Page 1

DOC272.53.90012

Instruction Sheet

FT660 and FT660sc dry standard quick check verification

Safety Information

Please read this entire document before unpacking, setting up, or operating this

equipment. Pay attention to all danger and caution statements. Failure to do so could

result in serious injury to the operator or damage to the equipment.

Make sure that the protection provided by this equipment is not impaired, do not use or

install this equipment in any manner other than that specified in this document.

Electrical equipment marked with this symbol may not be disposed of in European public disposal systems after

12 August of 2005. In conformity with European local and national regulations (EU Directive 2002/96/EC),

European electrical equipment users must now return old or end-of life equipment to the Producer for disposal at no

charge to the user.

Note: For return for recycling, please contact the equipment producer or supplier for instructions on how to return

end-of-life equipment, producer-supplied electrical accessories, and all auxiliary items for proper disposal.

General Information

This instruction sheet gives directions on how to use a dry standard to verify the

calibration of a FilterTrak 660 sc or FT660.

This instruction sheet is divided into two main sections:

Product Overview

The dry standard is based on the light scatter at very low turbidity levels and typically

measures between 15 and 75 mNTU. It has an assignable range through 1000 mNTU.

The value is very reliable when the dry standard is prepared and used as instructed.

Prerequisites

• Section 1 gives instructions on how to enable the dry standard software. It also

gives instructions on how to do dry standard verifications with the software. This

applies only to FT660 sc instruments.

• Section 2 gives instructions on how to do the general dry standard verification

procedure on instruments (including the FT660 sc) that do not use the dry

standard software. The procedure can be done on FT660 instruments that use the

AquaTrend

criteria, and the verification value.

®

controller by manually recording the baseline value, the pass / fail

In order to use the dry standard, FT660 and FT660 sc instruments must be fitted with a

special aperture plate. FT660 sc instruments can also be upgraded with software that

automatically finds and stores baseline and verification values.

Instruments made before April 2008 can be retrofitted with the necessary aperture plate

which can be installed by the customer. Refer to the instructions supplied with the aperture

plate. Software upgrades must be done by a Hach technician.

Starting in April of 2008, the dry standard aperture plate and software will be installed on

all FT660 sc laser turbidimeters at the time of manuifacture.

1

Page 2

FT660 and FT660sc dry standard quick check verification

Section 1 Verification of FT660 sc with dry standard and software

The FT660 sc software is designed to find and store a baseline value for the dry standard.

A baseline value must be found after the initial calibration. This value will be referenced for

subsequent verifications until the next calibration. When the instrument is recalibrated for

any reason, a new dry standard baseline value must be found.

Note: When not in use, keep the dry standard in the protective case.

1.1 Enable the dry standard software

1. From the sc100 menu, choose SENSOR SETUP.

2. Choose the sensor for which the dry standard is to be enabled.

3. Choose the CALIBRATE option and then select VERIFICATION.

4. Choose CVM SELECT and press ENTER.

5. Choose ENABLE and press ENTER.

6. Press ENTER to return to the CALIBRATION menu.

7. Select VERIFICATION, P/F Criteria to set the Pass or Fail Criteria to a value other

than the recommended default of ± 5 mNTU.

Note: The P/F Criteria menu option appears only if the CVM is set to ENABLE.

8. Use the arrow keys to adjust the PFC value and press ENTER. The allowable range is

between 5 mNTU (the default value) and 250 mNTU.

1.2 Assign a baseline value to the dry standard

Note: Assignment of a baseline value can be done only after the instrument has been

successfully calibrated.

1. Once a successful calibration has been done and the operator initials have been

entered, the display shows VERIFY CAL? Press ENTER to begin the verification

process.

