Page 1

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PROGRAMMER MANUAL

CONTENTS PAGE

1. INTRODUCTION............................ ........... ........... ........... ........ ........

2. CONNECTING POWER SUPPLY VIA G PIB INTERFACE..

1

1

3. CONNECTING POWER SUPPLY VIA RS232 INTERFACE 4

4.

INPUT AND OUTPUT QUEUE………………………………..

7

5. COMMANDS AND SYNTAX…………………………………. 7

6. DETAILS OF COMMAND REFERENCE…………………… 19

7. STATUS AND ERROR REPORTING………………………....

38

PROGRAMMER MANUAL

⎯ i ⎯

⎯ ii ⎯

Page 2

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PROGRAMMER MANUAL

1. INTRODUCTION

In the modern automatic measurement system, communication

between equipments and computers is essential. The measured

procedures can be varied with users’ testing programs, therefore, the

programmable power supply can be operated remotely from an

instrument controller or computer across the RS232 interface (optional)

or GPIB (optional).

Interface selection and setup

The GPIB address can be changed in normal op eration condition. Press

[SHIFT] key and [LOCAL] key on the front panel, in which the last

transmitting interface settings will be displayed. Select interface and

press [ENTER], then select the baud rate (or GPIB address) and press

[ENTER] to confirm the setting by using the knobs. Finally, select “save”

and press [ENTER] to store the setup.

2. CONNECTING THE PROGRAMMABLE POWER

SUPPLY VIA GPIB INTERFACE

PROGRAMMER MANUAL

L4 (Listener) : The power supply becomes a listener

when the controller sends its listen

address with the ATN (attention) line

asserted. The power supply does not

have listen only capability.

SR1 (Service Request) : The power su pply asserts the SRQ

(Service request) line to notify the

controller when it requires service.

RL1 (Remote/Local) : The power supply responds to both the

GTL(Go to Local) and LLO(Local Lock

Out) interface messages.

PP0 (Parallel Poll) : The power supply has no Parallel Poll

interface function.

DC1 (Device Clear) : The power supply has Device clear

capability to return the device to power

on status.

DT0 (Device Trigger) : The power supply has no Device Trigger

interface function.

C0 (Controller) : The power supply can not control other

devices.

The GPIB interface capabilities:

The GPIB interface of the programmable power supply correspond s to

the standard of IEEE488.1-1987, IEEE488.2-1992 and SCPI-1994. The

GPIB interface functions are listed as follows:

SH1(Source Handshake) : The power supply can transmit multilane

messages across the GPIB.

AH1(Acceptor Handshake) : The power supply can receive multilane

messages across the GPIB.

T6(Talker) : Talker interface function includes basic

talker, serial poll, and unaddress if MLA

capabilities, without talk only mode

function.

⎯ 1 ⎯

Notes for GPIB installation

When the programmable power supply is set up with a GPIB system,

please check the following things:

z Only a maximum of 15 devices can be connected to a single GPIB

bus.

z Do not use more than 20m of cable to connect devices to a bus.

z Connect one device for every 2m of cable used.

z Each device on the bus needs a unique device address. No two

devices can share the same device address.

⎯ 2 ⎯

Page 3

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PROGRAMMER MANUAL

z Turn on at least two-thirds of the devices on the GPIB system while

using the system .

z Do not use loop or parallel structure for the topology of GPIB

system.

Computer’s Connection

A personal computer with a GPIB card is the essential facilities in order

to operate the programmable power supply via GPIB interface.

The connections between power supply and computer are following:

I. Connect one end of a GPIB cable to the computer.

II. Connect the other end of the GPIB cable to the G PIB port on

the programmable power supply.

III. Turn on the programmable power supply.

IV. Turn on the computer.

The GPIB connection testing

If you want to test whether the GPIB connection is working or not, you

can send a GPIB command from computer. For instance, the query

command

*idn?

should return the Manufacturer, model number, serial number and

firmware version in the following format:

WK.TMPRO,PST-3202,A000000,FW1.00

If you do not receive a proper response from the power supply, please

check if the power is on, the GPIB address is correct, and all cable

connections are active.

PROGRAMMER MANUAL

3. CONNECTING THE PROGRAMMABLE POWER

SUPPLY VIA RS232 INTERFACE

The RS232 interface capabilit ies:

The RS232 interface provides a point-to-point conn ection between two

items of equipment such as a computer and the power supply. There are

some parameters you need to set on the both sides. Once you have set

these parameters, you can control the power supply through the RS232

interface.

z Baud rate: You can set rates of 1200, 2400, 4800 or 9600 b aud.

z Parity bit: none.

z Data bit: 8 bits.

z Stop bit: 1 stop bit.

z Data flow control: none.

