Page 1

DOC023.52.80221

FT660 sc

01/2012, Edition 2

User Manual

Page 2

Page 3

Table of Contents

Specifications..................................................................................................................................................................................3

General information.....................................................................................................................................................................4

Safety information..............................................................................................................................................................................4

Use of hazard information..................................................................................................................................................................4

Precautionary labels..........................................................................................................................................................................4

Certification........................................................................................................................................................................................5

Product overview...............................................................................................................................................................................5

Product components..........................................................................................................................................................................6

Installation.........................................................................................................................................................................................7

Installation guidelines.........................................................................................................................................................................7

Mechanical installation.......................................................................................................................................................................7

Instrument mounting...................................................................................................................................................................7

Electrical installation..........................................................................................................................................................................8

Connect an sc controller using Quick-connect fitting..................................................................................................................8

Plumbing............................................................................................................................................................................................8

Sample line considerations.........................................................................................................................................................8

Connect the sample stream........................................................................................................................................................8

Operation............................................................................................................................................................................................9

Using the sc controller.......................................................................................................................................................................9

Configure the instrument....................................................................................................................................................................9

Data logging.....................................................................................................................................................................................10

Calibration........................................................................................................................................................................................10

Prepare the StablCal® Standard...............................................................................................................................................10

Calibration notes.......................................................................................................................................................................10

Calibration procedure...............................................................................................................................................................10

Calibration verification......................................................................................................................................................................11

Types of verifications................................................................................................................................................................12

Verification procedure with a wet standard...............................................................................................................................12

Prerequisites for dry standard use............................................................................................................................................12

Verification with a dry standard and software...........................................................................................................................13

1

Page 4

Table of Contents

Enable the dry standard software......................................................................................................................................13

Assign a baseline value to the dry standard......................................................................................................................13

Verification procedure with dry standard and software......................................................................................................14

Verification with a dry standard without software......................................................................................................................15

Assign a baseline value to the dry standard......................................................................................................................15

Verification procedure with dry standard without software................................................................................................16

Calibration and verification history...................................................................................................................................................16

Maintenance...................................................................................................................................................................................16

Maintenance schedule.....................................................................................................................................................................17

Clean the instrument........................................................................................................................................................................17

How to clean spills....................................................................................................................................................................20

Troubleshooting..........................................................................................................................................................................20

Errors...............................................................................................................................................................................................20

Warnings..........................................................................................................................................................................................20

Diagnostics and Test menu.............................................................................................................................................................21

Theory of operation...................................................................................................................................................................22

RSD parameter................................................................................................................................................................................22

Correlation study between kaolin standards and measured turbidity......................................................23

Replacement parts and accessories...............................................................................................................................24

2

Page 5

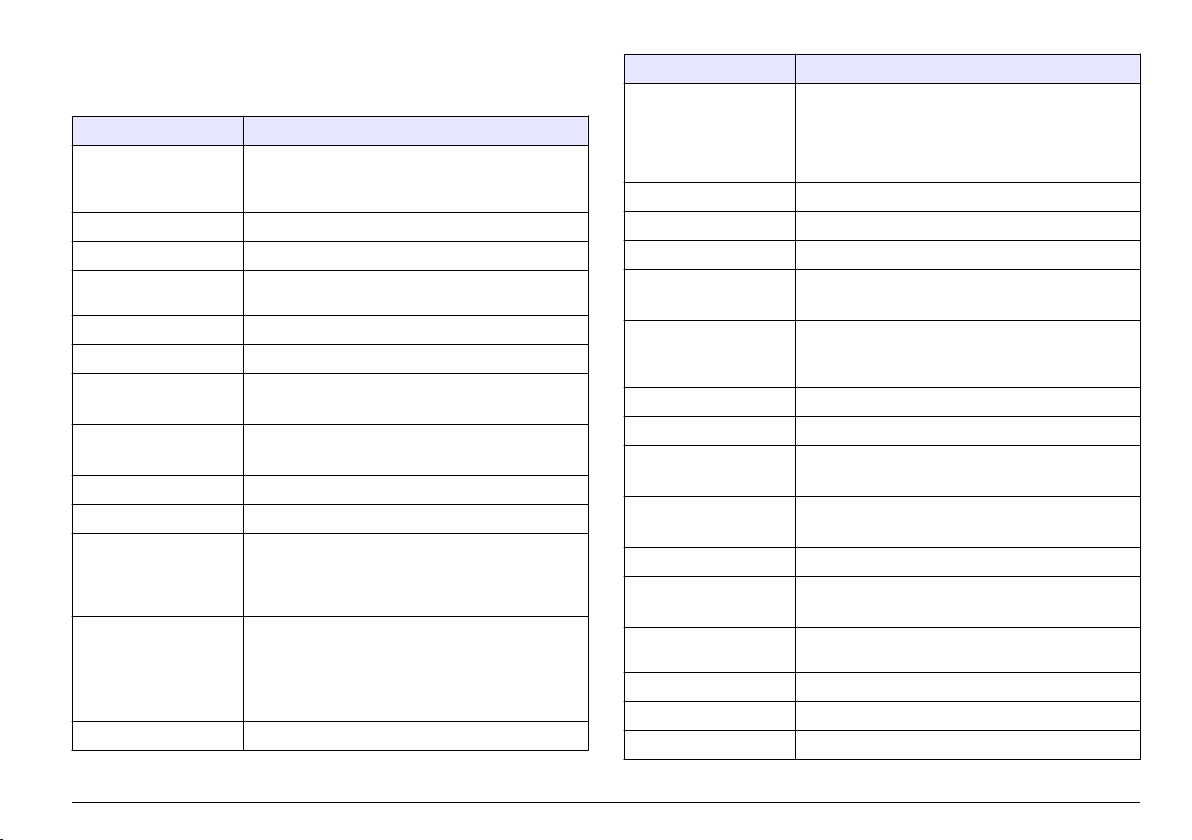

Specifications

Specifications are subject to change without notice.

Specification Details

Range 0.000–5000 milli-Nephelometric Turbidity Units

Measurement units mNTU, mFTU, NTU, FTU, mg/L, Degree

Over-range limit

Method compliance USEPA Approved for drinking water applications by

Lowest expected reading 7 mNTU

Accuracy ±3% of reading or ±5 mNTU (whichever is greater)

Repeatability ±0.42% at 50 mNTU

Resolution 0.001 mNTU on lowest range

Calibration Single point at 800 mNTU ±50 mNTU

Calibration frequency Every 3 months (or as per regulations)

Calibration (wet)

verification method

Calibration (dry)

verification method

Signal averaging No averaging, 6, 30, 60 or 90 seconds

*

(mNTU)

(0–5.0 NTU with +10% over-range limit)

+10%

Method 10133

±0.3% at 800 mNTU

0.1 mNTU on highest range

Pass/fail criteria or tolerance (standards less than

1000 mNTU): 25–50 mNTU

Pass/fail criteria or tolerance (standards greater than

1000 mNTU): 5%

Verification level: 20–50 mNTU

Performance default: ±5 mNTU of the identified

baseline value

Method precision: less than or equal to 5% relative

standard deviation (RSD)

Specification Details

Sample light source Class 1 Laser Product with embedded 7.5 mW,

Power requirement 10.5 to 13.2 VDC at 1.5 VA

Operating conditions 0 to 40 °C (32 to 100 °F), 5–95% non-condensing

Storage conditions –20 to 60 °C (–4 to 140 °F)

Sample requirements Temperature: 0 to 50 °C (32 to 121 °F)

Recorder output 0–20 mA or 4–20 mA

Sample inlet fitting ¼-in. NPT female, ¼-in. compression fitting

Drain fitting ½-in. NPT female, ½-in. hose barb

Tubing requirements Sample inlet: ¼-inch OD rigid or semi-rigid tubing

Dimensions

(W x D x H)

Mounting options Wall mounted or floor stand

Shipping weight Turbidimeter and controller—16.31 kg (13.5 lb)

ASTM conformance D6698 Standard test method for online measurement

Limit of detection (LOD) 0.296 mNTU (ISO 15839)

Protection class III

Pollution degree 2/II

670 nm, Class 3B Laser Source

Complies with 21 CFR 1040.10 except for deviations

pursuant to Laser Notice No. 50, dated June 24,

2007. FDA Laser Accession No. 9911570

Flow: 100–750 mL/minute (1.6–11.9 gal/hour)

The output span is programmable over any portion of

the 0.000–1000 mNTU range.

