GW Instek PSW 30-36, PSW 80-13.5, PSW 160-7.2, PSW 250-4.5, PSW 800-1.44 PROGRAMMING MANUAL

...Page 1

Multi-Range DC Power Supply

PSW Series

PROGRAMMING MANUAL

VERSION: 1.5

ISO-9001 CERTIFIED MANUFACTURER

Page 2

This manual contains proprietary information, which is protected by

copyright. All rights are reserved. No part of this manual may be

photocopied, reproduced or translated to another language without

prior written consent of Good Will company.

The information in this manual was correct at the time of printing.

However, Good Will continues to improve products and reserves the

rights to change specification, equipment, and maintenance

procedures at any time without notice.

Good Will Instrument Co., Ltd.

No. 7-1, Jhongsing Rd., Tucheng Dist., New Taipei City 236, Taiwan.

Page 3

Table of Contents

Table of Contents

SAFETY INSTRUCTIONS ................................................... 4

GETTING STARTED ........................................................... 8

PSW Series Overview ............................. 9

Appearance .......................................... 14

Configuration Settings ......................... 21

REMOTE CONTROL ........................................................ 29

Interface Configuration ........................ 30

Socket Server Examples ....................... 45

Command Syntax ................................. 49

Command List ..................................... 52

Status Register Overview ..................... 95

Error List ........................................... 106

APPENDIX ..................................................................... 115

PSW Default Settings ......................... 115

Error Messages & Messages .............. 118

LED Display Format ........................... 118

INDEX............................................................................ 119

3

Page 4

PSW Series Programming Manual

WARNING

Warning: Identifies conditions or practices that

could result in injury or loss of life.

CAUTION

Caution: Identifies conditions or practices that

could result in damage to the PSW or to other

properties.

DANGER High Voltage

Attention Refer to the Manual

Protective Conductor Terminal

Earth (ground) Terminal

SAFETY INSTRUCTIONS

This chapter contains important safety

instructions that you must follow during

operation and storage. Read the following before

any operation to insure your safety and to keep

the instrument in the best possible condition.

Safety Symbols

These safety symbols may appear in this manual or on the

instrument.

4

Page 5

SAFETY INSTRUCTIONS

Do not dispose electronic equipment as unsorted

municipal waste. Please use a separate collection

facility or contact the supplier from which this

instrument was purchased.

General

Guideline

CAUTION

Do not place any heavy object on the PSW.

Avoid severe impact or rough handling that

leads to damaging the PSW.

Do not discharge static electricity to the PSW.

Use only mating connectors, not bare wires, for

the terminals.

Do not block the cooling fan opening.

Do not disassemble the PSW unless you are

qualified.

(Measurement categories) EN61010-1:2010 and EN61010-2-030

specify the measurement categories and their requirements as

follows. The PSW falls under category II.

Measurement category IV is for measurement performed at the

source of low-voltage installation.

Measurement category III is for measurement performed in the

building installation.

Measurement category II is for measurement performed on the

circuits directly connected to the low voltage installation.

0 is for measurements performed on circuits not directly

connected to Mains.

Power Supply

WARNING

AC Input voltage range: 85VAC~265VAC

Frequency: 47Hz~63Hz

To avoid electrical shock connect the protective

grounding conductor of the AC power cord to

an earth ground.

Safety Guidelines

5

Page 6

PSW Series Programming Manual

Cleaning the PSW

Disconnect the power cord before cleaning.

Use a soft cloth dampened in a solution of mild

detergent and water. Do not spray any liquid.

Do not use chemicals containing harsh material

such as benzene, toluene, xylene, and acetone.

Operation

Environment

Location: Indoor, no direct sunlight, dust free,

almost non-conductive pollution (Note below)

Relative Humidity: 20%~ 85%

Altitude: < 2000m

Temperature: 0°C to 50°C

(Pollution Degree) EN61010-1:2010 and EN61010-2-030 specify the

pollution degrees and their requirements as follows. The PSW falls

under degree 2.

Pollution refers to “addition of foreign matter, solid, liquid, or

gaseous (ionized gases), that may produce a reduction of dielectric

strength or surface resistivity”.

Pollution degree 1: No pollution or only dry, non-conductive

pollution occurs. The pollution has no influence.

Pollution degree 2: Normally only non-conductive pollution

occurs. Occasionally, however, a temporary conductivity caused

by condensation must be expected.

Pollution degree 3: Conductive pollution occurs, or dry, non-

conductive pollution occurs which becomes conductive due to

condensation which is expected. In such conditions, equipment

is normally protected against exposure to direct sunlight,

precipitation, and full wind pressure, but neither temperature

nor humidity is controlled.

Storage

environment

Location: Indoor

Temperature: -25°C to 70°C

Relative Humidity: <90%

Disposal

Do not dispose this instrument as unsorted

municipal waste. Please use a separate collection

facility or contact the supplier from which this

instrument was purchased. Please make sure

discarded electrical waste is properly recycled to

reduce environmental impact.

6

Page 7

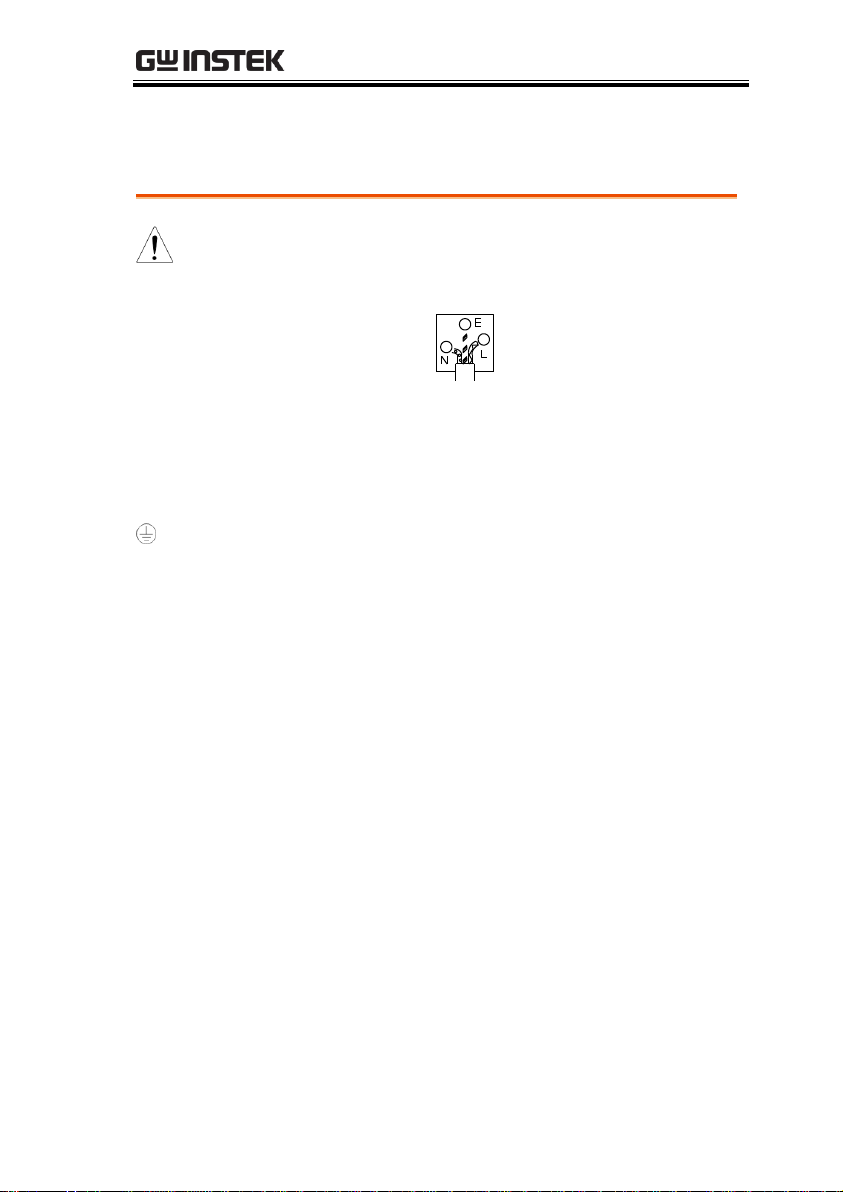

SAFETY INSTRUCTIONS

Green/ Yellow:

Earth

Blue:

Neutral

Brown:

Live (Phase)

Power cord for the United Kingdom

When using the power supply in the United Kingdom, make sure

the power cord meets the following safety instructions.

NOTE: This lead/appliance must only be wired by competent persons

WARNING: THIS APPLIANCE MUST BE EARTHED

IMPORTANT: The wires in this lead are coloured in accordance with the

following code:

As the colours of the wires in main leads may not correspond with

the coloured marking identified in your plug/appliance, proceed

as follows:

The wire which is coloured Green & Yellow must be connected to

the Earth terminal marked with either the letter E, the earth symbol

or coloured Green/Green & Yellow.

The wire which is coloured Blue must be connected to the terminal

which is marked with the letter N or coloured Blue or Black.

The wire which is coloured Brown must be connected to the

terminal marked with the letter L or P or coloured Brown or Red.

If in doubt, consult the instructions provided with the equipment

or contact the supplier.

This cable/appliance should be protected by a suitably rated and

approved HBC mains fuse: refer to the rating information on the

equipment and/or user instructions for details. As a guide, a cable

of 0.75mm2 should be protected by a 3A or 5A fuse. Larger

conductors would normally require 13A types, depending on the

connection method used.

Any exposed wiring from a cable, plug or connection that is

engaged in a live socket is extremely hazardous. If a cable or plug is

deemed hazardous, turn off the mains power and remove the cable,

any fuses and fuse assemblies. All hazardous wiring must be

immediately destroyed and replaced in accordance to the above

standard.

7

Page 8

PSW Series Programming Manual

PSW Series Overview ......................................................... 9

Series lineup .............................................................................. 9

Main Features ......................................................................... 10

Accessories ............................................................................. 11

Appearance ..................................................................... 14

PSW Front Panel ................................................................... 14

Rear Panel ............................................................................... 17

Configuration Settings..................................................... 21

GETTING STARTED

This chapter describes the power supply in a

nutshell, including its main features and front /

rear panel introduction, as well as an overview of

the configuration settings.

8

Page 9

GETTING STARTED

Note

Throughout the user manual, PSW 30, PSW 80,

PSW 160, PSW 250 or PSW 800 will refer to any of

the PSW models with a maximum voltage rating of

30V, 80V, 160V, 250V or 800V, respectively.

