Page 1

Catalog Number 8544

Sigma 900 Composite Sampler

INSTRUMENT MANUAL

© Hach Company, 2003. All rights reserved. Printed in the U.S.A. eac 07/03 2ed

Page 2

Visit http: //www.hach.com

Page 3

Table of Contents

Section 1 Specifications..................................................................................................................................... 5

Section 2 General Information.......................................................................................................................... 7

2.1 Instrument Description ........................................................................................................................................ 7

2.2 Interface Connectors........................................................................................................................................... 7

2.2.1 Receptacle Caps ....................................................................................................................................... 7

2.3 Front Panel .......................................................................................................................................................... 8

2.3.1 Keypad and Display................................................................................................................................... 8

2.3.2 Humidity Indicator ...................................................................................................................................... 8

2.4 Safety Information ............................................................................................................................................... 9

2.4.1 Use of Hazard Information....................................................................................................................... 10

2.4.2 Precautionary Labels............................................................................................................................... 10

2.4.3 Hazardous Locations ............................................................................................................................... 10

2.4.4 Confined Space Entry ............................................................................................................................. 11

2.4.5 Definition of Confined Space ................................................................................................................... 12

Section 3 Installation......................................................................................................................................... 13

3.1 Unpacking the Instrument ................................................................................................................................. 13

3.2 Selecting the Installation Site ............................................................................................................................ 13

3.3 Mounting the Sampler ....................................................................................................................................... 14

3.4 Attaching the Intake Line................................................................................................................................... 14

3.4.1 Vinyl Intake Tubing................................................................................................................................... 14

3.4.2 Teflon-Lined Polyethylene Intake Line ..................................................................................................... 14

3.5 Setting Up the Intake Line and Strainer ............................................................................................................ 15

3.6 Choosing Bottles ............................................................................................................................................... 15

3.7 Installing the Full Bottle Shut-Off ...................................................................................................................... 15

3.8 Power Connections ........................................................................................................................................... 16

3.9 12 V dc.............................................................................................................................................................. 17

3.10 Auxiliary Connection ....................................................................................................................................... 17

Section 4 Operation........................................................................................................................................... 21

4.1 Keypad and Key Functions................................................................................................................................ 21

4.2 Tips and Techniques for Programming the Instrument ..................................................................................... 22

4.3 Setting the Time and Date ................................................................................................................................ 23

4.4 Bottle Setup Mode ............................................................................................................................................ 23

4.5 Explanations of Program Messages ................................................................................................................. 24

4.6 Data Logging..................................................................................................................................................... 25

4.7 Manual Mode .................................................................................................................................................... 25

4.7.1 Manually Operating the Sample Pump .................................................................................................... 25

4.8 Measurements Triggered by Liquid Levels or Flow........................................................................................... 26

4.9 Programming the Sampler for Level Control ..................................................................................................... 27

4.10 Other Displayed Messages ............................................................................................................................. 27

4.11 Flow Proportional Operation ........................................................................................................................... 28

4.11.1 How to Calculate Pulses/Counts ........................................................................................................... 28

Page 3

8544TOC.fm Table of Contents

Page 4

Table of Contents

Section 5 Maintenance ..................................................................................................................................... 33

5.1 Cleaning the Sampler ....................................................................................................................................... 33

5.1.1 Cleaning the Sampler Housing................................................................................................................ 33

5.1.2 Cleaning the Sample Bottles ................................................................................................................... 33

5.1.3 Cleaning the Intake Tubing and Pump Tubing ......................................................................................... 33

5.1.4 No Lubrication Required .......................................................................................................................... 33

5.2 Pump Tubing Maintenance................................................................................................................................ 33

5.3 Upgrades, Repairs, General Maintenance ........................................................................................................ 33

5.4 Electrostatic Discharge (ESD) Considerations.................................................................................................. 33

5.5 Internal Maintenance Items............................................................................................................................... 33

5.6 Removing and Opening the Controller.............................................................................................................. 33

5.7 Re-installing the Bottom Panel.......................................................................................................................... 34

5.8 Internal Desiccant Module ................................................................................................................................ 35

5.9 Circuit Board Identification ............................................................................................................................... 35

5.10 Motor/Gear Box............................................................................................................................................... 36

5.11 Internal Case Humidity Indicator..................................................................................................................... 36

5.12 Internal Case Humidity Indicator..................................................................................................................... 36

5.13 Memory Battery .............................................................................................................................................. 36

Section 6 Contact Information for U.S.A. & Outside Europe................................................................... 37

Section 7 Contact Information for Europe ................................................................................................... 38

Section 8 Limited Warranty ............................................................................................................................. 39

Section 9 Parts and Accessories................................................................................................................... 41

Appendix A Programming Flow Chart ................................................................................................................. 43

Program Flow Chart ......................................................................................................................................... 43

Appendix B Batteries and Chargers .................................................................................................................... 45

Lead-Acid (Gel Cell) Batteries .......................................................................................................................... 45

Nickel-Cadmium Batteries ................................................................................................................................ 46

Appendix C Exploded View Drawings ................................................................................................................. 47

Exploded View (1 of 6) ..................................................................................................................................... 47

Exploded View (2 of 6) ..................................................................................................................................... 48

Exploded View (3 of 6) ..................................................................................................................................... 49

Exploded View (4 of 6) ..................................................................................................................................... 50

Exploded View (5 of 6) ..................................................................................................................................... 51

Exploded View (6 of 6) ..................................................................................................................................... 52

Page 4

Table of Contents

8544TOC.fm

Page 5

Section 1 Specifications

Specifications are subject to change without notice.

Controller Dimensions

Pump/Controller Housing

Sample Pump

Pump Body Impact/corrosion resistant, glass reinforced Delrin

Vertical Lift

Sample Transport Velocity 61 mm/sec. (2 ft/sec.) minimum, at 4.6 m (15 ft) vertical lift in a 3/8 in. ID intake tube

Pump Flow Rate 60 mL/sec at 0.91 m (3 ft) vertical lift in a 3/8 in. ID intake tube

Sample Volume Programmed in milliliters, in one mL increments from 10 to 9999 mL

Sample Volume Repeatability

Sampling Modes Supports 1 bottle. Composite Time, Composite Flow, and Level Actuation

Interval Between Samples

Intake Purge

Control Panel

Height: 34 cm (13.5 in.), Width 28 cm (11 in.), Depth 20.3 cm (8 in.) without wall

bracket, 33 cm (13 in.) deep with wall bracket

High impact injection molded ABS: submersible, watertight, dust tight, corrosion

and ice resistant; NEMA 4X, 6

High speed peristaltic, dual roller, with 9.53 ID x 15.9 mm OD (3/8 in. x 5/8 in.)

medical grade silicone rubber pump tube.

8.23 m (27 ft) maximum. Remote pump option recommended for lifts from 6.7 to

10.7 m (22 to 35 ft)

From 0.3 to 6.7 m (1 to 22 ft) vertical lift +/-5 mL typical for a 100 mL sample (+/5%)

Selectable in single increments from 1 to 9999 flow pulses (momentary contact

closure 25 msec. or 5-12 V dc pulse; 4-20 mA interface optional), or 1 to 9999

minutes in one minute increments.

Air purged automatically before and after each sample; duration automatically

compensated for varying intake line lengths.

18 key, 31 function membrane switch keypad with 18 character alphanumeric, liquid

crystal display. Self prompting/menu driven program.

Internal Clock Indicated real time and date; 0.007% time base accuracy

Programmable Delay Programmable sampler start time/date

Manual Sample Initiates a sample collection independent of program process

Records program start time and date, stores up to 400 sample collection

Data Logging

Automatic Shutdown

Intake Tubing

Intake Strainers

Power Requirements

ac Power Backup

Internal Battery

Overload Protection 5 amp dc line fuse; ac power pack; internal 1 amp ac line fuse

Temperature Range

times/dates, all program entries, operational status including number of minutes or

pulses to next sample, bottle number, number of samples collected, number

remaining, sample identification number.

Composite Mode: After preset number of samples have been delivered to

composite container, from 1 to 9999 samples, or upon full container.

6.4 mm (1/4 in.) and 9.5 mm (3/8 in.) ID vinyl to 9.5 mm (3/8 in.) ID Teflon-lined

polyethylene with protective outer cover

Choice of Teflon and 316 stainless construction, and all 316 stainless steel in

standard size and low profile for shallow depth applications

12 V dc-supplied by optional ac power converter or battery. Average current draw

with pump running: 2.25 amps dc, without pump running: 4 mA dc

Rechargeable 6 amp-hour gel lead acid battery takes over automatically with ac

line power failure. Integral trickle charger maintains battery at full charge

1.5 V dc lithium battery; maintains program logic and real time clock for five years.

Internal battery current draws less than 40 micro amps

General use: 0° to 50° C (32° to 122° F). LCD display operated from –10° to 70° C;

Storage –40° to 80° C

Page 5

8544specs.fm Specifications

Page 6

Visit http: //www.hach.com

Page 7

Section 2 General Information

2.1 Instrument Description

The instrument is designed to automatically collect and preserve samples

from a liquid source. The sampler is suitable for collection of conventional and

toxic pollutants and suspended solids.

The sampler collects samples on either a timed cycle basis, or in proportion to

flow when used in conjunction with a flow meter (flow meter connected to the

auxiliary connector). In the timed cycle mode, the interval between samples is

controlled by an integral quartz crystal clock. The sample interval may be set

from 1 to 9999 minutes, in one minute increments.

In the flow proportional mode, via an external flow meter, the interval between

samples may be set from 1 to 9999 flow pulses, in one pulse increments.

where each pulse represents a specific flow volume interval.

The number of minutes or flow intervals remaining unit the next sample is

shown on the control display. The program can be delayed by entering the

desired starting time and date on the sampler keypad.

The sampler utilizes a high speed peristaltic pump, for collection of the

sample liquid. The pump body is constructed of impact and corrosion

resistant plastic. Tubing is held firmly in place by the pump body haves-no

clamps are required. The intake line is air purged before and after each

sample. The duration of the pre and post sample purge automatically

compensates for different intake line lengths. The pump tubing is 0.95 cm

(3/8

in.) ID X 0.32 cm (1/8 in.) wall medical grade silicone rubber. Although

the pump is capable of vertical lifts up to 8.2 m (27 ft), lifts greater than 6.7 m

(22 ft) are not recommended unless the Remote Pump option is utilized. The

pump produces a sample transport velocity of 1 mps (3.3 fps) at 1 m (3 ft)

vertical lift. The sample is under pumped flow at all times from the source

stream to the sample container, thereby keeping solids in suspension.

