Page 1

49300-22

DR/2010

SPECTROPHOTOMETER

PROCEDURES MANUAL

© Hach Company, 1996–2000. All rights reserved. Printed in the U.S.A. ap/dk 12/99 7ed

jnb/dk 10/00 rev2

Page 2

2

Page 3

TABLE OF CONTENTS

INTRODUCTION .............................................................................................................. 11

Sample Procedure Explained .................................................................................................. 13

SECTION I CHEMICAL ANALYSIS INFORMATION......................................... 17

Abbreviations .......................................................................................................................... 17

Converting Chemical Species ................................................................................................. 18

Hardness Conversion ........................................................................................................... 19

Dissolved Oxygen................................................................................................................ 20

Sample Collection, Preservation and Storage ...................................................................... 22

Collecting Water Samples ................................................................................................ 25

Acid Washing Bottles....................................................................................................... 25

Correcting for Volume Additions ........................................................................................ 26

Boiling Aids ......................................................................................................................... 26

Sample Filtration.................................................................................................................. 27

Temperature Considerations ................................................................................................ 29

Sample Dilution Techniques................................................................................................ 29

Sample Dilution and Interfering Substances .................................................................... 30

Using Pipets and Graduated Cylinders ................................................................................ 31

Using the TenSette Pipet...................................................................................................... 32

Operating the TenSette Pipet............................................................................................ 32

Mixing Water Samples ........................................................................................................ 33

Using Sample Cells.............................................................................................................. 35

Orientation of Sample Cells.............................................................................................. 35

Care of Hach 1-inch Sample Cells.................................................................................... 35

Cleaning Sample Cells...................................................................................................... 35

Sample Cell Matching ...................................................................................................... 36

Volume Measurement Accuracy ...................................................................................... 37

Using AccuVac Ampuls ...................................................................................................... 37

Using Reagent Powder Pillows............................................................................................ 38

Using PermaChem Pillows .................................................................................................. 39

Using the Pour-Thru Cell..................................................................................................... 39

Reagent and Standard Stability............................................................................................ 40

Interferences............................................................................................................................ 41

pH Interference .................................................................................................................... 41

Accuracy and Precision........................................................................................................... 42

Standard Additions............................................................................................................... 43

3

Page 4

TABLE OF CONTENTS, continued

Method Performance............................................................................................................... 50

Estimated Detection Limit................................................................................................... 50

Precision .............................................................................................................................. 53

Estimating Precision......................................................................................................... 53

Selecting the Best Wavelength ............................................................................................... 54

Adapting HACH Procedures to Other Spectrophotometers................................................... 57

Preparing a Calibration Curve............................................................................................. 57

%T Versus Concentration Calibration ............................................................................. 57

Absorbance Versus Concentration Calibration ................................................................ 59

USEPA Approved and Accepted Definitions ......................................................................... 60

SECTION II SAMPLE PRETREATMENT ............................................................... 61

Digestion................................................................................................................................. 61

EPA Mild Digestion with Hot Plate for Metals Analysis Only........................................... 61

EPA Vigorous Digestion with Hot Plate for Metals Analysis Only ................................... 62

General Digesdahl Digestion (Not USEPA accepted) ........................................................ 63

Distillation .............................................................................................................................. 63

SECTION III WASTE MANAGEMENT AND SAFETY........................................ 65

Waste Management................................................................................................................. 65

Waste Minimization ............................................................................................................ 65

Regulatory Overview........................................................................................................... 65

Hazardous Waste Definition................................................................................................ 66

Characteristic Hazardous Waste Codes ............................................................................... 67

How to Determine if Waste is Hazardous ........................................................................... 67

Examples of Hazardous Waste............................................................................................ 68

Hazardous Waste Disposal.................................................................................................. 68

Management of Specific Wastes ......................................................................................... 69

Special Considerations for Cyanide Containing Materials .............................................. 69

Resources............................................................................................................................. 70

Material Safety Data Sheets.................................................................................................... 71

How to Obtain an MSDS..................................................................................................... 71

Sections of an MSDS........................................................................................................... 72

4

Page 5

TABLE OF CONTENTS, continued

Safety....................................................................................................................................... 74

Material Safety Data Sheet .................................................................................................. 74

Reading Labels Carefully .................................................................................................... 74

Protective Equipment........................................................................................................... 75

First Aid Equipment and Supplies ....................................................................................... 75

General Safety Rules............................................................................................................ 75

OSHA Chemical Hygiene Plan............................................................................................ 76

SECTION IV PROCEDURES ........................................................................................ 77

ALUMINUM, Aluminon Method........................................................................................... 79

ALUMINUM, Eriochrome Cyanine R Method...................................................................... 87

ARSENIC, Silver Diethyldithiocarbamate Method ................................................................ 95

BARIUM, Turbidimetric Method ......................................................................................... 103

BENZOTRIAZOLE, UV Photolysis Method ....................................................................... 111

BORON, Carmine Method.................................................................................................... 117

BORON, Low Range, Azomethine-H Method .................................................................... 121

BROMINE, DPD Method..................................................................................................... 129

CADMIUM, Dithizone Method............................................................................................ 137

CHLORIDE, Mercuric Thiocyanate Method........................................................................ 145

CHLORINE, FREE, DPD Method ....................................................................................... 149

CHLORINE, FREE, DPD Rapid Liquid Method ................................................................ 157

CHLORINE, FREE, HIGH RANGE, DPD Method............................................................. 163

CHLORINE, FREE, DPD Test ‘N Tube™ Method ............................................................. 169

CHLORINE, TOTAL, Ultra Low Range, DPD Method ...................................................... 175

CHLORINE, TOTAL, Ultra Low Range, DPD Method ..................................................... 183

CHLORINE, TOTAL, DPD Method .................................................................................... 191

CHLORINE, TOTAL, DPD Rapid Liquid Method ............................................................. 199

CHLORINE, TOTAL, HIGH RANGE, DPD Method ........................................................ 205

CHLORINE, TOTAL, DPD Test ‘N Tube™ Method.......................................................... 211

CHLORINE DIOXIDE, LR, Chlorophenol Red Method..................................................... 217

CHLORINE DIOXIDE, HR, Direct Reading Method.......................................................... 221

CHLORINE DIOXIDE, DPD Method.................................................................................. 223

5

Page 6

TABLE OF CONTENTS, continued

CHROMIUM, HEXAVALENT, 1,5-Diphenylcarbohydrazide Method.............................. 233

CHROMIUM, TOTAL, Alkaline Hypobromite Oxidation Method ................................... 239

COBALT, 1-(2-Pyridylazo)-2-Naphthol (PAN) Method ..................................................... 245

COLOR, NCASI 253, Platinum-Cobalt Method.................................................................. 249

COLOR, TRUE AND APPARENT, APHA Platinum-Cobalt Standard Method ............... 253

COPPER, Bicinchoninate Method........................................................................................ 257

COPPER, Porphyrin Method................................................................................................ 265

COPPER, AUTOCATALYTIC, Colorimetric Method........................................................ 271

CYANIDE, Pyridine-Pyrazalone Method ............................................................................ 277

CYANURIC ACID, Turbidimetric Method......................................................................... 287

FLUORIDE, SPADNS Method............................................................................................ 291

FORMALDEHYDE, MBTH Method .................................................................................. 299

HARDNESS, Calcium and Magnesium; Calmagite Colorimetric Method.......................... 303

HARDNESS, TOTAL, Ultra Low Range, Calcium and Magnesium Chlorophosphonazo

Colorimetric Method ......................................................................................................... 309

HARDNESS, TOTAL, Ultra Low Range, Calcium and Magnesium; Chlorophosphonazo

Rapid Liquid Method ........................................................................................................ 313

HYDRAZINE, p-Dimethylaminobenzaldehyde Method ..................................................... 319

IODINE, DPD Method ......................................................................................................... 325

IRON, FerroZine Method ..................................................................................................... 333

IRON, FerroZine Rapid Liquid Method............................................................................... 339

IRON, FERROUS, 1,10 Phenanthroline Method................................................................. 345

IRON, TOTAL, FerroMo™ Method.................................................................................... 349

IRON, TOTAL, FerroVer Method ....................................................................................... 353

IRON, TOTAL, TPTZ Method............................................................................................. 361

LEAD, Dithizone Method..................................................................................................... 369

LEAD, LeadTrak™ Fast Column Extraction Method.......................................................... 377

MANGANESE, HR, Periodate Oxidation Method .............................................................. 387

MANGANESE, LR, PAN Method....................................................................................... 391

MERCURY, Cold Vapor Mercury Concentration Method.................................................. 397

MOLYBDENUM, MOLYBDATE, HR, Mercaptoacetic Acid Method.............................. 413

MOLYBDENUM, MOLYBDATE, LR, Ternary Complex Method ................................... 421

6

Page 7

TABLE OF CONTENTS, continued

NICKEL, 1-(2 Pyridylazo)-2-Naphthol (PAN) Method ....................................................... 427

NICKEL, Heptoxime Method............................................................................................... 433

NICKEL, AUTOCATALYTIC, Photometric Method ......................................................... 439

NITRATE, LR, Cadmium Reduction Method...................................................................... 443

NITRATE, MR, Cadmium Reduction Method..................................................................... 449

NITRATE, HR, Cadmium Reduction Method...................................................................... 457

NITRATE, HR, Chromotropic Acid Method, Test ‘N Tube™ ............................................ 465

NITRITE, LR, Diazotization Method ................................................................................... 471

NITRITE, LR, Diazotization, NED Rapid Liquid Method................................................... 477

NITRITE, LR, Test ‘N Tube, Diazotization (Chromotropic Acid) Method......................... 483

NITRITE, HR, Ferrous Sulfate Method................................................................................ 487

NITROGEN, TOTAL, HR, Test ’N Tube™, TNT Persulfate Digestion Method................ 491

NITROGEN, AMMONIA, Nessler Method......................................................................... 499

NITROGEN, AMMONIA, Salicylate Method ..................................................................... 505

NITROGEN, AMMONIA, High Range, Test ’N Tube, Salicylate Method......................... 511

NITROGEN, AMMONIA, Low Range Test ‘N Tube, Salicylate Method .......................... 517

NITROGEN, MONOCHLORAMINE and FREE AMMONIA, Salicylate Method............ 523

NITROGEN, TOTAL, Test ’N Tube, TNT Persulfate Digestion Method ........................... 531

NITROGEN, TOTAL KJELDAHL, Nessler Method .......................................................... 539

NITROGEN, TOTAL INORGANIC, Test ‘N Tube, Titanium Trichloride Reduction ....... 549

ORGANIC CARBON, TOTAL, Low Range, Direct Method.............................................. 557

ORGANIC CARBON, TOTAL, High Range, Direct Method ............................................. 565

ORGANIC MATTER, Dichromate Method......................................................................... 573

OXYGEN, DISSOLVED, LR, Indigo Carmine Method...................................................... 579

OXYGEN, DISSOLVED, HR, HRDO Method ................................................................... 583

OXYGEN, DISSOLVED, SHR, Super High Range Method............................................... 587

OXYGEN DEMAND, CHEMICAL, Reactor Digestion Method........................................ 591

Colorimetric Determination, 0 to 150 mg/L COD ............................................................. 593

Colorimetric Determination, 0 to 1,500 and 0 to 15,000 mg/L COD................................ 595

OXYGEN DEMAND, CHEMICAL (COD), Dichromate Reflux Method .......................... 601

Colorimetric Determination............................................................................................... 603

Buret Titration.................................................................................................................... 605

OXYGEN DEMAND, CHEMICAL, Manganese III Digestion Method ............................. 611

7

Page 8

TABLE OF CONTENTS, continued

OXYGEN DEMAND, CHEMICAL, Manganese III Digestion Method............................. 615

OXYGEN SCAVENGERS, Iron Reduction Method for Oxygen Scavengers .................... 623

OZONE, Indigo Method....................................................................................................... 627

PALLADIUM, N,N'-Dimethyldithiooxamide Method ........................................................ 631

PCB IN SOIL, Immunoassay Method.................................................................................. 635

PHENOLS, 4-Aminoantipyrine Method .............................................................................. 645

PHOSPHONATES, Persulfate UV Oxidation Method........................................................ 651

PHOSPHORUS, REACTIVE, PhosVer 3 Method, Test ’N Tube Procedure ...................... 657

PHOSPHORUS, REACTIVE, (Also called Orthophosphate) Amino Acid Method ........... 663

PHOSPHORUS, REACTIVE, (Also called Orthophosphate) Molybdovanadate Method.. 669

PHOSPHORUS, REACTIVE, PhosVer 3 (Ascorbic Acid) Method.................................... 677

PHOSPHORUS, REACTIVE, LOW RANGE, Ascorbic Acid Rapid Liquid Method........ 685

PHOSPHORUS, REACTIVE, HIGH RANGE, Molybdovanadate Rapid Liquid Method . 691

PHOSPHORUS, REACTIVE, HR, Molybdovanadate Method, Test ’N Tube™ ............... 697

PHOSPHORUS, TOTAL, Acid Persulfate Digestion Method............................................. 703

PHOSPHORUS, TOTAL, PhosVer 3 with Acid Persulfate Digestion Test ‘N Tube.......... 707

PHOSPHORUS, TOTAL, HR, Molybdovanadate Method with Acid Persulfate Digestion,

Test ’N Tube™.................................................................................................................. 715

PHOSPHORUS, ACID HYDROLYZABLE, PhosVer3 with Acid Hydrolysis,................. 723

Test ’N Tube...................................................................................................................... 723

PHOSPHORUS, ACID HYDROLYZABLE, Hydrolysis to Orthophosphate Method........ 729

POLYACRYLIC ACID, Absorption-Colorimetric Method ................................................ 733

POTASSIUM, Tetraphenylborate Method........................................................................... 741

QUATERNARY AMMONIUM COMPOUNDS, Direct Binary Complex Method ........... 747

SELENIUM, Diaminobenzidine Method ............................................................................. 753

SILICA, HR, Silicomolybdate Method ................................................................................ 761

SILICA, LR, Heteropoly Blue Method ................................................................................ 767

SILICA, ULTRA LOW RANGE, Heteropoly Blue Method ............................................... 773

SILICA, ULR, Heteropoly Blue Rapid Liquid Method ....................................................... 779

SILVER, Colorimetric Method............................................................................................. 785

SODIUM CHROMATE, Direct Colorimetric Method ........................................................ 791

8

Page 9

TABLE OF CONTENTS, continued

SULFATE, SulfaVer 4 Method ............................................................................................ 795

SULFIDE, Methylene Blue Method* ................................................................................... 803

SURFACTANTS, ANIONIC, Crystal Violet Method.......................................................... 807

SUSPENDED SOLIDS, Photometric Method...................................................................... 811

TANNIN AND LIGNIN, Tyrosine Method ......................................................................... 815

THM Plus™: Trihalomethanes, ........................................................................................... 819

TOXTRAK TOXICITY TEST, Colorimetric Method ......................................................... 829

TPH IN SOIL, Immunoassay Method................................................................................... 835

TPH IN WATER, Immunoassay Method ............................................................................. 845

TURBIDITY, Attenuated Radiation Method (direct reading) .............................................. 853

VOLATILE ACIDS, Esterification Method......................................................................... 857

ZINC, Zincon Method........................................................................................................... 861

SECTION V GENERAL INFORMATION ............................................................... 867

HOW TO ORDER............................................................................................................ 869

REPAIR SERVICE .......................................................................................................... 870

WARRANTY ..................................................................................................................... 871

9

Page 10

10

Page 11

INTRODUCTION

This manual is divided into five sections:

Section I Chemical Analysis Information

This section applies to all the procedures. It provides background

information and reference/review material for the technician or chemist.

Commonly used techniques are explained in detail.

Section II Sample Pretreatment

This section provides a brief overview of sample pretreatment and three

digestion procedures. Two are USEPA digestions. The Hach Digesdahl

method is also included.

Section III Waste Management and Safety

Section 3 includes information an waste management, regulations, waste

disposal and resources on waste management. The Safety portion covers

reading an MSDS and general safety guidelines.

Section IV Procedures

Section 4 contains step-by-step illustrated instructions for measuring over

120 parameters. The steps also include helpful notes. Each procedure

contains information on sample collection, storage and preservation,

accuracy checks, possible interferences, summary of method and a list of

the reagents and apparatus necessary to run the test.

Section V Ordering Information

This section provides information needed for ordering, shipping, return of

items and Hach trademarks.

Before attempting the analysis procedures the analyst

should read the instrument manual to learn about the

spectrophotometer’s features and operation.

