Page 1

Instruction Sheet

Cleaning Unit

Safety Information

Please read this entire document before unpacking, setting up, or operating this

equipment. Pay attention to all danger and caution statements. Failure to do so could

result in serious injury to the operator or damage to the equipment.

Make sure that the protection provided by this equipment is not impaired, do not use or

install this equipment in any manner other than that specified in this document.

Use of Hazard Information

DANGER

Indicates a potentially or imminently hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING

Indicates a potentially or imminently hazardous situation which, if not avoided,

could result in death or serious injury.

DOC307.53.00747

Electrical equipment marked with this symbol may not be disposed of in European public disposal systems after

12 August of 2005. In conformity with European local and national regulations (EU Directive 2002/96/EC),

European electrical equipment users must now return old or end-of life equipment to the Producer for disposal at no

charge to the user.

Note: For return for recycling, please contact the equipment producer or supplier for instructions on how to return

end-of-life equipment, producer-supplied electrical accessories, and all auxiliary items for proper disposal.

Introduction

CAUTION

Indicates a potentially hazardous situation that may result in minor or moderate

injury.

Important Note: Indicates a situation which, if not avoided, may cause damage to the

instrument. Information that requires special emphasis.

Note: Information that supplements points in the main text.

Precautionary Labels

Read all labels and tags attached to the instrument. Personal injury or damage to the

instrument could occur if not observed. A symbol, if noted on the instrument, will be

included with a danger or caution statement in the manual.

The cleaning unit is designed for automatically cleaning the sensor cartridge membranes

(refer to Figure 1 on page 2). The streamlined design of the cleaning unit minimises the

points where interferences could occur. Refer to Figure 3 on page 3 for the cleaning unit

dimensions.

The cleaning unit is exactly matched to the sensors so that the sensor cartridge

membranes are kept clean even in difficult inlet applications. The cleaning head requires

compressed air (2 to 3.5 bar (29.01 to 50.76 psi) maximum) that is produced by a

compressor or supplied from an existing compressed air system.

Important Note: The compressed air must be oil free.

1

Page 2

Cleaning Unit

The manufacturer recommends using the High Output Airblast Cleaning System for the

compressed air supply; this is a compressor in a weather-proof plastic housing. This

complete system is operated through a relay in the sc100/sc1000 controller.

DANGER

Only qualified personnel should conduct the tasks described in this instruction

sheet.

CAUTION

Make sure the cleaning unit is disconnected from the compressed air during

installation and service work.

When using an external compressor or an existing compressed air system, a suitable

valve is required (and, if necessary, a pressure reducer) and can be configured through a

relay on the sc100/sc1000 controller.

