken using

a special tank edge fastening. Inside the module carrier there are two filter

modules (2); a filter membrane (3) is stretched over both sides of each of the

modules. The waste water sample is fed to a special duct system (4) via this

membrane.

NOTICE

Two tube metering pumps inside the control unit draw the sample alternately from

the two filter modules using a common 5 m long heated suction tube to the control

unit that is installed in close proximity to the sampling point. From there the

sample is pumped 2 m, 10 m, 20 m or 30 m, depending on the sample tube

connected, to the process instruments.

A venting device (5) underneath the filter modules largely prevents the adhesion

of solids to the filter membranes and significantly reduces the maintenance effort.

Two signal lamps (green and red) provide continuous visual indication of normal

operation, warnings and faults - this information is also provided electrically by two

floating relay contacts.

Fig. 2-1 Layout of the filter modules

6

Page 9

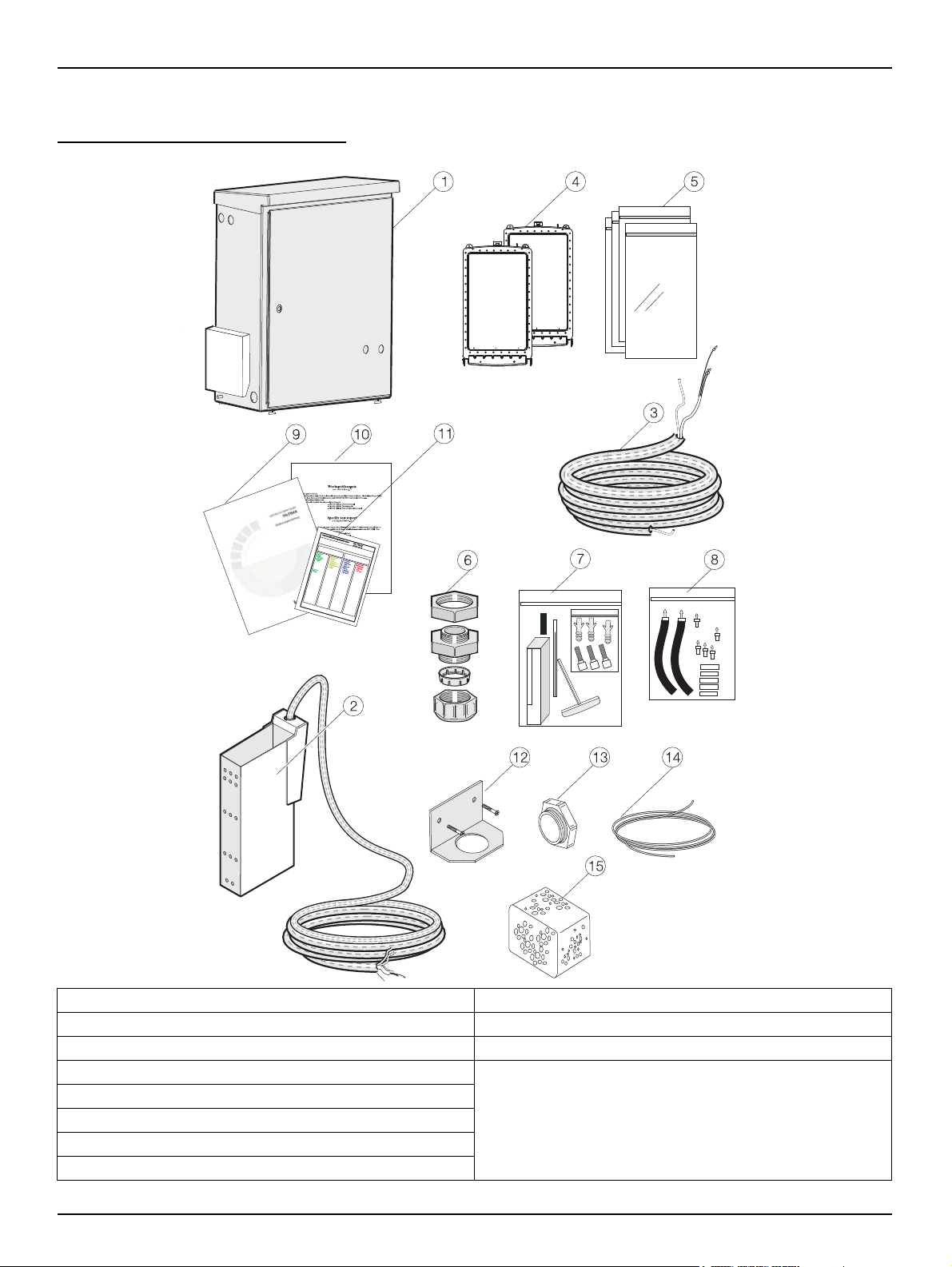

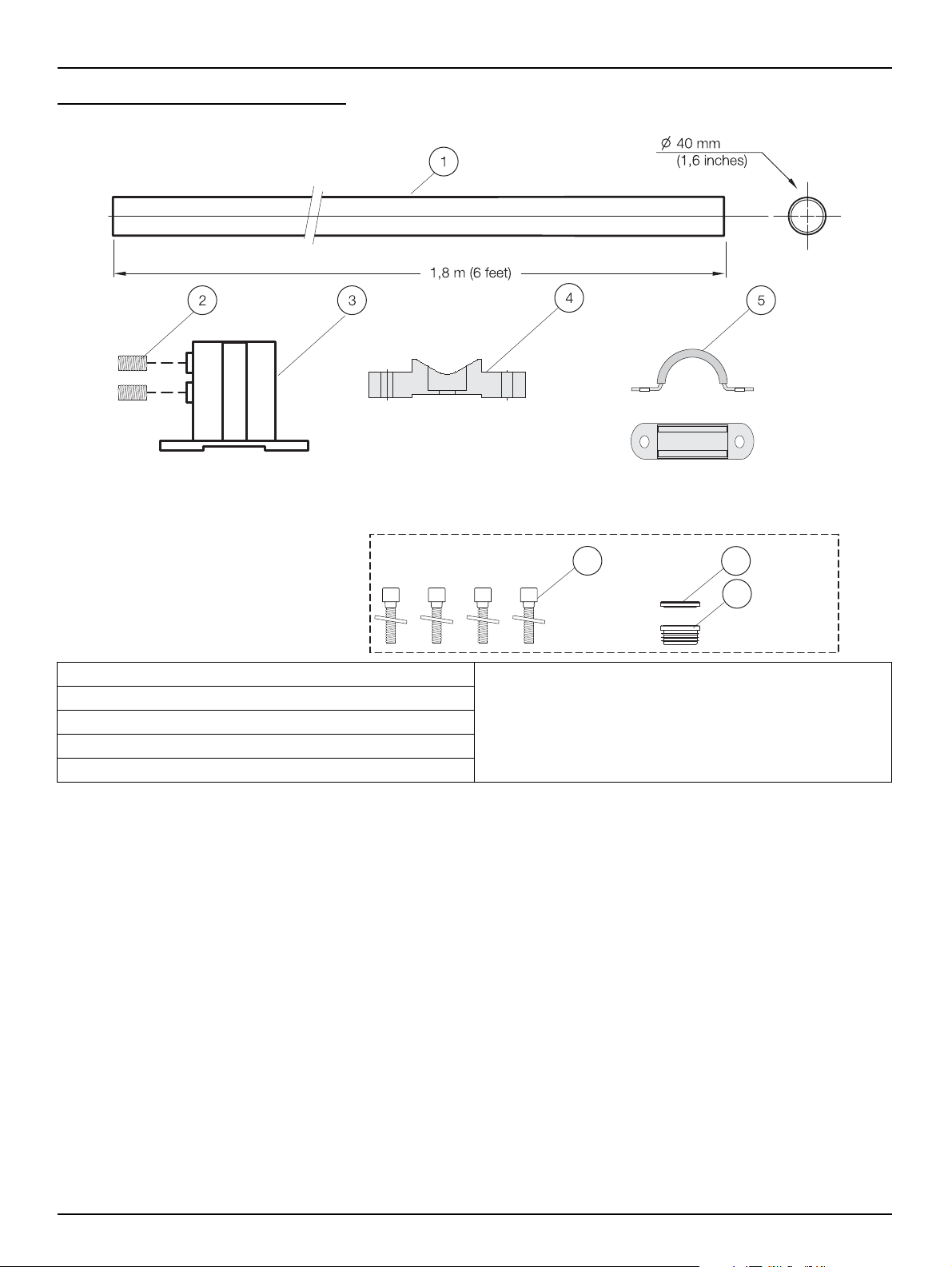

2.4 Items supplied