11

Page 12

INTRODUCTION, continued

Hach Company Trademarks

AccuGrow

AccuVac

AccuVer™

AccuVial™

Add-A-Test™

AgriTrak™

AluVer

AmVer™

APA 6000™

AquaChek™

AquaTrend

BariVer

BODTrak™

BoroTrace™

BoroVer

C. Moore Green™

CA 610™

CalVer

ChromaVer

ColorQuik

CoolTrak

CuVer

CyaniVer

Digesdahl

DithiVer

Dr. F. Fluent™

Dr. H. Tueau™

DR/Check™

EC 310™

FerroMo

FerroVer

FerroZine

FilterTrak™ 660

Formula 2533™

Formula 2589™

Gelex

®

®

®

®

®

®

®

®

®

®

®

®

®

®

®

®

®

®

H2O University™

H2OU™

Hach Logo

Hach One

Hach Oval

Hach.com™

HachLink™

Hawkeye The Hach Guy™

HexaVer

HgEx™

HydraVer

ICE-PIC™

IncuTrol

Just Add Water™

LeadTrak

M-ColiBlue24

ManVer

MolyVer

Mug-O-Meter

NetSketcher™

NitraVer

NitriVer

NTrak

OASIS™

On Site Analysis.

Results You Can Trust

OptiQuant™

OriFlow™

OxyVer™

PathoScreen™

PbEx

PermaChem

PhosVer

Pocket Colorimeter™

Pocket Pal™

Pocket Turbidimeter™

®

®

®

®

®

®

®

®

®

®

®

®

®

®

SM

®

®

®

Pond In Pillow™

®

ion

√

®

®

®

®

™

SM

®

®

®

®

®

®

SM

®

®

®

®

PourRite

PrepTab™

ProNetic™

Pump Colorimeter™

QuanTab

Rapid Liquid™

RapidSilver™

Ratio™

RoVer

sens

Simply Accurate

SINGLET™

SofChek™

SoilSYS™

SP 510™

Spec ™

StablCal

StannaVer

SteriChek™

StillVer

SulfaVer

Surface Scatter

TanniVer

TenSette

Test ‘N Tube™

TestYES!

TitraStir

TitraVer

ToxTrak™

UniVer

VIScreen™

Voluette

WasteAway™

ZincoVer

12

Page 13

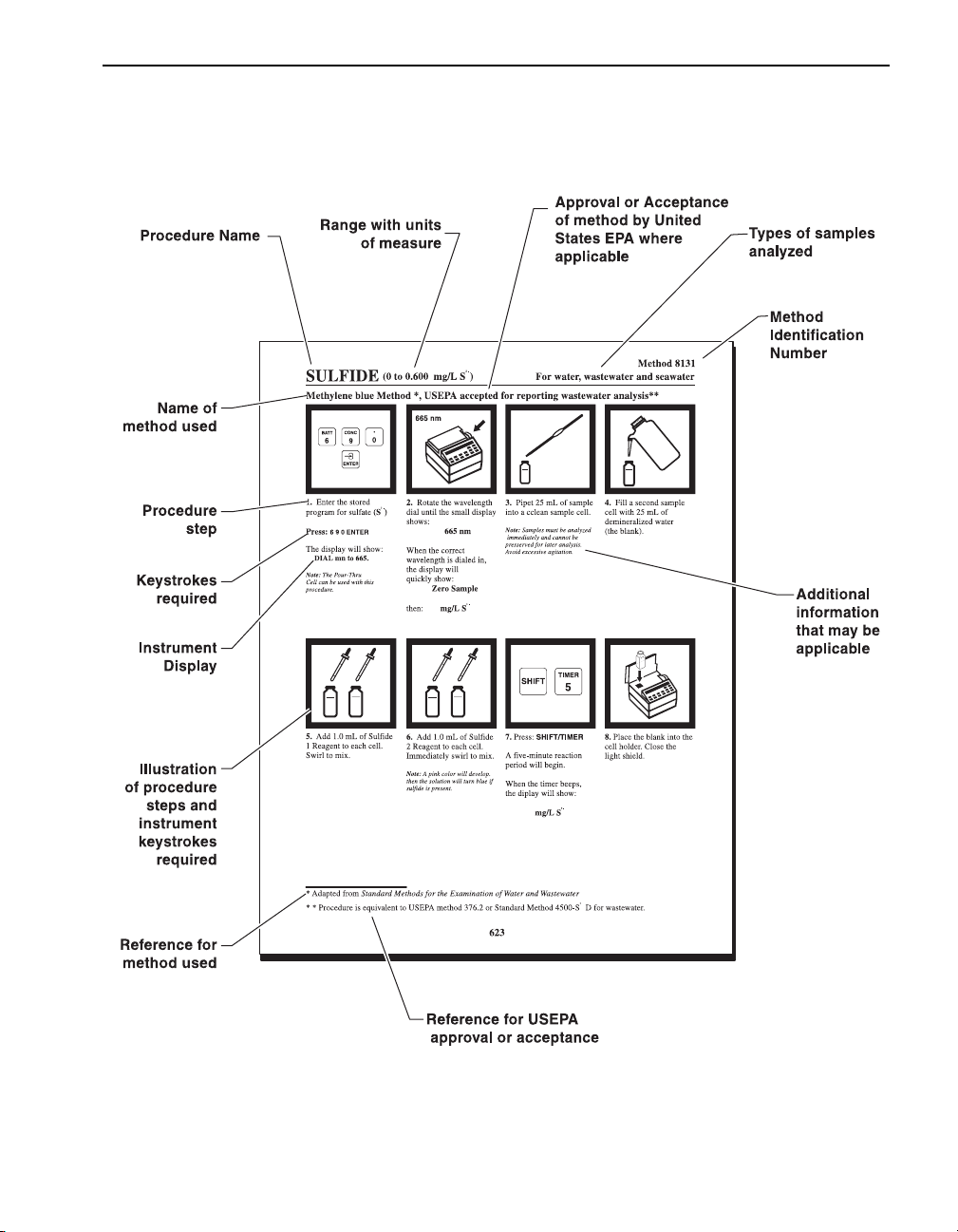

Sample Procedure Explained

13

Page 14

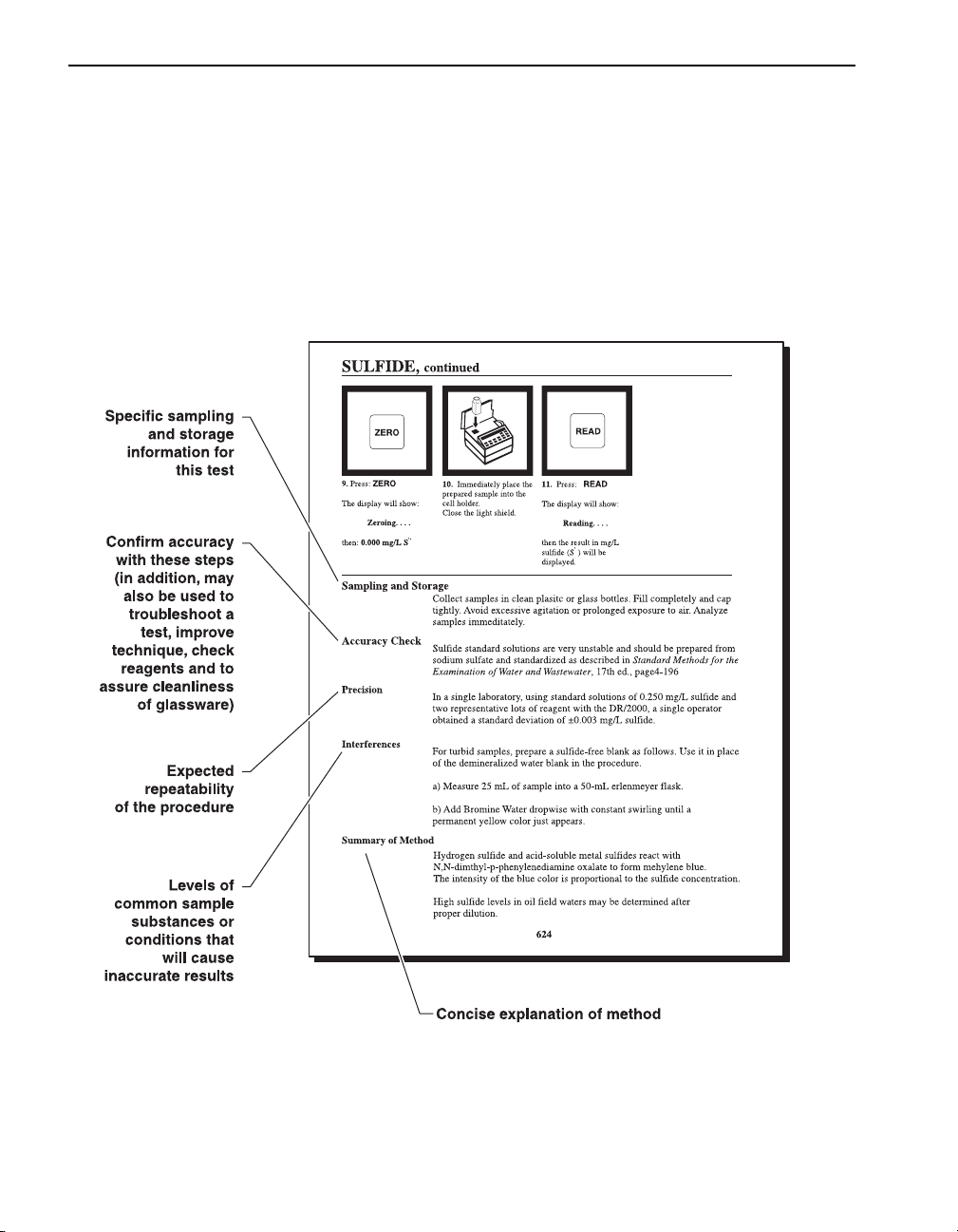

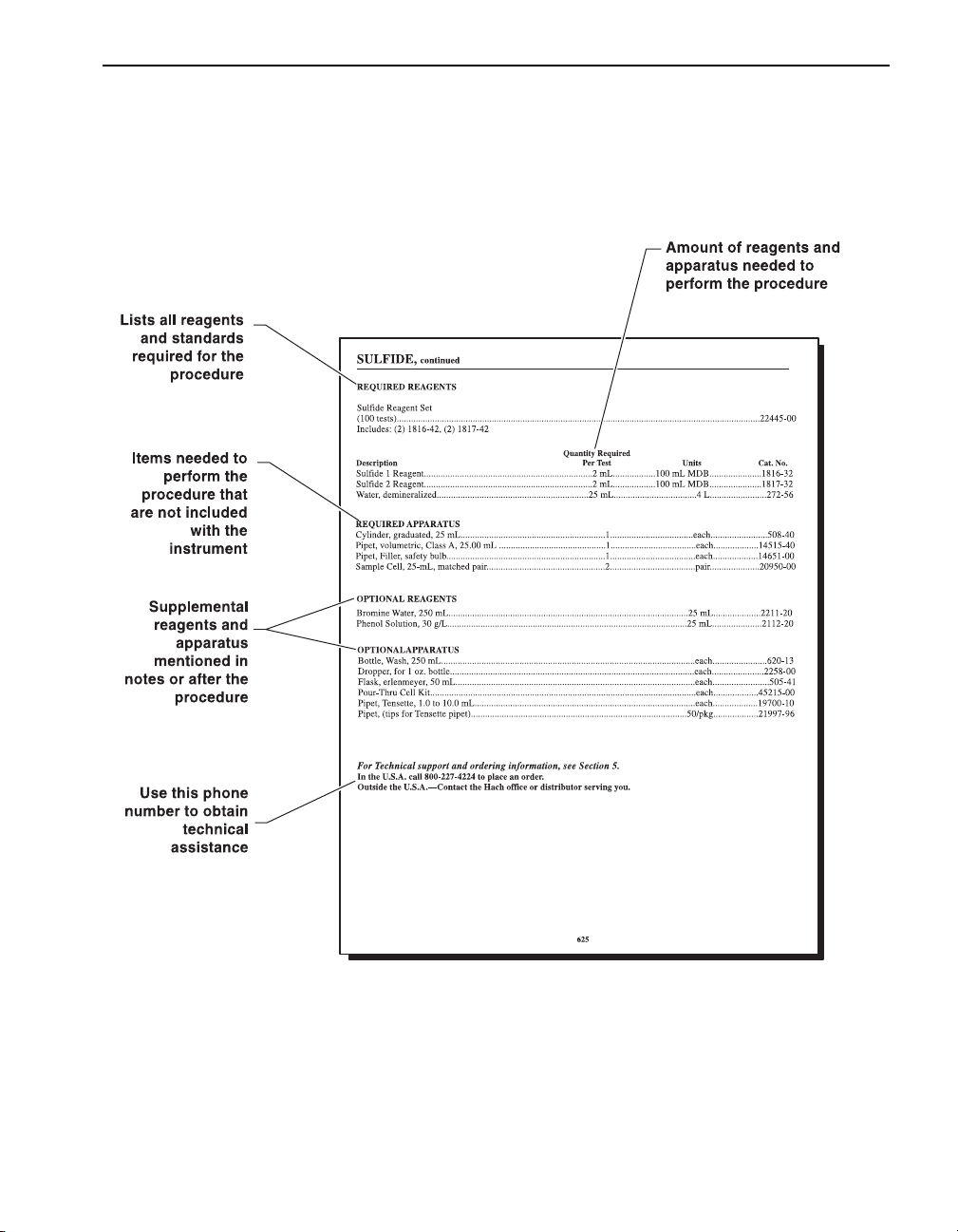

Sample Procedure Explained, continued

14

Page 15

Sample Procedure Explained, continued

15

Page 16

16

Page 17

SECTION I CHEMICAL ANALYSIS INFORMATION

Abbreviations

The following abbreviations are used throughout the text of the

procedure section:

Abbrev-

iation

°C degree(s) Celsius (Centigrade) HR high range

°F degree(s) Fahrenheit kg/ha kilograms per hectare

ACS

APHA

Standard

Methods

AV AccuVac MR medium range

Bicn bicinchoninate NIPDWR

CFR Code of Federal Regulations NPDES

conc concentrated P phosphorus

DB dropping bottle PCB Poly chlorinated biphenyl

EDL Estimated detection limit PV PhosVer

F&T free and total RL Rapid Liquid™

FAU

FM FerroMo

FV FerroVer

FZ FerroZine

gr/gal grains per gallon (1 gr/gal = 17.12 mg/L) USEPA

American Chemical Society reagent

grade purity

Standard Methods for the Examination of

Water and Wastewater, published jointly by

the American Public Health Association

(APHA), the American Water Works

Association (AWWA), and the Water

Environment Federation (WEF). Order from

Hach requesting Cat. No. 22708-00 or from

the Publication Office of the American Public

Health Association. This book is the

standard reference work for water analysis.

Many procedures contained in this manual

are based on Standard Methods.

Formazin Attenuation Units. Turbidity unit

of measure based on a Formazin stock

suspension.

g grams ULR Ultra low range

Definition

®

®

®

Abbrev-

iation

l or L

lbs/Ac pounds per acre

LR low range

MDL Method detection limit

MDB marked dropping bottle

mg/L milligrams per liter (ppm)

µg/L micrograms per liter (ppb)

ml or mL

SCDB self-contained dropping bottle

TNT Te s t ‘N Tube™

TPH Total petroleum hydrocarbons

TPTZ (2,4,6-Tri-(2-Pyridyl)-1,3,5-Triazine)

Liter. Volume equal to one cubic

decimeter (dm

(milliliter)-approximately the same as a

cubic centimeter (cc) or 1/1000 of a liter.

Also known as a “cc”.

