DOC022.52.90323

DR 3900

USER MANUAL

04/2013 Edition 3A

© HACH-LANGE GmbH, 2011, 2013. All rights reserved. Printed in Germany.

Table of contents

Section 1 Specifications ........................................................................................................................ 9

Section 2 General Information............................................................................................................. 11

2.1 Safety information............................................................................................................................. 11

2.1.1 Precautionary labels ................................................................................................................ 11

2.1.2 RFID module (not available on all models).............................................................................. 11

2.1.3 Chemical and Biological Safety ............................................................................................... 12

2.2 Overview of product.......................................................................................................................... 13

Section 3 Installation............................................................................................................................ 15

3.1 Unpack the instrument...................................................................................................................... 15

3.2 Operating environment ..................................................................................................................... 15

3.3 Front and back view.......................................................................................................................... 16

3.4 Power connections ........................................................................................................................... 17

3.5 Interfaces.......................................................................................................................................... 18

3.6 Cell compartments, cell adapters and light shield ............................................................................18

3.6.1 Cell compartments and adapters.............................................................................................18

3.6.2 Installation of cell adapter ........................................................................................................ 20

3.6.3 Use of the light shield for measurements................................................................................. 20

3.7 Beam path ........................................................................................................................................ 22

Section 4 Start up ................................................................................................................................. 23

4.1 Switch on the instrument, startup process........................................................................................ 23

4.2 Language selection........................................................................................................................... 23

4.3 Self-check ......................................................................................................................................... 23

4.4 Sleep mode....................................................................................................................................... 24

4.5 Power off the instrument................................................................................................................... 24

Section 5 Standard programs.............................................................................................................. 25

5.1 Overview........................................................................................................................................... 25

5.1.1 Tips for using the touch screen................................................................................................ 25

5.1.2 Use of the alphanumeric keypad .............................................................................................25

5.1.3 Main menu ............................................................................................................................... 26

3

Table of contents

5.2 Instrument Setup...............................................................................................................................27

5.2.1 Operator ID...............................................................................................................................27

5.2.1.1 Operator RFID tag (not available on all models) .............................................................28

5.2.2 Sample ID.................................................................................................................................28

5.2.2.1 Sample ID with scanner method 1...................................................................................30

5.2.2.2 Sample ID with scanner method 2...................................................................................30

5.2.3 Sample ID and operator ID with the optional RFID Sample ID Kit (not available on all models) .

31

5.2.4 Security settings.......................................................................................................................31

5.2.4.1 Assign operator security level..........................................................................................32

5.2.4.2 Deactivate password .......................................................................................................34

5.2.5 Date and time...........................................................................................................................35

5.2.6 Sound settings..........................................................................................................................36

5.2.7 PC and printer ..........................................................................................................................36

5.2.7.1 Printer setup ....................................................................................................................37

5.2.7.2 Print data .........................................................................................................................38

5.2.7.3 Print data continuously ....................................................................................................39

5.2.7.4 Network setup..................................................................................................................39

5.2.8 Power Management .................................................................................................................42

5.3 Save, recall, send and delete data....................................................................................................43

5.3.1 The data log .............................................................................................................................43

5.3.1.1 Auto/manual data storage ...............................................................................................43

5.3.1.2 Recall stored data from the data log................................................................................44

5.3.1.3 Send data from the data log ............................................................................................45

5.3.1.4 Delete stored data from the data log...............................................................................46

5.3.2 Control charts for data from the AQA Log................................................................................46

5.3.3 Store, recall, send and delete data from wavelength scan and time course............................48

5.3.3.1 Data storage from wavelength scan or time course ........................................................48

5.3.3.2 Recall stored data from wavelength scan or time course................................................49

5.3.3.3 Send data from wavelength scan or time course ............................................................49

5.3.3.4 Delete stored data from wavelength scan or time course ...............................................50

5.3.4 Data analysis............................................................................................................................50

5.3.4.1 Trends .............................................................................................................................51

5.3.4.2 Ratios ..............................................................................................................................52

5.3.4.3 Interference Check (not available on all models) ............................................................55

4

Table of contents

5.4 Stored Programs............................................................................................................................... 56

5.4.1 Select a saved test/method; entering user-specific basic data................................................ 56

5.4.2 Stored programs options.......................................................................................................... 56

5.4.3 Use of program timers ............................................................................................................. 57

5.4.4 Set the dilution factor ............................................................................................................... 58

5.4.5 Run a standard adjust.............................................................................................................. 59

5.4.6 Set the chemical form .............................................................................................................. 59

5.4.6.1 Change of the default setting of the chemical form......................................................... 60

5.4.7 Run a reagent blank................................................................................................................. 60

5.4.8 To carry out a multiple determination....................................................................................... 61

5.4.9 Analysis of samples ................................................................................................................. 61

5.4.10 Update/edit tests (not available on all models) ...................................................................... 62

5.4.10.1 General advices for program update and edit............................................................... 62

5.4.10.2 Manual update of test data ........................................................................................... 62

5.4.10.3 Program a new test....................................................................................................... 63

5.4.11 Add stored programs to the favorite programs list................................................................. 63

5.5 Barcode Programs............................................................................................................................ 64

5.5.1 Perform a barcode test ............................................................................................................ 64

5.5.2 Select the chemical evaluation form ........................................................................................65

5.5.2.1 Change of the default setting of the chemical form......................................................... 65

5.5.3 Basic test-specific and sample-specific data settings.............................................................. 65

5.5.4 Sample blank ........................................................................................................................... 67

5.5.5 Update/edit barcode tests........................................................................................................ 67

5.5.5.1 Update barcode tests with test packaging (not available on all models) ........................ 67

5.5.5.2 Manual update of a barcode test .................................................................................... 68

5.5.5.3 Manual check/revision of test data.................................................................................. 70

5.5.5.4 Update via the Internet.................................................................................................... 70

5.5.5.5 Program a new test......................................................................................................... 71

5

Table of contents

Section 6 Expanded programs.............................................................................................................73

6.1 User programs...................................................................................................................................73

6.1.1 Program a user method............................................................................................................73

6.1.1.1 Single wavelength settings..............................................................................................75

6.1.1.2 Multi wavelength settings ................................................................................................76

6.1.1.3 Calibration settings for single and Multi Wavelength mode.............................................78

6.1.1.4 Store a user program.......................................................................................................81

6.1.1.5 Additional user-defined parameters and functions..........................................................81

6.1.2 "Free programming" program type ...........................................................................................82

6.1.2.1 Measurement process.....................................................................................................84

6.1.2.2 Enter a new element of a measuring sequence ..............................................................84

6.1.2.3 Enter the calibration formula (evaluation formula)...........................................................87

6.1.2.4 Enter variables.................................................................................................................90

6.1.2.5 Save a free programming user program..........................................................................90

6.1.3 Select a user program..............................................................................................................90

6.1.4 Add, edit and delete user programs from the favorites list.......................................................90

6.1.4.1 Add to Favorites ..............................................................................................................91

6.1.4.2 Edit ..................................................................................................................................91

6.1.4.3 Delete program................................................................................................................92

6.2 Favorites ...........................................................................................................................................92

6.2.1 Recall a favorite program .........................................................................................................92

6.2.2 Delete a favorite program.........................................................................................................92

6.3 Standard Addition - monitoring/checking results...............................................................................93

6.3.1 Complete a standard addition ..................................................................................................94

6.4 Single Wavelength (absorbance, concentration and transmittance readings)..................................97

6.4.1 Set up Single Wavelength mode..............................................................................................97

6.4.2 Take single wavelength readings (single reading) ...................................................................99

6.5 Multi Wavelength mode – readings with more than one wavelength................................................99

6.5.1 Set the Reading mode at different wavelengths.......................................................................99

6.5.2 Complete a reading in the Multi Wavelength mode................................................................102

6.6 Wavelength Scan mode – recording of absorbance and transmission spectrums..........................102

6.6.1 Set up the wavelength scan ...................................................................................................103

6.6.2 Perform a wavelength scan....................................................................................................105

6.6.2.1 Navigation of the wavelength scan graph or a wavelength scan analysis.....................106

6.6.3 Work with reference scans.....................................................................................................106

6.7 Time course of absorbance/transmittance ......................................................................................108

6.7.1 Time course setup parameters...............................................................................................108

6.7.2 Time course scan reading......................................................................................................109

6.7.3 Analysis of time course data ..................................................................................................110

6.7.3.1 Navigation of a time scan or a time scan analysis.........................................................110

6

Table of contents

6.8 System Checks............................................................................................................................... 111

6.8.1 Instrument Information........................................................................................................... 111

6.8.2 Update the instrument software.............................................................................................111

6.8.3 Optical Checks....................................................................................................................... 112

6.8.3.1 Verification kit................................................................................................................ 112

6.8.3.2 Test solution.................................................................................................................. 113

6.8.3.3 Wavelength check.........................................................................................................115

6.8.3.4 Stray light check............................................................................................................ 115

6.8.3.5 Absorbance check ........................................................................................................ 116

6.8.4 AQA - Analytical Quality Assurance....................................................................................... 117

6.8.4.1 AQA Standard configuration ......................................................................................... 118

6.8.4.2 AQA Addition ................................................................................................................ 119

6.8.4.3 Multiple Determination .................................................................................................. 120

6.8.4.4 Dilution .......................................................................................................................... 121

6.8.4.5 Performing AQA measurement..................................................................................... 121

6.8.4.6 Pipette test set .............................................................................................................. 121

6.8.5 Instrument backup ................................................................................................................. 121

6.8.6 Service menu......................................................................................................................... 123

6.8.7 Service time ........................................................................................................................... 123

6.8.8 Lamps operating time ............................................................................................................ 123

6.9 Toolbar............................................................................................................................................ 124

6.9.1 Log on....................................................................................................................................124

6.9.2 Sample ID .............................................................................................................................. 124

6.9.3 Timer...................................................................................................................................... 125

6.9.4 AQA ....................................................................................................................................... 125

6.9.5 Trends.................................................................................................................................... 125

6.9.6 Link2SC ................................................................................................................................. 125

6.9.7 Website DR 3900................................................................................................................... 126

Section 7 Maintenance ....................................................................................................................... 127

7.1 Cleaning requirements.................................................................................................................... 127

7.1.1 Spectrophotometer ................................................................................................................ 127

7.1.2 Display ................................................................................................................................... 127

7.1.3 Cuvettes/cells......................................................................................................................... 127

7.2 Lamp replacement .......................................................................................................................... 128

7.3 Exchange of the replaceable cell compartment.............................................................................. 130

Section 8 Troubleshooting................................................................................................................. 133

Section 9 Replacement parts............................................................................................................. 137

9.1 Accessories .................................................................................................................................... 137

9.2 Replacement parts.......................................................................................................................... 138

7

Table of contents

Section 10 Contact..............................................................................................................................139

Section 11 Warranty, liability and complaints...................................................................................141

Appendix A Help Guide ......................................................................................................................143

A.1 Display of the Help Guide for stored programs..............................................................................143

A.2 Display of the Help Guide for barcode programs..........................................................................144

Index.....................................................................................................................................................147

