Page 1

EC1000 PROCESS

pH/ORP SYSTEM

INSTRUCTION MANUAL

48275-18

© Hach Company, 1994-1997. All rights are reserved. Printed in the U.S.A. al/dk 7/97 3ed

Page 2

2

Page 3

CERTIFICATION

Hach Company certifies this instrument was tested thoroughly, inspected, and found to

meet its published specifications when it was shipped from the factory.

The EC1000 Process pH/ORP System has been tested and is certified as indicated to the

following ins trumentation standards:

Product Safety

Listed by ETL to UL Standard 3101-1 (Listing # H0492805390)

Certified by ETL to CSA Standard C22.2 No. 142 (ETLc Certification # H 0492805390)

Certified by Hach Company to EN 61010-1 (IEC1010-1), supporting test records by

Intertek Testing Services

Immunity

EN 50081-2 (European Generic Immunity Standard) per 89/336/EEC EMC: Supporting

test records Amador (TUV Product Services), certified compliance by Hach Company.

Required Standard/s include:

IEC 801-2 & IEC 1000-4-2 Electro-Static Discharge

IEC 801-3 Radiated RF Electro-Magnetic Fields*

IEC 801-4 Electrical Fast Transients/Burst

Emissions

Emissions per 89/336/EEC EMC: Supporting test records by Intertek Tes ting Services

(ETL), certified compliance by Hach Company.

Required Standard/s include:

EN 55011 (CISPR 11) Emissions, Class B Limits

CANADIAN INTERFERENCE-CAUSING EQUIPMENT REGULATION, IECS-003, Class A

Supporting test records by Intertek Testing Services (ETL), certified compliance by

Hach Company.

This Class A digital apparatus meets all requirements of the Canadian InterferenceCausing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le

matériel brouilleur du Canada.

FCC PART 15, Class "A" Limits:

Supporting test records by Intertek Testing Services (ETL), certified compliance by

Hach Company.

This device complies wit h Par t 15 o f the F CC Rul e s. Op er at ion is s ubj ec t to th e following

two conditio ns:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may

cause undesired operation.

* Electromagnetic Radiation of 3 Volts /meter or greater can cause instrument inaccuracy. For complete accuracy details in an

RF environment, refer to the Supplementary Compliance Information in this manual.

3

Page 4

CER TIFICATION, continued

Changes or modifications to this unit not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against ha rmful interference w hen the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not ins ta ll ed an d use d in accordance with the instruction manual, may caus e

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference, in which case the user will be required to

correct the interference at his own expense.

Shielded cables must be used with this unit to ensure compliance with the Class A FCC

limits. Because this instrument operates on and generates radio frequency energy,

interference to radio and television reception may occur. If such interference does occur,

the operator should take the necessary steps to correct the interference. The following

techniques of reducing the interference problems are applied easily.

1. Disconnect power from the EC1000 Controller to verify that it is the source of

the interference.

2. If the EC1000 Controller is plugged into the same outlet as the device with which it is

interfering, try another outlet.

3. Move the EC1000 Controller away from the device receiving the interference.

4. Reposition the receiving antenna for the device receiving the interference.

5. Try combinations of the above.

4

Page 5

TABLE OF CONTENTS

CERTIFICATION ..........................................................................................................................................................3

SPECIFICATIONS ........................................................................................................................................................ 9

SAFETY PRECAUTIONS .......................................................................................................................................... 13

OPERATION .............................................................................................................................................................. 15

SECTION 1 GENERAL INFORMATION ........................................................................................................... 17

1.1 Instrument Description ...........................................................................................................................................17

1.2 EC1000 pH/ORP Controller ...................................................................................................................................17

1.3 Electrolyte Pump .................................................................................................................................................... 17

1.4 Hach One Process pH Electrode ............................................................................................................................ 21

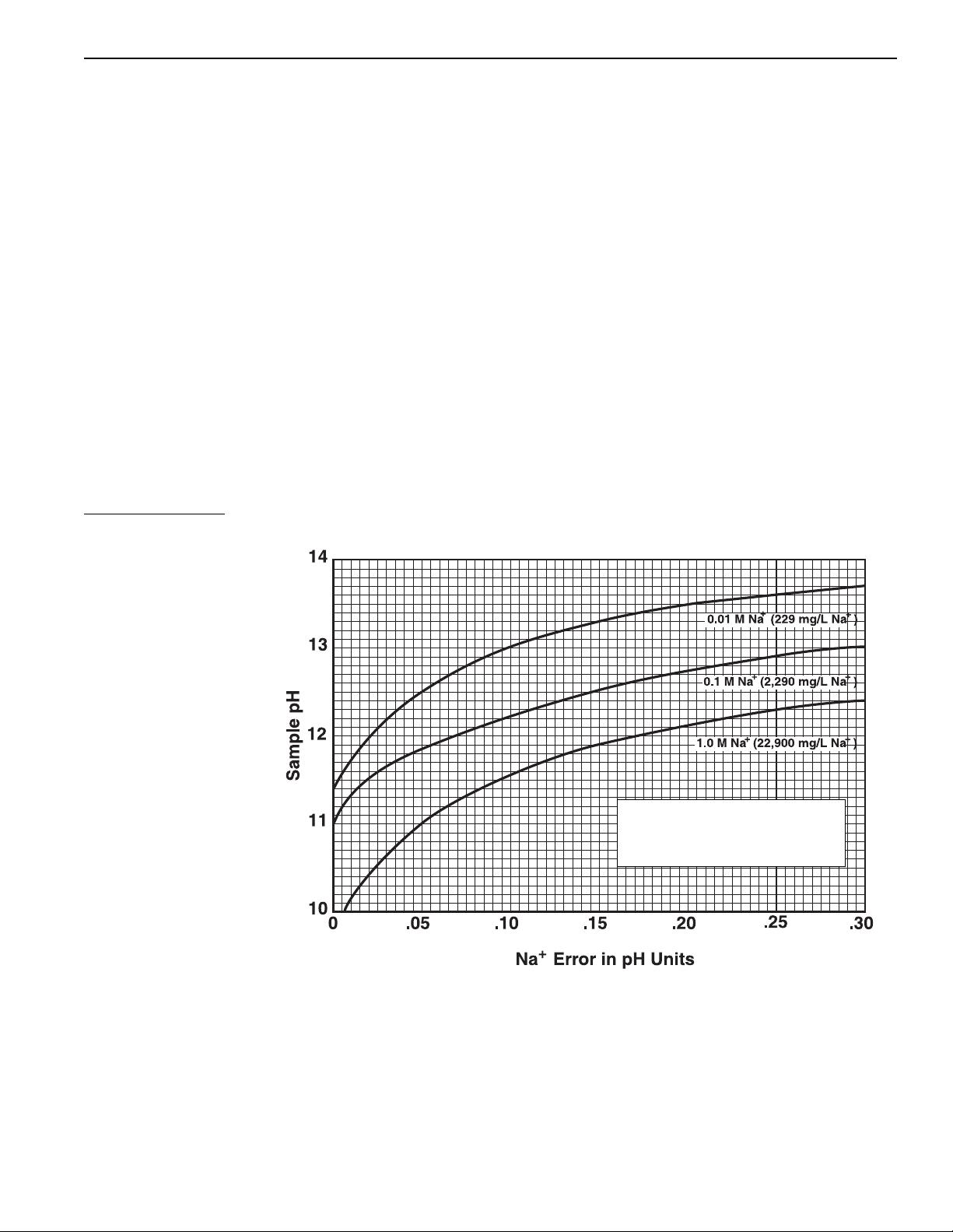

1.4.1 Sodium Error ..............................................................................................................................................21

1.5 Hach One ORP Electrode .......................................................................................................................................21

1.6 Industrial Process pH Electrode .............................................................................................................................22

1.7 Sample Handling System .......................................................................................................................................22

1.7.1 Submersible ................................................................................................................................................ 22

1.7.2 Flow-Thru Cell ...........................................................................................................................................22

1.7.3 In-Line ........................................................................................................................................................ 22

1.8 Principle of Operation ............................................................................................................................................ 23

SECTION 2 OPERATION ......................................................................................................................................25

2.1 Operating the User-Programmable Setup ...............................................................................................................25

2.1.1 Moving Around the Menu .......................................................................................................................... 25

2.1.2 Editing a Setup Value .................................................................................................................................25

2.1.3 Restoring Default Settings .......................................................................................................................... 27

2.2 Setup Menu ............................................................................................................................................................. 28

2.2.1 Alarms ........................................................................................................................................................ 28

2.2.2 Recorder Output ......................................................................................................................................... 29

2.2.3 PID Output ..................................................................................................................................................30

2.2.4 Recorder 2 ................................................................................................................................................... 33

2.2.5 Initial Setup .......................................... ......... ..............................................................................................33

2.2.5.1 Temperature Compensation Setup .................................................................................. .............33

2.2.6 Keylock ....................................................................................................................................................... 35

2.2.7 Reference Solution Timer ...........................................................................................................................36

2.2.8 Warnings ..................................................................................................................................................... 36

2.3 Calibration .............................................................................................................................................................. 37

2.3.1 pH Calibration ............................................................................................................................................38

2.3.1.1 Two-Point Calibration with Auto Recognition of Hach Buffers .................................................39

2.3.1.2 One-Point Grab Sample Calibration ............................................................................................ 40

2.3.1.3 Calibration Procedure Variations ................................................................................................. 40

2.3.1.4 One Point Calibration with a Buffer ............................................................................................ 41

2.3.1.5 Calibration Review .......................................................................................................................41

2.3.2 Temperature Calibration ............................................................................................................................. 41

2.3.3 ORP Calibration/mV Zero .......................................................................................................................... 42

2.3.3.1 Preamp Zero .................................................................................................. ......... ...................... 42

2.3.3.2 ORP Electrode Check ..................................................................................................................43

2.3.3.3 mV Offset ..................................................................................................................................... 43

5

Page 6

TABLE OF CONTENTS, continued

SECTION 3 SERIAL INTERFACE .......................................................................................................................45

3.1 Optional Serial Interface Board ..............................................................................................................................45

3.2 Data Communications Format/Setup ......................................................................................................................45

3.3 Print Format ............................................................................................................................................................45

3.4 Remote Input Commands ............................................... ........................................................................................46

SECTION 4 PID CONTROL ..................................................................................................................................49

4.1 pH Controller Basics ...............................................................................................................................................49

4.2 Instrument Settings .................................................................................................................................................49

4.2.1 Set Point ......................................................................................................................................................49

4.2.2 Dead Band ...................................................................................................................................................49

4.2.3 Preset ........................................................................................................................................................... 49

4.3 Gain .........................................................................................................................................................................49

4.3.1 Reset (Integral) ............................................................................................................................................52

4.3.2 Rate (Derivative) ................................................. ......... ...............................................................................52

4.3.3 Curve ........................................................................................................................................................... 52

INSTALLATION/MAINTENANCE .....................................................................................................................55

SECTION 5 INSTALLATION ...............................................................................................................................57

5.1 Unpacking the Instrument .......................................................................... ........................... ......... ......... ................57

5.2 Industrial Process pH Electrode Preparation ..........................................................................................................57

5.3 Mounting the Controller .........................................................................................................................................57

5.3.1 Panel Mounting ...........................................................................................................................................57

5.3.2 Wall Mounting ............................................................................................................................................59

5.3.3 Pole Mounting .............................................................. ......... ......................................................................59

5.4 Mounting the Pump .................................................................................................................................................59

5.5 Installing the pH/ORP Electrode ............................................................................................................................60

5.5.1 In-Line Electrode Installation .....................................................................................................................62

5.5.2 Submersible Sensor Installation ..................................................................................................................62

5.5.3 Flow-Thru Cell Installation .........................................................................................................................62

5.6 Wiring the Meter .....................................................................................................................................................63

5.6.1 Wire Preparation .........................................................................................................................................64

5.6.2 Power ...........................................................................................................................................................65

5.6.2.1 Line Voltage Selection for Meter ................................................................................................. 66

5.6.3 Alarms .........................................................................................................................................................66

5.6.4 Recorder and Controller ..............................................................................................................................66

5.6.5 Electrode Wiring .........................................................................................................................................67

5.6.6 Electrode Output Connections ....................................................................................................................67