Fig. 2-2 Items supplied

General information

1. Control unit 9. Operating instructions

2. LZX670 (230 V) module carrier with 5 m suction tube 10. Factory test certificate

3. Sample tube 2 m, 10 m, 20 m, 30 m 11. DOC273.xx.04006 Maintenance calendar

4. LZX677 Filter module (2)

5. EYV017 Plastic bag for filter module (4)

6. Cable gland M20 x 1.5 (2)

7. LZX702 Accessory set

8. LZX701 Tube adapter set

Included in accessory set LZX702

12. Mounting bracket for sample tube

13. Blanking plugs (2) + sealing rings (2)

14. HLS191 2/4 tube 6 m

15. Cleaning sponge

16. Clip

7

Page 10

General information

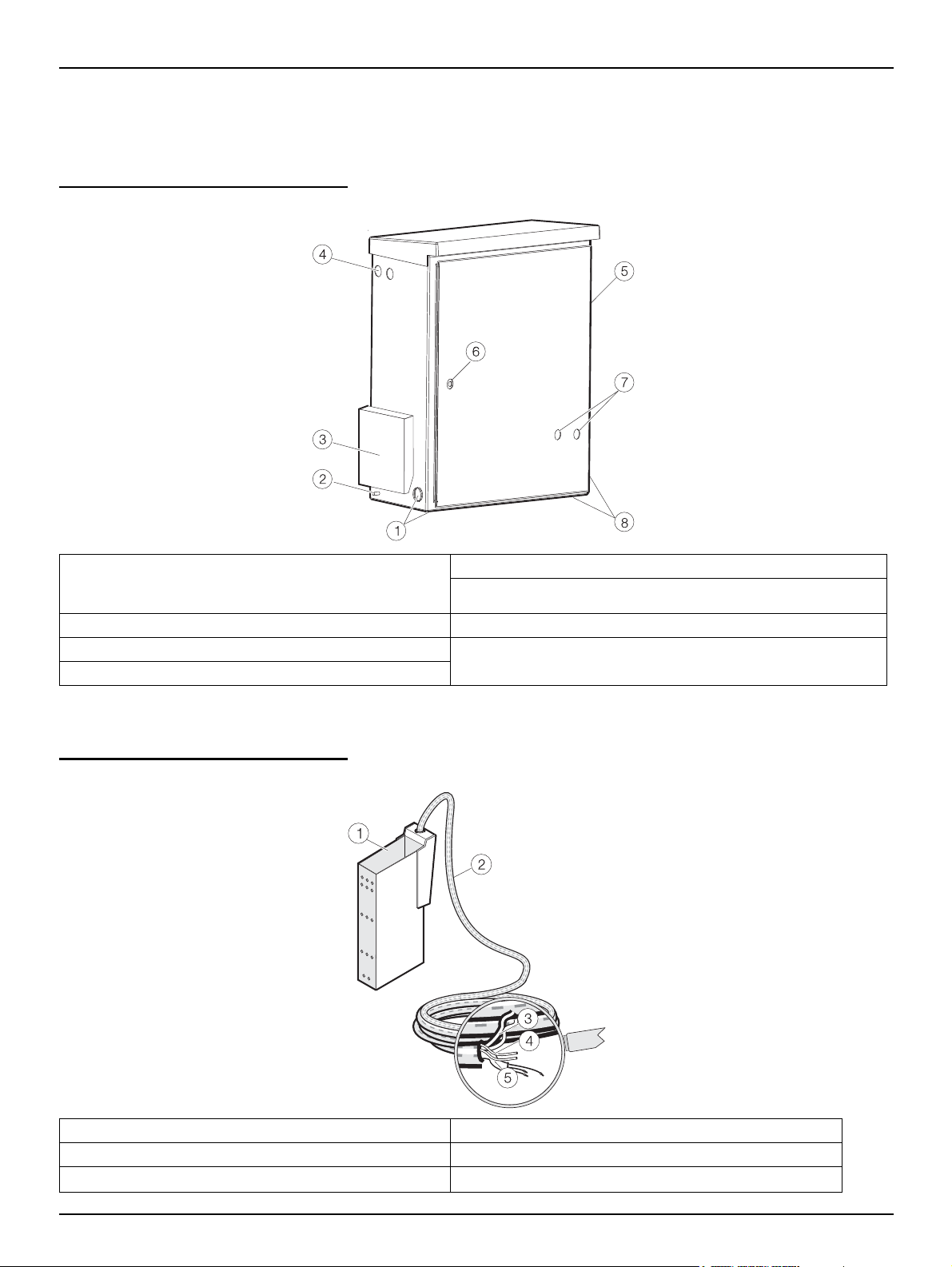

2.5 Instrument layout

2.5.1 Control unit

Fig. 2-3 Control unit

1. Suction tube connection (left or underneath on the left)

(Blanking plugs and sealing ring for the unused

opening)

2. Connection for equipotential bonding 7. Green and red signal lamps

3. Air filter cover (air inlet) 8. Sample tube connection (right or underneath on the right)

4. Cable gland for electrical connecting cable (2)

5. Air filter cover (air outlet)

6. Door lock

(Blanking plugs and sealing ring for the unused opening)

