Page 1

Programmable DC Electronic

Load

PEL-2000 Series

USER MANUAL

GW INSTEK PART NO. 82EL-20040MA1

ISO-9001 CERTIFIED MANUFACTURER

Page 2

March 2010

This manual contains proprietary information, which is protected by

copyright. All rights are reserved. No part of this manual may be

photocopied, reproduced or translated to another language without

prior written consent of the Good Will company.

The information in this manual was correct at the time of printing.

However, Good Will continues to improve products and reserves the

right to change specification, equipment, and maintenance

procedures at any time without notice.

Good Will Instrument Co., Ltd.

No. 7-1, Jhongsing Rd., Tucheng City, Taipei County 236, Taiwan.

Page 3

Table of Contents

Table of Contents

SAFETY INSTRUCTIONS ................................................... 5

GETTING STARTED ......................................................... 10

Main Features ...................................... 12

Series Overview ................................... 13

Package Contents and Accessories....... 15

Measurement Overview ....................... 16

Front Panel Overview ........................... 17

Display Overview – Mainframe ............ 22

Rear Panel Overview ............................ 25

Front Panel Overview – Load Module ... 28

LED Display Overview – Load Module .. 32

Installation .......................................... 35

Load Connections ................................ 43

Frame Link Connection ........................ 54

Channel Control Connection ................ 56

Go/NoGo Connection .......................... 59

OPERATING DESCRIPTION ............................................. 60

Operating Mode Description ............... 61

Run Program ........................................ 71

Sequence ............................................. 74

Parallel Dynamic Loading .................... 78

Configurations Description .................. 79

Interface and File System ..................... 89

TUTORIALS ..................................................................... 96

Local loads .......................................... 97

Single Channel Load ............................ 99

Programming ..................................... 101

Sequences .......................................... 103

3

Page 4

PEL-2000 Series User Manual

Frame Link ......................................... 104

Channel Control ................................. 106

General Configuration Options .......... 108

OPERATION ................................................................... 109

Local Mode Operation ....................... 112

Mainframe Basic Operation ............... 119

Channel Configuration ....................... 160

Mainframe Configuration ................... 180

Interface Configuration (settings) ...... 195

Save / Recall ...................................... 201

INTERFACE .................................................................... 232

Interface Configuration ...................... 233

FAQ ............................................................................... 241

APPENDIX ..................................................................... 242

Fuse Replacement .............................. 242

Battery Replacement .......................... 243

Firmware Update ............................... 244

Calibration ......................................... 245

Range Chart ....................................... 246

Default Settings ................................. 251

Specifications .................................... 253

Dimensions ....................................... 261

EC Declaration of Conformity ............. 263

INDEX ............................................................................ 264

4

Page 5

SAFETY INSTRUCTIONS

SAFETY INSTRUCTIONS

This chapter contains important safety

instructions that you must follow when operating

the PEL-2002/PEL-2004, and when keeping it in

storage. Read the following before operating the

PEL-2002/2004 to ensure your safety and to keep

the PEL-2000 series in the best possible condition.

Safety Symbols

These safety symbols may appear in this manual or on the PEL2002/2004.

WARNING

CAUTION

Warning: Identifies conditions or practices that

could result in injury or loss of life.

Caution: Identifies conditions or practices that

could result in damage to THE PEL-2002/2004 or

to other properties.

DANGER High Voltage

Attention Refer to the Manual

Protective Conductor Terminal

Earth (ground) Terminal

5

Page 6

PEL-2000 Series User Manual

Do not dispose electronic equipment as unsorted

municipal waste. Please use a separate collection

facility or contact the supplier from which this

instrument was purchased.

Safety Guidelines

General

Guideline

Do not place any heavy object on the PEL-

2002/2004.

CAUTION

Avoid severe impact or rough handling that

leads to damaging the PEL-2002/2004.

Do not discharge static electricity to the PEL-

2002/2004.

Do not block or obstruct the cooling fan vent

openings.

Do not perform measurement at circuits directly

connected to Mains (Note below).

Do not disassemble the PEL-2002/2004 unless

you are qualified as service personnel.

The equipment is not for measurements

performed for CAT II, III and IV.

(Measurement categories) EN 61010-1:2001 specifies the

measurement categories and their requirements as follows. The

PEL-2002/2004 falls under category I.

Measurement category IV is for measurement performed at the

source of low-voltage installation.

Measurement category III is for measurement performed in the

building installation.

Measurement category II is for measurement performed on the

circuits directly connected to the low voltage installation.

Measurement category I is for measurements performed on

circuits not directly connected to Mains.

6

Page 7

SAFETY INSTRUCTIONS

Power Supply

WARNING

Fuse

WARNING

Battery

WARNING

AC Input voltage: 115V/230V switchable,

50/60Hz

The power supply voltage should not fluctuate

more than 15%.

Connect the protective grounding conductor of

the AC power cord to an earth ground, to avoid

electrical shock.

Fuse type: T3.15A/250V

Make sure the correct type of fuse is installed

before power up.

To avoid fire, only replace the fuse with the

specified type and rating.

Disconnect the power cord before fuse

replacement.

Make sure the cause of a fuse blowout is fixed

before replacing the fuse.

Battery type: CR17345 (See page 243).

When replacing the battery ensure that the

correct make and model are used.

Cleaning the

PEL-2000

Disconnect the power cord before cleaning.

Use a soft cloth dampened in a solution of mild

detergent and water. Do not spray any liquid.

Do not use chemicals or cleaners containing

harsh material such as benzene, toluene, xylene,

and acetone.

7

Page 8

PEL-2000 Series User Manual

Operation

Environment

Storage

environment

Location: Indoor, no direct sunlight, dust free,

almost non-conductive pollution (Note below)

Temperature: 0°C to 40°C

Altitude: Up to 2000m

Transient Overvoltage on the main supply is

2500V.

(Pollution Degree) EN 61010-1:2001 specifies the pollution degrees

and their requirements as follows. THE PEL-2002/2004 falls under

degree 2.

Pollution refers to “addition of foreign matter, solid, liquid, or

gaseous (ionized gases), that may produce a reduction of dielectric

strength or surface resistivity”.

Pollution degree 1: No pollution or only dry, non-conductive

pollution occurs. The pollution has no influence.

Pollution degree 2: Normally only non-conductive pollution

occurs. Occasionally, however, a temporary conductivity caused

by condensation must be expected.

Pollution degree 3: Conductive pollution occurs, or dry, non-

conductive pollution occurs which becomes conductive due to

condensation which is expected. In such conditions, equipment

is normally protected against exposure to direct sunlight,

precipitation, and full wind pressure, but neither temperature

nor humidity is controlled.

Location: Indoor

Relative Humidity: < 80%

Disposal

8

Temperature: −10°C to 70°C

Do not dispose this instrument as unsorted

municipal waste. Please use a separate collection

facility or contact the supplier from which this

instrument was purchased. Please make sure

discarded electrical waste is properly recycled to

reduce environmental impact.

Page 9

SAFETY INSTRUCTIONS

Power cord for the United Kingdom

When using the PEL-2002/2004 in the United Kingdom, make sure

the power cord meets the following safety instructions.

NOTE: This lead/appliance must only be wired by competent persons

WARNING: THIS APPLIANCE MUST BE EARTHED

IMPORTANT: The wires in this lead are coloured in accordance with the

following code:

Green/ Yellow: Earth

Blue: Neutral

Brown: Live (Phase)

As the colours of the wires in main leads may not correspond with the coloured

marking identified in your plug/appliance, proceed as follows:

The wire which is coloured Green & Yellow must be connected to the Earth

terminal marked with either the letter E, the earth symbol

Green/Green & Yellow.

The wire which is coloured Blue must be connected to the terminal which is

marked with the letter N or coloured Blue or Black.

The wire which is coloured Brown must be connected to the terminal marked

with the letter L or P or coloured Brown or Red.

If in doubt, consult the instructions provided with the equipment or contact the

supplier.

This cable/appliance should be protected by a suitably rated and approved

HBC mains fuse: refer to the rating information on the equipment and/or user

instructions for details. As a guide, a cable of 0.75mm2 should be protected by a

3A or 5A fuse. Larger conductors would normally require 13A types,

depending on the connection method used.

Any exposed wiring from a cable, plug or connection that is engaged in a live

socket is extremely hazardous. If a cable or plug is deemed hazardous, turn off

the mains power and remove the cable, any fuses and fuse assemblies. All

hazardous wiring must be immediately destroyed and replaced in accordance

to the above standard.

or coloured

9

Page 10

PEL-2000 Series User Manual

GETTING STARTED

This chapter describes the features and functions of the

PEL-2002/2004, including the front and rear panel

appearance, panel installation and connection types. Use

the Tutorial section for quick access to step by step

instructions on the main functions.

Main Features ................................................................. 12

Series Overview ............................................................... 13

Package Contents and Accessories .................................. 15

Measurement Overview ................................................... 16

Front Panel Overview ...................................................... 17

Display Overview – Mainframe ........................................ 22

10

Page 11

GETTING STARTED

Rear Panel Overview ........................................................ 25

Front Panel Overview – Load Module ............................... 28

LED Display Overview – Load Module ............................. 32

Installation ..................................................................... 35

Load Module Installation ..................... 35

GPIB Installation ................................. 38

Rack Mount Installation ....................... 39

Channel Number .................................. 40

Power Up & Self Test ........................... 41

Load Connections ........................................................... 43

Precautions and Procedures ................ 43

Remote (Sense) Connection ................. 48

Single Load Connections ...................... 50

Parallel Load Connections.................... 52

Frame Link Connection .................................................... 54

Channel Control Connection ............................................ 56

Go/NoGo Connection ..................................................... 59

11

Page 12

PEL-2000 Series User Manual

Main Features

Description

The PEL-2002 and 2004 are multichannel

programmable DC electronic load mainframes.

The PEL-2002 mainframe is able to hold 2 load

modules, whilst the PEL-2004 is able to hold 4. The

flexible module configuration allows the

mainframes to either sink multiple loads

independently or large loads when used in

parallel.

The PEL-2000 series support three operation

modes: constant current (CC), constant voltage

(CV and CV+CC) and constant resistance (CR).

Constant current and constant resistance mode can

operate in either static or dynamic mode.

Feature Overview

12

Flexible operation with removable load modules

Multiple independent isolated channels

High performance, up to 5 digit resolution

High slew rate enabling a high response speed

High capacity when frame linked

Different load module types can be used in the

same mainframe

Supports rack mount installation (PEL-2004)

Supports frame link connections, with up to 4

slave units

Color LCD display

120 different sets of programmable sequences

Accurate load simulation using Sequences

4 panel setups

USB flash drive support

Page 13

GETTING STARTED

Interface

USB

RS-232C

GPIB (optional)

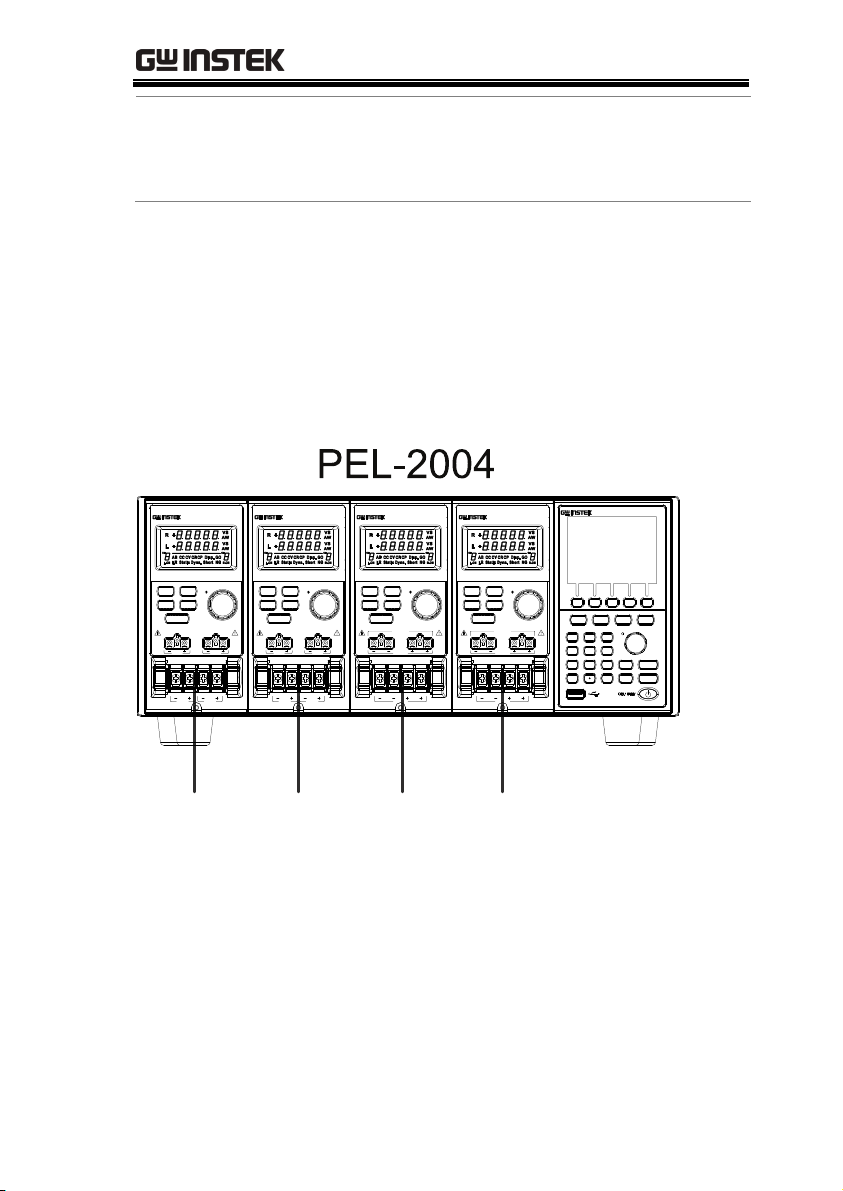

Series Overview

The PEL-2000 series comprises of two different Mainframes: the PEL2002 and the PEL-2004. The Mainframes differ by the number of load

modules that can be accommodated. The PEL-2002 has two load

module slots whilst the PEL-2004 has 4. There are 4 different load

module models, the PEL-2020, PEL-2030, PEL-2040 and PEL-2041.