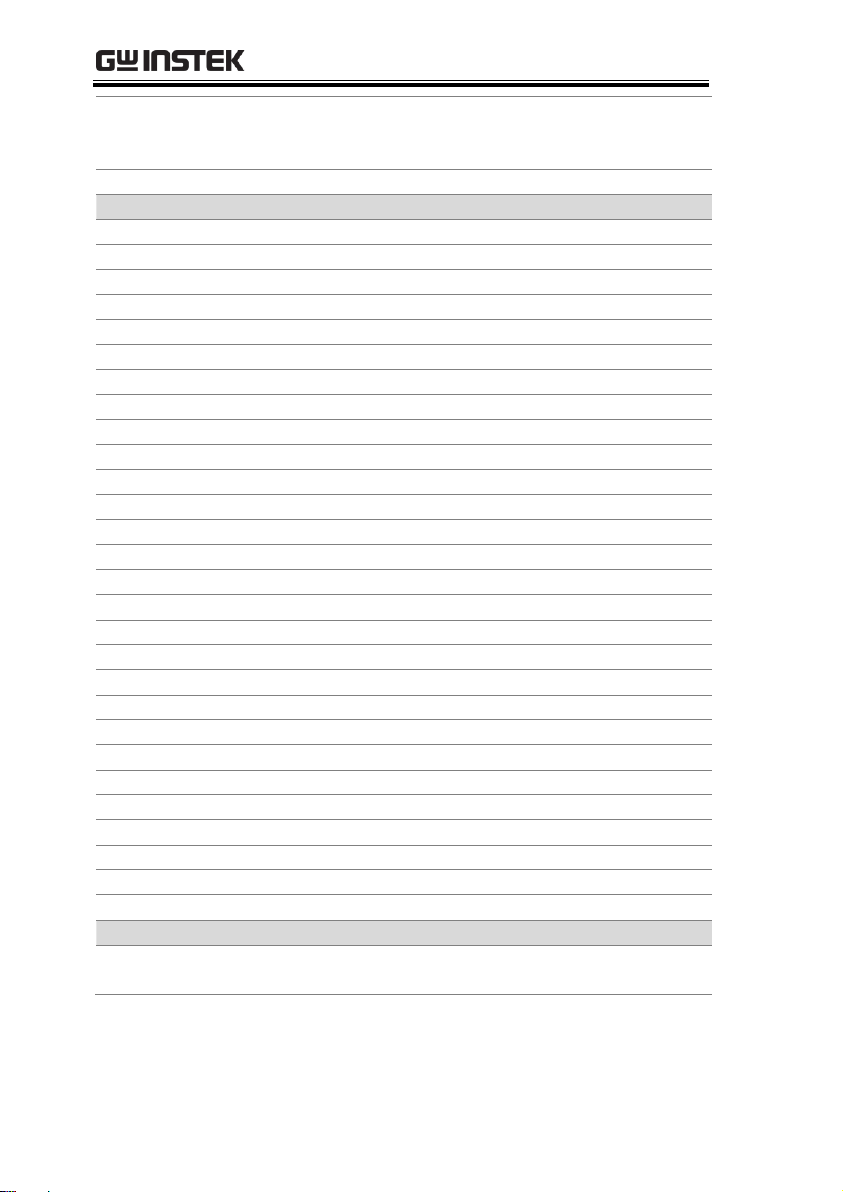

Model name

Type

Voltage Rating

Current Rating

Power

PSW 30-36

Type I

0~30V

0~36A

360W

PSW 80-13.5

Type I

0~80V

0~13.5A

360W

PSW 160-7.2

Type I

0~160V

0~7.2A

360W

PSW 250-4.5

Type I

0~250V

0~4.5A

360W

PSW 800-1.44

Type I

0~800V

0~1.44A

360W

PSW 30-72

Type II

0~30V

0~72A

720W

PSW 80-27

Type II

0~80V

0~27A

720W

PSW 160-14.4

Type II

0~160V

0~14.4A

720W

PSW 250-9

Type II

0~250V

0~9A

720W

PSW 800-2.88

Type II

0~800V

0~2.88A

720W

PSW 30-108

Type III

0~30V

0~108A

1080W

PSW 80-40.5

Type III

0~80V

0~40.5A

1080W

PSW 160-21.6

Type III

0~160V

0~21.6A

1080W

PSW 250-13.5

Type III

0~250V

0~13.5A

1080W

PSW 800-4.32

Type III

0~800V

0~4.32A

1080W

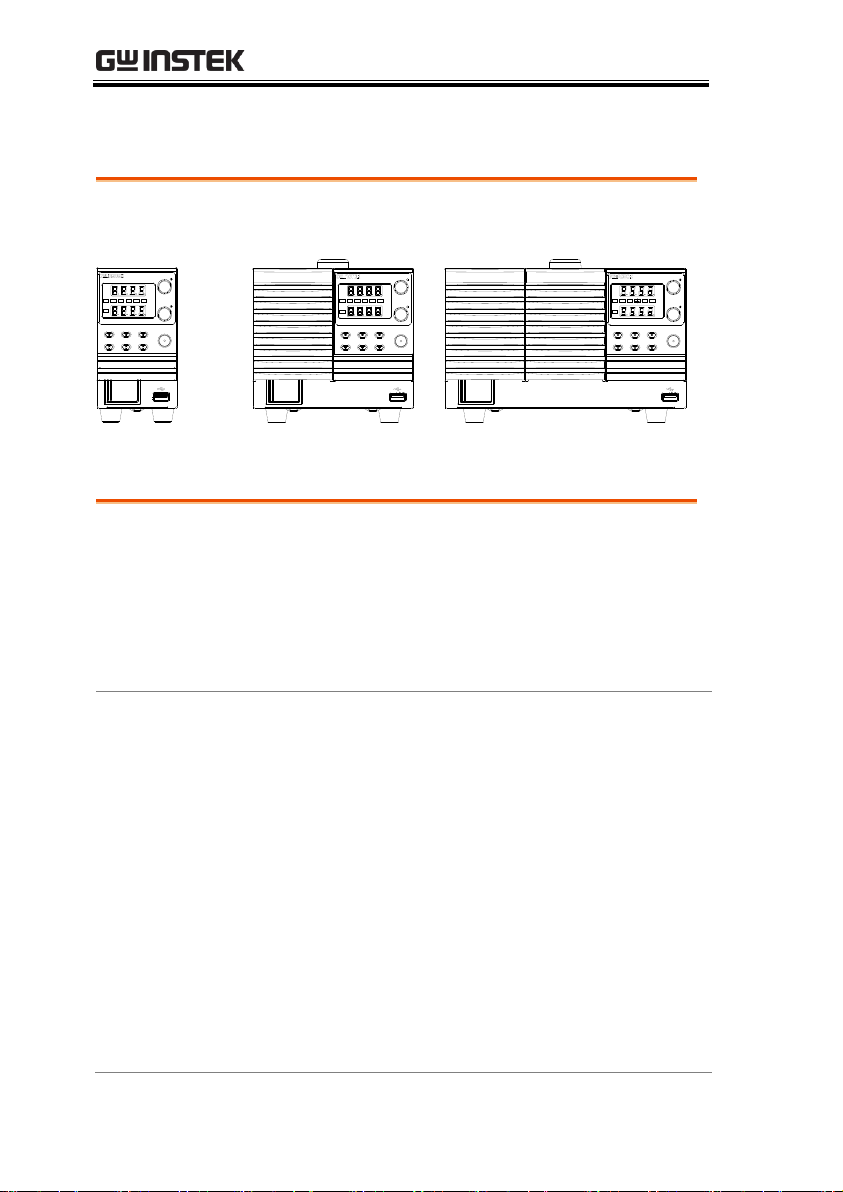

PSW Series Overview

Series lineup

The PSW series consists of 15 models, divided into 3 different

model types covering 3 power capacities: Type I (360 Watt), Type II

(720 Watt) and Type III (1080 Watt).

9

Page 10

PSW Series Programming Manual

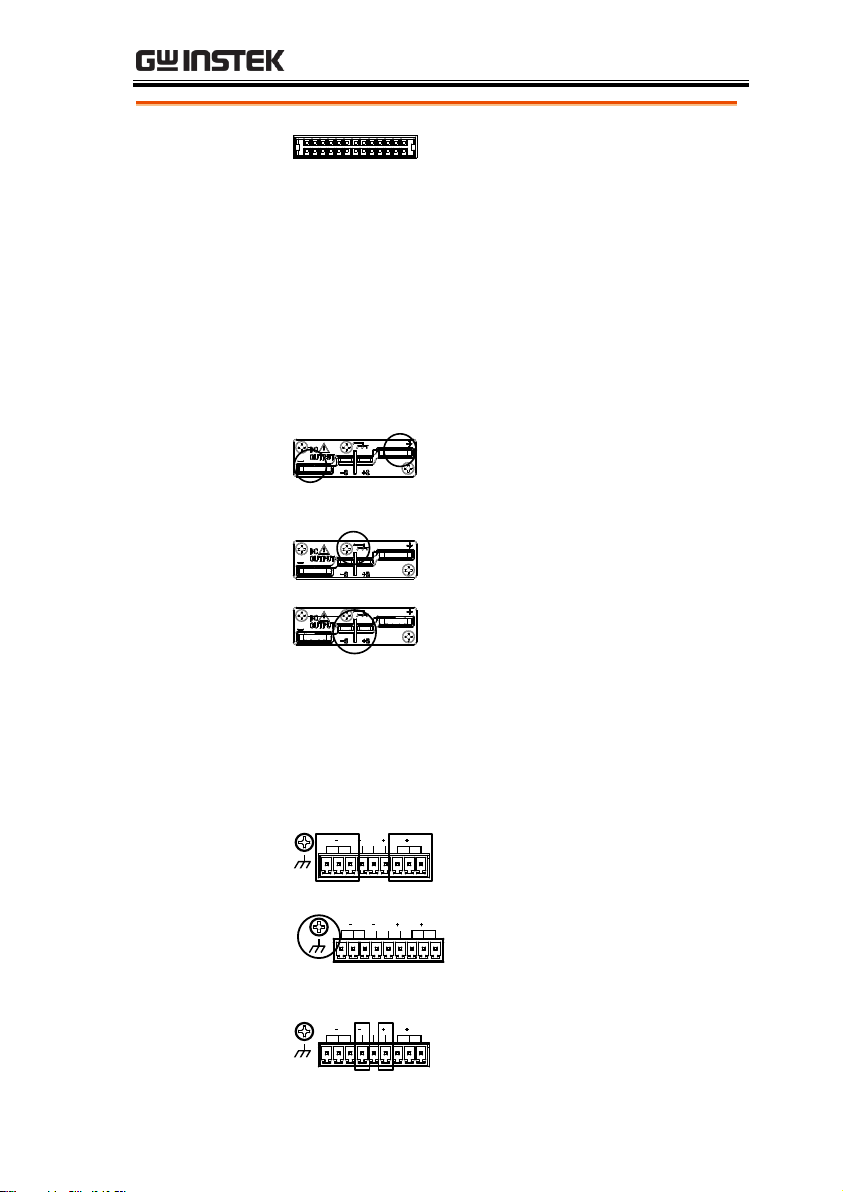

360 Watt models

Type I

A

W

V

W

%W10080604020

ISR

C C

DLY

ALM

RMT

C V

VSR

Function OVP/OCP Set

Output

PWR DSPLLock/LocalTest

PSW 30 -36

360W

Multi-Range DC Power Supply

Voltage

Current

720 Watt models

Type II

A

W

V

W

%W10080604020

ISR

C C

DLY

ALM

RMT

C V

VSR

Function OVP/OCP Set

Output

PWR DSPLLock/LocalTest

PSW 30 -72

720W

Voltage

Current

Multi-Range DC Power Supply

1080 Watt models

Type III

A

W

V

W

%W10080604020

ISR

C C

DLY

ALM

RMT

C V

VSR

Function OVP/OCP Set

Output

PWR DSPLLock/LocalTest

PSW 30 -108

1080W

Voltage

Current

Multi-Range DC Power Supply

Performance

High performance/power

Power efficient switching type power supply

Low impact on load devices

Fast transient recovery time of 1ms

Fast output response time

Features

OVP, OCP and OTP protection

Adjustable voltage and current slew rates

User adjustable bleeder control to quickly

dissipate the power after shutdown to safe

levels.

Extensive remote monitoring and control

options

Support for serial* and parallel connections.

*(30, 80, 160 volt models only)

Power on configuration settings.

Supports test scripts

Web server monitoring and control

Apart from the differences in output, each unit differs in size. The

720 and 1080 watt models are larger than the 360 watt models to

accommodate the increase in power.

Main Features

10

Page 11

GETTING STARTED

Interface

Ethernet port

Analog connector for analog voltage and current

monitoring

USB host and device port

Standard

Accessories

Part number

Description

CD-ROM

User manual,

programming manual

4323-30600101

Power cord (Type I/II)

4320-91001101

Power cord (Type III)

1042-SWLV0301

Output terminal cover

GTL-123

Test leads: 1x red, 1x black

GTL-240

USB Cable

PSW-004

Basic Accessory Kit:

M4 terminal screws and

washers x2, M8 terminal

bolts, nuts and washers x2,

Air filter x1, Analog control

protection dummy x1,

Analog control lock level x1

Optional

Accessories

Part number

Description

GET-001

Extended terminal

PSW-001

Accessory Kit:

Pin contact x10, Socket x1,

Protection cover x1

Accessories

Please check the contents before using the PSW.

PSW 30/80/160 Accessories

11

Page 12

PSW Series Programming Manual

PSW-002

Simple IDC

Tool

PSW-003

Contact

Removal Tool

PSW-005

Series operation cable for 2

units.

PSW-006

Parallel operation cable for

2 units.

PSW-007

Parallel operation cable for

3 units.

GRA-410-J

Rack mount adapter (JIS)

GRA-410-E

Rack mount adapter (EIA)

GUG-001

GPIB to USB adapter

GTL-240

USB Cable

57RG-30B00201

Large filter (Type II/III)

Download

Name

Description

psw_cdc.inf

USB driver

Standard

Accessories

Part number

Description

CD-ROM

User manual,

programming manual

4323-30600101

Power cord (Type I/II)

4320-91001101

Power cord (Type III)

1042-SWHV0301

High voltage output

terminal cover

GTL-240

USB Cable

39BT-50900401

High voltage output

terminal

PSW 250/800 Accessories

12

Page 13

GETTING STARTED

PSW-008

Basic Accessory Kit:

(Air filter x1, Analog control

protection dummy x1,

Analog control lock level x1

Optional

Accessories

Part number

Description

GET-002

Extended terminal

PSW-001

Accessory Kit:

Pin contact x10, Socket x1,

Protection cover x1

PSW-002

Simple IDC

Tool

PSW-003

Contact

Removal Tool

PSW-006

Parallel operation cable for

2 units.

PSW-007

Parallel operation cable for

3 units.

