Page 1

DC Power Supply

SPD-3606

USER MANUAL

GW INSTEK PART NO. 82PD-36060M0

This manual contains proprietary information, which is protected by

copyrights. All rights are reserved. No part of this manual may be

photocopied, reproduced or translated to another language without

prior written consent of Good Will company.

The information in this manual was correct at the time of printing.

However, Good Will continues to improve products and reserves the

rights to change specification, equipment, and maintenance

procedures at any time without notice.

ISO-9001 CERTIFIED MANUFACTURER

Good Will Instrument Co., Ltd.

No. 7-1, Jhongsing Rd., Tucheng City, Taipei County 236, Taiwan.

Page 2

TABLE OF CONTENTS

SPD-3606 User Manual

FAQ ................................................................................ 56

Table of Contents

SAFETY INSTRUCTION ..................................................... 5

OVERVIEW ........................................................................ 9

SPD-3606 Main Features......................10

Principle of Operation.......................... 11

Front Panel Overview........................... 14

Rear Panel Overview ............................17

CV/CC Crossover Characteristics ......... 18

SETUP............................................................................. 19

Installation Location ............................ 20

Power Up ............................................. 21

Over Voltage Protection Setup ............. 22

Load Cable Connection ........................ 24

Output On/Off..................................... 25

OPERATION.................................................................... 26

CH1/CH2 Independent Mode .............. 26

CH3 Independent Mode....................... 28

CH1/CH2 Tracking Series Mode........... 30

CH1/CH2 Tracking Parallel Mode ........ 36

APPENDIX ...................................................................... 57

Fuse Replacement................................ 57

Volume Guard (Optional).....................58

Specification ........................................59

Declaration of Conformity.................... 61

INDEX............................................................................. 62

REMOTE OUTPUT CONTROL.......................................... 39

PERFORMANCE VERIFICATION ...................................... 40

Output Voltage Verification.................. 42

Tracking Series Voltage Verification...... 45

Output Current verification.................. 47

OVP verification................................... 50

Recording Tables.................................. 54

3

4

Page 3

SAFETY INSTRUCTION

y

SPD-3606 User Manual

Safety Guidelines

General Guideline

• Do not place any heavy object on SPD-3606.

SAFETY INSTRUCTION

This chapter contains important safety instructions

that you must follow when operating SPD-3606

and when keeping it in storage. Read the

following before any operation to insure your

safety and to keep the best condition for SPD-3606.

Safety Symbols

These safety symbols may appear in this manual or on SPD-3606.

WARNING

CAUTION

Warning: Identifies conditions or practices that

could result in injury or loss of life.

Caution: Identifies conditions or practices that

could result in damage to SPD-3606 or to other

properties.

DANGER High Voltage

Attention Refer to the Manual

Protective Conductor Terminal

Earth (ground) Terminal

CAUTION

• Avoid severe impacts or rough handling that

leads to damaging SPD-3606.

• Do not discharge static electricity to SPD-3606.

• Do not block or obstruct the cooling fan vent

opening.

• Leave a space around SPD-3606, at least 3cm to

the left and right.

• Do not perform measurement at circuits directl

connected to Mains (Note below).

Power Supply

WARNING

• Do not disassemble SPD-3606 unless you are

qualified as service personnel.

(Measurement categories) EN 61010-1:2001 specifies the

measurement categories and their requirements as follows. SPD3606 falls under category I.

• Measurement category IV is for measurement performed at the

source of low-voltage installation.

• Measurement category III is for measurement performed in the

building installation.

• Measurement category II is for measurement performed on the

circuits directly connected to the low voltage installation.

• Measurement category I is for measurements performed on

circuits not directly connected to Mains.

• AC Input voltage: 115V/230V ±15%, 50/60Hz

• Connect the protective grounding conductor of

the AC power cord to an earth ground, to avoid

electrical shock.

Fuse

WARNING

5

6

• Fuse type: T10A/250V

• Make sure the correct type of fuse is installed

before power up.

Page 4

SAFETY INSTRUCTION

SPD-3606 User Manual

Cleaning SPD3606

Operation

Environment

Storage

environment

• To ensure fire protection, replace the fuse only

with the specified type and rating.

• Disconnect the power cord before fuse

replacement.

• Make sure the cause of fuse blowout is fixed

before fuse replacement.

• Disconnect the power cord before cleaning.

• Use a soft cloth dampened in a solution of mild

detergent and water. Do not spray any liquid.

• Do not use chemical or cleaner containing harsh

material such as benzene, toluene, xylene, and

acetone.

• Location: Indoor, no direct sunlight, dust free,

almost non-conductive pollution (Note below)

• Relative Humidity: < 80%

• Altitude: < 2000m

• Temperature: 0°C to 40°C

(Pollution Degree) EN 61010-1:2001 specifies the pollution degrees

and their requirements as follows. SPD-3606 falls under degree 2.

Pollution refers to “addition of foreign matter, solid, liquid, or

gaseous (ionized gases), that may produce a reduction of dielectric

strength or surface resistivity”.

• Pollution degree 1: No pollution or only dry, non-conductive

pollution occurs. The pollution has no influence.

• Pollution degree 2: Normally only non-conductive pollution

occurs. Occasionally, however, a temporary conductivity caused

by condensation must be expected.

• Pollution degree 3: Conductive pollution occurs, or dry, non-

conductive pollution occurs which becomes conductive due to

condensation which is expected. In such conditions, equipment

is normally protected against exposure to direct sunlight,

precipitation, and full wind pressure, but neither temperature

nor humidity is controlled.

• Location: Indoor

• Relative Humidity: < 70%

• Temperature: −10°C to 70°C

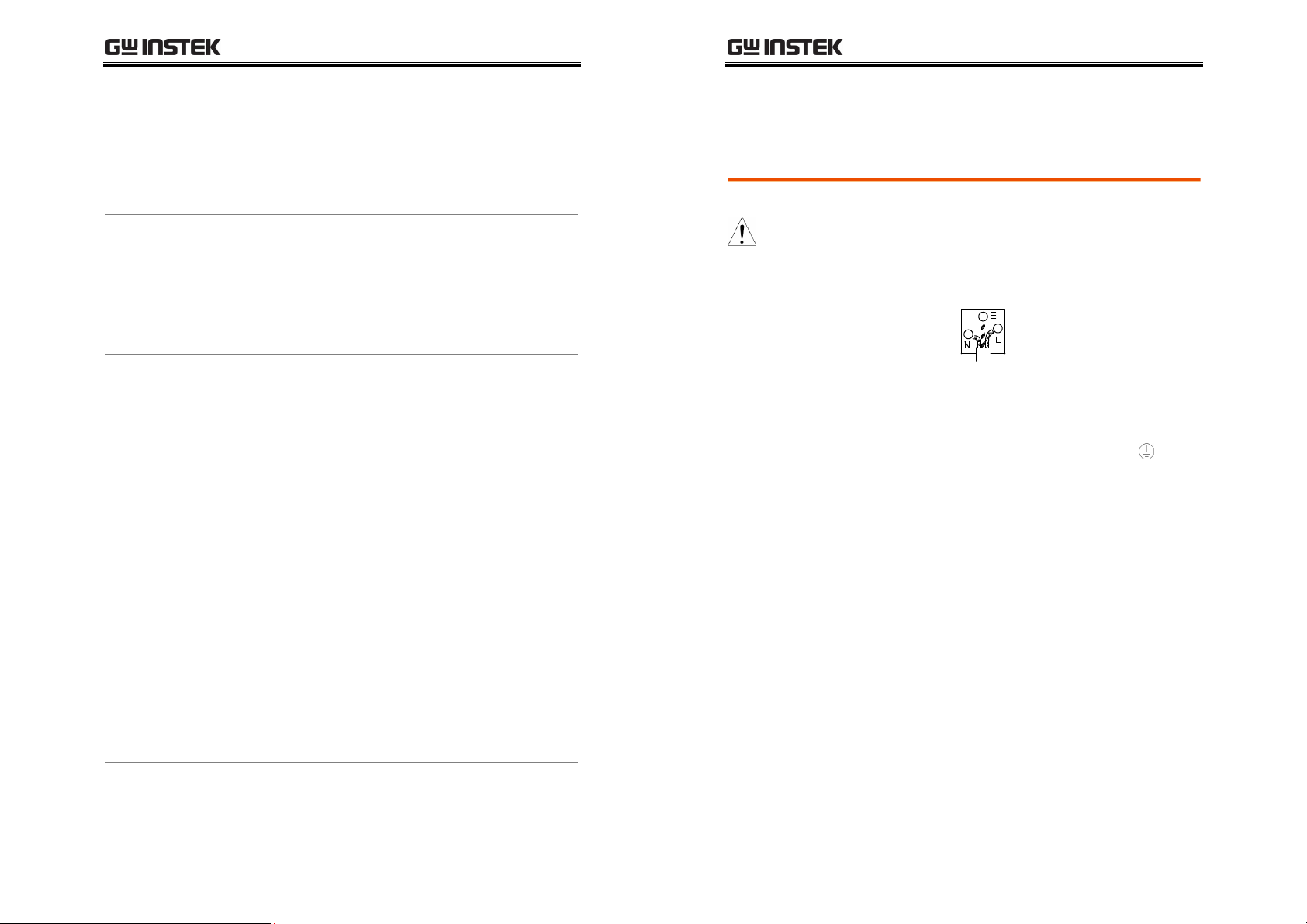

Power cord for the United Kingdom

When using SPD-3606 in the United Kingdom, make sure the power

cord meets the following safety instructions.

NOTE: This lead/appliance must only be wired by competent persons

WARNING: THIS APPLIANCE MUST BE EARTHED

IMPORTANT: The wires in this lead are coloured in accordance with

the following code:

Green/ Yellow: Earth

Blue: Neutral

Brown: Live (Phase)

As the colours of the wires in main leads may not correspond with the

colours marking identified in your plug/appliance, proceed as follows:

The wire which is coloured Green & Yellow must be connected to the

Earth terminal marked with the letter E or by the earth symbol

coloured Green or Green & Yellow.

The wire which is coloured Blue must be connected to the terminal

which is marked with the letter N or coloured Blue or Black.

The wire which is coloured Brown must be connected to the terminal

marked with the letter L or P or coloured Brown or Red.

If in doubt, consult the instructions provided with the equipment or

contact the supplier.

This cable/appliance should be protected by a suitably rated and

approved HBC mains fuse: refer to the rating information on the

equipment and/or user instructions for details. As a guide, cable of

2

0.75mm

should be protected by a 3A or 5A fuse. Larger conductors

would normally require 13A types, depending on the connection

method used.

