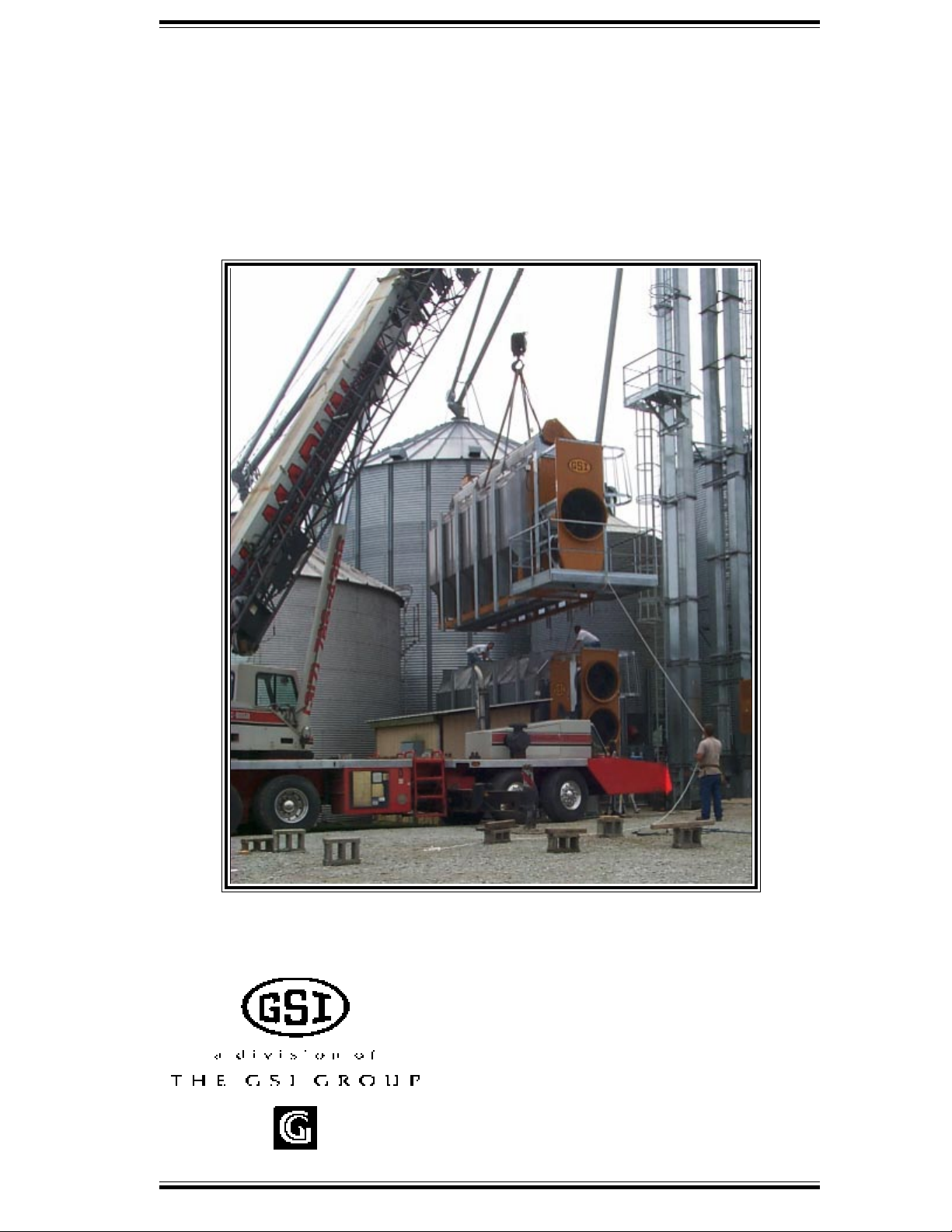

Page 1

Multi-Module Dryer Stacking

Manual

(Review of Stacking a Dryer)

PNEG-902

Page 2

Page 3

Multi - Module Stacking Manual

Contents

Warranty........................................................................................4

Safety Precautions........................................................................5

Stack dryer component callout.....................................................6

Module preparation......................................................................7

Crane bracket placement..............................................................8

Setting lower module on pedestals..............................................9

Anchoring lower module to foundation.....................................10

Installing support legs..................................................................11

