Page 1

18' Manual Batch

FOUNDA TION REQUIREMENTS

ALL FOUNDATION SPECIFICATIONS SHALL BE CONSTRUED AS RECOMMENDATIONS

ONLY. BECAUSE OF THE MANY VARIABLE CONDITIONS IN AN ACTUAL INSTALLATION,

GRAIN SYSTEMS, INC. ASSUMES NO LIABILITY FOR RESULTS ARISING FROM THE USE

OF SUCH RECOMMENDATIONS.

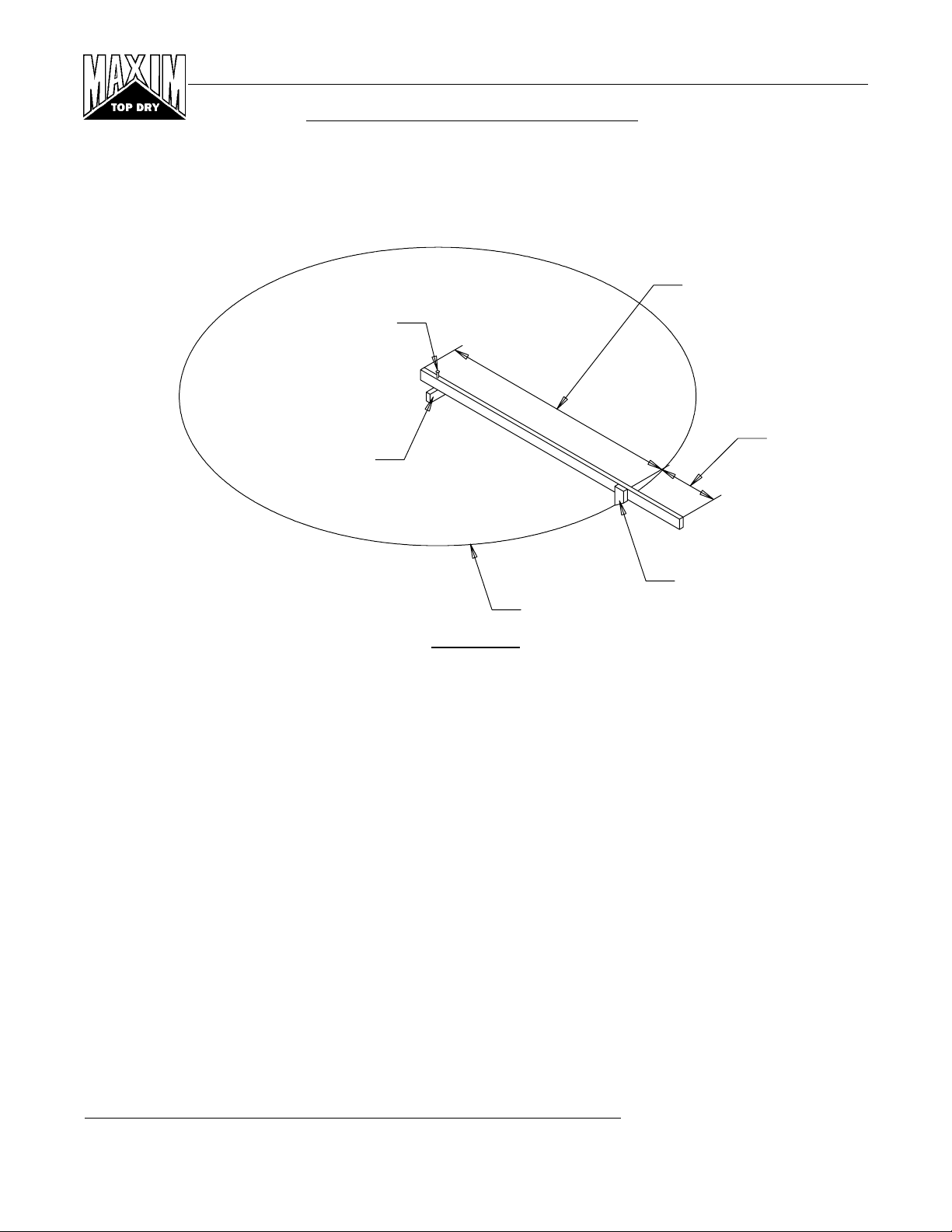

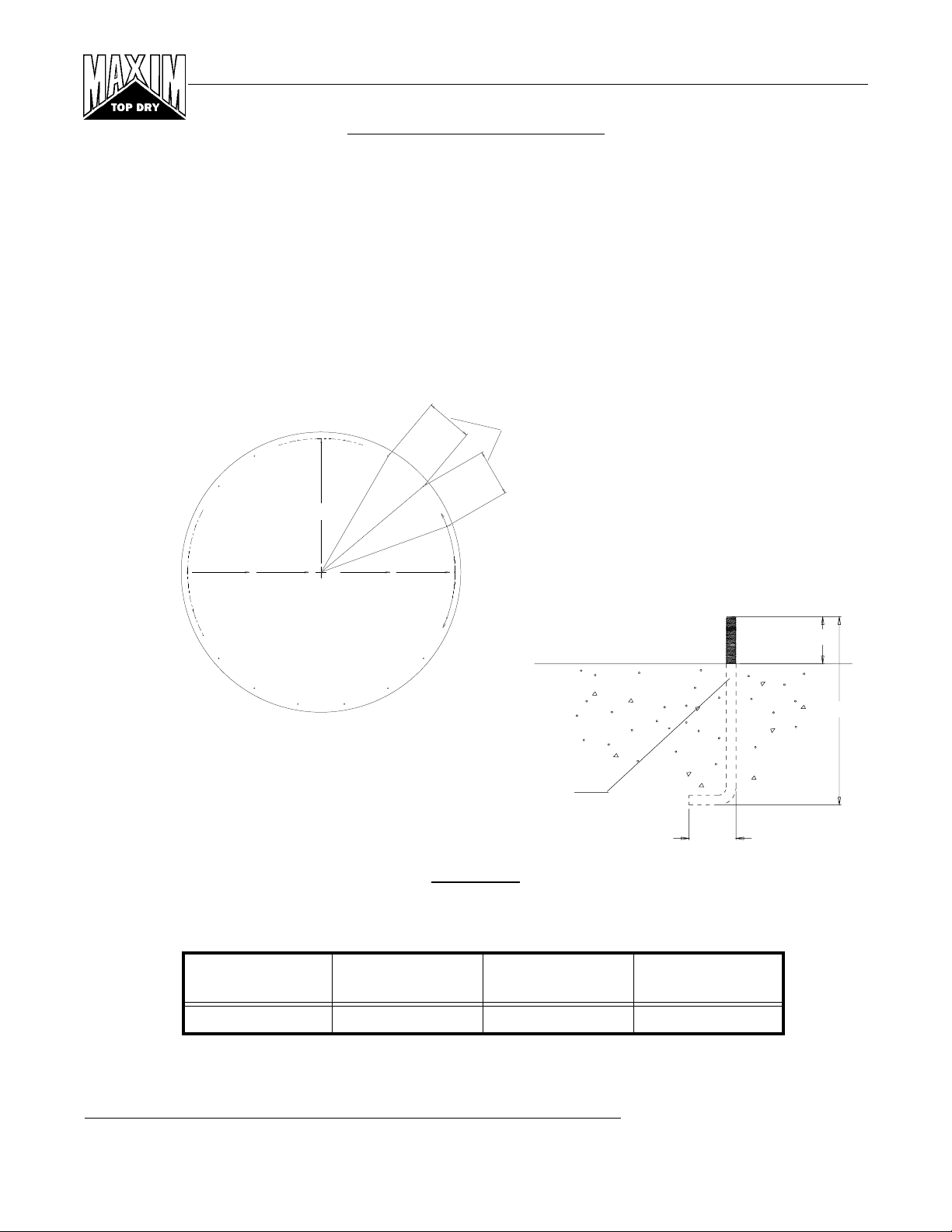

SITE PREPARATION

Foundation Radius

Spike

Two Feet

2 x 4 Center Stake

Pointed Stake

Foundation Line

Figure #1

1.SELECTING THE PROPER SITE

The selected site should be level, firm, and free from underlying debris. The bin can be installed satisfactorily

on slopes, but as the slope increases, additional labor and materials are required for the foundation. The

concrete foundation surface must be level. If some fill is required, it should be watered and tamped

thoroughly to prevent uneven settling from the weight of the bin. Naturally, the site must allow convenient

access for easy loading and unloading, plus provide additional space for future units. Also, consider the

positioning of handling equipment, availability of electricity, and the placement of fans, heaters, and gas

tanks.

2.SCRIBE THE DIAMETER

Having determined the center of the site, drive a small 2 x 4 in the ground to mark the center point of the

foundation. The top of the stake should be the same height as the finished foundation will be. Using one large

spike, nail a straight 2 x 4 (approximately 2 feet longer than the radius of the bin) to the top of the center stake.

This will enable it to swivel. Along the opposite end at a distance given in the foundation layout table, attach

a sharply pointed stake. The swiveling 2 x 4 will act as a compass, enabling you to scribe the correct diameter

of your foundation and later locate the anchor and stiffener bolt locations. (NOTE: Making the 2 x 4 two feet

longer than the radius will allow the 2 x 4 to also be used as a leveling device and for pulling concrete.)

Grain Systems, Inc. Assumption, Ill.

REV. 9-30-96

1

Page 2

18' Manual Batch

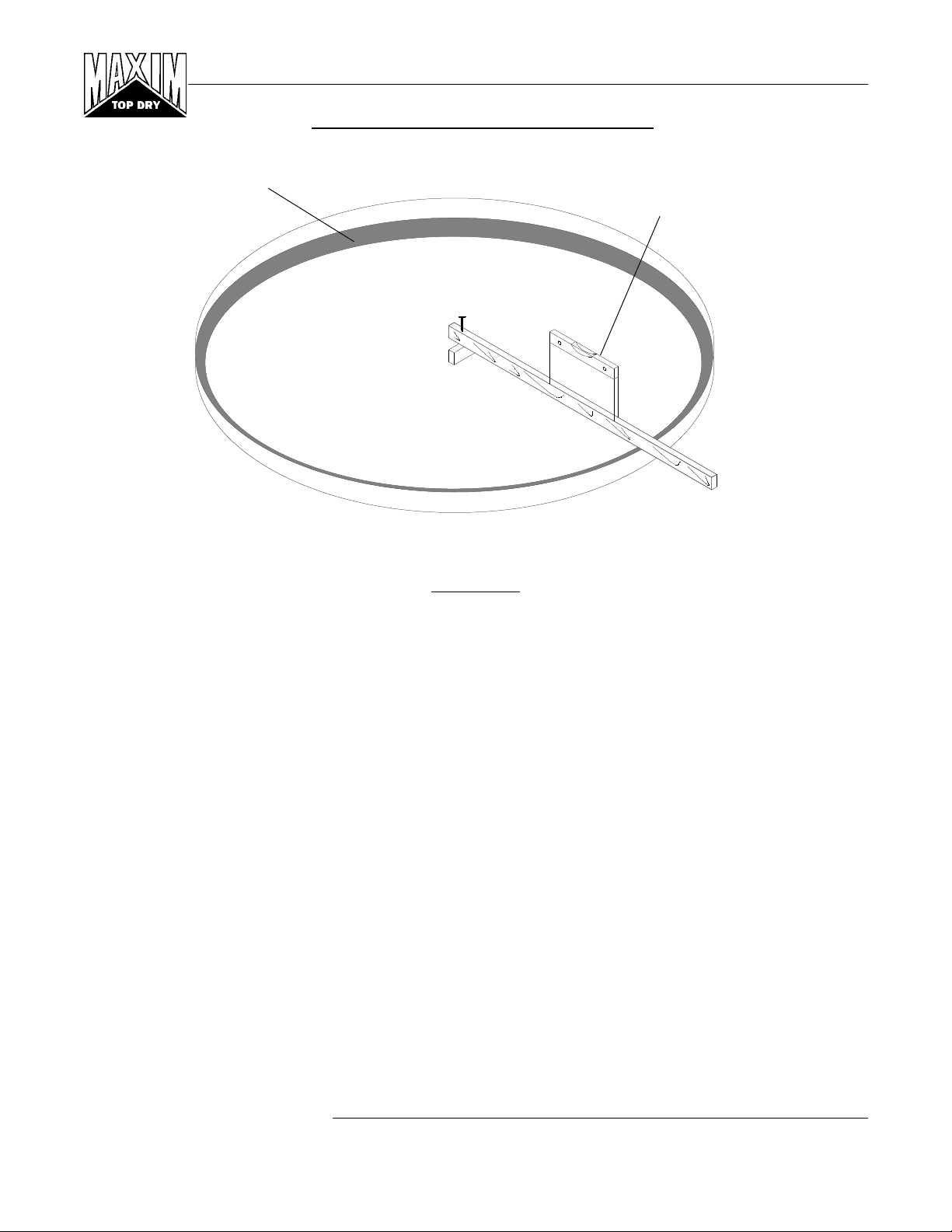

Footing Trench

CIRCULAR FOUNDATION FORM

Carpenter's Level

Figure #2

3.PREPARE THE FOUNDATION

Having scribed the diameter of your foundation, proceed by digging the footing of the foundation. This

consists of a large circular trench dug just inside the foundation line. (Refer to foundation details for necessary

information.) Once the footing has been dug, you are ready to build the forms. It is important that your form

be rigid enough to hold its shape against the poured concrete. Also, the foundation must be flat. Sloped floors

cannot be used in drying bins. A carpenter’s level placed on top of your 2 x 4 will enable you to set the top

of the forms to match the top of the center stake. Check the form work with a transit to ensure a uniform

elevation for the entire foundation.

Grain Systems, Inc. Assumption, Ill.

