Page 1

revised 2004revised 2004

revised 2004

revised 2004revised 2004

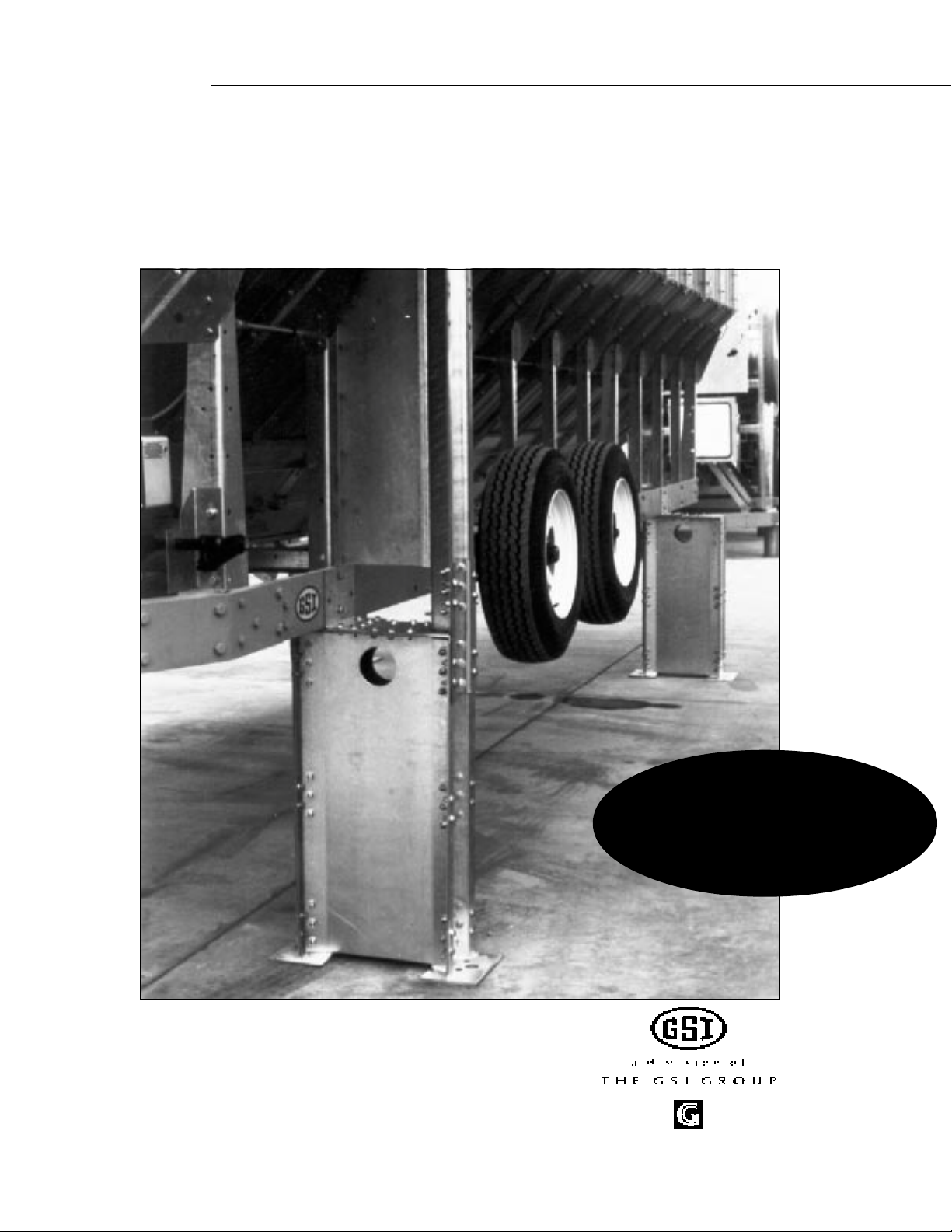

SERVICE PLATFORM &

STIFFENER INSTALLATION

PNEG-349REV

TWO & THREE

MODULE STACK DRYER

MODELS

Page 2

Service Platform & Stiffener

2

Page 3

Service Platform & Stiffener

Installation & Safety..............................................................................................4

Service Platform Installation..................................................................................5

Platform Support Channels..............................................................................6

Floor Support Angles.......................................................................................11

Inner Guard Rail...............................................................................................12

Outer Guard Rail Supports...............................................................................12

Platform Toe Board Angles And Flooring.......................................................13

Platform Guard Rails.......................................................................................17

Access Door.....................................................................................................18

Service Platform Parts......................................................................................22

Stiffener Installation..............................................................................................25

Stiffener Basket Location...............................................................................26

Stiffener Exploded View................................................................................27

TABLE OF CONTENTS

Stiffener Assembly.........................................................................................28

Special Buttress Assembly Instructions..........................................................29

Warranty..............................................................................................................30

3

Page 4

INSTALLATION & SAFETY

Service Platform and Stiffener Installation

Service Platform & Stiffener

Thank you for choosing a GSI product. It is designed

to be a reliable support system for GSI grain dryers.

This manual describes the installation of the GSI

platform and GSI stiffener package. These systems

are designed for multi-module grain dryers, and accommodate different dryer lengths.

The principal concern of the GSI Group, Inc.

("GSI") is your safety and the safety of others associated with grain handling equipment. This manual