Drain: ½-inch ID flexible plastic tubing

25.4 x 30.5 x 40.6 cm (10 x 12 x 16 in.)

Turbidimeter only—4.71 kg (10 lb)

of turbidity below 5 NTU

English 3

Page 6

*

The instrument range is from 0 to 5000 mNTU. The instrument is

guaranteed to meet specifications relative to accuracy, repeatability and

linearity up to 5000 mNTU. The instrument will still show a value above

5000 mNTU to the level of 5500 mNTU, but above 5000 mNTU,

measurement performance is not guaranteed. Between 5000 and

5500 mNTU, the warning alarm will flash to tell the operator that the

operating range has been exceeded. An over-range event is also logged.

All alarm setpoints are calculated based on the maximum value show

(5500 mNTU).

C A U T I O N

Indicates a potentially hazardous situation that may result in minor or moderate

injury.

Indicates a situation which, if not avoided, may cause damage to the instrument.

Information that requires special emphasis.

N O T I C E

General information

In no event will the manufacturer be liable for direct, indirect, special,

incidental or consequential damages resulting from any defect or

omission in this manual. The manufacturer reserves the right to make

changes in this manual and the products it describes at any time, without

notice or obligation. Revised editions are found on the manufacturer’s

website.

Safety information

Please read this entire manual before unpacking, setting up or operating

this equipment. Pay attention to all danger and caution statements.

Failure to do so could result in serious injury to the operator or damage

to the equipment.

Make sure that the protection provided by this equipment is not impaired.

Do not use or install this equipment in any manner other than that

specified in this manual.

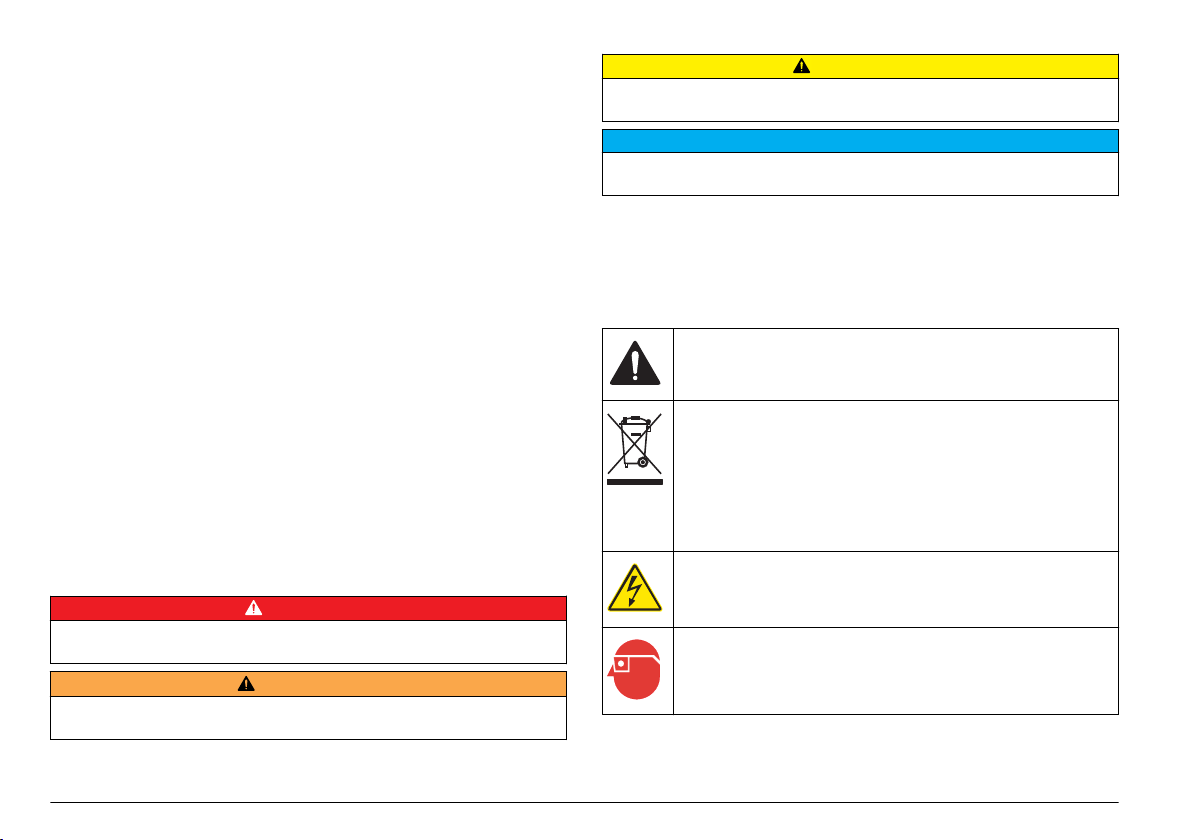

Use of hazard information

D A N G E R

Indicates a potentially or imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially or imminently hazardous situation which, if not avoided,

could result in death or serious injury.

W A R N I N G

Precautionary labels

Read all labels and tags attached to the instrument. Personal injury or

damage to the instrument could occur if not observed. A symbol, if noted

on the instrument, will be included with a danger or caution statement in

the manual.

This symbol, if noted on the instrument, references the instruction

manual for operation and/or safety information.

Electrical equipment marked with this symbol may not be disposed of

in European public disposal systems after 12 August of 2005. In

conformity with European local and national regulations (EU Directive

2002/98/EC), European electrical equipment users must now return

old or end-of-life equipment to the Producer for disposal at no charge

to the user.

Note: For return for recycling, please contact the equipment producer or supplier

for instructions on how to return end-of-life equipment, producer-supplied

electrical accessories, and all auxillary items for proper disposal.

This symbol indicates that a risk of electrical shock and/or

electrocution exists.

This symbol indicates the need for protective eye wear.

4 English

Page 7

This symbol indicates a laser device is used in the equipment.

This symbol, when noted on the product, identifies the location of a

fuse or current limiting device.

This symbol indicates that the marked item requires a protective earth

connection. If not provided with a plug on a cord, connect positive

earth to this terminal (U.S. cord set provides ground).

Certification

Canadian Radio Interference-Causing Equipment Regulation,

IECS-003, Class A:

Supporting test records reside with the manufacturer.

This Class A digital apparatus meets all requirements of the Canadian

Interference-Causing Equipment Regulations.

Cet appareil numèrique de la classe A respecte toutes les exigences du

Rëglement sur le matériel brouilleur du Canada.

FCC Part 15, Class "A" Limits

Supporting test records reside with the manufacturer. The device

complies with Part 15 of the FCC Rules. Operation is subject to the

following conditions:

1. The equipment may not cause harmful interference.

2. The equipment must accept any interference received, including

interference that may cause undesired operation.

