Page 1

LCR Meter

LCR-8230/8220/8210/8205

USER MANUAL

Rev. 1.00

ISO-9001 CERTIFIED MANUFACTURER

Page 2

This manual contains proprietary information, which is protected by

copyright. All rights are reserved. No part of this manual may be

photocopied, reproduced or translated to another language without

prior written consent of Good Will company.

The information in this manual was correct at the time of printing.

However, Good Will continues to improve products and reserves the

rights to change specification, equipment, and maintenance

procedures at any time without notice.

Good Will Instrument Co., Ltd.

No. 7-1, Jhongsing Rd., Tucheng Dist., New Taipei City 236, Taiwan.

Page 3

TABLE OF CONTENTS

Table of Contents

SAFETY INSTRUCTIONS ................................................... 5

GETTING STARTED ......................................................... 10

LCR-8200 Series Overview ............................................... 11

Appearance ..................................................................... 16

Set Up ............................................................................. 19

MEASURE (METER MODE) ............................................. 23

Setting comparator .......................................................... 44

Setting bin sorting ........................................................... 50

Setting FILE ..................................................................... 56

Setting USB disk.............................................................. 58

SWEEP (GRAPH MODE) .................................................. 60

Setting USB disk.............................................................. 83

LIST (MULTI STEP MODE) .............................................. 85

Setting bin sorting ......................................................... 110

Setting FILE ................................................................... 116

Setting USB disk............................................................ 118

CORRECTION (OPEN/SHORT) ..................................... 120

SYSTEM CONFIGURATION ........................................... 139

REMOTE CONTROL ...................................................... 147

Handler Overview .......................................................... 148

Configure Interface ........................................................ 157

COMMAND OVERVIEW ................................................ 164

Command Syntax ........................................................... 165

3

Page 4

LCR-8000 Series User Manual

Command error code ..................................................... 168

Command List ............................................................... 169

APPENDIX .................................................................... 220

Preset ............................................................................ 221

Specifications ................................................................ 223

Dimensions ................................................................... 230

Declaration of Conformity ............................................. 231

Measurement Basics ..................................................... 232

4

Page 5

SAFETY INSTRUCTIONS

WARNING

Warning: Identifies conditions or practices that

could result in injury or loss of life.

CAUTION

Caution: Identifies conditions or practices that

could result in damage to the LCR-8200 series

or to other properties.

DANGER High Voltage

Attention Refer to the Manual

Protective Conductor Terminal

Earth (ground) Terminal

SAFETY INSTRUCTIONS

This chapter contains important safety

instructions that you must follow during

operation and storage. Read the following before

any operation to ensure your safety and to keep

the instrument in the best possible condition.

Safety Symbols

These safety symbols may appear in this manual or on the

instrument.

5

Page 6

LCR-8000 Series User Manual

Do not dispose electronic equipment as unsorted

municipal waste. Please use a separate collection

facility or contact the supplier from which this

instrument was purchased.

General

Guideline

CAUTION

AC voltage input is strictly prohibited.

Do not place any heavy object on the

instrument.

Avoid severe impact or rough handling that can

lead to damaging the instrument.

Do not discharge static electricity to the

instrument.

Use only mating connectors, not bare wires, for

the terminals.

Do not perform measurement at the source of a

low-voltage installation or at building

installations (Note below).

Do not disassemble the instrument unless you

are qualified as service personnel.

Remove all test leads before disconnecting the

mains power cord from the socket.

If the equipment is used in a manner not

specified by the manufacturer, the protection

provided by the equipment may be impaired.

The device should be placed in a place where

the plug connected to it can be removed easily.

Safety Guidelines

6

Page 7

SAFETY INSTRUCTIONS

(Note) EN 61010-1:2010 specifies the measurement

categories and their requirements as follows. The

LCR-8200 Series doesn’t fall under category II, III

or IV.

Measurement category IV is for measurement

performed at the source of low-voltage

installation.

Measurement category III is for measurement

performed in the building installation.

Measurement category II is for measurement

performed on the circuits directly connected to

the low voltage installation.

Power Supply

WARNING

AC Input voltage: 100-240 VAC 50/60Hz

The power supply voltage should not fluctuate

more than 10%.

Connect the protective grounding conductor of

the AC power cord to an earth ground, to avoid

electrical shock.

Cleaning the

Instrument

Disconnect the power cord before cleaning.

Use a soft cloth dampened in a solution of mild

detergent and water. Do not spray any liquid.

Do not use chemicals containing harsh material

such as benzene, toluene, xylene, and acetone.

Operation

Environment

Location: Indoor, no direct sunlight, dust free,

almost non-conductive pollution (Note below)

Temperature: 0°C to 40°C

Humidity:

< 30°C: < 80%RH(non-condensing);

30°C~40°C: <70%RH(non-condensing);

>40°C: <50%RH (non-condensing)

Altitude: <2000m

7

Page 8

LCR-8000 Series User Manual

(Note) EN 61010-1:2010 specifies the pollution

degrees and their requirements as follows. The

LCR-8200 SERIES falls under degree 2.

Pollution refers to “addition of foreign matter,

solid, liquid, or gaseous (ionized gases), that

may produce a reduction of dielectric strength

or surface resistivity”.

Pollution degree 1: No pollution or only dry,

non-conductive pollution occurs. The pollution

has no influence.

Pollution degree 2: Normally only non-

conductive pollution occurs. Occasionally,

however, a temporary conductivity caused by

condensation must be expected.

Pollution degree 3: Conductive pollution occurs,

or dry, non-conductive pollution occurs which

becomes conductive due to condensation which

is expected. In such conditions, equipment is

normally protected against exposure to direct

sunlight, precipitation, and full wind pressure,

but neither temperature nor humidity is

controlled.

Storage

environment

Location: Indoor

Temperature: -10°C to 70°C

Humidity: <80%RH(non-condensing)

Disposal

Do not dispose this instrument as unsorted

municipal waste. Please use a separate collection

facility or contact the supplier from which this

instrument was purchased. Please make sure

discarded electrical waste is properly recycled to

reduce environmental impact.

8

Page 9

SAFETY INSTRUCTIONS

Green/ Yellow:

Earth

Blue:

Neutral

Brown:

Live (Phase)

Power cord for the United Kingdom

When using the unit in the United Kingdom, make sure the power

cord meets the following safety instructions.

NOTE: This lead/appliance must only be wired by competent persons

WARNING: THIS APPLIANCE MUST BE EARTHED

IMPORTANT: The wires in this lead are coloured in accordance with the

following code

As the colours of the wires in main leads may not correspond with

the coloured marking identified in your plug/appliance, proceed

as follows:

The wire which is coloured Green & Yellow must be connected to

the Earth terminal marked with either the letter E, the earth symbol

or coloured Green/Green & Yellow.

The wire which is coloured Blue must be connected to the terminal

which is marked with the letter N or coloured Blue or Black.

The wire which is coloured Brown must be connected to the

terminal marked with the letter L or P or coloured Brown or Red.

If in doubt, consult the instructions provided with the equipment

or contact the supplier.

This cable/appliance should be protected by a suitably rated and

approved HBC mains fuse: refer to the rating information on the

equipment and/or user instructions for details. As a guide, a cable

of 0.75mm2 should be protected by a 3A or 5A fuse. Larger

conductors would normally require 13A types, depending on the

connection method used.

Any exposed wiring from a cable, plug or connection that is

engaged in a live socket is extremely hazardous. If a cable or plug is

deemed hazardous, turn off the mains power and remove the cable,

any fuses and fuse assemblies. All hazardous wiring must be

immediately destroyed and replaced in accordance to the above

standard.

9

Page 10

LCR-8000 Series User Manual

LCR-8200 Series Overview ...............................................11

Series lineup ...................................................................... 11

Characteristics ................................................................... 12

Accessories........................................................................ 14

Package Contents .............................................................. 15

Appearance .....................................................................16

Front Panel ........................................................................ 16

Rear Panel ......................................................................... 18

Set Up .............................................................................19

Tilting the Stand ................................................................ 19

Power UP ........................................................................... 20

Connect to the test terminal ............................................. 21

GETTING STARTED

This chapter describes the LCR-8200 SERIES in a

nutshell, including accessories, package contents,

its main features and front / rear panel

introduction.

10

Page 11

GETTING STARTED

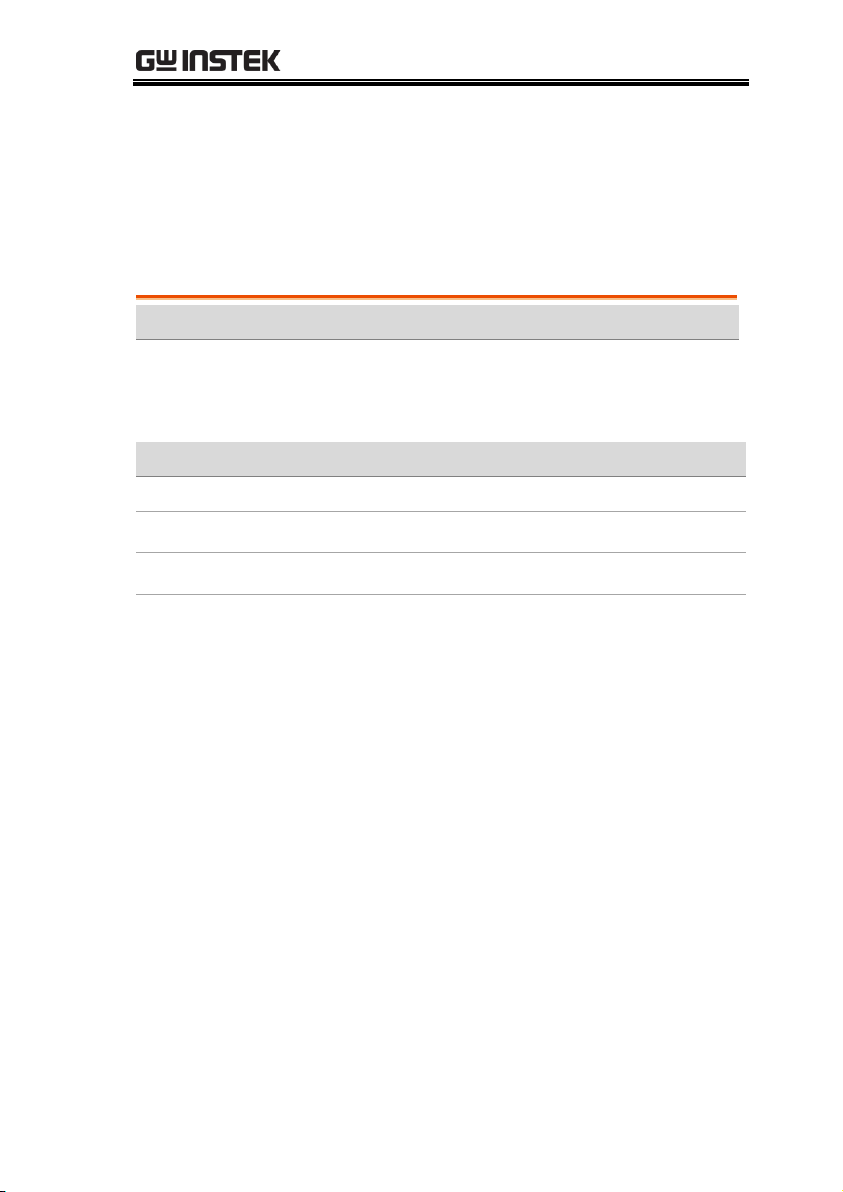

Model name

Basic accuracy

Test speed

Interface

LCR-8230/8220/

8210/8005

±0.08%

400 times/s

RS-232/USB/LAN

GPIB/Handler

Model name

Measurement frequency

LCR-8230

DC, 10~30MHz

LCR-8220

DC, 10~20MHz

LCR-8210

DC, 10~10MHz

LCR-8205

DC, 10~5MHz

LCR-8200 Series Overview

Series lineup

The LCR-8200 series consists of 4 models as list below.

11

Page 12

LCR-8000 Series User Manual

Performance

Signal source frequency range: DC, 10Hz ~

5/10/20/30MHz

Basic accuracy up to ±0.08%

Features

Signal source grade: 10mV ~ 2V / 100μA ~

20mA

ALC function

Output resistance 25Ω/100Ω, switchable

Parameters: |Z|, |Y|, θ, R, X, G, B, L, C, D, Q,

DCR, ESR, Vac, Iac, Vdc, Idc, etc.

Ultra-high measuring speed

Characteristics

Thank you for using LCR-8200 SERIES LCR Meter as your testing

instrument. This Manual contains the detailed installation steps. To

ensure personnel safety and to protect your equipment and data,

please check if the following accessories are fully supplied before

starting the installation.

The test frequency of the LCR-8200 SERIES LCR Meter is DC 10Hz30MHz and the test signal is 10mV-2Vrms and is suitable for the

LCR and DCR testes of AC signals. The measurement in a

continuously changing environment can be executed stage-by-stage

with the test frequency and grade, and high-speed continuous tests

can be performed under different test and mode conditions. The

machine also supports RS-232, USB, LAN and GPIB PC connection

capabilities to improve the design and test efficiency significantly.

The performance, convenience and operation flexibility of the LCR

Meter have become indispensable tools for the professional

measuring technicians.

Such meter can meet customer demands for price, speed, capacity,

accuracy and multi-function by its well-based flexibility in

combination and implementation. Therefore, it can be used in the

testing of a variety of components such as resister, capacitor,

inductor, oscillator, sensor, time-delay wire, filter and resonator.

12

Page 13

GETTING STARTED

Open circuit/short circuit/load calibration

function

Meter mode, multi step list mode, sweep mode

Up to four component parameters can be

selected in the electric meter mode. The

induction and DCR values can be measured and

displayed simultaneously

Up to 48 sets of multistep list programs can be

stored in the permanent memory and up to 15

test steps can be arranged in each program

7" 800*480 TFT LCD color screen

Ultra-low power consumption (<65VA) without

fans and zero noise

Interface

Rapid automation and data access function is

realizable for USB, LAN, GPIB and RS232

interfaces

PC connection data save software is stander

Auto component classification: Comparator

function and Handler BIN classification function

Input: Trigger signal.

13

Page 14

Accessories

Standard

Accessories

Part number

Description

01CR-82H000GT

LCR Meter

82CR-82H00E01

User Manual CD

82GW1SAFE0M01

Safety Instruction Sheet

Region dependent

Power Cord

LCR-06B

Test Fixture(Kelvin Clip)

Optional

Accessories

Part number

Description

LCR-05A

Test Fixture(DIP)

LCR-07

Test Fixture(Clip)

LCR-08A

Test Fixture(SMD)

LCR-10

Test Fixture(SMD)

LCR-15A

Test Fixture(SMD)

DC BIAS BOX

External DC Bias box

GTL-232

RS232C cable

GTL-246

USB cable

LCR-8000 Series User Manual

14

Page 15

GETTING STARTED

Opening

the box

Contents

(single unit)

Main unit

Test Fixture (Kelvin

Clip)

Power cord x1 (region

dependent)

User manual CD

Safety instruction sheet

Package Contents

Check the contents before using the instrument.

15

Page 16

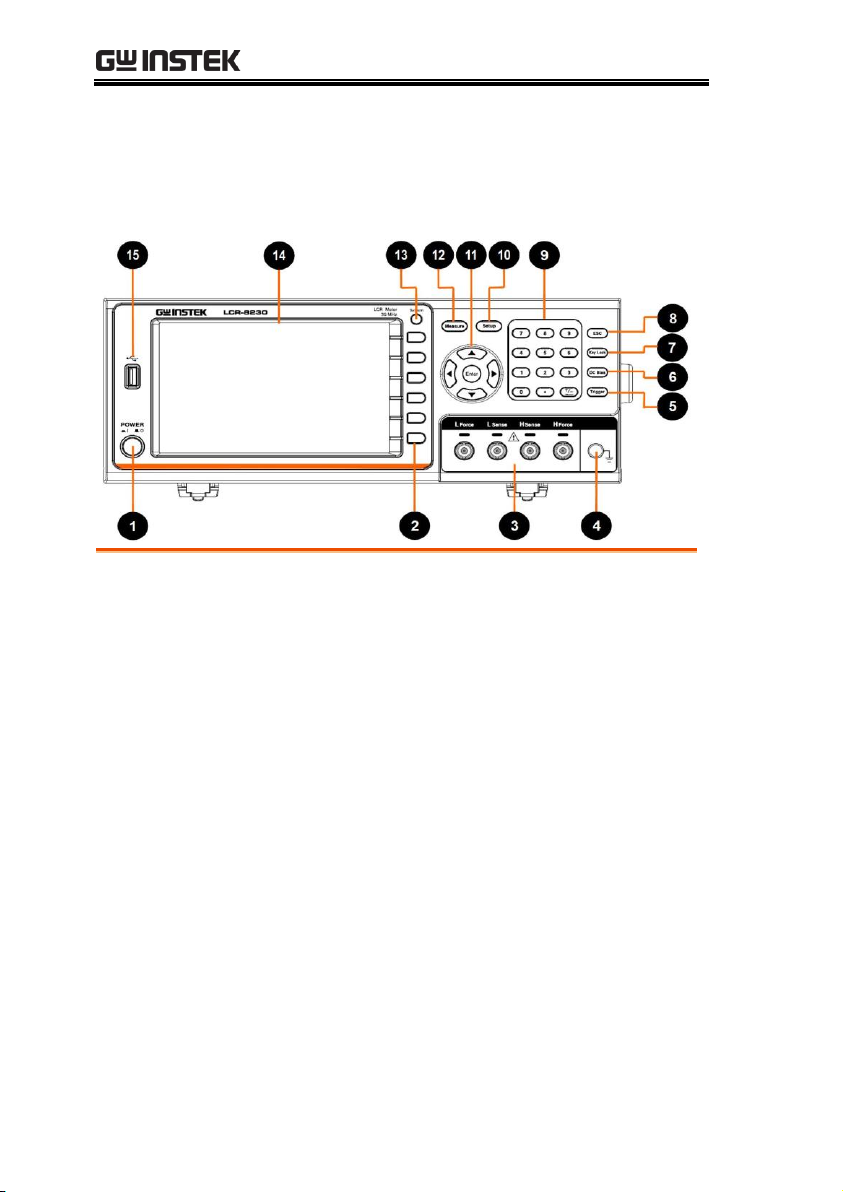

Appearance

1

Power

This key is used to turn the device

instrument on/off.

2

Function

For executing the function indicated

for the position corresponding to the

Function key.

Soft keys for use to select

corresponding option which located

on the right of the LCD screen.

3

Test

terminals

Test terminals are used to connect test

fixture.

4

Ground

Terminal

This terminal is used for grounding.

5

Trigger

If trigger mode is set to external, this

key can be used to measure trigger.

Front Panel

LCR-8000 Series User Manual

16

Page 17

GETTING STARTED

6

DC BIAS

For control the Bias unit and for

executing on/off.

7

Key Lock

The key will be locked to prevent from

controlling the push key and the

computer by both sides. To use the

keypad again, press this key again.

8

ESC Press this button to return the cursor

to the top left corner of the currently

displayed page or cancel current

setting.

