Page 1

DOC023.52.00024

Filter probe sc

Operation Manual

04/2013, Edition 2A

© HACH-LANGE GmbH, 2005, 2013. All rights reserved. Printed in Germany

Page 2

Page 3

Table of contents

Section 1 Specifications......................................................................................................................................... 3

Section 2 General information ............................................................................................................................... 5

2.1 Safety instructions.............................................................................................................................................. 5

2.1.2 Safety symbols used ................................................................................................................................ 5

2.1.3 General safety instructions ....................................................................................................................... 6

2.2 General .............................................................................................................................................................. 7

2.3 Product description ............................................................................................................................................ 7

2.3.1 Identification ............................................................................................................................................. 7

2.3.2 Principle of operation................................................................................................................................ 8

2.4 Items supplied.................................................................................................................................................... 8

2.4.1 Identification of the operating instructions ................................................................................................ 8

2.5 Target group for these operating instructions .................................................................................................... 9

2.6 Tasks and obligations of the operating organisation.......................................................................................... 9

2.6.1 Correct use ............................................................................................................................................... 9

2.7 Your service partner, contacting the manufacturer ............................................................................................ 9

2.7.1 Standards and declaration of conformity ................................................................................................ 10

2.7.2 Copyright ................................................................................................................................................ 10

Section 3 Installation ............................................................................................................................................ 11

3.1 Safety instructions............................................................................................................................................ 11

3.1.1 Safety measures prior to unpacking, connecting and operating............................................................. 11

3.1.2 Disposing of the packaging .................................................................................................................... 11

3.1.3 Preparing the installation ........................................................................................................................ 12

3.2 Drawing with dimensions ................................................................................................................................. 13

3.3 Installing the filtration probe sc ........................................................................................................................ 14

3.3.2 Installing filter module............................................................................................................................. 15

3.3.3 Installing filtration probe sc ..................................................................................................................... 16

3.4 Supply of power ............................................................................................................................................... 19

3.4.1 Connecting power cable ......................................................................................................................... 20

3.5 Connecting filtration probe sc to the data network ........................................................................................... 21

3.6 Connecting sample tubing ............................................................................................................................... 21

3.7 Connecting air tubing ....................................................................................................................................... 22

Section 4 System startup ..................................................................................................................................... 23

4.1 Initial commissioning........................................................................................................................................ 23

Section 5 Operation .............................................................................................................................................. 25

5.1 The operation concept ..................................................................................................................................... 25

5.1.1 Rectifying problems in normal operation ................................................................................................ 25

5.2 Normal operation ............................................................................................................................................. 25

5.2.1 Rectifying problems in operation ............................................................................................................ 25

Section 6 Maintenance and cleaning .................................................................................................................. 27

6.1 Maintenance and cleaning by the operator...................................................................................................... 27

6.1.1 Troubleshooting, error state diagnostics and repair ............................................................................... 27

6.2 Maintenance and cleaning by qualified personnel ........................................................................................... 30

6.2.1 Changing exhaust................................................................................................................................... 30

6.2.2 Changing air exhaust.............................................................................................................................. 31

1

Page 4

Table of contents

Section 7 Taking out of operation ....................................................................................................................... 33

7.1 Taking out of operation for a short period ........................................................................................................ 33

7.2 Taking out of operation for an extended period ............................................................................................... 33

7.3 Finally taking out of operation .......................................................................................................................... 33

7.4 Intermediate storage or storage....................................................................................................................... 33

Section 8 Replacement Parts, consumables, accessories ............................................................................. 35

8.1 Replacement parts and their order numbers.................................................................................................... 35

8.2 Accessories...................................................................................................................................................... 36

8.3 Optional accessories........................................................................................................................................ 36

Section 9 Contact ................................................................................................................................................. 39

Section 10 Warranty, liability and complaints .................................................................................................... 41

Index....................................................................................................................................................................... 43

2

Page 5

Section 1 Specifications

We reserve the right to make changes without notice.

