Page 1

59577-88

POCKET COLORIMETER™ II

ANALYSIS SYSTEMS

INSTRUCTION MANUAL

Iron

Molybdenum

Ozone

Zinc

© Hach Company, 2006. All rights reserved. Printed in the U.S.A. te/dk 12/06 3ed

Page 2

1—2

Important Note

This manual is intended for use with the following Pocket Colorimeter II

instruments:

The Pocket Colorimeter II instruments listed above are not interchangeable.

Iron Cat. No. 59530-16

Molybdenum Cat. No. 59530-10

Ozone Cat. No. 59530-04

Zinc Cat. No. 59530-09

Page 3

1—3

Table of Contents

Safety Precautions............................................................................................... 1—7

Laboratory Safety............................................................................................... 1—7

Use of Hazard Information................................................................................1—7

Precautionary Labels........ ....................................................... ....... ....................1—8

Specifications......................................................................................................... 1—9

Instrument Keys and Display..........................................................................1—13

Instrument Cap Cord.........................................................................................1—14

Iron, Total...............................................................................................................1—17

Measuring Hints ...............................................................................................1—17

Sampling and Storage......................................................................................1—26

Accuracy Check................ ....... ....................................................... ....... ...... .....1 —26

Standard Calibration Adjust Method...................... .......................................1—27

Method Performance........................................................................................1—27

Interferences......................................................................................................1—28

Summary of Method........................................................................................1—29

Reagents and Apparatus.................................................. ................................1—30

Page 4

1—4

Table of Contents, continued

Molybdenum, Molybdate, LR.........................................................................1—33

Measuring Hints................................................................................................1—33

Sampling and Storage......................................................................................1—38

Accuracy Check...................................... ....... ....... .............................................1—38

Interferences......................................................................................................1—38

Summary of Method.........................................................................................1—38

Replacement Parts.............................................................................................1—38

Molybdenum, Molybdate, HR.........................................................................1—39

Measuring Hints................................................................................................1—39

Sampling and Storage......................................................................................1—44

Accuracy Check...................................... ....... ....... .............................................1—44

Method Performance........................................................................................1—45

Standard Calibration Adjust Method..............................................................1—45

Interferences......................................................................................................1—46

Summary of Method.........................................................................................1—49

Ozone.......................................................................................................................1—53

Measuring Hints................................................................................................1—53

Sampling and Storage......................................................................................1—58

Stability of Indigo Reagent....................................... ....... ................................1—58

Page 5

1—5

Table of Contents, continued

Accuracy Check................ ....... ....................................................... ....... ...... .....1 —58

Spec

√™ Secondary Standards for Instrument Verification.............. ...... .....1 —5 9

Summary of Method........................................................................................1—61

Reagents and Apparatus.................................................. ................................1—62

Zinc...........................................................................................................................1—63

Measuring Hints ...............................................................................................1—63

Sampling and Storage......................................................................................1—68

Accuracy Check................ ....... ....................................................... ....... ...... .....1 —68

Method Performance........................................................................................1—69

Standard Calibration Adjust Method...................... .......................................1—69

Interferences......................................................................................................1—70

Waste Management..........................................................................................1—70

Summary of Method........................................................................................1—71

Reagents and Apparatus.................................................. ................................1—71

Instrument Operation.........................................................................................2—3

Key Functions..................................................... ....... ......................................... 2—3

Menu Selections.............................. ....................................................... ...... ....... 2—4

Switching Ranges...............................................................................................2—4

Setting the Time ................................................................................................. 2—4

Page 6

1—6

Table of Contents, continued

Recalling Stored Measurements........................................................................2—5

Battery Installation.............................................................................................2—6

Error Codes..............................................................................................................2—9

Error Messages ....................................................................................................2—9

Standard Calibration Adjust...........................................................................2—13

User-Entered Calibration.................................................................................2—15

Overview............................................................................................................2—15

Calibration Procedure Using Prepared Standards.........................................2—17

Entering a Predetermined Calibration Curve.......... .......................................2—20

Editing a User-entered or Factory Calibration Curve...................................2—22

Exiting the Calibration Routine......................... .............................................2—24

Deleting Calibration Points.......................... ....... ...... .......................................2—24

Retrieving the Factory Calibration ................................................................. 2 —25

Maximum/Minimum Displayed Value....................................................... ....2—26

Certification..........................................................................................................2—29

How to Order........................................................................................................2—35

Repair Service.......................................................................................................2—37

Warranty.................................................................................................................2—38

Page 7

1—7

Safety Precautions

Please read this entire manual before unpacking, setting up, or operating this

instrument. Pay particular attention to all danger and caution statements. Failure

to do so could result in serious injury to the operator or damage to the equipment.

To ensure the protection provided by this equipment is not impaired, do not use or

install this equipment in any manner other than that which is specified in

this manual.

Laboratory Safety

As part of good laboratory practice, pl eas e familiarize yourself with the reagents

used in these procedures. Read all product labels and the m aterial safety data

sheets (MSDS) before using them. It is always good practice to wear safety glasses

when handling chemicals. Foll ow instructions carefully. Rinse thoroughly if

contact occurs. If you have questions about reagents or procedures, please contact

the manufacturer or distributor.

Use of Hazard Information

If multiple hazards exist, this manu al wi ll use th e sign al wo rd (Danger, Caution,

Note) corresponding to the greatest hazard.

Page 8

1—8

Safety Precautions, continued

DANGER

Indicates a potentially or imminently hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation that may result in minor or

moderate injury.

NOTE

Information that requires special emphasis.

Precautionary Labels

Please pay particular attention to labels and tags attached to the instrument.

Personal in ju ry or damage to the instrument could occur if not observed .

This symbol, if noted on the instrume n t, referen ces the instruct io n manual

for operational and/or safety inform ation.

Page 9

1—9

Specifications

Lamp: Light emitting diode (LED)

Detector: Silicon photodiode

Photometric precision: ± 0.0015 Abs

Filter bandwidth: 15 nm

Wavelength: 600 nm

Absorbance range: 0–2.5 Abs

Dimensions: 3.2 x 6.1 x 15.2 cm (1.25 x 2.4 x 6 inches)

Weight: 0.2 kg (0.43 lb)

Sample cells: 25 mm (10 mL), AccuVac

®

Ampuls

Operating conditions: 0 to 50 °C (32 to 122 °F); 0 to 90% relative humidity

(noncondensing)

Power supply: Four AAA alkaline batteries; approximate life is 2000 tests*

* Backlight usage will decrease battery life.

Page 10

1—10

Page 11

1—11

OPERATION

DANGER

Handling chemical samples, standards, and reagents can be dangerous. Review the necessary

Material Safety Data Sheets and become familiar with all safety procedures before handling

any chemicals.

DANGER

La manipulation des échantillons chimiques, étalons et réactifs peut être danger euse. Lir e les Fiches

de Données de Sécurité des Produits (FDSP) et se familiariser avec toutes les procédures de sécurité

avant de manipuler tous les produits chimiques.

PELIGRO

La manipulación de muestras químicas, estándares y reactivos puede ser peligro s a. Revi se las fichas

de seguridad de materiales y familiarícese con los procedimientos de seguridad antes de manipular

productos químicos.

GEFAHR

Das Arbeiten mit chemischen Proben, Standards und Reagenzien ist mit Gefahren verbunden. Es

wird dem Benutzer dieser Produkte empfohlen, sich vor der Arbeit mit sicheren Verfahrensweisen

und dem richtigen Gebrauch der Chemikalien vertraut zu machen und alle entsprechenden

Materialsicherheitsdatenblätter aufmerksam zu lesen.

PERIGO

A manipulação de amostras, padrões e reagentes químicos pode ser perigosa. Reveja a folha dos

dados de segurança do material e familiarize-se com todos os procedimentos de segurança antes

de manipular quaisquer produtos químicos.

PERICOLO

La manipolazione di campioni, standard e reattivi chimici può essere pericolosa. La preghiamo di

prendere conoscenza delle Schede Techniche necessarie legate alla Sicurezza dei Materiali e di

abituarsi con tutte le procedure di sicurezza prima di manipolare ogni prodotto chimico.