Figure 1 Principle of operation of the cleaning unit

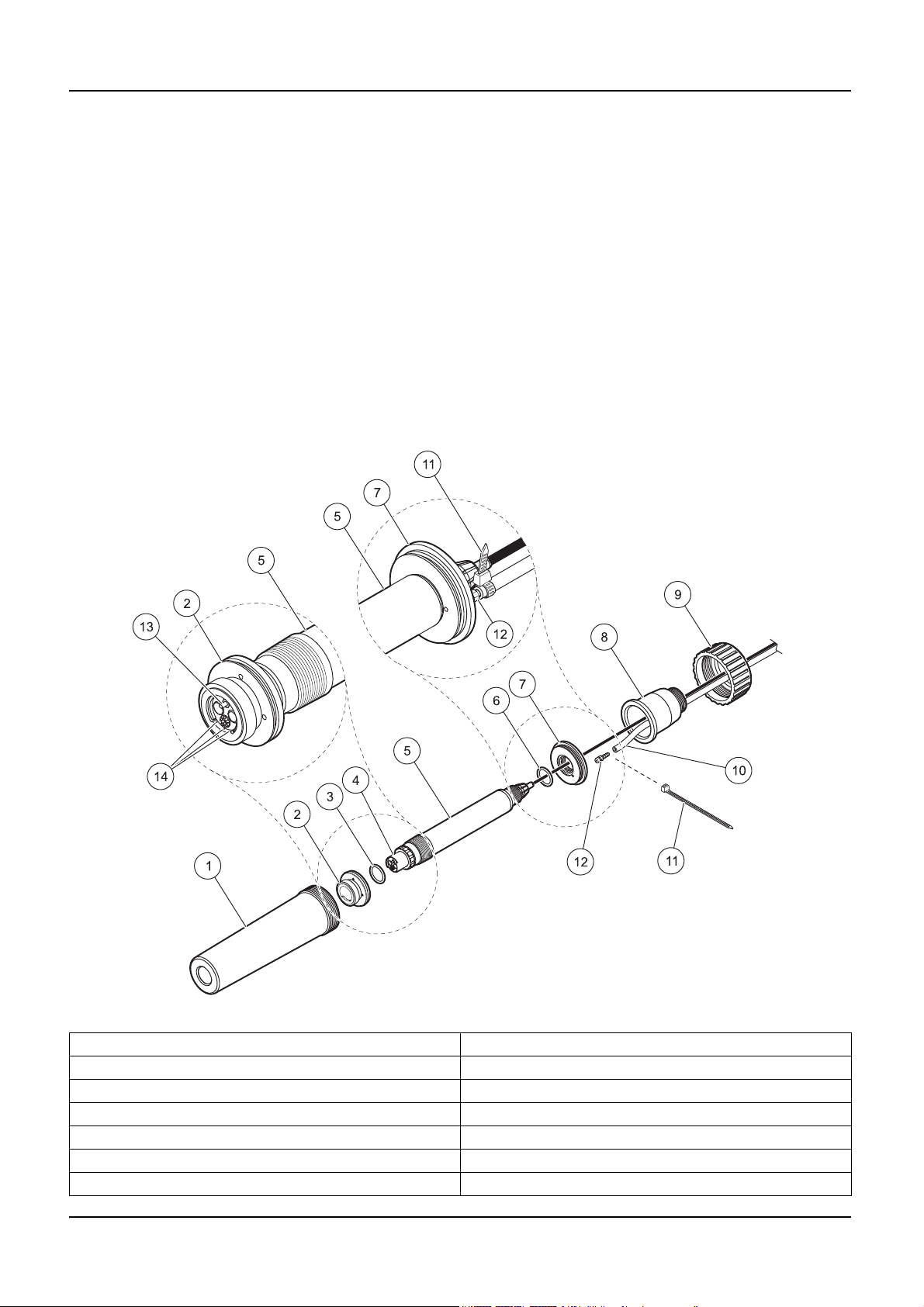

Unpacking the instrument

Verify that all items (refer to Figure 3 on page 3) are included. If any items are missing or

damaged, contact the manufacturer or a sales representative.

Do not send the items without contacting the manufacturer or a sales representative.

Note: Retain the original packaging materials. Instruments returned for service should be shipped in

the original packaging material to protect against damage during transportation.

2

Page 3

Cleaning Unit

Figure 2 Items supplied with the cleaning unit

1 Sleeve 7 Sleeve insert

2 Cleaning insert set (with 2 pre-assembled O-rings) 8 Male fitting (thread 1/8", for ID 6 mm tube)

3 Cleaning insert 9 Cable tie

4 O-ring 10 Adapter, 1.5 inch NPT external thread

5 Sleeve insert set (with 2 pre-assembled O-rings) 11 Union nut

6 O-ring

1

Items supplied are subject to change without notice

1

Dimensions

Figure 3 Dimensions

Installing the cleaning unit

Refer to Figure 4 on page 4 and the following instructions for installation.

1. Slide the O-ring (item 6) and the sleeve insert (item 7) over the sensor cable.

2. Put the O-ring over the thread of the sensor and attach the sleeve insert to the sensor.

3. Put the male fitting (item 12) into the sleeve insert (item 7). Hand-tighten to secure.

4. Put the air tubing

(item 11).

1

Use pressure and UV resistant tube with an inner diameter of 6 mm.

1

(item 10) into the male fitting and secure it using the cable-tie

3

Page 4

Cleaning Unit

5. Slide the O-ring (item 3) from the cleaning insert (item 2) set onto the sensor cartridge

(item 4).

6. Put the cleaning insert into the sensor cartridge. Make sure that the air outlet openings

(item 14) are opposite of the temperature sensor (item 13).