Notes for RS232 installation

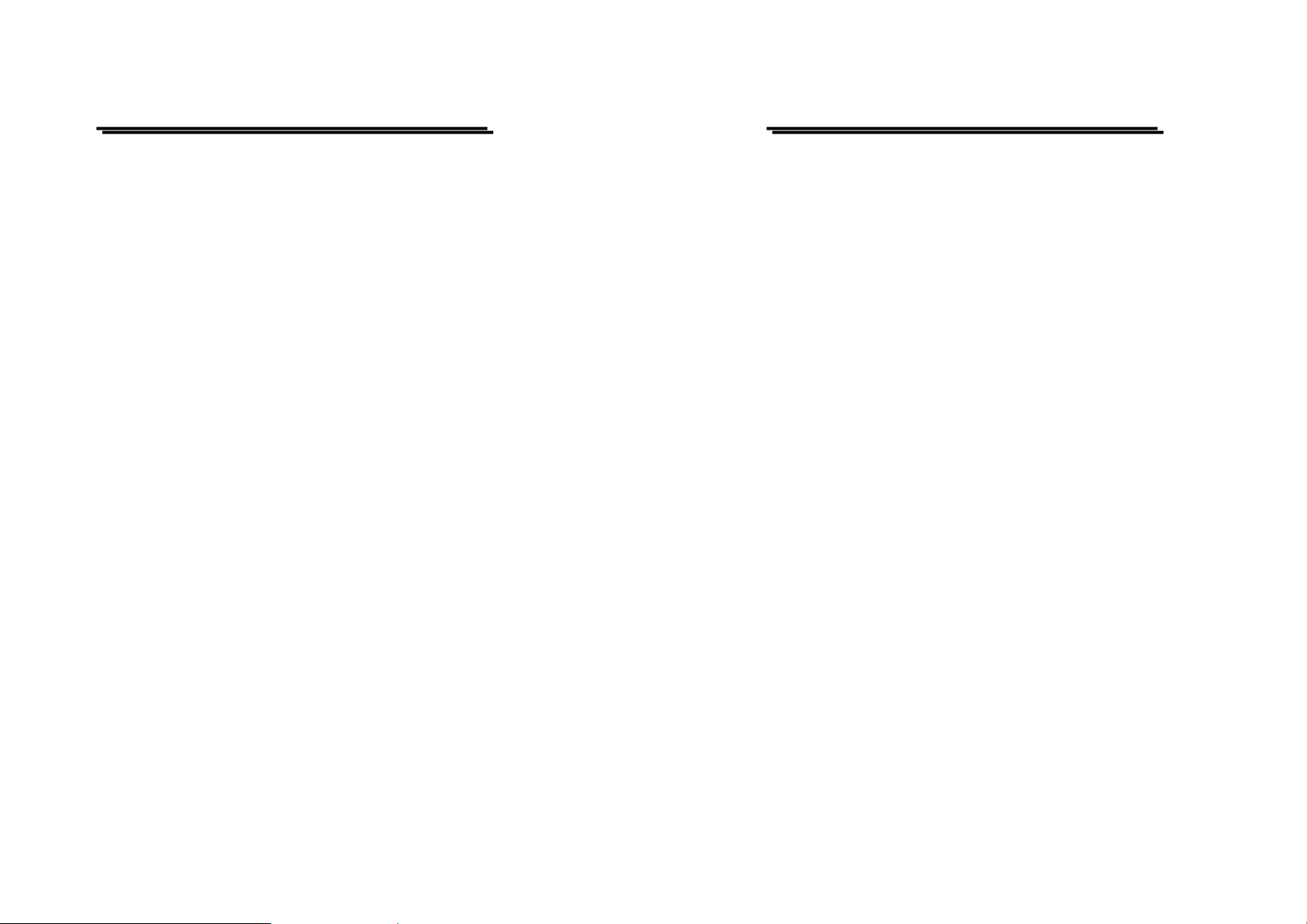

The power supply is a DTE device with a 9-pin D-type shell RS232

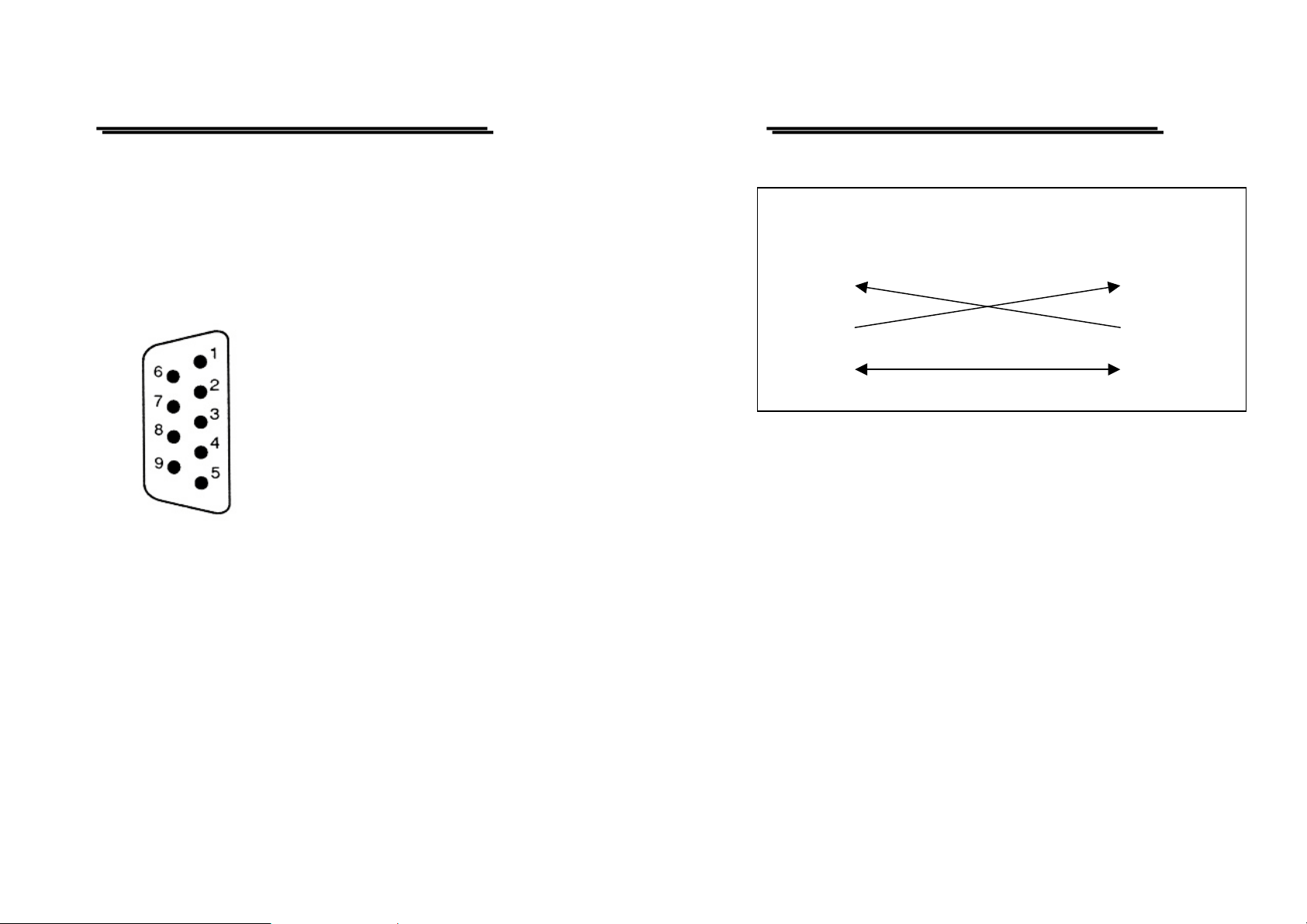

connector located on the rear panel. Figure 1 shows the equipment of 9pin connector (male) with its pin number assignments. Figure 2 shows

the wiring configuration for DB9 to DB9. When the p rogra mmab le pow er

supply is set up with a RS232 interface, please check the following

points:

z Do not connect the output line of one DTE device to the output line

of the other.

z Many devices require a constant high signal on one or more input

pins.

z Ensure that the signal ground of the equipment is connected to the

signal ground of the external device.

z Ensure that the chassis ground of the equipment is connected to the

chassis ground of the external device.

⎯ 3 ⎯

⎯ 4 ⎯

Page 4

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PROGRAMMER MANUAL

z Do not use more than 15m of cable to connect devices to a PC.

z Ensure the same baud rate is used on the dev ice as the one used on

PC terminal.

z Ensure the connector for the both side of cable and the internal

connected line are met the demand of the instrumen t.

1. No connection

2. Receive Data (RxD) (input)

3. Transmit Data (TxD) (ou tput)

4. No connection

5. Signal Ground (GND)

6. No connection

7. No connection

8. No connection

9. No connection

Figure 1 Pin assignments of the RS232 connector on the rear panel for DB-9-D

PROGRAMMER MANUAL

EQUIPMENT

(DB9, DTE)

Pin2

Pin3

COMPUTER

(DB9, DTE)

Pin2

Pin3

Pin5 Pin5

Figure 2 Wiring configuration for DB9 to DB9

Computer’s Connection

A personal computer with a COM port is the essential facilities in order

to operate the programmable power supply via RS232 inter face.

The connections between power supply and computer are as follows:

⎯ 5 ⎯

I. Connect one end of a RS232 cable to the computer.

II. Connect the other end of the cable to the RS232 port on the

programmable power supply.

III. Turn on th e progr ammab le power supply.

IV. Turn on the computer.

⎯ 6 ⎯

Page 5

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PROGRAMMER MANUAL

The RS232 connection testin g

If you want to test whether the RS232 connection is working o r not, you

can send a command from computer. For instance, using a terminal

program send the query command

*idn?

should return the Manufacturer, model number, serial number and

firmware version in the following format:

WK.TMPRO,PST-3202,A000000,FW1.00

If you do not receive a proper response from the power supply, please

check if the power is on, the RS232 baud rate are th e same on both sides,

and all cable connections are activ e.

4. INPUT AND OUTPUT QUEUE

The design of 128 bytes input queue and 128 bytes output queue for

storing the pending commands or return messages is to prevent the

transmitted commands of remote control and return messages from

missing. As the maximum stored capacity for Error/Event Queue is 20

groups of messages, it should be noted that input data exceeding the

capacity by using these buffers will cause data missing.

5. COMMANDS AND SYNTAX

The GPIB commands of the programmable power supply are

compatible with IEEE-488.2 and SCPI standards

SCPI

SCPI (Standard Commands for Programmable Instruments) is a standard

that created by an international consortium of the major test and

measurement equipment manufacturers. The IEEE-488.2

adopted by SCPI to provide common commands for the identical

functions of different programmable instruments.

