18' Autoflow

FOUNDATION REQUIREMENTS

ALL FOUNDATION SPECIFICATIONS SHALL BE CONSTRUED AS RECOMMENDATIONS ONLY.

BECAUSE OF THE MANY VARIABLE CONDITIONS IN AN ACTUAL INSTALLATION, GRAIN

SYSTEMS, INC. ASSUMES NO LIABILITY FOR RESULTS ARISING FROM THE USE OF SUCH

RECOMMENDATIONS.

SITE PREPARATION

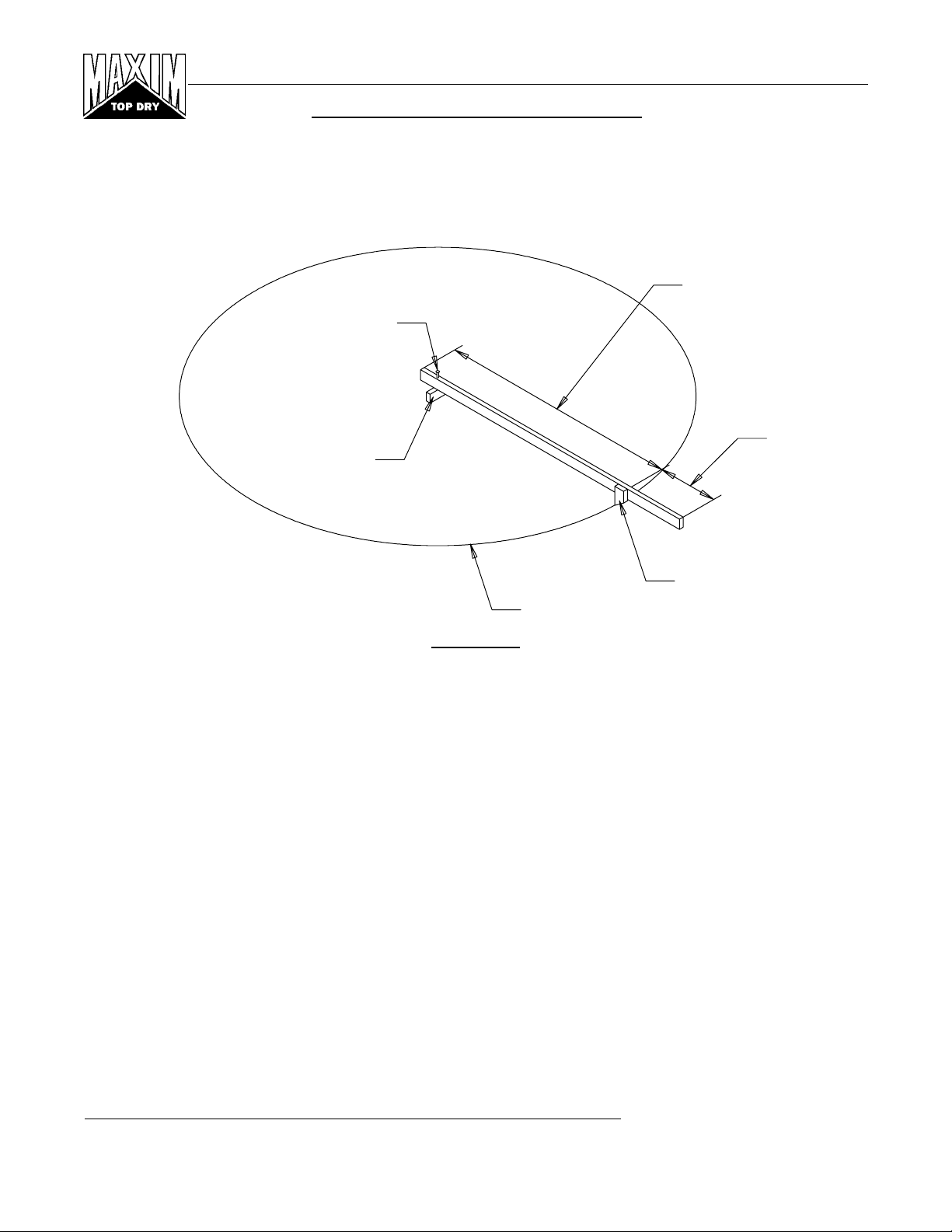

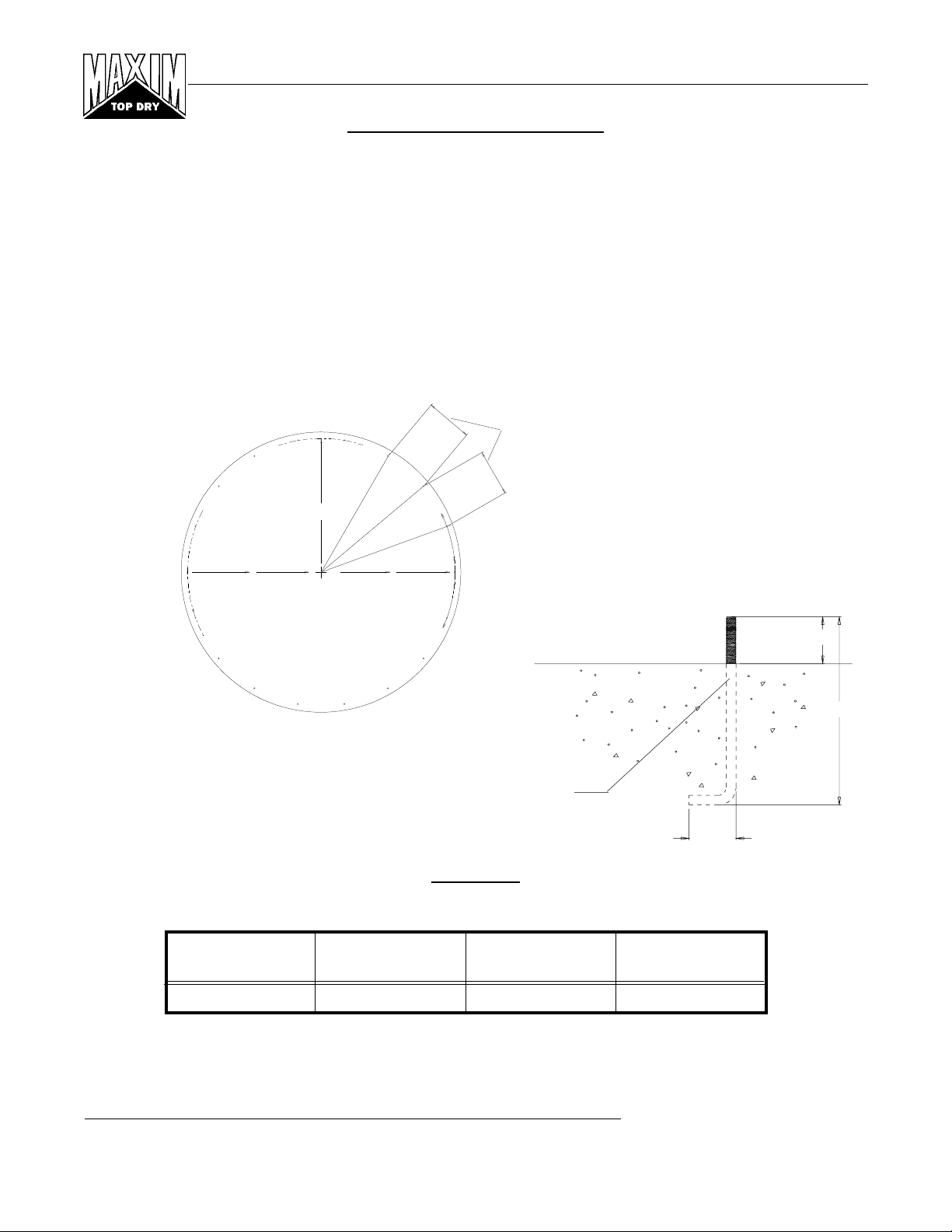

Foundation Radius

Spike

Two Feet

2 x 4 Center Stake

Pointed Stake

Foundation Line

Figure #1

1. SELECTING THE PROPER SITE

The selected site should be level, firm, and free from underlying debris. The bin can be installed satisfactorily

on slopes, but as the slope increases, additional labor and materials are required for the foundation. The

concrete foundation surface must be level. If some fill is required, it should be watered and tamped thoroughly

to prevent uneven settling from the weight of the bin. Naturally, the site must allow convenient access for easy

loading and unloading, plus provide additional space for future units. Also, consider the positioning of

handling equipment, availability of electricity, and the placement of fans, heaters, and gas tanks.

2. SCRIBE THE DIAMETER

Having determined the center of the site, drive a small 2 x 4 in the ground to mark the center point of the

foundation. The top of the stake should be the same height as the finished foundation will be. Using one large

spike, nail a straight 2 x 4 (approximately 2 feet longer than the radius of the bin) to the top of the center stake.

This will enable it to swivel. Along the opposite end at a distance given in the foundation layout table, attach

a sharply pointed stake. The swiveling 2 x 4 will act as a compass, enabling you to scribe the correct diameter

of your foundation and later locate the anchor and stiffener bolt locations. (NOTE: Making the 2 x 4 two feet

longer than the radius will allow the 2 x 4 to also be used as a leveling device and for pulling concrete.)

Grain Systems, Inc. Assumption, Ill.

