Page 1

Catalog Number 6120118

Digital PC sc and RC sc ¾-inch

Combination pH/ORP Sensor

USER MANUAL

October 2005, Edition 4

©Hach Company, 2004–2005. All rights reserved. Printed in the U.S.A. eac/dp

Page 2

Visit us at www.hach.com

Page 3

Table of Contents

Section 1 Specifications.........................................................................................................................................5

Section 2 General Information............................................................................................................................... 7

2.1 Safety Information............................................................................................................................................... 7

2.1.1 Use of Hazard Information......................................................................................................................... 7

2.1.2 Precautionary Labels................................................................................................................................. 7

2.2 General Sensor Information................................................................................................................................ 8

2.2.1 Sensor Body Styles ....................... ... .... ... ... ............................................................................................... 8

2.3 The Digital Gateway............................................................................................................................................ 9

2.4 Operating Precaution .......................................................................................................................................... 9

Section 3 Installation ............................................................................................................................................ 11

3.1 Wiring the sc Sensor to the Digital Gateway..................................................................................................... 11

3.2 Connecting/Wiring the Digital Gateway to the sc100 Controller ....................................................................... 13

3.2.1 Connecting the Digital Gateway Sensor in a Non-hazardous Location................................................... 13

3.2.1.1 Attaching the Digital Gateway with a Quick-connect Fitting in a Non-hazardous Location............13

3.2.1.2 Hard-wiring the Digital Gateway to the sc100................................................................................ 14

3.2.2 Connecting the Digital Gateway to a sc100 Controller in a Hazardous Location .................................... 15

3.2.2.1 Attaching the Digital Gateway with a Quick-Connect Fitting in a Hazardous Location.................. 16

3.3 Connecting the Sensor to the sc1000............................................................................................................... 16

3.3.1 Connecting the Sensor using the Quick-connect Fittings........................................................................16

3.4 Mounting the Digital Gateway ........................................................................................................................... 17

Section 4 User Interface and Navigation ............................................................................................................ 19

4.1 Using the sc100 Controller...................................... .......................................................................................... 19

4.1.1 Controller Display Features ..................................................................................................................... 20

4.1.2 Important Key Presses............................................................................................................................ 20

4.2 Using the sc1000 Controller.................................... .......................................................................................... 21

4.2.1 Display Features...................................................................................................................................... 21

4.2.1.1 Using the Pop-up Toolbar..............................................................................................................21

4.2.1.2 Using the Menu Windows .............................................................................................................. 21

4.2.1.3 Navigating the Menu Windows .... ... ... ............................................................................................. 22

Section 5 Operation .............................................................................................................................................. 25

5.1 Sensor Setup .................................................................................................................................................... 25

5.2 Sensor Data Logging ........................................................................................................................................ 25

5.6 pH Calibration ................................................................................................................................................... 28

5.6.1 One Point Automatic Calibration.............................................................................................................. 28

5.6.2 Two Point Automatic Calibration.............................................................................................................. 28

5.6.3 One Point Manual Calibration.................................................................................................................. 29

5.6.4 Two Point Manual Calibration .................................................................................................................. 29

5.7 ORP Calibration................................................................................................................................................ 30

5.7.1 One-point Manual Calibration.................................................................................................................. 30

5.8 Concurrent Calibration of Two Sensors for pH and ORP.................................................................................. 30

5.9 Adjusting the Temperature ................................................................................................................................ 31

Section 6 Maintenance ......................................................................................................................................... 33

6.1 Maintenance Schedule ..................................................................................................................................... 33

6.2 Cleaning the Sensor ......................................................................................................................................... 34

Section 7 Troubleshoot in g ................................................................................................................................... 35

7.1 Error Codes....................................................................................................................................................... 35

7.2 Warnings........................................................................................................................................................... 35

3

Page 4

Table of Contents

7.3 Troubleshooting the pH or ORP Sensor............................................................................................................35

Section 8 Replacement Parts and Accessorie s..................................................................................................37

8.1 Replacement Items, Accessories, and Reagent and Standards .......................................................................37

Section 9 How to Order.........................................................................................................................................39

Section 10 Repair Service.....................................................................................................................................40

Section 11 Limited Warranty................................................................................................................................41

Section 12 Compliance Information ....................................................................................................................43

B.1 pH Measurement Theory............................................................................................................................47

B.2 PID Controller Basics .................................................................................................................................48

4

Page 5

Section 1 Specifications

Specifications are subject to change without notice.

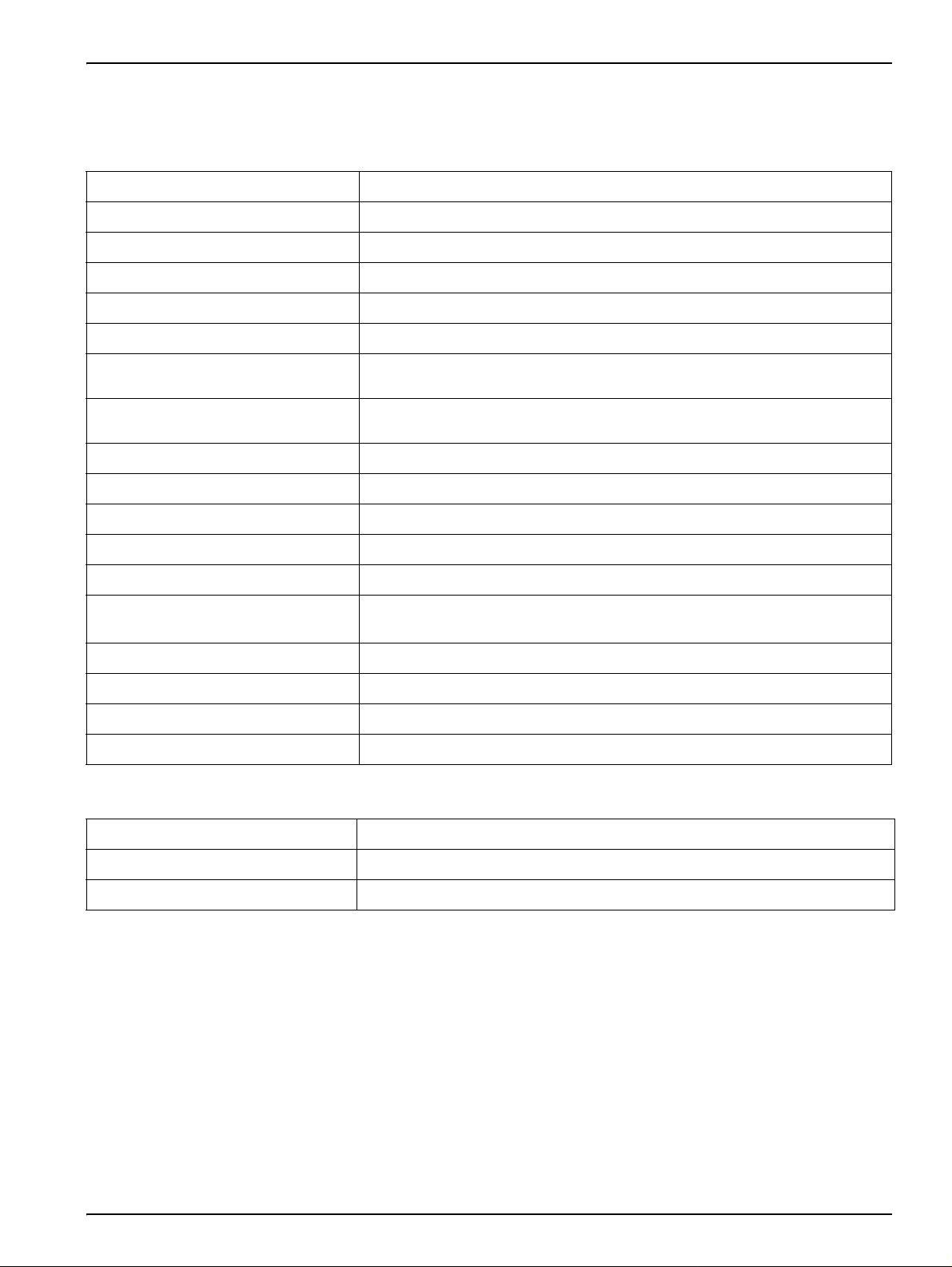

Table 1 Combination pH and ORP Sensor Specifications

Components Corrosion-resistant materials, fully-immersible probe with 4.6 m (15 ft) cable

Measuring Range (pH) 0 to 14 pH

Measuring Range (ORP) –2000 to +2000 mV

Measuring Range (Temperature) 0 to 105 °C (32 to 221 °F)

Probe Operating Temperature 0 to 105 °C (32 to 221 °F)

Probe Storage Temperature –30 to 70 °C (–22 to 158 °F); 0 to 95% relati ve humidity, non-condensing

Temperature Compensation

Accuracy (Analyzer only)

Stability (Analyzer only) 0.05% or span per 24 hours, non-cumulative

Repeatability (Analyzer only) 0.1% of span or better

pH: Pt 1000 ohm RTD

ORP: N/A

pH: 0.1% of span

ORP: Limited to calibration solution accuracy (± 20 mV)

Temperature Accuracy (Analyzer only) ±0.5 °C (±0.9 °F)

Temperature Drift (Analyzer only) Zero and Span: less than 0.03% of span per °C

Calibration Methods (Analyzer only) Two point automatic, one point automatic, two point manual, one point manual

Maximum Probe Immersion Depth/

Pressure

Sensor Interface Modbus from digital gateway

Probe Cable Length 4.6 m (15 ft)

Probe Weight Depends on selected sensor

Probe Dimensions See Figure 1 on page 8 through Figure 4 on page 9.

Submersible to 107 m (350 ft)/1050 kPa (150 psi)

Table 2 Digital Gateway Specifications

Weight 145 g (5 oz)

3

Dimensions 17.5 x 3.4 cm (7 x 1

Operating Temperature –20 to 60 °C (–4 to 140 °F)

/8 in.)

5

Page 6

Visit us at www.hach.com

Page 7

Section 2 General Information

2.1 Safety Information

Please read this entire manual before unpacking, setting up, or operatin g this equipment.

Pa y attentio n to all danger an d caution state ments. Failure to do so could result in serious

injury to the operator or damage to the equipment.

To ensure that the protection provided by this equipment is not impaired, do not use or

install this equipment in any manner other than that specified in this manual.

This product is acceptable for use in a Hazardous Location when used with an

sc100 Controller and installed per Control Drawing 58600-78 as described in the

sc100 Controller Man ual, Cat. No. 5860018.

2.1.1 Use of Hazard Information

DANGER

Indicates a potentially or imminently hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation that may result in minor or

moderate injury.

Important Note: Information that requires special emphasis.

Note: Information that supplements points in the main text.

2.1.2 Precautionary Labels

Read all labels and tags attached to the instrument. Personal injury or damage to the

instrument could occur if not observed

This symbol, if noted on the instrument, references the instruction manual for operation and/or safety information.

This symbol, when noted on a product enclosure or barrier, indicates that a risk of electrical shock and/or

electrocution exists.

This symbol, if noted on the product, indicates the need for protective eye wear.

This symbol, when noted on the product, identifies the location of the connection for Protective Earth (ground).

This symbol, when noted on the product, identifies the location of a fuse or current limiting device.

.

7

Page 8

General Information

2.2 General Sensor Information

Optional equipment, such as mounting hardware for the probe, is supplied with

instructions for all user installation tasks. Several mounting options are availa b le, allowing

the probe to be adapted for use in many different applications.