Any moulded mains connector that requires removal /replacement

must be destroyed by removal of any fuse & fuse carrier and disposed

of immediately, as a plug with bared wires is hazardous if a engaged in

live socket. Any re-wiring must be carried out in accordance with the

information detailed on this label.

or

7

8

Page 5

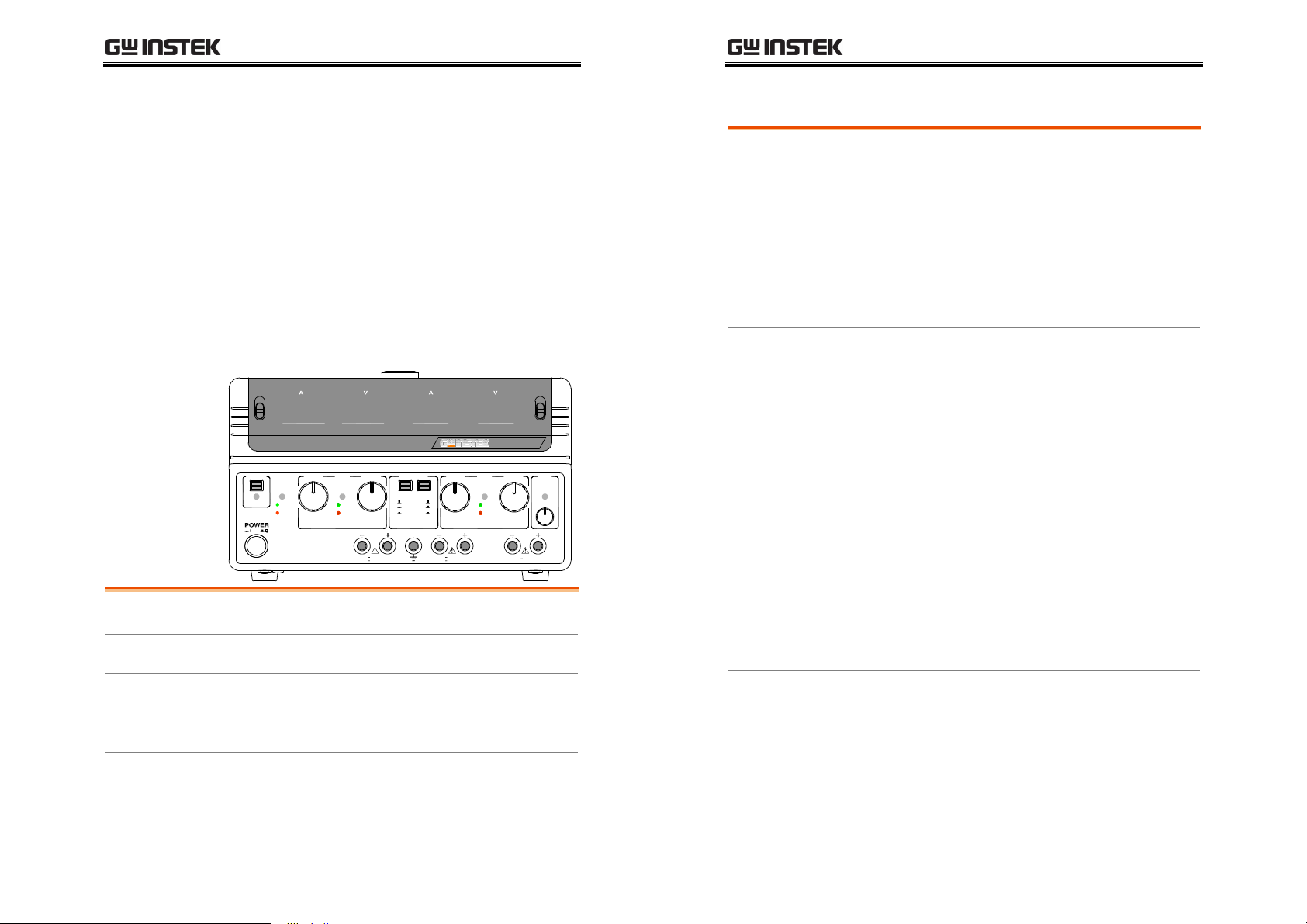

OVERVIEW

OVERVIEW

This chapter describes SPD-3606 in a nutshell,

including its main features and front / rear panel

introduction. After going through the overview,

follow the Setup chapter (page19) to properly

power up and set operation environment.

For initial inspection, refer to the Performance

verification chapter (page40).

SPD-3606 User Manual

SPD-3606 Main Features

Performance

Operation

• Low noise (≤ 50dB, Cooling fan controlled by

Heatsink temperature)

• High efficiency power conversion, minimum

70% with full load

• Fast Output On/Off response (≤100ms)

• Low temperature coefficient

(≤100ppm/°C+3mV, ≤150ppm/°C+3mA)

• Compact size, light weight (6kg)

• Constant voltage operation

SPD-3606

VOLTAGEVOLTAGE CURRENTCURRENT

0.1 5V , 3A

CH1

CH3

CH3

OVER LOAD

VOLTAGE

60V/3A

INDEP.

SERIES

0 60V , 3A

0 30V , 6A

CH1 / CH3CH2

30V/6A

Dual−Range DC Power Supply

OUTPUT CH2 CH1

O.V.P.

ON / OFF

SET C.V.

TRIP C.C.

SLAVE MASTER

C.V.

C.C.

PAR.

CH2 CH1 CH3GND

0 60V , 3A

0 30V , 6A

TRACKING

PARALLEL

Main Feature SPD-3606 Main Features .................................10

Theory Principle of Operation..................................... 11

Panel overview Front Panel Overview ......................................14

Rear Panel Overview........................................ 17

CV/CC CV/CC Crossover Characteristics..................... 18

• Constant current operation

• Tracking Series operation

• Tracking Parallel operation

• Output On/Off control

• 3 outputs with full Voltage control

• Output range selection for CH1 and CH2,

60V/3A or 30V/6A

Protection

Interface

• LED display

• Over voltage protection (OVP)

• Overload protection

• Reverse polarity protection

• Remote control output On/Off terminal

9

10

Page 6

OVERVIEW

y

SPD-3606 User Manual

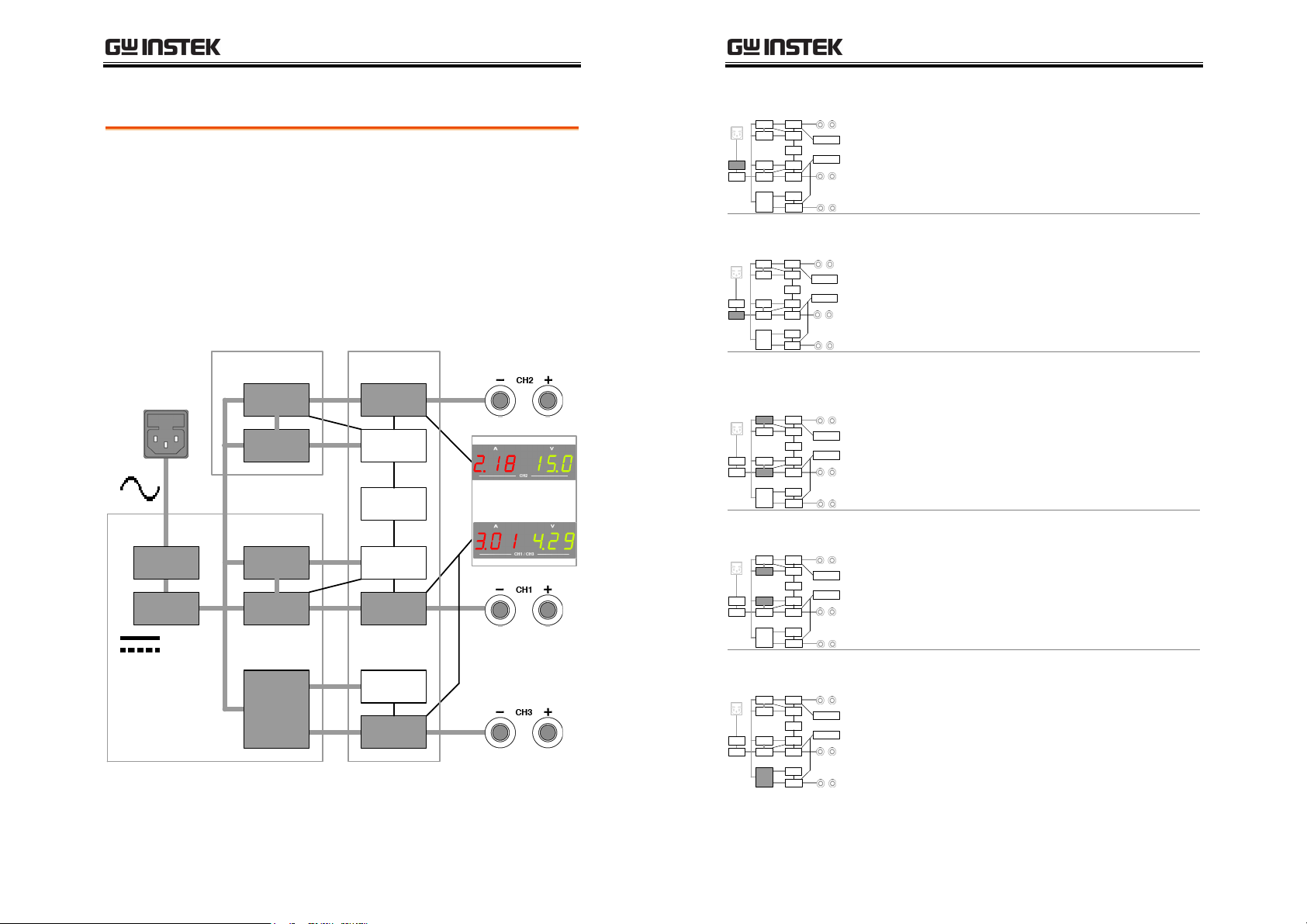

Principle of Operation

Block diagram

Power

Supply

EMI Filter

Rectifier/

Doubler

PCB A

Power supply converts the AC mains into DC

Power source for internal units. Channel 1/2/3

control and produce the actual DC output. Displa

shows output and OVP level, receiving feedback

from each channel. Internal components are placed

on four printed circuit boards, A ~ D.

Detailed description of each module starts on the

next page.

PCB B PCB C

CH2

Power

Stage

AUX

Power

CH1

AUX

Power

Power

Stage

CH3

Power

Stage

Output

Controller

Tracking

Controller

Controller

Output

Controller

Output

PCB D

Display

EMI Filter

Other than deleting conduction EMI (electromagnetic interference), the EMI unit contains

protective circuits such as Inrush current limit

resistor and Surge absorber. Internal units are

protected under power-up sequence, normal

Rectifier / Doubler

operation, and AC mains fluctuation.