Page 12

1—12

Page 13

1—13

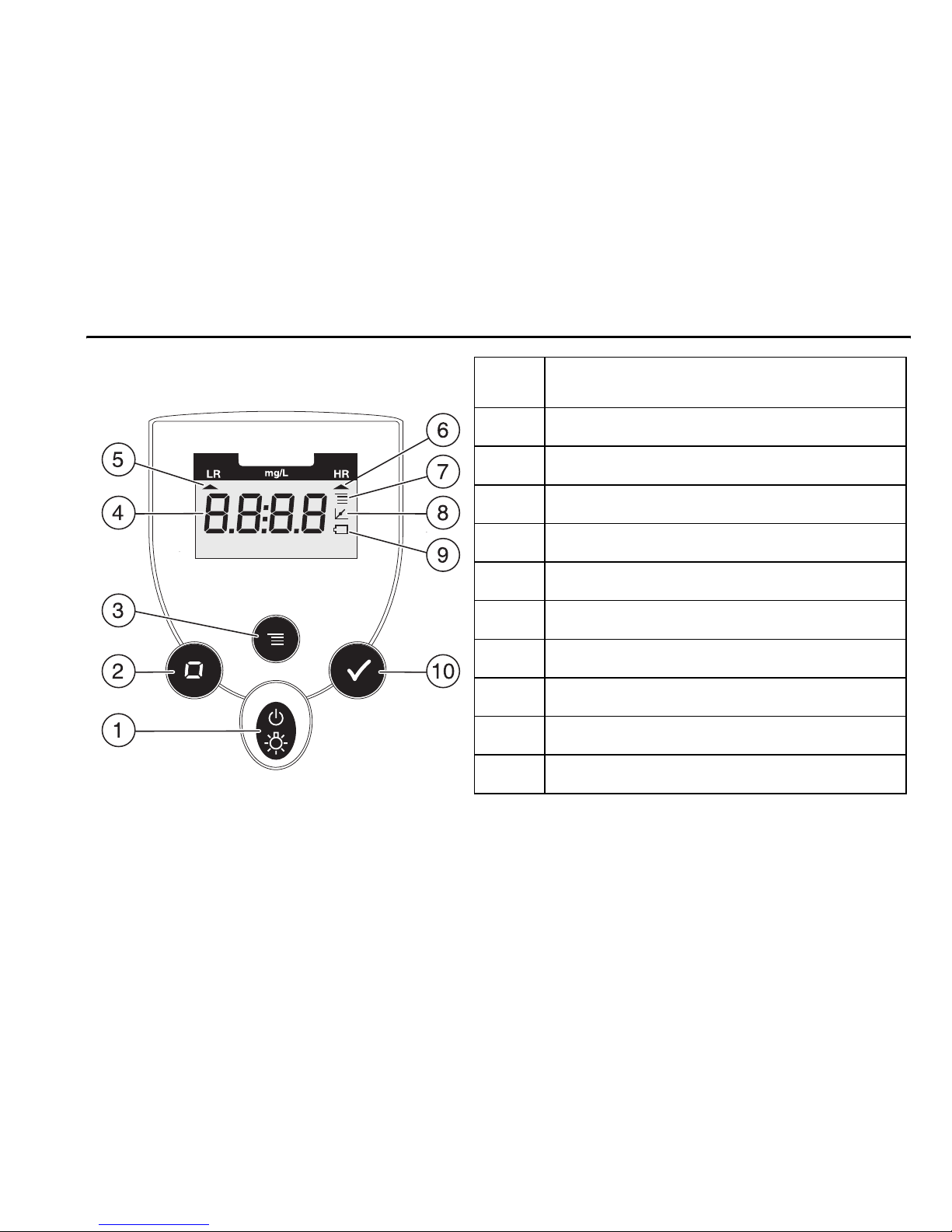

Instrument Keys and Display

Item

Description

1

POWER/BACKLIGHT Key

2

ZERO/SCROLL Key

3

MENU Key

4 Numeric Display

5 Range Indicator

6 Range Indicator

7 Menu Indicator

8 Calibration Adjusted Indicator

9 Battery Low Indicator

10

READ/ENTER Key

Page 14

1—14

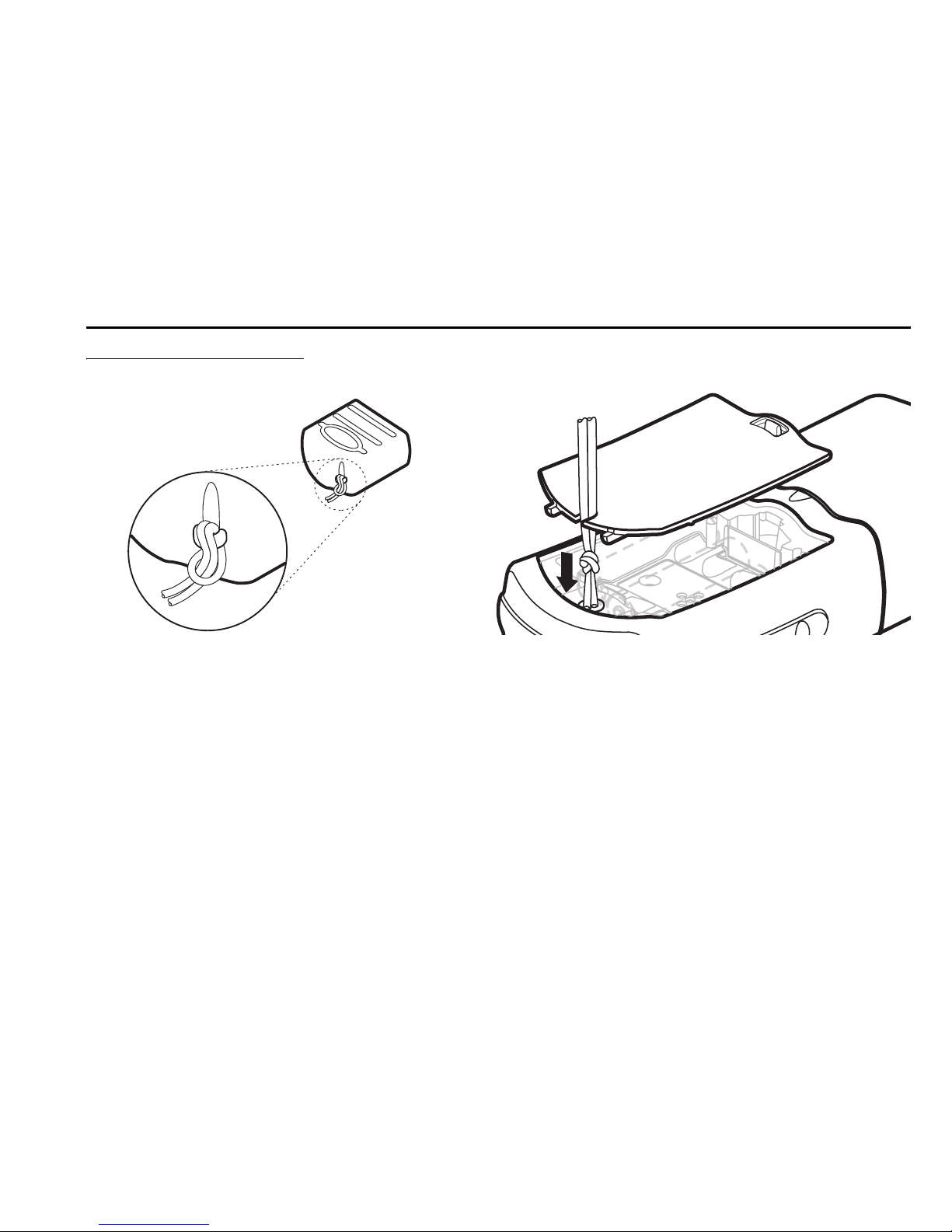

Instrument Cap Cord

The instrument cap for the Pocket Colorimeter™ II doubles as a light shield.

Accurate measurements cannot be obtained unless the sample or blan k is covered

with the cap. Use the instrument cap cord to secure the cap to the body of the

colorimeter and prevent loss of the cap. See Figu re 1 on page 1—15.

1. Loop the instrument cap cord through the ring on the cap.

2. Remove the battery compartment cover. Press the knotted end of the cord into

the hole indicated by the arro w.

3. Slide the cord into the slot on the battery compartment cover. Snap the cover

into place.

Page 15

1—15

Instrument Cap Cord, continued

Figure 1 Attaching the Instrument Cap Cord

Page 16

1—16

Page 17

1—17

Iron, Total (0.01 to 1.70 mg/L Fe)

Method 8 112

For water, wastewater, and seawater

TPTZ Method*

Measuring Hints

• Testing generally does not require digestion, however if the sample contains

particulate matter, digestion is required for total iron me asurem en t.**

• If samples cannot be analyzed immediately, see Sampling and Storage on

page 1—26.

• Wipe sample cells with a soft, dry cloth before placing in the instrument.

• After adding TPTZ reagent, a bl ue color will form if iron is present.

Note:

The Pocket Colorimeter™ II is designed to measure solutions contained in sample cells.

DO NOT

dip the meter in the sample or pour the sample directly into the cell holder.

* Adapted from G. Frederic Smith Chemical Co., 1980, The Iron Reagents, 3rd ed.

** See the Hach Water Analysis Handbook for further information concerning digestions.

Page 18

1—18

Iron, Total, continued

Using Powder Pillows

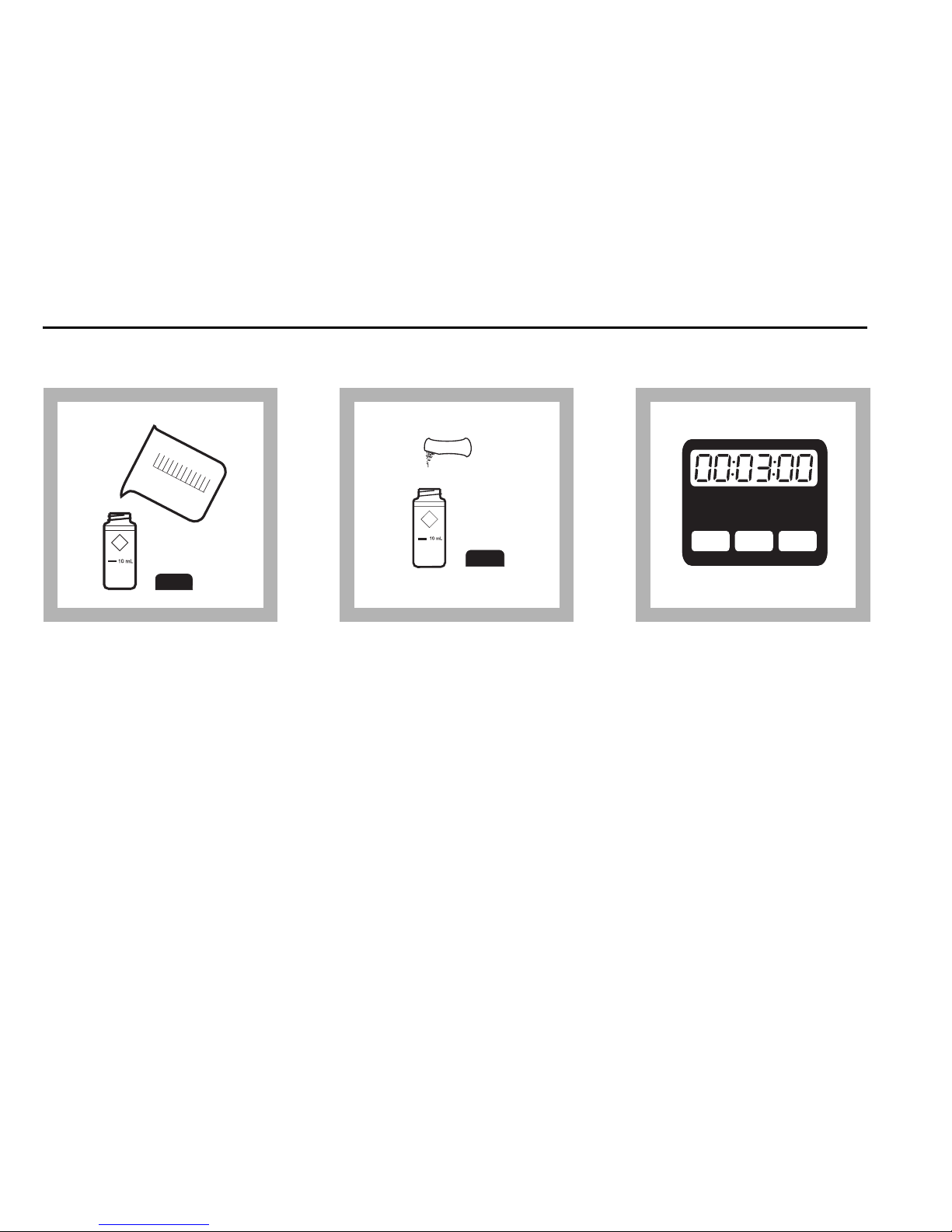

1.Fill a 10-mL cell to the

10 mL line with sample.

2.A dd the contents of one

Iron TPTZ Reagent Powder

Pillow to the cell (the

prepared sample). Cap and

shake for 30 seconds.

3.Wait at least 3 minutes

for full color development

before completing steps 4–

12.

HRS MIN SECHRS MIN SEC

Page 19

1—19

Iron, Total, continued

4.Fill a second sample cell

with 10 mL of sample (the

blank).

5.Pr ess the POWER key to

turn the meter on.

The arrow sh ould indicate

mg/L Fe.

Note:

See page 2—4 for

information on selecting the

correct range channel.

6.Wipe the sa mple cells

free of liquid or fingerprints.

Any liquid entering the

sample cell compartment

can cause damage to the

instrument.