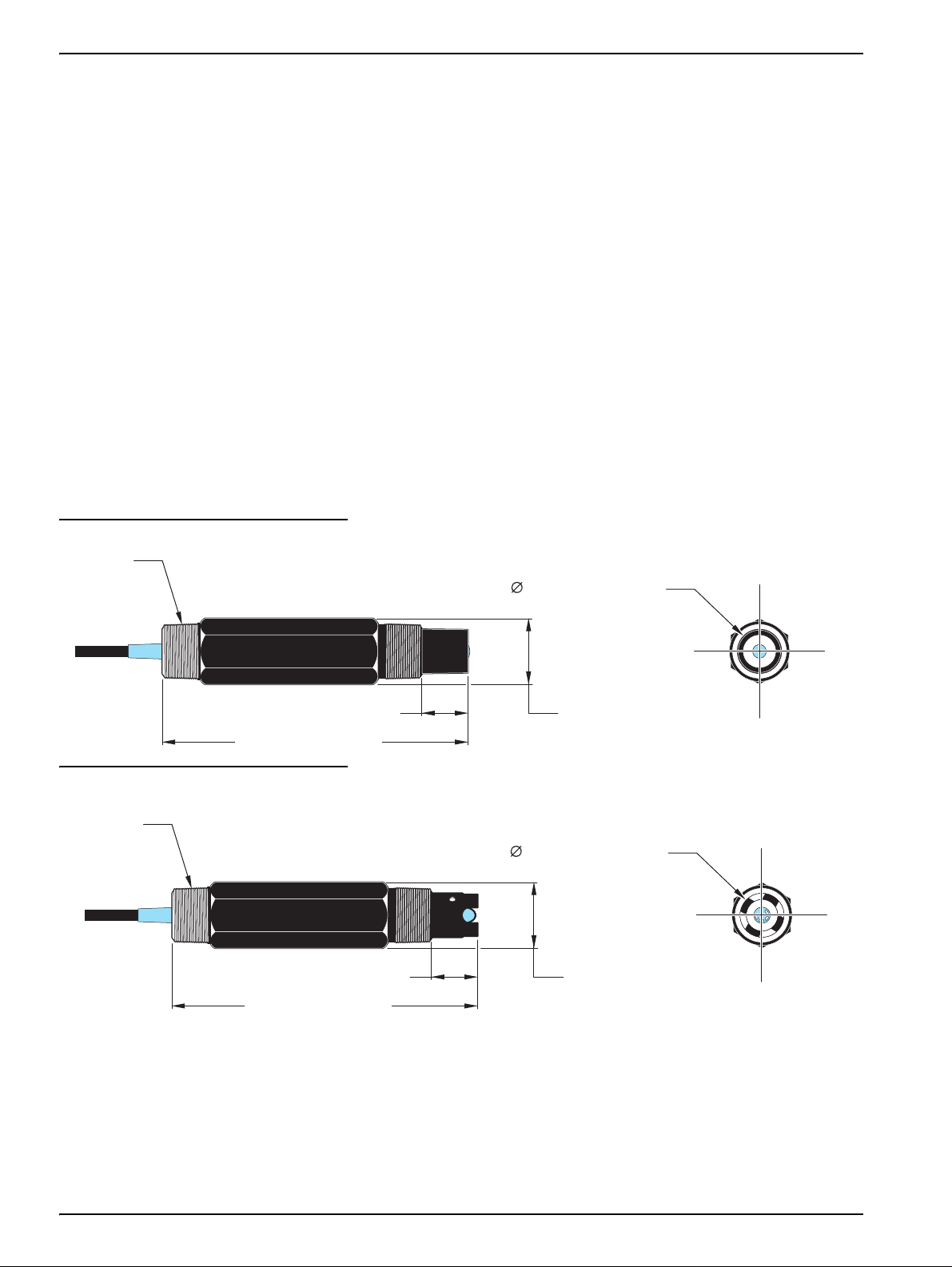

2.2.1 Sensor Body Styles

Combination pH and ORP sensors are available in three body styles:

• Convertible Body Style (Figure 1 and Figure 2)— has ¾-in. NPT threads at both

ends of the body for mounting in any of the following configurations:

• into a standard ¾-in. NPT pipe tee

• onto the end of a pipe for immersion into a vessel

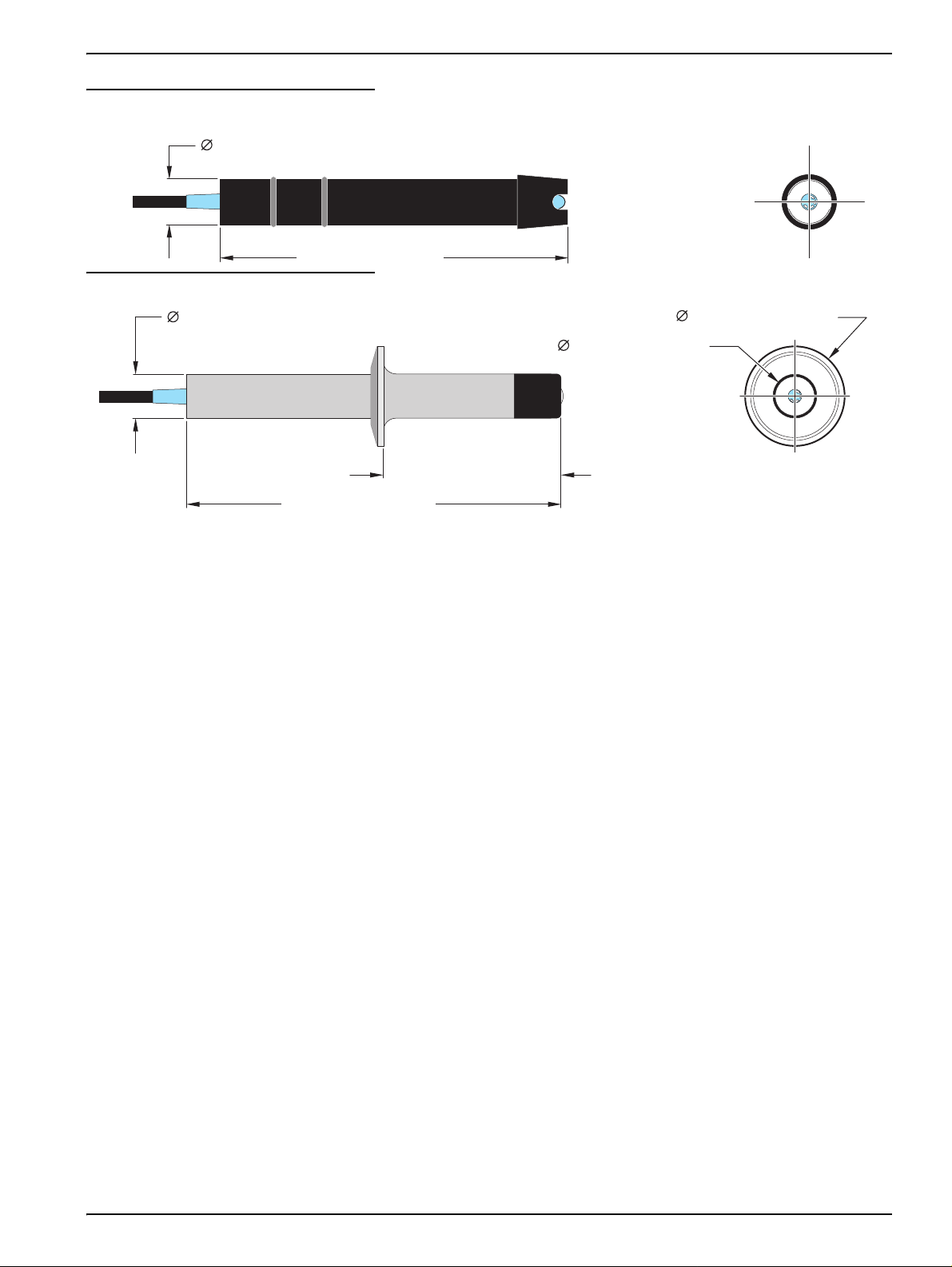

• Insertion Body Style (Figure 3)— for mounting into the pipe adapter of a ball valve

hardware assembly. This hardware enab les the sen sor to be inserted into or retracted

from the process without stopping the process flow.

• Sanitary Body Style (Figure 4)— features a built-in 2-in. flange for mounting into a

2-in. sanitary tee. Included with the sanitary-style sensor is a special cap and EDPM

compound gasket for use with the sanitary hardware.

Figure 1 Convertible Style Sensor with Flat Electrode

-inch NPT

Typical

22.9 mm (0.90 inch)

149.9 mm (5.9 inches)

Figure 2 Convertible-style Sensor with Dome Electrode

¾-inch NPT

Typical

22.9 mm (0.90 inch)

149.9 mm (5.9 inches)

22.2 mm (0.875 inch)

7.62 mm

(1.30 inches)

22.2 mm (0.875 inch)

7.62 mm

(1.30 inches)

8

Page 9

Figure 3 Insertion Style Sensor with Domed Electrode

22.2 mm (0.875 inches)

149.9 mm (5.9 inches)

Figure 4 Sanitary-style Sensor

General Information

22.2 mm (0.875 inches)

187.3 mm (7.37 inches)

2.3 The Digital Gateway

The digital gatewa y was de v eloped to pro vide a means to use e xisting analog sensors with

the new digital controllers . The gate w a y contains all the necessary software and hardw are

to interface with the controller and output a digital signal.

2.4 Operating Precaution

Before placing the pH or ORP sensor into operation, remove the protective cap to expose

the process electrode and reference junction. Save the protective cap for future use.

For short-term storage (when sensor is out of the process for more than one hour), fill the

protective cap with pH 4 buffer or DI water and place the cap back on the sensor. K ee ping

the process electrode and reference junction moist will avoid slow response when the

sensor is placed back in operation.

49.1 mm (1.96 inches)

22 mm (0.87 inches)

88.9 mm (3.5 inches)

For extended storage, repeat the short-term storage procedure every 2 to 4 weeks,

depending on the surrounding environmental conditions.

CAUTION

If the pH process electrode breaks, handle the sensor very carefully to

prevent injury.

The process electrode at the pH sensor tip has a glass bulb, which can break. Do not

subject this electrode to abrupt impact or other mechanical abuse.

The gold or platinum process electrode at the ORP sensor tip has a glass shank (hidden

by the salt bridge) which can break. Do not subject this electrode to impact or other

mechanical abuse.

9

Page 10

Visit us at www.hach.com

Page 11

Section 3 Installation

DANGER

Only qualified personnel should conduct the tasks described in this section of the

manual.

DANGER

Seul un technicien qualifié peut effectuer les tâches d'installation décrites dans

cette section du manuel.

The Combination pH/ORP Sensor can be used with either an sc100 or sc1000 controller.

Refer to section 3.2 on page 13 for sc100 installation instructions and section 3.3 on

page 16 for sc1000 installation instructions.

The sc sensor should be wired to the digital gate wa y bef ore connecting th e digital gatew a y

to the sc100 or sc1000 Controller. The digital gateway is designe d to provide a digital

interface to the appropriate digital controller. Refer to section 3.1 for more information.

3.1 Wiring the sc Sensor to the Digital Gateway

DANGER

The sc100 and certain versions of the sensor are suitable for use in Class 1,

Division 2, Groups A, B, C, D Hazardous Locations . See Control Drawing 58600-78

in the sc100 Controller Manual, Cat. No. 58600-18 for acceptable sensor versions

and installation requirements.