GRA-410-J

Rack mount adapter (JIS)

GRA-410-E

Rack mount adapter (EIA)

GTL-130

Test leads: 2x red, 2x black

GUG-001

GPIB to USB adapter

GTL-240

USB Cable

57RG-30B00201

Large filter (Type II/III)

Download

Name

Description

psw_cdc.inf

USB driver

13

Page 14

PSW Series Programming Manual

A

W

V

W

%W10080604020

ISR

C C

DLY

ALM

RMT

C V

VSR

Function OVP/OCP Set

Output

PWR DSPLLock/LocalTest

PSW 30 -72

720W

Voltage

Current

Multi-Range DC Power Supply

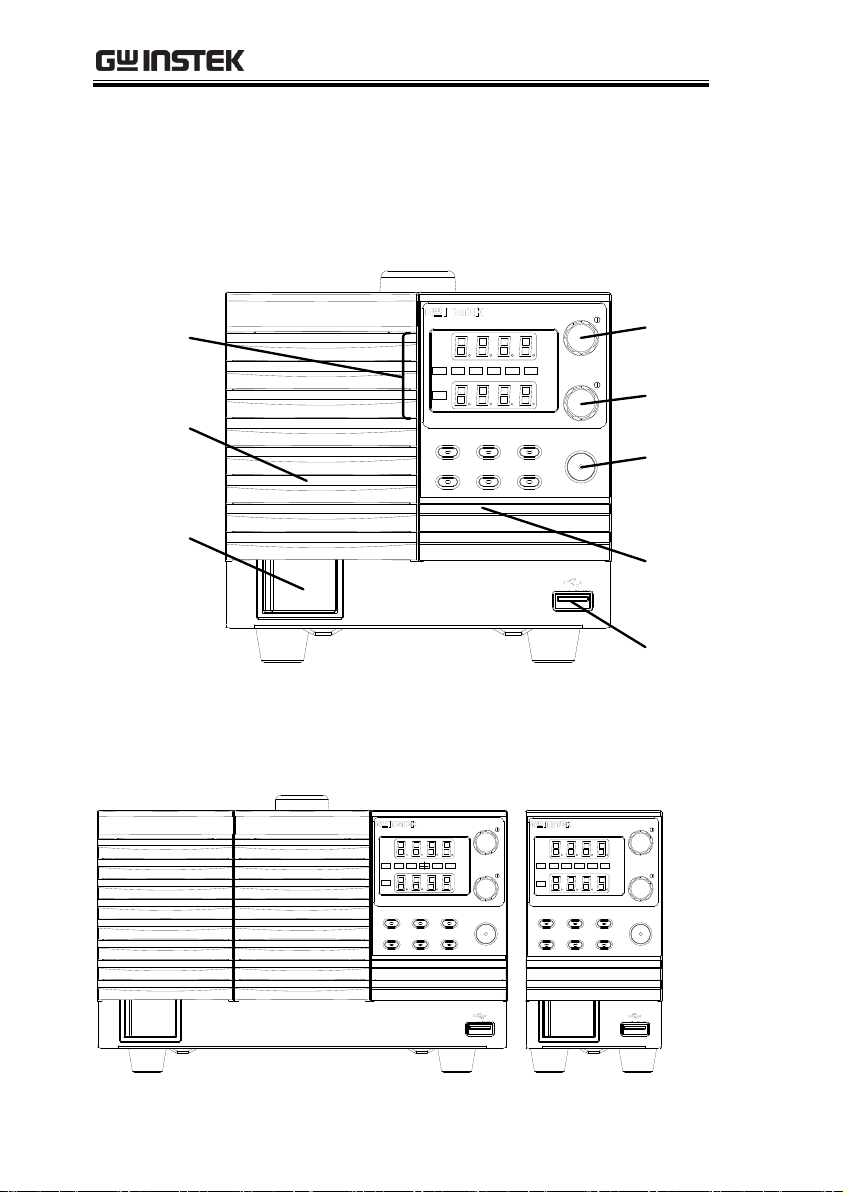

Current

knob

Output

key

Power

switch

Voltage

knob

USB A

port

Display

Cover

panel

Function

keys

1080W: PSW 30-108, 80-40.5, 160-21.6,

250-13.5, 800-4.32

360W: PSW 30-36,

80-13.5, 160-7.2,

250-4.5, 800-1.44

A

W

V

W

%W10080604020

ISR

C C

DLY

ALM

RMT

C V

VSR

Function OVP/OCP Set

Output

PWR DSPLLock/LocalTest

PSW 30- 108

1080W

Voltage

Current

Multi-Range DC Power Supply

A

W

V

W

%W10080604020

ISR

C C

DLY

ALM

RMT

C V

VSR

Function OVP/OCP Set

Output

PWR DSPLLock/LocalTest

PSW 30- 36

360W

Multi-Range DC Power Supply

Voltage

Current

Appearance

PSW Front Panel

720W: PSW 30-72, 80-27, 160-14.4, 250-9, 800-2.88

14

Page 15

GETTING STARTED

Function Keys

The Function keys along with the Output key will

light up when a key is active.

Function

The Function key is used to

configure the power supply.

OVP/OCP

Set the over current or over

voltage protection levels.

Set

Sets the current and voltage limits.

Test

Used to run customized scripts for

testing.

Lock/Local

Locks or unlocks the panel keys to

prevent accidentally changing

panel settings.

PWR DSPL

Toggles the display from viewing

V/AV/WA/W.

Display

Indicators

VSR

Voltage Slew Rate

C V

Constant Voltage Mode

RMT

Remote Control Mode

ALM

Alarm on

DLY

Delay Output

C C

Constant Current Mode

ISR

Current Slew Rate

15

Page 16

PSW Series Programming Manual

20 40 60

80 100 % W

Power bar

Indicates the current power output

as a percentage.

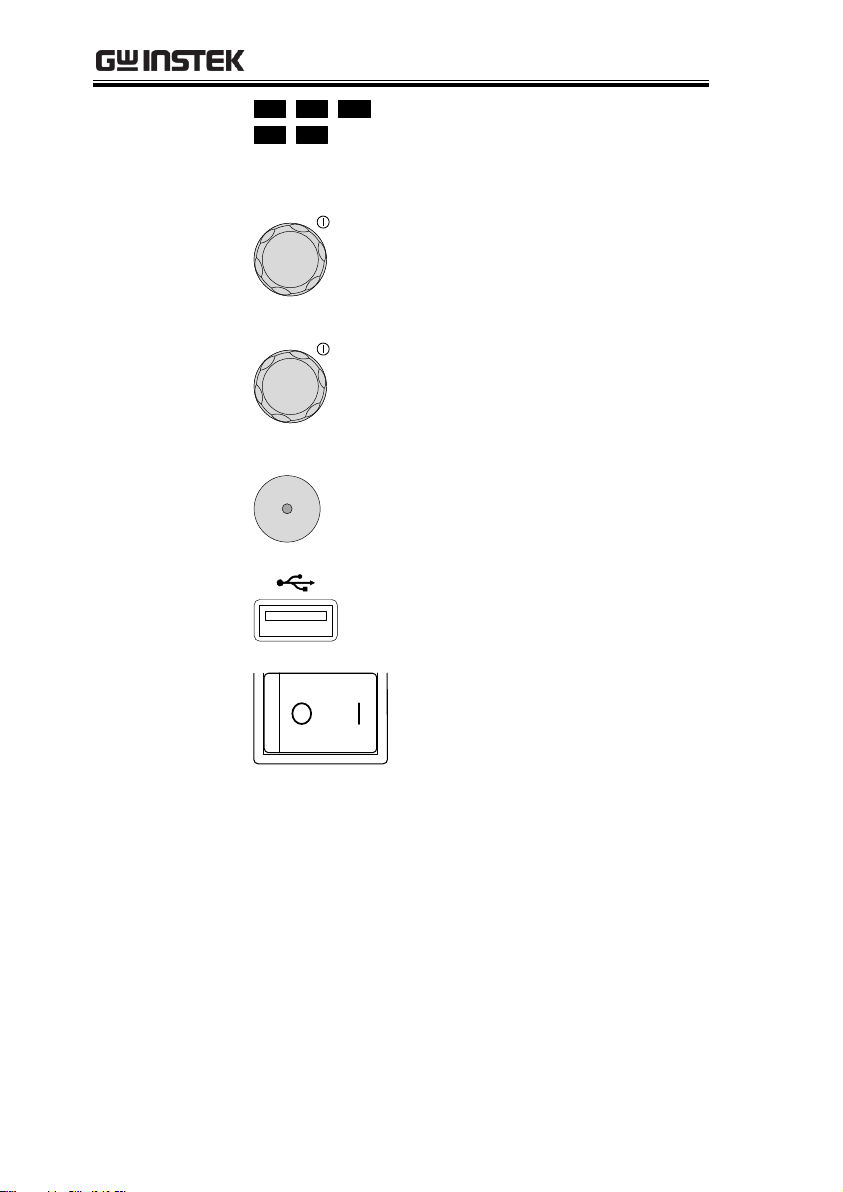

Voltage Knob

Voltage

Sets the voltage.

Current Knob

Current

Sets the current.

Output

Output

Press to turn on the output. The

Output key will light up when the

output is active.

USB

USB A port for data transfer,

loading test scripts etc.

Power Switch

Used to turn the power on/off.

16

Page 17

GETTING STARTED

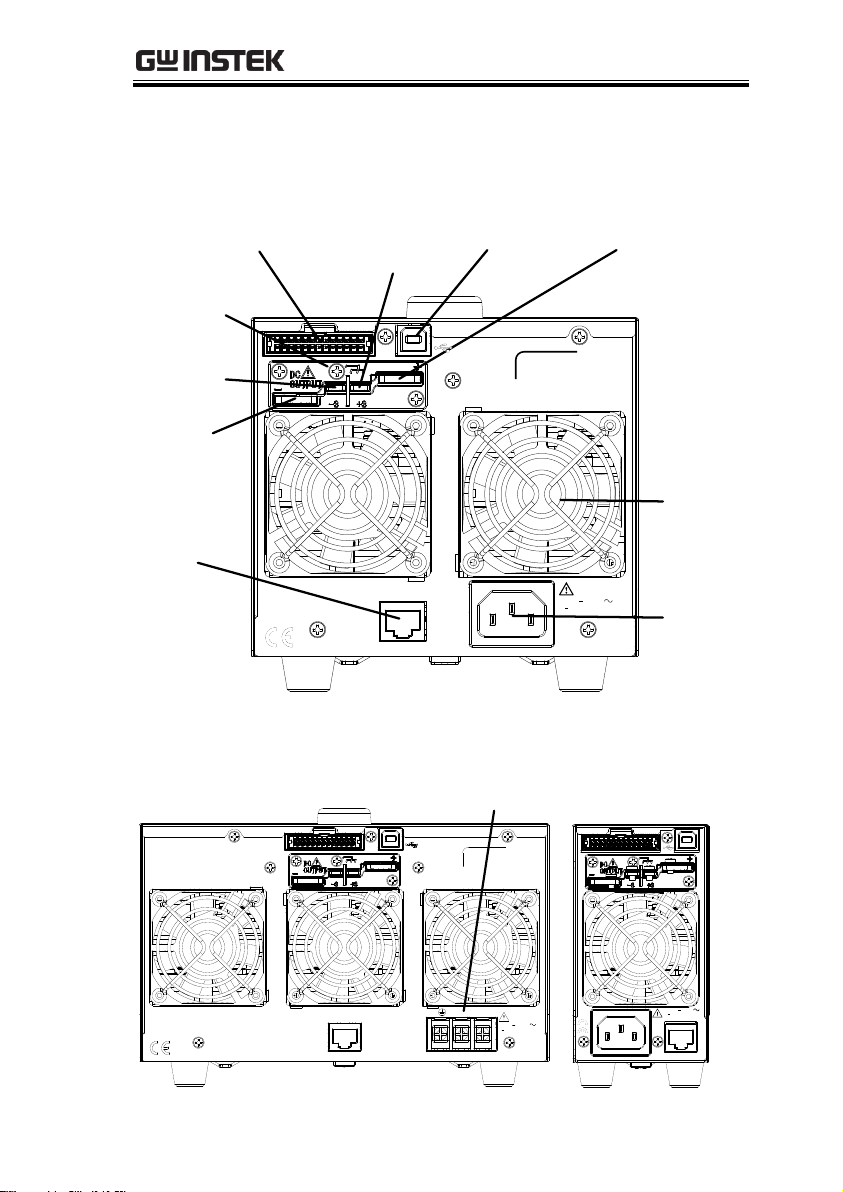

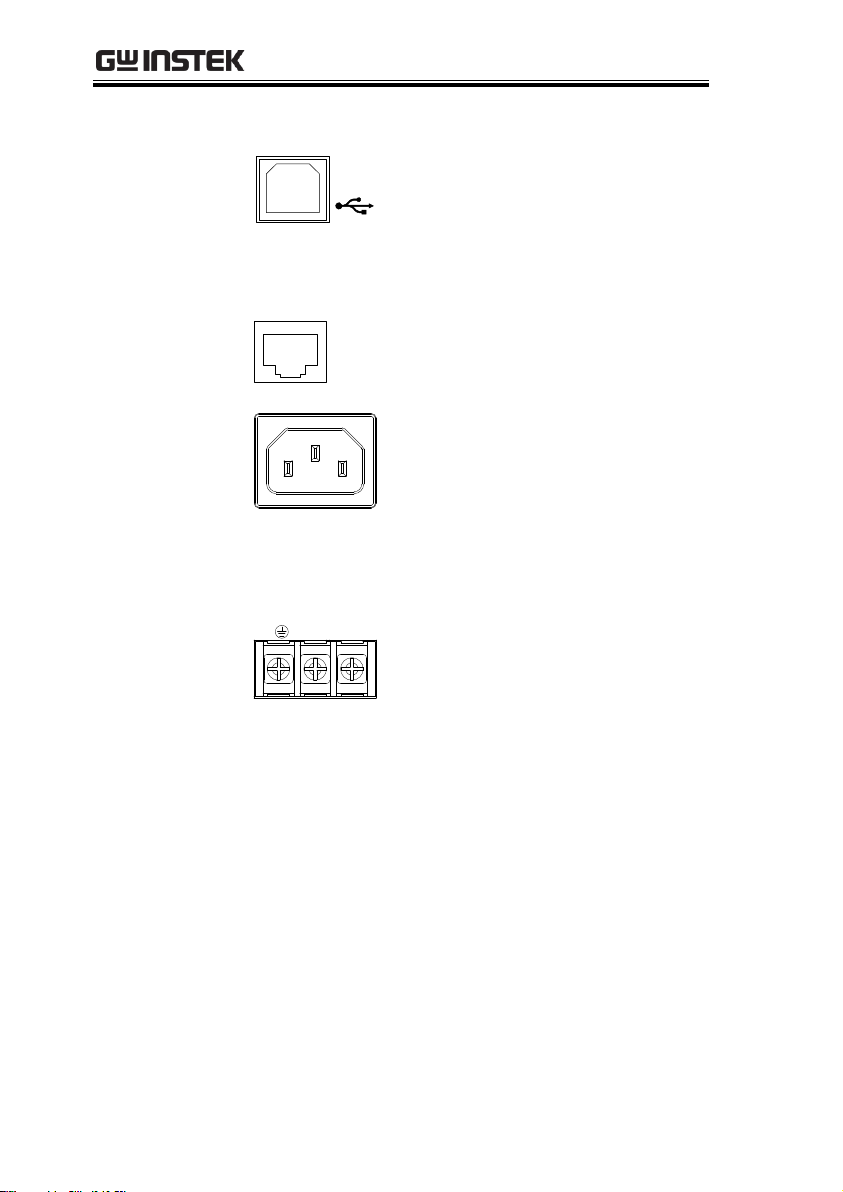

Output

terminal

(+)

Fan

Output

terminal (-)

USB B

port

LAN

AC Input

Senseterminal

Analog control

connector

LAN

100 240V

1000VA MAX.