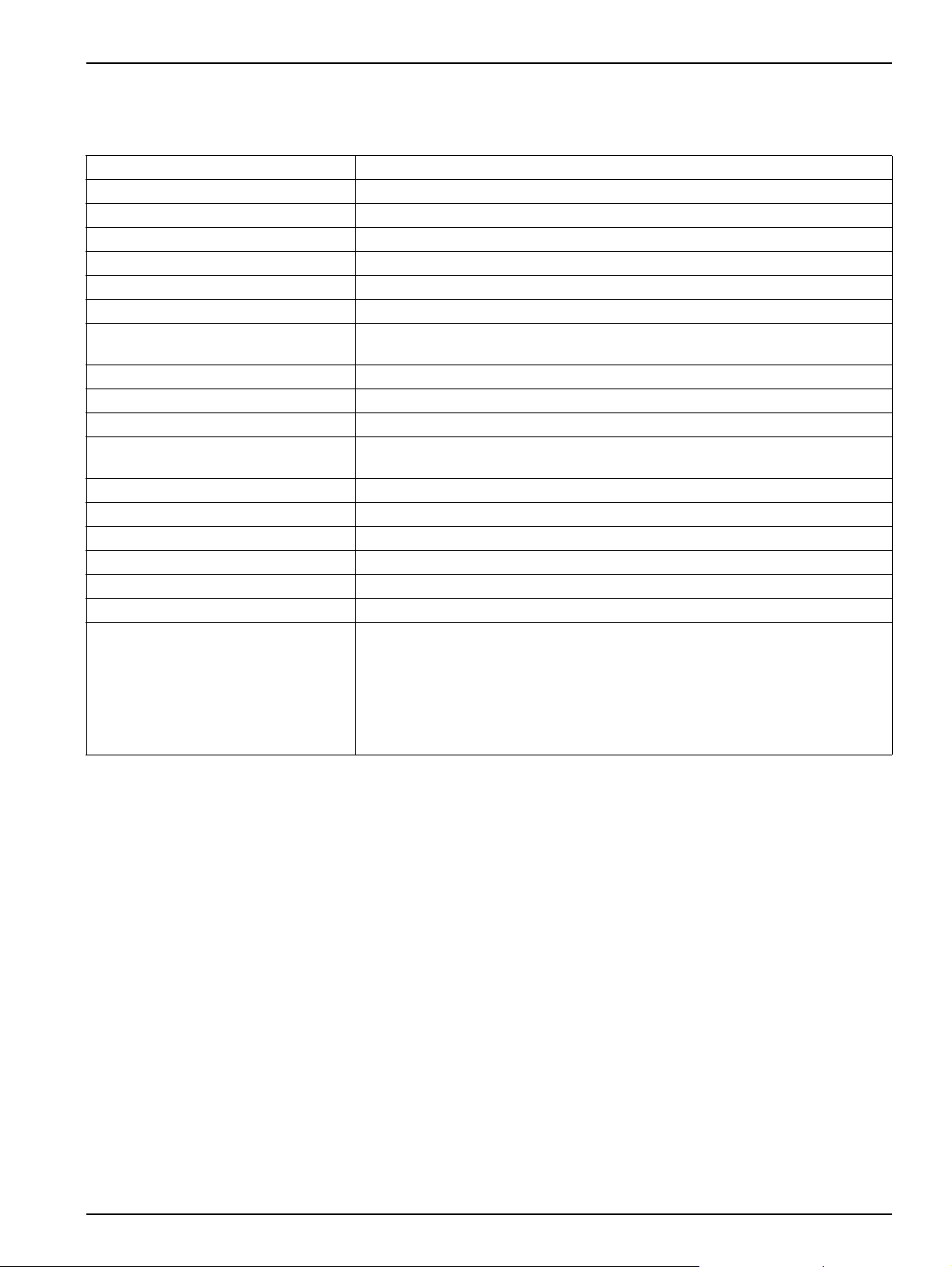

Table 1 Filtration probe sc specifications (in some cases optional extras)

Components Filter module with pump

Dimensions (W × H × D) 330 × 384 × 243 mm (13 × 15.12 × 9.57 inches)

Supply tubing 5 m or 10 m, depending on version

Enclosure Plastic enclosure, PPE, flammability class in accordance with UL 94

Mass Approx. 9.5 kg filter enclosure, approx. 8 kg tubing

Power supply Via analysis instrument

Electrical connection Via analysis instrument

Mean power consumption

Electrical fuse protection Via analysis instrument, via controller

Operating temperature 4 °C...40 °C (39 °F...104 °F), in water

Operating temperature sample tubing –20 °C...45 °C (–4 °F...113 °F); 95 % relative humidity, non-condensing

Storage temperature

Sample temperature 4 °C...40 °C (39 °F...104 °F), water temperature

Permissible sample flow speed max. 3 m/s, from 1 m/s: install only with protection against flow (accessory)

Permissible pH value of the sample 5–9

Maximum immersion depth 3 m (120 inch)

Fastening to the extension pipe 6 screws M5 × 10 mm

Filtrate flow rate

Cables and tubing on the probe pipe

400 VA (brief peak power consumption: 1000 VA),

(with 10 m heated filtration probe tubing)

–20 °C...60 °C (–4 °F...140 °F); 95 % relative humidity, non-condensing

Once the filter modules have become wet, they must be stored wet.

5 ml/minute, 4 out of 5 minutes

Outer sheath of the cables and tubing: UV and weather resistant

Total external diameter of the outer tubing: 32 mm (1.2 inch)

External diameter of the sample tubing 3.2 mm (0.12 inch)

External diameter of the return tubing: 6 mm (0.23 inch)

External diameter of the air tubing: 6 mm (0.23 inch)

External diameter of the data cable: 7.1 mm (0.28 inch)

External diameter of the power cable: 6.1 mm (0.23 inch)

3

Page 6

Specifications

4

Page 7

Section 2 General information

2.1 Safety instructions

Prior to unpacking, commissioning or operating the

instrument, read this manual in its entirety.

Please pay particular attention to all instructions on hazards

and safety. Otherwise there is a risk of serious injury to the

operator or damage to the instrument, or pollution.

The instrument is only allowed to be installed and used as per

the instructions in this manual.

2.1.1 Instructions on hazards in this manual

DANGER

Indicates a potentially hazardous situation or hazardous

situation that, if not avoided, could result in serious injuries or

fatality.

CAUTION

Indicates a possibly hazardous situation that could result in

light to moderate injuries.