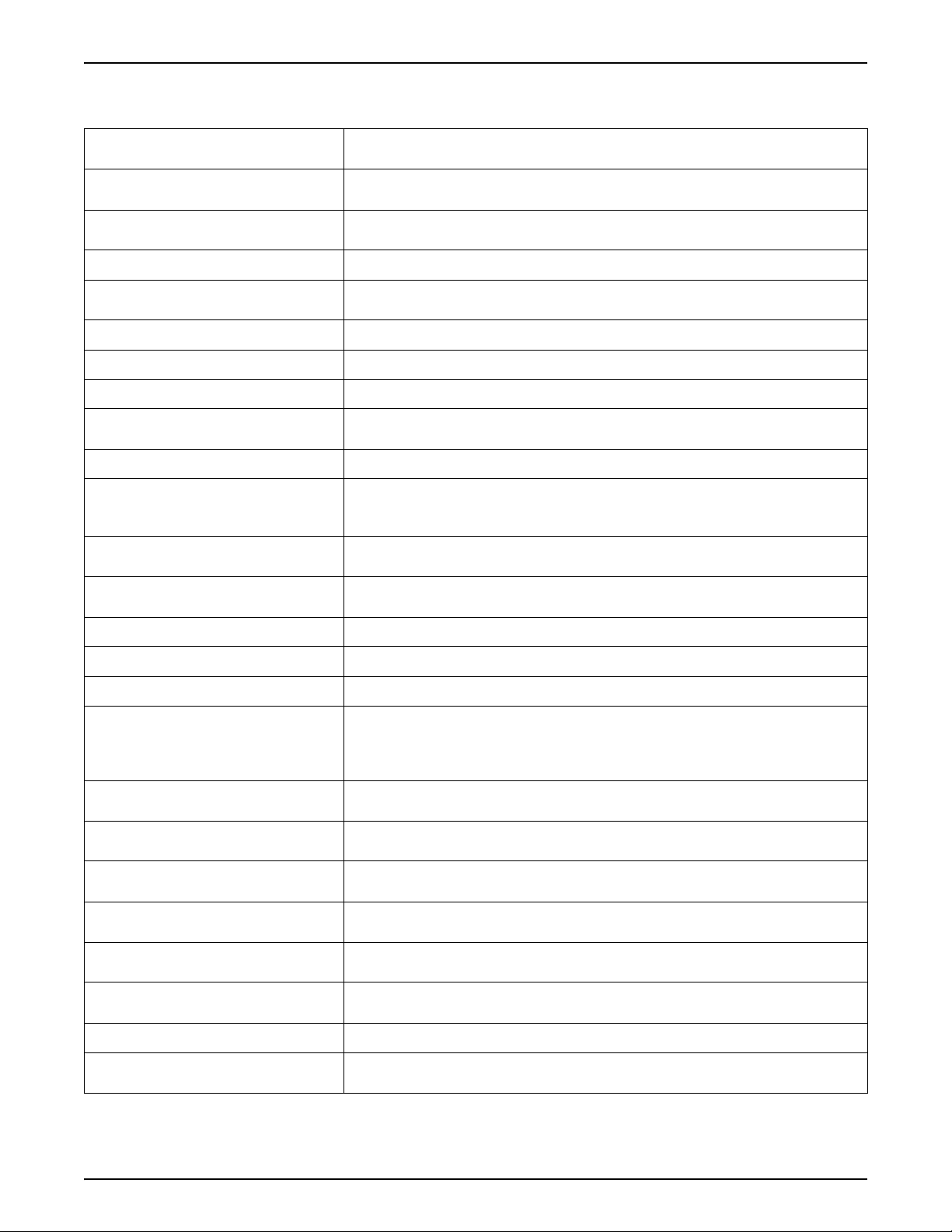

2.2 Interface Connectors

2.2.1 Receptacle Caps

The interface connectors are located on the left side of the controller housing.

The sampler comes standard with two interface receptacles:

• 12 V dc (Power Input)

• Auxiliary (Multi-purpose input/output port)

Interface receptacles are covered with push-on receptacle caps. These caps

protect the connector pins from dirt and moisture and should be attached to

any receptacle not in use.

Page 7

8544intro.fm General Information

Page 8

Section 2

Figure 1 Interface Connectors

1

2

1. 12 V dc 2. Auxiliary

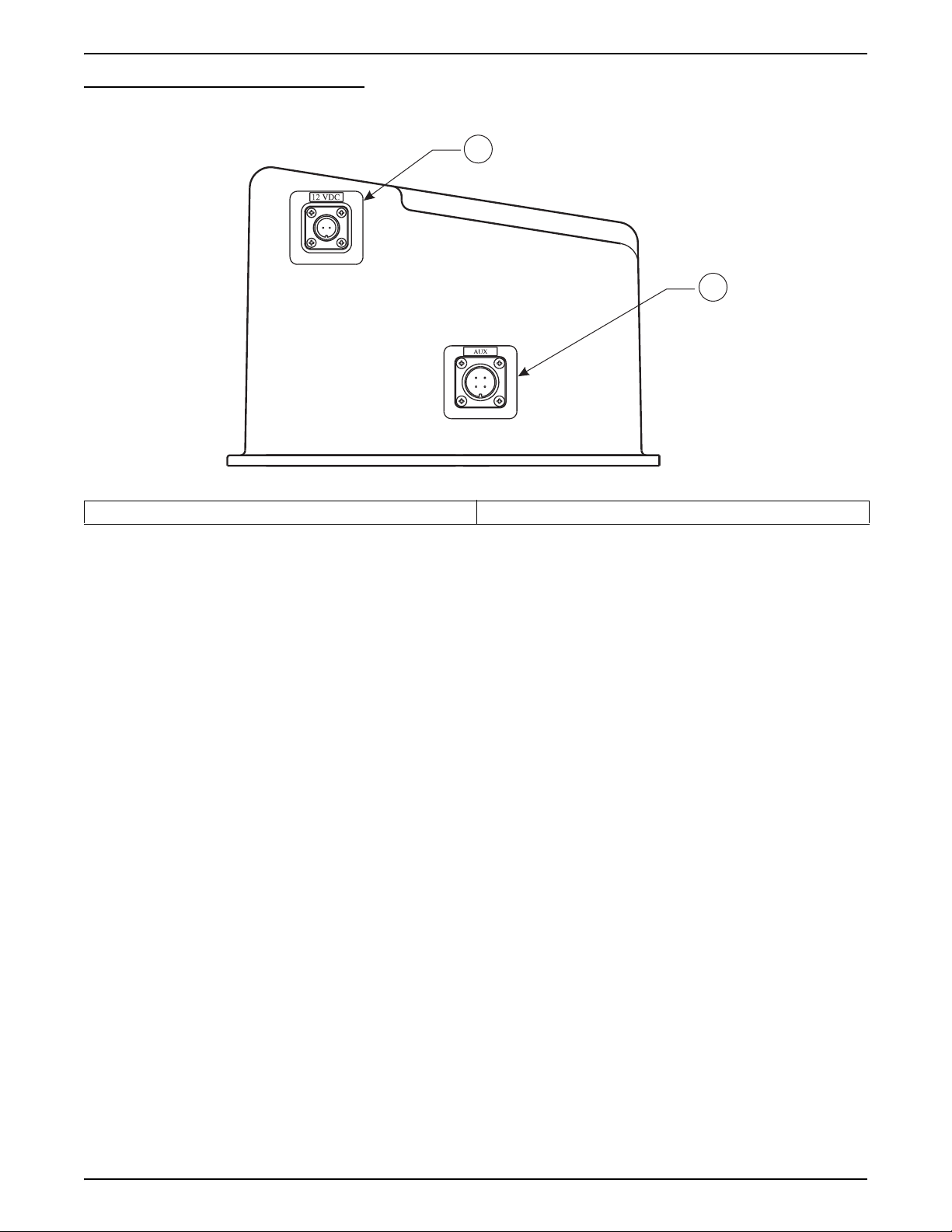

2.3 Front Panel

The front panel consists of the keypad, liquid crystal display, and the internal

case humidity indicator (

2.3.1 Keypad and Display

The sampler controller is equipped with a 24 character alphanumeric liquid

crystal display which automatically steps the user through the program

settings.

2.3.2 Humidity Indicator

The internal case humidity indicator (Cat. No. 2660) turns pink when the

internal case humidity exceeds 60 percent.

The sampler is equipped with an internal desiccant module (Cat. No. 8849) to

absorb any humidity trapped in the case during final assembly. Under normal

operating conditions, this desiccant provides long-term protection against

condensed moisture inside the case.

Replacement of the internal desiccant module is only necessary if the

indicator turns pink. See to

Figure 2).

section 5.8 on page 35 for details.

Page 8

Front Panel

8544intro.fm

Page 9

Figure 2 900 Composite Sampler

Section 2

1

7

6

2

3

4

5

1. Function Key 5. Power On Indicator LED

2. Peristaltic Pump 6. Desiccant Indicator

3. Peristaltic Pump Tubing 7. 24-character Alphanumeric Liquid Crystal Display

4. Tubing Clamp

2.4 Safety Information

Please read this entire manual before unpacking, setting up, or operating this

instrument.

Pay particular attention to all danger and caution statements. Failure to do so

could result in serious injury to the operator or

To ensure the protection provided by this equipment is not impaired, do not

use or install this equipment in any manner other than that which is specified

in this manual.

damage to the equipment.

Page 9

8544intro.fm Safety Information

Page 10

Section 2

2.4.1 Use of Hazard Information

If multiple hazards exist, this manual will use the signal word (Danger,

Caution, Note) corresponding to the greatest

DANGER

Indicates a potentially or imminently hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION

Indicates a potentially hazardous situation that may result in minor or moderate injury.

NOTE

Information that requires special emphasis.

2.4.2 Precautionary Labels

This symbol, if noted on the instrument, references the instruction manual for operation

and/or

safety information.

Read all labels and tags attached to the instrument. Personal injury or

damage to the instrument could occur if not

hazard.

observed.