2.5.2 Module carrier

Fig. 2-4 Module carrier

1. Module carrier 4. Sample suction tube 3.2 mm OD (2)

2. Suction tube 5 m 5. Connecting cable for the tube heater

3. Air tube 6 mm OD (2)

8

Page 11

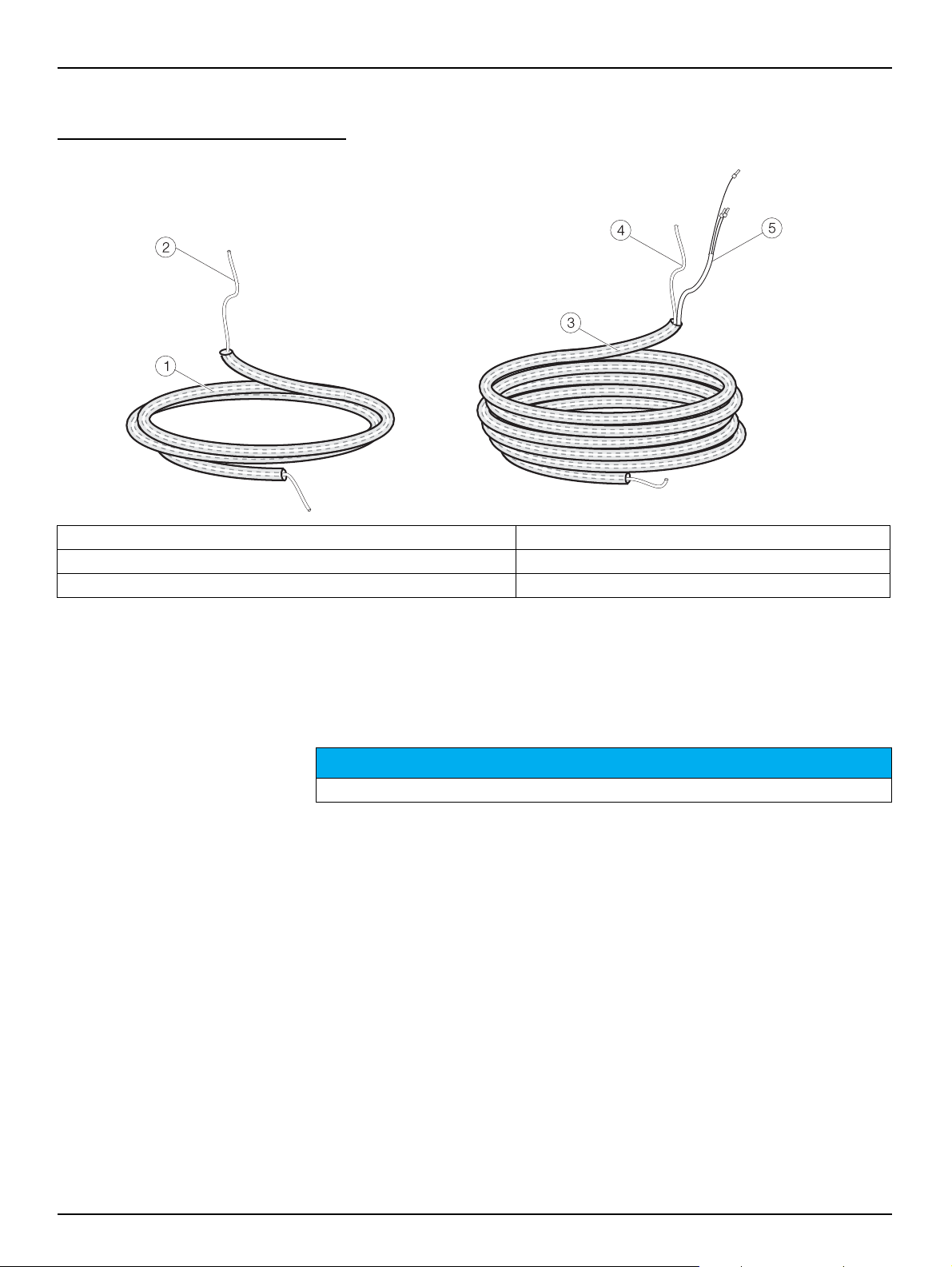

2.5.3 Sample tubes

Fig. 2-5 Sample tubes

General information

1. Sample tube 2 m, 23 mm (0.91 inch), not heated 4. Sample pressure tube 3.2 mm OD

2. Sample pressure tube 3.2 mm OD 5. Connecting cable for the tube heater

3. Sample tube 10 m, 20 m, 30 m, 23 mm (0.91 inch), heated

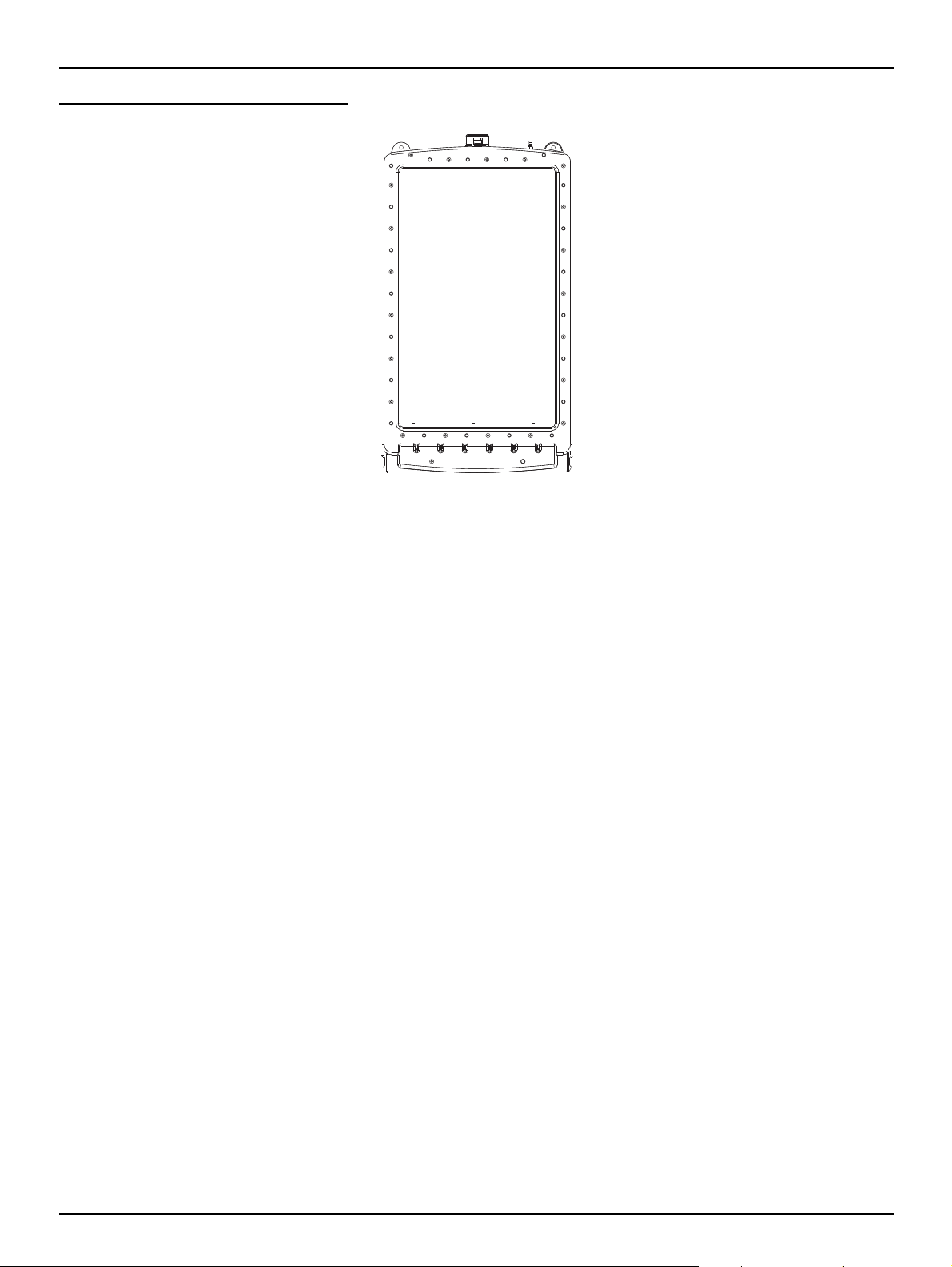

2.5.4 Filter modules

The two filter modules should only be installed during commissioning. Once

moistened, the filter membranes must not be allowed to dry out again and are

sealed in a plastic bag for protection.

NOTICE

The surface of the membrane is very delicate!

9

Page 12

General information

Fig. 2-6 Filter module

10

Page 13

Section 3 Installation

Only qualified experts should conduct the tasks described in this section.

Select an appropriate installation location for the instrument.

Plan out the mechanical mount before positioning poles or drilling holes. Make sure the

mount has a sufficient bearing capacity. The dowels must be selected and authorized

according to the condition of the wall.

The manufacturer shall accept no liability if the instrument is installed incorrectly.

Plan how to lay cables and tubes and their path in advance. Lay the tubes, data cables

and power cables without any bends and so they do not pose a tripping risk.

Do not connect the electrical supply to the mains until the instrument is completely wired

and protected against short circuits.

Sufficiently protect the electrical power supply against short circuits.

For the external power supply, always connect a residual-current circuit breaker (trip

current max.: 30 mA) between the mains and the system.

If the instrument is to be installed outdoors, connect a surge arrester between the mains

and the system.

Products intended by the manufacturer for outdoor use offer a higher level of protection

against the penetration of liquids and dust. If these products are connected to a mains

outlet with a cable and plug rather than a permanently connected cable, the plug and

outlet are much more susceptible to liquid and dust penetration. The operator must

sufficiently protect the plug and outlet against liquid and dust penetration in accordance

with local safety regulations. If the instrument is to be used outdoors, it must be

connected to a suitable outlet with a protection type of at least IP44 (splash protection).

DANGER

DANGER

WARNING

Electrical dangers and fire hazard. Use only the supplied power cable.

Only qualified experts may perform the tasks described in this section of the manual, in

compliance with all locally applicable safety regulations.

NOTICE

Protect the device against extreme temperatures from heaters, direct sunlight and other

heat sources.

CAUTION

Note the weight (control unit approx. 22 kg, module carrier with 5 m suction tube approx.

9 kg) of the instrument. Do not try to carry the instrument without help. Use only suitable

lifting devices for the transport.

