Page 1

DOC023.52.80034

CL17 Chlorine Analyzer

USER MANUAL

02/2014, Edition 9

© Hach Company, 2000, 2001, 2004, 2008, 2009-2011, 2013, 2014. All rights reserved. Printed in the U.S.A./Germany

Page 2

Page 3

Table of Contents

Section 1 Specifications.................................................................................................................... 3

Section 2 General information......................................................................................................... 5

2.1 Safety information........................................................................................................................ 5

2.1.1 Use of hazard information................................................................................................... 5

2.1.2 Precautionary labels ........................................................................................................... 5

2.2 General product information ........................................................................................................ 6

2.2.1 Instrument description......................................................................................................... 6

2.2.2 Method of analysis .............................................................................................................. 7

2.2.3 Theory of operation............................................................................................................. 8

Section 3 Installation.......................................................................................................................... 9

3.1 Unpack the instrument................................................................................................................. 9

3.2 Instrument environmental considerations .................................................................................... 9

3.3 Mount the instrument on the wall................................................................................................. 9

3.4 Plumbing connections................................................................................................................ 12

3.5 Installing the sample line............................................................................................................ 13

3.6 Sample conditioning................................................................................................................... 14

3.6.1 Assemble the sample conditioning kit............................................................................... 14

3.6.2 Use the sample conditioning kit ........................................................................................ 15

3.7 Optional air purge ...................................................................................................................... 18

3.8 Electrical connections ................................................................................................................ 18

3.8.1 Power connections............................................................................................................ 19

3.8.2 Wiring the instrument ........................................................................................................ 20

3.8.3 Voltage selection for alternate voltage operation.............................................................. 21

3.8.4 Alarm connections ............................................................................................................ 22

3.8.5 Recorder output connections ............................................................................................ 23

3.9 Install the pump/valve pinch plate.............................................................................................. 24

Section 4 System Startup................................................................................................................ 27

4.1 Install the reagents..................................................................................................................... 27

4.2 Install the stir bar........................................................................................................................ 28

4.3 Supply the sample .................................................................................................................... 29

4.4 Supply power to the analyzer..................................................................................................... 29

Section 5 Operation.......................................................................................................................... 31

5.1 Keypad and display information................................................................................................. 31

5.2 Instrument menu structure......................................................................................................... 32

5.2.1 Setup menu....................................................................................................................... 32

5.2.2 Alarm setup....................................................................................................................... 33

5.2.3 Set the recorder output span ............................................................................................ 34

5.2.3.1 Change to 0 to 20 mA output range......................................................................... 35

5.2.4 Maintenance menus..........................................................................................................35

5.3 Calibration.................................................................................................................................. 36

5.3.1 Calibration on known standards........................................................................................ 36

5.3.2 Calibration by comparison ................................................................................................ 37

Section 6 Maintenance .................................................................................................................... 39

6.1 Scheduled maintenance ........................................................................................................... 39

6.1.1 Replenish the reagents ....................................................................................................39

6.1.2 Replace the pump tubing .................................................................................................. 39

6.1.3 Replace the analyzer tubing ............................................................................................. 40

6.2 Unscheduled maintenance ....................................................................................................... 41

6.2.1 Fuse replacement ............................................................................................................ 41

6.2.2 Clean the instrument enclosure ........................................................................................ 42

6.2.3 Clean the colorimeter........................................................................................................ 42

1

Page 4

Table of Contents

6.2.4 Replace the sample conditioning filter ..............................................................................44

6.2.5 Reagent spill clean up .......................................................................................................44

Section 7 Troubleshooting..............................................................................................................45

7.1 Troubleshooting guide................................................................................................................45

7.2 System alarms............................................................................................................................46

7.3 System warnings ........................................................................................................................47

Section 8 Parts and accessories ...................................................................................................49

Section 9 Contact information .......................................................................................................51

Section 10 Certification....................................................................................................................53

10.1 FCC PART 15, Class "A" Limits ...............................................................................................53

Appendix A Network Interface Card .............................................................................................55

A.1 Attach the analyzer to the network using an AquaTrend interface ............................................55

A.2 Adding the measurement to a channel ......................................................................................56

A.3 Alarms and warnings .................................................................................................................56

A.4 Logging data using the serial input/output module ....................................................................56

A.5 Manually polling data .................................................................................................................57

A.6 Using the signal output module..................................................................................................57

A.7 Logging data using the MOD I/O module...................................................................................57

2

Page 5

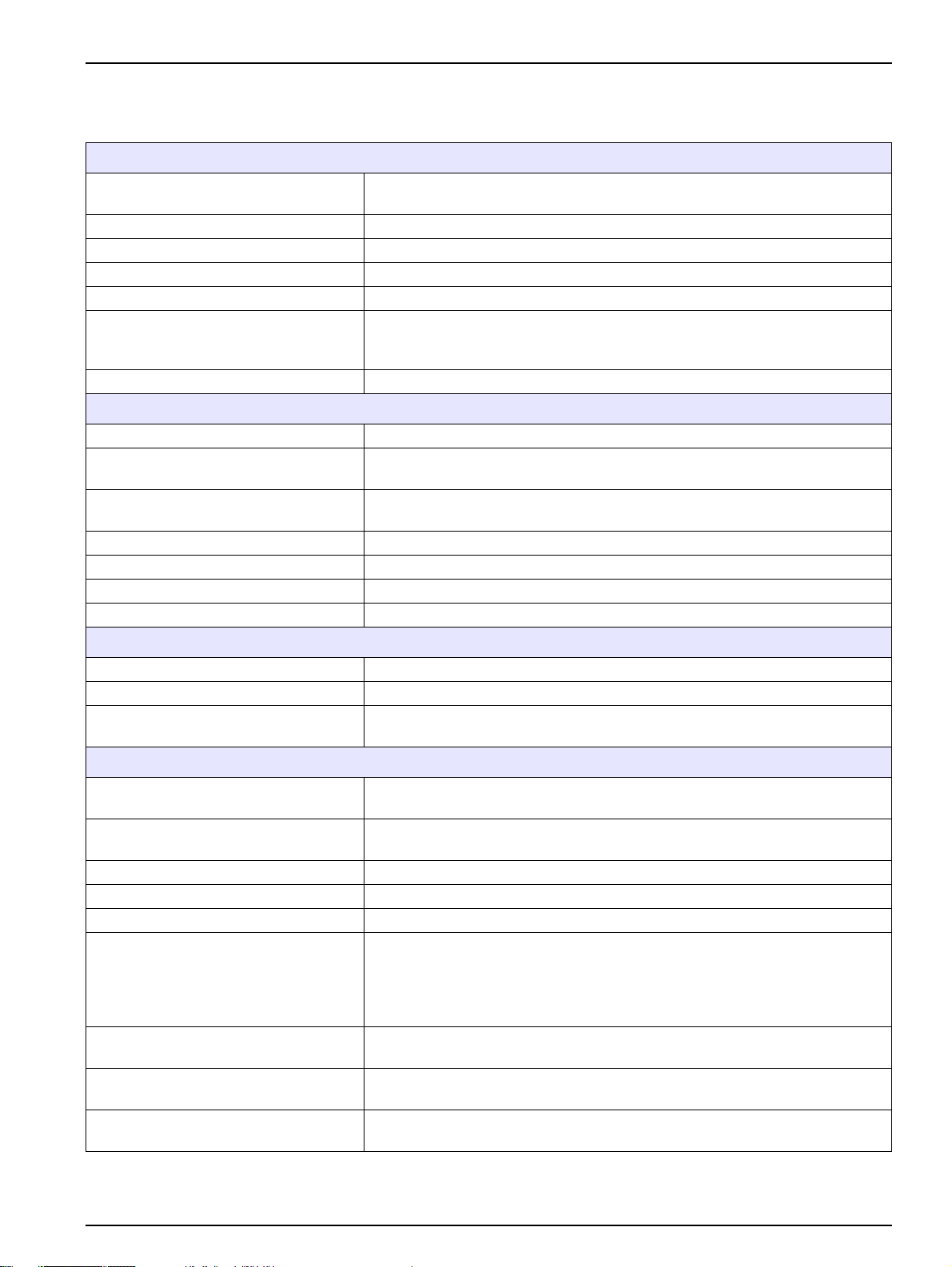

Section 1 Specifications

Specifications are subject to change without notice.

General

Display

Enclosure IP62-rated with the gasketed door latched

Instrument description 31.4 cm (W) x 45.4 cm (H) x 17.9 (D) (12.4 x 17.88 x 7.06 in.)

Mounting Wall mount

Instrument shipping weight 10.49 kg (23 lb)

Warranty

Certification CE approved. Listed to UL and CSA safety standards by ETL.

Sample Requirements

Sample flow rate to sample conditioning 200 to 500 mL/min

Inlet pressure to instrument

Inlet pressure to sampling conditioning

Sample temperature range 5 to 40 °C (41 to 104 °F)

Inlet fitting at instrument ¼-inch OD polyethylene tubing with quick-disconnect fitting

Drain fitting ½-inch hose barb

Sample conditioning Use provided sample conditioning

Regent/Standard Requirements

Maximum reagent usage One-half liter per month (each of the two reagents)

Reagent containers High-density polyethylene (2) ½-liter bottles

Reagent containment

Electrical

Power requirements

Power connection

Installation category II

Polution degree 2

Protection class I

Alarm relay outputs

Alarm connection

Recorder output

Recorder output connections

LCD, 3½-digit measurement readout and six-character alphanumeric scrolling

text line.

Hach Company warrants its products to the original purchaser against any

defects that are due to faulty material or workmanship for a period of one year

from the date of shipment unless otherwise noted in the product manual.

1 to 5 psig; 1.5 psig is optimum. Exceeding 5 psig can cause sample

tubing failure unless sample conditioning is used.

1.5 to 75 psig (with sample tube level with the bottom of the instrument—see

Figure 7 on page 16.)

Reagent bottles are contained inside the analyzer enclosure and are vented

externally.

100–115/230 VAC (selection switch inside instrument); 90 VA, 50/60 Hz, 2.5 Amp

fuse

Connection made by three wire barrier terminal block through a ½-inch conduit

hole in the case. Wire range: 18 AWG.

Two unpowered SPDT relays each rated at 5 A resistive, 240 V ac maximum.

Can function as sample set point alarms (high or low) or as a system warning

indicator or a system alarm indicator. Use either high voltage (greater than 30 V

RMS and 42.2 V PEAK or 60 V dc) or low voltage (less than 30 V RMS and 42.2

V PEAK or 60 V dc). Do not use a combination of high and low voltage.

Connection made by a removable three wire plug through a ½-inch conduit hole

in the case. Wire range: 12–18 AWG.

One isolated recorder output, 4–20 mA (can be adjusted to 0–20 mA).

Recommended load impedance 3.6 to 500 ohms

Connection made by a removable three wire plug through a ½-inch conduit hole

in the case. Wire range: 12–22 AWG.

3

Page 6

Specifications

Optical

Light source

Performance

Operating range 0–5 mg/L free or residual chlorine

Accuracy ±5% or ±0.03 ppm whichever is greater

Precision ±5% or ±0.01 ppm whichever is greater

Quantitation limit 0.09 ppm

Cycle time 2.5 minutes

Detection limit 0.03 ppm

Calibration Uses default calibration curve

Power switch User accessible power switch is required

Recorder One 4-20 mA/0–20 mA

Alarm relay outputs

Optional external outputs Hach AquaTrend

Environmental

Storage temperature range -40 to 60 °C (-40 to 140 °F)

Operating temperature range 5 to 40 °C (41 to 104 °F)

Humidity 90% at 40 °C (90% at 104 °F)

Air purge (optional) 0.1 CFM instrument quality air at 20 psig maximum, ¼-inch OD tubing

Altitude 2000 m (6561 ft)

Class 1 LED (light emitting diode) with a peak wavelength of 520 nm; 50,000

hours estimated minimum life

Two SPDT relays, 5A resistive load at 240 V ac. Can function as sample set

point alarms (high or low) or as a system warning indicator or a system alarm

indicator.

