Page 1

Catalog Number: 10-MAT-152

BioTector B7000 Online TOC TN Analyzer

USER MANUAL

March 2017, Edition 1

BS4ANP2 2.12d

Original Instructions in English

© Copyright BioTector 2017. All rights reserved. Printed by BioTector. Printed in the Republic of Ireland.

Page 2

Page 2

Table of Contents

SECTION 1 SAFETY PRECAUTIONS .......................................................................... 5

1.1 INFORMATION AND SAFETY SIGNS USED IN THE MANUAL ....................................................... 5

1.2 PRECAUTIONARY LABELS ATTACHED TO THE INSTRUMENT .................................................... 6

1.3 POTENTIAL SYSTEM SAFETY HAZARDS ................................................................................ 8

1.4 GENERAL SAFETY PRECAUTIONS ...................................................................................... 10

1.4 PRÉCAUTIONS GÉNÉRALES DE SÉCURITÉ ........................................................................... 10

1.4.1 Electrical and Burn Precautions .................................................................................................. 11

1.4.1 Précautions relatives à l’électricité et aux brûlures ..................................................................... 11

1.4.2 Carrier Gas and Exhaust Gas Precautions ................................................................................. 12

1.4.2 Précautions relatives au gaz porteur et d'échappement ............................................................. 12

1.4.3 Chemical Precautions ................................................................................................................. 13

1.4.3 Précautions chimiques ................................................................................................................ 13

1.4.4 Sample Stream Precautions ........................................................................................................ 14

1.4.4 Précautions relatives aux échantillons ........................................................................................ 15

SECTION 2 OPERATOR’S MANUAL ......................................................................... 16

SOFTWARE MENU DIAGRAM ......................................................................................................... 17

2.1 OPERATION MENU ............................................................................................................ 23

Start Stop .................................................................................................................................................. 23

Reagents Setup ........................................................................................................................................ 25

Install New Reagents ............................................................................................................................................ 25

Purge Reagents & Zero ........................................................................................................................................ 26

System Range Data ................................................................................................................................. 26

Manual Program ....................................................................................................................................... 27

Reaction Archive ...................................................................................................................................... 28

Fault Archive ............................................................................................................................................. 28

Time & Date .............................................................................................................................................. 29

Contact Information .................................................................................................................................. 29

2.2 CALIBRATION MENU.......................................................................................................... 30

Zero Calibration ........................................................................................................................................ 30

Span Calibration ....................................................................................................................................... 32

SECTION 3 TECHNICAL SPECIFICATIONS.............................................................. 34

SECTION 4 INTRODUCTION ...................................................................................... 37

4.1 BIOTECTOR MAJOR COMPONENTS .................................................................................... 37

4.1.1 Analysis Enclosure ...................................................................................................................... 37

4.1.2 Electronics Enclosure .................................................................................................................. 39

4.2 BIOTECTOR OPERATION ................................................................................................... 41

4.2.1 BioTector Oxidation Method ........................................................................................................ 41

4.2.2 BioTector Sample Injection ......................................................................................................... 42

4.2.3 BioTector Analysis Types ............................................................................................................ 42

4.2.3.1 TIC & TOC Analysis ........................................................................................................................... 44

4.2.3.2 TC Analysis ........................................................................................................................................ 44

4.2.3.3 VOC Analysis ..................................................................................................................................... 45

4.2.3.4 TC - TIC Analysis ............................................................................................................................... 46

4.2.3.5 TN Analysis ........................................................................................................................................ 47

SECTION 5 INSTALLATION ....................................................................................... 49

5.1 BASIC SYSTEM REQUIREMENTS ........................................................................................ 49

5.2 UNPACKING AND INSTALLATION ......................................................................................... 50

5.2.1 Analyzer Dimensions and Mounting ............................................................................................ 51

5.2.2 Wiring Power and Signal Terminals ............................................................................................ 53

5.2.3 Wiring External Power Disconnection Switch ............................................................................. 55

5.2.4 System Fuse Specifications ........................................................................................................ 56

5.3 CARRIER GAS AND REAGENT CONNECTIONS ...................................................................... 57

5.3.1 Carrier Gas Connection ............................................................................................................... 58

Page 3

Page 3

5.3.2 Reagent Connections .................................................................................................................. 60

5.4 SAMPLE, DRAIN AND EXHAUST CONNECTIONS ................................................................... 62

5.4.1 Sample Inlet Tube Position ......................................................................................................... 62

5.4.2 Drain, Bypass and Exhaust Connections .................................................................................... 64

SECTION 6 REAGENTS AND CALIBRATION STANDARDS.................................... 65

6.1 REAGENTS ....................................................................................................................... 65

6.2 CALIBRATION STANDARDS ................................................................................................ 66

SECTION 7 ANALYZER COMMISSIONING AND STARTUP .................................... 69

SECTION 8 SYSTEM SOFTWARE OPERATION ....................................................... 75

8.1 OPERATION MENU ............................................................................................................ 75

8.2 CALIBRATION MENU.......................................................................................................... 75

8.3 MAINTENANCE MENU ........................................................................................................ 75

8.3.1 DIAGNOSTICS MENU ................................................................................................................ 76

Process Test ......................................................................................................................................................... 77

Oxidation Phase Process Test .............................................................................................................................. 77

Pressure Test .................................................................................................................................................................. 77

Flow Test .......................................................................................................................................................................... 78

Ozone Test ...................................................................................................................................................................... 79

Sample Pump Test ......................................................................................................................................................... 81

pH Test ............................................................................................................................................................................. 82

Liquid Phase Process Test ................................................................................................................................... 86

Purge TN Cell Test ......................................................................................................................................................... 86

Clean TN Cell Test.......................................................................................................................................................... 86

Read DI Water Reference Test ..................................................................................................................................... 87

Read TN Sample Test .................................................................................................................................................... 88

Simulate ................................................................................................................................................................ 89

Oxidation Phase Simulate ............................................................................................................................................. 89

Liquid Phase Simulate .................................................................................................................................................... 93

Signal Simulate ..................................................................................................................................................... 95

Data Output .......................................................................................................................................................... 97

Send Reaction Archive ................................................................................................................................................... 98

Send Fault Archive........................................................................................................................................................ 101

Send Configuration ....................................................................................................................................................... 101

Send All Data ................................................................................................................................................................. 101

Input/Output Status ............................................................................................................................................. 102

Service ................................................................................................................................................................ 103

8.3.2 COMMISSIONING MENU ......................................................................................................... 104

Reaction Time ..................................................................................................................................................... 104

Sample Pump ..................................................................................................................................................... 105

Stream Program ................................................................................................................................................. 105

COD/BOD Program ............................................................................................................................................ 106

New Reagents Program ...................................................................................................................................... 107

Reagents Monitor ............................................................................................................................................... 107

Autocal Program ................................................................................................................................................. 108

4-20mA Program ................................................................................................................................................ 109

Relay Program .................................................................................................................................................... 111

Data Program ..................................................................................................................................................... 112

Information .......................................................................................................................................................... 112

8.3.3 SYSTEM CONFIGURATION MENU ......................................................................................... 113

Analysis Mode .................................................................................................................................................... 114

System Program ................................................................................................................................................. 115

Calibration Data .................................................................................................................................................. 122

Sequence Program ............................................................................................................................................. 122

Average Program .......................................................................................................................................................... 122

Cleaning Program ......................................................................................................................................................... 123

Zero Program................................................................................................................................................................. 124

Span Program ............................................................................................................................................................... 125

Reagents Purge ............................................................................................................................................................ 126

Pressure/Flow Test Program ....................................................................................................................................... 127

Output Devices ................................................................................................................................................... 128

Reaction Check .................................................................................................................................................. 130

Result Integration ................................................................................................................................................ 131

Fault Setup ......................................................................................................................................................... 132

Fault Status ......................................................................................................................................................... 134

Page 4

Page 4

CO2 Analyzer ..................................................................................................................................................... 135

Cooler Program .................................................................................................................................................. 135

Software Update ................................................................................................................................................. 136

Password ............................................................................................................................................................ 137

Language ................................................................................................ ............................................................ 137

Hardware Configuration ...................................................................................................................................... 137