11

Page 14

Installation

aaaa

aaaa

aaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

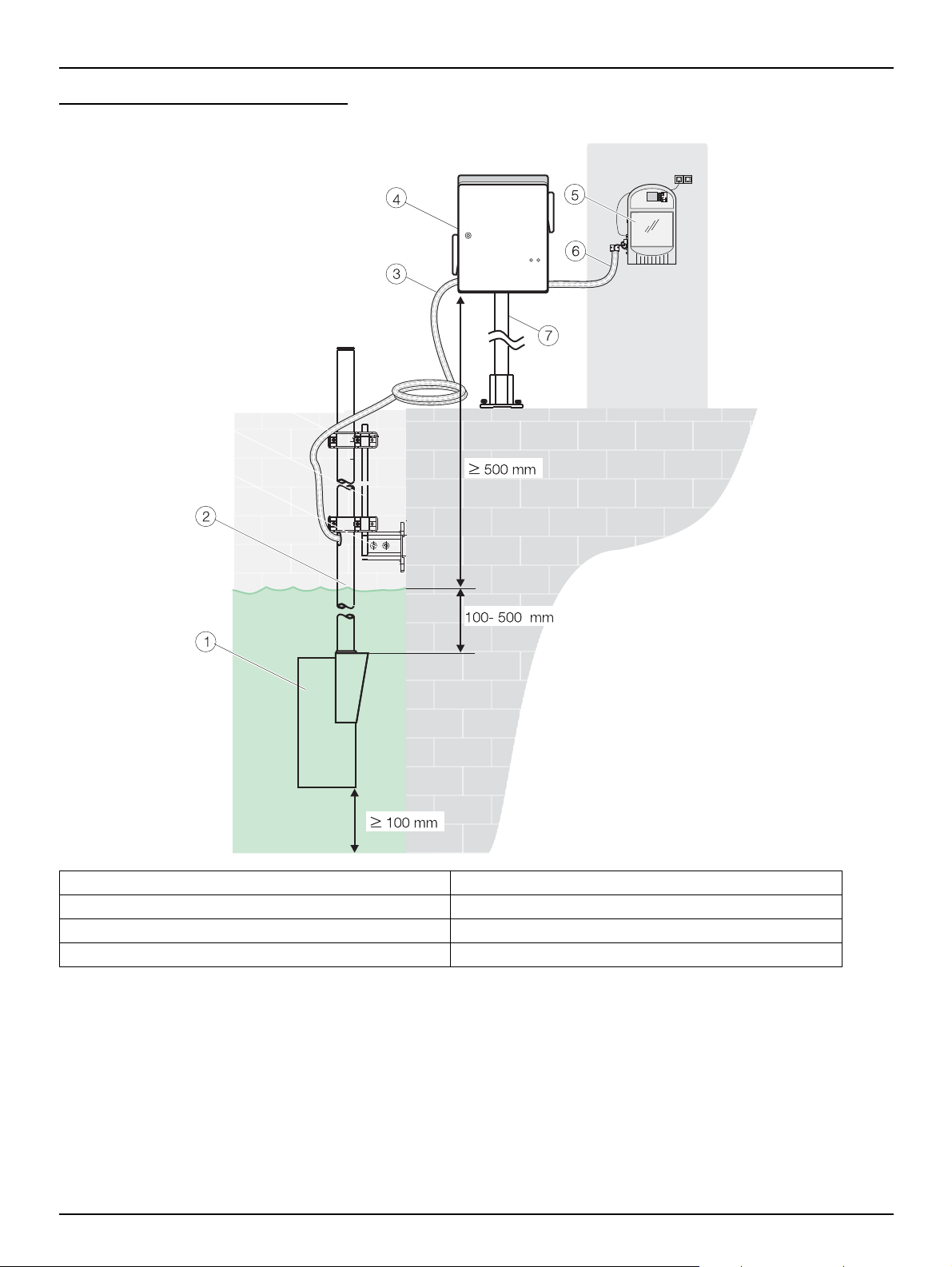

Fig. 3-7 Installation overview

1. Module carrier 5. Process instrument

2. Bracket FILTRAX module carrier (option) 6. Sample tube

3. Suction tube 5 m 7. Bracket FILTRAX control unit (option)

4. Control unit

12

Page 15

3.1 Mechanical installation

Select an appropriate installation location for the instrument.

Plan out the mechanical mount before positioning poles or drilling holes. Make sure the

mount has a sufficient bearing capacity. The dowels must be selected and authorized

according to the condition of the wall.

The manufacturer shall accept no liability if the instrument is installed incorrectly.

Plan how to lay cables and tubes and their path in advance.

Lay the tubes, data cables and power cables without any bends and so they do not pose

a tripping risk.

For information on installation with optional accessories, refer to the relevant installation

instructions.

The filter module should only be unpacked directly before commissioning and quickly

attached to the module carrier.

The filter membranes are shrink-wrapped in protective plastic; once they have been

moistened they must not be allowed to dry out.

Installation

DANGER

NOTICE

NOTICE

3.1.1 Dimensions

Fig. 3-8 Control unit

13

Page 16

Installation

Fig. 3-9 Module carrier and filter module

14

Page 17

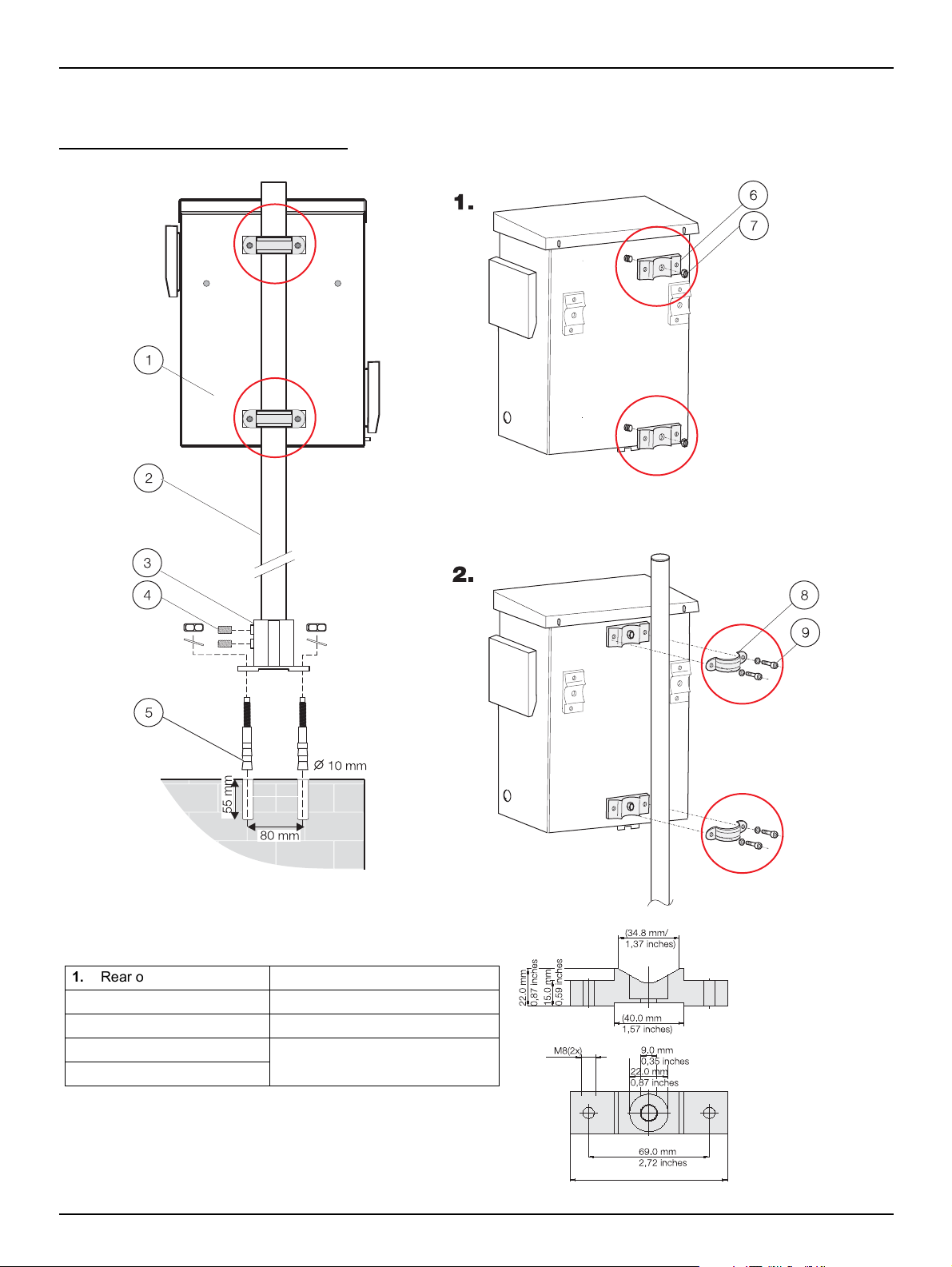

Fig. 3-10 Control unit bracket components

Installation

1. HRO304 supporting pipe 1.8 m

2. Setscrew M8 x 10 (2) in LZX416

3. ATS010 base

4. HHH277 bracket (2)

5. EHK063 pipe clamp (2)

6

Included in hardware LZX416:

6. Cheese head bolt M8 x 16 (4)

7. Blanking plug

8. Plug

7

8

15

Page 18

Installation

aaaa

aaaa

1. Rear of control unit 6. Bracket (2)

2. Supporting pipe 1.8 m 7. Nut M8 (2)

3. Base 8. Pipe clamp (2)

4. Setscrew M8 x 10 (2) 9. Cheese head bolt M8 x 16 (2)

+ washer (2)

5. Anchor (4)

3.2 Installing control unit with control unit bracket LZX676

Fig. 3-11 Installation of control unit bracket

16

Page 19

Fig. 3-12 Installation on a wall (hole diagram)

Procedure:

1. Make the two upper holes.

2. Use wall plugs and screws from the accessory set.

3. Fit instrument.

4. Mark third hole at the bottom and make hole.

5. Fit instrument.

At least

300 mm

Installation

17

Page 20

Installation

Fig. 3-13 Components for the module carrier bracket

1. (a) BRO060 mounting pipe 2.0 m for LZX414.00.00000

(b) BRO069 mounting pipe 2.0 m with slot on side for

LZX414.00.40000

Included in retaining clamp LZX200:

2. Clamp half (2)

3. Cheese head bolt M5 x 20 (6)

4. Clamp half with thread (2)

5. ATS010 base

6

5

6. HPL061 fastening lug

Included in hardware LZX416:

7. Cheese head bolt M8 x 40

8. Blanking plug

9. Plug

Included in hardware LZX417:

10. Flat seal

Included in hardware LZX702:

11. Cheese head bolt M3 x 10 (6)

8

9

10

11

7

18

Page 21

Fig. 3-14 Installation of module carrier

aa

aa

aa

Installation

1. Base 7. Fastening lug

2. Anchor (4) 8. Cheese head bolt M8 x 40

3. Blanking plug 9. Cheese head bolt M3 x 10 (6)

4. Plug 10. Flat seal

5. Mounting pipe 2.0 m for LZX414.00.00000 or mounting

pipe 2.0 m with slot on side for LZX414.00.40000

6. Retaining clamp

11. Module carrier

19

Page 22

Installation

3.3 Connecting tubes

Fig. 3-15 Preparation of suction tube connection

1. Protective tube (transport protection) 4. Cable gland M20 x 1.5

2. Shrink tube 5. Suction tube

3. Metal sleeve 6. Blanking plug

20

Page 23

Fig. 3-16 Preparation of sample tube connection

Installation

1. Protective tube (transport protection) 4. Cable gland M20 x 1.5

2. Shrink tube 5. Suction tube

3. Metal sleeve 6. Blanking plug

21

Page 24

Installation

Fig. 3-17 Layout of suction tube

1. Suction tube 4. Air tubes

2. Pipe heater connecting cable 5. Clip

3. Sample suction tubes

NOTICE

The tubes must be laid with the aid of the clips such that they cannot chaff due to the

vibration from the compressor!