®

Network Interface

4

Page 7

Section 2 General information

The information in this manual has been carefully checked and is believed to be

accurate. However, the manufacturer assumes no responsibility for any inaccuracies that

may be contained in this manual. In no event will the manufacturer be liable for direct,

indirect, special, incidental or consequential damages resulting from any defect or

omission in this manual, even if advised of the possibility of such damages. In the interest

of continued product development, the manufacturer reserves the right to make

improvements in this manual and the products it describes at any time, without notice or

obligation.

Revised editions are found on the manufacturer’s website.

2.1 Safety information

Please read this entire manual before unpacking, setting up or operating this equipment.

Pay attention to all danger, warning and caution statements. Failure to do so could result

in serious injury to the operator or damage to the equipment.

Make sure that the protection provided by this equipment is not impaired, do not use or

install this equipment in any manner other than that specified in this manual.

2.1.1 Use of hazard information

DANGER

Indicates a potentially or imminently hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING

Indicates a potentially or imminently hazardous situation which, if not av oided,

could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation that may result in minor or moderate

injury.

Notice: Indicates a situation that is not related to personal injury.

Important Note: Indicates a situation which, if not avoided, may cause damage to the

instrument. Information that requires sp ec ial em p has is.

Note: Information that supplements points in the main text.

2.1.2 Precautionary labels

Read all labels and tags attached to the instrument. Personal injury or damage to the

instrument could occur if not observed.

Electrical equipment marked with this symbol may not be disposed of in European public disposal systems after

12 August of 2005. In conformity with European local and national regulations (EU Directive 2002/96/EC),

European electrical equipment users must now return old or end-of life equipment to the Producer for disposal at no

charge to the user.

Note: For return for recycling, please contact the equipment producer or supplier for instructions on how to return

end-of-life equipment, producer-supplied electrical accessories, and all auxiliary items for proper disposal.

This is the safety alert symbol. Obey all safety messages that follow this symbol to avoid potential injury. If on the

instrument, refer to the instruction manual for operation or safety information.

This symbol indicates the need for protective eye wear.

5

Page 8

General information

2.2 General product information

2.2.1 Instrument description

DANGER

Chemical or biological hazards. If this instrument is used to monitor a treatment

process and/or chemical feed system for which there are regulatory limits and

monitoring requirements related to public health, public safety, food or beverage

manufacture or processing, it is the responsibility of the user of this instrument to

know and abide by any applicable regulation and to have suf ficient and appr opriate

mechanisms in place for compliance with applicable regulations in the event of

malfunction of the instrument.

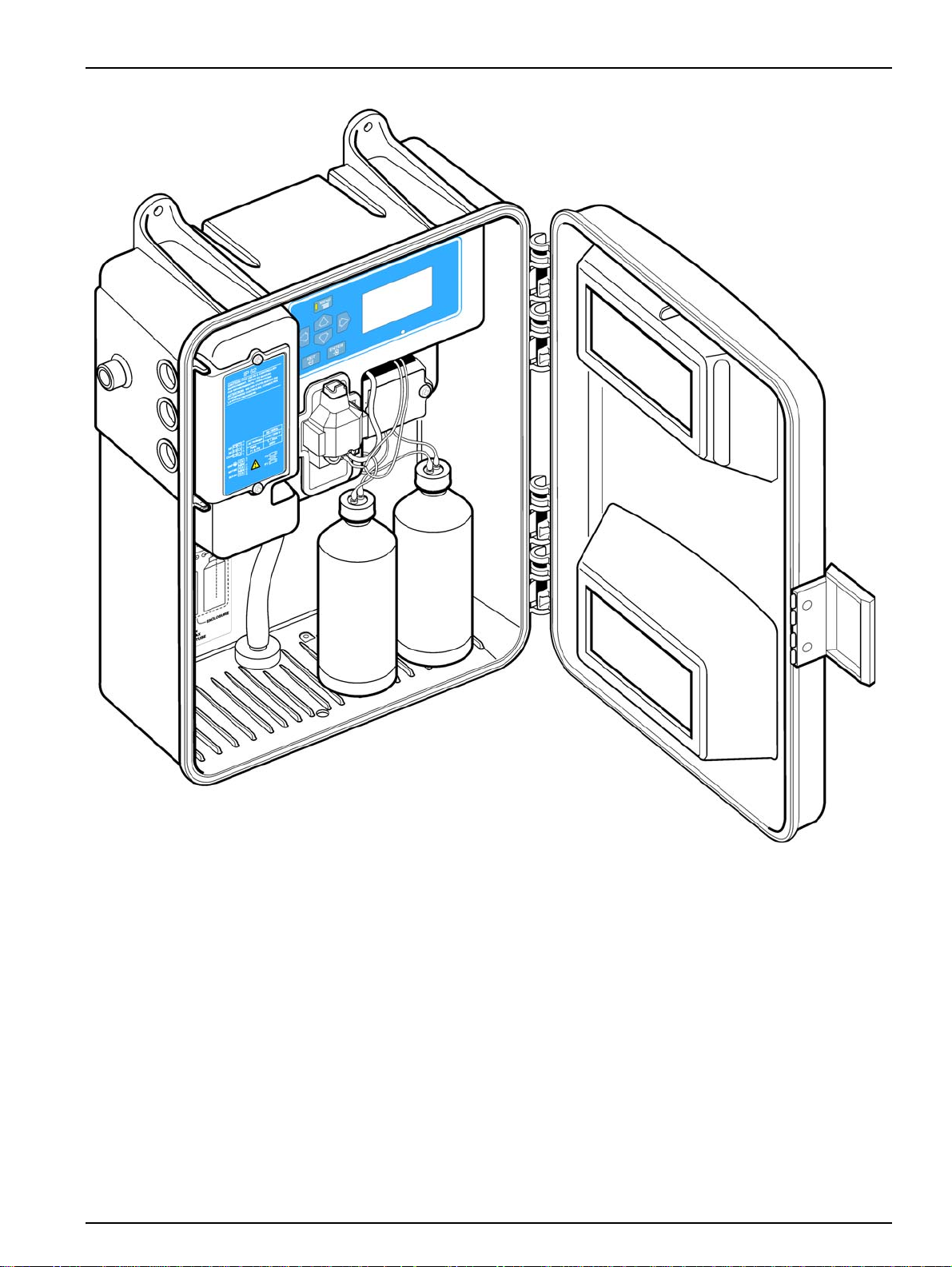

The Hach CL17 Chlorine Analyzer (Figure 1) is a microprocessor-controlled, process

analyzer designed to monitor a sample stream continuously for chlorine content. Either

free or total chlorine, in the range of 0 to 5 mg/L, can be monitored. The buffer and

indicator solutions used determine the choice for free or total chlorine analysis.

CAUTION

Fire hazard. This analyzer is intended to be used for aqueous samples only.

The CL17 Chlorine Analyzer enclosure is environmentally rated for IP62 per IEC 529.

The enclosure is dust-tight, and drip-resistant but is not designed for outdoor use.

The instrument uses a DPD Colorimetric Method which includes a

N,N-Diethyl-p-phenylenediamine (DPD) indicator and a buffer. The indicator and buffer

are introduced into the sample, causing a red color to form with an intensity proportional

to the chlorine concentration. Chlorine concentration, measured photometrically, is

displayed on the front panel, three-digit, LCD readout in mg/L Cl

A recorder output (4-20 mA) is available. Recorder span minimum and maximum values

in mg/L Cl

Programmable alarm circuits provide relay closures, both normally open and normally

closed, for two selectable chlorine level set points. Set points can be programmed by the

operator anywhere within the overall range. System warning and system alarm features

provide automatic, self-testing diagnostics that detect a number of possible malfunctions,

and provide alarm relay closures indicating a need for operator attention.

The CL17 analyzer can be purchased with a Hach Network Interface Card which allows

the CL17 to display its readings on an AquaTrend

PC via a Serial Interface Module.

Indicator and buffer reagents (473 mL of each) are placed in the instrument case in the

original factory-filled bottles. Reagents are replenished once a month.

The instrument is designed so electronic components are isolated from the hydraulic

components. Windows allow the operator to observe the display indicators and reagent

supply without opening the instrument enclosure.

are programmed by the operator at the analyzer keyboard.

2

®

display or allows data to be sent to a

.

2

6

Page 9

General information

2.2.2 Method of analysis

Free available chlorine (hypochlorous acid and hypochlorite ions) oxidizes the DPD

indicator reagent at a pH between 6.3 and 6.6 to form a magenta-colored compound. The

depth or intensity of the resulting color is proportional to the concentration of chlorine in

the sample. A buffer solution specifically for free chlorine maintains the proper pH.

Total available chlorine (free available chlorine plus combined chloramines) is determined

by adding potassium iodide to the reaction. Chloramines in the sample oxidize iodide to

iodine, which, along with any free available chlorine, oxidizes DPD indicator to form the

magenta color at a pH of 5.1. A different buffer solution containing potassium iodide

maintains reaction pH. After the chemical reaction is complete, the optical absorbance at

510 nm is compared to the absorbance measured through the sample before the

reagents were added. Chlorine concentration is calculated from the difference in

absorbance.

Figure 1 Chlorine analyzer

7

Page 10

General information

2.2.3 Theory of operation

The analyzer is designed to capture and analyze a portion of the sample every

2.5 minutes. The sample portion is captured in the colorimeter measuring cell where the

blank absorbance is measured. Measurement of sample blank absorbance allows

compensation for any turbidity or natural color in the sample, and provides an automatic

zero reference point. Reagents are added at this point to develop the magenta color,

which is measured and compared to the reference.

A linear peristaltic pump/valve module controls the flow of incoming sample and injects

metered volumes of the buffer and indicator reagents in a 2.5 minute cycle. The

pump/valve module uses a motor-driven cam to operate pinch blocks that squeeze

special thick-walled tubing against a fixed plate. The cycle operates as follows:

1. The sample inlet line is opened, allowing sample under pressure to flush sample

tubing and the colorimeter sample cell where the measurement is made.

2. The sample inlet line is closed, leaving fresh sample in the cell. Cell volume is

controlled by an overflow weir.

3. As the sample inlet line closes, reagent lines open, allowing buffer and indicator

solutions to fill tubing in pump/valve module.

4. A measurement of untreated sample is taken to determine an average reference

measurement prior to reagent addition.

5. The reagent outlet block opens, allowing buffer and indicator to blend and enter the

colorimeter cell to mix with the sample.

6. After a delay for the development of color, a measurement of treated sample is taken

to determine the chlorine concentration.

This sequence is repeated every 2.5 minutes.

8

Page 11

Section 3 Installation

DANGER

Electrocution and fire hazard. Only qualified personnel should conduct the tasks

described in this section of the manual.

3.1 Unpack the instrument

Remove the analyzer from its shipping carton and inspect it for any damage. Verify that

the Installation Kit, Cat. No. 5516400, and Maintenance Kit, Cat. No. 5444300, are

included aloing with the reagents.

If any items are missing or damaged, contact the manufacturer or distrubutor (outside the

US).

3.2 Instrument environmental considerations

The instrument enclosure is designed for general-duty, indoor installation with a nearly

constant ambient temperature between 5° and 40 °C (18° to 104 °F). The enclosure

environmental rating is IP62 with the door closed and latched. Do not mount the

instrument in direct sunlight; shield from dripping water.