AC

47 63Hz

SER.NO. LABEL

Sense+

terminal

Chassis

ground

1080W: PSW 30-108, 80-40.5, 160-21.6

360W: PSW 30-36,

80-13.5, 160-7.2

100 240VAC

1500VA MAX.

47 63Hz

LAN

LN

SER.NO. LABEL

AC Input

LAN

100 240V

47 63Hz 500VA MAX.

AC

Rear Panel

720W: PSW 30-72, 80-27, 160-14.4

17

Page 18

PSW Series Programming Manual

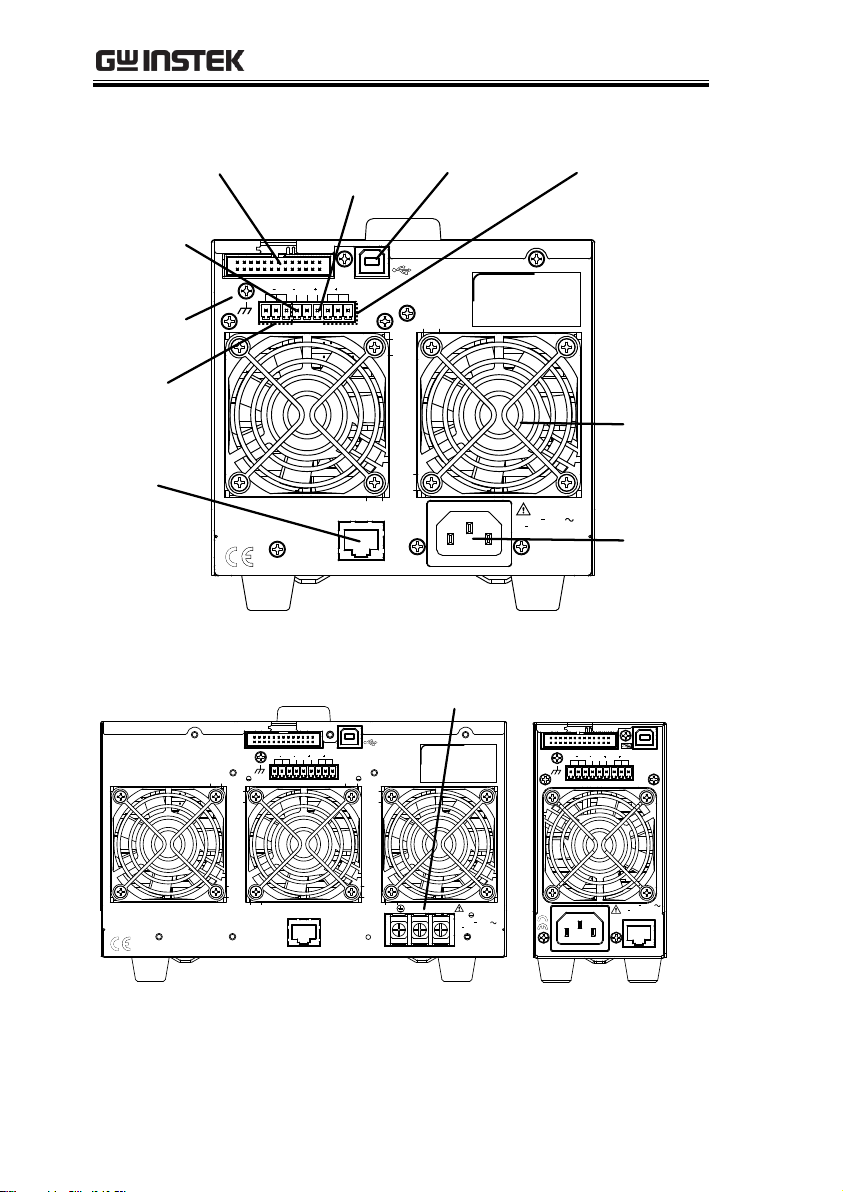

LAN

100 240V

1000VA MAX.

AC

47 63Hz

SER.NO. LABEL

V SN.C. S V

Output

terminals +V

Fan

Chassis

ground

USB B

port

LAN

AC Input

Senseterminal

Analog control

connector

Sense+

terminal

Output

terminals -V

1080W: PSW 250-13.5, 800-4.32

360W: PSW 250-4.5,

800-1.44

LAN

LN

SER.NO. LABEL

47 63Hz

1500VA MAX.

AC100 240V

V VSN.C. S

AC Input

LAN

100 240V

47 63Hz500VA MAX.

AC

V SN.C. S V

720W: PSW 250-9, 800-2.88

18

Page 19

GETTING STARTED

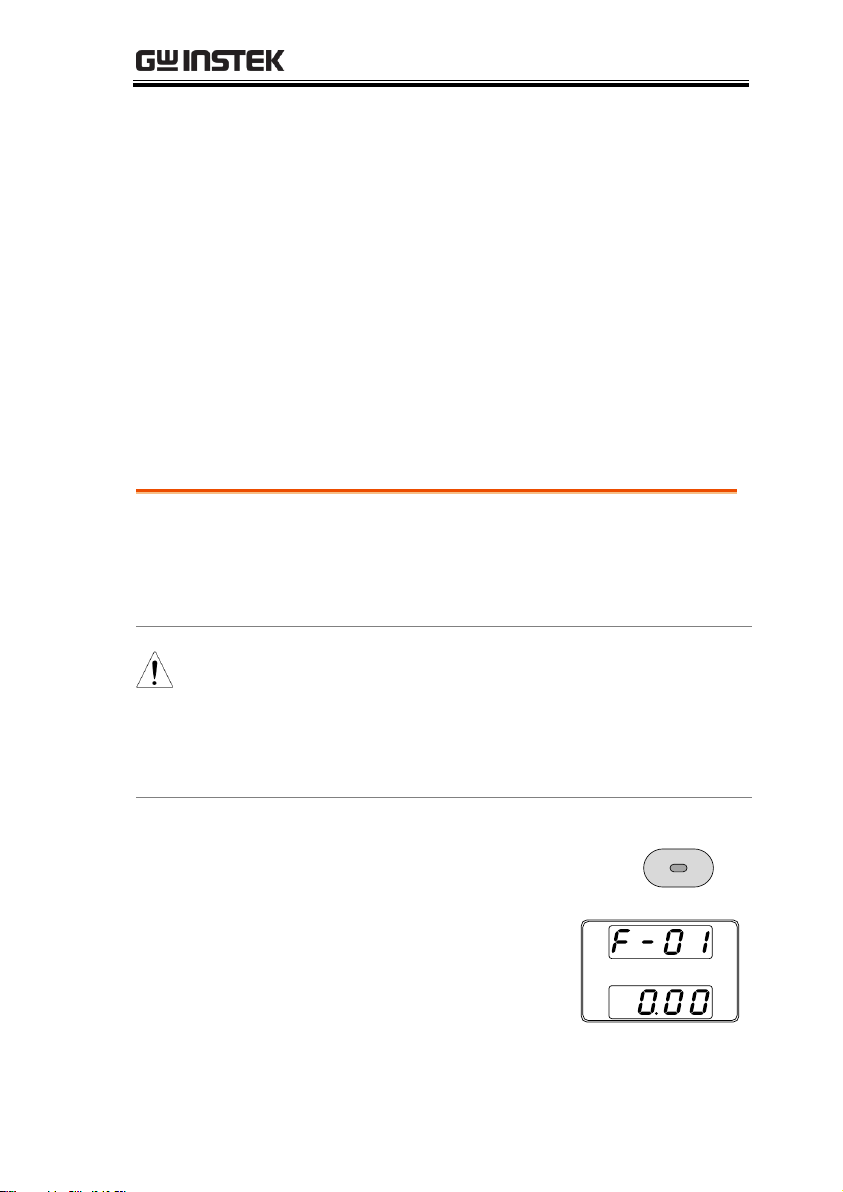

Analog Control

Connector

Standard 26 pin MIL connector

(OMRON XG4 IDC plug).

The analog control connector is

used to monitor current and voltage

output, machine status (OVP, OCP,

OTP etc.), and for analog control of

the current and voltage output.

Use an OMRON XG5 IDC socket as

the mating socket.

Output Terminals

(30, 80, 160 volt

models)

Positive (+) and negative (-) output

terminals.

Chassis ground

Sense (-S) and Sense (+S) terminals.

Output Terminals

(250, 800 volt

models)

The 250 and 800 volt models use a 9 pin connector

and a plug for the output and sense terminal

connections. The plug is a MC420-38109Z plug by

DECA SwitchLab Inc. This plug is also available

separately (GW part number 39BT-50900401).

V SN.C. S V

Positive (V+) and negative (V-)

output terminals (3 of each).

V SN.C. S V

Chassis ground

V SN.C. S V

Sense (-S) and Sense (+S)

terminals.

19

Page 20

PSW Series Programming Manual

USB B port

The USB B port is used for remote

control.

Fans

Temperature controlled fans

Ethernet Port

LAN

The ethernet port is used for remote

control and digital monitoring from

a PC.

Line Voltage

Input

(Type I/TypeII)

Type I: PSW 30-36/80-13.5/

160-7.2/250-4.5, 800-1.44

Type II: PSW 30-72/80-27/

160-14.4/250-9, 800-2.88

Voltage Input: 100~240 VAC

Line frequency: 50Hz/60 Hz

(Automatically switchable)

Line Voltage

Input

(Type III)

LN

Type III:

PSW 30-108/80-40.5/160-21.6/

250-13.5/800-4.32

Voltage Input: 100~240 VAC

Line frequency: 50Hz/60 Hz

(Automatically switchable)

20

Page 21

GETTING STARTED

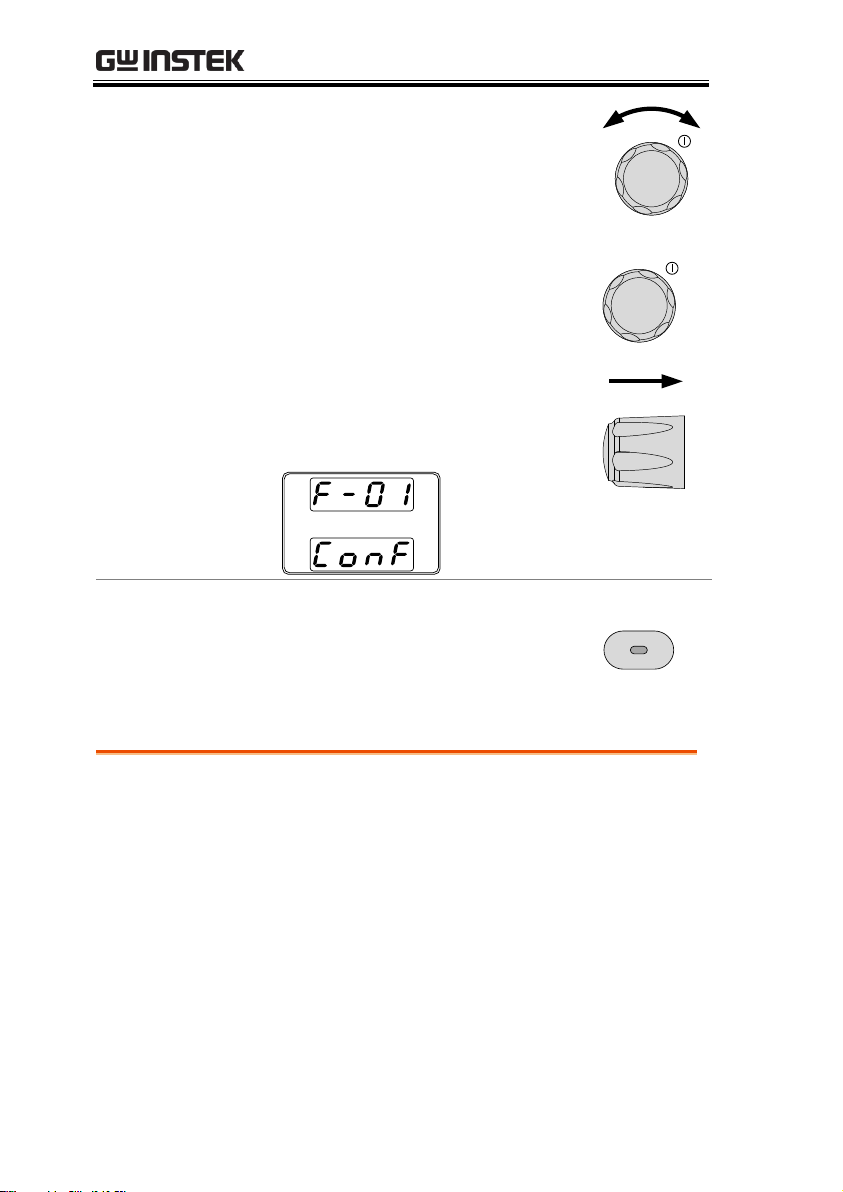

The normal function settings (F-01~F-61, F-88~F-

89) can be easily configured with the Function key.