This symbol, when noted on a product enclosure or barrier, indicates that a risk of electrical shock

and/or electrocution exists and indicates that only individuals qualified to work with hazardous voltages

should open the enclosure or remove the barrier.

This symbol, when noted on the product, identifies the location of a fuse or current limiting device.

This symbol, when noted on the product, indicates that the marked item can be hot and should not be

touched without care.

This symbol, when noted on the product, indicates the presence of devices sensitive to Electro-static

Discharge and indicates that care must be taken to prevent damage to them.

This symbol, when noted on the product, identifies a risk of chemical harm and indicates that only

individuals qualified and trained to work with chemicals should handle chemicals or perform

maintenance on chemical delivery systems associated with the equipment.

This symbol, if noted on the product, indicates the need for protective eye wear.

This symbol, when noted on the product, identifies the location of the connection for Protective Earth

(ground).

2.4.3 Hazardous Locations

The 900 Composite Sampler is not approved for use in hazardous locations

as defined in the National Electrical Code.

Page 10

Safety Information

DANGER

Although some Hach products are designed and certified for installation in

hazardous locations as defined by the National Electrical Code, many Hach

products are not suitable for use in hazardous locations. It is the responsibility

of the individuals who are installing the products in hazardous locations to

determine the acceptability of the product for the environment. Additionally, to

ensure safety, the installation of instrumentation in hazardous locations must be

per the manufacturer's control drawing specifications. Any modification to the

instrumentation or the installation is not recommended and may result in life

threatening injury and/or damage to facilities.

8544intro.fm

Page 11

Section 2

DANGER

Bien que certains produits Hach soient conçus et certifiés pour être installés

dans des endroits dangereux tels que définis par le National Electric Code, de

nombreux produits Hach ne conviennent pas pour de tels endroits. Il relève de la

responsabilité des personnes qui placent les produits dans des endroits

dangereux de déterminer s'ils sont adaptés à cet environnement. En outre, à des

fins de sécurité, le placement de machines dans des endroits dangereux doit

s'effectuer dans le respect des consignes des schémas de contrôle du fabricant.

Toute modification apportée aux machines ou tout déplacement de celles-ci est

déconseillé, car susceptible de provoquer des accidents matériels et/ou

corporels.

PELIGRO

Aunque algunos productos Hach están diseñados y homologados para su

instalación en entornos peligrosos, entendidos éstos conforme a la definición

del “National Electrical Code” (Reglamento Eléctrico Nacional), muchos de los

productos Hach no son aptos para su utilización en lugares peligrosos. Es

responsabilidad de quienes instalen los productos en entornos peligrosos el

asegurarse de la idoneidad de dichos productos para este tipo de entorno.

Además, para garantizar la seguridad, la instalación de los instrumentos en

lugares peligrosos deberá realizarse conforme a las especificaciones del plano

del fabricante. Se desaconseja cualquier modificación de los instrumentos o de

la instalación, ya que podría provocar lesiones corporales graves, e incluso

fatales, y/o daños materiales a los equipos.

2.4.4 Confined Space Entry

GEFAHR

Einige Hach-Produkte sind für den Einbau in explosionsgefährdeten Bereichen

gemäß den Festlegungen des National Electrical Code speziell geprüft und

zugelassen. Dies gilt jedoch keineswegs für das gesamte Hach-Produktangebot.

Die Entscheidung, ob ein Produkt für den Einsatz in explosionsgefährden

Bereichen geeignet ist oder nicht, bleibt in die Verantwortung des jeweiligen

Installateurs gestellt. Im Interesse der Sicherheit ist es zudem erforderlich, dass

ein etwaiger Einbau des Geräts in explosionsgefährdeten Bereichen genau nach

den Steuerungsanlagen-Zeichnungen des Herstellers erfolgt. Von der Vornahme

von Änderungen an meß- bzw. regeltechnischen Geräten bzw. abweichender

Installation wird dringend abgeraten, da hierdurch lebensbedrohliche Personenund/oder Sachschäden verursacht werden können!

PERICOLO

Nonostante alcuni prodotti Hach, siano predisposti e certificati per

l'installazione in ambienti pericolosi, come previsto dal Codice Normativo

Nazionale che concerne l'elettricità, è sconsigliabile utilizzare prodotti Hach in

ambienti considerati pericolosi. E' diretta responsabilità della persona che

installa lo strumento in un luogo ritenuto “pericoloso” appurare se lo strumento

è compatibile con tale ambiente. Inoltre, per maggior sicurezza, l'installazione

dello strumento in ambienti pericolosi deve seguire le specifiche di

progettazione del produttore. Si deve evitare qualunque manomissione allo

strumento o all'installazione, tali modifiche possono rappresentare una

minaccia per la vita delle persone e creare guasti.

Important Note: The following information is provided to guide users of 900

Composite Samplers on the dangers and risks associated with entry into confined

spaces.

On April 15, 1993, OSHA's final ruling on CFR 1910.146, Permit Required

Confined Spaces, became law. This new standard directly affects more than

250,000 industrial sites in the United States and was created to protect the

health and safety of workers in confined spaces.

Page 11

8544intro.fm Safety Information

Page 12

Section 2

2.4.5 Definition of Confined Space

A Confined Space is any location or enclosure that presents or has the

immediate potential to present one or more of the following conditions:

• An atmosphere with less than 19.5% or greater than 23.5% oxygen

and/or more than 10 ppm Hydrogen Sulfide (H

• An atmosphere that may be flammable or explosive due to gases, vapors,

mists, dusts, or fibers

• Toxic materials which upon contact or inhalation, could result in injury,

impairment of health, or death

Confined spaces are not designed for human occupancy. They have restricted

entry and contain known or potential hazards.

Examples of confined spaces include manholes, stacks, pipes, vats, switch

vaults, and other similar locations.

Standard safety procedures must always be followed prior to entry into

confined spaces and/or locations where hazardous gases, vapors, mists,

dusts, or fibers may be present.

S)

2

Before entering any confined space check with your employer for procedures

related to confined space entry.

Page 12

Safety Information

8544intro.fm

Page 13

Section 3 Installation

DANGER

Only qualified personnel should conduct the installation tasks described in this

section of the manual

3.1 Unpacking the Instrument

Remove the sampler from the shipping carton and inspect it for any damage.

Contact Hach Customer Service at 1-800-227-4224 if any items are missing

or damaged.

3.2 Selecting the Installation Site

The sampler is completely self-contained and may be located indoors or

outdoors without protection, between 0 to 50 °C (32 to 120 °F). Follow the

guidelines below and

and prevent cross-contamination between samples.

• Install the sampler as close to the source as site conditions permit. This

will increase pump tube life and optimize overall sampler performance.

• Mount the sampler to a stable flat surface using the wall mounting

bracket, Cat. No. 3596 (

• Install the sampler above the sample source, with the intake tubing

sloping downward to the sample.

Figure 3 to allow complete drainage of the intake line

Figure 4).

• Make sure the tubing is free of kinks or loops.