22

Page 25

Fig. 3-18 Laying sample tube

Installation

Note: the sample pressure tube (1) is pushed through the flowmeter from below and

fastened to the 90° fitting (3). The fixing screw (2) is then tightened lightly.

1. Sample pressure tube 4. Pipe heater connecting cable

2. Fixing screw 5. Sample tube

3. 90° fitting

23

Page 26

Installation

Fig. 3-19 Tube diagram

Note: always ensure that the tubes are laid correctly! The filter modules may be damaged

if sample is pumped back via the sample suction tubes (1)+(2)!

1. Sample suction tube, filter module A or B 4. Pump cartridges

2. Sample suction tube, filter module A or B 5. Metering tube

3. Connecting tube 6. Sample pressure tube

24

Page 27

3.4 Electrical connections

Use only earthed sockets for the connection of this device to the power supply.

If it is not clear whether the sockets are earthed, have this checked by a qualified

electrician.

In addition to supplying power, the power plug also serves to isolate the device quickly

from the mains where necessary.

The entire measurement system has two power plugs (measurement device and control

unit). During the disconnection from the mains, it must be made sure that the correct

power plug is pulled (e.g. labeling of the sockets).

This is recommended for long-term disuse and can prevent potential dangers in the

event of a fault.

Therefore make sure that the sockets to which the device is connected are easy to

reach by each user at all times.

On removal of the power plug (fixed installation of mains supply lead), a suitable bipolar

circuit breaker must be installed!

Installation

NOTICE

NOTICE

NOTICE

Pull out the power plug before opening the device.

WARNING

Only qualified experts may perform the tasks described in this section of the manual, in

compliance with all locally applicable safety regulations.

25

Page 28

Installation

Fig. 3-20 Terminal assignments

Sicherungen/Fuses

250 V

IEC

F1:

F2:

F3:

F4:

T3,15A L

T3,15A L

T6, 3A L

T6, 3A L

UL

T4A E

T4A E

T7A E

T7A E

1. Mains cable (power supply) 3. Heater connecting cable, sample tube

2. Earth connection 4. Heater connecting cable, suction tube

NOTICE

Route the signal lines (21, 22, 23, 24) separated from the power cable.

Table 3-1 Terminal assignments

Terminal no. Connection

1 N (230 V AC / 50-60 Hz, option: 115 V AC)

2 L (230 V AC / 50-60 Hz, option: 115 V AC)

7 N (sample tube heater)

8 N (suction tube heater)

9 L (sample tube heater)

10 L (suction tube heater)

18 Earth for screening signal wires

19 Earth for suction tube heater

20 Earth for sample tube heater

21/22 Floating fault signalling contacts (normally open)

23/24 Floating warning contacts (normally open)

26

Page 29

3.5 Connection to process instruments

The filtered sample passes through the sample pressure tube inside the sample

tube to the process instruments connected.

The bracket enables the sample tube to be fastened to a wall at a distance of

approx. 200 mm from the process instrument.

Fig. 3-21 Mounting bracket

Installation

1. Sample pressure tube 3. Cable gland M20 x 1.5

2. Bracket 4. Sample tube

27

Page 30

Installation

All the adapters necessary to the direct connection of the sample

pressure tube to the sample feed openings on the process instruments

are supplied in the tube adapter set LZX701 supplied.

If several instruments are supplied from one FILTRAX, the sample must

be provided from the first instrument to the next using the 2/4 tube to

ensure a short time delay.

Fig. 3-22 Connection of sample pressure tube

1. FILTRAX sample pressure tube 5. 4/6 tube

2. Sleeve 6. 2/4 tube

3. Quick-release connector 7. Small fitting

4. Large fitting

28

Page 31

Installation

29

Page 32

Section 4 Commissioning

4.1 Placing instrument in operation

NOTICE

The sample pressure tube must never be clamped such that it is blocked off - the

pressure build up would either result in damage to the tubes or the tube connections

would spring off!!

After assembly has been completed, you can place FILTRAX in operation.

For this purpose

1. Clip pump cartridges into the control unit

2. Unpack the two filter modules and carefully slide into the module carrier!

NOTICE

As far as possible do not touch the delicate filter membrane!

3. Fit the two thicker sample tubes and the two thinner air tubes to tube fittings of

appropriate size as per the figure

4. Plug into the mains and set instrument parameters (sec. 5 Software menu

system)

30

Page 33

Fig. 4-23 Inserting filter modules

Commissioning

31

Page 34

Commissioning

Menu

NO SAMPLE!

INTERVAL

PREPUMP

PREPUMP

4.2 Taking instrument out of operation

4.2.1 Filter modules

If the instrument is to be taken out of operation for an extended period, you should

clean the filter modules (sec. 6 Maintenance) and then protect against drying out.

For this purpose 4 plastic bags are supplied.

Fig. 4-24 Plastic bag

4.2.2 Control unit

On installation outdoors, the control unit should always be in operation so that the

temperature control can provide protection against overheating or freezing. When

the instrument is taken out of operation, the [+SERVICE] menu is opened or the

control unit removed:

• Prior to dismantling open the [+SERVICE] menu and remove suction and

sample tube

• Select [PREPUMP] command and leave the internal tubes to empty

• Then open [+SERVICE] menu again, release tension on pump cartridges

and unplug from the mains

32

Page 35

Commissioning

33

Page 36

Section 5 Operation

5.1 Using the keypad

All functions in the instrument are software-controlled. Operation is via menus

using the four keys below the display. The current sample volumes (1) for the two

filter modules and the operating state of the heating (2) can be seen on the

display during operation. To reach the menu level of the program, one of the four

function keys F1-F4 (3) must be pressed for 3 seconds.

The significance of the keys on the menus appears (sensibly abbreviated) in the

second line on the display (softkey function):

= Cancel

= Change the setting

= Back to the previous command

= Continue to the next command

Fig. 5-25 Display

1. Current sample volume (approx. ml/h) 3. Function keys

2. Operating state of the heating, alternatively:

messages, warnings, faults

34

Page 37

5.2 Menu overview

Menu level 1 Menu level 2

Operation

+DEVICEDATA

For setting the instrument parameters

+SIGNALS

For checking internal data in case of

service

CONTRAST

LANGUAGE

HEATER

HEAT.START

HEAT.STOP

WARNING<

FAULT<

DATE

TIME

PASSWORD

SW-VERSION

SW-CO.PROC.

MODUL A

MODUL B

TEMPERATURE (control unit)

AMPL.

MEAS-Z

MEAS

MEAS-F

+SERVICE

For maintenance and function tests

+OP.COUNTERS

(display only)

INTERVAL

EXTRACTION

PREPUMP

FILTERCLEANING

+OP.COUNTERS (display and reset)

+TEST OF FUNCT.

+SIGNALS

+DEVICEDATA

STATUS (output of detailed error messages and

acknowledgement)

CLEANED

MODUL A

MODUL B

PUMPTUBES

PUMPCASSETTES

PUMPWHEELS

AIRFILTER COMPRESSOR

AIRFILTER CASE

COMPRESSOR

35

Page 38

Operation

5.3 [+DEVICEDATA] menu

Instrument parameters for adaptation to the related conditions.

Note: While the instrument is in this menu, sample pumping continues. If a key is not

pressed for longer than ten minutes, the instrument automatically returns to the display of

the data on operation.

MENU

Command

Setting Description

+DEVICEDATA

CONTRAST

-90 to +90 Reading angle for the display

LANGUAGE

D, GB, NL, F, I, E, PL, S

HEATER

ON, OFF, TIMER (time control)

Default setting: TIMER

HEAT.START (only for [HEATER]:TIMER)

JAN to DEC,

Default setting: OCT

HEAT.STOP (only for [HEATER]:TIMER)

JAN to DEC,

Default setting: MRZ (March)

WARNING<

Operation of the tube heaters

Activation of the heater at the start of the month selected

Deactivation of the heater at the end of the month selected

200...800 ml/h in 10 ml steps

FAULT<

100...600 ml/h in 10 ml steps

DATE

Setting for the date

TIME

Setting for the time

PASSWORD

4-digits with numbers 1-4 Password protection on activation

SW-VERSION

Only for information Version of the instrument software

SW-CO.PROC.