9

Numeric

The numeric keypad is used to input

values for setting.

10

Setup

This key is used for entering

measurement setup page.

11

Arrow Keys

/Enter

The arrow keys are used to navigate

the cursor on the screen.

Enter key is used to confirm the value

which input from the numeric keypad.

When a flash drive is inserted from the

USB port on the front panel. Press

Enter to detecting USB disk and show

USB disk management page.

12

Measure

This key is used for entering

measurement setup page.

13

System

This key is used for entering system

setup page.

14

LCD

7” TFT- LCD display.

15

USB port

The Host port is a type A USB port for

logging data and connecting USB

memory devices only.

USB disk type: Flash drive only

Format: FAT32/exFAT

Max memory size: 128GB.

17

Page 18

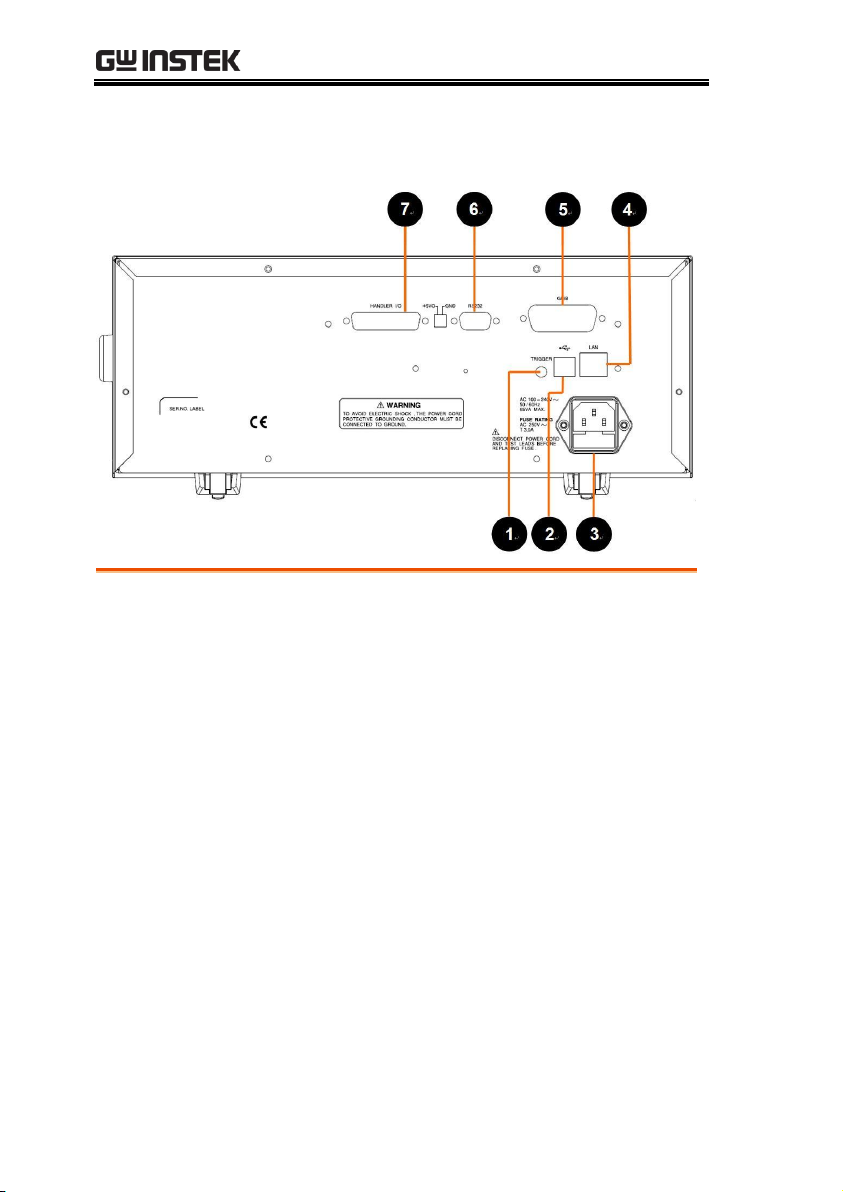

Rear Panel

1

TRIGGER

Trigger input port

2

USB

USB port (Type B)

This port is used for remote control.

3

Power Cord

Socket

Power Socket:

AC 100~240V, 50/60Hz, 65VA max

4

LAN

LAN port

5

GPIB

GPIB port

6

RS232

RS-232 port

7

Handler I/O

Handler I/O port

LCR-8000 Series User Manual

18

Page 19

GETTING STARTED

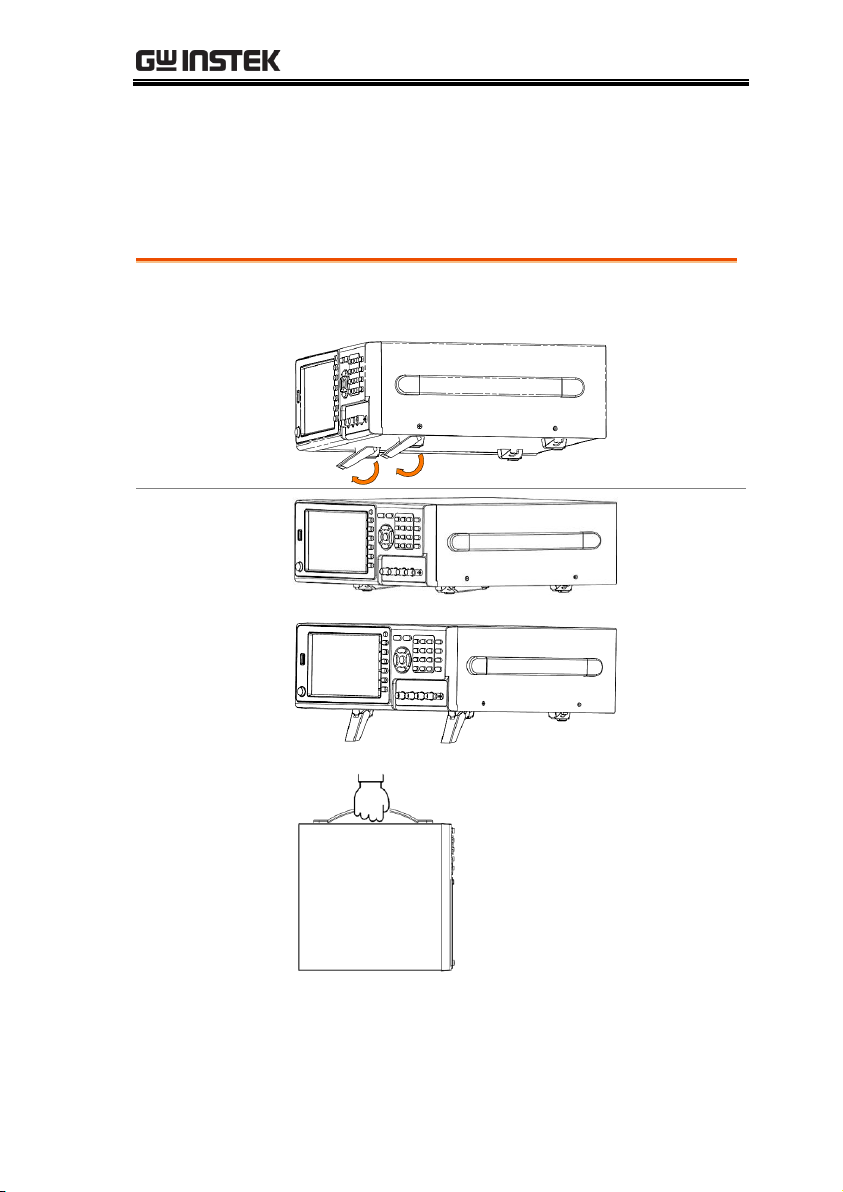

Lifting the instrument, starting from the front stand.

Horizontal

position

Tilt stand

position

Carry position

Set Up

Tilting the Stand

19

Page 20

Power UP

Steps

1. Insert the AC power cord into the power

socket.

2. Press the power button to turn the LCR-8200

series on.

3. The power button will Press down and the

LCR-8200 series will start to boot up.

LCR-8000 Series User Manual

20

Page 21

GETTING STARTED

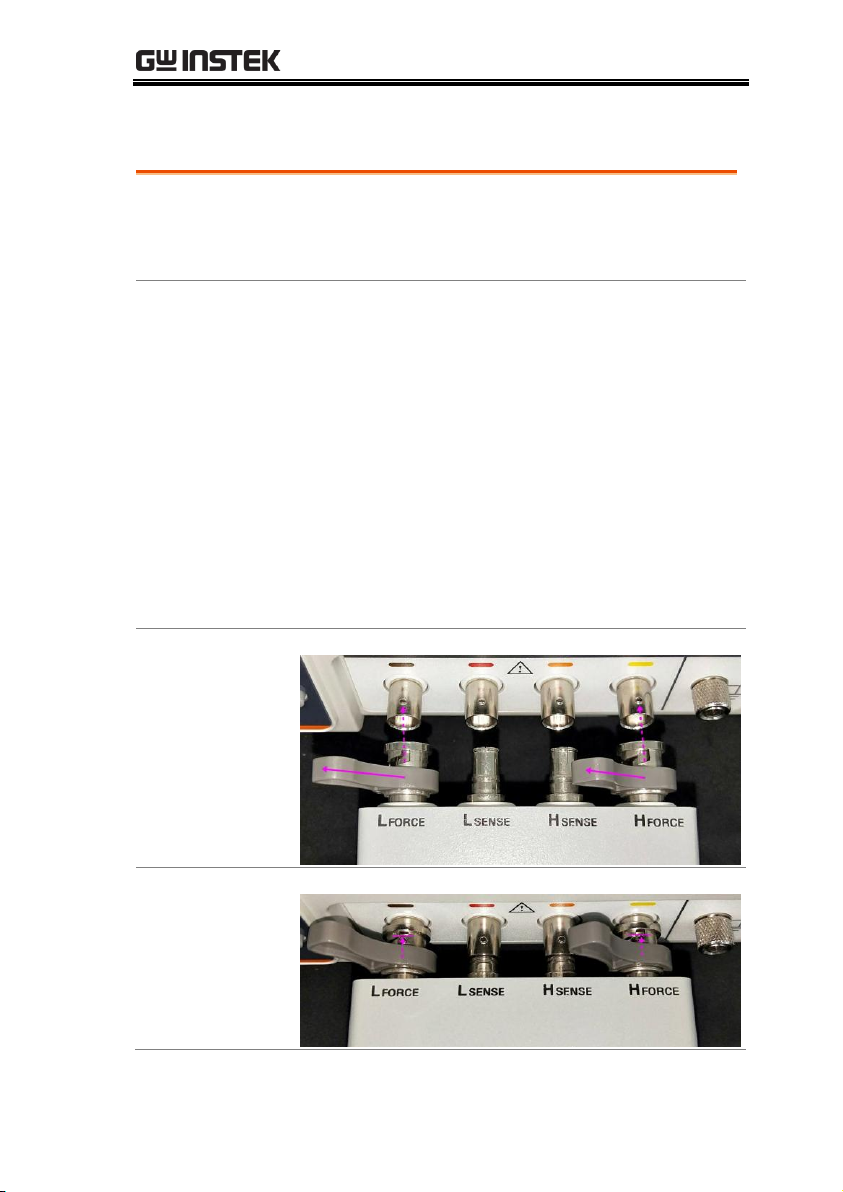

Background

Please use the test fixture to connect to the test

terminal for testing. Please follow the procedure

below to connect.

Steps

Please insert the test fixture into the terminal of

the test equipment correctly.

1. Turn the left and right handles of the test

fixture to turn the BNC notch to the top and align

the BNC bumps of the test equipment.

2. Test the fixture into the BNC terminal of the

test equipment.

3. Rotate the left and right handles of the test

fixture to the right and push the test fixture to the

end. As shown below.

Connection

diagram

1.

2.

Connect to the test terminal

21

Page 22

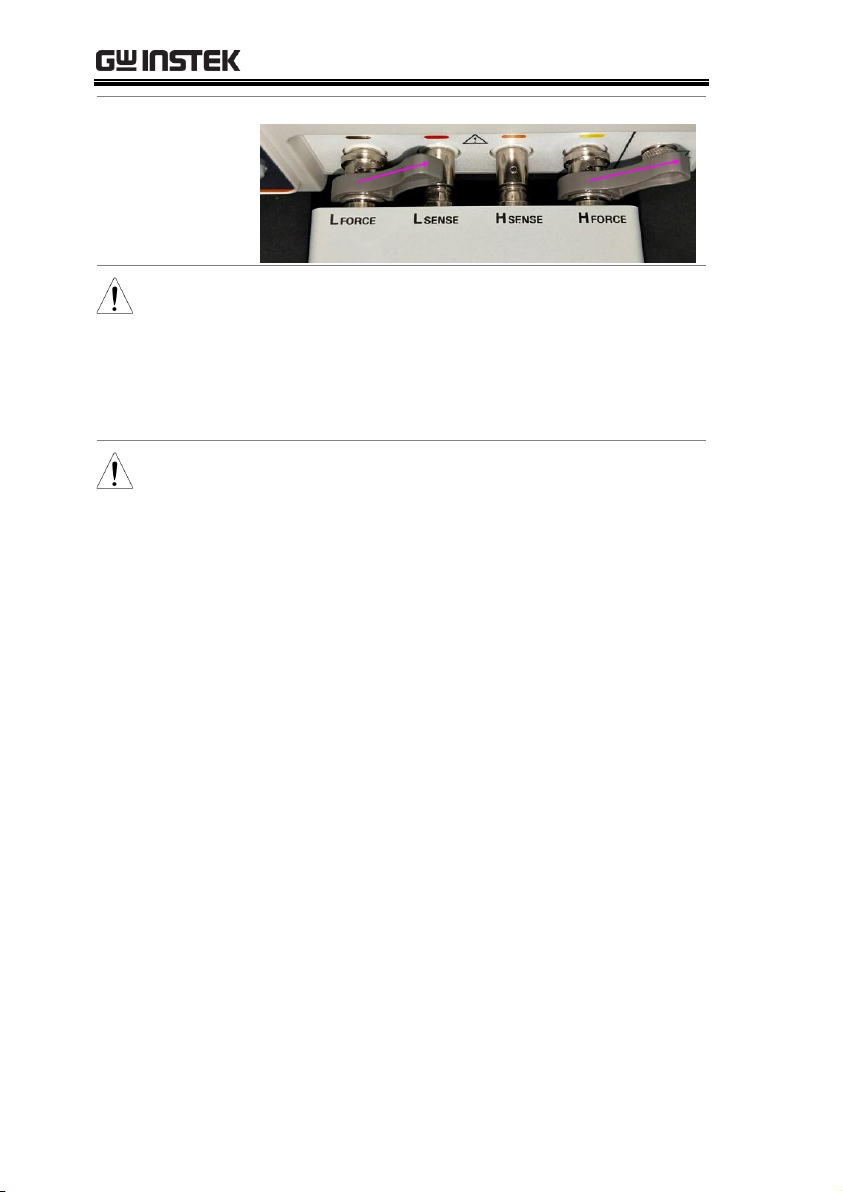

LCR-8000 Series User Manual

3.

Note

Avoid wrong connection, which would lead to

incorrect reading value.

In order to ensure the accuracy of the instrument,

please use the LCR-8200 optional accessories test

cable for test.

Warning

Before connecting the test leads, make sure the

test leads are not connected to any component to

avoid personal injury or damage to the

instrument.

22

Page 23

MEASURE (METER MODE)

Measure display area description ..................................... 24

Setting parameter .............................................................. 25

Setting frequency............................................................... 27

Setting speed ..................................................................... 29

Setting trigger mode ......................................................... 30

Setting measurement level/ALC/RO ................................ 32

Setting DC bias.................................................................. 34

Setting measurement AC range ........................................ 36

Setting measurement DC range ....................................... 37

Setting trigger delay timer................................................. 38

Setting AC/DC delay timer ................................................ 39

Setting average count ....................................................... 40

Setting display Vm/Im mode ............................................ 41

Setting beep mode ............................................................ 42

Setting statistics mode ..................................................... 43

Setting comparator .......................................................... 44

Setting bin sorting ........................................................... 50

Setting FILE ..................................................................... 56

Setting USB disk.............................................................. 58

MEASURE (METER

MODE)

In this chapter you will learn about all the

measurement-related settings. All the

measurement setting items can be found on the

[MEAS DISPLAY] [MEASURE MODE SETUP]

page.

23

Page 24

LCR-8000 Series User Manual

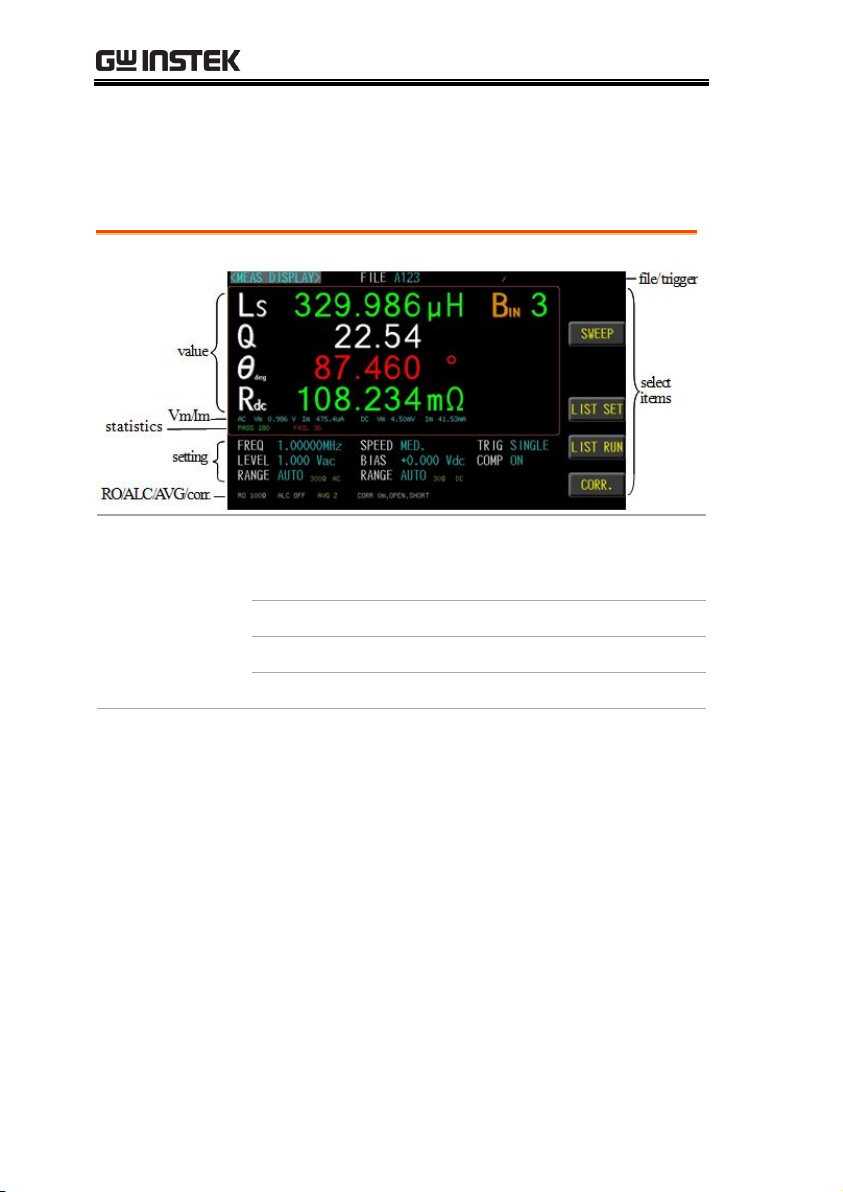

Available

parameter

SWEEP

Sweep mode page. Provides the

measurement value to graphic

curve function.