DANGER

Le sc100 et certaines versions du capteur peuvent être utilisés dans des endroits

dangereux de la Classe 1, Division 2, Gr oupes A, B, C, D . Reportez-v ous au schéma

de contrôle 58600-78 du Manuel du contrôl eur sc100, Réf. 58600-18 pour connaître

les versions des capteurs admises et les conditions d'installation.

1. Route the cable from the sensor through the strain relief in the digital gateway then properly terminate the wire ends (see Figure 5).

Note: Do not tighten the strain relief until the digital gateway is wired and the two halves are

threaded securely together.

2. Insert the wires as shown in Table 3 and Figure 6.

3. Make sure the O-ring is properly installed between the two halves of the digital

gateway and thread the two halves together. Hand tighten.

4. Tighten the strain relief to secure the sensor cable.

5. Connect the digital gateway to the controller.

• sc100 Non-hazardous Location–section 3.2.1.1 on page 13

• sc100 Hazardous Location—section 3.2.2.1 on page 16

• sc1000 Connection Instructions—Refer to section 3.3 on page 16.

11

Page 12

Installation

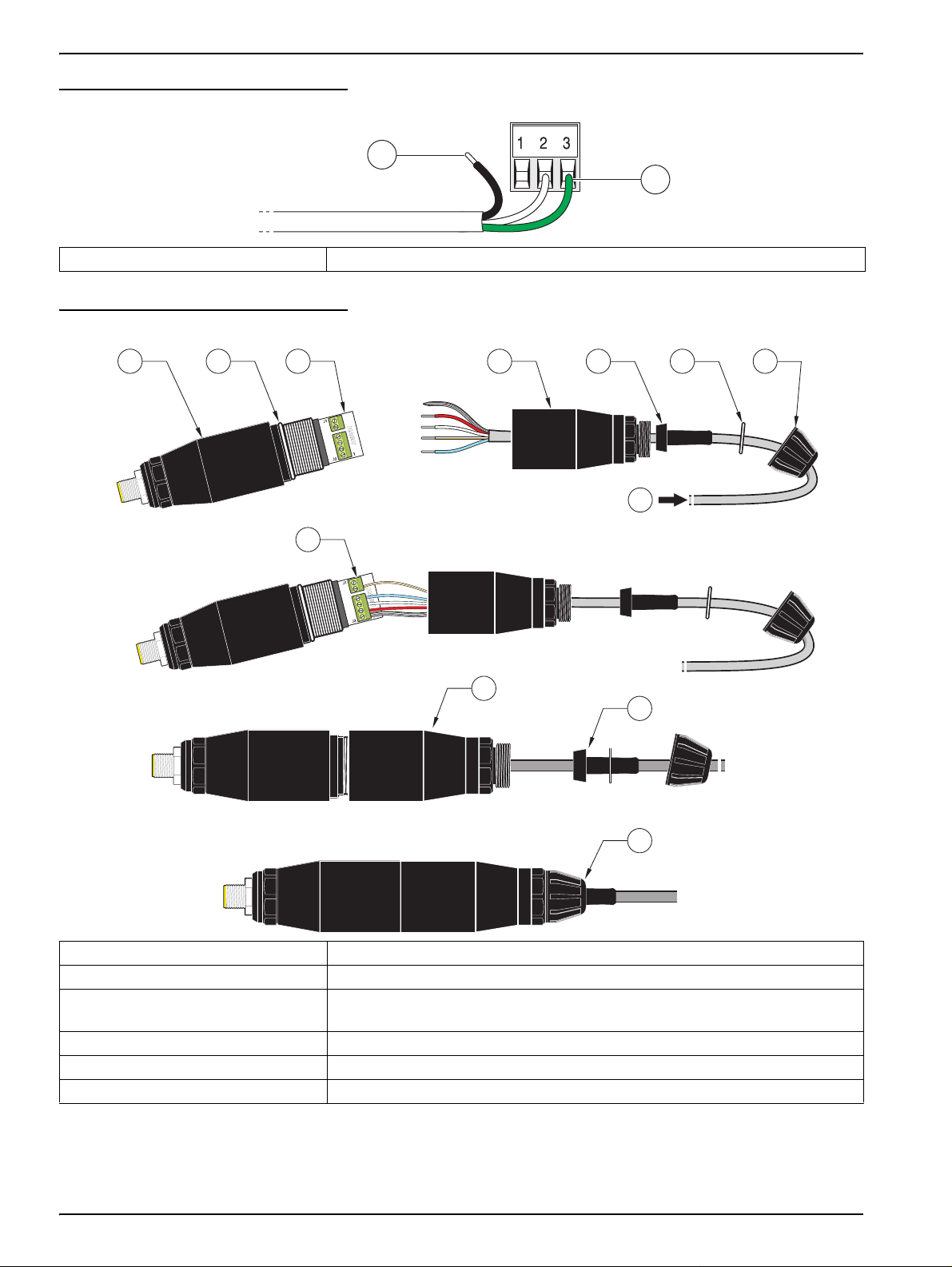

Figure 5 Proper Wire Preparation and Insertion

1

2

1. Strip ¼-inch of insulation. 2. Seat insulation against connector with no bare wire exposed.

Figure 6 Wiring and Assembling the Digital Gateway

11

6

8

7

1

METAL BRAID

RED

WHT

CLEAR

BLU

9

10

5432

12

1. Digital gateway front 7. Cord grip

2. O-ring 8. From sensor

3. Sensor wire connector 9. Insert wires into connector according to Table 3. Use the included 2 mm

screwdriver (Cat. No. 6134300) to secure connections.

4. Digital gateway back 10. Screw back of digital gateway onto front.

5. Cable bushing 11. Push cable bushing and anti-rotation washer into back.

6. Anti-rotation washer 12. Fasten cord grip securely. Assembly is complete.

12

Page 13

Table 3 Wiring the Digital Gateway (Cat. No. 6120800)

Installation

Sensor (wire color) Sensor Signal without Ground Rod Sensor Signal with Ground Rod

Metal Braid

White Temp + Temp + J3-2

Clear Active/Measuring Active/Measuring J1-5

not used not used not used J1-6

1

Some applications require the use of an external ground rod with the combination electrode. Use this wiring scheme for

these applications.

2

If Metal Braid is “tinned”, cut the tinned area off and twist the wire to inser t into connector.

3

Customer-supplied (required)

2

Red Temp – Temp – J3-3

Blue Ref Solution Ground J3-4

Jumper 2 from J3-1 to J3-3

3

Ref J3-1

1

Digital Gateway

3.2 Connecting/Wiring the Digital Gateway to the sc100 Controller

DANGER

The sc100 and certain versions of the sensor are suitable for use in Class 1,

Division 2, Groups A, B, C, D Hazardous Locations . See Control Drawing 58600-78

in the sc100 Controller Manual, Cat. No. 58600-18 for acceptable sensor versions

and installation requirements.

DANGER

Le sc100 et certaines versions du capteur peuvent être utilisés dans des endroits

dangereux de la Classe 1, Division 2, Gr oupes A, B, C, D . Reportez-v ous au schéma

de contrôle 58600-78 du Manuel du contrôl eur sc100, Réf. 58600-18 pour connaître

les versions des capteurs admises et les conditions d'installation.

The digital gateway should be wired to the sensor before connecting to the controller.

3.2.1 Connecting the Digital Gateway Sensor in a Non-hazardous Location

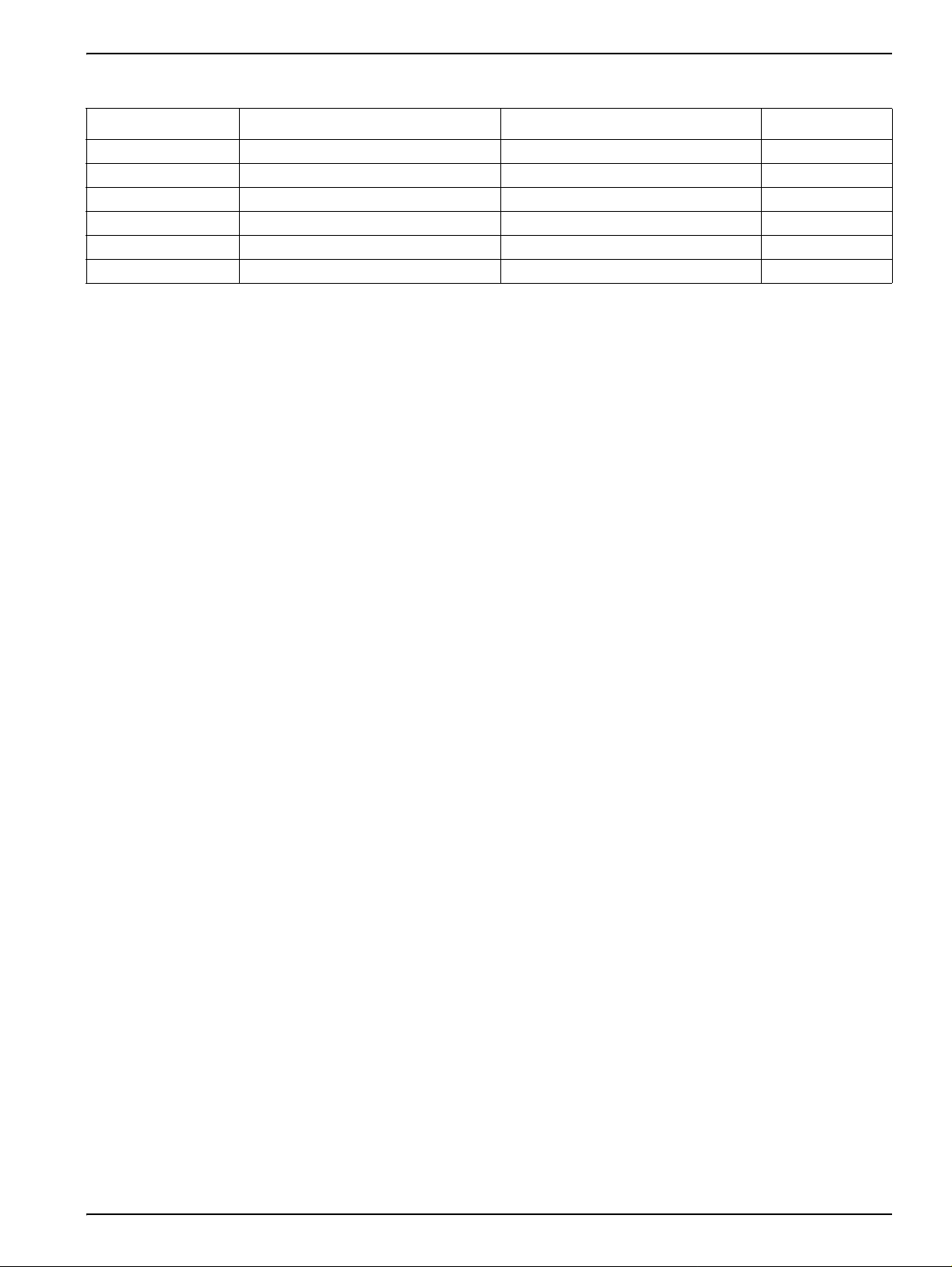

3.2.1.1 Attaching the Digital Gateway with a Quick-connect Fitting in a Non-hazardous Location

Important Note: The standard quick-connect f itting is NOT suitable for Class 1, Division 2

Hazardous Location installations without the connector lock installed, see section 3.2.1 on

page 13 for more information.