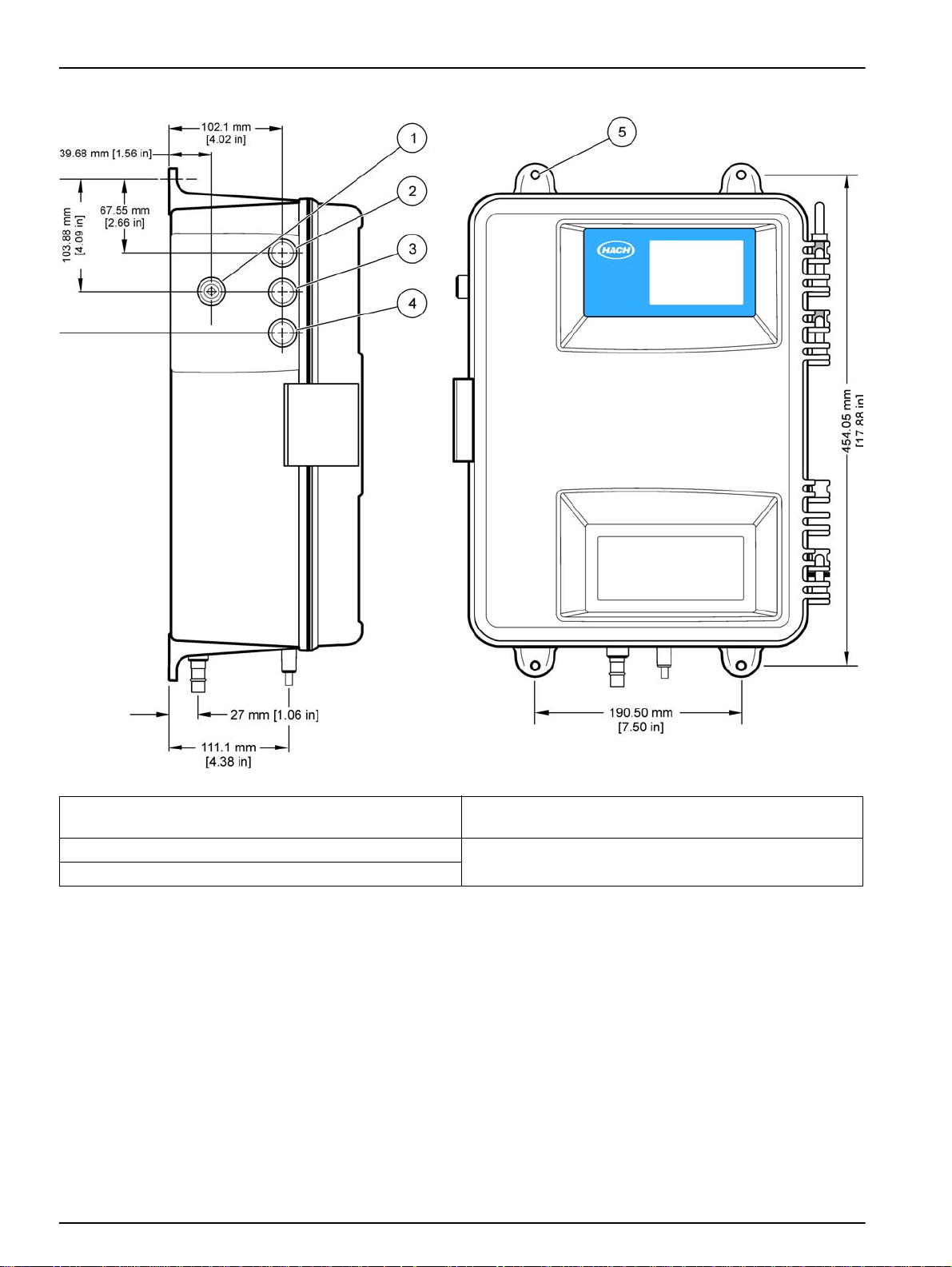

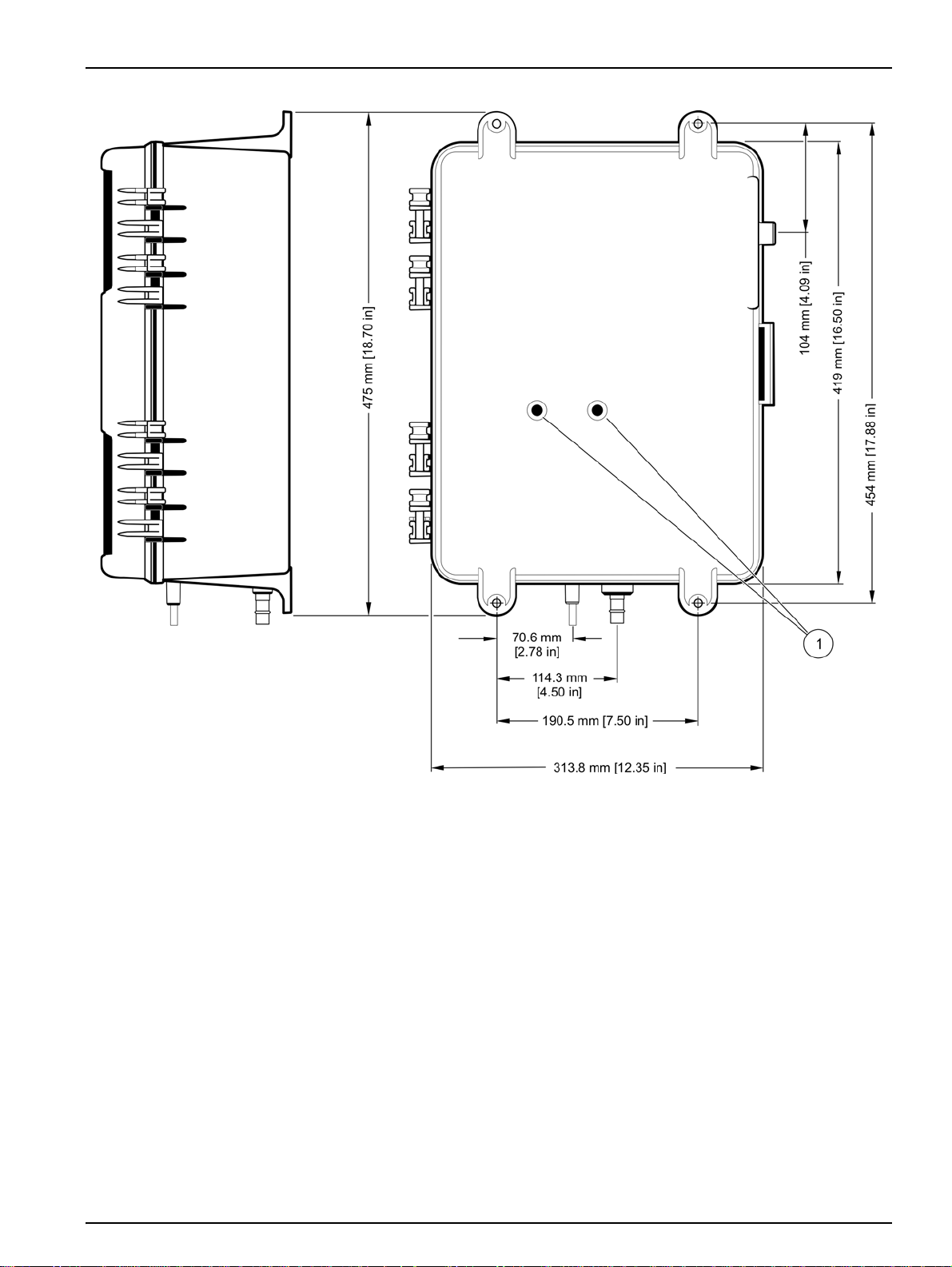

3.3 Mount the instrument on the wall

The instrument case is designed for wall mounting. Refer to Figure 2, Figure 3, and

Figure 4 for dimensions and other installation information. Use ¼-inch screws for

mounting. Mount the instrument as close to the sampling point as practical to ensure

complete purging of the sample line during each cycle. Leave adequate clearance at the

sides and bottom of the instrument case for plumbing and wiring connections.

9

Page 12

Installation

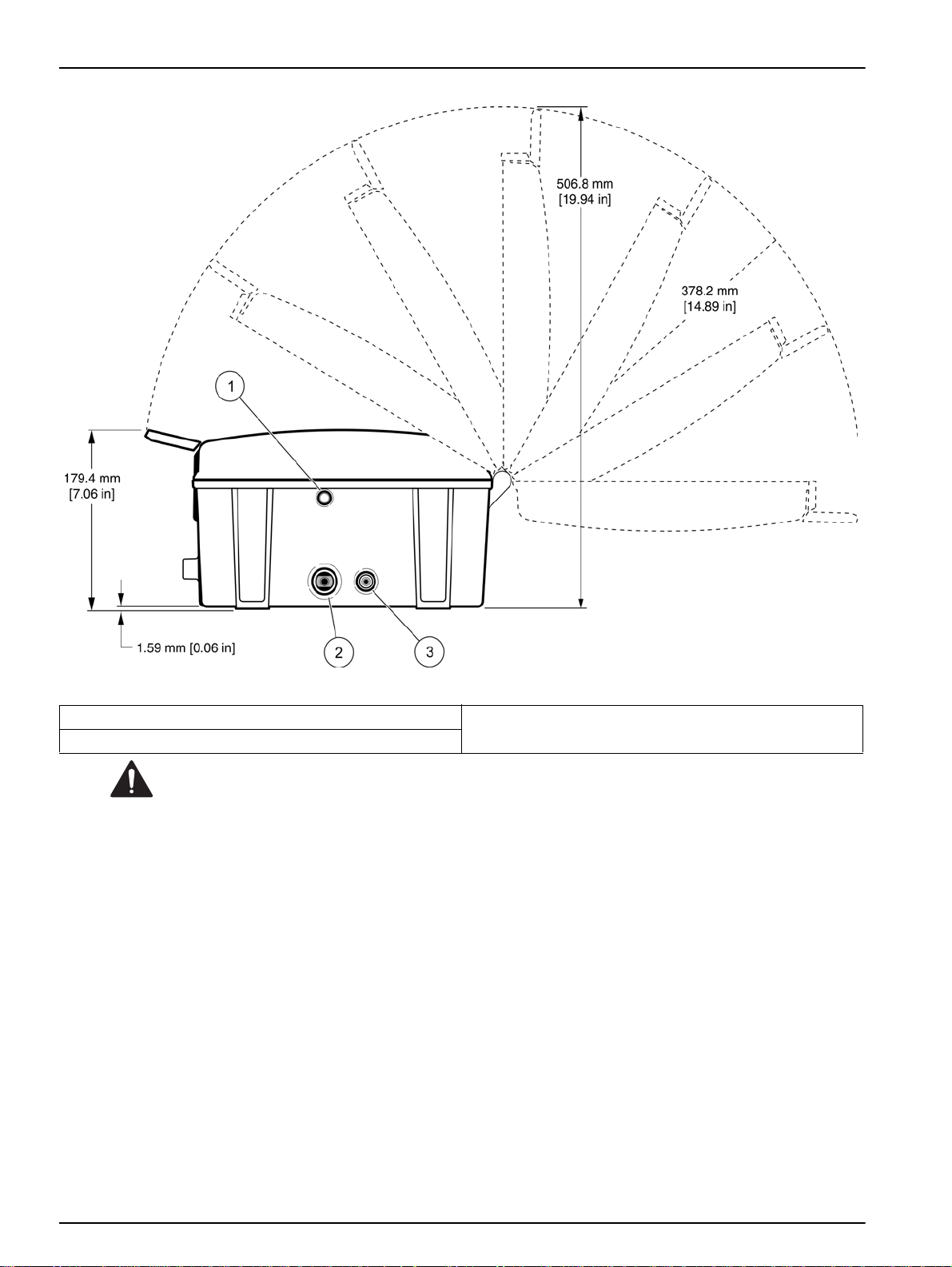

Figure 2 CL17 instrument dimensions (1 of 3)