Lifting upper module..................................................................12

Setting upper module in place.....................................................13

Securing upper module...............................................................14

Appendix A - Module finishing................................................15

Appendix B - Ladder cage installation......................................16

Notes...........................................................................................18

3--

Page 4

Multi - Module Stacking Manual

Warranty

THE GSI GROUP, INC. ("GSI") WARRANTS ALL PRODUCTS MANUFACTURED BY GSI TO BE FREE OF

DEFECTS IN MATERIAL AND WORKMANSHIP UNDER NORMAL USAGE AND CONDITIONS FOR A PE-

RIOD OF 12 MONTHS AFTER RETAIL SALE TO THE ORIGINAL END USER OF SUCH PRODUCTS. GSI'S

ONLY OBLIGATION IS, AND PURCHASER'S SOLE REMEDY SHALL BE FOR GSI, TO REPAIR OR REPLACE,

AT GSI'S OPTION AND EXPENSE, PRODUCTS THAT, IN GSI'S SOLE JUDGMENT, CONTAIN A MATERIAL

DEFECT DUE TO MATERIALS OR WORKMANSHIP. ALL DELIVERY AND SHIPMENT CHARGES TO AND

FROM GSI'S FACTORY WILL BE PURCHASER'S RESPONSIBILITY. EXPENSES INCURRED BY OR ON BE-

HALF OF THE PURCHASER WITHOUT PRIOR WRITTEN AUTHORIZATION FROM AN AUTHORIZED EM-

PLOYEE OF GSI SHALL BE THE SOLE RESPONSIBILITY OF THE PURCHASER.

EXCEPT FOR THE ABOVE STATED EXPRESS LIMITED WARRANTIES, GSI MAKES NO WARRANTY OF

ANY KIND, EXPRESSED OR IMPLIED, INCLUDING, WITHOUT LIMITATION, WARRANTIES OF MERCHANT-

ABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR USE IN CONNECTION WITH (i) PRODUCT MANU-

FACTURED OR SOLD BY GSI OR (ii) ANY ADVICE, INSTRUCTION, RECOMMENDATION OR SUGGESTION

PROVIDED BY AN AGENT, REPRESENTATIVE OR EMPLOYEE OF GSI REGARDING OR RELATED TO THE

CONFIGURATION, INSTALLATION, LAYOUT, SUITABILITY FOR A PARTICULAR PURPOSE, OR DESIGN

OF SUCH PRODUCT OR PRODUCTS.

IN NO EVENT SHALL GSI BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL OR CONSEQUEN-

TIAL DAMAGES, INCLUDING, WITHOUT LIMITATION, LOSS OF ANTICIPATED PROFITS OR BENEFITS.

PURCHASER'S SOLE AND EXCLUSIVE REMEDY SHALL BE LIMITED TO THAT STATED ABOVE, WHICH

SHALL NOT EXCEED THE AMOUNT PAID FOR THE PRODUCT PURCHASED. THIS WARRANTY IS NOT

TRANSFERABLE AND APPLIES ONLY TO THE ORIGINAL PURCHASER. GSI SHALL HAVE NO OBLIGA-

TION OR RESPONSIBILITY FOR ANY REPRESENTATIVE OR WARRANTIES MADE BY OR ON BEHALF OF

ANY DEALER, AGENT OR DISTRIBUTOR OF GSI.

GSI ASSUMES NO RESPONSIBILITY FOR FIELD MODIFICATIONS OR ERECTION DEFECTS WHICH

CREATE STRUCTURAL OR STORAGE QUALITY PROBLEMS. MODIFICATIONS TO THE PRODUCT NOT

SPECIFICALLY COVERED BY THE CONTENTS OF THIS MANUAL WILL NULLIFY ANY PRODUCT WAR-

RANTY THAT MIGHT HAVE BEEN OTHERWISE AVAILABLE.

THE FOREGOING WARRANTY SHALL NOT COVER PRODUCTS OR PARTS WHICH HAVE BEEN DAM-

AGED BY NEGLIGENT USE, MISUSE, ALTERATION OR ACCIDENT. THIS WARRANTY COVERS ONLY PROD-

UCTS MANUFACTURED BY GSI. THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WAR-

RANTIES EXPRESS OR IMPLIED. GSI RESERVES THE RIGHT TO MAKE DESIGN OR SPECIFICATION

CHANGES AT ANY TIME.