REV. 11-20-96

1

18' Autoflow

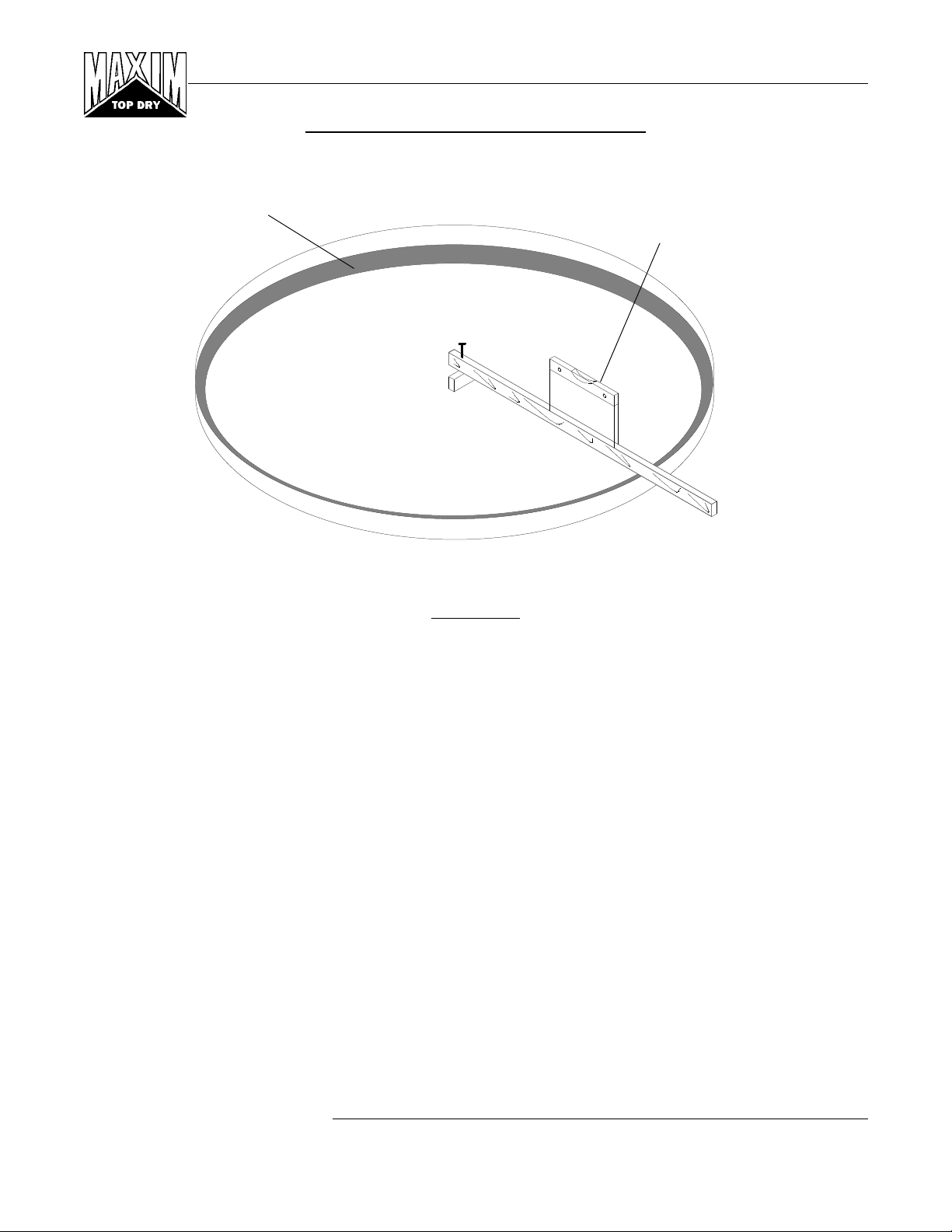

Footing Trench

CIRCULAR FOUNDATION FORM

Carpenter's Level

Figure #2

3. PREPARE THE FOUNDATION

Having scribed the diameter of your foundation, proceed by digging the footing of the foundation. This

consists of a large circular trench dug just inside the foundation line. (Refer to foundation details for necessary

information.) Once the footing has been dug, you are ready to build the forms. It is important that your form

be rigid enough to hold its shape against the poured concrete. Also, the foundation must be flat. Sloped floors

cannot be used in drying bins. A carpenter’s level placed on top of your 2 x 4 will enable you to set the top

of the forms to match the top of the center stake. Check the form work with a transit to ensure a uniform

elevation for the entire foundation.

Grain Systems, Inc. Assumption, Ill.