The Rectifier unit converts AC mains into DC

Power source. For 115V±15% AC, double-wave

rectification is used; for 230V±15% AC, full-wave

rectification. An internal selector automatically

switches the rectification circuit accordingly. The

final DC Voltage reaches 240V ~ 370V.

CH1/2 Power

Stage

The Power stage for Channel1 and 2 produce the

outputs using the combination of Half-bridge

converter and Linear regulator. The Half-bridge

converter adopts PWM (pulse-width modulation)

with high frequency switching. The Linear

regulator adjusts the output Voltage down to 0V.

CH1/2 AUX Power

The AUX Power for Channel 1 and 2 produces the

power source for auxiliary devices, such as

analog/digital controller, relay, LED display, and

cooling fan. Altogether four pairs of power source

are generated for different purpose: ±12V, +5V,

and +12V.

CH3 Power Stage

The Power stage for Channel 3 produces both the

channel output and the power source for auxiliary

devices. It uses the combination of Flyback

converter and Linear regulator, carrying lower

efficiency compared to Channel 1 and 2. The

flyback converter also produces ±12V for ICs and

4~8V settable Voltage.

11

12

Page 7

OVERVIEW

O.V.P

OUTPUT

SPD-3606 User Manual

CH1/2/3

Controller

Feedback control

unit

OVP setting unit

Fan control unit

Tr ac k in g

Controller

LED Display

The Controller for Channel 1, 2, and 3 takes care of

the interface between SPD-3606 and users. Several

sub-units comprise the Controller, including:

• Feedback control unit

• OVP setting unit

• Fan control unit

Detailed description of each unit follows.

The Feedback control unit receives the control

signal for Voltage/Current output level and the

level feedback signal from the actual output. The

difference between the two signals are amplified

and used as the control signal for the Power stage

to achieve stable output level.

The SVR (small variable resistor) sets the

protection point so that the OVP setting unit shuts

down the output when the output Voltage level

exceeds the configured level.

Using NTC (negative temperature coefficient)

resistor, the Fan control unit changes the control

Voltage for the cooling fan according to the

temperature change, achieving low-noise and

linear speed control.

The Tracking controller controls Channel 2 output

level when in tracking series or parallel mode. In

tracking series mode, Channel2 output Voltage is

controlled by Channel1 output Voltage level. In

tracking parallel mode, Channel2 output Current

is controlled by Channel1 output Current level.

The LED display shows the Channel 1/2/3 output

Voltage/Current level. The A/D converter

changes the analog signal coming from each

channel into digital format to be displayed.

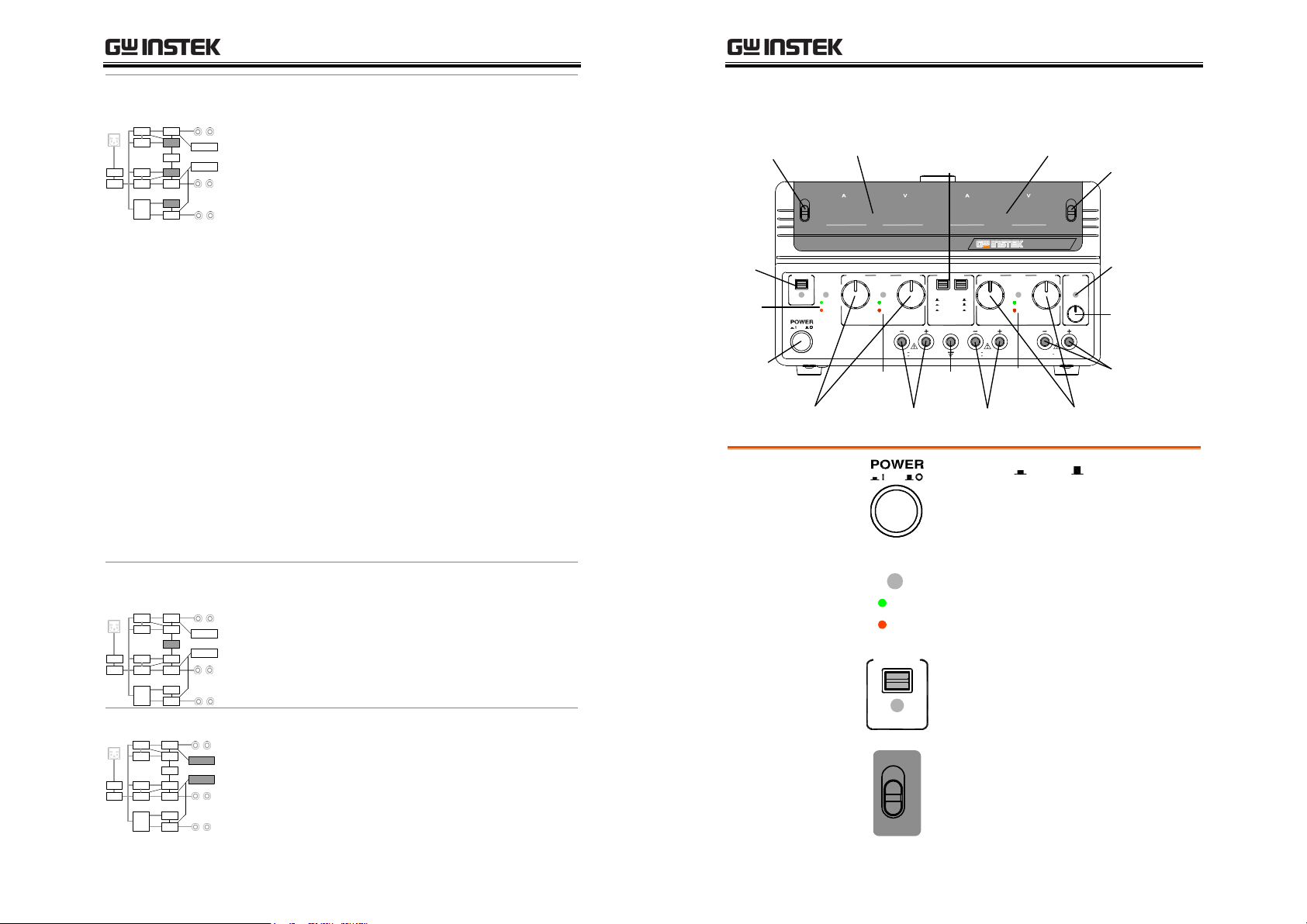

Front Panel Overview

Tracking Mode

Switches

CH2 CH1 CH3GND

0 60V , 3A

0 30V , 6A

Ground

TRACKING

SLAVE MASTER

C.V.

C.C.

PAR.

CH2

Te rm i na l

CH2 Output

Terminal

.

SET

TRIP

ON / OFF

60V/3A

Switch

60V/3A

30V/6A

Dual−Range DC Power Supply

Output

Key

OVP

OUTPUT CH2 CH1

ON / OFF

Indicator

Power

Switch

CH2 Output

Knob

Power switch

OVP indicator

Output Key

Output range

switch

CH2 MeterOutput Range

O.V.P.

SET C.V.

TRIP C.C.

Indicator

CH1/3 Meter

CH1/CH3

Meter Switch

CH1

CH1 / CH3CH2

CH3

SPD-3606

CH3 Overload

CH3

INDEP.

SERIES

PARALLEL

VOLTAGEVOLTAGE CURRENTCURRENT

OVER LOAD

VOLTAGE

Indicator

CH3 Voltage

Knob

0 60V , 3A

0 30V , 6A

CH1

0.1 5V , 3A

CH3 Output

Terminal

Indicator

CH1 Output

Te rm i na l

Turns On

CH1 Output

Knob

or Off the main power.

For power up sequence, see page20.

Turns green during the OVP setup.

Turns red (tripped) when the output

Voltage exceeds the setting. For

OVP details, see page22.

Turns the output On (green) or Off

(gray), all three channels at once.

Selects the output range, 60V/3A or

30V/6A.

13

14

30V/6A

Page 8

OVERVIEW

TRA

CKIN

g

OVE

L

OAD

SPD-3606 User Manual

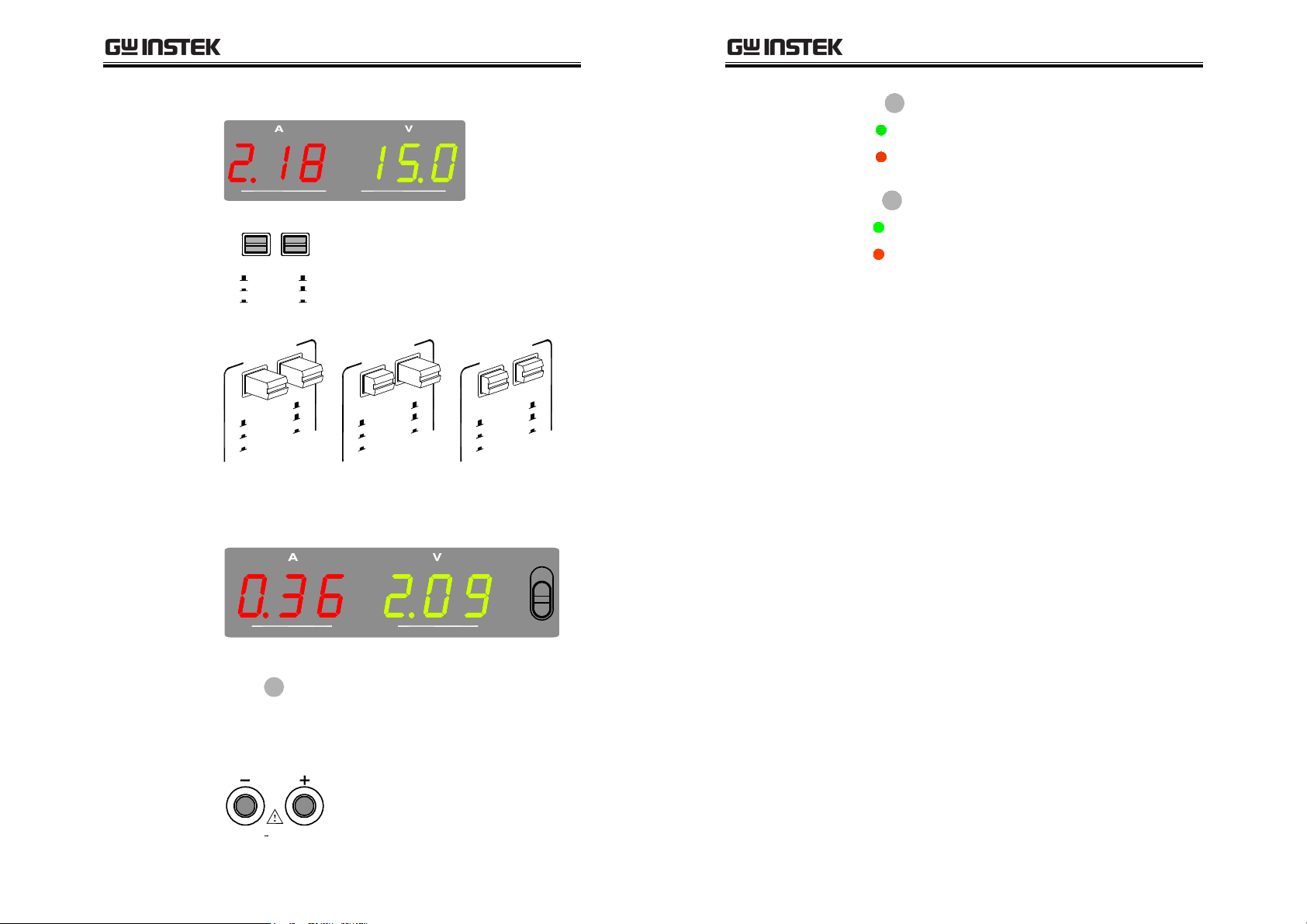

CH2 meter

Tracking mode

switches

CH1/3 meter +

switch

Displays Channel2 current (A) and voltage (V).