2. Choose DRY for the verification type and press ENTER.

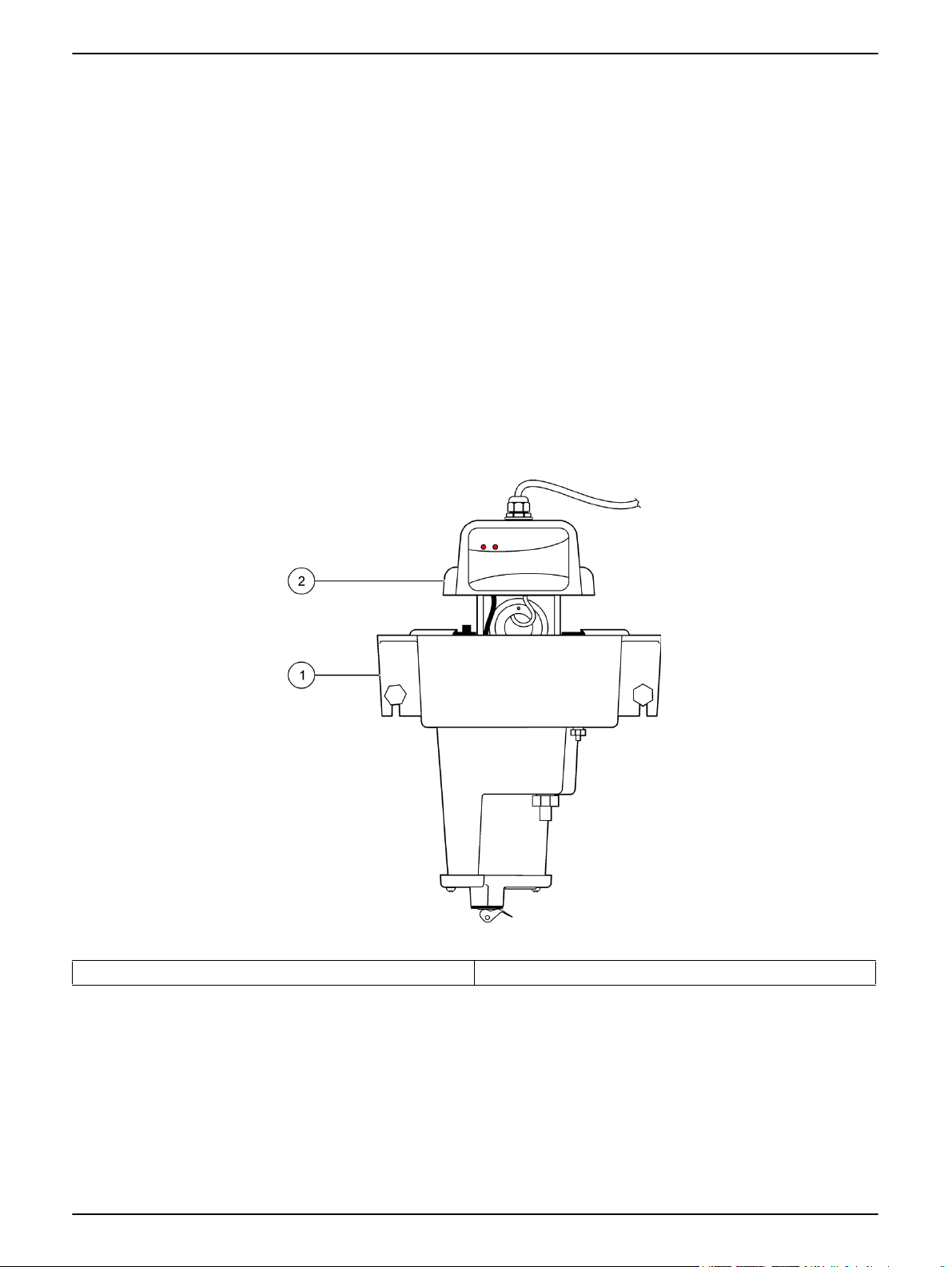

3. Remove the turbidimeter head. Refer to Figure 1 on page 3.

4. Remove the dry standard from the protective case and record the serial number

etched into the dry standard collar. Refer to Figure 2 on page 4. The serial number

must be entered to determine a baseline value.

5. Inspect the dry standard glass rod to make sure it is clean and free of chips and

scratches. Clean the device with the disposable wipes provided.

6. Dry the top

7. Insert the dry standard into the aperture plate. Make sure the alignment pin fits into the

notch. Refer to Figure 2 on page 4.

2

1

/3 of the dry standard and the top surface. Refer to Figure 2 on page 4.

Page 3

FT660 and FT660sc dry standard quick check verification

8. Rotate the dry standard approximately 1/8 of a turn to the right until the dry standard

locks into position. Refer to Figure 2 on page 4.

9. Dry off the remainder of the glass to remove any fingerprints and oils.

10. Place the turbidimeter head on the body. Make sure the head is correctly positioned

and press ENTER.