7. Put the sensor (item 5) into the sleeve (item 1).

8. Slide the adapter (item 8) over the sensor cable and the air tubing (item 10).

9. Slide the union nut (item 9) over the sensor cable and the air tubing.

10. Install all the parts and hand-tighten the union nut to secure.

11. Mount the cleaning unit on the 45° adapter. Refer to the Instruction Sheet supplied

with the Hand Rail Mounting.

12. Connect the system to the controller and the High Output Air Blast and configure the

system. Refer to Relay configuration on page 5.

Figure 4 Assembly of the cleaning unit

1 Sleeve 8 Adapter, 1.5 inch NPT external thread

2 Cleaning insert, (with 2 pre-assembled O-rings) 9 Union nut

3 O-ring 10 Air tubing

4 Sensor cartridge 11 Cable tie

5 Sensor 12 Male fitting

6 O-ring 13 Temperature sensor

7 Sleeve insert, (with 2 pre-assembled O-rings) 14 Air outlet openings

4

Page 5

Compressor configuration

CAUTION

Ensure the cleaning unit is disconnected from the compressed air during

installation and service work.

Refer to the High Output Air Blast System User Manual for more information.

Relay configuration

To operate the compressor or an external valve (on the usage of an external supply of

compressed air), use the relay settings of the sc controller (RTC function of the relay).

Cleaning Unit

5

Page 6

Contact Information

HACH Company

World Headquarters

P.O. Box 389

Loveland, Colorado

80539-0389 U.S.A.

Tel (800) 227-HACH

(800) -227-4224

(U.S.A. only)

Fax (970) 669-2932

orders@hach.com

www.hach.com

HACH LANGE GMBH

Willstätterstraße 11

D-40549 Düsseldorf

Tel. +49 (0)2 11 52 88-320

Fax +49 (0)2 11 52 88-210

info@hach-lange.de

www.hach-lange.de

DR. BRUNO LANGE AG

Juchstrasse 1

CH-8604 Hegnau

Tel. +41(0)44 9 45 66 10

Fax +41(0)44 9 45 66 76

info@hach-lange.ch

www.hach-lange.ch

Repair Service in the

United States:

HACH Company

Ames Service

100 Dayton Avenue

Ames, Iowa 50010

Tel (800) 227-4224

(U.S.A. only)

Fax (515) 232-3835

HACH LANGE LTD

Pacific Way

Salford

GB-Manchester, M50 1DL

Tel. +44 (0)161 872 14 87

Fax +44 (0)161 848 73 24

info@hach-lange.co.uk

www.hach-lange.co.uk

HACH LANGE FRANCE

S.A.S.

33, Rue du Ballon

F-93165 Noisy Le Grand

Tél. +33 (0)1 48 15 68 70

Fax +33 (0)1 48 15 80 00

info@hach-lange.fr

www.hach-lange.fr

Repair Service in Canada:

Hach Sales & Service

Canada Ltd.

1313 Border Street, Unit 34

Winnipeg, Manitoba

R3H 0X4

Tel (800) 665-7635

(Canada only)

Tel (204) 632-5598

Fax (204) 694-5134

canada@hach.com

HACH LANGE LTD

Unit 1, Chestnut Road

Western Industrial Estate

IRL-Dublin 12

Tel. +353(0)1 46 02 5 22

Fax +353(0)1 4 50 93 37

info@hach-lange.ie

www.hach-lange.ie

HACH LANGE SA

Motstraat 54

B-2800 Mechelen

Tél. +32 (0)15 42 35 00

Fax +32 (0)15 41 61 20

info@hach-lange.be

www.hach-lange.be

Repair Service in

Latin America, the

Caribbean, the Far East,

Indian Subcontinent, Africa,

Europe, or the Middle East:

Hach Company World

Headquarters,

P.O. Box 389

Loveland, Colorado,

80539-0389 U.S.A.

Tel +001 (970) 669-3050

Fax +001 (970) 669-2932

intl@hach.com

HACH LANGE GMBH

Hütteldorferstr. 299/Top 6

A-1140 Wien

Tel. +43 (0)1 9 12 16 92

Fax +43 (0)1 9 12 16 92-99

info@hach-lange.at

www.hach-lange.at

DR. LANGE NEDERLAND

B.V.