Page 20

1—20

Iron, Total, continued

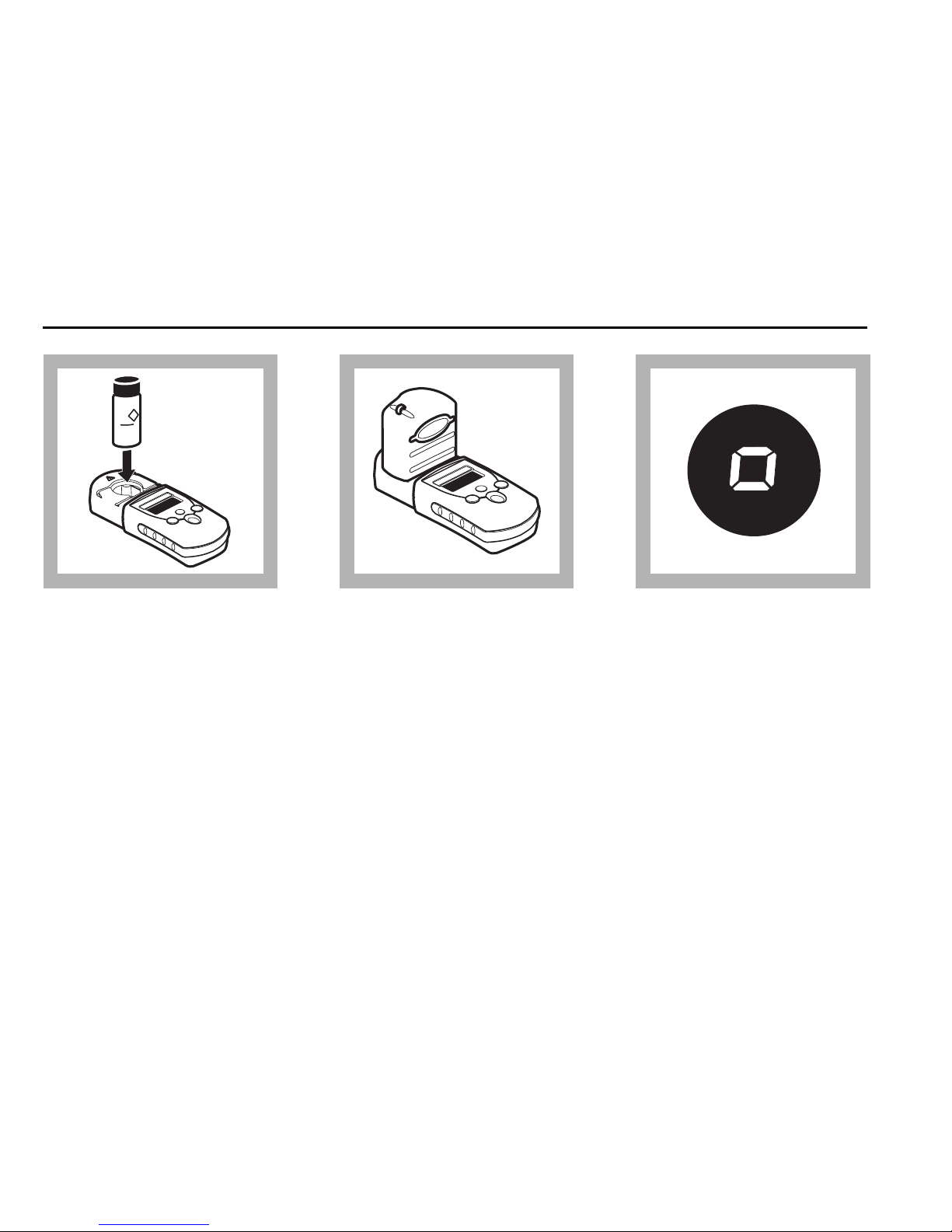

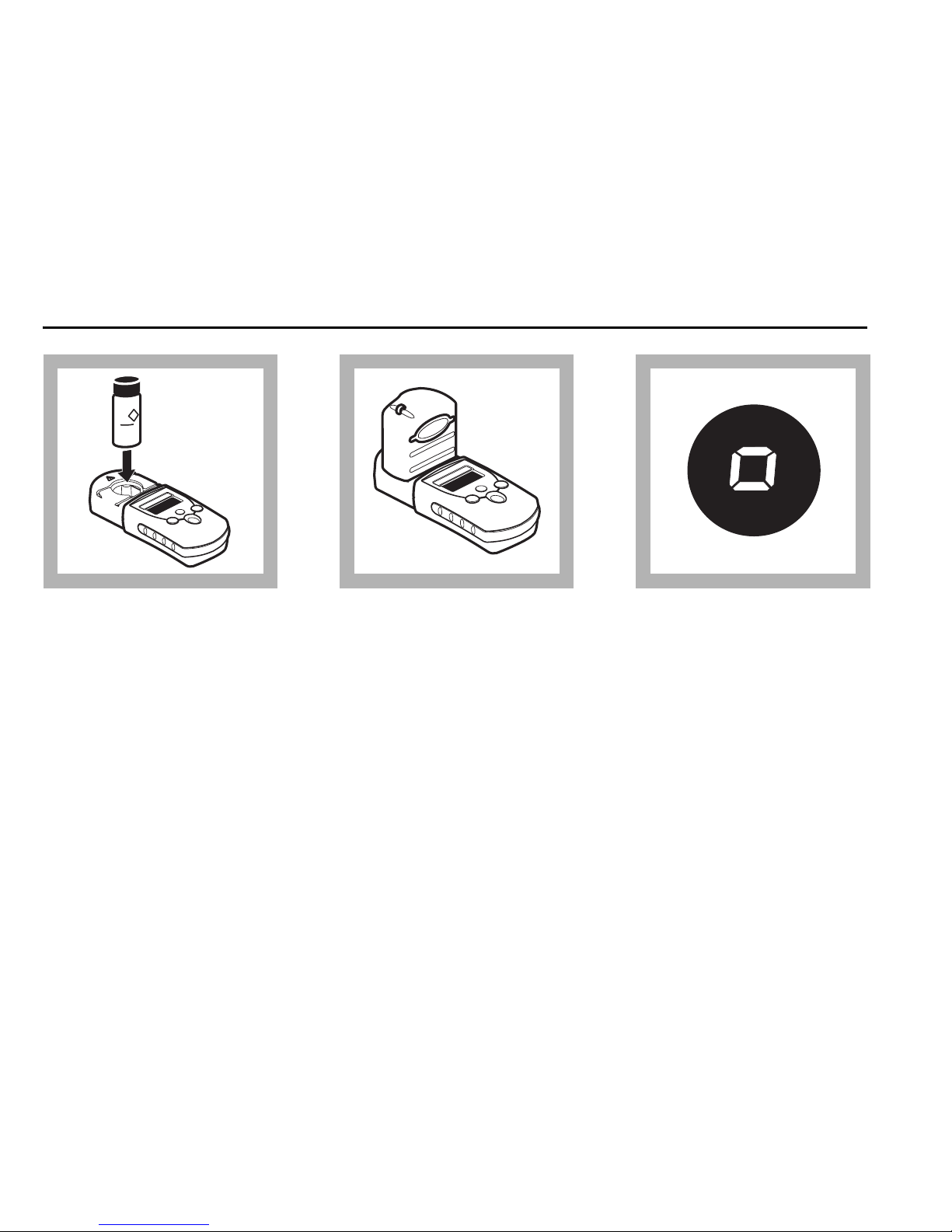

7.Place the blank in the

cell holder.

8.Cov er the blank with the

instrument cap.

9.Press ZERO/SCROLL.

The display will show

“- - - -” then “0.00”.

Remove the blank from the

cell holder.