2

REV. 1-25-96

Page 3

18' Manual Batch

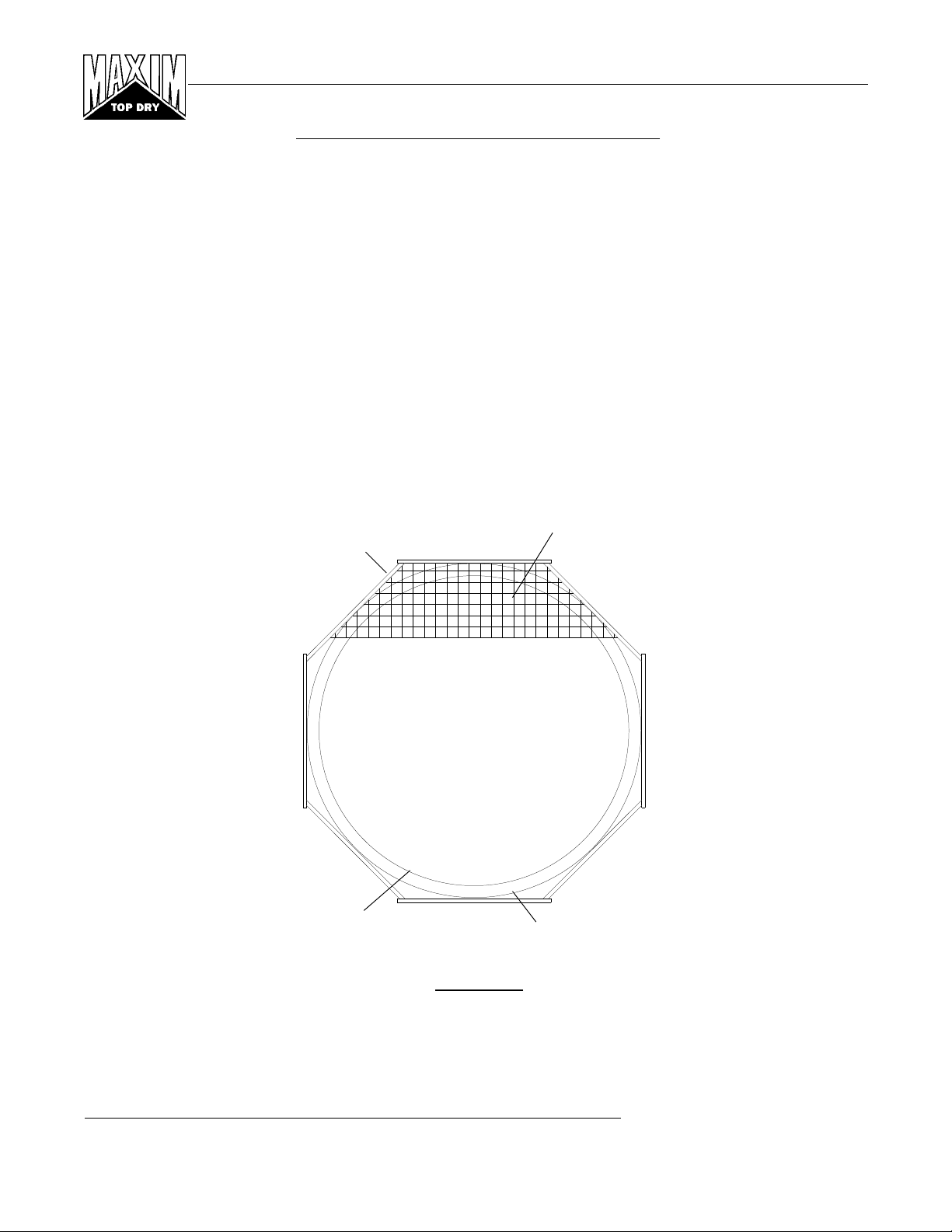

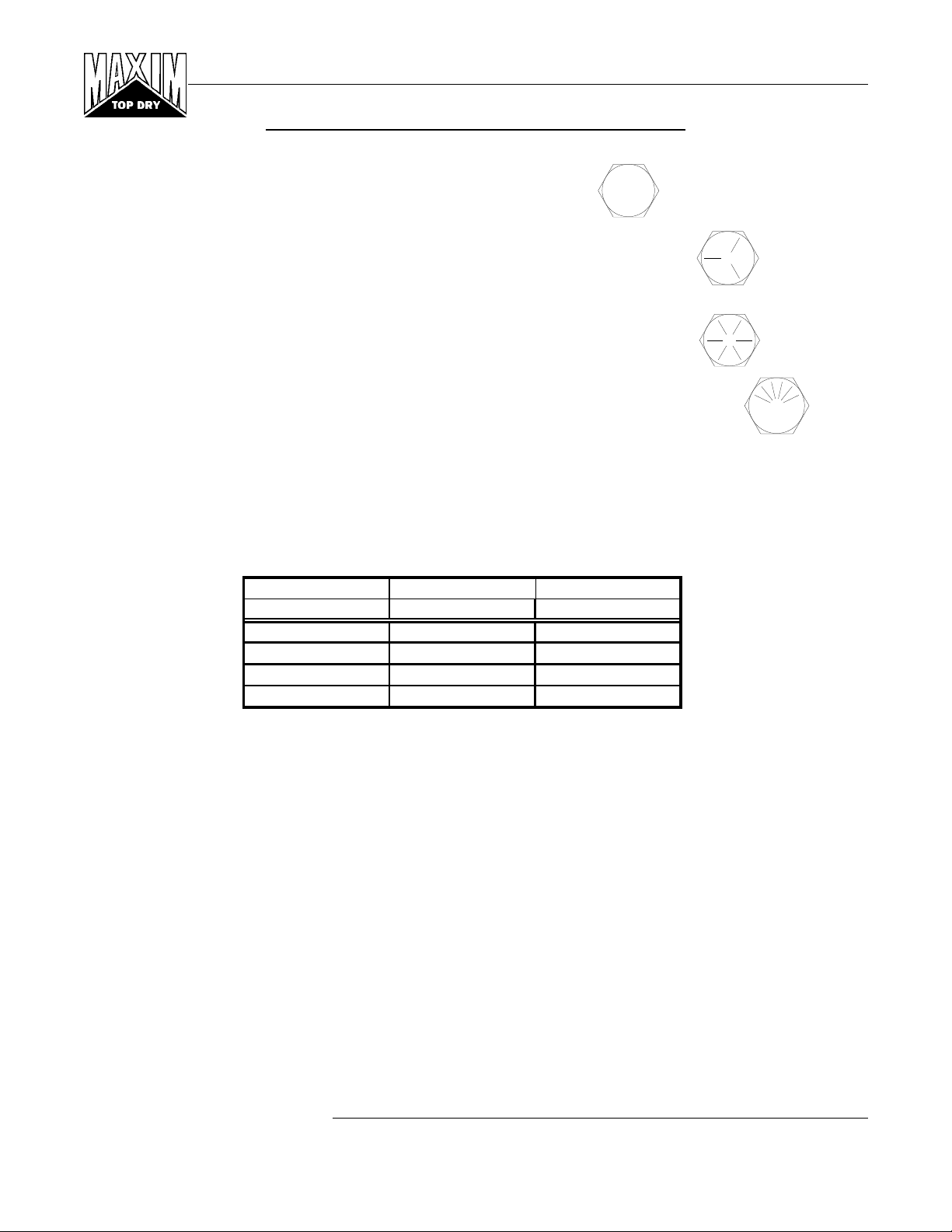

OCTAGONAL FOUNDATION FORM

There are two styles of foundation forms commonly used. The first is the circular form depicted in Figure

#2. The second style can be made of 2" x 8" boards set into a square with corners blocked off to form an

octagon. (See Figure #3 below.) This eight sided form will approximate a circle and can be constructed quite

easily.

When the foundation form is completed install reinforcement rods by either welding or wiring in place. Place

2" of compacted sand on the inside level of the foundation. The sand is then covered with a 4 mil plastic

moisture barrier. 6" x 6" wire mesh (2 mats), covering the entire area of the foundation, completes your

preparation of the bin’s foundation. You are now ready to begin pouring concrete.

NOTE: ALL CONCRETE IS TO HAVE A MINIMUM COMPRESSIVE STRENGTH OF 3,000 PSI

@ 28 DAYS.

6" x 6" Wire Mesh

2" x 8" Forms

Footing Trench

TOP VIEW

Figure #3

Foundation Line

Grain Systems, Inc. Assumption, Ill.

REV. 1-25-96

3

Page 4

18' Manual Batch

1234567890123456789012345

1

5

1

5

1

5

1

5

1

5

1

5

1

5

1

5

1

5

1

5

1

5

1

5

1

5

1234567890123456789012345

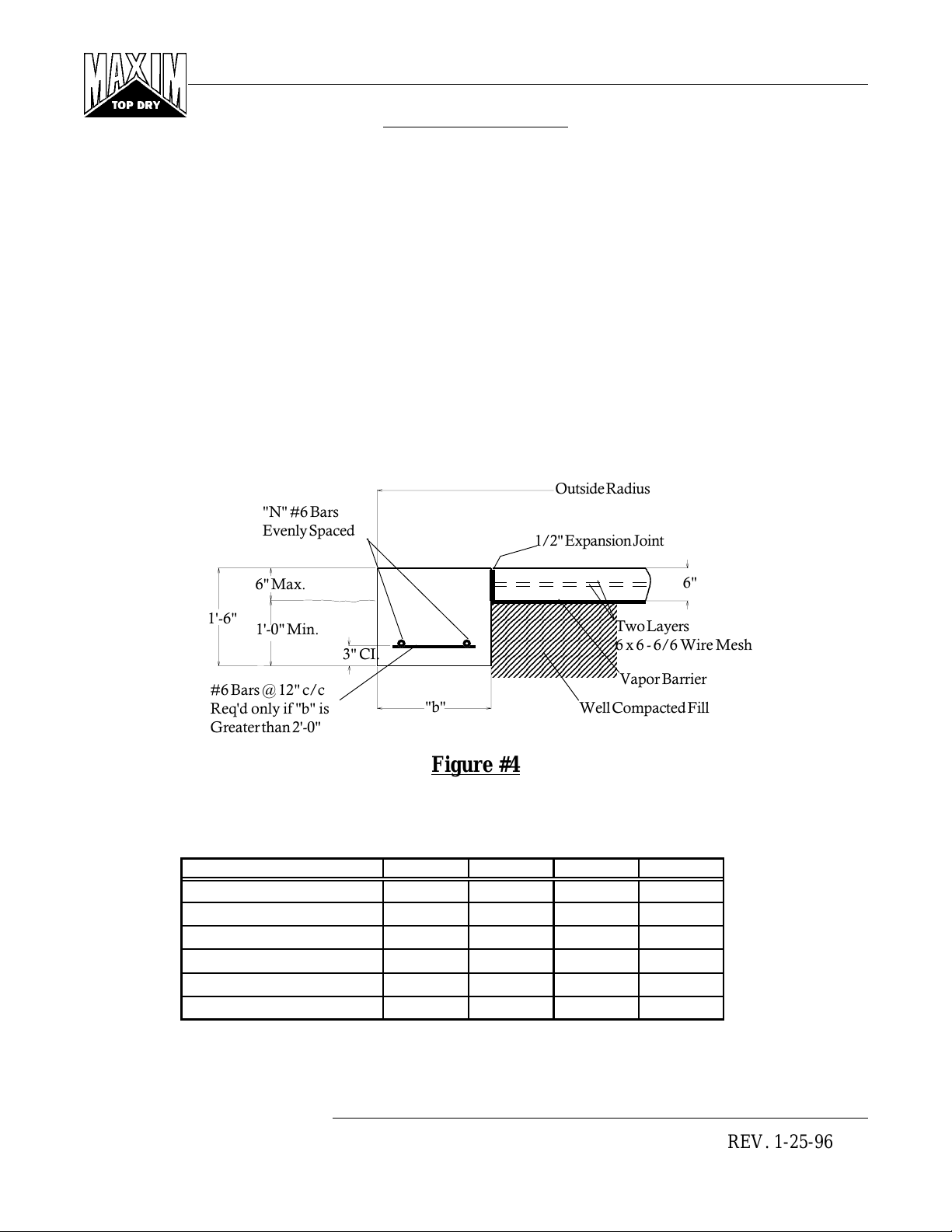

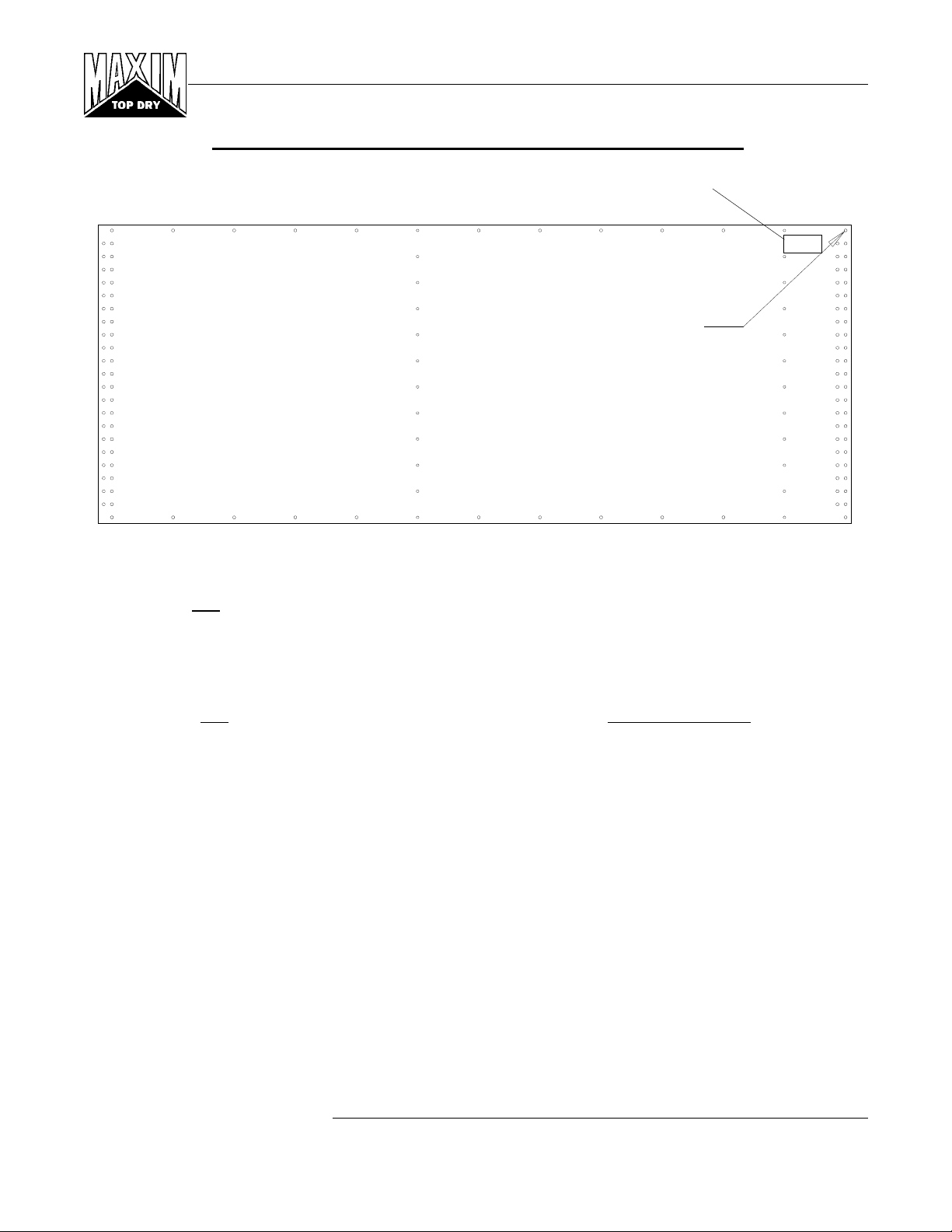

FROST FREE PAD

NOTES:

•Foundation site should be well drained and free of vegetation or debris.