Ensure the load is not connected.

Ensure the output is off.

Note

Function setting F-89 (Show Version) can only be

viewed, not edited.

Configuration settings F-90~F-95 cannot be edited

in the Normal Function Settings. Use the Power

On Configuration Settings. See page 22 for details.

Steps

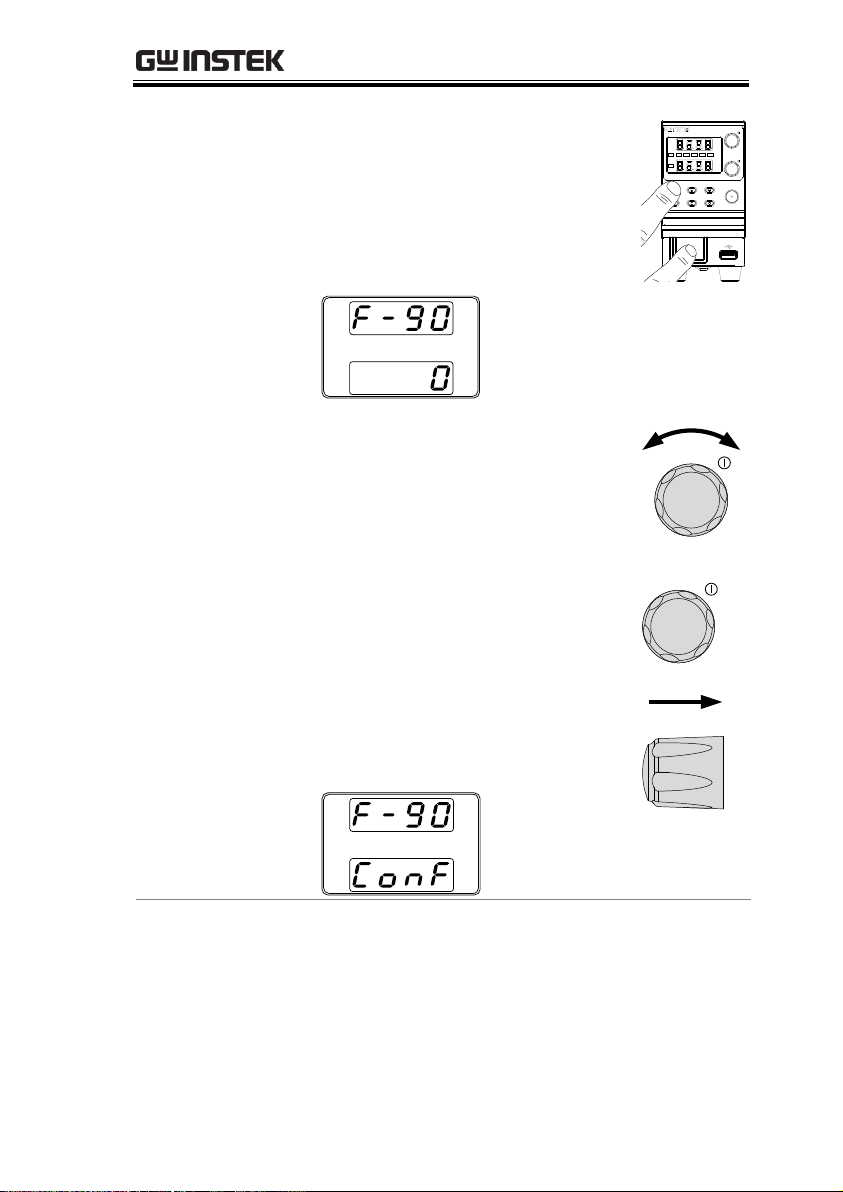

1. Press the Function key. The

function key will light up.

Function

2. The display will show F-01

on the top and the

configuration setting for

F-01 on the bottom.

Configuration Settings

Configuration of the PSW power supplies is divided into five

different configuration settings: Normal Function, USB/GPIB, LAN,

Power ON Configuration, Calibration Settings and System Settings.

Power ON Configuration differs from the other settings in that the

settings used with Power ON Configuration settings can only be set

during power up. The other configuration settings can be changed

when the unit is already on. This prevents some important

configuration parameters from being changed inadvertently. Power

On Configuration settings are numbered F-90 to F-95 and the other

configuration settings are numbered F-00 to F-61 and F-88 to F-89.

Setting Normal Function Settings

21

Page 22

PSW Series Programming Manual

3. Rotate the voltage knob to change

the F setting.

Voltage

Range

F-00~ F-61, F-88~F-89

4. Use the current knob to set the

parameter for the chosen F setting.

Current

5. Press the Voltage knob to save the

configuration setting. ConF will be

displayed when successful.

Voltage

Exit

Press the Function key again to exit

the configuration settings. The

function key light will turn off.

Function

Background

The Power On configuration settings can only be

changed during power up to prevent the

configuration settings being inadvertently

changed.

Ensure the load is not connected.

Ensure the power supply is off.

Setting Power On Configuration Settings

22

Page 23

GETTING STARTED

Steps

6. Hold the Function key whilst

turning the power on.

7. The display will show F-90 on the

top and the configuration setting

for F-90 on the bottom.

A

W

V

W

%W10080604020

ISR

C C

DLY

ALM

RMT

C V

VSR

Function OVP/OCP Set

Output

PWR DSPLLock/LocalTest

PSW 30 -36

360W

Voltage

Current

Multi-Range DC Power Supply

8. Rotate the voltage knob to change

the F setting.

Voltage

Range

F-90~ F-95

9. Use the current knob to set the

parameter for the chosen F setting.

Current

10. Press the Voltage knob to save the

configuration setting. ConF will be

displayed when successful.

Voltage

Exit

Cycle the power to save and exit the configuration

settings.

23

Page 24

PSW Series Programming Manual

Normal Function

Settings

Setting

Setting Range

Output ON delay time

F-01

0.00s~99.99s

Output OFF delay time

F-02

0.00s~99.99s

V-I mode slew rate select

F-03

0 = CV high speed priority

1 = CC high speed priority

2 = CV slew rate priority

3 = CC slew rate priority

Rising voltage slew rate

F-04

0.01V/s~60.00V/s (PSW 30-XX)

0.1V/s~160.0V/s (PSW 80-XX)

0.1V/s~320.0V/s (PSW 160-XX)

0.1V/s~500.0V/s (PSW 250-XX)

1V/s~1600V/s (PSW 800-XX)

Falling voltage slew rate

F-05

0.01V/s~60.00V/s (PSW 30-XX)

0.1V/s~160.0V/s (PSW 80-XX)

0.1V/s~320.0V/s (PSW 160-XX)

0.1V/s~500.0V/s (PSW 250-XX)

1V/s~1600V/s (PSW 800-XX)

Rising current slew rate

F-06

0.01A/s~72.00A/s (PSW 30-36)

0.1A/s~144.0A/s (PSW 30-72)

0.1A/s~216.0A/s (PSW 30-108)

0.01A/s~27.00A/s (PSW 80-13.5)

0.01A/s~54.00A/s (PSW 80-27)

0.01A/s~81.00A/s (PSW 80-40.5)

0.01A/s~14.40A/s (PSW 160-7.2)

0.01A/s~28.80A/s (PSW 160-14.4)

0.01A/s~43.20A/s (PSW 160-21.6)

0.001A/s ~ 9.000A/s (PSW 250-4.5)

0.01A/s ~ 18.00A/s (PSW 250-9)

0.01A/s ~ 27.00A/s (PSW 250-13.5)

0.001A/s ~ 2.880A/s (PSW 800-1.44)

0.001A/s ~ 5.760A/s (PSW 800-2.88)

0.001A/s ~ 8.640A/s (PSW 800-4.32)

Configuration Table

Please use the configuration settings listed below when applying

the configuration settings.

24

Page 25

GETTING STARTED

Falling current slew rate

F-07

0.01A/s~72.00A/s (PSW 30-36)

0.1A/s~144.0A/s (PSW 30-72)

0.1A/s~216.0A/s (PSW 30-108)

0.01A/s~27.00A/s (PSW 80-13.5)

0.01A/s~54.00A/s (PSW 80-27)

0.01A/s~81.00A/s (PSW 80-40.5)

0.01A/s~14.40A/s (PSW 160-7.2)

0.01A/s~28.80A/s (PSW 160-14.4)

0.01A/s~43.20A/s (PSW 160-21.6)

0.001A/s ~ 9.000A/s (PSW 250-4.5)

0.01A/s ~ 18.00A/s (PSW 250-9)

0.01A/s ~ 27.00A/s (PSW 250-13.5)

0.001A/s ~ 2.880A/s (PSW 800-1.44)

0.001A/s ~ 5.760A/s (PSW 800-2.88)

0.001A/s ~ 8.640A/s (PSW 800-4.32)

Internal resistance

setting

F-08

0.000Ω~0.833Ω (PSW 30-36)

0.000Ω~0.417Ω (PSW 30-72)

0.000Ω~0.278Ω (PSW 30-108)

0.000Ω~5.926Ω (PSW 80-13.5)

0.000Ω~2.963Ω (PSW 80-27)

0.000Ω~1.975Ω (PSW 80-40.5)

0.000Ω~22.222Ω (PSW 160-7.2)

0.000Ω~11.111Ω (PSW 160-14.4)

0.000Ω~7.407Ω (PSW 160-21.6)

0.00Ω ~ 55.55Ω (PSW 250-4.5)

0.00Ω ~ 27.77Ω (PSW 250-9)

0.00Ω ~ 18.51Ω (PSW 250-13.5)

0.0Ω ~ 555.5Ω (PSW 800-1.44)

0.0Ω ~ 277.8Ω (PSW 800-2.88)

0.0Ω ~ 185.1Ω (PSW 800-4.32)

Bleeder circuit control

F-09

0 = OFF, 1 = ON, 2 = AUTO

Buzzer ON/OFF control

F-10

0 = OFF, 1 = ON

Measurement Average

Setting

F-17

0 = Low, 1 = Middle, 2 = High

Lock Mode

F-19

0 = Panel lock: allow output off

1 = Panel lock: allow output on/off

USB/GPIB settings

Front panel USB State

F-20

0 = Absent, 1 = Mass Storage

Rear panel USB State

F-21

0 = Absent, 2 = USB-CDC, 3 = GPIBUSB adapter

25

Page 26

PSW Series Programming Manual

Rear panel USB mode

F-22

0 = Disable, 1 = GPIB-USB adapter,

2 = Auto detect speed, 3 = Full speed

only

GPIB address

F-23

0~30

LAN settings

MAC Address-1

F-30

0x00~0xFF

MAC Address-2

F-31

0x00~0xFF

MAC Address-3

F-32

0x00~0xFF

MAC Address-4

F-33

0x00~0xFF

MAC Address-5

F-34

0x00~0xFF

MAC Address-6

F-35

0x00~0xFF

LAN

F-36

0 = Disable, 1 = Enable

DHCP

F-37

0 = Disable, 1 = Enable

IP Address-1

F-39

0~255

IP Address-2

F-40

0~255

IP Address-3

F-41

0~255

IP Address-4

F-42

0~255

Subnet Mask-1

F-43

0~255

Subnet Mask-2

F-44

0~255

Subnet Mask-3

F-45

0~255

Subnet Mask-4

F-46

0~255

Gateway-1

F-47

0~255

Gateway-2

F-48

0~255

Gateway-3

F-49

0~255

Gateway-4

F-50

0~255

DNS address -1

F-51

0~255

DNS address -2

F-52

0~255

DNS address-3

F-53

0~255

DNS address-4

F-54

0~255

Sockets active

F-57

0 = Disable, 1 = Enable

Web Server active

F-59

0 = Disable, 1 = Enable

Web password active

F-60

0 = Disable, 1 = Enable

Web setting password

F-61

0000~9999

System Settings

Factory Set Value

F-88

0 = Disable

1 = Return to factory settings

26

Page 27

GETTING STARTED

Show Version

F-89

0, 1 = PSW version

2, 3 = PSW build year

4, 5 = PSW build month/day

6, 7 = Keyboard CPLD version

8, 9 = Analog-Control CPLD version

A, B = Reserved

C, D = Kernel build year

E, F = Kernel build month/day

G, H = Test command version

I, J = Test command build year

K, L = Test command build

month/day

M, N = USB Driver version.