Laan van Westroijen 2a

NL-4003 AZ Tiel

Tel. +31(0)344 63 11 30

Fax +31(0)344 63 11 50

info@hach-lange.nl

www.hach-lange.nl

HACH LANGE APS

Åkandevej 21

DK-2700 Brønshøj

Tel. +45 36 77 29 11

Fax +45 36 77 49 11

info@hach-lange.dk

www.hach-lange.dk

HACH LANGE LDA

Av. do Forte nº8

Fracção M

P-2790-072 Carnaxide

Tel. +351 214 253 420

Fax +351 214 253 429

info@hach-lange.pt

www.hach-lange.pt

HACH LANGE KFT.

Hegyalja út 7-13.

H-1016 Budapest

Tel. +36 (06)1 225 7783

Fax +36 (06)1 225 7784

info@hach-lange.hu

www.hach-lange.hu

HACH LANGE D.O.O.

Fajfarjeva 15

SI-1230 Domžale

Tel. +386 (0)59 051 000

Fax +386 (0)59 051 010

info@hach-lange.si

www.hach-lange.si

HACH LANGE AB

Vinthundsvägen 159A

SE-128 62 Sköndal

Tel. +46 (0)8 7 98 05 00

Fax +46 (0)8 7 98 05 30

info@hach-lange.se

www.hach-lange.se

HACH LANGE SP.ZO.O.

ul. Opolska 143 a

PL-52-013 Wrocław

Tel. +48 (0)71 342 10-83

Fax +48 (0)71 342 10-79

info@hach-lange.pl

www.hach-lange.pl

HACH LANGE S.R.L.

Str. Căminului nr. 3

Sector 2

RO-021741 Bucureşti

Tel. +40 (0) 21 205 30 03

Fax +40 (0) 21 205 30 03

info@hach-lange.ro

www.hach-lange.ro

ΗΑCH LANGE E.Π.Ε.

Αυλίδος 27

GR-115 27 Αθήνα

Τηλ. +30 210 7777038

Fax +30 210 7777976

info@hach-lange.gr

www.hach-lange.gr

HACH LANGE S.R.L.

Via Riccione, 14

I-20156 Milano

Tel. +39 02 39 23 14-1

Fax +39 02 39 23 14-39

info@hach-lange.it

www.hach-lange.it

HACH LANGE S.R.O.

Lešanská 2a/1176

CZ-141 00 Praha 4

Tel. +420 272 12 45 45

Fax +420 272 12 45 46

info@hach-lange.cz

www.hach-lange.cz

HACH LANGE

8, Kr. Sarafov str.

BG-1164 Sofia

Tel. +359 (0)2 963 44 54

Fax +359 (0)2 866 04 47

info@hach-lange.bg

www.hach-lange.bg

HACH LANGE E.P.E.

27, Avlidos str

GR-115 27 Athens

Tel. +30 210 7777038

Fax +30 210 7777976

info@hach-lange.gr

www.hach-lange.gr

HACH LANGE S.L.U.

Edif. Arteaga Centrum

C/Larrauri, 1C- 2ª Pl.

E-48160 Derio/Vizcaya

Tel. +34 94 657 33 88

Fax +34 94 657 33 97

info@hach-lange.es

www.hach-lange.es

HACH LANGE S.R.O.

Roľnícka 21

SK-831 07 Bratislava –

Vaj nory

Tel. +421 (0)2 4820 9091

Fax +421 (0)2 4820 9093

info@hach-lange.sk

www.hach-lange.sk

HACH LANGE SU

ANALİZ SİSTEMLERİ

LTD.ŞTİ.

Hilal Mah. 75. Sokak

Arman Plaza No: 9/A

TR-06550 Çankaya/ANKARA

Tel. +90 (0)312 440 98 98

Fax +90 (0)312 442 11 01

bilgi@hach-lange.com.tr

www.hach-lange.com.tr

HACH LANGE D.O.O.

Ivana Severa bb

42 000 Varaždin

Tel. +385 (0) 42 305 086

Fax +385 (0) 42 305 087

info@hach-lange.hr

www.hach-lange.hr

© Hach Lange GmbH, 2007–2009 Edition 2, Januar 2009 bb/ph/kt

Loading...

Loading...