The digital gateway is supplied with a keyed quick-connect fitting for easy attachment

to the controller, see Figure 7. Retain the connector cap to seal the connector opening in

case the sensor must be removed. Optional extension cables may be purchased to extend

the sensor cable length. If t he tota l cable length exceeds 100 m (328 ft), a termination bo x

must be installed. See Replacement Parts and Accessories on page 37.

13

Page 14

Installation

Figure 7 Attaching the Digital Gateway using the Quick-connect Fittings

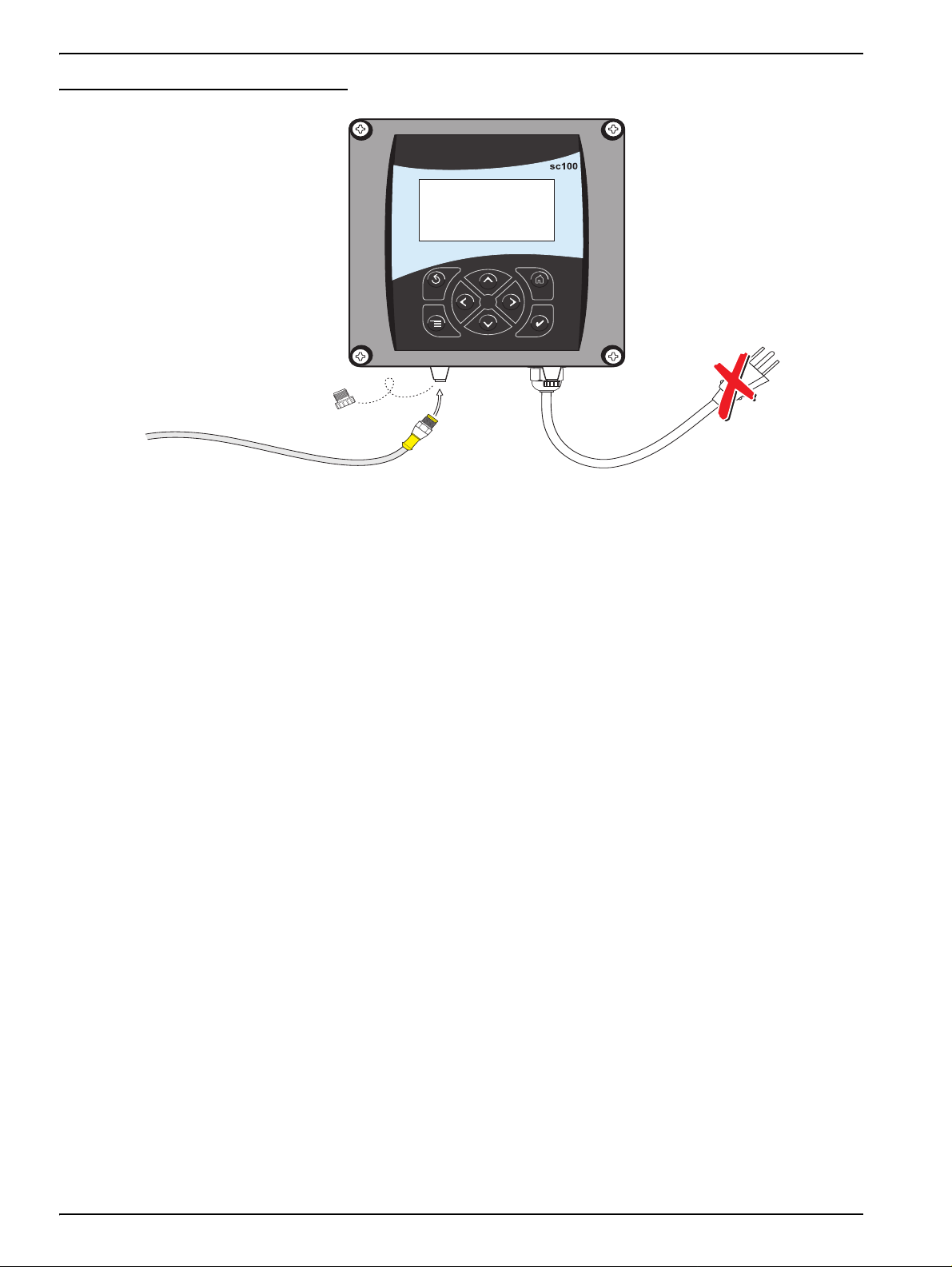

3.2.1.2 Hard-wiring the Digital Gateway to the sc100

Important Note: Hard-wiring the digital gateway to the sc100 is not an approved method

for Class 1, Division 2 Hazardous Locations.

1. Disconnect power to the controller if powered.

2. Open the controller cover.

3. Disconnect and remove the existing wires between the quick-connect and terminal

strip J5, see Figure 8 on page 15.

4. Remove the quick-conn ect fitting and wires and install the threaded plug on the opening to maintain the environmental rating.

5. Cut the connector from the sensor cable.

6. Strip the insulation on the cable back 1-inch. Strip ¼-inch of each individual wire end.

Note: Use of strain relief fitting other than Cat. No. 16664 may result in a hazard. Use only the

recommended strain relief fitting.

7. Pass the cable through conduit and a conduit hub or a strain relief fitting (Cat. No.

16664) and an available access hole in the controller enclosure. Tighten the fitting.

14

8. Reinstall the plug on the sensor access opening to maintain the envir onmenta l rati ng.

9. Wire as shown in Table 4 and Figure 8.

10. Close and secure the cover.

Page 15

Table 4 Wiring the Sensor at Terminal Block J5

1

1

+

DATA

+

OUT 2

– DATA

– OUT 2

SERVICE REQUEST

SHIELD/CHASSIS GND

+

V

+

OUT 1

GND

– OUT 1

2

2

3

3

4

4

5

5

6

PROBES

ANALOG OUTPUTS

PCB

CONNECTOR

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

NCNCNC

COMCOMCOM

NO

F1

F2

NONO

RELAY3RELAY2RELAY1

1

1

+

DATA

+

OUT 2

– DATA

– OUT 2

SERVICE REQUEST

SHIELD/CHASSIS GND

+

V

+

OUT 1

GND

– OUT 1

2

2

3

3

4

4

5

5

6

PROBES

ANALOG OUTPUTS

PCB

CONNECTOR

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

1

1

+

DATA+DATA

+

OUT 2+OUT 2

– DATA

– OUT 2

SERVICE REQUESTSERVICE REQUEST

SHIELD/CHASSIS GND

+V+

V

+

OUT 1+OUT 1

GND

– OUT 1

2

2

3

3

4

4

5

5

6

PROBES

ANALOG OUTPUTSANALOG OUTPUTS

PCB

CONNECTOR

PCB

CONNECTOR

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

DANGER - EXPLOSION HAZARD

DANGER - RISQUE D'EXPLOSION

DO NOT DISCONNECT WHILE CIRCUIT IS LIVE

UNLESS AREA IS KNOWN TO BE NON-HAZARDOUS.

NE PAS DEBRANCHER TANT QUE LE EST SOUS

TENSION, A MONIS QU'IL NE S'AGISSE D'UN

EMPLACEMENT NON-DANGEROUX

NCNCNC

COMCOMCOM

NO

F1

F2

NONO

RELAY3RELAY2RELAY1

1

1

+

DATA+DATA

+

OUT 2+OUT 2

– DATA

– OUT 2

SERVICE REQUESTSERVICE REQUEST

SHIELD/CHASSIS GND

+V+

V

+

OUT 1+OUT 1

GND

– OUT 1

2

2

3

3

4

4

5

5

6

PROBES

ANALOG OUTPUTSANALOG OUTPUTS

PCB

CONNECTOR

PCB

CONNECTOR

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

FIELD WIRING

INSULATION MUST

BE RATED TO

80° C MINIMUM

J1

J2

J4

NETWORK

INTERFACE

CARD

J3

U5

U9

S1

DANGER - EXPLOSION HAZARD

DANGER - RISQUE D'EXPLOSION

DO NOT DISCONNECT WHILE CIRCUIT IS LIVE

UNLESS AREA IS KNOWN TO BE NON-HAZARDOUS.

NE PAS DEBRANCHER TANT QUE LE EST SOUS

TENSION, A MONIS QU'IL NE S'AGISSE D'UN

EMPLACEMENT NON-DANGEROUX

Terminal Number Terminal Designation Wire Color

1 Data (+) Blue

2 Data (–) White

3 Service Request No Connection

4 +12 V dc Brown

5 Circuit Common Black

6 Shield Shield (grey wire in existing quick disconnect fitting)

Figure 8 Hard-wiring the Digital Gateway

J1

S1

J4

NETWORK

INTERFACE

CARD

J2

U5

U9

J3

+

DATA

+

DATA

SERVICE REQUEST

SERVICE REQUEST

+

V

+

V

J5J5

J5

J5

PCB

PCB

CONNECTOR

CONNECTOR

DANGER - EXPLOSION HAZARD

DANGER - EXPLOSION HAZARD

DO NOT DISCONNECT WHILE CIRCUIT IS LIVE

DO NOT DISCONNECT WHILE CIRCUIT IS LIVE

UNLESS AREA IS KNOWN TO BE NON-HAZARDOUS.

UNLESS AREA IS KNOWN TO BE NON-HAZARDOUS.

DANGER - RISQUE D'EXPLOSION

J6

DANGER - RISQUE D'EXPLOSION

NE PAS DEBRANCHER TANT QUE LE EST SOUS

NE PAS DEBRANCHER TANT QUE LE EST SOUS

TENSION, A MONIS QU'IL NE S'AGISSE D'UN

TENSION, A MONIS QU'IL NE S'AGISSE D'UN

EMPLACEMENT NON-DANGEROUX

EMPLACEMENT NON-DANGEROUX

ANALOG OUTPUTS

ANALOG OUTPUTS

+

+

+

+

FIELD WIRING

FIELD WIRING

INSULATION MUST

INSULATION MUST

BE RATED TO

BE RATED TO

80° C MINIMUM

80° C MINIMUM

OUT 2

OUT 2

OUT 1

OUT 1

Disconnect

Power

Installation

From Probe

3.2.2 Connecting the Digital Gateway to a sc100 Controller in a Hazardous Location

DANGER

The sc100 and certain versions of the sensor are suitable for use in Class 1,

Division 2, Groups A, B, C, D Hazardous Locations . See Control Drawing 58600-78

in the sc100 Controller Manual, Cat. No. 58600-18 for acceptable sensor versions

and installation requirements.

DANGER

Le sc100 et certaines versions du capteur peuvent être utilisés dans des endroits

dangereux de la Classe 1, Division 2, Gr oupes A, B, C, D . Reportez-v ous au schéma

de contrôle 58600-78 du Manuel du contrôl eur sc100, Réf. 58600-18 pour connaître

les versions des capteurs admises et les conditions d'installation.

Explosion hazard. Do not connect or disconne ct eq uipment unle ss po we r has been

switched off or the area is known to be non-hazardous.

DANGER

Risque d’explosion. Couper le courant ou s’assurer que l’emp lacement est designe

non dangereux avant de replacer le aucon composant.