8

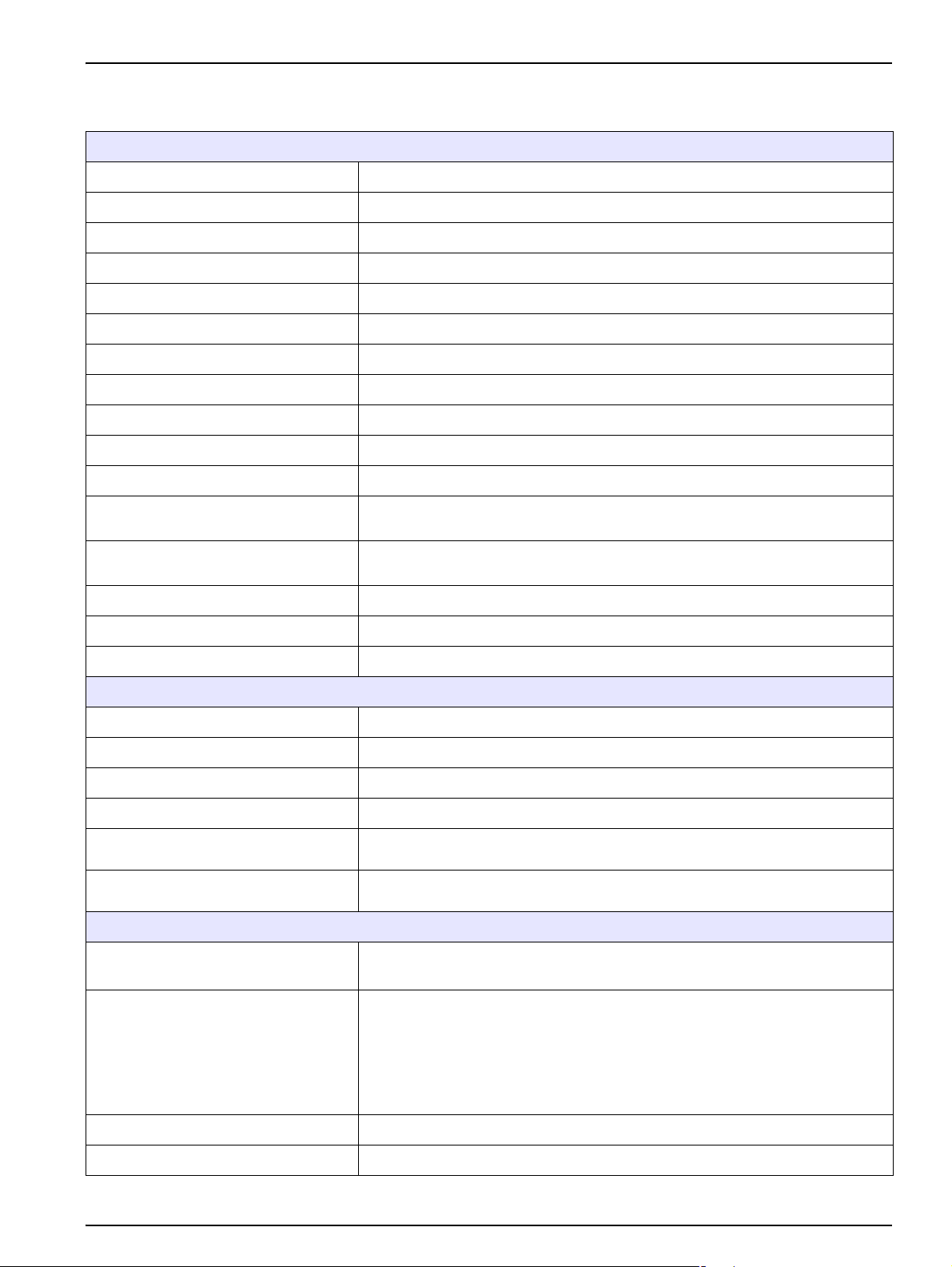

Section 1 Specifications

These are subject to change without notice!

Performance specifications

Display mode Transmittance (%), Absorbance and Concentration

Source lamp Halogen lamp

Wavelength range 320–1100 nm

Wavelength Accuracy ± 1.5nm (wavelength range 340–900 nm)

Wavelength reproducibility ± 0.1 nm

Wavelength resolution 1 nm

Wavelength calibration Automatic

Wavelength selection Automatic, based on method selection

Scanning speed ≥ 8 nm/s (in steps of 1 nm)

Spectral bandwidth 5 nm

Photometric measuring range ± 3.0 Abs (wavelength range 340–900 nm)

Photometric accuracy

Photometric linearity

5 m abs at 0.0–0.5 abs

1 % at 0.50–2.0 Ext

< 0.5 % to 2 Abs

≤1 % at > 2 Abs with neutral glass at 546 nm

Stray light < 0.1 %T at 340 nm with NaNO

Data log 2000 readings (Result, Date, Time, Sample ID, User ID)

User programs 100

Physical and environmental specifications

Width 350 mm (13.78 in)

Height 151 mm (5.94 in)

Depth 255 mm (10.04 in)

Mass 4200 g (9.26 lb)

Ambient operating requirements

Ambient storage requirements

Additional technical data

Power connector via external power

supply

Interfaces

10–40 °C (50–104 °F), maximum 80 % relative humidity (without condensate

formation)

–40–60 °C (–40–140 °F), maximum 80 % relative humidity (without condensate

formation)

Input: 100–240 V/50–60 Hz

Output: 15 V/40 VA

Use only shielded cable with maximum length of 3 m:

2× USB type A

1× USB type B

Use only shielded cable (for example STP, FTP, S/FTP) with maximum length of

20 m:

1× Ethernet

2

Housing rating IP40 (excluding interfaces and power supply)

Protection class Class I

9

Specifications

10

Section 2 General Information

2.1 Safety information

Read through the entire user manual carefully before you unpack

the device, set up and put into operation. Pay attention to all

danger and caution statements. Failure to do so could result in

serious injury to the operator or damage to the equipment.

To make sure that the protection provided by this instrument is

not impaired, do not use or install this instrument in any manner

other than that specified in these operating instructions.

Indicates a potentially or imminently hazardous situation that, if not

avoided, results in death or serious injury.

Indicates a potentially or imminently hazardous situation that, if not

avoided, may result in death or serious injury.

Indicates a potentially hazardous situation that may result in minor or

moderate injury.

DANGER

WARNING

CAUTION

Indicates a situation that, if it is not avoided, can lead to damage to

the device. Information that requires special emphasis.

Note: Information that supplements points in the main text.

2.1.1 Precautionary labels

Read all labels and tags attached to the instrument. Personal

injury or damage to the instrument could occur if not observed.

For symbols attached to the instrument, corresponding warning

notes are found in the user manual.

This symbol may be attached to the device and references the operation- and/or safety notes in the user manual.

Electrical equipment marked with this symbol may not be disposed of in European domestic or public disposal

systems after 12 August 2005. In conformity with the applicable provisions, consumers in the EU must return old

electrical equipment to the manufacturer for disposal from this date, at no charge to the user.

Note: For return for recycling, please contact the equipment manufacturer or supplier for instructions on how to

return end-of-life equipment, manufacturer-supplied electrical accessories, and all auxiliary items for proper disposal.

2.1.2 RFID module (not available on all models)

NOTICE

RFID technology is a radio application. Radio applications are

subject to national conditions of authorisation. The use of the

DR 3900 (model with RFID module) is currently permitted in the

following countries: EU, CH, NO, HR, RS, MK, TR, CY, US, CA,

AU, NZ. The manufacturer advises that the use of the DR 3900

(model with RFID module) outside of the above-mentioned

11

General Information

regions may contravene national laws. The manufacturer

reserves the right also to obtain authorisation in other countries.

In case of doubt, please contact the distributor.

The DR 3900 contains an RFID module to receive and transmit

information and data. The RFID module operates with a

frequency of 13.56 MHz.

WARNING

The spectrophotometer may not be used in dangerous environments.

The manufacturer and its suppliers reject any express or indirect

guarantee for use with high-risk activities.

Follow the following safety information, in addition to any local

guidelines in force.

Safety information for the correct use of the instrument:

• Do not operate the instrument in hospitals or comparable

establishments in proximity to medical equipment, like pace

makers or hearing aids.

• Do not operate the instrument near highly flammable

substances, such as fuels, highly combustible chemicals and

explosives.

2.1.3 Chemical and Biological Safety

• Do not operate the device near combustible gases, vapors or

dust.

• Do not vibrate or jolt the instrument.

• The instrument can cause interference in immediate

proximity to televisions, radios and computers.

• Do not open the instrument.

• Guarantee is voided if the instrument is not used in

accordance with the guidelines present in this document.

DANGER

Potential danger with contact with chemical/biological substances.

Working with chemical samples, standards and reagents can be

dangerous.

Make yourself familiar with the necessary safety procedures and the

correct handling of the chemicals before use and read and follow all

relevant safety data sheets.

With normal operation of this device the use of chemicals risking

health or biologically harmful samples can be required.

12

• Before handling these substances observe all danger notes

and safety information printed on the containers of the

original solutions and in the safety data sheet.

• Dispose of all consumed solutions in accordance with the

national regulations and laws.

• Select the type of protective equipment suitable to the

concentration and quantity of the dangerous material being

used.

2.2 Overview of product

General Information

The DR 3900 is a VIS spectrophotometer with a wavelength

range of 320 to 1100 nm. The instrument is delivered with a

complete series of application programs and supports several

languages.

The spectrophotometer DR 3900 contains the following programs

and operating types:

• Stored programs (pre-installed tests)

• Barcode Programs

• User Programs

• Favorites

• Single Wavelength

• Multi Wavelength

• Wavelength Scan

• Time course

The DR 3900 Spectrophotometer provides digital readouts in

direct concentration units, absorbance or percent transmittance.

When selecting a user-generated or programmed method, the

menus and prompts serve to direct the user through the test.

This menu system can also generate reports, statistical

evaluations of generated calibration curves and to report

instrument diagnostic checks.

13

General Information

14

Section 3 Installation

3.1 Unpack the instrument

WARNING

Electrical and fire hazards.

Only use the supplied benchtop power supply LZV844.

Only qualified experts may perform the tasks described in this section

of the manual, while adhering to all locally valid safety regulations.

The DR 3900 Spectrophotometer comes packaged with the

following items:

• DR 3900 spectrophotometer

• Dust cover

• USB dust cover, fitted as standard

• Benchtop power supply with power cord for EU

• Cell adapter A.

• Light shield, fitted as standard in the DR 3900

• Operator RFID tag (not available on all models)

3.2 Operating environment

• Basic operating instructions DR 3900, operating instructions

LINK2SC

Further information, detailed user manuals and documentation

are available on the website of the manufacturer.

Note: If any of these items are missing or damaged, please contact the

manufacturer or a sales representative immediately.

Observe the following points to allow the instrument to function

normally and give a long operating life.

• Position the instrument securely on a flat surface taking care

to remove any objects from under the device.

• The ambient temperature must be 10–40 °C (50–104 °F).

NOTICE

Protect the instrument from extreme temperatures from heaters,

direct sunlight and other heat sources.

• The relative humidity should be less than 80 %; moisture

should not condense on the instrument.

• Leave at least a 15 cm clearance at the top and on all sides

for air circulation to avoid overheating of electrical parts.

• Do not use or store the device in extremely dusty, humid or

wet places.

• Keep the surface of the instrument, the cell compartment and

all accessories clean and dry at all times. Immediately

remove splashes or spilt materials on or in the instrument

(refer to Section 7).