5.7 Pump Wiring ...........................................................................................................................................................68

5.7.1 Line Voltage Selection for Electrolyte Pump .............................................................................................69

SECTION 6 BASIC START-UP ..............................................................................................................................71

6.1 Introduction .............................................................................................................................................................71

6.2.1 Assembling the Electrolyte Line .................................................................................................................71

6.2.2 Connection to the Pump Module .................................................................................................................71

6.2.3 Connection to the pH Electrode ..................................................................................................................71

6.3 Purging the System .................................................................................................................................................72

6.4 Calibration ...............................................................................................................................................................73

SECTION 7 SERIAL INTERFACE .......................................................................................................................75

7.1 Installation ...............................................................................................................................................................75

7.2 RS-232C Interface Configuration ...........................................................................................................................77

7.3 Current Loop Configuration ...................................................................................................................................77

6

Page 7

TABLE OF CONTENTS, continued

SECTION 8 ELECTRODE AND PUMP MAINTENANCE ............................................................................... 81

8.1 Electrode Maintenance ...........................................................................................................................................81

8.1.1 General Electrode Maintenance .................... ......... ..................................................................................... 81

8.1.2 Removing Existing Electrode ..................................................................................................................... 81

8.1.3 Sensor Replacement ................................................................................................................................... 81

8.1.4 Replacing Electrolyte ................................................................................................................................. 82

8.1.5 Crystal Formation in Reference Tube ........................................................................................................84

8.1.6 Purging the System ..................................................................................................................................... 84

8.1.7 Storage and Conditioning ...........................................................................................................................84

8.1.7.1 pH Electrode Storage and Conditioning ......................................................................................84

8.1.7.2 ORP Electrode Storage and Conditioning ....................................................................................84

8.1.7.3 Industrial pH Electrode Shelf Life and Storage ...........................................................................86

8.1.8 pH Electrode Cleaning ................................................................................................................................ 86

8.1.9 ORP Electrode Cleaning .............................................................................................................................87

8.1.10 Industrial pH Electrode Cleaning ...............................................................................................................87

8.2 Pump Maintenance .................................................................................................................................................87

8.2.1 Changing Pump Tubing .............................................................................................................................. 87

8.3 Fuse Replacement ................................................................................................................................................... 88

8.3.1 Meter Fuse Replacement ............................................................................................................................ 88

8.3.2 Pump Fuse Replacement ............................................................................................................................ 90

8.4 Pump Motor Replacement ......................................................................................................................................90

SECTION 9 TROUBLESHOOTING .....................................................................................................................91

9.1 Troubleshooting the EC1000 Controller ................................................................................................................91

9.1.1 Test Diagnostic Menu .................................................................................................................................91

9.1.2 Error Codes .................................................................................................................................................94

9.1.3 System Warnings ........................................................................................................................................ 95

9.2 Troubleshooting the pH Electrode ......................................................................................................................... 96

9.3 Troubleshooting the ORP Electrode ............................................................................................................... 98

SECTION 10 SCHEMATICS ................................................................................................................................. 103

GENERAL INFORMATION ...............................................................................................................................107

REPLACEMENT PARTS ......................................................................................................................................... 109

HOW TO ORDER ......................................................................................................................................................113

REPAIR SERVICE .................................................................................................................................................... 114

APPENDIX A Process pH Electrode Without Internal Preamp ...........................................................................115

APPENDIX B Supplemental Compliance Information ......................................................................................... 117

INDEX ......................................................................................................................................................................... 119

7

Page 8

8

Page 9

SPECIFICATIONS

(Specifications subject to change without notice.)

CONTROLLER SPECIFICATIONS

Ranges: pH: -2 to 16 pH; mV: -2000 to +2000 mV; Temperature: -5 to +105 °C

Accuracy*: pH: ±0.02 pH; mV: ±1.0% of reading, ±35 mV non-calibrated;

Temperature: ±1.5 °C before calibration with electrode, ±0.4 °C after calibration with

electrode.

Resolution: pH: 0.01 pH; mV: 0.1 mV; Temperature: 0.1 °C

Repeatability: pH: ±0.02 pH; mV: ±0.1 mV; Temperature: ±0.2 °C

Temperature Calibration: 1 or 2 point with zero and slope adjustments

Temperature Compensation: -5 to +105 °C for Nearnst equation (auto/manual);

0 to 60 °C for auto buffer recognition

Solution Temperature Correction: Corrected to 25 °C, 0.1 to -0.1 pH units/ °C slope

Operating Temperature: -10 to 60 °C

Storage Temperature: -40 to 60 °C

Humidity Range: 5 to 90% RH non-condensing

Relative mV Adjus tment: The mV zero may be offset to any point in the ±2000 range

Alarms: Alarms 1 and 2: Usable in any of operating modes, (pH/mV/Temperature).

Programmable for either low or high set point alarm. Alarm relays SPDT with contacts

rated at 5A resistive load at 30 Vrms (42.4 Vpk).

Recorder O utput: Isolated 4-20 mA (adjustable to 0-20 mA at 900 ohms)

Controller Output: Proportional, Integral, Derivative. Addi tiona l resi stors can b e used to

provide 0 to 10 V, 0 to 1 V, or 0 to 100 mV outputs.

Input/Output (optional): RS-232C and 20 mA current loop

Signal Average: 0 to 10 seconds

Reading Update: Every 0.4 seconds

Power Requirements: 115/230 Vac (±17%), 50/60 Hz, 8 watts

Controller Enclosure: NEMA 4X/IP66 (rear connections). Suitable for 1/2- inch co nduit.

Wall, panel or pole mounted. For indoor use.

Controller Dimensions: 14.4 cm x 14.4 cm x 12.5 cm deep (5.67" x 5.67" x 4.9" deep).

Panel cutout size: 14 cm x 14 cm (5.5" x 5.5")

* Intermittent Electromagnetic Radiation of 3 Volts per meter or greater may cause measurement inaccuracy. For complete

accuracy details in an RF environment, see the Supplemental Compliance Information in this manual.

9

Page 10

SPECIFICATIONS, continued

Hach One® PROCESS pH SPECIFICATIONS

pH Range: 0 to 14 pH

Accuracy*: pH: ±0.02 pH; Temperature: ±1.5 °C before calibration, ±0.4 °C after

calibration

Repeatability: pH: ±0.02 pH (calibrated at 25 °C and measured at 25 °C);

Temperature: ±0.2 °C

Temperature Range: 0 to 60 °C

Pressure Range: 0 to 35 psi (241 kPa)

Slope: 58 mV± 2 mV/pH units at 28 °C

Reference Element: Ag/AgCl double junction

Electrode Diameter: 28.6 mm (1.125") at tip

Electrode Length: 20.3 cm (8")

Reference Tubing Length: 6.1 m (20 feet) optional 50 feet

Cable Length: 6.1 m (20 feet). Expandable to 1000 feet

Submersion Application: Operational to a depth of 40 feet

Electrical Output: Two 4-20 mA current loops, directly proportional to mV and

temperature

Electrode Housing: Kynar (lower body)/Noryl (polyphenylene oxide) (upper body)

Hach One ORP ELECTRODE SPECIFICATIONS

mV Range: -2000 to 2000 mV

Temperature Range: 0 to 60 °C

Pressure Range: 0 to 35 psi (241 kPa)

Accuracy*: mV: ±10 mV; Temperature: ±1.5 °C before calibration, ±0.4 °C after

calibration

Repeatability: mV: ±2 mV; Temperature: ±0.2 °C

Sensing Element: Platinum disc (99.998% pure)

Reference Element: Ag/AgCl double junction

Reference Potential: 32 ±5 mV vs. SCE

Electrode Diameter: 28.6 mm (1.125") at tip

Electrode Length: 20.3 cm (8")

Reference Tubing Length: 6.1 m (20 feet) optional 50 feet

Cable Length: 6.1 m (20 feet). Expandable to 1000 feet

Submersion Application: Operational to a depth of 40 feet

Electrical Output: Two 4-20 mA current loops, directly proportional to mV and

Temperature

Electrode Housing: Kynar (lower body)/Noryl (polyphenylene oxide) (upper body)

* Calibrated at 25 °C and measured at 25 °C and at atmospheric pressure.

10

Page 11

SPECIFICATIONS, continued

INDUSTRIAL PROCESS pH ELECTRODE SPECIFICATIONS

pH Range: 0 to 12 pH

Reproducibility: ±2% of reading

Temperature and Pressure Range: 0 to 80 °C at 0 to 100 psig; 0 to 100 °C at

ambient pressure

Slope: (pH 4 to pH 7) @ 25 °C: >170 mV

Reference Element: Ag/AgCl

Electrode Diameter: 28.2 mm (1.11") at tip

Electrode Length: 175 mm (6.9")

Electrode Housing: CPVC

PUMP MODULE SPECIFICATIONS

Pressure Range: 0 to 35 psi (241 kPa)

Operating Temperature Range: -20 to 60 °C

Humidity Range: 5 to 90% RH non-condensing

Reagent Usage: Reference solution capacity for a minimum of 1 month of operation

Power Requirements: 115/230 Vac (±17%), 50/60 Hz, 9 VA, 8 watts

Enclosure: NEMA 4X/IP66—Wall mounting, with 1/2-inch NPT for conduit

connections. For indoor use.

MOUNTING KIT SPECIFICATIONS

SUBMERSION APPLICATION

Maximum Submersion Depth: 40 feet (due to restrictions on reference tubing length)

Maximum Velocity at Electrode Tip: 15 km/hour

IN-LINE APPLICATION

Maximum Pressure: 35 psi (241 kPa)

Maximum Flow Rate: 40 L/minute

Minimum Flow Rate: 10 mL/minute

FLOW-THRU CELL APPLICATION

Maximum Flow Rate: 750 mL/m inu te

Minimum Flow Rate: 1 mL/minute

11

Page 12

12

Page 13

SAFETY PRECAUTIONS

Before attempting to unpack , set up, or oper ate this instrument, please read this entire

manual. Pay particula r atte ntion to all wa rnings , cautio ns and note s. F ail ure to do so cou ld

result in serious injury to the operator or damage to the equipment.

To ensure the protection provided by this equipment is not impaired, this equipment

MUST NOT be installed or used in any manner other than that which is specified in

this manual.

Use of Hazard Information

If multiple hazards exist, the signal word corresponding to the greatest hazard shall

be used.

DANGER

Indicates a potentially or imminently hazardous s ituation which, if not avoided, could r esult in

death or serious injury

CAUTION

Indicates a potentially hazardous situation that may result in minor or moderate injury

NOTE

Information that requires special emphasis

Precautionary Labels

Please pay particular attention to labels and tags attached to the instrument. Personal

injury or damage to the instrument could occur if not observed.

This symbol, if noted on the instrument, references the instruction manual for

operational and/or saf et y info rmation.

Section 5.4 Installing the pH/ORP Electrode

Section 5.5 Wiring Meter

Section 5.5.2 Power

Section 5.6 Wiring Pump

Section 7.1 Installation

Section 8.1.7 pH Electrode Cleaning

Section 8.1.8 ORP Electrode Cleaning

Section 8.1.9 Industrial pH Electrode Cleaning

13

Page 14

14

Page 15

OPERATION

WARNING

Handling chemical samples, standards, and reagents can be dangerous. Review the necessary

Material Safety Data Sheets and become familiar with all safety procedures before handling

any chemicals.

ADVERTENCIA

La manipulación de muestras químicas, patrones y reactivos puede ser peligrosa. Antes de

manipular cualquier productor químico, conviene leer las Fichas Técnicas de Seguridad y

familiarizarse con los procedimientos de sugeridad.

ADVERTÊNCIA

A manipulação de amostras, padrões e reagentes químicos pode se r perigosa. Reveja as necessárias

Fichas Técnicas de Segurança do Material e familiarizese com os procedimentos de segurança

antes de manipular quaisquer substãncias químicas.

ATTENTION

La manipulation des écha ntillons c himiqu es, étalo ns et réact ifs p eut êt re dan gereuse . Li re le s fi ches

de données de sécurité des produits nécessaires et se familiariser avec toutes les procédures de

sécurité av ant de manipuler tout produ it chimique.