DANGER

15

Page 16

Installation

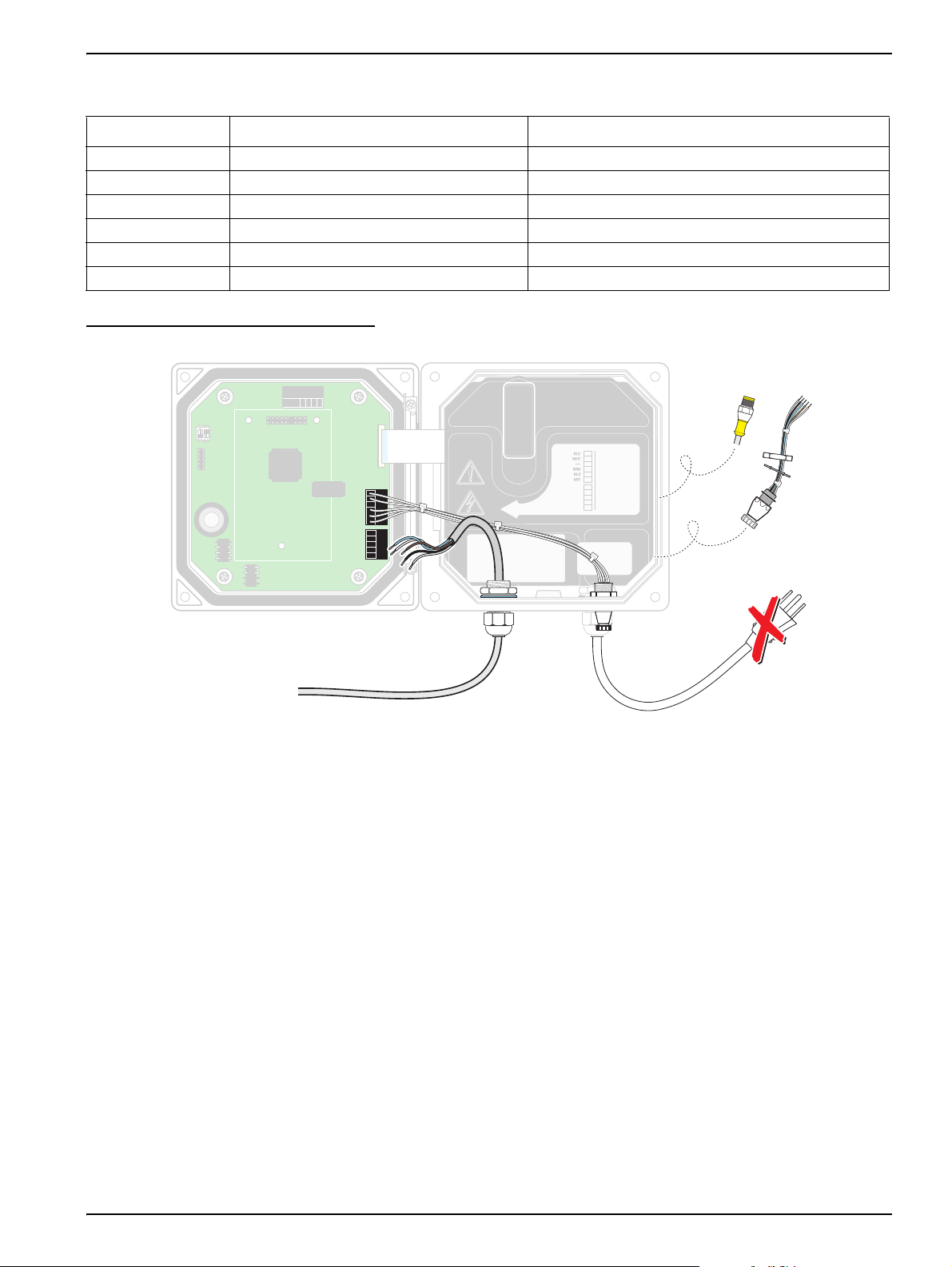

3.2.2.1 Attaching the Digital Gateway with a Quick-Connect Fitting in a Hazardous Location

The digital gateway is supplied with a keyed quick-connect fitting for easy attachment to

the controller , see Figur e 7 on page 14. For Hazardous Locations, a conn ector saf ety loc k

(Cat. No. 6139900) must be installed. Retain the connector cap to seal the connector

opening in case the sensor must be removed.

1. Remove the connector cap from the sc100 controller . Reta in the connector cap to seal the connector opening in case the sensor must be removed.

2. Connect the digital gateway connector to the sensor plug on the sc100.

3. Install the connector safety lock (Figure 9). Align the lock over the connecto r and

squeeze the two halv es together to loc k. To remo ve the connector saf ety loc k, insert a

small flat-blade screwdriver into the locking groove. Pivot the screwdriver away from

the groove and separate the two halves (Figure 9).

Figure 9 Installing the Connector Safety Lock

38.1 mm

(1.50 inches)

38.1 mm

(1.50 inches)

3.3 Connecting the Sensor to the sc1000

3.3.1 Connecting the Sensor using the Quick-connect Fittings

1. Unscrew the connector cap from the controller. Retain the connector cap to seal the

connector opening in case the sensor must be removed.

2. Push the digital gateway connector into the socket.

3. Hand-tighten the union nut.

Note: Do not use the middle connection for the sensors as this is reserved for the display module.

16

Page 17

3.4 Mounting the Digital Gateway

The digital gateway is supplied with a mounting clip for mounting to a wall or other flat

surface. See Figure 10 for dimensions. Use an appropriate fa stener to secure it to the wall,

see Figure 11. After the sensor is wired to the digital gateway and the two halves are

threaded together, place the mounting clip over the center of the digital gateway and

squeeze the clip together to secure.

Figure 10 Digital Gateway Dimensions

Installation

34.29 mm

(1.35 inches)

Figure 11 Mounting the Digital Gateway

1. Mounting Clip 3. Hex Nut, ¼-28

2. Screw, pan head, ¼-28 x 1.25-in. 4. Mount clip, insert digital gateway, squeeze clip closed.

184.15 mm (7.25 inches)

17

Page 18

Visit us at www.hach.com

Page 19

Section 4 User Interface and Navigation

4.1 Using the sc100 Controller

The front of the controller is shown in Figure 12. The keypad consists of the eight keys

described in Table 5.

Figure 12 Front of the Controller

1

sc100

5

2

3

4

1. Instrument display 5. IrDA window

2. BACK key 6. HOME key

3. MENU key 7. ENTER key

4. RIGHT, LEFT, UP , and DOWN keys

Table 5 Controller Key Functions/Features

Number Key Function

2 Moves back one level in the menu structure.

3

Moves to the main menu from other menus. This key is not active in menus where a selection or

other input must be made.

6

7

4 Navigates through the menus, changes settings, and increments and decrements digits.

5

6 Accepts an input value, updates, or accepts displayed menu options.

Moves to the Main Measurement screen from any other screen. This key is not active in menus

where a selection or other input must be made.

19

Page 20

User Interface and Navigation

4.1.1 Controller Display Features

When a sensor is connected and the controller is in measurement mode, the controller

automatically identifies the connected sensors and displays associated measurements.

The display will flash on st artup, whe n a sensor er ror has occur red, and wh en a sensor is

being calibrated.

An active system warning will cause the warning icon (a triangle with an exclamation point

inside) to be displayed on the right side of the display. See Figure 13.

Figure 13 Display

1

2

3

1. Status bar. Indicates the sensor name and status of relays. The relay letter is displayed when the relay is energized.

2. Main measurement 5. Warning icon area

3. Secondary measurement (if applicable) 6. Measurement units

SENSOR NAME:

7.00

pH

TEMP: 23.0°C

4. Parameter

4.1.2 Important Key Presses

• Press HOME then the RIGHT or LEFT key to display two readings when two sensors

are connected. Continue to press the

available display options as shown below.

RIGHT or LEFT key to toggle through the

4

5

6

20

• Press the

measurement display to display the secondary measurement (temperature) and

output information.

• When in Menu mode, an arr o w may appear on the right side of the display to indi cat e

that more menus are available. Press the

arrow direction) to display additional menus.

MAIN MENU

SENSOR DIAG

SENSOR SETUP

SYSTEM SETUP

TEST/MAINT

UP and DOWN keys to toggle the status bar at the bottom of the

SENSOR NAME:

7.00

TEMP: 23.0°C

SYSTEM SETUP

OUTPUT SETUP

RELAY SETUP

NETWORK SETUP

DISPLAY SETUP

SENSOR NAME:

7.00

OUTPUT1: 12.00 mA

SYSTEM SETUP

DISPLAY SETUP

SECURITY SETUP

LOG SETUP

CALCULATION

SENSOR NAME:

pH pHpH

7.00

pH

OUTPUT2: 12.00 mV

UP or DOWN key (corresponding to the

SYSTEM SETUP

SECURITY SETUP

LOG SETUP

CALCULATION

ERROR HOLD MODE

pHpH

Page 21

4.2 Using the sc1000 Controller

The sc1000 is a touch screen application. Use your fin ger to touch keys and menu

commands. In normal operation the touch screen displays the measured values for the

sensors selected.

4.2.1 Display Features

4.2.1.1 Using the Pop-up Toolbar

The pop-up toolbar provides access to the controller and sensor settings. The toolbar is

normally hidden from view. To view the toolbar, touch the bottom-left of the screen.

Figure 14 Pop-up Toolbar Functions

MAIN MENU–displays the Main Menu Structure

User Interface and Navigation

1 2 4

UP Arrow–scrolls up to the previous displayed value.

1

2

4

Displays one value.

Displays two values at the same time.

Displays four values at th e same time.

LIST–displays the list of connected devices and sensors.

DOWN Arrow–scro lls down to the next displayed value.

4.2.1.2 Using the Menu Windows

If the Menu butt on (from the pop -up toolba r) is selecte d, the Ma in Men u screen is o pened.

The Main Menu screen allows the user to view t he sensor status, configure the sensor

setup, system setup, and perform diagnostics.

The menu structure may vary depending on the configuration of th e system.

21

Page 22

User Interface and Navigation

Figure 15 Main Menu

2

3

4

5

MENU

SENSOR STATUS

1

SENSOR SETUP

6

SYSTEM SETUP

TEST/MAINT

1. Display Area

BACK

2.

3. FORWARD

4. ENTER–confirms the entry or selection.

HOME–changes to the display of measured values. The pop-up toolbar cannot open from the menu window. To view the

5.

Main Menu from this display, touch the Home button and then the bottom of the screen.

UP–scrolls up

6.

DOWN–scrolls down

7.

7

4.2.1.3 Navigating the Menu Windows

To view a menu item, touch the menu item or use the UP and DOWN keys to highlight the

item. The menu item remains highlighted for approximately 4 seconds after it is selected.

To view the highlighted command, select the area to the left of the men u item or select t he

ENTER button.

A “+” next to a menu command indicates there is a submenu. Touch the “+” to view the

submenu. An “i” next to a menu command indicates it is information only.

If a menu item is editable, highlight the item and touch the far-left part of the menu item

until it is highlighted and press

displayed to change an entry (Figure 17 on page 23) or a list box will be displayed

(Figure 18 on page 24).

Messages are displayed in the message window (Figure 19 on page 24).

If an entry is incorrect, repeat the entry with the correct values. If the entry is outside the

working range, a correction to the entry is made automatically.

ENTER or double-tap the highligh ted item. A k e ypad will be

22

Page 23

Figure 16 Changing a Menu Item

User Interface and Navigation

1. Display Area 5. HOME–changes to the display of measured values.

BACK 6. UP–scrolls up

2.

FORWARD 7. DOWN–scrolls down

3.

ENTER–confirms the entry or selection.

4.

Figure 17 Keypad

1 3

1 2 3 :

4 5 6 /

7 8 9 0

1. Enters numbers or the character as shown on the button.

2. Moves the cursor one position to the left or to the right.

3. Increase/Decrease a number or letter at the cursor position. Keep the button pressed to change the numbers/characters

continuously.

4. Deletes the character to the left of the cursor.

CANCEL–cancels the entry.

5.

ENTER–confirms the entry or selection.

6.