15

Installation

3.3 Front and back view

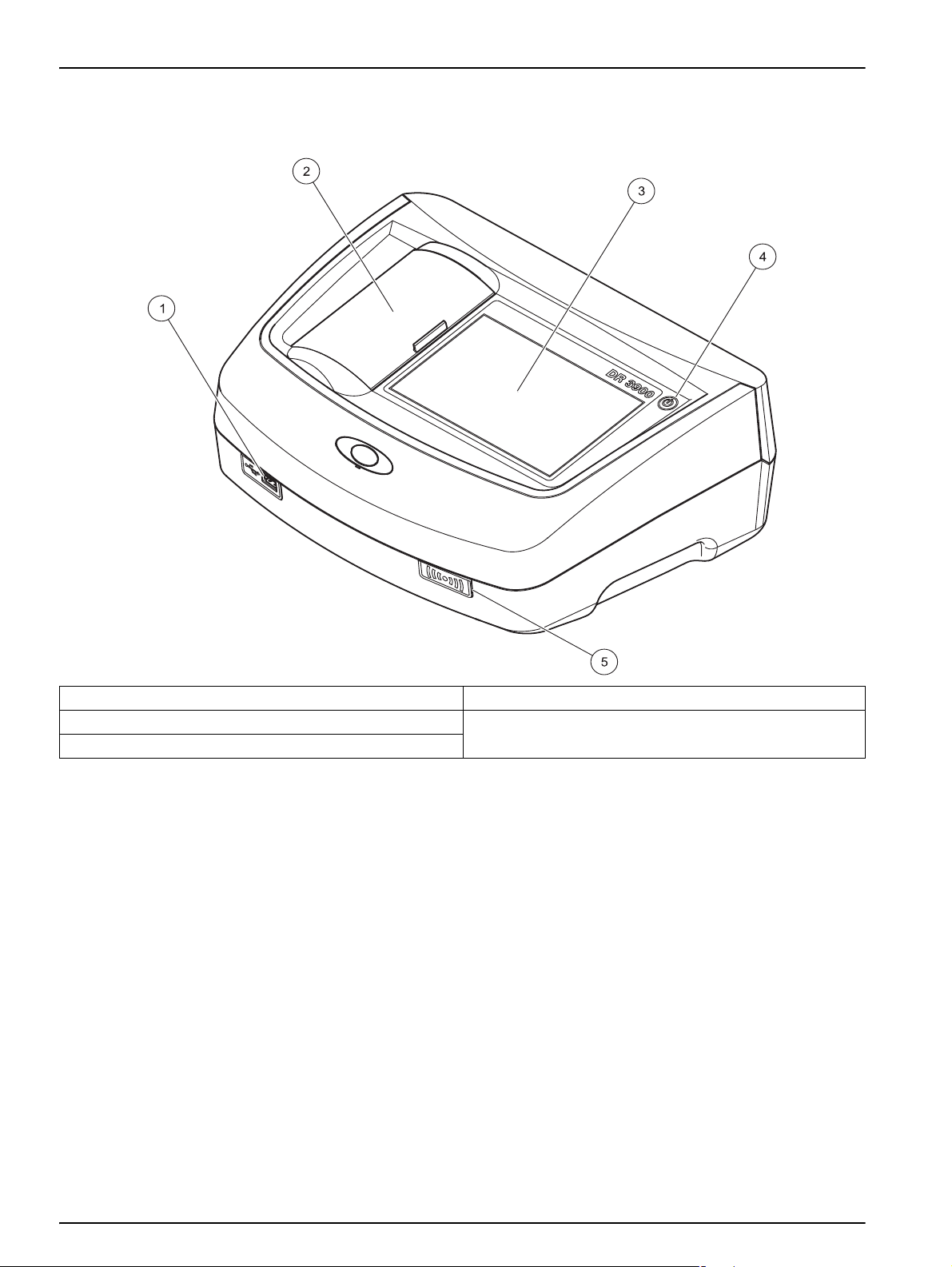

Figure 1 Front view

1 USB port type A 4 On/off switch

2 Cell compartment cover 5 RFID module (not available on all models)

3 Touch screen

16

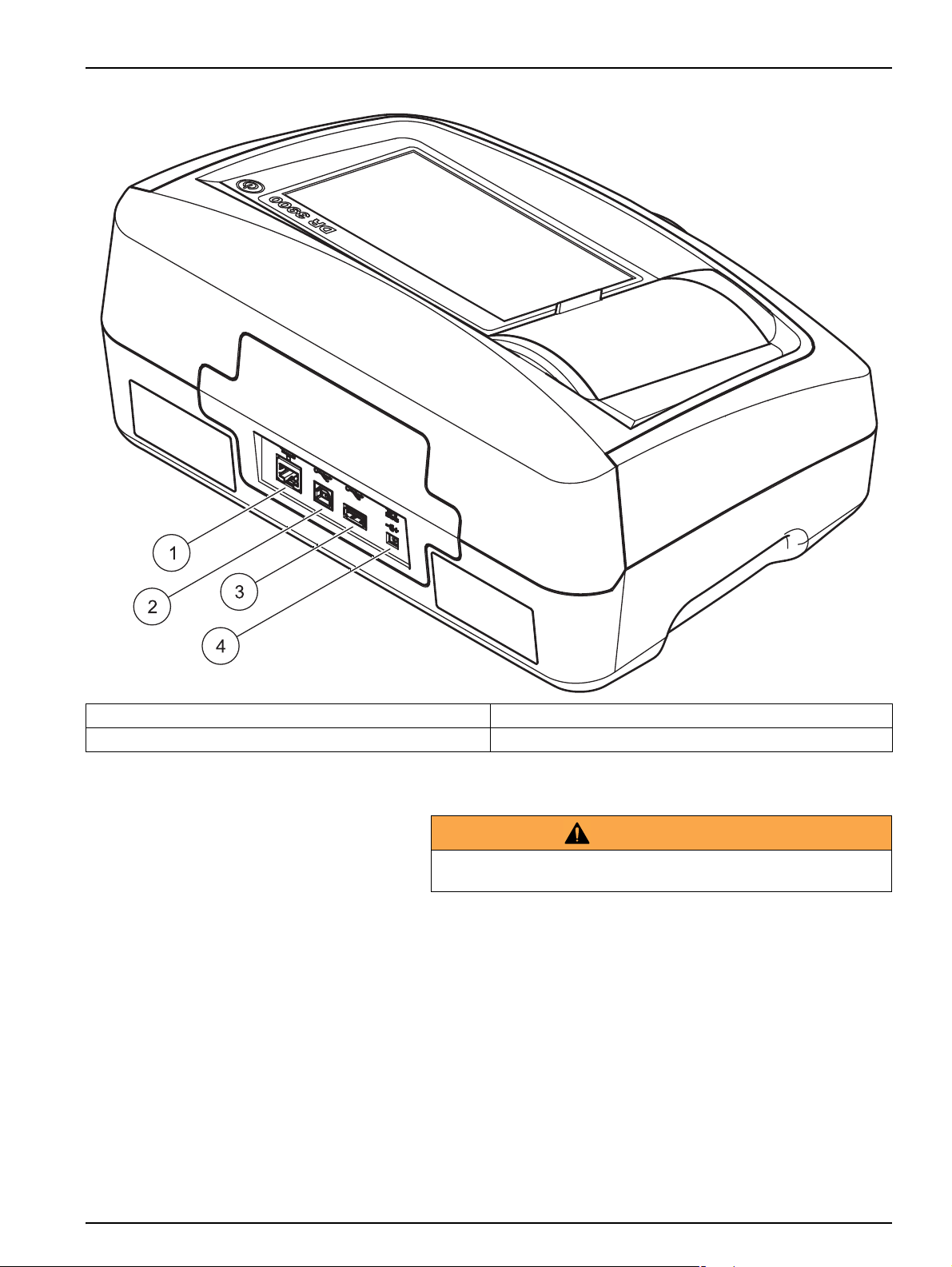

Figure 2 Back view

Installation

1 Ethernet port 3 USB port type A

2 USB port type B 4 Connection for benchtop power supply

3.4 Power connections

WARNING

Electrical and fire hazards.

Only use the supplied benchtop power supply LZV844.

1. Connect the power cable to the benchtop power supply.

2. Plug the benchtop power supply cable into the back of the

instrument (Figure 2, page 17).

3. Insert the power cable plug into a mains socket

(100–240 V~/50–60 Hz).

4. Turn on the power button next to the display to turn on the

power supply (Figure 1, page 16).

17

Installation

3.5 Interfaces

The DR 3900 features three USB ports and one Ethernet port as

standard, located on the front and rear sides of the instrument

(Figure 1 and Figure 2, page 17).

The USB type A ports are used for communications with a printer,

USB memory stick or keyboard. A USB memory stick can be

used to update the instrument software.

The USB type B port is used for communications with a PC. The

optional Hach Data Trans software (refer to Section 9, page 137)

must be installed on the PC for data transfer.

A USB hub may be used to connect several accessories at a

time.

Note: USB cables must not be longer than 3m.

These USB ports permit data to be exported to a printer or PC

and also allow the instrument software to be upgraded (refer to

section 6.8.2, page 111). The Ethernet port supports real-time

data transfer in local networks, LIMS systems or SC controllers.

Only use a shielded cable (e.g. STP, FTP, S/FTP) with a

maximum length of 20 m for the Ethernet port.

3.6 Cell compartments, cell adapters and light shield

3.6.1 Cell compartments and adapters

The DR 3900 has two cell compartments (Figure 3). Only one cell

type at a time can be used for a reading.

Cell compartment (1) for:

• 13 mm round cells

Note: Cell compartment (1) contains barcode detection for

cells.

Cell compartment (2) for:

The following cell types can be used in cell compartment (2).

• Without cell adapter A, 50-mm cells, 1-inch rectangular cells

and 1-inch flow cells can be used directly in cell compartment

(2).

• With cell adapter A: 10 mm rectangular cells, 1-inch round

cells and AccuVac® vials.

Note: These cells must be inserted using cell adapter A.

18

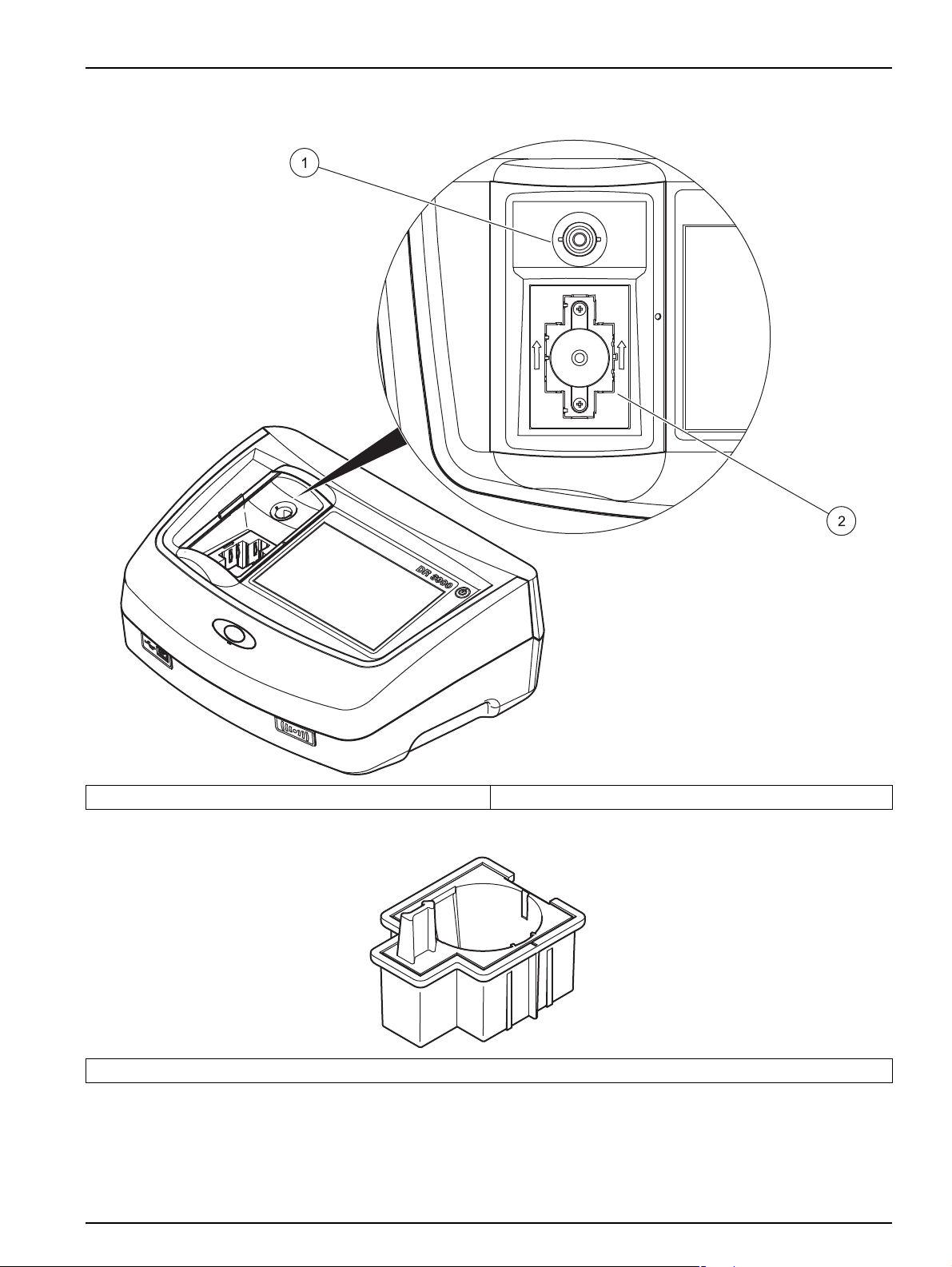

Figure 3 Cell compartments

Installation

1 Cell compartment for round cells (1) 2 Cell compartment for rectangular cells (2)

Figure 4 Cell adapter

Cell adapter A: 10-mm rectangular cells/1-inch round cell

19

Installation

3.6.2 Installation of cell adapter

Figure 5 Installation of a cell adapter

1. Open the cell compartment.

2. Place the cell adapter into cell compartment (2) so that the

arrow on the cell adapter points to the rear (Figure 5).

Note: The arrow on top of the cell adapter indicates the direction of

the light beam path.