SECTION 9 TROUBLESHOOTING OF SYSTEM FAULTS & WARNINGS .............. 138

9.1 BIOTECTOR FAULT CONDITIONS ...................................................................................... 138

9.2 BIOTECTOR WARNING CONDITIONS ................................................................................. 141

9.3 BIOTECTOR NOTIFICATION CONDITIONS .......................................................................... 146

SECTION 10 SERVICE AND MAINTENANCE ............................................................ 147

10.1 WEEKLY MAINTENANCE .................................................................................................. 147

10.2 SIX AND TWELVE MONTH SERVICE .................................................................................. 148

SECTION 11 SYSTEM REPLACEMENT AND SPARE PARTS .................................. 153

SECTION 12 WARRANTY AND EXCLUSIONS .......................................................... 154

SECTION 13 APPENDICES ......................................................................................... 155

APPENDIX 1 INSTRUCTIONS FOR CONNECTING PRINTER TO BIOTECTOR ................................... 155

APPENDIX 2 SETTING UP WINDOWS TO RECEIVE DATA FROM BIOTECTOR ................................ 156

APPENDIX 3 BIOTECTOR 4-20MA OUTPUT MODES .................................................................. 157

Appendix 3.1 Direct Mode .................................................................................................................. 157

Appendix 3.2 Stream Multiplex Mode ................................................................................................. 158

Appendix 3.3 Full Multiplex Mode ...................................................................................................... 162

Appendix 3.4 Result Update in Stream and Full Multiplex Modes ..................................................... 167

APPENDIX 4 GLOSSARY ......................................................................................................... 168

APPENDIX 5 CONTACT INFORMATION ...................................................................................... 171

Page 5

Page 5

Section 1 Safety Precautions

Please read this manual before unpacking, setting up, or operating the BioTector.

BioTector should only be used by qualified trained staff and for the purpose it is intended for. Do not use or

install this equipment in any way other than the methods specified in this manual. The procedures and

methods described in this manual are based on assuming the user have basic, fundamental background on

electronics, chemistry and analyzer equipment.

If the instructions in this manual are not followed, the operation and protection provided by the

equipment may be impaired.

1.1 Information and Safety Signs used in the Manual

When any supplementary information is required and if any hazards exist, the necessary information and

safety signs (Information, Caution, Warning and Danger) will be displayed for the corresponding section or

procedure in this manual.

Used to indicate supplementary information, to call attention to

recommendations, to simplify the operation and to guarantee the correct use

of the equipment.

Used when there is a danger of minor damage to the system if the user does

not follow precautions.

Used when there is a danger of minor injury or serious damage to the

system if the user does do not follow the precautions.

Used when failure to observe a safety precaution may result in serious injury

or death.

Caution

WARNING

DANGER

Page 6

Page 6

1.2 Precautionary Labels Attached to the Instrument

The labels and tags attached to the instrument are summarized below. Please read all labels and tags

attached to the instrument. If not observed, personal injury or damage to the instrument could occur.

This symbol, when displayed on the instrument, indicates that the user

must gather the necessary operation and/or safety information given in the

instruction manual.

This symbol, when attached on an enclosure, indicates an existing risk of

electrical shock and/or electrocution. Only qualified personnel should open

such enclosures and work with hazardous voltages.

This symbol, when displayed on a component, identifies that the

component surface can be hot. When it is necessary to work with this

component, it should be handled with care.

This symbol, when noted on a product, illustrates the risk of chemical harm

due to its corrosive, acidic, caustic or solvent nature. Only qualified and

trained staff should handle such chemicals.

This symbol, when noted on an analyzer, illustrates the risk of the presence

of toxic ozone gas produced in the analyzer. Only qualified and trained staff

should work with this analyzer.

This symbol, when displayed on the instrument, indicates the presence of

devices sensitive to Electro-Static Discharge (ESD). Prior to any work with

such components, the individual should be grounded via an earth strap to

prevent any possible damage.

This symbol, when displayed on the product, indicates that protective eye

wear must be used during the maintenance or service of the equipment.

This symbol, when used on the product, identifies the location of the

protective earth (ground) connection.

Page 7

Page 7

Electrical equipment marked with this symbol may not be disposed of in

European domestic or public disposal systems. Return old or end-of-life

equipment to the manufacturer for disposal at no charge to the user.

Page 8

Page 8

1.3 Potential System Safety Hazards

The potential safety hazards, which are associated with a running BioTector system, are as follows:

Electrical hazards

Potentially hazardous chemicals

Oxygen gas and components generating Ozone gas

Please read the instructions in this manual carefully before installing or starting the BioTector.

The manufacturer cannot accept liability for damages due to non-observance of this manual. Use of spare

parts not supplied by the manufacturer will invalidate the warranty. The manufacturer shall not be liable for

omissions or errors contained herein or for incidental or consequential damages in connection with the

furnishing, performance, or use of this material.

The information contained in this manual is subject to change without notice.

The information contained herein is protected by copyright. Reproduction, adaptation, or translation of any

part of this manual without prior written permission is prohibited, except as allowed under the copyright laws.

Product names mentioned herein are for identification purposes only and may be trademarks or registered

trademarks of their respective companies.

Where manuals are translated into several languages, the source language text is considered as the original.

Maintenance and operation should not be carried out unless personnel have been fully

trained in the operation of the BioTector.

Prior to working on the inside of the analyzer, the technician should be grounded via an

earth strap.

Caution

Page 9

Page 9

Ozone and Toxicity

Ozone is found in gaseous form as a natural ingredient of the earth's atmosphere. Some of the chemical and

physical properties of ozone are as follows:

Terms

Properties of Ozone (O3)

Molecule Weight

47.9982 g/g-mol

Boiling Point

-119 0.3 °C

Melting Point

-192.7 0.2 °C

Exposure to even low concentrations of ozone can be damaging to delicate nasal, bronchial and pulmonary

membrane. Symptoms of acute ozone toxification appear at a concentration of about 1 ppm by volume. The

type and severity of symptoms depend on the concentration and duration of exposure. In mild cases and in

the early phases of severe cases, symptoms will include one or more of the following:

Irritation or burning of the eyes, nose or throat

Lassitude

Frontal headache

Sensation of sub-sternal pressure

Constriction or oppression

Acid taste in mouth

Anorexia

In more severe cases, the symptoms may include dyspnoea, cough, choking sensation, tachycardia, vertigo,

lowering of blood pressure, severe cramping, chest pain, and generalized body pain. Pulmonary oedema may

develop with delayed onset, usually one or more hours after exposure.

Following severe acute ozone toxification, recovery is slow. In the few severe human cases reported, 10 -14

days of hospitalization were required. In these cases, minimal residual symptoms were present for as long as

9 months, but all cases eventually recovered completely.

The 1983 ACGIH has recommended a Threshold Limit Value (TLV) of 0.1 ppm (0.2 mg/m3) for ozone. The

safe level for short human exposure to concentrations of ozone in excess of 0.1 ppm (Threshold Limit Value)

is not known with certainty. The atmospheric concentration immediately hazardous to life is likewise not

known, but inhalation of 50 ppm for 30 minutes would probably be fatal. The odor threshold of ozone for a

normal person is 0.01 - 0.02 ppm by volume in air.

First Aid Treatment

Move the victim to an uncontaminated atmosphere. Control restlessness and pain by the administration of

sedatives and anodynes orally. Severe cases may require subcutaneous injections of small doses of

meperidine hydrochloride (Demerol) for relief of pain. Give oxygen inhalation by facemask when the acute

symptoms have subsided. Severe cases require hospitalization since deferred pulmonary oedema may

develop.

Page 10

Page 10

1.4 General Safety Precautions

Please pay attention to all caution, warning and danger statements at all times. Non-observance of the safety

instructions can result in serious personal injury, death or damage to the equipment. Therefore observe the

following:

Only engineers trained by the manufacturer should carry out maintenance on the BioTector.

The power supplies contain capacitors that are charged to hazardous voltages. After disconnecting

the main power, allow a minimum of one minute for discharge before opening the control section.

Never wash or spray the system with water. Do not allow water to enter the interior.