National Interim Primary Drinking

Water Regulations

National Pollutant Discharge

Elimination System

United States Environmental

Protection Agency

®

Definition

3

)

17

Page 18

SECTION I, continued

Converting Chemical Species

Species conversion factors for many commonly used substances are

preprogrammed into the DR/2010 (see Table 1). Conversions are method

specific and are viewable after taking the reading by pressing

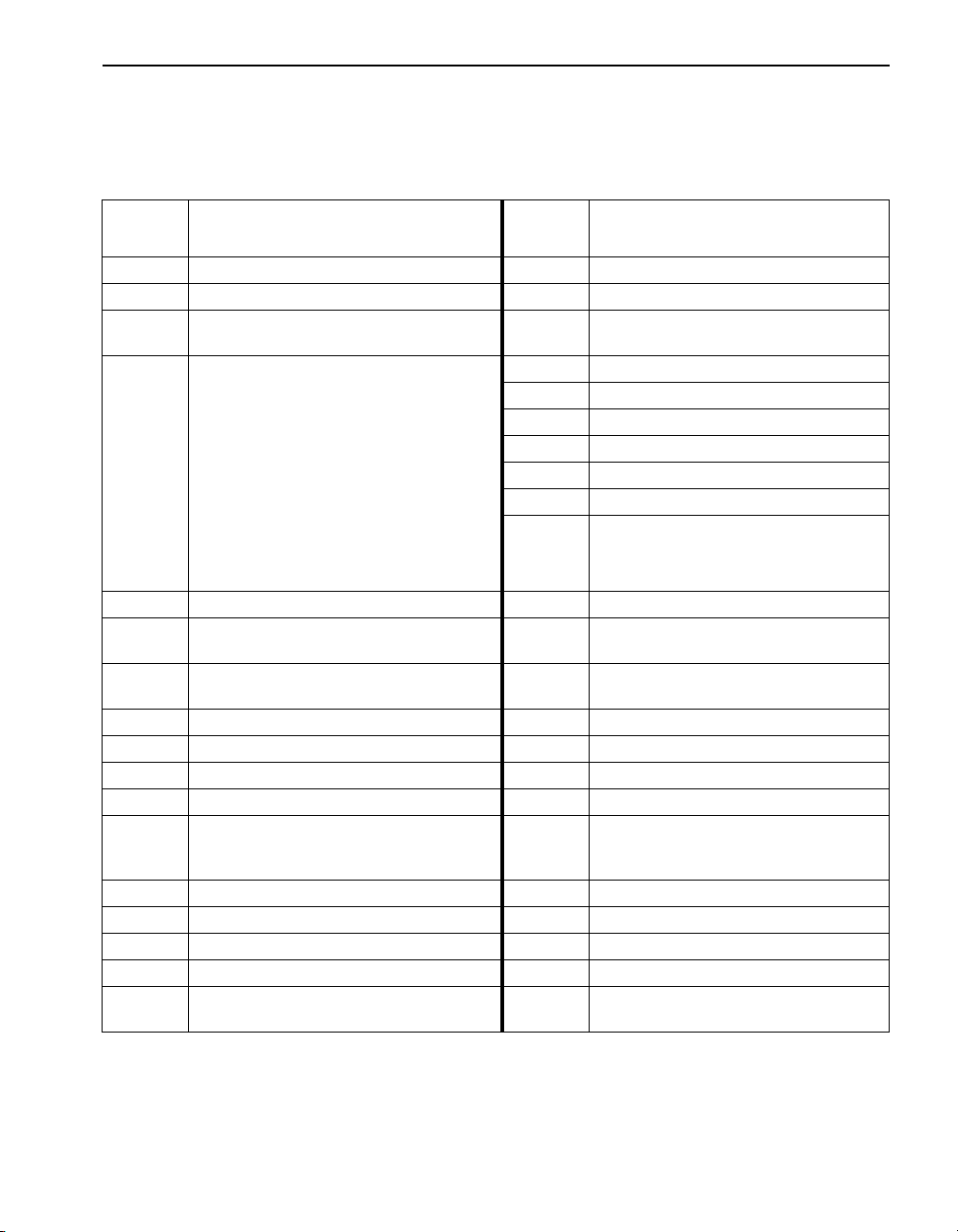

Table 1 Conversion Factors

To Convert From... To... Multiply By... Conversion used in program #

mg/L Al mg/L Al2O

mg/L B mg/L H

mg/L Ca-CaCO

mg/L CaCO

mg/L CaCO

3

3

3

3BO3

mg/L Ca 0.4004 220

mg/L Ca 0.4004 227

mg/L Mg 0.2428 227

3

1.8895 9, 10

5.7 45

µg/L Carbo. µg/L Hydro. 1.92 182

µg/L Carbo. µg/L ISA 2.69 182

µg/L Carbo. µg/L MEKO 3.15 182

mg/L Cr

mg/L Cr

mg/L Mg-CaCO

6+

6+

3

mg/L CrO

mg/L Na2CrO

mg/L Mg 0.2428 225

mg/L Mn mg/L KMnO

mg/L Mn mg/L MnO

mg/L Mo

mg/L Mo

6+

6+

mg/L MoO

mg/L Na2MoO

mg/L N mg/L NH

mg/L N mg/L NO

mg/L Na

mg/L Na

mg/L NH

mg/L NH

mg/L NH

mg/L NH

mg/L NO

mg/L NO

mg/L NO

µg/L NO

mg/L NO

µg/L NO

mg/L NO

mg/L PO

µg/L PO

mg/L PO

µg/L PO

mg/L SiO

µg/L SiO

CrO

2

4

CrO

2

4

Cl-N mg/L Cl

2

Cl-N mg/L NH2Cl 3.6750 386

2

-N mg/L NH

3

-N mg/L NH

3

-

2

-

2

-

-N mg/L NaNO

2

-

-N µg/L NaNO

2

-

-N mg/L NO

2

-

-N µg/L NO

2

-

-N mg/L NO

3

3-

4

3-

4

3-

4

3-

4

2

2

mg/L Cr

mg/L CrO

mg/L NaNO

mg/L NO

mg/L P 0.3261 480, 482, 485, 490, 492, 535

µg/L P 0.3261 488

mg/L P2O

µg/L P2O

mg/L Si 0.4674 651, 656

µg/L Si 0.4674 645

2-

4

4

4

-

4

2-

4

4

3

-

3

6+

2-

4

2

3

+

4

2

-

-N 0.3045 373

2

2

2

-

2

-

2

-

3

5

5

2.231 90, 95

3.115 90, 95

2.876 290, 295

2.165 290, 295

1.667 315, 320, 322

2.146 315, 320, 322

1.216 342, 343, 346, 347, 348

4.427 346, 347, 348

0.321 670

0.72 670

5.0623 386

1.216 380, 385, 387

1.288 380, 385, 387

1.5 373

4.926 345, 371, 375

4.926 376

3.284 345, 371, 375

3.284 376

4.427 344, 351, 353, 355, 359, 361

0.7473 480, 482, 485, 490, 492, 535

0.7473 488

18

CONC.

Page 19

SECTION I, continued

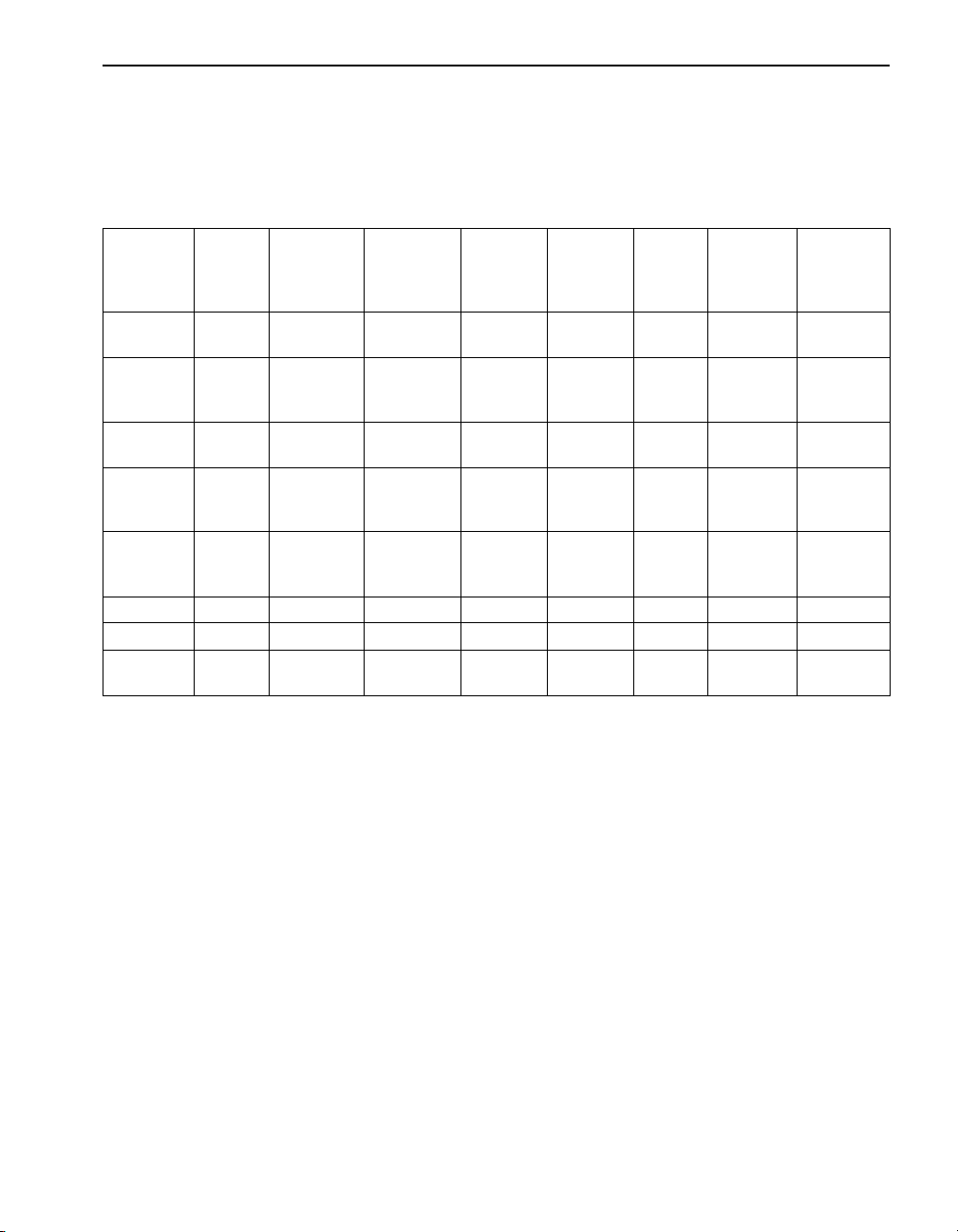

Hardness Conversion

Table 2 lists the factors for converting one unit of measure for hardness to

another unit of measure. For example, to convert mg/L CaCO

parts/100,000 CaO, multiply the value in mg/L x 0.056.

Table 2 Hardness Conversion Factors

Units of

Measure

mg/L

CaCO

English

British

3

gr/gal

(Imperial)

mg/L

CaCO

CaCO

1.0 0.07 0.058 0.1 0.056 0.02 5.6x10

3

14.3 1.0 0.83 1.43 0.83 0.286 8.0x10

3

American

gr/gal (US)

CaCO

gr/gal

CaCO

3

US gr/gal

CaCO

Fr. p/

17.1 1.2 1.0 1.72 0.96 0.343 9.66x10

3

10.0 0.7 0.58 1.0 0.56 0.2 5.6x10

100,000

CaCO

3

Ger. p/

17.9 1.25 1.04 1.79 1.0 0.358 1x10

100,000

CaO

meq/L 50.0 3.5 2.9 5.0 2.8 1.0 2.8x10

g/L CaO 1790.0 125.0 104.2 179.0 100.0 35.8 1.0 0.112

lbs./cu ft

CaCO

16,100.0 1,123.0 935.0 1,610.0 900.0 321.0 9.0 1.0

3

1 ‘epm/L, or ‘mval/L’