syntax has been

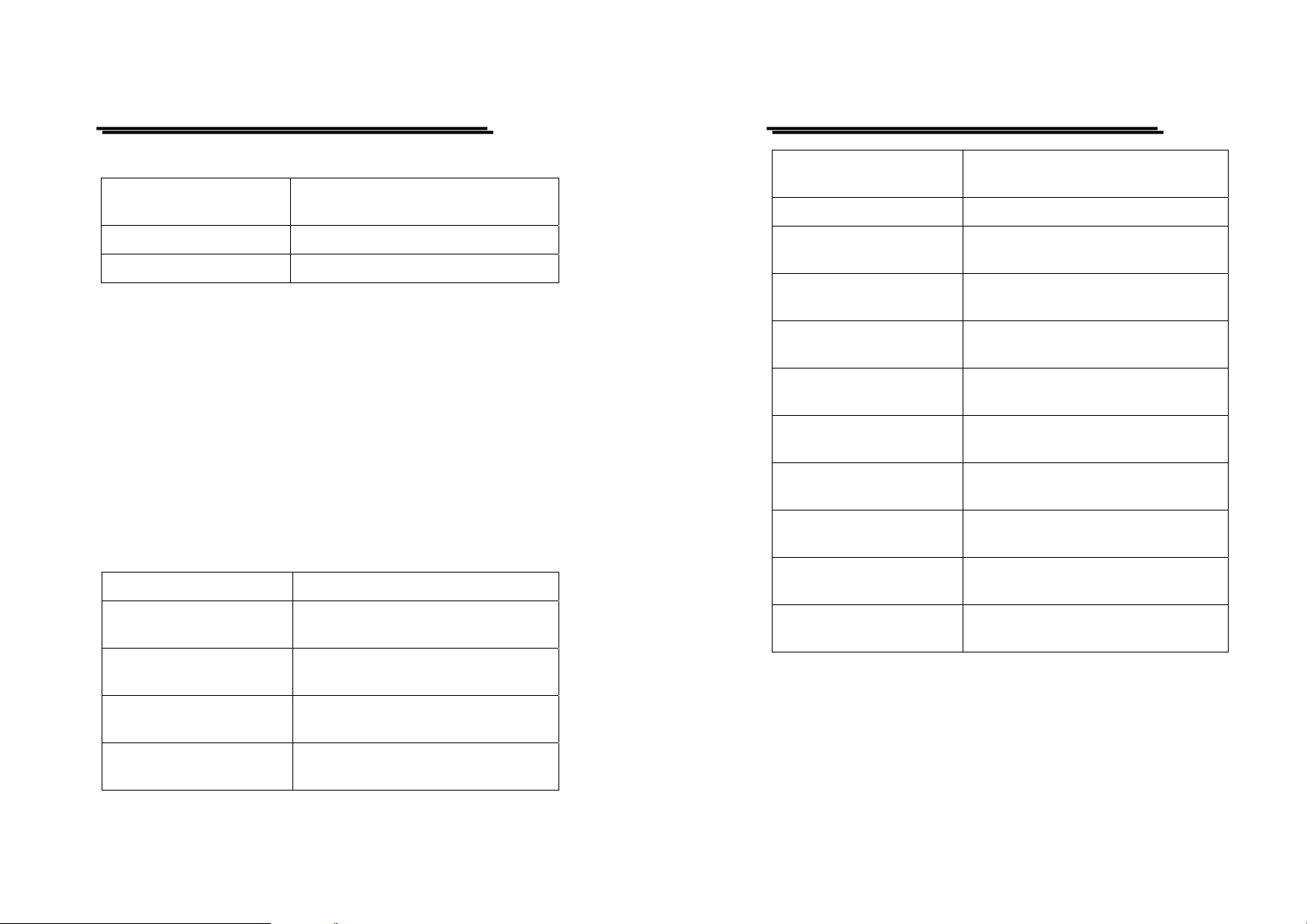

PROGRAMMER MANUAL

SCPI

Common Command & Queries

Syntax & Status Data Structure

Interface Function

AABBCCDD

SCPI

IEEE-488.2 IEEE-488.2

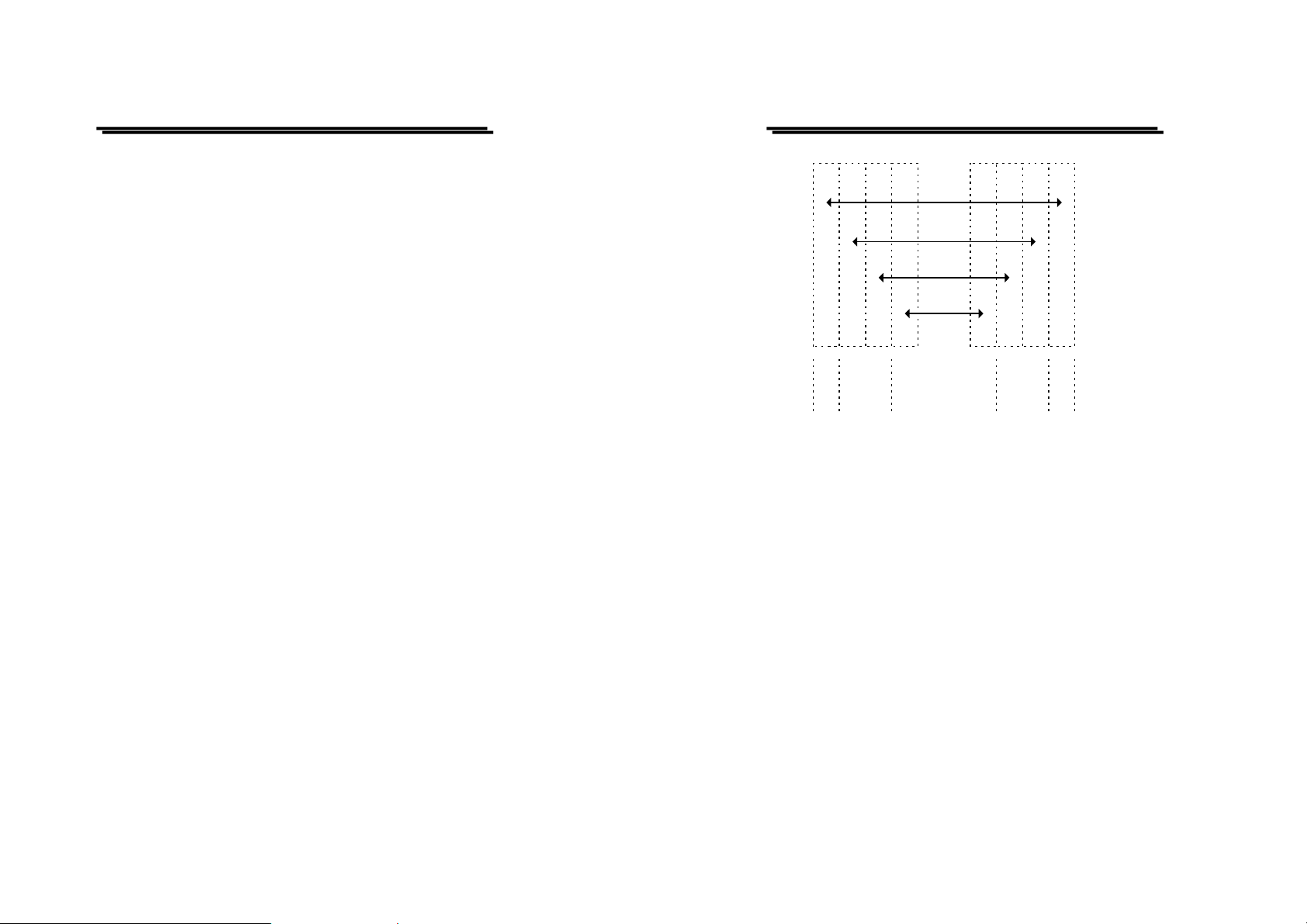

Figure 3 the relationship between IEEE-488.1, IEEE-488.2, and SCPI

SCPIIEEE-488.1

As shown in the figure 3, the IEEE-488.1 standard locates at layer A, the

layer A belongs to the protocol of interface function on the GPIB bus.

The source handshake (SH), acceptor handshake (AH) and talker are

included to this l ayer (10 int erf ace fun ctio ns to tall y).

At layer B, the syntax and data structure could be the e ssence of entire

IEEE-488.2 standard. The syntax defines the function of message

communication, which contain the <PROGRAM MESSAGE> (or simply

“commands”) and <RESPONSE MESSAGE>. The two kinds of messages

represent the syntax formation of device command and return value. The

data structure is the constitution of status reporting, which IEEE-488.2

standard have been defined.

The common commands and q ueries are included to layer C. Commands

and queries can be divided into two parts: mandatory and optional.

Commands modify control settings or tell the instrument to perform a

specific action. Queries cause the instrument to send data or status

information back to the computer. A question mark at the end of a

⎯ 7 ⎯

⎯ 8 ⎯

Page 6

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PROGRAMMER MANUAL

command identifies it as a query.

Layer D is interrelated with device information. Different devices have

different functions. SCPI command sets belong to this layer.

Command Syntax

If you want to transfer any instructions to an instrument, and comply

with SCPI, there are three basic elements must be included.

z Command header

z Parameter (if required)

z Message terminator or separator

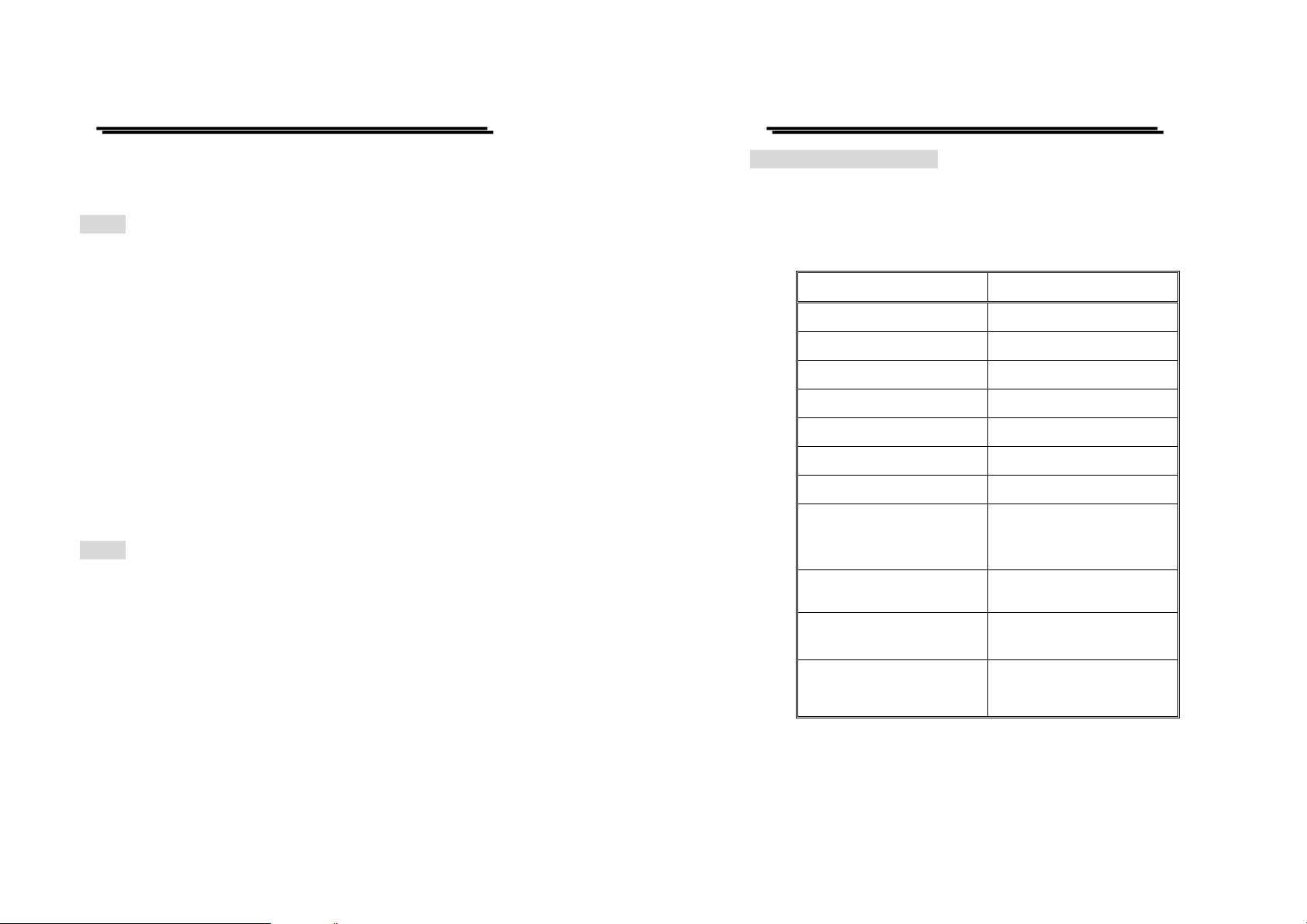

Command Header

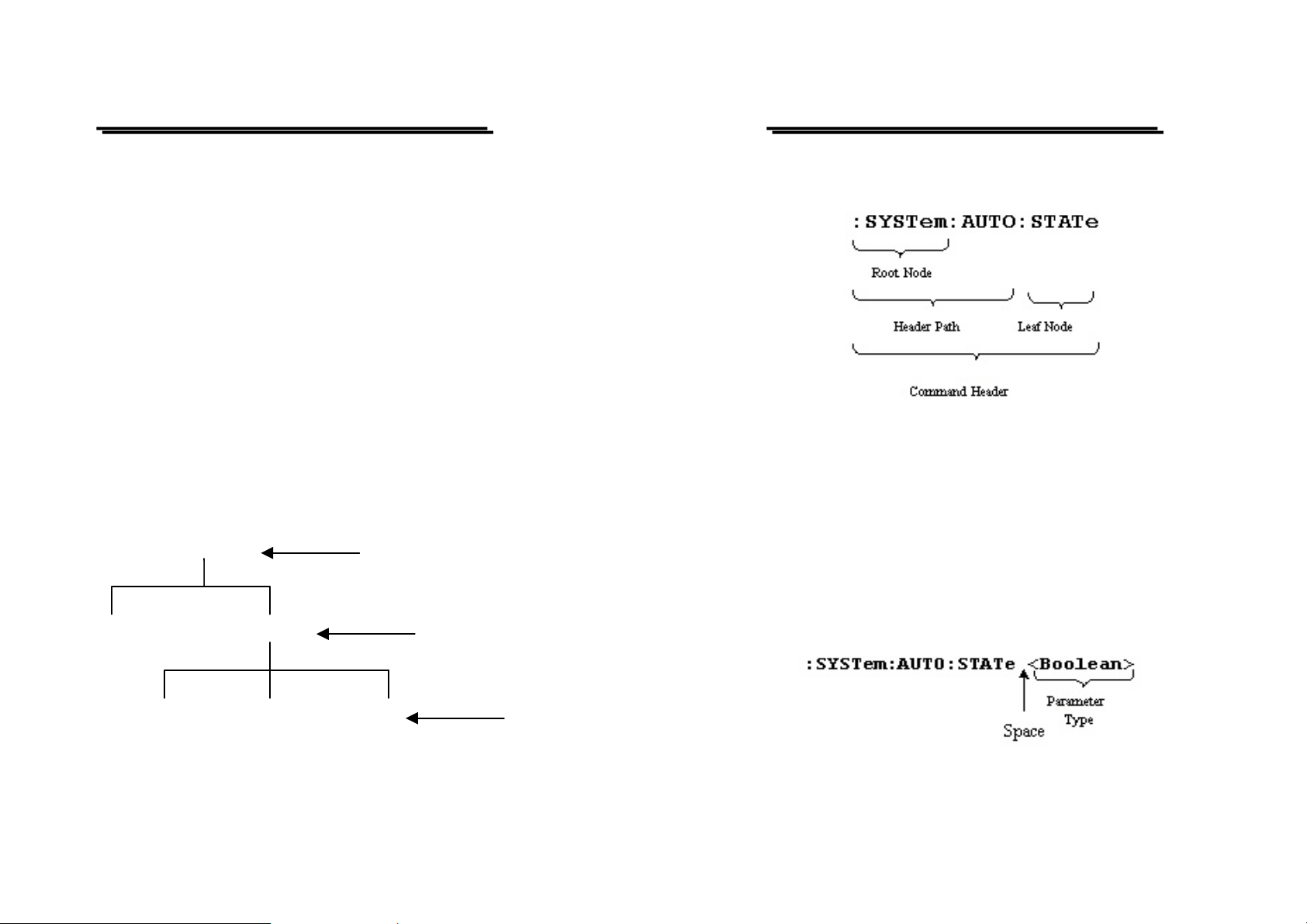

The command header has a hierarc hical structure tha t can be represented

by a command tree (Figure 4).