PRIOR TO INSTALLATION, PURCHASER HAS THE RESPONSIBILITY TO RESEARCH AND COMPLY

WITH ALL FEDERAL, STATE AND LOCAL CODES WHICH MAY APPLY TO THE LOCATION AND INSTAL-

LATION.

4--

Page 5

Multi - Module Stacking Manual

Safety Precautions

General Safety Statements

The GSI Group Inc.’s Principal concern is your safety and the safety of others associated with grain handling

equipment. We want to keep you as a customer. This manual is to help you understand safe operating procedures and some

problems which may be encountered by the operator and other personnel.

As owner and/or operator, it is your responsibility to know what requirements, hazards and precautions exist and

inform all personnel associated with, or in the area of the grain dryer. Safety precautions may be required from the personnel. Avoid any alteration to the equipment. Such alterations may produce a very dangerous situation, where serious injury

or death may occur.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible injury or death.

DANGER indicates an imminently hazardous situation which, if not

DANGER

WARNING

avoided, will result in death or serious injury

WARNING indicates a potentially hazardous situation which , if not

avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not

CAUTION

CAUTION

CAUTION used without the safety alert symbol indicates a potentially hazardous situation which, if not avoided, may result in property damage.

avoided, may result in minor or moderate injury.

BE ALERT!

Danger!

Personnel operating or working around electrical equipment should read this manual. This manual must

be delivered with equipment to its owner. Failure to read this manual and its safety instructions is a

misuse of the equipment.

Important!

This product may have sharp edges! To avoid injury handle sharp edges with caution and use

proper protective clothing and equipment at all times.

If you have any questions regarding installation and safety, please contact your GSI, Inc. representative.