DISPLAY

LOAD

V sense V sense

L

MAX

80VDC

80VDC

PEL-2020

STATIC/

DYNA.

SHORT

MAX MAX

L

DC Electronic Load

L

20A/ 80V,100W

20A/ 80V,100W

R

L

R

MAX

80VDC

80VDC

R

DC Electronic Load

5A/ 80V, 30W

L

40A/ 80V,250W

PEL-2030

R

STATIC/

R/LR/L

DYNA.

DISPLAY

SHORT

LOAD

V senseV sense

R

MAX

MAX

80VDC

80VDC

MAXMAX

80VDC

80VDC

R

L

DC ElectronicLoad

PEL-2040

70A/ 80V,350W

STATIC/

A/B

DYNA.

DISPLAY

SHORT

LOAD

V sense

MAX

80VDC

MAX

DC Electronic Load

PEL-2041

10A/ 500V,350W

STATIC/

A/B

DYNA.

SHORT

DISPLAY

LOAD

V sense

MAX

500VDC

MAX

500VDC80VDC

456

1

P0 LOCK

0

DC ElectronicLoad

PEL-2004

F1

LOCAL UTILITY

FILEFUNC

CHAN

P9P7 P8

9

87

P6P4 P5

P3P1 P2

PRESET

3

2

CAL.

ENTER

CLEAR

F5F4F3F2

HELP

SHIFT

ON/

LOAD

OFF

PEL-2040 PEL-2041PEL-2020 PEL-2030

13

Page 14

PEL-2000 Series User Manual

DISPLAY

LOAD

Vsense Vsense

L

MAX

80VDC

MAX MAX

80VDC

L

DC ElectronicLoad

20A/ 80V, 100W

L

PEL-2020

20A/ 80V, 100W

R

STATIC/

DYNA.

SHORT

R

MAX

80VDC

80VDC

R

DC ElectronicLoad

PEL-2040

70A/80V ,350W

STATIC/

A/BR/L

DYNA.

DISPLAY

SHORT

LOAD

Vsense

MAX

80VDC

MAX

80VDC

CHAN

78

12

0

PEL-2002

F1

F2 F3 F4 F5

FUNC FILE

P8P7 P9

P5P4 P6

P2P1 P3

CAL.

DC Electronic Load

UTILITYLOCAL

HELP

9

654

PRESET

SHIFT

3

LOCKP0

ON/

CLEAR

LOAD

ENTER

OFF

PEL-2020 PEL-2040

The 4 different load module models each differ in the amount of current,

voltage and power and the amount of channels that the load module

can accommodate. The procedures in this manual will be load module

model independent unless specifically stated. Below is a table showing

the basic differences between each load module model. For detailed

specifications, please see page 253.

Load Module Channels

Power (W)

CH L/R

Current (A)

Range

Voltage (V)

Low/High

PEL-2020

PEL-2030 (30/250W)

(100Wx2) 2 100/100 2/20 1-80

2 30/250 5/4/40 1-80

PEL-2040 1 350 7/70 1-80

PEL-2041 1 350 1/10 2.5-500

14

Page 15

GETTING STARTED

Package Contents and Accessories

The PEL-2000 electronic load generator has a number of standard

and optional accessories that can be ordered. For more information

please visit the GW Instek website at www.gwinstek.com

consult your authorized distributor for details.

Standard

Accessories

Power Cable Mains power cable (region dependent)

User Manual PEL-2000 Series Electronic DC load User Manual

GTL-120 Load cables 2X red, 2X black (per load module)

GTL-121 Remote sense cables , 1X red, 1X black (per load

Options Description

PEL-2020

Description

(region dependent)

module)

Load Module

or

PEL-2030

PEL-2040

PEL-2041

PEL-001 GPIB interface (Factory installed)

Optional

Accessories

PEL-002 PEL-2000 Rack Mount kit (handle only)

GTL-232 RS-232C

GTL-246 USB

GTL-248 GPIB cable

GTL-249 Frame link

Description

15

Page 16

PEL-2000 Series User Manual

Measurement Overview

The PEL-2000 series has a number of different operating modes that

are completely configurable. All the modes have customizable

Go/NoGo limits, range limits, timers, slew rates, alarms and

protection limits. To make tests, Programs and Sequences can be

created.

Function

Description

Constant Current

Mode (CC)

Constant Voltage

Mode (CV)

Constant

Resistance Mode

(CR)

Programmable

Sequences

(Prog.)

Sequences (Seq.)

In constant current mode, the PEL-2002/2004 will

sink a constant amount of current, regardless of

the voltage.

Under constant voltage mode, the voltage remains

unchanged, regardless of the current.

In constant resistance mode, the resistance load

will remain unchanged as the voltage and current

remain proportional.

The PEL 2000 series supports programming

sequences. With up to 120 different memory

settings in 12 programs with 10 sequences.

Used to create load profiles to accurately simulate

a load. Sequences can be created for each channel.

16

Page 17

GETTING STARTED

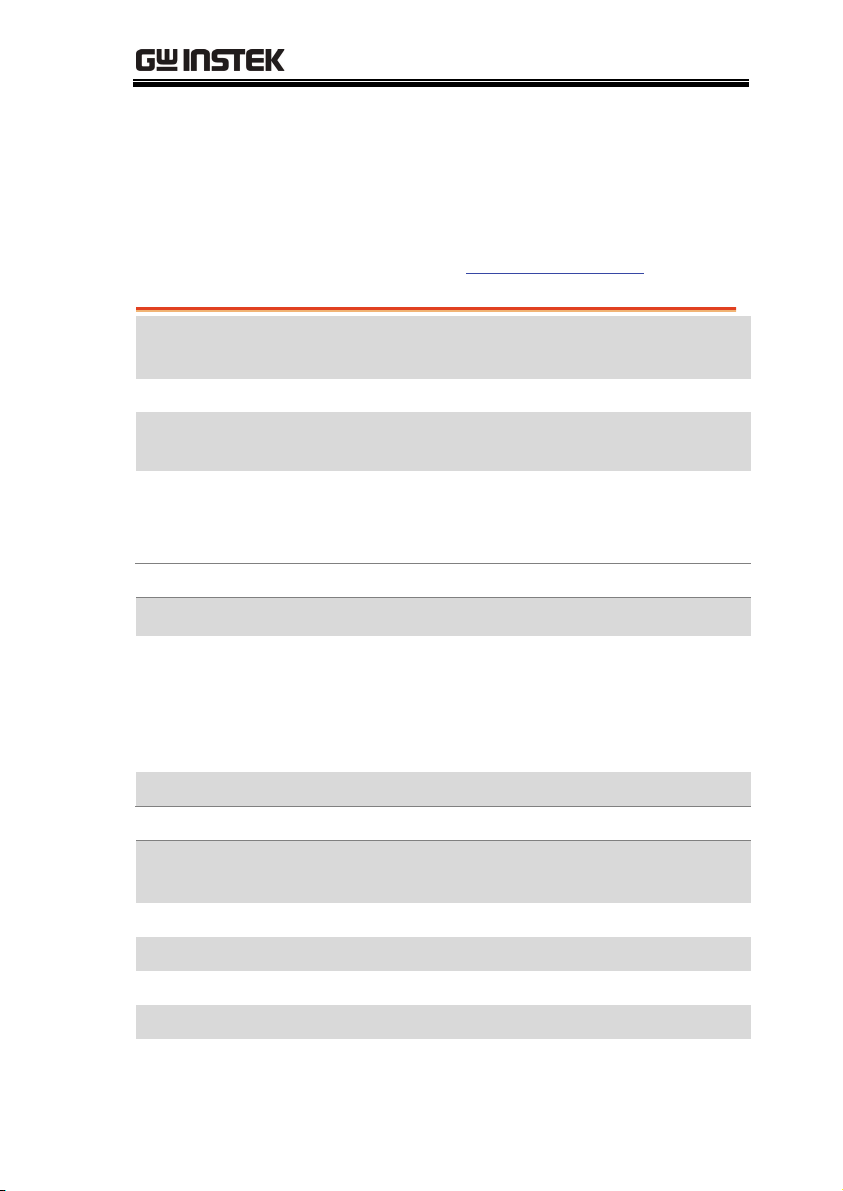

Front Panel Overview

LCD display

Function keys

System Keys

Number Pad

LCD display

PEL-2002

F1

LOCAL

CHAN

P9P7 P8

9

87

456

P0 LOCK

0

P6P4 P5

P3P1 P2

21

3

CAL.

CLEAR

FILEFUNC

ENTER

DC Electronic Load

F5F4F3F2

UTILITY

HELP

SHIFTPRESET

LOAD

320 by 240, TFT LCD display.

Selector

Knob

Operation

ON /

OFF

keys

PowerUSB input

Function keys

Assigned to the menu functions on

the bottom of the display.

17

Page 18

PEL-2000 Series User Manual

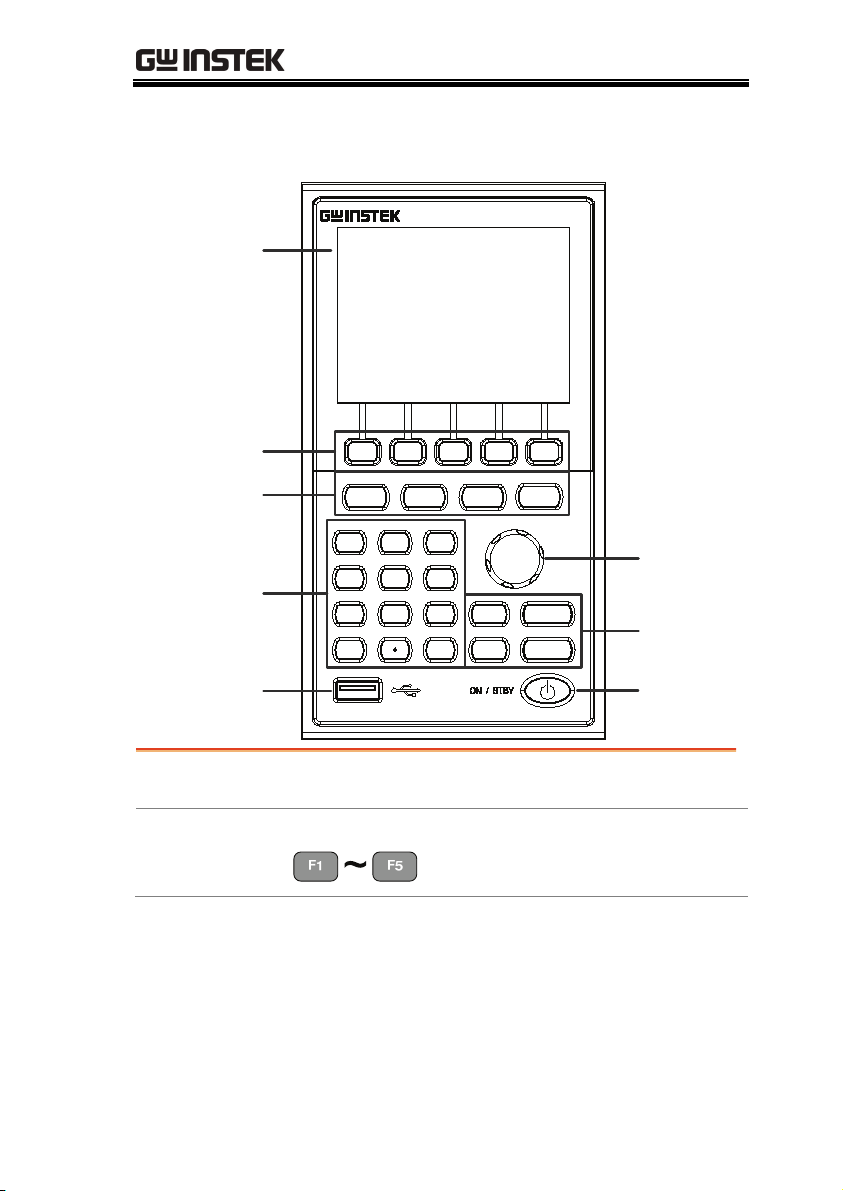

System Keys

CHAN/LOCAL is used to select

the load channel. Combined with

the shift key, Local is used to

activate/deactivate local control

(during remote control via the

interface or frame link

connections).

Brings up the

Channel Menu.

Used to activate

local control mode

during remote

control via the

interface

Used to access the Program or

Sequence menu.

Used to access the File menu.

Brings up the Help menu and

utility menu.

Provides help for

the last function

/key pressed.

Activates the

Utility Menu.