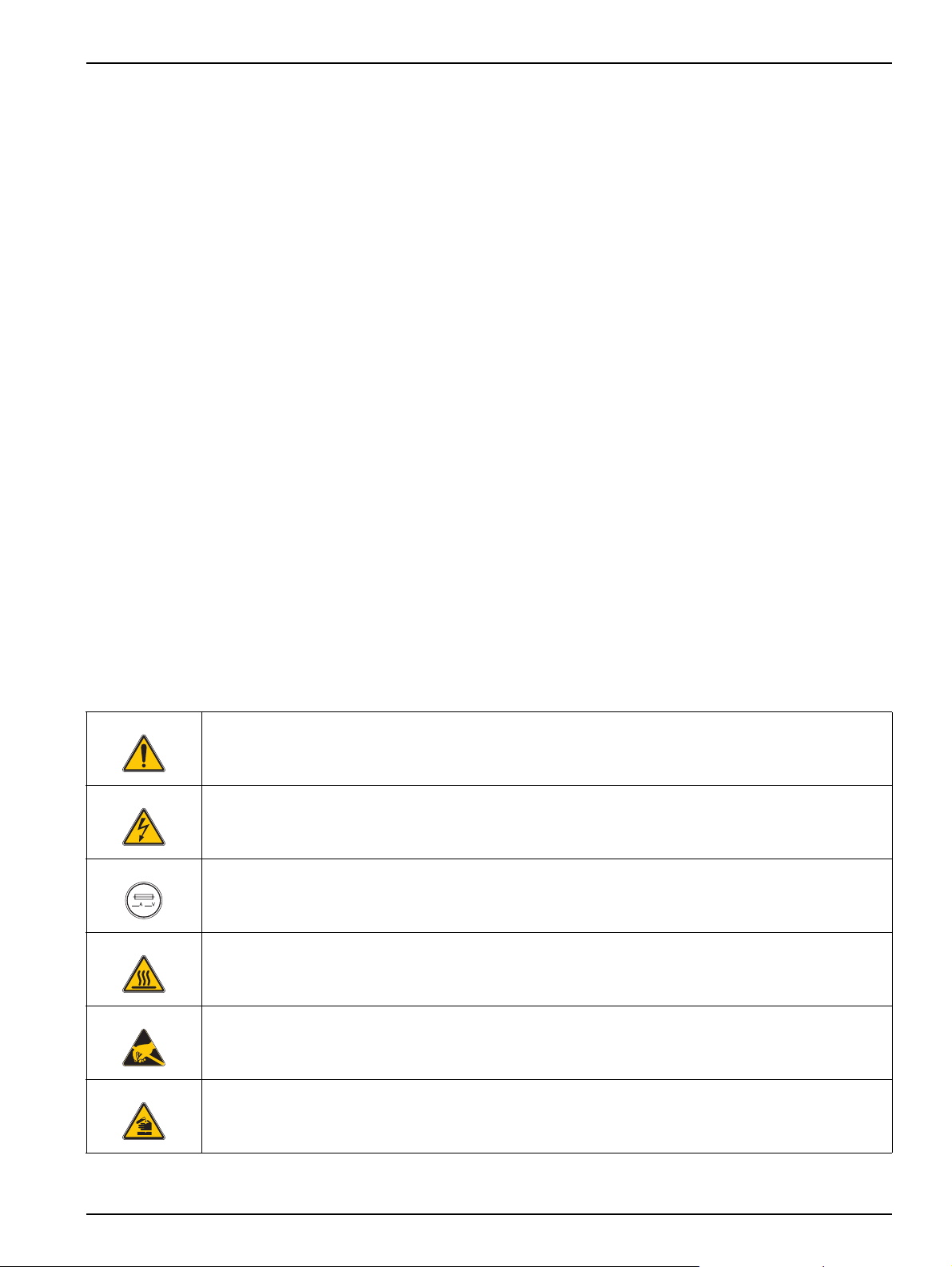

2.1.2 Safety symbols used

This symbol, if present on the instrument, refers to information in the operating instructions on safe

operation and / or instructions that provide safety information.

This symbol, if present on a enclosure or a protective cover for the instrument, identifies the risk of an

electric shock (which may under certain circumstances be fatal). Only personnel qualified for working on

hazardous voltages are allowed to open the enclosure or remove the protective cover.

This symbol, if present on the instrument, identifies the location of a fuse or current limit.

This symbol, if present on the instrument, identifies a part that may become hot and must not be touched

without taking precautions.

Important note: Information that is to be specifically highlighted.

Note: Information with additional aspects on the main text.

Observe all stickers and markings on the instrument. Otherwise

injuries, pollution or damage to the instrument may occur.

This symbol, if present on the instrument, indicates the presence of components that could be damaged by

electrostatic discharge. Appropriate precautions are to be taken.

This symbol, if present on the instrument, indicates the presence of dangerous chemical substances.

Chemicals are only allowed to be handled and maintenance on devices for supplying chemicals to the

instrument is only allowed to be performed by personnel qualified and trained for working with chemicals.

5

Page 8

General information

This symbol, if present on the instrument, identifies the location of the connection for the protective earth

(ground).

As of 12 August 2005, electrical appliances marked with this symbol are no longer allowed to be

disposed of in Europe in unsorted household or industrial waste. As per the applicable

regulations, from this date on consumers in the EU must return old appliances to the

manufacturer for disposal. This disposal is free of charge for the consumer.

Note: You can obtain instructions on the correct disposal of all (marked and unmarked) electrical products

that have been supplied or manufactured by Hach-Lange from your local Hach-Lange sales office.

When carrying or transporting the instrument/instrument components and if the total weight is

18-32 kg (39.7-70.5 lbs)

more than 18 kg, make sure that suitable lifting equipment is used and/or that the

instrument/instrument components are carried by 2 people.

2.1.3 General safety instructions

DANGER

Risk of electric shock!

Work on the electrical installation is only allowed to be

performed by an experienced electrician!

Always isolate the instrument from the mains during

installation work!

CAUTION

Observe applicable health and safety regulations!

Flows of sample of unknown composition can produce

hazards due to traces of chemicals, radiation or biological

effects.

Avoid unnecessary contact with the flows of sample of

unknown composition and take appropriate safety measures.

DANGER

Potential danger in the event of contact with

chemical/biological materials. Handling chemical samples,

standards and reagents can be dangerous. Familiarize

yourself with the necessary safety procedure s an d th e correc t

handling of the chemicals before the work and rea d and follow

all relevant safety data sheets.

Normal operation of this instrument may involve the use of

hazardous chemicals or biologically harmful samples.

• Observe all cautionary information printed on the original

solution containers and safety data sheet prior to their use.

• Dispose of all consumed solutions in accordance with national

regulations and laws.

• Select the type of protective equipment suitable to the

concentration and quantity of the dangerous material at the

respective work place.

6

Page 9

2.2 General

2.3 Product description

2.3.1 Identification

General information

In this section you will find information on:

• Instrument identification

• Items supplied

• Operating instructions

• Tasks and obligations of the operating organisation

• The manufacturer

• The declaration of conformity

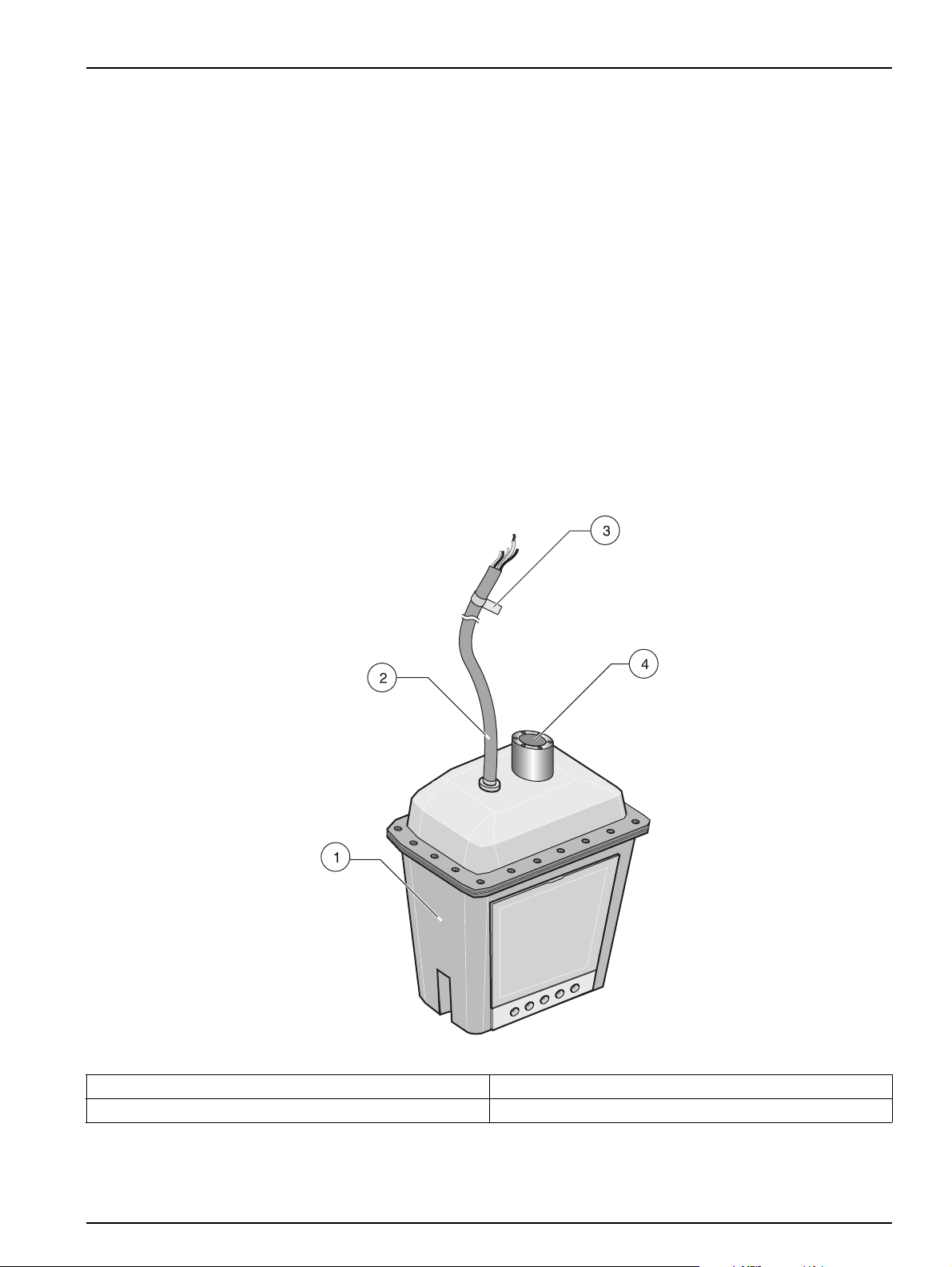

The filtration probe sc is controller-operated filtration system that is

immersed. It supplies an AMTAX sc or PHOSPHAX sc connected in

series with a filtered sample flow. The filtration probe sc features

automatic cleaning and is largely maintenance-free.

Figure1Filtration probesc

1 Filtration probe sc 3 Rating plate

2 Supply cable 4 Connection fastening system

7

Page 10

General information

2.3.1.1 Rating plate for the filtration probe sc

You will find the rating plate at the top end of the supply cable. On

the rating plate you will find

• The model number and the serial number,

• Information on the voltage and frequency for the electrical

connection and

• Information on the brief peak power consumption.

2.3.2 Principle of operation

The filtration probe sc draws in liquid through a filter system and

then pumps this sample flow to an analysis instrument connected in

series. After the analysis of the sample, the analysis instrument

pumps the sample (possibly mixed with chemicals) back to the tank

sampled or to a drain.

A cleaning device ensures the filter modules remain porous. The

filtration probe sc has a compressed air tube that terminates

underneath the filter modules. When compressed air flows out of

the air openings underneath the filter modules, the rising air

bubbles remove soiling from the filter modules. In this way the filter

modules remain porous and manual cleaning is largely

unnecessary.

2.4 Items supplied

Standard items supplied:

• Filtration probe sc

• These operating instructions

• 2 filter modules

• Small parts, cable, tubing and connector set and

• One cleaning sponge

2.4.1 Identification of the operating instructions

You will find a DOC number on the cover sheet so that you can

re-order these operating instructions. You can identify the issue of

the operating instructions using the date in the DOC number.

8

Page 11

2.5 Target group for these operating instructions

These operating instructions are directed at sewage treatment plant

operating organisations and trained and experienced staff sewage

treatment plant supervisors. It is assumed that these persons are

familiar with the operation of personal computers and have a sound

knowledge of

• Measurement and control systems,

• Electrical engineering,

• Water analysis and

• Chemistry

and have been adequately instructed on safety regulations.

Requirements and activities that go beyond the knowledge and

skills held by a sewage treatment plant supervisor must be

entrusted by this person to trained (e. g. electrical) specialists. Such

work is to be planned and co-ordinated in agreement with the

organisation or plant management.

2.6 Tasks and obligations of the operating organisation

General information

The organisation operating the plant must ensure only qualified and

trained personnel install, operate or otherwise use this probe. The

operating organisation must ensure the locally applicable

regulations are observed and that these operating instructions are

always available to the plant operators.

2.6.1 Correct use

Incorrect use of the filtration probe sc or its components

and / or its accessories can cause injury, damage or pollution.

Ensure the filtration probe sc and / or its components and / or

its accessories are only used correctly.

The filtration probe sc was developed for the filtration, supply and

disposal of liquid samples and for connection to an analysis

instrument. The primary area of application is water and waste

water analysis.

2.6.1.1 Incorrect use

Any other use or use beyond that defined above is considered

incorrect use and will also render void all claims under the

guarantee and warranty.

2.7 Your service partner, contacting the manufacturer

In section Contact on page 39 you will find addresses and

telephone numbers for the various contacts.

9

Page 12

General information

2.7.1 Standards and declaration of conformity

The filtration probe sc and its components comply with the

applicable standards and stipulations.

For the filtration probe sc we confirm compliance.

HACH LANGE GmbH is certified to DIN EN ISO9001.

You can obtain further information on certificates, the declaration of

conformity and standards on request.

2.7.2 Copyright

"Provision to third parties as well as the duplication of these

operating instructions, further processing and provision of their

content to third parties is not allowed unless expressly approved.

Contravention will result in the obligation to pay damages.

All rights reserved in the case of the award of a patent or

registration of a design." (In accordance with DIN 34, ISO 16016)

10

Page 13

Section 3 Installation

3.1 Safety instructions

In this section you will find information on the following for the

filtration probe sc

• Installing,

• Connecting,

• Connecting to the mains and

• Connecting to the data network.

DANGER

Prior to unpacking, commissioning or operating the

instrument, read all of this manual!

Pay particular attention to all instructions on hazards and

safety. Otherwise there is a risk of serious injury to the

operator or damage to the instrument, or pollution!

The analysis instrument and its peripherals a re only allowed to

be installed and connected by qualified personnel. Only use

appropriate (e. g. insulated) tools and observe the applicable

rules and regulations!

Incorrect connection to the data network or incorrect

configuration can result in damage to the modules and the

customer's network!

3.1.1 Safety measures prior to unpacking, connecting and operating

Ensure only trained and instructed personnel unpack, install,

connect or operate the filtration probe sc.

3.1.2 Disposing of the packaging

Protect the environment when disposing of the packaging and

observe locally applicable regulations

11

Page 14

Installation

3.1.3 Preparing the installation

DANGER

Risk of electric shock!

Plan the mechanical fastening before you position posts or

drill holes. Choose a suitable place to install the instrument.

Plan how the cables and tubing will be laid and their routes.

Note that the cables will need to be removed regularly.

Lay cables and tubing so they will not cause tripping and

without sharp bends. Note that the cables will need to be

removed regularly.

Do not connect the electrical power supply to the mains until

the instrument has been fully wired and fused.

Provide adequate fuse protection for the electrical power

supply.