LIST SET

List setting page.

LIST RUN

List run test page.

CORR.

Correction page.

Measure display area description

The measurement display is a Meter mode that provides a single

condition for numerical measurements.

24

Page 25

MEASURE (METER MODE)

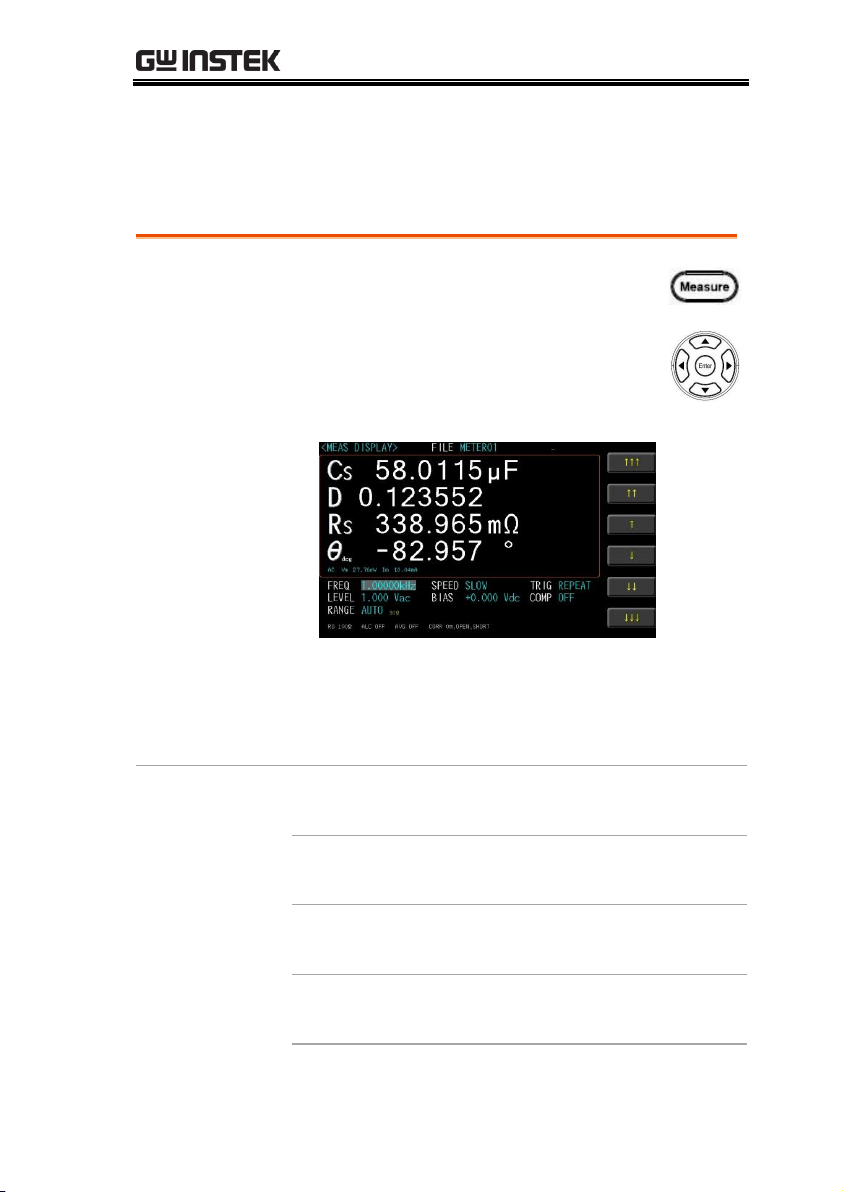

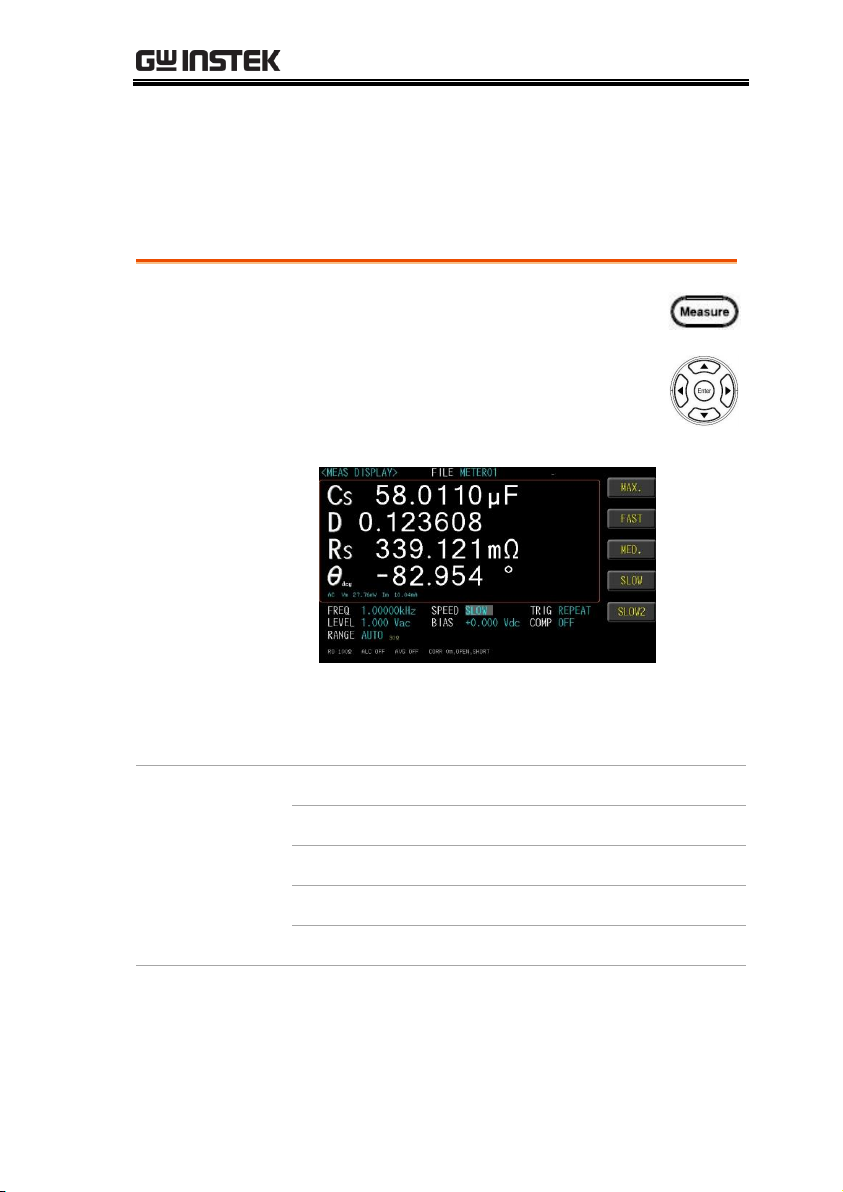

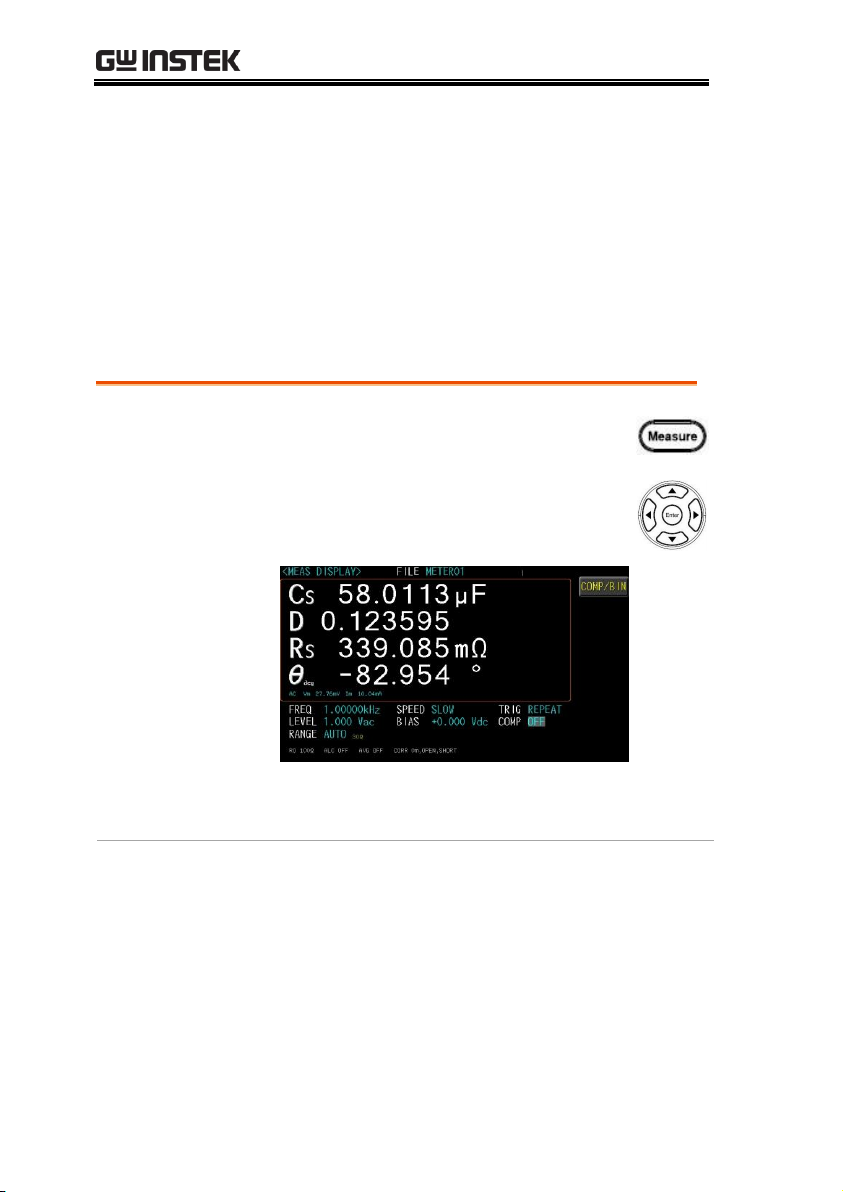

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page.

2. Use arrow keys to move the cursor

and select Parameter 1~4 item on the

[MEAS DISPLAY] page.

3. Use option key on the right of the LCD screen

to select a parameter for this measurement

item.

Parameter

Ls

Equivalent Series Inductance

Lp

Equivalent Parallel Inductance

Cs

Equivalent Series Capacitance

Cp

Equivalent Parallel Capacitance

Rdc

DC Resistance

Rs

Equivalent Series Resistance (ESR)

Rp

Equivalent Parallel Resistance

Z

Absolute value of impedance

θ

deg

Phase angle of impedance(degree)

θ

rad

Phase angle of impedance(radian)

Q

Quality Factor, (Q = 1/D)

D

Dissipation Factor

, Loss coefficient (tanδ)

Setting parameter

25

Page 26

LCR-8000 Series User Manual

R

Resistance

X

Reactance

Y

Absolute value of admittance

G

Conductivity

B

Susceptance

Note

Up to four component parameters can be selected

in the meter mode. The inductance and DCR

values can be measured and displayed

simultaneously.

26

Page 27

MEASURE (METER MODE)

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page.

2. Use arrow keys to move cursor and

select FREQ item on the [MEAS

DISPLAY] page.

3. Select option key on the right of the LCD

screen to adjust the frequency value by rough

or minor adjusting method or use the numeric

keypad to enter the test frequency.

Available

parameter

Increase the first digit of the frequency

value.

Increase the second digit of the frequency

value

Increase the third digit of the frequency

value

Decrease the third digit of the frequency

value

Setting frequency

The frequency range is 10Hz~5MHz/10MHz/20MHz/30MHz, and

the resolution is set at 6 digits..

27

Page 28

LCR-8000 Series User Manual

Decrease the second digit of the frequency

value

Decrease the first digit of the frequency

value

28

Page 29

MEASURE (METER MODE)

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page.

2. Use arrow keys to move cursor and

select SPEED item on the [MEAS

DISPLAY] page.

3. Use option key on the right of the LCD screen

to select a test speed for this measurement

item.

Available test

speed

MAX.

2.5ms(>10kHz)

FAST

50ms(>20Hz)

MED.

100ms

SLOW

300ms

SLOW2

600ms

Setting speed

LCR-8200 Series offers 5 test speeds (SLOW2, SLOW, MED., FAST

and MAX.). The slower the test, the more accurate and stable the

test result.

29

Page 30

LCR-8000 Series User Manual

Steps

1. Press the Setup button to enter [MEAS

SETUP] page.

2. Use arrow keys to move cursor and select

TRIGGER item on the [MEAS SETUP]

page.

3. Use option key on the right of the LCD screen to

select a trigger mode for this measurement item.

Available

parameter

REPEAT

Internal trigger mode is also known as

continuous test. The trigger signal

performs continuous test in accordance

with the SPEED setting.

Press the Trigger button to pause the

trigger to stop the measurement and

display the “TRIG HOLD” message on

the top of the LCD.

Again press the Trigger button to resume

continuous triggering.

SINGLE

External trigger mode, including

Manual/Handler/TRIGGER

Input/Remote control mode.

Setting trigger mode

LCR-8200 Series offers REPEAT and SINGLE mode.

30

Page 31

MEASURE (METER MODE)

Manual mode: The device performs a

measurement once the Trigger button is

pressed.

Handler mode: When a negative edge

pulse is received from the handler

interface on the rear panel, the device

performs a measurement cycle.

TRIGGER Input mode: When a

negative edge pulse is received from

the TRIGGER Input on the rear panel,

the device performs a measurement

cycle.

Remote control mode: When a

measurement command is sent from

the RS-232 or USB or GPIB interface,

the device performs a measurement

cycle.

31

Page 32

LCR-8000 Series User Manual

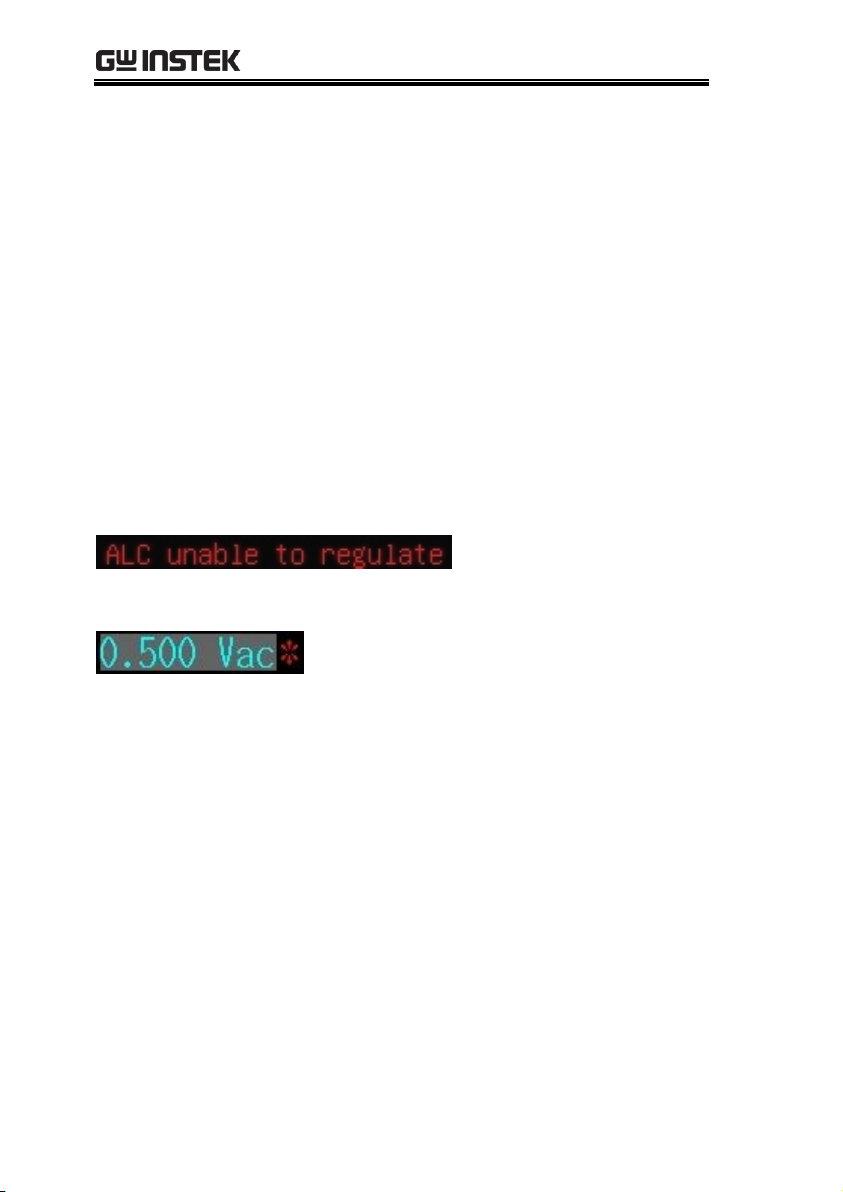

Setting measurement level/ALC/RO

LCR-8200 Series test signal voltage/current level can be set as the

effective value (RMS value) of a sine wave of the test frequency

from the unit’s internal oscillator. The voltage range is 10mV2Vrms and current range is 100uA-20mArms. 2Vrms can only be

used at <= 1MHz.

The ALC (automatic level control) feature adjusts the voltage across

the DUT or the current through the DUT to match the

voltage/current level setting. Using this feature, you can try to

ensure a constant signal level (voltage or current) is applied to the

DUT.

In situations when the actual measuring Vac or Iac goes beyond the

extent that the ALC can regulate, a warning message, “ALC unable

to regulate”, will be shown at the bottom of the screen.

An asterisk will be shown beside the LEVEL V or A unit when the

ALC is turned on.

The RO (output impedance) can be set to 25Ω or 100Ω.

The varied signal source output impedance will lead to the varied

current or the difference of measuring value. If selecting <25Ω>,

then the voltage range is 10mV~1Vrms and the current range is

400uA~40mArms. If it needs to compare test results with Keysight

select 100Ω.

32

Page 33

MEASURE (METER MODE)

Steps

1. Press the Measure button to enter [MEAS

DISPLAY] page.

2. Use arrow keys to move cursor and select

LEVEL item on the [MEAS DISPLAY]

page.