5--

Page 6

Multi - Module Stacking Manual

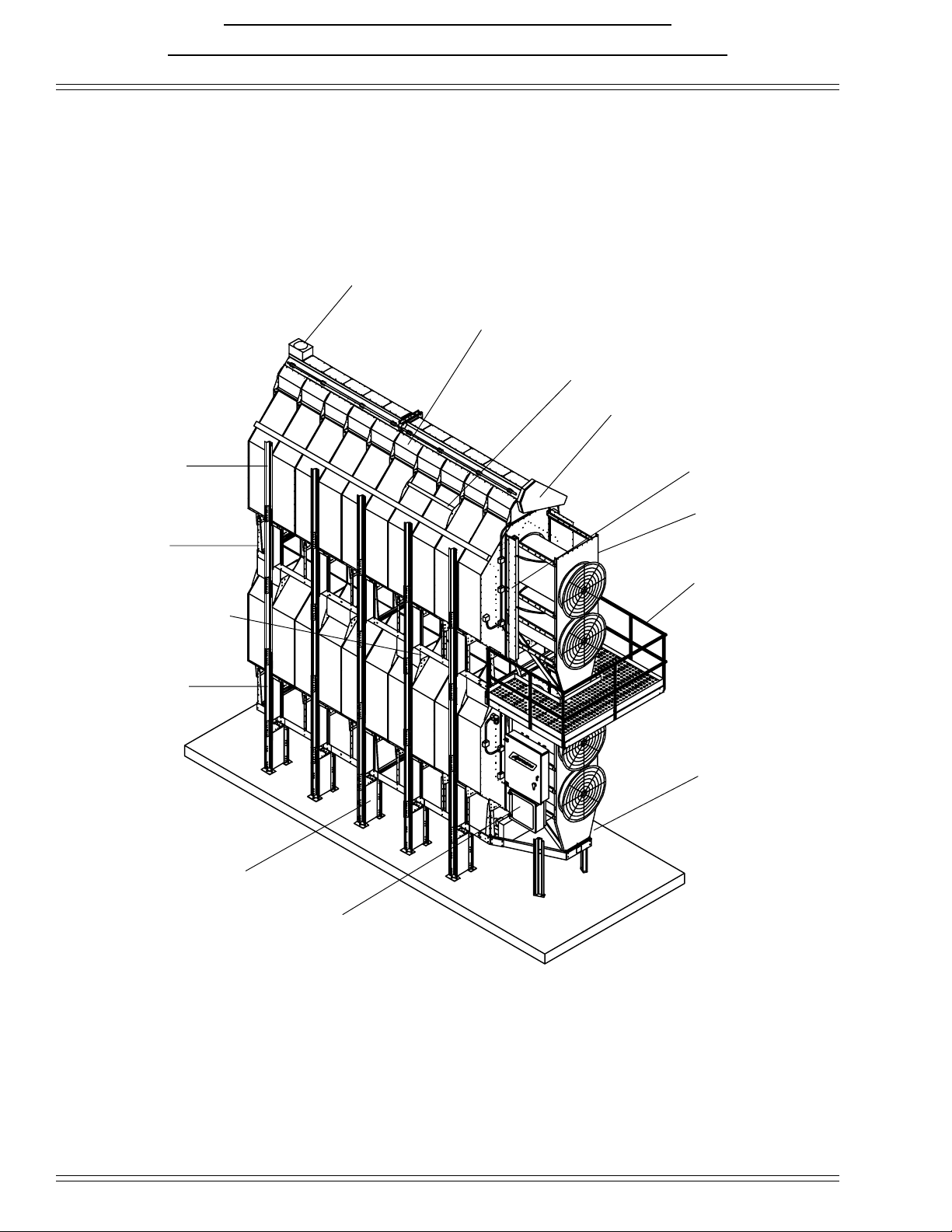

Stack Dryer Component Callout

The following information is intended to help outline the steps required in stacking a Network Dryer.

Fill Hopper

Wet Bin Assembly

Crane Brackets

Pulleys, Belts, & Guards

Module Stiffeners

Rear Ladders

& Safety Cages

Lower & Middle Module

Crane Brackets

Module Stiffeners

Stack Dryer

Pedestals & Legs

Control Box Wiring

Wiring Connections

Front Ladders,

& Cages

Platform Assembly

Fuel Connections

6--

Page 7

Multi - Module Stacking Manual

Module Preparation

CAUTION

This product may have sharp edges! To avoid injury handle sharp edges with caution and

use proper protective clothing and equipment at all times.

• Identify all parts shipped in crates or in the back of the dryer.

• Group parts for each of the assemblies together to have them at hand as needed.

• Attach the Rear Ladders and Safety Cages to the rear of all modules if not already installed (see

appendix B of this manual).

• Attach the Front Safety Cages to the Front Ladder of all modules (see appendix A of this manual).

See PNEG-1273 for reference.

• Raise the Top Auger to its installed position.

• Install the Wet Bin Side Panels and attach them to the Top Auger Housing.

• Install the Pulleys, Belts, and Guards to the Top Auger and/or to the Bottom Auger.

• Install the Fill Hopper.

See PNEG-349REV for reference.

• Assemble the Service Platform onto the Top Module and/or the Middle Module.

• Attach all of the Stiffener Supports each Module.

• Double check to see if all parts are installed as needed.

Proceed to the Crane Bracket Placement Section >>

7--

Page 8

Multi - Module Stacking Manual

Crane Bracket Placement

Install the Crane Brackets onto the modules if not already installed.

Crane Bracket Location

Base Modules and Middle

Modules utilize four crane

brackets. Brackets mount to

stack module support pads.

Lifting usually occurs between

the 2nd column from fan end to

the 6th column from fan end.

This will vary with model

number.

The module should remain

parallel to the earth as it is

lifted.

Base Module crane brackets

Top Modules utilize 2 crane

brackets with 4 lifting points

and a spreader bar between.

These mount to column seams

on the roof screen.

Lifting usually occurs between

the 2nd column from fan end to

the 6th column from fan end.

The module should remain

parallel to the earth as it is

lifted.

A crane of sufficient lifting

capability should be used.

Loads of 5,000 to 15,000

pounds should be expected.

Crane Brackets Installed

Top Module crane brackets

8--

Page 9

Multi - Module Stacking Manual

Setting Lower Module on Pedestals

Personnel working around this equipment while it is lifted into position must use extreme caution. Lifting equipment (crane and rigging) must be of proper lifting capability

for the unit size and weight. All local safety precautions and procedures must be followed.

1. Install stiffeners and service platform in accordance with PNEG-349REV. At each stiffener/

pedestal location remove the 1/2” bolts and nuts

that attach the dryer frame leg to the frame rail.