2

REV. 11-20-96

18' Autoflow

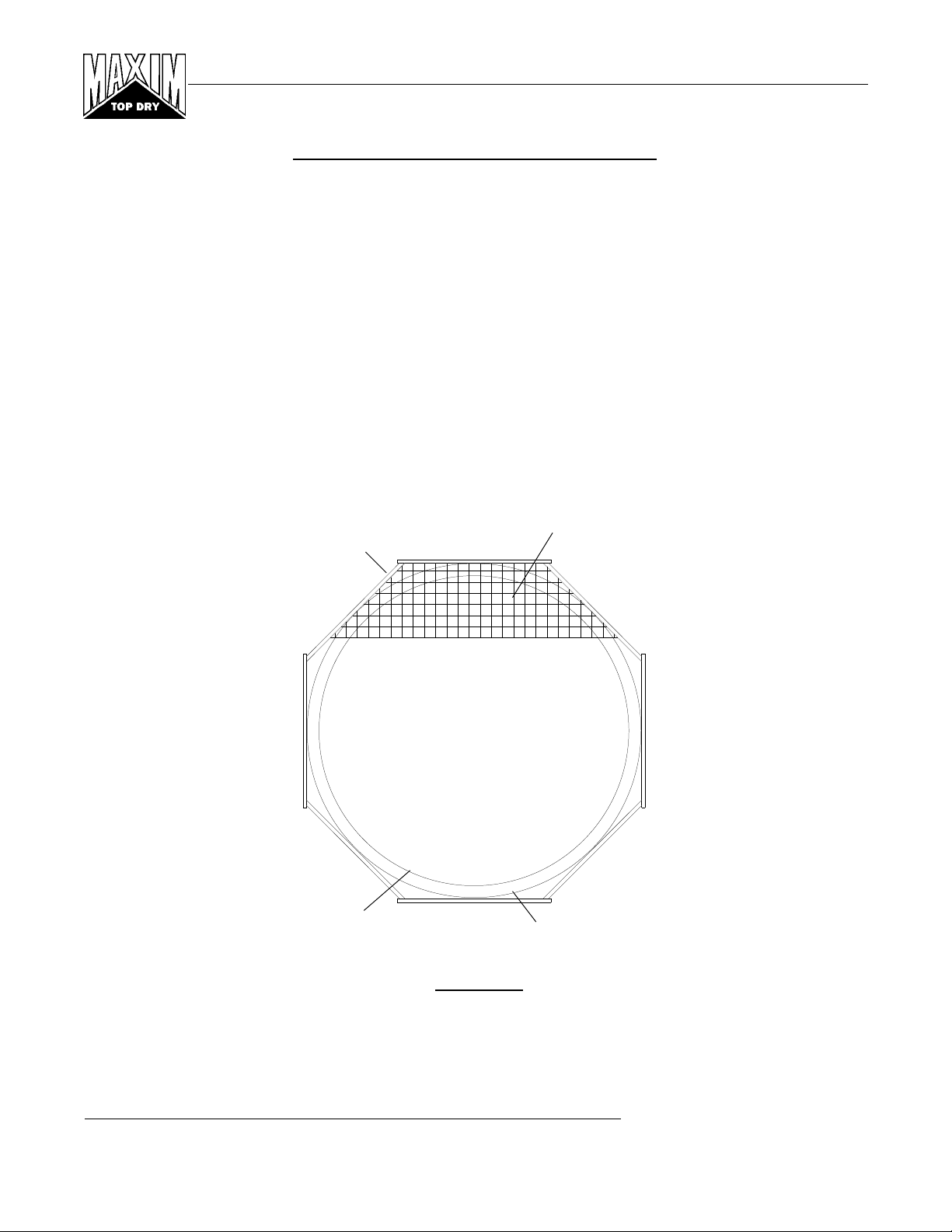

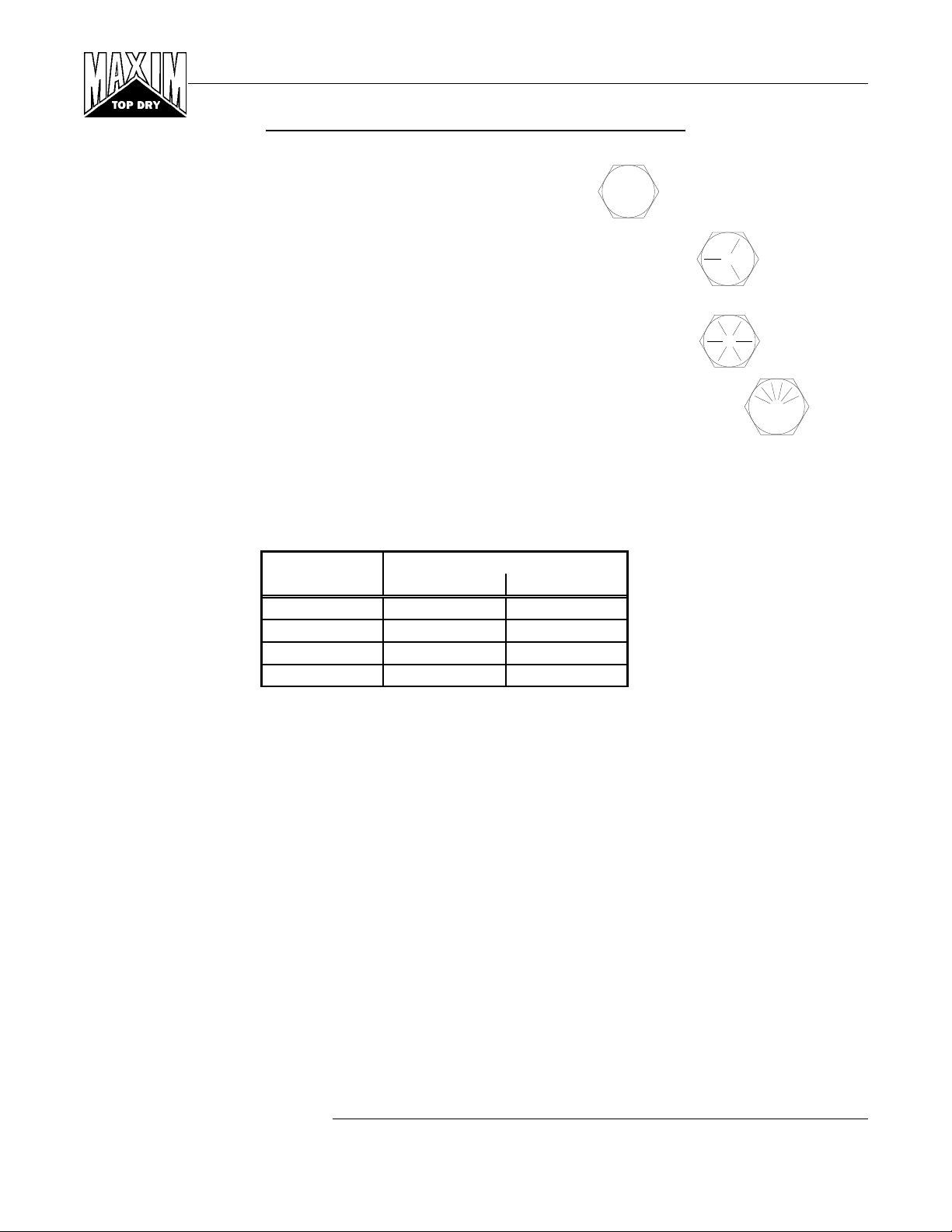

OCTAGONAL FOUNDATION FORM

There are two styles of foundation forms commonly used. The first is the circular form depicted in Figure #2.

The second style can be made of 2" x 8" boards set into a square with corners blocked off to form an octagon.

(See Figure #3 below.) This eight sided form will approximate a circle and can be constructed quite easily.

When the foundation form is completed install reinforcement rods by either welding or wiring in place. Place

2" of compacted sand on the inside level of the foundation. The sand is then covered with a 4 mil plastic

moisture barrier. 6" x 6" wire mesh (2 mats), covering the entire area of the foundation, completes your

preparation of the bin’s foundation. You are now ready to begin pouring concrete.

NOTE: ALL CONCRETE IS TO HAVE A MINIMUM COMPRESSIVE STRENGTH OF 3,000 PSI

@ 28 DAYS.

6" x 6" Wire Mesh

2" x 8" Forms

Footing Trench

Top View

Foundation Line

Figure #3

Grain Systems, Inc. Assumption, Ill.

3

REV. 11-20-96

18' Autoflow

1234567890123456789012345

1

5

1

5

1

5

1

5

1

5

1

5

1

5

1

5

1

5

1

5

1

5

1

5

1

5

1

5

1234567890123456789012345

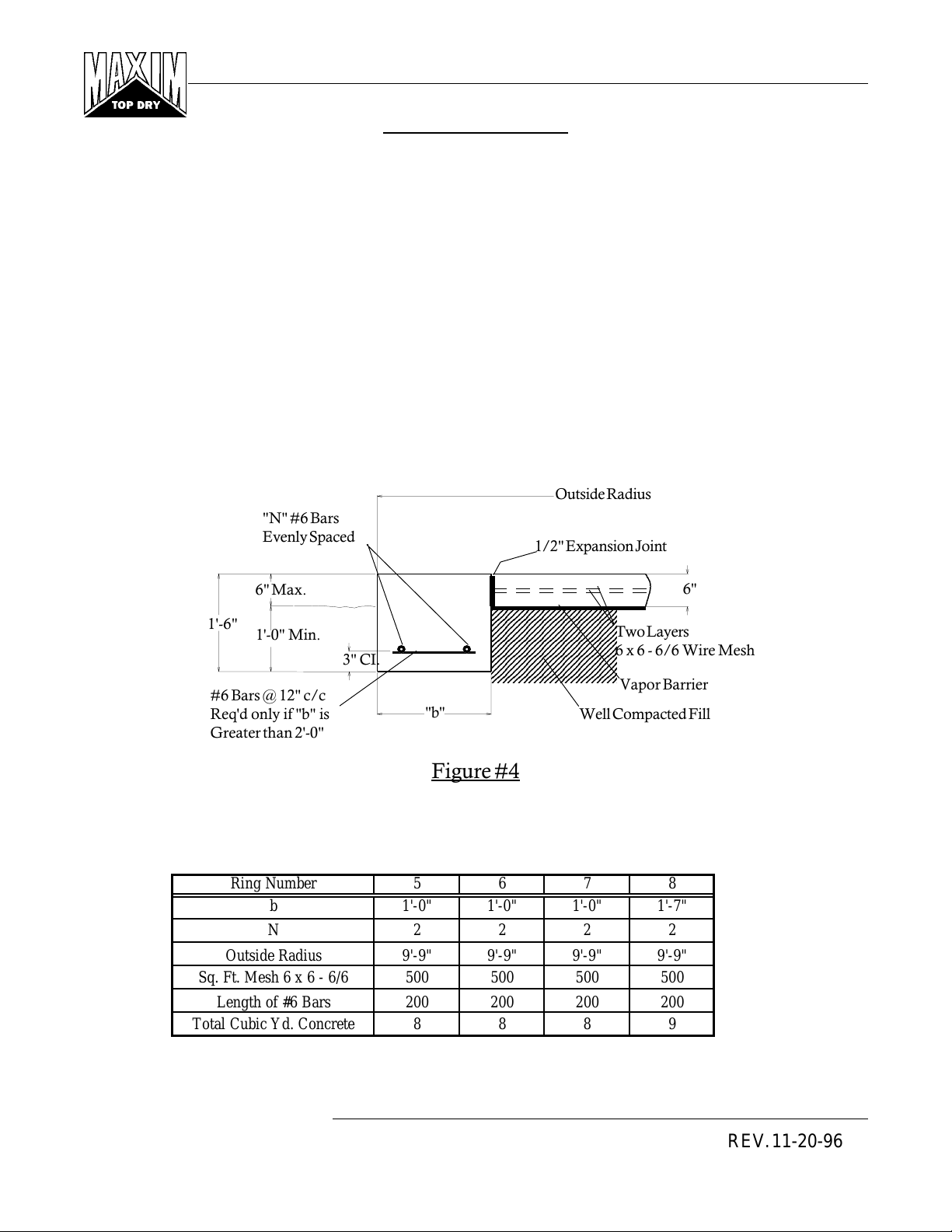

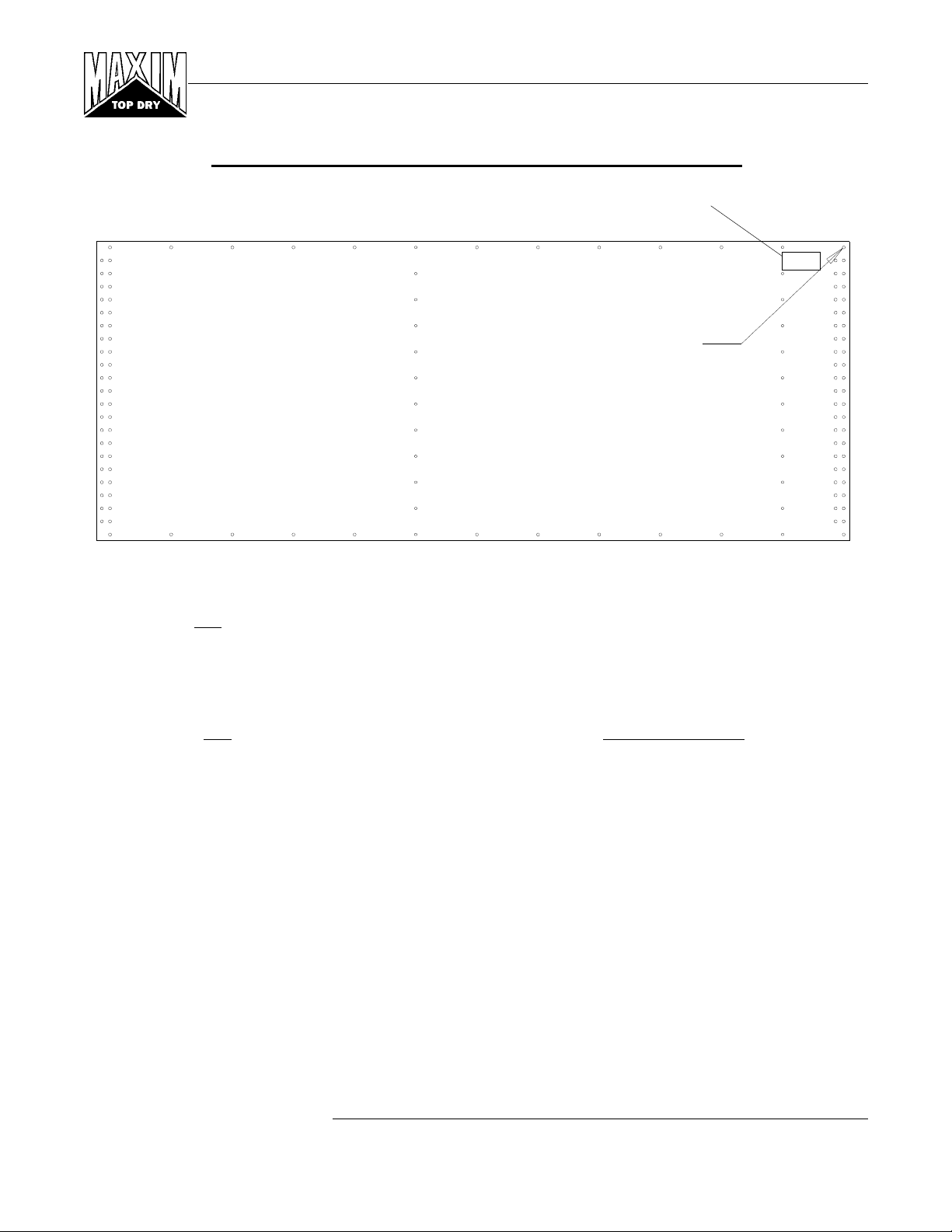

FROST FREE PAD

NOTES:

Foundation site should be well drained and free of vegetation or debris.