The top level of the tree is the root level. A root node is located at the

root level. A root node and one or more lower-level nodes form a header

path to the last node called the leaf node.

Root node

PROGRAMMER MANUAL

The command header is configured by header path and leaf node. Figure 5

shows the command header for the leaf node indicated in Figure 4.

Figure 5 Command Header

Parameter

If the commands have parameters, the values have to be included. In this

manual, when we expressed th e syntax of the co mmand, the < > s ymbols

are used for enclosing the par ameter type . For instance, the syntax of the

command in Figure 6 includes the Boolean parameter type.

Figure 4: Tree hierarchy

⎯ 9 ⎯

Lower-level node

Leaf Node

NOTE: Do not include the <, >, or | symbols when entering the actual

value for a parameter.

Figure 6 Command Header with Parameter

⎯ 10 ⎯

Page 7

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PROGRAMMER MANUAL

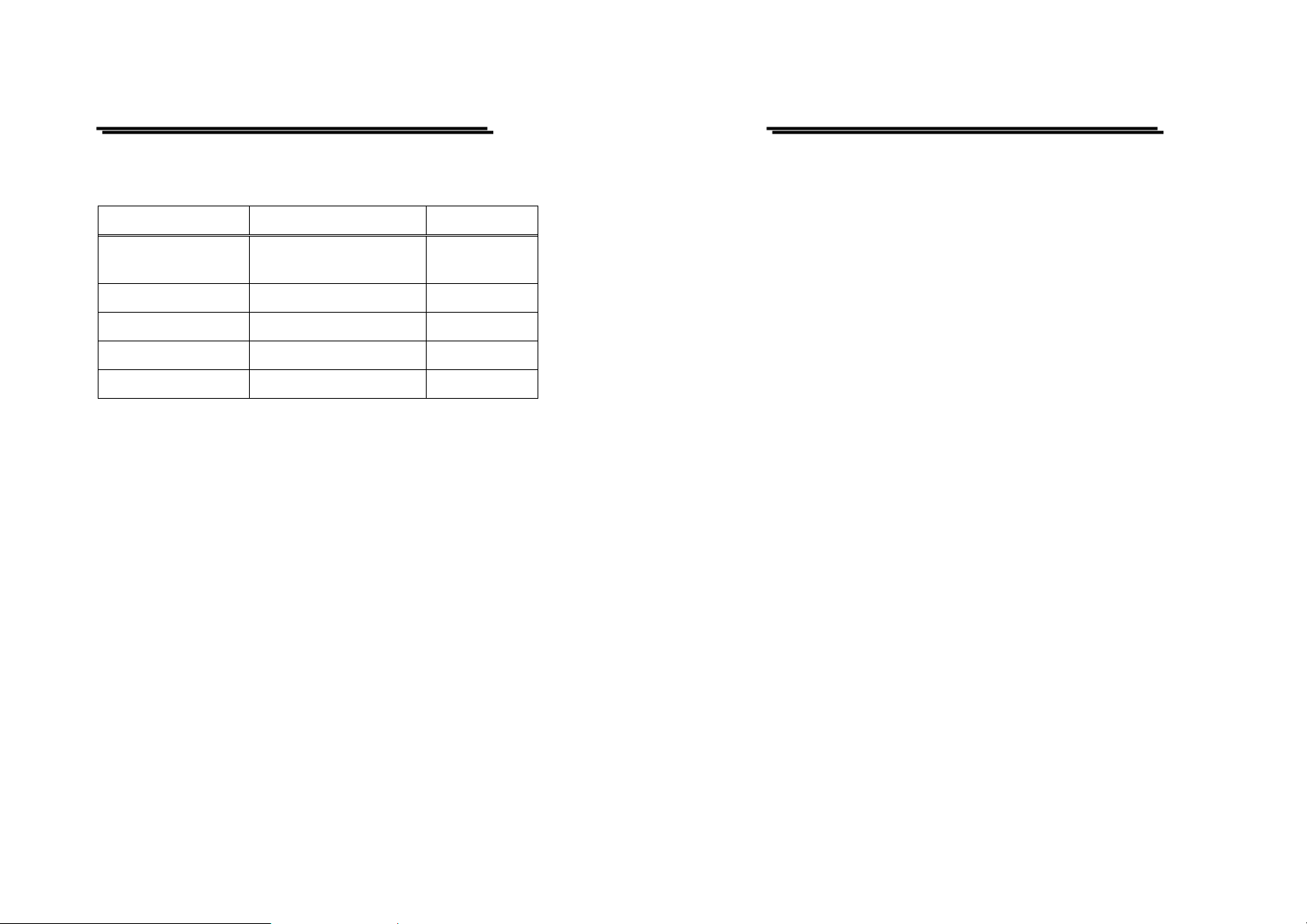

Table 1 defines the Boolean and other parameter types for the

programmable power supply.

Parameter Type Description Example

Boolean Boolean numbers or

0, 1

values

NR1 Integers 0, 1, 18

NR2 Decimal numbers 1.5, 3.141, 8.4

NR3 Floating point numbers 4.5E-1, 8.25E+1

String Alphanumeric characters “No error”

Table 1: Parameter Type s for Sy ntax Descript ions

Message Terminator and Message Separator

I. GPIB message terminators

In accordance with IEEE 488.2 standard, any of the following message

terminators are acceptable:

^

z LF

END Line feed code (hexade ci mal 0A ) with END

message

z LF Line feed code

z <dab>

^

END Last data byte with END message

These terminators are compatible with most application programs. A

semicolon separates one co mmand from another when the commands

appear on the same line.

PROGRAMMER MANUAL

II. RS232 message terminators

As there is no signal of end message on RS232 bus, therefore, use LF

as message terminator. When a series of commands are sent to the

instrument, it must add a LF to be a judgment for message terminator.

As for query command, the return message of the instrument is also

added a LF for PC to judge message terminator.

Entering Commands

The standards that govern the command set for the programmable power

supply allow for a certain amount of flexibility when you enter

commands. For instance, you can abbreviate many commands or

combine commands into one message that you send to the programmable

power supply. This flexibility, called friendly listening, saves

programming time and makes the command set easier to remember and

use.

Command Characters

The programmable power supplies are not sensitive to the case of

command characters. You can enter commands in either uppercase or

lowercase.

You can execute any command with white space characters. You must,

however, use at least one space between the parameter and the command

header

Abbreviating Commands

Most commands have a long form and a short form. The listing for

each command in this section shows the abbreviations in uppercase.

For instance, you can enter the query :CHANnel1:VOLTage 1.23

simply as :CHAN1:VOLT 1.23

⎯ 11 ⎯

⎯ 12 ⎯

Page 8

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PROGRAMMER MANUAL

Because the programmable power supply hypothesis that a command

starts from the root, you have the option of beginning the initial

command header with a colon (:).

Combining Commands

You can use a semicolon (;) to combine commands. But continuously

query command will cause message missing. For example:

CHAN1:VOLT ?;CURR ?

If the command that follows the semicolon has a different header path

from the root level, you must use a colon to force a return to the root

level:

:CHAN1:VOLT 1.23;:OUTP:COUP:TRAC 1

If the command that follows the semicolon has the same header path, you

may omit the colon and the path and state only the new leaf node. For

example:

:CHAN1:VOLT 12.34;CHAN1:CURR 1.55

is equal to

:CHAN1:VOLT 12.34;CURR 1.55

You can combine commands and queries into the same message. Note,

for example, the following comb ination :

:CHAN1:VOLT 12.34;VOLT ?

PROGRAMMER MANUAL

z

General Setting Commands

Table 2 lists the general setting commands that control and query the

settings of the power supply.

Table 2: General Setting Commands

Command Explanation

:CHANnel<x>:CURRent <NR2> ★1 Sets the value of current.

:CHANnel<x>:CURRent ? ★1 Return the value of current.

:CHANnel<x>:VOLTage <NR2> ★1 Sets the value of voltage.

:CHANnel<x>:VOLTage ? ★1 Return the value of voltage.

:CHANnel<x>:MEASure:CURRent ? ★1 Returns actual output current.

:CHANnel<x>:MEASure:VOLTage ? ★1 Returns actual output voltage.

:CHANnel<x>:PROTection:CURRent

<Boolean>

:CHANnel<x>:PROTection:CURRent ? ★1 Returns the state of the over-

:CHANnel<x>:PROTection:VOLTage

<NR2>

★1 Sets the overcurrent protection

(OCP) on or off.

current protection (OCP)

setting as either on or off.

★1 Sets the value of overvoltage

protection (OVP).

Synopsis of Commands

The tables in this section summarize the command of the programmable

power supply. These tables divide the commands into three functional

classifications:

z General Setting Commands

z Status Commands

z Miscellaneous Commands

The tables also provide a brief explanation of each command.

⎯ 13 ⎯

:CHANnel<x>:PROTection:VOLTage ? ★1 Returns the overvoltage

protection (OVP) setting.

:OUTPut:COUPle:TRACking <NR1> ★2 Sets the output of the power

supply working on Seriestracking or Parallel-tracking or

independent mode.

:OUTPut:COUPle:TRACking ? ★2 Returns the output of the power

supply working mode.

⎯ 14 ⎯

Page 9

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PROGRAMMER MANUAL

:OUTPut:PROTection:CLEar Clears over-voltage and over-current and

over temperature protection error message.

:OUTPut:STATe <Boolean> Sets the output state on or off.

:OUTPut:STATe ? Returns the output state on or off.

Remark:

The mark “★1” means the <X> for PSS and PSH series can only be 1.

The mark “★2” means the PSS and PSH series do not have the function.

z Status Commands

Table 3 lists the status commands that set and query the various

registers and queues that make up the status and event structure of the

programmable power supply.

Table 3: Status Commands

*CLS Clears the status data structures.

*ESE <NR1> Sets the Event Status Enable Register

(ESER).