•Foundation design is based on a minimum soil bearing capacity of 3,000 lb/ft2. If soil bearing capacity

is in doubt, contact a local soil testing engineer.

•Concrete shall have a minimum compressive strength of 3,000 PSI at 28 days.

•Requirements for reinforcement do not include overlap.

•Lap all circumferential bars 35 bar diameters and stagger all laps in plan 3'-0".

•All material used for back fill inside the ring wall should be a clean, well graded, crushed stone or sandgravel mixture. Back fill should be placed in 6" lifts and well compacted.

Outside Radius

"N" #6 Bars

Evenly Spaced

1/2" Expansion Joint

6" Max.

23456789012345678901234

23456789012345678901234

23456789012345678901234

1'-6"

1'-0" Min.

#6 Bars @ 12" c/c

Req'd only if "b" is

3" CI.

"b"

23456789012345678901234

23456789012345678901234

23456789012345678901234

23456789012345678901234

23456789012345678901234

23456789012345678901234

23456789012345678901234

23456789012345678901234

23456789012345678901234

23456789012345678901234

Well Compacted Fill

Two Layers

6 x 6 - 6/6 Wire Mesh

Vapor Barrier

Greater than 2'-0"

Figure #4

18' Diameter Bin

Ring Number 5678

b 1'-0" 1'-0" 1'-0" 1'-7"

N 2222

Outside Radius 9'-9" 9'-9" 9'-9" 9'-9"

Sq. Ft. Mesh 6 x 6 - 6/6 500 500 500 500

Length of #6 Bars 200 200 200 200

Total Cubic Yd. Concrete 8 8 8 9

6"

Grain Systems, Inc. Assumption, Ill.

4

REV. 1-25-96

Page 5

18' Manual Batch

ANCHOR BOLT LAYOUT

Refer to following diagram for proper bolt layout.

Having poured and leveled the concrete, use the center stake and straight 2" x 4" again to find bolt circle radius

for the outside stiffener bolts. Select a starting point and stretch a pre-measured chord along the imaginary

circle formed by the bolt circle radius. Consider the placement of these bolts so as not to interfere with the

positions of bin doors and transitions.

Work both directions from first anchor bolt location, this will help eliminate possible error in laying out

anchor bolts. On larger bins sight across starting anchor bolt and center pin and place anchor bolt on opposite

side of anchor bolt radius. From this point you can work both directions from both anchor bolts.

Bolt Chord

Bolt Radius

Starting

Point

Work Both

Sight Across

Directions

B-5217 5/8" ANCHOR

BOLT ASSEMBLY

Figure #5

5/8" Anchor Bolt Detail

Bin Diameter

18' 9'-3.1/16" 12

Bolt Circle

Radius

Number of

Anchors

3"

12"

3"

Bolt Chord

Distance

4'-9.1/2"

Grain Systems, Inc. Assumption, Ill.

REV. 7-9-96

5

Page 6

18' Manual Batch

HARDWARE/BOLTING REQUIREMENTS

NOTE: Grade 2 bolts are designated with a plain head.

NOTE: Grade 5 bolts are designated by 3 slash marks on the head.

All 5/16" diameter bolts are to be Grade 5 or higher.

NOTE: Grade 8 bolts are designated by 6 slash marks on the head.

NOTE: Grade 8.2 bolts are designated by 6 slash marks on the head in a

sunrise pattern.

All 3/8" diameter bolts are to be Grade 8 or 8.2.

IMPORTANT: Do not tighten bolts to exceed the torque specifications listed below.

TORQUE (ft. lb.)

BOLT SIZE MINIMUM MAXIMUM

5/16" - 18 15 20

3/8" - 16 35 42

7/16" - 14 65 72

1/2" - 13 95 105

CAUTION: UNDER NO CONDITION SHALL ANY OTHER BOLTS BE SUBSTITUTED FOR

THOSE SUPPLIED BY GRAIN SYSTEMS, INC.

IMPORTANT: HARDWARE USAGE - 20 gauge - 15 gauge sidewall sheets, use

5/16" x 3/4" bolts and nuts. (S-275)

14 gauge and 13 gauge sidewall sheets, use

5/16" X 3/4" bolts and nuts. (S-275)

- Use 5/16" x 1.1/4" (S-277) for attaching floor flashing to the sidewall.

Grain Systems, Inc. Assumption, Ill.

6

REV. 9-28-96

Page 7

18' Manual Batch

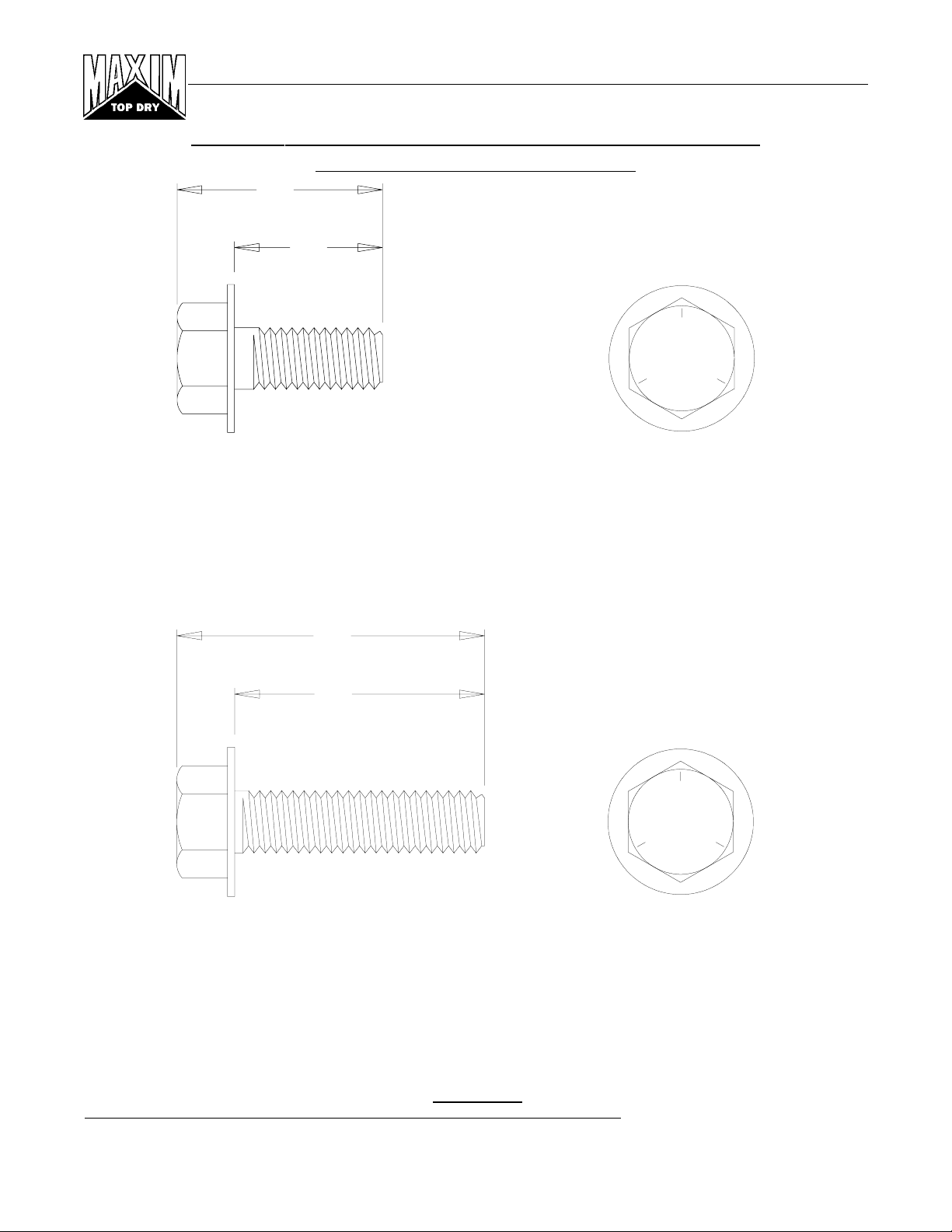

REFER TO TOP DRY TANK BOLTING REQUIREMENTS

FOR COMPLETE BOLT USAGE

.950"

.750"

GRADE 5

SIDE VIEW

TOP VIEW

S-275

.3125" x .750" pre-assembled with a steel backed neoprene washer.

This bolt is used to connect horizontal and vertical seams for 13 gage and thinner sidewall sheets to each

other, and to bolt the stiffeners to the sidewall sheets. It is also used in attaching roof panels to the top

sidewall sheet and attaching roof panels and flashing to the center collar.

1.437"

1.250"

GRADE 5

SIDE VIEW

TOP VIEW

S-277

.3125" x 1.250" pre-assembled with a steel backed neoprene washer.

This bolt is primarily used to connect roof panels together where they overlap. It is also used at the bottom

of the flat bottomed bins to attach the base angle to the sidewall sheet. A small number of these are provided for joints and FC-42076 splice plates for the stiffeners to sidewall connection.

Figure #6

Grain Systems, Inc. Assumption, Ill.

REV. 9-28-96

7

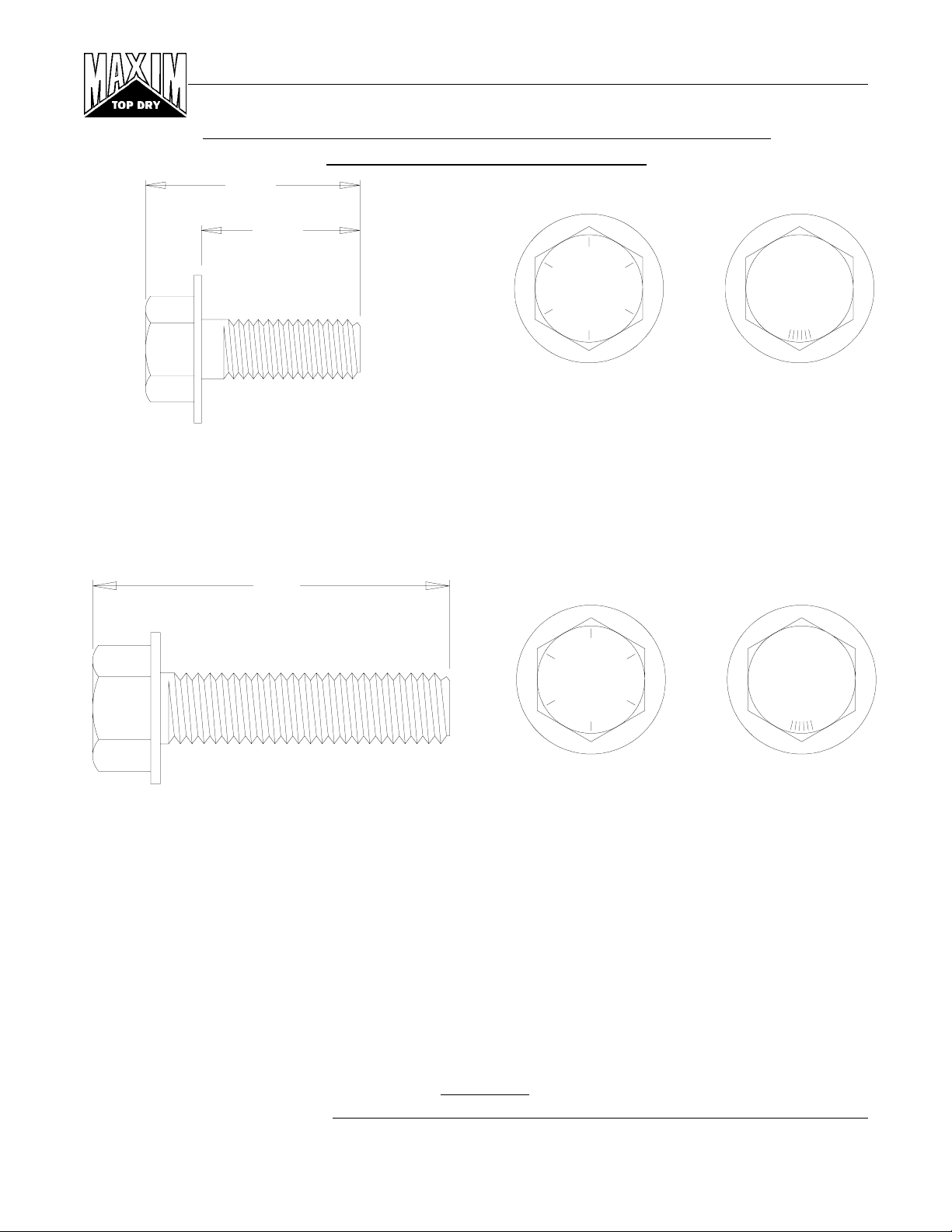

Page 8

18' Manual Batch

REFER TO TOP DRY TANK BOLTING REQUIREMENTS

FOR COMPLETE BOLT USAGE

1.377"

1.000"

GRADE 8.2

SIDE VIEW

GRADE 8

TOP VIEW

S-7927

.375" x 1.000" hex flanged head without a plastic sealing washer.