Protect the system from one-sided heat radiation, direct sunlight and vibration. System must be

installed in a dry, dust-free room. Special precautions are required in environments with corrosive

gases, vapors or explosion risk.

Please do not place anything on top of the system.

1.4 Précautions générales de sécurité

Prière d’être toujours attentif à toutes les notices de prudence, d’avertissement ou de danger. Le non respect

des instructions de sécurité peut engendrer la blessure grave d’individus, leur décès ou la dégradation du

matériel. Pour ces raisons, prière d’observer les règles suivantes:

Seuls les ingénieurs formés par le fabricant doivent réaliser des travaux de maintenance sur le

BioTector.

L’alimentation électrique contient des condensateurs qui sont chargés à des tensions dangereuses.

Après avoir débranché l’alimentation électrique, attendre au moins une minute pour permettre la

décharge avant d'ouvrir le boîtier de commande.

Ne jamais laver ou arroser l’appareil avec de l’eau. Ne pas laisser de l’eau pénétrer à l’intérieur.

Protéger l’appareil des radiations de chaleur sur un seul côté, des rayons directs du soleil et des

vibrations. L’appareil doit être installé dans une pièce sèche et sans poussière. Il est nécessaire de

prendre des précautions particulières dans les environnements contenant des vapeurs ou gaz

corrosifs ou ceux à risque d’explosion.

Prière de ne rien poser sur le dessus de l'appareil.

Page 11

Page 11

1.4.1 Electrical and Burn Precautions

During system installation, maintenance or servicing:

Isolate the system power lines before starting any work in the electronic enclosure.

All electrical work should be carried out by qualified electrical personnel only.

Comply with all local and national regulations when working with electrical connections.

Make sure the system is properly earthed (grounded) before switching on.

It is required to connect the mains through an external isolator (2-pole disconnection switch), and if

possible connect the mains through an earth leakage circuit breaker.

When working with hot surfaces, use protective gloves and handle the components with care.

1.4.1 Précautions relatives à l’électricité et aux brûlures

À l’installation de l’appareil, sa maintenance ou son entretien:

Isoler les fils électriques de l’appareil avant de commencer tout travail dans le boîtier électronique.

Seul le personnel électricien qualifié est habilité à effectuer tous travaux d’électricité.

Se conformer aux règlementations locales et nationales pour tout travail sur un branchement

électrique.

Avant de l’allumer, veiller à la bonne mise à la terre de l’appareil.

Le branchement sur le courant secteur doit obligatoirement se faire par l'intermédiaire d'un

interrupteur sectionneur externe (interrupteur bipolaire), et prévoyez si possible un disjoncteur

différentiel.

Utiliser des gants de protection pour les travaux sur les surfaces très chaudes et prendre soin en

manipulant les composants.

BioTector contains electrical components operating under high voltages.

Contact may result in electric shock and severe or fatal injury.

BioTector contient des composants électriques qui fonctionnent à des tensions

élevées. Un contact peut engendrer un choc électrique et des blessures graves

ou mortelles.

DANGER

DANGER

Page 12

Page 12

1.4.2 Carrier Gas and Exhaust Gas Precautions

BioTector uses oxygen (O2) gas as the carrier gas during its operation. The oxygen gas must be free of

carbon dioxide (CO2) and nitrogen (N2) gases. The average rate of oxygen consumption in BioTector is 22

L/hour (367 ml/min). Carbon dioxide filtered air, carbon dioxide and nitrogen contaminated oxygen gas are not

suitable for BioTector TOC TN analyzer. When handling oxygen:

The same precautions, which are required for any high pressure or compressed gas system, must be

taken to avoid accidents.

Comply with all local and national regulations and/or manufacturer's recommendations and guidelines

when working with oxygen.

If oxygen cylinders are used, they must be transferred safely using appropriate equipment (e.g. carts,

hand trucks etc.)

If oxygen cylinders are used, they should be labeled clearly for identification and well secured for

storage and transport.

Avoid the use of extensive number of adaptors and couplers.

Do not allow oxygen to come in direct contact with grease, oil, fat, and other combustible materials. If

uncertain how to handle oxygen cylinders and high concentration oxygen, contact your local oxygen

manufacturer.

If oxygen concentrator is used, take precautions to avoid a fire in the area of the concentrator, install

the concentrator only in a well ventilated area and comply with all local and national regulations.

Vent waste gases to atmosphere or to a well ventilated area making the necessary connections on system

exhaust. Under normal operating conditions, waste gases will contain oxygen, traces of carbon dioxide and

the traces of volatiles/gases which may exist in the sample stream. Under abnormal conditions, the waste

gases may contain traces of ozone.

1.4.2 Précautions relatives au gaz porteur et d'échappement

Pour son fonctionnement, BioTector emploie de l’oxygène (O2) comme gaz porteur. L’oxygène ne doit

comporter aucun gaz carbonique (CO2) ni d’azote (N2). Le taux moyen de consommation d’oxygène du

BioTector est de 22L/heure (367 ml/min). L’analyseur BioTector TOC TN ne tolère pas l’air filtré de gaz

carbonique ni l'oxygène contaminé de gaz carbonique et d'azote. À la manipulation de l’oxygène:

Afin d’éviter les accidents, prendre les mêmes précautions que pour tout appareil à haute pression ou

gaz comprimé.

Pour toute opération avec de l’oxygène, se conformer aux règlementations locales et nationales et/ou

aux recommandations et consignes du fabricant.

S’ils sont employés, les cylindres d’oxygène doivent être transportés en toute sécurité à l’aide du

matériel approprié (chariots, diables, etc.)

S’ils sont employés, les cylindres d’oxygène doivent être clairement étiquetés pour en permettre

l’identification et bien arrimés pour leur stockage et leur transport.

Éviter d’utiliser un nombre élevé d’adaptateurs et de dispositifs de couplage.

Ne pas laisser l’oxygène entrer en contact direct avec de la graisse, de l’huile, des matières grasses

ou d’autres matières combustibles. Veuillez contacter votre fabricant local d’oxygène si vous avez

des doutes sur la manière de manipuler les cylindres d’oxygène et l’oxygène de haute concentration.

Dans le cas où un concentrateur est employé, prendre les précautions nécessaires pour éviter un

incendie dans la zone du concentrateur, n’installer le concentrateur que dans un endroit bien ventilé

et se conformer aux règlementations locales et nationales.

Évacuer les gaz usés dans l’atmosphère ou dans un endroit bien ventilé en réalisant les branchements

voulus sur l'échappement de l’appareil. Dans des conditions normales de fonctionnement, les gaz usés

contiennent de l’oxygène, des traces de gaz carbonique et des traces de composants volatiles/gaz qui

peuvent être présents dans l’échantillon. Dans des conditions anormales, les gaz usés peuvent contenir des

traces d’ozone.

Page 13

Page 13

1.4.3 Chemical Precautions

A number of chemicals and compounds to be used with BioTector are listed in Section 6 Reagents and

Calibration Standards. Some of these compounds are harmful, corrosive, acidic and oxidizing. Appropriate

precautions must be taken when handling these chemicals or solutions prepared from these chemicals.

Physical contact with these chemicals and inhalation of any vapors must be minimized using appropriate

safety equipment.

1.4.3 Précautions chimiques

La liste de la Section 6 Réactifs et Standards de Calibration énumère un certain nombre de produits

chimiques et composés à utiliser avec BioTector. Certains de ces composés sont nocifs, corrosifs, acides et

oxydants. Il est essentiel de prendre les précautions appropriées lors de la manipulation de ces produits

chimiques ou des solutions dont ils sont la base.

Il est essentiel d’employer l’équipement de sécurité approprié afin de minimiser le contact direct avec ces

produits chimiques et l’inhalation de toutes vapeurs.