WARNHINWEIS

Da das Arbeiten mit chemikalischen Proben, Standards, Reagenzien und Abfällen mit Gefahren

verbunden ist, empfiehlt die Hach Company dem Benutzer dieser Produkte dringend, sich vor der

Arbeit mit sicheren Verfahrensweisen und dem richtigen Gebrauch der Chemikalien oder

Biogefahrgut vertraut zu machen und alle entsprechenden Materialsicherheitsdatenblätter

aufmerksam zu lesen.

15

Page 16

16

Page 17

SECTION 1 GENERAL INFORMATION

1.1 Instrument Description

The EC1000 Process pH/ORP Monitoring System consists of the Series EC1000

Controller, a Hach One Pump Module, and a Hach One Process pH or ORP Electrode

assembly. The system monitors a sample stream for its pH value within the range of 0 to

14, or its millivolt potential from -2000 to +2000 mV, and its temperature ranging from

0 to 60 ° C. The sys tem also indica tes when pr eset hi gh and low alarm limits are exceeded,

provides relay closures for external devices, and provides output currents to drive a

recorder and remote process control equipment. Each of these items are described in

detail in the following sections.

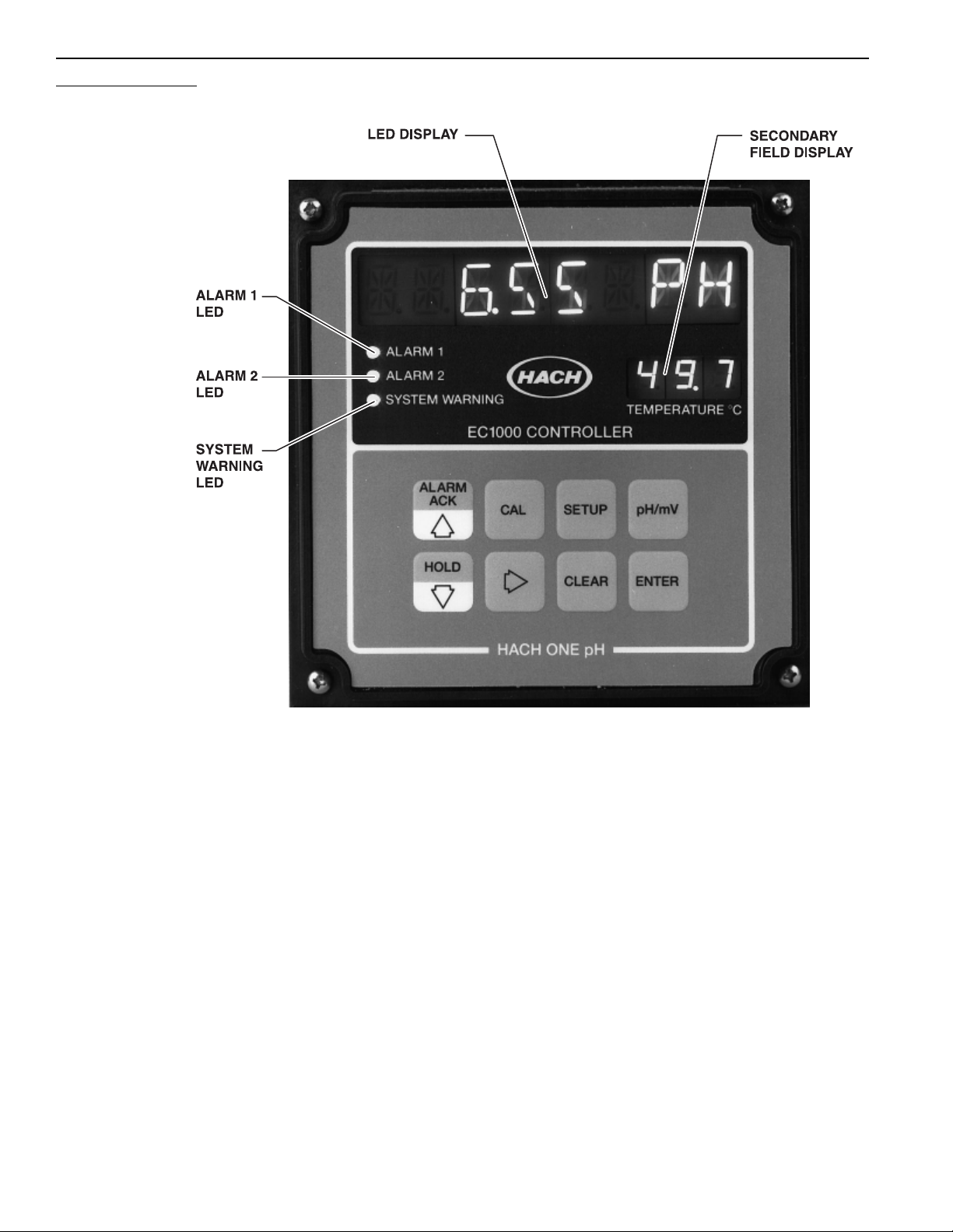

1.2 EC1000 pH/ORP Controller

The controller is menu driven with PID capability and is housed in a NEMA 4X/IP66

enclosure (see Figure 1 on page 18). It is set up to receive two current loop inputs from a

pH or ORP probe preamplifier, and to provide a continuous readout of the sample pH or

millivolt value as well as the sample temperature. Output capabilities of the controller

include two 4-20 mA outputs for recording and controlling pumps and optional RS-232C

and 20 mA current loop serial port. Alarm features include user programmable Alarm 1

and Alarm 2 setpoint selections for any one of the operating modes (pH, millivolt, or

temperature) with SPDT relay contacts. The alarm can be a combination of

operating modes:

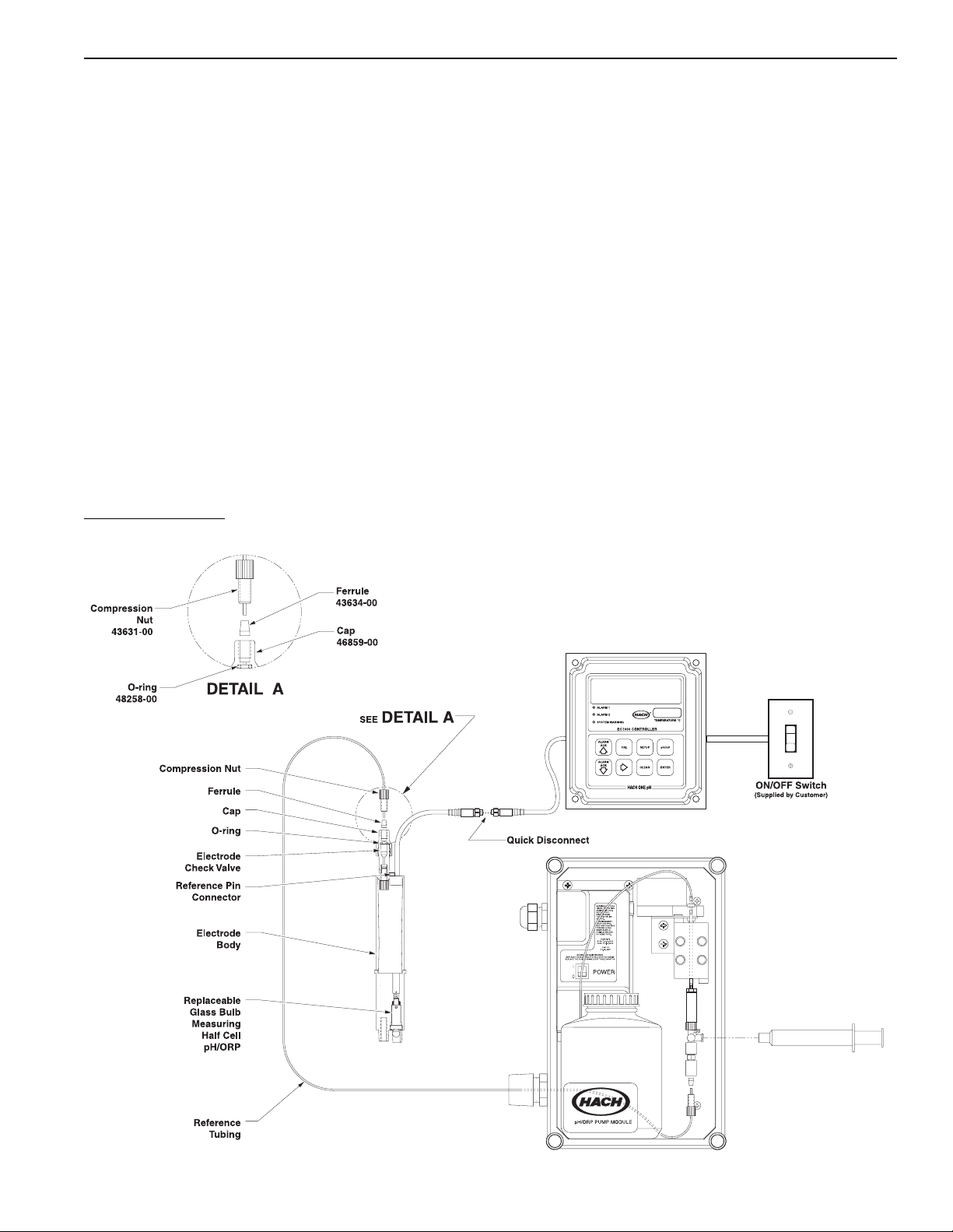

1.3 Electrolyte Pump

Note: The electrolyte

pump is not used with the

self-pressurized Industrial

Process pH Electrode with

self-pressurized

electrolyte, Cat. No.

48276-00. See Section 1 .6

Industrial Process pH

Electrode.

(Example 1)

Alarm 1-pH High Alarm

Alarm 2-Temperature High Alarm

(Example 2)

Alarm 1-pH Low Alarm

Alarm 2-Temperature Low Alarm

The EC1000 Controller can be mounted up to 1000 feet from the electrode. The pump

module can be mounted up to 50 feet from the electrode.

The pump used on this system is a low pressure linear peristaltic pump, whi ch opera tes up

to 35 psi. The pump is housed in a NEMA 4X enclosure, and allows for a maximum of

50 feet separation from the electrode. It continuously pumps electrolyte through a freeflowing junction in the electrode (500 mL of electrolyte [Cat. No. 24291-49]) lasts

approximately 30 days). The pump module contains a refillable electrolyte reservoir (see

Figure 2 on page 20).

17

Page 18

Figure 1 Controller Front Panel

18

Page 19

Table 1 Controller Front Panel

Item Name Function

1 LED Display Main display field. Consists of eight 14-segment alpha-numeric 0.54″ high red LED characters.

During normal operation, this field displays either the pH or mV value (depending on the mode of

operation selected). This field also displays menu messages, edit menu values, and error messages.

See

Figure 1

2 Secondary

Display Field

3 SETUP key This key enters the setup menu. The setup is entered when it is pressed.

4 pH/mV key During normal operation (instrument displaying pH/mV), this key toggles the reading between

5 ENTER key This key, within the menus, either moves a level deeper into the menus, or accepts an edited selection.

6 CLEAR key This key, within the menus, either clears changes in an edit portion of a menu, or backs up one menu

7 RIGHT

ARROW key

8 HOLD/DOWN

ARROW key

The secondary display fiel d consists of three 7-segment numeric 0.3″ high green LED digits.

During normal operation, this field displays temperature. In the setup menu, this field displays

abbreviations to help indicate which branch of the setup menu the operator is in. See

pH and mV. If the instrument is in any of the menus, pressing this key returns the instrument to

normal operation.

leve l. If this i nstrument i s in an ed it portion of a menu s elect ion, and the v alu e is cha nged, th en this k e y

restores the original value. Otherwise, this key causes the menu selection to back up one level; if the

menu is at the top level, this key returns the instrument to normal operation (instrument

displaying pH/mV).

This key, in an edit portion of a menu selection, selects the next digit to the right to edit. The selected

digit flashes. When the instrument is in one of the non-editing portions of the calibration/setup menus,

or in normal operation (instrument displaying pH/mV), this key is not valid; if pressed, an INVALID

message flashes on the main display.