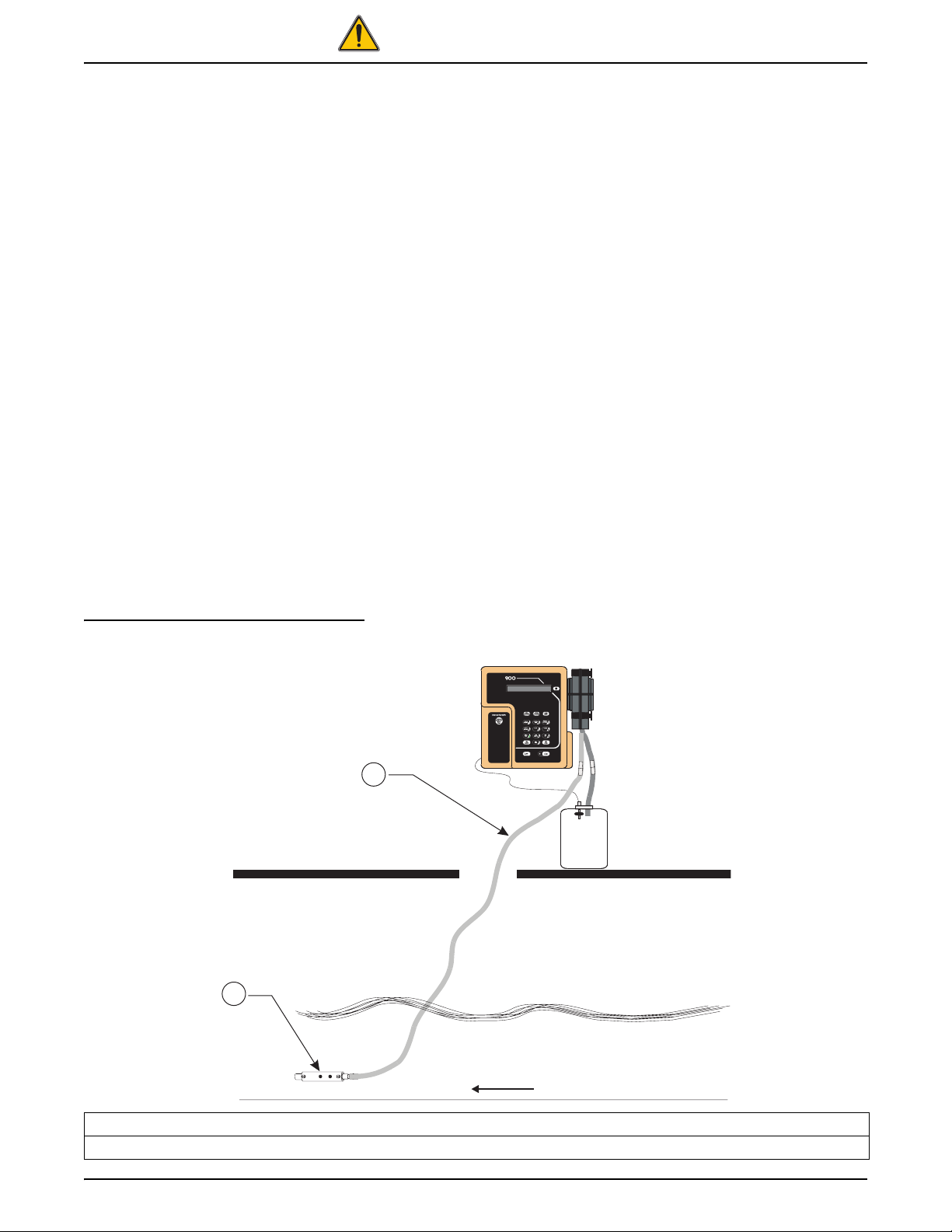

Figure 3 Placement of the Sampler

1

2

Flow

1. Slope tubing down to source (no loops, kinks, or excess tubing).

2. Locate strainer in an area of turbulent and well-mixed flow.

Page 13

8544install.fm Installation

Page 14

Section 3

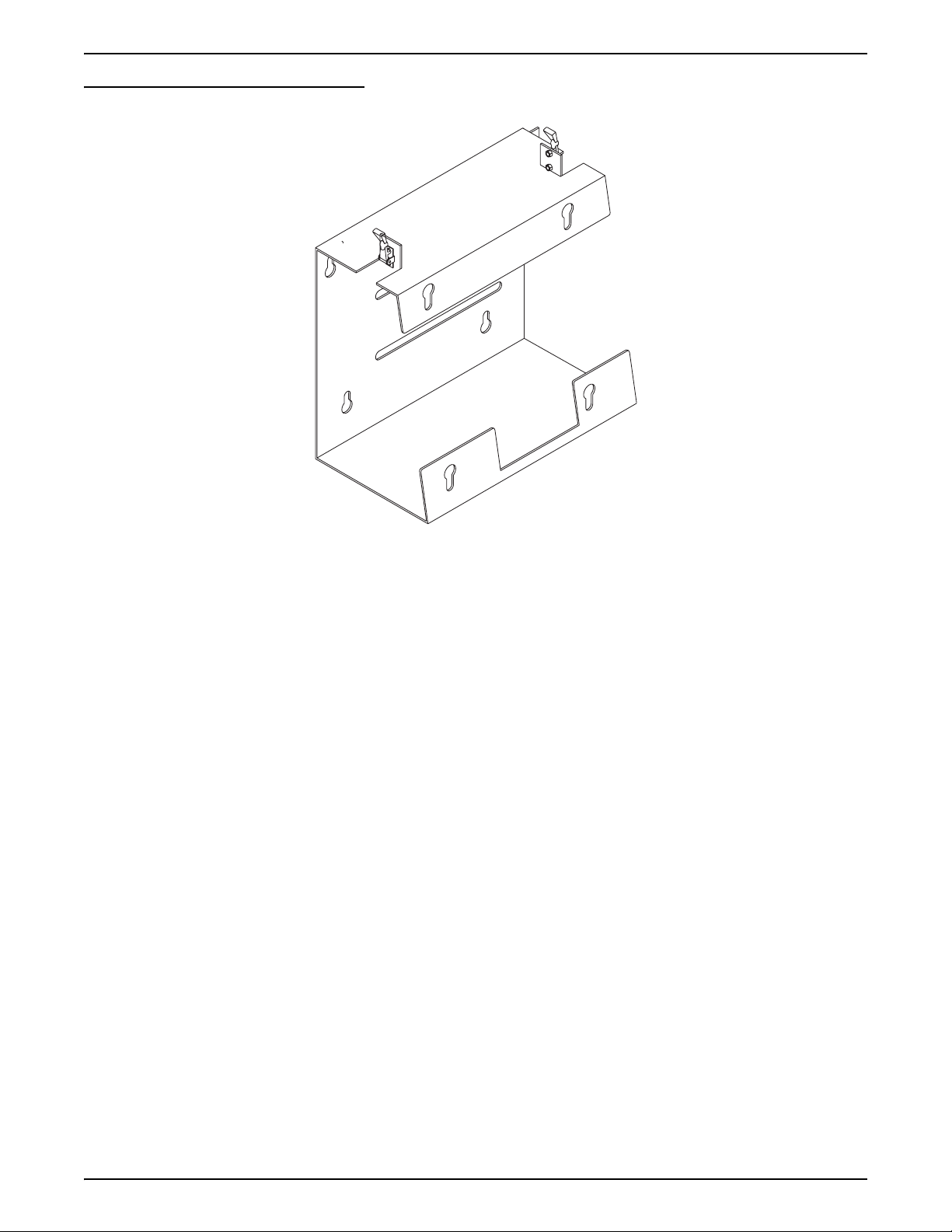

Figure 4 Wall Mount Bracket

3.3 Mounting the Sampler

Attach the wall mount bracket to a stable panel or wall (Figure 4). Mount the

bracket so the sample display and keypad are easily accessible. Mount the

sampler to the wall bracket using the four screws provided.

3.4 Attaching the Intake Line

3.4.1 Vinyl Intake Tubing

1. Push one end of the clear flexible PVC (vinyl) tube to the tapered end of

the intake strainer, until the tube is within 0.635 cm (¼ in.) of the solid

white Teflon strainer body.

2. Push the other end of the vinyl tube on to the stainless steel fitting

connector end that points away from the pump control housing.

3.4.2 Teflon-Lined Polyethylene Intake Line

The Connection Kit for Teflon-lined Tubing (Cat. No. 2186) contains two

identical assemblies, one for connecting the Teflon-lined tubing to the

stainless steel tubing connector and the other for connecting the intake

strainer.

1. Place the stainless steel hose clamp over the stainless steel fitting until it

abuts the shoulder of the tubing connector. Secure with a tubing clamp.

Page 14

Mounting the Sampler

2. Push the stainless steel fitting into the Teflon-lined tubing until it abuts the

shoulder of the stainless steel fitting.

3. Slide the stainless steel hose clamp over the silicone tubing, then push

the silicone tubing over the stainless steel fitting on the liquid sensor.

8544install.fm

Page 15

4. Slide the tubing clamp over the silicone tubing until it is over the stainless

steel fitting on the liquid sensor. Tighten to secure.

5. Repeat the procedure for the intake strainer.

3.5 Setting Up the Intake Line and Strainer

For each sampling location, the intake line should be as short as practical,

and be free of any sharp bends, coils, or loops. Install the intake line with a

downward slope from the sampler to the sample source because:

• This will assure the complete drainage of the intake line when it is air-

purged before and after each sample, and will help to prevent crosscontamination of the individual samples.

• Complete drainage is important in freezing conditions, as any liquid slugs

that remain could freeze and plug the line.

Place the sample intake and strainer in the mainstream of the sampling

source, in an area of turbulent and well-mixed flow.

Also, take in account the vertical location of the intake. A position too near the

surface may yield excess lighter materials, while a position too near the

bottom may yield excess heavy materials. The constituents of interest must

be considered when positioning the intake strainer.

