Page 1

Operator Quick Guide

ORBISPHERE 3650 ATEX

Revision D - 18/03/2008

Page 2

Operating Information

About this Guide

The information in this guide has been carefully

checked and is believed to be accurate. However,

Hach Ultra assumes no responsibility for any

inaccuracies that may be contained in this guide.

In no event will Hach Ultra be liable for direct,

indirect, special, incidental, or consequential

damages resulting from any defect or omission in

this guide, even if advised of the possibility of

such damages. In the interest of continued

product development, Hach Ultra reserves the

right to make improvements in this guide and the

products it describes at any time, without notice or

obligation.

Before Taking Measurements

IMPORTANT: Before taking any measurements,

please ensure that the conditions of use

correspond to the certification of the instrument

and the installation was performed as described

in the Operator’s Manual.

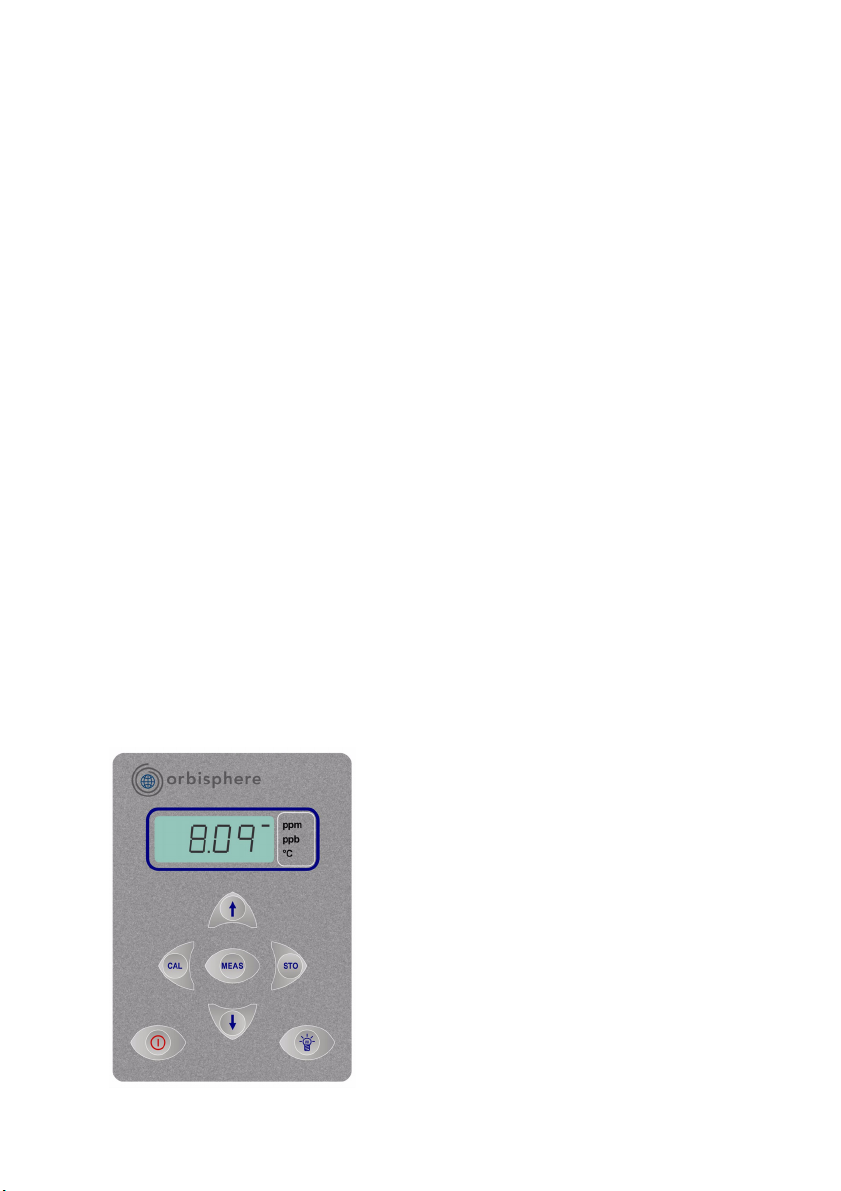

Instrument Controls

The front panel of the instrument has a three-digit

liquid crystal display (LCD).

The LCD includes a right-side marker to

distinguish between gas concentration and

temperature display. This marker also indicates

the measurement display units (ppm, ppb, or %)

depending on the instrument model.