*ESE? Returns contents of Event Status Enable

Register (ESER).

PROGRAMMER MANUAL

*SRE? Returns contents of Service Request

Enable Register (SRER).

*STB? Reads Status Byte Register (SBR).

:STATus:OPERation:COND

ition ?

:STATus:OPERation:ENAB

le <NR1>

:STATus:OPERation:ENAB

le ?

:STATus:OPERation:EVEN

t ?

Returns the contents of the OPERation

condition register. Returns NR1.

Sets the contents of the enable mask for the

OPERation event register.

Returns the contents of the enable mask for

the OPERation event register. Returns NR1.

Query the contents of the OPERation Event

register.

:STATus:PRESet Presets the OPERation and QUEStionable

status registers.

:STATus:QUEStionable:CO

NDition ?

:STATus:QUEStionable:EN

ABle <NR1>

:STATus:QUEStionable:EN

ABle ?

:STATus:QUEStionable:EV

ENt ?

Returns the contents of the OPERation

condition register. Returns NR1.

Sets the contents of the enable mask for the

QUEStionable enable re giste r.

Query the contents of the Questionable

Enable register.

Query the contents of the QUEStionable

Event register.

z Miscellaneous Commands

*ESR? Returns and clear the contents of Standard

Event Status Register (SESR).

*SRE <NR1> Sets contents of Service Request Enable

Register(SRER).

⎯ 15 ⎯

Table 4 lists the miscellaneous commands that control general

housekeeping functions of the programmable power supply.

⎯ 16 ⎯

Page 10

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PROGRAMMER MANUAL

Table 4: Miscellaneous Commands

*IDN? Returns instrument identification.

*OPC Reports when operation is complete by setting

the Operation Complete bit in SESR.

*OPC? Reports when operation is complete. Same as

*OPC except returns a 1 to the output queue

and dose not set the SESR bit.

*RCL ★Recall the setting data from the memory

which previous saved.

*RST Resets the protection levels and states, resets

the current and voltage levels to zero, sets the

output off, and sets memory section to 00.

*SAV ★Saves the setting data to memory.

*TST? Initiates internal self-test and reports results.

*WAI Wait to continue. This command forces

sequential operation of commands. This

command is required by IEEE-488.1-1987.

The power supply, however, forces sequential

operation of commands by design.

:SYSTem:AUTO:CYCLe

★Set number of times of execution.

<NR1>

:SYSTem:AUTO:CYCLe ? ★Query the setting of the number of times of

execution.

PROGRAMMER MANUAL

:SYSTem:AUTO:DELay

<NR1>

★ Set the delay time under the current

responding memory status.

:SYSTem:AUTO:DELay ? ★Query the setting of the delay time under

the current responding memory status.

:SYSTem:AUTO:END

<NR1>

★ Set the end memory section for auto

execute continuously.

:SYSTem:AUTO:END ? ★Query the end memory section for auto

execute continuously.

:SYSTem:AUTO:STARt

<NR1>

★ Set the start memory section for auto

execute continuously.

:SYSTem:AUTO:STARt ? ★Query the start memory section for auto

execute continuously.

:SYSTem:AUTO:STATe

★Sets Auto sequence on or off.

<Boolean>

:SYSTem:AUTO:STATe ? ★Returns Auto Sequence mode on or off.

:SYSTem:ERRor ? Read the next item from the error/event

queue.

:SYSTem:MEMory? ★Query the last memory location

:SYSTem:VERSion? Returns the SCPI version level.

Remark: The mark “★” means the PSS and PSH do not have the

function.

⎯ 17 ⎯

⎯ 18 ⎯

Page 11

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PROGRAMMER MANUAL

6. DETAILS OF COMMAND REFERENCE

Each command in this chapter will give a detailed description. The

examples of each command will be provided and what query fo rm might

return.

*CLS (no query form)

Function:

Clear all event status data register. This includes the Output Queue,

Operation Event Status Register, Questionable Event Status Register, and

Standard Event Status Register.

Syntax:

*CLS

Examples:

*CLS clears all event registers.

*ESE

Function:

Set or return the bits in the Event Status Enable Register (ESER). The

ESER enables the Standard Event Status Register (SESR) to be

summarized on bit 5 (ESB) of the Status Byte Register (SBR).

Syntax:

*ESE <NR1>

*ESE?

<NR1> is in the range from 0 through 255.

Returns:

<NR1> is a number from 0 to 255 that indicates the decimal value of the

binary bits of the ESER.

PROGRAMMER MANUAL

Examples:

*ESE 65 sets the ESER to bin ary 0100 0001.

If the ESER contains the binary value 1000 0010, the *ESE? will

return the value of 130.

*ESR? (query only)

Function:

Return and clear the contents of the Standard Event Status Register

(SESR).

Syntax:

*ESR?

Returns:

<NR1> is a number from 0 to 255 that indicates the decimal value of the

binary bits of the ESER.

Examples:

If the ESER contains the binary value 1100 0110, the *ESR? will

return the value of 198.

*IDN? (query only)

Function:

Return the unique identification code of the power supply.

Syntax:

*IDN?

Returns:

<string> includes Manufacturer, model number, serial number and

firmware version.

⎯ 19 ⎯

⎯ 20 ⎯

Page 12

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PROGRAMMER MANUAL

Examples:

*IDN? Returns

WK.TMPRO,PST-3202,A000000,FW1.00

*OPC

Function:

The command form (*OPC) sets the operation complete bit (bit 0) in the

Standard Event Status Register (SESR) when all pending operations are

finished.

The query form (*OPC?) tells the programmable power supply to place

an ASCII 1 in the Output Queue when the power supply completes all

pending operations.

Syntax:

*OPC

*OPC?

Returns:

1

*RCL

Function:

Recall the setting data from the memory saved previously. (The PSS and

PSH series do not have this function)

Syntax:

*RCL <NR1>

<NR1> is in the range from 0 through 99.

Examples:

*RCL 12 recalls the setting data stored in memory location 12.

PROGRAMMER MANUAL

*RST (no query form)

Function:

Set all control settings of power supply to their default values but does

not purge stored setting. The equivalent panel control will be set as

below:

Front Panel Control Default Setting

OUTPUT OFF

CURRENT SET 0

VOLTS SET 0

OCP SET OFF

DELAY 1 sec

AUTO SET OFF

RECALL (memory location) 00

OVP SET MAXimum (Please refer to

the user manual for the OVP

setting)

OUTPUT MODE (INDEP/

SERIES/PARALLEL)

STEP SET

RECALL RANGE

Syntax:

*RST

INDEP

MINIMUM (Please refer to

the user manual.)

START 00 END 05

CYCLE 1

⎯ 21 ⎯

⎯ 22 ⎯

Page 13

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PROGRAMMER MANUAL

*SAV

Function:

Save the setting data to a specific memory location (The PSS and PSH

series do not have this function).

Syntax:

*SAV <NR1>

<NR1> is in the range from 0 through 99.

Examples:

*SAV 01 saves the current setting data to memory location 1.

*SRE

Function:

Set the contents of the Service Request Enable Register (SRER). The

query form returns the contents of the SRER. Bit 6 of the SRER is always

zero. The bits on the SRER correspond to the bits on the SBR.

Syntax:

*SRE <NR1>

*SRE?

Returns:

<NR1> is in the range from 0 through 255.

PROGRAMMER MANUAL

decimal number representing the bits that are set (true) in the status

register.

Syntax:

*STB?

Returns:

<NR1> is in the range from 0 through 255.

Examples:

*STB? returns 81, if SBR contains the binary value 0101 0001.

*TST? (query only)

Function:

Self-test and te st th e RA M, RO M.

Syntax:

*TST?

Returns:

0|-300

Examples:

*TST? returns 0, if the test is suc cessfu l.

*TST? returns –300, if the test is unsuccessful.

Examples

*SRE 7 sets bits of the SRER to 0000 0111.

If the *SRE? returns 3, the SRER is set to 0000 0011.

*STB? (query only)

Function:

The query of the Status Byte register (SBR) with *STB? will return a

⎯ 23 ⎯

*WAI (no query form)

Function:

WAI prevents the programming instrument from executing further

commands or queries until all pending operations are finished .

Syntax:

*WAI

⎯ 24 ⎯

Page 14

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PROGRAMMER MANUAL

:CHANnel<x>:CURRent

Function:

Set or query the output current valu e of the specif ic channe l.

Syntax:

:CHANnel<x>:CURRent <NR2>

:CHANnel<x>:CURRent?

<x> can be 1 or 2 or 3, <NR2> Please refer to the specification.

<x> for PSS & PSH can only be 1.

Returns:

<NR2>

Examples:

:CHANnel1:CURRent 2.0 sets the channel 1 current limit to 2.0

amps.

:CHANnel1:CURRent? returns 0.012 if the channel 1 current limit

setting is 0.012 amps.

PROGRAMMER MANUAL

<NR2>

Examples:

:CHANnel1:VOLTage 12.0 sets the channel 1 voltage limit to 12.0

volts.

:CHANnel1:VOLTage? returns 2.34 if the channel 1 voltage limit

setting is 2.34 volts.

:CHANnel<x>:MEASure:CURRent?(Query Only)

Function:

Read the actual output current of the spec ific ch annel.

Syntax:

:CHANnel<x>:MEASure:CURRent?

<x> can be 1 or 2 or 3.

<x> for PSS & PSH can only be 1.

Returns:

<NR2>

:CHANnel<x>:VOLTage

Function:

Set or query the output voltage value of the sp ecific ch annel.

Syntax:

:CHANnel<x>:VOLTage <NR2>

:CHANnel<x>:VOLTage?

<x> can be 1 or 2 or 3, <NR2> Please refer to the specification.

<x> for PSS & PSH can only be 1.

Returns:

⎯ 25 ⎯

Examples:

:CHANnel1:MEASure:CURRent? might return 1.234 to indicate that

the load is drawing 1.234 A.

:CHANnel<x>:MEASure:VOLTage?(Query Only)

Function:

Read the actual output voltage of the spe cific ch anne l.

Syntax:

:CHANnel<x>:MEASure:VOLTage?

<x> can be 1 or 2 or 3.

⎯ 26 ⎯

Page 15

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PROGRAMMER MANUAL

<x> for PSS & PSH can only be 1.

Returns:

<NR2>

Examples:

:CHANnel1:MEASure:VOLTage? might return 11.55 to indicate the

voltage at the channel 1 output is 11.55 V.

:CHANnel<x>:PROTection:CURRent

Function:

Set or query the overcurren t p ro tection st atus o f the spec ific chann e l.

