Page 1

PNEG-338

Portable Dryer Installation

and Towing

Installation and Towing Manual

PNEG-338

Date: 11-28-12

Page 2

2PNEG-338 Portable Dryer Installation and Towing

Page 3

Table of Contents

Contents

Chapter 1 Introduction .......................................................................................................................................... 4

Chapter 2 Safety ..................................................................................................................................................... 5

Safety Guidelines .................................................................................................................................. 5

Emergency Stop Switch ................................... ... ... ... .... ... ... ... .... ... ... ..................................................... 6

Safety Instructions ..................... ... .... .......................................... ... ... ..................................................... 6

Safety Precautions .................................... ... .... .......................................... ... ... ... .................................. 7

Safety Sign-Off Sheet ........................................................................................................................... 8

Chapter 3 Safety Alert Decals ..................................... .... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... ................................... 9

Chapter 4 Transporting the Dryer ...................................................................................................................... 13

Chapter 5 Installation .......................................................................................................................................... 14

Location of the Dryer ..................................................................................................................... ... ... 14

Foundation .............................................................................................................................. ... ... ... ... 14

Supporting the Dryer ........................................................................................................................... 14

Supporting the Dryer with the Optional Steel Support Legs ................... .................... ................... ...... 14

Wet Grain Supply ... ... ... ... .... ... ... ... .... ... ... ... ... .... .......................................... ... ... ... .... ... ... ...................... 14

Dry Grain Removal .............................................................................................................................. 14

Chapter 6 Foundation Layout Typical of Dryer Line ........................................................................................ 16

Chapter 7 Foundation Specifications for Dryer ................................................................................................ 17

Chapter 8 Fuel Connection ................................................................................................................................. 18

Liquid Propane (LP) ........ .......................................... .... ... ... .......................................... ... ....... ... ... ...... 18

Natural Gas (N) ................................................................................................................................... 19

Chapter 9 Electrical Power Supply ..................................................................................................................... 21

Power Supply ...................................................................................................................................... 21

Transformers and Wiring Voltage Drop ............................................................................................... 21

Power Supply Disconnect ............................................................................................................. ... ... 21

Machine to Earth Grounding ............................................................................................................ ... 21

Proper Installation of Ground Rod ....................................................................................................... 22

Connecting Auxiliary Conveyors ......................................................................................................... 22

Chapter 10 Electrical Load Information ............................................................................................................. 23

Chapter 11 Warranty ............................................................................................................................................ 31

PNEG-338 Portable Dryer Installation and Towing 3

Page 4

1. Introduction

READ THIS MANUAL carefully to learn how to properly use and install equipment. Failure to do so could

result in personal injury or equipment damage.

INSPECT the shipment immediately upon arrival. The customer is responsible for ensuring that all

quantities are correct. The customer should report and note any damage or shortage on the bill of lading

to justify their claim to the transport company.

THIS MANUAL SHOULD BE CONSIDERED a permanent part of your equipment and should be easily

accessible when needed.

This warranty provides you the assurance that the company will back its products when defects appear

within the warranty period. In some circumstances, the company also provides field improvements, often

without charge to the customer, even if the product is out of warranty. Should the equipment be abused,

or modified to change its performance beyond the factory specifications, the warranty will become void

and field improvements may be denied.

4PNEG-338 Portable Dryer Installation and Towing

Page 5

2. Safety

DANGER

WARNING

CAUTION

NOTICE

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a

hazardous situation which, if not avoided, could result in

minor or moderate injury.

NOTICE is used to address practices not related to

personal injury.

DANGER indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

Personnel operating or working around electric fans should read this manual. This

manual must be delivered with the equipment to its owner. Failure to read this manual

and its safety instructions is a misuse of the equipment.

WARNING! BE ALERT!

Safety Guidelines

This manual contains information that is important for you, the owner/operator, to know and understand.

This information relates to protecting personal safety and preventing equipment problems. It is the

responsibility of the owner/operator to inform anyone operating or working in the area of this equipment

of these safety guidelines. To help you recognize this information, we use the symbols that are defined

below. Please read the manual and pay attention to these sections. Failure to read this manual and its

safety instructions is a misuse of the equipment and may lead to serious injury or death.

PNEG-338 Portable Dryer Installation and Towing 5

Page 6

2. Safety

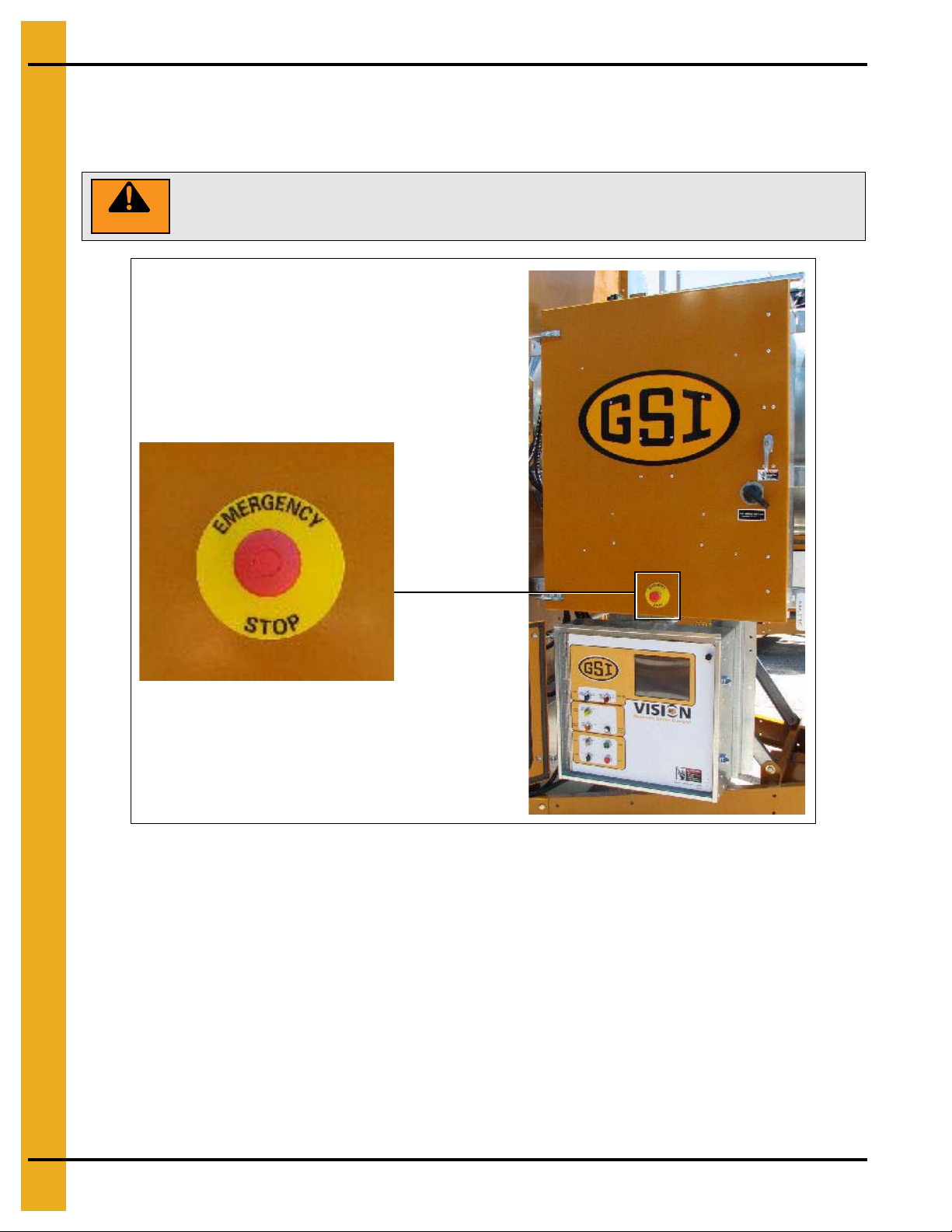

WARNING

Pushing the emergency stop switch does not interrupt the main power to the

upper control box panel.

Emergency Stop Switch

The emergency stop switch is located on the upper control box door. Pushing the emergency stop switch

will interrupt the control power and stop all dryer functions.

Figure 2A

Safety Instructions

Our foremost concern is your safety and the safety of others associated with this equipment. We want to

keep you as a customer. This manual is to help you understand safe operating procedures and some

problems that may be encountered by the operator and other personnel.

As owner and/or operator, it is your responsibility to know what requirements, hazards, and precautions

exist, and to inform all personnel associated with the equipment or in the area. Safety precautions may be

required from the personnel. Avoid any alterations to the equipment. Such alterations may p roduce a very

dangerous situation where SERIOUS INJURY or DEATH may occur.

This equipment shall be installed in accordance with the current installation codes and applicable

regulations, which should be carefully followed in all cases. Authorities having jurisdiction should be

consulted before installations are made.