is written to help you understand safe installation

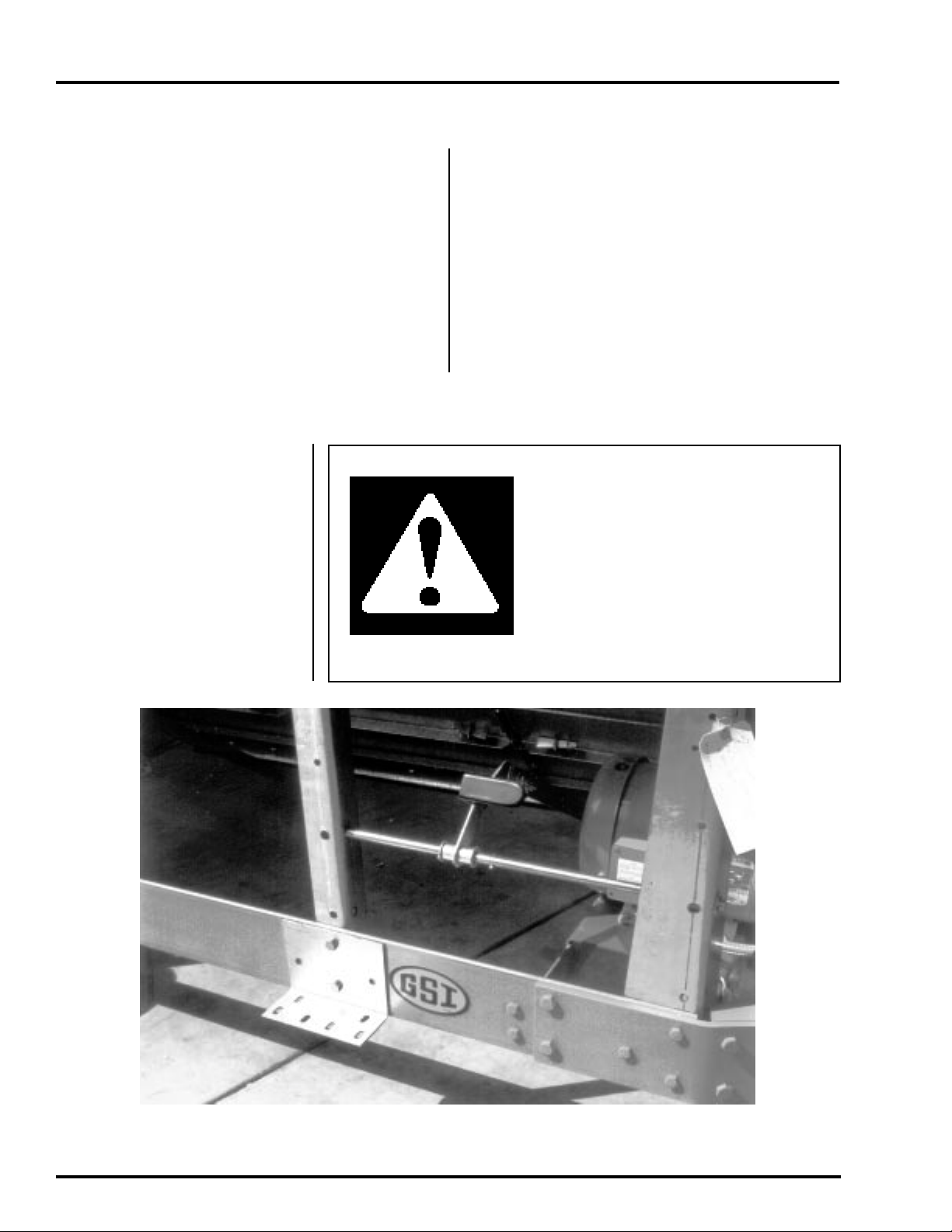

Safety Alert Symbol

The symbol shown is used to call

your attention to instructions concerning your personal safety.

Watch for this symbol; it points

out important safety precautions.

It means "ATTENTION",

"WARNING", "CAUTION", and

"DANGER". Read the message

and be cautious to the possibility of personal injury or death.

procedures, and some of the problems that may

be encountered by the operator or other personnel.

As owner and/or operator, it is your responsibility to know what requirements, hazards and

precautions exist, and to inform all personnel associated with the equipment, or who are in the

area. Avoid any alterations to the equipment.

Such alterations may produce a very dangerous

situation, where serious injury or death may occur.

WARNING! BE ALERT!

Personnel operating or working

around equipment should read this

manual. This manual must be delivered with the equipment to its owner.

Failure to read this manual and its

safety instructions is a misuse of the

equipment.

Stiffener caption.

4

Page 5

Service Platform & Stiffener

PLATFORM INSTALLATION

5

Page 6

PLATFORM INSTALLATION

Service Platform & Stiffener

Platform Support

Channels

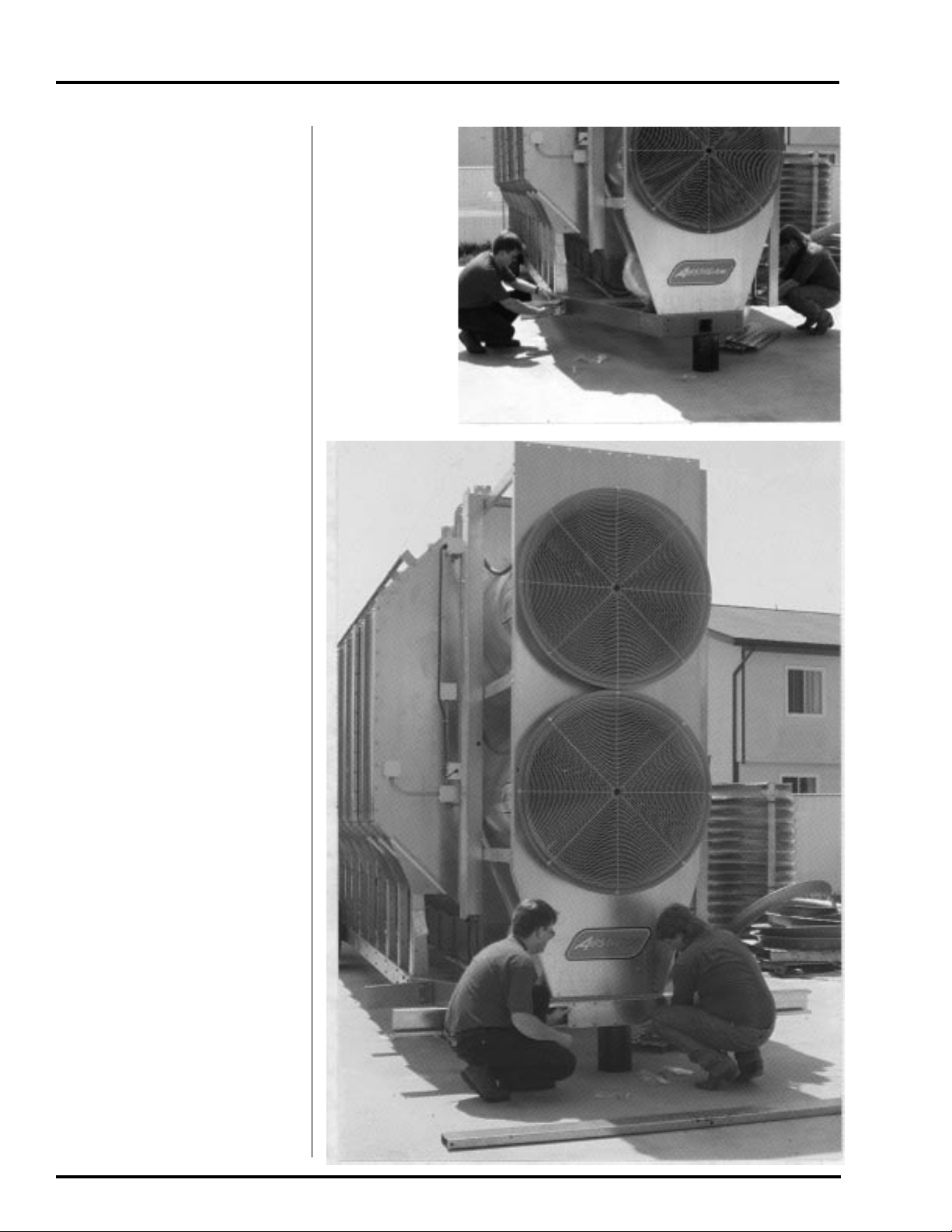

Airstream service platform units are

designed for use with Airstream two

and three module grain dryers. The

two module models require a service

platform on the upper module, and

the three module units use a platform

on both the upper and center mod-

ules.