Syntax:

:CHANnel<x>:PROTection:CURRent <Boolean>

:CHANnel<x>:PROTection:CURRent?

<x> can be 1 or 2 or 3, <Boolean> can be 0 (OFF) or 1(ON).

<x> for PSS & PSH can only be 1.

Returns:

0|1

Examples:

:CHANne1:PROTection:CURRent 0 sets the over-current protection

off.

If the overcurrent protection setting is on, the command

of :CHANne1:PROTection:CURRent? will return the value of 1.

PROGRAMMER MANUAL

Syntax:

:CHANnel<x>:PROTection:VOLTage <NR2>

:CHANnel<x>:PROTection:VOLTage?

<x> can be 1 or 2 or 3, <NR2> Please refer to the specification.

<x> for PSS & PSH can only be 1.

Returns:

<NR2>

Examples:

:CHANnel1:PROTection:VOLTage 12.0 sets the channel 1

overvoltage protection limit to 12.0 volts.

:CHANnel1:PROTection:VOLTage? returns 2.34 if the channel 1

overvoltage protection limit setting is 2.34 volts.

:OUTPut:COUPle:TRACking

Function:

Change the output of the channel 1 and channel 2 to series-tracking or

parallel-tracking or independent output mode (The PSS and PSH series

do not have this function).

Syntax:

:OUTPut:COUPle:TRACking <NR1>

:OUTPut:COUPle:TRACking?

<NR1> can be 0 (INDEPENDENT) or 1 (PARALLEL -TRACKING) or

2 (SERIES -TRACKING).

:CHANnel<x>:PROTection:VOLTage

Function:

Set or query the overvoltage protection value of the specific channel.

⎯ 27 ⎯

Returns:

0|1|2

⎯ 28 ⎯

Page 16

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PROGRAMMER MANUAL

Examples:

:OUTPut:COUPle:TRACking 2 set the output of the channel 1 and

channel 2 to series-tracking mode.

If the output is in the parallel-tracking mode, the command of

OUTPut:COUPle:TRACking? will return the value of 1.

OUTPut:PROTection:CLEar (no query form)

Function:

Clear all the protective messages (OTP, OVP, OCP) from the panel of the

device.

Syntax:

OUTPot:PROTection:CLEar

When the panel displays the protective message, no further setting can be

accepted by the device. Uses this command to clear the displayed

messages in order to execute further setting.

Examples:

OUTPot:PROTection:CLEar

PROGRAMMER MANUAL

Examples:

OUTPut:STATe 1 enables the power supply output.

If the power supply output is disabled, OUTPut:STATe? will return 0.

STATus:OPERation:CONDition? (query only)

Function:

Return the contents of the OPERation register. The programmable power

supplies, however, do not use the OPERation register to report any

conditions.

Syntax:

STATus:OPERation:CONDition?

Returns:

<NR1>

Examples:

STATus:OPERation:CONDition? returns 0.

STATus:OPERation:ENABle

OUTPut:STATe

Function:

Set the output state on or off.

Syntax:

OUTPut:STATe <Boolean>

OUTPut:STATe?

<Boolean> can be 0(OFF) or 1(ON).

Returns:

0|1

⎯ 29 ⎯

Function:

Set or query the enable mask that allows the masked conditions in the

event register to be reported in the summary bit. If a bit is 1 (true) in the

enable register and its associated event bit changes to 1 (true), the

associated summary bit will change to 1 (true). Even though this is a 16bit register, only 15 bits (bit 0 through bit 14) are used. Bit 15 always

reads 0.

Syntax

STATus:OPERation:ENABle <NR1>

STATus:OPERation:ENABle?

<NR1> is an integer from 0 to 32767.

⎯ 30 ⎯

Page 17

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PROGRAMMER MANUAL

Returns

<NR1>

Examples

STATus:OPERation:ENABle 32767 sets all 15 bits of the register

to 1.

If the STATus:OPERation:ENABle? returns 0, all 15 bits of the

register are 0.

STATus:OPERation:EVENt(query only)

Function:

Returns and clears the contents of the OPERation register.

Syntax:

STATus:OPERation:EVENt?

Returns:

<NR1>

Examples:

STATus:OPERation:EVENt? returns 0.

STATus:PRESet

Function:

Set the OPERation and QUESTionable enable registers to zeros.

Syntax:

STATus:PRESet

STATus:QUEStionable:CONDition? (query only)

Function:

Return the contents of the QUEStionable register. Reading the condition

PROGRAMMER MANUAL

register is non-destructive.

Syntax:

STATus:QUEStionable:CONDition?

Returns:

<NR1>

Examples:

STATus:QUEStionable:CONDition? returns 0.

STATus:QUEStionable:ENABle

Function:

Set or query the enable mask that allows the masked conditions in the

event register to be reported in the summary bit. If a bit is 1 (true) in the

enable register and its associated event bit changes to 1 (true), the

associated summary bit will change to 1 (true). Even though this is a 16bit register, only 15 bits (bit 0 through bit 14) are used. Bit 15 always

reads 0.

Syntax:

STATus:QUEStionable:ENABle <NR1>

STATus:QUEStionable:ENABle?

<NR1> is an integer from 0 to 32767.

Returns:

<NR1>

Examples:

STATus:QUEStionable:ENABle 32767 sets all 15 bits of the

register to 1.

If the STATus:QUEStionable:ENABle? returns 0, all 15 bi ts o f the

register are 0.

⎯ 31 ⎯

⎯ 32 ⎯

Page 18

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PROGRAMMER MANUAL

STATus:QUEStionable:EVENt(query only)

Function:

Return and clear the co ntents of the QUEStion able regis ter. Th e response

is a decimal value that summarizes the binary values of the set bits.

Syntax:

STATus:QUEStionable:EVENt?

Returns:

<NR1>

Examples:

STATus:QUEStionable:EVENt? returns 0.

SYSTem:AUTO:CYCLe

Function:

Set or query the number of times of execution (The PSS and PSH series do not

have this function.)

Syntax:

SYSTem:AUTO:CYCLe <NR1>

SYSTem:AUTO:CYCLe?

<NR1> is in the range from 0 through 99999 or infinite.

Returns:

<NR1>

Examples:

PROGRAMMER MANUAL

SYSTem:AUTO:DELay

Function:

Set the delay time under the current responding memory status

and PSH series do not have this function.)

(The PSS

Syntax:

SYSTem:AUTO:DELay <NR1>

SYSTem:AUTO:DELay?

<NR1> is in the range from 1 through 59999, its unit is 100ms.

Returns:

<NR1>

Examples:

SYSTem:AUTO:DELay 1 sets auto delay time at 100ms for the memory

of the specific section.

SYSTem:AUTO:DELay 1000 sets auto delay time at 100 seconds for

the memory of the specific section, no further setting of auto delay will

be done on next memory section until the previous auto delay is fulfilled.

If the command SYSTem:AUTO:DELay? Returns 5, means delay

500ms at the current memory section that displayed on the LCD panel.

SYSTem:AUTO:END

Function:

Set the end memory section for auto execute continuously

PSH series do not have this function.)

(The PSS and

SYSTem:AUTO:CYCLe 8 sets auto cycle on to repeat the setting 8

times.

SYSTem:AUTO:CYCLe 0 sets auto cycle on to repeat the setting

infinite.

If the command SYSTem:AUTO:CYCLe? Returns 0, means infinite.

⎯ 33 ⎯

Syntax:

SYSTem:AUTO:END <NR1>

SYSTem:AUTO:END?

<NR1> is in the range from 0 through 99 and must be large or equal to

⎯ 34 ⎯

Page 19

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PROGRAMMER MANUAL

the value of STA RT.

Returns:

<NR1>

Examples:

SYSTem:AUTO:END 8 sets auto end on from the memory of lo cation 8

of the current device.

If the command SYSTem:AUTO:END ? Ret u rns 99, mean s set th e

section 99 as the end.

SYSTem:AUTO:STARt

Function:

Set the start memory section for auto execute continuou sly

PSH series do not have this function.)

Syntax:

SYSTem:AUTO:STARt <NR1>

SYSTem:AUTO:STARt?

<NR1> is in the range from 0 through 99 and must be small or equal to

the value of END.

Returns:

<NR1>

Examples:

SYSTem:AUTO:STARt 0 sets auto start on from the memory of

location 0 of the current device.

If the command SYSTem:ATUO:STARt? Returns 2, means set the

section 2 as the start.

(The PSS and

PROGRAMMER MANUAL

SYSTem:AUTO:STATe

Function:

Set or return automatic sequence setting

have this function.)

(The PSS and PSH series do not

Syntax:

SYSTem:AUTO:STATe <Boolean>

SYSTem:AUTO:STATe?

<Boolean> can be 0(OFF) or 1(ON).

Returns:

0|1

Examples:

SYSTem:AUTO:STATe 1 sets auto sequence on.

SYSTem:ERRor? (query only)

Function:

Query the next error message from the Error/Event queu e. The result of

the query is the error number followed by the error text.

Syntax:

SYSTem:ERRor?

Returns:

<string>

Examples:

SYSTem:ERRor? returns 0, “No error”

⎯ 35 ⎯

⎯ 36 ⎯

Page 20

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PROGRAMMER MANUAL

SYSTem:MEMory? (query only)

Function:

Read the current memory se ction numb er disp layed on th e panel

and PSH series do not have this function.)

Syntax:

SYSTem:MEMory?

Returns:

<NR1>

SYSTem:VERSion? (query only)

Function:

Return the SCPI ve rsio n o f th e de v ice.

Syntax:

SYSTem:VERSion?