11. Enter the digits of the dry standard serial number and press ENTER.

12. Allow the instrument reading to stabilize. Press ENTER to accept the reading as the

baseline value.

Note: The user does have the option to push ENTER before the reading becomes stable.

However, this may cause inaccurate baseline values.

13. Remove the dry standard, replace the head and press ENTER to continue to

Measurement Mode. Place the dry standard back into the protective case.

Figure 1 Remove turbidimeter head

1 FT660 body 2 FT660 head

3

Page 4

FT660 and FT660sc dry standard quick check verification

.

Figure 2 Dry standard installation

1 Dry standard 6 Dry standard locking pin

2 Dry standard protective case 7 Aperture plate

3 Dry standard top surface 8 Turbidimeter head assembly

4 Disposable wipe 9 Aperture plate notch

5 Dry standard serial number

1.3 Perform a verification with the dry standard and the sc100 software

1. Choose MAIN MENU.

2. Choose SENSOR SETUP. Select the sensor for verification and press ENTER.

3. Choose CALIBRATE, VERIFICATION, PERFORM VERIFICATION.

4. Choose from Active, Hold, or Transfer outputs and press ENTER.

5. Select DRY for the verification type and press ENTER.

6. Verify that the serial number displayed matches the serial number etched on the dry

standard collar. Press ENTER.

7. Attach the dry standard to the turbidimeter head. Put the head on the instrument body

and push ENTER.

8. When the dry standard measurement is stable, push ENTER to accept the reading

shown. A GOOD VER (Good Verification) or BAD VER (Bad Verification) will appear.

A bad verification indicates the instrument failed to meet the PFC, or that the

instrument was unable to reach a stable reading.

Table 1 on page 6 can be used to interpret verification values and determine what

action should be taken. If the instrument consistently fails the verification process,

contact the manufacturer.

4

Page 5

FT660 and FT660sc dry standard quick check verification

9. When prompted, remove the dry standard and put the turbidimeter back on line. Push

ENTER.

10. Select the HOME key to show on-line measurements.

11. Wipe off the dry standard after removal and put it in the protective case.

Section 2 General procedure for dry standard verification without software

This procedure includes the initial assignment of the baseline value to the dry standard on

instruments without software. The procedure should be completed for each FT660 or

FT660sc laser nephelometer immediately after the instrument has been successfully

calibrated. The baseline value is used for instrument verifications performed between

calibrations.

Once the baseline value of the dry standard has been determined, manually record the

value. Also record the serial number of the dry standard and the serial number of the

FT660 instrument. A baseline value is valid only for the combination of dry standard and

instrument used to determine it.

Refer to Figure 2 on page 4 as necessary when performing the procedures below.

Note: When not in use, keep the dry standard in the protective case.

2.1 Assign a baseline value to the dry standard

1. Remove the dry standard from the protective case. Examine the dry standard to make

sure it is clean and free of chips or scratches.

2. Clean the dry standard with the disposable wipes provided.

3. Dry the top

4. Put the dry standard into the aperture plate. Make sure the alignment pin fits into the

notch. Refer to Figure 2 on page 4.

5. Turn the dry standard approximately

into position.

6. After the dry standard is attached to the turbidimeter head, clean the remainder of the

glass to remove fingerprints and oils.

7. Attach the turbidimeter head on the instrument body.

8. After the reading becomes stable, record the value shown in the display. This is the

first of 3 values which will be averaged to find a final baseline value.

1

/3 of the dry standard and the top surface.

1

/8 of a turn to the right to lock the dry standard

9. Remove and clean the dry standard. Attach the dry standard to the aperture plate and

put the turbidimeter head on the body. When the reading has stabilized, record the

value shown.

10. Repeat step 9 and record the value shown a third time.

11. Find the average of the three recorded values. This is the final baseline value for the

dry standard. This value will be compared to subsequent verification values for this

specific combination of dry standard and instrument.

5

Page 6

FT660 and FT660sc dry standard quick check verification

2.2 Verification procedure for the FT660 using the dry standard

1. Remove the dry standard from the protective case. Examine the glass and plastic to

make sure it is clean and free of chips and scratches.

2. Clean the device using the disposable wipes provided.

3. Dry the top

1

/3 of the dry standard and the top surface.