Changes or modifications to this equipment not expressly approved by

the party responsible for compliance could void the user's authority to

operate the equipment. This equipment has been tested and found to

comply with the limits for a Class A digital device, pursuant to Part 15 of

the FCC rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated

in a commercial environment. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference

to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference, in which case the user will be

required to correct the interference at their expense. The following

techniques can be used to reduce interference problems:

1. Disconnect the equipment from its power source to verify that it is or

is not the source of the interference.

2. If the equipment is connected to the same outlet as the device

experiencing interference, connect the equipment to a different

outlet.

3. Move the equipment away from the device receiving the interference.

4. Reposition the receiving antenna for the device receiving the

interference.

5. Try combinations of the above.

Product overview

D A N G E R

Chemical or biological hazards. If this instrument is used to monitor a

treatment process and/or chemical feed system for which there are

regulatory limits and monitoring requirements related to public health,

public safety, food or beverage manufacture or processing, it is the

responsibility of the user of this instrument to know and abide by any

applicable regulation and to have sufficient and appropriate

mechanisms in place for compliance with applicable regulations in the

event of malfunction of the instrument.

Although the sc controller is certified for Class 1, Division 2 Hazardous Locations,

it is only certified when installed with sensors listed in Control Drawings 5860078.

The sc controller and FT660 sc are NOT suitable for use in Class 1, Division

2 Hazardous Locations.

The FT660 sc is a continuous-reading instrument for filter management

(Figure 1). The FT660 sc is appropriate for ultra pure and all processes

that include clean water monitoring.

D A N G E R

English 5

Page 8

The status light on the head assembly is illuminated when an error

occurs and flashes when a warning occurs or the head assembly is not

installed correctly.

The back of the head assembly has a molded "lip" that may be used to

hang the head on the edge of the body of the instrument during

maintenance.

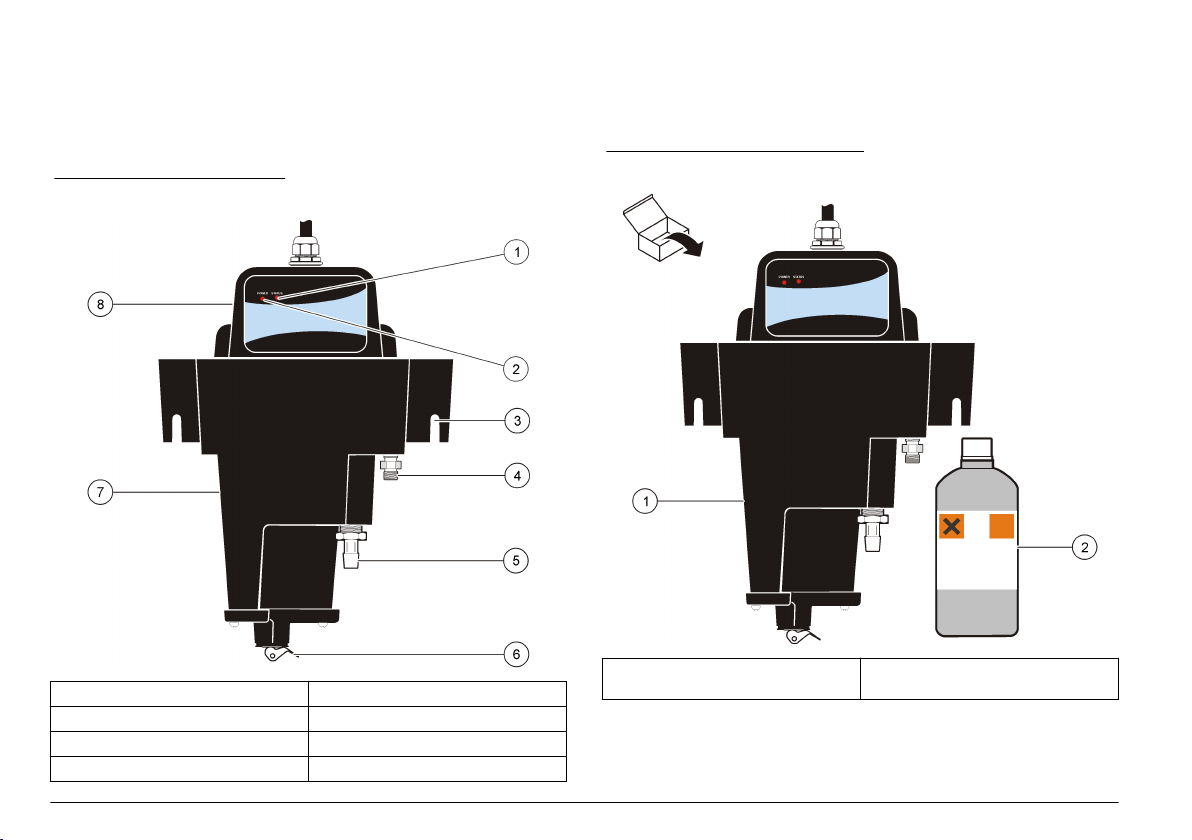

Figure 1 Instrument overview

Product components

Make sure that all components have been received (Figure 2). If any

items are missing or damaged, contact the manufacturer or a sales

representative immediately.

Figure 2 Instrument components

1 Status light 5 Drain fitting

2 Power light 6 Drain plug

3 Mounting bracket 7 Body of the instrument

4 Sample inlet fitting 8 Head assembly

6 English

1 FT660 sc turbidimeter 2 800 mNTU StablCal® Certified

Standard

Page 9

Installation

D A N G E R

Multiple hazards. Only qualified personnel must conduct the tasks

described in this section of the document.

Installation guidelines

N O T I C E

High internal temperatures will damage the instrument components.

• Do not operate the instrument in direct sunlight or next to a heat

source.

Install the instrument indoors in a clean environment with minimum

•

vibration.

Note: Particulate contamination from the surrounding area is a major cause of

error.

• Install the instrument level.

• Keep the flow rate and operating temperature as constant as possible

for best performance.