Page 14

Page 14

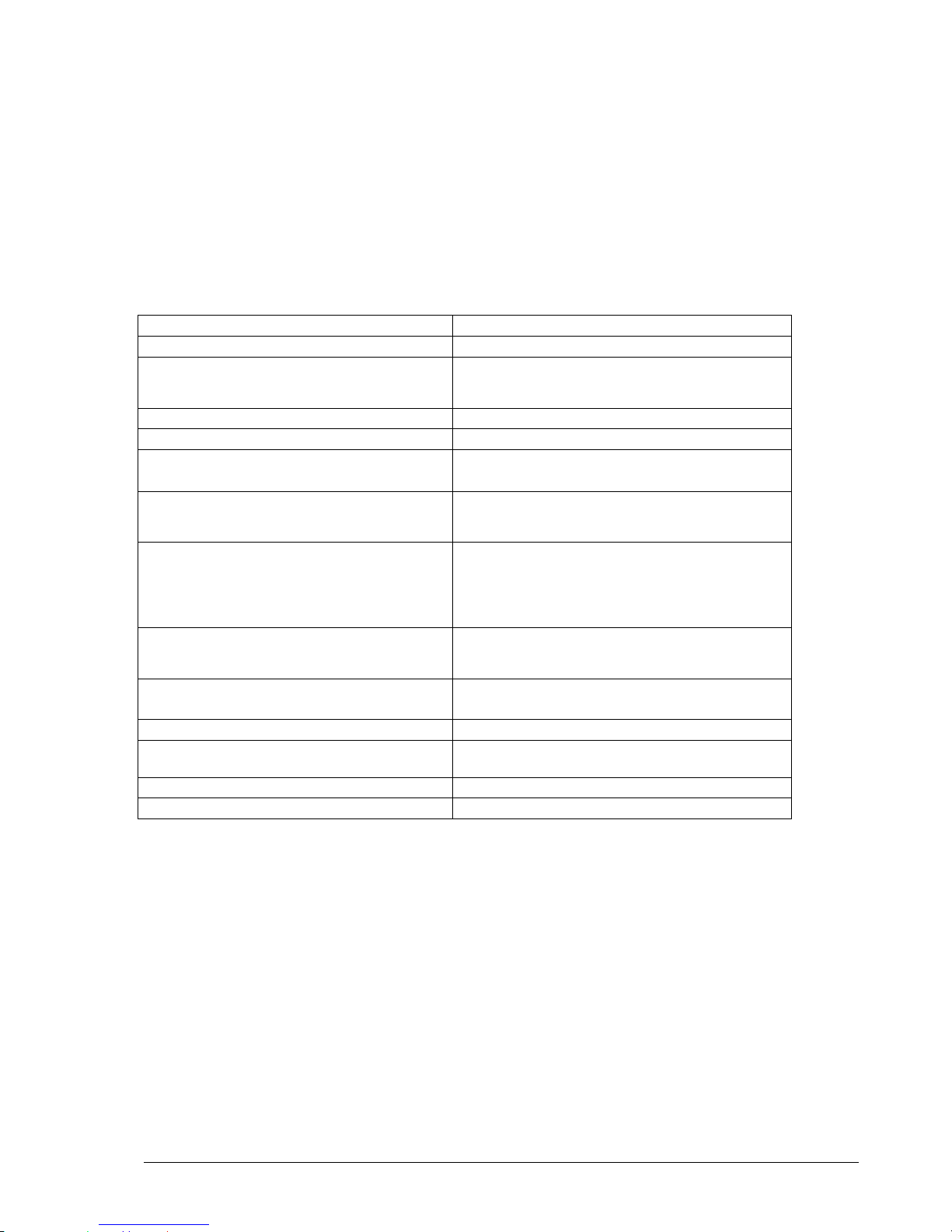

1.4.4 Sample Stream Precautions

The user is responsible to establish the potential hazard associated with each sample stream. Necessary

precautions must be taken, to avoid physical contact with any harmful sample stream, which may contain

chemical or biological hazards.

System components and their composition, which come in contact with the sample liquid and possible volatile

gases from the sample, are tabulated in table 1 below. If there are suspected compatibility issues between the

sample stream and BioTector components, please contact the manufacturer or the distributor.

Table 1 System components and their composition

Component

Material

Tubing

PFA (Per-fluoro-alkoxy)

Fittings

PFA (Per-fluoro-alkoxy)

Stainless Steel (SS-316)

PVDF (Poly-vinylidene-flouride)

Pump Tubing

EMPP (Elastomer-modified-poly-propylene)

Connectors

PP (Poly-propylene)

Connector & Valve Tubing

EMPP (Elastomer-modified poly-propylene)

Viton

Sample (ARS) Valve

PEEK (Poly-ether-ether-ketone)

PVDF (Poly-vinylidene-flouride)

Stainless Steel (SS-316)

Reactor

Hastelloy (C-276)

Stainless Steel (SS-316)

PFA (Per-fluoro-alkoxy)

PTFE (Poly-tetra-fluoro-ethylene)

Borosilicate Glass

Circulation Pump

Kalrez

PVDF (Poly-vinylidene-flouride)

Ceramic

Valve Seals

Kalrez

Viton

Oxidized Sample Catch-pot/Cleaning Vessel

Borosilicate Glass

NDIR CO2 Analyzer

Hastelloy (C-276)

Stainless Steel (SS-316)

NDIR CO2 Analyzer Lens

Sapphire

TN Measuring Cell

Quartz

Page 15

Page 15

1.4.4 Précautions relatives aux échantillons

L’usager assume la responsabilité d’établir le danger possible que représente chaque échantillon. Il est

essentiel de prendre les précautions voulues afin d’éviter le contact physique avec tout échantillon nocif qui

pourrait présenter un danger chimique ou biologique.

Le tableau 1 ci-dessous présente les composants de l’analyseur (et leur composition) qui entrent en contact

avec l’échantillon liquide et les éventuels gaz volatiles émanant de l’échantillon. Si vous soupçonnez des

problèmes de compatibilité entre l’échantillon et les composants BioTector, veuillez contacter le distributeur

ou le fabricant.

Tableau 1 Composants de l’analyseur et leur composition

Composant

Équipement

Tuyauterie

PFA (perfluoroalkoxy)

Installations

PFA (perfluoroalkoxy)

Acier inoxydable (SS-316)

PVDF (polyfluorure de polyvinylidène)

Tuyauterie de la pompe

PPMOD (polypropylène modifié par élastomère)

Connecteurs

PP (polypropylène)

Tuyauterie des connecteurs & vannes

PPMOD (polypropylène modifié par élastomère)

Viton

Vanne d’entrée de l’échantillon (sélection

automatique)

PEEK (polyéther éther cétone)

PVDF (polyfluorure de polyvinylidène)

Acier inoxydable (SS-316)

Réacteur

Hastelloy (C-276)

Acier inoxydable (SS-316)

PFA (perfluoroalkoxy)

PTFE (polytetrafluoroethylene)

Verre borosilicaté

Pompe de circulation

Kalrez

PVDF (polyfluorure de polyvinylidène)

Céramique

Joints des vannes

Kalrez

Viton

Bac de récupération/récipient de nettoyage de

l’échantillon oxydé

Verre borosilicaté

Analyseur infrarouge non diffuseur de CO2

Hastelloy (C-276)

Acier inoxydable (SS-316)

Lentille de l’analyseur infrarouge non diffuseur

de CO2

Saphir

Cellule de mesure de TN

Quartz

Page 16

Page 16

Section 2 Operator’s Manual

Membrane Keypad

The BioTector is equipped with a built-in microprocessor, which has been programmed to enable the user to

control the instrument using just six buttons of its membrane keypad. By pressing the appropriate button, the

user can move through the various levels of the software menu.

The functions of the 6 keys on the membrane keypad are described below:

The ESCAPE [ , ] key, which returns user to the previous screen, can also be used to cancel

programming entries. If the ESCAPE key is pressed for longer than 1 second the user returns to the main

menu.

The LEFT [ , ] and RIGHT [ , ] arrow keys are used for numerical entries and programming the

BioTector.

The UP [ , ] and DOWN [ , ] arrow keys are used for numerical entries and programming the

BioTector.

The ENTER [ √ , ] key, which advances user to the next screen, is also used to enter programmed

settings in the BioTector.

Screen Symbols

<

Selector. Used to designate the menu item being selected.

*

Highlighter. Used to highlight an active or ongoing function of the BioTector.

_

Blinking Cursor. Used to indicate current user position when setting changes are

being made.