During normal operation (instrument displaying pH/mV), this key functions as a hold. When pressed,

the outputs (alarm relays, recorder, and controller outputs) alternately hold at the current value, or

release to normal operation. When the outputs are held, the first character in the main display

flashes an H. (

appear.

the instrument is in one of the calibration/setup menus, this key scrolls down through the menu

selections. When the instrument is in an edit portion of a menu selection, this key decreases the

selected (flashing) digit.

9 ALARM ACK/

UP ARROW

key

10 CAL key This key enters the calibration menu. From th is menu, the pH electrode, temperature probe, and mV

11 System warning Red LED. Indicates a probe failure or controller malfunction. Refer to Table 4 on page 42 for specific

12 Alarm 2 Red LED. User programmable setpoint alarm. See

13 Alarm 1 Red LED. User programmable setpoint alarm. See

During normal operation (instrument displaying pH/mV), this key functions as an alarm acknowledge.

When pressed, the alarms are alternately disabled or enabled. When the alarms are disabled, the

three alarm indicators flash, and the alarm relays are in the non-alarm state. After the alarms are

disabled for 30 minutes, they automatically enable. When the instrument is in one of the

calibration/set up m en us, this key scrolls up through the me n u selections. When the instrument is in an

edit portion of a menu selection, this key increases the selected (flashing) digit.

offset can be calibrated, and the calibration reviewed.

system warnings tha t appe ar on t he ma in LED dis pla y. For most system warnings , th e use r mu st que ry

the system to determine the warning. See

.

Figure 1.

Note: The H appears only during normal operation; in the menus, the H does not

) After the outputs are in the hold state for 30 minutes, they automatically release. When

Figure 1

.

Figure 1.

Figure 1.

19

Page 20

Figure 2 Pump Module

20

Page 21

1.4 Hach One Process pH Electrode

The Hach One pH Electrode features a continuous, free-flowing reference junction to

assure a constant long-lasting reference potential. The electrode contains a replaceable

pH glass sensor (in bulb or flat configuration) a reference half cell, a temperature sensor,

and an internal preamp. The internal preamp produces two current loop signals, one for

mV and the other for temperature. The preamp allows for up to 1000 feet of separation

between the electrode and meter, and is operable up to a depth of 40 feet. The

electrode housing works in any of the sample handling systems described in Section 1.7

Sample Handling System.

1.4.1 Sodium Error

Acid error is ne gligibl e; neg ati v e sodium er ror , usually pr esent in al kaline s olutions, is lo w

even at pH values as high as 12. To determine the sodium error in pH units, measure the

apparent pH and sodium concentration of the test solution and determine the error from

Figure 3. Locate the point (on the appropriate pH horizontal grid line) representing the

sodium concentration based on the extrapolation between the 229, 2,290, and

22,900 = mg/L Na plots. Add the vertical grid line at that point to the apparent pH meter

reading. For example, a sample that reads pH 12 with a Na+ concentration of 0.5M has a

negative sodium error of approximately 0.12 pH units. Therefore, the actual pH of the

sample is 12.12.

Figure 3 Sodium Ion Error Graph

1.5 Hach One ORP Electrode

The Hach One ORP Electrode also features the continuous, free-flowing reference

junction, a temperature sensor, and a preamp. It is housed in the same electrode body as

the pH flat configured electrode (see Figure 4 on page 22). The replaceable sensor is a

Platinum disc sealed in glass. Select the mV readout for ORP applications.

TYPICAL SODIUM ERROR FOR

HACH ONE COMBINATION pH

ELECTRODE (AT 25 °C)

21

Page 22

Figure 4 Electrodes

1.6 Industrial Process pH Electrode

The Hach Industrial pH Electrode’s unique design does not use an electrolyte pump and

does not have a replaceable sensor. The low-maintenance electrode has self-pressurized

electrolyte and a flat electrode. The electrode features high temperature and pressure

resistance and is designed for traditional applications such as water and wastewater

analysis. The electrode is housed in a CPVC body with a built-in preamplifier and has the

same size and shape to fit all of the mounting configurations described in SECTION 5,

INST ALLATION.

1.7 Sample Handling System

Three sampling techniques can be used with the EC1000 pH/ORP System: submersible,

flow-thru cell, and in-line inst allations. Mounting kits are available fo r the different

applications. Refer to SECTION 5, INSTALLATION for detailed installation information.

1.7.1 Submersible

For the submersible application, mount the electrode to the end of a pipe using the

Submersible Mounting Kit (Cat. No. 46401-00), see Figure 15 on page 61, and place it in

a tank or non-flowing sample.

1.7.2 Flow-Thru Cell

The Flow-Thru Cell provides for atmospheric sampling of the process water, and easy

installation and removal of the electrode. Mounting Kit (Cat. No. 46403-00) is required,

see Figure 16 on page 61.

1.7.3 In-Line

For the in-line application, place the electrode directly in-line with the sample through a

“Tee” pipe fitting using the In-line Mounting Kit (Cat. No. 46402-00), see Figure 15 on

page 61. Pressure reducers may be required if the sample pressure is greater than 35 psig.

22

Page 23

1.8 Principle of Operation

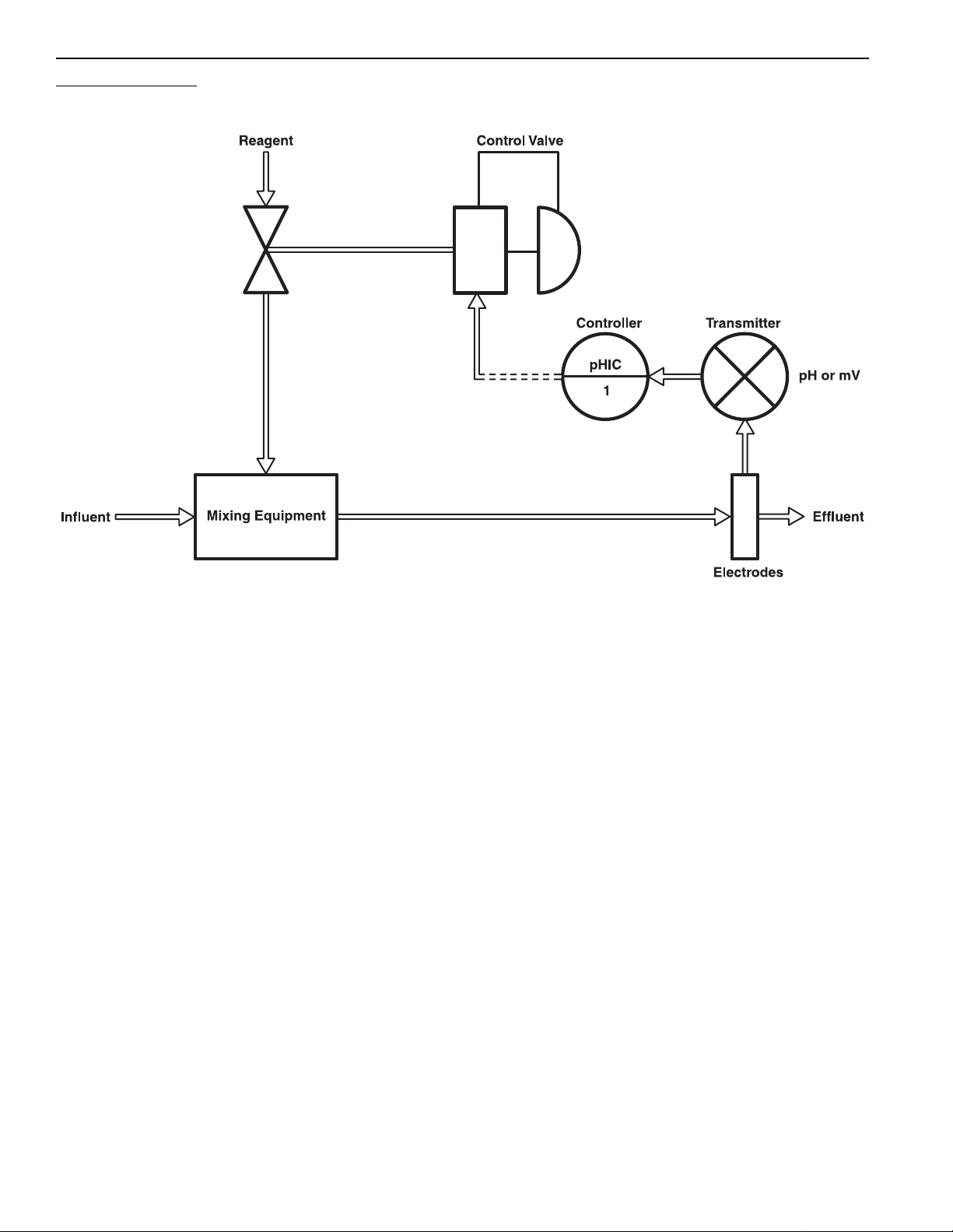

The EC1000 Process pH/ORP System consists of a combination pH or ORP electrode, a

controller, and a reference electrolyte pump (see Figure 5 on page 23). The electrode

consists of a pH or ORP measuring half cell and a double junction reference half cell,

which establish a potential characteristic of the sample. This potential is converted to a

proportional current by a built in preamplifier in order to stabilize the signal for long

distance transmission to the controller. Included in the electrode is a tem perature sensor

whose signal also is stab ilized and sent to the controller to allow for temperature

compensation or temperature correction of the pH/ORP measurement. Separate from the

controller and electrode is a reference electrolyte pump that supplies fresh electrolyte to

the reference half cell. The pumped electrolyte maintains an open reference junction

through a capillary outlet to produce a stable and constant reference potential.

Note: The electrolyte

pump is not used with the

self-pressurized Industrial

Process pH Electrode with

self-pressurized

electrolyte, Cat. No.

48276-00. See Section 1 .6

Industrial Process pH

Electrode.

Figure 5 System Components

As the electrode measures the pH (or mV) of the water source, a signal is transmitted to

the controller. If the pH (or mV) is outside the setpoint range, the controller can transmit

a current output signa l to a reagen t pump (or v alv e) tha t adds reage nt to a mix ing tank. See

Figure 6 on page 24 for details. As the reagent is added to th e water, the value of the pH

(or redox potent ia l) i s adjusted to fall within t he setpoint range. Refer to SECTION 4, PID

CONTROL, for a detailed discussion of this process.

23

Page 24

Figure 6 pH Control Loop

24

Page 25

SECTION 2 OPERATION

2.1 Operating the User-Programmable Setup

The EC1000 Controller is a menu-operated instrument. In the setup menu, each of

the instrument settings are grouped into submenus of common settings. For user

programming, move to the desired setting, and edit the current value. Refer to

Table 18 on page 99, which describes operation of the Diagnostic Test Menu.