18

Page 19

GETTING STARTED

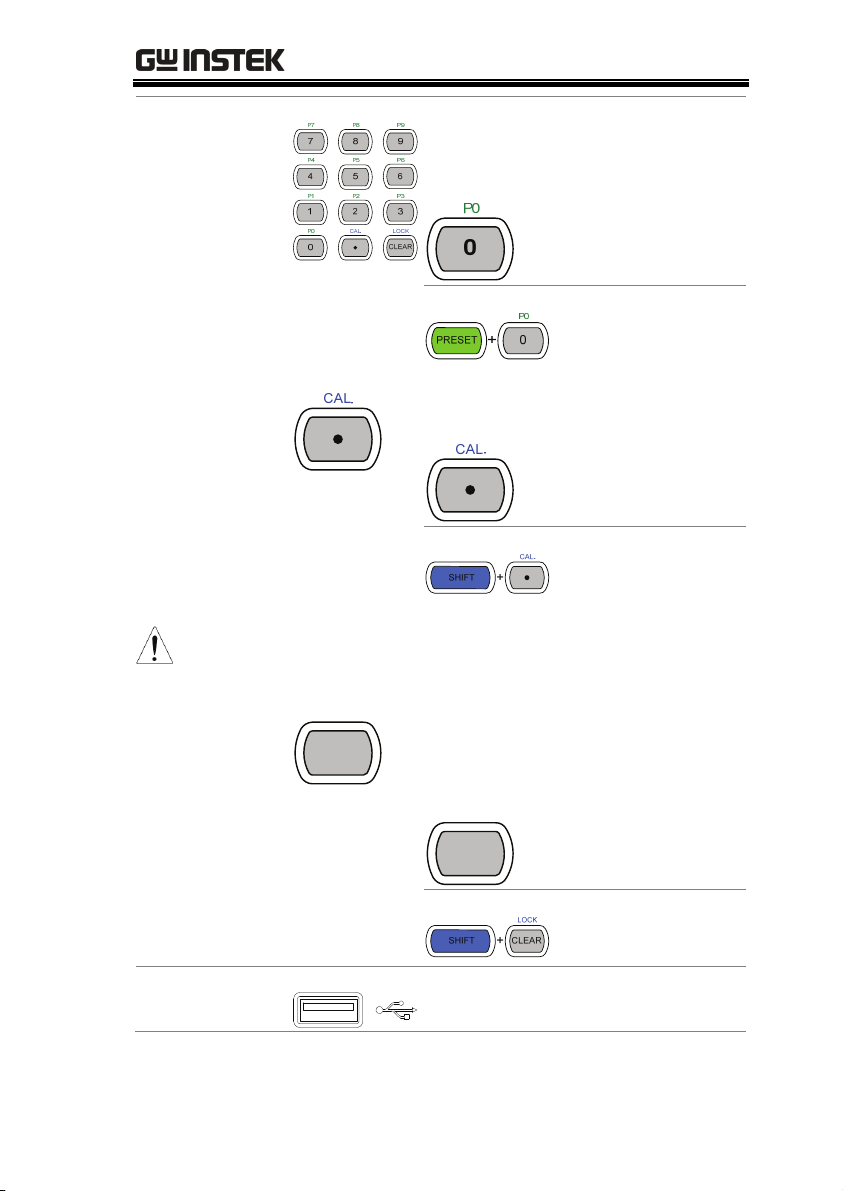

Number pad

Note

Enter numerical values, or to

save/recall presets (P0-P9).

Number values.

Preset numbers P0P9.

Decimal point and Calibration key

Decimal point.

Activate calibration

mode.

Please note, calibration mode is not supported.

Please see your distributor for calibration needs.

LOCK

CLEAR

Clears current values. Alternative

function locks the keys and the

Selector knob.

LOCK

CLEAR

Clears the current

value.

Locks all the keys

and Selector knob.

USB Input

USB flash memory slot.

19

Page 20

PEL-2000 Series User Manual

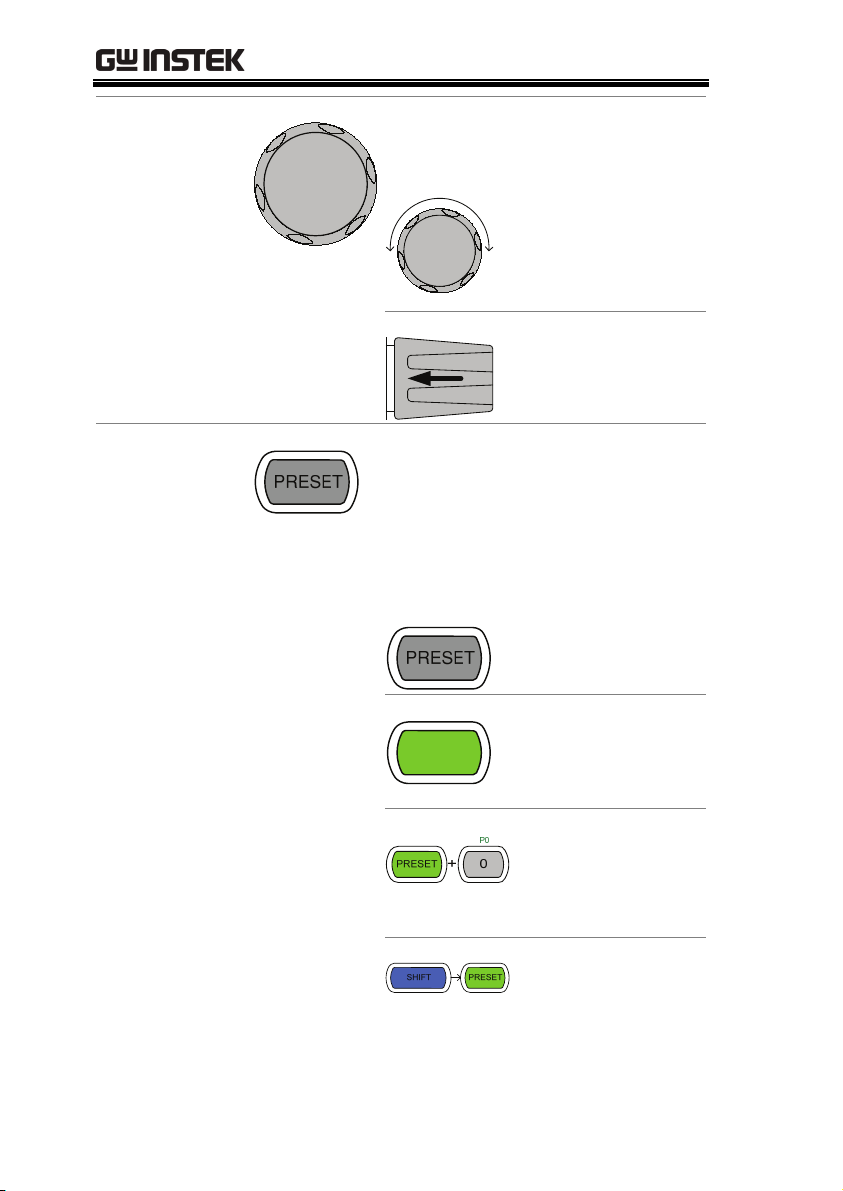

Selector Knob

Operation Keys

Used to select operations and to

increase/decrease values.

When turned left or

right moves the

cursor in menus or

changes the selected

item or value.

When pushed

down, acts as the

Enter key.

Saves and recalls preset settings

and values.

When pressed in combination with

the number pad, Presets P0-P9 can

be recalled or saved.

Inactive

Active. Used in

PRESET

combination with

the number pad

and/or shift key.

Press to recall a

channel preset

Hold to save a

channel preset

Press to recall all

channel presets.

Hold to save all

channel presets.

20

Page 21

GETTING STARTED

The shift key is used to access

alternate functions assigned to

select keys

Inactive

Active. When active

the shift key can be

used to access the

Local and Utility

menus.

Confirms selections.

Turns the current load/channel on

or off

Load is currently

off. (unlit)

Load is currently on.

(orange light)

Power

Turns the unit on or into standby

mode.

Standby mode.

On.

21

Page 22

PEL-2000 Series User Manual

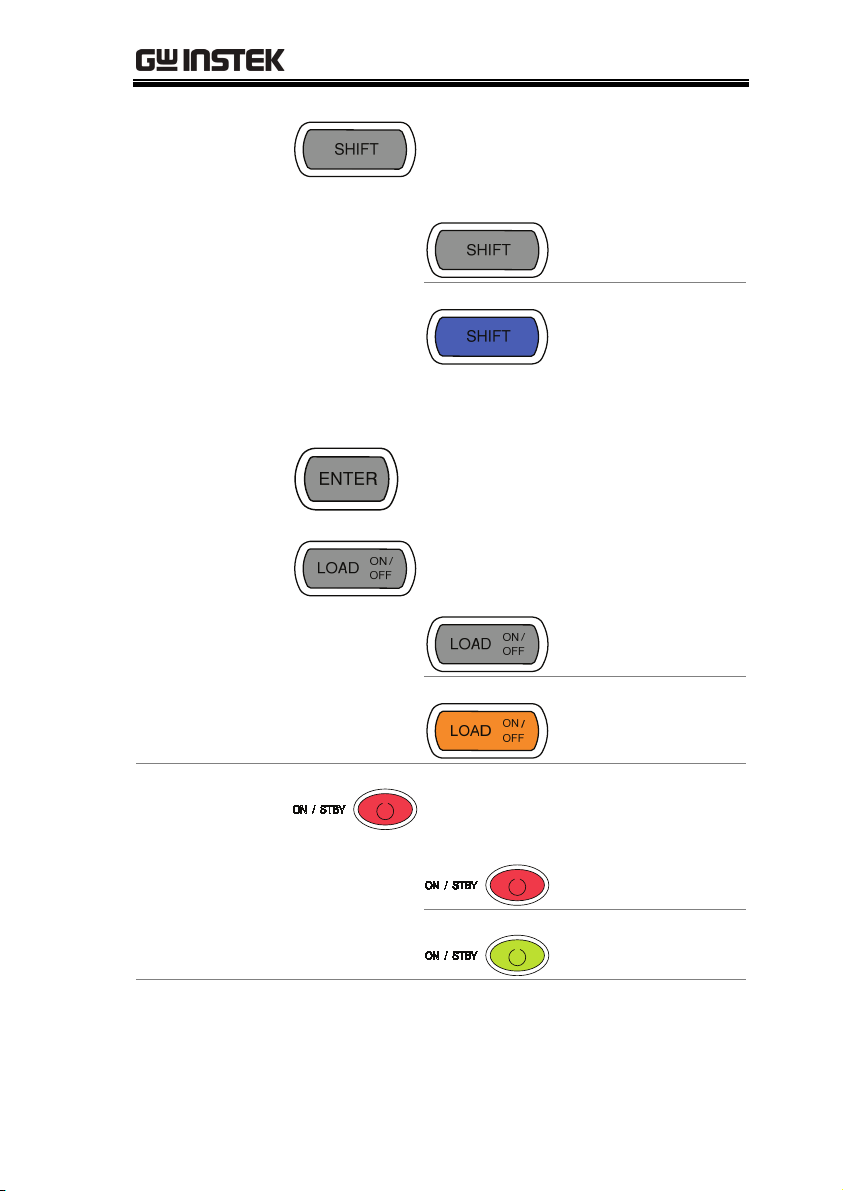

Display Overview – Mainframe

Mainframe Status

Panel

The Mainframe Status Panel displays the status of

the Mainframe interface, programs and alarm

status.

Frame Link

Status

FRM

FRS

Indicates Frame Link is

turned on and that the

mainframe is set as either

a master (FRM) or slave

(FRS) unit.

22

Page 23

GETTING STARTED

Current

Operation

Channel Status

Panel

Load Type

Interface Status

LOAD

LOAD

PROG

PROG

SEQ

SEQ

RS232

GPIB

The Load Type Icon

indicates if a Sequence

(SEQ) or Program

(PROG) is turned on. If

not then LOAD is

displayed as default.

When any Load type is

running, their icon will

turn orange.

The interface status icon

displays which interface

type is set.

USB

The Current Operation Channel Status panel

generally displays the status of the current

channel.