Foundation design is based on a minimum soil bearing capacity of 3,000 lb/ft2. If soil bearing capacity is in

doubt, contact a local soil testing engineer.

Concrete shall have a minimum compressive strength of 3,000 PSI at 28 days.

Requirements for reinforcement do not include overlap.

Lap all circumferential bars 35 bar diameters and stagger all laps in plan 3'-0".

All material used for back fill inside the ring wall should be a clean, well graded, crushed stone or sand-gravel

mixture. Back fill should be placed in 6" lifts and well compacted.

Outside Radius

"N" #6 Bars

Evenly Spaced

1/2" Expansion Joint

6" Max.

1'-6"

1'-0" Min.

#6 Bars @ 12" c/c

Req'd only if "b" is

3" CI.

"b"

23456789012345678901234

23456789012345678901234

23456789012345678901234

23456789012345678901234

23456789012345678901234

23456789012345678901234

23456789012345678901234

23456789012345678901234

23456789012345678901234

23456789012345678901234

23456789012345678901234

23456789012345678901234

23456789012345678901234

23456789012345678901234

Well Compacted Fill

Two Layers

6 x 6 - 6/6 Wire Mesh

Vapor Barrier

6"

Greater than 2'-0"

Figure #4

18' Diameter Bin

Ring Number 5678

b 1'-0" 1'-0" 1'-0" 1'-7"

N 2222

Outside Radius 9'-9" 9'-9" 9'-9" 9'-9"

Sq. Ft. Mesh 6 x 6 - 6/6 500 500 500 500

Length of #6 Bars 200 200 200 200

Total Cubic Yd. Concrete 8889

Grain Systems, Inc. Assumption, Ill.

4

REV. 11-20-96

18' Autoflow

ANCHOR BOLT LAYOUT

Refer to following diagram for proper bolt layout.

Having poured and leveled the concrete, use the center stake and straight 2" x 4" again to find bolt circle radius

for the outside stiffener bolts. Select a starting point and stretch a pre-measured chord along the imaginary

circle formed by the bolt circle radius. Consider the placement of these bolts so as not to interfere with the

positions of bin doors and transitions.

Work both directions from first anchor bolt location, this will help eliminate possible error in laying out anchor

bolts. On larger bins sight across starting anchor bolt and center pin and place anchor bolt on opposite side

of anchor bolt radius. From this point you can work both directions from both anchor bolts.

Bolt Chord

Bolt Radius

Starting

Point

Work Both

Sight Across

Directions

B-5217 5/8" ANCHOR

BOLT ASSEMBLY

Figure #5

5/8" Anchor Bolt Detail

Bin Diameter

18' 9'-3.1/16" 12

Bolt Circle

Radius

Number of

Anchors

3"

12"

3"

Bolt Chord

Distance

4'-9.1/2"

Grain Systems, Inc. Assumption, Ill.

REV. 11-20-96

5

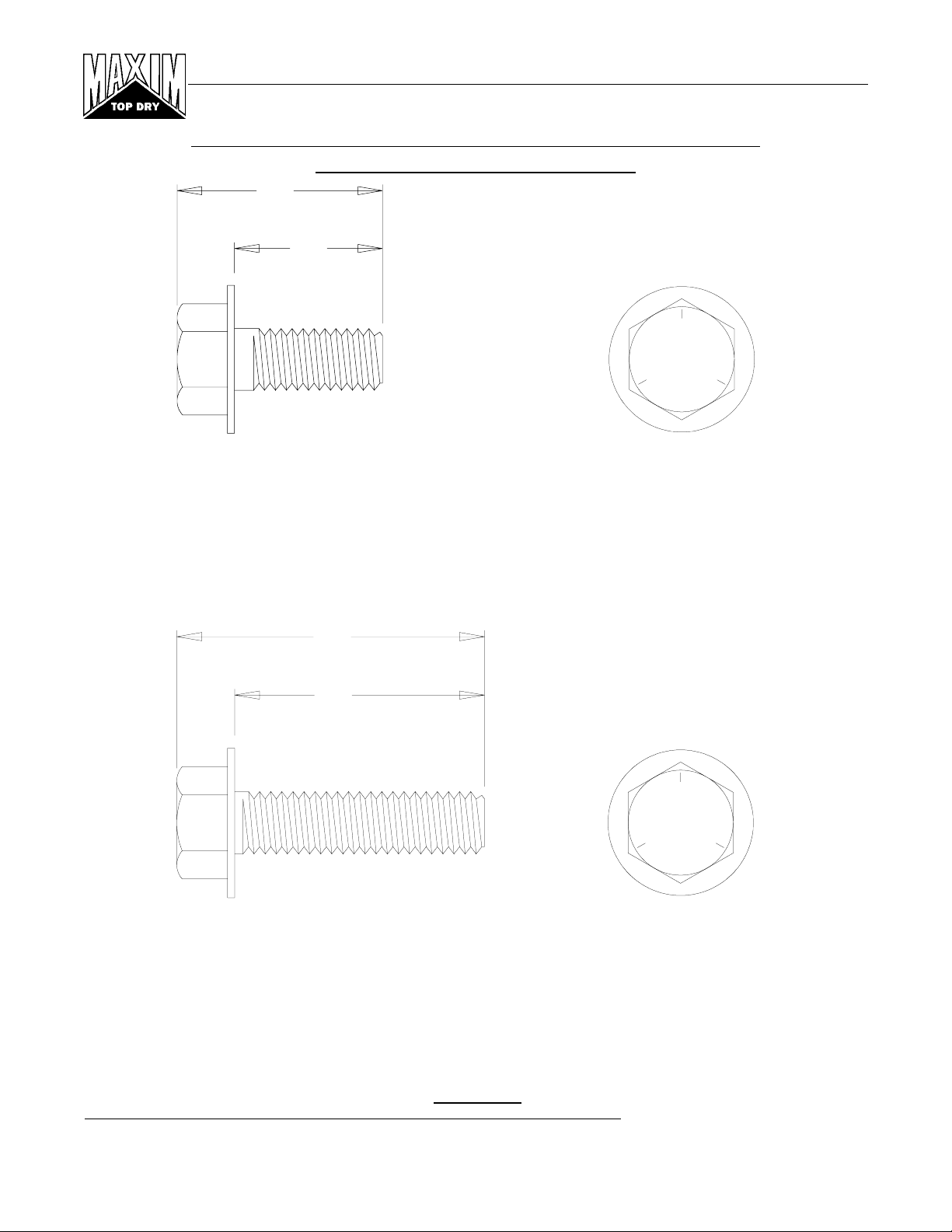

18' Autoflow

HARDWARE/BOLTING REQUIREMENTS

NOTE: Grade 2 bolts are designated with a plain head.

NOTE: Grade 5 bolts are designated by 3 slash marks on the head.

All 5/16" diameter bolts are to be Grade 5 or higher.

NOTE: Grade 8 bolts are designated by 6 slash marks on the head.

NOTE: Grade 8.2 bolts are designated by 6 slash marks on the head in a

sunrise pattern.

All 3/8" diameter bolts are to be Grade 8 or 8.2.

IMPORTANT: Do not tighten bolts to exceed the torque specifications listed below.

TORQUE (ft. lb.)

BOLT SIZE MINIMUM MAXIMUM

5/16" - 18 15 20

3/8" - 16 35 42

7/16" - 14 65 72

1/2" - 13 95 105

CAUTION: UNDER NO CONDITION SHALL ANY OTHER BOLTS BE SUBSTITUTED FOR

THOSE SUPPLIED BY GRAIN SYSTEMS, INC.

IMPORTANT: HARDWARE USAGE - 20 gauge - 15 gauge sidewall sheets, use

5/16" x 3/4" bolts and nuts. (S-275)

14 gauge and 13 gauge sidewall sheets, use

5/16" X 3/4" bolts and nuts. (S-275)

- Use 5/16" x 1.1/4" (S-277) for attaching floor flashing to the sidewall.

Grain Systems, Inc. Assumption, Ill.