2.1.1 Moving Around the Menu

After pressing the SETUP key to enter the menu, use the UP and DOWN ARROW keys to

scroll through the top level menu to the desired entry. Use the

into a submenu (use the

desired settin g is dis played, press t he

and change the value as needed. (Exit the menu at any time by pressing the

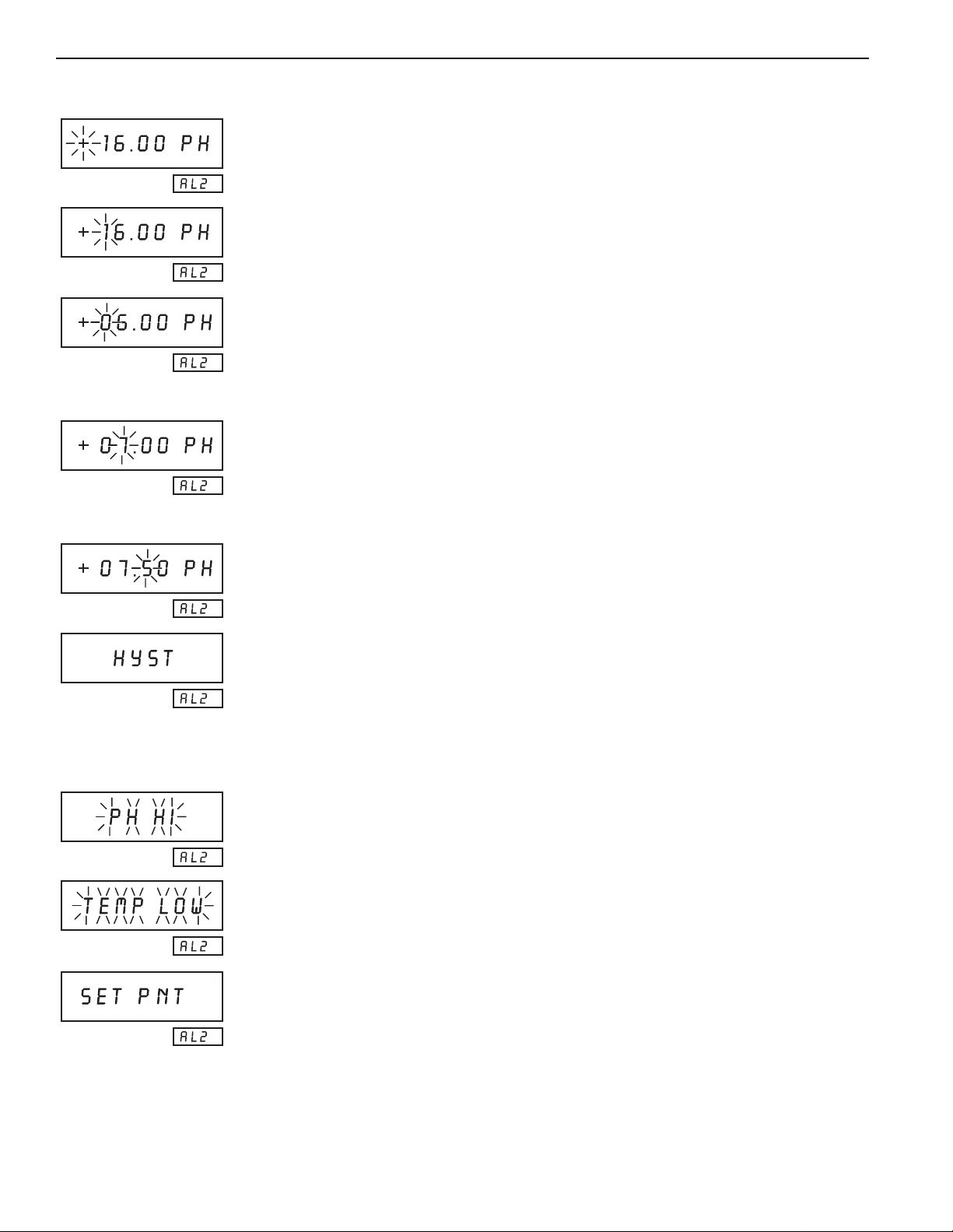

Example—checking or changing the ALARM2, SET PoiNT:

CLEAR key to back up to the next higher menu level). Once the

ENTER key to move down

ENTER key to dis play the curr ent v alue o f the setting ,

pH/mV key.)

1. Press

2. Press

SETUP to enter the SETUP menu.

ENTER to move into the ALARMS submenu.

3. Press the

4. Press

ENTER to move into the ALARM2 submenu.

5. Press the

6. Press

ENTER to display the ALARM2 set point.

DOWN ARROW key to scroll to the ALARM2 entry.

DOWN ARROW key to scroll to the SET PoiNT entry.

2.1.2 Editing a Setup Value

Two types of setup data require editing. The first is a number entry such as an alarm set

point. Any value in the set point range can be entered. When the number entry is selected

first, the first digit space displays a flashing

ARROW key alternates between the two signs. Pressing the RIGHT ARROW key moves to

the first digit. This digit flashes indicat ing that it can be edited. Pressing the

key increas es the digit v alue, and pressing the

The remaining digits are changed by repeating this process. When the whole number is

changed to the desired value, press the

during the editing process, the original value is restored by pressing the

+ or – sign character. Pressing the UP or DOWN

UP ARROW

DOWN ARR O W ke y decrease s the digit v alue.

ENTER key to save the new value. At any time

CLEAR key.

25

Page 26

Example—changing ALARM2, SET PoiNT from 16.00 pH to 7.50 pH:

1. First move to the

Around the Menu. Press

2. Press the

3. Press the

4. Press the

5. Press the

6. Press the

7. Press the

RIGHT ARROW key to move the flashing digit to the right.

DOWN ARROW key to change the 1 to 0.

RIGHT ARROW key to move to the next digit.

UP ARROW key to change the 6 to 7.

RIGHT ARROW key to move to the next digit.

UP ARROW key five times to change the 0 to 5.

ALARM2 set point entry as described in Section 2.1.1 Moving

ENTER.

8. Press

ENTER to save the new value.

The second type of setup data is discrete values such as the recorder mode where a pH,

mV, or temperature recorder mode is selected. In this case, the complete entry flashes.

Pressing the

the desired entry, press the

UP or DOWN ARROW key scrolls through the list of settings. After selecting

ENTER key to save the setting.

Example—changing ALARM2, MODE from a PH HI alarm to TEMP LOW alarm:

1. Select ALARM2, MODE as described in Section 2.1.1 Moving Around the Menu.

ENTER.

Press

2. Press the

3. Press

DOWN ARROW key five times to select the TEMP LOW alarm setting.

ENTER to save the new value.

26

Page 27

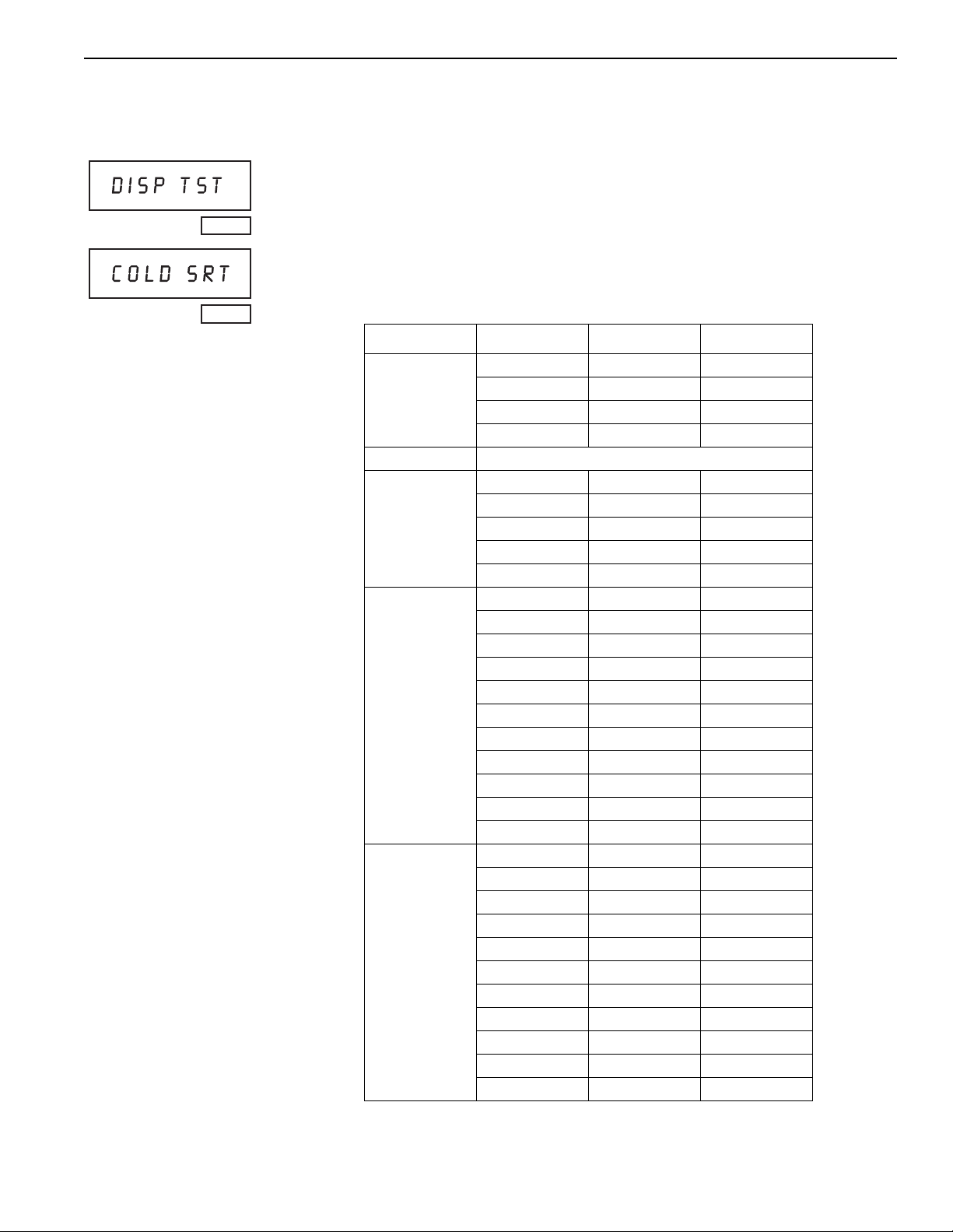

2.1.3 Restoring Default Settings

To clear all previous settings (not necessary on first time start-up), press CLEAR and

ENTER simultaneously and the D ISPlay TeST appears:

1. Press the

DOWN ARROW key to scroll down through the display test menu to

COLD StaRT.

2. Press

ENTER. This procedure returns all settings to the controller defaults. Table 2

shows all default values for the controller setup menu.

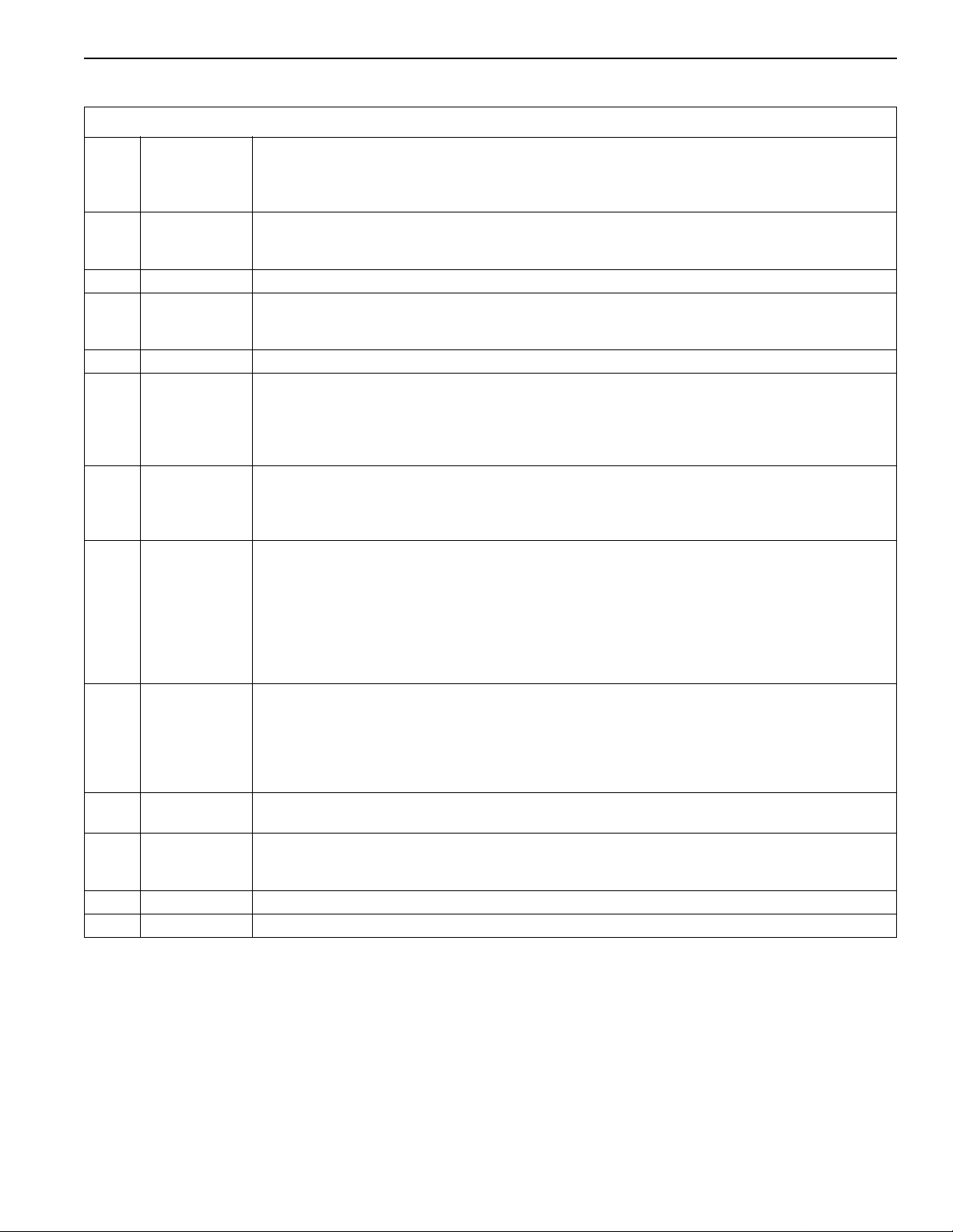

Table 2 Setup Menu Default Value

Menu Options Submenu Default

MODE — PH HI

ALARM1

ALARM2 [same as ALARM1]