Always connect a residual current circuit breaker (trigger

current max.: 30 mA) between the mains and the system!

If you install the instrument outside, provide overvoltage

protection between the mains and the system!

12

Page 15

3.2 Drawing with dimensions

Installation

Figure 2 Drawing with dimensions

13

Page 16

Installation

3.3 Installing the filtration probe sc

Important note: Improper assembly or installation of the filtration

probe sc or its components can result in injury or damage.

The filtration probe sc and its components are only allowed to be

installed by qualified and trained personnel.

Install the filtration probe sc prior to commissioning the analysis

instrument.

3.3.1 Sealing exhaust

If you do not dispose of the used sample via the filtration probe sc,

seal the exhaust.

1. Seal the exhaust using the sealing cap supplied.

14

Figure 3 Sealing exhaust

Page 17

3.3.2 Installing filter module

Installation

Important note: Do not let the filter modules dry out, as dry filter

modules will become unusable immediately and cannot be

repaired.

Never touch the filter surface, as the filter surface will be destroyed

by the grease from the skin.

Never immerse the filtration probe in water without filter modules,

as unfiltered water could block the filtration probe.

1. Insert the filter module in the bottom.

2. Pivot the filter module towards the inside and press onto the

frame until it engages.

Figure 4 Installation of the filter modules

3. Proceed with the second filter module on the other side in the

same way.

15

Page 18

Installation

3.3.3 Installing filtration probe sc

Important note: Only install the filtration probe sc using the rim

mounting system.

Figure 5 Installation parts rim mounting LZX414.00.50000

1 Mounting pipe 7 Cheese head screws M5 × 20 mm (6×)

2 Screws M5 × 16 mm (6×) 8 Flat bar

3 Quick-fit anchors (4) 9 Cheese head screws M8 × 40 mm (4×)

4 Base 10 Plug

5 Clamp half 11 Spring cotter

6 Clamp half with thread

16

Page 19

Installation

Figure 6 Installation of the rim mounting LZX414.00.5000

1 Base 6 Flat bar

2 Quick-fit anchors (4) 7 Screws

3 Plug 8 Screws M5 × 16 mm (6×)

4 Spring cotter 9 Filtration probe tubing

5 Mounting pipe 10 Filtration probe sc

Important note: Only install the filtration probe sc in flowing water

with protection against flow.

Install the filtration probe sc so that is it held min. 0.1 m and max.

3 m below the surface of the water.

In case of frost, insulate the first 10 cm of the tubing if the top edge

of the filtration probe sc is not at least 20 cm below the surface of

the water.

17

Page 20

Installation

Important note: Ensure the filtration probe sc is not in contact with

the base of the tank and cannot bang against the side walls.

Figure 7 Installation position for the filtration probe sc

18

Page 21

Installation

3.4 Supply of power

Figure 8 Installing with rim mounting

DANGER

Risk of electric shock!

Work on the electrical system is only allowed to be performed

by trained and experienced electricians.

19

Page 22

Installation

3.4.1 Connecting power cable

1. Open the analysis instrument to which the filtration probe sc is

to be connected.

2. Connect the earth wire (Figure 9-3) (see also the operating

instructions for the analysis instrument).

3. Connect the power cable to the filtration probe sc (Figure 9-2).

(see also the operating instructions for the analysis instrument)

4. Connect the power cable for the drain heating (optional

accessory) (Figure 9-1). (see also the operating instructions for

the analysis instrument)

Figure 9 Connecting power supply and heating to the filtration probe sc

1 Connection drain heating

(optional)

20

2 Filtration probe sc power

cable connection

3 Earth wire terminal strip 4 Filtration probe sc data

cable connection

Page 23

3.5 Connecting filtration probe sc to the data network

To ensure correct operation, the filtration probe sc must be

connected to the analysis instrument's data network. The analysis

instrument's data network sends the commands for self-cleaning

and transmits the module pressure value to the analysis instrument.

1. Connect the data cable connector to the socket on the analysis

instrument (Figure 9-4)

(see also the operating instructions for the analysis instrument).

3.6 Connecting sample tubing

Note: Pay attention to the markings on the tubing.

1. Connect the black sample return tubing (Figure 10-1) to the

sample outlet on the analysis instrument (see operating

instructions for the analysis instrument).

2. Connect the transparent sample feed tubing (Figure 10-2) to

the sample inlet on the analysis instrument (see operating

instructions for the analysis instrument).

Installation

Figure 10 Connecting sample tubing

1 Sample return 2 Sample feed

21

Page 24

Installation

3.7 Connecting air tubing

Note: Pay attention to the markings on the tubing.

1. Connect the white air tubing to the analysis instrument (see

operating instructions for the analysis instrument).

Figure 11 Connecting air tubing

22

Page 25

Section 4 System startup

Important note: Correct installation of the system is necessary to

ensure malfunction-free operation. Prior to initial commissioning,

ensure the system has been correctly installed and only author ised

persons have access to the system.

On initial commissioning, ensure all internal and external

expansions are correctly registered in the controller system.

4.1 Initial commissioning

1. Ensure the filtration probe sc is completely and correctly

installed.

2. Switch on the analysis instrument and check whether the

filtration probe sc is correctly registered in the system.

3. Follow the instructions in the operating instructions for the

analysis instrument.

The filtration probe sc is then ready for use.

23

Page 26

System startup

24

Page 27

Section 5 Operation

5.1 The operation concept

No actions are intended to be performed by the operator on the

filtration probe sc (except cleaning and replacement of the filter

modules). All commands and control instructions are sent

automatically by the analysis instrument connected or are made via

the controller. Read the operating instructions for the analysis

instrument and the controller thoroughly to ensure you can operate

the system safely, without errors and correctly.

5.1.1 Rectifying problems in normal operation

In normal operation only feasible, sensible entry options are

displayed. If you then enter incorrect values, these will be rejected.

If you have made incorrect entries, repeat the entry with the correct

values.

Note: If your entry was outside a logical working range, a correction is

made automatically. Note that the value is then still incorrect and must be

corrected.

5.2 Normal operation

In normal operation the filtration probe sc does not require

supervision, operation or maintenance.

5.2.1 Rectifying problems in operation

5.2.1.1 Problems with the sensors or the analysis instruments

If a sensor or analysis instrument is reporting errors or warnings, a

corresponding error will be displayed on the controller (see

operating instructions for the controller).

5.2.1.2 Module pressure value too low

If the filter modules block, the module pressure value in the filtration

probe sc drops.

Pressure value State Action

< 0.25 bar Blocked Replace filter modules

0.25 bar...0.45 bar Soiled Clean filter modules

> 0.45 bar ok No action

1. Clean or replace the filter modules (see Cleaning / replacing

filter modules" on page 28).