To the LCD's right is a label showing the

measurement units configured at the factory for

your application.

In addition to the controls indicated on the front

panel, there is also a pressure relief valve switch

on top of the instrument to enable atmospheric

pressure equilibrium for sensor calibration, or for

measurements in gaseous samples in % units.

The button in the bottom right corner backlights

the LCD for approximately three minutes. The

other push-button controls are:

• POWER turns instrument power on or

off. The instrument starts in

measurement mode

• MEAS places the instrument in

measurement mode

• CAL calibrates the analyzer against a

reference sample. This button can be

locked out from the WinLog97 PC

program

• STO stores a measurement value into

memory

• The × Ø keys toggle between gas

concentration and temperature

measurement displays in measurement

mode, increases or decreases the

storage number during storage or

memory view, or sets a calibration value

during calibration

• POWER + CAL sensor calibration

• POWER + STO starts automatic data

acquisition.

• POWER + × starts memory storage view

Page 2

Startup

To start the instrument, press the keyboard

POWER switch. When you turn power on, the

instrument displays its model number briefly, and

then starts in measurement mode.

The instrument can be operated independently,

making measurements as a portable analyzer.

You may store these measurement values for

later analysis via the WinLog97 program (on your

personal computer) or the memory view mode (on

the instrument).

Page 3

Measurement

Taking Measurements

Connect the top-mounted inlet to accept your

sample, typically this is accomplished by

connection to a sampling valve. The sample flow

can be regulated by the knurled stainless steel

knob on top of the flow chamber.

The LCD includes a right-side marker to

distinguish between gas concentration

measurements and temperature. To switch

between gas measurement and temperature

measurement, press the × Ø buttons. To

backlight the LCD for approximately three

minutes, press the Backlight button.

The analyzer will store up to 500 gas

measurement values, labeled by numbers 0

through 499, along with the current date and time

of each measurement. You have the choice of

acquiring this information manually or

automatically, as described below.

Automatic Data Acquisition

Before starting automatic measurement storage,

first select the sampling rate desired using the

Sampling Rate menu of the WinLog97 program.

Gas concentration measurements are displayed

for about two minutes. After two minutes the

instrument displays the sample number (starting

at 000), then the gas concentration measurement

value followed by [---] to indicate the

measurement is being stored.

This storage sequence repeats automatically, at

the rate specified.

To end automatic storage, switch the instrument

OFF (by pressing the POWER key) while it is in

normal measurement mode. Switching ON again

without holding down the STO button returns the

instrument to measurement mode.

