Haag-Streit Octopus 300 Perimeter Service manual

OCTOPUS

®

300

Service Manual

HS No. 7220084

8. Edition / 2014-08

HAAG-STREIT AG, Switzerland, Phone: +41 31 978 01 11, Fax: +41 31 978 02 82, info@haag-streit.com

HAAG-STREIT DEUTSCHLAND GmbH, Germany, Phone: +49 4103 709 02, Fax: +49 4103 709 370, info@haag-streit.de

HAAG-STREIT FRANCE, France, Phone +33 4 5009 0033, Fax +33 4 5009 7190, info@haag-streit.fr

HAAG-STREIT UK, United Kingdom, Phone +44 1279 414969, Fax +44 1279 635232, info@haag-streit.uk

HAAG-STREIT USA, INC., USA, Phone: +1 513 336 6858, Fax: +1 513 336 7828, octopus@haag-streit-usa.com

OCTOPUS 300 Service Manual HAAG STREIT No. 7220084

Tradition and Innovation

TABLE OF CONTENTS

1 PARTS DELIVERED ......................................................................................................................................................................3

2 SAFETY INSTRUCTIONS ..............................................................................................................................................................4

2.1 General ................................................................................................................................................ 4

2.2 Instrument Transportation ................................................................................................................... 4

2.3 Symbols ............................................................................................................................................... 5

Special Notices in the Text ............................................................................................................................ 5

3 INTRODUCTION ............................................................................................................................................................................6

3.1 OCTOPUS Perimeter 300 ................................................................................................................... 6

3.2 Instrument Table ................................................................................................................................. 7

3.3 Installation ........................................................................................................................................... 8

4 SOFTWARE .................................................................................................................................................................................10

4.1 Installation, Exchange, Upgrade ....................................................................................................... 10

4.2 Releasing Program Options .............................................................................................................. 10

5 PRINCIPLE OF OPERATION ......................................................................................................................................................12

5.1 Functional Diagram ........................................................................................................................... 12

5.2 Stimulus Intensity Control ................................................................................................................. 12

5.3 Background Intensity Control ............................................................................................................ 14

5.4 Reference Point................................................................................................................................. 14

5.5 Optics Module ................................................................................................................................... 15

6 CARE AND MAINTENANCE .......................................................................................................................................................16

6.1 Cleaning ............................................................................................................................................ 16

7 MAINTENANCE AND REPAIR ....................................................................................................................................................17

7.1 Housing (1805001) ............................................................................................................................ 17

7.2 Optical Unit (1802669) ...................................................................................................................... 18

7.3 Z-Shaft (1802190) ............................................................................................................................. 19

7.4 Fixation Target (1802206) ................................................................................................................. 20

7.5 Correction Lens Holder (1007496) .................................................................................................... 22

7.6 Background Module, Lamp house (1802247) ................................................................................... 26

7.7 Brightness Regulator Module (1802248) .......................................................................................... 27

7.8 Stimulus Projector OCTOPUS 301(1802249)/ Stimulus Projector OCTOPUS 300 (1802544) ........ 31

7.9 Touch Screen Module (new version with TFT display) – Part No. 1802870..................................... 32

7.10 Lift-/Swivel Unit (1802241) ................................................................................................................ 34

7.11 Headrest Assembly ........................................................................................................................... 36

7.12 Power Supply (1802199) ................................................................................................................... 38

7.13 Processor Board I (1802431), Processor Board II (1802654) .......................................................... 38

7.14 SDRAM Module (1802152) ............................................................................................................... 44

7.15 Interface Board (1802224), Ethernet Interface Board (1802671) ..................................................... 47

7.16 Connector Board (1802213) .............................................................................................................. 48

8 SERVICE PROGRAMS ................................................................................................................................................................49

8.1 Subassembly Test ............................................................................................................................. 49

8.2 Service/Diagnostic............................................................................................................................. 50

8.3 Printer ................................................................................................................................................ 56

8.4 Dongle Codes .................................................................................................................................... 56

8.5 Light Intensity Calibration .................................................................................................................. 56

8.6 Entering Parameters ......................................................................................................................... 56

8.7 Verifying Calibration Parameters ...................................................................................................... 57

8.8 Instrument Information ...................................................................................................................... 58

9 SYSTEM MESSAGES ..................................................................................................................................................................59

9.1 Messages .......................................................................................................................................... 59

9.2 Errors ................................................................................................................................................. 59

10 APPENDIX....................................................................................................................................................................................62

10.1 Technical Data .................................................................................................................................. 62

Page 2 / 64 OCTOPUS 300 Service Manual

Tradition and Innovation

1 PARTS DELIVERED

1 OCTOPUS perimeter 300 1802238

1 Set of accessories containing: 1802250

1 Patient response button 1802032

1 Dust cover 1802304

1 User's Manual 1802737

1 Ocular cover 1800339

3 Touch pens 1802303

1 Eye occluder (2 pieces) 1800339

2 FuesT3.15 A / 250 V 1801326

1 Allen (hexagon) wrench 2.5mm 1802338

1 Screwdriver 1802345

1 USB printer cable 1802347

1 Octopus VF Digest 1800092

1 FTP Server Installation 1802742

OCTOPUS 300 Service Manual Page 3 / 64

Tradition and Innovation

2 SAFETY INSTRUCTIONS

2.1 General

This instrument can only be used for the purpose as described in this manual.

The examination of the patients, the operation of the instrument and the interpretation of the results can only be performed by

persons who are experienced and who have been trained accordingly.

The instrument is to be installed on the height-adjustable table and employed in a dimly lit room in a medical area.

Keep this User's Manual there where persons who operate the instrument can consult it at all times. Guarantee claims can only

be valid when the instructions in the User's Manual are followed.

The doctor or operator is to instruct the patient in the safety instructions and check that they are observed.

Make sure that the instrument is connected only to the power source as defined on the perimeter rating plate. The on/off switch

does not separate the perimeter from the power lines. Before maintenance or cleaning work is performed, the power cord must

be removed from the wall socket.

Removal of the housings and repairs to the instrument are permitted only by trained and authorized technicians. Considerable

danger for the operator and patients can be caused by improper repairs.

Only original replacement parts and original accessories are permitted for repairs.

2.2 Instrument Transportation

Transport the instrument over large distances in the original packing. For short distances the instrument can be lifted using the two

lower housing sides. Two ribbed grips are provided on the left and right sides which prevent from slipping sideways.

Do not use the forehead rest of the perimeter as a carrying handle.

This plastic part is not adequate for the weight and can therefore break.

Page 4 / 64 OCTOPUS 300 Service Manual

2.3.1 Messages, Errors

Messages, information

Error messages

Warning

Warning against hazard

Tradition and Innovation

2.3 Symbols

Special Notices in the Text

Further safety instructions are put into the text as needed. They vary in importance and should help preclude risks for the patient and

operator, hinder damage to the perimeter and insure optimal functioning.

ATTENTION: Instruction which must be followed to preclude risks to the patient and operator.

WARNING: Instruction which must be followed to hinder damage to the perimeter.

TIP: Tip for insuring optimal functioning of the perimeter.