Power On Configuration Settings*

CV Control

F-90

0 = Panel control (local)

1 = External voltage control

2 = External resistance control

(Ext-R 10kΩ = Vo, max)

3 = External resistance control

(Ext-R 10kΩ = 0)

CC Control

F-91

0 = Panel control (local)

1 = External voltage control

2 = External resistance control

(Ext-R 10kΩ = Io,max)

3 = External resistance control

(Ext-R 10kΩ = 0)

Power-ON Output

F-92

0 = OFF at startup

1 = ON at startup

T001 ~ T010 = Run test script TXX at

start up

Master/Slave

F-93

0 = Master/Local

1 = Master/Parallel1

2 = Master/Parallel2

3 = Slave/Parallel

4 = Slave/Series (Only 30V, 80V, 160V

models)

External Out Logic

F-94

0 = High ON, 1 = Low ON

Power Switch trip

F-95

0 = Enable , 1 = Disable

Calibration Settings*

Calibration

F-00

0000 ~ 9999

27

Page 28

PSW Series Programming Manual

*Note

Power On and Calibration settings can only be set

during power up.

28

Page 29

REMOTE CONTROL

Interface Configuration ................................................... 30

Socket Server Examples ................................................... 45

Command Syntax ............................................................ 49

Command List ................................................................. 52

Status Register Overview ................................................. 95

Error List ........................................................................ 106

REMOTE CONTROL

This chapter describes basic configuration of

IEEE488.2 based remote control. For a command

list, refer to the programming manual,

downloadable from GW Instek website,

www.gwinstek.com

29

Page 30

PSW Series Programming Manual

USB Remote Interface .......................................................... 30

Configure GPIB Interface .................................................... 31

Configure Ethernet Connection .......................................... 32

USB Remote Control Function Check ............................... 34

Using Realterm to Establish a Remote Connection ......... 35

Web Server Remote Control Function Check ................... 39

Socket Server Function Check ............................................. 39

USB

configuration

PC side

connector

Type A, host

PSW side

connector

Rear panel Type B, slave

Speed

1.1/2.0 (full speed/high speed)

USB Class

CDC (communications device

class)

Panel operation

1. Connect the USB cable to the rear

panel USB B port.

2. Press the Function key to enter the

Normal configuration settings.

Page 21

Set the following USB settings:

F-22 = 2

Set the rear panel USB port to

USB-CDC.

Interface Configuration

USB Remote Interface

30

Page 31

REMOTE CONTROL

Configure GPIB

1. Ensure the PSW is off before proceeding.

2. Connect the USB cable from the rear panel

USB B port on the PSW to the USB A port on

the GPIB to USB adapter.

3. Connect a GPIB cable from a GPIB controller to

the GPIB port on the adapter.

Type B plug for

PSW series

Type A plug

From

computer

GUG-001

4. Turn the PSW on.

5. Press the Function key to enter the

Normal configuration settings.

Page 21

Set the following GPIB settings:

F-22 = 1

Set the rear panel USB port to

GPIB-USB (GUG-001)

F-23 = 0~30

Set the GPIB address (0~30)

GPIB constraints

Maximum 15 devices altogether, 20m cable

length, 2m between each device

Unique address assigned to each device

At least 2/3 of the devices turned On

No loop or parallel connection

Configure GPIB Interface

To use GPIB, the optional GPIB to USB (GUG-001) adapter must be

used. The GPIB to USB adapter must be connected before the PSW

is turned on. Only one GPIB address can be used at a time.

31

Page 32

PSW Series Programming Manual

Ethernet

configuration

Parameters

For details on how to configure the Ethernet

settings, please see the configuration table on

page 24.

MAC Address

(display only)

LAN

DHCP

IP Address

Subnet Mask

Gateway

DNS Address

Sockets Active

Web Server Active

Web Password Active

Web set password

0000~9999 (default 0000)

Configuration

This configuration example will configure the

PSW as a web server and use DHCP to

automatically assign an IP address to the PSW.

1. Connect an Ethernet cable from the

network to the rear panel Ethernet

port.

LAN

Configure Ethernet Connection

The Ethernet interface can be configured for a number of different

applications. Ethernet can be configured for basic remote control or

monitoring using a web server or it can be configured as a socket

server.

The PSW series supports both DHCP connections so the instrument

can be automatically connected to an existing network or

alternatively, network settings can be manually configured.

Web Server Configuration

32

Page 33

REMOTE CONTROL

2. Press the Function key to enter the

Normal configuration settings.

Page 21

Set the following LAN settings:

F-36 = 1

Enable LAN

F-37 = 1

Turn DHCP to enable

F-59 = 1

Turn the web server on

Note

It may be necessary to cycle the power or refresh

the web browser to connect to a network.

Configuration

This configuration example will configure the

PSW sockets server.

The following configuration settings will

manually assign the PSW an IP address and

enable the socket server. By default, the socket

server port number is 2268 and cannot be

configured.

1. Connect an Ethernet cable from the

network to the rear panel Ethernet

port.

LAN

2. Press the Function key to enter the

Normal configuration settings.

Page 21

3. Set the following LAN settings:

F-36 = 1

Enable LAN

F-37 = 0

Disable DHCP

F-39 = 172

IP Address part 1 of 4

F-40 = 16

IP Address part 2 of 4

F-41 = 5

IP Address part 3 of 4

F-42 = 133

IP Address part 4 of 4

F-43 = 255

Subnet Mask part 1 of 4

Sockets Server Configuration

33

Page 34

PSW Series Programming Manual

F-44 = 255

Subnet Mask part 2 of 4

F-45 = 128

Subnet Mask part 3 of 4

F-46 = 0

Subnet Mask part 4 of 4

F-43 = 172

Gateway part 1 of 4

F-44 = 16

Gateway part 2 of 4

F-45 = 21

Gateway part 3 of 4

F-46 = 101

Gateway part 4 of 4

F-57 = 1

Enable Sockets

Note

The socket function is only available for firmware

version V1.12 or above. See the user manual to

check your firmware version number.

Functionality

check

Invoke a terminal application such as Realterm.

The PSW will appear as a COM port on the PC.

To check the COM port No, see the Device

Manager in the PC. For WinXP; Control panel

→ System → Hardware tab.

Note

If you are not familiar with using a terminal

application to send/receive remote commands via

a USB connection, please page 35(Using Realterm

to Establish a Remote Connection) for more

information.

Run this query command via the terminal after

the instrument has been configured for USB

remote control (page 30).

*idn?

This should return the Manufacturer, Model

number, Serial number, and Firmware version

in the following format.

GW-INSTEK,PSW-XXX-X,TW123456,01.00.20110101

USB Remote Control Function Check

34

Page 35

REMOTE CONTROL

Manufacturer: GW-INSTEK

Model number : PSW-3036

Serial number : TW123456

Firmware version : 01.00.20110101

Background

Realterm is a terminal program that can be

used to communicate with a device attached to

the serial port of a PC or via an emulated serial

port via USB.

The following instructions apply to version

2.0.0.70. Even though Realterm is used as an

example to establish a remote connection, any

terminal program can be used that has similar

functionality.

Note

Realterm can be downloaded on Sourceforge.net

free of charge.

For more information please see

http://realterm.sourceforge.net/

Operation

1. Download Realterm and install according to the

instructions on the Realterm website.

2. Connect the PSW via USB (page 30).

3. Go to the Windows device manager and find

the COM port number for the connection.

For example, go to the Start menu > Control

Panel > Device Manager

Double click the Ports icon to reveal the

connected serial port devices and the COM port

for the each connected device.

Using Realterm to Establish a Remote Connection

35

Page 36

PSW Series Programming Manual

The baud rate, stop bit and parity settings can

be viewed for the virtual COM port by rightclicking connected device and selecting the

Properties option.

4. Start Realterm on the PC as an administrator.

Click:

Start menu>All Programs>RealTerm>realterm

Tip: to run as an administrator, you can right

click the Realterm icon in the Windows Start

menu and select the Run as Administrator

option.

36

Page 37

REMOTE CONTROL

5. After Realterm has started, click on the Port tab.

Enter the Baud, Parity, Data bits, Stop bits and

Port number configuration for the connection.

The Hardware Flow Control, Software Flow

Control options can be left at the default

settings.

Press Open to connect to the PSW.

37

Page 38

PSW Series Programming Manual

6. Click on the Send tab.

In the EOL configuration, check on the +CR and

+LF check boxes.

Enter the query:

*idn?

Click on Send ASCII.

7. The terminal display will return the following:

GW-INSTEK,PSW-XXX-X,TW123456,01.00.20110101

(manufacturer, model, serial number, version)

8. If Realterm fails to connect to the PSW, please

check all the cables and settings and try again.

38

Page 39

REMOTE CONTROL

Functionality

check

Enter the IP address of the power supply in a

web browser after the instrument has been

configured as a web server (page 32).

http:// XXX.XXX.XXX.XXX

The web browser interface appears.

Background

To test the socket server functionality, National

Instruments Measurement and Automation

Explorer can be used. This program is available

on the NI website, www.ni.com, via a search

for the VISA Run-time Engine page, or

“downloads” at the following URL,

http://www.ni.com/visa/

Requirements

Firmware: V1.12

Operating System: Windows XP, 7

Functionality

check

1. Start the NI Measurement and Automation

Explorer (MAX) program. Using Windows,

press:

Start>All Programs>National

Instruments>Measurement & Automation

Web Server Remote Control Function Check

Socket Server Function Check

39

Page 40

PSW Series Programming Manual

2. From the Configuration panel access;

My System>Devices and Interfaces>Network

Devices

3. Click Create New... .

4. Select Visa TCP/IP Resource.

2

3

4

40

Page 41

REMOTE CONTROL

5. Select Manual Entry of Raw Socket from the

popup window.

6. Click Next.

5

6

7. Enter the IP address and the port number of the

PSW. The port number is fixed at 2268.

8. Click the Validate button. A popup box will

appear when successful.

9. Click Next.

41

Page 42

PSW Series Programming Manual

8

9

7

10. Next configure the Alias (name) of the PSW

connection. In this example the Alias is:

PSW_DC1

11. Click finish.

10

11

12. The IP address of the PSW will now appear

under Network Devices in the configuration

panel. Select this icon now.

13. Press Open VISA Test Panel.

42

Page 43

REMOTE CONTROL

13

12

14. Click Configuration icon.

15. In the I/O Settings tab, select the Enable

Termination Character check box. Ensure Line

Feed - \n is selected as the line feed character.

16. Click Apply Changes.

14

15

16

17. Click the Input/Output icon.

18. Ensure *IDN?\n is selected in the Select or Enter

Command dropdown text box.

19. Click the Query button.

20. The *IDN? query should be returned to the

buffer area:

GW-INSTEK,PSW250-9,,01.54.20140313\n

43

Page 44

PSW Series Programming Manual

17

18

19

20

Note

For further details, please see the following

programming examples.

44

Page 45

REMOTE CONTROL

Visual Basic Example ............................................................ 45

C++ Example ........................................................................ 46

LabVIEW Example ............................................................... 48

Background

The following visual basic programming

example uses the VISA COM 3.0 Type Library.

The example will connect to the PSW using the

IP address of 172.15.5.133 over port 2268. The

program will send the *IDN? to the PSW, print

the return string and then close the connection.

Socket Server Examples

Visual Basic Example

45

Page 46

PSW Series Programming Manual

Background

The following program creates a connection to

the PSW and sets the voltage to 3.3 volts and

the current 1.5 amps. The voltage and current

reading is then read back and the connection is

closed.

Note

Add visa32.lib to the project library when

building the following sample program.

C++ Example

46

Page 47

REMOTE CONTROL

47

Page 48

PSW Series Programming Manual

Background

The following picture shows a LabView

programming example for the PSW.

LabVIEW Example

48

Page 49

REMOTE CONTROL

Compatible

Standard

IEEE488.2

Partial compatibility

SCPI, 1999

Partial compatibility

Command

Structure

SCPI commands follow a tree-like structure,

organized into nodes. Each level of the

command tree is a node. Each keyword in a

SCPI command represents each node in the

command tree. Each keyword (node) of a SCPI

command is separated by a colon (:).

For example, the diagram below shows an SCPI

sub-structure and a command example.

DC

MEASure

SCALar

POWer

VOLTage

CURRent

DC

DC

MEASure:SCALar:CURRent:DC?

Command types

There are a number of different instrument

commands and queries. A command sends

instructions or data to the unit and a query

receives data or status information from the

unit.

Command types

Simple

A single command

with/without a parameter

Example

*IDN?

Command Syntax

49

Page 50

PSW Series Programming Manual

Query

A query is a simple or

compound command

followed by a question mark

(?). A parameter (data) is

returned.

Example

meas:curr:dc?

Compound

Two or more commands on

the same command line.

Compound commands are

separated with either a semicolon (;) or a semi-colon and a

colon (;:).

A semi-colon is used to join

two related commands, with

the caveat that the last

command must begin at the

last node of the first

command.

A semi-colon and colon are

used to combine two

commands from different

nodes.

Example

meas:volt:dc?;:meas:curr:dc?