For ease of assembly, the plat-

form should be fully installed before

the module is lifted and installed.

Install the platform support

channels and related parts within the

platform package number one as fol-

lows:

1. If required, connect a platform

attachment bracket, D61-0054,

onto each side of the dryer as

shown. Using the existing large

bolts through the round set of

bracket holes.

Loosely connect the two

rear anchor channels, D61-0055,

to the platform attach brackets us-

ing 3/8" x 1" bolts with washers.

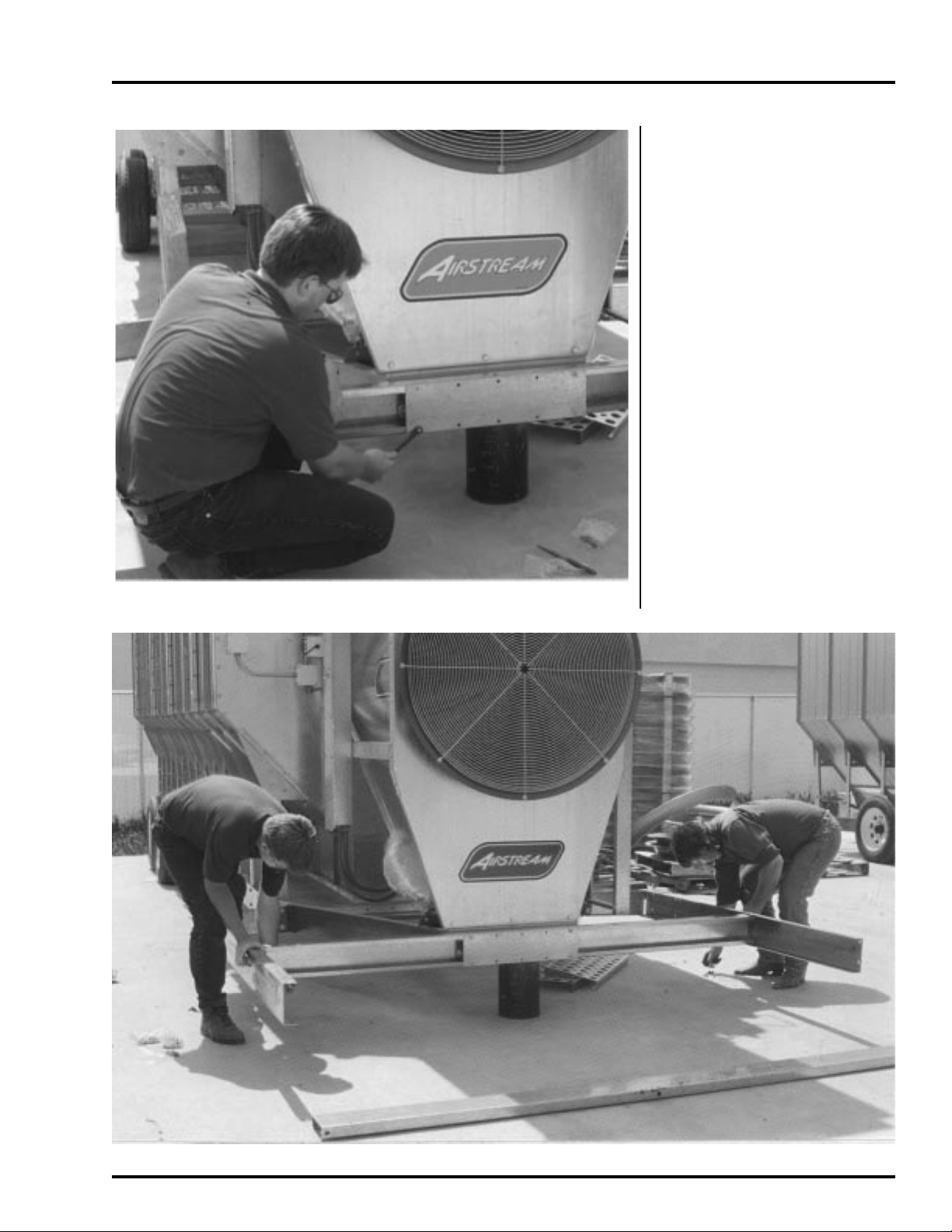

Figure 1, Right:

Connecting rear

anchor chan-

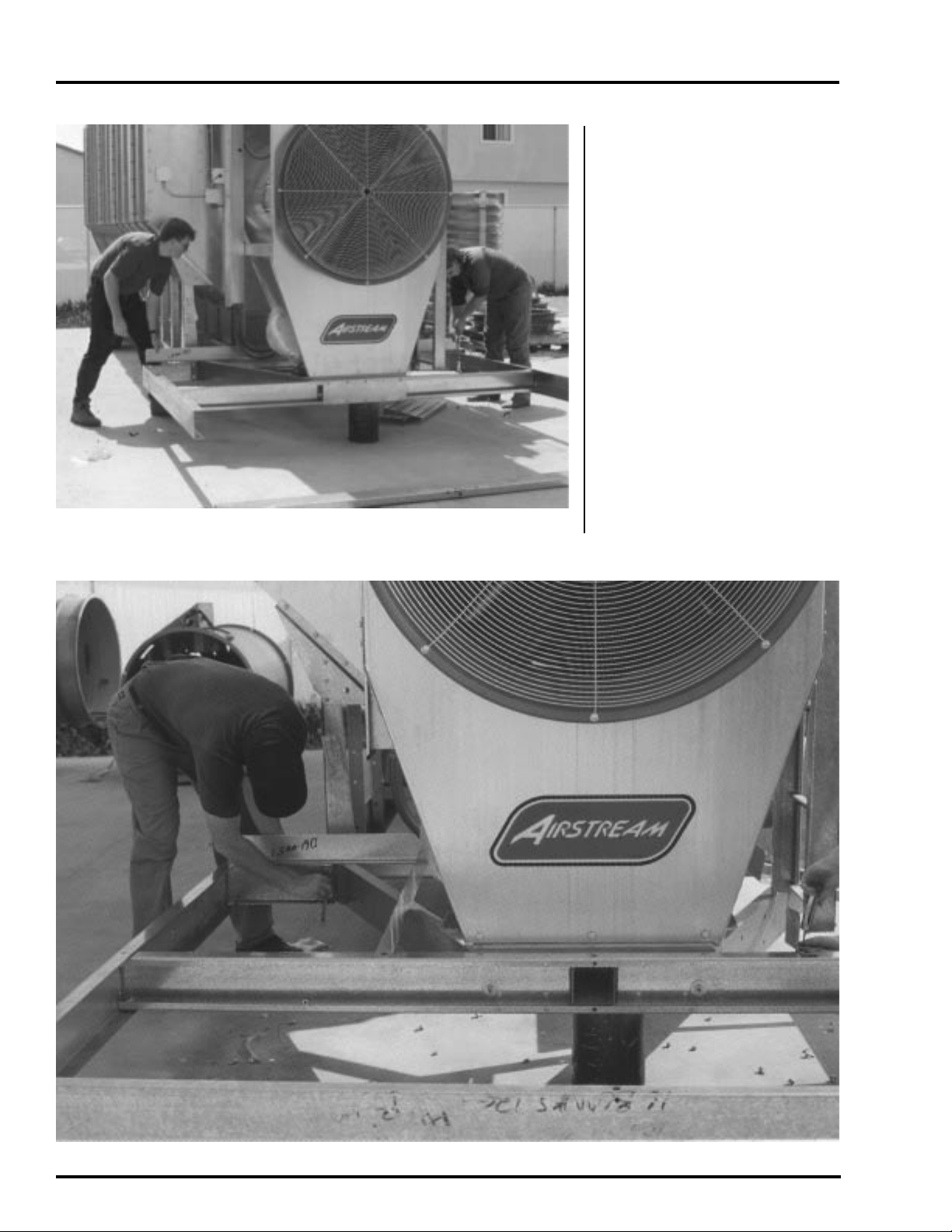

nels. Figure 2,

Below: Mount-

ing the main

support channel.

2. Remove hitch tongue from the

dryer, and support the front end

of the dryer under the frame side

rails.

Loosely connect the main

support channel, D01-2033, to

the front end of the dryer hitch

weldment. Use four 1/2" x

1- 1/2" bolts with washers on slot

ted side. The channel side with

the large round holes must be

up.

6

Page 7

Service Platform & Stiffener

PLATFORM INSTALLATION

3. Attach the D61-0056 reinforce-

ment plate to the main floor sup-

port channel using 5/16" x 3/4"

whiz bolts.

4. Position the left-hand side chan-

nel, D61-0058, and the right-

hand side channel, D61-0057,

so the sides with the dimpled

holes are up. Connect them to

the rear anchor channels and

the main support channel. Use

the special 5/16" diameter flat

head allen capscrews to secure

the top side of the two side chan-

nels. Use 5/16" x 3/4" bolts at

the bottom side.

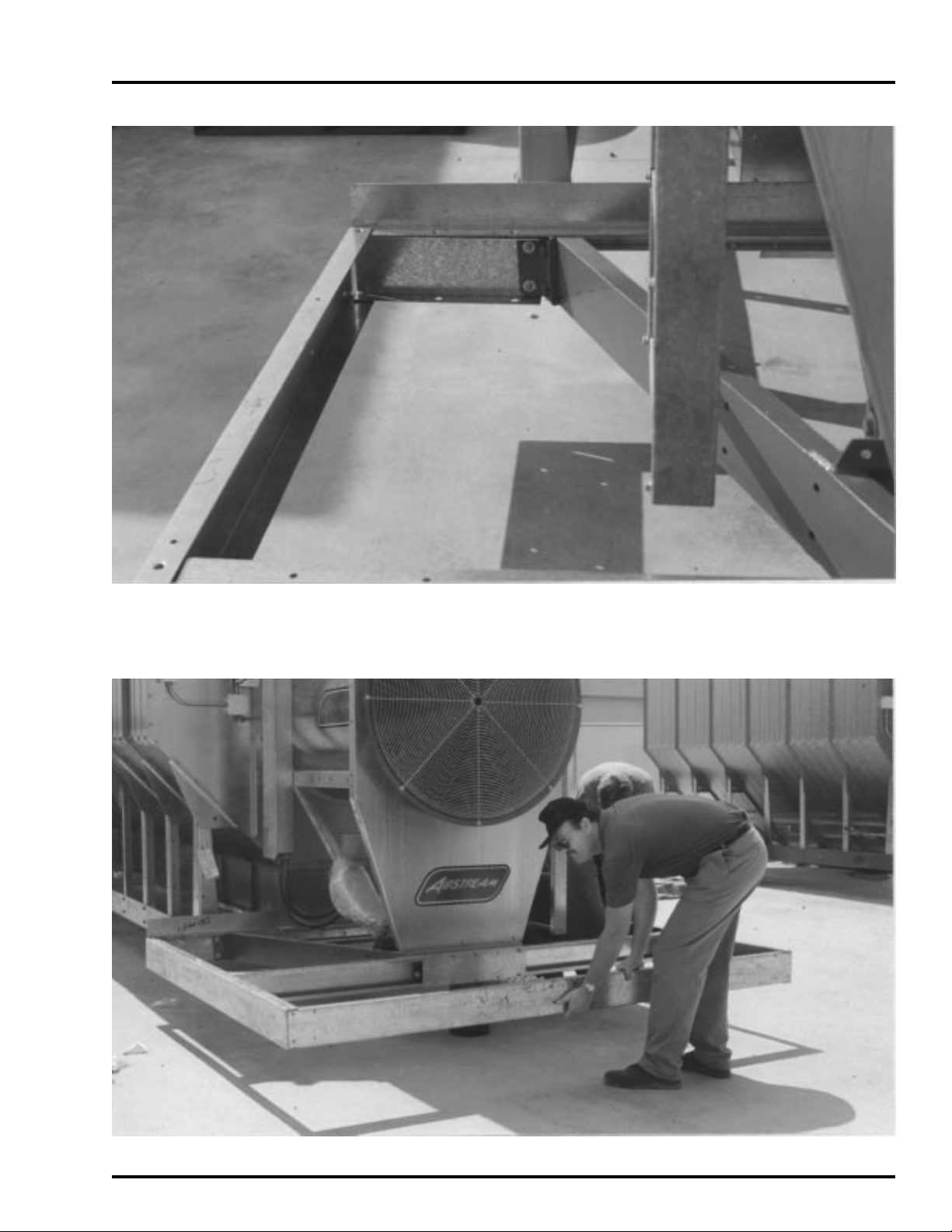

Figure 3: Bolting reinforcement plate to main support channel.