RECORDER

CONTROL

INIT SET

SET PNT — 16.00 PH

HYST — 0.10 PH

DLY TIME — 0 SEC

MODE — PH

WINDOW MINIMUM -2.00 PH

— MAXIMUM 16.00 PH

OUT TRIM 0 TRIM 1=4.00

— FS TRIM 1=20.00

MODE — PH

SET PNT — 7.00 PH

DEAD BD — 0.00 PH

PRESET — 50.0%

GAIN — 01.00

RESET — 00.00/HR

RATE — 00.00 MIN

TITR CUR CUR LINEAR+

—POINTS03

OUT TRIM 0 TRIM 1=4.00

— FS TRIM 1=20.00

°C COMP TYPE AUTO TC

— SET PNT 25.0 °C

— SOL TC 0.0 PH

SERIAL I/O BAUD 1200

— PARITY NONE

— DATA BIT 8

—STOP BIT2

— PRT DLY ENABLED

— PRT INTR 00 MINS

OUTPUT 2 — CONTROL

SIG AVG — 1 SEC

27

Page 28

2.2 Setup Menu

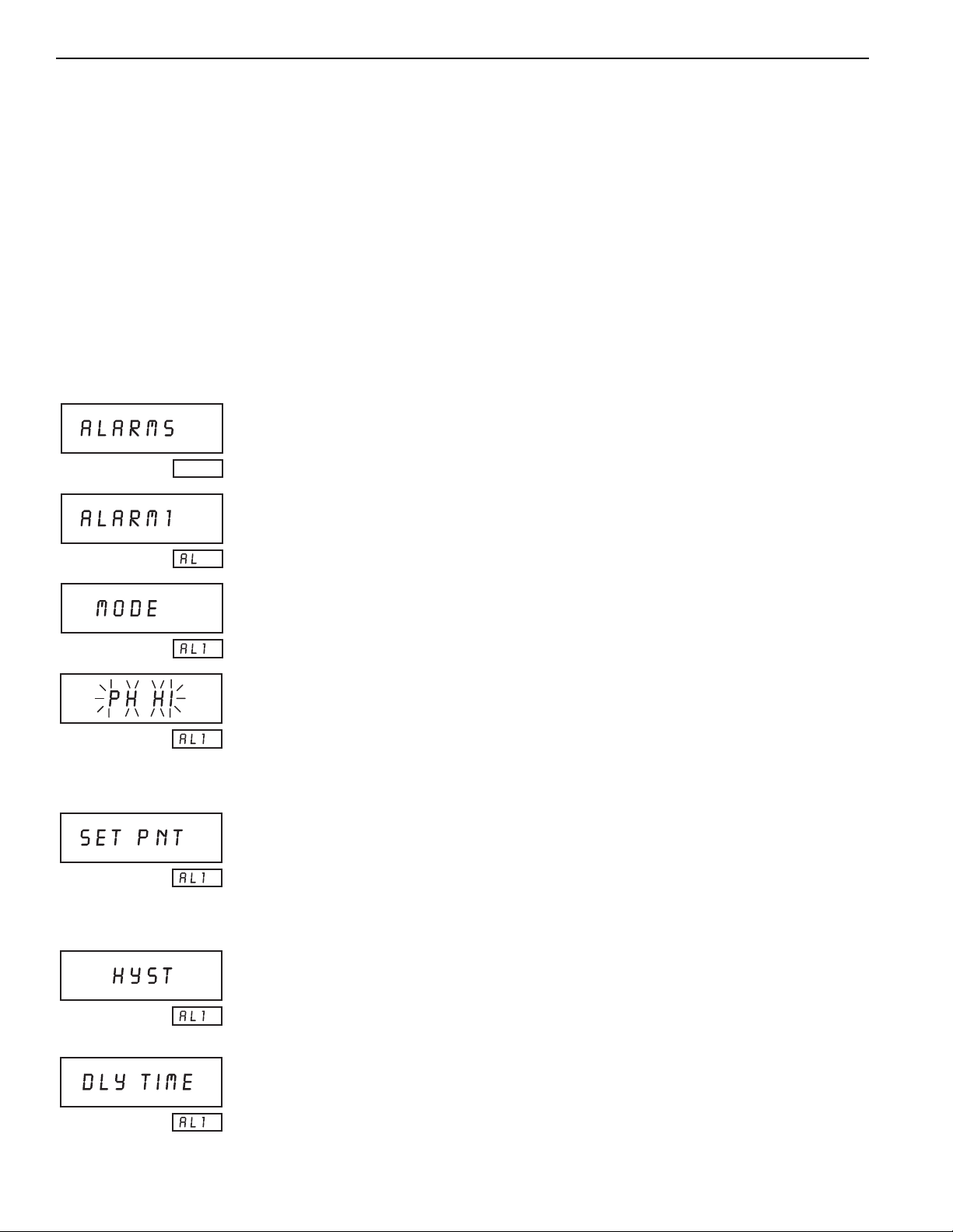

2.2.1 Alarms

Two independent programmable setpoint alarms are provided. Each alarm can be set to

operate on pH, mV, or temperature setpoints, and may b e programmab le to be either a high

alarm or a low al ar m. When the programmed setpoints are exceeded, the alarm LED turns

on. The alarm relay actuates when external power is brought to the relays. The instrument

also features programmable alarm hysteresis and delay time. Hysteresis is the difference

between the alarm turn on and turn off values. The delay time provides a delay, from the

time the alarm setpoint is excee ded, bef ore the alar m is actua ted .

The delay time is adjustable from 0 to 30 second s.

To check or program the alarm settings:

SETUP to call up the SETUP menu options.

Press

ENTER to move into the ALARMS submenu.

Press

ENTER to move into the ALARM1 submenu.

Press

The MODE menu is PH high/low, mV high/low, or temperature high/low.

ENTER to select the MODE menu.

Press

PH HI is the default. Scroll through the MODE menu by pressing the

UP ARROW key.

When the desired mode is displayed, press

ENTER to lock in the chosen MODE and move

DOWN ARROW or

to the next ALARM1 submenu.

ENTER. The current SET PoiNT value appears on the display.

Press

To change the value, move the flashing display by pressing the

and increase or decrease the value by pressing the

UP ARROW key.

When the value is set, press

ENTER. The current HYSTeresis appears on the display.

Press

ENTER.

DOWN ARROW key or the

RIGHT ARROW key

The hysteresis is adjustable from 0.01 to 2.0 pH, 0.1 to 100 mV, or 0.1 to 2.0 °C.

To change the value, move the flashing display by pressing the

increase or decrease the value by pressing the

DOWN or UP ARROW key.

RIGHT ARROW key and

ENTER.

Press

ENTER. The current DeLaY TIME will appear on the display. The ALARM1 delay

Press

time is adjustable from 0 to 30 seconds. Reset the delay time by pressing the

ARROW key and increase or decrease the value by pressing the DOWN ARROW key or

UP ARROW key.

the

RIGHT

28

Page 29

Press

ENTER. The DeLaY TIME is locked in, and the display returns to:

CLEAR. The display backs out to:

Press

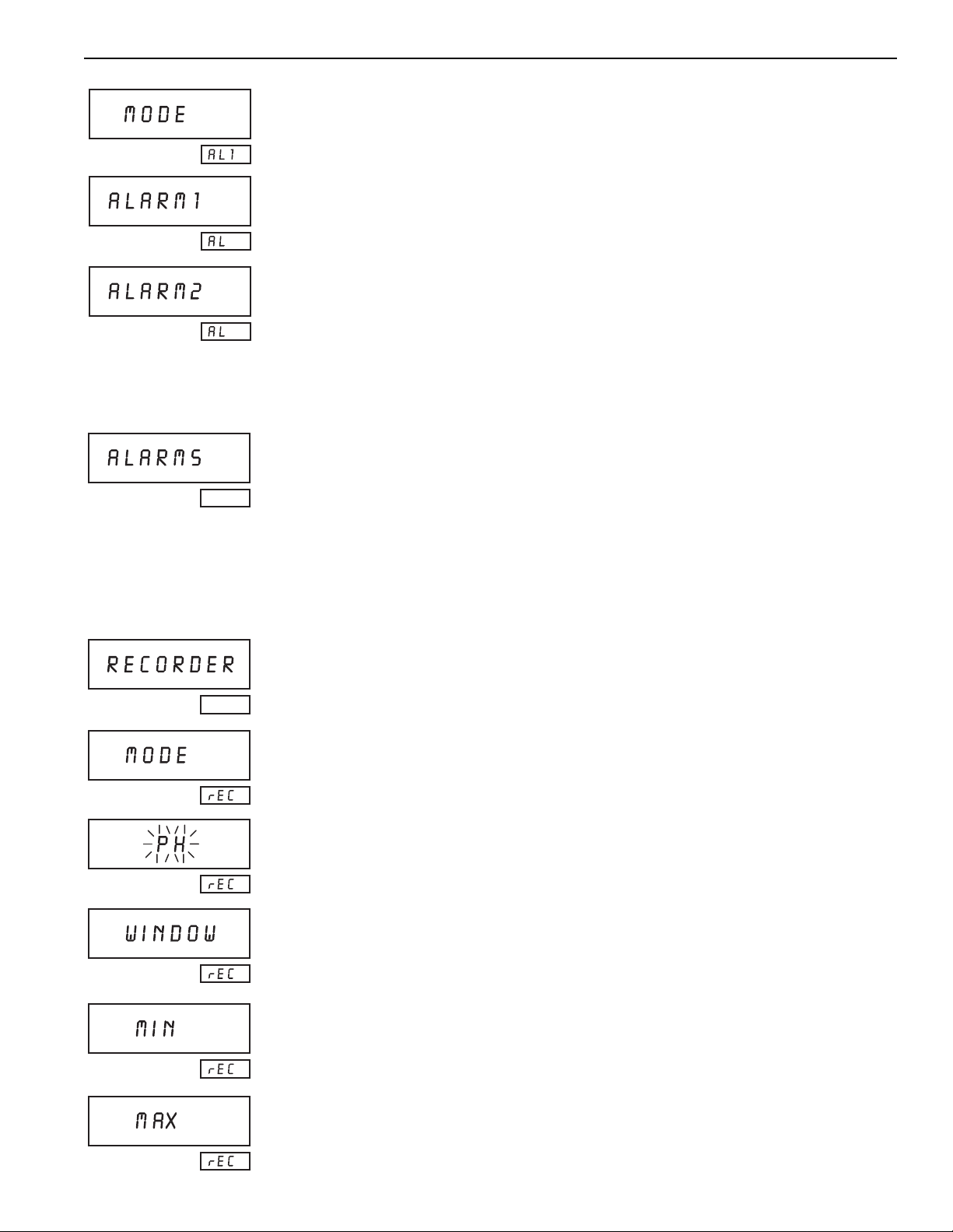

2.2.2 Recorder Output

Press the

DOWN ARROW key.

The ALARM2 submenu is identical to ALARM1 submenu: mode; set point; hysteresis;

and delay time are all selected identical to ALARM1.

CLEAR and then CLEAR again to back out to the top level of the menu, or press

Press

pH/mV to exit the menu.

An isolated 4-20 mA recorder output is provided. The output also can be adjusted to

0-20 mA, and with the addition of a resistor across the recorder output lines, can be setup

as a 0 to 100 mV, 0 to 1 V, or 0 to 10 V voltage output. See Section 5.6.4 Recorder and

Controller for resistor installation. The recorder can be set to cover any portion of the pH,

mV, or temperature measurement range. The zero and full scale mA output can be

trimmed from the ke yboard so the out put can be calibr ated to e xact ly 4-20 mA, or adjuste d

to match the zero and full scale on the recorder being used.