Only for information Version of the coprocessor software

Warning relay contact* set when the sample volume drops below

the amount set

Fault relay contact* set when the sample volume drops below the

amount set

*If the power supply is interrupted (power failure) both relay contacts are closed.

36

Page 39

5.4 [+SIGNALS] menu

MENU

Command

Description

+SIGNALS

MODUL A

Parameter for the flow rate in module A (single measurement),

approximately corresponds to a sample volume in ml/h

MODUL B

Parameter for the flow rate in module B (single measurement),

approximately corresponds to a sample volume in ml/h

TEMPERATURE (housing)

Temperature in the control unit in °C or °F

AMPL.

Photometer gain

Operation

The [+SIGNALS] menu is used for service and inspection by the manufacturer. It

is not needed for operation and the instrument settings.

Note: While the instrument is in this menu, normal operation continues. If a key is not

pressed for longer than ten minutes, the display automatically returns to the display of the

data on operation.

MEAS-Z

MEAS

MEAS-F

Level of the last valid zero measurement

Level of the last valid flow rate measurement

Current measured level

37

Page 40

Operation

5.5 [+OP.COUNTERS] menu

The [+OP.COUNTERS] menu provides information on the duration of the use of

the various instrument components and consumables. It is not needed for

operation and the instrument settings.

Note: While the instrument is in this menu, normal operation continues. If a key is not

pressed for longer than ten minutes, the display automatically returns to the display of the

data on operation.

MENU

Command

Description

+OP.COUNTERS

CLEANED

Month when cleaning was last performed, is automatically updated during [+FILTERCLEANING]

MODUL A

Operating time for filter module A in days

MODUL B

Operating time for filter module B in days

P.TUBES IN

Remaining operating time for both pump tubes in days (91 - 0 - negative number*)

P.CARTR.IN

Remaining operating time for both pump cartridges in days (365 - 0 - negative number*)

P.ROLL.IN

Remaining operating time for pump rollers in days (365 - 0 - negative number*)

AIR F.C.IN

Remaining operating time for the compressor air filter in days (365 - 0 - negative number*)

AIR F.H.IN

Remaining operating time for the two air filters in the control unit in days (91 - 0 - negative number*) - it is not

necessarily imperative to change the air filter on the air outlet side so frequently

COMP. IN

Remaining operating time for the compressor in days (730 - 0 - negative number*)

*If replacement date passed.

38

Page 41

5.6 [+SERVICE] menu

Operation

Important Note: All maintenance and service work apart from pure visual inspection must

be performed with the instrument in this menu!

When this menu is opened,

initially the message "OK - NO

SAMPLE!" appears to indicate

that on the activation of this

menu, sample feed to the

measuring instruments is

interrupted immediately!

Operation is only re-started

when this menu is actively left

using the keypad or a program

that is opened.

MENU

Command

Setting Description

+SERVICE

INTERVAL

30...300 s (default setting 60 s)

EXTRACTION

50...130% (default setting 100% = 900 ml/h this sample volume is produced on correct

installation under normal operating conditions

with clean filter modules)

PREPUMP

FILTERCLEANING

PHOTOMETER

ON/OFF Flow rate measurement can be switched on and off

If this menu is selected, then

• The pumps are stopped immediately

• The filter module venting is shut down

• The red signal lamp is illuminated

• The fault relay is set

• Only the temperature control and heater systems in the control unit and

the tubes remain active

The functions of the individual commands and sub-menus ([FILTERCLEANING],

[OP.COUNTERS], [+TEST OF FUNCT.]) are explained in detail in section 6

Maintenance and section 7 Faults, causes, rectification. They are not required for

normal operation.

Changeover interval for sample pumping between module A

and B

The volume pumped by the pumps is adjusted via the speed of

the pumps

For filling all tubes both pumps are operated simultaneously for

10 min.

The venting of the filter modules remains active - operation is

then re-started automatically

Menu-based cleaning of the filter modules, detailed description

in sec. 7.2 Maintenance - after each clean the date of the

operating counter [CLEANED] is automatically updated and

operation re-started

39

Page 42

Operation

MENU

Submenu

+SERVICE

+OP.COUNTERS

+TEST OF FUNCT.

Command Description

Open [+OP.COUNTERS] menu - all counters can now be

reset

Component Possible selections

compressor on, off

pump a (back and forward every 3 s), stop

pump b (back and forward every 3 s), stop

housing fan on, off

hous. heater on, off

heater tubes on, off

warning on, off

malfunction on, off

sensor a volume measurement a

sensor b volume measurement b

airvalve a op., cl.

airvalve b op., cl.

signallamps on, off (green/red simultaneously)

Every component listed can be operated and tested

individually

+SIGNALS

+DEVICEDATA

STATUS

Open [+SIGNALS] menu

Open [+DEVICEDATA] menu

Detailed fault description and acknowledgement

40

Page 43

Operation

41

Page 44

Section 6 Maintenance

Every 24 months

Replace

w Compressor

Weekly

Visual Inspection

w Sample Quality

w Device Function

w Air Filter

(Control Unit)

Every 3 months

Replace

w Pump Tubes

w Air Filter

(Control Unit)

Clean

w Filter Module

(if/as necessary)

w Sample Tubes

(if/as necessary)

Every 6 months

Check

w Air Filter

(Compressor)

w Pump Cartridges

w Pump Rollers

w Connecting Tubes

w Filter Module

w Elektronics

Every 12 months

Every 12 months

Replace Replace

w Air Filter w Air Filter

(Compressor) (Compressor)

w Pump Cartridges w Pump Cartridges

w Pump Rollers w Pump Rollers

w Connecting Tubes w Connecting Tubes

Number:

Place of sampling:

Installation Date: by:

Inspection and Maintenance as part of the

Service Contract

Maintenance by the

User

DOC273.52.04006.Jul03

FILTRAX

Maintenance Schedule

The manufacturer recommends taking out a service contract. This contract

extends the warranty to 5 years and ensures that all inspection and maintenance

work is performed by qualified personnel.

The maintenance to be performed by the user is then limited to regular visual

inspections, replacing consumables and cleaning, if necessary.

6.1 Maintenance work

The reliable and correct operation of this sample conditioning system can only be

ensured if the maintenance work is performed regularly as per the maintenance

calendar.

The necessary consumables are supplied or included in the set of annual

consumables.

The sample pressure tube must never be clamped such that it is blocked off - the

pressure build up would either result in damage to the tubes or the tube connections

would spring off!!

NOTICE

42

Page 45

6.1.1 Weekly

6.1.2 Every 3 months

Maintenance

Visual inspection

• General instrument function

• Function of the venting on the filter modules

• Quality of the filtered samples

• State of the air filter in the control unit

All maintenance work must

be performed in the [+SERVICE]

menu!

Fig. 6-26 Consumables after 3 months

Replacement of consumables and cleaning

• Replacement of the metering tubes

• Replacement of control unit air filter

(depending on condition only air inlet)

• Menu-based cleaning

(this cleaning interval can vary depending on the conditions)

Fig. 6-27 Metering tube replacement

43

Page 46

Maintenance

6.1.3 Every 12 or 24 months

Fig. 6-28

As part of the service contract by customer service:

after 12 months

• Replacement of the metering tubes together with the connecting tubes

• Replacement of the pump cartridges and pump rollers

• Replacement of compressor air filter

after 24 months

• Replacement of compressor

44

Page 47

6.1.4 Menu-based cleaning

Maintenance

DANGER

Potential danger with contact with chemical/biological substances.

Working with chemical samples, standards and reagents can be dangerous.

Make yourself familiar with the necessary safety procedures and the correct handling of

the chemicals before use and read and follow all relevant safety data sheets.

Normal operation of this device may require the use of samples that are

biologically unsafe.

WARNING

Observe all cautionary information printed on the original solution containers and safety

data sheets prior to their use.

Dispose of all consumed solutions in accordance with the local and national regulations

and laws.

Select the type of protective equipment suitable to the concentration and quantity of the

dangerous material being used.

Observe instructions and safety information (information on risks and safety) on the

containers for the chemicals used.

Wear safety clothing: Lab coat, Safety glasses, Rubber gloves

Action FILTRAX display

1. On all process instruments connected and on the FILTRAX open the [+SERVICE]

menu, then the [+FILTERCLEANING] menu.

2. Lift the module carrier out of the tank or flume and acknowledge with [ok].

3. Pull off the air and sample tubes connected to the module carrier, carefully pull out

the filter modules and acknowledge with [ok].

NOTICE

As far as possible do not touch the delicate membranes and never allow the membranes

to dry out, if necessary store the filter modules in the plastic bags supplied!

4. Carefully clean the filter modules using 5% chlorine bleach (sodium hypochloride) or

5% hydrochloric acid (for high iron concentrations) and a soft sponge, during this

process do not soil the air and sample suction pipe!

WARNING

Observe the safety precautions when handling the cleaning solution and wear

appropriate safety clothing!

The chlorine bleach must not come into contact with reagents containing acids, chlorine

gas will be formed!