Page 21

1—21

Iron, Total, continued

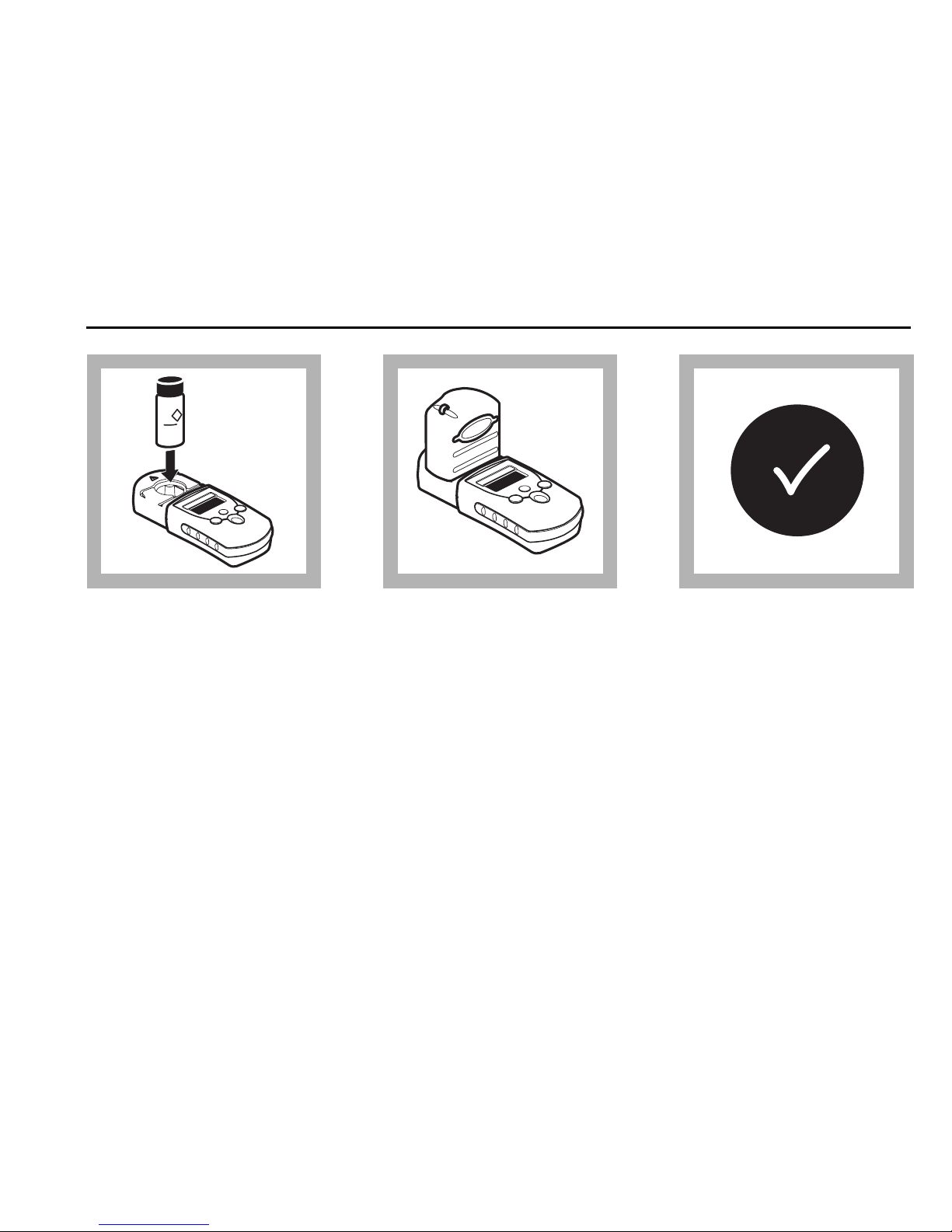

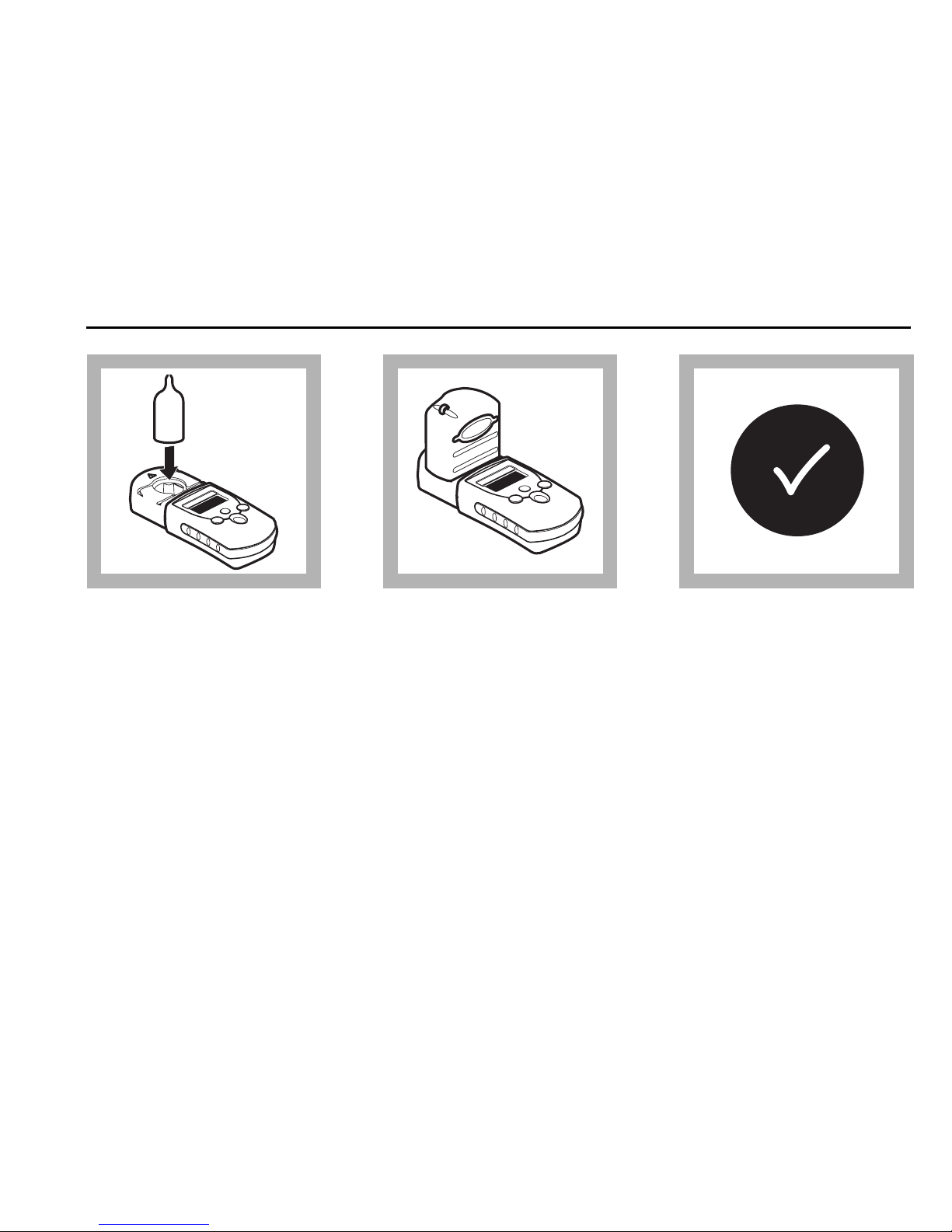

10. Place the prepared

sample in the cell holder.

11. Cover the sample cell

with the inst rument cap.

12.Press READ/ENTER.

The display will show

“- - - -” then “0.00”,

followed by results in mg/L

Iron.

Page 22

1—22

Iron, Total, continued

Using AccuVac® Ampuls

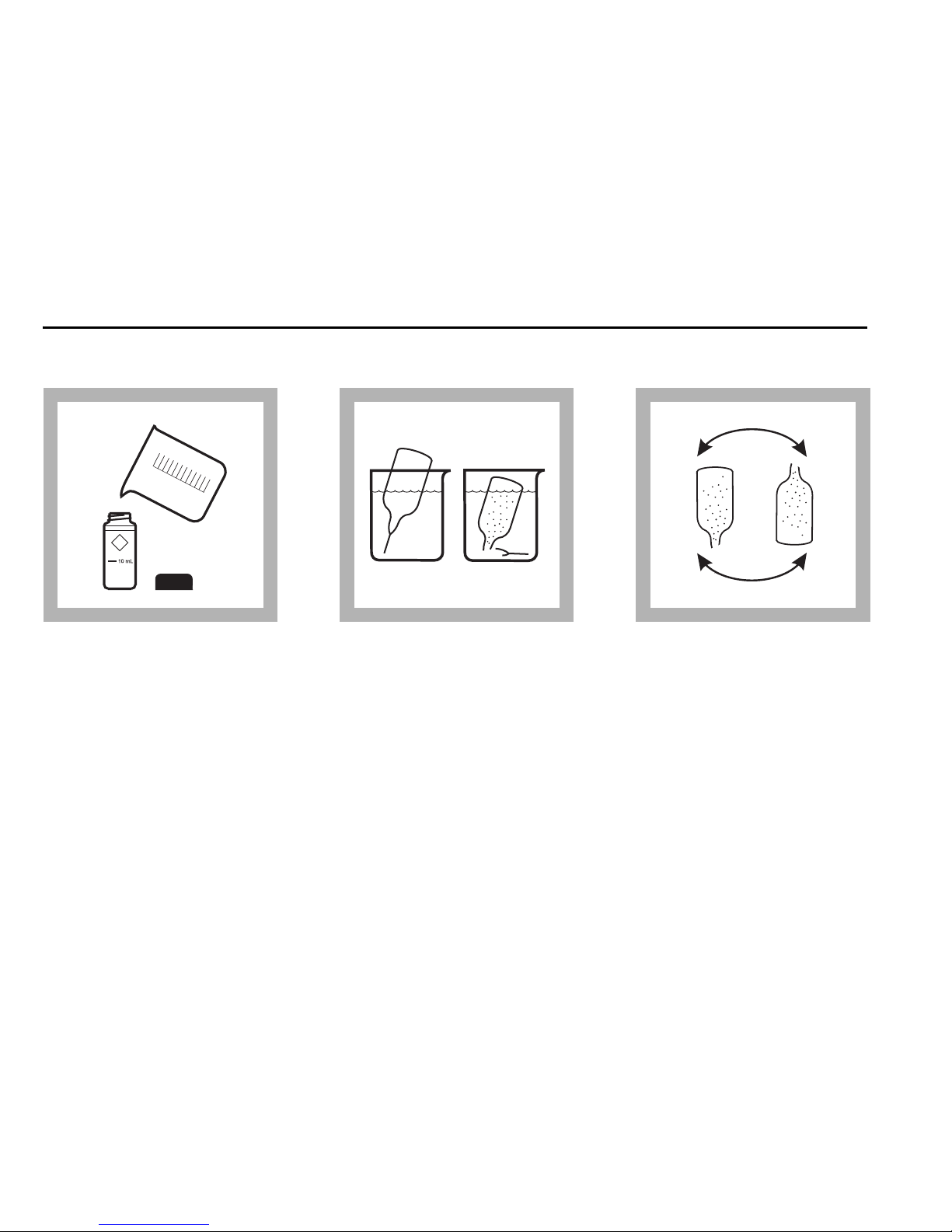

1.Fill a 10-mL cell to the

10 mL line with sample. Cap.

Collect at least 40 mL of

sample in a 50-mL beaker.

2.Fill an Iron TPTZ

Reagent AccuVac Ampul

with sample.

Note:

Keep the tip of the

ampule immersed until the

ampule fills completely.

3.Invert the ampule several

times to mix. Wipe off any

liquid or fingerprints.

Page 23

1—23

Iron, Total, continued

4.Wait at least 3 minutes

for full color development

before completing steps 5–

12.

5.Pr ess the POWER key to

turn the meter on.

The arrow sh ould indicate

mg/L Fe.

Note:

See page 2—4 for

information on selecting the

correct range channel.

6.Wipe the sa mple cells

free of liquid or fingerprints.

Any liquid entering the

sample cell compartment

can cause damage to the

instrument.

HRS MIN SECHRS MIN SEC

Page 24

1—24

Iron, Total, continued

7.Place the blank in the

cell holder.

8.Cov er the blank with the

instrument cap.

9.Press ZERO/SCROLL.

The display will show

“- - - -” then “0.00”.

Remove the blank from the

cell holder.

Page 25

1—25

Iron, Total, continued

10. Place the prepared

sample in the cell holder.

11. Cover the sample cell

with the inst rument cap.

12.Press READ/ENTER.

The display will show

“- - - -” then “0.00”,

followed by results in mg/L

Iron.

Page 26

1—26

Iron, Total, continued

Sampling and Storage

Collect samples in acid-washed glass or plastic bottles. Adjust the sample pH to 2

or less with Nitric Acid (about 2 mL per L). Store samples preserved in this manner

up to 6 months at room temperature. If reporting only dissolved iron, filter the

sample immediately after collection and before addition of nitric acid.

Before testing, adjust the pH of the stored sample to between 3 and 4 with 5.0 N

Sodium Hydrox ide Standard Solution. Do n ot exceed pH 5 as iron may precipitate.

Accuracy Check

Standard Additions Method

1. Using a graduated cylinder, measure 25.0 mL of sample into each of three

50-mL beakers.

2. Snap the neck off an Iron Standard Solution Voluette™ Ampule, 25 mg/L Fe.

3. Use a TenSette

®

Pipet to add 0.1 , 0.2 , and 0.3 mL of standa rd, r espect ively, to

the three 50-mL beakers. Swirl to mix.

4. Analyze each standard addition sample as described in the procedure. The iron

concentration should increase by 0.1 mg/L for each 0.1 mL of standard added.

Page 27

1—27

Iron, Total, continued

Note:

For analysis with powder pillows, transfer only 10 mL of solution to 10-mL sample cells.

Standard Solutions Method

Use a 1.00 mg/L Iron Standard Solution in place of the sample. Perform the Total

Iron procedure. Multiparameter standards that simulate typical drinking water

concentrations without dilution are available to confirm tests. See Optional

Reagents on page 1—31.

Standard Calibration Adjust Method

To perform a standard calibration adjustment using the 1.0 mg/L iron standard or

using an alternate concentration, see Standard Calibrat ion Adjust on page 2—13.

Method Performance

Typical Precision (95% Confidence Interval):

1.00 ± 0.02 mg/L Fe

Estimated Detection Limit:

EDL = 0.01 mg/L Fe

Page 28

1—28

Iron, Total, continued

Interferences

A sample pH of less than 3 or greater than 4 after the addition of reagent ma y

inhibit color formation, caus e th e devel op e d col or to fad e qu ickl y or result in

turbidity. Before the addition of reagent, use a pH meter or pH paper to measure the

pH in the sample. A d just the sa mple pH to bet ween 3 and 8 by dr opwise ad ditio n

of an appropriate amount of iron-free acid or base such as 1.0 N Sulfuric Acid

Standard Solution or 1.0 N Sodium Hydroxide Standard Solution. Make a volume

correction if significant volumes of acid or base are used.

Interference tests were performed usi ng an iron concentra tion of 0.5 mg/L. When

interferences occurred, the color formation was inhibited or a precipitate formed.

Page 29

1—29

Iron, Total, continued

The following do not interfere with the test when present up to the levels listed:

Summary of Method

The TPTZ Iron Reagent forms a deep blue-purple color with ferrous iron. The

indicator is combined with a reducing agent which converts precipitated or

suspended iron, such as rust, to the ferrous state. The amount of ferric iron present

can be determined as the difference between the results of a ferrous iron test and

the concentration of total iron.

Element Interference level Element Interference level

Cadmium 4.0 mg/L Manganese 50.0 mg/L

Chromium

(3+)

0.25 mg/L Mercury 0.4 mg/L

Chromium

(6+)

1.2 mg/L Molybdenum 4.0 mg/L

Cobalt 0.05 mg/L Nickel 1.0 mg/L

Copper 0.6 mg/L Nitrite Ion 0.8 mg/L

Cyanide 2.8 mg/L

Page 30

1—30

Iron, Total, continued

Reagents and Apparatus

Required Reagents (Using Powder Pillows)

Description Quantity Pe r Test Unit Cat. No.

TPTZ Iron Reagent Powder Pillows,

10 mL size................................................2 pillows...............100/pkg ........26087-99

Required Reagents (Using AccuVac® Ampuls)

TPTZ Low Range Iron Reagent AccuVac® Ampuls

1 ampul .................25/pkg .........25100-25

Required Apparatus (Using AccuVac® Ampuls)

Description Quantity Pe r Test Unit Cat. No.