6PNEG-338 Portable Dryer Installation and Towing

Page 7

2. Safety

CAUTION

Keep the dryer clean. Do not allow fine material to accumulate in the plenum

chamber or surrounding the outside of the dryer.

Safety Precautions

READ THESE INSTRUCTIONS BEFORE INSTALLATION AND OPERATION

SAVE FOR FUTURE REFERENCE

1. Read and understand the operating manual before trying to operate the dryer.

2. NEVER operate the dryer while the guards are removed.

3. Power supply should be OFF for service of electrical components. Use CAUTION in checking voltage

or other procedures that require the power to be ON.

4. Check for gas leaks at all gas pipe connections. If any leaks are detected, DO NOT operate dryer.

Shut down and repair before further operation.

5. NEVER attempt to operate the dryer by jumping or otherwise bypassing any safety devices on

the unit.

6. Set pressure regulator to avoid excessive gas pressure to burner during ignition and when burner is

in operation. DO NOT exceed maximum recommended drying temperature.

7. Keep the dryer clean. Clean grain is easier to dry. Fine material increases resistance to airflow

and requires removal of extra moisture. DO NOT allow fine material to accumulate in the

plenum chamber.

8. Keep auger drive belts tight enough to prevent slippage.

9. Use CAUTION in working around high speed fans, gas burners, augers and auxiliary conveyors

which can all START AUTOMATICALLY.

10. DO NOT operate in any area where combustible material will be drawn into the fan.

11. BEFORE attempting to remove and reinstall any propeller, read the procedure listed in the service

section of the manual.

12. Match the capacities of auxiliary conveyors to dryer auger capacities.

USE CAUTION IN THE OPERATION OF THIS EQUIPMENT

This dryer is designed and manufactured to maximize operator safety. However, grain dryers have

inherently hazardous components: a gas burner, high voltage electrical equipment, high speed rotating

parts, etc. It is not possible to fully safeguard again st all hazards withou t impeding efficient op eration and

reasonable access to components. Therefore, a careful and knowledgeable owner/operator is the best

insurance against an accident.

Use extreme caution when working around high speed fans, gas fired heaters, augers and auxiliary

conveyers, which may start without warning when the dryer is operating on automatic control.

Continued safe, dependable operation of automatic equipment depends, to a great degree, upon the

owner. For a safe and dependable drying system, follow the recomm endations within this manual and make

it a practice to regularly inspect the operation of the unit for any deve loping problems o r unsafe conditions.

Take special note of all safety precautions before attempting to operate the dryer.

PNEG-338 Portable Dryer Installation and Towing 7

Page 8

2. Safety

Safety Sign-Off Sheet

As a requirement of O.S.H.A., it is necessary for the employer to train the employee in the safe operating

and safety procedures for this equipment. This sign-off sheet is provided for your convenience and

personal record keeping. All unqualified persons are to stay out of the work area at all times. It is strongly

recommended that another qualified person who knows the shut down procedure be in the area in the

event of an emergency.