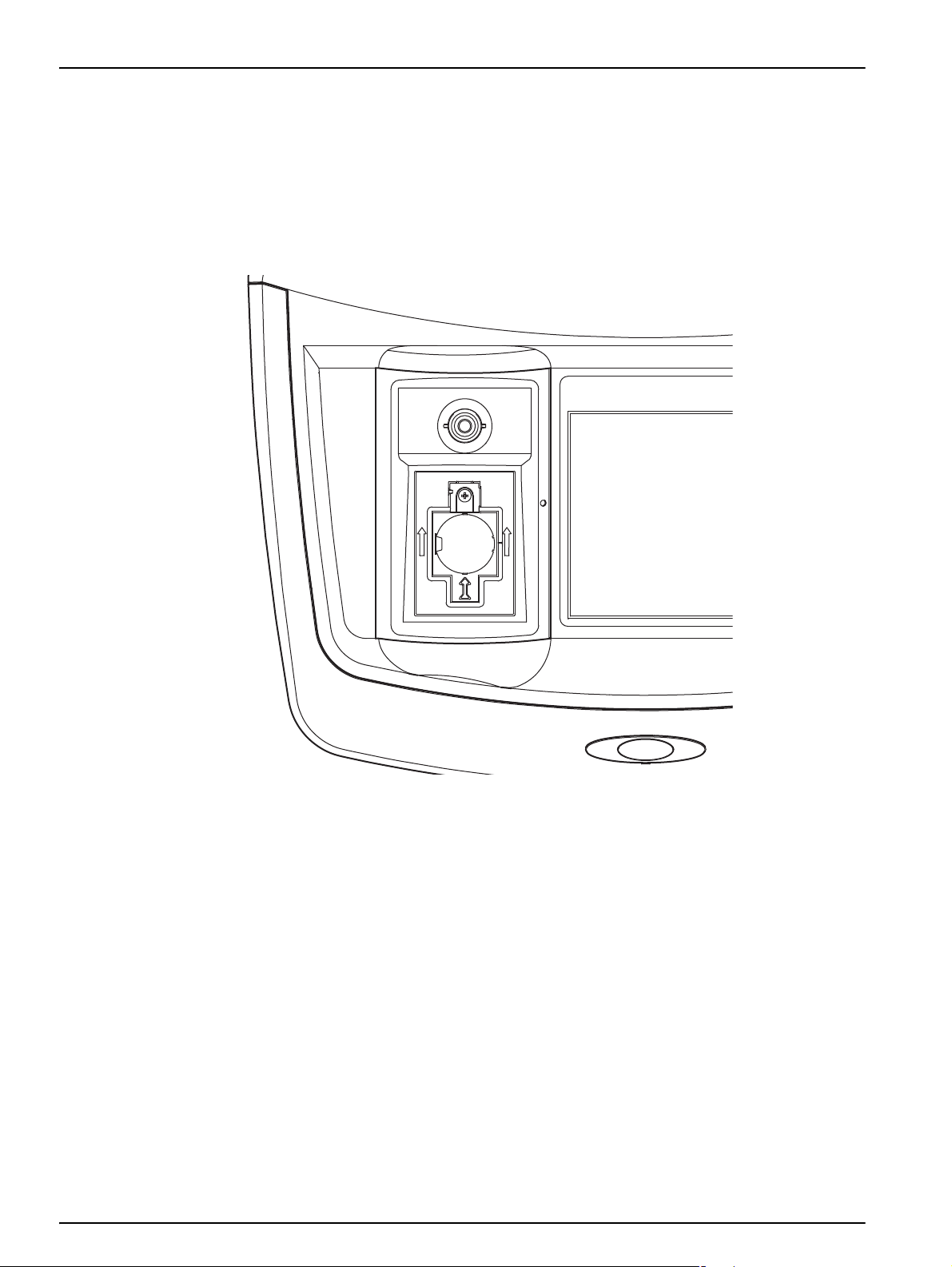

3.6.3 Use of the light shield for measurements

The light shield (Figure 6) prevents disruptive exposure to light

when 13 mm round cells are used in the cell compartment (1).

Insert the light shield into cell compartment (2) before performing

measurements in cell compartment (1).

The instrument is shipped with the light shield installed. Remove

the light shield before using cell compartment (2).

20

Figure 6 Light shield

Installation

Installation of the light shield

1. Open the cell compartment.

2. Place the light shield into cell compartment (2) so that the

arrow on the light shield points to the rear.

21

Installation

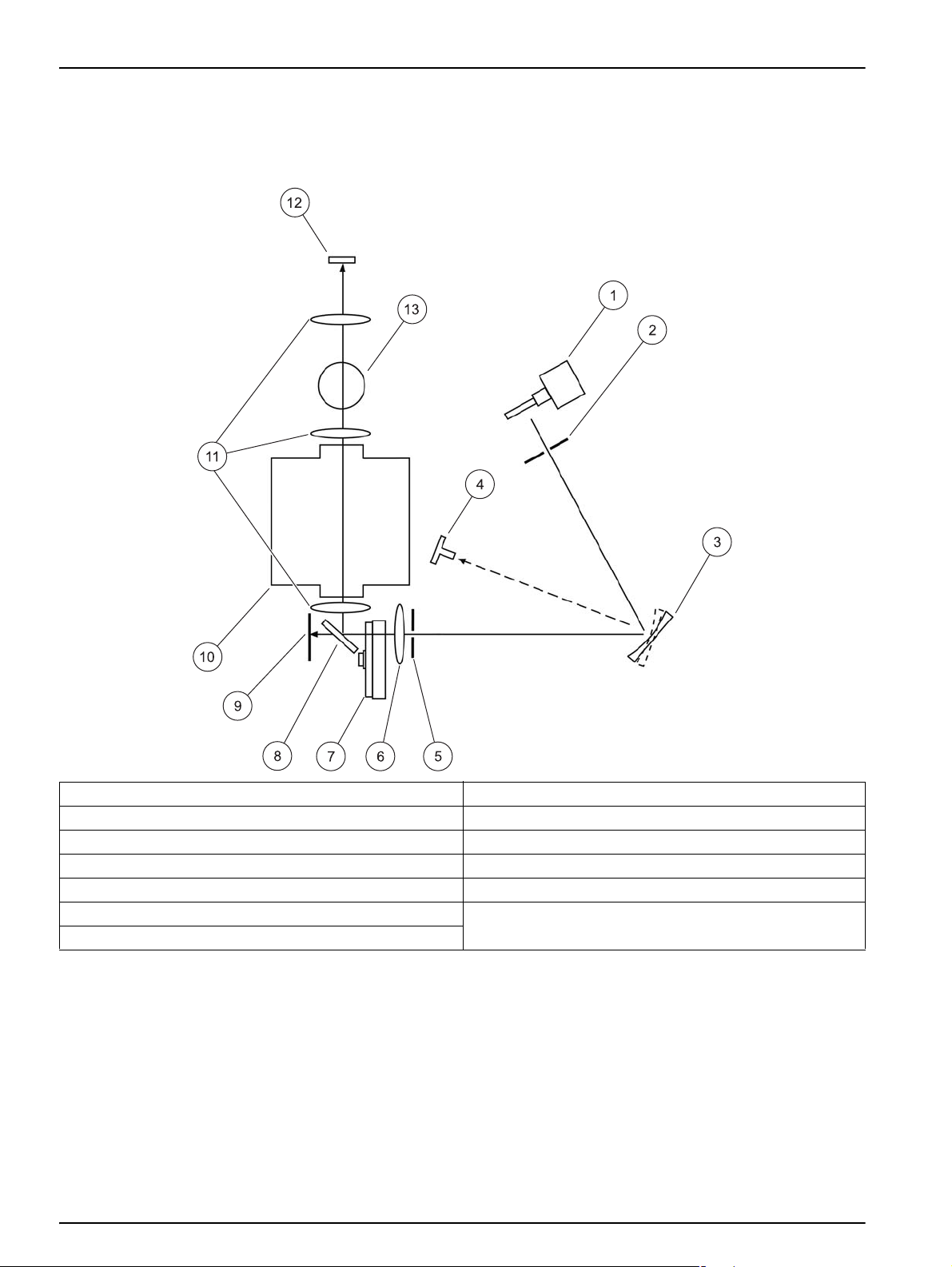

3.7 Beam path

Figure 7 Beam path

Figure 7 shows the beam path of the DR 3900.

1 Halogen lamp 8 Splitter mirror

2 Entrance slit 9 Reference element

3 Grating 10 Cell compartment (2) for rectangular cells

4 Grating angle indicator 11 Lens

5 Exit slit 12 Reading element

6 Lens 13 Cell compartment (1) for round cells

7 Filter wheel

22

Section 4 Start up

4.1 Switch on the instrument, startup process

1. Connect the power cable to the mains outlet.

2. Switch on the instrument by using the power button next to

the display.

3. The instrument starts automatically with a startup process

lasting approximately 45 seconds. The display shows the

logo of the manufacturer. At the end of the startup process, a

startup melody is heard.

Note: Wait approximately 20 seconds before switching on again so as

not to damage the electronics and mechanics of the instrument.

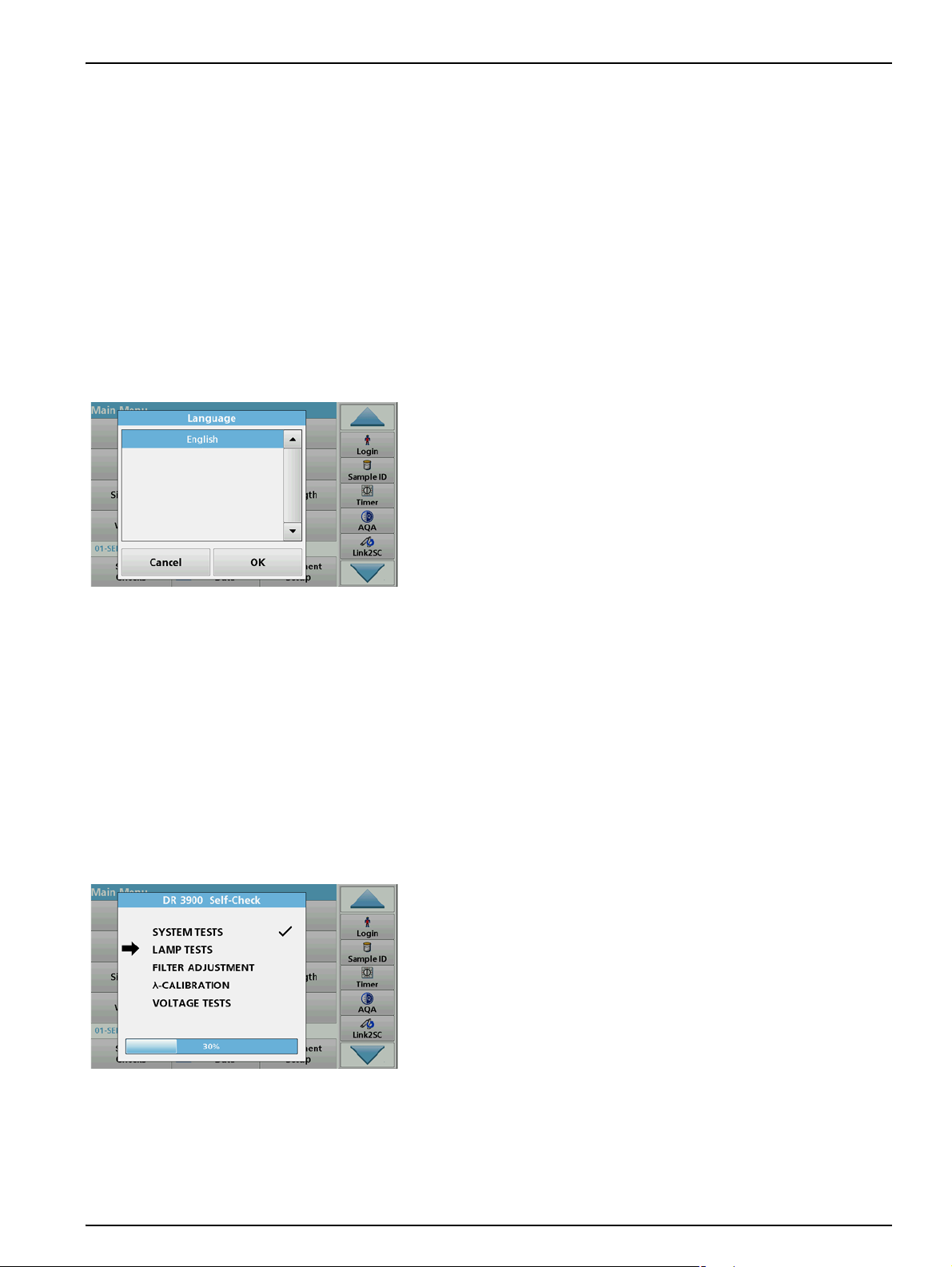

4.2 Language selection

The DR 3900 software includes several language options. The

first time the instrument is switched on, the language selection

screen will be shown automatically after the startup process.

1. Select the required language.

4.3 Self-check

2. Press OK to confirm the language selection. The self-check

will then start automatically.

Change the language setting

The instrument functions in the selected language until the option

is changed.

1. Turn the instrument on.

2. During the startup process, touch any point on the screen

and maintain contact until the option for selecting a language

is shown (approximately 45 seconds).

3. Select the required language.

4. Press OK to confirm the language selection. The self-check

will then start automatically.

Each time the instrument is powered up, a test program begins.

This procedure, which takes approximately two minutes, checks

the system, lamp, filter adjustment, wavelength calibration and

voltage. Each test that functions correctly is marked accordingly.

The Main Menu is displayed when diagnostics are completed.

Note: In the event of further error messages during the test program,

refer to Section 8, page 133.

23

Start up

4.4 Sleep mode

4.5 Power off the instrument

The instrument can be put into sleep mode.

1. Briefly press the power button next to the display.

The "Sleep mode" message is shown. The display will then

switch off automatically.

2. To switch on, press the power button next to the display.

The self-check will start automatically.

After that, the instrument is ready to use.

1. Press the power button next to the display for

approximately 5 seconds.

24

Section 5 Standard programs

5.1 Overview

5.1.1 Tips for using the touch screen

The whole screen responds to touch. To choose an option, tap

with a fingernail, fingertip, an eraser or a specialised stylus. Do

not touch the screen with sharp objects, such as the tip of a

ballpoint pen.