3. Use option key on the right of the LCD screen to

adjust the level value or use the numeric keypad to

enter the test level and select ALC/RO for this

measurement item.

Available

parameter

Increase 0.1Vac/1mAac of the level value

Decrease 0.1Vac/1mAac of the level value

ALC OFF

ALC function turn off

Shown at the bottom of the screen.

ALC ON

ALC function turn on

Shown at the bottom of the screen.

RO 100Ω

Set output impedance 100Ω

Shown at the bottom of the screen.

RO 25Ω

Set output impedance 25Ω

Shown at the bottom of the screen.

33

Page 34

LCR-8000 Series User Manual

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page.

2. Use arrow keys to move cursor and

select BIAS item on the [MEAS

DISPLAY] page.

3. Select option key on the right of the LCD

screen to adjust the frequency value by rough

or minor adjusting method or use the numeric

keypad to enter the DC Bias voltage.

4. Press the DC Bias button to output the

voltage and the DC Bias button will

illuminate. When the DC Bias is

output, the asterisk is displayed next

to the BIAS V unit.

Setting DC bias

LCR-8200 Series offers DC BIAS ±12V. When input is above the

instrument voltage range will be displayed “Out of range!”.

34

Page 35

MEASURE (METER MODE)

Available

parameter

Increase 1V of the DC Bias value

Increase 0.1V of the DC Bias value

Decrease 0.1V of the DC Bias value

Decrease 1V of the DC Bias value

35

Page 36

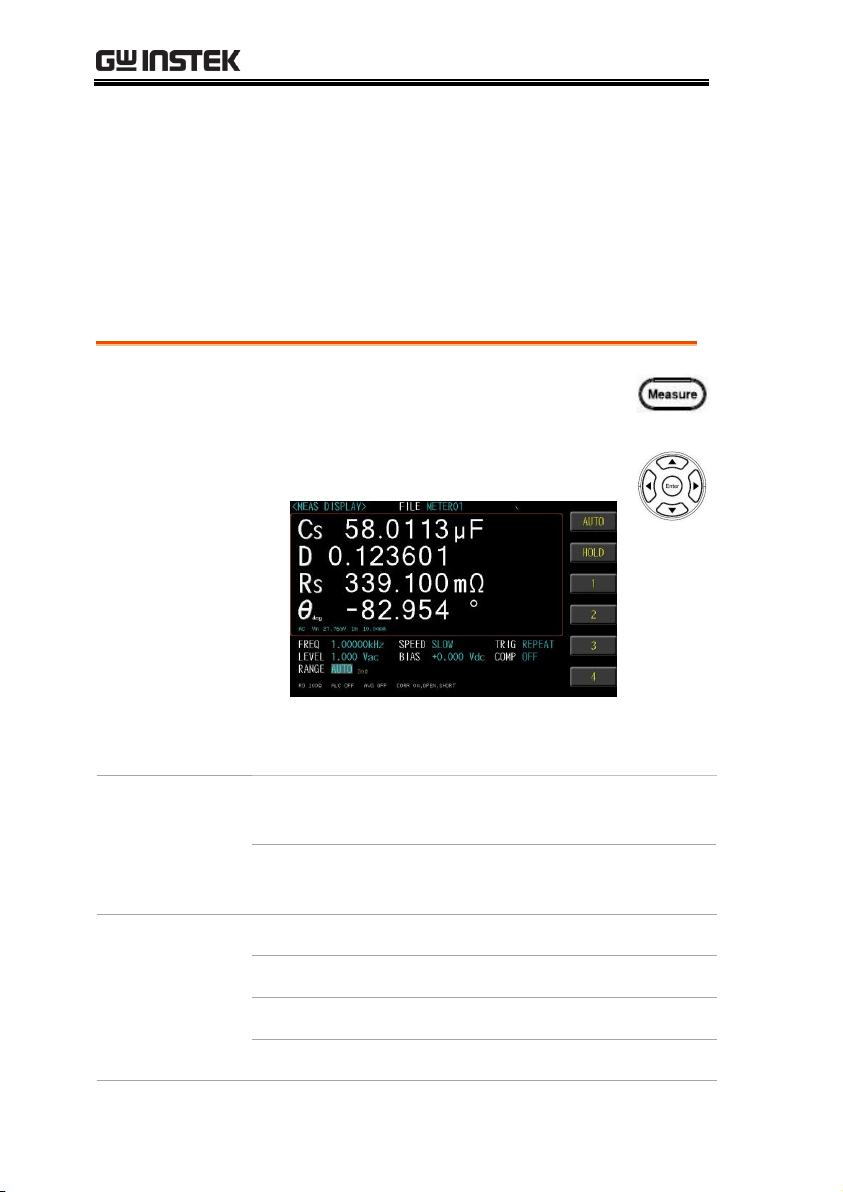

LCR-8000 Series User Manual

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page.

2. Use arrow keys to move the cursor to

corresponding measurement AC range.

3. Use option key on the right of the LCD screen to

select a desired measurement range.

Set up range

mode

AUTO

The device will automatically select the

best range to test.

HOLD

The device will always performance test

with a user-specified range.

Measurement

range

1

Set 30Ω range

2

Set 300Ω range

3

Set 3kΩ range

4

Set 30kΩ range

Setting measurement AC range

The range recommendation is set to [Auto] for better measurement

accuracy. The actual measured range will be displayed in the lower

left corner of the screen.

When set to [HOLD], faster measurement speeds can be achieved.

However, when the range is selected incorrectly, it will result in

inaccurate or incorrect values.

36

Page 37

MEASURE (METER MODE)

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page.

2. Use arrow keys to move the cursor to

corresponding measurement DC range.

3. Use option key on the right of the LCD screen to

select a desired measurement range.

Set up range

mode

AUTO

The device will automatically select the

best range to test.

HOLD

The device will always performance test

with a user-specified range.

Measurement

range

1

Set 30Ω range

2

Set 300Ω range

3

Set 3kΩ range

4

Set 30kΩ range

Setting measurement DC range

The range recommendation is set to [Auto] for better measurement

accuracy. The actual measured range will be displayed in the lower

center of the screen.

When set to [HOLD], faster measurement speeds can be achieved.

However, when the range is selected incorrectly, it will result in

inaccurate or incorrect values.

37

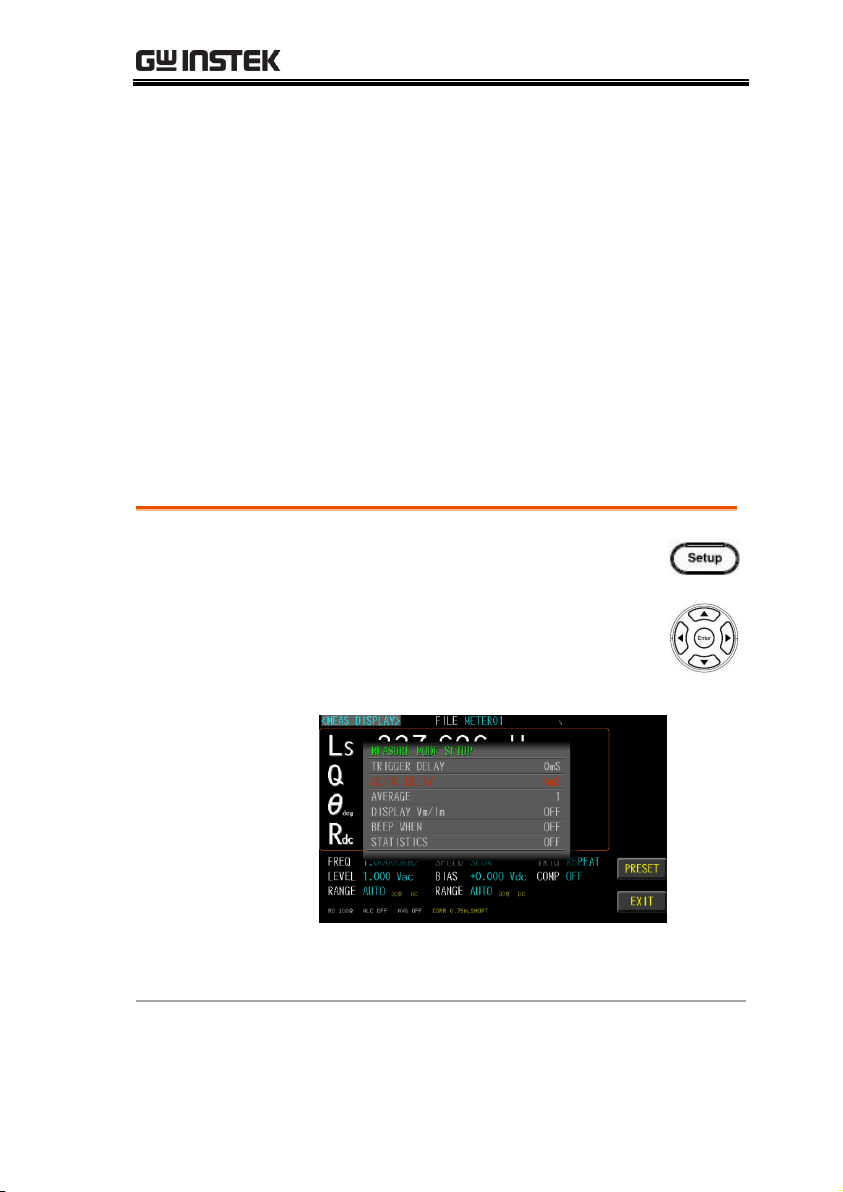

Page 38

LCR-8000 Series User Manual

Steps

1. Press the Setup button to enter

[MEASURE MODE SETUP] page.

2. Use arrow keys to move cursor and

select TRIGGER DELAY on the

[MEASURE MODE SETUP] page.

3. Use key pad to input delay timer value ,unit is

ms.

Setting trigger delay timer

LCR-8200 Series can set the delay time before each test by setting

trigger delay timer.

The delay time range is 0ms~5000ms.

38

Page 39

MEASURE (METER MODE)

Steps

1. Press the Setup button to enter

[MEASURE MODE SETUP] page.

2. Use arrow keys to move cursor and

select AC/DC DELAY on the

[MEASURE MODE SETUP] page.

3. Use key pad to input delay timer value ,unit is

ms.

Setting AC/DC delay timer

LCR-8200 Series can set the AC/DC delay time when Rdc

parameter enable .

The inductance and Rdc values can be measured and displayed

simultaneously.

When the inductance is measured by Rdc, a current flows through

the generated magnetic field. When the DC signal ends, the

inductance will generate a back electromotive force. If the AC

signal is subsequently sent out for measurement, the L value may

cause an error. To avoid this problem, you can set the AC/DC

delay timer to reduce the effect of back EMF on the measurement.

This delay timer will be executed both AC to DC and DC to AC.

The delay time range is 0ms~5000ms.

39

Page 40

LCR-8000 Series User Manual

Steps

1. Press the Setup button to enter

[MEASURE MODE SETUP] page.

2. Use arrow keys to move cursor and

select AVERAGE on the [MEASURE

MODE SETUP] page.

3. Use key pad to input average count value.

Note

This average count setting only works for the AC

measurement parameters, and the DCR

measurement does not perform the averaging

function.

Setting average count

This function is to perform multiple measurements and take an

average result from multiple measurements as the final display

value. The stability and reliability of the measurement results can

be improved by utilizing this function. The number of

measurements can be set from 1 to 64.

40

Page 41

MEASURE (METER MODE)

Steps

1. Press the Setup button to enter

[MEASURE MODE SETUP] page.

2. Use arrow keys to move cursor and

select DISPLAY Vm/Im on t he

[MEASURE MODE SETUP] page.

3. Use option key on the right of the LCD screen

to select a desired item.

Available

parameter

OFF

Turn off the Vm/Im display

ON

Turn on the Vm/Im display

Setting display Vm/Im mode

The test signal voltage and test signal current of the AC and the test

signal voltage and test signal current of the DC on the test object.

Turn on the Vm/Im display to help understand the setting status of

ALC and RO.

41

Page 42

LCR-8000 Series User Manual

Steps

1. Press the Setup button to enter

[MEASURE MODE SETUP] page.

2. Use arrow keys to move cursor and

select BEEP WHEN on the

[MEASURE MODE SETUP] page.

3. Use option key on the right of the LCD screen

to select a desired item.

Available

parameter

OFF

Turn off the beep function

PASS

Buzzer sounds when the test pass

FAIL

Buzzer sounds when the test fail

Setting beep mode

When the comparison function setting is turned on, the value

judgment result will be indicated by color, and the buzzer function

can be set to use the sound to know the measurement result.

42

Page 43

MEASURE (METER MODE)

Steps

1. Press the Setup button to enter

[MEASURE MODE SETUP] page.

2. Use arrow keys to move cursor and

select STATISTICS on the

[MEASURE MODE SETUP] page.

3. Use key pad to input average count value.

Available

parameter

OFF

Turn off the statistics display

ON

Turn on the statistics display

CLEAR

Clear statistics quantity

Setting statistics mode

When the comparison function setting is on, the statistics function

can be turned on to calculate the measurement quantity of PASS

and FAIL.

43

Page 44

LCR-8000 Series User Manual

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page.

2. Use arrow keys to move cursor and

select COMP item.

3. Use option key on the right of the LCD screen to

select COMP/BIN item.

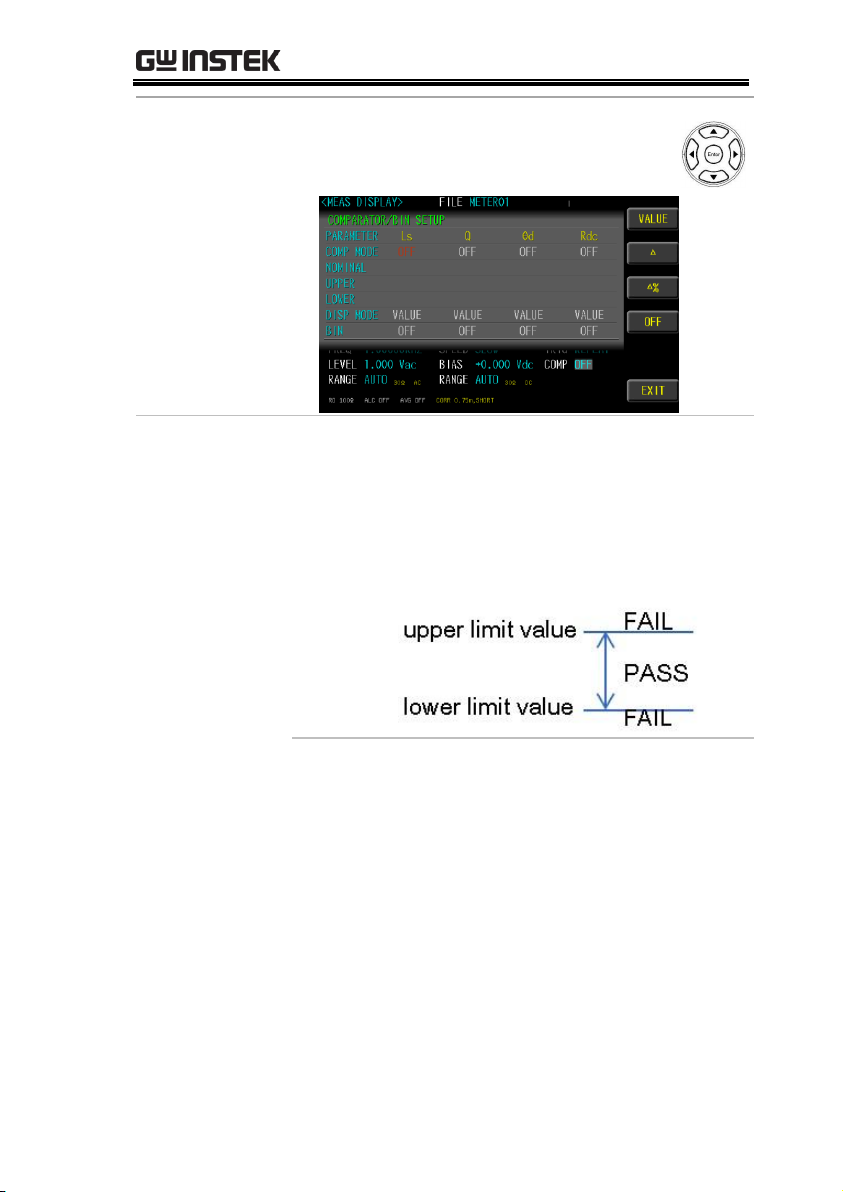

Setting comparator

In this section, user will learn how to set up comparator and bin

sorting. The device can perform comparator function for 1~4

parameter simultaneously or separately. Choose to set the bin

condition for each parameter, which can be divided into 2~9 classes.

Bin methods include equalization, sequence, tolerance and random;

limit value modes include measured values, tolerance values, and

tolerance %.

44

Page 45

MEASURE (METER MODE)

Set up comp

mode

4. Use arrow keys to select COMP

MODE.

Available options

VALUE

The measured values are compared.

Select this mode, the NOMINAL field

does not need to be set, just set the

UPPER and LOWER upper and lower

limits.

45

Page 46

LCR-8000 Series User Manual

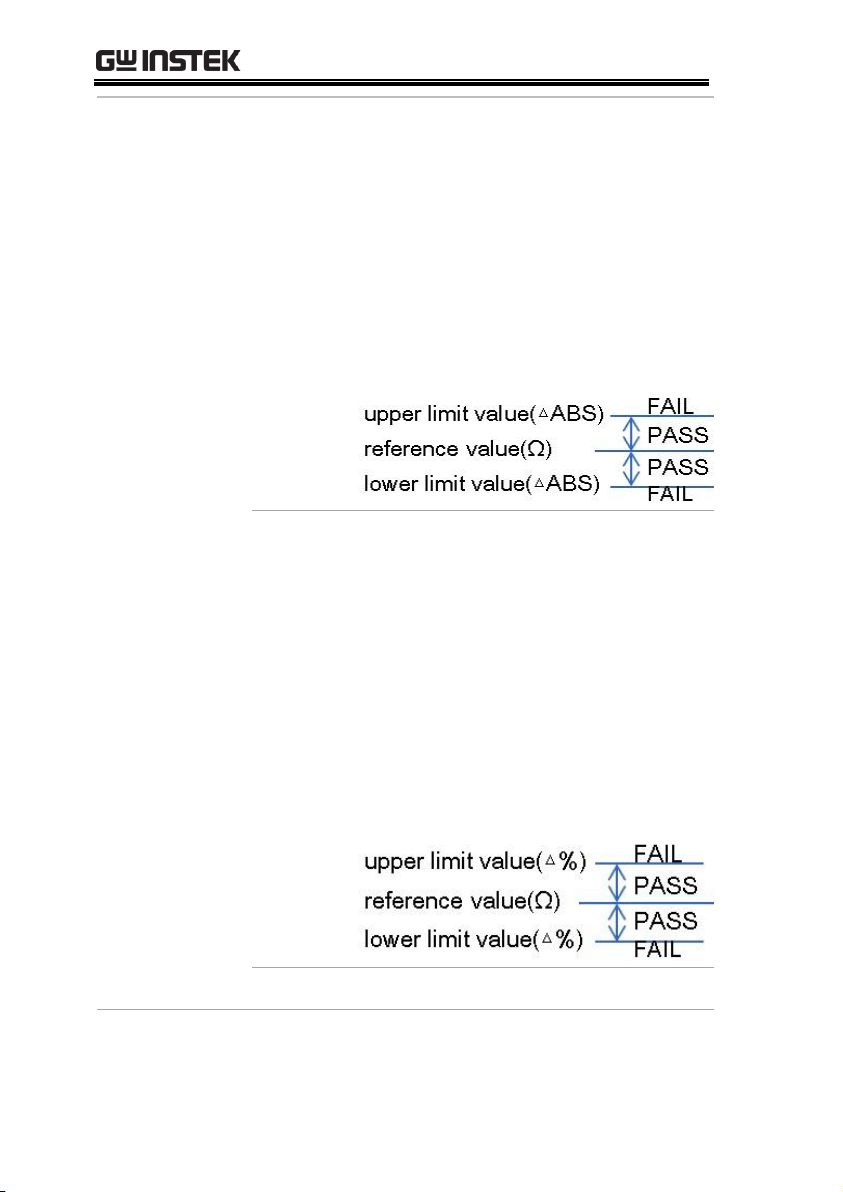

△

The difference between the measured

value and the NOMINAL value is

compared.