6

REV. 11-20-96

18' Autoflow

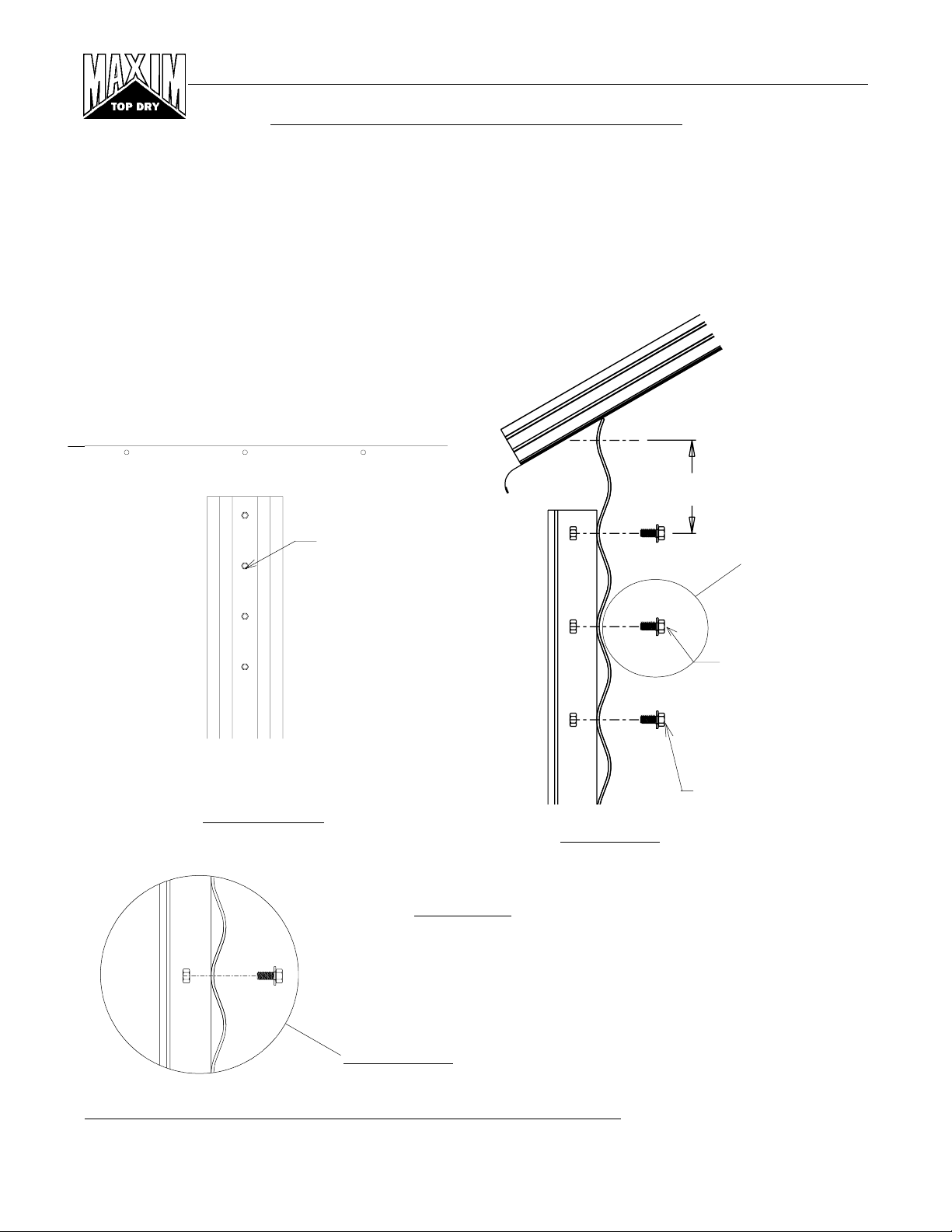

REFER TO TOP DRY TANK BOLTING REQUIREMENTS

FOR COMPLETE BOLT USAGE

.950"

.750"

GRADE 5

SIDE VIEW

TOP VIEW

S-275

.3125" x .750" pre-assembled with a steel backed neoprene washer.

This bolt is used to connect horizontal and vertical seams for 13 gage and thinner sidewall sheets to each

other, and to bolt the stiffeners to the sidewall sheets. It is also used in attaching roof panels to the top

sidewall sheet and attaching roof panels and flashing to the center collar.

1.437"

1.250"

GRADE 5

SIDE VIEW

TOP VIEW

S-277

.3125" x 1.250" pre-assembled with a steel backed neoprene washer .

This bolt is primarily used to connect roof panels together where they overlap. It is also used at the bottom

of the flat bottomed bins to attach the base angle to the sidewall sheet. A small number of these are provided

for joints and FC-42076 splice plates for the stiffeners to sidewall connection.

Figure #6

Grain Systems, Inc. Assumption, Ill.

REV. 11-20-96

7

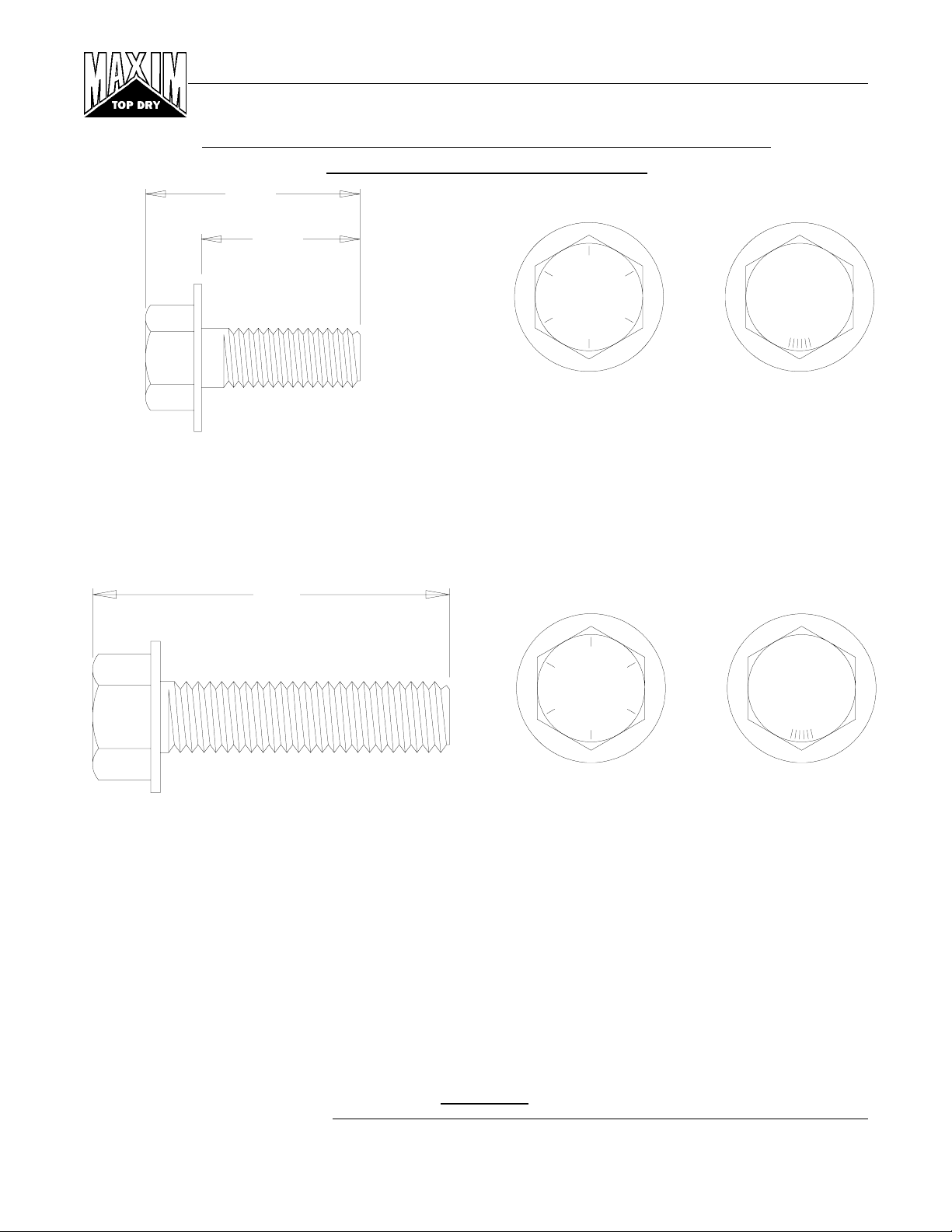

18' Autoflow

REFER TO TOP DRY TANK BOLTING REQUIREMENTS

FOR COMPLETE BOLT USAGE

1.377"

1.000"

GRADE 8.2

SIDE VIEW

GRADE 8

TOP VIEW

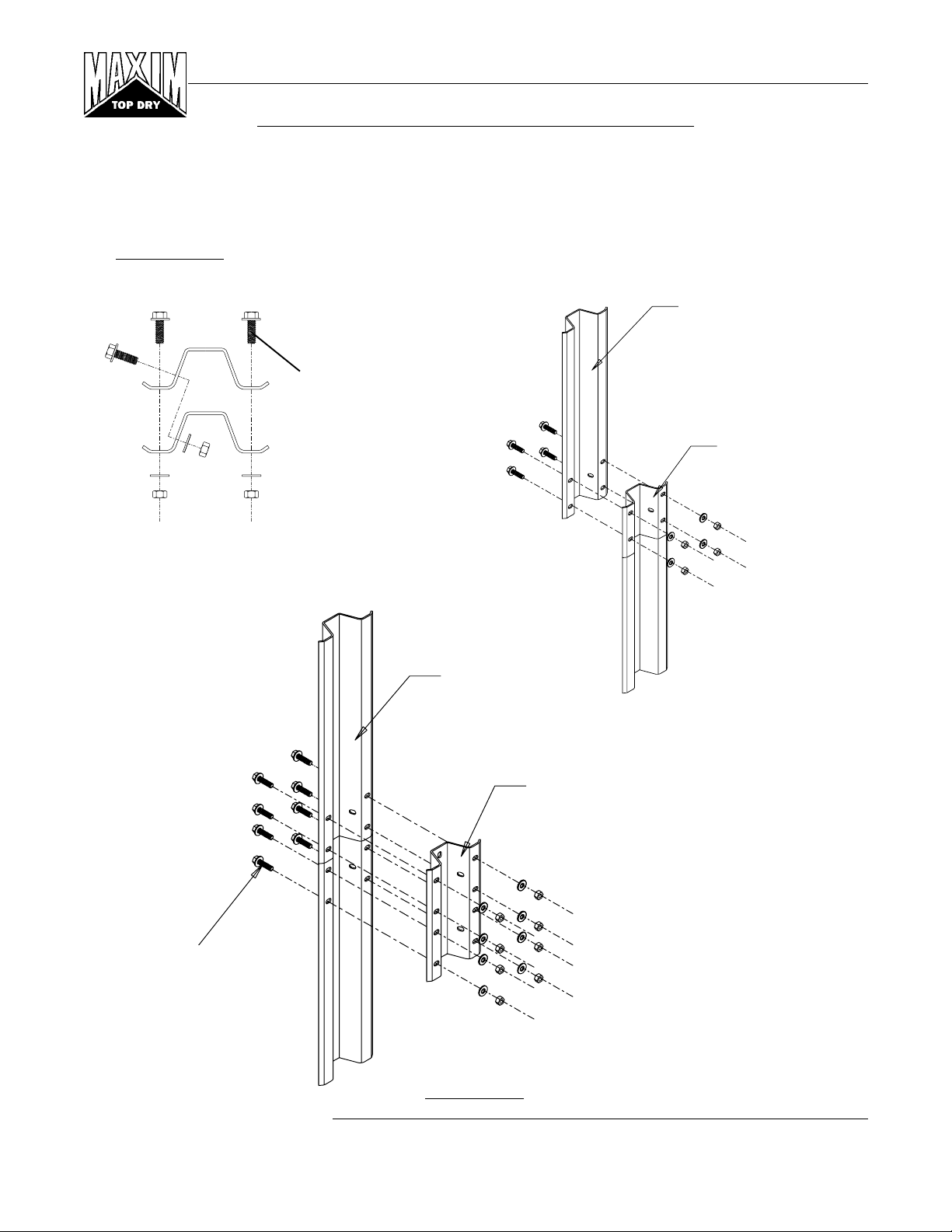

S-7927

.375" x 1.000" hex flanged head without a plastic sealing washer.