1 Air purge quick connect

.25 O.D. Polyethylene Tubing, (4743800)

2 Relay / alarm contact connections 5 4 x ¼” recommended mounting bolt

3 Network and 4-20 mA connections

4 Power connections

10

Page 13

Installation

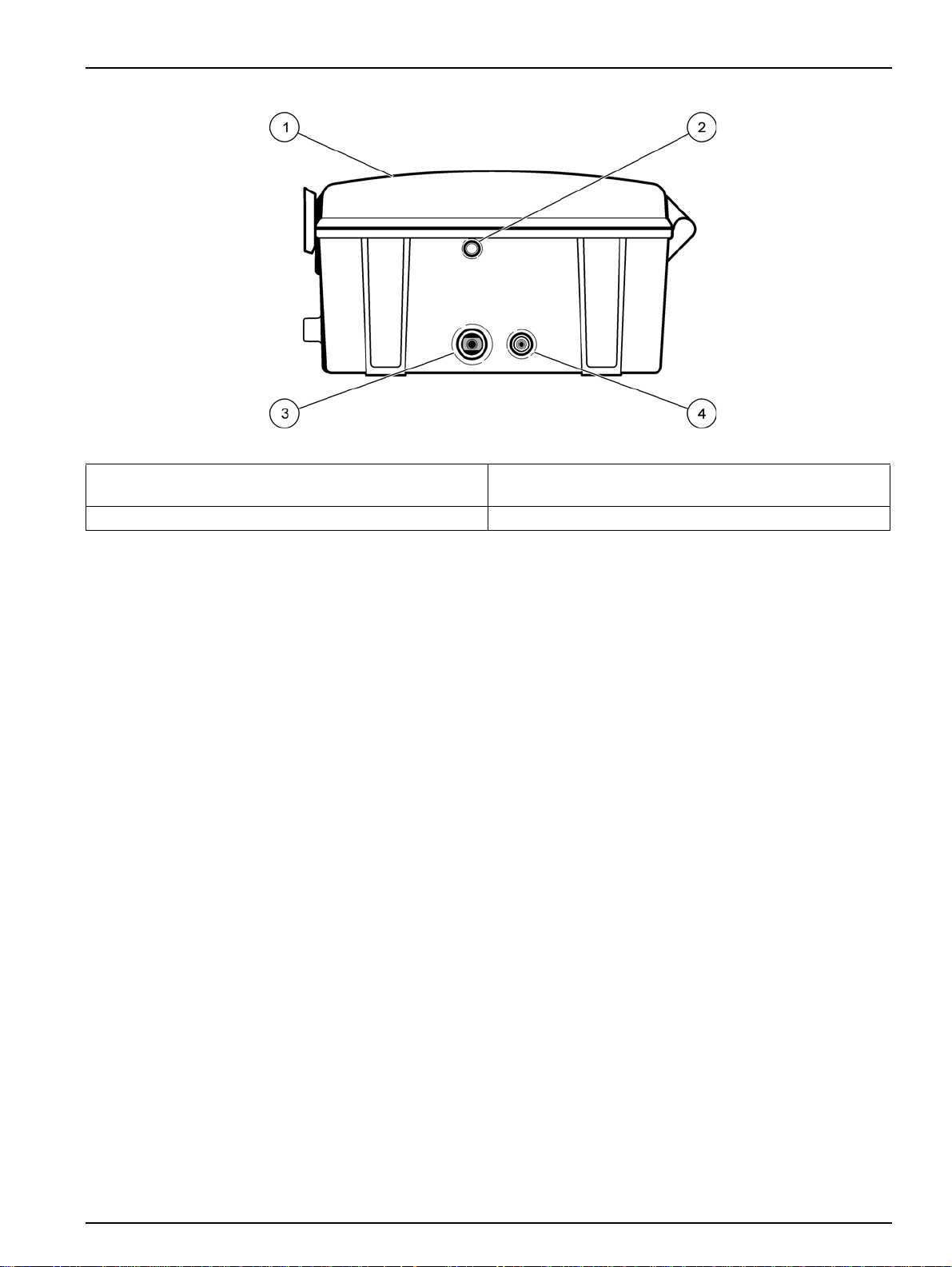

Figure 3 CL17 instrument dimensions (2 of 3)

11

Page 14

Installation

Figure 4 CL17 instrument dimensions (3 of 3)

1 Overflow drain, recommended .50 I.D. tubing 3 Sample inlet quick connect .25 O.D. Polyethylene tubing

2 .50 I.D. drain tube sample

(4743800)

3.4 Plumbing connections

Note: The sample drain contains analysis wastes, which include both sample and chemical

reagents. The enclosure drain produces no waste under normal use. However, in the event of spills

or leaks, some waste may be produced. Although the chemicals used are of low concentration, it is

best to check with local authorities concerning proper disposal of waste from this product.

Sample inlet and drain connections are made on the bottom of the instrument using a

quick connect fitting for ¼-inch OD tubing. Refer to Figure 5. Connect the ¼-inch O.D.

poly tubing by pushing it into the fitting. Two distinct “stops” will be felt as the tubing is

correctly attached. If the tubing is not properly seated, it will come loose when water

pressure is applied. The sample drain fitting is sized for ½-inch ID flexible tubing (not

supplied).

CAUTION

Fire hazard. This analyzer is intended to be used for water samples only.

Note: The ½-inch enclosure drain must have at least 3 feet of tubing installed to ensure the analyzer

remains dust-tight. Never plug the drain. The drain must remain open to remove sample water in the

event of a leak.

12

Page 15

Installation

Figure 5 Plumbing connections (bottom view)

1 Front of instrument 3 Sample drain. Instrument drain fitting is sized for ½ in.

ID flexible tubing

2 Enclosure drain 4 Sample inlet. Quick connect fitting for ¼ in. O.D. tubing

3.5 Installing the sample line

Selecting a good, representative sampling point is important for optimum performance of

the instrument. The sample analyzed must be representative of the condition of the entire

system. Erratic readings will be seen if sample is drawn from a location too close to

points of chemical additions to the process stream, if mixing is inadequate, or if the

chemical reaction is incomplete.

If the sample pressure into the instrument exceeds 5 psig at the analyzer inlet, flooding

and instrument damage may result unless the sample conditioning kit is installed.

Install sample line taps into the side or center of larger process pipes to minimize the

chance of ingesting sediment from the pipe line bottom or air bubbles from the top. A tap

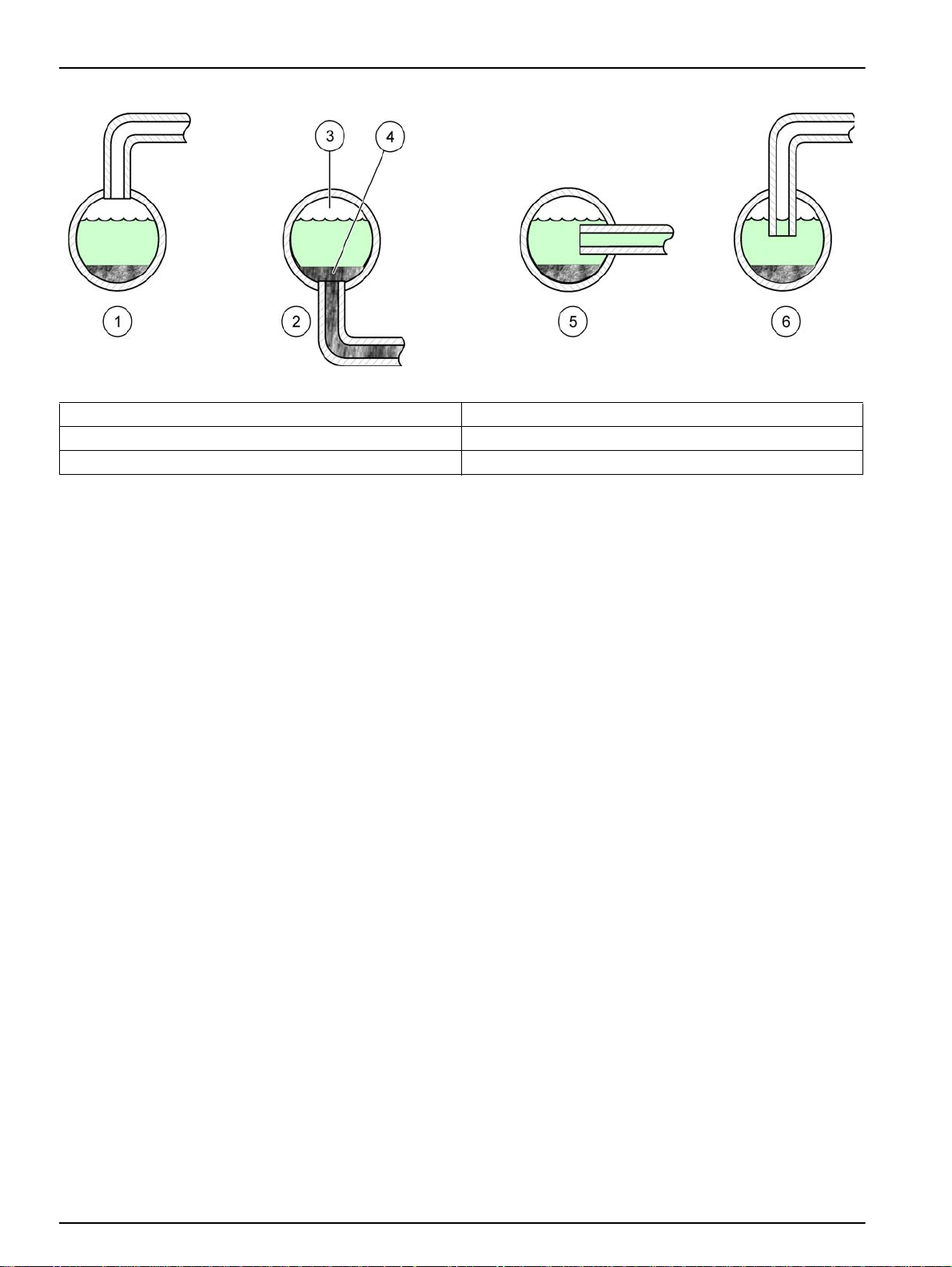

projecting into the center of the pipe is ideal. Refer to Figure 6.

13

Page 16

Installation

Figure 6 Sample line location in the process stream

1 Poor 4 Sediment (typical)

2 Poor 5 Good

3 Air (typical) 6 Best

3.6 Sample conditioning

All samples are “conditioned” using the single-sample, basic sample conditioning kit

shipped with each analyzer. The kit eliminates large particles using a 40-mesh strainer.

The ball valve on the raw sample inlet line may be used to control the amount of bypass

flow that is delivered to the filter. For dirty water, high bypass will adjust it to help keep the

strainer clean longer, or adjust it to any partially open position for continuous bypass.

Adjust the ball valve on the instrument supply line to control the flow rate of filtered

sample to the instrument.

Note: Installing the drain tee more than 2 feet above the instrument can result in excessive pressure

which may cause leaks.