This bolt is used to splice the stiffeners together on the flanges. A steel flat washer is used on the nut side

of the connection. They are also used on "c" channel splices and mounting "c" channel to wall bracket.

1.873"

GRADE 8.2

SIDE VIEW

GRADE 8

TOP VIEW

S-7928

.375" x 1.500" hex flanged head without a plastic sealing washer.

This bolt is used to attach the wall bracket to the sidewall and stiffener. A steel flat washer is used on the

nut side of the connection.

Note: The only washers shipped loose with the bins are the steel flat washers. The 5/16" steel flat washer

(S-845) is used where the base angle attaches to the sheet and some are used at the main eave clips. The

3/8" steel flat washers (S-248) are used at the stiffener splices and some are used in the roof rafter splices.

Figure #7

Grain Systems, Inc. Assumption, Ill.

8

REV. 9-30-96

Page 9

18' Manual Batch

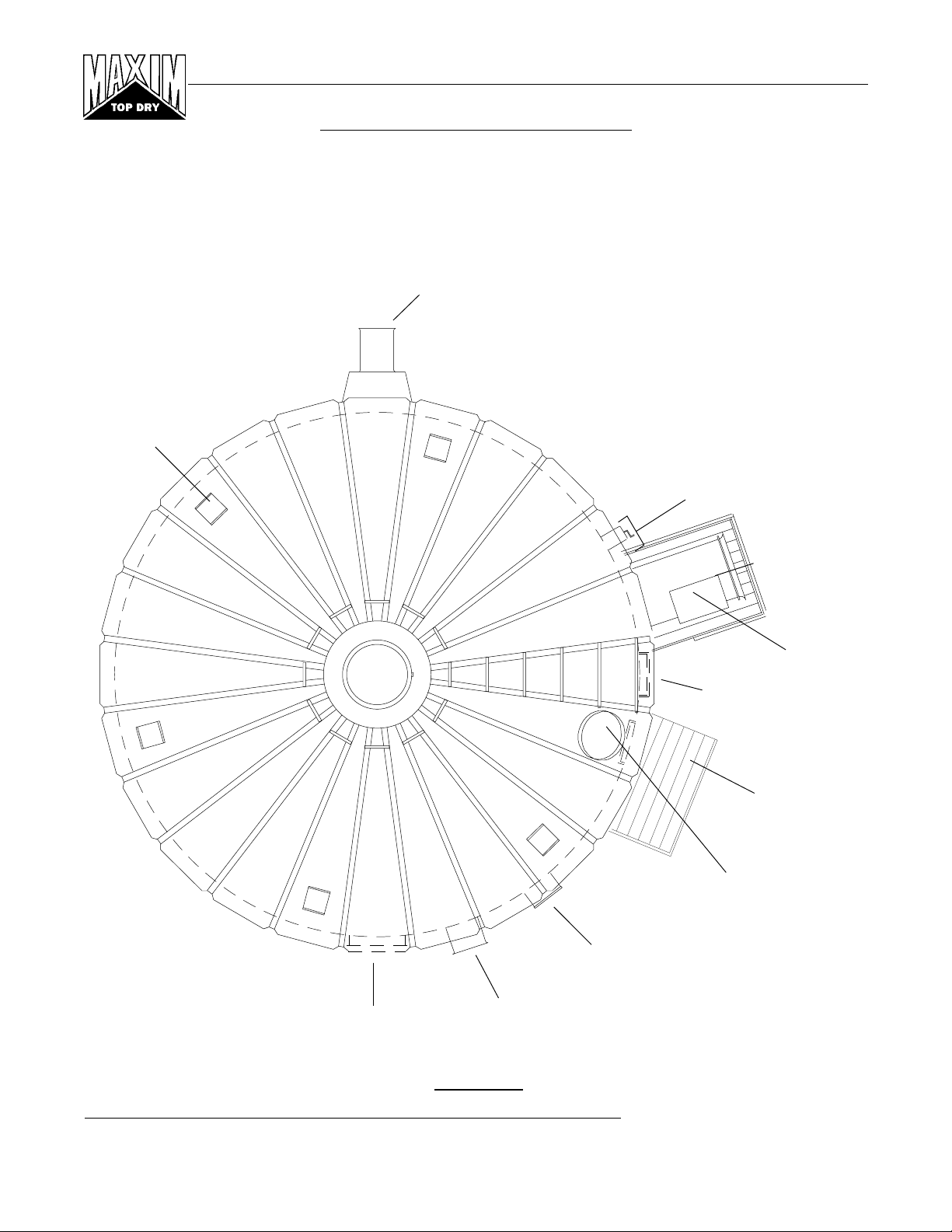

LOCATION OF ACCESSORIES

Below is a typical Top Dry bin layout showing suggested locations of Top Dry Accessories. When locating

the manway be sure the outside ladder will not interfere with other accessories below. Roof vents should be

spaced evenly around the roof. (Quantity will vary with individual systems.)

NOTE: The Top Dry system should be provided with a dependable equipment ground.

Aeration Fan &

Transition

Roof Vents

Manual Winch

2 Ring Door

Crop Dryer

Platform

Top Dry

Crop Dryer Unit

Outside Ladder

Access Door

Platform

Manway

Top Dry

Control Center

Unloading Auger

Figure #8

Grain Systems, Inc. Assumption, Ill.

REV. 9-30-96

9

Page 10

18' Manual Batch

VERY IMPORTANT!

DC-1174 (Top Decal)

Top of Sheet

Horizontal seam hole locations

determine top and bottom of sheet.

Sheet shown as viewed from the inside of bin.

Bottom of Sheet

All 4.00" corrugated sidewall sheets must be placed correctly.

Top

All 4.00" corrugated sidewall sheets have a top and bottom!

Failure to observe this will not allow the door to fit properly.

Carefully review the erection manual and place sidewall sheets as shown.

Grain Systems, Inc. Assumption, Ill.

10

REV. 9-30-96

Page 11

18' Manual Batch

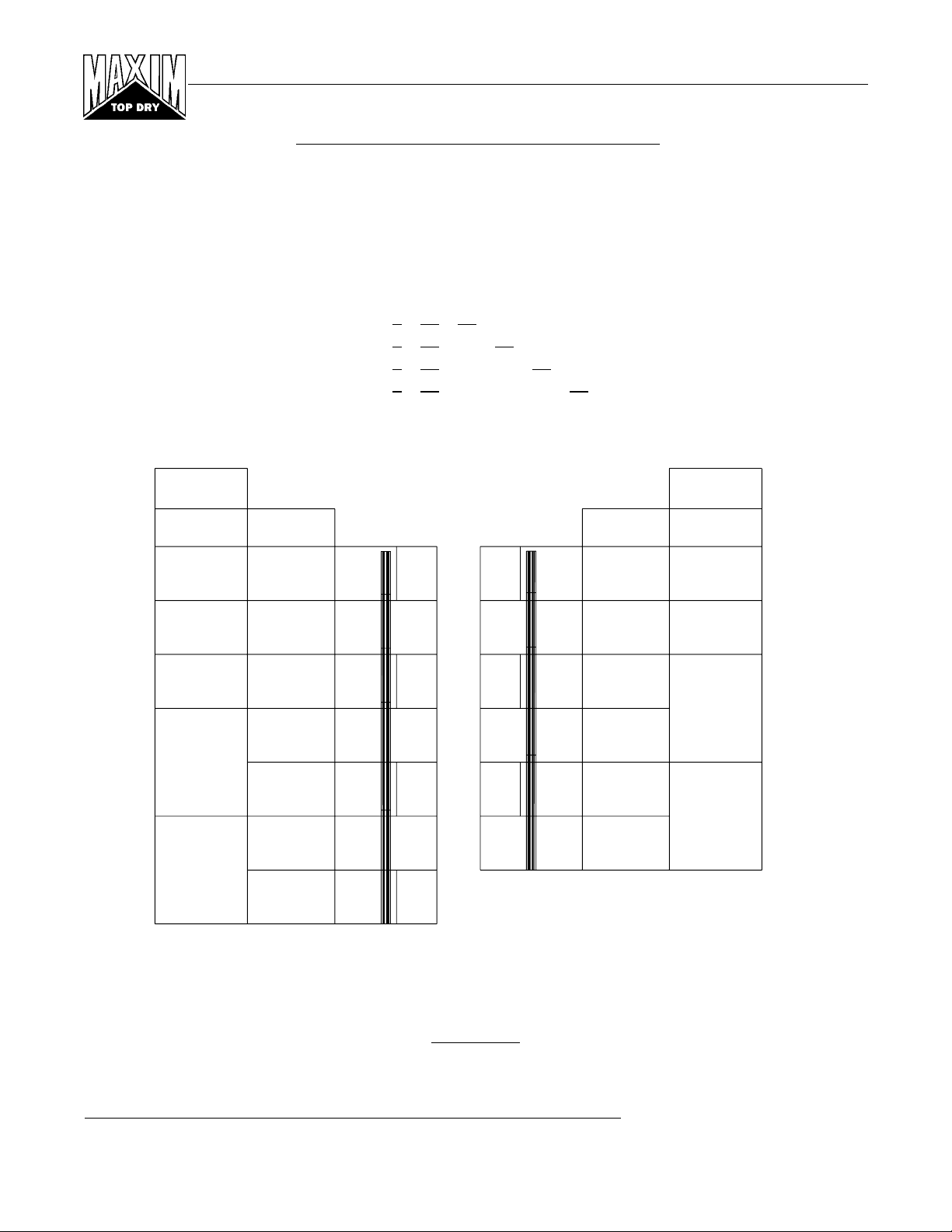

SIDEWALL & STIFFENER GAUGES

Door locations are shown by the underlined sidewall gauges. Actual gauge of the access door sheet located

just below the Top Dry floor is in parentheses.

Top Dry Bin

TDM18-4

TDM18-5

TDM18-6

TDM18-7

Odd Ring

Gauge

16-T*

16

16

Ring

1

2

3

Sidewall Gauges

20 20 20 20 (18)

20 20 20 20 20 (18)

20 20 20 20 20 20 (18)

20 20 20 20 20 20 20 (18)

18' Stiffener Layout

Ring

1

2

3

Even Ring

Gauge

16-T*

16

16

* Top stiffener

4

14

5

6

12

7

4

5

14

6

All Top Dry bin stiffeners are mounted on the outside of the bin. See stiffener instructions for stiffener joint

details and stiffener to sidewall attachment.

Figure #9

Grain Systems, Inc. Assumption, Ill.

REV. 9-30-96

11

Page 12

18' Manual Batch

D

P

L

h

Cod

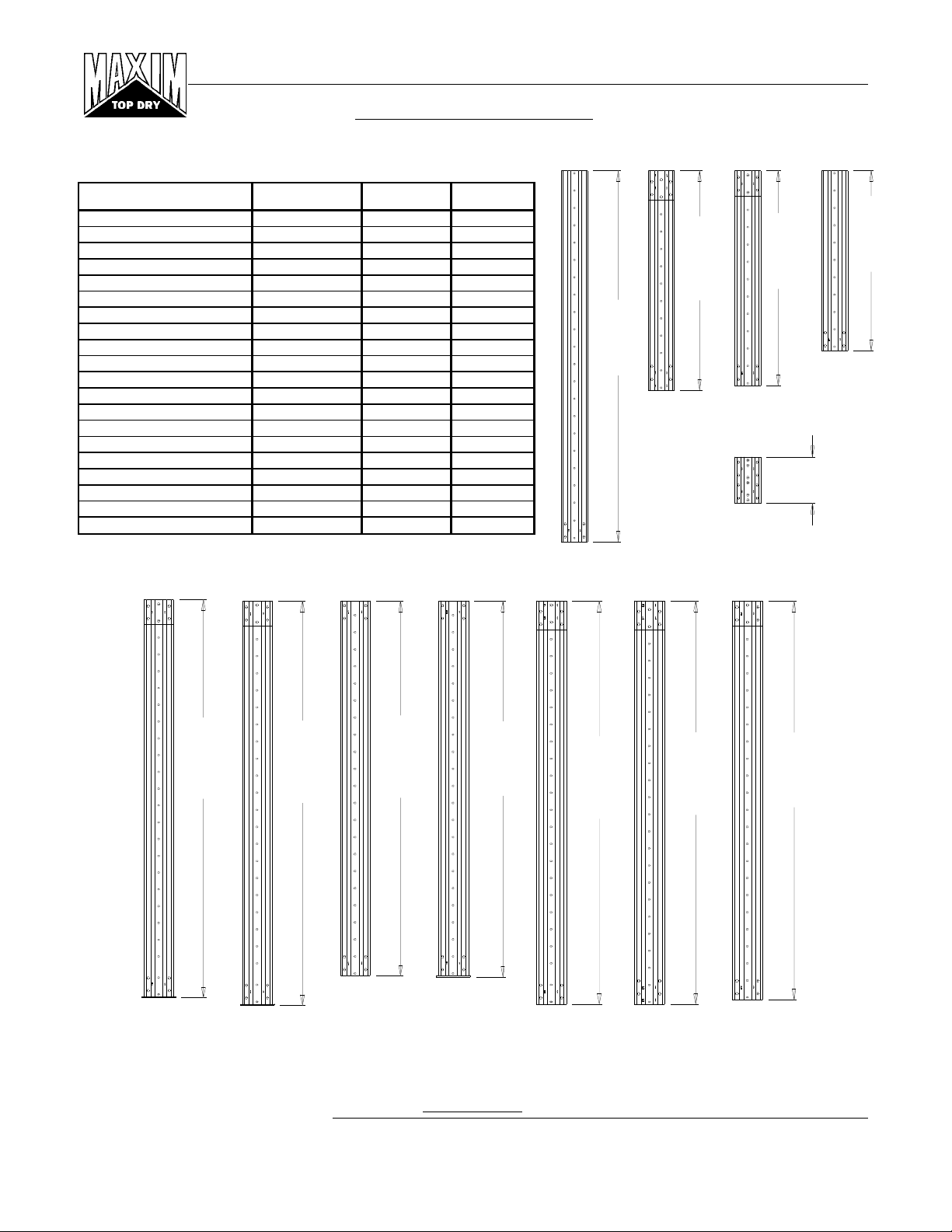

OUTSIDE STIFFENERS

• The XX in the part numbers at the bottom will identify the Stiffener's gauge.