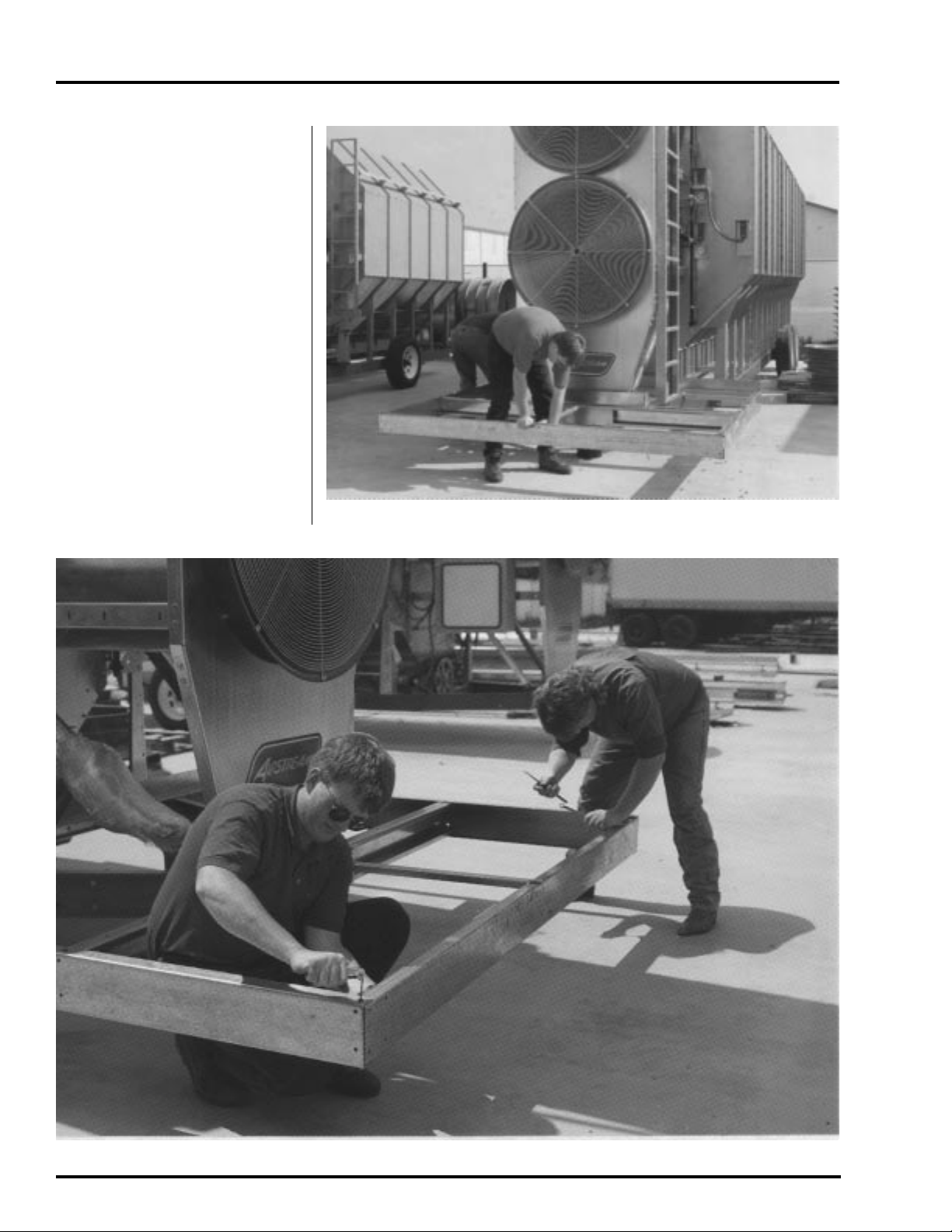

Figure 4: Attaching side channels.

7

Page 8

PLATFORM INSTALLATION

Service Platform & Stiffener

5. Position the rear angle tie, D01-

2034, and connect it onto the

rear anchor channels using

5/16" x 1" carriage head bolts.

6. Position the front channel, D61-

0061, so the side with the large

holes is up and connect it to

the two side channels. Use flat-

head allen capscrews to secure

the top side.

Figure 5: Placing rear tie angle on platform.

Figure 6: Tighten the rear frame tie angle to the side frame.

8

Page 9

Service Platform & Stiffener

PLATFORM INSTALLATION

Figure 7: Close-up of rear portion of frame.

Figure 8: Attaching front channel.

9

Page 10

PLATFORM INSTALLATION

7. Use two flathead allen capscrews

and connect the center floor

support, D61-0062, to the front

and main support channels.

8. Use a carpenter square and

check the squareness of the as-

sembled unit, between the main

channel and the side channels.

If necessary, shift the position

of the main channel slightly, us-

ing the slotted attaching holes,

until the unit is properly

squared. Then fully tighten all

channel bolts.

Service Platform & Stiffener

Figure 9: Center floor support placement.

10

Figure 10: Check for square and tighten bolts.

Page 11

Service Platform & Stiffener

Floor Support Angles

Install the floor support angles

as follows:

1. Use two flathead allen capscrews

and connect the left floor sup-

port angle, D01-2030, to the

rear angle tie and main sup-

port channel.

2. Connect the rear access door

support, D01-2037, frame be

tween the support angle and the

left-hand side channel.

PLATFORM INSTALLATION

3. Install the front access door

support frame, D01-2036, to

the side frame and front left-

hand floor support. Use the 5/

16" whiz bolts and nuts to bolt it in

place.

4. The forward frame goes under the

top edge of the side channel and

over the front left-hand floor sup-

port.

Figure 11: Installing forward frame on the access door.

D01-2030

D01-2037

D01-2036

Figure 12: Close-up of forward and rear door frame installation.

11

Page 12

PLATFORM INSTALLATION

Inner Guard Rail

Install the inner guard rail supports

and related parts within platform

package number two as follows:

1. Connect the right-hand rear in-

ner guard rail support angle (D01-

2041). Use 5/16" x 3/4" bolts.

2. Use 5/16" x 3/4" bolts and con-

nect the left-hand inner guard

rail support angle (D01-2042).

Service Platform & Stiffener

D01-2043

3. Connect a lower inner guard rail

angle on each side (D01-2043).