Use that hardware to attach a stiffener base connector clip (D01-1045).

BE ALERT!

D01-1045

2. Lift base module and position it in the location

the dryer is to occupy. NOTE: Crane brackets

may need to be adjusted to ensure that the

module will be parallel to the ground when

lifted. With the base module in position bolt a

pedestal to each stiffener base connector clip using 3/8”-16 x 1 1/2” bolts (S-7928).

Stiffener

Stiffener

splice

Stiffener

base con-

nector clip

Pedestal

Stiffener

3. With a stiffener splice (SS-7053), splice the

pedestal to stiffener at each pedestal location. Now

make sure any nuts and bolt used so far have all

been tightened.

9--

When splicing pedestal to

stiffener use 3/8”-16 X 1 1/2”

bolts (S-7928) where circled,

use 3/8”-16 x 1” (S-7927) in all

other holes.

Page 10

Multi - Module Stacking Manual

Anchoring Lower Module to Foundation

4. Set the lower module into final position and

check level. Use shims (SS-6953) to level lower

module if needed.

Shims

5. Anchor lower module to foundation. If anchor

bolts were not set when the concrete was poured,

then drill holes in the foundation to accept anchor

bolts (use 3/4” x 9 5/8” minimum anchors with

epoxy resin).

GSI has 1” x 12” anchor bolts (Part no. S-8957),

tubes of epoxy (GTC-0004), and mixing nozzles

for epoxy tubes (GTC-0005). An epoxy gun will

be needed.

Basket length 14' 18' 20' 22' 26'

No. of anchors needed 16 20 22 24 28

6. Attach front (BLK-10058) and back (BLK-

10057) leg anchor plates to legs using 5/16”-18 x

3/4” bolts (S-6606), and 5/16”-18 nuts (S-3611)

as shown in the photo on the right.

LEG STAND

BLK-10058

BLK-10057

10--

Page 11

Left rear support leg.

Multi - Module Stacking Manual

Installing Support Legs

Right rear support leg.

cotter pin &

clean out door

pivot shaft

shim

7. NOTE: If the dryer is a twenty foot dryer

then this step is not required. Use 1/2”-13 x 1

3/4” bolts (S-3883), and 1/2”-13 lock nut (S-6493)

to attach support leg assemblies to rear corners of

the dryer frame. Use the grey shim (D01-1221) to

fill the gap between the support leg and dryer

frame. On the right side it may be necessary to

remove the cotter pin and slide the clean out door

pivot rod forward enough to insert the top bolt.

support legs may

also be installed here

support leg

8. Use 1/2”-13 x 1 3/4” bolts (S-3883), and 1/2”13 lock nut (S-6493) to attach support legs to hitch

weldment as shown in left photo.

Once installed anchor the support legs to the foundation.

11--

Page 12

Multi - Module Stacking Manual

Lifting Upper Module

frame tie down (D61-0011)

9. Attach a frame tie down (D61-0011) at each of

the corners of the upper module frame using existing and supplied 1/2” bolt (S-3728), washer (S-

2120), and nut (S-6493) as shown in photos above.

10. Lift upper module and move into place over

lower module. Use a guide line to keep module

steady while it is being moved.

12--

Page 13

Multi - Module Stacking Manual

Setting Upper Module in Place

frame tie down

shim here (if

required)

11. Once upper module is in place over lower

module slowly start to lower upper module while

making sure that the frame tie downs (D61-0011)

come down to the outside of the module support

pads they will later be bolted to. Also you will

notice that the connecting section end (factory installed) has a tab that extends below module frame,

this tab will slide into the lower module just behind the plenum end panel.

12. When the upper module is set in place and

the crane is bearing none of the weight check the

upper module for level. It may be necessary to

shim the upper module to level it. If the upper

module is not level then place module support

shims (D61-0089) on the module support pads (it

may be necessary to raise the upper module a little

to place these shims).

module support

pad

shim here (if

required)

tab of connecting

section end

plenum end

panel

13--

Page 14

Multi - Module Stacking Manual

Securing Upper Module

splice all

stiffeners

13. Once the upper module is set and level use

1/2”-13 x 1 1/2” bolts (S-3728), 1/2” washers (S-

2120), 1/2”-13 lock nut (S-6493) and bolt the

frame tie down (D61-0011) on the upper module

to the module support pad of the lower module.