Menu Levels

There are three main menu levels in BioTector in addition to the reaction graph, reaction data and reagent

status screens:

Level 1 – Operation: This level controls the basic operation of the BioTector and allows access to

the archives.

Level 2 – Calibration: This level allows the user to run zero and span calibration cycles.

Level 3 – Maintenance: This level allows the user to test the individual components of the BioTector

for diagnostics, to download data, to program the software functions and to program the system

specific settings in the BioTector.

Page 17

Page 17

Software Menu Diagram

Page 18

Page 18

Startup State

When the BioTector is powered up, its LCD screen will automatically display the Reaction Data screen after a

delay of 60 seconds.

By pressing the ESCAPE key the user moves from the Reaction Data screen to the Reaction Graph screen.

Pressing the ENTER key on the Reaction Graph screens brings the user back to the Reaction Data screen.

Pressing ENTER key on the Reaction Data screen will bring up the select level screen, from where the user

can select the desired menu level using the UP or DOWN and ENTER keys.

Entry to each menu level can be controlled by numerical passwords. If the passwords are not set, pressing

the enter key will bring the user directly to the sub menu screen of the selected level. If the system has been

set up with passwords, the Password screen will appear and the password must be entered before access to

the selected level is allowed.

In all cases, pressing the ESCAPE key will return the user to the previous screen.

Screen Layout and System Message Priority

The system status messages are displayed on the top left hand side of the Reaction Data and Reagent

Status screens. On most other screens, only the screen name is displayed in this location.

System status messages are displayed in the following priority:

1. SYSTEM MAINTENANCE – the BioTector is in Maintenance mode, activated by the maintenance

switch.

2. SYSTEM FAULT – There is a fault on the BioTector. System is stopped.

3. SYSTEM WARNING – There is a warning on the BioTector. System is running.

4. SYSTEM NOTE – There is a notification on the BioTector. System is running.

5. SYSTEM CALIBRATION – The BioTector is calibrating. This could be Span Calibration, Span Check,

Zero Calibration or Zero Check.

6. System operation status. This could be one of either:

SYSTEM RUNNING – system is running.

SYSTEM STOPPED – system has been stopped by a fault or from the keypad.

REMOTE STANDBY – system has been put into standby mode remotely. System has stopped

analyzing.

The BioTector time and date is displayed on the top right side of each screen. When a

fault/warning/notification is logged in the system, a FAULT LOGGED message will alternate with the time/date

in this location until the fault/warning/notification has been corrected.

Changing most system settings are prevented when the BioTector is running.

Page 19

Page 19

Reaction Data

B I O T E C T O R R U N N I N G 0 9 : 1 7 : 2 8 1 2 - 0 9 - 0

2

0 9 : 2 7 : 0 2 1 2 - 0 9 - 0 2 R E A C T I O N S T A R T

T I C & T O C S T R E A M 2 R E A C T I O N T Y P E T O C R E A C T I O N P H A S E 1 R A N G E 2 6 5 s R E A C T I O N T I M E

3 6 0 s R E A C T I O N D U R A T I O N R E A C T I O N R E S U L T T I C m g C / l T O C m g C / l 0 9 : 1 7 : 0 2 1 2 - 0 9 - 0 2 S 1 √ 1 3 0 . 0 5 4 0 . 0 0 9 : 0 7 : 0 2 1 2 - 0 9 - 0 2 S 2 √ 3 . 6 3 . 6 0 8 : 5 7 : 0 2 1 2 - 0 9 - 0 2 S 3 √ 7 . 2 7 . 2 0 8 : 4 7 : 0 2 1 2 - 0 9 - 0 2 S 4 x 1 0 . 7 1 0 . 7 0 8 : 3 7 : 0 2 1 2 - 0 9 - 0 2 S 5 x 1 4 . 3 1 4 . 3

0 8 : 2 7 : 0 2 1 2 - 0 9 - 0 2 C F 0 . 9 7 . 9

The Reaction Data screen is the primary display screen on the BioTector for carbon (TIC, TOC, TC and VOC)

analysis.

This screen gives information on:

- The Reaction Start time.

- The Reaction Type, for example a TIC & TOC reaction, TC reaction, Cleaning Reaction.

- The Reaction Phase, for example if the reaction is currently in the TIC, Base Oxidation, TOC phase.

- The Range the BioTector is using to carry out its analysis.

- The Reaction Time, which is the current time in the reaction.

- The Reaction Duration, the overall duration of the reaction.

The Reaction Data screen also has an archive of the last 25 reactions. The most recent six reactions are

shown on the screen. In order to access the remaining reactions, use the DOWN or RIGHT keys to scroll

down, use the LEFT or UP keys to scroll up.

Each reaction record in the reaction archive contains:

- Start Time - reaction start time.

- Date - reaction date.

- Record Type, using the prefixes below:

S1 to S6 – reactions from stream 1 to stream 6.

M1 to M6 – reactions from manual sample stream 1 to manual stream 6.

√ – sample sensor detected the sample or there is no significant quantity of air bubbles in the

stream/manual grab sample lines.

x – sample sensor detected no sample or there is significant quantity of air bubbles in the

stream/manual grab sample lines.

CF – full cleaning reaction.

RW – reactor wash reaction.

RS – remote standby reaction.

ZC – zero calibration reaction.

ZK – zero check reaction.

ZM – manual zero adjust.

SC – span calibration reaction.

SK – span check reaction.

SM – manual span factor adjust.

A1 to A6 – 24 hours average result from stream 1 to stream 6.

- Reaction Results – reaction results according to the analysis type.

Page 20

Page 20

B I O T E C T O R R U N N I N G 0 9 : 1 7 : 2 8 1 2 - 0 9 - 0

2

0 9 : 2 7 : 0 2 1 2 - 0 9 - 0 2 R E A C T I O N S T A R T T N S T R E A M 2 R E A C T I O N T Y P E S M P L P U R G E R E A C T I O N P H A S E 1 R A N G E 8 5 s R E A C T I O N T I M E 3 6 0 s R E A C T I O N D U R A T I O N R E A C T I O N R E S U L T T N m g N / l

0 9 : 1 7 : 0 2 1 2 - 0 9 - 0 2 S 1 √ 4 1 . 0 0 9 : 0 7 : 0 2 1 2 - 0 9 - 0 2 S 2 √ 4 0 . 1 0 8 : 5 7 : 0 2 1 2 - 0 9 - 0 2 S 3 √ 4 9 . 5 0 8 : 4 7 : 0 2 1 2 - 0 9 - 0 2 S 4 x 4 1 . 1

0 8 : 3 7 : 0 2 1 2 - 0 9 - 0 2 S 5 x 4 0 . 3 0 8 : 2 7 : 0 2 1 2 - 0 9 - 0 2 S 6 3 9 . 9

If BioTector is built as a TOC TN analyzer, the analysis results of the relevant parameters (e.g. TN, COD,

BOD etc.) are also displayed on one or more screens.

These screen give information on:

- The Reaction Start time.

- The Reaction Type, for example a TN STREAM 2 reaction.

- The Reaction Phase, for example if the reaction is currently in the SAMPLE PURGE phase etc.

- The Range the BioTector is using to carry out its analysis.

- The current Reaction Time for the corresponding reaction.

- The Reaction Duration for the overall duration of the corresponding reaction.

Reaction Graph

1 0 1 . 5 [ k P a ] 0 9 : 1 7 : 2 8 1 2 - 0 9 - 0

2

T I C m g u 1 2 . 4 9 5 6 C O 2 T O C m g u

1 5 6 . 4

4 3 5 6 C O 2

0 s 1 2 0 s 2 4 0

s 3 6 0 s

1 0 . 0 l / h 2 6 C 5 6 C O 2 i

1 2 C O 2 z 2 6 5 s

The Reaction Graph screen gives information on the current reaction in progress, and allows the user to

monitor the progression of the reaction. This screen gives information on:

- The current atmospheric pressure, measured in kPa.

- The un-calibrated data from the reaction, for example TICmgu or TOCmgu without any compensation

for atmospheric pressure.

- The height of the CO2 peaks in each phase of the reaction.

- The current MFC flow in l/h.