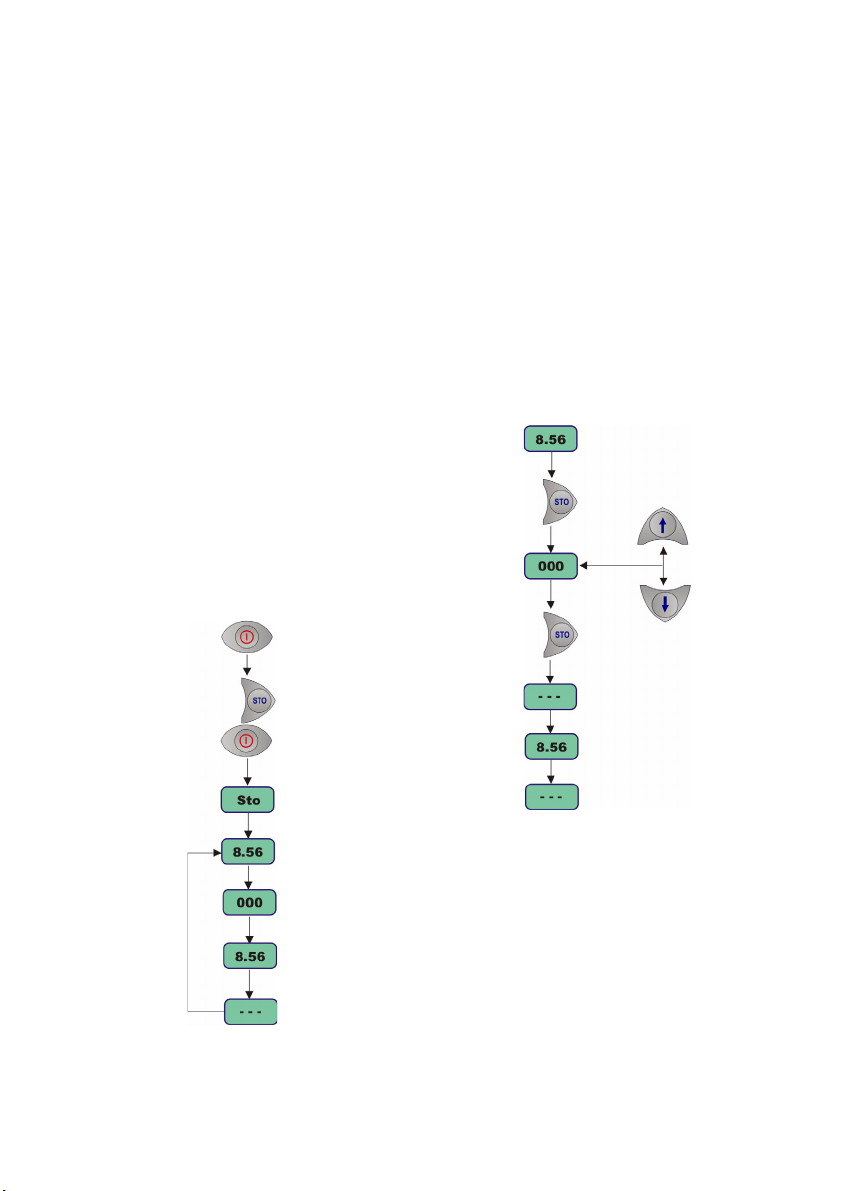

Manual Data Acquisition

Switch the instrument OFF (by pressing the

POWER key). Then hold down the STO button

while switching the instrument back ON. The LCD

displays the message Sto for about one second.

For the first measurement you wish to store, press

the STO button once to display a sample number.

The default sample number is 000 (for first time

access), or the last used memory position where

data was stored, incremented by a value of 1.

You can increase or decrease this number by

pressing the × Ø buttons within three seconds.

Press STO a second time, within five seconds of

the first. The instrument then displays the gas

concentration measurement value for about three

seconds, followed by a clearing message as the

value is stored.

Repeat the above steps to store additional

measurements.

Page 3

Page 4

Measurement (cont)

Viewing Stored Measurements

Switch the instrument OFF (by pressing the

POWER key). Hold down the × button while

switching the instrument back ON. The LCD

displays a sample location number.

Scroll through the numbered sample locations of

all the stored values using the × Ø buttons.

To view the actual gas concentration

measurement value at a particular sample

number, press the STO button. The LCD now

displays the stored value for that sample number.

Press STO a second time to return to the next

numbered location display, to continue scrolling

or view another stored value.

To return to the measurement mode, switch the

instrument OFF and then back ON again without

holding down any additional buttons.

Downloading Data

If you have made measurements and stored them

in the instrument, you should be ready to bring

them into the WinLog97 program for viewing,

copying, saving and printing. To download stored

data from the instrument to the PC, choose the

DownLoad data command from the Logger

menu.

The window displays the stored measurements

from the instrument showing the sample number,

gas concentration, a date and time stamp, and a

sample description.

Sample Description

For help in identifying the locations of various

sampling points that are stored by the analyzer,

you may choose the Sampling Point

Description command from the Logger menu.

The measurement values to be placed in

positions 0 through 499 can be described

however you wish. Double-click on a particular

position (or click Modify), then type a description

in the box.

Copy Data

To copy the results to the Windows Clipboard, so

that the data can be pasted into a spreadsheet,

word processor or other Windows program that

accepts tabular text information, choose the

Clipboard command from the Export menu.

Save Data

To save this list of measurements as a text file,

capable of being recalled by the WinLog97

program or imported as a file into other Windows

programs, choose the Save As command from

the File menu and enter the device and file name.

Print Data

To place this list of measurements into a tabular

format and send it to the printer, choose the Print

command from the File menu.

Clear Data

To clear all the values stored in the instrument,

choose the Clear Data command from the

Logger menu. Since this action will clear the

storage memory of the instrument, a warning

appears which you must confirm. Choose Clear

to start the memory clear operation.

Page 4

Page 5

Measurement (cont)

Timebase Updating Rate Max.

Samples

30 Seconds/Division 5 Secs/Sample 60

1 Minute/Division 5 Secs/Sample 120

10 Minutes/Division 5 Secs/Sample 1,200

30 Minutes/Division 9 Secs/Sample 2,000

1 Hour/Division 18 Secs/Sample 2,000

2.5 Hours/Division 45 Secs/Sample 2,000

Monitor Measurements in Real-Time

You may wish to analyze a particular sampling point via the WinLog97 program's Monitoring menu. To

use this Monitoring chart, the instrument must be connected to your PC.