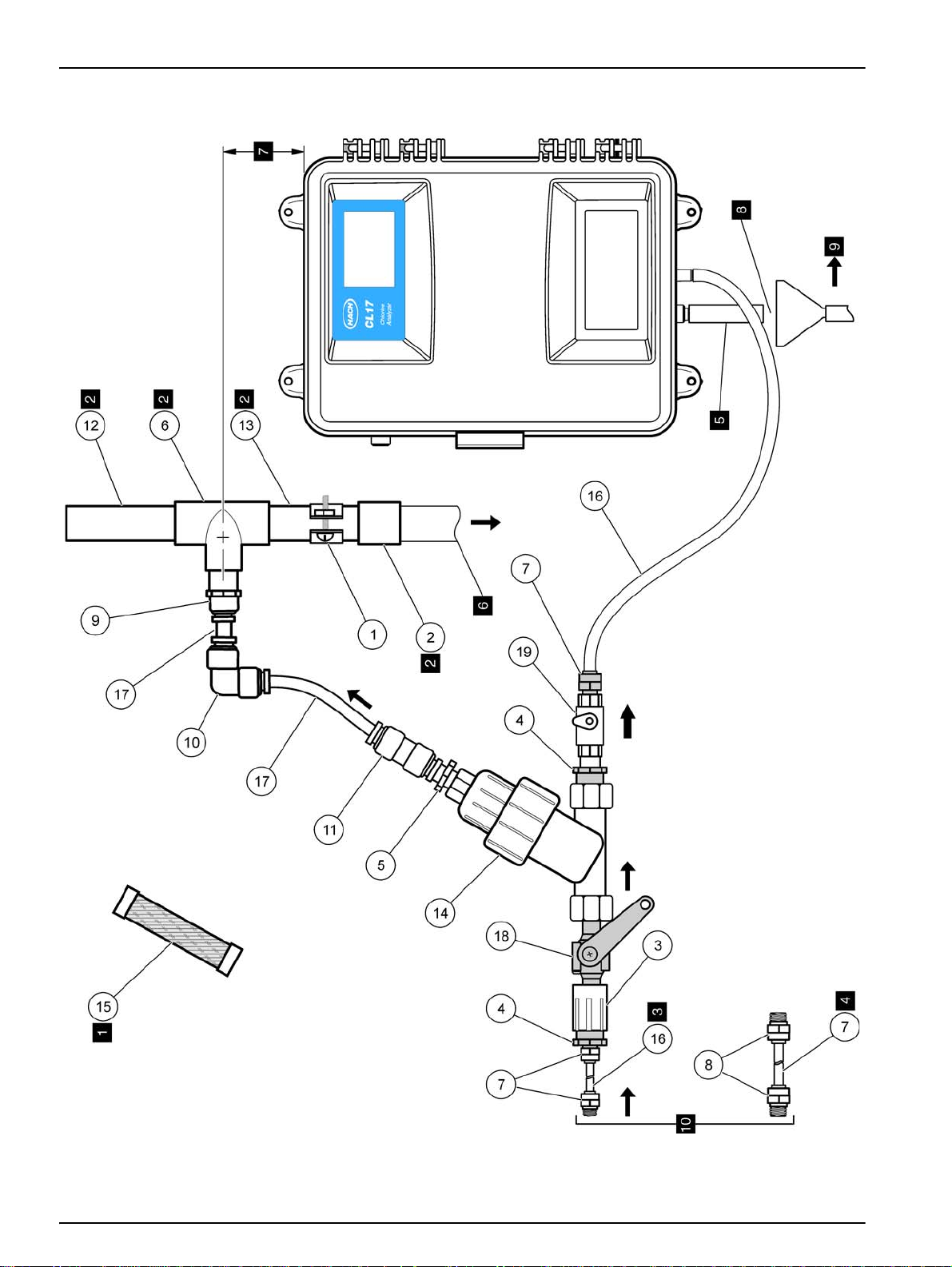

Mount the centerline of the bypass drain tee two feet above the instrument. Refer to

Figure 7. When properly mounted, the vacuum breaker design of the bypass drain tee

prevents negative sample pressure and establishes the needed positive sample pressure

for sample flow through the analyzer.

3.6.1 Assemble the sample conditioning kit

Refer to the complete system diagram in Figure 7 and the tips in Table 3 to assemble the

components.

• Seal all threaded fittings with two wraps of Teflon

• Two stops should be felt when installing tubing into the push-in fitting. The first is when

the tubing clears the gripper ring, and the second is when the tubing meets the bottom

of the itting. To prevent leaks, make sure to push the tubing all the way in.

®

tape (provided).

14

Note: To help grip the tubing, use rubber gloves or other material that grips and forcefully push the

tubing into the fitting. Two stops should be felt; otherwise the tubing will not be fully inserted and will

leak.

• Be sure to cut all tubing used in the push-in fittings with a sharp knife so the ends are

round, cleanly cut and not angled.

• The push-in fittings are designed for use with soft, ¼-inch OD plastic tubing as

included in the kit. Tubing material such as PTFE or HDPE is recommended. The

push-in fitting will not grip hard plastic or metal tubing and the tubing will slip out.

Page 17

3.6.2 Use the sample conditioning kit

Assemble the head height regulator (stand-pipe) and filter as shown in Figure 7. Make

sure the sample pressure to the sample conditioning is between 1.5 and 75-psig for

proper operation.

1. Set flow by adjusting the ball valve (item 18, in Figure 7). The valve is fully closed

when the lever is perpendicular to the valve body and fully open when the lever is

parallel with the valve body.

2. Observe the flow in the unfiltered sample bypass (clear tube, item 13 in

Figure 7). Make sure the flow is adjusted so there is always bypass flow.

3. Use the ball valve (item 19) to turn off sample flow to the instrument.

Installation

15

Page 18

Installation

16

Figure 7 Sample conditioning kit

Page 19

Installation

Table 1 Sample Conditioning Parts List (refer to Figure 7)

Item Description Qty Catalog Number

1 Clamp, Conduit Hanger, 1-inch 4 47349-00

2 Coupling, 1-inch, SCH 40, PVC pipe 1 54175-00

3 Coupling, ½-inch FPT x ½ FPT PVC 1 54176-00

4 Fitting, Reduce Bushing, PVC, Hex 2 23002-00

5 Fitting, Stem Adapter, ½-inch O.D., ¼ NPT 1 54180-00

6 Fitting, Tee, 1-inch x 1-inch 1 46622-00

7 Fitting, Tube, Connector, Male (¼-inch tubing) 3 51246-00

8 Fitting, Tube, Connector, Male (½-inch tubing) 2 51262-00

9 Fitting, Tube, ½-inch O.D. x ½-inch Male NPT 1 54178-00

10 Fitting, Tube, ½-inch O.D. Union Elbow 1 54179-00

11 Fitting, Tube, ½-inch O.D., Union Straight 1 54181-00

12 Pipe, Pre-cut Drain, 1-inch Diameter, PVC 1 51239-00

13 Pipe, Drain, Clear 1 54174-00

14

15 Teflon

16 Tubing, Polyethylene, 0.250 O.D., 0.040 W, Black 15 feet 30616-00

17 Tubing, Polyethylene, 0.500 O.D., 0.062 W, Black 10 feet 51159-00

18 Valve, Ball, PVC, ½ NPT, PVC 1 54177-00

19 Valve, Ball, PVC, ¼ NPT, PVC 1 51395-00

Strainer, Y-body 1 54183-00

Filter, 40-mesh Screen (provided with strainer and in Maintenance Kit, 55165-00) 1 54184-00

®

, Thread Tape, ¼-inch wide 1 70608-24

Table 2Sample condition kit parts list notes for Figure 7

The filter element is factory installed. A spare filter is provided in the Maintenance Kit.

Use PVC pipe cement to assemble. Leave pipe open to the atmosphere.

This the “Low Flow” option.

This the “High Flow” option.

1

/2 inch drain tube must have an air-break. (Must be supplied by the customer.)

The

Use the Unfiltered Sample Bypass to return to system under zero pressure, if possible, or to drain.

Use customer supplied PVC pipe as required to run to drain location.

Install the Sample Flow Regulator (Constant Head Device) 24 inches above the instrument.

Air Gap

Drain

Use either 7 and 16 or 8 and 17.

17

Page 20

Installation

3.7 Optional air purge

Air purge may be necessary if the analyzer is located in an environment with high

humidity and/or caustic vapors. The goal is to maintain a slight positive pressure in the

instrument with dry instrument air.

The air purge connection is located on the left side of the instrument enclosure.

To connect an air supply, remove the plug in the quick connect fitting then connect ¼-inch

poly tubing by pushing the tubing into the fitting. Two distinct “stops” will be felt as the

tubing is correctly attached. If the tubing is not properly seated, it will come loose when

air pressure is applied. Use only dry, oil-free instrument air at 15 scfh.

3.8 Electrical connections

All power connections are made through the conduit openings in the upper left side of the

instrument. The instrument is shipped with plugs in all of the conduit openings. Wire the

instrument for power, alarms, and relay connections using sealing-type conduit fittings, to

maintain the IP62 environmental rating.

If connections are not made through a conduit opening, install a liquid-tight seal in place

of the plugs to maintain the IEC 529 IP62 rating. Refer to Parts and accessories on

page 49.

Figure 8 Location of air purge and electrical connections

1 Intended for wiring relays. Use sealing type fittings. 3 Network and 4-20 mA connections. Use sealing type

fittings.

Note: If relay connections are not made, an liquid-tight seal

(4221000) must be installed to maintain the IEC 529 IP62

rating.

2 Optional air purge connection 4 Power connections. Use sealing type fittings.

18

Page 21

3.8.1 Power connections

DANGER

Electrocution hazard. Only qualified personnel should conduct the tasks desc ribed

in this section of the manual. Connect equipment in accordance with national,

state and local electrical codes.

Power connections are made at the terminal strip located in the left side of the electrical

compartment and are accessible when the customer access cover is opened. Refer to

Figure 9 and Figure 12.

For process or industrial applications, the national electrical codes of most countries

require that AC service feeds be hard-wired and contained in conduit systems. The CL17

Chlorine Analyzer has been designed to conform to this requirement.

Installation

Figure 9 Locating and removing customer access cover

1 Customer access cover 2 Use a torx-driver to remove the two screws that hold the

Customer Access Cover in place. Set cover aside.

Conduit is recommended for two reasons:

1. It is generally required by most local electrical codes.

2. Use of metal conduit can improve immunity to lightning surges and

AC power transients.

19

Page 22

Installation

Additionally, electrical and instrumentation standards require a local means of removing

power from the product. The instrument is supplied with a power on/off switch that is

located inside the instrument enclosure. To remove relay power from the

instrument, an external customer-supplied 5A fused switch or a 5A breaker is

required.

In hard-wired electrical applications, the power and safety ground service drops for the

instrument should be no longer than 6 meters (20 feet) unless metal conduit is used to

shield the AC power wiring. The wire should be 18 AWG.

In applications where power cords are allowed by local electrical codes and power surges

and transients are not a great concern, a sealing-type strain relief and power cord with

three 18 gauge conductors (including a safety ground wire) can be used. Refer to

Figure 10 for strain relief assembly. The length of the power cord must not exceed

3 meters (10 feet).

Figure 10 Assembling the optional power cord hardware

1 Wall section of the instrument closure

Description Item number

115V Power cord with strain relief 5448800

230V Power cord with strain relief 5448900

3.8.2 Wiring the instrument

Connect the unpowered wires to the instrument power terminal as follows:

1. Strip the outside insulation of each wire back ¼-inch. Refer to Figure 14 on page 23.

2. Connect the three wires to the terminal using the information in Table 3 and

Figure 11 on page 21.