• Do not place anything on top of the screen, to prevent

damage or scratches on the screen.

• Press buttons, words or icons to select them.

• Use scroll bars to move up and down long lists very quickly.

Press and hold the scroll bar, then move up or down to move

through the list.

• Highlight an item from a list by pressing it once. When the

item has been successfully selected, it will be displayed as

reversed text (light text on a dark background).

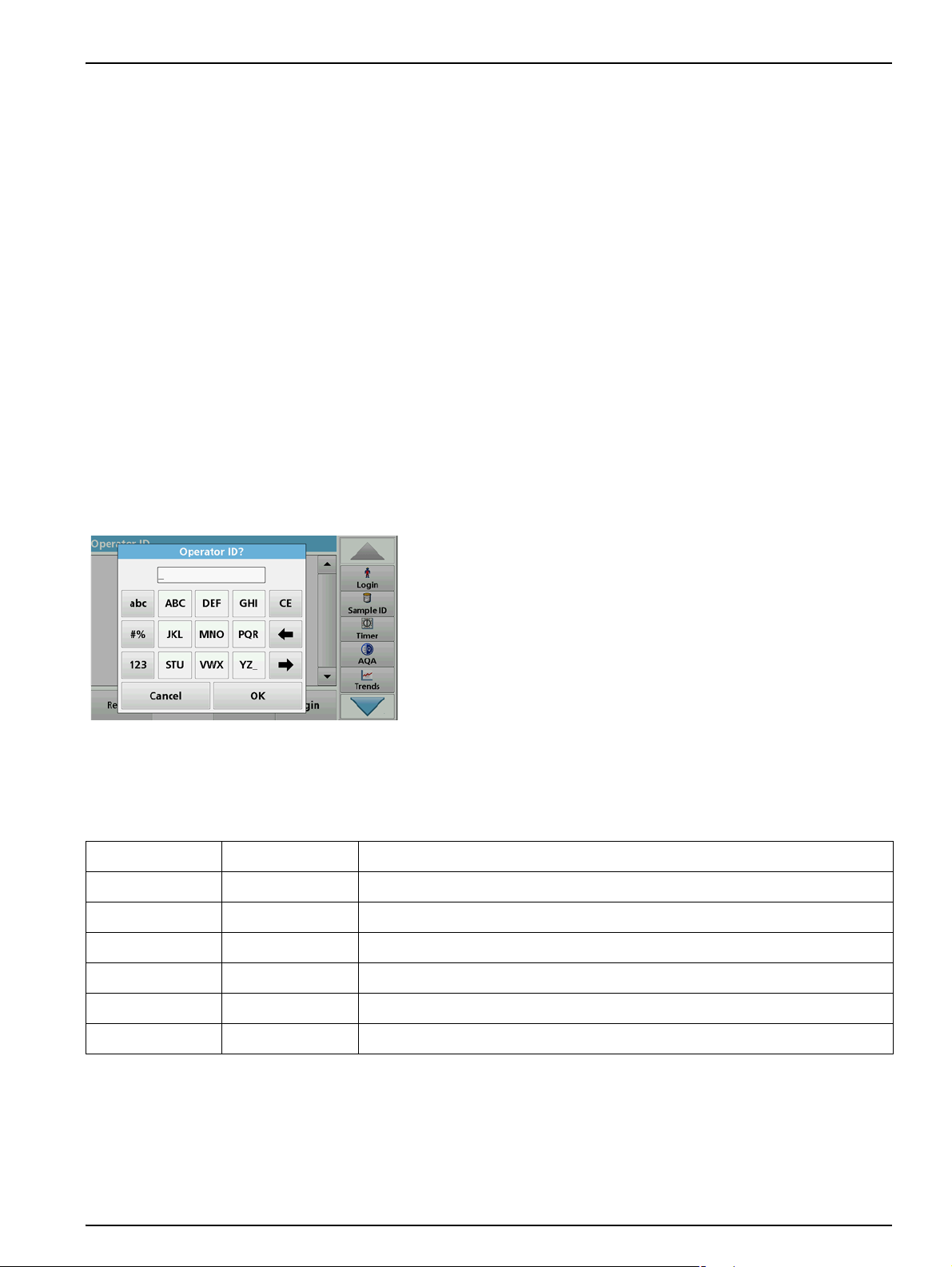

5.1.2 Use of the alphanumeric keypad

This display is used to enter letters, numbers and symbols as

needed when programming the instrument. Unavailable options

are disabled (grayed out). The icons on the right and left of the

screen are described in Table 1.

The central keypad changes to reflect the chosen entry mode.

Press a key repeatedly until the desired character appears on the

screen. A space can be entered by using the underscore on the

YZ_ key.

Press Cancel to cancel an entry, or press OK to confirm an entry.

Note: It is also possible to use a USB keyboard (with US keyboard

layout) or a hand-held USB barcode scanner (refer to Section 9,

page 137).

Table 1 Alphanumeric keypad

Icon / key Description Function

ABC/abc Alphabetic Toggles the character input mode between upper and lower case.

# % Symbols Punctuation, symbols and numerical sub- and superscripts may be entered.

123 Numeric For entering regular numbers.

CE Clear Entry Clear the entry.

Left Arrow Back Deletes the current character and goes back one position.

Right Arrow Next Navigates to the next space in an entry.

25

Standard programs

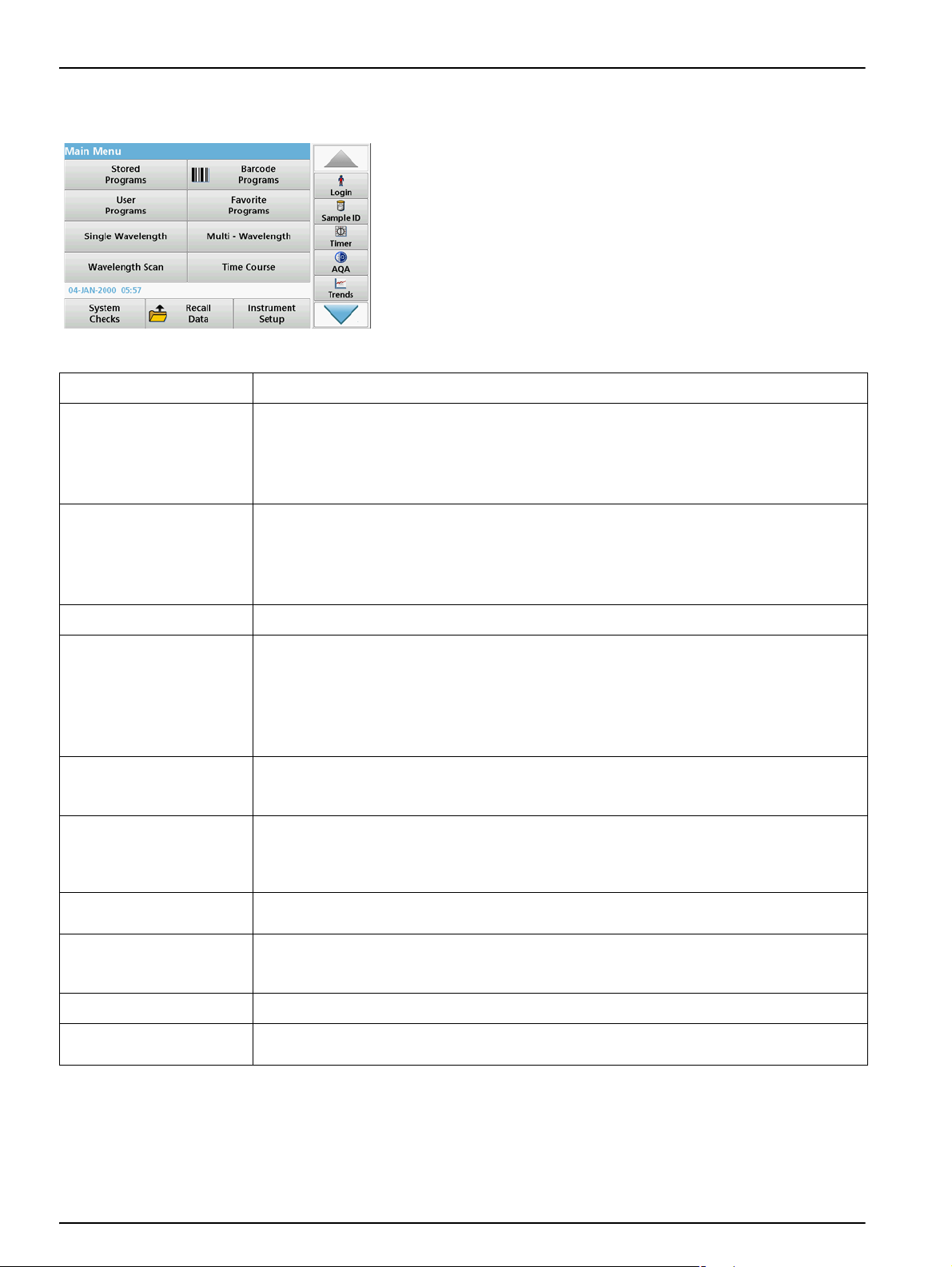

5.1.3 Main menu

Option Function

Stored programs are pre-programmed methods that make use of HACH chemicals and

Stored Programs /

Barcode Programs

(HACH-LANGE programs)

HACH-LANGE pipette tests.

The working procedures for HACH-LANGE tests are included in the test packs.

Further information, as well as illustrated, step-by-step process instructions for

analyses using HACH programs, are available on the website of the manufacturer.

User programs make "made to measure analysis" possible:

A variety of modes may be selected from the Main Menu. The

following table briefly describes each menu option.

There is a toolbar on the right-hand side of the screen. Press to

activate the various functions.

Table 2 Main Menu options

User Programs

• Users can program methods they have developed themselves

• Existing HACH and LANGE methods can be stored as user programs. The

HACH-LANGE tests can then be modified to suit the user's requirements.

Favorites List of methods/tests created by the user to suit his own requirements.

Single wavelength readings are:

Absorbance readings: The light absorbed by the sample is measured in absorbance units.

Single Wavelength

Multi Wavelength

Wavelength Scan

Time course

System checks

Recall measurement data Stored data can be called up, filtered, sent and deleted.

Instrument Setup

Transmittance reading (%): Measures the percent of the original light that passes through the

sample and reaches the detector.

Concentration readings: A concentration factor can be entered to enable the measured

absorbance values to be converted into concentration values.

In the Multi Wavelength mode, absorbance (Abs) or percentage transmittance (%T) is

measured at up to four wavelengths and absorbance differences and absorbance relationships

are calculated. Simple conversions into concentrations can also be carried out.

A wavelength scan shows how the light from a sample is absorbed over a defined wavelength

spectrum. This function can be used to determine the wavelength at which the maximum

absorbance value can be measured. The absorbance behavior is displayed graphically during

the scan.

The time scan records the absorbance or % transmittance at a wavelength over a defined

time.

The "System check" menu offers a number of options, including optical checks, output checks,

lamp history, instrument update, service time, settings for analytical quality assurance and

instrument backup.

In this mode, user-specific or method-specific settings can be entered: operator ID, sample ID,

date & time, sound, PC & printer, password, energy-saving mode and stored data.