OCTOPUS 300 Service Manual Page 5 / 64

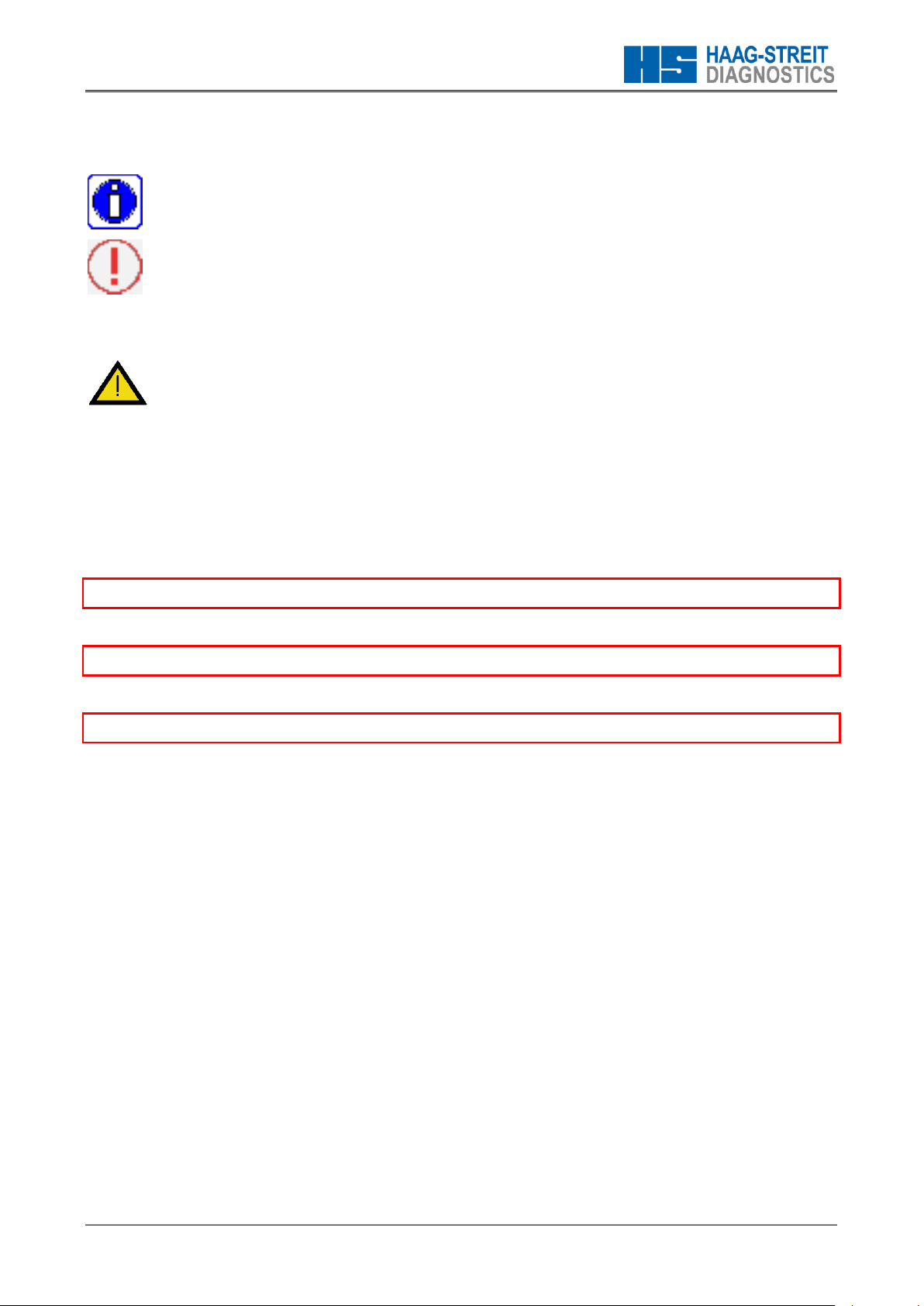

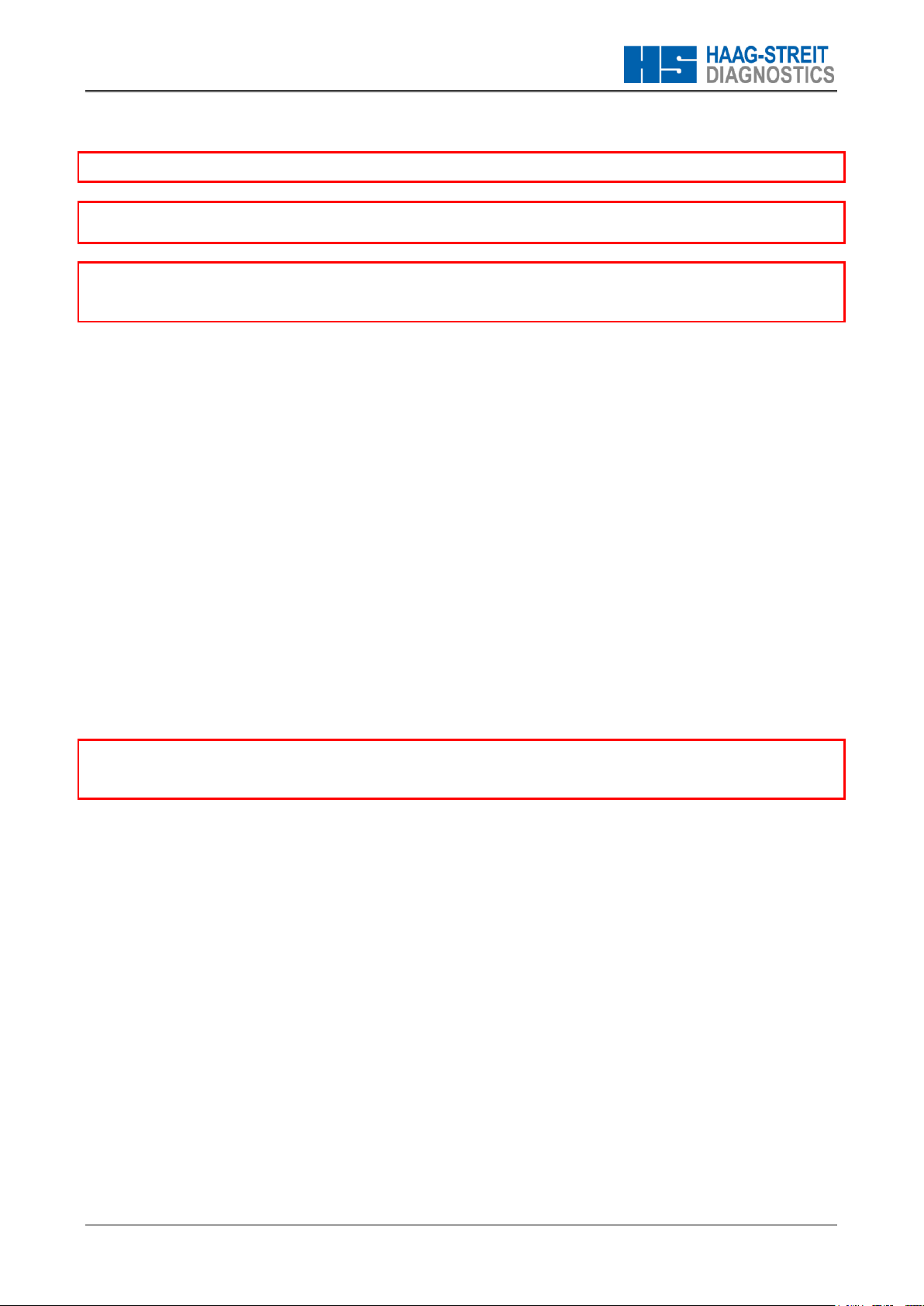

Figure 1

1 Optical unit with upper housing

2 Lower housing (left and right)

3 Grip locations (left and right)

4 Rotation and height adjustable instrument column for

fine positioning

5 Headrest with

6 Forehead rest with integrated sensors

7 Chin rest

8 Turning knob for chin rest positioning (rough

positioning)

9 Ocular

10 Trial lens holder with IR eye illumination

11 Connector for Patient response button

Figure 2

12 Turning knob for image focusing

13 Operating unit with LCD monitor and Touch module

14 Base with Connector panel and Power Supply

1

4

8

3

6

7 5 2

10

9

11

12

14

13

Tradition and Innovation

3 INTRODUCTION

3.1 OCTOPUS Perimeter 300

The OCTOPUS 300 s a direct projection perimeter for examinations of the central visual field (30°). It is a stand-alone system, which

means, the examination and control units are integrated into the instrument.