This bolt is used to splice the stiffeners together on the flanges. A steel flat washer is used on the nut side of

the connection. They are also used on "c" channel splices and mounting "c" channel to wall bracket.

1.873"

GRADE 8.2

SIDE VIEW

GRADE 8

TOP VIEW

S-7928

.375" x 1.500" hex flanged head without a plastic sealing washer.

This bolt is used to attach the wall bracket to the sidewall and stiffener . A steel flat washer is used on the

nut side of the connection.

Note: The only washers shipped loose with the bins are the steel flat washers. The 5/16" steel flat washer

(S-845) is used where the base angle attaches to the sheet and some are used at the main eave clips. The

3/8" steel flat washers (S-248) are used at the stiffener splices and some are used in the roof rafter splices.

Figure #7

Grain Systems, Inc. Assumption, Ill.

8

REV. 11-20-96

18' Autoflow

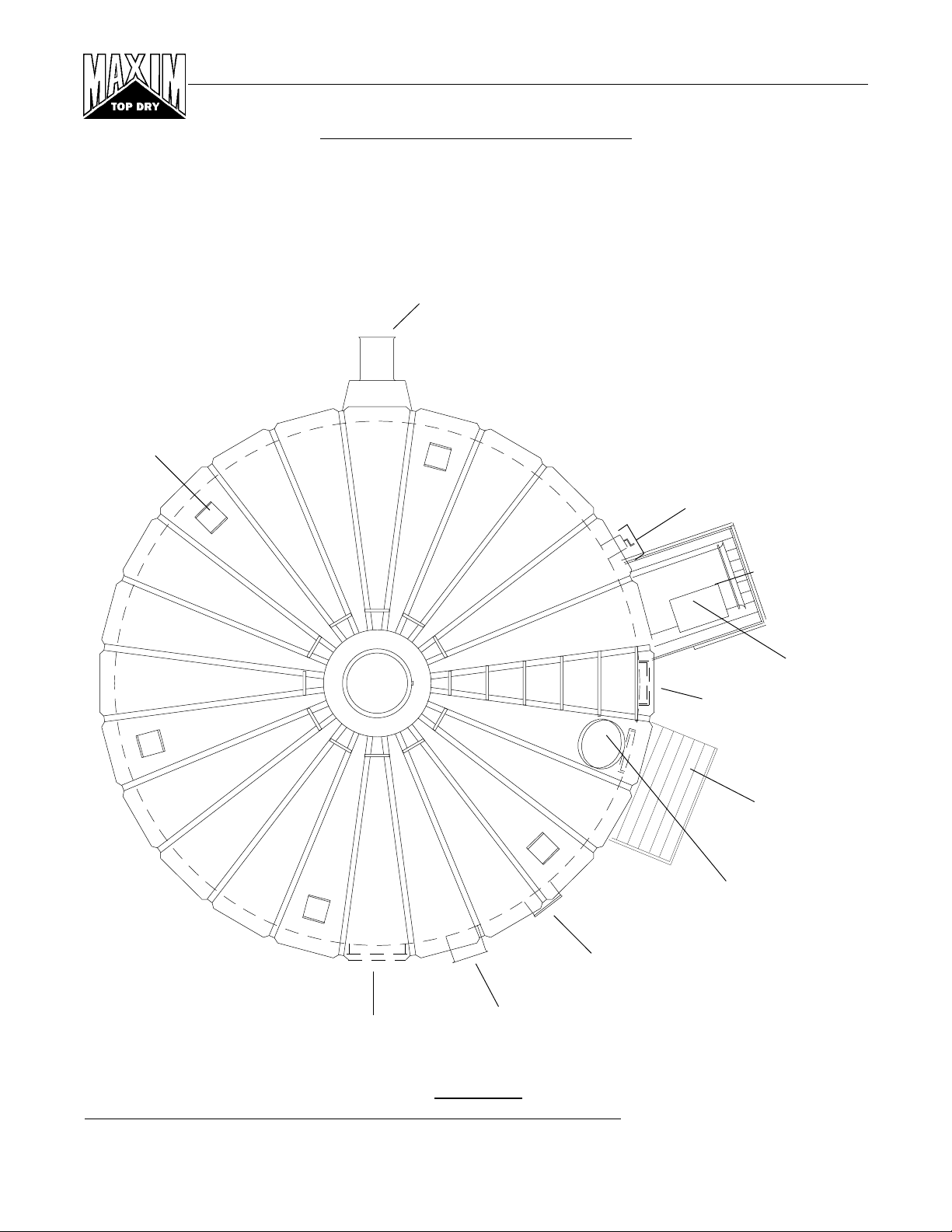

LOCATION OF ACCESSORIES

Below is a typical Top Dry bin layout showing suggested locations of Top Dry Accessories. When locating

the manway be sure the outside ladder will not interfere with other accessories below. Roof vents should be

spaced evenly around the roof. (Quantity will vary with individual systems.)

NOTE: The Top Dry system should be provided with a dependable equipment ground.

Aeration Fan &

Transition

Roof Vents

Manual Winch

2 Ring Door

Crop Dryer

Platform

Top Dry

Crop Dryer Unit

Outside Ladder

Access Door

Platform

Manway

Top Dry

Control Center

Unloading Auger

Figure #8

Grain Systems, Inc. Assumption, Ill.

9

REV. 11-20-96

18' Autoflow

VERY IMPORTANT!

DC-1174 (Top Decal)

Top of Sheet

Horizontal seam hole locations

determine top and bottom of sheet.

Sheet shown as viewed from the inside of bin.

Bottom of Sheet

All 4.00" corrugated sidewall sheets must be placed correctly.

Top

All 4.00" corrugated sidewall sheets have a top and bottom!

Failure to observe this will not allow the door to fit properly.

Carefully review the er ection manual and place sidewall sheets as shown.

Grain Systems, Inc. Assumption, Ill.

10

REV. 11-20-96

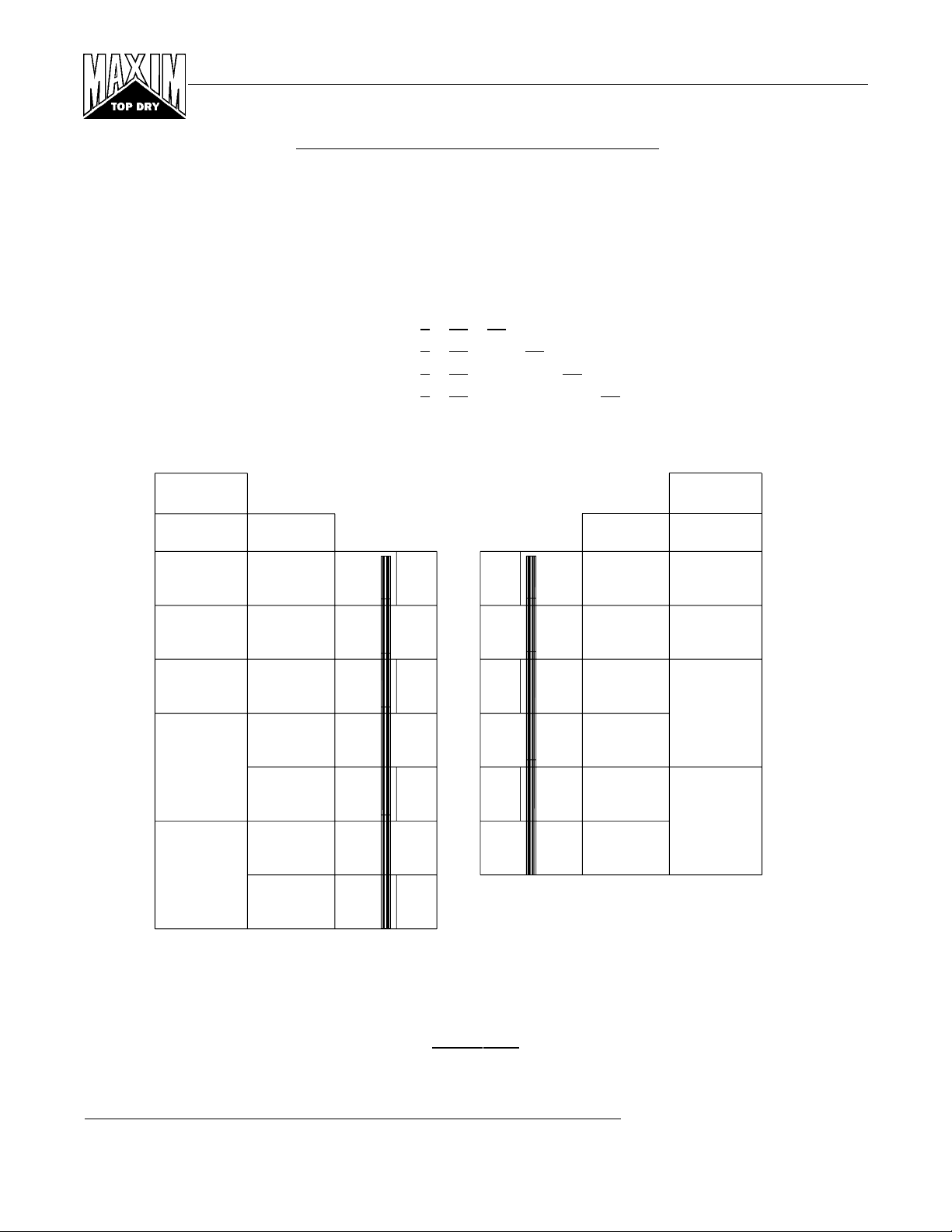

18' Autoflow

SIDEWALL & STIFFENER GAUGES

Door locations are shown by the underlined sidewall gauges. Actual gauge of the access door sheet located

just below the Top Dry floor is in parentheses.