Returns:

1994.0

(The PSS

PROGRAMMER MANUAL

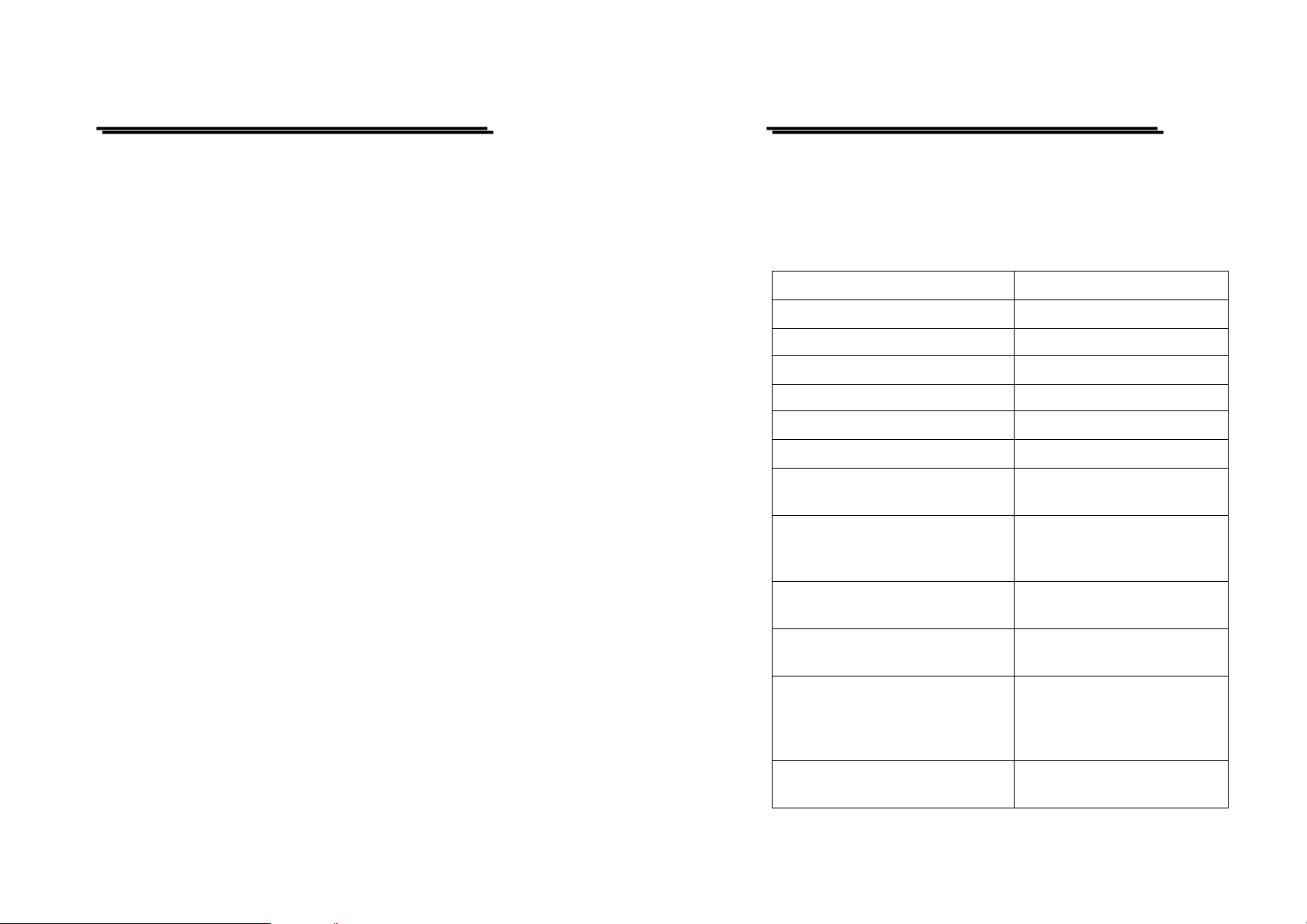

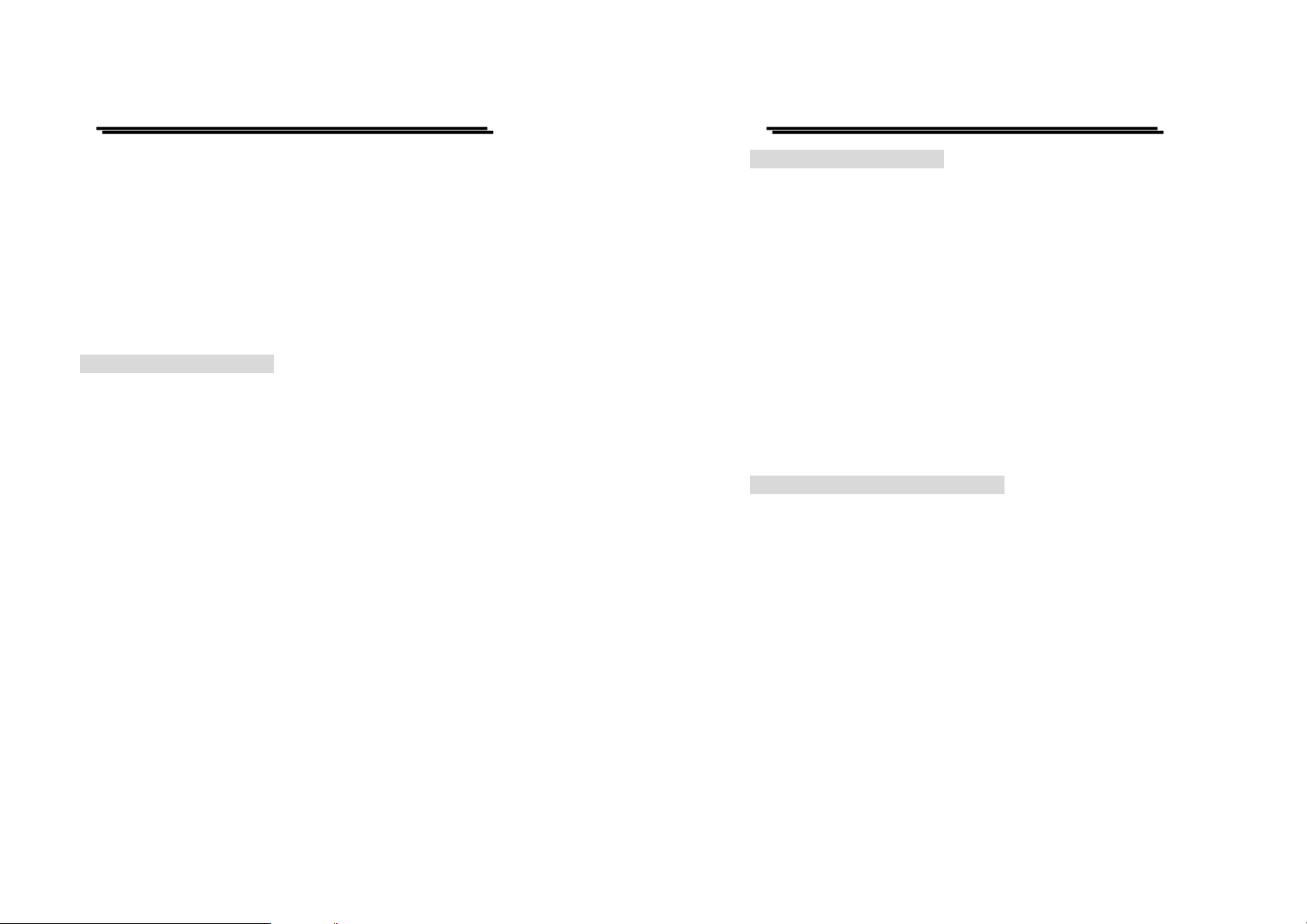

7. STATUS AND ERROR REPORTING

A set of status registers allows the user to quickly determine the

power supply’s internal processing status. The status register, as well as

the status and event reporting system, adhere to SCPI recommendations.

Structure of System

The sketch of the status and event reporting system is showed as

figure 7. Each component of th e sketch represents a set of register s and

queues that can read, rep ort, or enable the occurrence of certain ev ents

within the system.

If a specific event in the power supply sets a bit in a status register,

reading which can tell you what types of events have occurred.

Each bit in the status register corresponds to a bit in an enable register;

the enable bit must be high for the event to be reported to the Status Byte

Register.

A Service Request (SRQ) is the last event to occur. The SRQ requests an

interrupt on the GPIB to report events to the system controller.

Status Registers

⎯ 37 ⎯

There are two kinds of s tatus registers a re included to the programmabl e

power supplies.

z OPERation Status Registers ( CONDition, EVENt, and ENABle)

z QUEStionable Status Registers (CONDition, EVENt, and ENABle)

The lower level nodes: QUEStionable and OPERation each have three 16

bits registers: CONDition, EVENt, and ENABle. Figure 8 shows the

sequential relationship between these three types of registers and the

commands that relate to each register.

⎯ 38 ⎯

Page 21

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

Q UES tio n a b le

Status

Not Used

Not Used

Not Used

Not Used

Not Used

Not Used

Not Used

Not Used

Not Used

Not Used

Not Used

Not Used

Not Used

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Summary Voltage

Summary Current

Summary OVP

O P ERation

Status

0

Not Used

1

Not Used

2

Not Used

3

Not Used

4

Not Used

5

Not Used

6

Not Used

7

Not Used

8

Not Used

9

Not Used

10

Not Used

11

Not Used

12

Not Used

13

Not Used

14

Not Used

15

Not Used

Standard Event Status Registers

Operation Complete

Device Dependent Error

Execution Error

Command Error

0

1

Not Used

Query Error

2

3

4

5

User Request

6

7

Power On

Summary of IEEE 488.2 Status Structure Registers

PROGRAMMER MANUAL

Error/Event Queue

Output Queue

Status Byte Register

0

Not Used

1

Not Used

E/E

2

QUES

3

MAV

4

ESB

5

RQS/MSS

6

7

OPER

SRQ

PROGRAMMER MANUAL

To SBR

Condition

Register

Event

Register

Enable

Register

Figure 8: Status registers and related commands

The CONDition register is a read-only register which monitors the

present state of the instrument. The CONDition register updates in real

time and the inputs are not latched or buffered. When a condition

monitored by the CONDition register becomes true, the bit for that

condition also becomes true (1). When the condition is false, the bit is 0.

The read-only EVENt register latches any false-to-true change in

condition. Once the bit in the EVENt register is set, it is no longer

affected by changes in the corresponding bit of the CONDition register.

The bit remains set until the controller reads it. The command *CLS

(Clear Status) clears the EVENt register.

QUEStionable Status Registers.

Table 4 shows the bit designations of the 16 bit QUEStionable Status

Register.

Figure 7. A graphic representation of the status registers and their connections.