Choose Monitoring from

the WinLog97 menu to

bring up a chart display.

The chart shows the gas concentration (in blue), temperature (in red), and pressure (in green) as the sample is being measured by the instrument. The chart is updated directly from instrument measurements, at a rate determined by the time scale set in the TIMEBASE box at the lower right corner of the chart.

Click the TIMEBASE up/

the time scale of the divisions of the chart. Each division mark along the baseline (1, 2, ...10) can be

made to represent from 30 seconds to 2½ hours, providing from 5 minutes to 25 hours of continuously

displayed samples (as illustrated in the table).

Click on the Continuous box to enable or

disable continuous charting. When this box is

checked, the chart scrolls continuously after

reaching the 10 division, and the oldest

samples are lost off the left of the chart.

When Continuous is not checked, the chart

stops displaying new results after reaching

the 10 division, and all subsequent

measurements are lost.

Click the up/down pointers for each

measurement variable (GAS,

TEMPERATURE and PRESSURE) to

change the scaling of that value on the chart. The display of each measurement variable may be turned

on or off by choosing the appropriate On or Off switch.

A running display of latest sample Gas, Temperature and Pressure is also shown in the bottom-right

corner of the chart.

Use the buttons at the bottom of the chart to control real-time monitoring. Choose Go to clear the chart

and start real-time monitoring, Stop to stop monitoring and Copy to copy the data from the chart as text

information to the Windows Clipboard. This information can be pasted from the clipboard into any

Windows application, such as a spreadsheet or word processor.

Choose Close to close the Monitoring window.

down pointers to change

Page 5

Page 6

Instrument Configuration

The following commands are all available from

the Configuration menu in the WinLog97

software installed on your PC.

The instrument must be connected to your PC in

order to change its configuration.

INSTRUMENT - PC CONNECTION

The Serial port menu lets you choose one of four

serial communication ports. Usually, COM1 is

used to connect to a mouse, so try COM2 first.

SETTING SAMPLING INTERVALS

The analyzer can perform as a standalone data

acquisition device, automatically recording gas

measurements with the date and time, and storing

up to 500 of these values.

MEMBRANE SELECTION

You may find it necessary to use a different type

of membrane for different applications.

To re-configure the analyzer, choose Membrane

to bring up the box which reveals the membrane

models available.

CALIBRATION MODE

Use the Calibration mode command to select

how the sensor is to be calibrated.

Choose In Air to allow calibration of the sensor in

air, In Line to calibrate the sensor directly in the

sampling line, or In a Span Gas to calibrate in a

source of gas of known concentration.

Choosing Sampling Rate lets you select time

intervals (acquisition rate) for this storage

capability.

Page 6

CALIBRATION KEY STATUS

You can use the Calibration Key Status menu to

prevent an accidental sensor re-calibration from

the instrument keyboard.

Enable or Disable the instrument front panel

CAL button. Disabling the button will prevent

accidental sensor re-calibration.

Page 7

Instrument Configuration (cont)

CALIBRATION RANGE CHECKING

When calibration is performed for In Air and In a

Span Gas calibration modes, the sensor

measurement current is compared to an ideal

current for the selected membrane to determine

whether or not to complete the calibration. You

can use the Calibration Range Checking menu

to enable or disable sensor calibration range

checking in the instrument.

Choose Disabled to calibrate without checking

the value of the measurement current, within a

range of 0% to 999% of the ideal current. When

set to Enabled, at calibration the measurement

current should be between 25% and 175% of the

ideal current; if the value is outside of these limits,

the calibration fails and Err is displayed on the

instrument LCD.

INSTRUMENT CONFIGURATION REVIEW

To review if the instrument is set up as expected, choose the Configuration view command.

SPAN GAS

When calibrating the sensor in a span gas, use

the Span Gas menu to enter the span gas

concentration (as a %age) when using a span gas

as a calibration medium.

DUAL USE (MODEL 3650Ex/113 ONLY)

Use the Dual Use menu to change the

measurement phase (either dissolved or

gaseous) for the model 3650Ex/113 dual-use

analyzer.

Choose ppm (dissolved) to set the instrument for

dissolved measurement in liquids, or %

(gaseous) to set the instrument to gas phase

measurement.