Section 3

3.6 Choosing Bottles

A broad range of bottle configurations are available for the 900 Composite

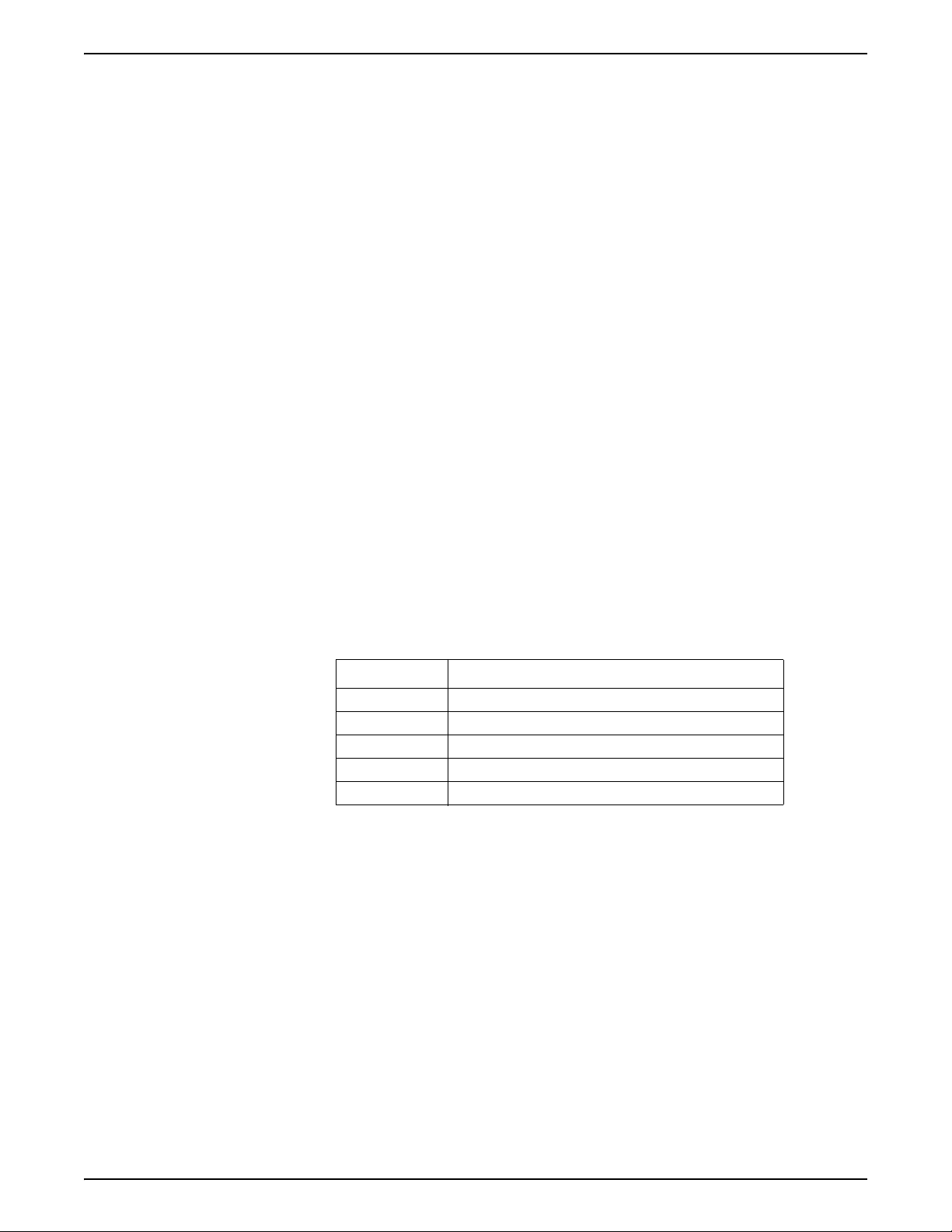

Sampler. Refer to

Size Material

9.5 L (3 gal) Polyethylene

11.4 L (2.5 gal) Glass

15.1 (4 gal) Polyethylene

20.1 L (5.5 gal) Polyethylene

22.7 L (6 gal) Polyethylene

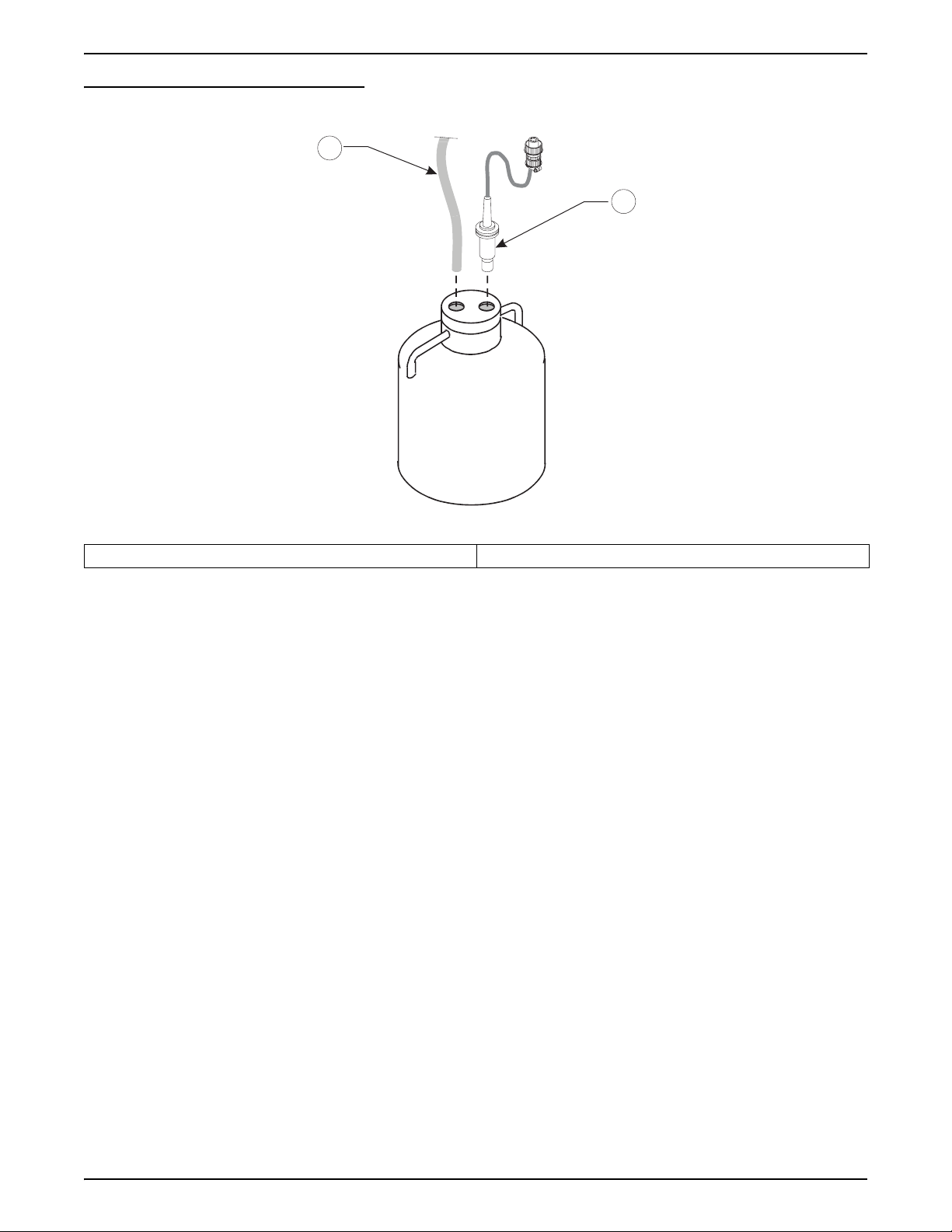

3.7 Installing the Full Bottle Shut-Off

Install the optional full bottle shut-off into the bottle cap using the attached

rubber grommet. Install the full bottle shut-off connector to the mating plug

which is attached tot he sampler back panel. Insert the sample tubing into the

cap of the bottle.

Page 15

8544install.fm Setting Up the Intake Line and Strainer

Page 16

Section 3

Figure 5 Full Bottle Shut-off

1

2

1. Sample Tubing 2. Full Bottle Shut-off

3.8 Power Connections

The sampler controller operated on 12 V dc which is supplied by an optional

ac/dc power converter and/or battery.

Note: Make sure both rubber holddowns are attached to the clips at

each end of the power supply.

The power supply (or battery) is placed in the compartment located directly

behind the controller. Pull the rubber hold-downs up and over the clips at each

end of the power supply (or battery) to hold it in place.

The short 2-pin cable on the power supply (or battery) connects the controller

receptacle labeled 12 V dc.

Batteries available from the manufacturer include a lead-acid gel battery, and

nickel-cadmium (Ni-Cad) battery (Cat. No. 1416). The 120 V ac to 12 V dc

power converter (Cat. No. 1440) includes a built-in lead-acid battery charger.

The Power Converter (Cat. No. 1443) contains a charger for Ni-Cad batteries.

230 V ac and 12 V dc power converters (Cat. No. 1441) are also available but

do not come equipped with a built-in battery charger. Stand-alone, wall mount

chargers are also available. See APPENDIX for details on batteries and

battery charging.

Important: Whenever electricity is present, there is a possibility of electrical

shock. Before connecting the sampler to an ac power source, the following

safety precautions should be taken:

Page 16

Power Connections

• Check the power source to make sure that it satisfies the ac power

requirements of the sampler.

• Make sure that all electrical installations and connections are in

accordance with national and local electrical codes.

8544install.fm

Page 17

3.9 12 V dc

Section 3

• Before performing any maintenance, disconnect the sampler from the

power source.

• Do not attempt to make any connection or otherwise handle the electrical

components of the sampler when connected to ac line power if the

immediate area is wet, or if hands or clothing are wet.

• If the circuit breaker or fuse in the ac power source is tripped, determine

the cause before restoring power to the sampler.

• Make sure the power circuit is grounded and protected with a Ground

Fault Interrupter (GFI).

This connection is for supplying power to the sampler controller electronics.

Power is normally supplied to the sampler controller electronics from either a

battery or a power supply located in the pocket directly behind the sampler

controller housing.

In the event of a power outage, an optional 12 V dc battery backup is available

(Cat. No. 1803). This power backup maintains power to the sampler when ac

power fails.

Tabl e 1 12 V dc Connector Pin Assignments

Pin Signal Description

A ground

B 12 to 17 V dc unregulated

3.10 Auxiliary Connection

The auxiliary interface connector is a general purpose input/output port. Each

signal is described in

Tabl e 2 Auxiliary Pin Assignments

Pin Signal Description Wire Color Purpose Rating

A 12 V dc White

B ground Blue

C Flow Pulse Input Ye l l o w

This pin can be used to power an external device or flow meter. Must

be used in conjunction with Pin B (ground).

Connected to dc ground and is isolated from the earth ground found

in the ac power line.

With the sampler is in Flow Proportional mode and connected to an

external flow meter, a 5 to 12 V dc input pulse lasting at least 25

milliseconds will cause the sampler to decrement one count. The

sampler is capable of accumulating from 1 to 9999 input pulses.

The 12 V dc line found on Pin A can be used directly with a simple

contact closure to Pin C or an external 5 to 12 V dc pulse may be

applied providing the ground side of the external signal is connected

to the sampler ground at Pin B. This count is actuated at the

beginning of the input signal (the leading edge of the pulse).

Tab l e 2 .

13.8 V dc

nominal

5 to 17 V dc

pulse with

duration of

at least

25 ms.

Page 17

8544install.fm 12 V dc

Page 18

Section 3

Table 2 Auxiliary Pin Assignments

Pin Signal Description Wire Color Purpose Rating

This line is held at 5 V dc inside the sampler. When shorted to

ground (Pin B), a signal is sent to the microprocessor inside the

sampler causing it to “wake up” and begin or resume the sampling

Liquid Level

D

Actuator/Auxiliary

Control Input

E Special Output Red

Program Complete

F

Output

Black

Green

program. It can be used in conjunction with a simple level float switch

to actuate the sampler when liquid id present or to take over after a

second sampler had finished its program. It may also be used with

any device (such as pH meter) which produces a dry contact output

to control the sampler in response to some user defined condition

(i.e. high or low pH); must be used in conjunction with Pin B

(ground).

Normally at 0 V dc, this line switches to 12 V dc upon any of the

selected event described in SECTION, PROGRAMMING.

Normally an open circuit, this line switches to ground for 90 seconds

at the conclusion of the sampling program. Used to “wake up”

another sampler to take over sampling or to signal an operator or

datalogger upon the completion of the sampling program.

Contact Closures

The sampler controller is capable of accumulating 1 to 9999 contact closures.

Each contact closure output from a flow meter represents a specific flow

volume.

24 V dc

(max) at

100 mA

(max)

N/A

N/A

Note: The sampler provides 12 V dc on Pin A of the Auxiliary Receptacle and this voltage is pulsed back to Pin C each time the contact closes on the external flow meter. The external flow meter must provide a dry contact closure.

Note: Older model 4–20 mA

interfaces (Cat. No. 913) require

correct loop polarity to properly

work. The newer generation

(Cat. No. 2020 series) interfaces are

not sensitive to loop polarity.

Some flow meters have an adjustable output, i.e. one contact closure for

every 100, 500, 1000, 10, 000 gallons of flow, etc., while others have a fixed

output. In either case, the contact closure signal is sent more frequently for

high flow rates, and less frequently for low flow rates. The sample frequency

will increase as the flow rate increases and likewise, will decrease as the rate

of flow decreases, thus taking samples in proportion to flow rate.

To connect the sampler to a flow meter, use Signal Cable (Cat. No. 940 or

540). To connect another brand of flow meter, use the Open-ended Signal

Cable (Cat. No. 941 or 541). A contact closure input signal corresponds to

Pins A and C on the Flow Meter/Auxiliary receptacle, and signal cable

connector. The signal cable wires are white and yellow respectively. Polarity is

not important unless the same closure signal is sent to more than one

sampler.