Note: 1 meq/L = 1N/1000

French

parts/

100,000

3

CaCO

3

German

Parts/

100,000

CaO

meq/L

1

g/L CaO

to German

3

lbs./cu ft

-4

6.23x10

-3

-3

1.07x10

-3

6.23x10

-2

1.12x10

-2

3.11x10

CaCO

8.9x10

3

-5

-4

-3

-4

-3

-2

19

Page 20

SECTION I, continued

Dissolved Oxygen

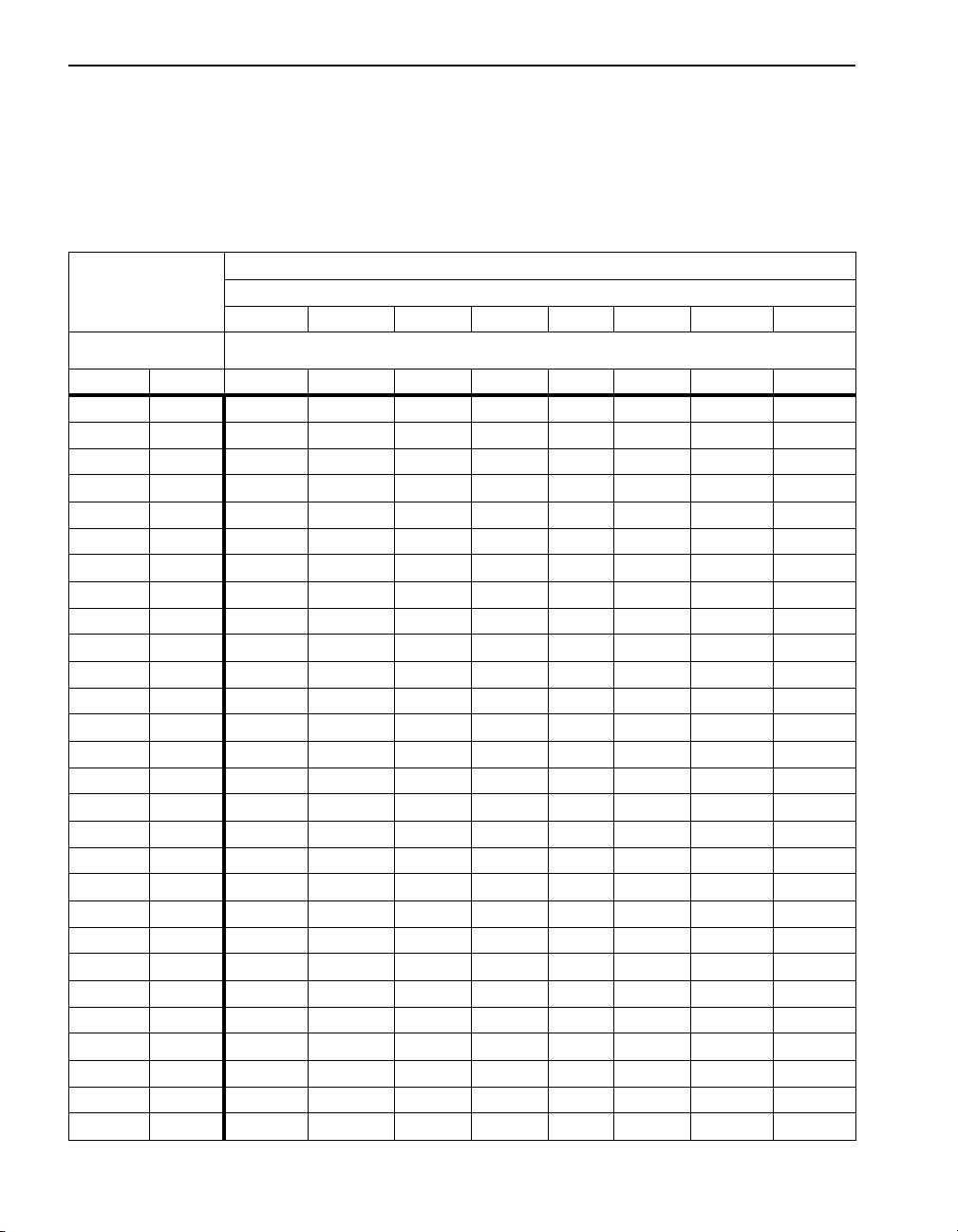

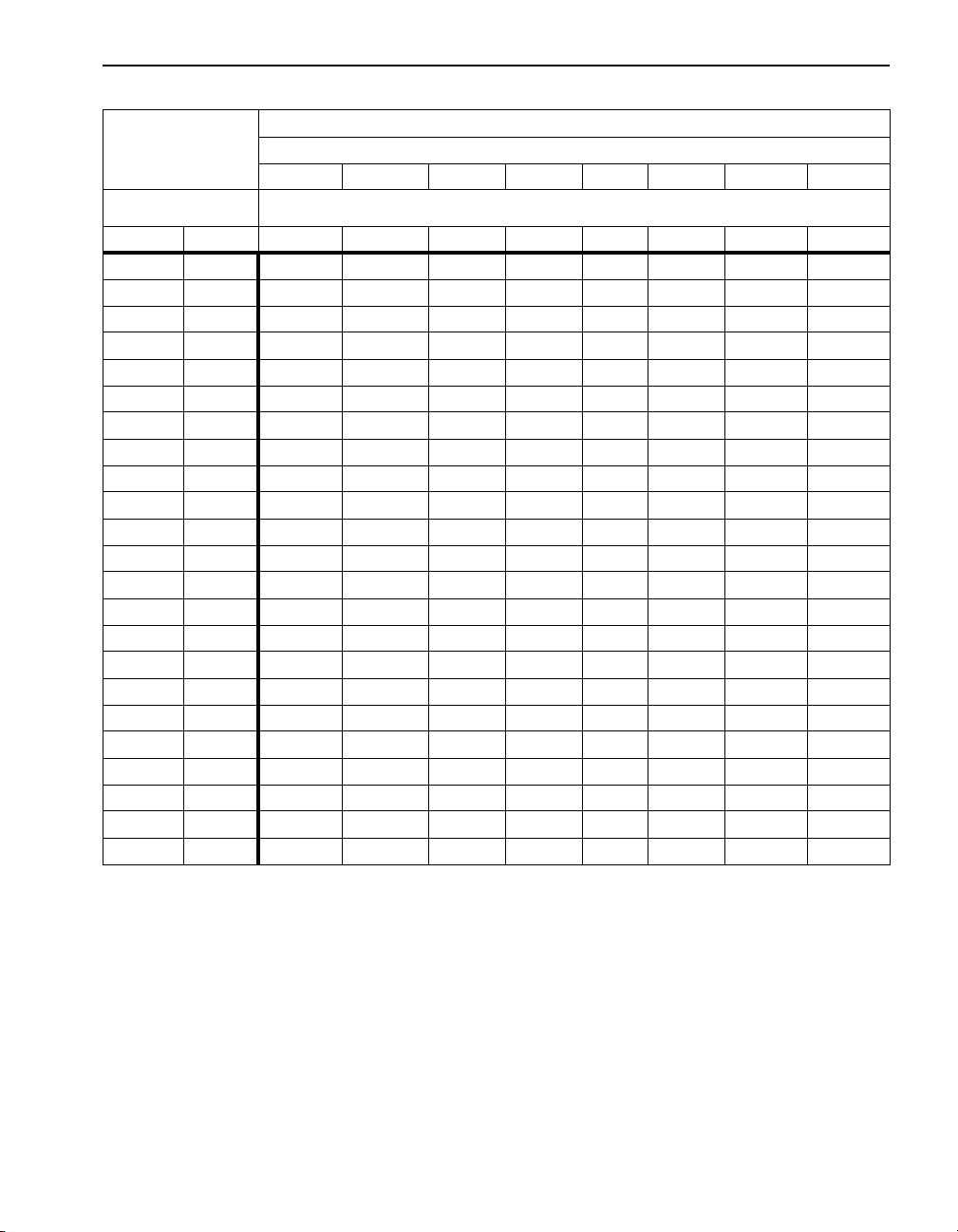

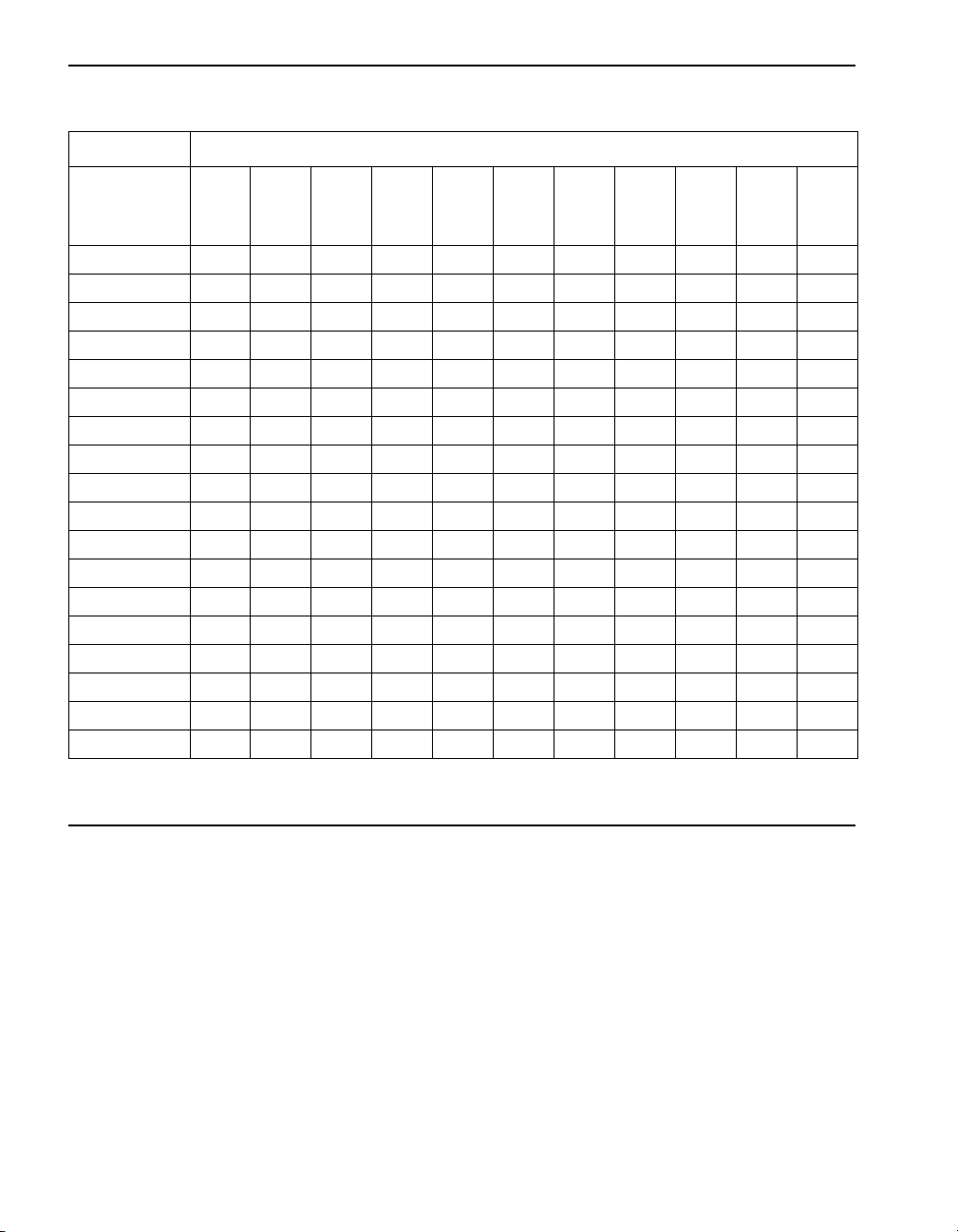

Table 3 lists the mg/L dissolved oxygen in water at saturation for various

temperatures and atmospheric pressures. The table was formulated in a

laboratory using pure water. The values given are only approximations for

estimating the oxygen content of a particular body of surface water.

Table 3 Dissolved Oxygen Saturation in Water

Pressure in Millimeters and Inches Hg

mm

775 760 750 725 700 675 650 625

Temp inches

°F °C 30.51 29.92 29.53 28.45 27.56 26.57 25.59 24.61

32.0 0 14.9 14.6 14.4 13.9 13.5 12.9 12.5 12.0

33.8 1 14.5 14.2 14.1 13.6 13.1 12.6 12.2 11.7

35.6 2 14.1 13.9 13.7 13.2 12.9 12.3 11.8 11.4

37.4 3 13.8 13.5 13.3 12.9 12.4 12.0 11.5 11.1

39.2 4 13.4 13.2 13.0 12.5 12.1 11.7 11.2 10.8

41.0 5 13.1 12.8 12.6 12.2 11.8 11.4 10.9 10.5

42.8 6 12.7 12.5 12.3 11.9 11.5 11.1 10.7 10.3

44.6 7 12.4 12.2 12.0 11.6 11.2 10.8 10.4 10.0

46.4 8 12.1 11.9 11.7 11.3 10.9 10.5 10.1 9.8

48.2 9 11.8 11.6 11.5 11.1 10.7 10.3 9.9 9.5

50.0 10 11.6 11.3 11.2 10.8 10.4 10.1 9.7 9.3

51.8 11 11.3 11.1 10.9 10.6 10.2 9.8 9.5 9.1

53.6 12 11.1 10.8 10.7 10.3 10.0 9.6 9.2 8.9

55.4 13 10.8 10.6 10.5 10.1 9.8 9.4 9.1 8.7

57.2 14 10.6 10.4 10.2 9.9 9.5 9.2 8.9 8.5

59.0 15 10.4 10.2 10.0 9.7 9.3 9.0 8.7 8.3

60.8 16 10.1 9.9 9.8 9.5 9.1 8.8 8.5 8.1

62.6 17 9.9 9.7 9.6 9.3 9.0 8.6 8.3 8.0

64.4 18 9.7 9.5 9.4 9.1 8.8 8.4 8.1 7.8

66.2 19 9.5 9.3 9.2 8.9 8.6 8.3 8.0 7.6

68.0 20 9.3 9.2 9.1 8.7 8.4 8.1 7.8 7.5

69.8 21 9.2 9.0 8.9 8.6 8.3 8.0 7.7 7.4

71.6 22 9.0 8.8 8.7 8.4 8.1 7.8 7.5 7.2

73.4 23 8.8 8.7 8.5 8.2 8.0 7.7 7.4 7.1

75.2 24 8.7 8.5 8.4 8.1 7.8 7.5 7.2 7.0

77.0 25 8.5 8.4 8.3 8.0 7.7 7.4 7.1 6.8

78.8 26 8.4 8.2 8.1 7.8 7.6 7.3 7.0 6.7

80.6 27 8.2 8.1 8.0 7.7 7.4 7.1 6.9 6.6

20

Page 21

SECTION I, continued

Table 3 Dissolved Oxygen Saturation in Water (continued)

Pressure in Millimeters and Inches Hg

mm

775 760 750 725 700 675 650 625

Temp inches

°F °C 30.51 29.92 29.53 28.45 27.56 26.57 25.59 24.61

82.4 28 8.1 7.9 7.8 7.6 7.3 7.0 6.7 6.5

84.2 29 7.9 7.8 7.7 7.4 7.2 6.9 6.6 6.4

86.0 30 7.8 7.7 7.6 7.3 7.0 6.8 6.5 6.2

87.8 31 7.7 7.5 7.4 7.2 6.9 6.7 6.4 6.1

89.6 32 7.6 7.4 7.3 7.0 6.8 6.6 6.3 6.0

91.4 33 7.4 7.3 7.2 6.9 6.7 6.4 6.2 5.9

93.2 34 7.3 7.2 7.1 6.8 6.6 6.3 6.1 5.8

95.0 35 7.2 7.1 7.0 6.7 6.5 6.2 6.0 5.7

96.8 36 7.1 7.0 6.9 6.6 6.4 6.1 5.9 5.6

98.6 37 7.0 6.8 6.7 6.5 6.3 6.0 5.8 5.6

100.4 38 6.9 6.7 6.6 6.4 6.2 5.9 5.7 5.5

102.2 39 6.8 6.6 6.5 6.3 6.1 5.8 5.6 5.4

104.0 40 6.7 6.5 6.4 6.2 6.0 5.7 5.5 5.3

105.8 41 6.6 6.4 6.3 6.1 5.9 5.6 5.4 5.2

107.6 42 6.5 6.3 6.2 6.0 5.8 5.6 5.3 5.1

109.4 43 6.4 6.2 6.1 5.9 5.7 5.5 5.2 5.0

111.2 44 6.3 6.1 6.0 5.8 5.6 5.4 5.2 4.9

113.0 45 6.2 6.0 5.9 5.7 5.5 5.3 5.1 4.8

114.8 46 6.1 5.9 5.9 5.6 5.4 5.2 5.4 4.8

116.6 47 6.0 5.9 5.8 5.6 5.3 5.1 4.8 4.7

118.4 48 5.9 5.8 5.7 5.5 5.3 5.0 4.8 4.6

120.2 49 5.8 5.7 5.6 5.4 5.2 5.0 4.7 4.5

122.0 50 5.7 5.6 5.5 5.3 5.1 4.9 4.7 4.4

21

Page 22

SECTION I, continued

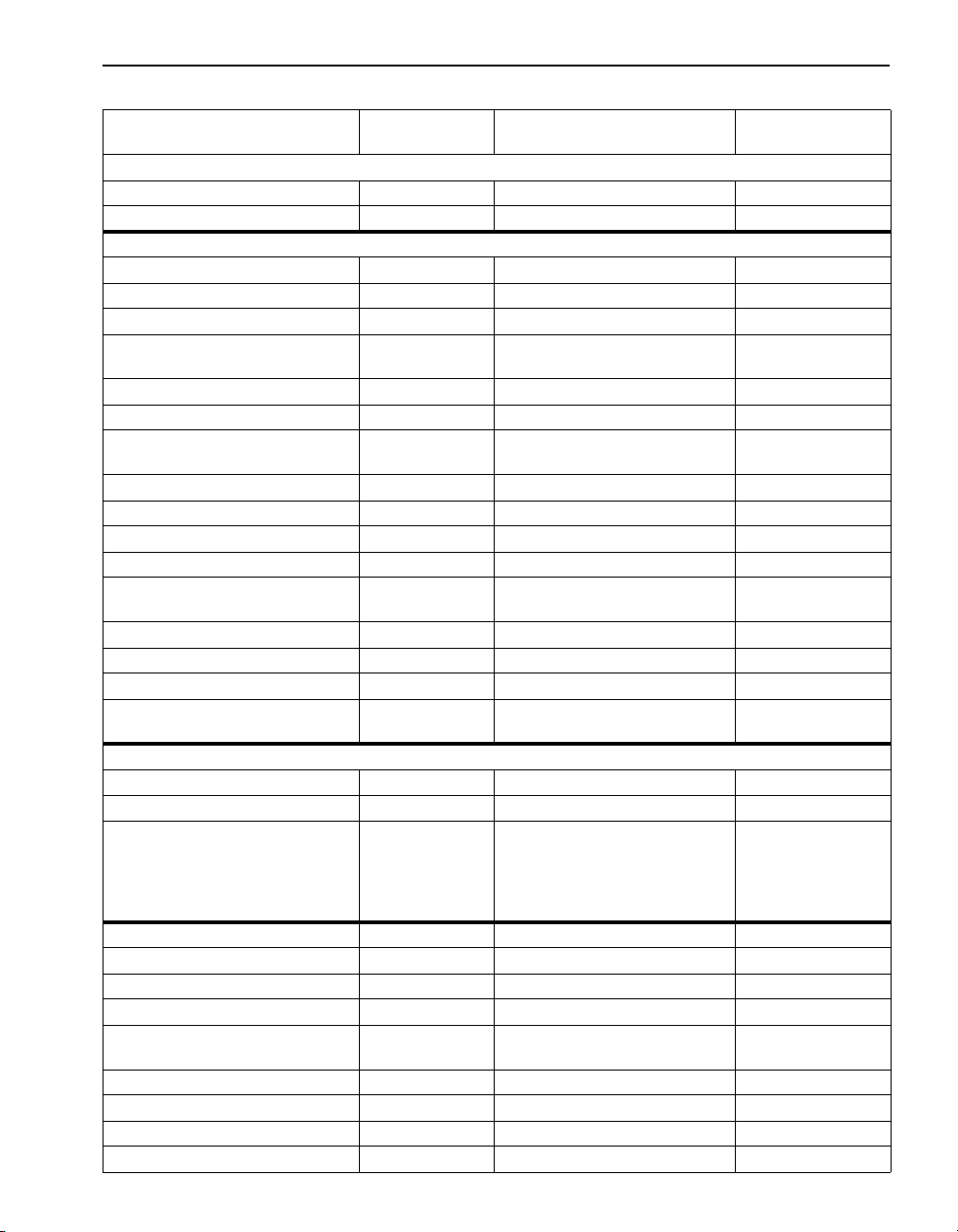

Sample Collection, Preservation and Storage

Correct sampling and storage are critical for accurate testing. For greatest

accuracy, thoroughly clean sampling devices and containers to prevent

carryover from previous samples. Preserve the sample properly; each

procedure has information about sample preservation.

• The least expensive containers are polypropylene or polyethylene.

• The best and most expensive containers are quartz or PTFE

(polytetrafluoroethylene, Teflon).

• Avoid soft glass containers for metals in the

microgram-per-liter range.

• Store samples for silver determination in light absorbing containers,

such as amber bottles.

Avoid contaminating the sample with metals from containers, distilled

water or membrane filters. Thoroughly clean sample containers as

described under Acid Washing Bottles.

Preservation slows the chemical and biological changes that continue

after collection. These changes may change the amount of a chemical

species available for analysis. Normally, analyze the samples as soon as

possible after collection, especially when the analyte concentration is

expected to be low. This also reduces the chance for error and

minimizes labor.

Preservation methods include pH control, chemical addition, refrigeration

and freezing. Table 4 gives the recommended preservation for various

substances. It also includes suggested types of containers and the

maximum recommended holding times for properly preserved samples.

Preserve aluminum, cadmium, chromium, cobalt, copper, iron, lead,

nickel, potassium, silver and zinc samples for at least 24 hours by adding

one Nitric Acid Solution Pillow 1:1 (Cat. No. 2540-98) per liter of

sample. Check the pH with pH indicator paper or a pH meter to assure

the pH is 2 or less. Add additional pillows if necessary. Adjust the sample

pH prior to analysis by adding an equal number of Sodium Carbonate

Anhydrous Powder Pillows (Cat. No. 179-98). Or raise the pH to 4.5

with Sodium Hydroxide Standard Solution, 1 N or 5 N.