G

INDEP.

SERIES

PARALLEL

Independent

G

N

I

K

C

A

R

T

.

P

E

D

N

I

S

E

I

R

E

S

L

E

L

L

A

R

A

P

CH2

Activates and selects the tracking

mode. For trackin

page30 (Series) and page36

(Parallel).

Tra c ki n g S eri es

G

N

I

K

C

A

TR

.

P

E

D

N

I

S

E

I

R

E

S

L

E

L

L

A

R

A

P

mode details, see

Tracking Parallel

G

N

I

K

C

A

R

T

.

EP

D

N

I

S

E

I

R

E

S

L

E

L

L

A

R

PA

Displays Channel1 or Channel3 current (A) and

voltage (V). The switch on the right selects the

channel, 1 (up) or 3 (down).

Channel1 CV/CC

indicator

Channel2

CV/CC/PAR

indicator

C.V.

C.C.

C.V.

C.C.

PAR.

Turns green when operating in

Constant Voltage (CV) mode, red in

Constant Current (CC) mode. For

CV/CC characteristics, see page18.

Independent mode:

Turns green in Constant Voltage

(CV) mode, red in Constant Current

(CC) mode.

Tracking parallel mode (page36):

When operating in the Tracking

Parallel mode, the Channel2

indicator always stays red (PAR).

Channel1 indicator shows the

CV/CC status.

CH1

Channel3

overload indicator

R

CH1 / CH 3

Turns red when Channel3 output

exceeds the current rating, 3A.

CH3

Channel3 switches from Constant

Voltage (CV) mode to Constant

Current (CC) mode.

Channel1/2/3

output terminal

CH3

0.1 5V , 3A

Accepts the load cables. For cable

connection details, see page24.

15

16

Page 9

OVERVIEW

g

C

g

SPD-3606 User Manual

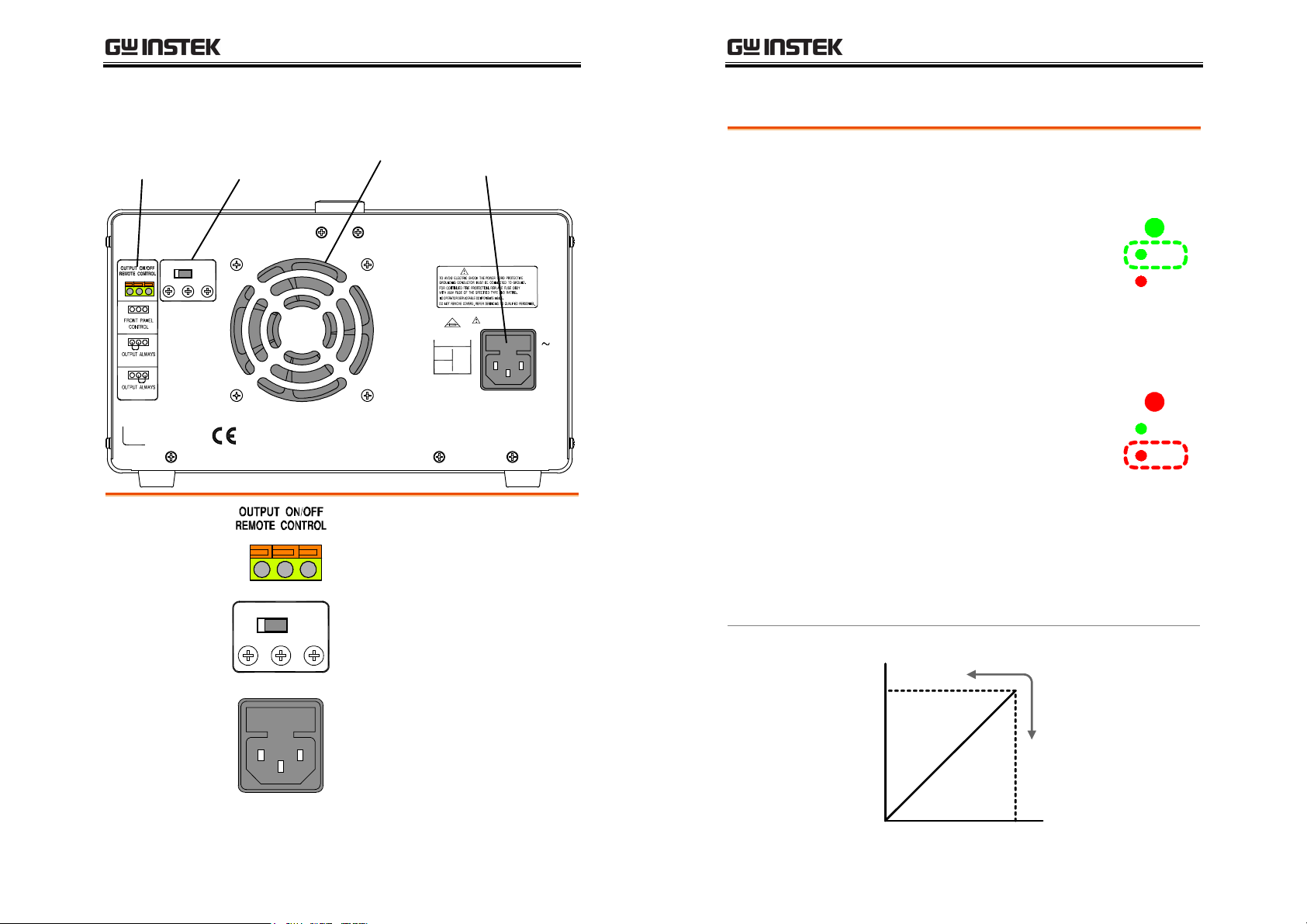

Rear Panel Overview

Remote Control

Terminal

OFF

ON

SER. NO. LB

Remote control

terminal

OVP setting point

Power cord / fuse

socket

OVP Settin

Point

O.V.P. SETNORMAL

CH3CH2CH1

O.V .P. SETNORMAL

CH3CH2CH1

Cooling Fan

Power Cord / Fuse

Socket

WARNING

DISCONNECT POWER CORD

BEFORE REPLACING FUSE

REPLACE FUSE

AS SPECIFIED

FUSE RATING

115V

230V

550 WATTS

900 VA MAX

50/60 H z

T10A

250V

AC

Accepts remote output On/Off

control connection. For details, see

page39.

Activates Over Voltage Protection

(OVP) and sets the protection

threshold for channel1/2/3. For

OVP setup details, see page22.

The power cord socket accepts the

AC mains: 115V/230V, 50/60Hz.

For power up details, see page20.

CV/CC Crossover Characteristics

Background

SPD-3606 automatically switches

voltage mode (CV) and constant current mode

(CC), according to load condition.

When the current level is smaller than

the output setting, SPD-3606 operates

in Constant Voltage mode. The

indicator on the front panel turns green

(C.V.) The Voltage level is kept at the

setting and the Current level fluctuates

according to the load condition until it

reaches the output current setting.

When the current level reaches the

output setting, SPD-3606 starts

operating in Constant Current mode.

The indicator on the front panel turns

red (C.C.) The Current level is kept at

the setting but the Voltage level

becomes lower than the settin

to suppress the output power level

from overload. When the current level

becomes lower than the setting, SPD3606 goes back to the Constant Voltage

mode.

Diagram

Vout

Vmax

Constant

Voltage

between constant

, in order

C.V.

.C.

C.V.

C.C.

The fuse holder contains the AC

Constant

Current

main fuse. For fuse replacement

details, see page57.

17

18

Imax

Iout

Page 10

SETUP

O

SETUP

This chapter describes how to properly power up

and configure SPD-3606 before the operation. For

checking the functionality, refer to the

Performance verification chapter, page40.