- The temperature in the analyzer.

- The CO2 instantaneous value (CO2i) and the CO2 zero value (CO2z) for the reaction.

- The reaction time.

Page 21

Page 21

Reagent Status

B I O T E C T O R R U N N I N G 0 9 : 1 7 : 2 8 1 2 - 0 9 - 0

2

A C I D M O N I T O R 2 5 . 0 l ~ 3 5 D A Y S B A S E M O N I T O R 2 5 . 0 l ~ 3 5 D A Y S H C l W A T E R M O N I T O R 1 0 . 0 l ~ 3 8 D A Y S

T N C L E A N I N G M O N I T O R 2 5 . 0 l ~ 1 5 0 D A Y S D I W A T E R M O N I T O R 2 5 . 0 l ~ 6 0 D A Y S N O T E : D A Y S L E F T I S A N E S T I M A T E B A S E D S Y S T E M C U R R E N T U S E

If the Reagent Status screen has been activated, the estimated number of days left for each reagent type is

shown on the display.

If the reagents run low, a LOW REAGENTS fault is activated. This fault has to be cleared by resetting the

reagent level in the Install New Reagents menu.

Note that the LOW REAGENTS fault can be set as a warning (where the common fault relay will activate) or a

notification, in which case a special programmable relay is required to signal the LOW REAGENTS condition.

Select Level

S E L E C T L E V E L 0 9 : 1 7 : 2 8 1 2 - 0 9 - 0

2

1 < O P E R A T I O N 2 C A L I B R A T I O N 3 M A I N T E N A N C E

This screen allows the user to access the operation, calibration and maintenance menus.

1. Operation. This menu gives access to the basic operation of the BioTector and allows access to the

archives. The level can be password protected using the Password menu.

2. Calibration. This menu allows the user to run zero and span calibration cycles. The level can be

password protected using the Password menu.

3. Maintenance. This menu allows the user to test the individual components of the BioTector for

diagnostics, to download data, to program the software functions and to program the system specific

settings in the BioTector. The sub menus in this level can be password protected using the Password

menu.

Page 22

Page 22

Enter Password

0 9 : 1 7 : 2 8 1 2 - 0 9 - 0

2

E N T E R P A S S W O R D F O R O P E R A T I O N S E C U R I T Y D O M A I N

[ 1 2 3 4 ]

The BioTector has separate passwords for all levels/security domains, which are operation, calibration

diagnostics, commissioning, system configuration and hardware configuration.

These passwords are programmable, and if a password has been set up for a particular level, then it must be

entered before the BioTector will grant access to the password-protected security domains.

Use of a higher-level password also allows access to lower levels/domains.

Page 23

Page 23

2.1 Operation Menu

Operation Menu Diagram

Operation menu allows the user to start and stop the analyzer. Menus related to system operation are also

accessed using this menu.

Start Stop

The user can Start or Stop the BioTector using the Start Stop menu.

1. Remote Standby. Remote Standby is an optional function, which is activated from Input 19 (by default) on

the Signal PCB (e.g. from a flow switch). A “REMOTE STANDBY” message is displayed on the top left

corner of the main Reaction Data screen to indicate that the BioTector is in remote standby state. When

remote standby signal is activated, the BioTector stops analyzing. All menu access and operational

functions remain as for BioTector normal running state. The BioTector runs one standby reaction every 24

hours, at the time programmed for the Pressure/Flow Test (at 08:15 AM by default). Sample is not taken

during the remote standby reaction (only acid and base reagents are used). This reaction is tagged as “RS”

(Remote Standby) in the system reaction archive. The 4-20mA signal or other output devices are not

updated. When remote standby signal is deactivated, the BioTector starts analyzing.

When remote standby signal is activated, the “Finish & Stop” or “Emergency Stop” must be selected before

using such functions as Install New Reagents, Zero and Span Calibrations, Process Tests etc. If the

BioTector is stopped using the “Finish & Stop” or “Emergency Stop” functions or automatically by a system

fault, it will not be possible to start the BioTector by the removal of the remote standby signal. The “Start”

function must be used to re-start the BioTector. When BioTector is started while the remote standby signal

is activated, BioTector goes into remote standby state. The manual grab sample analysis can be carried out

normally using the Manual Program menu when the BioTector is in remote standby state.

Maintenance should only be carried out when “SYSTEM STOPPED” message

is displayed on the top left corner of the main Reaction Data screen or when

the system is powered down. When “REMOTE STANDBY” or “SYSTEM

RUNNING” message is displayed on the screen, stop the BioTector using the

“Finish & Stop” or “Emergency Stop” function.

Caution

Page 24

Page 24

2. Start. This function starts the BioTector. When BioTector is started, the multi-stream operation sequence (if

programmed) is reset. BioTector performs Ozone Purge, Pressure/Flow Test, Reactor Purge and Analyzer

Purge sequences automatically before starting its analysis. Ozone Purge sequence purges any residual

ozone through the ozone destructor. Pressure/Flow Test sequence confirm that there is no gas leak and

there is no gas flow restriction in the BioTector. Reactor Purge sequence purges any liquid from the reactor

through the Sample Out Valve. Analyzer Purge sequence purges any CO2 gas from the CO2 Analyzer

through the Exhaust Valve.

3. Finish & Stop. When this function is activated from the keyboard, the BioTector stops as soon as its

present reaction is completed. An “*” is displayed to let the operator know the function has been activated.

4. Emergency Stop. When this function is activated the BioTector cancels the execution of the present

reaction and quickly stops operation after the Ozone Purge, Reactor Purge and CO2 Analyzer Purge

sequences. The Emergency Stop has highest priority, and always overrules the “Finish & Stop” function.

Quick Startup Function: During maintenance, system testing etc. it may be

necessary to quickly start and stop the BioTector to check various parameters.

Pressing the ENTER key for the “Start”, when the RIGHT ARROW key is also

pressed, bypasses the Pressure/Flow Test sequence, ensuring a quick startup.

When the quick startup function is used, system will log a “28_NO PRESSURE

TEST” warning in the fault archive and will start operation. The same warning will

also be logged, when the BioTector is started from the Reagents Setup, Manual

Program and Calibration menus using this function.

Page 25

Page 25

Reagents Setup

This menu allows the user to access the Reagent menus.

1. Install New Reagents. Menu used to install and prime the reagents in the BioTector. Any “85_Reagents

Low” and “20_No Reagents” warnings and notifications can also be reset in this menu.

2. Purge Reagents & Zero. Menu used to purge the reagents, and carryout a zero calibration cycle.

Install New Reagents

I N S T A L L N E W R E A G E N T S 0 9 : 1 7 : 2 8 1 2 - 0 9 - 0

2

C O N F I R M T H E F O L L O W I N G : 1 < N E W A C I D C O N N E C T E D 2 R E S E T A C I D M O N I T O R 2 5 . 0 l ~ 3 5 D A Y S 3 N E W B A S E C O N N E C T E D

4 R E S E T B A S E M O N I T O R 2 5 . 0 l ~ 3 5 D A Y S 5 N E W H C l W A T E R C O N N E C T E D 6 R E S E T H C l W A T E R M . 1 0 . 0 l ~ 3 8 D A Y S

7 N E W T N C L E A N I N G C O N N E C T E D 8 R E S E T T N C L E A N I N G M 2 5 . 0 l ~ 1 5 0 D A Y S 9 N E W D I W A T E R C O N N E C T E D

▼ N O T E : B I O T E C T O R W I L L R E - S T A R T W H E N T H E N E W R E A G E N T S C Y C L E I S C O M P L E T E

I N S T A L L N E W R E A G E N T S 0 9 : 1 7 : 2 8 1 2 - 0 9 - 0

2

C O N F I R M T H E F O L L O W I N G :

1 0 R E S E T D I W A T E R M O N 2 5 . 0 l ~ 6 0 D A Y S 1 5 N E W Z E R O W A T E R ( D I W ) C O N N E C T E D 1 6 5 0 . 0 m g C / l T I C S T A N D A R D C O N N E C T E D 1 7 3 5 0 . 0 m g C / l T O C S T A N D A R D C O N N E C T E D

1 8 1 0 0 . 0 m g N / l T N S T A N D A R D C O N N E C T E D 2 0 S T A R T N E W R E A G E N T C Y C L E

N O T E : B I O T E C T O R W I L L R E - S T A R T W H E N T H E N E W R E A G E N T S C Y C L E I S C O M P L E T E

The install new reagents procedure is an automatic procedure for installing new reagents, setting the zero

offset by Zero Calibration cycle, setting the reaction check levels and checking the span by Span Calibration

or Span Check cycles. Span Calibration or Span Check cycles are part of the Install New reagents sequence

if SPAN CALIBRATION or SPAN CHECK is activated in New Reagents Program menu. The basic Zero

Check/Calibration and Span Check/Calibration parameters (operation ranges, number of reactions, standard

solution concentrations etc.) are programmed in Zero Calibration and Span Calibration menus respectively.