Absolute value (Δ) = measure value –

nominal value

Select this mode, the NOMINAL value

and UPPER and LOWER upper and

lower limits must be set.

△%

The difference between the measured

value and the NOMINAL value is

compared with the percentage of the

NOMINAL value.

Deviation percentages (Δ%) = Absolute

value (Δ)/nominal value × 100%

Select this mode, the NOMINAL value

and UPPER and LOWER upper and

lower limits must be set.

OFF

Turn off the comparator function

46

Page 47

MEASURE (METER MODE)

Set up

nominal/upper/lo

wer

1. Use arrow keys to move cursor and

select NOMINAL or UPPER and

LOWER.

2. Use key pad to input value and unit.

Available options

NOMINAL

Compare nominal values. Set only

in the △ and △% modes.

UPPER

Comparison of upper limit

LOWER

Comparison of lower limit

Set up display

mode

3. Use arrow keys to move cursor and

select DISP MODE.

VALUE

Display measurement value

47

Page 48

LCR-8000 Series User Manual

△

Display the difference between the

measured value and the NOMINAL

value

△%

Display the difference between the

measured value and the NOMINAL

value is compared with the percentage

of the NOMINAL value.

Comparator

result display

4. Press the Measure button to enter

[MEAS DISPLAY] page. Comparator

result is Pass in green color or Fail in

red color.

Set up other

Parameter

5. Use the above steps to set other

fields.

48

Page 49

MEASURE (METER MODE)

Comparator

result display

6. Press the Measure button to enter

[MEAS DISPLAY] page. Comparator

result is Pass in green color or Fail in

red color.

49

Page 50

LCR-8000 Series User Manual

Steps

1. Use arrow keys to move cursor and

select BIN item.

2. Use option key on the right of the LCD screen to

select a desired item.

Available options

OFF

Turn off the bin function.

ON

Turn on the bin function. The SET BIN

option will be displayed.

SET

BIN

Set the parameters of the bin function.

Setting bin sorting

Choose to set the bin condition for each parameter, which can be

divided into 2~9 classes. Bin methods include equalization,

sequence, tolerance and random; limit value modes include

measured values, tolerance values, and tolerance %.

50

Page 51

MEASURE (METER MODE)

Set up parameter

3. Use arrow keys to select PARAMETER

item.

4. Use option key on the right of the LCD screen to

select a desired item. The MEAS DISPLAY has

selected parameters to have display options.

Available options

Off

Turn off the bin function.

PARA1(Ls)

Select the first measurement

parameter (Ls).

PARA2(Q)

Select the second measurement

parameter (Q).

PARA3(Θd)

Select the third measurement

parameter (

Θd).

PARA4(Rdc)

Select the fourth measurement

parameter (Rdc).

51

Page 52

LCR-8000 Series User Manual

Set up bin

number

7. Use arrow keys to move cursor and

select BIN NUMBER item.

8. Use key pad to input bin number value.(2~9)

Set up bin

method

9. Use arrow keys to move cursor and

select BIN METHOD item.

10. Use option key on the right of the LCD screen to

select a desired item.

52

Page 53

Available options

Equal

Sort by equally average. Set the

high/low value.

Sequential

Sort by order. Set each value.

Tolerance

Sort by order. Set each value.

Random

Sort by user. Set each range value.

MEASURE (METER MODE)

53

Page 54

LCR-8000 Series User Manual

Set up limit mode

11. Use arrow keys to move cursor and

select LIMIT MODE.

12. Use option key on the right of the LCD screen to

select a desired item.

Available options

VALUE

The measured values are compared.

Select this mode, the NOMINAL field

does not need to be set, just set the

UPPER and LOWER upper and lower

limits.

54

Page 55

MEASURE (METER MODE)

△

The difference between the measured

value and the NOMINAL value is

compared.

Absolute value (Δ) = measure value –

nominal value

Select this mode, the NOMINAL value

and UPPER and LOWER upper and

lower limits must be set.

△%

The difference between the measured

value and the NOMINAL value is

compared with the percentage of the

NOMINAL value.

Deviation percentages (Δ%) = Absolute

value (Δ)/nominal value × 100%

Select this mode, the NOMINAL value

and UPPER and LOWER upper and

lower limits must be set.

55

Page 56

LCR-8000 Series User Manual

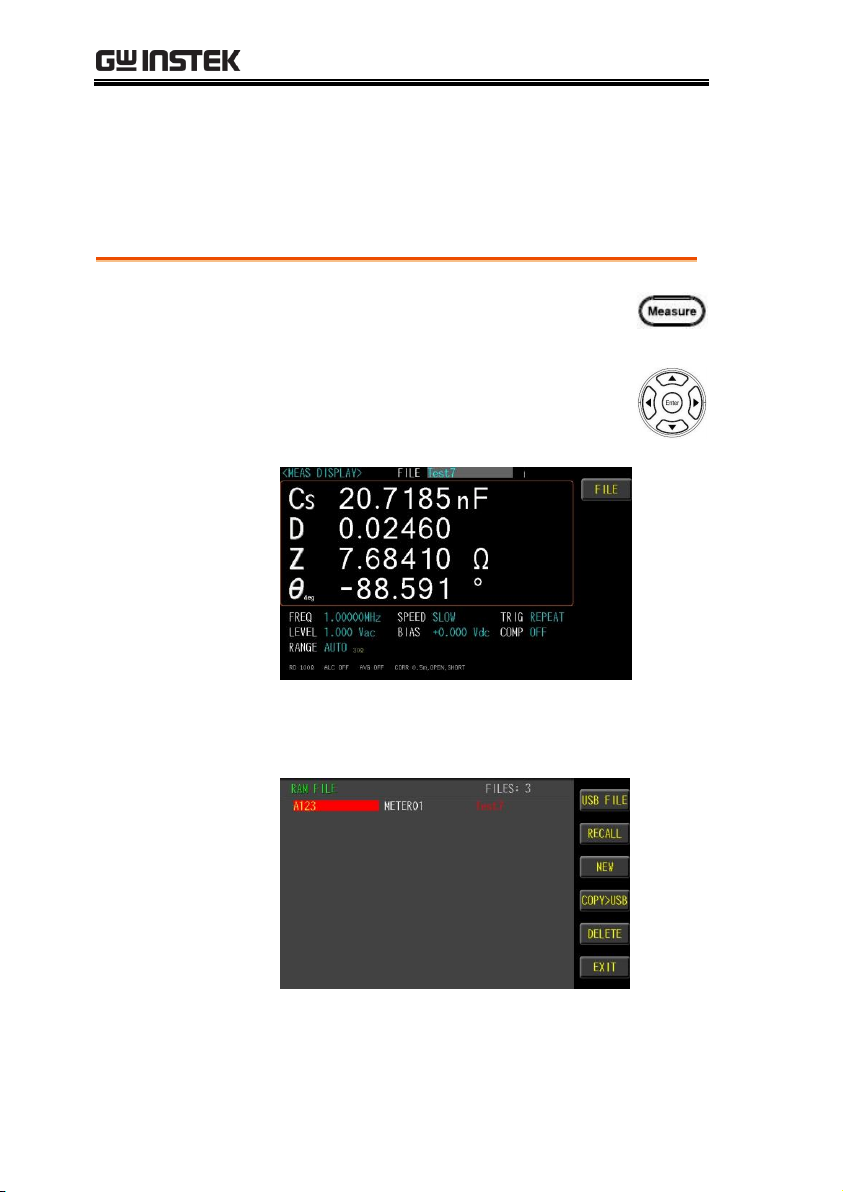

Steps

1. Press the Measure button to enter

[MEASURE DISPLAY] page.

2. Use arrow keys to move cursor and

select FILE on the [MEASURE

DISPLAY] page.

3. Use option key on the right of the LCD

screen to select FILE item.

4. Use option key on the right of the LCD screen

to select a desired item.

Setting FILE

The parameter can be saved in the flash Memory of the instrument.

The meter mode allows the user to access 99 setup groups.

56

Page 57

MEASURE (METER MODE)

Available

parameter

RECALL

load the files in the temporary files

for testing

NEW

Open an empty file and setting the

file name

SAVE AS

Save the test file in the RAM to

another file.

DELETE

Delete the file, the file which is

being used (red) cannot delete.

Note

The LCR-8200 uses the system's temporary files for

testing.

Use "RECALL" to load the files in the instrument

memory into the temporary files of the system.

The file font being used is red and cannot be

deleted. Any parameter change settings will be

saved in the original file instantly.

USB disks can only back up test files. If you want

to use this file, you need to copy the file to the

instrument memory using "COPY> RAM" and

then load it.

57

Page 58

LCR-8000 Series User Manual

Steps

1. Insert a USB disk for using as data recoding.

The instrument will automatically detect the

USB disk format. When it is available, the

USB menu will pop up.

2. Use option key on the right of the LCD

screen to select a desired item. When the USB

disk is plugged in, you can press the ENTER

button to pop up the USB menu.

Setting USB disk

USB disk can store test setup files and LCD screen images and

SWEEP measurement curves and magnitude data.

Available types and file formats:

USB disk type: Flash disk only.

Format: FAT32 / exFAT.

Max memory size: 128GB.

58

Page 59

MEASURE (METER MODE)

Available

options

Save screen

Save LCD screen images to USB disk.

Path>

USB:\LCR8200\SCREEN\SCNxxxx.BMP

File

management

USB file management.

Path> USB:\LCR8200\METER

Format USB

drive

Format the USB disk(FAT32)

59

Page 60

LCR-8000 Series User Manual

Sweep display area description ........................................ 61

Setting type ....................................................................... 62

Setting X-axis ..................................................................... 63

Setting start ....................................................................... 64

Setting stop ....................................................................... 65

Setting level/freq ............................................................... 66

Setting bias ........................................................................ 67

Setting trig ......................................................................... 68

Setting speed..................................................................... 70

Setting scale ...................................................................... 71

Setting func ....................................................................... 72

Setting para ....................................................................... 73

Setting Y-axis ..................................................................... 74

Setting ref .......................................................................... 75

Setting pos ........................................................................ 76

Setting div/decade ............................................................ 77

Setting sweep delay ........................................................... 78

Setting output impedance ................................................ 79

Setting keep previous trace .............................................. 80

Setting trace A/B color ...................................................... 82

Setting USB disk ..............................................................83

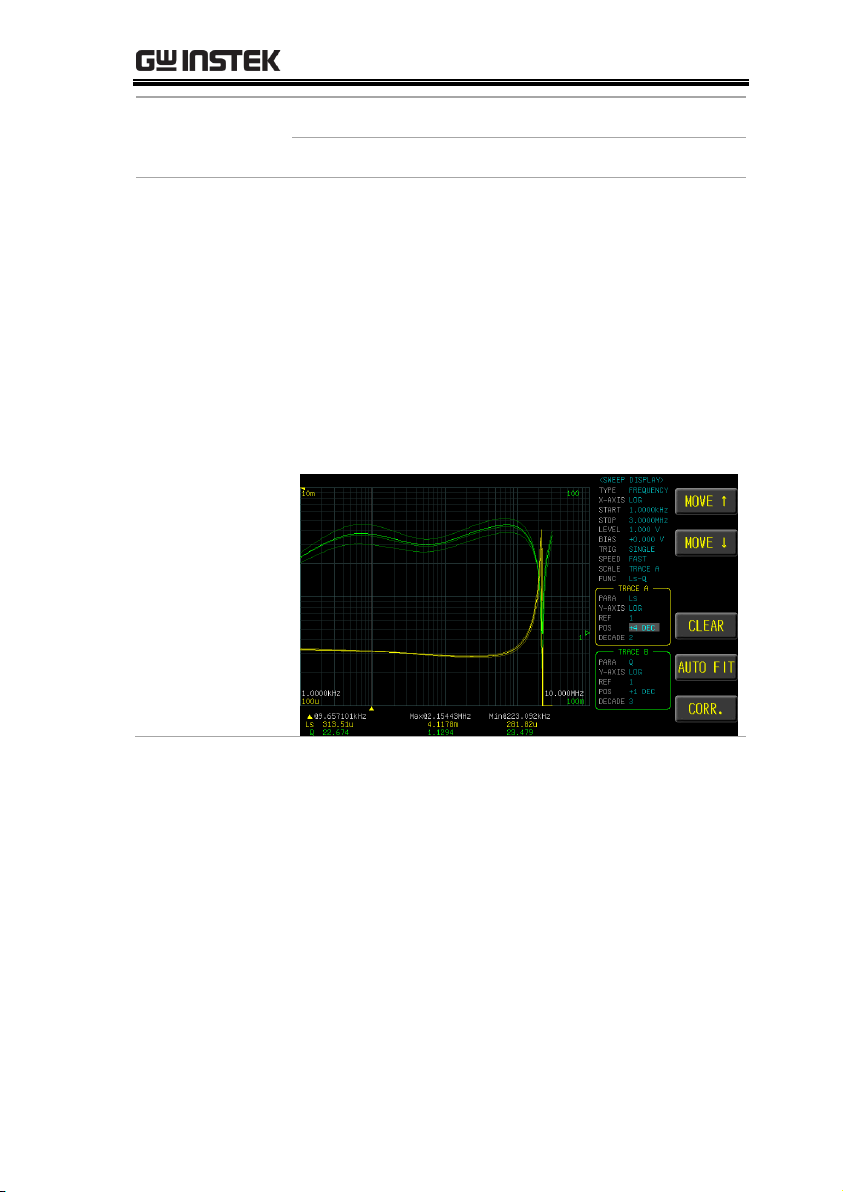

SWEEP (GRAPH MODE)

In this chapter you will learn about all the sweeprelated settings. All the sweep items can be found

on the [SWEEP DISPLAY] [SWEEP MODE

SETUP] page.

60

Page 61

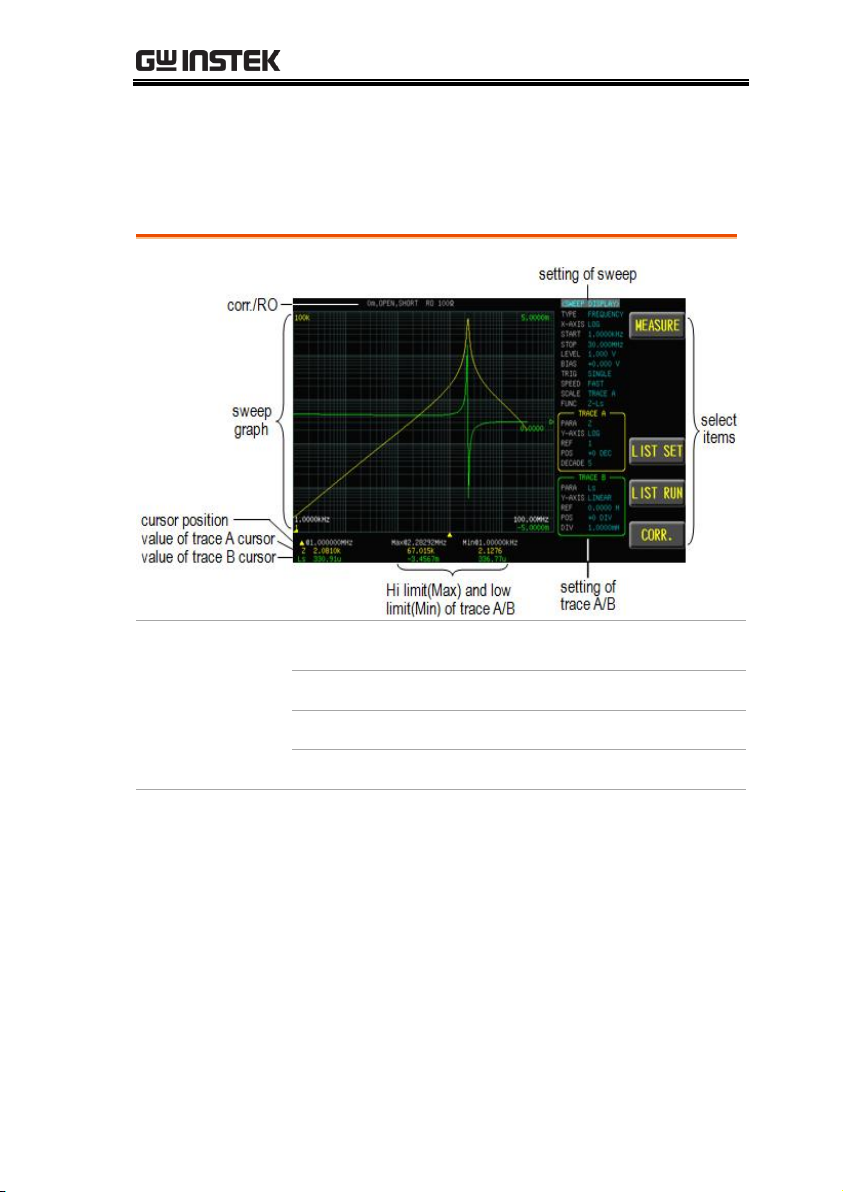

SWEEP (GRAPH MODE)

Available

parameter

MEASURE

Measure meter mode page.

LIST SET

List setting page.

LIST RUN

List run test page.

CORR.

Correction page.

Sweep display area description

The sweep display is a sweep graph mode that provides a sweep

range condition for graph measurements.