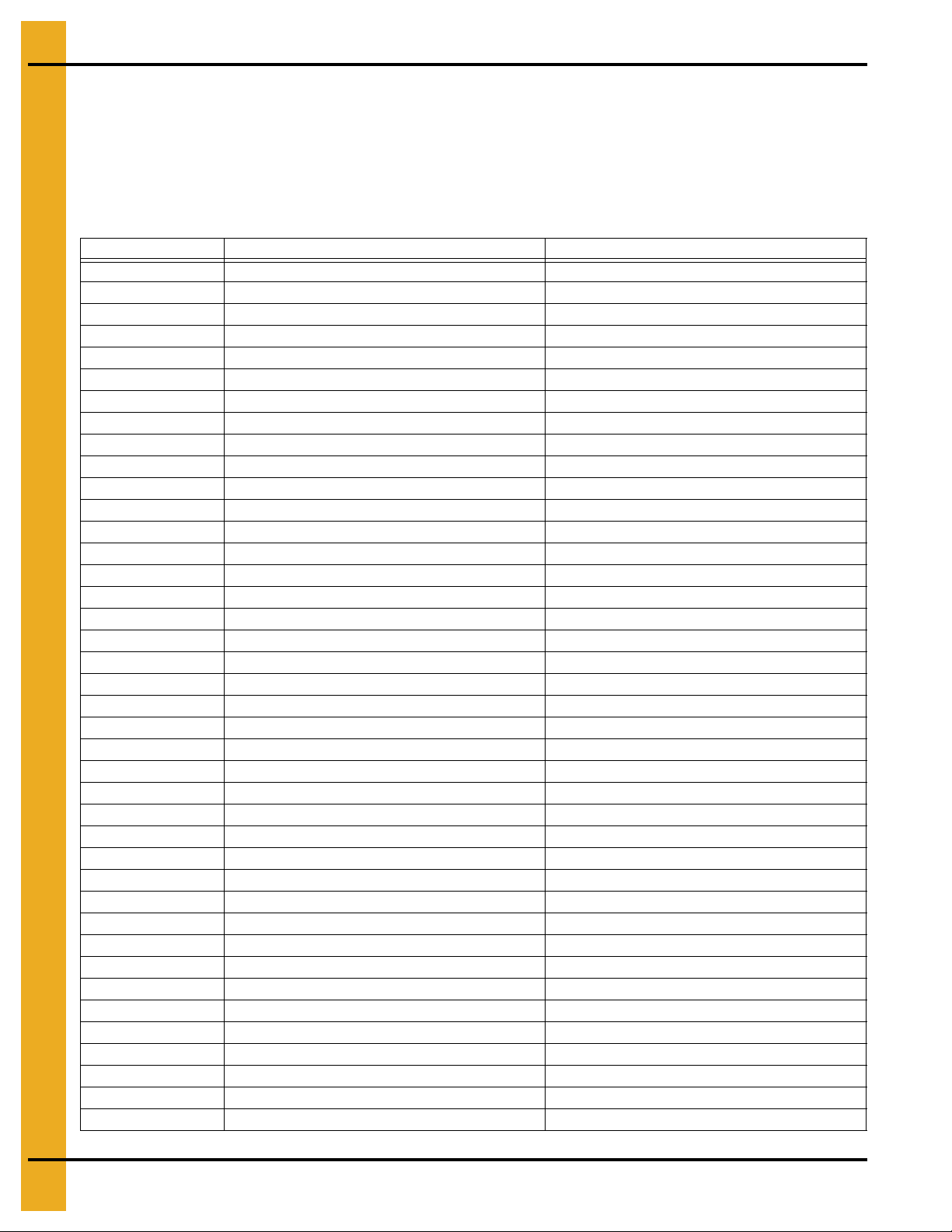

Date Employee Name Supervisor Name

8PNEG-338 Portable Dryer Installation and Towing

Page 9

3. Safety Alert Decals

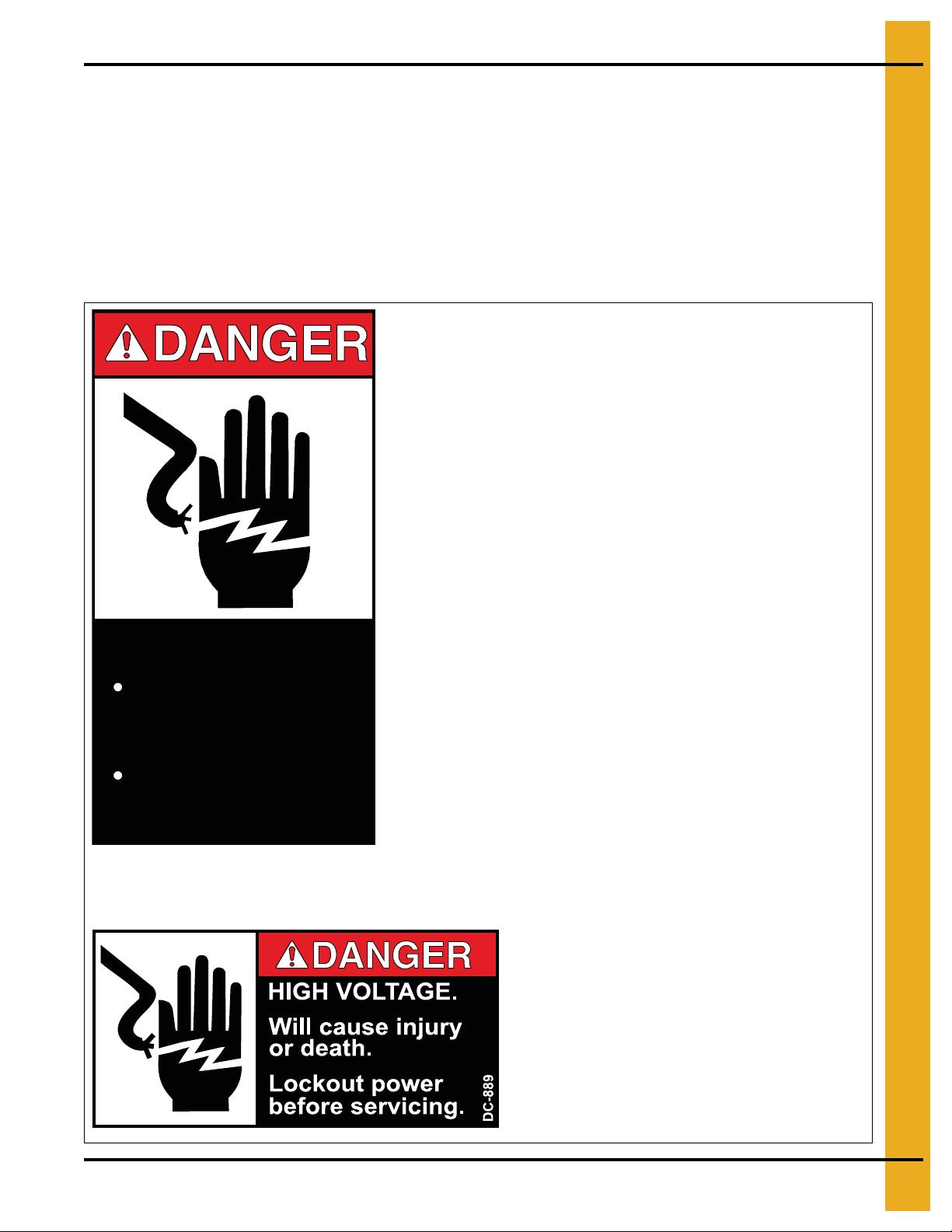

HIGH VOLTAGE.

Will cause serious

injury or death.

Lockout power

before servicing.

DC-1224

Decal: DC-889

Decal DC-889 has two (2) locations. One is located

inside the fan/heater control box and another one is

on the dryer upper control box door next to the main

power disconnect.

Decal: DC-1224

Decal DC-1224 is located in two (2) places on the fan/heater control box.

One is located on the lid and another one is on the front of the fan/heater

control box. An additional location for this decal is inside the upper control

box for the dryer.

The GSI Group recommends contacting your local power company and having a representative survey

your installation so the wiring is compatible with their system and adequate power is supplied to your unit.

Safety decals should be read and understood by all people in the grain handling area.

If a decal is damaged or is missing, contact:

Decals

1004 E. Illinois St.

Assumption, IL. 62510

Phone: 1-217-226-4421

A free replacement will be sent to you.

PNEG-338 Portable Dryer Installation and Towing 9

Page 10

3. Safety Alert Decals

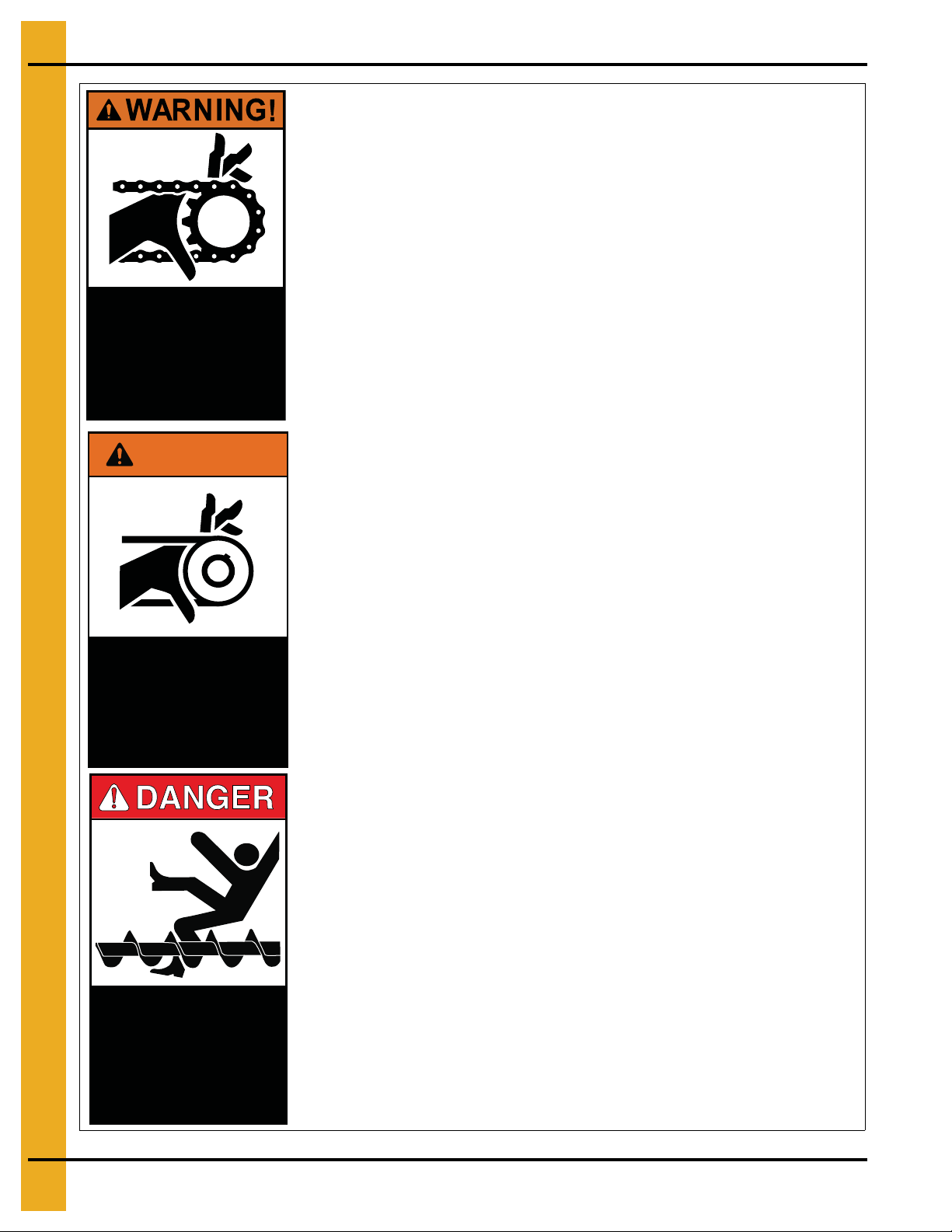

Moving parts can crush

and cut. Keep hands

clear. Do not operate

without guards in place.

Failure to do so could

result in serious injury.

DC-972

WARNING!

Automatically controlled

belt drive can start at

anytime. Keep hands

clear. Failure to do so

could result in serious

injury.

DC-971

Decal: DC-972

Decal DC-972 is located on the bottom auger belt guard and the front bearing plate (which

is visible when the bottom auger belt guard is removed). An alternate location would be at

the rear of the dryer for portable dryers equipped with the Front Discharge Option.

Decal: DC-971

Decal DC-971 is located on the bottom auger belt guard and the front bearing plate (which

is visible when the bottom auger belt guard is removed). An alternate location would be at

the rear of the dryer for portable dryers equipped with the

Front Discharge Option

.

An additional location for decal DC-971 is the top auger belt guard (one on the belt

guard cover and one inside on the belt guard body visible when the belt guard cover

is removed).

Decal: DC-974

Decal DC-974 has several different locations. Two (2) are located on the front end panel

below the fan/heater. Two (2) are located on the rear end panel below the rear access

door. T wo (2) are located on the auger discharge box (one on the outside top and one on

the inside of the flapper lid next to the discharge mercury switch). One more of these

decals is located inside the plenum on the rear plenum closure door just inside the rear

access door.

Rotating auger will crush

and cut. Auto equipment

can start at anytime. Do not

enter until electric power is

locked in off position. Failure

to do so will result in serious

10 PNEG-338 Portable Dryer Installation and Towing

injury or death.

DC-974

Page 11

3. Safety Alert Decals

DC-1227

Flame and pressure beyond

door can cause serious

injury. Do not operate with

service door removed. Keep

head and hands clear.

WARNING

Decal: DC-1227

Decal DC-1227 is located on the

fan/heater access door.

Decal: DC-1225

Decal DC-1225 is located on the

fan/heater access door.

Decal: DC-1229

Decal DC-1229 is located on each of

the meter roll access doors.

WARNING

Stay clear of rotating

blade. Blade could start

automatically. Can cause

serious injury. Disconnect

power before servicing.

WARNING

Rotating metering roll.

Equipment can start

automatically. Keep hands

PNEG-338 Portable Dryer Installation and Towing 11

clear. Can cause serious

injury. Disconnect power

before servicing.