4–20 mA Input

An optional interface unit is available (Cat. No. 2021) which converts a

4–20 mA flow meter output into a 12 V dc pulses. At 20 mA (100% flow rate),

the interface sends ten pulses per minute; at 4 mA (0% flow rate), the

interface sends zero pulses.

The interface has a 0.9 m (3 ft) cable with connector on one end, and a 3 m

(10 ft) cable with two open wire leads on the other. Insert the connector into

the sampler receptacle labeled “AUXILIARY”, located on the left side of the

control housing. For the 3 m (10 ft) cable, the wire with clear insulation is

POSITIVE (+) and the wire with black insulation is NEGATIVE (–).

Page 18

Auxiliary Connection

8544install.fm

Page 19

Figure 6 4–20 mA Interface and Pulse Duration Input

(+)

(-)

For details on programming the sampler for flow proportional operation, refer

to SECTION.

Splitter Interface

This splitter interface (Cat. No. 939) can be used if access to more than one of

the Auxiliary Receptacle functions is required simultaneously. Connecting the

interface to the 6-pin connector on the sampler provides three additional

connectors for use. Two or more interfaces may be connected in series to

allow for as many connections as desired.

Figure 7 Splitter Interface

Section 3

To Auxillary Connector

Page 19

8544install.fm Auxiliary Connection

Page 20

Visit http: //www.hach.com

Page 21

Section 4 Operation

4.1 Keypad and Key Functions

Figure 8 shows the 18-position keypad and 24-character alphanumeric

display.

Button Function

ON Energizes Sampler

OFF De-energizes sampler and halts program in progress

Initiates the sampling program and resets all counts to zero (including datalogger).

START PROGRAM

NEW PROGRAM Allows input of new sample program...programming choices appear on display.

YES/ENTER

NO/PASS

CLEAR ENTRY

DISPLAY FEEDBACK Displays program status and a review of the program.

CHANGE/HALT

RESUME PROGRAM Causes the program to continue from the point at which it is halted.

BOTTLE ADVANCE Feature not available with this model.

PUMP (Manual Mode) Pumps sample liquid (pump forward) when held. Pump stops when released.

PURGE (Manual Mode) Purges sample liquid (pump reverse) when held. Pump stops when released.

STOP PUMP (Manual Mode)

TAKE SAMPLE Initiates sample cycle independent of program.

TIME SET Allows setting real time and date

TIME READ

* (asterisk)

When the START PROGRAM button is pressed, all recorded data (program entries and

collected sample times/dates) are erased from memory. Always download recorded data

before pressing START PROGRAM.

Causes a positive response when a question appears on display; accepts new programmed

value or previously entered value.

Causes a negative response when a question appears on display; in standby state, the

software revision number is displayed.

Erases program value shown on display; when held for two seconds, permits enable/disable

of level actuation/auxiliary control.

Stops sampler program and places in standby state. When started, press this key prior to

making any program change and before pressing keys 4, 5, 6, 7, 8, 9, and NEW PROGRAM.

Stops pump when using PUMP LOCK (see *). When held for 3 seconds (with sampler in a

standby state), permits selection of other languages.

Causes real time and date to appear on display. When held for 3 seconds, display indicated

time and date each sample was taken (or missed).

During programming, causes program to back-step. After CHANGE/HALT, allows altering of

bottle parameters (container volume, etc.). After CHANGE/HALT, provides review of

parameters (i.e. number of bottles, volume of bottle(s), line length, etc.). After PUMP/PURGE,

(manual mode) activates PUMP LOCK. Pump runs forward (KEY 5) or reverse (KEY 6)

without holding key. KEY 7 stops the pump.

Page 21

8544operations.fm Operation

Page 22

Section 4

Figure 8 Front Panel

4.2 Tips and Techniques for Programming the Instrument

• The instrument beeps each time a key is pressed.

• After the ON button is presses, the display will show one of the following

messages: "Program Halted", "Program Running", "Program Complete",

or "Ready to Start".

• The program status changes to Program Complete when sampling is

complete and there are no samples to be taken or the optional full bottle

shut-off is actuated.

• When the program is stopped (an no changes to the program settings

were made while it was stopped), pressing the

prompt to resume the previously running program (an retain all logged

data) or Start From Beginning (and clear all logged data).

• When programming the instrument, pressing the * key causes the display

to back up to the previous field.

START PROGRAM key will

Page 22

Tips and Techniques for Programming the Instrument

8544operations.fm

Page 23

4.3 Setting the Time and Date

Before programming the sampler for the first time, check the real time clock

and date settings.

Section 4

Note: When setting the time and

date, the

back up to the previously flashing

character.

* key causes the display to

1. Check the real-time clock and date settings by pressing TIME/READ. The

display will show the time and date for several seconds:

10:35 AM 24OCT00

2. If the time or date are not correct, press TIME/SET. The time and date will

appear on the display, with the hour flashing.

3. Press the appropriate numerical key(s) for the correct hour. When the

correct hour flashes on the display, press

YES. This will cause the minutes

to flash on the display.

4. Using the same procedure, select the correct minutes and press YES. The am/pm indicator will flash.

5. If the desired indicator is flashing on the display, press YES. If the desired

indicator is not flashing, press

to

flash.

NO. This will cause the other indicator

6. Press YES. The month will begin to flash. Select the correct day, month

and year using the same procedure as you used to set the time.

7. After the correct year has been entered, the display will read

"Synchronize Time-enter at Time

display will read "Clock is Now Set

". Pressing YES will start the clock. The

".

4.4 Bottle Setup Mode

When programming the sampler for the first time, you must first access the

bottle setup mode which contains set-up information such as the units for

bottle volume (milliliters and gallons) and the bottle volume.

To access the Bottle Setup Mode, the sampler must be in standby state, the

program cannot be in progress or "running". The sampler is in standby state

when the display indicated any one of the following: "Ready to Start",

"Program Complete", or "Program Halted". If the display reads "Program

Running", press the

CHANGE/HALT key. This will halt the program, thus

placing the sensor in the “Program Halted” standby state.

1. With the sampler in standby state, press the * key. The display will read “Enter units for bottle volume, milliliters?”.

2. Press NO to cause other volume units to appear. When the desired units

appear on the display, press

YES.

3. The display will show "Volume = _ _ _ _ _ mL" (or "Volume = _ _ _ _ _

Gallons

"), whichever was chosen in the previous step.

4. Enter the volume for the individual sample bottle by pressing the

numerical keys.

5. Press YES to accept the volume.

This completes the bottle setup entries and the sampler is ready to program.

Page 23

8544operations.fm Setting the Time and Date

Page 24

Section 4

4.5 Explanations of Program Messages

Item

Number

Message Description of Message

1 READY TO START Indicates that a program is ready to start. To start, press START PROGRAM.

2 PROGRAM HALTED Indicates the sampling program has been interrupted.

Indicates that a program is in process. Keys 0, 1 and 2 are the only active keys while a

3 PROGRAM RUNNING

program is running. If running, halt the program (press HALT PROGRAM) before entering

a new program.

4 PROGRAM COMPLETE

RE-ENTER PROGRAM,

5

DEPRESS *

This message is displayed after program completion. To repeat the program, press

START PROGRAM. Press NEW PROGRAM to enter a different program.

When the sampler is on, this message will appear if the sampler was turned off during

program entry.

This is the first message in the programming sequence. If selected, the sampler will

6 PROGRAM DELAY

start only after the delay period elapses. A YES response causes message 6a to appear

on the display.

6a 10:35 AM 21JUL03

A time and date are displayed when YES is pressed in response to message 6. The

example to the left signifies 10:35 in the morning, on October 24, 2000.

If selected, the sampler will operate on a timed cycle basis. Press YES to prompt the

7 TIMED MODE

user to enter the number of minutes desired for the time interval between samples.

Press NO to prompt the question described in item 8.

7a INTV = _ _ _ _MIN Enter the value for the interval between samples (in minutes).

Press YES, the cause the sampler to operate on a flow proportional basis. It will prompt

8 FLOW MODE?

the you to enter the number of flow signals that you want the sampler to count down

between samples. Press

NO to prompt the question in item 7.

Enter the value for the number of pulses (counts) that you want to accumulate between

8a INTV = _ _ _ _CNTS

samples. To determine the appropriate number, refer to the programming instructions

for flow proportional operation in section 4.11.

Press NO to retain the previously entered program entries for all remaining programming

9 OTHER CHANGES

steps, and return to the "Ready to Start" standby state. Press

YES to change the

previously programmed entries for all items 10 through 16.

This message appears if only one bottle is entered for the total number of bottles in the

YES to the "Continuous Mode?" prompt to take samples at

NO to cause the display to read

10

COMPOSITE MODE,

CONTINUOUS MODE

parameter entry mode. Press

the programmed interval. The program will terminate only with a full bottle when using

the full bottle float switch (Cat. No. 8847). Press

"samples = _ _ _". This permits you to enter the desired number of samples, after which

the program will terminate.

11 CHANGE VOLUME?

12 SAMPLE VOL = _ _ _

13 CALIBRATE VOL?

Press NO to retain the sample volume from the previous program (programming items

13, a–h are skipped), and the display will prompt the message in item 14.

Enter the desired sample volume (in mL) to be delivered to the sample container each

time a sample is initiated.

This message appears after you enter sample volume. If greater volume accuracy is

desired, press

YES. Press NO to skip the calibration and go to the next step.

When YES is pressed the sampler will pump to collect one sample. The pump will first

13a READY TO PUMP?

pre-purge the intake line, draw sample liquid, and then post-purge.

Before pressing YES, pull the pump tubing off of the fitting where it enters the sampler

housing and place a graduated cylinder at the sample discharge point.

After pressing YES in response to item 13a, the pump will pre-purge the intake line and

begin pumping liquid into the graduated container. When the desired volume has been

13b STOP AT MARK

delivered, press STOP PUMP. The pump will then purge the intake tubing. The sampler

will hold the time to deliver the desired sample volume in memory. This timed volume is

repeated for subsequent samples.

Page 24

Explanations of Program Messages

8544operations.fm

Page 25

Section 4

Item

Number

13c TRY AGAIN?