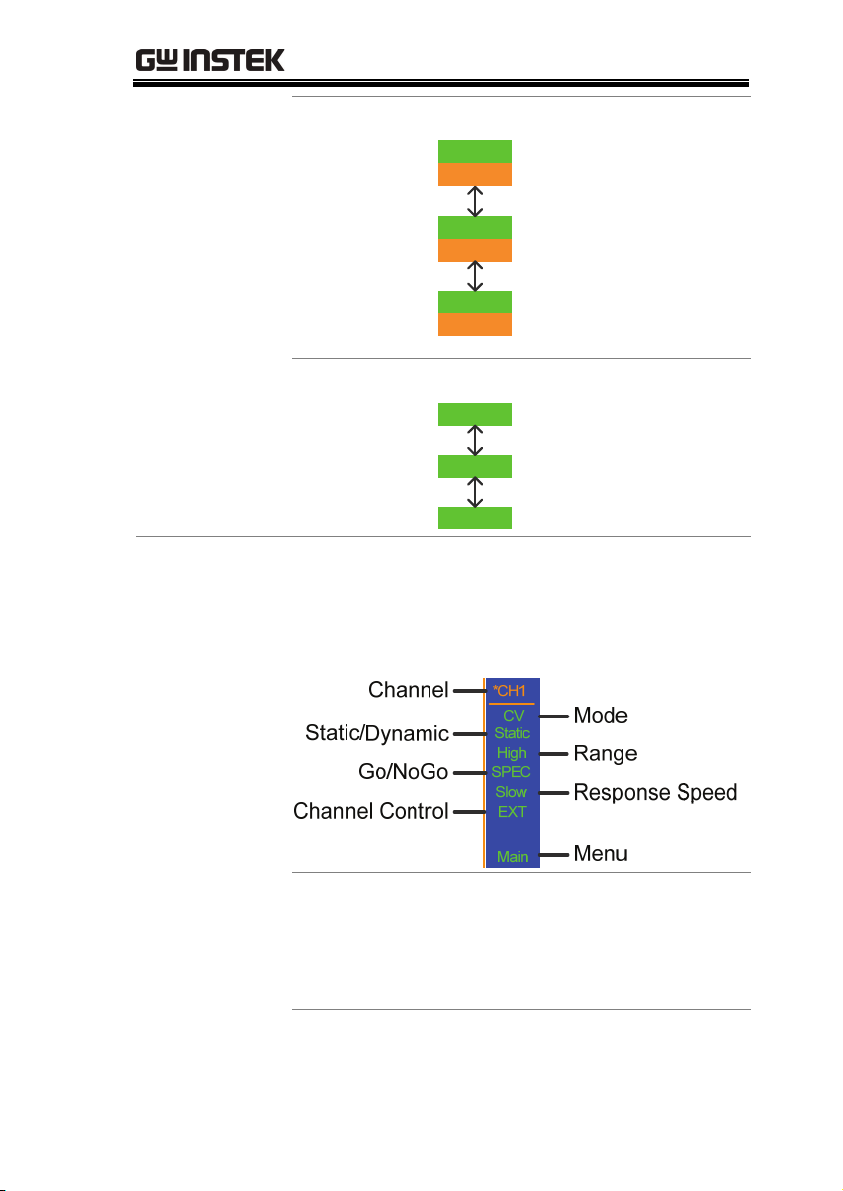

Channel *CH1~

*CH8

Displays the current

channel.

An asterisk * denotes

independent mode for

the channel.

23

Page 24

PEL-2000 Series User Manual

Mode CC

CR

Displays the current

mode.

CV

Static /

Dynamic

Range High

Displays whether the channel is in

Static or Dynamic mode.

Displays High or Low

Low

range.

Go/NoGo SPEC If Go/NoGo is turned

on, SPEC will be

displayed.

Response

Speed

Slow

Fast

In CV mode the response

speed will be shown,

Slow or Fast.

Channel

Control

EXT When Channel Control is

set to External, EXT will

be displayed.

Menu

Main

Conf

s_edit

File

s_loop

Shows the current menu.

= Chan menu

= ChanConfigure menu

= ChanSeq.Edit menu

= File menu

= ChanSeq.EditLoop

menu

Date and Time

Main Screen

Menu Icons

Main display screen

F1~F5

The date is displayed as

Month/Day/Year and the time is

set as a 24-hour time notation.

Each Menu Icon is controlled by

the F1~F5 function keys directly

below.

24

Page 25

GETTING STARTED

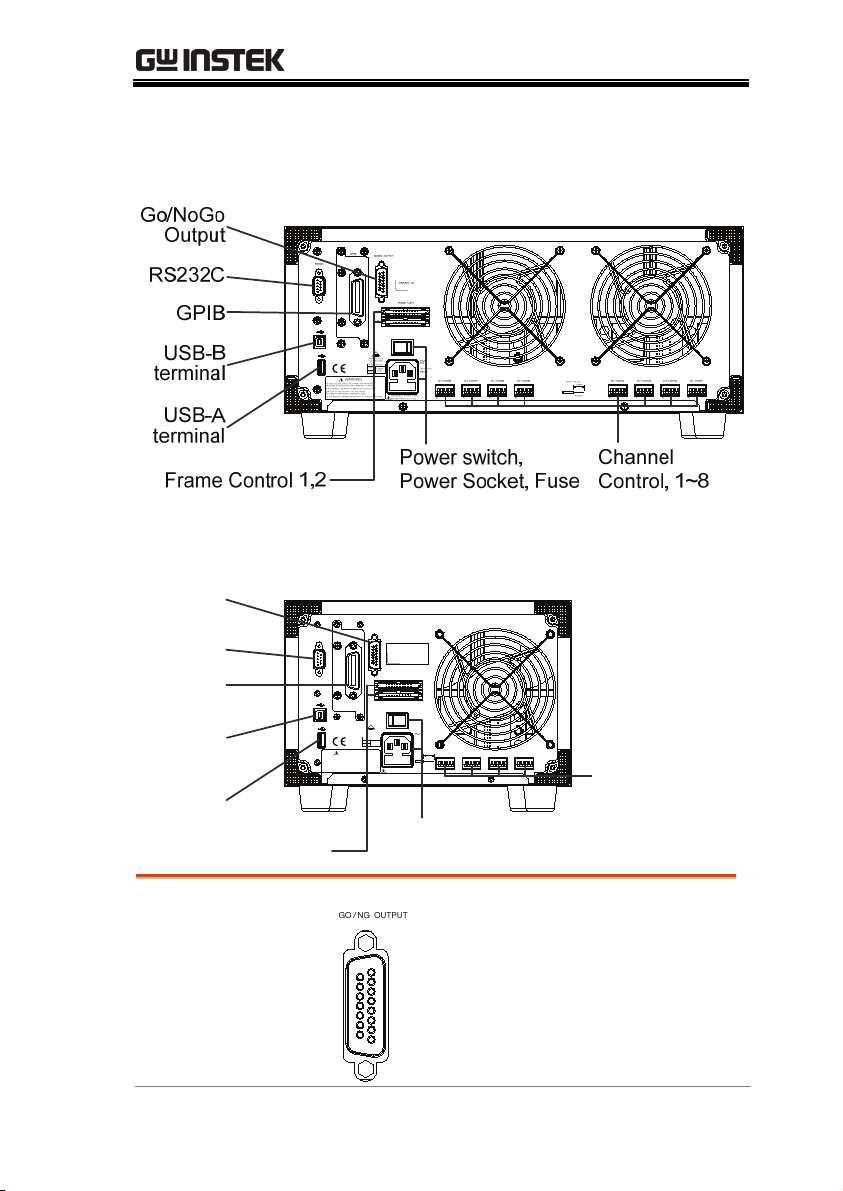

Rear Panel Overview

PEL-2004

PEL-2002

Go/NoGo

Output

RS232C

GPIB

GPIB

GO / NG OUTPUT

RS232C

SER. NO. LB

FRAME CONT

1

2

WARNING

TO AVOID ELECTRIC SHOCK THE POWER CORD PROTECTIVE

GROUNDING CONDUCTOR MUST BE CONNECTED TO GROUND.

FOR CONTINUED FIRE PROTECTION. REPLACE FUSE ONLY WITH

250V FUSE OF THE SPECIFIED TYPE AND RATING.

NO OPERATOR SERVICEABLE COMPONENTS INSIDE.

DO NOT REMOVE COVERS. REFER SERVICING TO QUALIFIED PERSONNEL.

REPLACE FUSE

AS SPECIFIED

AC

FUSE RATING

115V

T 3.15A

120 VA MAX

250V

230V

50/60 Hz

STRIP GAUGE

10.0 mm

CH CONT 41CH CONT 31CH CONT 21CH CONT 1

DISCONNECT POWER CORD

BEFORE REPLACING FUSE

AWG 24

1

Channel

Control, 1~4

USB-B

terminal

USB-A

terminal

Power switch,

Frame Control 1,2

Go/NoGo

Output

Power Socket, Fuse

The Go/NoGo Output

terminal outputs a pass

(high)/fail (low) voltage for

each channel.

See page 239, 59 for details.

25

Page 26

PEL-2000 Series User Manual

RS232 port/

GPIB port

USB-A(host)/

USB-B (device)

port

Frame Control

Port

The RS232 and GPIB port is

used for remote control

connections.

RS-232C: DB-9 pin male

GPIB: 24-pin female

See pages 233, 234 for remote

control details.

The USB-B (device) port, like

the RS232/GPIB port is used

for remote control. Like the

front panel, the USB-A port is

used for data storage.

See page 89 for interface

details.

The Frame Control port is

used for Frame Link

connections. Mainframes are

daisy-chained together. There

are two Frame control ports.

1: Slave

2: Master

Connection type: MIL 20-pin

connector.

For details about frame link

connections see page 54, 236.

Power Switch

26

External Power Switch

Page 27

GETTING STARTED

Power Socket/

Fuse

Channel

Control port

(1~8)

The power supply socket

accepts the AC mains Voltage.

The fuse holder is located

below the power socket.

Power: 50/60 Hz (180 VA)

Fuse: T3.15A/250V

For fuse replacement details

see page 242.

Each channel has a dedicated

Channel control port to

enable external monitoring

and control. The channel

control port has 6 wire sockets

that are screw-less and self

clamping.

Required wire gauge: 24

AWG

For connection or

specification details see pages

56 & 235.

27

Page 28

PEL-2000 Series User Manual

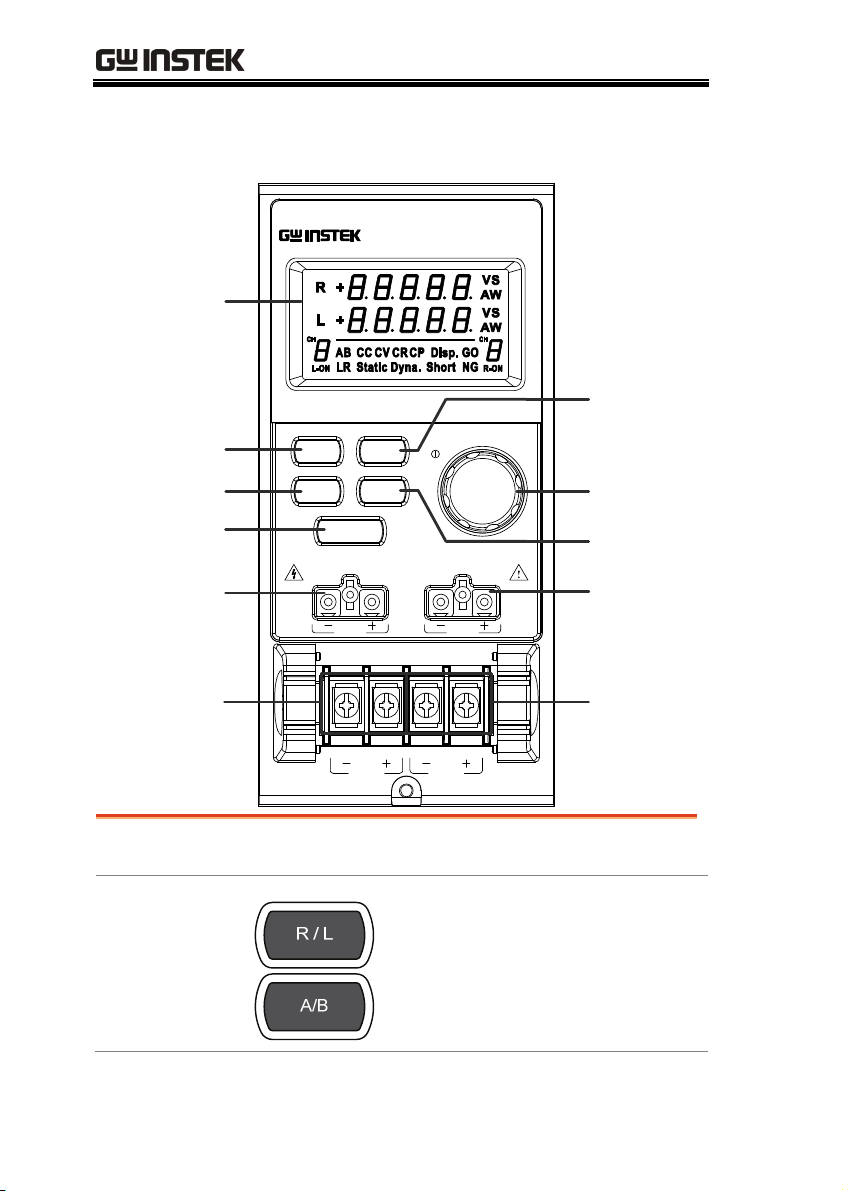

Front Panel Overview – Load Module

DC Electronic Load

L

20A / 80V , 100W

20A / 80V , 100W

R

MAX

80V DC

R

LED

display

R/L A/B Key

Display Key

Load Key

V Sense L

PEL-2020

R/L

DISPLAY

L

STATIC/

DYNA.

SHORT

LOAD

V sense V sense

MAX

80V DC

Static/

Dynamic

Key

Selector

Knob

Short Key

V Sense R

Terminals

(Left)

LED display

Right/Left Key

or

A/B Key

28

MAX MAX

80V DC

L

80V DC

R

2x5 digit custom LED display.

The L/R key is used to switch

between the right and left load

channel on a dual channel load

module. The A/B key is used to

switch between A&B Values for

single channel load modules.