Page 6 / 64 OCTOPUS 300 Service Manual

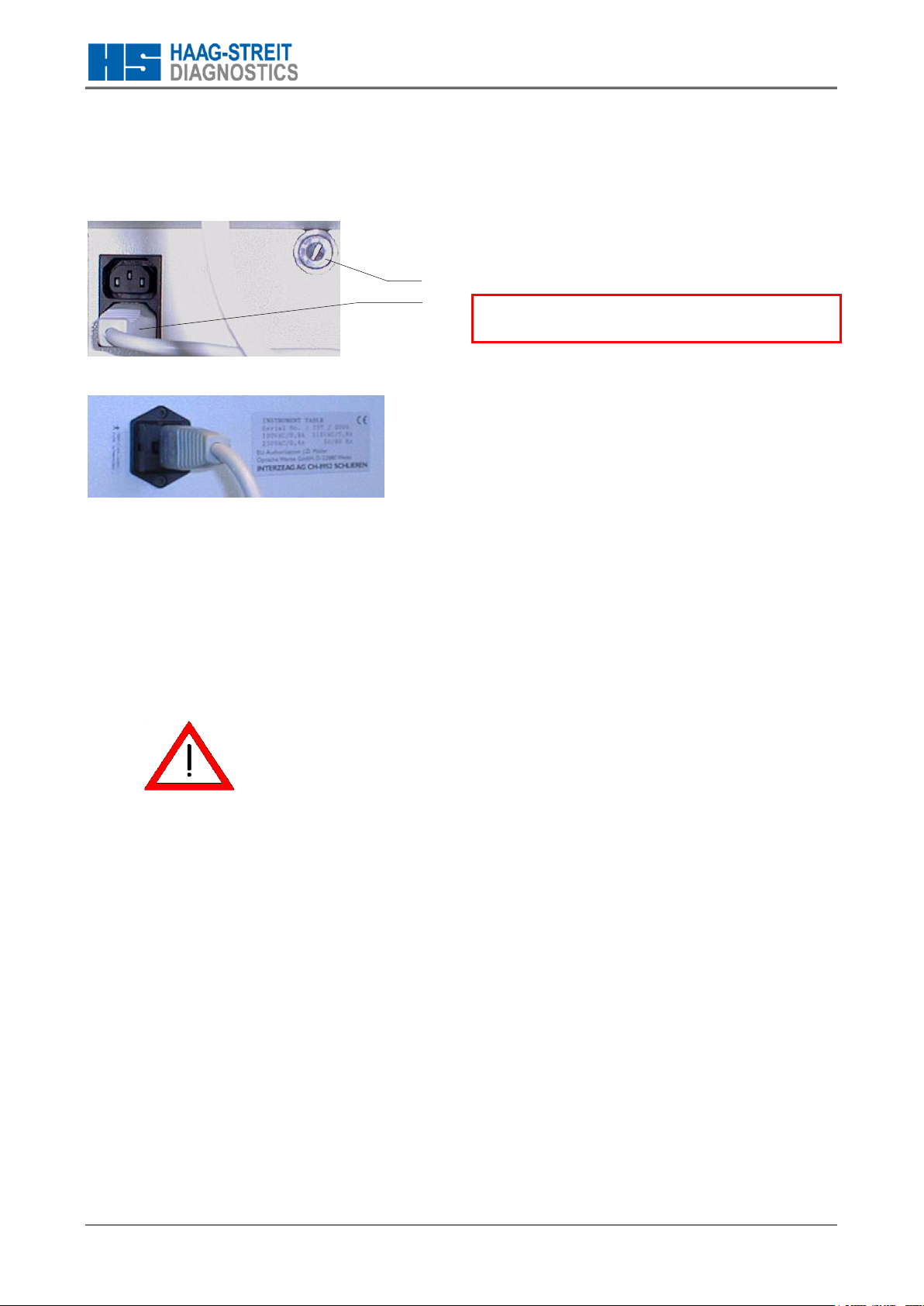

Figure 3

15 Connector panel with

16 Power switch

17 Power connector

18 Printer connector (USB)

19 Serial interface (RS 232)

20 Ethernet connector (OCTOPUS 311)

21 Ethernet control lights

22 Contrast LCD monitor

ATTENTION:

All external devices connected to the connector panel must comply with the corresponding safety

standards.

Figure 4

1 Table top with holder for patient response button

2 Electronics box

3 Patient response button

4 Electrical column

5 Table foot

Figure 5

Up / Down switch on the electronics box

ATTENTION: With patients in wheelchairs, care must be

taken when lowering the table that the table

plate does not come into contact with their

legs.

1 2 4

5 3 16

19

17

21

20

18

22

15

Tradition and Innovation

3.2 Instrument Table

An electrically adjustable instrument table (optional) makes it possible to comfortably adjust the height of the instrument to the

individual size of the patient.

OCTOPUS 300 Service Manual Page 7 / 64

Figure 6

6 Voltage selection switch on the electronics box

7 Power connector for attaching the OCTOPUS 300

WARNING: Be sure to set the correct voltage before

inserting the power cord connector.

Figure 7

Power connector socket with fuse holder on the electronics box

6

7

Do not use the forehead rest as a carrying

handle during unpacking or transportation!

Stirnstütze beim Auspacken oder

Transportieren nicht als Traggriff benutzen!

Ne pas utiliser l'appui-tête comme poignée

pendant le déballage ou pour transporter!

Tradition and Innovation

3.3 Installation

3.3.1 Instrument Table

The instrument table is delivered in a separate package. Utilize the instructions included with the table to put the table together and

take care to select the correct voltage before connecting the power cord.

3.3.2 OCTOPUS 300

Handle the instrument using both lower housing halves to lift it out of the packing. Two ribbed grips hinder sideways slipping.

Since the OCTOPUS 300 works without a cupola, a fully darkened room is not required. In order, though, to make the examination

conditions pleasant for the patient and for obtaining reliable results, the instrument is to be placed in the room so that no direct light

falls on the instrument or the patient.

The positioning between the patient and the operator or the operating panel can be so chosen that the room conditions are optimally

used.

Page 8 / 64 OCTOPUS 300 Service Manual

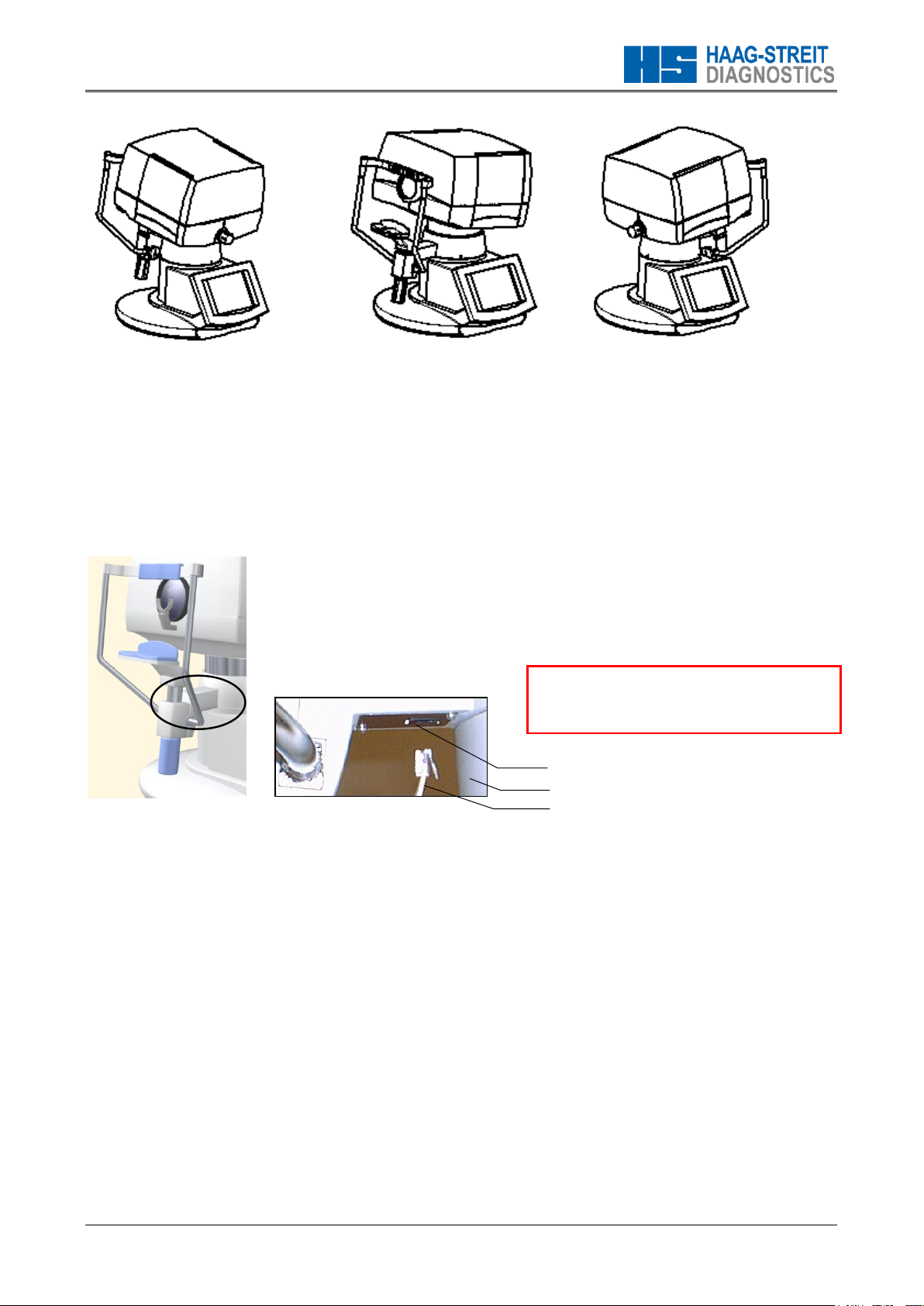

The patient sits across from

the operator

Figure 8

The patient sits on the

operator's left

The patient sits on the

operator's right

Figure 9

The connector housing for the ‘Patient response

button’ is accessible from below on the headrest

support. The catches on the Patient response button

connector are oriented in the direction of the

instrument column.