Example: FC-4205714 is a 2-Ring Standard Stiffener 14 Gauge.

Stiffener Overall Color

escription

2-Ring 10 Ga. (Base) FC-4207210 94 27/32" White

2-Ring 12 Ga. (Base) FC-4207212 94 27/32" Black

2-Ring 14 Ga. (Base) FC-4207214 94 27/32" Green

2-Ring 16 Ga. (Base) FC-4207216 93 13/16" Blue

2-Ring 8 Ga. (B ase ) FC-4207308 88 3/16" Yellow

2-Ring 8 Ga. FC-4206308 87 15/16" Yellow

2-Ring 10 Ga. Tr a ns. FC-42062 94 19/32" Purple

2-Ring 12 Ga. FC-4205712 94 19/32" Black

2-Ring 14 Ga. FC-4205714 94 19/32" Green

2-Ring 16 Ga. FC-4207516 93 9/16" Blue

2-Ring 18 Ga. FC-4207518 93 9/16" Orange

2-Ring 16 Ga. Top FC-4206516 85 9/16" Blue

2-Ring 18 Ga. Top FC-4206518 85 9/16" Orange

1-Ring 12 Ga. FC-4205912 50 19/32" Black

1-Ring 14 Ga. FC-4205914 50 19/32" Green

1-Ring 16 Ga. FC-4207416 49 9/16" Blue

1-Ring 18 Ga. FC-4207418 49 9/16" Orange

1-Ring Top 16 Ga. FC-4206616 41 7/16" Blue

1-Ring Top 18 Ga. FC-4206618 41 7/16" Orange

Splice FC-42076 10 11/16" ---

art No.

engt

e

85.9/16"

FC-42059XX

1 Ring

12 Ga.

14 Ga.

FC-42065XX

2 Ring Top

16 Ga.

18 Ga.

50.19/32"

FC-42074XX

1 Ring

16 Ga.

18 Ga.

FC-42076

Splice

10 Ga.

41.7/16"

49.9/16"

FC-42066XX

1 Ring Top

16 Ga.

18 Ga.

10.11/16"

93.13/16"

FC-4207216

2 Ring

16 Ga.

Base

Grain Systems, Inc. Assumption, Ill.

12

FC-42072XX

2 Ring

10 Ga.

12 Ga.

14 Ga.

Base

94.27/32"

FC-42063XX

2 Ring

8 Ga.

87.15/16"

FC-42073

2 Ring

8 Ga.

Base

Figure #10

88.3/16"

FC-42062

2 Ring

10 Ga.

Transitional

94.19/32"

FC-42057XX

2 Ring

12 Ga.

14 Ga.

94.19/32"

FC-42075XX

2 Ring

16 Ga.

18 Ga.

REV. 1-25-96

93.9/16"

Page 13

18' Manual Batch

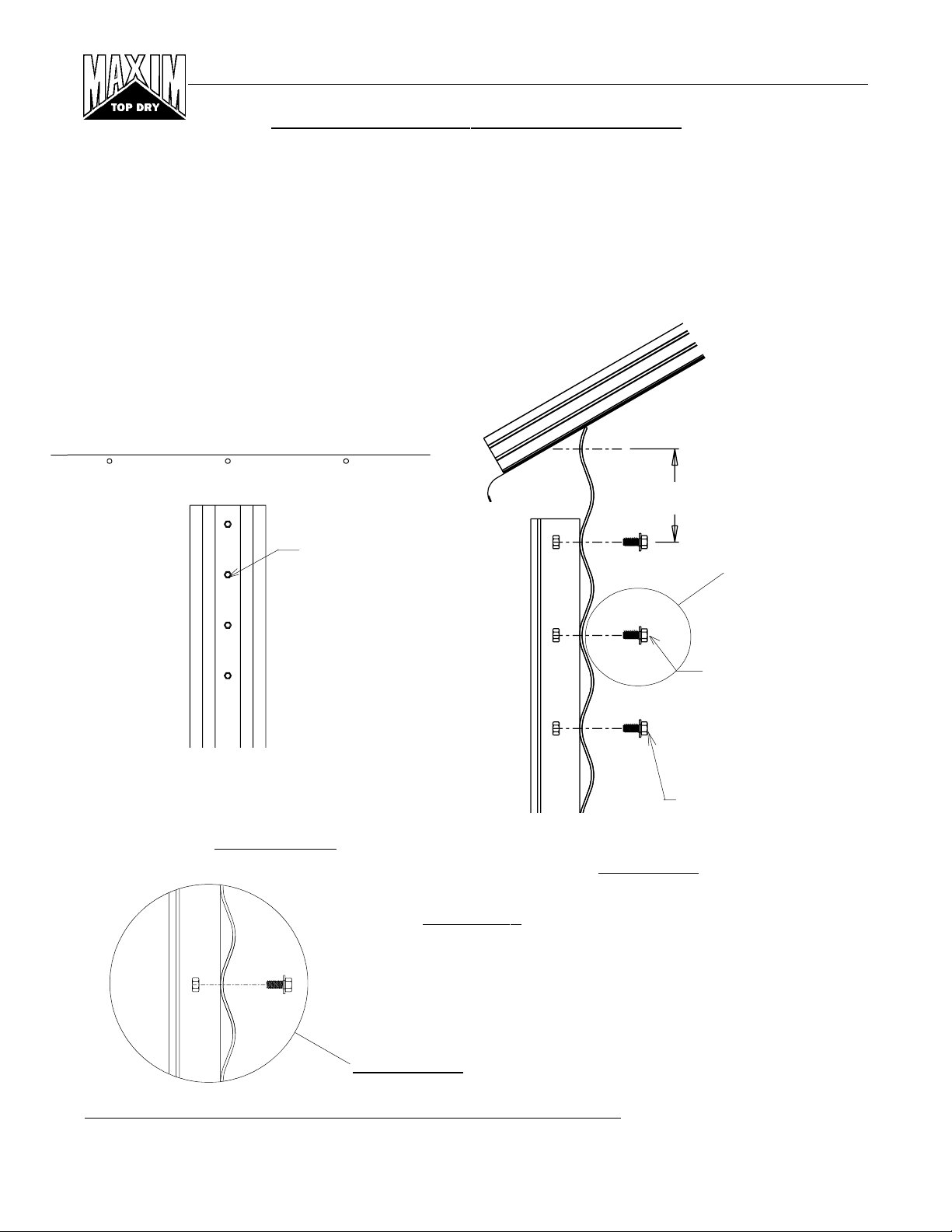

TOP STIFFENER STARTING LOCATION

Refer to Figure #11, for proper location of top stiffeners. On the overlap of the stiffeners, and on the splice, use

3/8" x 1" hex bolts, a washer on the nut side connection. Refer to the stiffener layout, Figure #9, for stiffener usage.

All stiffeners are outside the bin wall. Use 5/16" x 3/4" Grade 5 bin bolts with head and neoprene washer to the inside

of the bin wall. Refer to proper charts and illustrations on the previous two pages for proper location of stiffeners and

sidewall sheets.

4.00"

TOP STIFFENER

FRONT VIEW

DETAIL "A"

5/16" X 3/4" BIN BOLT

(S-275)

BOLT HEAD AND SEALING

WASHER MUST BE ON THE

INSIDE OF THE BIN.

SIDE VIEW

Figure #11

DETAIL "A"

Grain Systems, Inc. Assumption, Ill.

REV. 9-30-96

13

Page 14

18' Manual Batch

3/8" DIA. HEX FLANGED

HEAD BOLT (NO

SEALING WASHER)

USE 3/8" X 1.1/2"

BOLT, NUT AND WASHER

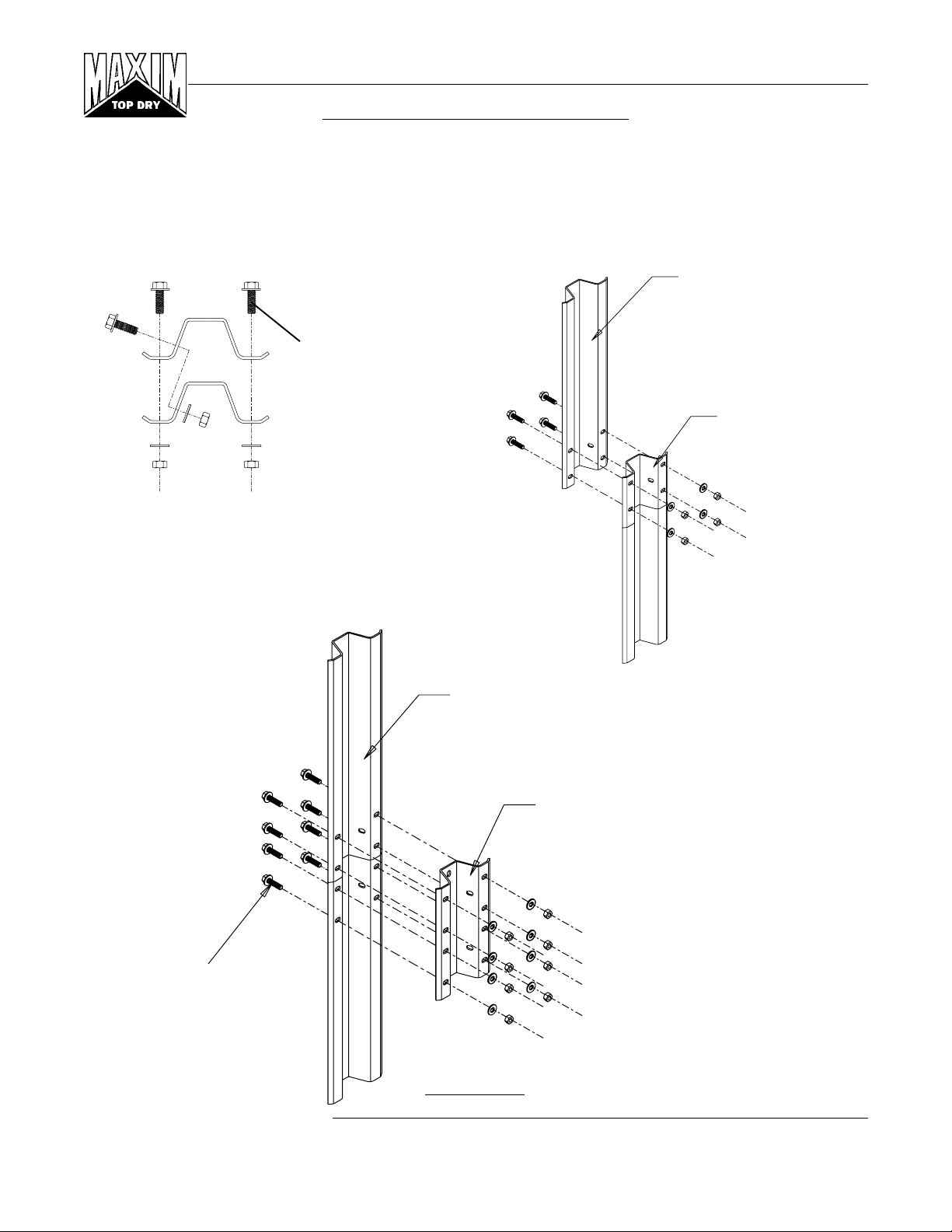

STIFFENER SPLICE DETAILS

FC-4207516 16 GA.

BLUE

FC-4207518 18 GA.

ORANGE

FC-4207516 16 GA.

BLUE

FC-4207518 18 GA.

ORANGE

SPLICE PLATE JOINT

(TOP VIEW)

3/8" DIA. HEX FLANGED

HEAD BOLT (NO

SEALING WASHER)

FC-4206308 8 GA.

YELLOW

FC-42062 10 GA.

PURPLE

FC-42076 SPLICE

OFFSET JOINT CONNECTION

DETAIL

Grain Systems, Inc. Assumption, Ill.