Terminals

(Right)

Page 29

GETTING STARTED

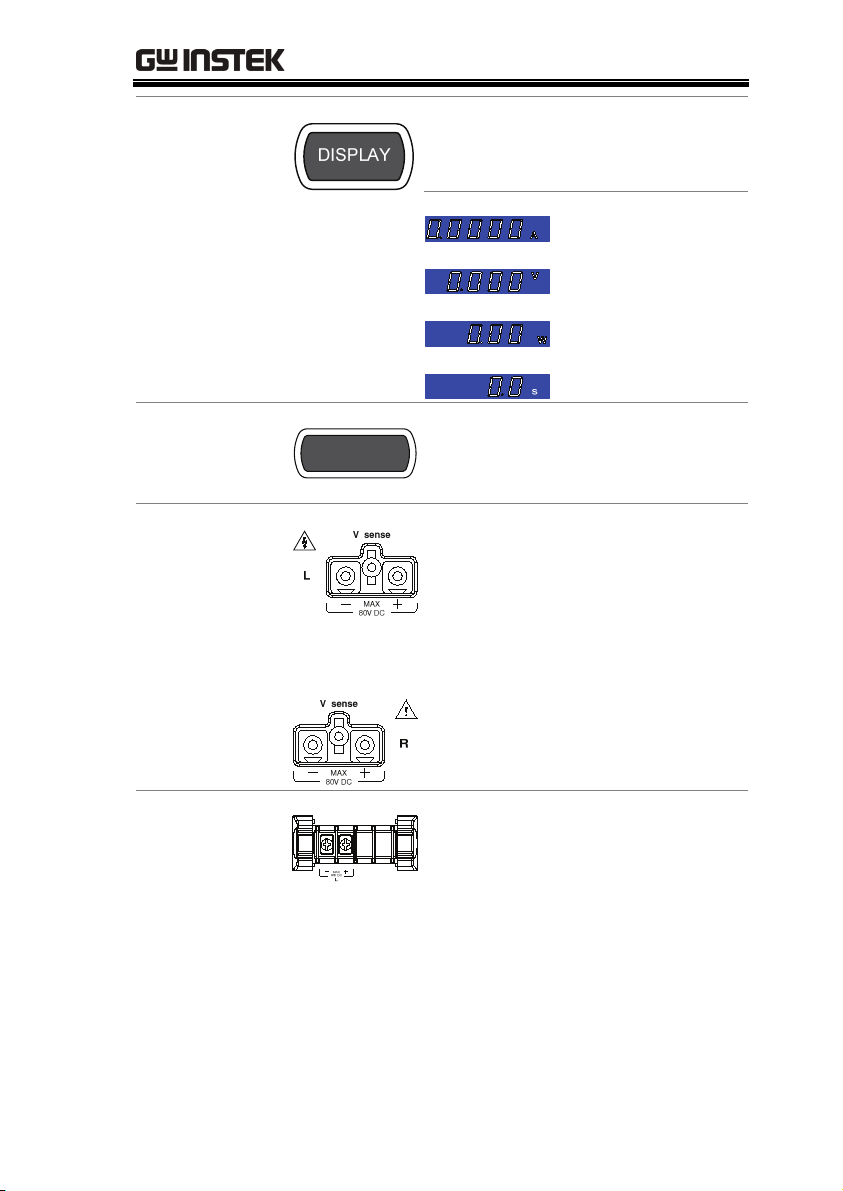

Display Key

Load Key

Left Voltage

Sense

Right Voltage

Sense

Used to alternate the display

output on the load module.

Current

Voltage

Power

Load time

LOAD

Activates the load for the active

channel. (Right or Left)(A or B)

The voltage sense terminals are

used when precise measurement is

needed. V Sense terminals are used

to compensate for voltage drops

across the main terminals caused

by the resistance of the load wires.

It is automatically activated when

connected to a DUT.

Positive and

Negative

Terminals Left

The terminals for both the left and

right side of a load can draw

differing amounts depending on

the load module specifications.

29

Page 30

PEL-2000 Series User Manual

Positive and

Negative

Terminals Righ t

Static/Dynamic

Selector Key

Selector Knob

(Load)

For 2 channel load modules, the left

terminals are used for the 1

st

channel and the right terminals are

used for the 2

nd

channel.

On single channel load modules,

the left terminals are the lower (-)

potential terminals, whilst the right

terminals are the positive (+)

potential terminals.

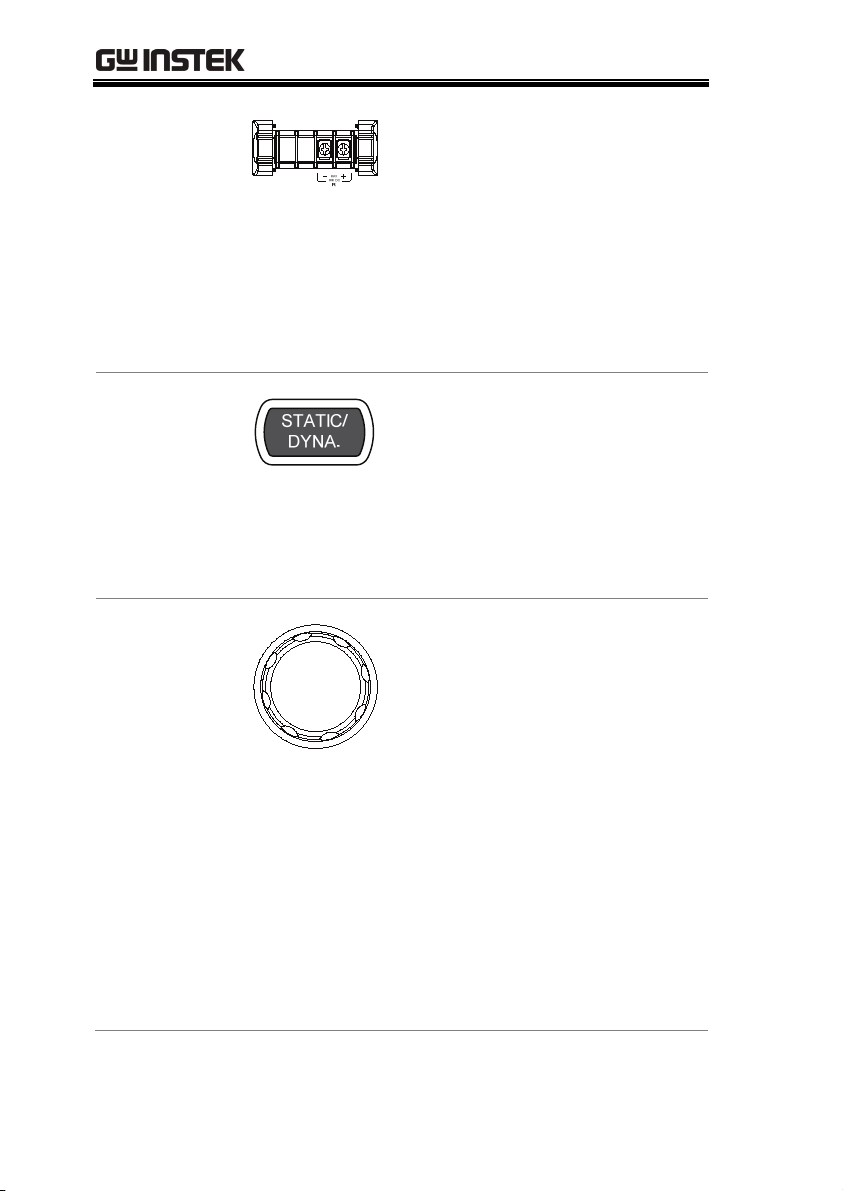

The STATIC/DYNA. Key manually

switches the load from Static

(manual) to Dynamic loads.

Dynamic loads are only supported

in CC and CR mode.

For more information see page 61 &

65.

The load Selector Knob is used to

edit and vary parameters for the

active channel on the local load.

Depending on the Mainframe

setup, the Selector Knob will either

only update the load (locally) or

will update both the local module

and the mainframe*. The Selector

knob can also be configured to

display measured or set values on

the local load module**.

* For more information on “Knob Type”, see

page 188.

** For more information on “Slave Knob”,

see page 192.

30

Page 31

GETTING STARTED

Short Key

The SHORT key is used to

manually short circuit the active

channel on the local active load.

When a load is off, the SHORT key

will toggle the Short key type.

Load on: Pressing or holding the

SHORT key will short the load,

depending on the short type

selected.

Hold: Hold the

SHORT key to short

the channel load.

Toggle: Press the

SHORT key to

toggle shorting the

load on or off.

31

Page 32

PEL-2000 Series User Manual

LED Display Overview – Load Module

1&2. Channel

Display

3&7. Channel

Number Indicator

or

Left and right channel indicator.

5 digit display.

Indicates the channel number

(1-8).

Indicates if the load is active on

the load module. (Dual channel

load modules)

Indicates if the load is on for

single channel load modules.

32

Page 33

GETTING STARTED

4. Mode Indicator

The Mode Indicator LEDs will indicate what the

current mode or settings are on the active

channel(s).

or

Value A or B for a single channel load

module. Applies to CR, CV, and CC

static mode only.

Constant Current Mode (CC) mode

activated.

Constant Voltage Mode (CV) mode

activated.

Constant Resistance Mode (CR).

Display is shown on dual channel load

modules when both left (L) and right (R)

channel information is displayed.

Press the Display button repeatedly to

show information for both channels.

Lights up when Go/NoGo is activated

and the load passes (GO) the Go/NoGo

limits.

or

L or R will light up when the left or right

channel is selected.

Lights up when in Static mode.

Lights up when in Dynamic mode.

33

Page 34

PEL-2000 Series User Manual

Lights up when a load is shorted.

Lights up when Go/NoGo is activated

and the load fails (NG) the Go/NoGo

limits.

5&6. Channel

Unit Indicators

The Unit Indicators display current the

unit.

Voltage

Resistance

Current

Power

34

Page 35

GETTING STARTED

Installation

The installation chapter describes how to load the different load

modules, install the optional GPIB card, the rack mount kit and

how to determine each channel number.

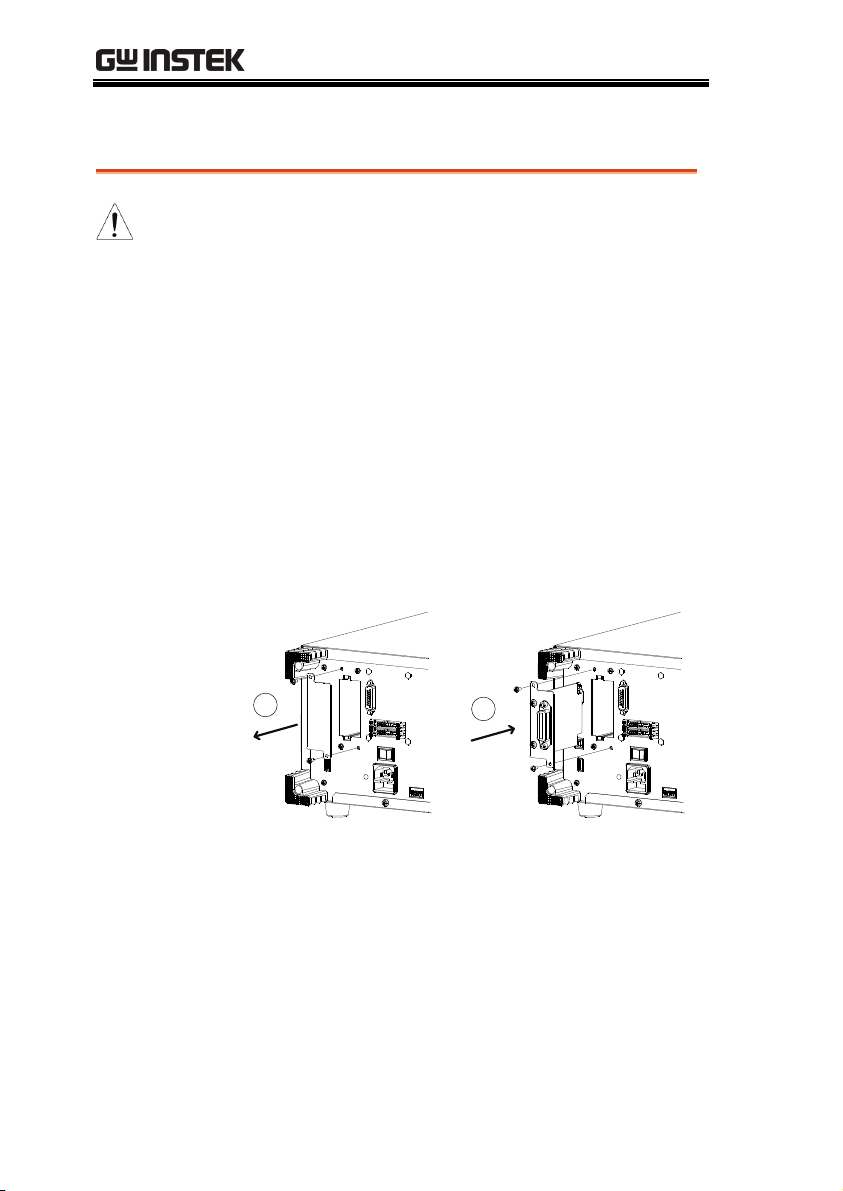

Load Module Installation

WARNING

Module

installation

Steps

To avoid static electricity, please use appropriate antistatic work practices.

The PEL-2004 and 2002 can accommodate 4 and 2

load modules, respectively. Module loads can have

1 or 2 channels. Installation of load modules is the

same for both models.

1. Ensure the PEL mainframe is

turned off from the rear panel.

Disconnect the power cord.

2. Slide the module onto the rails of an empty

load slot.

35

Page 36

PEL-2000 Series User Manual

36

3. Use the supplied screw to fix the module to the

load slot, located under the load terminals.

4. Install any additional modules as described

above.

5. If there are any slots empty, install the

supplied panel cover (GW Instek part number:

63FP-AG106501). The panel cover will improve

safety and increase air flow.

Page 37

GETTING STARTED

6. Use the supplied screws to fix the panel

cover(s) over the load slot.