ATTENTION: Besides the ‘Patient response

button’ no other cable should be

attached to the RJ11 connector.

Headrest support with connector

Instrument column

Connector with catches

Tradition and Innovation

Loosen the three Allen head screws roughly 2 turns counterclockwise on the perimeter of the headrest holder (Allen wrench is

included with the accessories) and turn the headrest together with the optical unit into the desired position. Tighten the three

Allen head screws again. A complete rotation around the column is blocked by a built in limit.

Place the instrument on the table so that the opening of the table foot and the headrest are in the same direction.

Connect the ‘Patient response button’ to the connector located on the support of the headrest.

Stick the connector plug so far into the connector housing that the catches audibly click. To remove the ‘Patient response

button’, press the catches in the direction of the headrest and pull out the cable downwards.

If the examination data are to be transmitted to a PC, connect the OCTOPUS 300 and the PC with the serial connection cable.

Plug the power cord in. The built in ‘Power supply’ works with the voltage specified in Chapter 10.1 'Technical Data'. A change

of voltage on the instrument is not required. If an instrument table was delivered with the unit, the OCTOPUS 300 can be

connected using the power socket in the electronics box of the instrument table.

OCTOPUS 300 Service Manual Page 9 / 64

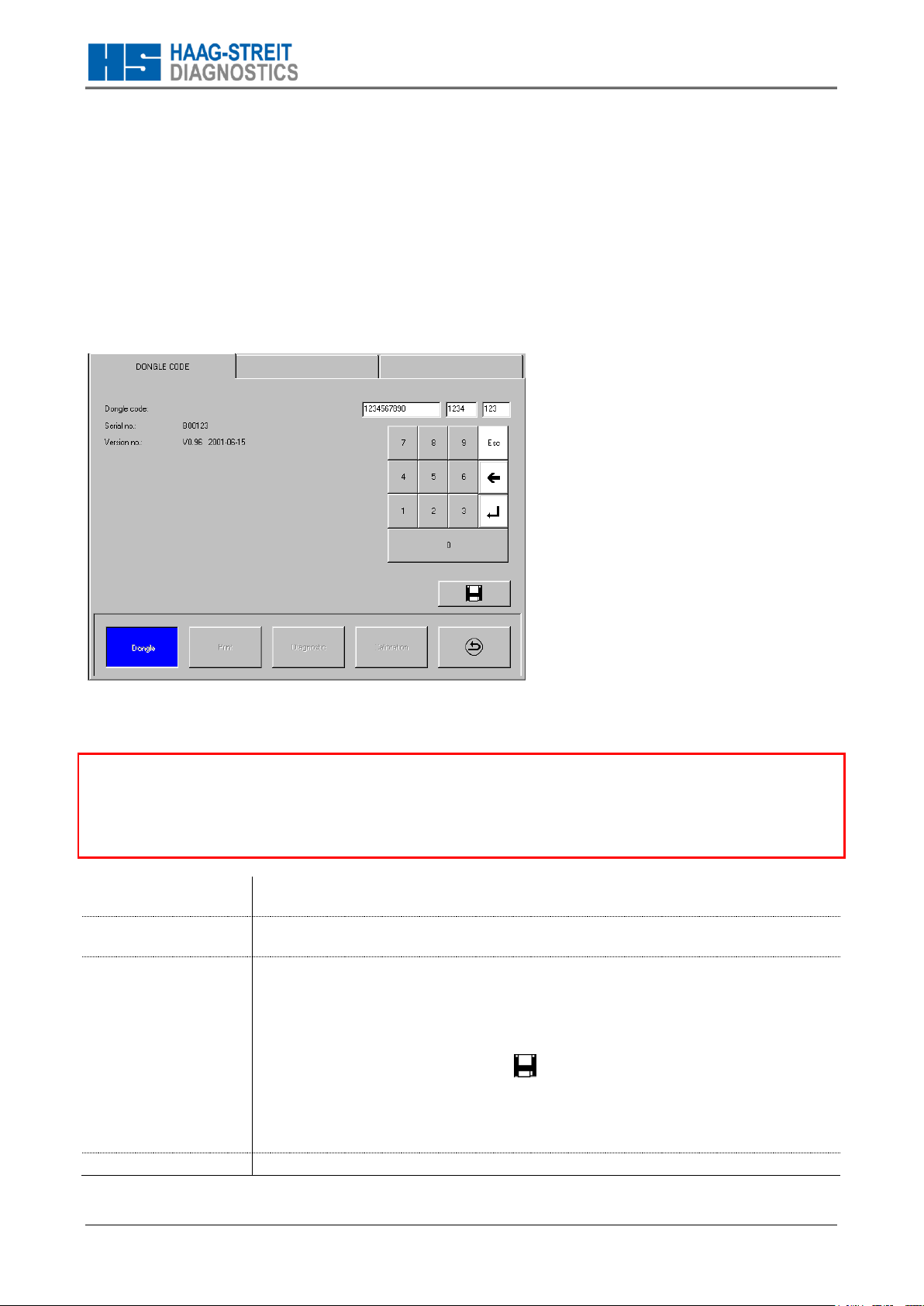

Dongle codes

Read out software master data

Actual dongle code

Serial no.

Software version

Enter new dongle code. The keyboard is

only released, when the serial number of

the instrument is stored in the memory.

To print out the complete instrument

information see Chapter 8.8 'Instrument

Information'.

Customer

Sends the serial no., software version and the complete dongle code to HAAG STREIT or the

representative and orders the desired supplementary function(s).

HAAG STREIT AG

Based on the serial no. and the present and ordered option(s), the new dongle code is computed

and given to the customer.

Customer

Enters the complete new dongle code into the OCTOPUS 300.

Open dongle code tab.

Click on 'Dongle code' entry field (numerical keyboard will be displayed).

Enter complete dongle code into the three entry fields.

Close keyboard with 'Esc'.

Save new dongle code by clicking on

Before the instrument saves the setting, the parameters are verified by the system. A faulty

dongle code will not be saved. The message 'Dongle Code not accepted' is displayed on the

screen. Delete wrong code and enter it the correct way.

OCTOPUS 300

The new additional functions are accessed via the graphical user interface.

Tradition and Innovation

4 SOFTWARE

4.1 Installation, Exchange, Upgrade

For application software installation and upgrade refer to Chapter 7.14.1 'SIM Flash Module, Application Software (1802222).

4.2 Releasing Program Options

Some of the functions of the OCTOPUS 300 are offered as options and are not accessible in the basic version of the software.

Basically all the functions are present in the software, but some can only be made accessible with a code. This code is delivered by

HAAG STREIT and is then entered by the customer or the service technician into the instrument. Information about such additional

functions can be obtained directly from HAAG STREIT or from your representative.

4.2.1 Procedure

Procedure to make additional functions accessible in the perimeter.

IMPORTANT: The 'Dongle code' function is only used, when additional program options have been purchased. To avoid

free access and faulty manipulations the function is protected. The 'Dongle' button is only released after the

two headrest sensors and the 'Dongle' button are pressed at the same time. As from Serial No. 1031 the

head rest sensors have been replaced with non-contact head sensors. In this case hold your hand (close) in

front of the head rest and simultaneously press the ‘Dongle’ button.

Page 10 / 64 OCTOPUS 300 Service Manual

D o n g l e c o d e

The complete dongle code consists of a multi-digit three part series of numbers (see

example on the left). Entering the code is done via 'Setup' – 'Service' – 'Dongle'

IMPORTANT: The additional functions are only made accessible when the dongle

code is entered without any mistakes into the instrument it was

created for.

1234567890

123

1234

Tradition and Innovation

4.2.2 Entering the Dongle Code

4.2.3 The Results of Code Mistakes

Every dongle code is unique and only valid for a specific instrument. Mistakes made while entering it or the entering of it into the

false instrument (false serial no.) have the consequence that only the basic functions are then accessible. Changing to the old code

is possible at all times.

