Page 1

Operator Quick Guide

ORBISPHERE 3625

Revision F - 04/04/2008

Page 2

Operating Information

About this Guide

The information in this guide has been carefully

checked and is believed to be accurate. However,

Hach Ultra assumes no responsibility for any

inaccuracies that may be contained in this guide.

In no event will Hach Ultra be liable for direct,

indirect, special, incidental, or consequential

damages resulting from any defect or omission in

this guide, even if advised of the possibility of

such damages. In the interest of continued

product development, Hach Ultra reserves the

right to make improvements in this guide and the

products it describes at any time, without notice or

obligation.

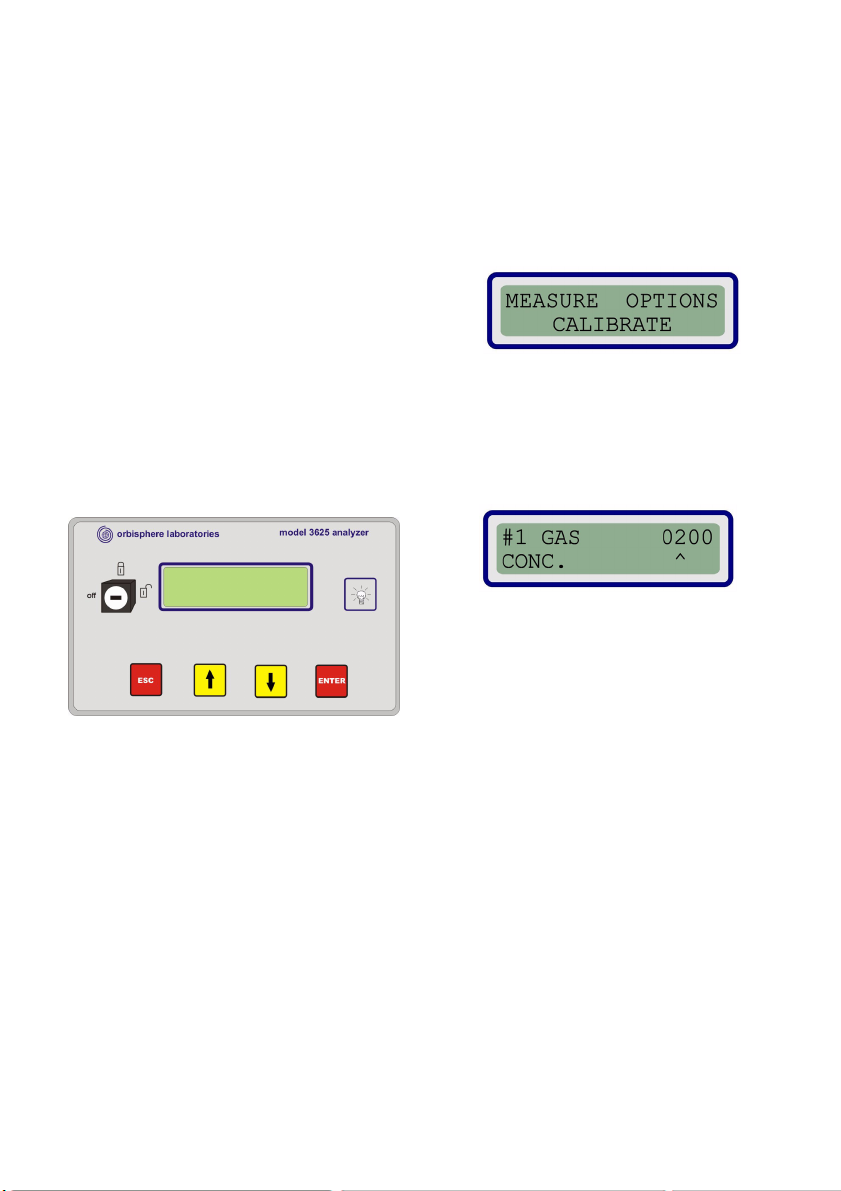

Instrument Controls

Delivered with the 29976 package piercer, is the

3625 indicating instrument. The front panel of the

instrument has several displays and controls.