50

Page 51

REMOTE CONTROL

Command Forms

Commands and queries have two different

forms, long and short. The command syntax is

written with the short form of the command in

capitals and the remainder (long form) in lower

case.

The commands can be written in capitals or

lower-case, just so long as the short or long

forms are complete. An incomplete command

will not be recognized.

Below are examples of correctly written

commands.

Long

form

STATus:OPERation:NTRansition?

STATUS:OPERATION:NTRANSITION?

status:operation:ntransition?

Short

form

STAT:OPER:NTR?

stat:oper:ntr?

Square Brackets

Commands that contain square brackets

indicate that the contents are optional. The

function of the command is the same with or

without the square bracketed items, as shown

below.

Both “DISPlay:MENU[:NAME]?” and

“DISPlay:MENU?” are both valid forms.

Command

Format

1.5,5.2

1 2 3 4 5

APPLY

1. Command header

2. Space

3. Parameter 1

4. Comma (no space

before/after comma)

5. Parameter 2

Parameters

Type

Description

Example

<Boolean>

Boolean logic

0, 1

51

Page 52

PSW Series Programming Manual

<NR1>

integers

0, 1, 2, 3

<NR2>

decimal

numbers

0.1, 3.14, 8.5

<NR3>

floating point

4.5e-1, 8.25e+1

<NRf>

any of NR1, 2, 3

1, 1.5, 4.5e-1

<block data>

Definitive length arbitrary block

data. A single decimal digit

followed by data. The decimal

digit specifies how many 8-bit

data bytes follow.

Message

Terminator

LF

Line feed code

Abort Commands

ABORt .................................................................................... 56

Apply Commands

APPLy ..................................................................................... 56

Display

Commands

DISPlay:MENU[:NAME] .................................................... 57

DISPlay[:WINDow]:TEXT:CLEar ..................................... 58

DISPlay[:WINDow]:TEXT[:DATA] .................................. 58

DISPlay:BLINk ...................................................................... 58

Initiate

Commands

INITiate[:IMMediate]:NAME ............................................. 59

Measure

Commands

MEASure[:SCALar]:CURRent[:DC] ................................... 60

MEASure[:SCALar]:VOLTage[:DC] .................................. 60

MEASure[:SCALar]:POWer[:DC] ....................................... 60

Command List

52

Page 53

REMOTE CONTROL

Output

Commands

OUTPut:DELay:ON ............................................................. 61

OUTPut:DELay:OFF ........................................................... 61

OUTPut:MODE .................................................................... 62

OUTPut[:STATe][:IMMediate] ........................................... 62

OUTPut[:STATe]:TRIGgered ............................................. 62

OUTPut:PROTection:CLEar .............................................. 63

OUTPut:PROTection:TRIPped .......................................... 63

Sense

Commands

SENSe:AVERage:COUNt ................................................... 64

Status

Commands

STATus:OPERation[:EVENt] ............................................ 65

STATus:OPERation:CONDition ....................................... 65

STATus:OPERation:ENABle ............................................. 65

STATus:OPERation:PTRansition ....................................... 66

STATus:OPERation:NTRansition ...................................... 66

STATus:QUEStionable[:EVENt] ....................................... 66

STATus:QUEStionable:CONDition .................................. 67

STATus:QUEStionable:ENABle ........................................ 67

STATus:QUEStionable:PTRansition .................................. 67

STATus:QUEStionable:NTRansition ................................. 67

STATus:PRESet..................................................................... 68

Source

Commands

[SOURce:]CURRent[:LEVel][:IMMediate][:AMPLitude] 69

[SOURce:]CURRent[:LEVel]:TRIGgered[:AMPLitude] .. 70

[SOURce:]CURRent:PROTection[:LEVel] ....................... 70

[SOURce:]CURRent:PROTection:STATe ......................... 71

[SOURce:]CURRent:SLEW:RISing .................................... 71

[SOURce:]CURRent:SLEW:FALLing ................................ 72

[SOURce:]RESistance[:LEVel][:IMMediate]

[:AMPLitude] .......................................................................... 72

[SOURce:]VOLTage[:LEVel][:IMMediate]

[:AMPLitude] .......................................................................... 73

[SOURce:]VOLTage[:LEVel]:TRIGgered[:AMPLitude] . 74

[SOURce:]VOLTage:PROTection[:LEVel] ....................... 74

[SOURce:]VOLTage:SLEW:RISing .................................... 74

[SOURce:]VOLTage:SLEW:FALLing ............................... 75

53

Page 54

PSW Series Programming Manual

Trigger

Commands

TRIGger:TRANsient[:IMMediate] ...................................... 76

TRIGger:TRANsient:SOURce ............................................ 76

TRIGger:OUTPut[:IMMediate] .......................................... 77

TRIGger:OUTPut:SOURce ................................................. 77

Trigger Command Examples ............................................... 77

System

Commands

SYSTem:BEEPer[:IMMediate] ............................................ 80

SYSTem:CONFigure:BEEPer[:STATe] ............................. 80

SYSTem:CONFigure:BLEeder[:STATe] ........................... 81

SYSTem:CONFigure:BTRip[:IMMediate] ......................... 81

SYSTem:CONFigure:BTRip:PROTection ........................ 81

SYSTem:CONFigure:CURRent:CONTrol ........................ 82

SYSTem:CONFigure:VOLTage:CONTrol ....................... 82

SYSTem:CONFigure:MSLave ............................................. 83

SYSTem:CONFigure:OUTPut:EXTernal[:MODE] ........ 83

SYSTem:CONFigure:OUTPut:PON[:STATe] ................. 84

SYSTem:COMMunicate:ENABle ....................................... 84

SYSTem:COMMunicate:GPIB[:SELF]:ADDRess ........... 85

SYSTem:COMMunicate:LAN:IPADdress ........................ 85

SYSTem:COMMunicate:LAN:GATEway ......................... 85

SYSTem:COMMunicate:LAN:SMASk ............................... 86

SYSTem:COMMunicate:LAN:MAC .................................. 86

SYSTem:COMMunicate:LAN:DHCP ................................ 86

SYSTem:COMMunicate:LAN:DNS ................................... 87

SYSTem:COMMunicate:LAN:HOSTname ....................... 87

SYSTem:COMMunicate:LAN:WEB:PACTive ................. 87

SYSTem:COMMunicate:LAN:WEB:PASSword ................... 88

SYSTem:COMMunicate:RLSTate .......................................... 88

SYSTem:COMMunicate:USB:FRONt:STATe .................. 89

SYSTem:COMMunicate:USB:REAR:STATe .................... 89

SYSTem:COMMunicate:USB:REAR:MODE ................... 89

SYSTem:ERRor ..................................................................... 89

SYSTem:KEYLock:MODE ................................................. 90

SYSTem:KLOCk ................................................................... 90

SYSTem:INFormation .......................................................... 90

SYSTem:PRESet .................................................................... 91

SYSTem:VERSion ................................................................. 91

54

Page 55

REMOTE CONTROL

Common

Commands

*CLS ........................................................................................ 92

*ESE ........................................................................................ 92

*ESR ........................................................................................ 92

*IDN ....................................................................................... 92

*OPC ....................................................................................... 93

*RST ........................................................................................ 93

*SRE ........................................................................................ 93

*STB ........................................................................................ 94

*TRG ....................................................................................... 94

*TST ........................................................................................ 94

*WAI ....................................................................................... 94

55

Page 56

PSW Series Programming Manual

ABORt .................................................................................... 56

ABORt

Set

Description

The ABORt command will cancel any triggered

actions.

Syntax

ABORt

APPLy ..................................................................................... 56

APPLy

Set

Query

Description

The APPLy command is used to set both the

voltage and current. The voltage and current will

be output as soon as the function is executed if the

programmed values are within the accepted range.

An execution error will occur if the programmed

values are not within accepted ranges.

The Apply command will set the voltage/current

values but these values will not be reflected on the

display until the Output is On or if the

DISPlay:MENU:NAME 3 (set menu) command is

used.

Syntax

Query Syntax

APPLy {<voltage>|MIN|MAX}[,{<current>|MIN|MAX}]

APPLy?

Abort Commands

APPLy Commands

56

Page 57

REMOTE CONTROL

Parameter

<voltage>

<NRf> 0% ~ 105% of the rated output

voltage.

<current>

<NRf> 0% ~ 105% of the rated output

current.

MIN

0 volts/0 amps

MAX

Maxium value for the present range.

Return parameter

<NRf>

Returns the voltage and current.

Example

APPL 5.05,1.1

Sets the voltage and current to 5.05V and 1.1A.

Query Example

APPL?

+5.050, +1.100

Returns voltage (5.05V) and current (1.1A) setting.

DISPlay:MENU[:NAME] .................................................... 57

DISPlay[:WINDow]:TEXT:CLEar ..................................... 58

DISPlay[:WINDow]:TEXT[:DATA] .................................. 58

DISPlay:BLINk ...................................................................... 58

DISPlay:MENU[:NAME]

Set

Query

Description

The DISPlay MENU command selects a screen

menu or queries the current screen menu.

Syntax

Query Sytax

DISPlay:MENU[:NAME] <NR1>

DISPlay:MENU[:NAME]?

Parameter/

Return parameter

<NR1>

Description

0

Measurement-Voltage / MeasurementCurrent

1

Measurement-Voltage / Measurement-Power

2

Measurement-Power / Measurement-Current

3

Set Menu

4

OVP / OCP Menu

5~99

Not Used.

100~199

F-00~99 Menu.

Display Commands

57

Page 58

PSW Series Programming Manual

Example

DISP:MENU:NAME 0

Sets the display to the Voltage/Current display screen.

DISPlay[:WINDow]:TEXT:CLEar

Set

Description

Clears the text on the main screen from the

DISPlay[:WINDow]:TEXT[:DATA] command .

Syntax

DISPlay[:WINDow]:TEXT:CLEar

DISPlay[:WINDow]:TEXT[:DATA]

Set

Query

Description

Sets or queries the data text that will be written to

the display. Writing to the display will overwrite

data that is currently on the screen. Overwriting a

display area with a shorter string may or may not

overwrite the screen. The string must be enclosed

in quotes: “STRING”. Only ASCII characters 20H

to 7EH can be used in the <string>.

Syntax

Query Syntax

DISPlay[:WINDow]:TEXT[:DATA] <string>

DISPlay[:WINDow]:TEXT[:DATA]?

Parameter/

Return parameter

<string>

ASCII character 20H to 7EH can be used to in

the string parameter. The string must be

enclosed in quotes: “STRING”

Example

DISP:WIND:TEXT:DATA “STRING”

Writes STRING to the display.

Query Example

DISP:WIND:TEXT:DATA?

“STRING”

Returns the text data string on the screen.

DISPlay:BLINk

Set

Query

Description

Turns blink on or off for the display.

Syntax

Query Syntax

DISPlay:BLINk { 0 | 1 | OFF | ON }

DISPlay:BLINk?

58

Page 59

REMOTE CONTROL

Parameter

0

<NR1>Turns blink OFF

OFF

Turns blink OFF

1

<NR1> Turns blink ON

ON

Turns blink ON

Return parameter

0

<NR1>Turns blink OFF

1

<NR1>Turns blink ON

Example

DISP:BLIN 1

Turns blink ON.

INITiate[:IMMediate]:NAME ............................................. 59

INITiate[:IMMediate]:NAME

Set

Description

The INITiate command starts the TRANsient or

OUTPut trigger.

See the trigger commands on page 76 for usage

details.

Syntax

INITiate[:IMMediate]:NAME {TRANsient|OUTPut}

Parameter

TRANSient

Starts the TRANsient trigger.

OUTPut

Starts the OUTPut trigger.

Example

INITiate:NAME TRANient

Starts the TRANSient trigger.

Initiate Commands

59

Page 60

PSW Series Programming Manual

MEASure[:SCALar]:CURRent[:DC] ................................... 60

MEASure[:SCALar]:VOLTage[:DC] .................................. 60

MEASure[:SCALar]:POWer[:DC] ....................................... 60

MEASure[:SCALar]:CURRent[:DC]

Query

Description

Takes a measurement and returns the average

output current

Syntax

MEASure[:SCALar]:CURRent[:DC]?

Return parameter

<NRf>

Returns the current in amps.

MEASure[:SCALar]:VOLTage[:DC]

Query

Description

Takes a measurement and returns the average

output voltage.

Syntax

MEASure[:SCALar]:VOLTage[:DC]?

Return

<NRf>

Returns the voltage in volts.

MEASure[:SCALar]:POWer[:DC]

Query

Description

Takes a measurement and returns the average

output power.

Syntax

MEASure[:SCALar]:POWer[:DC]?

Return

<NRf>

Returns the power measured in watts.

Measure Commands

60

Page 61

REMOTE CONTROL

OUTPut:DELay:ON............................................................. 61

OUTPut:DELay:OFF ........................................................... 61

OUTPut:MODE.................................................................... 62

OUTPut[:STATe][:IMMediate] ........................................... 62

OUTPut[:STATe]:TRIGgered ............................................. 62

OUTPut:PROTection:CLEar .............................................. 63

OUTPut:PROTection:TRIPped .......................................... 63

OUTPut:DELay:ON

Set

Query

Description

Sets the Delay Time in seconds for turning the

output on. The delay is set to 0.00 by default.