14

Figure #12

REV. 9-30-96

Page 15

18' Manual Batch

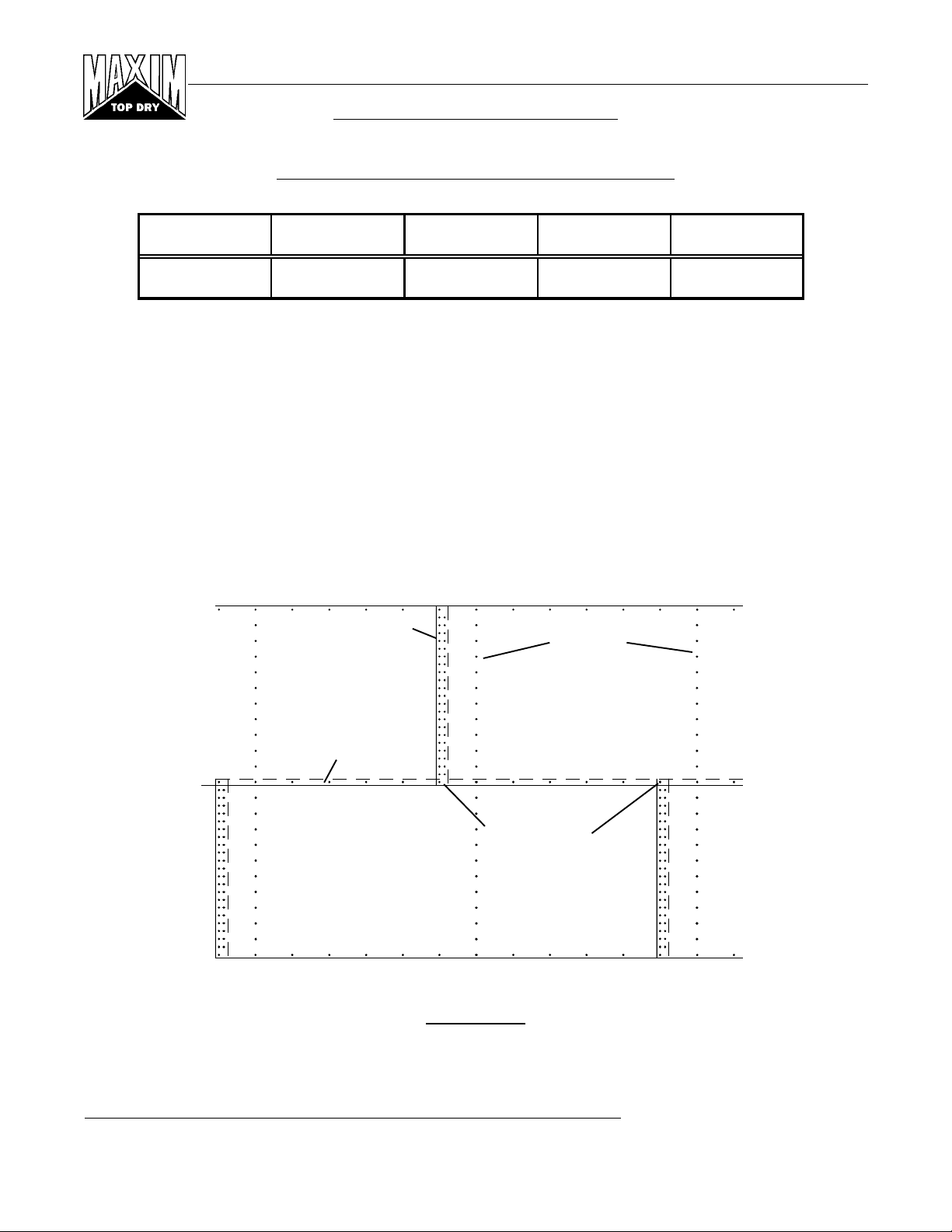

BOLTING REQUIREMENTS

2 STIFFENERS PER SIDEWALL SHEET

Sidew all Horizo ntal Vertical Stif fene r Overlap

Gauge Seam Seam To Sidewall Seam

17 Thru 20 5/16" x 3/4" 5/16" x 3/4" 5/16" x 3/4" 5/ 16" x 3/ 4"

[10] [42] [20] [2]

All bolts are standard bin bolts with neoprene washers. For horizontal and vertical seam bolts, the bolt head and

neoprene washers are on the outside of the bin.

Note: For the splice plates FC-42076 use 5/16" x 1.1/4" bolts for the stiffener to sidewall connections.

Standard (17 Gauge Thru 20 Gauge) Sheet Bolting Detail

(Viewed from outside of the bin)

Vertical Seam

Horizontal Seam

Overlap Seam

Stiffener to

Sidewall

Figure #13

Grain Systems, Inc. Assumption, Ill.

15

REV. 1-25-96

Page 16

18' Manual Batch

Even Ring Bins Odd Ring Bins

STIFFENER & SEAM LOCATIONS

Horizontal Seam

Horizontal Seam

Horizontal Seam

Horizontal Seam

Horizontal Seam

Horizontal Seam

Grain Systems, Inc. Assumption, Ill.

16

2 stiffeners per sidewall sheet

Top Dry stiffener starting location -18' to 36'

4" corrugation stiffener only

Figure #14

REV. 1-25-96

Page 17

18' Manual Batch

GAUGE COLOR CODE

22 White

20 Red

19 Black/Yellow

18 Orange

17 Pink/Light Blue

16 Blue

15 Brown/Red

14 Green

13 Yellow/Blue

12 Black

11 Pink

10 Light Blue

9 Blue/Orange

8 Yellow

Note: The rope caulking is installed before each sheet is assembled.

Apply rope caulking between the last vertical row of bolts and edge of

outside sheet. There is sufficient caulking for all vertical seams on

storage and drying bins. Wipe sheet clean where caulking is to be

applied.

Before bolting the sidewall sheets together, check that you have the

proper gauge steel for the first ring. The higher gauge numbers denote

the thinner materials. (For example: 20 gauge material is thinner than

14 gauge.) In erecting Top Dry grain bins the thinnest material always

goes on top. The first sidewall ring you assemble will be the second

ring from the top of your bin. Check the various gauges of your bin

with the Color Code Chart and begin building accordingly.

Once you have selected the proper gauge material, begin assembling

the sidewall sheets according to the instructions on the following page.

- For bolting specifications on stiffeners, see Figure #11.

CAULKING DETAIL

9.3/8" (23.813 cm)

Standard

Caulking

9.3/8" (23.813 cm)

Standard Sidewall Sheets

As Viewed From Outside

Figure #15

Grain Systems, Inc. Assumption, Ill.

REV. 1-25-96

17

Page 18

18' Manual Batch

SIDEWALL CONSTRUCTION INSTRUCTIONS

Left

Sidewall

Concrete

Foundation

Right

Sidewall

Figure #16

Using correct size bin bolts throughout, begin assembling sidewall sheets end to end (overlapping the same way

throughout) until the ring is complete. All body sheet bolts are to be installed with the bolt head and its neoprene washer

to the outside and the nut on the inside. Do not tighten bolts until all sheets are assembled and form a complete ring.

Tighten the bolts in sequence, starting from the center and work to the edge in both directions. This permits the sidewall

sheets to draw-up evenly.

After assembling the second ring, lift the top ring sheets in place, add top stiffeners, build the Top Dry floor, then the

roof.

Note: The sidewall sheets used for the top ring are punched to accommodate the eave flashing bolts.

Note: The fan entrance sheet and access door are located in the second ring. Attach the top stiffeners, leaving out

the (7) bolts indicated in Figure #15 at each stiffener location. Install the flashing bolts from the outside.

Top Two Rings

Eave flashing

holes

Leave these 7

bolts out of each

stiffener

TOP RING

SECOND RING

Figure #17

Grain Systems, Inc. Assumption, Ill.

18

REV. 9-30-96

Page 19

18' Manual Batch

STIFFENER AND BRACKET INSTALLATION

Install the stiffeners on the outside of the bin (as shown in Figure #14) and the wall brackets on the inside of the bin.

The wall brackets are to be positioned with the bracket's top hole matching the first hole up from the horizontal seam

(not counting the horizontal seam). Bracket to sidewall connection using a 3/8" x 1.1/2" bolt (S-2086), head outside,

with a neoprene washer (S-3558) against the wall on the inside, and a corrugation spacer (S-7041).

NOTE: It may be necessary to ream out sidewall holes with a drill and 3/8" bit for easier installation.

TD-100667

Wall Bracket

S-7041

Corrugation

Spacer

S-3558

Neoprene

Washer

S-7041

Corrugation

Spacer

TD-100667

Wall Bracket

Figure #18

TOP RING

S-3558

Neoprene

Washer

SECOND RING

Figure #19

Grain Systems, Inc. Assumption, Ill.

REV. 9-30-96

19

Page 20

18' Manual Batch

"C" CHANNEL INSTALLATION

Fasten the rolled "C" eave members to the wall brackets in the upper 2 holes of the top set of three (3) holes leaving

the bolts loose.

Install the splice plates at the rolled "C" eave member seams using 3/8" x 1" flanged hex bolts and nuts. Install bolts

as shown below. Tighten all bolts.

"C" Channel Attachment.

TD-100763

Eave "C" Channel

TD-100763

Eave "C" Channel

TD-100688

Eave Splice

Grain Systems, Inc. Assumption, Ill.

20

Figure #20

REV. 9-30-96

Page 21

18' Manual Batch

CENTER COLLAR ASSEMBLY

Add channel braces and brace plates to center collar as shown using 3/8" x 1" bolts and nuts. (Do not attach cross

channel until floor is done.)

TD-100460

TD-100459

Channel Brace Plate

Channel Brace

TD-100004

Center Collar Cross

Channel

(Don't install until floor

TD-100630

Center Collar

is completed)

Figure #21

Position the center collar at the center of the bin and raise it to approximately 7'-0.3/4" measuring from the

bottom edge of the collar to the concrete.

7'-0.3/4"

Figure #22

Grain Systems, Inc. Assumption, Ill.

REV. 9-30-96

21

Page 22

18' Manual Batch

RAFTER INSTALLATION & FLOOR SUPPORT ANGLE ATTACHMENT

When installing the rafters, set the lower clip end on the "C" eave member. Leave the bolts to the center collar and

the eave member loose until all rafters are in place. Use 3/8" x 1" hex bolts and nuts to connect the center collar and

eave member to three (3) rafters at 90 degrees to each other. These first three (3) rafters should all face the same

direction. Every other rafter should alternate direction. IMPORTANT: There are left & right rafters. Be sure to

alternate left, right, left, right, etc.. The floor sheet support purlins can now be installed using 5/16" x 3/4" bin bolts.

There are two (2) different lengths of purlins to fit between the rafters. Insert the straight tab of the purlin through

the upper slot in the left hand rafter when looking toward the bottom of the rafters. Bolt the bent end of the purlin to

the right hand rafter in the upper two (2) holes. After inserting the next purlin tab, bolt the first purlin tab to the second

purlin. Continue around the bin alternating lengths as the rafter facings did. Tighten all bolts.

Looking toward the sidewall

Floor Support Angle Assembly

TD-100768 Long

TD-100769 Short

Grain Systems, Inc. Assumption, Ill.

22

Figure #23

REV. 9-30-96

Page 23

18' Manual Batch

DUMP HOPPER INSTALLATION

Pre-assemble the dump hoppers, and flashing angles to the floor sheets. Place a dump hopper under the floor sheet

and align it with the pre-punched large hole. Place a flashing angle on top of the sheet across the outer edge of the

hopper entrance with the angles interior angle facing the wide sheet end. Screw down through the angle, sheet, and

hopper with 5/16" x 3/4" self-tapping screws.

TD-100654

Flashing Angle

Floor Sheet

TD-100767

TD-100647

Dump Hopper

Assembly

S-7221

5/16" x 3/4"

Self-Tapping Screws

Figure #24

FLOOR SHEET INSTALLATION

Now the assembled sheets can be placed over the rafter framework. As the sheets are placed and overlapped they are

to be screwed down to the rafters using 5/16" x 3/4" self-tapping screws, leaving the second and sixth holes empty.

18' Floor Sheets

TD-100767

Figure #25

Grain Systems, Inc. Assumption, Ill.

REV. 9-30-96

23

Page 24

18' Manual Batch

LEVELING BAND POST INSTALLATION

Install the leveling band posts on the floor as shown.

The second and sixth holes in the beam indicate the location of the leveling band posts. Attach posts with 5/16" x

1.1/4" bin bolts (S-277). In the second hole from the bottom of the sheet, there will be 6 posts (1 every third sheet).

In the sixth hole there will be 6 posts (1 every third sheet). After all of the posts have been installed fill the unused

holes with 5/16" x 1.1/4" bin bolts.

Optional Rotary Switch

S-277

5/16" x 1.1/4"

Bin Bolt

Leveling Band Post

6th hole from sidewall

Leveling Band Post

2nd hole from sidewall

Grain Systems, Inc. Assumption, Ill.

24

Figure #26

REV. 9-30-96

Page 25

18' Manual Batch

FLASHING BOLT INSTALLATION

Install the eave flashing bolts (5/16" x 1.1/4") through the sidewall and tighten first nut. Note at the vertical

sidewall seams, one bolt is turned around to avoid interference with eave flashing (refer to photo).

Eave Flashing Holes

Left bolt on the each vertical

sidewall seam level with the eave

flashing bolts (as viewed from

inside the bin) is to be installed bolt

in, nut out, as shown in the photo to

the right.

Figure #27

¯

¬

-

#10 Self-Drilling

Screws (S-280)

-

EAVE FLASHING INSTALLATION

Install the eave flashing centered on the floor sheet (1 per) with the bent edge towards

the sidewall install a fender washer (S-3671) and nut. Screw the flashing to the

flashing angle at the dump hopper opening with 5- #10 self drilling (S-280) screws

and screw the flashing pieces together where they overlap with 3 - #10 self drilling

(S-280) screws.

Floor Flashing Angle

(TD-100654)

Figure #28. Flashing Attachment. 1) Sidewall, 2)

Flashing TD-100648, 3) Floor sheet, 4) 5/16" x 1.1/4" bin

bolt. Note that there is a nut in between the sidewall sheet

and the flashing sheet.

Grain Systems, Inc. Assumption, Ill.

REV. 9-30-96

25

Page 26

18' Manual Batch

FLASHING SPLICE INSTALLATION

The flashing splice pieces can now be attached to the eave flashing to seal around the rib of the floor sheet as shown

with (S-280) #10 self-drilling screws. The flashing splice is a break apart piece. Attach the center piece in the center

so that it rests on top of the floor sheet rib. Break off the side pieces and place them such that they seal against the sides

of the ribs and attach each side piece with two screws. Make sure there are no gaps in the flashing.