The Key Switch should be turned to the

horizontal unlocked position to start the

instrument in measurement mode. The function

keys are only active if the key switch is in the

unlocked position. Use the vertical locked position

to avoid accidental modifications.

The Display has a two-line liquid crystal display

(LCD), having 16 characters per line.

A Light Button, when pressed, provides

illumination to the LCD for three minutes.

Four Function Keys provide simple operator

control over the instrument functions:

• ESC back one step.

• or move through the loop of

available data (selection blinks).

• ENTER confirm selection.

Main Menu

The main menu is reached by pressing ESC as

many times as needed:

• MEASURE: Measurement

• OPTIONS: Set up the instrument

• CALIBRATE: Calibration procedures

Entering Values

When entering numbers, several digits are

displayed. The caret symbol ^ represents the

cursor. After entering the last digit, the new value

is saved.

• increase or decrease the number

value

• ENTER move cursor one digit to right

• ESC move cursor one digit to left

• ENTER confirm last value entered

• move decimal point (when

applicable)

• ENTER confirm and exit

OrbiPack PC Software

The Beverage Package Analyzer system works

with the OrbiPack software. Ensure that:

• An RS232 cable is connected from your

PC to the instrument

• The PC is turned on

• The software is running

Page 2

Page 3

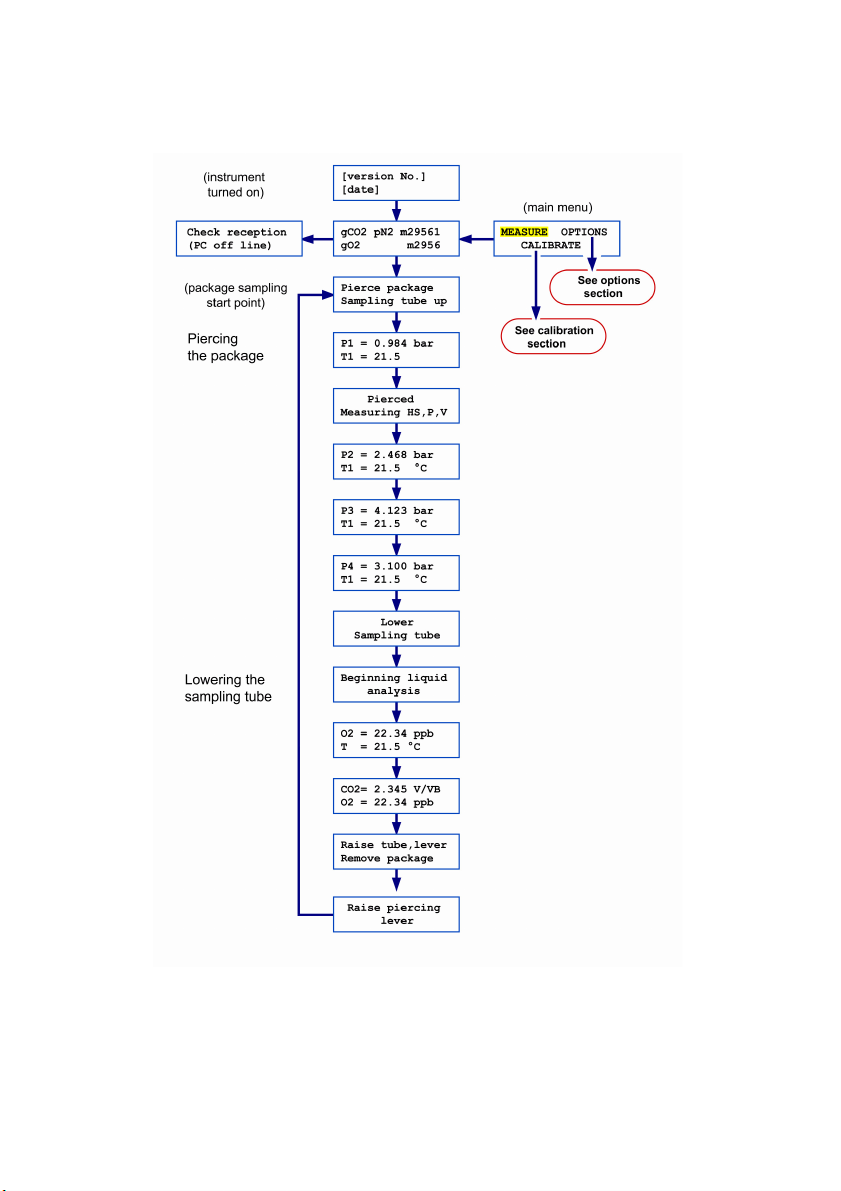

Measurement Menu

The flow chart below gives an overview of the MEASURE menu and sequence.

Page 3

Page 4

Measurement Process

Start the Instrument

The key switch on the instrument must remain in

the vertical position to perform measurements.

A configuration screen is displayed for a few

seconds, and then the message prompts you to

start the measurement sequence.

This message remains on for a few seconds, and

then the display shows the atmospheric pressure

(P1) and temperature (T1) in the analyzer

manifold. The pressure and temperature screen

alternates with the preceding message until you

either pierce a package (or press ESC to return to

the main menu).

Package Pressure Equalization

In order to perform an accurate analysis, partial

pressure in the package must be balanced

between the gas phase (headspace) and the

liquid phase (beverage). The packages to be

tested must be gently agitated in a longitudinal

direction for at least three minutes, using a

reciprocating shaker.

Prepare for Piercing

First, make sure the piercing knife used is correct

for the application (metal or plastic).

Check that the sampling tube is fully retracted

inside the piercing knife, and that the rubber seal

is in good condition and extends slightly below the

piercing knife tip.

To clamp a package into position, tilt the piercing