SPD-3606 User Manual

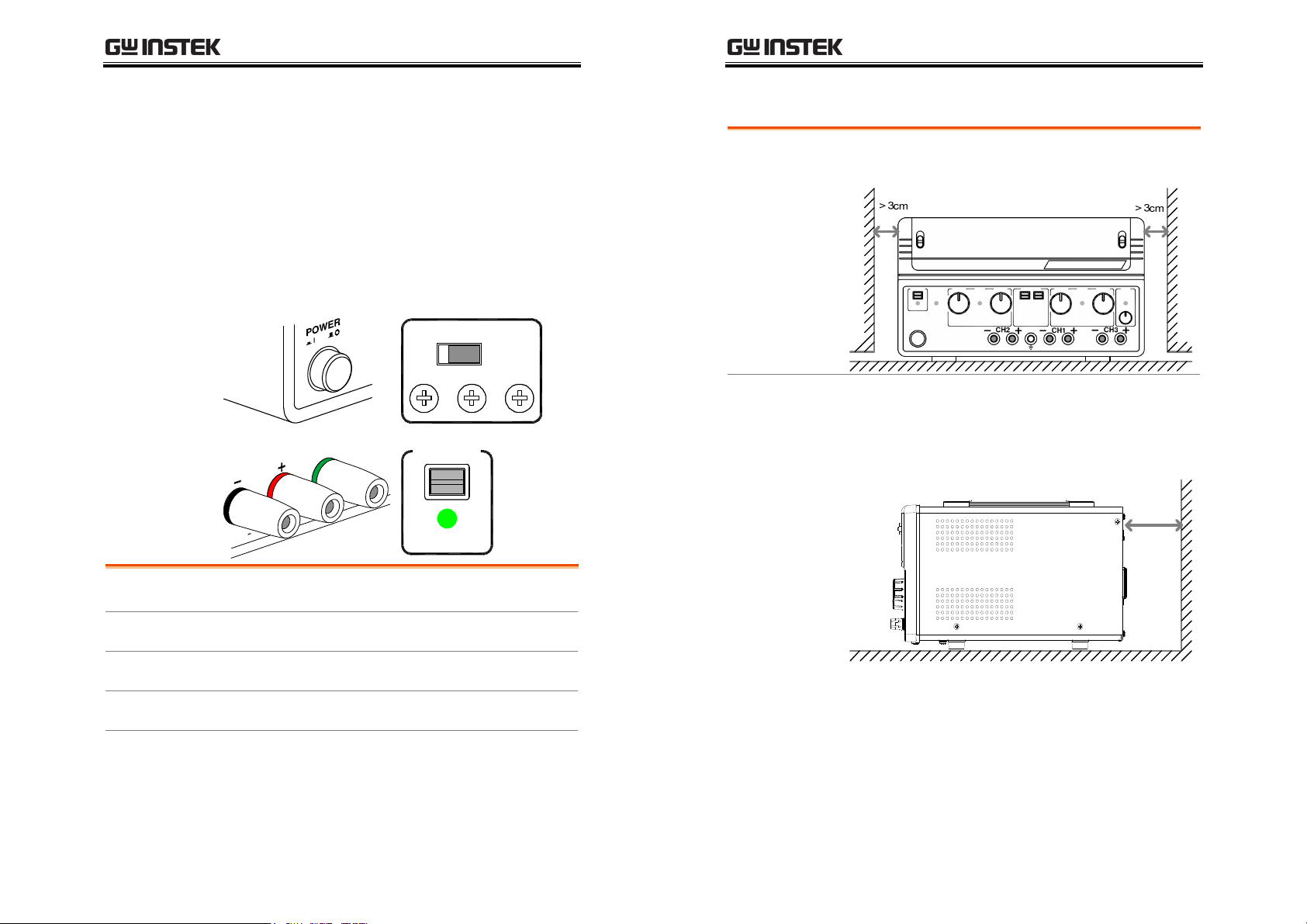

Installation Location

Ventillation space

Leave at least 3cm around SPD-3606, to the left and

right.

D

N

2

H

C

3

,

V

0

6

6

,

0

V

0

3

0

G

A

A

ON / OFF

O.V.P. SETNORMAL

CH3CH2CH1

UTPUT

Installation Installation Location........................................20

Power Power Up ........................................................21

OVP Over Voltage Protection Set.............................22

Load Wire Load Cable Connection....................................24

Output Output On/Off ................................................25

Cooling fan

opening

The cooling fan is located on the rear panel.

Allocate extra space on the back of SPD-3606 so

that the cooling fan opening would not become

blocked.

Cooling

Fan

19

20

Page 11

SETUP

O

SPD-3606 User Manual

Power Up

Power On

Press the Power switch to

turn On the power. The

CH1/CH2 indicators and

meters turn On.

CH1

VOLTAGECURRENT

MASTER

C.V.

C.C.

CH1

VOLTAGECURRENT

MASTER

C.V.

C.C.

CH2

CH2

SLAV E

CH2

SLAV E

C.V.

C.C.

PAR.

C.V.

C.C.

PAR.

VOLTAGECURRENT

VOLTAGECURRENT

CH1 / CH3

Over Voltage Protection Setup

Background

Over Voltage Protection (OVP) protects SPD and

DUT from excessive output Voltage. The user sets

the maximum output voltage limit before

operation. When the output voltage exceeds this

limit, the indicator shows the over voltage status

OVP setup

and the output is shut off immediately.

1. Slide the rear panel switch

to the “O.V.P. SET”

O.V.P. SETNORMAL

position.

2. The OVP indicator on the

front panel turns green,

indicating OVP setup.

.V.P.

SET

TRIP

3. The Voltage meters show the OVP setting level

instead of the output level. The Current meters

show zero (0.00).

CH3CH2CH1

CH2

Power Off

Press the Power switch

again to turn Off the

power. After two

seconds, the meters and

indicators turn Off.

CH1 / CH3

21

CH1 / CH3 CH1 / CH3

4. Adjust the OVP level

using the rear panel

terminal. The setting on

the front panel meter

changes accordingly.

Channel1

Channel2

22

Setting range

Channel3

DECREASE

CH1

1.0V ~ 67.0V

1.0V ~ 67.0V

0.1V ~ 6.0V

INCREASE

Page 12

SETUP

O

g

O

SPD-3606 User Manual

When OVP is

activated....

*

When setting the OVP for

channel3, select CH3 meter

using the CH1/CH3 meter

switch.

5. When finished, slide the

rear panel switch to the

“Normal” position. The

OVP indicator on the front

panel turns Off.

The OVP activates when one

of channel1/2/3 output

voltage exceeds the OVP

settin

. The indicator turns red

(tripped), and the output is

shut Off immediately.

O.V.P.

O.V.P.

SET

TRIP

OUTPUT

ON / OFF

SET

TRIP

CH1

CH3

Load Cable Connection

D

N

Standard

accessory

(GTL-104)

O. V.P. SETNORMAL

CH3CH2CH1

1. Turn the terminal

counterclockwise and

loose the screw.

2. Insert the cable

terminal.

H

C

1

0

6

0

0

3

0

2

.V.P.

SET

TRIP

.V.P.

SET

TRIP

OUTPUT

ON / OFF

3. Turn the terminal

clockwise and tighten

the screw.

Banana plug

Insert the plug into the

socket.

Wire type

When using load cables other than the attached,

make sure they have enough current capacity for

2

H

C

3

A

3

,

V

0

6

A

6

,

0

V

0

3

0

2

H

C

A

3

,

V

0

6

A

6

0

,

V

0

3

0

minimizing cable loss and load line impedance.

Voltage drop across a wire should not excess 0.5V.

The following list is the wire current rating at

450A/cm

2

.

G

2

A

3

,

V

A

6

,

V

D

N

G

D

N

G

Wire size (AWG) Maximum current (A)

20 2.5

18 4

16 6

14 10

12 16

23

24

Page 13

SETUP

P

U

P

U

TRA

CKIN

RALLE

L

O.V

OUT

PUT

Output On/Off

Panel operation

Automatic Output

Off

Remote control

CV/CC red

without output

Pressing the Output key

once Turns On the output, all

channels 1/2/3 at once.

Pressing again turns Off the

output.

Any of the following actions during output On

automatically turns it Off. They might involve

sudden and harmful change in the output level.

Change the range

Change the tracking SW

between independent /

series / parallel

OVP tripped

OVP SET mode

When in remote control

mode (page39), front panel

output control is disabled.

Red CV/CC indicator when

output Off indicates internal

error. Contact the service

center.

OUT

ON / OFF

OUTPUT

ON / OFF

60V/3A

30V/6A

INDEP.

SERIES

PA

O.V.P.

SET

TRIP

T

O.V.P. SETNORMAL

C.V.

C.C.

SPD-3606 User Manual

OUT

ON / OFF

OUTPUT

T

OPERATION

CH1/CH2 Independent Mode

ON / OFF

Background /

Connection

Channel1 and Channel2 outputs work

of each other and are separately controlled.

independent

G

.P.

SET

TRIP

CH3CH2CH1

Output rating

0 ~ 30V/0~6A or 0~60V/0~3A for each channel

CH2

CH2

LOAD

CH1

CH1

LOAD

Setting step

1. Select the output range,

60V/3A

CH1

60V/3A or 30V/6A. Set the

CH1/CH3 meter switch to

the CH1 position.

+

ON / OFF

30V/6A

CH3

25

26

Page 14

OPERATION

y

O

O

UTP

U

O

UTP

U

G

N

2. Set the tracking switch

position to INDEP,

+ .

I

K

C

A

R

T

.

P

E

D

N

I

S

E

I

R

E

S

L

E

L

L

RA

A

P

CH3 Independent Mode

Background /

Connection

SPD-3606 User Manual

Channel3 rating is 0.1 ~ 5V, maximum 3A. It works

independently from Channel1 and 2, regardless of

their modes.

3. Set the OVP if necessar

. For

.V.P.

details, see page22.

SET

TRIP

4. Connect the load to the front panel terminals,

channel1 +/−, channel2 +/−.

D

N

G

2

H

C

1

H

C

A

3

,

V

0

6

A

6

,

0

V

0

3

0

CH3

CH3

LOAD

A

3

,

V

0

6

A

6

,

0

V

0

3

0

CH1

VOLTAGECURRENT

5. Set the output Voltage and

Current using the control

knobs for each channel.

MASTER

CH2

SLAVE

C.V.

C.C.

VOLTAGECURRENT

Output rating

No Tracking

Series/Parallel

Setting step

0.1 ~ 5V, 3A maximum

Channel3 does not have Tracking Series/Parallel

mode. Also, Channel3 output is not affected by

Channel1 and 2 modes:

independent/series/parallel.

1. Set the CH1/CH3 meter

CH1

switch to the CH3 position.

C.V.

C.C.

PAR.

6. Press the Output key. The

T

T

CH3

Output indicator turns

green.

ON / OFF

ON / OFF

27

28

Page 15

OPERATION

y

O

E

ge

D

g

SPD-3606 User Manual

CV → CC

2. Set the OVP if necessar

. For

details, see page22.

3. Connect the load to the front

panel channel3 +/−

terminal.

4. Set the output Voltage using

the Channel3 Voltage

control knob.

5. Press the Output key. The

Output indicator turns

green.

When the output Current level

exceeds 3A, the overload

indicator turns red and

Channel3 operation mode

switches from Constant Volta

to Constant Current.

1

.

0

OUTPUT

ON / OFF

CH3

OVER LOAD

.V.P.

SET

TRIP

3

H

C

A

3

,

V

5

VOLTAG

OUTPUT

ON / OFF

CH3

OVER LOA

CH1/CH2 Tracking Series Mode

Background

Tracking series without common terminal

Connection

Tracking series operation doubles the Voltage

capacity of SPD-3606 by internally connecting

Channel1 (Master) and Channel2 (Slave) in serial

and combining the output to a single channel.

Channel1 (Master) controls the combined Voltage

output level.

The followin

describes two types of configuration

depending on the common ground usage.

CH2

CH1

Note: “overload” in this case

does not mean abnormal

LOAD

operation.

Output rating

Setting step

0 ~ 120V/0 ~ 3A or 0 ~ 60V/0 ~ 6A

1. Select the output range,

60V/3A

CH1

60V(120V)/3A or

30V(60V)/6A. Set the

CH1/CH3 meter switch to

the CH1 position.