2. Check all relevant settings.

If the problems have not been rectified, please contact customer

service.

25

Page 28

Operation

26

Page 29

Section 6 Maintenance and cleaning

CAUTION

When carrying or transporting the instrument/instrument

components and if the total weight is more than 18 kg, make

sure that suitable lifting equipment is used and/or that the

instrument/instrument components are carried by 2 people.

6.1 Maintenance and cleaning by the operator

• Regularly check the filtration probe sc for mechanical damage.

• Regularly check the filter modules for mechanical damage.

• Regularly check all connections for leaks and corrosion.

• Regularly check all cables and tubing for mechanical damage.

• Clean the filter modules using the damp sponge from the

accessories.

• Clean the filtration probe sc (not the filter modules) with a

cloth. You can use a brush for stubborn soiling.

6.1.1 Troubleshooting, error state diagnostics and repair

6.1.1.1 Module pressure value too low

Pressure value State Action

< 0.25 bar Blocked Replace filter modules

0.25 bar...0.45 bar Soiled Clean filter modules

> 0.45 bar ok No action

If the filter modules block, the module pressure value in the filtration

probe sc drops.

Clean the filter modules or replace the filter modules

(see Cleaning / replacing filter modules on page 28).

27

Page 30

Maintenance and cleaning

6.1.2 Cleaning / replacing filter modules

Note:

The filter modules are very delicate.

Only clean the filter modules very carefully using the damp sponge

supplied.

Clean the filter modules

• Regularly (min. every 3 months) or

• When the pressure values drop below 0.45 bar.

DANGER

Potential danger in the event of contact with

chemical/biological materials. Handling chemical samples,

standards and reagents can be dangerous. Familiarize

yourself with the necessary safety procedure s an d th e correc t

handling of the chemicals before the work and rea d and follow

all relevant safety data sheets.

Normal operation of this instrument may involve the use of

hazardous chemicals or biologically harmful samples.

• Observe all cautionary information printed on the original

solution containers and safety data sheet prior to their use.

• Dispose of all consumed solutions in accordance with national

regulations and laws.

• Select the type of protective equipment suitable to the

concentration and quantity of the dangerous material at the

respective work place.

NEVER use chlorine bleach together with hydrochloric acid

(Risk of the formation of chlorine gas).

For cleaning use chlorine bleach (5 %–10 %) OR hydrochloric

acid (5 %).

Avoid the contact of cleaning agents and soaps with filter

modules as these may render the filter modules unusable.

1. On the SENSOR SETUP menu on the analysis instrument,

choose the TEST/MAINT, SERVICE MODE command and

accept.

2. Take the filtration probe sc out of the tank.

3. Clean the filter modules carefully using the damp sponge

supplied.

28

4. Carefully lever the filter modules out of the holder using a

screwdriver.

5. Clean or replace the filter modules.

6. Fit the new or cleaned filter modules in the bottom.

Page 31

Maintenance and cleaning

7. Press up the filter modules against the enclosure until they

engage.

Figure 12 Changing filter module

8. Hang the filtration probe sc back in the tank.

9. On the SENSOR SETUP menu on the analysis instrument,

choose the TEST/MAINT and PREPUMPING PROBE

commands and accept.

10. Wait until the pumping operation is complete.

11. Leave the service state using the "Back" arrow.

12. Answer the SERV. HOLD MODE? prompt with NO/MEASURE

START.

13. On the SENSOR SETUP menu choose the MEASURING and

ON commands and accept.

Table 2 List of consumables and warranty periods

Designation Replace after Spare part No.

Filter module for filtration probe 1 year LZY140

29

Page 32

Maintenance and cleaning

6.2 Maintenance and cleaning by qualified personnel

The filtration probe sc is only allowed to be opened by qualified and

authorised service personnel.

The following consumables in the filtration probe sc should be

changed at regular intervals by the service personnel:

Table 3 List of consumables and warranty periods

Designation Replace after Warranty Spare part No.

Set of wear parts for sample pump

(Pump membrane + valves)

Exhaust (copper) 1 year 1 year LZY139

Exhaust (2 pcs.) for air cleaning

(Air exhaust set, incl. sealing and screws)

6.2.1 Changing exhaust

1 year, with 5 min. analysis interval

Otherwise 2 years

1 year 1 year LZY138

1 year LZY130

If you dispose of the used sample via the filtration probe sc, renew

the exhaust after 1 year.

1. Unscrew the exhaust from the enclosure.

30

Figure 13 Changing exhaust

2. Screw the new exhaust into the enclosure and tighten it

hand-tight.

Page 33

6.2.2 Changing air exhaust

Maintenance and cleaning

1. Undo the 12 screws for the outlet.

2. Replace the exhaust and the sealing.

3. Tighten the 12 screws hand-tight.

4. Change the exhaust on the other side of the filtration probe sc.

Figure 14 Changing air exhaust

31

Page 34

Maintenance and cleaning

32

Page 35

Section 7 Taking out of operation

7.1 Taking out of operation for a short period

No special measures are necessary for taking out of operation for a

short period (up to a week in frost-free ambient conditions).

Important note: If the supply of power to the controller is

interrupted, frost damage may occur.

Ensure the instrument and tubing cannot freeze.

1. Interrupt the measurement and switch the analysis instrument

to the service state.

7.2 Taking out of operation for an extended period

If the filter modules may dry out (e.g. on cleaning the tank), in case

of risk of frost or if the filtration probe sc is to be taken out of

operation for an extended period, please work through the following

list:

1. Take the analysis instrument out of operation in accordance

with the operating instructions for the analysis instrument.

2. Isolate the filtration probe sc from the mains.

3. Take the filtration probe sc out of the tank.

Important note: Do not let the filter modules dry out, as dry filter

modules will become unusable immediately and cannot be

repaired.

4. Dismantle the filter modules.

5. Store the filter modules in clean water.

6. Wrap the filtration probe sc in protective film or a dry cloth.

7. Store the filtration probe sc dry.

7.3 Finally taking out of operation

When you want to finally take the filtration probe sc out of

operation, proceed as described for intermediate storage.

7.4 Intermediate storage or storage

Proceed as for taking out of operation for an extended period.

33

Page 36

Taking out of operation

34

Page 37

Section 8 Replacement Parts, consumables,

accessories

8.1 Replacement parts and their order numbers

Item Description 1 Description 2 Order No.