Beaker, 50 mL ................................................... 1 ...........................each..........500-41H

Page 31

1—31

Iron, Total, continued

Optional Reagents

Description Unit Cat. No.

Hydrochloric Acid Solution, 1:1 6.0 N........................................500 mL.........884-49

Iron Standard Solution, 1 mg/L Fe..............................................500 mL.........139-49

Iron Standard Solution Voluette™ Ampules,

25 mg/L Fe, 10 mL......................................................................16/pkg.....14253-10

Nitric Acid, ACS................................................................ ....... ......500 mL.........152-49

Nitric Acid Solution, 1:1...............................................................500 mL.......2540-49

Sodium Hydroxide Standard Solution, 1.0 N................... 100 mL MDB.......1045-32

Sodium Hydroxide Standard Solution, 5.0 N................... 100 mL MDB.......2450-32

Drinking Water Quality Control Standard, mixed parameter

(copper, iron, and manganese...................................................500 mL.....28337-49

Sulfuric Acid Standard Solution, 1.000 N........................ 100 mL MDB.......1270-32

Wate r, deionized.............................. .......................................................4 L.........272-56

Page 32

1—32

Iron, Total, continued

Optional Apparatus

Description Unit Cat. No.

AccuVac® Snapper...............................................................................each ....24052-00

Beaker, 50 mL ......................................................................................each ......500-41H

Cylinder, graduated 25 mL............................................................. ....each . ......1081-40

Dropper, graduated, 0.5 and 1.0 mL marks..................................10/pkg....21247-20

pH Indicator Paper, 1 to 11 pH............. ..................................5 rolls/pkg .........391-33

sens

ion™1 Basic Portable pH Meter, with electrode .....................each .....51700-10

Pipet Filler, safety bulb.......................................................................each .... 14651-00

Pipet, serological, 2 mL ......................................................................each ....... 532-36

Pipet TenSette

®

, 0.1 to 1.0 mL ...........................................................each .....19700-01

Pipet Tips, for 19700-01 TenSette

®

Pipet..................................... 50/pkg .... 21856-96

Replacement Parts

Batteries, alkaline..............................................................................4/pkg ....46743-00

Instrument Cap/light shield................... ........................................... each ....59548-00

Instruction Manual.......................................................................... ....each ....59577-8 8

Sample Cells, 10-mL, with caps.......................................................6/pkg ....24276-06

Page 33

1—33

Molybdenum, Molybdate, LR (0.02 to 3.00 mg/L Mo)

Method 8169

For boiler and cooling tower waters

Ternary Complex Method

Measuring Hints

• The results can be expressed as mg/L molybdate (MoO

4

2–

) or mg/L sodium

molybdate (NaMoO

4

) by multiplying the mg/L molybdenum (Mo6+) result by

1.67 or 2.15, respectively.

• Wipe sample cells with a soft, dry cloth before placing in the instrument.

• After adding reagent, a green color will develop if molybdenum is present in

the sample.

Note:

The Pocket Colorimeter™ II is designed to measure solutions contained in sample cells.

DO NOT

dip the meter in the sample or pour the sample directly into the cell holder.

Page 34

1—34

Molybdenum, Molybdate, LR, continued

1.Pr ess t he POWER key to

turn the meter on.

The arrow should indicate

the low range channel (LR).

Note:

See page 2—4 for

information on selecting the

correct range channel.

2.Fill a 25-mL mixing

graduated cylinder to the

20-mL mark with sample.

3.Ad d the cont ents of o ne

Molybdenum 1 Reagent

Powder Pillow to the

cylinder. Stopper the

cylinder and inv ert or gently

shake until all particles are

dissolved.

Page 35

1—35

Molybdenum, Molybdate, LR, continued

4.Split the sample by filling

two 10-mL sample cells to

the 10-m L mark. Cap one of

the cells, this is the blank.

Note:

Exactly 10 mL is not

critical for the blank. Make

sure the other cell contains

10 mL.

5.Using the calibrated

dropper, add 0.5 mL of

Molybdenum 2 to the

sample in the uncapped 10mL cell. Cap the cell and

swirl to mix. Wait two

minutes for full color

development.

6.Wipe the sa mple cells

free of liquid. Any liquid

entering the sample cell

compartment can cause

damage to the instrument.

Page 36

1—36

Molybdenum, Molybdate, LR, continued

7.Place the blank in the

cell holder.

8.Cov er the blank with the

instrument cap.

9.Press ZERO/SCROLL.

The display will show

“- - - -” then “0.00”.

Remove the blank from the

cell holder.

Page 37

1—37

Molybdenum, Molybdate, LR, continued

10. Place the prepared

sample in the cell holder.

11. Cover the sample cell

with the inst rument cap.

12.Press READ/ENTER.

The display will show

“- - - -” then “0.00”,

followed by results in mg/L

Molybdenum.

Page 38

1—38

Molybdenum, Molybdate, LR, continued

Sampling and Storage

See Sampling and Storage on pa ge 1—44.

Accuracy Check

See Accuracy Check on page 1—44.

Interferences

See Interferences on page 1—46.

Summary of Method

See Summary of Method on page 1—49.

Replacement Parts

Replacement Parts on page 1—51

Page 39

1—39

Molybdenum, Molybdate, HR (0.1 to 12.0 mg/L Mo)

Method 8169

For boiler and cooling tower waters

Ternary Complex Method

Measuring Hints

• The results can be expressed as mg/L molybdate (MoO

4

2–

) or mg/L sodium

molybdate (NaMoO

4

) by multiplying the mg/L molybdenum (Mo6+) result by

1.67 or 2.15, respectively.

• Wipe sample cells with a soft, dry cloth before placing in the instrument.

• After adding reagent, a green color will develop if molybdenum is present in

the sample.

Note:

The Pocket Colorimeter™ II is designed to measure solutions contained in sample cells.

DO NOT

dip the meter in the sample or pour the sample directly into the cell holder.

Page 40

1—40

Molybdenum, Molybdate, HR, continued

1.Pr ess t he POWER key to

turn the meter on.

The arrow should indicate

the high range channel (HR).

Note:

See page 2—4 for

information on selecting the

correct range channel.

2.Fill a 25-mL mixing

graduated cylinder to the

5-mL mark with sample.

3.Dilute to the 20-mL

mark with deionized water.

Page 41

1—41

Molybdenum, Molybdate, HR, continued

4.A dd the contents of one

Molybdenum 1 Reagent

Powder Pillow to the

cylinder. Stopper the

cylinder and invert or gently

shake until all particles are

dissolved.

5.Split the sample by filling

two 10-mL sample cells to

the 10-m L mark. Cap one of

the cells, this is the blank.

6.Using the calibrated

dropper, add 0.5 mL of

Molybdenum 2 to the

sample in the uncapped

10-mL cell. Cap the cell and

swirl to mix. Wait two

minutes for full color

development.

Page 42

1—42

Molybdenum, Molybdate, HR, continued

7.Wipe the sample cells

free of liquid. Any liquid

entering the sample cell

compartment can cause

damage to the instrument.

8.Place the blank in the

cell holder.

9.Co ver the blank with the

instrument cap.

Page 43

1—43

Molybdenum, Molybdate, HR, continued

10. Press ZERO/SCROLL.

The display will show

“- - -” then “0.0”.

Remove the blank fro m the

cell holder.

11. Pla ce the prepared

sample in the cell holder.

Cover the sample cell with

the instrument cap.

12.Press READ/ENTER.

The display will show

“- - - -” then “0.00”,

followed by results in mg/L

Molybdenum.

Page 44

1—44

Molybdenum, Molybdate, HR, continued

Sampling and Storage

Collect samples in glass or plastic bottles.

Accuracy Check

Standard Additions Method

1. Snap the neck off a Molybdenum Sta ndard Solution as Mo 75 mg/L Voluette®

ampule.

2. Use a TenSette® Pipet to add 0.1 mL, 0.2 mL, and 0.3 mL of standard,

respectively, to three 20-mL samples. Mix each thorough ly.

3. Analyze each sample as described above. The molybdenum concentration

should increase appro xim ately 0. 38 mg/L for the low ra nge and 1.6 mg/L for

the high range for each 0.1 mL of standard added.

Standard Solutions Method

For the Low Range, use Class A glassware to prepare a 2.00-mg/L molybdenum

standard solution by pipetting 10 .00 mL of Molybdenum Standard Solution, 1 0.00mg/L, into a 50-mL volumetric flask. Dilute to the mark with deionized water. For

the High Range, use the 10.0 mg/L standard directly. Dilute to the mark with

deionized water. Prepare this solution daily. Perform the molybdenum procedure.

Page 45

1—45

Molybdenum, Molybdate, HR, continued

Method Performance

Typical Precision (95% Confidence Interval):

2.00 ± 0.02 mg/L Mo (LR)

10.0 ± 0.1m g/L Mo (HR)

Estimated Detection Limit:

EDL = 0.02 mg/L Mo LR

EDL = 0.1 mg/L Mo HR

Standard Calibration Adjust Method

To perform a standard calibration adjustment using the 2.00 and 1 0.0 molybdenum

standard or using an al ternate concentration, see Standard Calibration Adjust on

page 2—13.

Page 46

1—46

Molybdenum, Molybdate, HR, continued

Interferences

Interference studies were conducted by preparing a molybdenum standard solution

(2 mg/L Mo

6+

) as well as a solution of the potential interfering ion. When the

standard solution concentration changed by ± 5% with a given ion concentration,

the ion was considered an interference.

Large interferences are caused by some biocides common to cooling water tower

samples. Hach recommends testing the procedure on molybdenum standards in the

presence of the specific biocides in use to determine the feasibility of the ternary

complex chemistry.

.

Negative Interference:

Ion

Interferes at

(mg/L):

Ion

Interferes at

(mg/L):

Acrylates 790 Diethanoldithiocarba-mate 32

Alum 7 EDTA 1500

Aluminum 2 Ethylene Glycol 2%

(by volume)

Page 47

1—47

Molybdenum, Molybdate, HR, continued

AMP (Phosphonate) 15 Iron 200

Bicarbonate 5650 Lignin Sulfonate 105

Bisulfite 3300 Nitrite 350

1

Borate 5250 Orthophosphate 4500

Chloride 1400 Phosphonohydroxy-

acetic acid

32

Chromium (Cr

6+

) 4.51 Sulfite 6500

Copper 98

1

Read the molybdenum concentration immediately after the 2-minute reaction period

has ended.

Negative Interference: (Continued)

Ion

Interferes at

(mg/L):

Ion

Interferes at

(mg/L):

Page 48

1—48

Molybdenum, Molybdate, HR, continued

The presence of the phosphonate HEDP at concentrations up to 30 mg/L will

increase the apparent molybdenum concentration reading by approximately 10%

Positive Interference:

Ion Highest Concentration Tested (mg/L):

Benzotriazole 210

Carbonate 1325

Silica 600

No Interference:

Ion

Highest

Concentration

Tested (mg/L):

Ion

Highest

Concentration

Tested (mg/L):

Bisulfate 9600 Nickel 250

Calcium 720 PBTC (phosphonate) 500

Chlorine 7.5 Sulfate 12800

Magnesium 8000 Zinc 400

Manganese 1600

Page 49

1—49

Molybdenum, Molybdate, HR, continued

(positive interference). For these samples, multiply the value obtained in the final

step of the procedure by 0.9 to obtain the actual molybd enum concentration.

As the concentration of HEDP increases above 30 mg/L, a decrease in the

molybdenum concentration reading occurs (negative interference).