3. Ensure the voltage setting is correct and supply power to the instrument.

Table 3 Terminal wiring information

Wire color code for: Protective earth ground Hot or Ø1 Neutral or Ø2

North America Green Black White

IEC Green with yellow tracer Brown Blue

20

Page 23

Installation

Figure 11 Customer connections to analyzer

1 Relays 3 AC power: 100-115/230 VAC, 50/60 Hz, 90 VA fused at

2 Recorder

2.50A

Figure 12 Power connections

1 A method to remove power from the relays locally must

be available in case of an emergency or for servicing the

instrument.

2 Since the ON/OFF switch can be accessed without the

use of a tool an external switch is not required for

instrument power.

3.8.3 Voltage selection for alternate voltage operation

Note: The voltage selector switch must be set properly for the line voltage to be used. An improper

setting can result in serious damage to the instrument when power is applied. Refer to Figure 13.

The instrument is switched for 115-volt operation when it leaves the factory. To convert

the instrument for 230-volt operation, slide the AC line conversion switch (shown in

Figure 13) to the 230V position. The fuses used in this product are 5 mm x 20 mm. The

fuses used are approved for both North American and European use; they do not need to

be changed when voltage is converted.

21

Page 24

Installation

Figure 13 Voltage selector switch and fuse replacement

1 Voltage selection switch (SW1). Factory set at 115V. 4 Hot / Black Ø1

2 GND 5 Fuses (F1, F2) (T, 2.5A, 250V)

3 Neutral / White Ø2

3.8.4 Alarm connections

CAUTION

Fire hazard. Current to the relay contacts must be limited to 5 amps resistive. A

method to remove power from the relays locally must be available in case of an

emergency or for servicing the product. Power removal can be accomplished with

an external switch and a 5-amp fuse or with a switched 5-amp circuit breaker.

The analyzer contains two alarm relays designed for use with either high voltage (greater

than 30V-RMS and 42.2V-PEAK or 60 VDC) or low voltage (less than 30V-RMS and

42.2V-PEAK, or less than 60 VDC), but not a combination of both high and low voltage.

Refer to 3.8.5, Figure 11, and Figure 15 along with the instructions below for connection

information.

The Normally Open and Common relay contacts will be connected when an alarm

condition is active.

The relay connector accepts 18-12 AWG wire. Wire gauge should be determined by load

application. Wire gauge less than 18 AWG is not recommended.

22

1. Make sure no power is supplied to the instrument.

2. Strip the insulation on each wire back ¼-inch. Refer to Figure 14.

3. Remove the connector from the instrument if desired.

4. Insert the wire ends into the connector until the insulation seats against

the connector. Refer to Figure 14. (Do not seat the insulation under the terminal pinch

plates.)

5. Replace the connector if necessary and supply power to the instrument.

Page 25

Installation

1

2

Figure 14 Proper wire preparation and insertion

1 Strip ¼ in. of insulation 2 Seat insulation against connector with no bare wire

exposed.

Figure 15 Alarm connections

1 Current to the relay contacts must be limited to 5 amps.

Note: Make sure no power is supplied to the instrument.

2 J1 alarm connections terminal block: Terminal 1 = COM; Terminal 2 = NO; Terminal 3 = NC

3 J2 alarm connections terminal block: Terminal 1 = COM;

Terminal 2 = NO; Terminal 3 = NC

3.8.5 Recorder output connections

The recorder output is a 4–20 mA current-source output. Make recorder connections with

twisted-pair shielded wire and connect the shield at the recorder, controlled component

end or at the analyzer end. Do not connect the shield at both ends of the cable.

Make wiring connections at the analyzer end as follows:

1. Make sure no power is supplied to the instrument.

2. Remove the Customer Access Cover (refer to Figure 9 in the manual).

3. Strip the insulation on each wire back ¼-inch. Refer to Figure 14.

Note: Use a twisted-pair, shielded cable. Use of non-shielded cable may result in radio frequency

emission or susceptibility levels higher than allowed.

4. Route the wire through an available strain relief.

23

Page 26

Installation

5. Remove the connector from the instrument. Refer to Figure 16 on page 24for

connector position.

6. Insert the wire ends into the connector (refer to the table below) until the insulation

seats against the connector as shown in Figure 14. (Do not seat the insulation under

the terminal pinch plates.)

Recorder Wires Circuit Board Markings

Recorder + +

Recorder – –

Shield GND

7. Replace the connector and supply power to the instrument.

Figure 16 Recorder connections

1 Make sure no power is supplied to the instrument 2 Make sure no power is supplied to the relay

3.9 Install the pump/valve pinch plate

To eliminate the effects of constant pressure on the pump tubes during shipment and

storage, the pinch plate and screws for the pump/valve module are shipped in the

installation kit and the pump tubes are held in place with tape.

Reagent flow through the pump/valve module must be from bottom to top. If reversed,

fluid mixture will be pumped from the colorimeter sample cell, causing reagent bottles to

overflow.

Complete the assembly of the pump/valve module as follows:

1. Remove the tape.

2. Make sure the individual pinch blocks are positioned as shown in Figure 17, with the

dissimilar-shaped block on top.

3. Align the pinch plate on the pump/valve module (refer to Figure 18).

24

Page 27

Installation

4. Install the two screws through the pinch plate and into the pump/valve module.

Secure the pinch plate by turning the screws in small increments moving from one

screw to the other so that the plate is drawn down evenly. Tighten until the plate is

seated against the pump/valve module.

Figure 17 Installing pump/valve module pinch blocks

1 Pump/Valve module 3 The dissimilar-shaped block should be on top

2 Remove tape from tubes

25

Page 28

Installation

Figure 18 Aligning the pump/valve module pinch plate

1 Align pinch plate with pump/valve module 2 Install screws. (Advance the screws in small increments

moving from one screw to the other so that the plate is

drawn down evenly.)

26

Page 29

Section 4 System Startup

CAUTION

Chemical exposure hazard. To familiarize yourself with handling precautions,

dangers and emergency procedures, always re view the Materia l Safe ty Data Sheets

prior to handling containers, reservoirs, and delivery systems that contain

chemical reagents and standards. Protective eye wear is always recommended

when contact with chemicals is possible.

Preliminary tasks necessary for placing the instrument in operation are defined below in

their recommended sequence. Once these preliminary steps are performed, the

instrument will be operational.

4.1 Install the reagents

The analyzer requires two reagents, a buffer solution and an indicator (Table 4). Space is

provided in the instrument enclosure for a 500-mL bottle of each of the reagents. Two

reagents used in the chlorine analysis are installed in the analyzer hydraulic section and

replenished at monthly intervals. One is the buffer solution, Free Chlorine Buffer, Cat. No.

2314111, used to determine free available chlorine, or Total Chlorine Buffer, Cat. No.

2263511, used for total chlorine analysis. The buffer solutions are completely formulated

at the factory and are ready to install. Remove the cap and seal from the buffer solution

bottle and install the cap and tubing labeled BUFFER to the buffer solution bottle.

Note: It is normal for the reagent tubing to become discolored over time.

The second reagent, the indicator solution, must be prepared.

The indicator solution and indicator powder must be mixed just before use to ensure the

best instrument performance. Using the powder funnel provided in the maintenance kit,

add the contents of one bottle of DPD High Range Powder, Cat. No. 2297255, to a bottle

of Total Chlorine Indicator Solution, Cat. No. 2263411, or a bottle of Free Chlorine

Indicator Solution, Cat. No. 2314011. Stir or shake until the powder is dissolved

completely. Remove the cap from the reagent bottle and install the cap and tubing

labeled INDICATOR to the reagent bottle. Tubing should be inserted to the bottoms of the

bottles to prevent air from being drawn in when the level in the bottle drops.

Table 4 Buffer and indicator solutions

Test Type Required Reagent Item No. Reagent Set Item No.

Free Chlorine Buffer Solution 2314111

Free Chlorine

DPD Indicator Powder 2297255

Total Chlorine Buffer Solution 2263511

Total C hlo rine

DPD Indicator Powder 2297255

Remove each reagent bottle cap and replace it with the special two-part bottle cap that is

connected to the delivery tube inside the instrument.

2556900Free Chlorine Indicator Solution 2314011

2557000Total Chlorine Indicator Solution 2263411

27

Page 30

System Startup

4.2 Install the stir bar

A small stir bar for the sample cell in the colorimeter assembly is included in the

installation kit furnished with the instrument. The stir bar must be installed for the

instrument to operate properly.

Install the stir bar as follows:

Note: Make sure the stir bar drops down into the colorimeter and remains in the colorimeter.

1. Remove the plug in the top of the colorimeter.

2. Drop the stir bar into the hole. Refer to Figure 19. The bar should rest on the bottom

of the vertical bore.

3. Replace the plug.

Figure 19 Installing the stir bar

1 Remove the plug from the top hole of the colorimeter 3 Colorimeter assembly

2 Drop the stir bar into the hole and replace the plug. (The

stir bar is shown larger than actual size.)

28

Page 31

4.3 Supply the sample

Note: Make sure the pressure plate is securely attached to avoid backflow of the sample into

the reagents.

Start sample flow through the instrument by opening the supply valve (item 19 in Figure 7

on page 16). Allow the pressure in the tubing to stabilize and check for leaks.

Until the surface of the sample cell becomes completely wetted, bubbles may cling to the

sample cell and cause erratic readings. This condition is temporary. Its duration depends

on the sample properties.

4.4 Supply power to the analyzer

The power switch is located inside the enclosure door in the recessed area to the left of

the colorimeter block. Set the POWER (–/O) switch to ON (–) and allow the analyzer to

operate for approximately two hours to ensure the system is completely wetted with

reagents and sample.

System Startup

29

Page 32

System Startup

30

Page 33

Section 5 Operation

EXIT ENTER

Chlorine

mg/L

MENU

1

2

3

4

5

67 8

9

5.1 Keypad and display information

The instrument display defaults to normal Concentration Measurement Mode unless keys

are pressed to change it. Table 5 shows the functions for each key.

Figure 20 Analyzer keypad and display

Table 5 Keypad Description

Number Key Description

1

2

3

MENU

RIGHT ARROW

UP ARROW

4

5

6

7

8 Alarm LED Indicates an active alarm.

9 Display Screen Display area for measurement and menu information.

LEFT ARROW

DOWN ARROW

EXIT

ENTER

In measurement mode, pressing the

MAINTENANCE and SETUP menus.

Allows movement so different components of the display can be edited.

Active when the right arrow icon is shown on the display.

Use to scroll through menu options or edit display components.

Active when the up / down arrow icons are shown on the display.

Allows movement so different components of the display can be edited.

Active when the left arrow icon is shown on the display.

Use to scroll through menu options or edit display components.

Active when the up / down arrow icons are shown on the display.

Rejects an edited value or backs out of the menu structure.

Accepts an edited value, moves deeper into the menu structure, or accepts a menu option.

MENU key allows access to ALARM, RECORDER,

31

Page 34

Operation

5.2 Instrument menu structure

The major menus in the CL17 Analyzer consist of ALARMS, RECRDR, MAINT, and SETUP.

Press the

information on the functions of each of the menus and the submenus within them.

5.2.1 Setup menu

Day-to-day analyzer functions are accessed from the SETUP menu. To enter the SETUP

menu, press the

Press

UP or DOWN ARROW keys to access the menus. The sections below give

MENU key, then use the UP ARROW key to scroll to the SETUP option.

ENTER.

Scroll through the

ENTER to select the displayed menu option. Arrow icons are displayed if the display is

editable. Press the

information in Table 6 is in the order it appears in the

Menu option Description

The SIGAVG feature is used to average readings and prevent erratic recorder output signals.