30V/6A

29

30

CH3

Page 16

OPERATION

M

OUT

PUT

OUT

PUT

SPD-3606 User Manual

2. Set the tracking switch

position to Series,

3. Set the OVP if necessary. In

tracking series mode, set the

Channel2 (Slave) OVP setting to

the maximum level, so that the

OVP trips if the Channel1

(Master) setting is violated. For

OVP setup details, see page22.

4. Connect the load to the front panel terminals,

channel1+ & channel2− (Single supply).

2

H

C

A

3

,

V

0

6

A

6

,

0

V

0

3

0

G

N

I

K

C

A

R

+ .

T

.

P

E

D

N

I

S

E

RI

E

S

L

E

L

L

A

AR

P

7. Refer to the Channel1 (Master) meter and

indicator for the output setting level and

CV/CC status.

CH1

ASTER

O.V.P.

C.V.

C.C.

SET

TRIP

CH1 / CH3

Current level

Channel1 meter reading shows

the output Current. (Channel2

Current control must be in the

Maximum position).

Voltage level

Double the reading on the

Channel1 Voltage meter. (In the

above case, the actual output is

1

H

C

D

N

G

A

3

,

V

0

6

A

6

,

0

V

0

3

0

8. Press the Output key. The

Output indicator turns

green.

23.6 x 2 = 47.2V).

ON / OFF

ON / OFF

5. Turn up the Channel2

CURRENT

CH2

SLAV E

Current knob to maximum.

CH1

VOLTAGECURRENT

6. Set the output Voltage and

Current using the Channel1

(Master) knob.

MASTER

C.V.

C.C.

31

32

Page 17

OPERATION

SPD-3606 User Manual

Tracking series with common terminal

Connection

CH2

LOAD

Output rating

Setting step

0~60V/0~3A or 0~30V/0~6A for CH1 ~ COM

0~–60V/0~3A or 0~–30V/0~6A for CH2 ~ COM

1. Select the output range,

60V(120V)/3A or

30V(60V)/6A. Set the

CH1/CH3 meter switch to

the CH1 position.

COM

CH1

60V/3A

30V/6A

CH1

CH3

3. Set the OVP if necessary. In

tracking series mode, set the

Channel2 (Slave) OVP setting to

the maximum level, so that the

OVP trips if the Channel1

O.V.P.

SET

TRIP

(Master) setting is violated. For

OVP setup details, see page22.

4. Connect the load to the front panel terminals,

channel1+ & channel2−. Use Channel1 (−)

terminal as the common line connection.

D

N

G

2

H

C

A

3

,

V

0

6

A

6

,

0

V

0

3

0

1

H

C

A

3

,

V

0

6

A

6

,

0

V

0

3

0

Common

CH1

VOLTAGECURRENT

5. Set the output Voltage using

the Channel1 (Master)

Voltage knob. Refer to the

Channel1 (Master) meter for

MASTER

C.V.

C.C.

the output setting level.

G

2. Set the tracking switch

position to Series,

+ .

N

I

K

C

A

R

T

.

P

E

D

N

I

S

E

I

R

E

S

L

E

L

L

RA

A

P

33

CH1(+)~COM Voltage = 23.6V in the above case

CH2(–)~COM Voltage = –23.6V in the above case

34

CH1 / CH3

Page 18

OPERATION

OUT

PUT

OUT

PUT

C

S

CH1

VOLTAGECURRENT

CH1 / CH3

MASTER

CH2

SLAVE

C.V.

C.C.

PAR.

C.V.

C.C.

VOLTAGECURRENT

6. Set the output Current

separately, using both the

Channel1 (Master) and

Channel2 (Slave) Current

knob.

CH2

CH1(+)~COM Current = 1.84A in the above case

CH2(–)~COM Current = 2.18A in the above case

SPD-3606 User Manual

CH1/CH2 Tracking Parallel Mode

Background /

Connection

Tracking parallel operation doubles the Current

capacity of SPD-3606 by internally connecting

Channel1 (Master) and Channel2 (Slave) in parallel

and combining the output to a single channel.

Channel1 (Master) controls the combined output.

7. Press the Output key. The

Output indicator turns

green.

8. Refer to the Channel1

(Master) indicator for

ON / OFF

CH1

MASTER

CH1(+) ~ COM CV/CC

status, and the Channel2

(Slave) indicator for

CH2(–) ~ COM CV/CC

status.

C.V.

.C.

ON / OFF

CH2

LAVE

C.V.

C.C.

PAR.

CH2

CH1

LOAD

Output rating

0 ~ 30V/0 ~ 12A or 0 ~ 60V/0 ~ 6A

Setting step

1. Select the output range,

60V/3A

CH1

60V/3A(6A) or

30V/6A(12A). Set the

CH1/CH3 meter switch to

the CH1 position.

2. Set the tracking switch

position to Parallel,

+ .

30V/6A

CH3

G

N

I

K

C

A

R

T

.

P

E

D

N

I

S

E

I

R

E

S

L

E

L

L

A

R

A

P

35

36

Page 19

OPERATION

OUT

PUT

OUT

PUT

M

SPD-3606 User Manual

3. Set the OVP if necessary. In

tracking parallel mode, set

the Channel2 (Slave) OVP

setting to the maximum

level, so that the OVP trips if

the Channel1 (Master)

setting is violated. For OVP

setup details, see page22.

4. Connect the load to the front panel terminals,

channel1 +/−.

2

H

C

A

3

,

V

0

6

A

6

,

0

V

0

3

0

5. The Channel2 (Slave)

indicator turns red,

indicating Tracking Parallel

(PAR). The CV/CC status of

tracking parallel mode is

displayed in the Channel1

(Master) indicator.

O.V.P.

SET

TRIP

7. Refer to the Channel1 meter for the output

setting level.

CH1 / CH3

Current level

Double the reading on the

Channel1 meter. In the above

case, the actual output is 1.84 x 2

= 3.68A.

1

H

C

D

N

G

A

3

,

V

0

6

A

6

,

0

V

0

3

0

Voltage level

Channel1 meter reading shows

the actual output Voltage.

8. Press the Output key. The

Output indicator turns

CH1

ASTER

C.V.

C.C.

ON / OFF

C.V.

C.C.

PAR.

C.V.

C.C.

PAR.

green.

9. Refer to the Channel1

(Master) indicator for the

ON / OFF

CV/CC status.

CH1

VOLTAGECURRENT

6. Set the output Voltage and

Current using the Channel1

(Master) control knobs.

Channel2 control knobs are

MASTER

C.V.

C.C.

disabled.

37

38

Page 20

REMOTE OUTPUT CONTROL

SPD-3606 User Manual

REMOTE OUTPUT

CONTROL

Background

Wire connection

Remote control

Off (front panel

control)

The remote control terminal on the

rear panel can turn the output

On/Off, just like the Output key on

the front panel. This feature is useful

for automated measurement and

testing using externally connected

control device, such as in production

line or incoming quality inspection.

Connect the terminals using

bare wires. Use a minus

driver to push the orange

part, insert the wire, then

release the orange part.

When there is no connection,

Output On/Off is entirely

controlled from the front panel.

OUTPUT

2

ON / OFF

3

PERFORMANCE

VERIFICATION

1

Overview

Background

Verification item

Equipment

Digital Multimeter

Performance verification checks SPD functionality

before the operation or at the incoming inspection.

Recording tables are attached at the end of this

chapter.

• Output Voltage

• Tracking Series Voltage

• Output Current

• OVP

• DCV Accuracy < 0.1%

• DCA Accuracy < 0.5%

Output always Off

Output always On

When the left two terminals are

connected, the Output is always

Off. The front panel Output key is

disabled.

When the right two terminals are

connected, the Output is always

On. The front panel Output key is

disabled.

39

Multimeter

– SPD cable

Philips screw

driver

40

• DCA range: ≥ 12A

• Resolution ≥ 4 ½ digit

• Recommended model: GDM-8245, GDM-8246

• Voltage rating > 70V

• Current rating > 12A

• < 3mm (for OVP adjustment)

Page 21

PERFORMANCE VERIFICATION

OLT

A

CURRENT

CURRENT

SPD-3606 User Manual

Default SPD-3606 setting

The following is the required front and rear panel setting before

running each verification.

Range

OVP setting SW

Channel1/3 meter

SW

60V/3A

60V/3A

30V/6A

• Output Voltage

• Tracking Series

• OVP

Normal position

CH1 position

30V/6A

• Output Current

• Tracking Parallel

60V/3A

30V/6A

CH1

O.V.P. SETNO RMAL

Output Voltage Verification

Check item

Connection

CH3CH2CH1

Verification step

• Minimum output Voltage accuracy

• Maximum output Voltage accuracy

• Voltage meter accuracy (Output On)

• Voltage meter accuracy (Output Off)

SPD-3606

Digital Multimeter

V

A

1. Set the SPD panel according to the Default

setting list, page41.

CH1

0 60V , 3A

0 30V , 6A

Tra c ki n g S W

Channel1/2/3

Voltage knob

Channel1/2

Independent position,

Minimum position

Minimum position

+ .

CH3

G

N

I

K

C

A

R

T

.

P

E

D

N

I

S

E

I

R

E

S

L

E

L

L

A

R

A

P

V

GE

2. Connect SPD Channel 1 and

Digital Multimeter Voltage

terminal.

3. Power up SPD and Digital Multimeter.

4. Turn up the SPD Current knob to

the maximum.

Current knob

41

42

Page 22

PERFORMANCE VERIFICATION

UTPUT

UTPUT

VOLTA

g

0

6

A

A

SPD-3606 User Manual

Minimum output

Vol tag e

Channel1/2

Channel3

5. Turn On the SPD output.

6. Record the Multimeter reading as the Minimum

output Voltage. Here is the acceptance range.

< 0V

< 100mV

7. Turn up the SPD Voltage knob to

the maximum. Switch the

Multimeter Voltage terminal if

necessary.

Maximum output

Vol tag e

Channel1/2

Channel3

Vol tage meter

accuracy

8. Record the Multimeter readin

output Voltage. Here is the acceptance range.

61.5V ~ 62.5V

5.20V ~ 5.30V

9. Compare and record the difference between the

SPD Voltage meter and the Multimeter reading

as the Voltage meter accuracy (Out On).

Then turn the output Off,

and check the SPD

reading again (Out Off).

O

ON / OFF

as the Maximum

OUTPUT

ON / OFF

O

ON / OFF

GE

OUTPUT

ON / OFF

Example:

Multimeter (Out On) = 30.00V

Tolerance = ±(0.005*30 + 0.2) ≈ ±0.4V

Accepted SPD reading(Out On)= 29.6V~30.4V

Accepted SPD reading (Out Off)=29.6V~30.4V

Channel2

10. Connect the Multimeter to

CH2

SPD Channel2 and repeat step

4 to 9.