22

Page 23

SECTION I, continued

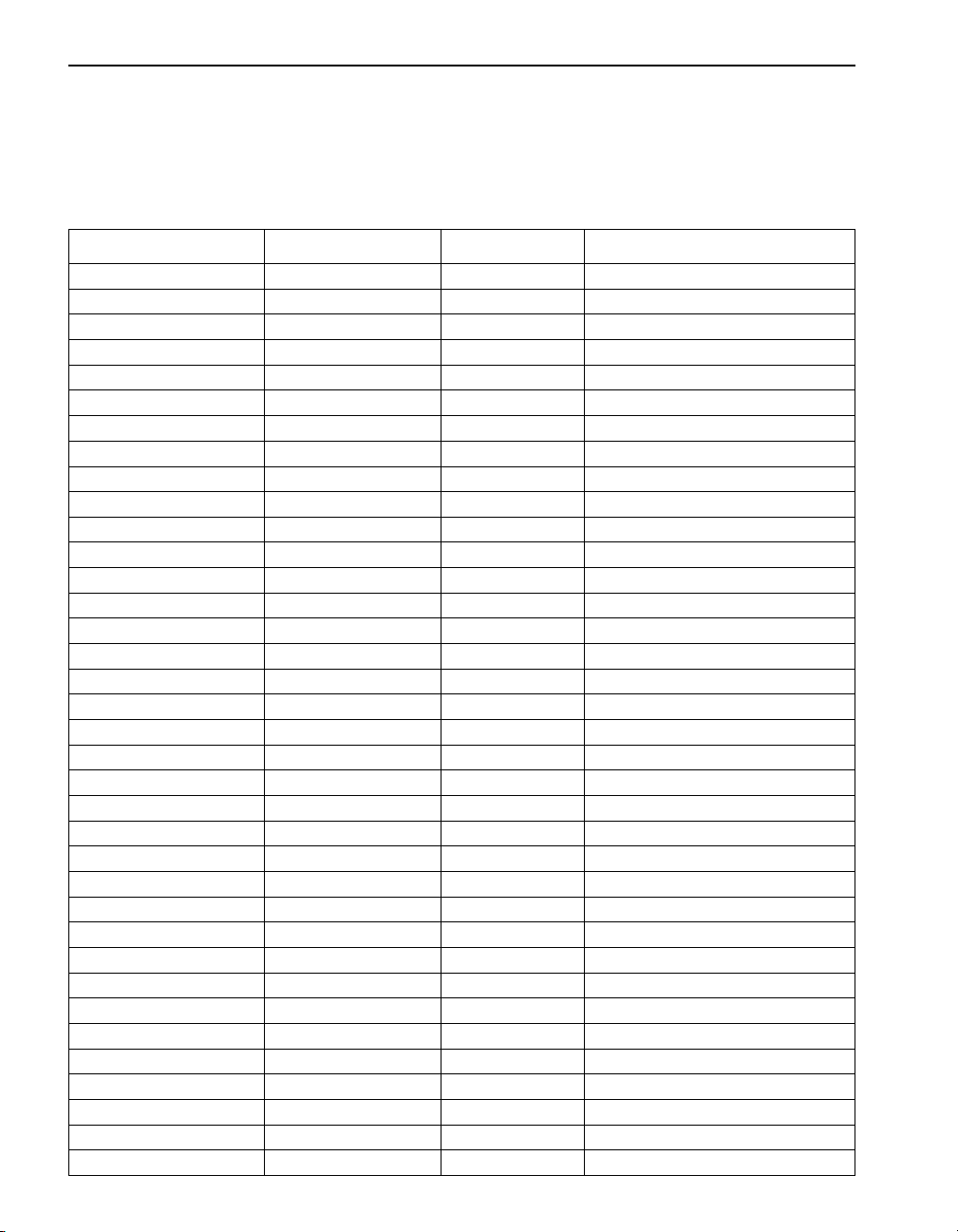

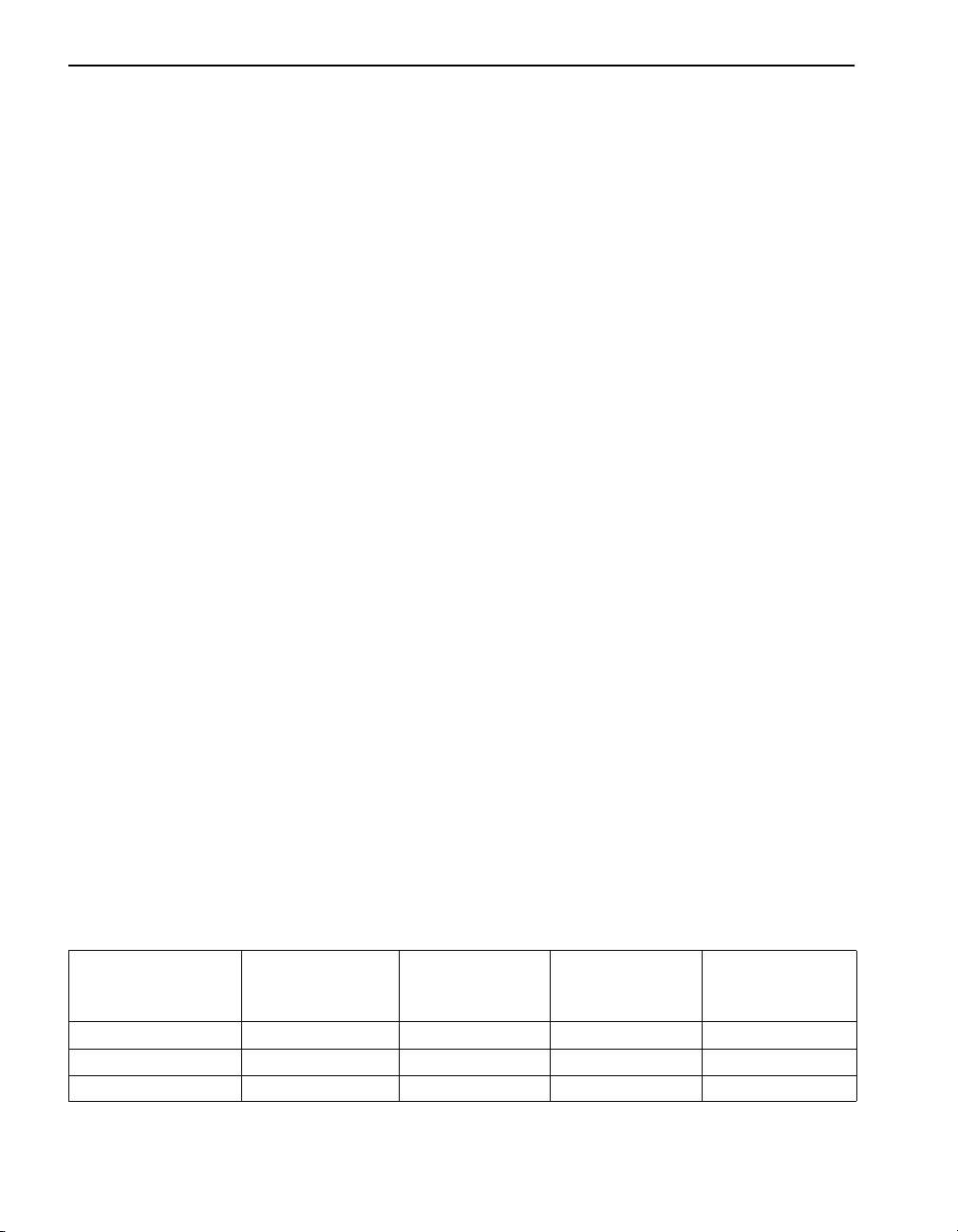

Table 4 Required Containers, Preservation Techniques and Holding Times

Parameter No./Name Container

2

Preservation

3,4

1

Maximum

Holding Time

5

Table 1A - Bacterial Tests

1-4. Coliform, fecal and total P,G Cool, 4°C, 0.008%, Na

5. Fecal streptococci P,G Cool, 4°C, 0.008%, Na

2S2O3

2S2O3

6

6

6 hours

6 hours

Table 1B - Inorganic Tests

1. Acidity P, G Cool, 4°C 14 days

2. Alkalinity P, G Cool, 4°C 14 days

4. Ammonia P, G Cool, 4°C, H

9. Biochemical oxygen demand

P, G Cool, 4°C 48 hours

to pH<2 28 days

2SO4

(BOD)

10. Boron P, PFTE or quartz HNO

to pH<2 6 months

3

11. Bromide P, G None required 28 days

14. Biochemical oxygen demand,

P, G Cool, 4°C 48 hours

carbonaceous

15. Chemical oxygen demand P, G Cool, 4°C, H

to pH<2 28 days

2SO4

16. Chloride P, G None required 28 days

17. Chlorine, total residual P, G None required Analyze immediately

21. Color P, G Cool, 4°C 48 hours

23-24. Cyanide, total and amenable

to chlorination

P, G Cool, 4°C, NaOH to pH>12, 0.6 g

ascorbic acid

6

14 days

7

25. Fluoride P None required 28 days

27. Hardness P, G HNO

to pH<2, H2SO4 to pH<2 6 months

3

28. Hydrogen ion (pH) P, G None required Analyze immediately

31, 43. Kjeldahl and organic

P, G Cool 4°C, H

to pH<2 28 days

2SO4

nitrogen

8

Metals

18. Chromium VI P, G Cool, 4°C 24 hours

35. Mercury P, G HNO

to pH<2 28 days

3

Metals, except boron, chromium VI

and mercury: 3, 5-8, 12, 13, 19, 20,

22, 26, 29, 30, 32-34, 36, 37, 45,

47, 51, 52, 58-60, 62, 63, 70-72, 74,

9

.

75

P, G HNO

to pH<2 6 months

3

38. Nitrate P, G Cool, 4°C 48 hours

39. Nitrate-nitrite P, G Cool 4°C, H

to pH<2 28 days

2SO4

40. Nitrite P, G Cool, 4°C 48 hours

41. Oil and grease G Cool, 4°C, HCl or H

42. Organic Carbon

P, G Cool, 4°C, HCl or H

to pH<2

H

3PO4

to pH<2 28 days

2SO4

SO4 or

2

28 days

44. Orthophosphate P, G Filter immediately; Cool, 4°C 48 hours

46a. Oxygen, dissolved probe G Bottle and top None required Analyze immediately

46b. Oxygen, dissolved, Winkler Do Fix on site and store in dark 8 hours

48. Phenols G only Cool 4°C, H

to pH<2 28 days

2SO4

23

Page 24

SECTION I, continued

Table 4 Required Containers, Preservation Techniques and Holding Times1 (continued)

Parameter No./Name Container

49. Phosphorus, elemental G Cool, 4°C 48 hours

50. Phosphorus, total P, G Cool, 4°C, H

53. Residue, total P, G Cool, 4°C7 days

54. Residue, filterable P, G Cool, 4°C7 days

55. Residue, Nonfilterable (TSS) P, G Cool, 4°C7 days

56. Residue, Settleable P, G Cool, 4°C 48 hours

57. Residue, volatile P, G Cool, 4°C7 days

61. Silica P, PFTE or quartz Cool, 4°C 28 days

64. Specific conductance P, G Cool, 4°C 28 days

65. Sulfate P, G Cool, 4°C 28 days

66. Sulfide

67. Sulfite P, G none required Analyze immediately

68. Surfactants P, G Cool, 4°C 48 hours

69. Temperature P, G None required Analyze immediately

73. Turbidity P, G Cool, 4°C 48 hours

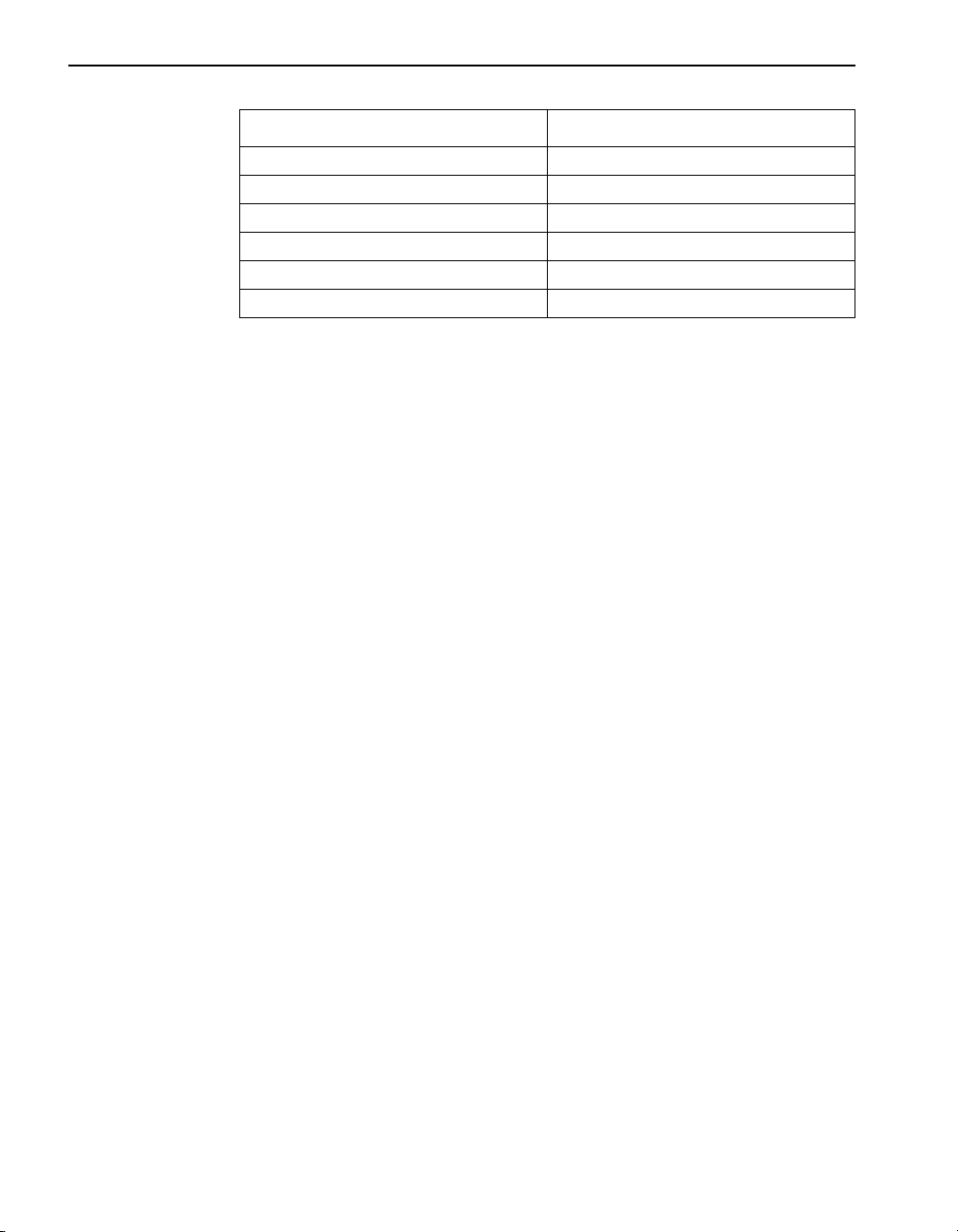

1 This table was adapted from Table II published in the Federal Register, July 1, 1997, 40 CFR, Part 136.3,

pages 26-27. Organic tests are not included.

2 Polyethylene (P) or glass (G).

3 Sample preservation should be performed immediately upon sample collection. For composite chemical samples

each aliquot should be preserved at the time of collection. When use of an automated sampler makes it impossible

to preserve each aliquot, then chemical samples may be preserved by maintaining at 4°C until compositing and

sample splitting is completed.

4 When any sample is to be shipped by common carrier or sent through United States Mails, it must comply with the

Department of Transportation Hazardous Material Regulations (49 CFR Part 172). The person offering such

material for transportation is responsible for ensuring such compliance. For the preservation requirements of Table

II, the Office of Hazardous Materials, Materials Transportation Bureau, Department of Transportation has

determined that the Hazardous Materials Regulations do not apply to the following materials: Hydrochloric acid

(HCl) in water solutions at concentrations of 0.04% by weight or less (pH about 1.96 or greater); Nitric acid (HNO

in water solutions at concentrations of 0.15% by weight or less (pH about 1.62 or greater); Sulfuric acid (H

water solutions at concentrations of 0.35% by weight or less (pH about 1.15 or greater); and Sodium hydroxide

(NaOH) in water solutions at concentrations of 0.080% by weight or less (pH about 12.30 or less).

5 Samples should be analyzed as soon as possible after collection. The times listed are the maximum times that

samples may be held before analysis and still be considered valid. Samples may be held for longer periods only if

the permitee, or monitoring laboratory, has data on file to show that the specific types of samples under study are

stable for the longer time, and has received a variance from the Regional Administer under §136.3(e). Some

samples may not be stable for the maximum time period given in the table. A permitee, or monitoring laboratory, is

obligated to hold the sample for a shorter time if knowledge exists to show that this is necessary to maintain sample

stability. See §136.3(e) for details. The term “analyze immediately” usually means within 15 minutes or less after

sample collection.