ENTER, use the UP and DOWN ARROW keys to select 1, 2, 3, or 4, then press ENTER to

Press

accept the displayed selection. Depending on the value selected, the last 1, 2, or 3 measurements

are averages and the reported concentration is the averaged values. Option 4 is a special filter,

which only reports the maximum value between the current reading and the last. This feature

SIGAVG

CAL ZERO

CAL STD

CAL DEFAULTS

OFFSET Press

reduces negative spikes due to bubbles and other abnormalities in the sample. The factory default

is 1. Press

Note: A properly maintained instrument in good working condition will read within the accuracy

specifications presented in Specifications on page 3. The calibration function should never be used

to force an analyzer that is not working correctly to display a correct reading. Calibrations are

intended for very small adjustments only.

This feature is used to offset the instrument zero using a prepared zero standard. If the offset is

too large, a marginal zero (MARG Z) warning will occur. Refer to Calibration on page 36.

This feature is used to adjust the analyzer slope using a prepared standard. If the adjustment is

too large, the analyzer will not accept it and a marginal gain (MARG G) warning will occur. The

new standard will not be accepted and it will have to be checked again using another method to

establish a more exact reading. Refer to Calibration on page 36.

(Calibration Default Settings) Press

defaults and set the Gain to 1.0 and the Offset to 0. Use this feature to remove calibrations that

are causing a MARG G or MARG Z to be displayed.

ENTER to momentarily display the current Zero correction factor. The factory default is 0.

SETUP menu options using the UP and DOWN ARROW keys. Press

EXIT key to back out of a menu and return to SETUP. The menu

SETUP menu.

Table 6 Setup menu options

EXIT to return to the SETUP menu.

ENTER to return the calibration settings back to factory

GAIN

DISPLAY TEST

RECMIN

RECMAX

REC ADJUST

32

Press

ENTER to momentarily display the current Gain correction factor. The factory default for gain

is 1, however, readings of 0.8 to 1.25 are acceptable.

ENTER to momentarily display all LCD segments to visually check that the complete display

Press

is functioning.

Recorder signal test. Press

and hold it there until the next analysis is complete.

Recorder signal test. Press ENTER to drive the Recorder output to its maximum (normally 20 mA)

and will hold it there until the next analysis is complete.

Note: To hold the signal longer, press the

MAINTENANCE. Press ENTER then scroll down to HOLD OUTPUTS and press ENTER again.

ENTER to modify the Recorder Minimum and Recorder Maximum values. Use this feature to

Press

offset the 4 or 20 mA output signal to force a chart recorder to read zero or full scale in case of a

small discrepancy. Use the

the UP and DOWN ARROW keys to adjust the value. Press ENTER to select. Press EXIT to accept

changes and return to SETUP.

Note: The numbers on the display are A/D counts and cannot be used to determine the recorder

setting.

ENTER to drive the Recorder output to its minimum (normally 4 mA)

MENU key then the DOWN ARROW key to scroll to

RIGHT and LEFT ARROW keys to select RECMIN or RECMAX then use

Page 35

Table 6 Setup menu options

Menu option Description

ENTER to momentarily turn the relays off, then sequentially turn on ALARM1 and ALARM 2.

RELAY TEST

1

REF

SAMPLE

ZERO

CYCLE TIME

POWER FAIL

WARNING

DIAG OUTPUT

KEYBOARD

LOCKOUT

LANGUAGE

DEFAULT SETUP

1

These functions are used by service technicians to troubleshoot the instrument.

1

1

1

Press

Automatically clears both alarms to complete the test.

Momentarily displays the last Reference A/D counts.

Momentarily displays the last Sample A/D counts.

Momentarily displays the last Zero A/D counts.

Momentarily displays the Motor On time (in seconds).

Sets the power fail warning to

between ON and OFF. Press ENTER to select. Press EXIT to accept changes and return to SETUP.

If the power fail warning is turned on and the power is interrupted, a system warning will be

generated when power is restored. The factory default is off.

Pressing

interfaces present will receive diagnostic data.

Press

displayed option. Press

functions are allowed and all diagnostics are disabled except this one. The factory default is OFF.

English language is the factory default. Spanish, French, and German can be enabled.

Press

key when the language of choice is displayed. Press the

SETUP.

Cold Start—Press

be lost. The display will show the software version number (V 1.2 for example) until the next

analysis is complete.

ENTER will momentarily indicate ON at the display and any optional LonWorks®

ENTER then use the ARROW keys to toggle between ON and OFF. Press ENTER to select the

ENTER then use the ARROW keys to move between the available options. Press the ENTER

ENTER to reset the instrument to factory defaults. All user-specified settings will

ON or OFF. Press ENTER then use the ARROW keys to toggle

EXIT to return to the SETUP menu. If the keyboard is locked out, no editing

Operation

EXIT key to accept changes and return to

5.2.2 Alarm setup

This menu accesses two unpowered alarm relays (AL1 and AL2), RECALL WARNINGS,

and

CLEAR WARNINGS. The alarm relays may be assigned to one of the alarm functions

listed below. Only one function can be assigned to each relay.

•LO—Alarm is triggered if concentration is less than or equal to the trip point. (0.0 mg/L

to 5.0 mg/L limits)

•HI— Alarm is triggered if concentration is greater than or equal to the trip point. (0.0

mg/L to 5.0 mg/L limits)

• SYSTEM ALARM (SA)—Activates an alarm when a system alarm occurs.

• SYSTEM WARNING (SW)—Activates an alarm when a system warning occurs.

In addition, alarm status can be obtained and alarms can be cleared using this menu.

The relay is activated when an alarm condition occurs. Either relay may be activated on a

high chlorine alarm, a low chlorine alarm or when a System Warning or System Alarm

occurs. Alarm relays can be used to control chemical feeds as an on/off control, by using

them as a high or low alarm set point.

The two alarm relays can also be used to bracket a specific control range by adding a

double-pole double-throw auxiliary relay and wiring it to electrically latch. This allows the

pump to be turned on at a low level and off at a higher level—with the concentration

dropping down in between.

33

Page 36

Operation

Perform the procedure below to assign functions to AL1 or AL2:

1. Press the

2. Press

MENU key. ALARMS will be displayed.

ENTER to select ALARMS. The screen will display AL1 (or AL2), and either the

alarm set point (HI or LO), SA (System Alarm), or SW (System Warning).

3. To change the AL1 (or AL2) assignment, press

ENTER again. The item to be changed

will flash. The arrow icons indicate active arrow keys. Scroll through the available

assignments. Press the

RIGHT ARROW key to change the value of the high or low

alarm.

4. Press

ENTER to select the displayed assignment.

5. Repeat the procedure to customize the other alarm relay.

In addition, a selection to recall or clear warnings is available. Access as follows:

1. Press the

a. Press

MENU key. ALARMS will be displayed.

ENTER to select ALARMS. The resulting screen will display AL1 (or AL2)

along with the alarm set point (HI or LO), SA (System Alarm), or SW (System

Warning).

2. Scroll through the options. When the appropriate option is displayed, press

• RECALL WARNINGS—Momentarily shows all active warnings then displays

DONE.

• CLEAR WARNINGS—Clears all resolved warnings then momentarily displays

OK.

ENTER.

3. Press

EXIT twice when done.

5.2.3 Set the recorder output span

This menu allows the Recorder Output High and Low limits to be set and also offers the

capability to use the ON SYSTEM ALARM option to communicate an alarm condition.

Use ON SYSTEM ALARM to send a signal to the control room using the recorder output,

to drive any device being controlled to full off, or to maintain the present level if the

analyzer goes into System Alarm status and shuts off.

The CL17 is supplied with the recorder output set at maximum range. At maximum range,

a chlorine concentration of 0 mg/L provides an output of 4 mA and a concentration of 5

mg/L gives an output of 20 mA. The output span can be adjusted to bracket any portion

of the 0–5 mg/L range with the

4–20mA signal. For instance, this function can be used to bracket a lower range for

increased recorder resolution.

For example: if chlorine concentration of your sample is normally 0.5–0.7 mg/L, the

recorder output span can be set for 0–1 mg/L (where 4 mA equals 0 mg/L and 20 mA

equals 1 mg/L).

Alternatively, the output can be bracketed between 2–4 mg/L to control chemical feeds, or

the signal can be inverted by assigning a higher mg/L reading for REC LO and a lower

mg/L reading to REC HI.

Initially, select an output span that will cover the expected range of chlorine concentration

in the sample. Determine the correct minimum and maximum values by monitoring

chlorine values in your sample over time. Adjust the minimum and maximum values if

necessary, to obtain the best span for your specific application.

34

Page 37

Operation

Adjust the recorder output minimum and maximum values using the analyzer keypad:

1. Press the

2. Scroll to

reading. Move to

3. Press

MENU key.

RECR DR menu and press ENTER. The display will show REC LO and a mg/L

REC HI or ON SYSTEM ALARM.

ENTER to change the displayed mg/L reading for REC LO or REC HI. The digit

to be changed will flash.

4. Change the digit or move to another digit. Appropriate values and selections are

shown below. When the value is correct, press

•REC LO—0.0 mg/L to 5.0 mg/L limits.

•REC HI— 0.0 mg/L to 5.0 mg/L limits.

• ON SYSTEM ALARM—Select minimum, maximum, or hold to define the recorder

output when a system alarm is initiated.

5. Press

EXIT to return to the main menu. Press EXIT again to return to normal

operation.

5.2.3.1 Change to 0 to 20 mA output range

Set the lower end of the output range to 0 mA instead of 4 mA as follows:

1. Press the

2. Scroll to

Note: A large number may be displayed for the minimum value, this number refers to counts, not

milliamps. Proceed with step 4.

MENU key then scroll to the SETUP menu. Press ENTER.

REC ADJUST and press ENTER.

ENTER to accept.

3. Adjust the displayed value to 0. Press ENTER to accept the value. Press EXIT twice to

return to normal operation.

5.2.4 Maintenance menus

The following selections allow the user to perform standard maintenance tasks. Use the

ARROW keys to scroll through the menu selections, then press ENTER to select the

displayed menu option.

•PRIME—This feature causes the analyzer to make 39 concurrent accelerated cycles

to prime the reagent lines. Press

analyzer will return to normal operation. To terminate the prime cycle before all 39

cycles are complete, press

•CLEAN—This feature stops the analyzer in the last portion of the measurement cycle.

Sample and reagents are left in the sample cell for cleaning purposes. The analyzer

remains in the clean mode for 60 minutes. To terminate the cycle earlier, press the

EXIT key. The analyzer will return to normal operation.

• HOLD OUTPUTS—This feature allows the alarms to be locked out and the recorder

output to be held at its present level for maintenance purposes. Activate this feature

as follows:

a. Press

b. To deactivate the feature, and return to normal operation, press the

ENTER to activate. At the end of 39 cycles, the

EXIT. The analyzer will return to normal operation.

ENTER then the UP ARROW key to activate for 60 minutes. The alarm LED

will be flashing.

then the

DOWN ARROW key until HOLD OUTPUTS is displayed.

MENU key

c. Press

d. Select

ENTER.

OFF and press ENTER again.

35

Page 38

Operation

5.3 Calibration

The CL17 Chlorine Analyzer is factory calibrated. A built-in electronic curve is

preprogrammed into the instrument. This instrument does not require recalibration

unless specified by your regulatory agency for compliance reporting purposes.

If you are required to do a two-point calibration or if your sample stream chlorine

concentration is typically less than 0.5 mg/L, follow the instructions in section 5.3.1. If

your sample stream chlorine concentration is typically greater than 0.5 mg/L, you can

perform a Calibration by Comparison as detailed in section 5.3.2.

If the calibration you perform requires you to adjust the CAL ZERO by more than 0.2

mg/L, a SYSTEM WARNING caused by a MARGINAL ZERO error will appear. Similarly,

adjusting the CAL STD by more than 10% (up or down) will produce a MARGINAL GAIN

ERROR.