Top Dry Bin

TDM18-4

TDM18-5

TDM18-6

TDM18-7

Sidewall Gauges

20 20 20 20 (18)

20 20 20 20 20 (18)

20 20 20 20 20 20 (18)

20 20 20 20 20 20 20 (18)

18' Stiffener Layout

Odd Ring

Gauge Ring Ring

16-T* 16-T*

16

16

1

2

3

1

2

3

Even Ring

Gauge

16

16

4

14

5

6

12

7

4

5

14

6

All Top Dry bin stiffeners are mounted on the outside of the bin. See stiffener instructions for stiffener joint

details and stiffener to sidewall attachment.

Figure #9

Grain Systems, Inc. Assumption, Ill.

REV. 11-20-96

11

18' Autoflow

D

P

L

h

Cod

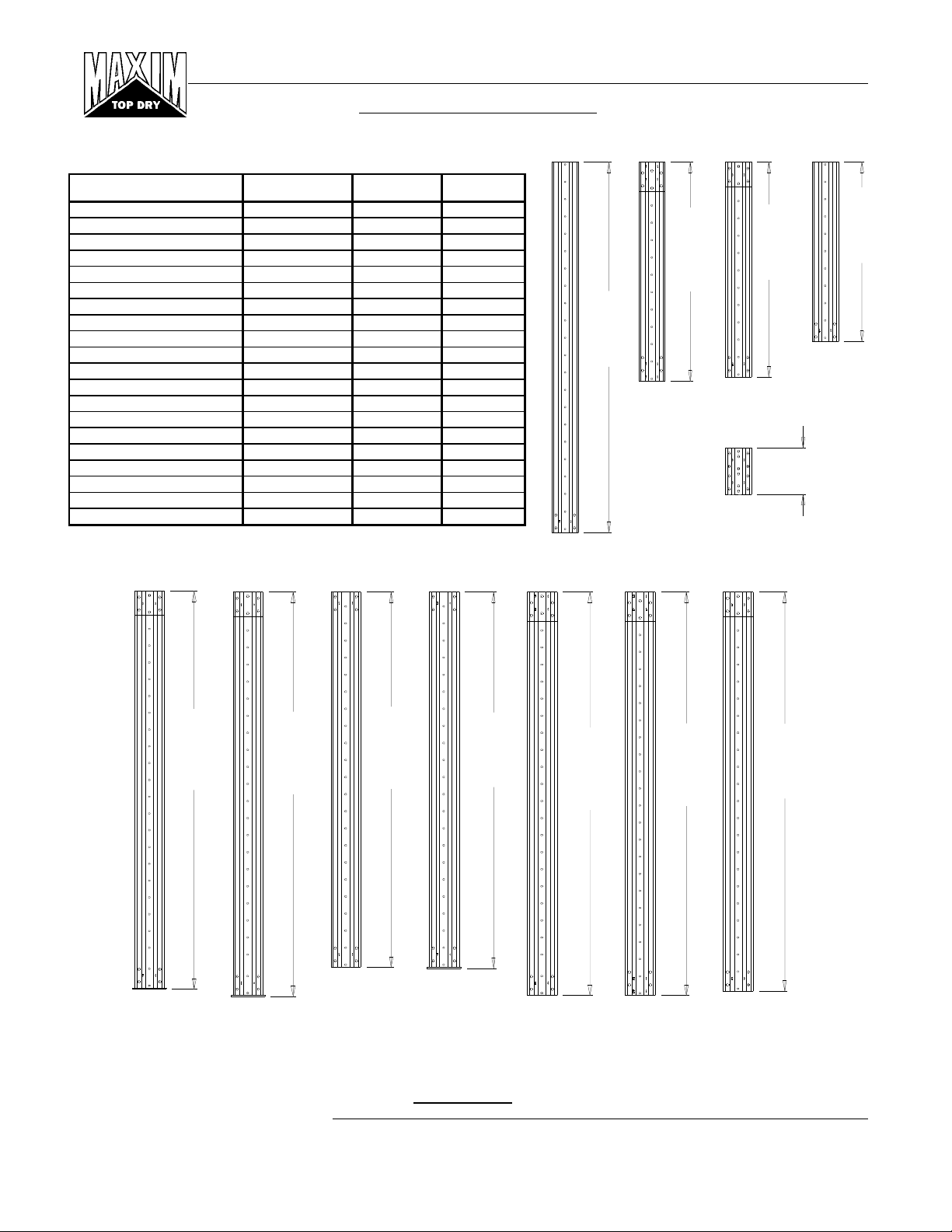

OUTSIDE STIFFENERS

The XX in the part numbers at the bottom will identify the Stiffener's gauge.

Example: FC-4205714 is a 2-Ring Standard Stiffener 14 Gauge.

Stiffener Overall Color

escription

2-Ring 10 Ga. (Base) FC-4207210 94 27/32" W hi te

2-Ring 12 Ga. (Base) FC-4207212 94 27/32" Black

2-Ring 14 Ga. (Base) FC-4207214 94 27/32" Green

2-Ring 16 Ga. (Base) FC-4207216 93 13/16" Blue

2-Ring 8 Ga. (B ase ) FC-4207308 88 3/16" Yellow

2-Ring 8 Ga. FC-4206308 87 15/16" Yellow

2-Ring 10 Ga. Tr a ns. FC-42062 94 19/32" Purple

2-Ring 12 Ga. FC-4205712 94 19/32" Black

2-Ring 14 Ga. FC-4205714 94 19/32" Green

2-Ring 16 Ga. FC-4207516 93 9/1 6" Blue

2-Ring 18 Ga. FC-4207518 93 9/1 6" Orange

2-Ring 16 Ga. Top FC-4206516 85 9/16" Blue

2-Ring 18 Ga. Top FC-4206518 85 9/16" Orange

1-Ring 12 Ga. FC-4205912 50 19/32" Black

1-Ring 14 Ga. FC-4205914 50 19/32" Green

1-Ring 16 Ga. FC-4207416 49 9/1 6" Blue

1-Ring 18 Ga. FC-4207418 49 9/1 6" Orange

1-Ring Top 16 Ga. FC-4206616 41 7/16" Blue

1-Ring Top 18 Ga. FC-4206618 41 7/16" Orange

Splice FC-42076 10 11/16" ---

art No.

engt

e

85.9/16"

FC-42059XX

1 Ring

12 Ga.

14 Ga.

FC-42065XX

2 Ring Top

16 Ga.

18 Ga.

50.19/32"

FC-42074XX

1 Ring

16 Ga.

18 Ga.

FC-42076

Splice

10 Ga.

41.7/16"

49.9/16"

FC-42066XX

1 Ring Top

16 Ga.

18 Ga.

10.11/16"

93.13/16"

FC-4207216

2 Ring

16 Ga.

Base

Grain Systems, Inc. Assumption, Ill.

FC-42072XX

12

2 Ring

10 Ga.

12 Ga.

14 Ga.

Base

94.27/32"

FC-4206308

2 Ring

8 Ga.

87.15/16"

FC-42073

2 Ring

8 Ga.

Base

Figure #10

88.3/16"

FC-42062

2 Ring

10 Ga.

Transitional

94.19/32"

FC-42057XX

2 Ring

12 Ga.

14 Ga.

94.19/32"

FC-42075XX

2 Ring

16 Ga.

18 Ga.

REV. 11-20-96

93.9/16"

18' Autoflow

TOP STIFFENER STARTING LOCATION

Refer to Figure #11, for proper location of top stiffeners. On the overlap of the stiffeners, and on the splice, use

3/8" x 1" hex bolts, a washer on the nut side connection. Refer to the stiffener layout, Figure #9, for stiffener usage.

All stiffeners are outside the bin wall. Use 5/16" x 3/4" Grade 5 bin bolts with head and neoprene washer to the inside

of the bin wall. Refer to proper charts and illustrations on the previous two pages for proper location of stiffeners and

sidewall sheets.

4.00"

FRONT VIEW

TOP STIFFENER

Figure #11

SIDE VIEW

DETAIL "A"

5/16" X 3/4" BIN

BOLT

(S-275)

BOLT HEAD AND SEAL-

ING WASHER MUST BE

ON THE INSIDE OF THE

BIN.

DETAIL "A"

Grain Systems, Inc. Assumption, Ill.