14 ENTER ID# Enter an optional identification number if desired.

15

Message Description of Message

If STOP PUMP was pressed before or after the desired rinse time, press YES to initiate

NO to view item 16.

DISPLAY FEEDBACK.

SETUP COMPLETE,

READY TO START

another rinse cycle. Press

This message indicates that all programming steps have been completed. Press START

PROGRAM

operating status, press

When you press START PROGRAM, all recorded data are erased from memory. Always

download recorded data before pressing START PROGRAM.

to begin. The display will read "Program Running". To review the program

4.6 Data Logging

The sampler records the time and date that each sample was collected, up to

400 samples. It also records the time and date of up to 24 missed samples.

1. To access information, the sampler must be in the "Program Halted" or "Program Complete" standby state.

2. Press TIME/READ for two seconds. The display will read "Samples Ta ke n" .

3. To display the time/date for each sample, press YES. To advance to the

next sample time/date, press

YES again–and so forth, until all are given.

4. To exit this routine, press NO. The time and date of any missed samples

are displayed after collected samples.

The sampler memory incorporates the “wrap around” method of data storage.

That is, when the memory becomes full, the oldest stored data (sample

number, time/date) are dropped as new data are received. The data logger

retains the 400 most recent times/dates for the collected samples.

4.7 Manual Mode

4.7.1 Manually Operating the Sample Pump

1. To manually operate the pump, place the sampler in standby state. The

sampler is in standby state when the display reads "Ready to Start",

"Program Halted", or "Program Complete".

2. To operate the pump, press either the PUMP or PURGE key. This will

cause "Manual Mode - Pump/Purge/Clear" to appear on the display.

Pressing the

direction as long as the key is held. Pressing the

pump to run in the reverse (purge) direction.

3. To run the pump continuously in either direction without having to hold

down the

"Lock-Pump/Purge" to appear on the display. Then press either

or

PURGE.

PUMP key causes the pump to run in the forward (sample)

PUMP or PURGE keys, press the * key. This will cause

PURGE key causes the

PUMP

4. To stop the pump, press STOP PUMP or turn the sampler off with the OFF

key. Pressing

8544operations.fm Data Logging

STOP PUMP returns the display to "Pump/Purge/Clear".

Page 25

Page 26

Section 4

5. To exit the manual mode, press CLEAR ENTRY. This returns the sampler

to the standby state.

While the sampler is in standby, a sample cycle can be initiated by pressing

the

TAKE SAMPLE key.

4.8 Measurements Triggered by Liquid Levels or Flow

The sampler can operate in any one of three control modes, using an external

controlling device (i.e. Liquid Level Actuator, Cat. No. 943, or an external flow

meter). In any of the three modes, the sampler remains in a standby state until

liquid at the sample source reaches a predetermined level. This feature may

be also used to access the setup of the storm water monitoring program, First

Flush. The three modes are described below:

Mode 1

The instrument collects a sample within the first minute that the liquid rises to

the predetermined level. After the first sample is taken, the sample interval

automatically resets to the programmed interval.

If the liquid falls below the predetermined level, the sampler continues

to

collect samples at the programmed time or flow interval, until the

program

ends.

Mode 2

The instrument collects a sample within the first minute that liquid rises to the

predetermined level. After the first sample is taken, the sample interval

automatically resets to the programmed interval. The sample program ends if

liquid falls below the predetermined level. If the liquid again rises to the

predetermined level, a sample is taken within the first minute and the interval

automatically resets to the programmed time or flow interval.

Mode 3

When the liquid rises to a predetermined level, a sample is not taken

immediately. A sample is taken only when liquid is at or above the

predetermined level and after the programmed sample interval has elapsed.

The interval between samples counts down and resets even when the liquid

level is below the predetermined (actuation) level. This mode is used to

synchronize sample collection with a real-time clock when sampling in the

time mode.

Page 26

Measurements Triggered by Liquid Levels or Flow

8544operations.fm

Page 27

4.9 Programming the Sampler for Level Control

Put the sampler in a standby state (i.e. "Program Halted", "Ready To Start" or

"Program Complete") hold

display to read

"Level Control?". The following messages may be displayed in

the level control program:

CLEAR ENTRY for two seconds. This will cause the

Section 4

Item

Number

1 LEVEL CONTROL

2 LEVEL START?

3 LEVEL START/STOP

4 SAMPLE ON LEVEL?

Message Description of Message

If you press NO, SPECIAL OUTPUT? will appear on the display. If you press YES, the

display shows item 2.

If you press YES, the sampler operates as described in Mode 1. If you press NO, the

display shows item number 4.

If you press YES, the sampler operates as described in Mode 2. If you press NO, the

display shows item number 5.

If you press YES, the sampler operates as described in Mode 3. If you press NO, the

display shows item number 1.

Note: In addition to the liquid level actuator, a Multi-purpose Half cable (Cat. No. 941

or 541) may be used to connect the sampler to any controlling device which

produces a dry contact closure upon a predetermined conditions. For example, a

pH meter with adjustable high/low set points can be used to control sampler

operation in any of the three level/auxiliary control modes.

4.10 Other Displayed Messages

Message Description of Message

YES/NO or * TO

BACKUP

WHILE RUNNING, KEY

0 - 1 - 2 ONLY

REVIEW RESULTS?

REVIEW PROGRAM?

LOW BATTERY This message indicates that the external battery is low and requires recharging.

This message appears if a key other than YES or NO is pressed and the displayed message is

followed by a question mark while in the Parameter Entry, Programming Running, or Time Set

modes.

This message appears if a key other than 0, 1, or 2 is pressed while the program is running. The

program must be halted (press the

Bottle Advance, Pump, Purge, Take Sample, New Program, etc.

This message appears if DISPLAY FEEDBACK is pressed and the sample program has been halted.

A YES response will cause the sample program results to appear. A NO response causes REVIEW

PROGRAM?

If you press the YES key, all programmed settings will appear on the display. Pressing the NO key

will place the sampler back into the standby state.

to appear.

2 key) before any manual operations are performed, such as

MEMORY POWER LOW This message indicates that the internal lithium battery is low and needs to be replaced.

PROGRAM STOPPED

DUE TO FULL BOTTLE

BOTTLE IS FULL

FULL BOTTLE or

PROGRAM HALTED

DUE TO FULL BOTTLE

8544operations.fm Programming the Sampler for Level Control

During composite mode, this message appears upon a full bottle condition. The program cannot

be restarted until the composite container is emptied and the float switch is in the lowered position.

If your instrument is programmed for single container composite sampling, this message appears

START PROGRAM key is pressed and the float switch is not in the lowered position. Because

if the

the same circuit path is used for the composite full bottle float switch (composite mode) and

bottle indicator (multiple bottle mode), this message will also appear if the START PROGRAM key

#1

is pressed with the sampler programmed for single container composite with the distributor

assembly in place, and the arm in the #1 bottle position. To correct this situation, remove the

distributor, install the composite container retainer, and press the

The full bottle float switch is in the raised position due to a full composite container. To resume the

program, exchange the full container with an empty one. With the float switch in the lowered

position, the program will resume within one minute.

START PROGRAM key.

Page 27

Page 28

Section 4

4.11 Flow Proportional Operation

4.11.1 How to Calculate Pulses/Counts

4.11.1.1 Flow Proportional Sampling Intervals—Using External Pulses

The sampler is equipped to receive either a momentary dry contact closure or

a +5 to +12 V dc pulse from a flow meter, where each pulse represents a

known flow increment.

For example, if the flow meter is set to send a flow pulse for every 1000

gallons of measured flow and the sampler can count 1 to 9999 flow pulses

between sample intervals, the sampler can be programmed to receive 10

pulses between samples to take one sample for every 10,000 gallons of liquid

flow.

To determine the number of flow pulses between sample intervals, determine

the total number of samples (represented by n in the following examples) to

be collected, and the period of time over which they are to be collected. Also

know the total flow, Q, during the sampling program. The following two-step

method should be useful for determining the value for

during setup.

INTV = _ _ _ _ CNTS

1. Determine f, where f represents the flow increment between samples and

n represents the total number of samples to be collected.

Q

f

----=

n

2. Multiply the flow increment between samples, f, by the pulse frequency

output of the flow meter (i.e. 1 pulse per 100 gallons, 1 pulse per 1,000

gallons, etc.). If the pulse frequency output of the flow meter is not known,

consult the flow meter manufacturer.

Note: The final result is not necessarily a whole number. You must round off the result

to the nearest whole number.

Example 1

You want to collect 35 samples over a 24-hour period. The total expected flow

over this period is 235,000 gallons. The flow meter pulse frequency is

one

pulse for every 100 gallons.

1. Determine the flow increment between samples:

Q

f

235,000 gallons

----

----------------------------------------- - 6,714 gallons/sample== =

n

35 samples

2. Multiply the flow increment, f, by the pulse frequency output of the flow meter.

Page 28

Flow Proportional Operation

1 pulse

6,714 gallons/sample

------------------------------

× 67.14 pulse/sample=

100 gallons

Therefore, the value for INTV = _ _ _ _ CNTS is 67.

(67.14 is rounded off to 67.)

Example 2

You want to collect 24 samples over an 8-hour period. The total expected flow

over this 8-hour period is 85,000 gallons. The flow meter pulse frequency

output is one pulse for every 50 gallons.

8544operations.fm

Page 29

Section 4

1. Determine the flow increment between samples:

Q

f

2. Multiply the flow increment, f, by the pulse frequency output of the flow meter.

3,542 gallons/sample

Therefore, the value for INTV = _ _ _ _ CNTS is 71.

Example 3

You want to collect 48 samples over a 16-hour period. The total expected flow

over this period is 1,750,000 gallons. The flow meter pulse frequency output is

one pulse for every 1,000 gallons.

1. Determine the flow increment between samples:

f

2. Multiply the flow increment, f, by the pulse frequency output of the flow meter.

85,000 gallons

----

-------------------------------------- - 3,542 gallons/sample== =

n

24 samples

Q

1,750,000 gallons

----

---------------------------------------------- - 36,458 gallons/sample== =

n

48 samples

1 pulse

---------------------------

× 70.84 pulse/sample=

50 gallons

1 pulse

36,458 gallons/sample

-----------------------------------

× 36.458 pulses/sample=

1,000 gallons

Therefore, the value for INTV = _ _ _ _ CNTS is 36.