lever backward, install a package on the mat, and

bring the lever to the vertical position. The

package must be vertical on the base mat, and

centered in the upper positioning plate. During the

analysis, the package must remain firmly

clamped; if not check the positioning device

height adjustment.

Following instructions given by the system, pierce

the package where the surface is smooth and flat,

to get a good seal.

Pierce the Package

When prompted, pull the piercing lever down all

the way in a uninterrupted move.

During analysis, any pressure leak past the

rubber seal will alter results. Do not release the

piercing lever until it is all the way down.

Headspace analysis is automatically triggered.

When complete, the display will prompt you to

lower the sampling tube.

Holding the piercing lever:

• Lower the sampling tube until all the way.

The product sampling and analysis is

then automatically triggered.

• Adjust the flow meter to 150 ml/min.

Visually check that the liquid in the tubing and flow

chambers is not foaming. Increase the forcing gas

pressure if necessary.

When analysis sequences are over, the display

will ask you to remove package.

• Raise the sampling tube to its upper

position, holding it only by the handle bar

• Lift the piercing lever all the way (past the

2 step device, if applicable)

• Remove the empty package

The instrument should display the Pierce

package message, saying that the equipment is

now ready for a new package sampling.

Daily Cleaning (user maintenance)

Every 8 hours of use or when a measurement

session is over, whichever comes first, the

sampling circuit must be flushed to remove any

product deposit in the sampling lines and

chambers.

Perform a measurement routine, using a package

filled with clean water and some non aggressive

liquid detergent (do not use caustic soda). Use

either:

• 0.5% bleach (sodium hypo chlorite) at

room temperature

• 5% Contrad (dilute caustic detergent) at

40° C

The measuring instrument waits for the evidence

of piercing to continue, so press ENTER to

bypass this step. Repeat this operation with two

packages filled with water low in dissolved

oxygen.

Let the system purge run for 5 minutes to purge

liquid out and dry the system.

Page 4

Page 5

Note :

OrbiPack PC Software

ACCESS

The software is password driven, so be sure you

have a valid username and password. Depending

on your access level, some of the following

options may not be available to you.

PROCESS BAR

To hide or display the process bar, select it from

the View menu. The process bar is displayed at

the bottom left of the application window. It shows

five boxes indicating the sequences of the current

analysis. They correspond to the display

messages on the measuring instrument.