REV. 11-20-96

13

18' Autoflow

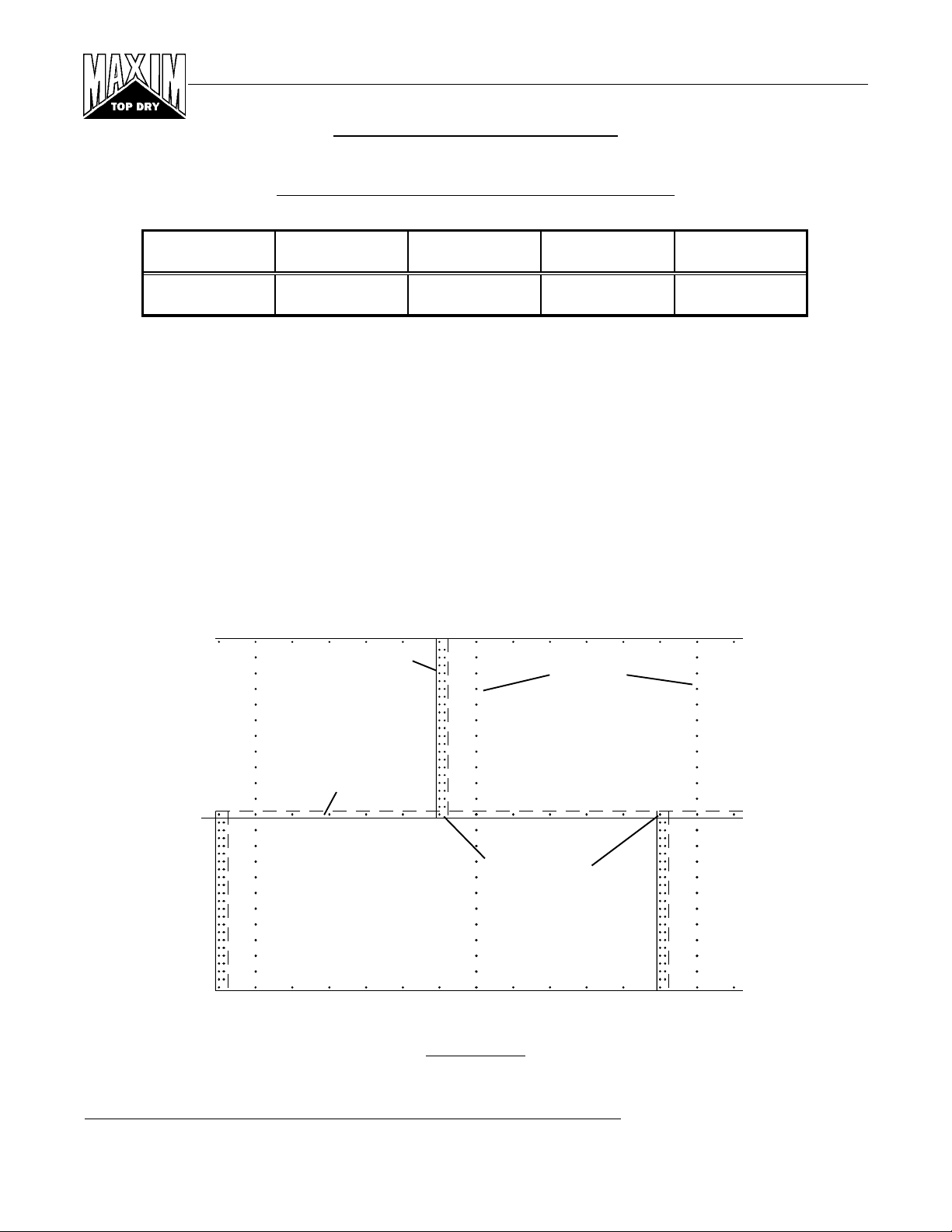

STIFFENER INSTALLATION & LOCATION

When installing bottom stiffeners, y ou may find that in some cases the stiffener with base plate attached

will not rest on the foundation (due to unlevel concrete, etc.) Shim plates have been furnished and should be

used to fill opening between base plate and concrete.

IMPORTANT: If shim plates are not used where required, the downward pressure of the stiff eners will

not be transferred directly to the foundation, and bin failure could result.

FC-4207516 16 GA.

BLUE

FC-4207518 18 GA.

ORANGE

3/8" DIA. HEX FLANGED

HEAD BOL T (NO

SEALING WASHER)

FC-4207516 16 GA.

BLUE

FC-4207518 18 GA.

ORANGE

USE 3/8" X 1.1/2"

BOL T, NUT AND W ASHER

SPLICE PLATE JOINT

(TOP VIEW)

3/8" DIA. HEX FLANGED

HEAD BOL T (NO

SEALING WASHER)

FC-4206308 8 GA.

YELLOW

FC-42062 10 GA.

PURPLE

FC-42076 SPLICE

OFFSET JOINT CONNECTION

DETAIL

Grain Systems, Inc. Assumption, Ill.

14

Figure #12

REV. 11-20-96

18' Autoflow

BOLTING REQUIREMENTS

2 STIFFENERS PER SIDEWALL SHEET

Sidew all Horizontal Ve rtical Stiffener Ove rlap

Gauge Seam Seam To Sidewall Seam

17 Thru 20 5/16" x 3/4" 5/16" x 3/4" 5/16" x 3/4" 5/ 16" x 3/ 4"

[10] [42] [20] [2]

All bolts are standard bin bolts with neoprene washers. For horizontal and vertical seam bolts, the bolt head and

neoprene washers are on the outside of the bin.

Note: For the splice plates FC-42076 use 5/16" x 1.1/4" bolts for the stiffener to sidewall connections.

Standard (17 Gauge Thru 20 Gauge) Sheet Bolting Detail

(Viewed from outside of the bin)

Vertical Seam

Horizontal Seam

Overlap Seam

Stiffener to

Sidewall

Figure #13

Grain Systems, Inc. Assumption, Ill.

REV. 11-20-96

15

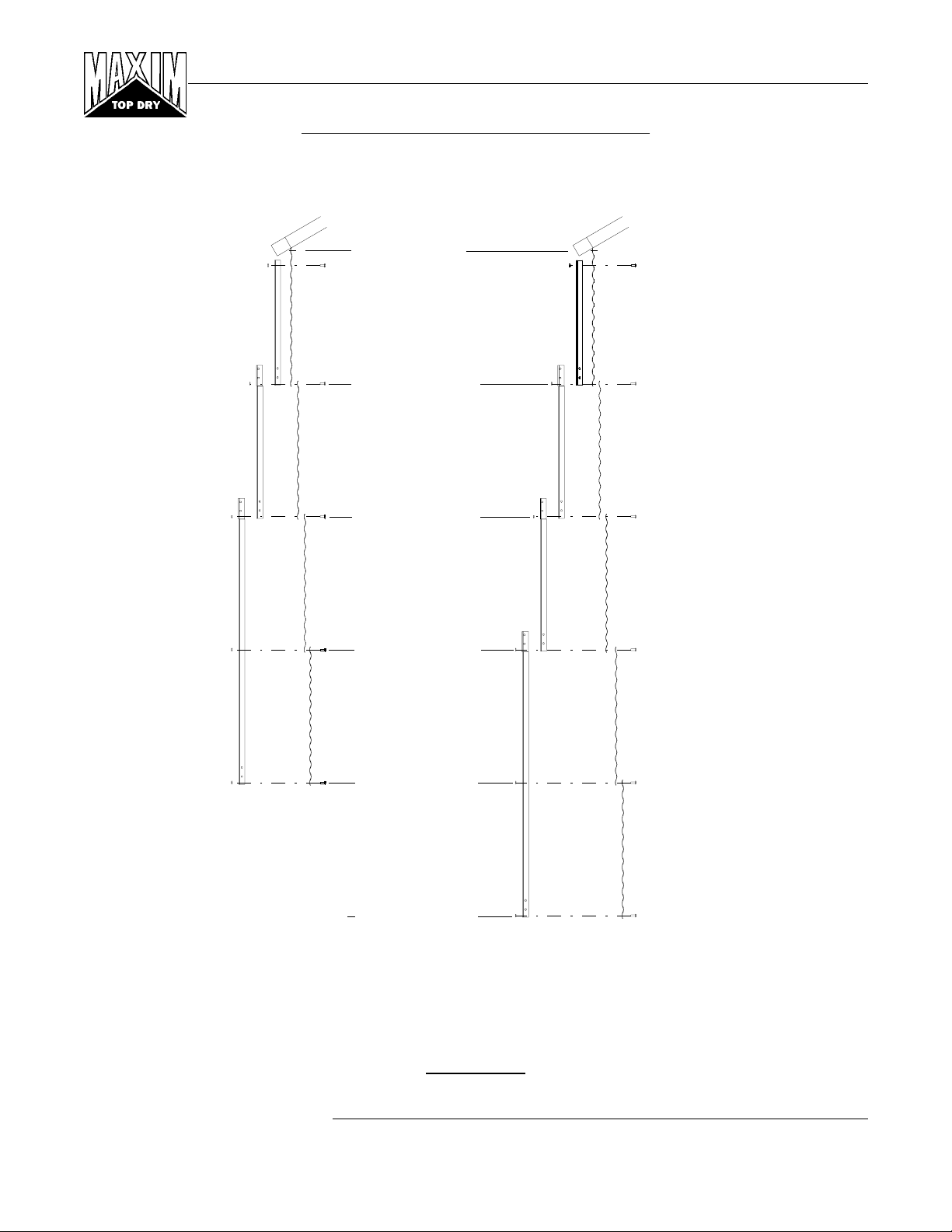

18' Autoflow

Even Ring Bins Odd Ring Bins

STIFFENER & SEAM LOCATIONS

Horizontal Seam

Horizontal Seam

Horizontal Seam

Horizontal Seam

Horizontal Seam

Horizontal Seam

2 stiffeners per sidewall sheet

Top Dry stiffener starting location -18' to 36'

4" corrugation stiffener only

Figure #14

Grain Systems, Inc. Assumption, Ill.

16

REV. 11-20-96

Loading...

Loading...