OCTOPUS 300 Service Manual Page 11 / 64

1

3

2

4

5

10

14

9

7

8

6

11

12

13

15

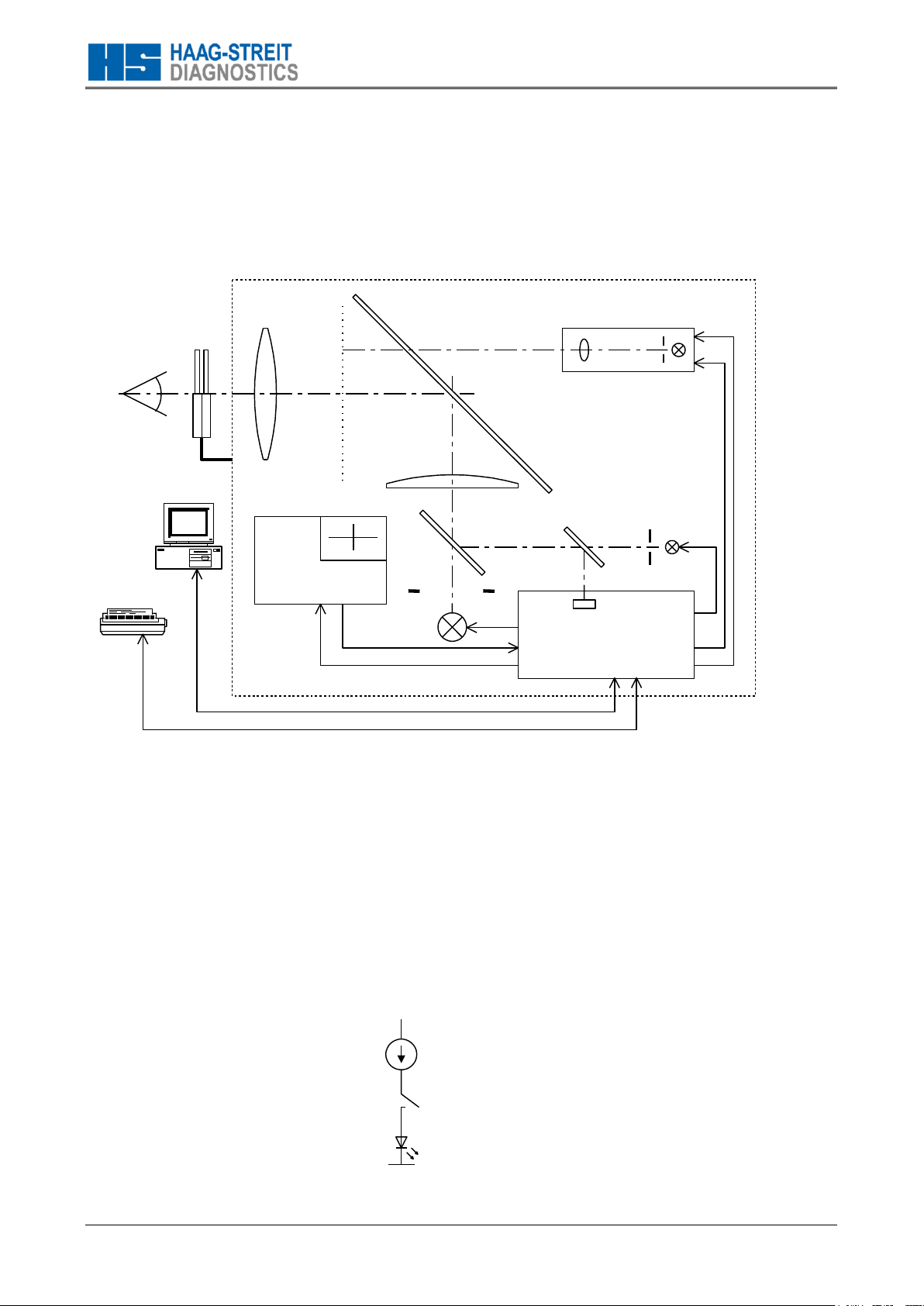

Figure 5-1: OCTOPUS 300

Functional diagram

1 Patient eye

9 Beam splitter 45°

2 Trial lens holder

10 Background illumination

3 Ocular

11 Electronics

4 Image plane

12 Fixation targets

5 Beam splitter 37°

13 Display/Touch module

6 Stimulus projection unit

14 External PC

7 Stimulus LED

15 External printer with USB interface

8 Condenser lens

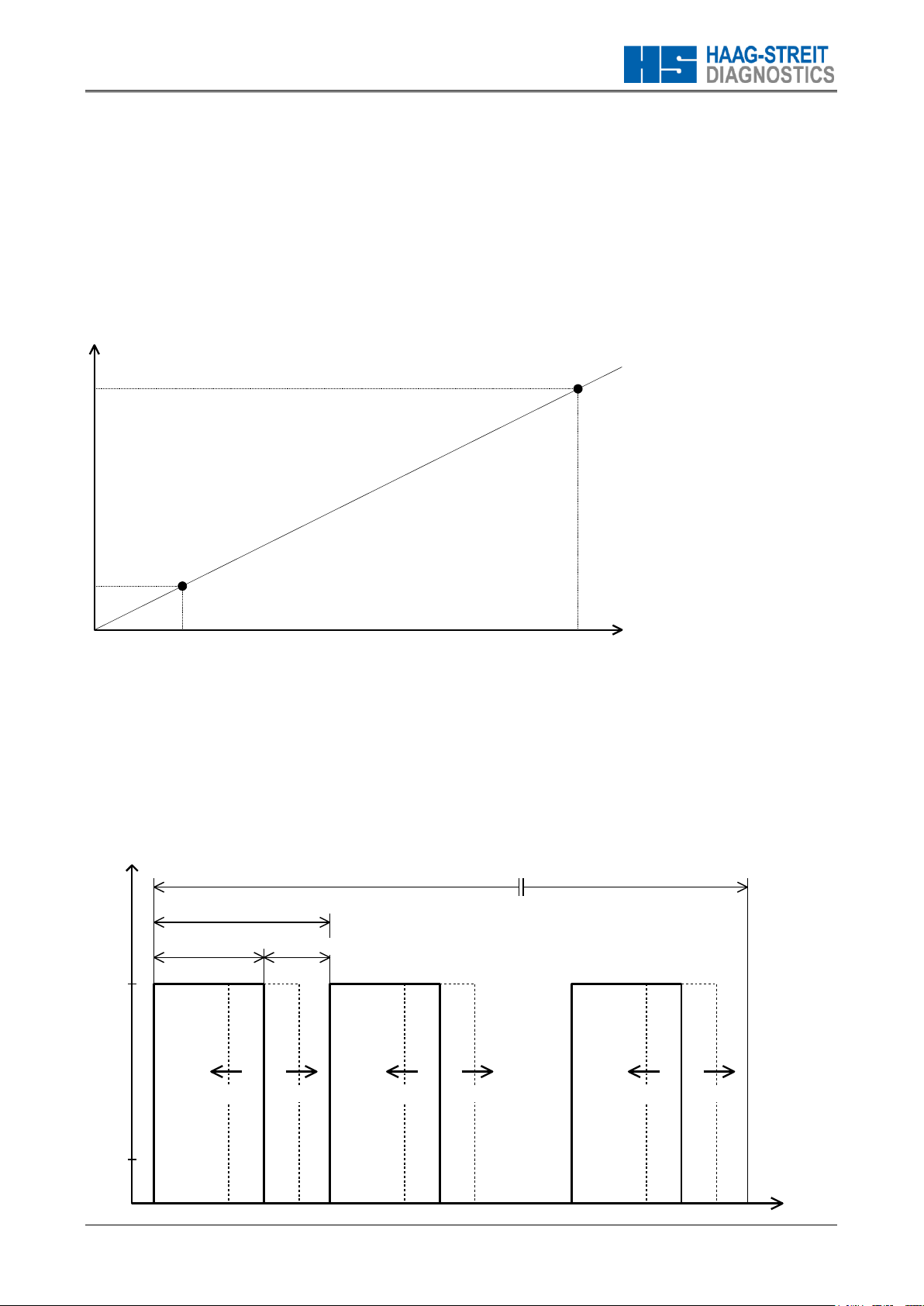

a) Two point current control (I)

b) Pulse-width modulation (S)

Figure 5-2: Principle of

stimulus generation

I (LED)

S (MOD)

Stimulus LED

Tradition and Innovation

5 PRINCIPLE OF OPERATION

HAAG-STEIT is the only company offering perimeters with direct projection systems (OCTOPUS 300, 1-2-3). By means of the

‘Optical unit’, which is replacing the cupola, stimuli are directly projected into the patient eye. This technique does not require dark

room condition to take a visual field.