When one analysis step is completed, the

corresponding box turns green. However, if a

problem is found, the box turns red. Click the Help

button for further details.

SOTWARE OPTIONS

You may set several options before performing a

measurement. Select Options from the Tools

menu and click the desired tab.

General

Error Messages

You can enable or disable warning messages for

errors that may occur during package analysis. If

one or more box is checked, and the

corresponding error occurs, a pop up window

displays the error and asks if you want to save the

data anyway.

Inter Process Communication

The software allows for communication with other

control and management systems such as

SCADA and LIMS, etc. The communication

option is used to define the necessary

parameters.

If using this option, you must have the

appropriate communications software installed

on your PC.

This option allows you to set several parameters,

such as the gas being measured, and whether to

capture the data after each measurement.

Calibration Management

Each time a calibration is successfully completed,

the measuring instrument sends a message to the

OrbiPack software that is saved together with the

current date and operator's name.

A calibration deadline date can be set, by

checking the Expiry check box.

Page 5

Page 6

OrbiPack PC software (cont)

PACKAGE SET-UP

Supervisor level is required to access Package

set-up in the Package menu.

Package Characteristics

Enter the data corresponding to the package to be

tested. Up to 500 different package specifications

can be saved.

Alarms

Various thresholds can be entered to trigger

alarms. The values exceeding these limits will

appear in red in the data file.

Offsets

The offset is a multiplication factor applied to the

measured data (e.g. an offset factor set at 1.01

will increase the value by 1%).

DATA TABLE SETTING

The options selected here defines the data

elements listed in the data table (i.e. the file of

measurement data).

Measurement Columns

This requires supervisor level access and can be

made during or after the measurement sequence.

Several columns can be displayed for analysis

purposes, regarding data, units, or resolution

(decimal position).

Raw Data Columns

This is useful for diagnostic and troubleshooting

operations. This concerns data received from the

instrument before any computations are applied.

Formula

Five formula lines are available to compute

different equations of solubility. This allows you to

create and compute a specific new parameter, or

a different CO

corresponding to the new formulae are displayed

in the data table.

Page 6

solubility equation. The columns

2

Units

Select the units to be used and displayed in the

table columns.

Page 7

Setting Instrument Options

The instrument is equipped with customized

features for specific applications. Select

OPTIONS from the main menu, and then use the

keys until your choice is flashing. Press

ENTER to select it.

MEMBRANES

The selection of a membrane is a compromise

between the frequency of sensor services

(calibration, maintenance) and the sensor

sensitivity. It is also dependent on plant conditions

(frequency of analysis, O

level being measured,

2

etc.).

The default membrane for the O

sensor is model

2

2956A. It allows measurements within the ppb

range. If sensor measure drifts, or sensor service

frequency is high (less than once a month), then

membrane model 2952A is recommended.

SERIAL OUTPUT

The serial RS-232 interface provides

communication with an external computer or

printer.

Print - Provides a formatted list of results as text

to a PC or printer.

PC Com - Communication link between the Orbi-

Pack software and the measuring instrument.

The instrument sends the results data, and the

PC sends the package setup data.

Diagnostic - Provides a formatted data list.

There are two diagnostic data formats, depending on whether the instrument is in measure or

calibrate mode.

Upload - A test function that generates a text file

of the measuring instrument memory.

CONTINUOUS PURGE

This is a test function. When enabled, the system

continuously purges the thermal conductivity

sensor, and displays the sensor voltages for a

100% purge gas.

SAMPLING SYSTEM PURGE

This command opens the purge gas to the

beverage sampling system. This is used to flush

and dry the system during daily maintenance.

This can also be used to rapidly bring the O

sensor inside the working range.

NITROGEN TC SENSOR CORRECTIONS

Humidity Factor Correction

Moisture may affect the N

sensor readings. Use

2

this option to set the humidity correction factor of

the N

sensor.

2

Oxygen Factor Correction

in the measured gas may affect the N2 sensor

O

2

readings. Use this option to set the oxygen

correction factor of the N

sensor.