Outer Guard Rail

Supports

Install outer guard rail support chan-

nels, door hinge channel and floor

panels contained within platform

package number two and number

three as follows:

1. Use 5/16" x 3/4" bolts and loosely

connect the seven guard rail

support channels (D61-0037) to

the platform support channels.

2. Connect the outer door hinge

channel (D61-0066) using 5/16"

x 3/4" bolts.

D01-2042

Figure 13: Location of inner guard rail support angles.

12

Figure 14: Install remaining support channels.

Page 13

Service Platform & Stiffener

PLATFORM INSTALLATION

Platform Toe Board

Angles And Flooring

Use 5/16" x 3/4" bolts and install the

platform floor toe board angles.

When two toe boards are listed, the

bottom toe board must be positioned

to capture the floor panels. The ad-

ditional upper toe board acts as a

narrow foot rail to provide added

safety protection. When connecting

upper toe boards, install bolts so the

head ends are located within the plat-

form. The long flanges of the toe

boards point up.

Figure 15: Connecting outer front toe board to guard rail support channels.

Figure 16: Connecting left-hand front toe board to guard rail support channel.

13

Page 14

PLATFORM INSTALLATION

Service Platform & Stiffener

1. Connect one left-hand outer rear

toe boards.

2. Connect the left-hand inner rear

toe board.

3. Connect one left-hand front toe

boards.

4. Connect one right-hand outer toe

boards.

5. Connect one outer front toe boards.

Figure 17: Installing four short floor panels.

14

Figure 18: Installing center long floor panels.

Page 15

Service Platform & Stiffener

PLATFORM INSTALLATION

Figure 19: Installing front long floor panel.

Figure 20: Installing the remaining toe boards.

6. Connect the right-hand inner toe

board.

7. Place the short wide floor pan-

els on the left-hand side of the

platform at the rear.

8. Place the four short floor panels on

the right-hand side at the rear.

9. Place the three long floor panels

across the front end of the platform.

10. Connect the remaining toe boards

around the platform.

15

Page 16

PLATFORM INSTALLATION

Service Platform & Stiffener

16

Figure 21: Installation of the short wide floor panel, left-hand outer rear toeboards and hinge channel.

Page 17

Service Platform & Stiffener

PLATFORM INSTALLATION

Platform Guard Rails

Use 5/16" x 3/4" bolts and install plat-

form guard rails within platform pack-

age # 4. Guard rails should be installed

so that the smooth rail surfaces and

bolt heads are within the compartment

to provide maximum body protection

from corners and angle edges.

1. Connect the upper side guard

rail onto each side.

2. Connect the upper front guard rail.

3. Connect two rear guard rails

onto each rear side of platform.

Figure 22, top: Installing front and

side upper guard rails. Figure 23,

above: Installing lower side guard

rails. Figure 24, right: Installing

4. Connect two lower front guard rails.

5. Connect the lower front side

guard rail, and the lower rear

side guard rail onto each side

platform. Connect the access

door clip on the left side of the

platform.

6. Fully tighten all guard rail bolts,

including the seven guard rail

support channels not tightened

earlier.

lower rear guard rail.

17

Page 18

PLATFORM INSTALLATION

Figure 25, right: Installing access

door. Figure 26, below: Make sure

door opens freely and lies on frame

angles.

Service Platform & Stiffener

Access Door

Install the platform access door and

related parts as follows:

1. Install access door in place with

the hinge ends located outward.

2. Use two 3/8" x 1-1/2" bolts as

hinge pins and install them with

the heads positioned inward.

3. Secure each hinge pin in place

by installing nuts on each side

of the outer channel leg. Adjust

the position of the hinge pins,

as necessary, to center the

door properly. Tighten nuts se-

curely to lock pins in place.

18

Inspect the completed service plat-

form unit. Make sure all parts are

properly installed and fully tight-

ened.

Page 19

Service Platform & Stiffener

PLATFORM INSTALLATION

Figure 27: Close-up of access door clip on guard rail.

Figure 28: Check to make sure every bolt is tight and door opens freely.