DC-1225

DC-1229

Page 12

3. Safety Alert Decals

Automatic equipment can

start at any time. Do not

enter until fuel is shut off

and electrical power is

locked in off position.

Failure to do so will result

in serious injury or death.

DC-973

Decal: DC-973

Decal DC-973 is located on the rear plenum access door (inside

and outside).

Decal: DC-388

Decal DC-388 is located on the hitch tongue.

Decal: DC-1249

Decal DC-1249 is located on the hitch tongue.

3/4" MINIMUM

BOLT DIAMETER

Hitch pin must be

securely fastened and

no less than 3/4" in

diameter. Failure to

follow installation

16-17"

instructions may result

in property damage.

DC-388

HUB TEMPERATURE

NO GREATER THAN 150°F

150°

TIGHTEN TO

90FT-LBS.

Dryer must be

towed empty and

in accordance

050

CHECK AFTER 50 MILES AND EVERY 200 MILES

100

150

55-60 PSI

COLD

200 250

with state and

provincial

regulations.

DC-1249

12 PNEG-338 Portable Dryer Installation and Towing

Page 13

4. Transporting the Dryer

Washers

Locking nut

3/4" Minimum bolt diameter

The dryer is available with an optional transport kit for transporting the unit by truck or tractor. Make certain

to observe the following safety precautions.

1. Recommended towing hitch height is 14"-17''. (See Figure 4A.)

Figure 4A Use a 14"-17'' Towing Hitch Height and a Safety Chain

2. Hitch bolt must be at least 3/4" in diameter and securely fastened with a locking nut, so it will not

come out during travel and the hitch will not bend. (See Figure 4B.)

3. Be sure to minimize vertical hitch play with washers. (See Figure 4B.)

Figure 4B A 3/4'' hitch bolt and washers fastened with

a locking nut at the bottom of the hitch.

4. Always use a safety chain. (See Figure 4A.)

5. Dryer must by towed empty and in accordance with applicable state or provincial regulations.

NOTE: NEVER tow dryer with grain or any other material inside of it.

6. Recommended tire pressure is 55-60 PSI (cold).

7. Maximum towing speed is 45 miles per hour or the speed limit, whichever is lower.

8. After the first 50 miles and every 200 miles thereafter, check the following:

a. Dryer wheel hub and spindle temperature immediately after stopping. Temperature should not

exceed 150°F. It may be hot to touch, but not melting lubricant.

b. Wheel lug nuts. They are factory torqued at 115 to 120 Ft. Lbs. Retighten, if required.

PNEG-338 Portable Dryer Installation and Towing 13

Page 14

5. Installation

Location of the Dryer

When considering the exact location of the dryer, also consider the wet grain supply and dry grain

discharge, as well as the location of storage bins and other grain handling equipment. Do not install the

dryer inside a building or in any other area where not allowed by electrical codes, fuel installation

regulations and/or insurance requirements. Maintain a minimum distance of at least three feet from other

structures, otherwise air flow problems may occur. (See Page 15.) Do not operate in an area where

combustible materials can be drawn into the fans or where load and unload augers can come in contact

with power lines.

Foundation

A reinforced concrete pad or similar permanent foundation is recommended for dryer stability.

See Pages 16 and 17 for details.

Supporting the Dryer

The wheels are to be used for transporting the dryer only when empty. Before loading any grain into the

dryer, the frame of the unit on each side must be supported. Place concrete blocks on each side, every

six feet of the frame, as well as at the hitch mount location with the hitch removed. The blocks must be

able to support the dryer as well as the additional weight of the grain when full. Use shims to provide

uniform, level support for all blocks. The dryer sho uld be at least 16'' off th e pad to allow for clean-out and

the use of auxiliary grain handling equipment. The hitch tongue should be removed, but the hitch assembly

and the fan support must be left on during operation; they are not part of the transport tie down assembly.

NOTE: Use a minimum of one support per each six feet of basket length on each side.

Supporting the Dryer with the Optional Steel Support Legs

Anchor points may be cast into the concrete slab or the dryer may be tied down by cables and turnbuckles

to anchors installed at the edge of the slab. This helps prevent overturn or lateral

movement by wind or other forces.

Wet Grain Supply

A wet grain holding bin provides gravity flow to the dryer or loading conveyor. This conveyor may be

electrically connected to the power circuit provided in the main control box. Initially, the dryer will fill

completely. During drying, the top auger will start and stop as required depending upon the dry grain

discharge rate and grain shrinkage to maintain the dryer fill. If the dryer does not fill within the pre-set

time on the Out of Grain Timer (see owner’s manual for instructions on setting this timer), the dryer will

shut down.

Dry Grain Removal

The dry grain is normally discharged out of the rear end of the dryer. Front discharge is an optional feature.

A take away system needs to be provided to remove grain from the drying system. This conveyor may be

electrically connected to the power circuit provided in the main control box.

14 PNEG-338 Portable Dryer Installation and Towing

Page 15

Figure 5A Diagram of Dryer Dimensions

5. Installation

Transport and Installation Dimensions

Driver

Model #

1108 11' 6'' 8' 13' 11' 8'' 10' 1'' 6' 5'' 8' 14' 9'' 16' 10''

1110 11' 6'' 8' 13' 11' 8'' 10' 1'' 6' 5'' 8' 16' 9'' 18' 10''

1112 13' 5'' 8' 14' 6'' 13' 2'' 11' 7'' 6' 5'' 8' 18 ' 9'' 20' 10''

1114 1214 13' 5'' 8' 14' 6'' 13' 2'' 11' 7'' 6' 5'' 8' 20' 9'' 22' 10''

1116 1216 13' 5'' 8' 14' 6'' 13' 2'' 11' 7'' 6' 5'' 8' 22' 9'' 24' 10''

1118 1218 13' 5'' 8' 14' 6'' 13' 2'' 11' 7'' 6' 5'' 8' 24' 9'' 26' 10''

1120 1220 13' 5'' 8' 14' 6'' 13' 2'' 11' 7'' 6' 5'' 8' 26' 9'' 28' 10''

1122 1222 13' 5'' 8' 14' 6'' 13' 2'' 11' 7'' 6' 5'' 8' 28' 9'' 30' 10''

1126 1226 13' 5'' 8' 14' 6'' 13' 2'' 11' 7'' 6' 5'' 8' 32' 9'' 34' 10''

1314 13' 5'' 8' 14' 6'' 13' 2'' 11' 7'' 6' 5'' 8' 20' 9'' 22' 10''

1318 13' 5'' 8' 14' 6'' 13' 2'' 11' 7'' 6' 5'' 8' 24' 9'' 26' 10''

1322 13' 5'' 8' 14' 6'' 13' 2'' 11' 7'' 6' 5'' 8' 28' 9'' 30' 10''

1214S 13' 5'' 11' 2'' 14' 6'' 13' 2'' 11' 7'' 6' 5'' 8' 20' 9'' 22' 9''

1218S 13' 5'' 11' 2'' 14' 6'' 13' 2'' 11' 7'' 6' 5'' 8' 24' 9'' 26' 10''

1220S 13' 5'' 11' 2'' 14' 6'' 13' 2'' 11' 7'' 6' 5'' 8' 26' 9'' 28' 10''

1222S 13' 5'' 11' 2'' 14' 6'' 13' 2'' 11' 7'' 6' 5'' 8' 28' 9'' 30' 10''

1226S 13' 5'' 11' 2'' 14' 6" 13' 2'' 11 ' 7'' 6' 5'' 8' 32' 9'' 34' 10''

160AB 11' 11'' 8' N/A 11' 8'' 10' 1'' 6' 5'' 8' 12' 9'' 14' 10''

210AB 11' 11'' 8' N/A 11' 8'' 10' 1'' 6' 5'' 8' 14' 9'' 16' 10''

300AB 13' 5'' 8' N/A 13' 3'' 11' 7'' 6' 5'' 8' 16' 9'' 18' 10''

375AB 13' 5'' 8' N/A 13' 3'' 11' 7'' 6' 5'' 8' 18' 9'' 20' 10''

400AB 13' 5'' 8' N/A 13' 3'' 11' 7'' 6' 5'' 8' 20' 9'' 22' 10''

415AB 13' 5'' 8' N/A 13' 3'' 11' 7'' 6' 5'' 8' 20' 9'' 22' 10''

600AB 13' 5'' 8' N/A 13' 3'' 11' 7'' 6' 5'' 8' 26' 9'' 28' 10''

ABCDEFGH

Transport

Height

Installed

Width

Installed

Wet Bin

Height

Standard

Height w/o

Wet Bin

Frame

Width

Transport

Width

Installed

Length

Transport

Length

PNEG-338 Portable Dryer Installation and Towing 15

Page 16

6. Foundation Layout Typical of Dryer Line

Figure 6A

16 PNEG-338 Portable Dryer Installation and Towing

Page 17

7. Foundation Specifications for Dryer

Minimum Bag Mix for Concrete Strength per Model Weight

Dryer Basket Length 6 8 10 12 14 16 18 20 22 26

Concrete Pad Size 12 x 16 12 x 18 12 x 20 12 x 22 12 x 24 12 x 26 12 x 28 12 x 30 12 x 32 12 x 36

Yards Concrete 5.3 5.9 6.5 7.1 7.7 8.3 8.9 9.2 10.1 11.3

Reinforcing Rods 20" each

Wire Mesh Sq. Ft. 192 216 240 264 288 312 336 360 384 432

Steel Legs (Minimum) 8 8 10 10 12 12 14 14 16 18

Anchors 4 4 4 6 6 6 8 8 8 10

Blocks 10 14 14 18 18 18 22 22 26 30

Foot of 2 x 6 10 14 14 18 18 18 22 22 26 30

Turnbuckles 44466688810

Estimated Manhours 8 10 12 14 18 18 20 22 24 28

Quantities are approximate and requirements may vary due to site elevations.