37

Page 38

PEL-2000 Series User Manual

GPIB Installation

WARNING

GPIB Card

installation

Steps

To avoid static electricity, please use appropriate antistatic work practices.

The PEL-2004 and 2002 has GPIB as an option (GW

Instek part no. PEL-001).

1. Ensure the mainframe is disconnected from

mains power.

2. Remove the screws from the GPIB cover plate

and remove the cover plate from the rear panel.

3. Slide the GPIB card into the slot and push

gently until the back plate is flush with the rear

panel.

1

2

4. Use the screws that were removed from step 1

to secure the GPIB card.

38

Page 39

GETTING STARTED

Rack Mount Installation

Background

Steps

PEL-2004

The PEL-2004 can be used in a standard 19” rack

mount enclosure with the optional rack mount kit

(GW Instek part no. 11EL-20040201). Each unit

requires a rack height of 4U with a 1U space for

ventilation top and bottom. The rear of the rack

mount enclosure must be free of obstruction to

allow heat to dissipate from the mainframe(s).

1. Screw the rack mount brackets as shown below

using the supplied bolts.

2. Insert into a standard 19” rack enclosure with

at least 1U of space top and bottom for

ventilation.

39

Page 40

PEL-2000 Series User Manual

Channel Number

Description

The channel number for a module load is

determined by which slot it occupies on the

mainframe chassis. There can be 1 or 2 channels

per slot, depending on the load module type.

The PEL2002 has two slots; The PEL-2004 has 4

slots. Channel 1 is the farthest away from the main

display panel and channel 8 (PEL2004) or channel

4 (PEL2002) is the closest to the main display

panel.

Below the PEL-2004 has all 4 slots occupied with

the PEL-2020, 2030, 2040 & 2041series load

modules (LM), respectively. The PEL-2020 & 2030

have 2 channels per load module, the PEL-2040 &

2041 have only 1. So the channel determination is:

LM1: CH1,CH2; LM2: CH3,CH4; LM3: CH5; LM4:

CH6.

DISPLAY

LOAD

V sense V sense

L

MAX

80VDC

80VDC

PEL-2020

STATIC/

DYNA.

SHORT

MAX MAX

L

DCElectronic Load

L

20A/80V ,100W

R

20A/80V ,100W

R

MAX

80VDC

80VDC

R

DC Electronic Load

5A/80V , 30W

L

40A/80V ,250W

R

PEL-2030

STATIC/

R/LR/L

DYNA.

DISPLAY

SHORT

LOAD

V senseV sense

L

R

MAX

MAX

80VDC

80VDC

MAXMAX

80VDC

80VDC

R

L

DCElectronic Load

PEL-2040

70A/80V ,350W

STATIC/

A/B

DYNA.

DISPLAY

SHORT

LOAD

V sense

MAX

80VDC

MAX

DC ElectronicLoad

PEL-2041

10A/500V ,350W

STATIC/

A/B

DYNA.

SHORT

DISPLAY

LOAD

V sense

MAX

500VDC

MAX

500VDC80VDC

PEL-2004

F2

F1

LOCAL UTILITY

FILEFUNC

CHAN

P9P7 P8

9

87

P6P4 P5

56

4

P3P1 P2

PRESET

3

1

2

CAL.

P0 LOCK

ENTER

CLEAR

0

DC ElectronicLoad

HELP

LOAD

F5F4F3

SHIFT

ON/

OFF

CH1

CH2

CH3

CH5 CH6

CH4

40

Page 41

GETTING STARTED

Power Up & Self Test

Panel operation

WARNING

1. Connect the power cord

to the power socket.

2. Turn the external power

switch on.

3. Hold the power button

on the front panel to

turn on the power.

The power button turns

green from red (standby).

Ensure that the power outlet has a ground socket. The

power outlet will have a ground connection if it is a 3

socket type.

Upon turning on, the Mainframe will perform a

self-test. The self-test checks the System, followed

by any attached channels.

41

Page 42

PEL-2000 Series User Manual

When the system check happens, the load modules

will display each channel as it is checked, then

display the current mode.

4. If any of the System checks fails, please power

down the load generator and reinstall the

appropriate load module(s).

5. To turn off the load

generator, hold the

power button for a few

seconds.

The PEL mainframe will

return to standby mode.

42

Page 43

GETTING STARTED

Load Connections

Precautions and Procedures

Intoduction

Wire Gauge

considerations

The PEL-2000 load generator supports a number of

different load configurations for flexible operation.

Single DUT, single load

Single DUT, parallel load

Multiple DUTs, multiple loads

Multiple DUTs, multiple mainframe loads

Single DUT, parallel mainframes

DC loads

Low voltage connections

The PEL-2000 also supports a number of different

control methods and interfaces. The connections

used are described here:

Frame link

Channel control

Go/NoGo

Before connecting the PEL-2000, wire gauge must

be taken into account. Load wires must be large

enough to resist overheating when a short-circuit

condition occurs as well as maintain a good

regulation. The size, polarity and length of a wire

are all factors in determining if a wire will

withstand short circuiting.

43

Page 44

PEL-2000 Series User Manual

Wire Selection

24 7.64

22 10.0

20 13.1

18 17.2

16 22.6

14 30.4

12 40.6

10 55.3

Load Line

Inductance

Considerations

Wires that are selected must be large enough to

withstand a short circuit and limit voltage drops to

no more than 2V per wire. Use the table below to

help make a suitable selection.

AWG Max Current A(Amp)

When using the PEL-2000 load generator, voltage

drop and voltage generated due to load line

inductance and current change must be taken into

account. Extreme changes in voltage may exceed

the minimum or maximum voltage limits.

Exceeding the maximum voltage limit may

damage the PEL-2000.

To determine the voltage generated, the following

equation can be used.

E = L x (∆ I / ∆ T)

E= voltage generated

L=load line inductance

∆ I= change of current (A)

∆ T= time (us)

Load line inductance (L) can be approximated as

1uH per 1 meter of wire. (∆ I / ∆ T) is the slew rate

in A/us.

44

Page 45

GETTING STARTED

The diagram above shows how changes in current can

affect voltage.

Limiting Load line

inductance

Load line inductance can be reduced by ensuring

load wires are as short as possible and by twisting

positive and negative load wires together. Current

change can be limited by limiting the slew rate

when switching.

“Twisted pair” will be shown on any connection

diagram where the load wires should be twisted

together.

45

Page 46

PEL-2000 Series User Manual

Load module

considerations

Connection

The PEL-2000 supports single and dual channel

load modules.

Single channel load modules have one bank of

negative terminals and one bank of positive

terminals. Each terminal pair has a 40A capacity.

For higher loads, each terminal can be wired in

parallel to increase capacity.

Dual channel load modules have one bank of

positive and negative terminals for each channel.

Single Channel Load

Module

Dual Channel Load

Module

Left channel

Right channel

MAX MAX

80V DC

80V DC

L

R

Follow the procedure below for all load

connections.

CAUTION

Steps

the DUT before making any connections.

1. Carefully lift the terminal covers.

2. Connect the positive (+) terminal on the load

module to the high potential output of the

DUT.

Ensure that power is off from the load generator and

3. Connect the negative (-) load terminal to the

low potential output of the DUT.

46

Page 47

GETTING STARTED

WARNING

CAUTION

4. Close the terminal cover securely. Ensure the

wires are secured properly and that the wires

are not exposed when the cover is in place.

Ensure that the wires are tied or twisted together to

prevent noise and inductance.

Ensure the polarity is correct before proceeding with

any connections. Using the wrong polarity could result

in reverse voltage damage.

DUT

Ensure the input voltage doesn’t exceed specifications.

Exceeding the voltage specifications could result in

damage to the instrument.

47

Page 48

PEL-2000 Series User Manual

Remote (Sense) Connection

Background

WARNING

Connection

The electronic load modules have two voltage

sense contacts: Vsense L(black), Vsense R(red).

Voltage sense can be used to help compensate for

long cable length. The longer the cable, the higher

the potential resistance and inductance, therefore a

short cable is best. Twisting the cable can help

reduce induced inductance and using the Vsense

terminals compensates the voltage drop seen

across the load leads, especially leads with higher

resistance. This is useful when used in CV or CR

mode.

VsenseR (red) must have a higher (+) potential than

VsenseL (black).

The diagram below shows how a DUT can be

connected using voltage sense. Note that the sense

wires are also twisted pairs.

Note

Input

smaller than 16 gauge.

The voltage sense terminals must use a wire gauge

of 16 to 14.

The wire gauge for the sense wires should be no

48

Page 49

GETTING STARTED

Remote Sense

Te rm i na l

connection

The voltage sense terminals use a screw-less clamp

connector. The clamp must be opened prior to

inserting a wire. Use a small screwdriver to push

the clamp release mechanism. Insert both wires

then release the clamp mechanism.

49

Page 50

PEL-2000 Series User Manual

Single Load Connections

Dual Channel

Load Module

Connection

Single Channel

Load Module

Connection

CAUTION

A dual channel load module can be used to sink

two loads concurrently.

On a single channel load module, the left terminals

are both negative (-), whilst the right terminals are

both positive (+). Note this also applies to the

voltage sense terminals.

For loads exceeding 40A, both positive and both

negative terminals must be used in parallel.

50

Page 51

GETTING STARTED

DC Connection

Low Voltage

Connection

For purely DC operation, a resistor and capacitor

can be connected in parallel to the electronic load

to reduce oscillation. The capacitor and resistor

values are dependent on the load settings. Ensure

the capacitor ripple current is within allowable

limits.

Using the load generator with low voltage loads is

generally limited to over 1 volt (load module

dependent). In order to support low voltage loads,

an auxiliary power supply is needed to boost the

voltage to a range suitable for the load generator.

Precautions:

Take into account the combined power of the

load and auxiliary power supply.

Make sure the auxiliary power supply is able

to provide enough current.

Take into account any noise or irregularities

from the auxiliary supply.

WARNING

The diagram below shows a typical connection.

Using an auxiliary power supply may induce reverse

current. The PEL-2000 series has reverse voltage

protection. For details see the protection section on

page 79.

51

Page 52

PEL-2000 Series User Manual

Parallel Load Connections

Parallel load

modules

Parallel load

When the power output of a DUT exceeds the

power rating of a channel or load module, the

channel terminals, load modules or mainframes

can be used in parallel to dissipate more power

when used in CC mode. Each channel will sink the

amount of current specified. The total power sunk

is the sum of all channels/modules. The amount of

power can vary from each channel. For example if

CH1 is 25A and CH2 is 20A, then the total current

sunk is 45A. Parallel loads are supported for both

static and dynamic loads (see page 78 for a

description on parallel dynamic loading).

-

Single Channel

Load Module

+

Single Channel

Load Module

DUT

-

-

+

+

-

Single Channel

Load Module

+

-

Single Channel

Load Module

+

Note

52

Please note that when using different load

modules in parallel, the slew rates may differ. See

the specifications for more details, page 253.

Page 53

GETTING STARTED

Parallel loads

using framelink

connections

Multi-output

power supply

load

The PEL-2000 mainframes can also be connected in

parallel. Please note, when using a frame link

connection there is a delay between the master and

the slave. Please see page 54 for details.

DUT

DUT

DUT

DUT

DUT

The PEL-2000 is also able to sink a number of loads

concurrently from multiple DUTs or sink a

number of loads from the same DUT (i.e. multiple

output power supply).

Master

Slave

Slave

Slave

Slave

Max 7kW

-

+

-

+

-

+

Multiple-output DUT

-

+

Twisted

Pair

Twisted

Pair

Twisted

Pair

Twisted

Pair

-

+

-

+

-

+

-

+

L

R

L

R

Dual channel

Load Module

Dual channel

Load Module

53

Page 54

PEL-2000 Series User Manual

Frame Link Connection

Background

Frame Link

Connection

Frame link control involves connecting multiple

mainframes using the frame link connections. Up

to 4 slave mainframes can be connected to the

master mainframe. The first mainframe (master)

can be used to control the other slave frames.

There is a delay time of 2ms between the master

and first slave mainframe, and 4ms, 6ms, and 8ms

to the second, third, and fourth slave mainframes,

respectively. The connectors used are standard

MIL 20-pin connectors. For pin arrangement see

page 236.

GPIB

GO/NG OUTPUT

RS232C

Master

(FRM)

RS232C

Slave

(FRS)

WARNING

TOAVOID ELECTRICSHOCK THEPOWER CORDPROTECTIVE

GROUNDINGCONDUCTORMUSTBE CONNECTEDTOGROUND.

FORCONTINU EDFIRE PROTECTION. REPLACE FUSEONL YWITH

250VFUSEOF THESPECIFIEDTYPEAND RATING.

NOOPERATOR SERVICEABLECOMPONENTS INSIDE.

DONOT REMOVE COVERS. REFERSER VICINGTO QUALIFIE DPERSONNEL .

GPIB

WARNING

TOAVOID ELECTRICSHOCK THEPOWER CORDPROTECTIVE

GROUNDINGCONDUCTORMUSTBE CONNECTEDTOGROUND.

FORCONTINU EDFIRE PROTECTION. REPLACE FUSEONL YWITH

250VFUSEOF THESPECIFIEDTYPEAND RATING.

NOOPERATOR SERVICEABLECOMPONENTS INSIDE.

DONOT REMOVE COVERS. REFERSER VICINGTO QUALIFIE DPERSONNEL .