Channel3

11. Switch the CH1/CH3

meter switch to CH3

position. Connect the

Multimeter to Channel3

CH1

CH3

0 60V , 3A

30V,

CH3

0.1 5V , 3

and repeat step 5 to 9.

* Skip step 4 since Channel 3 does not have

Current knob.

Channel1/2/3

Here is the acceptance range and example.

difference < ±(0.5% of reading +

2 digits) of Multimeter

43

44

Page 23

PERFORMANCE VERIFICATION

CURRENT

UTPUT

UTPUT

VOLTA

0

A

VOLTA

0

A

SPD-3606 User Manual

Tracking Series Voltage Verification

Check item

Connection

Verification step

• Minimum output Voltage accuracy

• Maximum output Voltage accuracy

SPD-3606

Digital Multimeter

V

A

1. Set the SPD panel according to the Default setting

list, page41, except for the tracking switch (see

below).

2. Set the tracking switch position

to Series,

+ .

3. Connect SPD Channel 1 and

Digital Multimeter Voltage

terminal.

4. Power up SPD and Digital Multimeter.

G

N

I

K

C

A

R

T

.

P

E

D

N

I

S

E

I

R

E

S

L

E

L

L

RA

A

P

CH1

0 60V , 3A

0 30V , 6A

5. Turn up the SPD Current

knob, both Channel1 and

Channel2, to the maximum.

6. Turn On the SPD output.

7. Turn up the SPD Channel1

O

ON / OFF

O

ON / OFF

GE

Voltage knob until the

Multimeter reading shows

CH2

0 60V , 3A

30V, 6

CH1

(1.000V)

1.000V.

Minimum

tracking series

output voltage

Channel2

8. Connect the Multimeter to

SPD Channel2 and record

the reading. Here is the

acceptance range.

0.985V ~ 1.015V

9. Connect Digital Multimeter

back to SPD Channel1.

0 60V , 3A

0 30V , 6A

10. Turn up the SPD Channel1

GE

Voltage knob until the

Maximum

tracking series

output voltage

Channel2

Multimeter reading shows

60.00V.

11. Connect the Multimeter to

SPD Channel2 and record

the reading. Here is the

acceptance range.

59.69V ~ 60.31V

CH2

0 60V , 3A

30V, 6

(60.00V)

45

46

Page 24

PERFORMANCE VERIFICATION

V

OLT

OUTPU

T

OUTPU

T

g

RRENT

g

0

A

SPD-3606 User Manual

Output Current verification

Check item

Connection

Verification step

• Minimum output Current accuracy

• Maximum output Current accuracy

• Current meter accuracy (Output On)

• Current meter accuracy (Output Off)

Digital Multimeter

1. Set the SPD panel according to the Default

setting list, page41.

2. Connect SPD Channel 1 and

Digital Multimeter Current

terminal.

3. Power up SPD and Digital Multimeter.

4. Turn up the SPD Voltage knob to

the maximum.

SPD-3606

V

A

CH1

0 60V , 3A

0 30V , 6A

AGE

Minimum output

Current

Channel1/2

6. Record the Multimeter readin

as the Minimum

output Current. Here is the acceptance range.

< 0A

7. Turn up the SPD Current knob to

CU

the maximum. Switch the

Multimeter Current terminal to

high current range.

Maximum output

Current

Channel1/2

Channel3

Current meter

accuracy

8. Record the Multimeter readin

as the Maximum

output Current. Here is the acceptance range.

6.15A ~ 6.25A

3.05A ~ 3.15A

9. Compare and record the difference between the

SPD Current meter and the Multimeter reading

as the Current meter accuracy (Out On).

Then turn the output Off,

and check the SPD

reading again (Out Off).

Channel1/2/3

Here is the acceptance range and example.

difference < ±(0.5% of reading +

OUTPUT

ON / OFF

OUTPUT

ON / OFF

2 digits) of Multimeter

Example:

Multimeter (Out On) = 3.000A

Tolerance = ±(0.005*3 + 0.02) ≈ ±0.04A

Accepted SPD reading(Out On)= 2.96A~3.04A

Accepted SPD reading (Out Off)= 2.96A~3.04A

5. Turn On the SPD output.

10. Connect the Multimeter to

SPD Channel2 and repeat step

CH2

4 to 9.

0 60V , 3A

ON / OFF

ON / OFF

47

48

30V, 6

Page 25

PERFORMANCE VERIFICATION

O.V

SPD-3606 User Manual

11. Connect the Multimeter

CH1

CH3

to SPD Channel3 and

repeat step 4, 5, 8, 9.

CH3

0.1 5V, 3A

* Skip step 6 and 7 since Channel 3 does not have

minimum current verification and Current knob.

OVP verification

Check item

Connection

Verification step

• OVP setting accuracy (Minimum)

• OVP functionality (Minimum)

• OVP setting accuracy (Maximum)

• OVP functionality (Maximum)

SPD-3606

(No connection)

1. Set the SPD panel according to the Default

setting list, page41.

2. Power up SPD.

3. Set the OVP setting switch to

the “O.V.P. SET” position.

O.V.P. SETNORMAL

CH3CH2CH1

SET

TRIP

CH1

.P.

4. The O.V.P. indicator on the

front panel turns green.

5. Turn down the OVP setting

O.V.P.

SET

TRIP

DECREASE

terminal to minimum.

49

50

Page 26

PERFORMANCE VERIFICATION

j

g

U

TPU

T

U

TPU

T

VOL

T

O.V.P

O.V

j

g

SPD-3606 User Manual

Minimum OVP

setting

6. Record the SPD Voltage meter reading as the

Minimum OVP setting accuracy. Here is the

acceptance range.

Channel1/2

Channel3

ust the OVP settin

7. Ad

≤ 1.0V

≤ 0.50V

DECREASE

terminal until the SPD

meter shows the exact

following value.

Channel1/2

Channel3

8. Set the OVP setting switch to

1.0V

0.50V

the “Normal” position. The

OVP indicator on the front

panel turns Off.

9. Turn On the SPD output.

10. Slowly turn up the

AGE

SPD Voltage knob

until the OVP

indicator turns red

(tripped).

O

ON / OFF

O.V.P.

SET

TRIP

CH1

INCREASE

O.V.P. SETNORMAL

CH3CH2CH1

O

ON / OFF

SET

TRIP

12. Turn Off the SPD output.

13. Set the OVP setting switch to

OUTPUT

ON / OFF

the “O.V.P. SET” position.

OUTPUT

O.V.P. SETNORMAL

ON / OFF

CH3CH2CH1

14. The O.V.P. indicator on the

front panel turns green.

15. Turn up the OVP setting

terminal to maximum.

O.V.P.

SET

TRIP

CH1

.P.

SET

TRIP

INCREASE

Maximum OVP

setting

Channel1/2

Channel3

.

Channel1/2

Channel3

16. Record the SPD Voltage meter reading as the

Maximum OVP setting accuracy. Here is the

acceptance range.

65.0 ~ 68.0V

6.00 ~ 7.00V

17. Ad

ust the OVP settin

terminal until the SPD

DECREASE

CH1

INCREASE

meter shows the exact

following value.

60.0V

5.0V

Minimum OVP

functionality

Channel1/2

Channel3

11. Record the SPD Voltage meter reading as the

Minimum range OVP functionality. Here is the

acceptance range.

0.5V ~ 1.5V

0.00V ~ 1.00V

51

52

18. Set the OVP setting switch to

the “Normal” position. The

OVP indicator on the front

panel turns Off.

O.V.P. SETNORMAL

CH3CH2CH1

Page 27

PERFORMANCE VERIFICATION

P

U

P

U

VOL

T

O.V.P

OUT

OUT

19. Turn On the SPD output.

T

T

Recording Tables

SPD-3606 User Manual

20. Slowly turn up the

AGE

SPD Voltage knob

until the OVP

indicator turns red

(tripped).

Maximum OVP

functionality

21. Record the SPD Voltage meter reading as the

Maximum range OVP functionality. Here is the

acceptance range.

Channel1/2

Channel3

22. Turn Off the SPD output.

23. Repeat step 3 to 22 for Channel2.

24. Repeat step 3 to 22 for Channel3.

59.2V ~ 60.8V

4.47V ~ 5.53V

ON / OFF

OUTPUT

ON / OFF

O.V.P.

SET

TRIP

ON / OFF

SET

TRIP

OUTPUT

ON / OFF

.

Output voltage verification (Minimum/Maximum)

Item Channel Min. limit Result Max. limit

Minimum

Output Voltage

CH1 –30mV 0mV

CH2 –30mV 0mV

CH3 0mV 100mV

CH1 61.5V 62.5V Maximum

Output Voltage

CH2 61.5V 62.5V

CH3 5.2V 5.3V

Output voltage verification (Meter accuracy)

Tolerance = ± (0.5%*Multimeter +0.2) V

Channel Multimeter Tolerance SPD (On)

SPD (Off)

Channel1 ~

Channel2 ~

Channel3 ~

Tracking series voltage verification

Item Channel Min. limit Result Max. limit

Tra c ki n g S eri es

Minimum

Tra c ki n g S eri es

Maximum

CH2 0.985V 1.015V

CH2 59.69V 60.31V

53

54

Page 28

PERFORMANCE VERIFICATION

Output current verification (Minimum/Maximum)

Item Channel Min. limit Result Max. limit

Minimum

Output Current

Output Current

CH3 3.05A 3.15A

CH1 –1mA 0mA

CH2 –1mA 0mA

CH1 6.15A 6.25A Maximum

CH2 6.15A 6.25A

Output current verification (Meter accuracy)

Tolerance = ± (0.5%*Multimeter +0.02) A

Channel Multimeter Tolerance SPD (On)

Channel1 ~

Channel2 ~

Channel3 ~

SPD (Off)

OVP verification

Item Channel Min. limit Result Max. limit

Minimum OVP

Setting

CH3 0.0V 0.1V

Functionality

CH3 0.00V 1.00V

Setting

CH3 6.0V 7.0V

Functionality

CH3 4.47V 5.53V

CH1 0.0V 1.0V

CH2 0.0V 1.0V

CH1 0.5V 1.5V Minimum OVP

CH2 0.5V 1.5V

CH1 65.0V 68.0V Maximum OVP

CH2 65.0V 68.0V

CH1 59.2V 60.8V Maximum OVP

CH2 59.2V 60.8V

SPD-3606 User Manual

FAQ

Q1. I cannot turn On the output (the Output key does not respond).