2

Temperature Correction

Significant changes in the sample temperature

influences the N

sensor reading. Use this option

2

to reduce this influence.

CHECK ROUTINE

This routine provides displays of the forcing gas

pressure, and allows you to check valve operation

on the system.

• Pressure - Forcing gas pressure check.

• ABC check - Automatic test routine for

manifold electro valves.

• D check - Automatic test routine for

pneumatic valves.

• Valve - This manual valve test function

allows you to individually open and close

each electro valve.

• Tub e - A test function for the positioning

switch on the sampling tube.

OXYGEN STABILITY

This option is used to monitor the O2 sensor.

When the O

on the PC screen will be displayed on a red

background.

stability criteria are not met, the data

2

2

Page 7

Page 8

Note :

Calibration

The flow chart below gives an overview of the calibration menu and sequences.

The following table shows the recommended sensor calibration interval for an average of 500 package

analyses per week. This proposed schedule should be modified accordingly for varying operating

conditions.

Sensor Calibration Interval

PT 1000 temperature sensor 1 year

Barometric (internal) pressure sensor (located inside instrument) 6 months

Package (external) pressure sensor (located inside manifold) 3 months

Electrochemical O

Electrochemical O

Thermal conductivity sensor 3 months

sensor with membrane 2952A

2

sensor with membrane 2956A (special)

2

4-6 weeks

2-4 weeks

The gas sensor should be calibrated after each membrane change. Wait a minimum of 30 minutes

before performing the calibration.

Page 8

Page 9

Calibration (cont)

PT-1000 TEMPERATURE SENSOR

This process requires the use of the 0°C simulator

(model 32116), supplied with your Beverage

Package Analyzer, and which plugs into the

PT1000 socket on the instrument’s back panel.

Prepare a package of water at room temperature,

and measure the temperature of water with a

certified thermometer and note this temperature.

Unplug the PT-1000 cable from the instrument

back panel, and select the PT-100, TWO POINT

calibration routine. Plug the simulator in the PT1000 socket, and when prompted for low point

temperature, enter 0°C. Select RESISTOR

calibration and when the low point voltage is

displayed, press ENTER.

Remove the simulator, and connect the PT 1000

cable. When prompted for high point temperature,

enter the previously noted water temperature.

Select LIQUID calibration, lower the sampling

tube into the water package, and press ENTER.

Wait until the voltage is stable, and press ENTER

to validate and calibrate.

BAROMETRIC PRESSURE SENSOR

Measure the barometric pressure using a certified

barometer in the location where the measuring

instrument is used. The reference barometric

pressure must be within ± 5 mbar.

If value is OK, press ESC. Otherwise enter the

barometric pressure in mbar and press ENTER.

PACKAGE PRESSURE SENSOR

For the external pressure sensor, connect a

certified pressure gauge to the forcing gas inlet

line. Adjust the forcing gas pressure to 4 bar

(gauge pressure).

It is recommended to use the TWO POINT

calibration procedure, which requires that you

work at two different pressures.

EC SENSOR (O

Two methods of calibrations are available:

• In air calibration: Expose sensor to

100% humid air (recommended)

• Direct calibration: Expose sensor to a

known source of O

flow chamber)

)

2

(requires an optional

2

To calibrate in air, remove the O

sensor (still

2

connected) from piercer, and wipe dry the sensor

protection grille. Put one drop of tap water in the

sensor storage cap. Install the cap sensor slightly

loose to avoid compressing the air inside.

Select O2 IN AIR from the calibration menu and

wait 5 minutes until the values displayed are

stable. Press ENTER to save the new calibration.

TC SENSOR (CO

2/N2

)

Four calibration methods are available:

• Partial pressure: Using a known

composition of CO

(or N2) at ~5 bar

2

(recommended)

• Fraction: Using a known composition

(preferably pure) of CO

(or N2) at

2

atmospheric pressure

• Calibration kit: Requires optional HUA

calibration kit. Using a known

concentration of dissolved CO

2

• Reference package: Using a package

with a known gas concentration content

as a reference

For the partial pressure method, use the

Orbisphere 32001.xxx calibration flow chamber.