To check or program the recorder settings, press the

SETUP key to call up the

SETUP menu.

Press the

DOWN ARROW key to scroll to:

This option controls the minimum and maximum outputs shown on the

RECORDER submenu:

ENTER.

Press

PH is the default. The mode options are: PH, MV, or TEMPerature. Select the mode by

pressing the

displayed, press

This option controls minimum and maximum settings on the recorder. Press

Press

Press

ARROW

Press

DOWN ARROW key or the UP ARROW key. When the desired MODE is

ENTER.

ENTER.

ENTER again to display the current MINimum value.

ENTER and change the value by pressing the RIGHT ARROW key and the DOWN

key or the UP ARROW key.

ENTER to advance to:

Press ENTER and change the cur ren t MAXimum value by pressing the RIGHT ARROW key

and the

DOWN ARROW key or the UP ARROW key.

29

Page 30

Press

ENTER to save the new value.

CLEAR. This backs out to the WINDOW menu of the RECORDER submenu.

Press

Next, press the

DOWN ARROW key to advance to:

The function of the OUTput TRIM adjustment is slightly different from the rest of the edit

functions. When the zero (min imum scale ) trim is se lected, th e recor der output is dri ve n to

zero (minimum scal e) , a nd the output value is displ aye d wi th the right hand digit flashing.

If the output is too lo w, pressing a nd hol ding t he

up. When the output is corre ct, re lease th e

DOWN ARROW key to adjust the setting. If a large adjustment is required (e.g., adjusting

the recorder zero from 4 mA to 0 mA), use the

digit to the left. When the

ENTER.

Press

ENTER to display and output the current recorder zero (in terms of mA output).

Press

Press the

Press

Press

Press the

Press

DOWN ARROW key or the UP ARROW key to adjust the output.

ENTER.

ENTER to display and output the current full scale recorder (in terms of mA output).

DOWN ARROW key or the UP ARROW key to adjust the output.

ENTER.

UP/DOWN ARROW keys are used, the output ramps faster.

UP ARROW ke y causes t he outp ut to ra mp

UP ARROW k ey. If the output is too hi gh, use th e

RIGHT ARROW key t o move the flashing

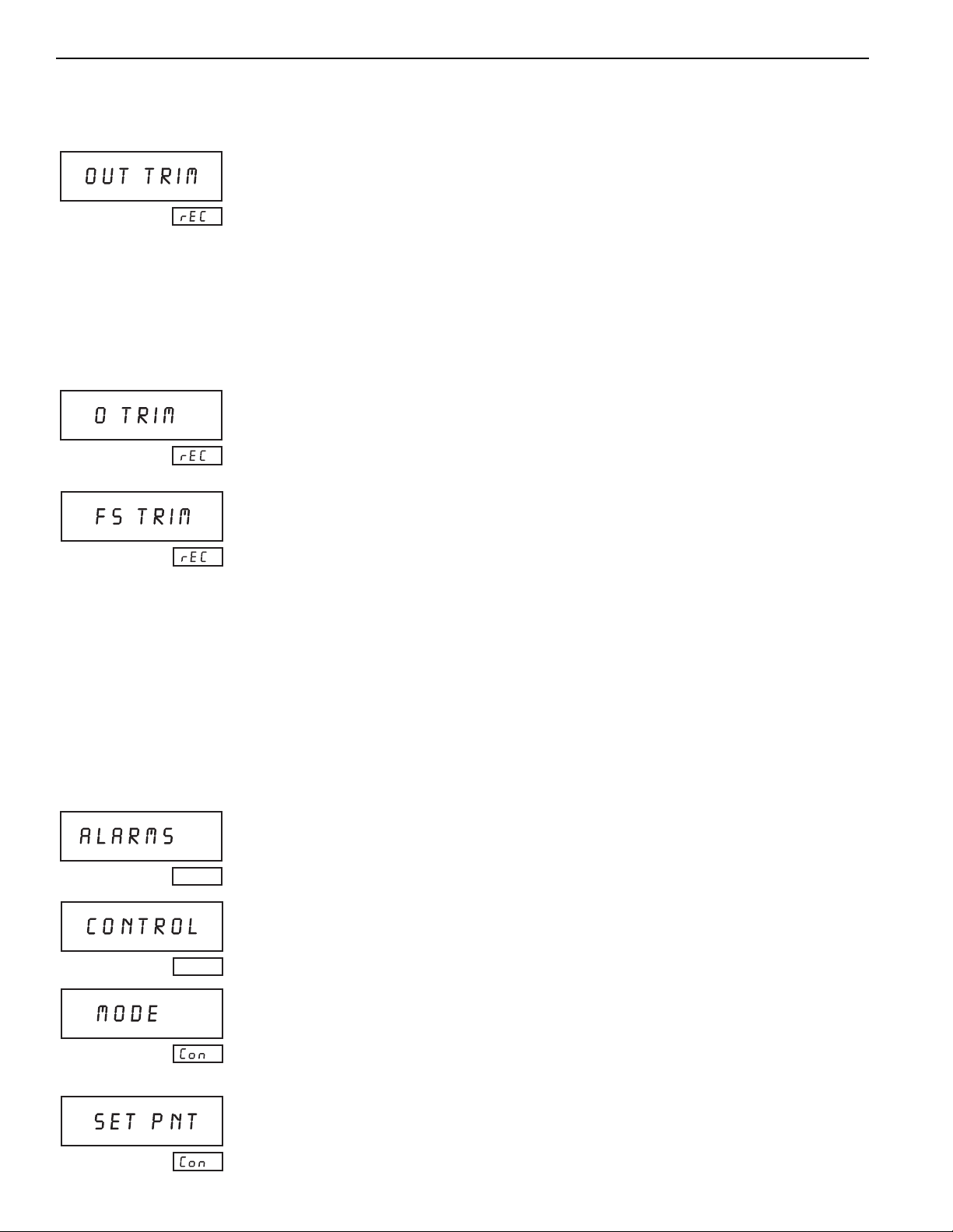

2.2.3 PID Output

CLEAR and then CLEAR again to back out to the top level of the menu or press the

Press

pH/mV key to exit the menu .

A second isolated 4-20 mA output is provided. This output can be selected to be either

a PID controller output or a second recorder output (see Section 2.2.5 Initial Setup, INIT

SET\OUTPUT 2). If the controller output is selected, the following menu entries are

displayed. Refer to SECTION 4 PID CONTROL for a full explanation of these settings.

To check or program the controller settings:

SETUP to call up the SETUP menu:

Press

Press the

Press

The controll er

Press

DOWN ARROW key and then the DOWN ARROW key again to scroll to:

ENTER.

MODE options are pH or mV.

ENTER. Toggle between pH or mV by pressing the DOWN ARROW key. When the

selection is made:

ENTER to save the pH or mV selection and advance to:

Press

30

Page 31

Press

ENTER.

The current v alue for SET P oiNT app ears on the disp lay. Change the v a lue by pr essi ng the

RIGHT ARROW key and the DOWN ARROW key or the UP ARROW key.

ENTER to save the SET PoiNT value and advance to:

Press

ENTER.

Press

The current value for DEAD BanD appears on the display. Change the value by pressing

RIGHT ARROW key and the DOWN ARROW key or the UP ARR OW key.

the

ENTER to save the DEAD BanD value and advance to:

Press

ENTER.

Press

The current setting for the Controller PRESET output appears on the display. Change

the value by pressing the

UPARROW key.

ENTER to save the PRESET value and advance to:

Press

ENTER.

Press

RIGHT ARROW key and the DOWN ARROW key or the

The current setting for the Controller GAIN appears on the display. Change the value by

pressing the

RIGHT ARROW key and the DOWN ARROW key or the UP ARROW key.

ENTER to save the GAIN value and advance to:

Press

ENTER.

Press

The current value for the Controller RESET action appears on the display. Change

the value by pressing the

UPARROW key.

ENTER to save the RESET value and advance to:

Press

ENTER.

Press

The current value for the Controller RATE action appears on the display. Press the

ARROW

Press

Press

key and the DOWN ARROW key or the UP ARROW key to change the value.

ENTER to save the RATE value and advance to:

ENTER.

RIGHT ARROW key and the DOWN ARROW key or the

RIGHT

Toggle between the TITRation CURve mode selections (linear +, linear -, curve) by

pressing the

DOWN ARROW key or the UP ARROW key.

The user must choose linear + or linear - unless a valid set of points is entered. Press

ENTER to save the value and advance to:

ENTER.

Press

Note: The following data

entry sequence is

dependent upon the

number of points selected

above (9).

Select the number of points desired on the TITRation CURve by pressing the

ARROW key and the DOWN ARROW key or the UP ARROW key.

RIGHT

(Range: 3 to 20)

Press ENTER. The display asks for percent of reagent addition (X axis) and pH or mV

value points (Y axis). Percentages and values must be entered in ascending and

descending order with a new entry for each point selected. The controller does not accept

31

Page 32

repeat percentages or values. When all entries are made, return to the Controller MODE

options and select CURVE.

Example—(Assuming PH was selected for the controller MODE)

Press

ENTER.

Select the percent (of reagent addition) for the first point (X axis) by pressing the

ARROW key and the DOWN ARROW key or the UP ARROW key.

ENTER.

Press

Select the PH value by pressing the

UP ARROW key.

RIGHT ARROW key and the DOWN ARROW key or the

RIGHT

The Controller prompts the user to continue entering the percentages and PH values

through nine entries (cor respond ing to number of point s sele cted) . The green LED d ispla y

continues to show which point selection is being made at any time even if the user scrolls

back to the beginning of the sequence.

ENTER then CLEAR followed by the DOWN ARROW key to advance to:

Press

The function of the output trim adjustment is slightly different from the rest of the edit

functions . When the zero (minimum scale) trim is selected, the con troller output is driven

to zero (minimum scale), and the output value is displayed with the right hand digit

flashing. If the output is too low, pressing and holding the

UP ARROW key causes the

output to ramp up.

When the output is correct, release the

DOWN ARROW key. If a large adjustment is requ ired (e.g., adjusting the controller zero

from 4 mA to 0 mA), use the

When the

UP or DOWN ARROW keys are used, the output ram ps faster.

RIGHT ARROW key to move the flashing digit to the left.

UP ARROW key. If the output is too high, use the

ENTER.

Press

ENTER.

Press

This is the trim controller zero setting (in terms of mA output).

Press the

Press

DOWN ARROW key or the UP ARROW key to adjust the output.

ENTER.

32

Page 33

Press

ENTER.

This is the trim controller full scale setting (in terms of mA).

2.2.4 Recorder 2

2.2.5 Initial Setup

Press the

Press

pH/mV key to exit the menu .

DOWN ARROW key or the UP ARROW key to adjust the output.

CLEAR three times. This bac ks out t o the top level of the menu, or you may pr ess th e

The second isolated 4-20 mA output is provided. This output can be selected to be either

a PID controller output or a second recorder output (see INIT SET\OUTPUT 2 in Section

2.2.5 Initial Setup). This menu is the same as the recorder menu (see Section 2.2.2

Recorder Output) except that the mode selection is limited to pH and mV.

The menu entry contains the temperature compensation (C COMP), SERIAL I/O,

OUTPUT 2, and SIGnal AVeraGing setup sub-menus.

The temperature compensation (C COMP) submenu selects between automatic and

manual temperature compensation. When automatic temperature compensation is

selected, the temperature reading from the temperature sensor built into the probe is used

to calculate the pH reading. When the manual temperature compensation is selected, the

value entered into the temperature setpoint is used to calculate the pH reading.

The solution temperature compensation (SOL TC) submenu allows for the compensation

of pH changes to the solution due to temperature. The default setting of 0 pH/°C has no

effect on the reading. For non-zero entries, the instrument subtracts the entry value times

the number of °C the solut ion i s above 25 °C. For ex ample, i f th e entr y is 0.0 10 pH/°C and

the temperature is 50 °C, the instrument will subtract 0.25 pH from the r eading. When the

entry is a non-zero value, an asterisk (*) will appear in the first display location to indicate

the solutio n temperature compensati on is active.