⎯ 39 ⎯

⎯ 40 ⎯

Page 22

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PROGRAMMER MANUAL

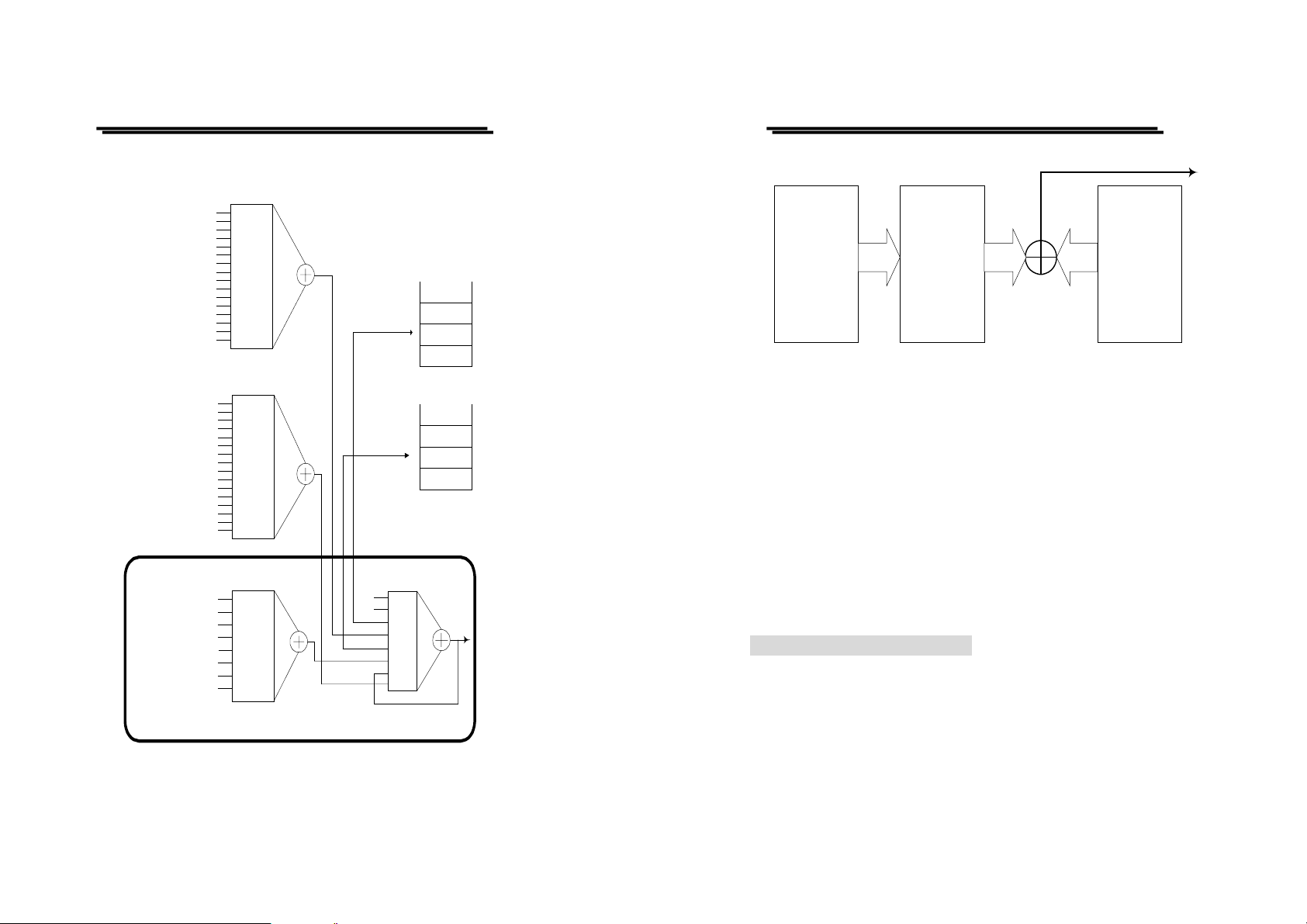

Table 4: QUEStionable Status Register

Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8

∗

NU NU NU NU NU Summary

OVP

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

NU NU NU NU NU NU

Summar

y Current

NU

Summary

Voltage

The command STATus:QUEStionable:CONDtion? Reads the

QUEStionable CONDition register but dose not clear it.

The command STATus:QUEStionable:EVENt? Reads the

QUEStionable EVENt Status register and clears it.

OPERation Status Regist ers

Table 5 shows the bit designations of the 16 bit OPERation Status

Register.

Table 5: OPERatio n S tat us R eg ister

Bit 15 Bit 14 Bit 13 Bit 12 Bi t 11 Bit 10 Bit 9 Bit 8

NU NU NU NU NU NU NU

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

NU NU NU NU NU NU NU NU

∗

NU: not used

PROGRAMMER MANUAL

Status Registers

There are two status registers are included to the power supply defined by

IEEE-488.1 and IEEE-488.2 standards.

z Status Byte Register (SBR)

z Standard Event Status Register (SESR)

Status Byte Register (SBR): The SBR (Table 6) summarizes the status of

all other registers and queues.

Table 6: Status Byte Register (SBR)

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

OPER RQS/MSS ESB MAV QUES E/E NU NU

The bit 0 and 1 are not used, so these bits are always zero. The bit 2

(Error and Event) indicates an error code is waiting to be read in the

Error Event Queue. The bi t 3 (QUES, QUEStionable) is the summary b it

for the QESR (QUEStionable Event Status Register). When the bit is

high it indicates that status is enabled and present in the QUES. The bit 4

(MAV, Message Available) indicates that output is available in the

output queue. The bit 5 (ESB, Event Status Bit) is the su mmary bit for

the Standard Event Status Register (SESR). When the bit is high it

indicates that status is enabled and present in the SESR. The bit 6 (RQS,

Request Service) is obtained from a serial poll and shows that the power

supply requests service from the GPIB controller. The bit 7 (OPER,

OPERation) is the summary bit for the OESR (OPERation EVENt

STATus Register).

⎯ 41 ⎯

⎯ 42 ⎯

Page 23

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PROGRAMMER MANUAL

Use the serial poll or the *STB? Query to read the contents of the SBR.

The bits in the SBR are set and clear ed depending on the contents of the

Standard Event Status Register (SESR), the Standard Event Status

Register (SESR), and the Output Queue.

Standard Event Status Register (SESR): Table 7 shows the SESR

Table 7: Standard Event Status Register (SESR)

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

PON URQ CME EXE DDE QYE NU OPC

The bit 0 (OPC, Operation Complete) shows that the operation is

completed. This bit is active when all pending operations are completed

following an *OPC command. The bit 1 is always z ero. The bit 2 (QYE,

Query Error) indicates a command or query protocol error. The bit 3

(DDE, Device Error) shows that a device error occurred. The bit 4 (EXE,

Execution Error) shows that an error occurred while the power supply

was executing a command or query. The bit 5 (CME, Command Error)

shows that an error occurred while the power supply was parsing a

command or query. The bit 6 (USR, User Request) indicates the LOCAL

button was pushed. The bit 7 (PON, Power On) shows that the power

supply was powered on.

Use the *ESR? Query to read th e SESR. Read th e SES R and cl ear the bits

of the registers so that th e regist er can accumulate information about new

events.

Enable Registers

The enable registers d etermine whether cer tain events are r eported to the

Status Byte Register and SRQ. The programmable power supply has the

PROGRAMMER MANUAL

following enable registers .

z Event St atus En able Reg ister ( ESE R)

z OPERation Enable Register

z QUEStionable Enable Reg ister

z Service Request Enable Reg ister (SRER)

When one of the bits of the en ab le reg ister s is h igh and the cor respon ding

bit in the status register is high, the enable registers will perform a logical

OR function, the output that controls the set bit of the Status Byte

Register is high.

Various commands set the bits in the enable registers. The following

sections describe the enable registers and the commands that set them.

Event Status Enable Register (ESER): The ESER controls which types of

events are summarized by the Event Status Bit (ESB) in the SBR. The

bits of the ESER correspond to the bits of the SESR.

Use the *ESE command to set the bits in ESER. Use the *ESE? query to

read it.

OPERation Enable Register: Even though the OPERation Enable

Register is presen t in the programmable power supplies, the OPERation

registers do not report any conditions.

QUEStionable Enable Register: The QUEStionable Enable Register

controls which types of events are summarized by the QUES status bit in

the SBR. Use the STATus:QUEStionable:ENABle command to set

the bits in the QUEStionable Enable register. Use the

STATus:QUEStionable:ENABle? query to read it.

Service Request Enable Register (SRER): The SRER controls which bits

in the SBR generate a service request.

Use the *SRE command to set the SRER. Use the *SRE? query to read

it.

⎯ 43 ⎯

⎯ 44 ⎯

Page 24

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PST & PSS & PSH SERIES PROGRAMMABLE POWER SUPPLY

PROGRAMMER MANUAL

Queues

The output queue is included to power supplies.

Output Queue: The programmable power supplies store query responses

in the output queue by succeeding the IEEE 488.2 protocol. If the power

supply receives a new command or query message after a message

terminator, the power supply will clear and reset this queue each time.

The computer must read a query response before it sends the next

command (or query) or it loses response to earlier quer ies.

Error/Event Queues

When an error or event occurs, the output queue s tores the message. Th e

output queue stores and reports the messages on a FIFO (first in first out)

state. The SYSTem:ERRor? query reads the next item from the output

queue. If output queue overflows, the error message is –350, “Queue

overflow”; the queue can’t store or report succeeding messages till it

is read or cleared.

Error Message

Table 8 lists the SCPI error messages for the programmable power

supplies.

Table 8 The error messages for the power supplies

SCPI Error Code and Description SESR Bit

0, “No error”

-100, “Command error” 5

-200, “Execution Error” 4

-221, “Settings conflict” 4

-221, “Settings conflict; Timer setting error” 4

-221, “Settings conflict; Overvoltage protection setting error” 4

-221, “Settings conflict; Voltage setting error” 4

PROGRAMMER MANUAL

-221, “Settings conflict; Current setting error” 4

-221, “Settings conflict; Recall setting error” 4

-221, “Settings conflict; Store setting error” 4

-222, “Data out of range” 4

-222, “Data out of range; Voltage too large” 4

-222, “Data out of range; Current too large” 4

-222, “Data out of range; Voltage too small” 4

-222, “Data out of range; Current too small” 4

-240, “Hardware Error” 4

-300, “Device-specific error” 3

-300, “Device-specific error; Overcurrent protection er ror” 3

-300, “Device-specific error; Overvoltage protection error” 3

-300, “Device-specific error; Overtemperature protection

error”

-300, “Device-specific error; Calibration current error” 3

-300, “Device-specific error; Calibration voltage error” 3

-300, “Device-specific error; Calibration overvoltage

protection error”

-310, “System error” 3

-313, “Calibration memory lost” 3

-330, “Self-test failed” 3

-330, “Self-test failed; CPU test error” 3

-330, “Self-test failed; RAM test error” 3

-330, “Self-test failed; ROM test error” 3

-330, “Self-test failed; DAC/ADC test error” 3

-350, “Queue overflow” 3

-410, “Query INTERRUPTED” 2

-420, “Query UNTERMINATED” 2

-430, “Query DEADLOCKED” 2

3

3

⎯ 45 ⎯

⎯ 46 ⎯

Loading...

Loading...