5.1 Functional Diagram

5.2 Stimulus Intensity Control

The required dynamic range of the stimulus intensity of 40 dB (1:10'000) is achieved with a combined control mode:

Page 12 / 64 OCTOPUS 300 Service Manual

I (LED) OP1

I (LED) OP2

I (LED)

L (asb)

L

min

= 40dB L

max

/100 = 20dB L

max

= 0dB

Operating point 1

Operating point 2

darker darkerdarker brighterbrighter brighter

Pulse 1

Pulse 20

Pulse 2

OP2

OP1

I (LED)

S (MOD) = on S (MOD) = off

Pulse of 5ms

Stimulus duration = 100ms (20 pulses)

t

Tradition and Innovation

5.2.1 Current Control

Two current reference values (operating points) are ascertained during the stimulus calibration procedure:

Operating point OP1: 0dB (max. stimulus intensity)

Operating point OP2: 20dB (max. stimulus intensity/100)

Thus the entire dynamic range is divided into two segments:

Segment 1 / operating point OP1: 20dB ... 0dB

Segment 2 / operating point OP2: 40dB ... 20dB

Figure 5-3: Stimulus LED current control

5.2.2 Pulse-width Modulation

A typical stimulus of 100ms duration is formed by a burst of 20 5ms pulses. The width (ratio LED switch-on/LED switch-off time) of

the 20 pulses can be increased or decreased by processor control in steps of 0.4s (12'500 steps for 5ms). With a longer switch-on

time the LED is emitting light for a longer time period, resulting to the human eye, which has an integrating characteristic, in an

impact of higher brightness. Pulse-width and light emission are proportional. Pulse-width modulation and stimulus duration are

controlled by the microprocessor software through logic timer signals.

OCTOPUS 300 Service Manual Page 13 / 64

Tradition and Innovation

Figure 5-4: Stimulus LED pulse-width modulation

5.3 Background Intensity Control

The light source for the background illumination consists of a number of white LED’s. During initialization of the perimeter the

background brightness is measured by a photo sensor and controlled by a DAC value. Pulse-width modulation is not used for

background illumination.

5.4 Reference Point

During initialization of the perimeter the stimulus projection unit is centered to the optical system (position x/y = 0/0). The photo

sensor for background illumination calibration is used as reference point.

Page 14 / 64 OCTOPUS 300 Service Manual

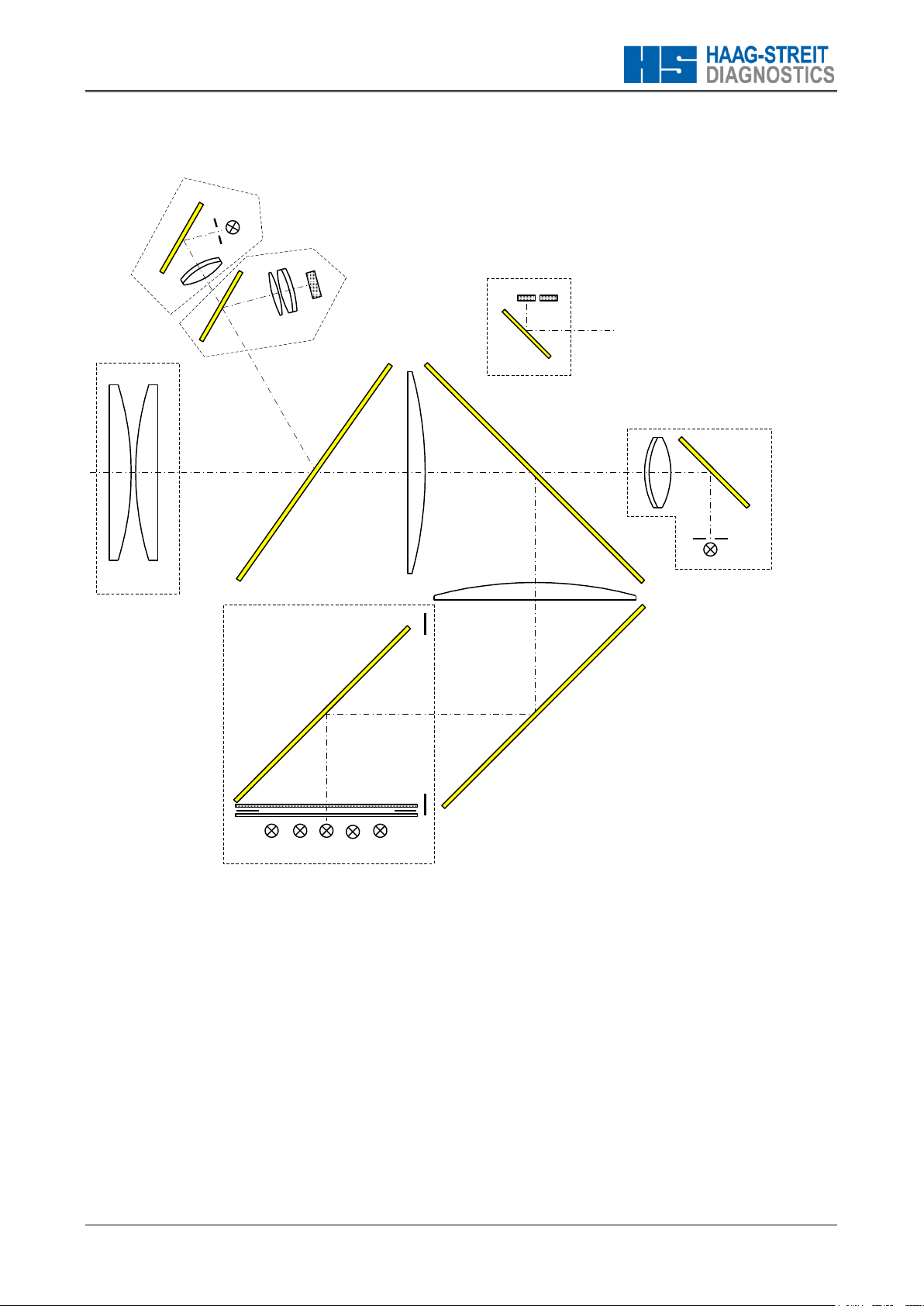

1

7

11

10

6

5

3

2

8

4

9

12

13

14

15

CCD camera

Fixation targets

Stimulus projection unit

Background illumination

Ocular

16

Light measurement

17

Figure 5-5: Optics module

1 Fixation targets

10 Stimulus LED

2 Fixation target objective lens

11 Condenser lens

3 CCD camera chip

12 Deflection mirror

4 Camera objective lens

13 Deflection mirror

5 Ocular lenses

14 Scatter pane

6 Beam splitter 37°

15 Background LED’s

7 Field lens

16 Compensation filter

8 Beam splitter 45°

17 Light measurement unit

9 Stimulus objective lens

Tradition and Innovation

5.5 Optics Module

OCTOPUS 300 Service Manual Page 15 / 64

Tradition and Innovation

6 CARE AND MAINTENANCE

6.1 Cleaning

It suffices to dust the instrument periodically with a soft cloth. More obstinate dirt particles can be removed using a soft cloth

dampened slightly with water or alcohol.

ATTENTION: Avoid making the instrument wet and never use any solvents.

6.1.1 Patient Response Button, Chin and Headrest, Turning Knobs and Eye Occluder

All of these parts are made from plastic which can be cleaned with no problems. In order to keep them hygienically clean, they

should be cleaned periodically with a cloth or cotton dampened with alcohol.

6.1.2 Ocular

Finger prints and dust can be removed with a moist soft cloth.

6.1.3 Monitor Screen, Touch Module

Finger prints and dust can be removed with a moist soft cloth.

Page 16 / 64 OCTOPUS 300 Service Manual

Tradition and Innovation

7 MAINTENANCE AND REPAIR

WARNING: Before opening the instrument make sure that the mains cable is separated from the instrument.

WARNING: Some of the modules need alignment after being exchanged. Therefore it is important to go through all the steps

described in exchanging the module that needs to be replaced.