61

Page 62

LCR-8000 Series User Manual

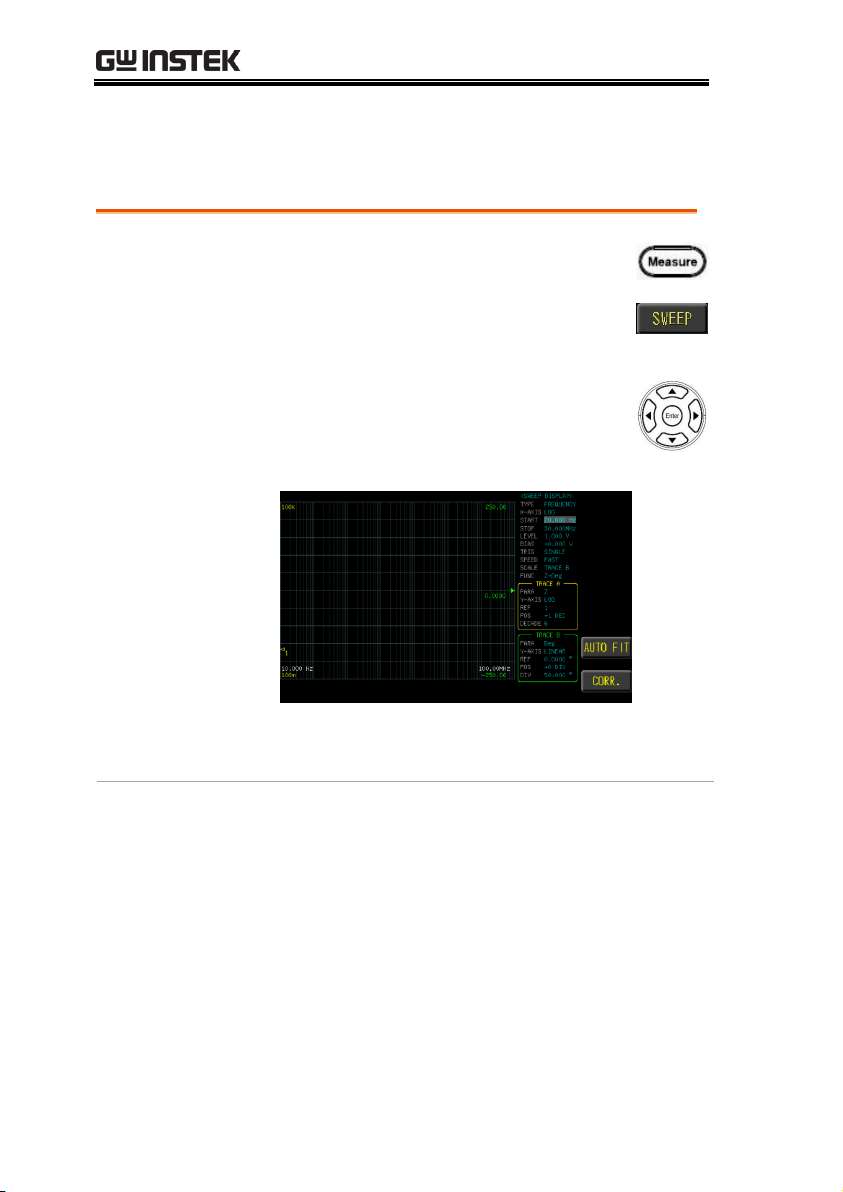

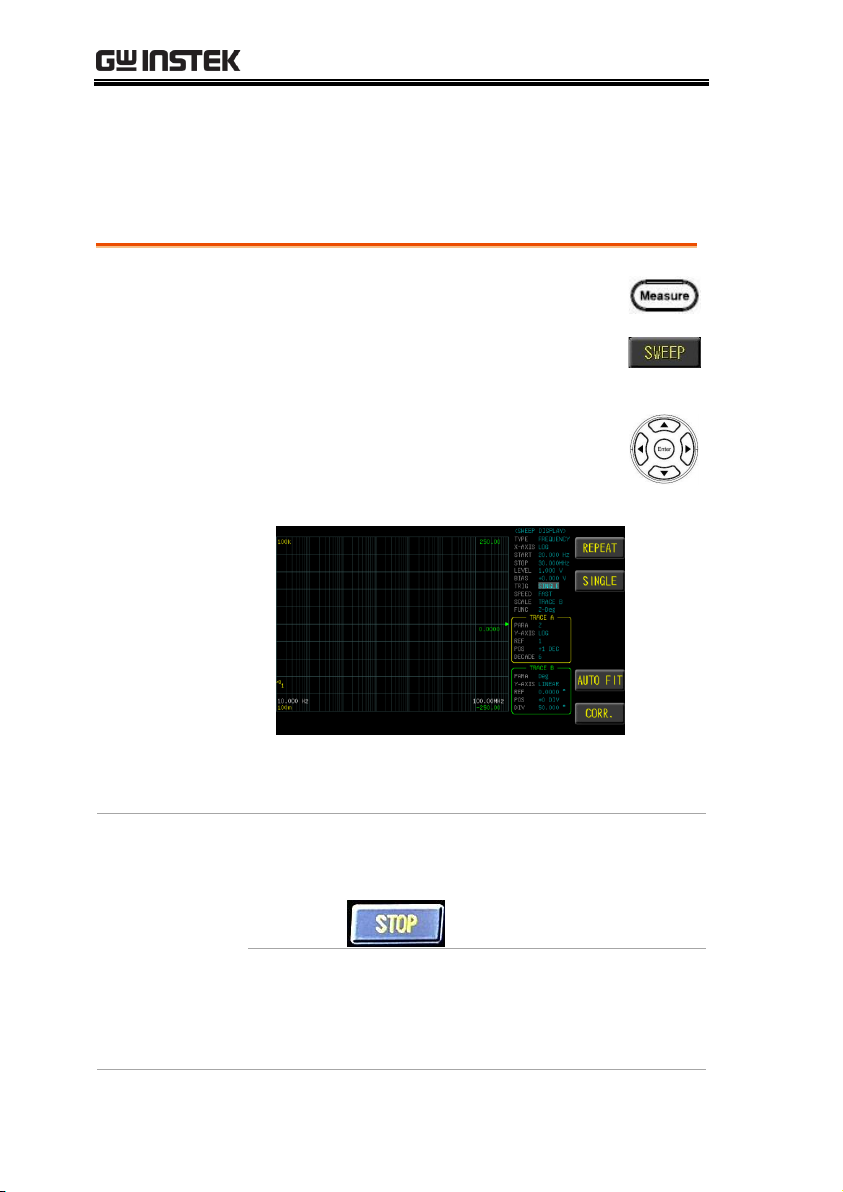

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page, and then press

the SWEEP function button on the

right side of the LCD to enter the

[SWEEP DISPLAY] page.

2. Use arrow keys to move the cursor and

select TYPE item on the [SWEEP

DISPLAY] page.

3. Use option key on the right of the LCD screen to

select a parameter for this sweep item.

Available

parameter

FREQ.

Change frequency range sweep

condition

Vac

Change Vac range sweep condition

Iac

Change Iac range sweep condition

AUTO

FIT

Automatically adjust the Y-axis scale

and position of the sweep graph

Setting type

Sweep type has 3 kinds, which are frequency, Vac and Iac, respectively.

62

Page 63

SWEEP (GRAPH MODE)

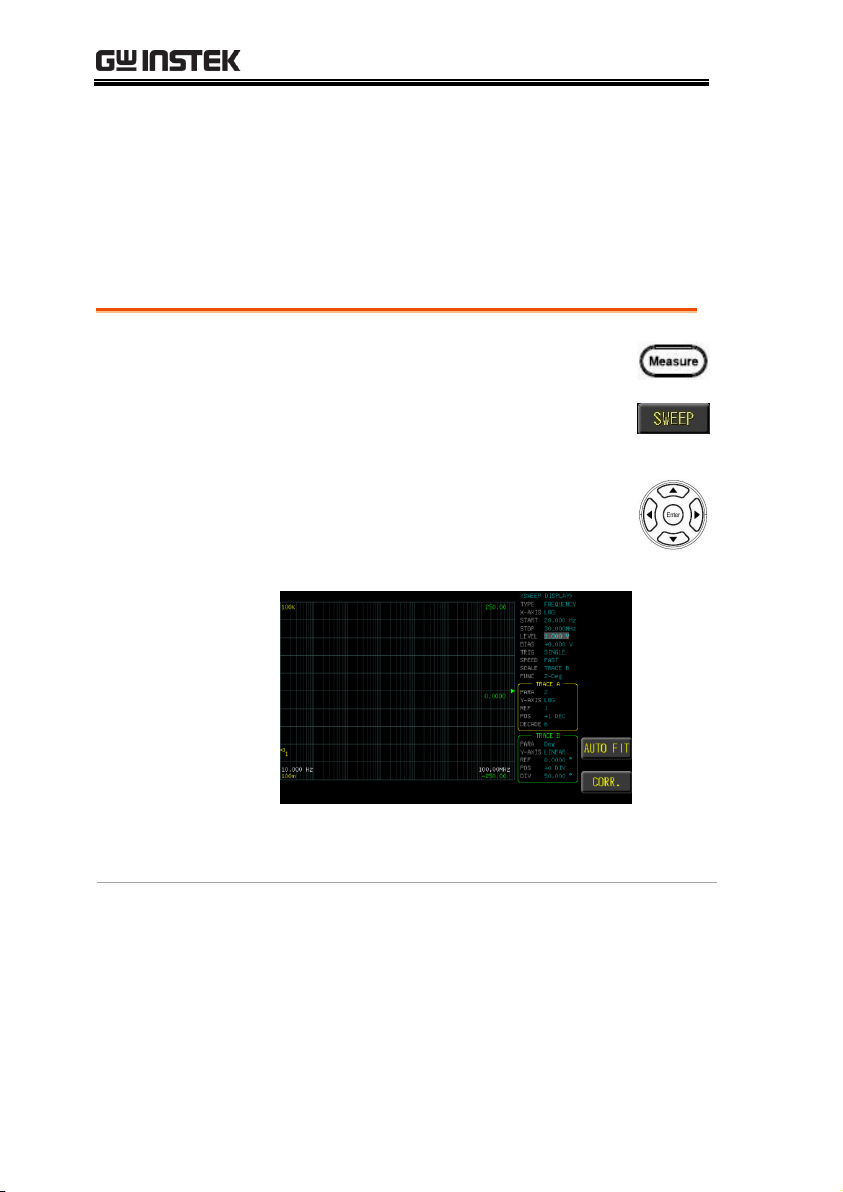

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page, and then

press the SWEEP function button on

the right side of the LCD to enter the

[SWEEP DISPLAY] page.

2. Use arrow keys to move cursor and

select X-AXIS item on the [SWEEP

DISPLAY] page.

3. Use option key on the right of the LCD screen

to select a parameter for this sweep item.

Available

parameter

LINEAR

The starting value to the ending value,

equal to 251 points

LOG

The starting value to the ending value,

use the logarithm to distinguish 267

points (maximum). Different points

depending on the status of the range

setting

AUTO

FIT

Automatically adjust the Y-axis scale

and position of the sweep graph

Setting X-axis

The X-axis scale shows 2 modes LINEAR and LOG.

63

Page 64

LCR-8000 Series User Manual

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page, and then press

the SWEEP function button on the

right side of the LCD to enter the

[SWEEP DISPLAY] page.

2. Use arrow keys to move the cursor and

select START item on the [SWEEP

DISPLAY] page.

3. Use the numeric keypad to enter the test

frequency (Vac or Iac) and unit.

Setting start

Sweep test condition start value. (frequency, Vac, Iac)

64

Page 65

SWEEP (GRAPH MODE)

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page, and then press

the SWEEP function button on the

right side of the LCD to enter the

[SWEEP DISPLAY] page.

2. Use arrow keys to move the cursor and

select STOP item on the [SWEEP

DISPLAY] page.

3. Use the numeric keypad to enter the test

frequency (Vac or Iac) and unit.

Setting stop

Sweep test condition stop value. (frequency, Vac, Iac)

65

Page 66

LCR-8000 Series User Manual

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page, and then press

the SWEEP function button on the

right side of the LCD to enter the

[SWEEP DISPLAY] page.

2. Use arrow keys to move the cursor and

select LEVEL/FREQ item on the

[SWEEP DISPLAY] page.

3. Use the numeric keypad to enter the test

Vac/Iac (frequency) and unit.

Setting level/freq

When performing a frequency sweep test, you need to set the test

voltage/current (Vac/Iac). If you are performing a voltage/current

scan test, you need to set the test frequency. The voltage range is

10mV-2Vrms and current range is 0.1mA-20mArms. 2Vrms can

only be used at <= 1MHz.

66

Page 67

SWEEP (GRAPH MODE)

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page, and then

press the SWEEP function button on

the right side of the LCD to enter the

[SWEEP DISPLAY] page.

2. Use arrow keys to move the cursor

and select BIAS item on the [SWEEP

DISPLAY] page.

3. Use the numeric keypad to enter the test dc

bias and unit.

Setting bias

LCR-8200 Series offers DC BIAS ±12V. BIAS has a set value, when

the trigger test starts, DC BIAS will automatically turn on the output,

and the DC BIAS button indicator will light up; at the end of the test,

DC BIAS will automatically turn off and the light will be off.

When input is above the instrument voltage range will be displayed

“Out of range!”.

67

Page 68

LCR-8000 Series User Manual

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page, and then

press the SWEEP function button on

the right side of the LCD to enter the

[SWEEP DISPLAY] page.

2. Use arrow keys to move the cursor

and select TRIG item on the [SWEEP

DISPLAY] page.

3. Use option key on the right of the LCD screen

to select a trigger mode for this sweep item.

Available

parameter

REPEAT

Continuous sweep test. Press the STOP

function button on the right side of the

LCD to stop the SWEEP test.

SINGLE

External trigger mode, including

Manual/Handler/TRIGGER

Input/Remote control mode.

Manual mode: The device performs a

Setting trig

Trig mode has REPEAT and SINGLE mode. Press the Trigger

button to start the sweep test once.

68

Page 69

SWEEP (GRAPH MODE)

sweep test once the Trigger button is

pressed.

Handler mode: When a negative edge

pulse is received from the handler

interface on the rear panel, the device

performs a sweep test cycle.

TRIGGER Input mode: When a

negative edge pulse is received from

the TRIGGER Input on the rear panel,

the device performs a sweep test

cycle.

Remote control mode: When a

measurement command is sent from

the RS-232 or USB or GPIB interface,

the device performs a sweep test

cycle.

69

Page 70

LCR-8000 Series User Manual

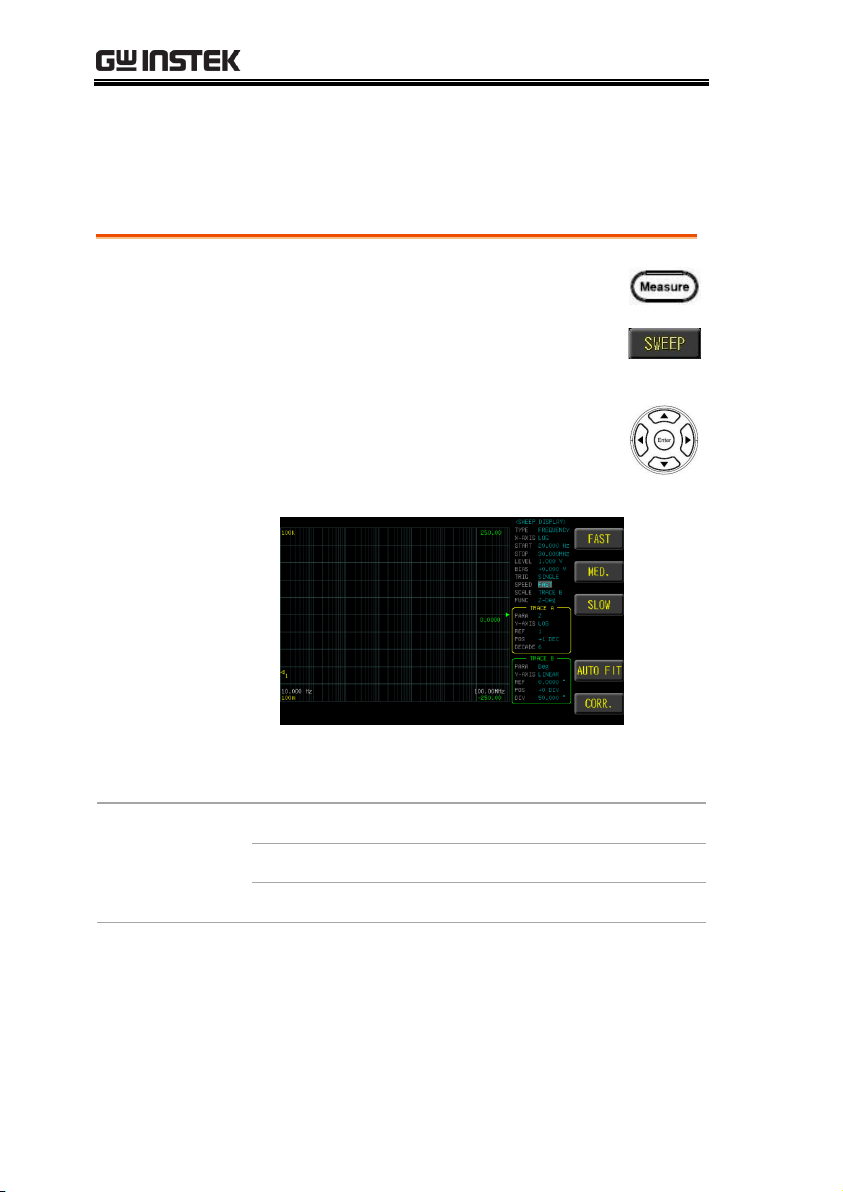

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page, and then

press the SWEEP function button on

the right side of the LCD to enter the

[SWEEP DISPLAY] page.

2. Use arrow keys to move the cursor

and select SPEED item on the [SWEEP

DISPLAY] page.

3. Use option key on the right of the LCD screen

to select a speed mode for this sweep item.

Available test

speed

FAST

2.5ms (>10kHz)

MED.

50ms (>20Hz)

SLOW

100ms

Setting speed

3 test speeds ( SLOW, MED., FAST). The slower the test, the more

accurate and stable the test result.

70

Page 71

SWEEP (GRAPH MODE)

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page, and then

press the SWEEP function button on

the right side of the LCD to enter the

[SWEEP DISPLAY] page.

2. Use arrow keys to move the cursor

and select SCALE item on the

[SWEEP DISPLAY] page.

3. Use option key on the right of the LCD screen

to select a scale type for this sweep item.

Available

parameter

TRACE A

Adjust with the trace A setting

TRACE B

Adjust with the trace B setting

AUTO

FIT

Automatically adjust the Y-axis scale

and position of the sweep graph

Setting scale

The scale of the Y-axis is displayed with the setting of trace A or

trace B.

71

Page 72

LCR-8000 Series User Manual

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page, and then

press the SWEEP function button on

the right side of the LCD to enter the

[SWEEP DISPLAY] page.

2. Use arrow keys to move the cursor

and select FUNC item on the [SWEEP

DISPLAY] page.

3. Use option key on the right of the LCD screen

to select a function type for this sweep item.

Setting func

Select the combination of parameters to be sweep test.

Func1-16: Z-Deg, Y-Deg, R-X, G-B, Z-Cs, Z-Cp, Z-Ls, Z-Lp, Cs-Rs,

Cp-Rp, Cp-G, Cs-D, Ls-Rs, Lp-Rp, Lp-G, Ls-Q.

FUNC selection If you do not have the desired test parameters, you

can go to the PARA item of TRACE A/B and select the required

test parameters.