5. After leaving to soak for 10 minutes, slide the filter modules directly back into the

module carrier, without prior rinsing with water, so that the sample tubes are cleaned

with the solution left in the filter - acknowledge cleaning with [ok].

6. Immerse module carrier again and acknowledge with [ok].

+FILTERCLEANING

NO SAMPLE!

REM.MOD.CARRIER

REMOVE MODUL

CLEAN MODUL

CLEAN MODUL

REPLACE MODUL

7. Activate cleaning of the sample pipes with the [PREPUMP] function

(600 seconds - counter counts backwards, the date for the operating time counter

[CLEANED] is now updated automatically).

After completion of the prepumping program, place all instruments connected back in

operation.

PREPUMP 600 s

45

Page 48

Maintenance

6.1.5 Cleaning with cleaning container (option)

Action FILTRAX display

1. On all process instruments connected and on the FILTRAX open the [+SERVICE]

menu to prevent the process instruments drawing in cleaning solution. Choose the

[+FILTERCLEANING] menu.

2. Lift the module carrier out of the tank or flume and accept with [ok].

3. Pull off the air and sample tubes connected to the module carrier, carefully pull out

the filter modules and acknowledge with [ok].

NOTICE

As far as possible do not touch the delicate membranes and never allow the membranes

to dry out.

4. Slide the filter modules into the cleaning container. Lay tubes as per diagram.

5. Carefully fill the cleaning container with 5% chlorine bleach (sodium hypochloride)!

WARNING

Observe the safety precautions when handling the cleaning solution and wear

appropriate safety clothing!

The chlorine bleach must not come into contact with reagents containing acids, chlorine

gas will be formed!

6. Soaking time: 10 minutes, then acknowledge with [ok]. Further clean or clean

mechanically in case of heavy soiling.

7. Activate the cleaning of the sample pipes using the [PREPUMP] function (counter

counts backwards from 600 s, the date for the operating time counter [CLEANED] is

now updated automatically).

8. Slide the filter modules back into the module carrier and immerse the module carrier

again at the location for the measurements.

[+FILTERCLEANING], NO SAMPLE

REM.MOD.CARRIER

REMOVE MODUL

CLEAN MODUL

REPLACE MODUL

PREPUMP 600 s (count down to 0)

46

Page 49

Maintenance

9. Open the [+SERVICE] menu and then the [PREPUMP] function.

10. 10-15 minutes later place all instruments back in operation.

[+SERVICE]

PREPUMP 600 s (count down to 0)

47

Page 50

Maintenance

6.1.6 Cleaning with cleaning set (option)

Action Menu/acknowledge

1. On all process instruments connected and on the FILTRAX open the

[+SERVICE] menu to prevent the process instruments drawing in cleaning

solution. Choose the [+FILTERCLEANING] menu.

2. Lift the module carrier out of the tank or flume and accept 2 x with [ok].

3. Carefully fill the cleaning bottle with 5% chlorine bleach (sodium hypochloride)!

[+FILTERCLEANING], NO SAMPLE

REM.MOD.CARRIER

REMOVE MODUL

WARNING

Observe the safety precautions when handling the cleaning solution and wear

appropriate safety clothing!

The chlorine bleach must not come into contact with reagents containing acids,

chlorine gas will be formed!

4. Pull off the sample tubes connected to the module carrier and acknowledge with

[ok]. Lay tubes as per diagram.

5. Activate the cleaning of the sample pipes using the [PREPUMP] function

(counter counts down from 600 s, the date for the operating time counter

[CLEANED] is now updated automatically).

6. Lay the tubes for the filter modules as before and immerse the module carrier

again at the location for the measurements.

7. Open the [+SERVICE] menu and then the [PREPUMP] function.

8. 10-15 minutes later place all instruments back in operation.

CLEAN MODUL

PREPUMP 600 s (count down to 0)

[+SERVICE]

PREPUMP 600 s (count down to 0)

48

Page 51

Section 7 Faults, causes, rectification

Note: FILTRAX has three different types of error messages

7.1 Messages

Only text is displayed referring to the need for the

replacement of consumables - the green signal lamp

remains active.

FAULT CAUSE RECTIFICATION

AIRFILTER COMP.

AIRFILTER CASE

PUMPWHEELS

PUMPCASSETTE

COMPRESSOR

The operating time counter for the compressor air

filter [AIR F.C.] has expired

The operating time counter for the control unit air

filter [AIR F.H.] has expired

The operating time counter for the pump rollers

[P.ROLL] has expired

The operating time counter for the pump

cartridges [P.CARTR.] has expired

The operating time counter for the compressor

[COMP.] has expired

Replace compressor air filter and reset operating

time counter

Replace control unit air filter and reset operating time

counter

Replace pump rollers and reset operating time

counter

Replace pump cartridges and reset operating time

counter

Replace compressor and reset operating time

counter

7.2 Warnings

Text is displayed, both signal lamps are active and the

warning relay contact is set. If possible rectify without delay!

FAULT CAUSE RECTIFICATION

PUMPTUBES

LESS SAMPLE

TEMPERATURE

TEST SETTINGS

The operating time counter for the pump tubes

[P.TUBES] has expired

The amount of sample from a module is below the

threshold set under [WARNING < ]

The temperature in the control unit is too high, the

filter module venting is shut down automatically

On the [+DEVICEDATA] menu some settings may

have been lost

Replace pump tubes and reset operating time

counter

Check all tubes, if necessary clean filter modules

Check fans in the control unit, if necessary replace

filter mats, reduce ambient temperature

Check all instrument settings on the [+DEVICEDATA]

menu and [+SERVICE] menu

49

Page 52

Faults, causes, rectification

7.3 Faults

Text is displayed, the red signal lamp is active and the fault

relay contact is set. Action must be taken immediately!

FAULT CAUSE RECTIFICATION

FAULT

PHOTOMETER

WARM UP MODE!

FAULT SAMPLE

FAULT DEVICE

TEMP.SENSOR

Electronic fault or

no measurable sample flow rate (e.g. valve faulty,

air bubbles due to lack of sample)

The temperature in the housing is <1 °C, the

instrument is warming up

The amount of sample from a module is below the

threshold set under [FAULT < ]

Serious electronic fault / bus fault

Normal operation is no longer possible!!

Temperature sensor faulty or not fitted

Normal operation is stopped because it is no

longer possible to regulate the temperature!

7.4 Voltage drop (power failure)

On a power failure both relay contacts are closed (warning

and fault signalling).

Check sample flow rate, if necessary clean sample

pipe, call customer service

Wait until the heater has raised the temperature in

the housing to > 1° C, the warm up phase then takes

a further 30 min. Keep door closed!

Check all tubes and pumps, if necessary clean filter

modules and sample pipe

Unplug from the mains for 1 min, if the fault is still

present

Call customer service

Check connection to temperature sensor,

Call customer service

50

Page 53

Section 8 Spare parts

Baysilone paste ..............................................................................................................................................EZH051

Sample tube 2 m unheated ............................................................................................................................ LZX675

Sample tube 10 m heated 230 V .................................................................................................................... LZX672

Sample tube 10 m heated 115 V .................................................................................................................... LZX671

Sample tube 20 m heated 230 V .................................................................................................................... LZX674

Sample tube 20 m heated 115 V .................................................................................................................... LZX673

Sample tube 30 m heated 230 V .................................................................................................................... LZX675

Filter mat set (8 pieces) for control unit .......................................................................................................... LZX017

Filter module completely packaged ................................................................................................................ LZX677

Plastic bag for storing filter module ...............................................................................................................EYV017

Set of tubes for one year ............................................................................................................................... LZX667

Set of annual consumables ............................................................................................................................ LZX018

Compressor 115 V.......................................................................................................................................... LZX025

Compressor 230 V.......................................................................................................................................... LZX024

Module carrier complete with 5 m suction tube 230 V.................................................................................... LZX670

Module carrier complete with 5 m suction tube 115 V.................................................................................... LZX669

Sample connecting tube (external), 6m, 2/4 mm black ..................................................................................HLS191

Pump cartridge .............................................................................................................................................. LZP777

Pump rollers 2-channel (5 pieces).................................................................................................................. LZX019

Valve (2/2 way) ............................................................................................................................................... LZV205

Accessories

Tank edge fastening, module carrier .............................................................................................. LZX414.00.00000

Tank edge fastening, module carrier

Bracket for control unit.................................................................................................................................... LZX676

Tube adapter set for instruments connected in series ................................................................................... LZX701

Pipe clamps .................................................................................................................................................. EHK063

Second fastening point for mounting pipe (for long struts) ............................................................................. LZX456

Cleaning container.......................................................................................................................................... LZX216

Cleaning set.................................................................................................................................................... LZX217

(mounting pipe with slot on side) ............................................... LZX414.00.40000

51

Page 54

52

Page 55

Section 9 Warranty and liability

The manufacturer warrants that the product supplied is free of material and

manufacturing defects and undertakes the obligation to repair or replace any

defective parts at zero cost.