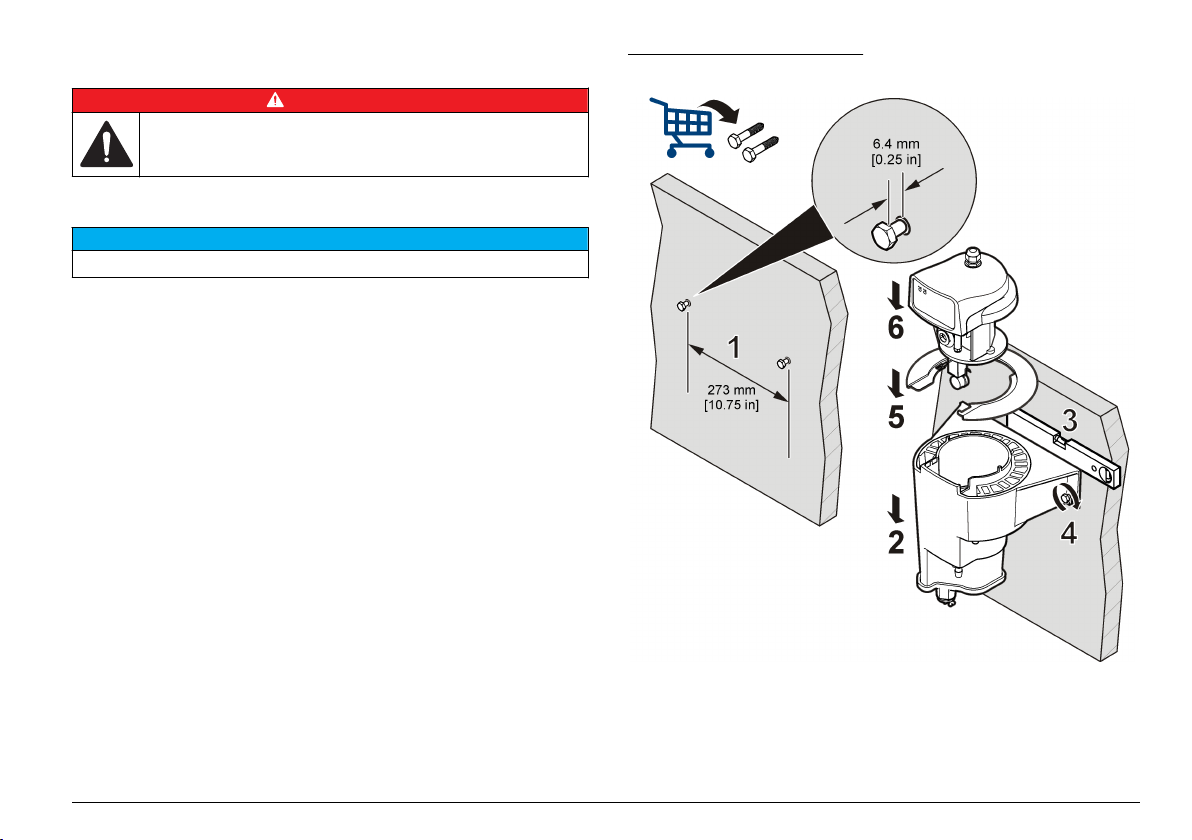

Mechanical installation

Instrument mounting

Install this instrument on a flat, vertical surface. Refer to the illustrated

steps in Figure 3. Mounting hardware (two ¼-20 bolts) is supplied by the

customer.

Install the instrument as near to the sampling point as possible to

minimize lag time of the sample flow.

Refer to Figure 4 for instrument dimensions and clearance

specifications.

Note: As an alternative, this instrument can be installed on the optional floor stand.

Figure 3 Instrument mounting

English 7

Page 10

Figure 4 Instrument dimensions

1 22 cm (10 in.) minimum clearance

Electrical installation

Connect an sc controller using Quick-connect fitting

The instrument can be connected to an sc controller using the keyed

quick-connect fitting (Figure 5). Extension cables are available. Retain

the connector cap to seal the connector opening in case the instrument

must be removed. Refer to the sc controller manual for more information.

Figure 5 Quick-connect fitting

Plumbing

Sample line considerations

Select a good, representative sampling point for optimum instrument

performance. The sample analyzed must be representative of the

conditon of the entire system.

To minimize erratic readings:

Draw samples from locations that are sufficiently distant from points of

•

chemical additions to the process stream

• Make sure samples are sufficiently mixed

• Make sure all chemical reactions are complete

Connect the sample stream

Connect sample inlet and drain lines to the fittings on the body of the

instrument (Figure 1 on page 6). Sample inlet and drain tubing are

supplied by the customer. Refer to Specifications on page 3 for tubing

requirements.

Install the sample line(s) into a larger process pipe to minimize

interference from air bubbles or pipeline bottom sediment. A sample line

going into the center of a process pipe is best.

8 English

Page 11

Figure 6 shows examples of good and bad methods of installing a

sample line into a process pipe.

Notes:

•

Keep the sample inlet and drain tubing as short as possible to

minimize lag time of the sample flow.

• Control the flow rate into the instrument with a flow restriction device

on the sample line. Refer to Specifications on page 3 for flow rate

specifications.

Note: Flow rates greater than 750 mL/minute will cause the instrument to

overflow into the drain, decrease the performance of the bubble trap and cause

incorrect readings.

Figure 6 Sampling methods

1 Air 2 Sample flow

Operation

Configure the instrument

Use the Configure menu to enter identification information and display

options for the instrument and to change options for instrument settings,

data handling and storage.

1. From the Main menu, select Sensor Setup, [Select Sensor],

Configure.

2. Use the arrow keys to select an option and confirm. To enter

numbers, characters or punctuation, push and hold the UP or DOWN

arrow keys. Push the RIGHT arrow key to advance to the next

space.

Option Description

BUBBLE

REJECT

SIGNAL AVG Select no signal averaging or the amount of time for

MEAS UNITS Select the measurement units to show on the display—

EDIT NAME Change the name to show on the display for the

SET

RESOLUTION

Enable or disable bubble reject—Yes (default) or No

Bubble reject is an averaging algorithm that

compensates for higher readings caused by entrained

air coming out of the solution in the sample chamber.

signal averaging—no averaging, 6, 30, 60 or 90 (default)

seconds.

mNTU (default), mFTU, NTU, FTU, mg/L or Degree.

instrument. The instrument name can be a maximum of

12-digits in any combination of symbols and alpha or

numeric characters.

Note: The serial number of the instrument is the default

name.

Set the number of significant digits to show on the

display (default=3).

Using the sc controller

Before using the instrument with an sc controller become familiar with

the operating mode of the sc controller. Refer to the sc controller user

manual and learn how to use and navigate the menu functions.

English 9

Page 12

Option Description

DATALOG

INTRVL

OFFSET Sets an offset of the value of the standard used for

Select the interval between saving data points to the

data log—30 seconds or 1, 5, 10 or 15 (default) minutes.

calibration (-50 to +50 mNTU, default=0).

The offset value is subtracted from the calibration

standard value shown on the sc controller.

The offset can be entered after a calibration is complete

and is based on independent turbidity measurement of

the calibration standard.

Note: The offset will not result in a calibration standard

value of less than zero on the sc controller.

Data logging

The sc controller provides one data log and one event log for each

instrument. The data log stores the measurement data at selected

intervals. The event log stores different types of events that occur on the

devices (i.e., configuration changes, alarms and warning conditions).

The data log and the event log can be saved in CSV format. Refer to the

sc controller user manual for instructions.

Calibration

Calibration is done in the body of the instrument or using the optional

calibration kit.

Calibration is done using 1 L of 800 ± 50 mNTU StablCal Stabilized

Formazin Certified Standard. Do not use other types or values of

standards. Do not use user-prepared formazin.

The performance specifications given in this manual are based on and

guaranteed only when calibration is done with StablCal Stabilized

Formazin Certified Standard for this instrument. The manufacturer

cannot guarantee the performance of the instrument if calibrated with copolymer styrenedivinylbenzene beads or other suspensions.

Prepare the StablCal®

• Before opening a StablCal Standard bottle, clean the exterior surface

of the bottle with clean water to remove dust or other debris.

Standard

• Gently invert the bottle for 1 minute (about 50 inversions). Do not

shake.

Note: The suspension is stable for 30–60 minutes after mixing.

The StablCal Certified Standard is stabilized formazin with a value that is

identified to within ± 1 mNTU. The value, specific to that particular lot of

product, is printed on the label. Lot-to-lot variation will be ± 50 mNTU

from the standard value, with a standard deviation of less than ± 5%

within a single lot.

Calibration notes

Calibrate the instrument before initial use.

•

• Calibrate the instrument every three months (or as set by regulatory

agencies).

• Calibrate the instrument after any significant maintenance or repair is

done on the instrument.

• Always clean the instrument immediately before calibration. Refer to

Clean the instrument on page 17.

• Operate the instrument at least 10 hours before calibration.

• For the best calibration, calibrate the instrument when it is at the same

temperature as the operating conditions.

• The Hold Outputs feature is automatically enabled during the zero

electronics and calibration procedure. The Hold Output feature holds

attached outputs at the before-calibration settings.

Calibration procedure

1. From the Main menu, select Sensor Setup, [Select Sensor],

Calibrate, StablCal Cal.

2. Select the available Output Mode (Active, Hold or Transfer) from the

list box and confirm.