Flow Proportional Sampling, External—Using 4–20 mA Signal Converted to Pulses, Flow Signal Interface

The Flow Signal Interface (Cat. No. 2020) is an optional 4–20 mA interface

that converts 4–20 mA current signals (from a flow meter) to 12

V dc pulses.

At 20 mA, the interface transmits ten 12-volt pulses per minute. As the current

signal decreases, the 12 V pulses decrease proportionally. Typically, users

collect a certain number of samples over a given period of time when

sampling in proportion to the flow rate.

To calculate the number of 12 V dc output pulses between samples,

determine the total number of samples (represented by n in the following

examples) that you want to collect, and the period of time over which you want

to collect them. Use the three-step method presented below to determine the

“Total Count” value that you will enter while programming the Setup section of

the sampler.

1. Calculate Q, where Q is the average flow rate (during the sampling program) divided by the maximum flow rate. (The maximum flow rate corresponds to the 20 mA output of the flow meter.)

2. Calculate t, where t is defined as a/n; n is the total number of samples collected over a given period of time; and a represents time in minutes, over which n samples are collected.

3. Multiply Q x t. Enter the result in the programming step:

INTV = _ _ _ _ CNTS.

Note: The product of Q x t is not necessarily a whole number. You must round off the

result to the nearest whole number.

Page 29

8544operations.fm Flow Proportional Operation

Page 30

Section 4

Use the following examples to help you determine the value that you need to

enter when programming for sampling based on counts.

Example 1

You want to collect 24 samples over a 24-hour period on a 4–20 mA flow

proportional basis.

Average Flow Rate = 3.5 mgd (average flow rate over the 24-hour period)

Maximum Flow Rate = 10 mgd

a = 1440 minutes

1. Calculate Q.

Average Flow Rate

Q

------------------------------------------------------

Maximum Flow Rate

3.5 mgd

--------------------- 0.35 mgd===

10 mgd

2. Calculate t.

a

t

1440 min

-- -

------------------------------ 60 min/sample== =

n

24 samples

3. Multiply Q x t.

0.35 mgd 60 min/sample× 21=

Therefore, the value entered for INTV = _ _ _ _ CNTS is 21.

Example 2

You want to collect 48 samples over a 24-hour period on a 4–20 mA flow

proportional basis.

Average Flow Rate = 1.75 mgd (average flow rate over the 24-hour period)

Maximum Flow Rate = 3 mgd

a = 1440 minutes

1. Calculate Q.

Average Flow Rate

Q

------------------------------------------------------

Maximum Flow Rate

1.75 mgd

------------------------ - 0.583 mgd===

3 mgd

2. Calculate t.

a

t

1440 min

-- -

------------------------------ 3 0 min/sample== =

n

48 samples

3. Multiply Q x t.

0.583 mgd 30 min/sample× 17.5=

Therefore, the value entered for INTV = _ _ _ _ CNTS is 18.

Page 30

Flow Proportional Operation

Example 3

You want to collect 96 samples over a 24-hour period on a 4–20 mA flow

proportional basis.

Average Flow Rate = 0.52 mgd (average flow rate over the 24-hour period)

Maximum Flow Rate = 2 mgd

a = 1440 minutes

1. Calculate Q.

Average Flow Rate

Q

------------------------------------------------------

Maximum Flow Rate

0.52 mgd

------------------------ - 0.26 mgd===

2.0 mgd

8544operations.fm

Page 31

2. Calculate t.

a

t

1440 min

-- -

------------------------------ - 15 min/sample== =

n

96 samples

3. Multiply Q x t.

Section 4

0.26 mgd 15 min/sample× 3.9=

Therefore, the value entered for INTV = _ _ _ _ CNTS is 4.

Example 4

You want to collect 32 samples over an 8-hour period.

Average Flow Rate = 70 gpm (average flow rate over the 8-hour period)

Maximum Flow Rate = 210 gpm

a = 480 minutes

1. Calculate Q.

Average Flow Rate

Q

------------------------------------------------------

Maximum Flow Rate

70 gpm

---------------------- - 0.33 gpm===

210 gpm

2. Calculate t.

a

t

480 min

-- -

------------------------------ - 15 min/sample== =

n

32 samples

3. Multiply Q x t.

0.33 mgd 15 min/sample× 4.9=

Therefore, the value entered for INTV = _ _ _ _ CNTS is 5.

Example 5

It is desired to collect 30 samples over a 2-day period.

Average Flow Rate = 0.25 cfs (average flow rate over the 48-hour period)

Maximum Flow Rate = 1 cfs

a = 2,880 minutes

1. Calculate Q.

Average Flow Rate

Q

------------------------------------------------------

Maximum Flow Rate

0.25 cfs

-------------------- - 0.25 cfs===

1 cfs

2. Calculate t.

a

t

2,880 min

-- -

------------------------------ - 96 min/sample== =

n

30 samples

3. Multiply Q x t.

0.25 cfs 96 min/sample× 24=

Therefore, the value entered for INTV = _ _ _ _ CNTS is 24.

You will notice from the previous five examples that the average and

maximum flow rate can be expressed in any units, i.e. mgd, gpm, cfs, etc.

However, express the average and maximum flow rate in the same units for

any given situation.

Page 31

8544operations.fm Flow Proportional Operation

Page 32

Visit http: //www.hach.com

Page 33

Section 5 Maintenance

DANGER

Only qualified personnel should conduct the installation tasks described in this

section of the manual

5.1 Cleaning the Sampler

5.1.1 Cleaning the Sampler Housing

The interior and exterior sampler housing may be cleaned with a damp

sponge and mild detergent. Do not use abrasive cleaners.

5.1.2 Cleaning the Sample Bottles

Clean the bottles using a brush and water with mild detergent, followed by a

fresh water rinse and a diluted water rinse. Glass bottles may also be

autoclaved.

5.1.3 Cleaning the Intake Tubing and Pump Tubing

Clean the tubing by pumping water with mild detergent or other cleaning

solution through the tubing, using the peristaltic pump in Manual Pump Mode.

Press the

5.1.4 No Lubrication Required

The 900 Composite Sampler does not require routine lubrication. Do not

lubricate the pump tube with petroleum jelly, silicone grease, oil, or any other

lubricant, as this will substantially reduce the life of the pump tube and roller

assembly.

MANUAL MODE soft key.

5.2 Pump Tubing Maintenance

5.3 Upgrades, Repairs, General Maintenance

5.4 Electrostatic Discharge (ESD) Considerations

5.5 Internal Maintenance Items

The following item requires access to the inside of the case for repairs:

• Internal desiccant module

• RAM memory battery

5.6 Removing and Opening the Controller

CAUTION Always power the unit OFF and then disconnect all cables from the 900 Composite sampler before removing the controller.

To remove the controller from the controller center section:

1. Turn the unit off by pressing the OFF key.

2. Disconnect and remove all cables to the controller housing, including the

distributor/full bottle shutoff cable.

3. Disconnect all tubing.

Page 33

8544Maintenance.fm Maintenance

Page 34

Section 5

4. Place the controller, face down, on a cloth-covered workbench to prevent

scratching the front panel.

5. Inside the Center Section, remove the four screws that fasten the Controller.

6. Lift the Center Section off the controller.

7. Remove the 17 screws from around the perimeter of the controller

back

panel.

8. Carefully pull open the bottom panel and let the attached connectors swing out of the way.

9. If necessary for the repair being performed, unplug the appropriate

connectors. Always note each connector location before unplugging

anything. Re-installing a plug into the wrong connector can cause

extensive damage.

Note: The front panel gasket has a light coating of grease to help assure a watertight

seal. Do not contaminate the grease or gasket area with dirt or debris during

servicing. Always replace the gasket if it is damaged or missing. Never

reassemble the case without the gasket properly installed.

5.7 Re-installing the Bottom Panel

Note: Always follow the procedure below when re-installing the 900 bottom panel.

Improper panel installation may result in damage to the instrument.

1. Hand tighten each nut until it makes contact with the panel.

2. Tighten the nuts in sequence shown in Figure 9 to 5 in.-lb (0.56 N-m).

3. Repeat the tightening procedure in the same sequence to 10 in.-lb

(1.13

N-m).

Figure 9 Tightening the Nuts on the Bottom Panel

110 2

9

17

8

11

3

12

4

13

Page 34

Re-installing the Bottom Panel

16

5

7

15

14

6

8544Maintenance.fm

Page 35

5.8 Internal Desiccant Module

The Internal Desiccant Module (Cat. No. 787) consists of a

moisture-absorbent material inside a poly bag. If the humidity indicator on the

front panel turns pink, replace the module and the back panel perimeter

gasket. The desiccant module is located under the CPU board.

Note: The desiccant module cannot be recharged by heating. Do not attempt to

the desiccant module in an oven to remove the moisture as this could be a

bake

fire hazard.

5.9 Circuit Board Identification

Figure 10 shows the 900 Composite Sampler circuit board, including:

• Placement of all connectors

• EPROM location

• Lithium Memory Battery

• Desiccant Module installation

Section 5

Figure 10 Circuit Board Description

10

9

8

7

blk

shld

wht

1

900 Main Circuit Board

2

3

4

5

6

rd

blk

Page 35

8544Maintenance.fm Internal Desiccant Module

Page 36

Section 5

1. Desiccant module slides under circuit board 6. J5 Distributor/Full Bottle Shut-off

2. J8 LCD Display 7. J2 12 V dc

3. J6 Auxiliary 8. J3 Fuse

4. J1 Liquid Sensor 9. J4 Motor

5. Lithium Memory Battery 10. J9 Keypad

5.10 Motor/Gear Box

The motor/gear box requires no regular maintenance. The special formulation

gears are self lubricating and require no oil or grease.

5.11 Internal Case Humidity Indicator

After replacing the desiccant module and re-sealing the case, the Internal

Case Humidity indicator disc (Cat. No. 2660) should return to its original blue

color. Replace the indicator disc if it fails to return to blue after replacing the

desiccant module. To replace the indicator disc, remove the bottom panel that

is held in place by a small clip and screw.

5.12 Internal Case Humidity Indicator

5.13 Memory Battery

The humidity indicator is located on the left front side of the controller. If the

humidity indicator is blue, the desiccant is dry. If the indicator turns pink or

white, inspect the electronics housing for seal failure and replace the

desiccant module.