2

4

5

6

23

Page 24

User Interface and Navigation

Figure 18 List Box

mg/l

g/l

ppm

mE

E

m-1

FNU

NTU

1. Scrolls up or down

CANCEL–cancels and entry.

2.

ENTER–confirms a selection.

3.

Figure 19 Message windo w

1

2

3

1

1. Scrolls up or down.

2. Displays the messages or warnings.

3. Displays details on the selected entry.

4. This button changes back to the previous display.

ENTER–confirms an entry.

5.

CANCEL–cancels an entry.

6.

2

COMMUNICATION ERROR

Ph [11f20030007]

3

4

5

6

24

Page 25

Section 5 Operation

5.1 Sensor Setup

When a sensor is initially installed, the serial number of the Digital Gateway will be

displayed as the sensor name. To change the sensor name refer to the following

instructions:

1. Select Main Menu.

2. From the Main Menu, select SENSOR SETUP and confirm.

3. Highlight the appropriate sensor if more than one sensor is attached and confirm.

4. Select CONFIGURE and confirm.

5. Select EDIT NAME and edit the name. Confirm or cancel to return to the Sensor

Setup menu.

5.2 Sensor Data Logging

The sc1000 controller provides a data log for each sensor.

The sc100 provides three data logs (one for each sensor and one for calculated values).

The data logs store the measurement data at selected intervals. The event log stores a

variety of events that occur on the devices such as configuration changes, alarms, and

warning conditions. The data logs are stor ed in a pa c ked binary format and the event logs

are stored in a CSV format. The logs can be downloaded through the digital network port,

service port, or the IrDA port. DataCom is needed for downloading logs to a computer.

5.3 Sensor Diagnostics Menu for pH and ORP

SELECT SENSOR (if more than one sensor is attached)

STATUS

ERROR LIST See section 7.1 on page 35.

WARNING LIST See section 7.2 on page 35.

5.4 pH Sensor Setup Menu

SELECT SENSOR (if more than one sensor is attached)

CALIBRATE (Main Menu Item)

1 POINT AUTO Calibration with a single buffer — normally pH 7.

2 POINT AUTO Calibration with two buffers — normally pH 7 and pH 4 or 10.

1 POINT MANUAL Calibration against a single known sample.

2 POINT MANUAL Calibration against two samples, both with a known pH.

TEMP ADJUST Adjust the displayed temperature by up to ± 15 °C.

DEFAULT SETUP Restores the system to the original factory calibration.

CONFIGURE

EDIT NAME Enter up to a 10-digit name in any combination of symbols and alpha or numeric characters.

SELECT MEASURE Select the appropriate measurement units to display.

DISPLAY FORMAT Select the measurement resolution (xx.xx pH or xx.x pH).

TEMP UNITS Choose from the displayed options (°C or °F).

LOG SETUP

Choose SENSOR INTERVAL to set the sensor log interval or select TEMP INTERVAL to set the

temperature log interval.

25

Page 26

Operation

5.4 pH Sensor Setup Menu (continued)

CONFIGURE (continued)

REJECT FREQ

FILTER Select 0–60 second signal averaging time.

TEMP ELEMENT Select type of temperature element from the displayed choices.

SELECT BUFFER Select the buffer type (standard 4, 7, 10 or DIN 19267) from the displayed choices.

PURE H20 COMP

CAL DAYS Number of days since the last calibration. Default notification at 60 days.

SENSOR DAYS Number of days the sensor has been in operation. Default notification at 365 days.

DEF AULT SETUP Resets all user-editable options to their factory-defaults.

DIAG/TEST

PROBE INFO

CAL DATA Displays the pH slope and the date of the last calibration.

SIGNALS

COUNTERS

Choose 50 or 60 Hz depending on the power line frequency for optimal noise rejection. Default is

60 Hz.

Allows the user to specify that ammonia, morpholine, or other user-defined electrolyte is being

used in the application, allowing a temperature-dependent linear slope factor to be applied to the

measured pH.

Display the sensor type, entered name of the sensor (Default: Digital Gateway serial number and

name), the sensor serial number, the software version number, and the sensor driver version

number.

SENSOR SIGNAL: Displays the sensor output in mV

SENSOR ADC COUNTS: Displays the sensor ADC counts

TEMP ADC COUNTS: Displays raw data for temperature ADC counts. ADC counts are

comparable to A/D counts and are for sensor electronic diagnostic purposes only.

ELECTRODE STATE: Identifies the state of the electrode (good or bad) depending on whether

the impedance is within preset limits.

ACTIVE ELECT: Displays th e impedance (Mohms) of the active electrode if Imped Status is set

to Enabled.

IMPED STATUS: Sensor diagnostic. Choose Enabled or Disabled.

SENSOR DAYS: Displays the cumulative days the sensor has been in use.

RESET SENSOR: Allows the sensor counter to be reset to zero.

ELECTRODE DAYS: Cumulative days the electrode has been inuse.

26

Page 27

Operation

5.5 ORP Sensor Setup Menu

SELECT SENSOR (if more than one sensor is attached)

CALIBRATE (Main Menu Item)

1 POINT MANUAL Calibration against a single known sample.

TEMP ADJUST Adjust the displayed temperature by up to ± 15 °C.

DEFAULT SETUP Restores the system to the original factory calibration.

CONFIGURE

EDIT NAME Enter up to a 10-digit name in any combination of symbols and alpha or numeric characters.

SELECT SENSOR Choose from the displayed sensor type (pH or ORP).

TEMP UNITS Choose from the displayed options (°C or °F).

LOG SETUP

AC FREQUENCY

FILTER Select 0–60 second signal averaging time.

TEMP ELEMENT Select type of temperature element from the displ ayed choices.

CAL DAYS Number of days since the last calibration. Default notification at 60 days.

SENSOR DAYS Number of days the sensor has been in operation. Default notification at 365 days.

IMPED LIMITS Set min/max electrode sensor impedance limits.

DEFAULT SETUP Resets all user-editable options to their factory-defaults.

DIAG/TEST

PROBE INFO

CAL DATA Displays the slope and the date of the last calibration.

SIGNALS

COUNTERS

Choose SENSOR INTERVAL to set the sensor log interval or select TEMP INTERVAL to set the

temperature log interval.

Choose 50 or 60 Hz depending on the power line frequency for optimal noise rejection. Default is

60 Hz.

Display the sensor type, entered name of the sensor (Default: Digital Gatewa y serial number and

name), the sensor serial number, the software version number, and the sensor driver version

number.

SENSOR SIGNAL: displays the sensor output in mV

SENSOR ADC COUNTS: displays the sensor ADC counts

TEMP ADC COUNTS: shows raw data for temperature ADC counts. ADC counts are comparab le

to A/D counts and are for sensor electronic diagnostic purposes only.

ELECTRODE STATE: Identifies the state of the electrode (good or bad) depending on whether

the impedance is within preset limits.

ACTIVE ELECT: Shows the impedance (Mohms) of the active electrode if Imped Status is set to

Enabled.

IMPED STATUS: Sensor diagnostic. Choose Enabled or Disabled.

SENSOR DAYS: displays the cumulative days the sensor has been in use.

RESET SENSOR: allows the sensor counter to be reset to zero.

ELECTRODE DAYS: Cumulative days the electrode has been in use.

27

Page 28

Operation

5.6 pH Calibration

The manufacturer offers one and two point automatic and manual calibrations for pH. An

automatic calibration identifies the buffer table corresponding to the chosen buffer and

automatically calibrates the probe after it stabilizes. A manual calibration is performed by

placing the pH sensor in any buffer or sample with a known value and then entering that

known value into the controller.

The value of the sample used in the manual calibration may be determined by laboratory

analysis or comparison reading.

5.6.1 One Point Automatic Calibration

1. From the Main Menu, select SENSOR SETUP and confirm.

2. Select the appropriate sensor if more than one is attached and confirm.

3. Select CALIBRATE and confirm.

4. Select 1 POINT AUTO. Select the available Output Mode (Active, Hold, or Transfer)

from the list box and confirm.

5. Move the clean probe to b uffer and confirm to continue.

6. Confirm when stable. A screen will display 1 Point Auto Complete and the slope

(XX.X mV/pH).

7. Return the probe to process.

5.6.2 Two Point Automatic Calibration

1. From the Main Menu, select SENSOR SETUP and confirm.

2. Select the appropriate sensor if more than one is attached and confirm.

3. Select CALIBRATE and confirm.

4. Select 2 POINT AUTO. Select the available Output Mode (Active, Hold, or Transfer)

from the list box and confirm.

5. Move the clean probe to Buffer 1 and confirm.

6. Confirm when stable.

7. Move the clean probe to Buffer 2 and confirm.

28

8. Confirm when stable. A screen will display 2 Po int Calibration Complete and the slope

(XX.X mV/pH).

9. Return the probe to process.

Page 29

5.6.3 One Point Manual Calibration

1. From the Main Menu, select SENSOR SETUP and confirm.

2. Select the appropriate sensor if more than one is attached and confirm.

3. Select CALIBRATE and confirm.

4. Select 1 POINT MANUAL. Select the availab le Output Mode (Active, Hold, or Transfer)

from the list box and confirm.

5. Move the clean probe to solution and confirm to continue.

6. Confirm when stable. Edit the solution value using th e keypad and confirm.

7. Confirm when stable. A screen will display 1 Point Manual Complete and the slope

(XX.X mV/pH).

8. Return the probe to process.

5.6.4 Two Point Manual Calibration

Operation

1. From the Main Menu, select SENSOR SETUP and confirm.

2. Select the appropriate sensor if more than one is attached and confirm.

3. Select CALIBRATE and confirm.

4. Select 2 POINT MANUAL CAL. Select the available Output Mode (Active, Hold, or

Transfer) from the list box and confirm.

5. Move the clean probe to Solution 1 and confirm.

6. Confirm when stable. Edit the solution value using th e keypad and confirm.

7. Move probe to solution 1 and confirm.

8. Confirm when stable. Edit the solution value using th e keypad and confirm.

9. A screen will display 2 Point Manual Cal Complete and the slope (XX.X mV/pH).

10. Return the probe to process.

29

Page 30

Operation

5.7 ORP Calibration

5.7.1 One-point Manual Calibration

The manufacturer offers a one point manual calibration for ORP. The value of the sample

used in the manual calibration may be determined by laboratory analysis or comparison

reading.

1. From the Main Menu, select SENSOR SETUP and confirm.

2. Select the appropriate sensor if more than one is attached and confirm.

3. Select CALIBRATE and confirm.

4. Select 1 POINT MANUAL CAL. Select the available Output Mode (Active, Hold, or

Transfer) from the list box and confirm.

5. Move the clean probe to Solution and confirm.

6. Confirm when stable. Edit the solution value using the keypad and confirm.

7. A screen will display 1 Point Manual Complete and the slope (XX.X mV).

8. Return the probe to process.

5.8 Concurrent Calibration of Two Sensors for pH and ORP

1. Begin a calibration on the first sensor and continue until “Wait to Stabilize”

is displayed.

2. Select LEAVE and confirm. The display will return to the main measurement screen. The reading for the sensor currently being calibrated will flash.

3. Begin the calibration for the second sensor and continue until “Wait to Stabilize” is displayed.

4. Select LEAVE and confirm. The display will return to the main measurement screen and the reading for both sensors will flash. The calibration for both sensors are now running in the background.

5. To return to the calibration of either sensor select SENSOR SETUP from the Main Menu and confirm. Select the appropriate sensor and confirm.