3. Remove the head assembly and bubble trap cover from the body of

the instrument. Refer to Figure 7.

4. Make sure that the body of the instrument is drained completely.

5. Enter the turbidity value that is on the label of the StablCal Standard

bottle and confirm.

10 English

Page 13

6. Put a funnel at the end of the bubble trap and slowly put 800 mNTU

StablCal Standard in the funnel to fill the body. Refer to Figure 7.

7. Put the bubble trap cover and head assembly on the body of the

instrument.

Note: If the head assembly is not correctly installed, the laser will not turn on

and the reading on the display will be near 0.000 mNTU or a negative value.

The red status light on the instrument will also flash one time per second.

8. When the turbidity reading is stable (and after greater than

5 minutes), confirm to accept the reading.

9. When the display shows "GOOD CAL! GAIN: X.XX ENTER TO

CONT.", confirm to save the turbidity value.

Note: If the display shows "BAD CAL!", confirm to do the calibration again or

exit.

10. When the display shows "VERIFY CAL?", confirm to do a calibration

verification or exit without verification.

11. Do a calibration verification or enter the operator initials to complete

the calibration.

12. When the display shows "RETURN SENSOR TO MEASURE

MODE", confirm.

Figure 7 Calibrate the instrument

1 Head assembly 4 Funnel

2 800 mNTU StablCal® Certified

Standard

3 Bubble trap 6 Bubble trap cover

5 Body of the instrument

Calibration verification

Do a calibration verification immediately after every calibration.

Subsequent verifications are referenced to the initial verification.

Do a calibration verification monthly between calibrations.

A calibration verification is a check that is done to make sure that the

instrument is working correctly and calibrated.

English 11

Page 14

Types of verifications

Wet or dry standards can be used to do calibration verifications.

To do a wet standard verification, refer to Verification procedure with a

wet standard on page 12.

To do a dry standard verification, refer to Prerequisites for dry standard

use on page

12 and then either:

• Verification with a dry standard and software on page 13—Applies

to instruments with dry standard software.

• Verification with a dry standard without software on page 15—

Applies to instruments that do not have dry standard software.

Verification procedure with a wet standard

Wet standard verification is done using 1 L of StablCal Stabilized

Formazin Certified Standard (0–5500 mNTU) for this instrument . Do not

use other standards. Do not use user-prepared formazin.

Note: For the best verification results, clean the instrument before doing a wet

standard verification. Refer to Clean the instrument on page 17.

Note: On the sc controller, there is no option to set the pass or fail criteria (PFC)

for a wet verification. The default PFC is ± 50 mNTU (0.050 NTU) or 5% of the

reading, whichever is greater.

1. From the Main menu, select Sensor Setup, [Select Sensor],

Calibrate, Verification, Perform Ver.

2. Select the available Output Mode (Active, Hold or Transfer) from the

list box and confirm.

3. Select WET for the verification type and confirm.

4. Enter the turbidity value that is on the label of the StablCal Standard

bottle and confirm.

5. When the display shows "DRAIN AND CLEAN BODY. ENTER TO

CONT.", fully flush the body of the instrument with water that is less

than 50 mNTU (0.05 NTU).

a. Remove the head assembly and bubble trap cover from the body

of the instrument. Refer to Figure 7 on page 11.

b. Put an empty container under the instrument.

c. Remove the drain plug from the bottom of the body of the

instrument. Refer to Figure 1 on page 6.

Note: There is no risk of laser exposure with the drain plug removed. The

laser is disabled when the head assembly is removed.

d. Fully flush the body of the instrument with water that is less than

50 mNTU (0.05 NTU).

e. Install the drain plug in the instrument.

6. Prepare the StablCal standard. Refer to Prepare the StablCal

Standard on page

10.

®

7. Put a funnel at the end of the bubble trap and slowly put the StablCal

Standard in the funnel to fill the body. Confirm. Refer to Figure 7

on page 11.

8. Put the bubble trap cover and head assembly on the body of the

instrument.

9. When the turbidity reading is stable (and after greater than

5 minutes), confirm to accept the reading.

10. If "GOOD VER" (good verification) is shown:

a. Select ENTER INITIALS and confirm.

b. Enter operator initials and confirm.

c. Select RETURN SENSOR TO MEASURE MODE and confirm.

11. If "BAD VER" (bad verification) is shown:

a. To do the calibration verification again, confirm.

Note: If the verification fails two times, “Please Recalibrate” is shown, then

the display returns to the Calibrate Menu. Verification cannot be done until

the instrument is recalibrated.

b. To exit, push BACK.

Note: The bad verification is saved in the verification history.

Prerequisites for dry standard use

In order to use the dry standard, the instrument must have a special

aperture plate. Refer to Figure 8 on page 14. The instrument can also

have a software upgrade to install dry standard software.

Instruments made before April 2008 do not have the special aperture

plate. Customers can order and install the special aperture plate.

Installation instructions are provided with the aperture plate.

12 English

Page 15

Instruments made before April 2008 do not have dry standard software

installed. Software upgrades must be done by the manufacturer.

Starting in April of 2008, the aperture plate and dry standard software

will be installed on instruments at the time of manufacture.

Verification with a dry standard and software

This procedure includes instructions on how to:

•

Enable the dry standard software and set the pass or fail criteria for

verification

• Find and save a baseline value for the dry standard using the dry

standard software

• Do a dry standard verification using the dry standard software

Find and save the baseline value for the dry standard immediately after

the instrument is calibrated and after every subsequent calibration. Refer

to Assign a baseline value to the dry standard on page 13.

The baseline value is referenced for subsequent calibration verifications

until the next calibration.

Note: When not in use, keep the dry standard in the protective case.

Enable the dry standard software

1. From the Main menu, select Sensor Setup, [Select Sensor],

Calibrate, Verification, CVM Select, Enable.

2. To set the pass or fail criteria to a value other than the recommended

default (± 5 mNTU):

a. Select Verification, P/F Criteria.

Note: The P/F Criteria menu option is available only if CVM is set to

ENABLE in step 1.

b. Use the arrow keys to change the PFC (pass or fail criteria) value

and confirm.

The PFC range is 5–250 mNTU.

Assign a baseline value to the dry standard

1. After the instrument is calibrated and the operator initials have been

entered, the display shows "VERIFY CAL?". Confirm to start the

verification process.

2. Select DRY for the verification type and confirm.

3. Remove the head assembly from the body of the instrument.

4. Remove the dry standard from the protective case. Refer to Figure 8.

5. Record the serial number of the dry standard. Refer to Figure 8.

6. Clean, dry and inspect the dry standard.

a. Use the disposable wipes provided to clean the dry standard.

b. Use a dry cloth to dry the top 1/3 of the dry standard. Refer to

Figure 8.

c. Make sure that the glass of the dry standard is free of chips and

scratches.

7. Install the dry standard.

a. Put the dry standard in the aperture plate. Make sure that the

locking pin goes in the notch in the aperture plate. Refer to

Figure 8.

b. Turn the dry standard 1/8 of a turn clockwise until the dry standard

locks in position.

c. Use a dry cloth to remove any fingerprints and oils from the glass

of the dry standard.

8. Put the head assembly on the body of the instrument.

9. Enter the serial number of the dry standard, then confirm.

10. When the instrument reading is stable, confirm to accept the reading

as the baseline value.

11. Remove the dry standard from the instrument.

a. Remove the head assembly from the body of the instrument.

b. Turn the dry standard 1/8 of a turn counter-clockwise, then

remove the dry standard from the aperture plate.

c. Put the head assembly on the body of the instrument.