Setup times do not include site preparation and pouring concrete pad.

6 6 7 7 7 8 8 8 9 10

PNEG-338 Portable Dryer Installation and Towing 17

Page 18

8. Fuel Connection

See Fuel Specification Chart

on Page 19 for recommended

line use.

Liquid Propane (LP)

Liquid Draw

The dryers have internal vaporizers and are designed to operate on liquid draw from the supply tank. The

tank should be 1000 gallons or larger and should not have a regulator mounted to it. The connection to

the dryer should be with a flexible hose designed for LP gas, See Chart on Page 19 for proper size.

Consult your LP gas dealer for proper fittings, connection hose and safety controls required to meet local

standards and to conform with National Fire Protection Association standards. The piping train on the

dryer includes strainer, pressure relief valve, electronic safety shut off valve (on some models) and a

pressure regulator between the vaporizer and burner.

Ammonia Tanks

Do not use tanks which have previously been used for ammonia or fertilizer solutions. These substances

are extremely corrosive and will damage fuel supply and burner parts.

Oil or Water in Tanks

With liquid draw from the supply tank, any water or oil present in the tank may freeze in the pipe train or

controls causing damage. To make sure the tank is free of moisture, it can be purged with methanol. Avoid

tanks which may contain an accumulation of oil or heavy hydrocarbon from long use on a vapor withdrawal

system.

Figure 8A Grain dryer connected to a liquid propane tank.

18 PNEG-338 Portable Dryer Installation and Towing

Page 19

8. Fuel Connection

See Fuel Specifications Chart on

Page 20 for required pressure and

typical maximum fuel flow rates.

See Fuel Specifications Chart

on Page 20 for recommended

line size.

Fuel System Specifications and Recommendations (LP) Liquid Propane

Dryer

Model #

1108 3,000,000 33 1/2'' 1/4''

1110 3,500,000 38 1/2'' 9/32''

1112 4,500,000 49 1/2'' 21/64''

1114 5,750,000 63 1/2'' 11/32''

1116 5,750,000 63 1/2'' 11/32''

1118 6,750,000 74 1/2'' 3/8''

1120 7,500,000 82 1/2'' 25/64''

1122 8,750,000 96 3/4'' 7/16''

1126 10,250,000 112 3/4'' 29/64''

1214 6,200,000 68 3/4'' (U)9/32'' (L)7/32''

1216 7,200,000 79 3/4'' (U)21/64'' (L)7/32''

1218 7,200,000 79 3/4'' (U)21/64'' (L)7/32''

1220 8,500,000 93 3/4'' (U)11/32'' (L)1/4''

1222 9,750,000 107 3/4'' (1)3/8'' (1)1/4''

1226 10,500,000 115 3/4'' (1)25/64'' (1)1/4''

1314 8,100,000 88 3/4'' (3)7/32''

1318 8,100,000 88 3/4'' (3)7/32''

1322 8,100,000 88 3/4'' (3)7/32''

160AB 3,000,000 33 1/2'' 1/4''

210AB 3,500,000 33 1/2'' 1/4''

300AB 4,500,000 49 1/2'' 21/64''

375AB 5,500,000 60 1/2'' 21/64''

400AB 5,500,000 60 1/2'' 21/64''

415AB 7,000,000 66 1/2'' (2)9/32''

600AB 9,000,000 98 3/4'' (2)21/64''

* The minimum size of the fuel line for distances of 30.48 m (100 ft.).

Maximum Heat

Capacity BTU Per Hour

Maximum Fuel Flow

Gals Per Hour

Fuel Line Size* Heater Orifice Drill Size

Natural Gas (N)

Gas Volume and Pressure

The dryer is designed to operate on natural gas having a heat value of approximately 1000 BTU per cubic

foot. The dryer is equipped with a natural gas supply pipe system connected to the heater solenoid valves.

A regulated pressure of 10 PSI must be provided at the connection to the dryer, with gas available in

sufficient volume to maintain the operating pressure.

Figure 8B Grain dryer connected to a natural gas supply tank.

PNEG-338 Portable Dryer Installation and Towing 19

Page 20

8. Fuel Connection

Fuel System Specifications and Recommendations (N) Natural Gas

Dryer

Model #

1108 3,000,000 3,000 1-1/4'' 3/8''

1110 3,500,000 3,500 1-1/4'' 13/32''

1112 4,500,000 4,500 1-1/2'' 1/2''

1114 5,750,000 5,750 1-1/2'' 33/64''

1116 5,750,000 5,750 1-1/2'' 33/64''

1118 6,750,000 6,750 2'' 35/64''

1120 7,500,000 7,500 2'' 37/64''

1122 8,750,000 8,750 2'' 19/32''

1126 10,250,000 10,250 2'' 41/64''

1214 6,200,000 6,200 1-1/2'' (1)13/32'' (1)5/16''

1216 7,200,000 7,200 2'' (1)1/2'' (1)5/16''

1218 7,200,000 7,200 2'' (1)1/2'' (1)5/16''

1220 8,500,000 8,500 2'' (1)33/64'' (1)3/8''

1222 9,750,000 9,750 2'' (1)35/64'' (1)3/8''

1226 10,500,000 10,500 2'' (1)37/64'' (1)3/8''

1214S 6,000,000 6,000 1-1/2'' (2)3/8''

1218S 6,000,000 6.000 1-1/2'' (2)13/32''

1220S 9,000,000 9,000 2'' (2)1/2''

1222S 9,000,000 9,000 2'' (2)1/2''

1226S 13,500,000 13,500 2'' (2)17/32''

1314 8,100,000 8,100 2'' (3)5/16''

1318 8,100,000 8,100 2'' (3)5/16''

1322 8,100,000 8,100 2'' (3)5/16''

160AB 3,000,000 3,000 1-1/4'' 3/8''

210AB 3,500,000 3,500 1-1/4'' 13/32''

300AB 4.500,000 4,500 1-1/2'' 1/2''

375AB 5,500,000 5,500 1-1/2'' 33/64''

400AB 5,500,000 5,500 1-1/2'' 33/64''

415AB 7,000,000 7,000 2'' (2)13/32''

600AB 9,000,000 9,000 2'' (2)1/2''

* The minimum size of the fuel line for distances of 30.48 m (100 ft.).

Maximum Heat

Capacity BTU Per Hour

Maximum Fuel Flow

Cubic Feet Per Hour

Fuel Line Size* (Dia.) Heater Orifice Drill Size

Figure 8C The fuel connection point is equipped with a

Y-strainer and Maxon safety valve.

20 PNEG-338 Portable Dryer Installation and Towing

Page 21

9. Electrical Power Supply

Power Supply

An adequate power supply and proper wiring are important factors for maximum performance and long

life of the dryer. Electrical service must be adequate to prevent low voltage damage to motors and co ntrol

circuits. (See Electrical Load Information on Pages 23-30.) Power supply for single phase models must

include a neutral wire.

Transformers and Wiring Voltage Drop

Advise the service representative of the local power supplier that an additional load will be placed on the

line. Check the KVA rating of transformers, considering total horsepower load. The power supply wiring,

main switch equipment and transformers must provide adequate motor starting and operating voltage.

Voltage drop during motor starting should not exceed 14% of normal voltage. After motor is running at full

speed, it should be within 8% of normal voltage. Check electrical load information

HP ratings and maximum amp loads.

(See Pages 23-30)

for

Power Supply Disconnect

All dryers are equipped with a power disconnect switch in the power box to permit total power shut down

before opening the power box door, as required for inspection and service. The power disconnect switch

is located on the power box door for quick shut down.