Top Ring

TD-100649

Eave Flashing

Splice

(as viewed from inside the bin)

TD-100648

Eave Flashing

#10 Self-drilling Screws

(S-280)

OUTER DUMP CHUTES

Bolt a TD-100598 angle dam to each dump chute using (3)1/4" x 5/8" bolts and nuts, as shown below. Use 1/4" x

5/8" bolts and double nuts to fasten dump chutes to hopper. Do not tighten first nut down. Lock second nut to first

nut and make sure chutes raise and lower FREELY!

TD-100647

Dump Hopper Assembly

TD-100598

Angle Dam

TD-100017

Dump Chute

S-1429

1/4" x 5/8" Bolt

S-1102

1/4" Nut (1 per bolt)

S-1102

1/4" Nut (2 per bolt)

Lock together. Don't

tighten first nut down

Grain Systems, Inc. Assumption, Ill.

26

Figure #29

REV. 9-30-96

Page 27

18' Manual Batch

CENTER CONE ASSEMBLY

Bolt the sections together to form perforated cone as shown below. Use 1/4" x 5/8" bolts and nuts to attach sections together.

Flat Overhead View

CENTER CONE INSTALLATION

TD-100219

Perforated Cone

Section (6 Required)

Side Formed View

Formed Overhead View

1/4" x 5/8" Bolts & Nuts

Install cone over the center collar. Fasten Cone Assembly with (12) #10 x 3/4" self-drilling screws (S-280).

#10 x 3/4" Self-Drilling Screw

(12 Equally Spaced)

Figure #30

Grain Systems, Inc. Assumption, Ill.

REV. 9-30-96

27

Page 28

18' Manual Batch

ROOF ASSEMBLY

SPECIAL INSTRUCTIONS

It is now time to assemble the roof. When starting, align manway and ladder such that it coordinates with the other

accessories and does not interfere. The roof is assembled according to the instructions in the roof hardware box,

WITH THE FOLLOWING EXCEPTIONS:

1. Locate eave clips so that a roof sheet will be centered over sidewall ladder.

2. Four eave clip shims per eave clip must be installed.

3. Use TD-100274 Roof Brackets shipped in the Top Dry hardware rather than the brackets shipped in the roof

hardware.

Eave Clip Assembly

TD-100045 (4)

Eave Clip Shim

TD-100274

Roof Bracket

R-007-2

Small Eave Clip

Top Ring Sidewall Sheet

Figure #31

LEVELING BAND LOCATION

Position leveling bands as shown in the drawings below.

Use (2) 5/16" x 3/4" bin bolts to attach bands to posts. Also use 5/16" x 3/4" bin bolts to join band sections. Note

that band sections connect to each other only at endmost holes until completing the circle where an overlap

may occur.

Outer Leveling Bands

TD-100662 15.2"

6.3/8"

Inner Leveling Bands

TD-100661 10"

6.13/16"

4.3/8"

TD-100660 7.2"

TD-100661 10"

2.3/16"

Grain Systems, Inc. Assumption, Ill.

3 Band Sections per Ring

13 Holes Between Posts

28

4.3/8"

TD-100660 7.2"

TD-100661 10"

.3/16"

6 Band Sections per Ring

27 Holes Between Posts

Figure #32

REV. 9-30-96

Page 29

18' Manual Batch

PULLEY ASSEMBLY

Finish assembling the center collar by adding the cross channel. Position the pulley assembly to the cross channel in

the middle of the center collar assembly. Use a 3/8" x 1" hex head cap bolt to fasten assembly to the cross channel.

Position the pulley in the direction of the desired winch location on the sidewall.

TD-100022 Pulley Bracket

S-4750 1/2" x 1.1/2"

S-845 Flatwasher

Shoulder Bolt (Round Head)

S-396 3/8" Nut (2)

TD-100089

Pulley Assembly

S-3949 3/8" x 1" Hex Bolt

Field drill (5) 3/8" diameter holes as shown below. Attach the pulley assembly with 5/16" x 3/4" bolts with the

neoprene on the inside of the bin.

12" from center of hole on the overlap

Bottom edge of top ring

(horizontal seam)

between top sidewall sheet and second

ring sidewall sheet

TD-100038 Lg.

Pulley Bracket

S-4749 1/2" x 1.1/4"

Shoulder Bolt

TD-100089

Pulley Assembly

Figure #33

Field drill 1/2" dia. hole

TD-100039

Sm. Pulley Bracket

S-845 Flatwasher

S-396 3/8" Nuts

Grain Systems, Inc. Assumption, Ill.

REV. 9-30-96

29

Page 30

18' Manual Batch

DUMP CHUTE CHAIN ASSEMBLY

Attach all 18 dump chute chains directly to the lift plate as shown in diagram below.

Install all chains using "S" hooks (S-4692) to attach the chains to the dump chutes and lift plates. Keep excess chain

at the lift plate. Adjust the chains until the chutes are approximately level when the lift plate is in the closed (up)

position. Once the chains are uniformly adjusted, crimp the "S" hooks closed. Check when attaching the "s" hook to

the end link on a chain that the end has not been cut open. If this is found remove the end link or shift up and use the

next link in chain. The lift plate should be approximately 12" down from the cross channel when the chutes are level.

Chain leading to outer chutes

(82") Adjust length as required

TD-100205

Center Lift Plate

(TD-100801)

Crimp "S" hooks after

final chute adjustment

Loop in Cable

Cable Clamp

S-4693

Chutes in closed position

Center Collar

Cross Brace

12" when chutes

are level(closed)

To sidewall pulley

assembly

Lift Plate

Grain Systems, Inc. Assumption, Ill.

30

Figure #34

REV. 9-30-96

Page 31

18' Manual Batch

Roof Ladder

Field cut notch

Support Channel

Note: Field cut rounded notches

in the outer leveling band(s)

where the two roof support

Round corners to

prevent tearing

channels hang from the roof ribs.

Top Leveling Band

Figure #35

WINCH ASSEMBLY

Complete erection of bin. Install winch as shown using 5/16" x 3/4" bin bolts to attach to the sidewall. The cable clamps

from either side of the pulley on the cross channel should be removed and the dump chutes pulled tightly shut. Check

for the uniformity of the chains on the dump chutes and readjust if needed. The downward travel of the chutes must

be limited to prevent damage on new Top Dry bins. This can be done after the bin is complete and the cable stop bracket

and clamp is set to indicate when the dump chutes are fully closed. Open the chutes until the cable clamp is about 30"

above the cable stop bracket. Attach another cable clamp just below the small outside pulley bracket making sure it

is tight.

TD-100040

Winch Stop Bracket

S-4691

Winch

Outside pulley

brackets

Cable clamp

Cable stop

TD-100041

Winch Mount Bracket

Figure #36

Cable clamp to

limit downward

travel of chutes

Sidewall

30"

Grain Systems, Inc. Assumption, Ill.

REV. 9-30-96

31

Page 32

18' Manual Batch

TD-100099

Fan Adapter (28")

FAN ENTRANCE SHEETS

24" thru 36" Fans

TD-100680

36" Fan Entrance Sheet

TD-100206

Fan Adapter-Blank

TD-100098

Fan Adapter (24")

Figure #37

Grain Systems, Inc. Assumption, Ill.

32

REV. 9-30-96

Page 33

ACCESS DOOR WELDMENT ASSEMBLY

DOOR COVER

ACD-4504

ACD-4513

ACD-4514

3/8" X 1.1/2" FULL THREADS

ACD-4515 (2)

**3/8" WASHERS

(USE AS NEEDED)

INNER DOOR ACD-4508

S-3867 (2)

ACD-4509

18' Manual Batch

ACD-4510 (2)

3/8" X 1" BOLTS

Grain Systems, Inc. Assumption, Ill.

#10 SCREWS

REV. 9-30-96

33

ACD-4505

5/16" X 3/4" BOLTS

5/16" X 3/4" BOLT & NUT

ACCESS DOOR WELDMENT

Figure #38

**THE QUANTITY OF 3/8" WASHERS

NEEDED MAY VARY DEPENDING ON

THE SIDEWALL GAUGES.

Page 34

18' Manual Batch

LIFTING JACKS & BRACKETS

NOTE: The number of lifting jacks required is best determined by personal experience. Factors such as bin

size, soil compaction, wind velocity, jack design, etc., are all to be considered when deciding how many to

use. If in doubt, use one jack on every other stiffener. GSI recommends heavy duty jacks rated at 6,000 lbs.

or more.

TD-100724

Optional

Lifting jack

bracket

Figure #39

Remember to attach lifting brackets to the stiffeners. A special optional lifting bracket is available from

G.S.I.

Anchor all jacks securely and raise the bin just high enough to assemble the next ring. When lifting your bin,

raise all jacks at an equal rate. This will prevent the bowing of previously assembled rings and make for easier

hole alignment. Bolt the next ring to the inside of the second ring. Be sure to stagger the sheets and select

the proper gauge material. Lower the bin on the foundation after assembling and tightening the bolts on the

new ring. Now rebolt the lifting straps, continue ring additions until you are ready for door installation.

Lifting Jacks

Figure #40

Grain Systems, Inc. Assumption, Ill.

34

REV. 1-25-96

Page 35

DETAILED LAYOUT FOR PROPER LOCATION OF PLATFORMS

Outside

Ladder

TDP-5008

Sidewall Brace

18' Manual Batch

Grain Systems, Inc. Assumption, Ill.

REV. 1-25-96

35

Inside

Ladder

Access Door Platform

TD-100686

Small Platform

Vertical Support

Small Platform

Figure #41

Page 36

18' Manual Batch

ACCESS DOOR PLATFORM

Before assembly of any platform, read the entire instructions to assure proper placement and assembly.

Refer to Figure #41 for proper location of access door platform. Begin by assembling the access door platform support

frame using 5/16" x 3/4" truss head bolts and nuts. When attaching platform vertical support to bin sidewall field drill

(16) 3/8" diameter holes for each support spaced every 4". Be sure and use 5/16" x 3/4" bin bolt on vertical support

to sidewall. Special attention should be taken when assembling the platform support that the support brace is placed

correctly.

Now proceed to the platform floor. Align holes on platform floor with holes on platform support and bolt together

using 5/16" x 3/4" truss head bolt and nuts. Next, assemble handrail posts, handrails, and handrail braces.

7th hole

3rd hole

9

1

11th hole

2

5

4

5

8

&

13

7

10

6

11

IMPORTANT: Position support

Platform Support

TDP-5009

Figure #42

as shown for proper fit.

Key Part No. Description Quantity Weight

1 LS-371 Platform Vertical Angle 42" 3 11.38

2 TDP-5000 Handr ail 59" 2 10.15

3 TDP-5002 Handr ail 30" 2 10.15

4 TDP-5003 Handrail Brace 36.29/32" 2 6. 34

5 T DP-5005 Floor Brace 58.1/2" 3 26.11

6 TDP-5006 Platform Floor 37.7/8" 2 38.23

7 T DP-5007 Support Brace 50.21/32" 2 15.08

8 TDP-5008 Sidewall Brace 58" 2 19.65

9 TDP-5009 Platform Support 43.1/2" 2 12.95

10 TDP-5010 Platform Floor Splice 37.1/2" 1 6.24

11 TDP-5011 Platform Toe Plate 29.3/4" 1 3.29

12 TDP-5014 Access Door Pack age Hard wa re 1 5.4 1

13 TDP-5008N Sidewall Brace 2.66" 2 16. 61

3

Grain Systems, Inc. Assumption, Ill.

36

REV. 9-30-96

Page 37

18' Manual Batch

SMALL PLATFORM ASSEMBLY

For 36" Fans and Smaller or

with #1 fan when two 36" or smaller fans are installed

Before assembling any platform, read all of the instructions first to assure proper placement and assembly.

Refer to Figure #41 for proper location of small platform. Begin by assembling the small platform support frame using

3/8" x 1" bolts on all connections. Use 5/16" x 1.1/4" bin bolt to attach platform vertical supports to sidewall stiffeners.

Be sure and locate the 5/16" x 1.1/4" bolts from the inside of the bin to the outside. This will provide maximum weather

protection.

12

12"

13

Horizontal Seam

14

Small Platform

36" Fans and Smaller

TD-100092

Figure #43

Key Part No. D escription Quantity Weight

1 TD-100051 Channel Bracket 8 3.90

2 TD-100052 Handrai l Post 49.3/4" 4 31.69

3 TD-100059 Long Toeboard 78.1/2" 2 10.96

4 TD-100060 Short Toeboard 54.1/2" 1 3.80

5 TD-100061 Long Handrail 78.1/2" 4 37.52

6 TD-100062 Short Handrail 54.1/2" 2 13.02

7 TD-100064 Floor Plank 78" 11 112.87

8 TD-100066 "X" Brace Strap 60" 4 7.26

9 TD-100067 Mid Channel Support 74" 2 32.73

10 TD-100070 Side Channel Support 78.1/2" 2 41.26

11 TD-100072 E nd Ch an n el Support 78.1/2" 2 41.60

12 TD-100686 Vertical Support 70" 2 43.11

13 TD-100083 Support Channel 80.7/8" 2 32.98

14 TD-100084 Kn ee Brace 83.5/8" 2 23.67

15 TD-100090 Small Platform Hardware Package 1 8.96

Grain Systems, Inc. Assumption, Ill.

REV. 9-30-96

37

Page 38

18' Manual Batch

1

11

SMALL PLATFORM

36" Fans and Smaller

TD-100092

Position the vertical support

to the existing sidewall

stiffeners as shown in Figure

#41 and double nut with 5/16"

nuts.

8

10

9

6

4

7

5

When bolting stiffener to sidewall

at locations where platform

supports are to be attached, use

(25) 5/16" x 1.1/4" bin bolts, heads

2

to inside. Start 12 inches below

horizontal seam of second and third

rings from top. See Figure #41.