Page 7

Page 8

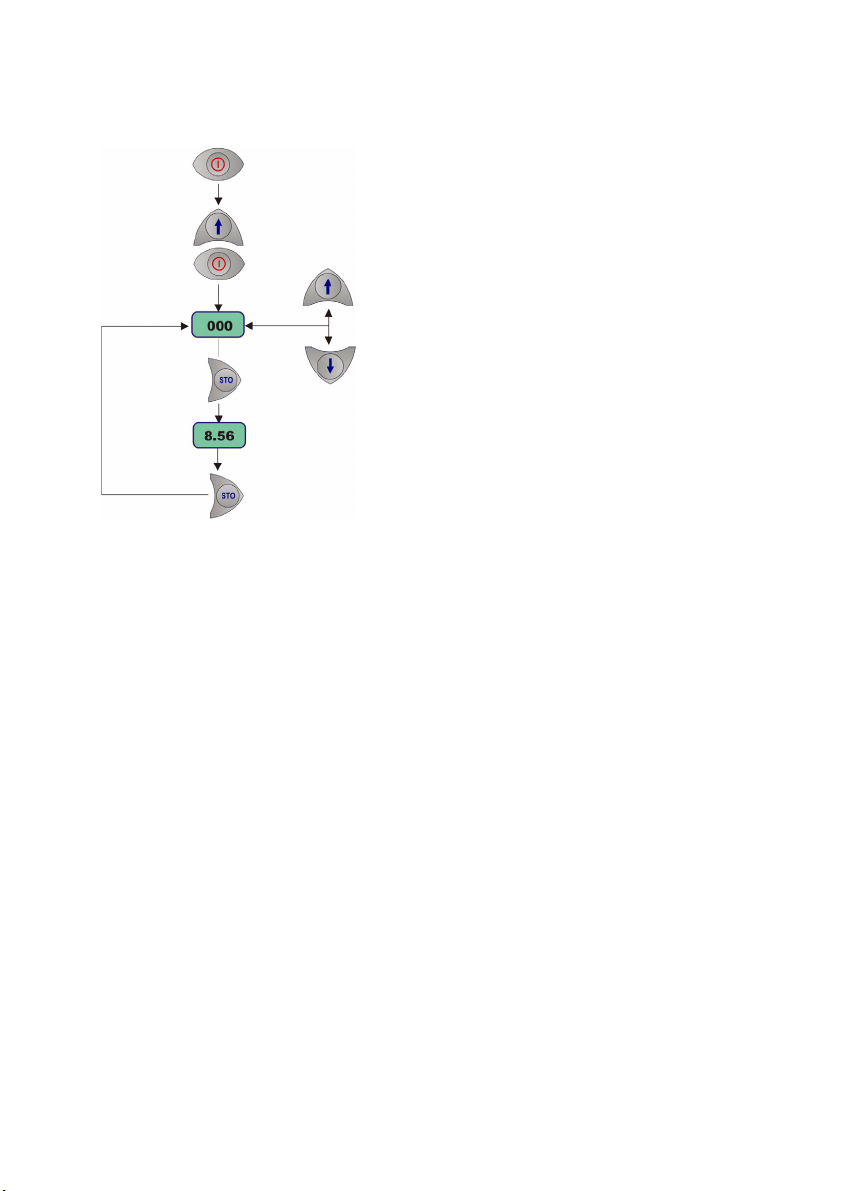

Calibration

BAROMETRIC PRESSURE SENSOR

The instrument internal barometric pressure

sensor is calibrated at the factory, and normally

requires no further attention. However, you may

wish to calibrate it against your own

instrumentation, or simply check the instrument

for accuracy.

Select Troubleshooting, Pressure Calibration

from the WinLog97 program, and enter the

current atmospheric pressure, in mbars, in the

calibration pressure entry box.

GAS SENSOR

The sensor can be calibrated either in air or

directly in line in a liquid sample. Additionally,

oxygen sensors can be calibrated using a span

gas.

To perform a calibration, you must first choose

which method you wish to use. The mode of

calibration may be selected using the WinLog97

program. Alternatively, you can select the mode

of calibration using the instrument front panel

buttons.

Switch the instrument power OFF. Switch the

instrument on by holding down the CAL button,

and then pressing the POWER button at the same

time. The instrument display will show either Air

for in air calibration, LI for in line calibration, or

SPA for span gas calibration

Use the × Ø buttons to change the mode to your

choice and press the STO button to set the

selected mode.