The SERIAL I/O submenu sets up the RS232 C operation. Refer to SECTION 3 SERIAL

INTERFACE for a full e xplanation of these settings. OUTPUT 2 selects between a second

recorder output and a PID controller output.

The SIGnal AVeraGe entry changes the signal averaging to provide a more quiet signal

when the sample is erratic. The range of adjustment is 0 (no signal averaging) to 10

seconds signal average.

To ch eck or program the initial setups refer to the following sections.

2.2.5.1 Temperature Compensation Setup

SETUP to call up the Setup menu:

Press

Press the

Press

DOWN ARROW key three tim es to scroll to:

ENTER to move into the temperature compen sation (C COMP) submenu.

33

Page 34

Press

ENTER.

ENTER to choose the temperature compensation mode (automatic [AUTO TC] or

Press

manual [MAN TC]).

AUTOmatic Temperature Compensation is the default. If MANual Temperature

Compensation is chosen, press the

ENTER.

Press

ENTER. The current SET PoiNT appears on the display.

Press

DOWN ARROW key or the UP ARROW key to toggle to:

Change the SET PoiNT (Range -5.0 to 105.0 °C) by pressing the

followed by the

DOWN ARROW key or the UP ARROW key.

RIGHT ARROW key

Press ENTER to save the value and advance to:

ENTER.

Press

ENTER. The current SOLution Temperature Compensation appears on the display.

Press

Change the SOLution TC (Range: -0.100 pH to +0.100 pH) by pressin g the

key followed by the

ENTER, CLEAR and then the DOWN ARROW key to proceed to the SERIAL inte rface

Press

DOWN ARROW key or the UP ARROW key.

RIGHT ARROW

submenu.

ENTER.

Press

ENTER.

Press

Toggle between baud rates (300, 600, 1200, 2400, 4800, 9600) by pressing the

ARROW

Press

Press

Change the display by pre ssing the

or the

key or the UP ARROW key.

ENTER when the desired rate is selected.

ENTER. The PARITY menu is ODD, EVEN or NONE (default is NONE).

RIGHT ARROW key followed by the DOWN ARROW key

UP ARROW key.

34

DOWN

Page 35

Press

ENTER.

The DATABIT menu is 7 or 8. Select the value by pressing the

UP ARROW key.

ENTER.

Press

The STOPBIT menu is 1 or 2. Select the value by pressing the

UP ARROW key.

ENTER.

Press

ENTER followed by the DOWN ARROW key or the UP ARROW key to toggle between

Press

ENABLED and DISABLED. Press

ENTER.

DOWN ARROW key or the

DOWN ARROW key or the

The PRinT INTerval setting ra nge is 00 to 99 mi nutes. 00 tu rns the print inte rv al of f. Ma ke

a selection by pressing the

UP ARROW key.

ENTER.

Press

RIGHT ARROW key followed by the DOWN ARROW key or the

PRinT LiSTing appears on the display.

ENTER. A listing of the instrument setup is sent to the printer. Then, OK appears on

Press

the display momentarily and the display automatically backs out to BAUD.

2.2.6 Keylock

Note: The initial keyboard

lockout code is 0000, but is

user programmable. Refer

to Section 9.1.1 Test

Diagnostic Menu for

information on

programming the k ey board

lockout code.

CLEAR followed by the DOWN ARROW key. This backs out to:

Press

ENTER followed by the DOWN ARROW key or the UP ARROW key to toggle between

Press

CONTROL and RECORD2 modes.

ENTER.

Press

ENTER.

Press

This displays the pH SIGnal AVeraGe value (00 to 10 seconds), 03 seconds is the default.

Change the display by pres sing th e

UP ARROW key.

or the

ENTER followed by CLEAR to back out to the top le vel menu, or press the pH/mV key

Press

RIGHT ARROW key followed by the DOWN ARROW key

to exit the menu.

T o pre v ent unauthori zed or accident al progra mming changes, a k eyboard lockout or secure

mode is provided using a password. In the locked mode, all program m enus may be

viewed, but no changes to the settings or operations are allowed. If a change is attempted,

the display will flash LOCKED to indicate that the keyboard is locked out.

The keyboard may be locked, unlocked, or temporarily (30 minutes) unlocked.

35

Page 36

To set the keyboard lockout status, press

SETUP to call up the setup menu:

Press the

To call up the keyboard lockout code entry, press

Using the

To key in the keyboard lockout code entry, press

If the code is correct, the sub menu is entered.

Scroll to the desired lockout status by pressing the

UPARROW key.

When the selection is made, press

CLEAR to back out to the top level of the menu or press the pH/mV key to exit

Press

the menu.

2.2.7 Reference Solution Timer

Note: The reference

solution timer is not used

with the non-refillable

Industrial Process pH

Electrode, Cat. No.

48276-00. However,

operators using the

Industrial Electrode are

required to reset the timer

as described.

UP ARROW key three times to scroll to:

ENTER.

UP ARROW and DOWN ARROW keys, enter the lockout code.

ENTER.

DOWN ARROW key or the

ENTER.

2.2.8 Warnings

A referenc e electrolyte timer is provided, which indicates when the reference electrolyte

bottle needs to be filled. Reset the timer each time the electrolyte reservoir is filled. At the

end of 30 days, the timer times out, and a system warning is displayed.

To reset the timer, press

Press the

UP ARROW twice to scroll to:

To reset the timer when adding new electrolyte to the system, press

ENTER.

Press

The display indicat es OK momen tari ly and retu rns t o TiMeR ReSeT . Press

out to the top level menu, or press

SETUP to call up the setup menu.

ENTER.

CLEAR to back

pH/mV to exit the menu.

System warnings ar e pro vided to indi cate p ossibl e probl ems in t he meter and/or elect rode.

If any system warning is pre sent, the system warning LED on the front panel lights. Th e

WARNINGS entry of the setup menu is used to display and clear the warnings. Refer to

36

Page 37

SECTION 9 TROUBLESHOOTING for additional information on the system warnings.

To display or clear the WARNINGS, press

SETUP to call up the setup menu:

Note: The probe errors

and the reference timer

time-out require the cause

of the fault to be corrected

before they will clear.

Press the

Press

Press

UP ARROW key to scroll to:

ENTER.

ENTER. The system displays the Warning Codes s hown in Table 3. Additional det ails

about the warning can be found in Section 9.1.2 Error Codes and Section 9.1.3 System

Warnings. The warning codes appear momentarily followed by CLeaR WaRNing.

Table 3 Warning Codes

CODE MESSAGE CAUSE

E00 EE FAIL EEPROM failure

E01 REF TIME reference timer time-out

E02 SOFT SRT software restart

E03 COLD SRT cold restart

E04 PROBE ER pH probe open

E05 PROBE ER pH probe shorted

E06 PRO BE ER temperature probe open

E07 PROBE ER temperature probe shorted

E08 MARG CAL marginal pH offset

E09 MARG CAL marginal pH gain

E10 MARG CAL marginal temperature offset

E11 MARG CAL marginal temperature gain

E12 PWR FAIL power failure

2.3 Calibration

Press ENTER to CLeaR WaRNings on the display.

Use this menu to calibrate the pH (or ORP) electrode, review the pH calibration, calibrate

the temperature sensor, and adjust the mV offset. The calibration menu is entered by

pressing the CAL ke y. The first disp lay to appe ar is STD 1 , foll o wed by STD 2 (after STD

1 is completed), GRAB SMP, REVIEW, TEMP, and MV ZERO. The user may then scroll

up or down through the first level of the menu to make adjustments to each calibration.

(Note: If the keyboard is locked, only the REVIEW sub menu may be entered.)

37

Page 38

WARNING

To familiarize yo urself

with handling

precautions, dangers and

emergency procedures,

always review the

Material Safety Data

Sheets prior to handling

containers, reservoirs,

and delivery systems that

contain chemical reagents

and standards. Protective

eye wear always is

recommended when

contact with chemicals

is possible.

ADVERTENCIA

Para familiarizarse con las precauciones de manipu lación, los peligros y los prcedimientos

de emergencia, siempre estudie las Hojas de Datos de Seguridad de los Materiales antes de

manipular recipientes, depósitos y sistemas de entrega que contengan reactivos y patrones

químicos. Siempre se recomienda el uso de protectores oculares cuando sea posible el contacto

con productos químicos.

AVISO

Para familiarizar-se com as precauções de manipulação, riscos e procedimentos de emergência,

examine sempre o Folheto de Dados de Segurança antes de manipular os recipientes, tanques e

sistemas de distribuição que contenham reagentes químicos e outros elementos padronizados.

Se recomenda sempre o uso de protetores para olhos, quando possa acontecer contato com os

produtos químicos.

ATTENTION

Pour se familiariser avec les précautions à prendre lors de la manipula tion, les dangers et les

procédures d'urgence, toujours lire les Fiches de Données de Sécurité des Produits avant de

manipuler les récipients, les réservoirs et les tèmes de distribution contenant les réactifs

chimiques et les solutions étalons. Il est toujours recommandé de porter des lunettes de

protection lorsqu'un contact avec les produits chimiques est possible.

WARNHINWEIS

Es wird dringend empfohlen, die Sicherheitsdatenblätter vor der Handhabung von Behältern,

Tanks und Zufuhrsystemen, die chemische Reagenzien und Standardsubstanzen en thalten,

aufmerksam durchzulesen, damit Sie sich mit den beim Umgang mit diesen Chemikalien

notwendigen Vorsichtsma ßnahmen, Risiken und Notfallschutzmaßnahmen vertraut machen,

Es wird empfohlen, in allen Situatione n, in denen mit einem Kontakt mit Chemikalien zu

rechnen ist, eine Schutzbrille zu tragen.

2.3.1 pH Calibration

There are several ways to calibrate the pH electrode. The two recommended methods are

given in the ne xt se ctions. Th e fi rst meth od is a t wo-point calibrati on with b uf f ers. Use this

method on new electrodes and periodically on electrodes already in use.

The frequency of recalibrat ion is deter mined by the ac curacy de sired and th e applicati on in

which the electrode is used.

The second procedure listed is a one-point grab sample calibration. This method provides

for a one-point calibration without removing the electrode from service; perform it

periodically after a two-point calibration. Variations of these two calibration procedures

are give n in Section 2.3.1.3 Calibration Procedure Variations.

Stability Indicator

A stability indicator is activated during the calibration to assist the user in determining a

stable input re ading. The d ecimal point bl inks when t he instr ument de termin es a read ing is

unstable. The decimal point stops blinking when the instrument determines the reading is

stable. Use this indication to decide when to press the

ENTER key, or use your own

judgement. Stability is determined when the mV reading changes at a rate less than

1mV/minute.

Marginal Calibration Indication

During a calibration, a mar ginal message is displa yed if the of fs et is great er than ±100 mV

or if the slope is o utside t he range of 50.6 to 71.2 mV. The system warning ind icator l ights,

but the calibration is accepted.

This warning indicates the calibration is outside the normal range. Repeat the calibration

or clean or replace the electrode.

38

Page 39

Invalid Calibratio n Indication

During a calibration, if the offset is greater than ±300 mV, or if the slope is outside

the range of 44.2 to 89.5 m V, an invalid message is displayed and the calibration is

not accepted.

2.3.1.1 Two-Point Calibration with Auto Recognition of Hach Buffers

The buffers used in a two point calibration should bracket the pH range of the sample.

The following procedure uses the pH 4.01 (Cat. No. 22269-66) and pH 7.00

(Cat. No. 22270-66) Hach buffers supplied with the instrument, but a pH 10.00 Hach

buff er (Cat. No. 22271- 66) can be use d as one of the b uffers. If buffers othe r than the ones

listed above are used, refer to Section 2.3.1.3 Calibration Procedure Variations.

1. Prepare a pH 4.01 Hach Buffer (Cat. No. 22269-66) and a pH 7.00 Hach Buffer

(Cat. No. 22270-66) by dissolving the contents of one powder pillow in 50 mL of

deionized water, and mix.

2. Remove the electrode from the sample solution and clean if needed (see Section 8.1

Electrode Maintenance).

3. Rinse the electrode with deionized water and then place the electrode in prepared pH

4.01 buffer (Cat. No. 22269-66).

4. Press