72

Page 73

Setting para

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page, and then

press the SWEEP function button on

the right side of the LCD to enter the

[SWEEP DISPLAY] page.

2. Use arrow keys to move the cursor

and select PARA item on the [SWEEP

DISPLAY] page.

3. Use option key on the right of the LCD screen

to select a parameter for this sweep item.

SWEEP (GRAPH MODE)

Select test parameters of trace A or trace B.

73

Page 74

LCR-8000 Series User Manual

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page, and then

press the SWEEP function button on

the right side of the LCD to enter the

[SWEEP DISPLAY] page.

2. Use arrow keys to move cursor and

select Y-AXIS item on the [SWEEP

DISPLAY] page.

3. Use option key on the right of the LCD screen

to select a parameter for this sweep item.

Available

parameter

LINEAR

The starting value to the ending value,

equal to 400 points

LOG

The starting value to the ending value,

use the logarithm to distinguish 400

points (maximum). Different points

depending on the status of the range

setting

AUTO

FIT

Automatically adjust the Y-axis scale

and position of the sweep graph

Setting Y-axis

The Y-axis scale shows 2 modes LINEAR and LOG of trace A or

trace B.

74

Page 75

SWEEP (GRAPH MODE)

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page, and then

press the SWEEP function button on

the right side of the LCD to enter the

[SWEEP DISPLAY] page.

2. Use arrow keys to move the cursor

and select REF item on the [SWEEP

DISPLAY] page.

3. Use option key on the right of the LCD screen

to select a scale type for this sweep item.

Available

parameter

MOVE↑

Reference point scale is adjusted

downwards

MOVE↓

Reference point scale is adjusted

upwards

AUTO

FIT

Automatically adjust the Y-axis scale

and position of the sweep graph

Setting ref

Set the Y-axis reference point scale for trace A or B. This parameter

can be set by selecting LINEAR in Y-axis.

75

Page 76

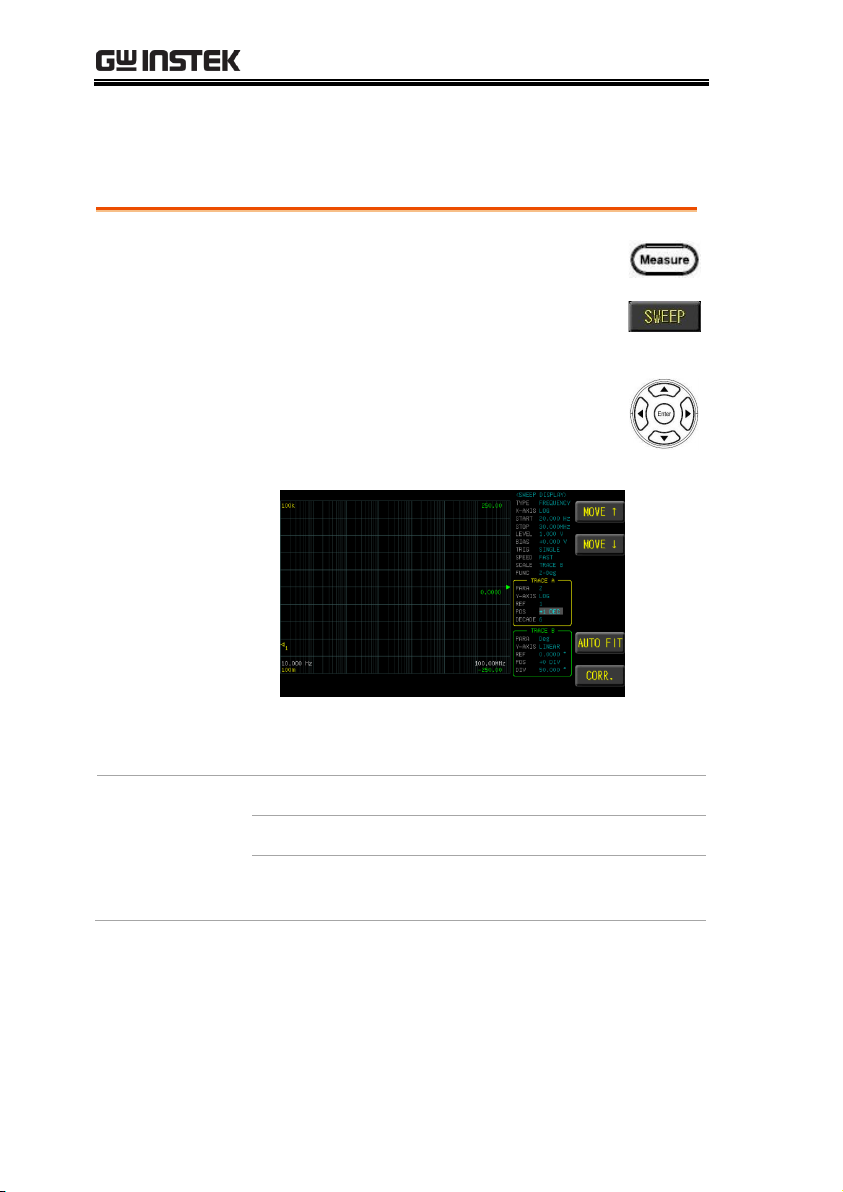

Setting pos

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page, and then

press the SWEEP function button on

the right side of the LCD to enter the

[SWEEP DISPLAY] page.

2. Use arrow keys to move the cursor

and select POS item on the [SWEEP

DISPLAY] page.

3. Use option key on the right of the LCD screen

to select a scale type for this sweep item.

Available

parameter

MOVE↑

Move the sweep graphic up

MOVE↓

Move the sweep graphic down

AUTO

FIT

Automatically adjust the Y-axis scale

and position of the sweep graph

LCR-8000 Series User Manual

Move the graphic of trace A or trace B.

76

Page 77

SWEEP (GRAPH MODE)

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page, and then

press the SWEEP function button on

the right side of the LCD to enter the

[SWEEP DISPLAY] page.

2. Use arrow keys to move the cursor

and select DIV (LINEAR) or

DECADE (LOG) item on the [SWEEP

DISPLAY] page.

3. Use option key on the right of the LCD screen

to select a scale type for this sweep item.

Available

parameter

ZOOM-

Scale of each interval becomes larger

ZOOM+

Scale of each interval becomes smaller

AUTO

FIT

Automatically adjust the Y-axis scale

and position of the sweep graph

Setting div/decade

The scale of the Y-axis is displayed with the setting of trace A or

trace B.

77

Page 78

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page, and then

press the SWEEP function button on

the right side of the LCD to enter the

[SWEEP DISPLAY] page, and press

the Setup button to enter [SWEEP

MODE SETUP] page.

2. Use arrow keys to move the cursor

and select SWEEP DELAY item on the

[SWEEP MODE SETUP] page.

3. Use the numeric keypad to enter the time (ms).

LCR-8000 Series User Manual

Setting sweep delay

Set the sweep test the delay time between each test point and point.

The delay time range is 0ms~5000ms.

78

Page 79

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page, and then

press the SWEEP function button on

the right side of the LCD to enter the

[SWEEP DISPLAY] page, and press

the Setup button to enter [SWEEP

MODE SETUP] page.

2. Use arrow keys to move the cursor

and select OUTPUT IMPEDANCE

item on the [SWEEP MODE SETUP]

page.

3. Use the numeric keypad to enter the time (ms).

Available

parameter

100Ω

Set output impedance to 100Ω

25Ω

Set output impedance to 25Ω

SWEEP (GRAPH MODE)

Setting output impedance

The output impedance can be set to 25Ω or 100Ω.

The varied signal source output impedance will lead to the varied

current or the difference of measuring value. If selecting <25Ω>,

then the voltage range is 10mV~1Vrms and the current range is

400µA~40mArms.

If need to compare test results with Keysight select 100Ω.

79

Page 80

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page, and then

press the SWEEP function button on

the right side of the LCD to enter the

[SWEEP DISPLAY] page, and press

the Setup button to enter [SWEEP

MODE SETUP] page.

2. Use arrow keys to move the cursor

and select KEEP PREVIOUS TRACE

item on the [SWEEP MODE SETUP]

page.

3. Use option key on the right of the LCD screen

to select a desired item.

LCR-8000 Series User Manual

Setting keep previous trace

Save sweep graph for part alignment or adjustment.

80

Page 81

SWEEP (GRAPH MODE)

Available

parameter

OFF

Save sweep graph turn off

ON

Save sweep graph turn on

Function

Description

Multiple parts are compared to the measurement

curve, this function can be turned on, and the

parts are measured in order to understand the

difference.

A single part or circuit can be measured before

adjustment. Turn on this function and adjust it

after making adjustments to understand the

difference in adjustment.

Use the CLEAR function key to clear the all

graph.

81

Page 82

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page, and then

press the SWEEP function button on

the right side of the LCD to enter the

[SWEEP DISPLAY] page, and press

the Setup button to enter [SWEEP

MODE SETUP] page.

2. Use arrow keys to move the cursor

and select TRACE A/B COLOR item

on the [SWEEP MODE SETUP] page.

3. Use option key on the right of the LCD screen

to select a desired color.

Available

parameter

COLOR-

Adjust color down

COLOR+

Adjust color up

LCR-8000 Series User Manual

Setting trace A/B color

Set the display color of trace A or trace B.

82

Page 83

SWEEP (GRAPH MODE)

Steps

1. Insert a USB disk for using as data

recoding. The instrument will

automatically detect the USB disk format.

When it is available, the USB menu will

pop up.

2. Use option key on the right of the LCD

screen to select a desired item. When the

USB disk is plugged in, you can press the

ENTER button to pop up the USB menu.

Setting USB disk

USB disk can store test setup files and LCD screen images and

SWEEP measurement curves and magnitude data.

Available types and file formats:

USB disk type: Flash disk only.

Format: FAT32 / exFAT.

Max memory size: 128GB.

83

Page 84

LCR-8000 Series User Manual

Available

options

Save screen

Save LCD screen images to USB disk.

Path>

USB:\LCR8200\SCREEN\SCNxxxx.B

MP

Save sweep

graphic

Save sweep graph to USB disk.

Path>

USB:\LCR8200\SWEEP\SWPxxxx.BMP

Save sweep

data

Save sweep measure data to USB disk.

Path>

USB:\LCR8200\SWEEP\SWPxxxx.CSV

Format USB

drive

Format the USB disk(FAT32)

84

Page 85

LIST (MULTI STEP MODE)

LIST SET/LIST RUN display area description .................. 86

Setting step ....................................................................... 87

Setting parameter .............................................................. 89

Setting frequency............................................................... 91

Setting level ....................................................................... 92

Setting DC bias.................................................................. 93

Setting speed ..................................................................... 94

Setting delay ...................................................................... 95

Setting comp mode ........................................................... 96

Setting trigger mode ....................................................... 100

Setting trigger delay ........................................................ 103

Setting OUTPUT IMPEDANCE ....................................... 104

Setting ALC ...................................................................... 105

Setting beep when ........................................................... 106

Setting range hold ........................................................... 107

Setting fail reset .............................................................. 108

Setting statistics .............................................................. 109

Setting bin sorting ......................................................... 110

Setting FILE ................................................................... 116

Setting USB disk............................................................ 118

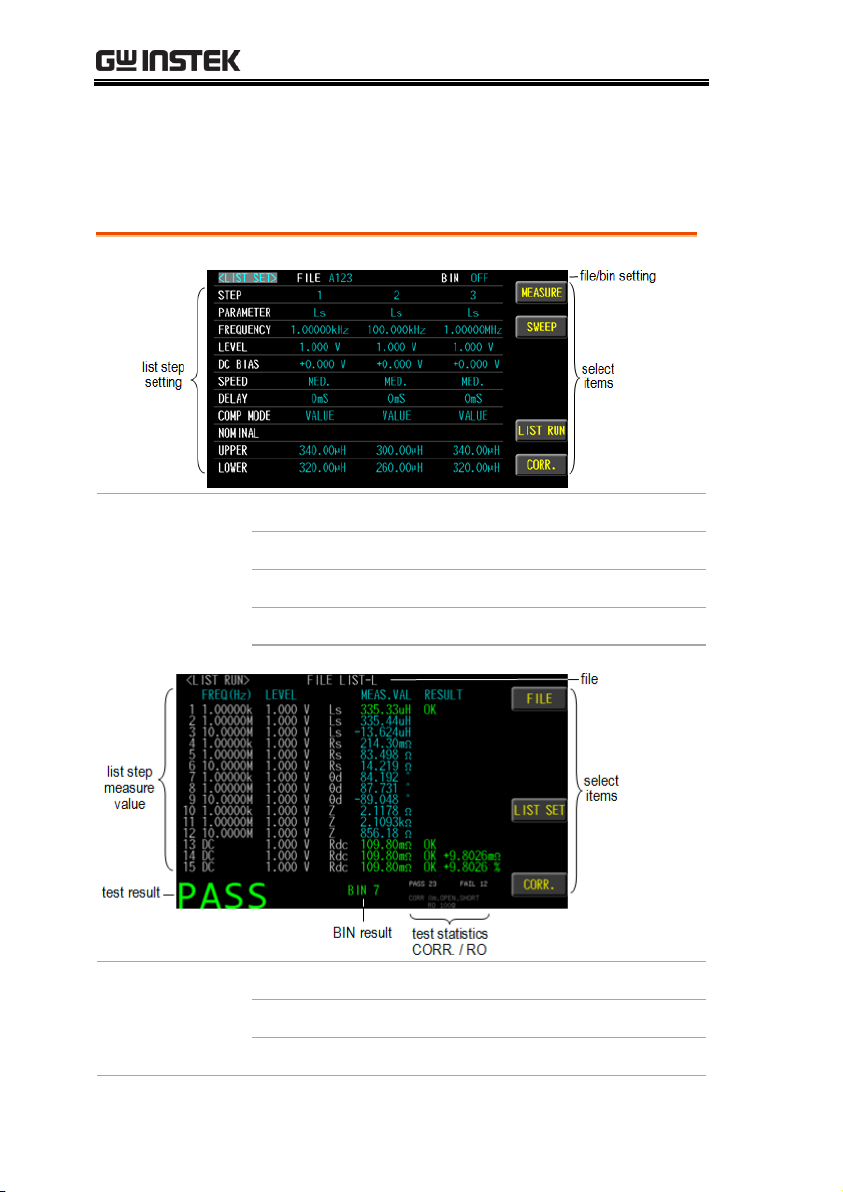

LIST (MULTI STEP MODE)

In this chapter you will learn about all the listrelated settings. All the list setting items can be

found on the[LIST SET] [LIST MODE SETUP]

[LIST RUN] page.

85

Page 86

LCR-8000 Series User Manual

Available

parameter

MEASURE

Meter mode page

SWEEP

Sweep mode page.

LIST RUN

List run test page

CORR.

Correction page

Available

parameter

FILE

List file management

LIST SET

List setting page

CORR.

Correction page

LIST SET/LIST RUN display area description

The list measurement display is a multi-step mode that provides

simultaneous multi-condition measurement for the part.