6 Should only be used in the presence of residual chlorine.

7 Maximum holding time is 24 hours when sulfide is present. Optionally all samples may be tested with lead acetate

paper before pH adjustments in order to determine if sulfide is present. If sulfide is present, it can be removed by the

addition of cadmium nitrate powder until a negative spot test is obtained. The sample is filtered and then NaOH is

added to pH 12.

8 Samples should be filtered immediately on-site before adding preservative for dissolved metals.

9 Numbers refer to parameter number in 40 CFR, Part 136.3, Table 1B.

2

P, G Cool 4°C, add zinc acetate plus

Preservation

sodium hydroxide to pH>9

3,4

to pH<2 28 days

2SO4

Maximum

Holding Time

7 days

2SO4

5

) in

)

3

24

Page 25

SECTION I, continued

Collecting Water Samples

Obtain the best sample by careful collection. In general, collect samples

near the center of the vessel or duct and below the surface. Use only clean

containers (bottles, beakers). Rinse the container several times first with

the water to be sampled.

Take samples as close as possible to the source of the supply. This lessens

the influence the distribution system has on the sample. Let the water run

long enough to flush the system. Fill sample containers slowly with a

gentle stream to avoid turbulence and air bubbles. Collect water samples

from wells after the pump has run long enough to deliver water

representative of the ground water feeding the well.

It is hard to obtain a truly representative sample when collecting surface

water samples. Obtain best results by testing several samples. Use

samples taken at different times from several locations and depths. The

results can be used to establish patterns for that particular body of water.

Generally, as little time as possible should elapse between collecting the

sample and analyzing it.

Depending on the test, special precautions in handling the sample may be

necessary. This prevents natural interferences such as organic growth or

loss or gain of dissolved gases. Each procedure describes sample

preservatives and storage techniques for samples that are held for testing.

Acid Washing Bottles

If a procedure suggests acid-washing, use the following procedure:

Use chromic acid or chromium-free substitutes to remove organic

deposits from glass containers. Rinse containers thoroughly with water

to remove traces of chromium.

a) Clean the glassware or plasticware with laboratory detergent

(phosphate-free detergent is recommended).

b) Rinse well with tap water.

c) Rinse with a 1:1 Hydrochloric Acid Solution or 1:1 Nitric Acid

Solution. The nitric acid rinse is important for testing for lead.

d) Rinse well with deionized water. Up to 12-15 rinses may be

necessary if chromium is being determined.

e) Air dry.

25

Page 26

SECTION I, continued

Wash glassware for phosphate determinations with phosphate-free

detergents and acid-wash with 1:1 HCl. Thoroughly rinse the glassware

with deionized water. For ammonia and Kjeldahl nitrogen, rinse with

ammonia-free water.

Correcting for Volume Additions

If you use a large volume of preservative, correct for the volume of

preservative added. This accounts for dilution due to the acid added to

preserve the sample and the base used to adjust the pH to the range of the

procedure. This correction is made as follows:

1. Determine the volume of initial sample, the volume of acid and base

added, and the total final volume of the sample.

2. Divide the total volume by the initial volume.

3. Multiply the test result by this factor.

Example:

A one-liter sample was preserved with 2 mL of nitric acid. It was

neutralized with 5 mL of 5 N sodium hydroxide. The result of the analysis

procedure was 10.00 mg/L. What is the volume correction factor and

correct result?

Boiling Aids

Total Volume 1000 mL 2 mL 5 mL++ 1007 mL==

1.

1007

------------- 1.007 volume correction factor==

2.

1000

10.0 mg/L 1.007× 10.07 mg/L correct result==

3.

Hach 1:1 Nitric Acid Pillows contain 2.5 mL of acid: correct for this

volume. The addition of a Sodium Carbonate Power Pillow neutralizes the

1:1 Nitric Acid Pillow does not need to be corrected for.

Boiling is necessary in some procedures. Using a boiling aid such as

boiling chips (Cat. no. 14835-31) reduces bumping. Bumping is caused

by the sudden, almost explosive conversion of water to steam as it is

heated. Avoid bumping; it may cause sample loss or injury.

Make sure the boiling aids will not contaminate the sample. Do not use

boiling aids (except glass beads) more than once. Loosely covering the

sample during boiling will prevent splashing, reduce the chances of

contamination and minimize sample loss.

26

Page 27

SECTION I, continued

Sample Filtration

Filtering separates particles from the aqueous sample. Filtration uses a

medium, usually filter paper, to retain particles but pass solution. This is

especially helpful when sample turbidity interferes with analysis. Two

general methods of filtration are gravity and vacuum. Gravity filtration

uses gravity to pull the sample though the filter paper. Vacuum filtration uses

suction and gravity to move the sample through the filter. An aspirator or

vacuum pump creates the suction. Vacuum filtration is faster than gravity

filtration. Vacuum filter (see Figure 1) as follows:

1. Using tweezers, place a filter paper into the filter holder.

2. Place the filter holder assembly in the filtering flask. Wet the filter

with deionized water to ensure adhesion to the holder.

3. Position the funnel housing on the filter holder assembly.

4. While applying a vacuum to the filtering flask, transfer the sample to

the filtering apparatus.

5. Slowly release the vacuum from the filtering flask and transfer the

solution from the filter flask to another container.

Figure 1 Vacuum Filtration

REQUIRED APPARATUS FOR VACUUM FILTRATION

Description Unit Cat. No.

Filter Discs, glass 47 mm.................................................................. 100/pkg................2530-00

Filter Holder, membrane ......................................................................... each..............13529-00

Flask, filter, 500 mL ................................................................................ each..................546-49

Pump, vacuum, hand operated ................................................................each..............14283-00

OR

Pump, vacuum, portable, 115 V ..............................................................each..............14697-00

Pump, vacuum, portable, 230 V ..............................................................each..............14697-02

27

Page 28

SECTION I, continued

Many of the procedures in this manual use gravity filtration. The only

labware required is filter paper, a conical funnel and a receiving flask.

This labware is included under Optional Equipment and Supplies at the

end of a procedure. Gravity filtration is better for retaining fine particles.

For faster filtering, add solution until the filter paper cone is three-fourths

filled. Never fill the cone completely. Gravity filter (see Figure 2)

as follows:

1. Place a filter paper into the funnel.

2. Wet the filter with deionized water to ensure adhesion to the funnel.

3. Place the funnel into an erlenmeyer flask or graduated cylinder.

4. Pour the sample into the funnel.

Figure 2 Gravity Filtration

REQUIRED APPARATUS FOR GRAVITY FILTRATION

Description Unit Cat No.

Cylinder, graduated, 100 mL ...................................................................each ................. 508-42

Funnel, poly, 65 mm ................................................................................each ............... 1083-67

Filter Paper, 12.5 cm ................................................................................each ............... 1894-57

Flask, erlenmeyer, 125 mL ......................................................................each ................. 505-43

Testing for metals requires acid and heat to pretreat the sample. Since

these conditions destroy filter paper, vacuum filtration with glass fiber

filter discs is recommended. Also, glass filter discs, unlike paper, do not

retain colored species.

28

Page 29

SECTION I, continued

Temperature Considerations

For best results, most tests in this manual should be performed with

sample temperatures between 20 °C (68 °F) and 25 °C (77 °F). If a

test requires closer temperature control, notes in the procedure will

indicate this.

Sample Dilution Techniques

Ten and 25 mL are the volumes used for most colorimetric tests.

However, in some tests, the color developed in the sample may be too

intense to be measured. Unexpected colors may develop in other tests.

In both cases, dilute the sample to determine if interfering substances

are present.

To dilute the sample easily, pipet the chosen sample portion into a clean

graduated cylinder (or volumetric flask for more accurate work). Fill the

cylinder (or flask) to the desired volume with deionized water. Mix well.

Use the diluted sample when running the test.

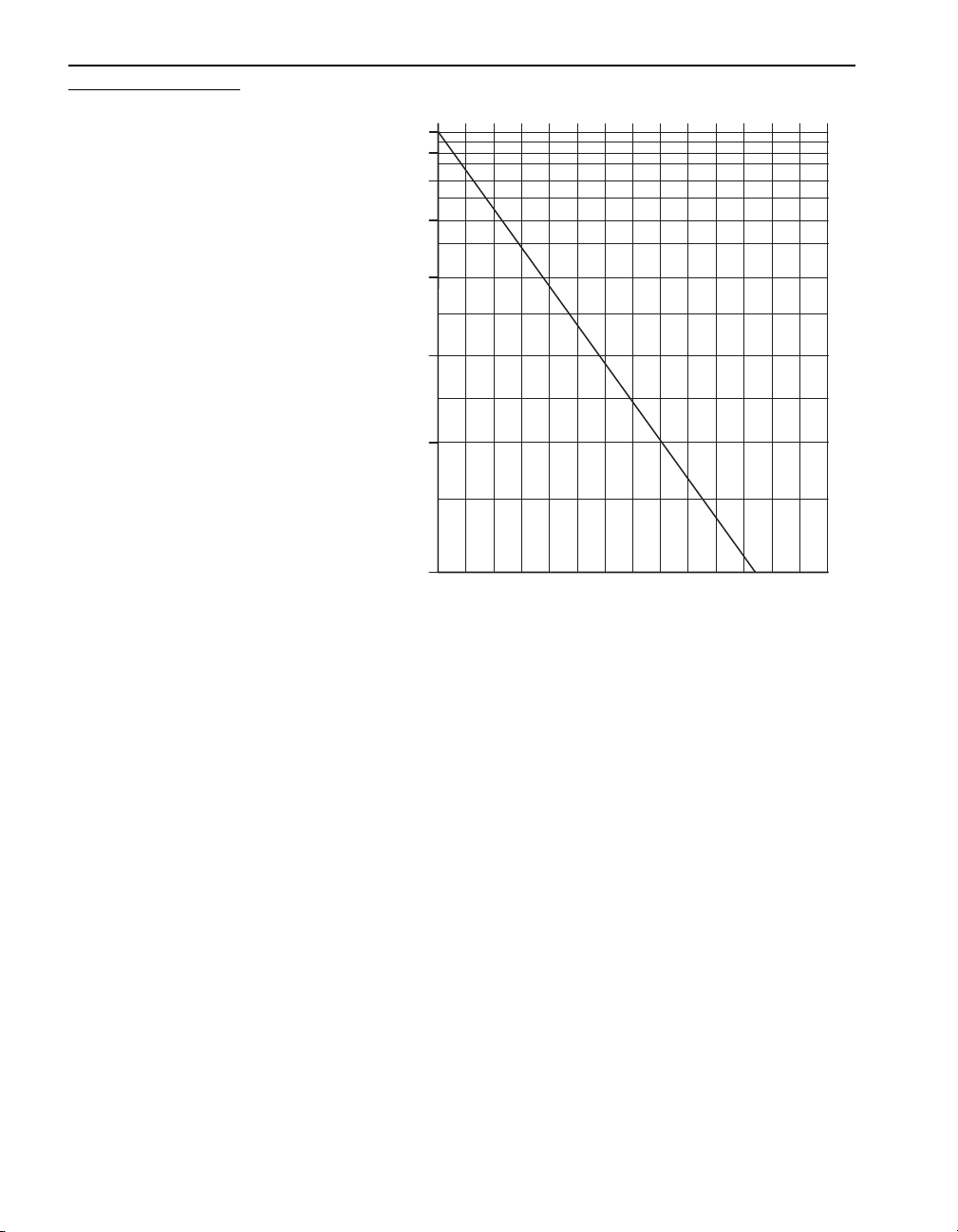

To help with dilutions, Table 5 shows the amount of sample used, the

amount of deionized water used to bring the volume up to 25 mL and the

multiplication factor.

The concentration of the sample is equal to the diluted sample reading

multiplied by the multiplication factor.

More accurate dilutions can be done with a pipet and a 100-mL

volumetric flask (see Table 6 for more information). Pipet the sample and

dilute to volume with deionized water. Swirl to mix.

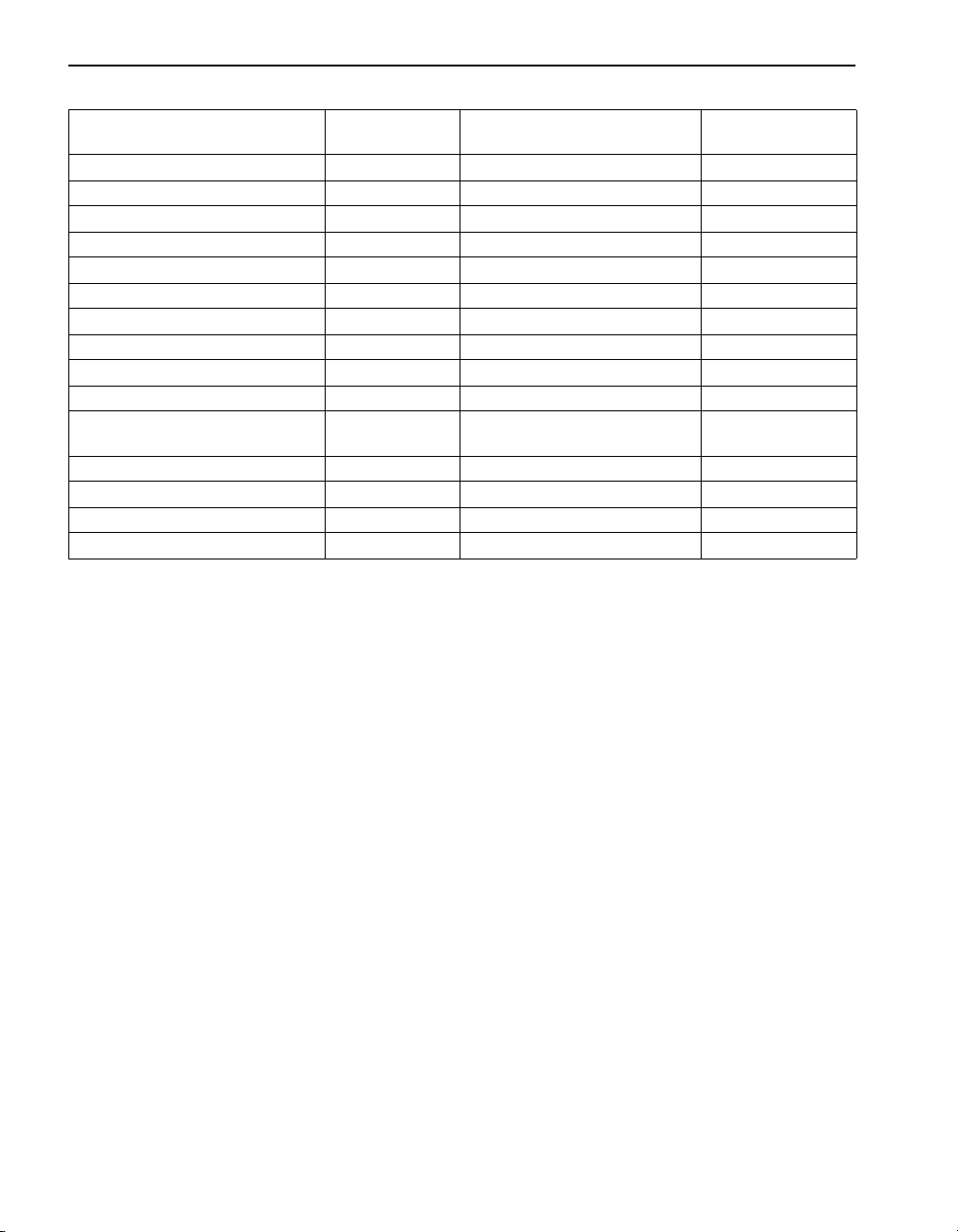

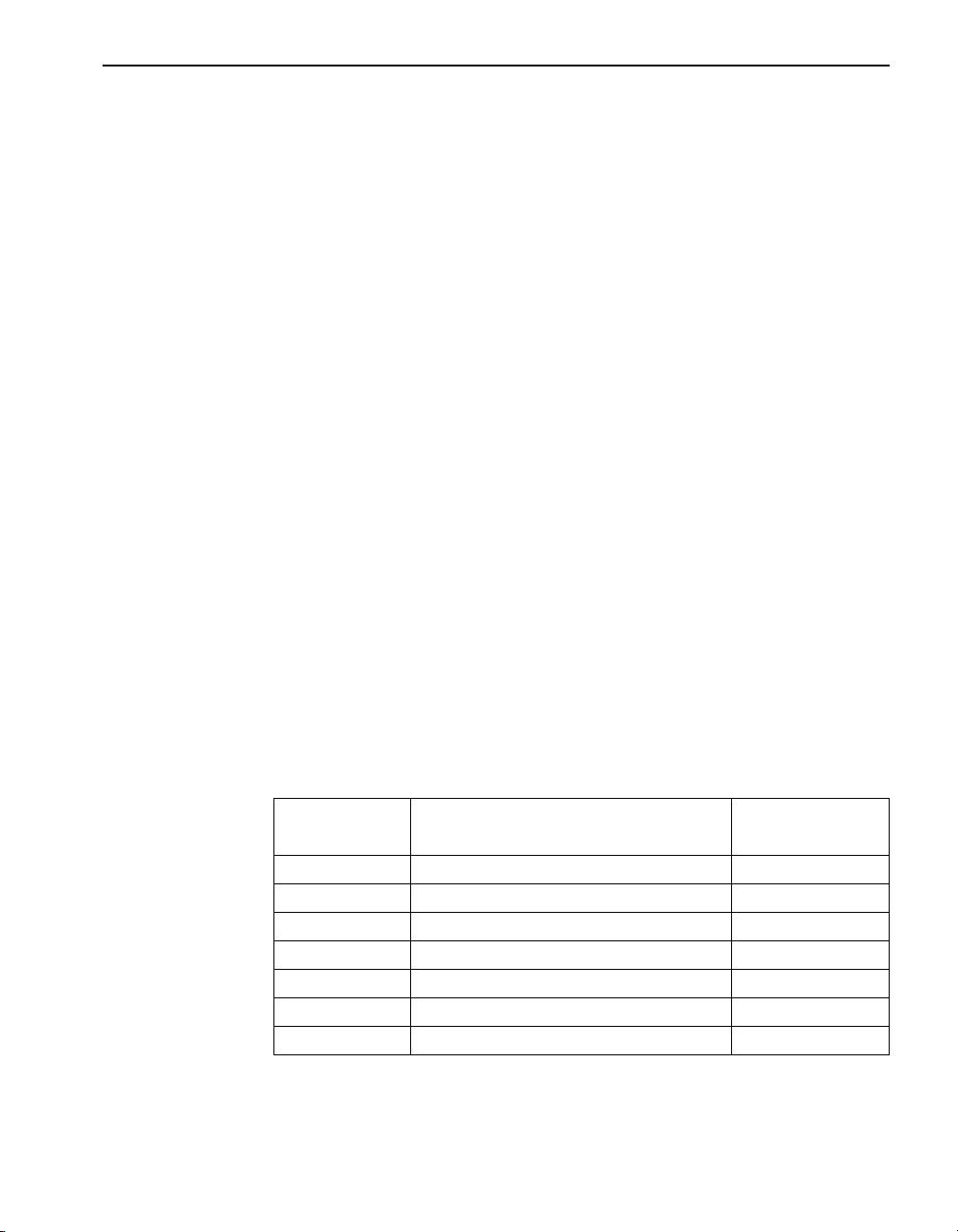

Table 5 Sample Dilution Volumes

Sample

Volume (mL)