The warranty period for instruments is 24 months. If a service contract is taken out

within 6 months of purchase, the warranty period is extended to 60 months.

With the exclusion of the further claims, the supplier is liable for defects including

the lack of assured properties as follows: all those parts that, within the warranty

period calculated from the day of the transfer of risk, can be demonstrated to have

become unusable or that can only be used with significant limitations due to a

situation present prior to the transfer of risk, in particular due to incorrect design,

poor materials or inadequate finish will be improved or replaced, at the supplier's

discretion. The identification of such defects must be notified to the supplier in

writing without delay, however at the latest 7 days after the identification of the

fault. If the customer fails to notify the supplier, the product is considered

approved despite the defect. Further liability for any direct or indirect damages is

not accepted.

If instrument-specific maintenance and servicing work defined by the supplier is to

be performed within the warranty period by the customer (maintenance) or by the

supplier (servicing) and these requirements are not met, claims for damages due

to the failure to comply with the requirements are rendered void.

Any further claims, in particular claims for consequential damages cannot be

made.

Consumables and damage caused by improper handling, poor installation or

incorrect use are excluded from this clause.

The manufacturer process instruments are of proven reliability in many

applications and are therefore often used in automatic control loops to provide the

most economical possible operation of the related process.

To avoid or limit consequential damage, it is therefore recommended to design the

control loop such that a malfunction in an instrument results in an automatic

change over to the backup control system; this is the safest operating state for the

environment and the process.

53

Page 56

Warranty and liability

54

Page 57

Section 10 Contact

HACH Company

World Headquarters

P.O. Box 389

Loveland, Colorado

80539-0389 U.S.A.

Tel (800) 227-HACH

(800) -227-4224

(U.S.A. only)

Fax (970) 669-2932

orders@hach.com

www.hach.com

HACH LANGE GMBH

Willstätterstraße 11

D-40549 Düsseldorf

Tel. +49 (0)2 11 52 88-320

Fax +49 (0)2 11 52 88-210

info@hach-lange.de

www.hach-lange.de

HACH LANGE GMBH

Rorschacherstrasse 30a

CH-9424 Rheineck

Tel. +41 (0)848 55 66 99

Fax +41 (0)71 886 91 66

info@hach-lange.ch

www.hach-lange.ch

Repair Service in the

United States:

HACH Company

Ames Service

100 Dayton Avenue

Ames, Iowa 50010

Tel (800) 227-4224

(U.S.A. only)

Fax (515) 232-3835

HACH LANGE LTD

Pacific Way

Salford

GB-Manchester, M50 1DL

Tel. +44 (0)161 872 14 87

Fax +44 (0)161 848 73 24

info@hach-lange.co.uk

www.hach-lange.co.uk

HACH LANGE FRANCE

S.A.S.

8, mail Barthélémy Thimonnier

Lognes

F-77437 Marne-La-Vallée

cedex 2

Tél. +33 (0) 820 20 14 14

Fax +33 (0)1 69 67 34 99

info@hach-lange.fr

www.hach-lange.fr

Repair Service in Canada:

Hach Sales & Service

Canada Ltd.

1313 Border Street, Unit 34

Winnipeg, Manitoba

R3H 0X4

Tel (800) 665-7635

(Canada only)

Tel (204) 632-5598

Fax (204) 694-5134

canada@hach.com

HACH LANGE LTD

Unit 1, Chestnut Road

Western Industrial Estate

IRL-Dublin 12

Tel. +353(0)1 460 2522

Fax +353(0)1 450 9337

info@hach-lange.ie

www.hach-lange.ie

HACH LANGE NV/SA

Motstraat 54

B-2800 Mechelen

Tel. +32 (0)15 42 35 00

Fax +32 (0)15 41 61 20

info@hach-lange.be

www.hach-lange.be

Repair Service in

Latin America, the

Caribbean, the Far East,

Indian Subcontinent, Africa,

Europe, or the Middle East:

Hach Company World

Headquarters,

P.O. Box 389

Loveland, Colorado,

80539-0389 U.S.A.

Tel +001 (970) 669-3050

Fax +001 (970) 669-2932

intl@hach.com

HACH LANGE GMBH

Hütteldorfer Str. 299/Top 6

A-1140 Wien

Tel. +43 (0)1 912 16 92

Fax +43 (0)1 912 16 92-99

info@hach-lange.at

www.hach-lange.at

DR. LANGE NEDERLAND

B.V.

Laan van Westroijen 2a

NL-4003 AZ Tiel

Tel. +31(0)344 63 11 30

Fax +31(0)344 63 11 50

info@hach-lange.nl

www.hach-lange.nl

HACH LANGE APS

Åkandevej 21

DK-2700 Brønshøj

Tel. +45 36 77 29 11

Fax +45 36 77 49 11

info@hach-lange.dk

www.hach-lange.dk

HACH LANGE LDA

Av. do Forte nº8

Fracção M

P-2790-072 Carnaxide

Tel. +351 214 253 420

Fax +351 214 253 429

info@hach-lange.pt

www.hach-lange.pt

HACH LANGE KFT.

Vöröskereszt utca. 8-10.

H-1222 Budapest XXII. ker.

Tel. +36 1 225 7783

Fax +36 1 225 7784

info@hach-lange.hu

www.hach-lange.hu

HACH LANGE AB

Vinthundsvägen 159A

SE-128 62 Sköndal

Tel. +46 (0)8 7 98 05 00

Fax +46 (0)8 7 98 05 30

info@hach-lange.se

www.hach-lange.se

HACH LANGE SP. ZO.O.

ul. Krakowska 119

PL-50-428 Wrocław

Tel. +48 801 022 442

Zamówienia: +48 717 177 707

Doradztwo: +48 717 177 777

Fax +48 717 177 778

info@hach-lange.pl

www.hach-lange.pl

HACH LANGE S.R.L.

Str. Căminului nr. 3,

et. 1, ap. 1, Sector 2

RO-021741 Bucureşti

Tel. +40 (0) 21 205 30 03

Fax +40 (0) 21 205 30 17

info@hach-lange.ro

www.hach-lange.ro

HACH LANGE S.R.L.

Via Rossini, 1/A

I-20020 Lainate (MI)

Tel. +39 02 93 575 400

Fax +39 02 93 575 401

info@hach-lange.it

www.hach-lange.it

HACH LANGE S.R.O.

Zastrčená 1278/8

CZ-141 00 Praha 4 - Chodov

Tel. +420 272 12 45 45

Fax +420 272 12 45 46

info@hach-lange.cz

www.hach-lange.cz

HACH LANGE

8, Kr. Sarafov str.

BG-1164 Sofia

Tel. +359 (0)2 963 44 54

Fax +359 (0)2 866 15 26

info@hach-lange.bg

www.hach-lange.bg

HACH LANGE S.L.U.

Edificio Seminario

C/Larrauri, 1C- 2ª Pl.

E-48160 Derio/Vizcaya

Tel. +34 94 657 33 88

Fax +34 94 657 33 97

info@hach-lange.es

www.hach-lange.es

HACH LANGE S.R.O.

Roľnícka 21

SK-831 07 Bratislava –

Vaj nory

Tel. +421 (0)2 4820 9091

Fax +421 (0)2 4820 9093

info@hach-lange.sk

www.hach-lange.sk

HACH LANGE SU

ANALİZ SİSTEMLERİ

LTD. ŞTİ.

Ilkbahar mah. Galip Erdem

Cad. 616 Sok. No:9

TR-Oran-Çankaya/ANKARA

Tel. +90312 490 83 00

Fax +90312 491 99 03

bilgi@hach-lange.com.tr

www.hach-lange.com.tr

55

Page 58

Contact

HACH LANGE D.O.O.

Fajfarjeva 15

SI-1230 Domžale

Tel. +386 (0)59 051 000

Fax +386 (0)59 051 010

info@hach-lange.si

www.hach-lange.si

HACH LANGE OOO

Finlyandsky prospekt, 4A

Business Zentrum “Petrovsky

fort”, R.803

RU-194044, Sankt-Petersburg

Tel. +7 (812) 458 56 00

Fax. +7 (812) 458 56 00

info.russia@hach-lange.com

www.hach-lange.com

ΗΑCH LANGE E.Π.Ε.

Αυλίδος 27

GR-115 27 Αθήνα

Τηλ . +30 210 7777038

Fax +30 210 7777976

info@hach-lange.gr

www.hach-lange.gr

HACH LANGE D.O.O.

Ivana Severa bb

HR-42 000 Varaždin

Tel. +385 (0) 42 305 086

Fax +385 (0) 42 305 087

info@hach-lange.hr

www.hach-lange.hr

HACH LANGE MAROC

SARLAU

Villa 14 – Rue 2 Casa

Plaisance

Quartier Racine Extension

MA-Casablanca 20000

Tél. +212 (0)522 97 95 75

Fax +212 (0)522 36 89 34

info-maroc@hach-lange.com

www.hach-lange.ma

56

Loading...

Loading...