12. Confirm to go to Measurement Mode.

English 13

Page 16

13. Push HOME to show the online measurements.

14. Put the dry standard in the protective case.

Figure 8 Install the dry standard

1 Dry standard 5 Locking pin

2 Protective case 6 Notch in the aperture plate

3 Top of the dry standard 7 Head assembly

4 Serial number 8 Aperture plate

Verification procedure with dry standard and software

1. From the Main menu, select Sensor Setup, [Select Sensor],

Calibrate, Verification, Perform Ver.

2. Select the available Output Mode (Active, Hold or Transfer) from the

list box and confirm.

3. Select DRY for the verification type and confirm.

4. Remove the dry standard from the protective case. Refer to Figure 8

on page

14.

5. Make sure that the serial number on the display is the same as the

serial number on the dry standard, then confirm. Refer to Figure 8

on page

14.

6. Remove the head assembly from the body of the instrument.

7. Clean, dry and inspect the dry standard.

a. Use the disposable wipes provided to clean the dry standard.

b. Use a dry cloth to dry the top 1/3 of the dry standard. Refer to

Figure 8 on page 14.

c. Make sure that the glass of the dry standard is free of chips and

scratches.

8. Install the dry standard.

a. Put the dry standard in the aperture plate. Make sure that the

locking pin goes in the notch in the aperture plate. Refer to

Figure 8 on page 14.

b. Turn the dry standard 1/8 of a turn clockwise until the dry standard

locks in position.

c. Use a dry cloth to remove any fingerprints and oils from the glass

of the dry standard.

9. Put the head assembly on the body of the instrument.

10. When the instrument reading is stable, confirm.

"GOOD VER" (good verification) or "BAD VER" (bad verification) is

shown. If "BAD VER" is shown, the instrument did not to meet the

PFC (pass or fail criteria), or the instrument was not able to get a

stable reading. Use Table 1 to identify the result and what action

should be done.

11. Remove the dry standard from the instrument.

a. Remove the head assembly from the body of the instrument.

b. Turn the dry standard 1/8 of a turn counter-clockwise, then

remove the dry standard from the aperture plate.

c. Put the head assembly on the body of the instrument.

12. Confirm to go to Measurement Mode.

13. Push HOME to show the online measurements.

14. Put the dry standard in the protective case.

14 English

Page 17

Table 1 Interpretation of verification values

Verification values Result identified Suggested action

± 5 mNTU of the

2

baseline

- 5 mNTU (or less) of

the baseline

+ 5 mNTU (or

greater) of the

baseline

2**

*

If the instrument consistently does not meet the PFC, contact the

manufacturer.

**

A significantly low value is 25% or less of the expected value. A significantly

low value may occur because the light source or detector is not working

correctly. If the verification value is consistently significantly low, send the

instrument to the manufacturer for service.

The instrument is

calibrated.

The instrument is not

calibrated.

The instrument body

may be contaminated.

There may be fluid on

the optical surface of the

dry standard.

None

1. Clean the instrument.

2. Do the verification again.

3. Recalibrate the instrument

if necessary.

4. If recalibrated, assign a

new baseline value.

1. Clean the body of the

instrument, bubble trap,

detector and dry standard.

2. Recalibrate the instrument.

3. Assign a new baseline

value.

Verification with a dry standard without software

This procedure includes instructions on how to:

Assign an initial baseline value to the dry standard without dry

•

standard software

• Do a dry standard verification without dry standard software

Find and store the baseline value for the dry standard immediately after

the instrument is calibrated and after every subsequent calibration. Refer

to Assign a baseline value to the dry standard on page 15.

The baseline value is referenced for subsequent calibration verifications

until the next calibration.

Note: This procedure can be done on instruments that use the AquaTrend

controller by manually recording the baseline value for the dry standard, pass or fail

criteria (PFC) for verification and verification value.

Note: When not in use, keep the dry standard in the protective case.

®

Assign a baseline value to the dry standard

1. Remove the head assembly from the body of the instrument.

2. Remove the dry standard from the protective case. Refer to Figure 8

on page 14

.

3. Clean, dry and inspect the dry standard.

a. Use the disposable wipes provided to clean the dry standard.

b. Use a dry cloth to dry the top 1/3 of the dry standard. Refer to

Figure 8 on page 14.

c. Make sure that the glass of the dry standard is free of chips and

scratches.

4. Install the dry standard.

a. Put the dry standard in the aperture plate. Make sure that the

locking pin goes in the notch in the aperture plate. Refer to

Figure 8 on page 14.

b. Turn the dry standard 1/8 of a turn clockwise until the dry standard

locks in position.

c. Use a dry cloth to remove any fingerprints and oils from the glass

of the dry standard.

5. Put the head assembly on the body of the instrument.

6. When the instrument reading is stable, record the value.

This value is one of three values that will be used to calculate an

average value. The average value will be the final baseline value.

7. Prepare the dry standard to be measured again.

a. Remove the head assembly from the body of the instrument.

b. Turn the dry standard 1/8 of a turn counter-clockwise, then

remove the dry standard from the aperture plate.

c. Do steps 3–5.

8. When the instrument reading is stable, record the value.

English 15

Page 18

9. Do step 7 again.

10. When the instrument reading is stable, record the value.

11. Calculate and record the average of the three recorded values. The

average value is the final baseline value for the dry standard for this

specific instrument.

12. Near the final baseline value, record the serial number of the

instrument and the serial number of the dry standard. Refer to

Figure 8 on page

Note: The final baseline value for the dry standard is applicable only for the

combination of the dry standard and the instrument used to measure the dry

standard.

13. Remove the dry standard from the instrument.

a. Remove the head assembly from the body of the instrument.

b. Turn the dry standard 1/8 of a turn counter-clockwise, then

remove the dry standard from the aperture plate.

c. Put the head assembly on the body of the instrument.

14. Put the dry standard in the protective case.

Verification procedure with dry standard without software

1. Do steps 1– 5 of Assign a baseline value to the dry standard

on page 15.

2. When the instrument reading is stable, record the value.

3. Use Table 1 on page 15 to identify the result and what action should

be done.

Note: Table 1 on page 15 assumes a PFC (pass or fail criteria) of ± 5 mNTU.

4. Remove the dry standard from the instrument.

a. Remove the head assembly from the body of the instrument.

b. Turn the dry standard 1/8 of a turn counter-clockwise, then

remove the dry standard from the aperture plate.

c. Put the head assembly on the body of the instrument.

5. Put the dry standard in the protective case.

14.

Calibration and verification history

The calibration and verification history logs contain information on the

last 12 calibrations and the last 12 verifications.

To access the calibration history logs, select Sensor Setup, [Select

Sensor], Calibrate, Cal History.

To access the verification history logs, select Sensor Setup, [Select

Sensor], Calibrate, Verification.

Push confirm to move through a history log. After all 12 entries are

shown, the display goes back to the menu. Push BACK

the menu.

A verification history entry shows the:

• Value of the certification standard used

• Turbidity reading at verification

• Operator initials

• Date and time

A calibration history entry shows the:

• Gain value

• Operator initials

• Date and time

Notes:

• History data is saved as first in, first out. When a history log is full, the

newest entry is saved and the oldest entry in the log is deleted.

• When the instrument is received from the factory, default values or

blank spaces are shown for the history information. Those values are

replaced with real data as the history log is filled.

to go back to

Maintenance

D A N G E R

Multiple hazards. Only qualified personnel must conduct the tasks

described in this section of the document.

16 English

Page 19

Maintenance schedule

N O T I C E

The laser module and detector system are not user-servicable items. Contact

Technical Support for replacement.

Clean the instrument at least once a month. The instrument may need to

be cleaned more frequently depending on water quality.

Clean the instrument

W A R N I N G

Do not remove the bottom plate of the instrument or drain plug when

the head assembly is installed and the instrument is in operation. Risk

of exposure to Class 3B Radiation will result.