19

Page 20

PLATFORM INSTALLATION

Service Platform & Stiffener

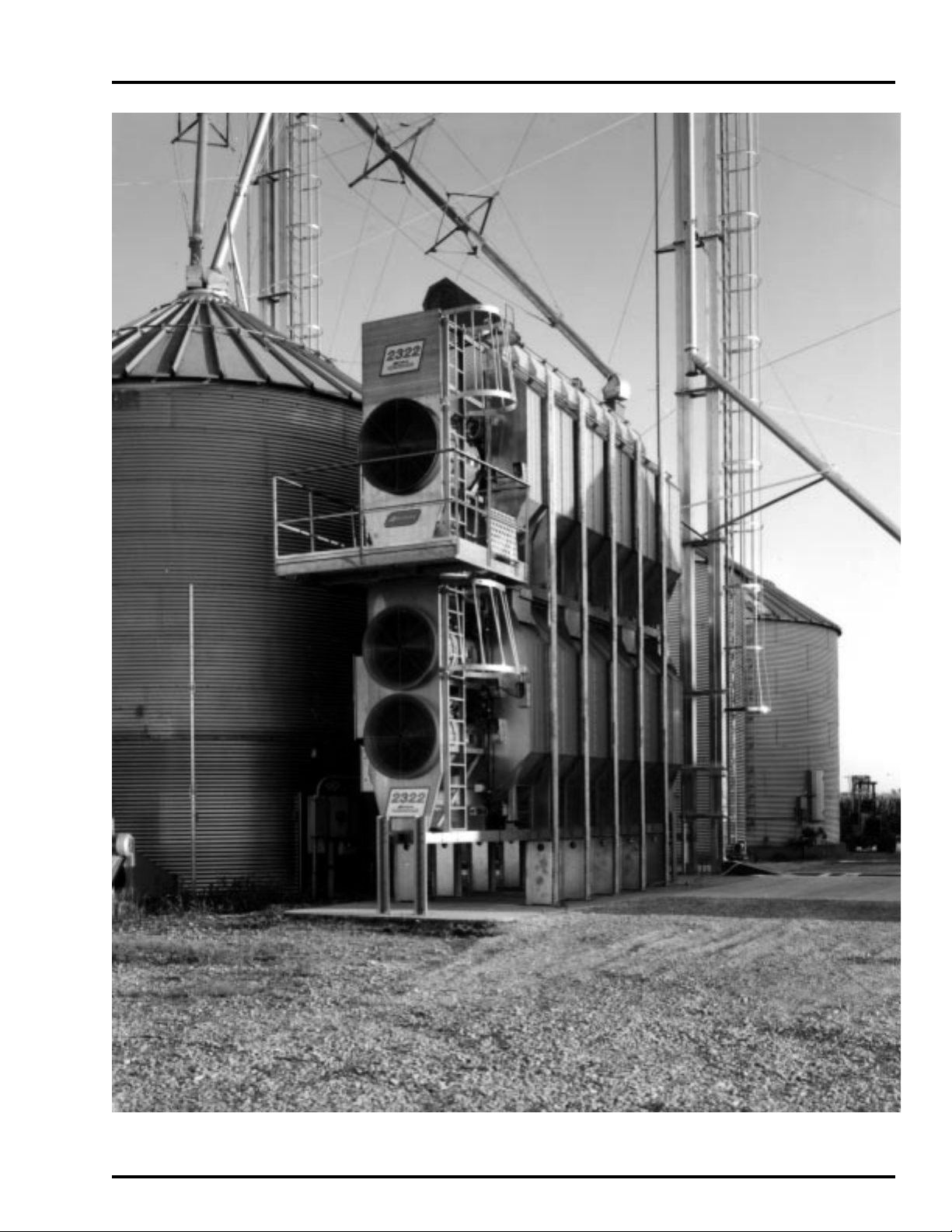

20

Figure 29: Finished platform on an Airstream upper module.

Page 21

Service Platform & Stiffener

PLATFORM INSTALLATION

Figure 30: Ladder side view of platform on a dryer module.

21

Page 22

PLATFORM INSTALLATION

Service Platform Parts

Platform Support Channels and Floor Support Angles

Service Platform & Stiffener

Item

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Item

15

16

17

18

19

Part Number

D61-0055

D01-2034

D01-2033

D61-0058

D61-0057

D61-0061

D61-0062

D01-2029

D01-2030

D01-2037

OBSOLETE

D01-2028

D61-0056

D01-2036

Part Number

D01-2042

D01-2050

D01-2041

D61-0037

D61-0066

Description

Rear Anchor Channels

Rear Angle Tie

Main Support Channel (102" long)

Left-hand Side Channel (82" long)

Right-hand Side Channel (82" long)

Front Channel (102" long)

Center Floor Support (35" long)

Right-hand Floor Support Angle

Left-hand Floor Support Angle

Access Door Frame

Front Left-hand Support Angle

Inner Front Toe Board (44" long)

Reinforcement Plate

Access Door Forward Frame

Inner and Outer Guard Rail Supports

Description

Left-hand Inner Guard Rail Support Angle (44" long)

Right-hand Front Inner Guard Rail Support Angle (42" long)

Right-hand Rear Inner Guard Rail Support Angle (44" long)

Outer Guard Rail Support Channels (50.5")

Outer Door Hinge Channel (9" long)

Quantity

Per Platform

2

1

1

1

1

1

1

1

1

1

1

1

1

1

Quantity

Per Platform

1

1

1

7

1

Item

20

21

22

23

24

25

26

27

28

29

Item

30

31

32

33

34

35

36

36

37

Part Number

D01-2039

D01-2038

D61-0069

D61-0045

D01-2048

D61-0044

D61-0042

D01-2049

D61-0043

D01-0581

Part Number

D01-2047

D01-2046

D01-2043

D61-0032

D61-0033

D61-0034

D01-2045

D01-2044

D61-0054

Floor Panels and Floor Toe Board Angles

Description

Left-hand Rear Floor Panels (30" long)

Right-hand Rear Floor Panels (30" long)

Front Section Floor Panels (102" long)

Left-hand Outer Rear Toe Boards (15" long)

Left-hand Inner Rear Toe Boards (11" long)

Right-hand Front Toe Boards (35.5" long)

Right-hand Outer Toe Board (82" long)

Right-hand Inner Toe Board (34" long)

Outer Front Toe Boards (105.25" long)

Platform Access Door

Floor Panels and Floor Toe Board Angles

Description

Upper Side Guard Rails (80" long)

Upper Front Guard Rail (105" long)

Rear Guard Rails (31-1/4" long)

Lower Front Side Guard Rails (53-1/8" long)

Lower Front Side Guard Rails (35-1/4" long)

Lower Rear Side Guard Rails (44-5/8" long)

Guard Rail Inside Right

Guard Rail Inside Left

Platform Attach Bracket

Quantity

Per Platform

1

4

3

2

1

2

2

1

2

1

Quantity

Per Platform

2

1

4

2

2

2

1

1

2

22

Page 23

Service Platform & Stiffener

PLATFORM INSTALLATION

Items 9 & 11 are now

one part.

Figure 31: Breakdown of platform parts.

23

Page 24

PLATFORM INSTALLATION

Service Platform & Stiffener

24

Figure 32: Breakdown of platform floor parts.

Page 25

Service Platform & Stiffener

STIFFENER INSTALLATION

25

Page 26

STIFFENER BASKET LOCATION

Service Platform & Stiffener

26

Figure 33: Location of stiffener angles on basket based on lenght.

Page 27

Service Platform & Stiffener

STIFFENER EXPLODED VIEW

Figure 34: Exploded view of stiffener.

27

Page 28

STIFFENER ASSEMBLY

Service Platform & Stiffener

General

This is a guide for assembling and mounting the new

Stack Dryer Stiffener Package to the Airstream

Stack Series grain dryers. It contains exploded

diagrams and text explaining the basic assembly.

Please study this carefully before beginning the

assembly and use it as a reference guide.

Stiffener Attach Angles

The Left Hand Attach Angle (D01-0873) and Right

Hand Attach Angle (D01-0874) are installed at the

factory during basket assembly. A comparison

should be made with the dryer to be installed and

Figure 33 to make sure the angles are installed in

the correct positon. A check should be made to see

if the Attach Angle points in the same direction as

the dryer leg directly below it. If the Attach Angles

are in the wrong location or point in the wrong

direction, the Attach Angles should be moved

before proceeding with the assembly.

Base Module Connector Clip

The Base Module Connector Clip should be attached to the Base Module of the dryer before

setting the dryer into place. The Connector Clip

attaches at the same place the Gusset Support Leg

attaches to the Frame Rail of the dryer. One at a

time, unbolt the Gusset Support Leg and bolt the

Connector Clip to the outside of the Frame Rail.

Stack Stiffener Leg Channel

The next step in assembling the Stack Stiffener

Package should be the attachment of the Stack

Stiffener Leg Channel (D01-0877). The Leg

Channel attaches to the Dryer Gusset Support Leg

below the Stiffener Attach Angle on the dryer

basket (Figure 1). This should be done for each

module at this time.

Stack Stiffener Base Unit

The Stack Stiffener Base Unit is assembled at the

factory. This component assembly should be set

into place in the locations specified in the Stack

Dryer Concrete Specification Drawings.