Set of seals for filtration probe incl. O-ring, connector press. sensor LZY121

-- Set of wear parts for sample pump incl. membrane, valves, screws LZY130

-- Tubing for filtration probe FEP tubing 1 × 3.1 mm, 1.00 m LZY131

-- Air tubing for filtration probe 4/6 mm, PUR-H LZY132

1 Sample tubing 230 V, 5 m incl. top cover and adaptor LZY112

1 Sample tubing 115 V, 5 m incl. top cover and adaptor LZY113

1 Sample tubing 230 V, 10 m incl. top cover and adaptor LZY114

1 Sample tubing 115 V, 10 m incl. top cover and adaptor LZY115

2 Top cover filtration probe (plastic part) LZY116

3 Enclose filtration probe (plastic part) without top cover LZY117

5 Sealing top cover for filtration probe LZY119

6 Set of screws for filtration probe (28 pieces) LZY120

9 Adaptor suction side LZY128

-- Set of screws (4 of each type used) LZY314

10 Adaptor physical page LZY129

12 Card filtration probe with press. sensor ZBA804 YAB042

13 Set of fittings 3.2 mm (4 pieces) LZY111

14 T-fitting 4/6 mm LZY133

15 Fitting for tubing DN 4/6 LZY134

16 Elbow fitting 4/6 mm LZY135

17 Fitting for exhaust valve incl. O-ring LZY136

18 Humidity sensor incl. connector LZY137

20 Exhaust (copper) LZY139

21 Adaptor for filtration probe with flange + screws LZY118

22 Safety cover filtration probe incl. pads and screws LZY122

23 Exhaust valve 230 V incl. cable, connector, fittings, screws LZY123

23 Exhaust valve 115 V incl. cable, connector, fittings, screws LZY124

24 Sample pump 230 V incl. sleeve cable and connector LZY125

24 Sample pump 115 V incl. sleeve cable and connector LZY126

25 Sleeve nut with sealing LZY127

26 Exhaust (2 pcs.) for air cleaning incl. sealing/screws LZY138

27 Coupling piece incl. screws LZY265

28 Locking screw probe adaptor LZY213

29 Seal for filter module O-ring 7,50 × 2,50 (4 pieces) LZY142

30 Filter module for filtration probe LZY140

31 Adaptor for filtration module including sealing LZY141

32 Connection tubing for filtr. probe 4/6 mm, PTFE 25 cm LZY253

35

Page 38

Replacement Parts, consumables, accessories

8.2 Accessories

Description 1 Description 2 Order No.

Sponge EZZ062

Set of small parts 2 spring cotter with chains + 6 screws LZY245

8.3 Optional accessories

Description Description 2 Order No.

Rim mounting for filtration probe sc LZX414.00.50000

Rail mounting for filtration probe sc LZX414.00.60000

Protection against flow LZY317

36

Page 39

Replacement Parts, consumables, accessories

37

Page 40

Replacement Parts, consumables, accessories

38

Page 41

Section 9 Contact

HACH Company

World Headquarters

P.O. Box 389

Loveland, Colorado

80539-0389 U.S.A.

Tel (800) 227-HACH

(800) -227-4224

(U.S.A. only)

Fax (970) 669-2932

orders@hach.com

www.hach.com

HACH LANGE GMBH

Willstätterstraße 11

D-40549 Düsseldorf

Tel. +49 (0)2 11 52 88-320

Fax +49 (0)2 11 52 88-210

info@hach-lange.de

www.hach-lange.de

HACH LANGE GMBH

Rorschacherstrasse 30a

CH-9424 Rheineck

Tel. +41 (0)848 55 66 99

Fax +41 (0)71 886 91 66

info@hach-lange.ch

www.hach-lange.ch

Repair Service in the

United States:

HACH Company

Ames Service

100 Dayton Avenue

Ames, Iowa 50010

Tel (800) 227-4224

(U.S.A. only)

Fax (515) 232-3835

HACH LANGE LTD

Pacific Way

Salford

GB-Manchester, M50 1DL

Tel. +44 (0)161 872 14 87

Fax +44 (0)161 848 73 24

info@hach-lange.co.uk

www.hach-lange.co.uk

HACH LANGE FRANCE

S.A.S.

8, mail Barthélémy Thimonnier

Lognes

F-77437 Marne-La-Vallée

cedex 2

Tél. +33 (0) 820 20 14 14

Fax +33 (0)1 69 67 34 99

info@hach-lange.fr

www.hach-lange.fr

Repair Service in Canada:

Hach Sales & Service

Canada Ltd.

1313 Border Street, Unit 34

Winnipeg, Manitoba

R3H 0X4

Tel (800) 665-7635

(Canada only)

Tel (204) 632-5598

Fax (204) 694-5134

canada@hach.com

HACH LANGE LTD

Unit 1, Chestnut Road

Western Industrial Estate

IRL-Dublin 12

Tel. +353(0)1 460 2522

Fax +353(0)1 450 9337

info@hach-lange.ie

www.hach-lange.ie

HACH LANGE NV/SA

Motstraat 54

B-2800 Mechelen

Tel. +32 (0)15 42 35 00

Fax +32 (0)15 41 61 20

info@hach-lange.be

www.hach-lange.be

Repair Service in

Latin America, the

Caribbean, the Far East,

Indian Subcontinent, Africa,

Europe, or the Middle East:

Hach Company World

Headquarters,

P.O. Box 389

Loveland, Colorado,

80539-0389 U.S.A.

Tel +001 (970) 669-3050

Fax +001 (970) 669-2932

intl@hach.com

HACH LANGE GMBH

Hütteldorfer Str. 299/Top 6

A-1140 Wien

Tel. +43 (0)1 912 16 92

Fax +43 (0)1 912 16 92-99

info@hach-lange.at

www.hach-lange.at

DR. LANGE NEDERLAND

B.V.

Laan van Westroijen 2a

NL-4003 AZ Tiel

Tel. +31(0)344 63 11 30

Fax +31(0)344 63 11 50

info@hach-lange.nl

www.hach-lange.nl

HACH LANGE APS

Åkandevej 21

DK-2700 Brønshøj

Tel. +45 36 77 29 11

Fax +45 36 77 49 11

info@hach-lange.dk

www.hach-lange.dk

HACH LANGE LDA

Av. do Forte nº8

Fracção M

P-2790-072 Carnaxide

Tel. +351 214 253 420

Fax +351 214 253 429

info@hach-lange.pt

www.hach-lange.pt

HACH LANGE KFT.

Vöröskereszt utca. 8-10.

H-1222 Budapest XXII. ker.

Tel. +36 1 225 7783

Fax +36 1 225 7784

info@hach-lange.hu

www.hach-lange.hu

HACH LANGE AB

Vinthundsvägen 159A

SE-128 62 Sköndal

Tel. +46 (0)8 7 98 05 00

Fax +46 (0)8 7 98 05 30

info@hach-lange.se

www.hach-lange.se

HACH LANGE SP. ZO.O.

ul. Krakowska 119

PL-50-428 Wrocław

Tel. +48 801 022 442

Zamówienia: +48 717 177 707

Doradztwo: +48 717 177 777

Fax +48 717 177 778

info@hach-lange.pl

www.hach-lange.pl

HACH LANGE S.R.L.