WARNING: Electronic circuits of the OCTOPUS 300, particularly the 'Processor board', the 'Interface board' and the LEDs in

the 'Background LED module' are all very sensitive to electrostatic charges. Keep all modules in static shielding

bags for storage, transportation and shipping.

Besides an ordinary set of regular tools the following tools and instruments are recommended:

Set of Allan- (hexagonal) wrenches, metric 1.3 to 8mm

Set of Torx screwdrivers (the sizes in this manual refer to the screwdriver size)

Universal digital voltmeter, range 200mV to 250V

Cleaning Materials

Can of compressed air

Lens tissue

Lens cleaner (diluted alcohol)

Cotton swabs

Whenever possible, field repairs of the OCTOPUS 300 should be restricted to module exchange. The sub module (part) causing a

problem should be localized with the help of the service manual and error list. It should then be replaced with an exchange module.

7.1 Housing (1805001)

Housing left

Housing right

Housing top

NOTE: If the 'Housing' is removed, the perimeter will only initialize and calibrate correctly if it is placed in an entirely dark

environment. The covers can temporarily be put back in place for its operation and to run the 'Service programs'

such as the 'General test' in a semi-dark room.

Removal

Remove the 'Housing top' by removing the four Phillips (M4) screws in each outer corner from the bottom part of the 'Housing

left' and 'Housing right' (see Figure 7-1).

OCTOPUS 300 Service Manual Page 17 / 64

Figure 7-1

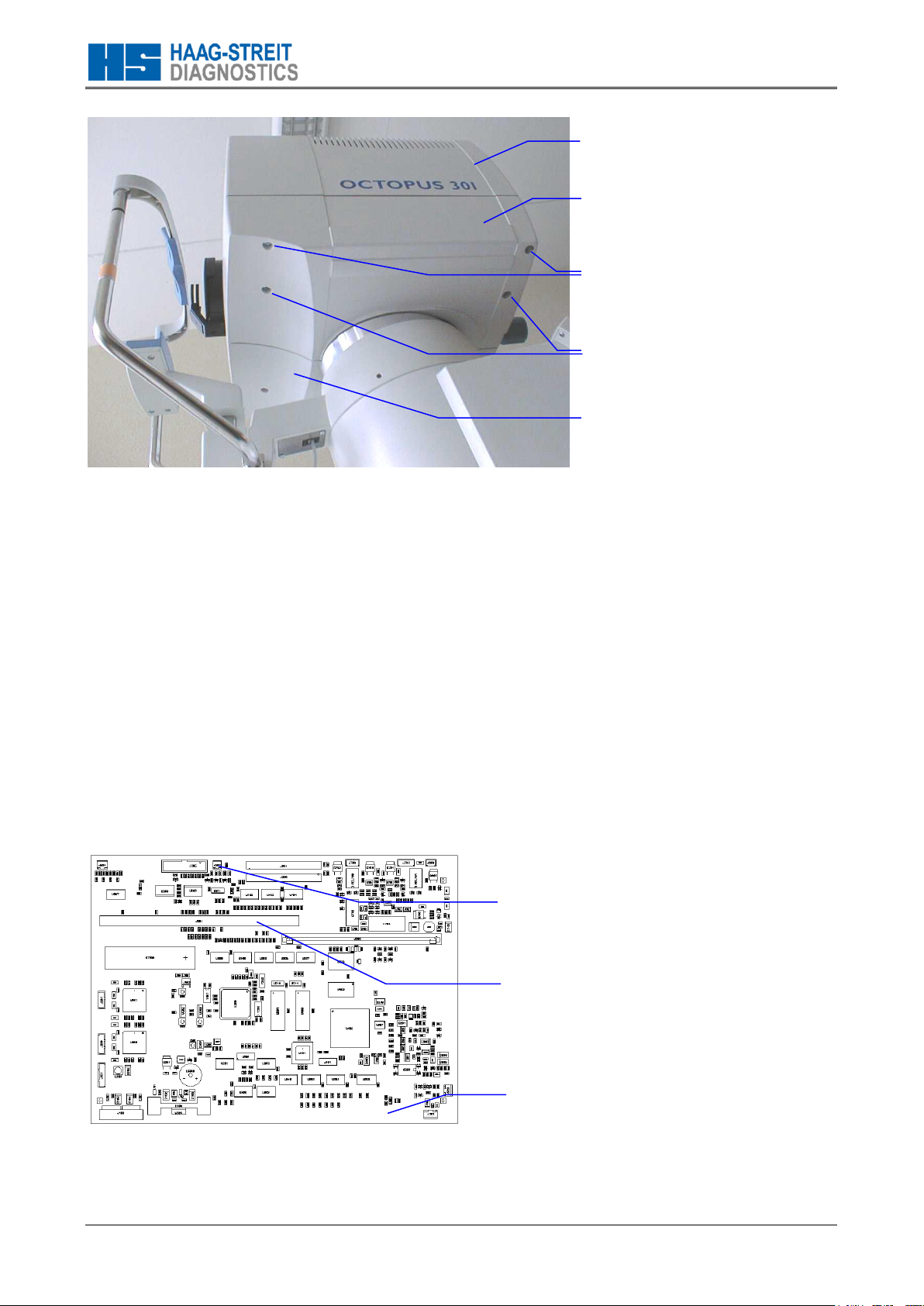

Figure 7-2: Processor board

Housing right

Housing top

Screws to remove 'Housing top'

(in the same position on both sides)

Screws to remove Housing right

Housing left

Position of the cable 'LCD' (50 pin)

SD RAM module

Connector 'Switches' (6 pin)

Tradition and Innovation

Once the screws have been removed, simply lift the 'Housing top' and place it on a clean surface.

Remove the 'Housings left' and 'Housing right' by removing the 4 Phillips (M4) screws in each inner corner from the bottom of

the 'Housings left-/right' (see Figure 7-1). The Optical unit can be swung in a left/right movement for easy access. Remove the

'Housing left-/right' by gently lifting both parts out of the instrument. Place both parts on a clean surface.

Reassembly

Reassemble in reverse order to removal.

Check

Once reassembled check that the screws have been tightened and that the 'Housing' is clean.

7.2 Optical Unit (1802669)

Removal

Remove the 'Housing' (see Chapter 7.1).

Remove the bottom 5 connectors of the 'Interface board'. Remove the screw and washer holding the 'Grounding cable'

connected to the 'Optical unit'.

On the 'Processor board' disconnect the cable 'Switches' (6 pin) and the cable 'LCD' (50 pin).

Page 18 / 64 OCTOPUS 300 Service Manual

Figure 7-3

Figure 7-4

Nuts holding the 'Optical unit' to the

'Z-shaft'

Processor board

LCD cable

Fixation target

Interface board

Swivel ring

SIM Flash module

Tradition and Innovation

Cut the tie-wraps, holding the cables to the 'Optical unit'.

Remove the 'Touch screen module' (see Chapter 7.9), then remove the 'Power connector' from TB2 (see Chapter 7.12).

Remove the 4 nuts holding the 'Optical unit' to the 'Z-shaft'. See Figure 7.4.

Gently lift out the 'Optical unit', at the same time glide the 'Power connector' through the slot in the 'Z-shaft'. Be careful not to

damage any wires. Place the unit on a flat, dust-free surface.

Reassembly

Reassemble in reverse order to removal.

Check

Are all cables connected?

Are the four nuts holding the 'Optical unit' to the 'Z-shaft' back in place and tightened correctly.

Have all the cut tie-wraps been replaced by new ones.

After reassembly, run 'General test' to verify faultless operation. Regarding the 'Service Programs', refer to chapter 8.