4. Put the dry standard into the aperture plate. Make sure the alignment pin fits into the

notch. Refer to Figure 2 on page 4.

5. Turn the dry standard approximately

1

/8 turn to the right to lock the dry standard into

position.

6. Dry off the remainder of the glass to remove fingerprints and oils.

7. Attach the turbidimeter head on the body.

8. When the reading becomes stable record the value shown.

9. Interpret the results. Refer to Table 1 as a guide. The table assumes a PFC of ±5

mNTU (the default value).

.

Table 1 Interpretation of values

Verification Value Interpretation Suggested Action

Within 5 mNTU of baseline Successful verification None

5 mNTU or greater below baseline Instrument out of calibration

Possible contamination of turbidimeter

5 mNTU or greater above baseline

body. Possible fluid on dry standard

optical surface.

Clean instrument and repeat

verification. Calibrate if necessary.

Clean body, bubble trap, detector and

dry standard. Calibrate instrument and

assign new baseline value.

Note: A significantly low value (25% or more below the expected value) can be an indication that the

light source or detector is failing. If the operator repeatedly experiences verification failures with

significantly low values, the instrument must be sent back to the manufacturer for repair.

Replacement parts and accessories

Description

FT660 sc Verification Quick Check (CVM) Kit, includes: 6735500

• Dry standard

• Protective case for dry standard

• Disposable wipes

• Instruction sheet

1

Aperture plate

for dry standard, with replacement screws 6735600

• Aperture plate replacement instruction sheet

1

Included on FT660 sc instruments made after April 2008

Item no.

6735800

6735400

2097000

DOC272.xx.90012

DOC273.xx.90049

6

Page 7

Contact Information

HACH Company

World Headquarters

P.O. Box 389

Loveland, Colorado

80539-0389 U.S.A.

Tel (800) 227-HACH

(800) -227-4224

(U.S.A. only)

Fax (970) 669-2932

orders@hach.com

www.hach.com

HACH LANGE GMBH

Willstätterstraße 11

D-40549 Düsseldorf

Tel. +49 (0)2 11 52 88-320

Fax +49 (0)2 11 52 88-210

info@hach-lange.de

www.hach-lange.de

DR. BRUNO LANGE AG

Juchstrasse 1

CH-8604 Hegnau

Tel. +41(0)44 9 45 66 10

Fax +41(0)44 9 45 66 76

info@hach-lange.ch

www.hach-lange.ch

Repair Service in the

United States:

HACH Company

Ames Service

100 Dayton Avenue

Ames, Iowa 50010

Tel (800) 227-4224

(U.S.A. only)

Fax (515) 232-3835

HACH LANGE LTD

Pacific Way

Salford

GB-Manchester, M50 1DL

Tel. +44 (0)161 872 14 87

Fax +44 (0)161 848 73 24

info@hach-lange.co.uk

www.hach-lange.co.uk

HACH LANGE FRANCE

S.A.S.

33, Rue du Ballon

F-93165 Noisy Le Grand

Tél. +33 (0)1 48 15 68 70

Fax +33 (0)1 48 15 80 00

info@hach-lange.fr

www.hach-lange.fr

Repair Service in Canada:

Hach Sales & Service

Canada Ltd.

1313 Border Street, Unit 34

Winnipeg, Manitoba

R3H 0X4

Tel (800) 665-7635

(Canada only)

Tel (204) 632-5598

Fax (204) 694-5134

canada@hach.com

HACH LANGE LTD

Unit 1, Chestnut Road

Western Industrial Estate

IRL-Dublin 12

Tel. +353(0)1 46 02 5 22

Fax +353(0)1 4 50 93 37

info@hach-lange.ie

www.hach-lange.ie

HACH LANGE SA

Motstraat 54

B-2800 Mechelen

Tél. +32 (0)15 42 35 00

Fax +32 (0)15 41 61 20

info@hach-lange.be

www.hach-lange.be

Repair Service in

Latin America, the

Caribbean, the Far East,

Indian Subcontinent, Africa,

Europe, or the Middle East:

Hach Company World

Headquarters,

P.O. Box 389

Loveland, Colorado,

80539-0389 U.S.A.