REPLACEFUSE

REPLACEFUSE

ASSPECIFIED

FUSERATING

115V

230V

GO/NG OUTPUT

ASSPECIFIED

FUSERATING

115V

230V

SER.NO. LB

FRAME CONT

1

2

AC

T3.15A

180V AMAX

250V

50/60Hz

DISCONNECTPO WERCORD

BEFOREREPLAC INGFUSE

SER.NO. LB

FRAME CONT

1

2

AC

T3.15A

180V AMAX

250V

50/60Hz

DISCONNECTPO WERCORD

BEFOREREPLAC INGFUSE

FRAME CONT

1

2

STRIP GAUGE

10.0mm

AWG24

STRIP GAUGE

10.0mm

AWG24

Output

CH CONT11CH CONT21CHC ONT31CH CONT4

1

Input

Output

CH CONT11CH CONT21CHC ONT31CH CONT4

1

2

CH CONT51CHCO NT61CH CONT71CHC ONT8

1

1

FRAME CONT

1

2

2

CH CONT51CHCO NT61CH CONT71CHC ONT8

1

GPIB

GO/NG OUTPUT

RS232C

Slave

(FRS)

REPLACEFUSE

ASSPECIFIED

FUSERATING

115V

230V

WARNING

TOAVOID ELECTRICSHOCK THEPOWER CORDPROTECTIVE

GROUNDINGCONDUCTORMUSTBE CONNECTEDTOGROUND.

FORCONTINU EDFIRE PROTECTION. REPLACE FUSEONL YWITH

250VFUSEOF THESPECIFIEDTYPEAND RATING.

NOOPERATOR SERVICEABLECOMPONENTS INSIDE.

DONOT REMOVE COVERS. REFERSER VICINGTO QUALIFIE DPERSONNEL .

SER.NO. LB

FRAME CONT

1

2

AC

T3.15A

180V AMAX

250V

50/60Hz

DISCONNECTPO WERCORD

BEFOREREPLAC INGFUSE

1

FRAME CONT

1

2

CH CONT51CHCO NT61CH CONT71CHC ONT8

1

Input

STRIP GAUGE

10.0mm

AWG24

CH CONT11CH CONT21CHC ONT31CH CONT4

1

54

Page 55

GETTING STARTED

Insertion

Removal

The first mainframe that is connected is the master

frame; any additional frames are slave units. The

ribbon cable connects to the master from connector

2, and the slave from connector 1. Each successive

slave unit is connected in a cascading manner the

same way.

Ensure the Mainframes are turned off before

connecting the ribbon cables. Push the cable into

the frame link connector. Ensure the arrows line

up. The latches will close when the connection is

complete. To remove, pull the latches out and

connector will come out.

WARNING

Ensure all the mainframes are off and disconnected

from mains power before connecting.

55

Page 56

PEL-2000 Series User Manual

Channel Control Connection

Background

The Channel Control connecters are located on the

rear panel of each mainframe. There are two

channel control connectors for each load slot, one

for each channel, if applicable. The channel control

connector is used to externally:

Turn on/off loads.

Supply a reference voltage.

Monitor the load input.

For further details on channel control and the

interface see pages 85, 235.

GPIB

GO/ NGOUTPUT

RS232C

TOAVOID ELECTRICSHOCK THEPOWER CORDPROTECTIVE

GROUNDINGCONDUCTORMUST BECONNECTEDTO GROUND.

FORCONTINUED FIRE PROTECTION.R EPLACE FUSEON LYWITH

250VFUSE OFTHE SPECIFIEDTYPE ANDRATING.

NOOPERATOR SERVICEABLECOMPONENTS INSIDE.

DONOT REMOVECOVERS. REFERSERVICING TOQUALIFIED PERSONNEL.

WARNING

REPLACEFUSE

ASSPECIFIED

FUSERATING

115V

230V

T3.15A

1

2

250V

SER.NO. LB

FRAME CONT

DISCONNECT POWERCORD

BEFOREREP LACINGFUSE

AC

180 VAMAX

50/60Hz

CH CONT8

1

CH CONT7

1

CH CONT6

1

CH CONT5

1

STRIPGAUGE

CH CONT4

10.0mm

AWG 24

1

CH CONT3

1

CH CONT2

1

CH CONT1

1

The Channel Control input/output pin layout is shown

below.

56

Page 57

GETTING STARTED

External Voltage

Connection

WARNING

Load on

connection

The external voltage reference input must be

between 0~10V.

Ensure the external voltage reference is stable and has

low noise. The External Voltage should be no more

than 10V.

No more than 12 volts may be used as an external

voltage. More than 12 volts may damage the load

generator.

To turn a load on, an active low voltage (0-1V)

must be applied across Load On (pin 5) and GND

(pin 1), similarly an active high voltage (4-5V)

must be applied to turn a load off. The Load On

input must be TTL.

57

Page 58

PEL-2000 Series User Manual

Voltage and

Current Monitor

Output

Connector

Connection

The Voltage Monitor Output (VMON) and Current

Monitor Output (IMON) output the load input

voltage and load input current as a percentage of

rating current/voltage. Where 0 volts = 0% rating

and 10 volts = 100% load input rating voltage or

current.

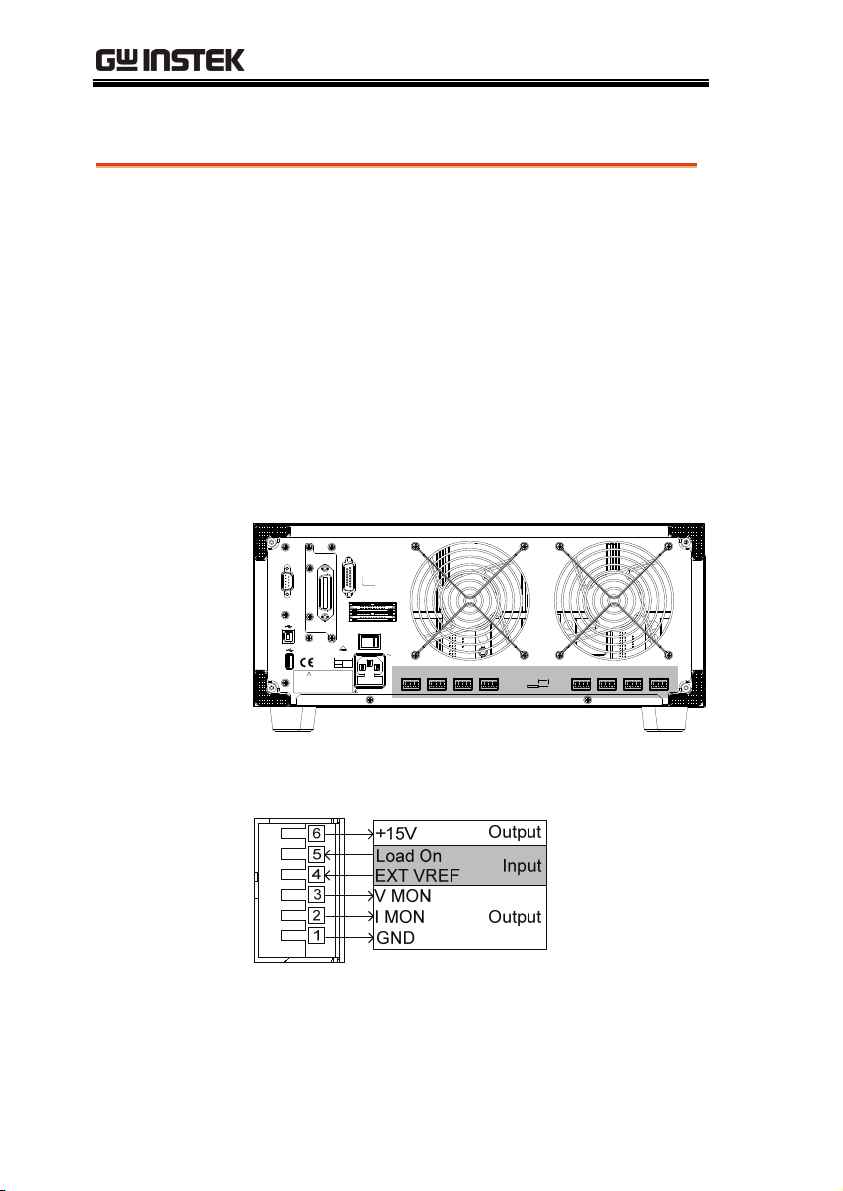

The voltage monitor output is across pins 1 & 3,

and the current monitor output is across pins 1 &

2. Pin 6 outputs a +15V reference voltage.

Below shows the pin configuration of the voltage

and current monitor outputs.

The channel control connector is a screw less

clamp connector. The internal clamp mechanism

must be opened before a wire can be inserted. To

open the internal clamp, push the button above the

wire socket, to close, release the button. Ensure at

least 10mm is striped from the wire. The diagram

below shows the wire insertion procedure.

All connections to the channel control connector must

WARNING

use a 24 AWG wire gauge.

58

Page 59

GETTING STARTED

Go/NoGo Connection

Background

The Go/NoGo port is a 15 socket port. Each

channel has a dedicated line for a Go/NoGo

output. The ports are open-collector with active

low (1.1V) indicating a pass and active high (30V)

as fail (an alarm). The Go/NoGo terminal is a DB15 female.

For more details on the Go/NoGo interface see

page 239.

59

Page 60

PEL-2000 Series User Manual

OPERATING

DESCRIPTION

Operating Mode Description ........................................... 61

Constant Current Mode ........................ 61

Constant Resistance Mode ................... 65

Constant Voltage Mode ........................ 68

Run Program ................................................................... 71

Sequence ........................................................................ 74

Parallel Dynamic Loading ................................................ 78

Configurations Description.............................................. 79

Protection Modes ................................. 79

Operating Configurations ..................... 81

Channel Control ................................... 85

Interface and File System ................................................ 89

Interface .............................................. 89

File System .......................................... 89

File Format .......................................... 94

60

Page 61

GETTING STARTED

Operating Mode Description

There are three basic operating modes: constant current (CC),

Constant Resistance (CR), and Constant Voltage (CV/CV+CC). All

channels operate using any of the modes. Each mode has a number

of configurable options including slew rate, levels, protection

modes, Go/NoGo and extensive save options.

Constant Current Mode

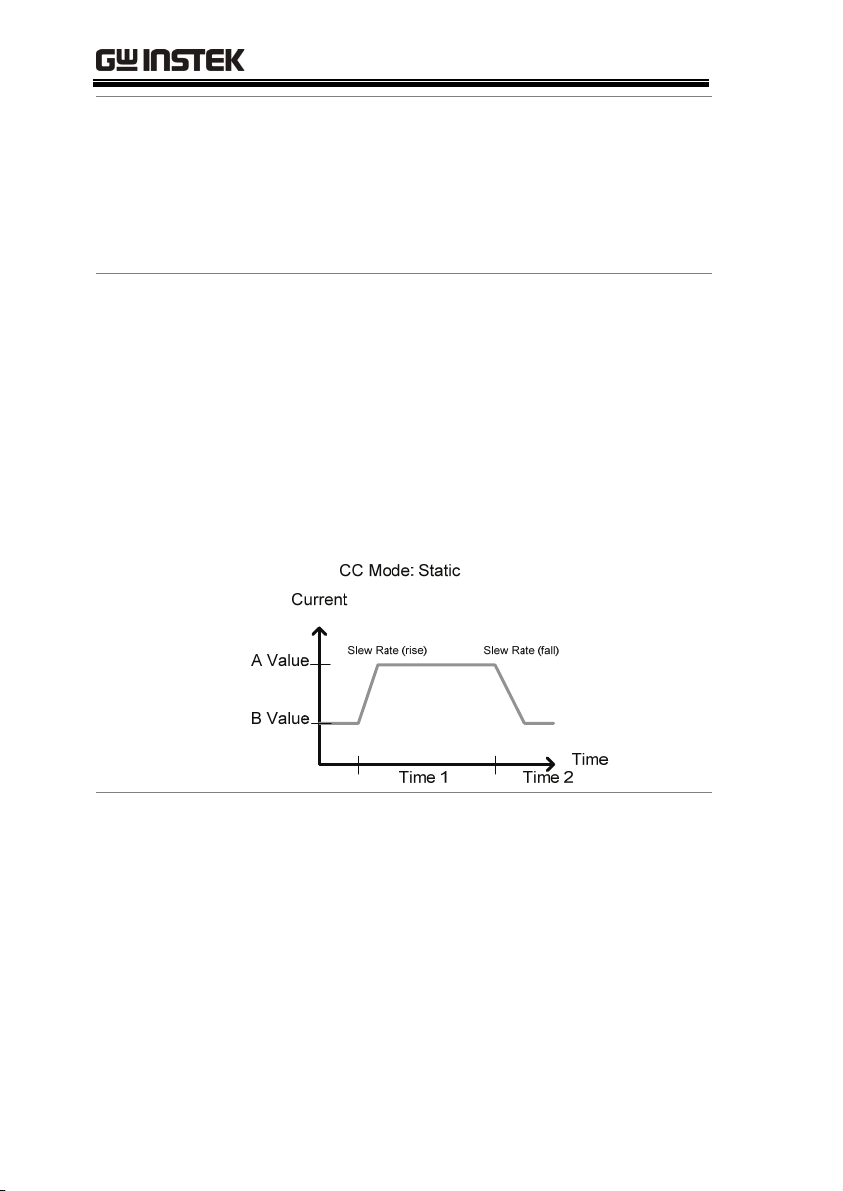

Background

In Constant Current Mode the load units will sink

the amount of current programmed. Regardless of

the voltage, the current will stay the same. There

are two ranges in CC mode: High and Low. There

are two main modes in CC mode: Static and

Dynamic. Static mode can be used for stability tests

and dynamic mode can be used to test transient

load conditions.