Str. Căminului nr. 3,

et. 1, ap. 1, Sector 2

RO-021741 Bucureşti

Tel. +40 (0) 21 205 30 03

Fax +40 (0) 21 205 30 17

info@hach-lange.ro

www.hach-lange.ro

HACH LANGE S.R.L.

Via Rossini, 1/A

I-20020 Lainate (MI)

Tel. +39 02 93 575 400

Fax +39 02 93 575 401

info@hach-lange.it

www.hach-lange.it

HACH LANGE S.R.O.

Zastrčená 1278/8

CZ-141 00 Praha 4 - Chodov

Tel. +420 272 12 45 45

Fax +420 272 12 45 46

info@hach-lange.cz

www.hach-lange.cz

HACH LANGE

8, Kr. Sarafov str.

BG-1164 Sofia

Tel. +359 (0)2 963 44 54

Fax +359 (0)2 866 15 26

info@hach-lange.bg

www.hach-lange.bg

HACH LANGE S.L.U.

Edificio Seminario

C/Larrauri, 1C- 2ª Pl.

E-48160 Derio/Vizcaya

Tel. +34 94 657 33 88

Fax +34 94 657 33 97

info@hach-lange.es

www.hach-lange.es

HACH LANGE S.R.O.

Roľnícka 21

SK-831 07 Bratislava –

Vaj nory

Tel. +421 (0)2 4820 9091

Fax +421 (0)2 4820 9093

info@hach-lange.sk

www.hach-lange.sk

HACH LANGE SU

ANALİZ SİSTEMLERİ

LTD.ŞTİ.

Ilkbahar mah. Galip Erdem

Cad. 616 Sok. No:9

TR-Oran-Çankaya/ANKARA

Tel. +90312 490 83 00

Fax +90312 491 99 03

bilgi@hach-lange.com.tr

www.hach-lange.com.tr

39

Page 42

Contact

HACH LANGE D.O.O.

Fajfarjeva 15

SI-1230 Domžale

Tel. +386 (0)59 051 000

Fax +386 (0)59 051 010

info@hach-lange.si

www.hach-lange.si

HACH LANGE OOO

Finlyandsky prospekt, 4A

Business Zentrum “Petrovsky

fort”, R.803

RU-194044, Sankt-Petersburg

Tel. +7 (812) 458 56 00

Fax. +7 (812) 458 56 00

info.russia@hach-lange.com

www.hach-lange.com

ΗΑCH LANGE E.Π.Ε.

Αυλίδος 27

GR-115 27 Αθήνα

Τηλ . +30 210 7777038

Fax +30 210 7777976

info@hach-lange.gr

www.hach-lange.gr

HACH LANGE D.O.O.

Ivana Severa bb

HR-42 000 Varaždin

Tel. +385 (0) 42 305 086

Fax +385 (0) 42 305 087

info@hach-lange.hr

www.hach-lange.hr

HACH LANGE MAROC

SARLAU

Villa 14 – Rue 2 Casa

Plaisance

Quartier Racine Extension

MA-Casablanca 20000

Tél. +212 (0)522 97 95 75

Fax +212 (0)522 36 89 34

info-maroc@hach-lange.com

www.hach-lange.ma

40

Page 43

Section 10 Warranty, liability and complaints

HACH LANGE GmbH warrants that the product supplied is free of

material and manufacturing defects and undertakes the obligation

to repair or replace any defective parts at zero cost.

The warranty period for instruments is 24 months. If a service

contract is taken out within 6 months of purchase, the warranty

period is extended to 60 months.

With the exclusion of the further claims, the supplier is liable for

defects including the lack of assured properties as follows: all those

parts that, within the warranty period calculated from the day of the

transfer of risk, can be demonstrated to have become unusable or

that can only be used with significant limitations due to a situation

present prior to the transfer of risk, in particular due to incorrect

design, poor materials or inadequate finish will be improved or

replaced, at the supplier's discretion. The identification of such

defects must be notified to the supplier in writing without delay,

however at the latest 7 days after the identification of the fault. If the

customer fails to notify the supplier, the product is considered

approved despite the defect. Further liability for any direct or

indirect damages is not accepted.

If instrument-specific maintenance and servicing work defined by

the supplier is to be performed within the warranty period by the

customer (maintenance) or by the supplier (servicing) and these

requirements are not met, claims for damages due to the failure to

comply with the requirements are rendered void.

Any further claims, in particular claims for consequential damages

cannot be made.

Consumables and damage caused by improper handling, poor

installation or incorrect use are excluded from this clause.

HACH LANGE GmbH process instruments are of proven reliability

in many applications and are therefore often used in automatic

control loops to provide the most economical possible operation of

the related process.

To avoid or limit consequential damage, it is therefore

recommended to design the control loop such that a malfunction in

an instrument results in an automatic change over to the backup

control system; this is the safest operating state for the environment

and the process.

41

Page 44

Warranty, liability and complaints

42

Page 45

Index

A

Accessories .................................................................. 35

C

Changing air exhaust.................................................... 31

Cleaning .................................................................27

Connecting air tubing.................................................... 22

Connecting sample tubing............................................ 21

Consumables..........................................................30

Copyright ...................................................................... 10

, 30

, 35

D

Disposal

Packaging .............................................................. 11

Drawing with dimensions.............................................. 13

E

Exhaust

Changing................................................................ 30

Sealing ................................................................... 14

F

Filter module

Installation.............................................................. 15

Filter modules

Cleaning / replacing ............................................... 28

Filtrate flow rate .............................................................. 3

M

Maintenance........................................................... 27, 30

Module pressure value too low..................................... 25

O

Operating instructions

Identification............................................................. 8

Operating temperature ................................................... 3

Order numbers ............................................................. 35

P

Packaging..................................................................... 11

Personnel, qualified...................................................... 11

Power supply.................................................................. 3

Pressure value ....................................................... 25

Problem rectification..................................................... 25

, 27

R

Replacement parts ....................................................... 35

S

Sample temperature....................................................... 3

T

Taking out of operation................................................. 33

The declaration of conformity ....................................... 10

Troubleshooting............................................................ 27

I

Installation .................................................................... 14

Preparing ............................................................... 12

Intermediate storage..................................................... 33

Items supplied ................................................................ 8

U

Use

Correct ..................................................................... 9

Incorrect................................................................... 9

43

Page 46

44

Loading...

Loading...