26

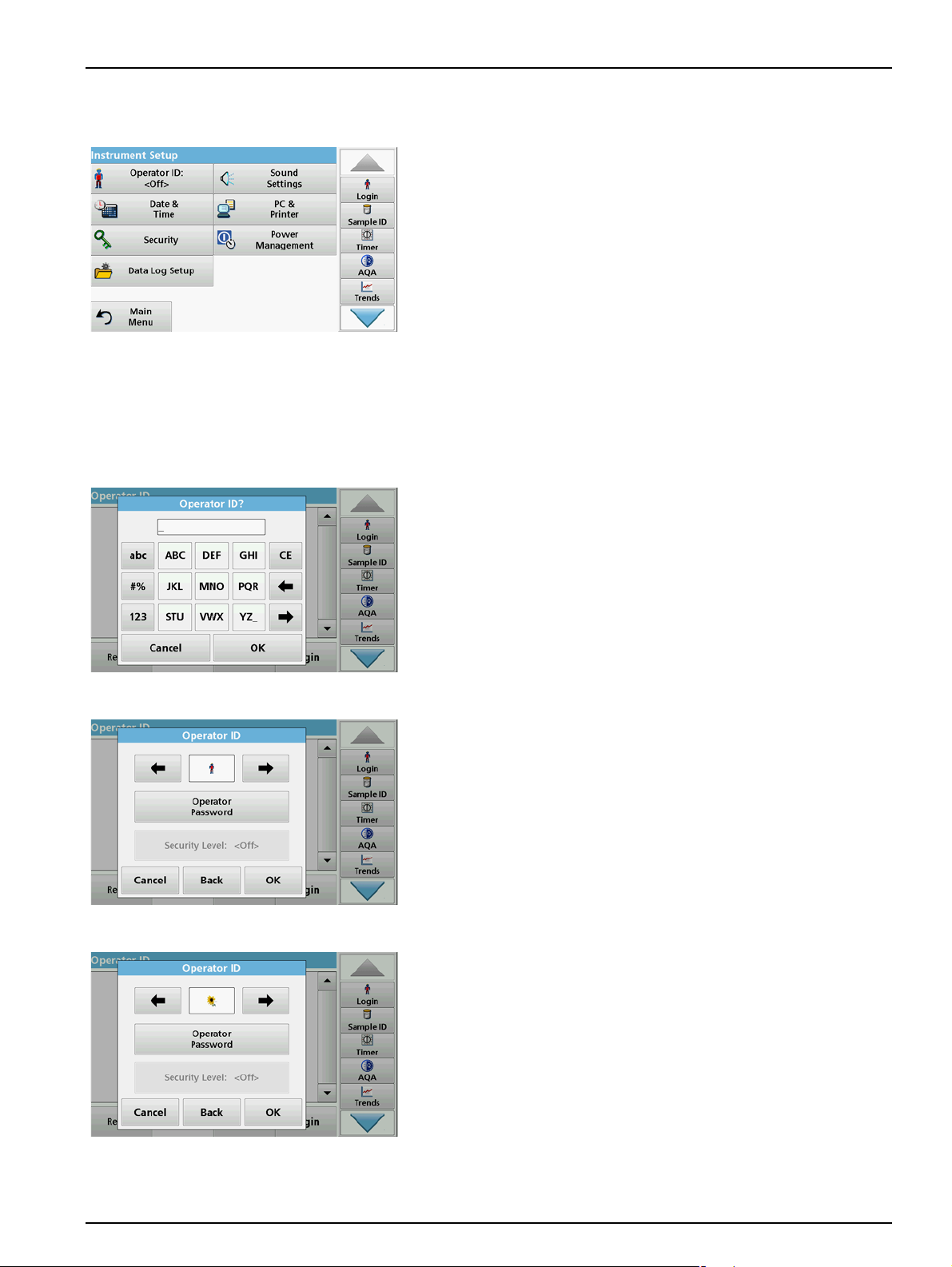

5.2 Instrument Setup

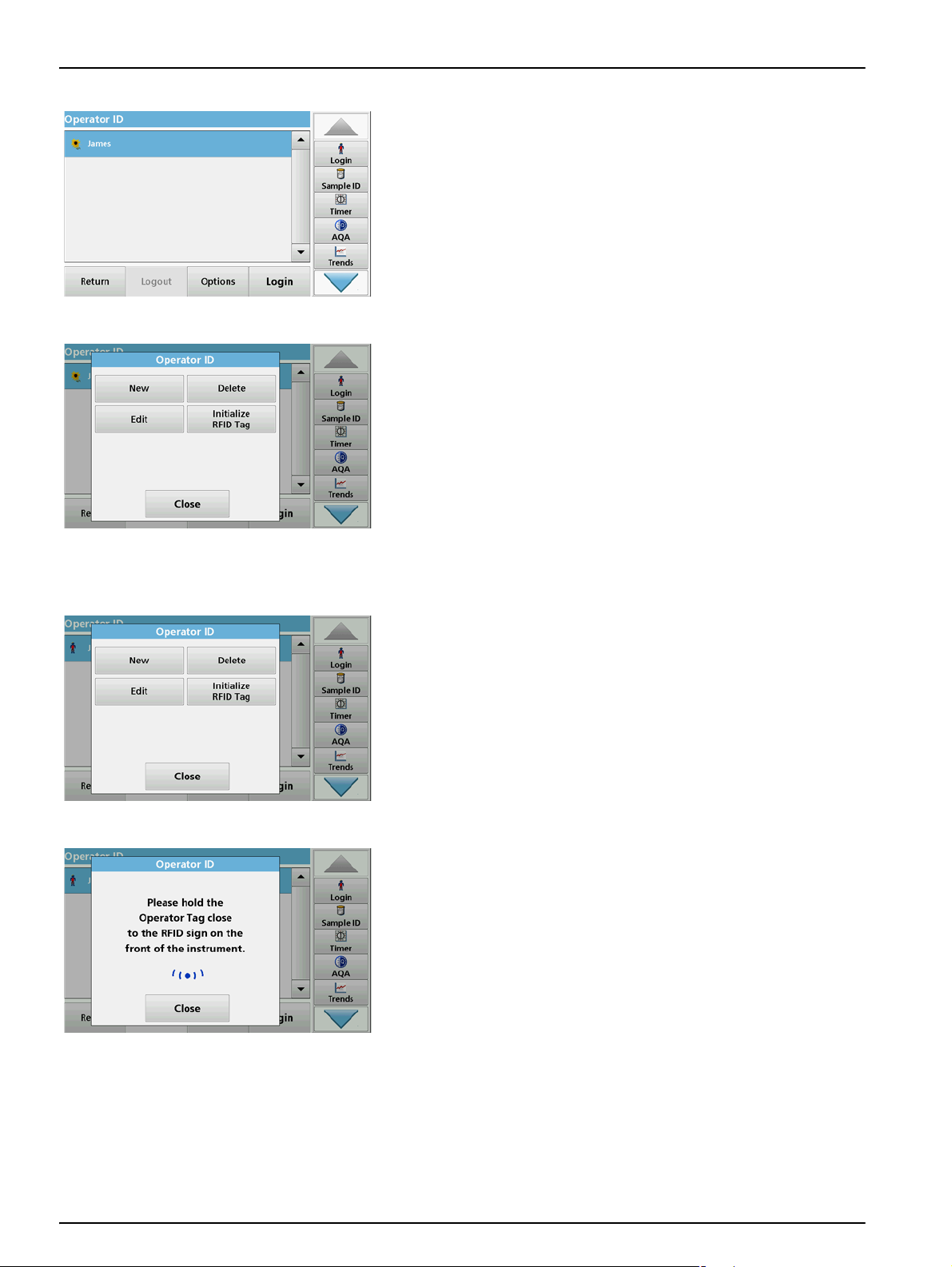

5.2.1 Operator ID

Standard programs

1. Select Instrument Setup in the Main Menu.

A selection of functions appears in order to configure the

functions of the instrument.

Use this option to enter up to 30 sets of operator initials (up to ten

characters each) into the instrument. This feature helps record

which operator measured each sample.

1. Press Operator ID in "Instrument Setup".

2. Press Options>New to enter a new operator ID.

Note: If no operator ID has yet been entered, the alphanumeric

keyboard is immediately displayed.

3. Use the alphanumeric keypad to enter a new operator ID.

4. Press OK to confirm the entry.

5. Choose an icon for the operator ID using the Left Arrow and

Right Arrow.

6. Press Operator Password to protect the operator ID with a

password.

7. Use the alphanumeric keyboard to enter an operator

password.

8. Press OK to confirm the entry.

9. Press Cancel to delete the complete entry for the operator

ID.

Press Back to reach to the input screen for operator ID.

Press OK to confirm the entry. The following screen is

displayed.

27

Standard programs

10. With Back the device returns to the menu "Instrument

Setup".

Press Logout to log out of an active operator ID.

Press Login to activate a selected operator ID.

Press Options to enter, change or delete additional operator

IDs. The following screen is displayed.

11. Press New to enter another operator ID.

Press Delete to delete an operator ID.

Press Edit to edit an operator ID.

Press Initialize RFID Tag to write the operator ID to an

optional operator RFID tag (not available on all models).

Refer to section 5.2.1.1 for more information.

5.2.1.1 Operator RFID tag (not available on all models)

1. Define an operator ID (refer to section 5.2.1).

2. Press Initialize RFID Tag.

3. Follow the instructions on screen and hold the operator RFID

tag over to the front-right of the RFID module.

A sound indicates that the write process has been sucessful.

4. The operator RFID tag can be newly written at any time. To

do so, confirm the "Overwrite Operator ID" message with OK

and enter the password if the old operator ID is protected

with a password.

If the operator RFID tag is successfully overwritten, a

message confirming this will briefly be shown on the display.