Tel +001 (970) 669-3050

Fax +001 (970) 669-2932

intl@hach.com

HACH LANGE GMBH

Hütteldorferstr. 299/Top 6

A-1140 Wien

Tel. +43 (0)1 9 12 16 92

Fax +43 (0)1 9 12 16 92-99

info@hach-lange.at

www.hach-lange.at

DR. LANGE NEDERLAND

B.V.

Laan van Westroijen 2a

NL-4003 AZ Tiel

Tel. +31(0)344 63 11 30

Fax +31(0)344 63 11 50

info@hach-lange.nl

www.hach-lange.nl

HACH LANGE APS

Åkandevej 21

DK-2700 Brønshøj

Tel. +45 36 77 29 11

Fax +45 36 77 49 11

info@hach-lange.dk

www.hach-lange.dk

HACH LANGE LDA

Av. do Forte nº8

Fracção M

P-2790-072 Carnaxide

Tel. +351 214 253 420

Fax +351 214 253 429

info@hach-lange.pt

www.hach-lange.pt

HACH LANGE KFT.

Hegyalja út 7-13.

H-1016 Budapest

Tel. +36 (06)1 225 7783

Fax +36 (06)1 225 7784

info@hach-lange.hu

www.hach-lange.hu

HACH LANGE AB

Vinthundsvägen 159A

SE-128 62 Sköndal

Tel. +46 (0)8 7 98 05 00

Fax +46 (0)8 7 98 05 30

info@hach-lange.se

www.hach-lange.se

HACH LANGE SP.ZO.O.

ul. Opolska 143 a

PL-52-013 Wrocław

Tel. +48 (0)71 342 10-83

Fax +48 (0)71 342 10-79

info@hach-lange.pl

www.hach-lange.pl

HACH LANGE S.R.L.

Str. Leonida, nr. 13

Sector 2

RO-020555 Bucuresti

Tel. +40 (0) 21 201 92 43

Fax +40 (0) 21 201 92 43

info@hach-lange.ro

www.hach-lange.ro

HACH LANGE S.R.L.

Via Riccione, 14

I-20156 Milano

Tel. +39 02 39 23 14-1

Fax +39 02 39 23 14-39

info@hach-lange.it

www.hach-lange.it

HACH LANGE S.R.O.

Lešanská 2a/1176

CZ-141 00 Praha 4

Tel. +420 272 12 45 45

Fax +420 272 12 45 46

info@hach-lange.cz

www.hach-lange.cz

HACH LANGE

8, Kr. Sarafov str.

BG-1164 Sofia

Tel. +359 (0)2 963 44 54

Fax +359 (0)2 866 04 47

info@hach-lange.bg

www.hach-lange.bg

HACH LANGE S.L.U.

Edif. Arteaga Centrum

C/Larrauri, 1C- 2ª Pl.

E-48160 Derio/Vizcaya

Tel. +34 94 657 33 88

Fax +34 94 657 33 97

info@hach-lange.es

www.hach-lange.es

HACH LANGE S.R.O.

Roľnícka 21

SK-831 07 Bratislava –

Vaj nory

Tel. +421 (0)2 4820 9091

Fax +421 (0)2 4820 9093

info@hach-lange.sk

www.hach-lange.sk

HACH LANGE SU

ANALİZ SİSTEMLERİ

LTD.ŞTİ.

Hilal Mah. 75. Sokak

Arman Plaza No: 9/A

TR-06550 Çankaya/ANKARA

Tel. +90 (0)312 440 98 98

Fax +90 (0)312 442 11 01

bilgi@hach-lange.com.tr

www.hach-lange.com.tr

HACH LANGE D.O.O.

Fajfarjeva 15

SI-1230 Domžale

Tel. +386 (0)59 051 000

Fax +386 (0)59 051 010

info@hach-lange.si

www.hach-lange.si

© Hach Company, 2008. All rights reserved. Printed in the U.S.A. Edition 1 March 2008 kw/kt

ΗΑCH LANGE E.Π.Ε.

Αυλίδος 27

GR-115 27 Αθήνα

Τηλ. +30 210 7777038

Fax +30 210 7777976

info@hach-lange.gr

www.hach-lange.gr

HACH LANGE E.P.E.

27, Avlidos str

GR-115 27 Athens

Tel. +30 210 7777038

Fax +30 210 7777976

info@hach-lange.gr

www.hach-lange.gr

Page 8

Loading...

Loading...