14. Use 3/8”-16 x 1” (S-7927), 3/8”-16 nut (S-

968), and a stiffener splice (SS-7053) to splice the

stiffeners of the lower module to the upper module.

15. Use 3/8”-16 x 1” (S-7927), 3/8”-16 nut (S-

968) to connect the top angle bracket of the lower

module to the frame tie channel of the upper module. There may be a small gap between these two

parts, if so, the 5/16” bolts connecting the top angle

bracket to the lower module can be loosened just

enough to adjust the height of this bracket (the

holes are slotted). Be careful not to loosen the

bolts too much because as you will see there is no

convenient way to get to the nuts on these bolts.

If the bolts are loosened just enough to adjust this

bracket they can be retightened without having to

hold the nut on the other side.

frame tie down

module support

pad

frame tie channel

16. If you are stacking a three module dryer perform step 9-15 for placing the third module.

top angle

bracket

14--

Page 15

Multi - Module Stacking Manual

Appendix A - Module Finishing

Electrical Safety

Provision of an adequate and safe power supply to the Stack Dryer unit is essential to

your safety. GSI recommends that a competent and qualified electrician undertake all

electrical wiring. All wiring is to be installed to the National Standards and Regulations relevant to your Country and Region.

A Mains Power Isolator should be installed with the Stack Dryer unit and is essential

for your safety. This should be installed as indicated in the enclosed installation instructions and in accordance with the relevant Directives in force.

• Connect wiring between modules making sure all connections are secure.

• Contact the Electrical Service Provider to connect power.

Fuel Safety

Provision of an adequate and safe fuel supply to the Stack Dryer unit is essential to

your safety. GSI recommends that a competent and qualified fuel serviceman undertake all fuel connections. All fuel connections are to be installed to the National

Standards and Regulations relevant to your Country and Region.

A Mains Fuel Isolator should be installed with the Stack Dryer unit and is essential for

your safety. This should be installed as indicated in the enclosed installation

instructions.

• Connect fuel connections between modules making sure all connections are secure and no leaks

are present.

• Contact the Fuel Service Provider to connect fuel supply.

15--

Page 16

Multi - Module Stacking Manual

Appendix B - Ladder Cage Installation

1. To install the safety cage for the rear ladder of the bottom

module first connect two large bell hoop halves together

(LS-4352) together , and connect two small bell hoop halves

(LS-4351) together. Then attach a safety cage bracket (LS-

4349) to each end of those assemblies. Use 5/16”-18 X 3/4”

bin bolts (S-275), and 5/16”-18 nuts (S-3611), see photos at

the bottom.

2. Use five 44” safety cage vertical supports (LS-4353) and

connect the small and large bell hoops assembled in the previous step using 5/16”-18 X 3/4” bin bolts (S-275), and 5/

16”-18 nuts (S-3611). NOTE: Leave one side of this as-

sembly open so the rear access door on the dryer will

not be obstructed.

3. Now locate the safety cage bolt holes on the ladder (see

photo right). Use 5/16”-18 X 3/4” bin bolts (S-275), and 5/

16”-18 nuts (S-3611) to install safety cage onto the ladder.

safety cage bolt holes

safety cage bolt holes

LS-4349 (safety

cage brackets)

LS-4351 (small

bell hoop halves)

16--

Page 17

Multi - Module Stacking Manual

Appendix b - Ladder Cage Installation

4. Assembly the front ladder safety cage the same

way and with the same hardware only use seven

44” safety cage vertical supports (LS-4353).

See photo on the right.

LS-4353

D61-0110

5. Assembly eight small hoop halves to make four

small safety cage hoops. Connect these hoops together with five 34” vertical supports (D61-0110),

and ten 44” vertical supports (LS-4353) to make

the cage assembly for the upper module rear ladder shown in the photo on the left.

17--

Page 18

Multi - Module Stacking Manual

Notes

18--

Page 19

Multi - Module Stacking Manual

Notes

19--

Page 20

1004 E. Illinois St.

Assumption, IL 62510

Phone 217-226-4421

Fax 217-226-4498

August 2004

Loading...

Loading...