3

Grain Systems, Inc. Assumption, Ill.

38

Figure #44

REV. 9-30-96

Page 39

18' Manual Batch

CROSS OVER PLATFORM ASSEMBLY (For use with stairs)

TDP-5013

Before assembly of any platform, read the entire instructions to assure proper placement and assembly.

Refer to Figure #41 for proper location of cross over platform. Begin by assembling the cross over platform support

frame using 5/16" x 3/4" truss head bolts and nuts. When attaching platform vertical support to bin sidewall field drill

(16) 3/8" diameter holes for each support spaced every 4". Be sure and use 5/16" x 3/4" bin bolt on vertical support

to sidewall. Special attention should be taken when assembling the platform support that the support brace is placed

correctly.

Now proceed to the platform floor. Align holes on platform floor with holes on platform support and bolt together

using 5/16" x 3/4" truss head bolt and nuts. Next, assemble handrail posts, handrails, and handrail braces.

2

7

5

3

1

8

4

6

Figure #45

Key Part No. Description Quantity Weight

1 LS-371 Platform Vertical Angle 2 7.59

2 TDP-5001 Handrail 27" 2 4.63

3 TDP-5003 Handrail Brace 36.29/32" 2 6.34

4 T DP-5004 Short Floor Brace 26.1/2" 3 11.85

5 TDP-5006 Platform Floor 37.7/8" 1 19.11

6 T DP-5007 Support Brace 50.21/32" 2 15.08

7 TDP-5008 Sidewall Brace 58" 2 19.65

8 TDP-5009 Platform Support 43.1/2" 2 12. 95

TDP-5015 Cross Over Plat. Hdw. Pack. 1 3.95

Grain Systems, Inc. Assumption, Ill.

REV. 9-30-96

39

Page 40

18' Manual Batch

PERFORATED CENTER BAND

Drill (6) 3/8" diameter holes equally spaced as shown above for top band clips. Attach clips using 5/16"

x 3/4" bin bolts. Add perforated band sections. Note that these do not attach to the leveling bands but

hang down on the inside of the top inner leveling band.

Measure down 24.1/2"

from first hole in roof

sheet and drill hole for

band clip.

Roof Sheet

TD-100107

Top Band Clip

(6) Equally spaced

Grain Systems, Inc. Assumption, Ill.

40

TD-100545

(3) Perforated Band

Figure #46

REV. 9-30-96

Page 41

18' Manual Batch

OPTIONAL ROTARY SWITCH ROOF LOCATION

Overhead View of optional rotary Switch Location

Fill Spout

Optional Rotary Switch

OPTIONAL ROTARY SWITCH PANEL LOCATION

Drill 2" diameter holes through roof panels at locations shown above. Use a mounting plate as a pattern and drill

(4) 3/8" holes through roof panels at each switch location so the plate can be bolted to the roof.

Field Drill 2" Hole

Top Dry Bin

Diameter

18'

"A"

23.50"

Figure #47

Grain Systems, Inc. Assumption, Ill.

REV. 9-30-96

41

Page 42

18' Manual Batch

INSTALLATION OF OPTIONAL ROOF-MOUNTED LEVEL SWITCHES

Attach flex-coupling to the power-pak and install roll pin. Apply teflon tape or pipe sealant (not included) to power-pak pipe threads and thread power-pak into mounting plate coupling. Conduit opening

in power-pak should be at right angles to roof rib or face toward eave.

Caulk underside of mounting plate above and both sides of 2" hole. Bolt to roof panel.

Overflow Level Switch

TAF-6103

1

2

30º Roof Panel

3

4

5

Figure #48

Key Part No. Description Quantity Weight

1 TD-100076 Rotary Switch Power-Pak 1 3.50

2 TD-100627 Roof Moun t Coup lin g Weld ment 1 2.14

3 TD-100075 Flex-Coupling 1 0.50

4 S-7241 1/8" x 1. 1/ 4" Cotter Pin 2 0.02

5 T AF-6086 3-Vane Paddle 1 0.75

* T AF-6097 Hardware Package 1 0.98

-- PNEG-300 Rotary Switch Instructi ons 1 0.04

-- S-275 5/16" - 18 x 3/4" Bin Bolt 6 0.16

-- S-3651 Tube Seal 1 0.74

-- S-396 5/16" - 18 Hex Nut 6 0.06

-- S-7241 1/8" x 1.1/4" Cotter Pin 2 0. 02

* Hardware Package not

shown

- Included in Hardware

Package

Grain Systems, Inc. Assumption, Ill.

42

REV. 9-30-96

Page 43

18' Manual Batch

INSTALLATION OF OPTIONAL WALL-MOUNTED ROTARY SWITCH

Wall Mount Rotary Switch

TAF-6106

2

Outside of bin

5

sidewall

IMPORTANT:

Inside of bin

sidewall

5

Inside of bin

sidewall

4

3

2.66" Corrugation

2

4

3

4.00" Corrugation

Note: Wall mounted

switch must be located at

least 3' below the bottom

of the fan opening.

Outside of bin

sidewall

1

Figure #49

Key Part No. Description Quantity Weight

1 TD-100076 Rotary Switch Power-Pak 1 3.50

2 TD-100629 Roof Moun t Coup lin g Weld ment 1 2.14

3 TD-100075 Flex-Coupling 1 0.50

4 S-7241 1/8" x 1. 1/ 4" Cotter Pin 2 0.02

5 T AF-6085 1-Vane Paddle 1 0.75

* T AF-6097 Hardware Package 1 0.98

-- PNEG-300 Rotary Switch Instructi ons 1 0.04

-- S-275 5/16" - 18 x 3/4" Bin Bolt 6 0.16

-- S-3651 Tube Seal 1 0.74

-- S-396 5/16" - 18 Hex Nut 6 0.06

-- S-7241 1/8" x 1.1/4" Cotter Pin 2 0. 02

Grain Systems, Inc. Assumption, Ill.

REV. 9-30-96

43

Page 44

18' Manual Batch

TRANSITION INSTALLATION (TR-4734)

BEFORE CUTTING THE OPENING CHECK THAT TR-4734 IS THE TRANSITION THAT WAS

ORDERED.

When installing the GSI aeration transition, it will be necessary to field cut a hole into the bottom sidewall

ring (usually straight across from the unload auger). Refer to diagram for proper dimensions of cutout. The

base angle will also need to be cut at entrance collar cutout. Take note of the diagram showing the 1"

dimension from bottom of entrance collar side bracket to concrete. This is important for proper fit of

transition.

NOTE: Entrance collar side bracket must be bolted on the inside of the bin sidewall.

AS VIEWED FROM INSIDE BIN

Part No. Description Quantity

S-275 5/16" - 18 3/4" Bin Bolt Grade 5 125

S-280 #10 - 16 x 5/8" Self Drill Screw 10

CH-6873 Tube Caulk - Silicone 1

S-396 5/16" - 18 Hex Nut Grade 2 125

S-7264 Spec Neoprene Seal Strip W/ADH 10 Ft

Grain Systems, Inc. Assumption, Ill.

44

Note: Entrance collar side

bracket (TR-4731) flange

must be installed to the

inside of the bin sidewall.

Figure #50

REV. 9-30-96

Page 45

18' Manual Batch

TRANSITION ASSEMBLY (TR-4734)

* Hardware Package

not shown

- Included in

Hardware Package

Key Part Number Description

1 TR-4724-1 Transition side

1 TR-4724-2 Transition side

2 TR-4767 Transition faceplate

3 TR-4726 Top en t ran ce coll a r piece

4 TR-4727 Bottom entrance collar

5 TR-4728 Sizing angle

6 TR-4729 Transition bottom

7 TR-4730 Transition top

8 TR-4731 En trance collar si de brack e t

Sizing angle is to be

installed on inside of bin

sidewall sheet as shown.

The flanges on transition top are to go

on the outside of transition sides. The

flanges on transition bottom are to go

on the inside of transition sides.

Figure #51

Grain Systems, Inc. Assumption, Ill.

REV. 9-30-96

45

Page 46

18' Manual Batch

TWO RING DOOR INSTALLATION INSTRUCTIONS

Before starting to install, be sure the correct door has been received.

4.00" Corrugation

WD-6133 18' Bins

Figure #52

1.) Remove inner door panels, and outer door cover. Apply double row of rope caulk along door

flanges, noting how door and bin sheets lap. The top of the door frame goes to the inside of the

sidewall and the bottom of the door frame goes to the outside of the sidewall sheet. With inner

door panels and outer door cover removed set door frame into opening. Insert a bolt at the

(4) corners of door frame and sidewall, do not tighten until completing step #2.

2.) Reinstall inner door panels at original locations. Close latch bars to lock panels in place. Be sure

that panels are fully seated over all bearing pins. Install inner panel hinge assemblies per

illustration instructions with hinges. Note: do not distort door frame with use of alignment

or drift punches - if necessary, drill or ream holes to insert bolts in door frame. Now

tighten frame bolts starting at center and working toward top and bottom on each side

3.) Keep inner panels latched and loosen all bearing pin bolts. Retighten all bearing pin bolts.

This makes loading on pins uniform for easier operation of panels.

4.) If some latch bars are loose or require excessive force to lock, loosen hex socket capscrews

and adjust in or out until latch bars operate smoothly. Check that the panels are fully seated

over all bearing pins.

5.) Re-install outer cover. Adjust outer door hinges and latches as required.

6.) Assemble door hold back as shown on next page. Open door cover until it approaches the bin

wall. Hook retaining bracket over lower latch mount and position the door hold back against bin

wall in a valley. Drill a 3/8" hole through the bin wall and bolt the door hold back to the bin.

Grain Systems, Inc. Assumption, Ill.

46

REV. 9-30-96

Page 47

DOOR FRAME ASSEMBLY

2-RING DOOR ASSEMBLY

18' Manual Batch

Grain Systems, Inc. Assumption, Ill.

REV. 9-30-96

47

DOOR HOLD BACK DETAIL

Figure #53

Page 48

Grain Systems, Inc. Assumption, Ill.

48

KEY DESCRIPTION 4.00" CORR. 4. 0 0" CORR. DIAMETER DIAMETER

1 OUTER DOOR COVE R WD-039 WD-039 1 1

2 OUTER COVER LATCH BRACKET WD-2854 WD-2854 2 2

3 OUTER COVER HINGE BRACKET WD-225 WD-225 2 2

4 DOOR COVER BRACE SECTION WD-035 WD-035 4 4

5 DOOR RETAINER WD-033 WD-033 3 3

6 OUTER COVER LATCH MO UNT B ASE WD-6124 WD-6124 2 2

7 OUTER COVER HINGE BASE WD-6066 WD-6066 2 2

8 BOTTOM INNER DOOR HINGE WD-6055 WD-6055 1 1

9 MIDDLE INNER DOOR HINGE WD-6056 WD-6056 2 2

10 TOP INNER DOOR HINGE WD-6054 WD-6054 1 1

11 RUBBER TRIM SEAL STRIP S-4380 S-4380 2.1/4 FT. 2.1/4 FT.

12 LATCH BAR WD-6039 WD-6039 3 3

13 INNER PANEL LATCH - RIGHT HAND WD-6037 WD-6037 3 3

14 INNER PANEL LATCH - LEFT HAND WD-6038 WD-6038 3 3

15 1/2" X 1" HEX SOCKET CAPSCREW S-7160 S-7160 6 6

16 LATCH BUSHING WD-6040 WD-6040 6 6

17 LONG BEARING PIN WD-6079 WD-6079 38 38

18 INNER PANEL REINFORCING ANGLE WD-61 25 WD-6125 6 6

19 BOTTOM INNER DOOR PANEL WD-6128 WD-6128 1 1

20 MIDDLE INNER DOOR PANEL WD-6127 WD-6127 1 1

21 TOP INNER DOOR PANEL WD-6126 WD-6126 1 1

22 BOTTOM INNER DOOR PORT HOLE COVER WD-6028 WD-602 8 1 1

23 INNER DOOR HINGE STRAP WD-6053 WD-6053 6 6

24 DOOR HOLD BACK BRACKET WD-1302 WD-1302 1 1

25 DOOR HOLD BACK EXTENSION WD-6110 WD-6110 1 1

REV. 1-25-96

PARTS LIST FOR 2-RING DOORS

18' Manual Batch

PART NUMBER PART NUMBER QUANTITY QUANTITY

12'-27' BIN DIA. 30'-60' BIN DIA. 12'-27' BIN 30'-60' BIN

Page 49

18' Manual Batch

WD-041-1

OPTIONAL BIN STEP ASSEMBLY

WD-042

WD-041-2

WD-1984

Field drill holes in sidewall

sheet on ridge of corrugation.

Center bin step under door

Figure #54

Grain Systems, Inc. Assumption, Ill.

REV. 9-30-96

49

Page 50

18' Manual Batch

BASE ANGLE

B-6753

Once the door frame has been placed and secured, continue adding necessary sidewall ring(s). To the lower

edge of the bottom ring, attach the base angle ring. Before lowering the bin, apply (optional) mastic sealer

to the entire underneath side of the base angle. (See below.) Next, lower the bin onto the foundation and

check for an adequate seal.

5/16" x 1.1/4"

Bin Bolt

B-6753

Base Angle

(Optional)

Mastic Sealer

FC-42077

Base Stiffener

Shim

IT IS IMPORTANT THE

STIFFENER BE FULLY

SUPPORTED BY THE SHIM

PLATE(S) (FC-42077) TO FILL

ANY GAP BETWEEN BASE

PLATE AND CONCRETE.

BASE STIFFENER SHIM

Farm-Com Base

Stiffener Weldment

Once the bin is set down and

sealed place shims under

stiffeners so that they all are

supported to the concrete.

Tighten anchor bolts.

Figure #55

Grain Systems, Inc. Assumption, Ill.

50

REV. 9-30-96

Loading...

Loading...