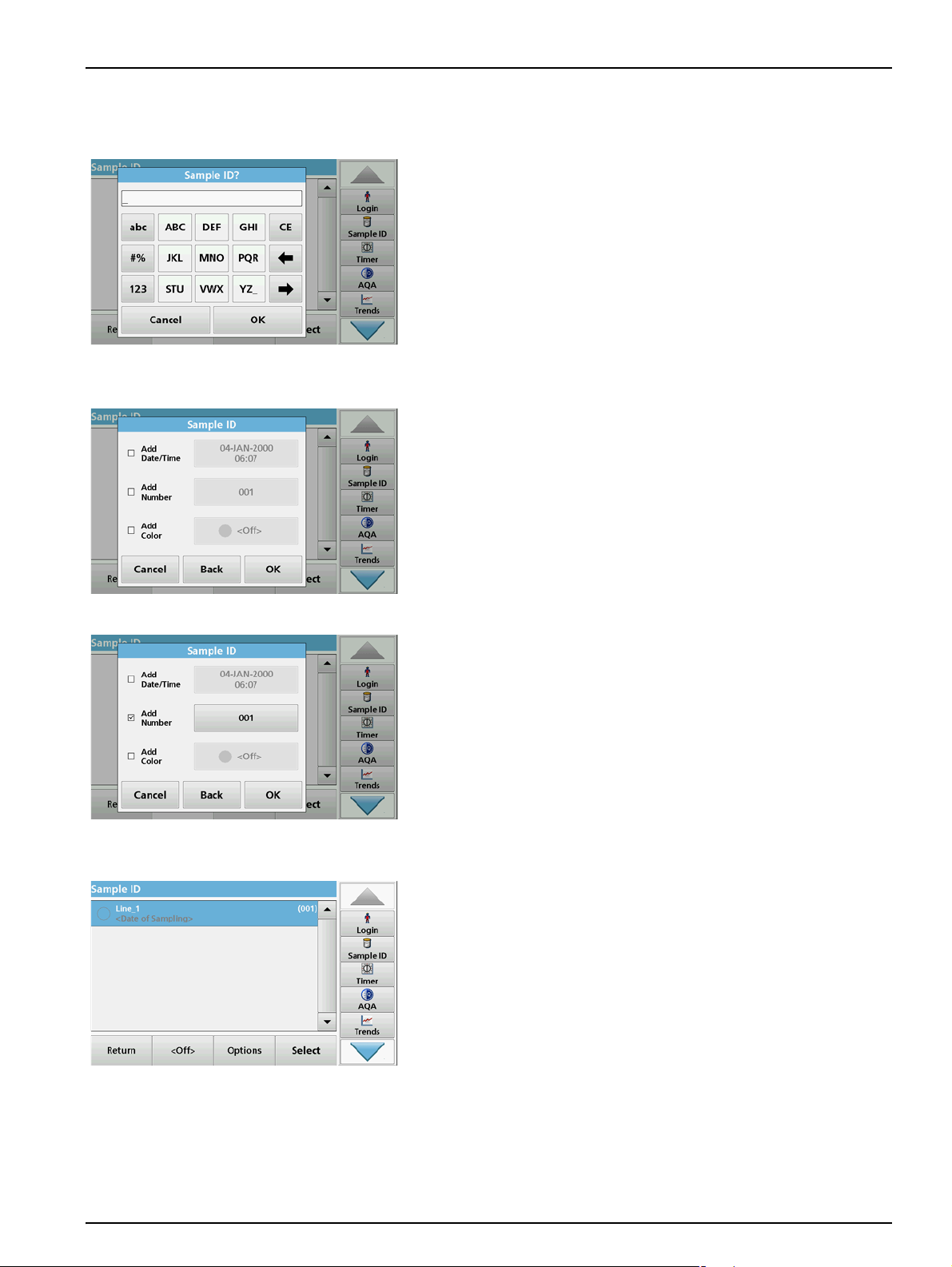

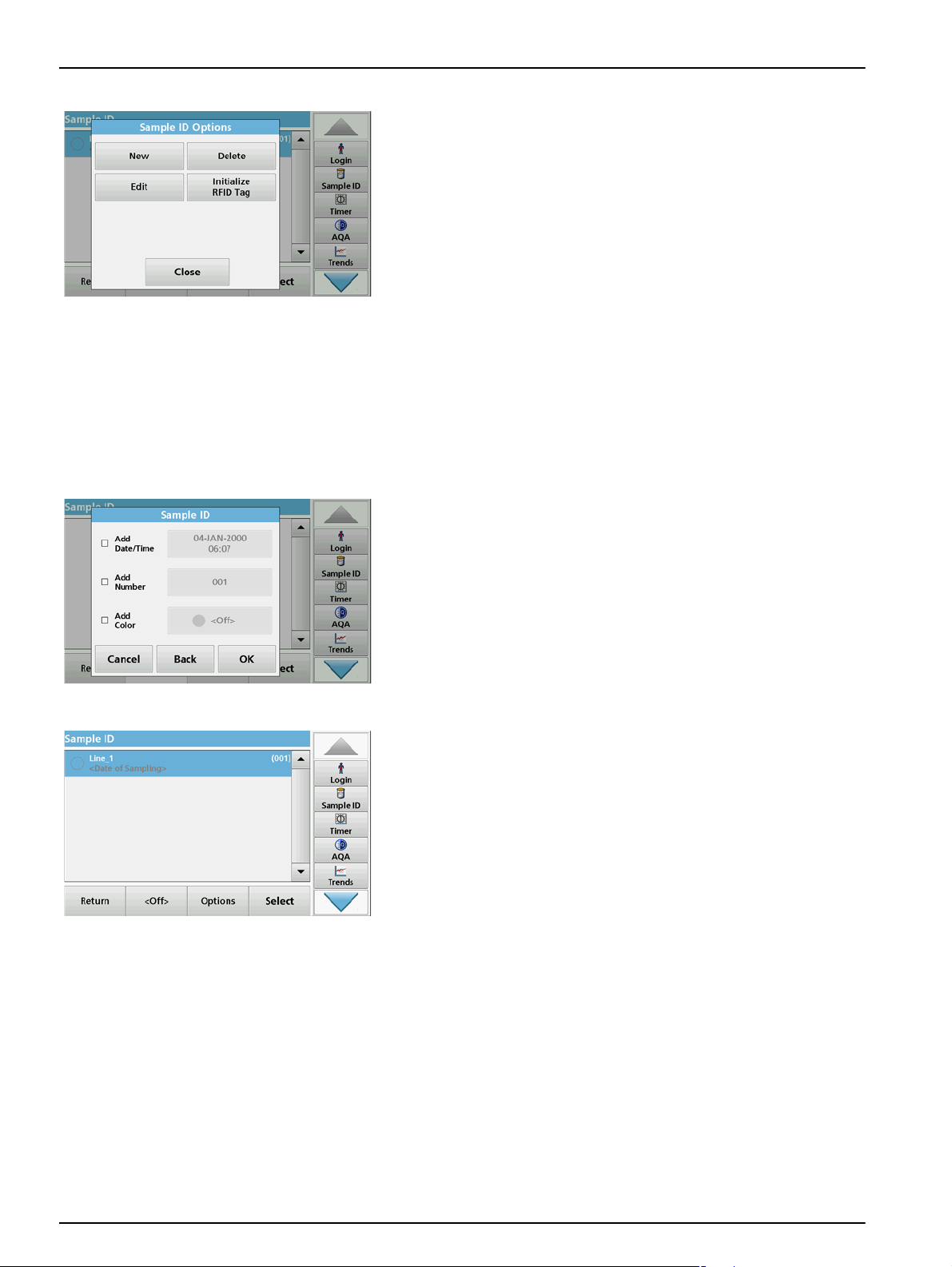

5.2.2 Sample ID

28

The operator is logged on and the operator ID is shown in the

toolbar.

Use this option to enter up to 100 Sample Identification tags (up

to 20 characters each) into the instrument. Sample IDs can be

Standard programs

used to specify the sample location or other sample specific

information, for example.

1. Press Sample ID in the toolbar on the right.

2. Press New to enter a new sample ID.

Note: If no sample ID has been entered yet, the alphanumeric

keyboard is immediately displayed.

3. Use the alphanumeric keypad to enter a new Sample ID.

Note: If a USB Barcode handset scanner (refer to section 5.2.2.1,

page 30 ) is connected, Sample IDs can also be scanned.

4. Press OK to confirm the entry.

5. Assign the current time and date, a sequential number or a

colour to the sample ID.

6. To number the sample IDs sequentially—e.g. Inflow (01)

etc.—press Add Number.

• Use the arrow keys to specify the first number of the

sequence.

• Use the key between the arrow keys to enter the first

number of the sequence using the alphanumeric keypad.

7. Press OK to return to the "Instrument Setup" menu.

The Sample ID is activated. Each Sample ID is automatically

numbered in ascending order after a reading. The number is

shown in parentheses behind the Sample ID.

8. Press Back to return the instrument to the "Instrument

Setup" menu.

Press Off to switch off the active sample ID.

Press Select to activate the selected sample ID.

Use Options to enter, change or delete additional sample

IDs. The following screen is displayed:

29

Standard programs

9. Press New to enter another sample ID.

5.2.2.1 Sample ID with scanner method 1

1. Connect the scanner to the USB port.

2. Press Sample ID>Options and New.

3. Read barcode with scanner.

4. The sample ID can have the current date and time, a

Press Delete to delete a sample ID.

Press Edit to edit a sample ID.

Press Initialize RFID Tag to write the sample ID to an

optional location RFID tag (not available on all models).

Successful connection is indicated by a sound.

sequential number and a colour allocated to it.

Select the required options or a colour.

5. Press OK to confirm the entry.

6. Press New again and repeat the process for each barcode.

5.2.2.2 Sample ID with scanner method 2

1. Read the sample ID on the screen with the barcode scanner

and perform measurement.

The barcode is stored along with the reading, but is not

adopted into the list of sample IDs.

30

Note: To delete a sample ID, select the ID and press Delete.

Note: A sample ID can be entered or changed in Reading Mode. On the

results screen, press Options>More>Instrument Setup. If a Sample ID

is already assigned, select the "Sample ID" symbol in the result display.

Standard programs

5.2.3 Sample ID and operator ID with the optional RFID Sample ID Kit (not available on

all models)

The optional RFID Sample ID Kit consists of:

• A LOC 100 RFID Locator

• An operator RFID tag

• Five location RFID tags and

• Three sample bottle RFID labels each, in black, red, green,

blue and yellow

The operator and location RFID tags can be written to and read in

by the RFID module in the DR 3900 as often as required.

More information can be found in the user manual for the

LOC 100 RFID Locator.

5.2.4 Security settings

The "Security" menu contains a variety of security settings to

control access to various functions.

All functions can be allocated to three different security levels:

• not secured: every operator can make changes in this area.

• one key: every operator assigned this security level can

make changes to non-secured functions and functions with

one key.

• two keys: every operator assigned this security level can

make changes in all functions

1. Press Security in the "Instrument Setup" menu.

2. In order to open the Security List, assign a password as

security administrator. Press Security Password.

3. Use the alphanumeric keypad to enter a new security

password (up to 10 characters) and press OK to confirm.

31

Standard programs

4. Press Security List to access various functions with security

level 1 or 2.

5. Select the required function and press Setup.

5.2.4.1 Assign operator security level

6. Select the required security level (two keys, one key or off)

and confirm using OK.

7. Confirm the Security List using OK to return to the

"Security" menu.

8. Press On to activate the new settings of the security list.

9. Press OK to return to the "Instrument Setup" menu.

Note: The alphanumeric keypad for entering the password appears

when a user tries to reach a locked setting.

32

Every operator with an operator ID can be assigned a security

level. This is connected to the operator password. Setup must be

coordinated with the security administrator and the operator.

Standard programs

1. Select Operator ID from "Instrument Setup".

2. Enter the security password and confirm by pressing OK.

3. Set up an operator ID (refer to section 5.2.1).

4. Press Operator Password.

5. Enter the operator password and confirm with OK.

6. Press Security Level <Off>

7. Enter the security password and confirm with OK.

The current security level for the selected operator is shown.

8. Select the required security level for this operator ID and

confirm with OK.

33

Standard programs

9. Press OK.

The operator ID is displayed with the selected security level.

10. Activate the selected operator ID by pressing Login.

11. Enter the operator password.

12. Confirm with OK and return to "Instrument Setup".

5.2.4.2 Deactivate password

1. Press Security in the "Instrument Setup" menu.

2. Enter the security password and confirm with OK.

3. Press Off to deactivate the settings of the Security List.

4. Press OK and return to the "Instrument Setup" menu.

Note: Use this function to delete the former password or to enter a new

one.

34

5.2.5 Date and time

Standard programs

1. Press Date & Time in the "Instrument Setup".

2. Select a Date Format for the date.

3. Press OK to confirm the entry.

4. Select a Time Format for the time.

5. Press OK to confirm the entry.

6. Press OK to confirm the entry.

35

Standard programs

5.2.6 Sound settings

7. Enter the current date and time. Change the information

using the arrow keys.

8. Press OK to confirm the entry.

The instrument then returns to "Instrument Setup".

1. Press Sound Settings in "Instrument Setup".

The following options will be displayed:

• All: Activates/deactivates a sound with a variable volume for

every function, with the exception of the timer.

• Touch screen: Activates/deactivates a short sound with

variable volume every time the screen is touched.

• Reading done: Activates/deactivates a short sound with

variable volume when the reading is done.

•Timer: Sets short/long sound with variable volume when

timer has ended.

•Startup: Activates/deactivates a startup melody with variable

volume when the test program is started.

• Warning: Activates/deactivates a short sound with variable

volume if there is an error message.

• RFID done: Activates/deactivates a short sound with variable

volume when a RFID transfer is done.

• Shutdown: Activates/deactivates a short sound with variable

volume when shutting down.

2. Select the required action.

3. Press Setup and complete the required settings.

4. Press OK to confirm the entry.

5. Press OK to confirm the entry.

The instrument then returns to "Instrument Setup".

5.2.7 PC and printer

36

The DR 3900 features an Ethernet port and two USB ports on the

rear of the instrument, as well as one USB port on the front (refer

to Figure 1 and Figure 2, page 17). These interfaces can be used

for exporting data and graphics to a printer, updating data and

Standard programs

transferring data to a PC and in a network. These interfaces can

be used for the connection of a USB stick, an external USB

keyboard or a USB Barcode handset scanner.

Note: Various accessories can also be connected simultaneously using

a USB hub.

A USB memory stick is used to update data, refer to

section 6.8.2, page 111.

Note: A shielded USB cable must not be longer than 3m!

Table 3 USB connector

Interfaces Description

USB (Type A) This USB port can be used to connect a printer, a USB memory stick or a keyboard.

USB (Type B)

Ethernet

5.2.7.1 Printer setup

This USB port is only intended for the connection of the DR 3900 to a PC (with installation of the

corresponding software).

The Ethernet port is intended for data transfer to a PC without installed software or in a local

network . Only use a shielded cable (e.g. STP, FTP, S/FTP) with a maximum length of 20 m for

the Ethernet port.

1. Press PC & Printer in "Instrument Setup".

A list with information about the connections opens.

2. Press Printer.

3. Press Setup to display the Printer Setup screen.

37

Standard programs

Printer Setup:

• Resolution: Font size

• Paper: Paper size

Note: If an optional Thermal Printer is connected, the function "Auto

Send" on/off is available.

4. Press Resolution to select the print quality.

Select between:

• 100 dpi,

• 150 dpi and

• 300 dpi.

5. Press OK to confirm the entry.

5.2.7.2 Print data

Note: Press OK again to return to the "Instrument Setup" menu.

6. Press Paper to select the paper size.

Select between:

• Letter,

• Monarch,

• Executive,

• A4.

7. Press OK to confirm the entry.

Note: Press OK again to return to the "Instrument Setup" menu.

1. Press Recall Data from the Main Menu.

2. Select the data source, where the data to be printed are

stored.

A list is displayed. Data can be filtered. Refer to

section 5.3.1.2, page 44 for more information.

38

3. Press the Printer icon to send the data (table, curve)

immediately to the printer.

4. Highlight Single point, Filtered data or All data and press

OK to confirm.

Send data... appears on the display until the data is

printed.

5.2.7.3 Print data continuously

5.2.7.4 Network setup

Standard programs

If all readings are to be printed out automatically straight after

measurement, the use of a continuous form printer is

recommended, e.g. the 4" paper thermal printer. Refer to

Section 9, page 137.

1. Connect the thermal printer to a USB type A port.

2. Press PC & Printer in the "Instrument Setup" menu.

A list with information about the connections opens.

3. Highlight Printer.

4. Press Setup to display the Printer Setup screen.

5. Select Auto-Send: On to send all measured data

automatically to the Thermal printer.

The DR 3900 supports communication in local networks. To

establish Ethernet communication in networks, special

configuration is required. The manufacturer recommends support

from a network administrator. Only use a shielded cable

(e.g. STP, FTP, S/FTP) with a maximum length of 20 m for the

Ethernet port. This section describes the setting options for the

photometer in relation to network communication.

The connection parameters must be configured for data transfer

to a PC or connection to a network.

1. Press PC & Printer in "Instrument Setup".

2. Press Network>Setup.

3. Press On.

4. Press IP address.

An IP address is used to send data from a sender to a

pre-defined recipient.

• If the IP for the DR 3900 is automatically issued in the

network, no further settings are necessary. A hostname

can optionally be assigned.