If either of these errors occur, reset the instrument to the default calibration (refer to

section 5.2), check the standards, and repeat the calibration. If the error messages

persist, contact the Customer Service department.

5.3.1 Calibration on known standards

CAUTION

Chemical exposure hazard. To familiarize yourself with handling precautions,

dangers and emergency procedures, always review the M aterial Safety Data She ets

prior to handling containers, reservoirs, and delivery systems that contain

chemical reagents and standards. Protective eye wear is always recommended

when contact with chemical s is pos s ib le .

This procedure provides the best over all accuracy by establishing the zero mg/L

reference and the span setting. Perform the calibration as follows:

1. Prepare a zero chlorine reference solution by adding approximately 4 mL of Ferrous

Ammonium Sulfate, Cat. No. 181133NC, to approximately 2 liters of the normal

sample or chlorine-free demineralized water.

Note: Enter the zero value before the chlorine standard value.

2. Place a container of zero reference water above the analyzer with at least two feet of

head. Plumb the system to enable the sample flow to be shut off so the zero

reference water can enter the analyzer in its place. Allow the analyzer to run on zero

reference water for approximately 10 minutes.

3. When the readings are stable, set the zero reference.

a. Enter the

b. Press the

c. Press

d. Press

4. Prepare a chlorine standard solution with a value between 3 and 5 mg/L. Determine

the value of the standard to the nearest 0.01 mg/L.

5. Remove the container of zero reference water and substitute the chlorine standard

solution. Allow the analyzer to run on the standard solution for approximately 10

minutes.

SETUP menu.

DOWN ARROW key until CAL ZERO is displayed.

ENTER to display the current measured value.

ENTER to force the value to zero.

36

6. When the readings are stable, enter the

7. Press

ENTER when CAL STD is displayed. The current measured value is displayed.

SETUP menu.

Page 39

8. Press ENTER and edit the value. Press ENTER again to accept the value.The

measured value will be forced to the entered value. Press the

return to normal display mode.

9. Remove the standard and restore sample flow to the analyzer. The instrument is now

calibrated.

5.3.2 Calibration by comparison

Note: Make sure sample chlorine concentration is relatively stable before taking a grab sample for

laboratory analysis. Perform the laboratory analysis as quickly as possible.

Calibration by comparison involves analyzing the sample stream with a reliable, accurate

laboratory method, such as a DPD spectrophotometric or amperometric titration method

then setting the analyzer to match. Accuracy specifications over the full 0 to 5 mg/L range

cannot be assured unless the sample chlorine concentration used for calibration is

greater than 3.0 mg/L. Setting the calibration at a lower concentration may provide

accuracy at that point but can cause large errors in other portions of the span.

Perform a calibration by comparison as follows:

1. When the sample chlorine concentration is relatively stable, obtain a grab sample for

analysis.

2. Perform a laboratory analysis (DPD spectophotometric or amperometric titration

method) on the grab sample and record the value.

Operation

EXIT key three times to

3. Enter the

4. Press

5. Press

ENTER when CAL STD is displayed. The current measured value is displayed.

ENTER and edit the value to match the value from the laboratory analysis.

Press

ENTER again to accept the value. The measured value will be forced to the

entered value.

6. Press the

SETUP.

EXIT key three times to return to normal display mode.

37

Page 40

Operation

38

Page 41

Section 6 Maintenance

DANGER

Multiple hazards. Only qualified personnel should conduct the tasks described in

this section of the manual.

CAUTION

Chemical exposure hazard. To familiarize yourself with handling precautions,

dangers and emergency procedures, always re view the Materia l Safe ty Data Sheets

prior to handling containers, reservoirs, and delivery systems that contain

chemical reagents and standards. Protective eye wear is always recommended

when contact with chemicals is possible.

6.1 Scheduled maintenance

6.1.1 Replenish the reagents

One 500-mL bottle each of buffer and indicator solution lasts approximately one month.

Discard the old containers with any unused contents and install the new bottles as

described in section 4.1 on page 27.

6.1.2 Replace the pump tubing

Over a period of time, the clamping action of the pump/valve module will soften the tubing

and cause it to collapse and obstruct liquid flow. This breakdown is accelerated at high

temperatures. The following replacement schedules, based on ambient operating

temperature, are recommended:

• Below 27 °C (80 °F), replace at six-month intervals.

• Above 27 °C, replace at three-month intervals.

Pump tube replacement procedure:

1. Shut off sample flow to the instrument and set the POWER (I/O) switch to OFF (O).

2. Remove the screws securing the pinch plate to the pump/valve module. Refer to

section 3.9 on page 24. Loosen in small increments, moving from one screw to the

other to allow tension to be relieved evenly. Remove the plate.

3. Disconnect the pump tubes from the inlet and outlet fittings and discard the tube

assemblies.

4. Cut four 2-inch lengths of 1/16-inch ID tubing (white). Install one 1/16-to 1/8-barb

elbow fittings in one of the 1/16-inch ID tubes (white) and 1/16-inch barb union fittings

in the three remaining tubes. Although one of the pump tubes is not used for fluid

flow, it must be included to provide even compression on all four tubes.

5. Install the two screws through the pinch plate and into the pump/valve module. When

securing the pinch plate, advance the screws in small increments moving from one

screw to the other so that the plate is drawn down evenly. Tighten until snug, do not

overtighten.

6. Set the POWER (I/O) switch to ON (I) and restore sample flow through the

instrument. Allow the instrument to run for approximately one hour to fill the reagent

lines.

39

Page 42

Maintenance

6.1.3 Replace the analyzer tubing

Remaining tubing in the analyzer should be replaced annually.

The maintenance kit is available with the tubing harnesses assembled (6868800) or

unassembled (6868900) If you have ordered the unassembled maintenance kit, use

Figure 21 and Table 7 on page 41 to determine the tubing lengths and positions.

When installing new tubing it is helpful to dip the ends in hot water before making the

connections. It also is recommended that one tube at time be removed and replaced.

Numbers on the illustration correspond to the item numbers listed in the legend where the

size, catalog number, and quantity also are given. The length given in Table 7 tells how

long that particular tubing segment at a time should be; the operator must cut a piece to

that length from a coil of the proper tubing.

The catalog number given for the tubing in the legend identifies the coil of tubing to cut

the segment from and not the number of the segment itself.

DPD Reagent tubing may darken before the scheduled replacement time but that will not

affect the performance of the instrument.

Table 8 gives information about the air purge, case drain, sample drain, and sample-in

specifications and locations. Refer to Figure 21.

40

Figure 21 Plumbing diagram

Page 43

Maintenance

Table 7 Replacement Tubing Lengths for Figure 21

Item Description Length (Qty) From... To... Item Number

11/8"

2 1/32" ID, 3/32" OD 7.0 inches (2) Pump Body Out Y-Fitting 44253-00

3 1/16" ID, 3/32" OD 2.0 inches (4) Pump Body In Pump Body Out 42717-00

4 0.062 ID, 0.125" OD 6.0 inches (2) Reagent Bottle Cap Pump Body In 42076-00

5 0.062" ID, 0.125" OD 6.0 inches (2) Reagent Bottle Cap Reagent Vent Fitting 42076-00

6 1/32" ID, 3/32" OD 7.0 inches (2) Reagent Bottle Bottom Reagent Bottle Cap 45524-00

7 1/8" ID, 1/4" OD 7.0 inches (1) Sample Bypass Tee Pump Body In 43293-00

8 1/8" ID, 1/4" OD 1.5 inches Sample Bypass Tee Sample Inlet Fitting 43293-00

9 1/4" OD x 0.04 W, Black varies (1) Sample Conditioning Out Case Fitting 30616-00

10 1/2"

11 1/32"

12 1/32" ID, 3/32" OD 1.0 inch (1) Y-Fitting Colorimeter 44253-00

13 0.500” ID, 11/16” OD 12 inches Colorimeter Drain Fitting 54108-00

ID, 1/4" OD 4.5 inches (1) Pump Body Out Colorimeter 43293-00

ID varies (1) Instrument Drain Customer Drain (not supplied)

ID, 3/32" OD 3 inches Sample Bypass Tee Drain fitting 44253-00

Table 8 Drain, air purge, sample-in, and enclosure locations

A Air purge, 0.01 CFM at 20 PSIG max, ¼ in. O.D. tube

B Case drain, ½ in. I.D. tube

C Sample drain, ½ in. I.D. tube

D Sample in, 5 PSIG max, ¼ in. O.D. tube

EEnclosure

6.2 Unscheduled maintenance

6.2.1 Fuse replacement

The T, 2.5A, 250V fuse used in this instrument is used for both 115V and 230V operation.

DANGER

Electrocution hazard. Remove power from the instrument when removing or

installing a fuse.

DANGER

Fire hazard. For continued protection against fire, replace the fuse only with a fuse

of the same type and rating.

Fuse replacement procedure:

1. Make sure there is no power supplied to the instrument. the instrument power switch

does not remove power from the fuses, Power must be disconnected remotely to

remove power from the fuses.

2. Remove the customer access cover.

3. Locate the fuse holders (near the terminal strip in the customer wiring compartment).

Refer to Figure 13 on page 22.

4. Remove the two fuses (F1 and F2) and replace them with two new fuses with the

same specifications (T, 2.5A, 250V). Refer to Parts and accessories on page 49.

5. Reinstall the customer access cover and resupply power.

41

Page 44

Maintenance

6.2.2 Clean the instrument enclosure

With the enclosure securely latched, use a soft cloth and a mild detergent to wipe the

outside of the enclosure. Do not allow moisture to enter the enclosure.

6.2.3 Clean the colorimeter

The colorimeter measuring cell may collect sediment or develop a film growth on the

inside walls. Cleaning with an acid solution and a cotton swab on a monthly basis is

recommended. Depending on sample conditions, it may be necessary to clean the cell

more often.

CAUTION

Chemical exposure hazard. The chemicals used in this procedure may be

hazardous if inappropriately handled or accidentally misused. Please read all

warnings on the reagent labels. Protective eye wear is always recommended when

contact with chemicals is possible.

Colorimeter cell cleaning procedure:

1. Press the

appears. Press

2. Press the down

MENU key, then press the down ARROW key until the MAINT menu

ENTER.

ARROW key to scroll to the CLEAN option. Press ENTER.

3. Refer to Figure 22 and locate the colorimeter.

4. Remove the rubber plug on the top of the colorimeter assembly.

5. Remove the magnetic stir bar using a bent steel paper clip as a retrieval tool. Refer

to Figure 22.

6. Wait until

CLEAN flashes on the status line of the display, then fill the colorimeter with

19.2 N Sulfuric Acid Standard Solution (203832).

Note: Lower normality sulfuric acid will NOT be sufficient for cleaning the colorimeter.

7. Allow the sulfuric acid to stand in the colorimeter for 15 minutes.

8. Insert a wooden or paper cotton-tipped swab

*

into the opening and move it up and

down with a gentle scrubbing action, cleaning the interior surfaces of the colorimeter

cell. Clean the stir bar with the cotton swab (Figure 23).

9. Install the stir bar.

10. Replace the rubber plug on the top of the colorimeter assembly and make sure the

cover is on the viewing port of the colorimeter.

11. Press the

EXIT key to immediately return to normal operation; the instrument will

return to normal operation automatically after 60 minutes.

*

Do not use a plastic swab when cleaning the colorimeter with sulfuric acid. The the acid will dissolve the plastic.

42

Page 45

Maintenance

Figure 22 Removing the stir bar

1 Remove the plug from the top hole of the colorimeter. 3 Colorimeter assembly

2 Gently insert a straightened paper clip into the hole at