The comprehensive Zero Check/Calibration and Span Check/Calibration parameters are programmed in Zero

Program and Span Program menus respectively.

Page 26

Page 26

To run the Install New Reagents cycle, the BioTector must be stopped. Confirm that all or the corresponding

new reagents have been installed on the BioTector, for instance for acid reagent, select New Acid Connected,

and press the ENTER key. A tick mark will appear as confirmation that the new acid has been connected.

Note that when one or more reagent volumes are updated in Reagents Monitor menu, system automatically

resets the new reagents volumes in this menu and also updates the figures displayed in the main Reagents

Status screen.

All reagents volumes can be reset while system is running. This function allows the user to top up the

reagents, preferably HCl Water (if installed in systems built with FMI Heavy Duty Circulation Pump), TN

Cleaning Solution and DI Water, without stopping the system. However, when Acid and/or Base are replaced

or topped up, system requires a new Zero Calibration cycle. A “ZERO CALIBRATION REQUIRED” warning

will be displayed on the screen when RESET ACID MONITOR and/or RESET BASE MONITOR are selected.

Therefore, it is strongly recommended to stop the BioTector and activate the Start New Reagent Cycle or to

run the Zero Calibration cycle using the Zero Calibration menu. It is important that Zero Water (DI Water) is

connected to BioTector’s Zero Water port before the Install New Reagent cycle is started. Unlike BioTector

TOC analyzers, in BioTector TOC TN analyzers, Zero Water is required so that the correct zero offset (Zero

Adjust) values are set for TN analysis. Failure to do so may have an impact on system zero response and the

analysis results.

When all or the necessary reagents have been confirmed to be connected and reset in this menu, and when

Start New Reagent Cycle is selected, the Install New Reagents cycle will be executed. It is the responsibility

of the user to make sure that all reagent volumes are programmed correctly in Reagents Monitor menu, the

reset of the reagents monitoring are carried out correctly in Install New Reagents menu and finally if

necessary the Zero Calibration cycle is activated either with the Start New Reagent Cycle function in Install

New Reagents menu or with the Run Zero Calibration function in Zero Calibration menu.

The Install New Reagents cycle consists of the following steps:

1. Reagent Purge: System purges and fills all reagent lines with the new reagents.

2. Zero Calibration: The Zero Adjust (zero offset) level is set for all analysis ranges, and the Reaction

Check level for TOC is updated (if the CO2 LEVEL is programmed as AUTO in Reaction Check

menu).

3. If Span Calibration or Span Check is activated in New Reagents Program menu, a Span Calibration

or Span Check is carried out.

Once the procedure is completed the BioTector either stops or returns online, depending on the programmed

setting of AUTOMATIC RE-START in New Reagents Program menu.

Purge Reagents & Zero

The Purge Reagents & Zero function is an automatic procedure to purge the reagents, to set the zero offset

and to set the reaction check levels in the BioTector. The program settings for the Reagent Purge are set up

in the Reagents Purge menu.

1. Purge Reagents & Zero. This option allows the user to run the Purge Reagents & Zero cycle.

System Range Data

This menu displays the system specific analysis range data for all measured components (e.g. TIC, TOC, TN,

etc.). BioTector can be calibrated with up to 3 analysis ranges for each measured component. When a

specific component of a sample (e.g. TOC) is measured at a specific range (e.g. Range 2), the analysis of

any other components (e.g. TN etc.) of the sample are also carried out at the same analysis range.

Page 27

Page 27

Manual Program

M A N U A L P R O G R A M 0 9 : 1 7 : 2 8 1 2 - 0 9 - 0

2

1 < R U N A F T E R N E X T R E A C T I O N 2 R U N A F T E R 1 0 : 3 0 3 R E T U R N T O O N - L I N E S A M P L I N G Y E S

4 R E S E T M A N U A L P R O G R A M 5 6 M A N U A L 1 , 4 R A N G E 1 7 M A N U A L 2 , 4 R A N G E 3 8 M A N U A L 3 , 4 R A N G E 2 9 M A N U A L - , - - - R A N G E - 1 0 M A N U A L - , - - - R A N G E - 1 1 M A N U A L - , - - - R A N G E -

1 2 M A N U A L - , - - - R A N G E - 1 3 M A N U A L - , - - - R A N G E - ▼

Manual Program menu allows the user to run system in manual operation mode in order to analyze

samples/standards or a sequence of samples/standards manually. This is achieved by one or a set of manual

valves installed in the system. The manual analysis sequence can be started at the end of the current

reaction, or at a time set by the user. When the manual sequence is complete, the system can be

programmed to return online automatically. Note that all cleaning cycle, pressure/flow tests, zero or span

cycles are interrupted by the manual operation mode. The Sample Pump reverse operation is also disabled

during the manual operation mode by default, unless a Manual Bypass Valve is installed in the system and

the REVERSE time is programmed for the corresponding Manual Valve in Sample Pump menu. All items in

this menu can be modified when the BioTector is running unless:

- No manual valves have been defined in the Output Devices menu.

- The manual mode is currently running.

- The manual mode is scheduled to start when the current reaction is completed.

Note that the Manual mode always starts at the first programmed valve, and works its way down the

programmed sequence.

1. Run After Next Reaction. To start the manual operation mode sequence after the next reaction the

BioTector is currently running, press the ENTER key at this menu item. An “*” will indicate that this

function has been selected. If the BioTector is stopped, then the Manual mode starts immediately. To

deactivate this function before the manual operation mode has started, press the ENTER key again, or

activate an alternative function. In systems built with the remote control of Manual Program option, the

remote signal (Manual Mode Trigger from Input 7) activates the Run After Next Reaction function.

2. Run After 00:00. Similar to menu option 1 above, but the manual operation mode starts after the

programmed time.

3. Return to On-line Sampling. This menu item allows the user to specify whether the BioTector should

stop or return to online monitoring when the manual operation sequence is complete.

4. Reset Manual Program. Use this function to reset all the programmed settings to their default values.

6. - 30. Manual. In order to analyze one or a number of samples/standards using the manual operation mode,

first connect the sample/standard to the manual port/s outside the BioTector. Then, select the

corresponding Manual Valve in this menu (the first setting). Then, enter the number of samples (number

of analysis reactions) to be taken through each Manual Valve (the second setting). Finally select the

correct analysis range (RANGE 1, 2 or 3) if the concentration levels of the sample/standard are known

(see System Range Data menu to view the available system ranges and to select the correct operation

range). If the concentration levels of the samples/standards are not known, select AUTO so that

BioTector can automatically select the optimum analysis range. When RANGE is programmed as AUTO,

a minimum of five analysis reactions is recommended (the second setting) so that BioTector can find the

optimum operation range with its automatic exceedance tracking function. When AUTO option is

selected, depending on analysis range and system response, the first two or three analysis results may

need to be discarded.

Page 28

Page 28

Reaction Archive

The Reaction Archive holds information on TIC, TOC, TC, VOC, COD, BOD, TN, stream valve, reaction

range, start time and related analysis information for the last 9999 reactions. If the archive is full, then every

new reaction overwrites the oldest one in the archive. As the Reaction Archive contains 9999 events, the user

must first enter the date at which the viewing of the archive starts. The Enter Date menu allows the user to

specify the date of the first displayed reaction from the archive.