25.0 0.0 1

12.5 12.5 2

1

10.0

1

5.0

1

2.5

1

1.0

1

0.250

1 For sample sizes of 10 mL or less, use a pipet to measure the sample into the graduated

cylinder or volumetric flask.

mL deionized Water Used

to Bring the Volume to 25 mL

15.0 2.5

20.0 5

22.5 10

24.0 25

24.75 100

Multiplication

Factor

29

Page 30

SECTION I, continued

Table 6 Multiplication Factors for Diluting to 100 mL

Sample Volume (mL) Multiplication Factor

1 100

250

520

10 10

25 4

50 2

Sample Dilution and Interfering Substances

Sample dilution may influence the level at which a substance may

interfere. The effect of the interferences decreases as the dilution

increases. In other words, higher levels of an interfering substance can be

present in the original sample if it is diluted before analysis.

An Example:

Copper does not interfere at or below 100 mg/L for a 25.00 mL sample in a

procedure. If the sample volume is diluted with an equal volume of water, what is

the level at which copper will not interfere?

Total volume

------------- ----------------- ----------- Dilution factor=

Sample volume

25

----------- 2=

12.5

Interference Level Dilution Factor× Interference level in sample=

100 2× 200=

The level at which copper will not interfere in the undiluted sample is at or below

200 mg/L.

30

Page 31

SECTION I, continued

Using Pipets and Graduated Cylinders

When small sample quantities are used, the accuracy of measurements is

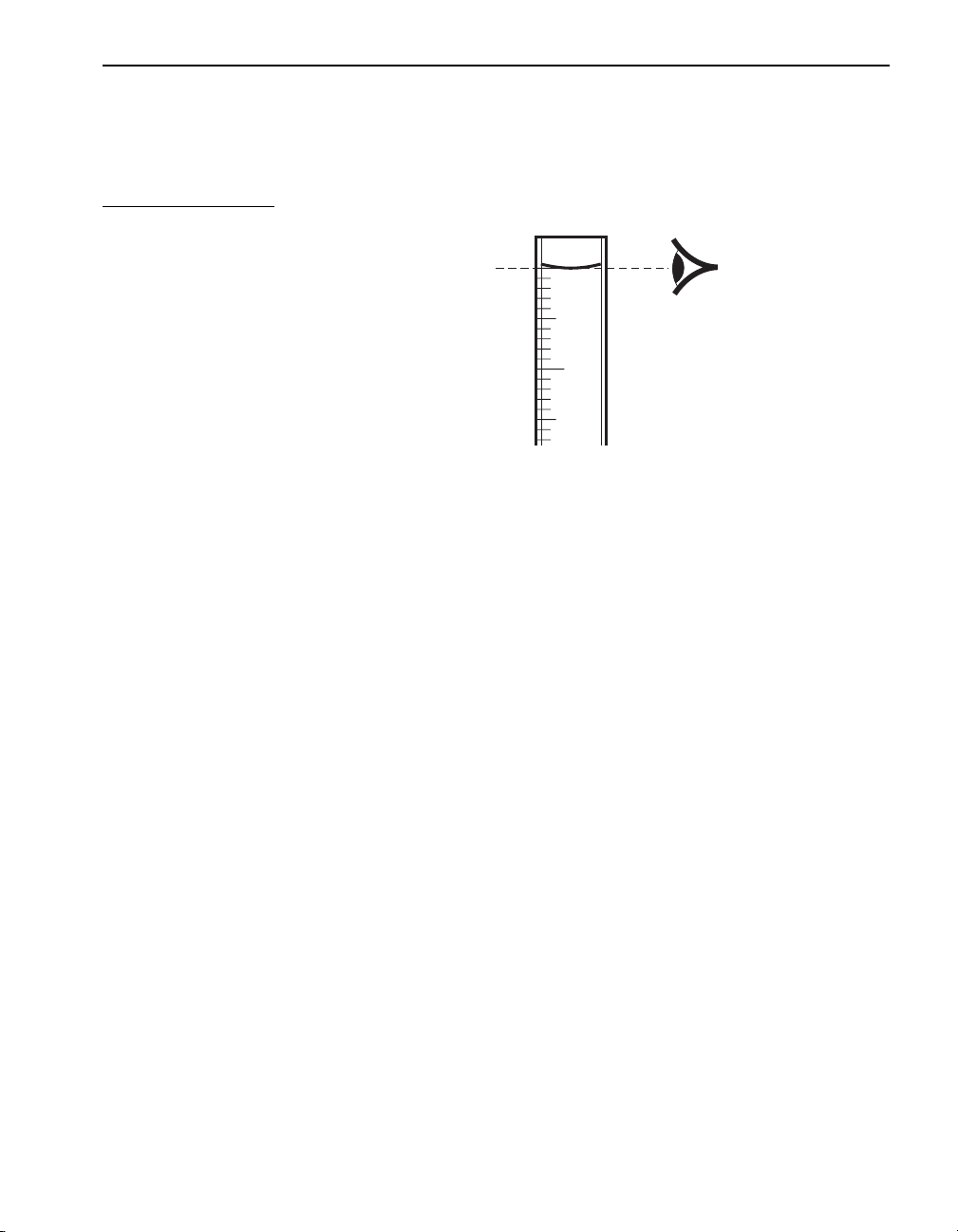

important. Figure 3 illustrates the proper way of reading the sample level

or the meniscus formed when the liquid wets the cylinder or pipet walls.

Figure 3 Reading the Meniscus

Rinse the pipet or cylinder two or three times with the sample to be tested

before filling. Use a pipet filler or pipet bulb to draw the sample into the

pipet. Never pipet chemical reagent solutions or samples by mouth. When

filling a pipet, keep the tip of the pipet below the surface of the sample as

the sample is drawn into the pipet.

50

45

40

35

Serological pipets have marks that indicate the volume of liquid delivered

by the pipet. The marks may extend to the tip of the pipet or may be only

on the straight portion of the tube. If the marks are only on the straight

part of the tube, fill serological pipets to the zero mark and discharge the

sample by draining the sample until the meniscus is level with the desired

mark. If the serological pipet has marks extended to the tip of the pipet,

fill the pipet to the desired volume and drain all the sample from the pipet.

Then blow the sample out of the pipet tip for accurate measurements.

Volumetric (transfer) pipets have a bulb in the middle and a single ring

above the bulb to indicate the volume of liquid when it is filled to the

mark . To discharge a volumetric pipet, hold the tip of the pipet at a slight

angle against the container wall and drain. Do not attempt to discharge the

solution remaining in the tip of the pipet after draining. Volumetric pipets

are designed to retain a small amount of sample in the pipet tip.

If sample drops stay on the walls of the pipet, the pipet is dirty and is not

delivering the correct amount of sample. Wash the pipet thoroughly with a

laboratory detergent or cleaning solution and rinse several times with

deionized water.

31

Page 32

SECTION I, continued

Using the TenSette Pipet

For best results use a new tip each time you pipet. After several uses, the

pipet tip may retain some liquid, causing inaccurate delivery. Each pipet is

supplied with 100 tips; order Hach replacement tips for best results.

Always use careful, even hand movements for best reproducibility. If the

pipet does not operate smoothly, disassemble and coat the piston and

retainer with high-quality stopcock grease. Also coat the metering turret

lightly with grease. Refer to the TenSette Pipet manual.

For best pipetting accuracy, the solution and the room temperature should

be between 20-25 °C.

Never lay the pipet down with the liquid in the tip. Solution could leak

into the pipet and cause corrosion.

Operating the TenSette Pipet

1. Attach a clean tip by holding the pipet body in one hand and gently

pressing the large end of the pipet tip onto the tapered end of the

pipet. Be sure a good seal is obtained.

2. Turn the turret cap to align the desired volume with the mark on the

pipet body.

3. Using a smooth motion, press down on the turret cap until it reaches

the stop. Immerse the tip about 5 mm (1/4 inch) below the solution

surface to avoid drawing air into the pipet. Do not insert the tip any

deeper or the delivery volume may be affected.

4. While maintaining a constant pressure, allow the turret to return

slowly to the extended position. A rapid return may affect the

delivery volume.

5. With the turret up, take the tip out of the solution and move it to the

receiving vessel. Do not press on the turret cap while moving the pipet.

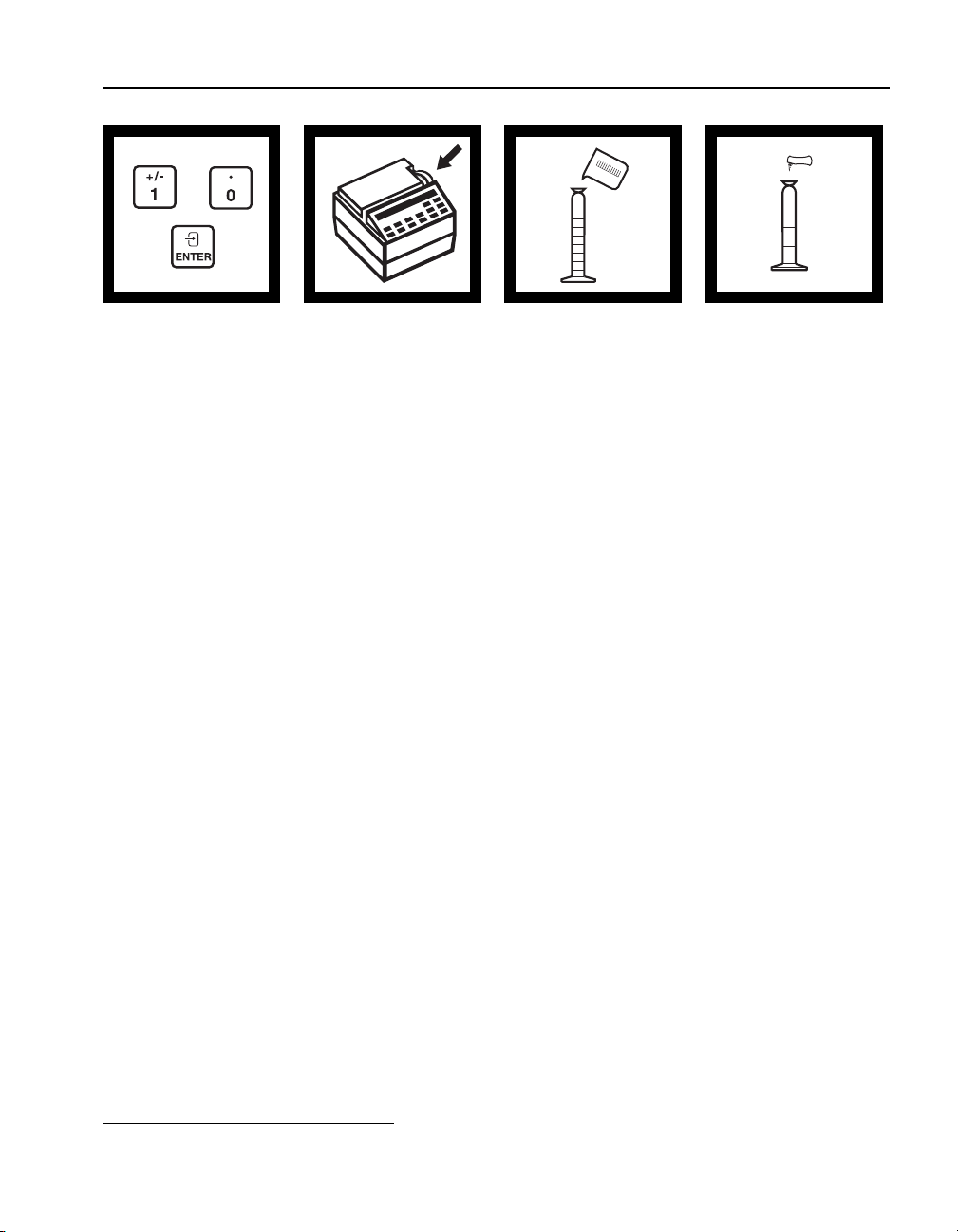

STEP 3 STEP 4 STEP 5

32

Page 33

SECTION I, continued

6. Use the thumb and forefinger to twist the turret cap to the next higher

volume position to ensure quantitative transfer of the sample.

The “F” position provides full blowout.

7. With the tip in contact with the side of the receiving vessel, slowly

and smoothly press down on the turret cap until it reaches the stop and

the solution is completely discharged.

Mixing Water Samples

The following two methods may be helpful in tests that require mixing

sample with chemicals (usually indicated by “swirl to mix” instructions).

1. When mixing sample in a square sample cell, swirl with a simple

2. Swirling is recommended when mixing samples in a graduated

This swirling procedure is the most gentle and offers the least interference

from the atmosphere when testing for carbon dioxide and other gases.

Both methods are simple but take a bit of practice in order to obtain the

best results.

STEP 6

STEP 7

twisting motion; see Figure 4. Grasp the neck of the cell with the

thumb and index finger of one hand. Rest the concave bottom of the

cell on the tip of the index finger of other hand. Mix by rotating the

cell quickly one way and then in the reverse direction.

cylinder or a titration flask. Grip the cylinder (or flask) firmly with the

tips of three fingers; see Figure 5. Hold the cylinder at a 45-degree

angle and twist the wrist. This should move the cylinder in an

approximately 12-inch circle, creating enough rotation to complete

the mixing in a few turns.

33

Page 34

SECTION I, continued

Figure 4 Swirling a Sample Cell

Figure 5 Swirling a Graduated Cylinder

34

Page 35

SECTION I, continued

Using Sample Cells

Orientation of Sample Cells

Two types of matched sample cells are shipped with the DR/2010; a

matched pair of taller 25 mL sample cells and a shorter matched pair of

10 mL sample cells. Both types are matched with the spectrophotometer

light beam passing through the side with the fill mark and the opposite

side. Matched pairs have been tested and paired so that significant error

will not be introduced because of variations in the glass. A solution in

both cells should give the same absorbance (±0.002 Abs). For more

information, see Sample Cell Matching, below.

To minimize variability of measurements using a particular cell, always

place the cell into the cell holder with the same orientation. The cells are

placed in the instrument with the fill marks facing left (viewer’s left).

In addition to proper orientation, the sides of the cells should be

free of smudges, fingerprints, etc. to ensure accurate readings. Wipe

the sides of the cells with a soft cloth to clean the surface before

taking measurements.

Care of Hach 1-inch Sample Cells

Store sample cells in their boxes when not in use to protect them from

scratching and breaking. It is good laboratory practice to empty and

clean sample cells after analyses are complete--avoid leaving colored

solutions in the cells for extended periods of time. Finish the cleaning

procedure with a few rinses of deionized water and allow to dry.