Machine to Earth Grounding

A Machine to Earth Ground Rod must be installed at the dryer. Place the ground rod that comes standard

within eight feet of the dryer and attach it to the dryer control panel with at least a #6 solid, bare, copper

ground wire and the clamp provided. The grounding rod located at the power pole will not provide

adequate grounding for the dryer. Proper grounding will provide additional safety in case of any short and

will ensure long life of all circuit boards, the SCR drive and the ignition system. The ground rod must be in

accordance with local requirements.

Figure 9A Installation of a ground rod (standard with dryer purch ase) specifically

for the grain dryer is necessary for safety and equipment preservation.

PNEG-338 Portable Dryer Installation and Towing 21

Page 22

9. Electrical Power Supply

Proper Installation of Ground Rod

The rod should not be driven into dry ground. Follow these instructions for proper installation.

1. Dig a hole large enough to hold one to two (2) gallons of water.

2. Fill hole with water.

3. Insert rod through water and “jab” it into the ground.

4. Continue “jabbing” the rod up and down. This allows the water to work its way into the ground,

allowing it to be completely inserted into the ground. This method of installation also assures good

contact with the surrounding soil, thereby making a proper ground.

5. Connect the bare, copper ground wire to the rod with the proper clamp.

6. Connect ground wire to control panel with the ground lug provided in the control box.

7. Ground wire must not have any breaks or splices. Do not use insulated wire for

grounding applications.

Connecting Auxiliary Conveyors

The auxiliary load and auxiliary unload augers or conveyors can be wired directly to the dryer. Electrical

Load Information on Pages 23-30 shows the maximum horse power and amps of auxiliaries that can be

wired to the dryer. If an auxiliary motor is larger than recommended, it must be powered from a source

outside the dryer and must use a separate contactor and overload protection device for each motor.

However, the operation of the auxiliaries can be performed by the control panel.

22 PNEG-338 Portable Dryer Installation and Towing

Page 23

10. Electrical Load Information

The following charts provide information for the electrician wiring the grain dryer and are a reference

guide for parts. You should contact the local power company and have a representative survey the

installation to see that the wiring is compatible with their system and that adequate power is supplied to

the unit. Remember that the only thing connected to the recommended service amps should be the

grain dryer.

Adhere to all electrical safety practices and codes. (Refer to the National Electrical Code Standard

handbook by the National Fire Protection Association.) A qualified electrician must make all electrical

wiring installations.

Dryer

Model #

1108

1110

1112

*Auxiliaries run through load and unload breakers.

Subject to change without notification.

Voltage Motor HP

Top Auger 1.5 8

1 PH 230V

3 PH 220V

3 PH 440V

1 PH 230V

3 PH 220V

3 PH 440V

1 PH 230V

3 PH 220V

3 PH 440V

Bottom Auger 1 6.5 60

Fan 10 to 12 48 100

(2) Auxiliary (2) 7.5 62 *

Top Auger 1.5 5

Bottom Auger 1 3.4 50

Fan 10 to 12 33 60

(2) Auxiliary (2) 7.5 40 *

Top Auger 1.5 2.5

Bottom Auger 1 1.7 60

Fan 10 to 12 16.5 60

(2) Auxiliary (2) 7.5 20 *

Top Auger 2 14

Bottom Auger 1.5 8 60

Fan 10 to 12 48 100

(2) Auxiliary (2) 7.5 62 *

Top Auger 2 6.2

Bottom Auger 1.5 5 50

Fan 10 28 60

(2) Auxiliary (2) 7.5 40 *

Top Auger 2 3.1

Bottom Auger 1.5 2.5 60

Fan 10 14 60

(2) Auxiliary (2) 7.5 20 *

Top Auger 2 14

Bottom Auger 1.5 8 60

Fan 10 to 17 78 100

(2) Auxiliary (2) 7.5 62 *

Top Auger 2 6.2

Bottom Auger 1.5 5 50

Fan 15 39 60

(2) Auxiliary (2) 7.5 40 *

Top Auger 2 3.1

Bottom Auger 1.5 2.5 60

Fan 15 19.5 60

(2) Auxiliary (2) 7.5 20 *

Fuel Load

Amps

Maximum Amps

with Auxiliaries

153 62.5 200

104 41.4 150

57 20.7 150

162 70 225

101 39.2 150

56 19.6 150

196 100 300

114 50.2 175

62 25.1 150

Minimum

Amps

Recommended

Service in Amps

Branch Breaker

in Amps

60

50

60

60

50

60

60

50

60

PNEG-338 Portable Dryer Installation and Towing 23

Page 24

10. Electrical Load Information

Dryer

Model #

1114

1116

1118

1120

1122

*Auxiliaries run through l oad and unload breakers.

Voltage Motor HP

Top Auger 5 26

1 PH 230V

3 PH 220V

3 PH 440V

1 PH 230V

3 PH 220V

3 PH 440V

3 PH 220V

3 PH 440V

3 PH 220V

3 PH 440V

3 PH 220V

3 PH 440V

Bottom Auger 5 26 100

Fan 10 to 17 78 100

(2) Auxiliary (2) 7.5 62 *

Top Auger 5 13.2

Bottom Auger 5 13.2 60

Fan 15 39 60

(2) Auxiliary (2) 10 52 *

Top Auger 5 6.6

Bottom Auger 5 6.6 60

Fan 15 19.5 60

(2) Auxiliary (2) 10 26 *

Top Auger 5 26

Bottom Auger 5 26 100

Fan 10 to 17 78 100

(2) Auxiliary (2) 7.5 62 *

Top Auger 5 13.2

Bottom Auger 5 13.2 60

Fan 15 39 60

(2) Auxiliary (2) 10 52 *

Top Auger 5 6.6

Bottom Auger 5 6.6 60

Fan 15 19.5 60

(2) Auxiliary (2) 10 26 *

Top Auger 5 13.2

Bottom Auger 5 13.2 60

Fan 20 50 90

(2) Auxiliary (2) 10 52 *

Top Auger 5 6.6

Bottom Auger 5 6.6 60

Fan 20 25 60

(2) Auxiliary (2) 10 26 *

Top Auger 7.5 20

Bottom Auger 7.5 20 90

Fan 25 64 90

(2) Auxiliary (2) 15 78 *

Top Auger 7.5 10

Bottom Auger 7.5 10 60

Fan 25 32 60

(2) Auxiliary (2) 15 39 *

Top Auger 7.5 20

Bottom Auger 7.5 20 90

Fan 30 74 90

(2) Auxiliary (2) 15 78 *

Top Auger 7.5 10

Bottom Auger 7.5 10 60

Fan 30 37 60

(2) Auxiliary (2) 15 39 *

Fuel Load

Amps

Maximum Amps

with Auxiliaries

231 130 350

145 65.4 200

78 32.7 150

231 130 350

145 65.4 200

78 32.7 150

158 76.4 250

84 38.2 150

219 104 300

115 52 200

231 114 300

120 57 200

Minimum

Amps

Recommended

Service in Amps

Branch Breaker

in Amps

100

60

60

100

60

60

60

60

90

60

90

60

24 PNEG-338 Portable Dryer Installation and Towing

Page 25

10. Electrical Load Information

Dryer

Model #

1126

1214

1216

*Auxiliaries run through load and unload breakers.

Voltage Motor HP

Top Auger 10 26

3 PH 220V

3 PH 440V

1 PH 230V

3 PH 220V

3 PH 440V

1 PH 230V

3 PH 220V

3 PH 440V

Bottom Auger 10 26 90

Fan 40 102 125

(2) Auxiliary (2) 15 78 *

Top Auger 10 13

Bottom Auger 10 13 60

Fan 40 51 90

(2) Auxiliary (2) 15 39l *

Top Auger 5 26

Bottom Auger 5 26 100

Top Fan 10 to 12 48 100

Bottom Fan 10 to 12 48 100

(2) Auxiliary (2) 7.5 62 *

Top Auger 5 13.2

Bottom Auger 5 13.2 60

Top Fan 10 28 60

Bottom Fan 10 to 12 33 60

(2) Auxiliary (2) 10 52 *

Top Auger 5 6.6

Bottom Auger 5 6.6 60

Top Fan 10 14 60

Bottom Fan 10 to 12 16.5 60

(2) Auxiliary (2) 10 26 *

Top Auger 5 26

Bottom Auger 5 26 100

Top Fan 10 to 17 78 100

Bottom Fan 10 to 12 48 100

(2) Auxiliary (2) 7.5 62 *

Top Auger 5 13.2

Bottom Auger 5 13.2 60

Top Fan 15 39 60

Bottom Fan 10 to 12 33 60

(2) Auxiliary (2) 10 52 *

Top Auger 5 6.6 60

Bottom Auger 5 6.6

Top Fan 15 19.5 60

Bottom Fan 10 to 12 16.5 60

(2) Auxiliary (2) 10 26 *

Fuel Load

Amps

Maximum Amps

with Auxiliaries

277 154 400

143 77 250

252 148 300

170 87.4 225

90 43.7 150

286 178 400

183 98.4 225

96 49.2 150

Minimum

Amps

Recommended

Service in Amps

Branch Breaker

in Amps

90

60

100

60

60

100

60

60

PNEG-338 Portable Dryer Installation and Towing 25

Page 26

10. Electrical Load Information

Dryer

Model #

1218

1220

1222

1226

*Auxiliaries run through l oad and unload breakers.