Highly buffered samples or extreme sample pH may exceed the buffering capacity

of the reagent and require sample pretreatment. Adjust the sample pH to between

3 and 5 by using a pH meter or pH paper and add, drop-wise, an appropriate

amount of acid or base such as 1.0 N Sulfuric Acid Standard Solution or 1.0 N

Sodium Hydroxide Solution. If significant volumes of acid or base are used, a

volume correction should be made. Divide the total volume (sample + acid + base)

by the original volume and multiply th e test result by this factor.

After several samples have been analyzed, the sample cells may exhibit a slightly

blue buildup. Eliminate buil du p wit h a ri nse of Hydroch loric Acid Solution, 1:1.

Summary of Method

Molybdate is determined with the ternary complex method by the reaction of

molybdate molybdenum with an indicator and a sensitizing agent yielding a stable

blue complex. While molybdate (MoO

4

2–

) is the actual chemical species involved

in the chemistry, the instrument displays the result as molybd enum, Mo.

Page 50

1—50

Molybdenum, Molybdate, HR, continued

Required Reagents

Description Unit Cat. No.

Molybdenum, Molybdate Reagent Set,

20-mL sample........................................................................... 100 tests ....24494-00

Includes:

Molybdenum 1 Reagent Powder Pillow, 100/pkg

Molybdenum 2 Reagent Solution, 50 mL

Optional Reagents

Hydrochloric Acid Solution, 1:1, 6.0 N...................................... 500 mL ........ 884-49

Molybdenum Standard Solution, 10 mg/L as Mo......................100 mL .... 14187-42

Sodium Hydroxide Standard Solution, 1.000 N...............100 mL MDB .......1045-32

Optional Reagents, continued

Description Unit Cat. No.

Sulfuric Acid Standard Solution, 1.000 N.........................100 mL MDB .......1270-32

Wate r, deionized....................................................................... ....... ......4 L ........ 272-56

Page 51

1—51

Molybdenum, Molybdate, HR, continued

Optional Apparatus

Cylinder, mixing, 25-mL....................... ....... ......................................each.....20886-40

Funnel, poly, 65-mm..........................................................................each.......1083-67

Filter paper, folded, 12.5-cm.......................................................pkg/100.......1894-57

Flask, volumetric, 50-mL...................................................................each. ....145 74-41

Pipet, TenSette

®

, 0.1 to 1.0-mL .........................................................each.....19700-01

Pipet, volumetric, 10-mL, Class A ....................................................each.....14515-38

Pipet Filler, safety bulb......................................................................each.....14651-00

Pipet Tips, TenSette

®

(for 19700-01)........................ ....... ..............pkg/50.....21856-96

Replacement Parts

Batteries, alkaline, AAA...................................................................pkg/4.....46743-00

Instrument Cap/light shield............................................. ....... ....... ....each.....59548-00

Instruction Manual.............................................................................each .....59577-88

Sample Cells, 10-mL, with caps......................................................pkg/6.....2427 6-0 6

Page 52

1—52

Page 53

1—53

Ozone (0.01 to 0.25 mg/L O

3

—LR and 0.01 to 0.75 mg/L O3—MR)

For water

Method 83 11

Indigo Method (Using AccuVac® Ampuls)*

Measuring Hints

• Ozone sample cannot be stored , th ey must be a nalyzed im media tely to a void

ozone loss.

• For best results, clean collection containers after each use.

• If the ozone concentration exceeds the upper limit of the test, the color will not

develop properly. The display will show “overrange” (flashing) when the

concentration is exceeded.

• If the reading is over 0.25 mg/L us ing the low range, repeat the test using

mid-range ampules and the mid-range of the instrument. If the concentration

is over 0.75 mg/L, dilute the sample with high quality water that is ozone-free

and repeat the test. Multiply the result by the appropriate dilution factor. Some

loss of ozone may occur during dilution.

Note:

The Pocket Colorimeter™ II is designed to measure solutions contained in sample cells.

DO NOT

dip the meter in the sample or pour the sample directly into the cell holder.

* Adapted from Standard Methods for the Examination of Water and Wastewater.

Page 54

1—54

Ozone, continued

1.Pr ess t he POWER key to

turn the meter on.

The arrow should indicate

LR when using the Low

Range ampules or should

indicate MR when using the

mid-range ampules .

Note:

See page 2—4 for

information on selecting the

correct range channel.

2.Gently collect at least 40

mL of sample in a 50-mL

beaker.

Note:

Samples must be

analyzed immediately and

cannot be preserved for later

analysis.

3.Collect at least 40 mL of

ozone-free water (blank) in

another 50-mL beaker.

Note:

Ozone-free water used

for the blank may be

deionized or tap water if

samples do not contain

significant color or turbidity.

Page 55

1—55

Ozone, continued

4.Fill one Indigo Ozone

Reagent AccuVa c Ampul of

the appropriate range with

the sample and another

ampule with the blank.

Keep the tip immersed while

the ampule fills completely.

5.Gently but quickly in vert

both ampules sev eral times

to mix. Wipe off any liquid

or fingerprints.

Note:

Do not shake the

ampules. Shaking will result

in a loss of ozone.

Note:

Part of the blue color

will be bleached if ozone is

present.

6.Place the blank in the

cell holder.

Page 56

1—56

Ozone, continued

7.Cov er the blank with the

instrument cap.

8.Press ZERO/SCROLL.

The display will show

“- - - -” then “0.00”.

Remove the blank fro m the

cell holder.

9.Place the pr epared

sample into the cell holder.

Page 57

1—57

Ozone, continued

10. Cover the sample cell

with the instrument ca p.

11. Press READ/ENTER.

The display will show

“- - - -” then “0.00”,

followed by results in mg/L

Ozone (O

3

).

Page 58

1—58

Ozone, continued

Sampling and Storage

The main consideration when collecting a sample is preventing the escape of ozone

from the sample. The sample should be collected gently and analyzed immediately.

W arming the sample or dist urbing the sample by stirring or shaking will result in ozone

loss. After collecting the sample, do not transfer it from one container to another unless

absolutely necessary.

Stability of Indigo Reagent

Indigo is light-sensitive. Therefore, the AccuVac Ampuls should be kept in the dark at

all times. However, the indigo solution decomposes slowly under room light after filling

with sample. The blank ampule can be used for multiple measurements during the

same day.

Accuracy Check

Standard solutions for ozone are difficult and time-consuming to prepare. Errors can

occur if proper attention to details is not taken while preparing the standards. The

manufacturer prepares the calibration curve under rigorous analytical laboratory

conditions and recommends using the factory calibration.

Page 59

1—59

Ozone, continued

A user calibration or a user-prepared ozone standard may be required by a

regulatory official or agency . Two options are available on the Pock et Colorimeter

II to meet this requirement.

An ozone standard may be prepared and used to validate th e ca lib ra tion curve

using the Standard Calibr ation A djust feature (s ee Standard Calibration Adjust on

page 2—13). The concentration of the prepared standard must be determined with

an alternate instrument such as a spectrophotometer, colorimeter, amperometric

titration or by an alternate method. The concentration of the ozon e standard for

the Low Range procedure must be between 0.1 0 and 0.20 mg/L ozone a nd between

0.30 and 0.70 mg/L ozone for the mid-range procedure.

In addition, a user-generated calibration curve can be made and programmed into

the Pocket Colorimeter II. See User-Entered Calibration on page 2—15.

Specê Secondary Standards for Instrument Verification

(Mid-range Only)

Note:

Due to improvements in the optical system of the Pocket Colorimeter™ II, the tolerance

ranges and values on the Certificate of Analysis of previously purchased Spec

√

standards

may no longer be valid. Obtain a new set of standards, or use the Pocket Colorimeter II to

assign new values to existing standards.

Page 60

1—60

Ozone, continued

Spec√ Secondary Standards are available to quickly check the repeatability of the

Pocket Colorimeter II instrument. After in it ial m easu rem en ts for the Spec√

standards are collected, the standards can be re-checked as often as desired to

ensure the instrument is working consistently.

The standards do not ensure reagent quality nor do they ensure the accuracy of the

test results. Analysis of real standard solutions using the kit reagents is required to

verify the accuracy of the entire Pocket Colorimeter system. The Spec√ Standards

should NEVER be used to calibrate the instrument. The certificate of analysis lists

the expected value and tolerance for each Spec√ Standard.

Note:

Before proceeding, make sure the instrument is in the mid-range (MR). See Switching

Ranges on page 2—4.

Using the Spec√ Standards

1. Place STD 1 into the cell holder with the alignment mark facing the keypad.

Tightly cover the cell with the in st rum ent cap.

2. Press

ZERO. The display will show “0.00”.

3. Place the blank cell into the cell holder. Tightly cover the cell with the

instrument cap.

4. Press

READ/ENTER. Record the concentration measurement.

Page 61

1—61

Ozone, continued

5. Repeat steps 1– 4 with cells labeled STD 2 and STD 3.

6. Compare these measurements with previous measurements to verify the

instrument is performing consistently. (If these are the first measurements,

record them for comparison with later meas urements.)

Note:

If the instrument is user-calibrated, initial standard measurements of the Spec √

Standards will need to be performed again for the user calibration.

Summary of Method

The reagent formulation adjusts the sample pH to 2.5 after the ampule has filled.

The indigo reagent reacts immediately and quantitatively with ozone.

The blue color of indigo is bleached in proportion to the amount of ozone present

in the sample. Other reagents in the formulation prevent chlorine interference. No

transfer of sample is necessary in the procedure. Therefore, ozone loss due to

sampling is eliminated.

Page 62

1—62

Ozone, continued

Reagents and Apparatus

Required Reagents

Select one or both based on sample range:

Description Unit Cat. No.

Low Range Ozone AccuVac® Ampuls, 0 to 0.25 mg/L............... 25/pkg .... 25160-25

Mid-Range Ozone AccuVac

®

Ampuls, 0 to 0.75 mg/L............... 25/pkg .....25170-25

Required Apparatus (Using AccuVac® Ampuls)

Beaker, 50 mL ......................................................................................each ......500-41H

Optional Reagents

Spec√ Secondary Standards, Ozone, mid-range.......................... ....... ....... ... 2 7080-00

Replacement Parts

Batteries, alkaline..............................................................................4/pkg ....46743-00

Instrument Cap/light shield................... .............................................each .... 46704-00

Instruction Manual.......................................................................... ....each ....59577-8 8

Page 63

1—63

Zinc (0.02 to 3.00 mg/L Zn)

For water and wastewater

Method 8009

Zincon Method* USEPA Approved for wastewater (digestion required)**

Measuring Hints

Caution! The reagent used in step 3 contains cyanide and is very poisonous

if taken internally or if the vapors are inhaled. Do not add to a sample with

a pH of less than 4. See Sampling and Storage for pH adjustment.

• Testing for non-reporting purposes generally does not require sample

digestion. However, if the sample contains particulate matter, digestion is

required for total zinc measurement.

• Use only glass stoppered cylinders in the procedure.

• Wipe sample cells with a soft, dry cloth before placing in the instrument.

Note:

The Pocket Colorimeter™ II is designed to measure solutions contained in sample cells.

DO NOT

dip the meter in the sample or pour the sample directly into the cell holder.

* Adapted from Standard Methods for the Examination of Water and Wastewater, 15th ed.

244 (1980).

** Federal Register, 45(105) 36 1 66 (May 29, 198 0). See the Hach Water Analysis Handbook

for further information concerning digestions.

Page 64

1—64

Zinc, continued

1.Pr ess t he POWER key to

turn the meter on.

The arrow should indicate

mg/L Zn.

Note:

See page 2—4 for

information on selecting the

correct channel.