Individual procedures often recommend specific cleaning methods

for special circumstances.

Cleaning Sample Cells

Most laboratory detergents can be used at recommended concentrations.

Neutral detergents such as Neutracon are safer if regular cleaning is

required, as in the case of protein residues.

If using a detergent, you can speed cleaning by increasing the temperature

or using an ultrasonic bath.

Rinsing is more efficient when using distilled water.

35

Page 36

SECTION I, continued

Sample Cell Matching

Sample cells shipped with the DR/2010 are matched and distortion-free.

Nicks and scratches from normal use can cause an optical mismatch

between two sample cells and introduce error in the test results. This type

of error can sometimes be avoided by optically re-matching the sample

cells as follows:

1. Turn the instrument on and select the constant-on mode. Wait 5

minutes for the lamp to warm up.

2. Enter the stored program for absorbance. Press

will show:

Abs.

0 ENTER. The display

3. Rotate the wavelength dial until the small display shows 510 nm or

the wavelength commonly used.

4. Pour at least 25 mL (10 mL for 10-mL cells) of deionized water into

each of two sample cells.

5. Place one sample cell into the cell holder. Orient the fill mark to the

left. Close the light shield.

6. Press:

ZERO. The display will show: 0.000 Abs.

7. Place the other sample cell into the cell holder using the same

orientation as in step 5. Close the light shield.

8. Wait about 3 seconds for the reading to stabilize. Record the result.

Two sample cells are matched when their absorbance readings are within

0.002 Abs of each other. If the cells do not match, there are two

alternative options to purchasing a new set.

If more than two sample cells are on hand, repeat steps 7-8 for with these

cells to determine if any match the original cell. If two cells match, mark

them appropriately and keep them as a set.

As a last option, change the orientation of the cells to find a matched

configuration. Repeat the steps above for two sample cells, placing both

cells in the cell compartment with the fill marks facing forward. If the

absorbance reading of the second cell is within +/- 0.002, the cells can be

used as a matched set in that particular orientation. All future work with

this particular set would require the same orientation. If necessary, repeat

matching process with different orientations as needed.

36

Page 37

SECTION I, continued

If the sample cells cannot be matched within ±0.002 Abs, they may still

be used by compensating for the difference. For example, if the second

cell reads 0.003 absorbance units higher than the first cell, correct future

readings (when using these two cells) by subtracting 0.003 absorbance

units (or the equivalent concentration) from the reading. Likewise, if the

second cell reads -0.003 absorbance units, add that value to the reading.

Volume Measurement Accuracy

The 10-and 25-mL sample cells supplied with the spectrophotometer have

fill marks to indicate either 10 mL or 25 mL. The fill marks are intended

to measure the volume to be analyzed. Do not use these fill marks to

perform sample dilutions.

If a sample must be diluted, use a pipet, graduated mixing cylinder and/or

a volumetric flask for accurate measurement. When diluting, accuracy is

important because a slight mistake in measuring a small sample will cause

a substantial error in the result. For instance, a 0.1-mL mistake in the

dilution of a 1.0-mL final volume produces a 10% error in the test result.

Volumes for standard additions can be measured in the 25-mL cells, but

it is not recommended for the 10-mL cells due to a potentially excessive

relative error. An error of 0.5 mL in 25 mL is only 2%, while a 0.5 mL

error in 10 mL is 5%.

For 10 mL standard additions, follow this procedure:

1. Pipet 10.0 mL of sample into a clean, dry 10 mL cell

2. Add the standard (spike) to a 25 mL portion of sample in a 25-mL

3. Transfer 10 mL to another 10-mL cell (use fill mark) for analysis.

Using AccuVac Ampuls

AccuVac ampuls contain pre-measured powder or liquid in optical-quality

glass ampuls.

1. Collect the sample in a beaker or other open container.

2. Place the ampul tip well below the sample surface and break the tip

(the unspiked sample).

mixing cylinder. Stopper and mix thoroughly.

off (see Figure 6) against the beaker wall. The break must be far

enough below the surface to prevent air from being drawn in as the

level of the sample lowers (the AccuVac Breaker may be used instead

of breaking the ampul against the beaker side).

37

Page 38

SECTION I, continued

3. Invert the ampul several times to dissolve the reagent. Do not place

your finger over the broken end; the liquid will stay in the ampul

when inverted. Wipe the ampul with a towel to remove fingerprints,

and other marks.

4. Insert the ampul into the AccuVac adapter in the DR/2010 and read

the results directly.

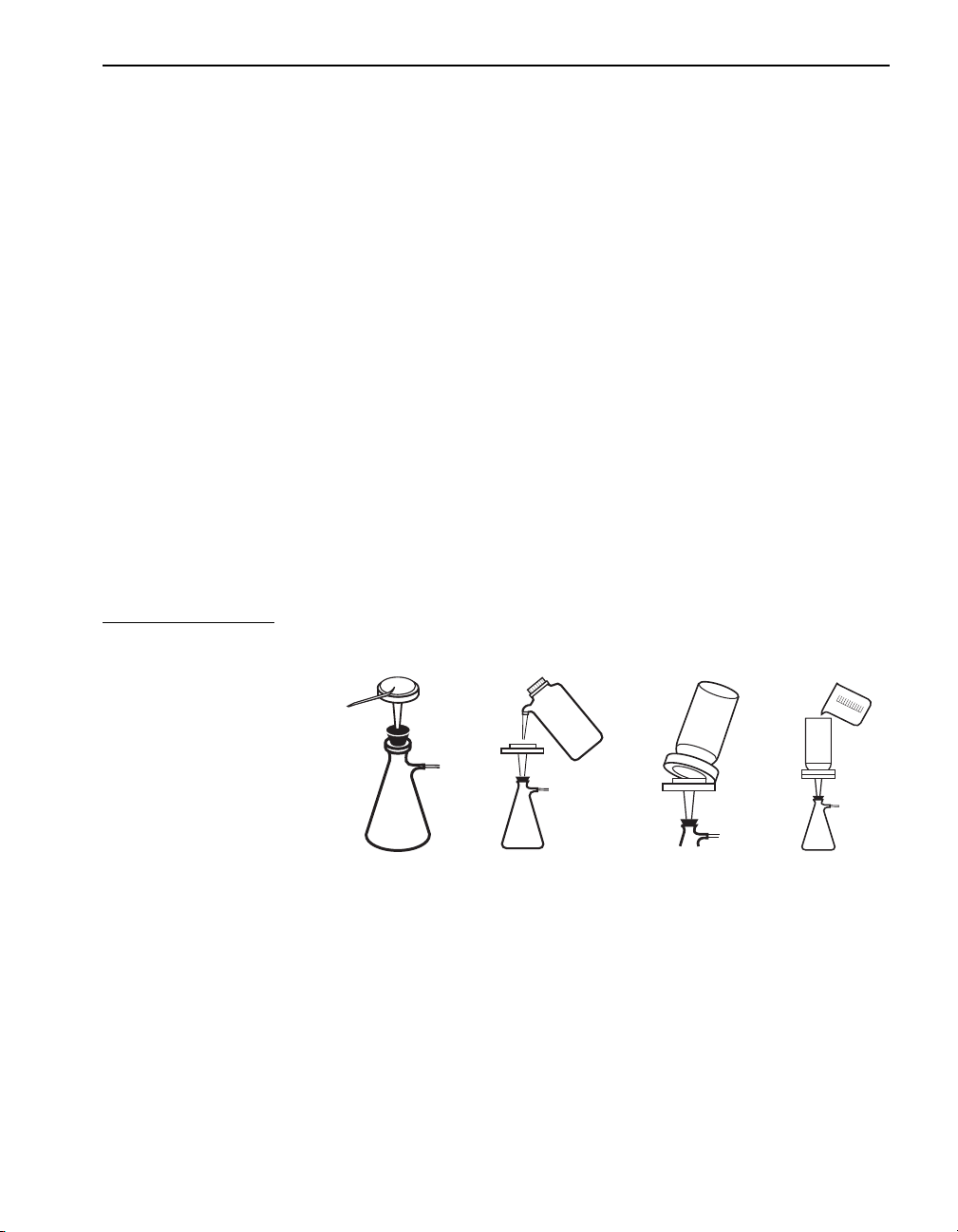

Figure 6 Using AccuVac Ampuls

1. 2.

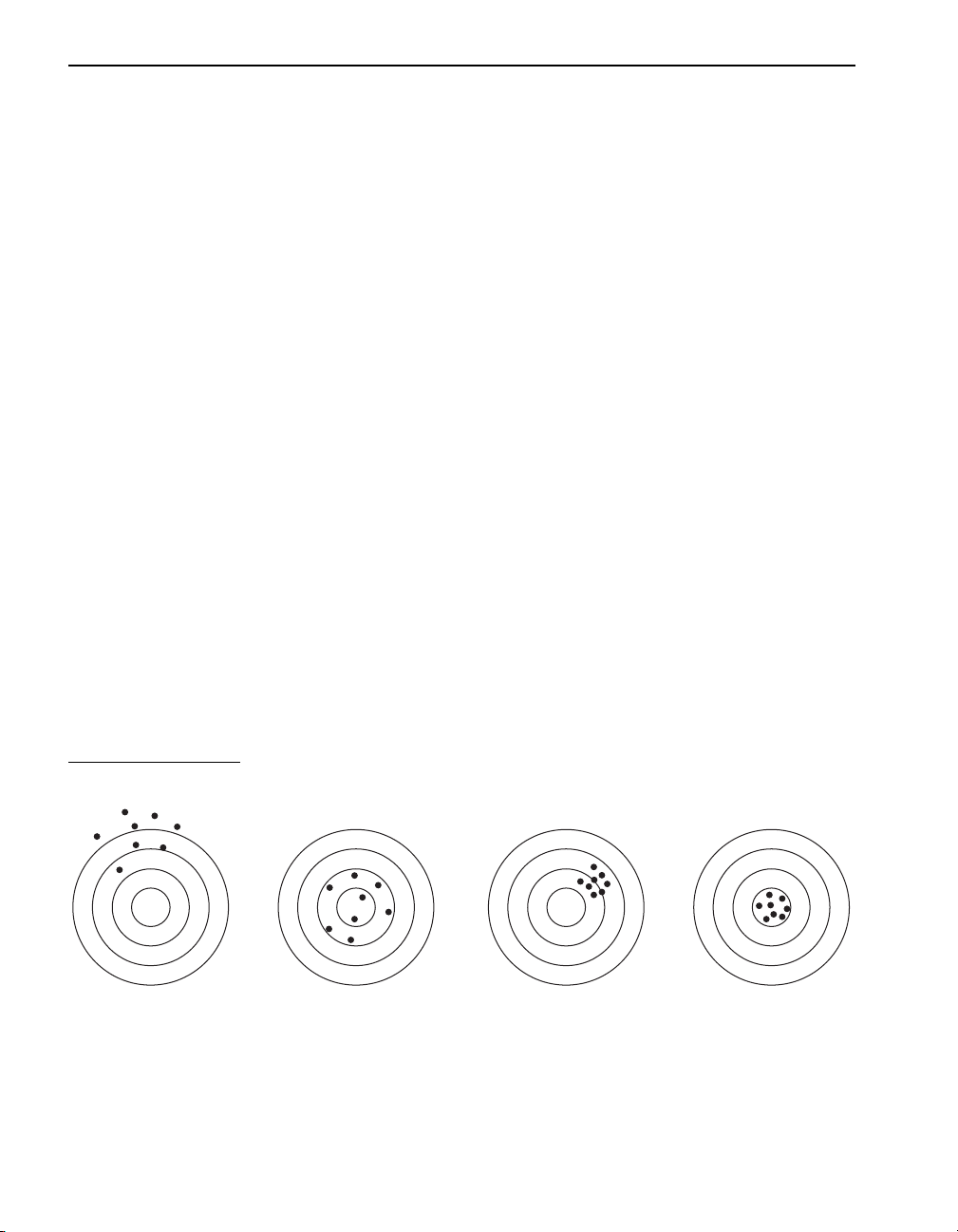

Using Reagent Powder Pillows

Hach uses dry powdered reagents when possible. This minimizes leakage

and deterioration problems. Some powders are packaged in individual,

pre-measured, polyethylene “powder pillows” or foil pillows called

PermaChem

Open the powder pillows with nail clippers or scissors; see Figure 7.

®

3.

4.

pillows. Each pillow contains enough reagent for one test.

Figure 7 Opening Powder Pillows

38

Page 39

SECTION I, continued

Using PermaChem Pillows

1. Tap the pillow on a hard surface to collect the powdered reagent in

the bottom.

2. Tear (or cut) across, from A to B, holding the pillow away from

your face.

3. Using two hands, push both sides toward each other to form a spout.

4. Pour the pillow contents into the sample cell and continue the

procedure according to the instructions.

Figure 8 Opening PermaChem Pillows

1. Tear 2. Push 3. Pour

BA

Using the Pour-Thru Cell

The Pour-Thru Cell is an optional accessory that improves accuracy and

makes measuring more convenient. It gives better results when measuring

at very low levels because it avoids any error that may result between

optical differences from single sample cells. Installation instructions for

the Pour-Thru Cell are given in the Instrument Manual. Each procedure

notes if the Pour-Thru Cell can be used; some procedures will not allow

the use of a Pour-Thru cell.

The DR/2010 offers many methods that use 10-mL sample sizes. The

Pour-Thru Cell cannot be used for procedures that use 10-mL sample

sizes and reagents. This volume does not flush the cell well enough to

avoid sample carryover errors. When possible, 25-mL reagents are listed

for those who prefer to use the Pour-Thru Cell.

When the procedure instructs you to place a 25-mL sample cell into the

cell holder, pour the solution into the funnel of the installed Pour-Thru

Cell Assembly (unless noted in the procedure).

Avoid spilling solution onto the instrument. The funnel height and

orientation may be adjusted for easier pouring.

39

Page 40

SECTION I, continued

The funnel height also determines the speed of sample flow through the

cell. The higher the funnel, the faster the flow. When properly adjusted,

the funnel drains completely with the final level of liquid in the tube about

5 cm (2 inches) below the tip of the funnel. This adjustment minimizes air

bubbles in the cell.

Measurement or instrument commands should only be made after the

solution has stopped flowing through the cell.

Occasionally, remove the Pour-Thru Cell to check for accumulation

of film on the windows. If the windows appear hazy, soak the cell in a

detergent bath and rinse thoroughly with deionized water. The cell may

be dissembled for cleaning. Do not over-tighten the screws during reassembly as the threads are easily stripped.

Always rinse thoroughly with deionized water after each series of tests,

or more often if specified in the procedure.

Caution:

Do not use or clean the Pour-Thru Cell with organic solvents such as acetone,

chloroform, toluene or cyclohexanone.

Reagent and Standard Stability

Hach always strives to make stable formulations and package them to

provide maximum protection. Most chemicals and prepared reagents do

not deteriorate after manufacture. However, the way they are stored and

the packaging can affect how long the reagents are stable. Light, bacterial

action, and absorption of moisture and gases from the atmosphere can

affect shelf life. Some chemicals may react with the storage container

or they may react with other chemicals.

Chemicals supplied with the DR/2010 Spectrophotometer have an

indefinite shelf life when stored under average room conditions, unless

the packaging says something different. Product labels state any special

storage conditions required. Otherwise, store reagents in a cool, dry, dark

place for maximum life. It is always good practice to date chemicals when

you receive them. Use older supplies first. If in doubt about the reagent

shelf life, run a standard to check its effectiveness.

40

Page 41

SECTION I, continued

Interferences

Substances in the sample may interfere with a measurement. Hach

mentions common interferences in the test procedures. The reagent

formulations eliminate many interferences. You can remove others with

sample pretreatments described in the procedure.

If you get an unusual answer, a color that you don’t expect, or you notice

an unusual odor or turbidity, the result may be wrong. Repeat the test on a

sample diluted with deionized water; see Sample Dilution Techniques.

Compare the result (corrected for the dilution) with the result of the

original test. If these two are not close, the original result may be wrong

and you should make an additional dilution to check the second test (first

dilution). Repeat this process until you get the same corrected result twice

in a row.

More information about interferences and methods to overcome them is

contained in Standard Additions and the General Introduction section of

APHA Standard Methods. Hach urges the analyst to obtain this book and

refer to it when problems are encountered.

pH Interference

Many of the procedures in this manual only work within a certain pH

range. Hach reagents contain buffers to adjust the pH of the typical

sample to the correct pH range. However, the reagent buffer may not be

strong enough for some samples. This occurs most often with highly

buffered samples or samples with extreme sample pH.

The Sampling and Storage section of each procedure gives the proper pH

range for the sample.

Adjust the sample to the proper pH range before testing. If this

information is not given, follow these steps:

1. Measure the pH of your analyzed sample with a pH meter. For

measuring K