The sensor is exposed to a known composition of

CO

(or N2) between 3 and 5 bar absolute

2

pressure (ideally close to the partial pressure

being measured), measured with an external

certified pressure gauge having a precision of ± 5

mbar.

Disconnect the external temperature sensor cable

and remove the sensor from the piercer. If the

sensor head is wet, rinse the tip with water, and

dry with a tissue. Make sure that the grille in the

front of the sensor is clean and dry.

Insert the sensor into the calibration flow chamber

and connect a source of calibration gas to the flow

chamber inlet. Close the flow chamber outlet

valve to build up the requested pressure in the

system.

Select PARTIAL PRESSURE from the calibration

menu and enter the absolute pressure of the

calibration gas. After 3 stable calibration cycles,

the calibration should be complete.

Page 9

Page 10

Measurement Troubleshooting

The following table lists possible measurement errors.

Symptom Probable Cause Corrective Action Sensor

No power.

Instrument does not start.

No display or backlight.

Downward drift during

measurement.

Low reading.

High reading.

High/low readings.

Unstable reading during

calibration.

Calibration impossible

Erratic readings.

Forcing gas pressure

P3 ≈ P4 during

measurement cycle.

Incorrect voltage.

Blown fuse.

Purge gas pressure too low.

Sample flow stopped. Correct and start a new test.

Leak in purge gas. Check line for leaks with soapy water.

Sample flow too low.

Incorrect calibration in gas (wet

membrane & protection grille ?)

Calibration values entered did

not match sample used.

Calibration gas flow restricted,

generating pressure pulse.

Improperly mounted protection

cap or membrane.

Leaking purge gas solenoid

valve in TC sensor.

Water condensation into the

thermal conductivity element.

Product in manifold electro

valves.

Check connections.

Check instrument voltage label on the

instrument rear panel.

Unplug the instrument and replace the

fuse.

Adjust pressure at regulator to get over

3 bubbles per second from sensor exit

tube (immerged in water).

Adjust sample flow according to

procedure.

Re calibrate the sensor according to

procedure.

Check that the entered numerical data

and units fit the gas concentration or

pressure.

Make sure calibration gas flows freely;

unscrew sensor collar ¼ turn to create a

leak, thus increasing gas flow during

calibration.

Sensor needs servicing.

Check purge gas sequence. If purge

gas solenoid leaks during measurement

phase (more than 1 bubble in 15

seconds), the sensor needs servicing.

In Options menu, turn on Continuous

Purge mode overnight to dry the sensor

cell.

Water condensation may seriously

damage the TC sensor cell.

Perform cleaning and testing of the

manifold valves.

CO

2

CO

2

CO

2

O

2

/CO

O

2

/CO

O

2

CO

2

O2/CO

CO

2

CO

2

2

2

2

Page 10

Page 11

Instrument Error Messages

The following table lists possible instrument error messages.

Message Reason Action

Prg

Purge gas failure Restore purge gas to specifications

Damaged sensing element

Perform the Continuous Purge test

Return sensor to Orbisphere

Chk Purge voltage drifting

Lmt Ramp limit violated

Too low

Too high

Check

Reception

Change the

Filter

Calibration out of

Bounds

Forcing gas pressure is insufficient to lift

the liquid to the sensors

Forcing gas pressure exceeds the limit set

in the OrbiPack 4.00 software for this

package type

The PC communication has failed

The gas filter in manifold may be clogged Replace the gas filter

Wrong membrane installed

Perforated or torn membrane

Two membranes instead of one

(or the opposite)

Check purge gas

Perform the Continuous Purge test

Reduce gas permeation

Perform the Continuous Purge test

Check forcing gas pressure

Verify that the forcing gas pressure is set at 500

mbar higher than the package pressure (P2)

Check forcing gas pressure, and check

OrbiPack 4.00 software max press. set limit.

Verify that the forcing gas pressure is set at 500

mbar higher than the package pressure (P2)

Check PC cable connection

Verify correct PC link and setup

Correct accordingly

Page 11

Page 12

Loading...

Loading...