Voltage Motor HP

Top Auger 5 26

Bottom Auger 5 26 100

1 PH 230V

3 PH 220V

3 PH 440V

1 PH 230V

3 PH 220V

3 PH 440V

3 PH 220V

3 PH 440V

3 PH 220V

3 PH 440V

Top Fan 10 to 17 78 100

Bottom Fan 10 to 12 48 100

(2) Auxiliary (2) 7.5 62 *

Top Auger 5 13.2

Bottom Auger 5 13.2 60

Top Fan 15 39 60

Bottom Fan 10 to 12 33 60

(2) Auxiliary (2) 10 52 *

Top Auger 5 6.6

Bottom Auger 5 6.6 60

Top Fan 15 19.5 60

Bottom Fan 10 to 12 16.5 60

(2) Auxiliary (2) 10 26 *

Top Auger 7.5 31

Bottom Auger 7.5 31 100

Top Fan 10 to 17 78 100

Bottom Fan 10 to 12 48 100

(2) Auxiliary (2) 7.5 62 *

Top Auger 7.5 20

Bottom Auger 7.5 20 90

Top Fan 15 39 60

Bottom Fan 10 to12 33 60

(2) Auxiliary (2) 15 78 *

Top Auger 7.5 10

Bottom Auger 7.5 10 60

Top Fan 15 19.5 60

Bottom Fan 10 to 12 16.5 60

(2) Auxiliary (2) 15 39 *

Top Auger 7.5 20

Bottom Auger 7.5 20 90

Top Fan 20 50 90

Bottom Fan 10 to 12 33 60

(2) Auxiliary (2) 15 78 *

Top Auger 7.5 10

Bottom Auger 7.5 10 60

Top Fan 20 25 60

Bottom Fan 10 to 12 16.5 60

(2) Auxiliary (2) 15 39 *

Top Auger 10 26

Bottom Auger 10 26 90

Top Fan 25 64 90

Bottom Fan 10 to 12 33 60

(2) Auxiliary (2) 15 78 *

Top Auger 10 13

Bottom Auger 10 13 60

Top Fan 25 32 60

Bottom Fan 10 to 12 16.5 60

(2) Auxiliary (2) 15 39 *

Fuel Load

Amps

Maximum Amps

with Auxiliaries

286 178 400

183 98.4 225

96 49.2 150

298 188 400

229 112 300

123 59 200

241 123 350

129 64.5 200

271 149 350

144 77.5 200

Minimum

Amps

Recommended

Service in Amps

Branch Breaker

in Amps

100

60

60

100

90

60

90

60

90

60

26 PNEG-338 Portable Dryer Installation and Towing

Page 27

10. Electrical Load Information

Dryer

Model #

1214S

1218S

1220S

1222S

*Auxiliaries run through load and unload breakers.

Voltage Motor HP

Top Auger 5 26

1 PH 230V

3 PH 220V

3 PH 440V

1 PH 230V

3 PH 220V

3 PH 440V

1 PH 230V

3 PH 220V

3 PH 440V

1 PH 230V

3 PH 220V

3 PH 440V

Bottom Auger 5 26 C303B 100

(2) Fans (2) 10 to 12 96 F614B 100

(2) Auxiliary (2) 7.5 62 C330B *

Top Auger 5 13.2

Bottom Auger 5 13.2 C163B 60

(2) Fans (2) 10 to 12 66 C366B 60

(2) Auxiliary (2) 10 52 C303B *

Top Auger 5 6.6

Bottom Auger 5 6.6 C867A 60

(2) Fans (2) 10 to 12 33 C180B 60

(2) Auxiliary (2) 10 26 C163B *

Top Auger 5 26

Bottom Auger 5 26 100

(2) Fans (2) 10 to 12 96 100

(2) Auxiliary (2) 7.5 62 *

Top Auger 5 13.2

Bottom Auger 5 13.2 60

(2) Fans (2 ) 10 56 60

(2) Auxiliary (2) 10 52 *

Top Auger 5 6.6

Bottom Auger 5 6.6 60

(2) Fans (2) 10 28 60

(2) Auxiliary (2) 10 26 *

Top Auger 7.5 31

Bottom Auger 7.5 31 100

(2) Fans (2) 10 to 17 156 100

(2) Auxiliary (2) 7.5 62 *

Top Auger 7.5 20

Bottom Auger 7.5 20 90

(2) Fans (2) 15 78 60

(2) Auxiliary (2) 15 78 *

Top Auger 7.5 10

Bottom Auger 7.5 10 60

(2) Fans (2) 15 39 60

(2) Auxiliary (2) 15 39 *

Top Auger 7.5 31

Bottom Auger 7.5 31 100

(2) Fans (2) 10 to 17 156 100

(2) Auxiliary (2) 7.5 62 *

Top Auger 7.5 20

Bottom Auger 7.5 20 90

(2) Fans (2) 15 78 60

(2) Auxiliary (2) 15 78 *

Top Auger 7.5 10

Bottom Auger 7.5 10 60

(2) Fans (2) 15 39 60

(2) Auxiliary (2) 15 39 *

Fuel Load

Amps

Maximum Amps

with Auxiliaries

252 148 350

176 92.4 225

93 46.2 150

252 148 350

165 82.4 225

87 41.2 150

332 218 400

235 118 300

123 59 200

332 218 400

235 118 300

123 59 200

Minimum

Amps

Recommended

Service in Amps

Branch Breaker

in Amps

C303B 100

C163B 60

C867A 60

100

60

60

100

90

60

100

90

60

PNEG-338 Portable Dryer Installation and Towing 27

Page 28

10. Electrical Load Information

Dryer

Model #

1226S

1314

1318

1322

*Auxiliaries run through l oad and unload breakers.

Voltage Motor HP

Top Auger 10 26

3 PH 220V

3 PH 440V

1 PH 230V

3 PH 220V

3 PH 440V

1 PH 230V

3 PH 220V

3 PH 440V

Bottom Auger 10 26 90

(2) Fans (2) 25 128 90

(2) Auxiliary (2) 15 78 *

Top Auger 10 13

Bottom Auger 10 13 60

(2) Fans (2) 25 64 60

(2) Auxiliary (2) 15 39 *

Top Auger 5 26

Bottom Auger 5 26 100

Top Fan 10 to 12 48 100

Mid.Fan 10 to 12 48 100

Bottom Fan 10 to 12 48 100

(2) Auxiliary (2) 7.5 62 *

Top Auger 5 13.2

Bottom Auger 5 13.2 60

Top Fan 10 to 12 33 60

Mid.Fan 10 to 12 33 60

Bottom Fan 10 to 12 33 60

(2) Auxiliary (2) 10 52 *

Top Auger 5 6.6

Bottom Auger 5 6.6 60

Top Fan 10 to 12 16.5 60

Mid.Fan 10 to 12 16.5 60

Bottom Fan 10 to 12 16.5 60

(2) Auxiliary (2) 10 26 *

Top Auger 7.5 31

Bottom Auger 7.5 31 100

Top Fan 10 to 12 48 100

Mid.Fan 10 to 12 48 100

Bottom Fan 10 to 12 48 100

(2) Auxiliary (2) 7.5 62 *

Top Auger 7.5 20

Bottom Auger 7.5 20 90

Top Fan 10 to 12 33 60

Mid.Fan 10 to 12 33 60

Bottom Fan 10 to 12 33 60

(2) Auxiliary (2) 15 78 *

Top Auger 7.5 10

Bottom Auger 7.5 10 60

Top Fan 10 to 12 16.5 60

Mid.Fan 10 to 12 16.5 60

Bottom Fan 10 to 12 16.5 60

(2) Auxiliary (2) 15 39 *

Fuel Load

Amps

Maximum Amps

with Auxiliaries

307 180 400

158 90 200

307 196 400

214 125.4 250

112 62.7 200

318 206 400

260 139 350

135 69.5 200

Minimum

Amps

Recommended

Service in Amps

Branch Breaker

in Amps

90

60

100

60

60

100

90

60

28 PNEG-338 Portable Dryer Installation and Towing

Page 29

10. Electrical Load Information

Dryer

Model #

160AB

210AB

300AB

375AB

*Auxiliaries run through load and unload breakers.