86

Page 87

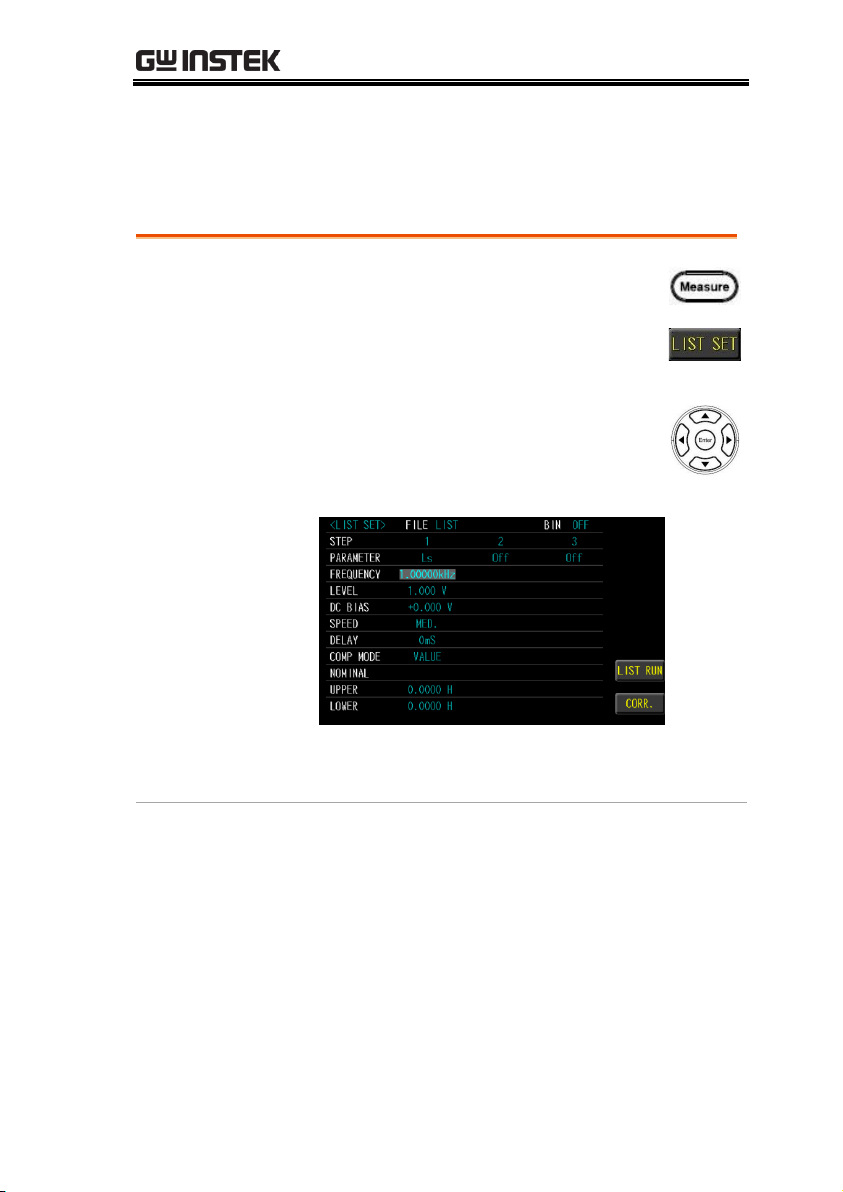

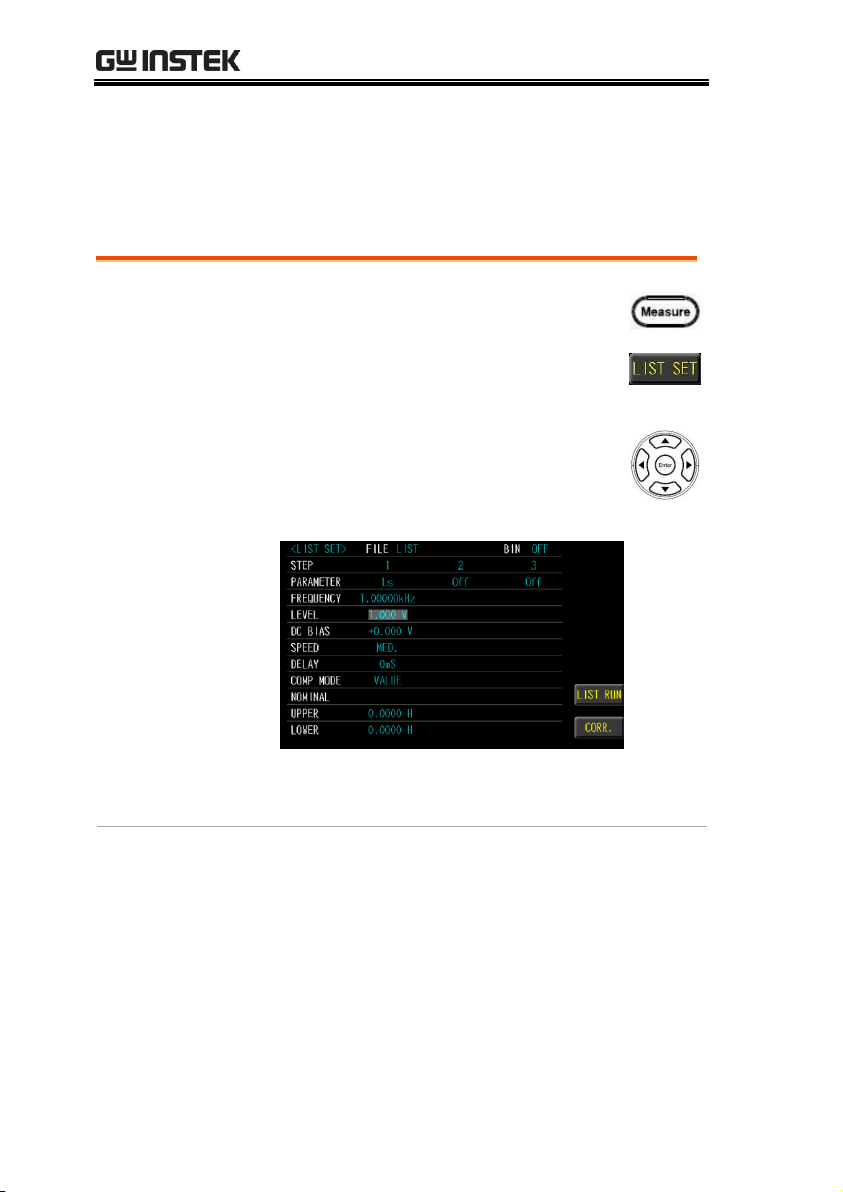

Setting step

Steps

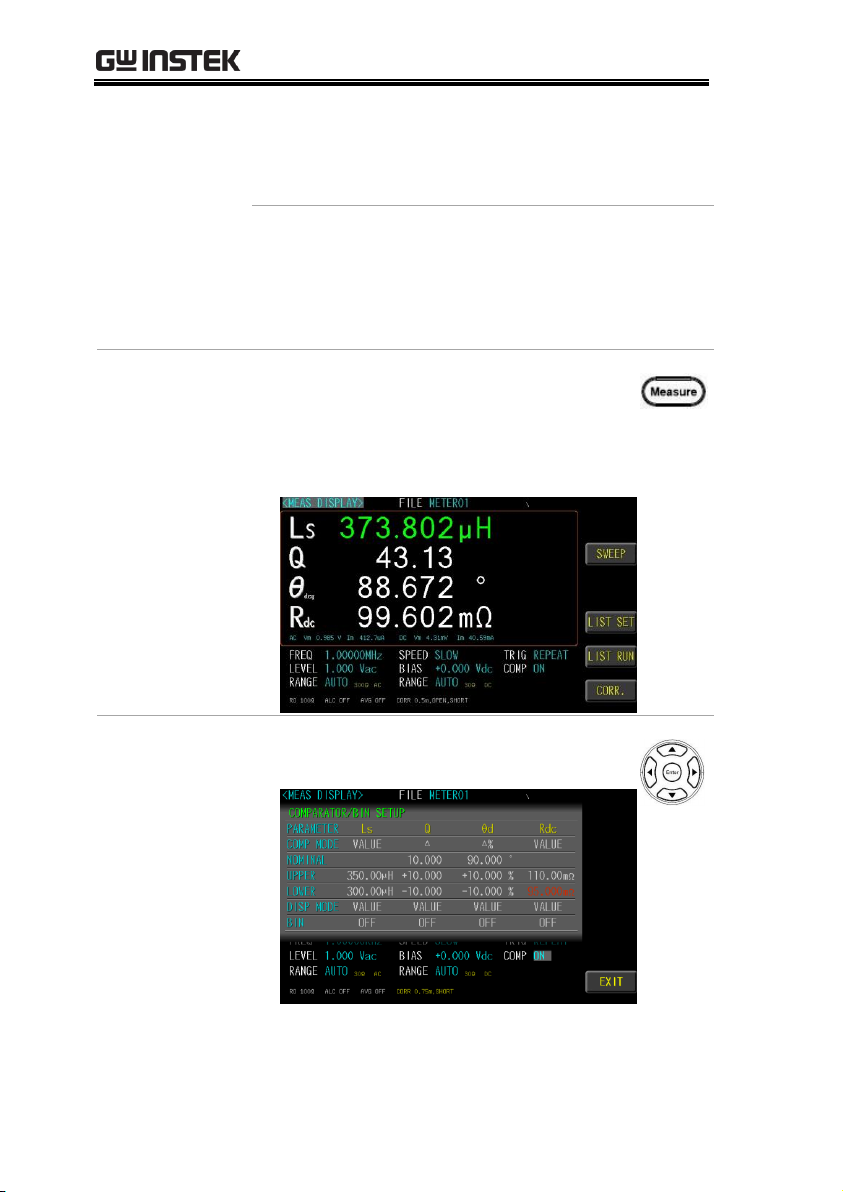

1. Press the Measure button to enter

[MEAS DISPLAY] page, and then

press the LIST SET function button

on the right side of the LCD to enter

the [LIST SET] page.

2. Use arrow keys to move cursor and

select STEP item on the [LIST SET]

page.

3. Use option key on the right of the LCD screen

to select a desired item.

LIST (MULTI STEP MODE)

LIST SET has 15 steps to set.

87

Page 88

Available

parameter

COPY

Copy the cursor where the step is

added to the next step.

Copy setp1 to setp2.

INSERT

Insert a blank step in the cursor step to

the next step.

Insert blank step in the next step of

step1.

DELETE

Delete the cursor step.

Delete step3

LCR-8000 Series User Manual

88

Page 89

LIST (MULTI STEP MODE)

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page, and then

press the LIST SET function button

on the right side of the LCD to enter

the [LIST SET] page.

2. Use arrow keys to move cursor and

select PARAMETER item on the [LIST

SET] page.

3. Use option key on the right of the LCD screen

to select a parameter for this measurement

item.

Parameter

Ls

Equivalent Series Inductance

Lp

Equivalent Parallel Inductance

Cs

Equivalent Series Capacitance

Cp

Equivalent Parallel Capacitance

Rdc

DC Resistance

Rs

Equivalent Series Resistance (ESR)

Rp

Equivalent Parallel Resistance

Z

Absolute value of impedance

θ

deg

Phase angle of impedance(degree)

Setting parameter

89

Page 90

LCR-8000 Series User Manual

θ

rad

Phase angle of impedance(radian)

Q

Quality Factor, (Q = 1/D)

D

Dissipation Factor

, Loss coefficient (tanδ)

R

Resistance

X

Reactance

Y

Absolute value of admittance

G

Conductivity

B

Susceptance

90

Page 91

LIST (MULTI STEP MODE)

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page, and then

press the LIST SET function button

on the right side of the LCD to enter

the [LIST SET] page.

2. Use arrow keys to move cursor and

select FREQUENCY item on the [LIST

SET] page.

3. Use the numeric keypad to enter the test

frequency.

Setting frequency

The frequency range is 10Hz~5MHz/10MHz/20MHz/30MHz, and

the resolution is set at 6 digits..

91

Page 92

LCR-8000 Series User Manual

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page, and then

press the LIST SET function button

on the right side of the LCD to enter

the [LIST SET] page.

2. Use arrow keys to move cursor and

select LEVEL item on the [LIST SET]

page.

3. Use the numeric keypad to enter the test

voltage/current.

Setting level

Test signal voltage/current level can be set (RMS value). The

voltage range is 10mV-2Vrms and current range is 0.1mA20mArms. 2Vrms can only be used at <= 1MHz..

92

Page 93

LIST (MULTI STEP MODE)

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page, and then

press the LIST SET function button

on the right side of the LCD to enter

the [LIST SET] page.

2. Use arrow keys to move cursor and

select DC BIAS item on the [LIST

SET] page.

3. Use the numeric keypad to enter the test DC

Bias.

Setting DC bias

DC BIAS range is -12V~+12V. When input is above the instrument

voltage range will be displayed “Out of range!”. The test step has DC

BIAS. When this step is tested, the instrument will automatically

execute the DC BIAS output, and the DC Bias button will light up and

will automatically turn off at the end of the step.

93

Page 94

LCR-8000 Series User Manual

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page, and then

press the LIST SET function button

on the right side of the LCD to enter

the [LIST SET] page.

2. Use arrow keys to move cursor and

select SPEED item on the [LIST SET]

page.

3. Use option key on the right of the LCD screen

to select a test speed item.

Available test

speed

MAX.

2.5ms(>10kHz)

FAST

50ms(>20Hz)

MED.

100ms

SLOW

300ms

SLOW2

600ms

Setting speed

5 test speeds (SLOW2, SLOW, MED., FAST and MAX.). The slower

the test, the more accurate and stable the test result.

94

Page 95

LIST (MULTI STEP MODE)

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page, and then

press the LIST SET function button

on the right side of the LCD to enter

the [LIST SET] page.

2. Use arrow keys to move cursor and

select DELAY item on the [LIST SET]

page.

3. Use the numeric keypad to enter the delay

time.

Setting delay

Set the delay time before each test step. The delay time range is

0ms~5000ms.

95

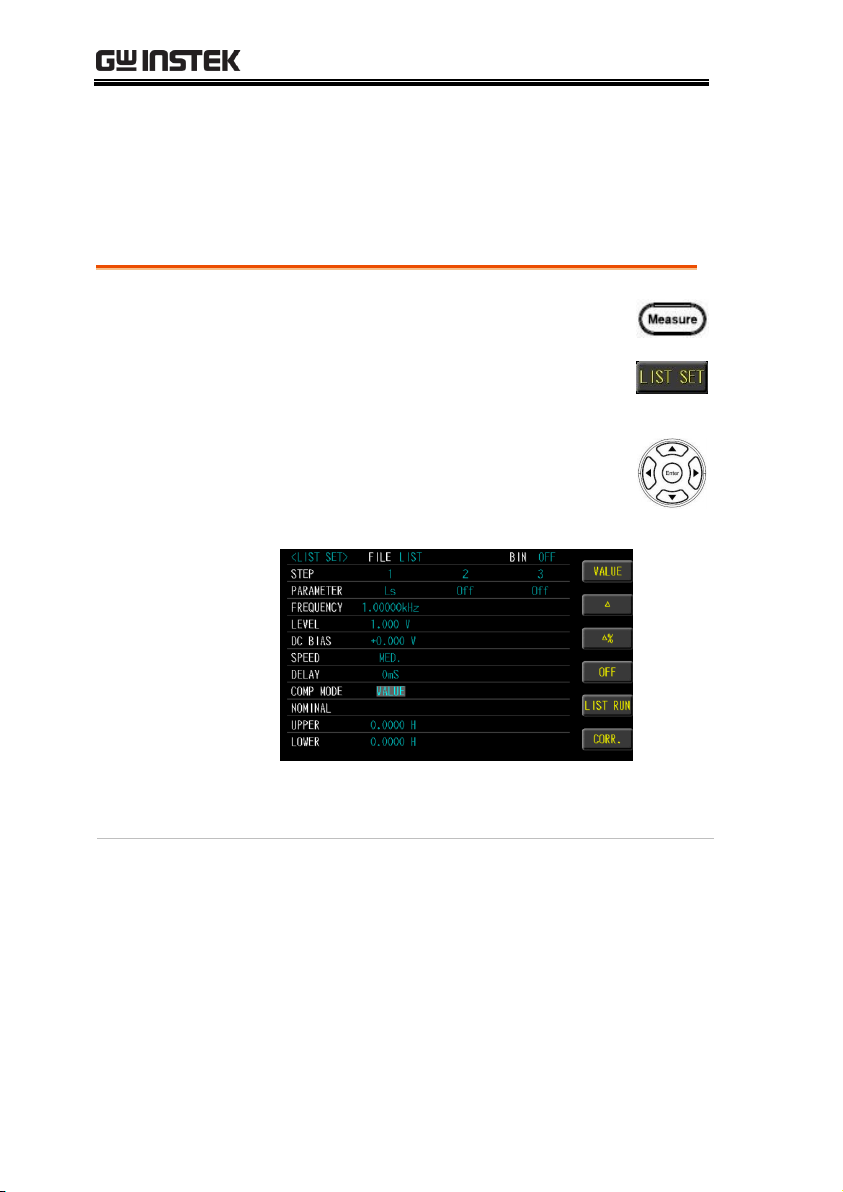

Page 96

LCR-8000 Series User Manual

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page, and then press

the LIST SET function button on the

right side of the LCD to enter the [LIST

SET] page.

2. Use arrow keys to move cursor and

select COMP MODE item on the [LIST

SET] page.

3. Use option key on the right of the LCD screen to

select a mode for this setup.

Setting comp mode

The comparison function settings of 1 to 15 steps can be performed

separately. The comparison mode has measured values, tolerance

values and tolerance %.

96

Page 97

Available options

VALUE

The measured values are compared.

Select this mode, the NOMINAL field

does not need to be set, just set the

UPPER and LOWER upper and lower

limits.

△

The difference between the measured

value and the NOMINAL value is

compared.

Absolute value (Δ) = measure value –

nominal value

Select this mode, the NOMINAL value

and UPPER and LOWER upper and

lower limits must be set.

LIST (MULTI STEP MODE)

97

Page 98

LCR-8000 Series User Manual

△%

The difference between the measured

value and the NOMINAL value is

compared with the percentage of the

NOMINAL value.

Deviation percentages (Δ%) = Absolute

value (Δ)/nominal value × 100%

Select this mode, the NOMINAL value

and UPPER and LOWER upper and

lower limits must be set.

OFF

Turn off the comparator function

Set up

nominal/upper/

lower

4. Use arrow keys to move cursor and

select NOMINAL or UPPER and

LOWER.

5. Use key pad to input value and unit.

Available options

NOMINAL

Compare nominal values. Set only

in the △ and △% modes.

98

Page 99

LIST (MULTI STEP MODE)

UPPER

Comparison of upper limit

LOWER

Comparison of lower limit

Comparator

result display

6. Press the LIST RUN function button on

the right side of the LCD to enter [LIST

RUN] page and press the Trigger

button to run test. Comparator result is

Pass in green color or Fail in red color.

99

Page 100

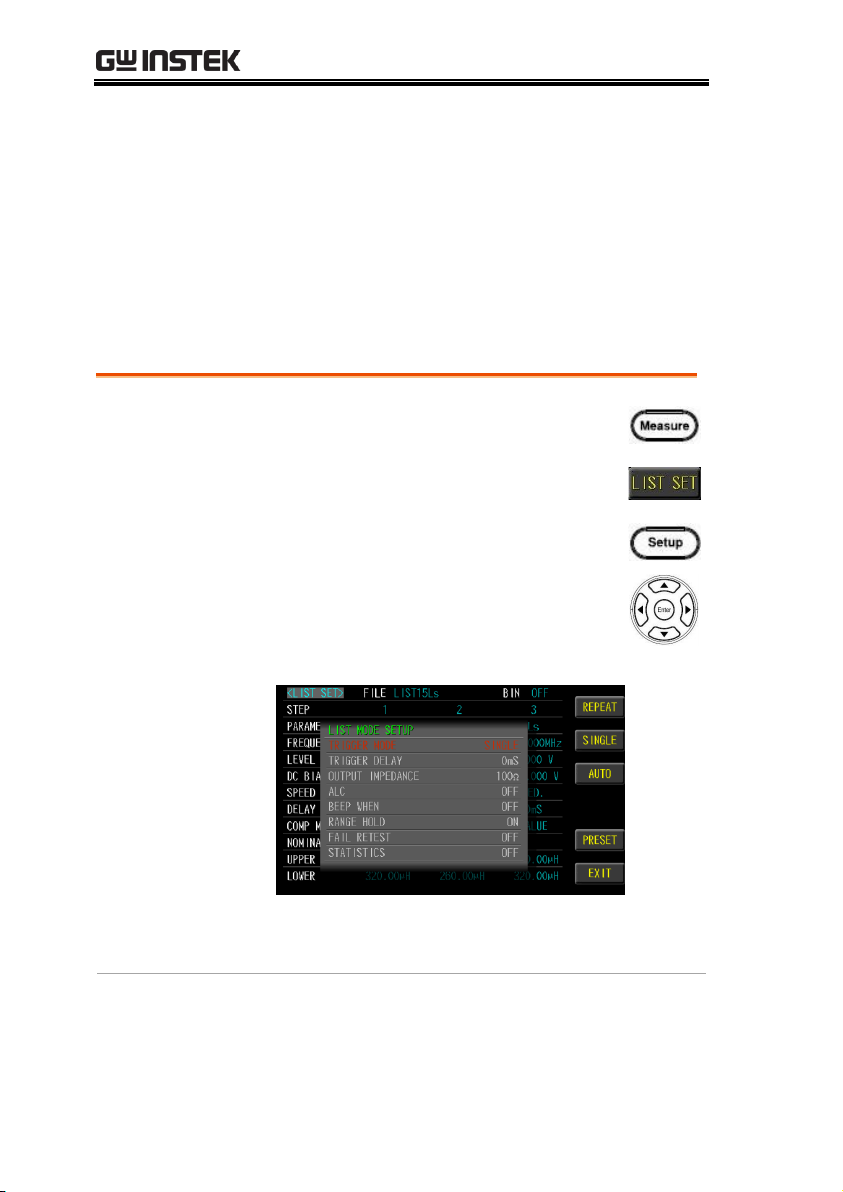

Steps

1. Press the Measure button to enter

[MEAS DISPLAY] page, and press the

LIST SET function button on the right

side of the LCD to enter the [LIST SET]

page, and then press the Setup button

to enter [LIST MODE SETUP] page.

2. Use arrow keys to move cursor and

select TRIGGER MODE item on the

[LIST MODE SETUP] page.

3. Use option key on the right of the LCD screen

to select a desired item.

LCR-8000 Series User Manual

Setting trigger mode

List test step offers REPEAT and SINGLE and AUTO mode.

When the part is tested manually, it is traditionally necessary to

connect the object to be tested, and then press the TRIGGER button

or use the foot switch to start the measurement. Sometimes the

measurement result is wrong because it is not matched, which is

time-consuming and labor-intensive. Switch to AUTO mode and

use automatic trigger to measure, save time and accuracy.

100

Loading...

Loading...