2.Fill a 25-mL mixing

graduated cylinder to the

20-mL mark with sample.

3.Ad d the cont ents of o ne

ZincoVer

®

5 Reagent Powder

Pillow to the cylinder.

Stopper the cylinder and

invert or gently shake until

all particles are dissolved.

Page 65

1—65

Zinc, continued

4.Measure 10 mL of the

solution into a 10-mL

sample cell (the blank)

leaving exactly 1 0 mL in the

mixing cylinder.

5.Us e the calibrated

dropper to add 0.5 mL of

cyclohex a none to the

sample remaining in the

mixing cylinder. Stopper and

shake for 30 seconds. Wait

three minutes but no longer

than 15 minutes for full

color development before

performing step 6.

6.Fill a clean 10-mL

sample cell to the 10-mL

mark with the solution in

the mixing cylinder. This i s

the prepared sample.

Page 66

1—66

Zinc, continued

7.Place the blank in the

cell holder.

8.Cov er the blank with the

instrument cap.

9.Press ZERO/SCROLL.

The display will show

“- - - -” then “0.00”.

Remove the blank from the

cell holder.

Page 67

1—67

Zinc, continued

10. Place the prepared

sample in the cell holder.

11. Cover the sample cell

with the inst rument cap.

12.Press READ/ENTER.

The display will show

“- - - -” then “0.00”,

followed by the results in

mg/L Zn.

Page 68

1—68

Zinc, continued

Sampling and Storage

Collect sample in acid-washed plastic or glass bottles. For storage, adju st the pH to 2 or

less with nitric acid (about 2 mL per liter). The preserved samples can be stored for up

to six months at room temperature. Adjust the pH to between 4 to 5 with 5.0 N Sodium

Hydroxide bef ore analysis. Never add the reagent to samples with p H less than 4. Do not

exceed pH 5, as zinc may be lost as a precipitate.

Accuracy Check

Standard Additions Method

1. Snap the neck off a Zinc Standard Solution Voluette® Ampule, 25 mg/L.

2. Use a TenSette

®

Pipet to add 0.1 mL, 0.2 mL and 0.3 mL of standard, respectively,

to three 25-mL samples. Mix each thoroughly.

3. Analyze 20 mL of each sample as described above. The zinc concentration should

increase 0.1 mg/L for each 0.1 mL of standard added.

Page 69

1—69

Zinc, continued

Standard Solution Method

Prepare a 2.00 mg/L zinc standard by diluting 2.00 mL of Zinc Standard Solution,

100 mg/L as Zinc, to 100 mL. Use volumetric pipets and flasks. Perform the

procedure as described above.

Method Performance

Typical Precision (95% Confidence Interval):

2.00 ± 0.08 mg/L Zn

Estimated Detection Limit:

EDL = 0.02 mg/L Zn

Standard Calibration Adjust Method

To p erform a standard calibration adjust ment using the 2.00 mg/L zinc standard, or

to use an alternative concentration, see Standard Calibration A djust on page 2—13.

Page 70

1—70

Zinc, continued

Interferences

The following may interfere when present in concentrations exceeding those

listed:

Large amounts of organic material may interfere. Digest the sample to eliminate

this interference. Highly buffered samples or extreme sample pH may exceed the

buffering capacity of the reagents and require sample pretreatment.

Waste Management

ZincoV er 5 reagent contains potassium cyanide. Cyanide solutions are regulated as

hazardous wastes by the Federal RCRA. Cyanide should be collected for disposal as

a reactive (D003) waste. Be sure that cyanide solutions are stored in a caustic

solution with pH >11 to prevent release of hydrogen cyanide gas.

Aluminum 6 mg/L Iron (ferric) 7 mg/L

Cadmium 0.5 mg/L Manganese 5 mg/L

Copper 5 mg/L Nickel 5 mg/L

Page 71

1—71

Zinc, continued

Summary of Method

Zinc and other metals in the sample are complexed with cyanide. The addition of

cyclohexanone causes a selective release of zinc. The zinc then reacts with

2-carboxy-2'-hydroxy-5'-sulfoformazyl benzene (Zincon) indicator to form a

blue-colored species. The blue color is masked by the brown color from the

excess indicator. The intensity of the blue color is proportional to the amount of

zinc present.

Reagents and Apparatus

Required Reagents

Description Cat. No.

Zinc Reagent Set (100 tests)............................................................................24293-00

Includes:

(1) Cyclohexanone, 100 mL MDB

(1) ZincoVer® 5 Reagent Powder Pillows, 100/pkg

Required Apparatus

Cylinder, graduated mixing, 25-mL........... ....... ...... .........................each.....2088 6-4 0

Page 72

1—72

Zinc, continued

Optional Reagents

Description Cat. No.

Hydrochloric Acid, 6.0 N.............................................................. 50 0 mL ........ 884-49

Nitric Acid, 1:1.............................................................................. 500 mL ...... 2540-49

Sodium Hydroxide Standard Solution, 5.0 N....................59 mL SCDB ...... 2450-26

Wate r, deionized....................................................................... ....... ......4 L ........ 272-56

Zinc Standard Solution, 100 mg/L...............................................100 mL ......2378-42

pH Indicator paper, 1-11 pH ........................ ....... ....................5 rolls/pkg .........391-33

Zinc Standard Solution Voluette

®

Ampules,

25 mg/L as Zn, 10-mL................................................................ 16/pkg....14246-10

Optional Apparatus

Flask, volumetric, 100-mL................................................ ....... ...........each ....14574-42

Pipet, volumetric, 2.00 mL.................................................................each .... 14515-36

Pipet Filler, safety bulb.......................................................................each .... 14651-00

Replacement Parts

Batteries, alkaline..............................................................................4/pkg ....46743-00

Instrument Cap/light shield................... .............................................each ....59548-00

Instruction Manual.......................................................................... ....each . ...59577-88

Sample Cells, 10-mL, with caps.......................................................6/pkg ....24276-06

Page 73

2—1

Section 2

Instrument Manual

Page 74

2—2

Page 75

2—3

Instrument Operation

Key Functions

Key Description Function

POWER On/Off/Backlight

To turn on the backlight, turn on the instrument, then

press and hold the power key until the backlight turns

on. Press and hold again to turn off the backlight. This

key functions the same in all instrument modes and

ranges.

ZERO/SCROLL In measurement mode, sets the instrument to zero.

In menu mode, scrolls through menu options. Also

scrolls numbers when entering or editing a value.

READ/ENTER In measurement mode, initiates sample measurement.

In menu mode, selects a menu option. When entering

numbers, moves one space to the right and executes

the function when the entry is complete.

Page 76

2—4

Instrument Operation, continued

Menu Selections

Press the MENU key to access the menu selections.

Switching Ranges

1. Press the MENU key. The display will sho w “SE L”. A flashing arrow indicates

the current range.

2. Press the

READ/ENTER key to toggle between ranges.

3. Press

MENU again to accept and exit back to the measurement screen.

Setting the Time

1. Press the MENU key, then press the ZERO/SCROLL ke y un til th e di spla y shows

a time in the “00:00” format.

MENU Enter/Exit the menu mode

Press and hold for approximately 5 seconds to enter

user-entered method mode.

Key Description Function

Page 77

2—5

Instrument Operation, continued

2. Press READ/ENTER. The digit to be edited will flash.

3. Use the

ZERO/SCROLL key to change the entry, then press READ/ENTER to

accept and advance to the next digit. The time is entered in 24-hour format.

Recalling Stored Measurements

1. Press the MENU key, then press the ZERO/SCROLL key until the display shows

RCL. The instrument automatically stores the last 10 measurements.

2. In RCL, press

READ/ENTER to recall the stored measurements, beginning with

the most recent measurement taken. The meter stores the measurement

number as 0 1 (most recent) through 1 0 (oldest), the time the measurement was

taken, and the measurement value. The

ZERO/SCROLL key allows for selection

of a specific measurement by number. The

READ/ENTER key scrolls thro ugh all

stored data points.

Page 78

2—6

Instrument Operation, continued

Battery Installation

Figure 1 on page 2—7 provides an exp lod ed vi ew of battery installation.

1. Unhook the latch and remove the bat tery co mpartment cover. The polarities

are shown on the battery holder.

2. Place the four batteries provided with the instrument in the holder as indicated

and replace the battery compartment cover. The display will show the software

version number (e.g., “P 1.6”) after correct battery installation.

When replacing discharged batteries, always replace the complete set of four

alkaline batteries. Rechargeable batteries are not recommended and cannot be

recharged in the instrument.

Note:

The Low Battery icon will appear on the display when the batteries have 10 % battery life

remaining. The battery icon will flash when the batteries are too low to complete

measurements. See Instrument Keys and Display on page 1—13.

Page 79

2—7

Instrument Operation, continued

Figure 1 Battery Installation

Page 80

2—8

Page 81

2—9

Error Codes

When the instrument canno t perfo r m th e funct io n in it iat ed by the operator, an

error message will appear in the display. Refer to the appropriate message

information below to determine what the problem is and how it can be corrected.

Resolve error messages in the order that they appear on the display. Service Centers

are listed in page 2—37.

Error Messages

1. E-0 No Zero (User mode)

Error occurs when trying to read a standard in the user calibration mode

before setting the meter to zero.

• Zero the instrument on an appropriate blank.

2. E-1 Ambient Light Er ro r

There is too much light present to take a valid measurement.

• Verify instrument cap is correctly seated.

• If the problem persists, contact a Service Center (page 2—37).

Page 82

2—10

Error Codes, continued

3. E-2 LED Error

The LED (light source) is out of regulation.

• Replace batteries.

• Verify LED lights up (inside the cell holder) when the READ/ENTER or

ZERO/SCROLL key is pressed.

• If the problem persists, contact a Service Center (page 2—37).

Note: When an E-1 or E-2 error occurs on a measurement, the display will show “_.__”. (The

decimal place is determined by the chemistry.) If the E-1 or E-2 error occurs while

zeroing the meter , the meter will require the user to re-zero.

4. E-3 Standard Adjust Error

The value obtained on the prepared standard exceeds the adjustment limits

allowed for the standard concentration, or the concentration of the standard is

outside the concentration range allowed for standard calibration adjust.

• Prepare the standard and rerun according to the procedure.

• Prepare a standard at or near the recommended concentrations given in the

procedure.

• Verify that the concentration of the standard ha s been entered correctly.

Page 83

2—11

Error Codes, continued

• If the problem persists, contact a Service Center (page 2—37).

5. E-6 Abs Error (User mode )

Indicates that the absorbance value is invalid, or indicates an attempt to make

a curve with less than two points.

• Enter or measure the absorbance value again.

• If the problem persists, contact a Service Center (page 2—37).

6. E-7 Standard Value Error (User mode)

Standard concentratio n is equ al to another standard concentr ation that is

already entered.

• Enter the correct standard concentration.

• If the problem persists, contact a Service Center (page 2—37).

7. E-9 Flash Error

The meter is unable to save data.

• If the problem persists, contact a Service Center (page 2—37).

Page 84

2—12

Error Codes, continued

8. Underrange—flashing number below stated test range

• Verify instrument cap is correctly seated.

• Check zero by measuring a blank. If error recurs, re-zero the instrument.

• If the problem persists, contact a Service Center (page 2—37).

Note: See Maximum/Minimum Displayed Value on page 2—26 for more information.

9. Overrange—flashing number above stated test range

Note: Flashing value will be 10% over the upper test limit.

• Check for light blockage.

• Dilute and retest sample.

Note: See Maximum/Minimum Displayed Value on page 2—26 for more information.