Go/NoGo is supported for both High and Low

range as well as Static and Dynamic mode.

CC Mode

Load Current

Load Input Voltage

61

Page 62

PEL-2000 Series User Manual

Range

Static Functions

Static Mode:

Single Channel

Load module.

There are two selectable ranges for constant current

mode: high and low range.

Low range has a higher resolution, but a lower

range. If the current exceeds the Low Range, High

range must be used.

Static mode tests the stability of the voltage output

from a power source. Single channel load modules

can have two 2 current levels A (A Vaue) & B (B

Value). A & B have the same range. Pressing the

A/B key on the module load will cycle through the

A and B states. Alternatively, the mainframe can

select A or B Value.

Dual channel load modules only have one current

level (A Value) per channel in static mode.

Dynamic

Functions

Dynamic load functions allow you to set load

levels (Level1, Level2), load time (Timer1, Timer2),

and the slew rate (rising, falling). Depending on

the settings, the load will switch automatically

between levels 1 and 2.

Dynamic loading can be used for charge discharge

cycle testing etc.

62

Page 63

GETTING STARTED

Slew rate

Go/NoGo

The slew rate is the rate at which the current will

increase to a set level. There are two slew rates:

rising slew rate & falling slew rate. In CC mode the

slew rate is defined as A/uS.

As can be seen above, the rising and falling slew

rate need not be the same.

Using Go/NoGo, the Center, High and Low

voltage limits can be set for both Static and

Dynamic modes. A delay time of up to 1 second

can also be set.

63

Page 64

PEL-2000 Series User Manual

CC Mode: Static:Go/NoGo

Current

Load

Current

Low

Go

High

NoGoNoGo

Voltage

GO is specified as between the Low and High

Go/NoGo limits. NoGo is specified as outside the

Go/NoGo limits.

64

Page 65

GETTING STARTED

Constant Resistance Mode

Background

Resistance Range

In Constant Resistance Mode the load units will

linearly sink current and voltage to match a set

resistance. CR mode has two different values

(single load modules), two different ranges and

rising and falling slew rates. Like CC mode,

Constant resistance mode supports both dynamic

and static loads. As with the other modes,

Go/NoGo is supported.

CR Mode

Load Input

Voltage

R

Load Current

e

c

n

a

t

s

i

s

e

There are two ranges: High and Low. The Low

range is used for low voltage ranges, whilst the

High range uses high voltage ranges. The current

range always remains in High range, regardless of

the selected voltage range.

Static Functions

A/B range

For static mode, single channel load modules have

two resistance levels, A & B Value. The A/B key

can be used to switch between these resistance

levels. Dual channel load modules only have one

resistance level, A Value.

65

Page 66

Single Load

Module

PEL-2000 Series User Manual

Dynamic

Functions

Slew Rate

Go/NoGo

CR mode supports Dynamic loading. Dynamic

load has two resistance levels (Level 1&2), and two

timers (Timer 1&2) to switch between the

resistance levels. Rising and falling slew rates can

be set to determine the speed at which the load

generator switches between load levels.

The rising and falling slew rate (A/uS) determines

the speed at which the load levels change from A

to B Value (Static mode) or from Level1 to 2

(Dynamic mode) and vice versa.

Go/NoGo is also supported. Center, High and

Low limits can be set as either percentages or

voltage values. A delay time of up to 1 second can

also be set.

66

Page 67

GETTING STARTED

67

Page 68

PEL-2000 Series User Manual

Constant Voltage Mode

Background

In Constant Voltage Mode the load units will sink

current whilst keeping the voltage constant.

Single channel load modules support 2 values (A

Value, B Value) and have an adjustable cut-off

current limit. Dual channel load modules only

have A value.

Response speed can also be set to fast (Fast) or slow

(Slow). The response speed relates to the slew rate

of the current response.

Constant voltage mode only operates in high

range.

Go/NoGo functionality is also supported either as

a percentage or as a current value.

Voltage levels

Two voltage levels can be set: A & B (single

channel load module).

68

Page 69

GETTING STARTED

CV + CC

Voltage

A value

B value

CV Mode

Time

When using CV mode, a current limit can be set for

CV + CC mode.

When the voltage input is greater than A Value

(load voltage) then the channel will operate in CV

mode if the input current is less than the current

limit. When the input current exceeds the current

limit, the channel will operate in CC mode.

When the voltage input is less than A Value (load

voltage) current stops flowing.

69

Page 70

PEL-2000 Series User Manual

Response Speed

Go/NoGo

Response speed can be set to fast or slow. Fast

response and slow response is determined by the

load module specifications. Slow response speeds

are suitable for large loads as quick current

changes will induce induction which can cause

large voltage drops. The PEL series will try to

rectify any voltage drops. However if voltage

drops are too large, they may cause the load

generator to go into oscillation. Large voltage

drops caused by line voltage induction may

damage the machine.

Range Fast Slow

1kHz 100Hz

Go/NoGo testing can be with either current

(Ampere) values (High, Low) or percentage values

(Center, High %, Low %). A delay time of up to 1

second can also be set.

70

Page 71

GETTING STARTED

Run Program

Background

Program

Sequence

The Program function on the PEL-2000 series

supports a total of 12 different programs at any one

time with 10 sequences to each program. Up to 12

programs can be chained together. The Program

function is able to create a number of Go/NoGo

tests.

A program sequence is simply a single load test. A

program is a battery of each of these tests run in

succession. Each sequence loads the settings for

each channel from Memory Data (Memory MXXX).

The Memory Data stores settings such as the

operating mode and range for each channel. Each

sequence loads all channels at the same time, unless

programmed otherwise. Sequences for each

channel run synchronously.

Memory M001~M120

On-Time 0.1 ~ 60.0

Short-time Off – 0.1 ~ On-time

Each Sequence has a number of configuration

options that apply to all the channels equally.

Sequence Item Parameter Range

Run Auto – Skip – Manual

Off-Time Off – 0.1 ~ 60.0

71

Page 72

PEL-2000 Series User Manual

y

P/F-Time Off – 0.1 ~ (On-time+Off-time)-0.1

Short Channel CH1 ~ CH8

Program

Sequences are run sequentiall

There are 10 Sequences in each Program.

If less than 10 Sequences are desired for a Program,

any additional Sequences can be skipped (not run).

Sequence 2 & 3 are skipped.

Program Chain

Any of the 12 programs can be chained together to

create a Program Chain. Unlike Program

Sequences, Program Chains need not be run

sequentially in numerical order. Any program can

be chained to any program. It is possible to chain

programs into an infinite loop to continue a

program indefinitely.

to create a Program.

Above, a program chain running sequences out-oforder.

72

Page 73

GETTING STARTED

Go/NoGo Results

If Go/NoGo limits have been configured, the

Pass/Fail results for each channel will be displayed

for all the sequences and programs.

73

Page 74

Sequence

PEL-2000 Series User Manual

Background

Load Profiling

The Sequence function is used to create high

resolution load simulations. Each Sequence can be

configured to create a unique load profile to

accurately simulate loads in real time. Sequences

are only applicable for CC (Static) and CR (Static)

modes.

Note: Sequences are not to be confused with the

sequences used to create a program. They are not

the same and cannot be used interchangeably.

Sequences (SEQ memory) cannot be used in

Programs and Programs cannot load Sequences.

The Sequence function is able to simulate a load to

a high resolution. Each channel is able to change its

load sink within 100us per point independently.

When used in parallel, multiple loads can be sunk

concurrently to simulate the loads placed on

multiple output power sources.

The diagram below shows the load profile of a

DUT at start-up.

74

Page 75

GETTING STARTED

Points

Loop

Up to 120 points can be used with each Sequence.

Each point can have a different duration, slew rate

and value.

A new point can be inserted or deleted at any stage

of a Sequence. Any new points that are inserted

will have a value averaged from its neighbors as

default.

Point1

Point2

Point4

Point5

Point6

Point3

Point7

A new point is inserted after Point 3.

Sequences can be programmed to loop a number

of times starting from any point in the sequence.

Point1

Point2

Point4

Point3

From Point3 the sequence is looped two times.

75

Page 76

PEL-2000 Series User Manual

On end load

Trig Out

If more than one Sequence is programmed on the

mainframe, the On End Load function allows a

Sequence to configure its load on or off at the end

of its sequence until the last sequence ends. After

the last sequence ends, all loads are turned off.

This function is ineffective if only one Sequence is

active. This is as the On End Load time and the

time of the last sequence will be the same.

End of

Sequences

The Trigger Out function allows a trigger sequence

signal to be output from a channel via PIN 4 on

Frame Link connector 1 when using Sequences.

The Trig Out function is used from the Channel

Duration menu.

Point1

Point2

Point3

Point4

Point5

Point6

As can be seen above, a trigger sequence signal is

output for every rising edge point.

76

Page 77

GETTING STARTED

Channel Duration

Time Setting

The Channel Duration Time Setting feature allows

the point time duration of one Sequence to be

imported by another Sequence. If the receiving

sequence doesn’t have enough points, more will be

created (without values).

For example, the sequences for CH1 and CH2 are

shown below. CH1 has a total of 6 points with long

durations, whilst CH2 has only 2 points, looped 5

times. The points from CH2 are also significantly

shorter in duration.

Point1

Point2

Point3

Point4

Point5

Point6

Point2

Point1

Below shows the resulting sequence when CH1

imports CH2. CH1 imports the duration time

settings and number of points from CH2, but not

the value data.

77

Page 78

PEL-2000 Series User Manual

Parallel Dynamic Loading

Background

The PEL-2000 series of DC electronic loads support

parallel dynamic loading. This simply means that

when the load modules of a mainframe are

connected in parallel and set to dynamic mode,

they can perform dynamic tests synchronously

following the same clock. Under dynamic mode,

load current or resistance is pulsed between two

preset levels. When used in parallel, higher

powered outputs can be tested. This ability gives

the PEL-2000 series the flexibility to perform

dynamic tests over a wide range or power outputs.

For connection details see the Parallel Load

Connections section on page 52.

The diagram below shows how two load modules

are able to sink a higher load when used in parallel

under dynamic mode.

78

Page 79

GETTING STARTED

Configurations Description

There are a number of different configurations for the PEL series

including protection modes, operating configurations, and file

system configurations. The Configuration Description section

describes what the different configurations are used for and how

they can be relevant to different operations.

Protection Modes

Background

The PEL 2000 series include a number of protection

modes: Over Current Protection, Over Voltage

Protection and Over Power Protection.

The protection modes are useful to protect both the

load modules and the DUT(s). A buzzer can be set

to notify when a protection setting has been

tripped. When a protection feature is activated and

has been tripped then the load unit will display an

alarm. The Mainframe will also display an alarm.

When an alarm has been tripped the load will stop

sinking current/voltage. There are three Over load

protection settings: ON, OFF and Clear.

03/02/09

10 : 30

Alarm

CH1

CC

Dyna

High

Conf

Protection

Other

Go-NoGo

Previous

Configure

Menu

79

Page 80

PEL-2000 Series User Manual

Over Current

Protection

OCP level

Over Voltage

Protection

When a load unit is operating in CR or CV mode,

the unit may need over current protection to

prevent excessive current being sunk. Over current

protection stops the load from sinking more current

than its recommended limit which can cause

damage to the unit.

CV Mode: OCP

I

V

CR Mode: OCP

V

e

c

n

a

t

s

i

s

e

R

OCP level

Over voltage protection is used to limit the amount

of voltage sunk. If the OVP trips, the PEL series

load will stop sinking voltage.

CC Mode: OVP

Load Current

I

Load Input Voltage

Over Power

Protection

Over power protection is used when the power

range exceeds the specifications of the load. When

OPP is tripped power will cease to be sunk.

80

Page 81

GETTING STARTED

Reverse voltage

Protection

Reverse voltage protection prevents reverse voltage

damage to the PEL-2000 series up to the specified

rating. When Reverse voltage protection has been

tripped an alarm tone will sound until the reverse

voltage is removed.

For more details please see the specifications.

Under voltage

Protection

Under voltage protection will turn off the load

when the voltage drops below a set limit.

Operating Configurations

Background

CC Vrange

There are number of operating configuration

settings. Configuration settings are for the

following:

CC Vrange, Von Voltage, Von Latch, Short Key, CH

Cont, Independent load sync, D-time and Step

resolution settings.

CC Vrange (page 165) is used to set the voltage

range as High or Low for CC mode. CC voltage

range is dependent on the load module

specifications.

81

Page 82

PEL-2000 Series User Manual

Von Voltage

Von Voltage is the voltage limit at which the load

will start to sink current. There are two operation

modes for Von Voltage: Von latched:ON and Von

latched:OFF.

Latched: ON will sink current when Von has been

tripped, and will continue to sink current even if

the voltage drops below the Von Voltage.

Von Latched: OFF will sink current when Von has

been tripped, but will stop sinking current when

the voltage drops below the Von Voltage setting.

As can be seen in the diagram below, when Von-Latch

is set to off, the load module will start to sink current

when the Von-voltage limit has been tripped. It will

stop sinking current when the output drops below the

Von voltage limit.

82

Page 83

GETTING STARTED

Short

Note

CH CONT

When short mode is on, the load unit can simulate a

short circuit.

Shorting can be individually set for each channel

when programming sequences.

To initiate a short circuit manually, the short key is

used. It can be used at any time during an

operation. It will not affect the settings. After a