Base Unit Hardware

The connection of the Stack Stiffener Base Unit to

the Stack Base Module is completed using the

following hardware in the hardware package.

TRAP

REBMUN

842-S.hsawnorihguorw"8/321

654-Stunxeh61-"8/36

0605-Stlobnib"5.1x61-"8/36

NOITPIRCSED.YTQ

Stack Stiffener Installation

With the Stiffener Base Unit in place and all other

preparations finished, the Stack Stiffeners should be

attached to the dryer modules. Starting with the

base module of the dryer, the first stiffener should be

attached so that the bottom of the stiffener is even

with the frame. The top three holes should be left

open for later attachment of a stiffener splice. The

second stiffener can be attached to the stiffener

angle on the basket above the first with approximately 19.25” above the attach angle. The bottom

three holes should be left open for the splice. The

stiffeners can now be sliced together using the

Stiffener Splice (SS-7053). The base module is

now ready to be set into place on the stiffener base

units. Once the base module is in place, the Connector Clip should be bolted to the Base Unit. A

Stiffener Splice should be bolted on to connect the

Stiffener to the Base Unit. Assembly is shown in

Figure 35.

28

Page 29

Service Platform & Stiffener

SPECIAL BUTTRESS ASSEMBLY

Figure 35: Base module stiffener assembly.

The Second and Third Module Stiffeners are assembled the same way as the base module with only

minor variations. For the second module approximately 8.088" of stiffener should be left below the

frame of the module. Approximately 11.26" should

be left above the attach angle at the top. The splice

should be bolted as on the first module. For the third

module approximately 16.176" of stiffener should be

left below the frame of the module. Approximately

3.26" should be left above the attach angle at the top.

Splice the stiffener as before.

Splices should be used to connect the stiffeners as the

dryer modules are stacked. All bolts should be

checked and made tight to complete the installation.

Figure 36: Second module stiffener assembly.

Figure 37: Third module stiffener assembly.

29

Page 30

WARRANTY

THE GSI GROUP, INC. ("GSI") WARRANTS ALL PRODUCTS MANUFACTURED BY GSI TO BE

FREE OF DEFECTS IN MATERIAL AND WORKMANSHIP UNDER NORMAL USAGE AND CON-

DITIONS FOR A PERIOD OF 12 MONTHS AFTER RETAIL SALE TO THE ORIGINAL END USER

OF SUCH PRODUCTS. GSI'S ONLY OBLIGATION IS, AND PURCHASER'S SOLE REMEDY SHALL

BE FOR GSI, TO REPAIR OR REPLACE, AT GSI'S OPTION AND EXPENSE, PRODUCTS THAT, IN

GSI'S SOLE JUDGMENT, CONTAIN A MATERIAL DEFECT DUE TO MATERIALS OR WORK-

MANSHIP. ALL DELIVERY AND SHIPMENT CHARGES TO AND FROM GSI'S FACTORY WILL

BE PURCHASER'S RESPONSIBILITY. EXPENSES INCURRED BY OR ON BEHALF OF THE PUR-

CHASER WITHOUT PRIOR WRITTEN AUTHORIZATION FROM AN AUTHORIZED EMPLOYEE

OF GSI SHALL BE THE SOLE RESPONSIBILITY OF THE PURCHASER.

EXCEPT FOR THE ABOVE STATED EXPRESS LIMITED WARRANTIES, GSI MAKES NO WAR-

RANTY OF ANY KIND, EXPRESSED OR IMPLIED, INCLUDING, WITHOUT LIMITATION, WAR-

RANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR USE IN

CONNECTION WITH (i) PRODUCT MANUFACTURED OR SOLD BY GSI OR (ii) ANY ADVICE,

INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT, REPRESEN-

TATIVE OR EMPLOYEE OF GSI REGARDING OR RELATED TO THE CONFIGURATION, INSTAL-

LATION, LAYOUT, SUITABILITY FOR A PARTICULAR PURPOSE, OR DESIGN OF SUCH PROD-

UCT OR PRODUCTS.

Service Platform & Stiffener

IN NO EVENT SHALL GSI BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL OR CON-

SEQUENTIAL DAMAGES, INCLUDING, WITHOUT LIMITATION, LOSS OF ANTICIPATED PROF-

ITS OR BENEFITS. PURCHASER'S SOLE AND EXCLUSIVE REMEDY SHALL BE LIMITED TO

THAT STATED ABOVE, WHICH SHALL NOT EXCEED THE AMOUNT PAID FOR THE PRODUCT

PURCHASED. THIS WARRANTY IS NOT TRANSFERABLE AND APPLIES ONLY TO THE ORIGI-

NAL PURCHASER. GSI SHALL HAVE NO OBLIGATION OR RESPONSIBILITY FOR ANY REP-

RESENTATIVE OR WARRANTIES MADE BY OR ON BEHALF OF ANY DEALER, AGENT OR

DISTRIBUTOR OF GSI.

GSI ASSUMES NO RESPONSIBILITY FOR FIELD MODIFICATIONS OR ERECTION DEFECTS

WHICH CREATE STRUCTURAL OR STORAGE QUALITY PROBLEMS. MODIFICATIONS TO THE

PRODUCT NOT SPECIFICALLY COVERED BY THE CONTENTS OF THIS MANUAL WILL NUL-

LIFY ANY PRODUCT WARRANTY THAT MIGHT HAVE BEEN OTHERWISE AVAILABLE.

THE FOREGOING WARRANTY SHALL NOT COVER PRODUCTS OR PARTS WHICH HAVE

BEEN DAMAGED BY NEGLIGENT USE, MISUSE, ALTERATION OR ACCIDENT. THIS WAR-

RANTY COVERS ONLY PRODUCTS MANUFACTURED BY GSI. THIS WARRANTY IS EXCLU-

SIVE AND IN LIEU OF ALL OTHER WARRANTIES EXPRESS OR IMPLIED. GSI RESERVES THE

RIGHT TO MAKE DESIGN OR SPECIFICATION CHANGES AT ANY TIME.

PRIOR TO INSTALLATION, PURCHASER HAS THE RESPONSIBILITY TO RESEARCH AND

COMPLY WITH ALL FEDERAL, STATE AND LOCAL CODES WHICH MAY APPLY TO THE LO-

CATION AND INSTALLATION.

30

Page 31

Page 32

1004 E. Illinois St., Box 20

Assumption, IL 62510-0020

phone: 217-226-4421

fax: 217-226-4420

www.grainsystems.com

October 1998

REVISED August 2004

Loading...

Loading...