Each reaction record in the reaction archive contains:

- Start Time - reaction start time, which is displayed without seconds in this menu

- Date - reaction date

- Reaction Type - with the prefixes below:

S1 to S6: Reactions from stream 1 to stream 6.

M1 to M6: Reactions from manual sample stream 1 to manual stream 6.

√ Sample sensor detected the sample or there is no significant quantity of air

bubbles in the stream/manual grab sample lines.

x Sample sensor detected no sample or there is significant quantity of air

bubbles in the stream/manual grab sample lines. See Sample Status in Fault

Setup section for details.

CF: Full cleaning reaction.

RW: Reactor wash reaction.

RS: Remote standby reaction.

ZC: Zero calibration reaction.

ZK: Zero check reaction.

ZM: Manually input zero adjust.

SC: Span calibration reaction.

SK: Span check reaction.

SM: Manually input span adjust.

A1 to A6: 24 hours average result from stream 1 to stream 6.

The user can navigate through the displayed reactions individually by pressing the UP and DOWN keys each

time, or can navigate in steps of 10 reactions using the LEFT and RIGHT keys. Depending on system

analysis type (e.g. VOC, TC –TIC etc.) and system display options (e.g. COD and/or BOD) settings, BioTector

displays additional reaction data held on additional Reaction Archive screens. To access the screens, press

the ENTER key, and to return to the previous screen, press the ESCAPE key.

Fault Archive

In the Fault Archive menu, the user can view the last 99 faults/warnings logged in the system, confirm if the

faults/warnings are current or not, and acknowledge current faults/warnings. If the archive is full, then every

new faults/warnings overwrites the oldest one in the archive. The user can navigate through the displayed

reactions individually by pressing the UP and DOWN keys each time, or can navigate in steps of 10 reactions

using the LEFT and RIGHT keys.

The faults/warnings archive events are divided into three categories:

- Fault: Faults are categorized as events, which stop BioTector operation. The 4-20mA signals are set

to the fault level, and the fault relay is activated. The BioTector cannot be started unless the fault in

the archive has been acknowledged.

- Warning: Warning is a minor fault, which does not require the BioTector to stop. The 4-20mA signals

are not changed, only the fault relay is activated.

- Notification: A notification is and information (e.g. “86_Power Up”, “87_Service Time Reset” etc.)

displayed on the screen.

To acknowledge any current faults/warnings marked with an “*” in the archive, first identify and locate the

faults/warnings. See Section 9 Troubleshooting of System Faults and Warnings. Follow the necessary

troubleshooting procedures to solve the problem. Acknowledge the fault by pressing the ENTER key in the

Fault Archive menu. Please note that there are system faults (e.g. 05_Pressure Test Fail), which cannot be

acknowledged by the user. Such faults are reset and acknowledged automatically by the system when

system is started, when system is rebooted or when the fault condition is solved.

Page 29

Page 29

Time & Date

This menu allows the system time and date to be set by the user. To change the system time or date (hours,

minutes, seconds, day, month and year), press the ENTER key, enter the new time and date and press the

ENTER key again.

In order to change the system date format, press the ENTER key, select new date format from the following

day, month and year options: DD-MM-YY, MM-DD-YY, YY-MM-DD and press the ENTER key again.

When the time is changed, it is possible for the BioTector to automatically start up if the

new time is after the startup time for a scheduled task, for example the startup time for

a manual sample sequence in Manual Program menu.

Contact Information

Contact Information menu displays the manufacturer/distributor contact details.

Page 30

Page 30

2.2 Calibration Menu

Calibration menu allows the user to calibrate the analyzer. Zero and Span Calibration menus allow the user to

run the zero and span calibration cycles for a single range or for all system ranges available.

Calibration Menu Diagram

Zero Calibration

Z E R O C A L I B R A T I O N 0 9 : 1 7 : 2 8 1 2 - 0 9 - 0

2

1 < T O C Z E R O A D J U S T 1 0 . 0 [ 0 . 0 ] 2 2 0 . 0 [ 0 . 0 ] 3 3 0 . 0 [ 0 . 0 ] 4 T N Z E R O A D J U S T 1 0 . 0 [ 0 . 0 ] 5 2 0 . 0 [ 0 . 0 ] 6 3 0 . 0 [ 0 . 0 ]

1 3 R U N R E A G E N T S P U R G E 1 4 R U N Z E R O C A L I B R A T I O N 1 5 R U N Z E R O C H E C K 1 6 R 1 R 2 R 3

1 7 Z E R O P R O G R A M 6 , 4 , 4 1 8 Z E R O A V E R A G E 4 , 2 , 2 1 9 2 0 - - > Z E R O P R O G R A M

Zero Calibration menu allows the user to enter the suggested Zero Adjust values, to start the Reagent Purge

cycle, to start the Zero Calibration and Zero Check cycles and to program the number of zero reactions run at

each range.

1.-6. TOC/TN Zero Adjust. The TOC/TN Zero Adjust is used to compensate any organic carbon and nitrogen

contamination in the Acid and Base reagents and any absorbed CO2 in the Base reagent. The Zero

Adjust values are generated automatically by the system for each range when the zero calibration cycle is

completed without any system warnings. Zero Calibration cycle is activated by selecting the RUN ZERO

CALIBRATION function in this menu.

The TOC Zero Adjust values are the Zero Offset values in mgC/l measured by the CO2 Analyzer. The TN

Zero Adjust values are the Zero Offset Absorbance values measured by the Photometer.

When a Zero Check cycle is run using the RUN ZERO CHECK function, the system only checks the zero

response at each range and displays the suggested Zero Adjust values in brackets “[ ]” for all ranges next

to the current Zero Adjust settings. When a Zero Check cycle is completed, if necessary the suggested

Zero Adjust values can be programmed manually by entering the corresponding suggested Zero Offset

values for each range (1, 2 and 3) for each parameter in this menu. When the Zero Adjust settings are

entered manually, system logs this information in the reaction archive with the prefix “ZM” (Zero Manual).

ENTER PASSWORD CALIBRATION ZERO CALIBRATION

SPAN CALIBRATION

Page 31

Page 31

13. Run Reagents Purge. The RUN REAGENTS PURGE function is used to prime all reagents in the

BioTector. If necessary, the pump operation time for Reagent Purge cycle can be increased in the

Reagents Purge menu.

14. Run Zero Calibration. Each time BioTector reagents are replaced or topped up and each time a service

is carried out, it is strongly recommended to use the RUN ZERO CALIBRATION function so that the

system can set the zero offset values automatically. The zero calibration reactions operate in the same

manner as a normal reaction, but BioTector takes DI Water through the Zero Water port. To start the zero

calibration cycle, first connect Zero Water (DI Water) to the BioTector Zero Port. Press the ENTER key at

this menu item. An “*” will indicate that the function is running. At the end of the Zero Calibration cycle,

the following settings are checked and updated:

1. The TOC Zero Adjust settings for each range are updated automatically by the system using the

un-calibrated TOC measurement (not the results seen on the LCD screen). If a Zero Check is

used to check the zero offset, the suggested values are shown in brackets “[ ]” next to the actual

Zero Adjust settings.

2. The TN Zero Adjust settings for each range are updated by using the un-calibrated TN

absorbance data (not the results shown on the LCD display). If a Zero Check is used to check the

zero setting, the suggested values are shown in brackets “[]” next to the actual TN Zero Adjust

settings.

3. If the CO2 LEVEL is set as AUTO for automatic updating in the Reaction Check menu, then the

reaction check CO2 Level is also updated automatically.

4. The CO2 Level is also checked against the BASE CO2 ALARM setting in Fault Setup menu. If the

measured CO2 Level is greater that the BASE CO2 ALARM value, system generates a “52_HIGH

CO2 IN BASE” warning.

15. Run Zero Check. Zero Check cycle is similar to the Zero Calibration above, but BioTector does not

update any of the Zero Adjust or CO2 Level settings. System only checks the BASE CO2 ALARM

described above.

17. Zero Program. Zero Program function allows the user to program the number of zero reactions run at

one or more ranges (R1, R2 and/or R3) for all measured parameters. When the number of zero

calibration reactions for one or two of the ranges is set to zero, system runs the zero cycle on the