6. The calibration in progress will be displayed. Continue with the calibration.

30

Page 31

5.9 Adjusting the Temperature

View or change the temperature using the steps below:

1. From the Main Menu, select SENSOR SETUP and confirm.

2. Select the appropriate sensor if more than one is attached and confirm.

3. Select CALIBRATE and confirm.

4. Select TEMP ADJUST and confirm.

5. Select MEASURED TEMP and confirm.

6. The temperature will be displayed. Select the temperature to edit and confirm.

Operation

31

Page 32

Visit us at www.hach.com

Page 33

Section 6 Maintenance

DANGER

Only qualified personnel should conduct the tasks described in this section of the

manual.

DANGER

Seul un technicien qualifié peut effectuer les tâches d'installation décrites dans

cette section du manuel.

DANGER

Explosion hazard. Do not connect or disconne ct eq uipment unle ss po we r has been

switched off or the area is known to be non-hazardous.

DANGER

Risque d’explosion. Couper le courant ou s’assurer que l’emp lacement est designe

non dangereux avant de replacer le aucon composant.

DANGER

Explosion hazard. Substitution of components may impair suitability for Class 1,

Division 2.

DANGER

Risque d’explosion. La substitution de composants peut rendre ce materiel

inacceptable pour les emplacements de Classe 1, Division 2.

6.1 Maintenance Schedule

Maintenance Task 90 days Annually

Clean the sensor

Inspect sensor for damage x

Calibrate Sensor (if required by regulatory agency) Per the schedule mandated by your regulatory agency.

1

Cleaning frequency is application dependent. More or less frequent cleaning will be appropriate in some applications.

1

x

33

Page 34

Maintenance

6.2 Cleaning the Sensor

CAUTION

Before cleaning with acid, determine if the chemical reaction between the acid and

the sample will create a hazardous chemical reaction. (For example, do not put a

sensor that is used in a cyanide bath directly into a strong acid for cleaning

because this chemical combination may produce poisonous cyanide gas.)

DANGER

Acids are hazardous. Always wear appropriate eye protection and clothing in

accordance with material safety data sheet recommendations.

1. Clean the exterior of the sensor with a stream of water. If debris remains remove loose contaminate buildup by carefully wiping the entire measuring end of the sensor with a soft clean cloth. Rinse the sensor with clean, warm water.

2. Prepare a mild soap solution of warm water and dish de terg en t o r oth er no n-abrasive soap that does not contain lanolin.

Note: Lanolin will coat the glass process electrode and can adversely affect sensor performance.

3. Soak the sensor for 2 to 3 minutes in the soap solution.

4. Use a small soft-bristle brush and scrub the entire measuring end of the sensor,

thoroughly cleaning the electrode and re ference junction surfaces. If surf ace de posits

cannot be removed by detergent solution cleaning, use muriatic acid (or other dilute

acid) to dissolve them. The acid should be as dilute as possible, do not use stronger

than 3% HCL. Experience will determine whic h acid to use and the appropriate

dilution ratio. Some stubborn coatings may require a different cleaning agent. For

assistance, contact Technical and Customer Service (U.S.A. only) on page 39.

5. Soak the entire measuring end of the sensor in dilute acid fo r no more than 5 minutes . Rinse the sensor with clean, warm water then place the sensor back into the mild soap solution for 2 to 3 minu tes to neutralize any remaining acid.

6. Remove the sensor from the soap solutio n, and rinse the senso r again in clean, warm water.

7. After cleaning, always calibrate the measurement system. Refer to section 4.7 on

page 25 or section 4.8 on page 29.

34

Page 35

Section 7 Troubleshooting

7.1 Error Codes

When a sensor is experiencing an error condition, the sensor reading on

the measurement screen will flash and all relays and analog outputs associated with this

sensor will be held. The following conditions will cause the sensor reading to flash:

• Sensor calibration

• Relay timer washing cycle

• Loss of communication

Highlight the Sensor Diag menu and press

determine the cause of the error. Errors are defined in Table 6.

Table 6 Error Codes

Displayed Erro r Definition Resolution

ADC FAILURE System measurement fails Contact Technical Consulting Services.

ENTER. Highlight Errors and press ENTER to

7.2 Warnings

A sensor warning will leave all menus, relays, and outputs functioning normally, but will

cause a warning icon to flash on the right side of the display. Highlight the Sensor Diag

menu and press

A warning may be used to trigger a relay and users can set warning levels to define the

severity of the warning. Warnings are defined in Table 7.

Displayed Warning Definition Resolution

PROBE OUT RANGE Measured pH/ORP exceeds the expected value range. Contact Technical Consulting Services.

TEMP OUT RANGE

FLASH FAILURE System flash memory write has failed. Contact Technical Consulting Services.

REF ELECTRODE

Measured temperature exceeds the expected val ue

range.

Standard Electrode is not performing within the required

specifications.

ENTER to determine the cause of the warning.

Table 7 Warning Codes

Contact Technical Consulting Services.

Contact Technical Consulting Services.

7.3 Troubleshooting the pH or ORP Sensor

Clean the sensor using the procedure described in section 6.2 on page 34 and then

calibrate the sensor as shown in section 4.7 on page 25 or section 4.8 on page 29.

If the measuring system cannot be calibrated after cleaning, contact Technical and

Customer Service (U.S.A. only) on page 39.

35

Page 36

Visit us at www.hach.com

Page 37

Section 8 Replacement Parts and Accessories

8.1 Replacement Items, Accessories, and Reagent and Standards

Item Description QTY Catalog Number

Instruction manual, Combination pH System, English each 6120118

Cable, sensor extension, 1 m (3 ft) each 6122400

Cable, sensor extension, 7.7 m (25 ft) each 5796000

Cable, sensor extension, 15 m (50 ft) each 5796100

Cable, sensor extension, 31 m (100 ft) each 5796200

Connector Safety Lock each 6139900

Termination box each 586700

Plug, sealing, conduit opening each 5868700

Strain relief, Heyco each 16664

Buffer, pH 7 500 mL (1 pint) 2283549

Buffer, pH 4 500 mL (1 pint) 2283449

Buffer, pH 10 500 mL (1 pint) 2283649

Buffer, pH 7 1 gallon 2283556

Buffer, pH 4 1 gallon 2283456

Buffer, pH 10 1 gallon 2283656

ORP Standard Solution, 200 mV 500 mL (1 pint) 25M2A1001-1 15

ORP Standard Solution, 600 mV 500 mL (1 pint) 25M2A1002-115

ORP Standard Solution, 200 mV 1 gallon 25M2A1001-123

ORP Standard Solution, 600 mV 1 gallon 25M2A1002-123

37

Page 38

Visit us at www.hach.com

Page 39

Section 9 How to Order

U.S.A. Customers

By Telephone:

6:30 a.m. to 5:00 p.m. MST

Monday through Friday

(800) 227-HACH (800-227-4224)

By Fax:

(970) 669-2932

By Mail:

Hach Company

P.O. Box 389

Loveland, Colorado 80539-0389 U.S.A.

Ordering information by e-mail: orders@hach.com

Information Required

• Hach account number (if available) • Billing address

• Your name and phone number • Shipping address

• Purchase order number • Catalog number

• Brief description or model number • Quantity

International Customers

Hach maintains a worldwide network of dealers and distrib utors. To locate the

representative neare st you, send an e-mail to: intl@hach.com or contact:

Hach Company World Headquarters; Loveland, Colorado, U.S.A.

Telephone: (970) 669-3050; Fax: (970) 669-2932

Technical and Customer Service (U.S.A. only)

Hach Technical and Customer Service Department personnel are eager to answer

questions about our products and their use. Specialists in analytical methods, they are

happy to put their talents to work for you.

Call 1-800-227-4224 or e-mail techhelp@hach.com

39

Page 40

Section 10 Repair Service

Authorization must be obtained from Hach Company before sending any items for

repair. Please contact the Hach Service Center serving your location.

In the United States:

Hach Company

Ames Service

100 Dayton Avenue

Ames, Iowa 50010

(800) 227-4224 (U.S.A. only)

FAX: (515) 232-3835

In Canada:

Hach Sales & Service Canada Ltd.

1313 Border Street, Unit 34

Winnipeg, Manitoba

R3H 0X4

(800) 665-7635 (Canada only)

Telephone: (204) 632-5598

FAX: (204) 694-5134

E-mail: canada@hach.com

In Latin America, the Caribbean, the Far East, Indian Subcontinent, Africa, Europe, or the Middle East:

Hach Company World Headquarters,

P.O. Box 389

Loveland, Colorado, 80539-0389 U.S.A.

Telephone: (970) 669-3050

FAX: (970) 669-2932

E-mail: intl@hach.com

40

Page 41

Section 11 Limited Warranty

Hach Company warrants its products to the original purchaser against any defects that are due to faulty material or workmanship for a period of one year from date of shipment unless otherwise noted in the product manual.

In the event that a defect is discovered during the warranty period, Hach Company agrees that, at its

option, it will repair or replace the defective product or refund the purchase price excluding original

shipping and handling charges. Any product repaired or replaced under this warranty will be warranted

only for the remainder of the original product warranty period.

This warranty does not apply to consumable products such as chemical reagents; or consumable components of a product, such as, but not limited to, lamps and tubing.

Contact Hach Company or your distributor to initiate warranty suppor t. Products may not be returned without authorization from Hach Company.

Limitations

This warranty does not cover:

• Damage caused by acts of God, natural disaster, labor unrest, acts of war (declared or undeclared),

terrorism, civil strife or acts of any governmental jurisdiction

• Damage caused by misuse, neglect, accident or improper application or installation

• Damage caused by any repair or attempted repair not authorized by Hach Company

• Any product not used in accordance with the instru ctions furnished by Hach Company

• Freight charges to return merchandise to Hach Company

• Freight charges on expedited or express shipment of warranted parts or product

• Travel fees associated with on-site warranty repair

This warranty contains the sole express warranty made by Hach Company in connection with its

products. All implied warranties , including without limitat ion, the warr anties of merchantability and fitness

for a particular purpose, are expressly disclaimed.

Some states within the United States do not allow the disclaimer of implied warranties and if this is true

in your state the above limitation may not apply to you. This warranty gives you specific rights, and you

may also have other rights that vary from state to state.

This warranty constitutes the final, complete, and exclusive statement of warranty terms and no person is authorized to make any other warranties or representations on behalf of Hach Company.

Limitation of Remedies

The remedies of repair, replacement or refund of purchase price as stated above are the exclusive

remedies for the breach of this warranty. On the basis of strict liability or under any other legal theory, in

no event shall Hach Company be liable for any incidental or consequential damages of any kind for

breach of warranty or negligence.

41

Page 42

Visit us at www.hach.com

Page 43

Section 12 Compliance Information

Hach Company certifies this instrument was tested thoroughly, inspected and found to

meet its published specifications when it was shipped from the factory.

The Model sc100 Controller/sc1000 Controller and the pH Combination sensor has

been tested and is certified as indicated to the following instrumentatio n standards:

Product Safety

UL 61010A-1 (ETL Listing # 65454)

CSA C22.2 No. 1010.1 (ETLc Certification # 65454)

Certified by Hach Co. to EN 61010-1 Amds. 1 & 2 (IEC1010-1) per 73/23/EEC,

supporting test records by Intertek Testing Services.