7.3 Z-Shaft (1802190)

OCTOPUS 300 Service Manual Page 19 / 64

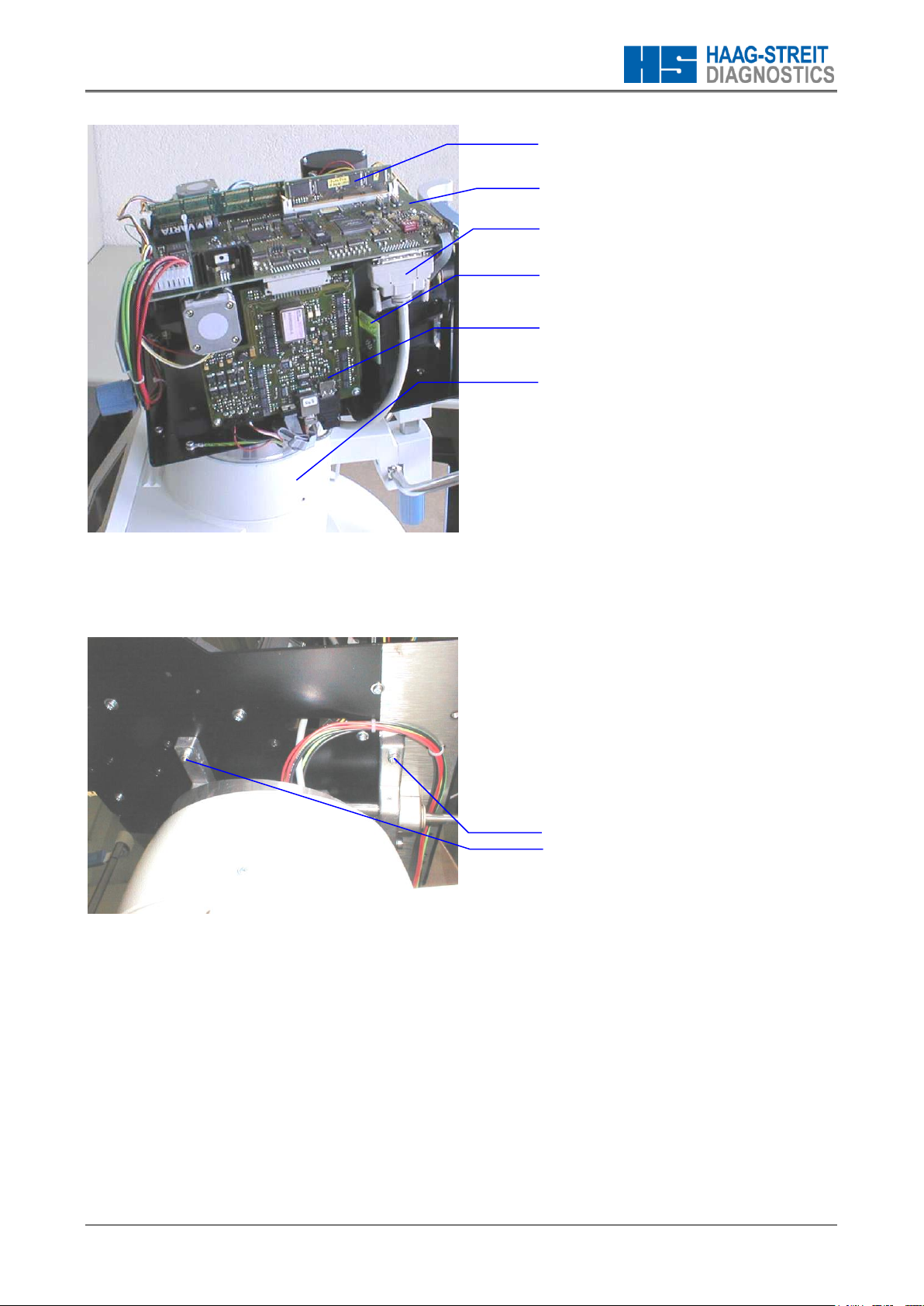

Figure 7-5

3 torx screws (size 25).

Tradition and Innovation

Removal

Remove 'Housing' and 'Optical unit' as described in Chapter 7.1 and 7.2.

Remove the 3 torx screws (size 25) which are fastened down onto the 'Lift-/ swivel unit' from the top. See Figure 7-5.

Gently lift up the 'Z-shaft', at the same time thread the connectors that were loosened in Chapter 7.1 and 7.2 through the slots in

the 'Z-shaft'.

Place the 'Z-shaft' on a clean surface.

Reassembly

Reassemble in reverse order to removal.

Check

Before mounting the 'Optical unit' be sure that all the connectors and cables have been passed through the slot in the 'Z-shaft'.

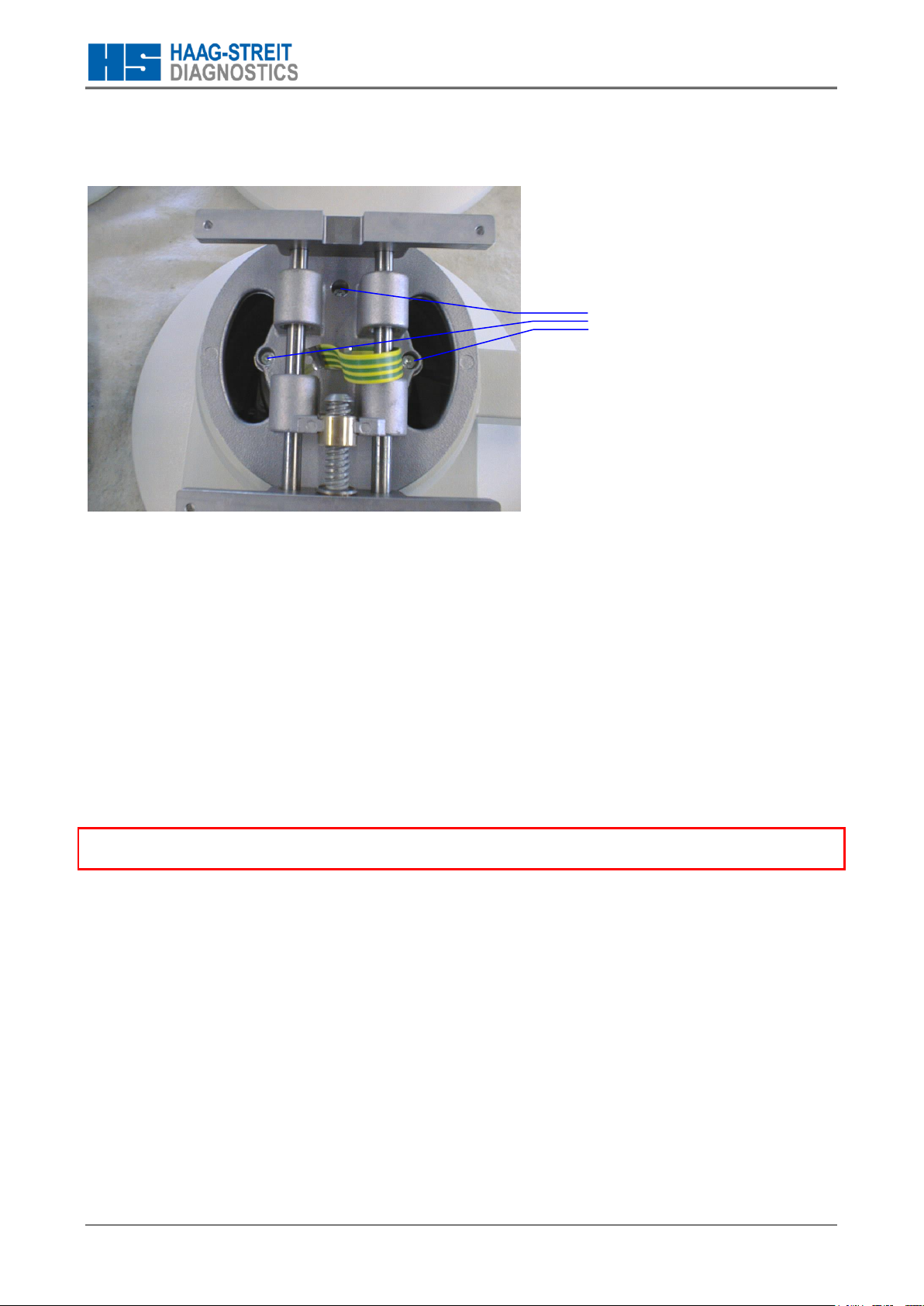

7.4 Fixation Target (1802206)

7.4.1 Fixation Board (1802207)

NOTE: If the 'Fixation board' is defective there is no need to replace the entire 'Fixation target', one can simply remove

the 'Fixation board' from the 'Fixation target' by following the steps below.

Removal

Remove the housing (see Chapter 7.1)

Remove the 10 pin flat cable from the 'Fixation board'.

Remove the torx screw (size 15) holding the 'Fixation target' to the 'Optical unit'. Simply lift the 'Fixation target' out of the two

guide pins.

Remove the two hexagon socket screws (wrench size 2,5) and washer holding the 'Fixation board' to the 'Fixation target'.

The 'Fixation board' can simply be removed.

Reassembly

Reassemble in reverse order. Before remounting the 'Housing', go through the check procedure below.

Page 20 / 64 OCTOPUS 300 Service Manual

Loading...

Loading...