A1. The following scenarios are possible.

• The rear panel remote control terminal is in the Off position. In

this case, set it to the On position or deactivate remote control. For

details, see page39.

• The OVP setting switch on the rear panel is on the SET side. In

this case, set the switch to the Normal side.

• The OVP indicator is red. In this case, change the OVP setting to

higher value or remove the over voltage condition.

Note that in several conditions, the Output key automatically turns

Off to avoid harmful condition. For details, see page25.

Q2. The CV/CC indicator is red (Constant Current) while the output is Off.

A2. This indicates there is an internal error. Contact the service

center.

Q3. The meter does not match the real value.

A3. The following scenarios are possible.

• Make sure the rear panel OVP setting is in the “Normal” position.

If the OVP switch is in the “SET” position, the meter might show

the OVP setting, not the output value. For OVP details, see page22.

• If you are using Channel1 or Channel3, make sure the meter

switch on the right side is in the correct position. Channel1 and 3

share the same meter.

For more information, contact your local dealer or GWInstek at

www.gwinstek.com.tw

55

56

/ marketing@goodwill.com.tw.

Page 29

APPENDIX

g

SPD-3606 User Manual

Volume Guard (Optional)

APPENDIX

Fuse Replacement

Step

1. Take off the power cord and remove the fuse

socket using a minus driver.

N

N

O

C

S

I

D

E

R

O

F

E

B

E

S

U

F

E

C

A

D

L

E

P

I

F

E

I

R

C

E

P

S

S

A

G

N

I

T

A

R

E

S

U

F

V

A

5

0

1

1

1

T

V

0

5

2

V

0

3

2

S

T

T

A

W

X

A

0

5

M

5

A

V

0

0

9

z

H

0

6

/

0

5

2. Replace the fuse in the holder.

N

N

O

C

S

I

D

E

R

O

F

E

B

E

S

U

F

E

C

A

D

L

E

P

I

F

E

I

R

C

E

P

S

S

A

G

N

I

T

A

R

E

S

U

F

V

A

5

0

1

1

1

T

V

0

5

2

V

0

3

2

S

T

T

A

W

X

A

0

5

M

5

A

V

0

0

9

z

H

0

6

/

0

5

Background

The volume guard is an optional item which

replaces the Channel 1 and 2 output knobs to

prevent accidentally changing the output level.

This feature is useful for automated testin

at fixed

output level, such as assembly line inspection.

D

R

O

C

R

E

W

E

O

S

P

U

T

F

C

G

E

N

I

C

A

L

P

E

R

Applicable knobs

• Channel 1 Voltage and Current knob

• Channel2 Voltage and Current knob

CH2

CH1

E

G

A

T

L

O

Attach volume

guard

1. Pull out the original

knob (Channel2

current knob for

example).

T

N

E

R

R

U

C

V

2

H

C

E

V

A

L

S

.

V

.

C

.

C

.

C

.

R

A

P

E

G

D

R

O

C

R

E

W

E

O

S

P

U

T

F

C

G

E

N

I

C

A

L

P

E

R

2. Insert and screw the

volume guard to fix its

T

N

E

R

R

U

C

position.

A

T

L

O

V

2

H

C

E

V

A

L

S

.

V

.

C

.

C

.

C

.

R

A

P

E

G

A

T

L

O

3. To change the output

level, use a minus

T

N

E

R

R

U

C

screwdriver from the

opening of the volume

guard.

V

2

H

C

E

V

A

L

S

.

V

.

C

.

C

.

C

.

R

A

P

Rating

T10A/250V

57

58

Page 30

APPENDIX

Specification

Output Ratings CH1/CH2

Independent

CH1/CH2

Series

CH1/CH2

Parallel

CH3

Vol tag e

Regulation

Line

Load

Ripple & Noise

Recovery Time

Current

Line

Regulation

Load

Tr ac k in g

Ripple & Noise

Tracking Error

Operation

Series

Regulation

Ripple & Noise

0 ~ 30V / 0 ~ 6A

0 ~ 60V / 0 ~ 3A

0 ~ 60V / 0 ~ 6A

0 ~ 120V / 0 ~ 3A

0 ~ 30V / 0 ~ 12A

0 ~ 60V / 0 ~ 6A

0.1 ~ 5V / 3A

≤ 0.01% + 3mV

≤ 0.01% + 5mV

(rating current ≤ 6A)

≤ 0.01% + 8mV

(rating current ≤ 12A)

≤ 5mVrms (5Hz ~ 1MHz)

≤ 50mV

(20Hz ~ 20MHz)

P-P

≤ 100µs (50% load change,

minimum load 0.5A)

≤ 0.2% + 3mA

≤ 0.2% + 3mA

≤ 3mArms

≤ 0.5% + 10mV of Master

≤ 300mV

≤ 10mVrms (5Hz ~ 1MHz)

≤ 100mVpp (20Hz ~ 20MHz)

SPD-3606 User Manual

Output On/Off

Response Time

Vol tage Do wn

Vol tage Up

(10% ~ 90%)

≤ 100ms (≤95% rating load)

≤ 100ms (≥10% rating load)

(90% ~ 10%)

OVP

Meter Type

Accuracy

Resolution

Insulation

Accuracy

Chassis and

± (0.5% of reading + 0.5V)

3 ½ digits 0.5" LED display

± (0.5% of reading + 2 digits)

100mV/10mA

100MΩ or above (DC 1000V)

Te rm i na l

Chassis and AC

100MΩ or above (DC 1000V)

cord

Temperature

Coefficient

Remote Control

Fan Nois e

Operation

Environment

Storage

Environment

Power Source

Accessories

Vol tag e

Current

≤ 100ppm/°C+3mV

≤ 150ppm/°C+3mA

Output On/Off

≤ 50dB

Ambient temperature 0 ~ 40°C

Relative humidity ≤ 80%

Ambient temperature –10 ~ 70°C

Relative humidity ≤ 70%

AC 115V/230V±15%, 50/60Hz

User manual x 1, Power cord x 1

Test lead GTL-104 x 2, GTL-105 x 1

Dimensions

Weight

255 (W) x 145 (H) x 265 (D) mm

Approx. 6kg

59

60

Page 31

APPENDIX

Declaration of Conformity

We

GOOD WILL INSTRUMENT CO., LTD.

(1) No.7-1, Jhongsing Rd., Tucheng City, Taipei County, Taiwan

(2) No. 69, Lu San Road, Suzhou City (Xin Qu), Jiangsu Sheng, China

declare, that the below mentioned product

Type of Product: Power Supply

Model Number: SPD-3606

are herewith confirmed to comply with the requirements set out in the

Council Directive on the Approximation of the Law of Member States

relating to Electromagnetic Compatibility (2004/108/EC, 89/336/EEC,

92/31/EEC, 93/68/EEC) and Low Voltage Directive (73/23/EEC,

93/68/EEC).

For the evaluation regarding the Electromagnetic Compatibility and

Low Voltage Directive, the following standards were applied:

◎ EMC

EN 61326-1: 2006 Electrical equipment for measurement, control and

laboratory use –– EMC requirements

Conducted Emission

Radiated Emission

ClassA

EN 55011: 1998 + A1:1999 +

A2:2002

Current Harmonics

EN 61000-3-2: 2000 + A2:2005

Voltage Fluctuations

EN 61000-3-3: 1995 + A1:2001

Electrostatic Discharge

EN 61000-4-2: 1995 + A1:1998 +

A2:2001

Radiated Immunity

EN 61000-4-3: 2002 + A1:2002

Electrical Fast Transients

EN 61000-4-4: 2004

+A2:2005

------------------------- Surge Immunity

EN 61000-4-5: 1995 + A1:2001

------------------------- Conducted Susceptibility

EN 61000-4-6: 1996 + A1:2001

------------------------- Power Frequency Magnetic Field

EN 61000-4-8: 1993 + A1:2001

------------------------- Voltage Dip/ Interruption

EN 61000-4-11: 2004

◎ Safety

Low Voltage Equipment Directive 73/23/EEC & amended by 93/68/EEC

Safety Requirements

IEC/EN 61010-1: 2001

SPD-3606 User Manual

INDEX

block diagram, system.............. 11

caution symbol............................. 5

cleaning the instrument.............. 7

constant current mode.............. 18

constant voltage mode.............. 18

cooling fan.................................. 20

noise level spec ............................. 60

safety instruction ............................ 6

CV/CC

indicator overview ....................... 16

overview ........................................ 18

default setting for verification . 41

EN 55011..................................... 61

EN 61000..................................... 61

EN61010

declaration of conformity............ 61

measurement category .................. 6

pollution degree.............................. 7

environment

operation.......................................... 7

specification................................... 60

storage .............................................. 7

front panel diagram .................. 14

fuse

rating .............................................. 57

replacing ........................................ 57

safety instruction ............................ 6

socket overview ............................ 17

ground symbol............................. 5

list of features............................. 10

load connection

independent mode ....................... 26

procedure....................................... 24

tracking parallel............................ 36

tracking series ......................... 30, 33

wire type ........................................ 24

meter

ch1/ch3 switch.............................. 28

faq.................................................... 56

OVP mode ..................................... 22

multimeter for verification ....... 40

output current

recording table ........................54, 55

specification................................... 59

verification..................................... 47

output on/off

faq.................................................... 56

key overview................................. 14

61

62

Page 32

INDEX

manual............................................ 25

remote............................................. 39

response time spec ....................... 60

output range

independent mode ....................... 26

specification................................... 59

switch overview............................ 14

tracking parallel............................ 36

tracking series ......................... 30, 33

output voltage

recording table ........................54, 55

specification................................... 59

technical background................... 13

verification............................... 42, 45

overload indicator

description ..................................... 29

overview ........................................ 15

OVP

automatic output off .................... 25

indicator overview ....................... 14

recording table .............................. 55

setting terminal overview ........... 17

setup ............................................... 22

verification..................................... 50

when activated.............................. 23

power supply

power on/off................................. 21

safety instruction ............................ 6

socket overview ............................ 17

specification................................... 60

switch overview............................ 14

rear panel diagram.....................17

remote output control

disable manual control ................ 25

setup ............................................... 39

terminal overview ........................ 17

service operation

about disassembly .......................... 6

contact point.................................. 56

tracking mode

parallel............................................ 36

parallel indicator overview......... 16

series ............................................... 30

specification................................... 59

tracking series

common ground ........................... 33

tracking switch

automatic output off .................... 25

independent mode ....................... 27

overview ........................................ 15

tracking parallel............................ 36

tracking series ................... 31, 33, 45

UK power cord.............................8

ventillation space requirement.20

volume guard ............................. 58

warning symbol ...........................5

63

Loading...

Loading...