Personal injury hazard. Never remove covers from the instrument. This is a laserbased instrument and the user risks injury if exposed to the laser.

W A R N I N G

Sediment of the size that passes through with filter effluent is difficult to

see. Reading accuracy may be affected if the instrument is not cleaned

at regular intervals. Noise (fluctuation) in the reading may indicate the

need to clean the instrument.

Refer to the illustrated steps to clean the instrument.

Make sure to remove debris from internal corners and other internal

areas that are difficult to access.

Do a calibration verification after this procedure is complete if a

calibration will not be done immediately.

Required tools and materials:

•

Soft brush

• Test tube brush

• Cleaning solution (25 mL of household bleach in 3.78 L of water or

1 mL laboratory detergent (i.e., Liqui-nox) in 1L of water)

• Water that is less than 50 mNTU (0.05 NTU)

Note: Put the cleaning solution in a container that can hold all of the bubble trap.

English 17

Page 20

1 2

18 English

Page 21

3 4

English 19

Page 22

How to clean spills

C A U T I O N

Chemical exposure hazard. Dispose of chemicals and wastes in

accordance with local, regional and national regulations.

1. Obey all facility safety protocols for spill control.

2. Discard the waste according to applicable regulations.

Troubleshooting

Problem Possible cause Resolution

Low (< 1) or negative

readings

Errors

When an error occurs:

The reading on the measurement screen flashes.

•

• All outputs are held.

• The red status light on the instrument turns on.

To access the current instrument errors, select Diagnostics, [Select

Sensor], Error List.

Head assembly is not

correctly installed on the

body of the instrument

Laser failure Contact Technical Support.

PMT/Electronics failure

Correctly install the head

assembly on the body of the

instrument. If not, the red

status light will flash.

Select an error and confirm to identify the cause of the error. Refer to

Table 2.

Table 2 Error list

Error Possible cause Resolution

A/D FAILURE A/D conversion failure Contact Technical Support.

LASER FAILURE Laser did not work correctly

FLASH FAILURE Data log and event log not

LOW SIGNAL

ERROR

and is turned off

working

Signal is too low (less than

3.0 mNTU)

Make sure that the head

assembly is installed

correctly. If not, the red

status light will flash.

Contact Technical Support.

Warnings

When a warning occurs:

•

A warning icon flashes and a message is shown on the bottom of the

measurement screen.

• The red status light on the instrument starts flashing.

Warnings do not affect the operation of menus, relays and outputs.

To access the current instrument warnings, select Diagnostics, [Select

Sensor], Warning List.

Select a warning and confirm to identify the cause of the warning. Refer

to Table 3.

20 English

Page 23

Note: A warning can be used to trigger a relay. The sc controller can be used to

set warning levels to identify the severity of the warning. Refer to the sc controller

user manual.

Table 3 Warning list

Warning Definition Resolution

DARK READING Dark reading identifies

too much light (greater

than 50 mNTU).

TEMPERATURE The internal temperature

of the head assembly is

greater than 50 °C

(122 °F).

5 VOLT The monitored voltage is

outside the range 4.5–

5.5 V.

VOLTAGE IN The monitored voltage is

outside the range of

9.08–14.3 V.

LASER V The laser voltage is out

of the operating range of

4.55–5.5 V.

LASER I The laser current is out of

operating range of 25–

75 mA.

1. Make sure that the head

assembly is correctly

installed on the body of

the instrument.

2. From the Main menu,

select Sensor Setup,

[Select Sensor],

Calibrate, 0 Electronics.

Make sure that the operating

environment is within the

specifications. Refer to

Specifications on page 3.

If the operating environment

is within specifications,

contact Technical Support.

Contact Technical Support.

Table 3 Warning list (continued)

Warning Definition Resolution

DATA LOG FULL Only 30 minutes of

EVENT LOG FULL Only 30 minutes of

OUTPUT MODE

NOT NORMAL

PMT VOLTAGE The PMT voltage is out of

REFERENCE

VOLTAGE

storage space is

available in the data log.

storage space is

available in the event log.

The instrument is being

calibrated.

operating range of

11.77–15.94 V.

The reference voltage is

out of operating range of

2.41–2.59 V.

Download the log from the sc

controller to prevent loss of

data.

Complete calibration and/or

calibration verification.

Contact Technical Support.

Diagnostics and Test menu

The diagnostic and test menu shows current information about the

instrument. Refer to Table 4.

To access the diagnostic and test menu, select Sensor Setup, [Select

Sensor], Diag/Test.

Table 4 DIAG/TEST menu

Option Description

SOFTWARE VERS. Shows the installed software version.

SERIAL NUMBER Shows the serial number of the instrument.

INT TEMP Shows the internal temperature of the instrument

DEFAULT SETUP Sets the settings to the factory default settings. Makes the

POWER CHECK Shows the electrical statistics for the instrument.

electronics in °C.

current calibration invalid.

English 21

Page 24

Table 4 DIAG/TEST menu (continued)

Option Description

SERVICE MODE Enable or disable service mode—On or Off (default).

SERVICE DIAGS Passcode protected. Menu options are only available to

service personnel.

Theory of operation

The FilterTrak 660 sc nephelometer uses nephelometric detection of

light scatter from particles in a sample. The optical design is shown in

Figure 9. The geometry of the incident light source and the centerline

into the detector receive fiber is fixed at 90 degrees, which is consistent

with the detection angle associated with current nephelometry

technology.

The light source is a laser diode with a wavelength of 660-nm. The

response system is optimized to detect this specific wavelength. In

addition, the incident light is collimated into a narrow beam, resulting in a

relatively high beam power density. This high power density results in

higher scattered intensity from smaller particles. In addition, the portion

of the narrow beam that passes through the sample without being

scattered is absorbed by a light trap at the bottom of the nephelometer

body. These features combined to create a measurement system with

dramatically lower stray light.

The FilterTrak 660 sc nephelometer detection apparatus is coupled with

fiber optic technology to convey the scattered light signal to the detector.

The high power source and very sensitive detector combine to produce a

strong signal even at the lowest of turbidity levels. The optimization of

the optical components results in an increase in sensitivity of more than

two orders of magnitude over the sensitivity that is achieved with the

best turbidimeters in use today. This allows for a very stable baseline

capable of detecting a change in turbidity down to 0.05 mNTU

(1.000 NTU = 1000 mNTU). Since sensitivity is defined as the detection

of a change in turbidity, the lowest numerical value that an instrument

can read is not as significant as the smallest change that it can detect.

Figure 9 Laser nephelometer optical configuration

1 Laser module 5 Light receiver

2 Light detector 6 Water level

3 Optical fiber 7 Aperture

4 Scattered light 8 Incident light beam

RSD parameter

The FilterTrak 660 sc offers a complementary parameter to the laser

nephelometry measurement. This parameter is known as the relative

standard deviation (RSD). RSD is a dimensionless parameter that

provides a quantative assessment of the variability (fluctuation) of the

laser turbidity measurement. Studies have shown that the baseline of a

turbidity measurement will often increase in fluctuation before the actual

22 English

Page 25

laser turbidity measurement will begin to increase in response to a

particle event. In addition, the RSD parameter has been shown to be

more sensitive to a turbidity event in addition to serving as a precursor

event to a turbidity spike. The Hach Technical Information bulletin

"Introduction to Laser Nephelometry: An Alternative to Conventional

Particulate Analysis Methods", Literature piece 7044, Appendix B

provides more information on the application and use of the RSD

parameter.