• If the instrument address is fixed, the connection must be

configured.

39

Standard programs

5. Select Fix to configure the IP address.

6. Press IP address and enter the address.

In conjunction with the IP address of an instrument, the subnet

mask establishes which IP addresses are located within the local

network.

7. Press Subnet Mask and enter the address.

A Gateway enables data communication in networks that are

based on varying protocols.

8. Press Default Gateway and enter the address.

9. Press OK to confirm the entry.

40

Standard programs

10. Press Network Server: <Off> to determine the target site for

the data transfer.

11. Select Netdrive and run Netdrive Setup.

Alternatively, select FTP and run FTP Setup.

The procedures are completely identical. As an example,

Netdrive Setup is described here.

The target site can be defined by IP address or a server name.

12. Press IP-Address and enter the IP address or select Server

Name and enter the server name.

13. Press Data Folder and enter the target folder name.

Note: A folder with the selected name must exist on the target

system. Additionally, the folder must be shared with the operator,

using the corresponding password.

14. Press OK to confirm the entry.

41

Standard programs

User and password must be identical to the settings on the

target system.

15. Press User and enter the username.

16. Press OK to confirm.

17. Press Password and enter the password.

18. Press OK to confirm the entry.

19. Press Factory Default to restore the Network Settings to the

factory defaults.

5.2.8 Power Management

1. Press Power Management in "Instrument Setup".

2. Select Sleep Timer and press OK.

3. Select the required time span after which the instrument will

go into energy-saving sleep mode if it is not used (refer to

section 4.4, page 24), and confirm with OK.

42

4. Select Power Off Timer and press OK.

5. Select the required time span after which the instrument will

automatically be powered off if it is not used, and confirm

with OK.

6. Press OK to confirm the entry.

The instrument then returns to "Instrument Setup".

5.3 Save, recall, send and delete data

5.3.1 The data log

The data log can store up to 2000 readings saved by the

following programs:

• Stored Programs,

• Barcode Programs,

Standard programs

5.3.1.1 Auto/manual data storage

• User programs,

• Favorites,

• Single Wavelength and

• Multi Wavelength.

A complete record of the analysis is stored, including the Date,

Time, Results, Sample ID and Operator ID.

The data storage parameter indicates whether data is to be

stored automatically or manually (in which case the user has to

decide which data to store).

1. Press Data Log Setup in the "Instrument Setup" menu.

• When the setting Auto Store: On is activated, the

instrument will store all measurement data automatically.

• When the setting Auto Store: Off is activated, the

instrument will not store any measurement data.

However, this setting can be changed on the results

screen, via Options>Auto Store: On. The reading

currently shown in the display is then stored.

2. Specify the output format of data to be exported using Send

Data Format. Select xml or csv.

3. Press OK to confirm the entry.

The instrument then returns to "Instrument Setup".

Note: When the instrument memory (data log) is full, the oldest data is

automatically deleted allowing the new data to be stored.

43

Standard programs

5.3.1.2 Recall stored data from the data log

1. Press Recall Data in the Main Menu.

2. Press Data Log.

A listing of the stored data is displayed.

3. Press Filter: On/Off.

The function Filter Settings is used to search for specific

items.

4. Activate On. The data can now be filtered using the following

selection criteria.

• Sample ID

• Operator ID

• Start Date

• Parameter

or any combination of the four.

5. Press OK to confirm the selection.

The chosen items are listed.

44

5.3.1.3 Send data from the data log

Standard programs

6. Press View Details to get more information.

Data is sent from the internal data log as an XML (Extensible

Markup Language) file or as a CSV (Comma Separated Value)

file, to a directory with the name DataLog on a USB mass storage

device or a network drive. The file can then be processed using a

spreadsheet program. The file name has the format:

DLYear-Month-Day_Hour_Minute_Second.csv or

DLYear-Month-Day_Hour_Minute_Second.xml.

To send data to a printer, refer to section 5.2.7.2, page 38.

1. Plug the USB storage device into the USB type A port on the

DR 3900, or connect the DR 3900 to a network drive (refer to

section 5.2.7.4, page 39).

2. Press Recall Data from the Main Menu.

3. Select the data category to be transferred, e.g. Data Log.

A list of the selected measurement data is displayed.

4. Press Options and then the PC & Printer icon.

45

Standard programs

5. Select the data to be sent.

6. Press OK to confirm.

Note: The number in parentheses is the total number of data sets

assigned to this selection.

5.3.1.4 Delete stored data from the data log

1. Press Recall Data from the Main Menu.

2. Press Data Log>Options>Delete.

3. Highlight Single point, Filtered data or All data and press

The following options are available:

• Single point: only this selected reading will be sent

•Filtered data: only readings that correspond to the set

filters will be sent

• All data: all data in the selected data category will be

sent.

OK to confirm.

Note: The number in parentheses is the total number of data sets

assigned to this selection.

5.3.2 Control charts for data from the AQA Log

1. Press Recall Data in the Main Menu.

2. Press AQA Log.

A listing of the stored data is displayed.

46

3. Press Filter: On/Off.

4. Activate On.

5. Select a required parameter.

6. Press OK to confirm the selection.

The chosen items are listed.

7. Press Options>Control Chart.

Standard programs

8. Press Standard Control Chart to choose the control chart

of the selected standard.

The measured standard concentrations are displayed

graphically with the control limits and date.

47

Standard programs

9. Press Range Control Chart to select the control chart of the

range in % for multiple determinations.

The range in % is displayed graphically with the control limits

and date.

5.3.3 Store, recall, send and delete data from wavelength scan and time course

The instrument can store 20 datasets for the Wavelength Scan

and 20 datasets for the Time Course. The data must be stored

manually after it is displayed.

5.3.3.1 Data storage from wavelength scan or time course

1. Press the Folder icon in the "Options" menu after a reading

is taken.

The Store Data list will be displayed.

2. Press Store to save the current scan to the highlighted

numbered line.

48

Note: Scans can be overwritten.

5.3.3.2 Recall stored data from wavelength scan or time course

1. Press Recall Data from the Main Menu.

a. Select Wavelength Scan or Time Course to recall data.

b. If a program is already running, press

Options>More>Recall Data.

2. Select the required data.

3. Tap on Graph to display details.

Note: Press View Summary to return to the "Recall Data" list.

Standard programs

4. Press Tabl e to look at the details.

Note: Press View Summary to return to the "Recall Data" list.

5.3.3.3 Send data from wavelength scan or time course

There are two ways to recall sent data to a USB memory stick,

printer or PC with Hach Data Trans.

Option 1:

1. Press Recall Data in the Main Menu and then Wavelength

Scan or Time Course.

2. Press Options and then the PC & Printer icon to send the

data to a USB memory stick, to a printer or to a PC with

Hach Data Trans.

• When a printer is connected, select how to send the data

to the printer (graph, table or both graph and table).

49

Standard programs

• If a USB memory stick is connected, the files will be

automatically sent to the USB memory stick as xml or csv

files in the file folder "WLData (data of a wavelength

scan) or "TCData" (data of a time course).

The file name will be formatted as: "ScanData_X.csv"

(Wavelength Scan Data) or "TCData_X.csv" (Time Course

Data).

X = number of scans (1–20).

For further processing use a spreadsheet program.

Note: The message, "Data already present. Overwrite?" is displayed if

the files are already stored. Press OK to overwrite the stored data.

Option 2:

1. Press Wavelength Scan or Time Course and then

Options>More>Send Data to send the data to a USB

memory stick or to a printer.

• When a printer is connected, select how to send the data

to the printer (graph, table or both graph and table).

• If a USB memory stick is connected, the files will be

automatically sent to the USB memory stick as xml or csv

files in the file folder "WLData (data of a wavelength

scan) or "TCData" (data of a time course).

The file name will be formatted as: "ScanData_X.csv"

(Wavelength Scan Data) or "TCData_X.csv" (Time Course

Data).

X = number of scans (1–20).

For further processing use a spreadsheet program.

5.3.3.4 Delete stored data from wavelength scan or time course

1. Press Recall Data in the Main Menu and then Wavelength

Scan or Time Course.

A listing of the stored data is displayed.

2. Highlight any data to delete.

3. Press Delete in the "Options" menu and press OK to

confirm.

5.3.4 Data analysis

50

Consistent use of the sample ID function is necessary for all data

analysis functions. Only data with identical sample IDs can be

used in data analysis functions.

Use the Trends function to display a time-variation curve for the

stored readings for each parameter and location. The

concentration of the the corresponding parameter is shown

graphically over time.

5.3.4.1 Trends

Standard programs

Use the Ratio function to monitor the parameter relationships at a

particular location and display them in a graph.

Use the Interference Check function to display analyses with the

same sample IDs and unfavourable levels of ion interference.

1. Press Recall Data>Data analysis.

2. Choose Trends and press OK to confirm.

Alternatively, choose Trends from the toolbar.

3. Press Options>New.

4. Select the required parameter and press Next to confirm.

5. Select the required sample ID and press Next to confirm.

6. Select the required operator ID and press Next to confirm.

51

Standard programs

7. Select the required data analysis interval or the start and end

date, and press Next to confirm.

8. Set an upper and lower control limit and press Next to

confirm.

5.3.4.2 Ratios

9. All of the selected functions are dispalyed in Trend Settings.

Press OK to confirm.

10. Select the required trend with the created settings from the

list. Press Select.

The trend can be displayed in several formats, as a line or a

point.

11. Select Information to see an overview of the parameter

information.

12. Select Options>Add Data to add more readings to the

trend.

13. Select Options>Ratio:Off to activate the Ratio function.

The ratio corresponds to the first row of readings selected.

52

The Ratio function is based on the precise classification of

samples by their sample locations using the optional accessories

"LOC 100 RFID Locator" and "RFID Sample ID Kit". The precise

sample location, date and time are attached automatically. Ratio

analysis calculates a ratio between two or three parameters. The

last defined parameter is represented by 1. The first or second

parameters are calculated as a ratio against this, e.g. 4:2:1.

1. Select Recall Data>Data analysis.

2. Select Ratios.

Standard programs

If a ratio analysis has already been carried out, a list of the

defined analyses will be displayed.

3. Press Options.

4. Press New, to define a new ratio analysis.

53

Standard programs

5. Select the required sample ID and press Next to confirm.

6. Select parameter I with the greatest concentration and press

Next to confirm.

7. Select parameter II with the middle concentration and press

Next to confirm.

8. Select parameter III with the smallest concentration and

press Next to confirm.

54

Standard programs

9. Select the required data analysis interval.

It is possible to select a fixed interval and an specific

customised interval with start and end dates.

10. Press OK to confirm.

11. Choose an upper and lower control limit for the first and

second parameters and press Next to confirm.

12. All of the selected functions are displayed in Ratio Settings.

Press OK to confirm.

13. Select the ratio with the defined settings from the ratio

directory. Press Select.

A table with the defined values is shown.

Values outside the defined limits are displayed in red.

5.3.4.3 Interference Check (not available on all models)

The DR 3900 automatically tests for interfering ions. Typical

interferences, such as chloride for nitrate, are recognised from

defined concentrations and a warning is displayed. This check is

only carried out for barcode tests that are indicated with identical

sample IDs.

55

Standard programs

5.4 Stored Programs

Example:

Analysis of ammonium with barcode test LCK303 and recording

of the readings. According to the LCK303 ion interference table,

nitrate concentrates > 50 mg/L will interfere with the analysis.

The instrument displays a warning if the same sample ID has a

value > 50 mg/L for nitrate.

1. Select Recall Data>Data analysis>Interference Check to

activate a check.

Over 200 pre-programmed processes can be recalled via the

Stored Programs menu. Stored Programs do not include any

barcode tests.

5.4.1 Select a saved test/method; entering user-specific basic data

1. Press Stored Programs in the Main Menu to view an

alphabetical list of stored programs with program numbers.

The "Stored Programs" list will appear.

2. Highlight the required test.

Note: Select the program by name or scroll through the list using the

arrow keys. Highlight the program or press Select by No. to search

for a specific program number. Press OK to confirm.

3. Press Start to run the program. The respective

measurement window is displayed.

Note: All corresponding data (wavelength, factors and constants) is

already preset.

4. Follow the chemical procedural instructions. Further

information is available on the website of the manufacturer.

Note: To display the procedural instructions in the display, press the

info icon. This option is not available for all tests.

5.4.2 Stored programs options

56

1. Press Stored Programs in the Main Menu. Select the

required process and press Start.

2. Press Options to enter specific data. The following

describes the options Table 4.

Table 4 Stored programs options

Options Description

More For further Options

Standard programs

Store Off/On

% Trans/Conc/Abs To switch to % transmittance, concentration or absorbance readings

Send Data icon /

Send Data

Timer icon

Dilution Factor Off/On

Standard Addition

Standard Adjust

Chemical Form Some of the stored tests/methods allow selection of the chemical form and measuring range.

Reagent Blank