In a Span Gas Calibration

The span gas calibration procedure may be used

if you have a source of gas with a known

concentration of O

type of calibration, the instrument must be set for

calibration In a Span Gas. The Windows

WinLog97 program must also be used in this

procedure.

displayed.

When the reading is stable, press CAL again.

If the new calibration current is within 25% to

175% of the ideal current, the instrument displays

CAL and returns to the measurement mode.

Calibration is now complete, the sensor is

calibrated, and you can proceed with your

measurements.

If the new calibration current is not within this

range, the instrument displays Err and returns to

measurement mode. The system will not

calibrate, and it is likely that a sensor service will

be required.

(in% units). To perform this

2

Switch on the instrument, if

necessary, and wait a minute or

so for the displayed

measurement to settle. Then

expose the sensor to a span gas

sample with a known oxygen

concentration. Enter the

percentage of oxygen in the

span gas using the WinLog97

program.

Press the CAL button.

Remember, this button may

have been locked out to prevent

an accidental reset.

A brief clearing [---] message

appears. Press CAL again

within a 3 second period. The

percentage of the measured

current to the ideal one is

Page 8

Page 9

Calibration (cont)

In Line Calibration

The in line calibration procedure can be used to

calibrate the sensor directly in line, against a

liquid sample with a known dissolved oxygen

concentration.

To perform this type of calibration, the instrument

must be set for calibration In line. Switch on the

instrument, if necessary, and wait a minute or so

for the displayed measurement to settle.

Expose the sensor to a liquid sample with a

known gas concentration.

In Air Calibration (oxygen sensors only)

The oxygen sensor can be accurately calibrated

in air. To perform this type of calibration, the

instrument must be set for calibration In air.

You can perform this procedure with the sensor

connected to the instrument, but without the flow

chamber mounted.

The membrane must be dry, and prior to

calibrating it may be necessary to remove the

screw-on protection cap and its optional grill to

make sure that the components are not damp.

Switch on the instrument, if necessary, and wait a

minute or so for the displayed measurement to

settle.

Press the CAL button. Remember, this button

may have been locked out to prevent an

accidental reset.

A brief clearing [---] message appears. Press

CAL again within a 3 second period. A

measurement will flash on the LCD, showing the

oxygen concentration of the calibration sample.

Assuming you know the gas content to be a

certain value, you can adjust the displayed value

with the × Ø keys.

When the reading is adjusted to the known

concentration, press CAL again. The instrument

displays CAL and returns to the measurement

mode.

The process is then exactly the same as for

calibration in a span gas, detailed previously.

Page 9

Page 10

Troubleshooting

You may wish to use the Troubleshooting menu

to make sure that the instrument is configured

correctly for your application, and is in good

working order.

The instrument must be connected to your PC to

perform these tests.

SERIAL LINK TEST

Normally, the instrument will inform you of a

disconnected RS-232 (serial) link when

appropriate. However, you can confirm a good

connection using the Serial Link Test option, and

echoing a test message via the instrument.

Enter text characters in the Text to be sent box,

then click Send. If the serial link is operating

correctly, the exact same text will be displayed

back from the instrument in the Echo box.

KEYBOARD TEST

The Keyboard Test option will reveal whether all

the instrument buttons are functioning correctly.

Type a number in the Number box (you may also

select one of three units positions for the LCD's

rightmost indicator bar as well). Then choose

Send. The number and indicator bar placement

should appear on your instrument LCD.

CLOCK SETTINGS

Choose the Clock settings option to set the date

and time in the instrument.

ANALOG VOLTAGES VIEW

The Analog Voltage View option gives a realtime look at voltages used by the system to

transmit information about sensor current,

temperature and pressure. This is useful when

trying to identify an instrument problem with an

Orbisphere service representative either on-site

or over the phone.

Press any one of the instrument's buttons (except

the on/off button) for a full second or more. The

appropriate square on-screen should darken.

DISPLAY TEST

Choosing the Display Test option lets you

perform a one-way communication between

computer and instrument.

Page 10

The voltage limits for normal operation are:

• Current channel: -1.5 V to +1.5 V

• Temperature channel: +10 mV to +4 V

• Pressure channel: -100 mV to +100 mV

MEASUREMENTS VIEW

The Measurements View option confirms, on

your PC monitor, what your instrument should be

displaying on the LCD for gas concentration and

sample temperature.

Page 11

Page 11

Page 12

Loading...

Loading...