Immunity

This equipment was tested for industrial level EMC per:

EN 61326 (EMC Requirements for Electrical Equipment for Measurement, Control

and Laboratory Use)

Company, certified compliance by Hach Company.

per 89/336/EEC EMC: Supporting test records by Hach

Emissions

Standards include:

IEC 1000-4-2:1995 (EN 61000-4-2:1995) Electrostatic Discharge Immunity (Criteria

B)

IEC 1000-4-3:1995 (EN 61000-4-3:1996) Radiated RF Electromagnetic Field

Immunity (Criteria A)

IEC 1000-4-4:1995 (EN 61000-4-4:1995) Electrical Fast Transients/Burst (Criteria B)

IEC 1000-4-5:1995 (EN 61000-4-5:1995) Surge (Criteria B)

IEC 1000-4-6:1996 (EN 61000-4-6:1996) Conducted Disturbances Induced by RF

Fields (Criteria A)

IEC 1000-4-11:1994 (EN 61000-4-11:1994) Voltage Dip/Short Interruptions (Criteria

B)

Additional Immunity Standard/s include:

ENV 50204:1996 Radiated Electromagnetic Field from Digital Telephones (Criteria A)

This equipment was tested for Radio Frequency Emissions as follows:

Per 89/336/EEC EMC: EN 61326:1998 (Electrical Equipment for measurement,

control and laboratory use—EMC requirements) Class “A” emission limits . Supporting

test records by Hewlett Pac kard, Fort Collins, Colorado Hardware Test Center (A2LA #

0905-01) and certified compliance by Hach Company.

Standards include:

EN 61000-3-2 Harmonic Disturbances Caused by Electrical Equipment

EN 61000-3-3 Voltage Fluctuation (Flicker) Disturbances Caused by Electrical

Equipment

Additional Emissions Standard/s include:

EN 55011 (CISPR 11), Class “A” emission limits

43

Page 44

Compliance Information

Canadian Interference-causing Equipment Regulation, IECS-003, Class A

Supporting test records by Hewlett Packard, F ort Collins, Colorado Hardware Test Center

(A2LA # 0905-01) and certified compliance by Hach Company.

This Class A digital apparatus meets all requirements of the Canadian InterferenceCausing Equipment Regulations.

Cet appareil numèrique de la classe A resp ecte toutes les e x igences du Rëg lement sur le

matÈriel brouilleur du Canada.

FCC PART 15, Class “A” Limits

Supporting test records by Hewlett Packard, Fort Collins, Colorado Hardware Test Center

(A2LA # 0905-01) and certified compliance by Hach Company.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

two conditions:

(1) this device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

Changes or modifications to this unit not expressly approved by the party responsible for

compliance could void the user's authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manua l,

may cause harmful interfer ence to radio co mmunications. Operation of this equi pment in a

residential area is likely to cause harmful interference, in which case the user will be

required to correct the interference at his own expense. The following techniques of

reducing the interference problems are applied easily.

1. Disconnect the Controller from its power source to verify that it is or is not the sour ce of the interference.

2. If the Controller is connected into the same outlet as the de vice with which it is interfering, try another outle t.

3. Move the Controller away from the device receiving the interference.

4. Reposition the receiving antenna for the device receiving the interference.

5. Try combinations of the above.

44

Page 45

Appendix A Modbus Register Information

Table 8 Sensor Modbus Registers

Group Name T ag Name

Tags SensorMeasTag 40001 Integer 1 R Se nsor measurement tag

Measurements pHMeas 40002 Float 2 R pH /ORP measurement

Tags TempMeasTag 40004 Integer 1 R Temperature measurement tag

Measurements TempDegCMeas 40005 Float 2 R Temperature measurement

Configuration SensorName 40007 String 6 R/W Sensor name

Tags FuncCode 40013 Integer 1 R/W Function code tag

Tags NextState 40014 Integer 1 R/W Next state tag

Configuration MeasType 40015 Integer 1 R/W Measurement type—pH or ORP

Configuration TempUnits 40016 Integer 1 R/W Temperature units—C or F

Configuration pHFormat 40017 Integer 1 R/W pH display format

Configuration TaggedPhFormat 40018 Long 2 R pH display tagged format

Configuration Filter 40020 Integer 1 R/W Sensor filter

Configuration TempElementType 40021 Integer 1 R/W Temperature element type

Tags TempUserValueTag 40022 Integer 1 R Temperature user value tag

Configuration TempUserDegCValue 40023 Float 2 R/W Temperature user value

Configuration pHBuffer 40025 Integer 1 R/W pH buffer type

Configuration PureWaterCompType 40026 Integer 1 R/W Pure H

Configuration PureWaterCompUser 40027 Float 2 R/W Pure H

Calibration OutputMode 40029 Integer 1 R/W Output mode

Calibration CalLeave 40030 Integer 1 R/W Cal leave mode

Calibration CalAbort 40031 Integer 1 R/W Cal abort mode

Tags CalEditValueTag 40032 Integer 1 R Cal edit value tag

Calibration CalEditPhValue 40033 F loat 2 R/W Cal edit value

Diagnostics pHSlope 40035 Float 2 R pH slope

Diagnostics SoftwareVersion 40037 String 6 R Software version

Diagnostics SerialNumber 40043 String 6 R Serial number

Diagnostics pHOffset 40049 Float 2 R pH offset

Diagnostics OrpOffset 40051 Float 2 R Orp offset

Calibration CalCode 40053 Integer 1 R Cal code

Configuration SensorLogInterval 40054 Integer 1 R/W Sensor data log interval

Configuration TempLogInterval 40055 Integer 1 R/W Temperature data log interval

Diagnostics pHmV 40056 Float 2 R pH mV

Diagnostics ProdDate 40058 Date 2 R/W Production date

Diagnostics StdElectrode 40060 Float 2 R Standard electrode impedance

Diagnostics RefElectrode 40062 Float 2 R Reference electrode impedance

Diagnostics LastCalDate 40064 Date 2 R Last calibration date

Diagnostics SensorDays 40066 Integer 1 R Sensor running days

Diagnostics ElectrodeDays 40067 Integer 1 R Electrode running days

Diagnostics ElectrodeStatus 40068 Integer 1 R Electrode status

Diagnostics SensorType 40069 Integer 1 R Sensor type

Configuration RejectFrequency 40070 Integer 1 R/W Reject frequency

Diagnostics DeviceDriver 40071 String 5 R Device driver

Register #Data

Type

Length R/W Description

O compensation type

2

O compensation user val

2

45

Page 46

Modbus Register Information

Table 8 Sensor Modbus Registers

Group Name Tag Name

Configuration CalWarningDays 40076 Integer 1 R/W Calibration warning days

Configuration SensorWarningDays 40077 Integer 1 R/W Sensor warning days

Register #Data

Type

Length R/W Description

46

Page 47

Appendix B General pH Information

B.1 pH Measurement Theory

pH is the negative logarithm of the hydrogen ion activity and a measure of the acidity or

alkalinity of a solution.

pH = –log A[H+]

pH is normally measured using a glass electrode and a reference electrode.

The glass electrode acts as a transducer, converting chemical energy (the hydrogen ion

activity) into an electrical energy (measured in millivolts). The reaction is balanced and the

electrical circuit is completed by the flow of ions from the reference solution to the solution

under test.

The electrode and reference solution together develop a voltage (emf) whose magnitude

depends on the type of reference electrode, the internal construction of the glass

electrode, the pH of the solution and the temperature of the solution. This voltage is

expressed by the Nernst Equation:

E = Eo – (2.3 RT/F) x log A[H+]

– (slope) x log A[H+]

E = E

o

where:

E = the emf of the cell

E

= the zero potential (isopotential) of the system. It depends on the internal

o

construction of the glass and reference electrodes.

R = gas constant

T = temperature in Kelvin

A[H+] = activity of the hy dr ogen ion (a ssumed to be eq uivalent to the concentration of

hydrogen ions)

F = Faraday constant

For every unit change in pH (or decade change in ion concentration) the emf of the

electrode pair changes by 59.1 6 m V at 2 5 °C. This value is known as the Nernstian Slope

of the electrode.

The pH electrode pair is calibrated using solutions of know n and constant hydrogen ion

concentration, called buffer solutions. The buffer solutions are used to calibrate both the

electrode isopotential and slope.

47

Page 48

General pH Information

B.2 PID Controller Basics

A pH control loop operates as follows: The pH meter measures the value of the pH in the

effluent, and, if the pH is different from the setpoint, the controller actuates the reagent

pump (or valv e) that adds reagent to a mixing tank. The added reagent adjusts the pH

value of the process.

The physical layout of the loop, the sizing of the pump (valve), type of mixing tank, and

location of the pH electrodes all have a major impact on the ultimate performance of the

loop, after the controller is tu ned for optimal performance. The largest single performance

factor is the delay time around the loop. This includes the response time of the

electrode/meter, time required to deliver the reagent to the process water, time required

for the reagent to mix with and react with the process water, and the time re quired to

deliver the completely mixed water to the electrode. If the delay times are too long or the

mixing is not complete, the control will be poor regardless of how well the controller is

tuned.

The Process pH Meter uses a PID (proportional, integral (reset), deriv ative (rate) control)

control algorithm. Each of the instrument settings along with their effects on the control

loop, are described below.

Mode

Manual: The manual output is specified in percent of full-scale PID output

(4–20 mA) and is commonly used for testing the output device.

Auto: Allows the process to be controlled automatic ally us ing information specified in the

Phase, Setpoint, Proportional Band, Integral, and Derivative menus as follows:

Phase

Direct: The control output action will cause the process value to increase.

Reverse: The control output action will cause the process value to decrease.

Setpoint

The setpoint is defined as the desired process value in pH

Proportional Band

The proportional band is the range in pH from the setpoint value where the controller

provides proportional control. For example, the desired setpoint for the process is pH 7.0

and the process requires that a reagent must be added to the process w a ter to bring it up

to pH 7.0. If the proportional band is set to pH 1.0, the controller will provide proportional

output control over the range of pH 6.0 to 8.0. When the process is at pH 6.0, the

controller will provide a 100% control output level (assuming that Phase is set to Direct).

When the process is at pH 7.0, the proportional control will provide a 0% control output

level. When the process is at pH 6.5 the proportional control will provide a 50% output.

The output action is equal to the difference between the setpoint and the process value,

divided by the proportional band value.

48

Page 49

General pH Information

Integral

The integral value is used to reduce the steady state err or , bet ween the proce ss v alue and

the setpoint, to zero. For example, assume a process can be manually controlled at a level

of pH 8.0 by sending a 35% control output level to a reagent pump. Now, say that the

system is set up for the controller to provide proportional only control, with the controller

setpoint set to pH 8.0 and the proportional band set to pH 1.0. Note that the nearer the

process gets to the pH 8.0 setpoint, the lower the control output level is. In fact, when the

process is at pH 8.0, the output level will be 0%. Since the process requires that the pump

be operated at 35% for the process to reach pH 8.0, its apparent that proportional-only

control will never quite reach the desired setpoint of pH 8.0. This is where the integral

control comes in.

Integral control can be thought of as adding up the output action from the proportional

control over time. For e xample, the proportional control output reaches a steady state level

of 5%. If the integral time is set to five minutes, the integral action of the controller will add

an additional 5% to the controller output level over a 5-minute interval. The integral action

is additive, so for every 5-minute interval an additional 5% is added to the controller's

output level. This will allow the controller to bring the process to the desired setpoint level.

Note that the longer the integral time setting, the longer it takes for the integral action to

affect the process. The integral control action is disabled by setting it to zero. Note that the

integral time is in minutes.

Derivative

Derivative control is used to adjust the control output level based upon the rate at which

the process value is approaching or passing the setpoint. De rivative control action would

be used in cases where the process value can r apidly ramp up and o versho ot the setpoint.

The derivative setting is in minutes. The output action of the derivative control is equal to

the rate of change of the pro cess (in pH units per m inute) times t he derivativ e time , divided