Syntax

Query Syntax

OUTPut:DELay:ON <NRf>

OUTPut:DELay:ON?

Parameter

<NRf>

0.00~99.99 seconds, where 0=no delay.

Return parameter

<NRf>

Returns the delay on time in seconds until the

output is turned on.

OUTPut:DELay:OFF

Set

Query

Description

Sets the Delay Time in seconds for turning the

output off. The delay is set to 0.00 by default.

Syntax

Return Syntax

OUTPut:DELay:OFF <NRf>

OUTPut:DELay:OFF?

Parameter

<NRf>

0.00~99.99 seconds, where 0=no delay.

Return parameter

<NRf>

Returns the delay off time in seconds until the

output is turned off.

Output Commands

61

Page 62

PSW Series Programming Manual

OUTPut:MODE

Set

Query

Description

Sets the PSW output mode. This is the equivalent

to the F-03 (V-I Mode Slew Rate Select) settings.

Syntax

Return Syntax

OUTPut:MODE {<NR1>|CVHS|CCHS|CVLS|CCLS}

OUTPut:MODE?

Parameter

0

CV high speed priority

CVHS

CV high speed priority

1

CC high speed priority

CCHS

CC high speed priority

2

CV slew rate priority

CVLS

CV slew rate priority

3

CC slew rate priority

CCLS

CC slew rate priority

Return parameter

<NR1>

Returns the output mode.

OUTPut[:STATe][:IMMediate]

Set

Query

Description

Turns the output on or off.

Syntax

Query Syntax

OUTPut[:STATe][:IMMediate] { OFF | ON | 0 | 1 }

OUTPut[:STATe][:IMMediate]?

Parameter

0

<NR1> Turns the output off.

OFF

Turns the output off.

1

<NR1> Turns the output on.

ON

Turns the output on.

Return parameter

<NR1>

Returns output status of the instrument.

OUTPut[:STATe]:TRIGgered

Set

Query

Description

Turns the output on or off when a software trigger

is generated.

Syntax

Query Syntax

OUTPut[:STATe]:TRIGgered { OFF | ON | 0 | 1 }

OUTPut[:STATe]:TRIGgered?

62

Page 63

REMOTE CONTROL

Parameter

0

<NR1>Turns the output off when a software

trigger is generated.

OFF

Turns the output off when a software trigger

is generated.

1

<NR1>Turns the output on when a software

trigger is generated.

ON

Turns the output on when a software trigger

is generated.

Return parameter

<NR1>

Returns output trigger status of the

instrument.

OUTPut:PROTection:CLEar

Set

Description

Clears over-voltage, over-current and overtemperature (OVP, OCP, OTP) protection circuits.

It also clears the shutdown protection circuit. The

AC failure protection cannot be cleared.

Syntax

OUTPut:PROTection:CLEar

OUTPut:PROTection:TRIPped

Query

Description

Returns the state of the protection circuits (OVP,

OCP, OTP).

Query Syntax

OUTPut:PROTection:TRIPped?

Return parameter

0

<NR1>Protection circuits are not tripped.

1

<NR1>Protection circuits are tripped.

63

Page 64

PSW Series Programming Manual

SENSe:AVERage:COUNt ................................................... 64

SENSe:AVERage:COUNt

Set

Query

Description

Determines the level of smoothing for the average

setting. This is the equivalent to the F-17 function

setting.

Syntax

Query Syntax

SENSe:AVERage:COUNt {<NR1>| LOW | MIDDle |

HIGH}

SENSe:AVERage:COUNt?

Parameter

0 | LOW

Low level of smoothing.

1 | MIDDle

Middle level of smoothing.

2 | HIGH

High level of smoothing.

Return parameter

<NR1>

Returns the level of smoothing.

0

Low level of smoothing.

1

Middle level of smoothing.

2

High level of smoothing.

Example

SENSe:AVERage:COUNt 1

Sets the level of smoothing to middle.

Sense Commands

64

Page 65

REMOTE CONTROL

STATus:OPERation[:EVENt] ............................................ 65

STATus:OPERation:CONDition ....................................... 65

STATus:OPERation:ENABle ............................................. 65

STATus:OPERation:PTRansition ....................................... 66

STATus:OPERation:NTRansition ...................................... 66

STATus:QUEStionable[:EVENt] ....................................... 66

STATus:QUEStionable:CONDition .................................. 67

STATus:QUEStionable:ENABle ........................................ 67

STATus:QUEStionable:PTRansition .................................. 67

STATus:QUEStionable:NTRansition ................................. 67

STATus:PRESet .................................................................... 68

STATus:OPERation[:EVENt]

Query

Description

Queries the Operation Status Event register and

clears the contents of the register.

Syntax

STATus:OPERation[:EVENt]?

Return

<NR1>

Returns the bit sum of the Operation Status

Event register.

STATus:OPERation:CONDition

Query

Description

Queries the Operation Status register. This query

will not clear the register.

Syntax

STATus:OPERation:CONDition?

Return

<NR1>

Returns the bit sum of the Operation

Condition register.

STATus:OPERation:ENABle

Set

Query

Description

Sets or queries the bit sum of the Operation Status

Enable register.

Status Commands

65

Page 66

PSW Series Programming Manual

Syntax

Query Syntax

STATus:OPERation:ENABle <NRf>

STATus:OPERation:ENABle?

Parameter

<NRf>

0~32767

Return parameter

<NR1>

0~32767

STATus:OPERation:PTRansition

Set

Query

Description

Sets or queries the bit sum of the positive

transition filter of the Operation Status register.

Syntax

STATus:OPERation:PTRansition <NRf>

STATus:OPERation:PTRansition?

Parameter

<NRf>

0~32767

Return parameter

<NR1>

0~32767

STATus:OPERation:NTRansition

Set

Query

Description

Sets or queries the bit sum of the negative

transition filter of the Operation Status register.

Syntax

Query Syntax

STATus:OPERation:NTRansition <NRf>

STATus:OPERation:NTRansition?

Parameter

<NRf>

0~32767

Return parameter

<NR1>

0~32767

STATus:QUEStionable[:EVENt]

Query

Description

Queries the bit sum of the Questionable Status

Event register. This query will also clear the

contents of the register.

Query Syntax

STATus:QUEStionable[:EVENt]?

Parameter

<NRf>

0~32767

Return parameter

<NR1>

0~32767

66

Page 67

REMOTE CONTROL

STATus:QUEStionable:CONDition

Query

Description

Queries the status (bit sum) of the Questionable

Status register. This query will not clear the

register.

Query Syntax

STATus:QUEStionable:CONDition?

Parameter

<NRf>

0~32767

Return parameter

<NR1>

0~32767

STATus:QUEStionable:ENABle

Set

Query

Description

Sets or queries the bit sum of the Questionable

Status Enable register.

Syntax

Query Syntax

STATus:QUEStionable:ENABle <NRf>

STATus:QUEStionable:ENABle?

Parameter

<NRf>

0~32767

Return parameter

<NR1>

0~32767

STATus:QUEStionable:PTRansition

Set

Query

Description

Sets or queries the bit sum of the positive

transition filter of the Questionable Status register.

Syntax

Return Syntax

STATus:QUEStionable:PTRansition <NRf>

STATus:QUEStionable:PTRansition?

Parameter

<NRf>

0~32767

Return parameter

<NR1>

0~32767

STATus:QUEStionable:NTRansition

Set

Query

Description

Sets or queries the negative transition filter of the

Questionable Status register.

Syntax

Query Syntax

STATus:QUEStionable:NTRansition <NRf>

STATus:QUEStionable:NTRansition?

67

Page 68

Parameter

<NRf>

0~32767

Return parameter

<NR1>

0~32767

STATus:PRESet

Set

Description

This command resets the ENABle register, the

PTRansistion filter and NTRansistion filter on the

Operation Status and Questionable Status

Registers. The registers/filters will be reset to a

default value.

Default Register/Filter Values

Setting

QUEStionable Status Enable

0x0000

QUEStionable Status Positive Transition

0x7FFF

QUEStionable Status Negative Transition

0x0000

Operation Status Enable

0x0000

Operation Status Positive Transition

0x7FFF

Operation Status Negative Transition

0x0000

Summary: The Questionable Status Enable

registers and the Operation Status Enable registers

are both reset to 0.

The Questionable Status and Operation Status

Positive Transition filters are all set high (0x7FFF)

and the Negative Transition filters are all set low

(0x0000). I.e., only positive transitions will be

recognized for the Questionable Status and

Operation Status registers.

Syntax

STATus:PRESet

PSW Series Programming Manual

68

Page 69

REMOTE CONTROL

[SOURce:]CURRent[:LEVel][:IMMediate][:AMPLitude] 69

[SOURce:]CURRent[:LEVel]:TRIGgered[:AMPLitude] .. 70

[SOURce:]CURRent:PROTection[:LEVel] ....................... 70

[SOURce:]CURRent:PROTection:STATe ......................... 71

[SOURce:]CURRent:SLEW:RISing .................................... 71

[SOURce:]CURRent:SLEW:FALLing ................................ 72

[SOURce:]RESistance[:LEVel][:IMMediate]

[:AMPLitude] .......................................................................... 72

[SOURce:]VOLTage[:LEVel][:IMMediate][:AMPLitude] 73

[SOURce:]VOLTage[:LEVel]:TRIGgered[:AMPLitude] . 74

[SOURce:]VOLTage:PROTection[:LEVel] ....................... 74

[SOURce:]VOLTage:SLEW:RISing .................................... 74

[SOURce:]VOLTage:SLEW:FALLing ............................... 75

[SOURce:]CURRent[:LEVel][:IMMediate]

[:AMPLitude]

Set

Query

Description

Sets or queries the current level in amps. For

externally set current levels (from the analog

control connector) the set current level is returned.

Syntax

[SOURce:]CURRent[:LEVel][:IMMediate][:AMPLitude]

{<NRf>|MIN|MAX}

Query Syntax

[SOURce:]CURRent[:LEVel][:IMMediate][:AMPLitude]?

[MIN|MAX]

Parameter/Return

<NRf>

0~105% of the rated current output level.

MIN

Minimum current level.

MAX

Maximum current level.

Example

SOUR:CURR:LEV:IMM:AMPL? MAX

37.800

Returns the maximum possible current level in amps.

Source Commands

69

Page 70

PSW Series Programming Manual

[SOURce:]CURRent[:LEVel]:TRIGgered

[:AMPLitude]

Set

Query

Description

Sets or queries the current level in amps when a

software trigger has been generated.

Syntax

[SOURce:]CURRent[:LEVel]:TRIGgered[:AMPLitude]

{<NRf>|MIN|MAX}

Query Syntax

[SOURce:]CURRent[:LEVel]:TRIGgered[:AMPLitude]?

[MIN|MAX]

Parameter/Return

<NRf>

0%~105% of the rated current output in amps.

MIN

Minimum current level.

MAX

Maximum current level.

Example

SOUR:CURR:LEV:TRIG:AMPL? MAX

37.800

Returns the maximum possible current level in amps.

[SOURce:]CURRent:PROTection[:LEVel]

Set

Query

Description

Sets or queries the OCP (over-current protection)

level in amps.

Syntax

[SOURce:]CURRent:PROTection[:LEVel]

{<NRf>|MIN|MAX}

Query Syntax

[SOURce:]CURRent:PROTection[:LEVel]? [MIN|MAX]

Parameter/Return

<NRf>

OCP range in Amps.

MIN

Minimum current level.

MAX

Maximum current level.

Example

SOUR:CURR:PROT:LEV? MIN

+3.600

Returns the minimum possible current level in amps.

70

Page 71

REMOTE CONTROL

[SOURce:]CURRent:PROTection:STATe

Set

Query

Description

Turns OCP (over-current protection) on or off.

Syntax

[SOURce:]CURRent:PROTection:STATe {0|1|OFF|ON}

Query Syntax

[SOURce:]CURRent:PROTection:STATe?

Parameter/Return

0

<NR1> Turns the buzzer off.

OFF

Turns the OCP off.

1

<NR1> Turns the OCP on.

ON

Turns the OCP on.

Return parameter

<Bool>

Returns the protection status (0 or 1).

Example

SOUR:CURR:PROT:STAT OFF

Turns OCP off.

[SOURce:]CURRent:SLEW:RISing

Set

Query

Description

Sets or queries the rising current slew rate. This is

only applicable for CC slew rate priority mode.

Syntax

Query Syntax

[SOURce:]CURRent:SLEW:RISing {<NRf>|MIN|MAX}

[SOURce:]CURRent:SLEW:RISing? [MIN|MAX]

Parameter/Return

<NRf>

0.01A/s~72.00A/s (PSW 30-36)

0.1A/s~144.0A/s (PSW 30-72)

0.1A/s~216.0A/s (PSW 30-108)

0.01A/s~27.00A/s (PSW 80-13.5)

0.01A/s~54.00A/s (PSW 80-27)

0.01A/s~81.00A/s (PSW 80-40.5)

0.01A/s~14.40A/s (PSW 160-7.2)

0.01A/s~28.80A/s (PSW 160-14.4)

0.01A/s~43.20A/s (PSW 160-21.6)

0.001A/s ~ 9.000A/s (PSW 250-4.5)

0.01A/s ~ 18.00A/s (PSW 250-9)

0.01A/s ~ 27.00A/s (PSW 250-13.5)