Page 85

2—13

Standard Calibration Adjust

The Pocket Colorimeter™ II instrument is factory-calibrated and ready for use

without user calibration. Use of the factory calibration is recommended unless the

user is required to generate a calibration. The Standard Calibration Adjust can be

used to meet regulatory requirements.

This feature allows the factory default calibration curve to be adjusted with a

known standard. Use the standard described in the procedure.

1. Place a blank in the meter (in measurem ent mo de). Press

ZERO/SCROLL.

2. Place the reacted standard in the meter. Press

READ/ENTER.

3. Press

MENU, then press ZERO/SCROLL until the display shows “SCA”.

4. Press

READ/ENTER to display the standa rd calibration adjust valu e.

5. Press

READ/ENTER to adjust the curve to the displayed value. The meter will

return to the measurement mode and the Calibration Adjusted icon will appear

in the display window .

If an alternate concentration is used, or if a standard concentration is not given:

6. Repeat steps 1–4.

Page 86

2—14

Standard Calibration Adjust, continued

7. Press ZERO/SCROLL to access the Edit function, then press READ/ENTER to

begin editing. The digit to be edited will flash. Use the

ZERO/SCROLL key to

change the entry, then press

READ/ENTER to accept and advance to the

next digit.

When the last digit is entered, press

READ/ENTER and the meter will adjust the

curve to the value entered. The meter will return to measurement mode and the

Calibration Adjusted icon will appear in the display window.

To turn off Standard Calibration Adjust (SCA):

1. Press

MENU.

2. Press

ZERO/SCROLL until “SCA” app e ars in the displa y.

3. Press

READ/ENTER, then press ZERO/SCROLL until “Off” appears in the display.

4. Press

READ/ENTER to turn off SCA.

Note: Perform another standard calibration adjust to turn SCA on again.

Note: For meters with factory-calibrated ranges or methods, Standard Calibration Adjust

(SCA) will be disabled when a user-entered method is programmed into the meter. To

turn SCA back on, restore the meter to factory default calibration. See Retrieving the

Factory Calibration on page 2—25.

Page 87

2—15

User-Entered Calibration

Overview

The Pock et Colorimeter™ II will accept a user-prepared calibration curve. The curve

can extend from 0 to 2.5 absorbance. A user-prepared calibration curve may be

entered into any channel that does not contain a factory-progr ammed curve. These

channels are labeled “abs” on instruments having a single factory calibration or

are labeled “1” and “2” on the uncalibrated single wavelength instruments. Any

chemistry that can be run at the instrument wavelength may be user-entered in

these channels.

Using prepared standard solutions that cover the range of interest, th e mete r

generates a calibration curve by calculatin g th e stra igh t-l in e segments between

each standard entered. A calibration curve may be entered using the keypad.

Factory-entered calibration curves may also be recalculated or adjusted using the

same procedure.

To enter the user-entered calibration mode, press the

MENU key and hold it down

until the display shows “USER” (about 5 seconds), followed by “CAL”. Press

ZERO/SCROLL to scroll through the options.

Note: If the meter does not display USER followed by CAL after pressing the

MENU

key, the

factory calibration cannot be modified on this channel.

Page 88

2—16

User-Entered Calibration, continued

• CAL—Used to enter and edit standard values and measure absorbance values,

or review the existing calibration.

• Edit—Used to enter and edit standard values and ab sorbance values with the

keypad or review the existing calibration. Used to enter a predetermined

calibration curve.

• dFL—Used to return the instrument back to the default factory calibration.

User-entered calibrations are stored upon exit from the calibration or

edit modes.

Note: To return to factory settings, following the instructions in Retrieving the Factory

Calibration on page 2—25.

If the instrument is shut off or loses power during data entry, all edits will be lost.

Automatic shut-off in user-entered cali br at io n entry mode is 60 minutes.

CAL and Edit Submenus

In CAL mode, standard values are entered and absorbance values are measured. In

Edit mode, standard and absorbance values are entered.

• To select CAL from the User menu, press READ/ENTER.

• To sel ect Edit from the User menu, press ZERO/SCROLL and READ/ENTER.

Page 89

2—17

User-Entered Calibration, continued

• Once in the CAL or Edit optio n, press the READ/ENTER key to navigate through

each option.

Note: Press

ZERO/SCROLL

to quickly scroll through each option.

Calibration Procedure Using Prepared Standards

Note:

Deionized water or a reagent blank can be used to zero during the calibration procedure.

Calibrations generated with deionized water as the zero will give less accurate results if

the reagent blank is significantly more turbid or colored than deionized water. Use the

deionized water or the reagent blank as the zero concentration point (S0) in the following

calibration procedure.

1. Turn on the instrument and select the range to be calibrated. An arrow at the

top of the display will point to the selected range. To change ranges, press the

MENU key, then use the READ/ENTER ke y to to gg le bet w een range s 1 and 2.

Press

MENU again to return to measurement mode.

2. Follow the procedure for the chemical method to be calibrated . Prepare a

reagent blank (if needed) and a standard solution. Allow the color to

develop fully.

Page 90

2—18

User-Entered Calibration, continued

3. Insert the reagent blank or deionized water into the meter and cover with the

cap. Press the

ZERO/SCROLL key . The meter will display “- - - -”, followed by

“0.000”. This initializes (zeroes) the meter.

4. Press the

MENU key and hold it down until the display shows “USER”, followed

by “CAL”. Press

READ/ENTER to enter the calibration mode.

5. In factory-calibrated meters, S0 will appear in the display.

Note: When recalibrating a factory-calibrated meter or range, RES (resolution) cannot

be changed.

6. In uncalibrated meters or meters with ranges labeled Abs, “RES” will appear.

Press

ZERO/SCROLL to review the current resolution (decimal placement). Press

ZERO/SCROLL again to accept the current resolution. To change the resolution,

press

READ/ENTER, then ZERO/SCROLL to change the resolution. Press

READ/ENTER to accept the new resolution. “S0” will appear on the display.

7. Press the

READ/ENTER key again, then enter the blank value.

Note: Press the

READ/ENTER

key to move from digit to digit. Use the

ZERO/SCROLL

key to

change the number.

8. After completing entry of the blank value, press the READ/ENTER key. The

display will show “A0”.

Page 91

2—19

User-Entered Calibration, continued

9. Insert the reagent blank or deionized water into the cell holder. Cover the

blank with the instrument cap.

10. Press the

READ/ENTER key . The meter will measure and display the absorbance

value for “S0”.

11. Remove the sample blank. Press the

ZERO/SCROLL key . “S1” will appear. Press

the

READ/ENTER key, then enter the fir st standard value.

Note: Press the

READ/ENTER

key to move from digit to digit. Use the

ZERO/SCROLL

key to

change the number.

12. After completing entry of the first standard value, press the READ/ENTER key.

The display will show “A1”.

13. Insert the first reacted standard solution into the cell holder. Cover the

prepared standard with the instrument cap.

14. Press the

READ/ENTER key . The meter will measure and display the absorbance

value for S1.

15. The calibration is complete with two points. If addi tional standards are

required, press

ZERO/SCROLL until “Add” appears on the display. Repeat

steps 11–14 to enter additional standards.

Page 92

2—20

User-Entered Calibration, continued

16. Press the MENU key twice to exit and accept the changes. The instrument will

use this calibration to determine the displayed concentration of future sample

measurements.

Entering a Predetermined Calibration Curve

Note: Entering a predetermined calibration curve requires at least two data pairs. Each data

pair requires a concentration value and the absorbance value for the given

concentration. Up to 10 data pairs may be entered. This procedure uses the

Edit mode.

1. Turn on the instrument and select the range to be calibrated. An arrow at the

top of the display will point to the selected range. To change ranges, press the

MENU key, then use the READ/ENTER key to to gg le bet ween range s 1 an d 2.

Press

MENU again to return to measurement mode.

2. Press the

MENU key and hold it down until the display shows “USER”, followed

by “CAL”. Press

ZERO/SCROLL to scroll to EDIT. Press READ/ENTER.

3. In uncalibrated meters or in Abs range, “RES” will appear. Press ZERO/SCROLL.

To change the resolution (decimal placement), press

READ/ENTER. Press

ZERO/SCROLL to select the new resolution, then press READ/ENTER to accept.

“S0” will appear on the display.

Page 93

2—21

User-Entered Calibration, continued

4. Enter the concentration value and absorbance value of the first data pair

(S0, A0).

5. To enter the S0 value, press

READ/ENTER. Use the ZERO/SCROLL key to select

the numerical value, then press the

READ/ENTER key to accept the entry and

advance to the next decimal place. Repeat this sequence until the S0

concentration value is entered.

6. After editing the S0 value, press

READ/ENTER to accept. “A0” will appear on

the display.

7. To enter the absorbance value for S0, press the

READ/ENTER key to go to entry

mode. Use the

ZERO/SCROLL key to select th e numerical value, then press the

READ/ENTER key to accept the entry and advance to the next decimal place.

Repeat this sequence until the absorbance value for S0 is entered.

8. After enterin g A0, press

READ/ENTER to accept. “S1” will appear on the

display.

9. Repeat steps 5 through 8 for each standard value and absorbance value pair in

the calibration curve

Note: After A1 is entered, Add will appear in the display. If additional data pairs are to be

entered, press

READ/ENTER

and continue with step 9.

Page 94

2—22

User-Entered Calibration, continued

10. When all the calibration data has been entered, press MENU twice to return to

the measurement mode.

Editing a User-entered or Factory Calibration Curve

1. Press the MENU key and hold it down until the display shows “USER”, followed

by “CAL”. Press

ZERO/SCROLL until EDIT appears.

Note: If the meter does not display USER followed by CAL after pressing the

MENU

key, the

factory calibration cannot be modified on this channel.

2. Press the READ/ENTER key to enter Edit mode. In factory-calibrated meters,

“S0” will appear in the display.

Note: When editing a factory-calibrated meter or range, RES (resolution) cannot be changed.

Note: When RES or S0 appears in the display, press

ZERO/SCROLL

to quickly scroll to the

data to be edited.

3. In uncalibrated meters or in Abs range, “RES” will appear . Press ZERO/SCROLL

to review the current resolution. Press

ZERO/SCROLL again to accept the

displayed resolution. To change the resolution (decimal placement), press

READ/ENTER. Press ZERO/SCROLL to select the new resolution, then press

READ/ENTER to accept. “S0” will appear on the di splay.

Page 95

2—23

User-Entered Calibration, continued

4. Press READ/ENTER. The current concentration value for S0 will appear on the

display.

5. To edit the S0 value, press

READ/ENTER. Use the ZERO/SCROLL key to select the

numerical value, then press the

READ/ENTER key to accept the entry and

advance to the next decimal place. Repeat this sequence until the S0

concentration value is entered.

6. After editing the S0 value, press

READ/ENTER to accept. “A0” will appear on

the display.

7. To edit the absorbance value for S0, press th e

READ/ENTER key to go to entry

mode. Use the

ZERO/SCROLL key to select th e numerical value, then press the

READ/ENTER key to accept the entry and advance to the next decimal place.

Repeat this sequence until the absorbance value for S0 is entered.

8. After editing A0, press

READ/ENTER to accept. “S1” will appear on the display .

9. Repeat steps 4 through 8 for each standard value and absorbance value pair in

the calibration curve.

10. When all calibration data has been reviewed or edited, “ADD” will appear in

the display.

Page 96

2—24

User-Entered Calibration, continued

11. Press READ/ENTER to add more calibration points, or press MENU twice to

return to the measurement mode.

Note: When a factory calibration curve has been edited, the “calibration adjust” icon will

appear in the display.

Exiting the Calibration Routine