Voltage Motor HP

Top Auger 1 6.5

Bottom Auger 1 6.5 50

1 PH 230V

3 PH 220V

3 PH 440V

1 PH 230V

3 PH 220V

3 PH 440V

1 PH 230V

3 PH 220V

3 PH 440V

1 PH 230V

3 PH 220V

3 PH 440V

Fan 10 to 12 48 60

(2) Auxiliary (2) 7.5 62 *

Top Auger 1 3.4

Bottom Auger 1 3.4 60

Fan 10 to 12 33 60

(2) Auxiliary (2) 7.5 40 *

Top Auger 1 1.7

Bottom Auger 1 1.7 60

Fan 10 to 12 16.5 60

(2) Auxiliary (2) 7.5 20 *

Top Auger 2 14

Bottom Auger 2 14 60

Fan 10 to 12 48 100

(2) Auxiliary (2) 7.5 62 *

Top Auger 2 6.2

Bottom Auger 2 6.2 50

Fan 10 28 60

(2) Auxiliary (2) 7.5 40 *

Top Auger 2 3.1

Bottom Auger 2 3.1 60

Fan 10 14 60

(2) Auxiliary (2) 7.5 20 *

Top Auger 3 17.7

Bottom Auger 3 17.7 60

Fan 10 to 17 78 100

(2) Auxiliary (2) 7.5 62 *

Top Auger 3 8.6

Bottom Auger 3 8.6 60

Fan 15 39 60

(2) Auxiliary (2) 7.5 40 *

Top Auger 3 4.3

Bottom Auger 3 4.3 60

Fan 15 19.5 60

(2) Auxiliary (2) 7.5 20 *

Top Auger 3 17.7

Bottom Auger 3 17.7 60

Fan 10 to 17 78 100

(2) Auxiliary (2) 7.5 62 *

Top Auger 3 8.6

Bottom Auger 3 8.6 60

Fan 15 39 60

(2) Auxiliary (2) 7.5 40 *

Top Auger 3 4.3

Bottom Auger 3 4.3 60

Fan 15 19.5 60

(2) Auxiliary (2) 7.5 20 *

Fuel Load

Amps

Maximum Amps

with Auxiliaries

151 61 200

102 39.8 150

56 19.9 150

169 76 225

102 40.4 150

56 20.2 150

212 113.4 300

121 56.2 175

65 28.1 150

212 113.4 300

121 56.2 175

65 28.1 150

Minimum

Amps

Recommended

Service in Amps

Branch Breaker

in Amps

50

60

60

60

50

60

60

60

60

60

60

60

PNEG-338 Portable Dryer Installation and Towing 29

Page 30

10. Electrical Load Information

Dryer

Model #

400AB

415AB

600AB

*Auxiliaries run through l oad and unload breakers.

Voltage Motor HP

Top Auger 5 26

1 PH 230V

3 PH 220V

3 PH 440V

1 PH 230V

3 PH 220V

3 PH 440V

1 PH 230V

3 PH 220V

3 PH 440V

Bottom Auger 5 26 100

Fan 10 to 17 78 100

(2) Auxiliary (2) 7.5 62 *

Top Auger 5 13.2

Bottom Auger 5 13.2 60

Fan 15 39 60

(2) Auxiliary (2) 10 52 *

Top Auger 5 6.6

Bottom Auger 5 6.6 60

Fan 15 19.5 60

(2) Auxiliary (2) 10 26 *

Top Auger 5 26

Bottom Auger 5 26 100

Fan (2) 10 to 12 96 100

(2) Auxiliary (2) 7.5 62 *

Top Auger 5 13.2

Bottom Auger 5 13.2 60

Fan (2) 10 56 60

(2) Auxiliary (2) 10 52 *

Top Auger 5 6.6

Bottom Auger 5 6.6 60

Fan (2) 10 28 60

(2) Auxiliary (2) 10 26 *

Top Auger 7.5 31

Bottom Auger 7.5 31 100

Fan (2) 10 to 17 156 100

(2) Auxiliary (2) 7.5 62 *

Top Auger 7.5 20

Bottom Auger 7.5 20 90

Fan (2) 15 78 60

(2) Auxiliary (2)15 78 *

Top Auger 7.5 10

Bottom Auger 7.5 10 60

Fan (2) 15 39 60

(2) Auxiliary (2) 15 39 *

Fuel Load

Amps

Maximum Amps

with Auxiliaries

231 130 350

145 65.4 200

78 32.7 150

252 148 350

165 82.4 225

82 41.2 150

332 218 400

235 118 300

123 59 200

Minimum

Amps

Recommended

Service in Amps

Branch Breaker

in Amps

100

60

60

100

60

60

100

90

60

30 PNEG-338 Portable Dryer Installation and Towing

Page 31

11. Warranty

9101239_1_CR_rev7.DOC (revised July 2009)

GSI Group, LLC Limited Warranty

The GSI Group, LLC (“GSI”) warrants products which it manufactures to be free of defects in materials and workmanship

under normal usage and conditions for a period of 12 months after sale to the original end-user or if a foreign sale,

14 months from arrival at port of discharge, whichever is earlier. The end-user’s sole remedy (and GSI’s only obligation)

is to repair or replace, at GSI’s option and expense, products that in GSI’s judgment, contain a material defect in materials

or workmanship. Expenses incurred by or on behalf of the end-user without prior written authorization from the GSI

Warranty Group shall be the sole responsibility of the end-user.

Warranty Extensions:

The Limited Warranty period is extended for the following products:

Product Warranty Period

Performer Series Direct Drive Fan Motor 3 Years

AP Fans and Flooring

Cumberland

Feeding/Watering

Systems

Grain Systems Grain Bin Structural Design 5 Years

Grain Systems

Farm Fans

Zimmerman

All Fiberglass Housings Lifetime

All Fiberglass Propellers Lifetime

Feeder System Pan Assemblies 5 Years **

Feed Tubes (1-3/4" and 2.00") 10 Years *

Centerless Augers 10 Years *

Watering Nipples 10 Years *

Portable and Tower Dryers 2 Years

Portable and Tower Dryer Frames and

Internal Infrastructure †

5 Years

* Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 25%

5 to 7 years - end-user pays 50%

7 to 10 years - end-user pays 75%

** Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 50%

† Motors, burner components

and moving parts not included.

Portable dryer screens included.

Tower dryer screens not included.

GSI further warrants that the portable and tower dryer frame and basket, excluding all auger and auger drive components,

shall be free from defects in materials for a period of time beginning on the twelfth (12

and continuing until the sixtieth (60

th

) month from the date of purchase (extended warranty period). During the extended

th

) month from the date of purchase

warranty period, GSI will replace the frame or basket components that prove to be defective under normal conditions

of use without charge, excluding the labor, transportation, and/or shipping costs incurred in the performance of this

extended warranty.

Conditions and Limitations:

THERE ARE NO WARRANTIES THAT EXTEND BEYOND THE LIMITED WARRANTY DESCRIPTION SET FORTH

ABOVE. SPECIFICALLY, GSI MAKES NO FURTHER WARRANTY OF ANY KIND, EXPRESS OR IMPLIED,

INCLUDING, WITHOUT LIMITATION, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE OR USE IN CONNECTION WITH: (I) PRODUCT MANUFACTURED OR SOLD BY GSI OR (II) ANY ADVICE,

INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT, REPRESENTA TIVE OR

EMPLOYEE OF GSI REGARDING OR RELATED TO THE CONFIGURATION, INSTALLATION, LAYOUT, SUITABILITY

FOR A PARTICULAR PURPOSE, OR DESIGN OF SUCH PRODUCTS.

GSI shall not be liable for any direct, indirect, incidental or consequential damages, including, without limitation, loss of

anticipated profits or benefits. The sole and exclusive remedy is set forth in the Limited Warranty, which shall not exceed

the amount paid for the product purchased. This warranty is not transferable and applies only to the original end-user. GSI

shall have no obligation or responsibility for any representations or warranties made by or on behalf of any dealer, agent

or distributor.

GSI assumes no responsibility for claims resulting from construction defects or unauthorized modifications to products

which it manufactured. Modifications to products not specifically delineated in the manual accompanying the equipment at

initial sale will void the Limited Warranty.

This Limited Warranty shall not extend to products or parts which have been damaged by negligent use, misuse, alteration,

accident or which have been improperly/inadequately maintained. This Limited Warranty extends solely to products

manufactured by GSI.

Prior to installation, the end-user has the responsibility to comply with federal, state and local codes which apply to the

location and installation of products manufactured or sold by GSI.

PNEG-338 Portable Dryer Installation and Towing 31

Page 32

This equipment shall be installed in accordance with

the current installation codes and applicable

regulations, which should be carefully followed in all

cases. Authorities having jurisdiction should be

consulted before installations are made.

Copyright © 2012 by GSI Group

Printed in the USA

GSI Group

1004 E. Illinois St.

Assumption, IL 62510-0020

Phone: 1-217-226-4421

Fax: 1-217-226-4420

www.gsiag.com

CN-302607

Loading...

Loading...