The sensitivity of the RSD parameter is directly related to the instrument

design of the FT660 sc nephelometer. This is due to the optical creation

of a very small analysis volume within the turbidity sensor. (The analysis

or view volume is that volume of sample within the turbidimeter body that

is in view by the detector window.) This volume is small but well defined

by the optical design. This volume also contains a high energy density

from the incident light beam, which can easily be scattered by a single or

low number of particles. When a particle passes through the view

volume, there is a rapid increase in the scattered light signal while that

particle is in the view volume. When the particle passes out of the view

volume, the signal decreases rapidly. The change in signal is infrequent

and this instability of signal is quantified by the RSD parameter.

The RSD value is calculated as the standard deviation divided by the

mean for a given set of measurements. The result is multiplied by

100 and is expressed as a percent. Equation 1 provides the calculation

used to determine the RSD value:

RSD = (standard deviationn ÷ meann) × 100

Where n = number of measurements used

The RSD calculation is accomplished through a process of evaluating

the most recent seven displayed turbidity measurements. From the

seven measurements, the standard deviation and the average are

calculated. The value is then displayed on the secondary measurement

line of the SC controller. When a new turbidity measurement is

displayed, the value replaces the oldest of the seven measurements and

the RSD is recalculated and displayed. This is referred to as the

continuous RSD measurement and it is updated once every second.

The RSD parameter is treated as a separate and independent

monitoring parameter relative to the laser turbidity measurement. The

parameter is updated every second, which is the same rate the laser

turbidity value is updated. The parameter is best used as an early

warning parameter to an impending turbidity event and as a

complementary parameter to the turbidity parameter. (A turbidity spike

will also be complemented by a spike in the RSD parameter.) The

parameter has been designed to be very responsive to particles in the

1–10 μm range at very low concentrations. While the laser turbidity

parameter is currently approved for regulatory monitoring, the RSD

parameter is not a regulatory approved monitoring parameter.

Correlation study between kaolin standards and measured turbidity

A study was done on the FilterTrak 660 sc (FT660 sc) laser

nephelometer to identify the specific correlation between kaolin and the

NTU value recorded using the FT660 sc. Two sets of kaolin standards

were prepared for turbidity measurement. Each set was prepared from

an independent lot of kaolin stock standard that was supplied by the

manufacturer. Each test standard was prepared using ultra-filtered water

immediately before measurement.

After preparation, each standard was put in the FT660sc, starting with

the lowest value. Measurements on the standard were done at 30second intervals, and 15 to 25 measurements were recorded for each

standard. From the measurement on a specific test standard, the

respective average and standard deviation was calculated.

Table 5 shows the:

•

Averaged turbidity measurements from each of the two lots of kaolin

standard

• Pooled standard deviation from these two lots of kaolin standards

• 95% confidence interval (predicted) and the percent error expected in

the preparation for each standard value

The results show a strong correlation between mg/L kaolin and NTU.

The correlation is better than one percent over the measurement range

of the FT660 sc. The summarized correlation values for the entire study

are shown in Table 6.

Even though there was a strong correlation between the mg/L and the

NTU values when using the FT660 sc, the reproducibility of these

measurements was not good at the lowest two kaolin standards. This is

shown in Table 5, where the pooled standard deviations and predicted

English 23

Page 26

95% confidence intervals are very high. The error was primarily traced to

the lot-to-lot variability in the preparation and subsequent measurement

for each standard.

From the data collected in this study, it was identified that 1.0 mg/L

kaolin is equivalent to 1.0 NTU turbidity.

Table 5 Summary: Correlation between kaolin mg/L values and

NTU turbidity values on the FT660 sc

Standard

value

(theoretical) in

mg/L kaolin

0.10 0.098 0.0273 0.0546 55.6%

0.20 0.169 0.0594 0.1187 70.3%

0.41 0.339 0.0239 0.0479 14.1%

0.80 0.754 0.0504 0.1009 13.4%

1.01 0.999 0.0534 0.1069 10.7%

1.20 1.186 0.0414 0.0829 7.0%

1.59 1.573 0.0870 0.1740 11.1%

1.80 1.850 0.0487 0.0974 5.3%

2.10 2.065 0.0480 0.0960 4.6%

2.40 2.338 0.0466 0.0932 4.0%

Averaged

turbidity in

NTU for

kaolin lots A

and B

Pooled

standard

deviation

for kaolin

lots A and

B

Predicted

95%

confidence

range +/-NTU

from the

averaged

kaolin value

Percent

uncertainty at

95%

confidence

Table 6 Statistical summary of the correlation between mg/L kaolin

and NTU

Pooled standard

deviation for kaolin lots

A and B

Slope Correlation

coefficient

0.9932 0.9990 0.6804

Averaged % error

(over the full range)

Replacement parts and accessories

Note: Product and Article numbers may vary for some selling regions. Contact the

appropriate distributor or refer to the company website for contact information.

Replacement parts

Description Quantity Item no.

Cover, bubble trap 1 5201200

Drain plug for the FT660 sc 1 4411600

Body of the FT660 sc 1 5230300

Head assembly of the FT660 sc

Sensor cap 1 5791100

*

Only compatible with 5230300.

Accessories

Description Quantity Item no.

Aperture plate 1 6735600

Cleaning brush 1 68700

Calibration kit

(includes the calibration body, 1 L of

800 mNTU StablCal Standard and a funnel)

Deionized (demineralized) water 1 L 27256

*

1 6016100

1 5236400

24 English

Page 27

Replacement parts and accessories (continued)

Description Quantity Item no.

Detergent, Liquinox 0.946 L 2088153

Drain assembly funnel 1 5237100

Dry standard quick check verification (VQC)

kit, includes:

- Dry standard 1 6735800

- Protective case for the dry standard 1 6735400

- Disposable wipes 1 2097000

Floor stand 1 57432-00

Flow meter, 500–700 mL/minute 1 4028200

Funnel 1 5237100

Load termination box

*

Plug, sealing, conduit opening 1 5868700

100 mNTU, StablCal Certified Standard for

verification of the FT660 sc

300 mNTU, StablCal Certified Standard for

verification of the FT660 sc

500 mNTU, StablCal Certified Standard for

verification of the FT660 sc

800 mNTU, StablCal® Certified Standard for

calibration and verification of the FT660 sc

**

1000 mNTU (1.00 NTU), StablCal Certified

Standard for verification of the FT660 sc

Strain relief, Heyco 1 16664

Tubing, sample in, ¼-inch O.D., Polyethylene 0.3 m (1 ft) 4215200

Tubing, sample out, ½-inch I.D., ¾-inch O.D.,

Tygon R3603

1 6735500

1 5867000

1 L 27233-53

1 L 26979-53

1 L 26980-53

1 L 2788453

1 25897-56

0.3 m (1 ft ) 5126300

*

Required if the distance between the instrument and sc controller is greater

than 31 m (101 ft)

**

EDA approved for calibration.

English 25

Page 28

26 English

Page 29

Page 30

HACH COMPANY World Headquarters

P.O. Box 389, Loveland, CO 80539-0389 U.S.A.

Tel. (970) 669-3050

(800) 227-4224 (U.S.A. only)

Fax (970) 669-2932

orders@hach.com

www.hach.com

©

Hach Company/Hach Lange GmbH, 2011-2012. All rights reserved. Printed in Germany.

HACH LANGE GMBH

Willstätterstraße 11

D-40549 Düsseldorf, Germany

Tel. +49 (0) 2 11 52 88-320

Fax +49 (0) 2 11 52 88-210

info@hach-lange.de

www.hach-lange.de

HACH LANGE Sàrl

6, route de Compois

1222 Vésenaz

SWITZERLAND

Tel. +41 22 594 6400

Fax +41 22 594 6499

Loading...

Loading...